Patents

Literature

36results about How to "Avoid repeated positioning errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

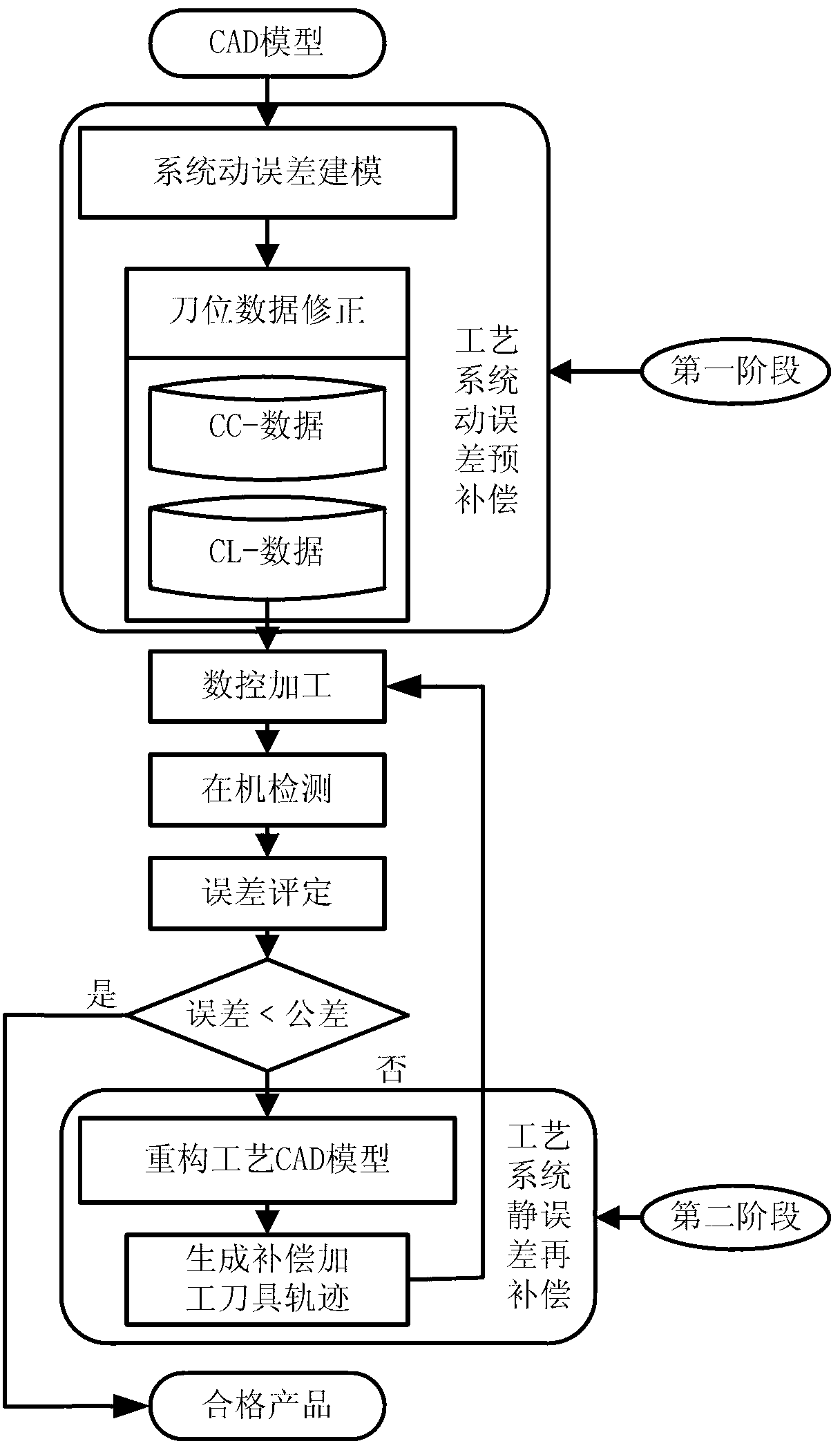

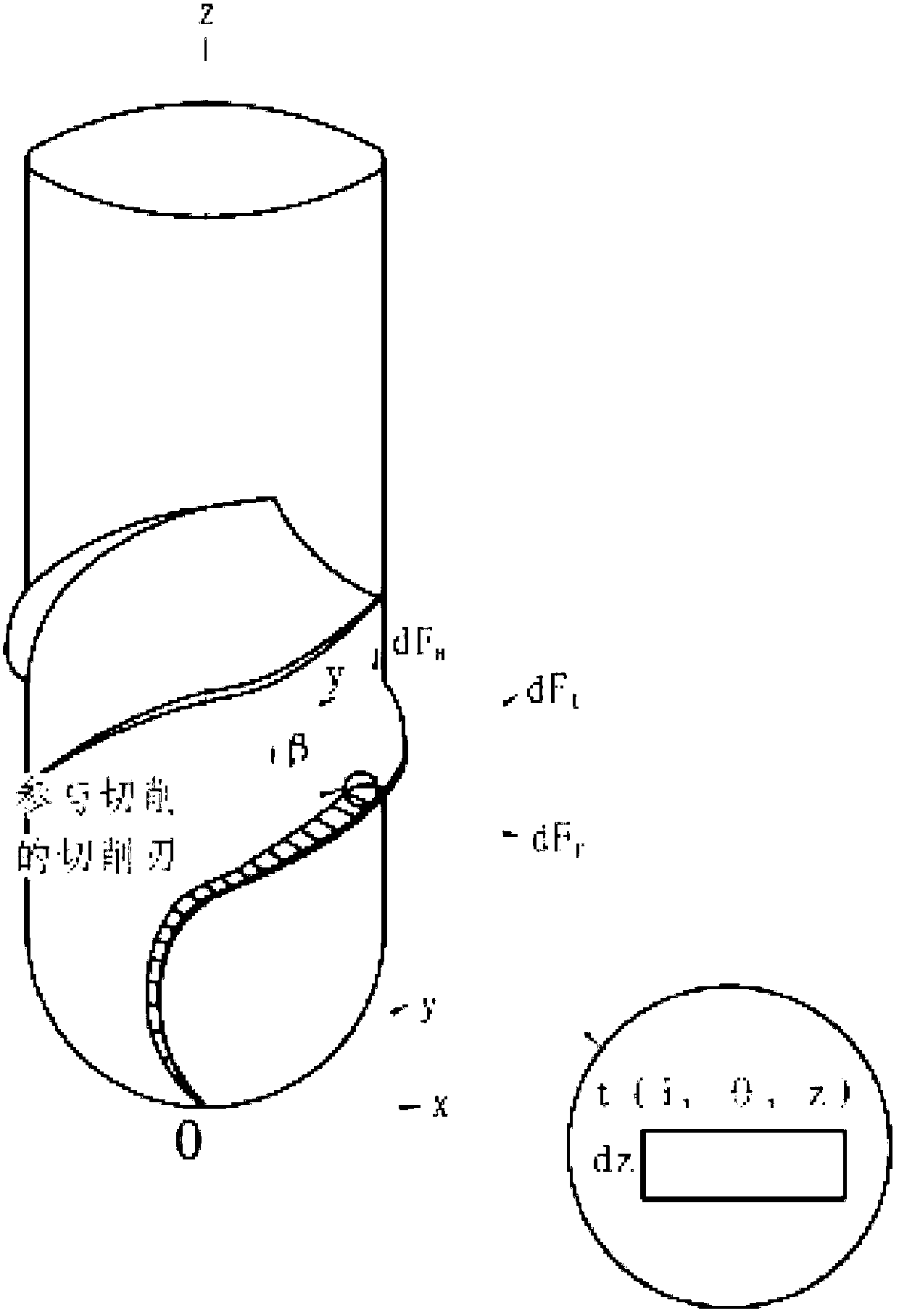

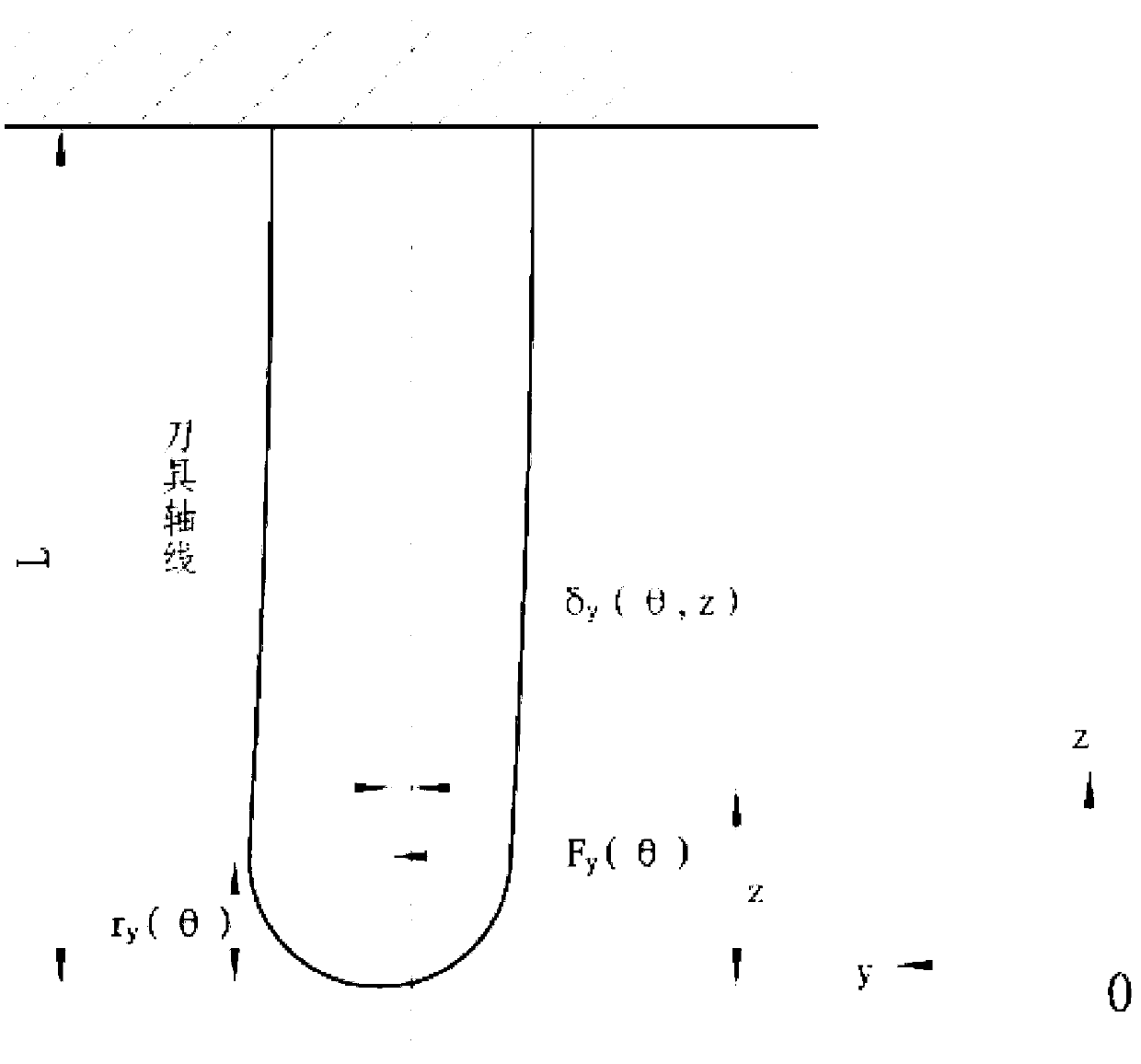

In-process evaluation based complex spatial surface error feedback compensating method

ActiveCN103218475AAvoid repeated positioning errorsReduce handlingSpecial data processing applicationsComputer Aided DesignCutter location

The invention discloses an in-process evaluation based complex spatial surface error feedback compensating method. The method comprises the following steps of processing a complex surface cutting force module through a ball-end cutter, performing dynamic compensation for a target cutter location point for workpiece pre-processing; performing in-process detection for the pre-processed workpiece to obtain geometrical information of an actual contour; evaluating error for the pre-processed workpiece through a contour degree error evaluation model; when the contour error is greater than tolerance, determining a compensation point position U1 corresponding to each contact point; guiding the compensation point position corresponding to each contact point to three-dimensional CAD (Computer-Aided Design) to obtain a compensating process contour to generate a compensating processing tool track; and performing static compensation and processing for the pre-processed workpiece and finishing the flow. Under the premise of ensuring the processing precision of part surface, the processing precision of the part is detected in process without investing fund to purchase more detection devices, so that the conveying and loading time of workpieces is shortened.

Owner:TIANJIN SAIXIANG TECH

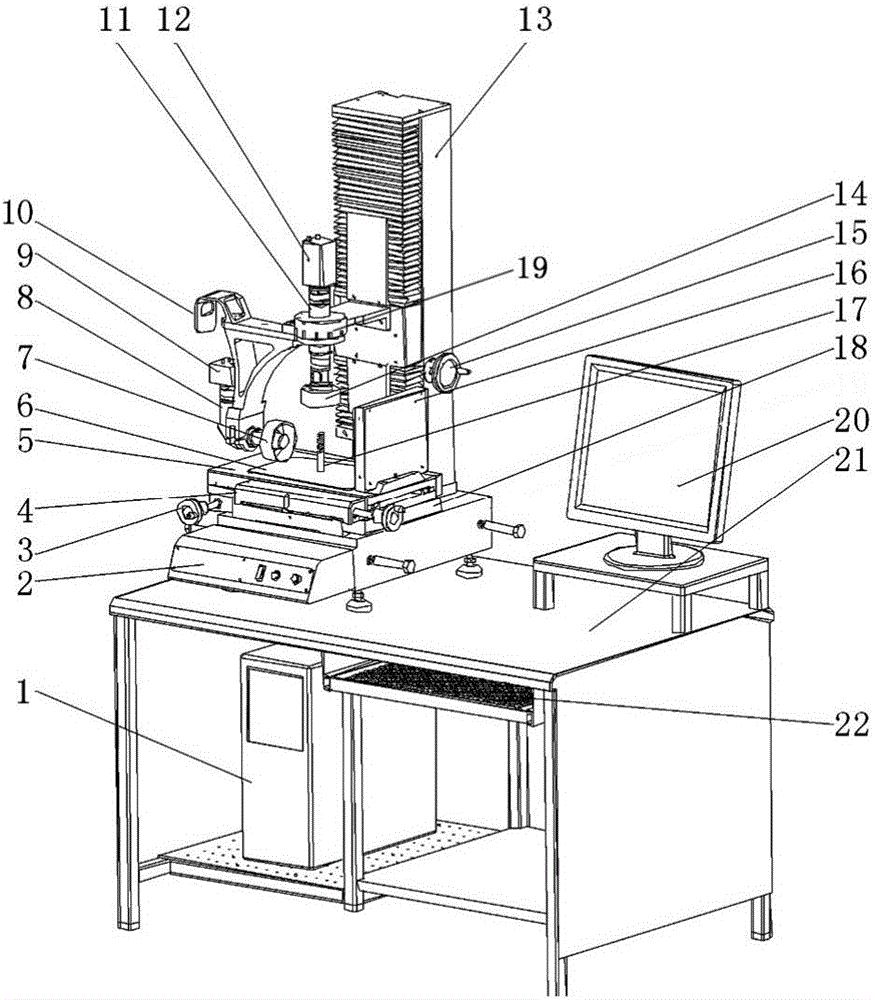

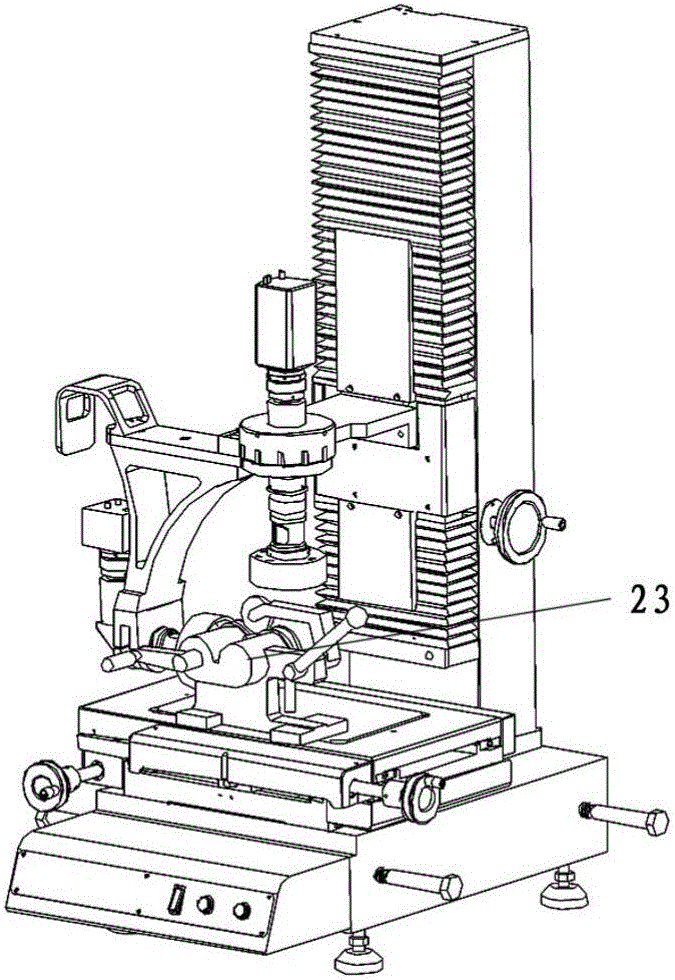

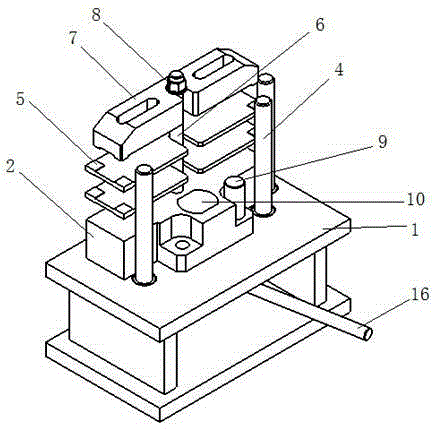

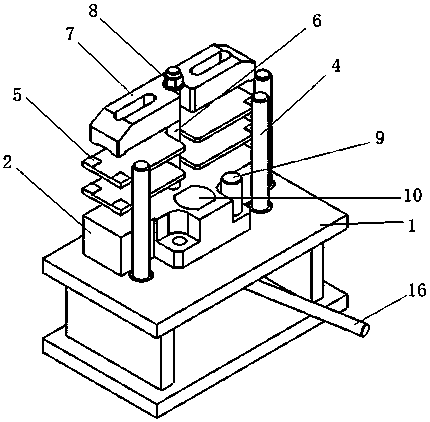

Image measurement tool system and method

InactiveCN105674882ARealize measurementAdd alignment functionUsing optical meansCamera lensDisplay device

The invention relates to an image measurement tool system, and the system comprises a sheet metal instrument stand, a display, a computer host, a mouse keyboard, a console, a workbench moving mechanism, a lifting mechanism, a working table, a glass block, a clamping tool for clamping a cutter, a bottom light source plate, a lateral image collection device, and a longitudinal image collection device. The mouse keyboard and the display are respectively connected with the computer host, and the computer host is connected with the console. The workbench moving mechanism and the lifting mechanism are disposed on the console and are connected with the console. The working table is disposed above the workbench moving mechanism, and the glass block is disposed on the upper surface of the working table. The clamping tool is disposed at the central part of the glass block. The longitudinal image collection device is fixed on the lifting mechanism, and the lateral image collection device is rotatingly connected along the axis of the longitudinal image collection device through an angle rotating device. The bottom light source plate is disposed on the working table, and is disposed at a side of a longitudinal camera lens.

Owner:东莞市嘉腾仪器仪表有限公司

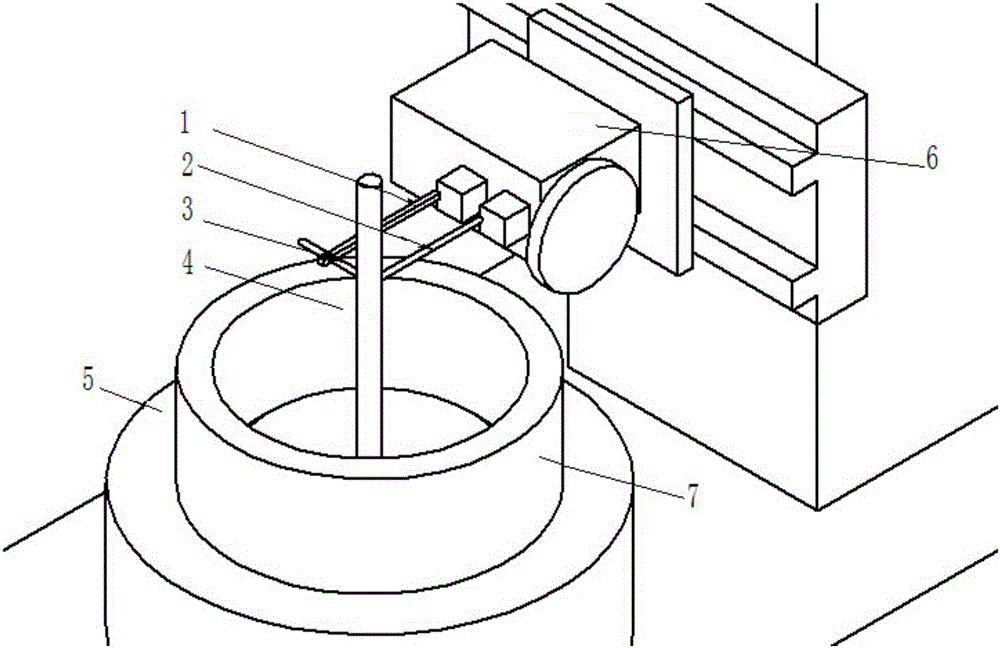

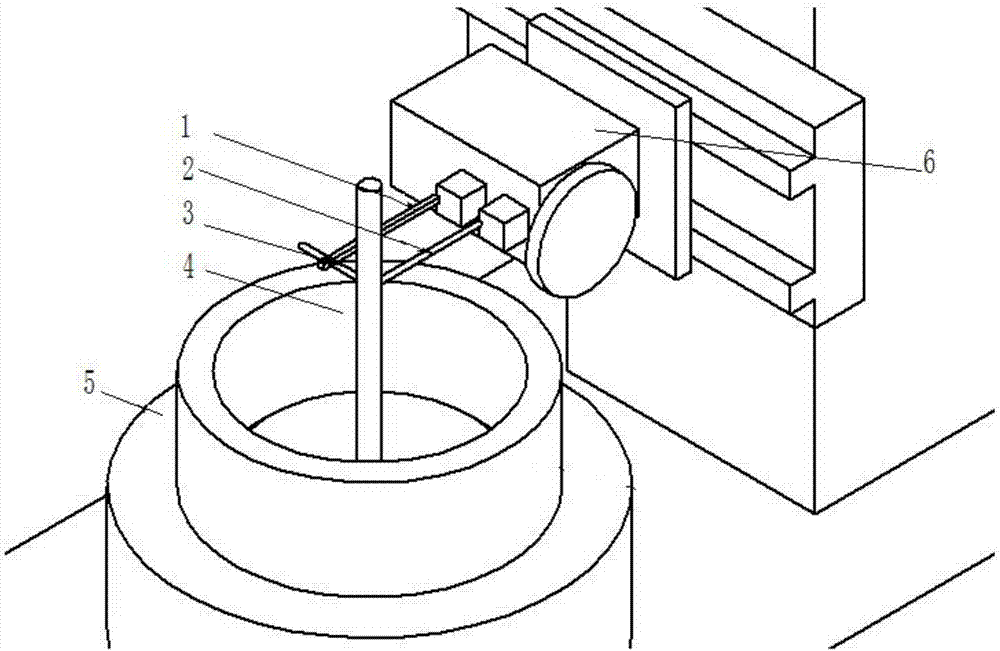

Numerically controlled lathe-based contour laser online measurement device and method for rotary type structure characteristic parts

ActiveCN107238352APrecise positioningImprove adaptabilityUsing optical meansPoint cloudMeasurement device

The invention relates to a numerically controlled lathe-based contour laser online measurement device and a method thereof for rotary type structure characteristic parts, and designs an adjustable and detachable clamp for clamping a sensor. An assembly body is arranged on the tool rest of a lathe in the side edge positioning mode, and the position and orientation calibration of a measuring head is conducted based on a ceramic standard ball. After that, a measuring program is called, and the distance value between the curved-surface discrete point of a part and the measuring head is measured. In combination with the coordinates of the lathe, a one-dimensional distance value is converted into a three-dimensional coordinate value by adopting a compiling algorithm, and then point cloud data are obtained. The point cloud data are analyzed and processed, and a model of the point cloud data is reconstructed. Compared with a theoretical model, an error value and a generation reason thereof are analyzed. Therefore, the high-efficiency precise online measurement of the contour profile of a rotary part is realized. According to the invention, the online measurement and the error analysis for the contours of rotary type structure characteristic parts can be realized. The device and the method are fast in measurement speed and high in precision, thus having a good practical value and an excellent application prospect in the field of non-contact laser online measurement and research.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

