Patents

Literature

477 results about "Machining vibrations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machining vibrations, also called chatter, correspond to the relative movement between the workpiece and the cutting tool. The vibrations result in waves on the machined surface. This affects typical machining processes, such as turning, milling and drilling, and atypical machining processes, such as grinding. A chatter mark is an irregular surface flaw left by a wheel that is out of true in grinding or regular mark left when turning a long piece on a lathe, due to machining vibrations.

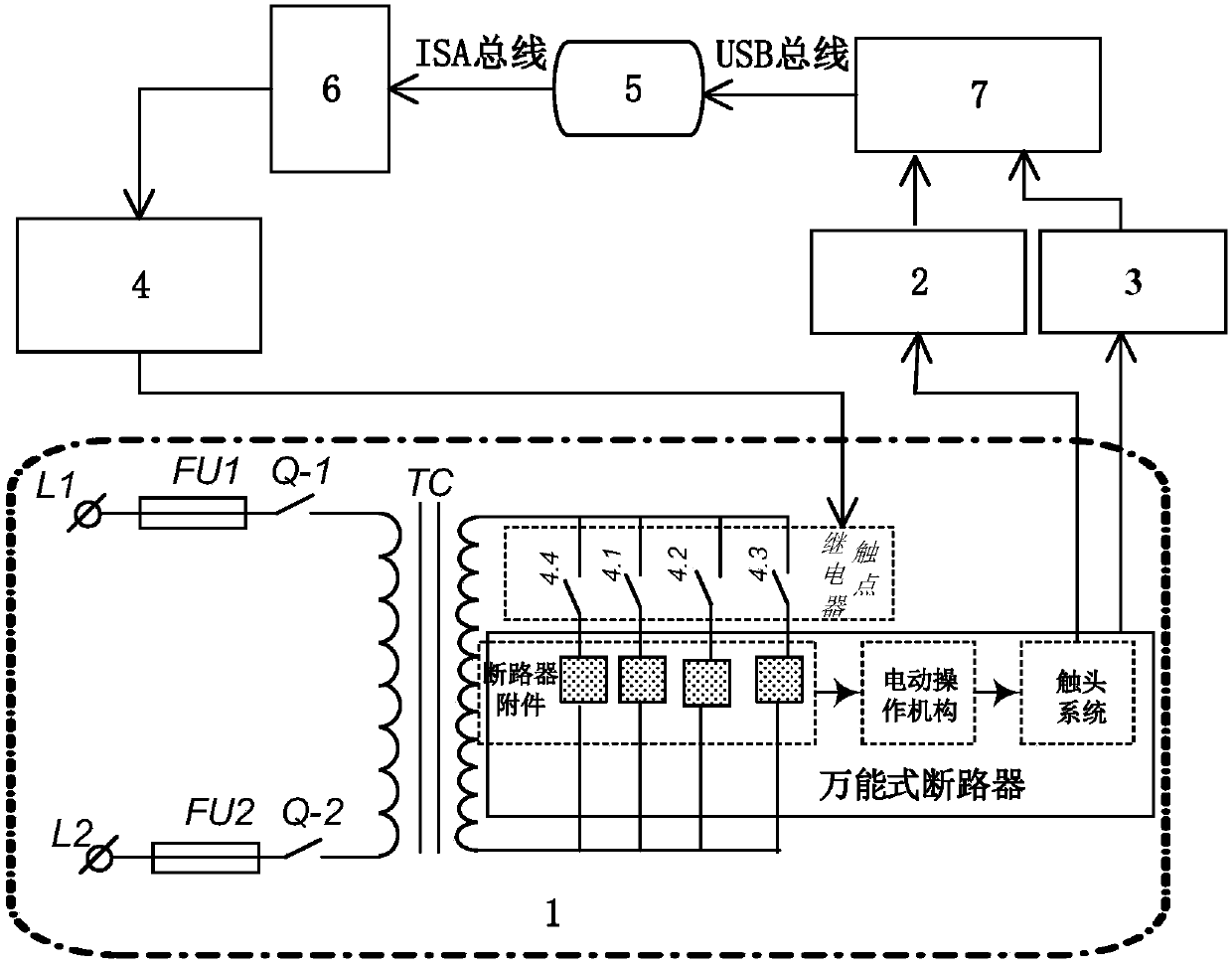

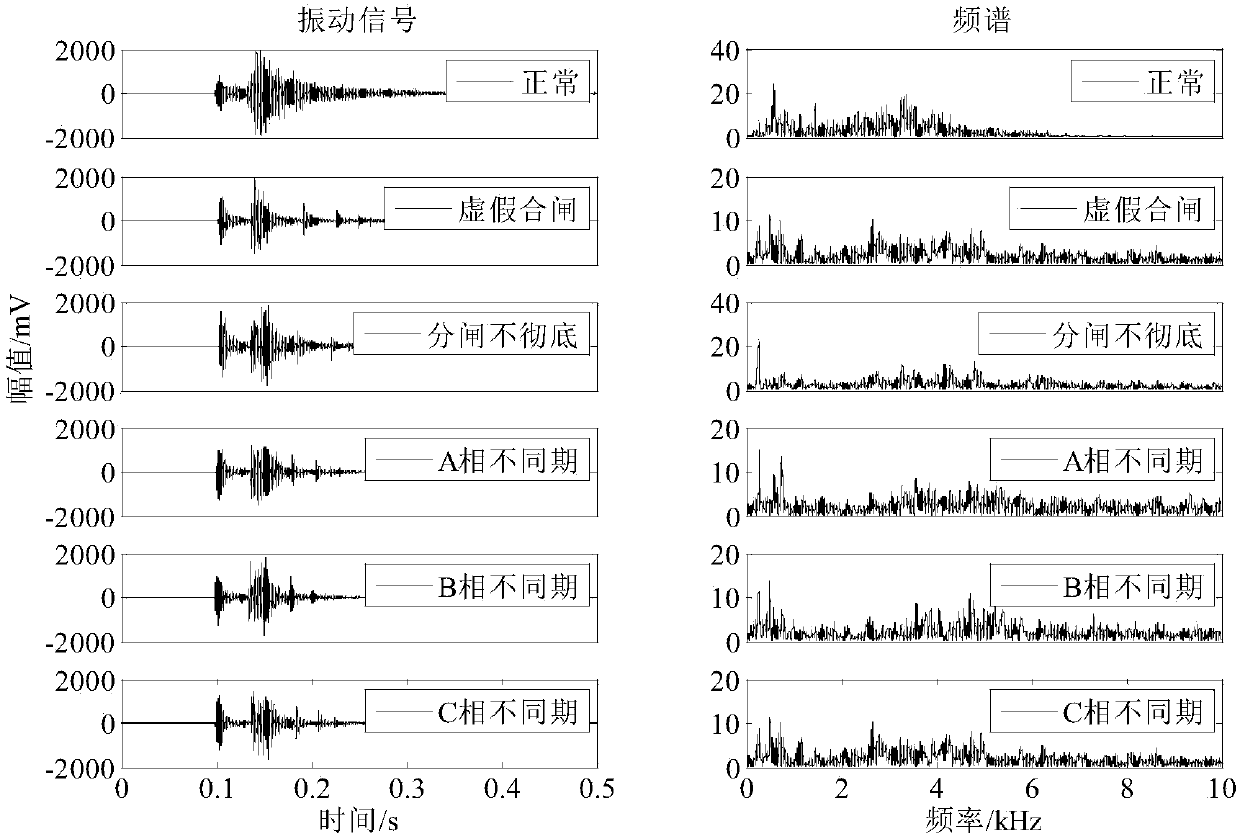

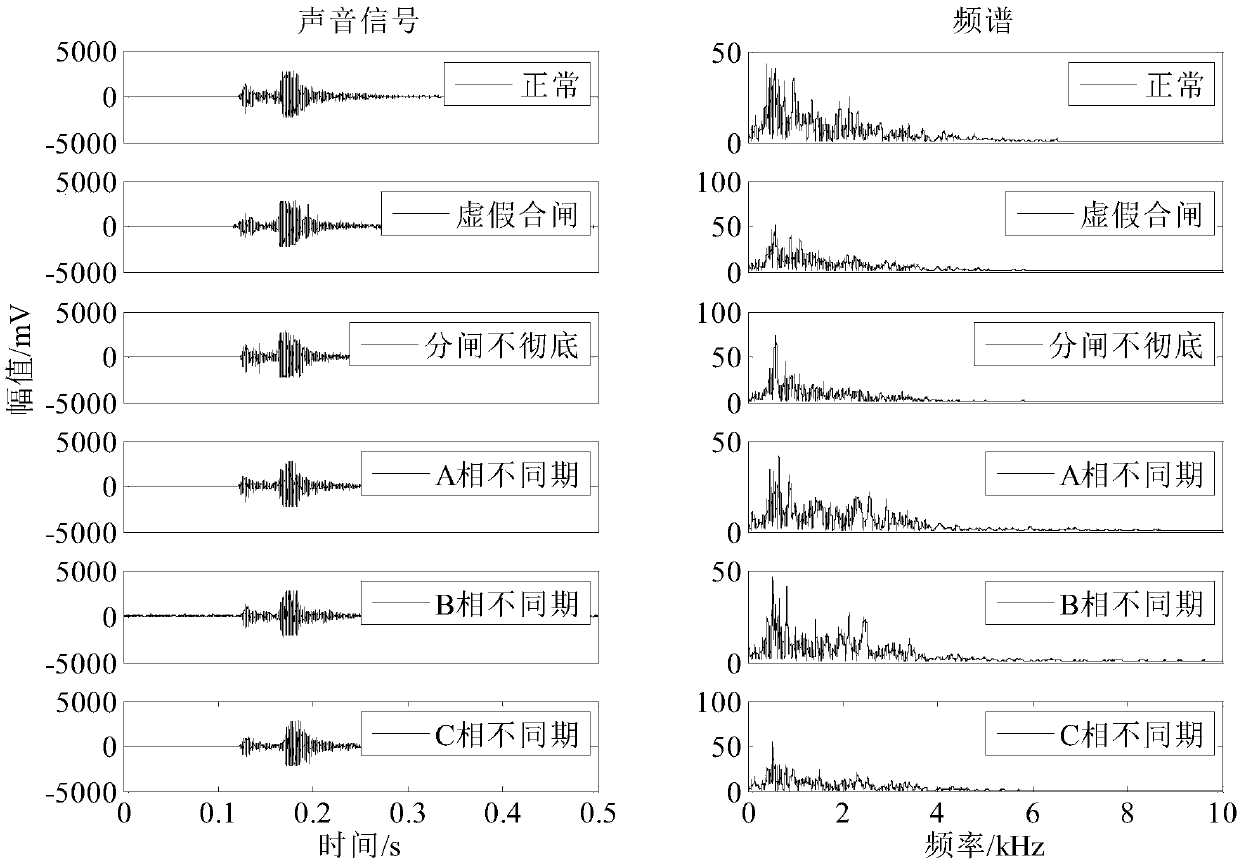

Universal circuit breaker mechanical fault diagnosis method based on feature fusion of vibration and sound signals

InactiveCN106017879AImprove reliabilityThe detection method is simpleMachine part testingCircuit interrupters testingDiagnostic Radiology ModalityMachining vibrations

The invention provides a universal circuit breaker mechanical fault diagnosis method based on feature fusion of vibration and sound signals. The method includes steps of 1, collecting machine vibration signals and machine sound signals during an engaging and disengaging process of a universal circuit breaker; 2, adopting an improved wavelet packet threshold value denoising algorithm for denoising; 3, adopting a complementary total average empirical mode decomposition algorithm for extracting a plurality of solid mode function components reflecting state information of engagement and disengagement actions of the circuit breaker from the denoising signals; 4, determining the number Z of the solid mode function components; 5, calculating the energy ratio, the sample ratio and the power spectrum entropy as three types of features; 6, adopting a combination core principal component analysis method for performing dimension reduction on a feature sample with unified three types of features of the vibration and the sound signals and obtaining M principle components; 7, establishing a related vector machine based sequence binary tree multiple classifier model.

Owner:HEBEI UNIV OF TECH

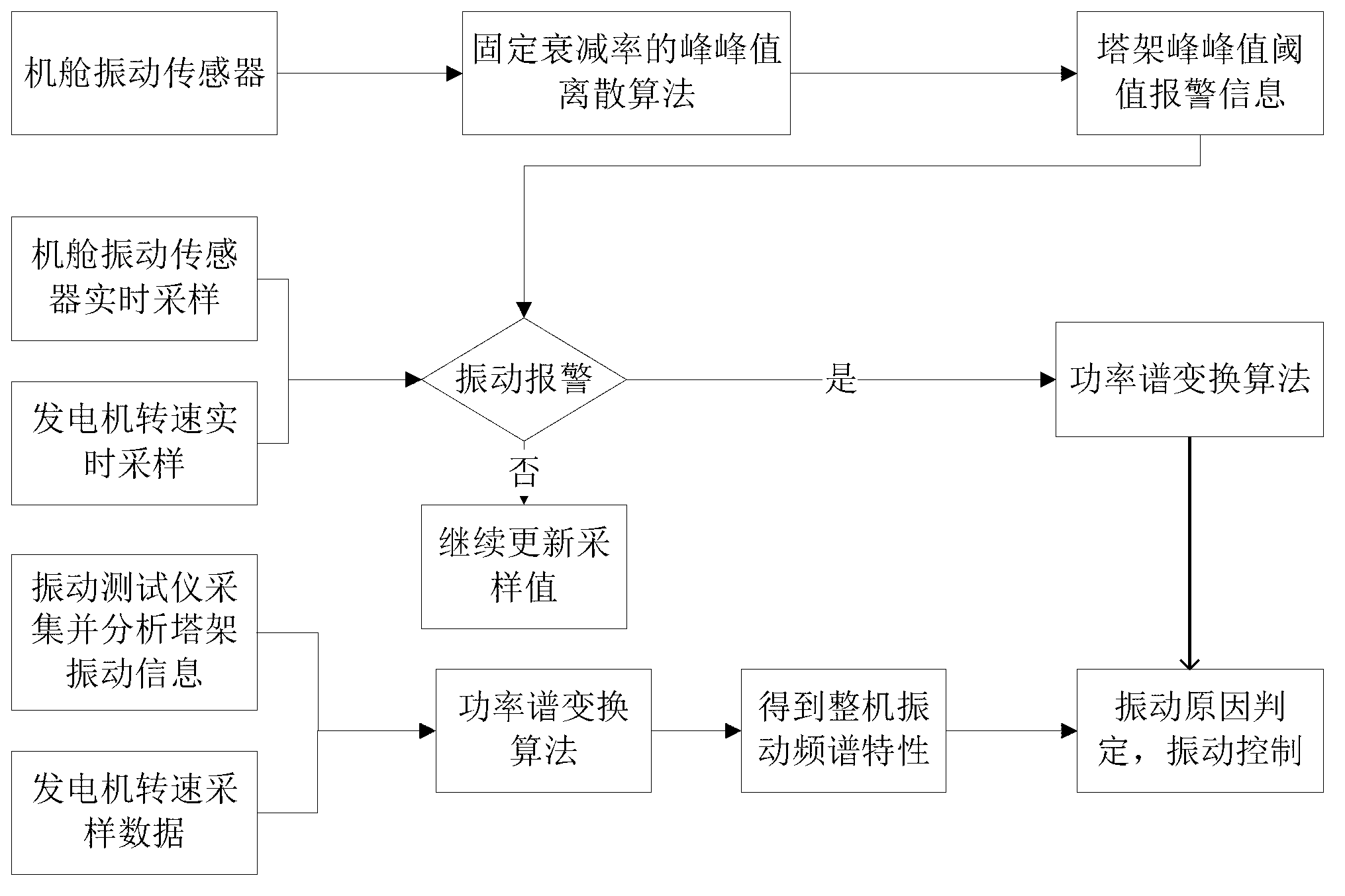

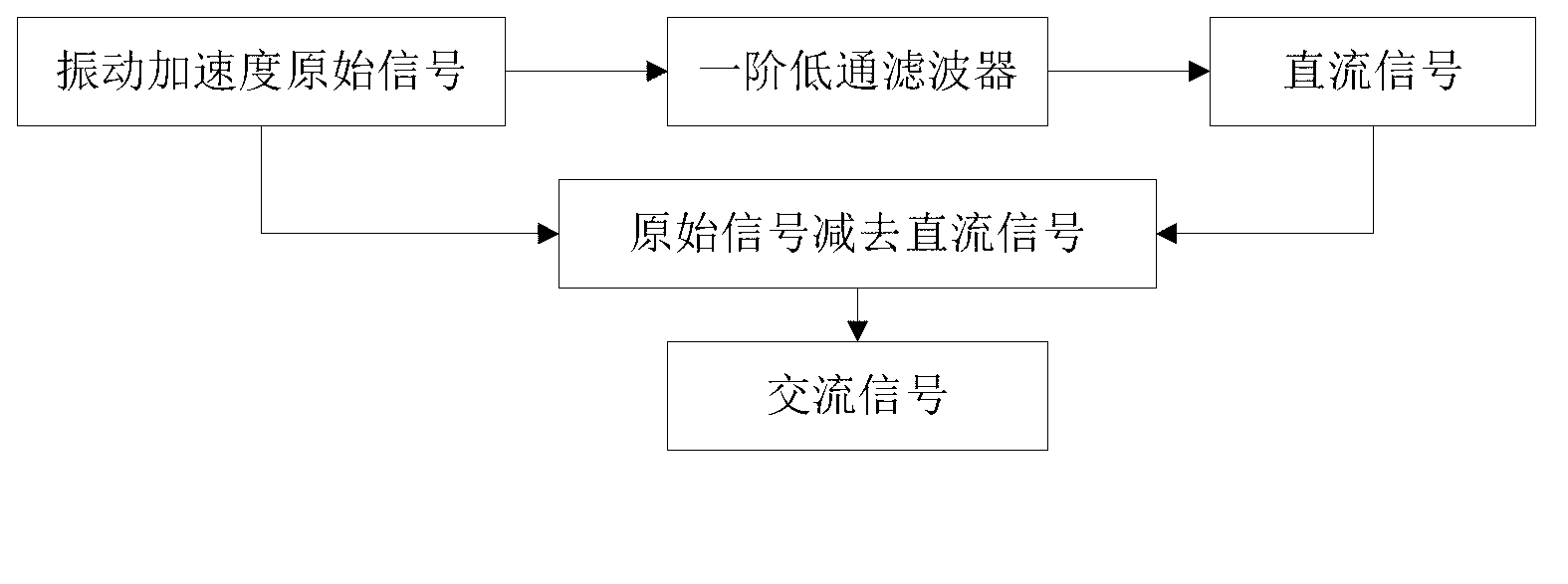

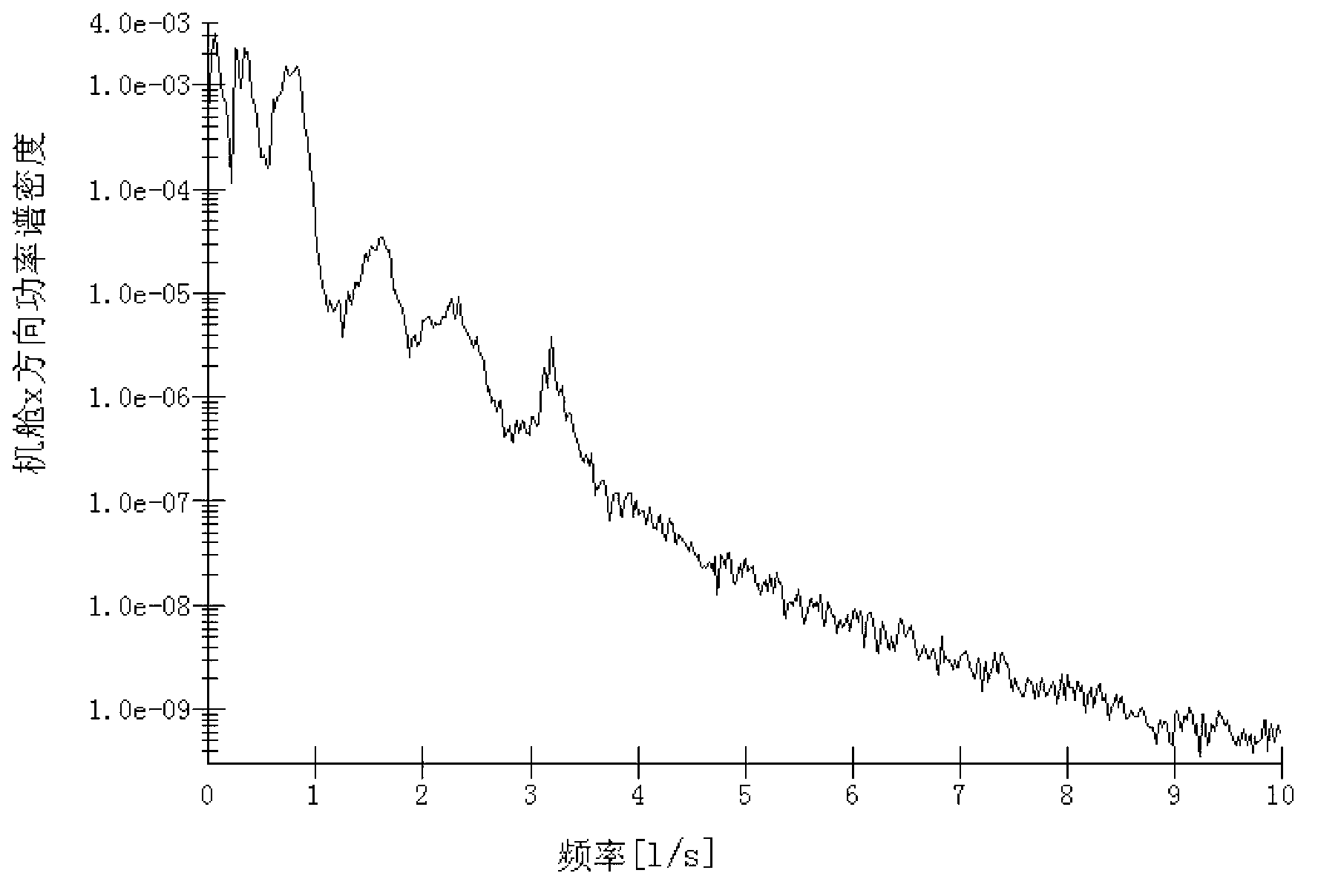

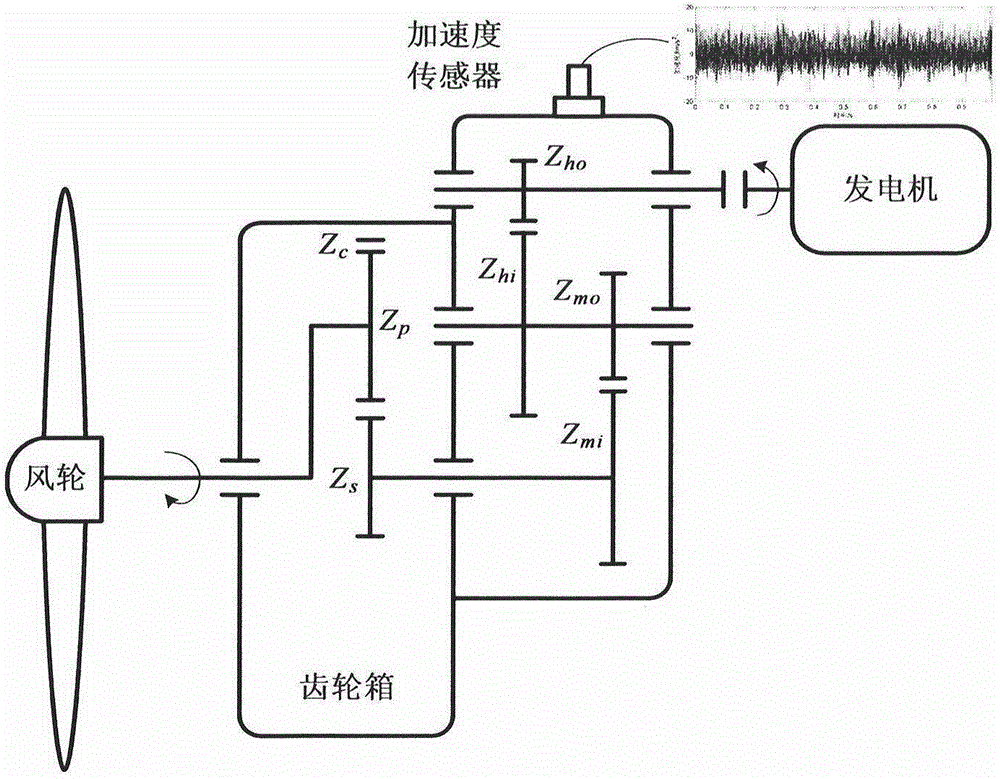

Vibration control method for wind generator set tower

ActiveCN103321854AAvoid dependencyAvoid instabilityWind energy generationWind motor componentsMachining vibrationsFrequency spectrum

The invention discloses a vibration control method for a wind generator set tower. The method comprises the steps of collecting motor rotation speed data in real time and utilizing a cabin vibration sensor to collect vibration signals; converting the collected vibration signals into vibration signal peak-to-peak values, and when the vibration signal peak-to-peak values exceed a set alarm value, triggering vibration alarm and performing real-time frequency spectrum characteristic analysis; obtaining real-time frequency spectrum characteristics and a wind wheel rotating speed value at the time; comparing a complete machine vibration frequency point corresponding to the wind wheel rotating speed value in complete machine vibration frequency characteristics obtained in advance and energy concentration degree under the frequency in a real-time frequency spectrum characteristic spectrum, and analyzing vibration reasons and correspondingly performing vibration reduction processing according to the different reasons. According to the vibration control method, the reasons for causing complete machine vibration are distinguished through a spectral analysis algorithm, so that cabin vibration of a wind generator is controlled to guarantee complete machine safety, times of shutdown caused by vibration is reduced, and the wind generator set utilization rate is improved.

Owner:STATE GRID CORP OF CHINA +2

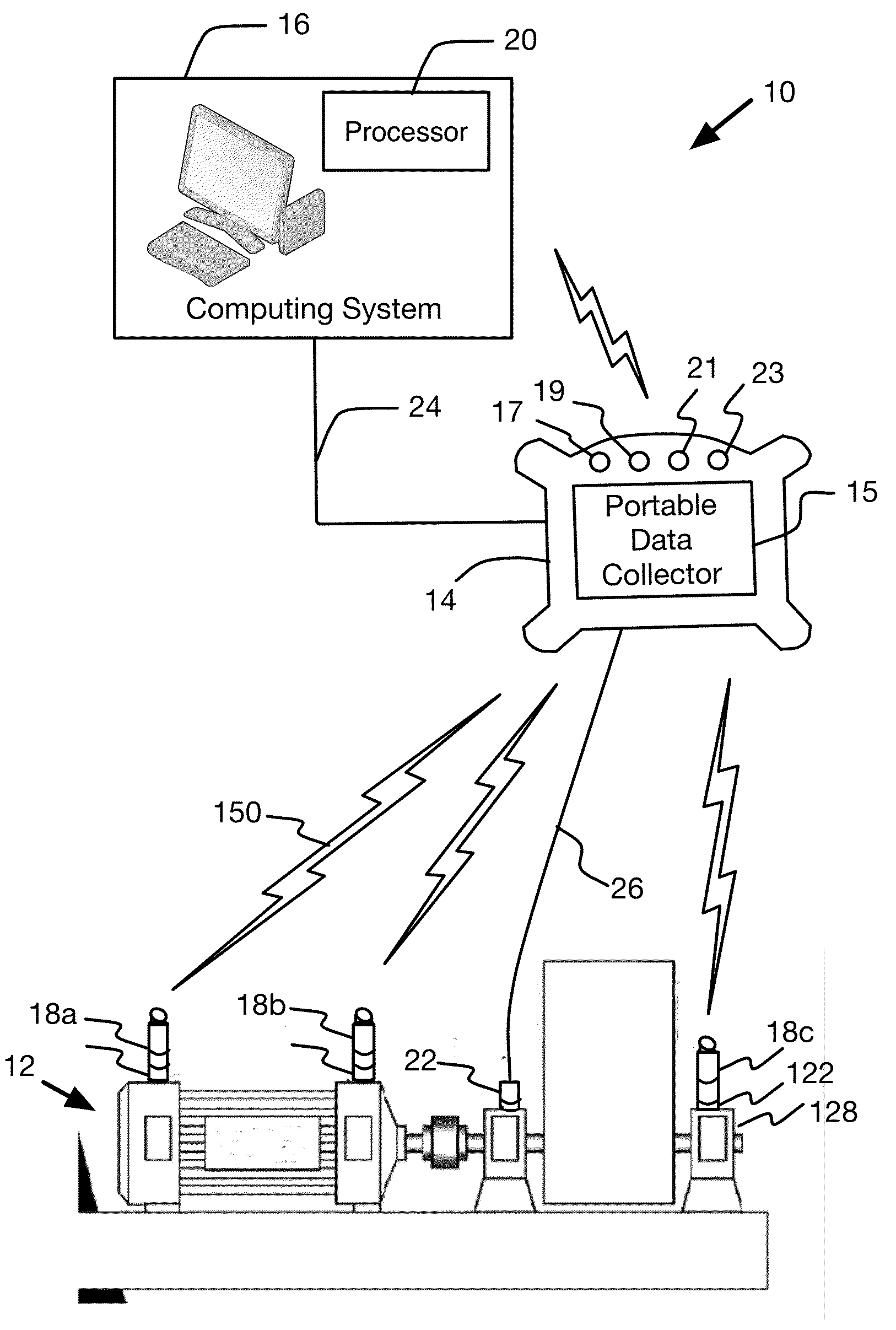

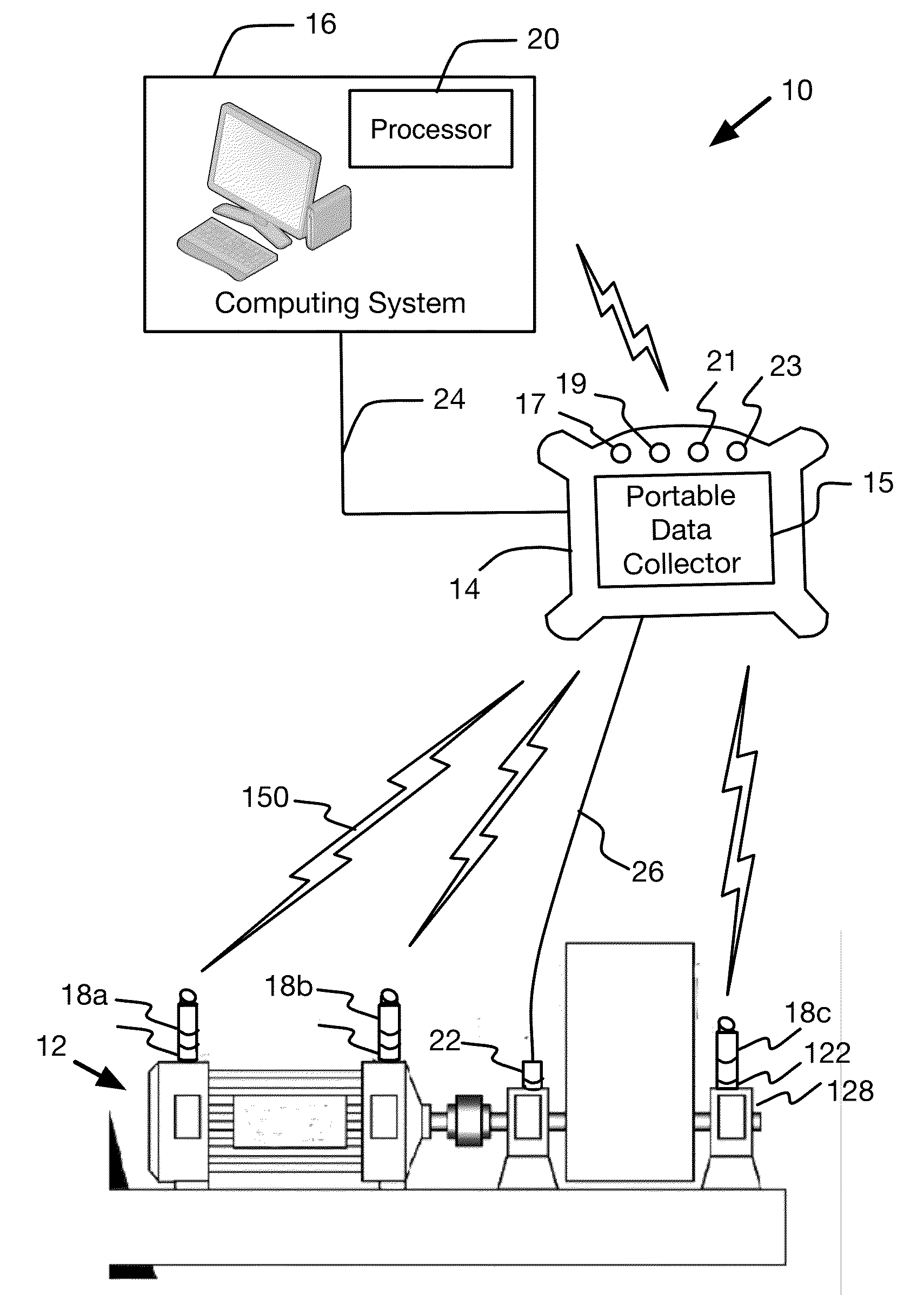

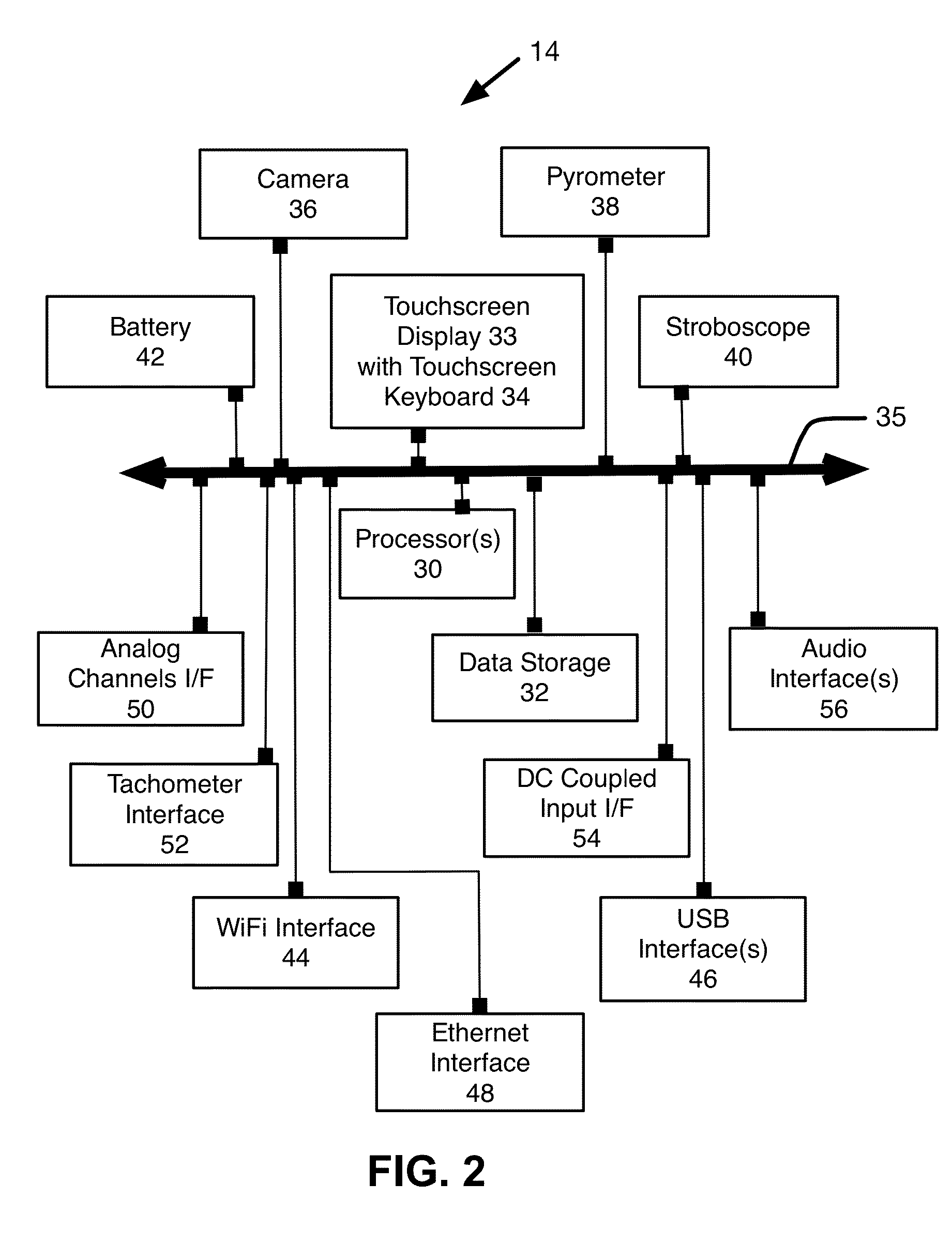

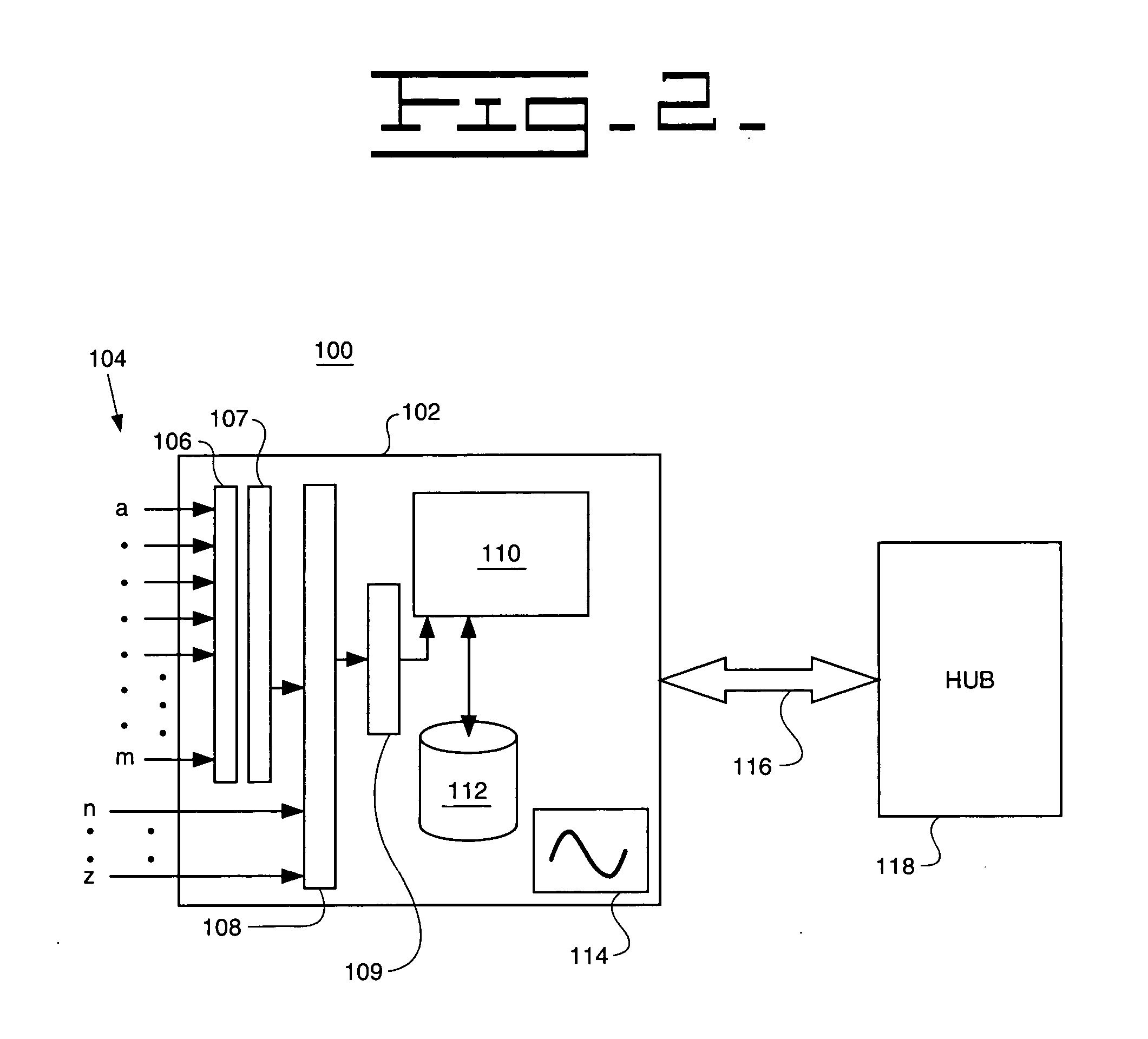

Wireless Collection and Analysis of Machine Data

ActiveUS20160041068A1Improved operator safetyReduce riskAcceleration measurement using interia forcesStructural/machines measurementMachining vibrationsAccelerometer

A sensor unit is configured as a single body, removably mounted in its entirety to a test point location on a machine so machine vibrations propagate into the single body. Within are an accelerometer, circuit board, wireless interface, signal processor, and battery. The sensor unit transmits sensor data wirelessly in real time to a data collection unit. A technician with data collection unit in hand goes from machine to machine, along a route of multiple test point locations on multiple machines, mounting and dismounting the sensor unit and collecting machine vibration data. The sensor unit is configured to reduce frequency response impacts of the mass and volume of the circuit board, wireless interface, signal processor, and battery on dynamic behavior of the sensor unit with respect to machine vibrations to achieve a frequency response rating comparable to a wired sensor.

