Compound vibrating well-drilling tool

A drilling tool and compound vibration technology, applied in the direction of vibration drilling, etc., can solve the problems of low drilling efficiency and achieve the effects of prolonging the life of the drill bit, increasing the rate of penetration, and reducing the cost of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In this embodiment, the place where the drilling fluid enters the drilling tool is defined as the upper part, and the place where the drilling fluid exits the drilling tool is defined as the lower part; each sub joint mentioned below has a hollow channel for the liquid to flow.

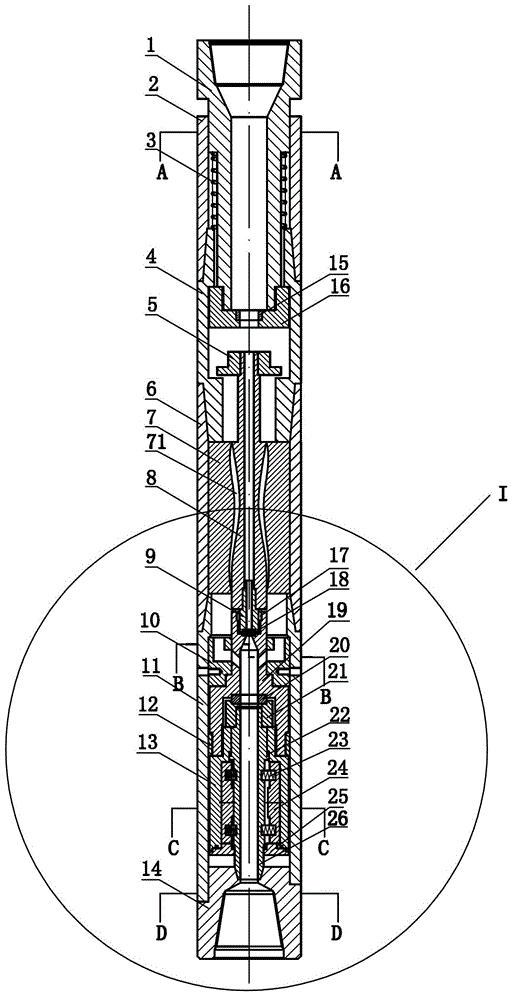

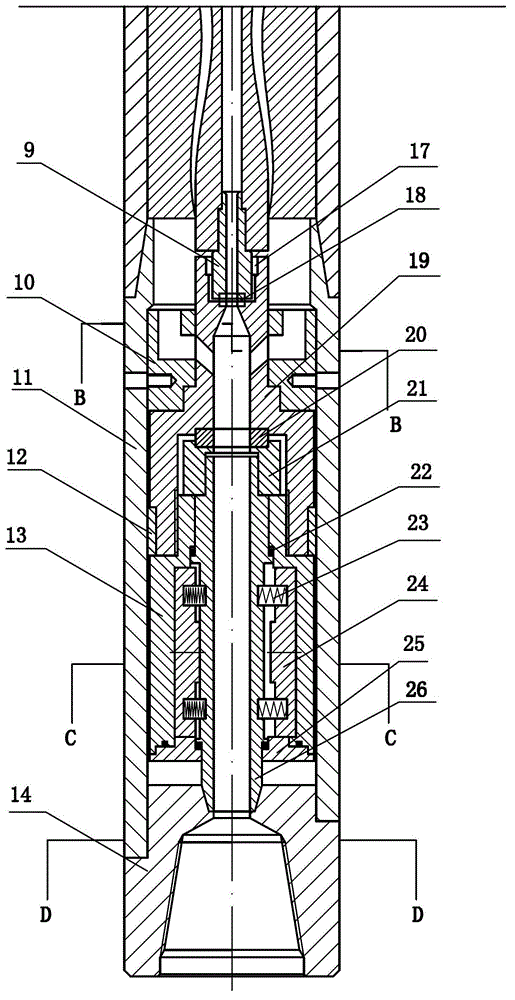

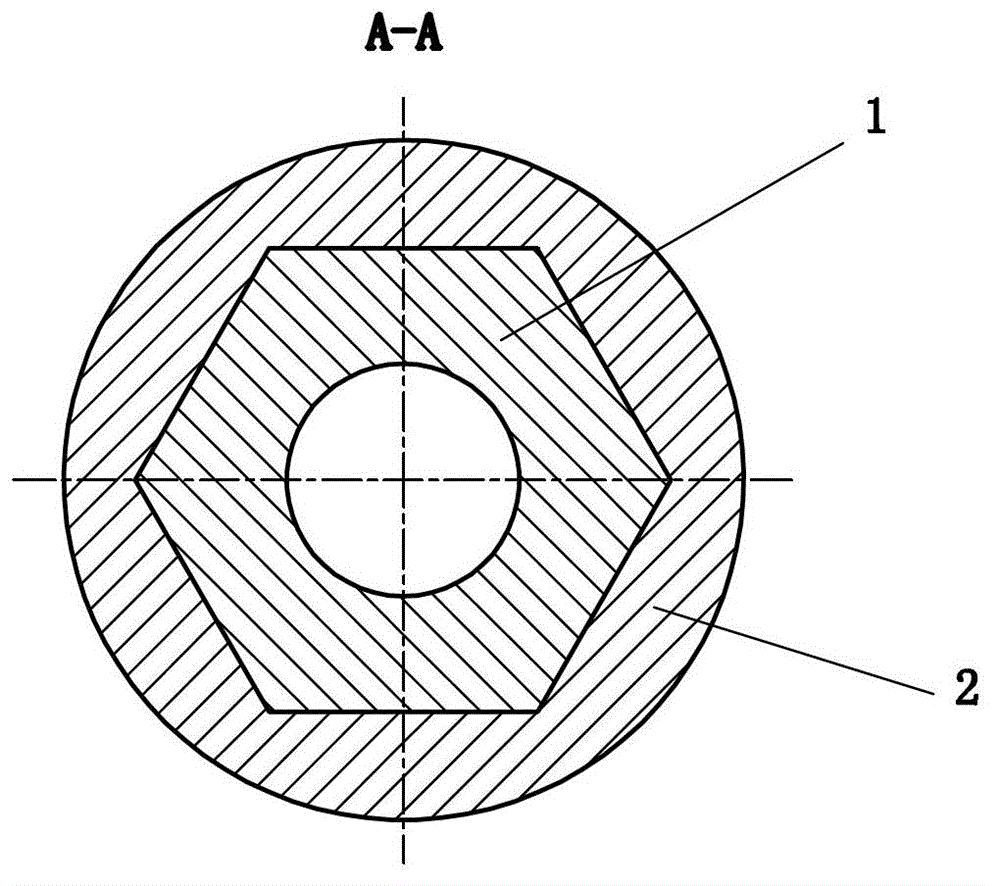

[0029] Such as figure 1 and figure 2 As shown, it is an embodiment of the composite vibration drilling tool of the present invention, including a sleeve, which includes an upper sleeve 2, a middle sleeve 6 and a lower sleeve 11; wherein, the upper sleeve 2 and the middle sleeve The cylinders 6 are connected by double male sleeves 4 . The sleeve adopts a split structure, which facilitates the installation and disassembly of its internal components, and is easy to manufacture.

[0030] A vibrating nipple 1 is installed inside the upper sleeve 2, and the bottom of the vibrating nipple 1 is threadedly connected with a vibrating nipple chuck 16. The bottom of the vibrating nipple chuck 16 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com