Patents

Literature

237 results about "Electrochemical anodization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biocompatible Coated Nanostructured Titanium Surfaces

InactiveUS20100028387A1Promote bone growthStrong cell adhesionBiocideTetrapeptide ingredientsNano sizeCell adhesion

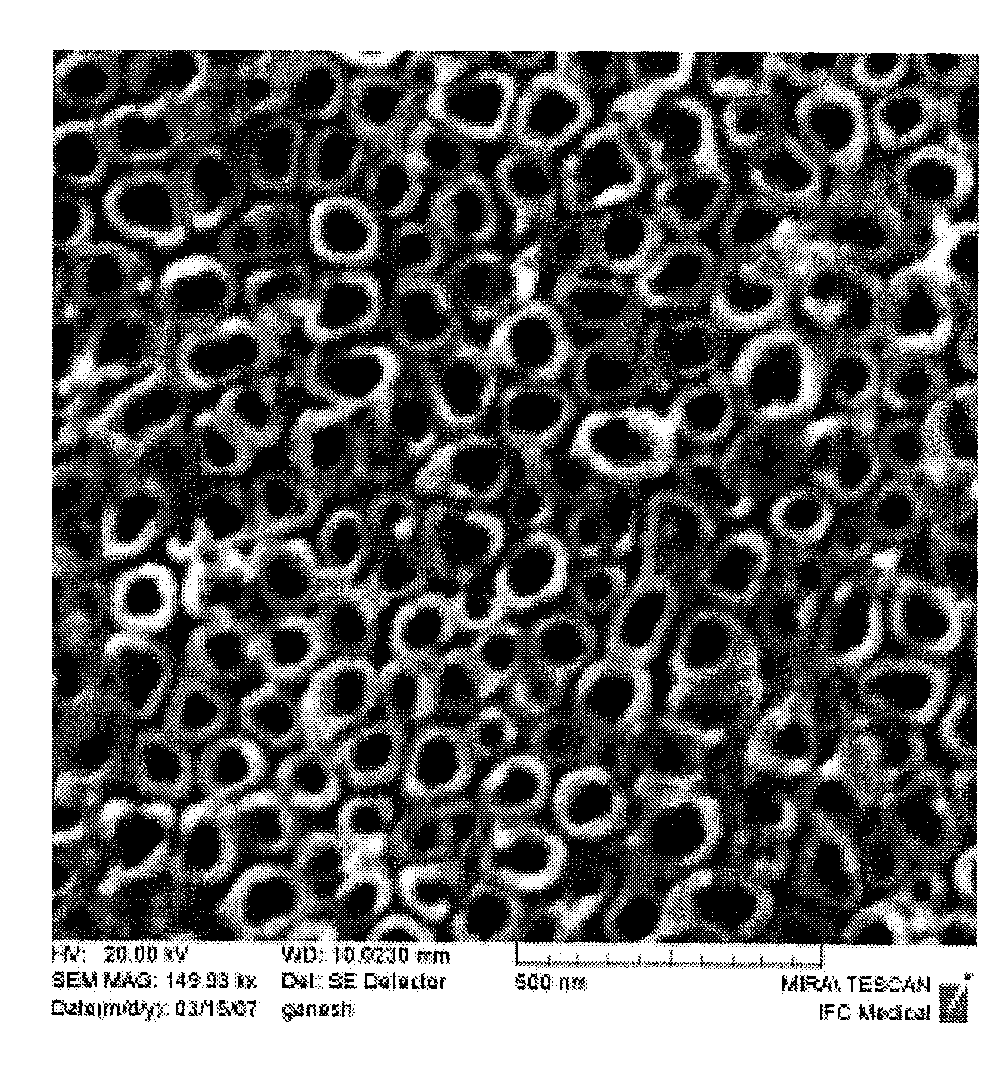

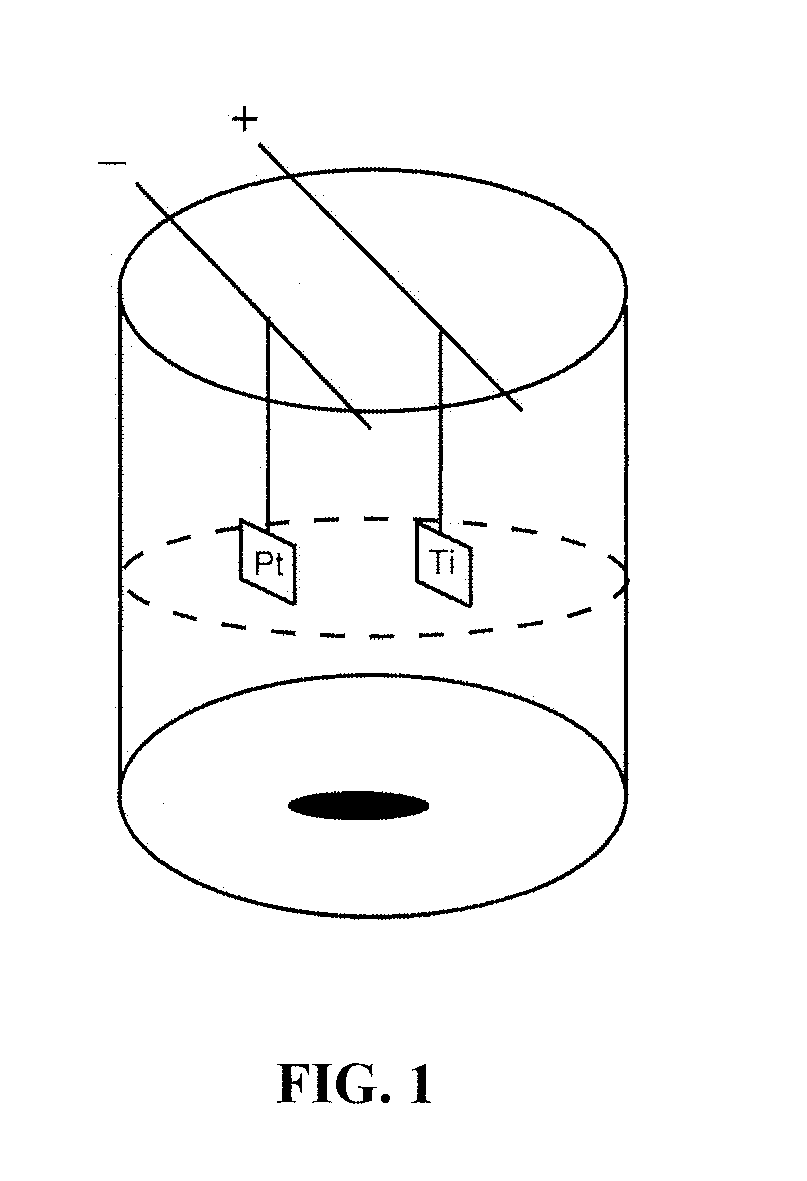

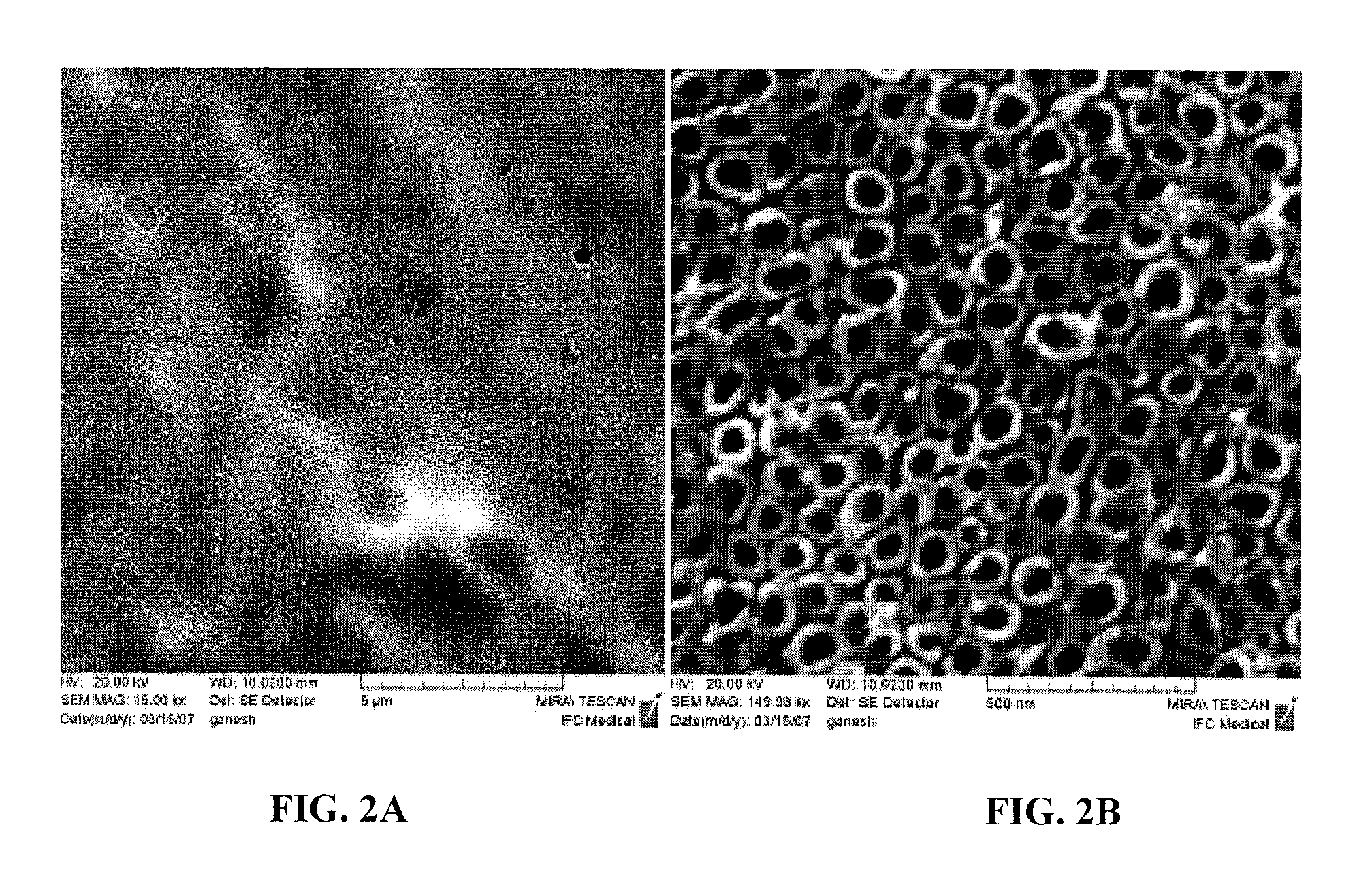

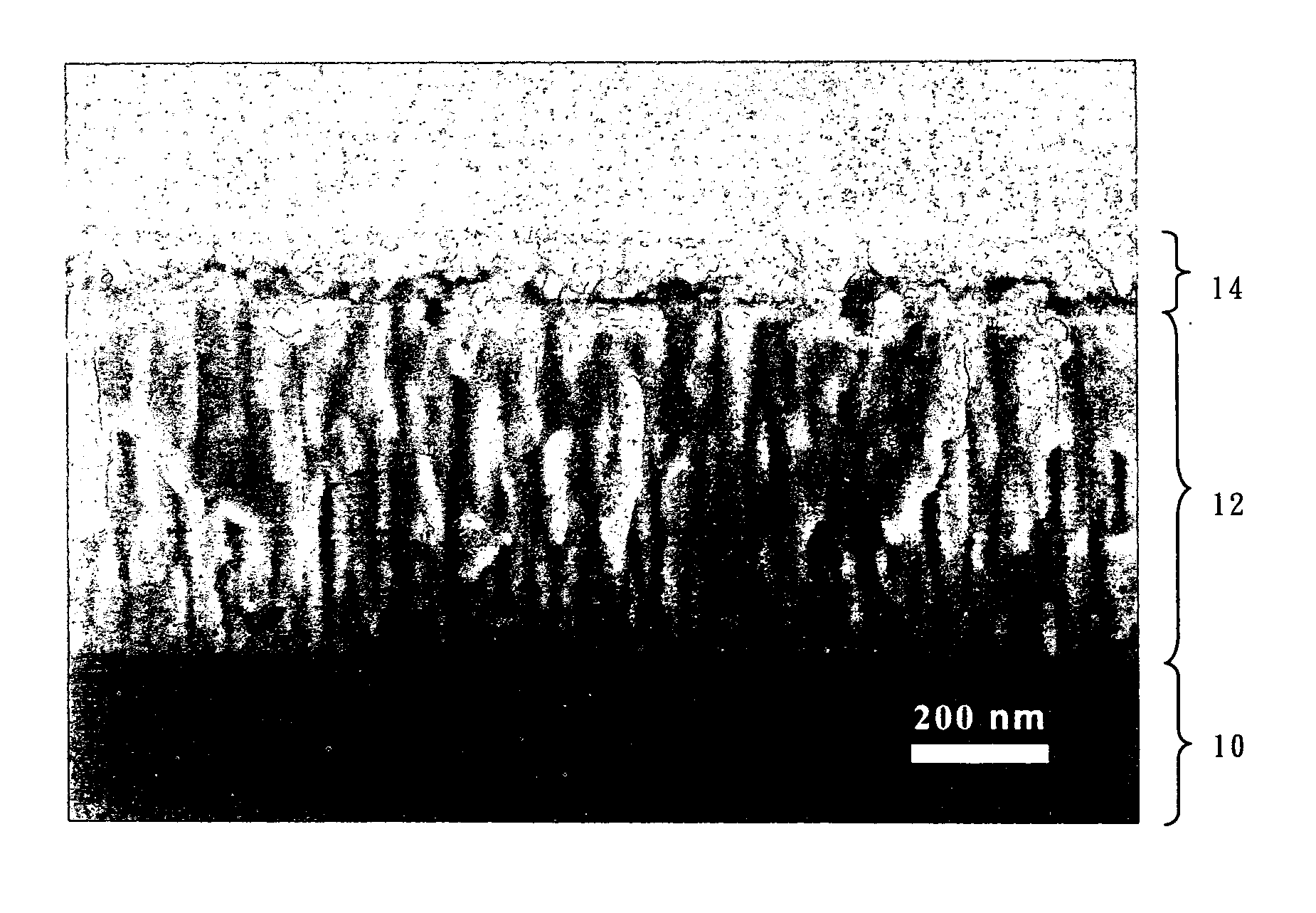

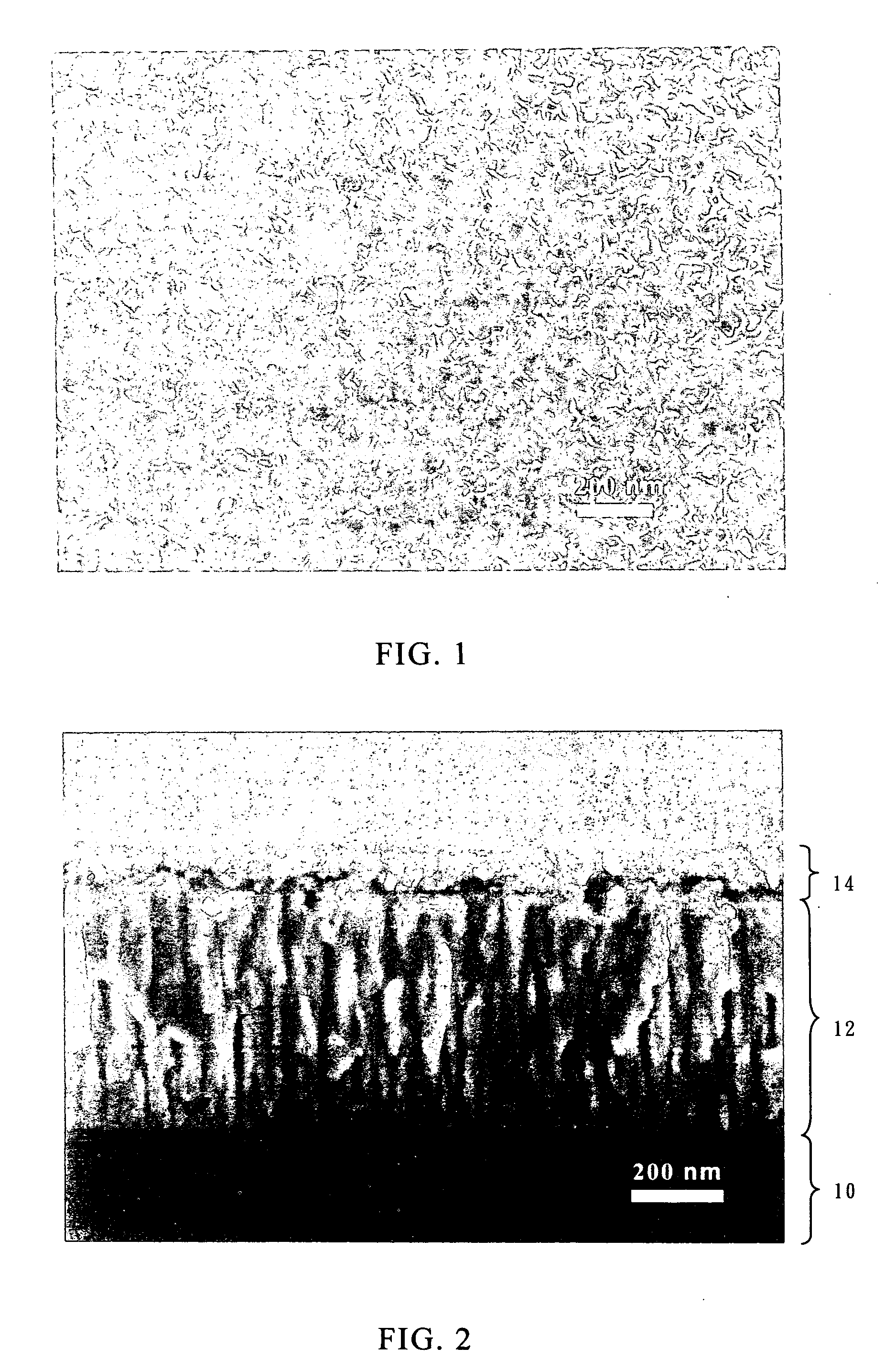

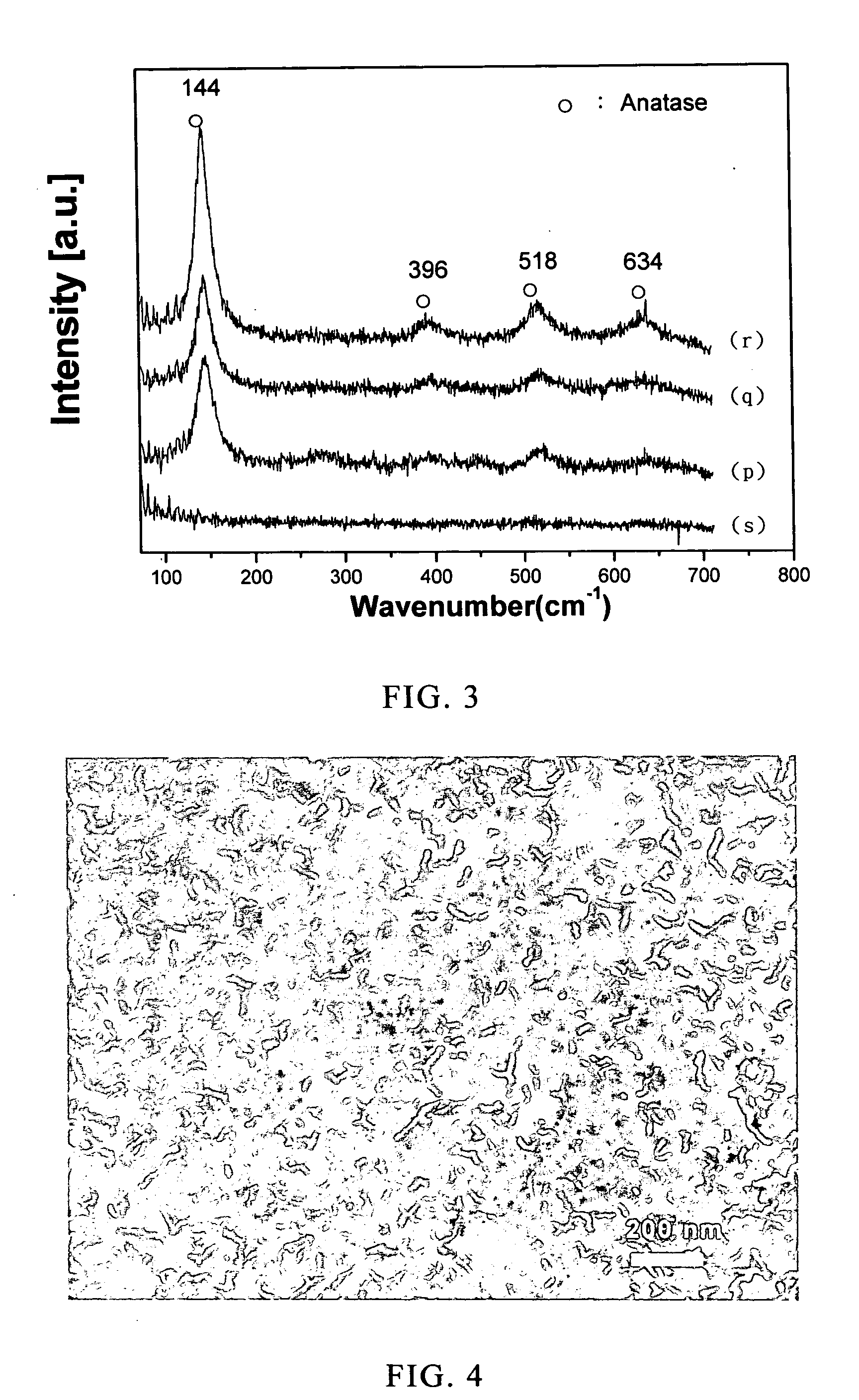

Bioactive molecules have been coated on nanotubular structured titanium substrates by molecular plasma deposition. The coatings promote cell adhesion and are particularly suited for orthopedic implants that provide improved bone cell adhesion and new tissue growth. Nanodimensional features on titanium substrates are engineered using electrochemical anodization techniques. The nanostructured surfaces provide superior support for a wide selection of polypeptide coatings.