Owner:ACOEM FRANCE

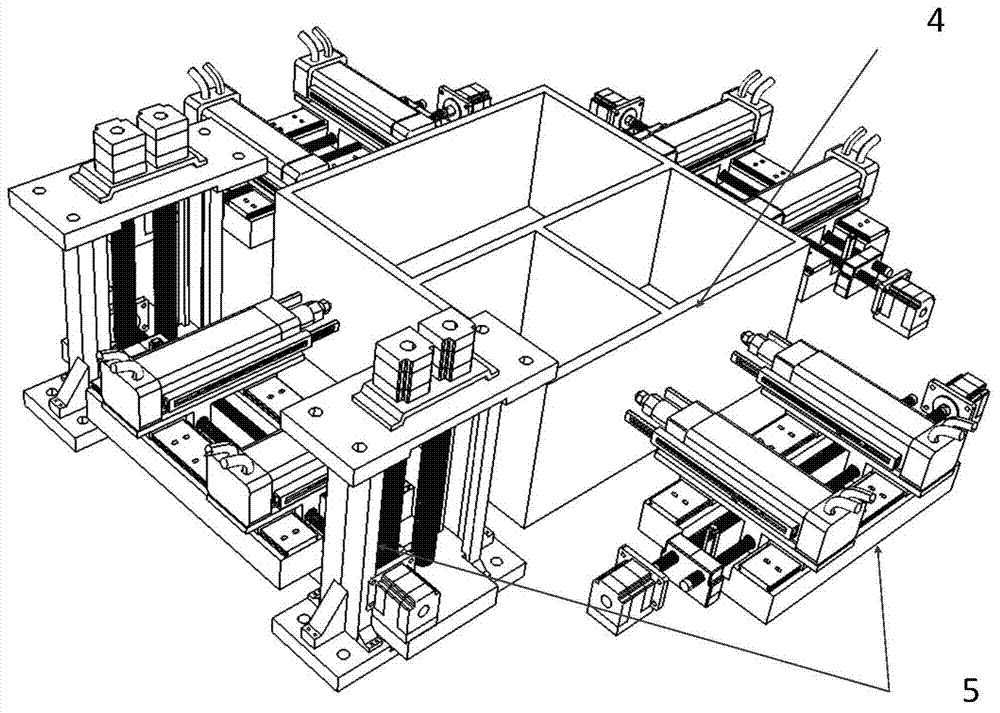

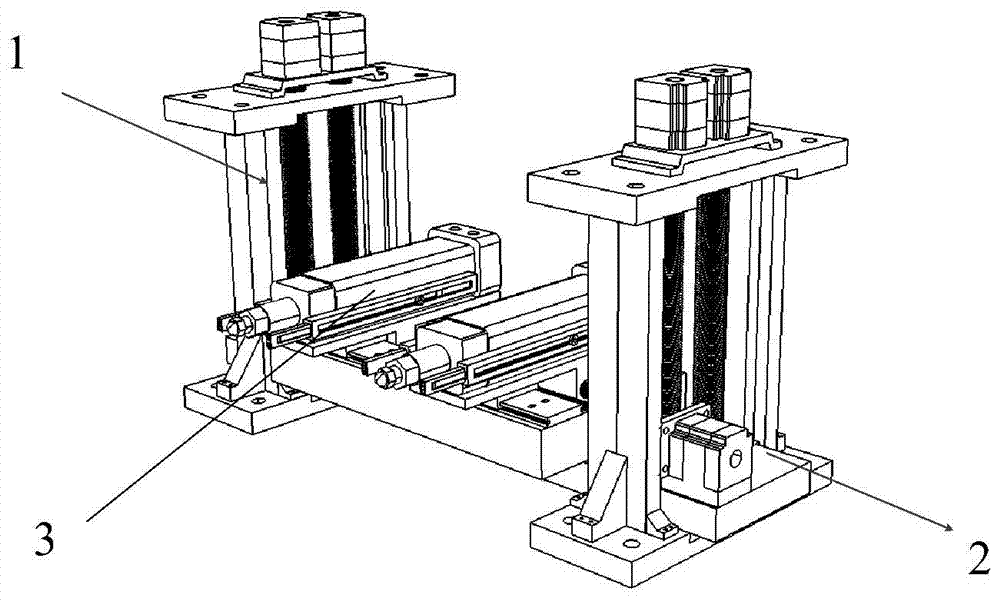

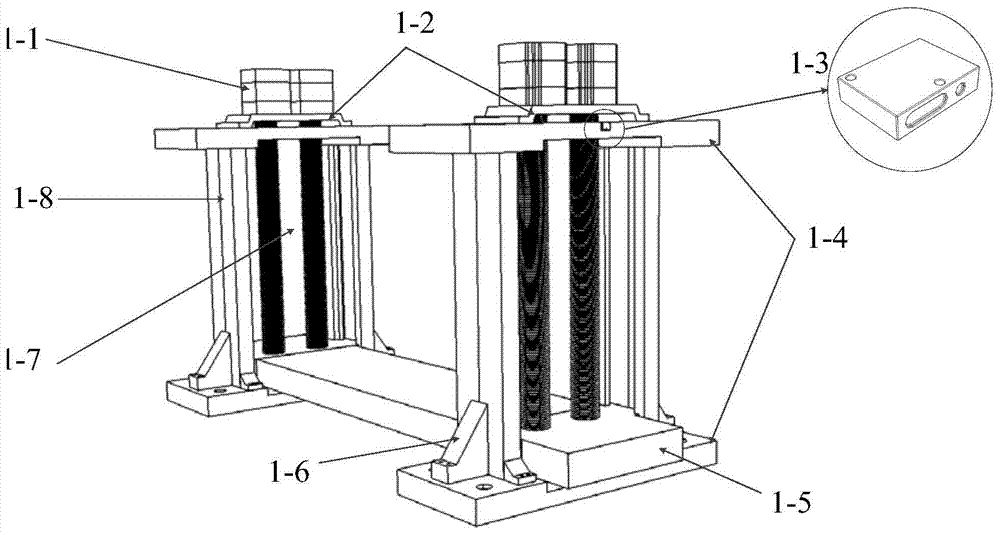

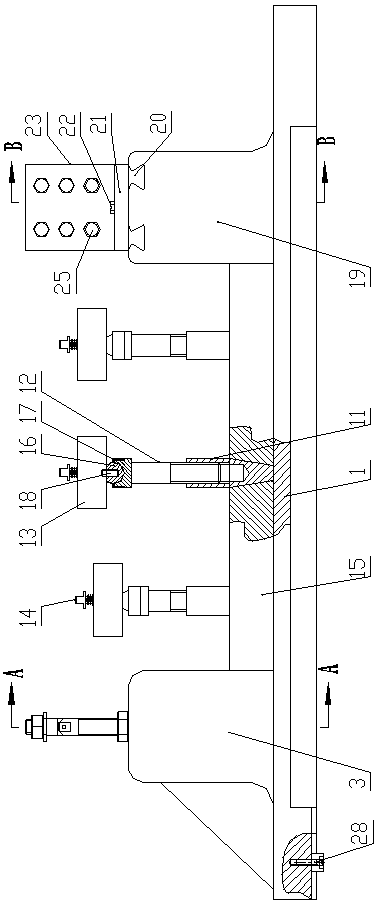

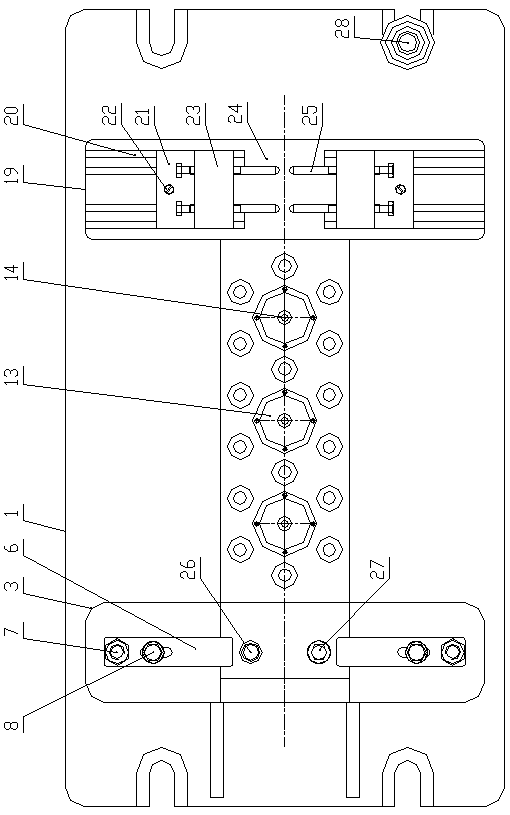

Flexible clamp device for weak rigidity workpieces

InactiveCN103481094AGuaranteed ToleranceReduce distortionMeasurement/indication equipmentsLarge fixed membersMachining vibrationsPersonal computer

The invention provides a flexible clamp device for weak rigidity workpieces. The flexible clamp device for the weak rigidity workpieces is formed by a plurality of clamp assemblies jointly; every clamp assembly is formed by an execution module, an information collection module and a control module; every execution module comprises a clamping mechanism, a lifting mechanism and a horizontal moving mechanism; the clamping mechanisms are driven by the lifting mechanisms and the horizontal moving mechanisms to ascend, descend and horizontally move; every lifting mechanism comprises a lifting platform; the horizontal moving mechanisms are fixedly arranged on the lifting mechanisms; the clamping mechanisms are fixedly arranged on the horizontal moving mechanisms; every information collection module comprises a vibration displacement sensor, a vertical displacement sensor, a horizontal displacement sensor and a pressure sensor; every control module comprises an information collection card, a PC (Personal Computer) machine and a controller; the information collection cards are connected with the sensors; the PC machines are used for processing information of the information collection modules; the operation of the mechanisms is controlled by the controllers. According to the flexible clamp device for the weak rigidity workpieces, the size of clamping force and the position the clamping force taking effect on can be adjusted automatically, the integral deformation of the workpieces is reduced, and meanwhile the machining vibration of the workpieces is restrained and the milling stability of the workpieces is improved.

Owner:WUHAN UNIV OF TECH

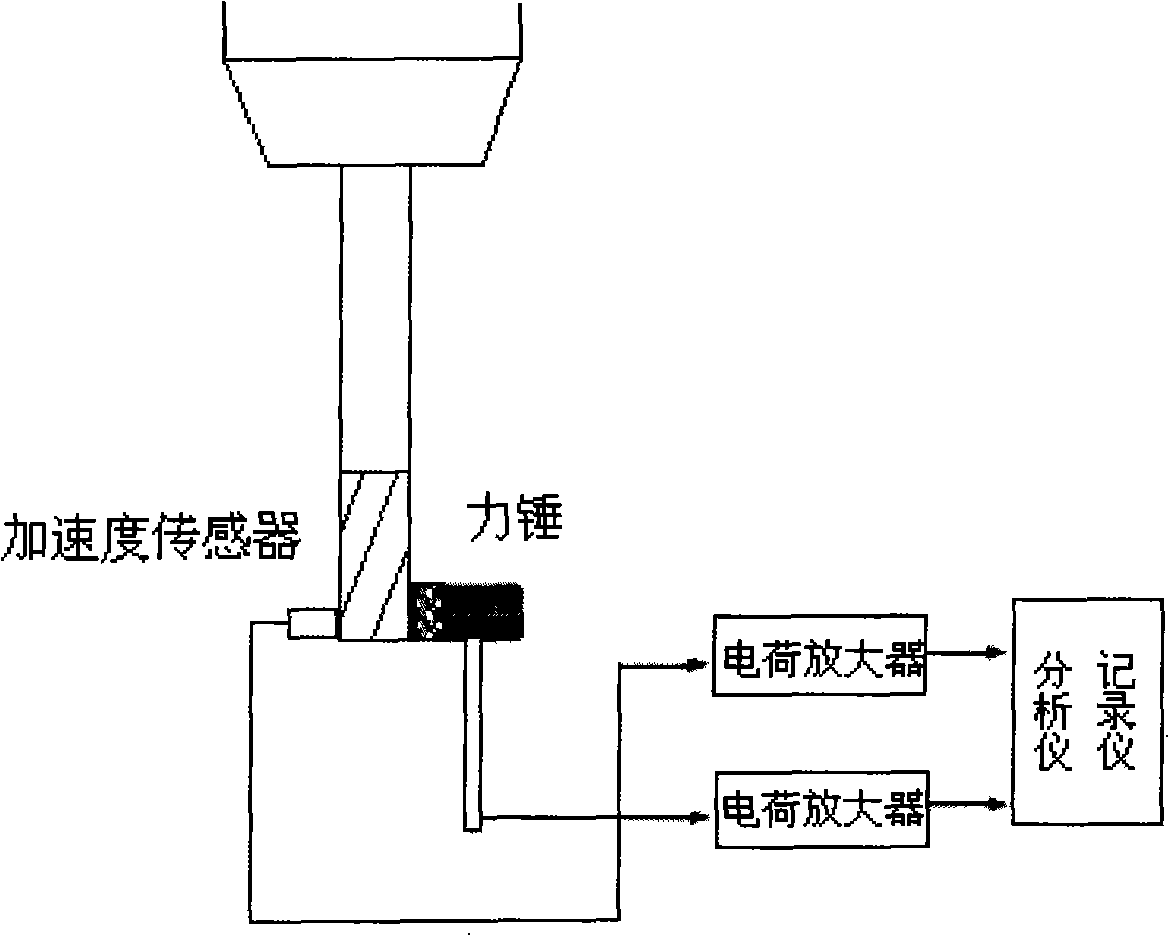

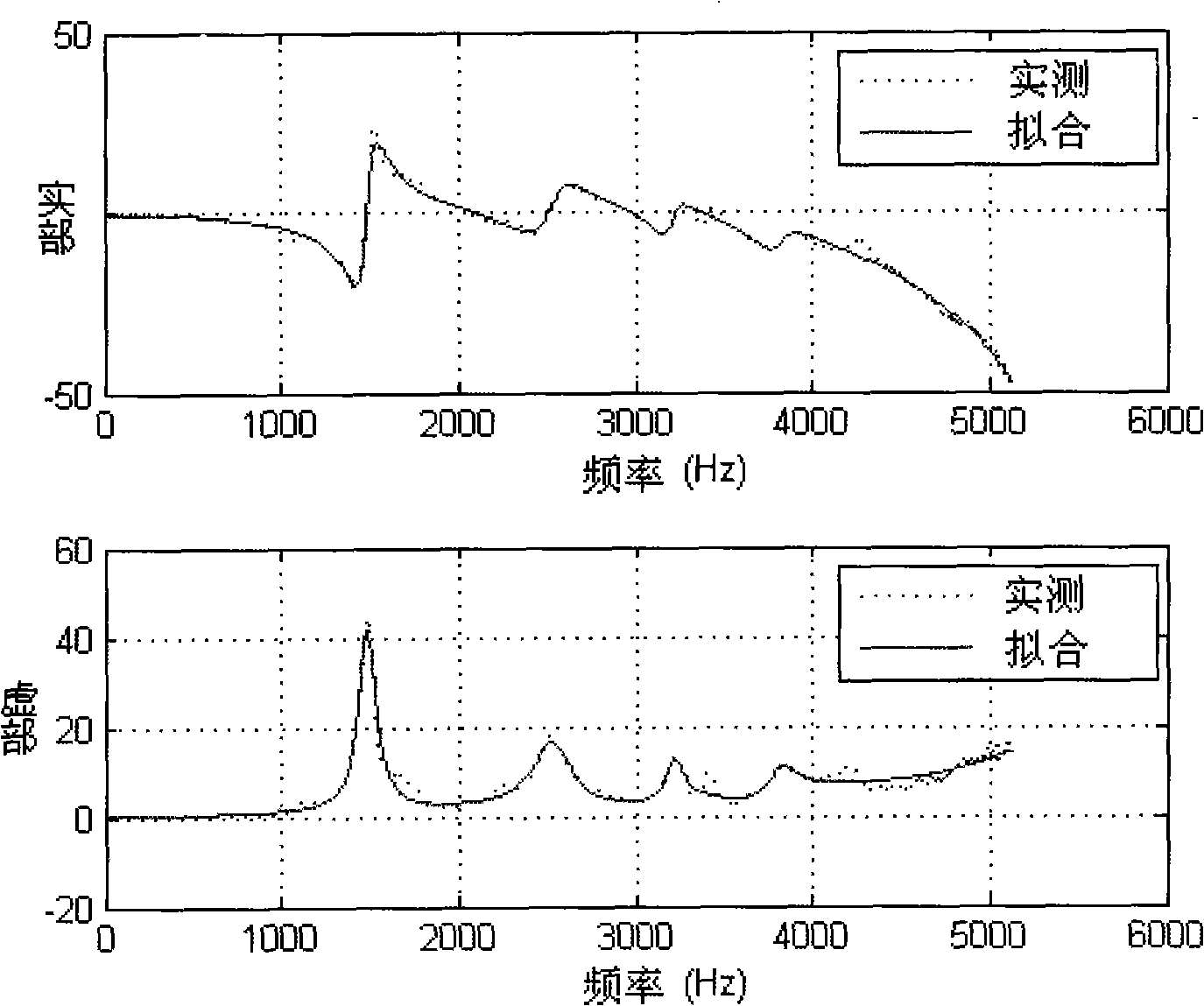

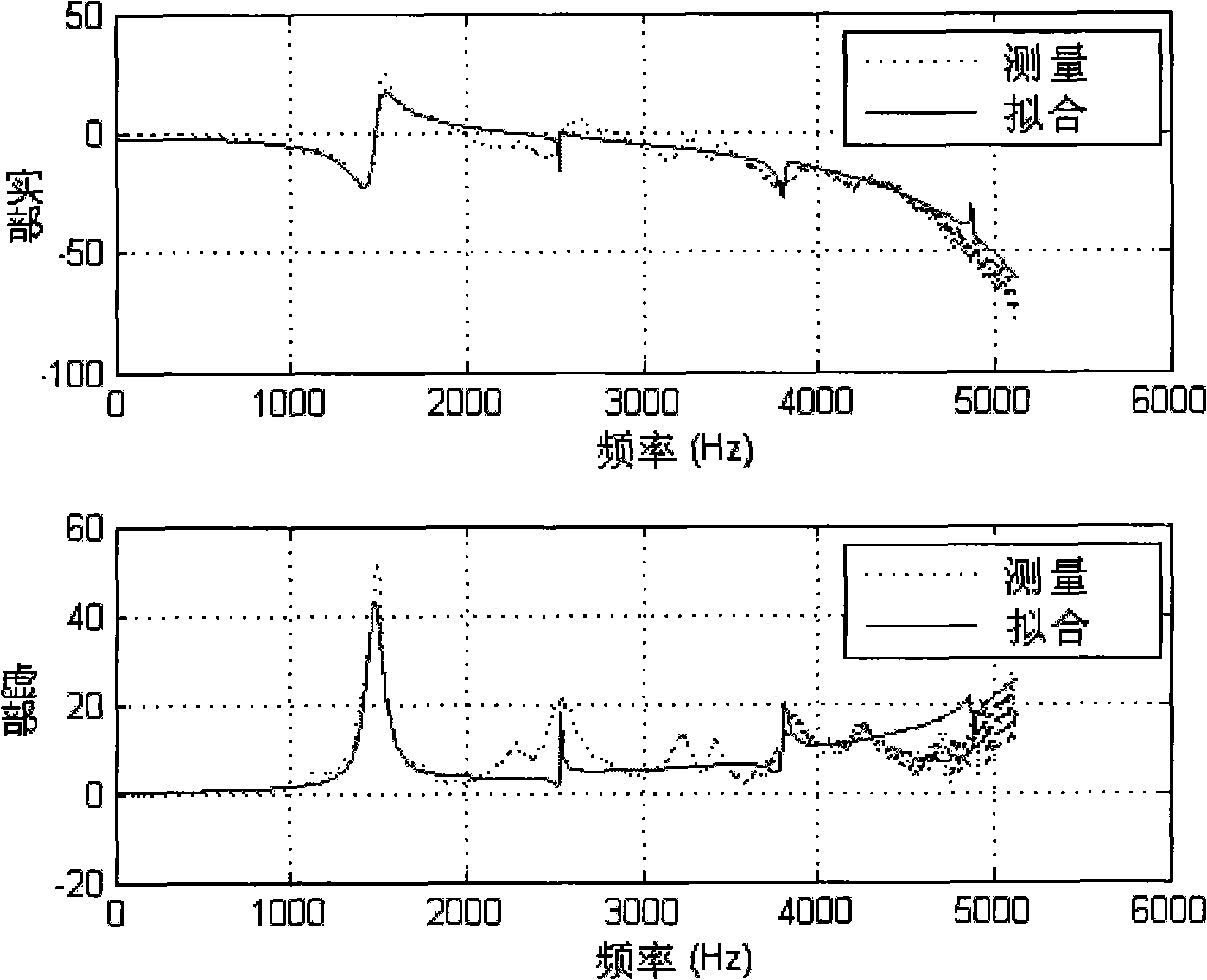

Cutting tool mode parameter uncertain curve five-shaft numerical control process parameter optimizing method

InactiveCN101493686AReach the goal of optimization of processing parametersImprove accuracyProgramme controlComputer controlMachining vibrationsNumerical control

The invention provides a method for optimizing uncertain curve-surface five-axis numerical control process parameter of the cutter modal parameters, belonging to the technical field of computer numerical control machining. The method for optimizing the machining process parameter comprises the steps as follows: firstly, the uncertain area of the cutter system modal parameter is obtained; a five-axis milling machining dynamic model is established; the input parameter of the model comprises a cutter system modal parameter area, a cutting force coefficient, a cutter geometry and a cutter path; the five-axis milling machining vibration stabilization curve is calculated; and by taking the five-axis milling machining vibration stabilization curve as a constraint, the process parameter optimization model is established and worked out by a sequence nonlinear planning method so as to obtain the optimized process parameter. As the invention considers the uncertainty of the cutter system modal parameter and is closer to the real machining condition, thus improving the exactness of the vibration prediction during the machining.

