A hydraulic torsional pulse impactor for drilling speed increase

An impactor and hydraulic impact technology, applied in the direction of drilling with vibration, can solve the problems of unsatisfactory use effect, only generate circumferential impact force, generate axial impact force, etc. Service life, the effect of improving the ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

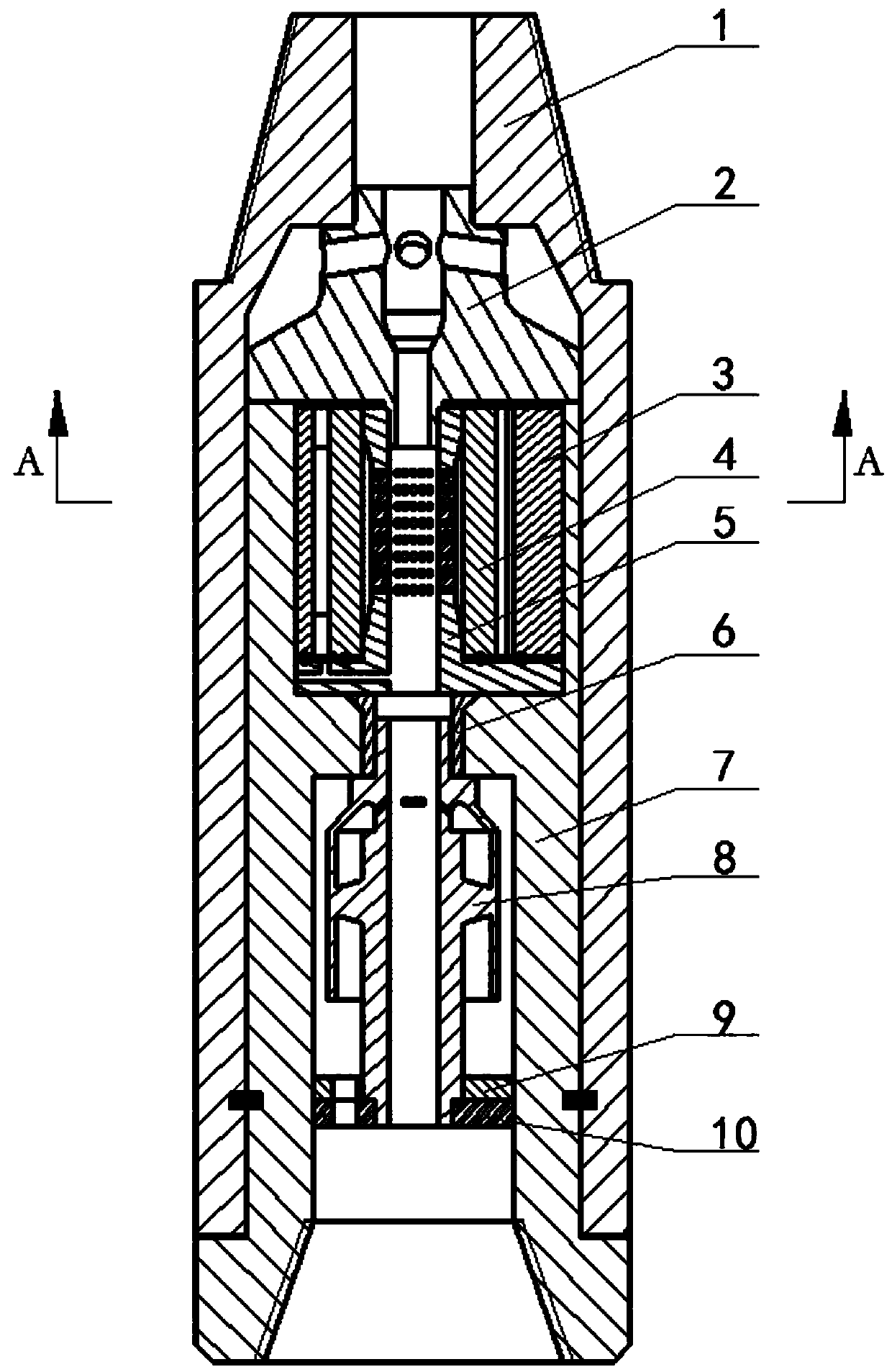

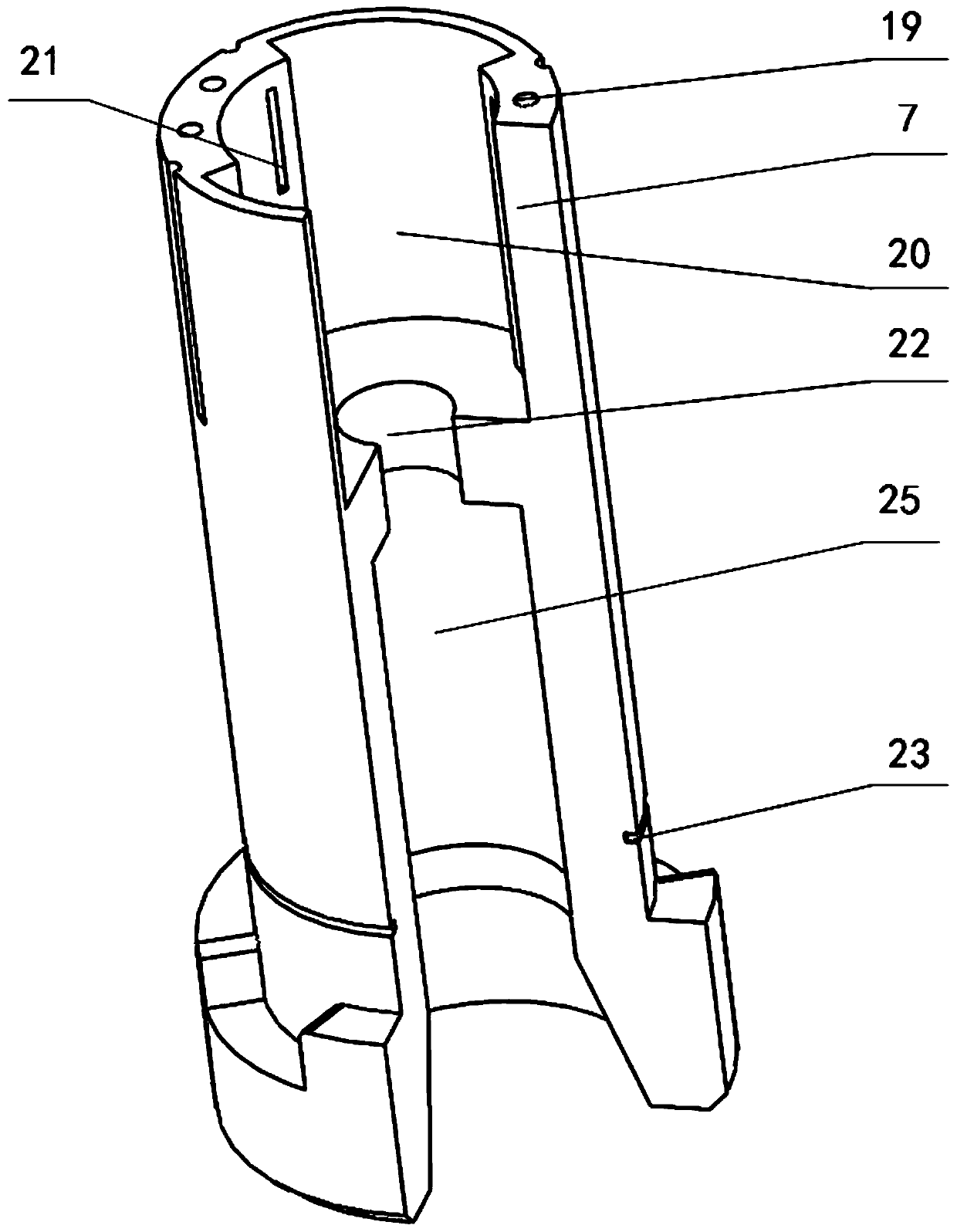