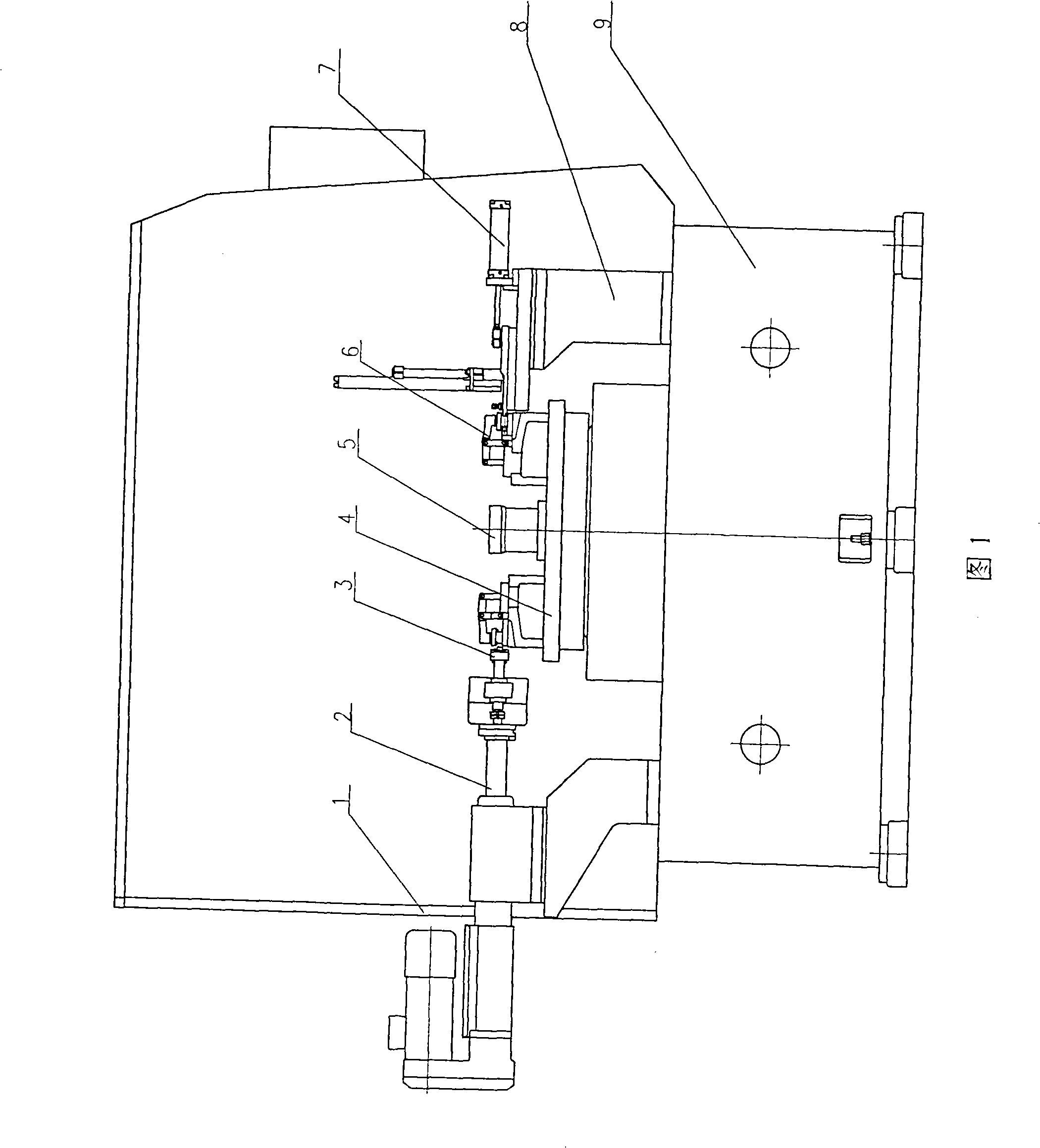

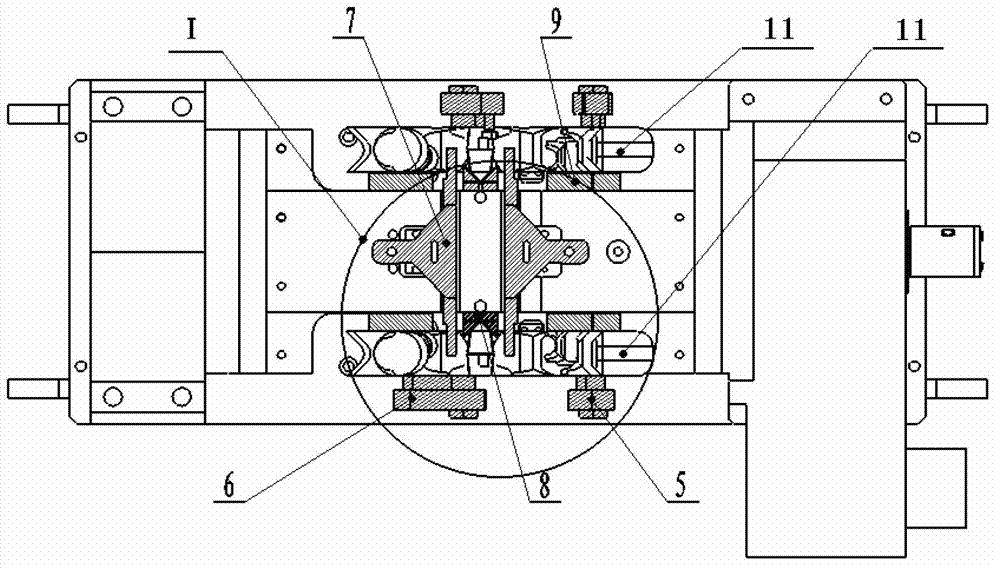

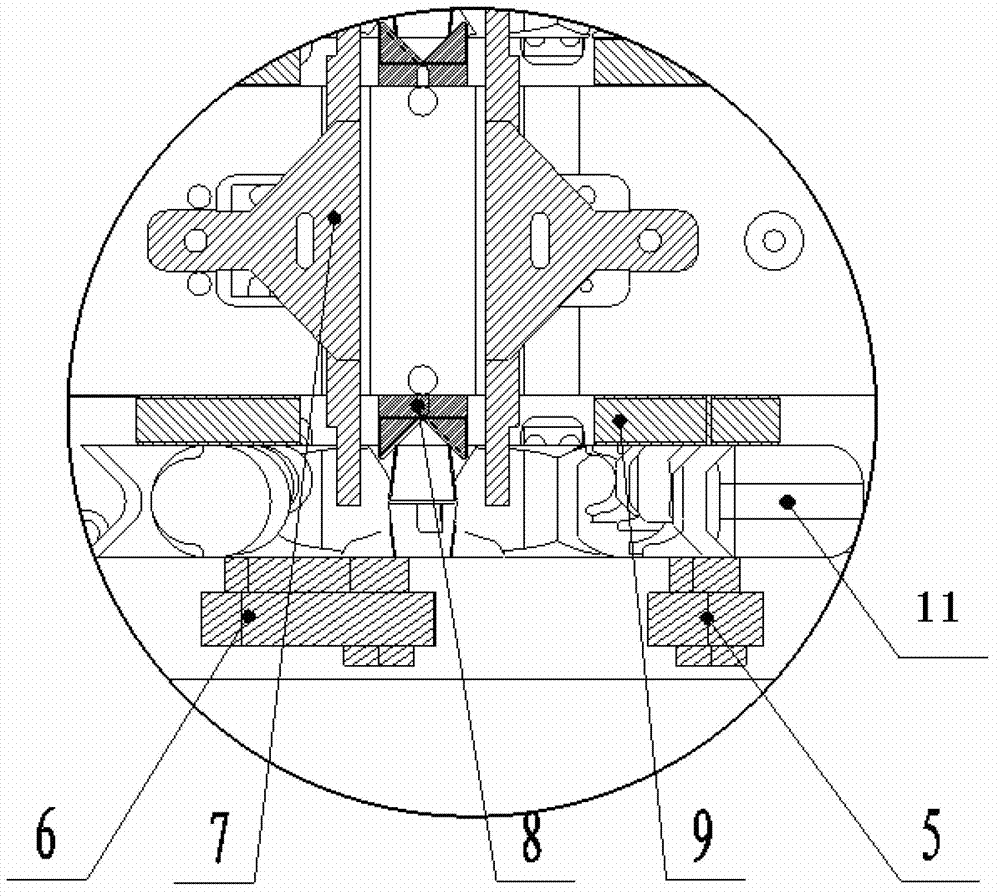

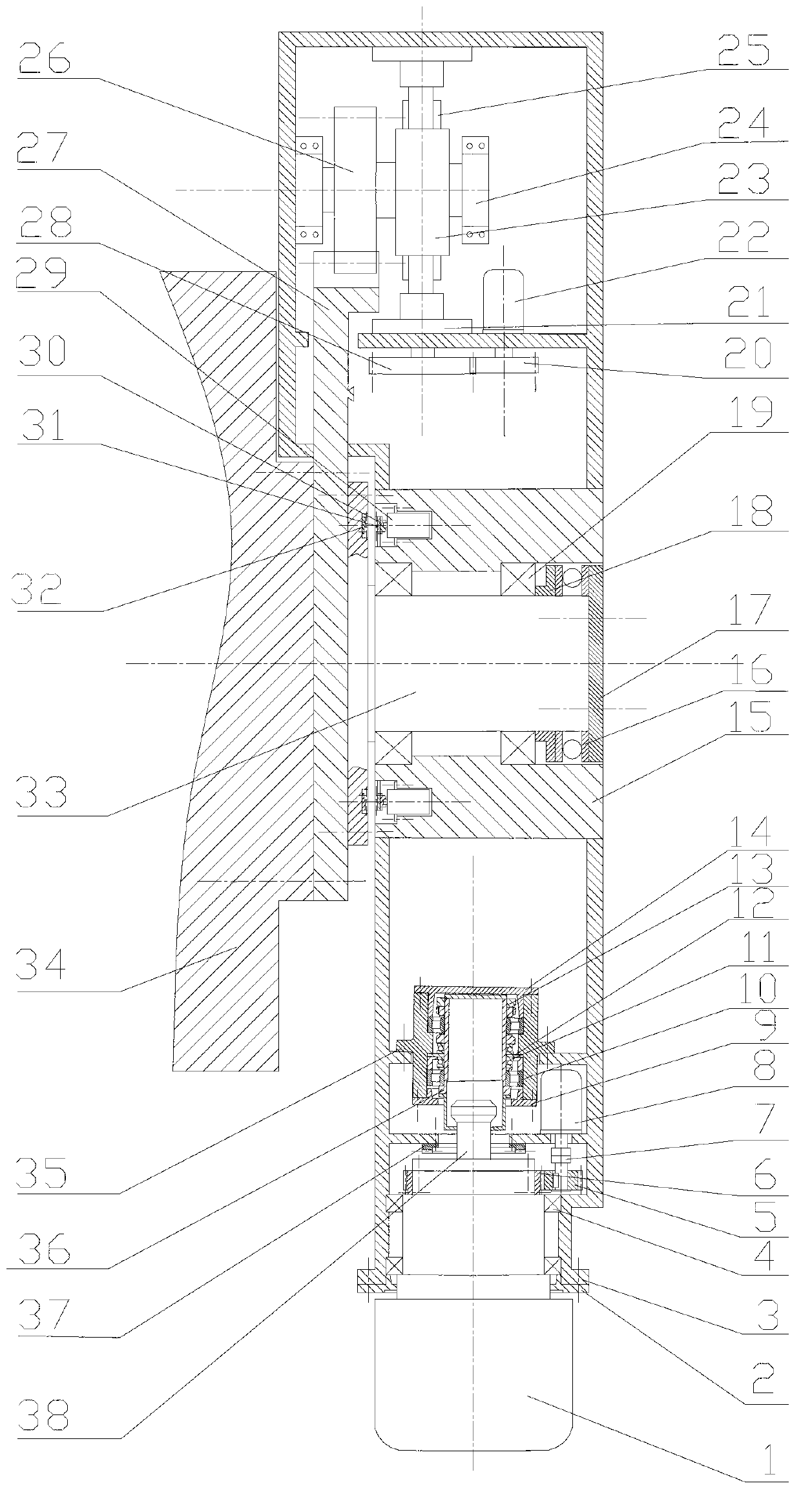

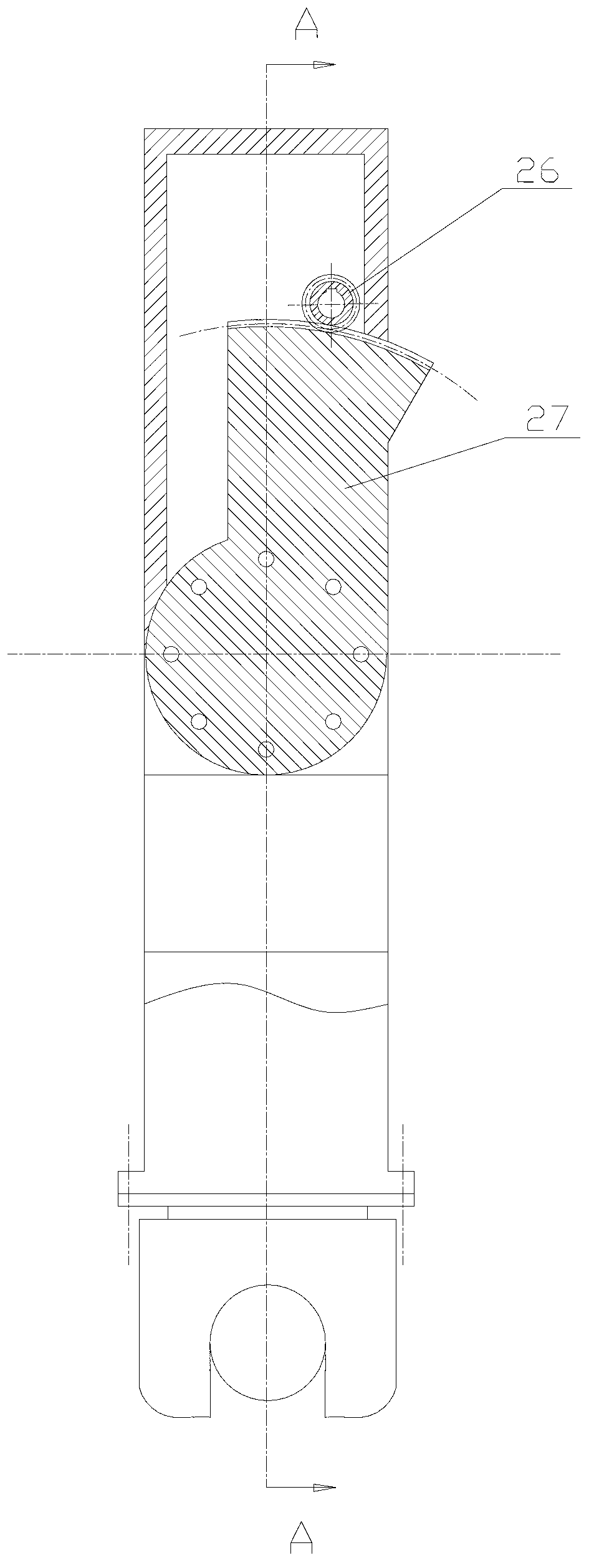

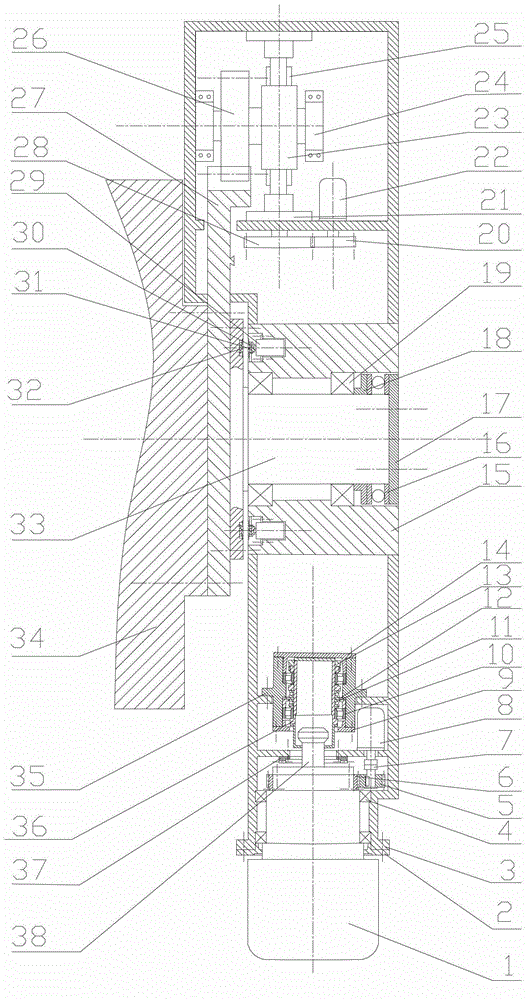

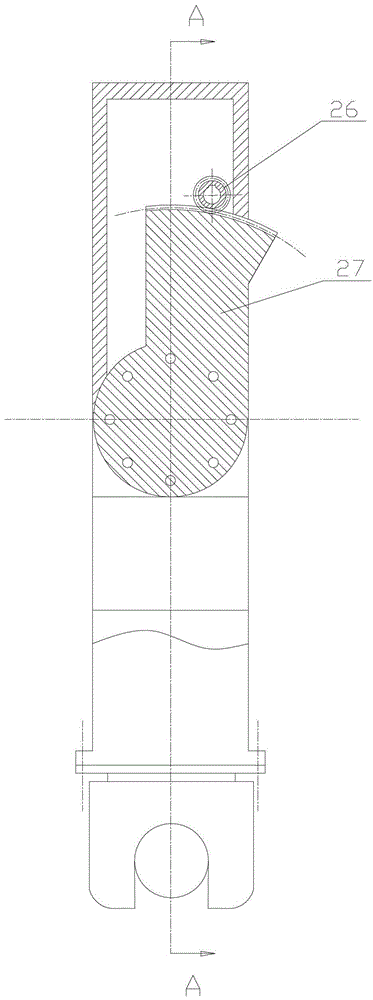

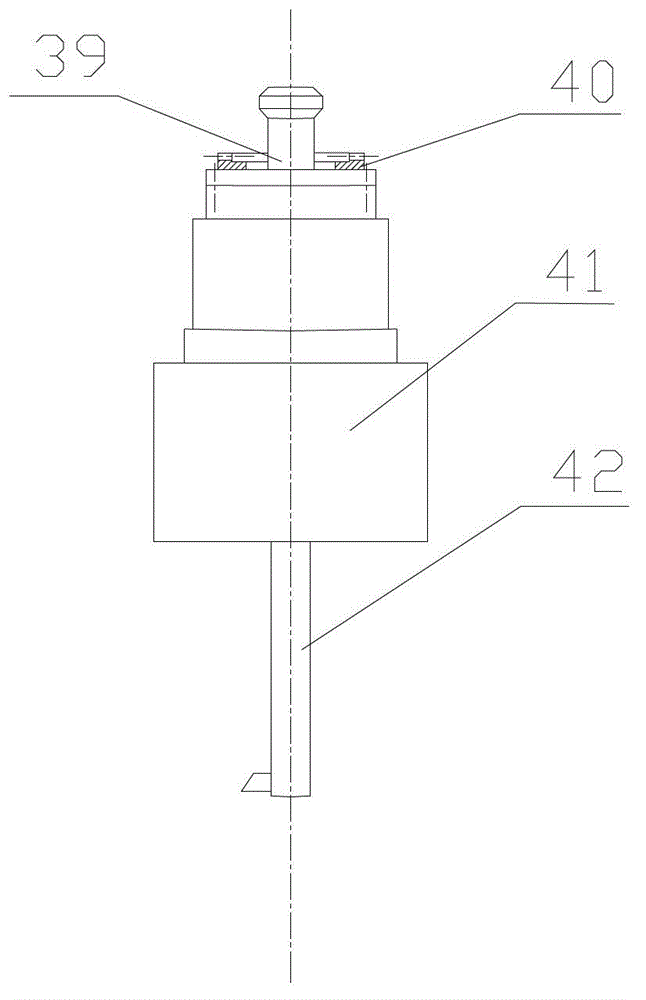

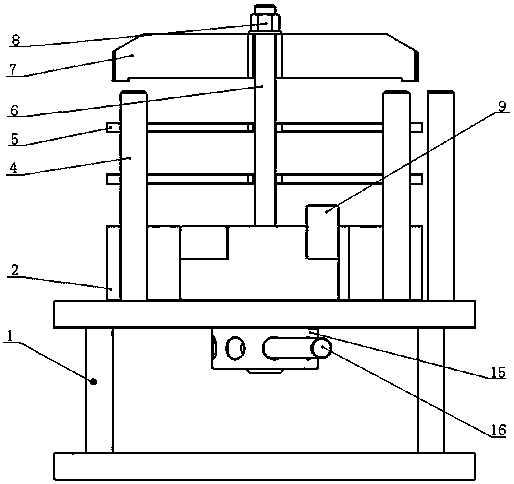

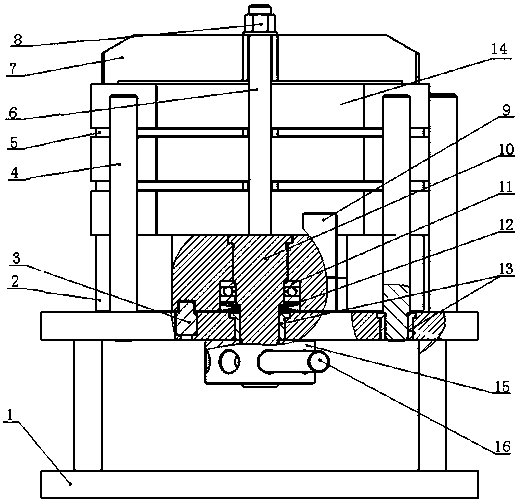

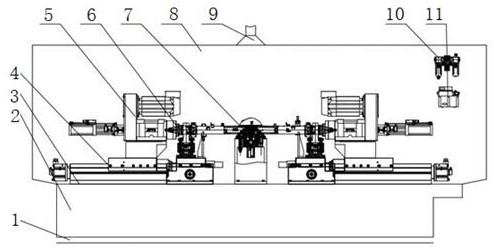

Machine special for link lever eight-station borehole

InactiveCN101318302AMeet efficiencyFulfil requirementsMetal working apparatusEngineeringPosition error

The invention relates to a special connecting rod drilling machine with eight stations. The machine tool is wholly and protectively arranged on an integrated casting machine tool bed, a rotary worktable is fixed on the integrated casting machine tool bed, a fixture part is fixed on the rotary worktable, an oil rotary distributor is fixed in the center the rotary worktable, a unit head and a base seat of a loading and unloading device are fixed on the integrated casting machine tool bed; a loading device, a two-axis drilling through center oil hole unit head, a two-axis drilling and counterboring center oil hole unit head, a two-axis drilling center oil hole unit head, an unloading device, a four-axis tapping unit head and a blowing detecting device are all fixed on the unit head and the base seat of the loading and unloading device; a two-axis running drilling template is connected with the two-axis drilling through center oil hole unit head via a guide rod, and a four-axis running drilling template is connected with a four-axis drilling connecting thread bottom hole unit head via the guide rod. The special drilling machine has the advantages of completing processes that need to be processed by a single device in a machine tool, avoiding repetitive position error, simplifying the process, meeting the processing requirement of high efficiency and high precision of parts and being suitable for mass production.

Owner:南京聚星机械装备股份有限公司

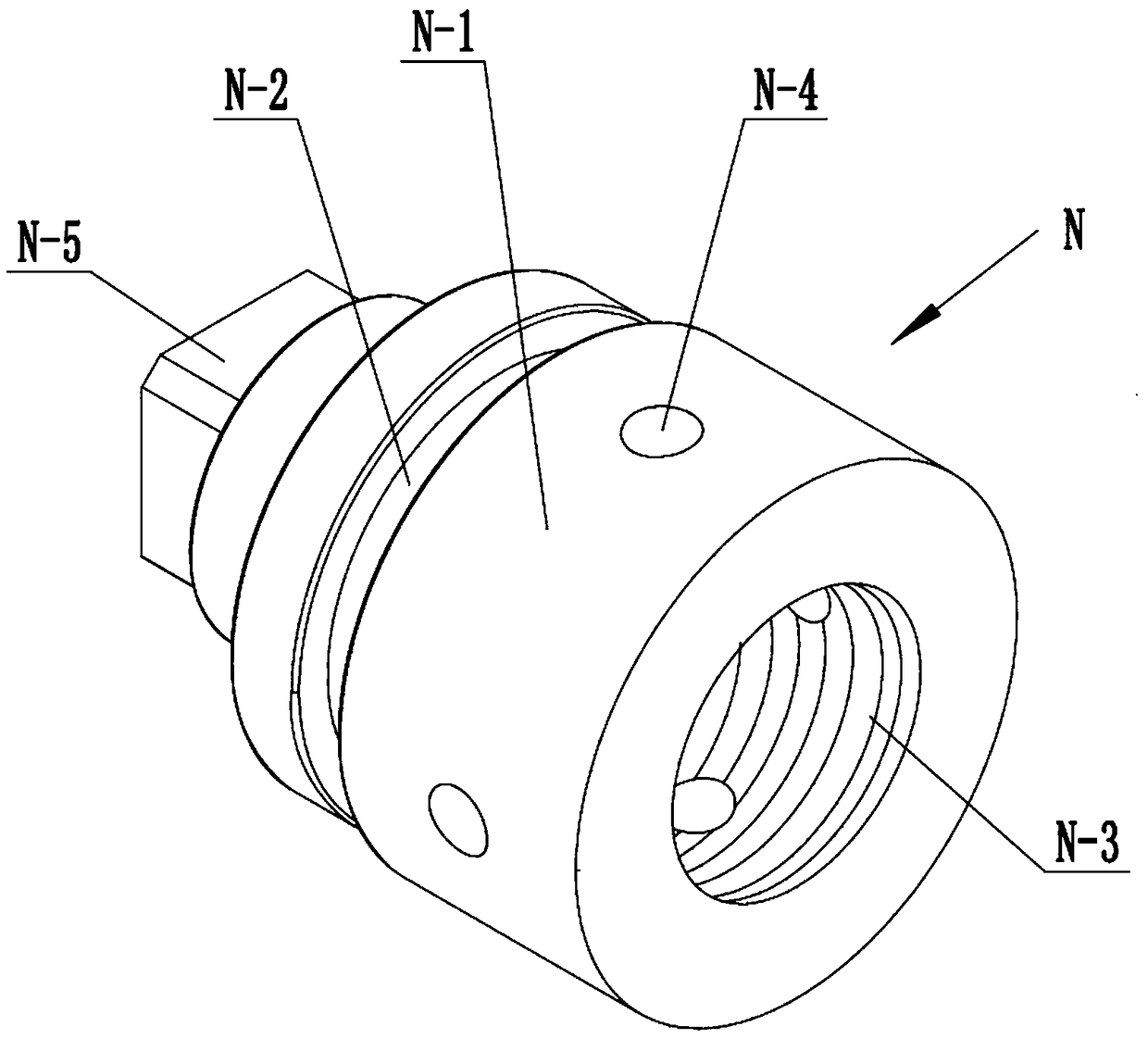

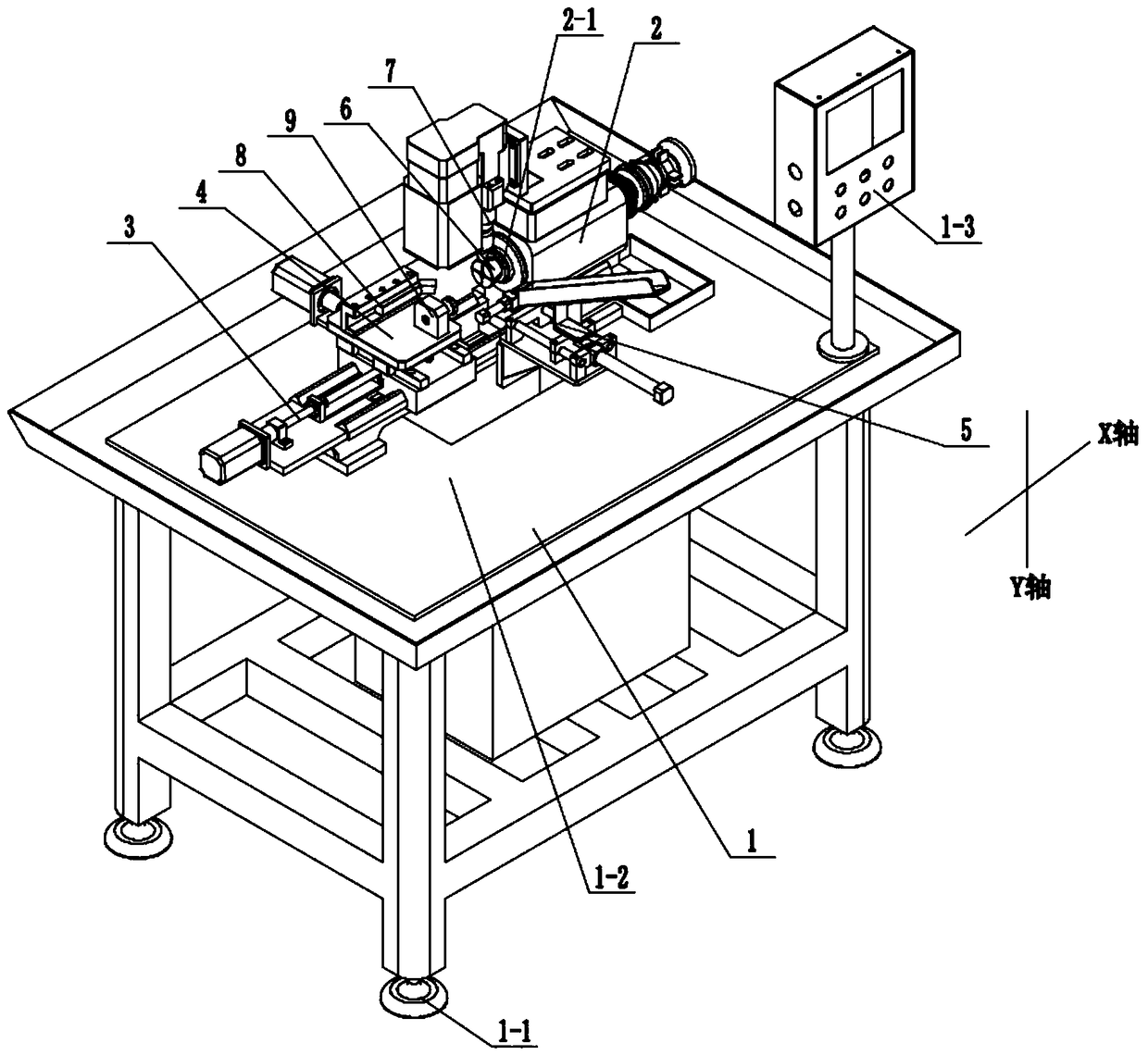

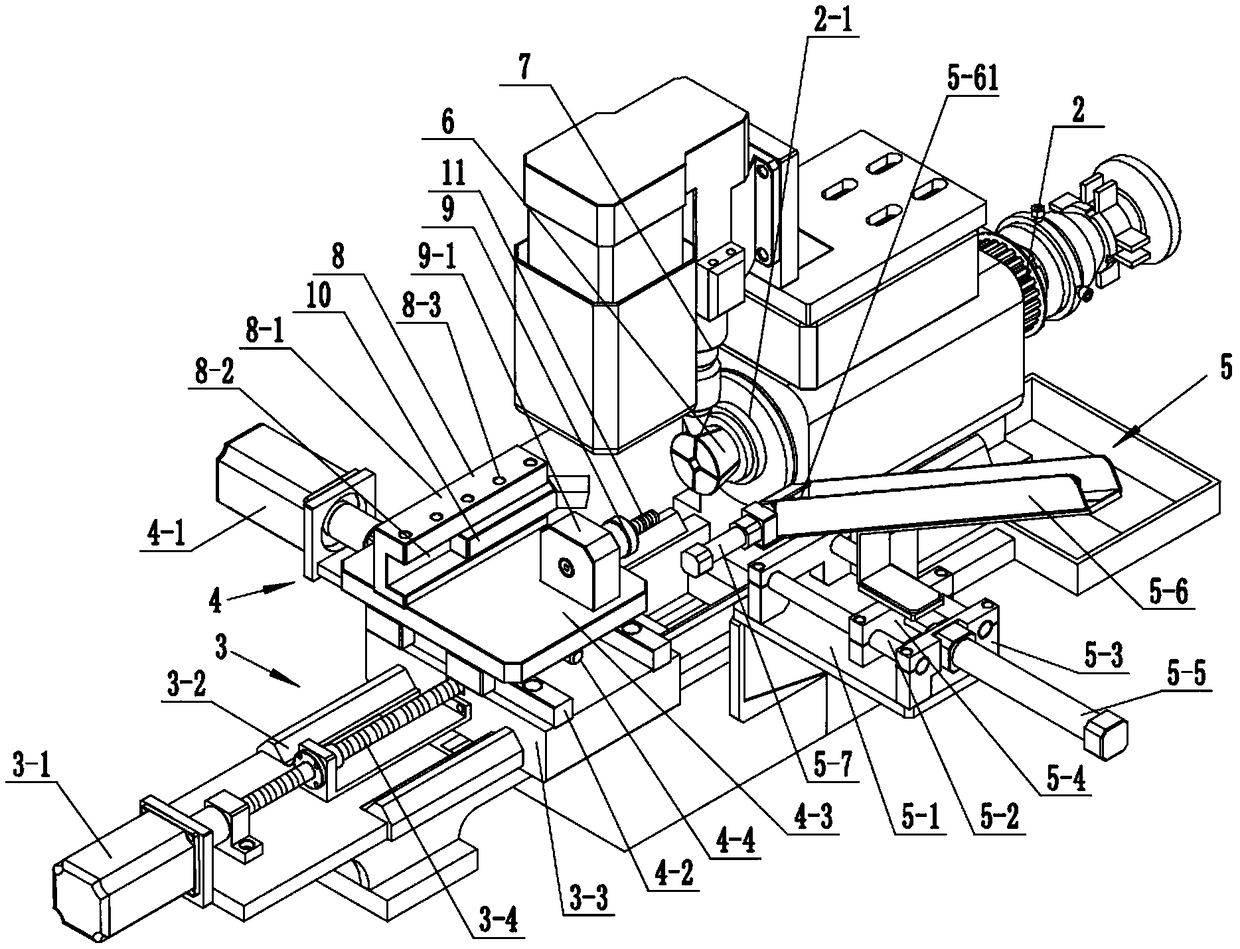

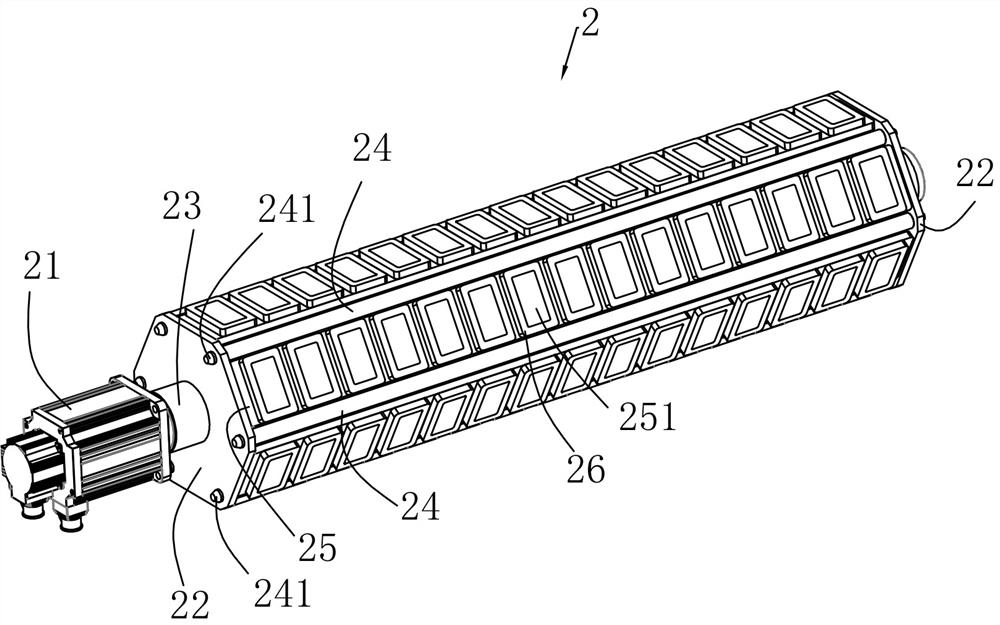

Numerical-control machining equipment for machining shaft bushings

ActiveCN108971992AAvoid manual clampingAvoid repeated positioning errorsWork clamping meansFeeding apparatusNumerical controlEngineering

