Patents

Literature

37results about How to "Reduce axial friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

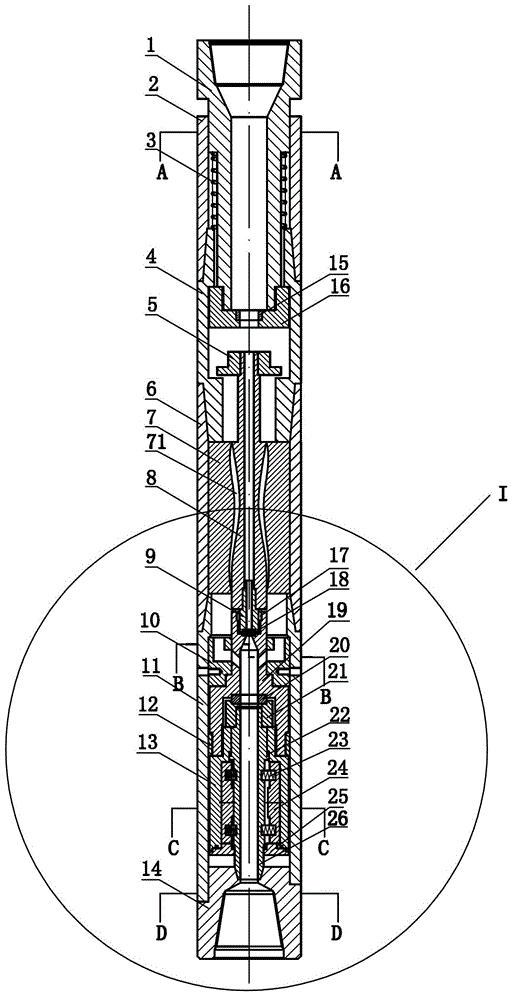

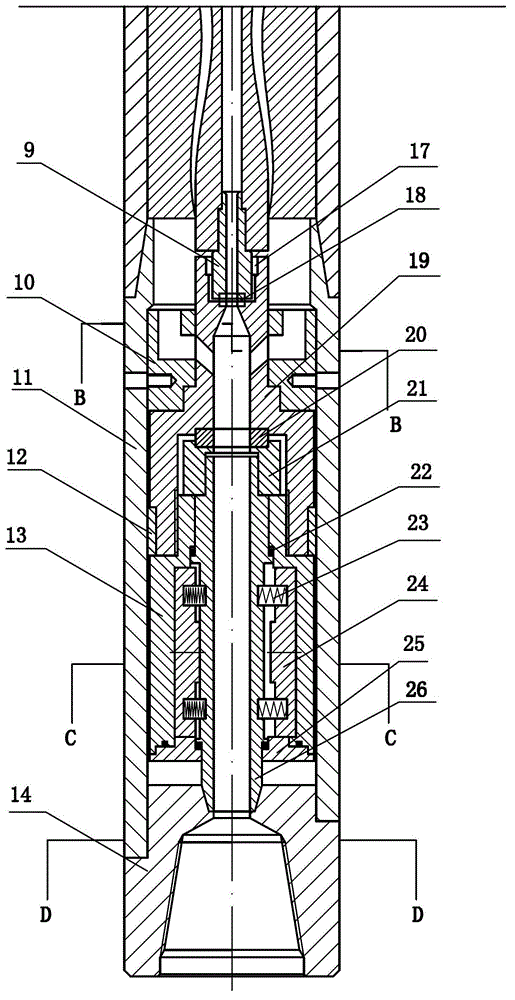

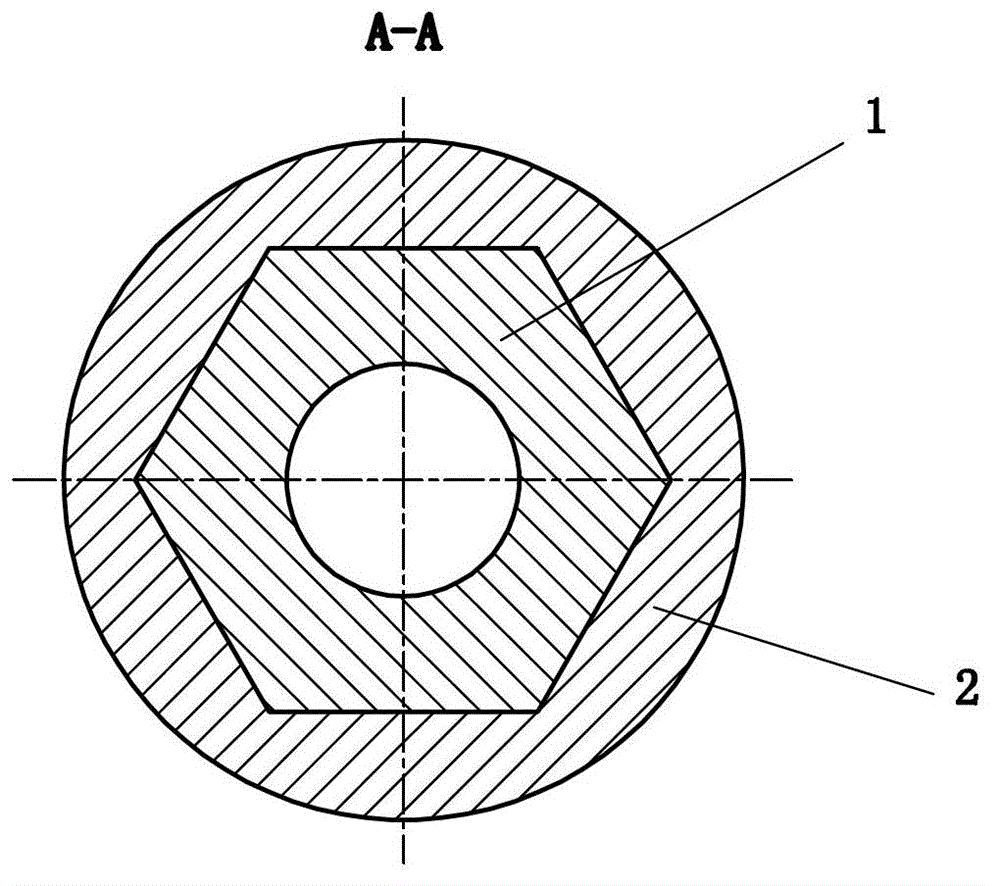

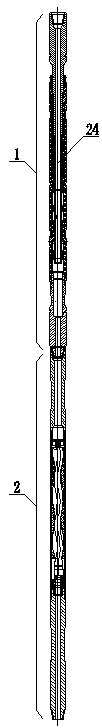

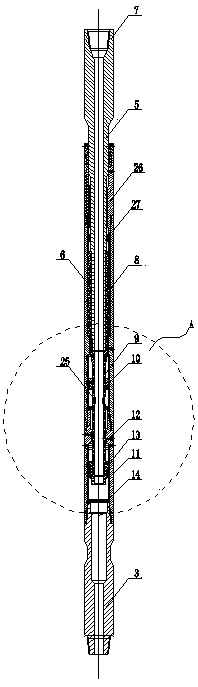

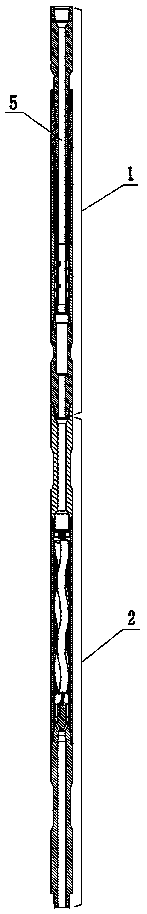

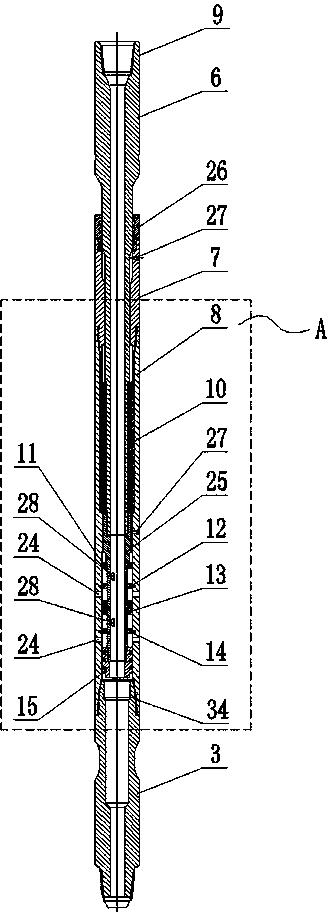

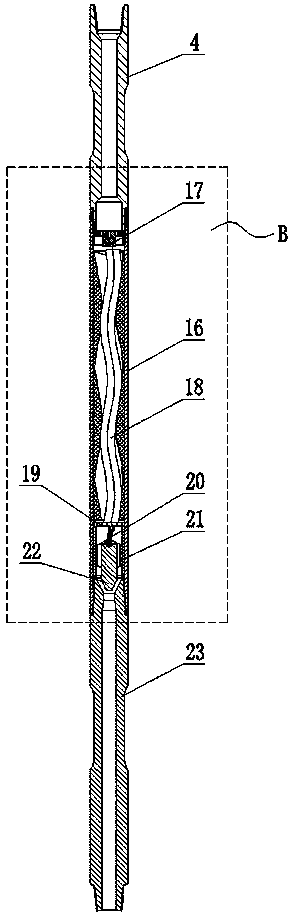

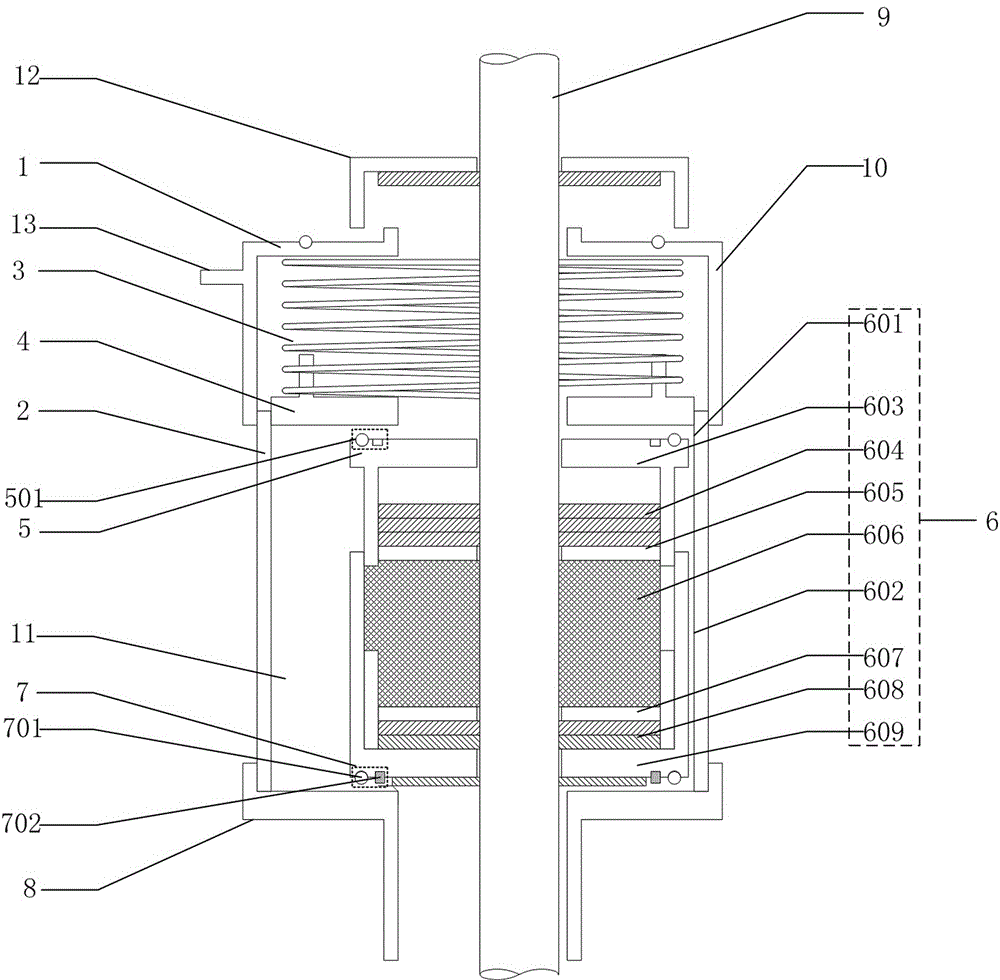

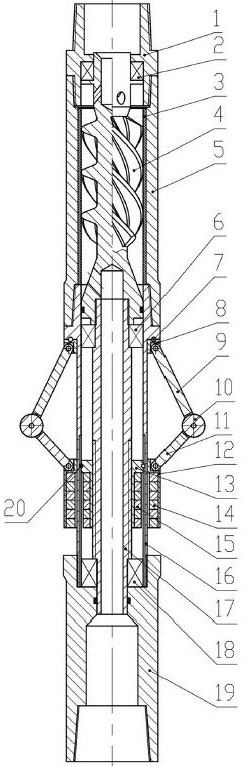

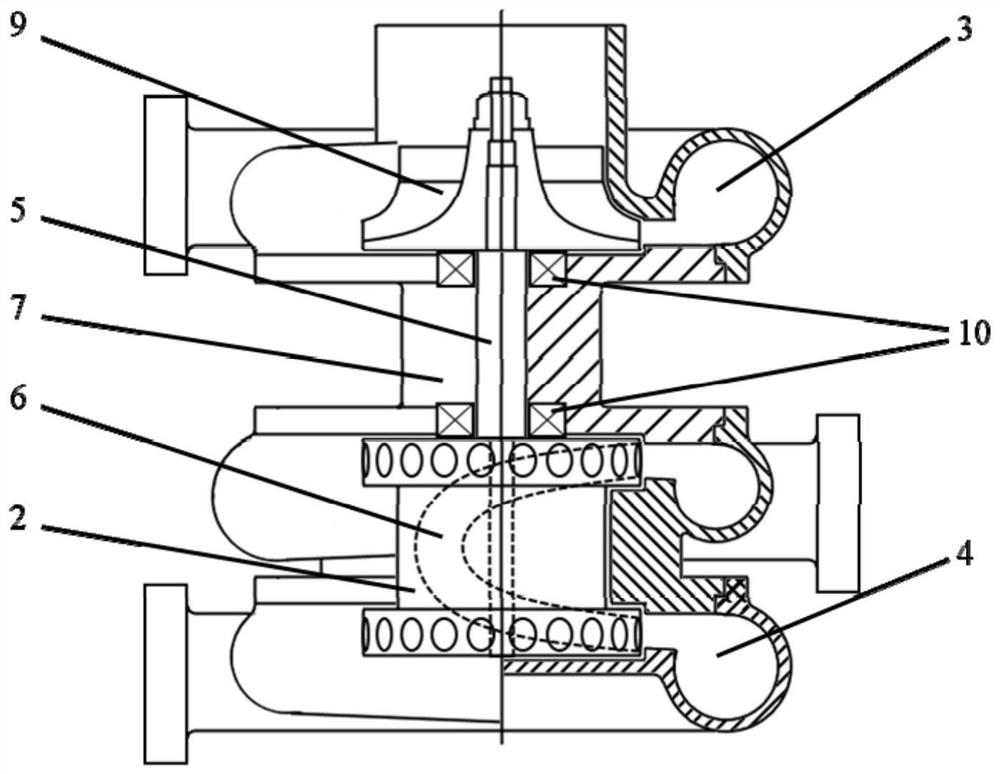

Compound vibrating well-drilling tool

ActiveCN102747958AEliminate \"drag\"Eliminates \"stick-slip\" phenomenonVibration drillingHydraulic cylinderWell drilling

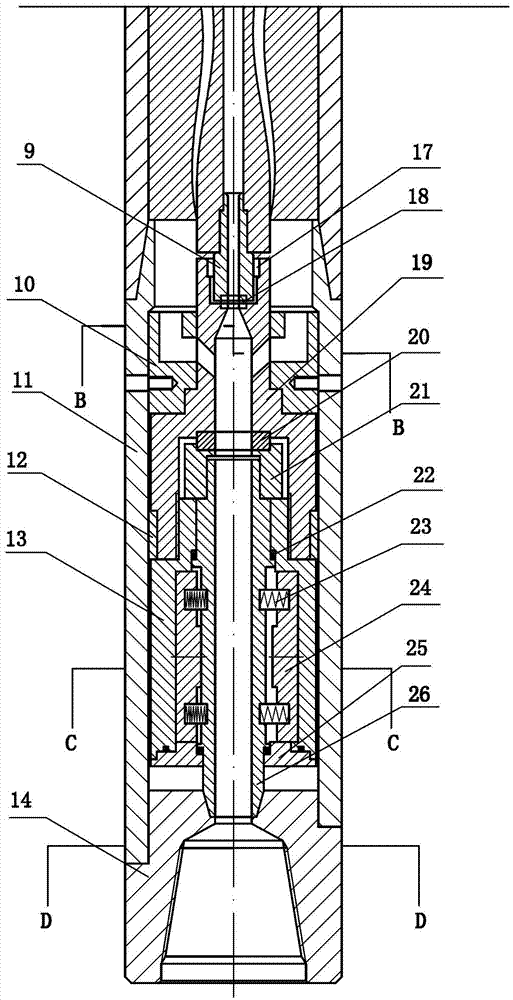

The invention discloses a compound vibrating well-drilling tool which comprises a sleeve, a vibrating short joint, a vibrating short joint chuck, a screw motor, a conversion short joint connected with the lower end of the screw motor, an annular disc sleeved at the upper end of the conversion short joint, a hydraulic cylinder installed at the lower end of the conversion short joint, an impact short joint arranged in an inner cavity of the hydraulic cylinder and a torque transmitting short joint, wherein the vibrating short joint, the vibrating short joint chuck, the screw motor, the conversion short joint, the annular disc, the hydraulic cylinder, the impact short joint and the torque transmitting short joint are arranged in sequence from top to bottom. The well-drilling tool can be installed at different positions in a well-drilling column, the drilling column generate axial and circumferential high frequency compound vibration through the tool, and phenomena including 'pulling press' and 'stick slip' in the large-inclination well drilling process are eliminated, thereby remarkably improving mechanical drilling speed, prolonging the service life of a drill bit and reducing well-drilling cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

