Patents

Literature

285 results about "Nanohole array" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

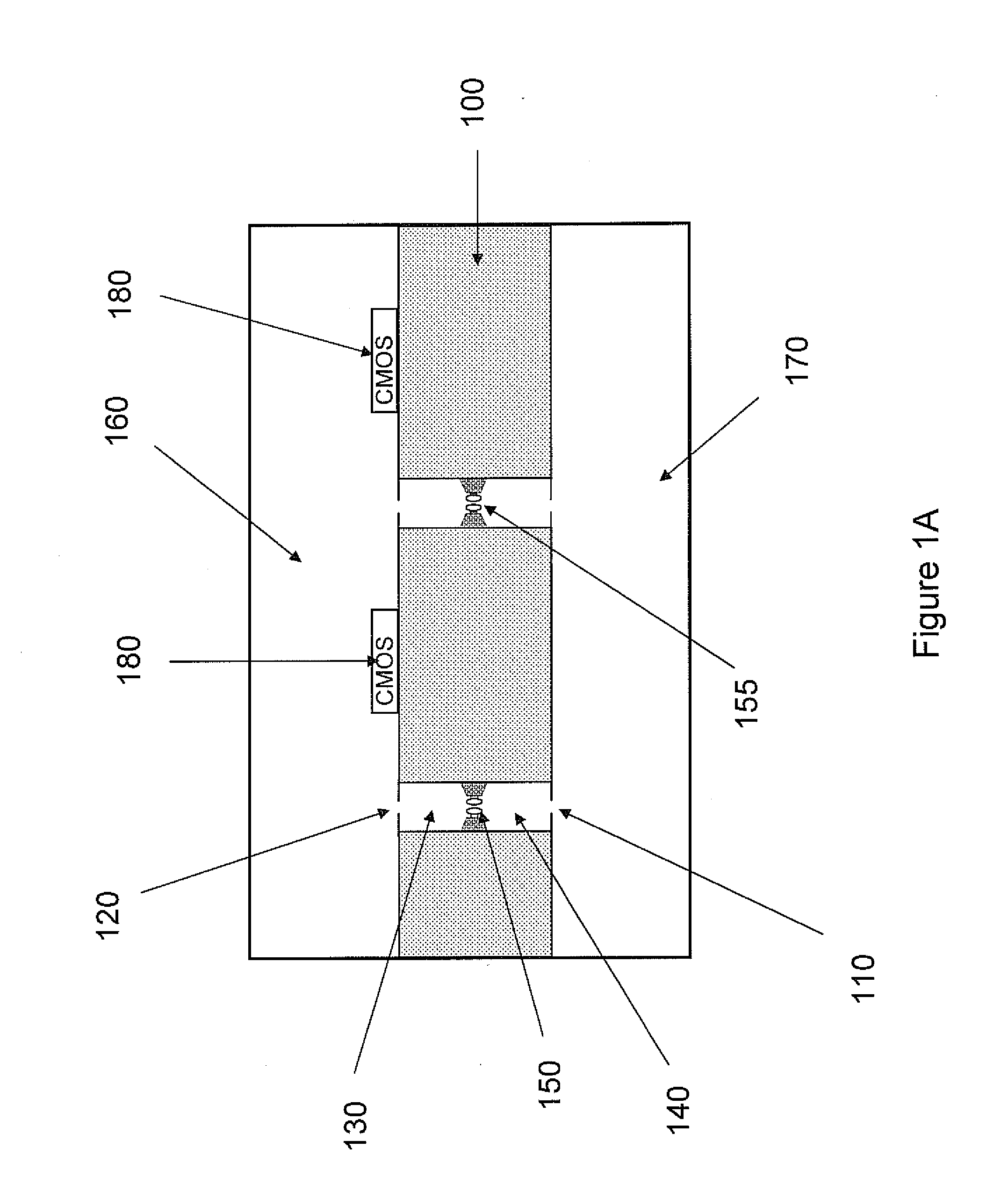

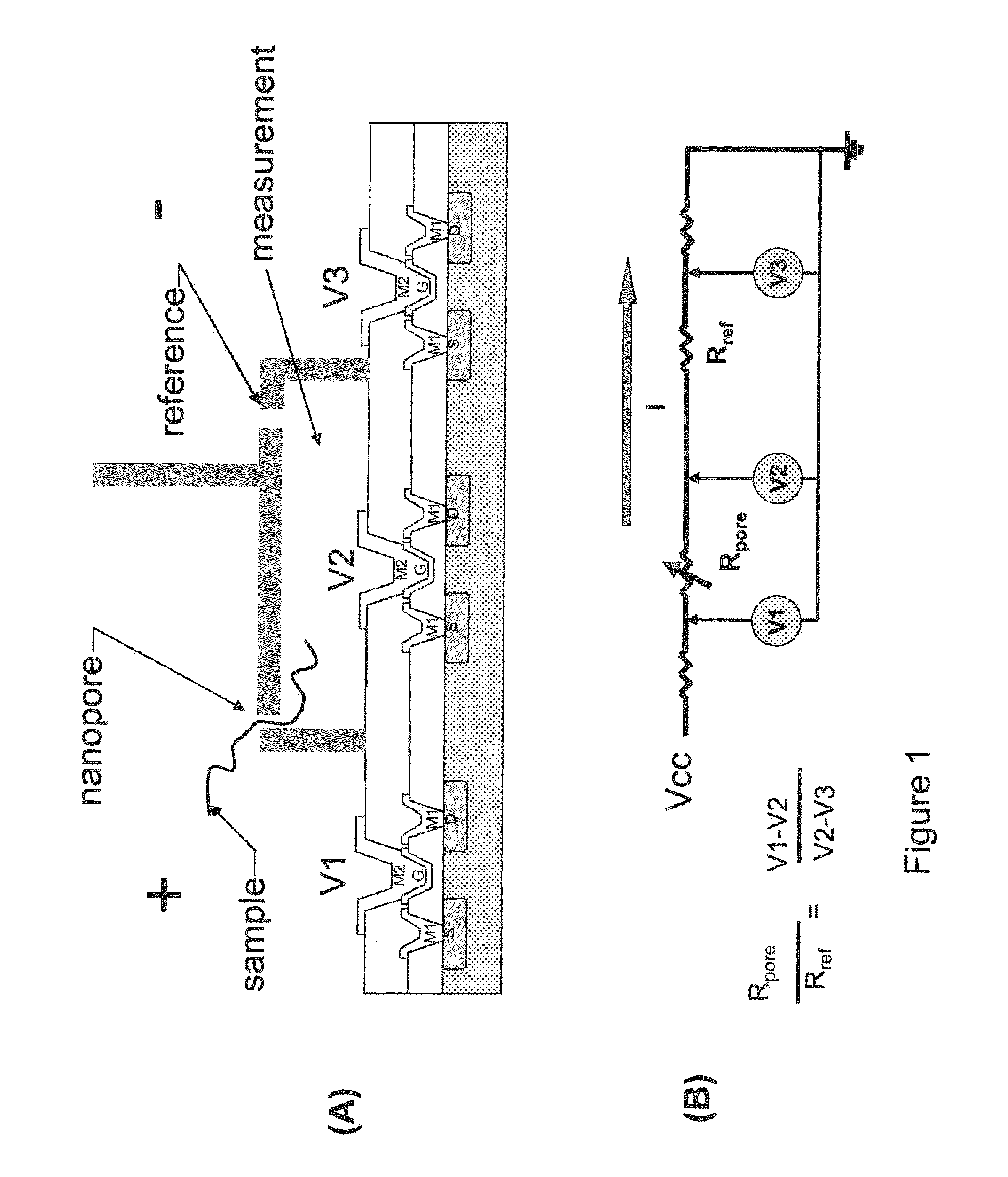

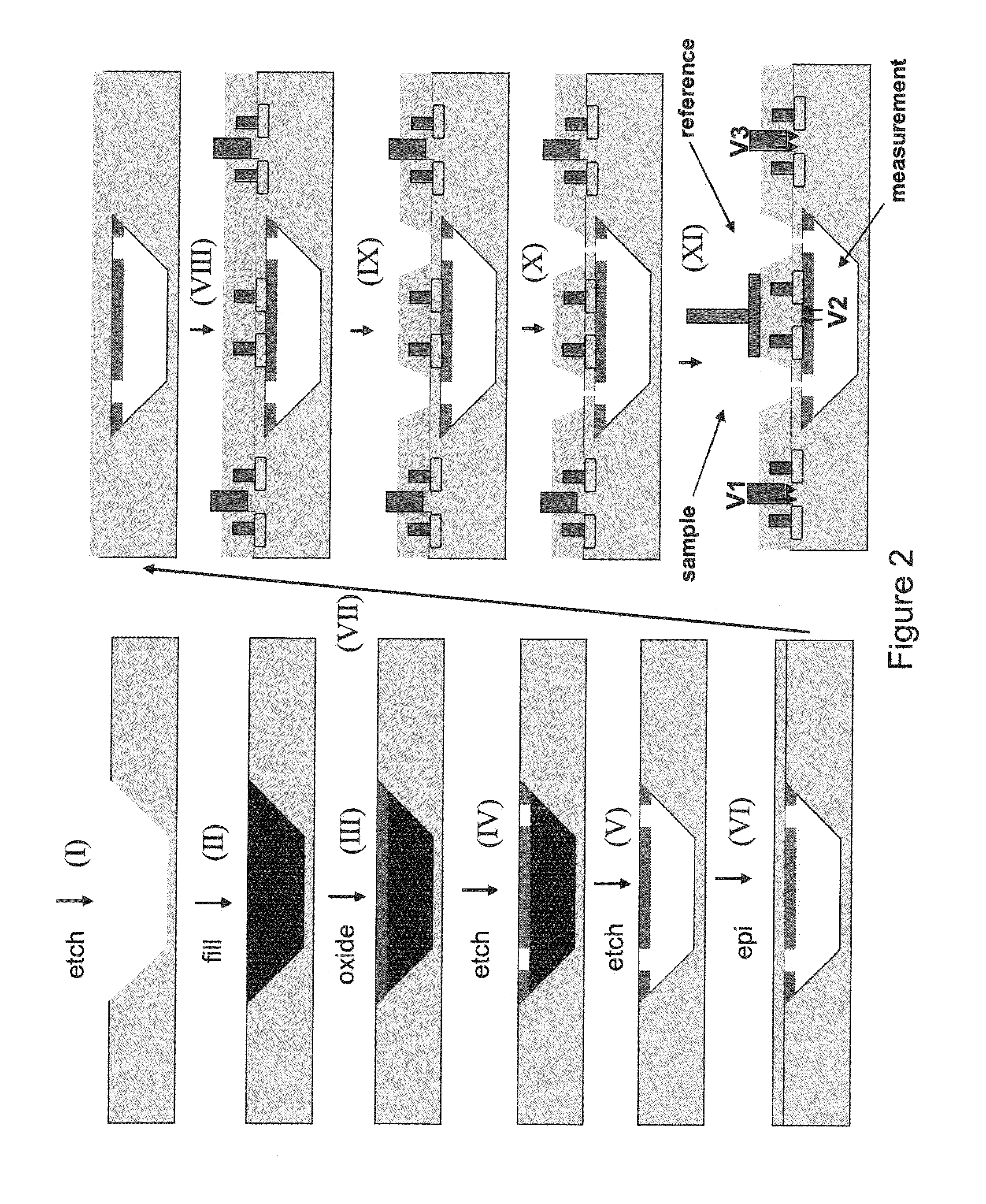

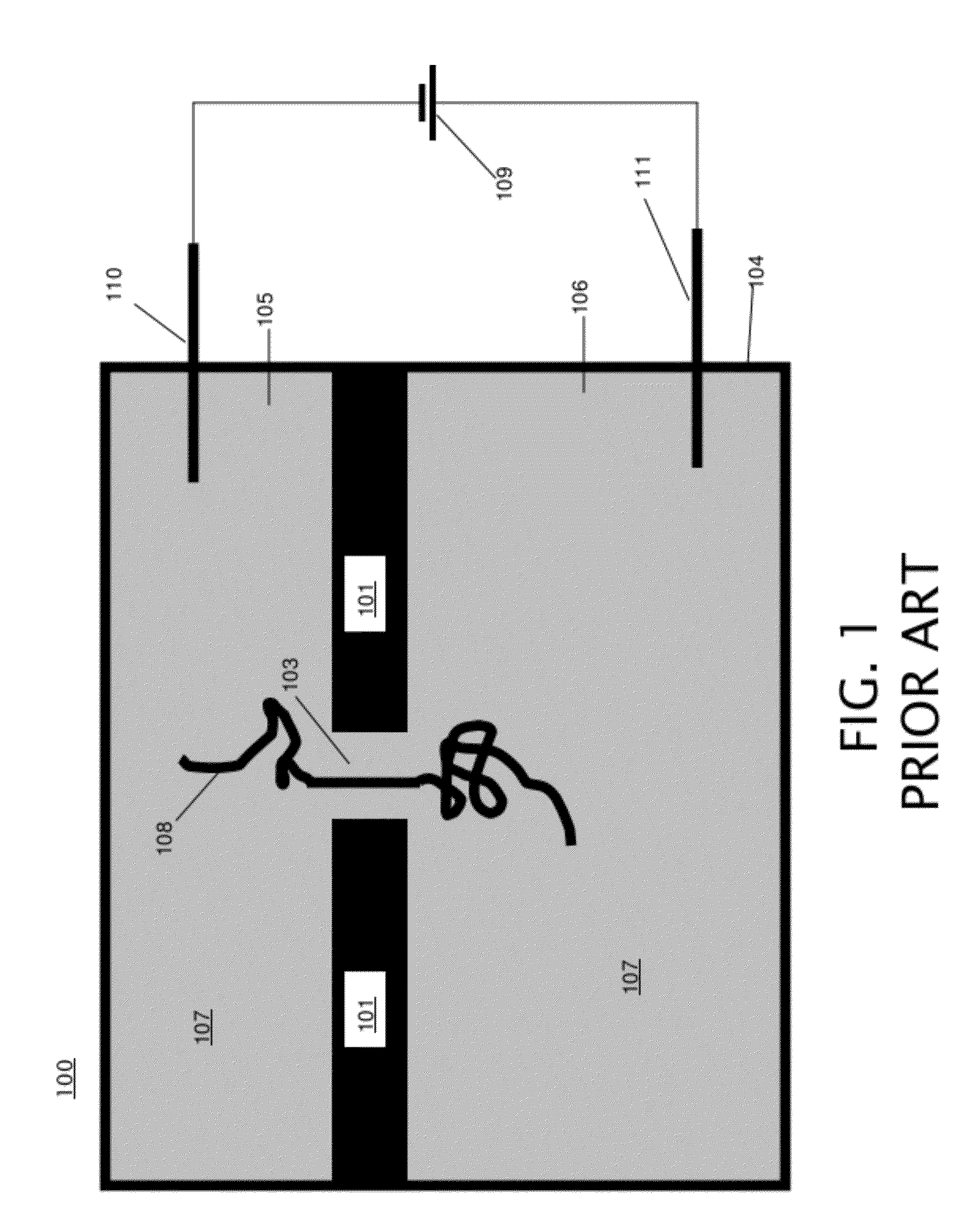

Nanopore sequencing devices and methods

ActiveUS20100331194A1Microbiological testing/measurementMaterial analysis by electric/magnetic meansCMOSElectrical resistance and conductance

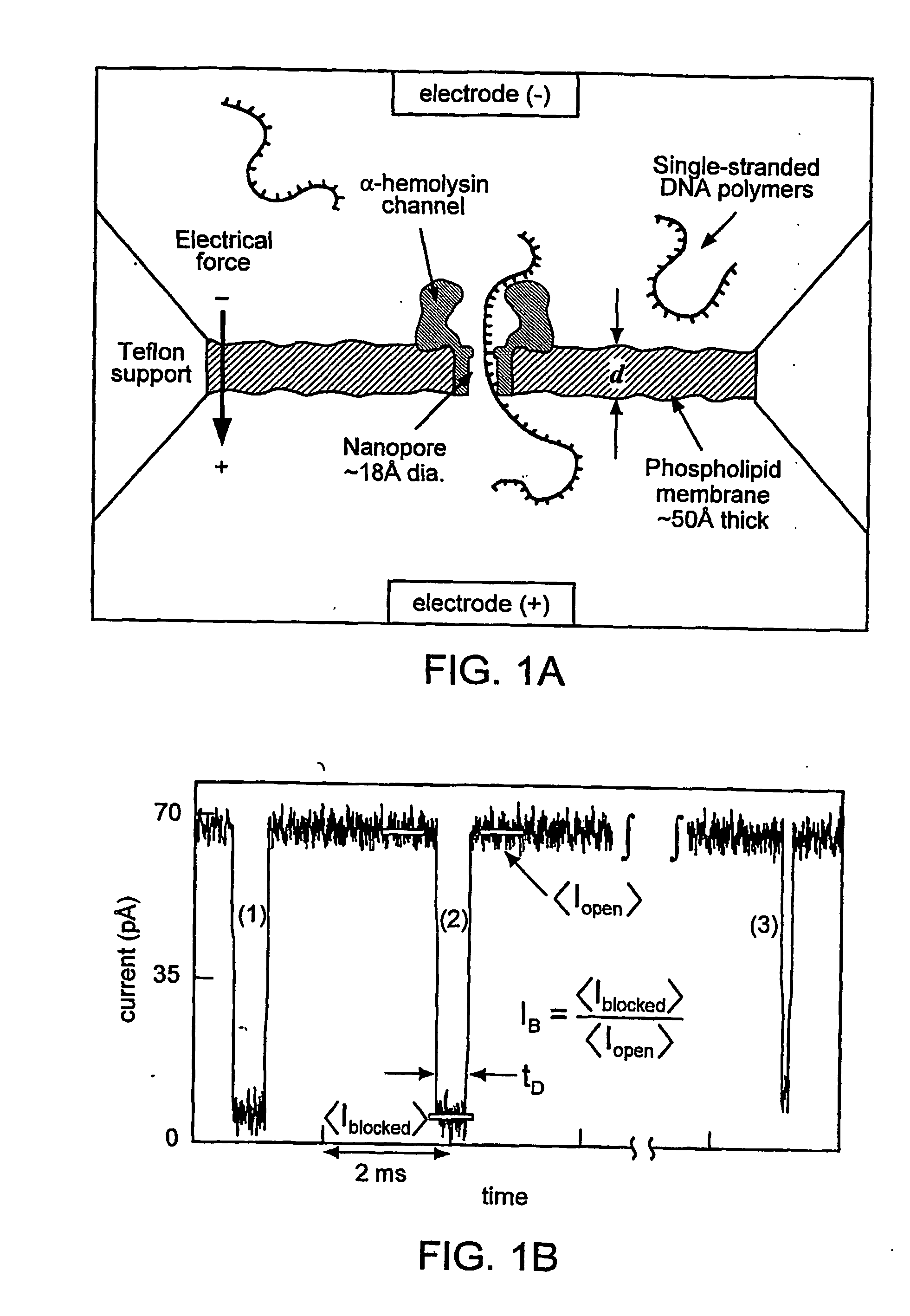

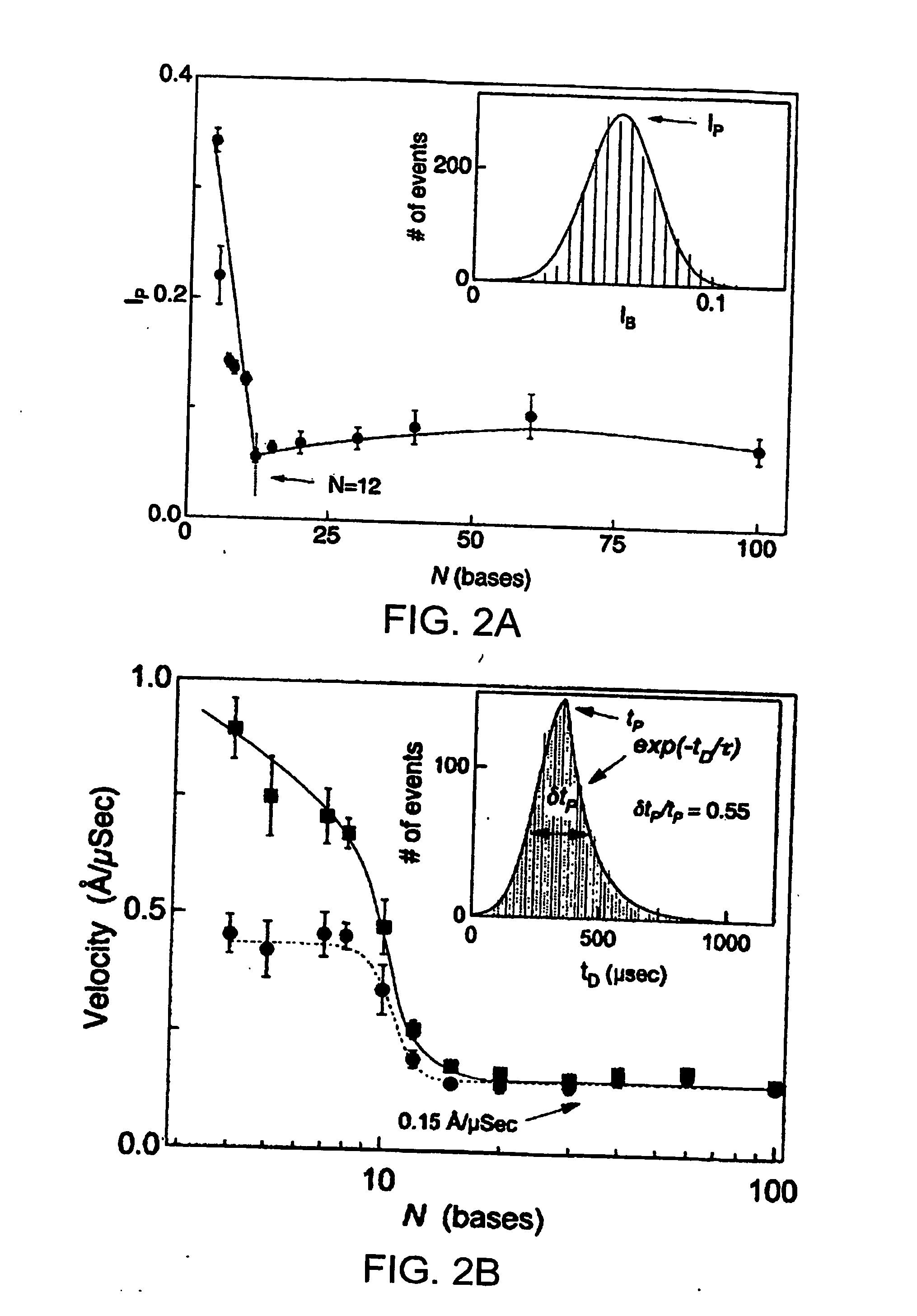

The invention relates to devices and methods for nanopore sequencing. The invention includes arrays of nanopores having incorporated electronic circuits, for example, in CMOS. In some cases, the arrays of nanopores comprise resistive openings for isolating the electronic signals for improved sequencing. Methods for controlling translocation of through the nanopore are disclosed.

Owner:PACIFIC BIOSCIENCES

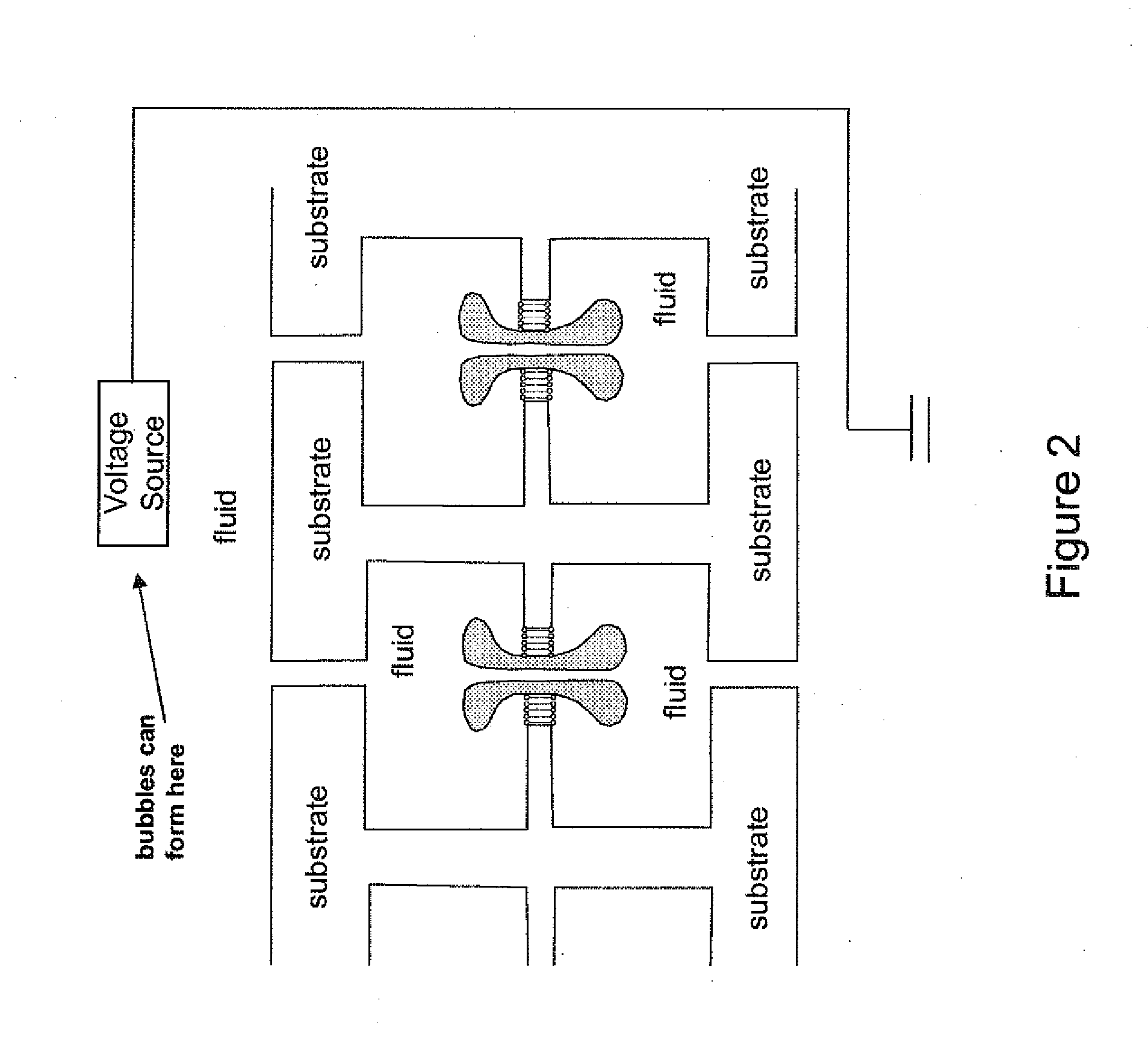

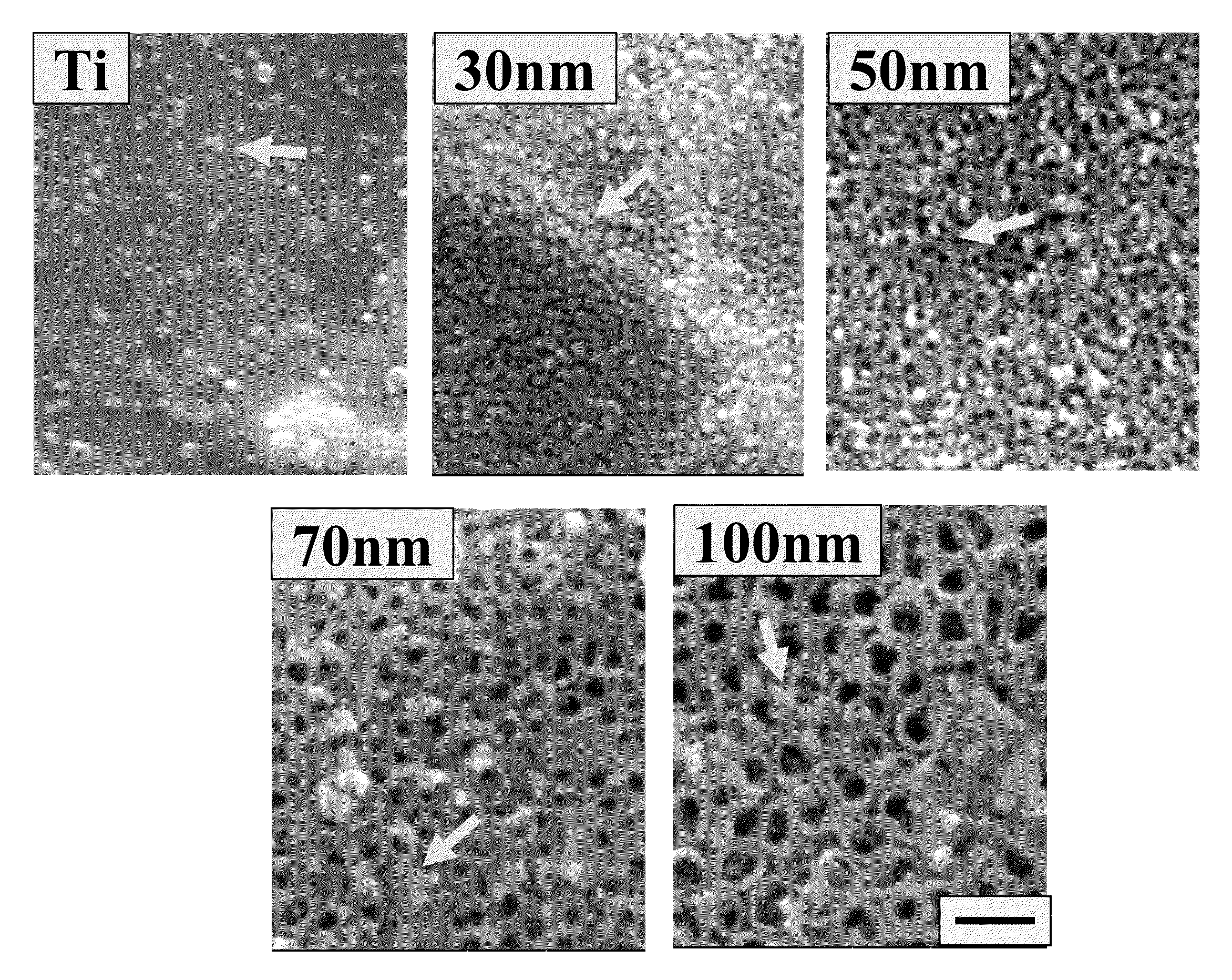

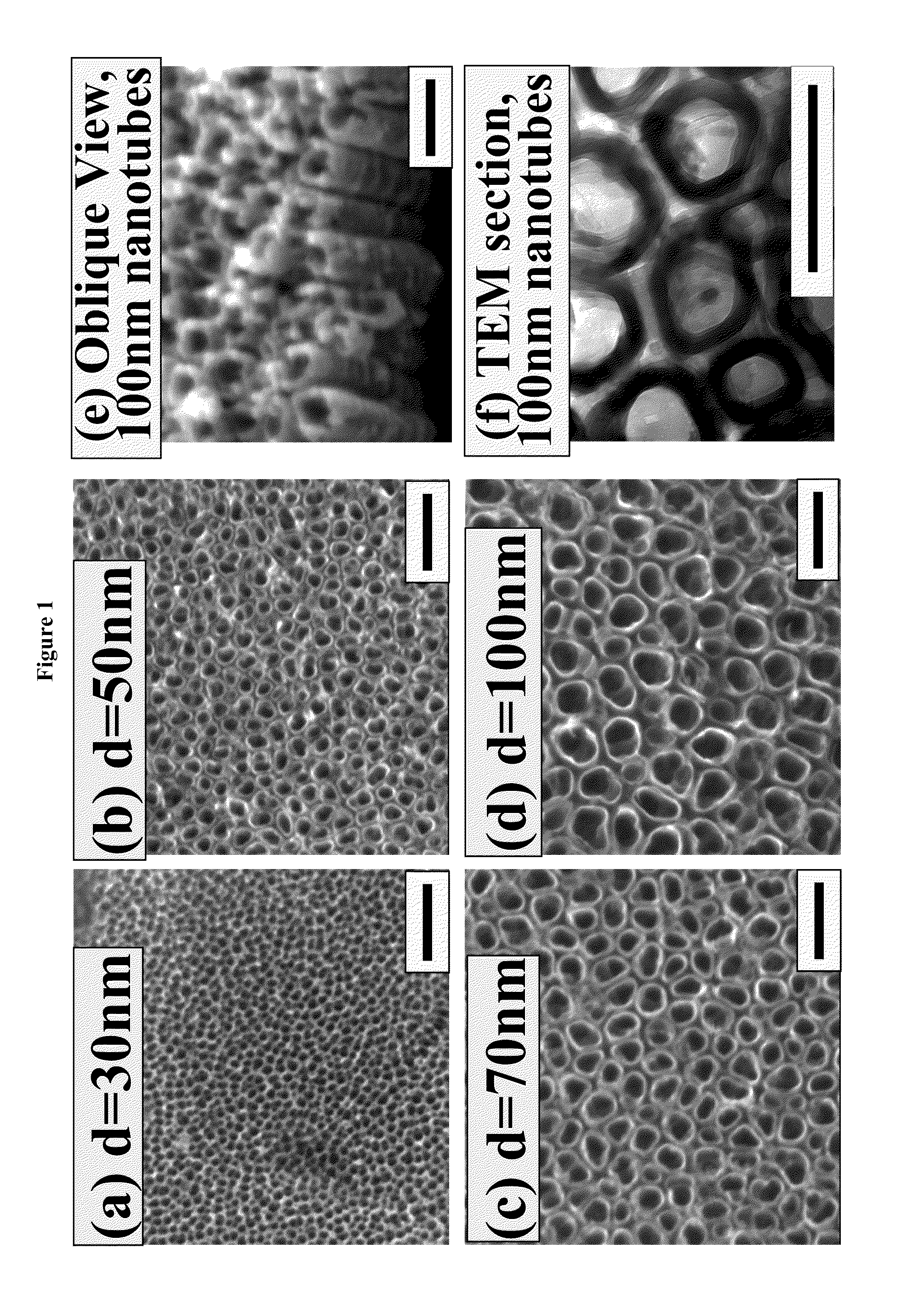

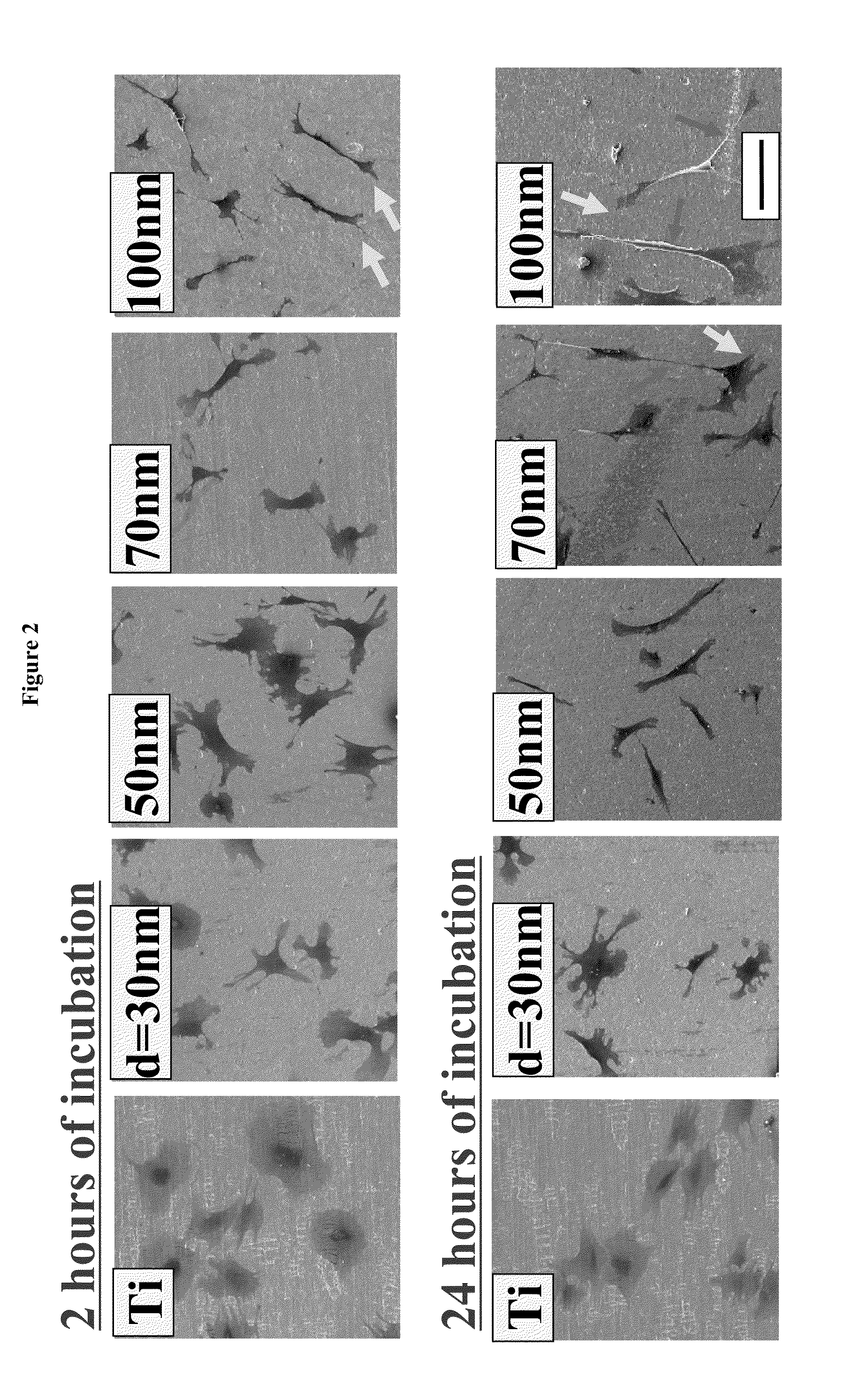

Articles comprising large-surface-area bio-compatible materials and methods for making and using them