The invention discloses numerical-control machining equipment for machining shaft bushings. The numerical-control machining equipment is characterized by comprising a rack, a spindle box, an X-axis feeding mechanism, a Y-axis feeding mechanism, a bushing feeding mechanism, a bushing clamp and a drilling machine; the bushing clamp is arranged on the spindle of the spindle box and is used for clamping the bushings to be machined; the X-axis feeding mechanism comprises a first servo motor, an X-axis guide rail, an X-axis sliding seat and an X-axis threaded rod; the Y-axis feeding mechanism comprises a second servo motor, a Y-axis guide rail, a Y-axis sliding seat and a Y-axis threaded rod; the bushing feeding mechanism comprises a feeding base, a Y-axis guiding rod, a guiding-rod support, a feeding sliding seat, a Y-axis driving cylinder, a feed slot and an X-axis pushing cylinder; the drilling machine is located above the bushing clamp; a turning tool rest and a tap holder are arranged on the Y-axis sliding seat. By the arrangement, a series of automatic machining of stepped outer wall surfaces, inner threaded holes, radial holes and the like on the bushings can be achieved, workingefficiency can be increased by times, high machining precision is achieved, and production cost is greatly reduced.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

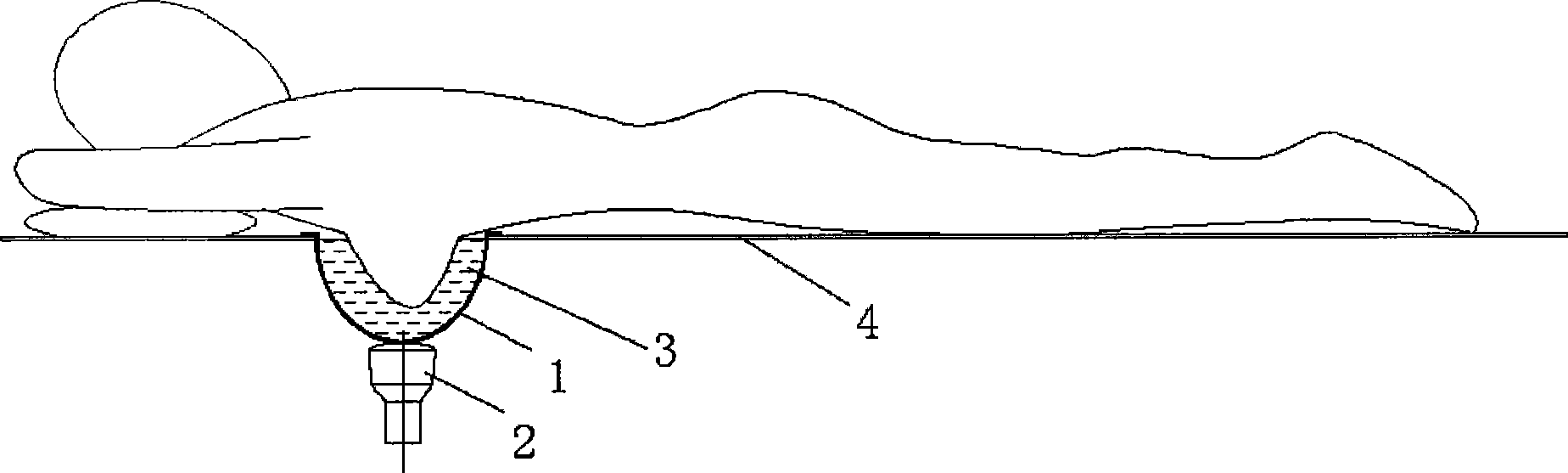

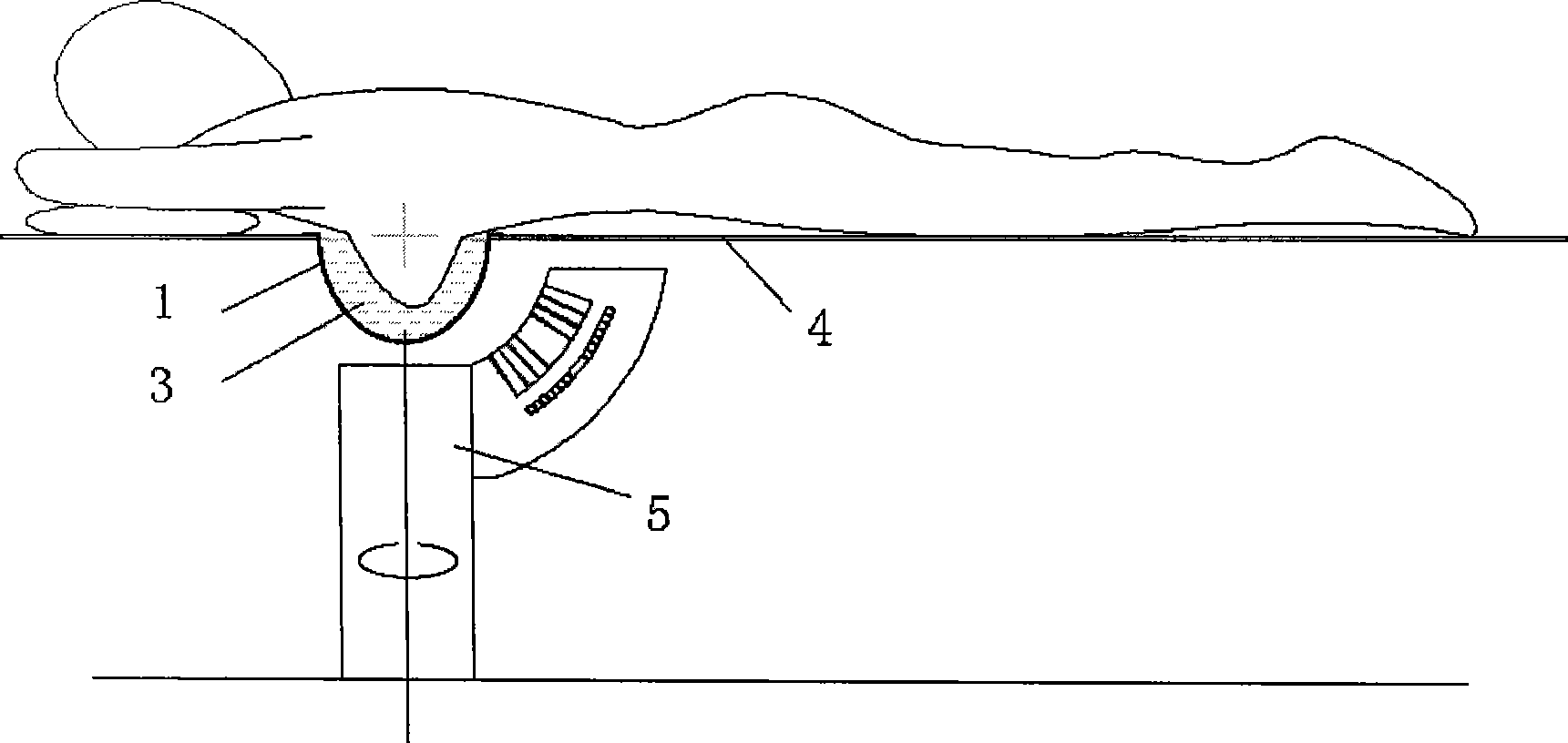

Glandula mammaria positioning device

InactiveCN101427940AEasy to calculateAvoid damageDiagnosticsRadiation therapyRadiation exposureComputer science

Owner:李大梁

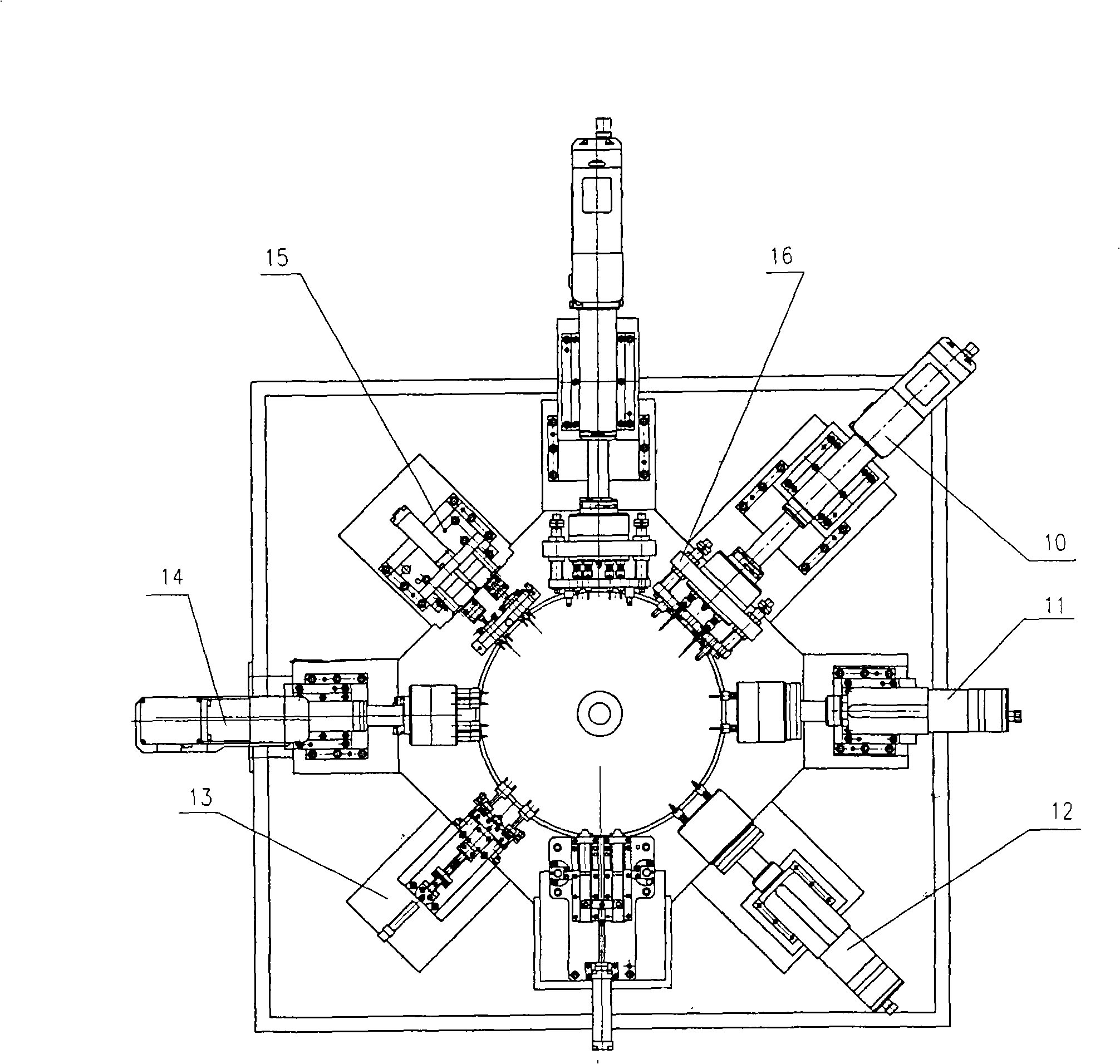

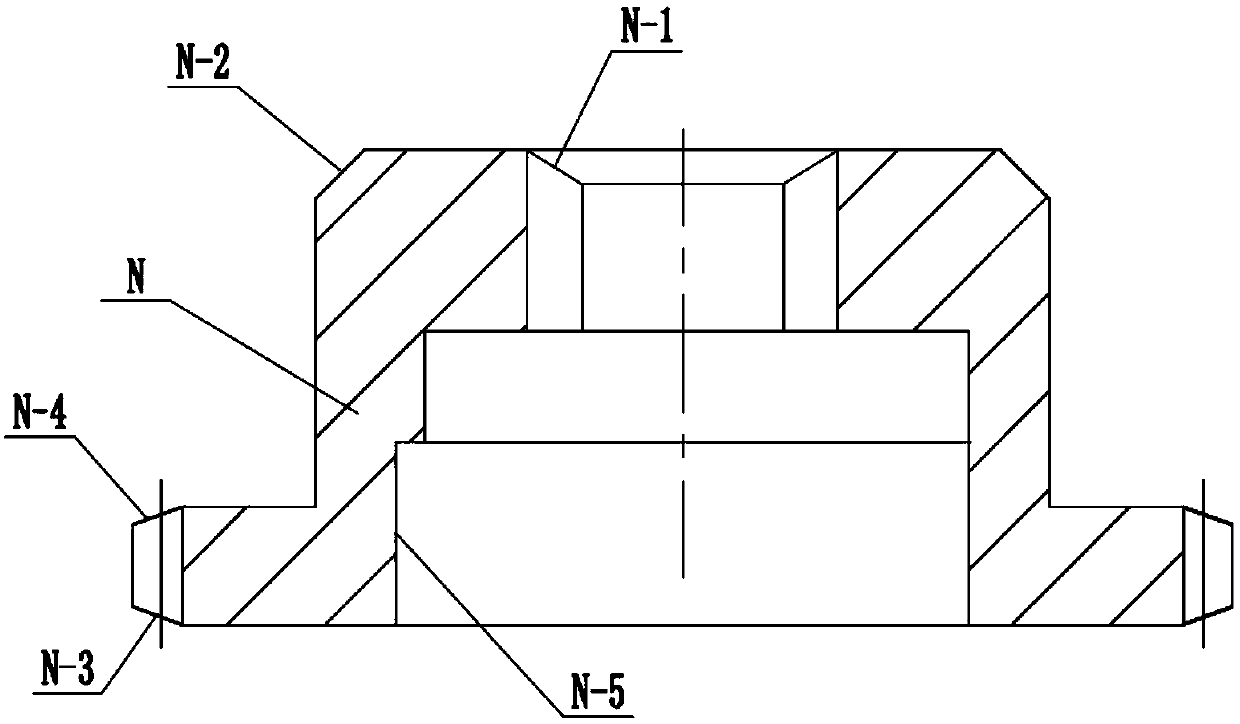

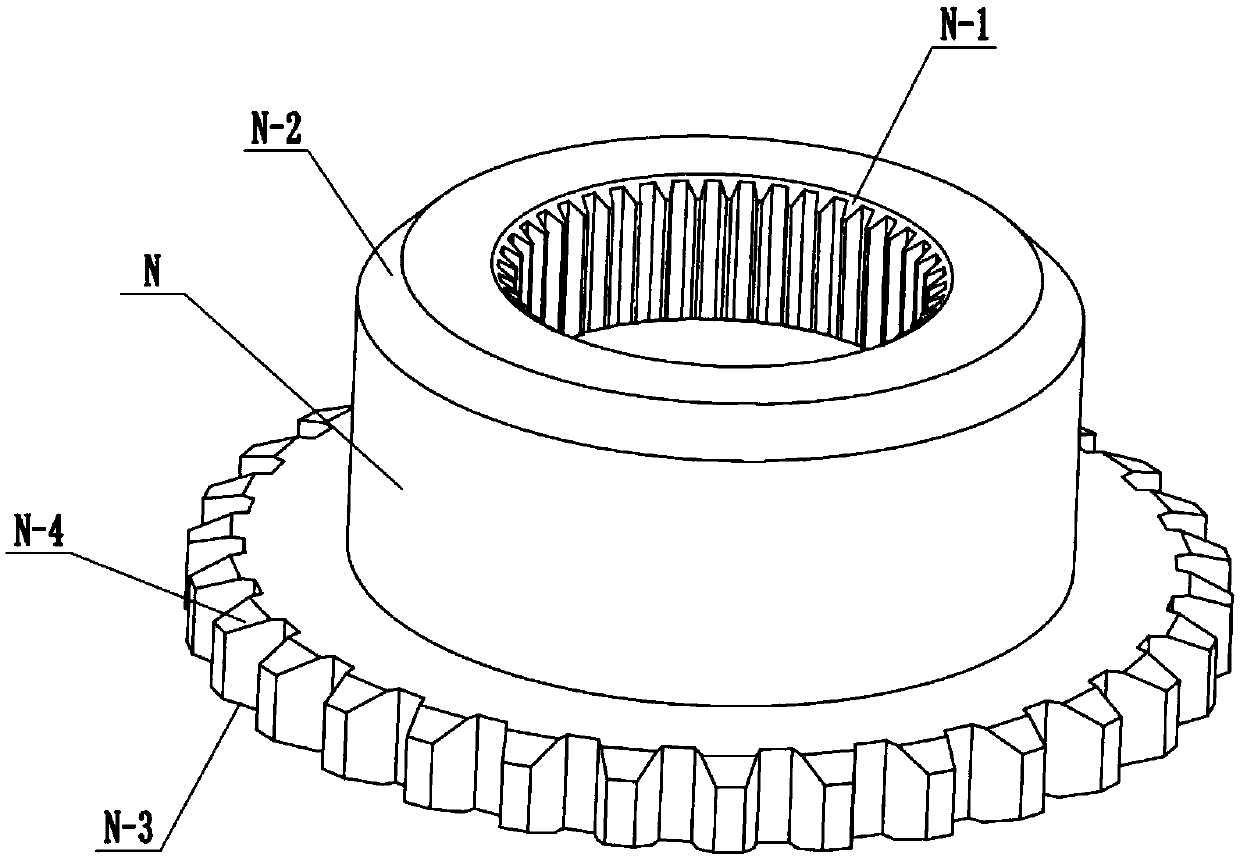

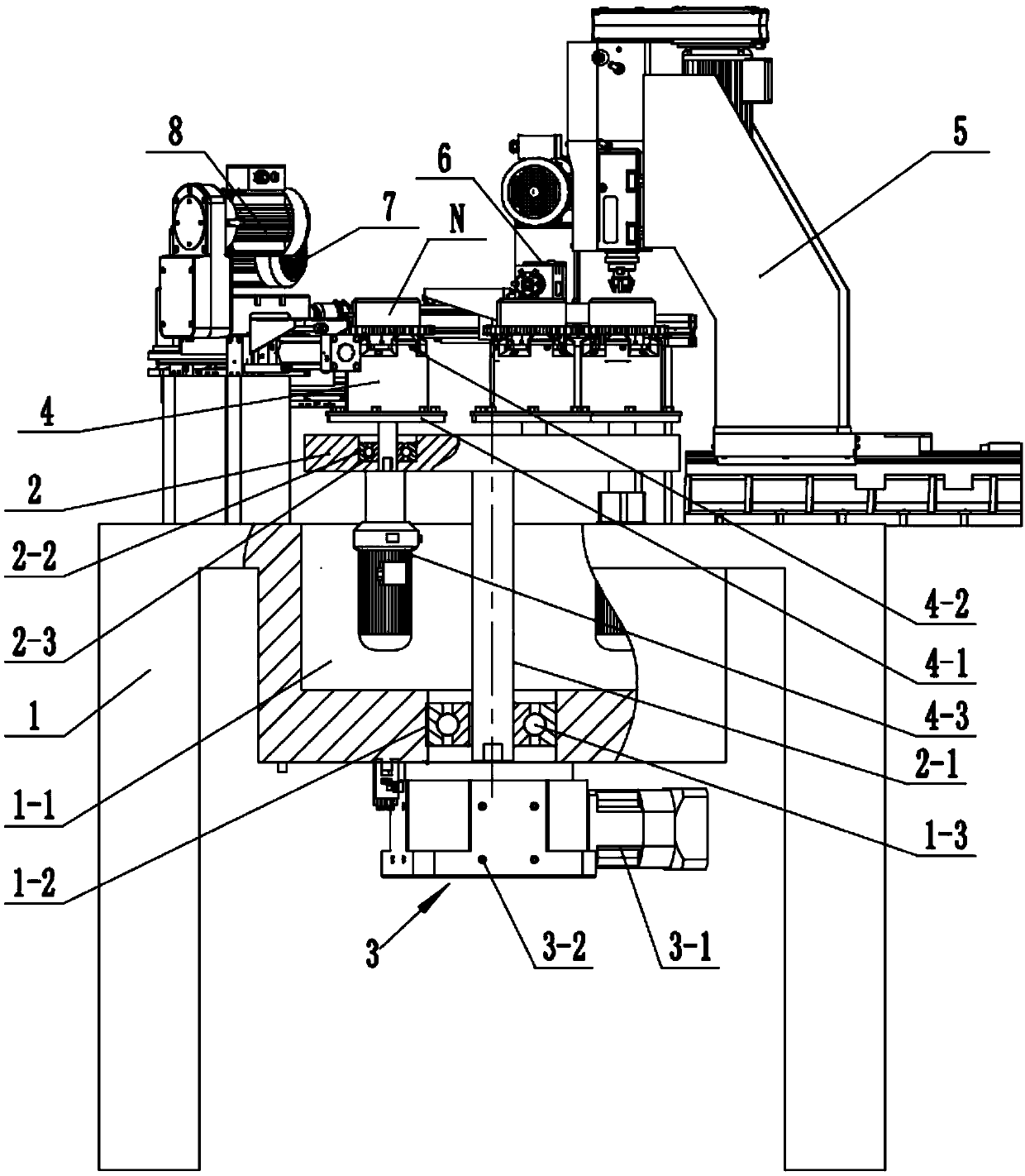

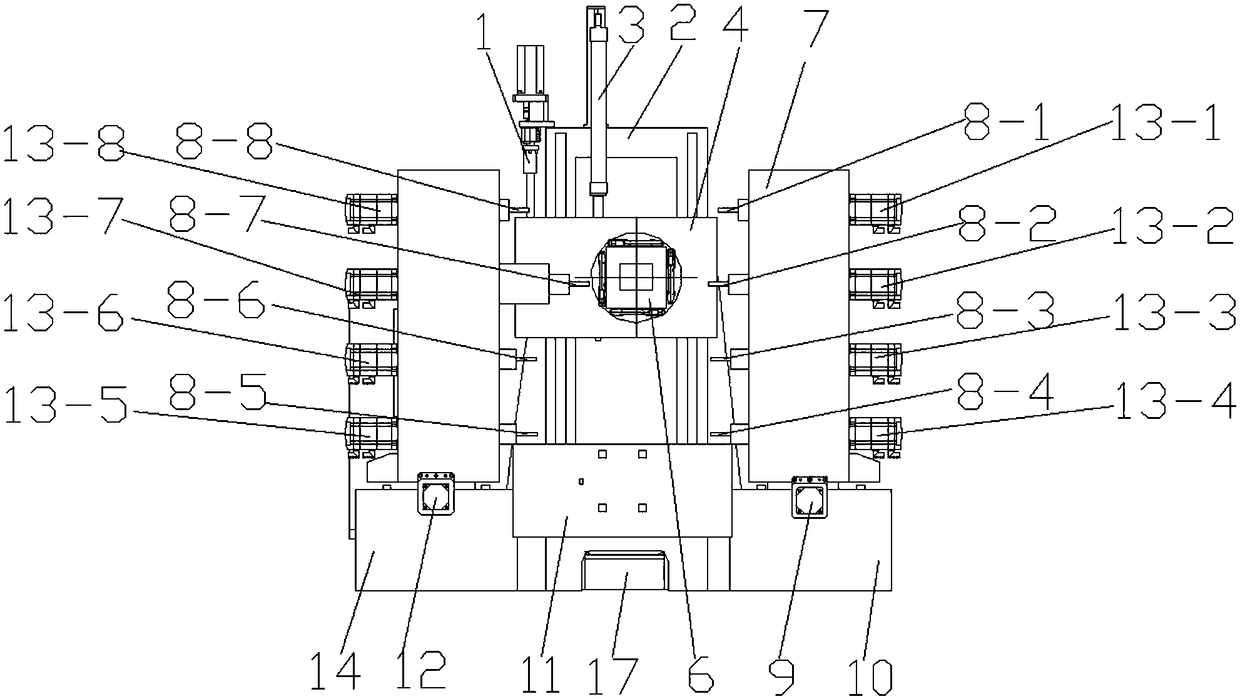

Gear ring support machining equipment

InactiveCN109663986AAvoid repeated positioning errorsHigh positioning accuracyPositioning apparatusGear-cutting machinesSpeed reductionMachining

The invention discloses gear ring support machining equipment. The gear ring support machining equipment is characterized in that a rack, a rotation disc, an indexing drive mechanism, five stations, afirst chamfering machine, a second chamfering machine, a third chamfering machine and a fourth chamfering machine are included; the rotation disc is rotationally arranged on the rack, and the five stations are arranged on the rotation disc and evenly distributed in the circumferential direction of the rotation disc; the indexing drive mechanism comprises a speed reduction motor and an indexing device, and the output end of the speed reduction motor is connected with the rotation disc through the indexing device; and the first chamfering machine, the second chamfering machine, the third chamfering machine and the fourth chamfering machine correspond to the positions of the four stations in a one-to-one manner. By means of the gear ring support machining equipment, after a gear ring supportis clamped one time, a first chamfer, a second chamfer, a third chamfer and a fourth chamfer can be machined on the gear ring support, the work efficiency can be improved in a multiplied manner, andthe production cost is reduced.

