Method for preparing nanometer patterning bipolymer brush

A polymer brush and patterning technology, which is applied in the field of preparation of binary polymer brushes, can solve problems such as lack of universality, and achieve the effects of eliminating processing steps, easy operation of the process, and simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

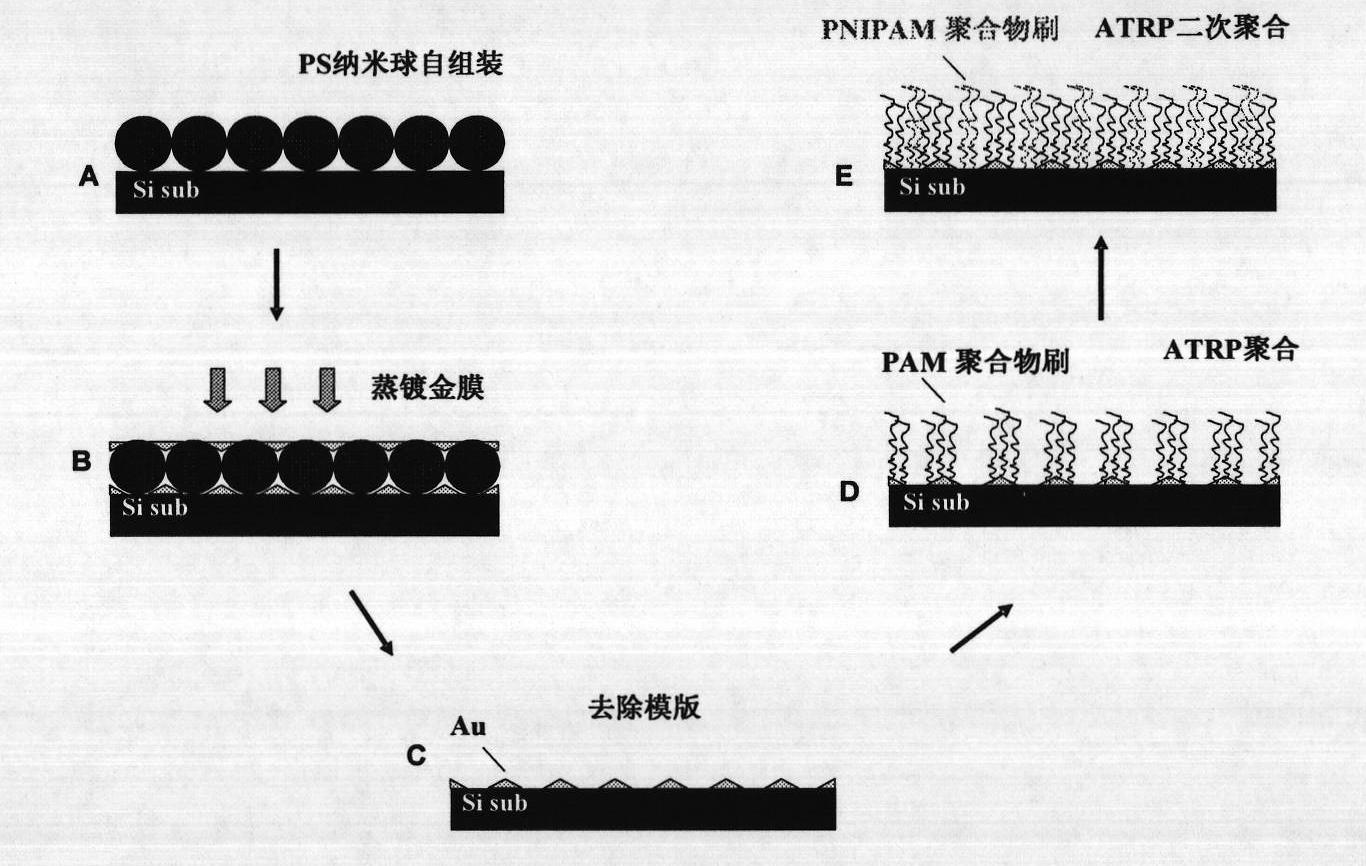

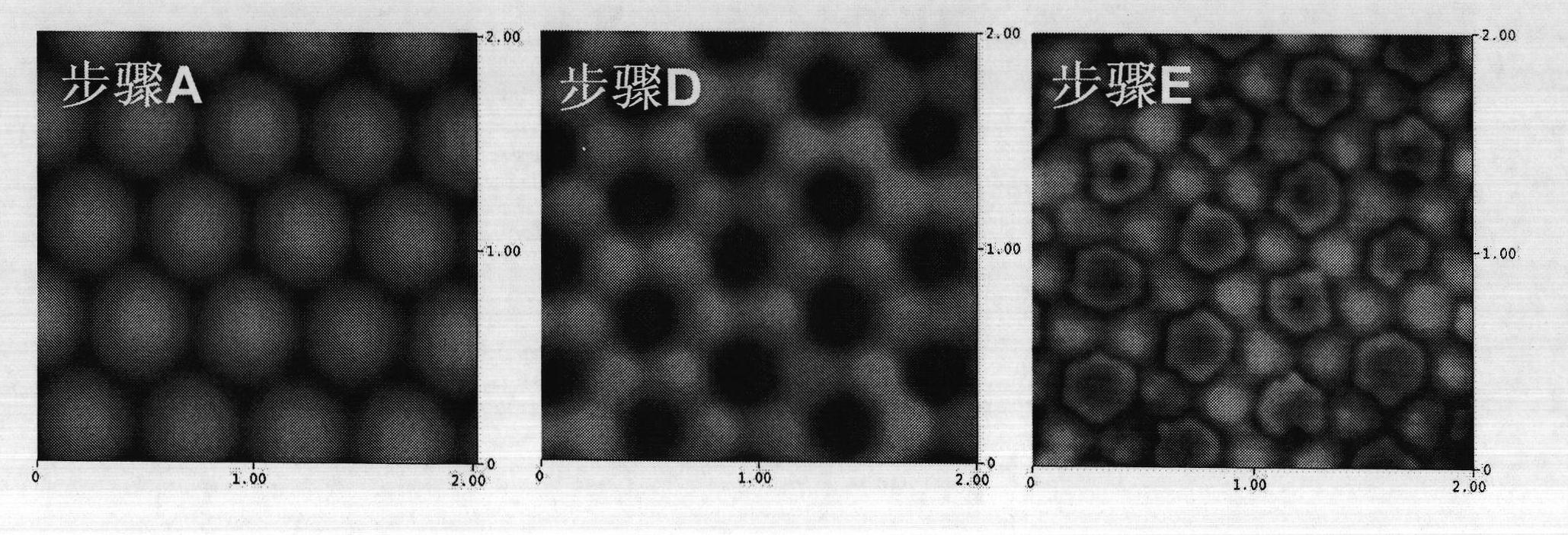

[0031] Embodiment 1, prepare patterned PAM / PNIPAM binary polymer brush

[0032] according to figure 1 The process flow shown was carried out.

[0033] (1) After cleaning the silicon wafer, treat it with a mixture of concentrated sulfuric acid (mass concentration: 98%) and hydrogen peroxide (mass concentration: 30%) (mixing ratio: 7:3, v / v) at 120°C for 2 hours, A silicon substrate with a hydrophilic surface is obtained.