Owner:METASCAPE

Titanium dioxide film synthesizing method and the product thereof

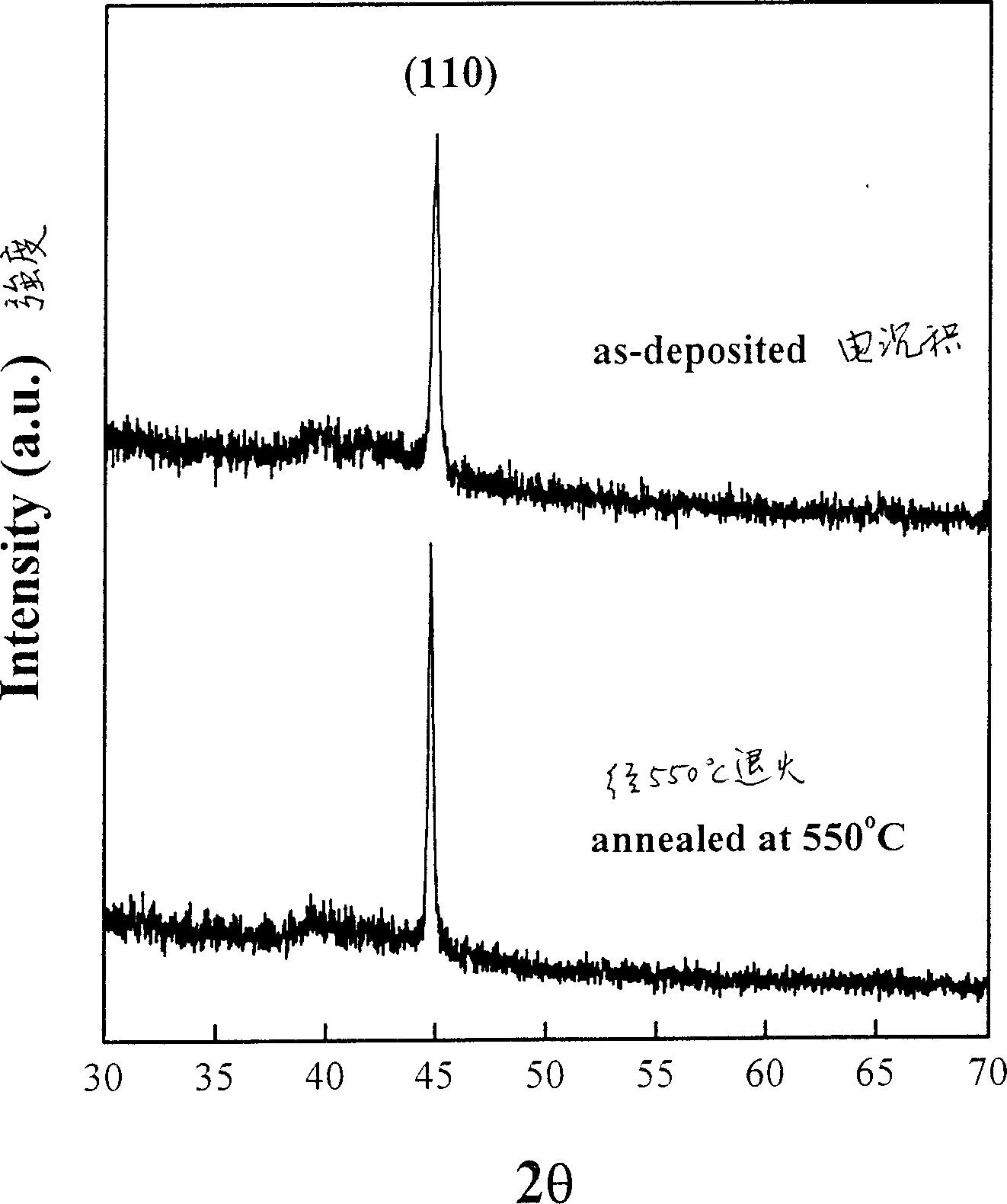

InactiveUS20050103639A1Surface reaction electrolytic coatingElectrochemical anodizationRoom temperature

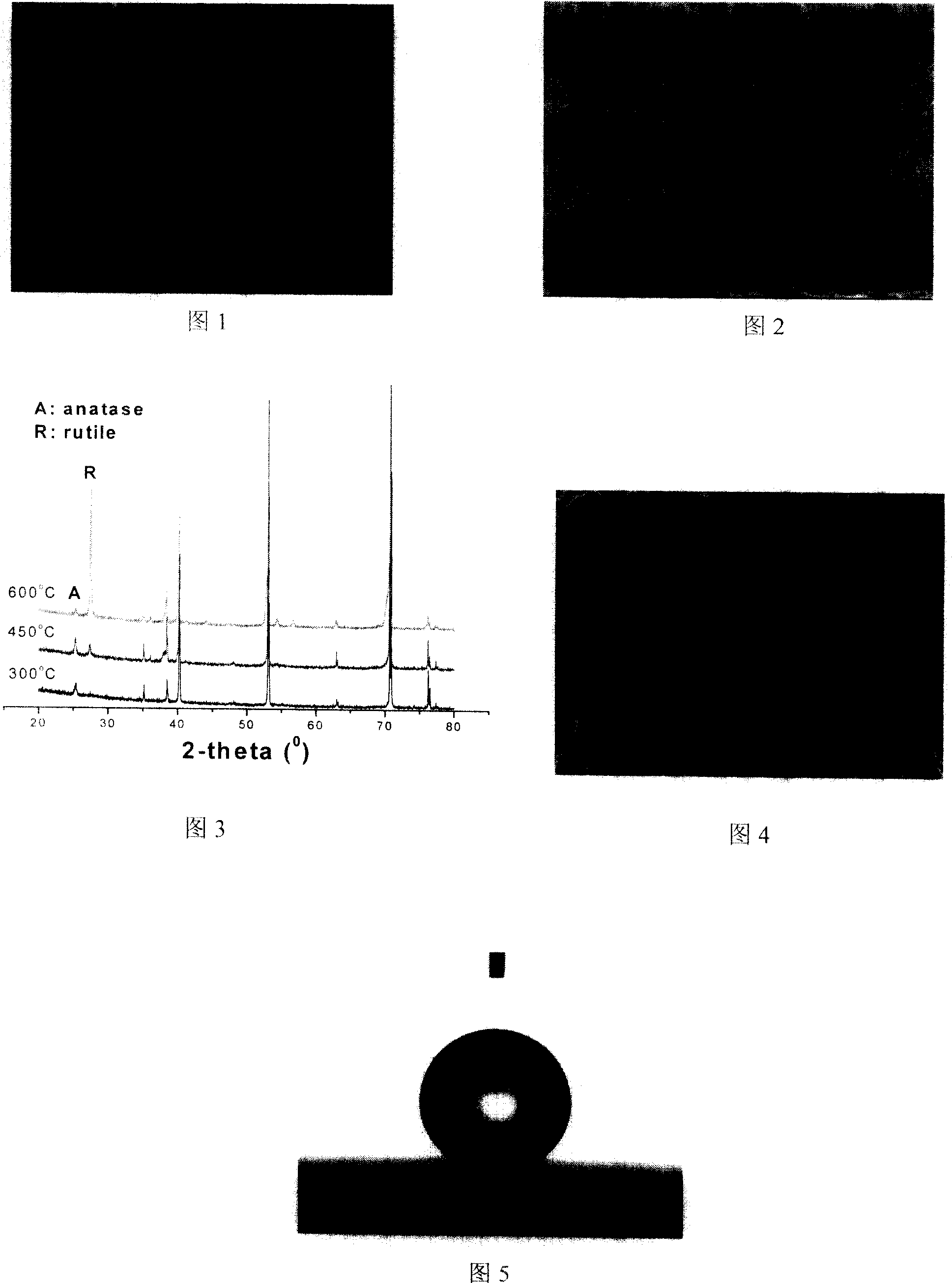

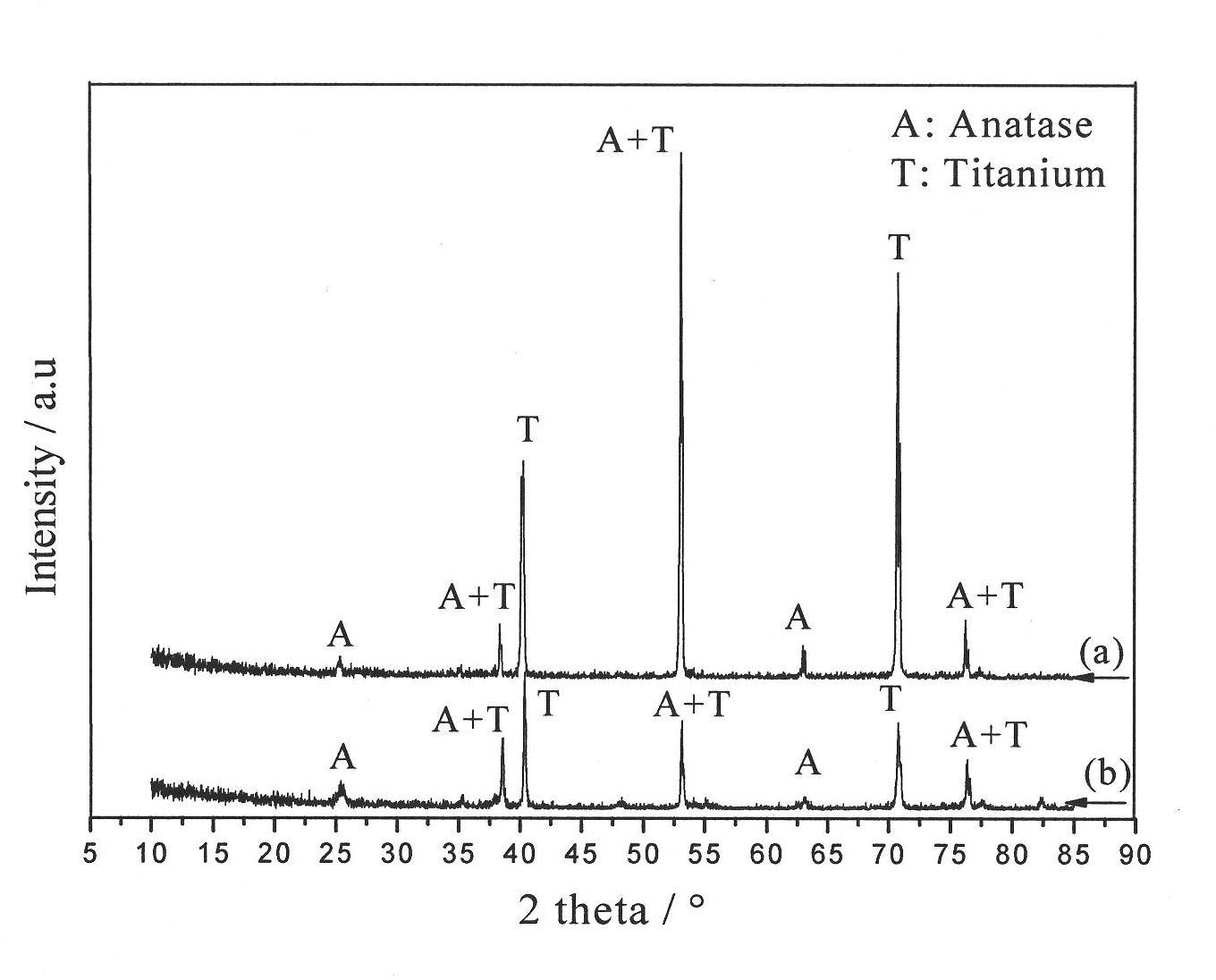

A titanium dioxide films synthesizing method includes the step of coating a titanium film on the surface of a homogenous (or heterogeneous) substrate, and the step of using the titanium-coated substrate as anode in an electrolyte to synthesize an nano-structured titanium dioxide film with single anatase phase on the surface of the titanium film by employing electrochemical anodic oxidation at room temperature.

Owner:LU FU HSING +1

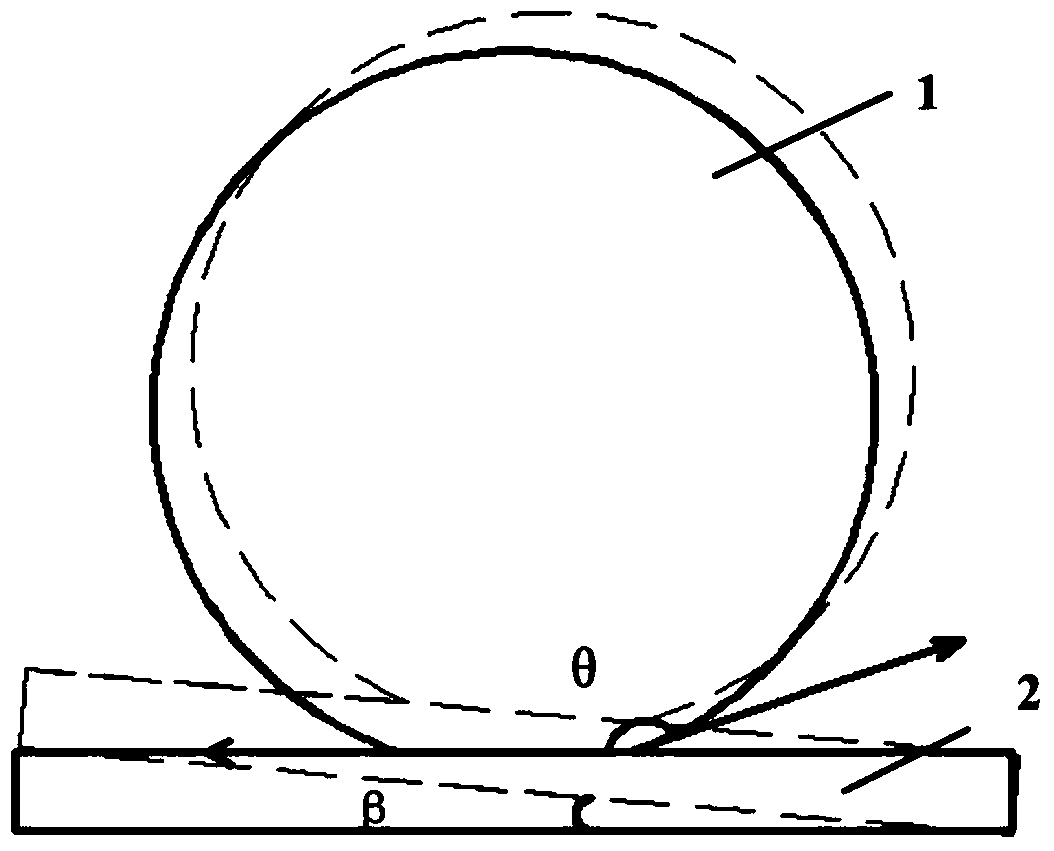

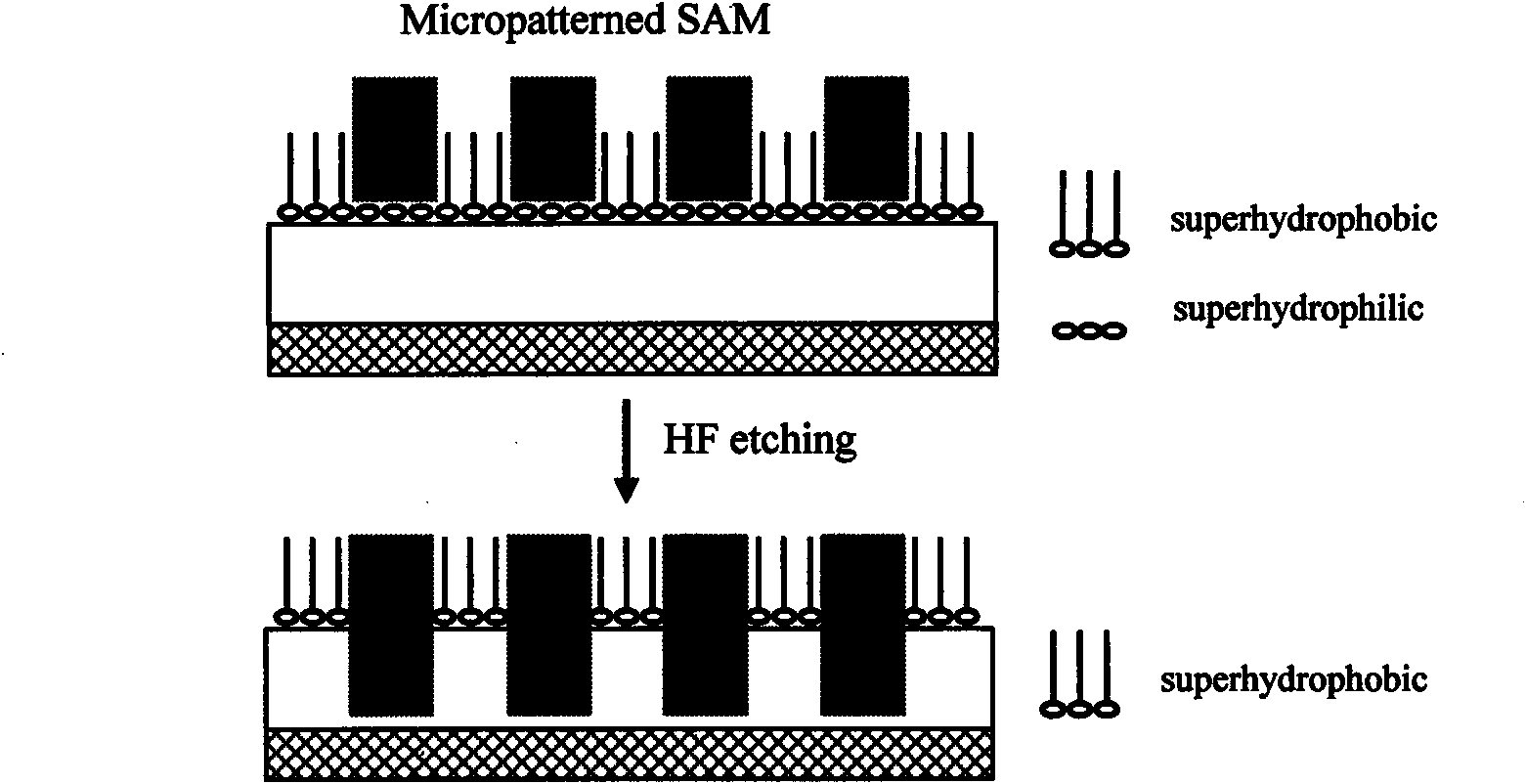

Construction method of titanium surface micrometre-grade pattern based on ultra-hydrophilic/ultra-hydrophobic characteristic

InactiveCN101016642APracticalImprove controllabilitySurface reaction electrolytic coatingElectrochemical anodizationUltraviolet lights

The invention discloses a construction method of titanium surface micron-size picture based on super hydrophilic / super hydrophobic peculiarity, which comprises the following steps: pre-processing the surface of base material; allocating electrolytic solution; controlling voltage and temperature; proceeding electro chemical anodic oxidation; getting titanium oxide nanometer structure array film layer; proceeding heat treatment; getting example; soaking in fluorine silicane methanol solution at 10-240 min; getting out; drying at 120-160 deg.c; getting super hydrophobic TiO2 nanometer structure array film layer; covering photomask; irradiating with ultraviolet light; getting the final picture.

Owner:XIAMEN UNIV

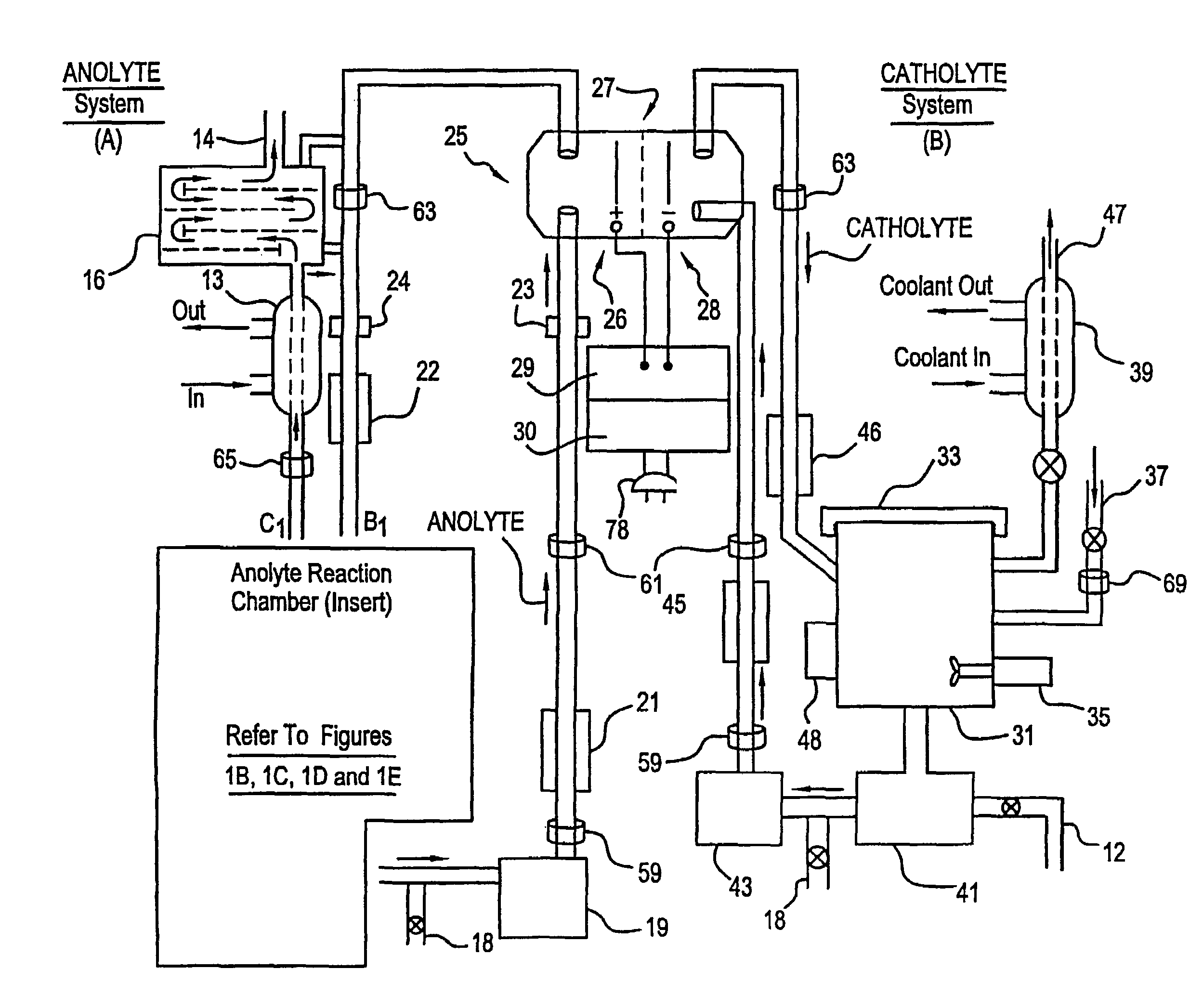

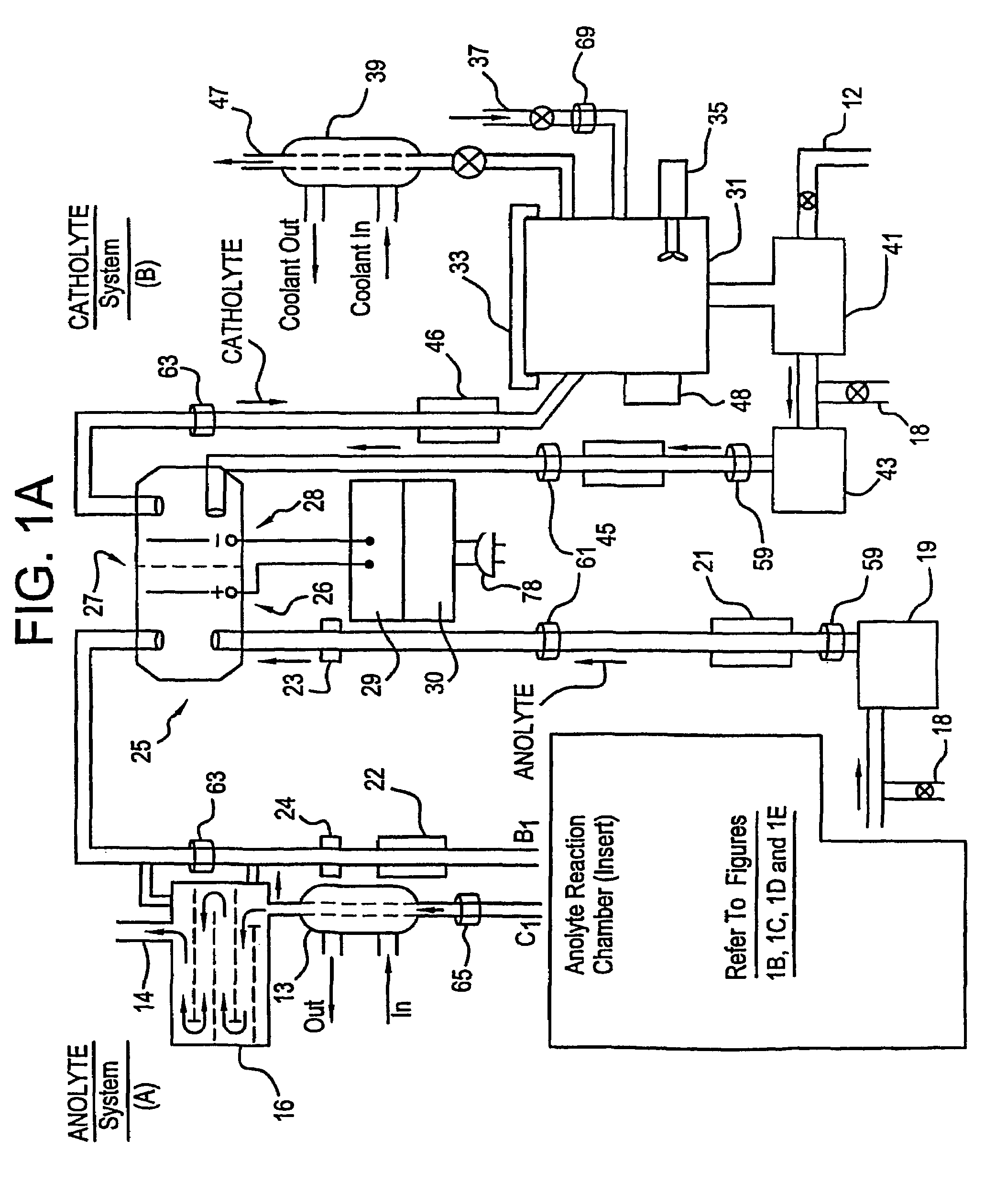

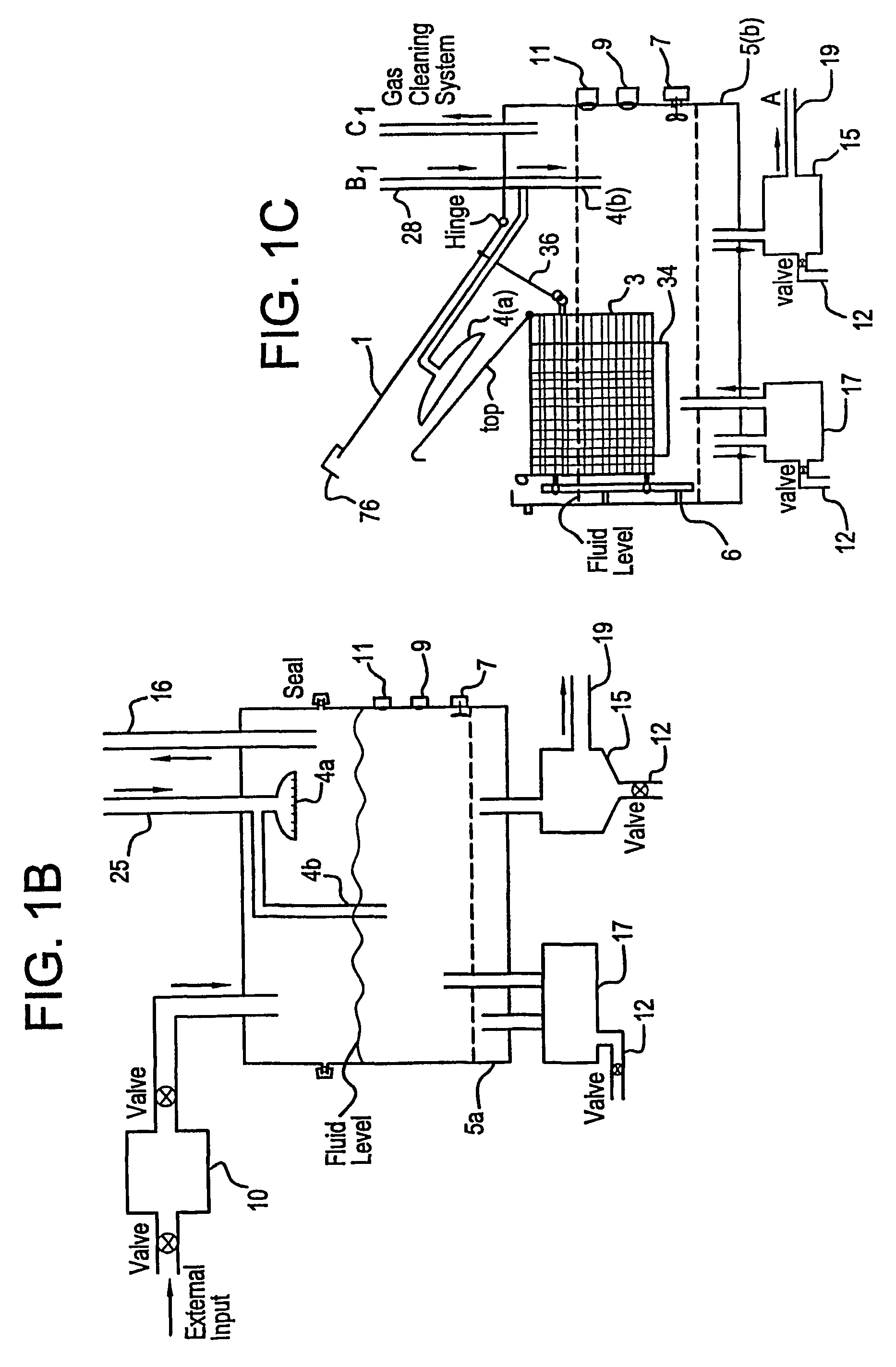

Mediated electrochemical oxidation of organic waste materials

InactiveUS7611620B2Easy accessSave energyCellsLiquid separation by electricityFuranElectrochemical anodization

A mediated electrochemical oxidation process is used to treat and destroy organic waste materials. The materials are introduced into an apparatus containing an electrolyte having the oxidized form of one or more redox couples. The oxidized couples oxidize the organic waste materials and are converted into their reduced form. The reduced forms are reoxidized by electrochemical anodic oxidation in the anode compartment of an electrochemical cell or reaction with the oxidized form of other redox couples. The redox cycle continues until the desired degree of oxidation is reached. The process takes place at temperatures between ambient and approximately 100° C., to avoid the formation of dioxins or furans. The oxidation process may be enhanced by the addition of reaction enhancements, such as: ultrasonic energy and / or ultraviolet radiation.

