Patents

Literature

433results about How to "Improve quality consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

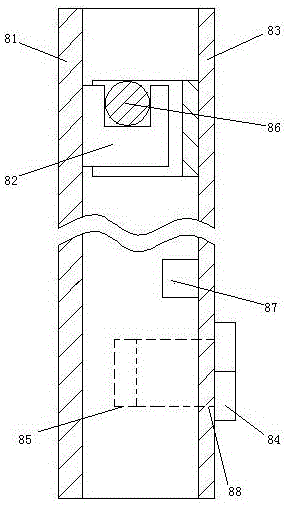

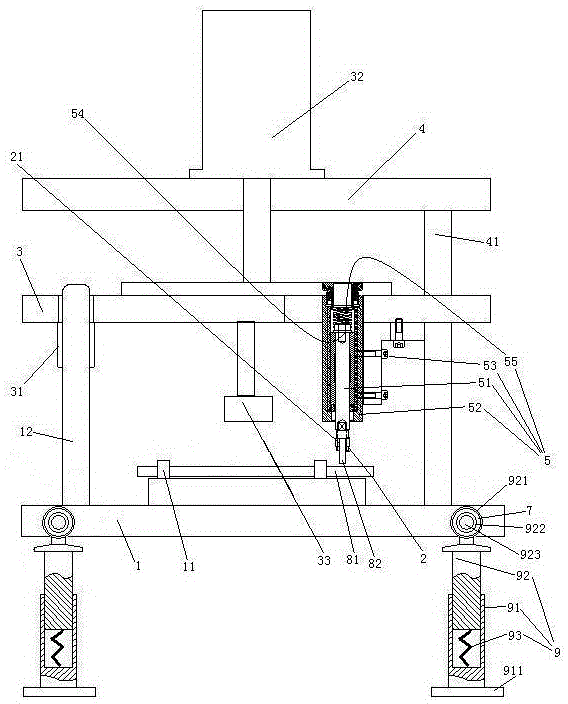

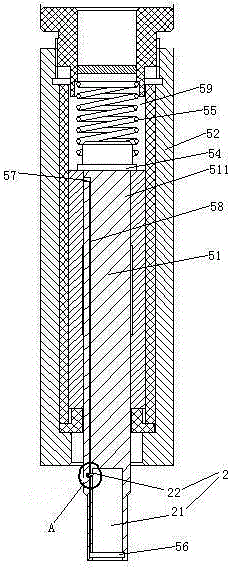

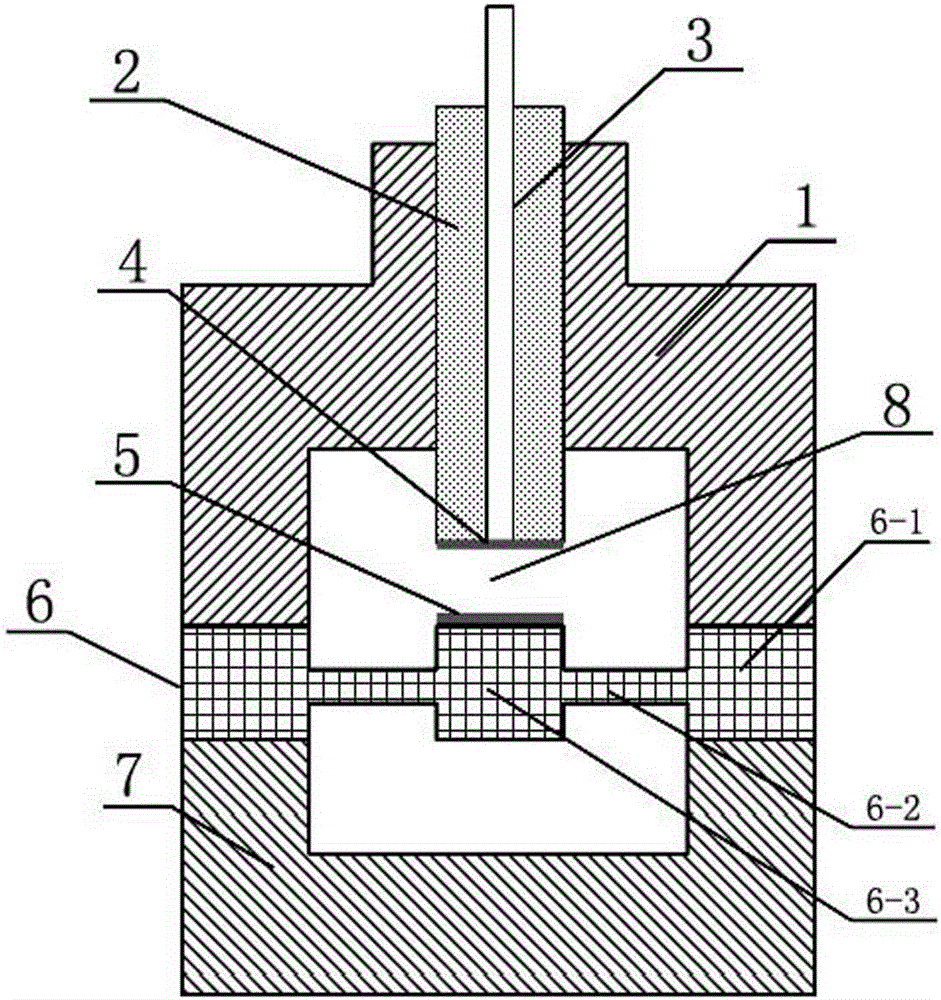

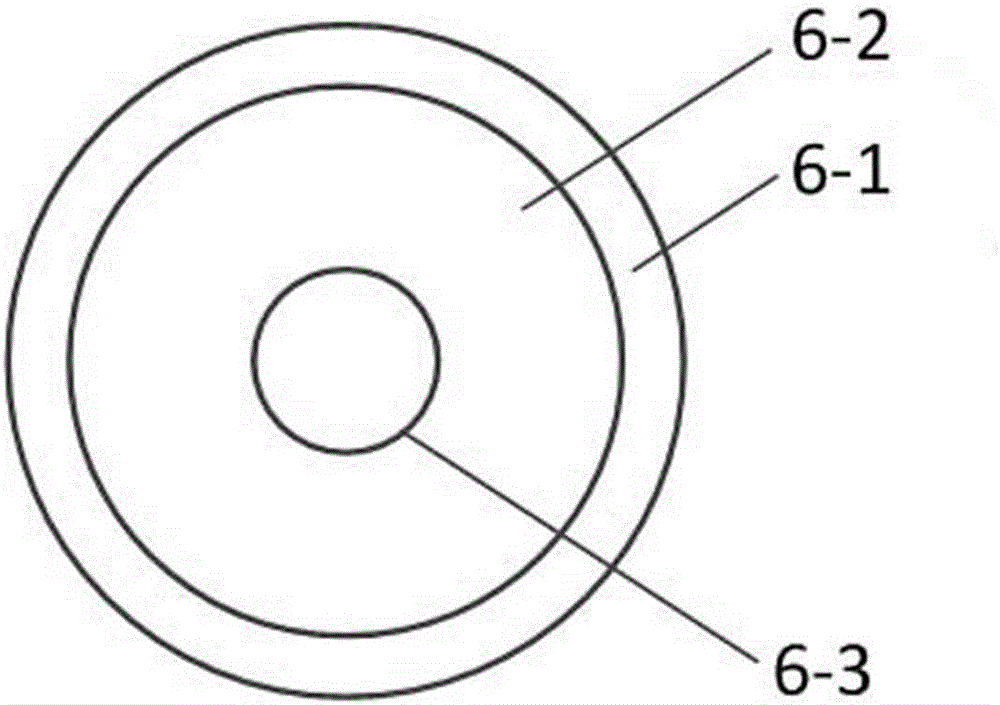

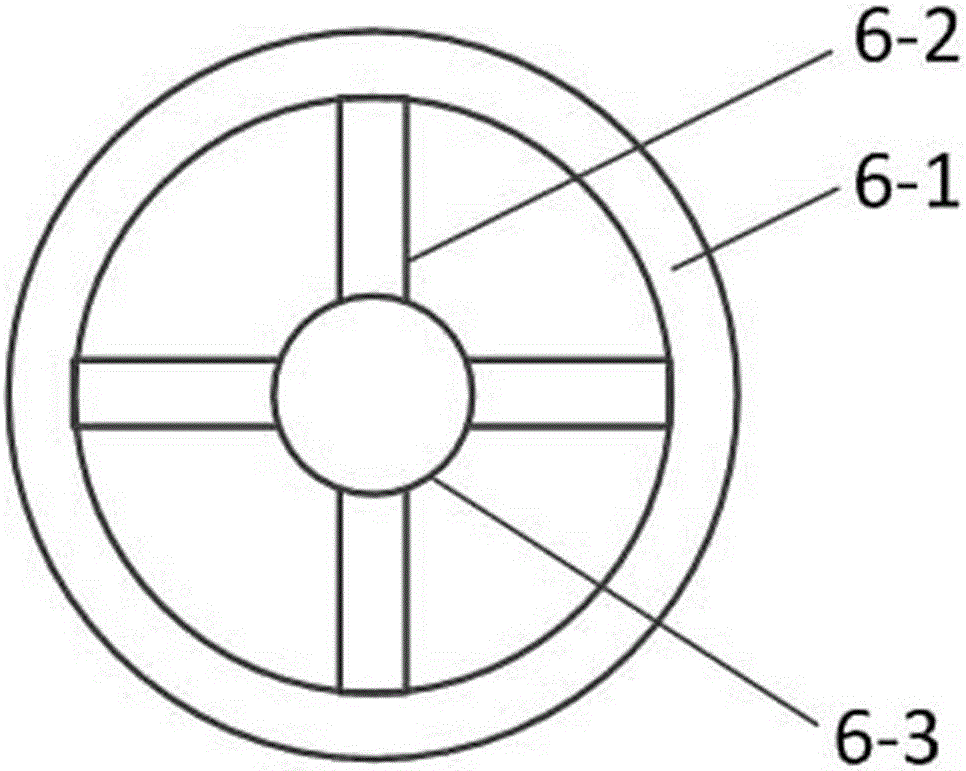

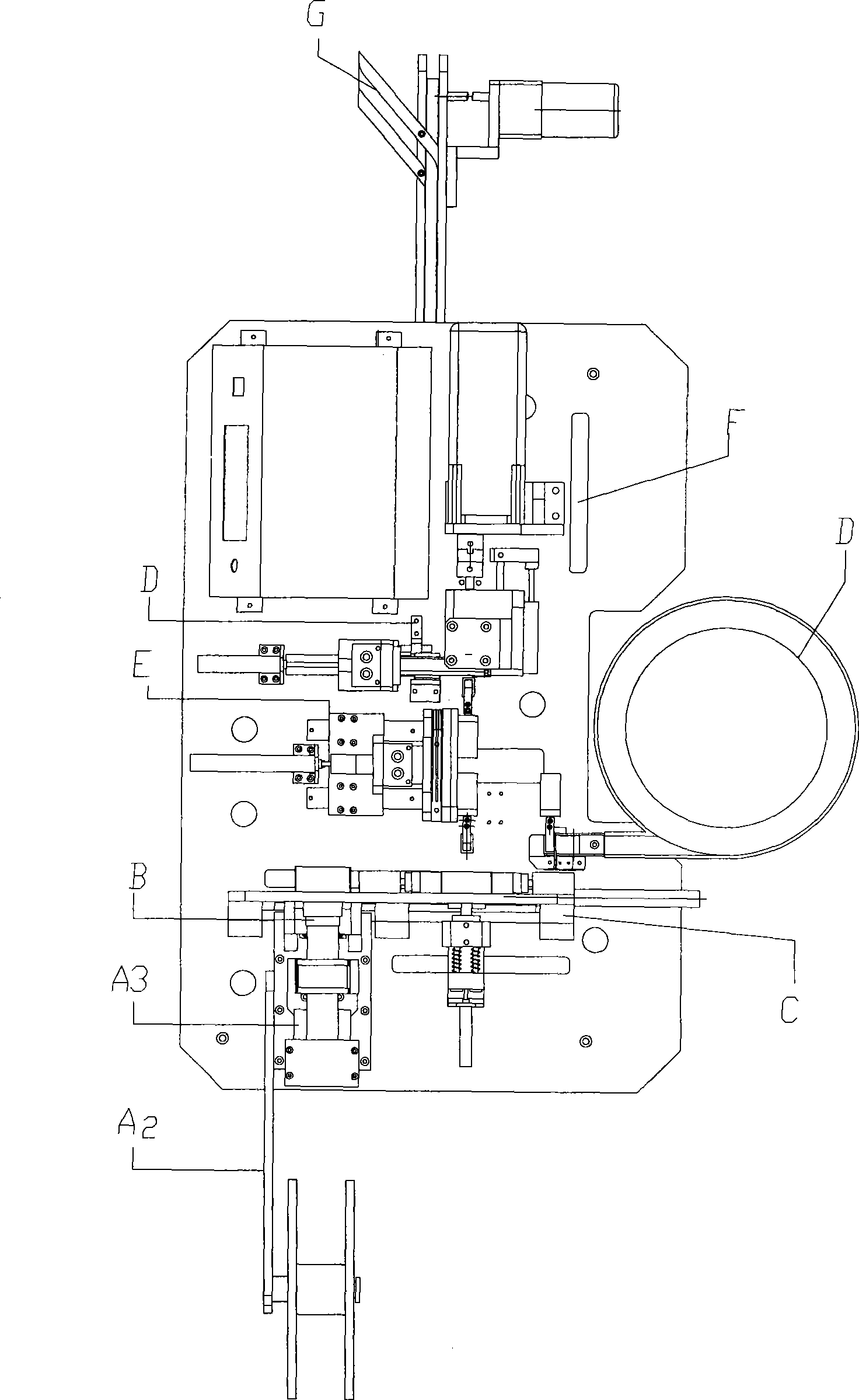

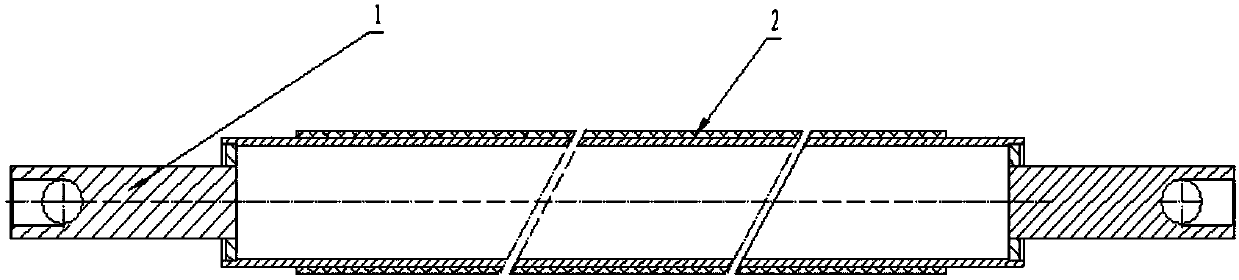

Welding device for side sealing plate barb of switch cabinet

InactiveCN105057865AImprove connection strengthImprove quality consistencyResistance electrode holdersWelding/cutting auxillary devicesRubber ringElectricity

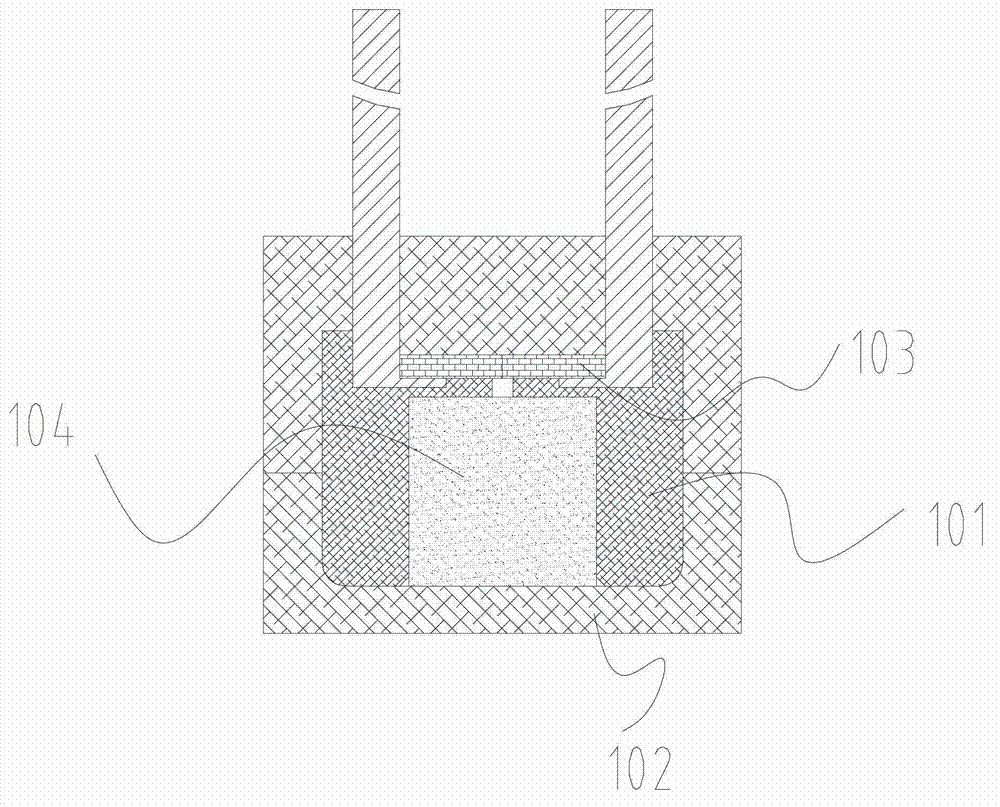

The invention relates to the technical field of manufacturing of low-voltage drawer-type switch cabinets and discloses a welding device for a side sealing plate barb of a switch cabinet. The welding device comprises an electric welding machine, a spot welding gun, supporting pillars, a lower base, an electric conduction block, a suspending plate and an upper seat. The electric welding machine is provided with two electrodes, and the spot welding gun is connected with one of the electrodes. Clamps are arranged on the lower seat, and the suspending plate is connected with the upper seat through an air cylinder. The electric conduction block is connected to the suspending plate. The electric conduction block is electrically connected with the other electrode. The spot welding gun is connected to the suspending plate and is provided with a barb fixing structure. The supporting pillars comprise damper springs, upper sections and lower sections, wherein the upper sections and the lower sections are sleeved together. The upper ends of the upper sections are provided with connecting rings, inner rings are arranged in the connecting rings in a penetrating mode, the inner rings and the connecting rings are connected together through rubber rings, and connecting pins connected to the lower seat are arranged in the inner rings in a penetrating mode. The welding device has the advantages that a welded part does not need to be fixed manually, and the vibration isolation effect is good; the problems that much effort is cost in welding and the welding quality is poor due to welding by manually fixing the welded part are solved.

