Patents

Literature

49results about How to "Reduce stick-slip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

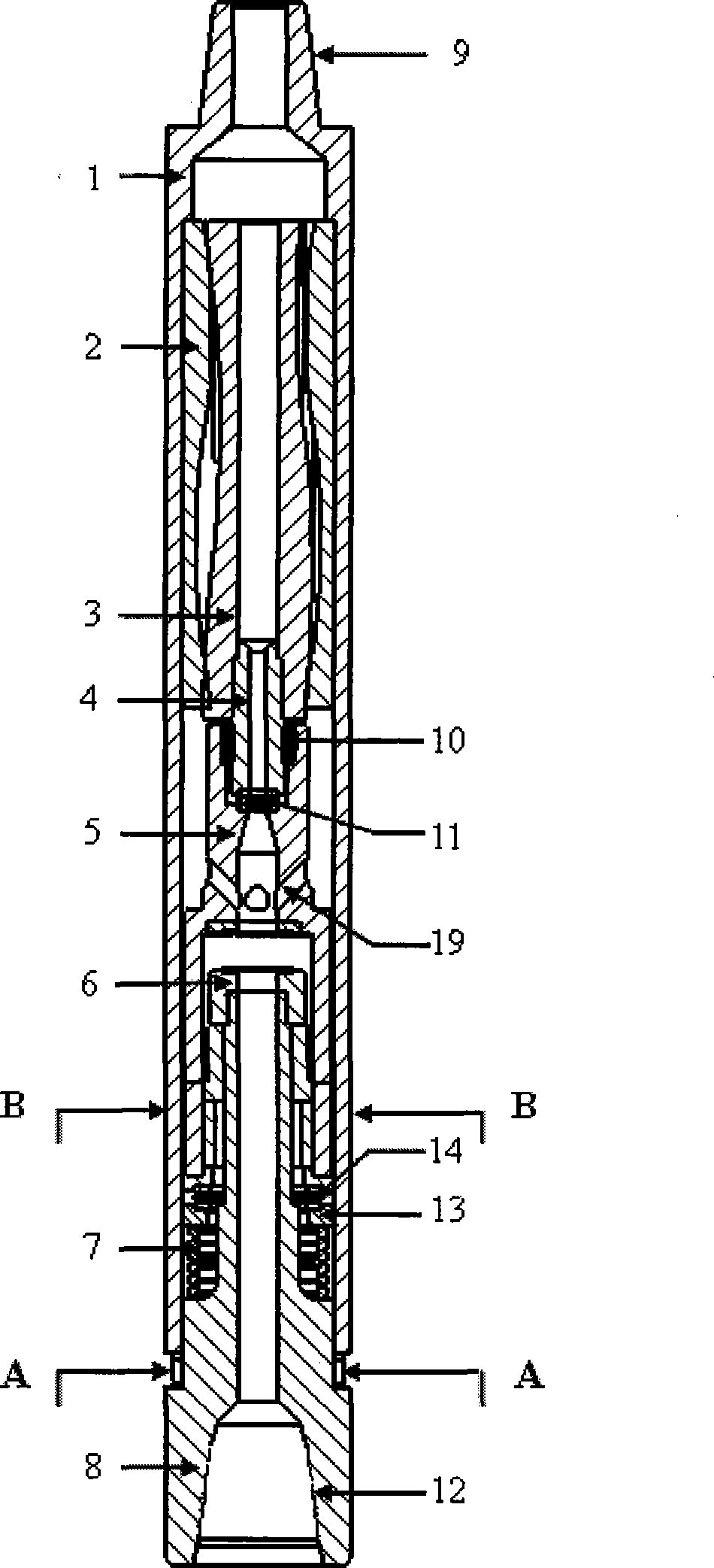

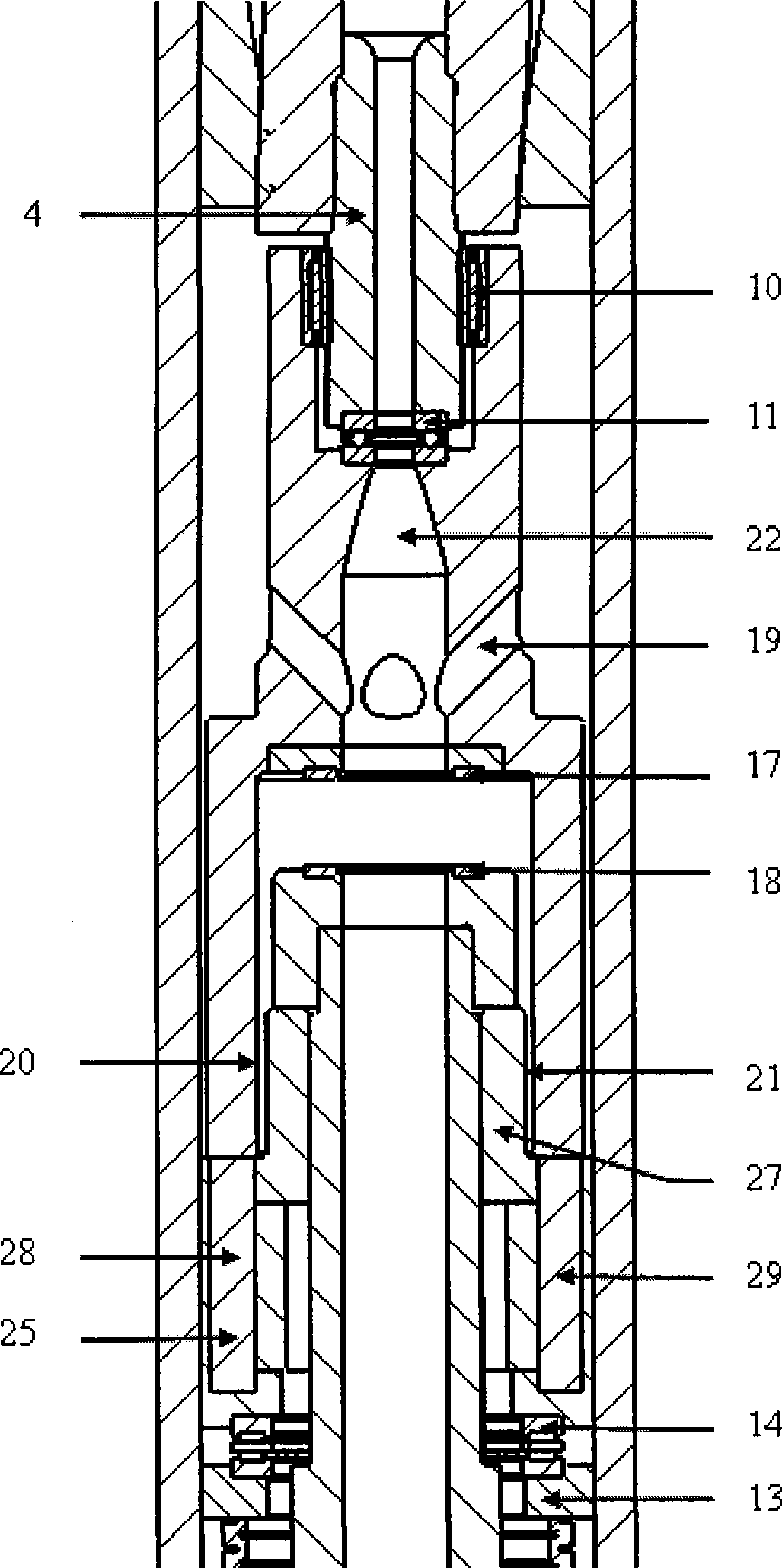

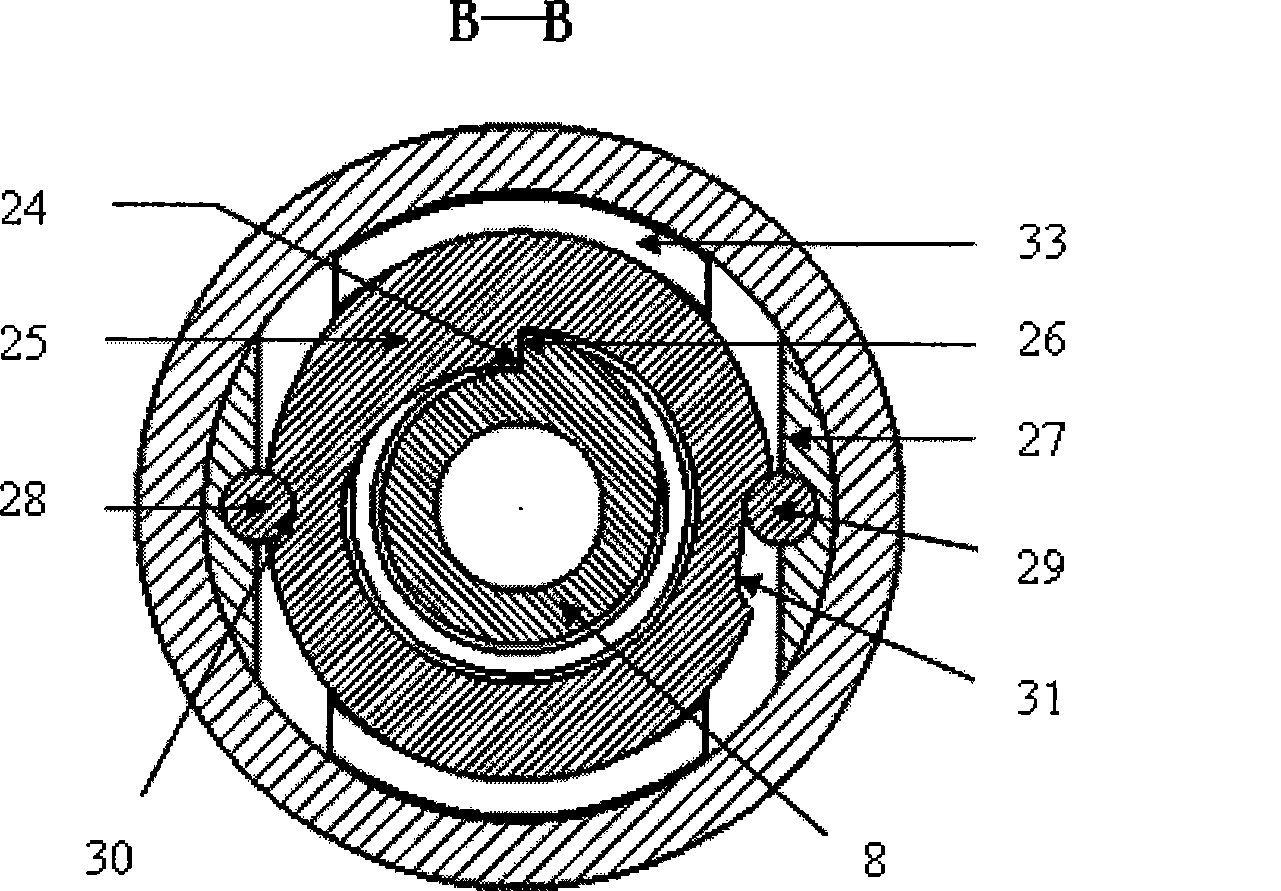

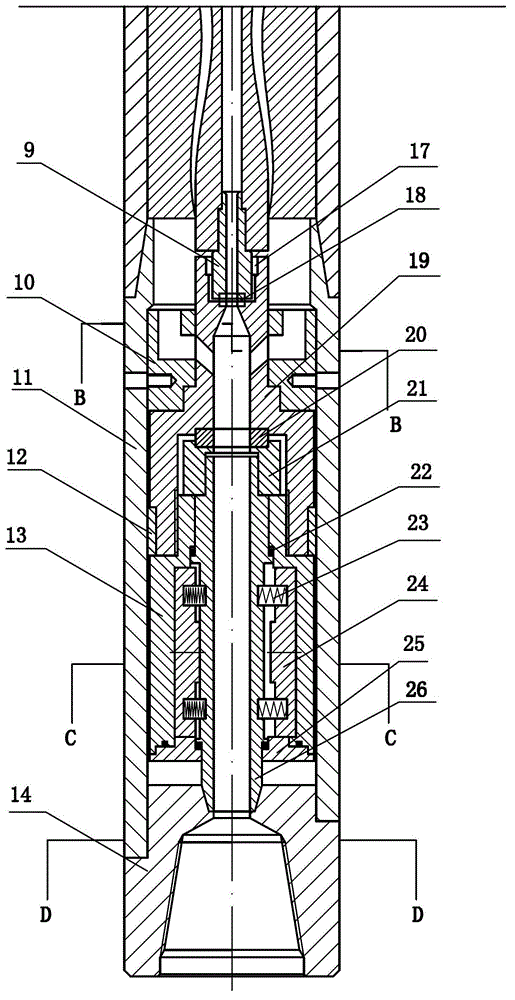

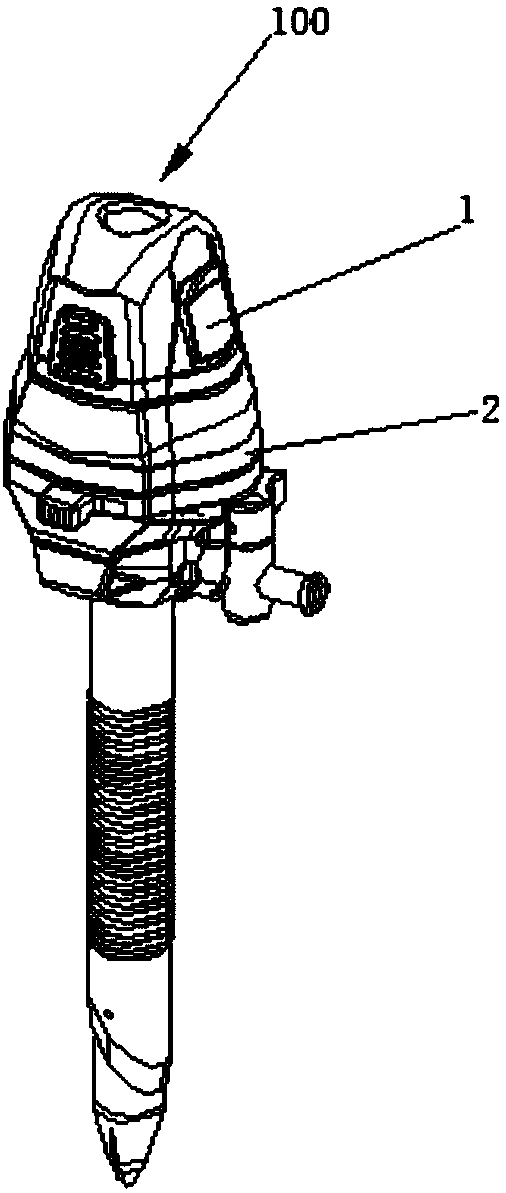

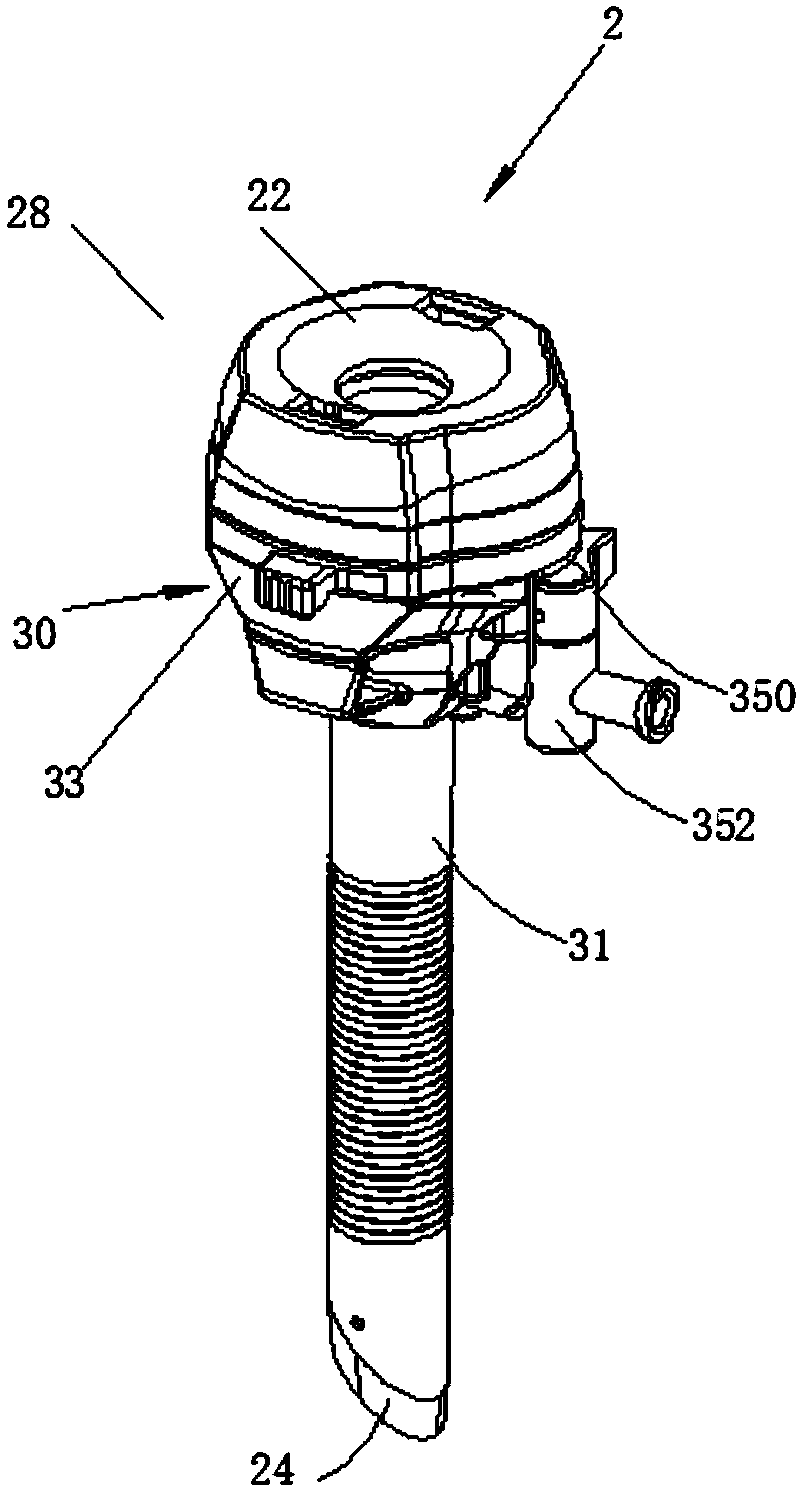

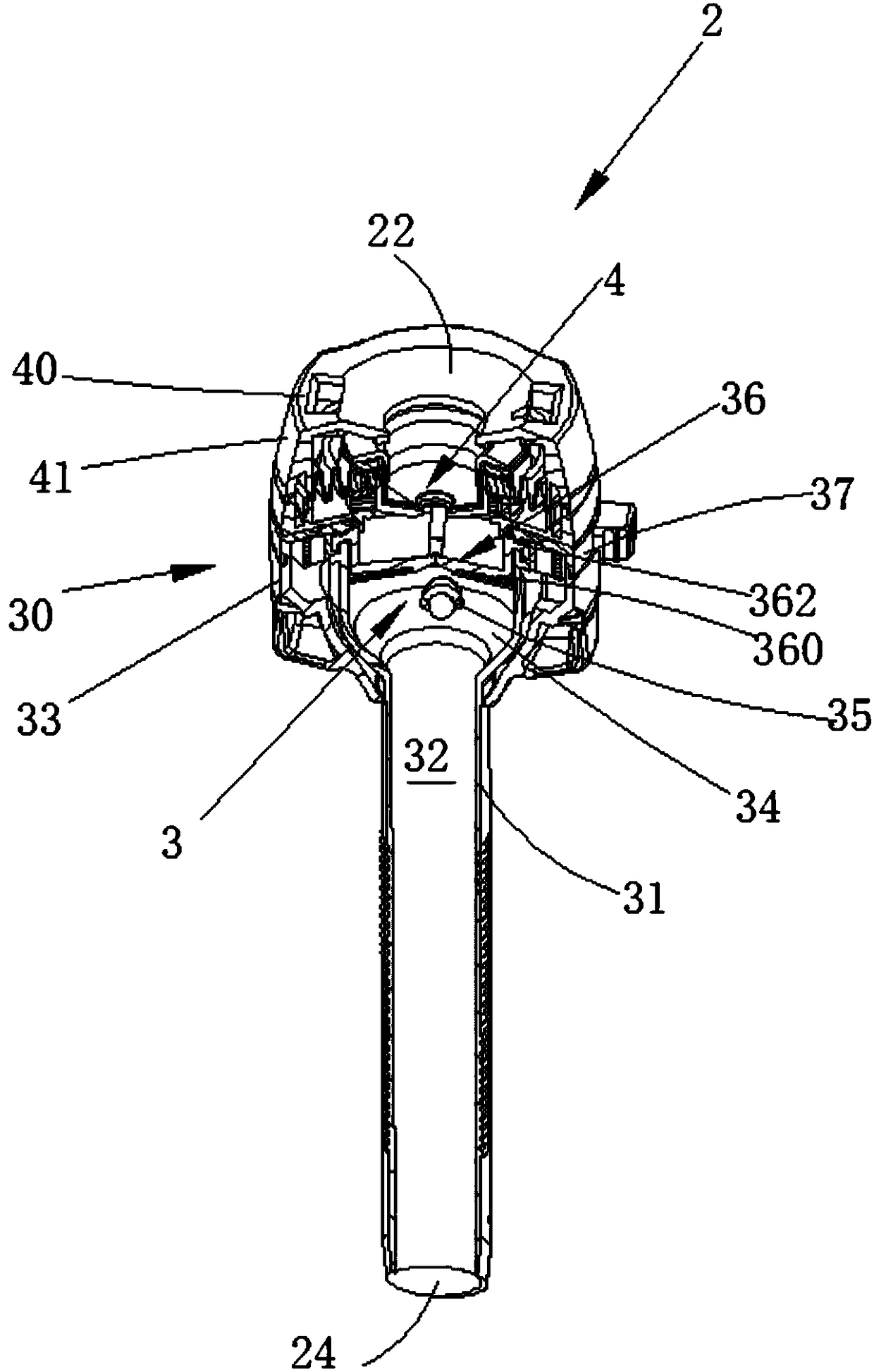

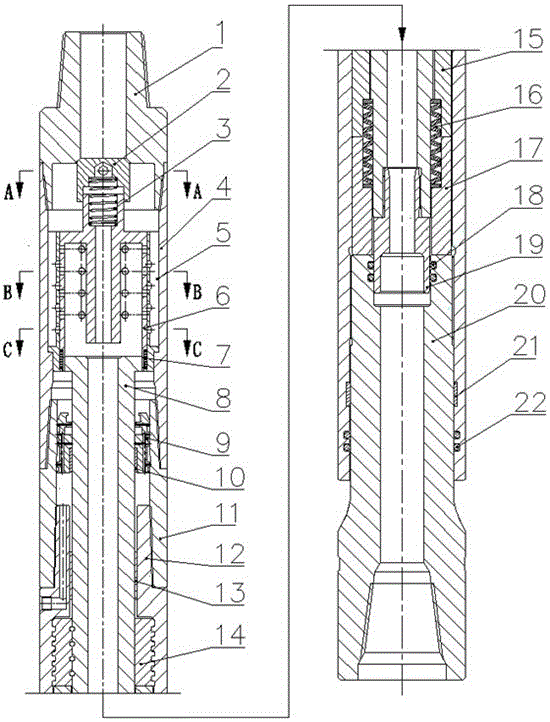

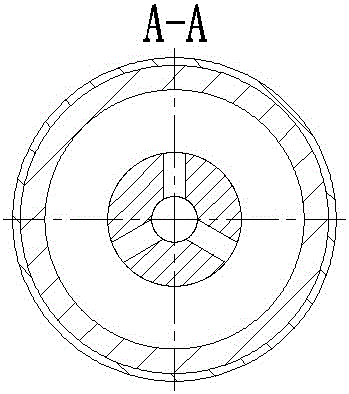

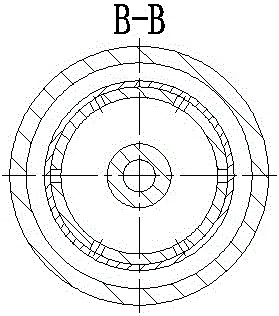

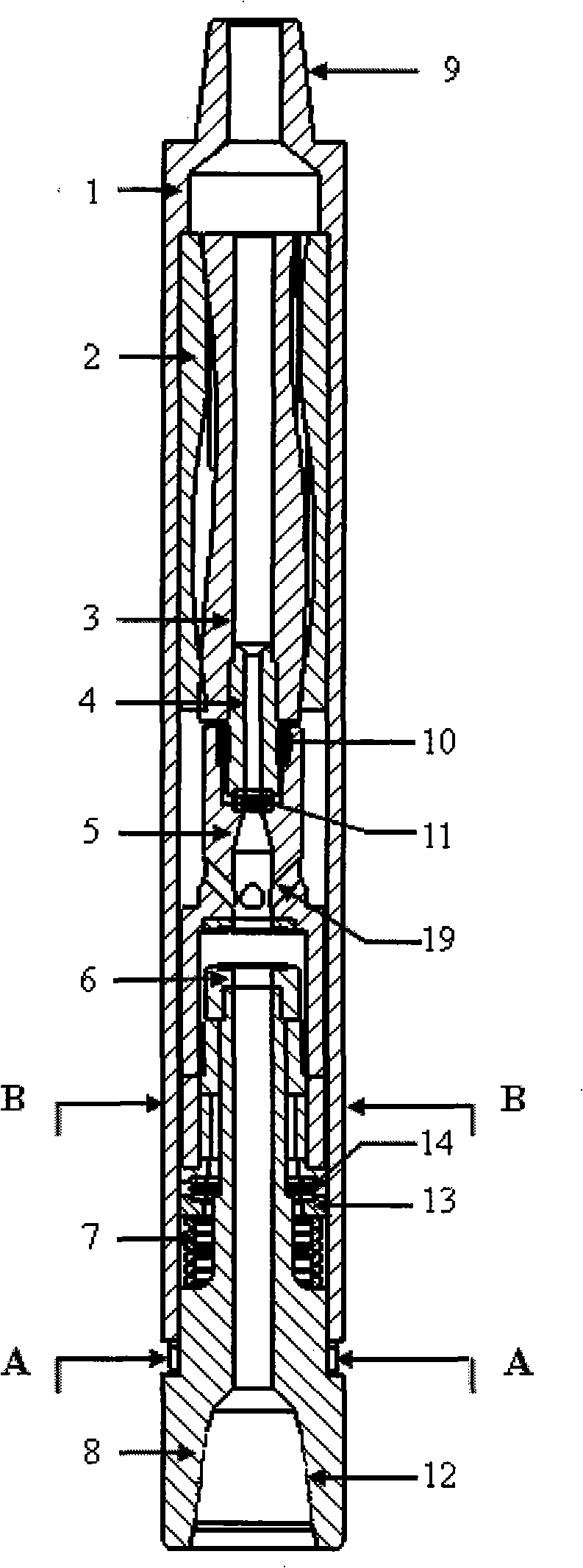

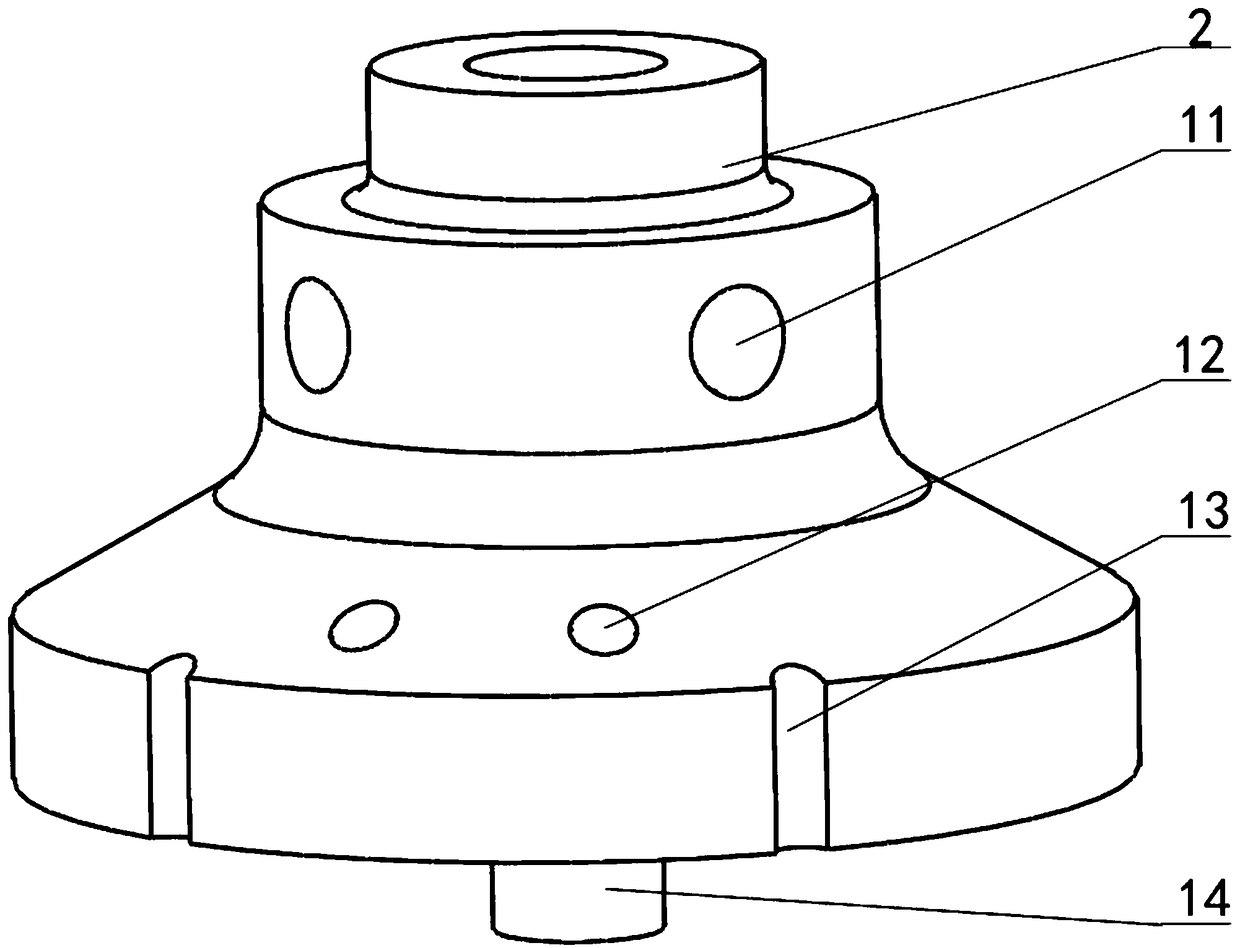

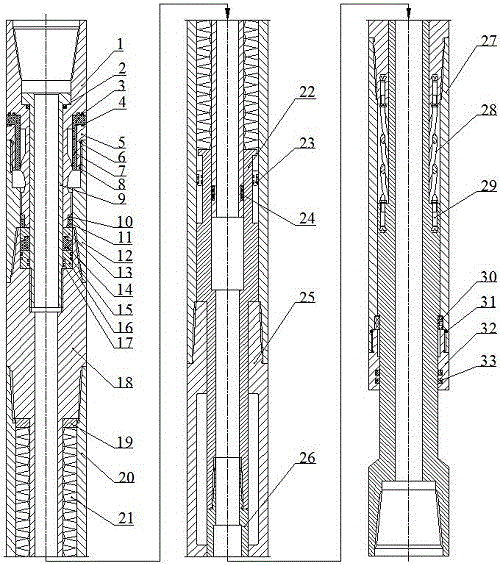

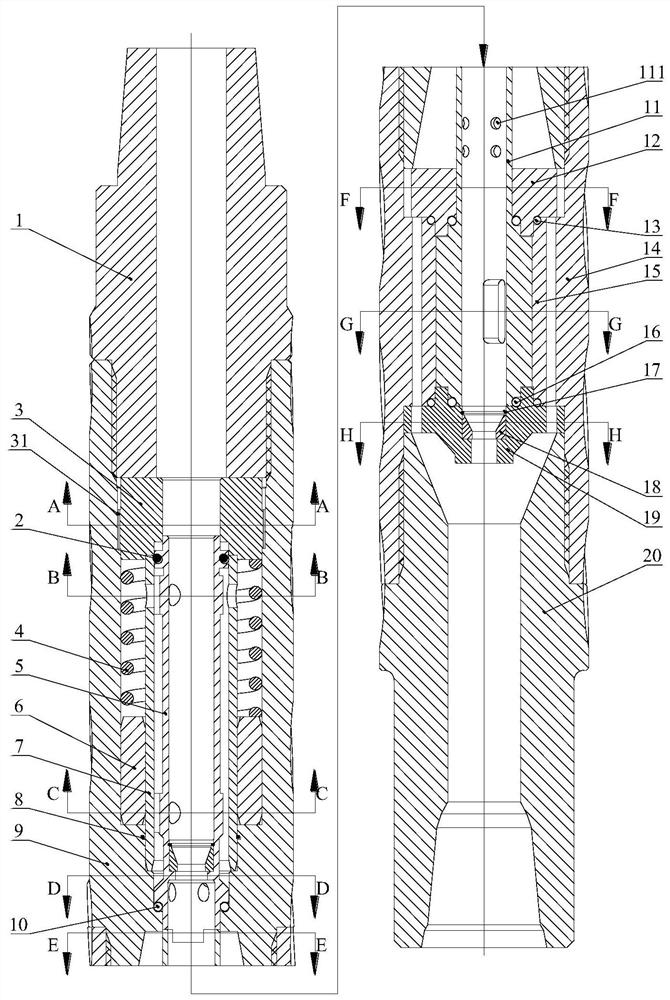

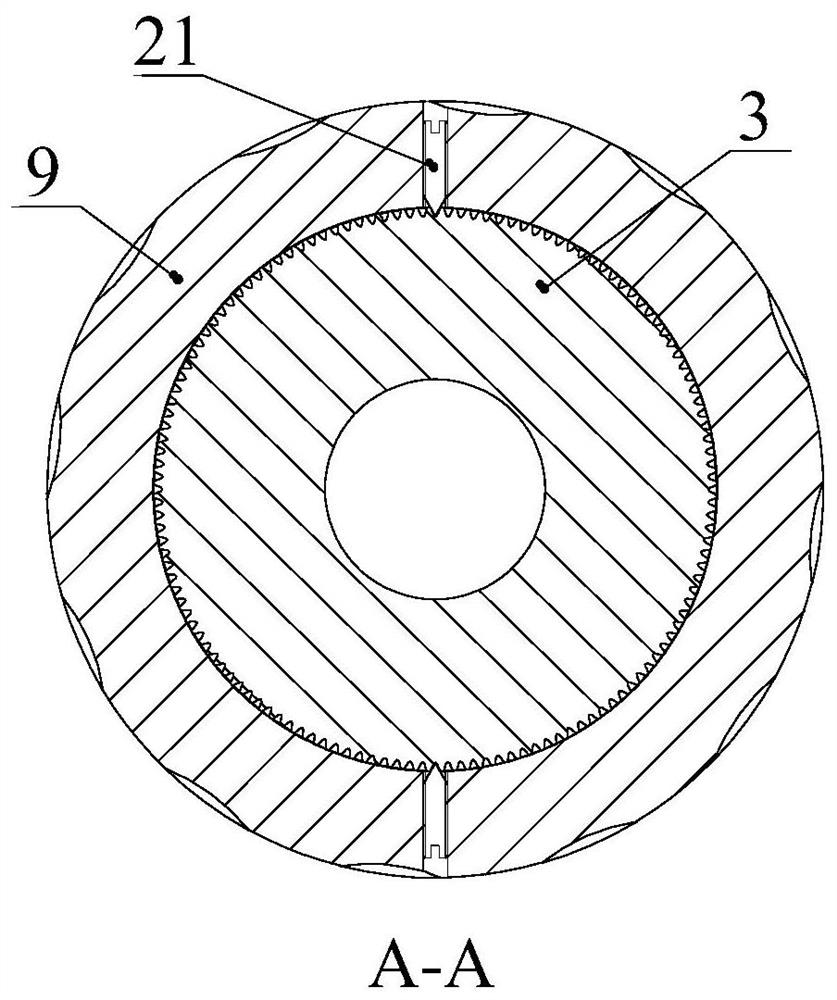

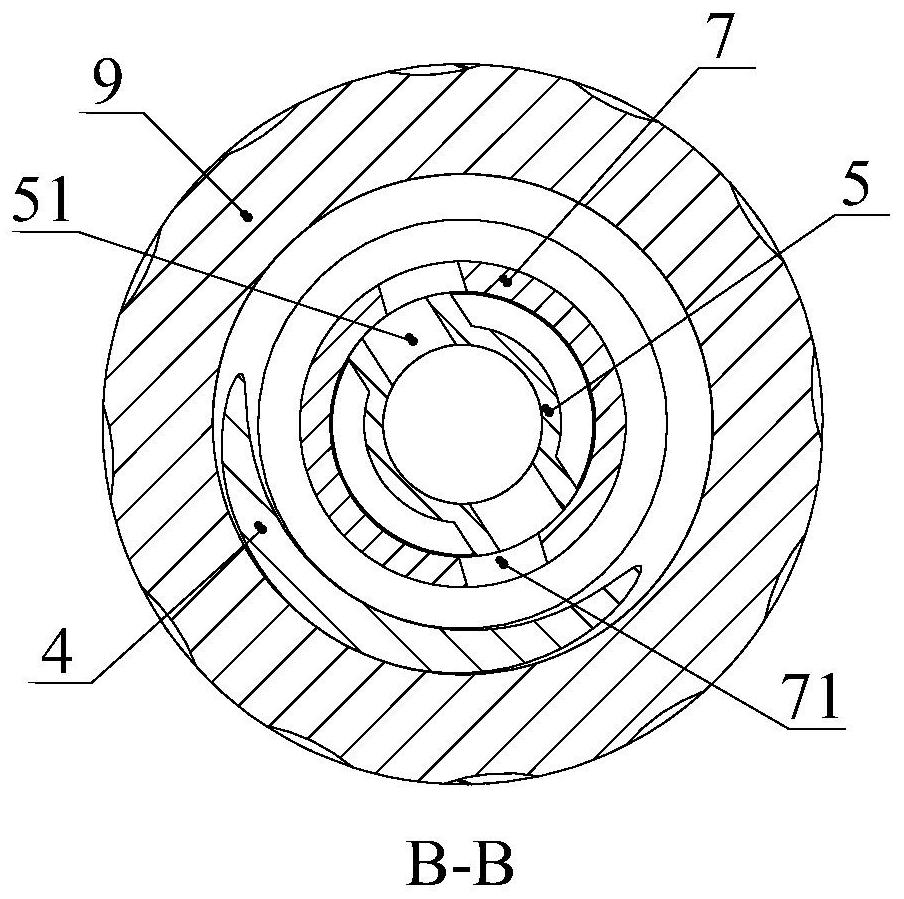

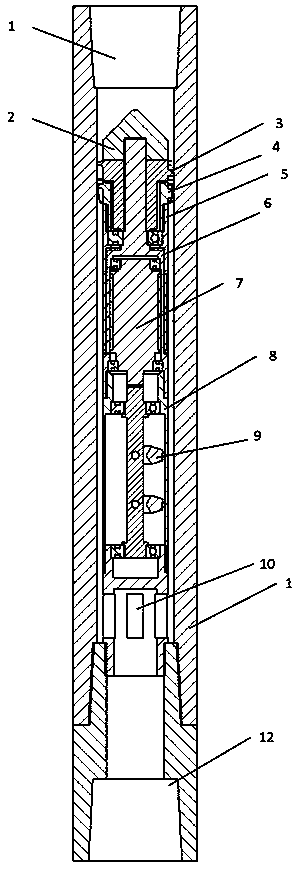

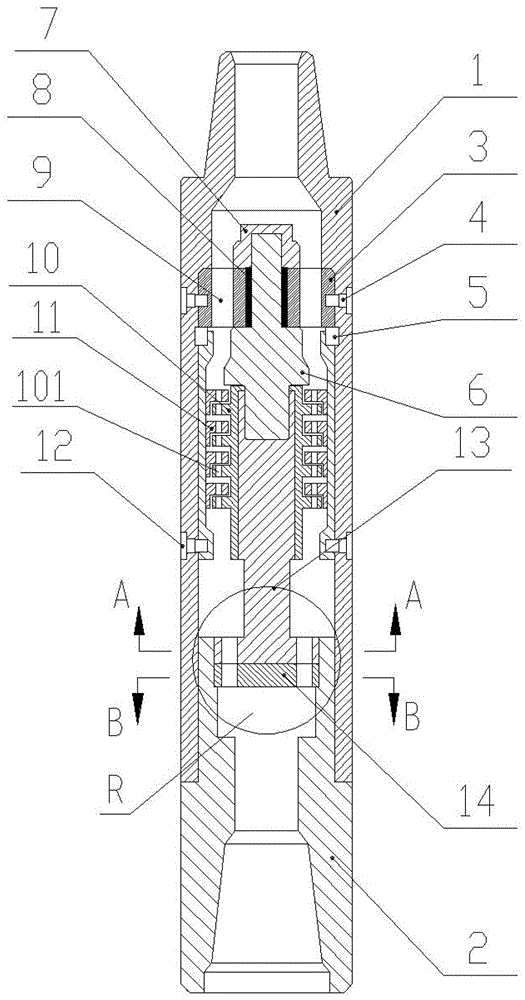

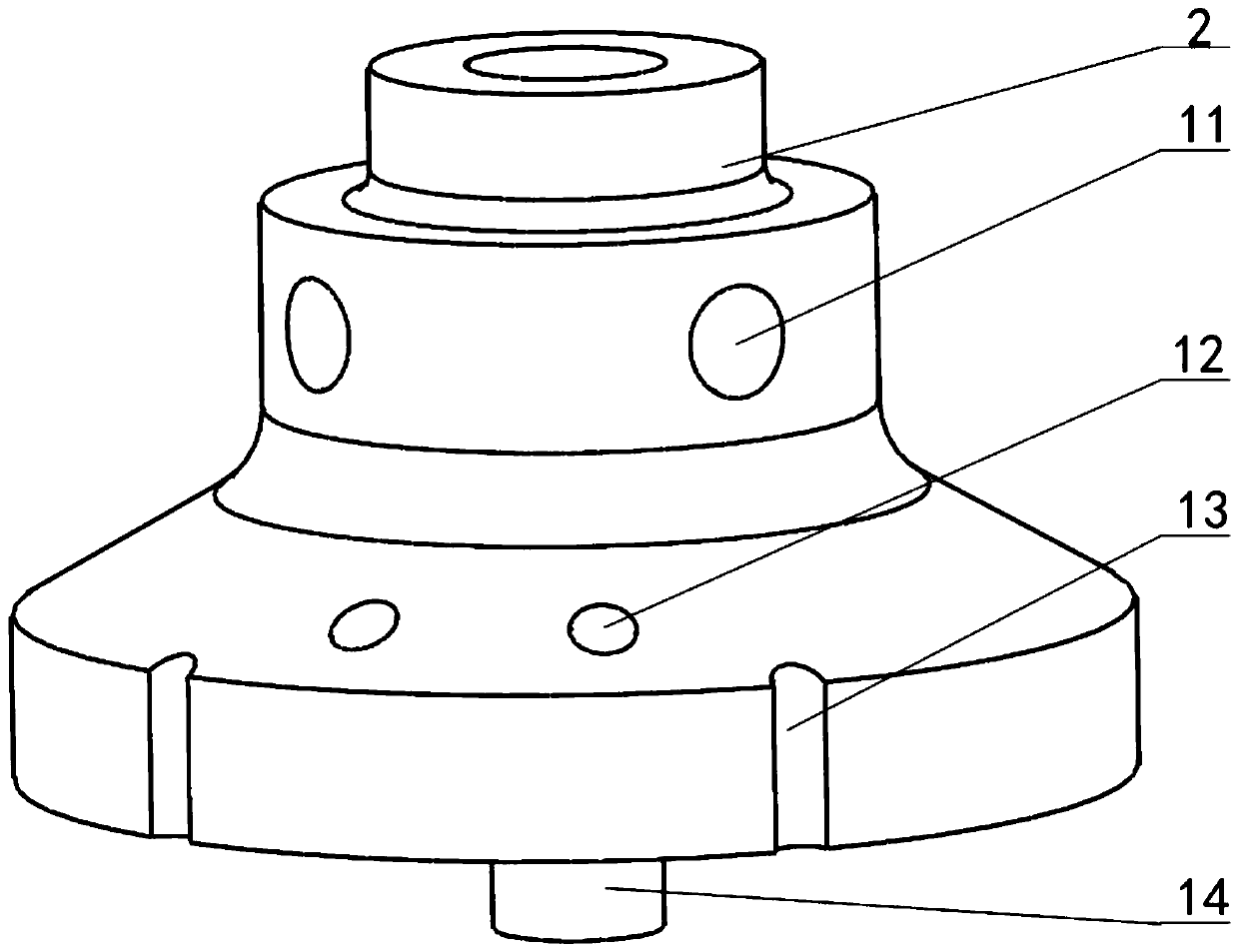

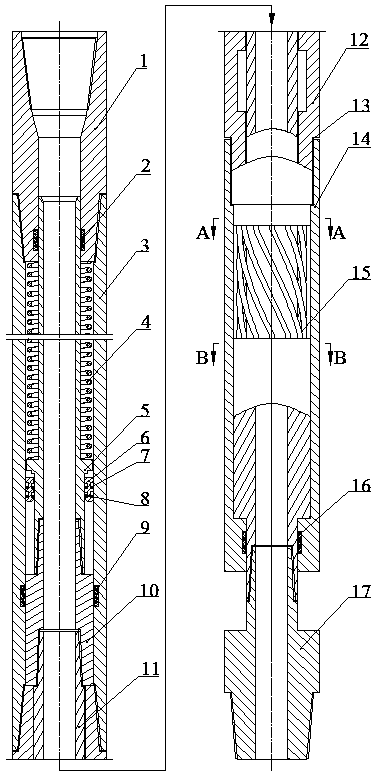

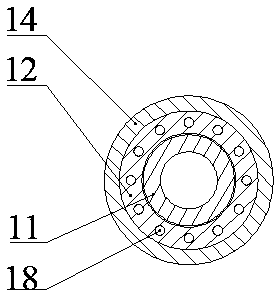

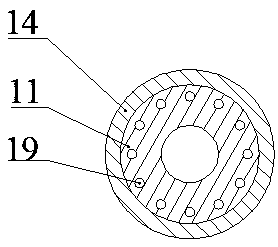

Torsional impact drilling tool

ActiveCN101463709AReduce stick-slipReduce the possibility of failureVibration drillingRate of penetrationDrive shaft

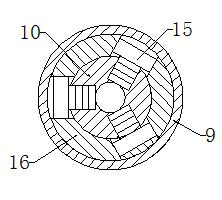

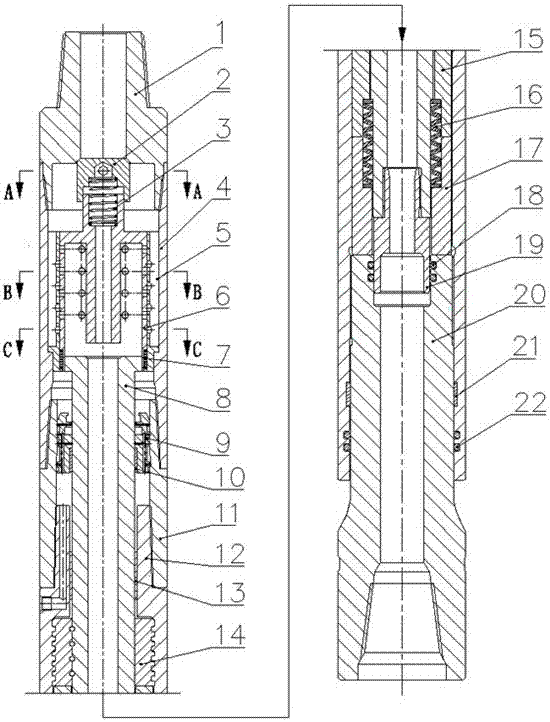

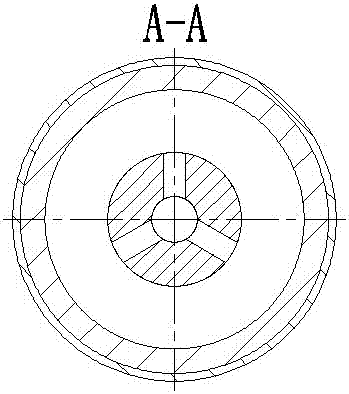

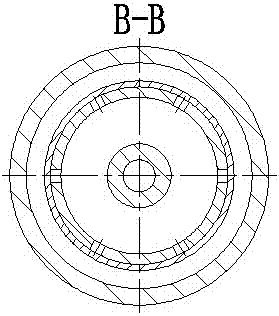

The invention relates to a torsional impact drilling tool used for applying low amplitude high frequency torsional impact to a drill bit during a drilling process, which can increase the drilling efficiency and the service life of the drill bit and lesson the tripping operation and the drilling cost. The technical scheme of the torsional impact drilling tool is as follows: a housing is connected with a short section of a drilling column led into the drill bit by a spline, and is positioned by a shaft shoulder; a screw motor rotor and a screw motor stator form a screw motor, the screw motor rotor is eccentrically connected to a transmission shaft by a universal shaft and two bearings, and four diversion holes are arranged on the transmission shaft; the lower end of the transmission shaft is connected with a carrier with a cavity; a sliding impactor is arranged in the cavity and is fixed by pins, and an impact hammer is arranged in the sliding impactor; a falling prevention ring is connected with the housing by screw threads; and the damping shaft shoulder on the short section of the drilling column led into the drill bit is matched with the impact hammer of the sliding impactor to form a ratchet wheel structure. The torsional impact drilling tool has simple structure, and can be used in hard strata of a deep well; and as being short, the tool is also applicable to the deflecting operation and can be used in crooked well holes, thereby reducing the phenomenon of stick-slip of the drill bit and improving the rate of penetration.