Owner:SCIMIST LNC

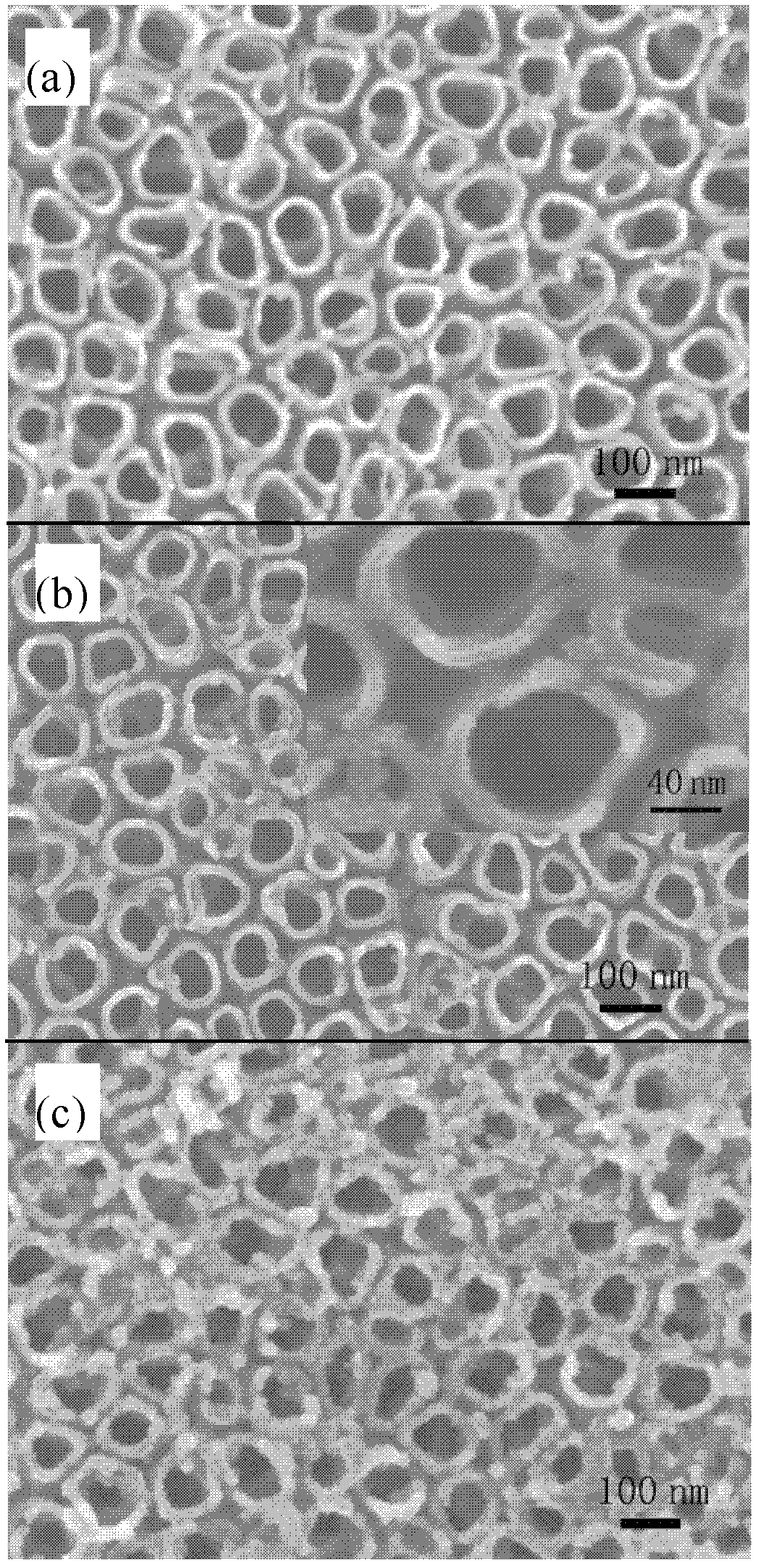

Method for preparing titanium dioxide nano tube array on titanium-substrate material surface

InactiveCN101191248AEasy to controlSimple and fast operationSurface reaction electrolytic coatingAir atmosphereTio2 nanotube

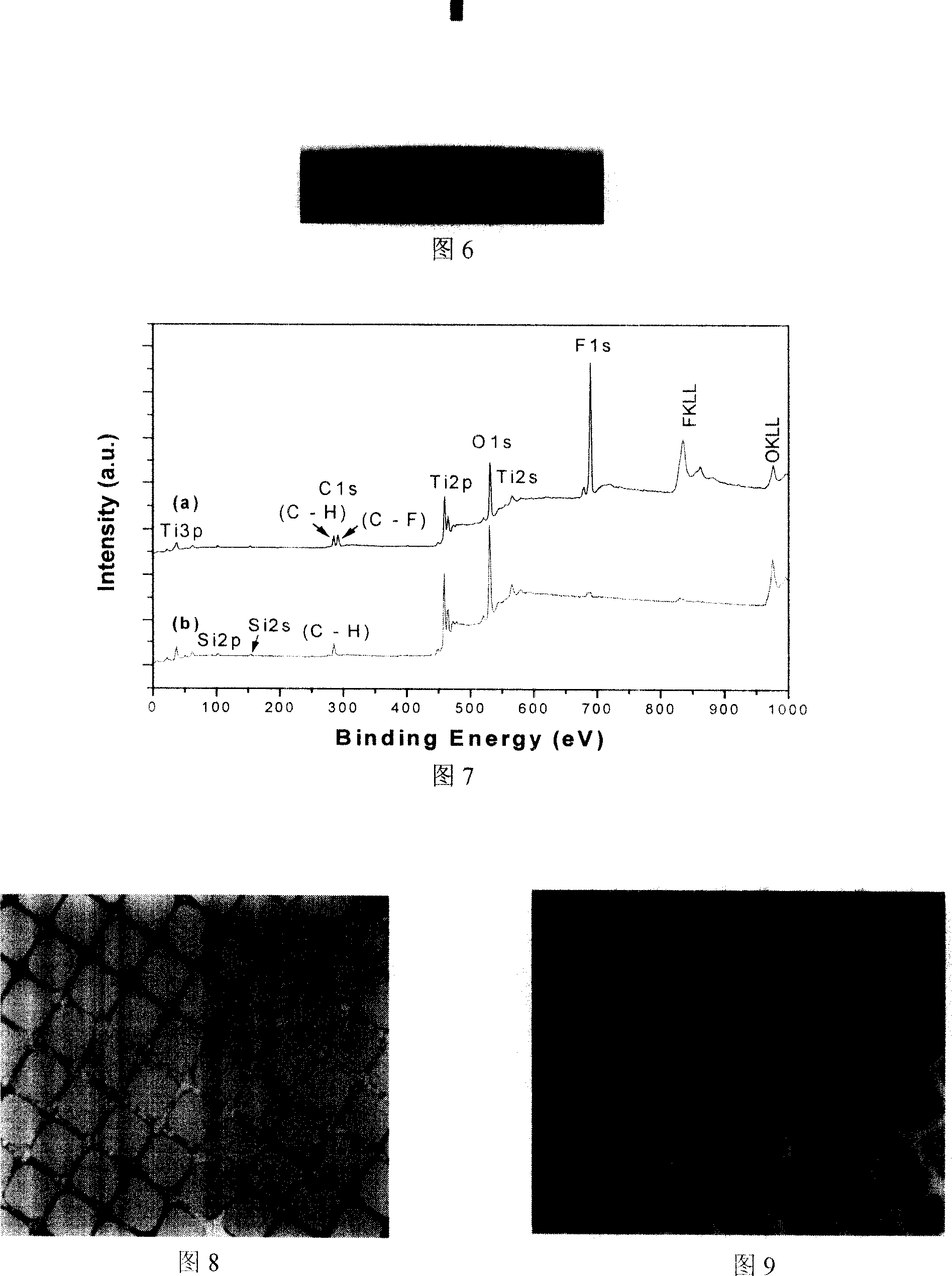

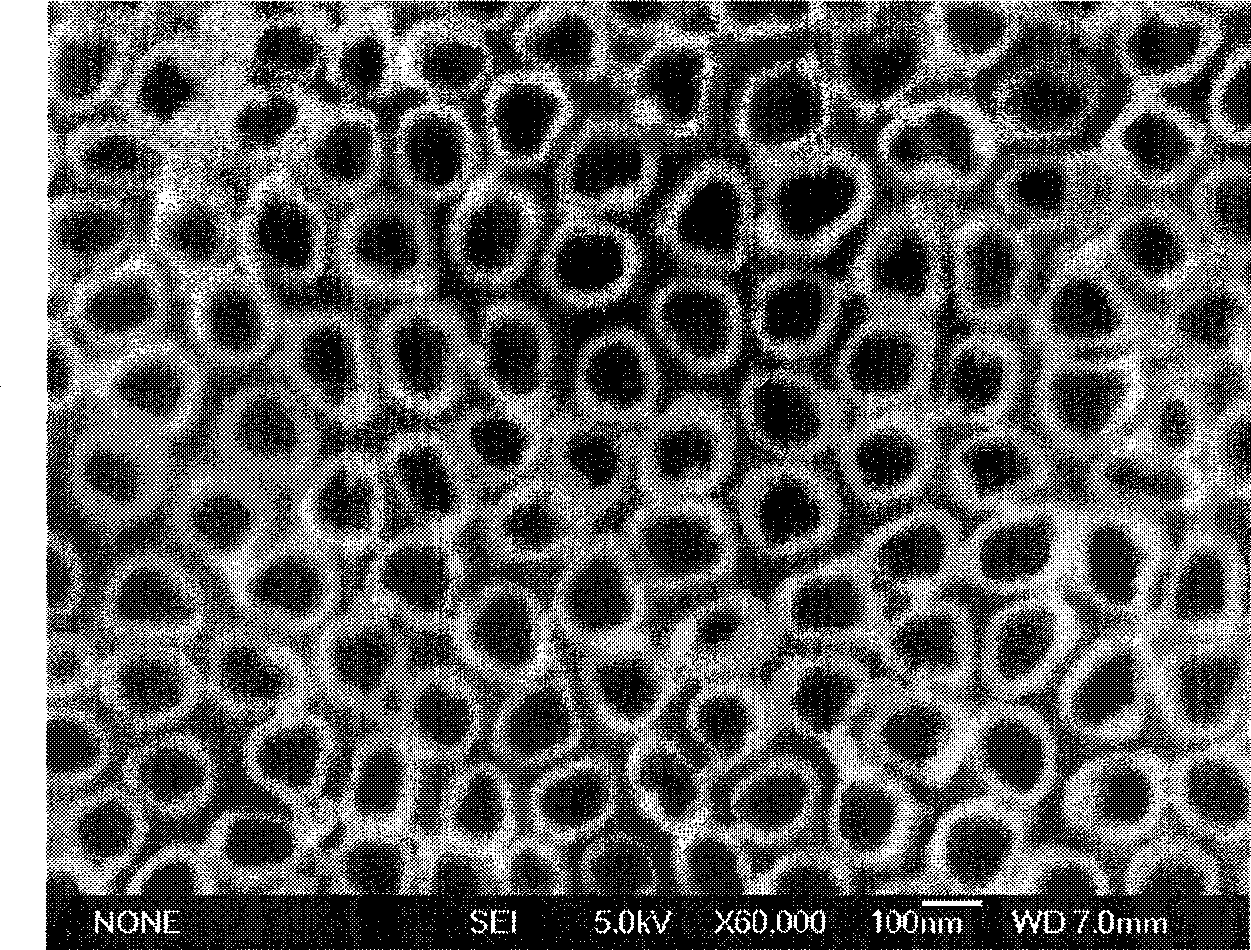

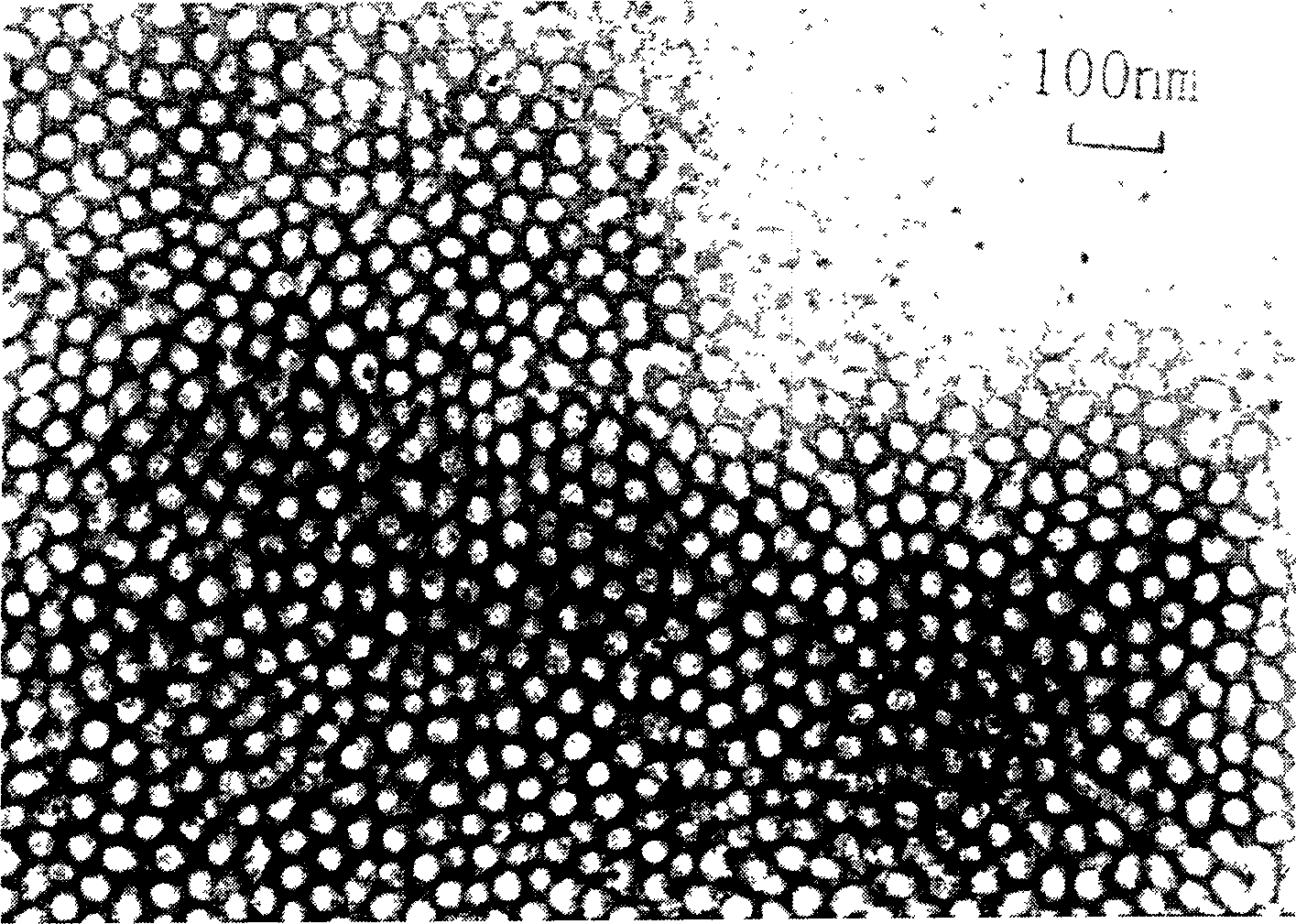

The invention discloses a method by which titanium dioxide nanometer tube array layer is prepared on surface of titanium base material, wherein the titanium base materials undergo the surface pretreatment and receive the electrochemistry anodic oxidation treatment in the electrolyte containing the HF acid, the components of the mixed electrolyte are that the ammonium dihydrogen phosphate is 1 to 3mol / L and the hydrofluoric acid is 0.2 to 0.4mol / L, as a result, the amorphous form titanium dioxide nanometer tube surface structure is achieved; the subsequent heat treatment condition is that under air atmosphere, the rate of temperature rise is 3 DEG C / min, the heat is preserved for 3 hours at the temperature of 450 DEG C, the anatase titanium dioxide nanometer tube array layer is achieved after being cooled in the furnace to the room temperature. The electrolyte system prepared based on the method of the invention can control the balance of oxidation and the corrosion within a relatively long time, thereby preferably realizing the control on the shape of the titanium dioxide nanometer tube. The invention has the advantages of easy operation, low cost and orientated and order distribution of the prepared titanium dioxide nanometer tube array; moreover, the amorphous form titanium dioxide nanometer tube is generated normal to the direction of the base; the tube diameter is 80 to 100nm, the wall thickness is 18 to 21nm, the tube length is 0.7 to 2.0um, thereby the specific surface area is large.

