A device and processing method for electrophoresis-assisted micro-ultrasonic or micro-rotating ultrasonic polishing of micro-holes

A technology of rotating ultrasonic and ultrasonic processing, which is applied in the field of electrophoresis-assisted micro-ultrasonic or micro-rotating ultrasonic polishing micropores, and in the field of polishing micropores. The effect of reducing adverse effects and avoiding repeated positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

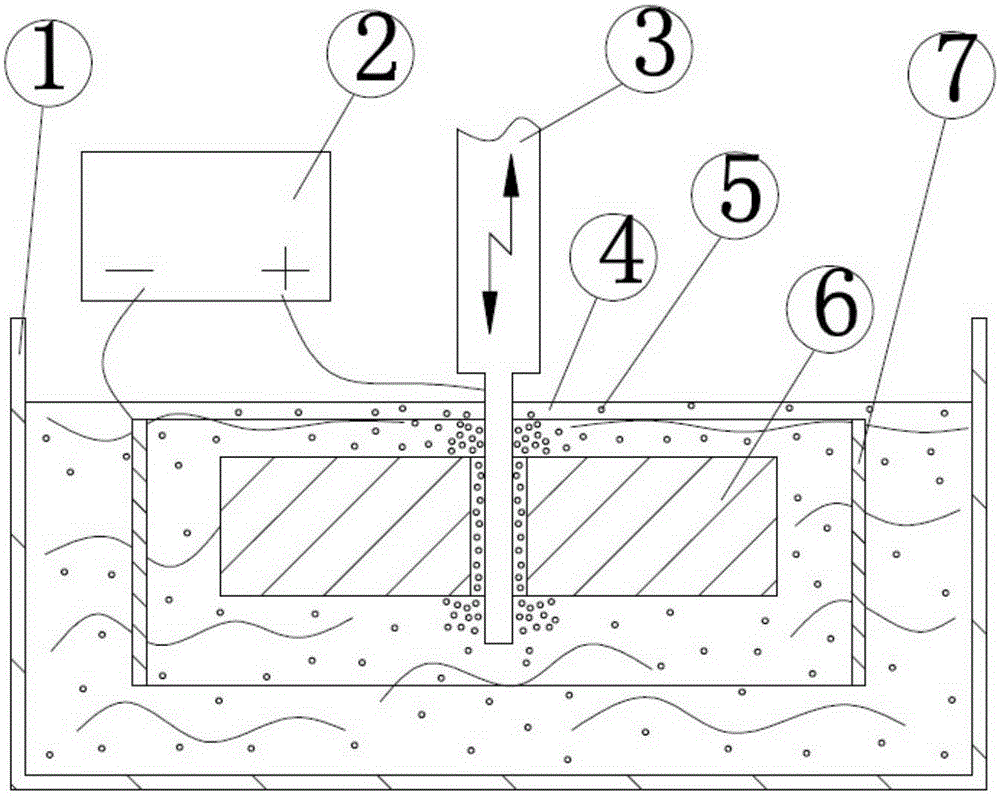

[0028] like figure 1 As shown, an electrophoresis-assisted micro-ultrasonic polishing micropore device includes a micro-ultrasonic machine tool, a working fluid tank 1, an electrophoretic DC power supply 2, a microtool 3, a working fluid 4, ultrafine abrasive particles 5, and a microporous workpiece 6. The electrophoresis auxiliary circular electrode 7; the micro-ultrasonic machine tool includes a spindle system, a power supply system, and a spindle micro-ultrasonic longitudinal vibration system; the electrophoretic DC power supply 2 passes through the power supply system, and its positive pole is connected to the micro tool 3, and its positive pole is connected to the micro tool 3. The negative electrode is connected to the electrophoresis auxiliary circular electrode 7; the ultrafine abrasive particles 5 are distributed in the working fluid 4, and the working fluid 4 is placed in the working fluid tank 1, wherein the average particle diameter of the ultrafine abrasive particl...

Embodiment 2

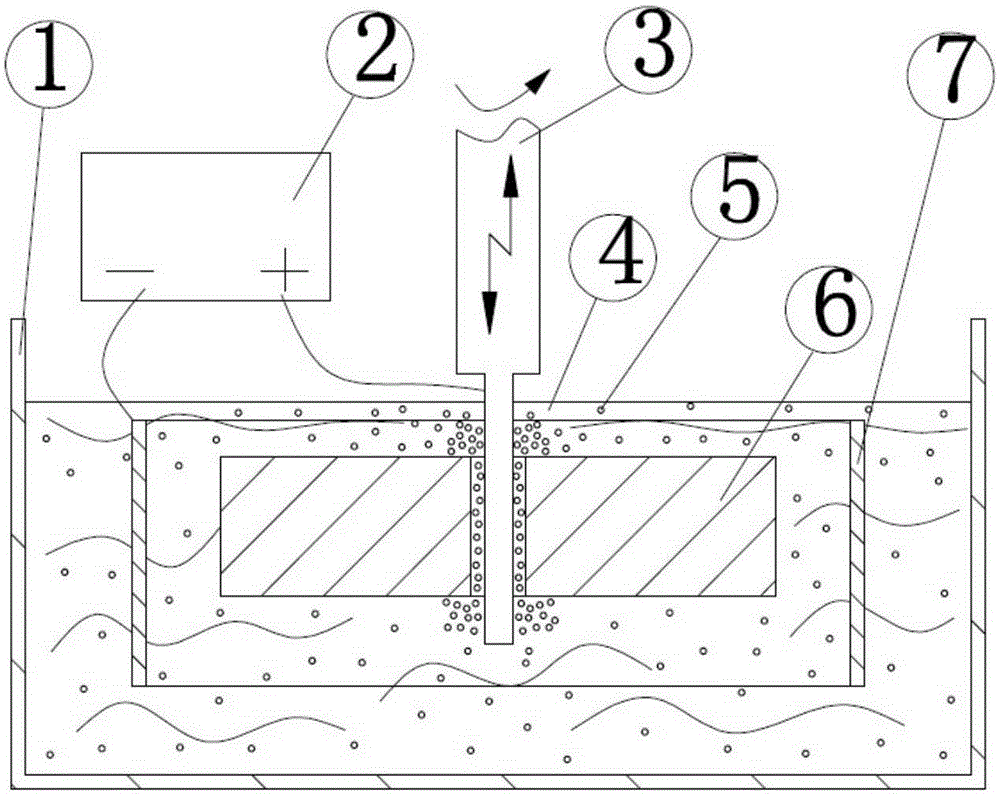

[0037] like figure 2 As shown, an electrophoresis-assisted micro-rotary ultrasonic polishing micropore device includes a micro-ultrasonic machine tool, a working liquid tank 1, an electrophoretic DC power supply 2, a micro-tool 3, a working liquid 4, ultra-fine abrasive particles 5, and a micro-porous workpiece 6 , electrophoresis auxiliary circular electrode 7; the micro-ultrasonic machine tool includes a spindle system, a power feed system, and a spindle micro-ultrasonic longitudinal vibration system; the electrophoretic DC power supply 2 passes through the power feed system, and its positive pole is connected to the micro tool 3, Its negative electrode is connected to the electrophoresis auxiliary circular electrode 7; the ultrafine abrasive particles 5 are distributed in the working fluid 4, and the working fluid 4 is placed in the working fluid tank 1, wherein the average particle diameter of the ultrafine abrasive particles 5 is less than 1 micron ; The microporous work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com