ActiveUS20100303722A1Improve cell adhesionAccelerated cell growth characteristicImmobilised enzymesBioreactor/fermenter combinationsCell culture mediaBone growth

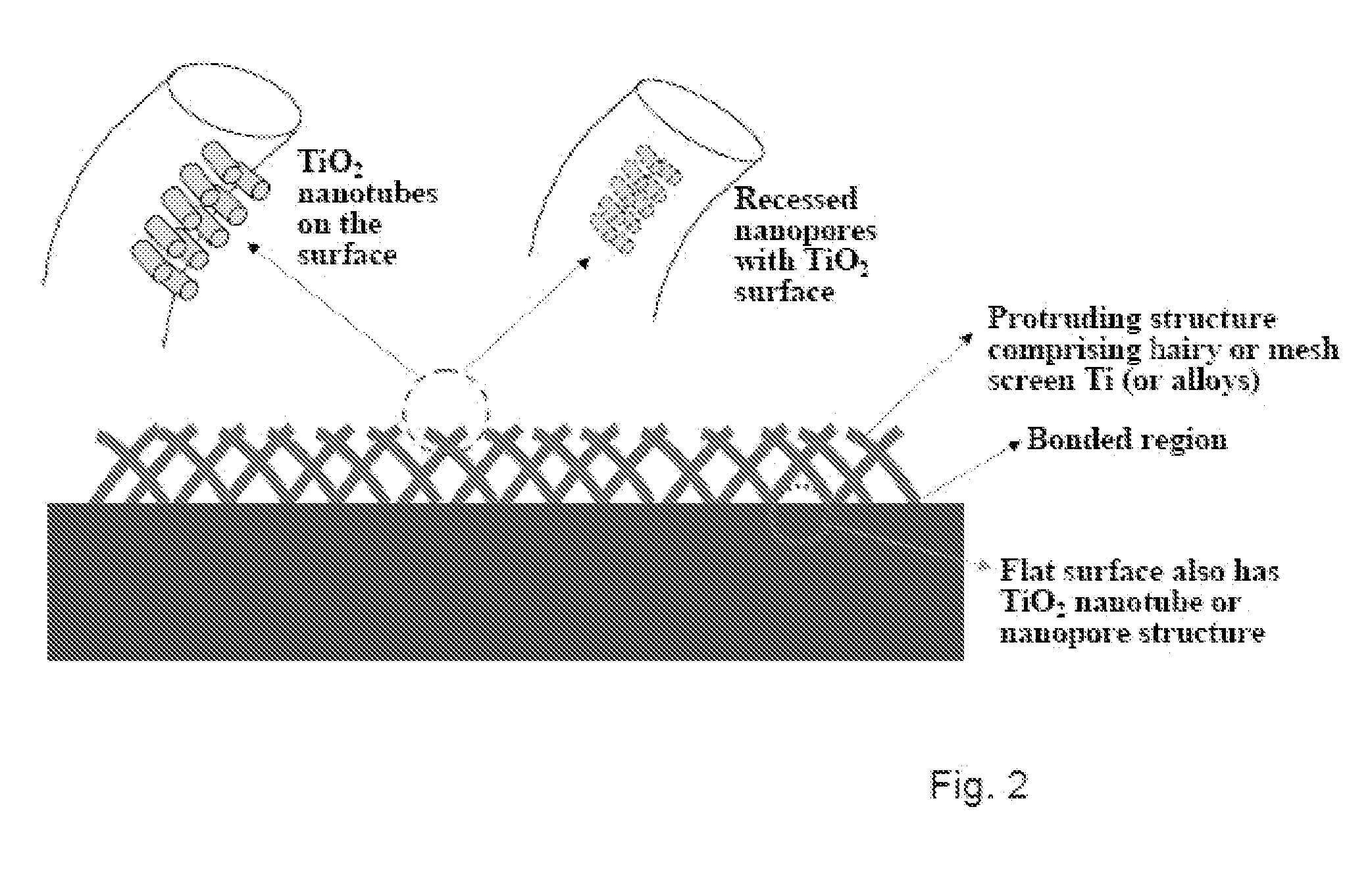

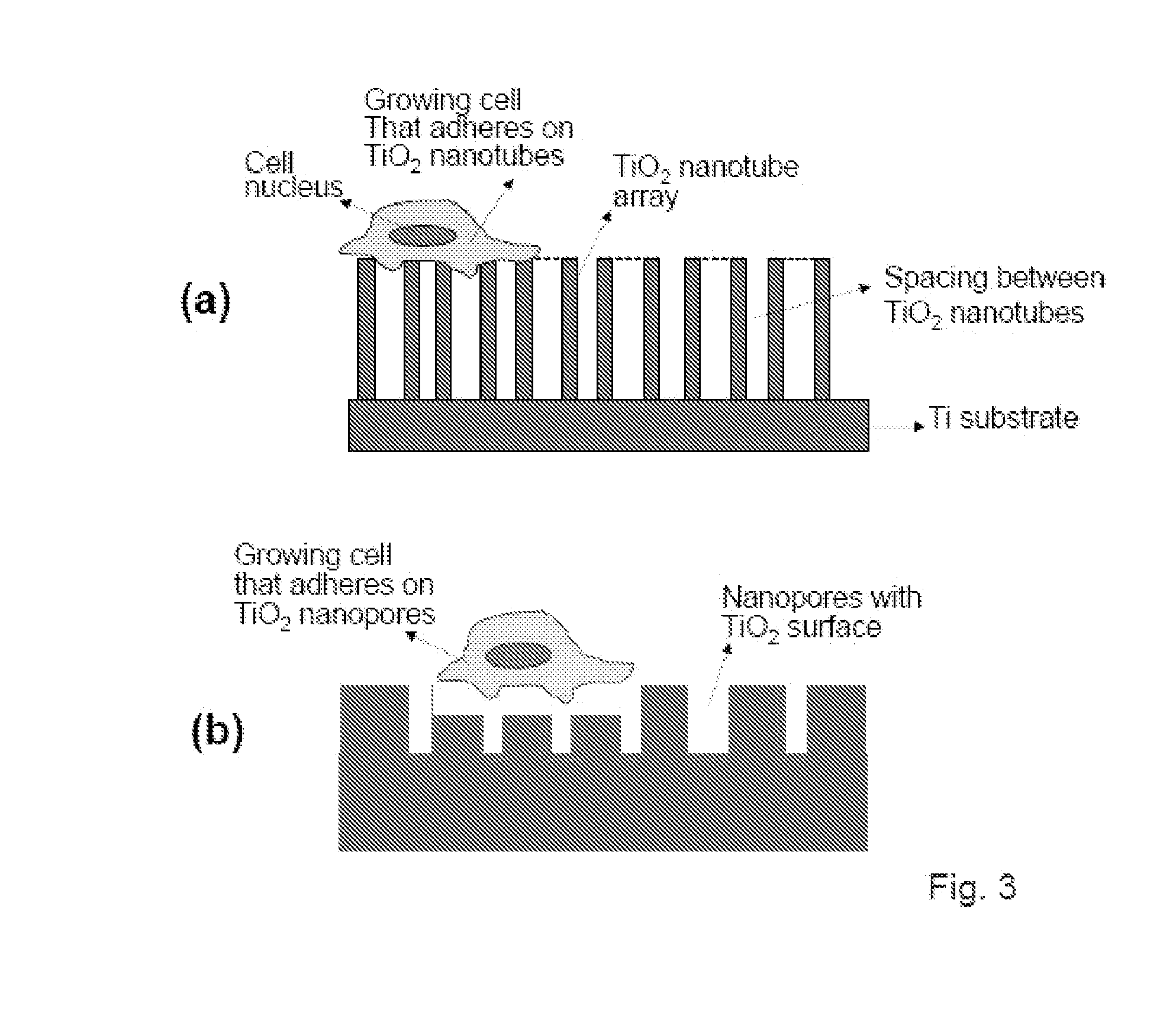

The present invention provides articles of manufacture comprising biocompatible nanostructures comprising significantly increased surface area for, e.g., organ, tissue and / or cell growth, e.g., for bone, tooth, kidney or liver growth, and uses thereof, e.g., for in vitro testing of drugs, chemicals or toxins, or as in vivo implants, including their use in making and using artificial tissues and organs, and related, diagnostic, screening, research and development and therapeutic uses, e.g., as drug delivery devices. The present invention provides biocompatible nanostructures with significantly increased surface area, such as with nanotube and nanopore array on the surface of metallic, ceramic, or polymer materials for enhanced cell and bone growth, for in vitro and in vivo testing, cleansing reaction, implants and therapeutics. The present invention provides optically transparent or translucent cell-culturing substrates. The present invention provides biocompatible and cell-growth-enhancing culture substrates comprising elastically compliant protruding nanostructure substrates coated with Ti, TiO2 or related metal and metal oxide films.

Owner:RGT UNIV OF CALIFORNIA

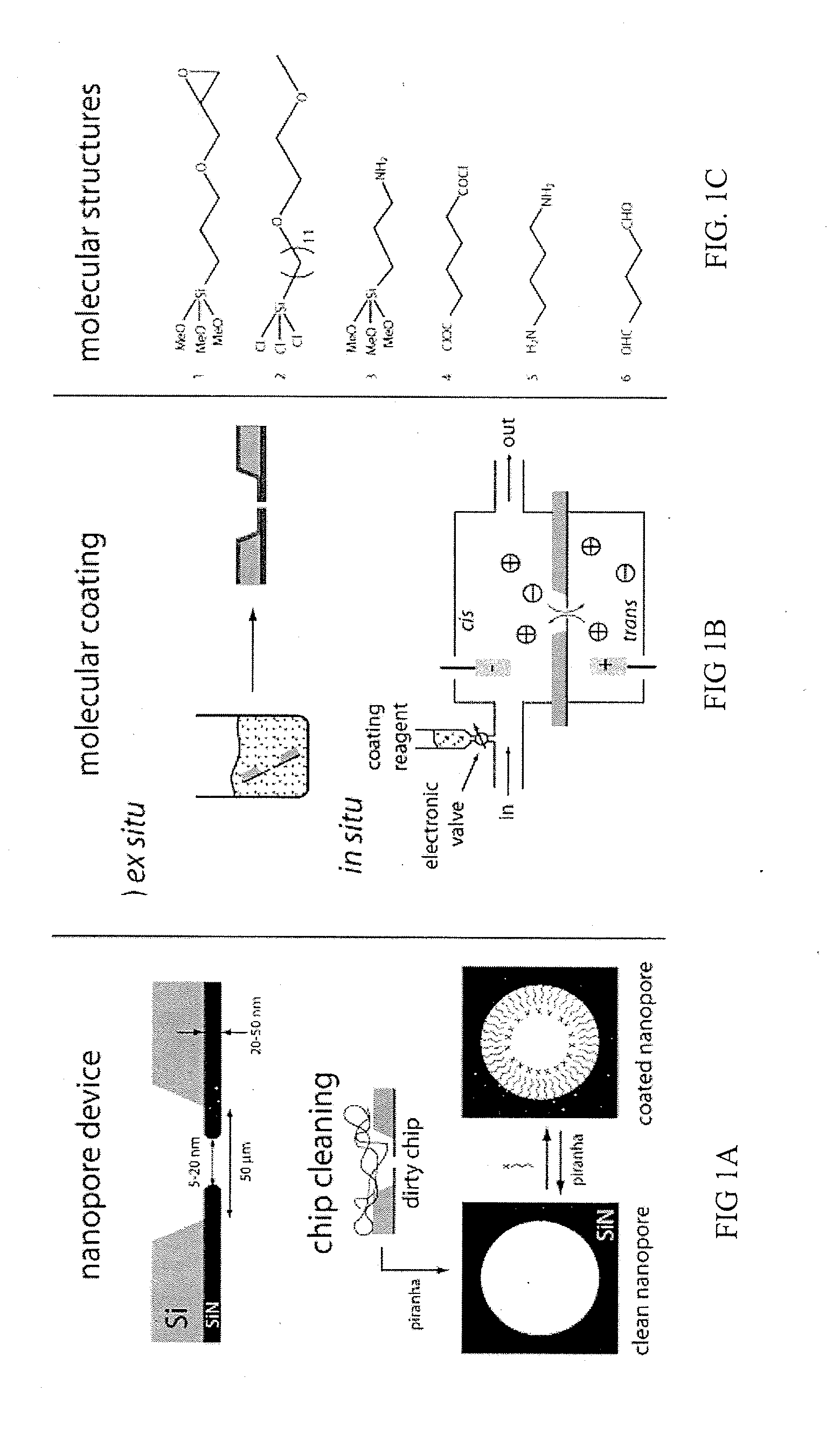

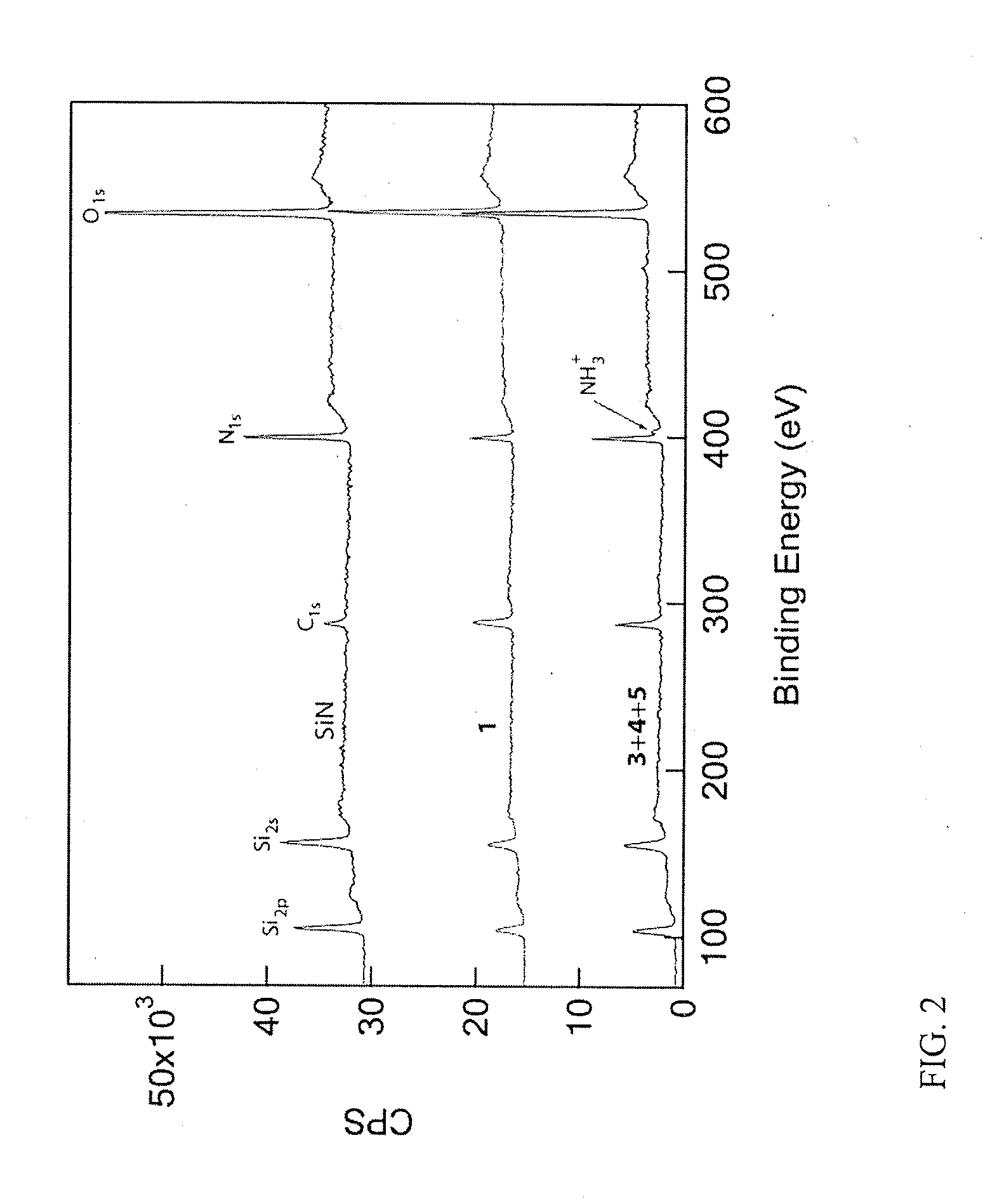

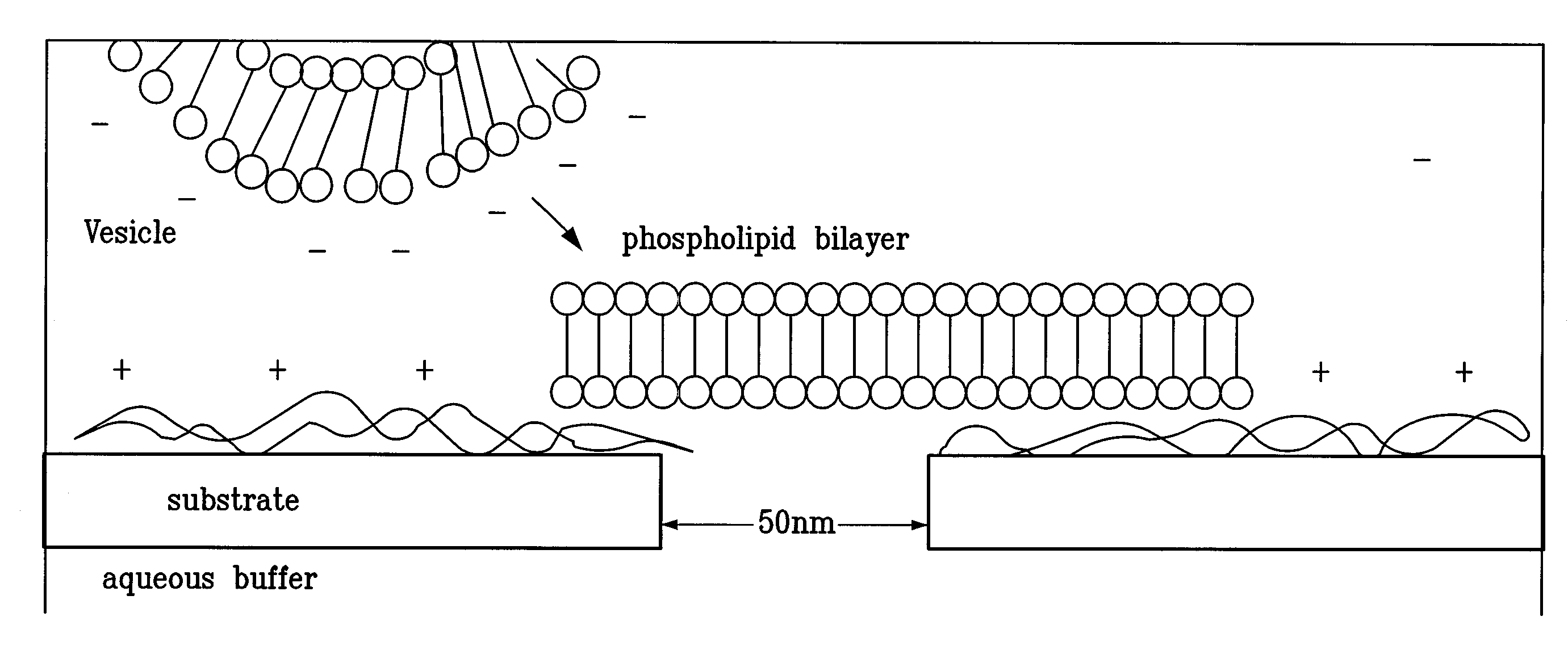

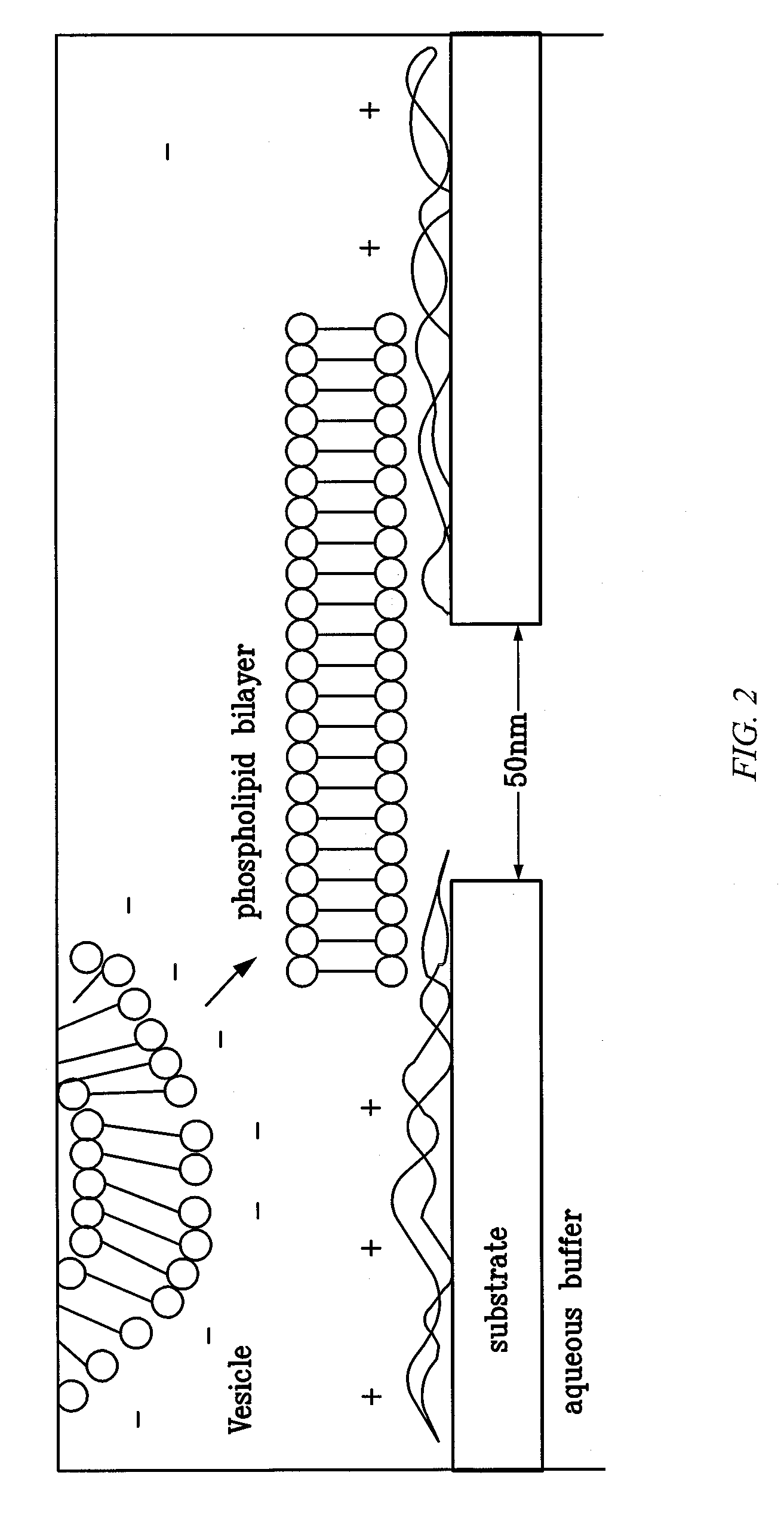

Chemical functionalization of solid-state nanopores and nanopore arrays and applications thereof

ActiveUS20110053284A1Avoid stickingChemiluminescene/bioluminescenceMaterial analysis by electric/magnetic meansBiopolymerElectron

Chemical functionalization of solid-state nanopores and nanopore arrays and applications thereof. Nanopores are extremely sensitive single-molecule sensors. Recently, electron beams have been used to fabricate synthetic nanopores in thin solid-state membranes with sub-nanometer resolution. A new class of chemically modified nanopore sensors are provided with two approaches for monolayer coating of nanopores by: (1) self-assembly from solution, in which nanopores −10 nm diameter can be reproducibly coated, and (2) self-assembly under voltage-driven electrolyte flow, in which 5 nm nanopores may be coated. Applications of chemically modified nanopore are provided including: the detection of biopolymers such as DNA and RNA; immobilizing enzymes or other proteins for detection or for generating chemical gradients; and localized pH sensing.

Owner:TRUSTEES OF BOSTON UNIV

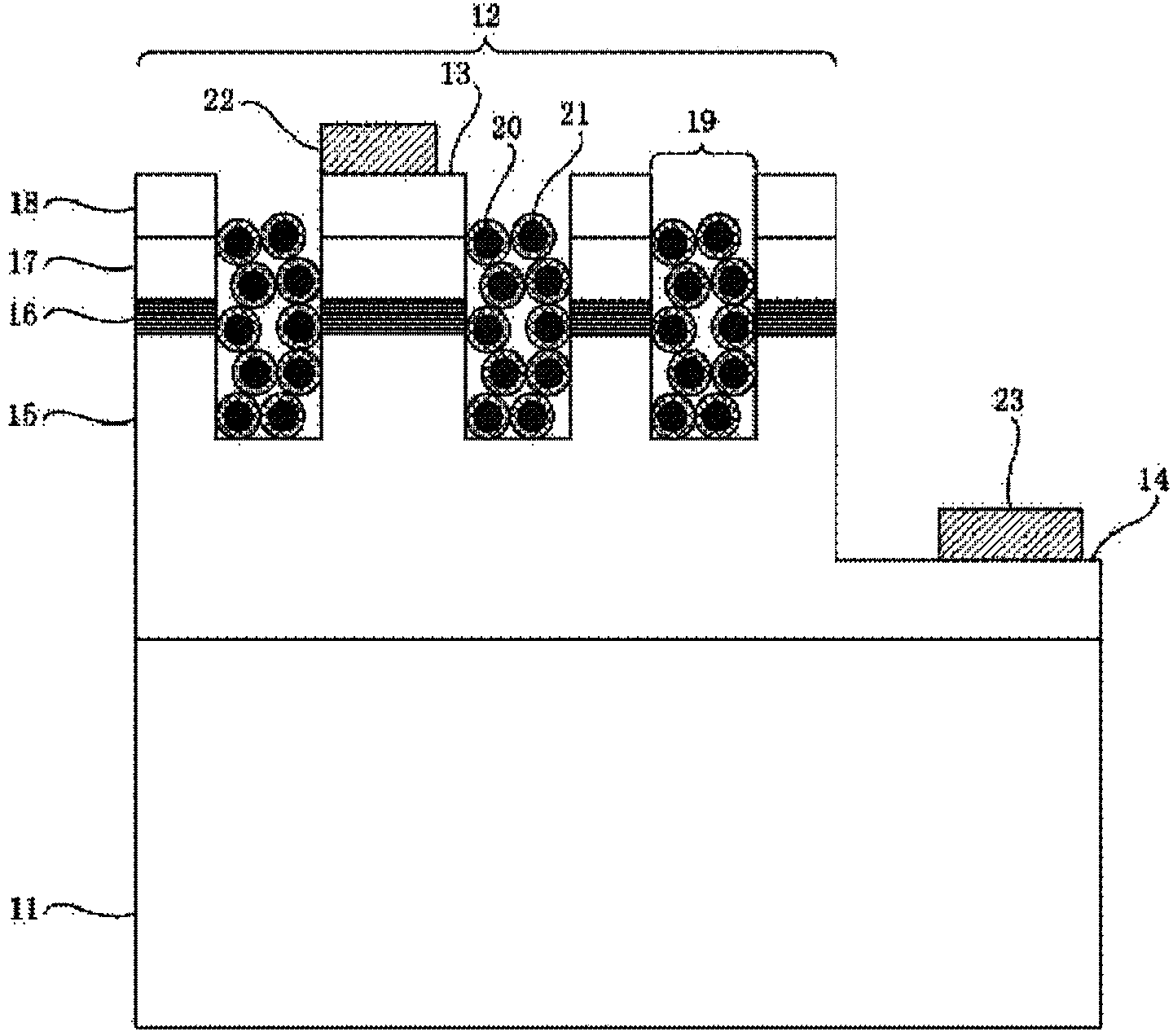

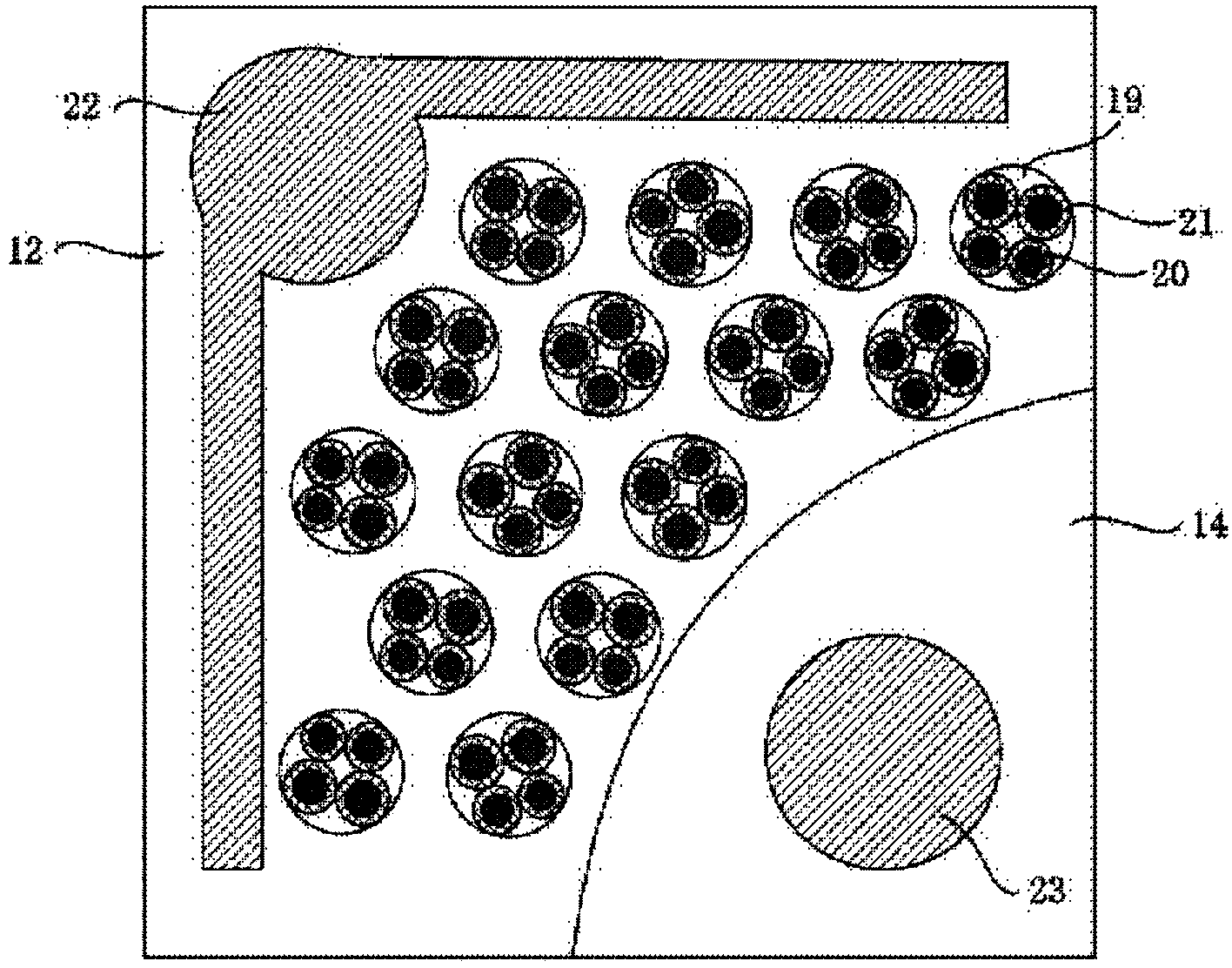

Nanopore arrays and sequencing devices and methods thereof

Provided are devices comprising one or more nanoscale pores for use in, inter alia, analyzing various biological molecules. Also provided are methods for the fabrication of nanoscale pores in solid-state substrates, methods for functionalizing nanopores in solid-state substrates, and methods for sequencing polymers using devices containing nanoscale pores.