Owner:SOUTHWEST JIAOTONG UNIV

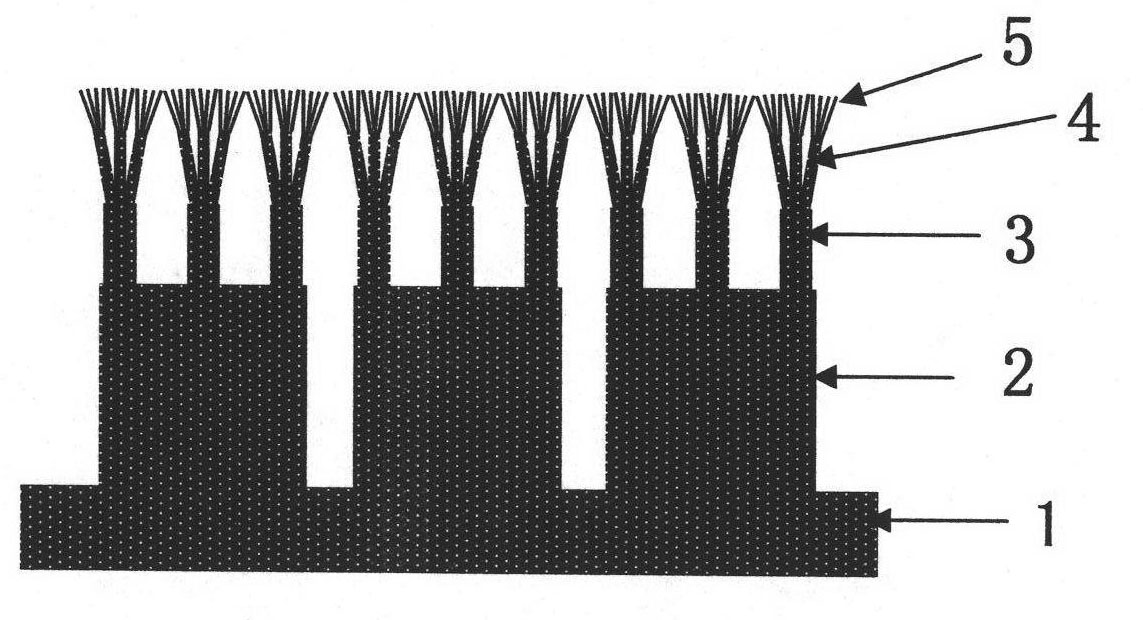

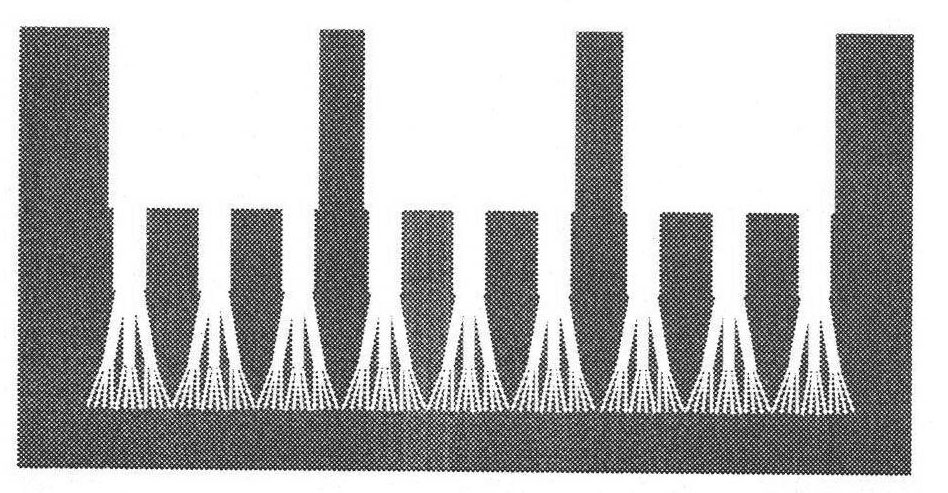

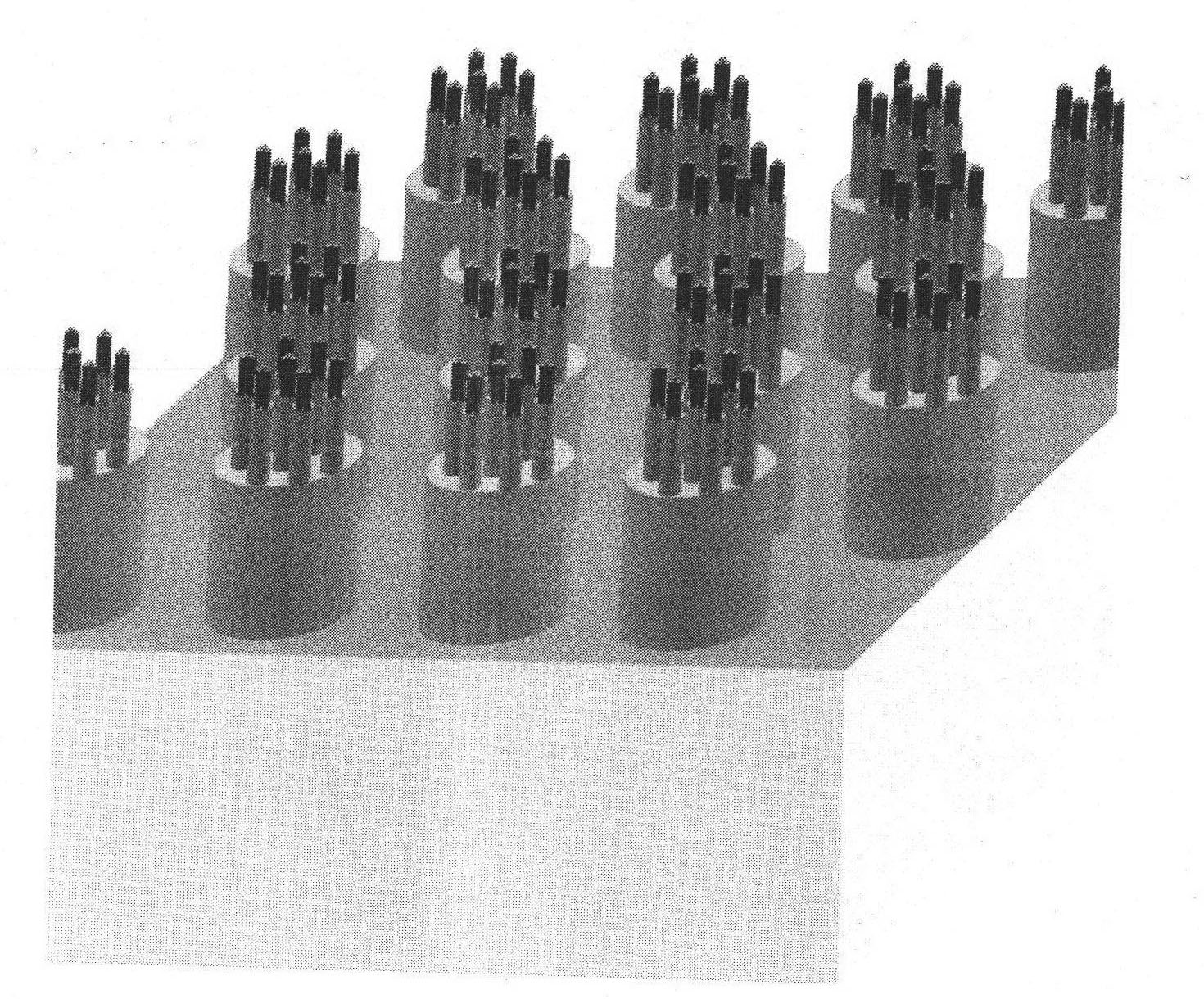

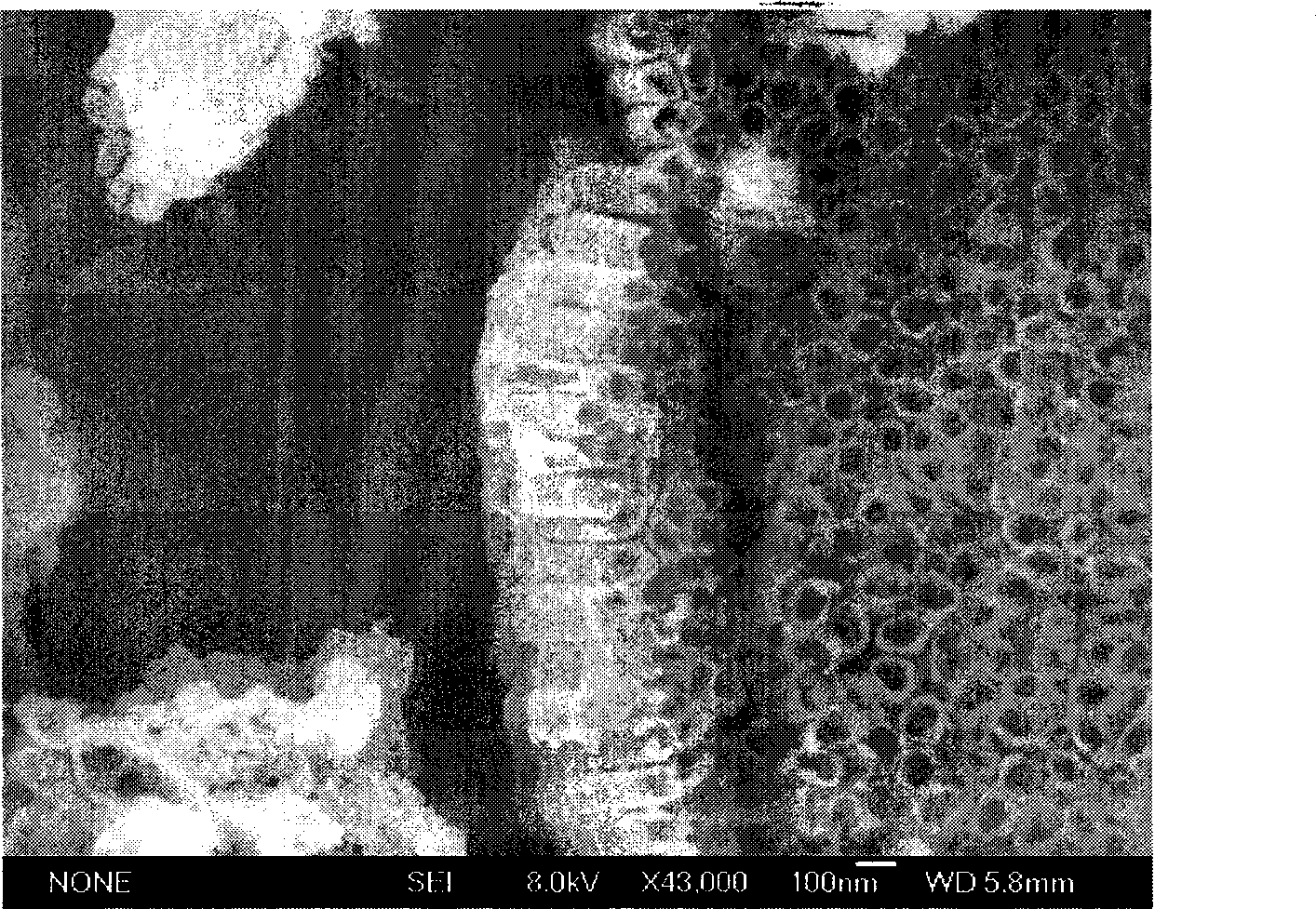

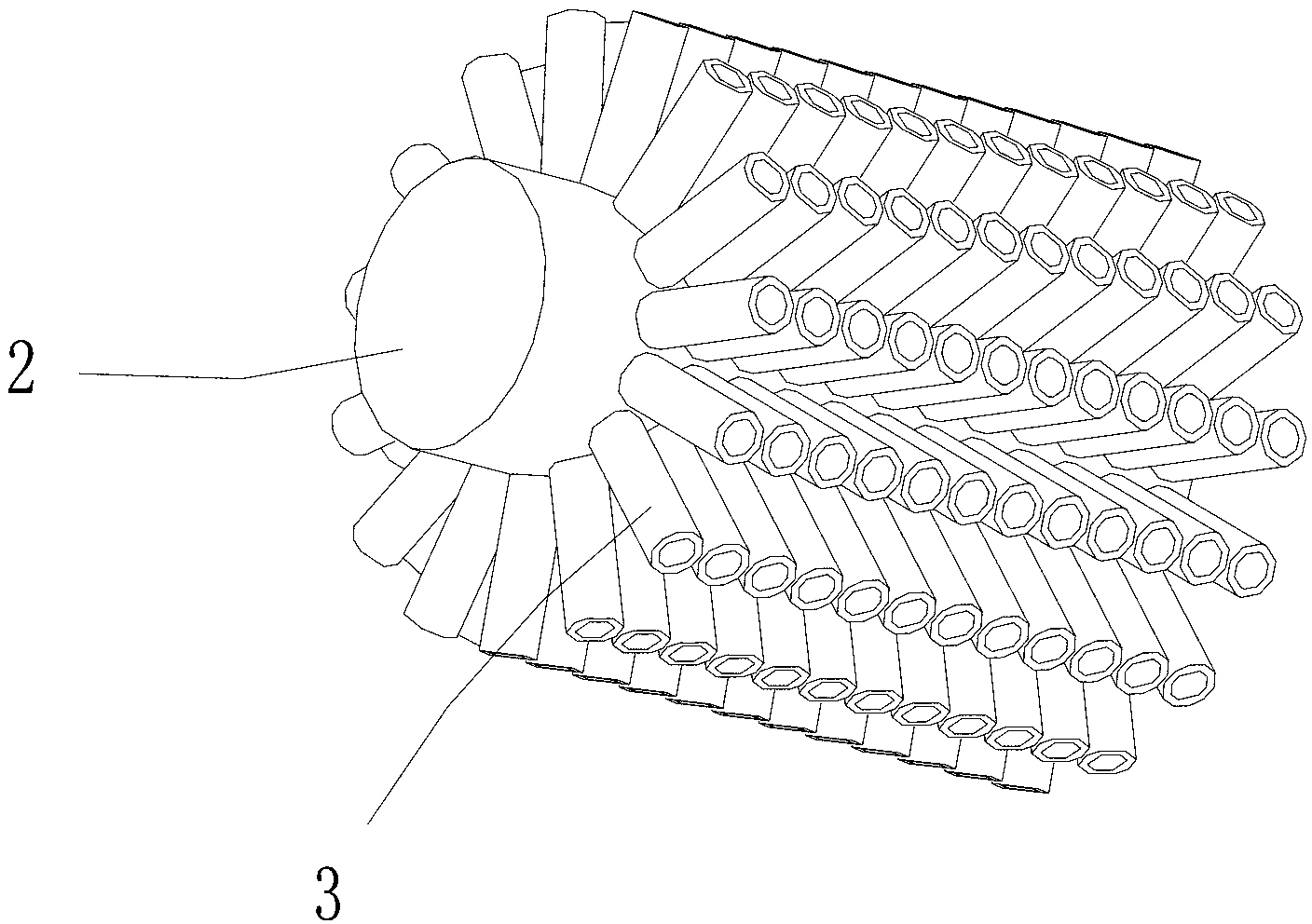

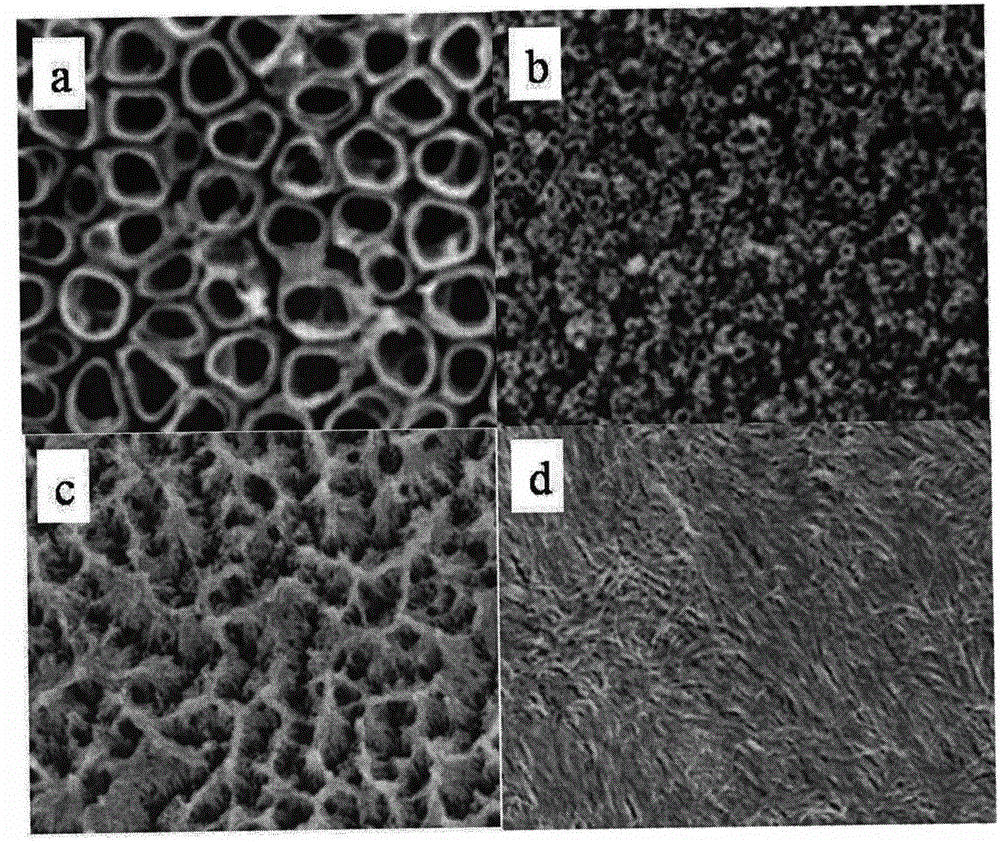

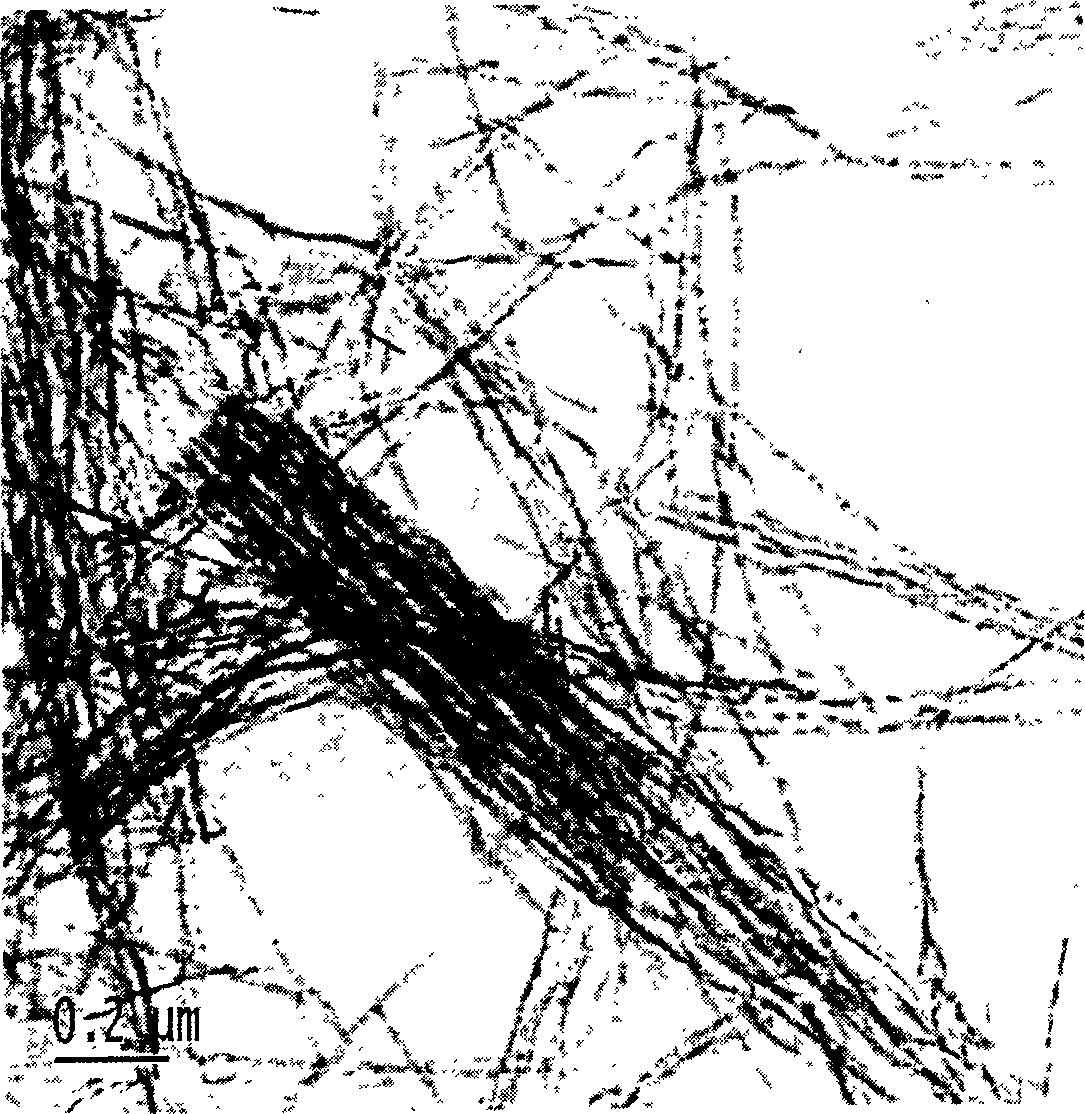

Cross-scale biomimetic micro-nano branch structure array and preparation method thereof

InactiveCN101774528AAchieving cross-scale integrationSolution controllableAnodisationNanostructure manufactureMicro nanoElectrochemical anodization

The invention discloses a cross-scale biomimetic micro-nano branch structure array and a preparation method thereof, which relate to the field of micro-nano materials and robots, particularly relate to a biomimetic adhesive material and a preparation method thereof and also relate to an electrochemical anodic oxidation process. The cross-scale biomimetic micro-nano branch structure array consists of a substrate and a micro-nano multilevel branch structure array, wherein the micro-nano multilevel branch structure array at least comprises a primary micron cylindrical structure array and a branch micro-nano cylindrical structure array. The preparation method thereof comprises the following steps of: firstly, etching an aluminum template with an argon ion beam to obtain an aluminum template with a primary micron hole array; secondly, preparing a micro-nano branch structure array in a definite point and direction on the template array by an electrochemical anodic oxidation process; thirdly, performing film extrusion and curing on the template by a polymer replica method; and finally, removing the template for forming to obtain the desired micro-nano structure array to form a biomimetic dry adhesive material. The cross-scale biomimetic micro-nano branch structure array and the preparation method thereof use electric characteristics to effectively solve the control problem of from micron to nanometer cross-scale branch structure arrays and have a great significance for the development of biomimetic adhesive materials and related dry biomimetic robots.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

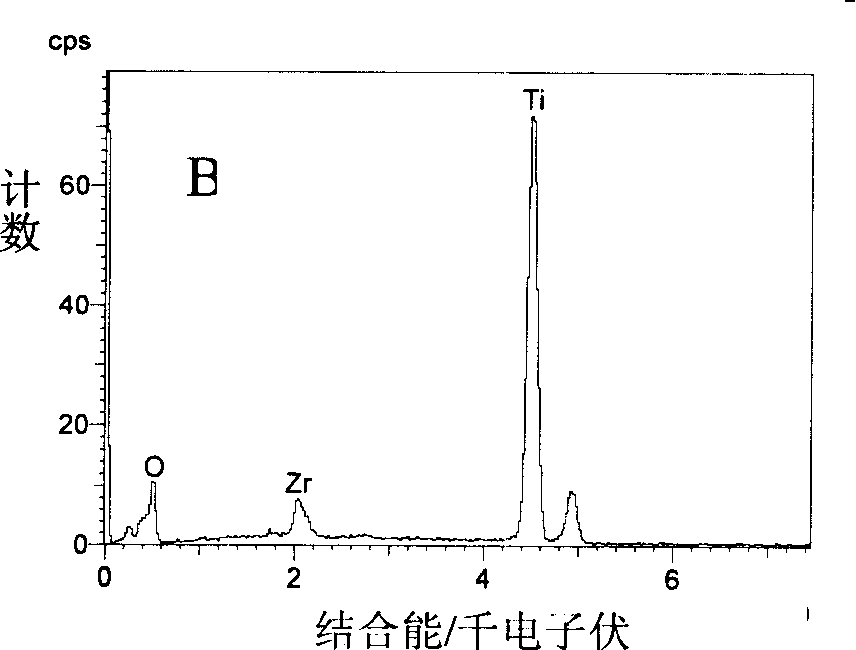

Process for preparing cationic nanotube array intermingling titanium oxide

InactiveCN101204649ADoping achievedImprove controllabilityPhysical/chemical process catalystsSurface reaction electrolytic coatingElectronic structureTio2 nanotube

The invention relates to a preparation technique of cation-doped titanium oxide nanotube arrays, in particular to a method of acquiring cation-doped titanium oxide nanotube arrays that have high photo-catalytic activity in situ on a titanium alloy matrix through electrochemistry and anodic oxidation process, and doped titanium oxide nanotube on atomic scale is acquired. Titanium alloy with homogeneous component is obtained by melting process, and the titanium alloy is adopted as matrix for anodic oxidation, so as to acquire titanium oxide nanotube arrays that are evenly doped with one kind or a plurality kinds of cations; by controlling content of alloying elements, titanium oxide nanotube with controllable doping amount and doped atomic scale can be acquired, and the diameter of electronic structure of the titanium oxide nanotube can be regulated, thus further improving solar rays performance of the titanium oxide nanotube in photocatalysis, and the titanium oxide nanotube arrays can hopefully be applied in hydrogen production from water by photodecomposition.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

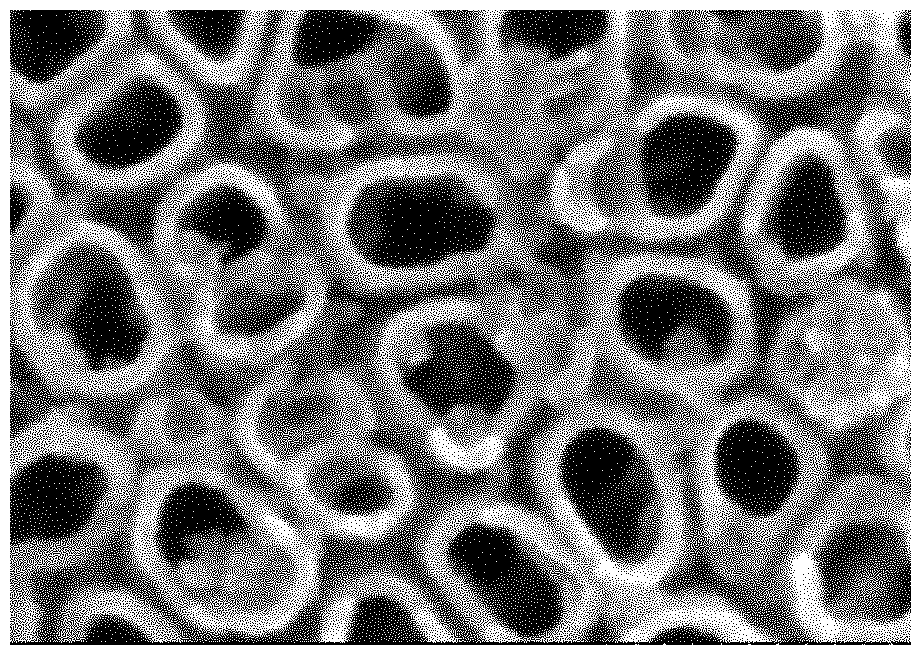

Method for preparing cuprous oxide composite titanium dioxide nanotube array

InactiveCN101956223AEnables controlled depositionIncreased photocatalytic ratePolycrystalline material growthSurface reaction electrolytic coatingWater bathsComposite film

The invention discloses a method for preparing a cuprous oxide composite titanium dioxide nanotube array, which relates to a nanotube. The method comprises the following steps of: cleaning and pre-processing the surface of a substrate material; preparing 0.1 to 1.5 weight percent of aqueous solution of hydrogen fluoride into an electrolyte, performing electrochemical anode oxidization on the substrate material, namely forming a layer of ordered TiO2 nanotube array film with controllable size on the surface of the substrate material, and performing thermal treatment on the film; preparing ethanol solution with copper salt concentration of 0.014 to 4mol / L, adding 0.001 to 0.06mmol of polyvinylpyrrolidone into the ethanol solution, after the solution is uniformly dispersed, putting the obtained film into the solution, putting the film in a water bath, adding 0.01 to 0.80mol of glucose and 0.10 to 0.95mol of NaOH, and performing ultrasonic treatment and then taking the film out; and performing thermal treatment on the obtained composite film in vacuum at the temperature of between 50 and 200 DEG C for 1 to 5 hours to obtain the cuprous oxide composite TiO2 nanotube array.