Owner:张进

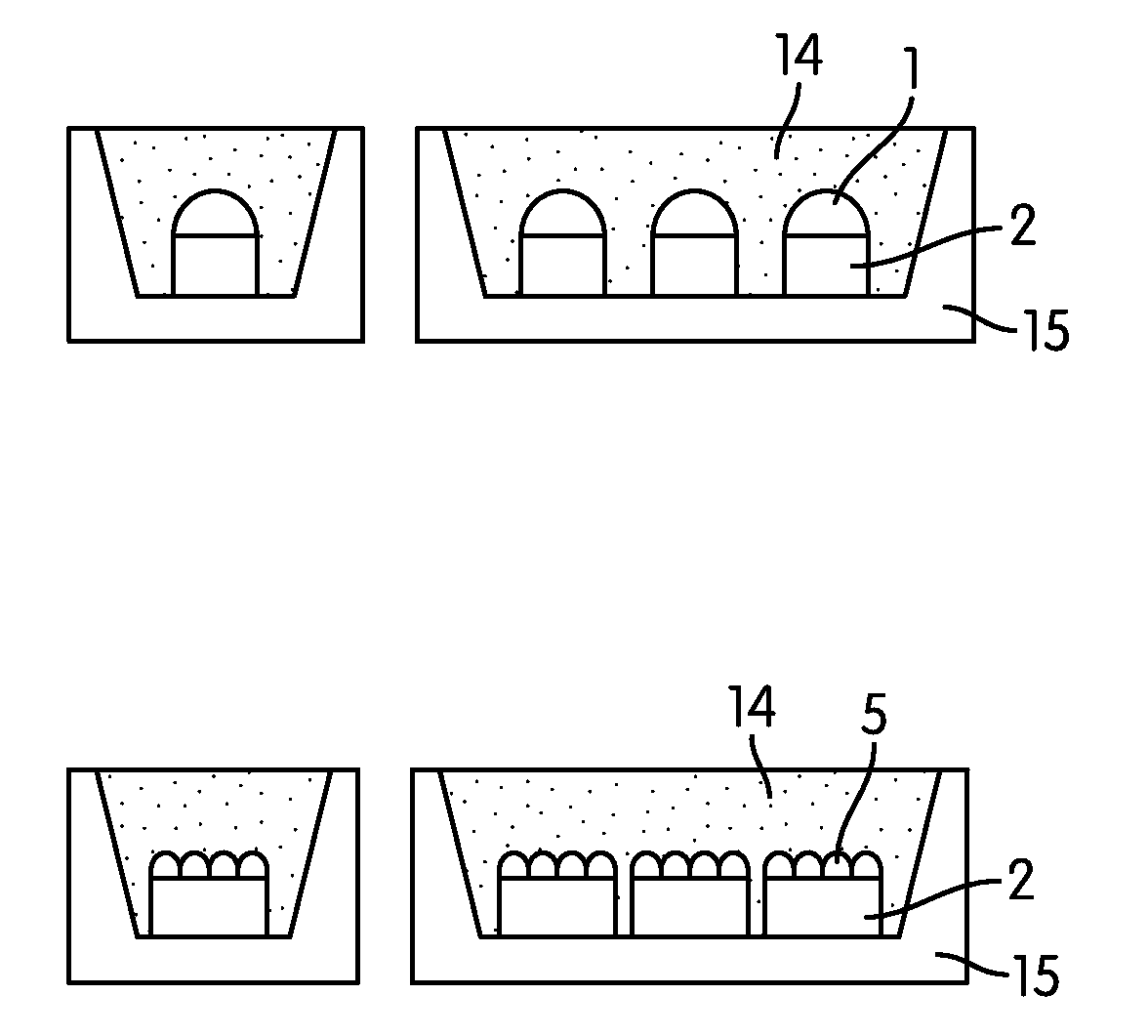

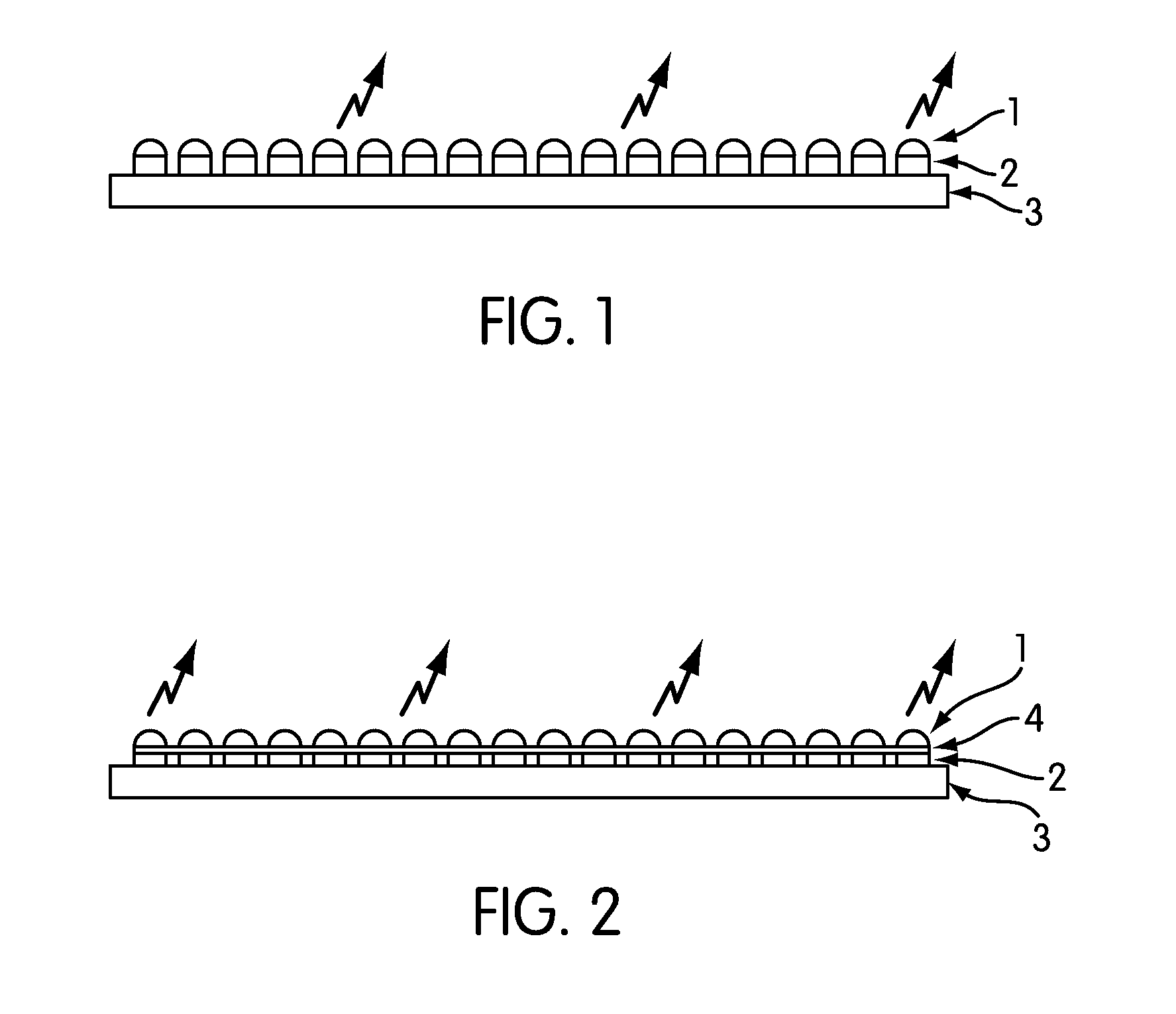

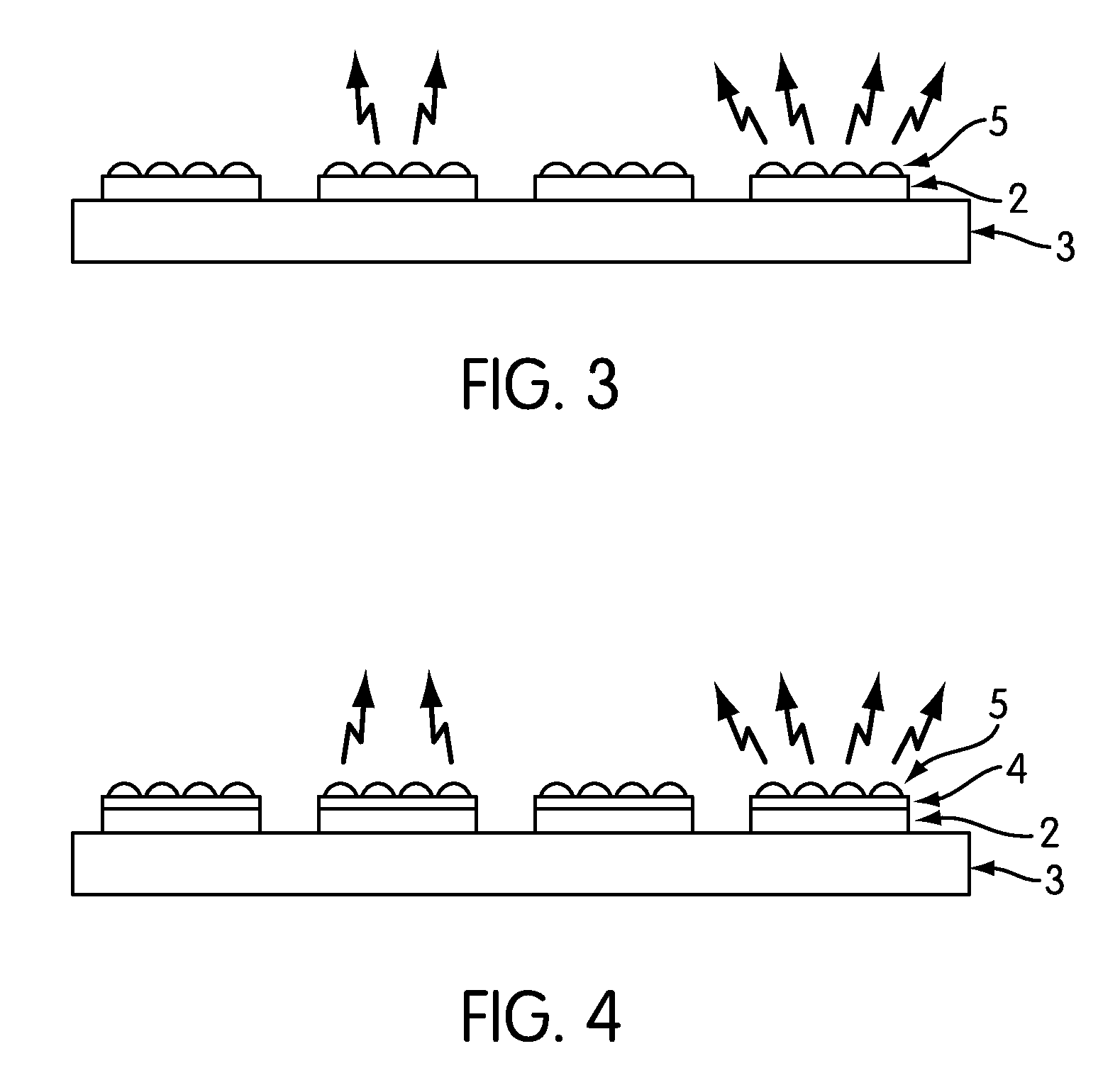

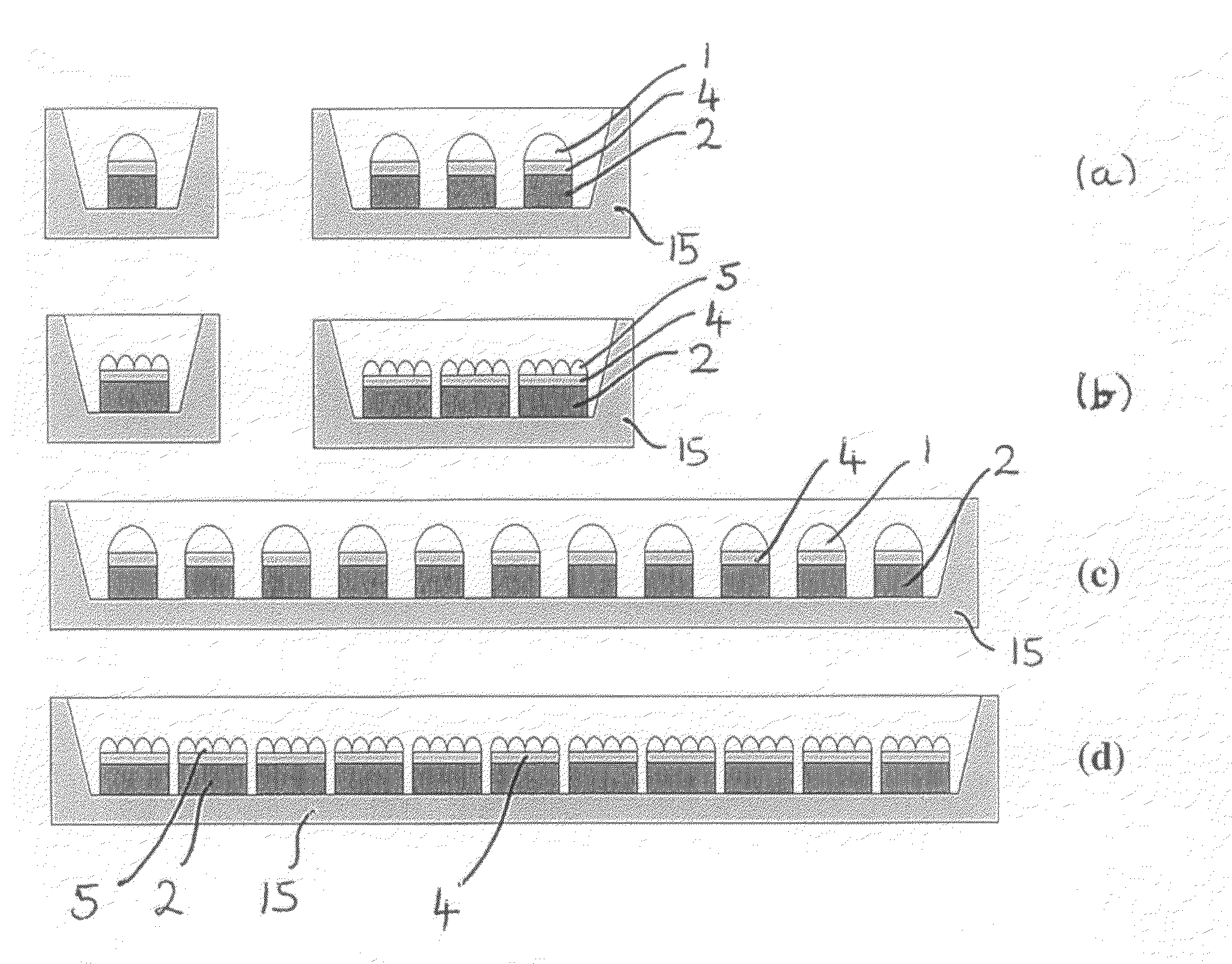

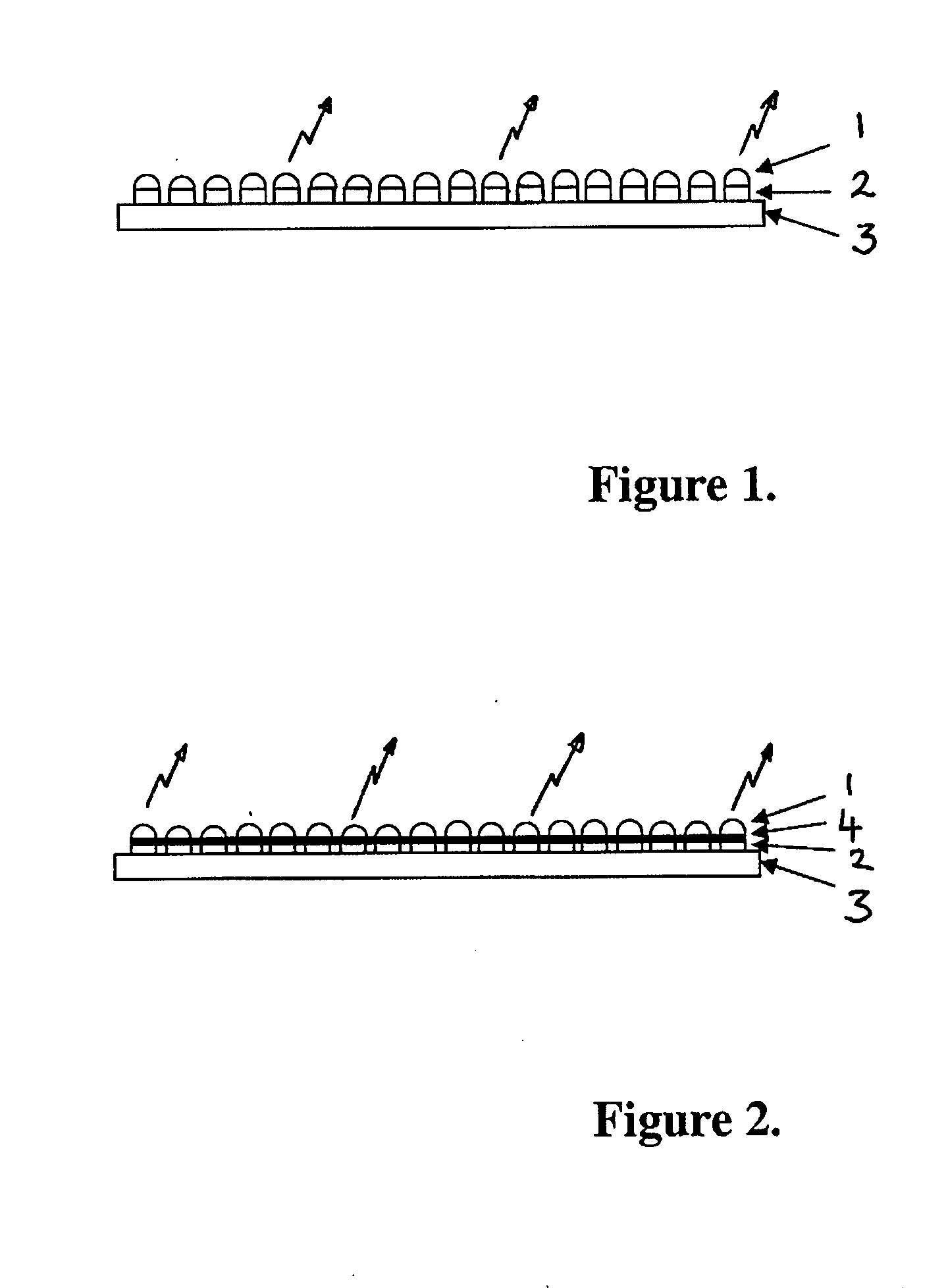

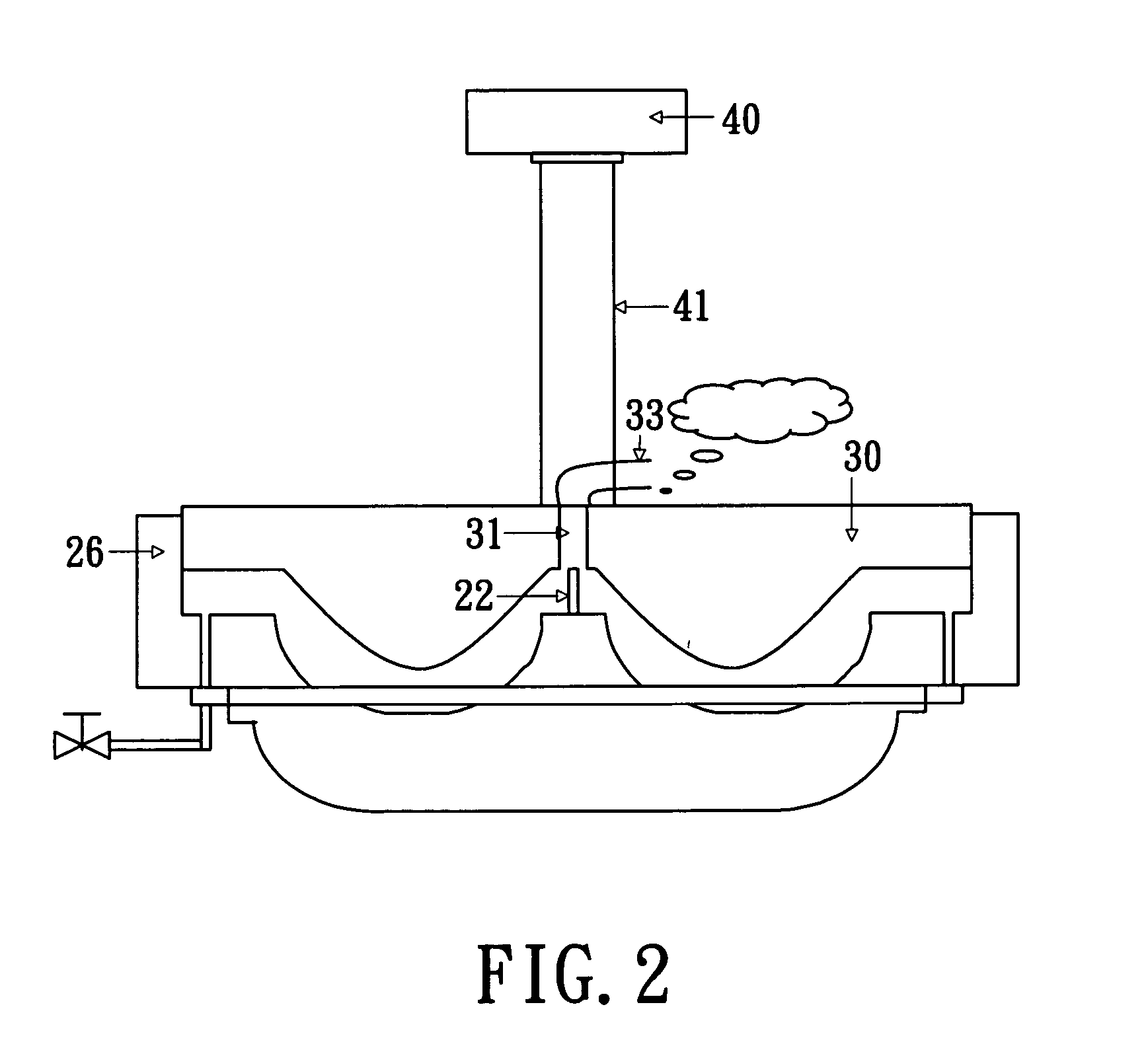

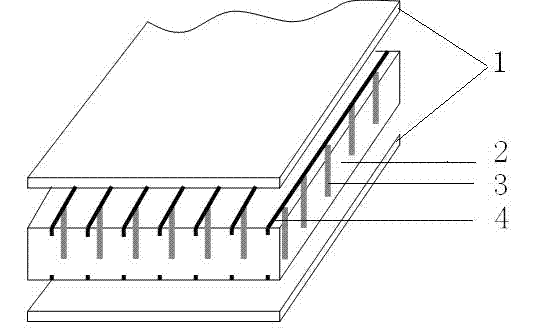

LED assembly with an LED and adjacent lens and method of making same

InactiveUS7737636B2Efficient extractionGood colorDischarge tube luminescnet screensLamp detailsLed arrayLight emitting device

An LED assembly having an LED and a lens disposed adjacent to a light emitting surface of the LED. The area of cross-section of the lens projected onto the light emitting surface of the LED is substantially equal to or less than the area of the LED's light emitting surface. The light emitting device can comprise an array of LEDs and an array of lenses, in which at least one lens is associated with each member of the LED array and wherein the area of a cross-section of each lens projected onto the light emitting surface of its associated LED is substantially equal to or less than the area of the LED's light emitting surface.

Owner:INTEMATIX

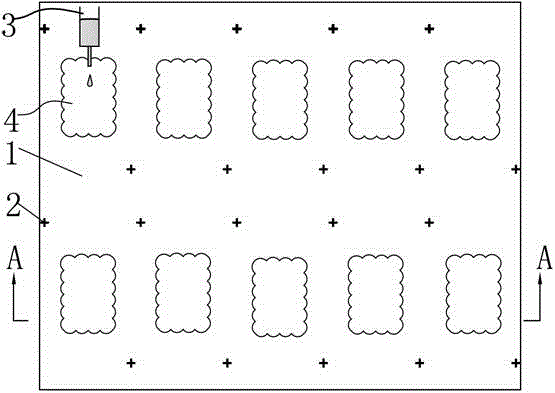

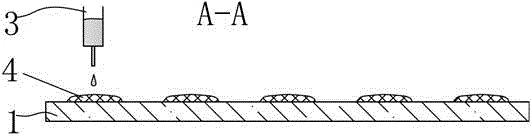

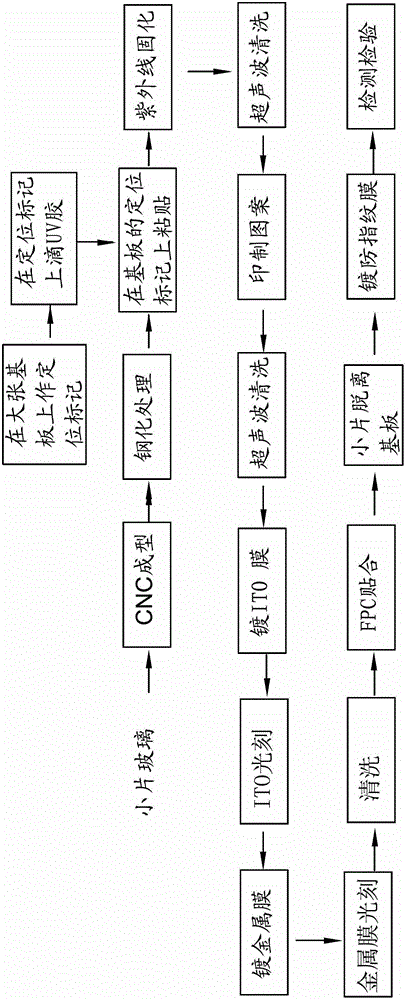

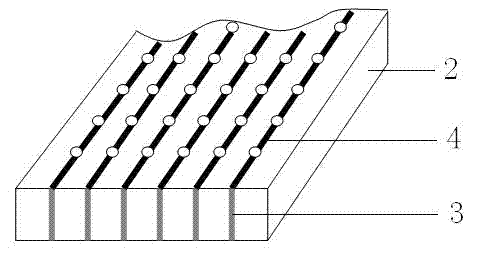

Method for manufacturing capacitive touch screen

InactiveCN102722301AGuaranteed StrengthExtended service lifeInput/output processes for data processingNumerical controlIndium tin oxide

The invention relates to a capacitive touch screen used on electronic equipment, in particular to a method for manufacturing the capacitive touch screen. The method mainly comprises the following steps of: cutting large glass into small pieces; performing computer numerical control (CNC) machining; making charged coupled device (CCD) positioning marks