Owner:TRUSTEES OF BOSTON UNIV

Methods and Devices for Correlated, Multi-Parameter Single Cell Measurements and Recovery of Remnant Biological Material

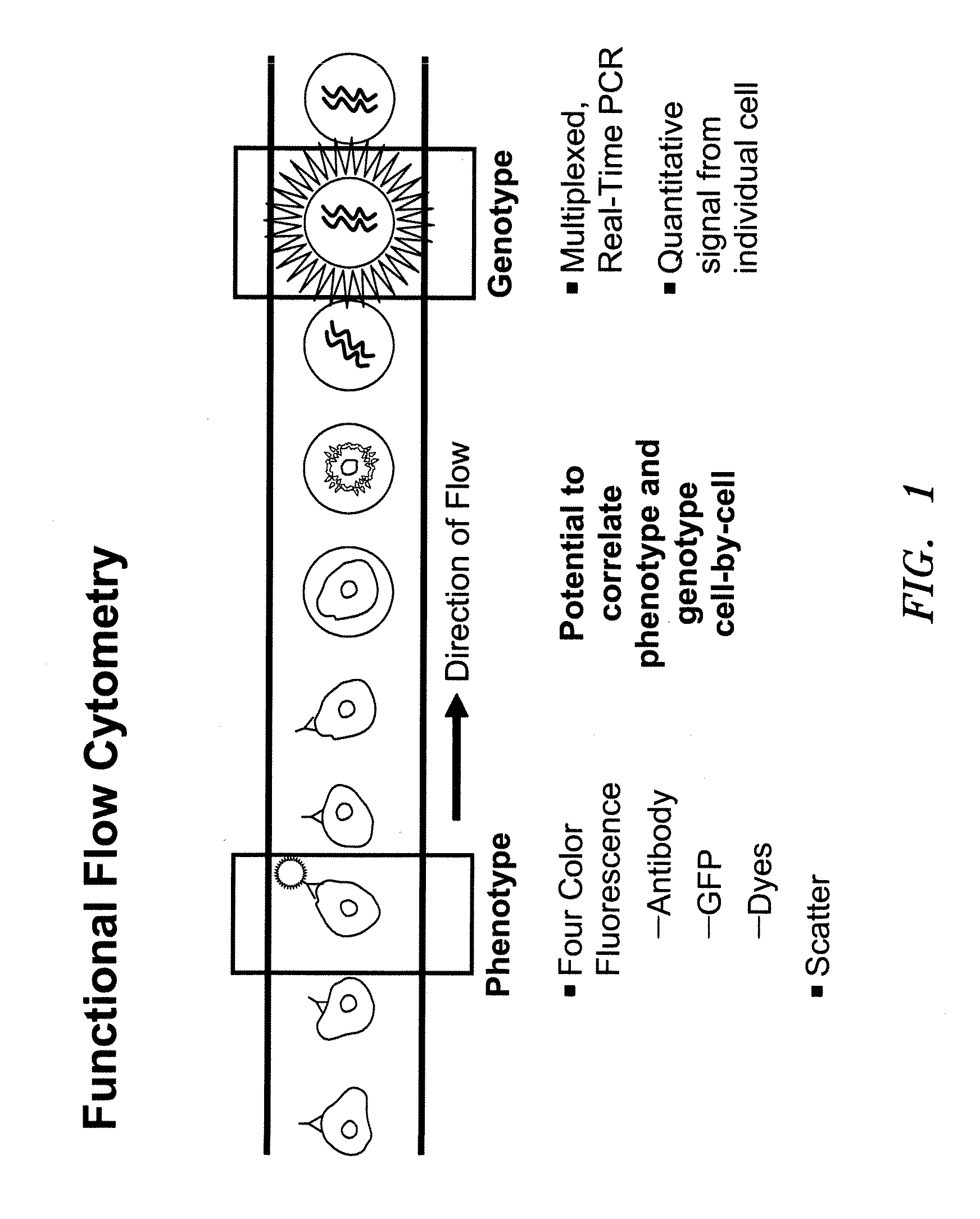

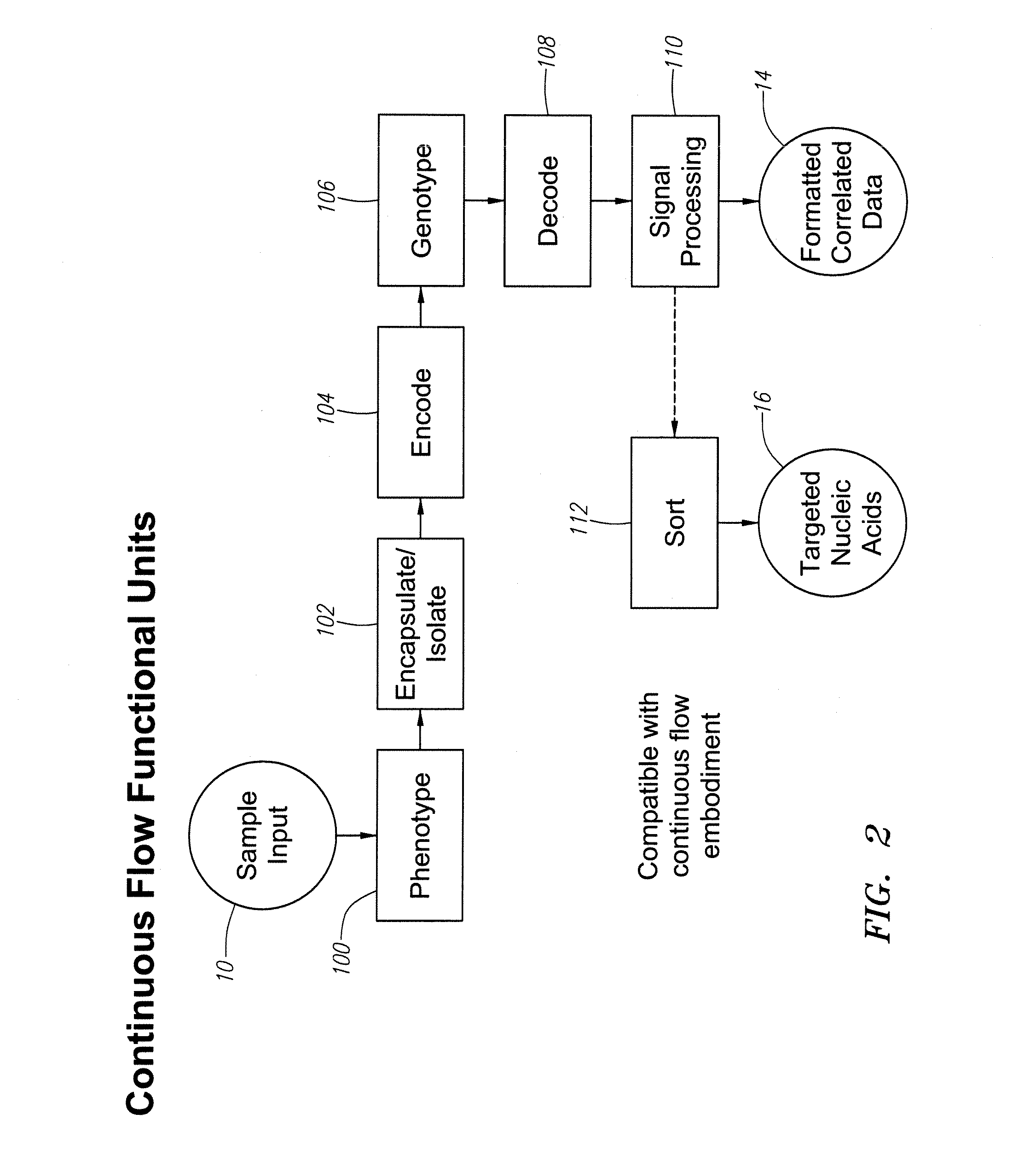

InactiveUS20090042737A1Reduces number of point of interrogationHeating or cooling apparatusLibrary screeningPhenotype genotypeGenotype Analysis

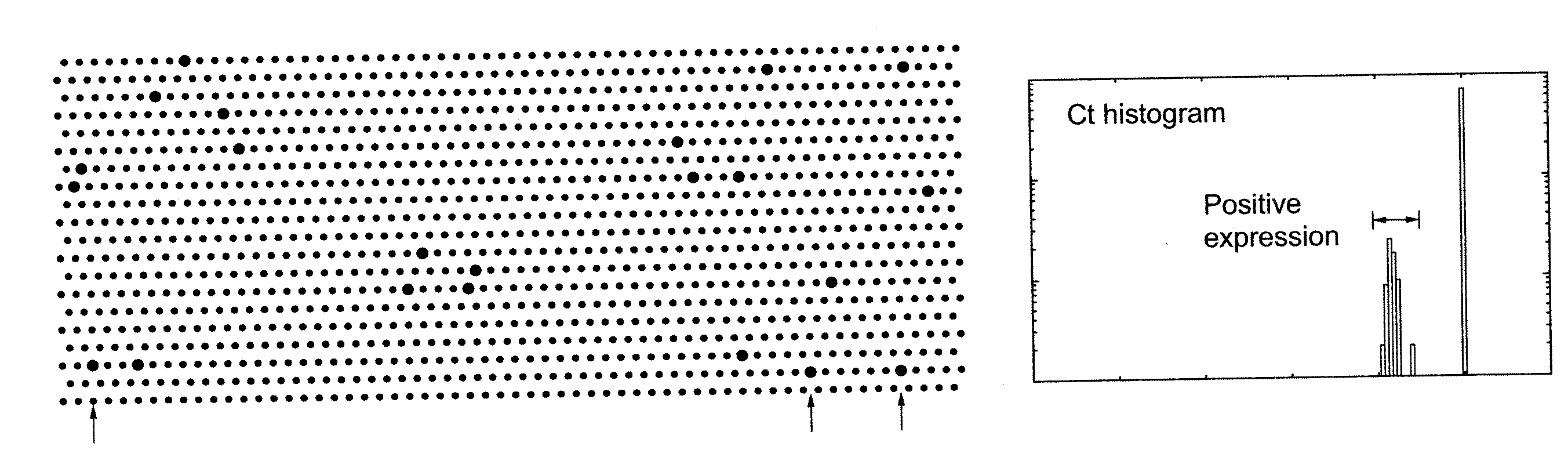

Methods and apparatus are provided for analysis and correlation of phenotypic and genotypic information for a high throughput sample on a cell by cell basis. Cells are isolated and sequentially analyzed for phenotypic information and genotypic information which is then correlated. Methods for correlating the phenotype-genotype information of a sample population can be performed on a continuous flow sample within a microfluidic channel network or alternatively on a sample preloaded into a nano-well array chip. The methods for performing the phenotype-genotype analysis and correlation are scalable for samples numbering in the hundreds of cells to thousands of cells up to the tens and hundreds of thousand cells.

Owner:PROGENITY INC

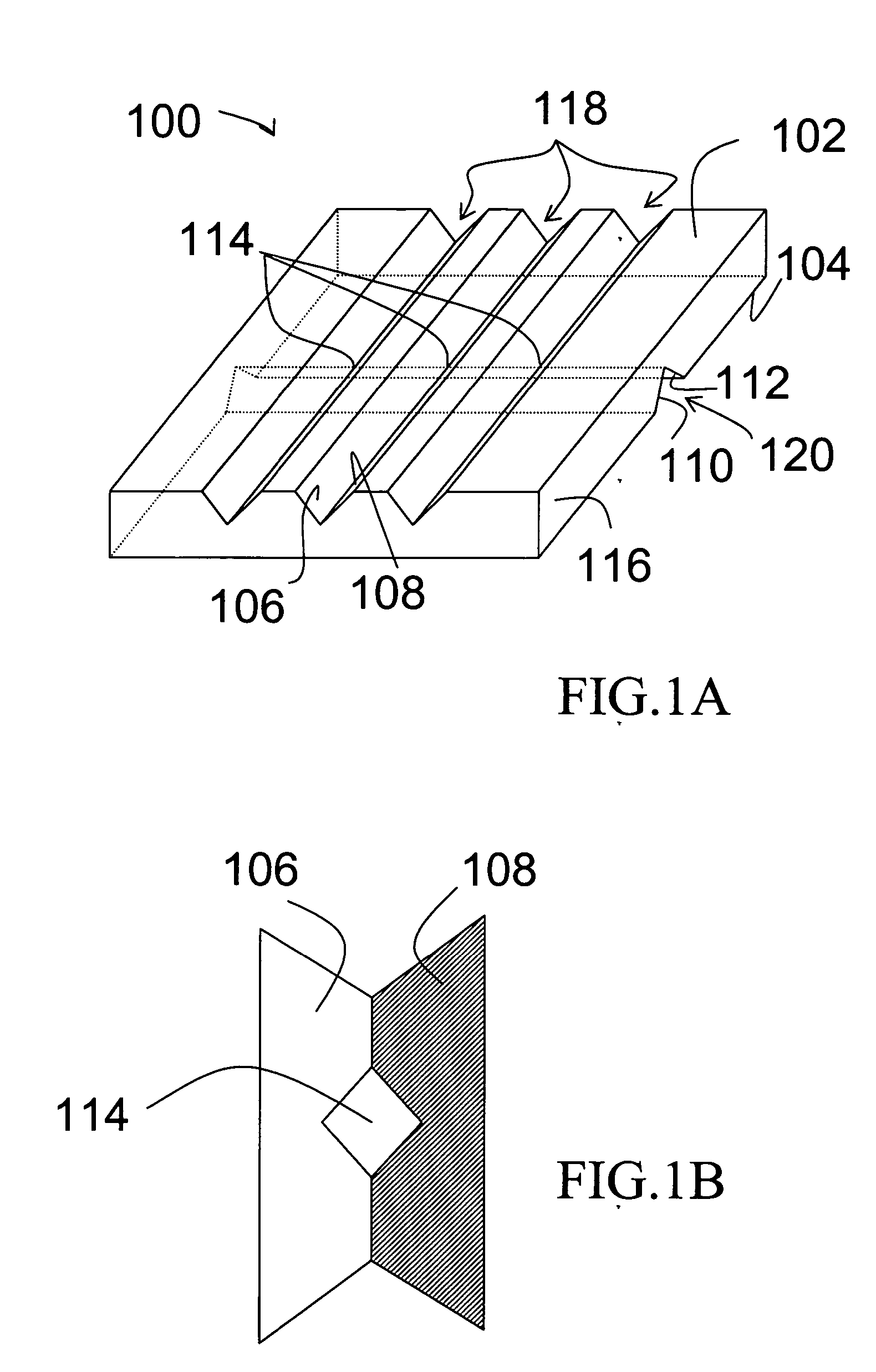

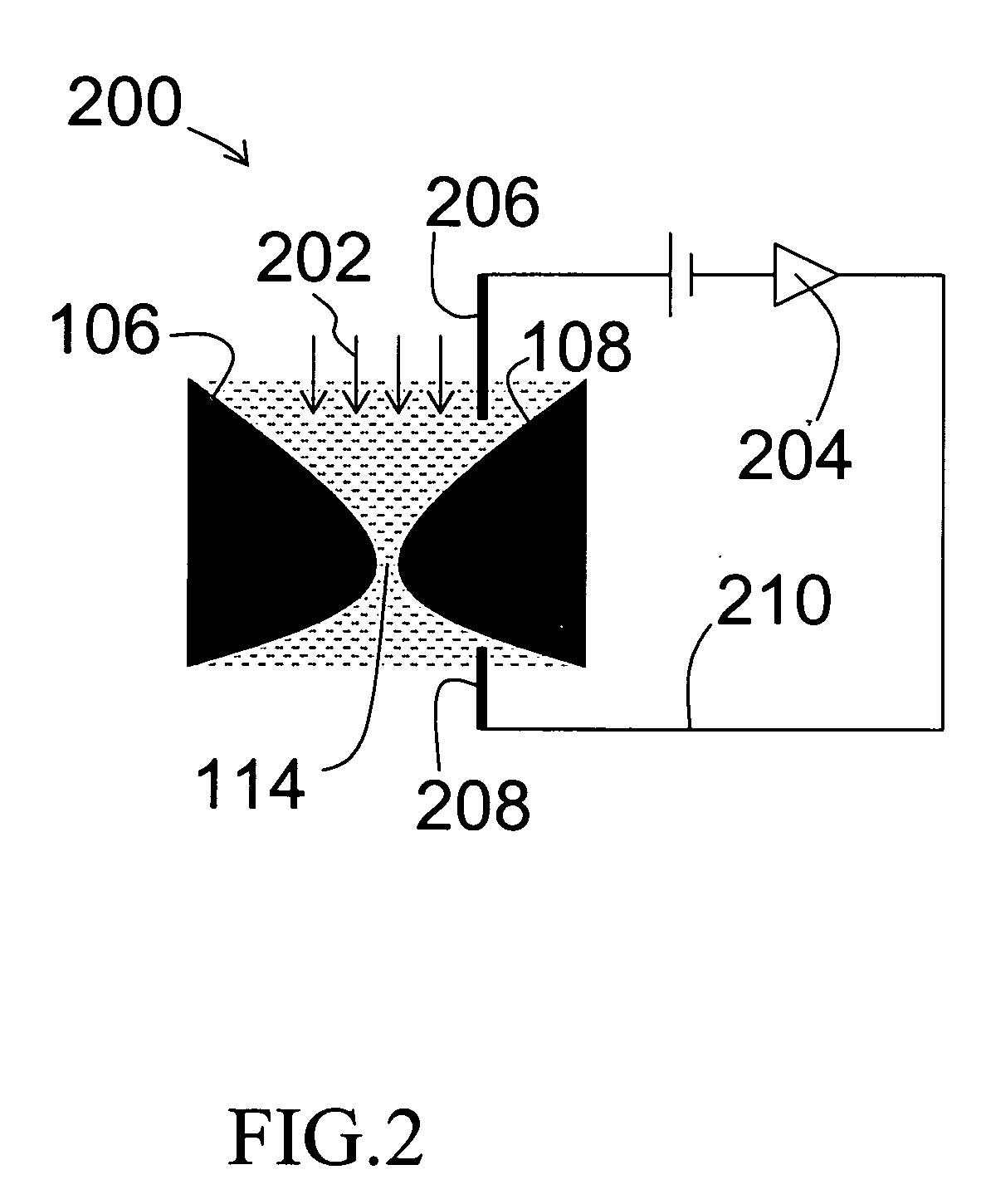

Addressable nanopores and micropores including methods for making and using same

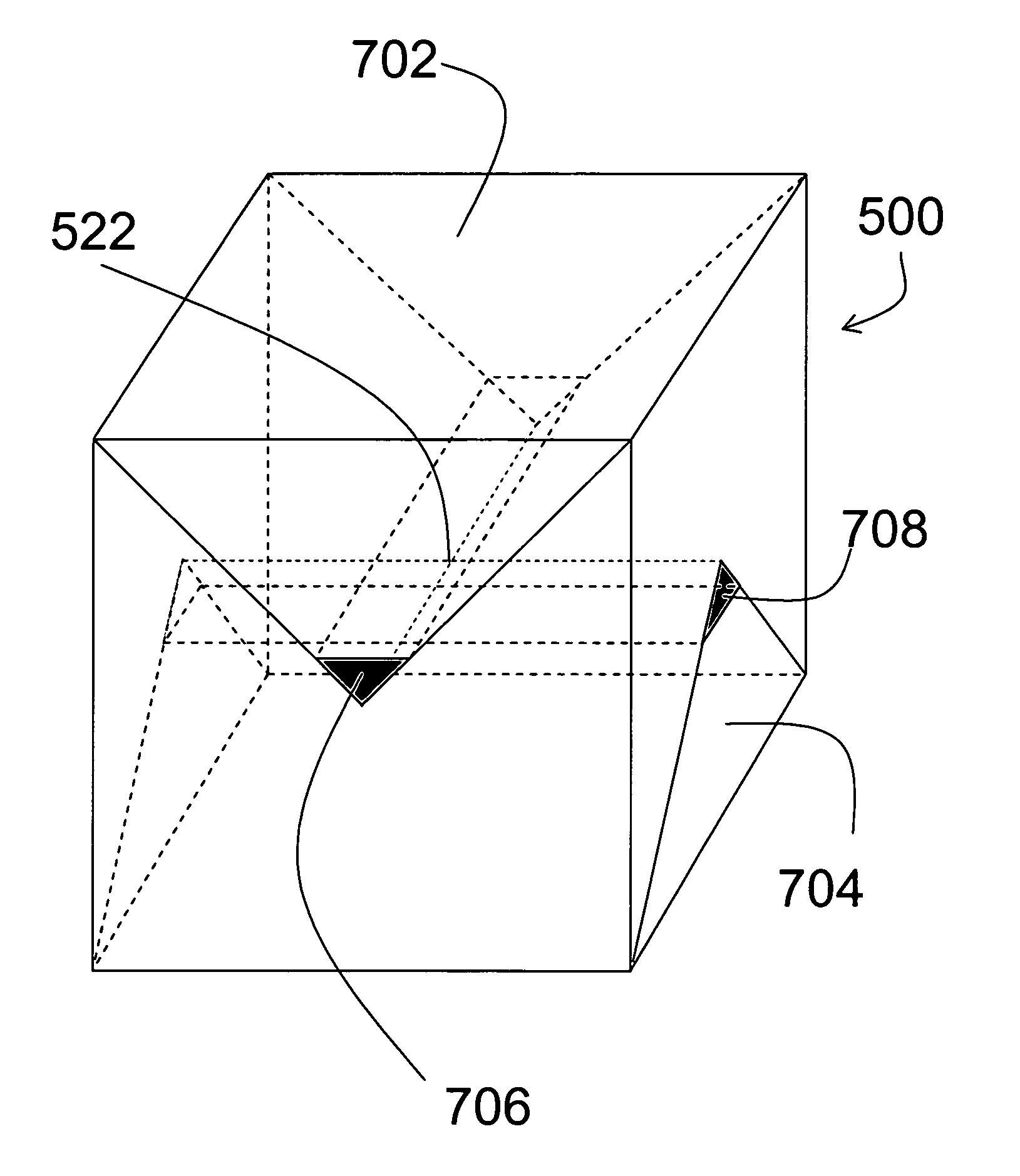

ActiveUS20050127035A1Reduce the overall diameterEasy to controlBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringNanopore

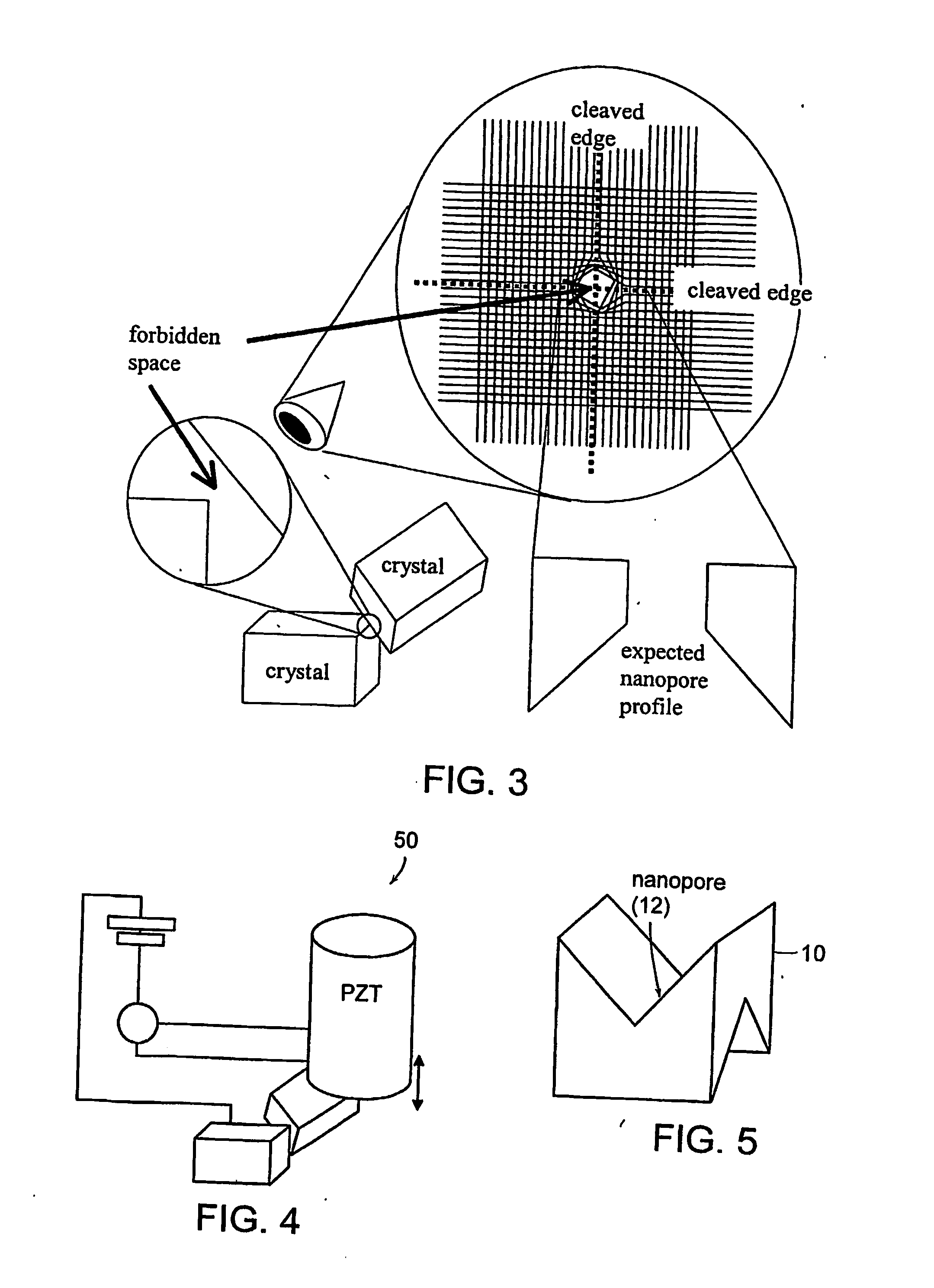

Featured are devices and systems embodying one or more electrically-addressable-solid-state nanopores useful for sensing and / or characterizing single macromolecules as well as sequencing DNA or RNA. In one aspect of the present invention, there is featured a linear or 2-D electrically-addressable array of nanopores, where the nanopores are located at points of intersections between V-shaped grooves formed in an upper surface of the insulating member and a V-shaped groove formed in a lower surface of the insulating member. In another aspect of the present invention the solid-state nanopore of the present invention the width and / or length of the nanopore is defined or established by sharp edges of cleaved crystals that are maintained in fixed relation during the formation of the insulating member including the nanopore.

Owner:BROWN UNIVERSITY +1

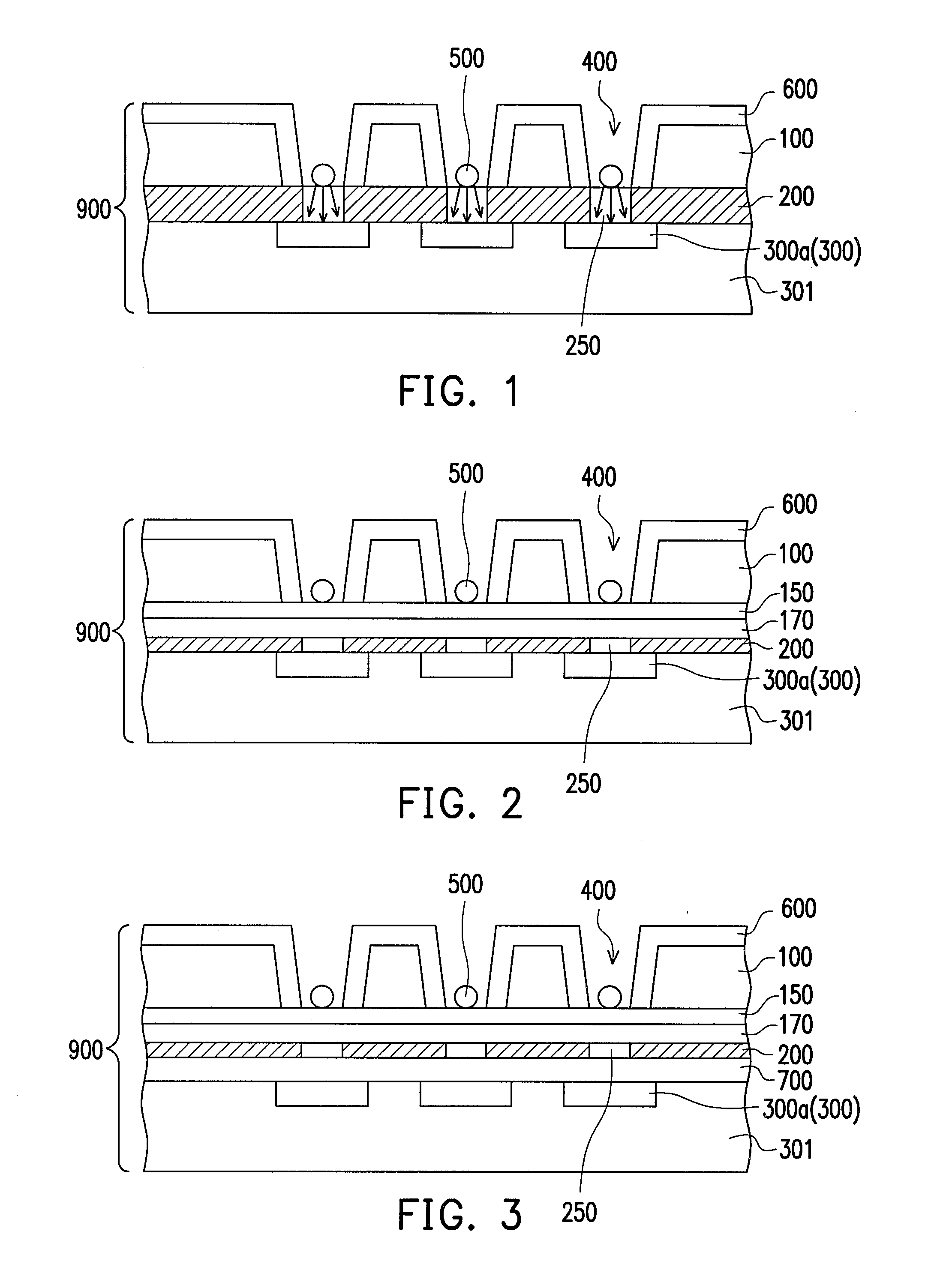

Apparatus for single molecule detection and method thereof

InactiveUS20120156100A1Analysis by electrical excitationSemiconductor/solid-state device manufacturingFluorescenceDetector array

The present invention directs to a detection apparatus for detecting the fluorescence signal emitting from a single and individual analyte molecule. By integrating the excitation light source, the detector array and the nanowell array all together within the detection apparatus, the single analyte molecule trapped in the nanowell can be excited by the light source and emits fluorescence signal to the detector array.

Owner:IND TECH RES INST

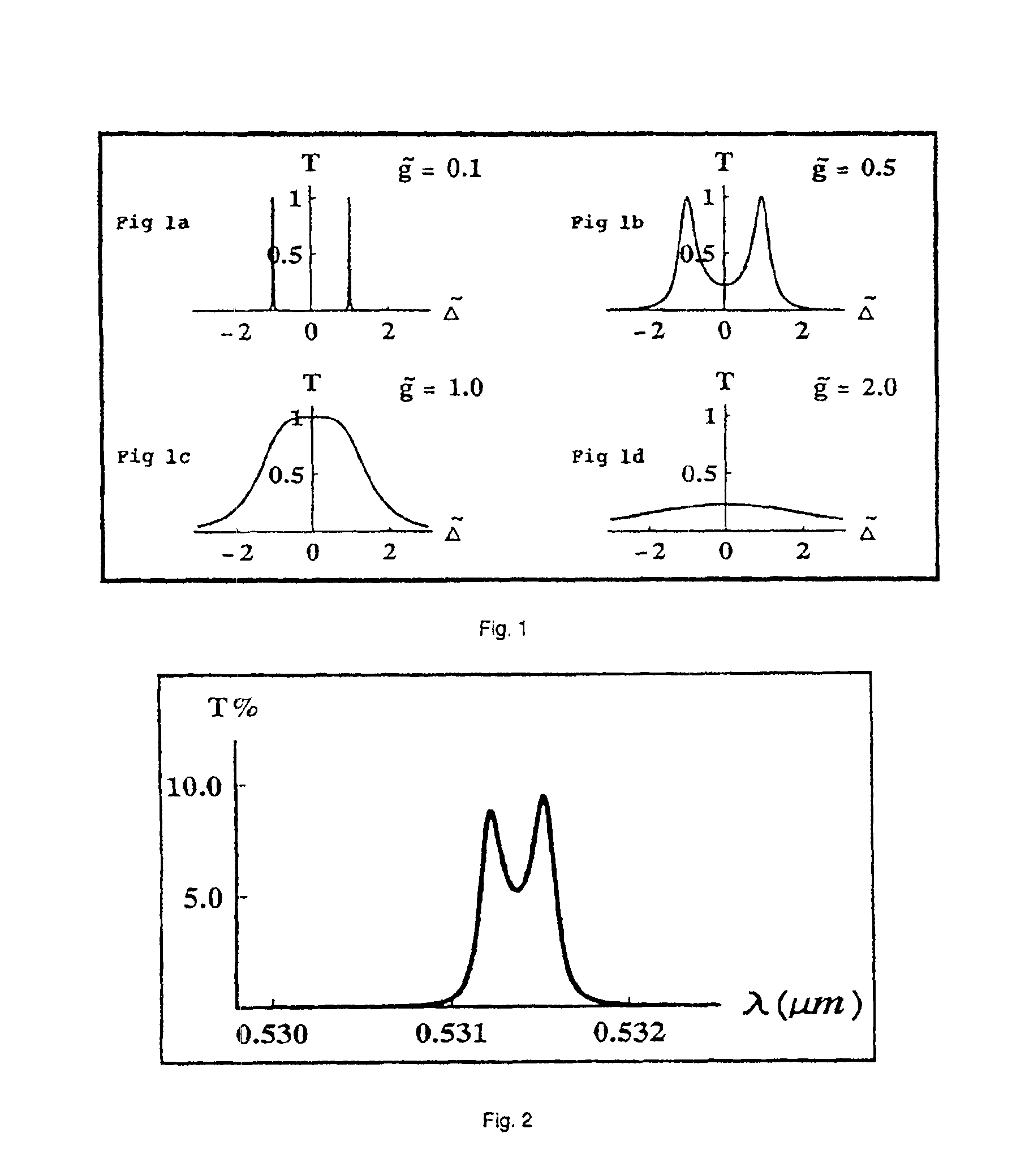

Plasmonic nanophotonics methods, materials, and apparatuses

Controlling, guiding, manipulating, and circuiting light and performing surface-enhanced spectroscopy in a medium comprising plasmonic nanomaterials via the excitation of plasmon modes in the materials. The plasmonic nanomaterials are based on metal films with or without arrays of nanoholes and / or on metal nanowires and / or spheroids. Also devices and methods employing such plasmonic nanomaterials.

Owner:NEW MEXICO STATE UNIV TECH TRANSFER

Nanopores, methods for using same, methods for making same and methods for characterizing biomolecules using same

InactiveUS20070042366A1Bioreactor/fermenter combinationsBiological substance pretreatmentsNanoporeDNA

Featured are devices and systems embodying one or more solid-state nanopores useable for sensing and / or characterizing single macromolecules as well as sequencing DNA or RNA and / or determining RNA secondary structures. In once solid state nanopore of the present invention the width and / or length of the nanopore is defined or established by sharp edges of cleaved crystals that are maintained in fixed relation during the formation of the insulating member including the nanopore. In another aspect of the present invention, there is featured a linear or 2-D electrically addressable array of nanopores, where the nanopores are located at points of intersections between grooves formed in an upper surface of the insulating member and a groove formed in a lower surface of the insulating member.