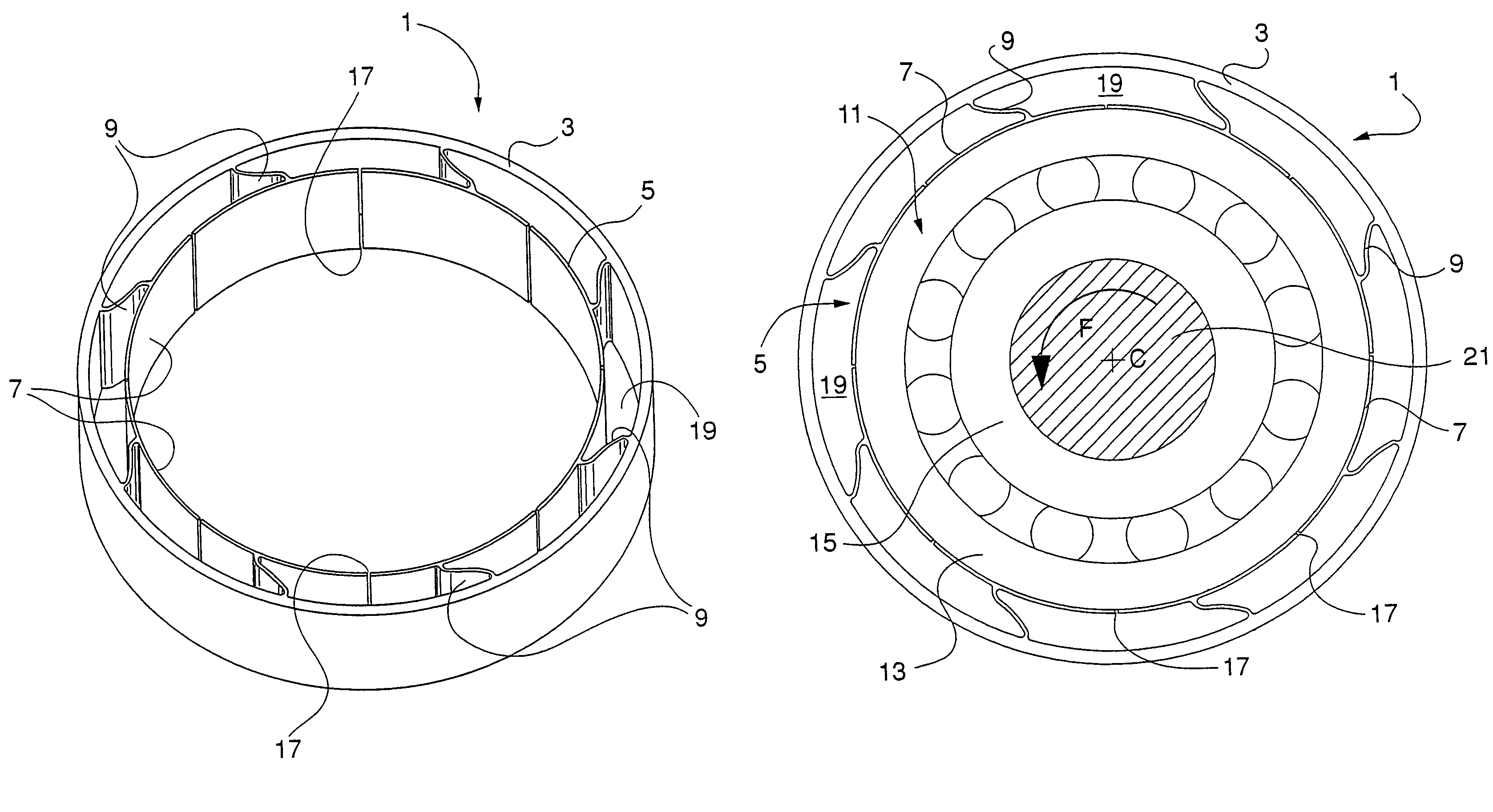

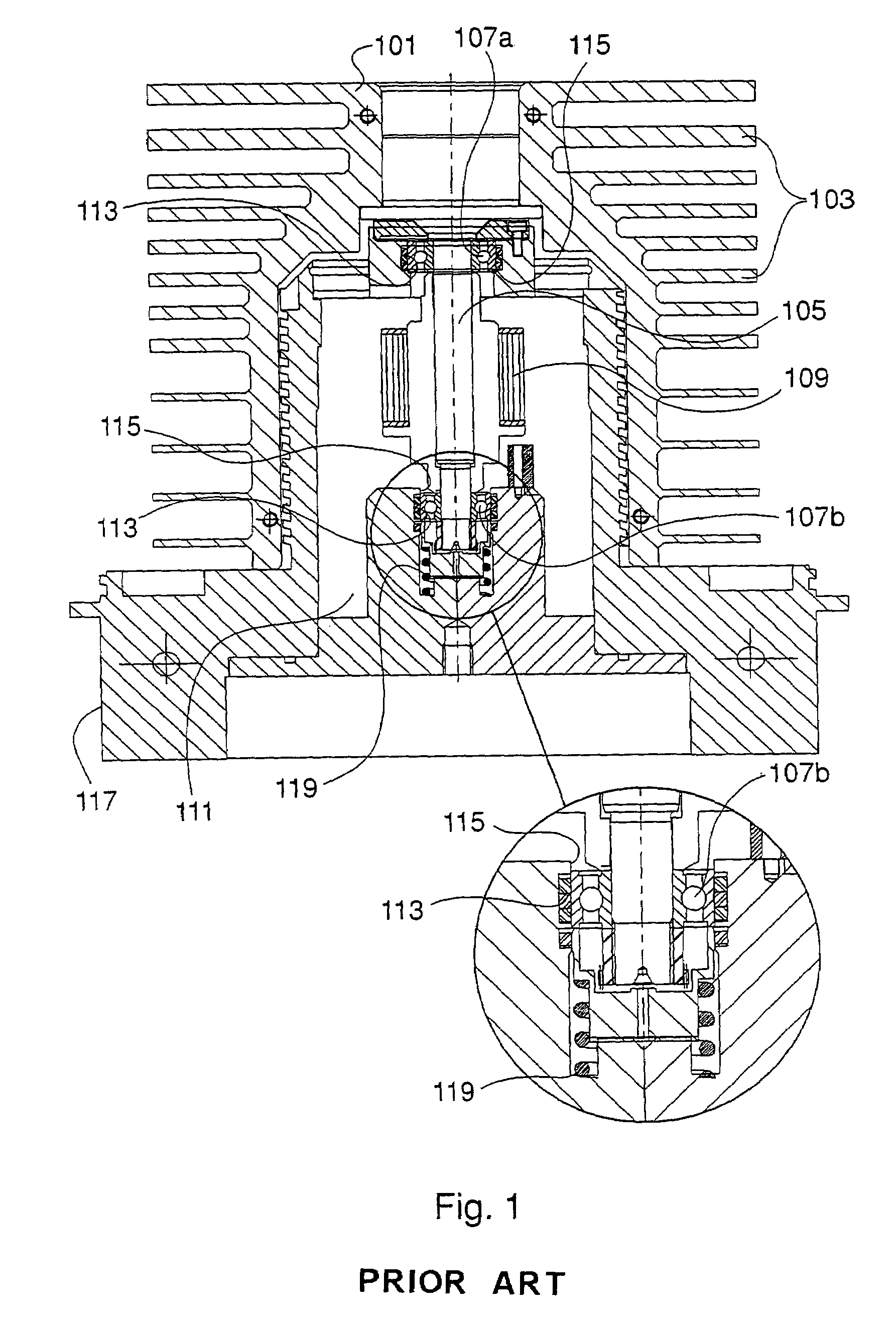

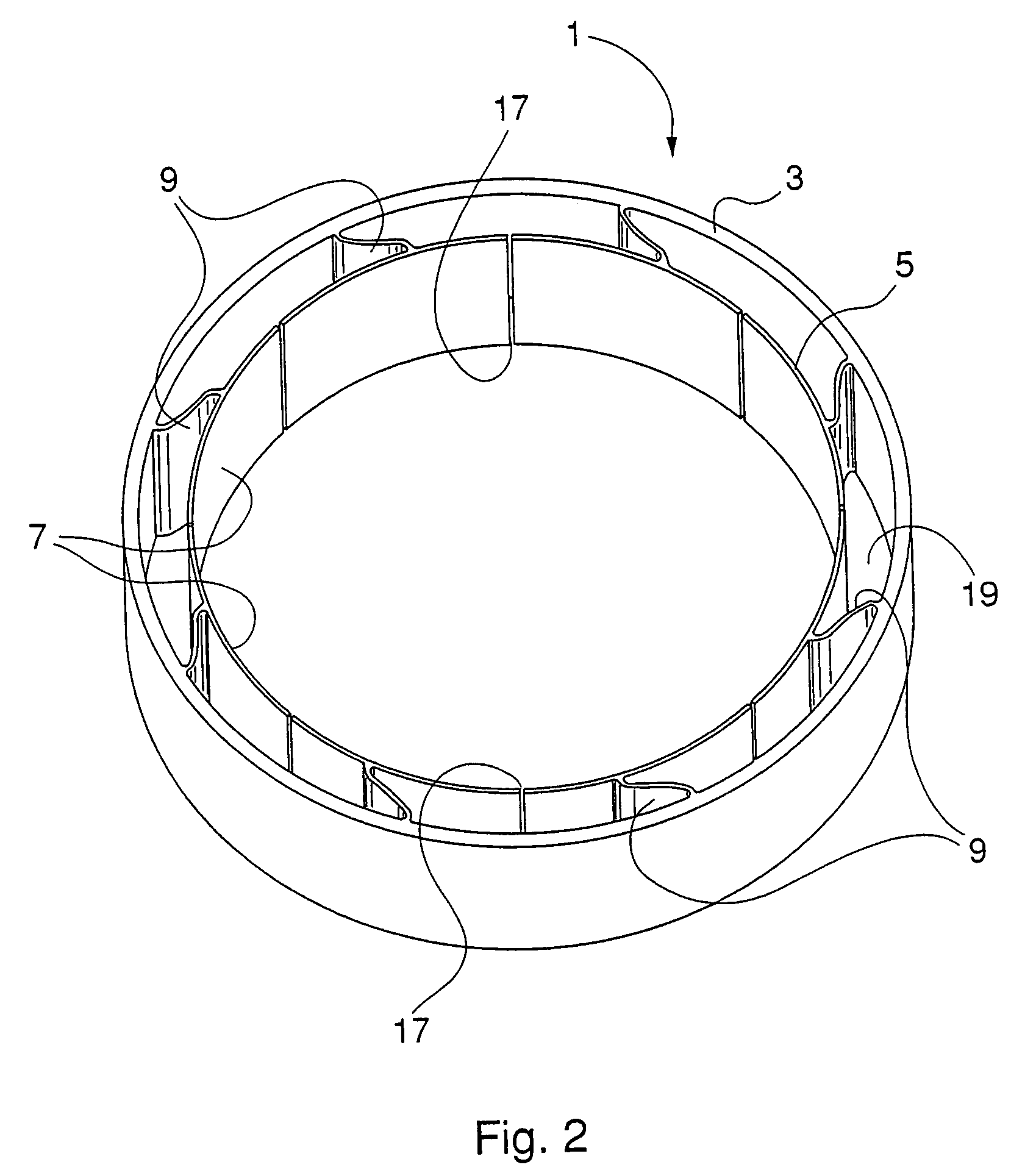

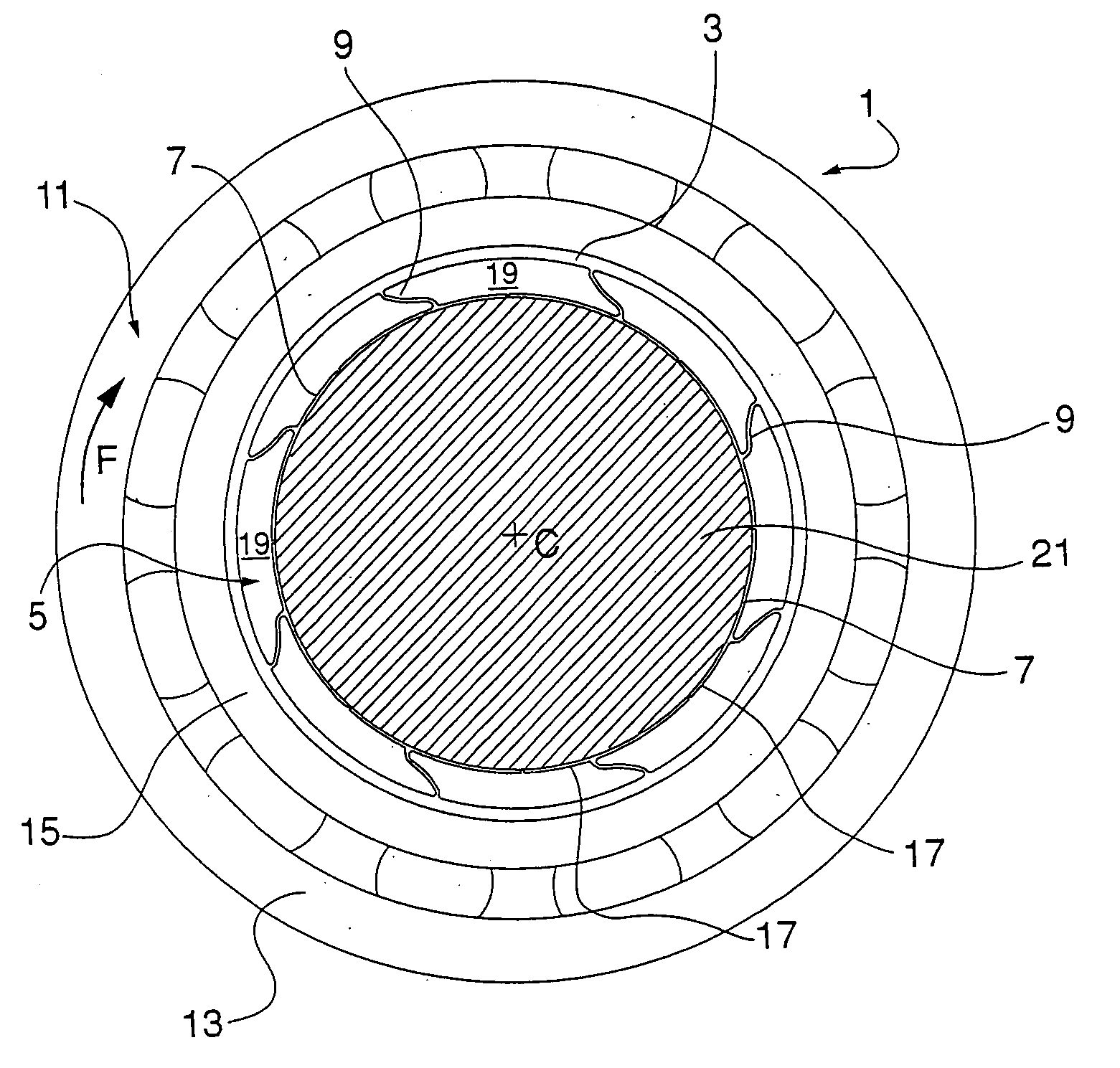

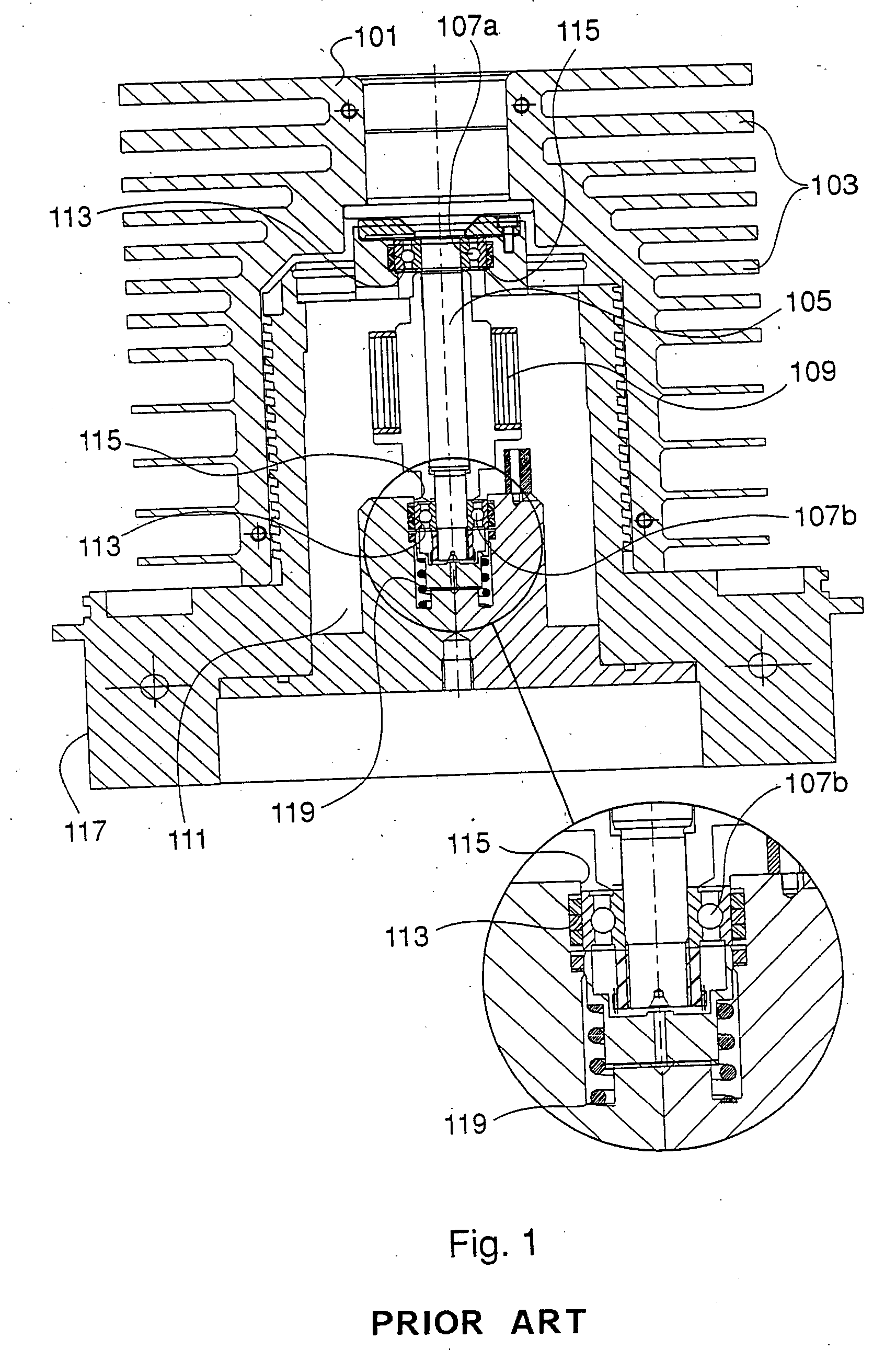

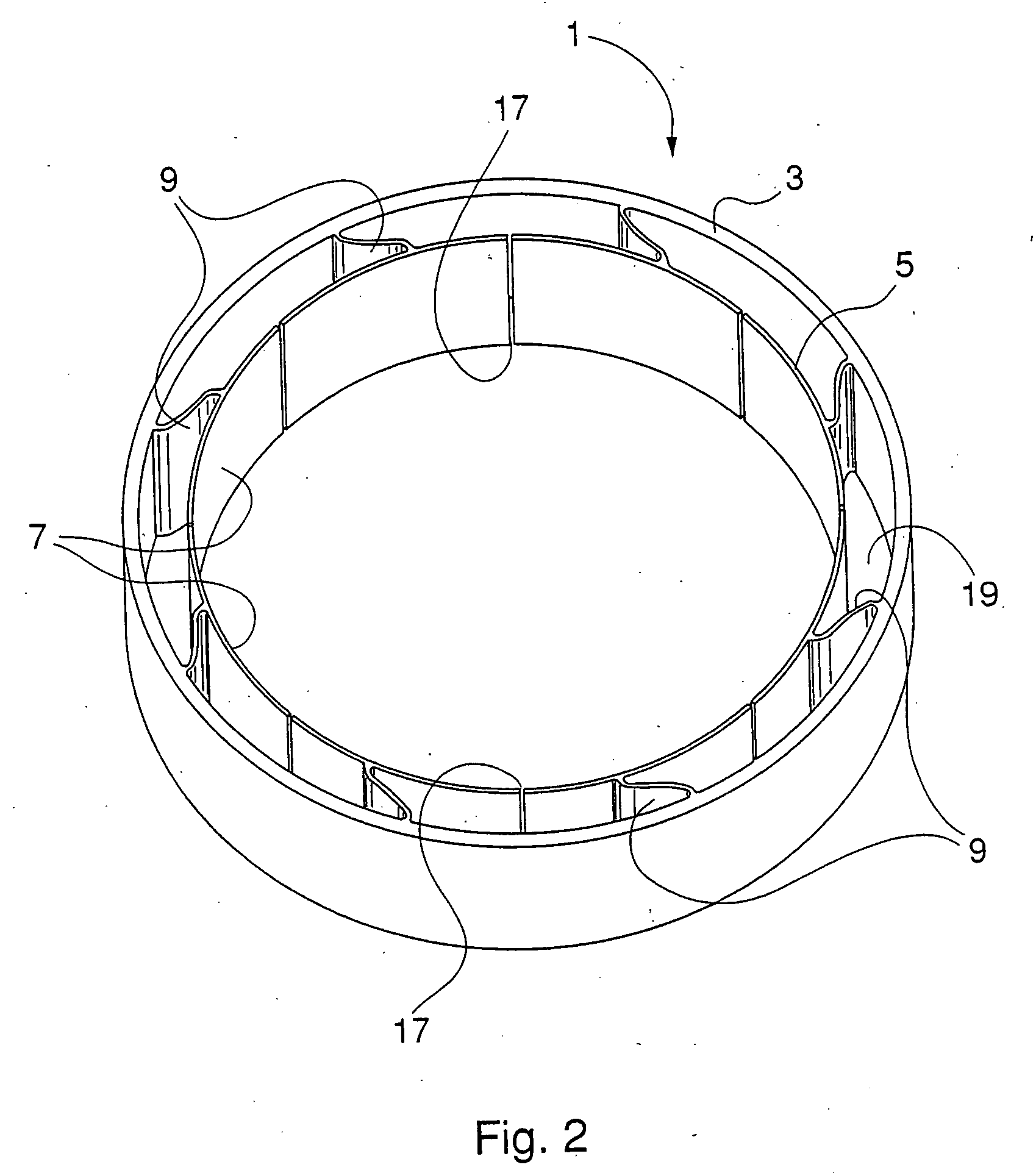

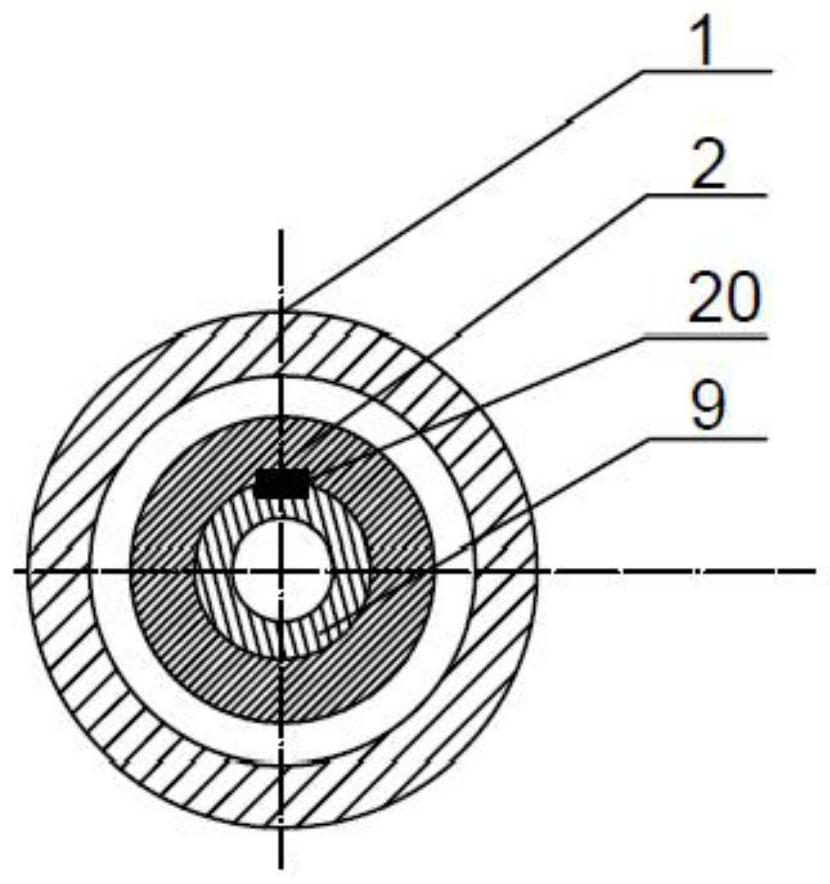

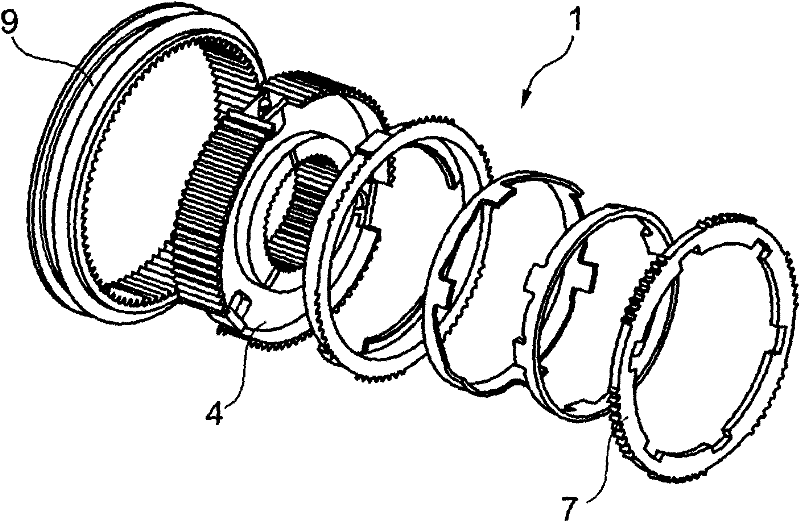

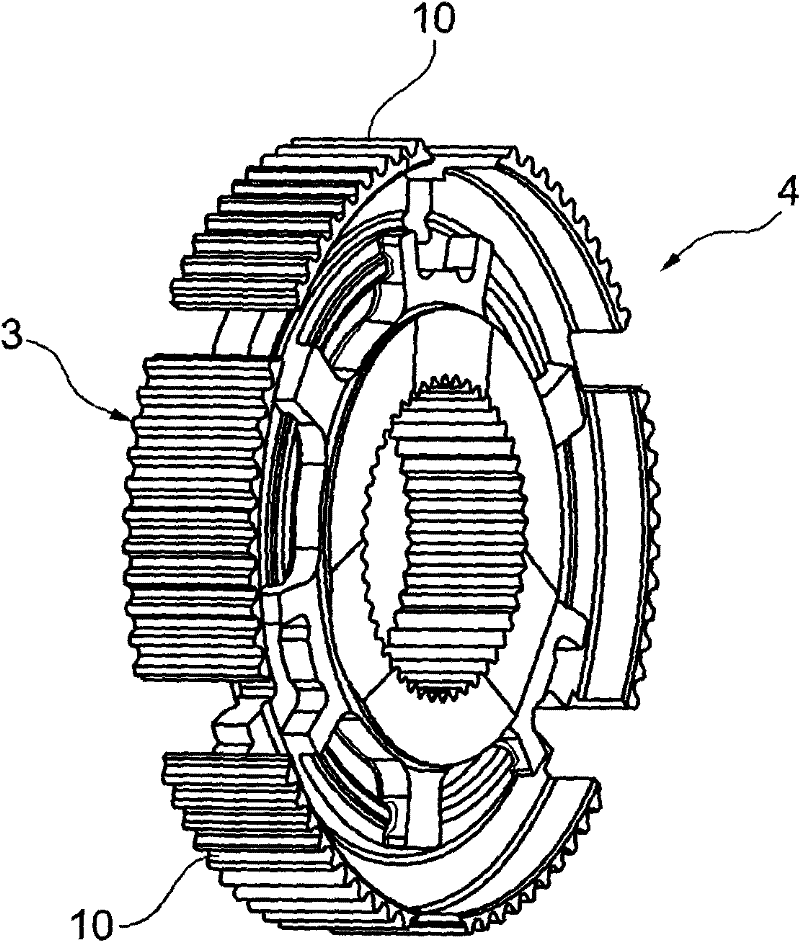

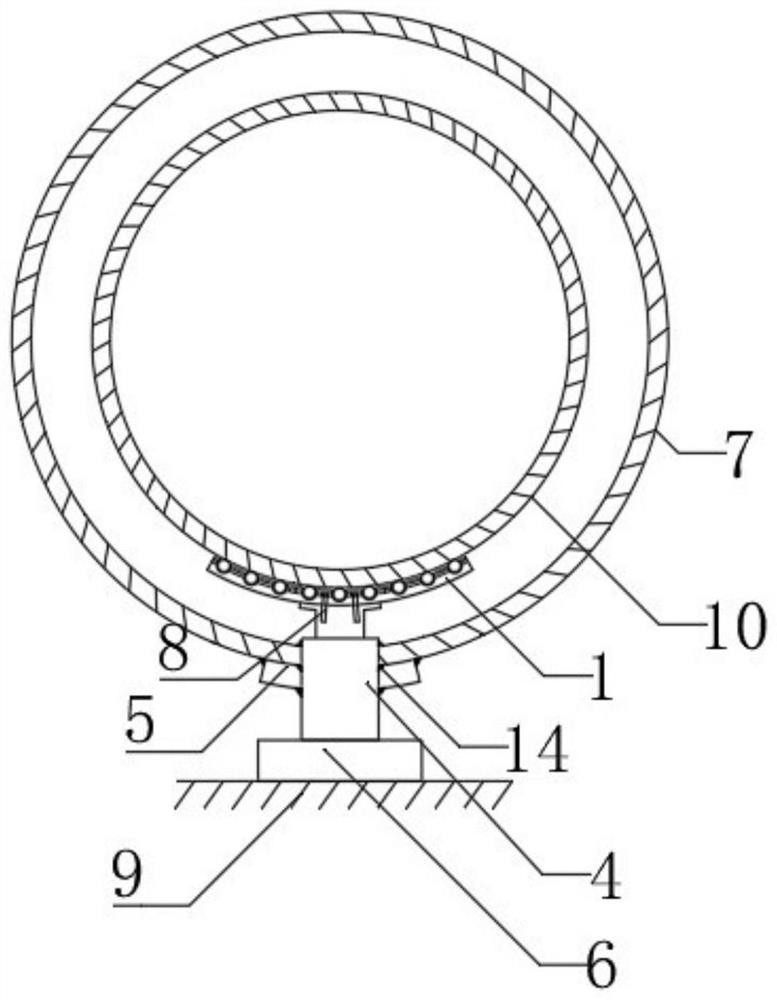

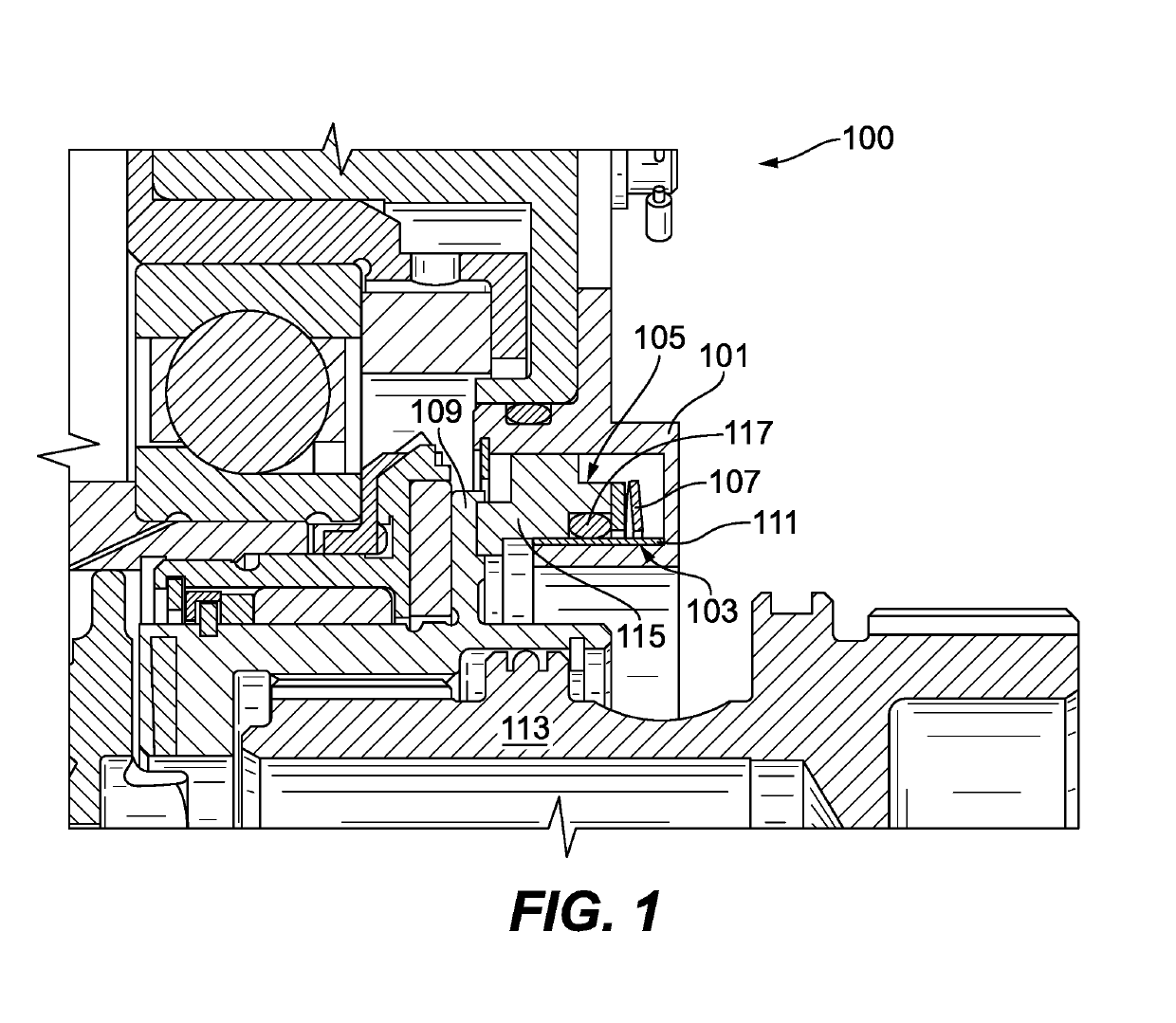

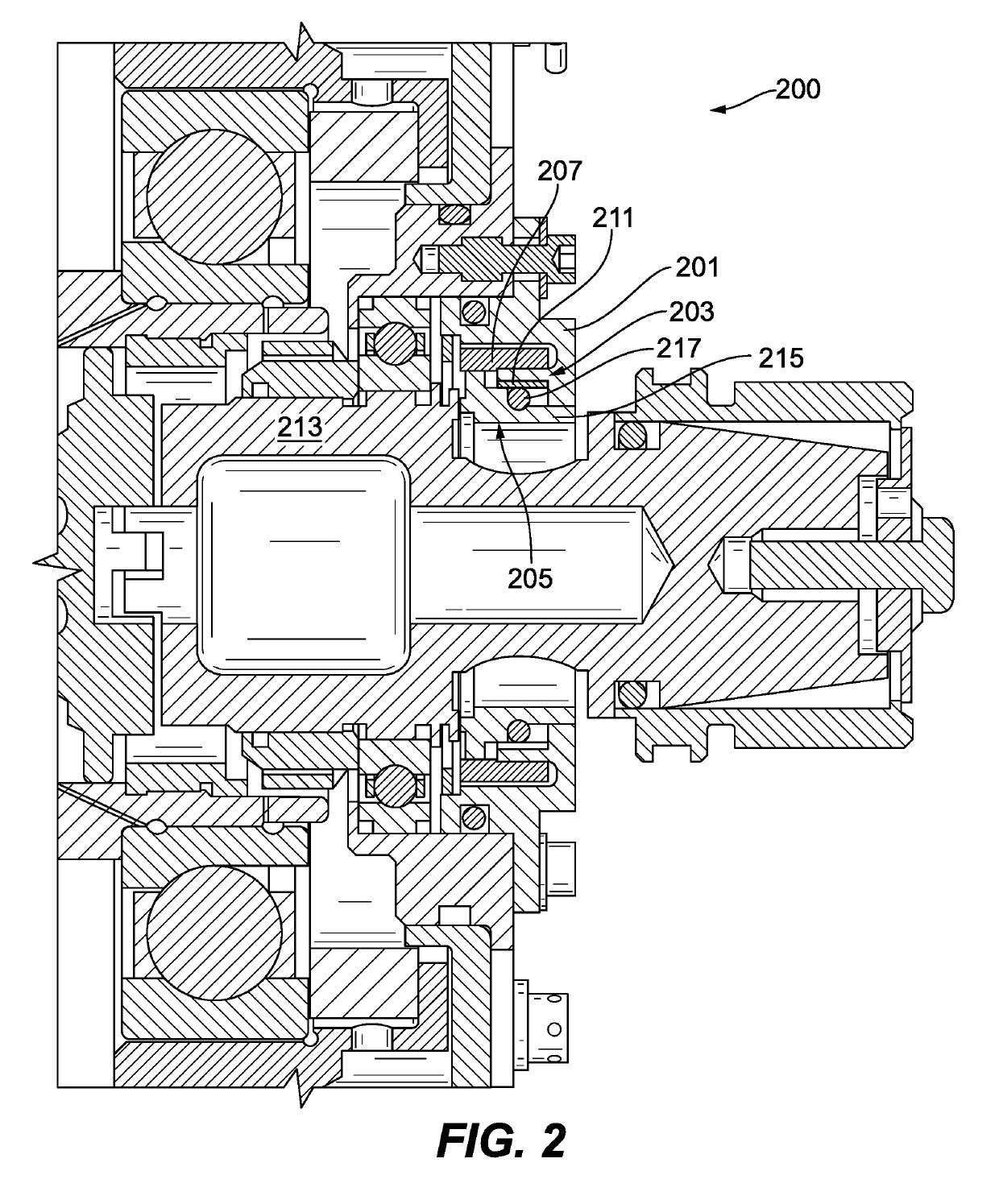

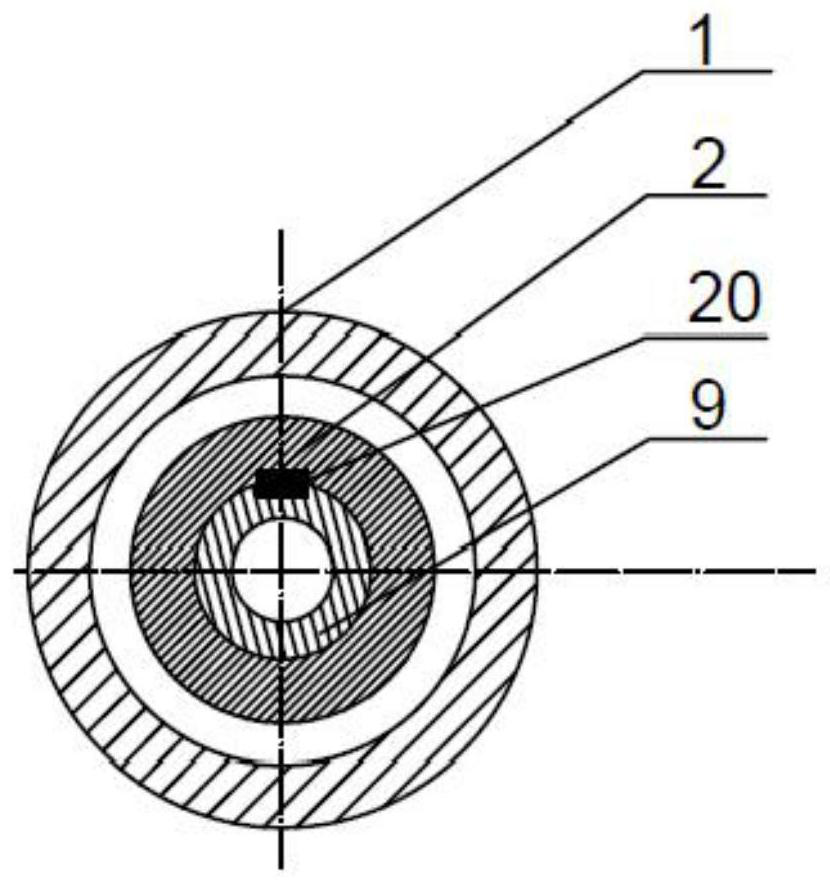

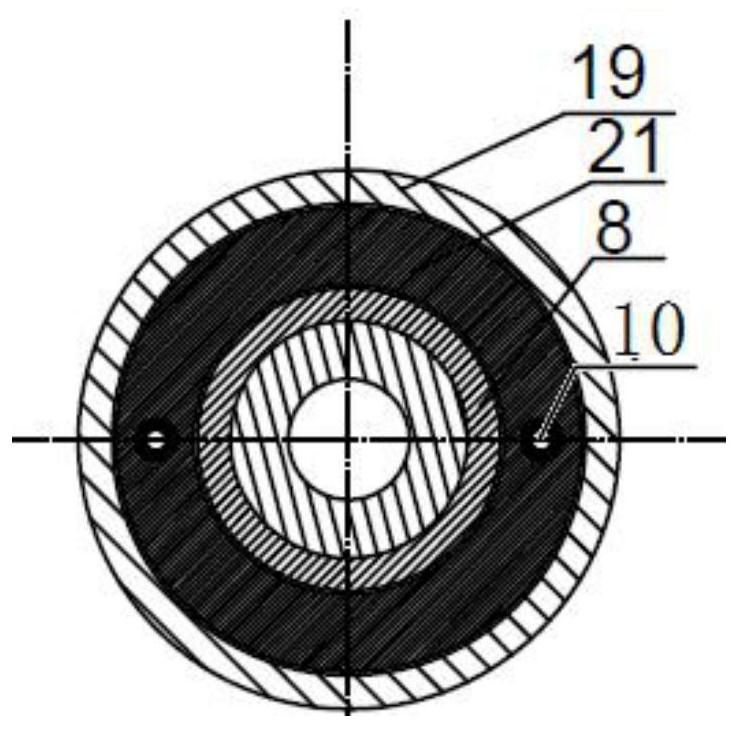

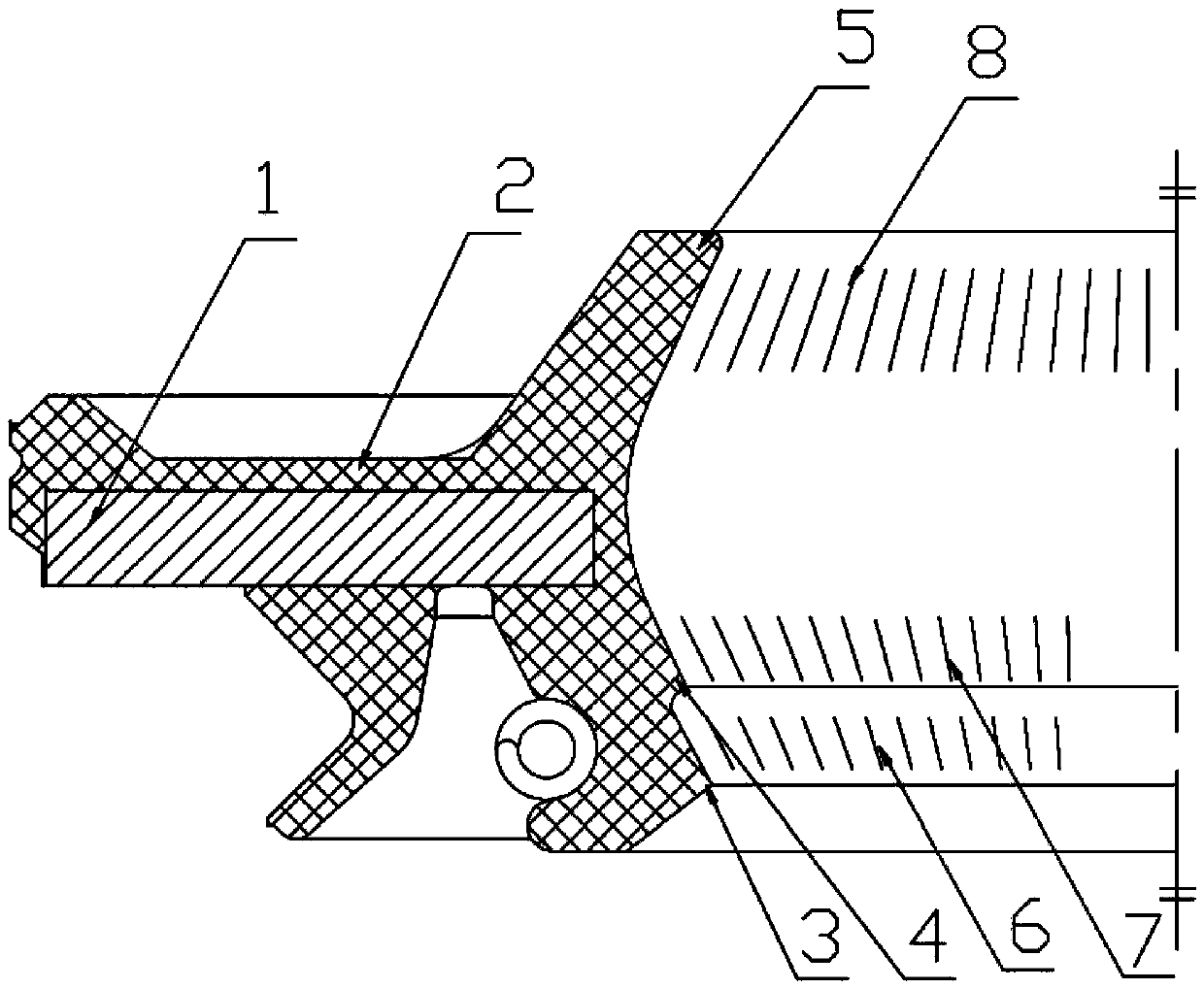

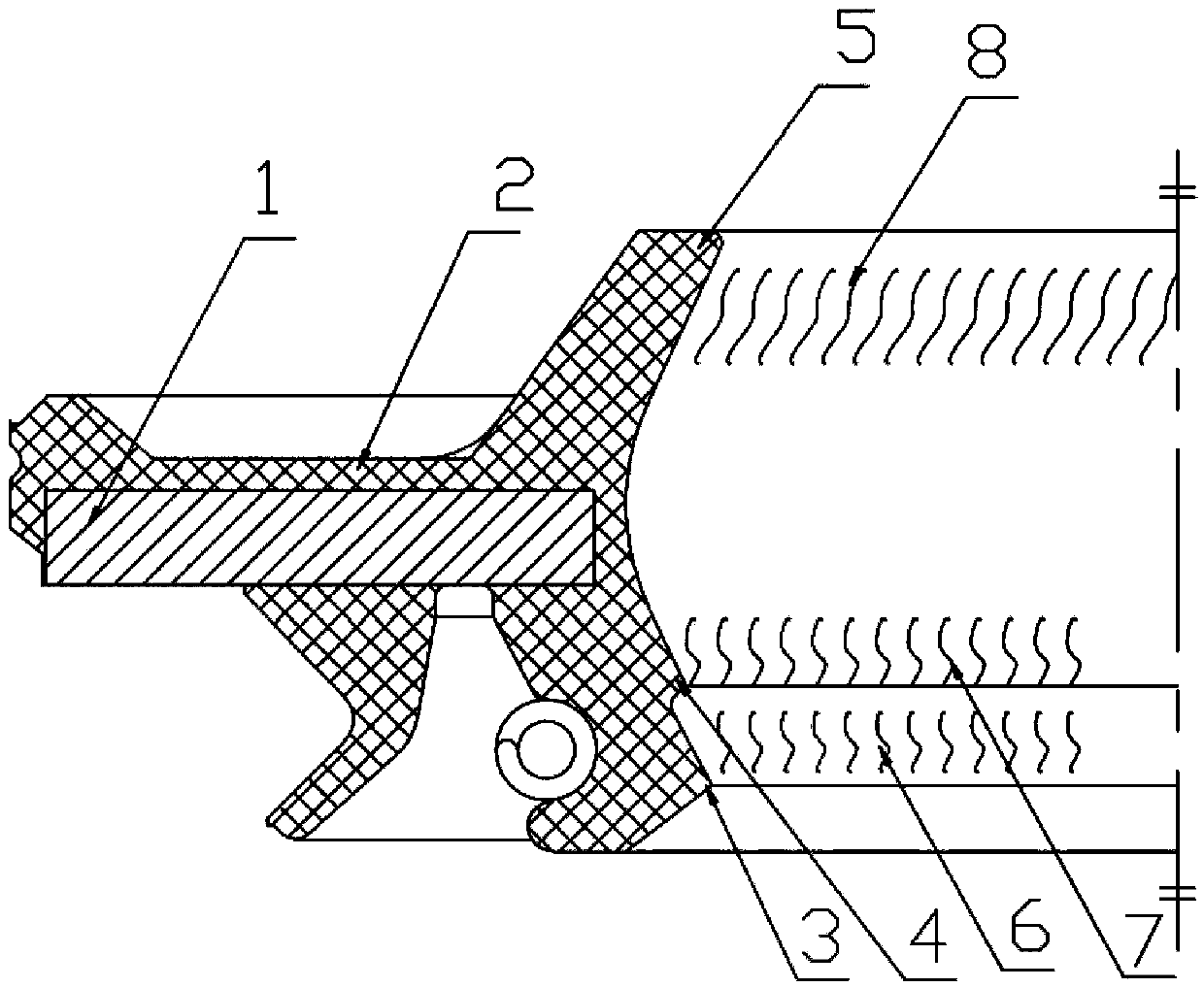

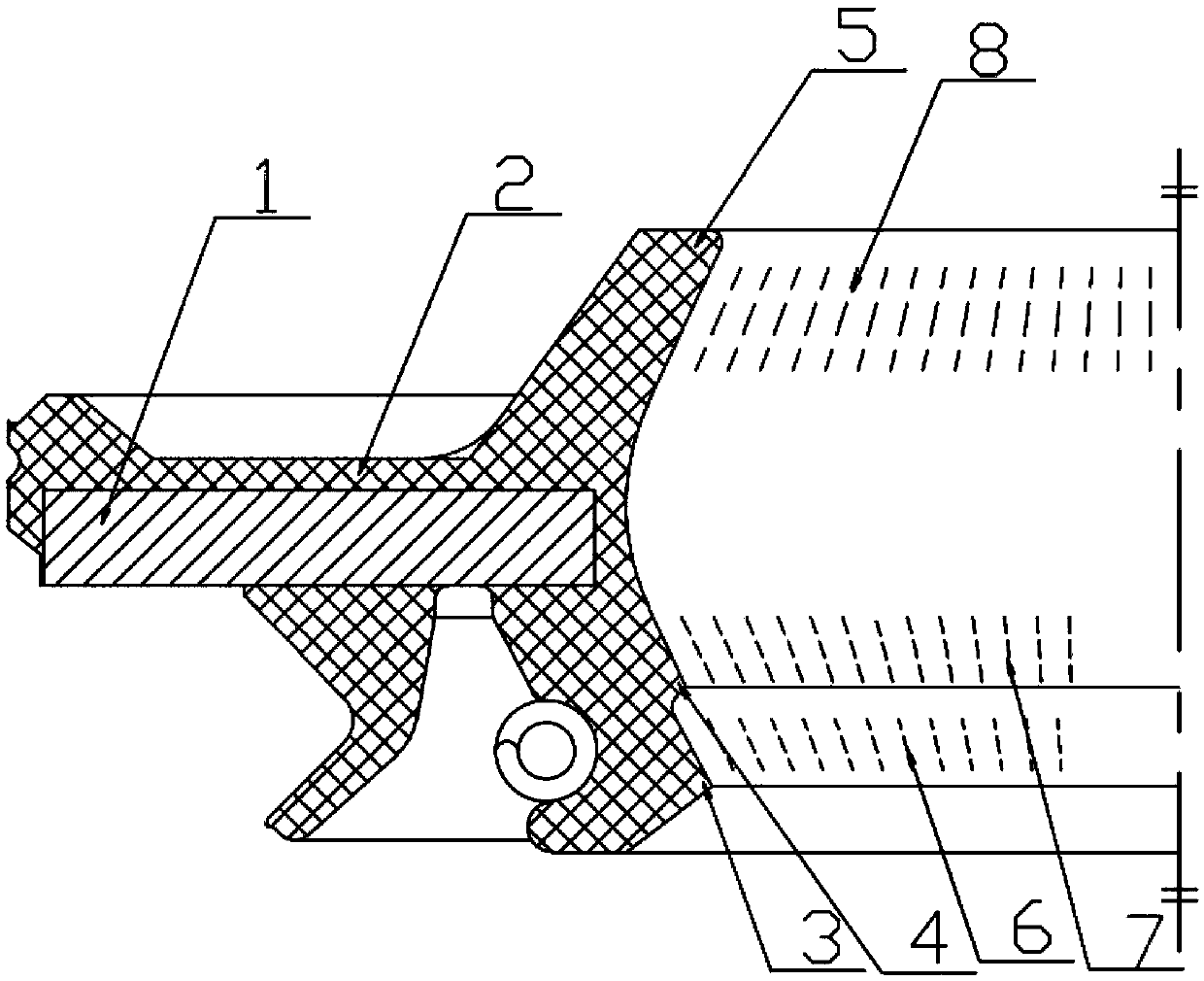

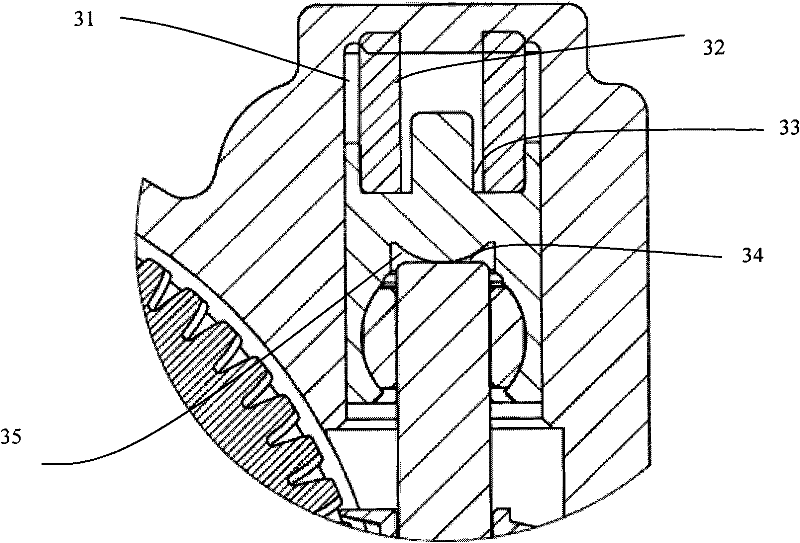

Annular support for rolling bearings

InactiveUS7553123B2Avoid vibrationReduce axial frictionPump componentsNon-positive displacement enginesRolling-element bearingEngineering

Owner:VARIAN SPA

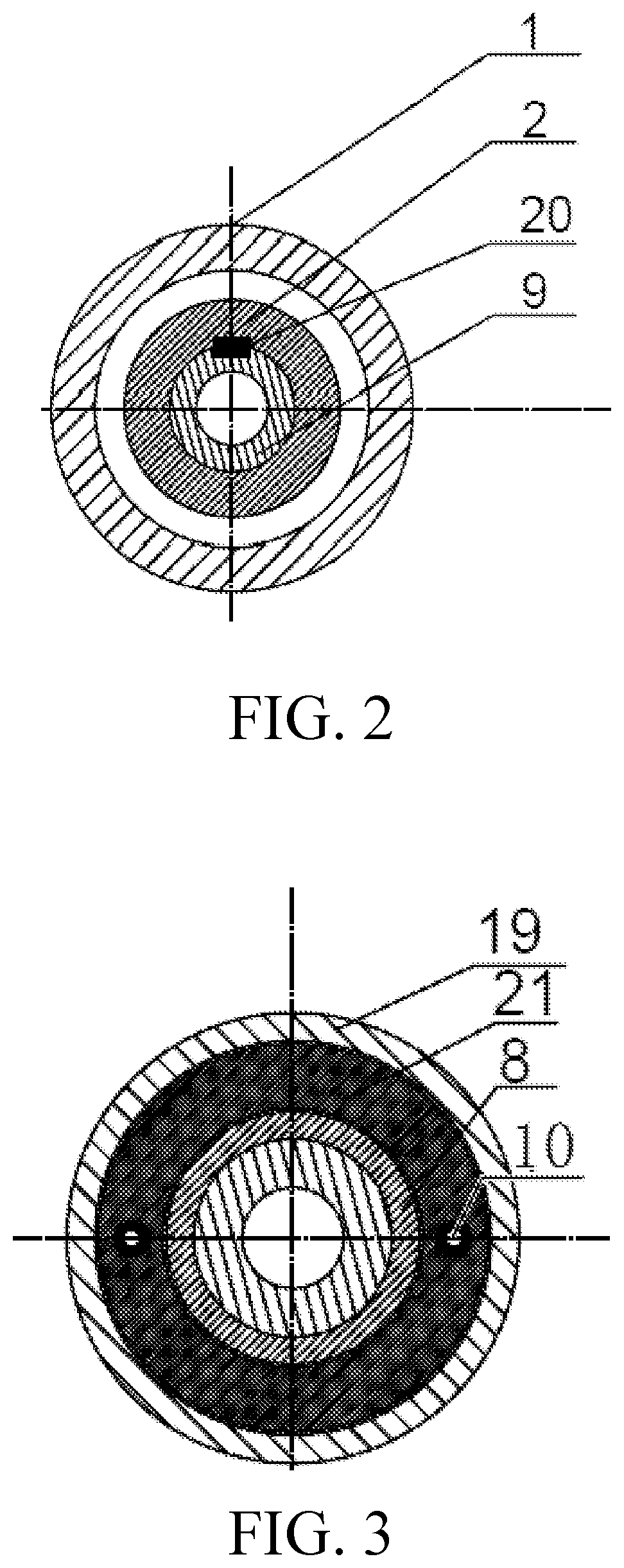

