Integral permeability testing machine for self circulation measuring for perpendicular and horizontal permeability coefficient

A technology of permeability coefficient and permeameter, which is applied in the field of comprehensive permeameter, which can solve the problems of applying normal pressure, slow sample saturation speed and inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

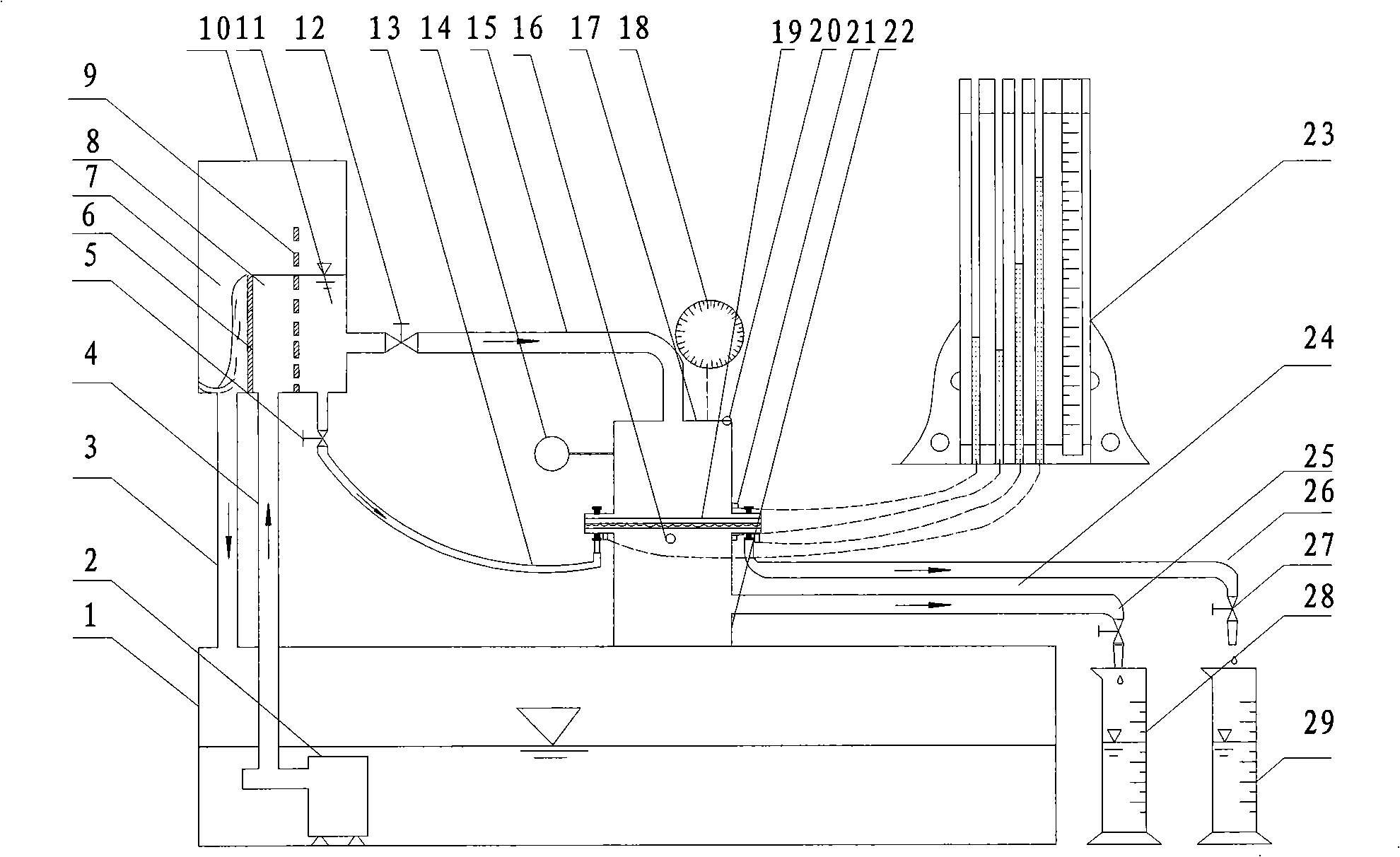

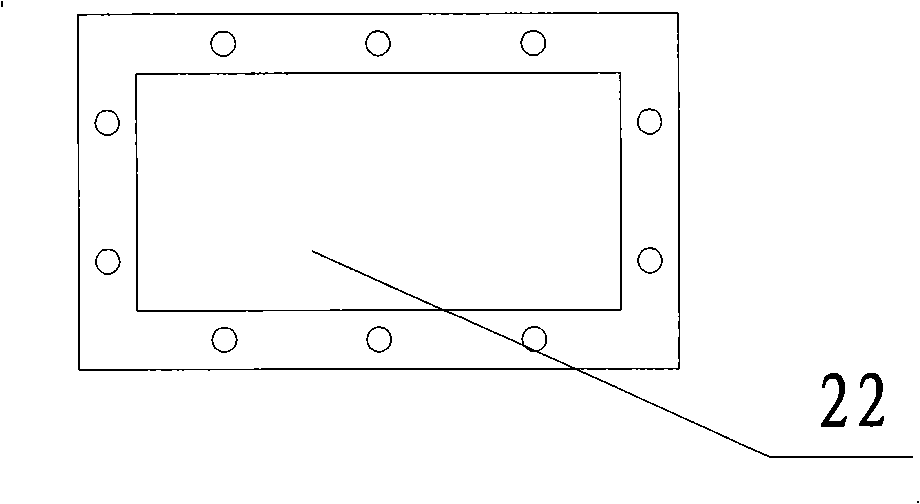

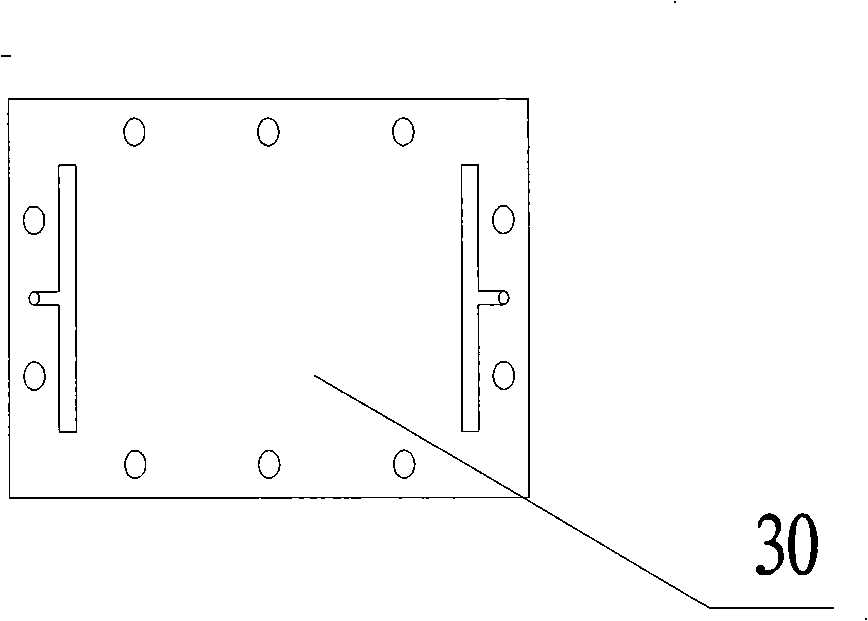

[0022] As shown in the figure, the comprehensive penetrometer for measuring vertical and horizontal permeability coefficients has a constant pressure water tank 10, and an overflow plate 6 and a water stabilizing plate 9 are arranged in the constant pressure water tank 10, and the water stabilizing plate 9 is provided with water stabilizing holes laterally. , the overflow plate 6 and the water stabilizing plate 9 divide the interior of the constant pressure water tank 10 into an overflow zone 7, a water inlet zone 8 and a water stabilizing zone 11. The pipe 15 is connected with the upper pressure chamber 17, the bottom of the overflow area 7 is connected with the return pipe 3, the bottom of the water inlet area 8 is connected with the water inlet pipe 4, and the bottom of the stable water area 11 is connected with one end of the water supply pipe 13 through the water supply valve 5 , the lower end of the return pipe 3 is connected to the water storage tank 1, the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com