Owner:NABSYS 2 0 +1

Nanopore sequencing using ratiometric impedance

ActiveUS9017937B1Different levelDifferent modulus propertyMicrobiological testing/measurementMaterial analysisPotential measurementCMOS

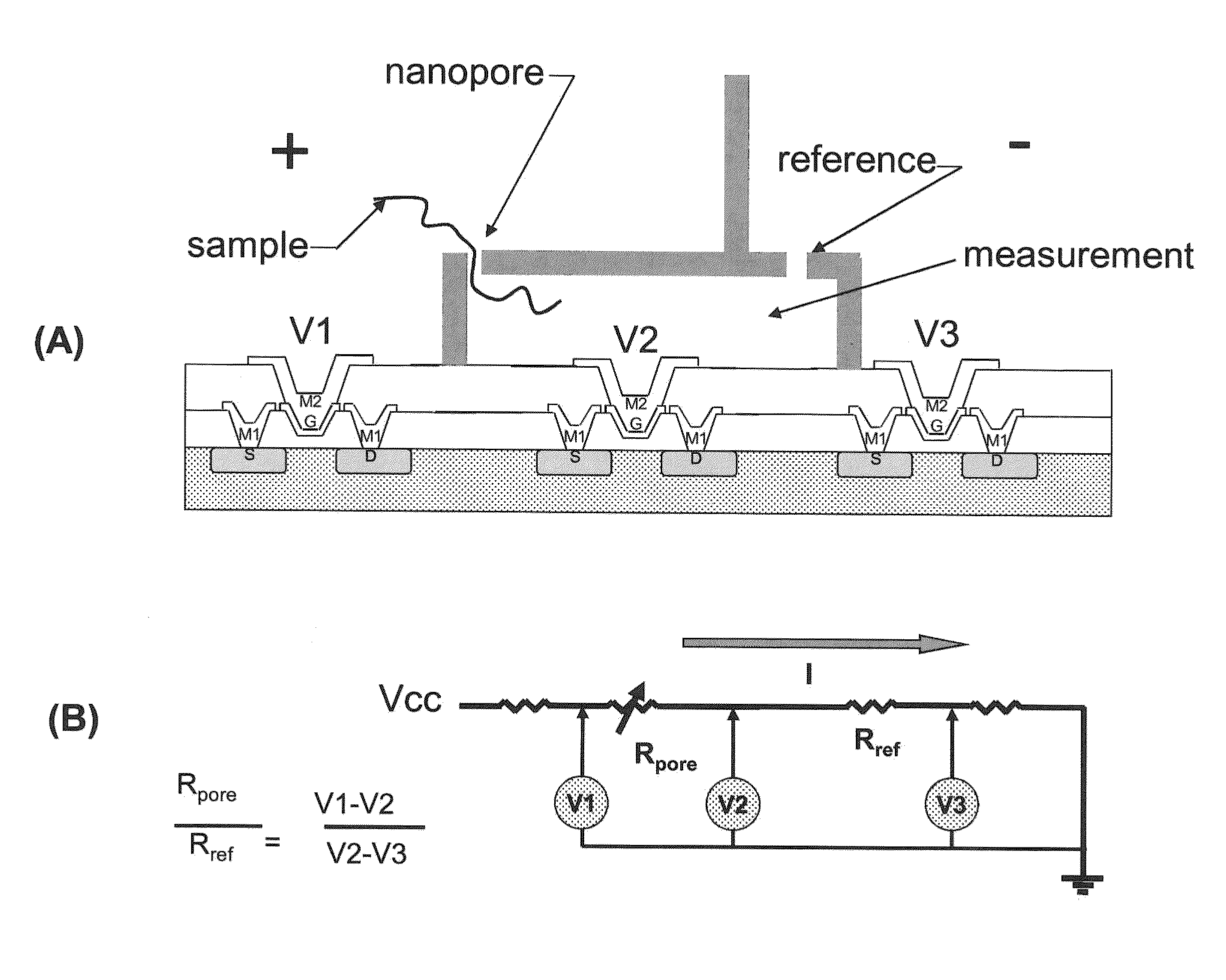

The invention relates to devices and methods for nanopore sequencing. The invention includes arrays of nanopores having incorporated electronic circuits, for example, in CMOS. The invention includes devices having sample and reference pores connecting sample, measurement and reference chambers, wherein potential measurements in each chamber is used to provide an accurate determination of current through a sample nanopore, improving nanopore sequencing.

Owner:PACIFIC BIOSCIENCES

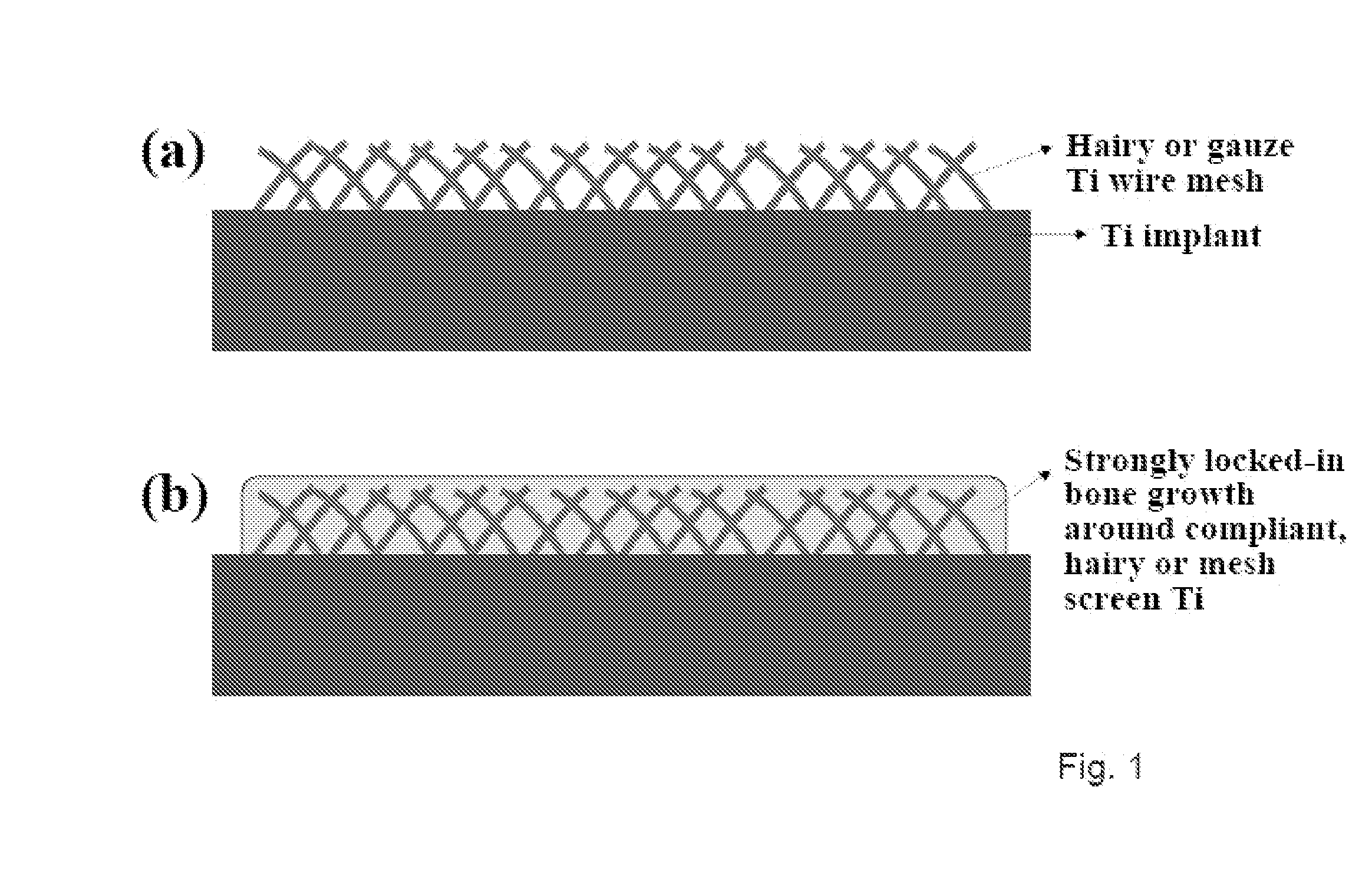

Articles comprising nano-materials for geometry-guided stem cell differentiation and enhanced bone growth

InactiveUS20110085968A1Improve stabilityGood biocompatibilityBiocideIn-vivo radioactive preparationsCell culture mediaBone growth

The present invention provides articles of manufacture comprising biocompatible nanostructures comprising significantly increased surface area for, e.g., organ, tissue and / or cell growth, e.g., for bone, tooth, kidney or liver growth, and uses thereof, e.g., for in vitro testing of drugs, chemicals or toxins, or as in vivo implants, including their use in making and using artificial tissues and organs, and related, diagnostic, screening, research and development and therapeutic uses, e.g., as drug delivery devices. The present invention provides biocompatible nanostructures with significantly increased surface area, such as with nanotube and nanopore array on the surface of metallic, ceramic, or polymer materials for enhanced cell and bone growth, for in vitro and in vivo testing, cleansing reaction, implants and therapeutics. The present invention provides optically transparent or translucent cell-culturing substrates. The present invention provides biocompatible and cell-growth-enhancing culture substrates comprising elastically compliant protruding nanostructure substrates coated with Ti, TiO2 or related metal and metal oxide films.

Owner:RGT UNIV OF CALIFORNIA

Plasmonic nanophotonics methods, materials, and apparatuses

Controlling, guiding, manipulating, and circuiting light and performing surface-enhanced spectroscopy in a medium comprising plasmonic nanomaterials via the excitation of plasmon modes in the materials. The plasmonic nanomaterials are based on metal films with or without arrays of nanoholes and / or on metal nanowires and / or spheroids. Also devices and methods employing such plasmonic nanomaterials.

Owner:NEW MEXICO STATE UNIV TECH TRANSFER

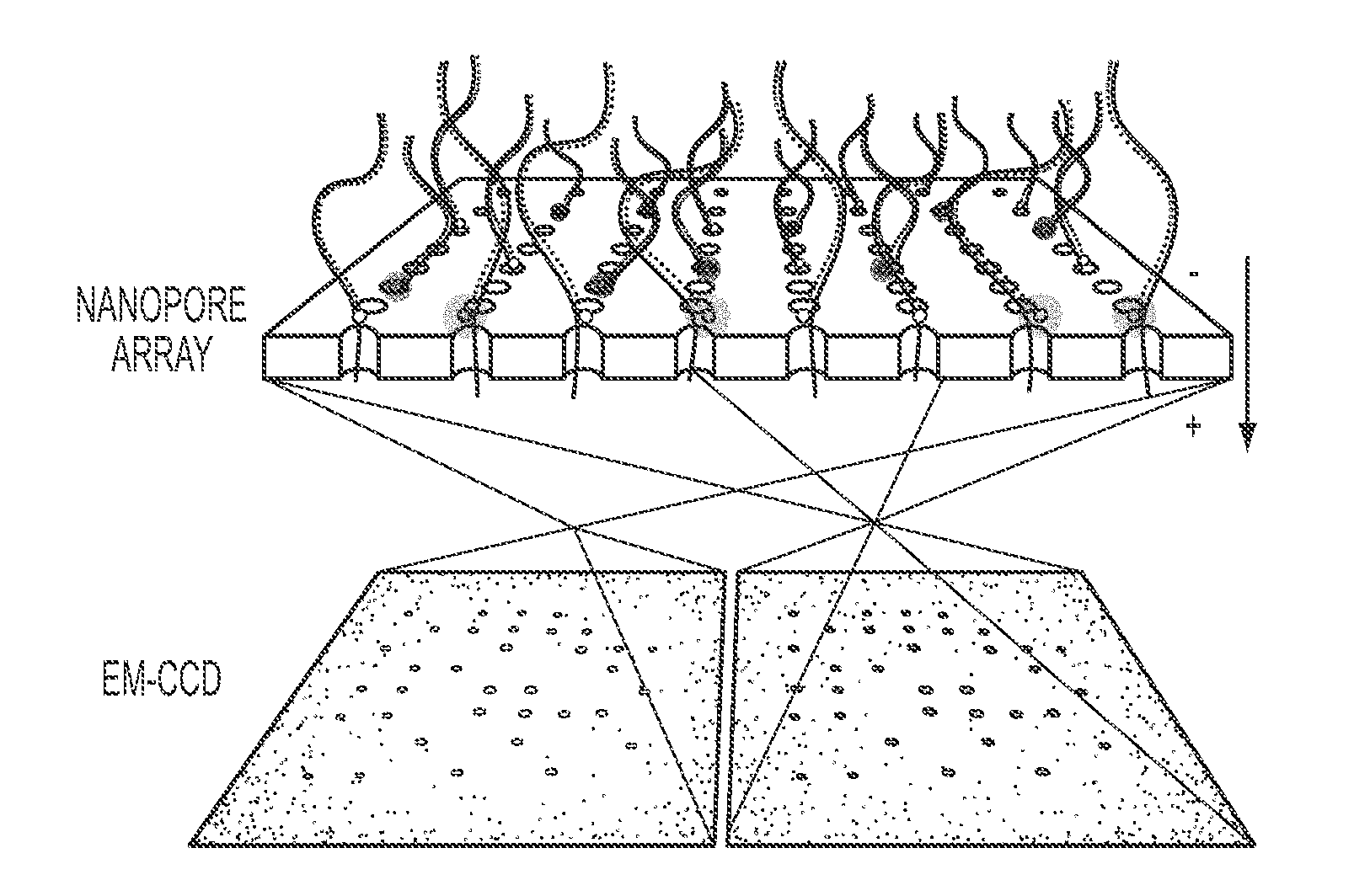

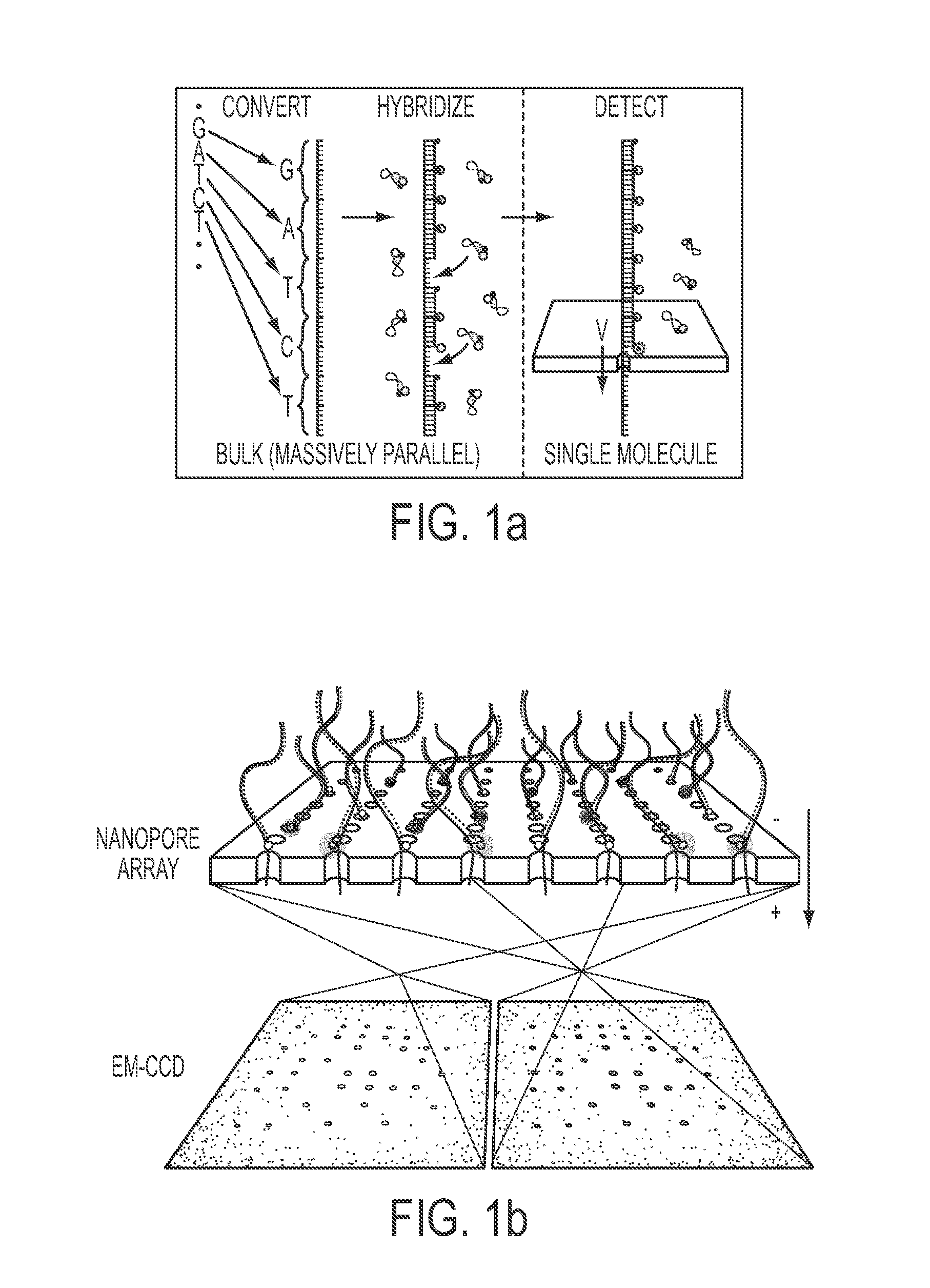

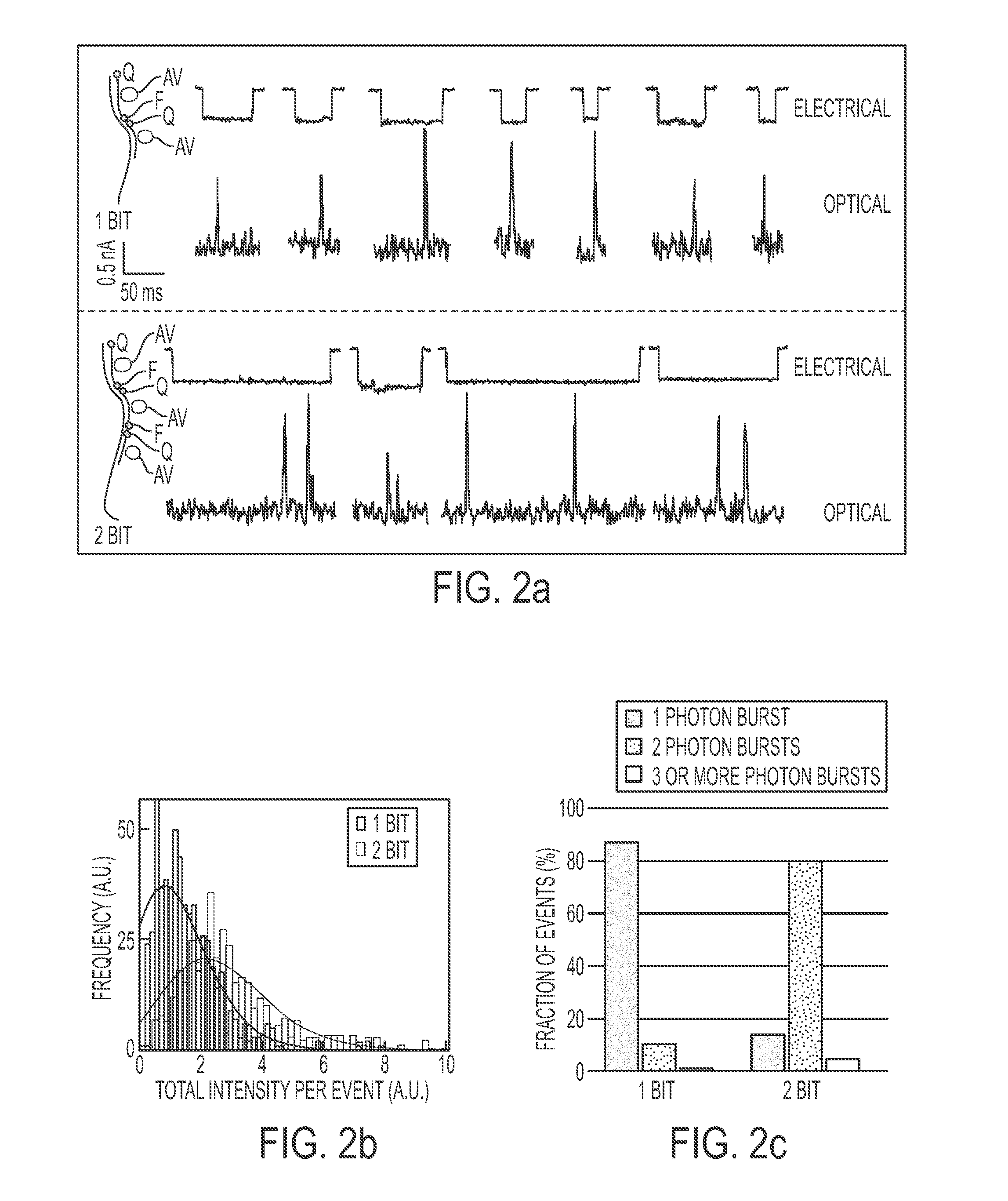

Use of Nanopore Arrays For Multiplex Sequencing of Nucleic Acids

InactiveUS20130256118A1Electrolysis componentsVolume/mass flow measurementNucleic acid sequencingNanopore

Described are techniques for optical detection of single molecule signals from a nanopore array for analysis of nucleic acid sequences. These techniques are useful for rapid multiplexed DNA sequencing.

Owner:TRUSTEES OF BOSTON UNIV

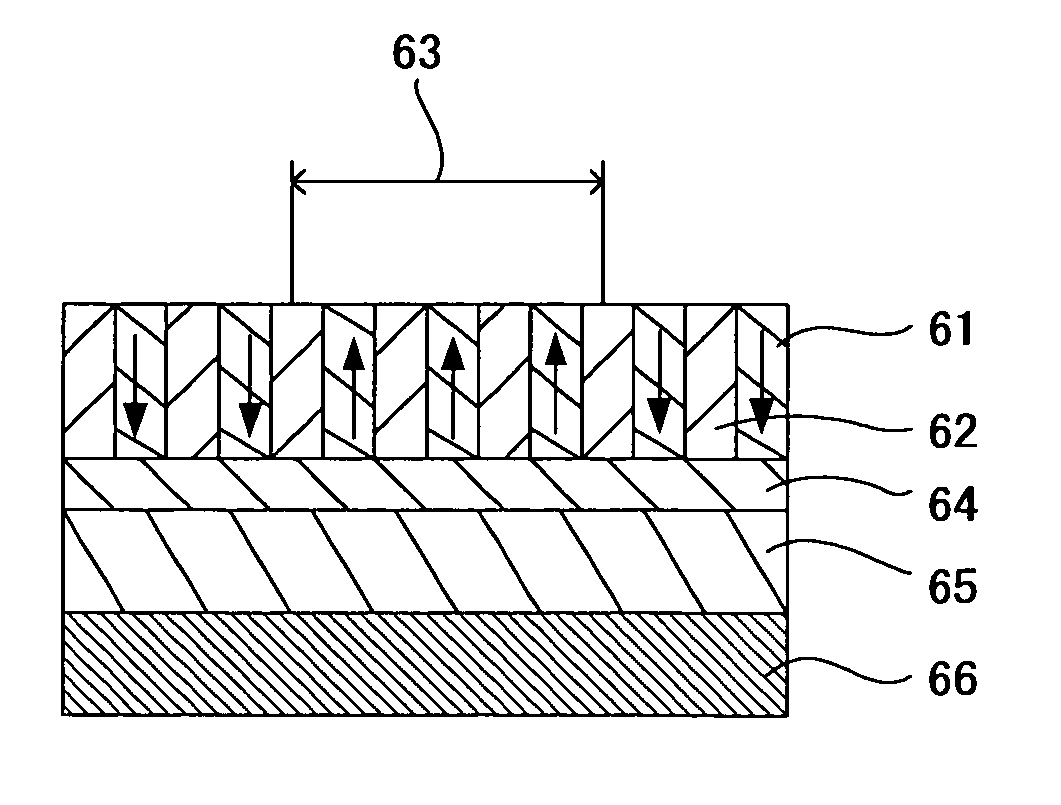

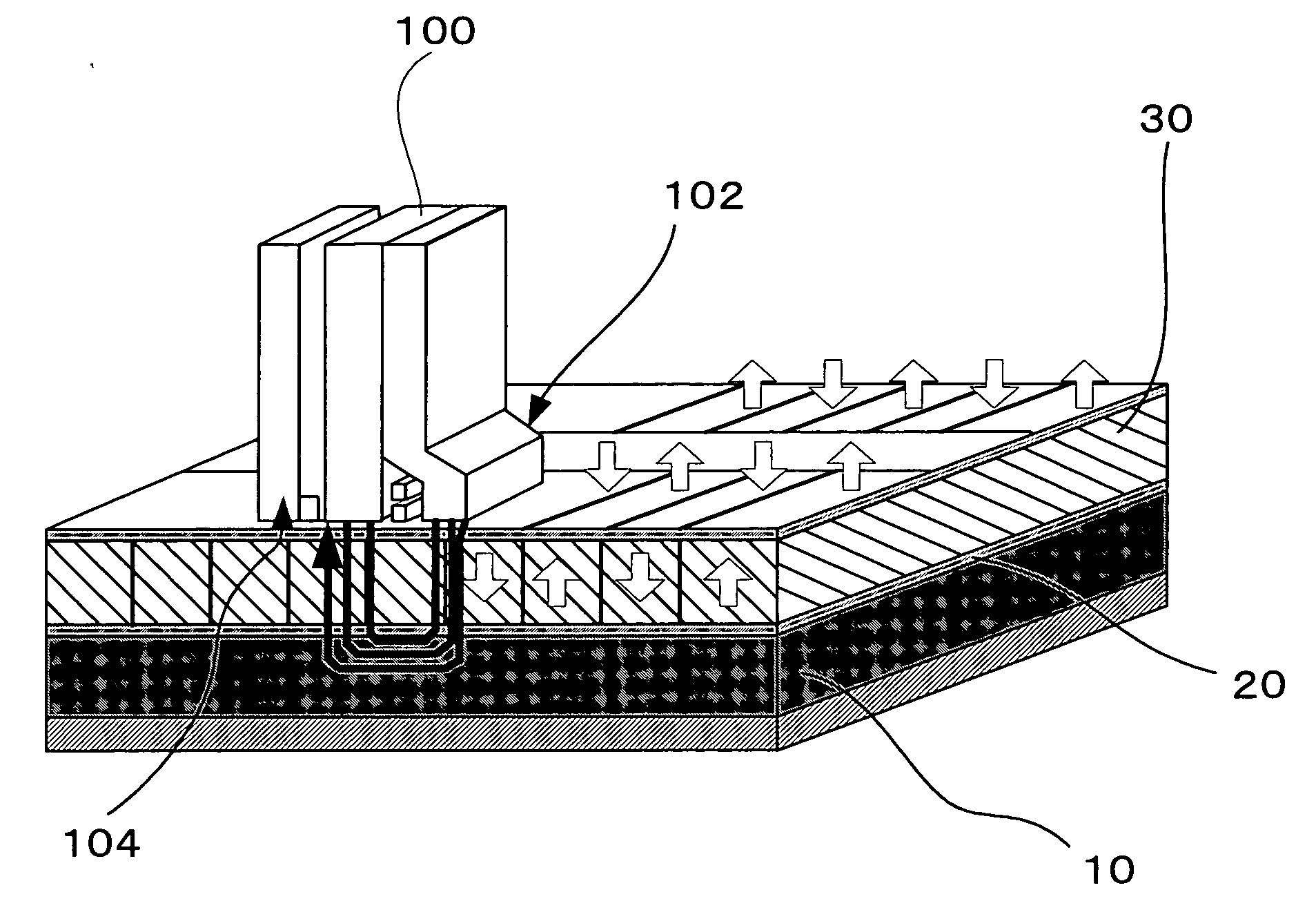

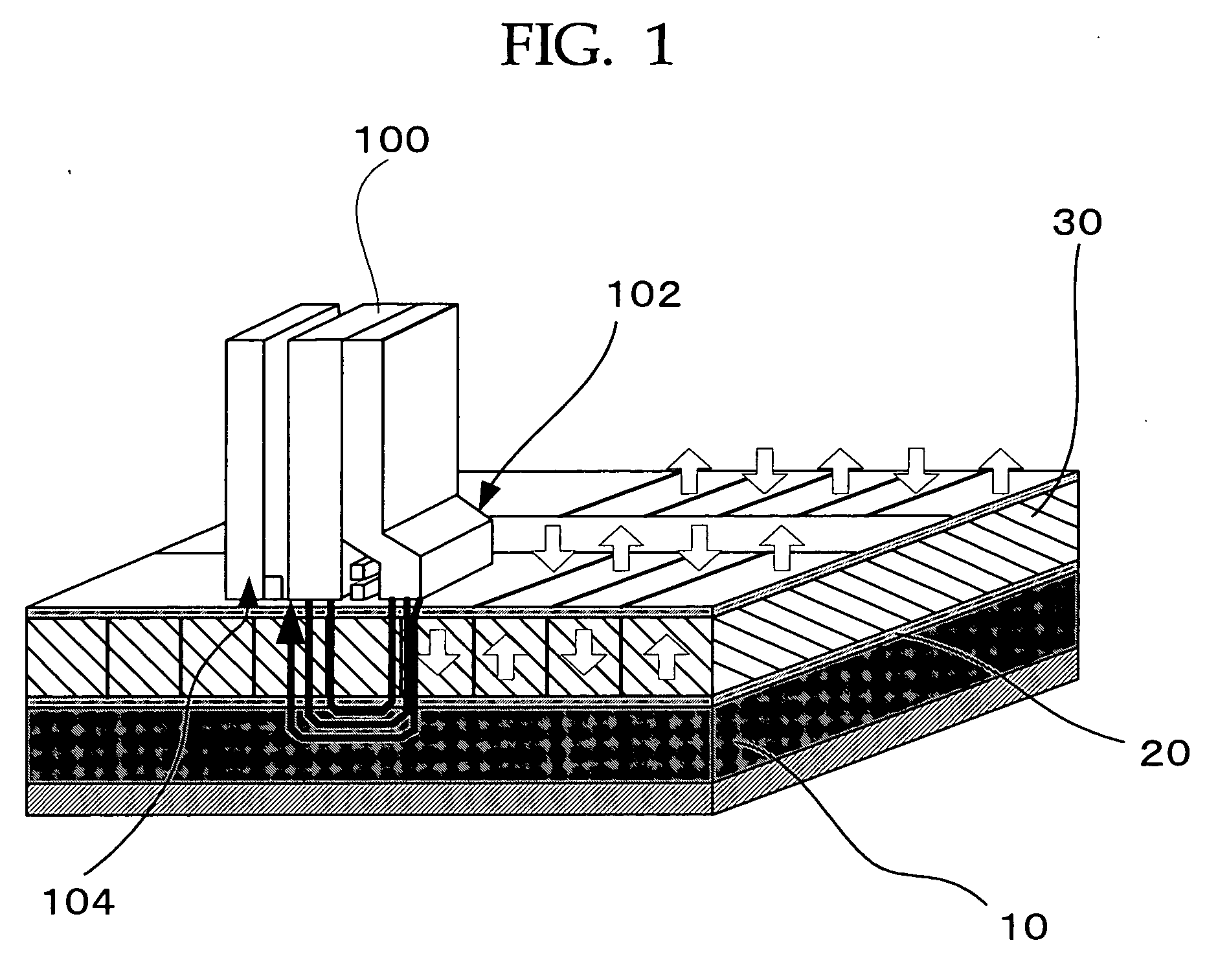

Nanoholes and production thereof, stamper and production thereof, magnetic recording media and production thereof, and, magnetic recording apparatus and method

InactiveUS20050249980A1Efficient preparationLow costMaterial nanotechnologyMagnetic materials for record carriersPorous layerEngineering

A nanohole structure includes a metallic matrix and nanoholes arrayed regularly in the metallic matrix, in which the nanoholes are spaced in rows at specific intervals to constitute rows of nanoholes. The rows of nanoholes are preferably arranged concentrically or helically. The nanoholes in adjacent rows of nanoholes are preferably arranged in a radial direction. The width of each row of nanoholes preferably varies at specific intervals in its longitudinal direction. A magnetic recording medium includes a substrate, and a porous layer on or above the substrate. The porous layer contains nanoholes each extending in a direction substantially perpendicular to a substrate plane, containing at least one magnetic material therein, and is the above-mentioned nanohole structure.