on the upper surface of a large transparent substrate in an array mode according to the size of product glass, and dispensing an ultraviolet (UV) adhesive in the position range of each CCD positioning mark; performing chemical strengthening to form the product glass; accurately superposing the product glass to the CCD positioning marks of the large transparent substrate, adhering and curing; plating an indium tin oxide (ITO) film on each piece of product glass, and photoetching; plating a metal film, and photoetching; attaching to a flexible printed circuit board (FPC); and separating the product glass from the large transparent substrate. By the method, a module which consists of two glass substrate products in the prior art is formed by one piece of product glass, so that the defects in the prior art can be overcome, machining efficiency is effectively improved, yield is high, and production cost is reduced.

Owner:ZHEJIANG XINGXING TECH CO LTD

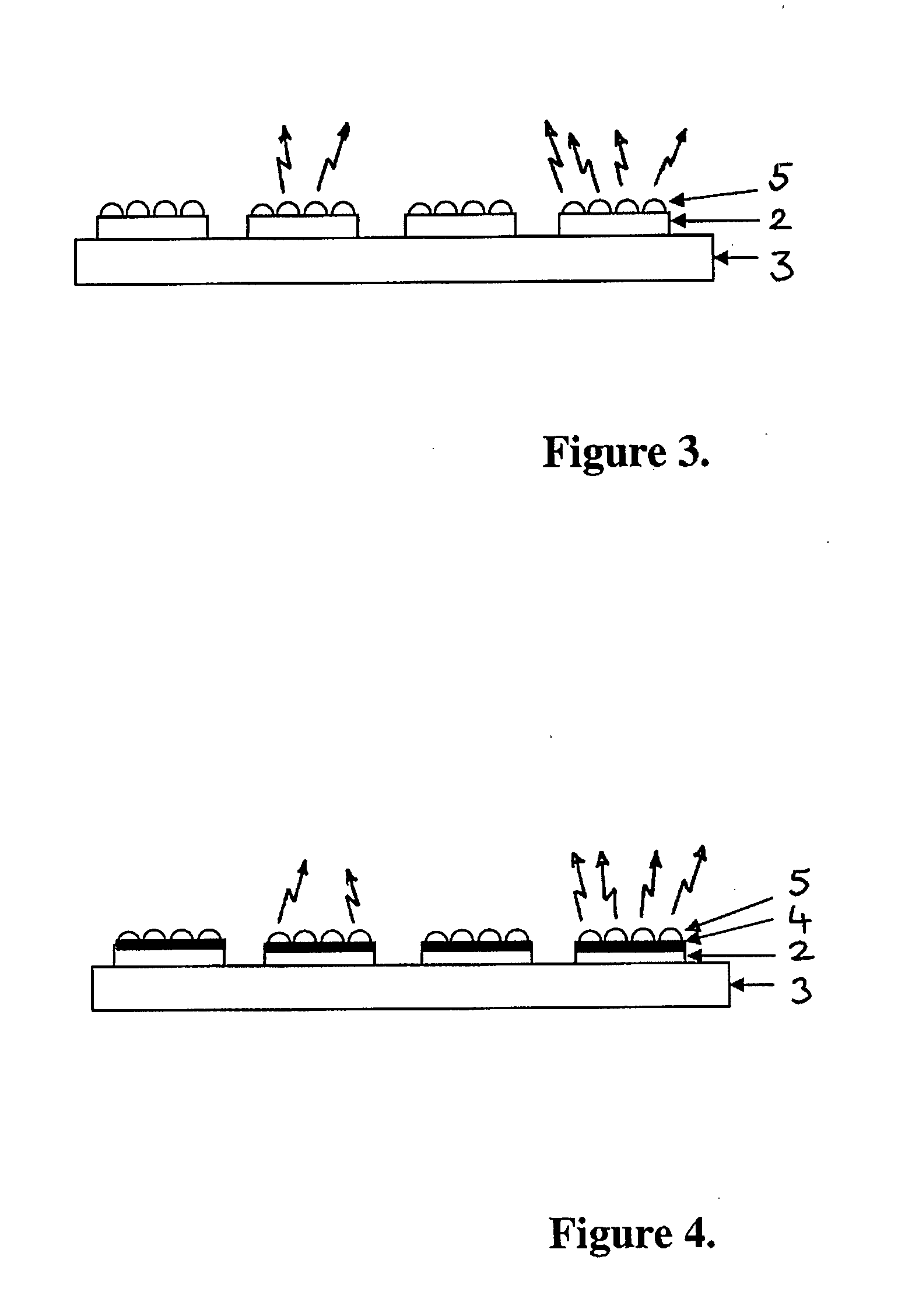

Light emitting diode assembly and method of fabrication

InactiveUS20080111141A1Light extraction efficiencyExcellent luminescence conversionDischarge tube luminescnet screensLamp detailsLed arrayLight emitting device

An LED assembly comprises an LED and a lens disposed adjacent to a light emitting surface of the LED. The area of cross-section of the lens projected onto the light emitting surface of the LED is substantially equal to or less than the area of the LED's light emitting surface. The light emitting device can comprise an array of LEDs and an array of lenses, in which at least one lens is associated with each member of the LED array and wherein the area of a cross-section of each lens projected onto the light emitting surface of its associated LED is substantially equal to or less than the area of the LED's light emitting surface.