Owner:SHANGHAI JIAO TONG UNIV

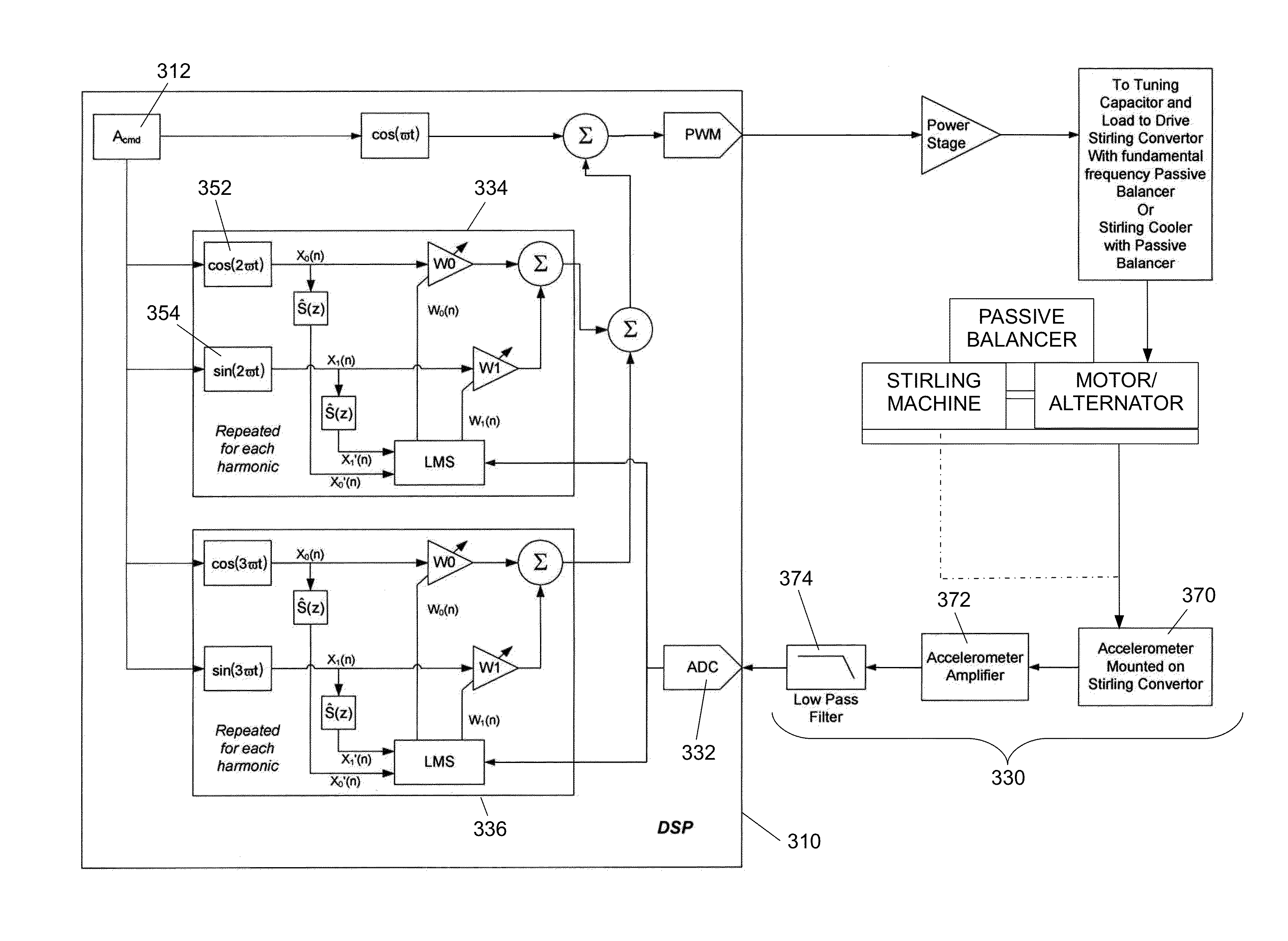

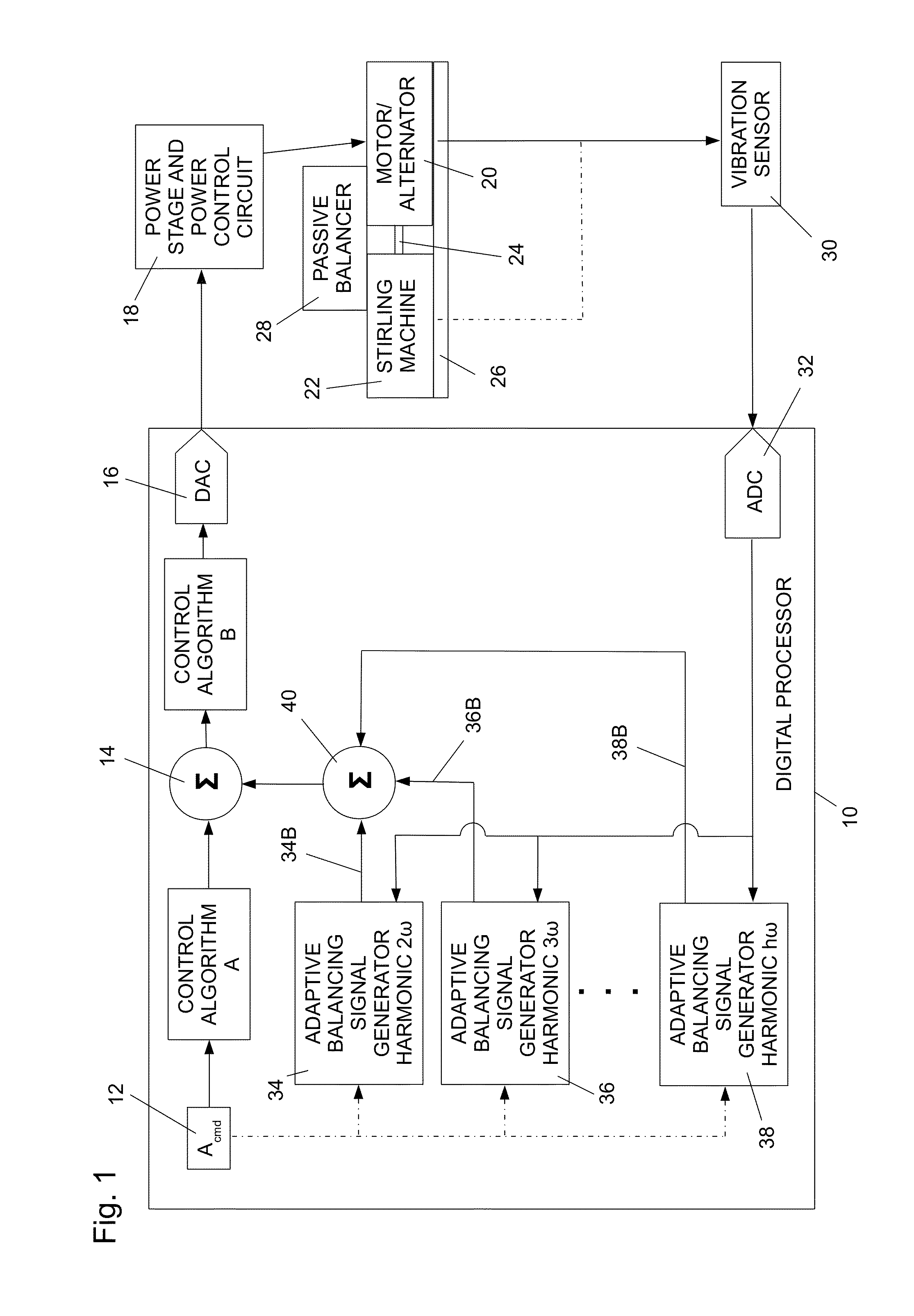

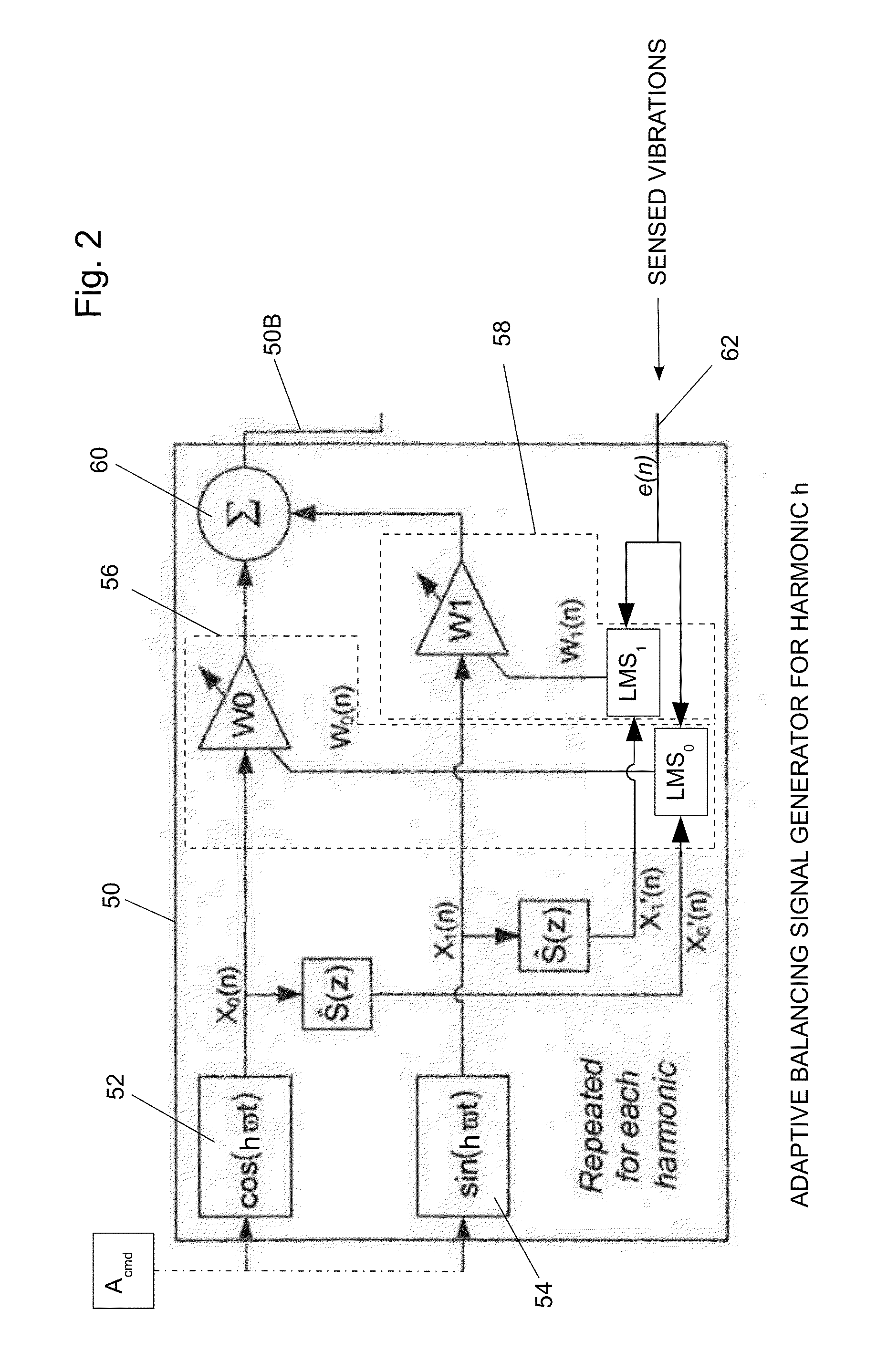

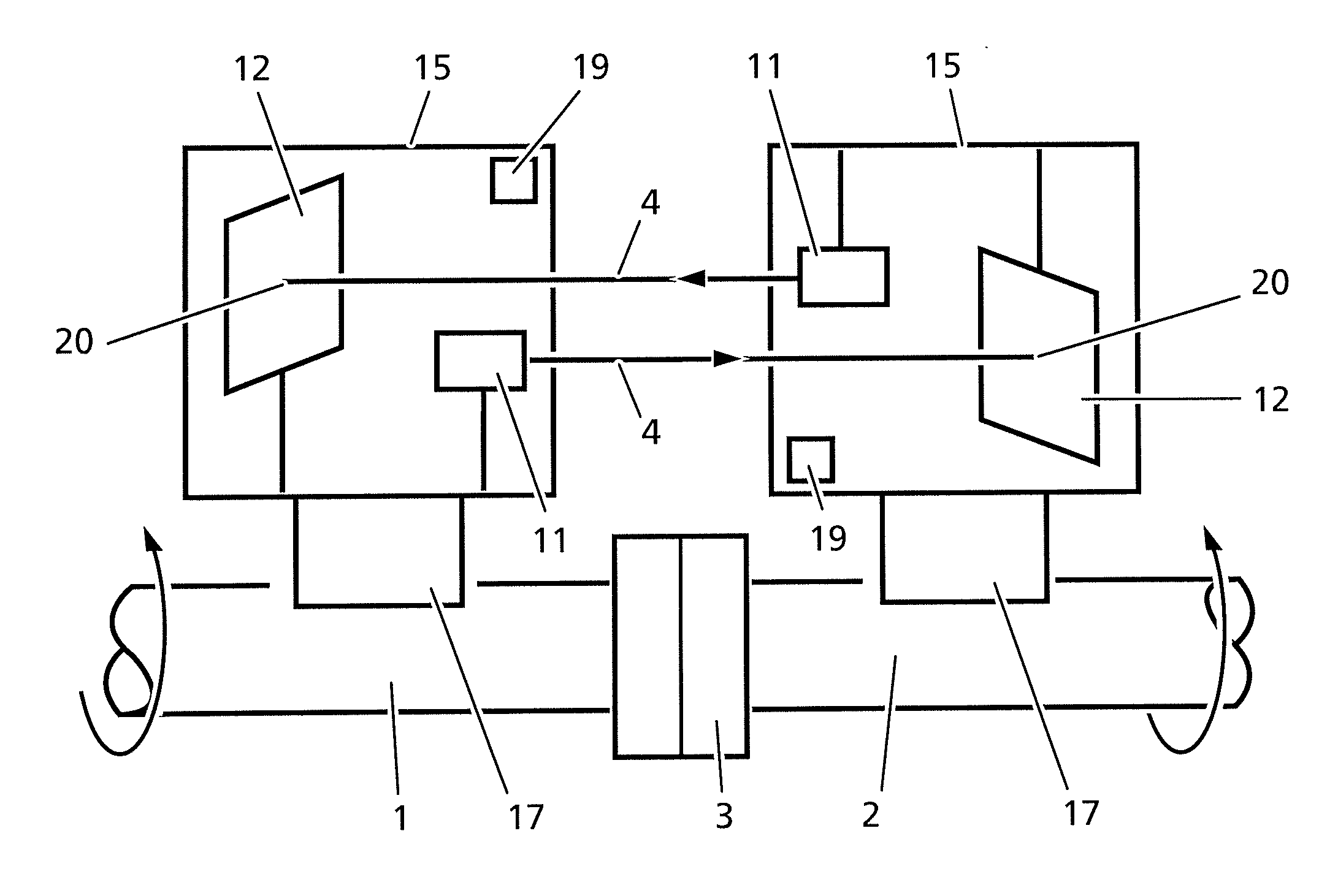

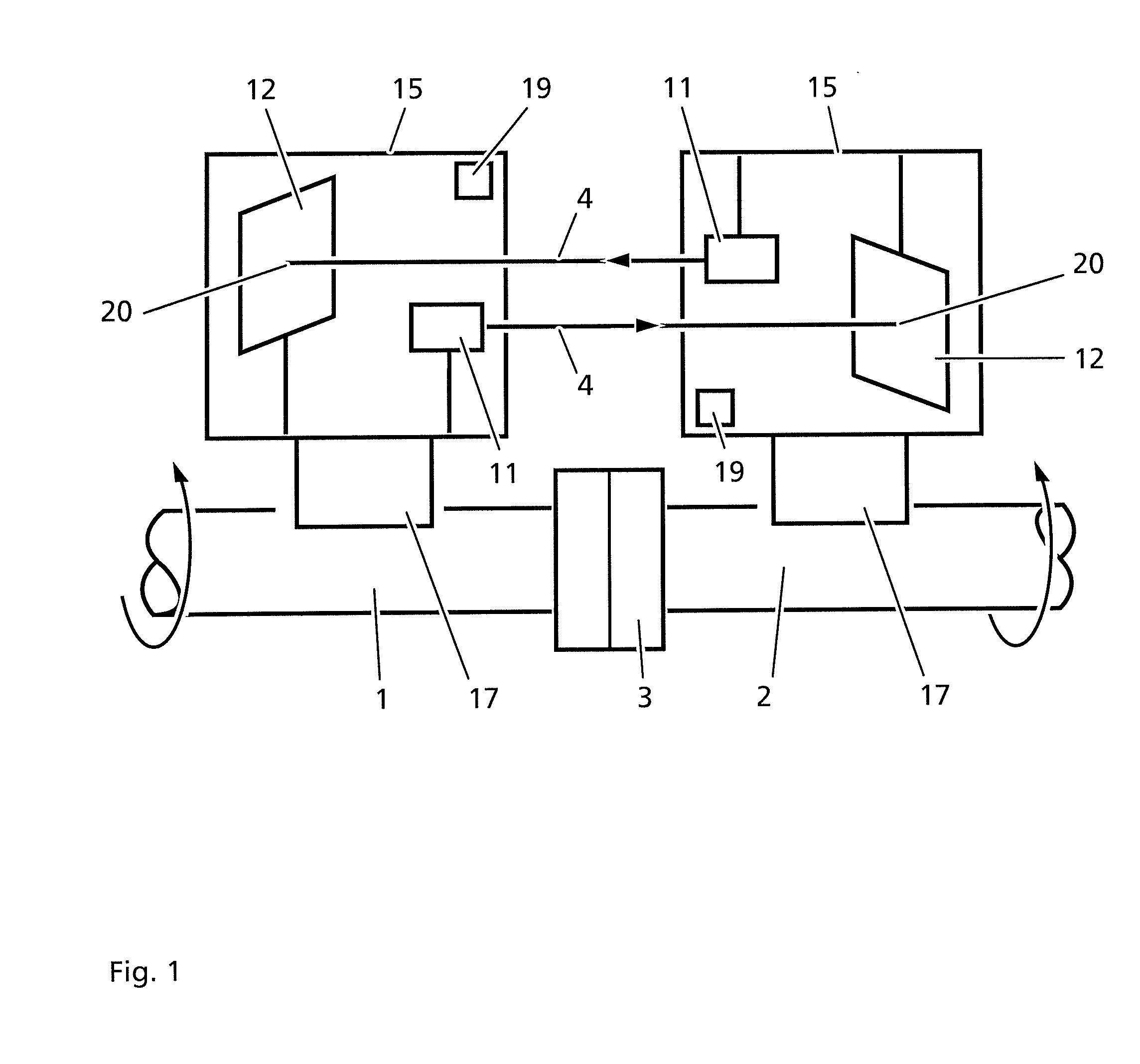

Balancing Vibrations At Harmonic Frequencies By Injecting Harmonic Balancing Signals Into The Armature Of A Linear Motor/Alternator Coupled To A Stirling Machine

ActiveUS20140015497A1Vibration minimizationMechanical oscillations controlEmergency protective circuit arrangementsAdaptive filtering algorithmMachining vibrations

Vibrations at harmonic frequencies are reduced by injecting harmonic balancing signals into the armature of a linear motor / alternator coupled to a Stirling machine. The vibrations are sensed to provide a signal representing the mechanical vibrations. A harmonic balancing signal is generated for selected harmonics of the operating frequency by processing the sensed vibration signal with adaptive filter algorithms of adaptive filters for each harmonic. Reference inputs for each harmonic are applied to the adaptive filter algorithms at the frequency of the selected harmonic. The harmonic balancing signals for all of the harmonics are summed with a principal control signal. The harmonic balancing signals modify the principal electrical drive voltage and drive the motor / alternator with a drive voltage component in opposition to the vibration at each harmonic.

Owner:SUNPOWER

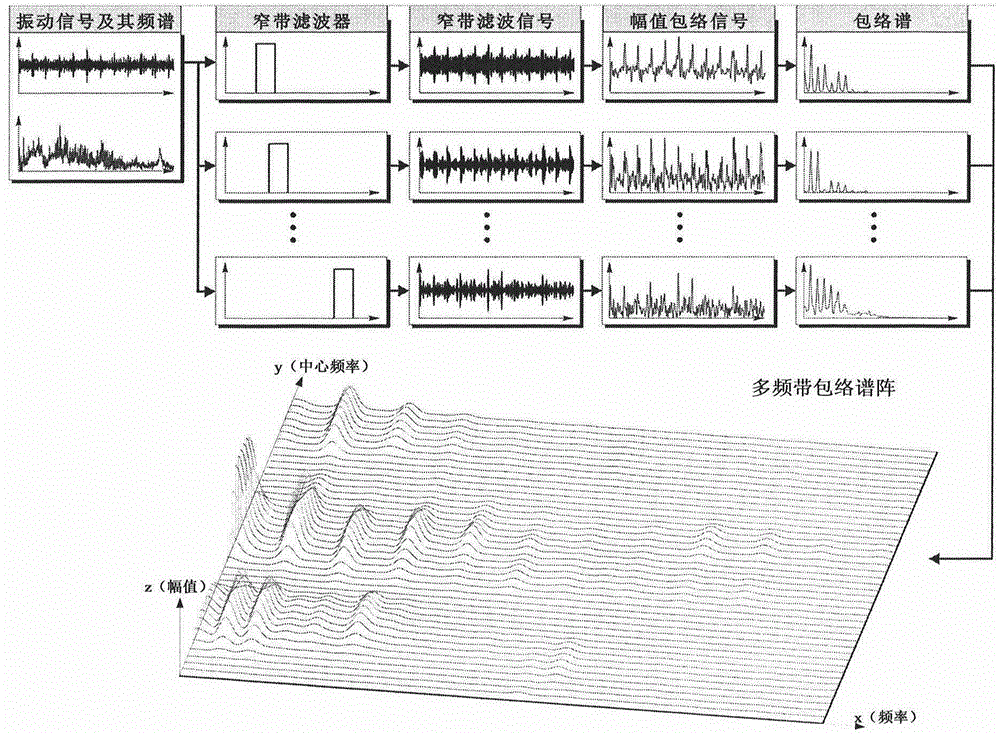

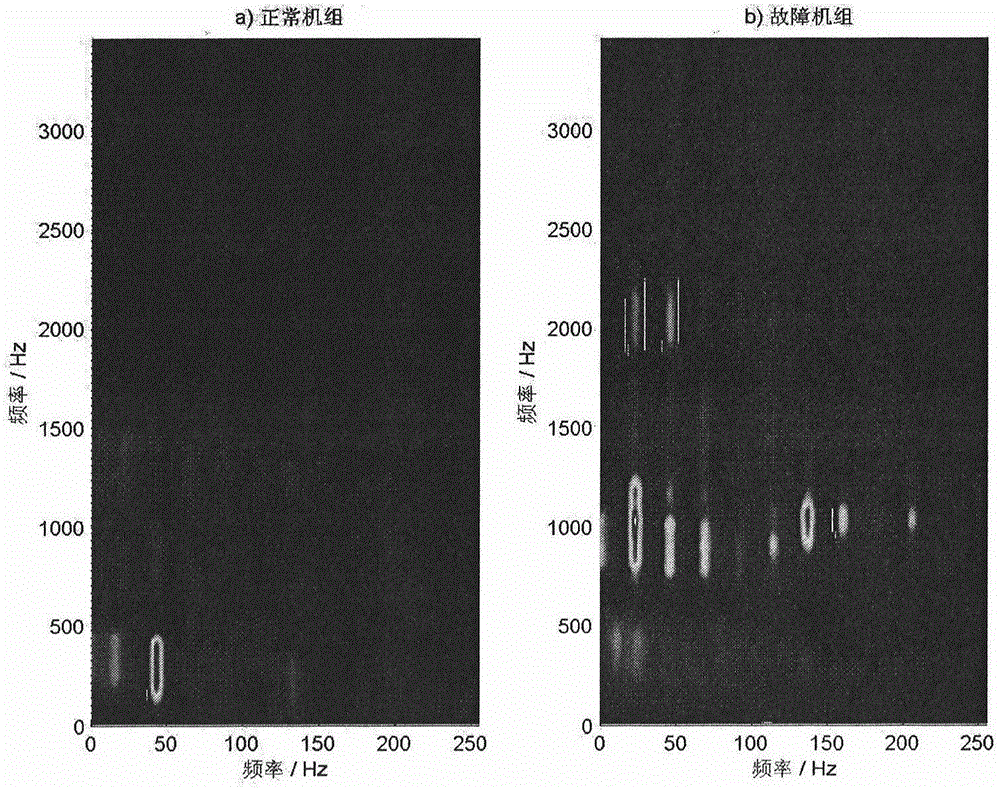

Multiband envelope spectrum array used for rotating machine fault diagnosis

InactiveCN104596756AImprove intelligenceOvercoming frequencyMachine gearing/transmission testingMachining vibrationsVibration amplitude

The invention belongs to the field of mechanical device vibration monitoring and fault diagnosis, and particularly relates to a multiband envelope spectrum array used for rotating machine fault diagnosis. Vibration signals of different frequency bands are obtained by conducting multi-narrow-band filtering on a rotating machine vibration signal which is picked up, the envelop demodulation analysis is conducted on the multiple sets of vibration signals of different frequency bands, and envelop spectrums of the multiple sets of signals are obtained and converted into the three-dimensional envelop spectrum array (graph) with vibration frequencies as x-axis coordinates, narrow-band filtering central frequencies as y-axis coordinates and vibration amplitudes as z-axis coordinates. On the basis of the spectrum envelope array, the fault modulation frequency, the fault occurrence part and the fault damage degree of a rotating machine can be rapidly and visually judged, and the intelligent fault diagnosis can be conveniently achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

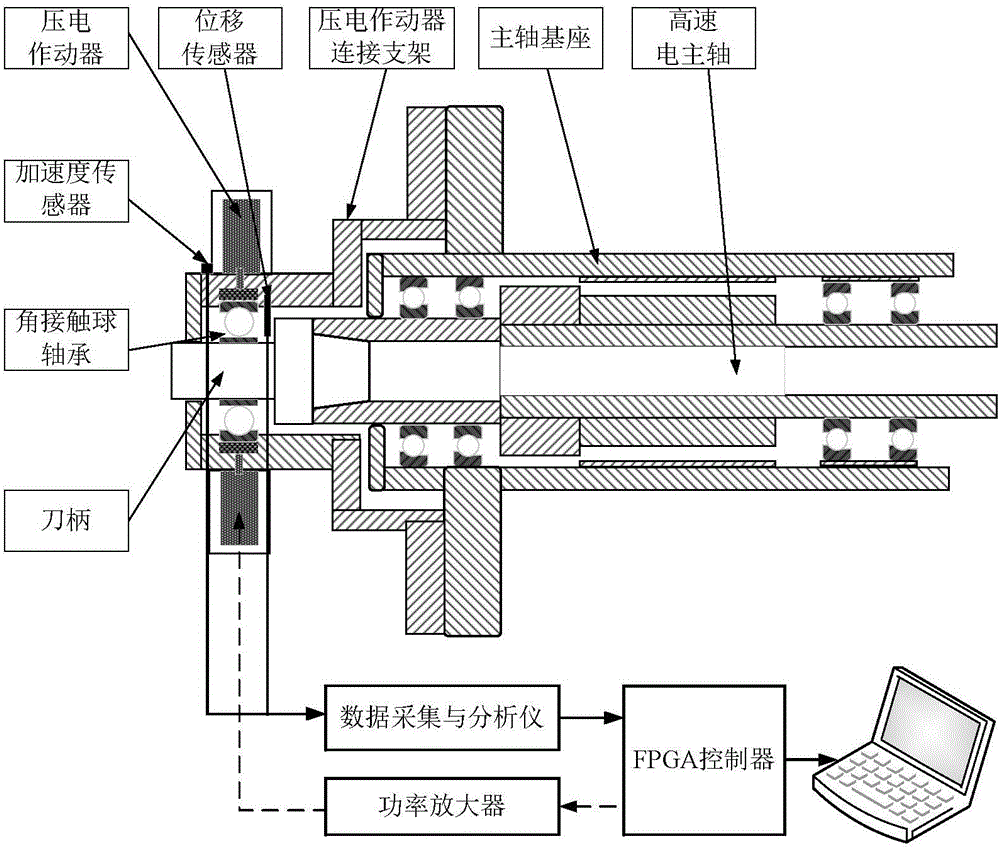

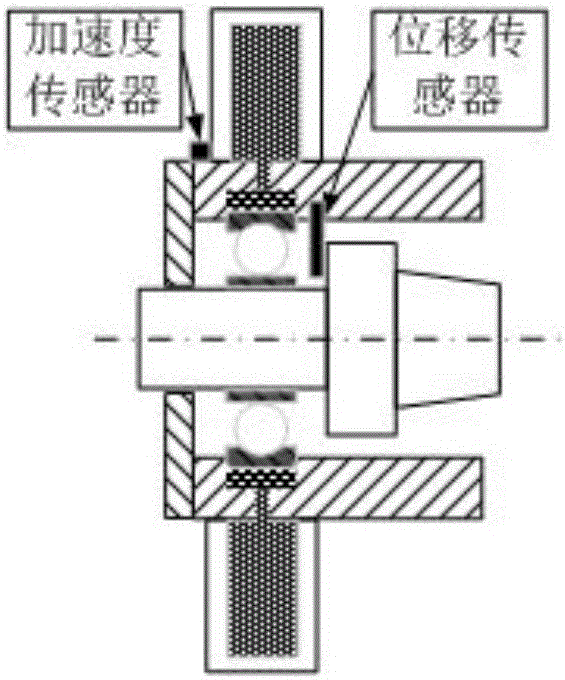

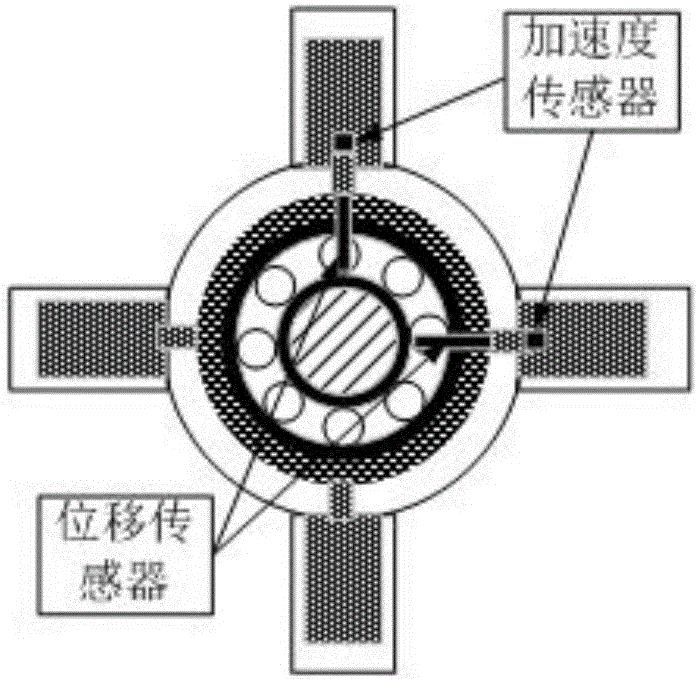

Intelligent detection and active inhibition device for fluttering of high-speed milling electric spindle

ActiveCN105965320AReach function extensionRealize visualizationAutomatic control devicesSubsonic/sonic/ultrasonic wave measurementMachining vibrationsAudio power amplifier

The invention discloses an intelligent detection and active inhibition device for fluttering of a high-speed milling electric spindle. According to the device, in the milling process, a vibration signal of a spindle tool handle is collected in real time through built-in acceleration sensors, built-in displacement sensors and an external data collection and analysis meter; the acceleration vibration signal is analyzed in real time through a modern signal processing method, so that intelligent detection of milling fluttering is achieved; and if fluttering occurs, the vibration information collected by the displacement sensors is transmitted into an FPGA controller, the controller carries out adaptive optimization, a driving signal is output, a piezoelectric actuator is driven by a power amplifier to operate, mutual offset of secondary vibration and machining vibration of the piezoelectric actuator is achieved, and intelligent and active inhibition of the fluttering is achieved. Visual displaying and monitoring of the state information, comprising vibration, displacement, temperature and the like, of the whole system can be achieved on a computer in real time in the machining process. The intelligent detection and active inhibition device for the fluttering of the high-speed milling electric spindle can effectively improve milling stability, milling quality and milling efficiency.

Owner:XI AN JIAOTONG UNIV

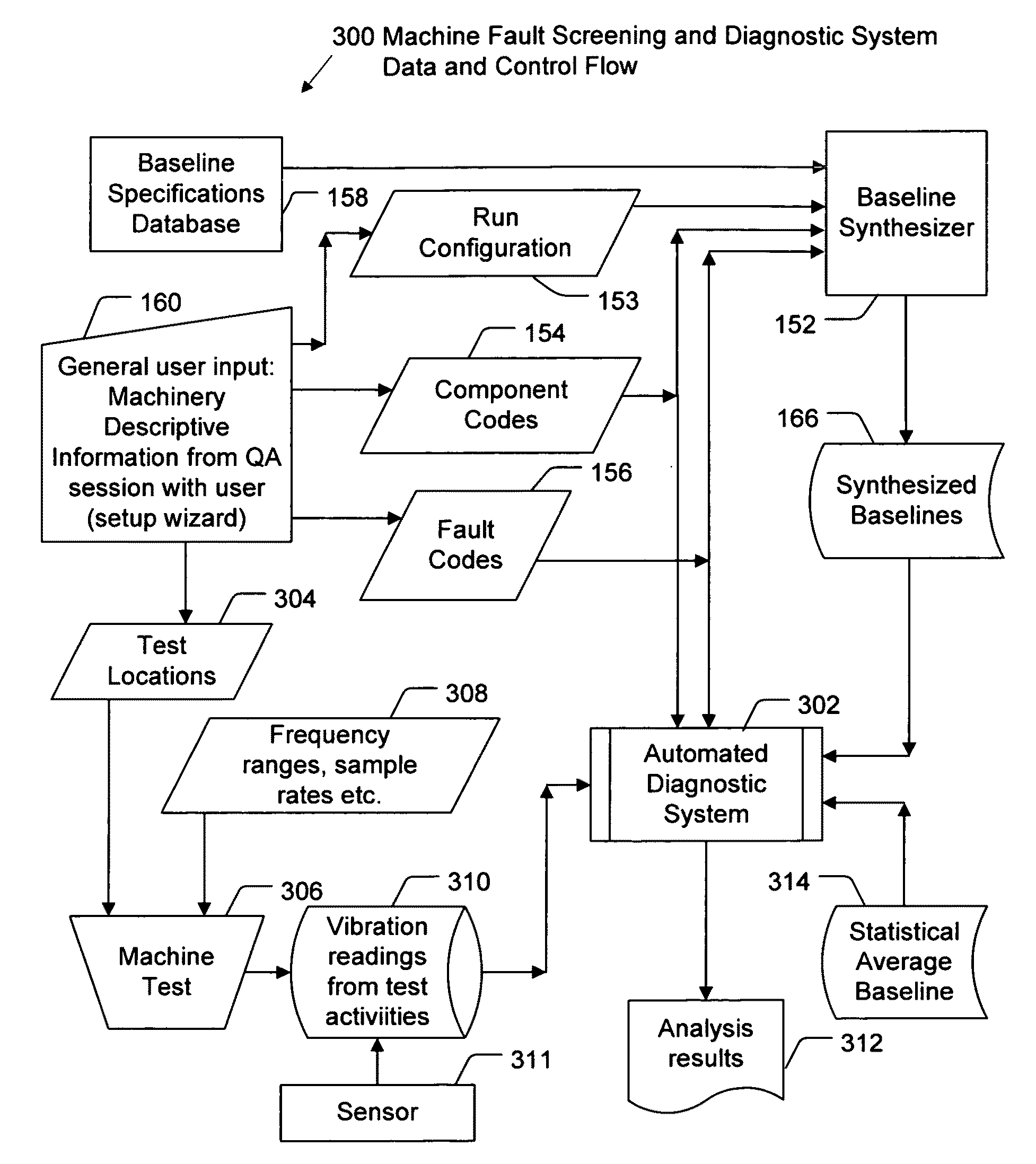

Machine vibration baseline synthesizer

ActiveUS20090292505A1Vibration measurement in solidsMachine part testingVibration amplitudeForce frequency

Machine vibration baselines are synthesized without averaging historical vibration data. Instead machinery configuration information is used, including data about the machine train, the machine's rotating components, and the machine speeds. For each component being considered, a plurality of parameters is identified for deriving baseline portions. The parameters for one component are used to identify baseline vibration amplitude floor values, vibration amplitudes at frequencies corresponding to various harmonics of a rotational speed, and vibration amplitudes corresponding to forcing frequencies and their harmonics / sidebands. Parameters for other components also may be used to identify amplitudes at harmonic frequencies and forcing frequencies.

Owner:SYMPHONYAI IND PLANT PERFORMANCE INC

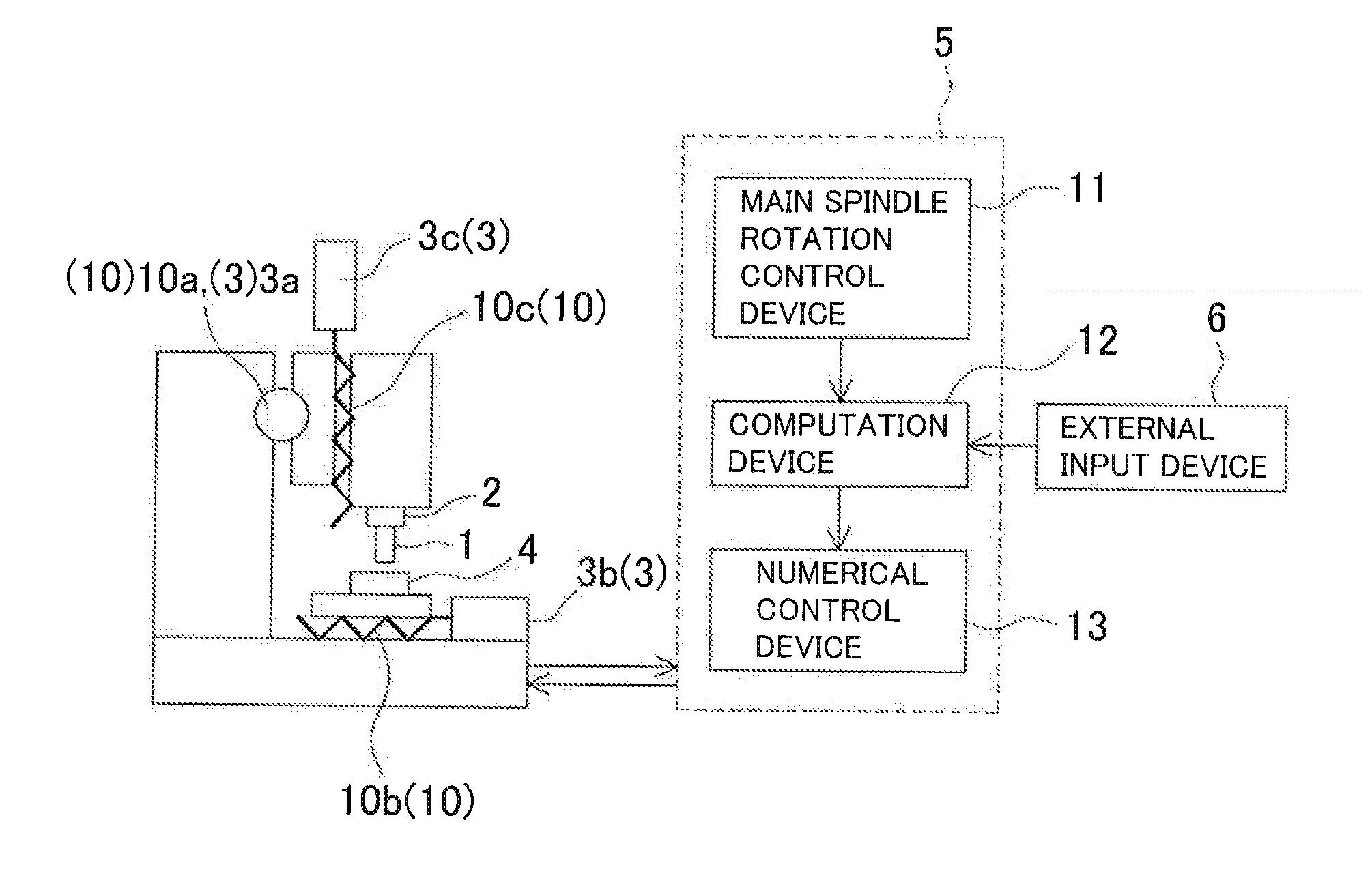

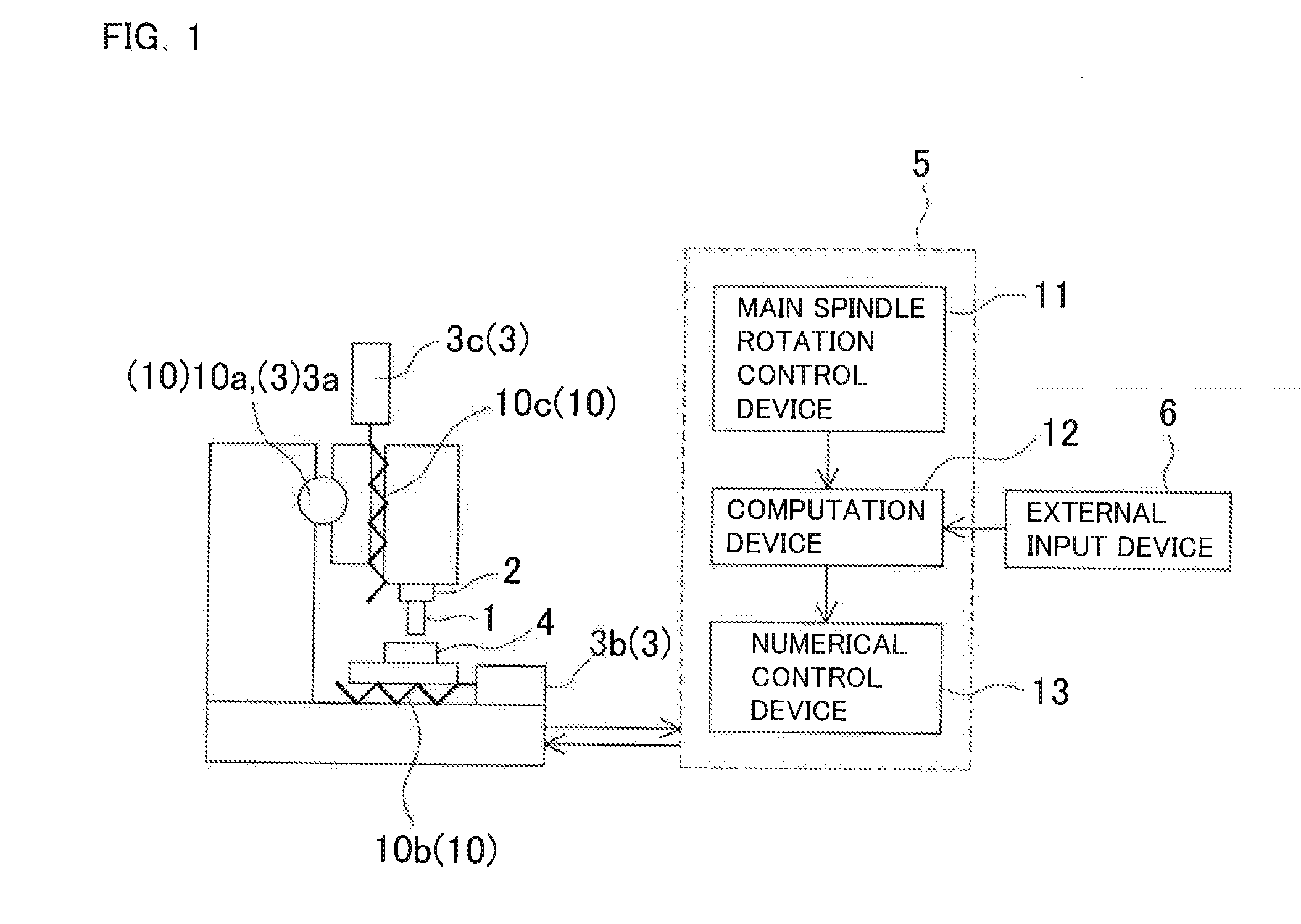

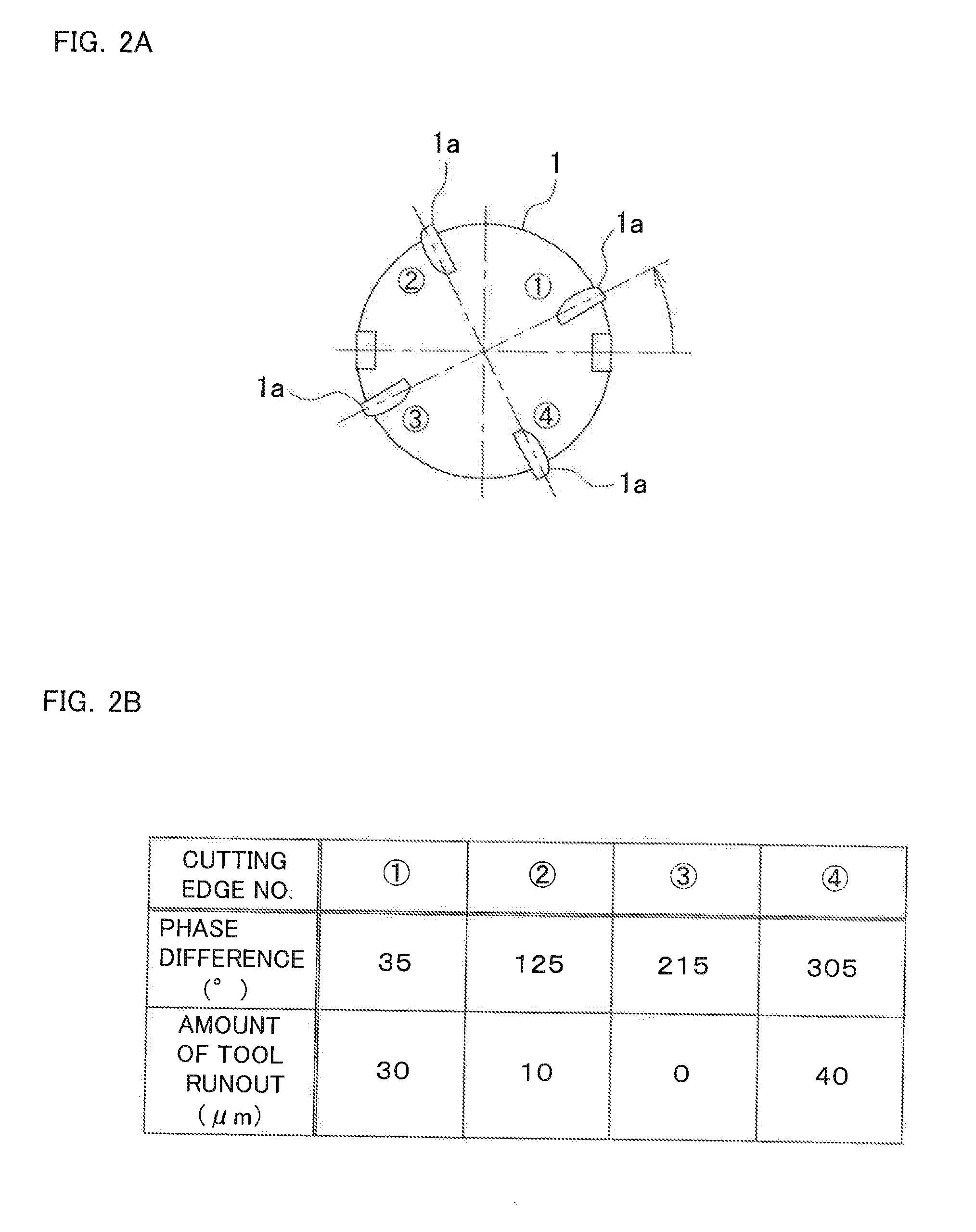

Machining vibration suppressing method and machining vibration suppressing apparatus for machine tool

ActiveUS20130309034A1Suppressing chatter vibrationSuppressing tool chippingProgramme controlAutomatic control devicesNumerical controlMachining vibrations

An apparatus includes an external input device that allows setting of the amount of runout and the phase of each cutting edge, a computation device that acquires the rotational phase of a tool and that computes the angular velocity and the phase of vibration of two, X-axis and Y-axis, feed shafts on the basis of the input amount of runout and angular velocity of each cutting edge to generate a feed shaft control signal, and a numerical control device that controls feed in the X-axis and the Y-axis directions. The numerical control device relatively vibrates a workpiece in synchronization with the angular velocity of the tool on the basis of the results of computation performed by the computation device.