Owner:FUJITSU LTD +1

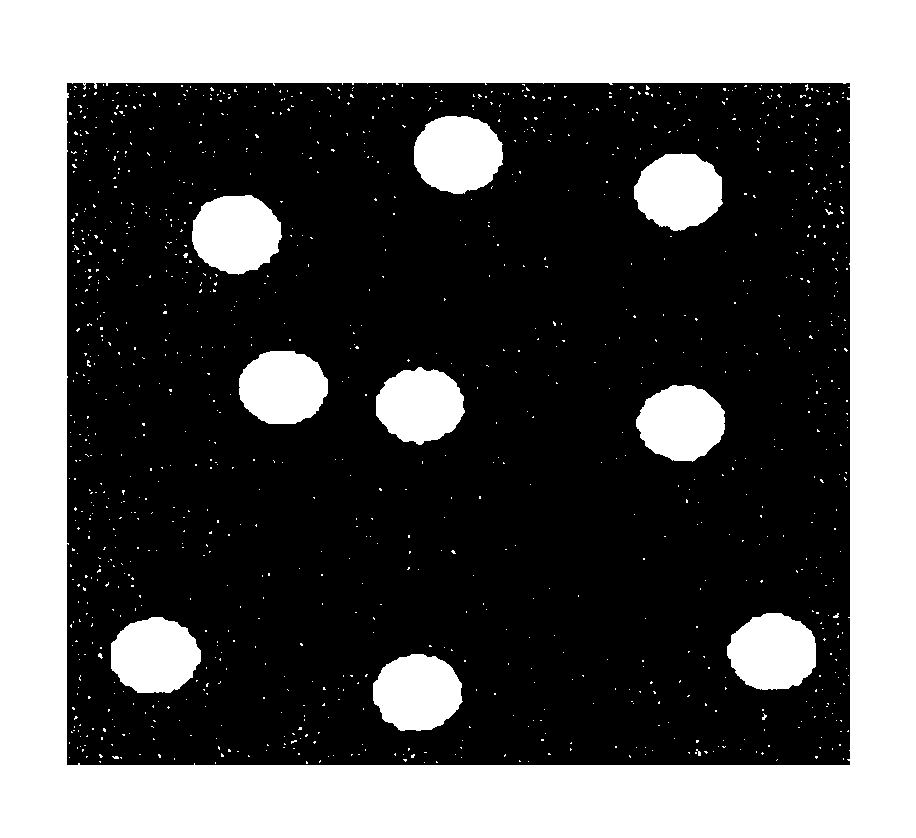

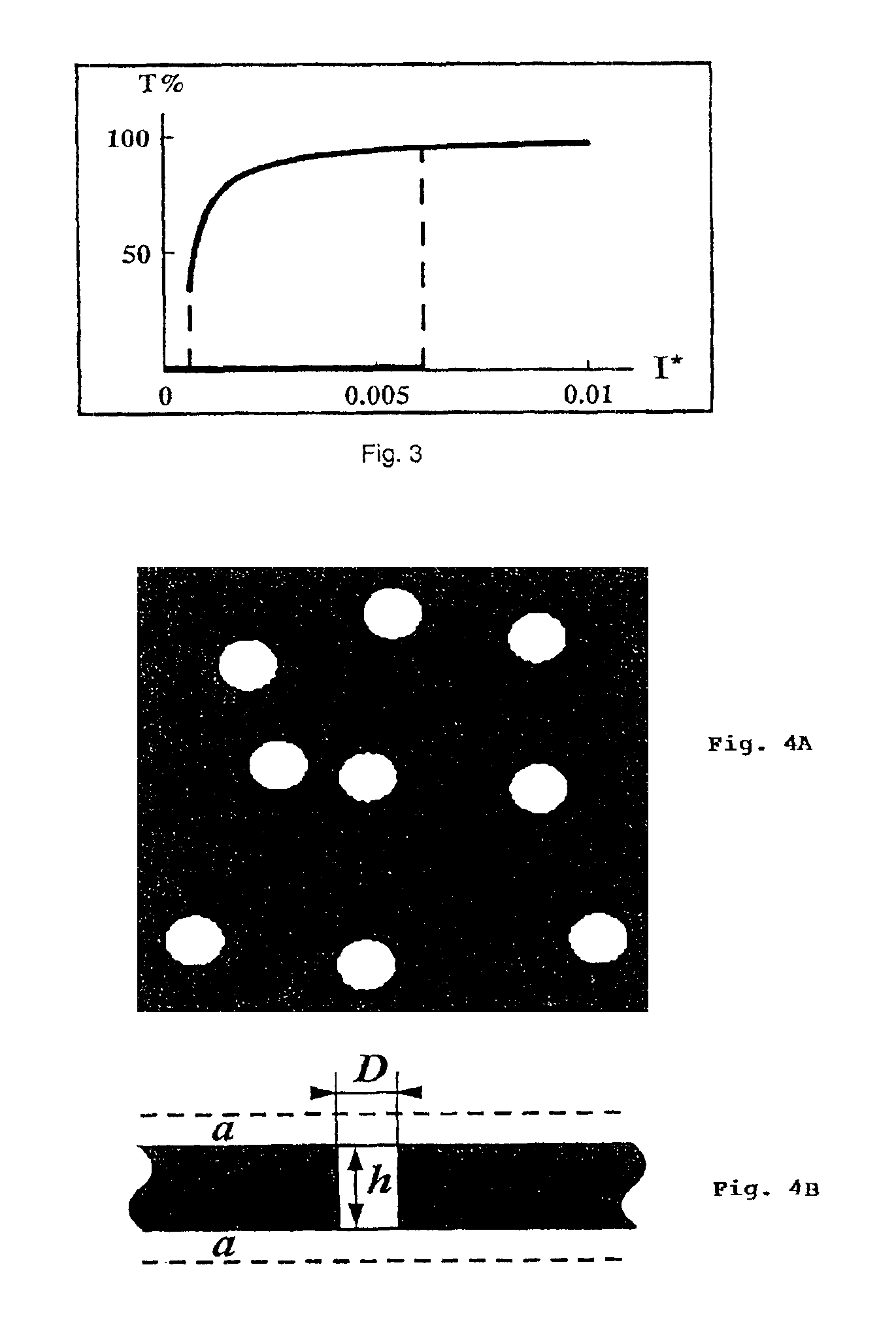

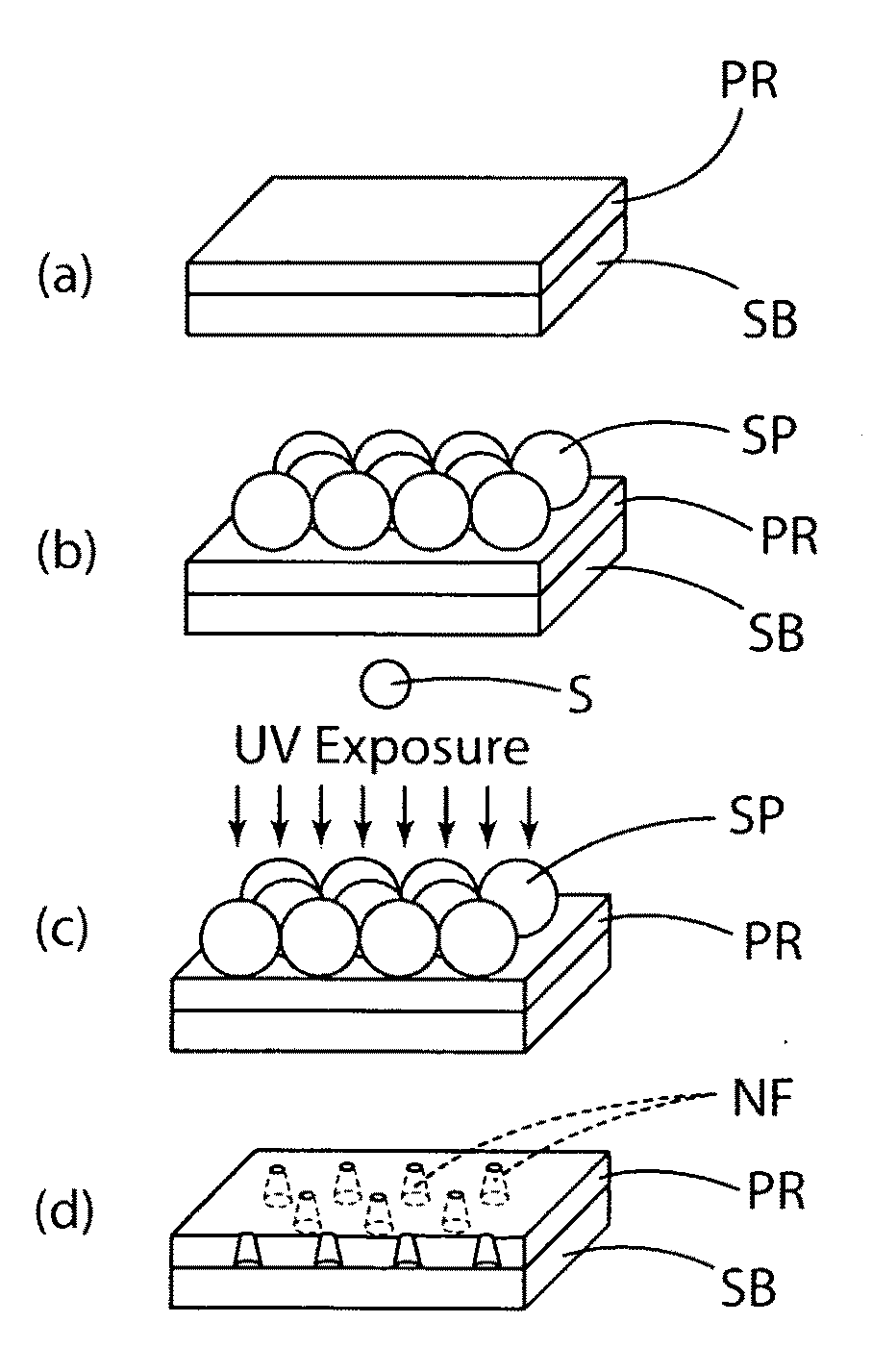

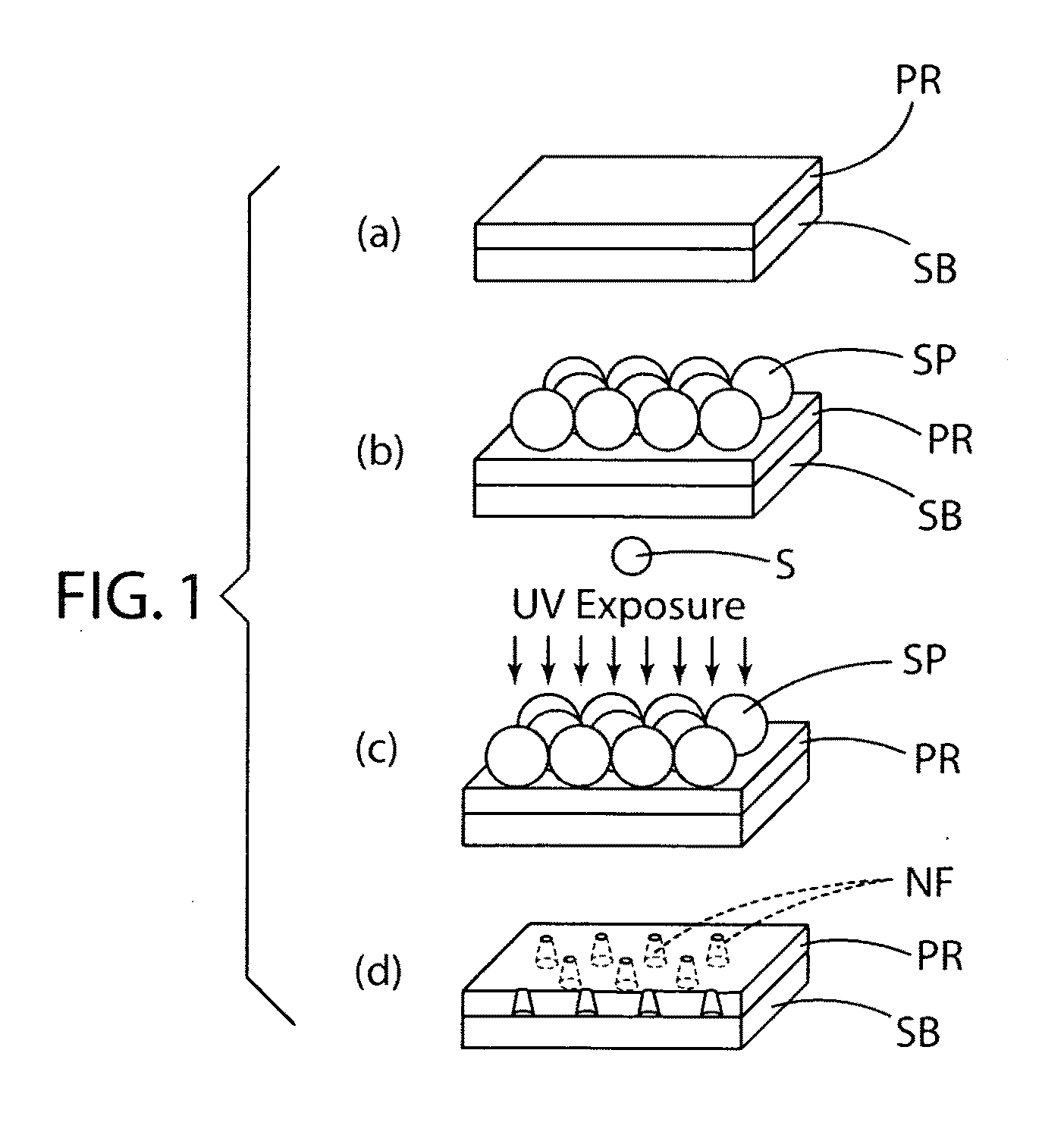

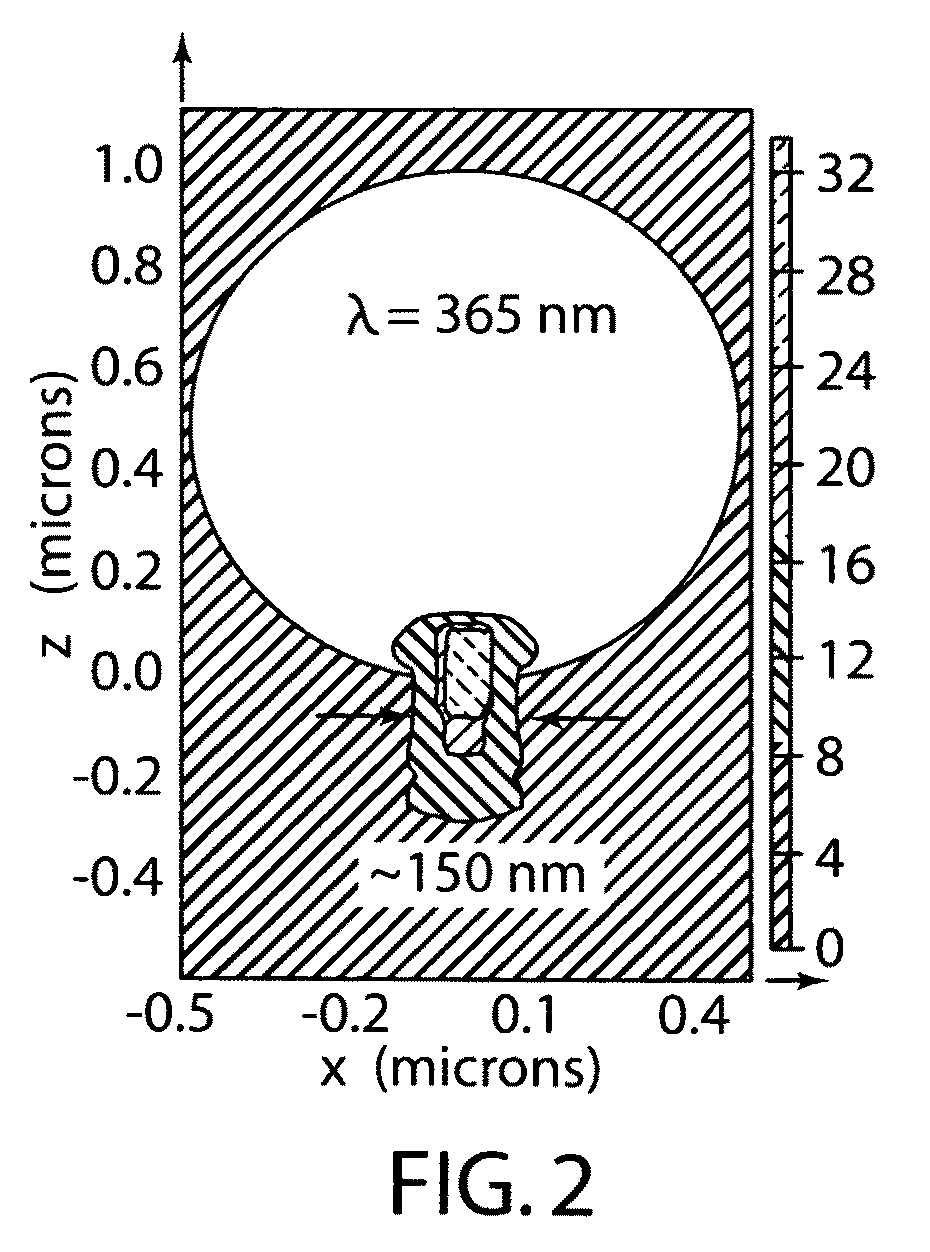

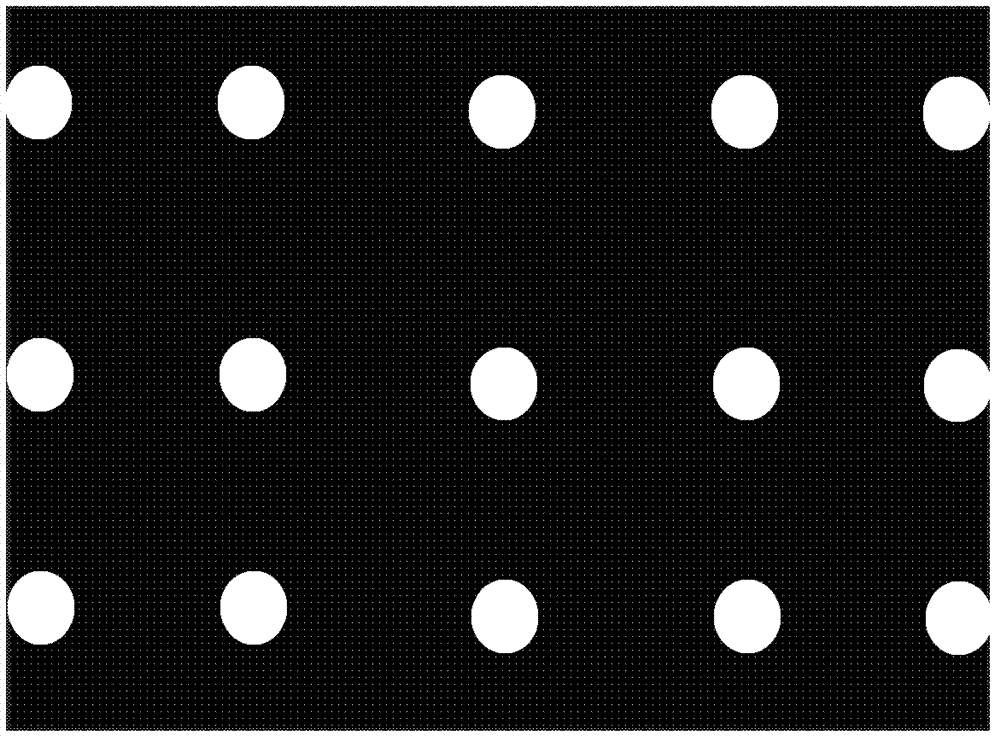

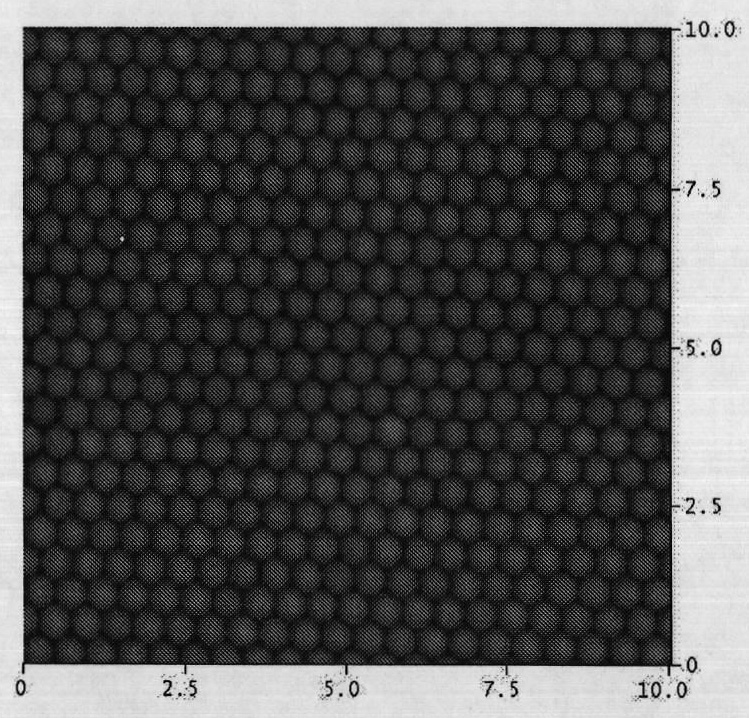

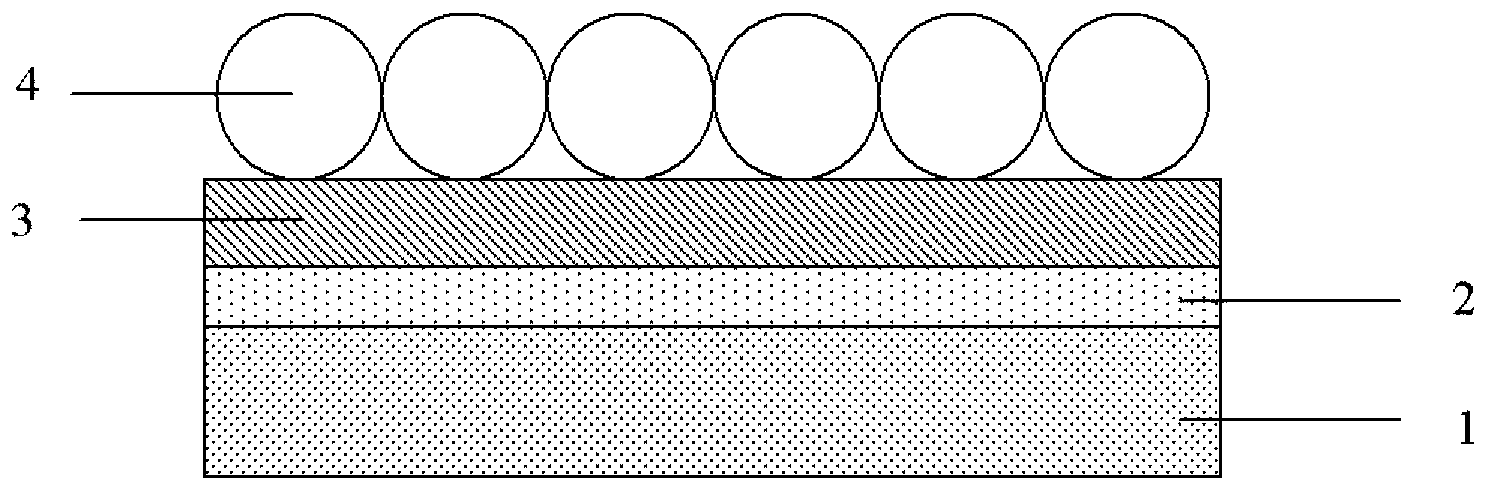

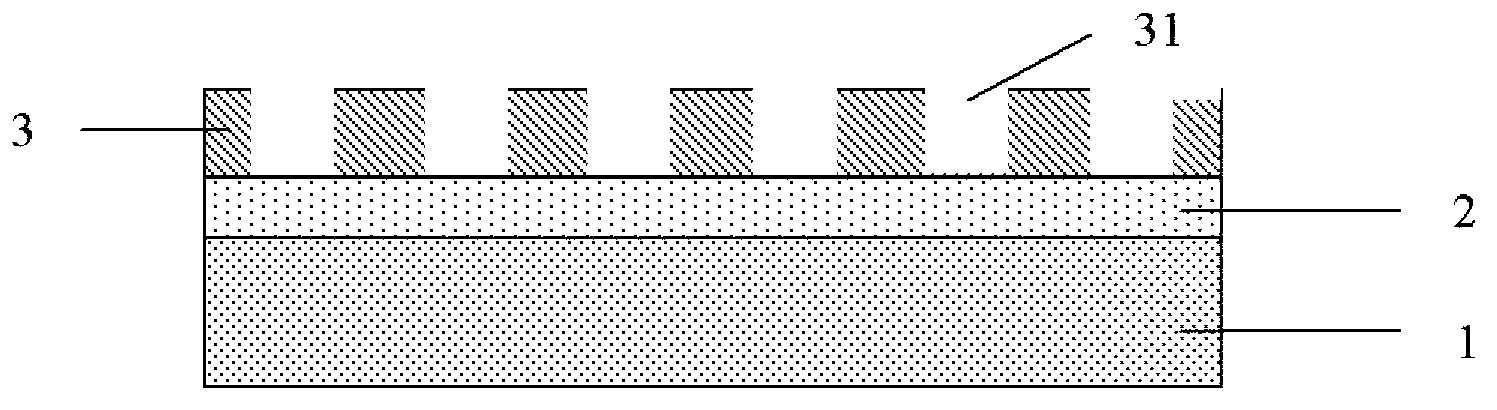

Process for formation of highly uniform arrays of nano-holes and nano-pillars

A photolithography method of patterning photoresist involves disposing a two-dimensional array of focusing particles of spherical or other shape on the photoresist and illuminating the particles on the photoresist to generate deep, sub-wavelength patterns on the photoresist. When developed, a positive photoresist layer generates a two-dimensional array of micro- or nano-holes on the developed photoresist. When developed, a negative photoresist layer generates a two-dimensional array of micro- or nano-pillars on the developed photoresist.

Owner:NORTHWESTERN UNIV

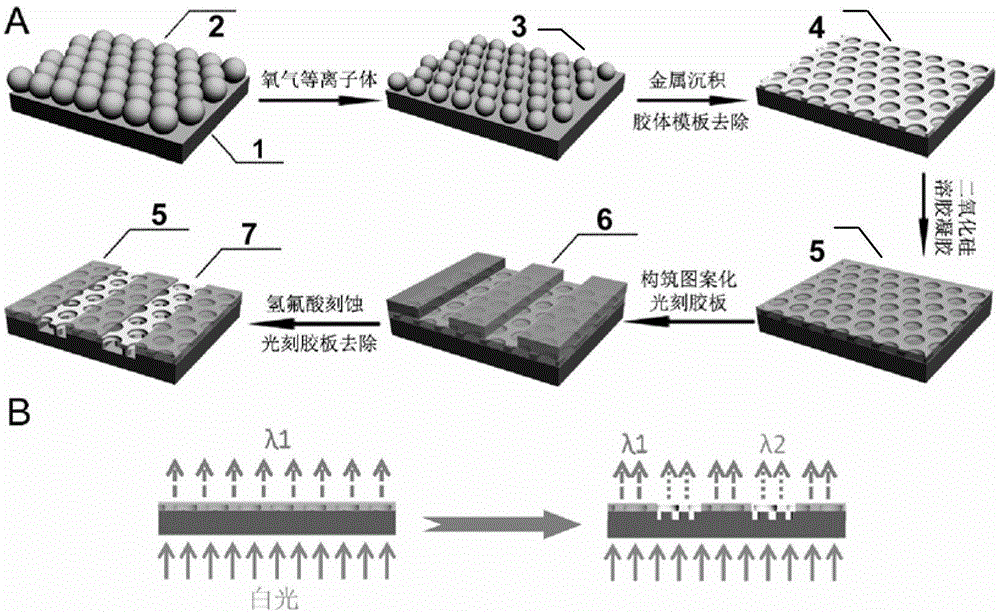

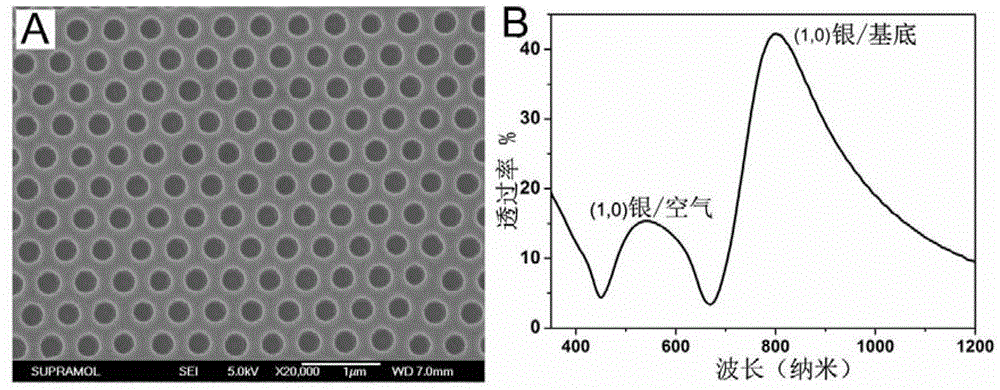

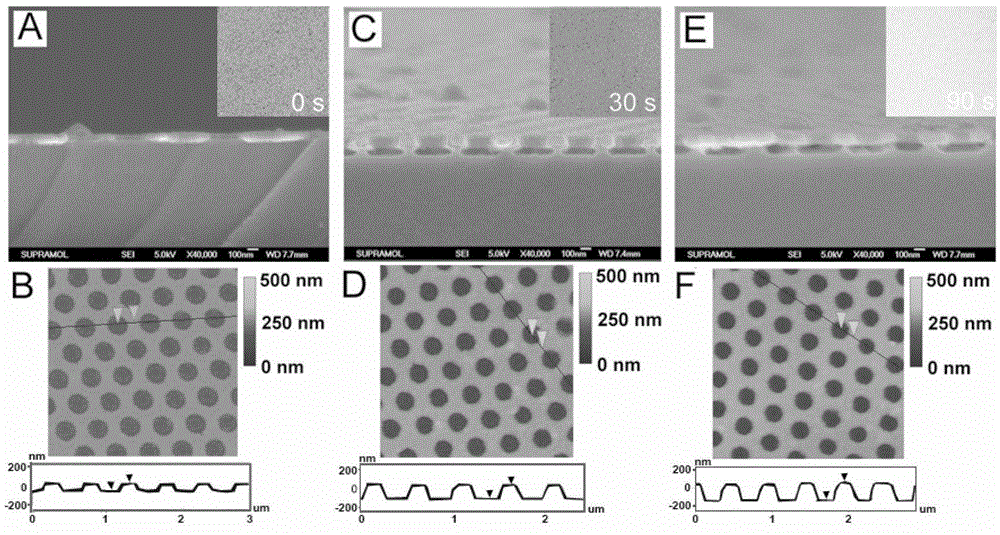

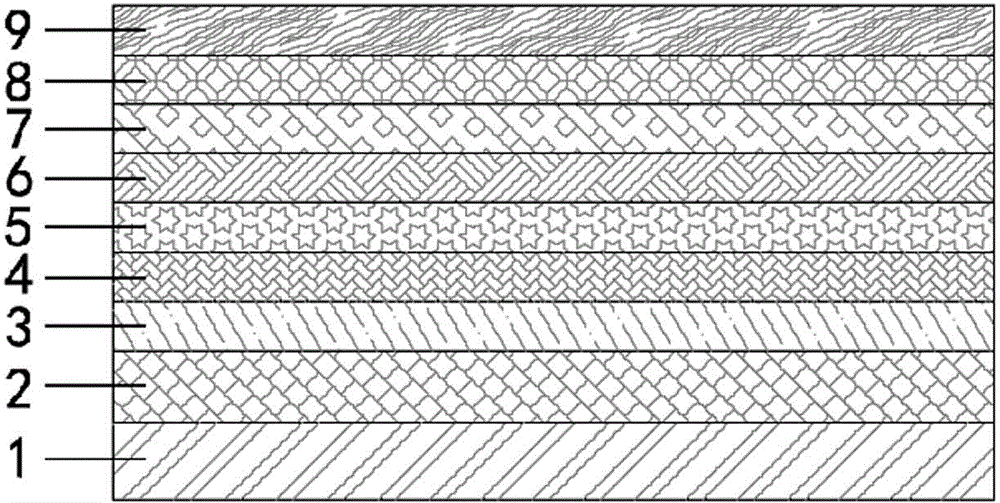

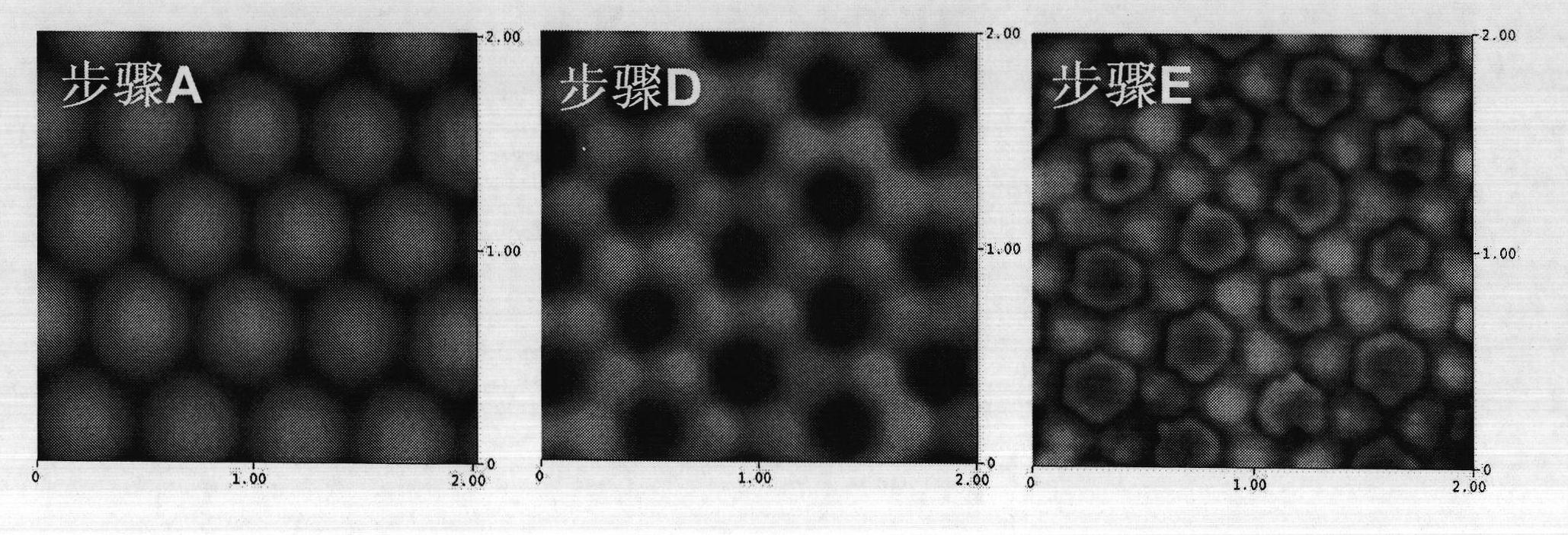

Preparation method of panchromatic structural color or color variation pattern array

InactiveCN103145095AThe method involved is simpleControllable methods involvedDecorative surface effectsChemical vapor deposition coatingDielectricPolystyrene

The invention discloses a preparation method of a panchromatic structural color or color variation pattern array, belongs to the technical field of materials, and in particular relates to a method for preparing a panchromatic structural color or color variation pattern array by regulating the environment dielectric constants of an upper interface and a lower interface of a noble metal nanopore array. The preparation method comprises the following steps of: cleaning and surface hydrophilization treatment, the preparation of polystyrene single layer colloidal crystals, the construction for covering the noble metal nanopore array by a silicon oxide layer, the construction of a suspension noble metal nanopore array, selective regulation and control of the environment dielectric constant around the noble metal nanopore array and the like. The obtained noble metal nanopore array has a transmission peak adjustable within a visible light wave band (350nm-800nm), so that different single-color patterns or color patterns are shown, the apparent color of a single color sample can be changed along with the change of the external environment dielectric constant; and color change, disappear and reproduction of the array patterns can be realized for the color pattern sample along with the change of the external environment dielectric constant.