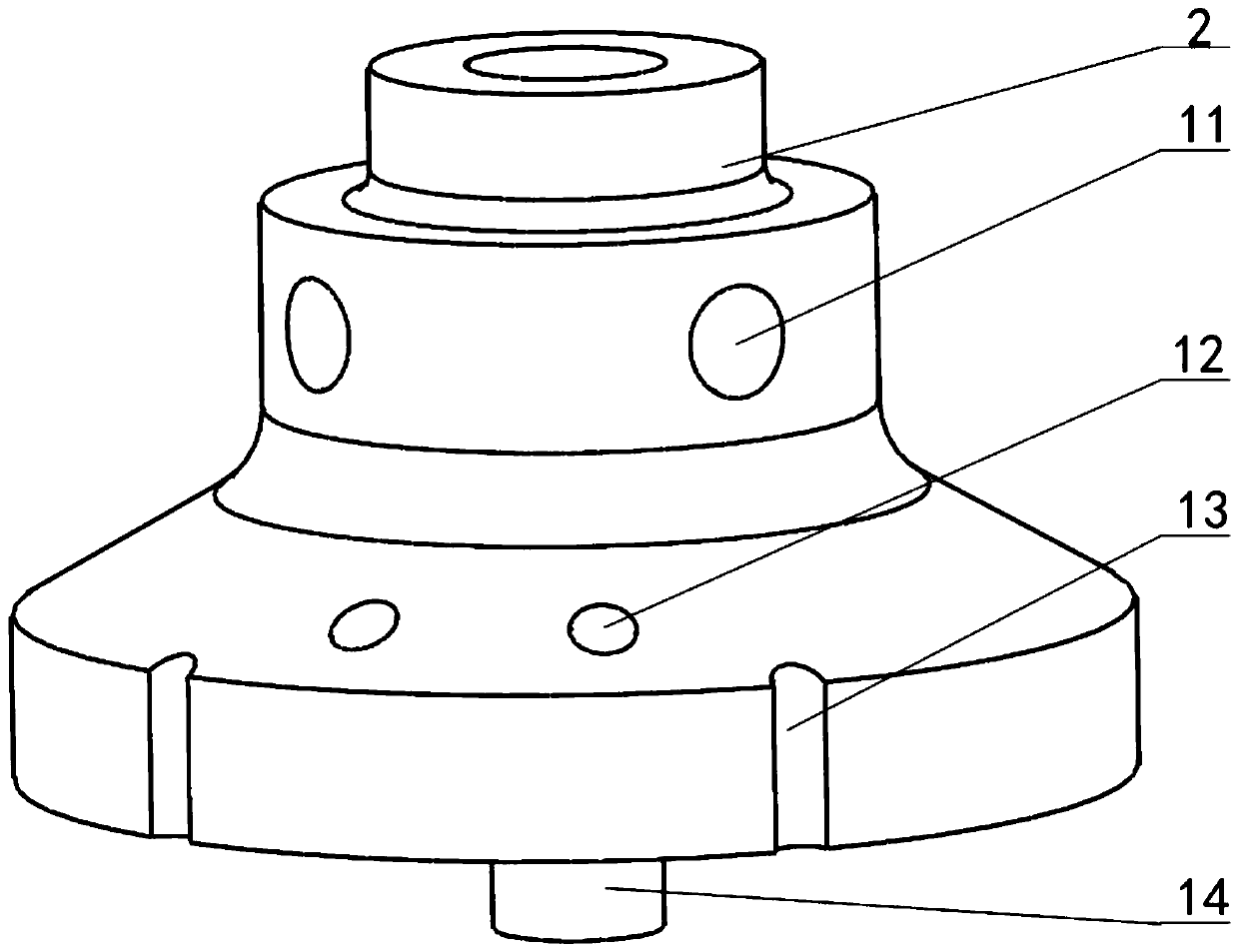

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, a hydraulic torsional pulse impactor for drilling speed increase includes a suspension outer cylinder 1; a suspension inner cylinder 7 is arranged inside the suspension outer cylinder 1; a hydraulic torsional impact generator 20 is arranged at the upper end of the suspension inner cylinder 7; The pulse generator 25, the hydraulic torsional impact generator 20 includes the inner shunt seat 5, the start commutator 4, the hydraulic impact hammer 3 and the hydraulic impact seat 19, and the hydraulic pulse generator 25 includes the hydraulic cyclone 8, Upper disc valve 9 and lower disc valve 10;

[0034] The suspension inner cylinder 7 can rotate inside the suspension outer cylinder 1. The upper part of the suspension inner cylinder 7 is designed as a hydraulic shock seat 19. The inner wall of the hydraulic shock seat 19 is symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com