Owner:OKUMA CORP

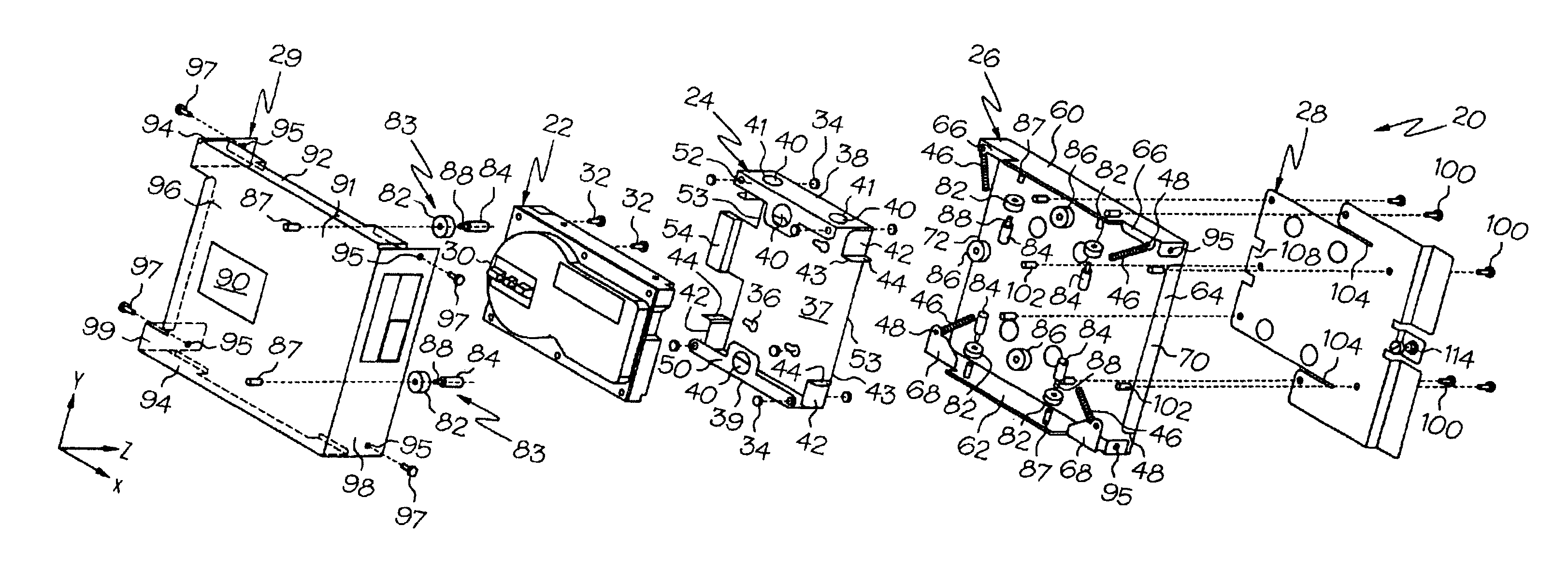

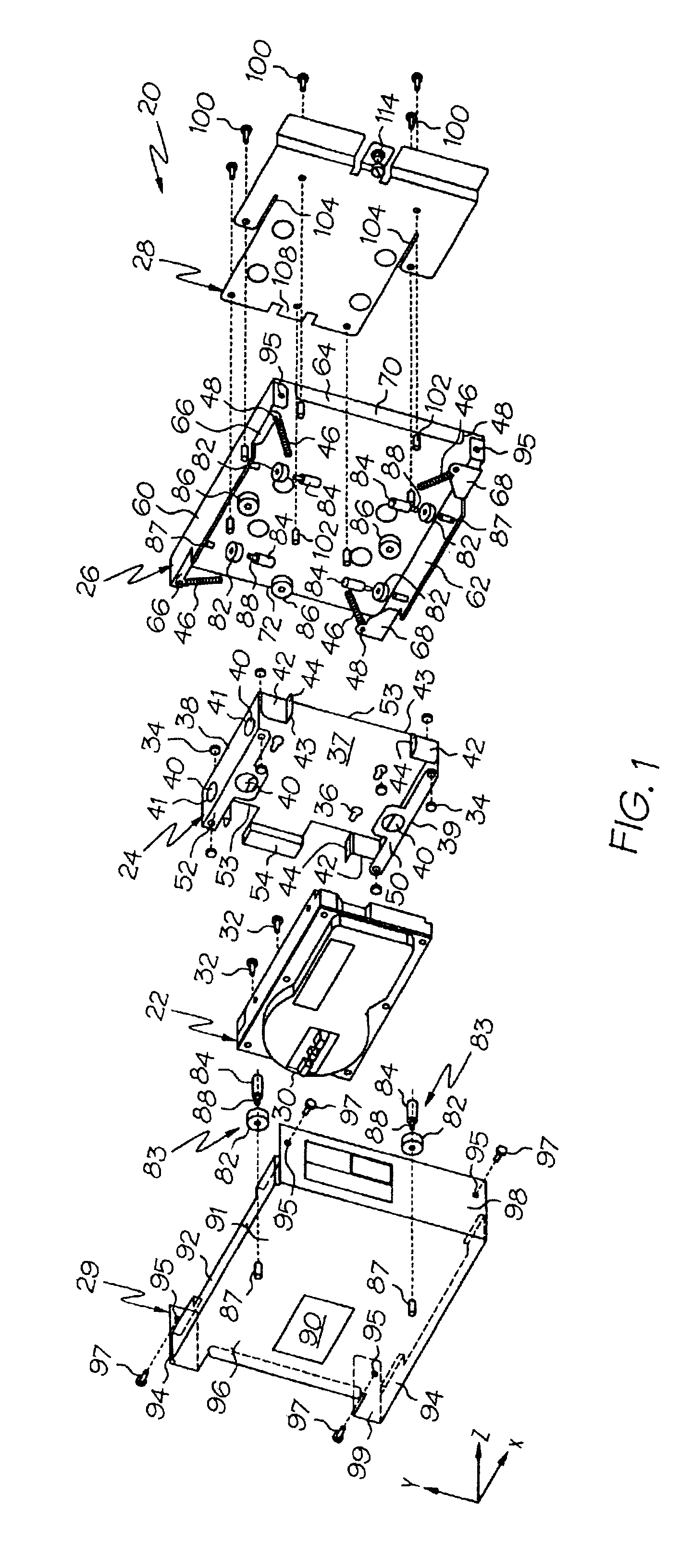

Disk drive mounting system for absorbing shock and vibration in a machining environment

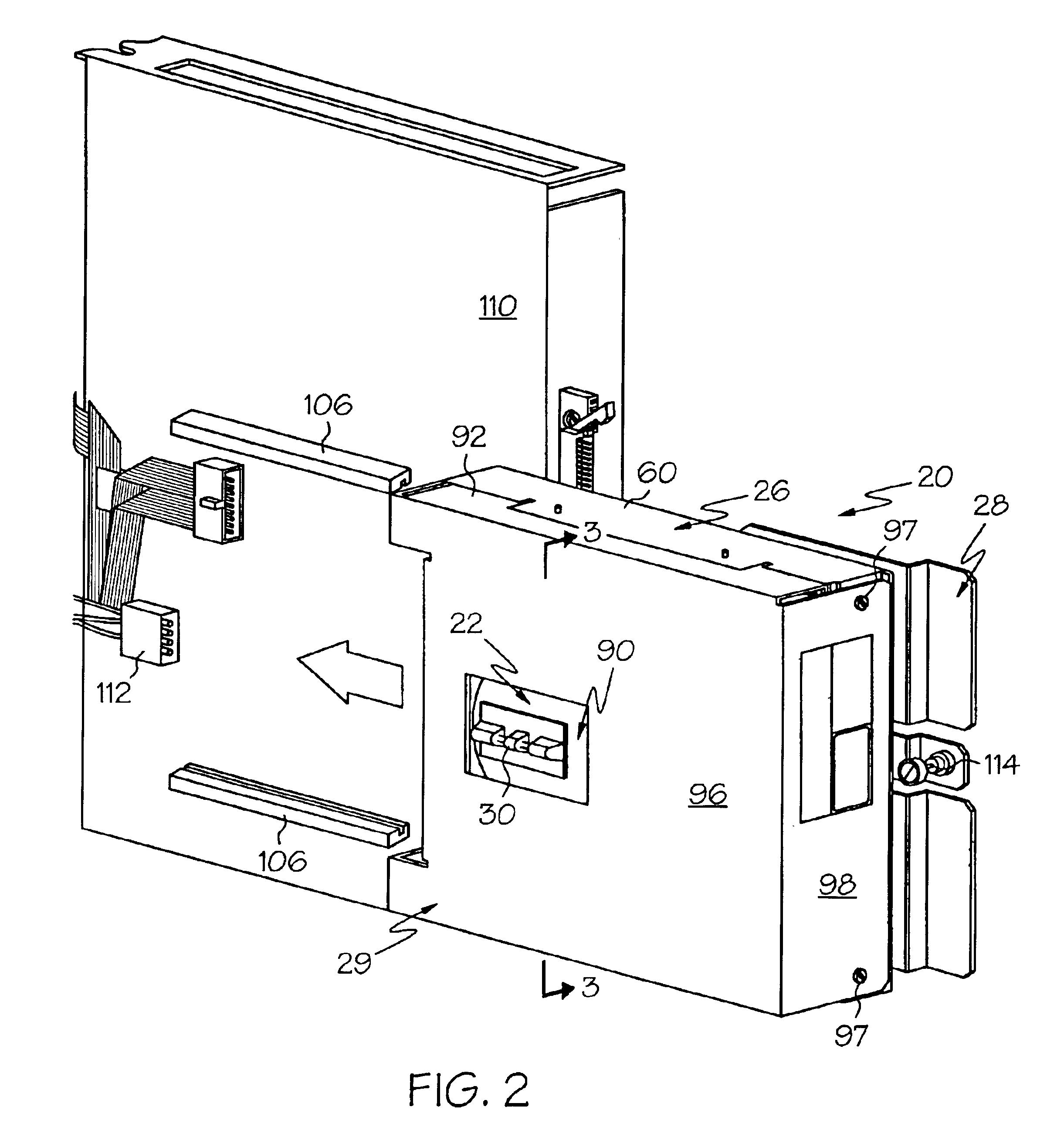

InactiveUS6822858B2Effective isolationEffectively isolates vibration encountered in machining environmentApparatus modification to store record carriersDigital data processing detailsMachining vibrationsHard disc drive

A disk drive mounting system for isolating a disk drive assembly from machine vibration and shock. In one embodiment, the system includes a suspension frame and a disk drive assembly mounted to the frame using biased vibration isolation members, such as springs, which are each substantially aligned through the center of mass of the disk drive assembly. Accordingly, vibrational forces can be transmitted through the center of mass of the disk drive assembly. Preferably, the disk drive assembly includes a mounting chassis which holds a hard disk drive and includes openings through which damping bumpers can extend. In this embodiment, the bumpers each have a base portion and an extension portion, the extension portion extending through the openings in the mounting chassis to limit the transfer of shock to the disk drive. The bumpers can be attached to the suspension frame and / or to a protective cover for the assembly. Preferably, a slide bracket is provided to allow the system to be easily mounted to a machine tool system surface.

Owner:SIEMENS IND INC

Method For Identifying A Fault In An Electrical Machine

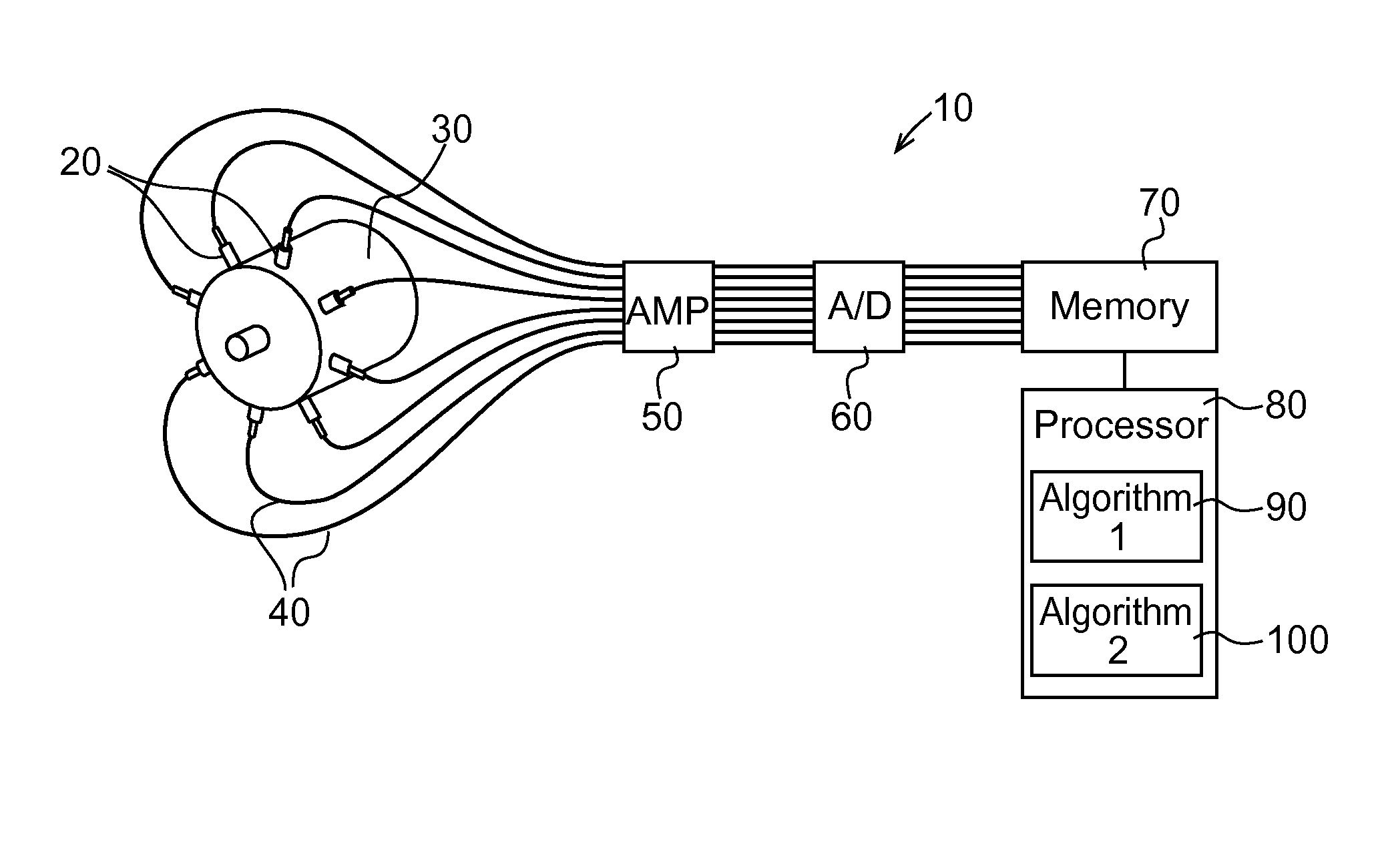

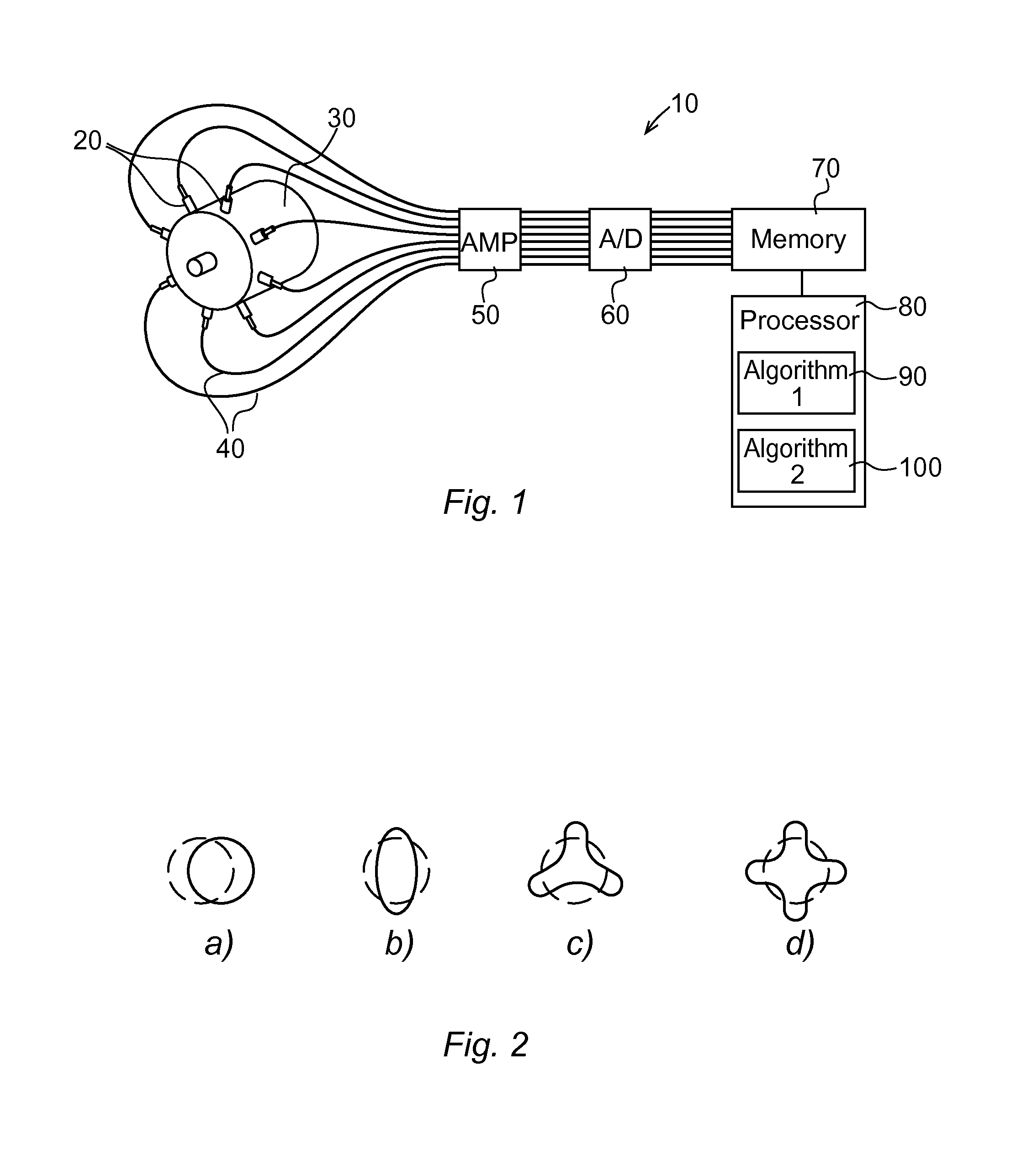

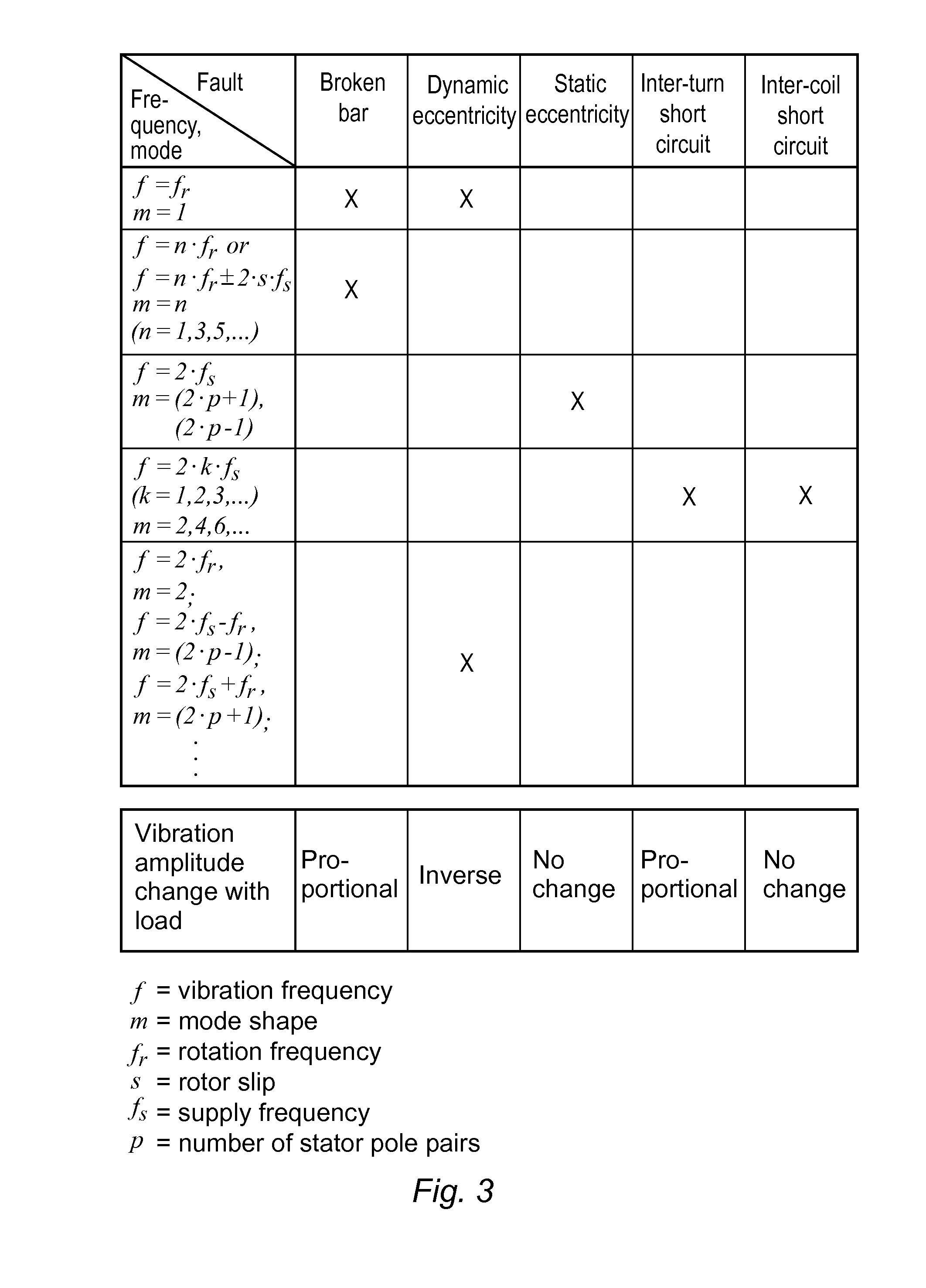

ActiveUS20140109679A1Reliable identificationImprove reliabilityVibration measurement in solidsMachine part testingMachining vibrationsStator

For identifying a fault in an electrical machine vibration is measured in a plurality of radial directions of the stator. On the basis of the vibration measurements a vibration frequency and a mode shape of the vibration at this frequency is determined. Characteristics of the vibration in terms of both the vibration frequency and the mode shape are used to identify a fault condition of the electrical machine.