Owner:XIAMEN UNIV

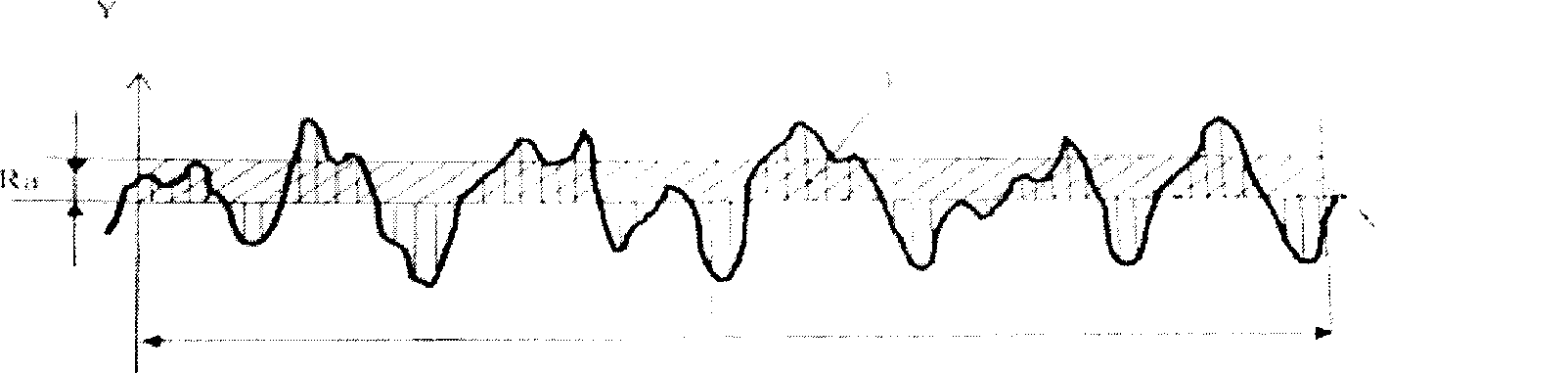

Treatment method of metal printing plate surface for offset-printing plate-making

ActiveCN101422992AHas the ability to absorb inkAvoid AnodizingPrinting pre-treatmentElectrochemical anodizationPolymer coatings

The invention belongs to the field of printing plate materials, relates to a metal plate base without electrochemistry anodic oxidation treatment, in particular to a treatment method of the surface of the metal plate base used for offset printing plate-making. The metal plate base used for offset printing is not treated by anodic oxidation and directly uses sand paper of different sand meshes for evenly sanding the surface thereof in transverse direction and longitudinal direction, so as to lead the surface of the metal plate base to have even roughness (Ra equals to 0.6-3Mum), the sanded metal plate base is washed and dried and the surface thereof is coated by hydrophilic polymer coating and then dried to obtain the metal plate base used for offset printing plate-making. The contact angle between the obtained metal plate base used for offset printing plate-making and the water is 2.0-76.2 degrees.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Titanium-based oxide acid resistant anode and preparation method thereof

InactiveCN102268689AStrong acid resistanceSolution to short lifeSurface reaction electrolytic coatingSolid state diffusion coatingFiberElectrolysis

The invention provides a titanium-based oxide acid resistant anode and a preparation method thereof, and specifically to an electrode catalyst used in the process of electrolysis and a preparation method thereof, belonging to the technical field of electrochemical engineering. The invention is characterized in that: the titanium-based oxide acid resistant anode is especially applicable to electrolysis with oxygen evolution and organic electrolysis and has a long life in a sulfuric acid solution; the anode comprises an electrode matrix, an intermediate transition layer and an active coating; the preparation method for the anode comprises the steps of preparing Ti / Tio2NT by electrochemical anodization in ionic liquid and forming Ti / TiO2NT / C+N+B by co-cementation of B, C and N under the catalytic cementation of rare earth at first or preparing Ti / C+N+B through surface alloying of titanium matrix and forming Ti / C+N+B / TiO2NT through anodization heat treatment at first, applying the graphite fiber loaded intermediate transition layer of Sn, Sb, rare earth and like next, and preparing the PbO2 or MnO2 active coating at last. The titanium-based oxide acid resistant anode prepared through the preparation method provided in the invention has a service life more than 160 hours.

Owner:TAIYUAN UNIV OF TECH

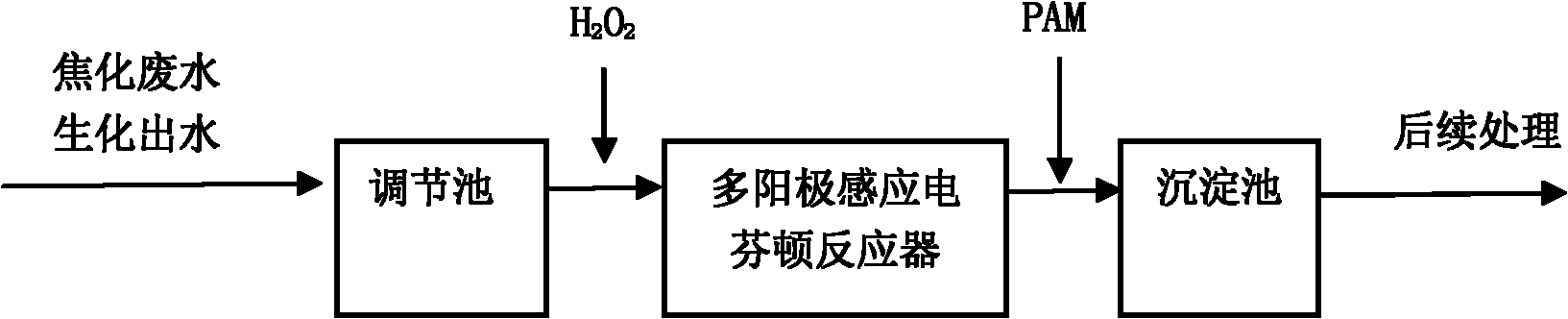

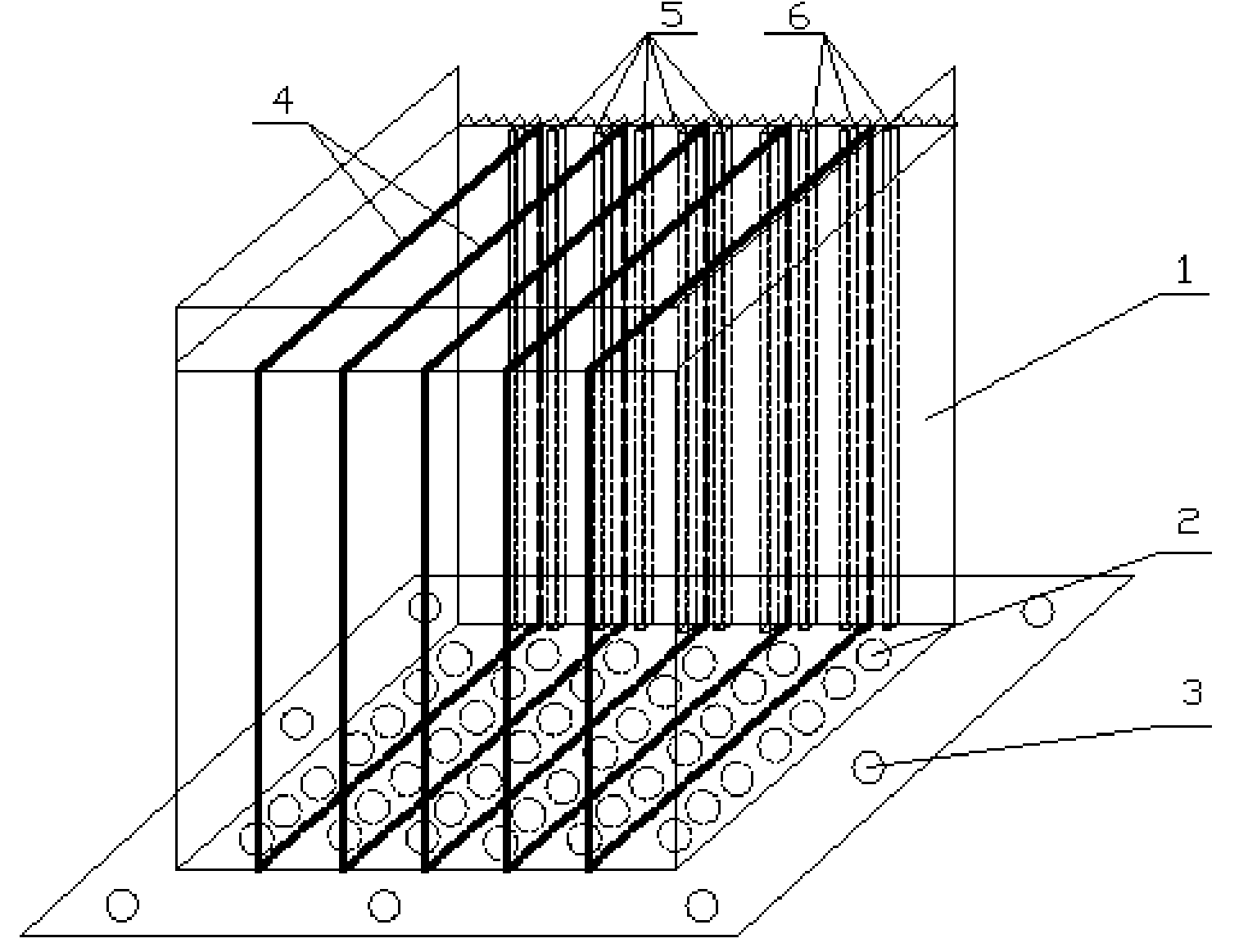

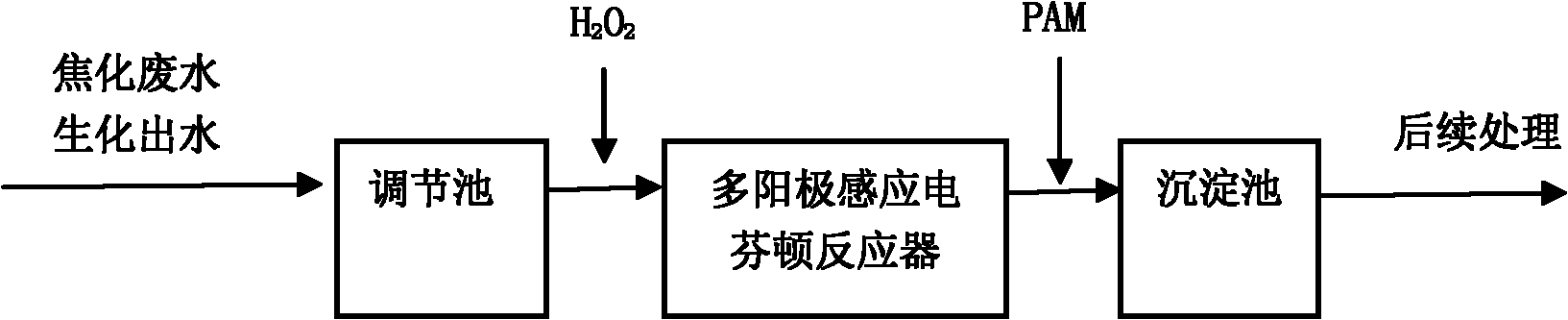

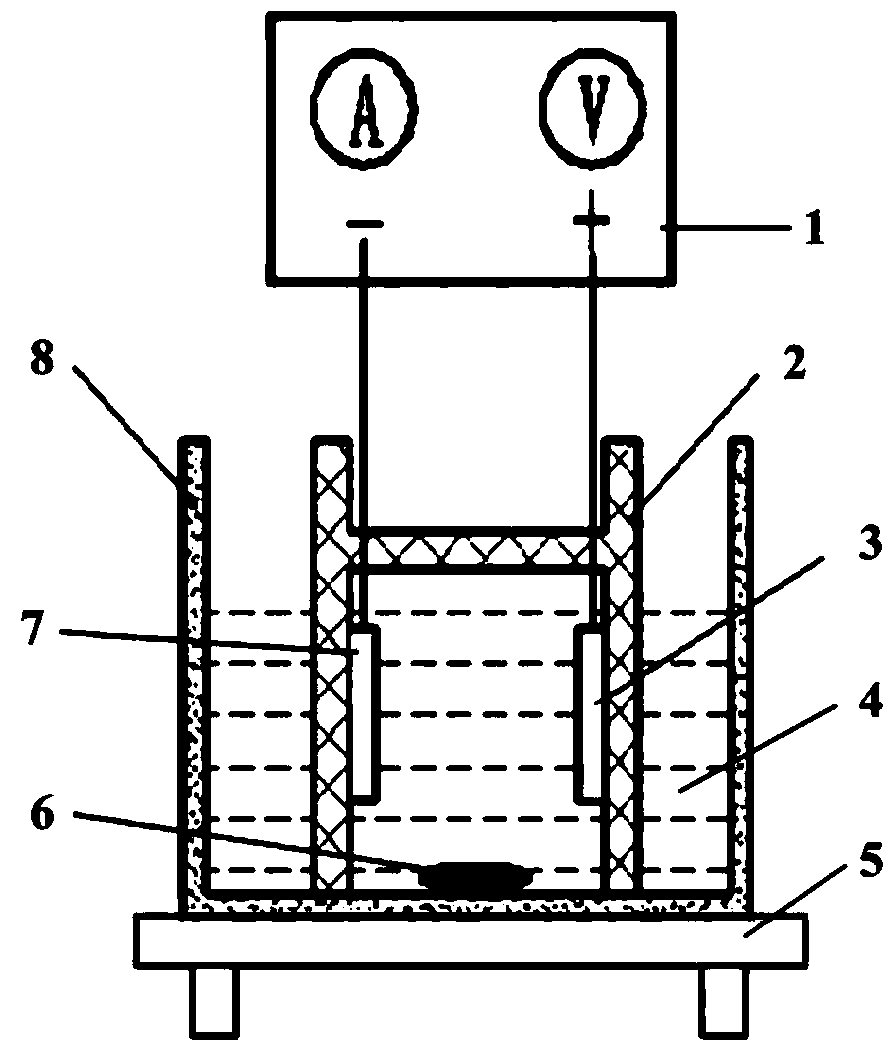

Method and device for treating coking waste water by electro-Fenton-coagulation combination

InactiveCN102139980AEfficient oxidative decompositionReduce consumptionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationElectrochemical responseFlocculation

The invention relates to a method for treating coking waste water by electro-Fenton-coagulation, which comprises the following steps of: regulating the pH value of effluent in a biochemical unit to be between 3 and 4; allowing the effluent to enter an electrochemical reaction unit, removing organic pollutants in the coking waste water under the action of electrochemical anode oxidation, electro-Fenton oxidation and electric coagulation, and adding H2O2 in the reaction process; and regulating the pH value of the treated effluent to be between 7 and 8, allowing the effluent to enter a flocculation precipitation unit, performing flocculation precipitation, and discharging clear water. The invention also provides an electrochemical reactor for realizing the method. The method and the device can be used for performing advanced treatment on the coking waste water, and also can be used for the advanced treatment on the waste water in other industries.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

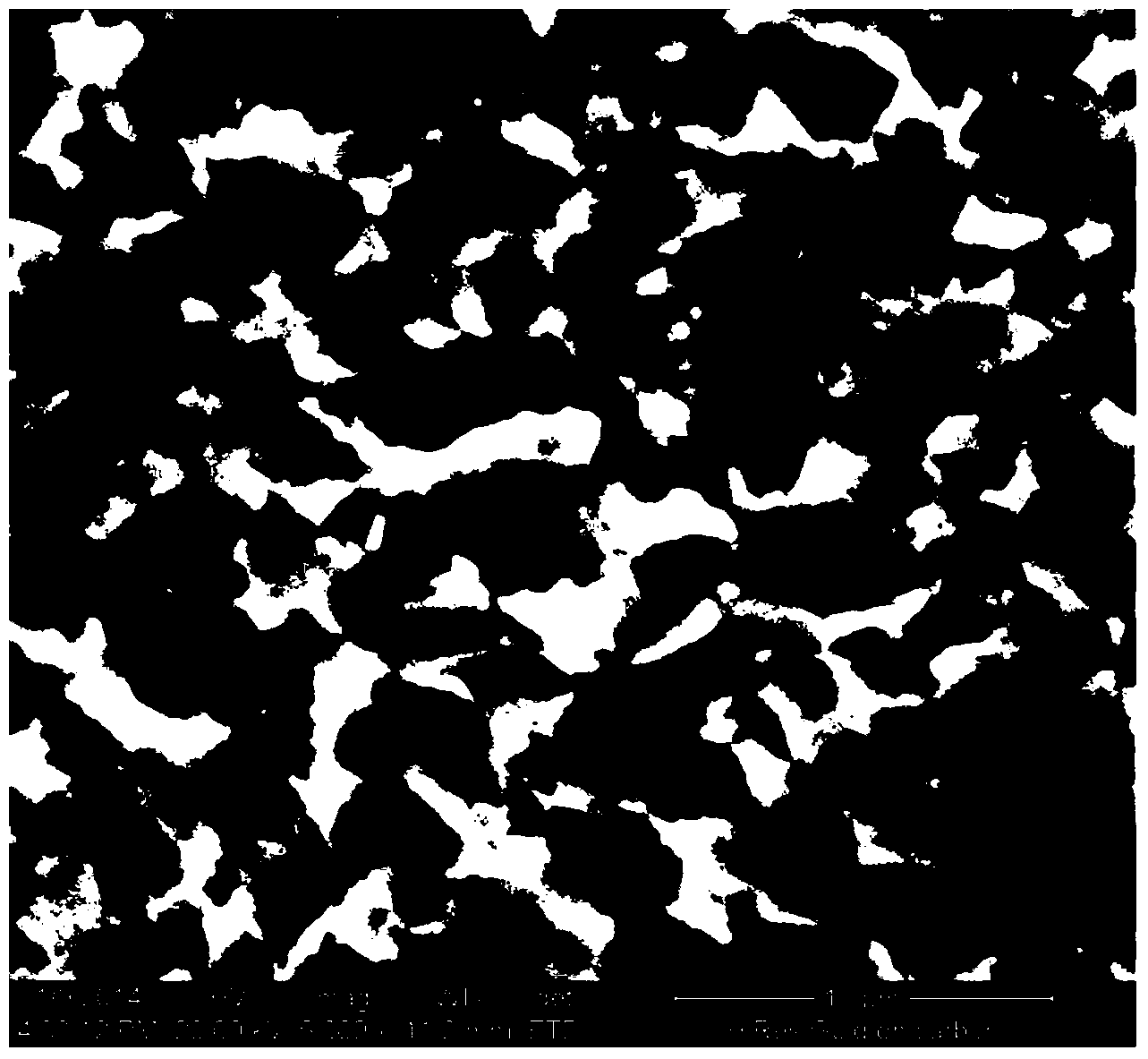

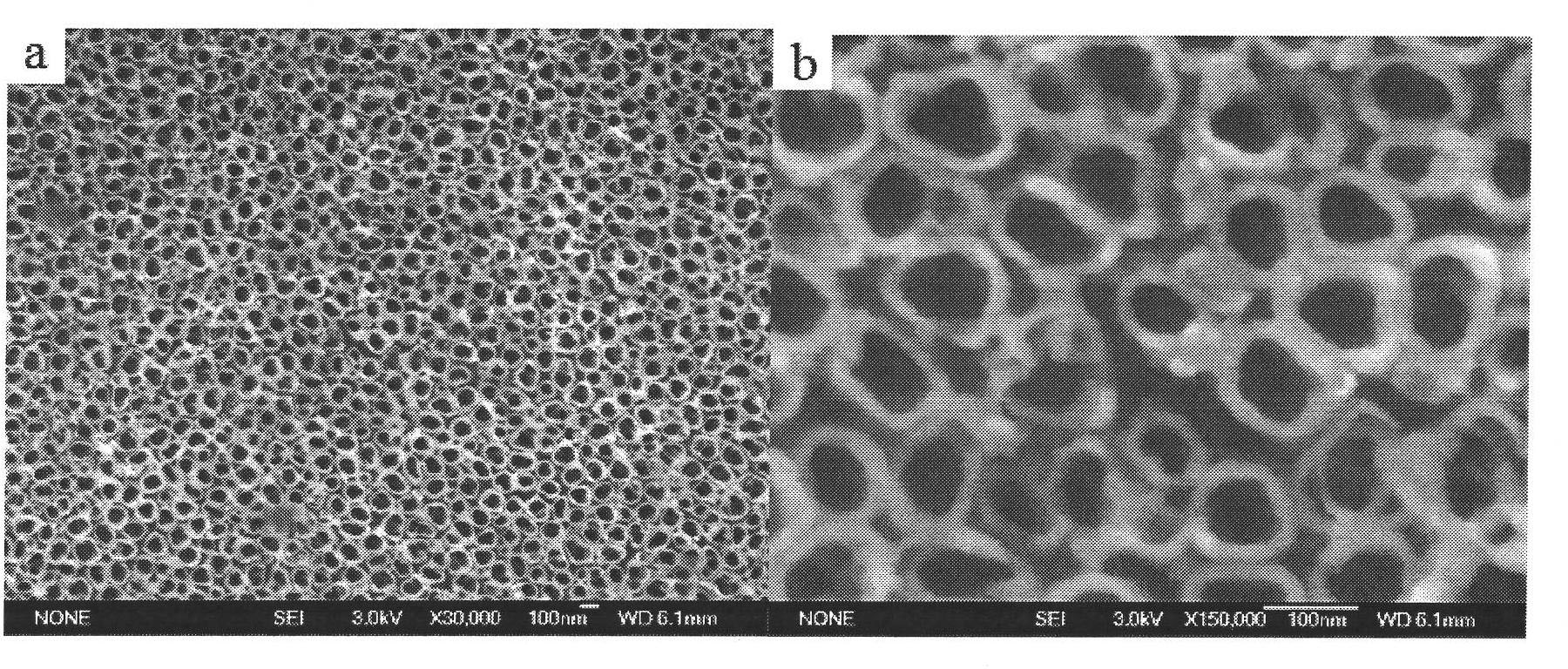

Nanopore array film on stainless steel surface and preparation method thereof

InactiveCN102268713ALess investmentLow priceMaterial nanotechnologyAnodisationElectrochemical anodizationElectrochemistry

The invention particularly relates to a stainless steel surface nano-pore array film and a preparation method thereof. The technical scheme is that: stainless steel treated by surface pretreatment is used as an anode and is placed in a phosphate buffer solution to perform electrochemical anodic oxidation treatment; the time for the electrochemical anodic oxidation treatment is 0.1-4 h; a nano-pore array film is obtained on the treated stainless steel surface; the voltage for the electrochemical anodic oxidation is 10-80 V, and the temperature for the electrochemical anodic oxidation is -5 to 40 DEG C. The preparation method of the invention is simple, effective, environment-friendly, and low in cost; the stainless steel surface nano-pore array prepared by the method has a structured and ordered structure, a high density, a controllable pore diameter and pore depth, and no other impurity elements intervened, is firmly combined with the substrate, and has strong corrosion resistance andhigh hardness.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing titanium-alloy super-hydrophobic surface with low roughness

ActiveCN103966643AReduce roughnessImprove hydrophobicitySurface reaction electrolytic coatingElectrochemical anodizationMetallic materials

The invention provides a method for preparing a super-hydrophobic surface with low roughness on titanium alloy, belongs to the field of surface treatment on metal materials, and relates to a technical method for preparing a titanium-alloy super-hydrophobic surface by adopting electrochemical anodic oxidation in an alkaline solution. The titanium-alloy super-hydrophobic surface with the low roughness is prepared by the adoption of the electrochemical anodic oxidation in the alkaline solution, and the method comprises the following steps: adopting metallographic abrasive paper to polish the titanium alloy; putting the polished titanium alloy into acetone, ethanol and deionized water respectively for ultrasonic cleaning in order to eliminate oil stain; placing a titanium-alloy plate adopted as the anode and a graphite plate adopted as the cathode in parallel symmetrically, and connecting the titanium-alloy plate, which is connected with the positive pole, and the graphite plate, which is connected with the negative pole, with a direct current supply through conducting wires respectively; conducting anodic oxidation; after the anodic oxidation, putting the titanium alloy into the deionized water for ultrasonic cleaning. The method is economical, high-efficient, simple in technology and good in controllability; particularly, the prepared super-hydrophobic surface is low in roughness.

Owner:DALIAN UNIV OF TECH

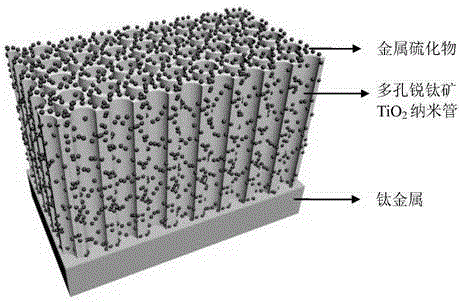

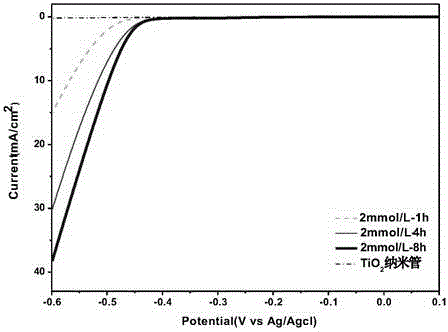

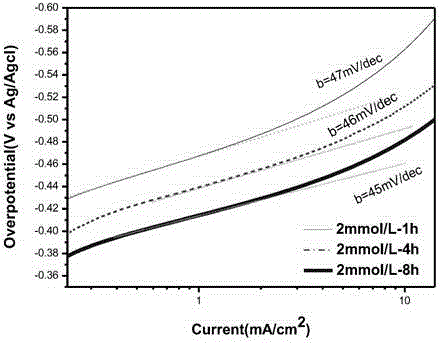

Metal sulfide electrode with hydrogen reduction activity and preparation method of metal sulfide electrode

InactiveCN104313637AThe synthesis method is simpleLow costElectrodesPorous substrateReduction Activity

The invention discloses a metal sulfide electrode with a hydrogen reduction catalytic function and a preparation method of the metal sulfide electrode, belonging to the fields of inorganic chemistry and catalysis. The electrode contains metal titanium, porous anatase TiO2 nanotubes grown on the surface of titanium and metal sulfide nanoparticles loaded on the surfaces of the nanotubes. The preparation method comprises the following steps: firstly preparing the anatase TiO2 nanotubes with a porous structure on the surface of metal titanium by an electrochemical anode oxidation method; then placing the TiO2 nanotubes into a solution containing molybdenum ions or tungsten ions, and irradiating ultraviolet light on the surface; and reducing the molybdenum ions or the tungsten ions by utilizing the photocatalytic reduction of the TiO2 nanotubes under the ultraviolet light to generate MoS2 or WS2 nanoparticles. The metal sulfide electrode prepared by the preparation method disclosed by the invention shows hydrogen reduction catalytic activity and has the characteristics of low cost, simple preparation method and environmental friendliness. In the metal sulfide electrode disclosed by the invention, a metal sulfide catalyst is directly loaded on a conductive porous substrate to form the electrode and can be directly applied to hydrogen reduction reaction, and the catalyst particles do not need to be fixed.