Owner:INTEMATIX

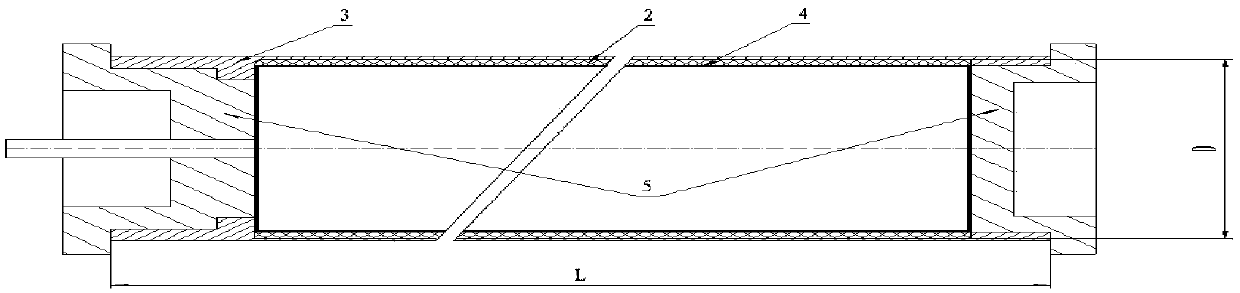

Optical fiber MEMS Fabry-Perot acceleration sensor and manufacturing method thereof

InactiveCN105158506AAvoid electromagnetic interferenceReduce volumeAcceleration measurementTemperature resistanceTemperature coefficient

The invention provides an optical fiber MEMS Fabry-Perot acceleration sensor and a manufacturing method thereof. The acceleration sensor is mainly composed of a shell, an optical fiber, an acceleration sensitive element and a pedestal. The shell, the acceleration sensitive element and the pedestal of the sensor are processed by adopting an MEMS technology. Fixing of the pedestal, the acceleration sensitive element and the shell is realized via an MEMS bonding technology. The optical fiber is fixed in an optical fiber bushing. Fixing of the optical fiber and the shell is realized via a fusion welding technology. A mass block is processed at the center of the acceleration sensitive element via the MEMS technology, and the mass block on the light emergent surface of the optical fiber and the acceleration sensitive element is arranged in parallel so that a Fabry-Perot cavity is formed, and high-sensitivity measurement can be realized. The optical fiber MEMS Fabry-Perot acceleration sensor has advantages of small size, mass production, great consistency, low temperature coefficient and high temperature resistance so that acceleration measurement under conventional and special environments can be met.

Owner:ZHONGBEI UNIV

Method for producing bricks from silt and sludge

InactiveCN101830687AWon't breakSolve processing problemsCeramic materials productionClaywaresBrickLand resources

The invention discloses a method for producing bricks from silt and sludge, which comprises the following steps of: stacking silt and sludge of which the water content is 80-85% in a parking field to enable the water content of the silt and the sludge to be less than or equal to 60% for standby; conveying the silt and the sludge of which the water content is less than or equal to 60% to a primary stirrer through a feeding box for stirring together with fly ash, rice chaffs or wood flour, coal slag and black sand to enable the water content of the mixture to be less than or equal to 30%; putting the mixture in an aging field for aging to enable the water content of the mixture to be less than or equal to 22%; conveying the mixture to a secondary stirrer through the feeding box, and adding water or fly ash according to the degree of dryness and wetness to obtain a blank preparing material of which the water content is less than or equal to 20%; preparing the blank preparing material into a wet blank of which the water content is 17.8-18.8% through extruding and cutting devices; and roasting to obtain a finished product brick. In the method of the invention, silt and sludge are used as main raw materials for producing bricks; on one hand, clay does not need to be used, and the cultivated land can not be destroyed; and on the other hand, the invention solves the problem of treatment of silt and sludge, saves land resources and has obvious effect of environmental protection.

