In-process evaluation based complex spatial surface error feedback compensating method

A technology of error feedback and compensation method, which is applied in special data processing applications, instruments, electrical digital data processing, etc. It can solve problems such as limited range of processing, insufficient error feedback compensation function, and surface geometric error evaluation. The effect of handling and loading time and avoiding repeated positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

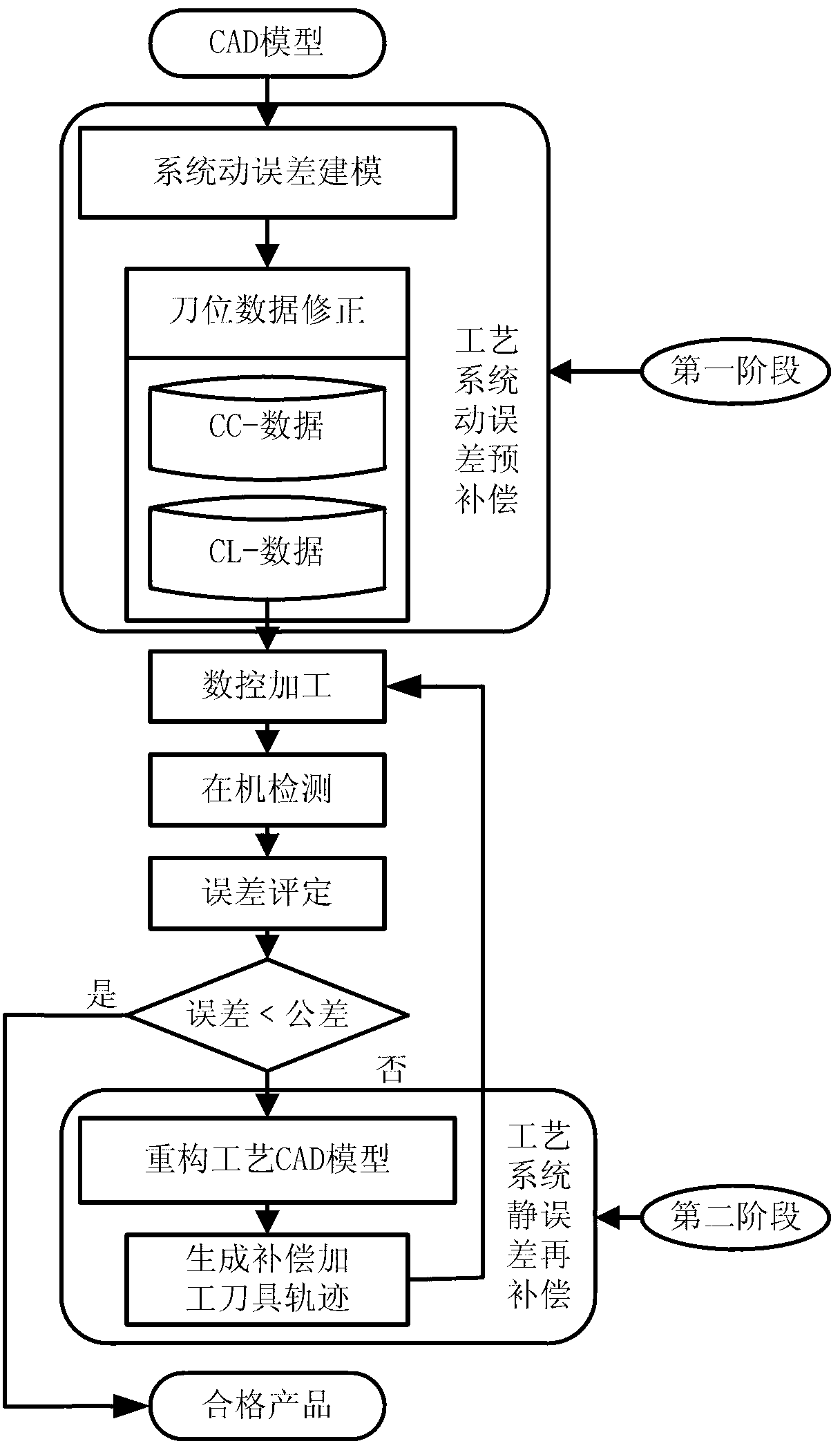

[0038] In order to improve the processing accuracy of the part profile, avoid repeated positioning errors of the workpiece caused by off-line detection, and reduce the time for transporting and loading the workpiece, the embodiment of the present invention provides a complex space profile error feedback compensation method based on on-machine evaluation, see figure 1 , see the description below:

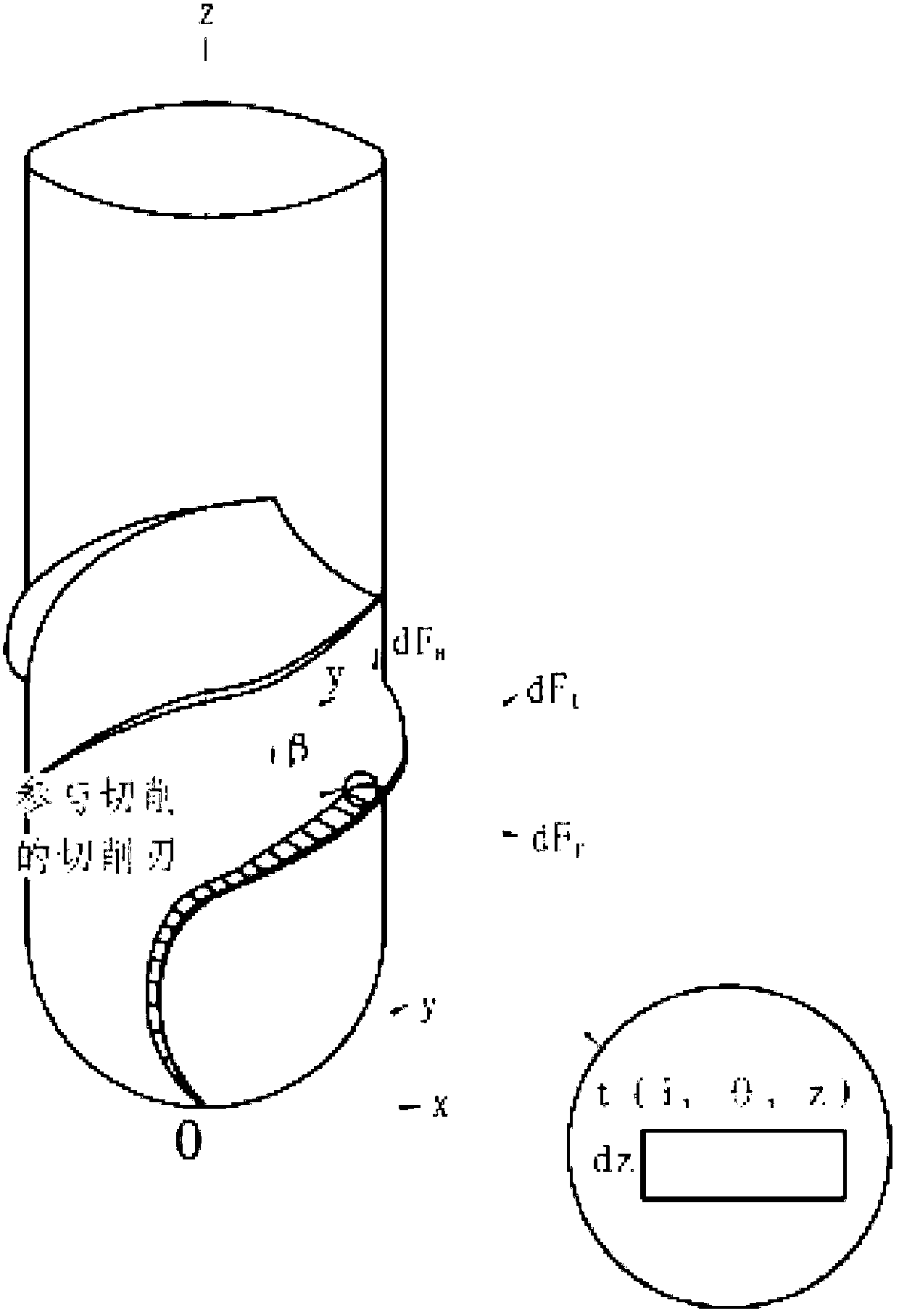

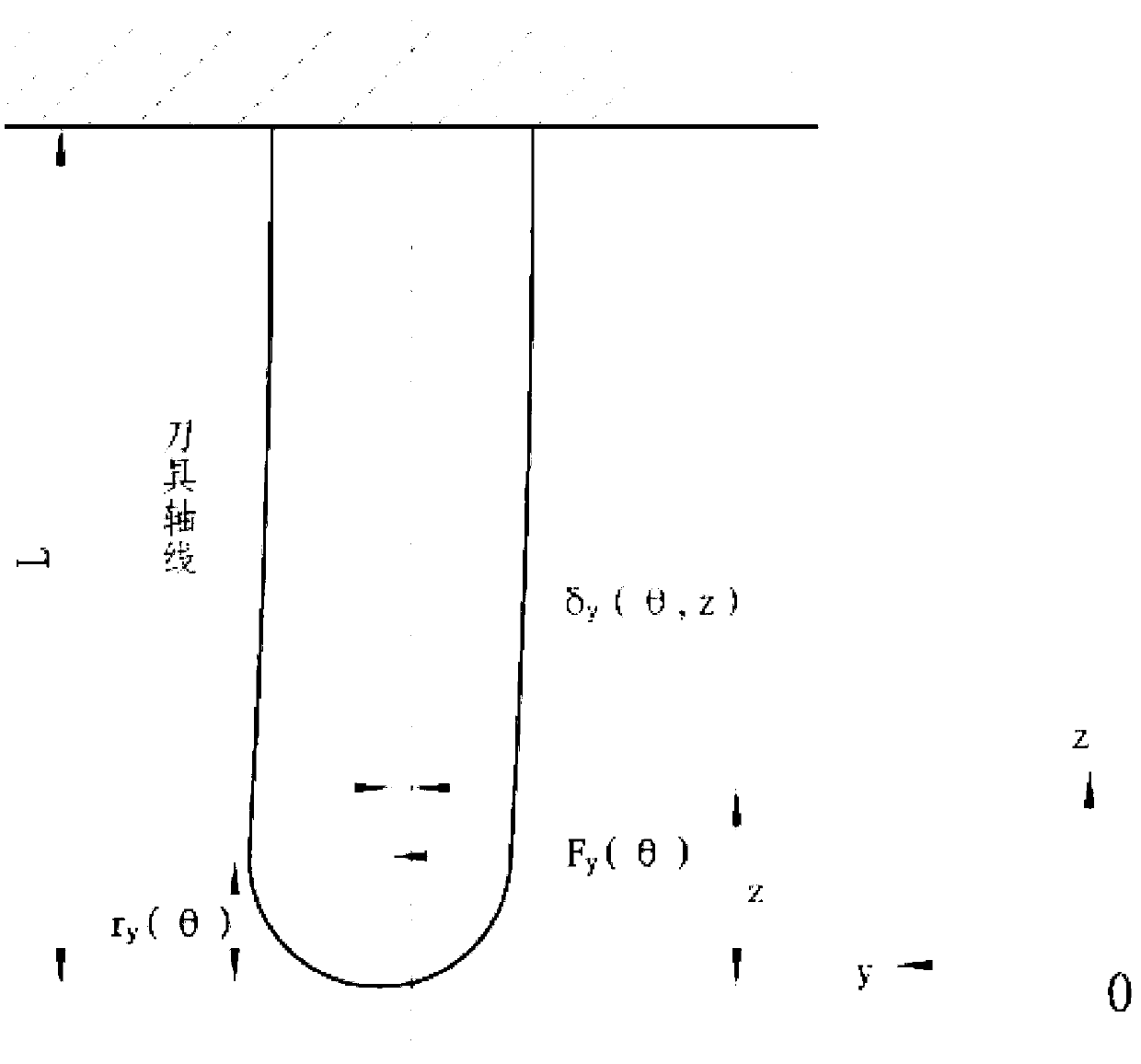

[0039] In the process of NC machining, due to the different effects of errors of different natures in the process system on the workpiece error, this method divides the error compensation of the process system into two stages, namely, the pre-compensation of the dynamic error of the process system and the re-compensation of the static error of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com