Owner:BEIHANG UNIV

Process for preparing photocatalyst composite material

InactiveCN1724143AGuaranteed efficientIncrease the reaction areaCatalyst activation/preparationSuperimposed coating processElectrochemical anodizationRare earth

A composite photo-catalyst for cleaning air and treating drinking water and sewage is prepared from foam metal or metallic net through electrochemical anodizing to its surface, flash plating in the low-concentration aqueous solution containing Cu and RE to form binding layer and diffusing layer, electrophoresis in the organo-titanium sol with photo-catalytic activity, drying in air and low-temp sintering. It has high specific surface area, photo-catalytic activity and antibacterial performance.

Owner:SHANGHAI EAWADA ENVIRONMENTAL TECH CO LTD

Titanium alloy surface self-lubricating layer and preparation method thereof

InactiveCN101519783ASurface reaction electrolytic coatingSolid/suspension decomposition chemical coatingTio2 nanotubeElectrochemical anodization

The invention relates to a titanium alloy surface self-lubricating layer and a preparation method thereof, which belong to the technical field of mechanical lubrication. The structure of the self-lubricating layer is as follows: titanium-dioxide nanometer-tube arrays are formed on the titanium alloy surface, and solid lubricating agent is filled into titanium-dioxide nanometer tubes. The preparation of the self-lubricating layer is as follows: the surface of a titanium alloy matching part forms a titanium-dioxide nanometer-tube array film by an electrochemical anode oxidizing way, and annealing treatment is carried out in the air; and hollow cage-shaped tungsten-disulfide nanometer solid lubricating agent is filled in the nanometer tubes. In the mutual-friction process of the matching part, the nanometer solid lubricating agent in a composite layer is released to give excellent self-lubricating performance to the titanium alloy, is suitable for no-oil lubricating occasions of high and low temperatures, vacuum, pollution avoidance and no maintenance, and has an important application prospect in high-tech fields relevant to mechanical transmission.

Owner:JILIN UNIV

Method for micro-processing patterned surface based on super hydrophilic-super hydrophobic characteristic template

The invention provides a method for micro-processing a patterned surface based on a super hydrophilic-super hydrophobic characteristic template, and relates to a super hydrophilic-super hydrophobic characteristic template. The invention provides a method for micro-processing the patterned surface based on a super hydrophilic-super hydrophobic characteristic template, which has the advantages of strong practicability, easy operation, strong controllability and simple equipment, and is based on a super hydrophilic-super hydrophobic characteristic template technique and suitable for common laboratories. The method comprises the following steps of: performing the electrochemical anode oxidation of a substrate to obtain a membranous layer with a nano-ordered TiO2 nano-array structure, performing heat treatment on the membranous layer, t cooling the membranous layer to obtain a sample, soaking the sample in solution of fluorine silicane methanol, taking the sample out, and drying the sample to obtain the super hydrophobic TiO2 nano-structure array membranous layer; covering a photomask on the surface of the membranous layer, and obtaining a super hydrophilic-super hydrophobic pattern of which the size and the shape are consistent with those of the photomask on the surface of the substrate by ultraviolet irradiation; and preparing the surface micron-nano structure of which the pattern size and the shape are consistent with those of the photomask by taking the super hydrophilic-super hydrophobic pattern as the template through acid or alkali wet chemical etching microprocessing.

Owner:XIAMEN UNIV

Preparation method of nanometer ordered structure biomaterial membranous layer based on super hydro philic/hydro phobic characteristic template

ActiveCN100998892AStrong chemical forceImprove performanceProsthesisTio2 nanotubeElectrochemical anodization

A process for preparing a biologic membrane layer with ordered nanostructure and based on the superhydrophilic / superhydrophobic template includes such steps as electrochemically anodizing on Ti-based material to obtain an ordered TiO2 nanotube array membrane, modifying by FsA-13 to obtain superhydrophobic TiO2 nanotube array membrane, covering with mask, ultraviolet irradiating to obtain a superhydrophiclic pattern, and cathode electrochemical deposition or electrophoretic directional deposition to form a surficial nano-CaP ceramic layer.

Owner:BEIJING NATON TECH GRP CO LTD

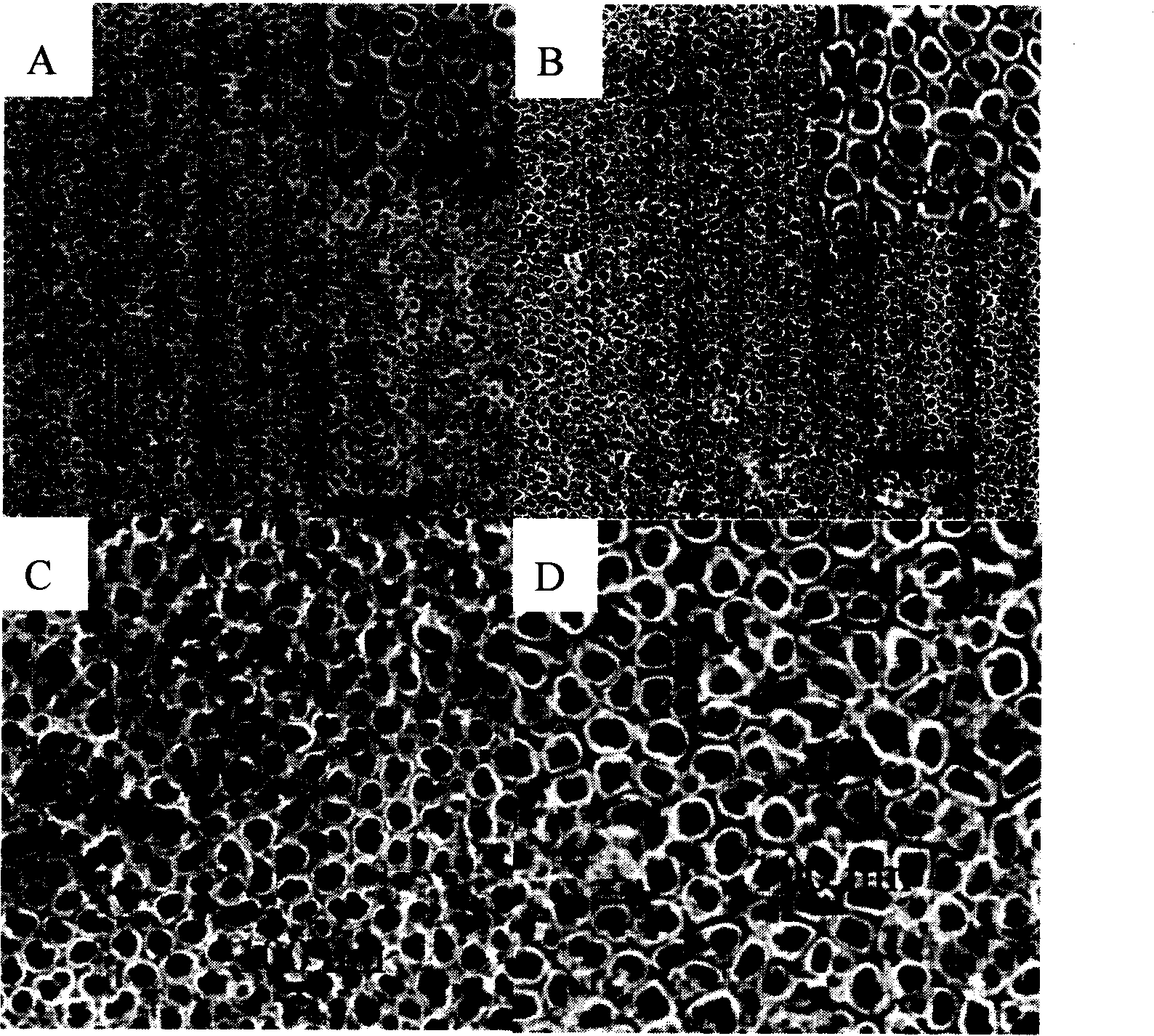

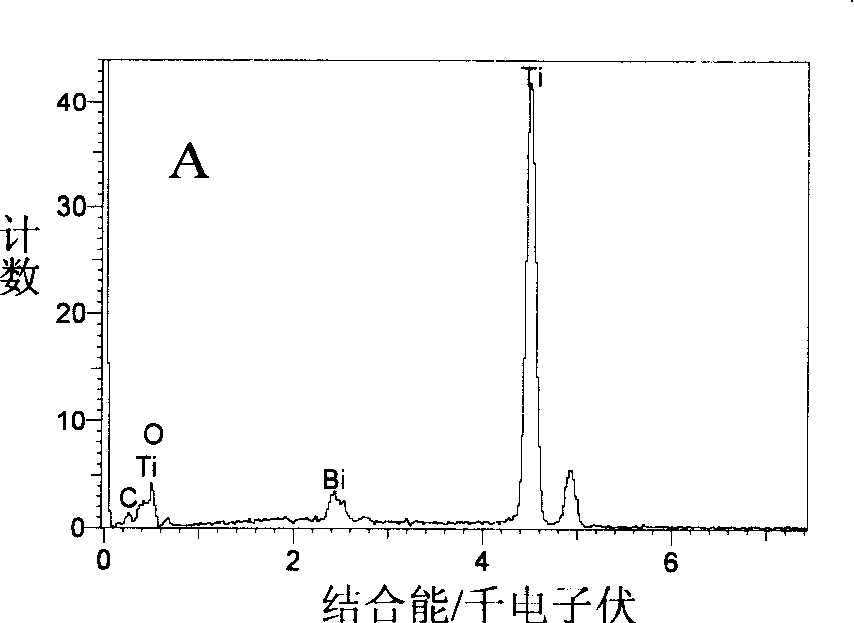

Method for preparing beta-Bi2O3/TiO2-NTs composite photocatalyst with high stability visible light catalytic activity

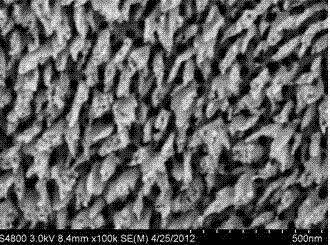

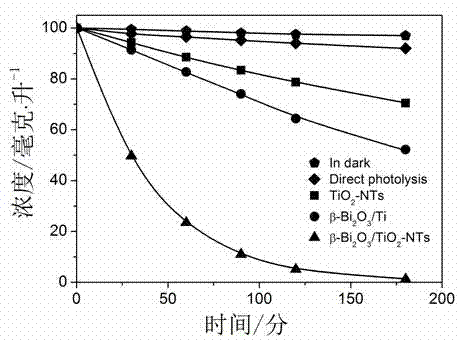

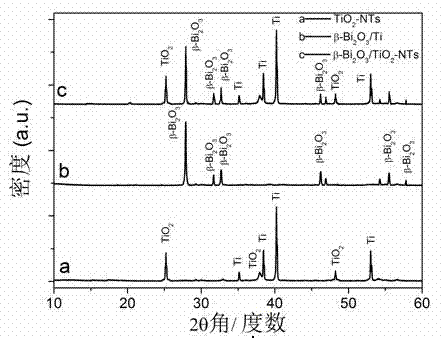

ActiveCN102962051AVisible light catalytic activity is highHigh visible light photocatalytic performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsValence bandTube furnace

The invention relates to a method for preparing beta-Bi2O3 / TiO2-NTs composite photocatalyst with high stability visible light catalytic activity. The method is characterized in that an electrochemical anodization method is adopted; a layer of upright and orderly TiO2-NTs nanotubes are pre-grown on a Ti plate for serving as a middle layer; Bi nano-particles are subjected to pulse electrodeposition in bismuth nitrate solution; and then the mixture is finally placed in oxygen atmosphere of a tube furnace for calcining to form a beta-Bi2O3 crystal form to prepare the beta-Bi2O3 / TiO2-NTs composite photocatalyst. Compared with the conventional alpha-Bi2O3 and TiO2 photocatalysts, the visible-light response of the beta-Bi2O3 / TiO2-NTs composite photocatalyst is prolonged to 495nm. Compared with the conventional beta-Bi2O3 photocatalyst, the valence band electric potential of the beta-Bi2O3 / TiO2-NTs composite photocatalyst is increased to 2.28ev, the hole oxidative capacity is strengthened, and the stability is greatly improved.

Owner:TONGJI UNIV

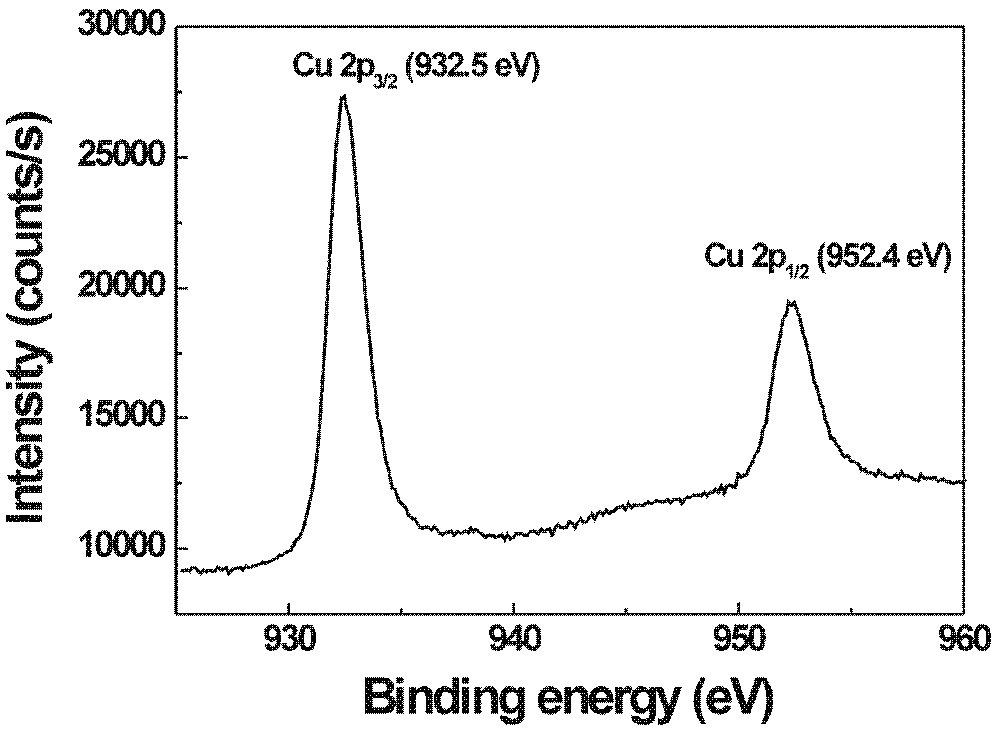

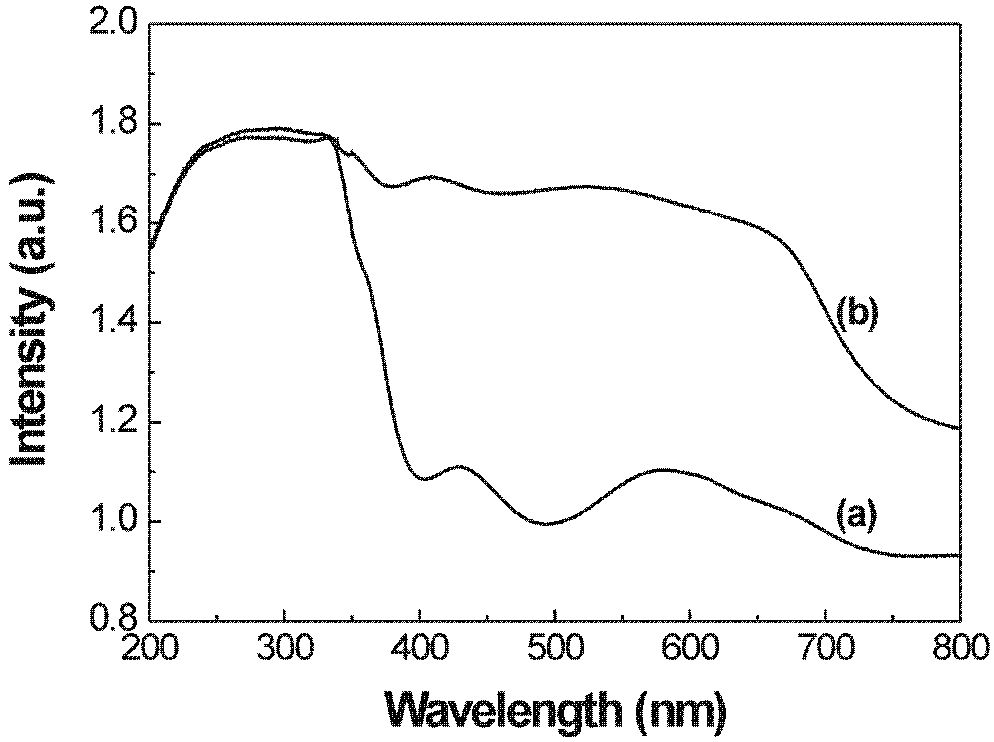

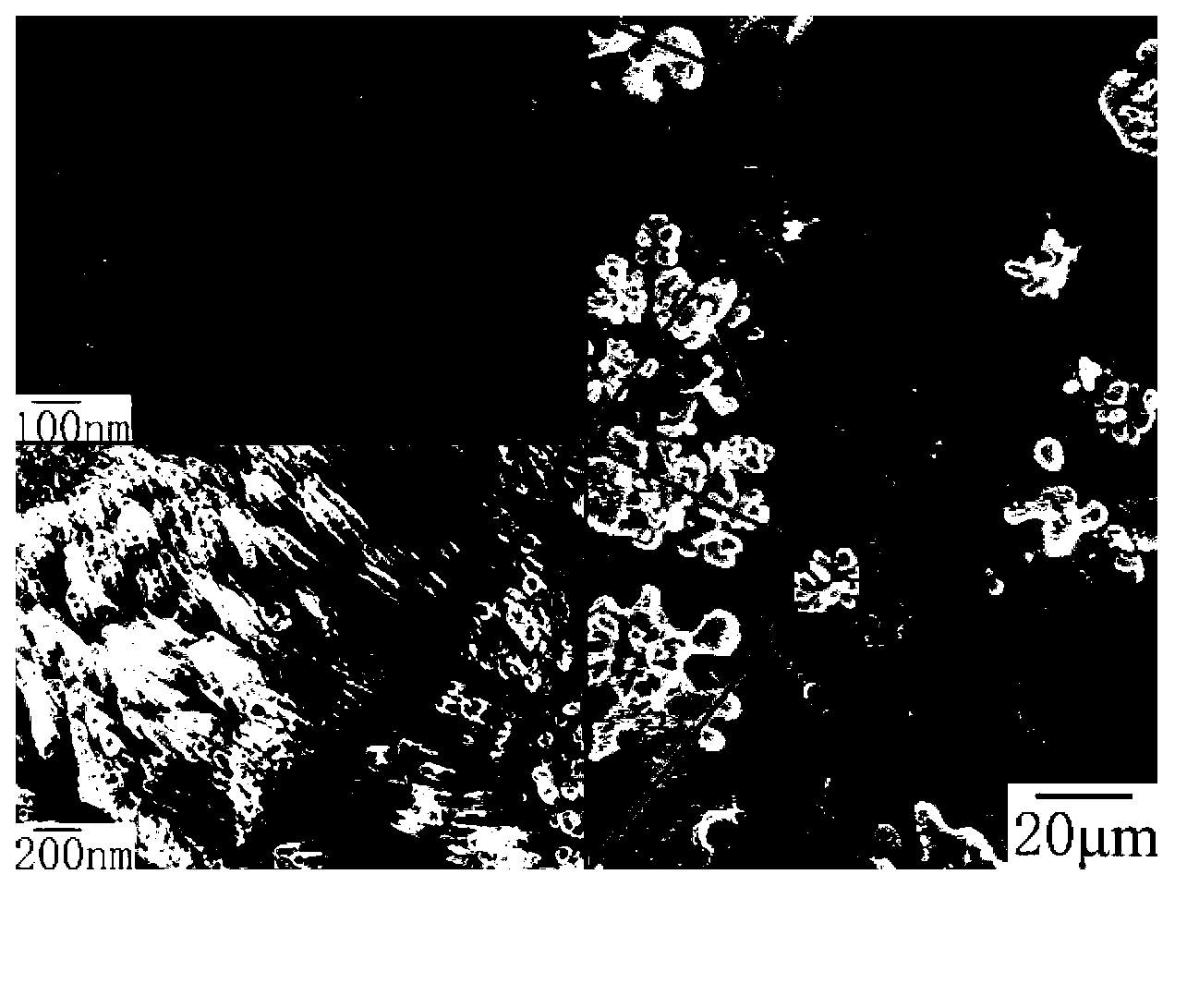

Cu-doping modified TiO2 photocatalyst and preparation method thereof

InactiveCN103007938AAchieve recyclabilityHigh degree of controllabilitySurface reaction electrolytic coatingCatalyst activation/preparationTio2 nanotubeElectrochemical anodization

The invention discloses a Cu-doping modified TiO2 photocatalyst. The Cu-doping modified TiO2 photocatalyst grows on a copper-titanium alloy wire or bar base body and has a two-dimensional structure on the peripheral surface of the copper-titanium alloy wire or bar base body, and the structural unit of the Cu-doping modified TiO2 photocatalyst is a Cu-doping TiO2 nanotube. The invention also discloses a preparation method of the Cu-doping modified TiO2 photocatalyst. The preparation method can be used for directly growing a Cu-doping TiO2 nanotube array which has the two-dimensional structure and higher visible light response property on the copper-titanium alloy wire or bar base body through an electrochemical anode oxidation method. The Cu-doping TiO2 photocatalyst with the two-dimensional structure, which is disclosed by the invention, enlarges the specific area of a TiO2 photocatalyst and effectively extends the forbidden bandwidth of the TiO2 photocatalyst, thereby outstandingly enhancing the adsorptive capacity on a degradation product and obtaining the high-efficiency absorption on a solar spectrum; and the Cu-doping TiO2 photocatalyst is conductive to improving the visible light catalytic activity and has the advantages of good recoverability of the TiO2 photocatalyst, simple process, low cost and high controllable degree.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

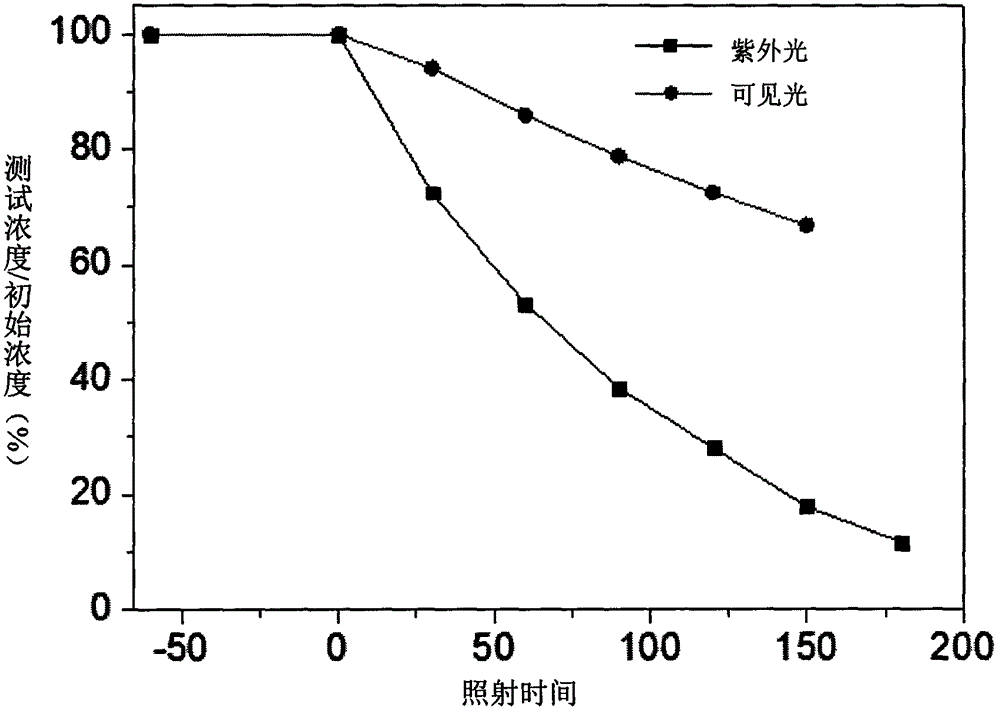

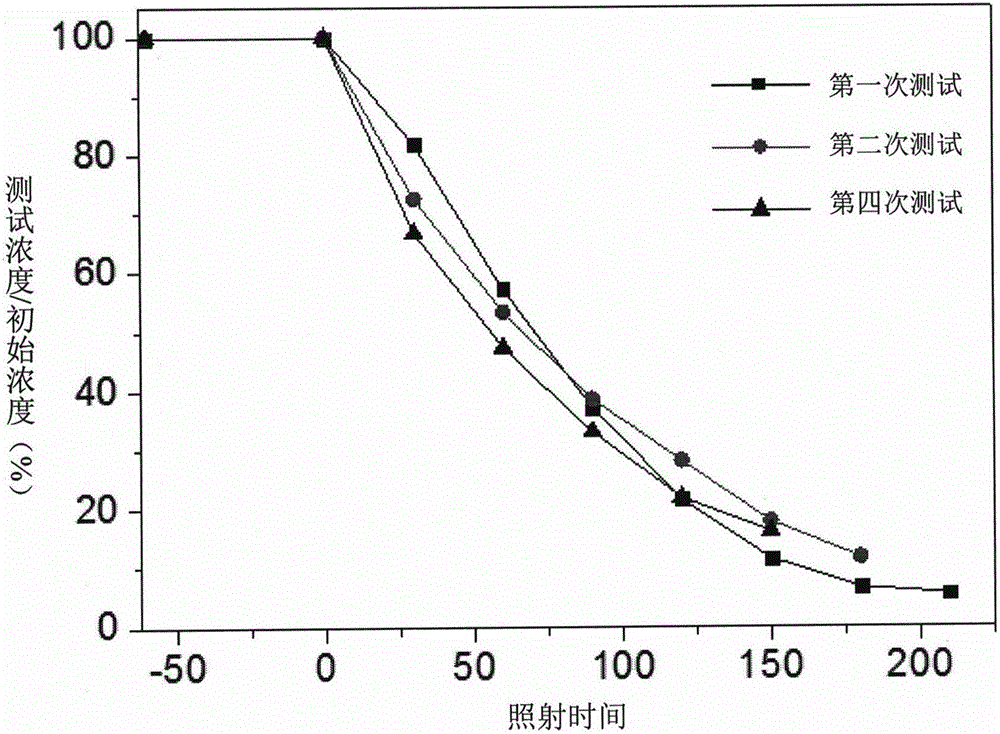

Anodic oxidation preparation method for titanium dioxide nanotube array photocatalyst for degrading rhodamine B

InactiveCN105951154ASynthesis is simple and controllableEasy to recyclePhysical/chemical process catalystsWater/sewage treatment by irradiationElectrochemical anodizationUltraviolet lights

The invention discloses an anodic oxidation preparation method for titanium dioxide nanotube array photocatalyst for degrading rhodamine B. The method comprises the following steps that a titanium sheet is cleaned and used as an electrochemical anodizing substrate material; different systems of electrolytes are prepared; a titanium dioxide nanotube array is prepared through a certain duration of electrochemical anodizing oxidation under a certain voltage; the titanium dioxide nanotube array with the corresponding crystal form is obtained through thermal treatment; and the obtained titanium dioxide nanotube array is used for degrading an organic dyestuff rhodamine B solution under ultraviolet light and visible light. The rhodamine B solution is basically and completely degraded within 3 hours through the titanium dioxide nanotube array under the irradiation of ultraviolet light, and the degradation effect is still good after repeat for 3-5 times. Meanwhile, the catalyst has a certain degradation effect under the visible light. The catalyst preparation method is simple, and the catalyst is convenient to recycle, has good degradation effect on the rhodamine B and is good in stability and repeatability.

