Preparation method of anodic-aluminum-oxide-based nano imprinting template

A nano-imprinting and anodizing technology, applied in nanotechnology, coating, surface reaction electrolytic coating, etc., can solve problems such as non-reusability, poor structural order, and AAO film damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] In this embodiment, sapphire is used as the rigid substrate 1, and the method of wet etching the sapphire is adopted, and the mask adopts a hard mask. The preparation method of the nanoimprint template based on anodized aluminum in this embodiment includes the following steps :

[0079] 1) Aluminum flakes with a purity of 98% and a thickness of 300 μm were mixed with a mixed solution of perchloric acid and ethanol (HClO at 5° C. 4 :C 2 h 5 OH=1:4, volume ratio) for electrochemical polishing.

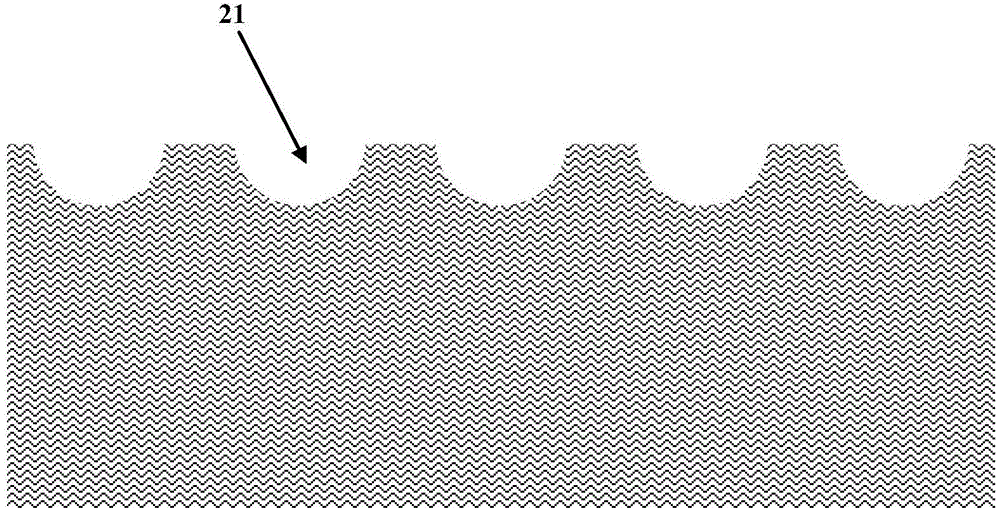

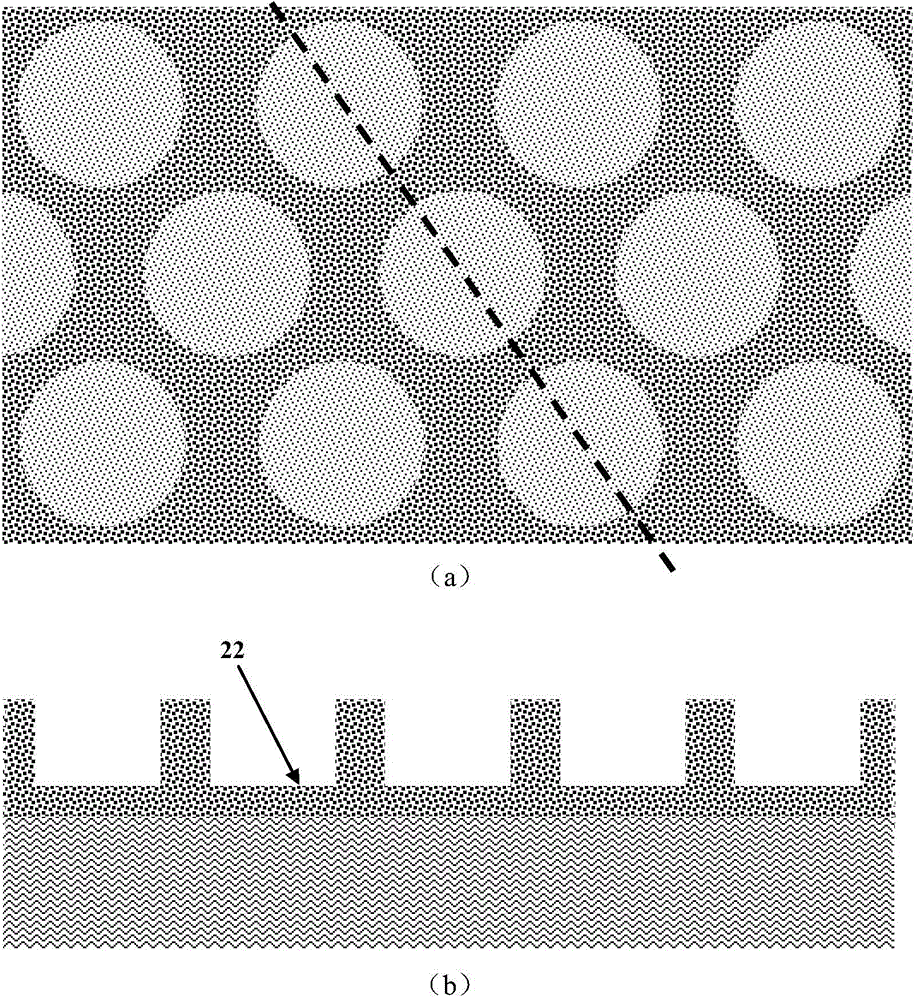

[0080] 2) Perform an anodic oxidation reaction in a 0.005-0.5mol / L phosphoric acid solution at 1°C to produce a disordered nanoporous structure. However, as the reaction progresses, a self-assembled preliminary order is gradually formed at the bottom of the alumina. Nanohole array, the reaction time is 8h.

[0081] 3) Soak in a mixed solution of chromic acid and phosphoric acid (mass fraction of chromic acid is 20%, mass fraction of phosphoric acid is 6%) at 80°C for 6 hours t...

Embodiment 2

[0092] In this embodiment, sapphire is used as a rigid substrate, a method of dry etching sapphire is adopted, and a hard mask is used as a mask. The method for preparing an AAO-based nanoimprint template in this embodiment includes the following steps:

[0093] 1) to 7) are the same as in Embodiment 1.