Owner:CHONGQING KANGTIAN GEAR

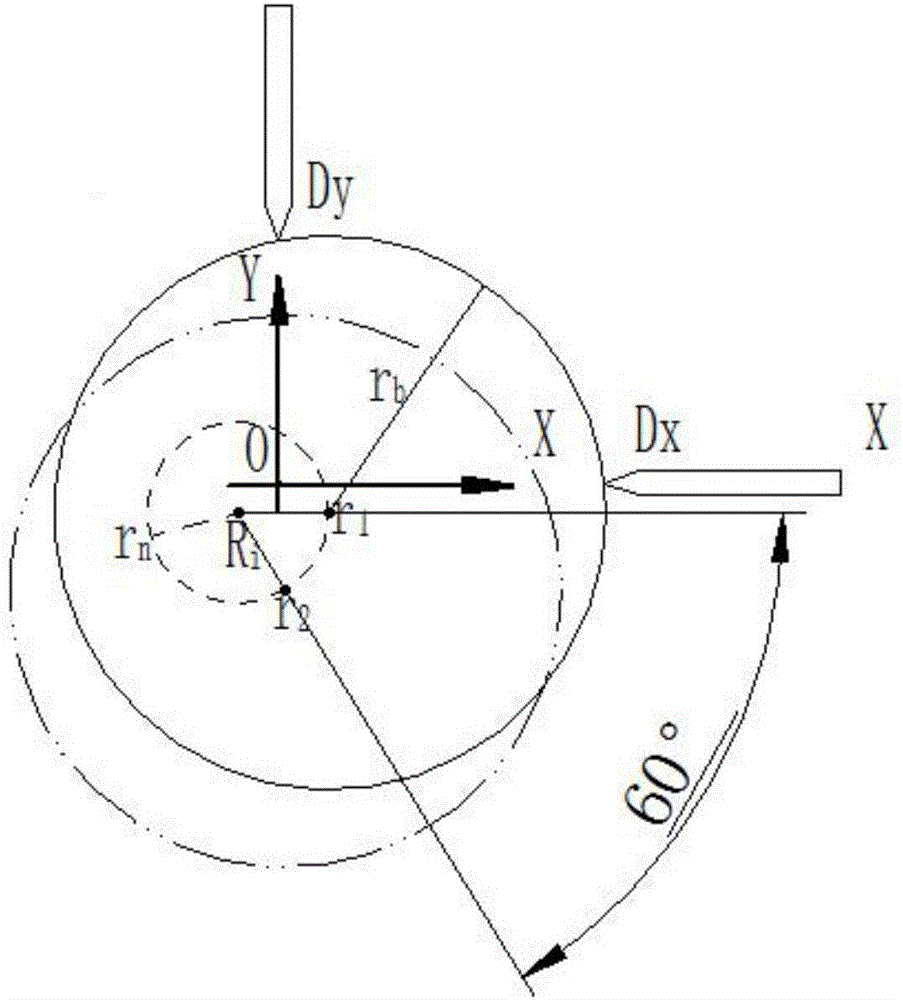

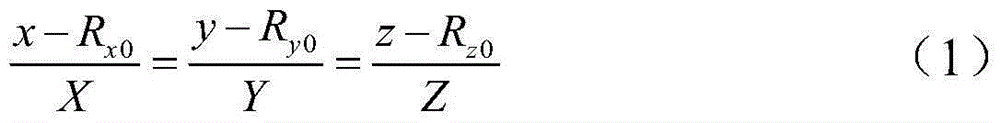

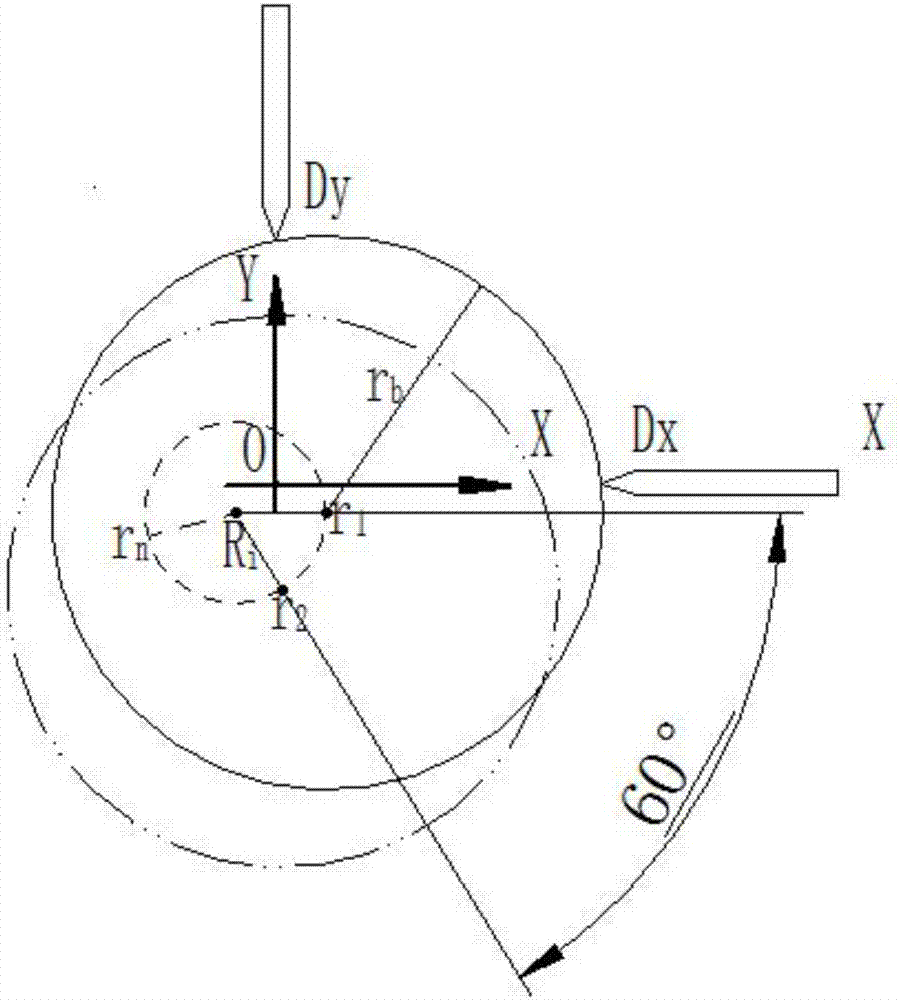

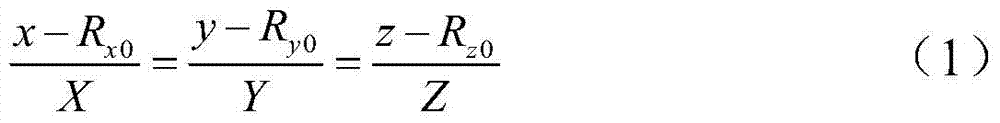

Device and method for measuring thermal error at working state of gear grinding machine

InactiveCN105058163AHigh measurement accuracyGood compensationMeasurement/indication equipmentsGear grindingEngineering

The present invention discloses a device for measuring thermal errors at a working state of a gear grinding machine. The device comprises a temperature measuring part and a displacement measuring part, the temperature measuring part comprises a temperature sensor arranged on the main heating part of the gear grinding machine, the displacement measuring part comprises an X-direction displacement sensor and a Y-direction displacement sensor which are fixed on a main shaft base of the gear grinding machine through a support, the X-direction displacement sensor and the Y-direction displacement sensor contact with a detection rod, and the detection rod is fixed on a rotary table. Also disclosed is a method for measuring thermal errors by using the device. The method comprises displacement measurement, detection rod circle centre coordinate sequence calculation, system error removal, rotary table axis expression calculation and thermal error modeling. According to the device, the X-direction displacement sensor and the Y-direction displacement sensor are arranged on the gear grinding machine, and temperature sensors are arranged on main heating parts of the gear grinding machine; and by using the device for thermal error measurement, the measuring precision is high and a compensation result is excellent. The device is simple in structure, and the measuring method is easy to learn and easy to popularize.

Owner:XIAN UNIV OF TECH

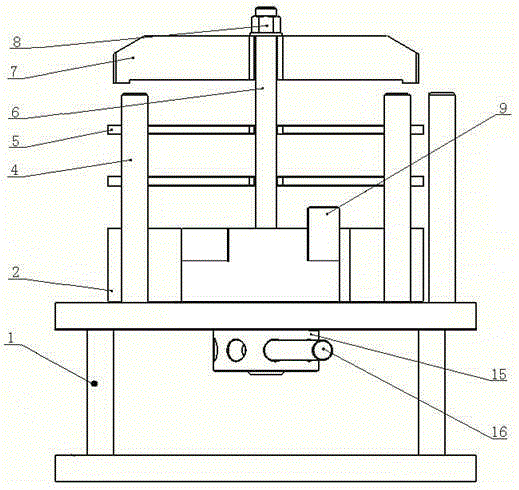

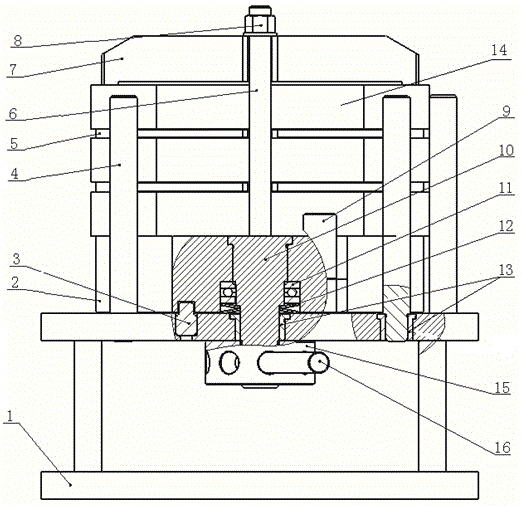

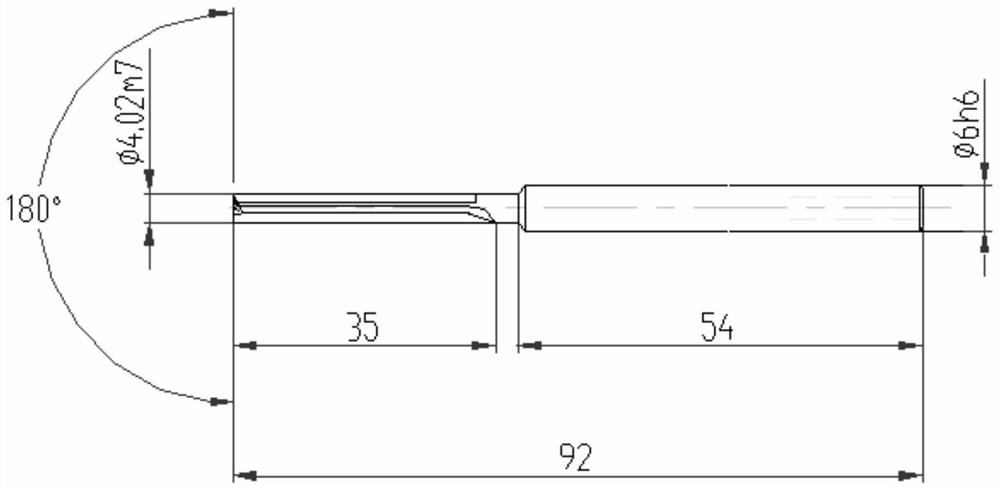

Special tool for processing end surface of bearing cover

ActiveCN105290838AImprove work efficiencyReduce labor intensityPositioning apparatusMetal-working holdersPosition errorMechanical engineering

The invention provides a special tool for processing the end surface of a bearing cover. The special tool comprises a die holder, wherein the upper end surface of the die holder is connected with a rotating module, and the periphery of the bottom end of a pin shaft positioned in the rotating module is orderly sleeved with a plane bearing and a belleville spring; the bottom end of the pin shaft penetrates through the die holder to be connected with a locknut; the rotating module rotates round the pin shaft on the die holder and is positioned with the die holder through a positioning bolt; the upper end of the rotating module is connected with a central stud, the central stud is movably sleeved with a backing plate and a pressing plate, and a flanged nut is arranged at the top end of the central stud; a positioning column used for positioning the outer wall of the rotating module is clamped on the die holder positioned outside the rotating module. The special tool adopts the 180 degrees of rotation of the rotating module to meet the processing of the two parallel surfaces of the bearing cover, therefore realizing the purpose that one-time clamping meets the processing of two working procedures, greatly improving the processing efficiency and precision, and avoiding a repetitive position error.

Owner:ANHUI HELI CO LTD

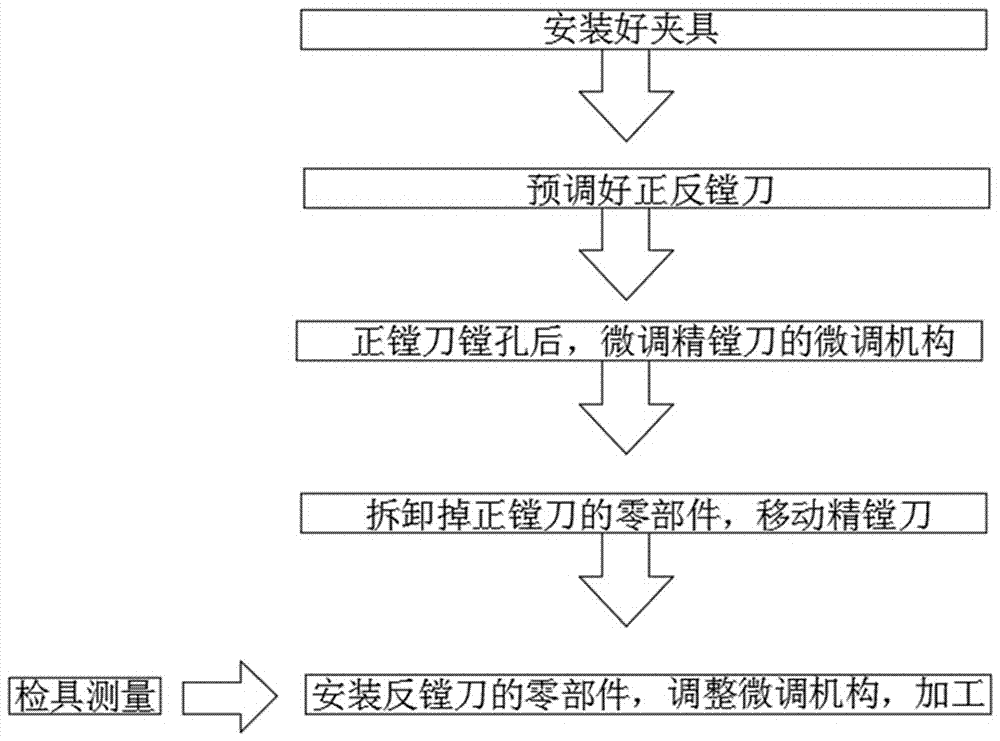

Machining method for ensuring coaxiality of spacing ring part

InactiveCN107159920AAvoid repeated positioning errorsEnsure high precision coaxiality requirementsPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a machining method for ensuring coaxiality of a spacing ring part, and belongs to the technical field of improving coaxiality precision. The machining method is simple and wide in using range, and can be promoted to solve similar problems, the machining precision is high, repetitive positioning errors of movement of a machine tool main shaft are avoided, the requirement of high precision coaxiality of holes is ensured, the market prospects are broad, and the machining method for ensuring coaxiality of the spacing ring part is worth promoting and using.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