Owner:SOUTHWEST PETROLEUM UNIV

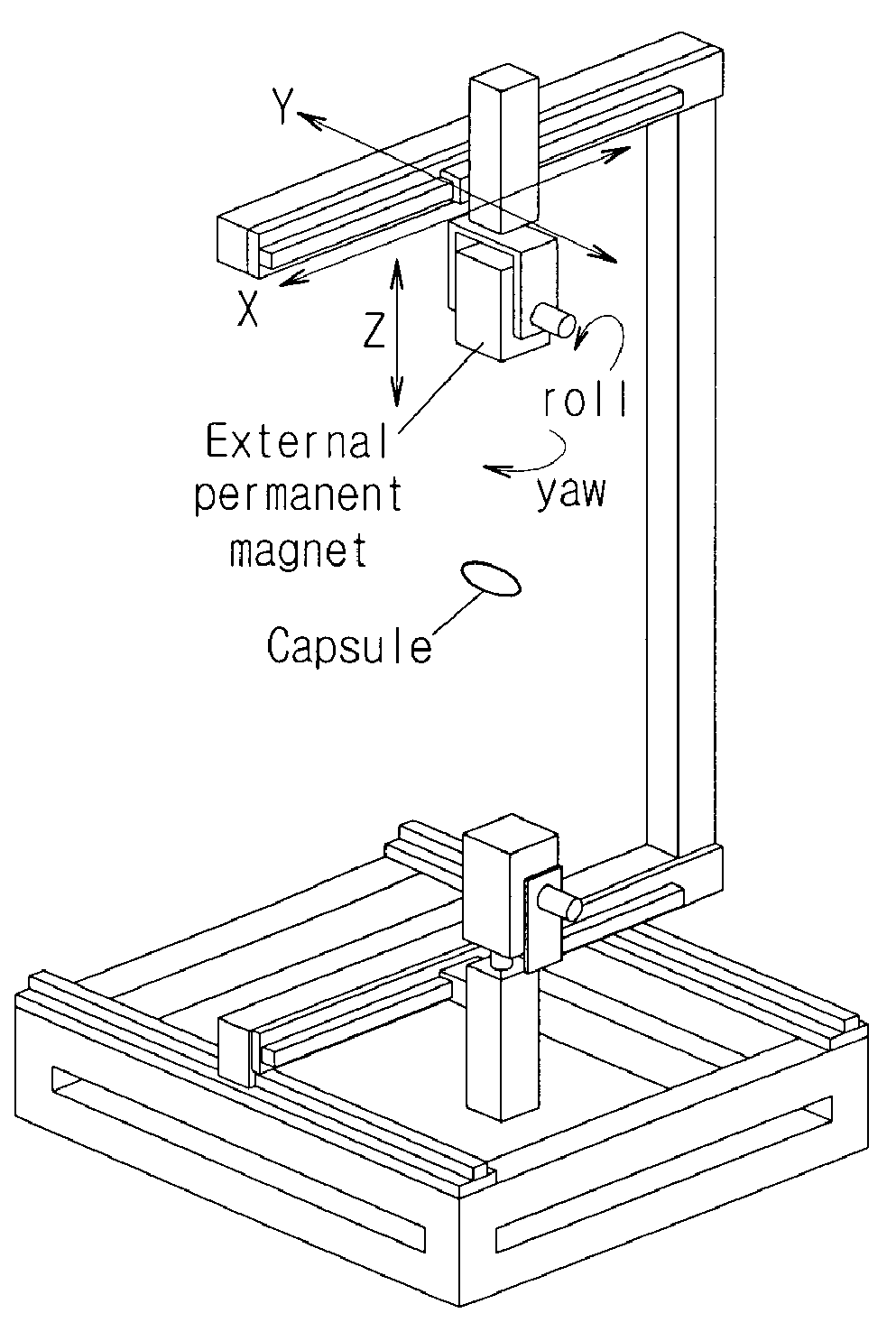

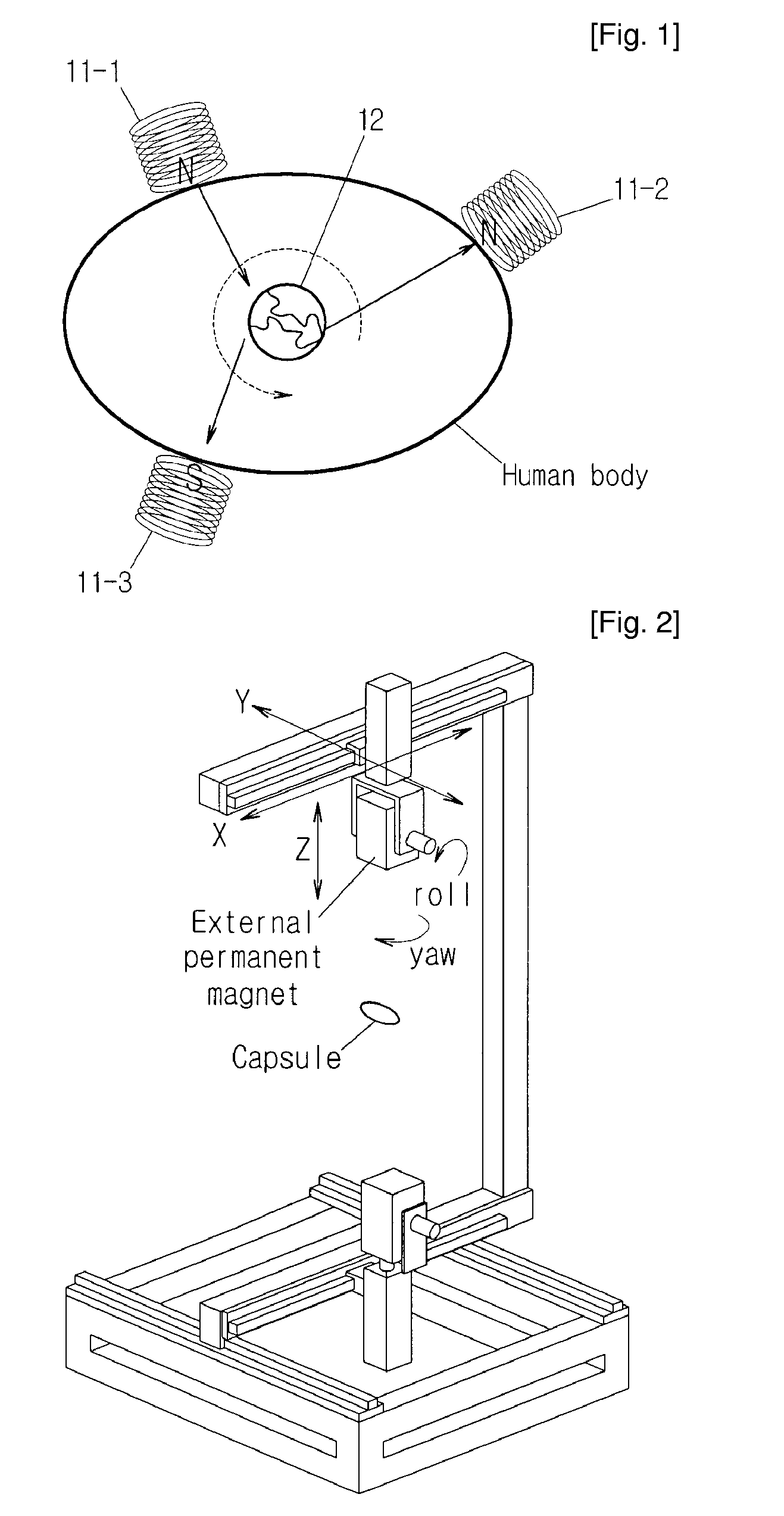

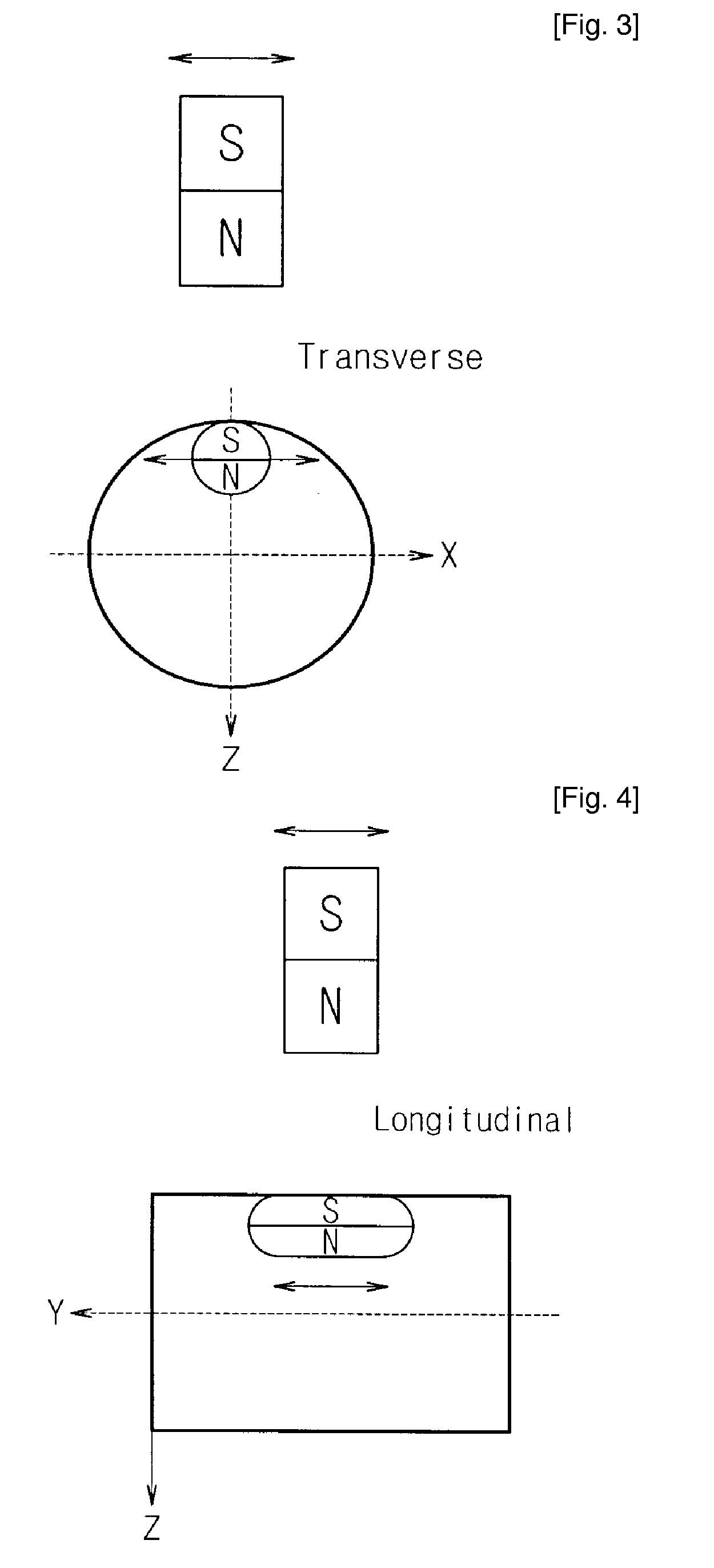

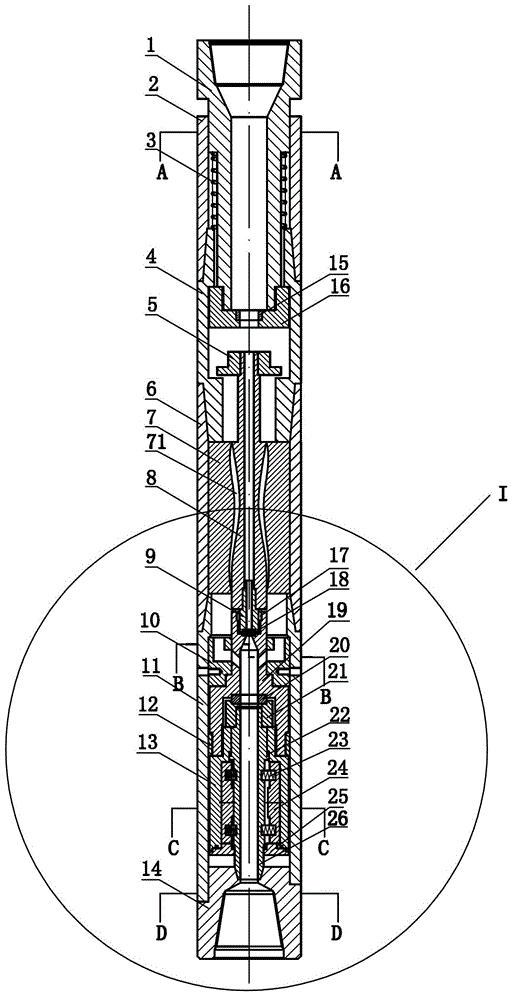

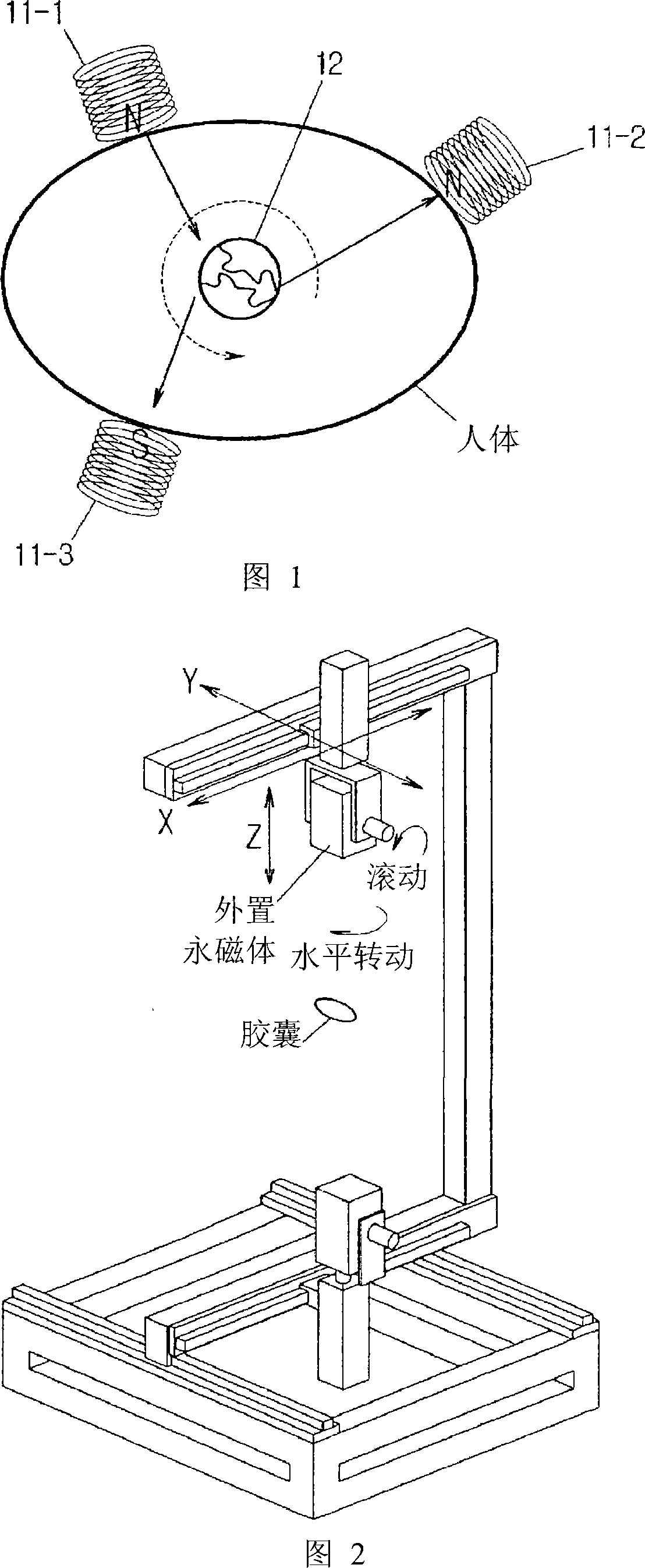

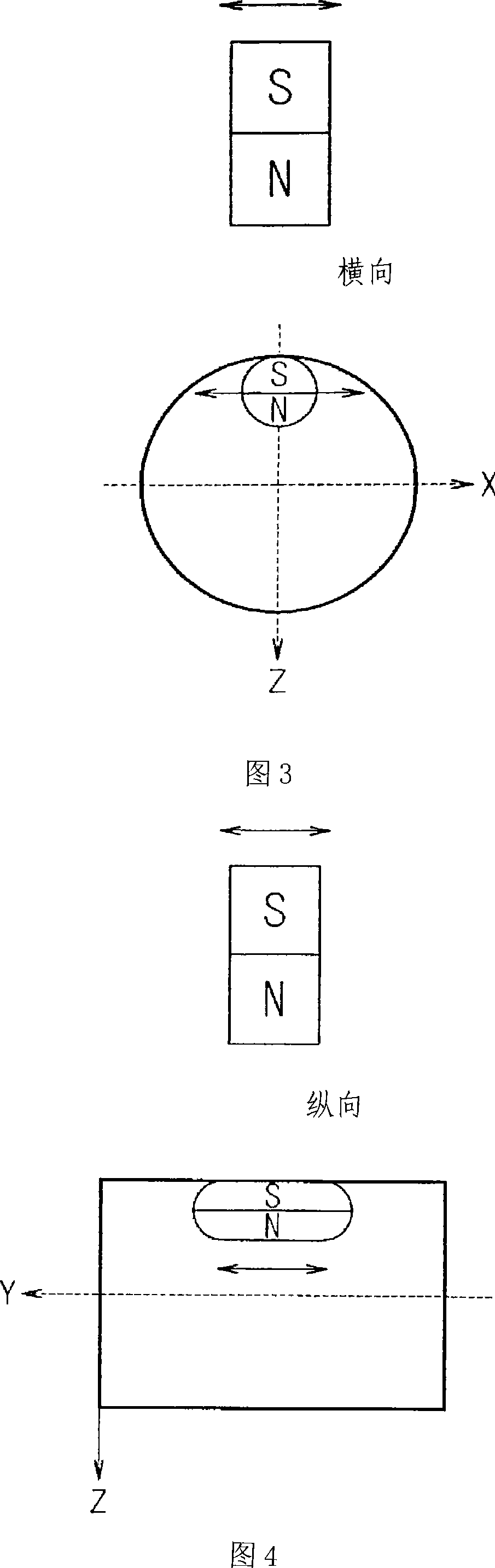

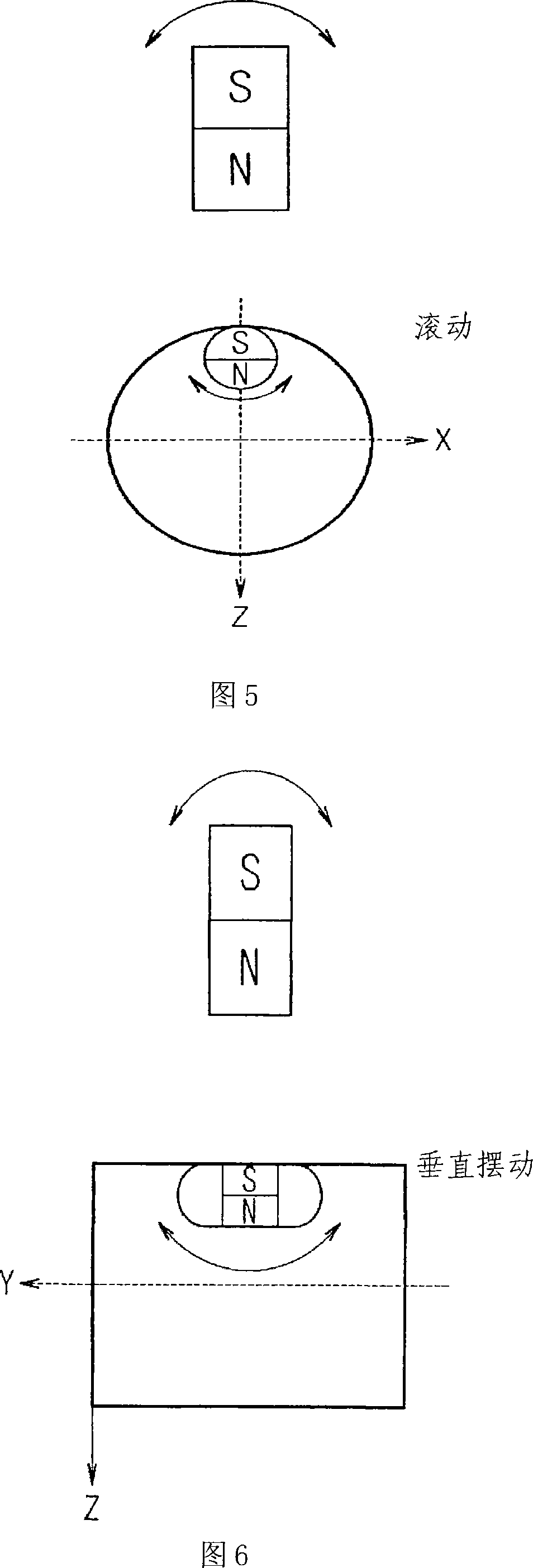

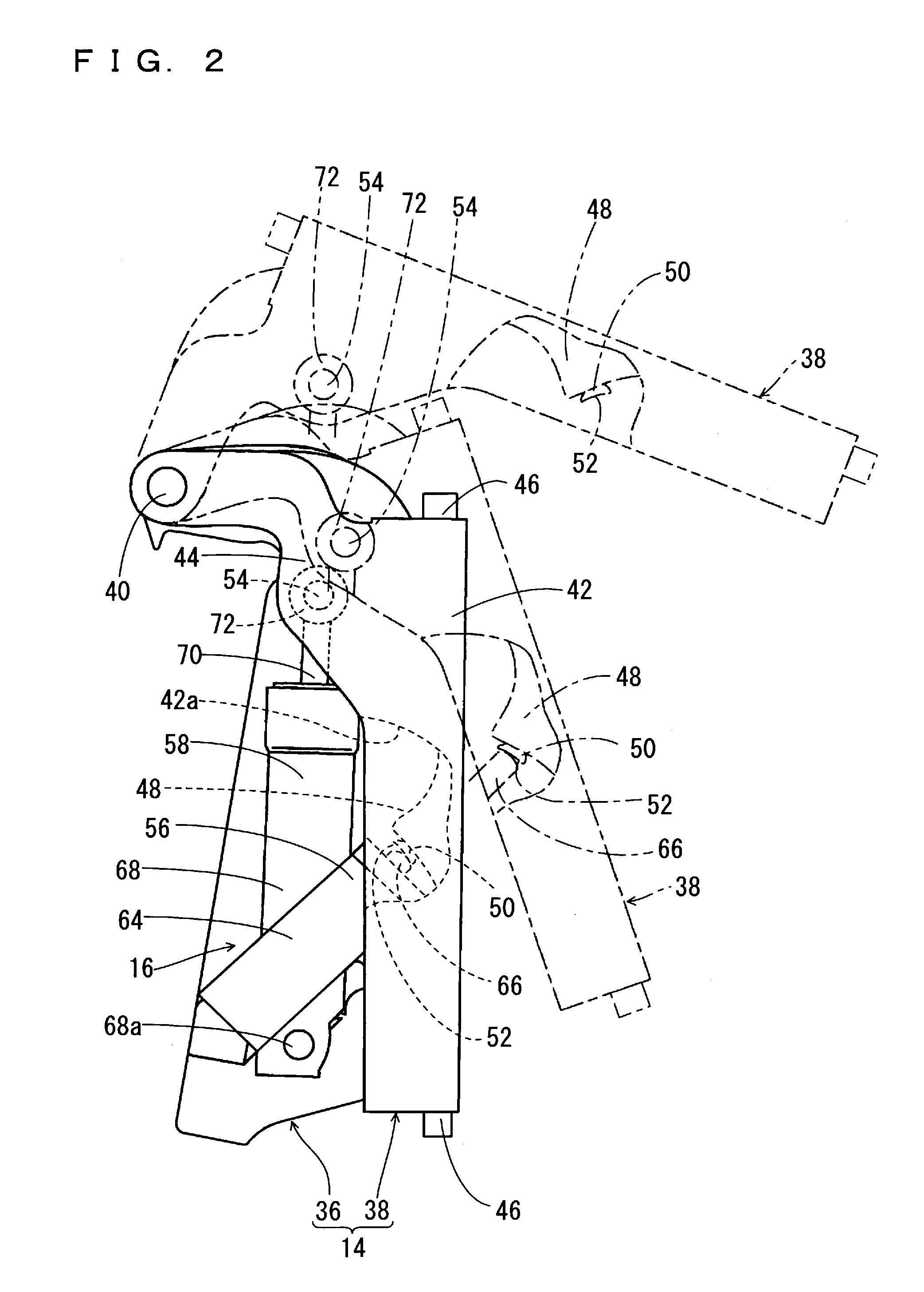

Capsule Type Endoscope Control System

InactiveUS20080300458A1Easy to operateReduce stick-slipEndoscopesDiagnostic recording/measuringMagnetic tension forceWireless transmission

Disclosed is a capsule type endoscope control system which can move to any position, rotate or stop the capsule type endoscope in a human body by a remote control system outside the human body. There is provided a capsule type endoscope control system comprising: a medical capsule equipped with at least one permanent magnet, comprising a wireless transmission circuit for transmitting a series of signals to outside of the body; 2-DOF rotary joint unit for rotating an external permanent magnet in at least two directions, the external permanent magnet applying magnetic magnet forces to the permanent magnets provided in the capsule; a distance sensor for measuring a distance between the external permanent magnet and a surface of the human body; a cartesian coordinate robot for moving the external permanent magnet; a bed for supporting the human body, the bed being able to roll within a certain degree; and a remote control unit outside the human body for controlling operations of the 2-DOF rotary joint unit, the bed and the cartesian coordinate robot.

Owner:KOREA INST OF SCI & TECH

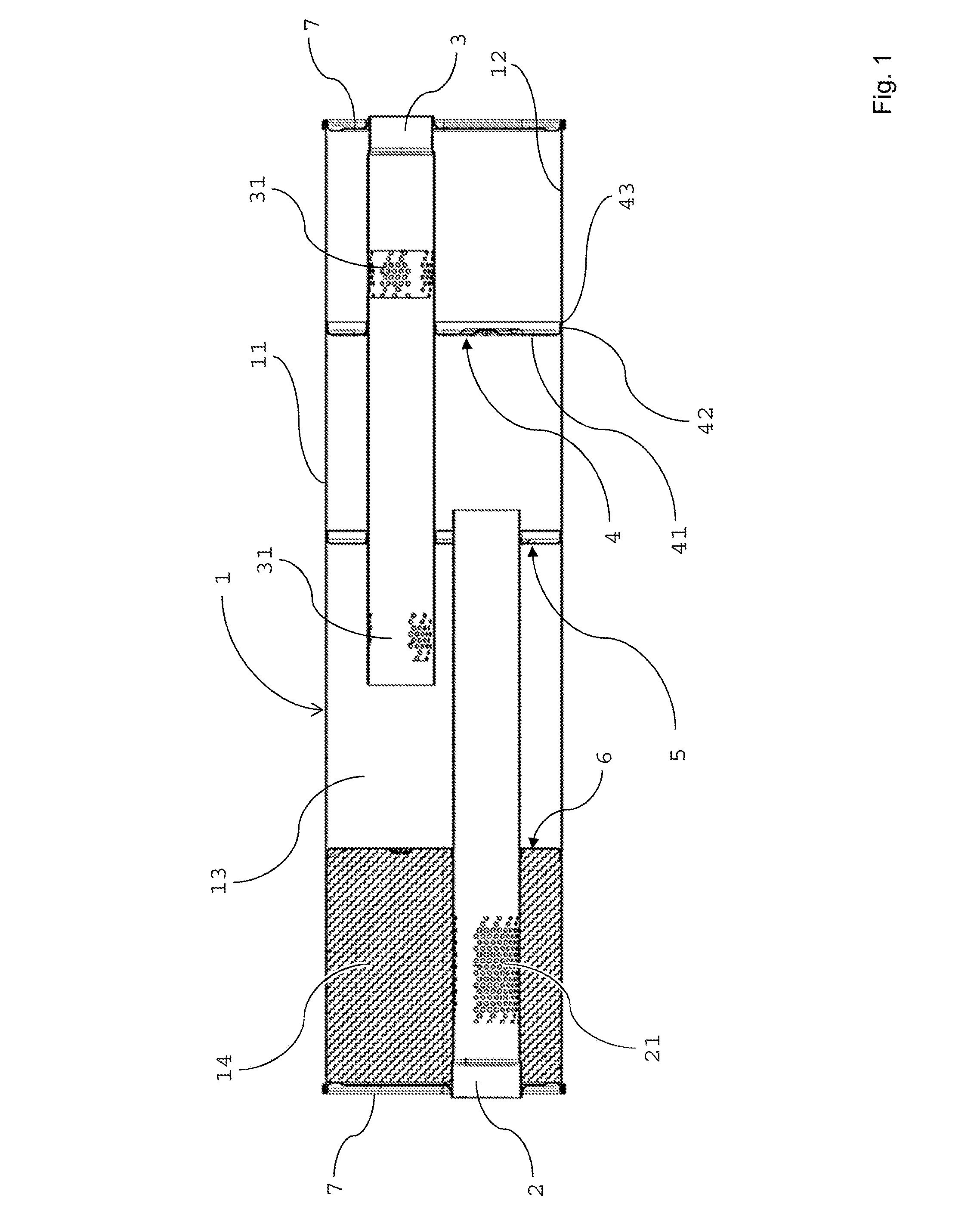

Compound vibrating well-drilling tool

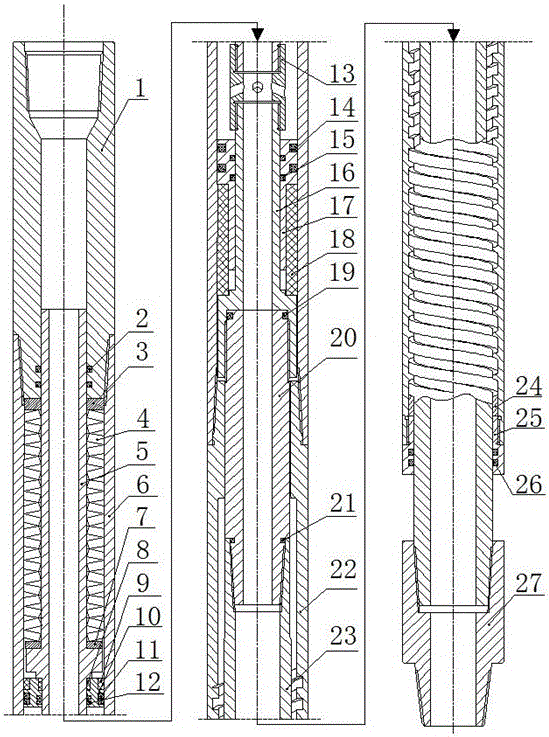

ActiveCN102747958AEliminate \"drag\"Eliminates \"stick-slip\" phenomenonVibration drillingHydraulic cylinderWell drilling

The invention discloses a compound vibrating well-drilling tool which comprises a sleeve, a vibrating short joint, a vibrating short joint chuck, a screw motor, a conversion short joint connected with the lower end of the screw motor, an annular disc sleeved at the upper end of the conversion short joint, a hydraulic cylinder installed at the lower end of the conversion short joint, an impact short joint arranged in an inner cavity of the hydraulic cylinder and a torque transmitting short joint, wherein the vibrating short joint, the vibrating short joint chuck, the screw motor, the conversion short joint, the annular disc, the hydraulic cylinder, the impact short joint and the torque transmitting short joint are arranged in sequence from top to bottom. The well-drilling tool can be installed at different positions in a well-drilling column, the drilling column generate axial and circumferential high frequency compound vibration through the tool, and phenomena including 'pulling press' and 'stick slip' in the large-inclination well drilling process are eliminated, thereby remarkably improving mechanical drilling speed, prolonging the service life of a drill bit and reducing well-drilling cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Capsule type endoscope control system

InactiveCN101001563AAvoid damageControl movementEndoscopesDiagnostic recording/measuringMagnetic tension forceWireless transmission

Disclosed is a capsule type endoscope control system which can move to any position, rotate or stop the capsule type endoscope in a human body by a remote control system outside the human body. There is provided a capsule type endoscope control system comprising: a medical capsule equipped with at least one permanent magnet, comprising a wireless transmission circuit for transmitting a series of signals to outside of the body; 2-DOF rotary joint unit for rotating an external permanent magnet in at least two directions, the external permanent magnet applying magnetic forces to the permanent magnets provided in the capsule; a distance sensor for measuring a distance between the external permanent magnet and a surface of the human body; a cartesian coordinate robot for moving the external permanent magnet; a bed for supporting the human body, the bed being able to roll within a certain degree; and a remote control unit outside the human body for controlling operations of the 2-DOF rotary joint unit, the bed and the cartesian coordinate robot.

Owner:KOREA INST OF SCI & TECH

Puncturing device, sealing assembly and sealing film for puncturing device

InactiveCN108652712AIncreasing the thicknessIncrease tensile stiffnessCannulasSurgical needlesHermetic sealEngineering

The invention discloses a sealing film for a puncturing device. The sealing film includes a proximal opening, a distal opening and a sealing wall extending from the distal opening to the proximal opening. The distal opening is formed by a sealing lip for accommodating an inserted apparatus and forming hermetic seal. The sealing wall includes a proximal surface facing towards the proximal opening and a distal surface deviating from the proximal opening. The sealing wall is provided with a plurality of protruding portions, the protruding portions extend radially from the distal opening to the proximal opening, the thickness of the protruding portions is greater than the average thickness of the sealing wall, and the protruding portions are disposed on the distal surface and / or disposed on the proximal surface. The protruding portions disposed on the distal surface increase the thickness of a local area of the distal surface, increase the tensile rigidity of the sealing film in the axialdirection, and reduce the true contact area between an instrument and the sealing film, therefore the frictional resistance and stick slip are reduced, and at the same time, the probability of occurrence of sealing film introversion is reduced.

Owner:FENGH MEDICAL CO LTD

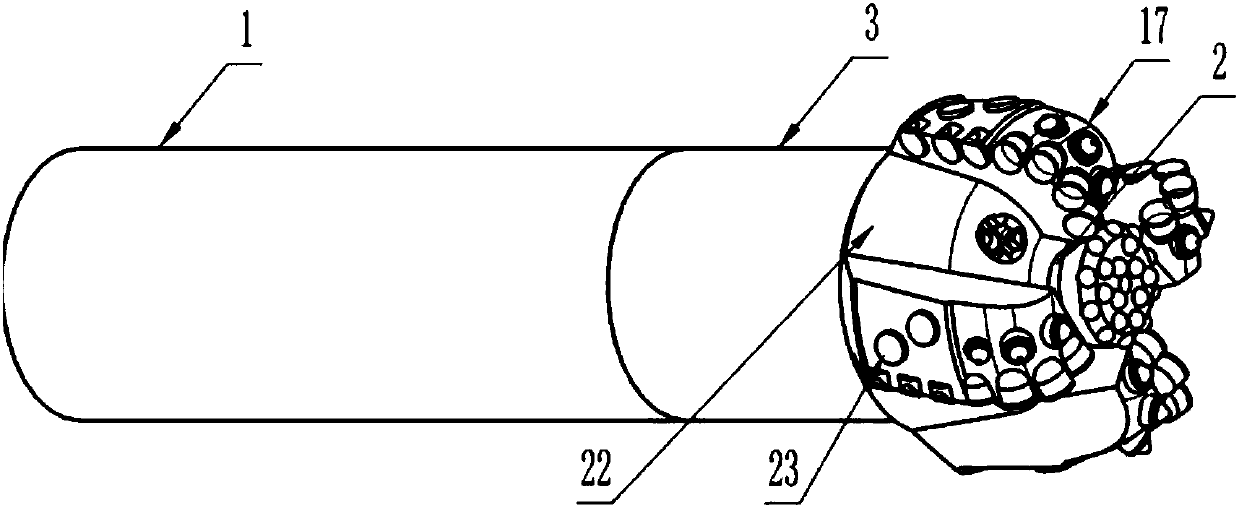

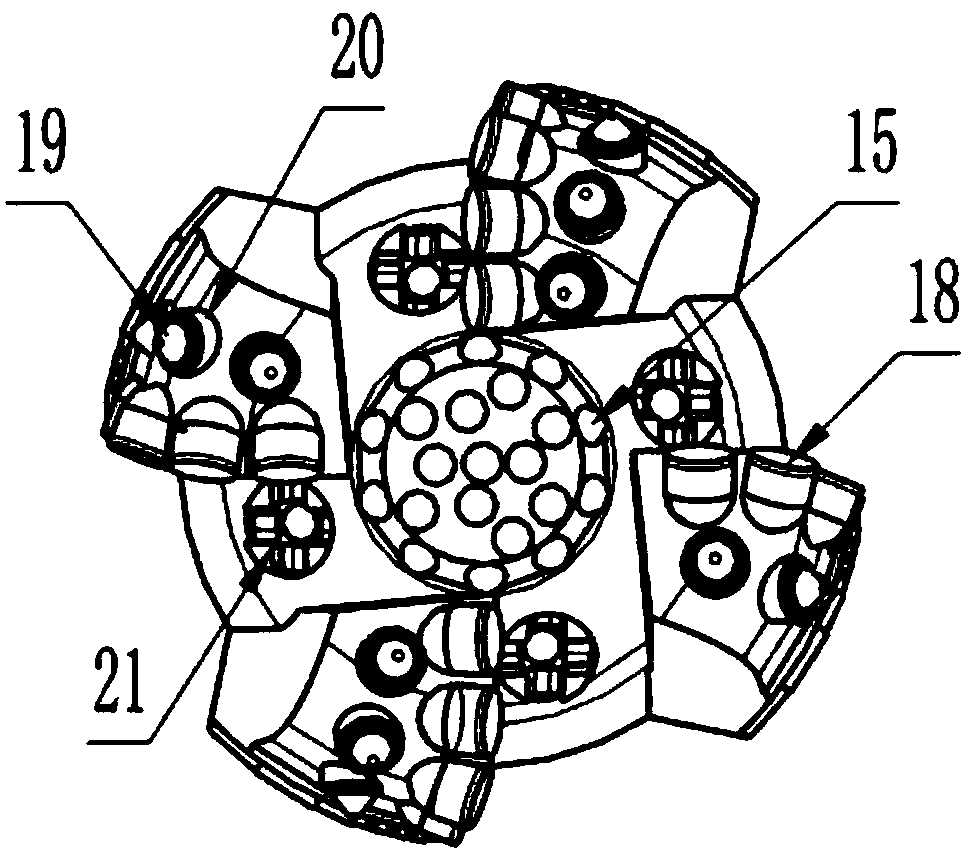

Punching-shear composite drill bit for hard rock drilling

ActiveCN107842317AReduced compressive strengthLow shear strengthDrill bitsTectonic stressPre cracking

The invention discloses a punching-shear composite drill bit for hard rock drilling. The punching-shear composite drill bit comprises three parts of an impactor, an internal punching bore bit and an external cutting drill bit, a lower joint of the impactor can be in threaded connection with the external cutting drill bit, and the upper part of the internal punching bore bit is connected with the impactor in a spline mode; and the lower end face of the internal punching bore bit extends out of the surface of the external cutting drill bit, the central axis of the internal punching bore bit is parallel to or coincident with the central axis of the external cutting drill bit, distributed teeth on the internal punching bore bit and distributed teeth on the external cutting drill bit are combined and can completely cover a downhole, and distributed teeth on the internal punching bore bit and the distributed teeth on the external cutting drill bit are independent of each other. In this way,rock crushing through shearing and rock crushing through impact are creatively combined together, a rock stratum at the hole bottom is pre-cracked first through the internal punching bore bit, the whole tectonic stress of the rock stratum is destroyed, the strength of compression resistance and shearing resistance of rock is reduced so that PDC column teeth and PDC cone teeth can more easily cut / plough-cut the rock, and the rock-breaking efficiency of the super hard rock stratum is greatly improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

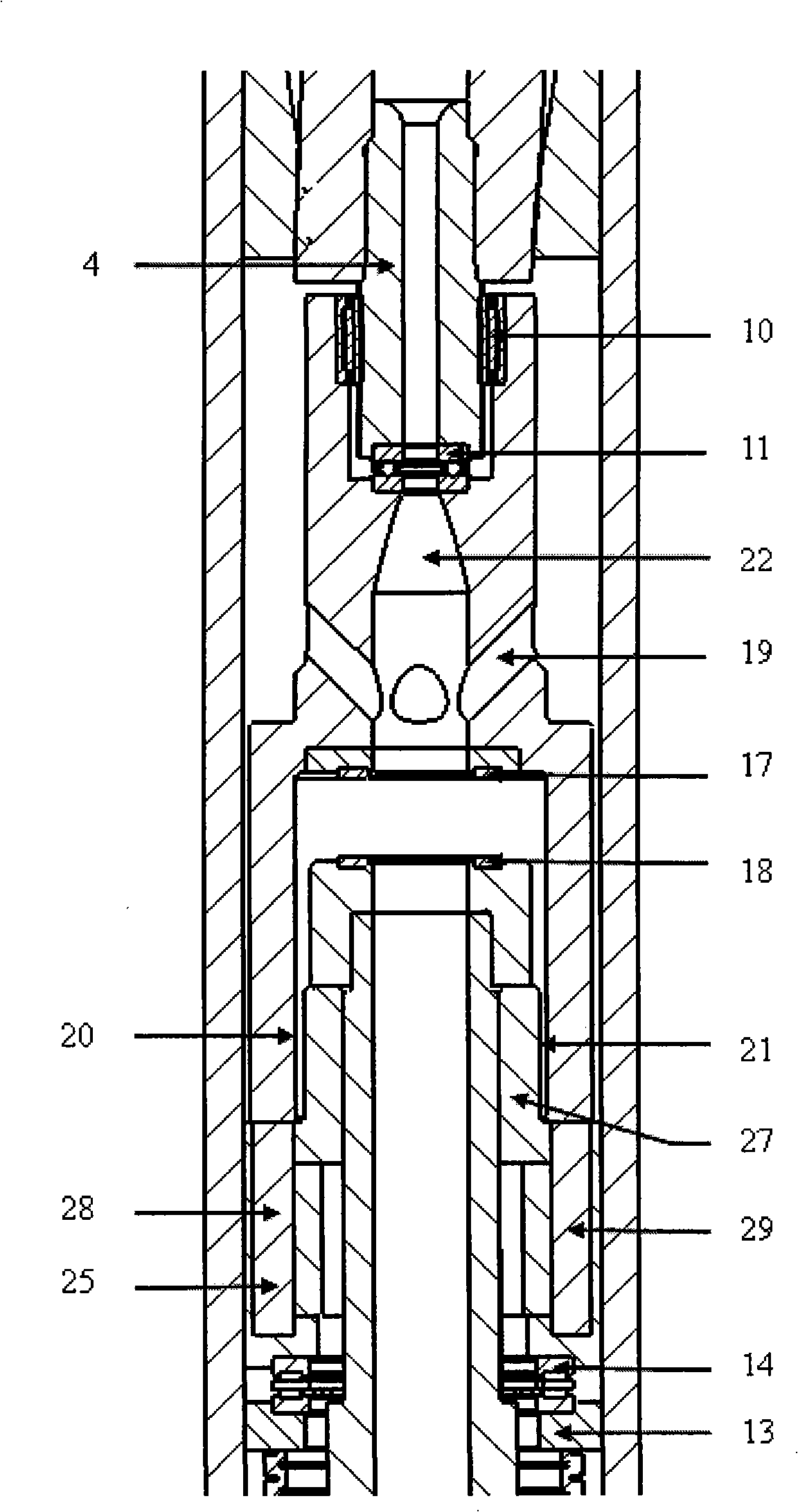

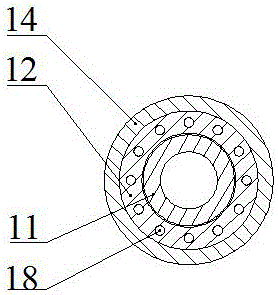

Jet type torsional impact drilling tool

ActiveCN103774983AIncreased torque averageReduce stick-slipReciprocating drilling machinesConstructionsWorking lifeWell drilling

