Multipoint flexible rolling supporting head for mirror image machining device

A technology of mirror processing and support head, used in metal processing equipment, metal processing mechanical parts, supports, etc., can solve the problems of small support area and difficult control, to ensure processing accuracy, reduce system control difficulty, and increase support Effective area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

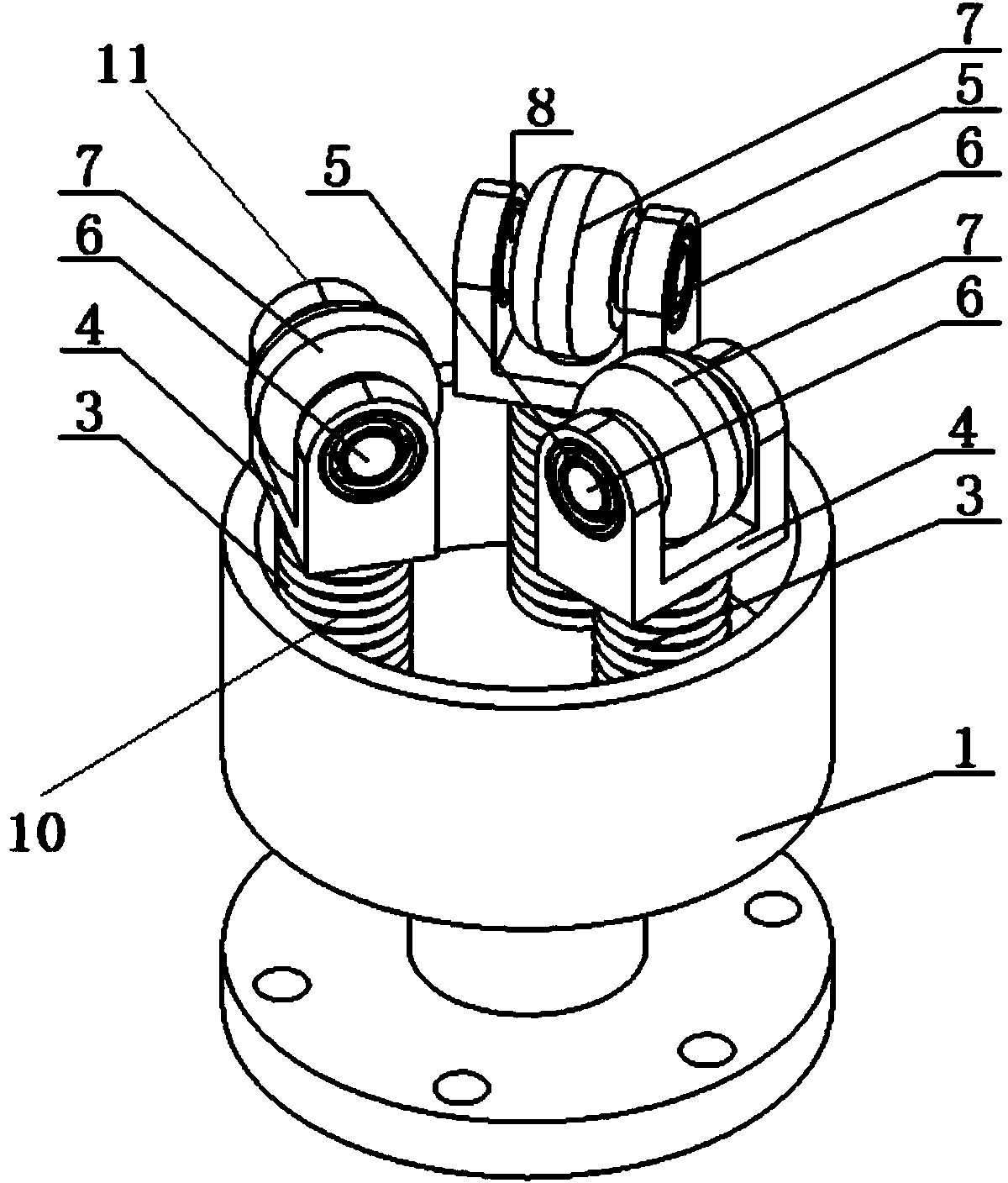

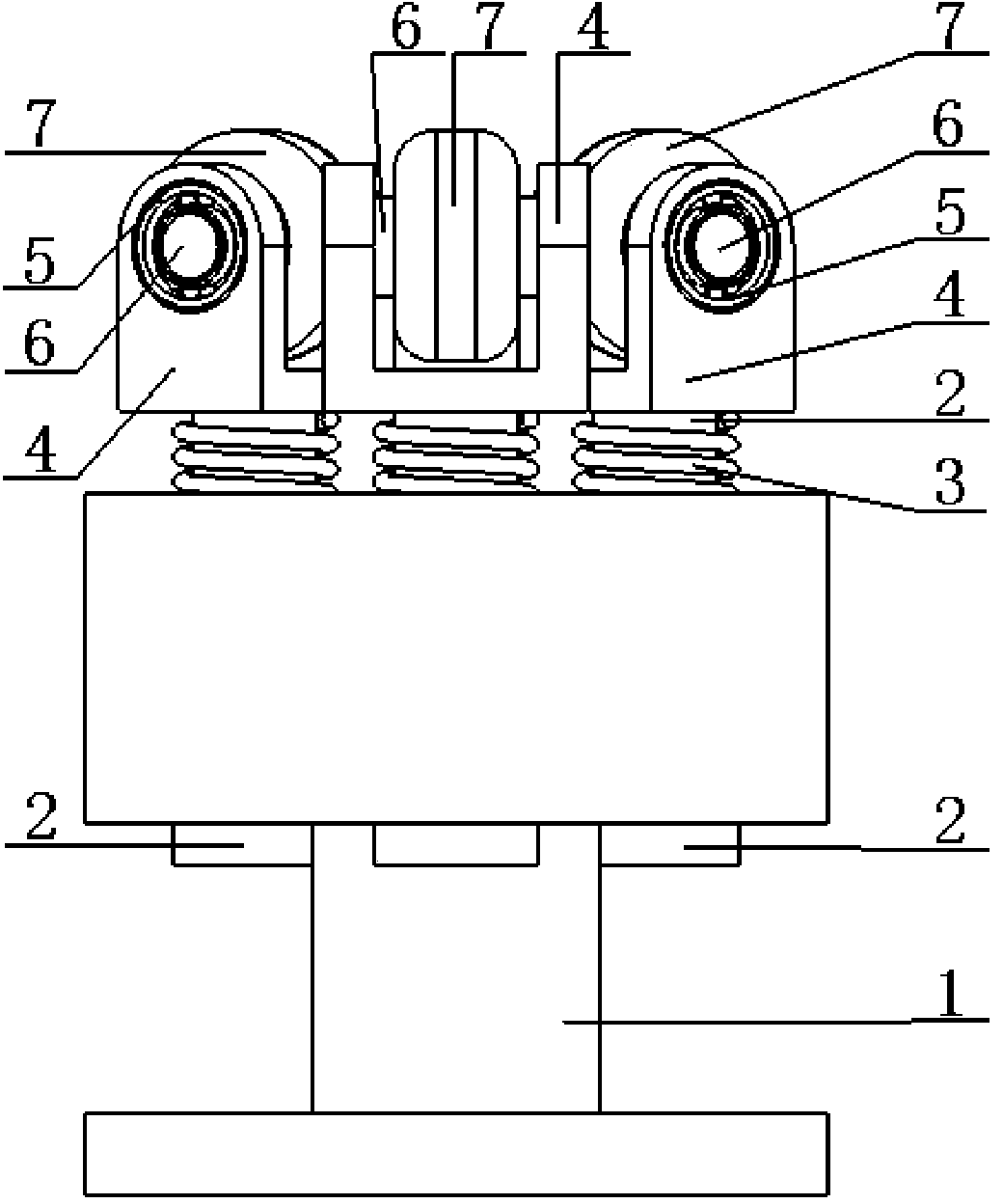