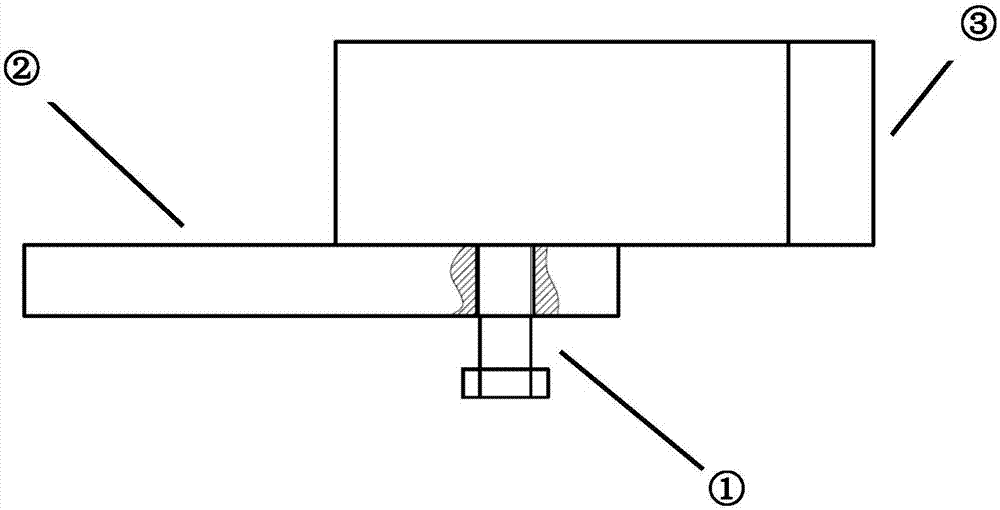

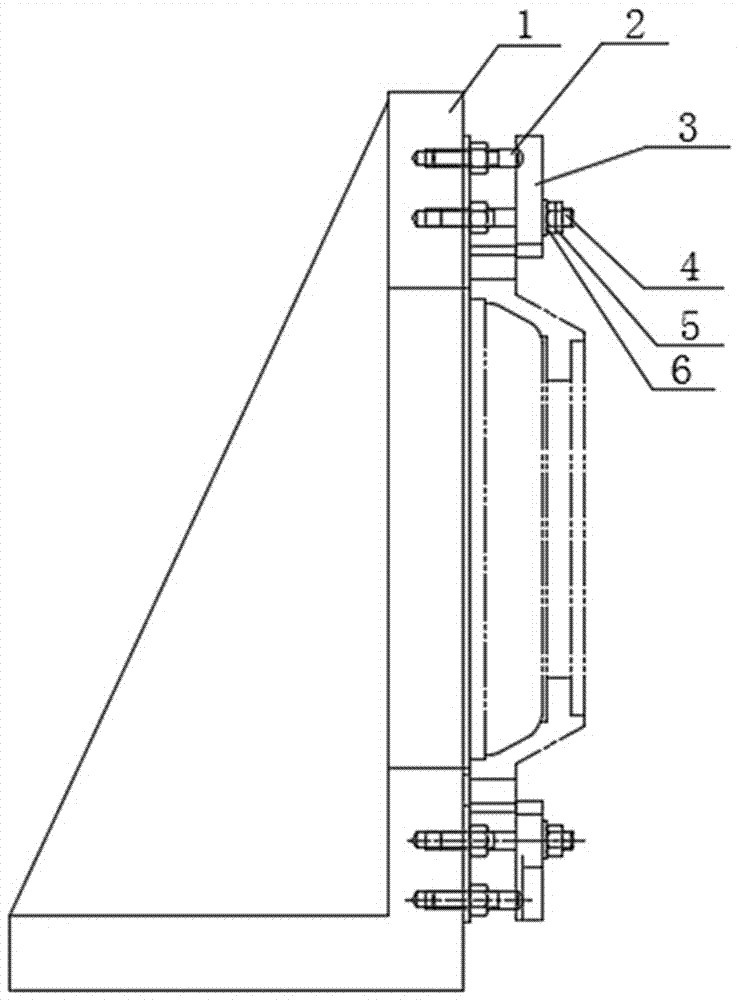

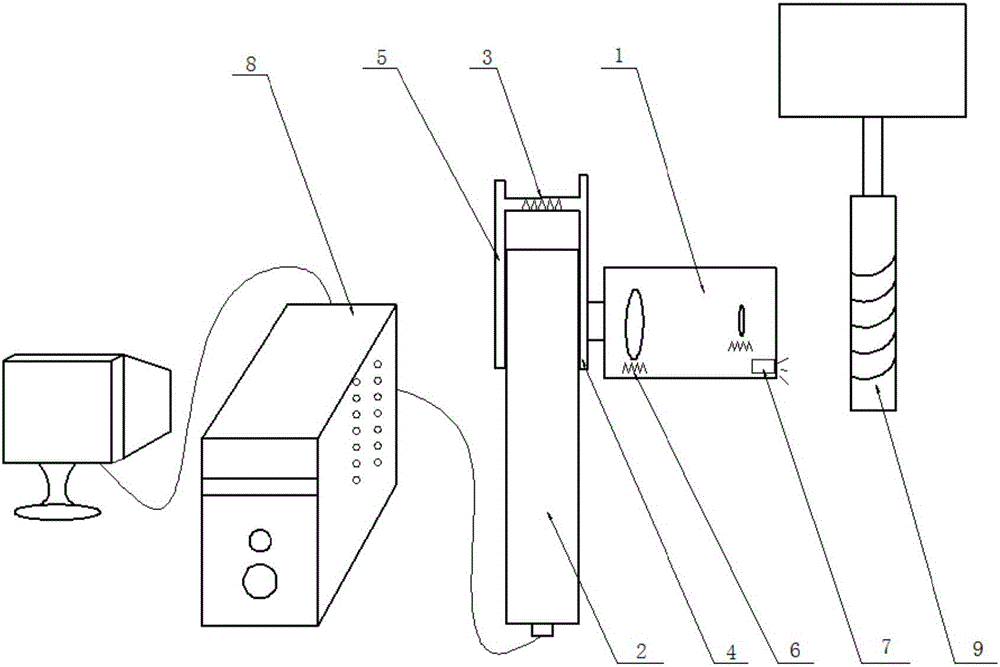

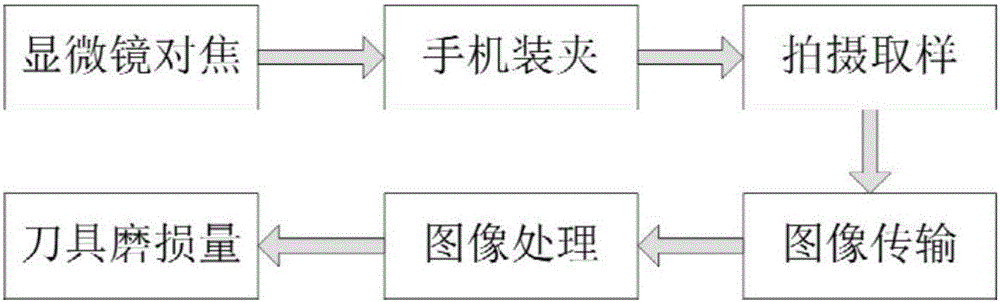

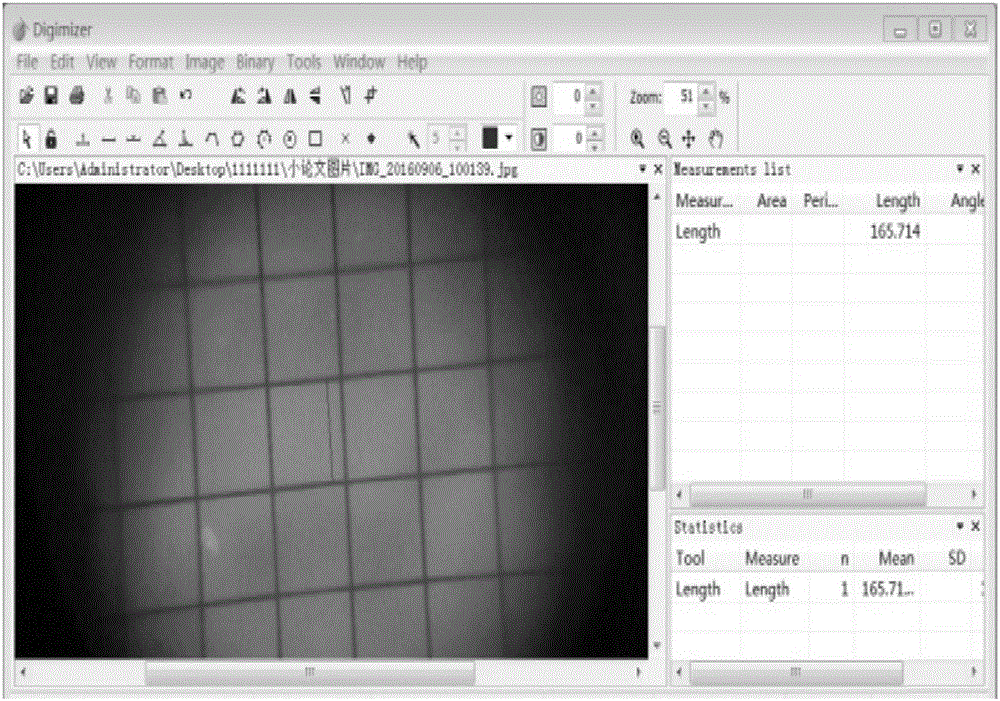

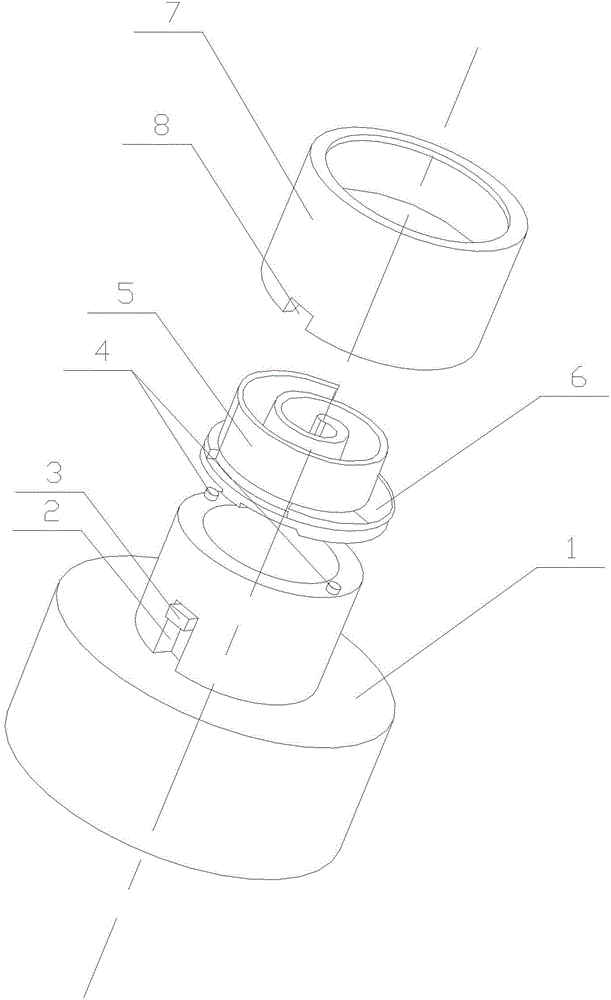

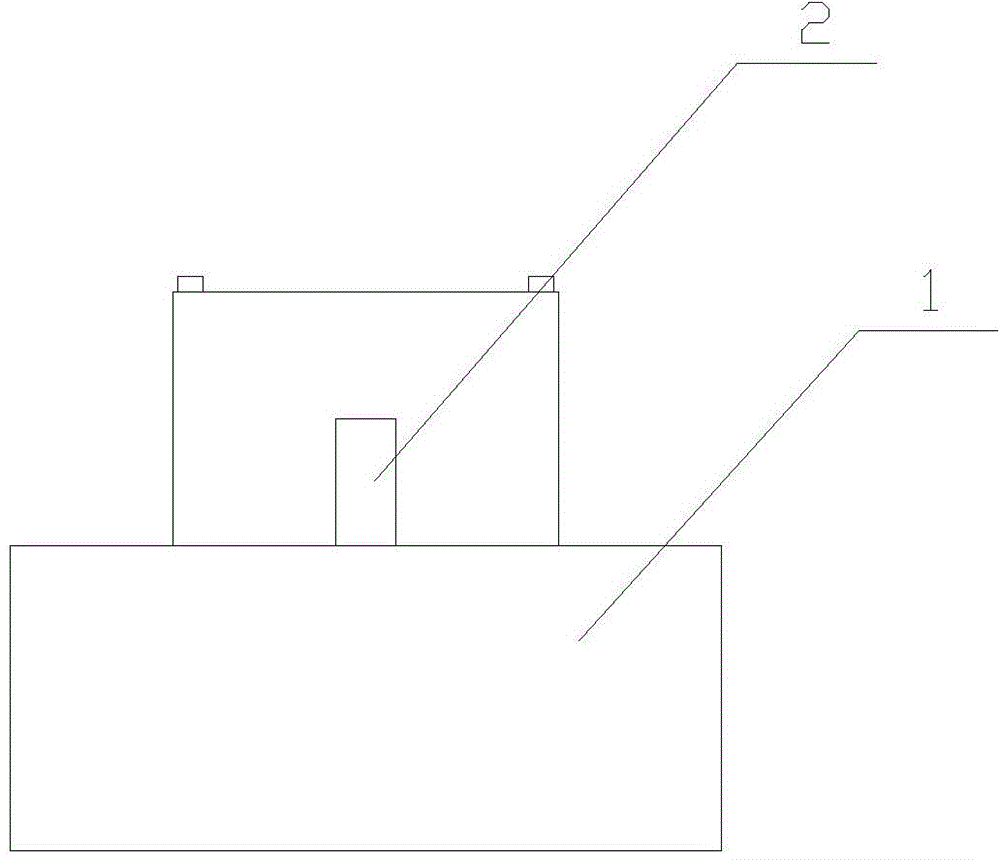

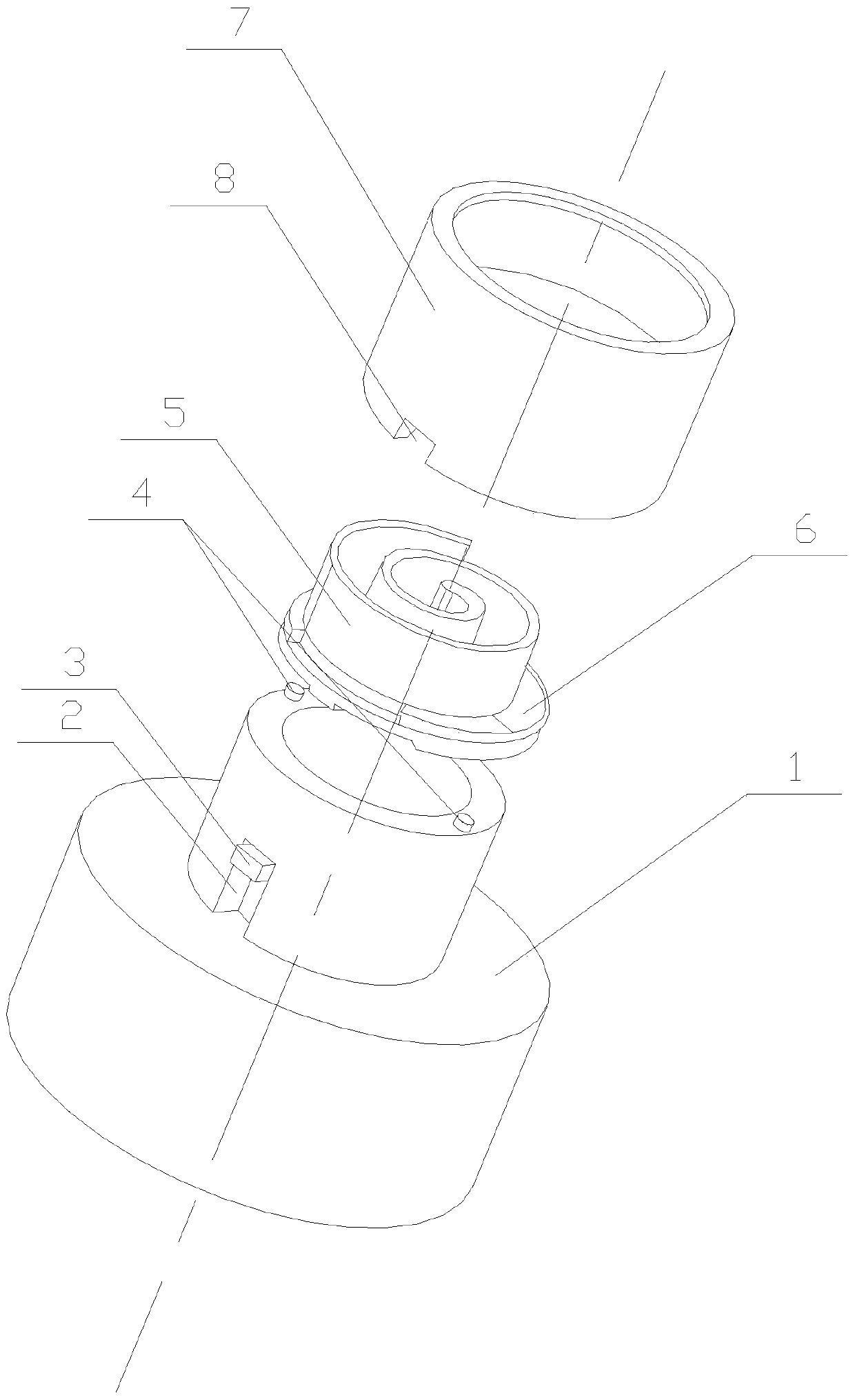

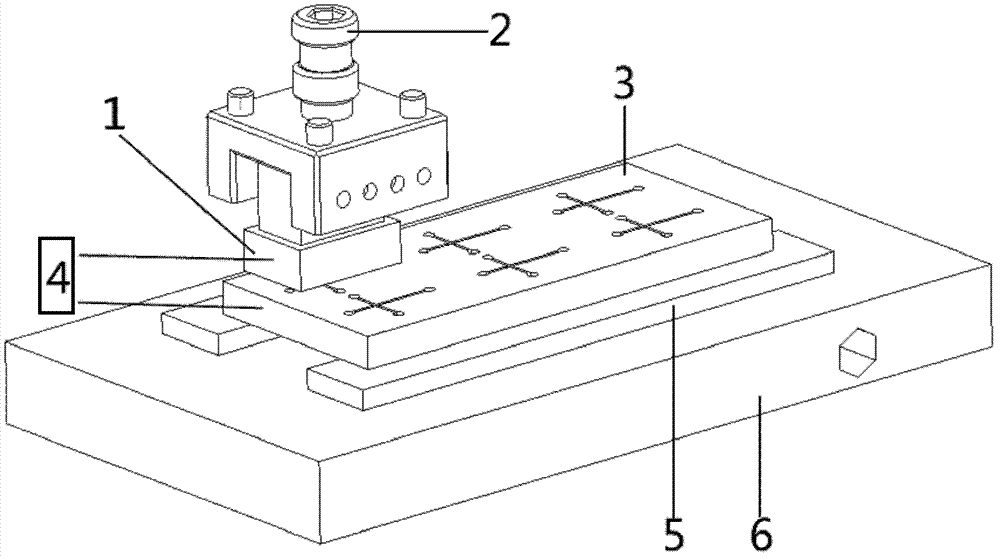

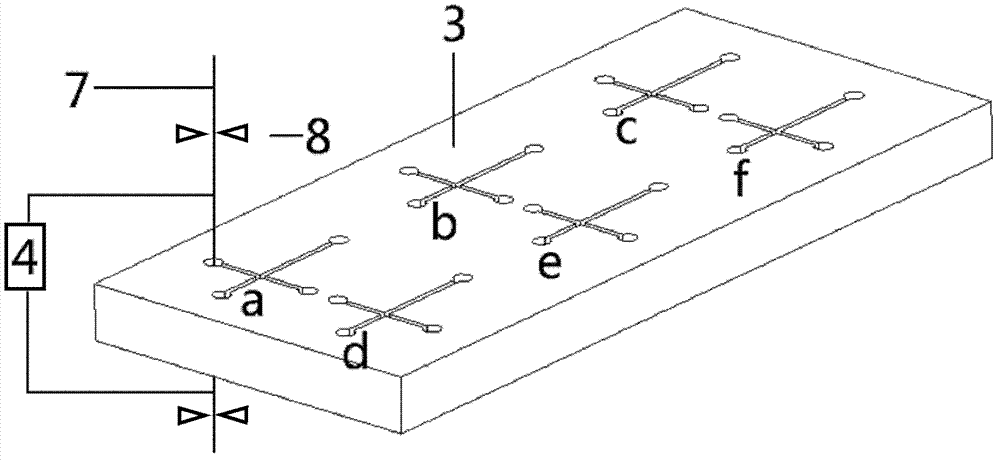

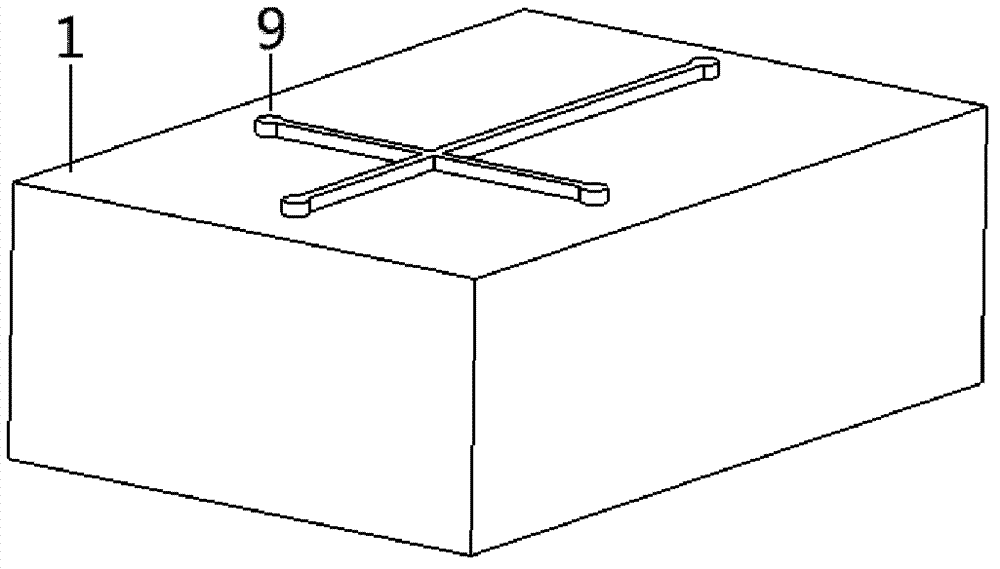

Portable cutter wear measurement apparatus

InactiveCN106546175ASimple structureEasy to useUsing optical meansImage processing softwareEngineering

Disclosed is a portable cutter wear measurement apparatus. The apparatus is characterized by comprising a miniaturized microscope (1), a mobile phone (2) and an elastic mobile phone clamp (3), wherein an ocular lens end of the miniaturized microscope (1) is installed on one clamping jaw (4) of the elastic mobile phone clamp (3) in a rotating mode, the clamping jaw (4) is provided with a through hole, the through hole is opposite to a shooting lens of the mobile phone (2), another clamping jaw (5) of the elastic mobile phone clamp is clamped on the front surface of the mobile phone (2), and the mobile phone (2) processes a shot picture by use of its own image processing software or sends the shot picture through a data line to a computer (8) preinstalled with the image processing software for analysis so as to obtain cutter wear data. The structure is simple, the application is convenient, real-time rapid detection can be performed without removing a cutter from a knife rest, wear conditions can be obtained timely, and a basis can be provided for replacing or reconditioning the cutter.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

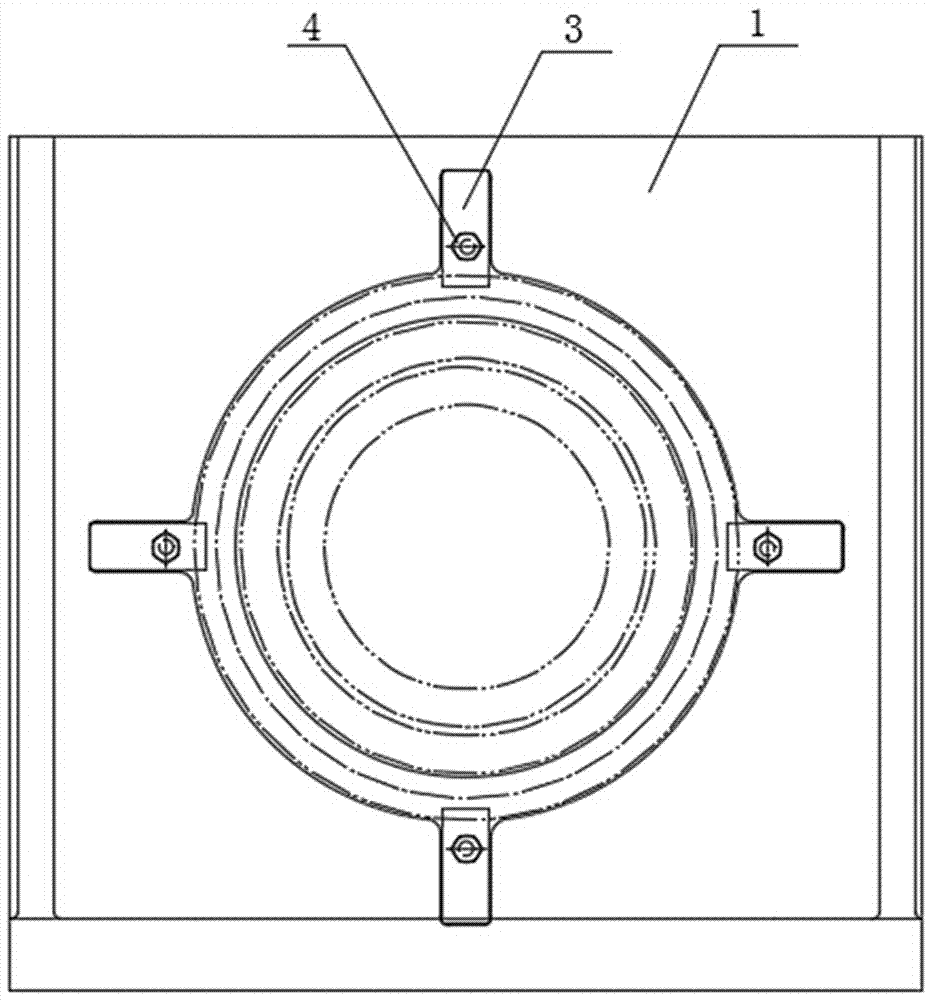

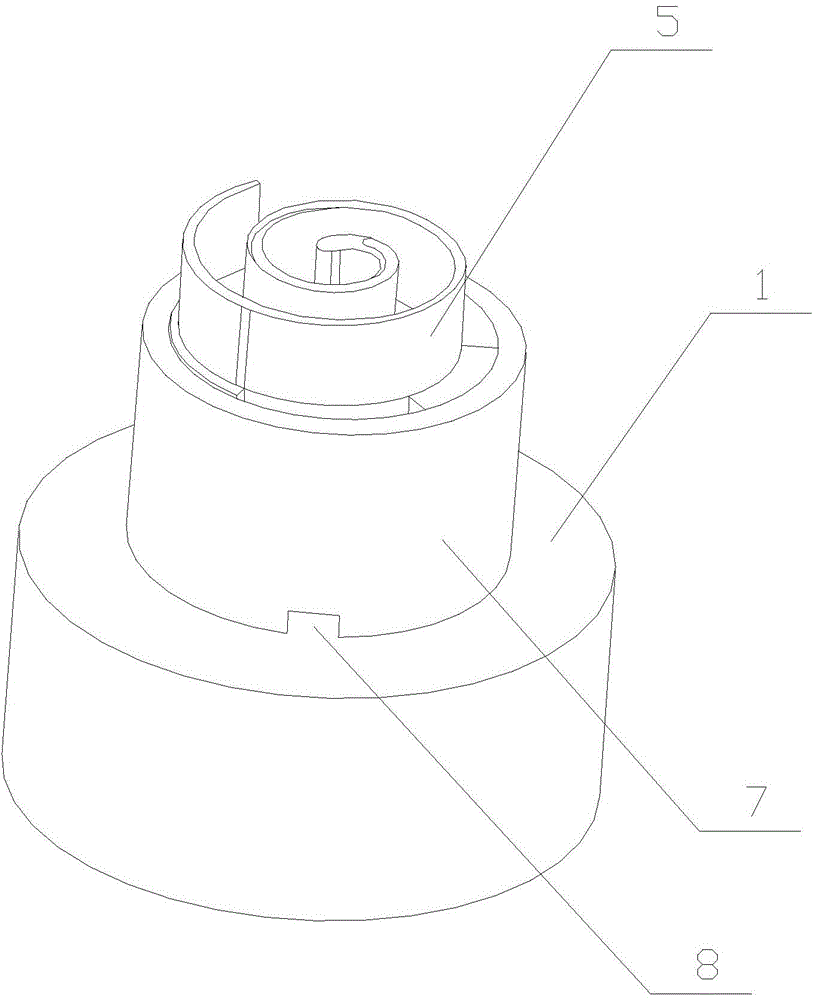

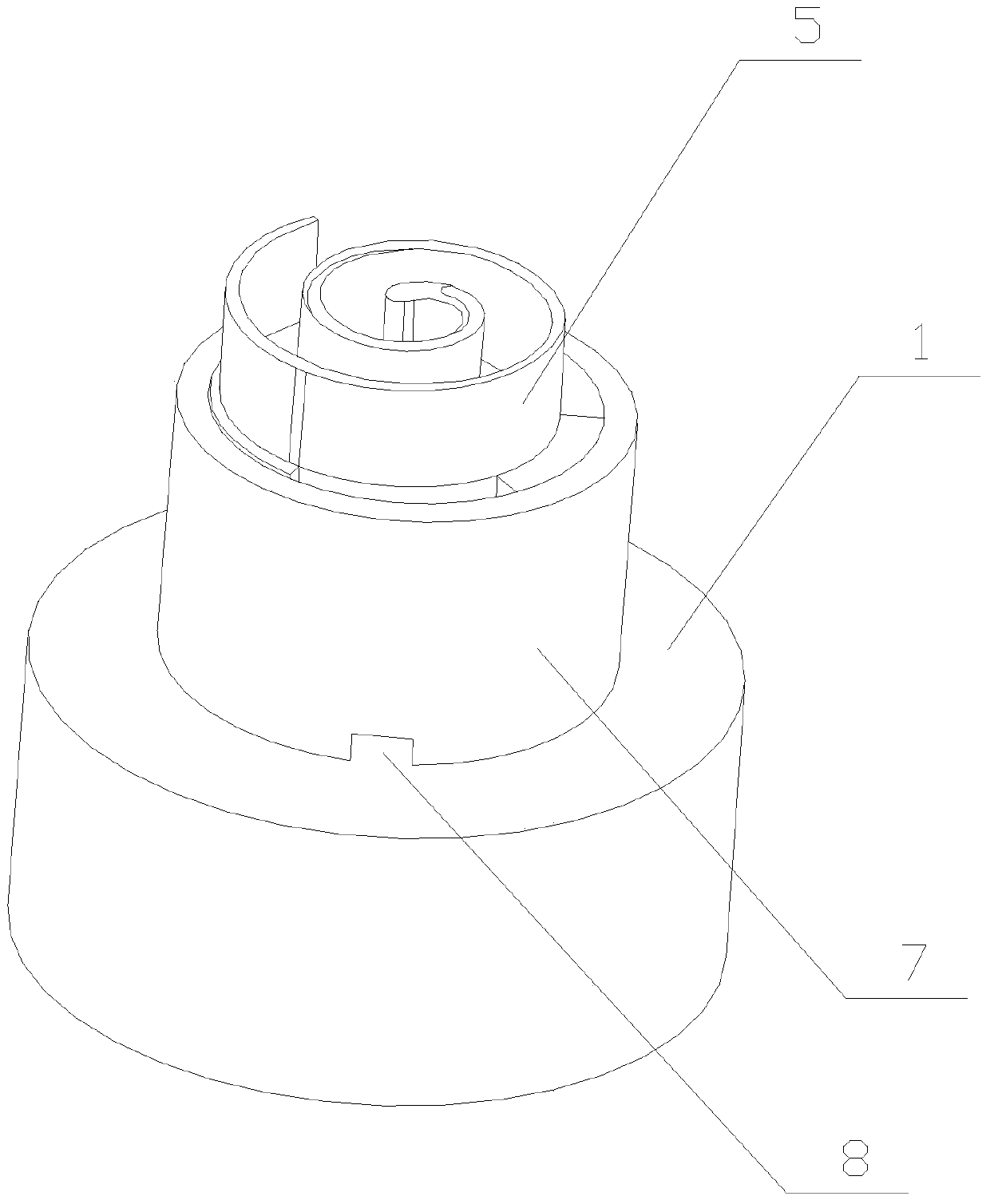

Machining tooling for scroll plate of scroll compressor

ActiveCN105834797AReasonable structural designEasy to operatePositioning apparatusMetal-working holdersMachine toolScroll compressor

The invention discloses a machining tooling for a scroll plate of a scroll compressor, and relates to the field of the scroll compressor. A clamp base is provided with a clamping groove; a pressing plate is arranged in the clamping groove; the pressing plate is connected to a main shaft of an air cylinder; the main shaft of the air cylinder is arranged in the clamp base; two sides of the upper end surface of the clamp base are provided with two symmetrical pins; pin holes are formed in positions corresponding to the pins, of the lower end surface of a the scroll plate step; the scroll plate step is snapped onto the upper end surface of the clamp base; the upper end of the scroll plate step is provided with the scroll plate; the lower end of a sleeve is provided with a sleeve key groove; the sleeve sleeves the clamp base through a position corresponding to the pressing plate, of the sleeve key groove; and the upper end of the sleeve is tightly pressed the scroll plate step. According to the machining tooling, through an air cylinder pull-down locking manner and a scroll plate positioning manner, errors of repeated positioning can be avoided; and the machining tooling can conveniently and rapidly clamps the scroll plates, can clamp a plurality of the scroll plates at the same time, reduce the times of changing tools due to machine tool idling, and improve the machining efficiency, and is high in machining consistency.

