Hundred-bead supporting plate device for preventing shield tunneling machine from head falling and construction method thereof

A shield machine and pallet technology, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of receiving construction failure, difficult construction quality, unevenness, etc., to reduce axial friction, simplify construction procedures, The effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

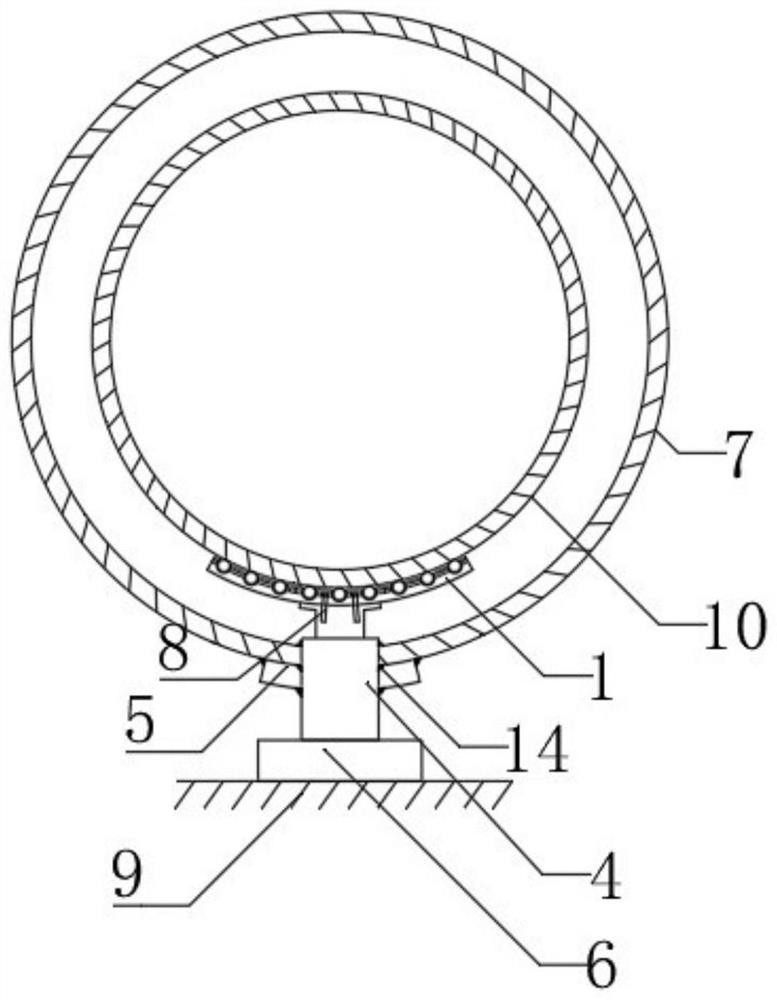

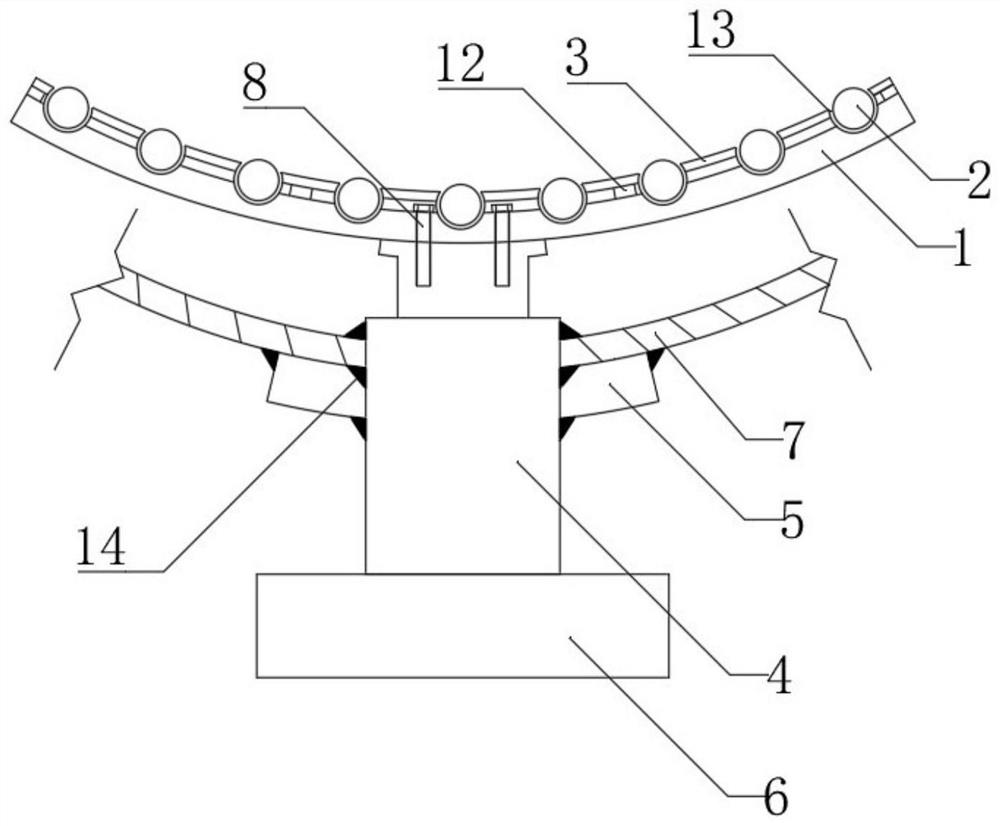

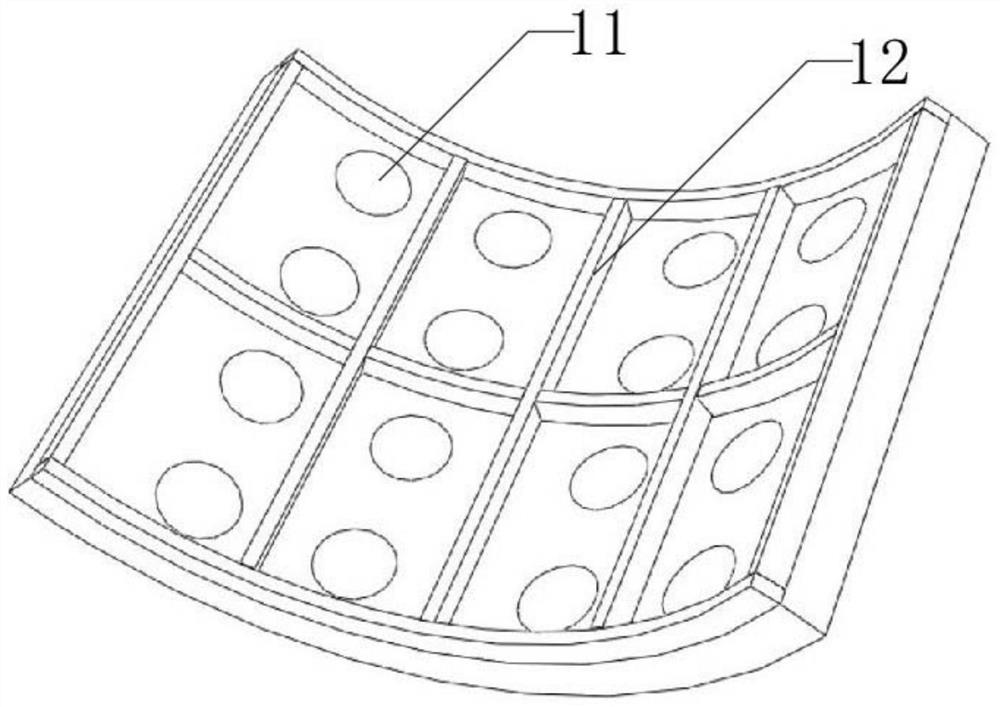

[0041] Example: such as Figure 5 As shown, it is a unit structure of double ball pallets. The bottom of the steel sleeve 7 is provided with two holes for the jack 4 to pass through. The axis extension lines of the two jacks 4 are connected to the steel sleeve. The axes of 7 intersect vertically, and the tops of the two jacks 4 are connected with elongated bead supporting plate units. Two sets of jacks 4 are provided in this embodiment, and are not limited to two sets of jacks 4. The tops of each set of jacks 4 are A bead supporting plate unit is connected to receive the shield machine 10 more stably.

[0042] Construction method:

[0043] Step 1, at the inside chamfer 14 of the round hole of the reinforcing collar 5 and the outer surface of the orifice of the steel sleeve 7, the outer surface is firmly welded, and its periphery is firmly welded with the outer surface of the steel sleeve 7;

[0044] Step 2, pass the jack 4 through the round hole of the reinforcing collar 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com