Owner:JILIN UNIV

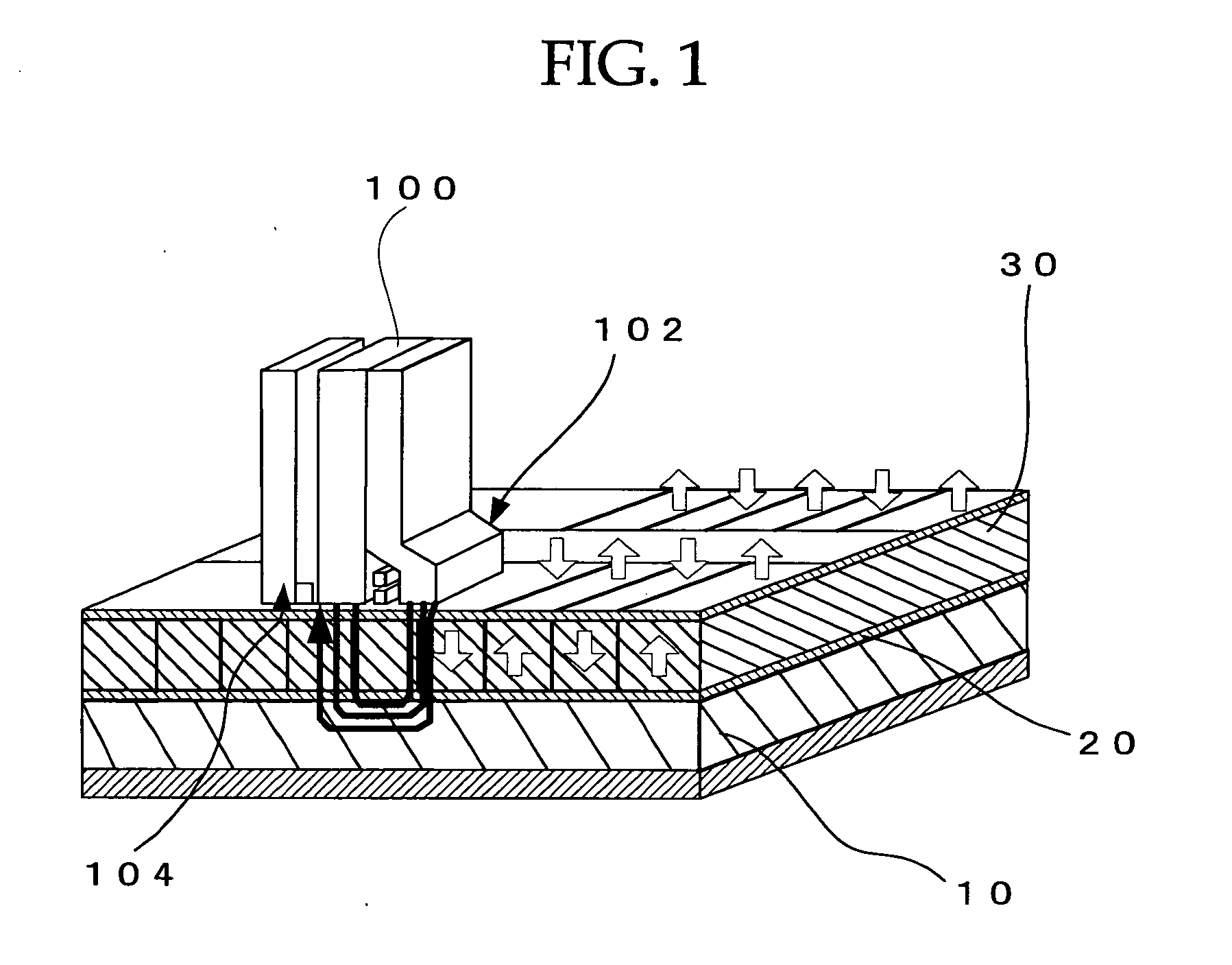

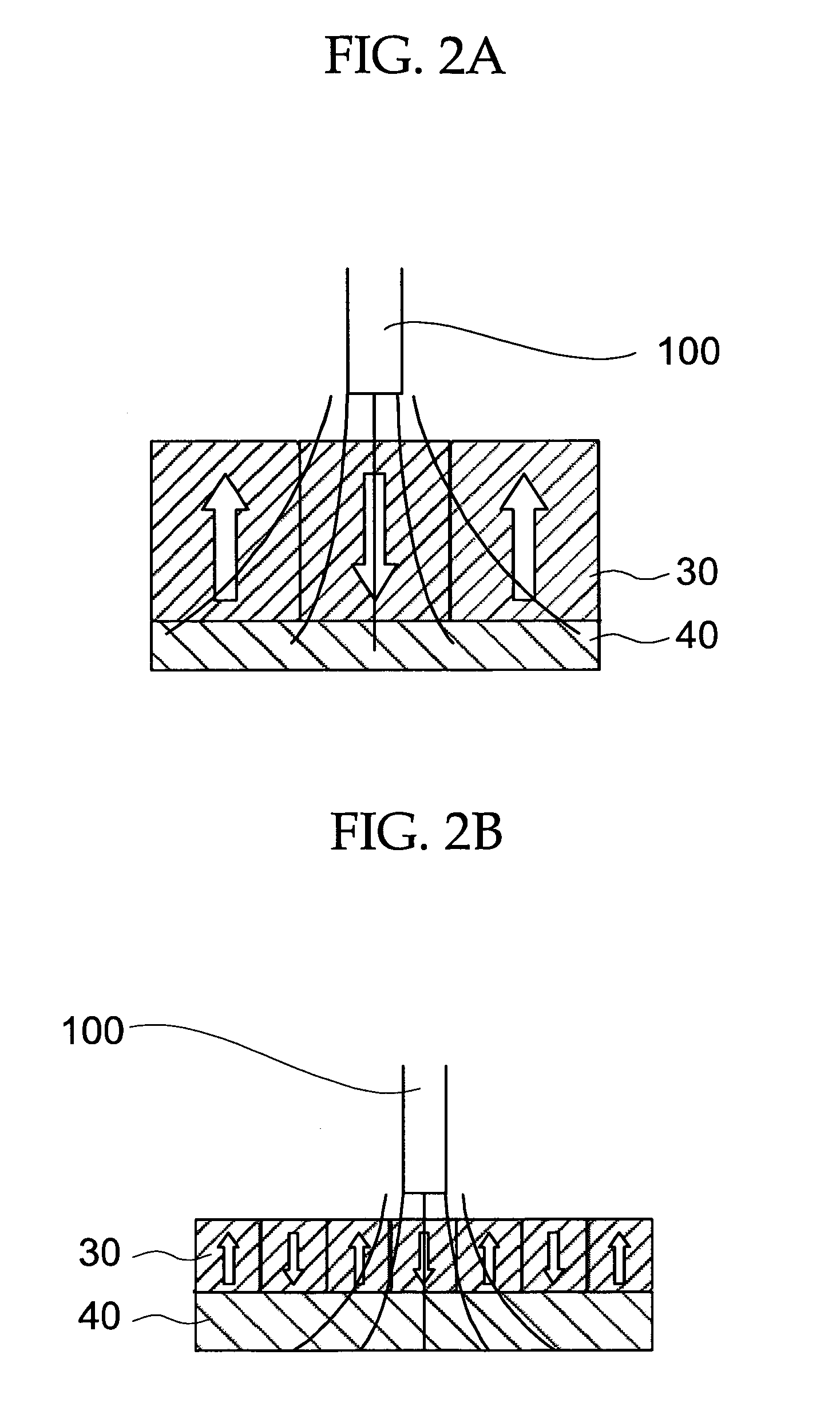

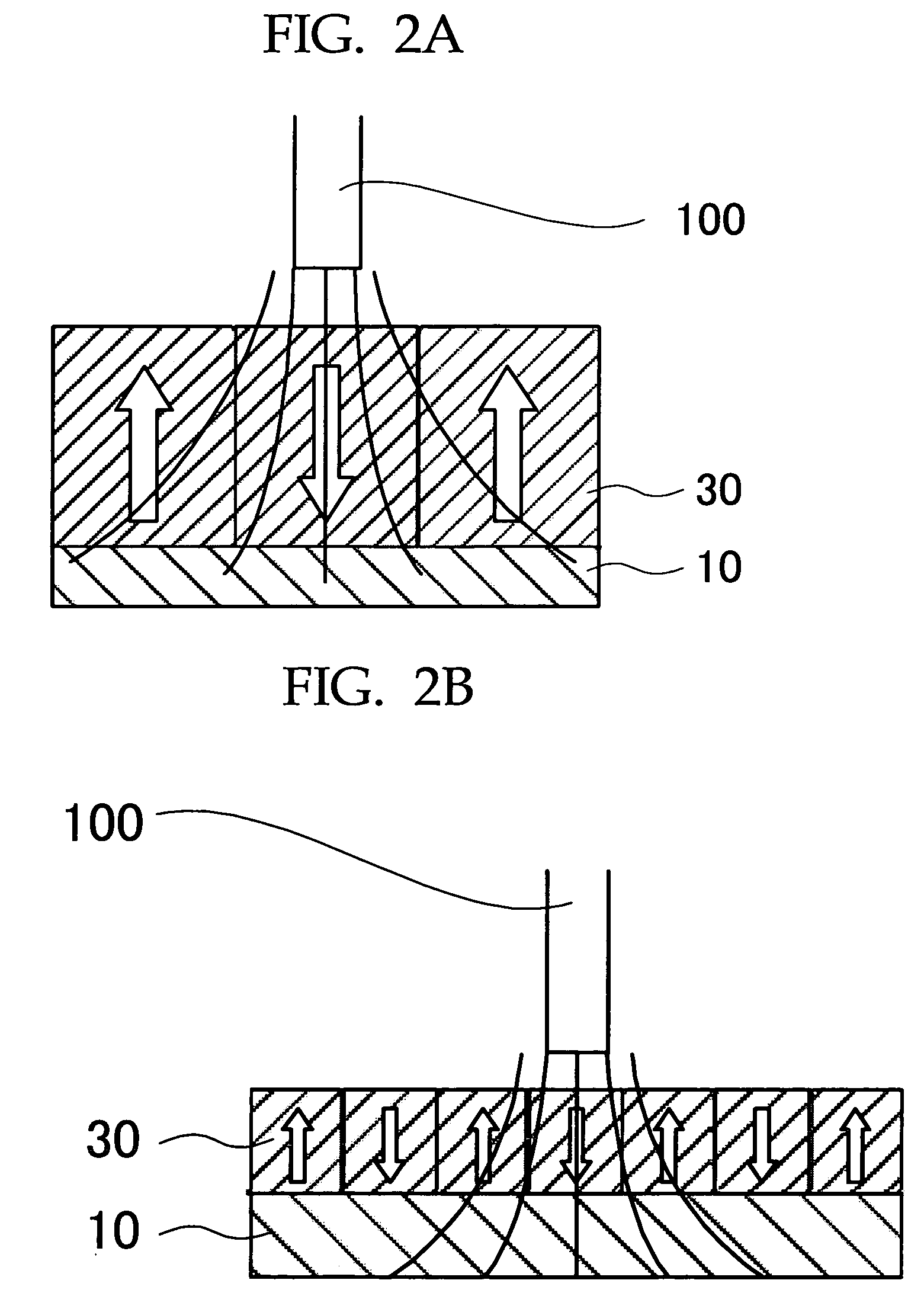

Nanohole structure and method for producing the same, stamper and method for producing the same, magnetic recording medium and method for producing the same, magnetic recording device, and magnetic recording method

InactiveUS20060286345A1Produced easily and economicallyEasy to trackMechanical working/deformationLayered productsHigh densityPorous layer

The object of the present is to provide high-quality magnetic recording media capable of easy tracking, and allowing high-density recording, high-speed recording, and higher capacity without increasing the write-current at magnetic heads. The nanohole structure comprises a metal or metal-compound base material and plural arrays of nanoholes, wherein the plural arrays of nanoholes are respectively arranged into regular alignments, the regular alignments are different between adjacent arrays, and the regular alignments are alternately disposed within the metal or metal-compound base material. The magnetic recording medium according to the present invention comprises a substrate, a porous layer into which plural nanoholes are formed, and a magnetic material within the plural nanoholes, wherein the plural nanoholes are formed in a direction approximately vertical to the plane of the substrate, the porous layer is a nanohole structure according to the present invention

Owner:YAMAGATA FUJITSU

III-nitride semiconductor/quantum dot hybrid white light LED device and preparing method thereof

ActiveCN104868023AImprove luminous efficiencyHigh color rendering indexSemiconductor devicesEnergy transferColor rendering index

The invention discloses an III-nitride semiconductor / quantum dot hybrid white light LED device. According to the invention, an ordered nano-pore array is arranged outside the regions of a p type electrode and an n type electrode. The nano-pore array penetrates from the surface of the device through a quantum well active layer to the inner part of an n type nitride layer. The nano-pore array is internally filled with II-VI quantum dots. The invention further discloses a preparing method of the III-nitride semiconductor / quantum dot hybrid white light LED device. Non-radiative composite energy transferring between an indium gallium nitrogen (InGaN) quantum well and excitons in the II-VI quantum dots is utilized by the device to improved the light emitting efficiency of the device; in addition, by changing the types and the ratio of the filling quantum dots, the wavelength and the intensity of emitted light is adjusted, and the white light LED device with the nitride / quantum dot hybrid structure is capable of realizing a superhigh color rendering index.

Owner:NANJING UNIV

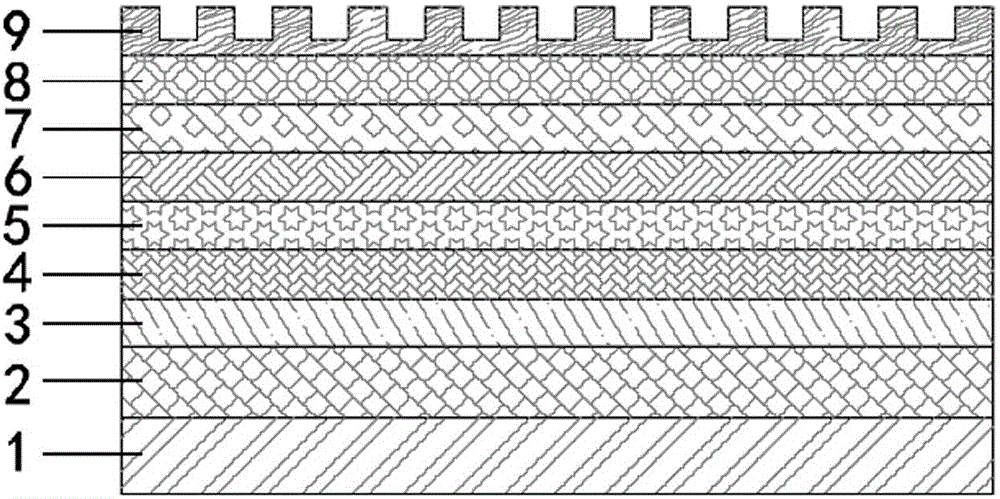

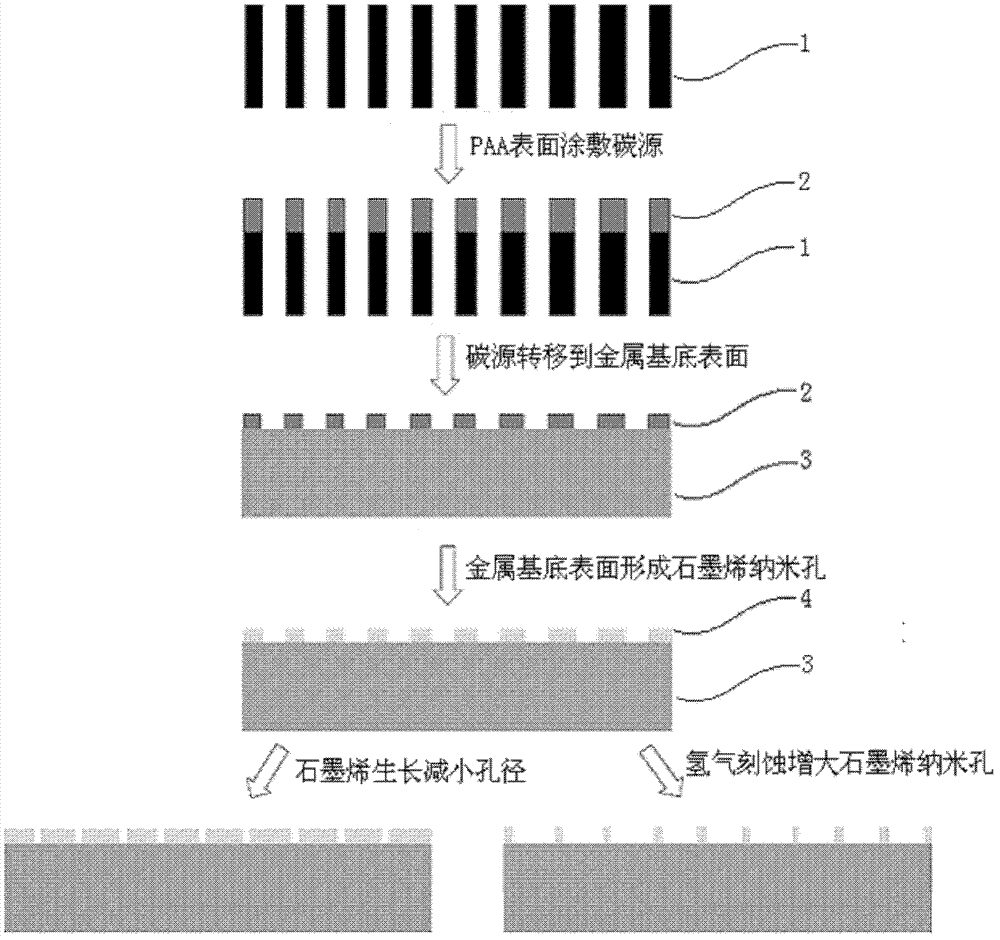

Method for preparing graphene nanopore array through chemical vapor deposition by using porous anodic alumina (PAA) as template

The invention provides a method for preparing a graphene nanopore array, which comprises the following steps: 1) coating a carbon source solution on the surface of a porous anodic alumina (PAA) template; 2) pressing the PAA template with the carbon source coated on the surface (obtained in the step 1)) on the surface of a metal base, peeling the PAA template, and ensuring that the carbon source is reserved on the surface of the metal base and the carbon source reserves a pattern which is consistent with that on the surface of the PAA template; and 3) performing annealing treatment on the obtained metal base in the presence of a mixed gas flow of hydrogen gas and argon gas, thus converting the carbon source into the graphene nanopore array. The nanopore array obtained by the invention is an interconnected nanopore array structure rather other a single nanopore or several nanopores; and the pore size of the nanopores can be regulated through the template effect of the PAA itself, and can be further regulated through growing and etching in the later stage. Thus, the pore size controllability is very excellent.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

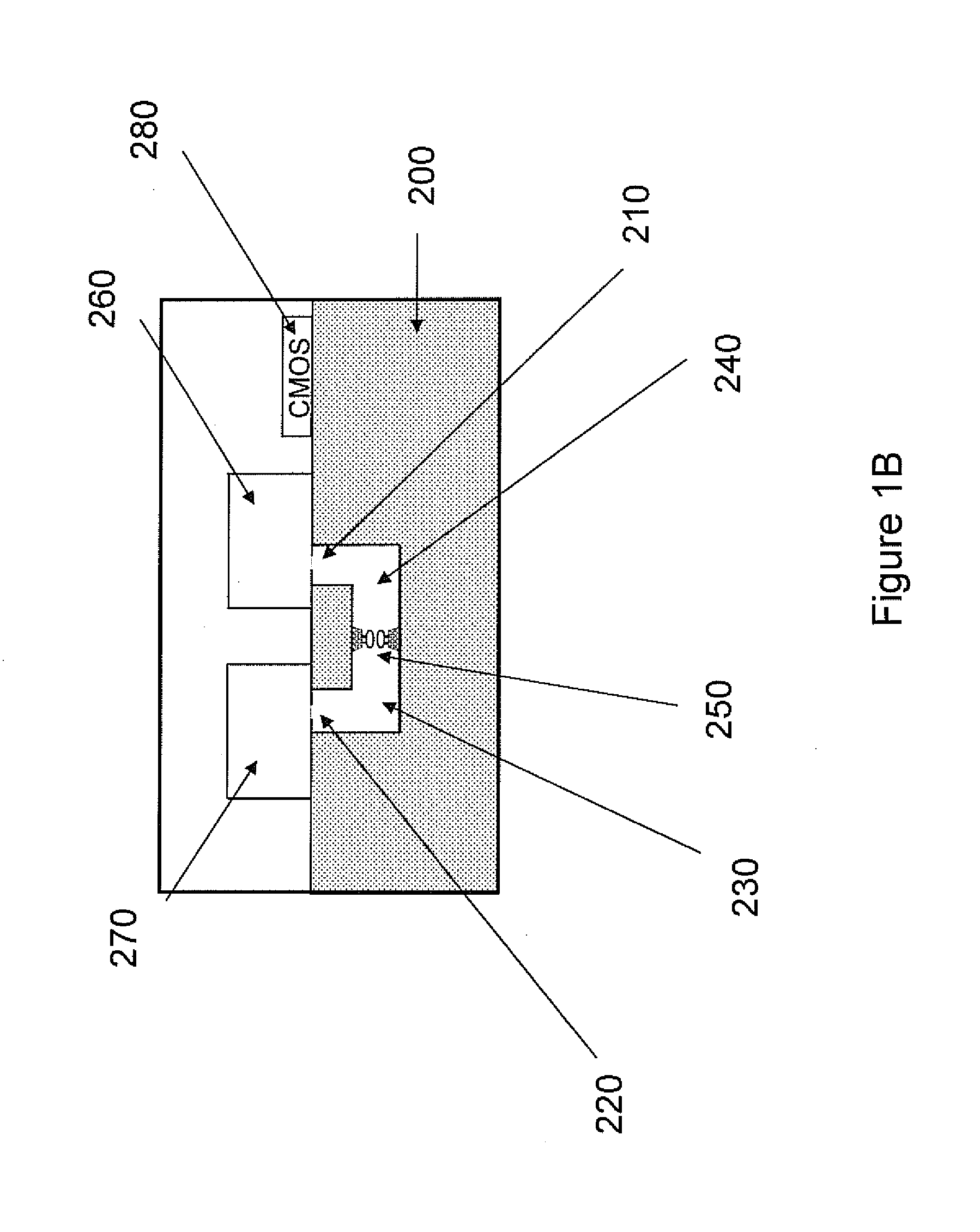

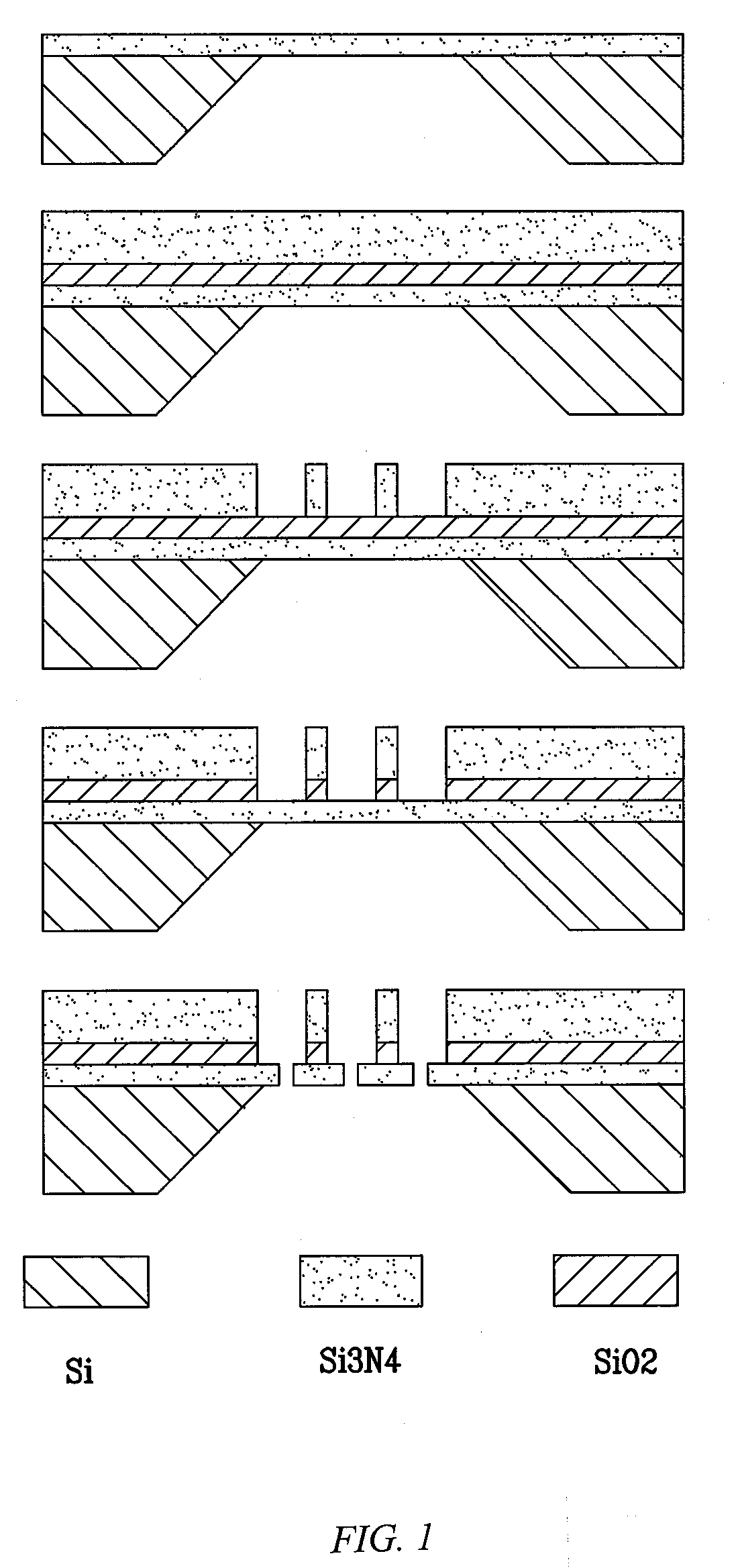

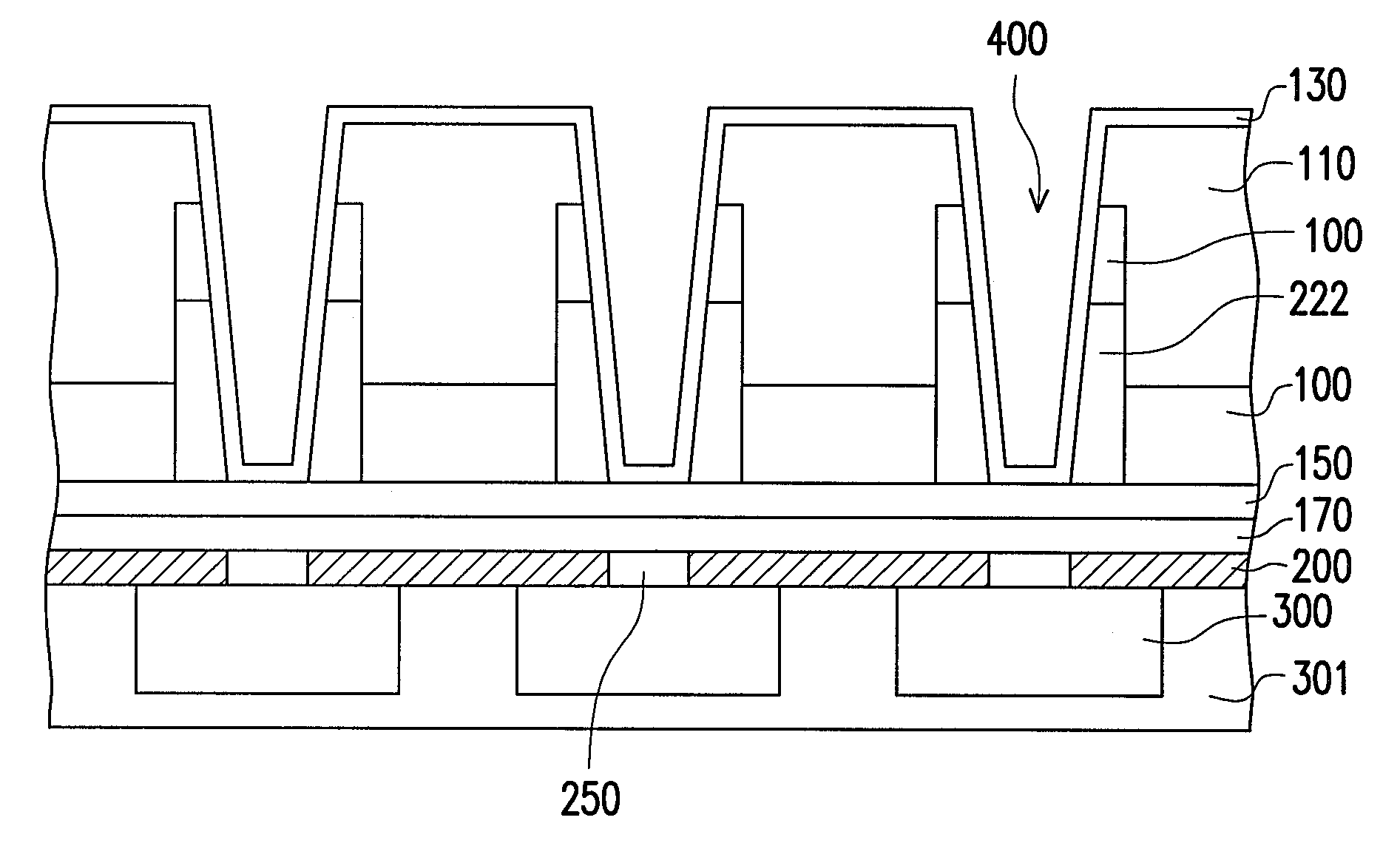

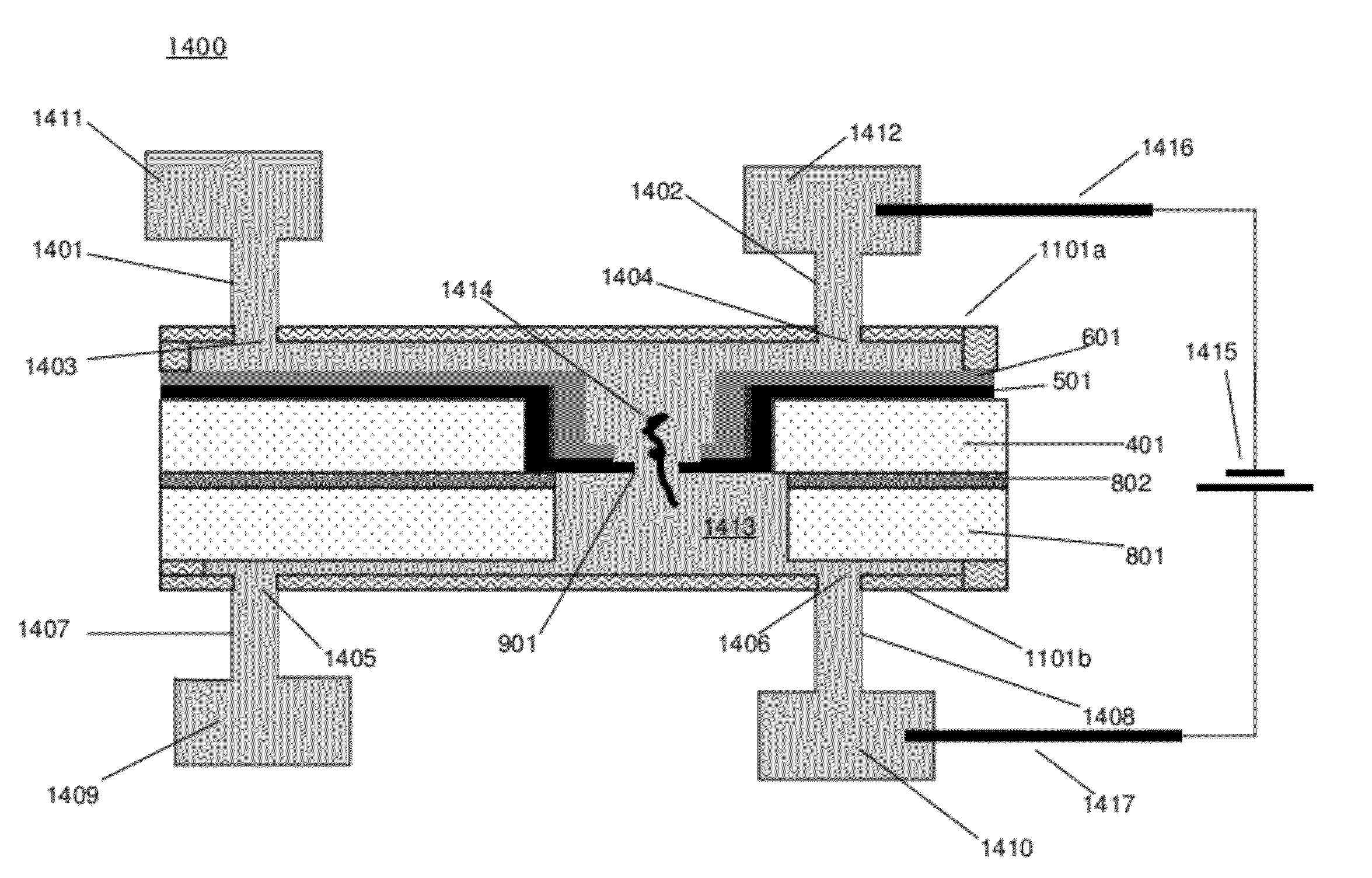

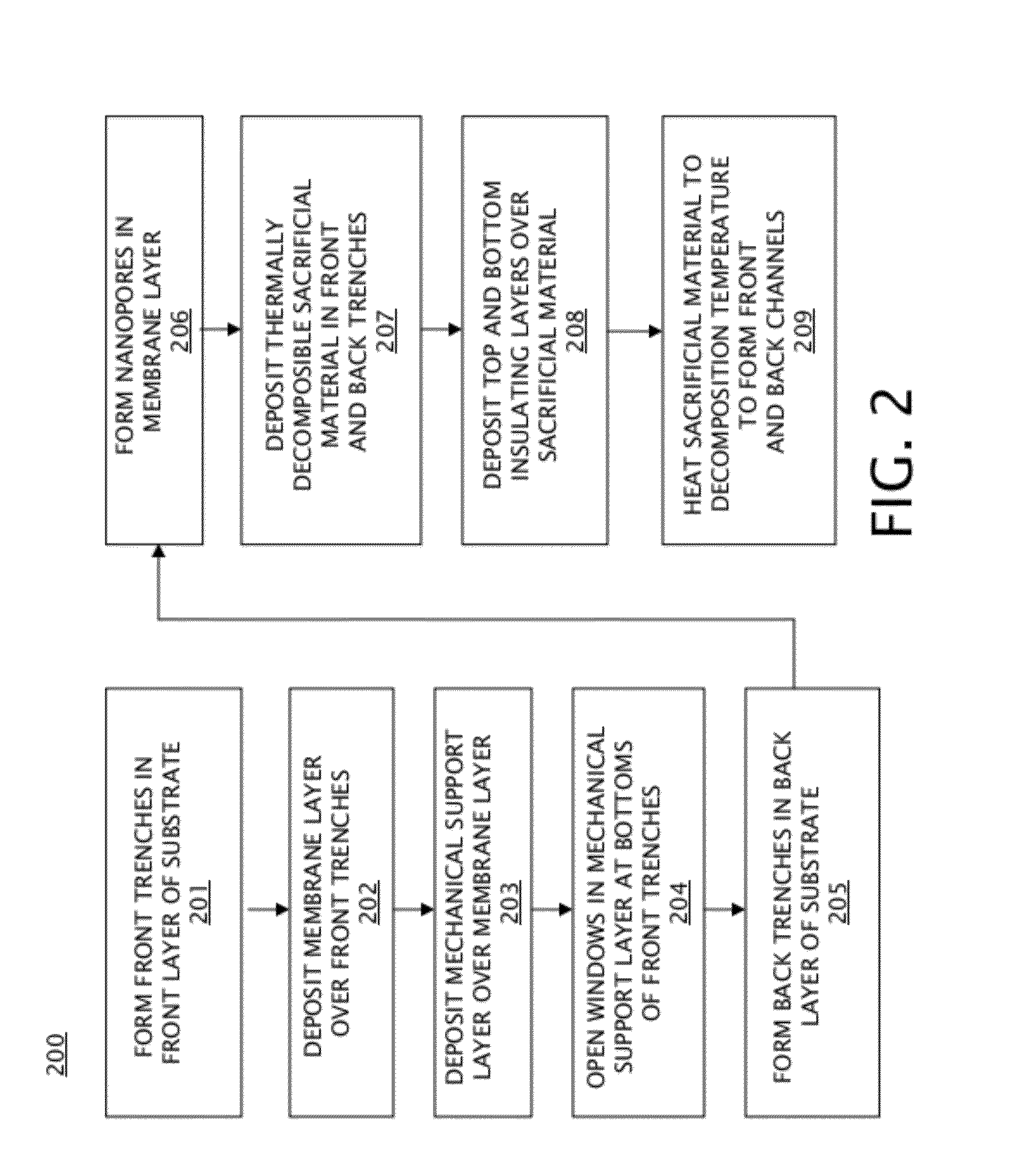

Self-sealed fluidic channels for nanopore array

InactiveUS20120267729A1Solid-state devicesMaterial analysis by electric/magnetic meansEngineeringNanopore

A method of forming a nanopore array includes patterning a front layer of a substrate to form front trenches, the substrate including a buried layer disposed between the front layer and a back layer; depositing a membrane layer over the patterned front layer and in the front trenches; patterning the back layer and the buried layer to form back trenches, the back trenches being aligned with the front trenches; forming a plurality of nanopores through the membrane layer; depositing a sacrificial material in the front trenches and the back trenches; depositing front and back insulating layers over the sacrificial material; and heating the sacrificial material to a decomposition temperature of the sacrificial material to remove the sacrificial material and form pairs of front and back channels, wherein the front channel of each channel pair is connected to the back channel of its respective channel pair by an individual nanopore.