Owner:邢台癸酉新能源科技有限公司

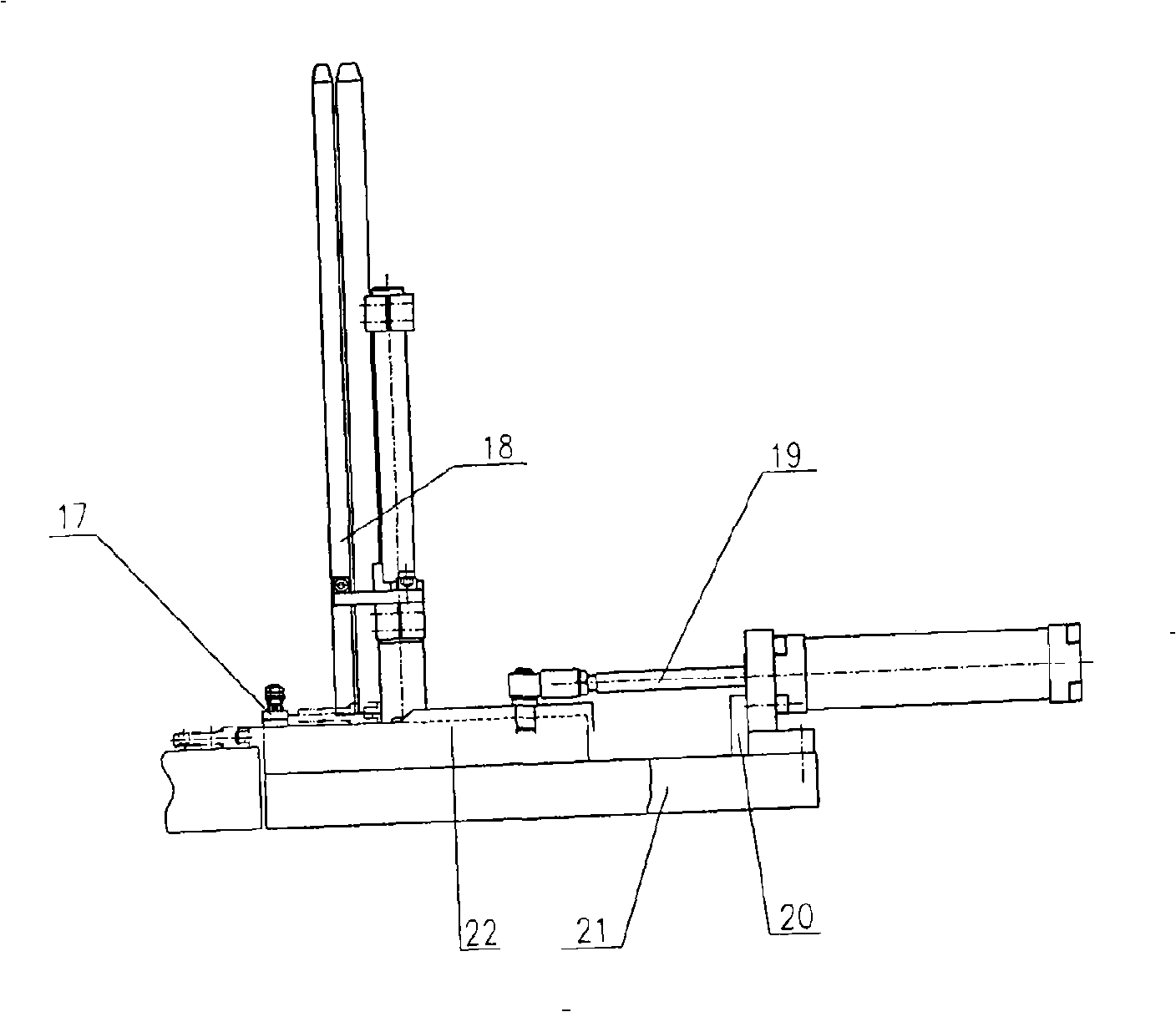

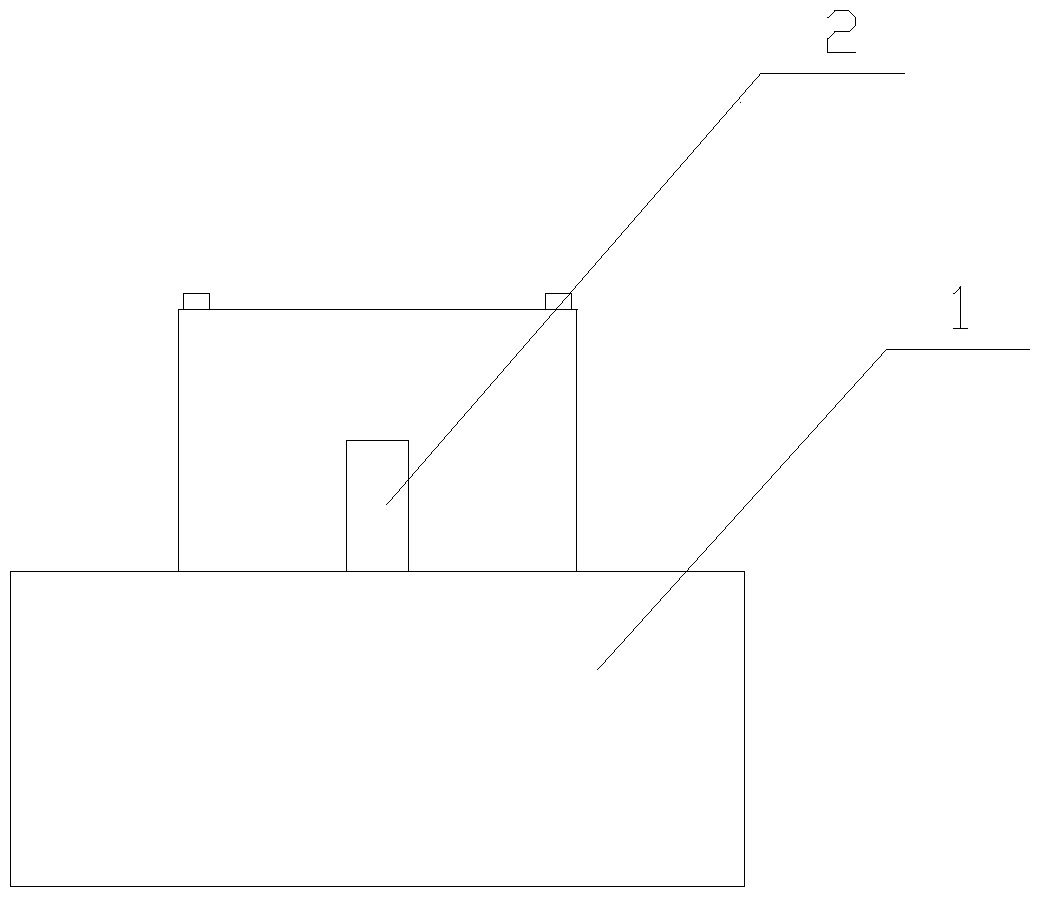

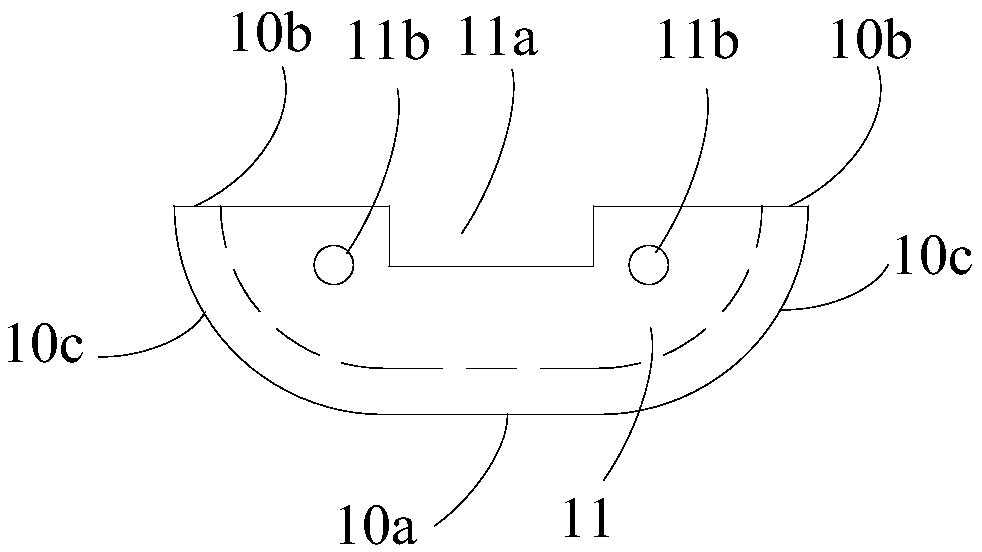

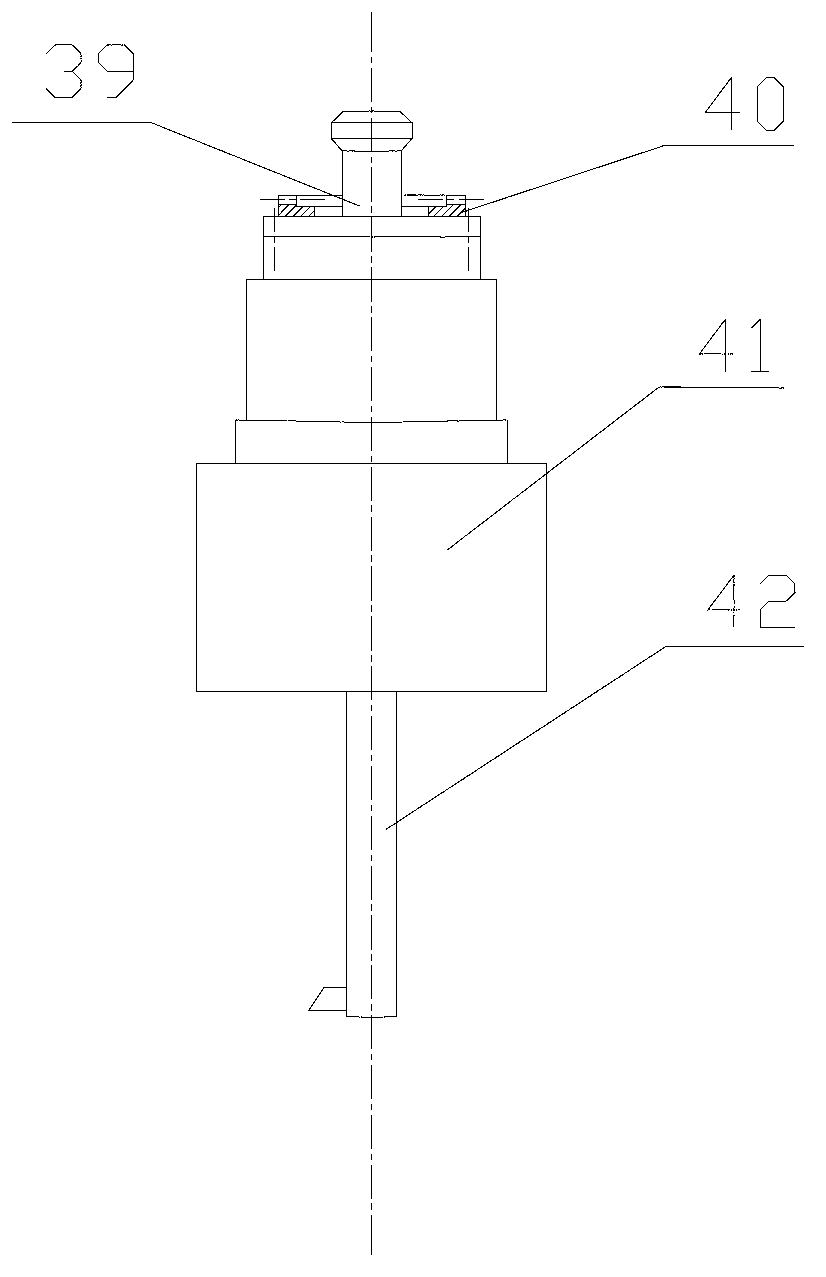

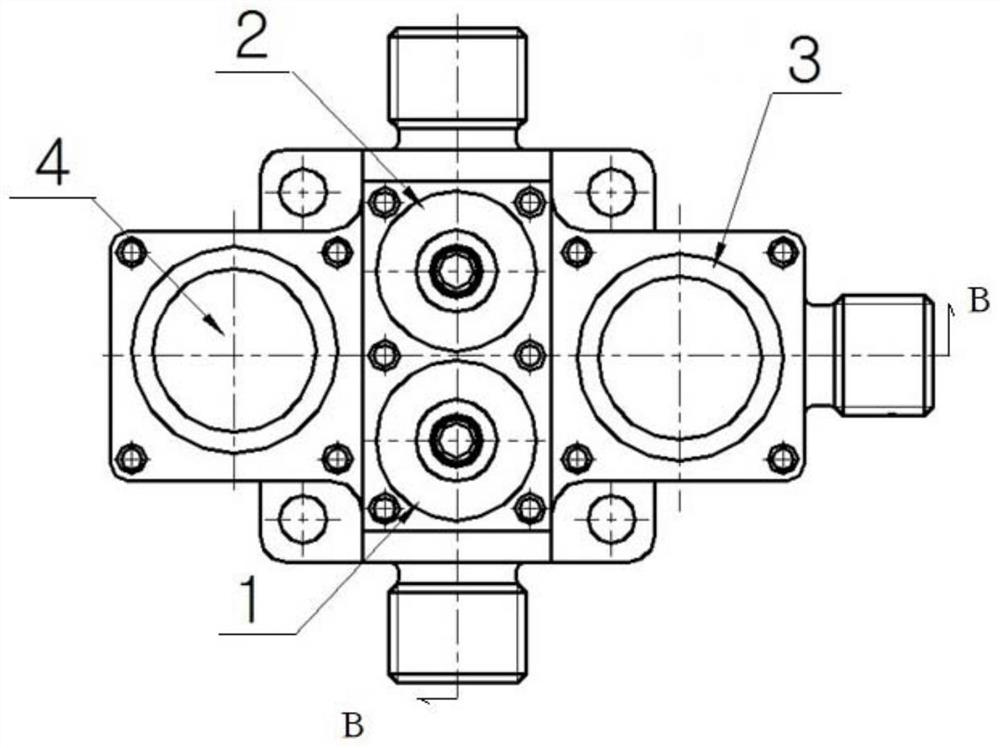

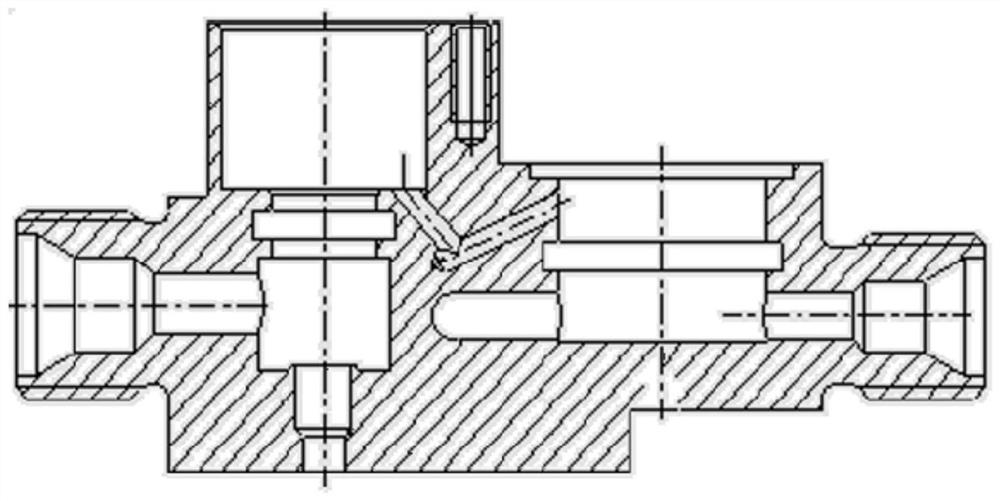

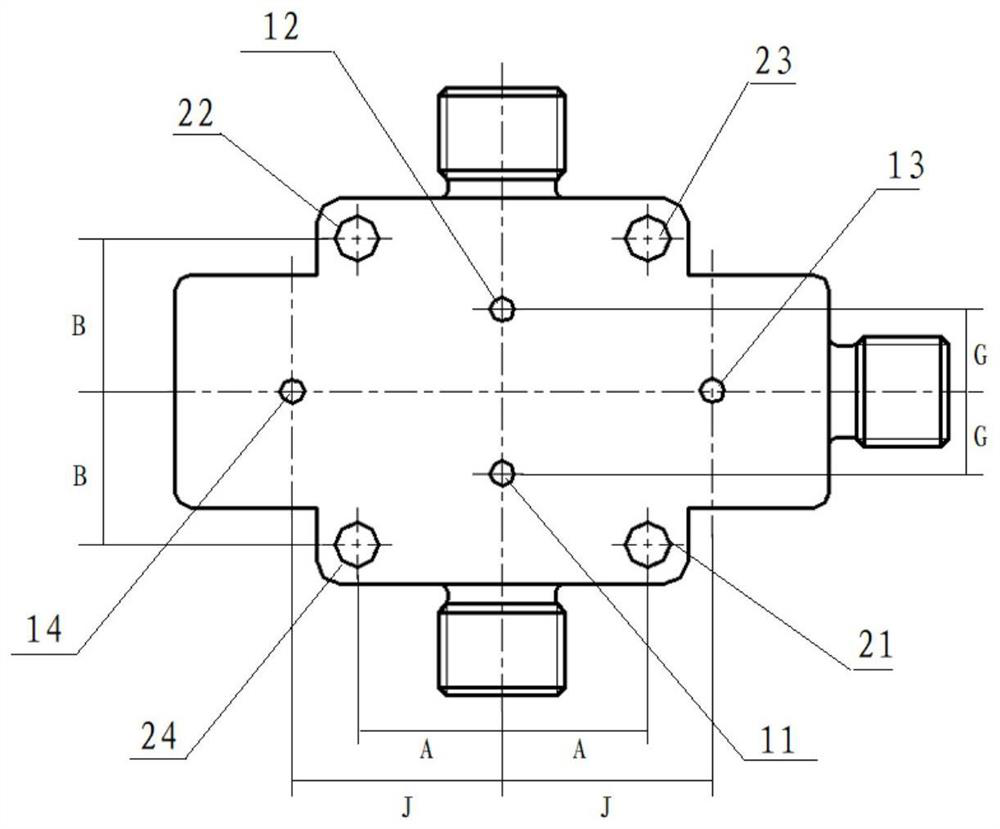

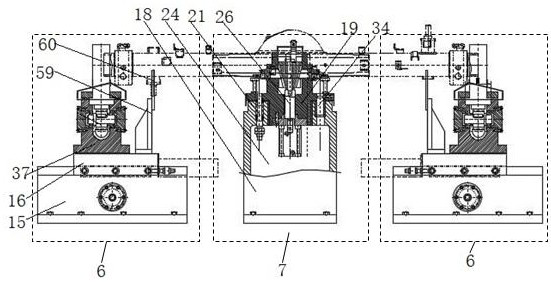

Positioning clamping device for mining vertical-ring connector chain rings

InactiveCN102922324AAvoid repeated positioning errorsControl process errorPositioning apparatusMetal-working holdersEngineeringMachining process

The invention relates to a positioning clamping device for mining vertical-ring connector chain rings. The device is characterized by comprising a numerical control rotation disc (1), a rotation tail stock (2) and a connection bridge plate (4), wherein the numerical control rotation disc (1) and the rotation tail stock (2) are arranged on a large base plate (3), two ends of the connection bridge plate (4) are connected with the numerical control rotation disc (1) and the rotation tail stock (2) respectively, and a positioning clamping fixture is fixedly arranged on the connection bridge plate (4). The positioning clamping device for mining vertical-ring connector chain rings has the advantages that machining tasks of matching positions of a vertical-ring connector chain ring can be completed through one-step clamping, multi-process repeated positioning errors are prevented, errors in a machining process are controlled effectively, and the production efficiency is improved; the positioning clamping device is simple and convenient to operate and reduces the operator labor intensity effectively; and the positioning clamping device is high in positioning accuracy, forging errors of batch blank parts can be adjusted flexibly, and quality problems of blank part alignment are controlled effectively.

Owner:NINGXIA TIANDI BENNIU IND GRP

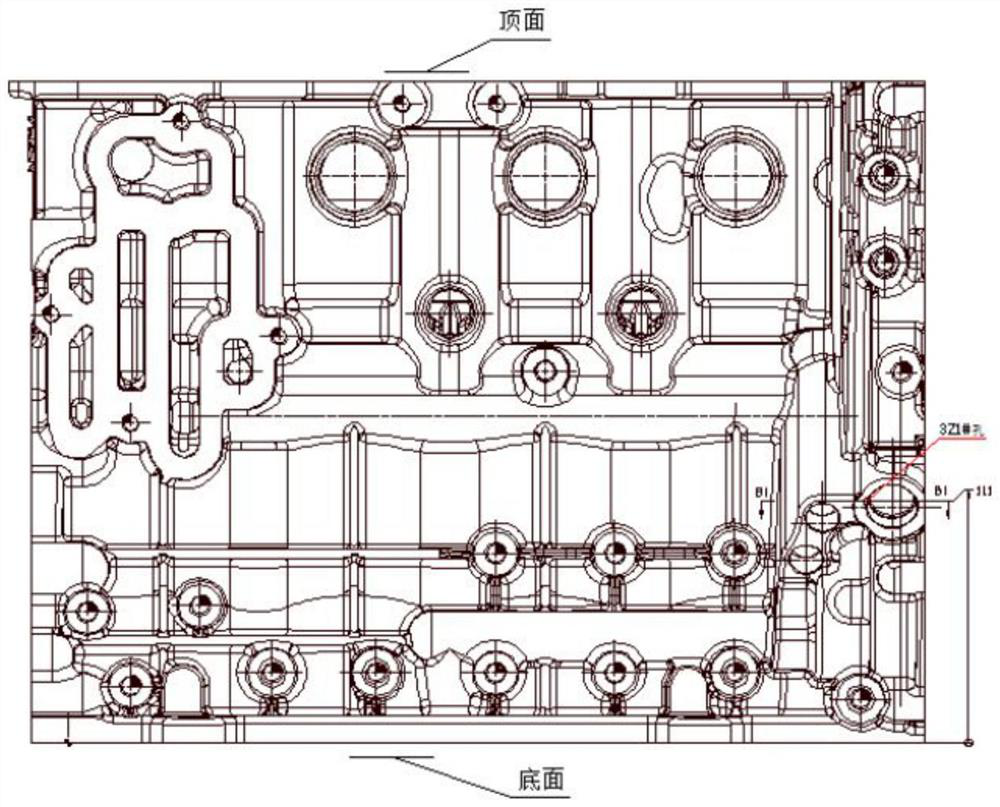

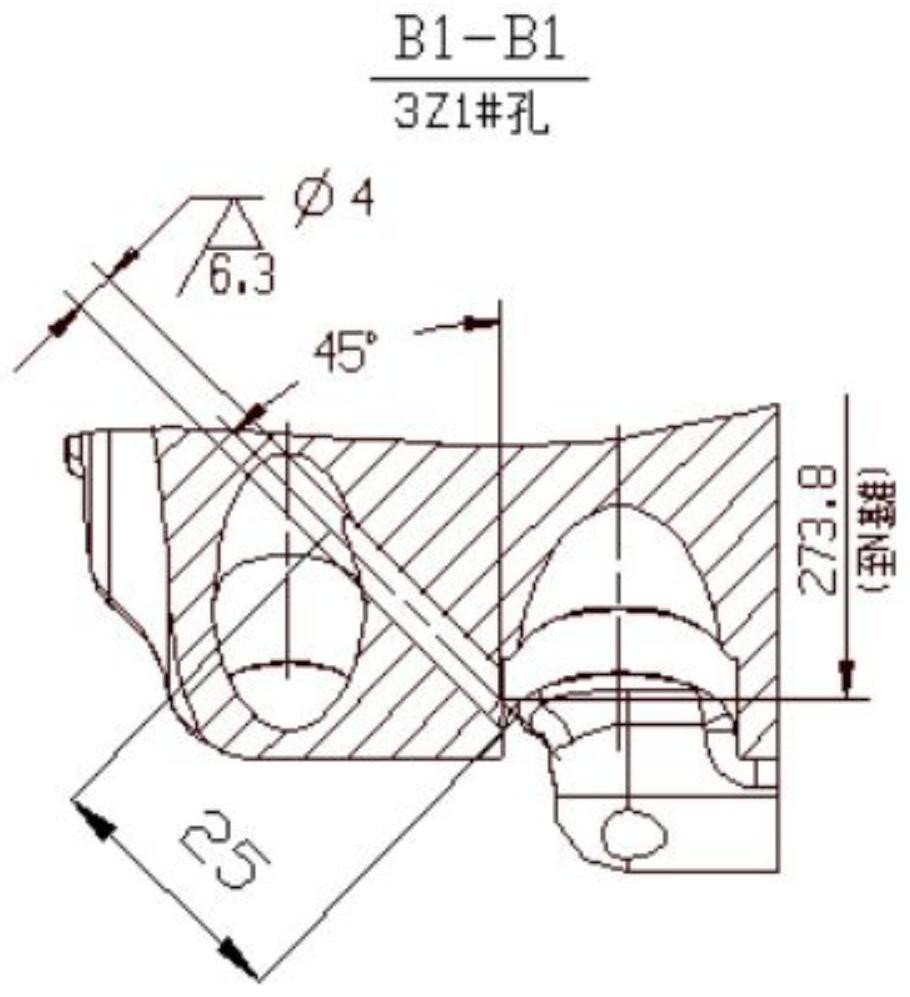

Machining method of shallow inclined hole of cylinder block

The invention relates to a machining method of a shallow inclined hole of a cylinder block. The method comprises the steps that a pre-drilled hole is adopted as a guiding hole for subsequent machining, fast moving to a safety plane is performed, pre-drilling is conducted, then fast retreating to the safety plane is performed, and then machining is performed with given cutting parameters of the tool design, wherein the depth of the pre-drilled hole is controlled at about 2 times of the hole diameter of the machined hole, a tool adopts small feed during pre-drilling, the hole diameter of the machined hole is small, the hole is shallow, the orifice surface is irregular, and a certain included angle is formed between the axis of the hole and the orifice surface. By adopting the machining method for machining, the advantages of high machining efficiency, low tool cost and high dimensional precision of the hole are achieved.

Owner:KUNMING YUNNEI POWER

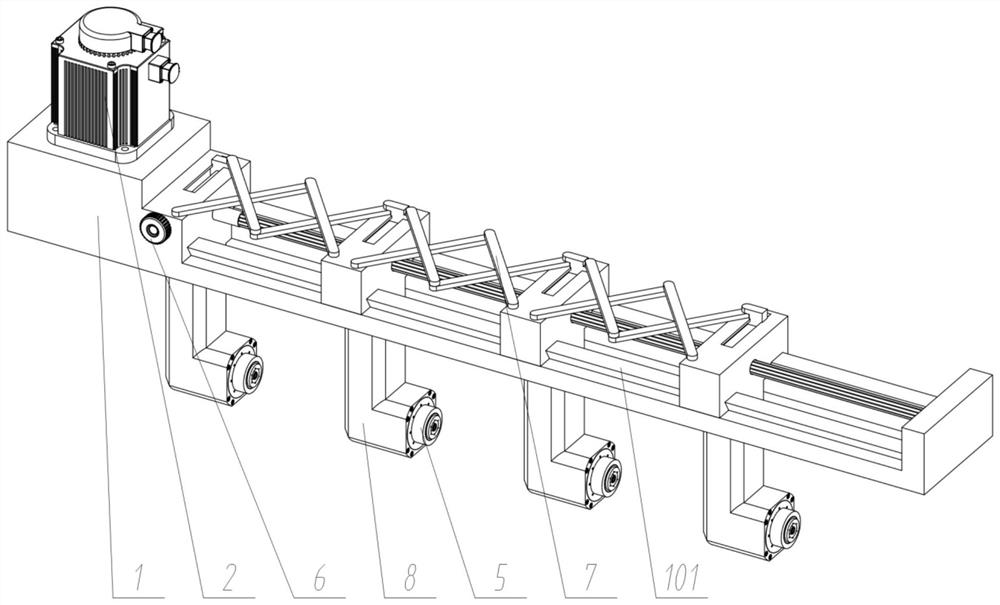

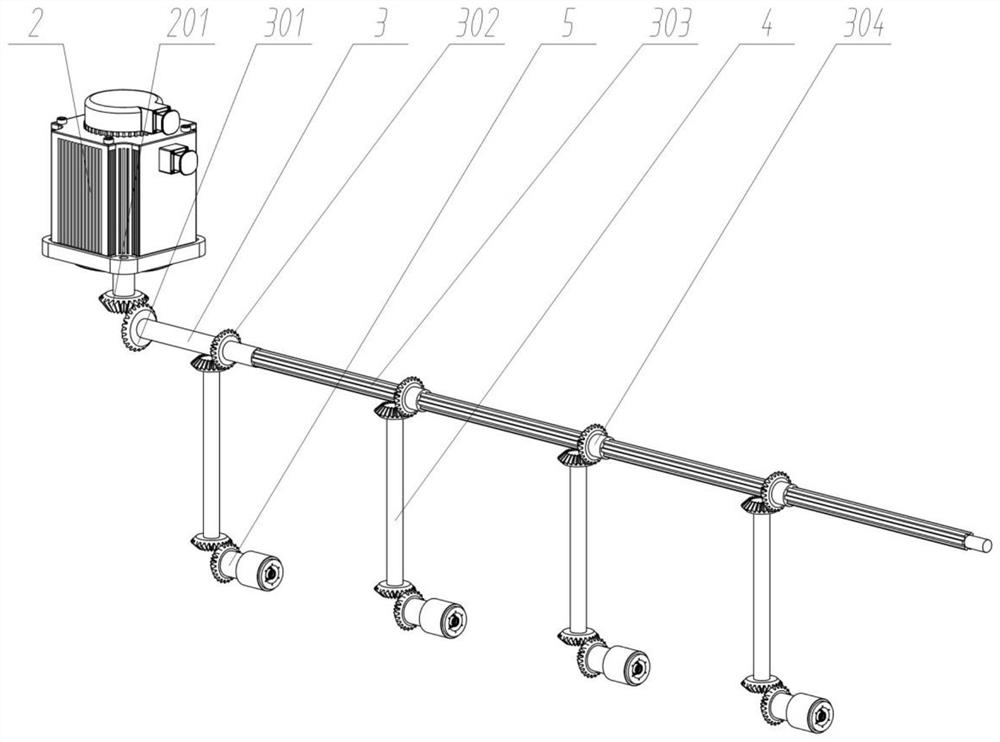

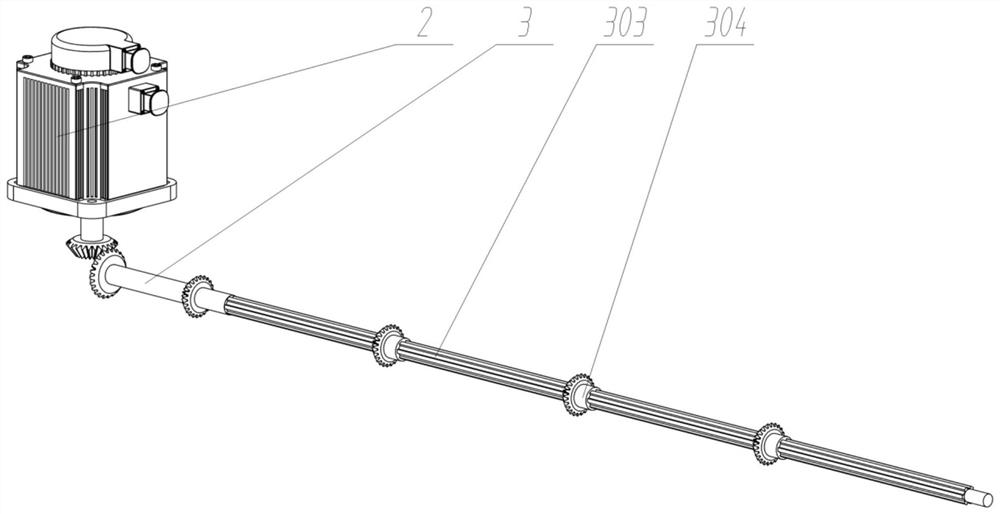

Matched drill boom facility of mining equipment bucket

PendingCN113059209ADrilling to achieveEven distance adjustmentLarge fixed membersBoring/drilling machinesStructural engineeringMachining

The invention discloses a matched drill boom facility of a mining equipment bucket, relates to the technical field of equipment processing, and solves the problems that repeated positioning errors easily occur during the processing of existing bucket lug plate holes, the form and location tolerance of the bucket lug plate holes is influenced, and the bucket lug plate holes are inconsistent. The matched drill boom facility comprises a drill boom body, wherein the top of the left side of the drill boom body is fixedly connected with a group of drilling driving pieces, a group of drilling middle transmission transverse shafts are rotationally connected into the drill boom body, and four groups of drilling bases are uniformly arranged at the lower part of the drilling boom body. By arranging the four groups of drilling bases, four groups of holes in a vertical plate can be drilled at the same time, the working efficiency is improved, meanwhile, repeated positioning errors are avoided, the machining precision is guaranteed, the problem that bucket lug plate holes are inconsistent is effectively solved, meanwhile, the distances between the four groups of drilling bases are evenly adjusted and can be adjusted according to needs in use, machining of buckets of different models is met, practicability is improved, and adjusting operation is easy.