Owner:常州市振东新型节能建筑材料厂

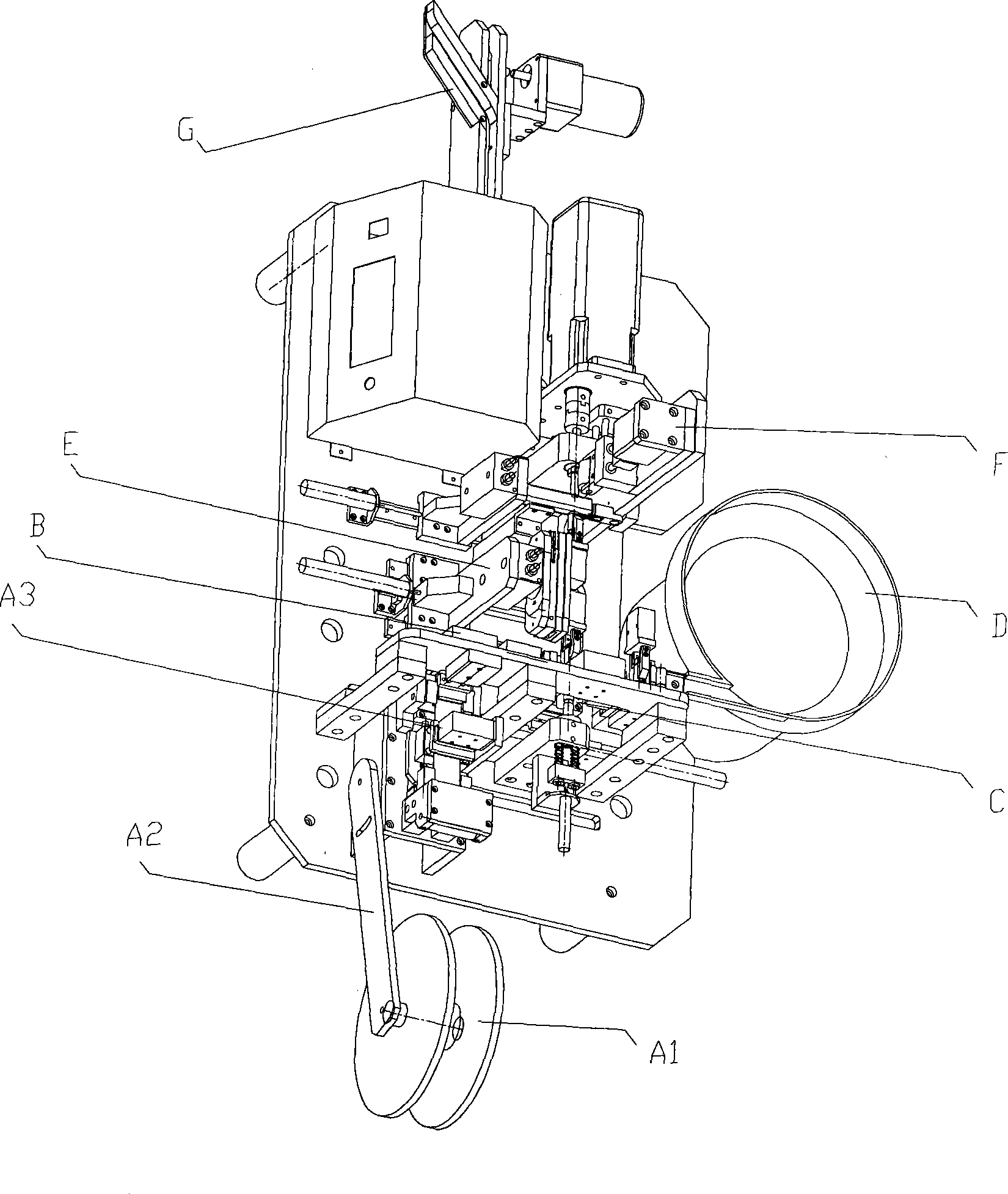

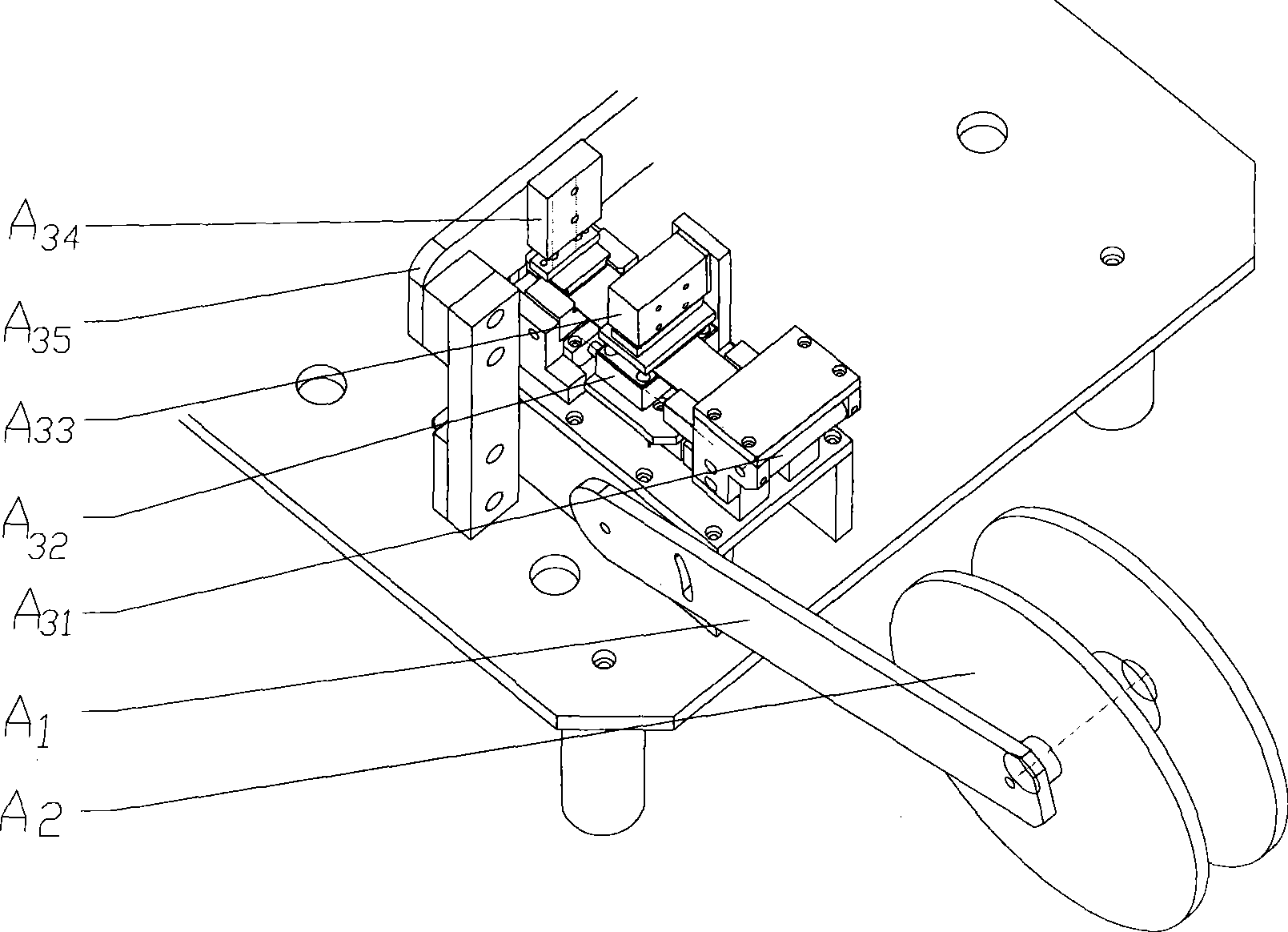

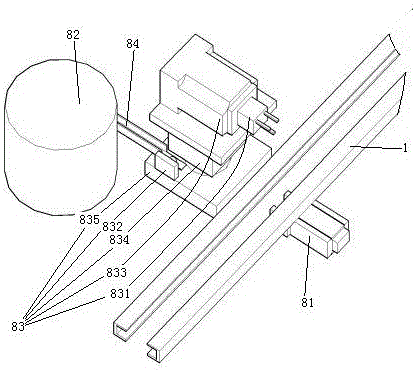

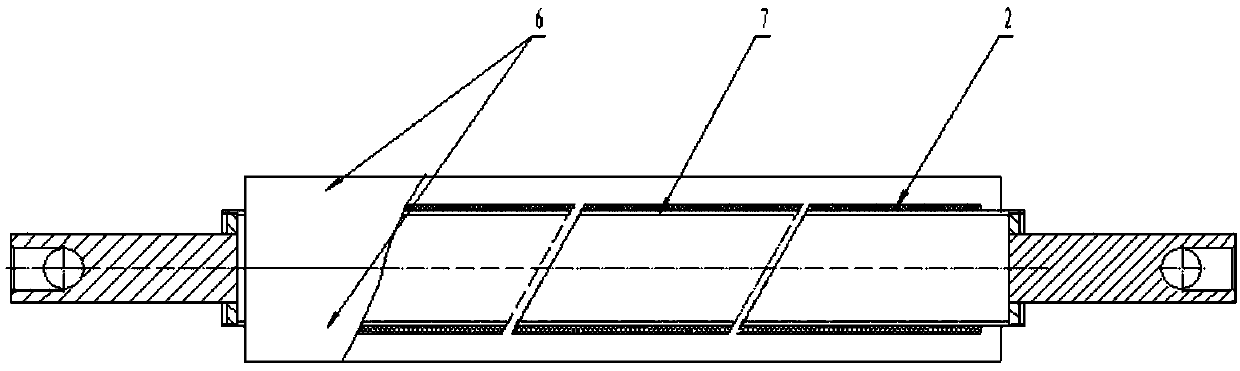

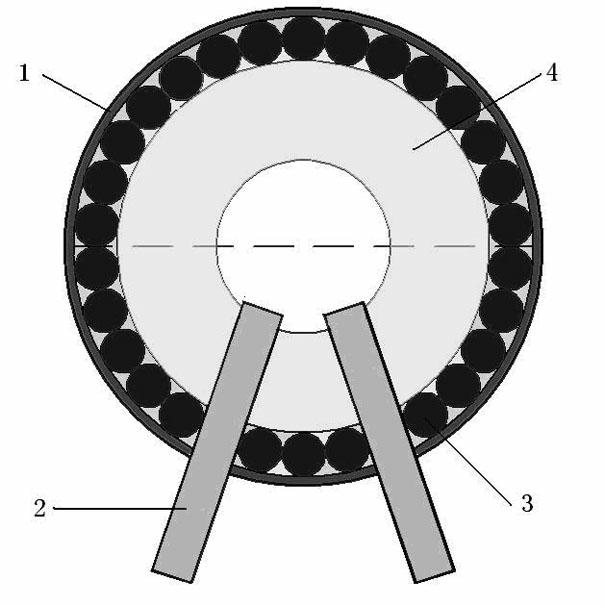

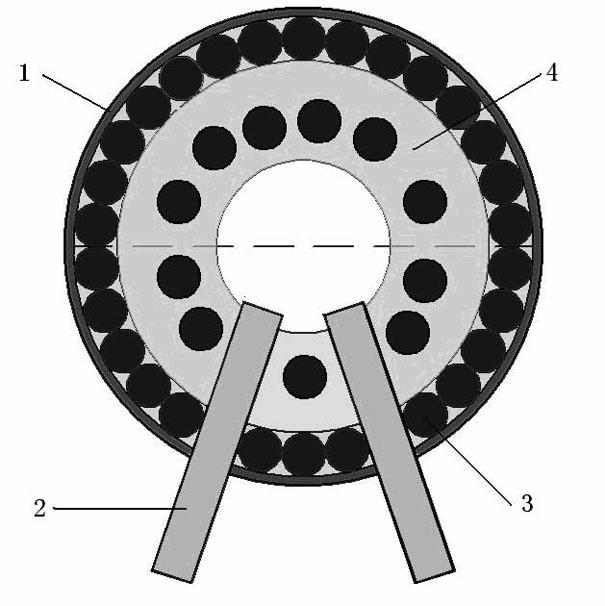

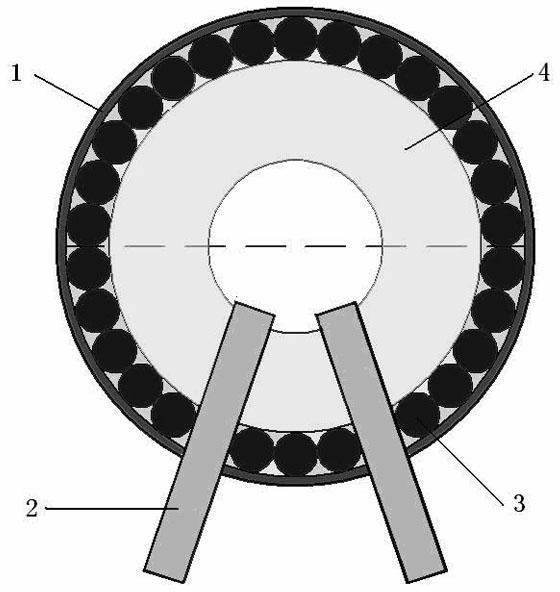

Lithium plate machining device

ActiveCN101399372AReduce labor intensityIncrease productivityFinal product manufactureSecondary cellsHermetic sealLithium metal

The invention discloses an apparatus for processing a lithium piece. The apparatus comprises a frame and a machine table on the frame, a controlled atmosphere chamber is arranged on the table, the table covered by the controlled atmosphere chamber is sequentially equipped with a lithium piece winding up roller, a lithium piece feeding device, a lithium piece cutting device, as well as a lithium piece reeling device and a steel shell conveying device which are paratactic, besides, the table is further provided with a device for putting the lithium piece into the steel shell, a lithium piece rolling device, a discharging device and the like, wherein, the controlled atmosphere chamber is connected with the machine table in a hermetic seal manner and the chamber is full of dry air or dry gas which is inert in relation to lithium metal. The apparatus effectively solves the problems of the traditional manual processing course such as easy sticking of the lithium piece to a knife, difficult forming and stripping, low manual efficiency and high comprehensive cost. The apparatus significantly reduces the labor intensity of workers, greatly improves the production efficiency, and effectively reduces the comprehensive cost of the product.

Owner:EVE ENERGY CO LTD

Buried and embedded copper block PCB manufacturing method

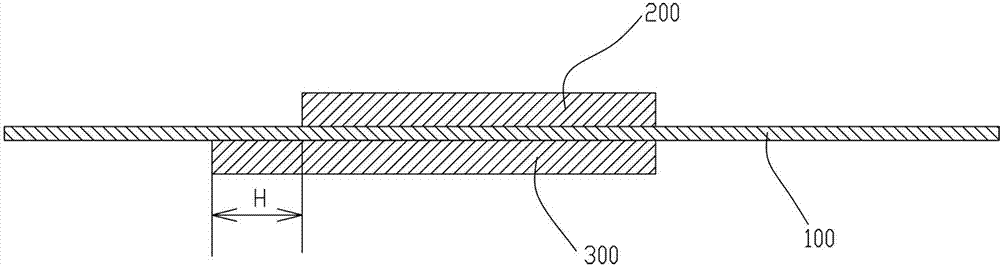

InactiveCN104853523AReduce offsetReduce friction damageMultilayer circuit manufacturePrinted circuit non-printed electric components associationMetallurgyEngineering

The invention discloses a buried and embedded copper block PCB manufacturing method, which comprises steps of laminating treatment of a buried copper block, groove milling, gold immersion, laminating treatment of an embedded copper block and the like. The step of lamination of the buried copper block comprises a buried copper block lamination pre-treatment process. The buried copper block lamination pre-treatment process comprises groove treatment on the edge of the bottom part of the copper block, round corner treatment on the edge of the copper block, and chamfer treatment on the edge corner of the copper block. The step of lamination of the embedded copper block comprises an embedded copper block lamination pre-treatment process, which comprises groove treatment on the edge of the bottom part of a groove hole into which the copper block needs to be embedded, round corner treatment on the edge of the groove hole into which the copper block needs to be embedded and chamfer treatment on the edge corner of the groove hole into which the copper block needs to be embedded. The buried and embedded copper block PCB manufacturing method has the advantages of high product yield, high production efficiency, good quality consistency and simple operation.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

Process for production of precipitated lignin from black liquor and precipitated lignin produced by the process

ActiveUS20130131326A1Increase productionImproved propertyLignin derivativesPulp by-products recoveryBlack liquorIncrease temperature

The present invention relates to a process tor the production of precipitated lignin from black liquor wherein the process comprises the steps of providing a black liquor stream treating the black liquor at an increased temperature and precipitating the lignin from the heat treated black liquor. The present invention further relates to precipitated lignin produced according to the process and use of the precipitated lignin produced.

