Downhole high frequency pressure pulse generator

A technology of pressure pulse and generating device, applied in the direction of flushing wellbore, wellbore/well components, earth-moving drilling, etc., to achieve the effect of improving rock breaking efficiency, reducing stick-slip, and prolonging the life of the drill bit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

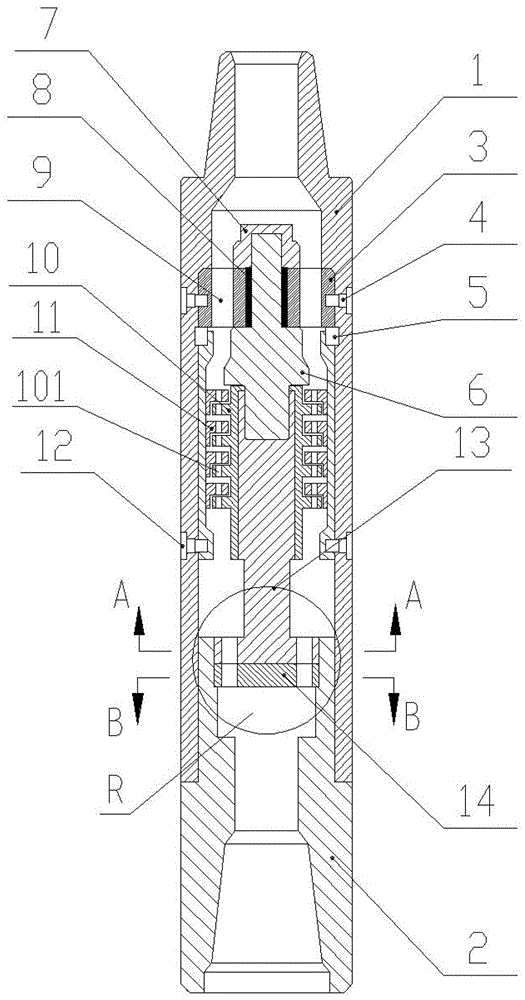

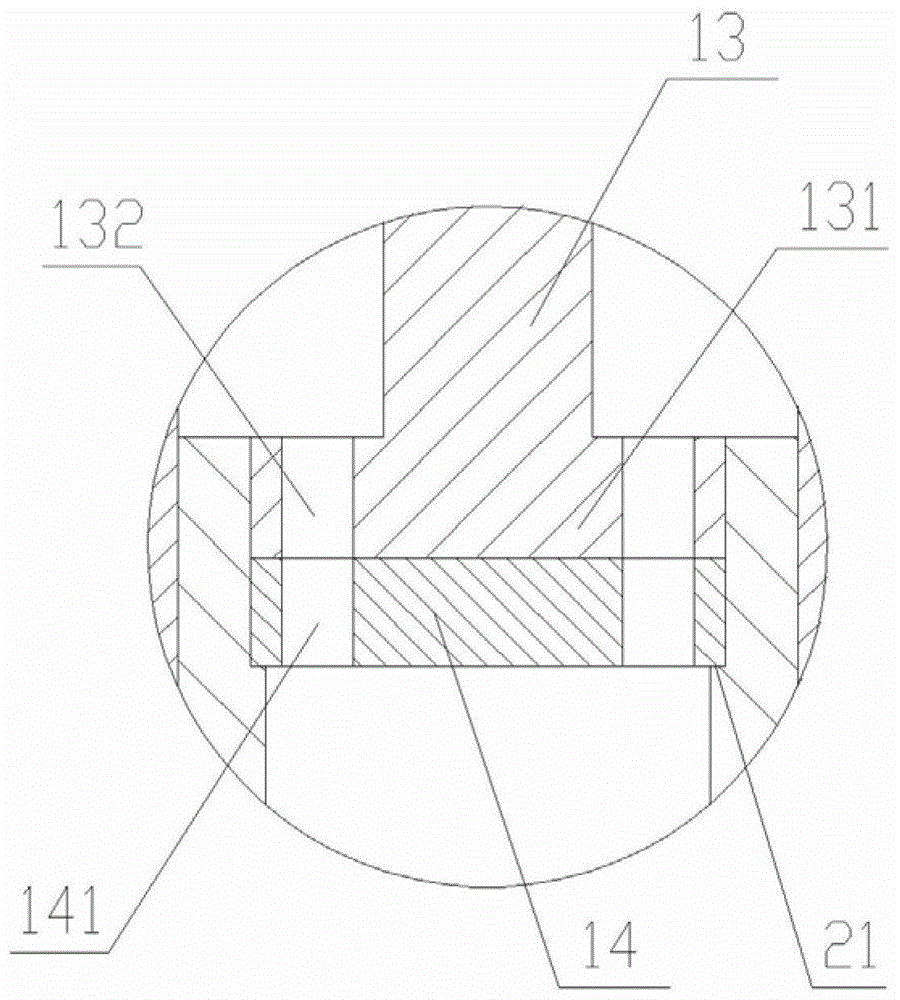

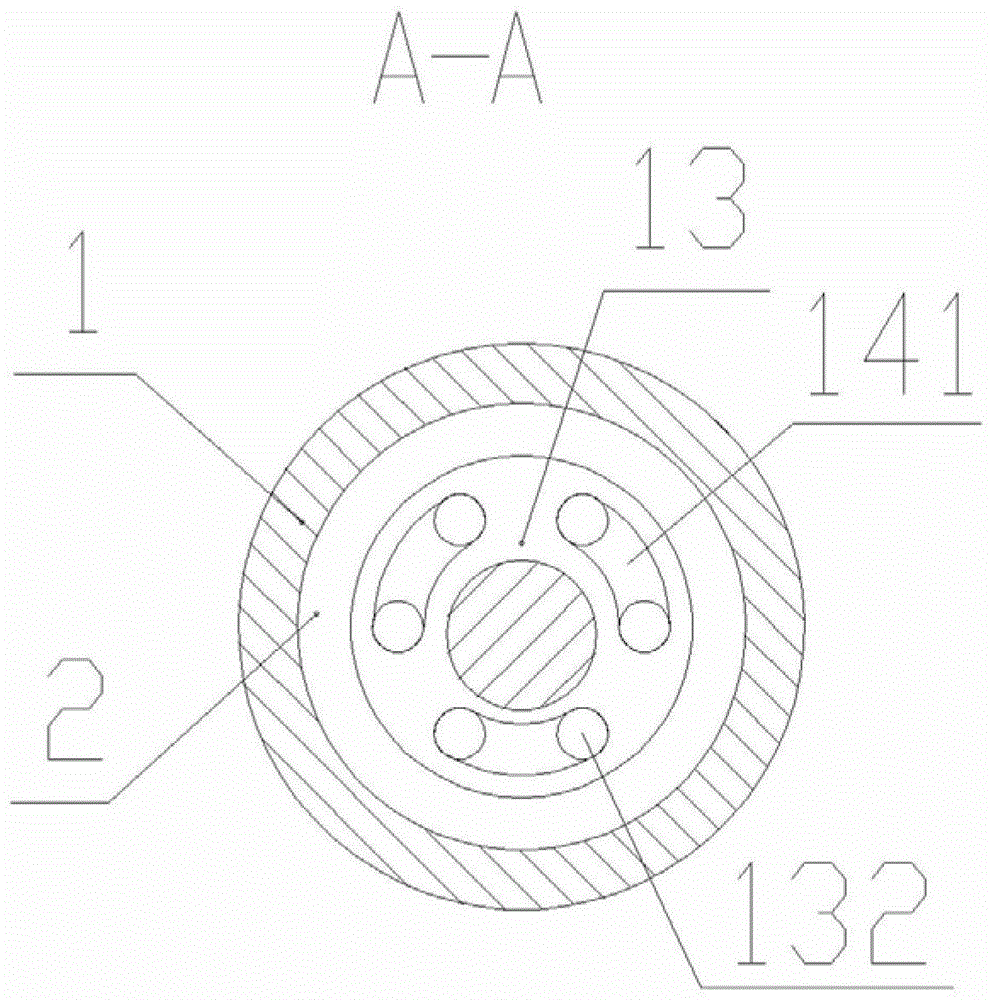

[0023] This embodiment provides a downhole high-frequency pressure pulse generator, see figure 1 , the downhole high-frequency pressure pulse generating device includes: a generator casing 1 and a drill nipple 2, the generator casing 1 is a hollow structure, and the hollow interior of the generator casing 1 is used for installing other components of the downhole high-frequency pressure pulse generating device parts. The first end of the generator housing 1 has a connecting joint for connecting with external equipment; the second end of the generator housing 1 is provided with an internal thread, and the generator housing 1 is fixedly connected to the drill nipple 2 at the second end , correspondingly, the connecting end of the drill sub-section 2 is provided with an external thread, and the generator casing 1 and the drill sub-section 2 are connected to each other through the internal and external threads provided on them.

[0024] continue to see figure 1 , The inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com