Owner:CHINA JILIANG UNIV

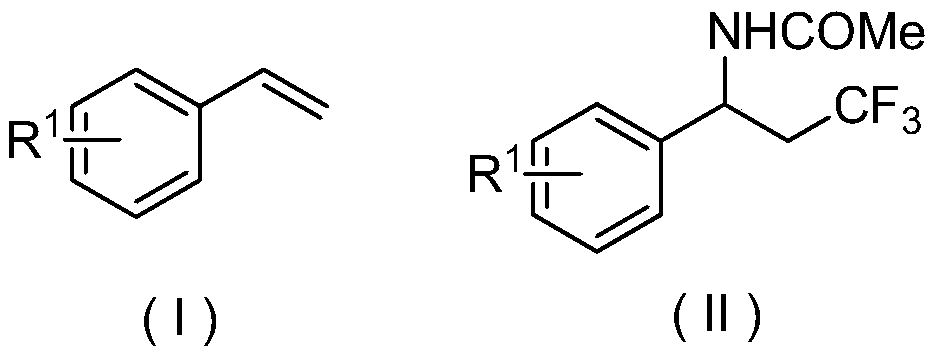

Electrochemical preparation method of beta-trifluoromethylamide compounds

ActiveCN109972165AReduce usageSimple conditionsElectrolytic organic productionElectrodesDistillationElectrochemical anodization

The invention discloses an electrochemical preparation method of beta-trifluoromethylamide compounds. The method comprises the following step: preparing the beta-trifluoromethylamide compounds by using an aryl acetylene compound and a trifluoromethyl source as raw materials through an electrochemical anodic oxidation method. The preparation method further comprises the step of purifying the product obtained by the electrochemical anodic oxidation method, wherein the purification treatment comprises the following processes: after the reaction is completed, adding ethyl acetate for a quenching reaction, adding saturated brine, performing washing, separating the organic phase, performing extraction on the aqueous phase by using ethyl acetate for 3-5 times, merging the organic phase, adding anhydrous sodium sulfate for drying, performing reduced-pressure distillation to remove a solvent, and performing column chromatography to obtain the higher-purity beta-trifluoromethylamide compounds. Compared with the prior art, the solution provided by the invention has the advantages of simple and convenient operation, low production costs and a high yield.

Owner:WUYI UNIV

Iron-cobalt alloy nano linear array permanent-magnetic film material and its preparation

InactiveCN1529330AImprove permanent magnet performanceHigh curie temperatureInorganic material magnetismMagnetic film to substrate applicationFerrocobaltElectrochemical anodization

In the invention, pore templet in Nano alumina is prepared by method of electrochemic anode oxidation, and nano line array of ferrocobalt is prepared by method of electrochemic deposition. Diameter of line array of ferrocobalt is in 10nm-50nm, constituent of ferrocobalt is as CoxFe1-x , 20 more than or equal to 20 and less than or equal to 0.60. low temperature annealing of Nano line array of ferrocobalt obtained from electrochemic deposition obtains thin film material of permanent magnetism, performances of which are best when content of cobalt is 30%-40%, and diameter of Nano line is as 10nm-22nm.

Owner:NANJING UNIV

Preparation method of zinc-doped titanium dioxide nano-tube array

InactiveCN102485968AEvenly distributedOrderly rowsSurface reaction electrolytic coatingTio2 nanotubeElectrochemical anodization

The invention belongs to the technical field of photoelectric materials and specially, relates to a preparation method of a zinc-doped titanium dioxide nano-tube array. The preparation method comprises the following steps that 1, an electrolyte of a HF aqueous solution having HF content of 0.3 to 1.0 wt%, an anode of pure titanium foil subjected to surface pretreatment and a cathode of a Pt sheet undergo an electrochemical anodization reaction under direct voltage of 10 to 50V to produce a titanium dioxide nano-tube array; and the titanium dioxide nano-tube array as a cathode, an anode of a platinum sheet and an electrolyte of a Zn(NO3) solution having concentration of 0.1 to 0.5mol / L undergo an electrochemical deposition reaction under direct voltage of 0.3 to 1.0V so that zinc is added into titanium dioxide nano-tube layers and the zinc-doped titanium dioxide nano-tube array is obtained. The preparation method provided by the invention has the advantages that ion implantation time is short; and doped ions Zn<2+> can enter into a titanium dioxide nano-tube under a electric field force and capillary action so that the zinc-doped titanium dioxide nano-tube array having good photoelectric properties and a light absorption range widen to a visible light range is prepared.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Metal and plastic binding method

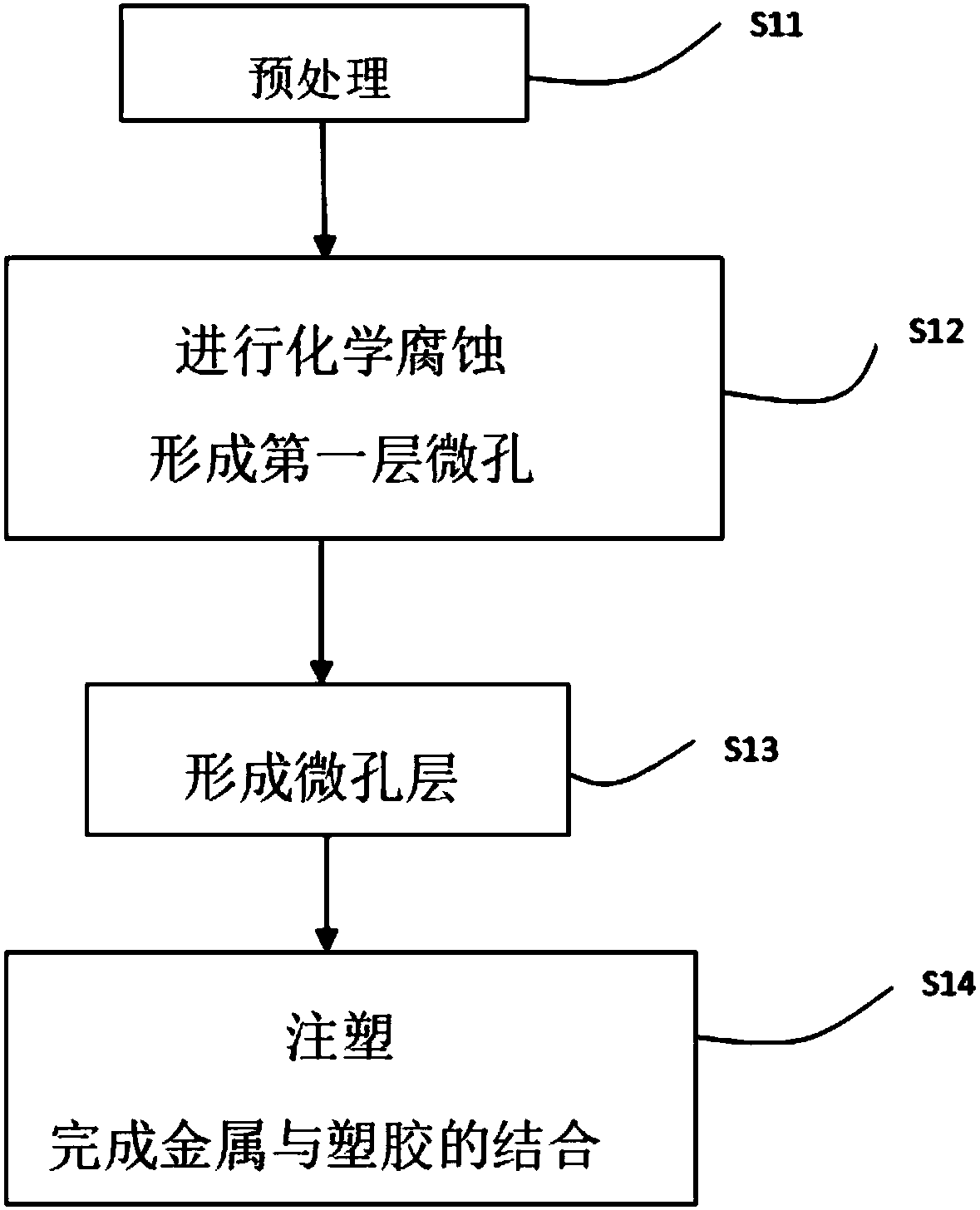

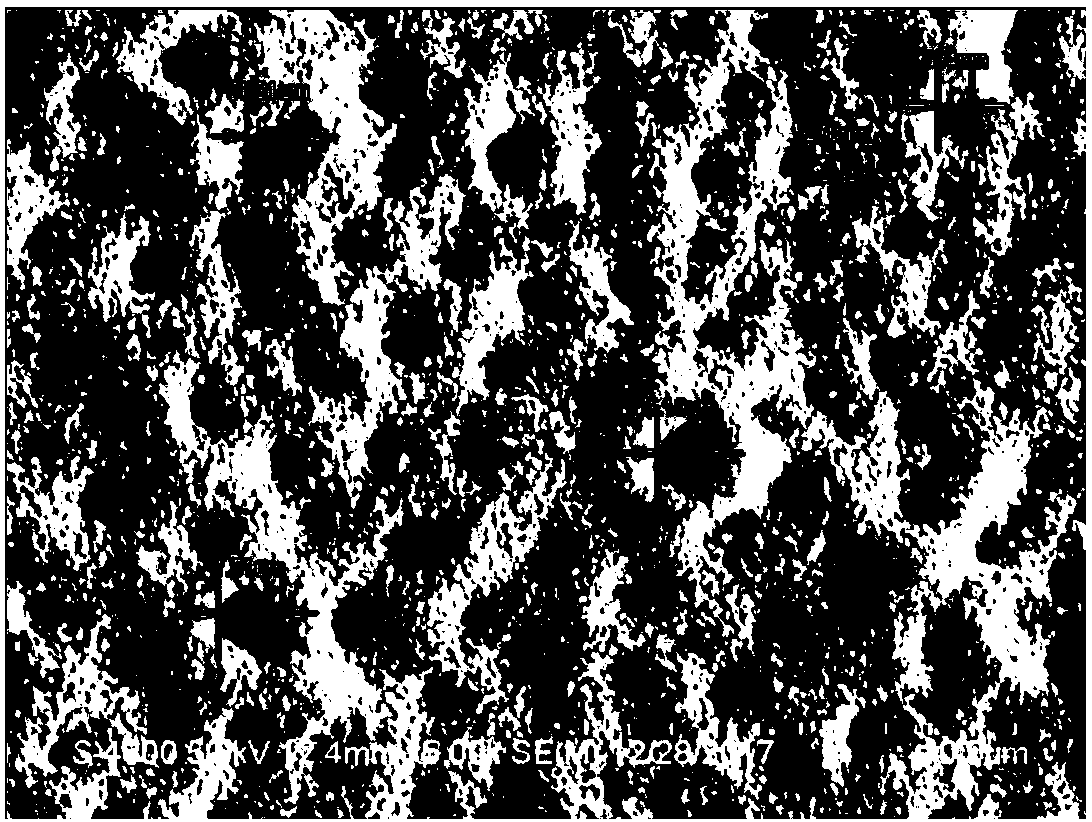

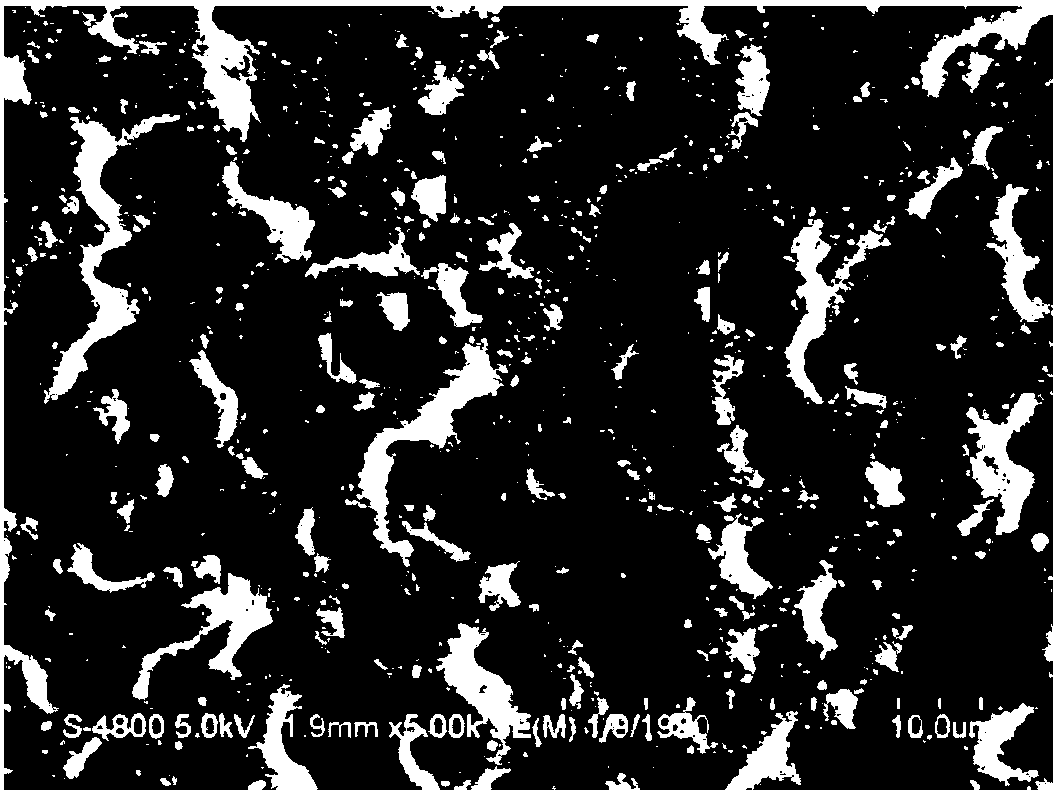

PendingCN108327167AImprove bindingImprove stabilityCoatingsElectrochemical anodizationChemical corrosion

The invention provides a metal and plastic binding method. The metal and plastic binding method is characterized in that through chemical corrosion, a first layer of micropores which are 50-500 nanometers in depth and 10-100 nanometers in diameter is formed; electrochemical anodic oxidation reaction is carried out on the basis of the first layer of micropores, so that a second layer of microporesis formed and an overlapped micropore layer is obtained; and an electrolytic solution adopted in the electrochemical anodic oxidation reaction contains organic amine, so that the micropore layer contains an organic amine component when the micropore layer is formed. With the adoption of the metal and plastic binding method, the binding force of metal and plastics is improved, and the binding stability of the metal and the plastics is also improved.

Owner:广州凯腾新材料科技有限公司

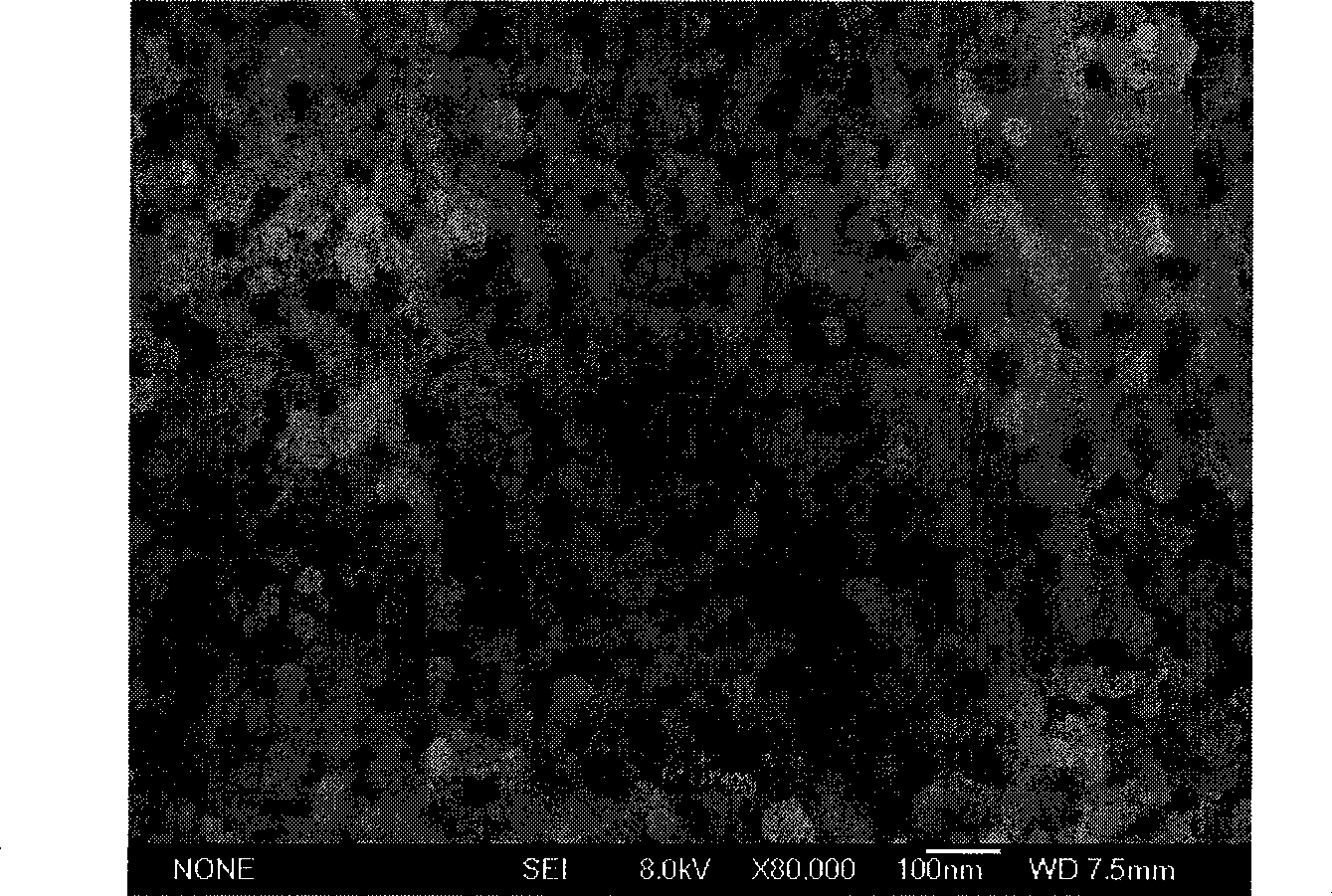

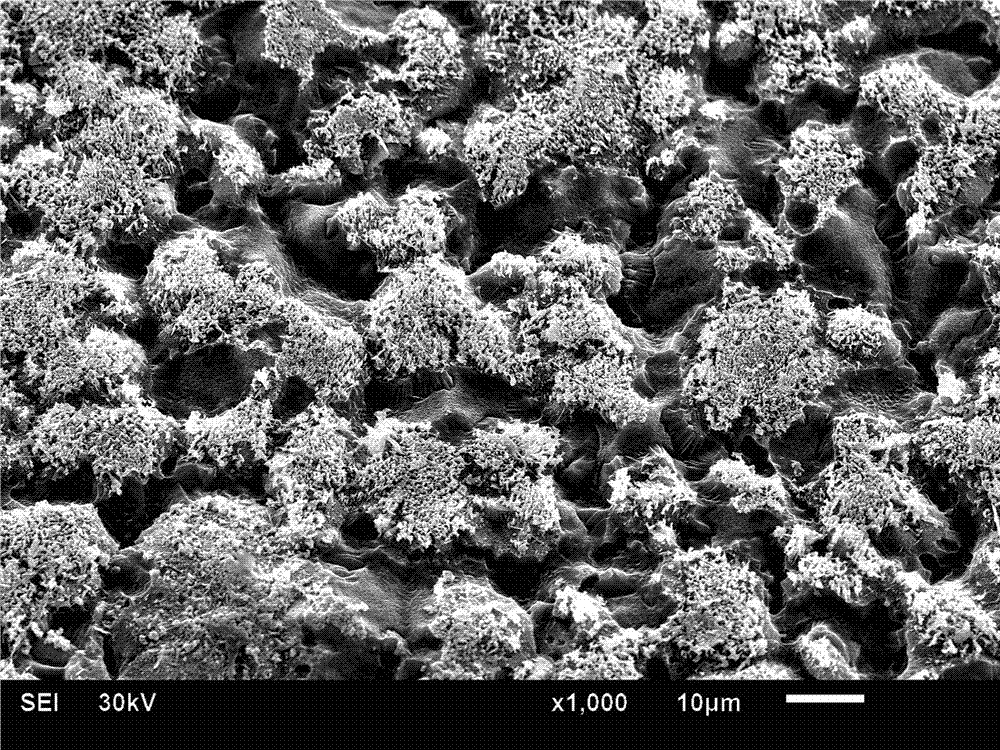

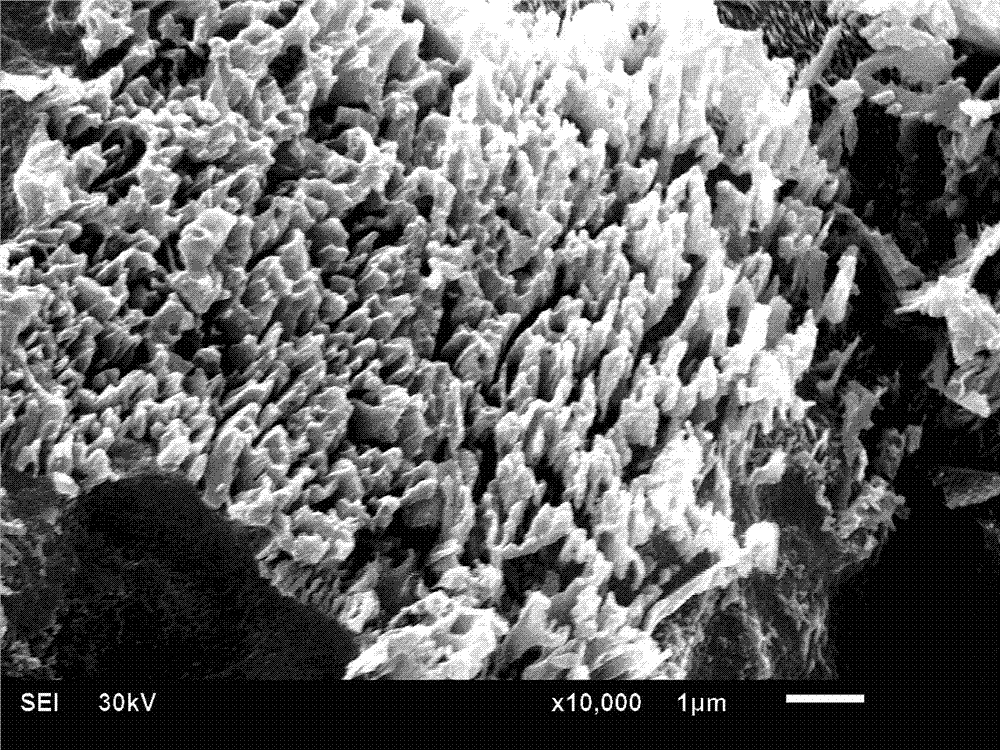

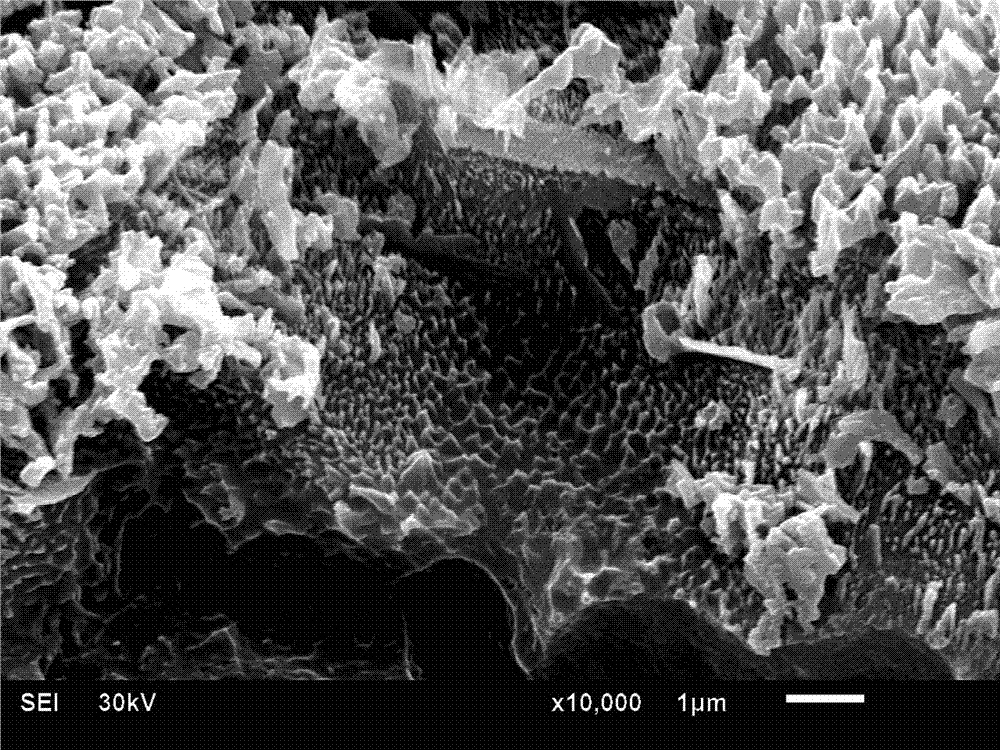

Titanium or titanium-alloy material with micron-nano coarse-structure surface and preparation method thereof