The invention relates to a jet type torsional impact drilling tool. The jet type torsional impact drilling tool comprises an upper connector, an outer shell, a float valve, a valve seat spreader plate, a jet element, a jet spreader plate, a punch hammer, an impact transmission cylinder and a spring. The upper connector is fixedly connected with the outer shell, the outer shell is fixedly connected with the impact transmission cylinder, the float valve, the valve seat spreader plate, the jet element, the jet spreader plate and the spring are located in the outer shell, and the punch hammer is arranged in the transmission cylinder. According to the jet type torsional impact drilling tool, the attachment jet element generates alternating jet to drive the punch hammer to swing left and right, and the punch hammer collides with and impacts on the transmission cylinder to make underground torque greatly fluctuate; compared with a conventional drilling mode, the mean value of the torque of an underground drill bit is increased, the torque of the underground drilling tool is made to greatly fluctuate at high frequency in the drilling process, the stick slip phenomenon of the drill bit is alleviated, the probability of bit bouncing is reduced, and drilling efficiency is improved. The drilling tool is fewer in movable parts and quick-wear parts, long in normal work life, and high in safe reliability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

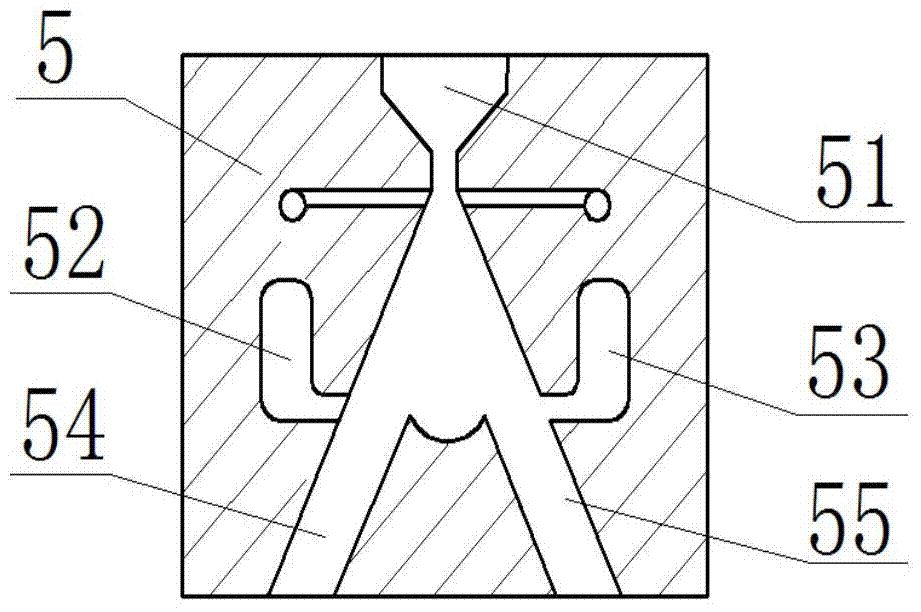

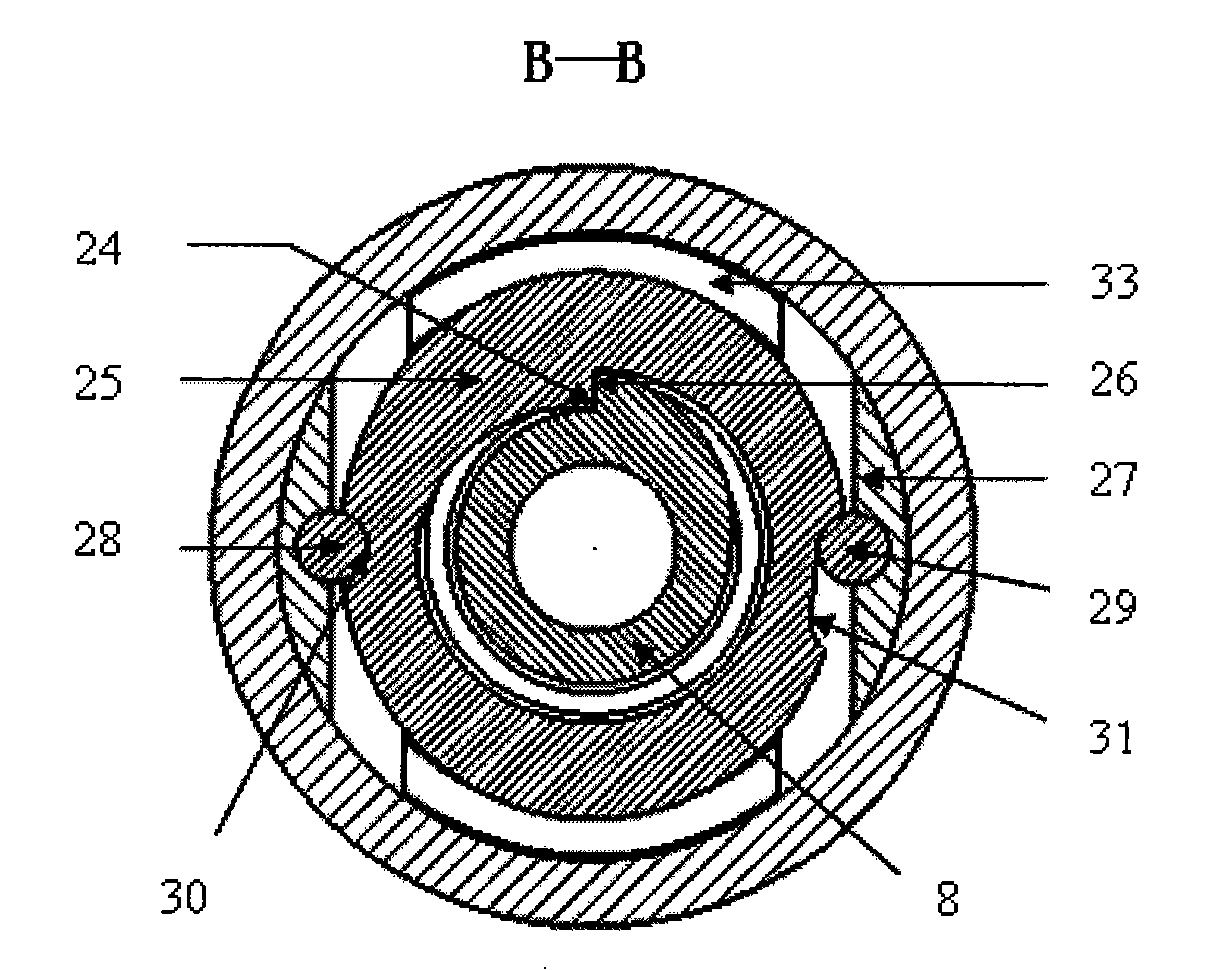

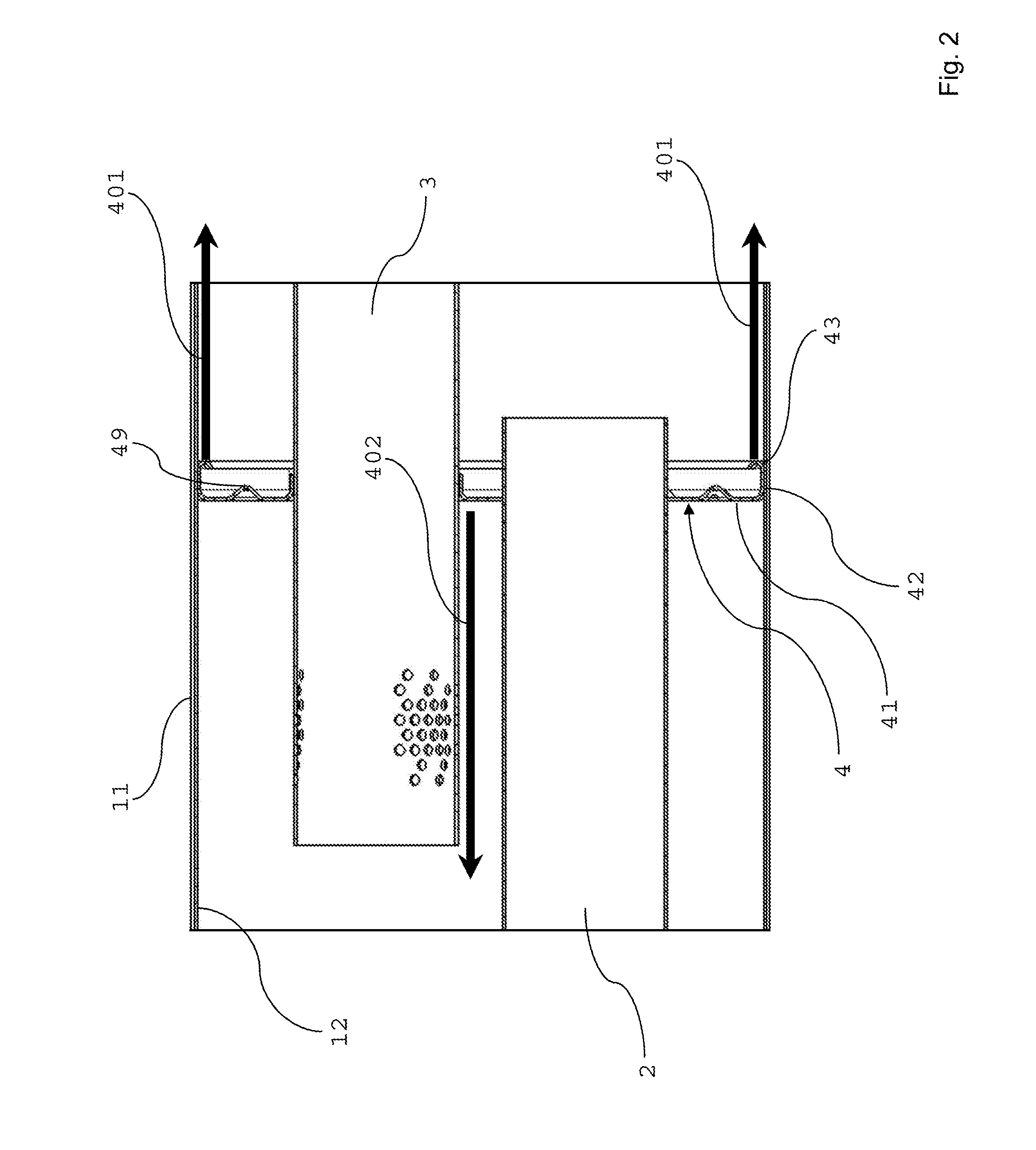

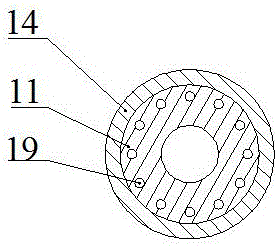

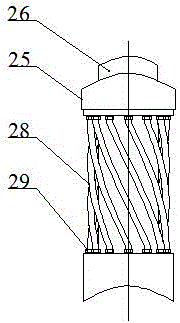

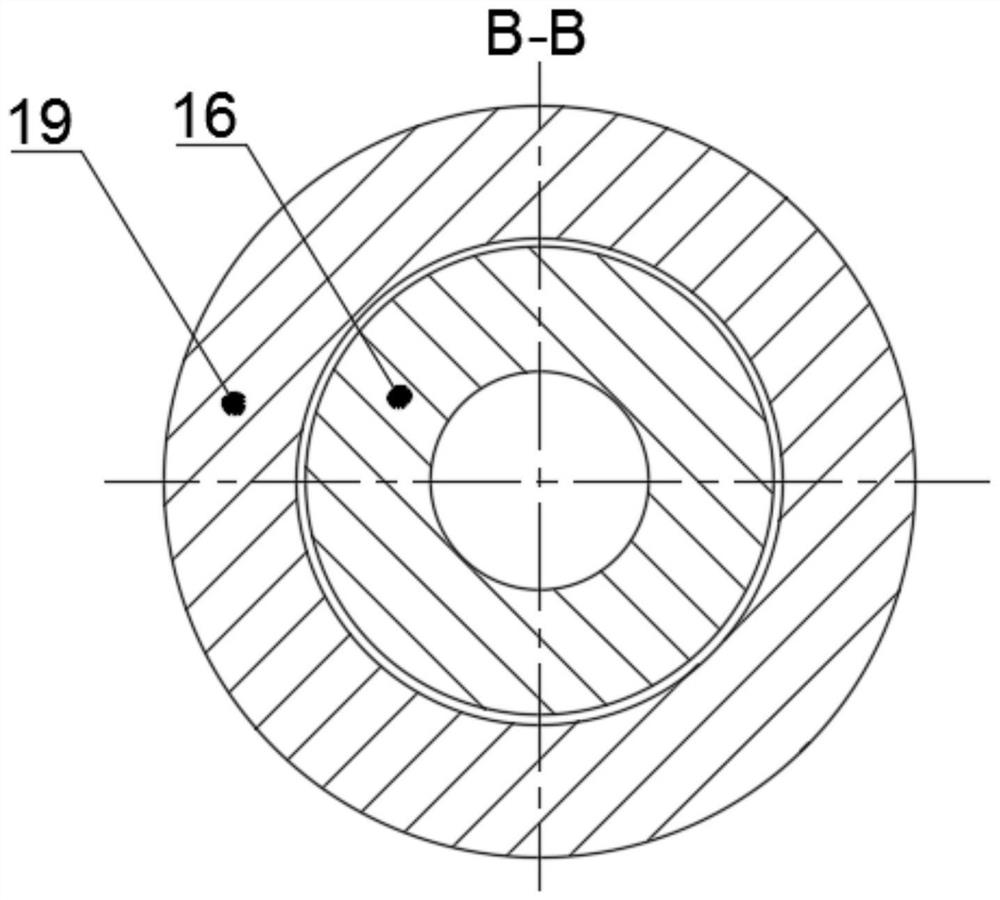

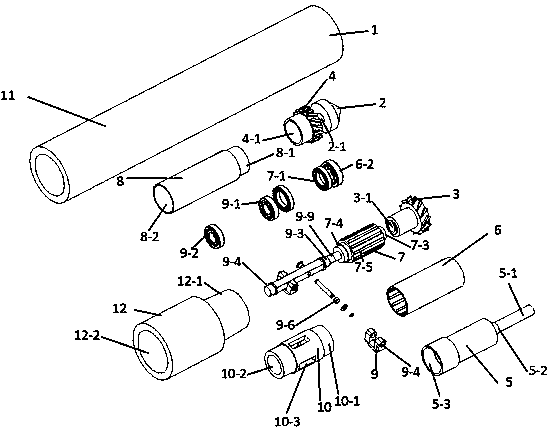

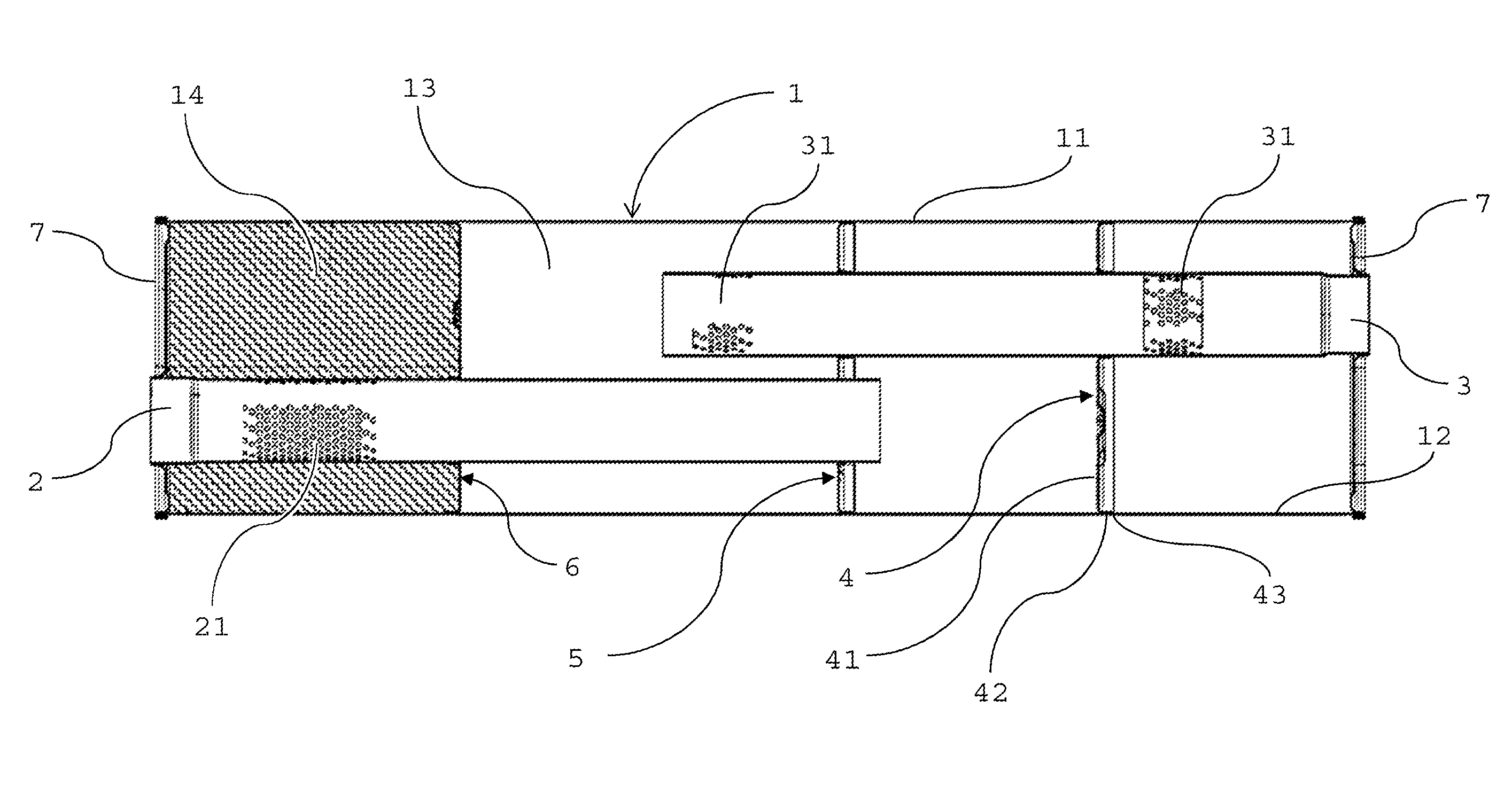

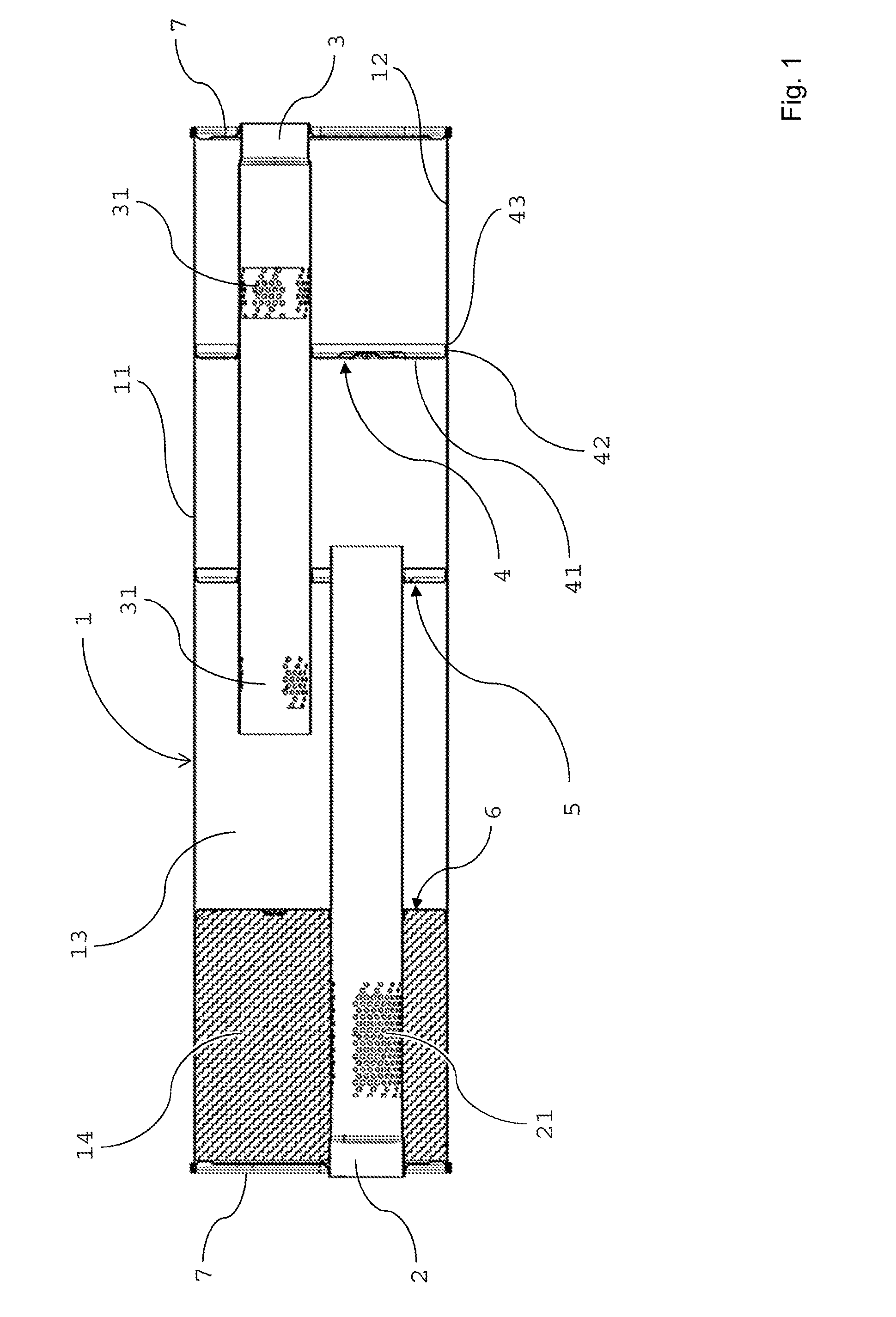

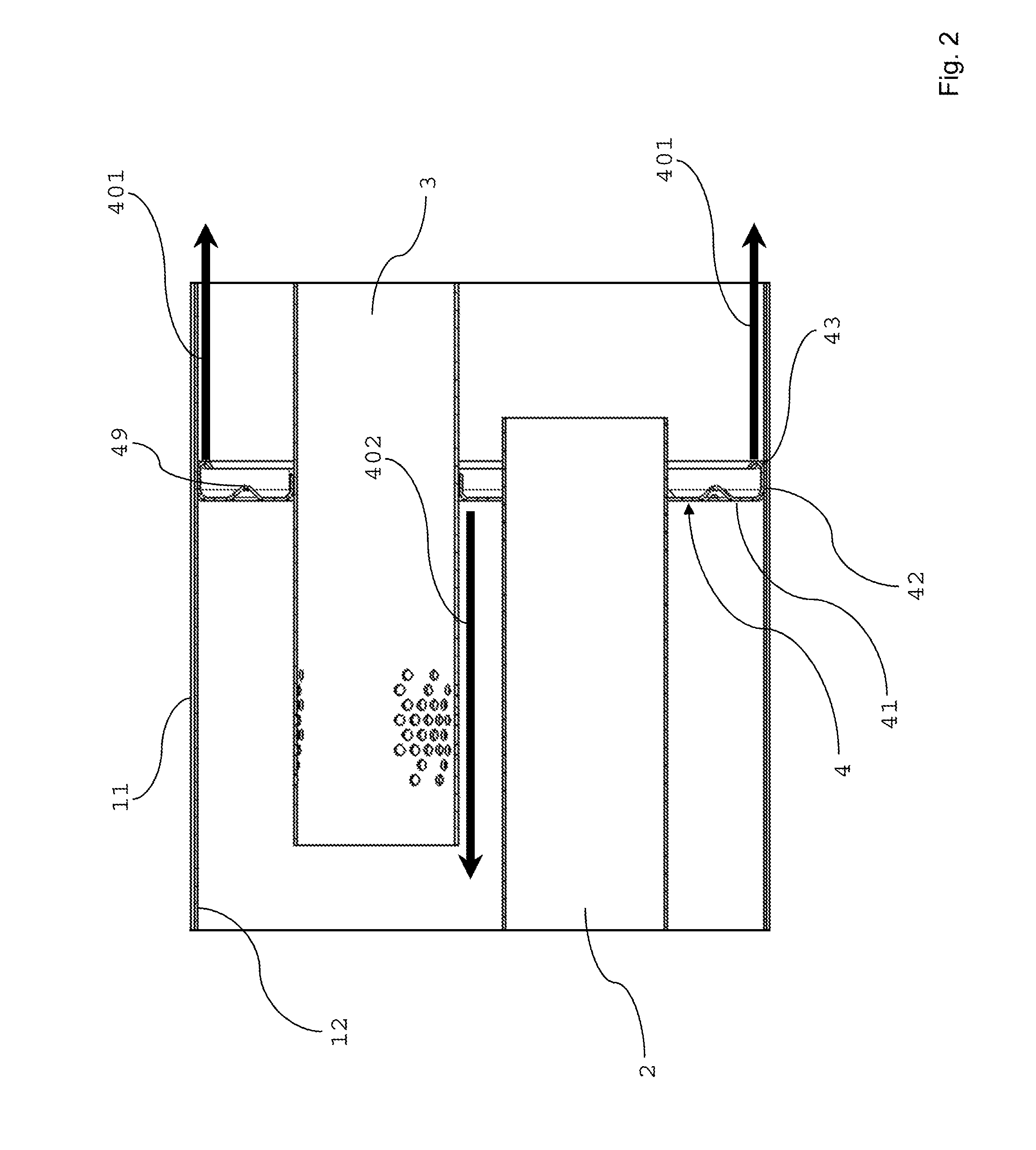

Spiral double-stage compounding impacting device for drilling well speed raising and effect enhancing

InactiveCN105909166AReduce supplyImprove rock breaking efficiencyReciprocating drilling machinesConstructionsUpper jointSpray nozzle

The invention relates to a spiral double-stage compounding impacting device for drilling well speed raising and effect enhancing in the fields of oil drilling, geological drilling and the like. The pressure of slurry can be converted into spiral impact of a center pipe. The spiral double-stage compounding impacting device has the technical scheme that an upper joint, an upper casing, a middle joint, a lower casing and a lower joint are sequentially matched through screw threads; a cavity is formed after the fixation; a valve body, a valve body spring, a driving hammer, a center pipe, a disc spring and an impact spray nozzle are sequentially arranged in the cavity from top to bottom; the driving hammer and an inner tube realize the axial positioning through an inner tube spring; through holes are uniformly formed in the peripheral direction; and a spiral bearing groove is formed in the outer surface of the center pipe. According to the tool, the driving hammer is driven to move in the axial direction through slurry pressure; the center pipe is subjected to axial impact; under the joint effects of the driving hammer, the disc spring and a spiral bearing, the center pipe drives the impact spray nozzle to generate the periodic spiral impact on the lower joint, and the impact acts on a lower part drilling tool; the rock breaking efficiency of a drill bit can be effectively improved; the drilling cost is reduced; and meanwhile, the occurrence of a stick-slip phenomenon is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