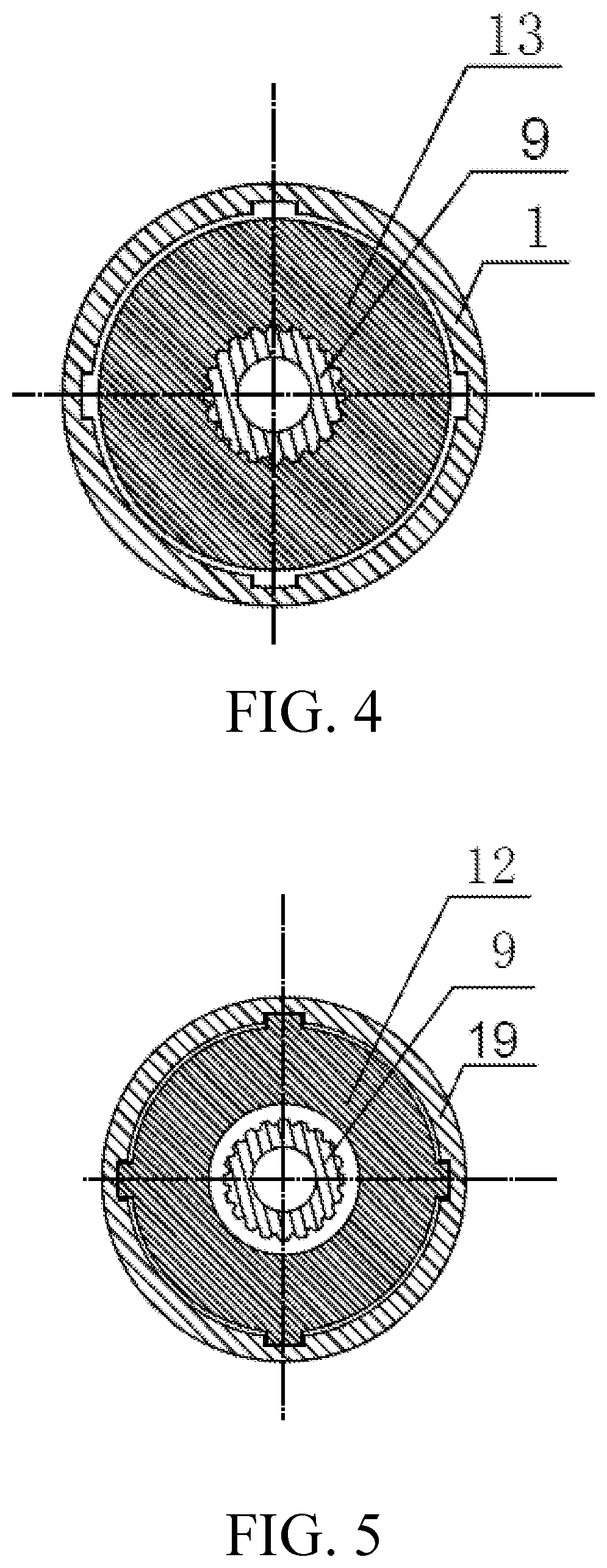

Annular support for rolling bearings

InactiveUS20060018774A1Avoid vibrationReduce axial frictionPump componentsNon-positive displacement enginesRolling-element bearingEngineering

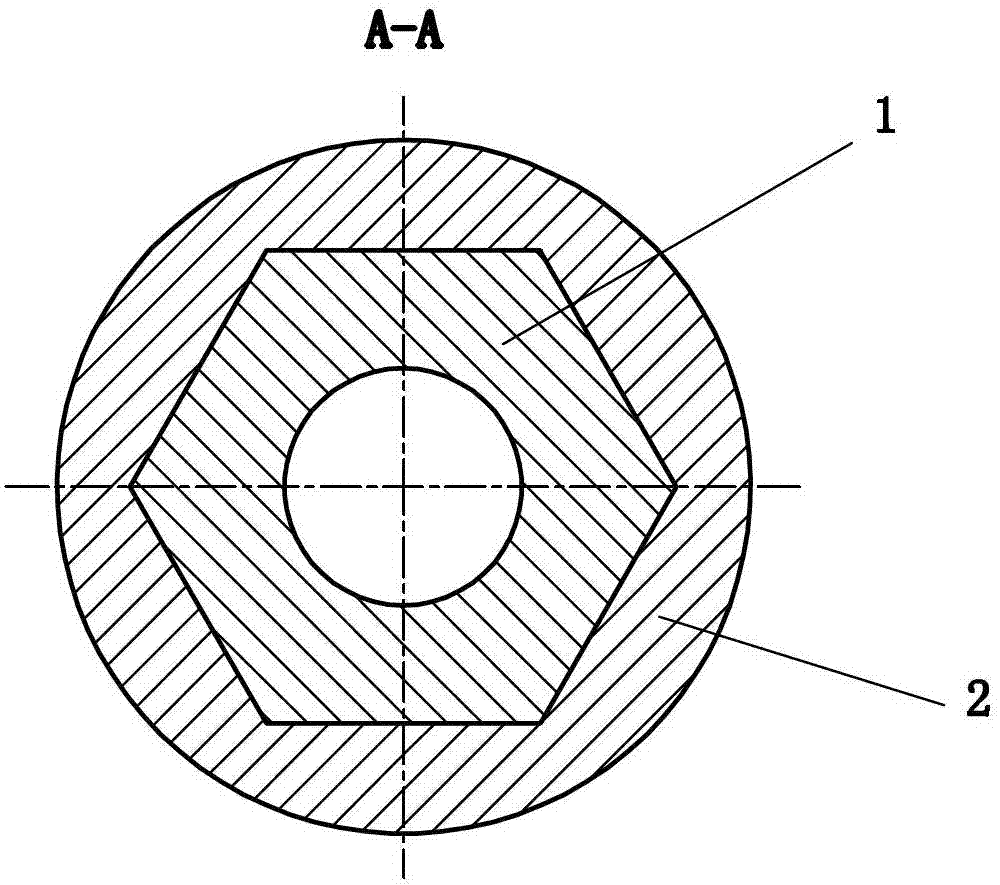

A support ring (1) for rolling bearings (11), especially for rolling bearings applied to rotors with very high rotation speed, such as rotors of rotary vacuum pumps, the ring comprising a pair of concentric cylindrical shells (3, 5) connected together by a plurality of oblique radial plates (9), at least one of said shells (3, 5) being circumferentially broken so as to define a plurality of shoes (7), each shoe being connected to at least one of the radial plates (9) in such a manner as to define shoe portions or arcs (A1, A2) of different length, wherein the plates (9) are resilient and allow for the radial displacement of the shoes (7) so as to restrain vibrations of the rotating portion.