Owner:张芳

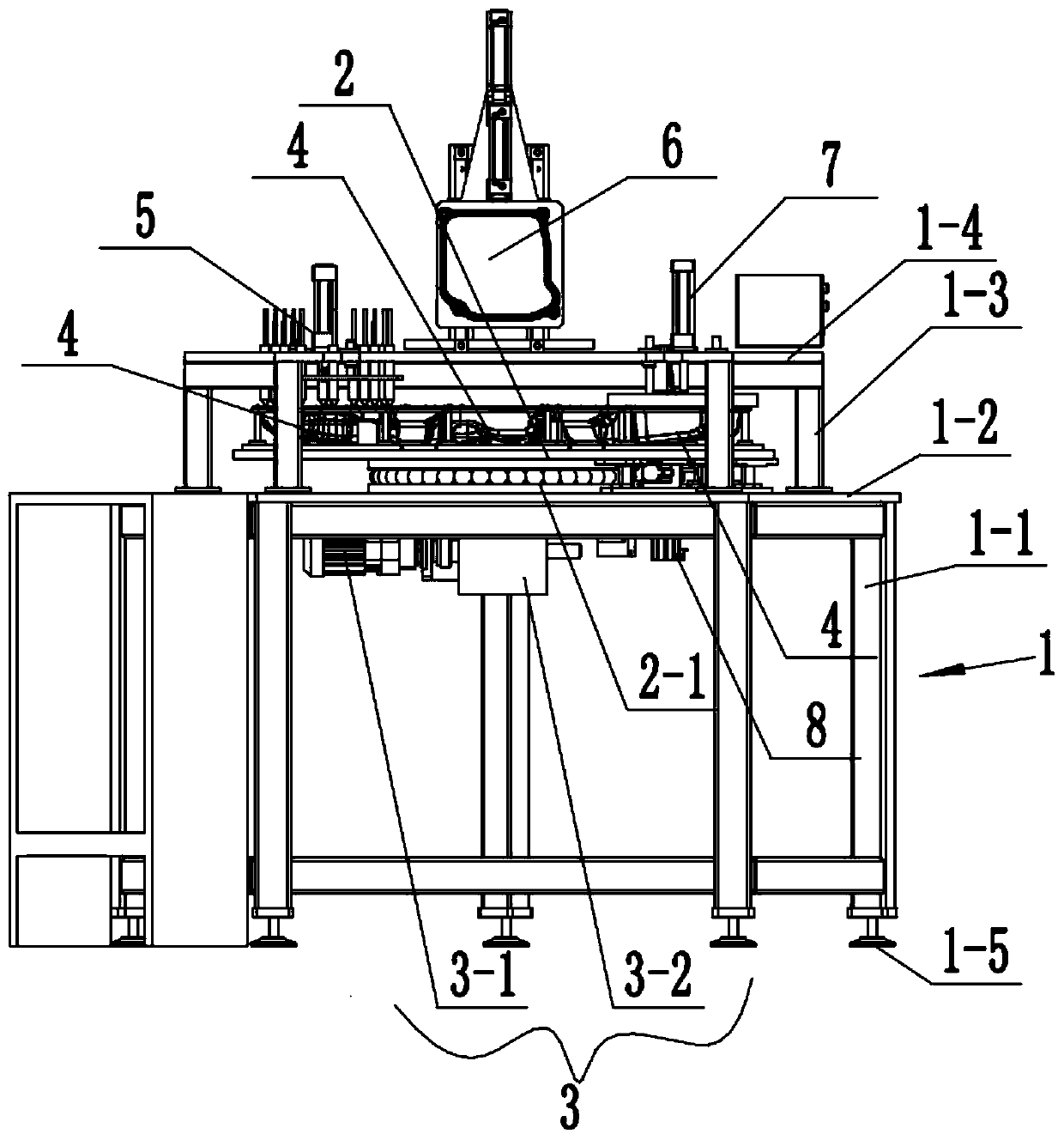

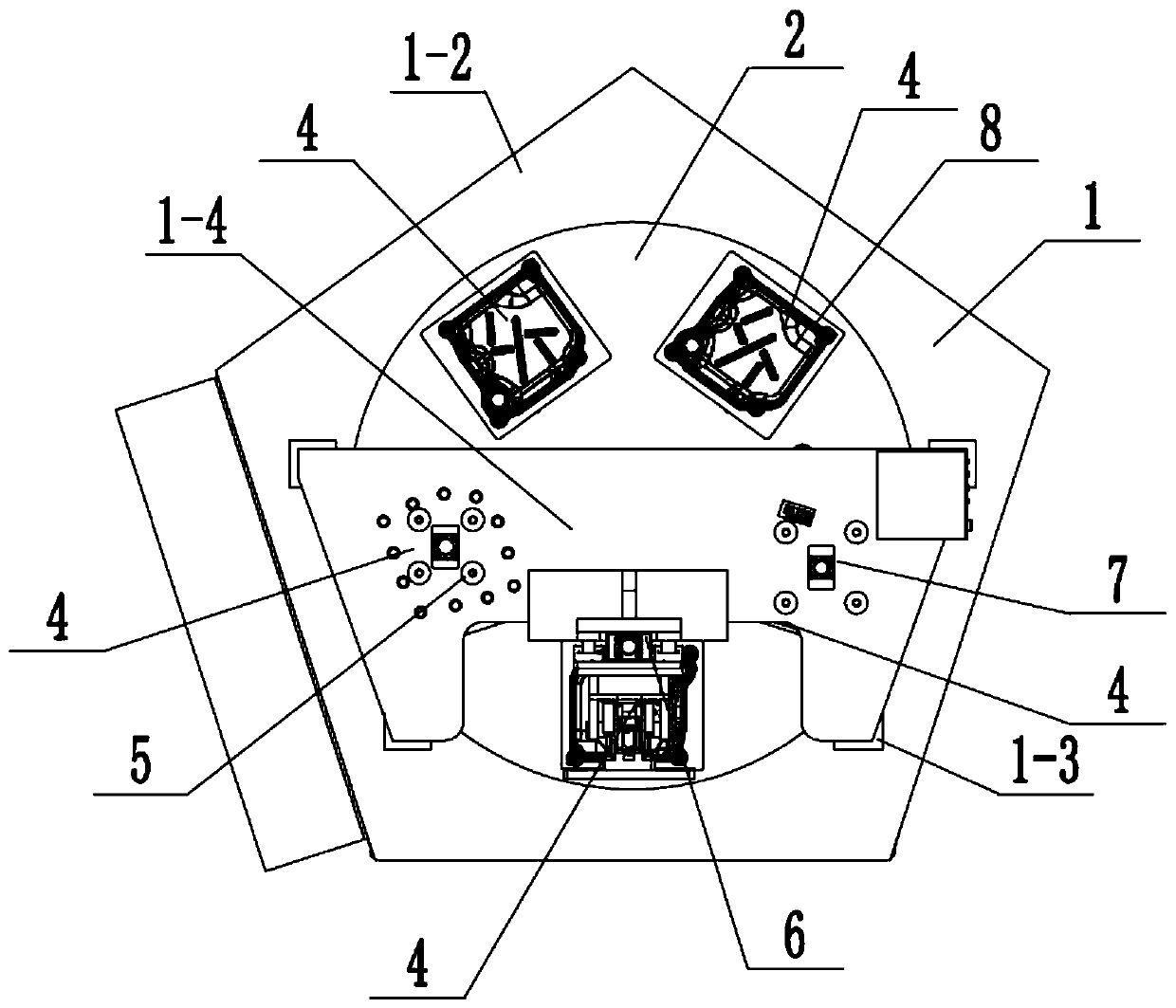

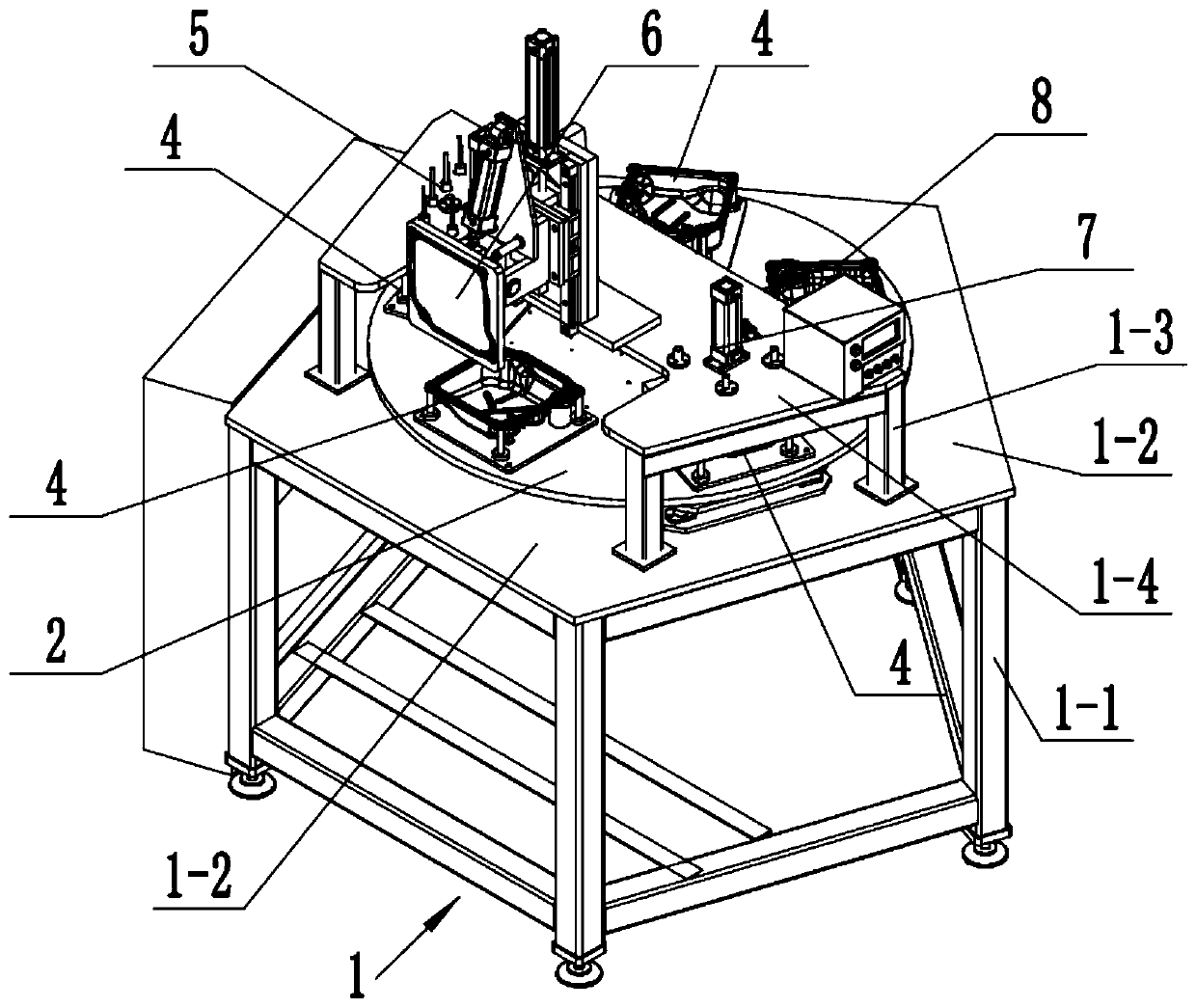

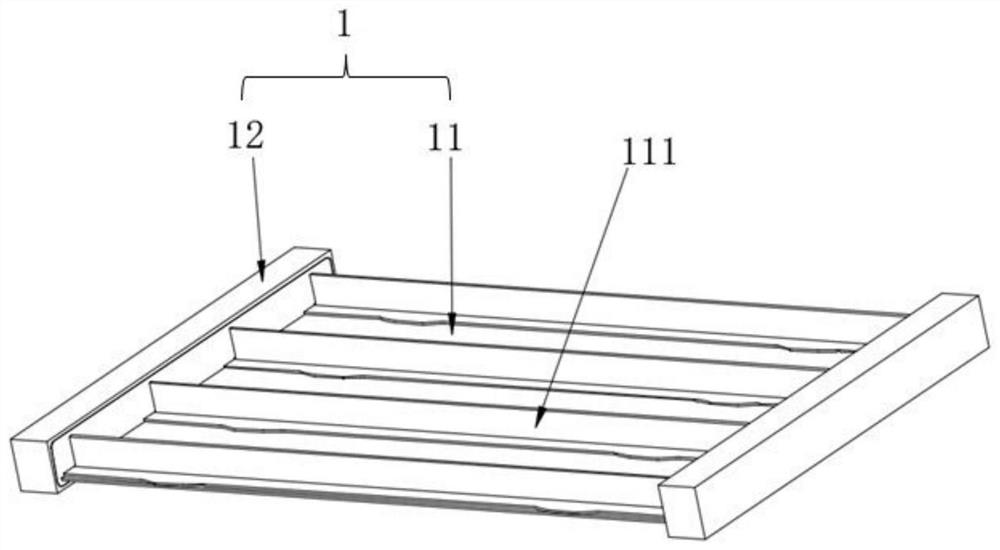

Gearbox assembling production facility

InactiveCN110181272AAvoid repeated positioning errorsImprove assembly accuracyLiquid surface applicatorsAssembly machinesElectric machineryIndustrial engineering

The invention discloses a gearbox assembling production facility. The gearbox assembling production facility is characterized by comprising a machine frame, a rotary table, a driving mechanism, an adhesive dispensing device, a gasket installation device, a gasket reshaping device and a jacking device. The rotary table is installed on the machine frame in a rotatable mode. The driving mechanism comprises a motor and a graduator. The output end of the motor is connected with the rotary table through the graduator. Five gearbox locating tools are arranged on the rotary table and uniformly distributed in the circumferential direction of the rotary table. The adhesive dispensing device, the gasket installation device, the gasket reshaping device and the jacking device correspond to the positions of the four gearbox locating tools in a one-to-one mode and are distributed in sequence. Each gearbox locating tool comprises a tool base plate, a locating pad and multiple locating pins. The gearbox assembling production facility can achieve the purpose of sequentially conducting the feeding and clamping work, the adhesive dispensing work, the gasket installation work, the gasket levelling workand the part discharging work on a gearbox, the occupied space is small, only one-time clamping is required in the whole assembling process, the working efficiency can be improved manyfold, and the production cost is reduced.

Owner:重庆市綦江区自力汽配有限公司

A processing tool for the scroll disk of a scroll compressor

ActiveCN105834797BReduce the number of empty tool changesReasonable structural designPositioning apparatusMetal-working holdersMachine toolComputer engineering

The invention discloses a processing tool for a scroll disc of a scroll compressor, which relates to the field of scroll compressors. A clamping groove is arranged on the base of the clamp, and a pressing plate is arranged in the holding groove. The pressing plate is connected with the main shaft of the cylinder, and the main shaft of the cylinder is arranged on In the fixture base, two pins are symmetrically arranged on both sides of the upper end surface of the fixture base, and pin holes are arranged on the lower end surface of the scroll step corresponding to the positions of the pins, and the scroll step and the upper end surface of the fixture base are locked together. Then, the upper end of the scroll step is provided with a scroll, and the lower end of the sleeve is provided with a sleeve keyway, and the sleeve is sleeved on the fixture base through the sleeve keyway corresponding to the position of the pressure plate, and the upper end of the sleeve and the scroll The steps press against each other. It adopts the method of pulling down the cylinder to lock and the positioning of the scroll to avoid the error of repeated positioning. The processing efficiency is improved, and the processing consistency is extremely high.

Owner:邢台癸酉新能源科技有限公司

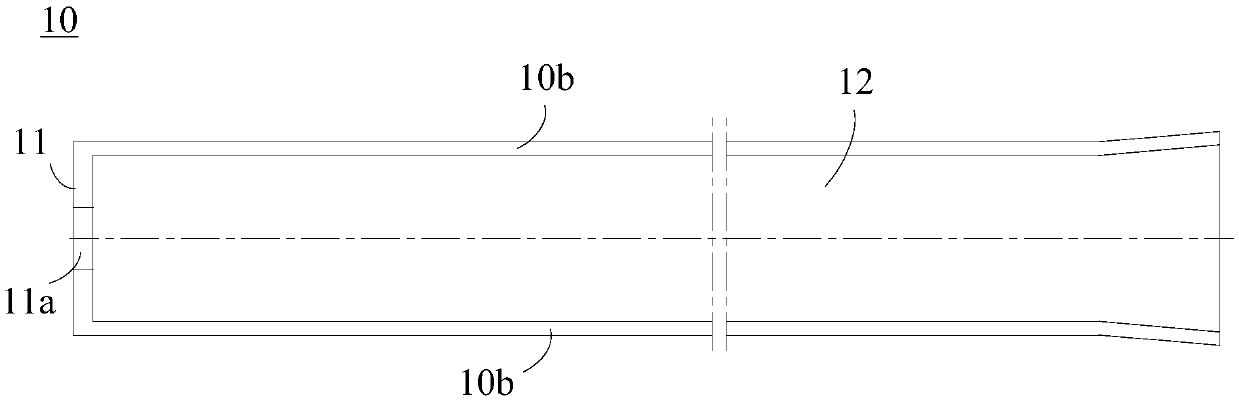

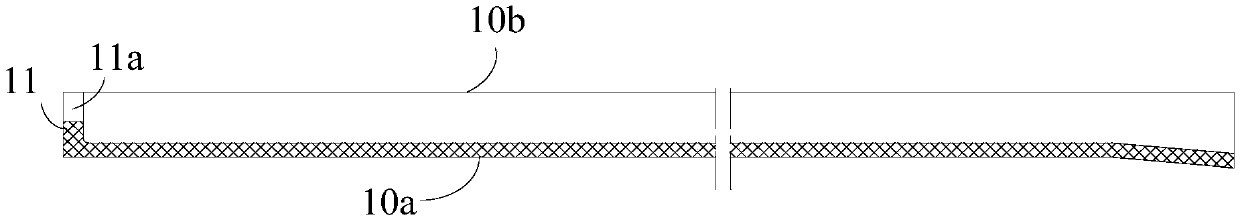

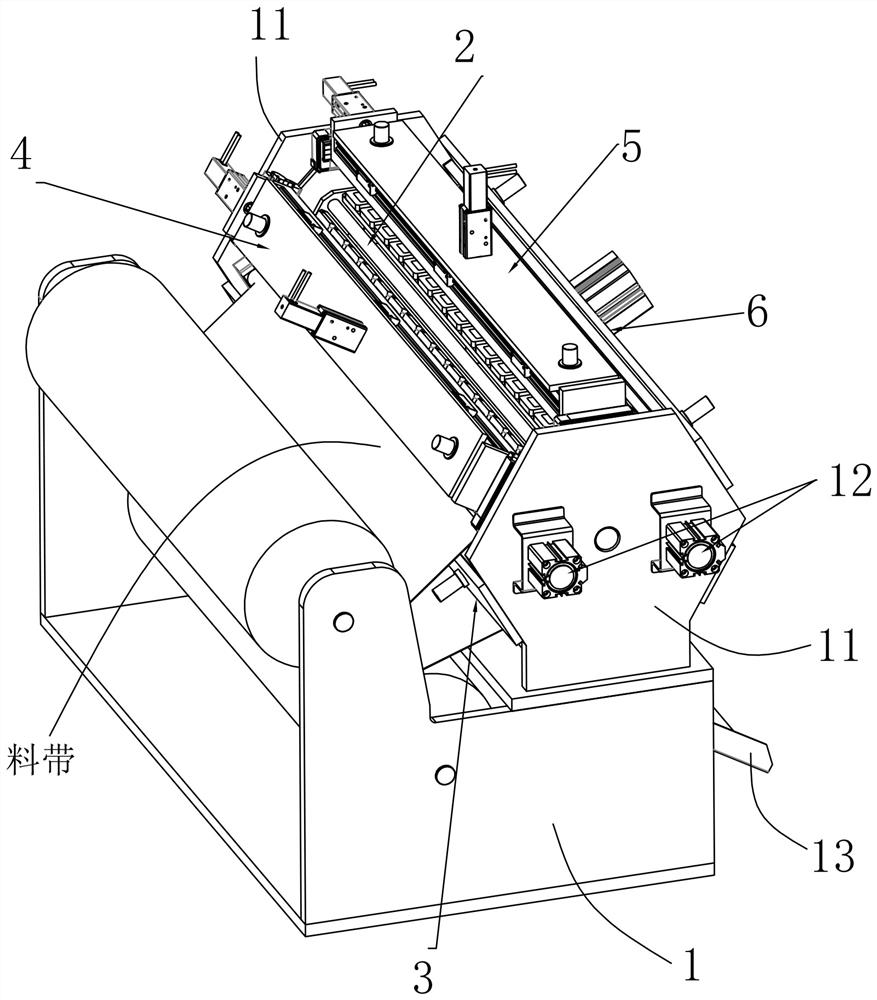

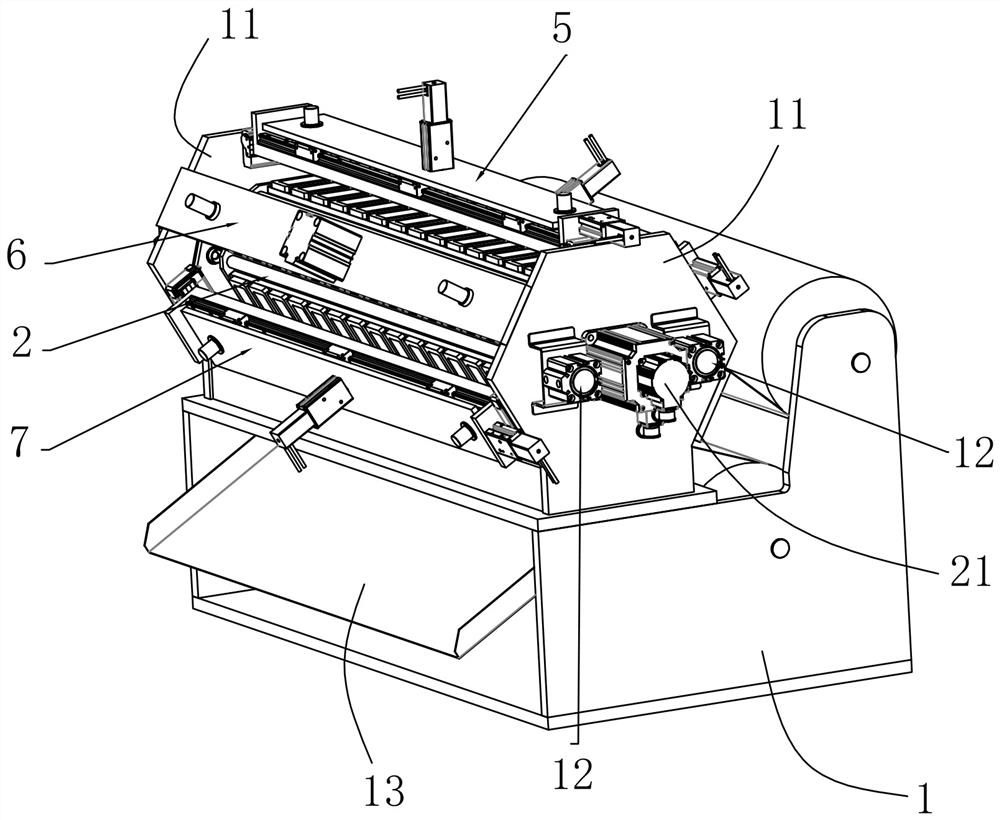

Machining device and method of kidney-shaped half pipe

ActiveCN109532062AAvoid deformationAvoid repeated positioning errorsTubular articlesEngineeringMachining

The invention discloses a machining device and method of a kidney-shaped half pipe. The machining device includes a base, a plurality of horizontal supporting plates, a plurality of first vertical supporting plates and a plurality of second vertical supporting plates. The multiple horizontal supporting plates, the multiple first vertical supporting plates and the multiple second vertical supporting plates are arranged on the base, first stopping blocks are arranged on the multiple horizontal supporting plates, and second stopping blocks are arranged on the multiple first vertical supporting plates and the multiple second vertical supporting plates so that the multiple horizontal supporting plates can support the kidney-shaped half pipe in the vertical direction. The first stopping blocks and the second stopping blocks are both used for being bonded with the kidney-shaped half pipe, thus the kidney-shaped half pipe can be supported in the lateral direction, and the deformation of the kidney-shaped half pipe due to the action of gravity is prevented. Meanwhile, by bonding a plurality of first reference blocks and a plurality of second reference blocks to the kidney-shaped half pipe,the multiple first reference blocks and the multiple second reference blocks can provide a benchmark for the machining of the kidney-shaped half pipe, thus repeated positioning errors caused by the deformation of the kidney-shaped half pipe are avoided, and the machining accuracy is improved.

Owner:WUHAN MARINE MACHINERY PLANT

Plane milling and boring machine tool rest

InactiveCN103273093AAvoid repeated positioning errorsEasy to replaceMetal-working apparatusTool bitMilling cutter

The invention discloses a plane milling and boring machine tool rest comprises a milling tool bit, a boring tool bit, a ram, a central shaft, an indexing mechanism and a tool rest body. The tool rest body is rotationally connected with the central shaft. The milling tool bit or the boring tool bit is mounted at one end of the tool rest body. The indexing mechanism is fixedly connected with the tool rest body. The milling tool bit comprises a five-axis milling head and a milling head pull rod which are fixedly connected. The boring tool bit comprises a boring tool rest pull rod, a lower-end fluted disc, a boring tool rest and a boring tool bar, wherein the boring tool rest pull rod and the lower-end fluted disc are fixedly connected at the upper end of the boring tool rest, and the boring tool bar is fixedly connected at the lower end of the boring tool rest. By the boring tool rest pull rod, indexing adjustment of the ram in a range of 1-20 degrees can be achieved, simple switch of the milling tool bit and the boring tool bit can be achieved, especially in machining of large workpieces, complex curve face milling, taper hole boring and excircle surface cutting can be completed after one-step mounting, machining efficiency and precision of the large workpieces are increased greatly, repeated positioning errors caused by secondary clamping are avoided.

Owner:JIANGSU UNIV OF SCI & TECH

Plane milling and boring machine tool rest

InactiveCN103273093BAvoid repeated positioning errorsEasy to replaceMetal-working apparatusTool bitMilling cutter

The invention discloses a plane milling and boring machine tool rest comprises a milling tool bit, a boring tool bit, a ram, a central shaft, an indexing mechanism and a tool rest body. The tool rest body is rotationally connected with the central shaft. The milling tool bit or the boring tool bit is mounted at one end of the tool rest body. The indexing mechanism is fixedly connected with the tool rest body. The milling tool bit comprises a five-axis milling head and a milling head pull rod which are fixedly connected. The boring tool bit comprises a boring tool rest pull rod, a lower-end fluted disc, a boring tool rest and a boring tool bar, wherein the boring tool rest pull rod and the lower-end fluted disc are fixedly connected at the upper end of the boring tool rest, and the boring tool bar is fixedly connected at the lower end of the boring tool rest. By the boring tool rest pull rod, indexing adjustment of the ram in a range of 1-20 degrees can be achieved, simple switch of the milling tool bit and the boring tool bit can be achieved, especially in machining of large workpieces, complex curve face milling, taper hole boring and excircle surface cutting can be completed after one-step mounting, machining efficiency and precision of the large workpieces are increased greatly, repeated positioning errors caused by secondary clamping are avoided.

Owner:JIANGSU UNIV OF SCI & TECH

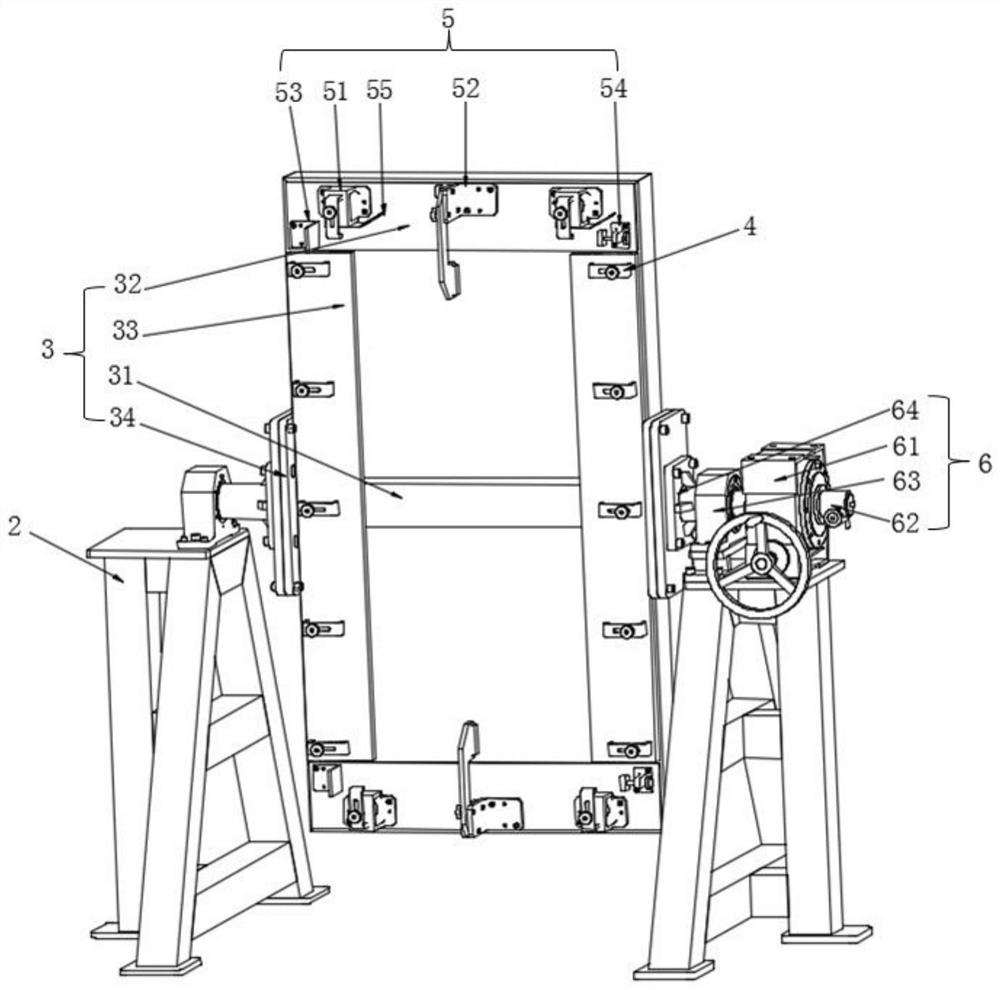

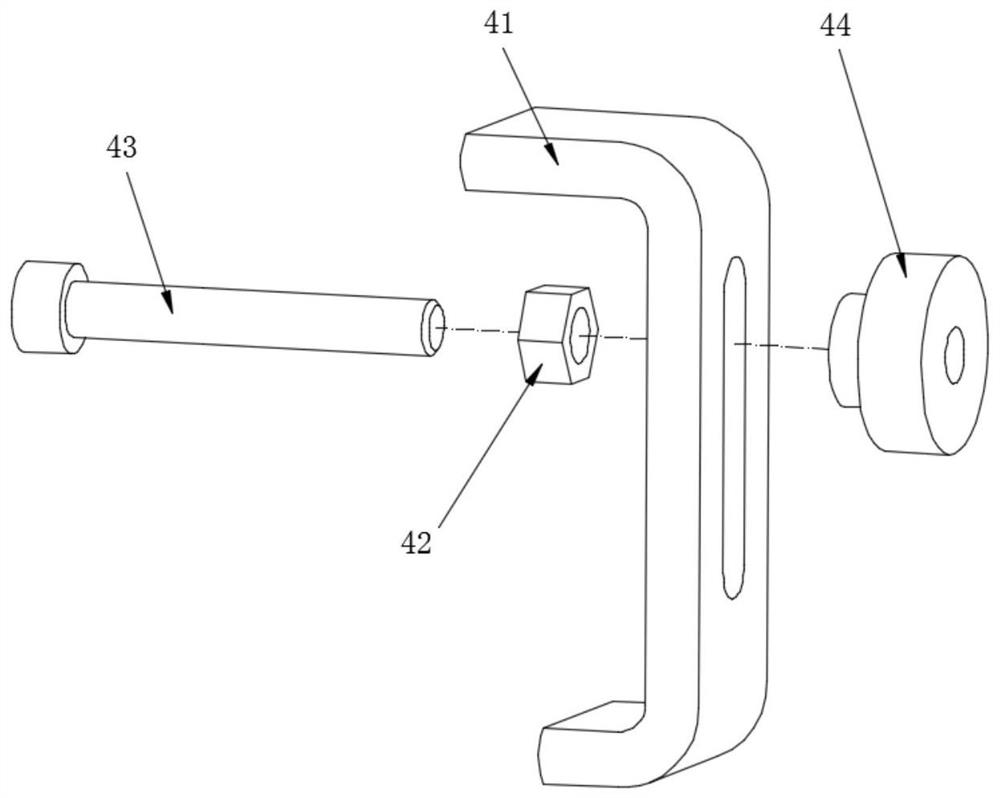

Glue filling clamp and glue filling method for stiffened wallboard compression test piece

PendingCN113670683AStable positionEnsure safetyMachine part testingPreparing sample for investigationStructural engineeringCompression test

The invention discloses a glue filling clamp and a glue filling method for a stiffened wallboard compression test piece. The clamp structure comprises a stand column, a frame, a pressing assembly, a positioning assembly and a turnover assembly, the stand column is fixedly installed on the ground through an expansion foundation bolt after being leveled, the turnover assembly is arranged at the upper end of the stand column, a shaft support of the turnover assembly is fixedly connected with the frame, the positioning assemblies are transversely arranged on the upper and lower sides of the frame, and the pressing assemblies are longitudinally arranged on the left and right sides of the frame. The stiffened wallboard compression test piece is fixed and accurately positioned on the inner side of the glue filling clamp through the pressing assembly and the positioning assembly, and the stiffened wallboard compression test piece is subjected to turnover glue filling through the turnover assembly.