Owner:STORA ENSO OYJ

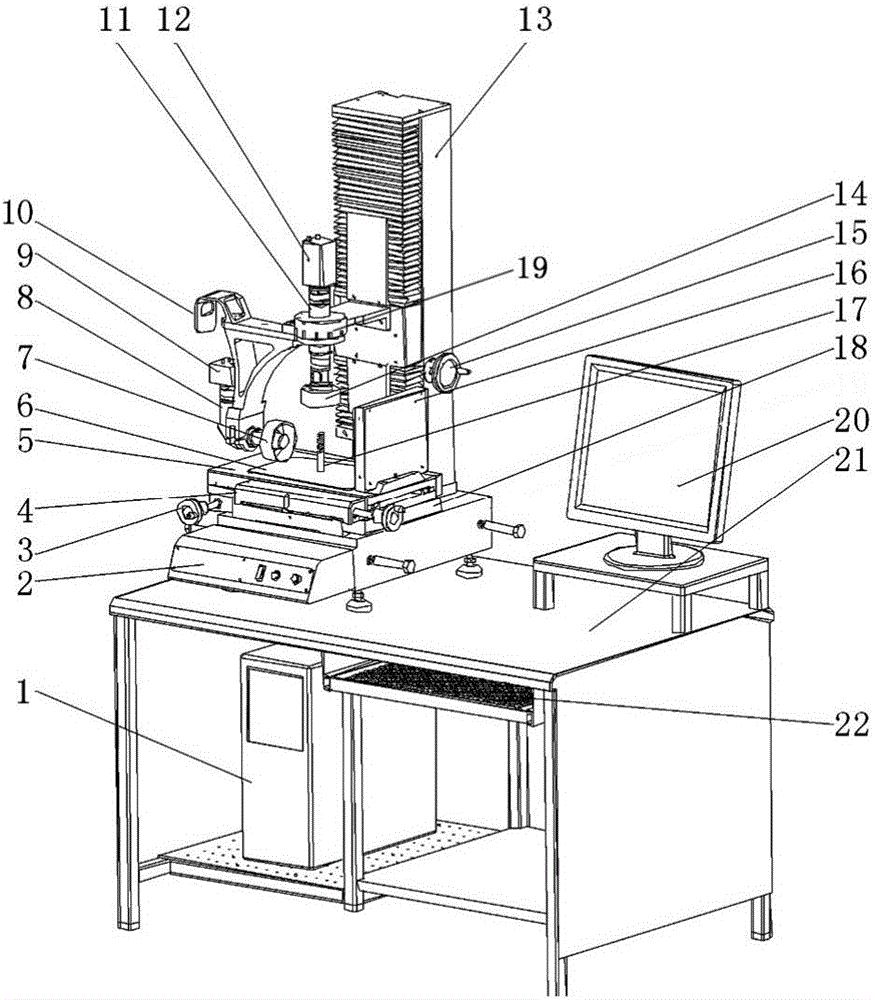

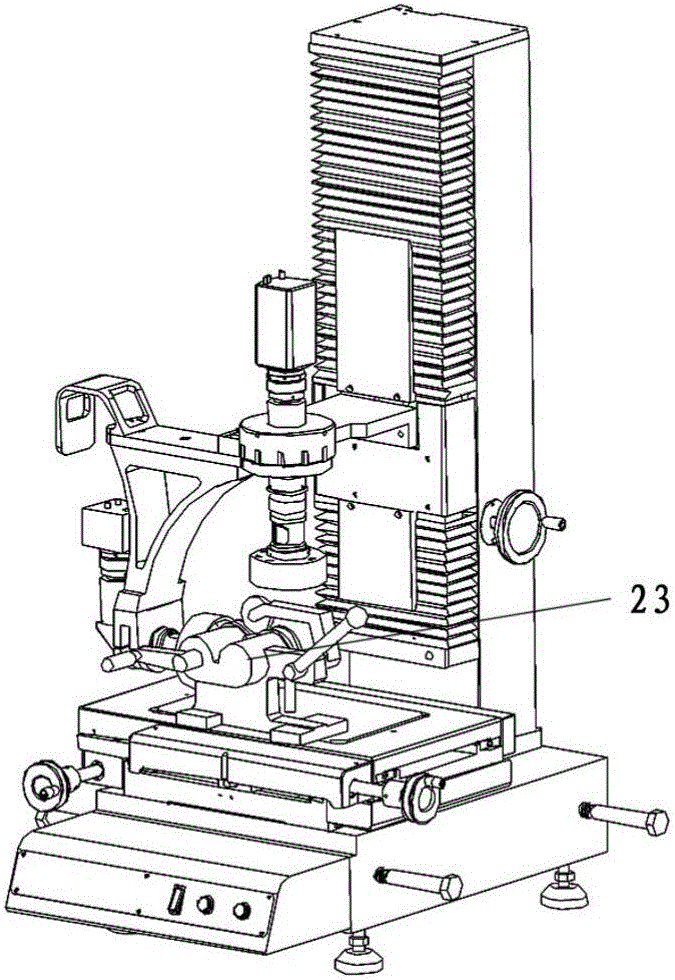

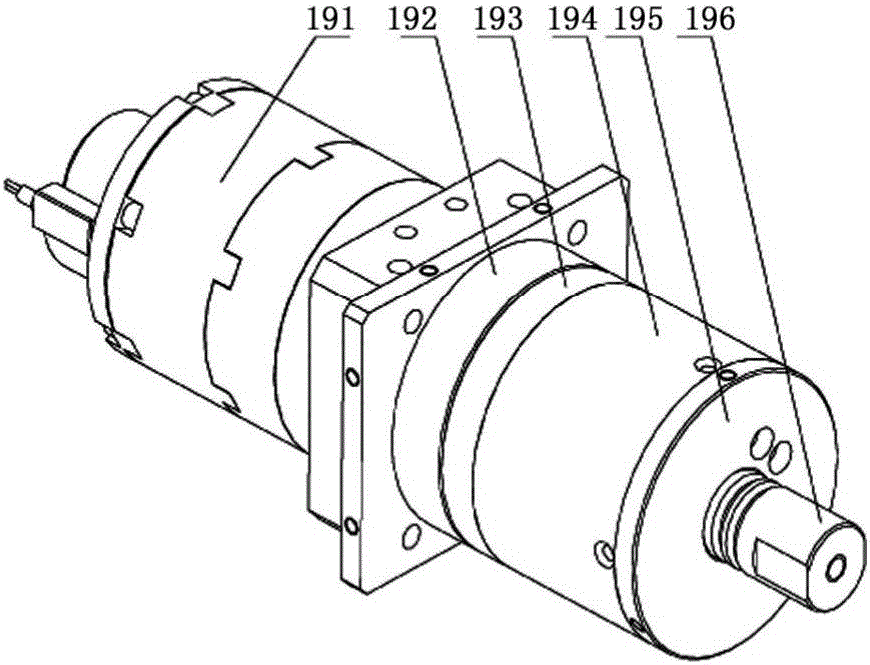

Image measurement tool system and method

InactiveCN105674882ARealize measurementAdd alignment functionUsing optical meansCamera lensDisplay device

The invention relates to an image measurement tool system, and the system comprises a sheet metal instrument stand, a display, a computer host, a mouse keyboard, a console, a workbench moving mechanism, a lifting mechanism, a working table, a glass block, a clamping tool for clamping a cutter, a bottom light source plate, a lateral image collection device, and a longitudinal image collection device. The mouse keyboard and the display are respectively connected with the computer host, and the computer host is connected with the console. The workbench moving mechanism and the lifting mechanism are disposed on the console and are connected with the console. The working table is disposed above the workbench moving mechanism, and the glass block is disposed on the upper surface of the working table. The clamping tool is disposed at the central part of the glass block. The longitudinal image collection device is fixed on the lifting mechanism, and the lateral image collection device is rotatingly connected along the axis of the longitudinal image collection device through an angle rotating device. The bottom light source plate is disposed on the working table, and is disposed at a side of a longitudinal camera lens.