Owner:VARIAN INC

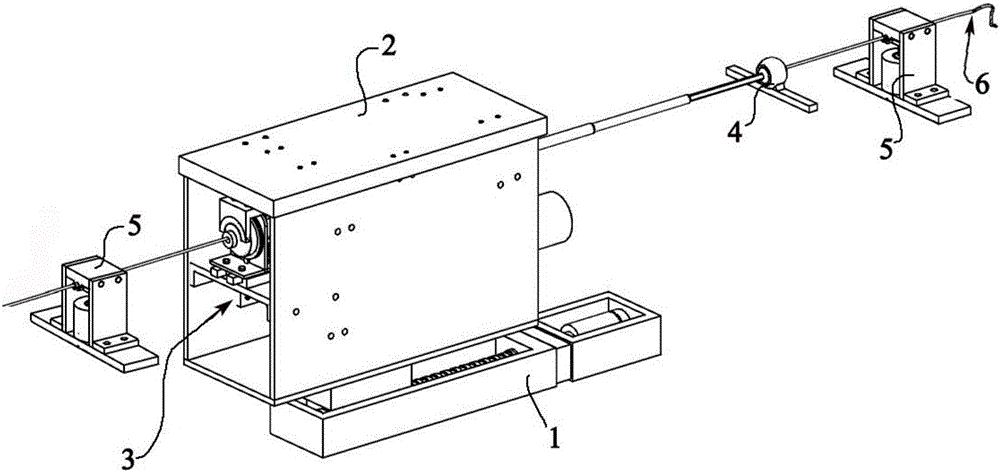

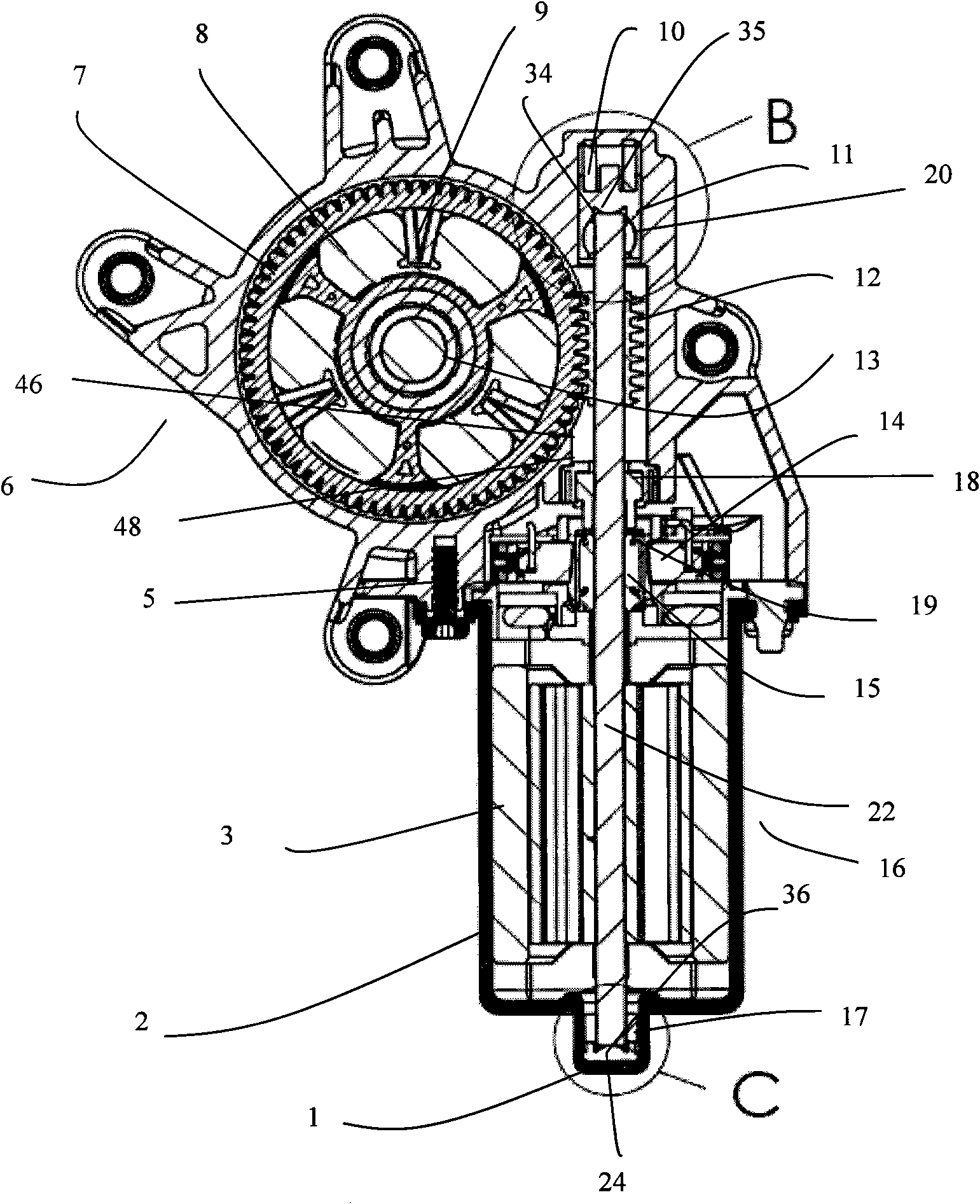

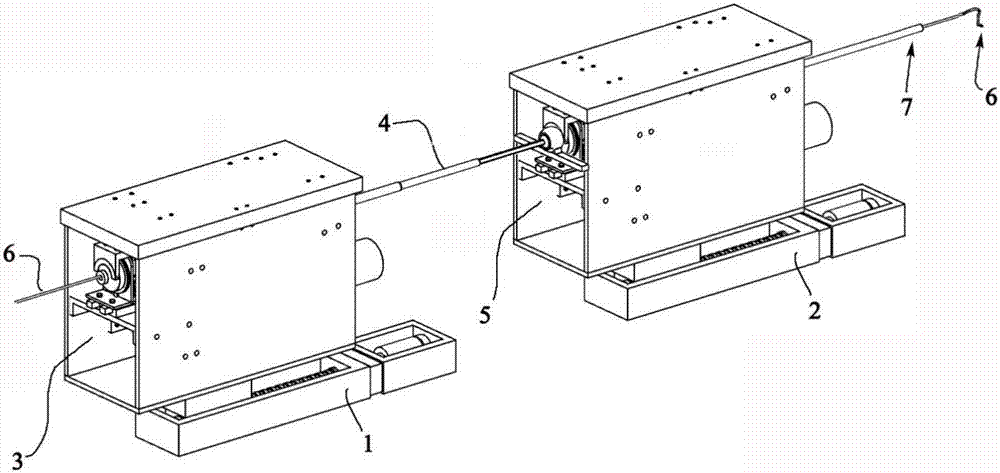

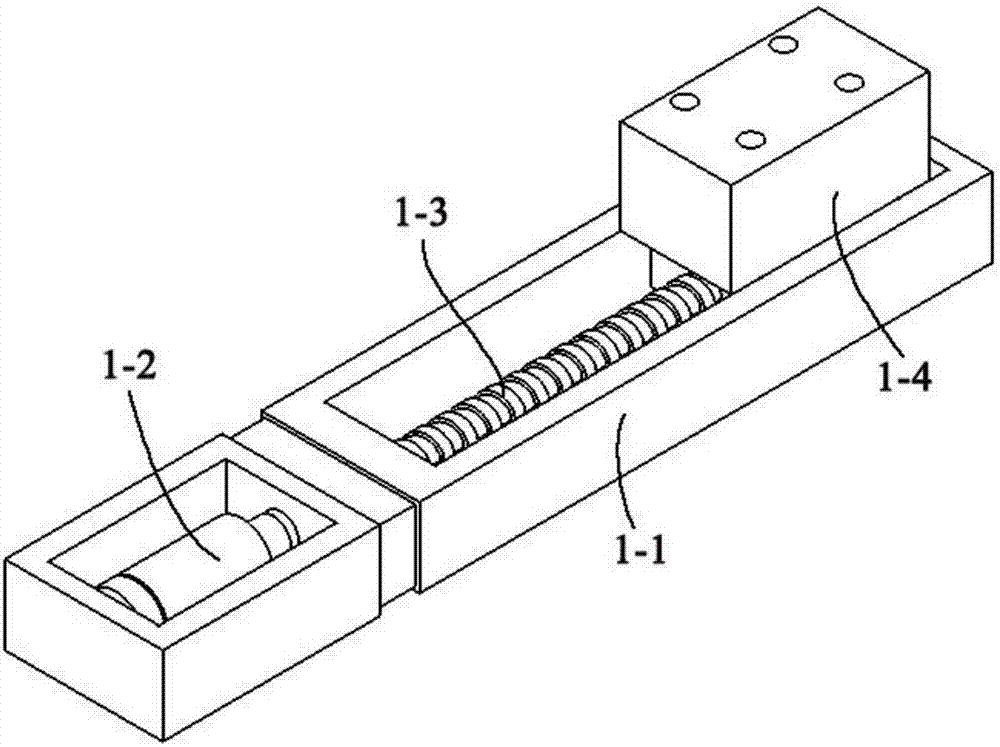

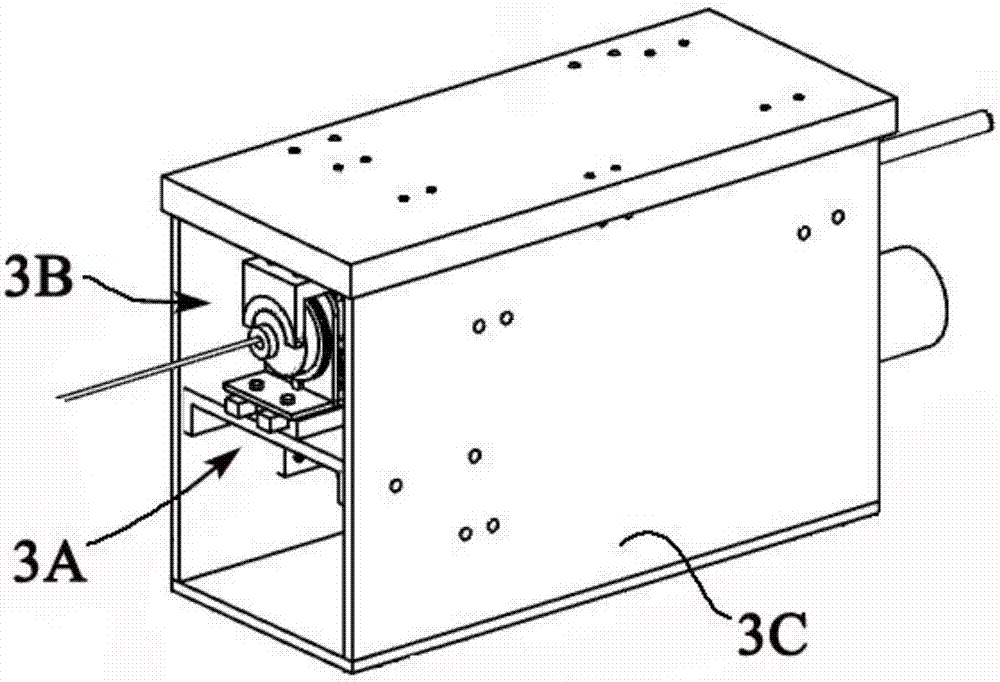

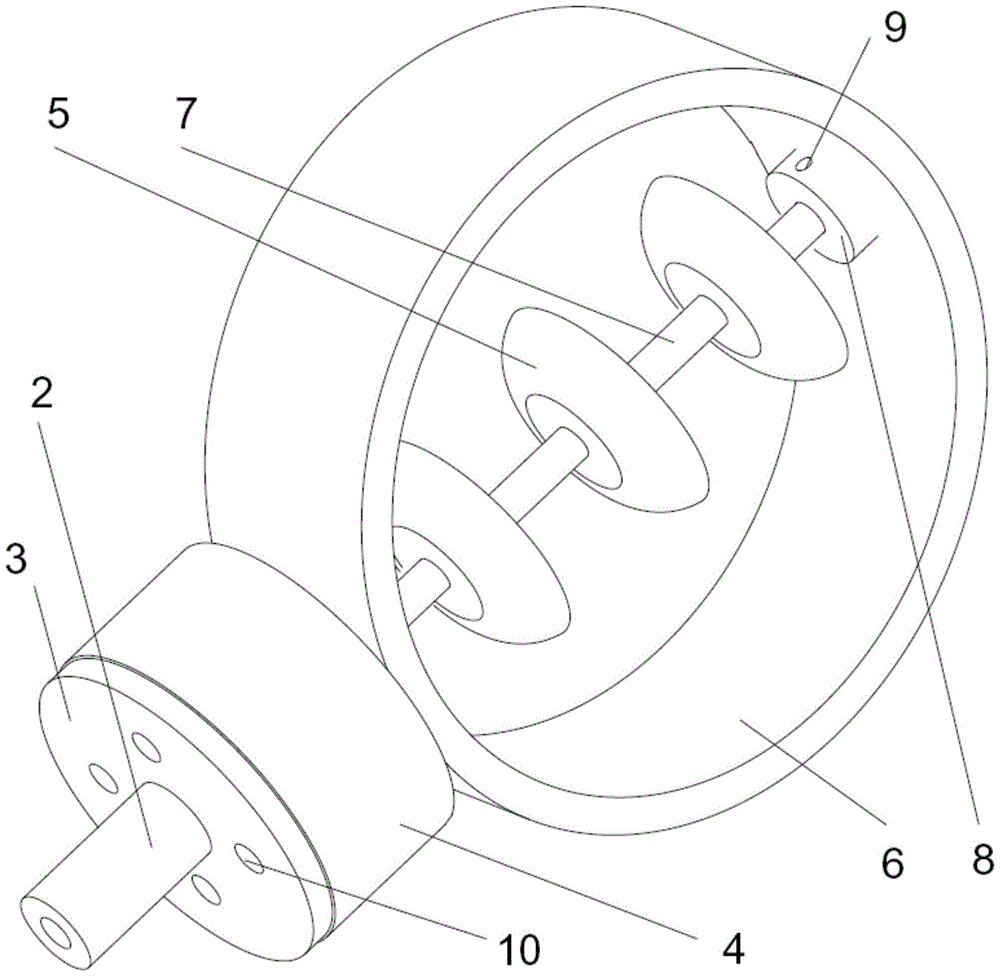

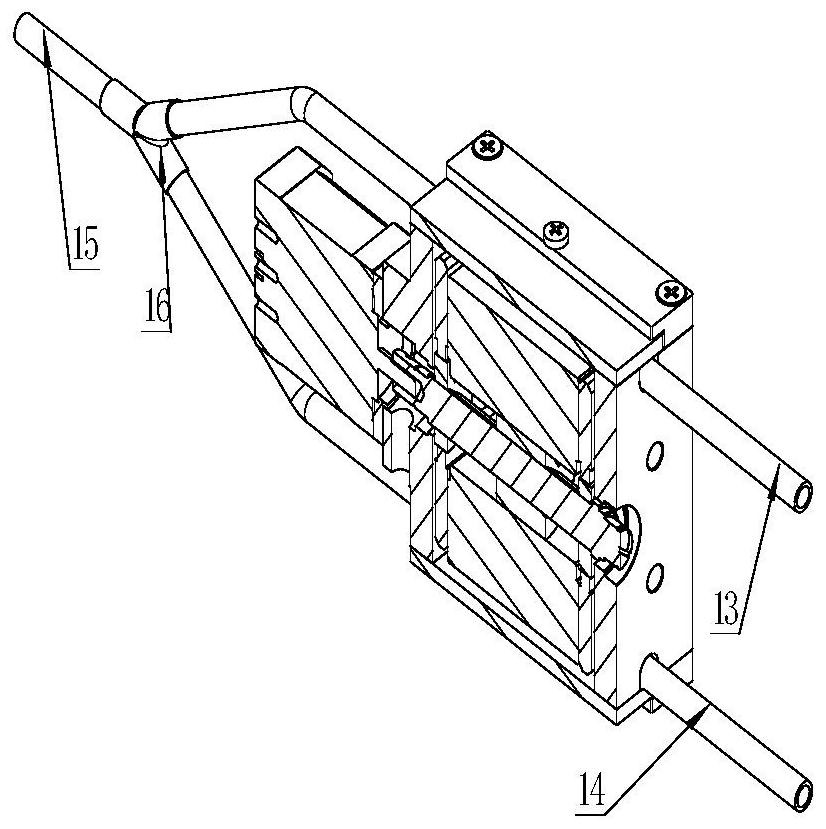

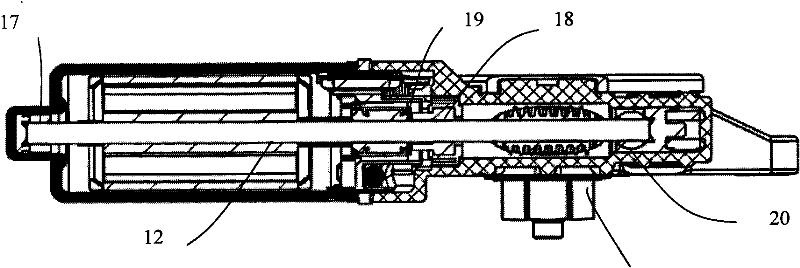

Master-slave intervention operation robot slave side operating device and control method thereof

ActiveCN105796179ADoes not affect operationAvoid excessive bendingSurgical robotsEngineeringGuide wires

The invention discloses a master-slave intervention operation robot slave side operating device and a control method thereof, and belongs to the technical field of machinery manufacturing. The device comprises a mobile platform, a shell, a body, a telescoping mechanism, two locking switching mechanisms and a guide wire; the shell is installed on a base of the mobile platform, the body is assembled in the shell, one end of the telescoping mechanism is fixedly connected with the shell, the other end of the telescoping mechanism is fixedly connected with an operating table, and the two locking switching mechanisms are arranged on the outer side of the shell and the outer side of the telescoping mechanism respectively. According to the master-slave intervention operation robot slave side operating device, by optimally designing the slave side body, the telescoping mechanism and the locking switching mechanisms, the problems that guide wire pushing is bent, the pushing force is difficult to measure, assembling and disassembling are inconvenient, and guide clamping and loosening switching is uncontrollable are solved, and the advantages of being reasonable in structure, easy to machine and manufacture and convenient to control are achieved.

Owner:SHENZHEN INST OF ADVANCED BIOMEDICAL ROBOT CO LTD

Low-friction oil seal for shock absorber

ActiveCN103244686AReduce coefficient of frictionKeep radial force constantEngine sealsEngineeringShock absorber

The invention relates to a sealing element, in particular to a low-friction oil seal for a shock absorber. The oil seal comprises a framework and an oil seal body. The oil seal body comprises at least one sealing lip and a dust-proof lip. The oil seal is characterized in that axial parallel veins are arranged on annular sealing surfaces formed by the sealing lips. The sealing lips comprise a first sealing lip and a second sealing lip, and first axial parallel veins and second axial parallel veins are arranged on the annular sealing surfaces formed by the first sealing lip and the second sealing lip respectively. Third axial parallel veins are arranged on an annular sealing surface formed by the dust-proof lip. The low-friction oil seal has the advantages that forming of critical lubricating oil film between contact surfaces of the sealing surfaces and a shock absorber shaft is facilitated, so that the contact area is reduced; and lubricating oil can be stored between the axial veins conveniently, so that the friction coefficient between the oil seal and the shock absorber shaft is reduced, the friction between the oil seal and the shock absorber shaft is reduced on the premise that the radial sealing force is not changed, and the service life of the oil seal is increased.

