Motor assembly as well as positioning installation method thereof

A motor and assembly technology, applied in the field of motor assembly and its positioning and installation, can solve the problems of increased cost, high requirements on gasket materials, and large motor string movement, etc., to reduce friction and motor string movement, reduce material and Processing cost, effect of reducing skew and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further elaborate the technical means and effects adopted by the present invention to achieve the predetermined purpose, please refer to the following detailed description and accompanying drawings of the present invention. It is believed that the purpose, characteristics and characteristics of the present invention should be able to gain a deep and specific understanding from this , however, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

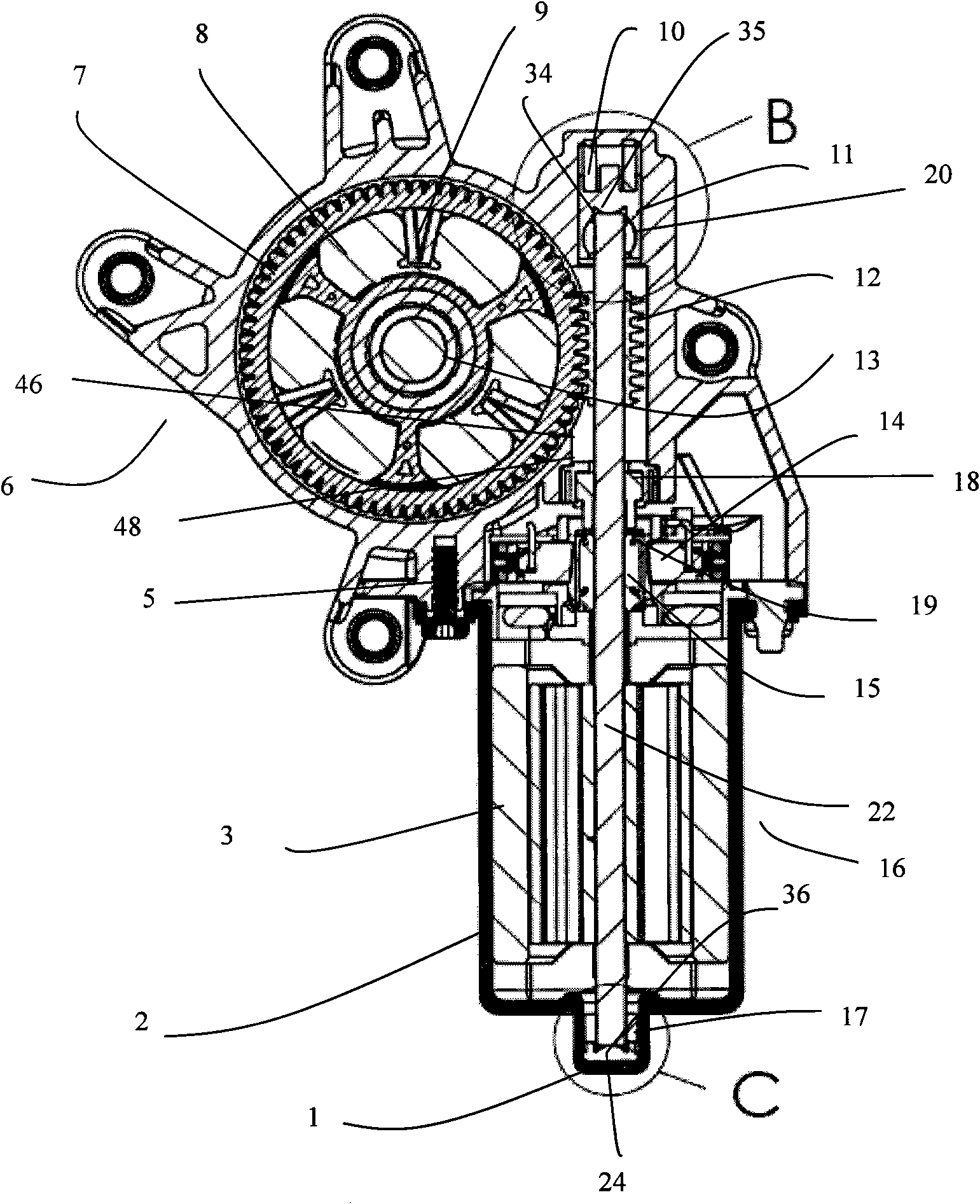

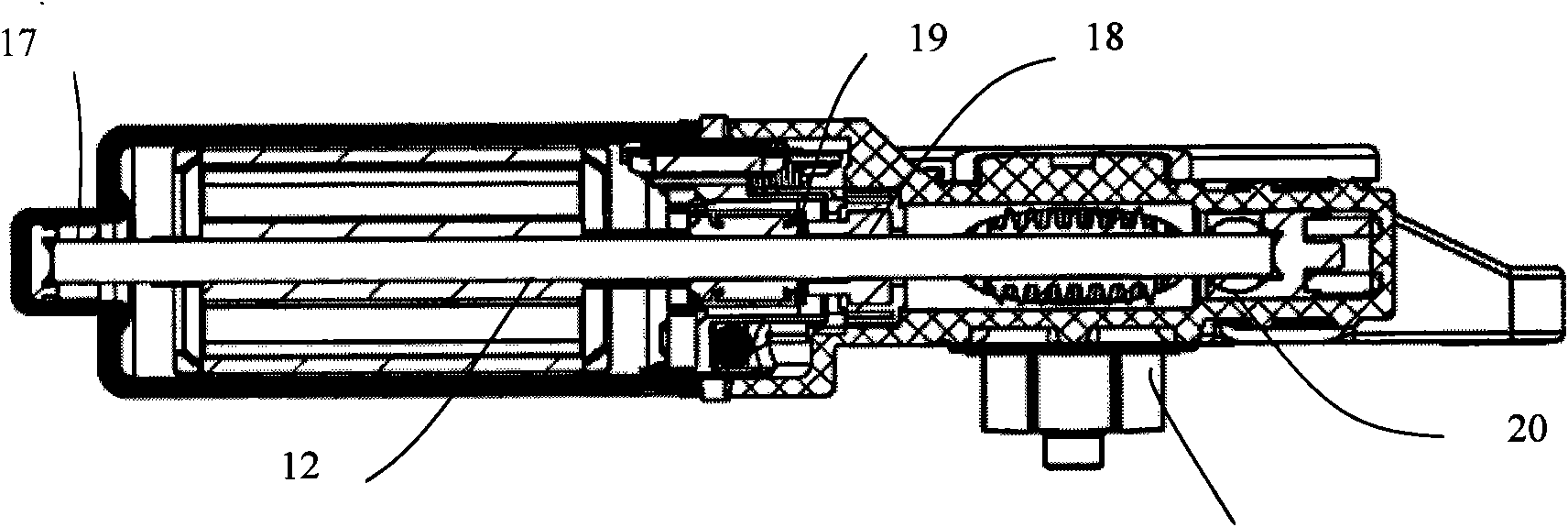

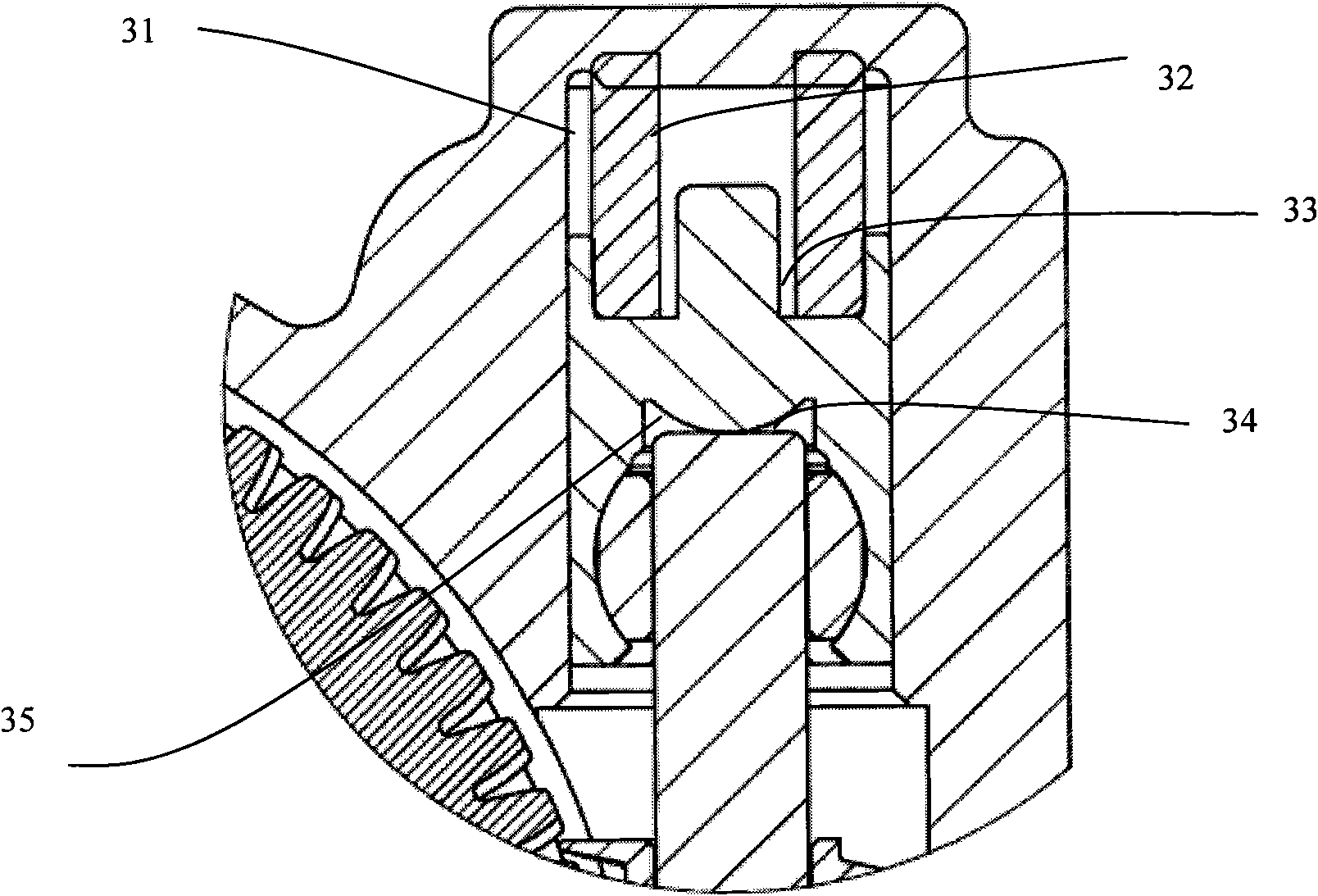

[0045] Such as Figure 1-4As shown, the present invention provides a motor assembly, which includes: a motor 16, and a gearbox 6 connected to the motor 16, the motor 16 includes a motor housing 2, an armature shaft 22 installed in the motor housing 2, The thrust plate 1 installed on the bottom of the motor housing 2, and the straight bearing 17 press-fitted on the thrust plate 1; the gear box 6 includes an output gear shaft 21, and a drive p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com