Owner:XI'AN AIRCRAFT INTERNATIONAL

Rotary ic card punching and milling equipment

ActiveCN112518334BGuaranteed accuracyIncrease productivityOther manufacturing equipments/toolsPositioning apparatusSurface finishEngineering

The invention discloses a rotary IC card punching and milling equipment, comprising a frame, the frame is provided with two regular hexagon-shaped side plates arranged opposite to each other, and the two side plates are both provided with positioning mechanisms; A station rotating mechanism rotatably connected between the middle parts of the two side plates and in the form of a regular hexagonal column, and a card cutting station and a square groove rough milling station correspondingly arranged between the opposite sides of the two side plates in the circumferential direction. , square groove fine milling station, square groove size detection station, circular groove milling station; the invention forms a rotary multi-station cyclic operation, realizes the combination of card cutting, rough milling, fine milling and detection, and has high production efficiency , The dimensional accuracy and surface finish are higher, so that the product qualification rate is greatly improved, no repeated positioning is required, the accumulation of repeated positioning errors is avoided, and the dimensional accuracy of the square groove is guaranteed.

Owner:宁波阅荷思山智能科技有限公司

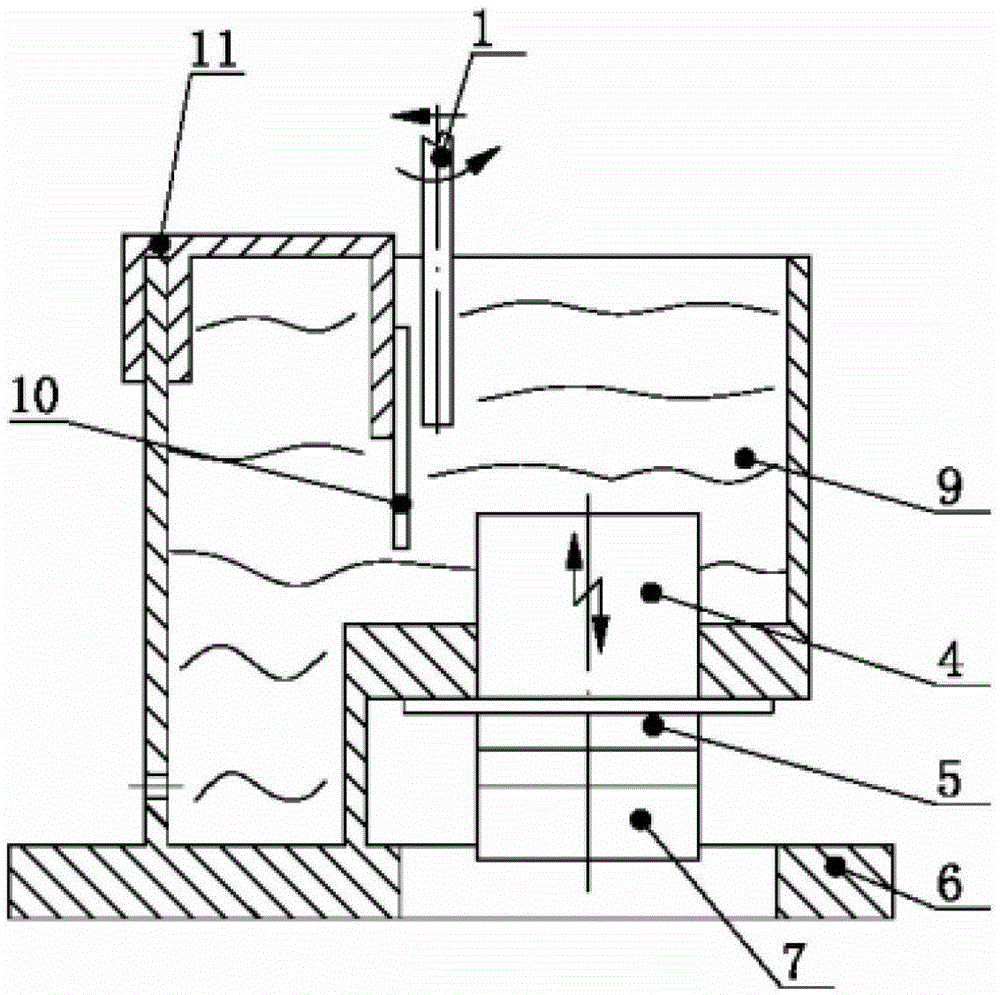

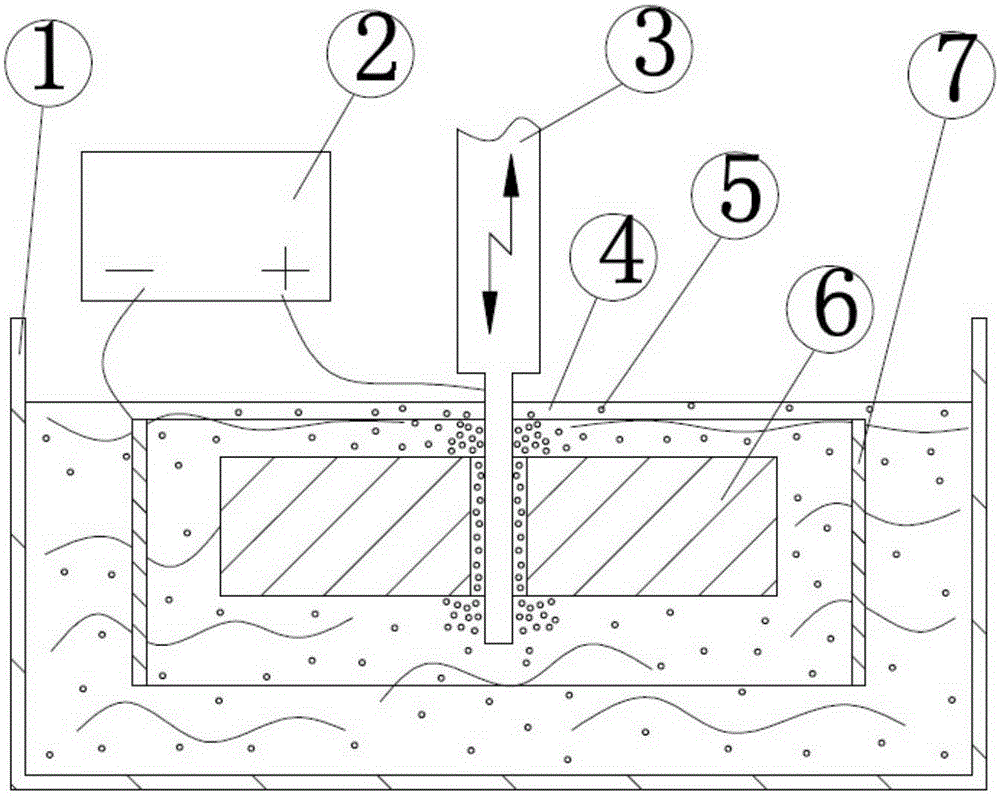

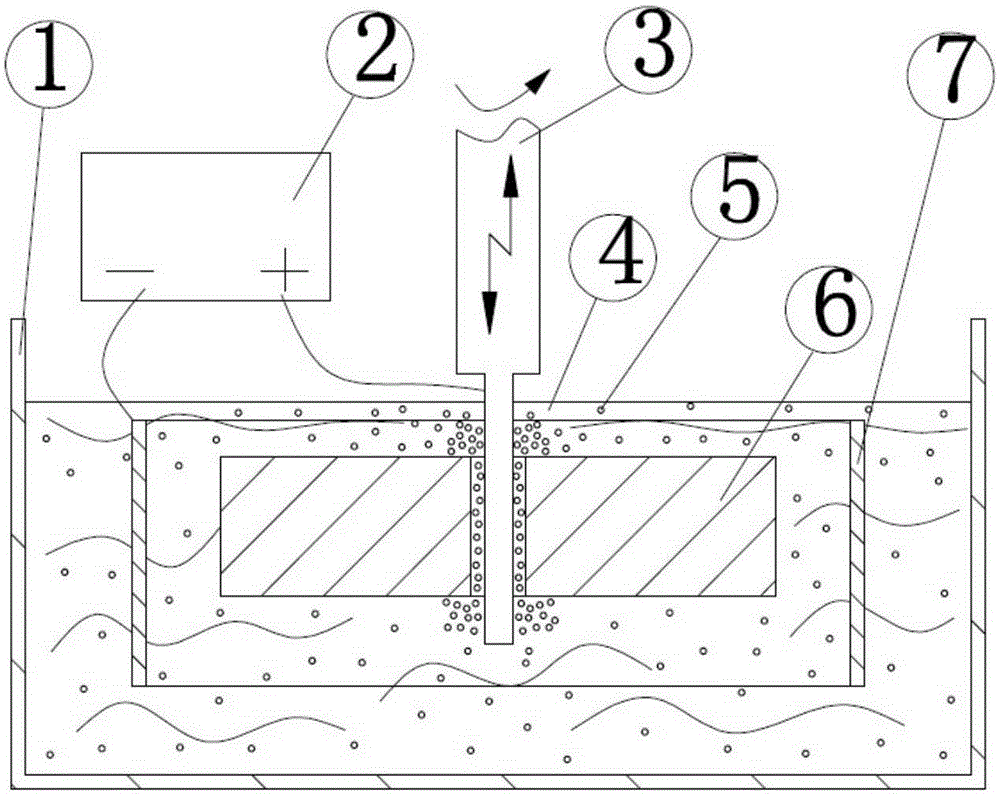

Electrical discharge machining method of die inserted block for forming microstructure

ActiveCN102357688BCompensation lossStable positionElectrical-based machining electrodesWire cuttingElectrical polarity

The invention relates to a method for manufacturing an electrode by adopting a multi-station combining method and machining a die inserted block for forming a microstructure by using the electrode, which belongs to the technical fields of special machining and micromachining. The method comprises two steps, i.e. combined electrode machining by electrical discharge wire-cutting and microstructure machining by electrical discharge forming. A plurality of discharge stations of which the narrow slit widths sequentially and gradually decrease are machined on the same electrode material by using the electrical discharge wire-cutting, the gradually-decreased values of the narrow slit widths are equivalent to the variable quantity of electrode scaling dimensions from rough machining to finish machining in the electrical discharge forming. When the electrical discharge forming is carried out, the positions of a workpiece and the electrode are exchanged, the polarity of a pulse power supply is reversed, and the workpiece carries out servo-feeding machining on the electrode so as to finish discharging machining on each station. The method provided by the invention has the effects and benefits that the error in repeatedly positioning caused by exchanging electrodes is avoided, the vibration error caused by the servo motion of an electrode with a heavier weight and a larger volume is avoided, both the manufactured micro inserted block and the manufactured microstructure are die steel and have high hardness, long service lives, good surface quality and mirror effects.

Owner:DALIAN UNIV OF TECH

Thermal error measurement device and measurement method of gear grinding machine in working state

InactiveCN105058163BHigh measurement accuracyGood compensationMeasurement/indication equipmentsGear grindingEngineering

Owner:XIAN UNIV OF TECH

A special tool for processing the end face of the support cover

ActiveCN105290838BImprove work efficiencyReduce labor intensityPositioning apparatusMetal-working holdersPosition errorMechanical engineering

Owner:ANHUI HELI CO LTD

A processing tool and processing method for a multi-cavity product

ActiveCN112059658BQuick changeIncrease productivityPositioning apparatusMetal-working holdersCircular discProcess engineering

The invention provides a processing tool and a processing method for a multi-cavity product. The processing tool is designed according to the structural characteristics of the multi-cavity product. The processing tool includes a fixture body, a positioning pin and a connecting device, and the fixture body is a stepped circular structure. , the position of the axis on the big-end disc is set with a center hole, and eight threaded holes are processed on both sides of the center hole to match the process holes on the multi-cavity product; the positioning pin is a stepped circular structure, and the big end and the processing tooling Cooperate with the center hole on the top, and the small end extends out of the center hole to match the positioning hole on the multi-chamber product. During processing, use the positioning pin as a reference, cooperate with four sets of threaded connectors passing through the product process hole and the threaded hole of the processing tool to accurately locate the position of the inner cavity of the product. The invention can process four inner cavities with one set of tooling, which solves the problems of long positioning and alignment time, large repeated positioning error, low speed during processing and easy to cause product surface crushing in traditional processing methods, effectively improves production efficiency and Ensure product quality.

Owner:XIAN SPACE ENGINE CO LTD

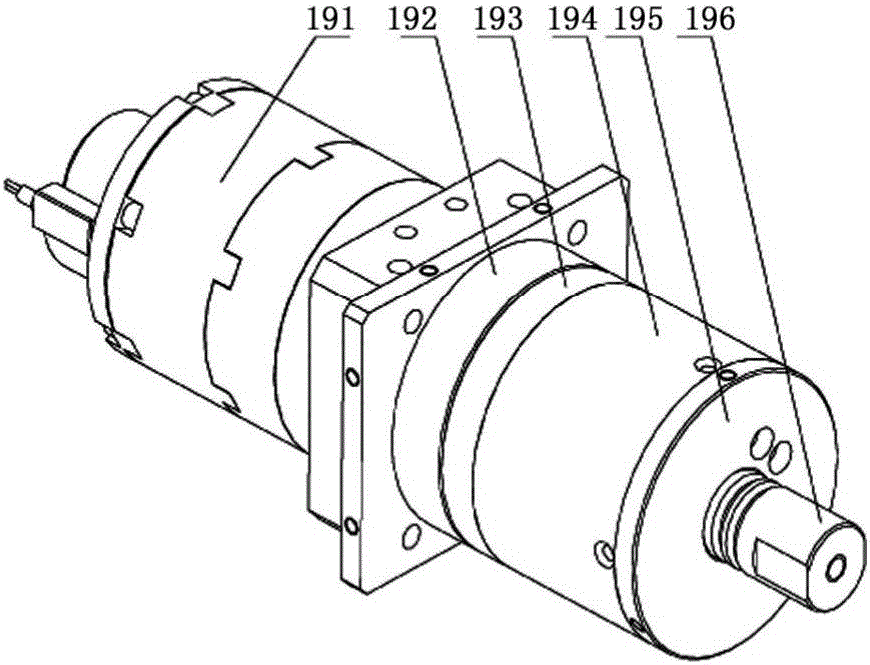

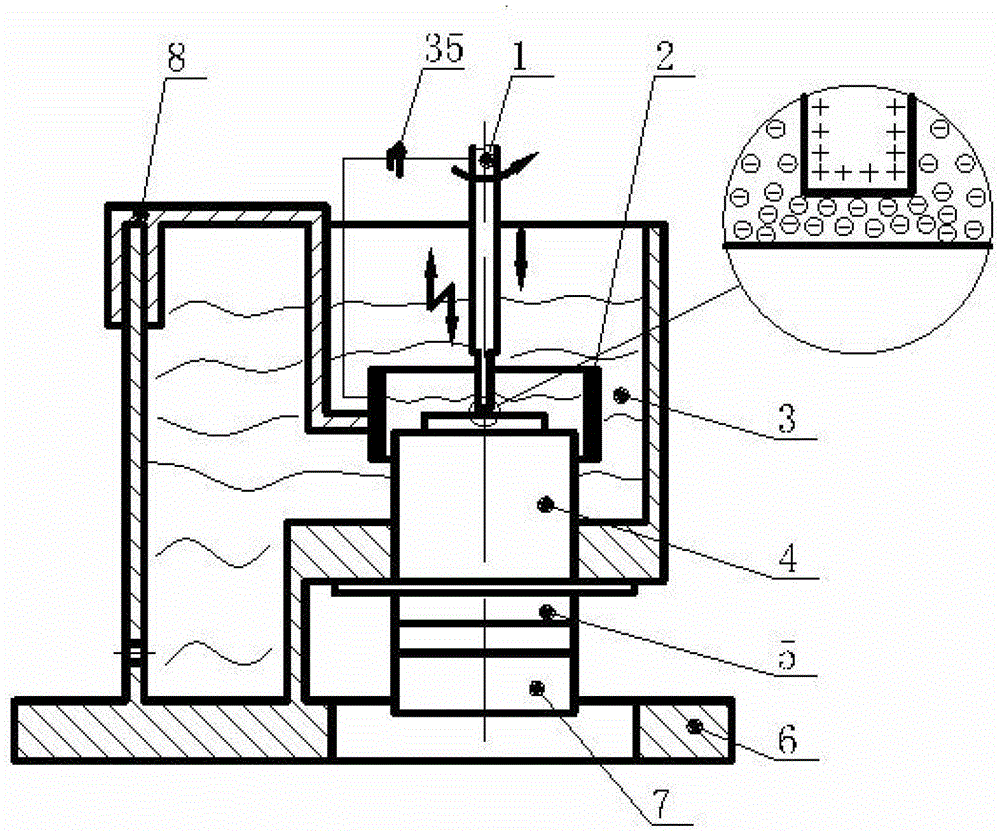

An electrophoresis-assisted micro-ultrasonic processing machine tool and processing method

Owner:GUANGDONG UNIV OF TECH

A special machine tool for rear axle housing boring

ActiveCN113478264BEliminate angular positioning errorsTension holdFeeding apparatusPositioning apparatusStructural engineeringMachine tool

The invention discloses a special machine tool for boring rear axle housings, which includes a bed and a fixture. The fixture includes an intermediate positioning mechanism for positioning the pipa holes of the rear axle housing arranged in the middle of the upper surface of the bed, and symmetrically arranged on the intermediate positioning mechanism. The centering clamping mechanism on both sides, the middle positioning mechanism includes the clamping body and the floating plate arranged on the clamping body, and the centering tensioning mechanism is arranged in the floating plate; the invention uses the V-shaped block of the centering clamping mechanism to carry out rear axle The two ends of the shell are clamped to perform axial positioning and eliminate the positioning error caused by the machining error of the outer circle of the shaft at both ends; The end face of the pipa hole is supported, and the support nails float with the floating plate to eliminate the processing error of the end face of the pipa hole; the rear axle housing is accurately positioned and clamped to ensure that the bearing hole of the boring bridge tube is concentric with the outer circle.

Owner:NANJING INST OF TECH

A device and processing method for electrophoresis-assisted micro-ultrasonic or micro-rotating ultrasonic polishing of micro-holes

The invention relates to polishing of inner surfaces of metal or non-metal hard and brittle material micropores and particularly relates to a device for polishing the micropores through electrophoresis auxiliary micro-ultrasonic or micro-rotating ultrasonic and a processing method. Electrophoresis auxiliary processing and the micro-ultrasonic processing are combined together; under the adsorption action of electrophoresis, ultra-fine abrasive particles are adsorbed to the surface a fine tool; the fine tool penetrates through a micropore workpiece under the driving of a servo feeding system of a micro-ultrasonic processing machine tool; the fine tool vibrates at high frequency along the axial direction to drive working liquid to disturb severely, so that the ultra-fine abrasive particles can frictionize the inner surface of the micropore workpiece in a sliding manner to fulfill the aim of polishing the micropore workpiece; the polishing of the micropores with the diameters of less than or equal to 100 microns can be realized by implementing the processing of micropore polishing through the electrophoresis auxiliary micro-ultrasonic or micro-rotating ultrasonic; the utilization rate of the ultra-fine abrasive particles is increased, and the roughness of the inner surfaces of the micropores can be reduced.

Owner:GUANGDONG UNIV OF TECH

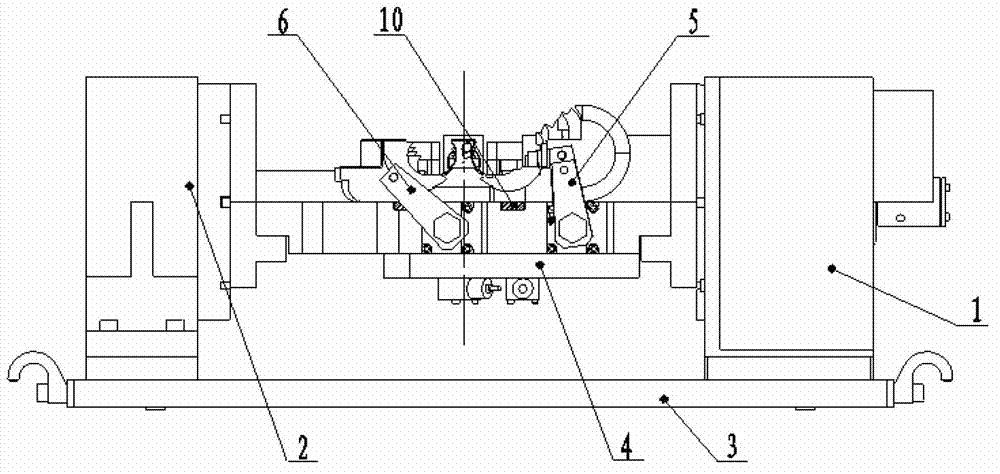

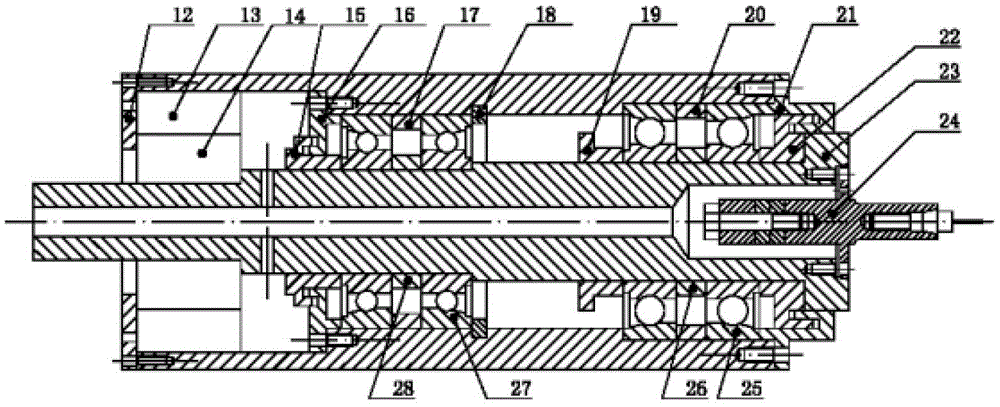

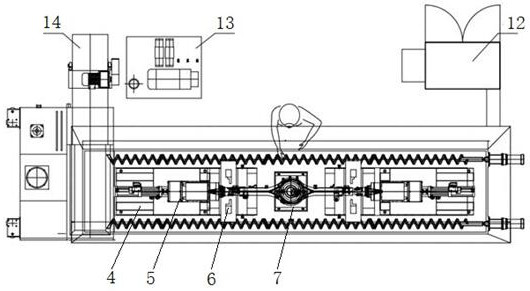

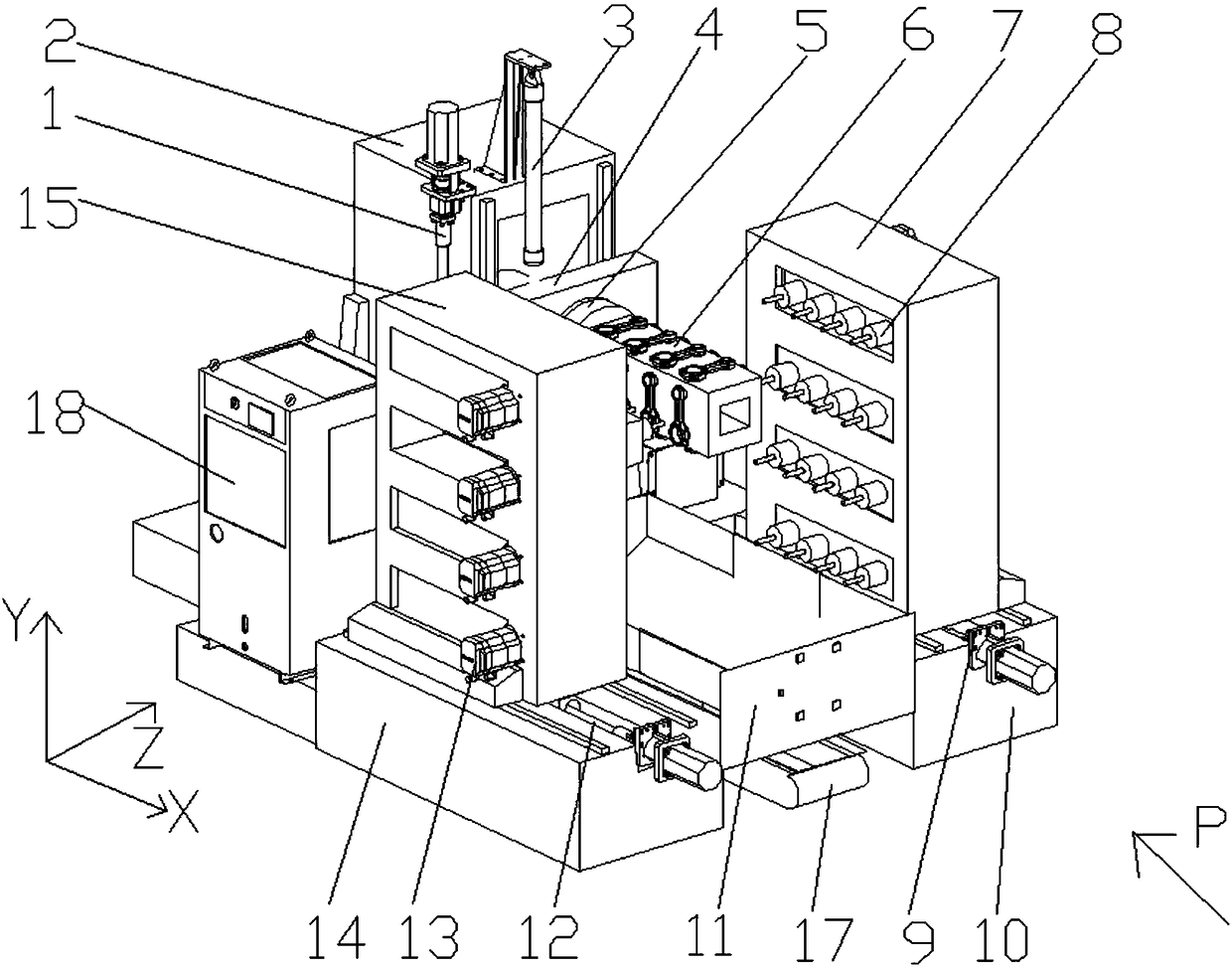

A multi-spindle multi-station connecting rod flexible processing equipment

InactiveCN105817958BEasy to reorganizeEasily reconfigurableMetal working apparatusFeed driveMachining

The invention discloses flexible machining equipment of multi-main shaft and multi-station connecting rods. A bed body of an X axle is arranged on one side of a Y-axle stand column and a bed body (2); a main shaft box body (7) of the X axle is mounted on the bed body of the X axle; a balance device (3) is mounted on the Y-axle stand column and the bed body, and is connected with a Y-axle ram (4); the Y-axle ram is mounted on the Y-axle stand column and the bed body through a Y-axle feed driving system; a revolving worktable (6) with hydraulic fixtures is mounted on the Y-axle ram through an A-axle revolving head (5); multiple positioning and mounting holes of machined workpieces are formed in the revolving worktable with the hydraulic fixtures; multiple main shaft-cutter systems (8) are arranged in the main shaft box body of the X axle; four sets of fixtures are mounted on the revolving worktable with the hydraulic fixtures, and are corresponding to the main shaft-cutter systems on the main shaft box body of the X axle in number; and each set of fixtures can synchronously clamp multiple parts to synchronously participate in cutting. The flexible machining equipment is compact in structure, realizes high automation, and can reduce the labor cost.

Owner:XI AN JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com