Owner:ABB (SCHWEIZ) AG

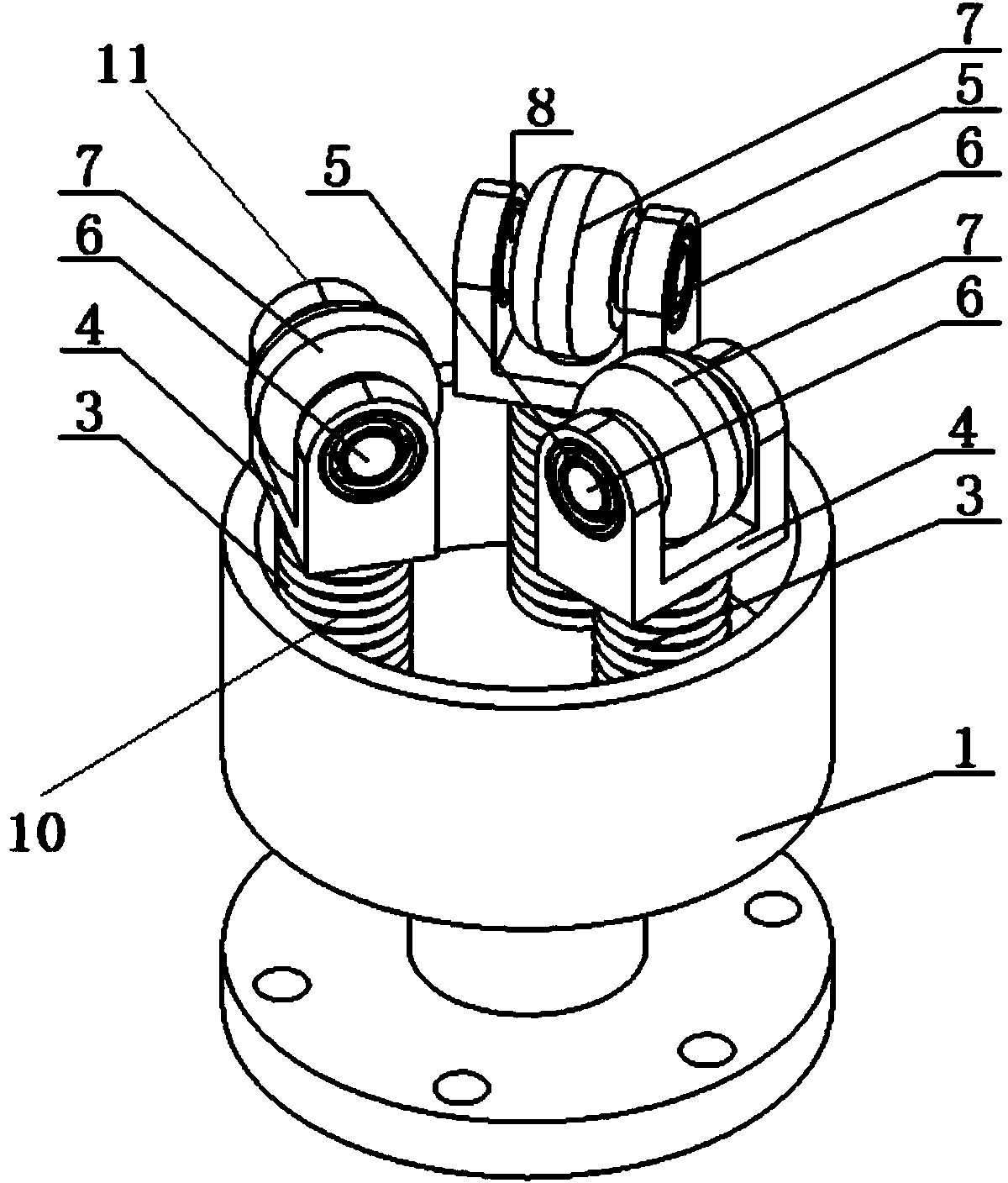

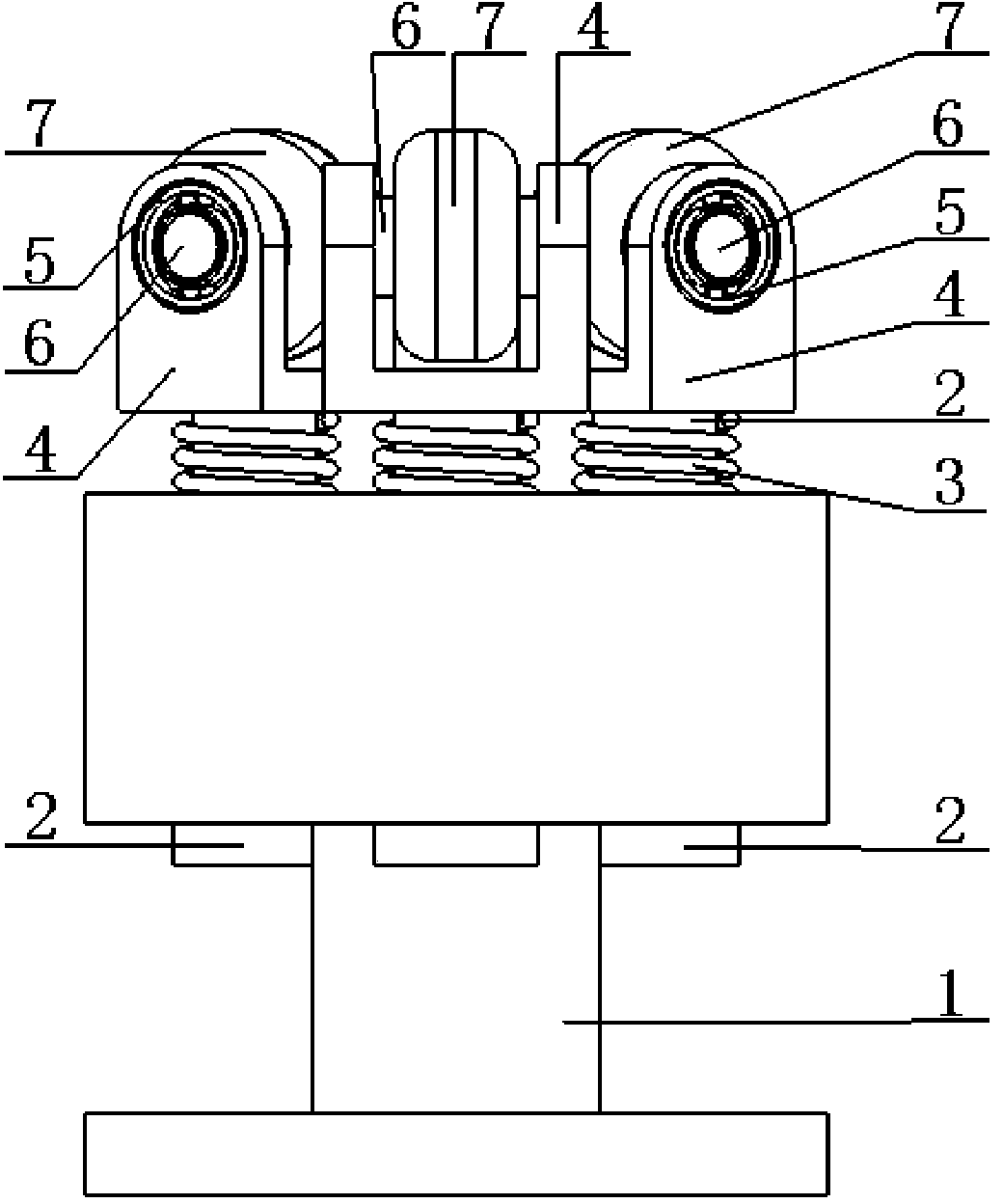

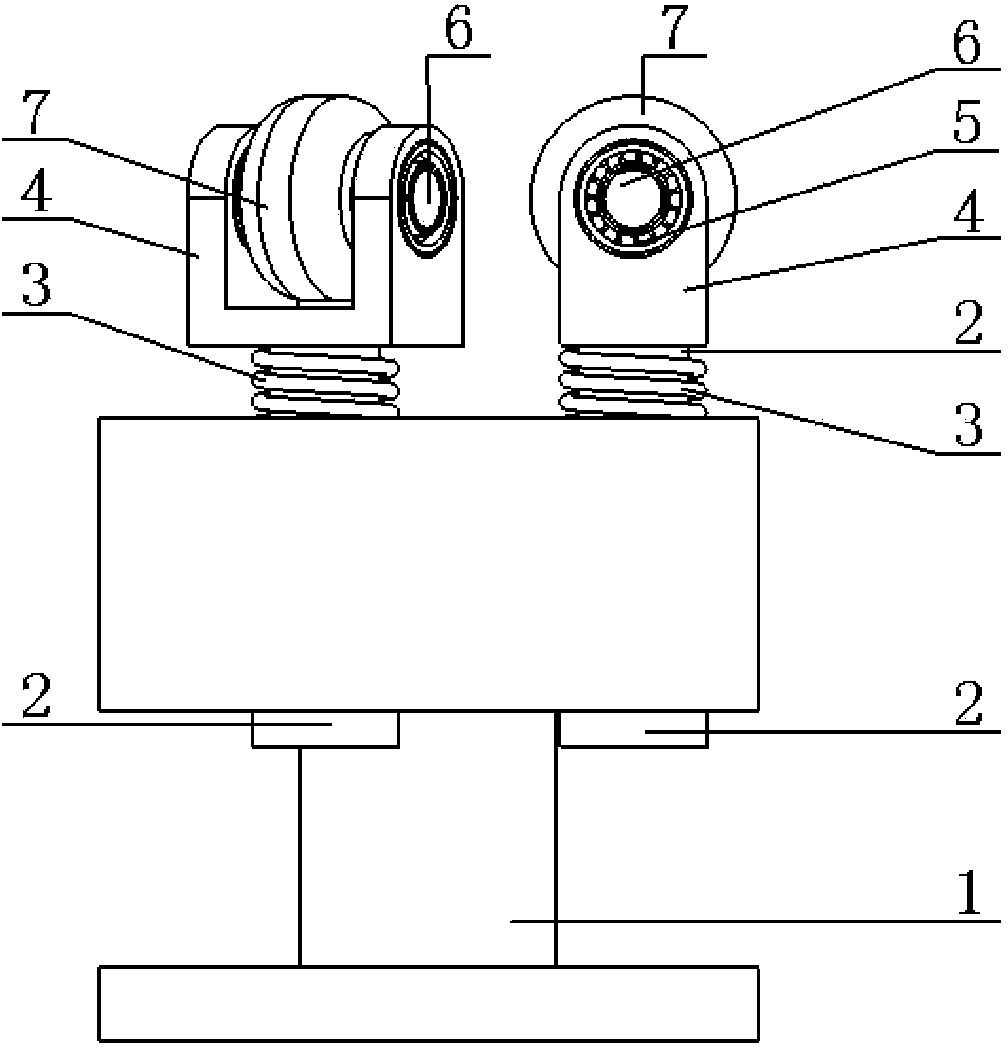

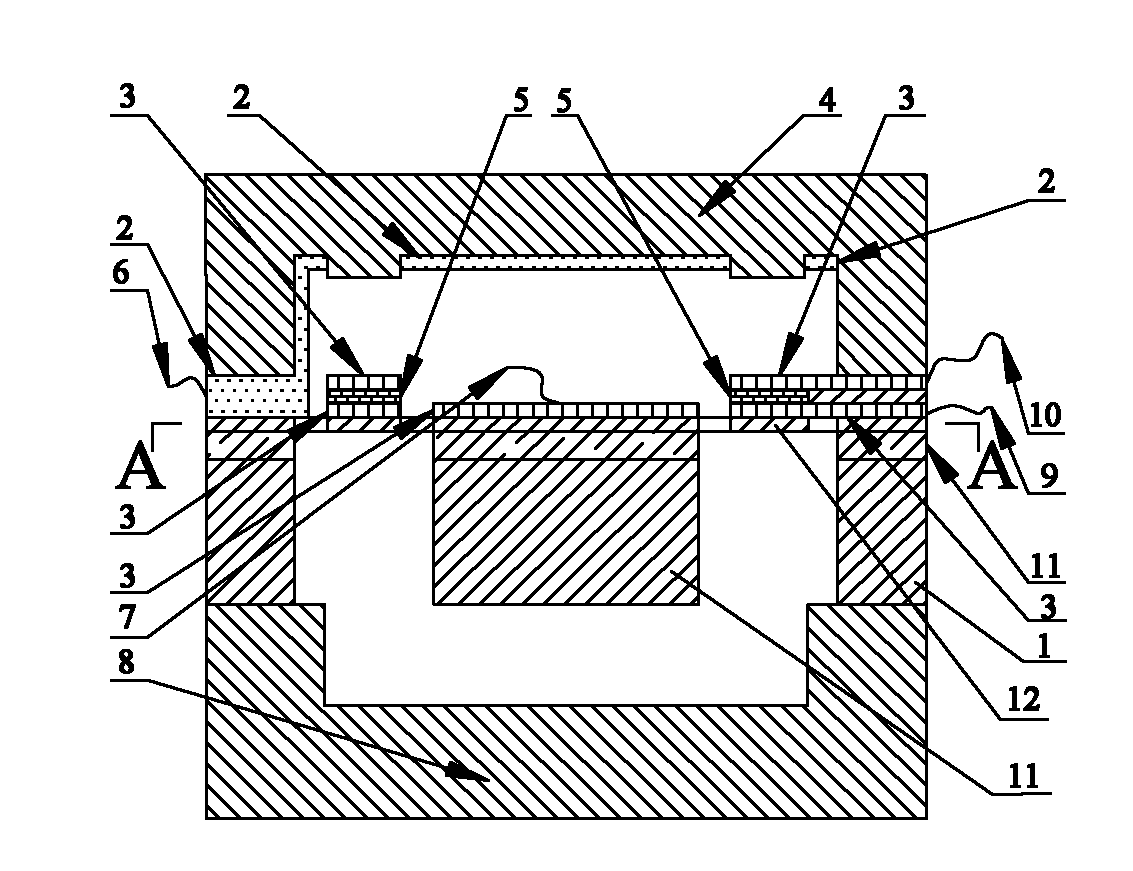

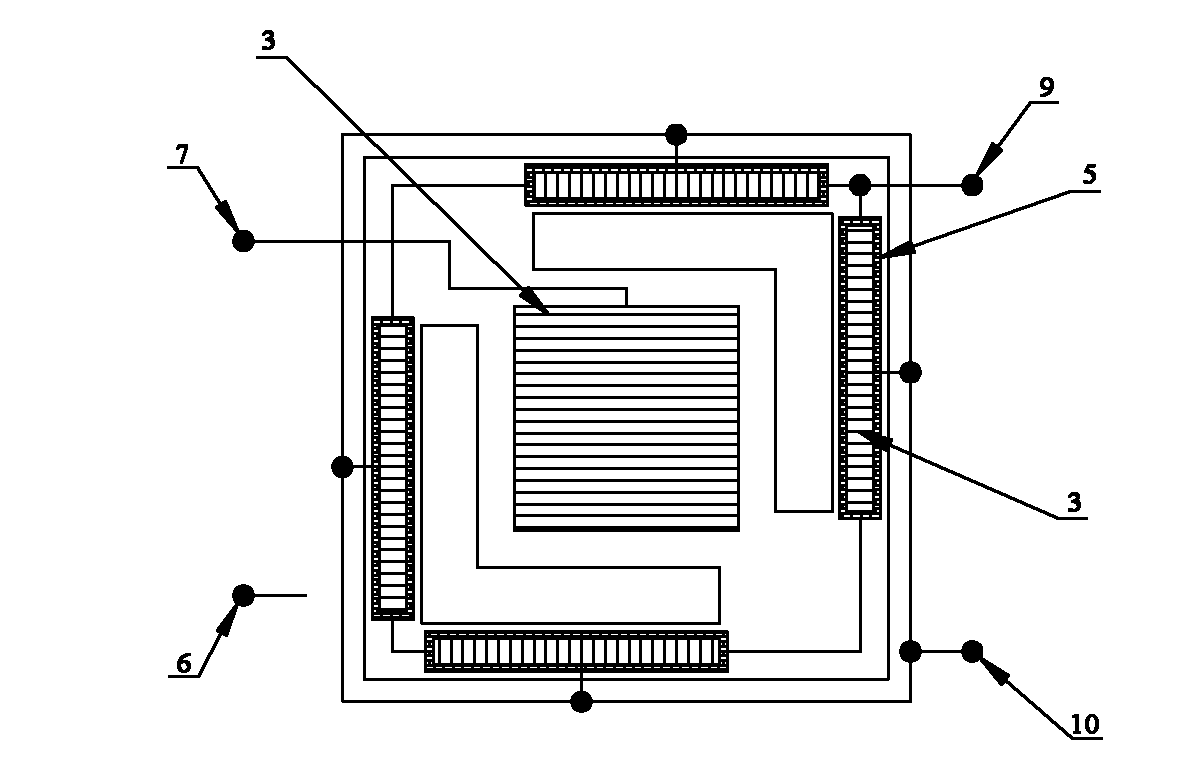

Multipoint flexible rolling supporting head for mirror image machining device

InactiveCN104002161AGuaranteed machining accuracyIncrease the effective area of supportPositioning apparatusMaintainance and safety accessoriesMachining vibrationsEngineering

The invention discloses a multipoint flexible rolling supporting head for a mirror image machining device. The multipoint flexible rolling supporting head comprises a base, a plurality of elastic supporting rods and a plurality of flexible rolling parts. The bottoms of the elastic supporting rods are arranged on the base and are arranged in a circumferential array mode. The top ends of the elastic supporting rods are connected with the flexible rolling parts respectively, when a cutter at a thin-wall workpiece machining side begins to conduct machining, the base moves along with the cutter at the same speed and in the same direction, the centers of all the elastic supporting rods are in mirror symmetry with the cutter, and machining vibration of a thin-wall workpiece is relieved. According to the multipoint flexible rolling supporting head, the effective supporting area is enlarged, the vibration of the workpiece can be effectively relieved, and accurate machining of thin-wall components is achieved.

Owner:SHANGHAI JIAO TONG UNIV

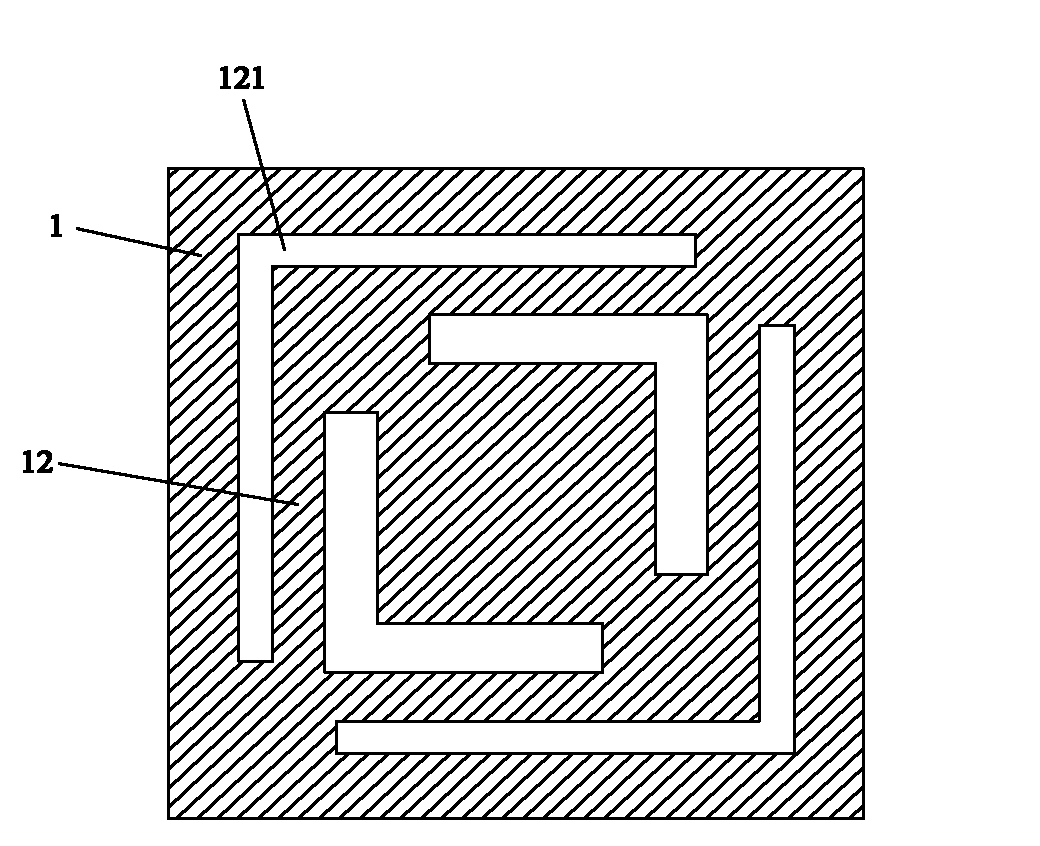

Piezoelectric-static compound micro machine vibration energy collector and manufacture method thereof

InactiveCN102570902AAvoid instabilityAchieve self-supplyPiezoelectric/electrostriction/magnetostriction machinesDecorative surface effectsCapacitanceMachining vibrations

The invention relates to a piezoelectric-static composite micro machine vibration energy collector and a manufacture method of the collector, and relates to an energy collecting device. The piezoelectric-static composite micro machine vibration energy collector comprises a chip main body and a chip external circuit, wherein the chip main body is of a three-layer laminated structure, and the chip main body comprises an upper glass piece device, an SOI (Silicon On Insulator) piece device, a lower glass piece device, a piezoelectric ceramic wafer device, a piezoelectric ceramic wafer electrode and a variable capacitance plate electrode. The chip external circuit is provided with a rectification circuit, a filter capacitor, a first switch, a second switch and an energy storage capacitor, or is provided with a rectification circuit, a filter capacitor, a first switch, a second switch and an energy storage capacitor and a variable capacitance plate starting power supply. The manufacture method comprises the following steps of: manufacturing the lower glass piece device; manufacturing the SOI piece device; manufacturing the upper glass piece device; assembling; and connecting the chip external circuit. According to the collector and the manufacture method, the process is simple, the defects of poorer device stability and performance and the like caused by,manufacturing a PZT (Piezoelectric Transducer) by using the traditional sol gel can be overcome, and wide band and high efficiency collection of energy can be realized.

Owner:XIAMEN UNIV +1

Device for measuring the relative alignment of two articles, method for determining a quality characteristic and vibration measurement device and method

ActiveUS20110113888A1Simplification of handling of measurementEasy to measureVibration measurement in solidsSubsonic/sonic/ultrasonic wave measurementVibration measurementMachining vibrations

An alignment device with one or two optoelectronic transmitting and / or receiving units and an evaluation unit. At least one optoelectronic transmitting and / or receiving unit contains an inclinometer. Furthermore, the transmitting and / or receiving unit is connected to a vibration sensor which can be the inclinometer. Both the result of the alignment process and also the result of the vibration measurement are communicated to the user as an easily understandable characteristic on a display of the evaluation unit. For vibration measurement at a non-rotating part of a machine, an accelerometer / inclinometer sensor may be used for measuring acceleration forces resulting from machine vibrations to be measured and for measuring gravity and an electronic evaluation unit determining the orientation of the sensor with regard to gravity from a stationary component of the sensor output and determining sensor orientation from evaluation of non-stationary components of sensor output.

Owner:PRUTECHNIK DIETER BUSCH AG

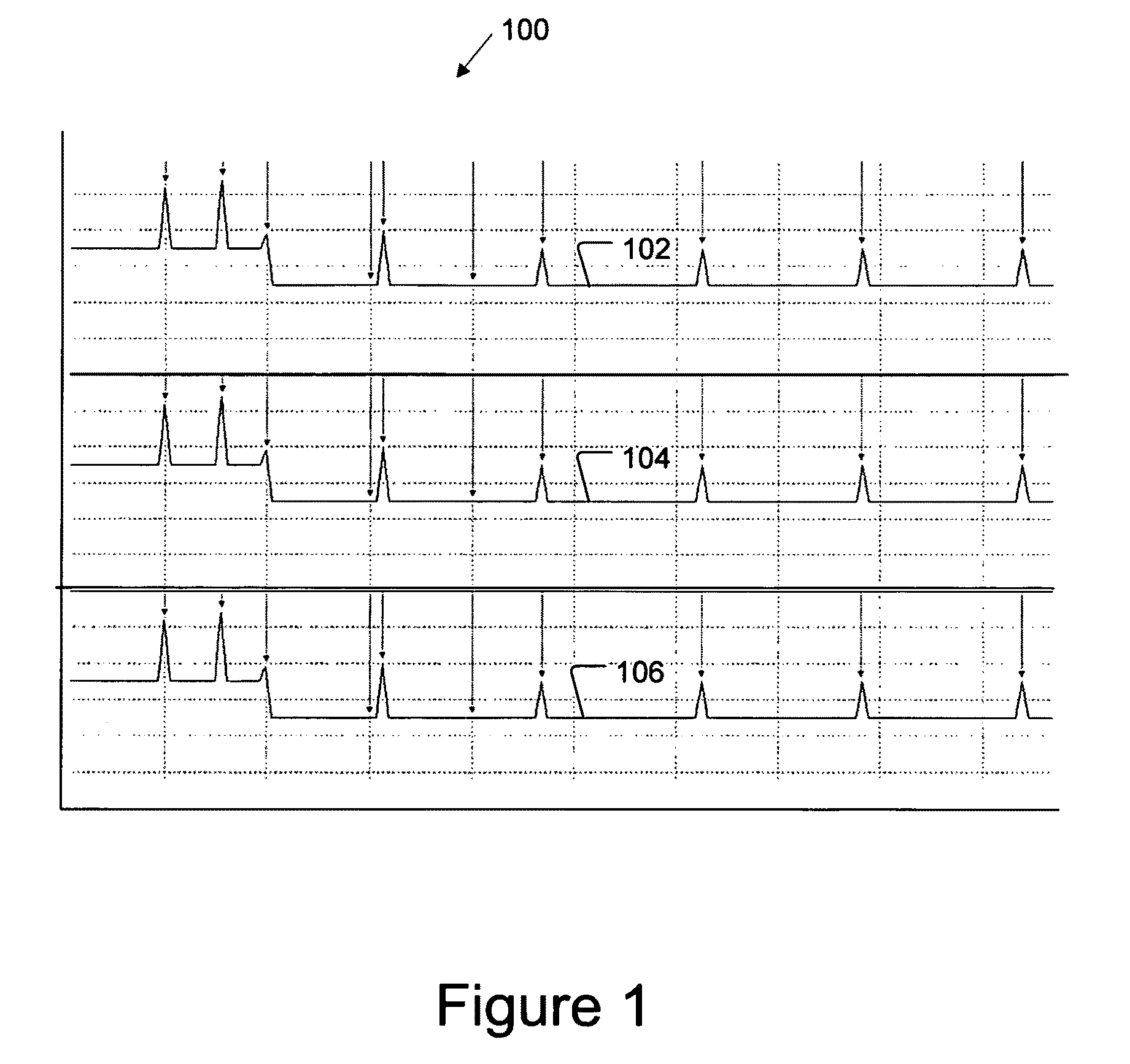

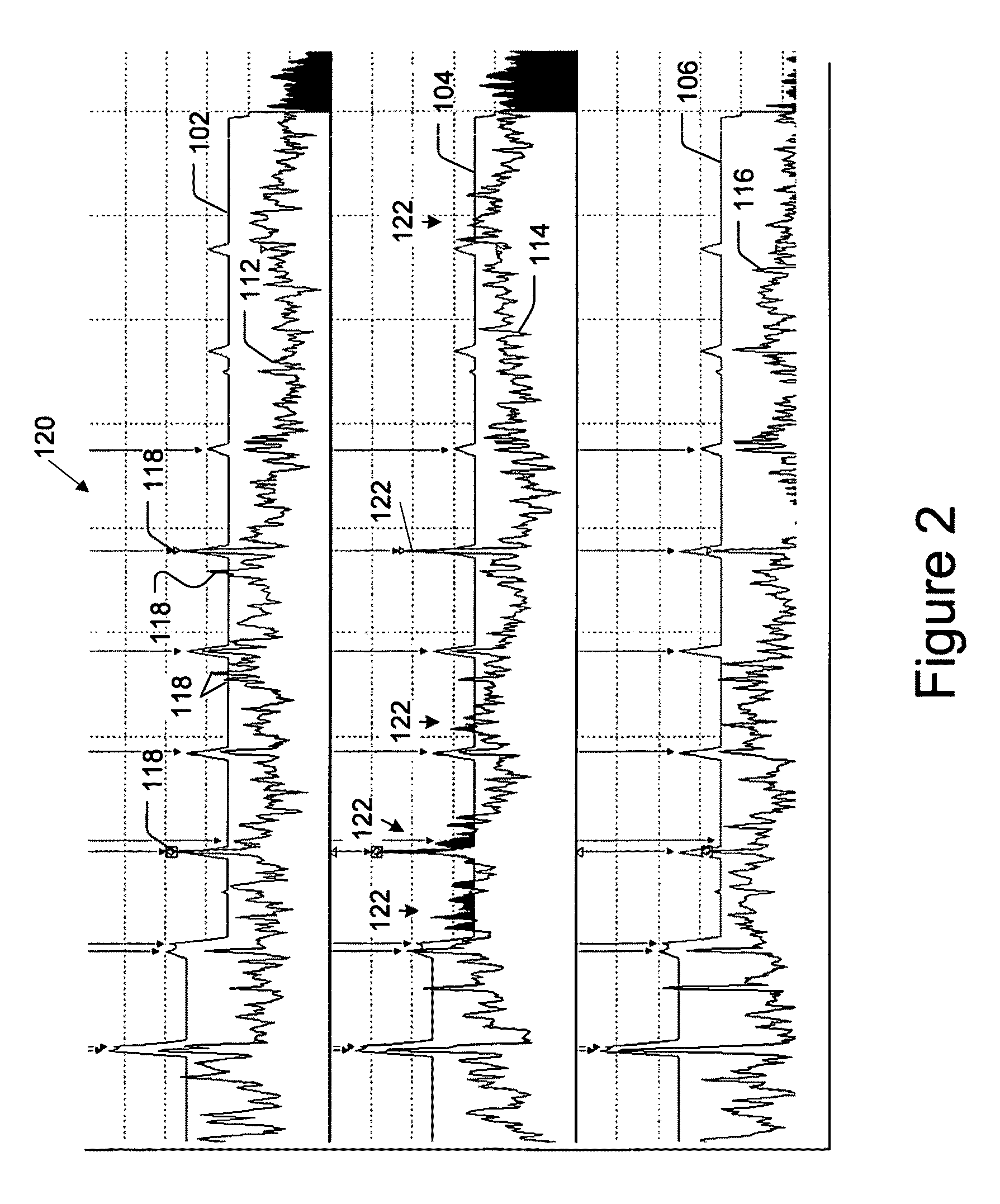

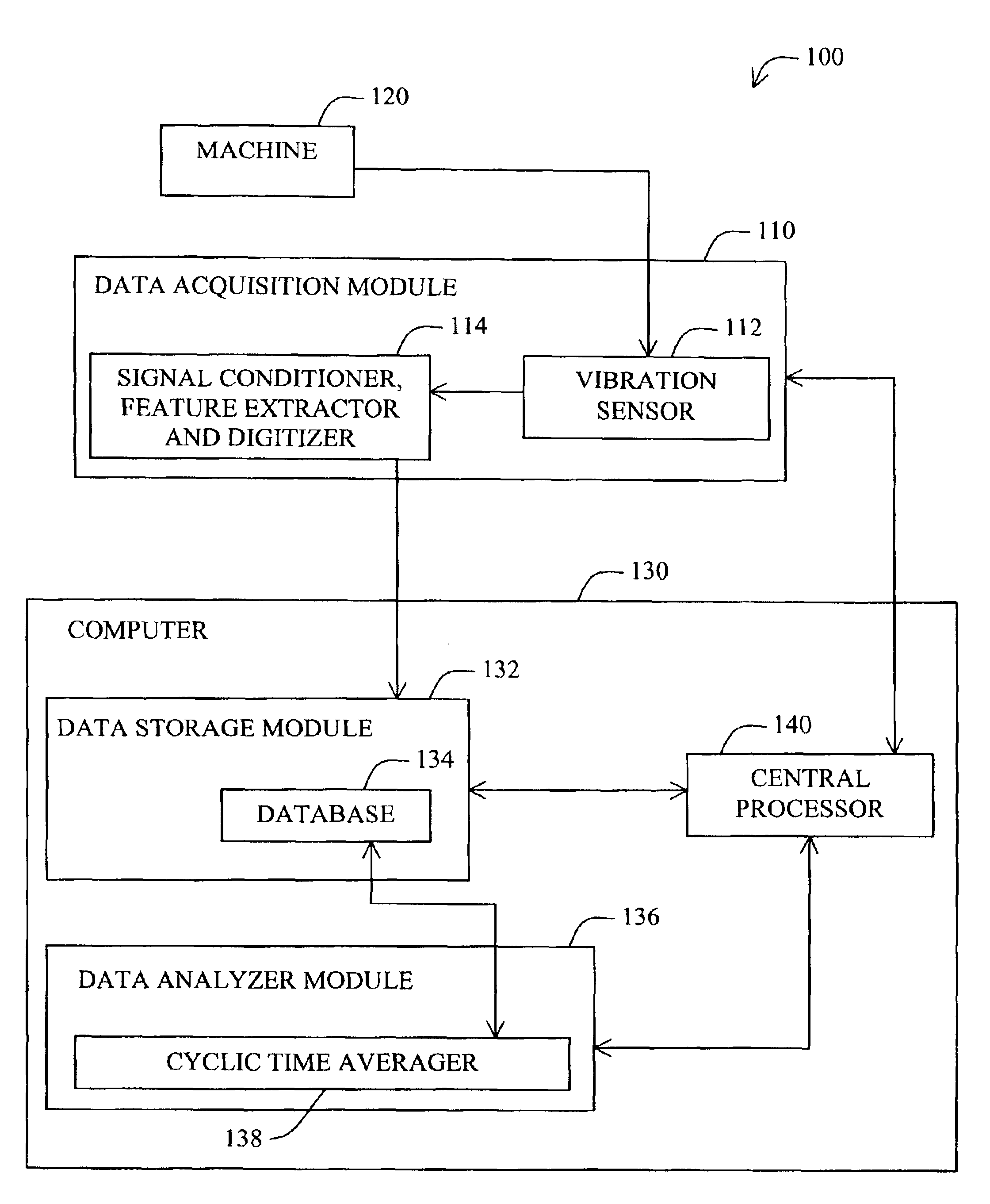

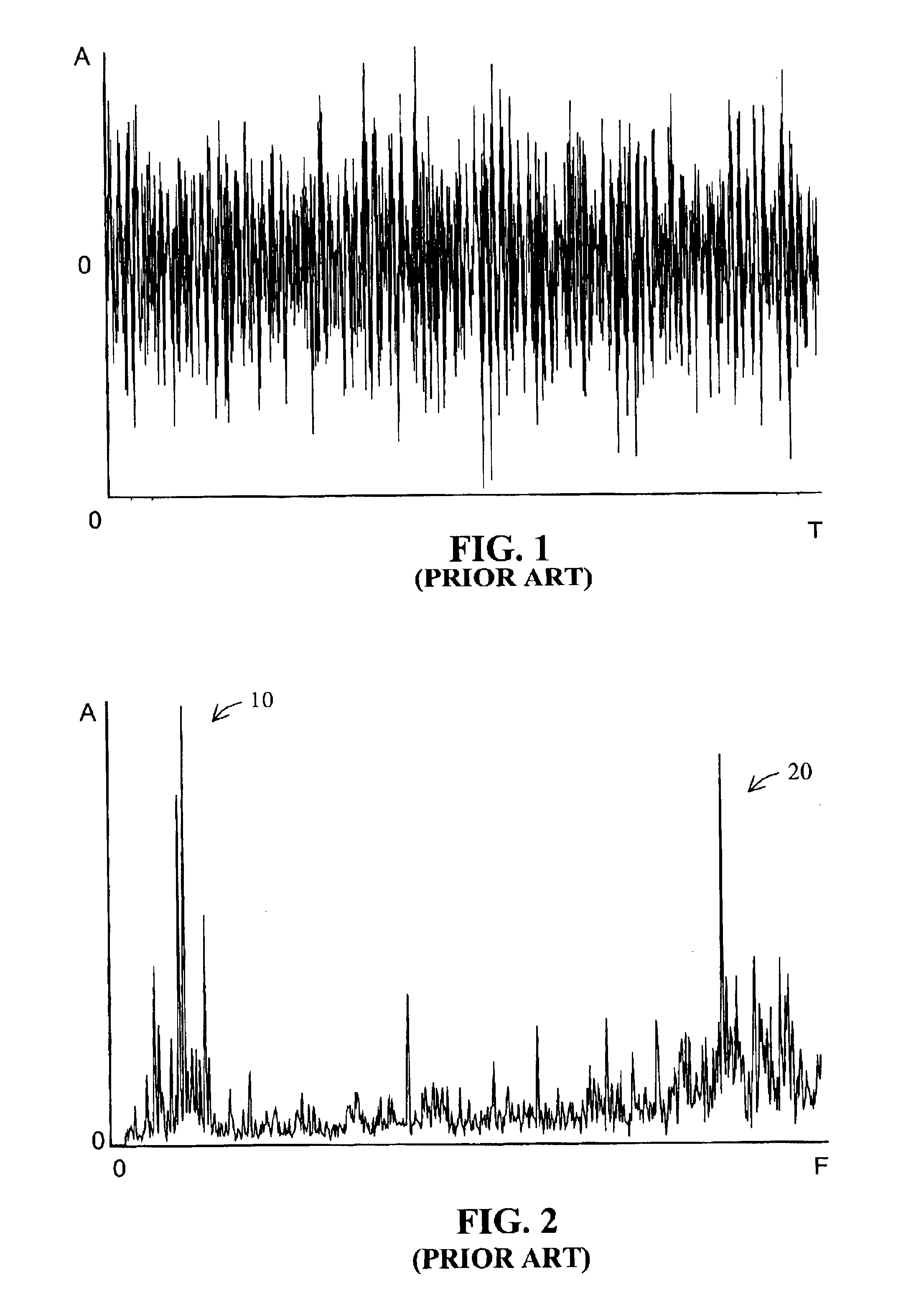

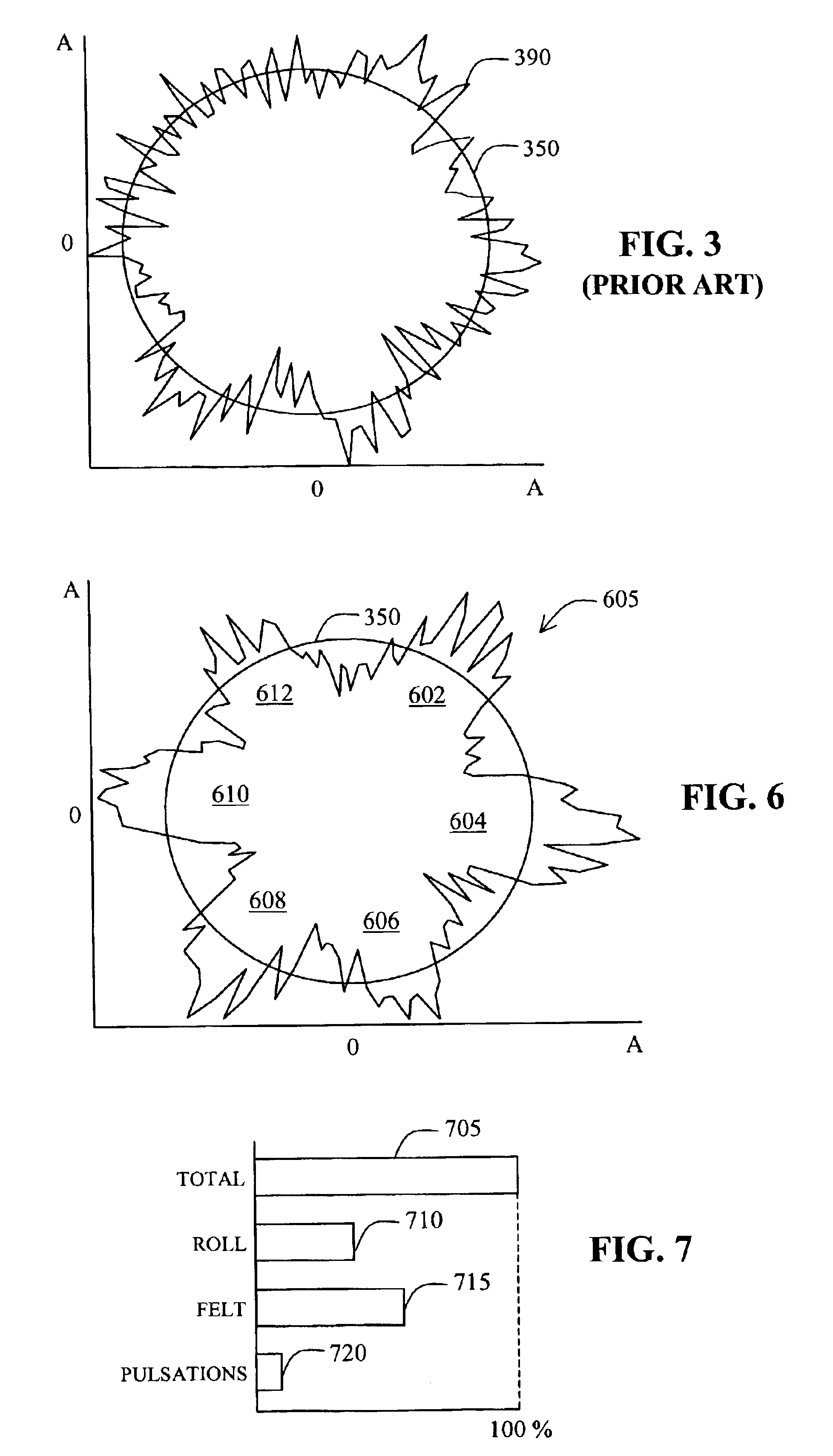

Cyclic time averaging for machine monitoring

The condition of a machine is monitored with cyclic time averaging, a technique of allocating vibration energy to particular sources in a complex signal. The cyclic time averaging method is directed at processing time-domain vibration data of the machine to produce an averaged time waveform over a selected cyclic time period. Utilizing cyclic time averaging, the systems and methods analyze machine vibration signals to detect and evaluate specific sources of enemy contribution to the vibration energy of the machine. It is not necessary to employ a triggering signal to obtain the averaged time waveform.

