Image measurement tool system and method

A tool system and image measurement technology, applied in measurement devices, instruments, optical devices, etc., can solve problems such as limited measurement function and accuracy, inability to meet requirements, and inability to detect accurate data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

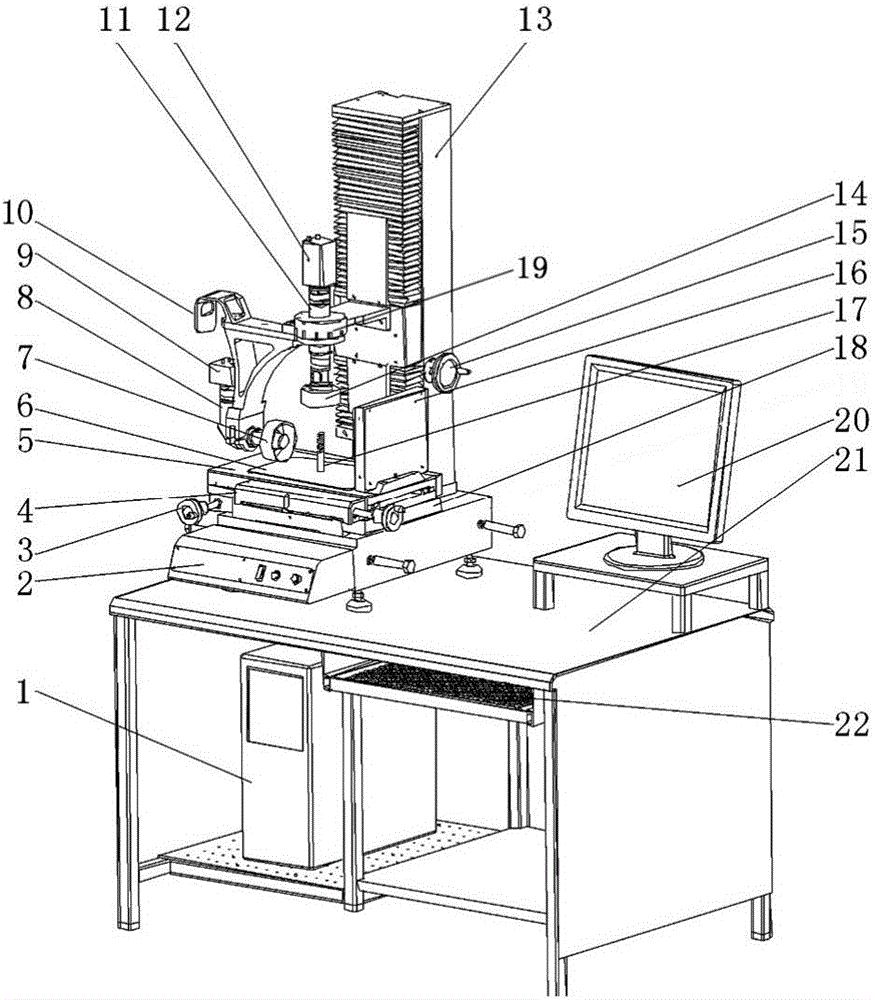

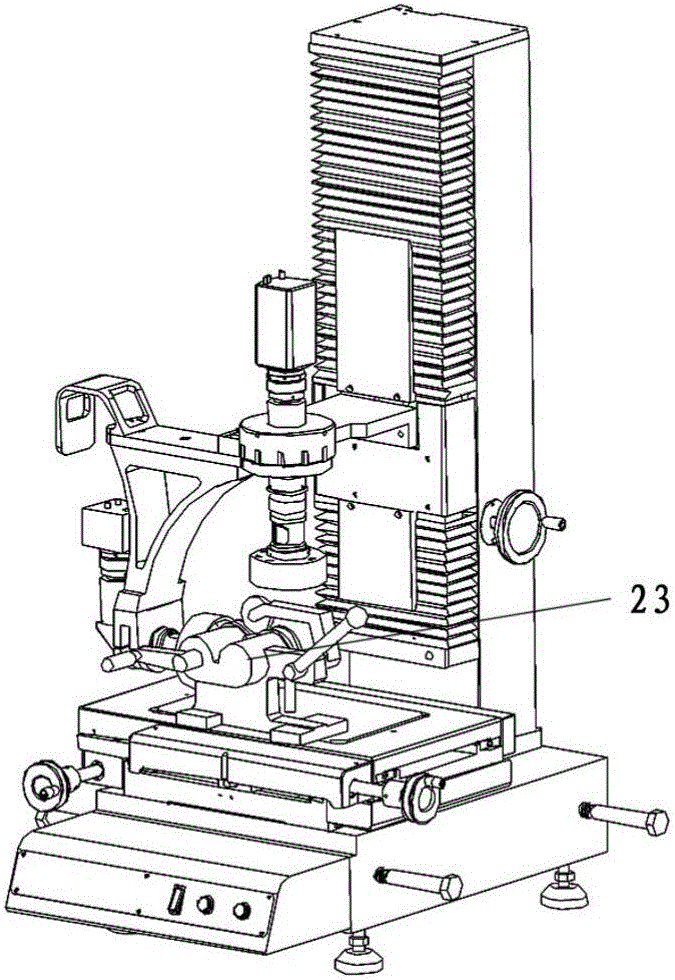

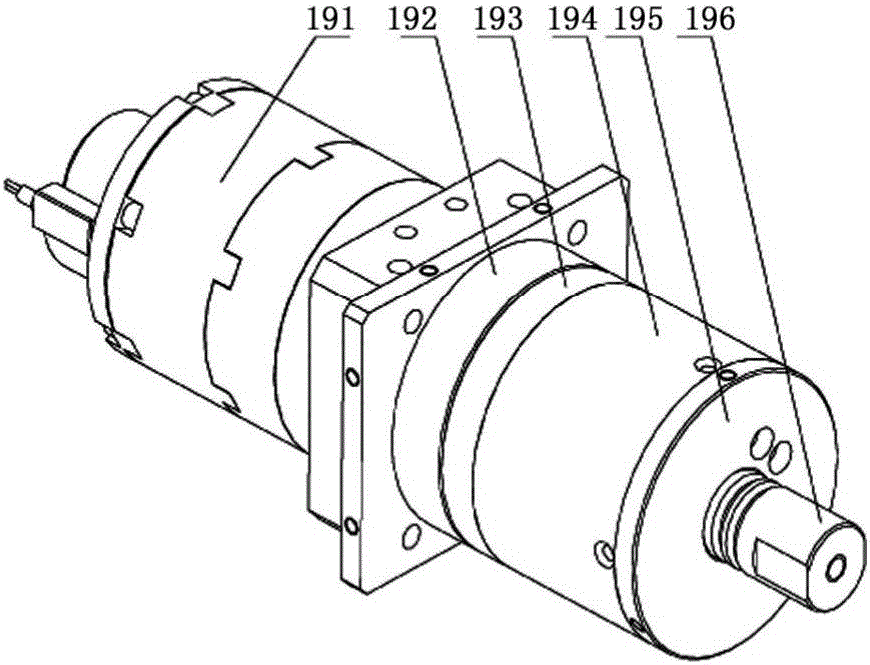

[0026] see Figure 1-4As shown, the present invention relates to an image measuring tool system, including a sheet metal instrument base 21, a display 20, a computer host 1, a mouse and keyboard 22, and a console 2. The console 2, the mouse and keyboard 22, the computer host 1 and Display 20 is arranged on the sheet metal instrument seat 21, and described mouse and keyboard 22 and display 20 are respectively connected with host computer 1, and host computer 1 is connected with console 2, also includes workbench moving mechanism 18, lifting mechanism 14, worktable 5. Glass block 6, fixture 17 for clamping the cutting tool to be tested, bottom light source plate 16, horizontal image acquisition device, longitudinal image acquisition device, described workbench moving mechanism 18 and lifting mechanism 14 are arranged on the console 2 and are connected with The console 2 is connected, the operating stroke of the workbench moving mechanism 18 is 200x100mm, the workbench 5 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com