Owner:东莞市嘉腾仪器仪表有限公司

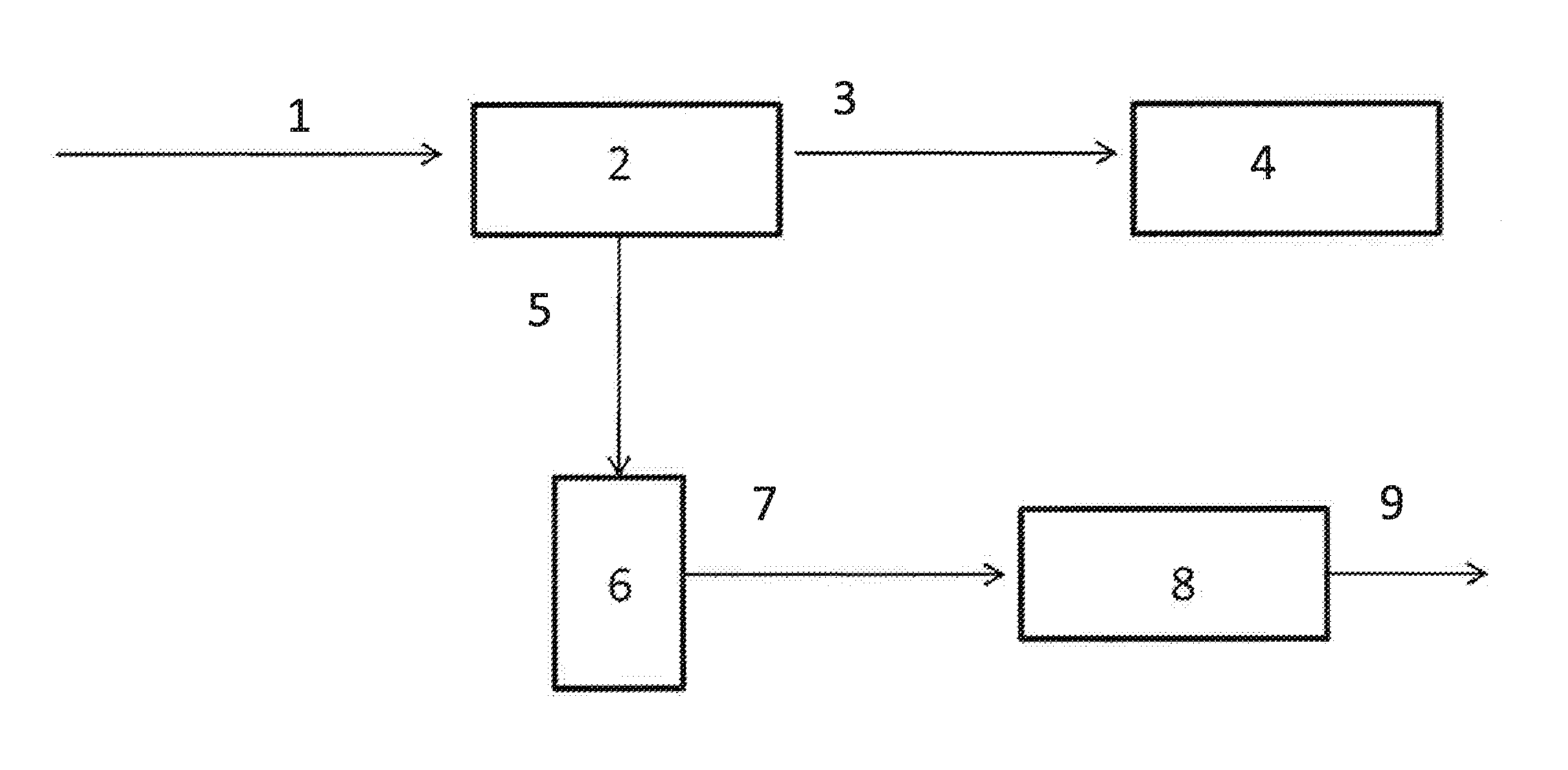

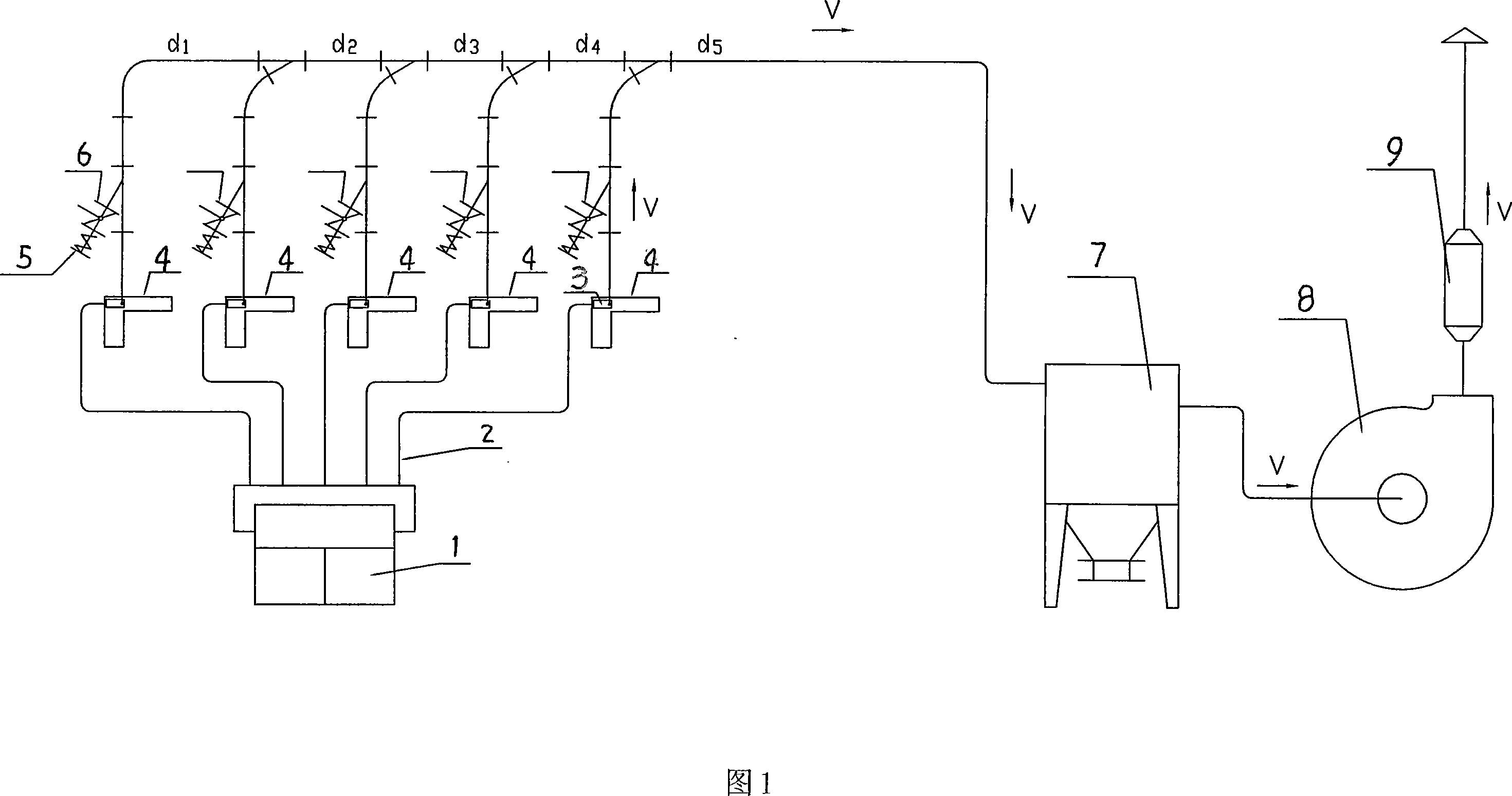

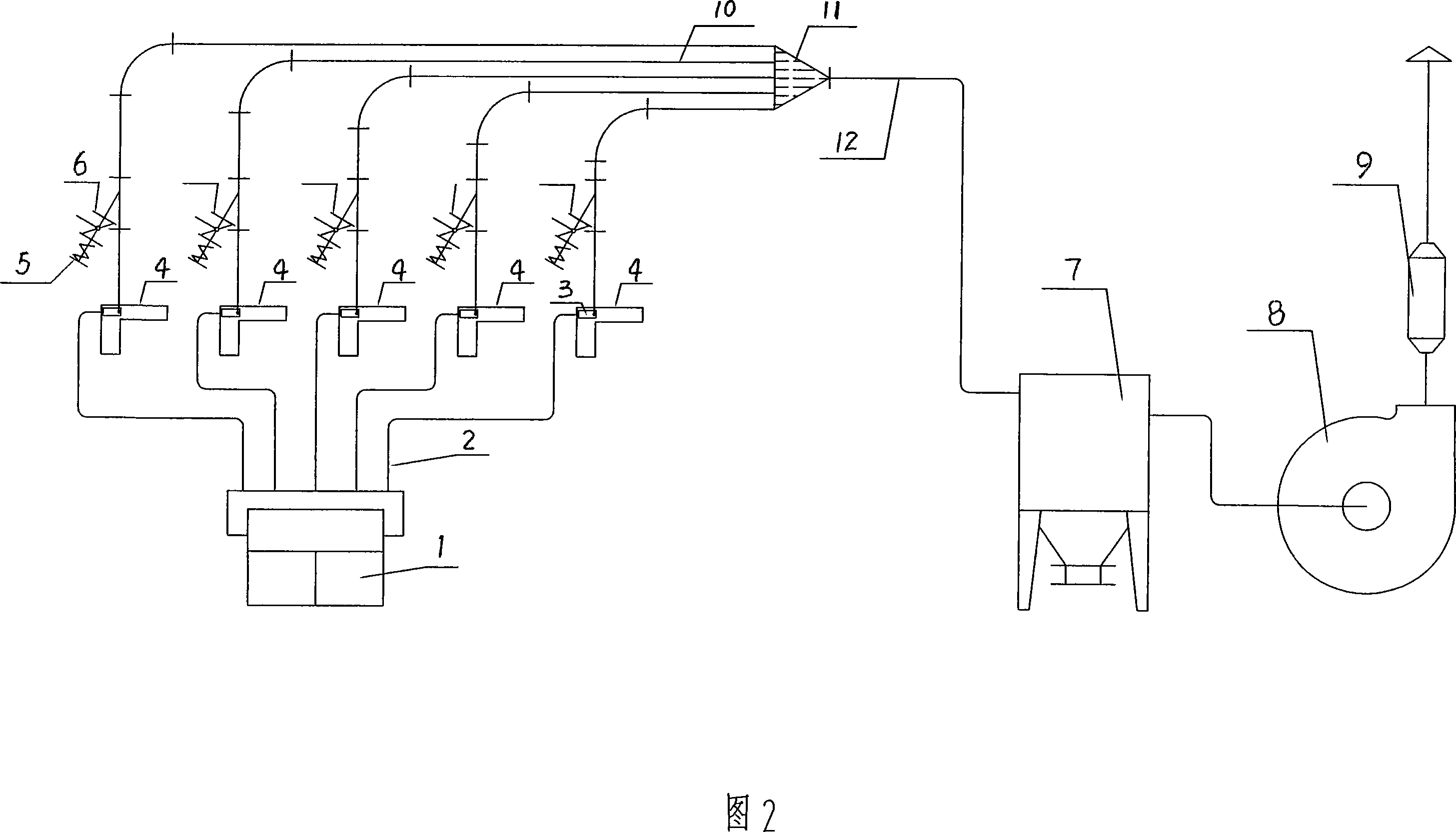

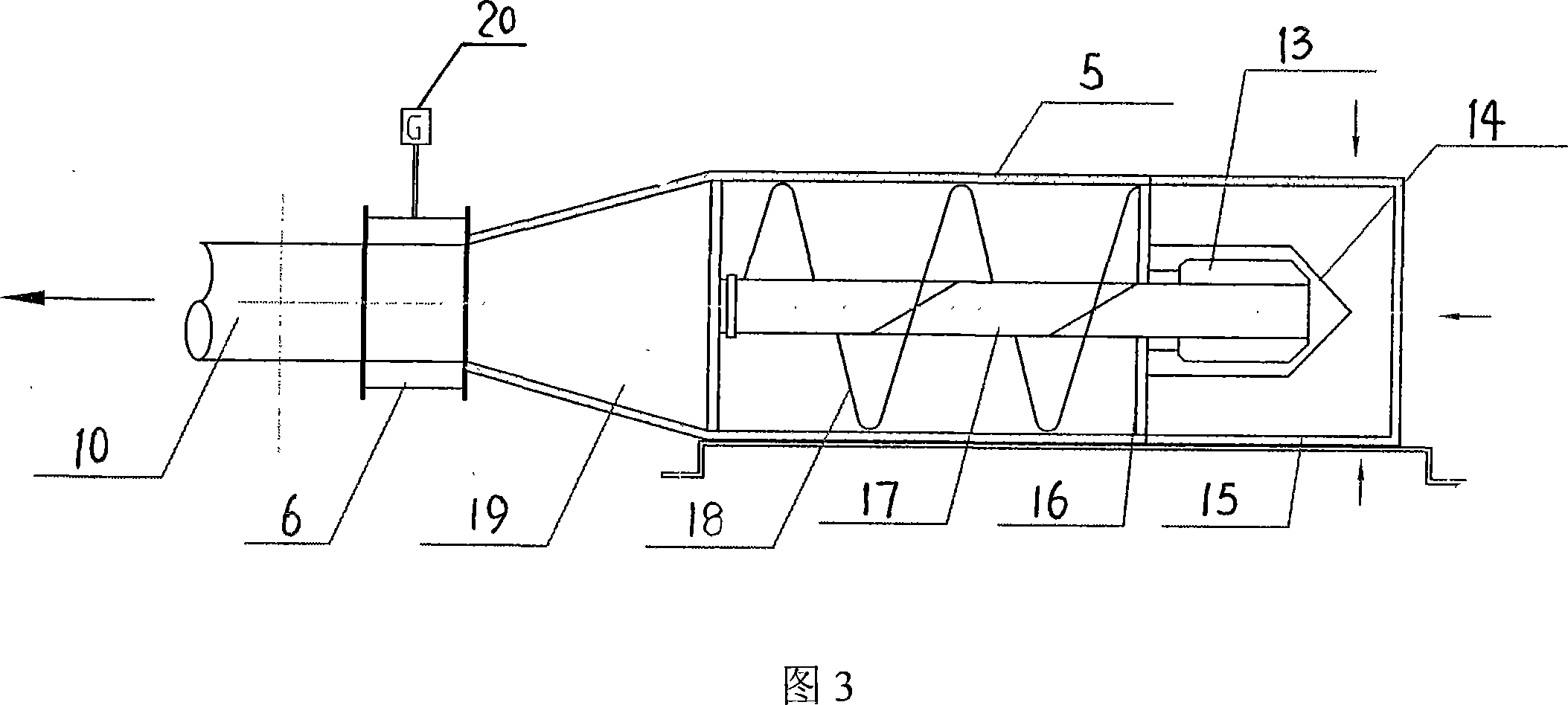

Binary isogram replacing constant-speed pneumatic conveying method

ActiveCN101134531ADampen wild swingsGuaranteed uptimeCigarette manufactureBulk conveyorsMaterial consumptionWorking set

The binary equivalent substitution constant speed pneumatic conveying process for multiple branch pipe negative pressure dilute phase pneumatic conveying system features that in a working set possessing branch pipes with pneumatic valve and damper and when some branch pipe is cut off suddenly, each of the other branch pipes inside the system is equivalently supplemented with corresponding air quantity and wind pressure. The process can convey material reliably and fluently in balance with minimized physical and chemical damage, and reach the aims of lowering material consumption, lowering cost and raising product quality.

Owner:邝勇兴

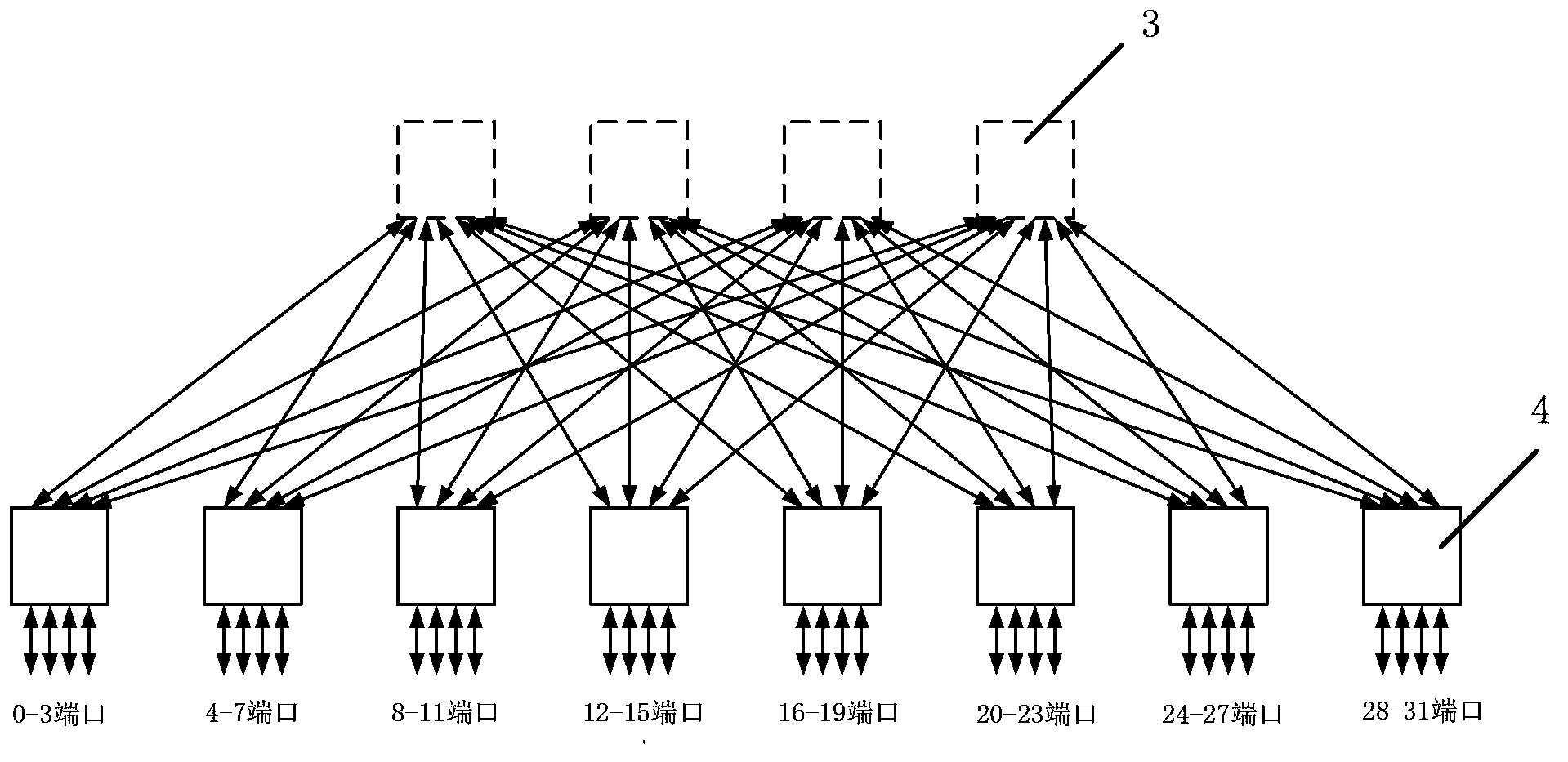

Substrate/multi-chip-integrated large port interconnection chip and realization method thereof

ActiveCN103413796AManufacturing technology requirements are lowIncrease flexibilitySemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyEngineering

The invention provides a multilayer wiring substrate / multi-chip integration-based large port interconnection chip interconnection construction and physical realization method and relates to a multi-chip interconnection structure, a multi-chip interconnection structure construction method, multi-chip layout, substrate pin array partitioning and distribution, distribution of high-speed differential signal pin pairs, effective partition of substrate wiring and a partition method of the substrate wiring as well as a corresponding multi-chip interconnection chip device which are applicable to substrate integration. According to the invention, large-port interconnection chips can be effectively and equivalently realized based on substrate encapsulation size. Compared with a