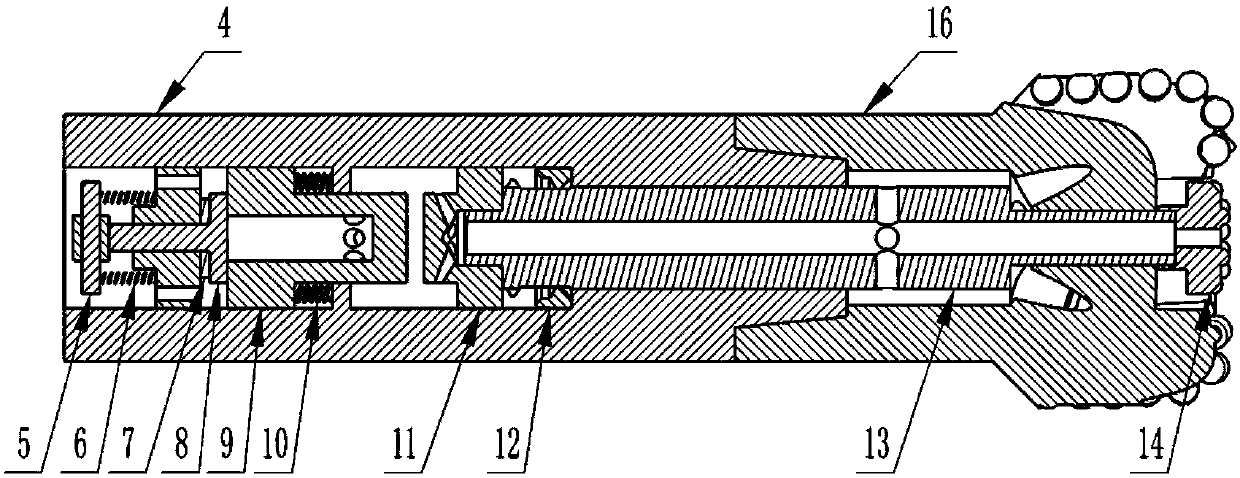

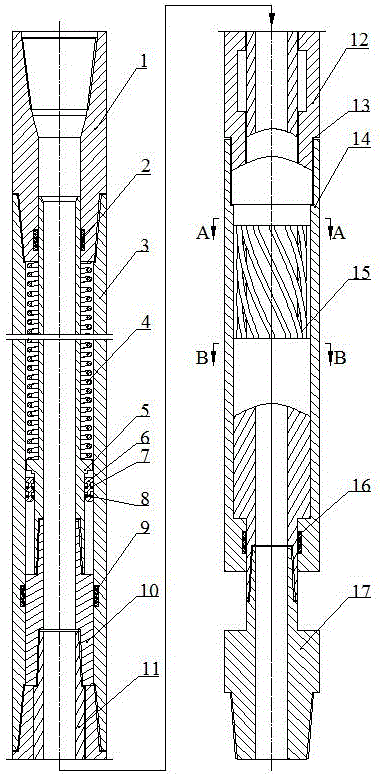

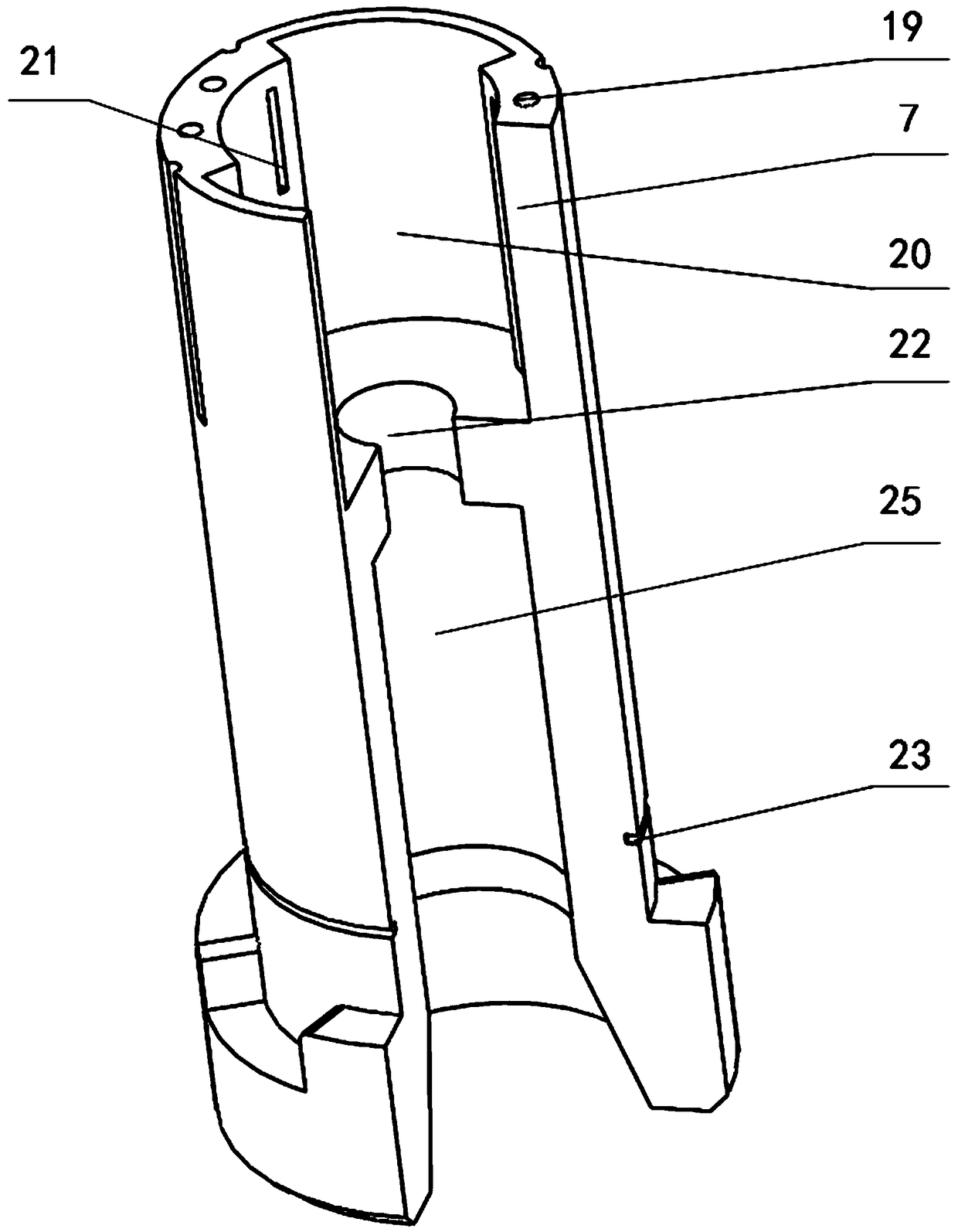

Torsional impact drilling tool

ActiveCN101463709BReduce stick-slipReduce the possibility of failureVibration drillingDrive shaftRate of penetration

The invention relates to a torsional impact drilling tool used for applying low amplitude high frequency torsional impact to a drill bit during a drilling process, which can increase the drilling efficiency and the service life of the drill bit and lesson the tripping operation and the drilling cost. The technical scheme of the torsional impact drilling tool is as follows: a housing is connected with a short section of a drilling column led into the drill bit by a spline, and is positioned by a shaft shoulder; a screw motor rotor and a screw motor stator form a screw motor, the screw motor rotor is eccentrically connected to a transmission shaft by a universal shaft and two bearings, and four diversion holes are arranged on the transmission shaft; the lower end of the transmission shaft is connected with a carrier with a cavity; a sliding impactor is arranged in the cavity and is fixed by pins, and an impact hammer is arranged in the sliding impactor; a falling prevention ring is connected with the housing by screw threads; and the damping shaft shoulder on the short section of the drilling column led into the drill bit is matched with the impact hammer of the sliding impactor to form a ratchet wheel structure. The torsional impact drilling tool has simple structure, and can be used in hard strata of a deep well; and as being short, the tool is also applicable to the deflecting operation and can be used in crooked well holes, thereby reducing the phenomenon of stick-slip of the drill bit and improving the rate of penetration.

Owner:SOUTHWEST PETROLEUM UNIV

Muffler for an exhaust system of an internal combustion engine

ActiveUS20160281559A1Increase dampingIncrease contactSilencing apparatusMachines/enginesInterior spaceEngineering

A muffler for an exhaust system of an internal combustion engine, comprises a housing comprising a shell having an inner wall, an inlet pipe and an outlet pipe, the inlet pipe and the outlet pipe extending into an inner space of the housing, for conveying an exhaust gas stream into and out of the inner space of the housing, at least one baffle arranged in the inner space of the housing, the baffle comprising a baffle plate, the baffle plate having a circumference, and a baffle lip arranged at the circumference of the baffle plate, the baffle lip engaging the inner wall of the shell and having an end portion, wherein the end portion of the baffle lip is curved inwardly away from the inner wall of the shell.

Owner:BOSAL EMISSION CONTROL SYST

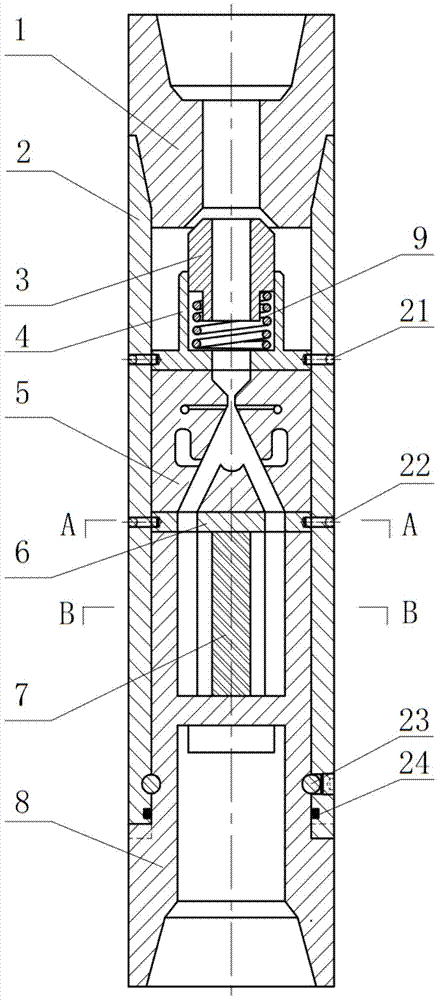

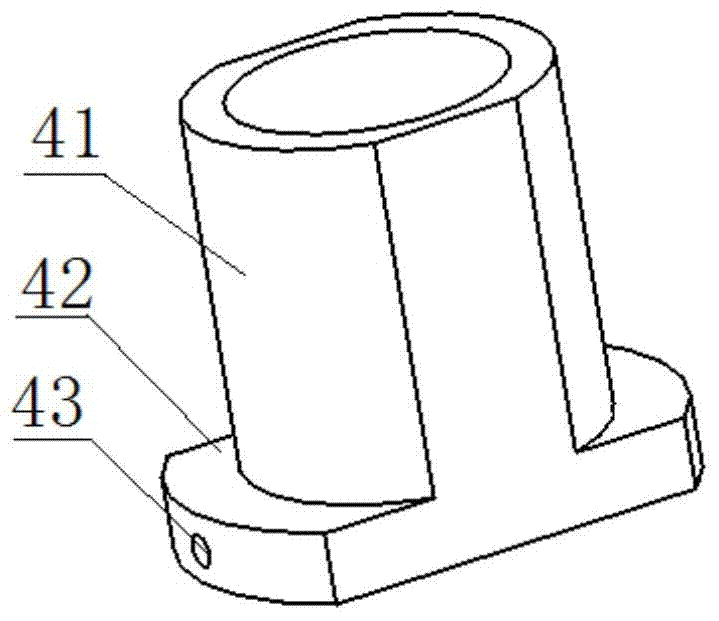

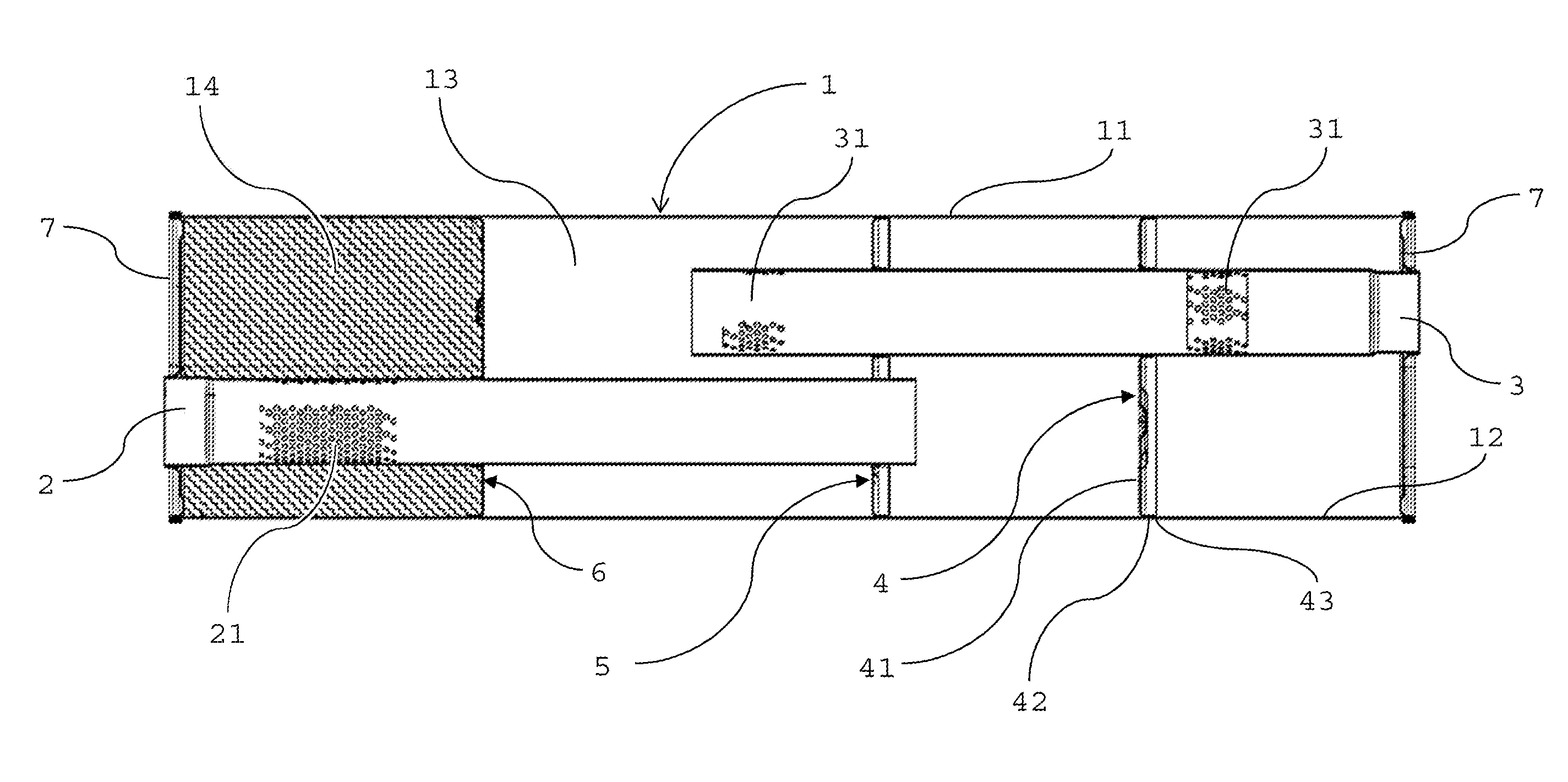

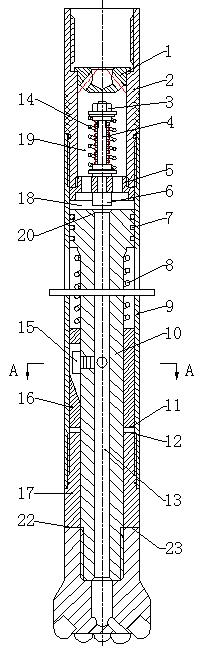

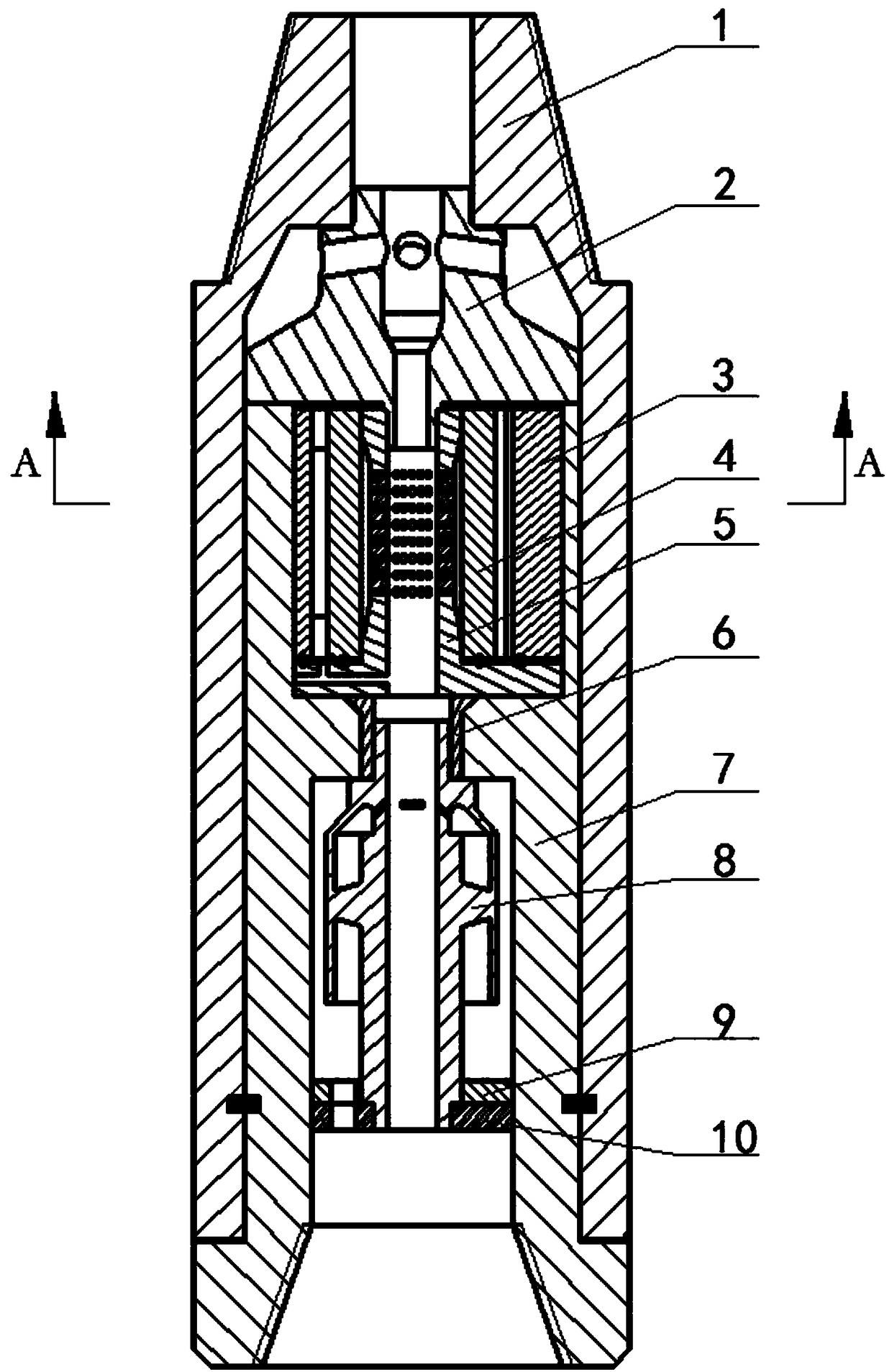

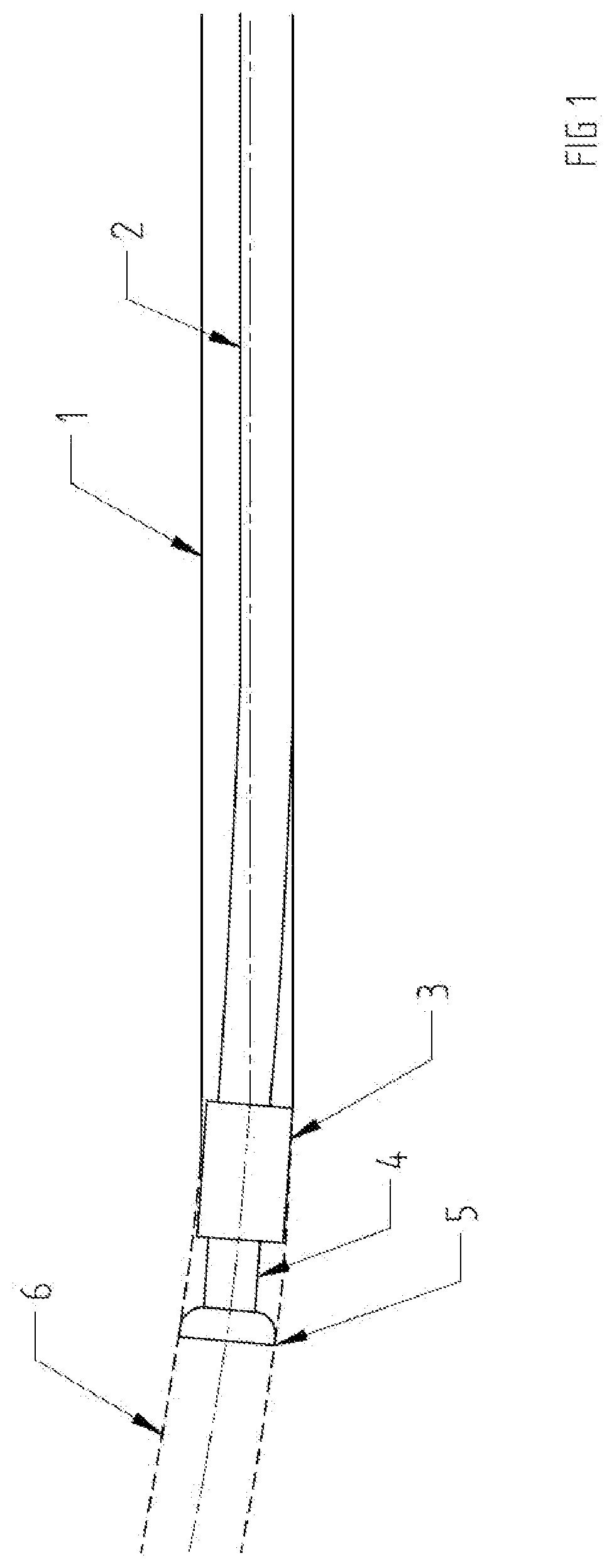

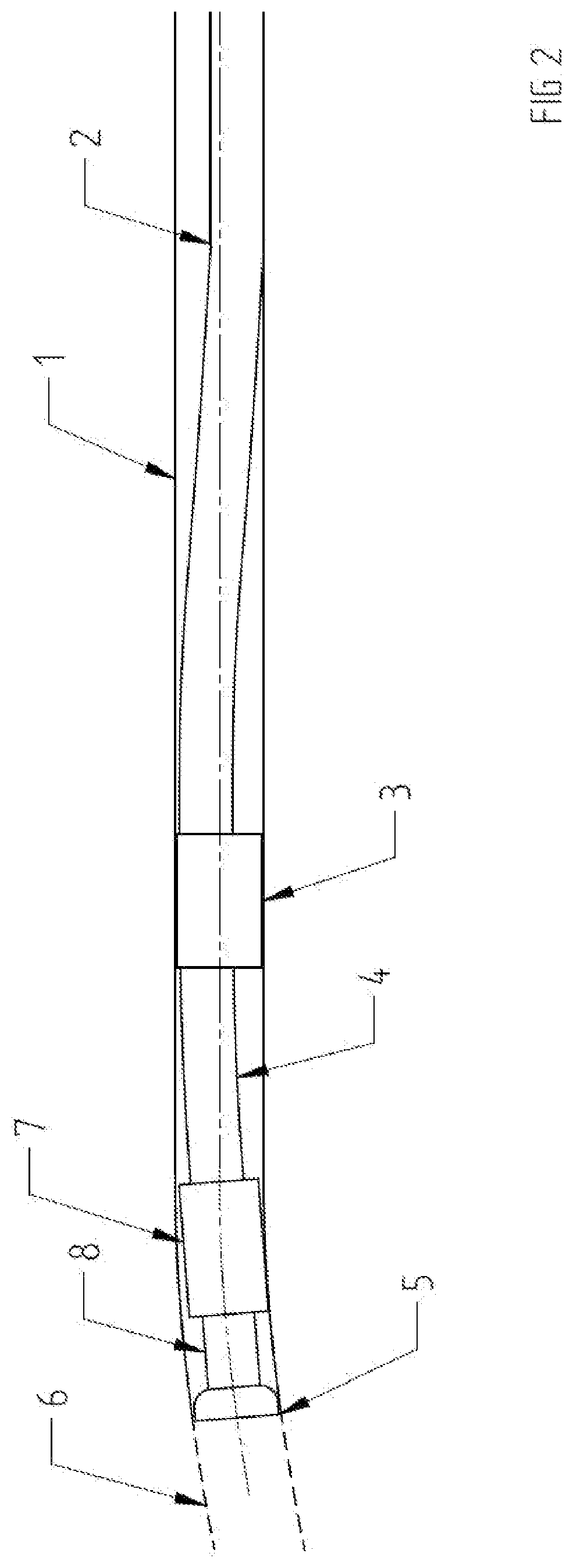

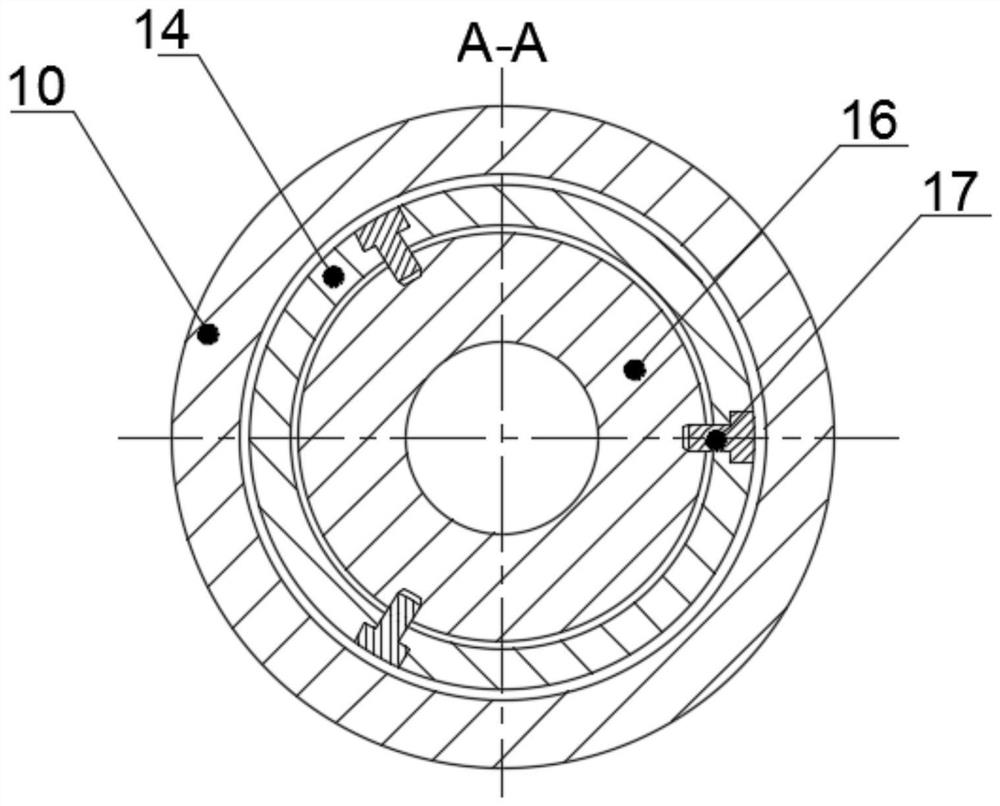

Reciprocating percussive-rotary drilling tool

The invention discloses a percussive-rotary drilling tool which is used for providing reciprocating percussion and torque simultaneously during well drilling and can improve drilling efficiency and mechanical drilling rate, and reduce drilling cost. The technical scheme is that: a flow controller is arranged in an upper joint and an automatic valve device below the flow controller is connected with an inner hole of the upper joint through a thread; the automatic valve device, a shell, and an upper end face of a central spindle form a cavity with a variable volume; a flow channel is formed in the middle of the central spindle; a sealing member is arranged between an outer wall of the upper end of the central spindle and an inner wall of the shell; a thread of the lower part of the central spindle is used for connecting a drill bit; and a rotation device is provided with a spiral groove, cylinder followers of the rotation device are arranged on the central spindle, and the bottom of the rotation device is provided with an unidirectional lower pawl surface which is matched with an unidirectional upper pawl surface on the upper part of a bearing joint. The percussive-rotary drilling tool has a simple structure, is suitable for well repairing and drilling operation, and can provide torque and percussion energy, reduce the phenomenon that the drilling bit is sticky and slippery, accelerate mechanical drilling rate, improve drilling efficiency and reduce drilling cost.

Owner:SOUTHWEST PETROLEUM UNIV

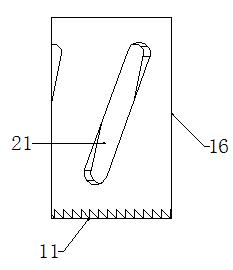

Stagnation-prevention drilling tool capable of reducing stick slip phenomenon through multi-head helical pair

ActiveCN106050160AIncreased versatilityRealize reciprocating motionDrilling rodsDrilling casingsSmall amplitudeDrive shaft

The invention relates to a stagnation-prevention drilling tool capable of reducing a stick slip phenomenon through a multi-head helical pair. The stagnation-prevention drilling tool is installed on the upper portion of a drill bit in a thread connection mode and comprises an upper assembly, a vibration absorption assembly and a lower assembly. The rear end of the vibration absorption assembly is provided with an upper connector assembly, and the front end of the vibration absorption assembly is provided with the lower assembly. Vibration generated in the work process of the tool is absorbed through disc springs connected in series, a pressure cavity and a rubber spring. Through matching of a spiral outer shell and a spiral transmission shaft, the multi-head helical pair is formed. When the reaction torque acting on the drill bit is increased and a stick slip or clamping phenomenon occurs, the spiral transmission shaft rotates backwards relative to the spiral outer shell, and therefore small-amplitude reverse rotation is applied to the drill bit. The reaction force of the ground to the drill bit is lowered, stress of the drill bit reaches balance again, and therefore efficient rock breaking with the drill bit is realized. According to the stagnation-prevention drilling tool capable of reducing the stick slip phenomenon through the multi-head helical pair, the vibration generated during rock breaking with the drill bit can be absorbed, the stick slip phenomenon is reduced, and continuous drilling of the drill bit is guaranteed.

Owner:沛县东宝机电设备有限公司

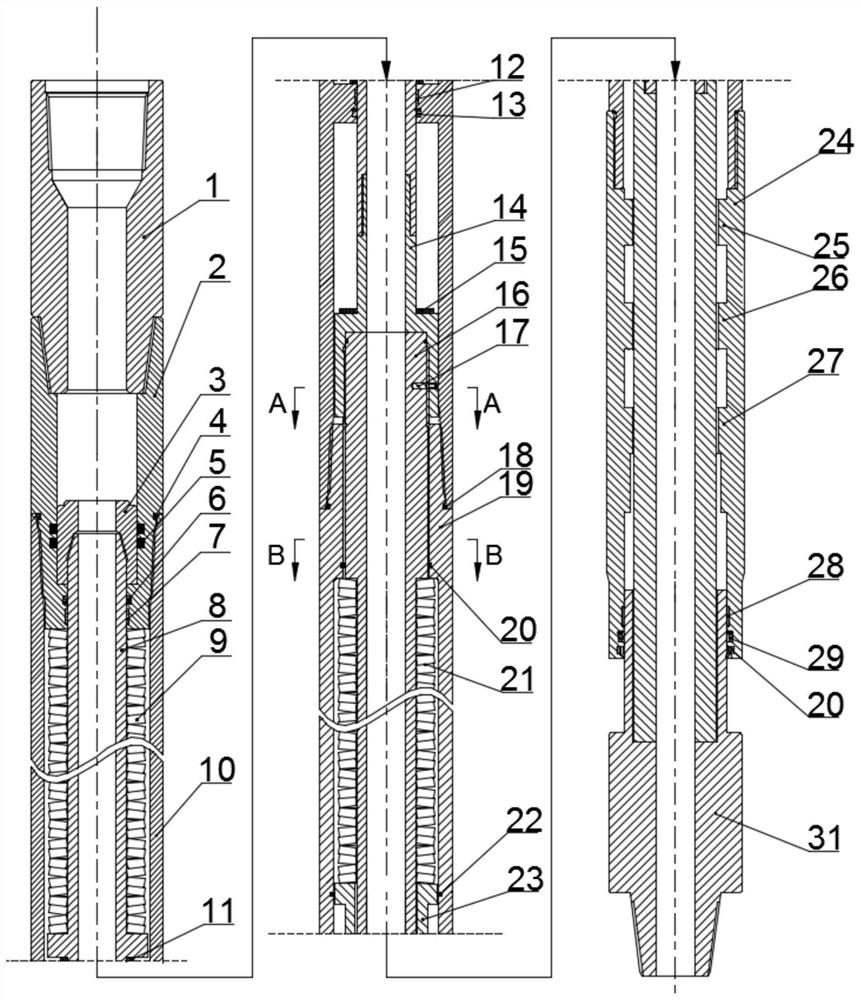

Anti-seizing tool capable of avoiding drill clamping and reducing sticky slipping

ActiveCN106567681AExtend your lifeAvoid drill stickingDrilling rodsDrilling casingsEngineeringDrill bit

The invention discloses an anti-seizing tool capable of avoiding drill clamping and reducing sticky slipping to solve the problem that the rock breaking efficiency is low due to clamping and slipping in the drilling process. According to the main technical scheme, an upper connector, an upper shell, an adapter and a lower shell are sequentially connected through a thread; a compression spring is mounted on a compression spring guide rod, the low end of the compression spring guide rod pushes an anti-falling connector to enable a mandrel to stretch, and the anti-falling connector is connected with a mandrel thread and axially positioned through an adapter shaft shoulder; a steel wire rope system is arranged in a left-rotation mode, the upper and lower ends of the steel wire rope system are separately fixed to the lower end of the adapter and fixed into a circular groove in the upper end of a mandrel boss, the upper and lower ends of steel wire ropes are mounted by 30-40 degrees in an inclined mode, and the steel wire ropes are in a tensional state initially; during work, drilling pressure is transferred to the mandrel through the compression spring, and torque is transferred to the mandrel through the steel wire rope system; and when the mandrel rotates backwards, the steel wire rope system retracts to enable the mandrel to compress the compression spring to axially retract so as to decrease the cutting depth of a drill bit, and the drill bit is in a rock mass in the whole process.