The invention relates to a titanium or titanium-alloy material with a micron-nano coarse-structure surface and a preparation method thereof. According to the material, micron-scale concave-convex structures are distributed on the surface of the titanium or titanium-alloy material, and nano-scale spur structures are distributed on the surfaces of the micron-scale concave-convex structures. The preparation method comprises the steps of sanding, polishing and cleaning the surface of the titanium or titanium-alloy material, and then, carrying out electrochemical anodizing in an electrolyte containing hydrofluoric acid and an acid additive, so as to form a microscopic coarse structure, which is formed by multiple micron-nano concave-convex structures, on the surface of the titanium or titanium-alloy material. The material has the advantages that the combination with a titanium substrate is firm, the falling off is difficult, the biological activity, surface area and surface energy are higher, the material can be applied to a wide range of fields of photocatalysts, solar cells, bio-implants and the like, a better effect can be obtained, and the preparation method is low in cost and is simple and convenient in operation.

Owner:SICHUAN UNIV

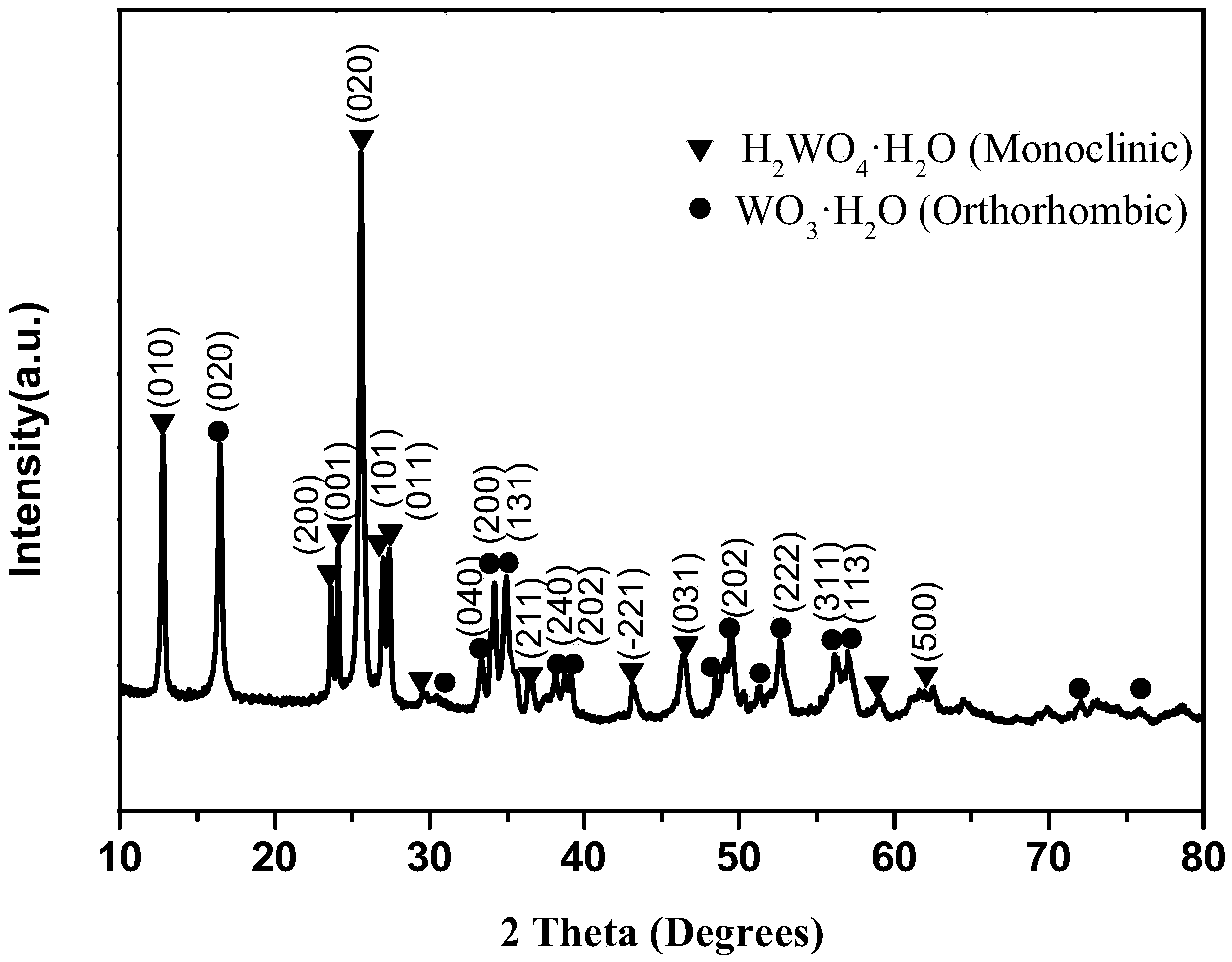

Electrochemical method for preparing tungsten trioxide nanosheets

ActiveCN108034982AHigh powder outputStable in natureSurface reaction electrolytic coatingNanotechnologyElectrochemical anodizationReaction temperature

The invention provides an electrochemical method for preparing tungsten trioxide nanosheets. The method is characterized in that metal tungsten serves as a substrate, in the organic solvent electrolyte containing ionic liquid, and an electrochemical anodic oxidation method is adopted to prepare nano-scale flaky-structure tungsten trioxide powder material; the tungsten oxide nanosheets of differentsize structures are obtained by controlling electrolyte components, the reaction temperature, the oxidation voltage and the oxidation time; and the prepared tungsten trioxide nanosheets are regular in structure and uniform in size, and have relatively large specific surface area. According to the electrochemical method for preparing the tungsten trioxide nanosheets, the preparation process is simple, operation is simple and convenient, the requirement for reaction equipment is low, and being economical and efficient is achieved; and the prepared tungsten trioxide nanosheet powder is high in yield and stable in property, the utilization rate of the powder to the metal tungsten substrate is high, the economic benefit is high, and a wide application prospect in the aspect of industrial application is achieved.

Owner:ZHEJIANG UNIV OF TECH

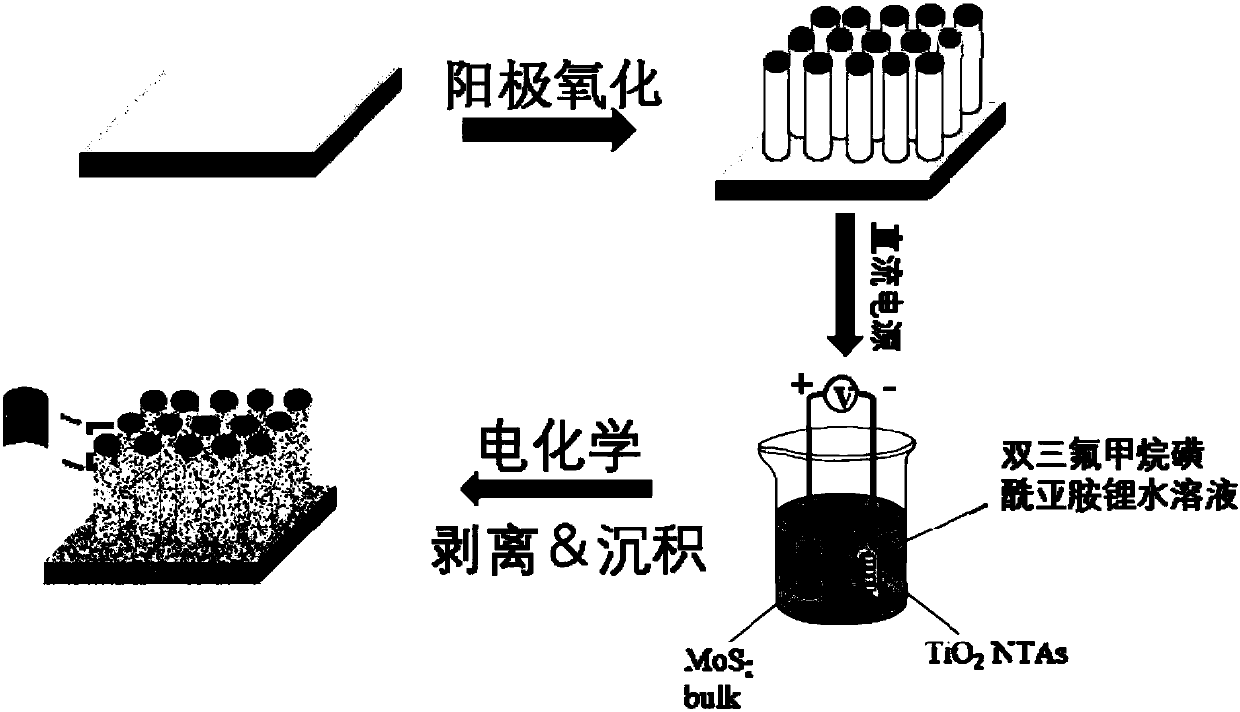

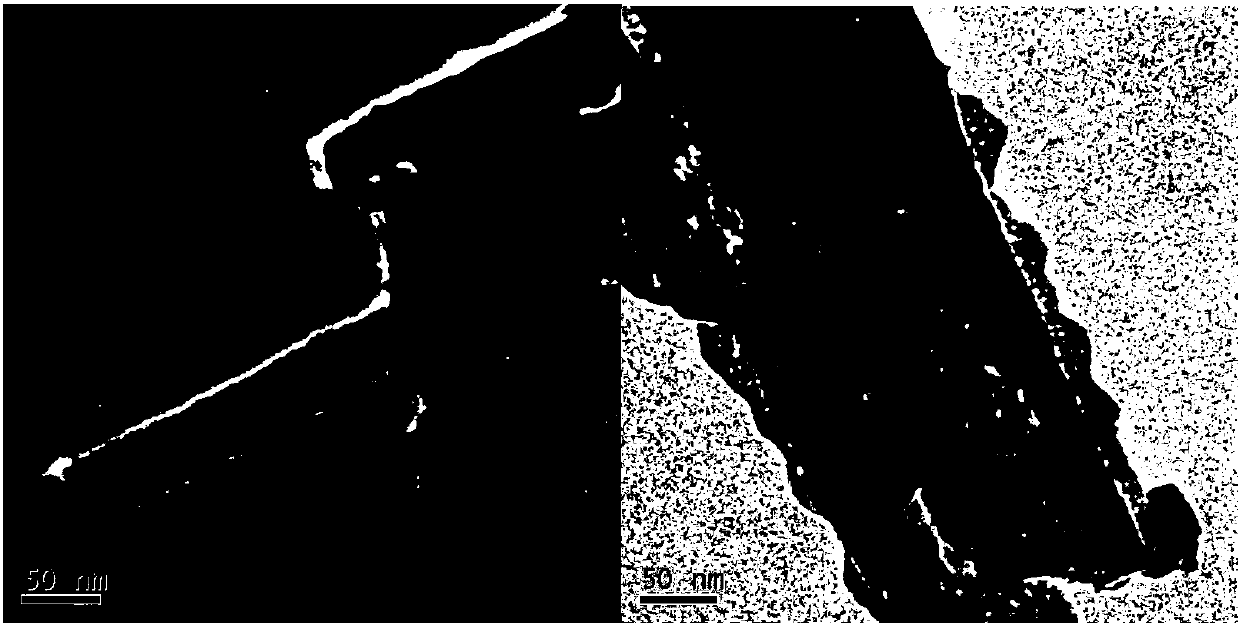

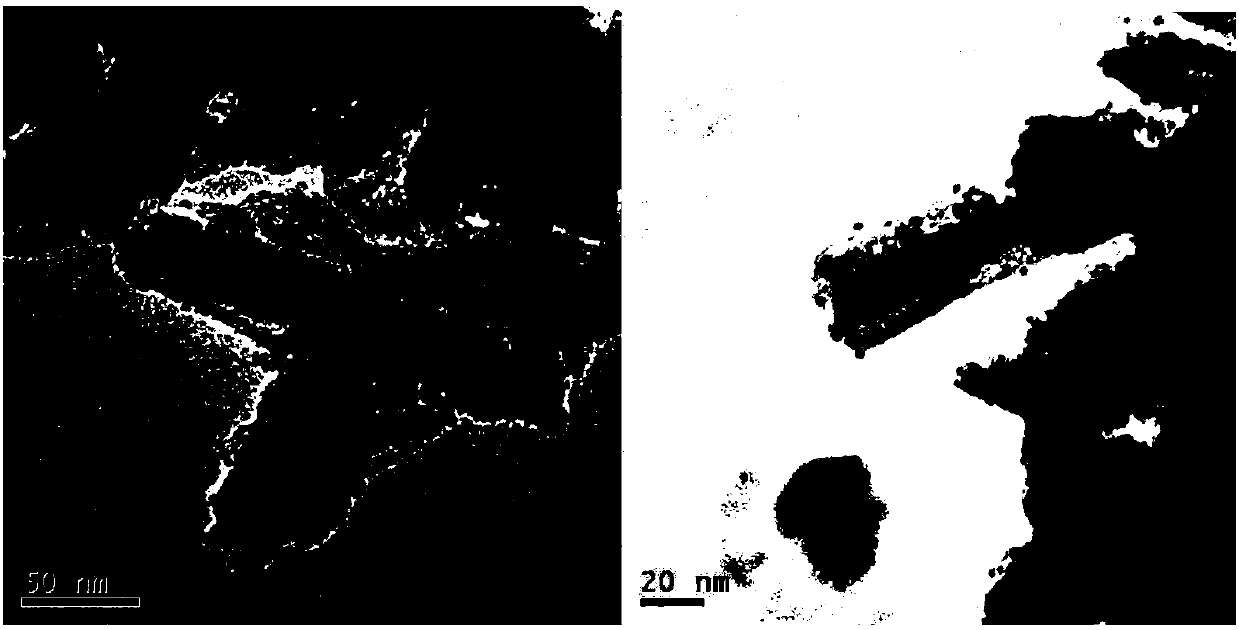

Preparing method for electro-deposition molybdenum disulfide quantum dot modified titanium dioxide nanotube array

ActiveCN107723777AEvenly dispersedEnhanced light absorptionElectrolytic inorganic material coatingSurface reaction electrolytic coatingElectrochemical anodizationPhotocatalytic degradation

The invention discloses a preparing method for an electro-deposition molybdenum disulfide quantum dot modified titanium dioxide nanotube array. The preparing method includes the steps that firstly, cleaning pretreatment is conducted on the surface of a substrate material; an ethylene glycol solution containing ammonium fluoride and water is prepared to serve as an electrolytes, the titanium substrate material is subjected to electrochemical anodic oxidation and is arranged in a muffle furnace to be roasted; then powdery molybdenum disulfide is prepared into piece-shaped molybdenum disulfide through an infrared tablet machine; and finally, by means of a direct-current pressure stabilizing power source, a molybdenum disulfide piece serves as an anode, the titanium dioxide nanotube array serves as the cathode, and a lithium bisimide solution serves as an electrolyte for conducting electrolytic stripping to deposit molybdenum disulfide quantum dots. The titanium dioxide nanotube array cancontrollably deposit the molybdenum disulfide quantum dots, and the TiO2 photo-catalytic efficiency can be improved; and the light absorption capability is improved, a composite material is used for forming a P-N node, and the photo-catalytic degradation capability of electrodes on organic pollutants can be improved when the P-N node is applied to photocatalysis.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST

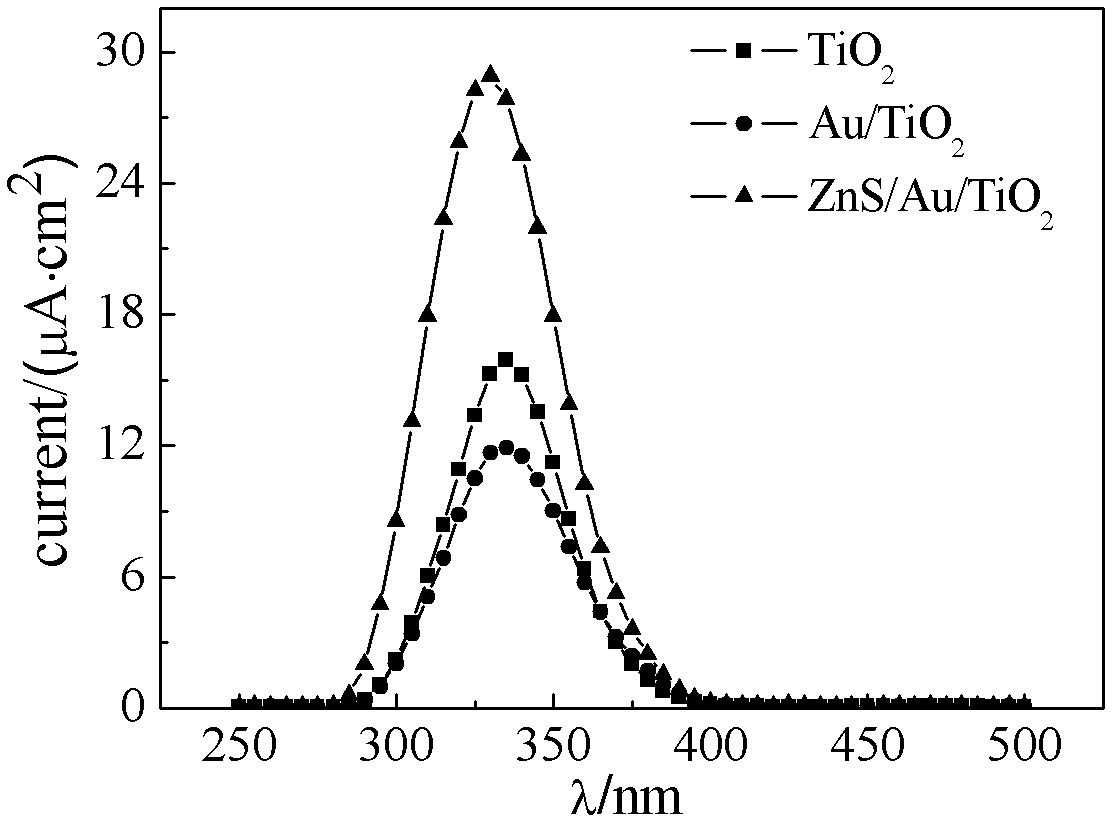

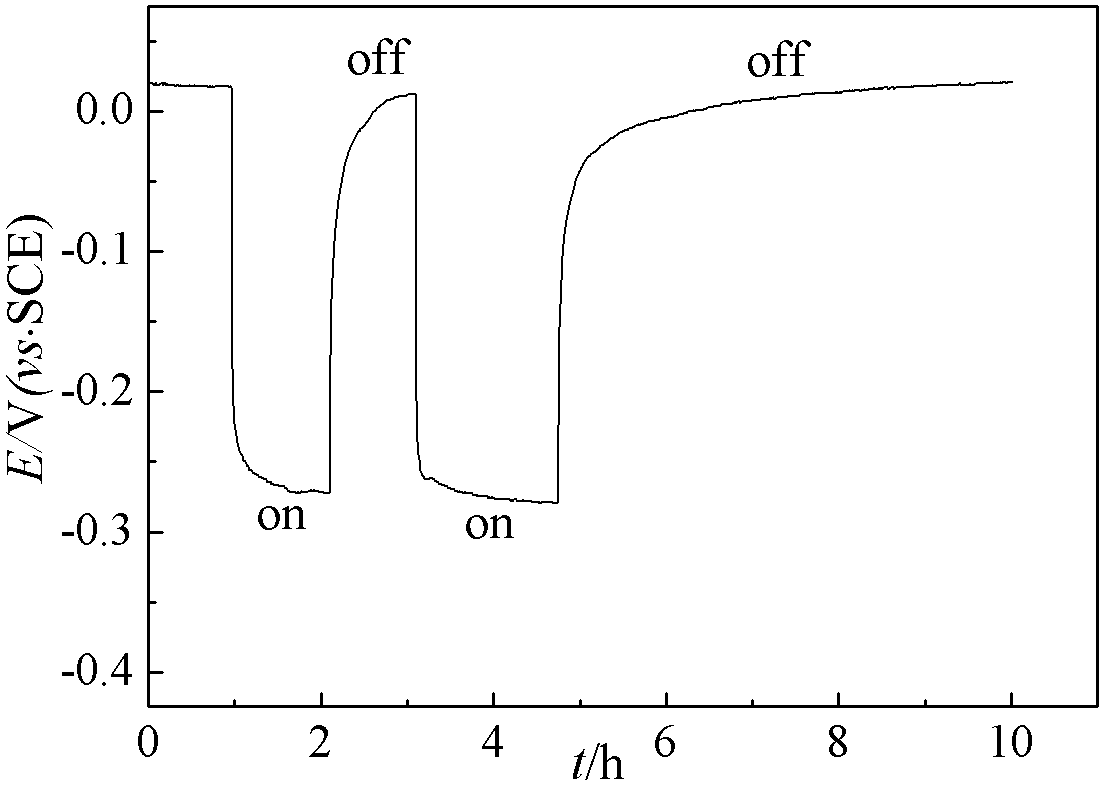

Preparation method of photo-anode of ZnS/Au/TiO2 nano composite film

InactiveCN102360958AAchieve separationAvoid contactLight-sensitive devicesSolid-state devicesComposite filmElectrochemical anodization

Owner:XIAMEN UNIV

PbO2 electrode with high oxygen evolution potential and long service life and preparation method thereof

InactiveCN102043004AIncrease the amount of assemblySolve the shortcomings of weak combinationMaterial electrochemical variablesLead nitrateElectrochemical anodization

The invention relates to a PbO2 electrode with high oxygen evolution potential and long service life and a preparation method thereof. The preparation method comprises the following steps of: pre-growing a layer of erect and orderly TiO2-NTs nanotubes, used as an interlayer, on a Ti plate by using an electrochemical anodization method; and then electrically depositing PbO2 in a lead nitrate solution containing fluorine macromolecules to prepare an F-PbO2 / TiO2-NTs / Ti electrode. Compared with a traditional PbO2 electrode, the PbO2 electrode disclosed in the invention has high oxygen evolution potential of more than 2.4 V and long service life of longer than 20 years.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com