A high temperature gas spiral purification device

A purification device and high-temperature gas technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problem of inability to meet resource recycling and environmental protection, energy-saving and high-efficiency development, inability to adapt to high-temperature gas purification occasions, high-temperature gas can not directly To achieve the effect of enhanced separation effect and efficiency, excellent purification and separation effect, stable and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

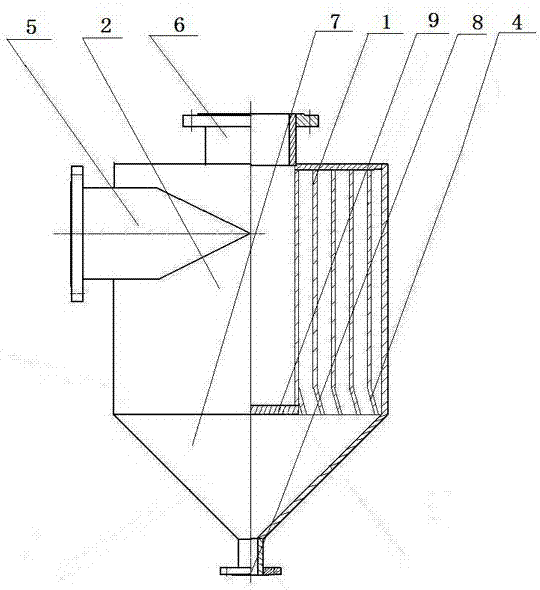

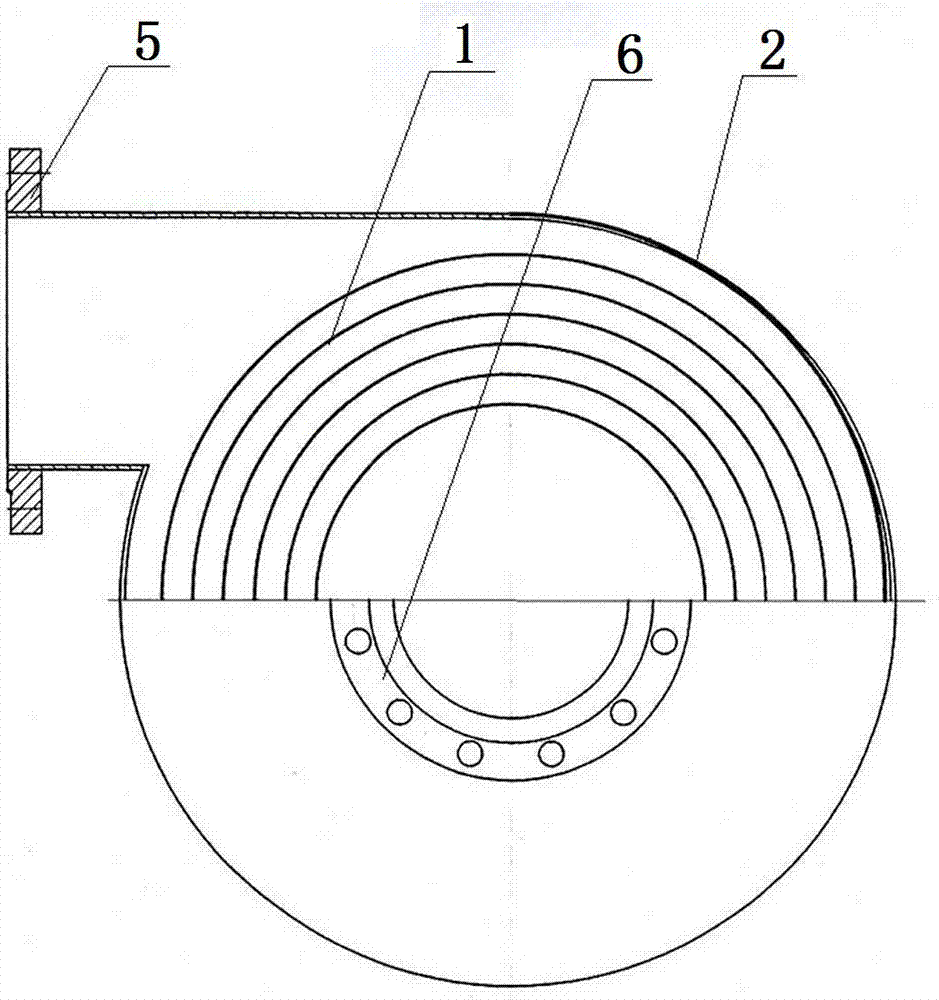

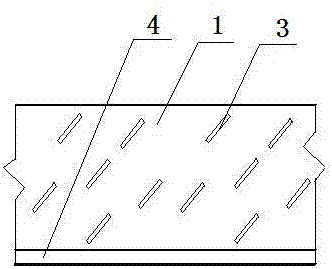

[0010] Figure 1-Figure 3 The high-temperature gas spiral purification device shown in the present invention is a novel spiral purification device designed on the basis of the prior art. Its middle part is the spiral purification main body 2 that is made of spiral plate 1, and described spiral plate 1 is on the inner plate surface, is provided with several slat-shaped collision protrusions 3 with the same inclination angle, and the collision protrusions 3. Arrange and combine according to the quincunx shape and distribute evenly in the horizontal direction. At the same time, the bottom plate part is set as an anti-flooding chamfer 4 inclined to the outside. The inclination angle, length and width of the collision protrusion 3, the inclination angle and height of the anti-flooding chamfer 4 and the size of the blanking gap can be determined according to the actual situation. In general, the inclination angle of the collision protrusion 3 is 40-45° and the inclination angle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com