[0094] 8) successively adopt acetone, ethanol and deionized water to clean the surface of the rigid substrate 1, after cleaning, vapor-deposit a layer of material Ni with a high selection ratio on the surface of the rigid substrate as a hard mask 5 with a thickness of 100nm; , Spin-coat 400nm-thick nano-imprint adhesive on the hard mask; for hard masks with poor adhesion, it is necessary to spray the corresponding tackifier on the hard mask before coating the nano-imprint adhesive; After the nano-imprint glue 6, it is pre-baked under high temperature conditions, the temperature is 100°C, and the time is 5 minutes.

[0095] 9) with embodiment one.

[0096] 10) remove the resid...

Embodiment 3

[0100] In this embodiment, sapphire is used as the rigid substrate, the method of dry etching sapphire is adopted, and the nano-imprint glue is used as the mask. The preparation method of the AAO-based nano-imprint template in this embodiment includes the following steps :

[0101] 1)~3) are the same as embodiment one.

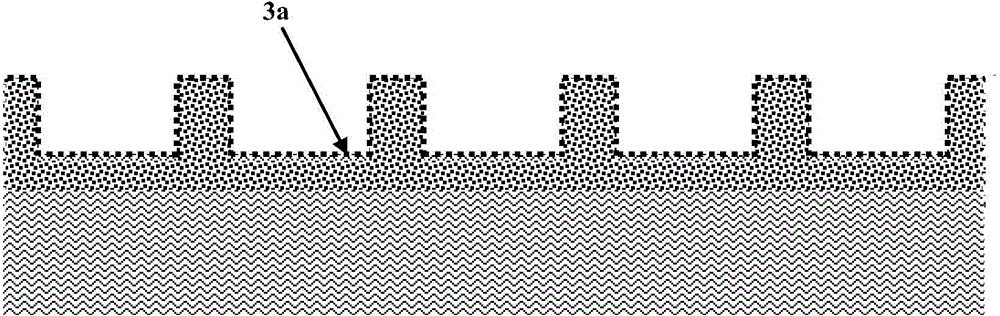

[0102] 4) Since the nano-imprinting glue is used as a mask in step 11), and the selection ratio of nano-imprinting glue and sapphire etching is small, the depth of the hole array of nano-imprinting glue must reach more than 1 μm, so the hole of AAO is required. The depth needs to be more than 1 μm, and the time for controlling the secondary anodic oxidation reaction should be more than 10 minutes, so that the depth of the orderly and periodic nanohole array reaches more than 1 μm, and the others are the same as in the first embodiment.

[0103] 5) to 7 are the same as in Embodiment 1.

[0104] 8) Use acetone, ethanol and deionized water to clean the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com