Owner:YANTAI RUNFUXIANG OIL SEAL

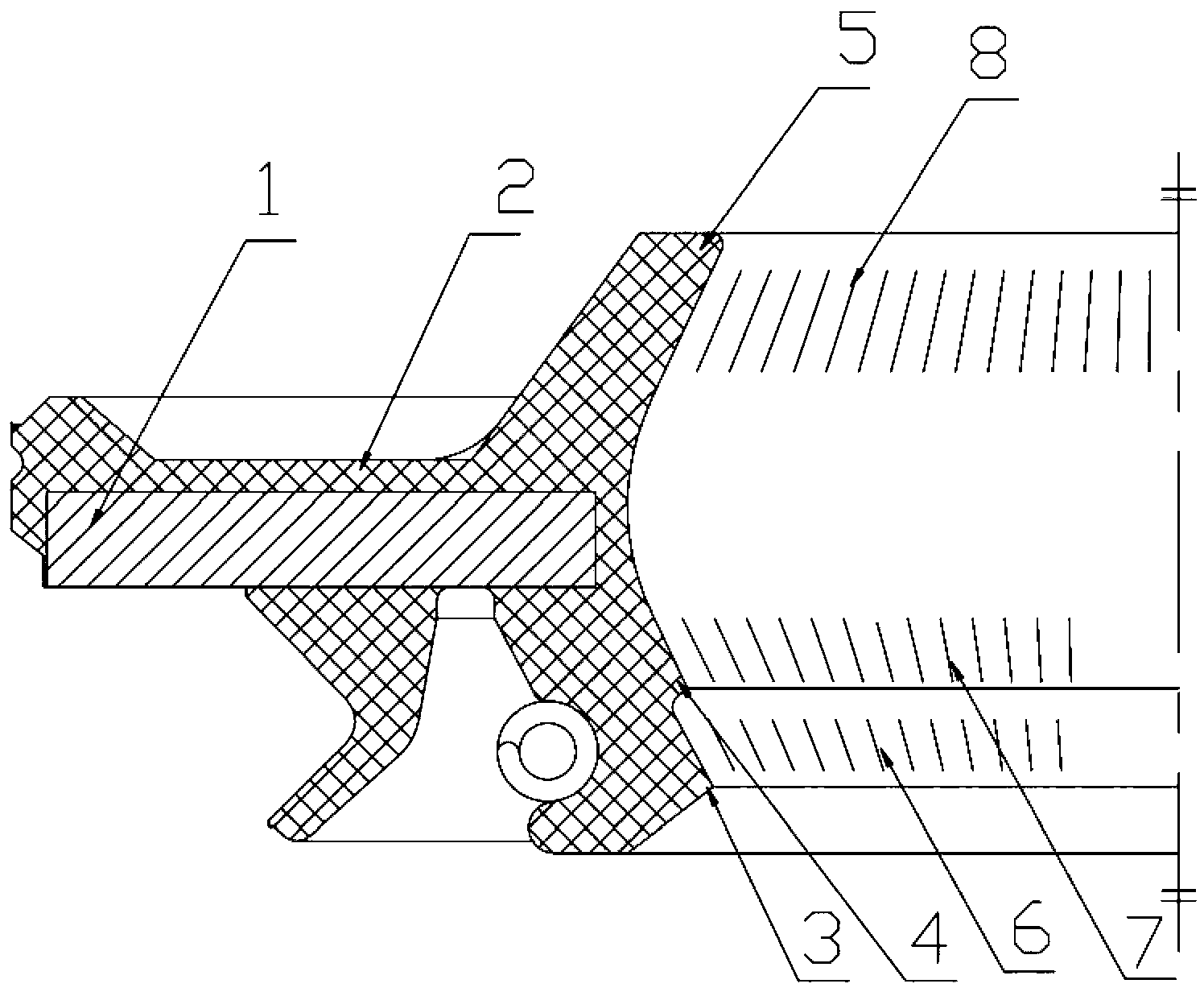

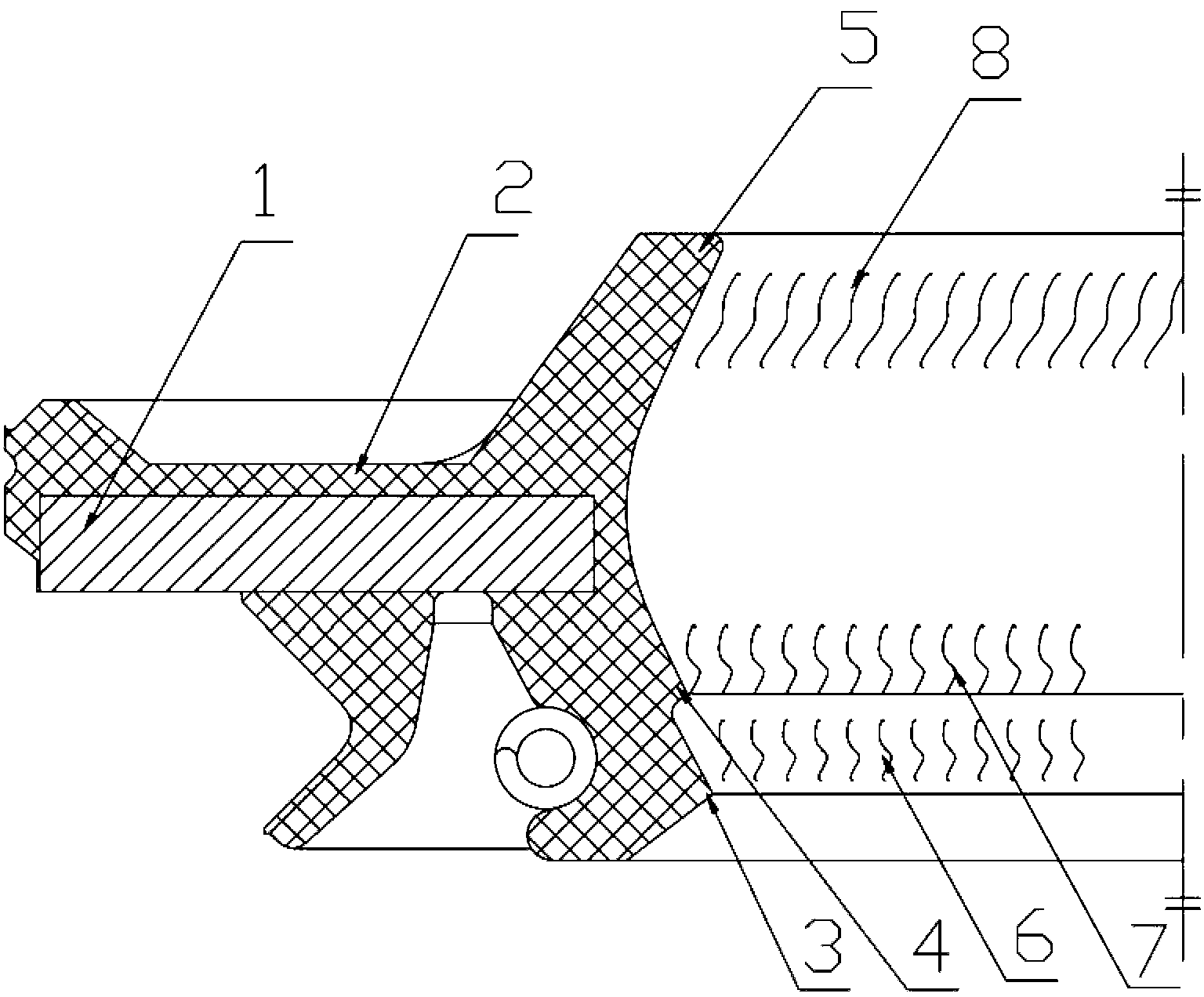

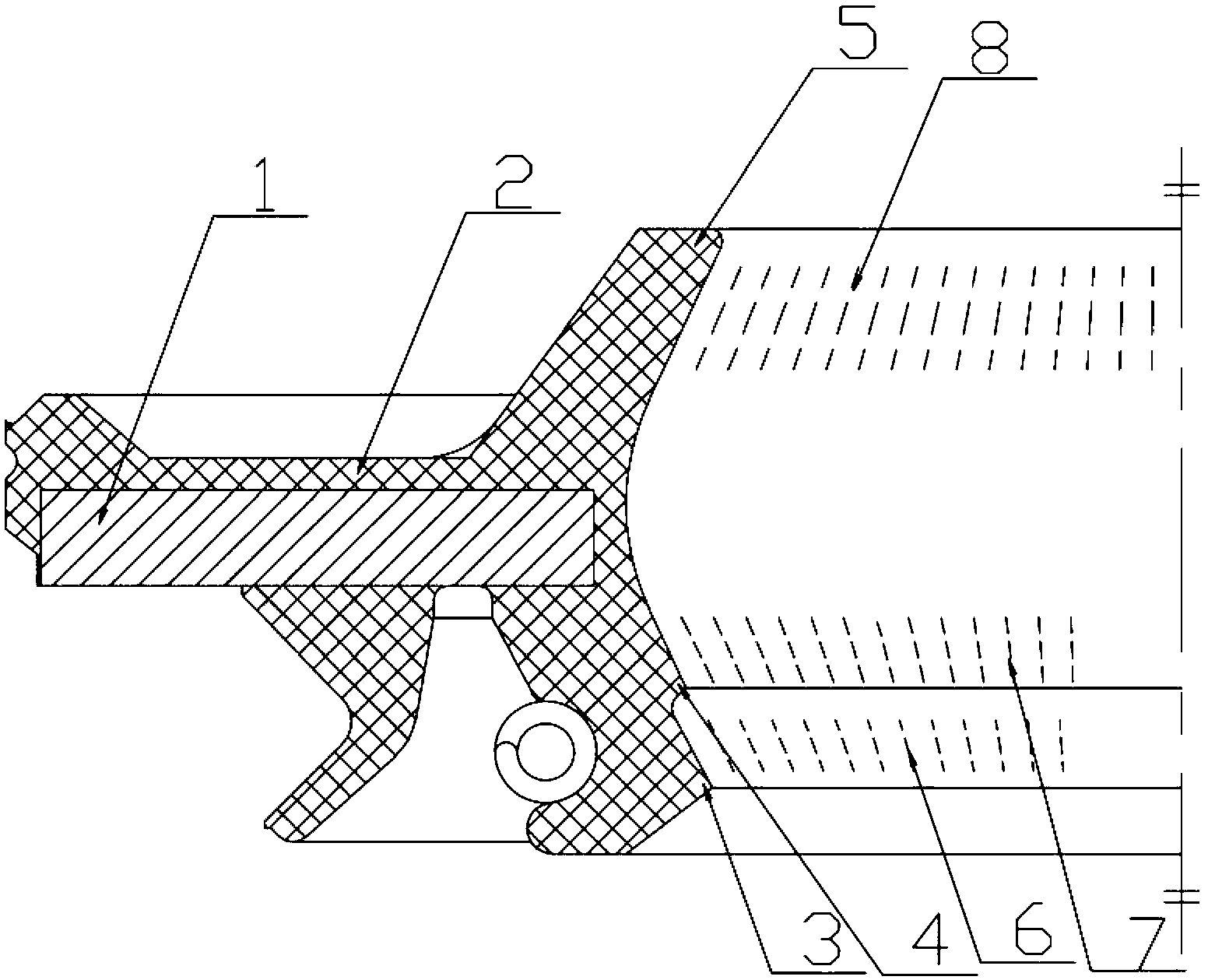

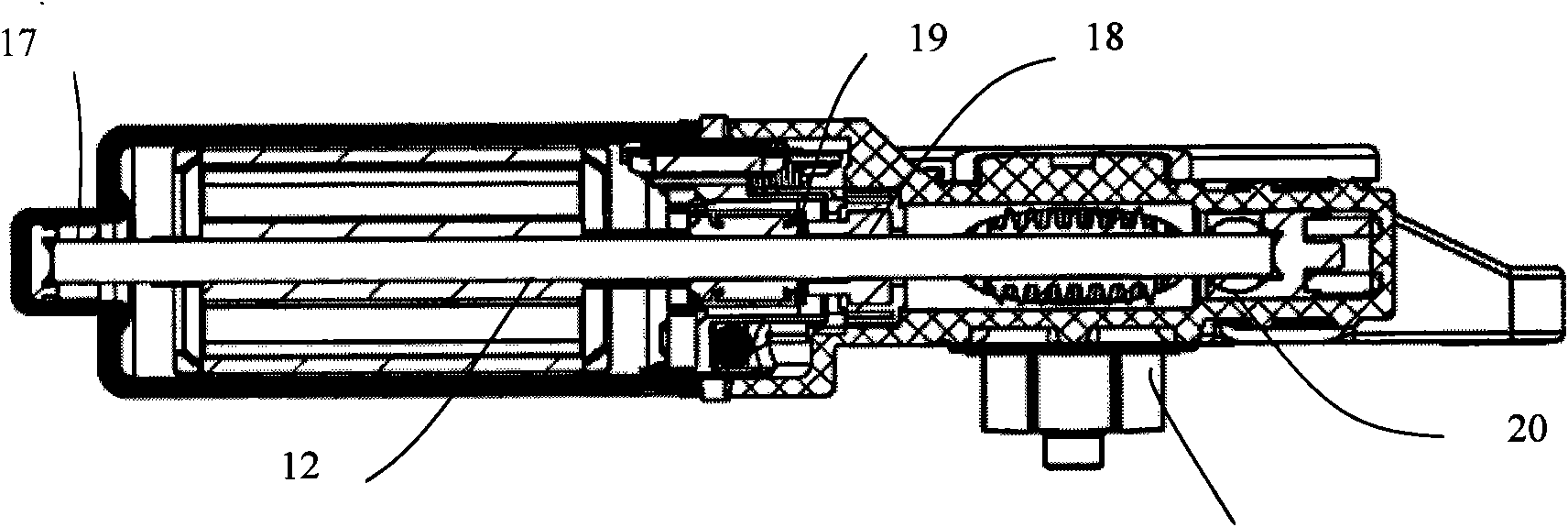

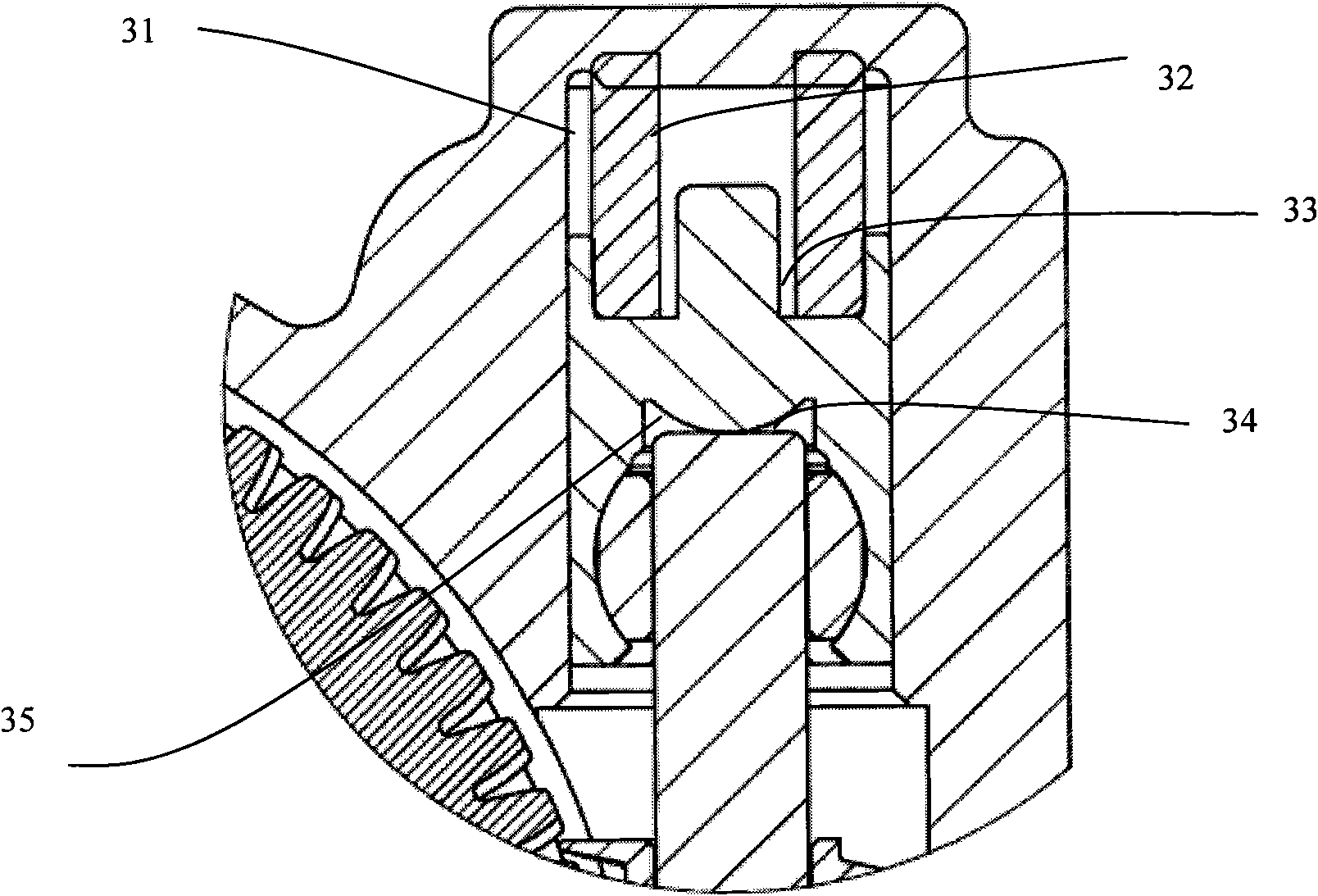

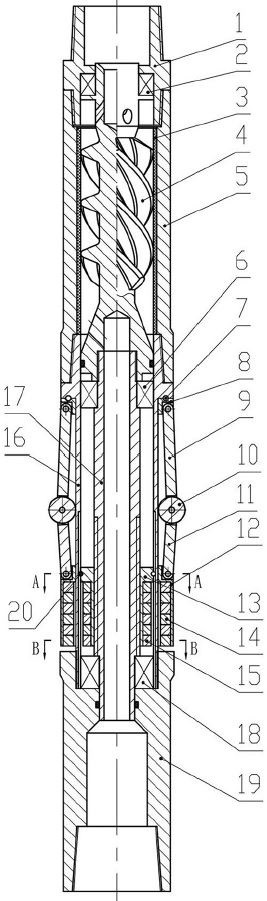

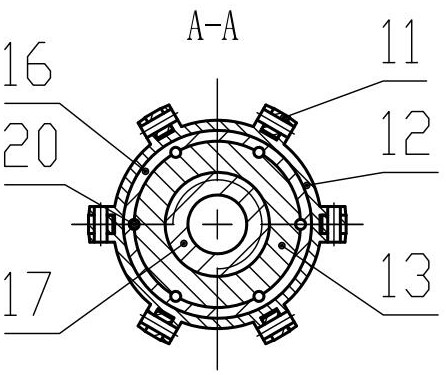

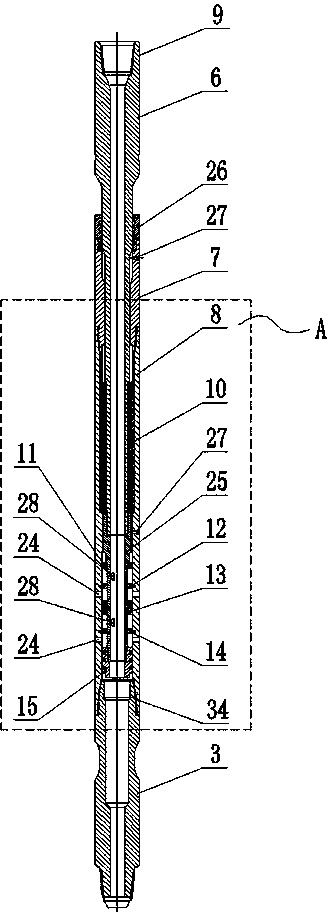

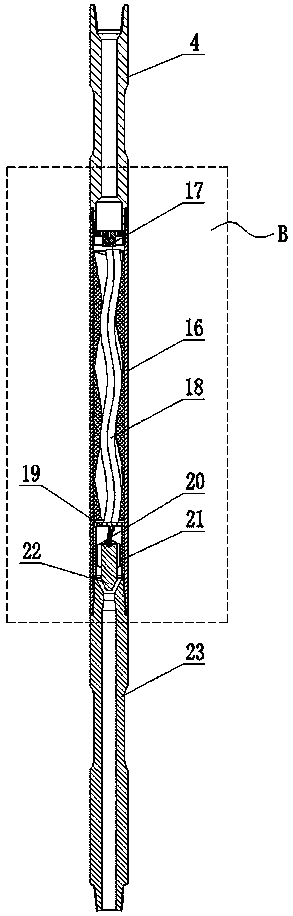

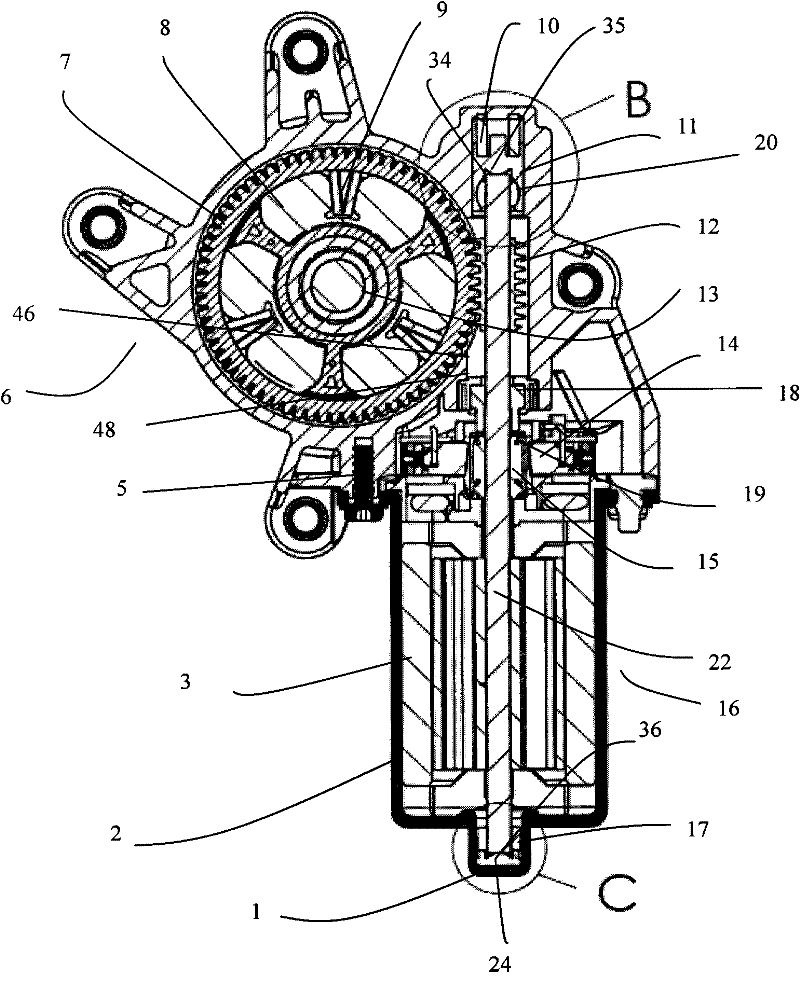

Rhythm-type high-frequency hydraulic pulse oscillation resistance-reducing actuator

PendingCN109403866AReduce axial frictionAvoid damageDirectional drillingVibration drillingUpper jointStatic friction

The invention discloses a rhythm-type high-frequency hydraulic pulse oscillation resistance-reducing actuator, and belongs to the technical field of petroleum operation equipment. The rhythm-type high-frequency hydraulic pulse oscillation resistance-reducing actuator is composed of a peristaltic short section and a power short section which are combined; the peristaltic short section and the powershort section are each in a hollow tubular shape; the peristaltic short section is in threaded connection with an upper joint on the upper part of the power short section through a lower joint on thelower part of the peristaltic short section, so that a pulse channel is formed between the peristaltic short section and the power short section; a lower opening of the upper joint is connected witha stator sleeve; a screw rotor is arranged in the stator sleeve in a matched mode; the upper end of the screw rotor is in clearance fit with a rotor front support, and a rotating valve disc is coaxially fixed to the lower end of the screw rotor; the rotating valve disc is in eccentric clearance fit with a fixed valve disc fixed to the stator sleeve; and a lower opening of the stator sleeve is connected with a drilling tool lower joint. According to the rhythm-type high-frequency hydraulic pulse oscillation resistance-reducing actuator, static friction is converted into dynamic friction with the tiny amplitude, axial friction and circumferential friction are reduced, and thus the problems of motor back-pressure, drill bit damage, drilling tool over-compression, drilling tool jamming, torquefluctuation, drilling tool reversing risk increasing, drilling tool fatigue and the like are solved.

Owner:大庆东油研创科技研发有限公司

Motor assembly as well as positioning installation method thereof

InactiveCN101841207AImprove output efficiencyReduce axial frictionManufacturing dynamo-electric machinesMechanical energy handlingVibrating stringCushion

The invention relates to a motor assembly and a location and installation method thereof. The motor assembly comprises a motor and a gear box connected with the motor, wherein, the motor comprises a motor shell, an armature shaft arranged in the motor shell, a push stopping plate arranged at the bottom of the motor shell and a straight bearing arranged on the push stopping plate; the gear box comprises an output gear shaft, a drive disk which drives the output gear shaft to rotate, a gear, a butter cushion arranged in the inner cavity of the gear, a straight bearing assembly and a supporting seat provided with a bearing; the push stopping plate and the supporting seat are respectively provided with a spherical surface; the armature shaft passes through the straight bearing, the straight bearing assembly and the inner hole of the bearing in the supporting seat in sequence, and the two end surfaces of the push stopping plate are respectively contacted with the spherical surfaces of the push stopping plate and the supporting seat; the armature shaft is provided with a worm and is provided with a commutator; the worm is positioned between the straight bearing assembly and the supporting seat; the worm drives the gear in the gear box to rotate along the rotation of the armature shaft. The invention can reduce string vibration of motor output shaft at rating load, lower the noise of the motor, and improve output efficiency of the motor.

Owner:SHENZHEN CREATIVE & BRIGHT PRECISION PLASTIC MOLD

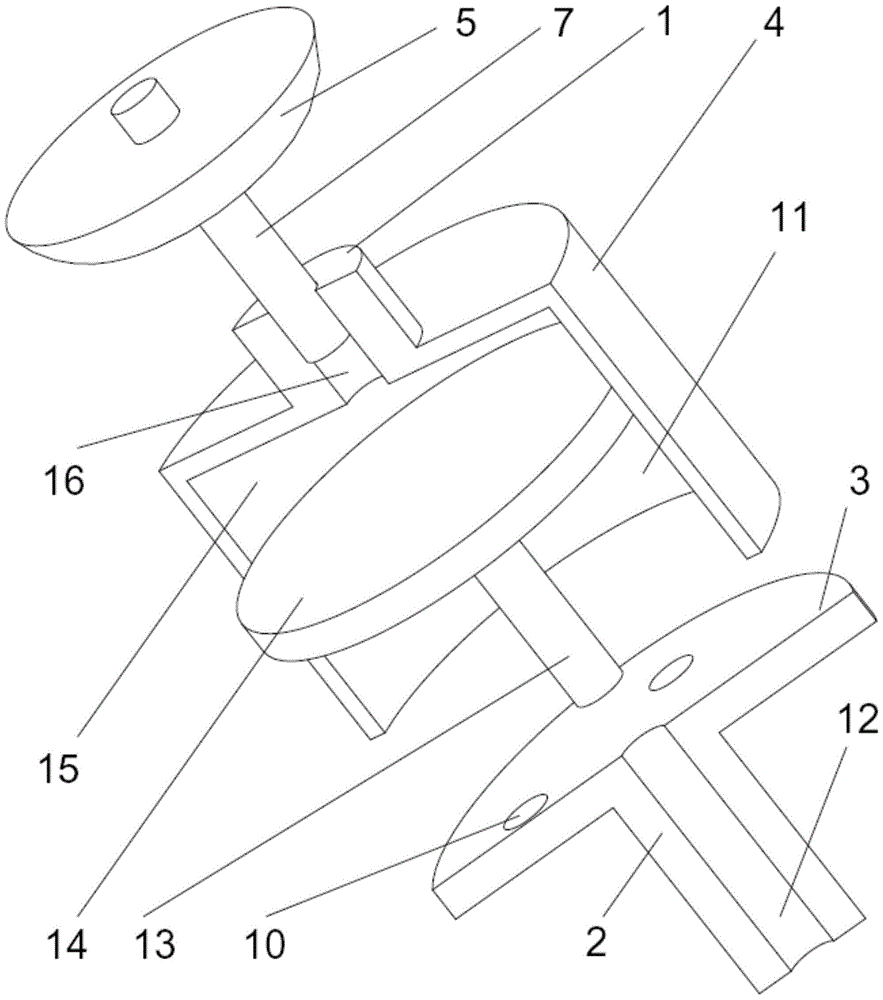

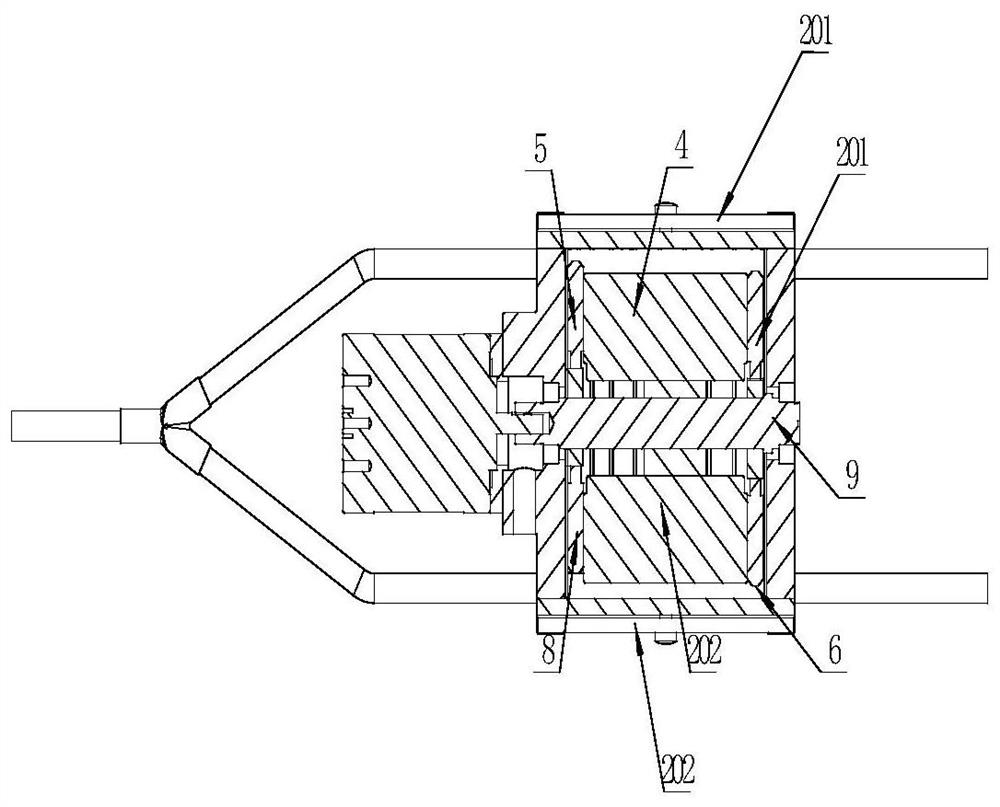

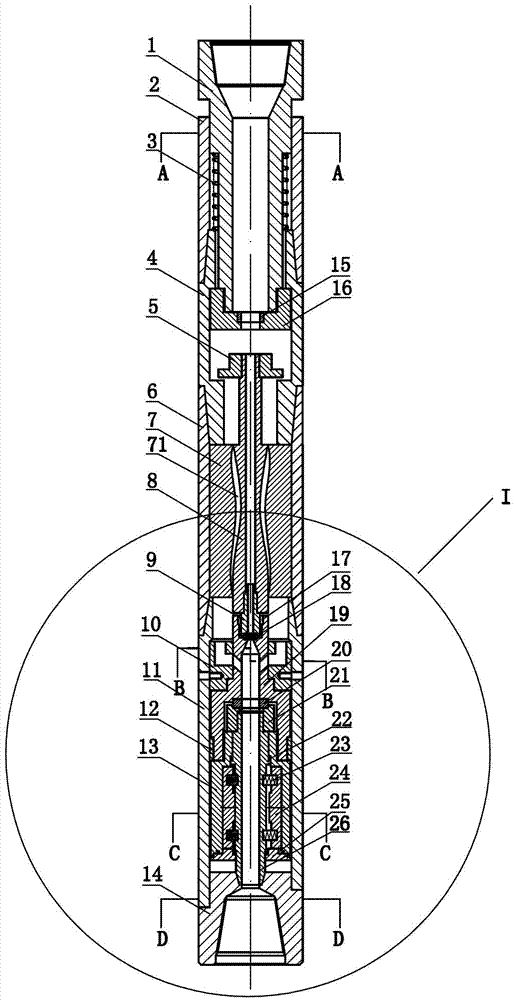

Automatic reactive torque balancing device for screw drill, drilling pipe string and method

ActiveCN111852334ASimple structureReduce maintenance costsDrilling rodsDirectional drillingFriction torqueThermodynamics

The invention provides an automatic reactive torque balancing device for a screw drill, a drilling pipe string and a method. The device comprises an upper joint, a core tube, a lower joint and an automatic balancing component, wherein an inner cavity of the core tube communicates with the downstream screw drill, so that the drilling fluid from the inner cavity of the upper joint can flow to the screw drill through the inner cavity of the core tube in order to enable the screw drill to drill; the lower joint is fixedly arranged at the lower end of the core tube; the automatic balancing assemblyis arranged between the outer wall of the core tube and the inner wall of the upper joint, and the automatic balancing component is driven by the liquid pressure generated by a part of the drilling fluid flowing into the inner cavity of the upper joint, wherein when the displacement of the drilling fluid is equal to a first predetermined value, the friction torque generated between the upper joint and the core tube is equal to the reactive torque generated on a shell of the screw drill for directional drilling; and when the displacement of the drilling fluid is higher than the first preset value, the friction torque generated between the upper joint and the core tube is larger than the reactive torque generated on the shell of the screw drill, so that the core tube drives the shell of thescrew drill to rotate for composite drilling.