Owner:GLOBALFOUNDRIES US INC

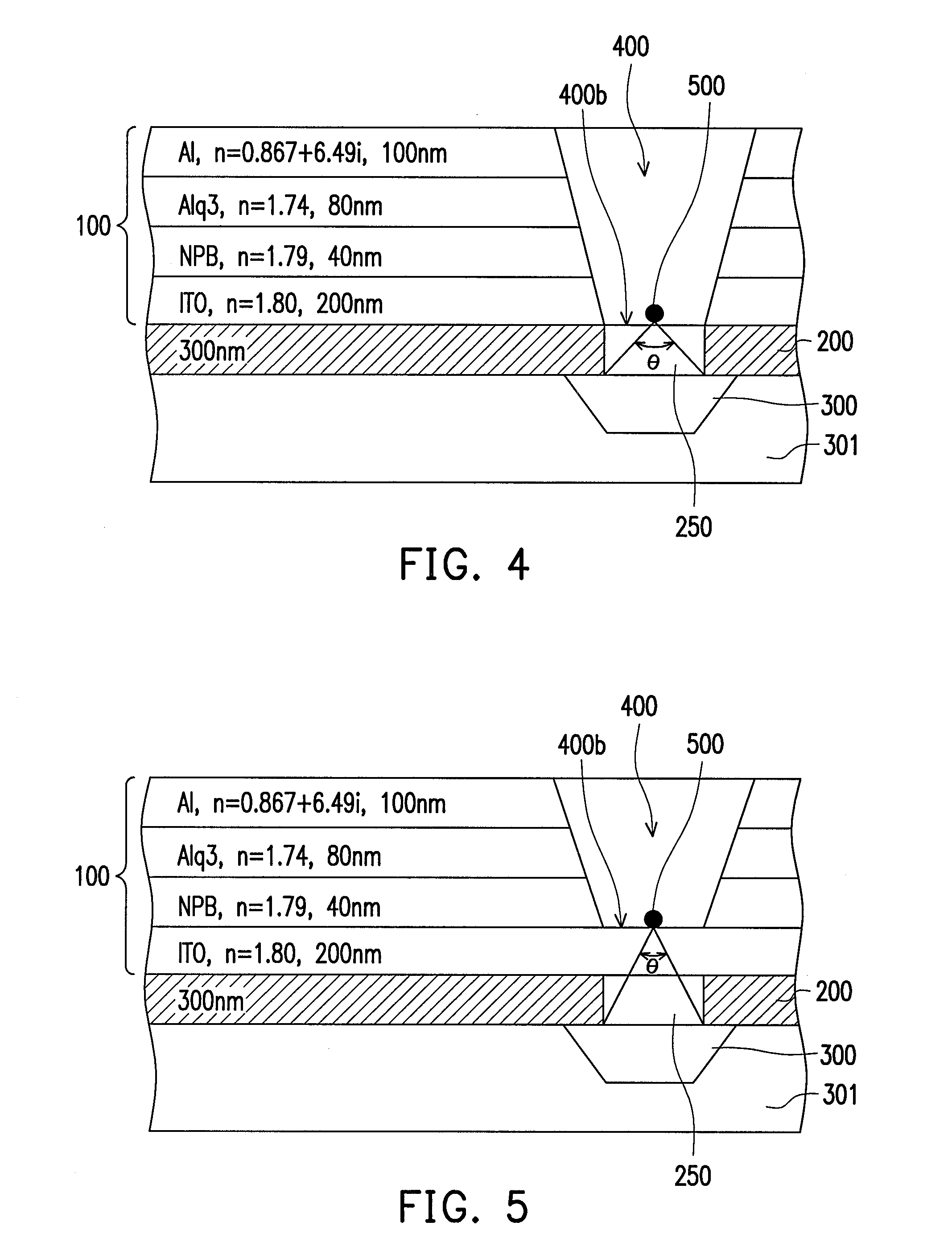

Manufacturing method of surface-plasmon-enhanced GaN-based nanopore LED

InactiveCN104051587AClose coupling distanceExcellent electrical propertiesSemiconductor devicesPower flowNanoparticle

A manufacturing method of a surface-plasmon-enhanced GaN-based nanopore LED includes the following steps of firstly, sequentially growing an n-type InAlGaN layer, a non-doped or doped multi-quantum-well layer, a p-type InAlGaN layer and a current expansion layer on a substrate; secondly, conducting downward etching on the current expansion layer into the n-type InAlGaN layer through a photo-etching and dry-etching process so that a GaN-based LED structure nanopore array can be formed; thirdly, conducting downward etching on the portion, located on one side of the GaN-based LED structure nanopore array, of the upper surface of the current expansion layer to form a tabletop, wherein the etching depth is larger than the depth of nanopores of the GaN-based LED structure nanopore array; fourthly, manufacturing a p electrode on part of the upper surface of the current expansion layer through a photo-etching, evaporating and adhesive tape stripping process; fifthly, manufacturing an n electrode on the tabletop; sixthly, filling the nanopores of the GaN-based LED structure nanopore array with multiple spherical metal nanometer particles with non-conductive film wrapping on the outer surfaces to form a nuclear shell metal nanometer spherical layer, and completing manufacturing.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Preparation method for metal Nano structure array

ActiveCN101746714AIncrease the areaHigh densityNanostructure manufactureMulti materialMetallic materials

The invention discloses a preparation method for a metal Nano structure array. The preparation method adopts a silicon slice as a substrate, and silica Nano spheres are coated on the surface of the substrate of the silicon slice in a rotary manner after being uniformly dispersed so as to form a single-layer sequential silica Nano sphere compact array; a single-layer sequential silica Nano sphere non-compact array is formed by adopting an induction coupling plasma etching method; a metal layer is deposited on the non-compact array and the silica Nana spheres are removed, so as to obtain a metal Nano hole array reticle mask; corrosion is carried out on the silicon slice by combining different corroding properties of different silicon slices, so as to obtain Nano structure array templates with different characteristics in shape and appearance after the reticle mask is removed; finally, different metal materials are deposited on the templates, and the multi-material metal Nano structure array with diversified characteristics in shape and appearance can be obtained after the templates are separated. With the advantages of low cost, high efficiency, good compatibility and the like, the preparation method provides convenience for studying the optical nature, magnetic performance, catalytic property and the like of the metal Nano structure array.

Owner:NAT UNIV OF DEFENSE TECH

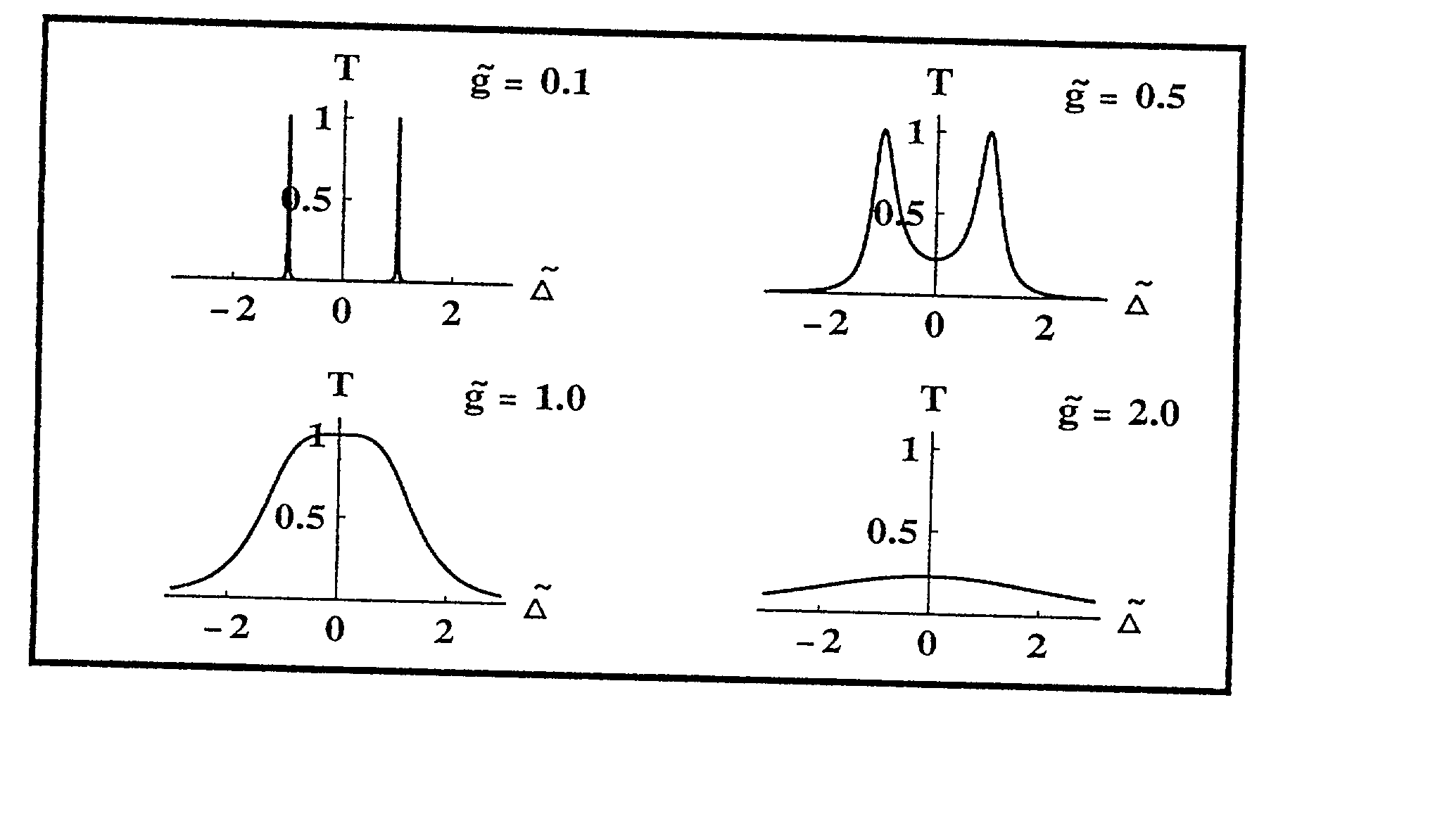

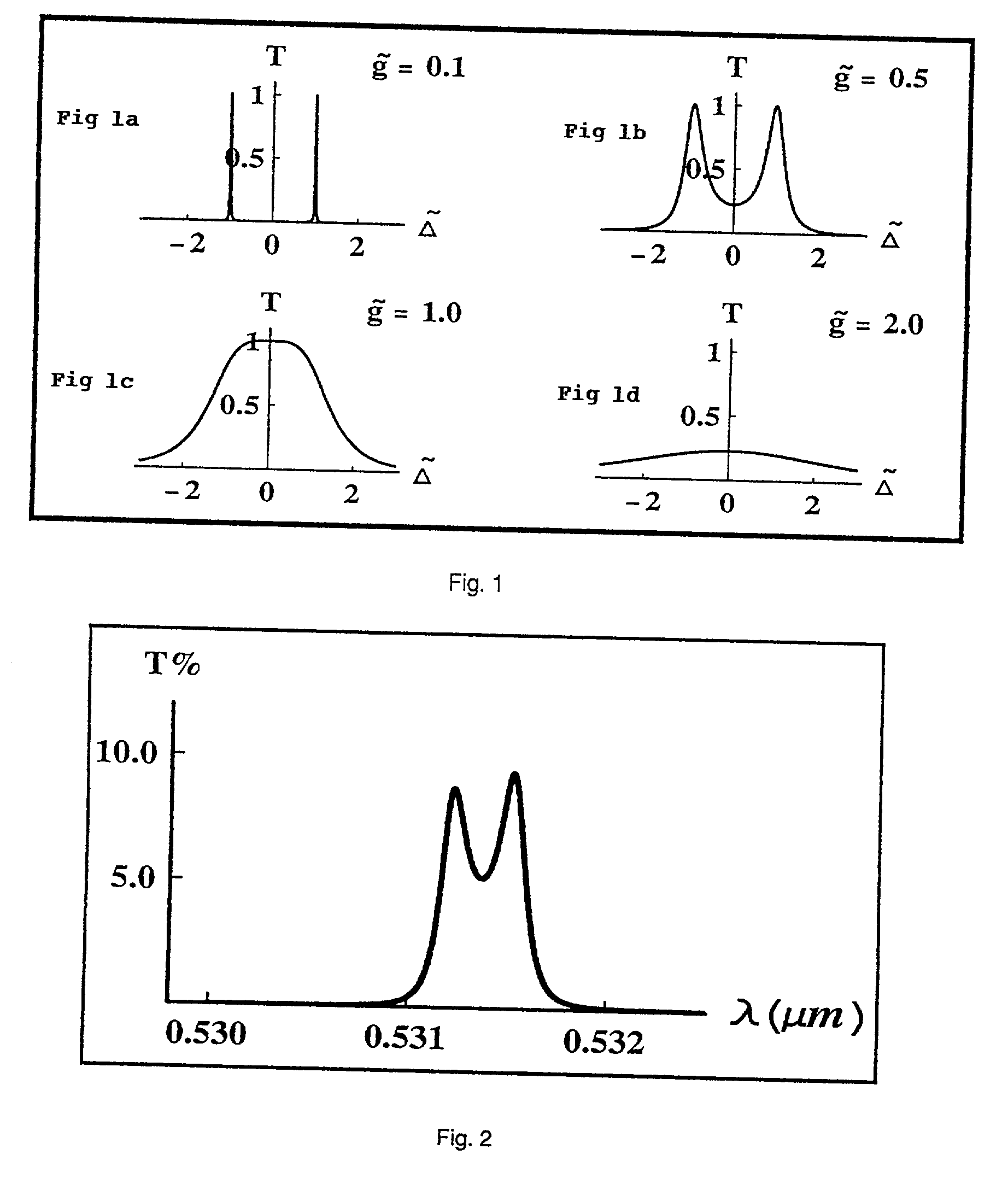

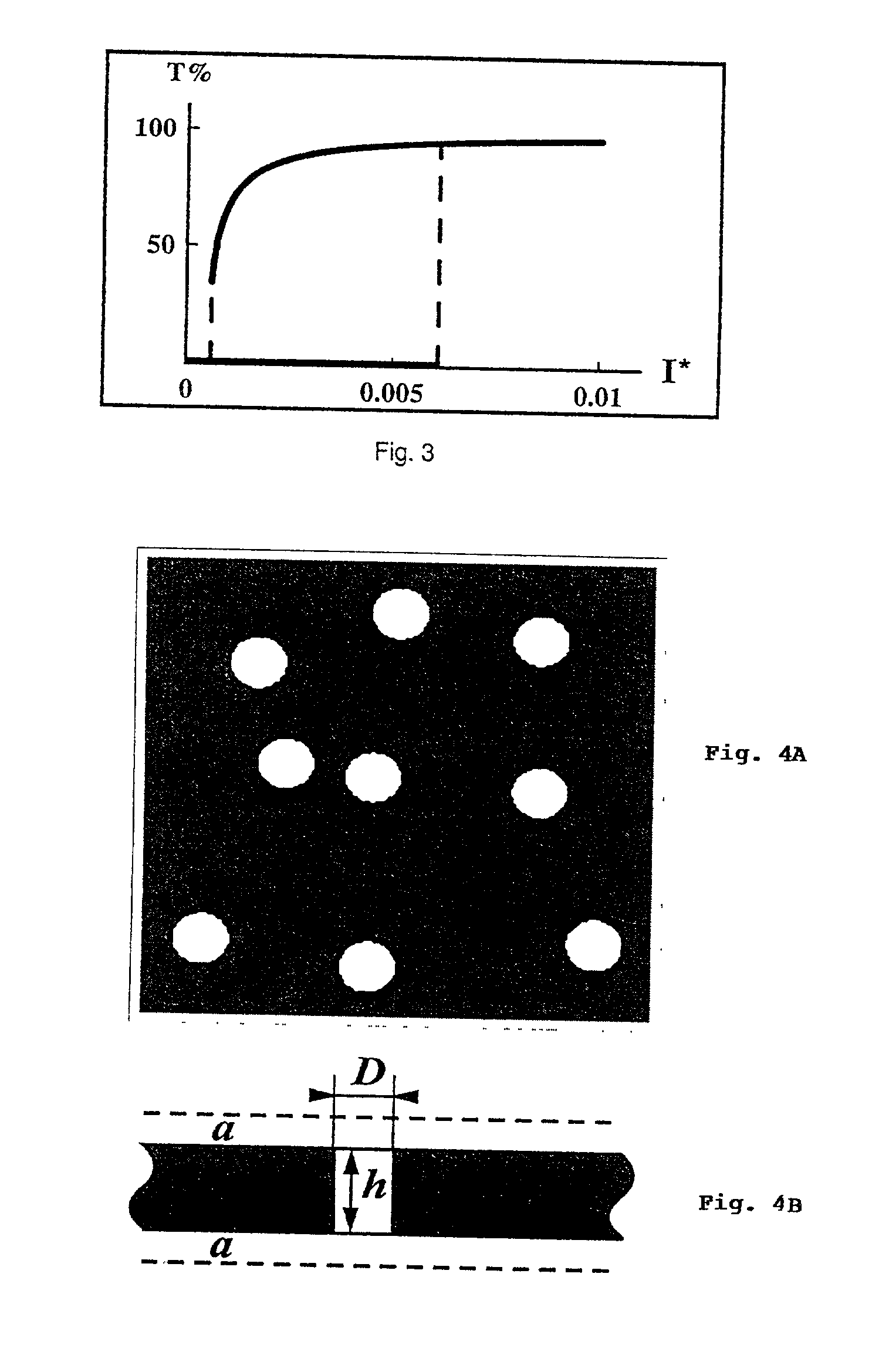

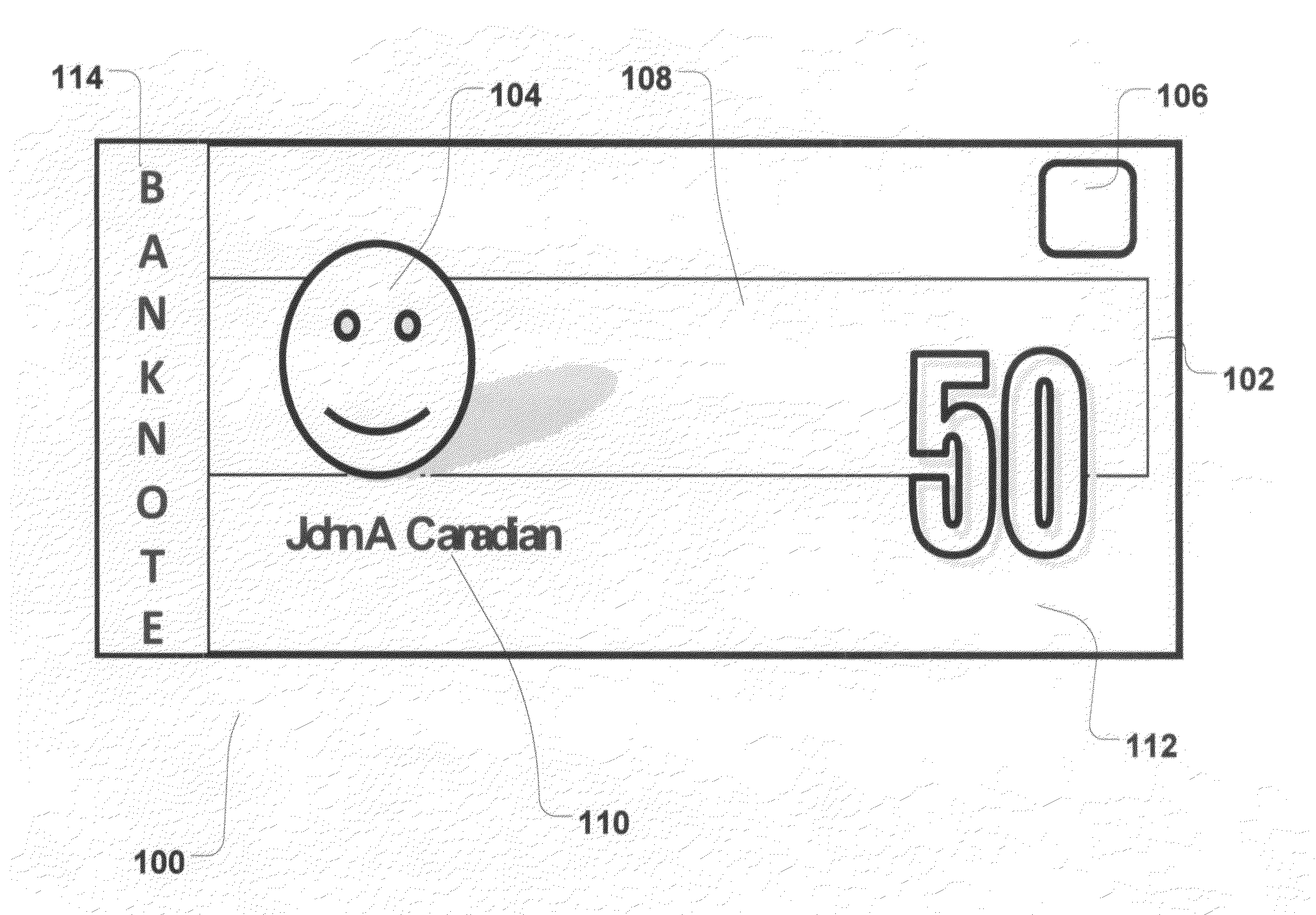

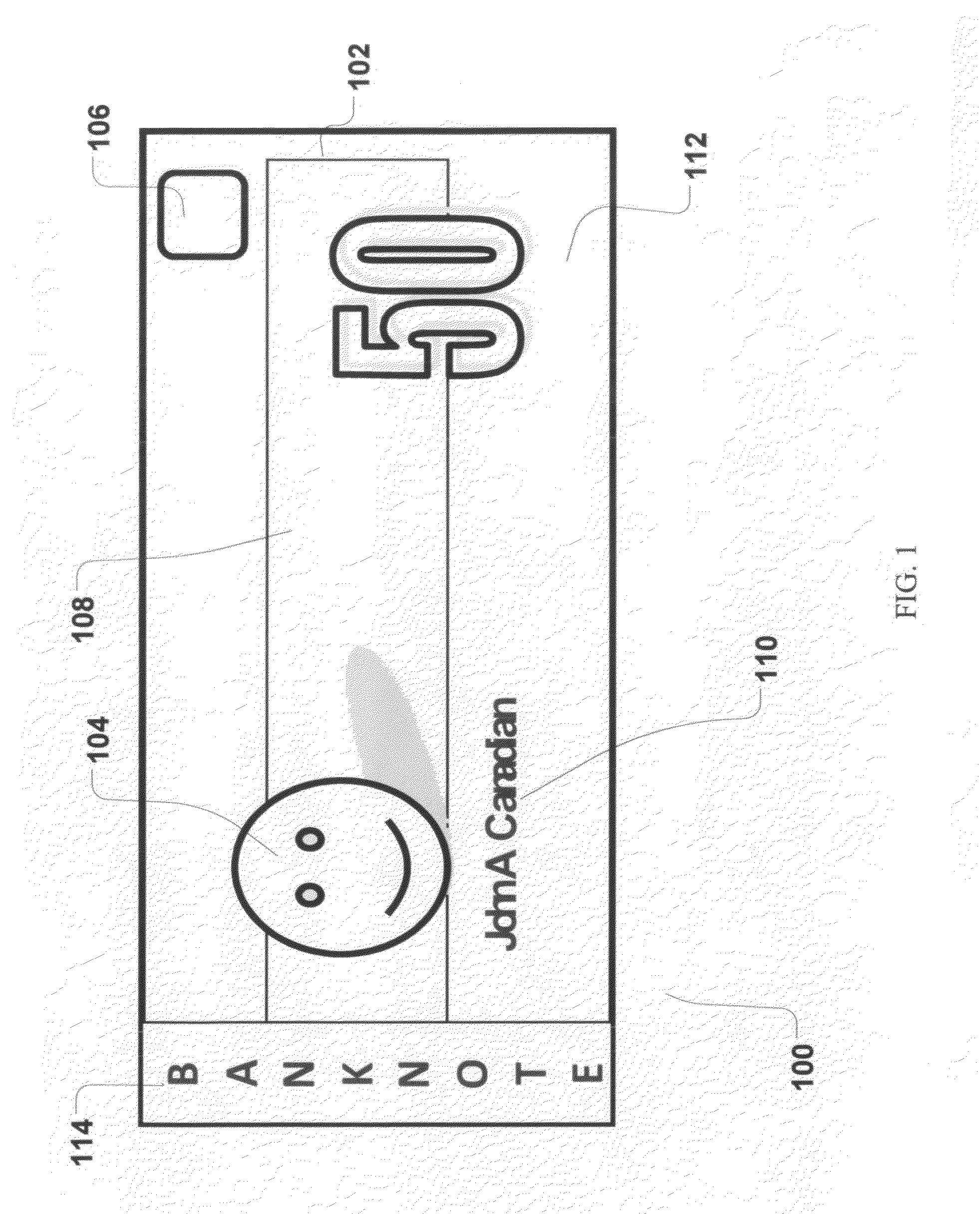

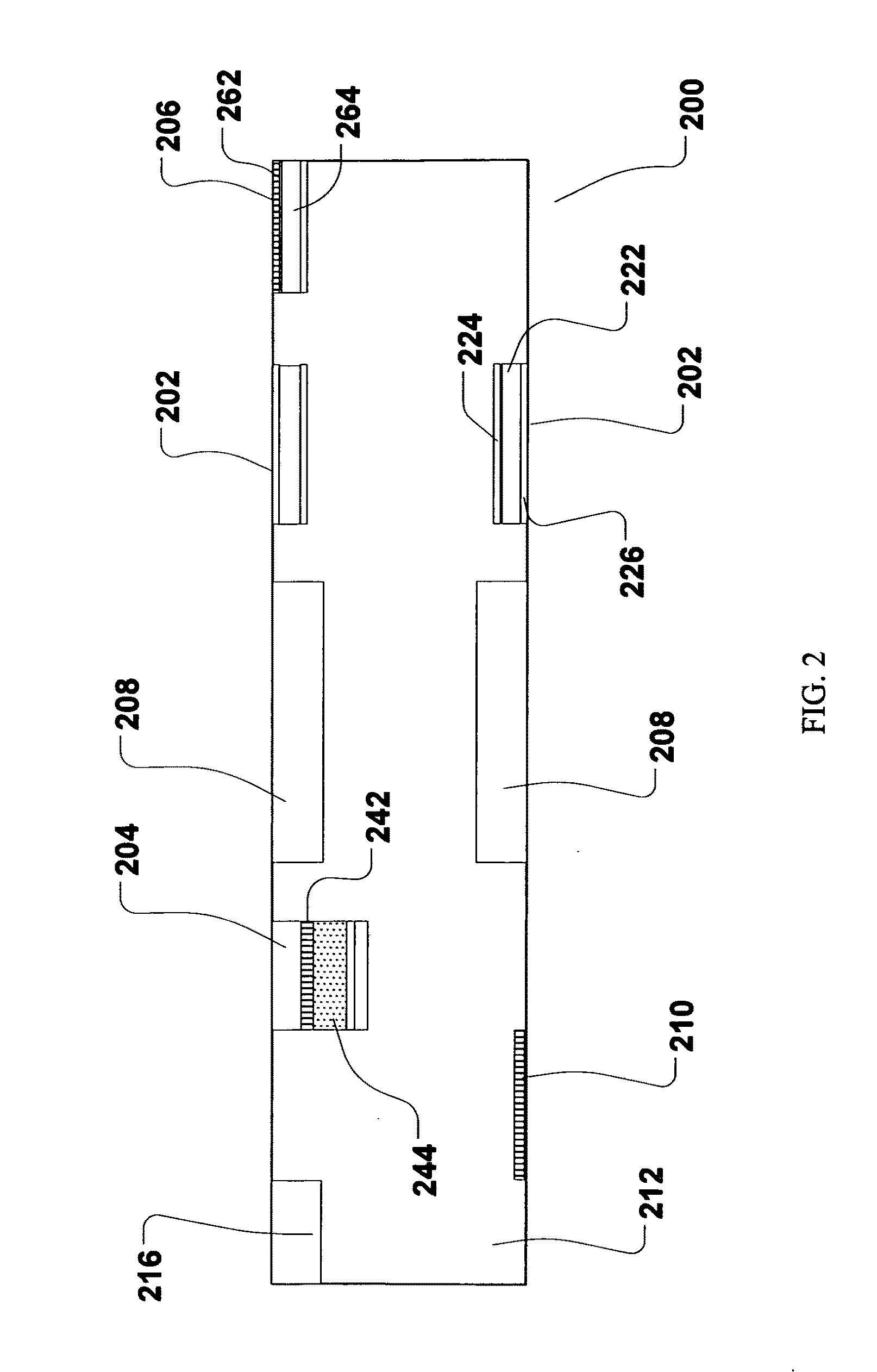

Security document with electroactive polymer power source and nano-optical display

ActiveUS20100271174A1Address limitationsElectric signal transmission systemsNanotechLaser lightOpto electronic

A security document is disclosed which includes an electrical circuit embedded in a document substrate, where the electrical circuit includes a power source with at least one electroactive polymer power generator, and an optical display including at least one electroluminescent display element and at least one nanohole array which forms a layer of the electroluminescent display element. A method of authenticating a security document is also disclosed, the method including illuminating an encoded nanohole array in the security document with a focused light beam or laser light source emitting at least one defined wavelength of incident light, detecting a transmitted portion of the incident light transmitted through the nanohole array with an optoelectronic sensor, analyzing at least one wavelength of the transmitted portion of light to produce a detected signal, and comparing the detected signal with an authentication signal to authenticate the security document.