Owner:沛县昌运机械制造有限公司

Hydraulic torsion pulse impactor for drilling acceleration

ActiveCN109025827AExtended service lifeReduce stick-slipVibration drillingMechanical energyPetroleum

The invention relates to the technical field of petroleum drilling, in particular to a hydraulic torsion pulse impactor for drilling acceleration. According to the impactor, a suspension inner drum isarranged in a suspension outer drum, the suspension inner drum can rotate in the suspension outer drum, the upper portion of the suspension inner drum is designed as a hydraulic impact base, two sector-shaped power cavities are symmetrically formed in the inner wall of the hydraulic impact base, multiple second circulation grooves are formed in the outer wall of the hydraulic impact base and communicated with a circulation passage in the side wall of the hydraulic impact base, and a flow diversion pressing cover is connected to the upper end of the hydraulic impact base. A high-frequency torsion impact force is circumferentially supplied to a PDC drill bit, and a pulse impact force is provided axially; therefore, an assistance is provided for breaking rock through the drill bit, the sticky degree of a drilling column is decreased, the mechanical drilling speed is increased, tools are simple in structure, few fragile components are adopted, and the energy of drilling liquid is ingeniously converted into mechanical energy in order to increase the drilling speed and prolong the service life of the drill bit.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

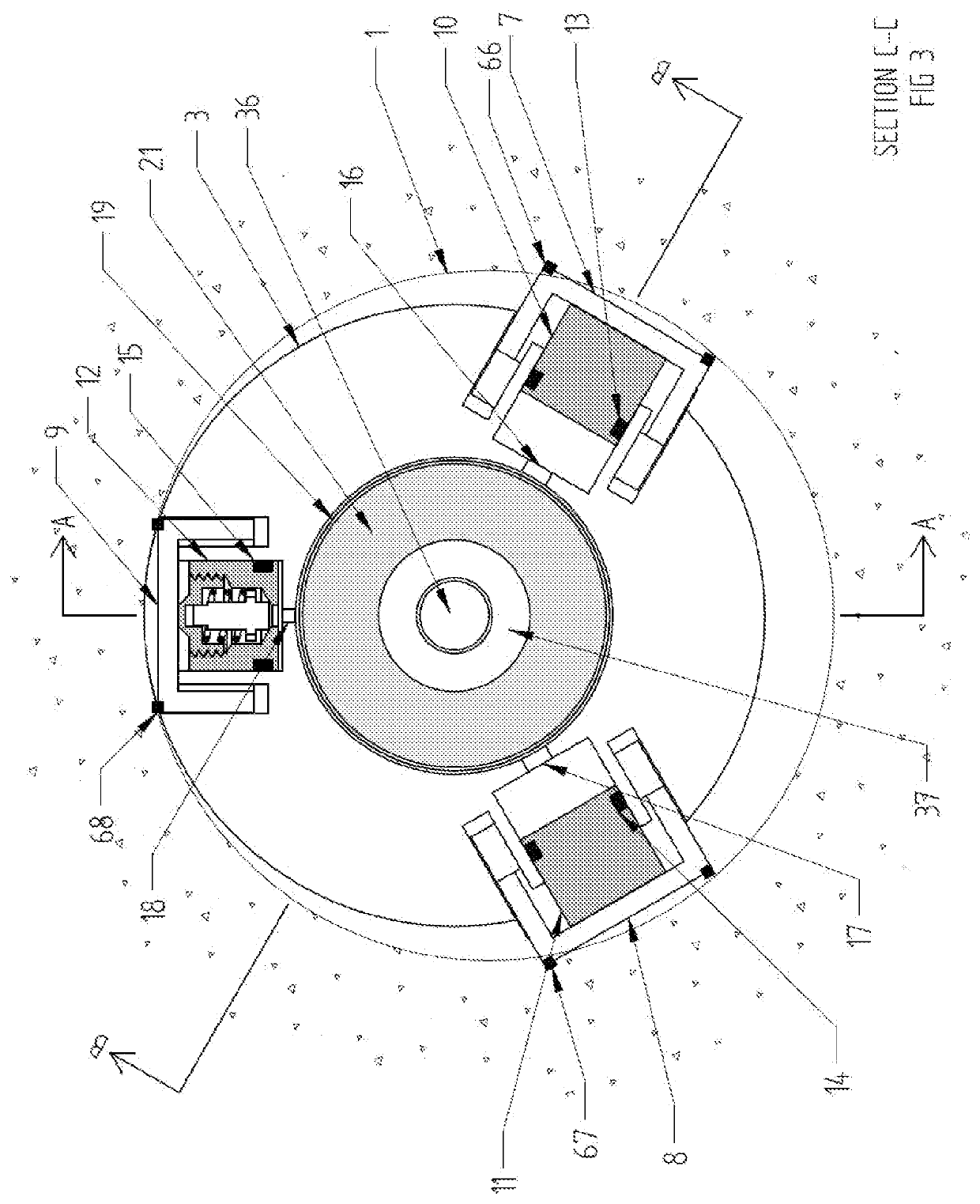

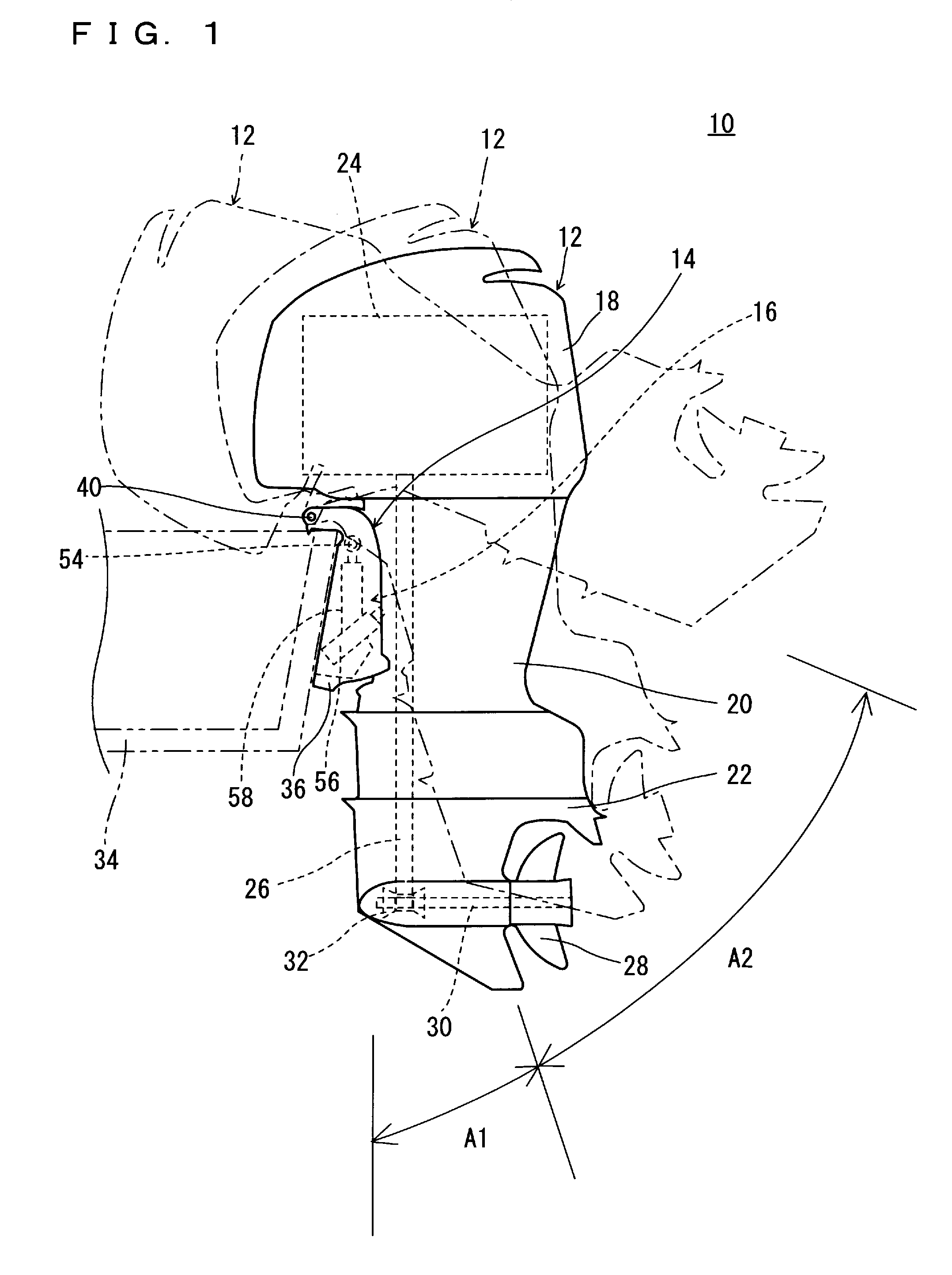

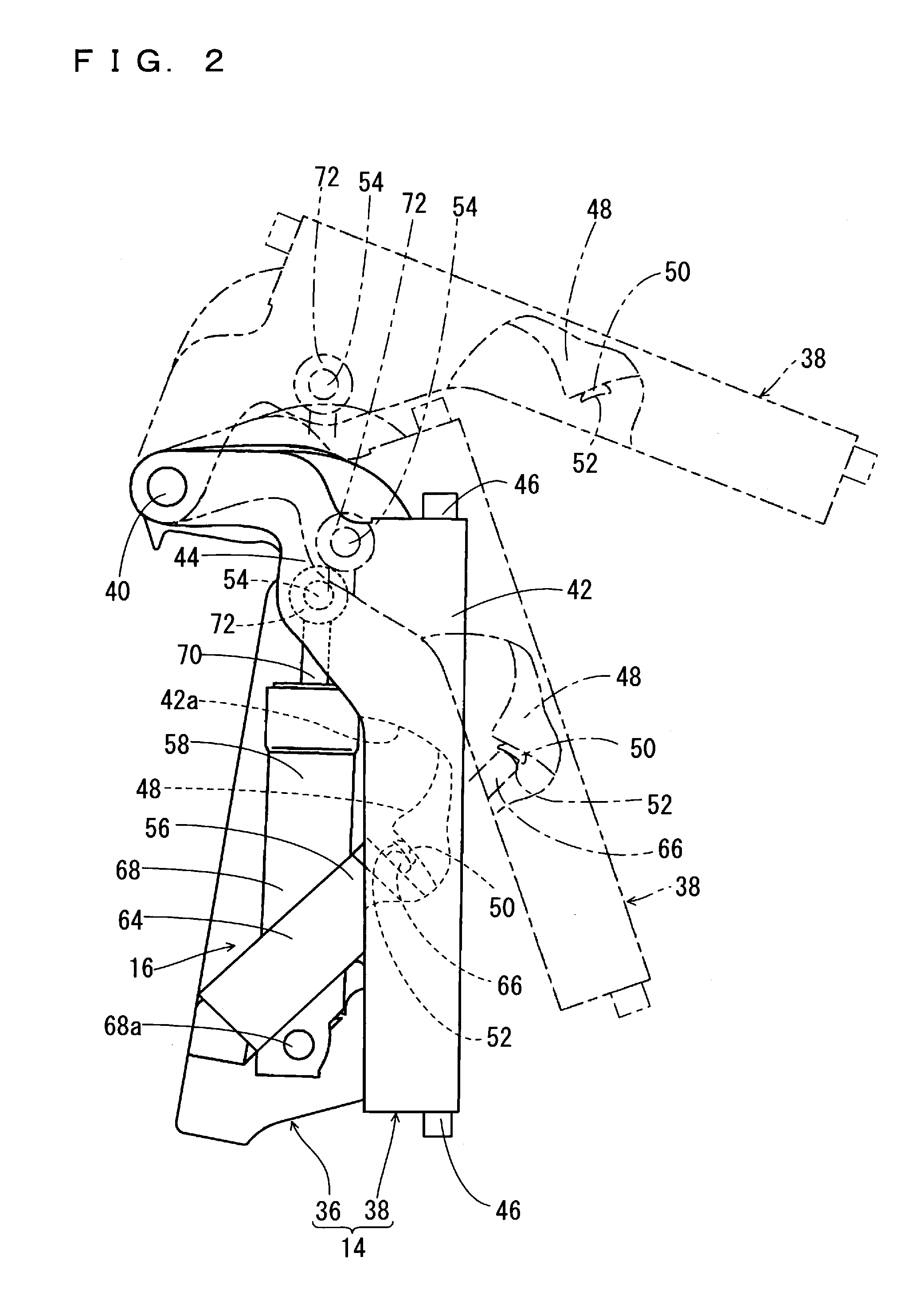

Simple Rotary Steerable Drilling System

ActiveUS20200318437A1Low rate of fluid flowReduce differential pressureSurveyDrilling rodsPressure.driveEngineering

A steering collar for deflecting a drill string in a borehole to cause the borehole to be drilled in a different direction. The steering collar surrounds a hollow drive shaft which is driven by the drill string. During normal drilling operations, the steering collar does not rotate with the drive shaft. The steering collar has three sets of pistons operated by the pressure of the drilling fluid, one set of which is pressure relieved. Drill fluid that is pumped down the drill string flows into the hollow drive shaft and through ports to activate the pistons which thereby force corresponding pads outwardly into contact with the sidewall of the borehole. Since the one set of pistons is pressure relieved, it does not force its pad against the borehole sidewall with as much pressure as the other two sets of pistons force their pads against the sidewall of the borehole. Accordingly, the steering collar is deflected laterally in the borehole so that the drill bit is also steered laterally to cause drilling in a different direction. In order to reorient the steering collar in the borehole, the steering collar can be locked to the drive shaft so that when the drill string is rotated, the steering collar is also rotated so that it is moved to a new angular position in the borehole.