Owner:CHINA PETROLEUM & CHEM CORP +1

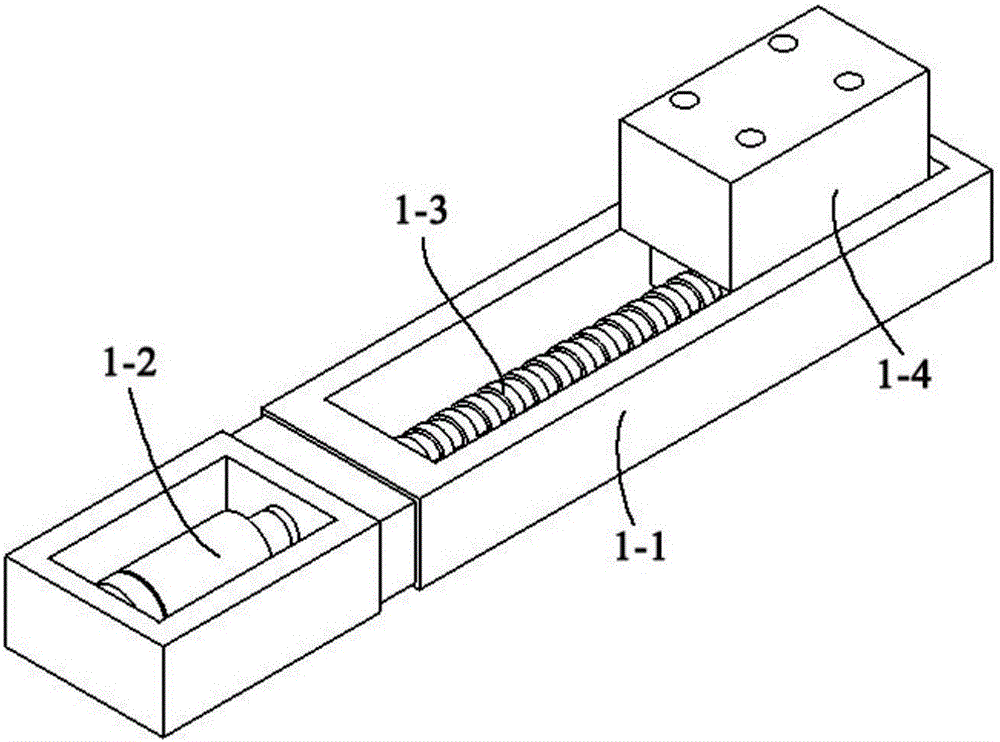

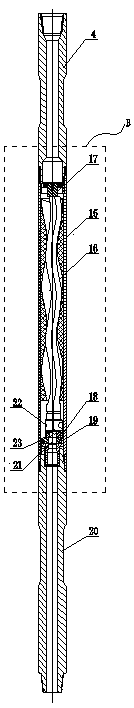

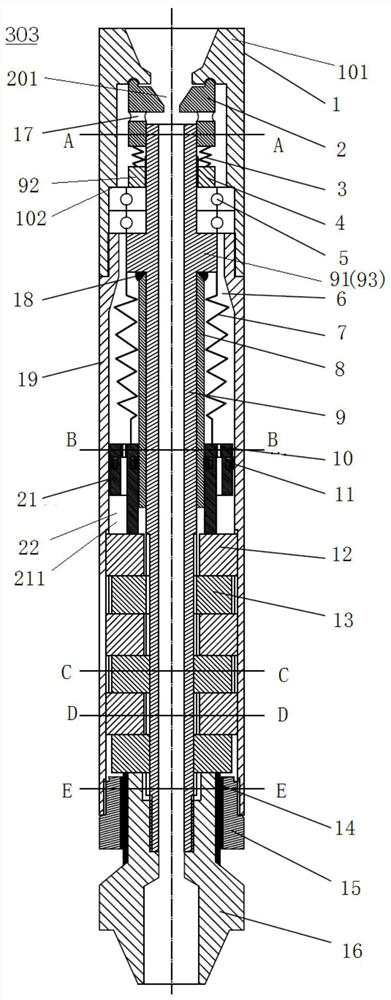

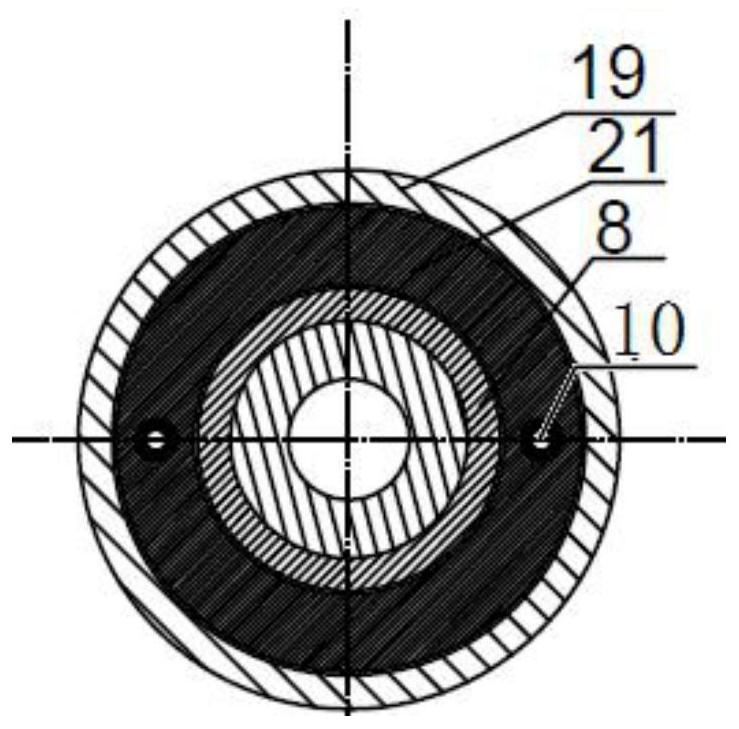

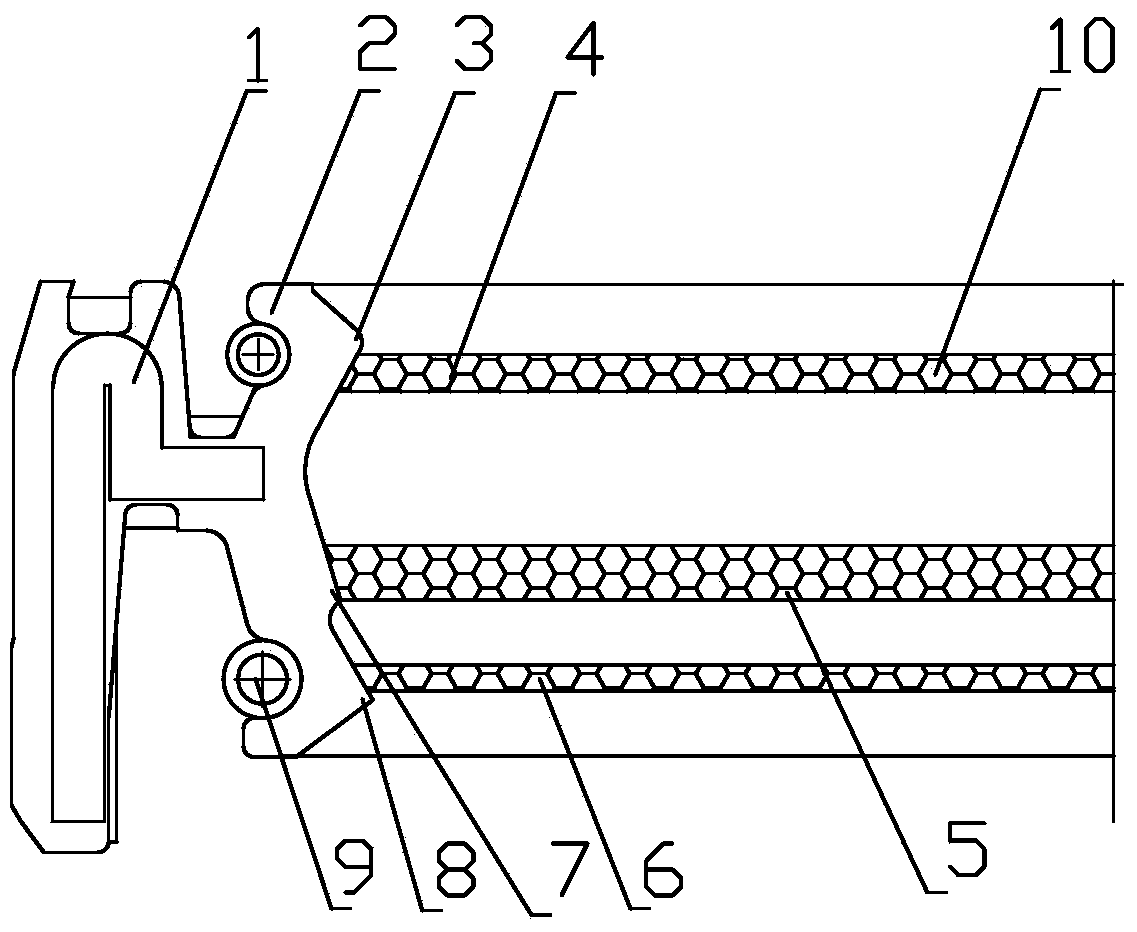

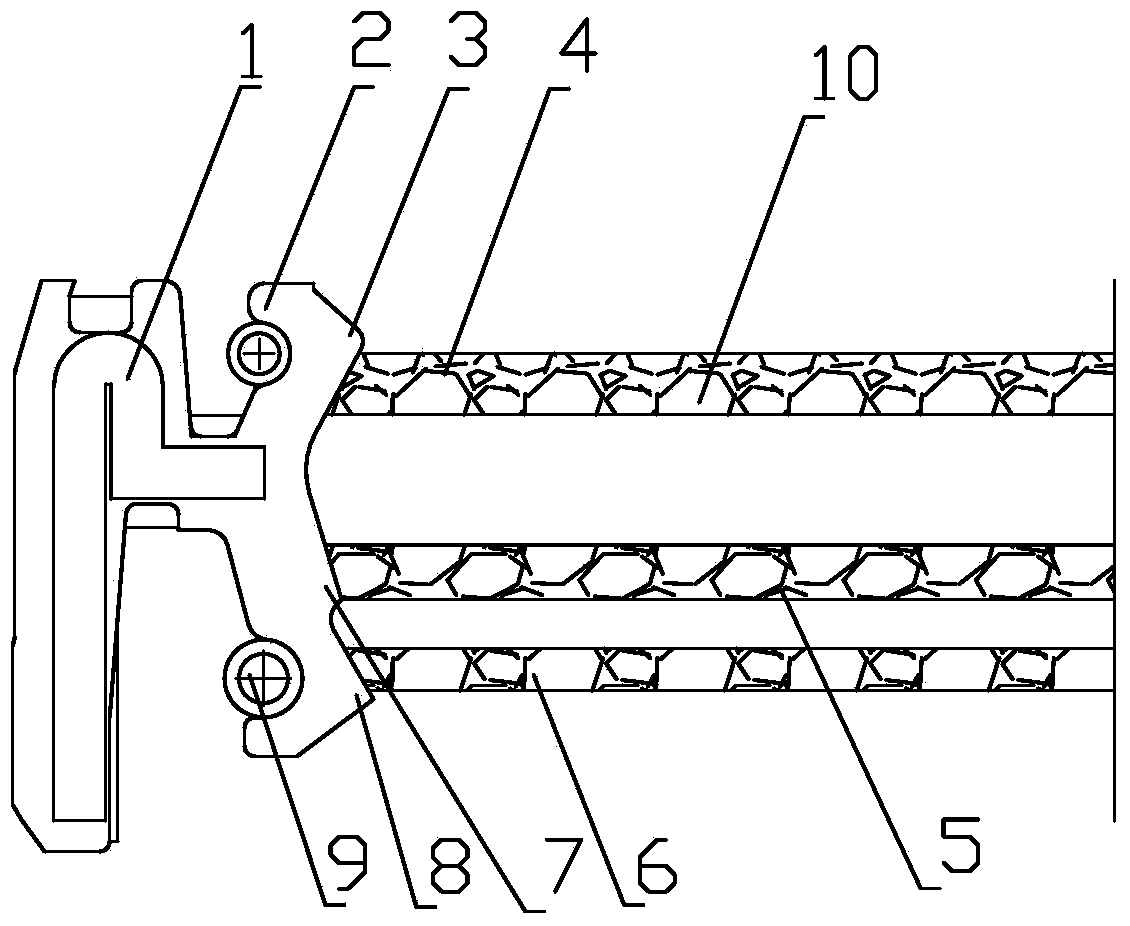

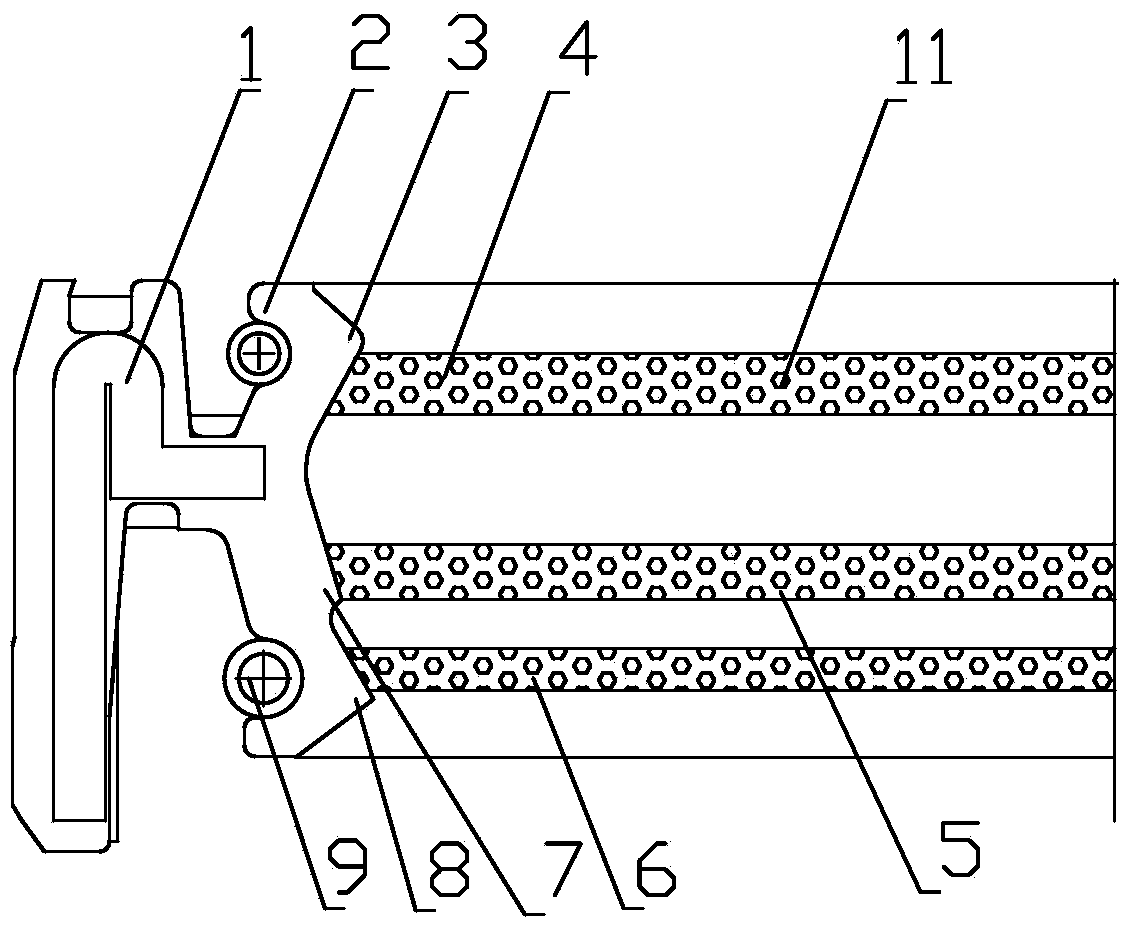

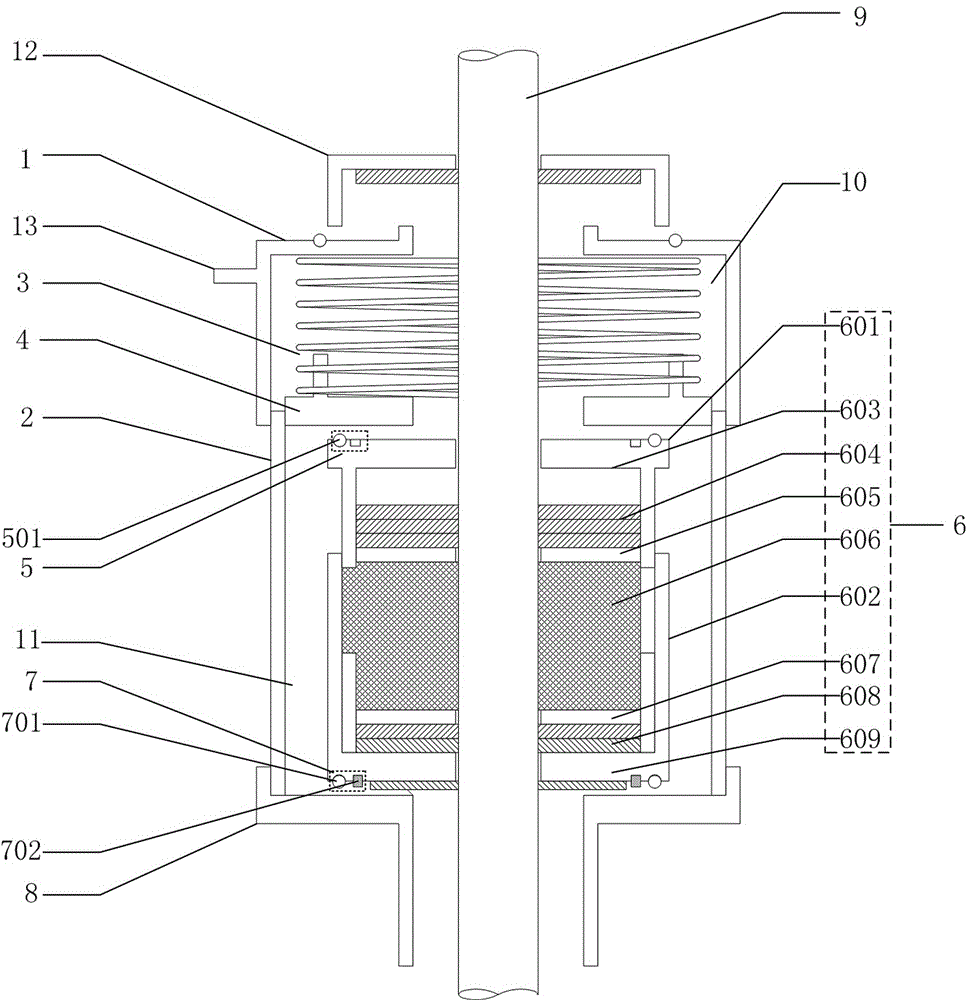

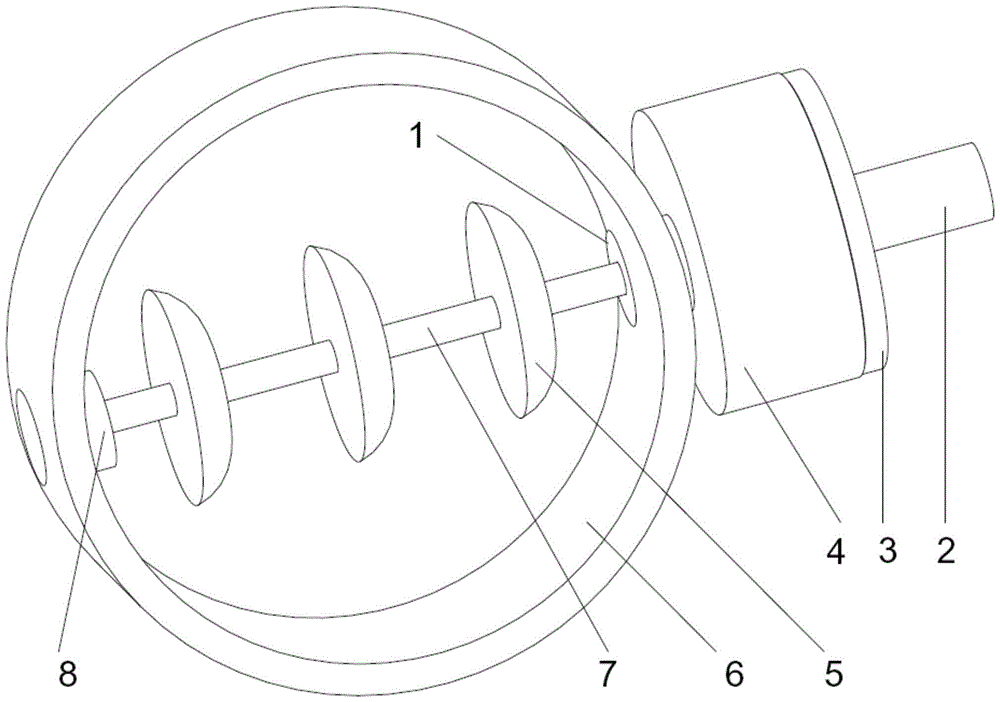

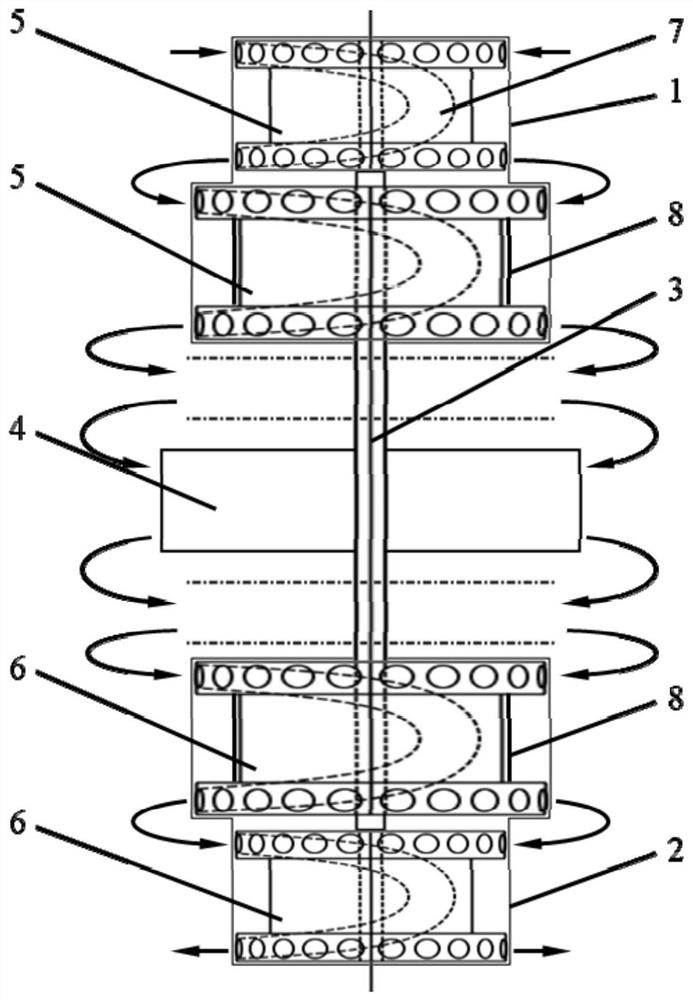

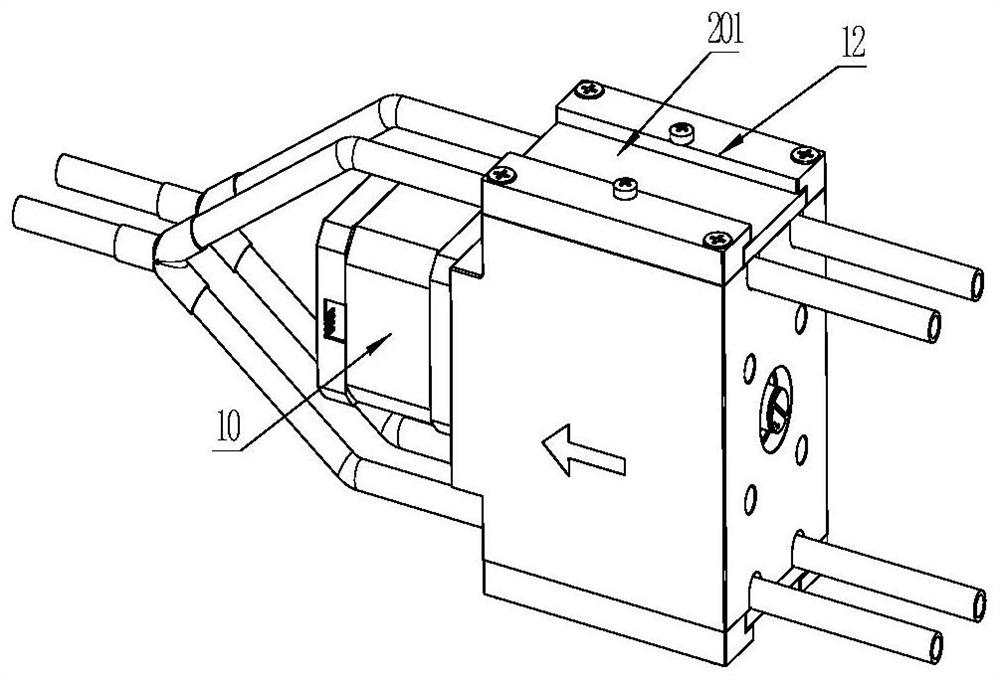

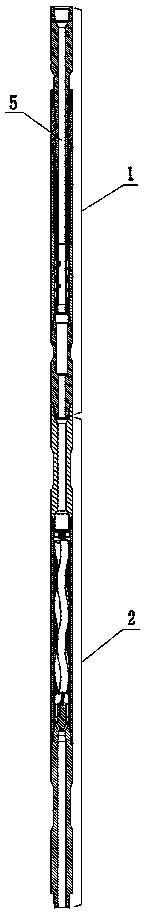

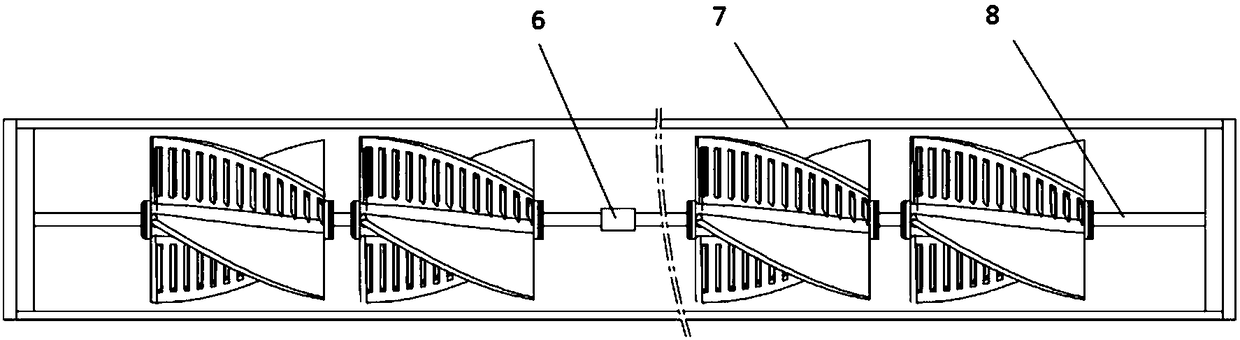

Reciprocating type low-pressure and high-frequency hydraulic power pulse vibrator

ActiveCN110593762ALow pressure lossReduce axial frictionVibration drillingWell drillingControl theory

The invention relates to a reciprocating type low-pressure and high-frequency hydraulic power pulse vibrator and belongs to the field of vibration or oscillation method well drilling. The reciprocating type low-pressure and high-frequency hydraulic power pulse vibrator is composed of a vibration short joint and a power short joint. The vibration short joint is formed in the manner that a spline core shaft is inserted in a spline outer cylinder and a piston outer cylinder, and a disc spring is installed in the circular clearance between the middle portion of the spline core shaft and the pistonouter cylinder. The lower end of the spline core shaft is fixedly connected with a piston inner cylinder. A piston I, a piston II and a piston III are sequentially fixed to the piston inner cylinderfrom top to bottom, and an isolation ring I and an isolation ring II are fixed to the inner surfaces of the parts, between the piston II and the piston II and between the piston II and the piston III,of the piston outer cylinder correspondingly. A spiral worm is arranged in a stator sleeve in the axial direction, the lower end of the spiral worm abuts against a disc support, and a connecting rodhinged to the lower end face of the spiral worm is hinged to the center position of the upper end of a vibrator valve cone which is arranged in the stator sleeve in a clearance fit manner. By means ofthe reciprocating type low-pressure and high-frequency hydraulic power pulse vibrator, the pressure loss of the tool can be reduced by 45%, and meanwhile the problems of motor backing pressure, drillhead damage, drilling tool clamping, torque fluctuation, drilling tool fatigue and the like are solved.

Owner:合力(天津)能源科技股份有限公司

Low-friction reciprocating motion seal component

ActiveCN103742651AReduce contact areaEasy to storeEngine sealsSpringsReciprocating motionEngineering

The invention relates to the technical field of seal components and particularly discloses a low-friction reciprocating motion seal component. The low-friction reciprocating motion seal component comprises an annular support frame and an annular elastic seal body, wherein the annular elastic seal body comprises at least one seal lip. The low-friction reciprocating motion seal component is characterized in that a concave-convex girdle is arranged on an annular seal surface on which the seal lip is formed, and a plurality of projections or pits are arranged on the concave-convex girdle; the seal lip comprises a first seal lip and a second seal lip, and a first concave-convex girdle and a second concave-convex girdle are respectively arranged on annular seal surfaces which are formed by the first seal lip and the second seal lip; the projections or the pits are in a shape of a semi-sphere, a box, a truncated cone or a polygonal frustum. The low-friction reciprocating motion seal component has the beneficial effects that friction between the seal body and a shaft is reduced under the condition of ensuring that the seal body has sufficient radial seal pressure, so that the motion friction of a reciprocating mechanism is reduced; the service lives of the seal body and the motion shaft are prolonged under the condition of ensuring seal.