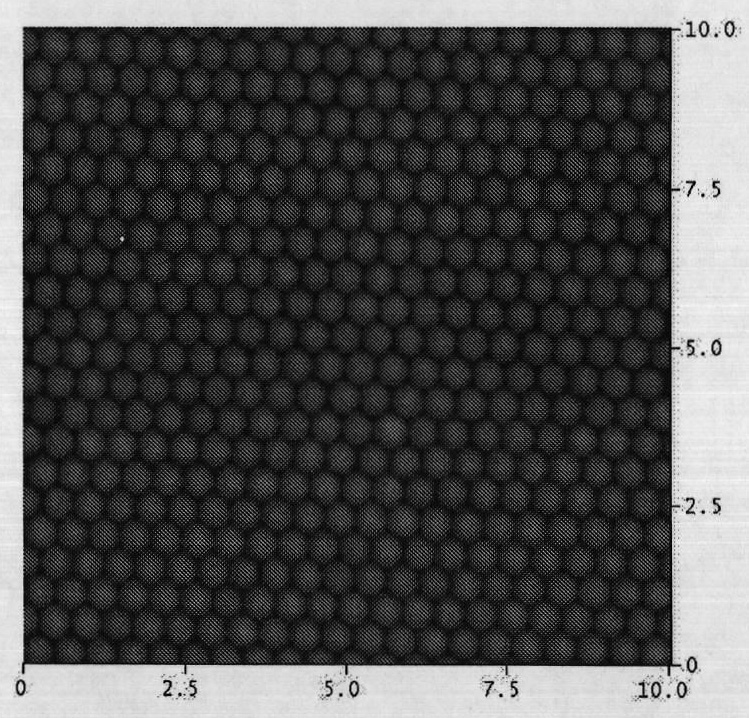

[0034] (2) Disperse polystyrene (PS) microspheres with a particle diameter of 500 nm in a water / ethanol mixture (mixing ratio 1:1, v / v) to obtain a suspension of PS microspheres with a mass concentration of 5%. liquid. Take about 2 μL of the above-mentioned PS microsphere suspension and drop it on the above-mentioned silicon substrate, and let the PS microspheres be assembled by spin coating at a speed of 1000 rpm on a desktop homogenizer to obtain a hexagonal stacked nanosphere array pattern (see figure 2 ).

[0035] (3) A 5nm Cr coating and a 10nm Au ...

Embodiment 2

[0041] Embodiment 2, preparation patterned PDMAEMA / PNIPAM binary polymer brush

[0042] (1) According to the steps (1)-(3) of Example 1, a silicon substrate with a hole array pattern was prepared.

[0043] (2) Put the above sample into a methanol solution (10 mM) containing 11-mercaptoundecanol to react for 24 hours, then take it out, rinse and dry it. Weigh 20ml of cyclohexane in a glass reaction bottle, add 100μL of triethylamine and 200μL of 2-BiB, and stir well. Add a silicon substrate and seal the bottle mouth, react at 10°C for 30min. After the sample was reacted, it was washed and dried, and then the surface polymerization was carried out.

[0044] (3) Dissolve 1g of DMAEMA monomer, 20mg of CuCl, and 200μl of PMDETA (pentamethyldiethylenetriamine) in a mixed solvent of 10ml of methanol and water (1:1v / v), and sonicate in the absence of oxygen Mix well, and transfer the solution to another glass reactor containing the substrate for polymerization to obtain a patterned...

Embodiment 3

[0048] Embodiment 3, preparation patterned PAM / PDMAEMA binary polymer brush

[0049] (1) According to the steps (1)-(3) of Example 1, a substrate with a hole array pattern was prepared.

[0050] (2) Put the above sample into an ethanol solution (1 mM) containing 11-mercaptoundecanol to react for 24 hours, then take it out for rinsing and blow dry. Weigh 20 g of dichloromethane into a glass reaction vial, add 60 μL of triethylamine and 120 μL of 2-BiB, and stir well. Add the substrate and seal the bottle mouth, react at 0°C for 20min. After the sample was reacted, it was washed and dried, and then the surface polymerization was carried out.

[0051] (3) Dissolve 0.5g of AM monomer, 10mg of CuCl, and 100μl of PMDETA in a mixed solvent of 5ml of methanol and water (1:1v / v). Polymerization was carried out in another glass reactor of the sheet to obtain a patterned PAM monopolymer brush.

[0052] (4) Put the above sample into NaN 3 DMF solution (0.01M), react at room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com