Owner:GRAY

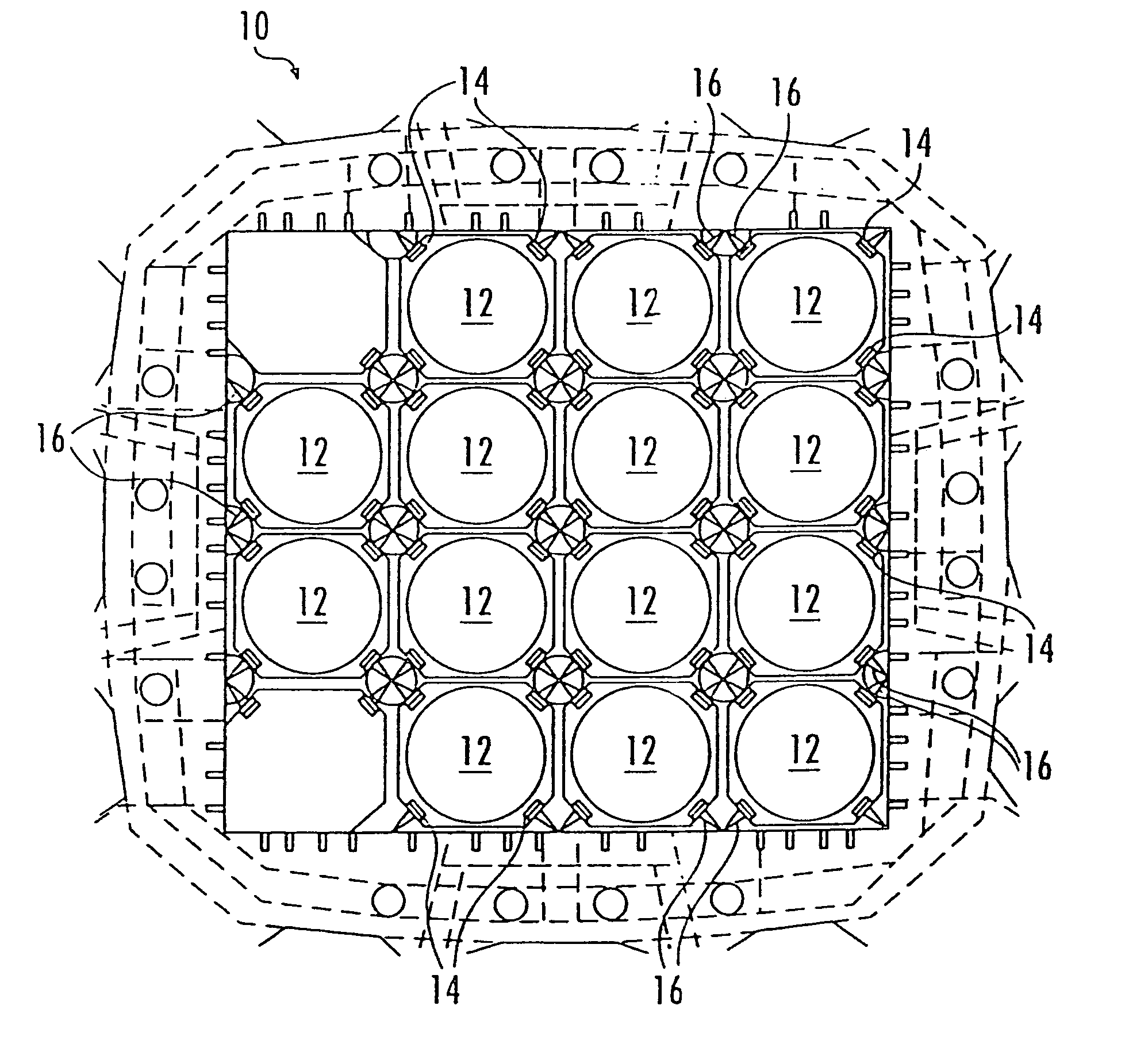

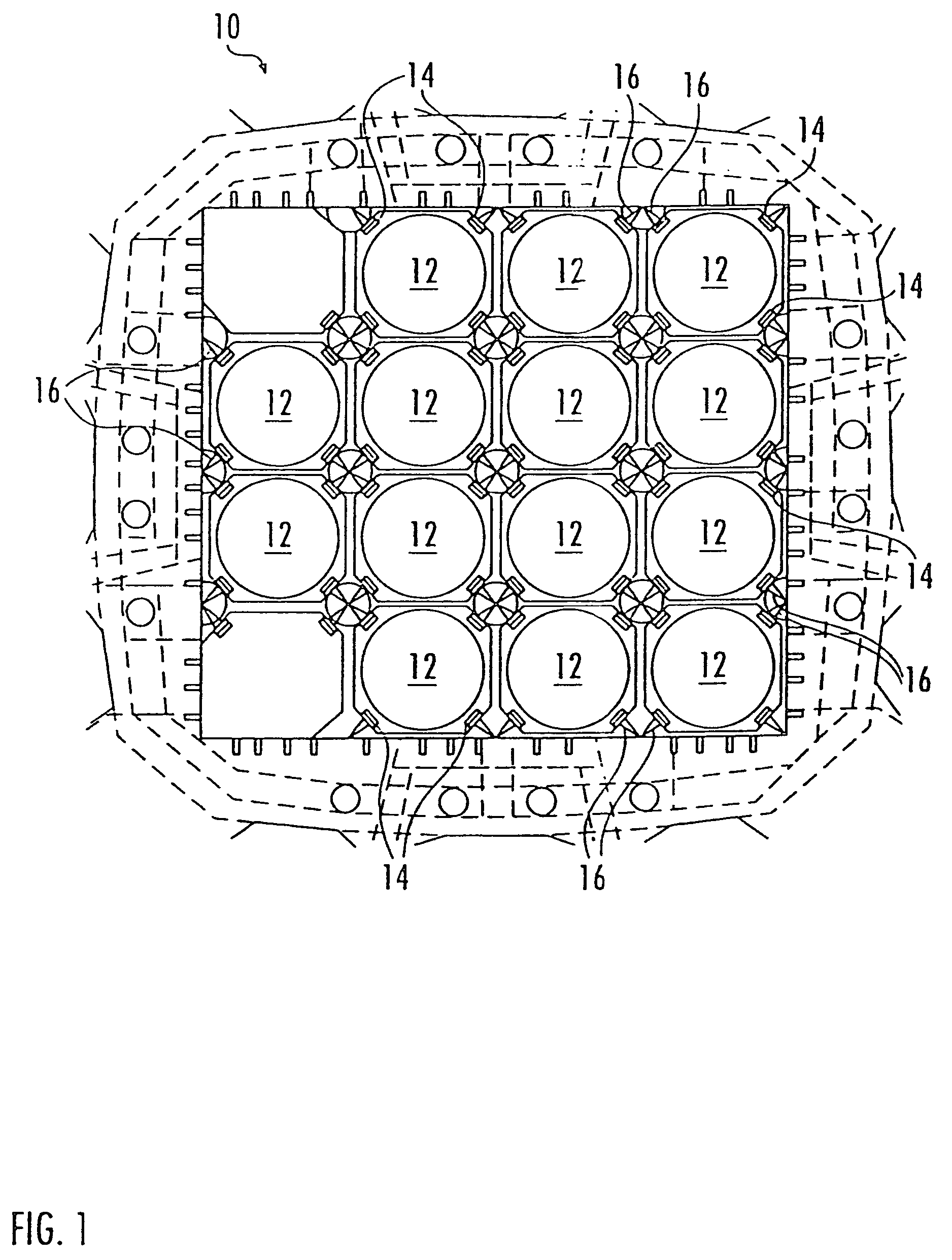

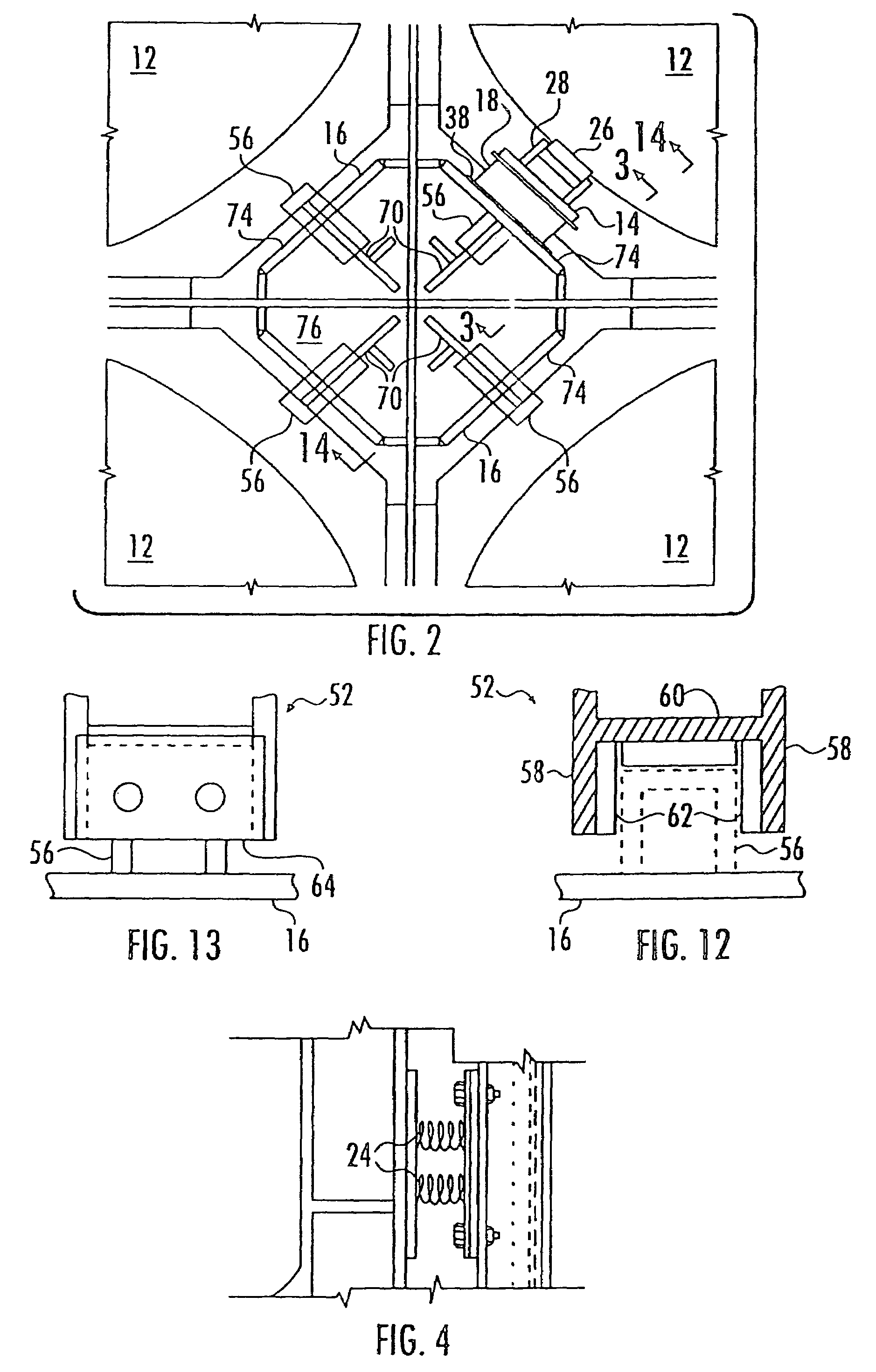

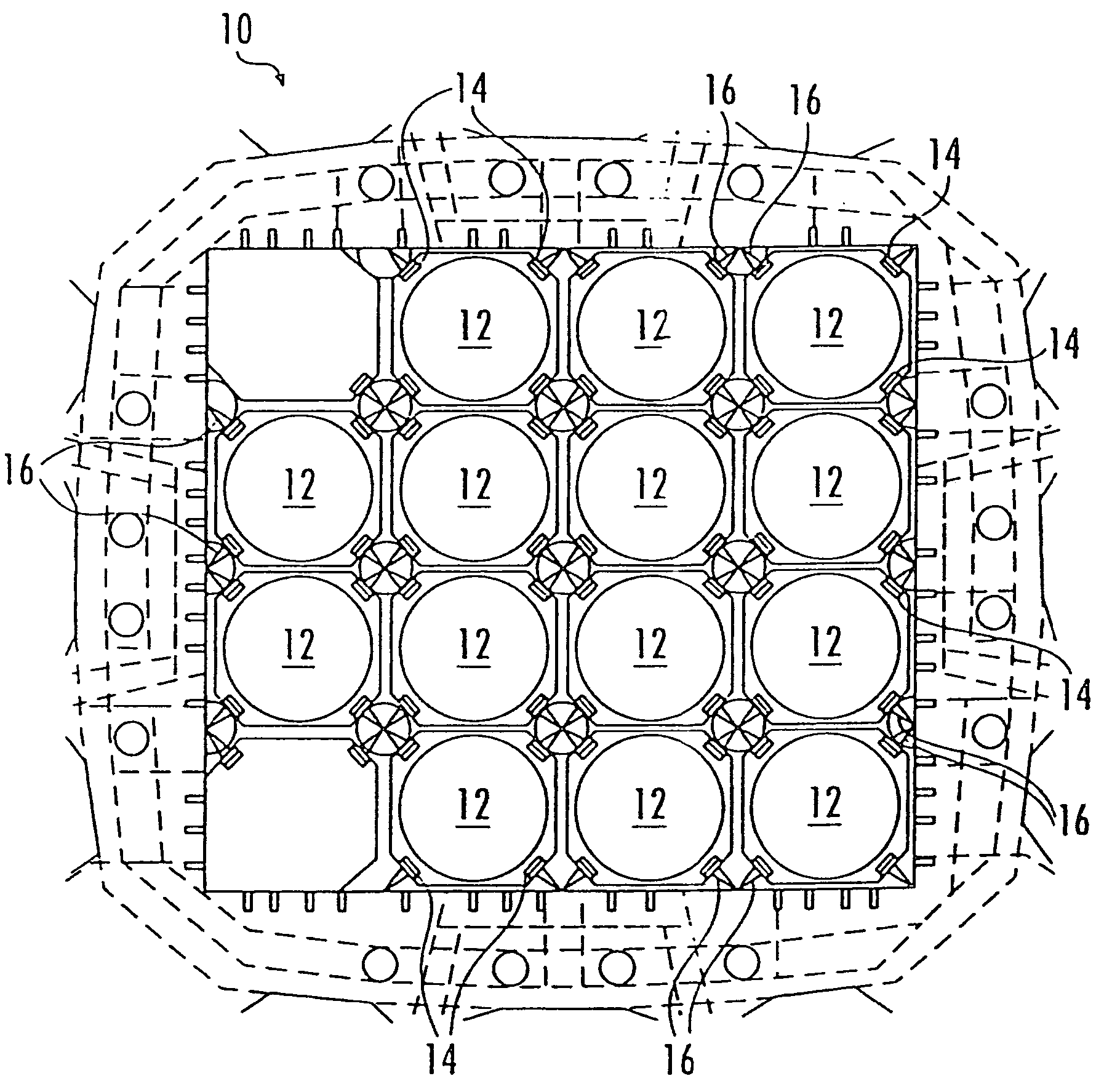

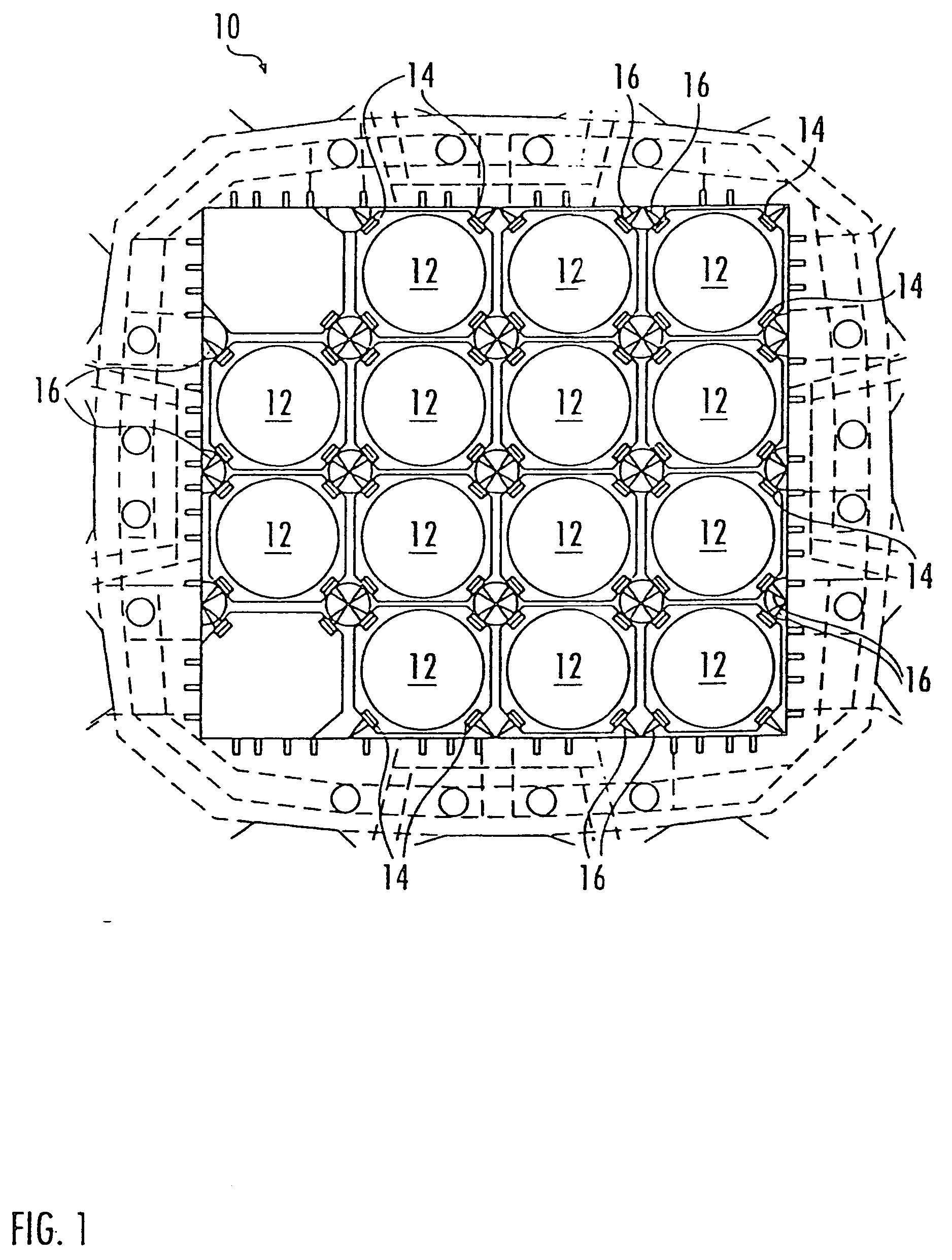

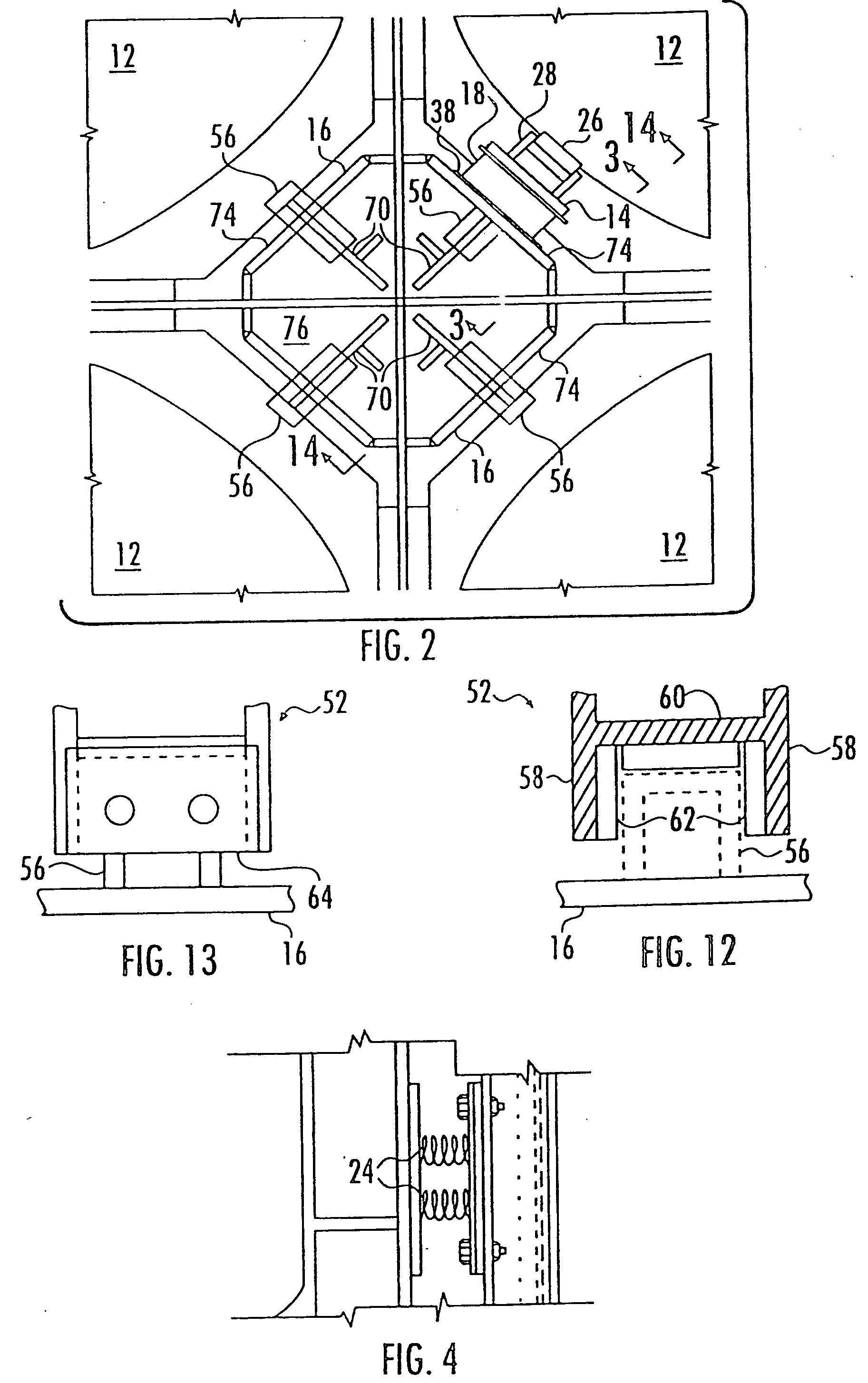

Compliant buoyancy can guide

InactiveUS7096958B2Protection from damageReduce stick-slipVessel cleaningDrilling rodsEngineeringBuoyancy function

A floating offshore platform, of the type having a buoyancy can disposed within a support structure, includes a can guide assembly that has at least two compliant compression pads that are configured and arranged to provide a non-linear load-versus-deflection characteristic in response to impact loads generated by the impact of the can against the guide assembly. At least one of the compression pads is substantially stiffer (less compliant) than the other pad. The pads are arranged so that the relatively soft pad absorbs the impact load before the relatively stiff pad is engaged. In one embodiment, first, second, and third compression pads are arranged vertically, the upper and lower pads being softer (more compliant) than the middle pad. In another embodiment, a first, relatively soft, compression pad coaxially surrounds a second, relatively stiff compression pad.

Owner:TECH FRANCE SA

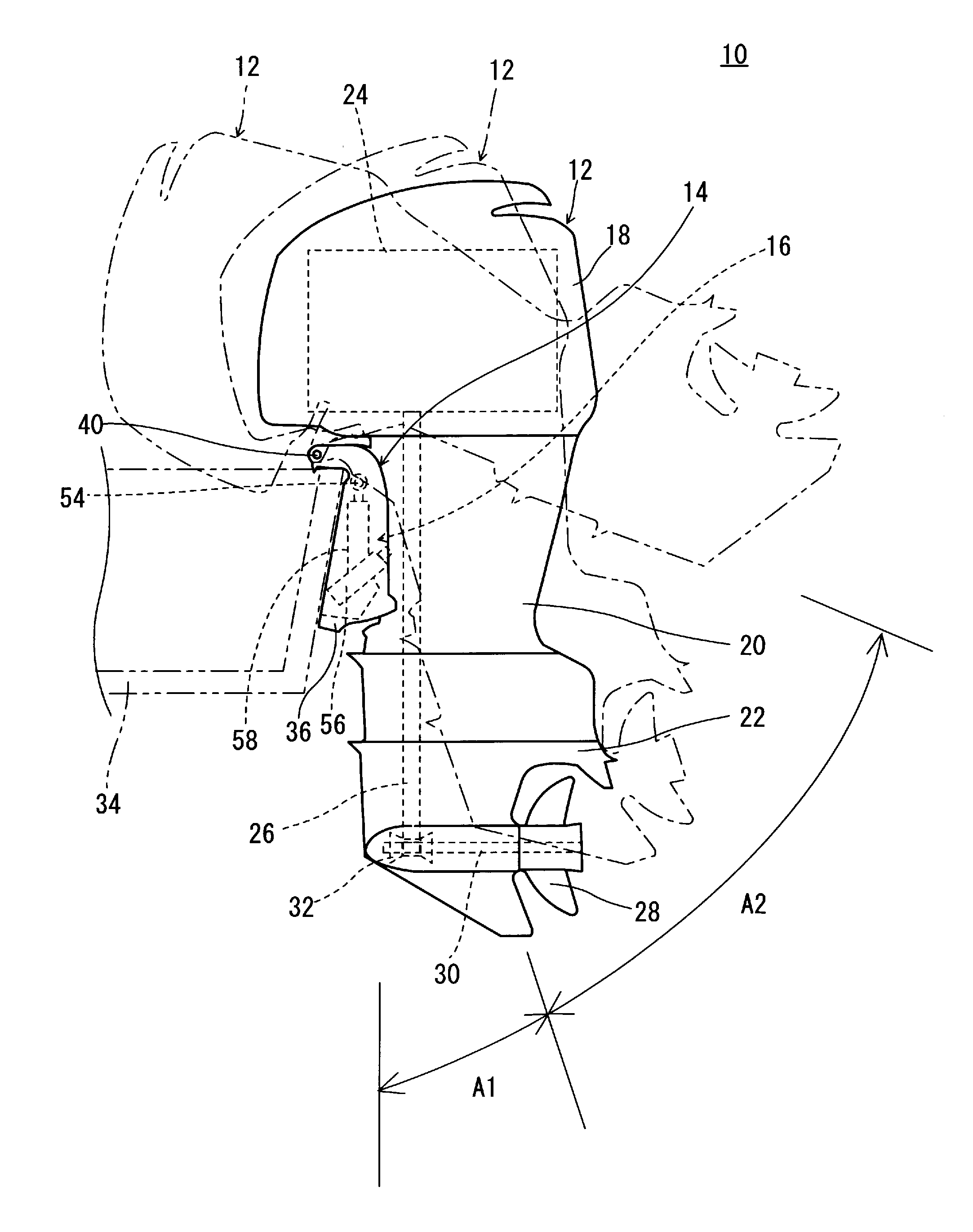

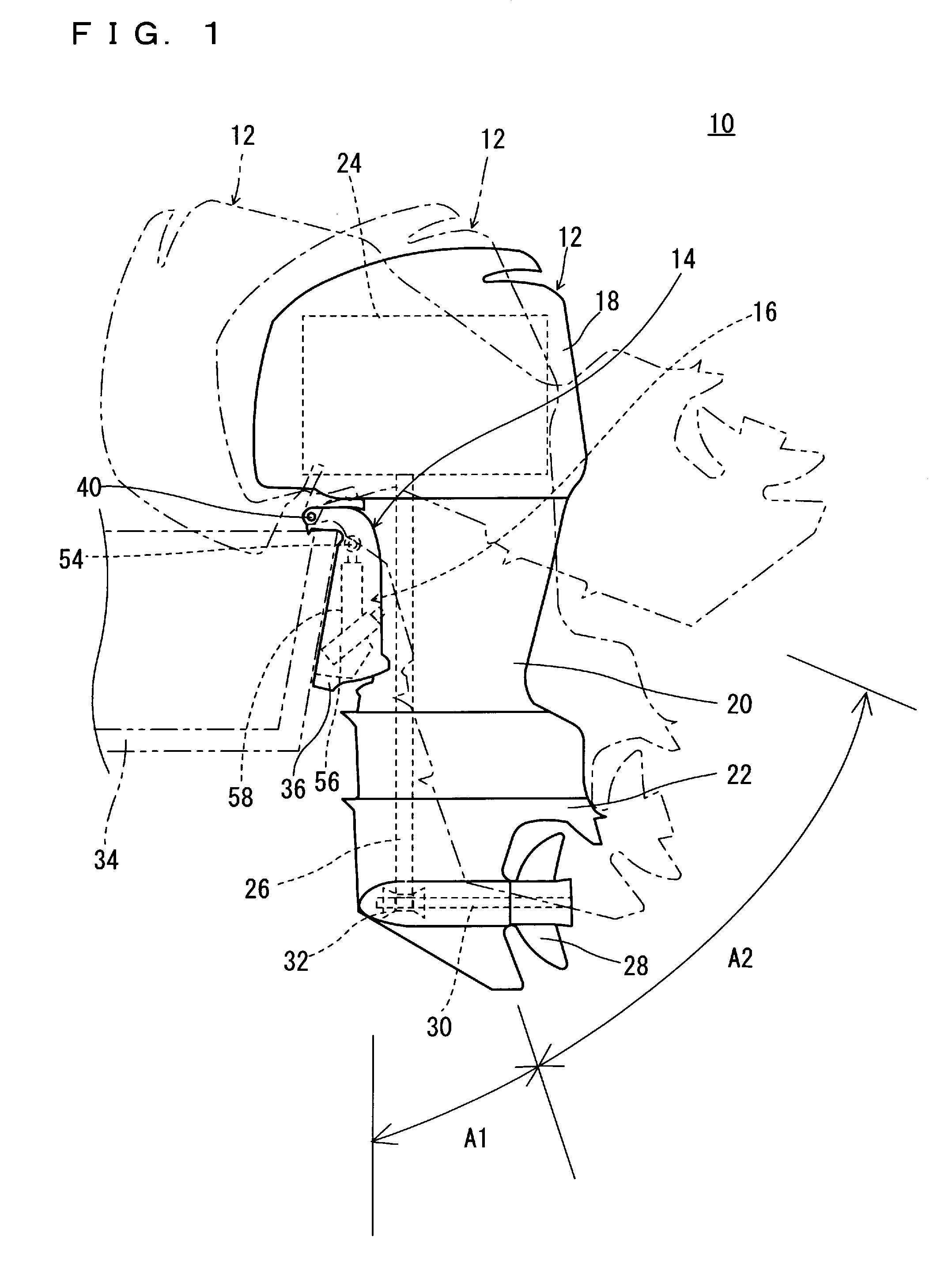

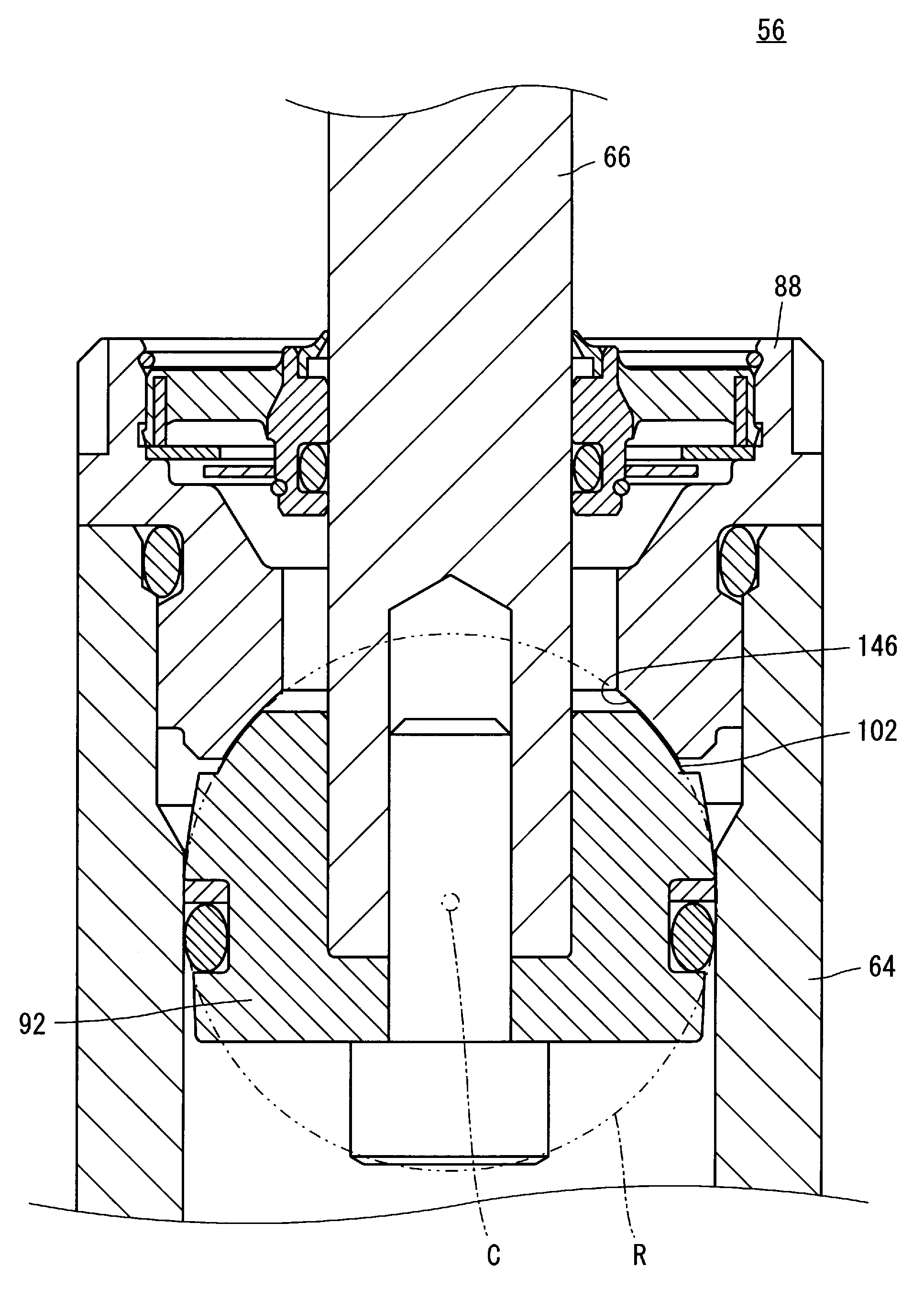

Hydraulic cylinder device and boat propelling apparatus including the same

ActiveUS20100285706A1Reduce stick-slipPropulsion power plantsOutboard propulsion unitsHydraulic cylinderMechanical engineering

A trim device includes a trim cylinder, a piston, a piston rod and a support member. The piston is slidable inside the trim cylinder, in the axial direction of the trim cylinder. The piston rod is connected with the piston and moves in the axial direction of the trim cylinder following the movement of the piston. The support member is slidable relative to the piston rod and arranged to support the piston rod so that the piston rod's axial center can become tilted with respect to the axial center of the cylinder.

Owner:YAMAHA MOTOR HYDRAULIC SYST

A Method Of And A Device And An Electronic Controller For Mitigating Stick-slip Oscillations In Borehole Equipment

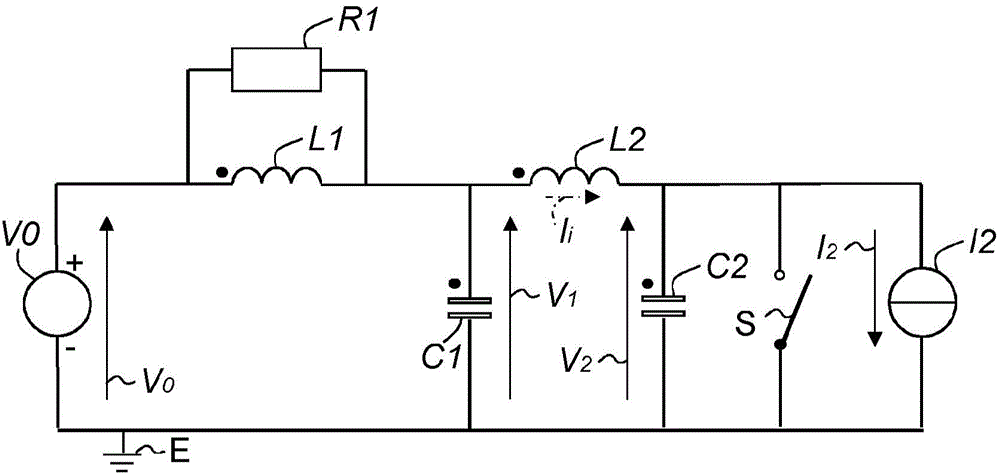

ActiveCN104040111AReduce stick-slip oscillationsReduce stick-slipMechanical oscillations controlBorehole/well accessoriesComputational modelLower limit

A method for mitigating stick-slip oscillations in borehole equipment while drilling a borehole in an earth formation is described. The borehole equipment is modelled by a computational model for computer simulation. The model has elements representing a particular mechanical and physical behavior of the borehole equipment. In a simulated stick mode of the borehole equipment, physical quantities are loaded to the elements, which quantities represent an initial state of the borehole equipment prior to a transition from stick mode to slip mode. From a simulation of such transition, a time response of rotational speeds of a drive system and bottom hole assembly of the borehole equipment is recorded and a lower limit of the rotational speed of the drive system is determined for which the rotational driven speed of the bottom hole assembly is zero.

Owner:ENGIE电气工程有限公司

Spiral double-stage composite impactor for drilling speed increase and efficiency increase

InactiveCN105909166BReduce supplyImprove rock breaking efficiencyConstructionsReciprocating drilling machinesWell drillingUpper joint

The invention relates to a spiral double-stage compounding impacting device for drilling well speed raising and effect enhancing in the fields of oil drilling, geological drilling and the like. The pressure of slurry can be converted into spiral impact of a center pipe. The spiral double-stage compounding impacting device has the technical scheme that an upper joint, an upper casing, a middle joint, a lower casing and a lower joint are sequentially matched through screw threads; a cavity is formed after the fixation; a valve body, a valve body spring, a driving hammer, a center pipe, a disc spring and an impact spray nozzle are sequentially arranged in the cavity from top to bottom; the driving hammer and an inner tube realize the axial positioning through an inner tube spring; through holes are uniformly formed in the peripheral direction; and a spiral bearing groove is formed in the outer surface of the center pipe. According to the tool, the driving hammer is driven to move in the axial direction through slurry pressure; the center pipe is subjected to axial impact; under the joint effects of the driving hammer, the disc spring and a spiral bearing, the center pipe drives the impact spray nozzle to generate the periodic spiral impact on the lower joint, and the impact acts on a lower part drilling tool; the rock breaking efficiency of a drill bit can be effectively improved; the drilling cost is reduced; and meanwhile, the occurrence of a stick-slip phenomenon is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

Anti-stagnation tool based on flexible rods

InactiveCN106050154AReduce axial and torsional vibrationsExtend your lifeDrilling rodsDrilling casingsPetroleumDrill bit

The invention discloses an anti-stagnation tool based on flexible rods and belongs to the field of drilling of ultra-deep petroleum wells. By the adoption of the anti-stagnation tool based on the flexible rods, the problem that the rock breaking efficiency is lowered due to the fact that a drill bit gets stuck or slides in the drilling process is solved. According to the main technical scheme, a vibration reduction assembly, an upper shell, a middle shell and a lower shell are connected in sequence through threads; the lower end of a combined disc spring pushes an anti-falling pipe to make a central pipe stretch, and the anti-falling pipe is positioned in the axial direction through an upper connector shaft shoulder of the middle shell; a flexible rod system rotates leftwards, and the upper end and the lower end of the flexible rod system are fixed in circular grooves in the lower end of the middle shell and the upper end of a central pipe boss correspondingly; the flexible rods are installed in the way that the upper ends and the lower ends of the flexible rods are inclined by 30-40 degrees and are in the stretching state initially; during operation, the drilling pressure is transmitted to the central pipe through the combined disc spring, and the torque is transmitted to the central pipe through the flexible rod system; and when the central pipe rotates reversely, the flexible rod system contracts, the combined disc spring is compressed by the central pipe to contract in the axial direction to reduce the cutting depth of the drill bit, and the drill bit is in a rock stratum all the time in the whole process.

Owner:SOUTHWEST PETROLEUM UNIV

Control device for composite directional drilling and using method

ActiveCN114109251AEasy to installImprove performanceDrilling rodsDirectional drillingWell drillingControl engineering

The invention discloses a control device for composite directional drilling and a using method. The control device comprises an upper connector, a reset module, an execution control module, an auxiliary module, an anti-falling module and a lower connector. According to the technical scheme, during composite drilling, splines of the control device are in a meshed state, and a mandrel drives a shaft bottom drilling tool assembly connected with a lower connector to rotate together; during directional sliding drilling, the drilling pressure is increased, the drilling pressure is transmitted to the upper connector from an upper drill column, a disc spring in the control device is compressed, a spline is in a disengaged state, and the shell will not drive the mandrel to rotate; when the drilling pressure is reduced, the control device resets by means of thrust of the disc spring, the spline is in the meshed state again, and at the moment, the composite drilling state is achieved. According to the control device for achieving composite directional drilling through the bit pressure, switching between composite drilling and directional sliding drilling can be achieved, the drilling efficiency is improved, the drilling jamming risk is reduced, and cost is greatly saved.

Owner:SOUTHWEST PETROLEUM UNIV +1

Hydraulic cylinder device and boat propelling apparatus including the same

ActiveUS8707854B2Reduce stick-slipEngine sealsOutboard propulsion unitsHydraulic cylinderMechanical engineering

A trim device includes a trim cylinder, a piston, a piston rod and a support member. The piston is slidable inside the trim cylinder, in the axial direction of the trim cylinder. The piston rod is connected with the piston and moves in the axial direction of the trim cylinder following the movement of the piston. The support member is slidable relative to the piston rod and arranged to support the piston rod so that the piston rod's axial center can become tilted with respect to the axial center of the cylinder.

Owner:YAMAHA MOTOR HYDRAULIC SYST

Composite impactor

The invention belongs to the technical field of petroleum drilling, and particularly relates to a composite impactor. According to the specific technical scheme, the composite impactor is characterized in that the two ends of the composite impactor are detachably connected with an upper drilling tool and a drill bit in a threaded mode respectively, the composite impactor comprises an axial impactpart, a torsional impact part and an auxiliary part, an impact hammer of the axial impact part axially impacts an upper shell under the combined action of a spring and high-pressure drilling fluid togenerate axial impact force, a pendulum bob of the torsional impact part impacts a lower shell in a torsional mode under the action of high-pressure drilling fluid to generate torsional impact force,a reversing switch and a central pipe are connected together in an inserted mode, and meanwhile reversing is conducted on torsional impact and axial impact respectively. According to the composite impactor, the impact hammer and the pendulum bob are pushed by the high-pressure drilling fluid to generate axial impact and torsional impact respectively, the mechanical drilling speed is effectively increased, the stick-slip phenomenon at a drill string system or the drill bit is reduced, and the composite impactor is stable and reliable in an underground complex and variable environment.

Owner:SOUTHWEST PETROLEUM UNIV +1

Compliant buoyancy can guide

InactiveUS20050051338A1Protection from damageReduce stick-slipVessel cleaningDrilling rodsEngineeringElectrical and Electronics engineering

A floating offshore platform, of the type having a buoyancy can disposed within a support structure, includes a can guide assembly that has at least two compliant compression pads that are configured and arranged to provide a non-linear load-versus-deflection characteristic in response to impact loads generated by the impact of the can against the guide assembly. At least one of the compression pads is substantially stiffer (less compliant) than the other pad. The pads are arranged so that the relatively soft pad absorbs the impact load before the relatively stiff pad is engaged. In one embodiment, first, second, and third compression pads are arranged vertically, the upper and lower pads being softer (more compliant) than the middle pad. In another embodiment, a first, relatively soft, compression pad coaxially surrounds a second, relatively stiff compression pad.

Owner:TECH FRANCE SA

Downhole gas phase space rotary swing drilling tool and implementation method thereof

The invention relates to a gas phase space rotary swing drilling tool for drilling and a mud guide-out method. The gas phase space rotary swing drilling tool comprises a liquid separation cover, a liquid separation wheel, a turbine, a coupling cylinder, a magnetic coupling rotor, a coupling inner shaft, a pendulum cylinder, pendulums, a backflow joint, an outer cylinder and a lower joint. The gasphase space rotary swing drilling tool is mounted between a drill bit and a drill collar. Mud in a drilling well enters from a mud inlet and is guided and impacts on the turbine through the liquid separation cover and the liquid separation wheel, the turbine rotates rapidly, the magnetic coupling rotor drives the coupling inner shaft to rotate synchronously, and the coupling inner shaft which is connected with the pendulums in the pendulum cylinder transmits rotating force to the pendulums to rotate at high speed, so that drilling mud flows along an annular space between the outer cylinder andthe pendulum cylinder into the backflow joint, flows into the lower joint through a hole of the backflow joint, and is guided into the next part of the drilling tool. The gas phase space rotary swingdrilling tool has the effects that drilling dragging and sticking and slipping are reduced, the drilling efficiency is improved, the jamming accidents of the drilling tool are reduced, and the gas phase space rotary swing drilling tool can be applied to an existing drilling system without modifying the existing drilling system.

Owner:金冰兰

Muffler for an exhaust system of an internal combustion engine

ActiveUS9534522B2Reduce contact lengthIncreasing curvature angleSilencing apparatusMachines/enginesInterior spaceEngineering

A muffler for an exhaust system of an internal combustion engine, comprises a housing comprising a shell having an inner wall, an inlet pipe and an outlet pipe, the inlet pipe and the outlet pipe extending into an inner space of the housing, for conveying an exhaust gas stream into and out of the inner space of the housing, at least one baffle arranged in the inner space of the housing, the baffle comprising a baffle plate, the baffle plate having a circumference, and a baffle lip arranged at the circumference of the baffle plate, the baffle lip engaging the inner wall of the shell and having an end portion, wherein the end portion of the baffle lip is curved inwardly away from the inner wall of the shell.