Owner:YANTAI RUNFUXIANG OIL SEAL

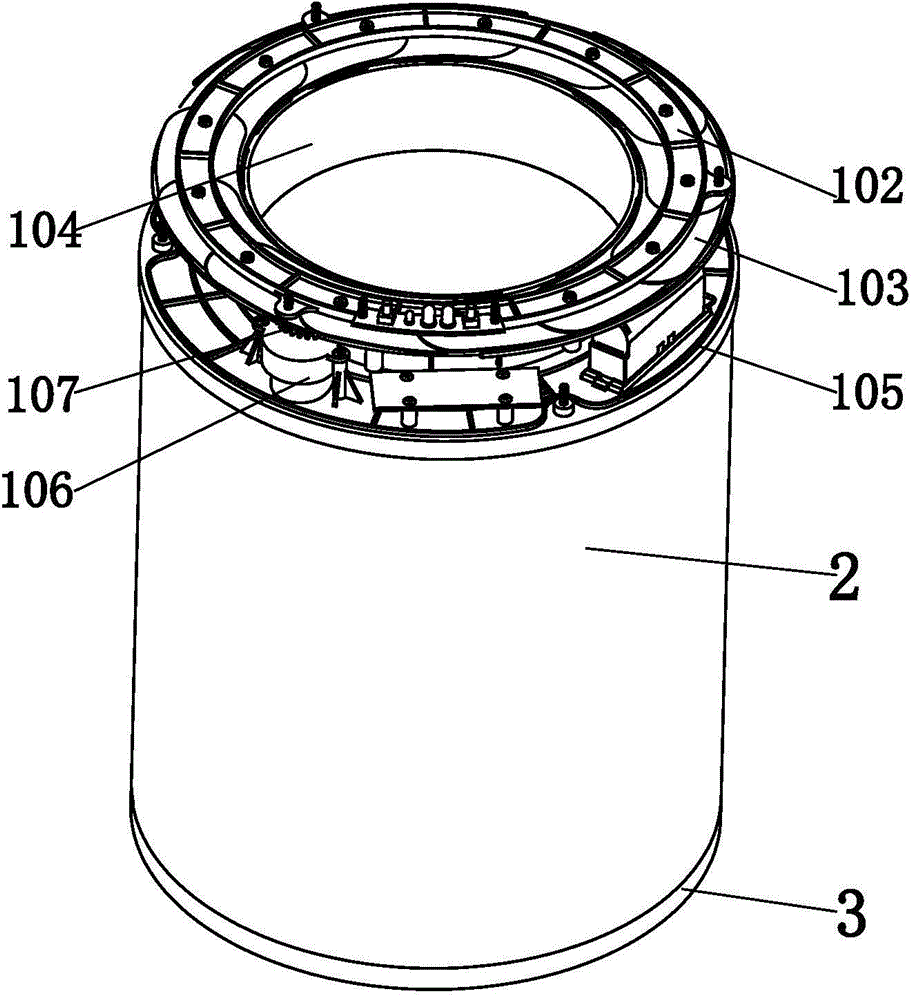

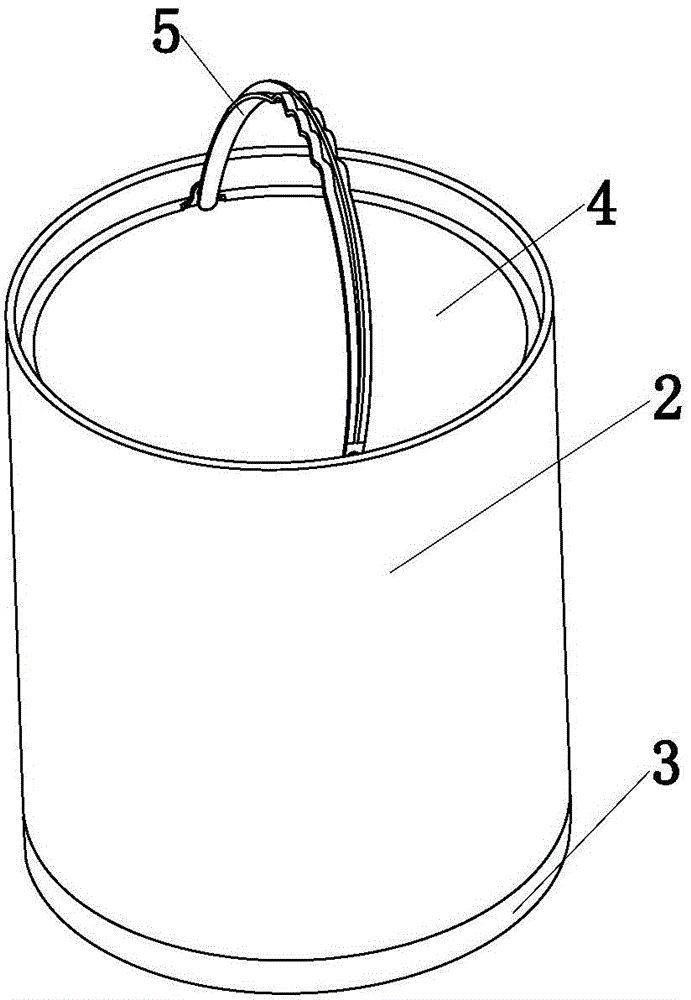

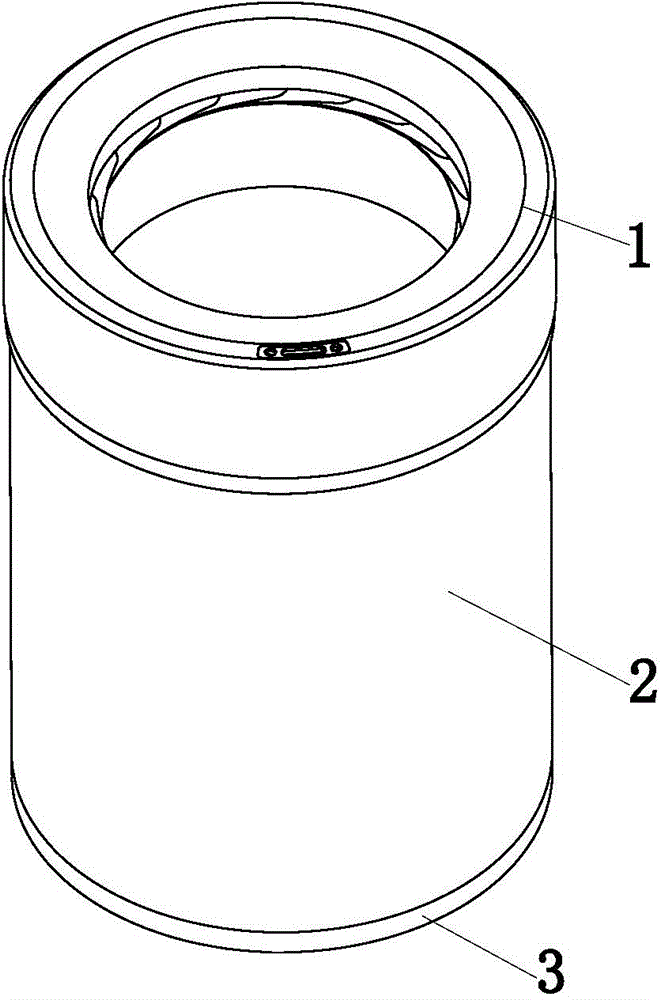

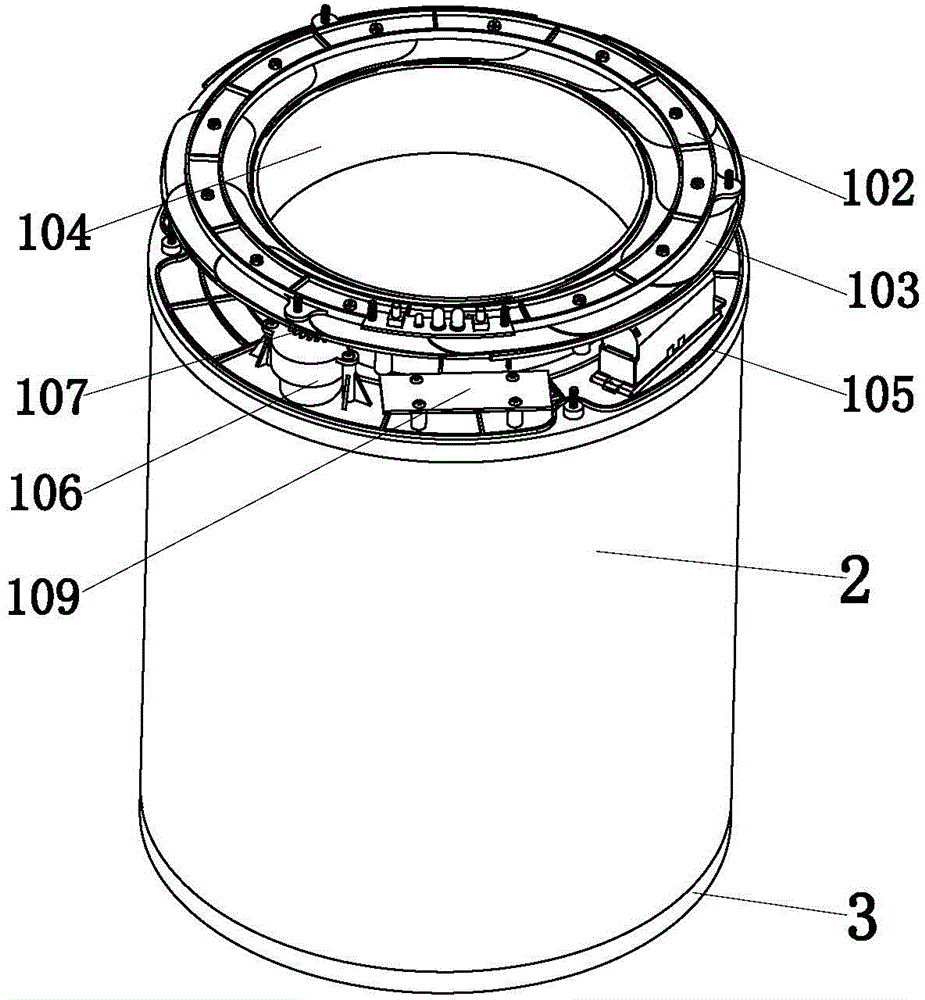

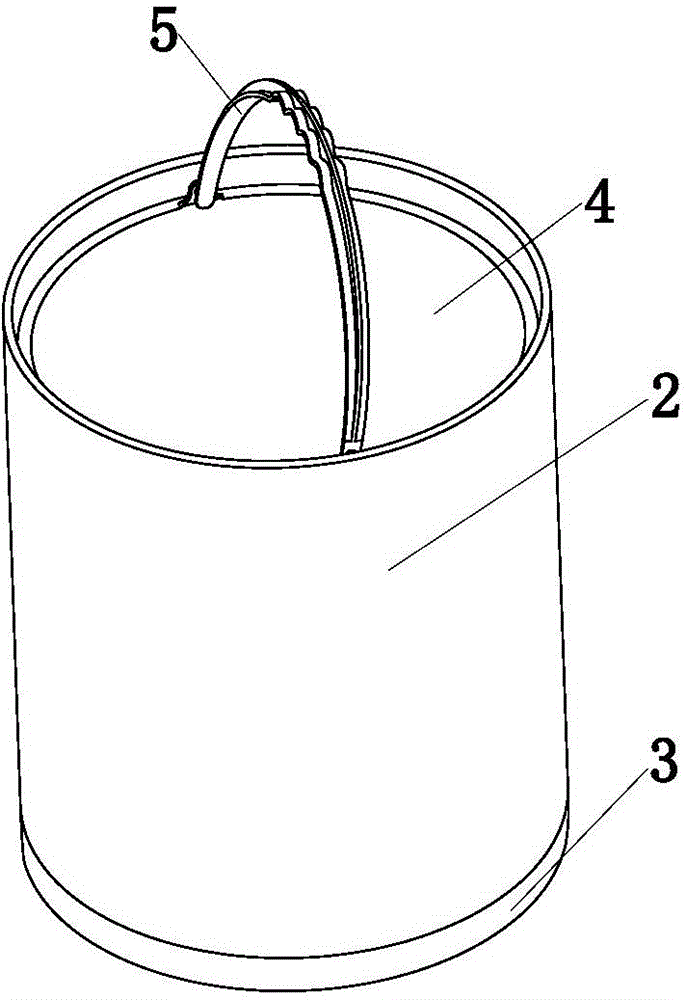

Rotary vane type garbage can

The invention relates to a rotary vane type garbage can which comprises a can cover, a can body, a can bottom, an inner can and a lifting handle, wherein the can cover is arranged right above the can body; the can bottom is positioned under the can body; the inner can is positioned inside the can body; the inner can is arranged on the upper end face of the can bottom; two lifting lugs are symmetrically arranged at upper ends of the inner can; the lifting handle is arranged between the two lifting lugs of the inner can; four annular buckles are symmetrically arranged above the can bottom and are clamped at the lower end of the can body. According to the rotary van type garbage can disclosed by the invention, the can bottom adopts a buckle connection mode, so the rotary vane type garbage can is easy for manufacturing and is simple in structure; in addition, workers can conveniently assemble the rotary vane type garbage can; the opening and closing functions can be quickly realized. The rotary vane type garbage can has the advantages of simple structure, simplicity and convenience for operation, good sealing performance, short reaction time of vanes, low driving sound of gears, small size, low cost, good appearance and shape effects and the like.

Owner:WUHU LANREN INTELLIGENT TECH

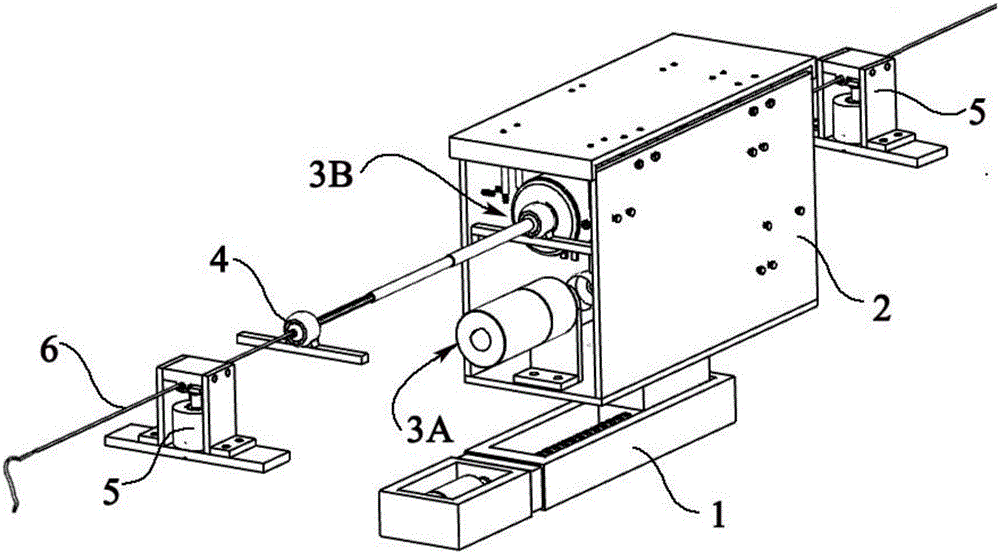

An interventional surgery robot and its control method for collaboratively pushing a catheter guide wire

ActiveCN105662586BImprove operating precisionImprove surgical efficiencyOperating tablesSurgical robotsSurgical robotEngineering

The invention discloses an interventional operation robot where a catheter and a guide wire are cooperatively pushed and a control method thereof and belongs to the technical field of machine manufacturing.The robot comprises a guide wire moving platform, a catheter moving platform, a guide wire operation end, a supporting guide frame, a catheter operation end, the guide wire and the catheter.The two ends of the supporting guide frame are connected with the guide wire operation end and the catheter operation end respectively.The catheter penetrates through the catheter operation end, and the guide wire is arranged in the catheter and penetrates into the guide wire operation end.Meanwhile, the invention further discloses the control method of the robot.By means of the guide wire operation end and the catheter operation end, movement of the guide wire and movement of the catheter are controlled respectively so that the catheter and the guide wire can be operated according to specific operation of a doctor, it is guaranteed that the guide wire and the catheter can be pushed cooperatively in the operation process, operation actions of the doctor can be completely simulated, and the robot has the advantages of being reasonable in structure, convenient to control and the like.

Owner:SHENZHEN INST OF ADVANCED BIOMEDICAL ROBOT CO LTD

Rotary blade type intelligent trash can and control circuit thereof

ActiveCN104443951ASmall openingNot easy to spillProgramme controlComputer controlMotor driveComputer module

The invention relates to a rotary blade type intelligent trash can and a control circuit thereof. The rotary blade type intelligent trash can comprises a can cover, a can body, a can bottom, an inner can and a handle, wherein the can cover is arranged over the can body; the can bottom is located under the can body; the inner can is located in the can body and installed on the upper end face of the can bottom; the handle is installed between two lifting lugs of the inner can; four annular hasps are symmetrically arranged on the upper side of the can bottom and are clamped to the lower end of the can body. The control circuit comprises a master control module, an H bridge motor drive module, an infrared detection module, a signal amplification module, an indication module and a phase reversal module, wherein the infrared detection module is used for forming an electric pulse signal, the signal amplification module is used for amplifying the electric pulse signal of the infrared detection module, and the phase reversal module is used for providing a switch signal to the master control module. The rotary blade type intelligent trash can and the control circuit thereof can achieve the rapid and intelligent opening and closing function, and have the advantages that the structure is simple, operation is simple and convenient, closing performance is good, blade response time is short, gear transmission noise is low, the size is small, cost is low and the appearance shape effect is good.

Owner:WUHU LANREN INTELLIGENT TECH

Follow-up type automatic compensation polished rod sealing device

InactiveCN105971544AUniform and stable penetrationAvoid corrosionSealing/packingOil fieldEngineering

The invention provides a follow-up type automatic compensation polished rod sealing device and belongs to the technical field of oil field machinery. The follow-up type automatic compensation polished rod sealing device comprises a sealing cover, a sealing shell, a pressure adjusting spring, a translation pressing plate, an upper follow-up platform, a follow-up packing box, a lower follow-up platform and a sealing foundation support; the follow-up packing box is in close contact with a polished rod, parallel movement in any direction in the horizontal plane is conducted by means of the upper follow-up platform and the lower follow-up platform, and the problem of eccentric wear is effectively solved; the follow-up packing box is provided with compensation packing and centralization packing, close contact with the polished rod can be achieved under continuous pressure, the sealing effect is improved, and packing wear can be compensated continuously; an annular cavity formed by a sealing cover retaining ring and the sealing shell is filled with lubricating oil and can provide continuous lubrication and oil seal for the upper follow-up platform, the lower follow-up platform, the polished rod and even the packing, radial and axial friction is reduced, meanwhile multiple purposes of saving energy, sealing, prolonging the service life and the like are achieved, and the follow-up type automatic compensation polished rod sealing device can be widely applied to wellhead sealers of oil field pumping units with rods.

Owner:HARBIN UNIV OF SCI & TECH +1

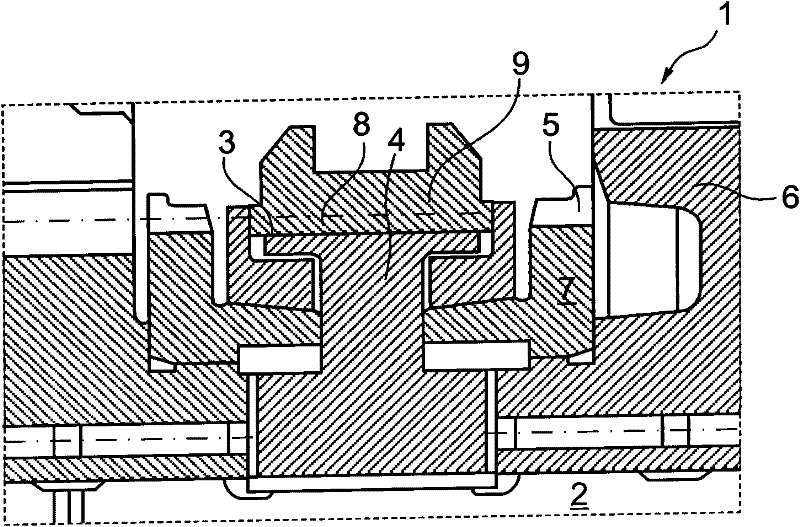

Transmission

InactiveCN102235438AIncrease tilt DOFReduce axial frictionInterengaging clutchesControl devicesEngineeringClutch

A transmission having at least one shaft, on which a guide sleeve which has a first external toothing system is arranged fixedly so as to rotate with it and at least one slider sleeve which has an internal toothing system is arranged, it being possible to adjust the slider sleeve between a disengaged position, in which the internal toothing system and a second external toothing system on a clutch element are not operatively connected, and an engaged position, in which the internal toothing system meshes with the second external toothing system. The internal toothing system and / or the first external toothing system are / is configured in such a way that there is merely punctiform contact between them in the engaged position. As a result, in particular, an undesired gear disengagement can be suppressed.

Owner:DR ING H C F PORSCHE AG +1

Universal-type flow meter based on wing principle

InactiveCN105675068ASmall pressure lossGood sensing repeatabilityVolume/mass flow by differential pressureAerospace engineeringStreamflow

The invention discloses a general-purpose flowmeter based on the wing principle, which includes a wing-type sensing element arranged in a pipeline, and a detection signal transmission device connected with the sensing element; the sensing element includes a plurality of spaced distribution and The disc wings are coaxially connected in series through the shared wing shaft arranged horizontally. The wing axis is perpendicular to the pipe axis, and the cross section of the disc wing is D-shaped; The pipe wall on the side of the arc curved surface is provided with a supporting cylinder sleeve, and the outer end of the supporting cylinder sleeve protrudes from the pipe; the two ends of the shared wing shaft are respectively erected at two corresponding places on the pipe wall through the shaft sleeve and the supporting cylinder sleeve; The wing shaft is rotatable and can translate left and right; the detection signal transmission device is connected to the pressure transmitter through the end face of the common wing shaft on the side of the curved surface of the D word through a hydraulic jack type pressure amplifying device. High reliability and sensitivity, free pipeline layout, convenient maintenance, small pressure loss, simple structure, and can adapt to various fluid measurement.

Owner:FUJIAN YUNCHUANG INTEGRATED TECH SERVICES

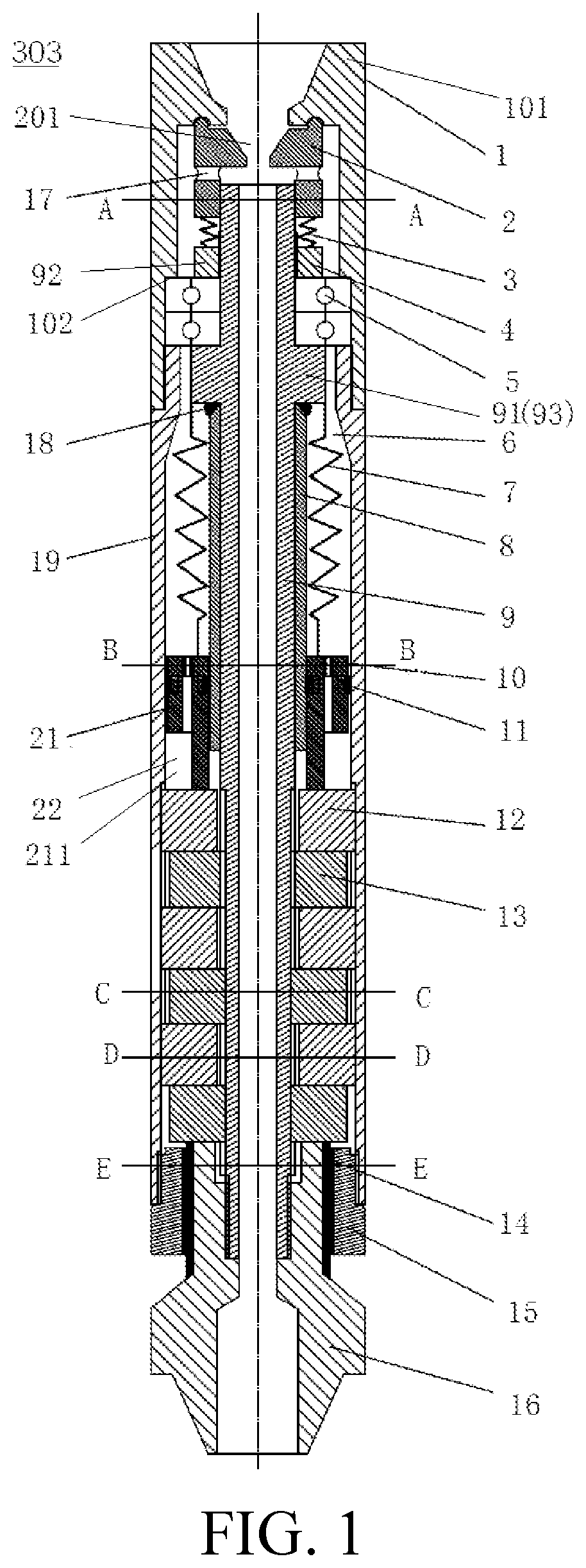

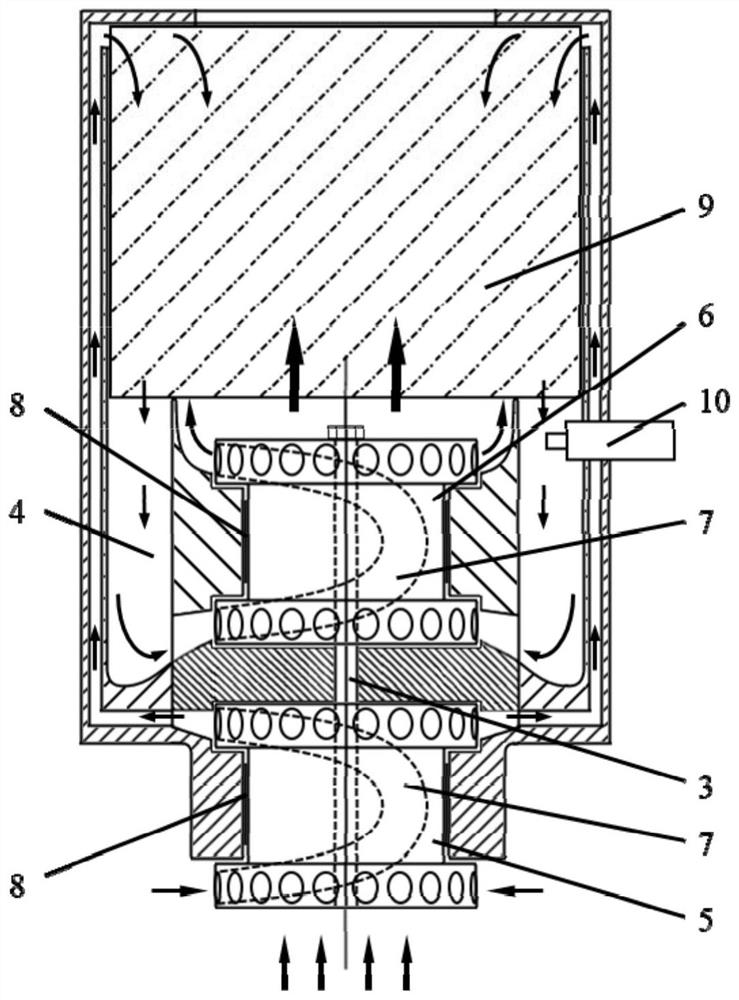

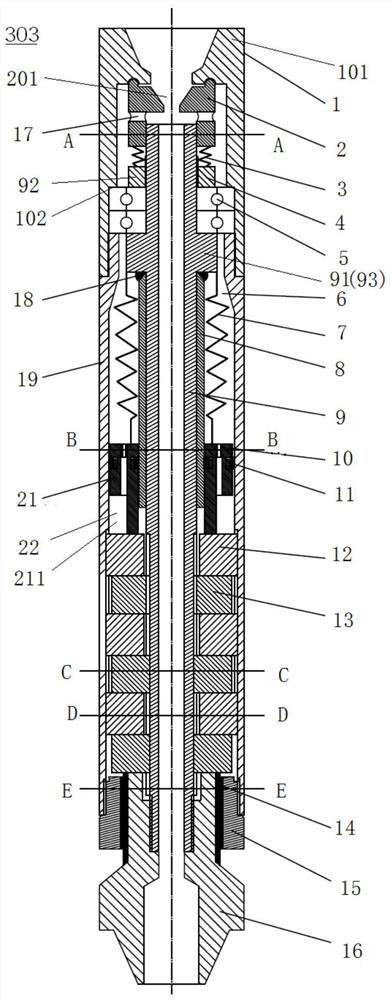

Reactive torque automatic balancing device for screw drilling tool, drilling string, and method

PendingUS20220316312A1Simple structureLow costDrilling rodsDirectional drillingThermodynamicsUpper joint

A reactive torque automatic balancing device for a screw drilling tool includes an upper joint (1); a core cylinder (9) having an inner chamber in communication with the screw drilling tool (305) located downstream, so that drilling fluid from the inner chamber of the upper joint (1) flows to the screw drilling tool (305) through the inner chamber of the core cylinder (9) to allow the screw drilling tool to perform drilling; a lower joint (16) fixedly arranged at a lower end of the core cylinder (9); and an automatic balancing assembly, which is arranged between an outer wall of the core cylinder (9) and an inner wall of the upper joint (1), and driven by hydraulic pressure generated by a part of the drilling fluid flowing through the inner chamber of the upper joint (1).