Owner:SKF USA INC

Artificial intelligence device and corresponding methods for selecting machinability data

InactiveUS20080255684A1Easy to solveInference methodsSpecial data processing applicationsMain processing unitMachining vibrations

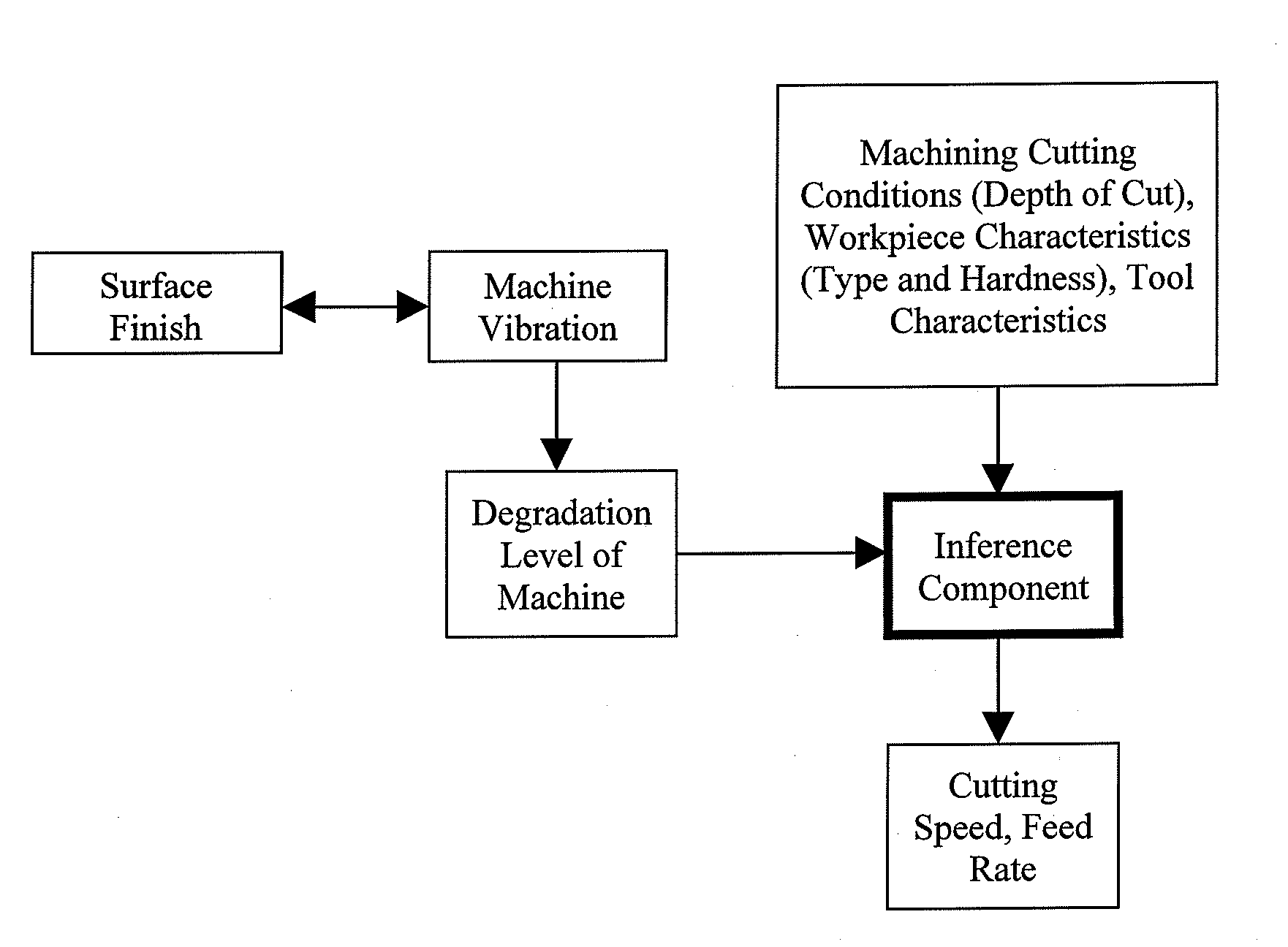

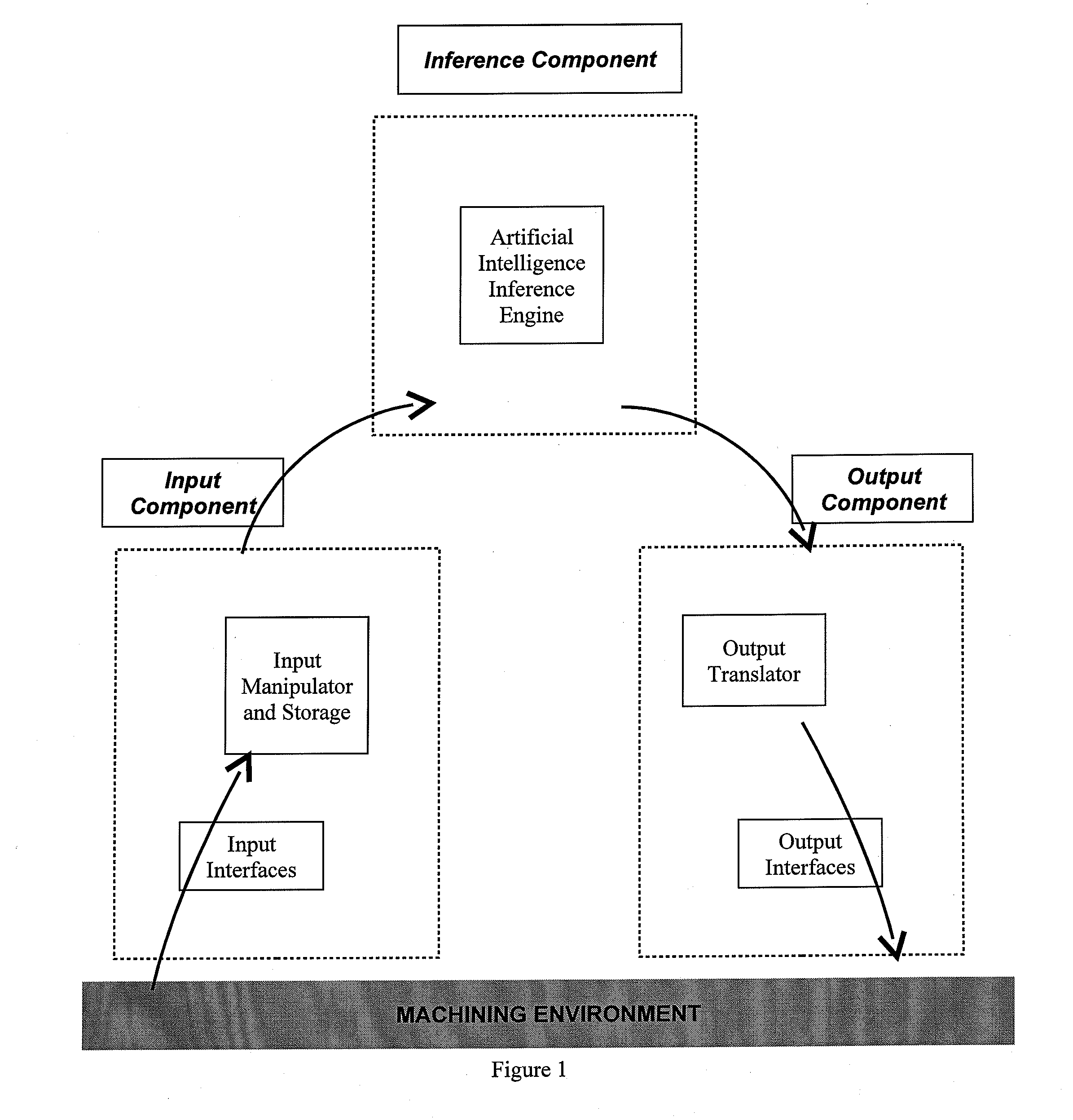

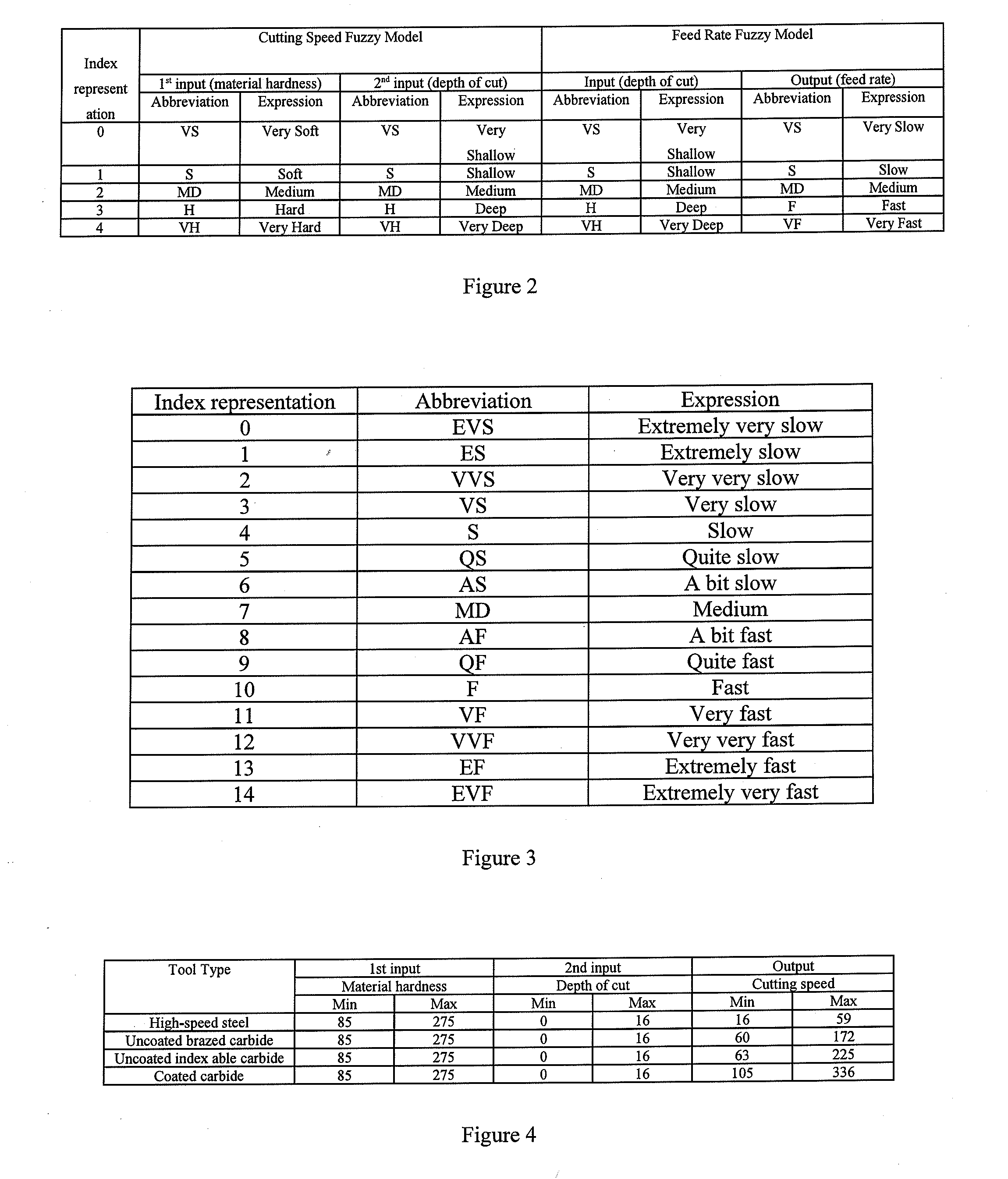

The present invention describes a device incorporating artificial intelligence and corresponding methods for recommending an optimal machinability data selection, especially with machine performance degradation. The device comprises of a first component, which feeds the system with necessary inputs. A second component, which is the main processing unit, acts as an inference engine to predict the outputs. The last component interprets the outputs, conveys the processed outputs to target location and converts them into necessary tasks. The inputs are identified as the machining operations, work piece material, machining tool type, and depth of cut. The input includes machine performance characteristics as well, that is the degradation level of the machine which interrelates with machine vibration and surface finishing. The outputs are the machining parameters, comprising of the optimal cutting speed and feed rate. The inference engine can be established with fuzzy logic, neural network or neural-fuzzy.

Owner:UNIVERSITI PUTRA MALAYSIA

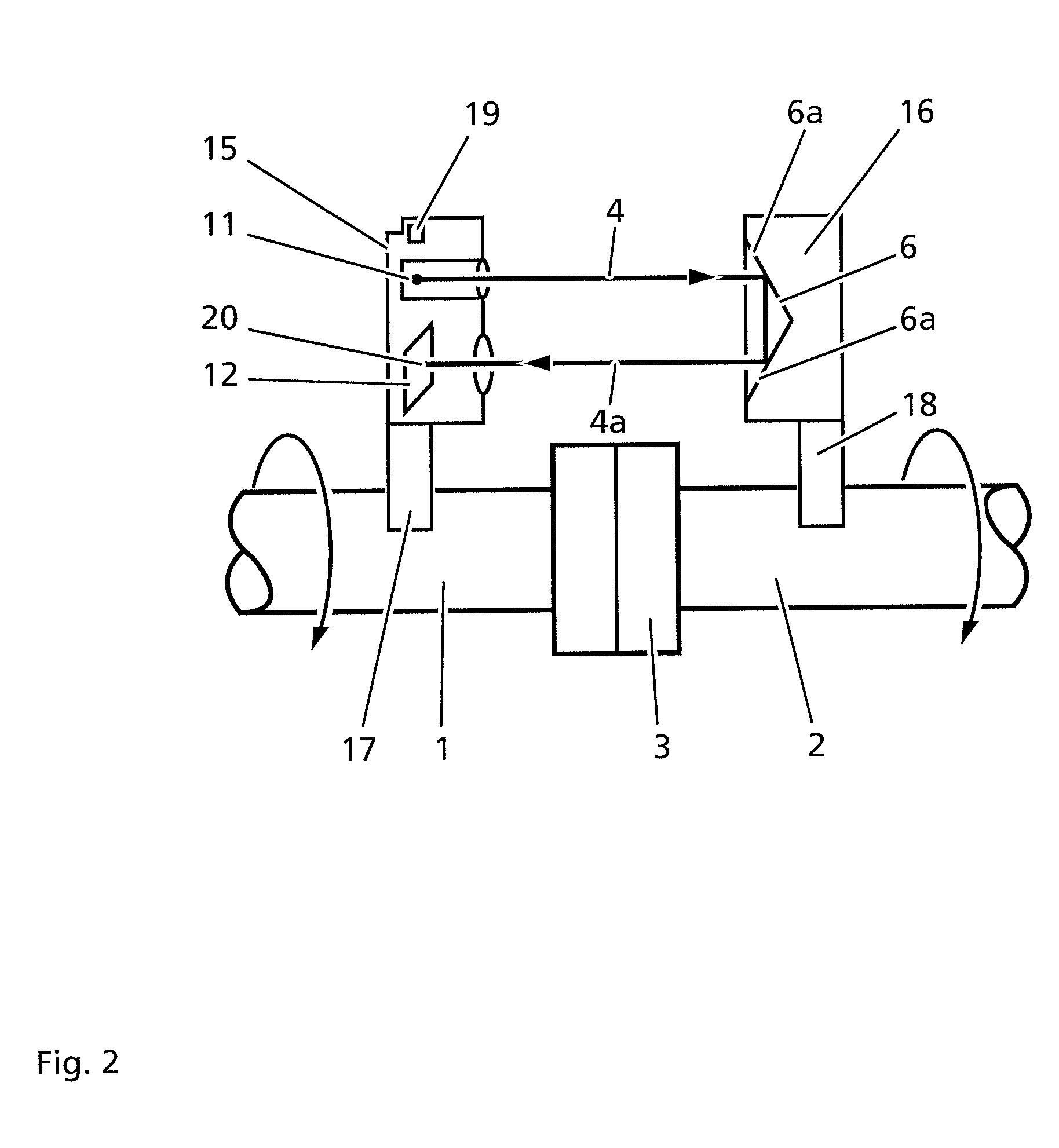

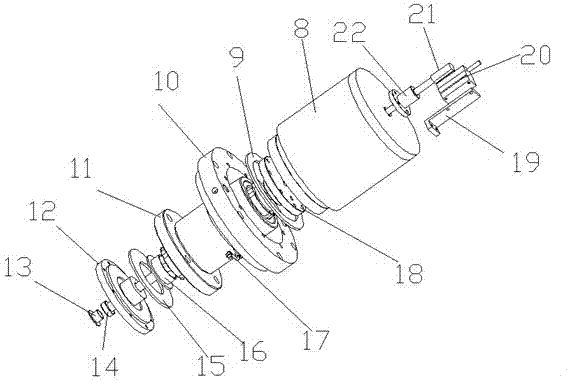

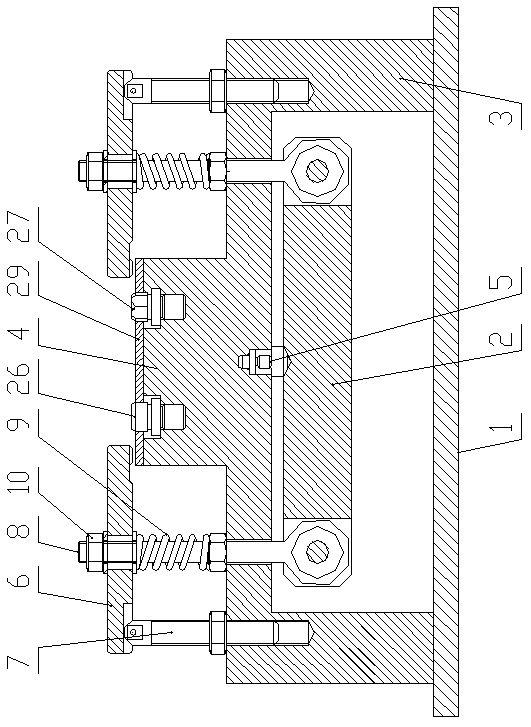

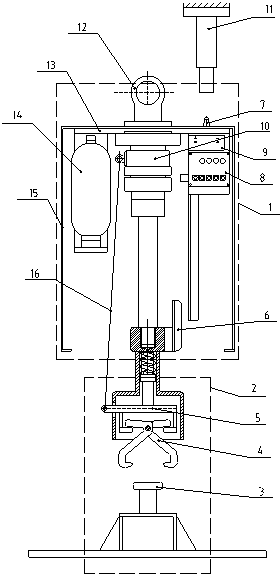

Electrochemical machining vibro-feed movement implementation device

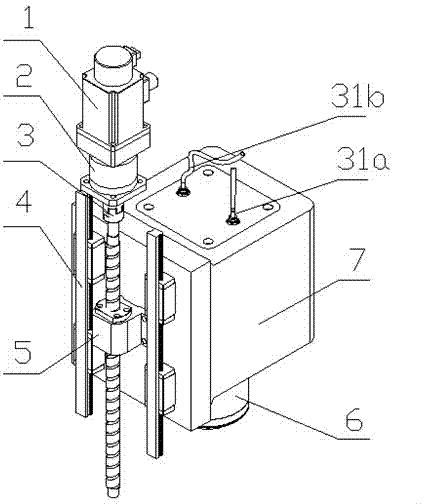

InactiveCN103028795AHigh vibration frequencySteplessly adjustable vibration amplitudeElectrochemical machining apparatusElectrical-based auxillary apparatusMachining vibrationsElectric machine

The invention discloses an electrochemical machining vibro-feed movement implementation device, which belongs to the electrochemical machining field. The device comprises a servo feed movement device and a vibration device, wherein the vibration device is installed on the servo feed movement device via a sliding seat; the vibration device comprises a voice coil motor; the top end of a voice coil motor rotor is fixedly provided with a connecting block; the connecting block is connected with an electric conduction block via a transmission mechanism; and the electric conduction block is used for clamping a tool cathode. According to the electrochemical machining vibro-feed movement implementation device disclosed by the invention, the feed movement is realized by a servo motor, a lead screw and a guide rail pair, the voice coil motor is used for driving so as to realize the vibro-movement, and the two mutually-parallel movements are compounded to realize the vibro-feed movement of the tool cathode. According to the movement implementation device, the electrolysate discharge problem in the electrochemical machining process can be effectively solved, an electrolysate flow field is effectively improved so as to easily realize small-gap electrochemical machining, and a purpose of improving the electrochemical machining precision and stability is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

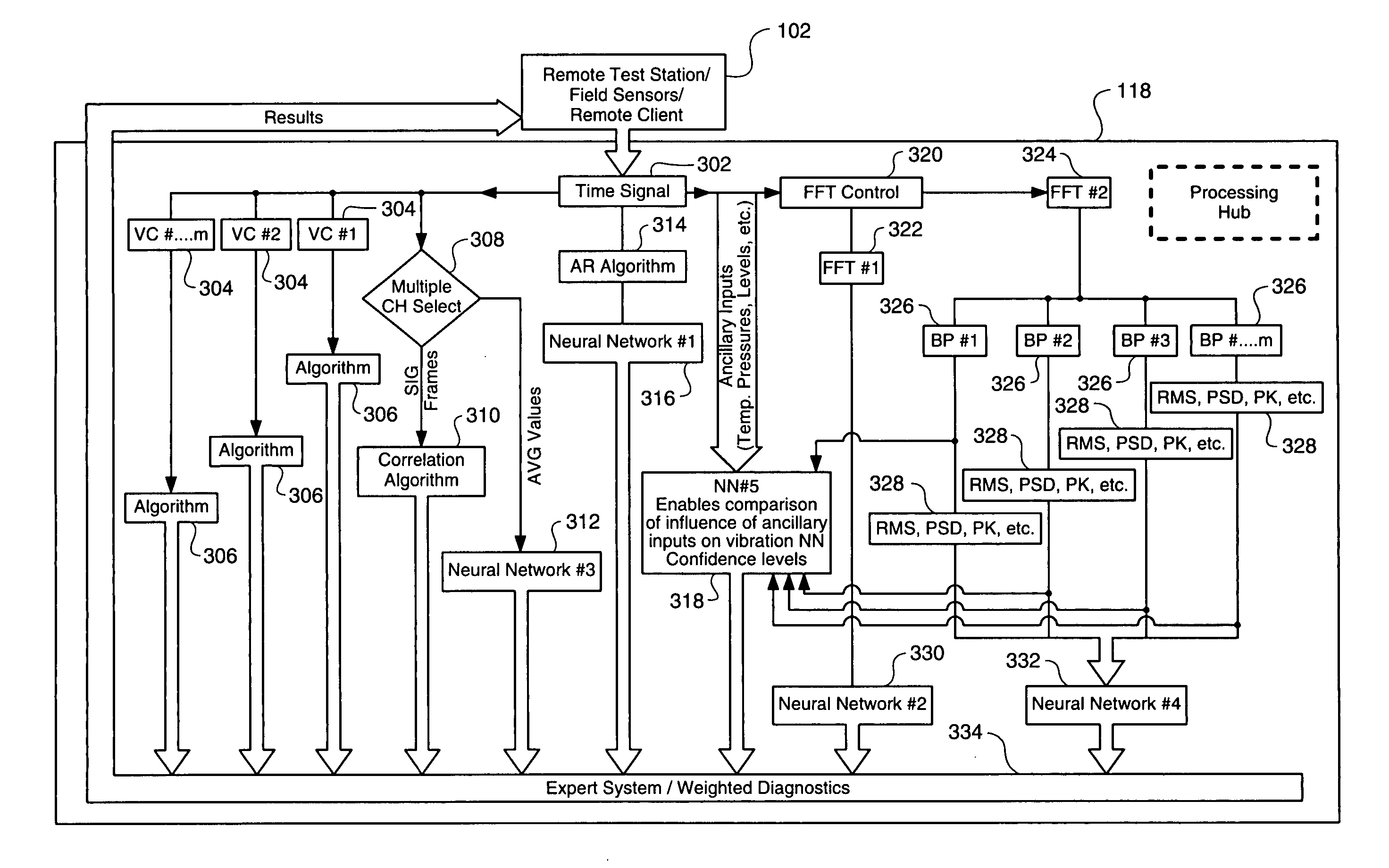

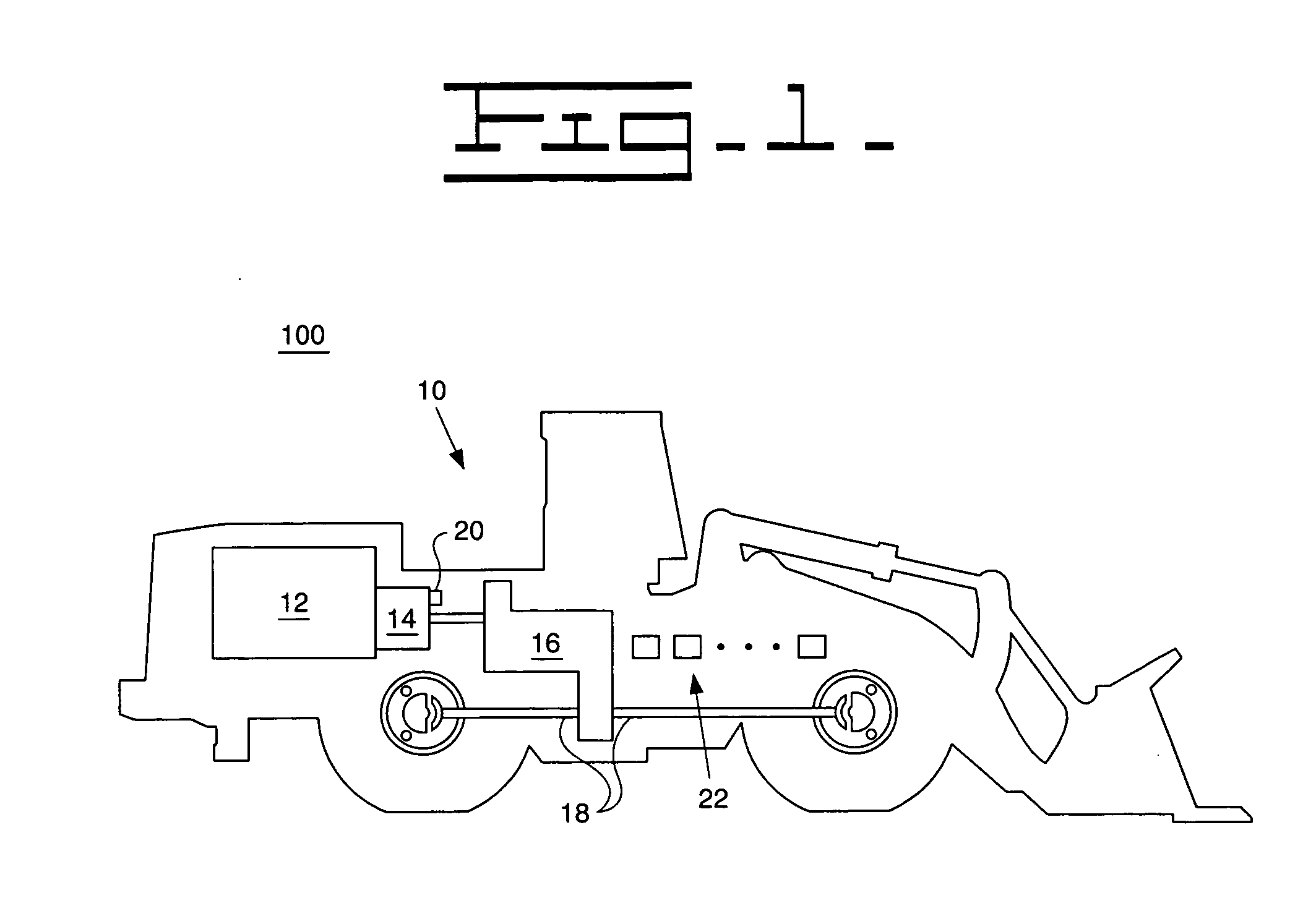

Vibration analysis system and method for a machine

InactiveUS20060122809A1Vibration measurement in solidsInternal-combustion engine testingMachining vibrationsEngineering

A system and method for detecting and analyzing anomalies in a machine during operation. The system and method includes at least one sensor configured to detect characteristics of the machine indicative of machine vibration, at least one other sensor configured to detect characteristics of the machine indicative of other than machine vibration, a plurality of neural networks to receive input data, at least one neural network receiving vibration data from the at least one sensor, and at least one other neural network receiving non-vibration data from the at least one other sensor, and an expert system to receive output data from the neural networks and responsively analyze machine operation for anomalies.

Owner:CATERPILLAR INC

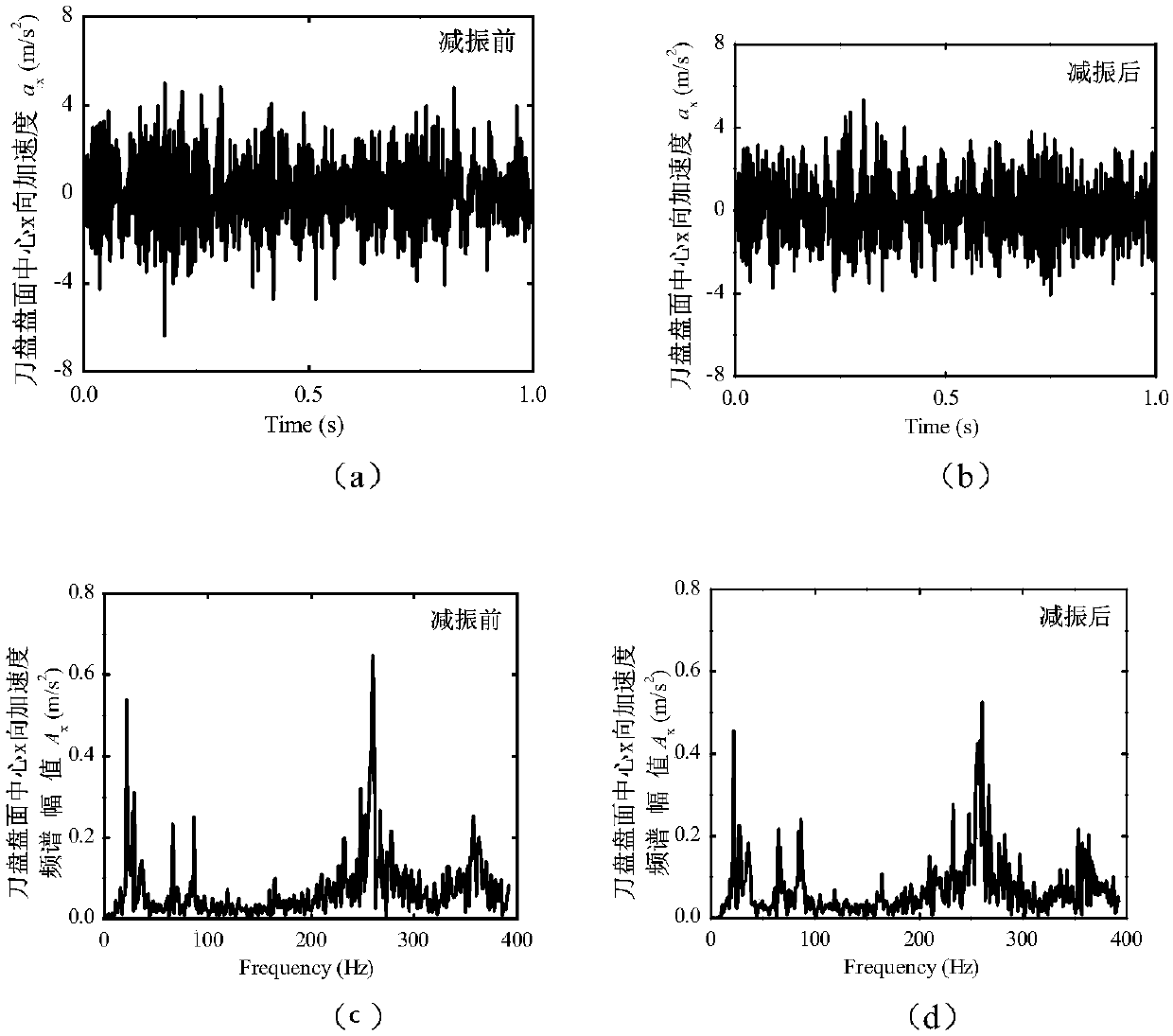

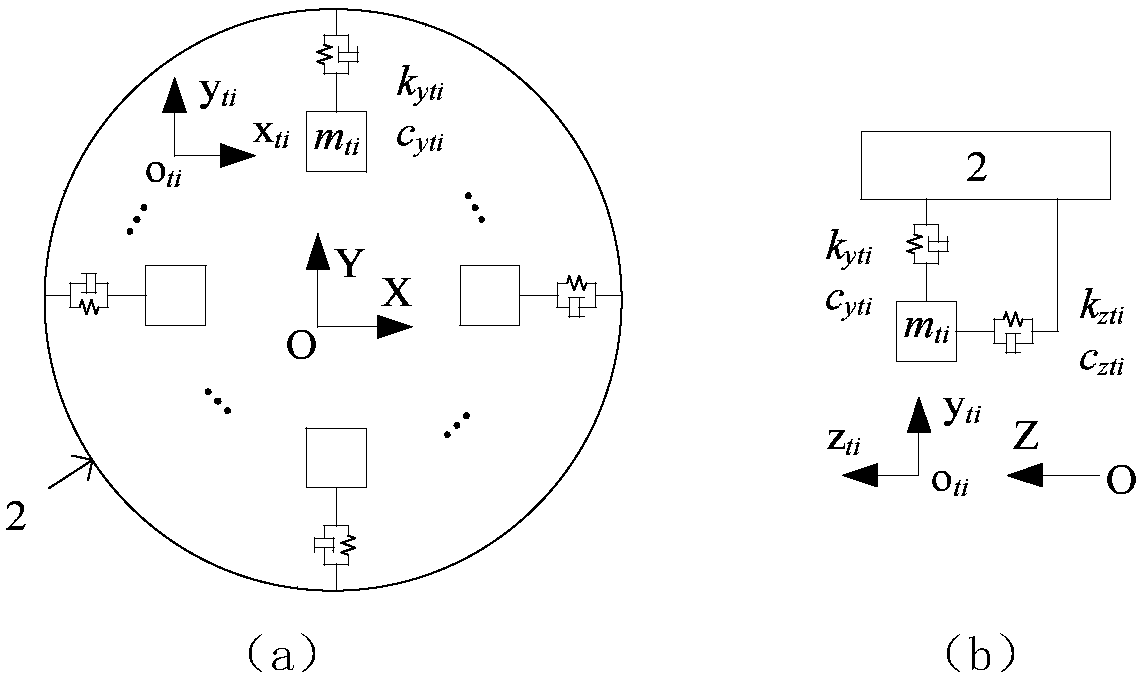

Hard rock road-header damping design method based on multi-tuning mass damper

ActiveCN107480400AEasy processing and installationUse impactGeometric CADDesign optimisation/simulationMachining vibrationsDynamic models

The invention provides a hard rock road-header damping design method based on a multi-tuning mass damper. The hard rock road-header damping design method comprises the steps of establishing a hard rock road-header whole-machine rigid-flexible coupling multi-body dynamics model; 2, calculating hob dynamic rock breaking force and shield-surrounding rock mutual acting force and simulating hard rock road-header vibration exciting force; 3, analyzing and evaluating hard rock road-header driving performance and the whole-machine vibration level; 4, installing the multi-tuning mass damper on a hard rock road-header gearbox; 5, determining the quantity, distribution mode, mass, rigidity and damping of damper bodies in the multi-tuning mass damper by minimizing a minimal whole-machine vibration level index value or a maximal whole-machine vibration level index value of a minimal driving performance index. By arranging the multi-tuning mass damper on the hard rock driving gearbox and optimizing parameters of the multi-tuning mass damper, on the basis of improving or maintaining the hard rock road-header driving performance, the whole-machine vibration can be effectively lowered, and the damage to key parts caused by strong vibration can be avoided or lowered.

Owner:SHANGHAI JIAO TONG UNIV

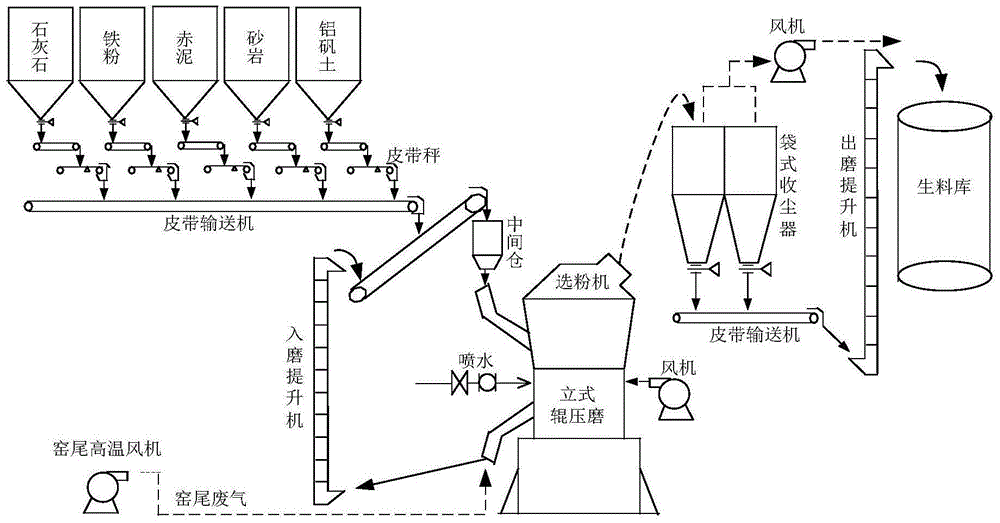

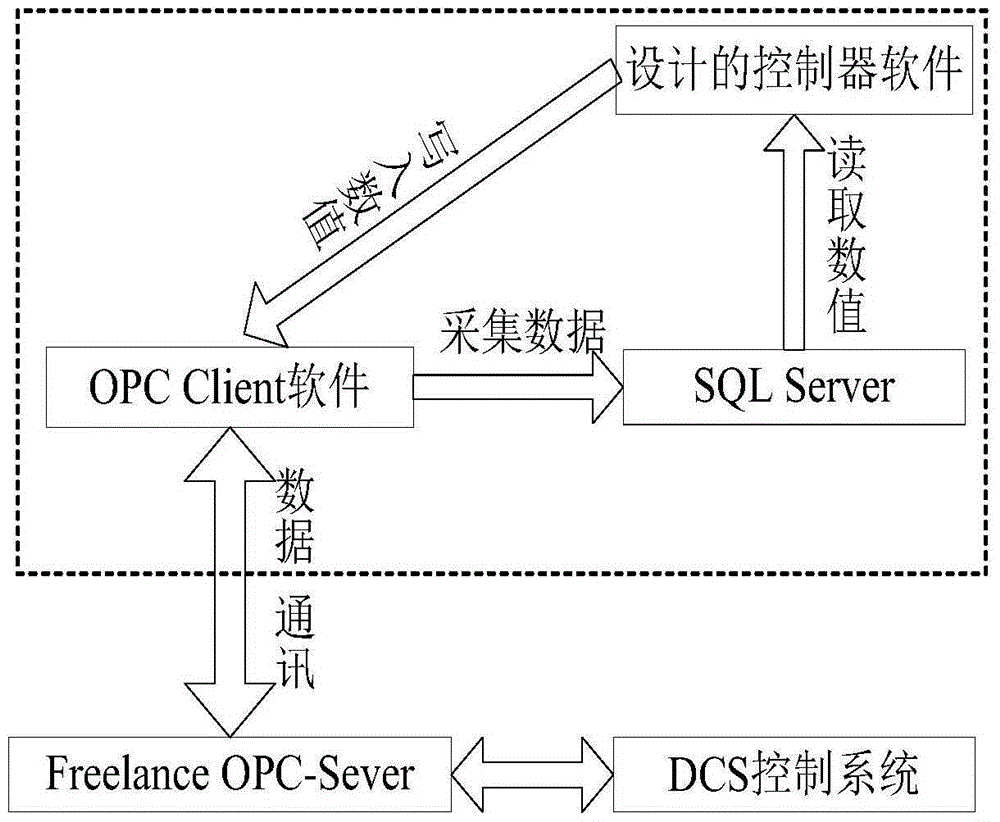

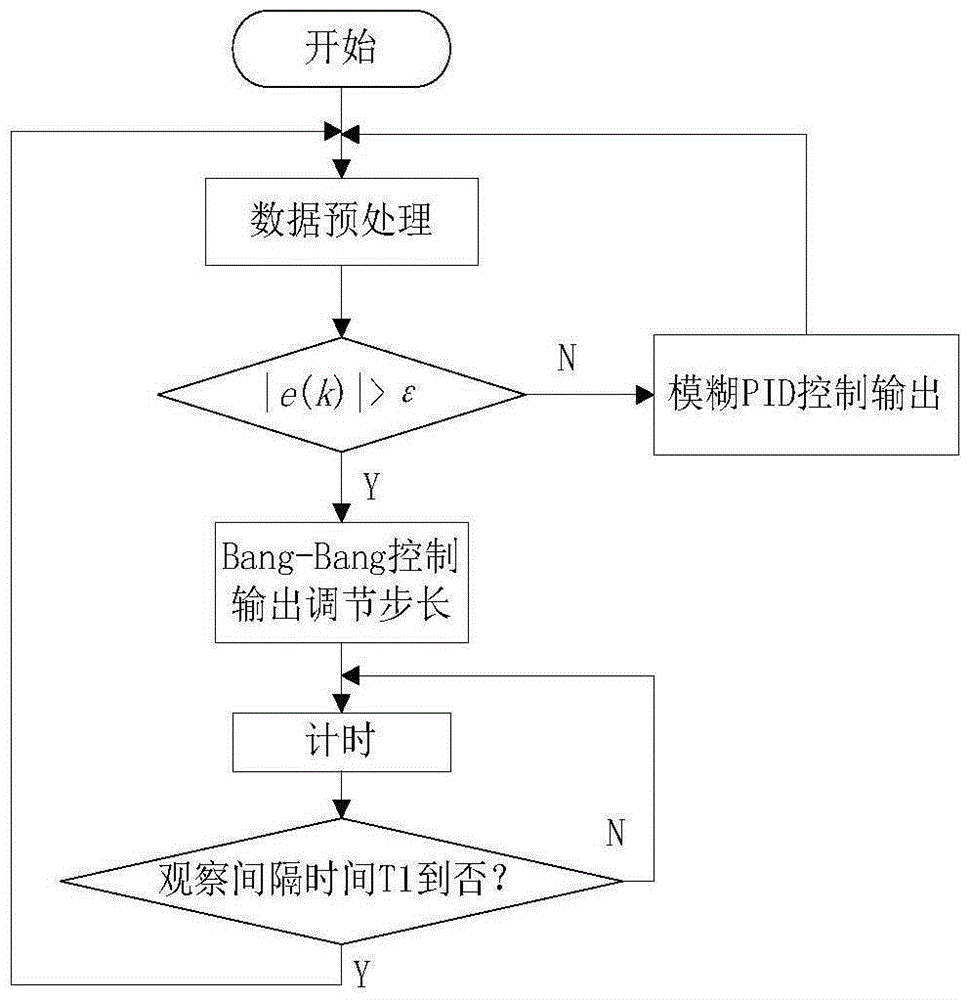

Raw material grinding automatic control method

InactiveCN105182740ASpeed up tracking error convergenceImprove dynamic performanceNumerical controlAdaptive controlMachining vibrationsAutomatic control

The invention discloses a raw material grinding automatic control method. In an automatic state, During amplitude control of a lifting and falling roller, an amplitude scope is tested mainly through observation and lifting and falling operation of a grinding roller is carried out. During control of water pump opening, operation conditions of a material layer thickness and a mill output temperature are integrated, a pid fuzzy control operation method is employed, and the water pump opening value is adjusted to achieve stabilization control effects. During the feed control link, feed quantity is controlled according to a current of a milling machine and a current of a powder selection machine and furthermore the current and the amplitude of the milling machine are stabilized. The problem that parameter adjustment cannot be tracked rapidly in a routine PID is avoided, according to characteristics that fuzzy control is independent from an accurate mathematic model and suitable for non-linear and large time delay production processes, by utilization of fuzzy PID and Bang-Bang control methods, a tracking error convergence speed is quickened, thus the vertical milling control process has a stable dynamic performance, milling machine vibration is reduced, the yield is raised and accurate and rapid control effects are achieved.

