Construction method of titanium surface micrometre-grade pattern based on ultra-hydrophilic/ultra-hydrophobic characteristic

A super-hydrophobic, micron-scale technology, applied in the field of titanium surface, can solve the problems of practical application limitations, complex preparation process, unstable substrate material, etc., and achieve the effect of simple equipment, simple operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

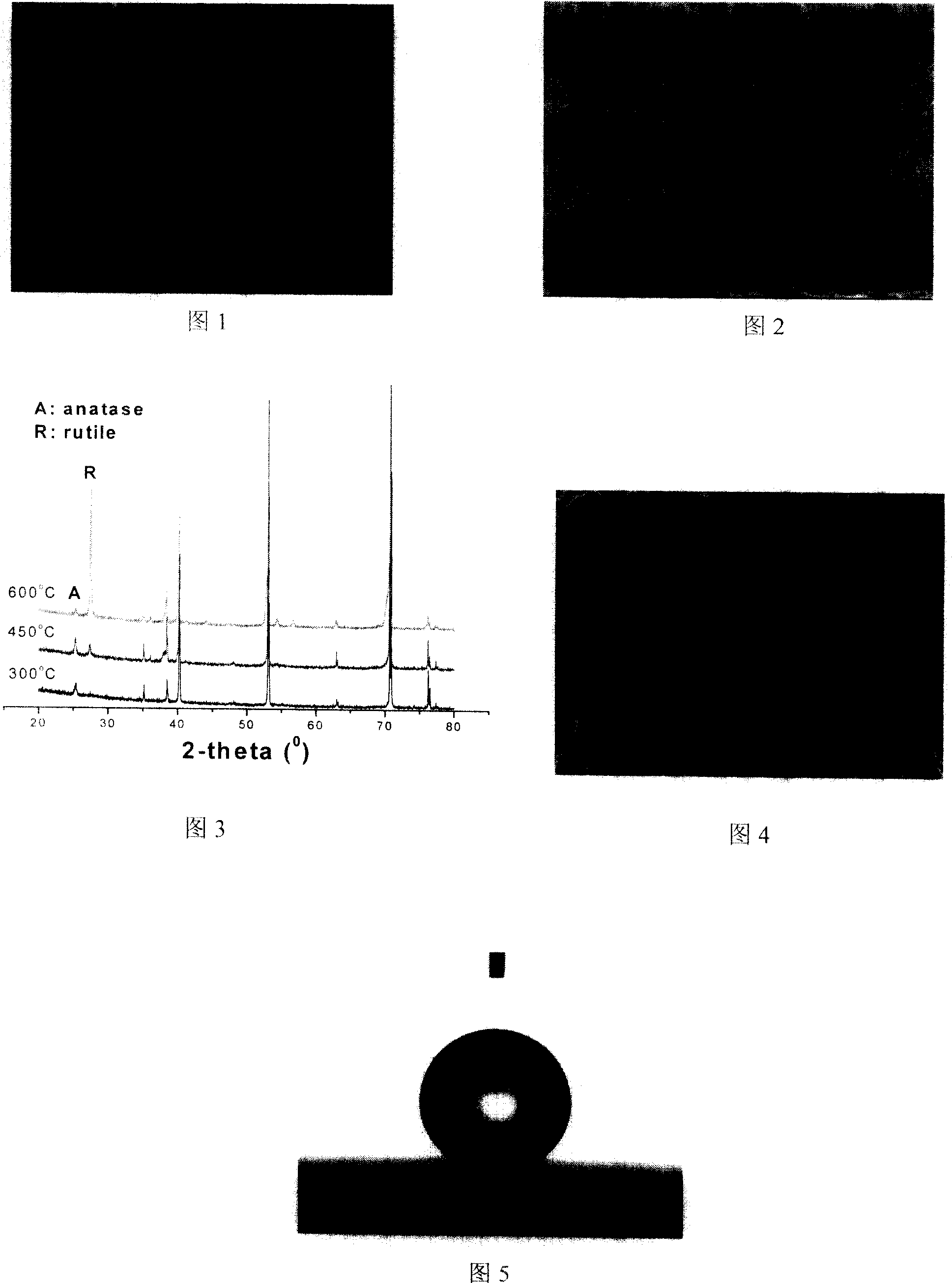

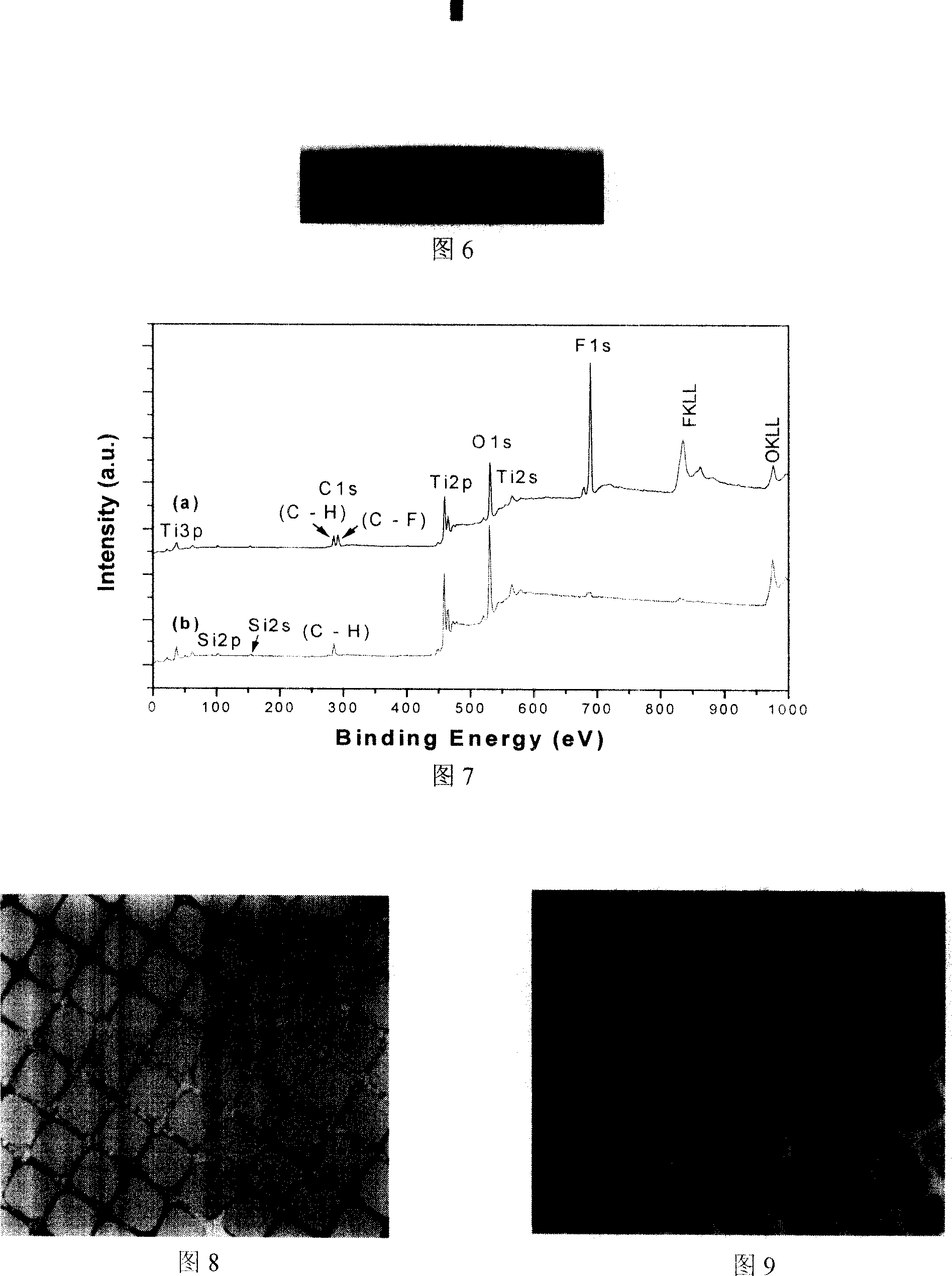

[0024] Embodiment 1: The base material is a pure titanium plate with a thickness of 2mm, the surface is mechanically polished to a mirror surface with metallographic sandpaper, and ultrasonically cleaned with absolute ethanol and deionized water, dried for later use; the electrolyte is prepared as 0.5wt% HF, and the voltage is controlled 20V, at room temperature, use platinum as the counter electrode for electrochemical anodization for 20min, that is, a layer of light red ordered titanium dioxide nanotube film layer is obtained on the surface of the titanium substrate (see TiO2 in Figure 1 2 FESEM image of the film layer), the inner diameter of the tube is 80-90nm, and the thickness of the film layer is about 400nm. Figure 2 is the corresponding TiO 2 FESEM (JSM-6700F, JEOL, Japan) image of the side of the nanotube array. It can be seen that TiO 2 The upper and lower dimensions of the nanopore or tube are basically the same, the upper end is open and the bottom is closed. T...

Embodiment 2

[0030] Embodiment 2: Adopt 400 order photomasks, other preparation conditions are the same as embodiment 1, can be on titanium surface TiO 2 The surface of the nanostructure array film layer is prepared to form a square array of circular superhydrophobic regions with a diameter of 50 μm and a center interval of 65 μm, and a superphilic / superhydrophobic pattern formed by other superhydrophilic regions.

Embodiment 3

[0031] Embodiment 3: with titanium alloy as base material, adopt 300 purpose photomasks, other preparation conditions are the same as embodiment 1, can be on the titanium alloy surface TiO 2 A hexagonal array formed by circular superhydrophobic regions with a diameter of 55 μm and a center interval of 90 μm was prepared on the nanostructure array film layer, and a superphilic / superhydrophobic pattern formed by other superhydrophilic regions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com