Owner:CHINA PETROCHEMICAL CORP +1

Vertical streamline tunnel wheel gas turbine

InactiveCN112096521AImprove stabilityHigh strengthPump componentsBlade accessoriesCombustion chamberAir bearing

The invention discloses a vertical streamline tunnel wheel gas turbine, and belongs to the field of gas turbines. The vertical streamline tunnel wheel gas turbine comprises a gas compressor, a combustion turbine, a shaft and a combustion chamber, wherein the gas compressor and the combustion turbine are installed at the upper end and the lower end of the shaft to form a gas turbine rotor, the combustion chamber is located between the gas compressor and the combustion turbine, and the shaft is vertically arranged to form a vertical structure. The vertical streamline tunnel wheel gas turbine adopts streamline tunnel turbines and gas compressor wheels, is mounted in a vertical structure in cooperation with an external contour type air bearing, and can achieve the beneficial effects of improving the rotating speed, improving the reliability, reducing the leakage loss, reducing the size and the weight and the like.

Owner:萍乡北京理工大学高新技术研究院

A centralizer with self-adaptive variable diameter

ActiveCN112593869BEasy to sendAvoid risk of leakageDrilling rodsDrilling casingsUpper jointEngineering

The invention relates to a centralizer with self-adaptive variable diameter used in the field of oil and gas well engineering. It solves the problems of poor centering of the drill string and high frictional resistance of the drill string. The technical solution is: the upper end of the stator shell is connected with the lower end of the upper joint with screws, and the lower end of the stator shell is connected with the upper end of the connecting cylinder with a thread; the rubber stator is fixed in the inner cavity of the stator shell; the screw rotor is placed in the inner cavity of the rubber stator, and the bearing a is installed in the screw. The upper end of the outer circle of the rotor; the transmission screw is placed in the inner cavity of the connecting cylinder, and the transmission screw rotates flexibly in the inner cavity of the connecting cylinder; the upper end of the lower joint is connected with the lower end of the connecting cylinder with screws; the lower end of the roller and the support arm a is hinged, and the roller and the support arm b The lower end is hinged. The present invention can realize the function of effectively changing the diameter in the downhole, the roller and the well wall are fully attached, and the drill string is well centered; the roller and the well wall are purely rolling, the axial friction between the drill string and the well wall is small, and the drill string is fed convenient.

Owner:SOUTHWEST PETROLEUM UNIV

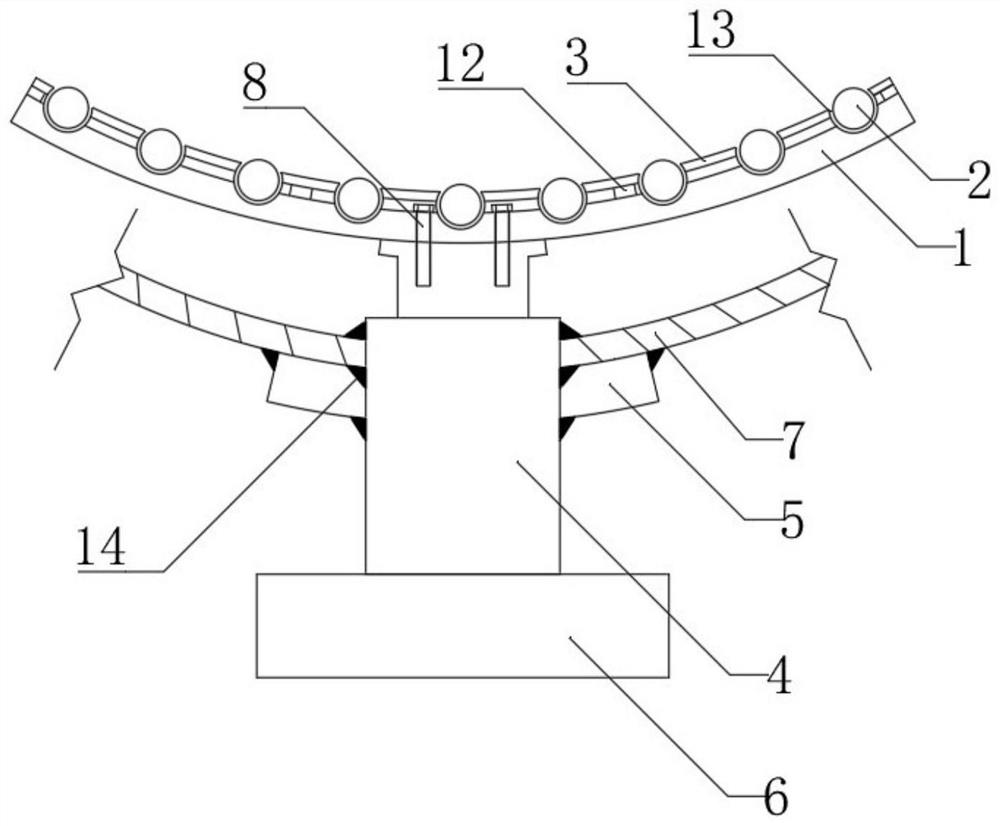

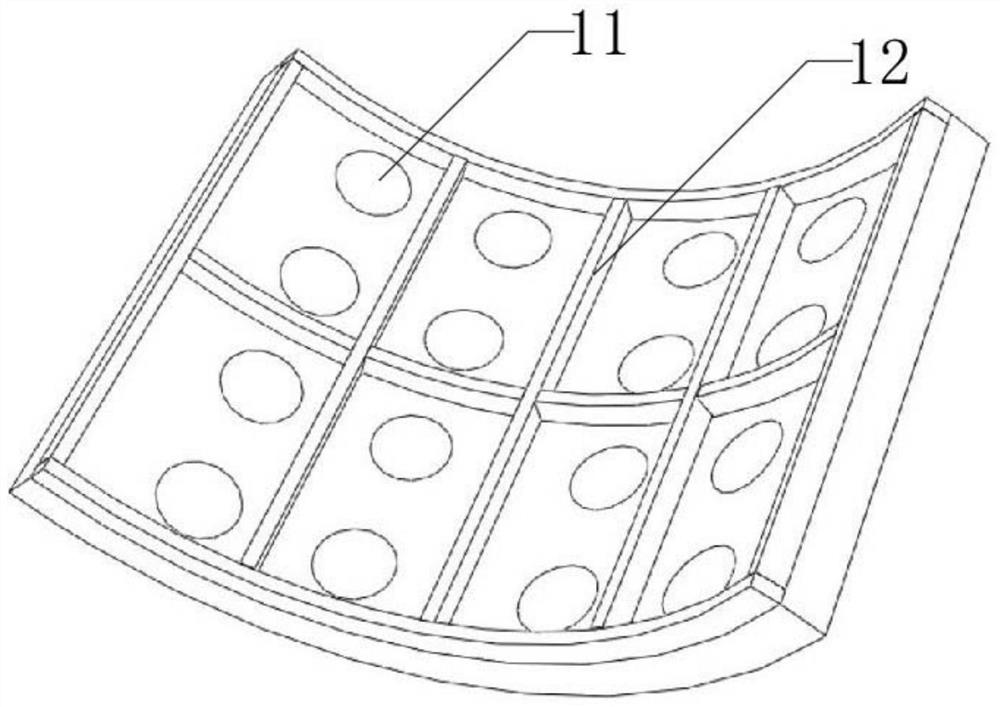

Hundred-bead supporting plate device for preventing shield tunneling machine from head falling and construction method thereof

The invention relates to the technical field of underground tunnel excavation construction, in particular to a hundred-bead supporting plate device for preventing a shield tunneling machine from headfalling and a construction method thereof. The device comprises hundred-bead supporting plate units, a jack, a base and a steel sleeve; the bottom of the steel sleeve is provided with a hole opening used for being penetrated by the jack; the output end of the jack is fixedly connected with the bottoms of the hundred-bead supporting plate units; the outer wall of the jack is welded to the hole opening; the bottom of the jack is connected with the top of the base located on the ground of a receiving well; each hundred-bead supporting plate unit comprises an arc-shaped supporting plate, balls, alimiting strip and an arc-shaped cover plate; each arc-shaped supporting plate is a steel plate of an arc-shaped structure; the curvature of each arc-shaped supporting plate is the same as the curvature of the outer surface of the shield tunneling machine; and semispherical grooves used for containing the balls are evenly distributed in the upper surface of each arc-shaped supporting plate. According to the hundred-bead supporting plate device for preventing the shield tunneling machine from head falling and the construction method thereof, the construction risk is greatly reduced, the grouting construction requirement in the steel sleeve is greatly reduced, environmental protection is achieved, the construction difficulty is reduced, the construction cost is saved, and the construction progress is accelerated.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +2

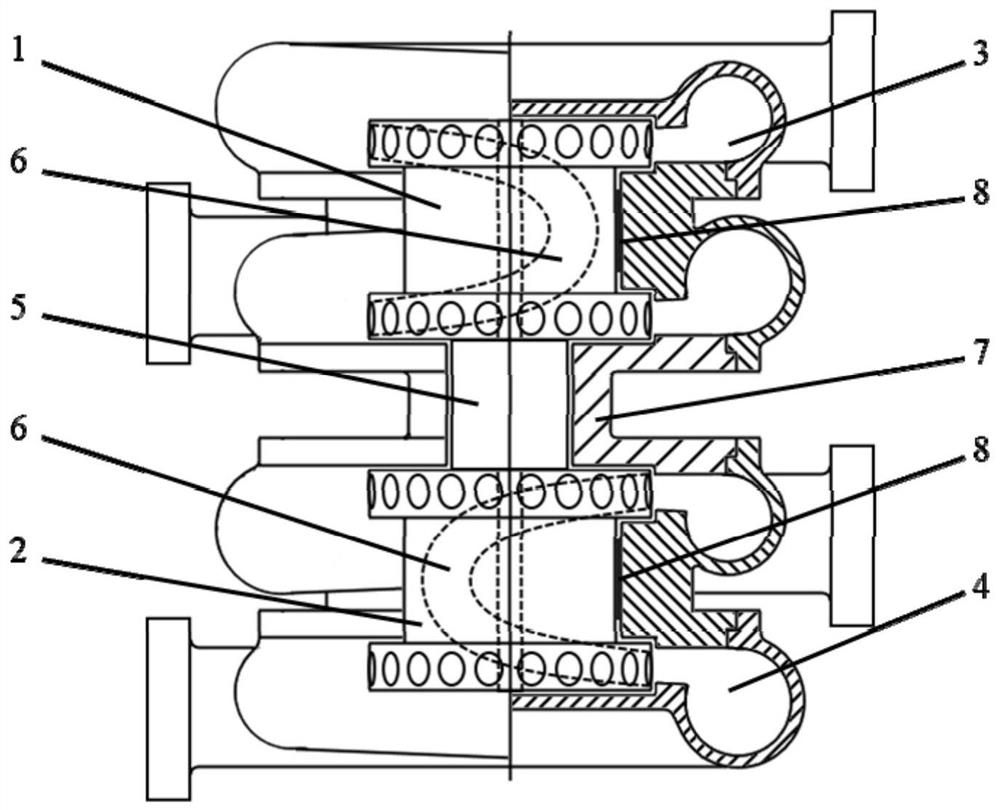

Squeezing type peristaltic pump

PendingCN114658638AReduce axial frictionReduce fatigue damagePositive displacement pump componentsFlexible member pumpsPeristaltic pumpReciprocating motion

The extrusion type peristaltic pump comprises a body, a transmission part, a first pressing unit, a second pressing unit, a limiting plate and a hose, the limiting plate is fixedly connected with the body, and the hose comprises a first branch pipe and a second branch pipe; the first branch pipe is arranged between the limiting plate and the first pressing unit, and the first pressing unit is driven by the transmission part to do reciprocating motion and used for pressing the first branch pipe; the second branch pipe is arranged between the limiting plate and the second pressing unit; the second pressing unit is driven by the transmission part to reciprocate and used for pressing the second branch pipe, the first branch pipe and the second branch pipe are alternately pressed, and the hose continuously discharges liquid. According to the scheme, the first branch pipe and the second branch pipe alternately extrude and convey the fluid to the gathering pipe, finally continuous conveying of the fluid in the gathering pipe is achieved, fluid cutoff is avoided, the flow stability in the fluid conveying process is improved, and pulsation is reduced.

Owner:BAODING LEAD FLUID TECH

Rotational mechanical systems having reduced friction sealing surfaces

InactiveUS20190157938A1Reduce axial frictionEasy to trackEngine sealsPower installationsMechanical systemCoating

In accordance with at least one aspect of this disclosure, a stationary housing for a rotational mechanical device includes an interior sealing surface configured to receive a rotationally stationary seal assembly that is allowed to move axially to track a journal shaft, wherein the interior sealing surface includes an anti-frictional coating.

Owner:HAMILTON SUNDSTRAND CORP

Anti-torque automatic balancing device, drilling string and method for screw drilling tools

ActiveCN111852334BSimple structureReduce maintenance costsDrilling rodsDirectional drillingFriction torqueThermodynamics

The present invention proposes a kind of anti-twist automatic balance, drilling pipe string and method for screw drilling tools. The device includes an upper sub; The drilling fluid in the inner cavity can flow to the screw drilling tool through the inner cavity of the core barrel to make the screw drilling tool drill; the lower joint fixed at the lower end of the core barrel; the lower joint arranged between the outer wall of the core barrel and the inner wall of the upper joint an automatic balancing assembly driven by hydraulic pressure generated by a portion of the drilling fluid flowing through the inner cavity of the upper sub, wherein friction occurs between the upper sub and the core barrel when the displacement of the drilling fluid is equal to a first predetermined value The torque is equal to the reaction torque generated on the casing of the screw drilling tool for directional drilling. When the drilling fluid displacement is higher than the first predetermined value, the friction torque generated between the upper joint and the core barrel is greater than that on the casing of the screw drilling tool. The generated reaction torque makes the core barrel drive the casing of the screw drilling tool to rotate for compound drilling.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reciprocating low pressure high frequency hydraulic pulse vibrator

ActiveCN110593762BLow pressure lossReduce axial frictionVibration drillingCircular discWell drilling

The invention relates to a reciprocating type low-pressure and high-frequency hydraulic power pulse vibrator and belongs to the field of vibration or oscillation method well drilling. The reciprocating type low-pressure and high-frequency hydraulic power pulse vibrator is composed of a vibration short joint and a power short joint. The vibration short joint is formed in the manner that a spline core shaft is inserted in a spline outer cylinder and a piston outer cylinder, and a disc spring is installed in the circular clearance between the middle portion of the spline core shaft and the pistonouter cylinder. The lower end of the spline core shaft is fixedly connected with a piston inner cylinder. A piston I, a piston II and a piston III are sequentially fixed to the piston inner cylinderfrom top to bottom, and an isolation ring I and an isolation ring II are fixed to the inner surfaces of the parts, between the piston II and the piston II and between the piston II and the piston III,of the piston outer cylinder correspondingly. A spiral worm is arranged in a stator sleeve in the axial direction, the lower end of the spiral worm abuts against a disc support, and a connecting rodhinged to the lower end face of the spiral worm is hinged to the center position of the upper end of a vibrator valve cone which is arranged in the stator sleeve in a clearance fit manner. By means ofthe reciprocating type low-pressure and high-frequency hydraulic power pulse vibrator, the pressure loss of the tool can be reduced by 45%, and meanwhile the problems of motor backing pressure, drillhead damage, drilling tool clamping, torque fluctuation, drilling tool fatigue and the like are solved.

Owner:HELI TECH ENERGY CO LTD

A low-friction shock absorber oil seal

ActiveCN103244686BReduce coefficient of frictionKeep radial force constantEngine sealsEngineeringShock absorber

The invention relates to a sealing element, in particular to a low-friction oil seal for a shock absorber. The oil seal comprises a framework and an oil seal body. The oil seal body comprises at least one sealing lip and a dust-proof lip. The oil seal is characterized in that axial parallel veins are arranged on annular sealing surfaces formed by the sealing lips. The sealing lips comprise a first sealing lip and a second sealing lip, and first axial parallel veins and second axial parallel veins are arranged on the annular sealing surfaces formed by the first sealing lip and the second sealing lip respectively. Third axial parallel veins are arranged on an annular sealing surface formed by the dust-proof lip. The low-friction oil seal has the advantages that forming of critical lubricating oil film between contact surfaces of the sealing surfaces and a shock absorber shaft is facilitated, so that the contact area is reduced; and lubricating oil can be stored between the axial veins conveniently, so that the friction coefficient between the oil seal and the shock absorber shaft is reduced, the friction between the oil seal and the shock absorber shaft is reduced on the premise that the radial sealing force is not changed, and the service life of the oil seal is increased.

Owner:YANTAI RUNFUXIANG OIL SEAL

Motor assembly as well as positioning installation method thereof

InactiveCN101841207BImprove output efficiencyReduce axial frictionManufacturing dynamo-electric machinesMechanical energy handlingEngineeringVibrating string

The invention relates to a motor assembly and a location and installation method thereof. The motor assembly comprises a motor and a gear box connected with the motor, wherein, the motor comprises a motor shell, an armature shaft arranged in the motor shell, a push stopping plate arranged at the bottom of the motor shell and a straight bearing arranged on the push stopping plate; the gear box comprises an output gear shaft, a drive disk which drives the output gear shaft to rotate, a gear, a butter cushion arranged in the inner cavity of the gear, a straight bearing assembly and a supporting seat provided with a bearing; the push stopping plate and the supporting seat are respectively provided with a spherical surface; the armature shaft passes through the straight bearing, the straight bearing assembly and the inner hole of the bearing in the supporting seat in sequence, and the two end surfaces of the push stopping plate are respectively contacted with the spherical surfaces of the push stopping plate and the supporting seat; the armature shaft is provided with a worm and is provided with a commutator; the worm is positioned between the straight bearing assembly and the supporting seat; the worm drives the gear in the gear box to rotate along the rotation of the armature shaft. The invention can reduce string vibration of motor output shaft at rating load, lower the noise ofthe motor, and improve output efficiency of the motor.

Owner:SHENZHEN CREATIVE & BRIGHT PRECISION PLASTIC MOLD

Vertical streamline tunnel wheel supercharger

InactiveCN112096511AAvoid influenceImprove stabilityInternal combustion piston enginesPump componentsAir bearingTurbocharger

The invention discloses a vertical streamline tunnel wheel supercharger, and belongs to the field of turbochargers. The vertical streamline tunnel wheel supercharger comprises a streamline tunnel typeair compressor wheel, a streamline tunnel type turbine, an air compressor shell, a turbine shell and a rotating shaft, wherein the streamline tunnel type gas compressor wheel and the streamline tunnel type turbine are installed at the two ends of the rotating shaft correspondingly so that a supercharger rotor can be formed, the rotating shaft is vertically arranged and forms a vertical structure.According to the vertical streamline tunnel wheel supercharger, the streamline tunnel type turbine and the gas compressor wheel are adopted and matched with an external contour type air bearing to beinstalled in a vertical structure, and the beneficial effects of improving the rotating speed, improving reliability and stability, reducing leakage losses and reducing the size and the weight can beachieved.

Owner:科诺泰博(北京)科技有限公司

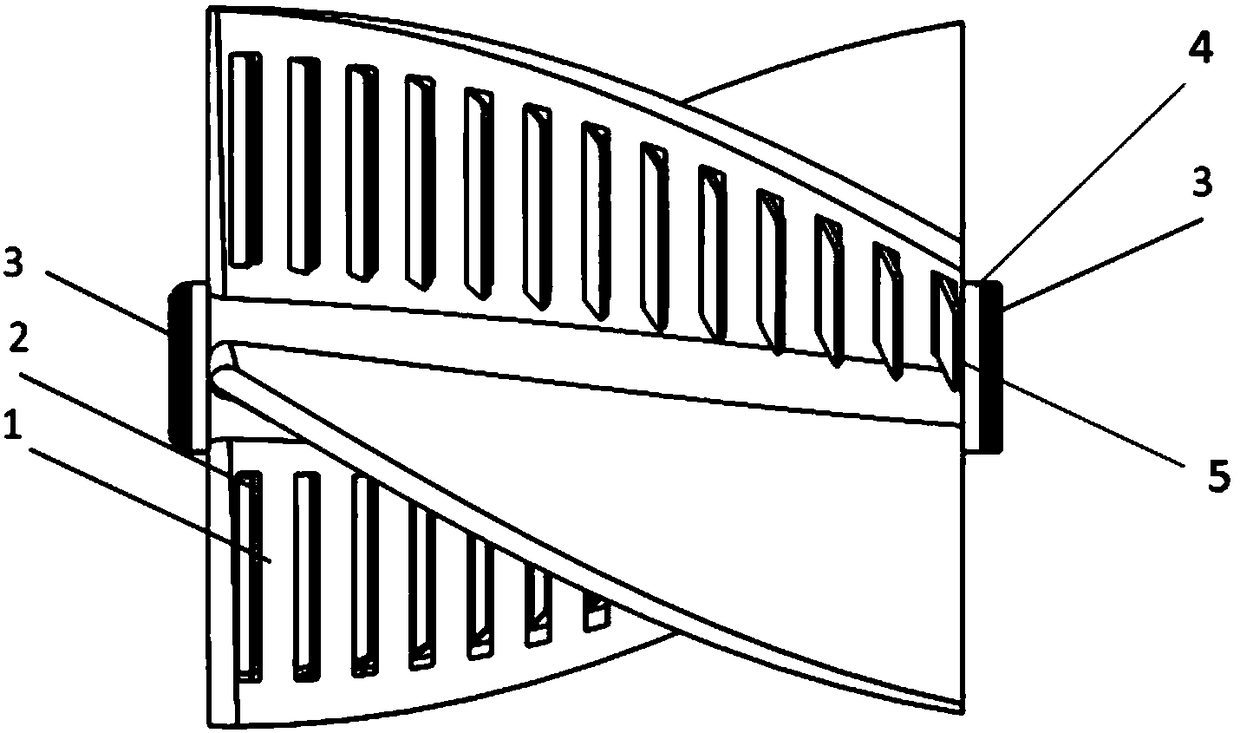

Magnetic Bionic Blade Rotor in Heat Exchange Tubes

ActiveCN106403699BReduce manufacturing costReduce wearCorrosion preventionHeat transfer modificationEngineeringHelix

The invention aims at designing rotors of a novel structure. Rectangular open hole structures are arranged on the surfaces of blades of the rotors; spiral small blade structures opposite to the overall direction of the blades are arranged at rectangular open holes; and meanwhile, magnets are attached to the two ends of a hollow shaft of each rotor. According to the rotors of the structure, the frictional resistance between the adjacent rotors is obviously reduced, and the fluid resistance is reduced; meanwhile, the strengthened heat transfer performance and the self-cleaning performance of the rotors are not reduced; and the strengthened heat exchange performance and the descaling performance of the rotors can be further improved.

Owner:BEIJING UNIV OF CHEM TECH

Compound vibrating well-drilling tool

ActiveCN102747958BReduce axial frictionReduce "drag pressure" phenomenonVibration drillingHydraulic cylinderWell drilling

The invention discloses a compound vibrating well-drilling tool which comprises a sleeve, a vibrating short joint, a vibrating short joint chuck, a screw motor, a conversion short joint connected with the lower end of the screw motor, an annular disc sleeved at the upper end of the conversion short joint, a hydraulic cylinder installed at the lower end of the conversion short joint, an impact short joint arranged in an inner cavity of the hydraulic cylinder and a torque transmitting short joint, wherein the vibrating short joint, the vibrating short joint chuck, the screw motor, the conversion short joint, the annular disc, the hydraulic cylinder, the impact short joint and the torque transmitting short joint are arranged in sequence from top to bottom. The well-drilling tool can be installed at different positions in a well-drilling column, the drilling column generate axial and circumferential high frequency compound vibration through the tool, and phenomena including 'pulling press' and 'stick slip' in the large-inclination well drilling process are eliminated, thereby remarkably improving mechanical drilling speed, prolonging the service life of a drill bit and reducing well-drilling cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

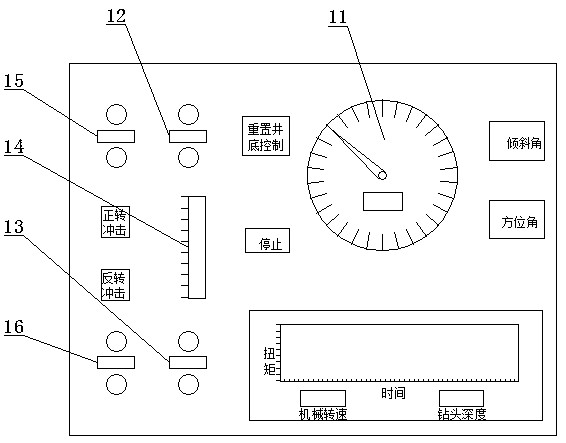

Automatic ground control device and method for downhole quick orientation and collimation

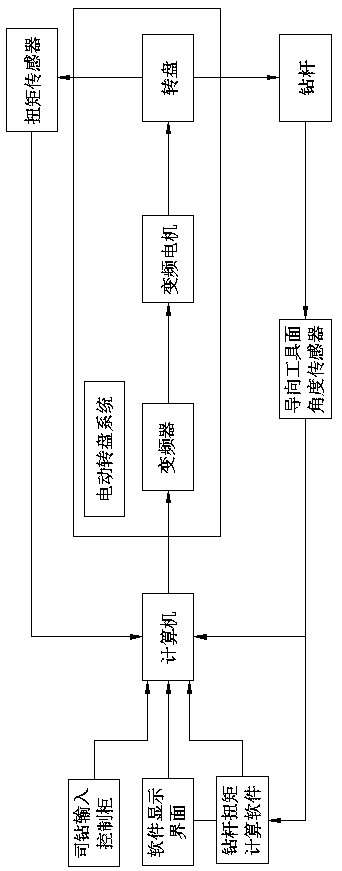

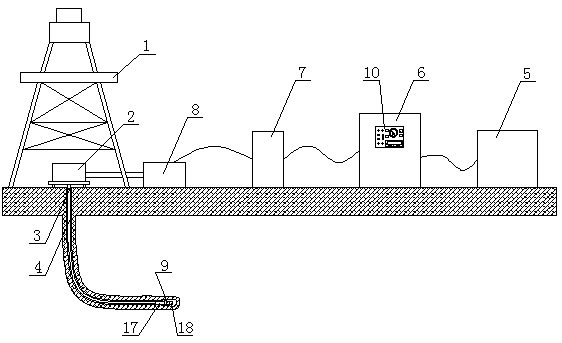

InactiveCN110821405AReduce purification efficiencyImprove track qualityDirectional drillingAutomatic control for drillingFrequency changerAutomatic control

The invention relates to an automatic ground control device and method for downhole quick orientation and collimation, and belongs to the technical field of design of petroleum drilling tools. The automatic ground control device is composed of a rotary plate, a computer and a torque sensor, the rotary plate is arranged on a derrick, a variable frequency motor, a frequency converter, the computer and a driller input control cabinet are installed on one side of the rotary plate in sequence, a drilling pipe is installed on the rotary plate, and the portion, close to the rotary plate, of the drilling pipe is provided with the torque sensor electrically connected with the computer. The end tip of the drilling pipe is provided with a drill tip through a guide motor. The control method comprisesthe following steps of data collection, data processing and control. According to the control device and method, the drilling pipe does stop rotating in the control process, during the drilling period, the drill tip does not leave from a downhole, and during drilling, correction of a tool face can be conducted. In this way, the borehole purifying efficiency can be improved, the axial friction generated when a drill string moves forwards can be reduced, and the problems are solved that in an existing drilling process, the borehole purifying efficiency is low, the axial friction generated when the drill string moves forwards is high, and the guide motor is prone to speed loss.

Owner:YANGTZE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com