Owner:UNIV OF JINAN +1

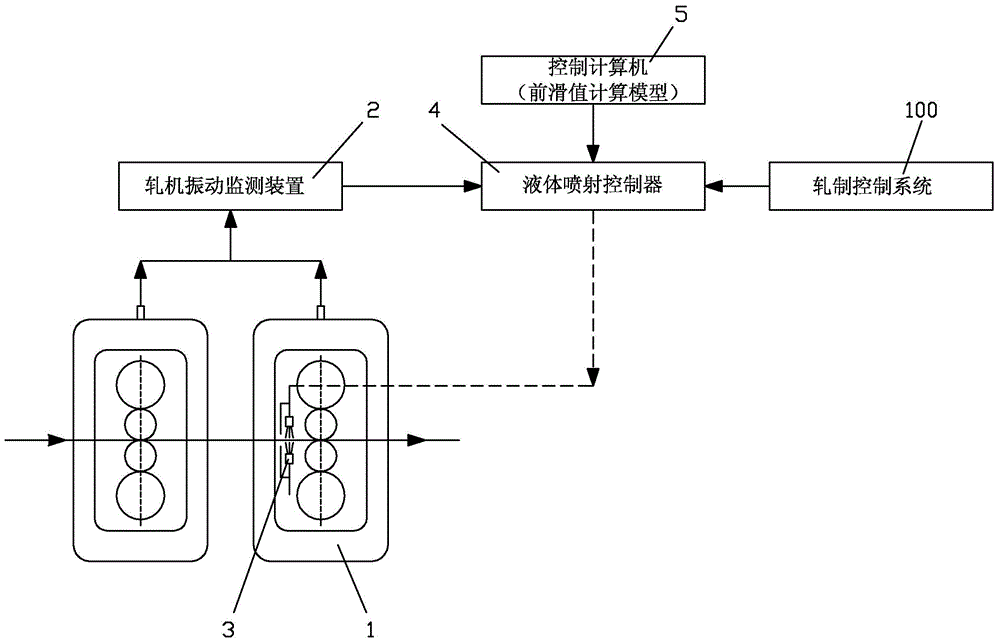

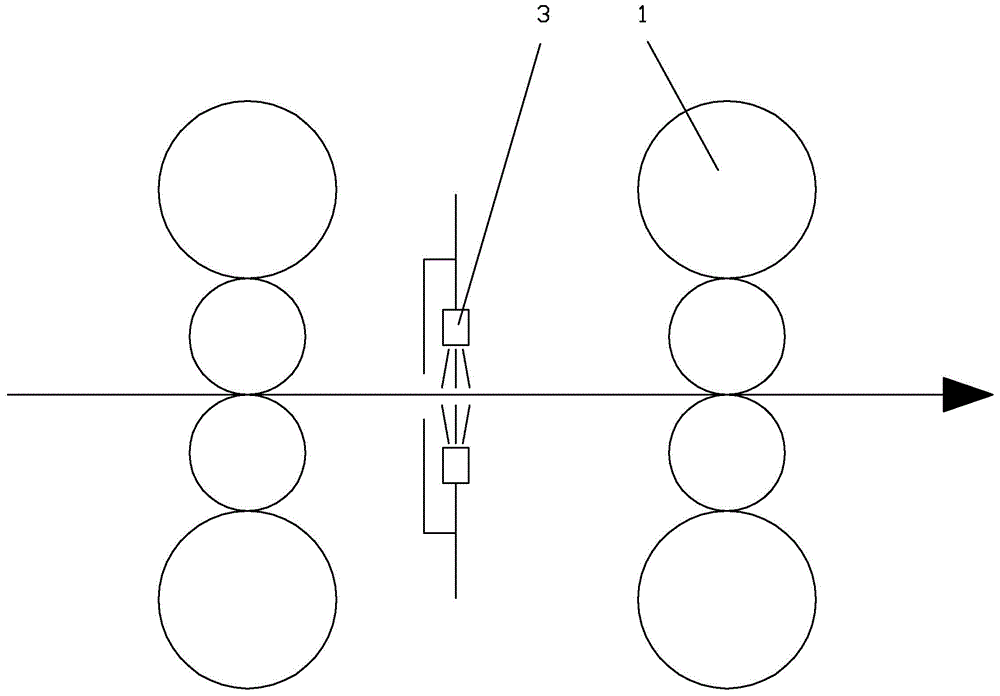

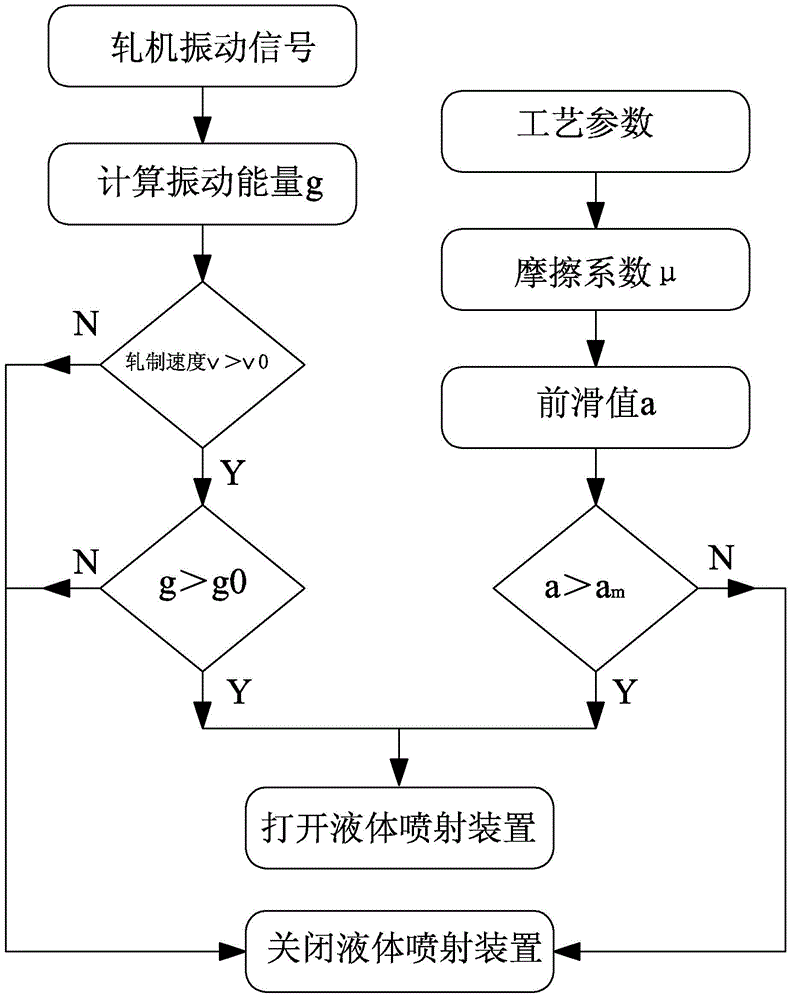

Vibration inhibiting method of cold continuous rolling unit

ActiveCN105522000AReduce vibrationWork treatment devicesRoll mill control devicesMachining vibrationsForward sliding

The invention discloses a vibration inhibiting method of a cold continuous rolling unit. The method comprises the following steps: 1) arranging a cold rolling unit vibration monitoring device on a fifth or fourth rack of the cold continuous rolling unit which is a five-rack continuous rolling machine, namely, mounting a vibration sensor on a rack housing; transmitting a rolling machine vibration signal to a data acquiring device through the vibration sensor; acquiring and processing the vibration signal through the data acquiring device, and then supplying to the rolling machine vibration monitoring device; determining whether the rolling machine vibrates by the rolling machine vibration monitoring device according to the energy magnitudeof the vibration signal; 2) arranging liquid jetting devices which can independently adjust the flow rate in front of an emulsified liquid jetting beam at an inlet of the fifth or fourth rack of the rolling machine, and jetting the liquid on the upper surface and the lower surface of a strip belt; and 3) determining to start or stop the liquid jetting devices according to the energy value of the of the rolling machine vibration signal monitored by the rolling machine vibration monitoring system or a forward sliding value calculated by a forward sliding value calculating model.

Owner:BAOSHAN IRON & STEEL CO LTD

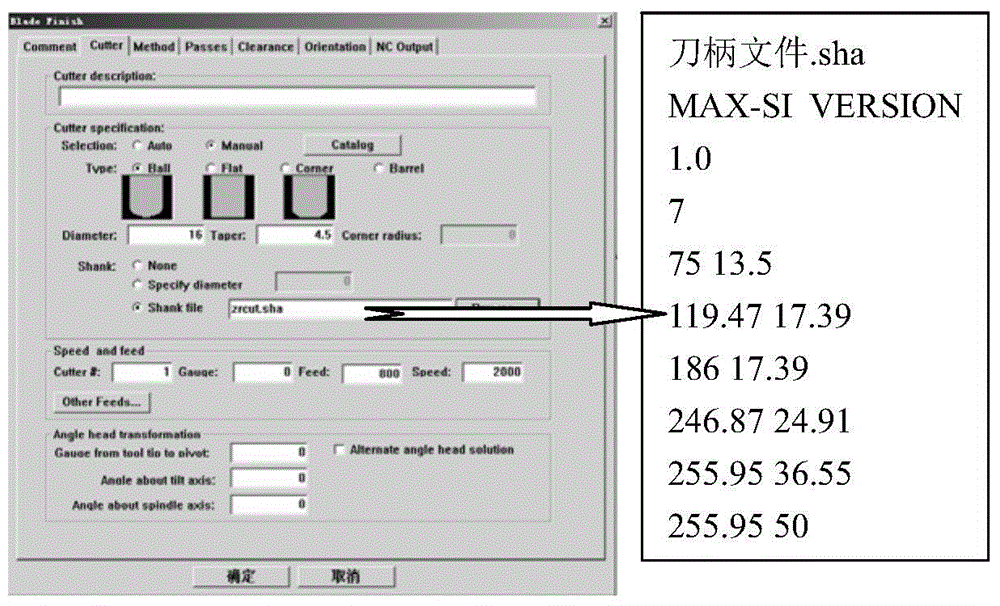

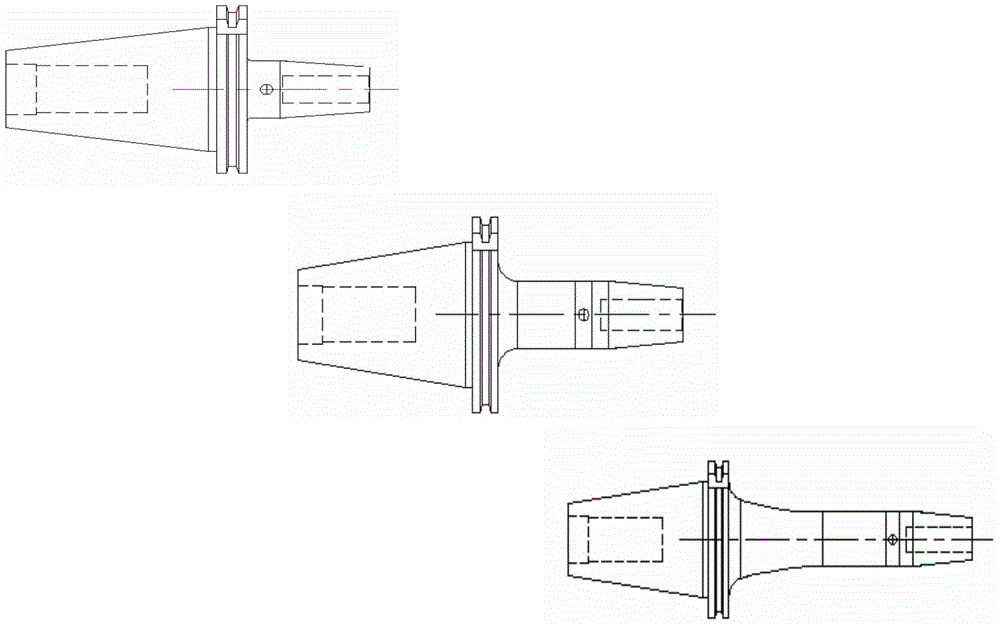

Long-cantilever large-scale integral blade-disc blade one-step milling method

ActiveCN104475841ASolve the long hanging problemIncrease overhangWorkpiecesMilling equipment detailsMachining vibrationsMilling cutter

The invention provides a long-cantilever large-scale integral blade-disc blade one-step milling method and belongs to the technical field of aeroengines. The long-cantilever large-scale integral blade-disc blade one-step milling method comprises the following steps of 1, cutter selection, 2, five-axis processing anti-interference calculation, 3, five-axis processing cutter locus design: 1), integral spiral cutter locus design and 2), blade root and channel cutter locus design, and 4, milling. The long-cantilever large-scale integral blade-disc blade one-step milling method adopts an integral spiral milling cutter locus mode, realizes precise milling of blades by one-step clamping, eliminates secondary clamping errors, prevents butt joint milling gear marks and effectively control processing deformation. A gradient cutter handle is used, stretches into a cavity groove and carries out milling so that the overhanging length of the cutter is at most shortened by 4 times than that of the cutter with the same size, processing vibration is effectively controlled, blade surface vibratory lines are eliminated and part surface quality is improved by one grade. Through the long-cantilever large-scale integral blade-disc blade one-step milling method, the non-standard cutter is changed to form a standard cutter so that all milling cutter standardization is realized, milling efficiency is greatly improved and machining efficiency is improved by 33%.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

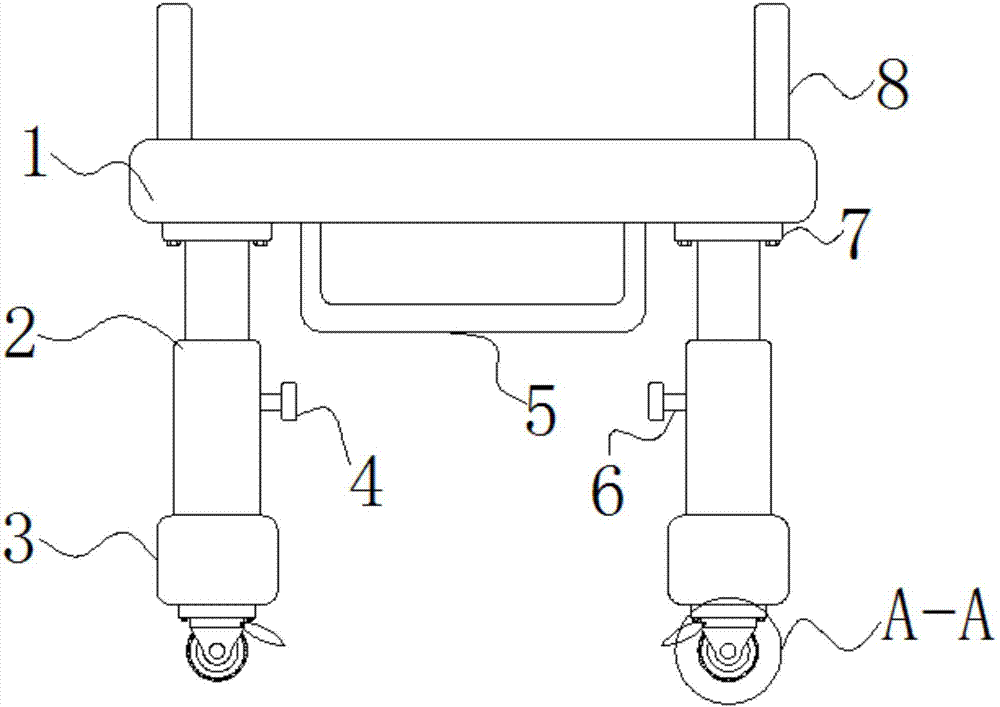

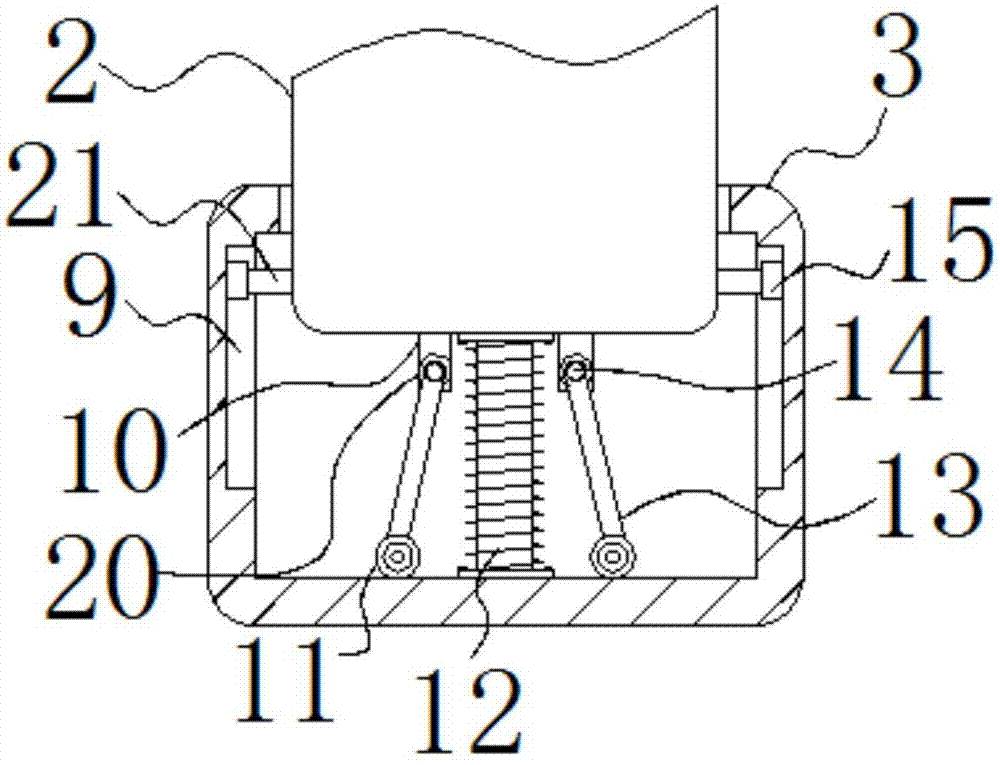

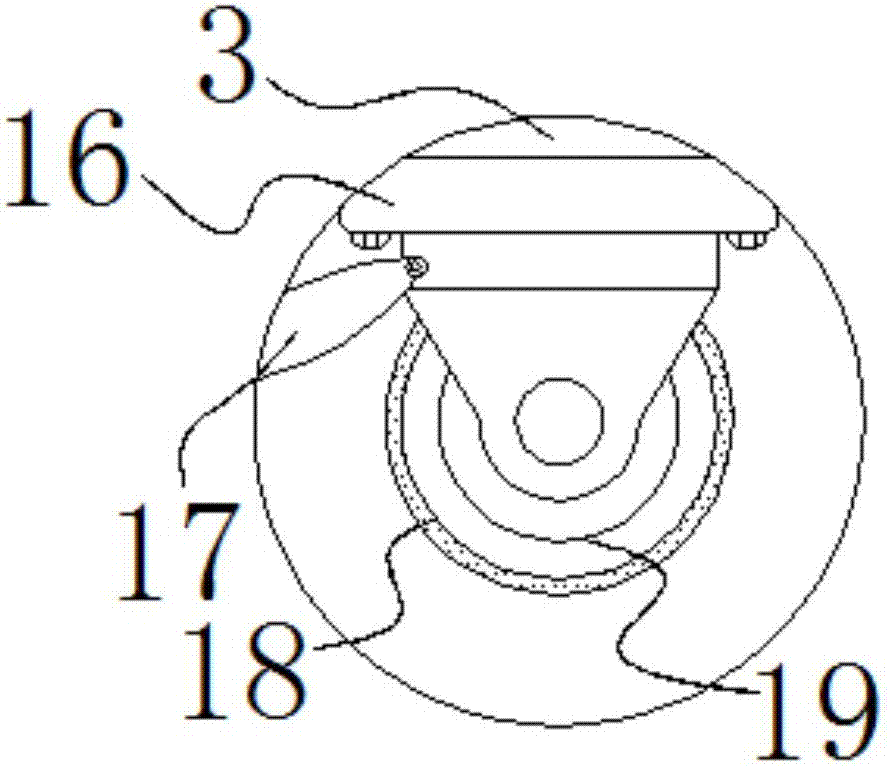

Rack with automatic damping function

InactiveCN106979447AGuaranteed uptimeReduce vibrationNon-rotating vibration suppressionStands/trestlesMachining vibrationsDamping function

The invention discloses a frame with an automatic shock absorbing function, which includes a support plate, support frames are arranged on both sides of the top of the support plate, and fixed plates are fixedly connected to both sides of the bottom of the support plate. The bottom of the fixed plate is provided with a telescopic rod, the inner side of the telescopic rod is provided with an adjusting rod, the inner side of the regulating rod is provided with an operating handle, the bottom of the telescopic rod is provided with a shock absorber, and the bottom of the telescopic rod runs through to the inner cavity of the shock absorber. The present invention can effectively damp the textile frame by setting chute, connecting rod, pulley, damping spring, movable rod, movable shaft, slider, through hole and sliding rod, which can effectively reduce the vibration of the textile machine. The vibration generated during the working process of the textile frame solves the problem that the textile machine frequently breaks due to the large vibration of the textile frame during the working process.

Owner:浙江高派机器人科技有限公司

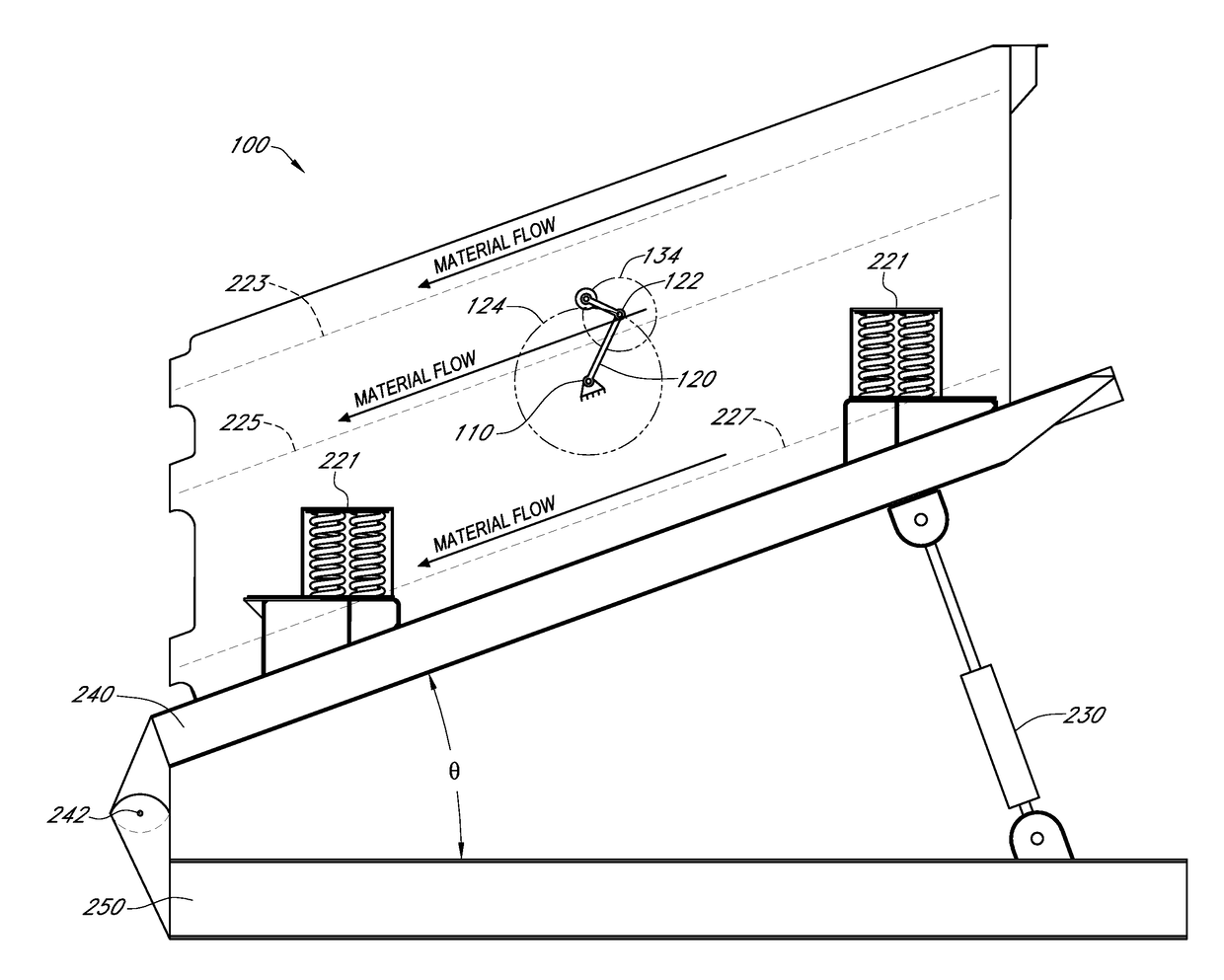

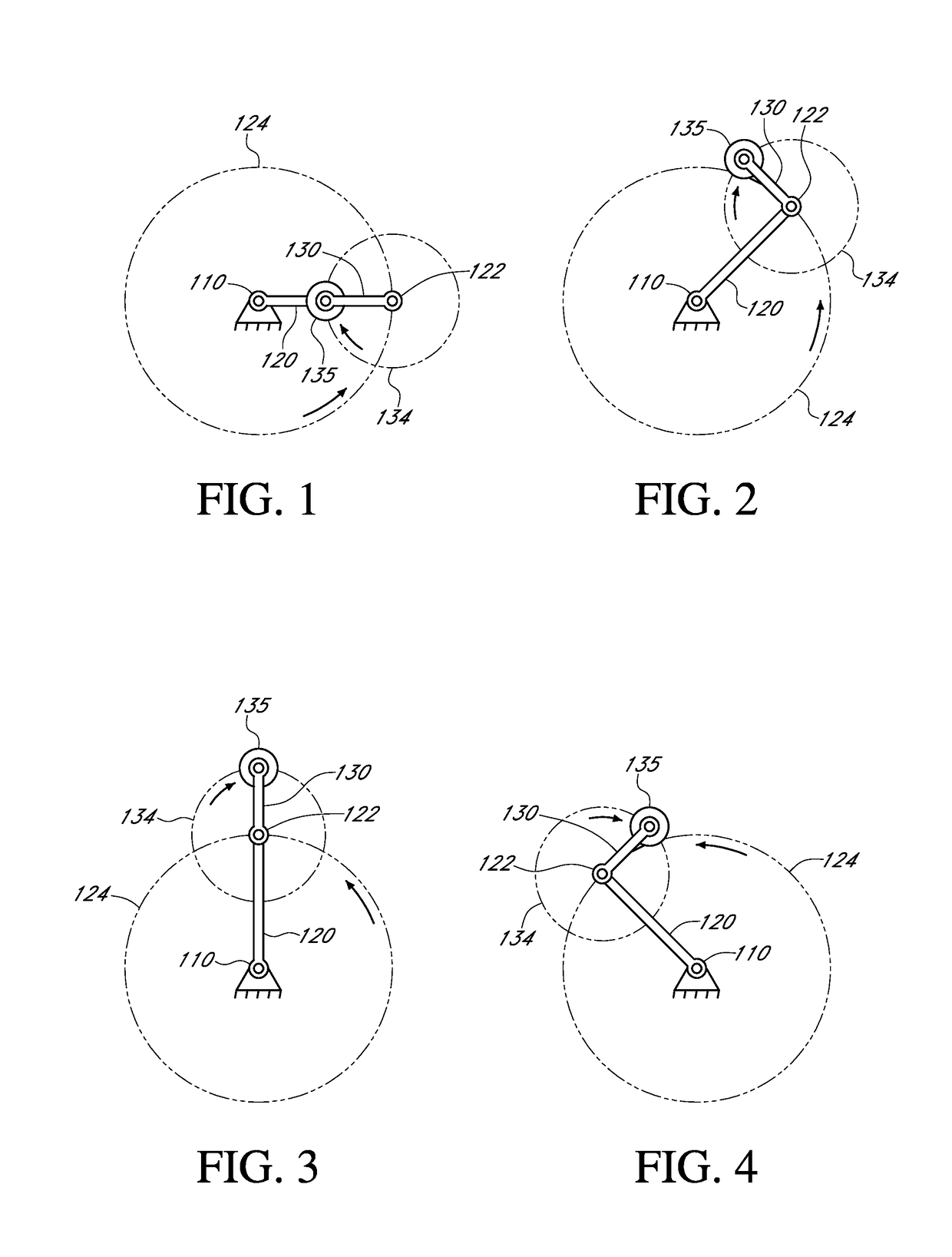

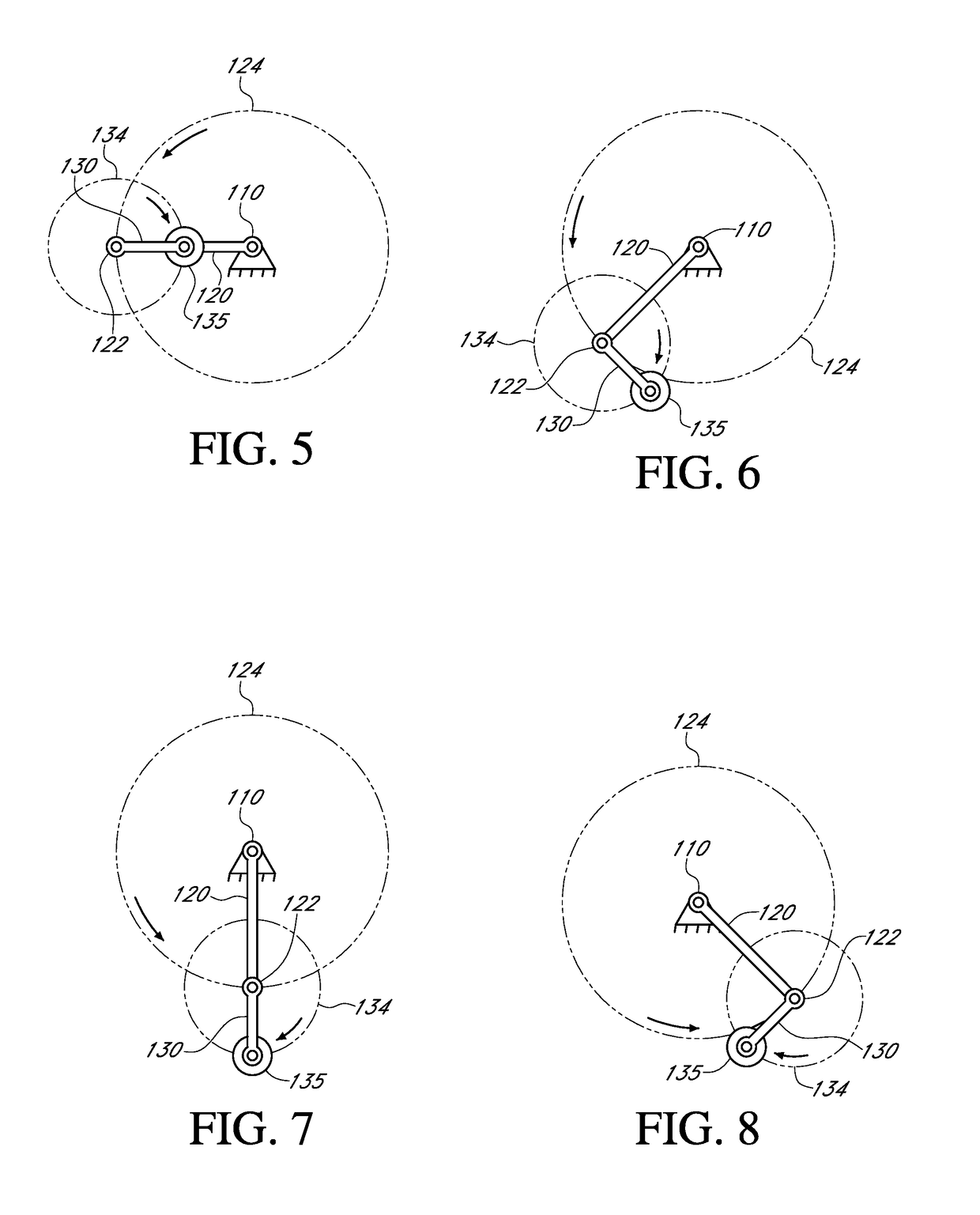

Non-circular acceleration mechanism for a single shaft screen

A single shaft material processing vibrating screen is described which provides for non-circular acceleration (elliptical and otherwise). The system includes a main eccentric is rotated a first direction and a secondary eccentric orbits the main eccentric in an opposite direction.The orbiting is accomplished by either long and short arms or by eccentric flywheels. The size and shape of elliptical / non-circular motion is adjustable by varying mass of main and secondary eccentrics, length of long and short arms or the size of eccentric flywheels.