Owner:BOSAL EMISSION CONTROL SYST

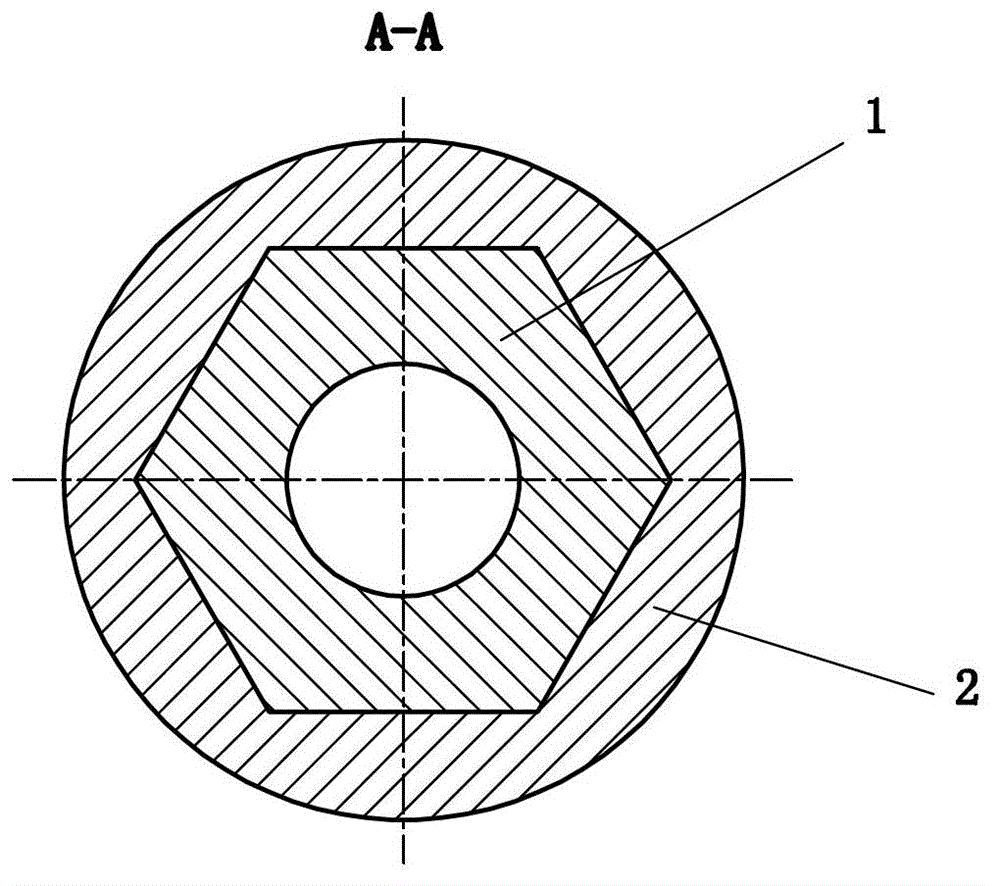

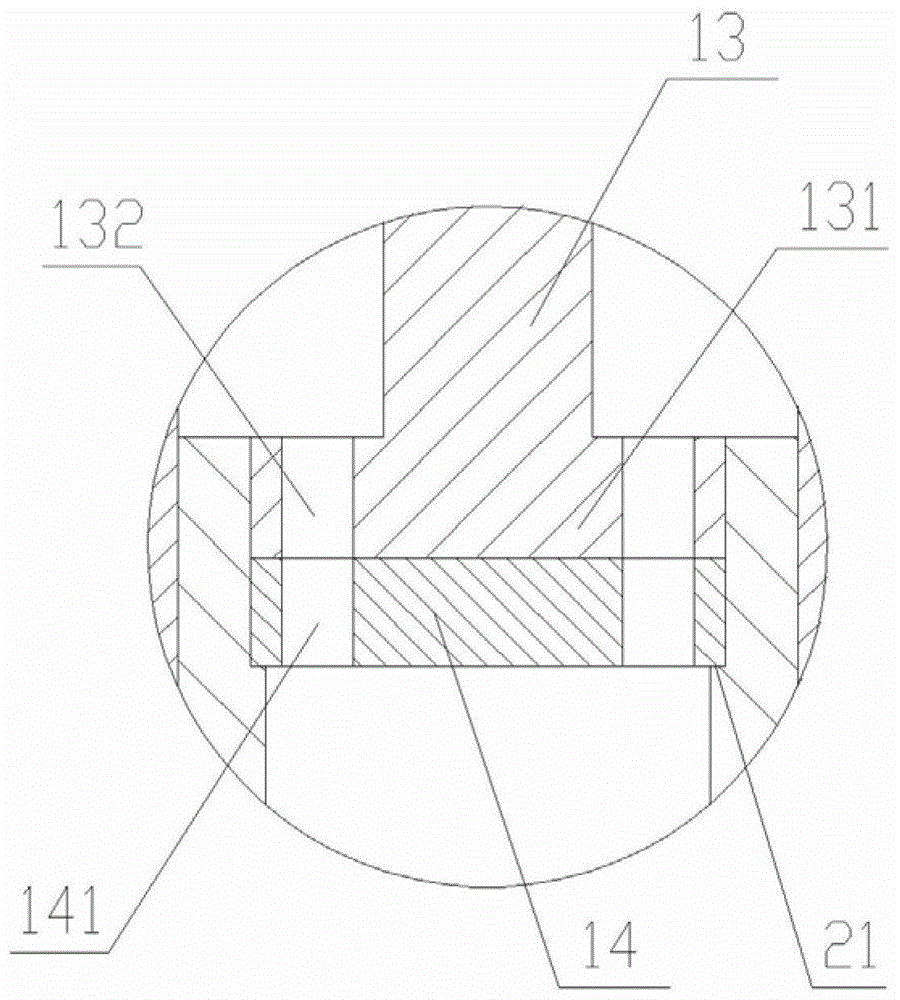

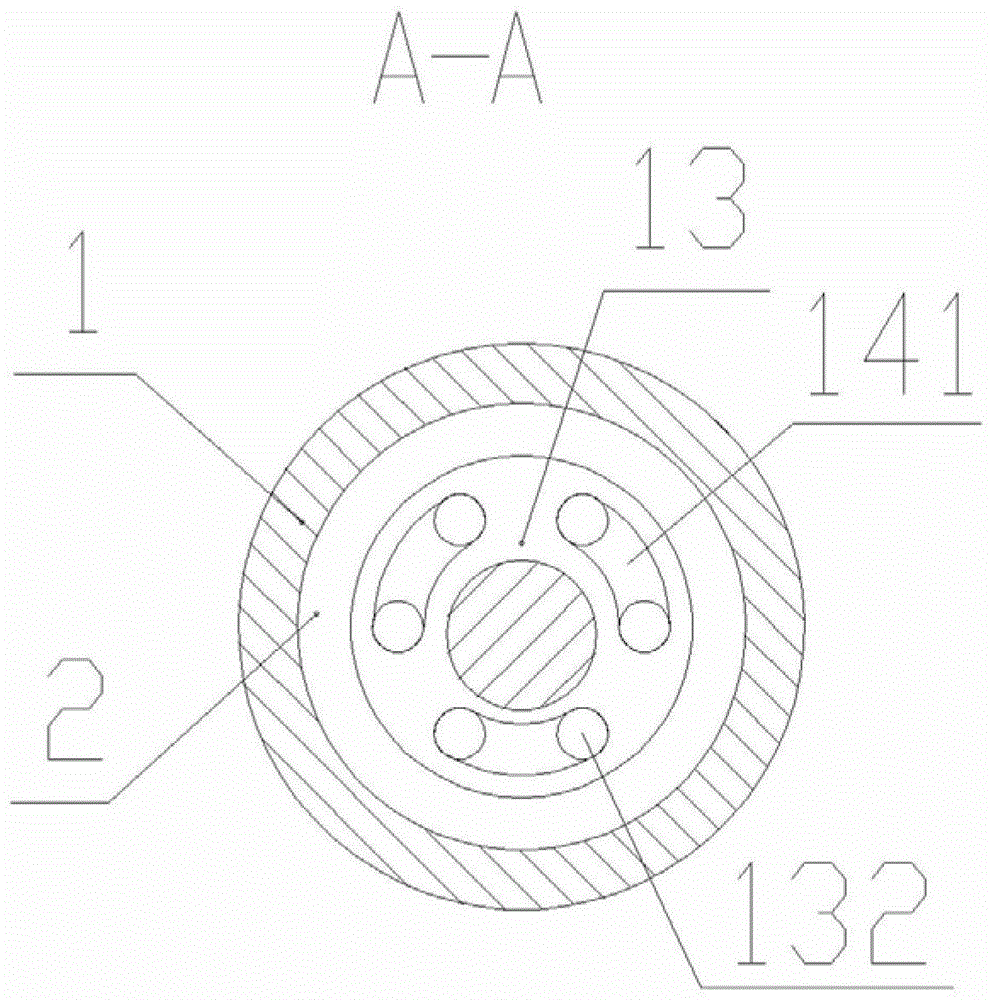

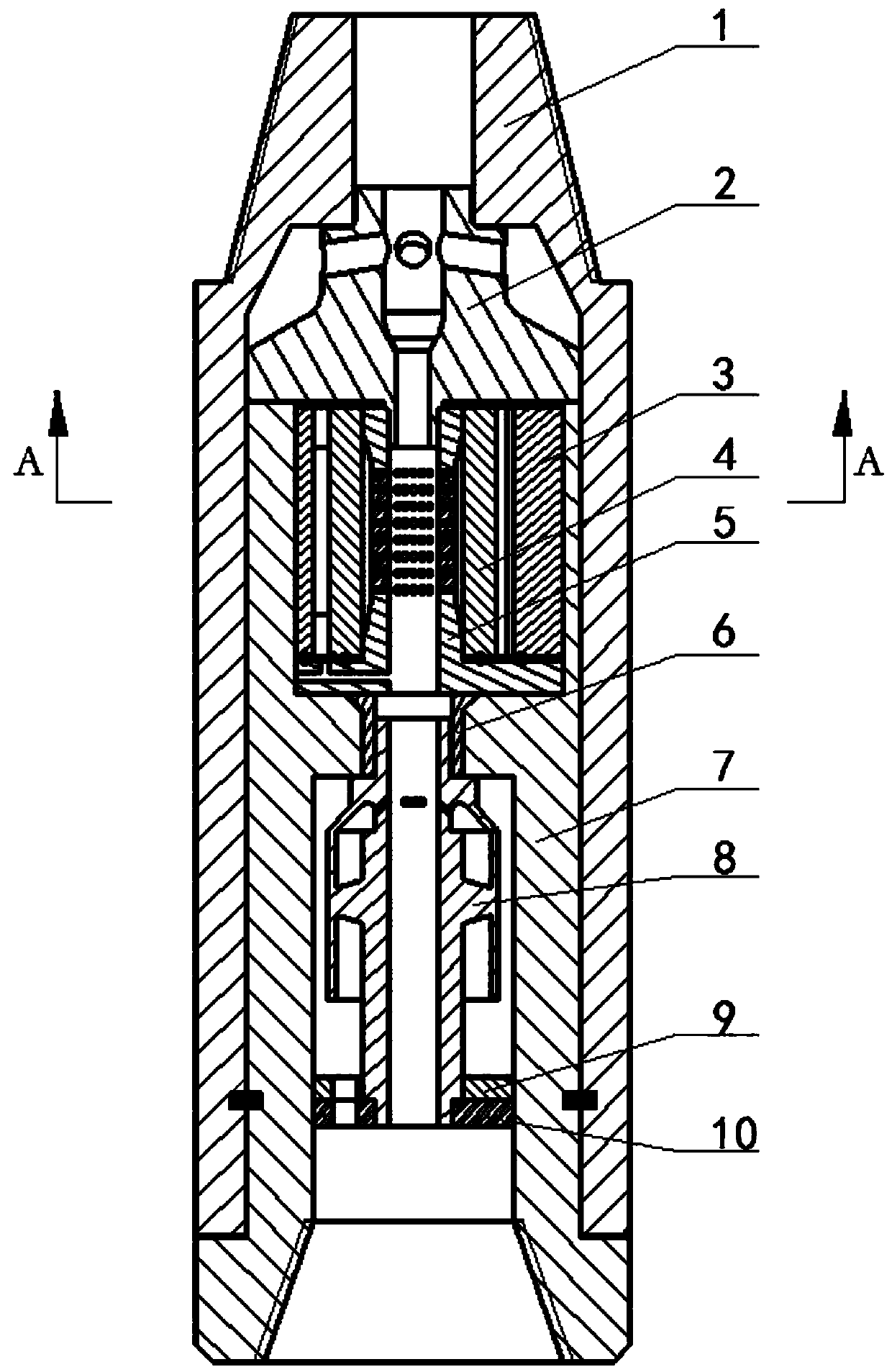

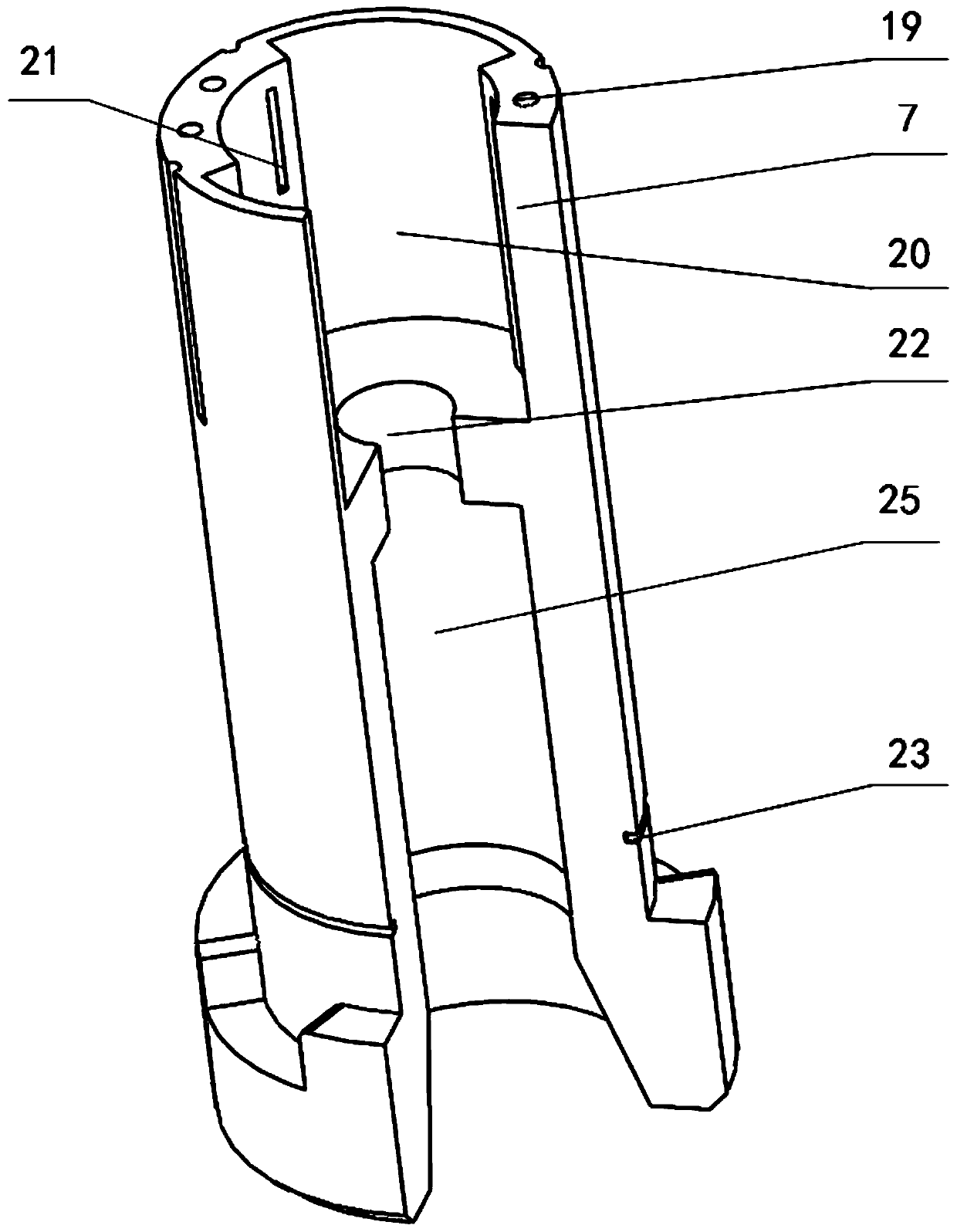

Downhole high frequency pressure pulse generator

The invention discloses an underground high-frequency pressure pulse generator. The underground high-frequency pressure pulse generator comprises a generator housing (1) and a bit short section (2); a connecting shaft (6) and a transmission shaft (13) are arranged inside the generator housing (1) in turn; a power drilling tool rotor (10) and a power drilling tool stator (11) which are matched with each other are arranged between the transmission shaft (13) and the generator housing (1); one end of the transmission shaft (13) is provided with a flange plate (131); a throttle plate (14) is arranged to be closely connected with the flange plate (131); the flange plate (131) is provided with a water hole (132); the throttle plate (14) is provided with a water channel (141). Compared with the existing drilling device, high-frequency pressure pulses are applied to a bit and accordingly the underground environment can be improved, the cuttings carrying capacity of the drilling fluid can be improved, the hold-down effect of the drilling fluid can be effectively reduced, and the drilling speed can be improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A hydraulic torsional pulse impactor for drilling speed increase

ActiveCN109025827BExtended service lifeReduce stick-slipVibration drillingWell drillingMechanical energy

The invention relates to the technical field of petroleum drilling, in particular to a hydraulic torsion pulse impactor for drilling acceleration. According to the impactor, a suspension inner drum isarranged in a suspension outer drum, the suspension inner drum can rotate in the suspension outer drum, the upper portion of the suspension inner drum is designed as a hydraulic impact base, two sector-shaped power cavities are symmetrically formed in the inner wall of the hydraulic impact base, multiple second circulation grooves are formed in the outer wall of the hydraulic impact base and communicated with a circulation passage in the side wall of the hydraulic impact base, and a flow diversion pressing cover is connected to the upper end of the hydraulic impact base. A high-frequency torsion impact force is circumferentially supplied to a PDC drill bit, and a pulse impact force is provided axially; therefore, an assistance is provided for breaking rock through the drill bit, the sticky degree of a drilling column is decreased, the mechanical drilling speed is increased, tools are simple in structure, few fragile components are adopted, and the energy of drilling liquid is ingeniously converted into mechanical energy in order to increase the drilling speed and prolong the service life of the drill bit.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

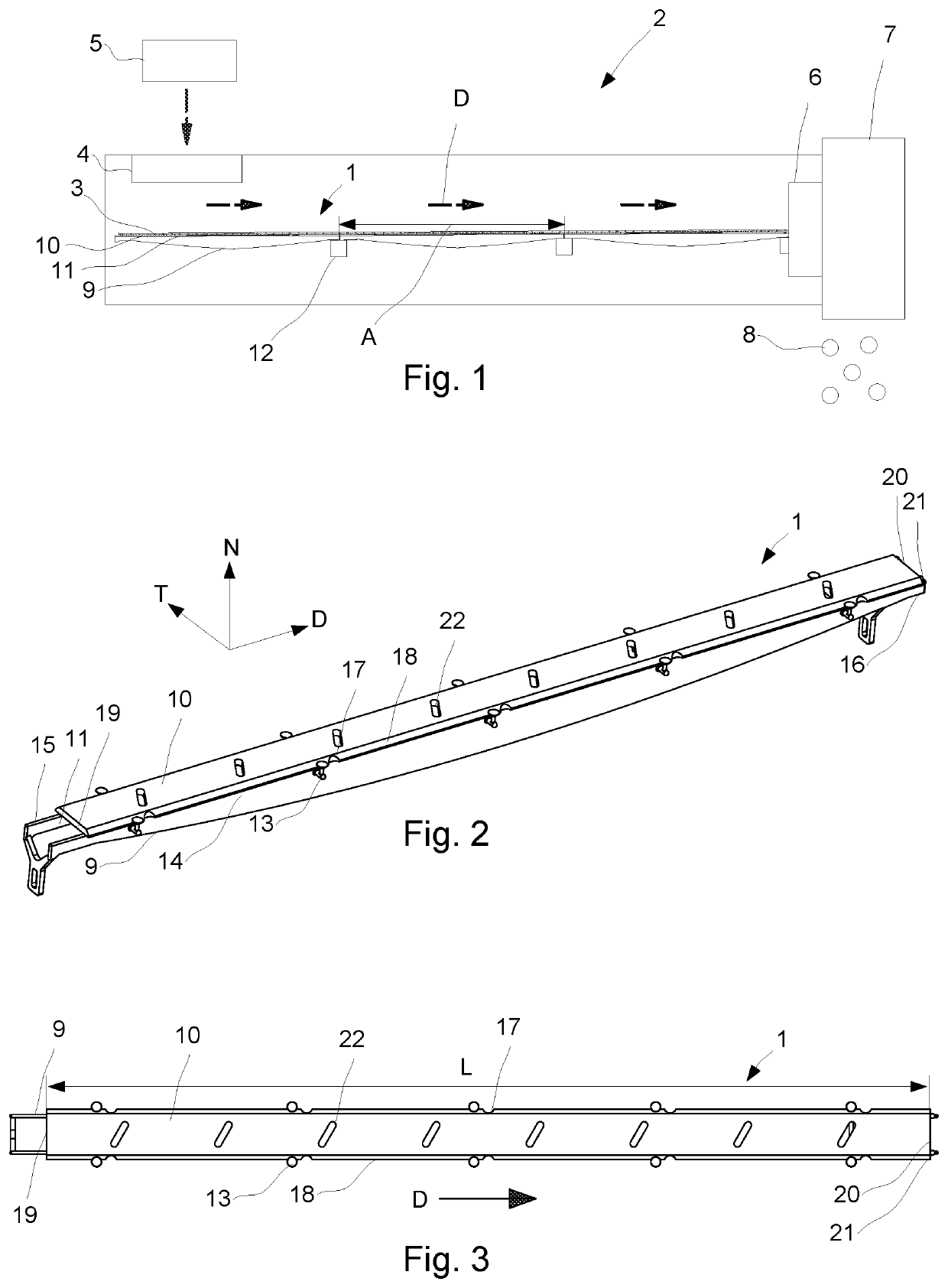

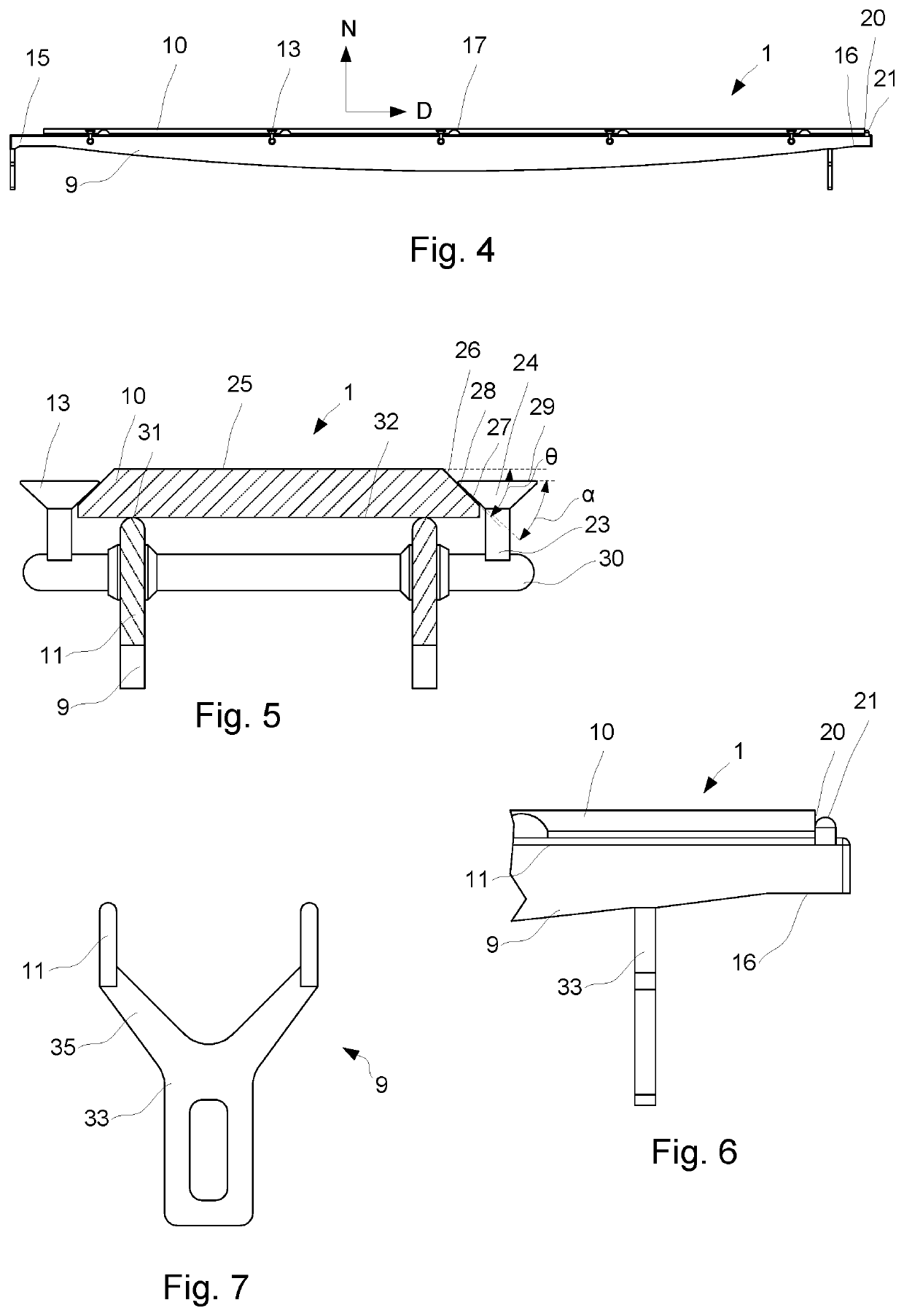

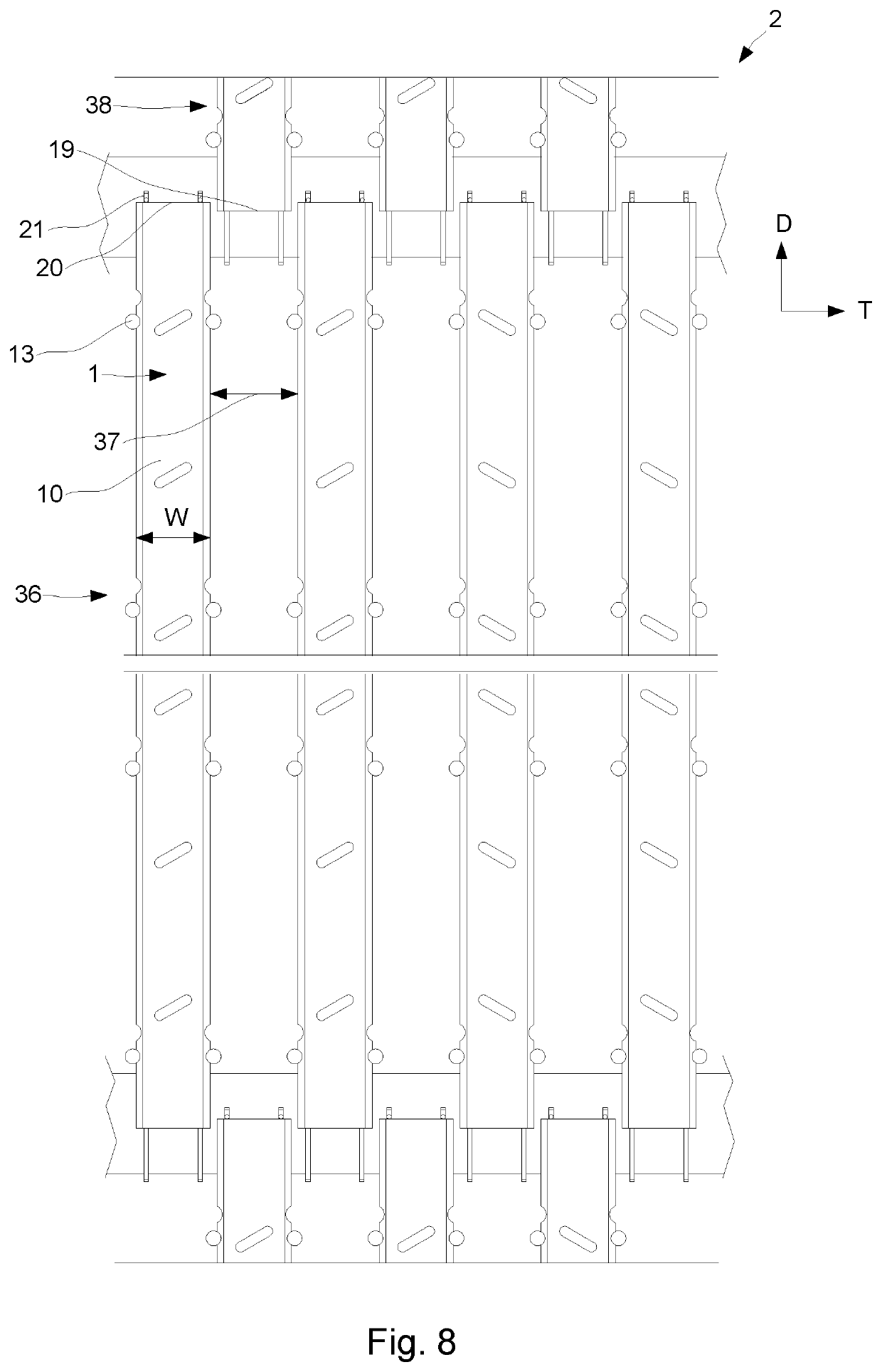

Support structure for whey draining belt

PendingUS20220192217A1Extend belt lifeReduce coefficient of frictionCheese manufacturePlastic materialsPhysical chemistry

A support structure for a whey draining belt includes a beam formed of a metal material, and a slide plate formed of a plastic material and fixedly connectable to an upper part of the beam for allowing the whey draining belt to slide over the slide plate.

Owner:TETRA LAVAL HLDG & FINANCE SA

Anti-Stage Tools to Avoid Sticking and Reduce Stick-Slip

ActiveCN106567681BReduce stick-slipDrilling smoothlyDrilling rodsDrilling casingsEngineeringScrew thread

The invention discloses an anti-seizing tool capable of avoiding drill clamping and reducing sticky slipping to solve the problem that the rock breaking efficiency is low due to clamping and slipping in the drilling process. According to the main technical scheme, an upper connector, an upper shell, an adapter and a lower shell are sequentially connected through a thread; a compression spring is mounted on a compression spring guide rod, the low end of the compression spring guide rod pushes an anti-falling connector to enable a mandrel to stretch, and the anti-falling connector is connected with a mandrel thread and axially positioned through an adapter shaft shoulder; a steel wire rope system is arranged in a left-rotation mode, the upper and lower ends of the steel wire rope system are separately fixed to the lower end of the adapter and fixed into a circular groove in the upper end of a mandrel boss, the upper and lower ends of steel wire ropes are mounted by 30-40 degrees in an inclined mode, and the steel wire ropes are in a tensional state initially; during work, drilling pressure is transferred to the mandrel through the compression spring, and torque is transferred to the mandrel through the steel wire rope system; and when the mandrel rotates backwards, the steel wire rope system retracts to enable the mandrel to compress the compression spring to axially retract so as to decrease the cutting depth of a drill bit, and the drill bit is in a rock mass in the whole process.

Owner:沛县昌运机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com