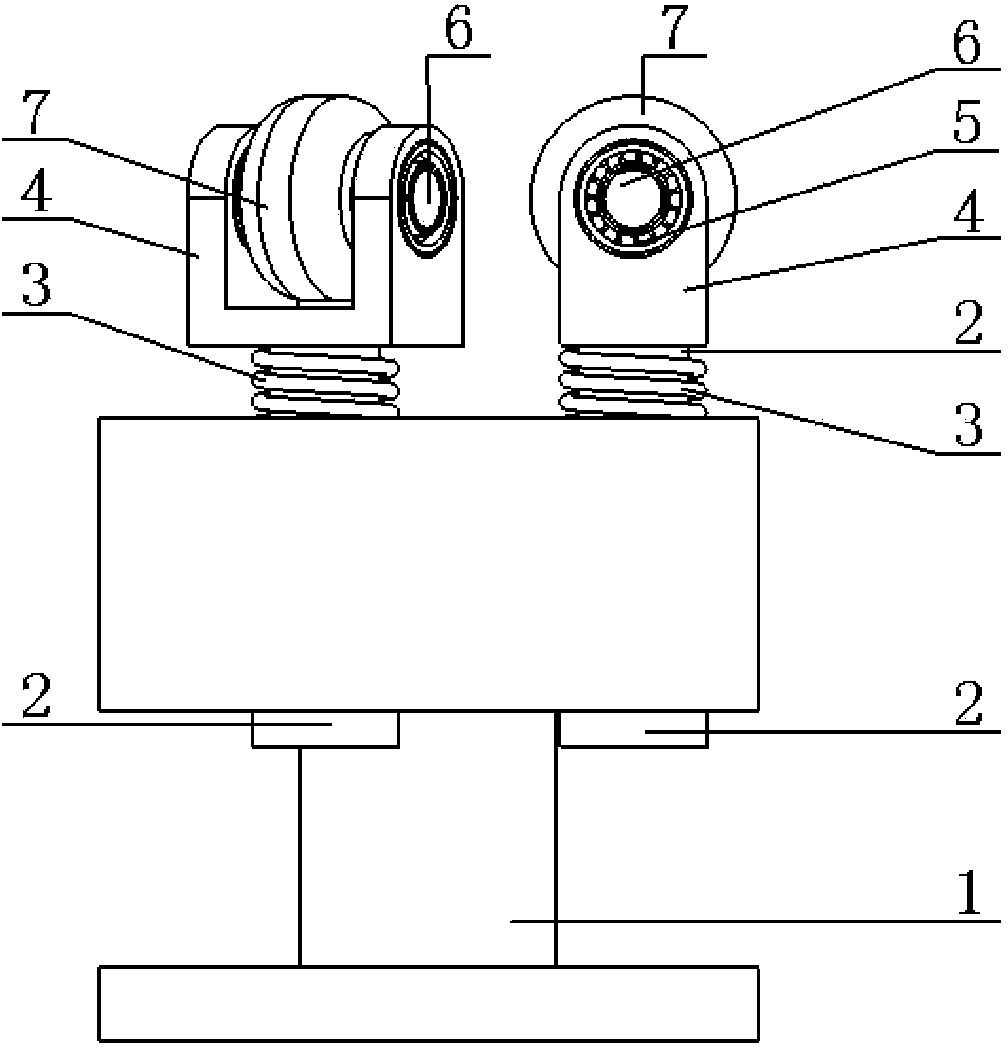

[0019] Such as Figure 1 to Figure 5 As shown, this embodiment includes: a base 1, several elastic support rods 10 and several flexible rolling parts 11, wherein: the bottoms of several elastic support rods 10 are arranged on the base 1 and arranged in a circular array, and each elastic support rod 10 The tops of the tops are respectively connected with a flexible rolling part 11. When the tool on the processing side of the thin-walled workpiece starts to process, the base 1 moves with the tool at the same speed and direction, so that the center of each elastic support rod 10 is mirror-symmetrical to the tool, reducing the Machining vibration of small thin-walled workpieces;

[0020] The specific parameter setting rules of the described circular array arrangement are:

[0021] The base 1 includes: a fixed platform at the bottom, a connecting column in the middle, and a hollow cylindrical structure working part with one side opening at the top, wherein: the bottom surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com