Owner:NANOTECH SECURITY

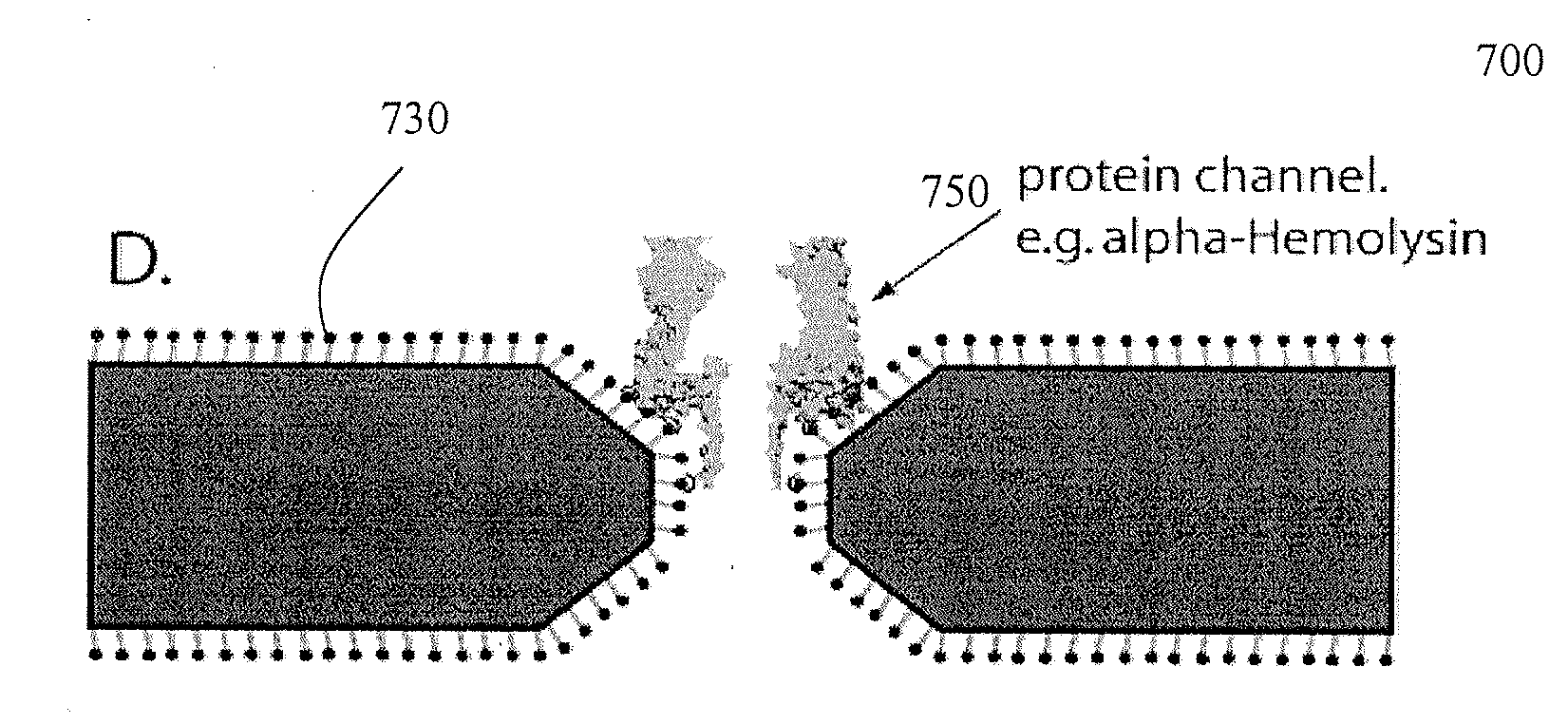

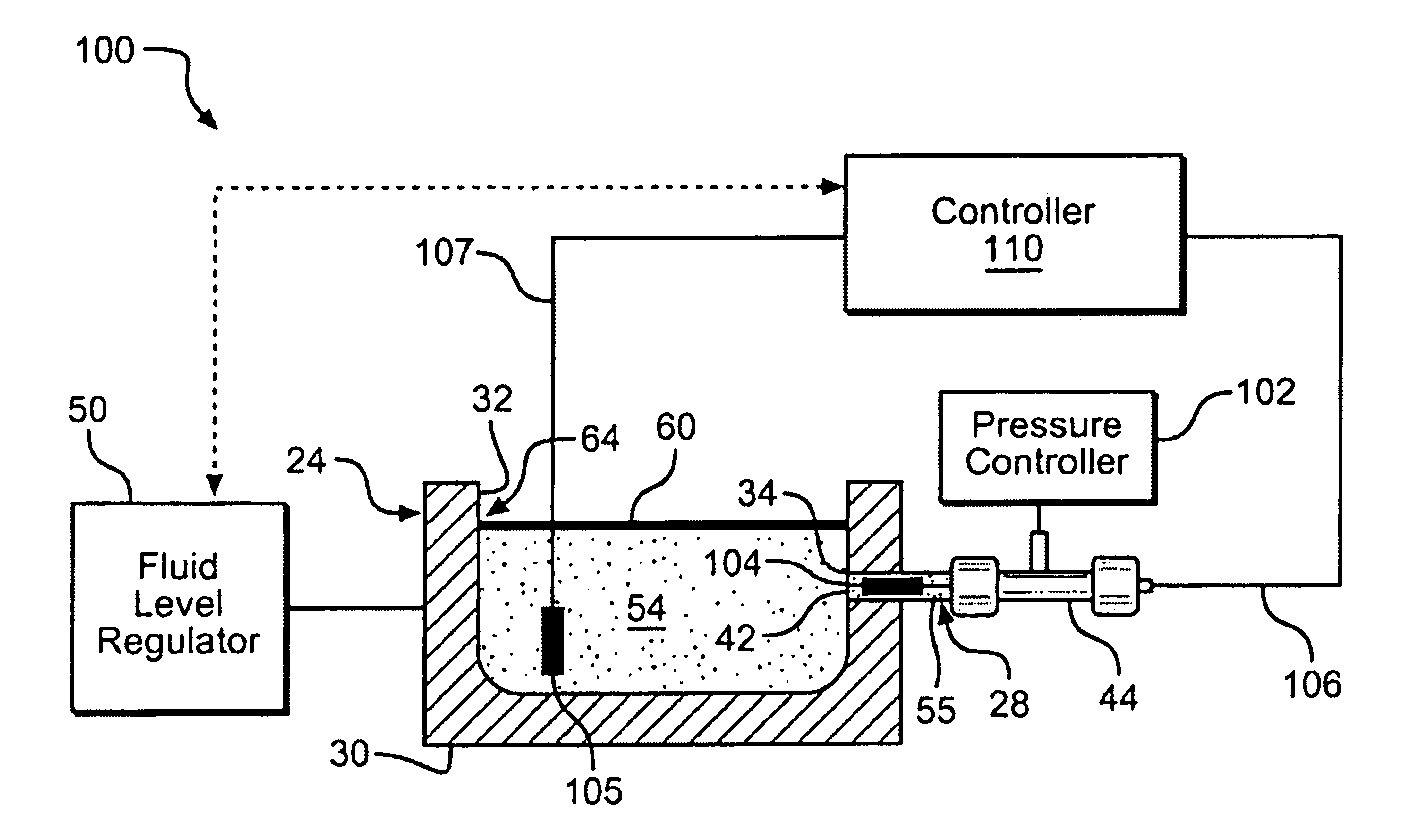

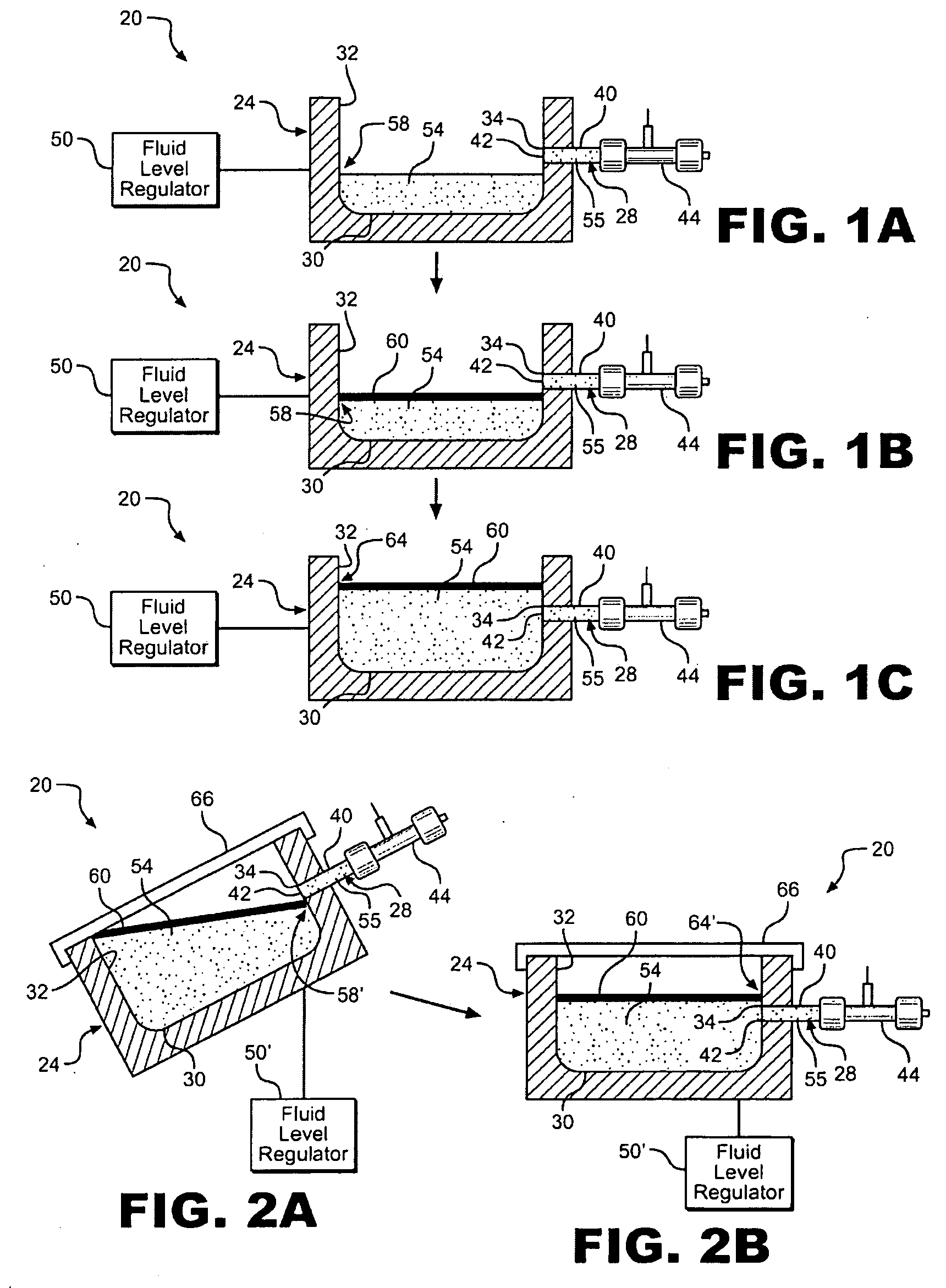

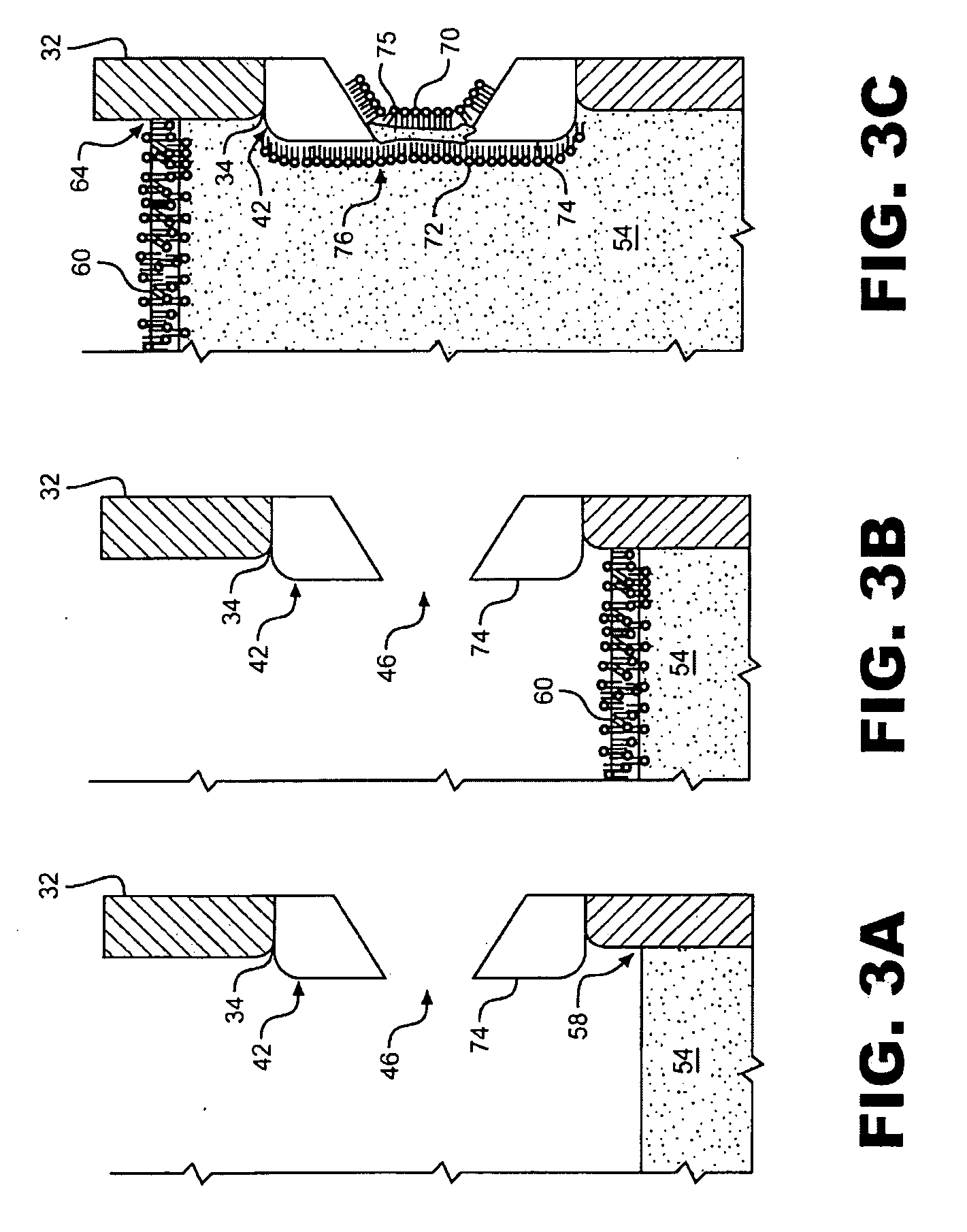

Method and Apparatus for Single Side Bilayer Formation

ActiveUS20090142504A1Avoids significant learning curveResistance/reactance/impedenceConductive materialLipid formationFeedback control

An apparatus for single-sided bilayer formation includes a first fluid chamber including a sidewall and a second fluid chamber extending through the sidewall. A barrier wall separates the first and second fluid chambers and includes a nanopore therein across which a planar lipid bilayer (PLB) is formed. In use, an electrolyte is added to the first and second fluid chambers and a lipid / organic solvent mixture is added to the first fluid chamber to form a lipid / organic solvent layer. The electrolyte level within the first fluid chamber is adjusted such that the lipid layer is raised above the barrier wall and a PLB is formed. Electrolyte levels may be adjusted manually or utilizing a fluid level regulator with or without feedback control. Optionally, the apparatus may be in the form of a nanopore array. The apparatus may be incorporated into an ion channel sensing system wherein an electrical current through each PLB is separately recorded.

Owner:ELECTRONICS BIOSCI

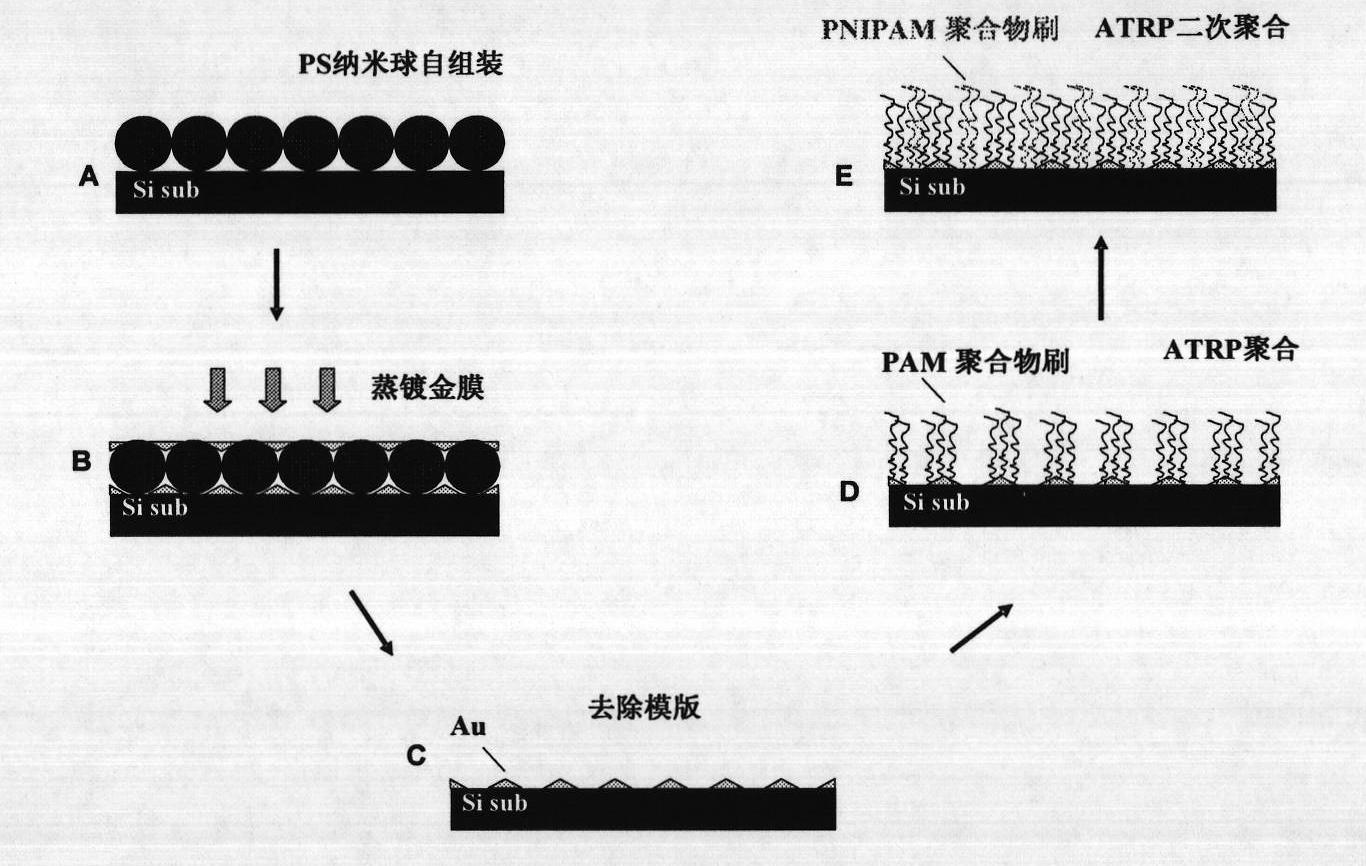

Method for preparing nanometer patterning bipolymer brush

The invention discloses a method for preparing a nanometer patterning bipolymer brush. The method for preparing a nanometer patterning bipolymer brush combines a nanosphere etching print method and a surface controlled polymerization method together. Polystyrene nanospheres are assembled on a substrate to obtain a hexagonal heaped sphere array pattern which is used as a mask for carrying out surface gold spraying, after small spheres are removed, a regular nanopore array pattern of which the surface component consists of gold and silicon, and surface polymerization is respectively initiated on the gold and the silicon twice to obtain the nano-scale bipolymer brush. The method is simple and efficient, the size of the pattern can be conveniently regulated by using the small spheres with different diameters, and a functional patterning polymer brush can be prepared with the method.

Owner:INST OF CHEM CHINESE ACAD OF SCI

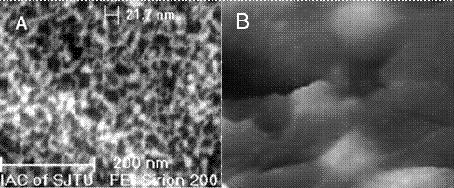

Preparation method and application of metal surface-etched nanoporous array

InactiveCN102552977AThe method is simpleEasy to operatePolycrystalline material growthSurgeryTitanium surfaceInternal bone fixation

The invention relates to application of pure titanium and titanium alloy (hereinafter called titanium) surface-etched TiO2 nano-porous array appearance in preparing human metal implant which can be a dental implant, a bone implant, a fixing plate and a fixing nail, wherein the appearance is to prepare a TiO2 nano-porous array structure on the titanium surface. The invention also provides an optimal preparation method of the appearance. The preparation method has the advantages that: the preparation can be performed at normal temperature and normal pressure; the prepared TiO2 nano-porous array is regular; and the method is relatively simple in process, convenient for operation, low in cost and short in process flow. The prepared titanium surface nano-porous array structure has selective effect to different types of cells, so that the success rate of implant can be greatly increased; the nano-porous array structure can inhibit fibroblast from adhering or multiplying on the surface of the structure, so that the success rate of bone and dental implant operation and bone internal fixation can be greatly improved; and therefore, the preparation method is a bone implant material and bone fixation material surface appearance modification method with clinical application prospect.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

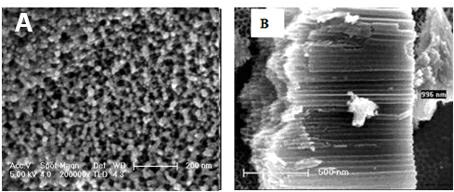

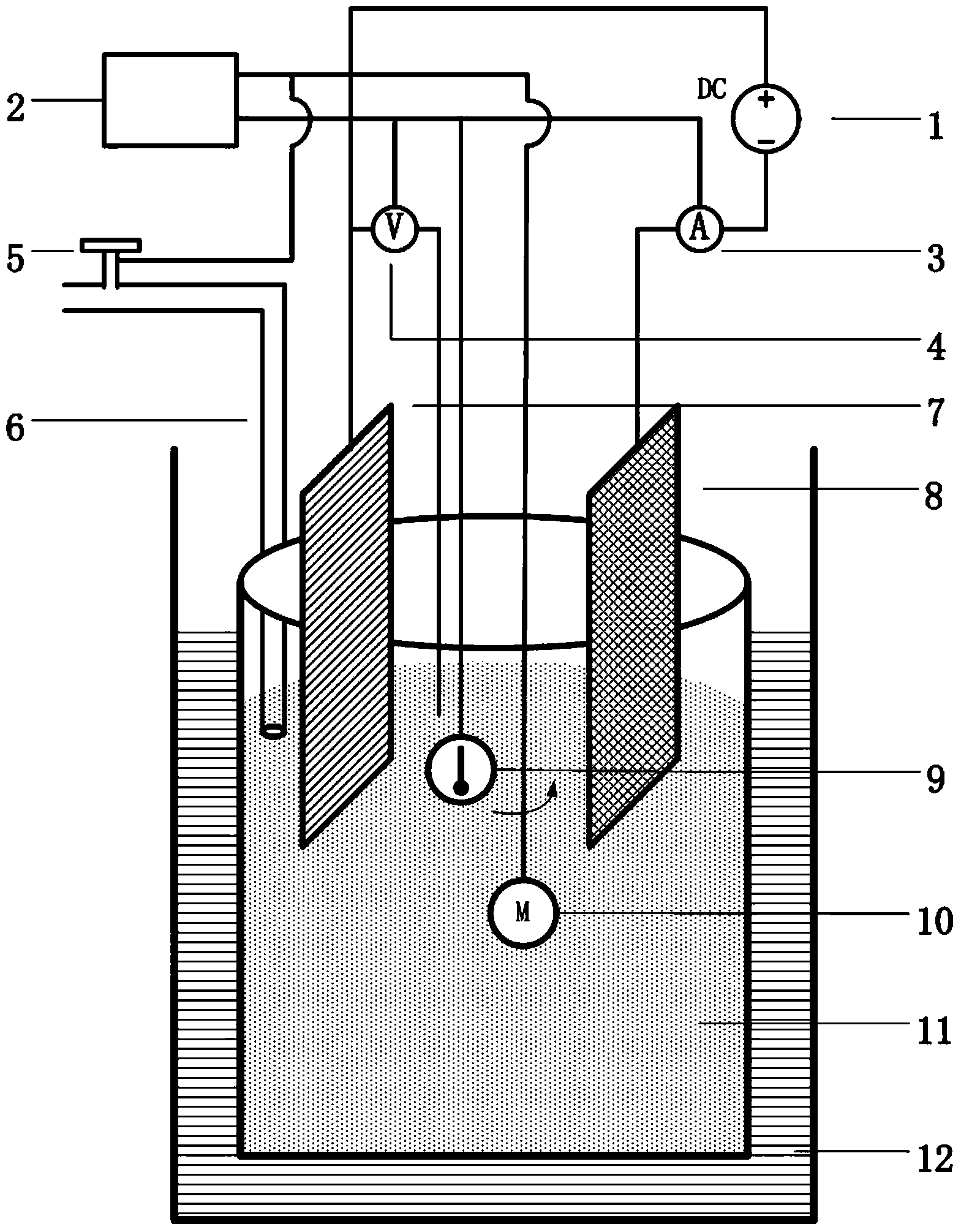

Nanopore array film on stainless steel surface and preparation method thereof

InactiveCN102268713ALess investmentLow priceMaterial nanotechnologyAnodisationElectrochemical anodizationElectrochemistry

The invention particularly relates to a stainless steel surface nano-pore array film and a preparation method thereof. The technical scheme is that: stainless steel treated by surface pretreatment is used as an anode and is placed in a phosphate buffer solution to perform electrochemical anodic oxidation treatment; the time for the electrochemical anodic oxidation treatment is 0.1-4 h; a nano-pore array film is obtained on the treated stainless steel surface; the voltage for the electrochemical anodic oxidation is 10-80 V, and the temperature for the electrochemical anodic oxidation is -5 to 40 DEG C. The preparation method of the invention is simple, effective, environment-friendly, and low in cost; the stainless steel surface nano-pore array prepared by the method has a structured and ordered structure, a high density, a controllable pore diameter and pore depth, and no other impurity elements intervened, is firmly combined with the substrate, and has strong corrosion resistance andhigh hardness.

Owner:WUHAN UNIV OF SCI & TECH

Process for preparing porous anode aluminium oxide mould of height ordered by mixed acid electrolyzing liquid

InactiveCN1793437AOxidation voltage decreasedReduce thicknessSurface reaction electrolytic coatingAnodic Aluminum OxideAnode

The invention relates to a method used mixed acid electrolyte to manufacture high ordered multi-hole anodic alumina die plate. In order to further reduce oxidation voltage, barrier layer thickness, and increase nanometer hole array orderliness, the alumina die plate is manufactured as follows: using the mixed acid of sulfuric acid and oxalic acid as electrolyte; their content are 100-200g / L and 50-150g / L; de-oiling; oxide layer removing; electro polishing; double steps anodic oxidation manufacturing multi-hole anodic alumina die plate. The invention reduces reduce oxidation voltage and barrier layer thickness to make nanometer hole diameter rise from 20nm to 45-55nm. This is good for the further application of multi-hole alumina die plate.

Owner:HARBIN INST OF TECH

Preparation methods of nanopore-arrayed anodic alumina membrane and nanopore-arrayed anodic alumina microchannel plate

InactiveCN104233430AOvercoming noiseOvercoming temporal resolutionSurface reaction electrolytic coatingCold cathode manufactureDark count rateSilicate glass

The invention relates to preparation methods of a nanopore-arrayed anodic alumina membrane and a nanopore-arrayed anodic alumina microchannel plate. The preparation method of the nanopore-arrayed anodic alumina membrane comprises the following steps of preparation of an alumina membrane and directional pore broadening. The preparation method of the nanopore-arrayed anodic alumina microchannel plate comprises the following steps of preparation of an alumina membrane, directional pore broadening and preparation of a microchannel plate. According to the preparation methods of the nanopore-arrayed anodic alumina membrane and the nanopore-arrayed anodic alumina microchannel plate, the technical bottleneck that the channel aperture of the traditional lead-containing silicate glass microchannel plate cannot be easily reduced is overcome; the difficult problems that the area of the microchannel plate is increased if the ultra-small aperture of the microchannel plate is realized and the like are solved; and the excellent properties of the microchannel plate are achieved, i.e., the space resolution and time resolution of the microchannel plate are improved, the gain is increased, the dark count rate is decreased, the area array is enlarged, a higher temperature can be borne and the like.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

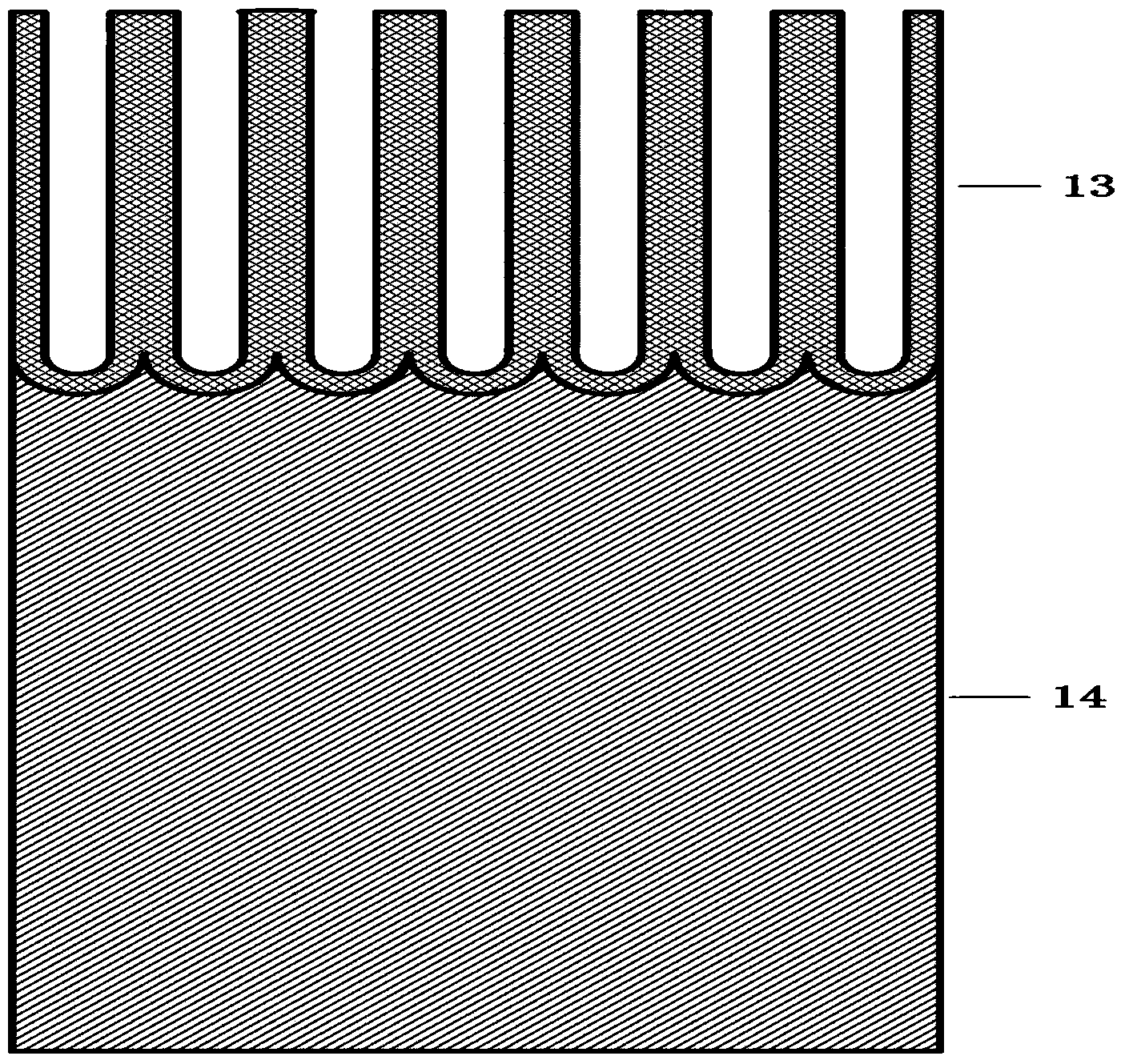

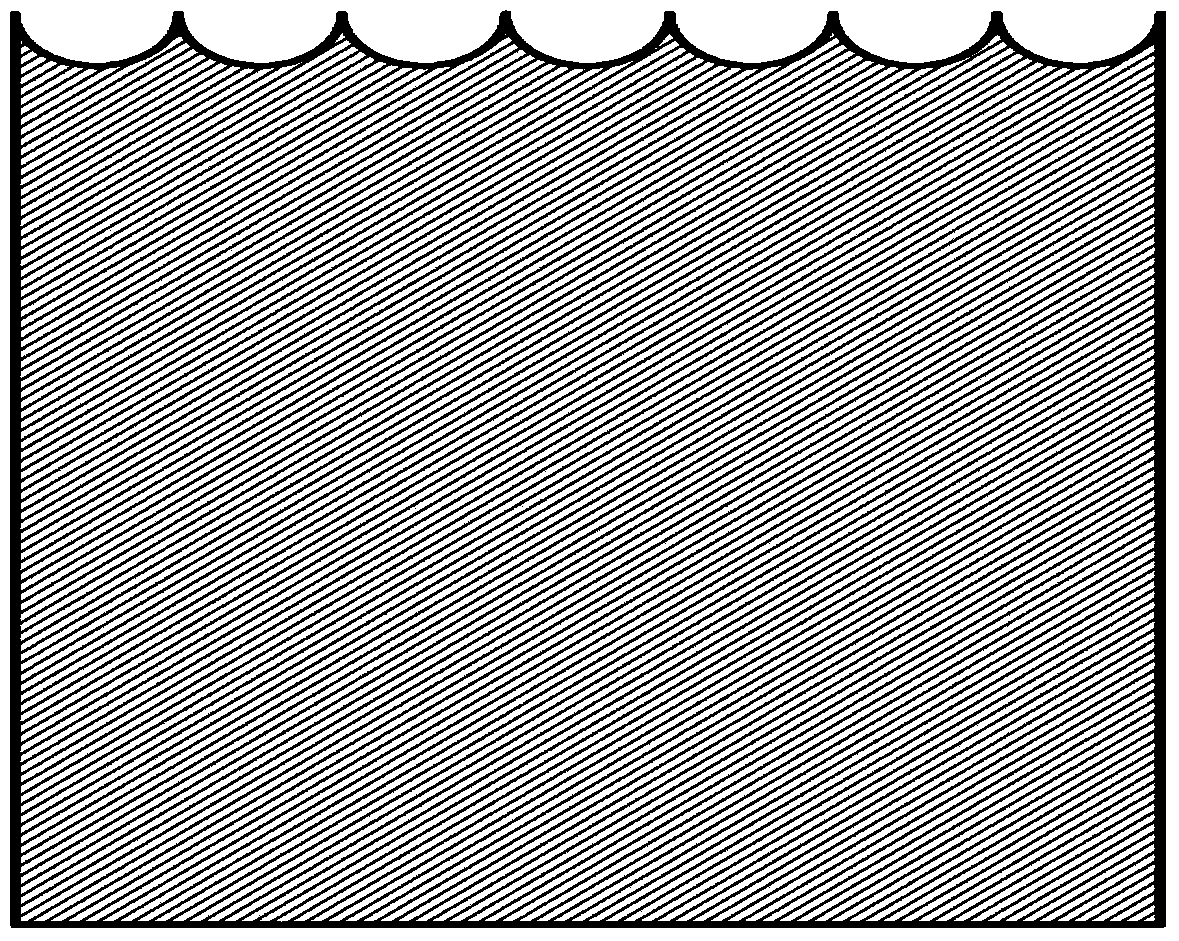

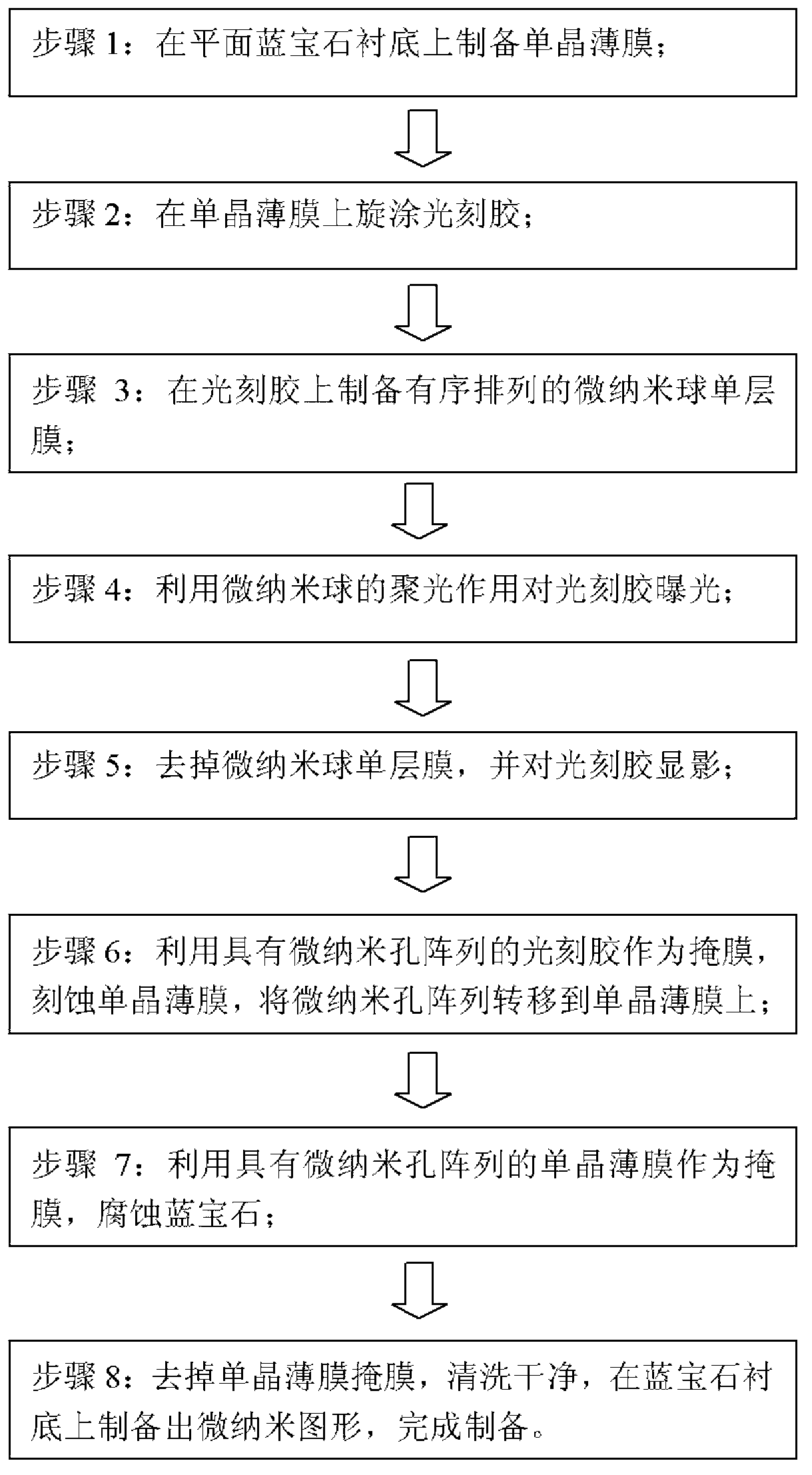

Method for manufacturing micro-nano graph on sapphire substrate

InactiveCN103311097AReduce dislocation densityImprove crystal qualityPhotomechanical apparatusSemiconductor/solid-state device manufacturingMicro nanoSingle crystal

A method for manufacturing a micro-nano graph on a sapphire substrate comprises the steps of S1, manufacturing a monocrystal film on the sapphire substrate; S2, rotationally coating a layer of photoresist on the monocrystal film; S3, preparing a sequentially arrayed micro-nano ball monolayer film on the photoresist; S4, carrying out exposure on the photoresist by a photoetching machine by the light condensing function of micro-nano balls; S5, removing the micro-nano ball monolayer film and developing the sequentially arrayed photoresist micro-nano hole array; S6, transferring the micro-nano hole array onto the monocrystal film by a dry etching method to form the monocrystal film micro-nano hole array on the monocrystal film; S7, taking the monocrystal film micro-nano hole array as a mask for wet etching the sapphire substrate, thus obtaining sequential micro-nano graph array on the sapphire substrate; and S8, finishing the manufacturing after the monocrystal film mask is removed.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com