Owner:TEREX USA

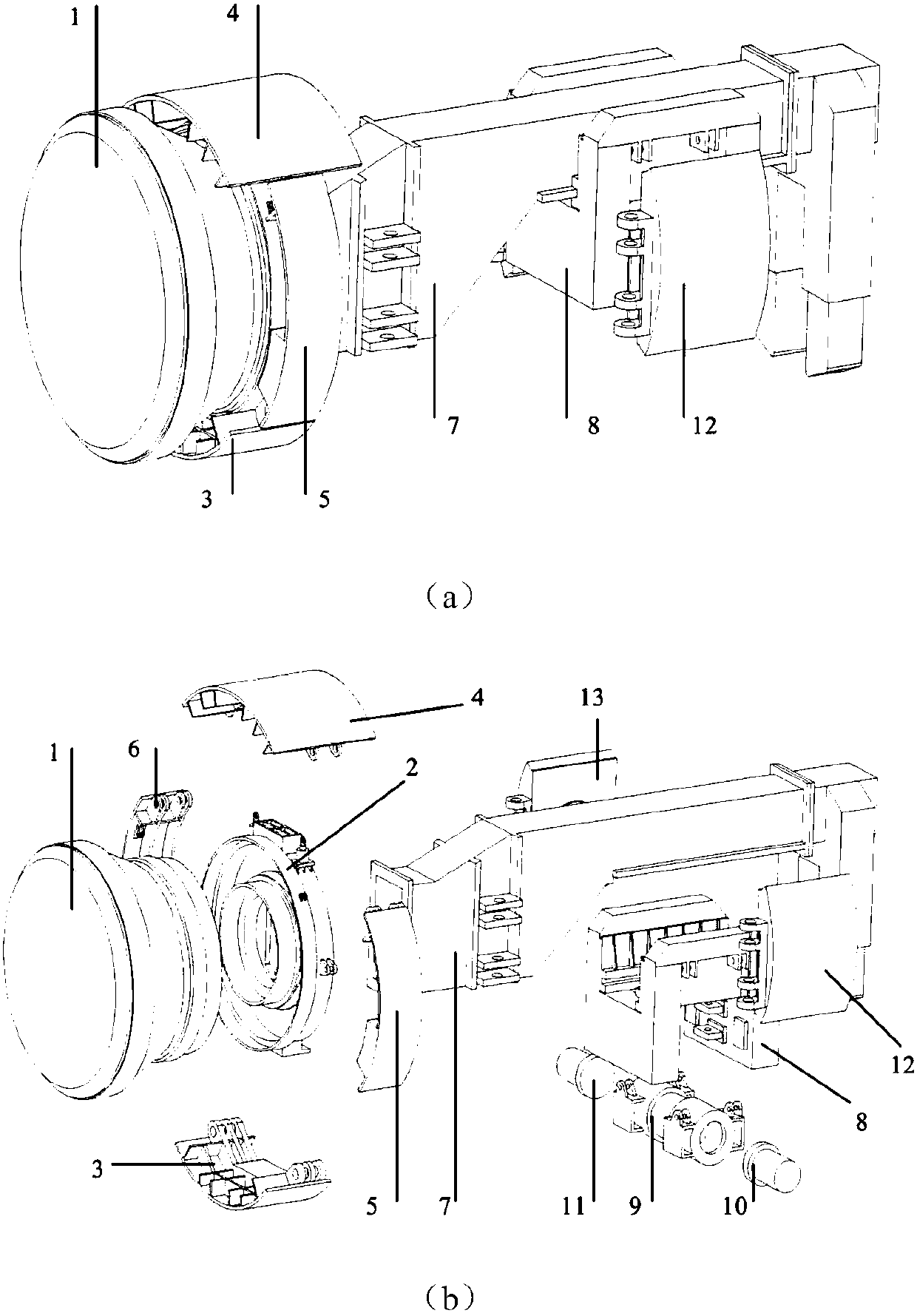

Special flexible fixture for machining vibration control of complex thin-wall blade parts

PendingCN110653627AEffective clampingSolve difficult clampingLarge fixed membersPositioning apparatusMachining vibrationsVibration control

The invention discloses a special flexible fixture for machining vibration control of complex thin-wall blade parts. The special flexible fixture comprises a bottom plate, wherein a double-pressing plate linkage mechanism, an auxiliary supporting mechanism and a multi-point ejector pin clamping mechanism are sequentially arranged on the bottom plate from left to right; a plurality of the auxiliarysupporting mechanisms are provided; the height of each auxiliary supporting mechanism is adjustable. According to the special flexible fixture, the multi-point ejector pin clamping mechanism is adopted, and the problem that the thin-wall part of the free curved surface is difficult to clamp is solved.; on the basis of positioning and clamping, a magneto-rheological material with controllable performance is adopted, small displacement sensitivity, high output damping and good high-frequency response performance of cutting machining are adopted to control the damping support, so that the rigidity of the machining process is enhanced, and the machining precision of the workpiece is improved; and when a similar part of another size is machined, under the condition that the layout condition ofthe original fixture is not changed, the magnetic rheological damper with different sizes can be replaced by adjusting the distance between the multi-point clamping mechanisms, so that the clamping of the existing workpiece can be met.

Owner:HENAN POLYTECHNIC UNIV

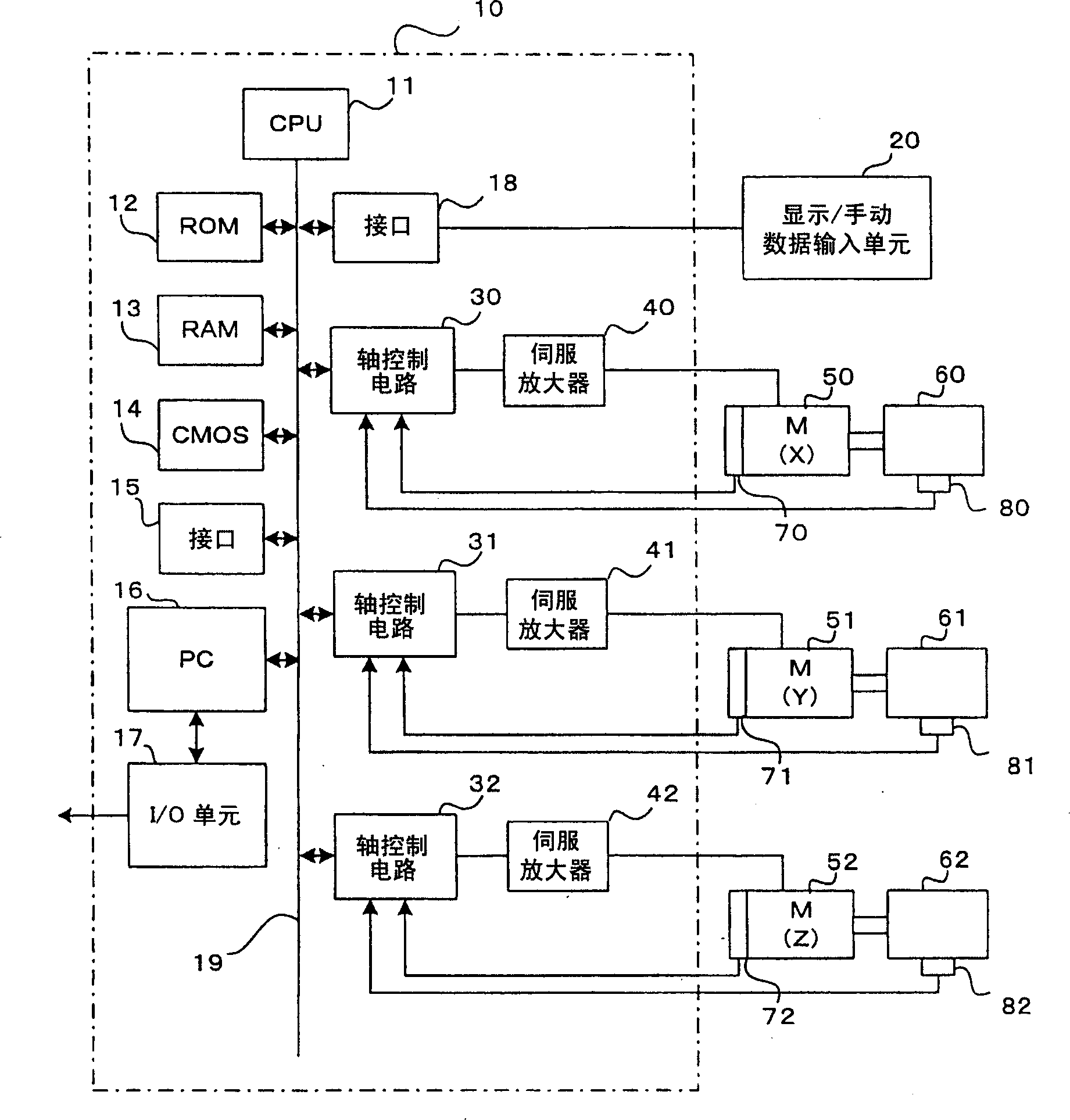

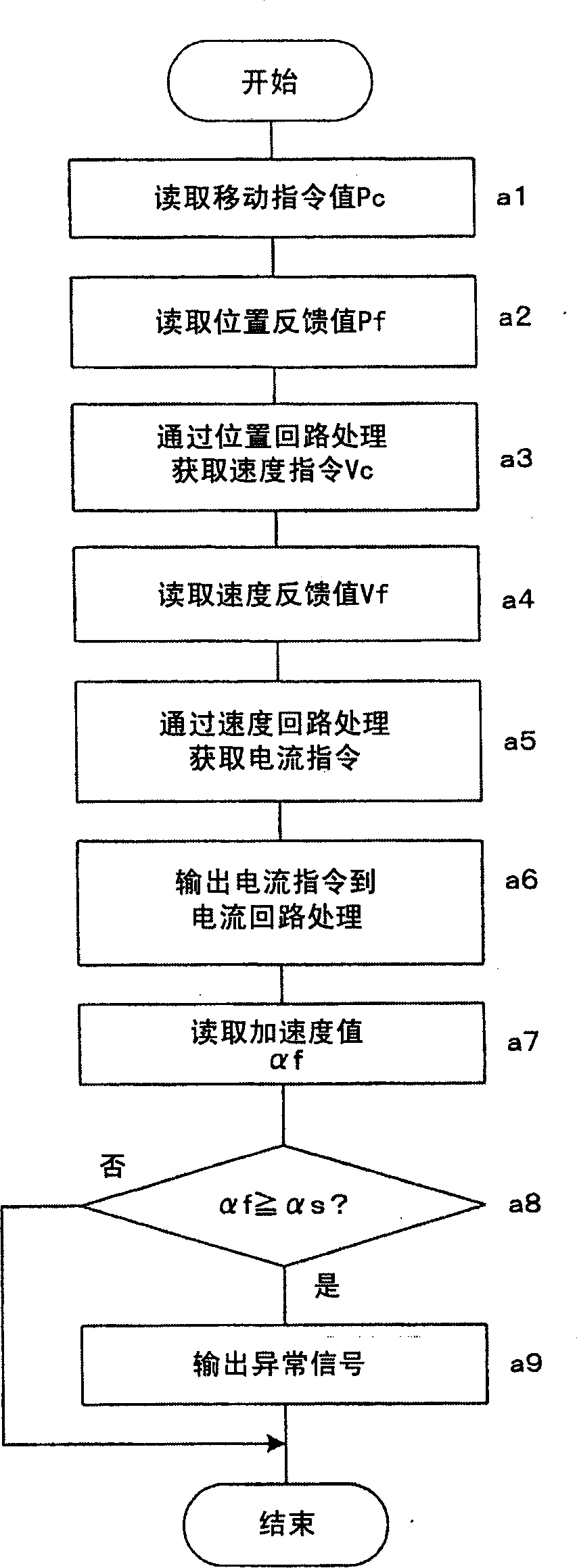

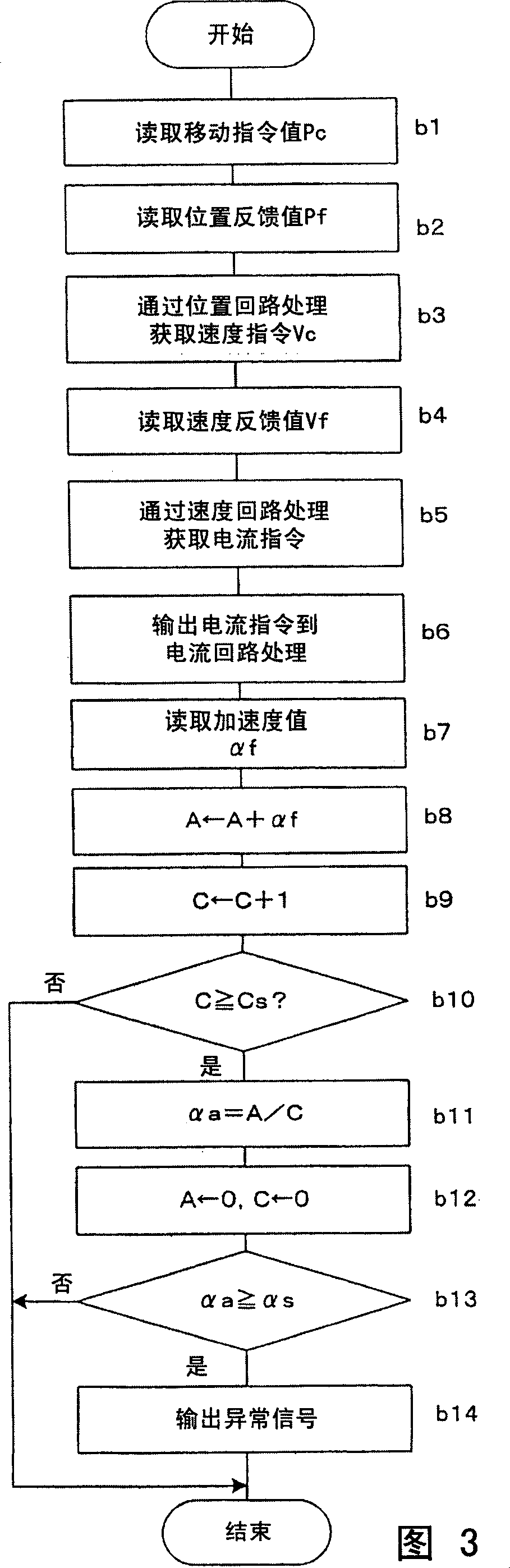

Controller

InactiveCN1781658AAvoid downtimeDetect vibrationProgramme controlAutomatic control devicesMachining vibrationsPower flow

It is disclosed that it is used to detect the maintenance needs and abnormal operation of the machine due to the long-term change resulting in the reduction of power. The acceleration detection device is attached to the driven element driven by the servo motor. The processor of each axis control circuit for feedback control of servo motor position and speed performs position and speed feedback control processing for each position / speed control cycle, thereby acquiring current commands and outputting the commands to current loop processing. The detected acceleration value αf is read from the acceleration detection means. When the detected acceleration value is not less than the threshold αs, an abnormal signal is output to display a warning and stop the machine from working. Since the acceleration of the driven element is directly detected by the acceleration detection device, it is possible to safely detect machine abnormalities such as common vibrations due to machine aging, collision of the driven element with other objects, or breakage of the element.

Owner:FANUC LTD

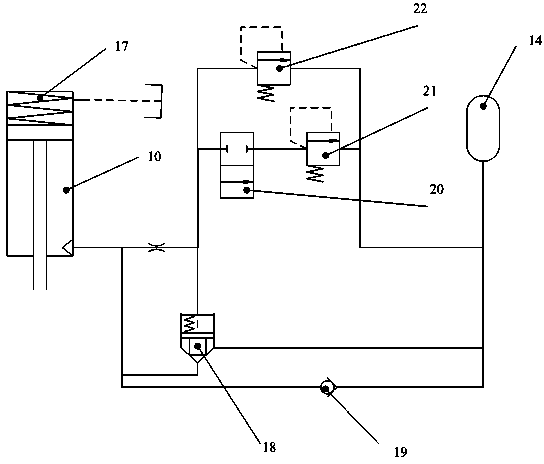

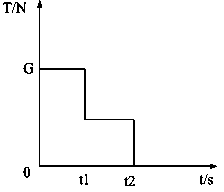

Segmented retardant discharging device

InactiveCN104444756AHydraulic pressure reductionReduce reboundServomotor componentsAccumulator installationsMachining vibrationsHooking

The invention discloses a segmented retardant discharging device. The segmented retardant discharging device comprises an automatic hooking device and a retarder, wherein the automatic hooking device is positioned below the retarder and is connected with the retarder, a spring feeler lever is arranged above the retarder, and the retarder is internally provided with a hydraulic oil path used for controlling hydraulic pressure of the retarder. According to the segmented retardant discharging device disclosed by the invention, by reducing the hydraulic pressure of the retarder in a grading mode, tensile force of a steel wire rope for hanging a heavy hammer is gradually reduced, and the heavy hammer is subjected to putting down in a stair-shaped slow descending mode from a step releasing mode, so that impact to a system due to heavy hammer release is reduced, the rebound of a cargo boom is small, the rope disordering probability of the steel wire rope is low, the abrasion of the automatic hooking device is slight, the whole machine vibration is slight, and the service life is long.

Owner:刘洋

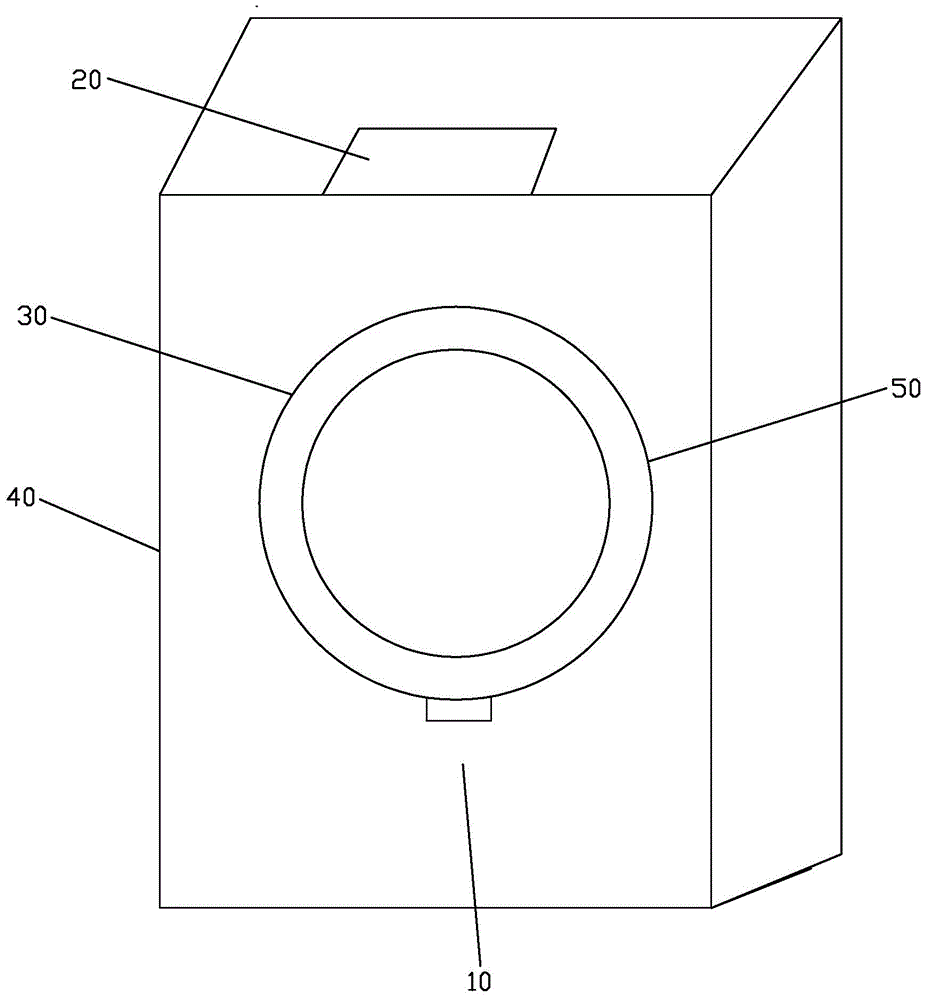

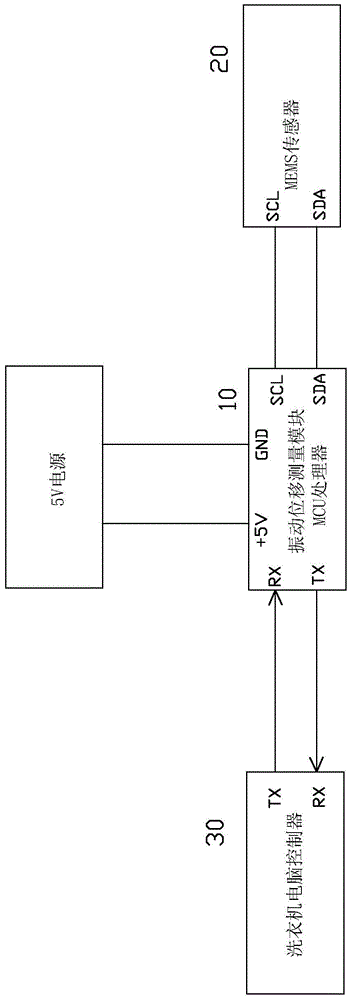

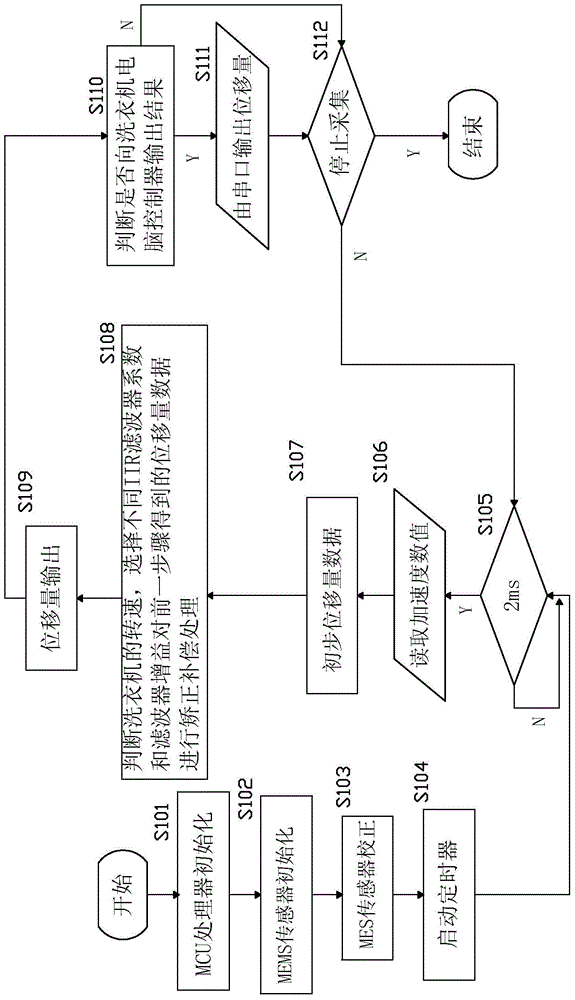

Method for detecting washing machine vibration displacement data based on MEMS sensor

ActiveCN104947371AEliminate vibration interference signalsImprove efficiencyControl devices for washing apparatusTextiles and paperIir filteringMachining vibrations

The invention relates to a method for detecting washing machine vibration displacement data based on an MEMS sensor. The method comprises the steps that triaxial acceleration data of a washing machine external barrel are collected by the MEMS sensor; the triaxial acceleration data are converted into corresponding displacement data through the quadratic integral; before conversion, an IIR filter is adopted for filtering away data with the signal frequency lower than the preset frequency; after conversion, the rotating speed of a washing machine is judged, and different IIR filter coefficients and filter gains are selected based on the rotating speed of the washing machine for carrying out correcting and compensation on the displacement data obtained in the previous step, so that various vibration interference signals existing in the washing machine running process are eliminated, and vibration displacement data output with the high precision is obtained. Vibration displacement data are filtered two times, so that the vibration displacement data with the high precision are obtained, the current vibration displacement data are output to a washing machine computer controller in real time, the rotating speed of a washing machine running motor is controlled, the washing program is optimized, the washing machine working noise is lowered, and the washing efficiency is improved.

Owner:厦门翰普电子有限公司

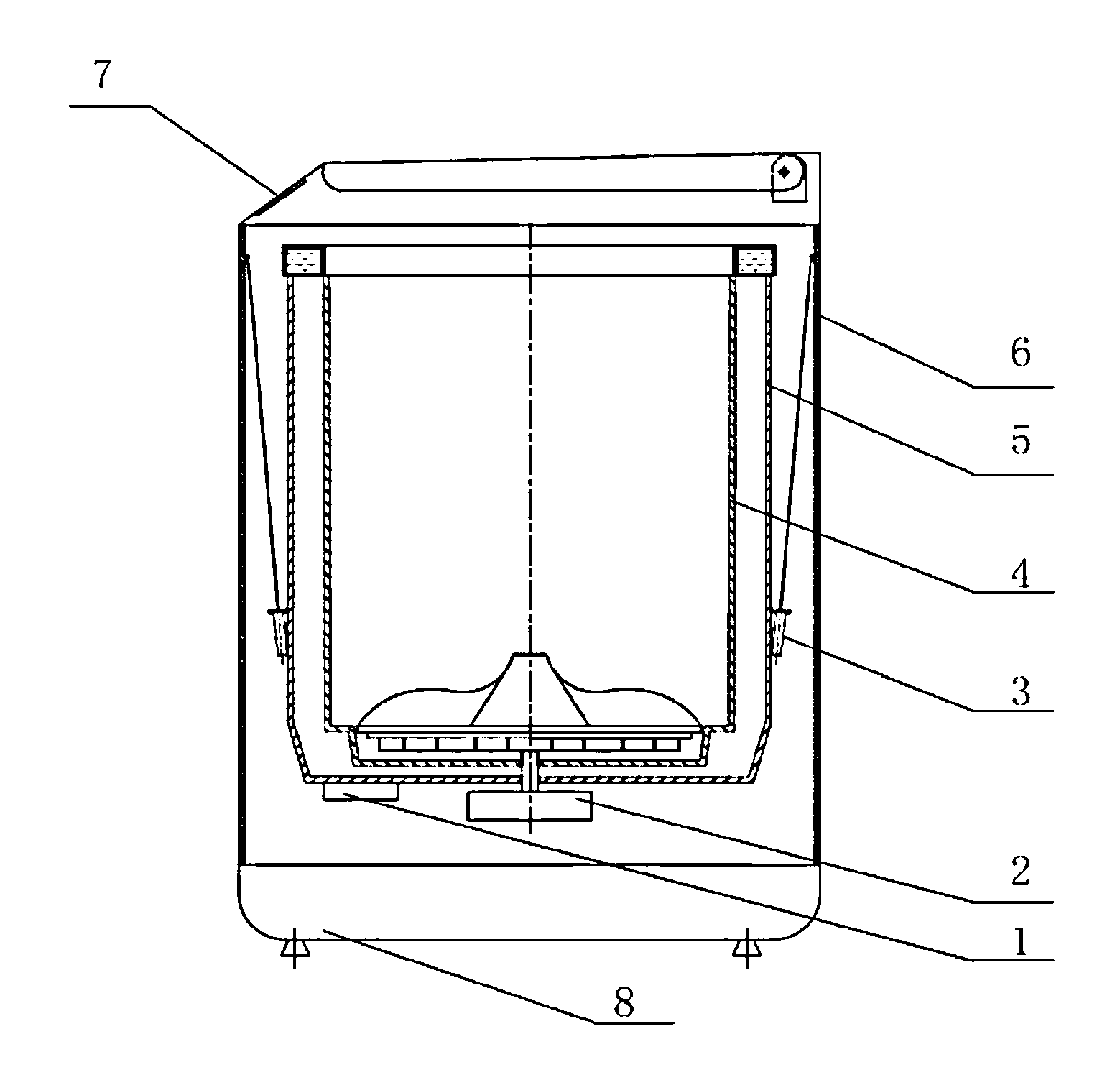

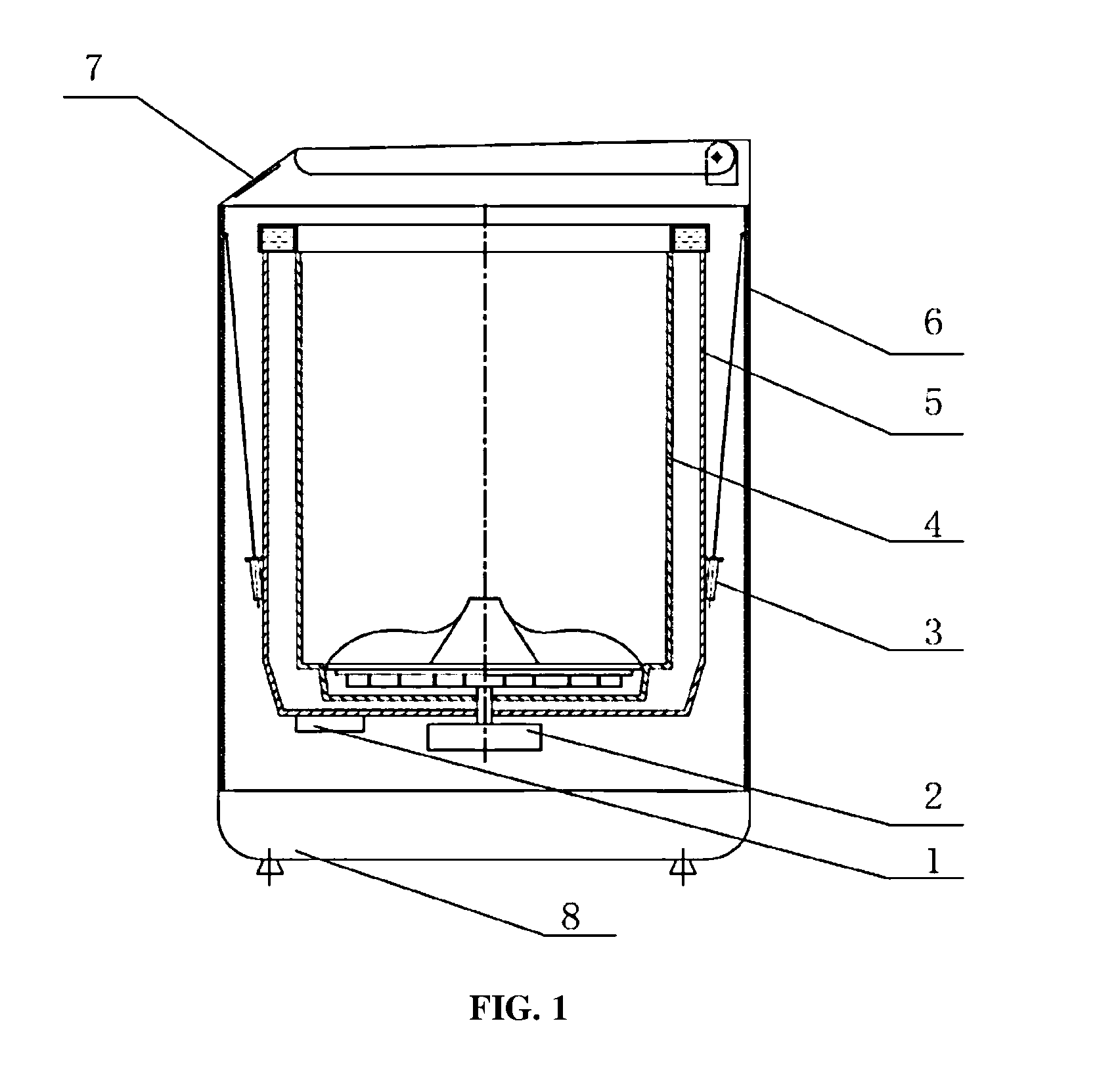

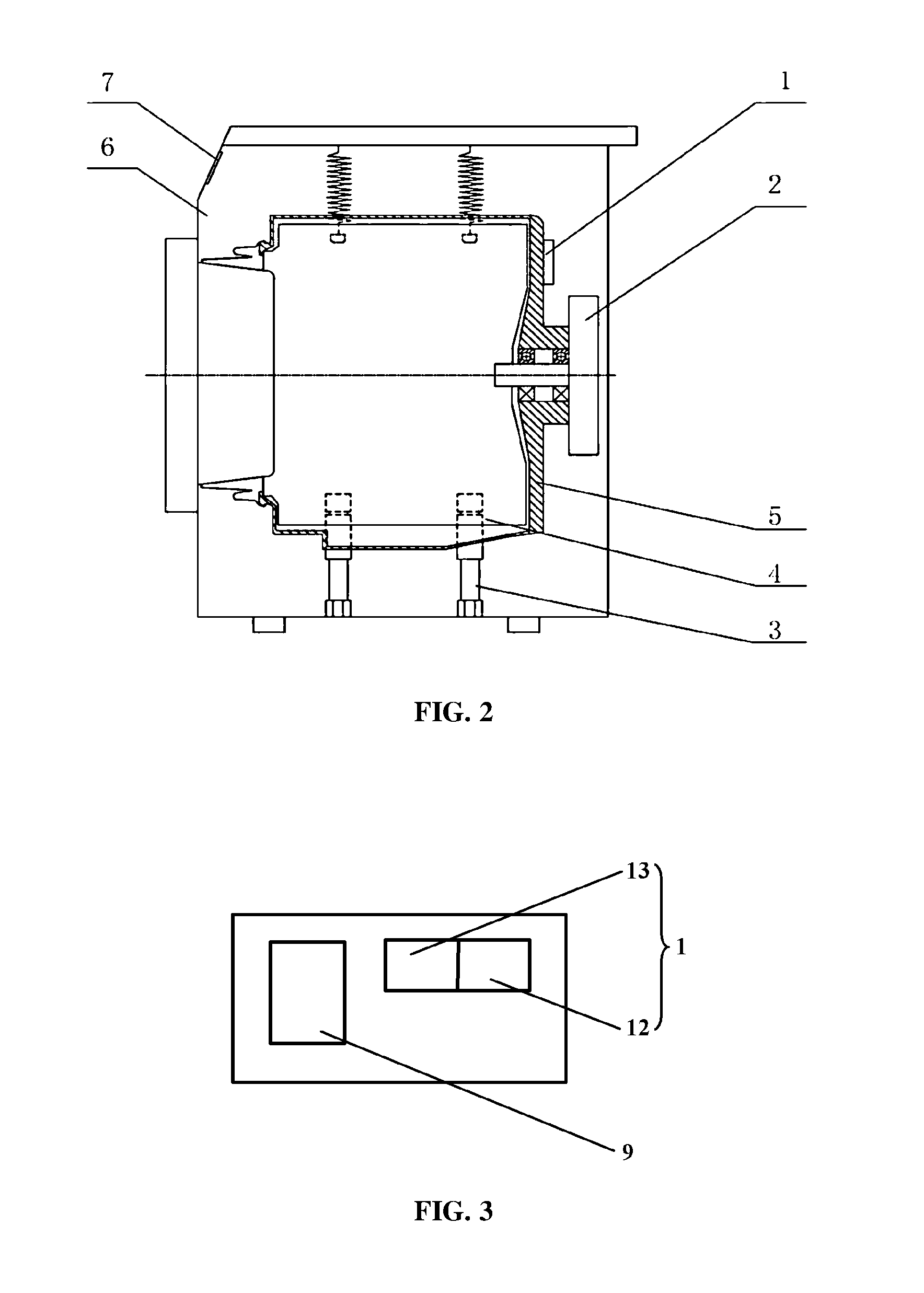

Vibration-reducing washing machine and vibration-reducing method for washing machine

InactiveUS20160312394A1Vibration is efficiently and quicklyEfficiently and quickly vibrationOther washing machinesControl devices for washing apparatusMachining vibrationsControl signal

A vibration-reducing washing machine and a vibration-reducing method therefor. The washing machine has an outer drum, a cabinet, a motor, a main control panel, a damper device, and a vibration detection and control module fixed to the washing machine and connected to the main control panel. The vibration detection and control module detects and calculates vibration data and generates a control signal. The method includes setting a fixed tolerance for washing machine vibration, detecting and calculating vibration data, and comparing the vibration data with the fixed tolerance, and when the detected vibration data exceeds the fixed tolerance, adjusting working parameters of the motor and adjusting a damping magnitude of the damper device until the vibration data detected subsequently is maintained within the range of the fixed tolerance.

Owner:HAIER GRP CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com