corresponding single-chip integration implementation method, the method of the invention can support multiple kinds of interconnection structures, and is compatible with interconnection sub-chips be of a variety of micro-system structures, can effectively utilize the characteristics of different functional interconnection sub-chips, and has better performance in implementation cost of the chips, scalability, flexibility, compatibility and the like; and at the same time, the method of the invention has lower requirements for manufacturing technology for realizing a required integrated circuit and can provide interconnection chips having different specifications and different number of ports, and can more flexibly adapt to market demands.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

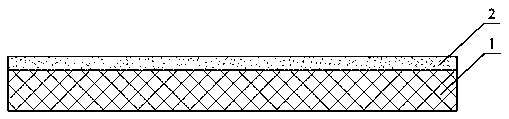

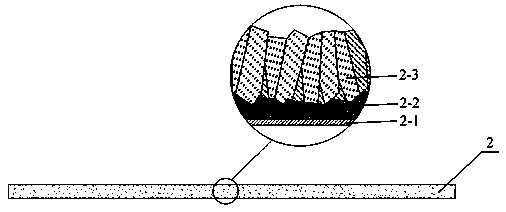

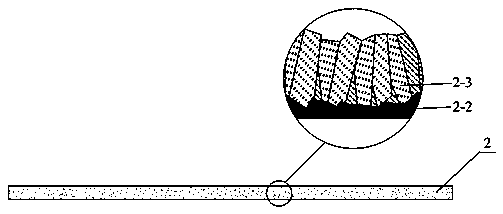

Preparation method of high-quality self-support diamond thick film

ActiveCN105506576AGood quality consistencyAvoid localized or penetrating cracksChemical vapor deposition coatingMethaneMaterials science

The invention discloses a preparation method of a high-quality self-support diamond thick film. The preparation method comprises the following steps: preparing a high-quality self-support diamond film which is 0.5 to 0.7 mm thick according to a chemical vapor deposition method; conducing grinding and polishing on a nucleation surface of the high-quality self-support diamond film, removing residual carbonide, and preparing a high-quality diamond film which is 1 to 3 mm thick on the treated nucleation surface by taking the treated nucleation surface as a base body, wherein during the two preparation processes, once the thickness of the diamond film is increased by 50 to 100 [mu]m, the methane flow rate is reduced by 0.5 to 1 percent of an initial methane flow rate. The high-quality self-support diamond thick film prepared according to the preparation method is high in quality uniformity, has no crack, and is high in mechanical strength.

Owner:山西新碳超硬材料科技有限公司

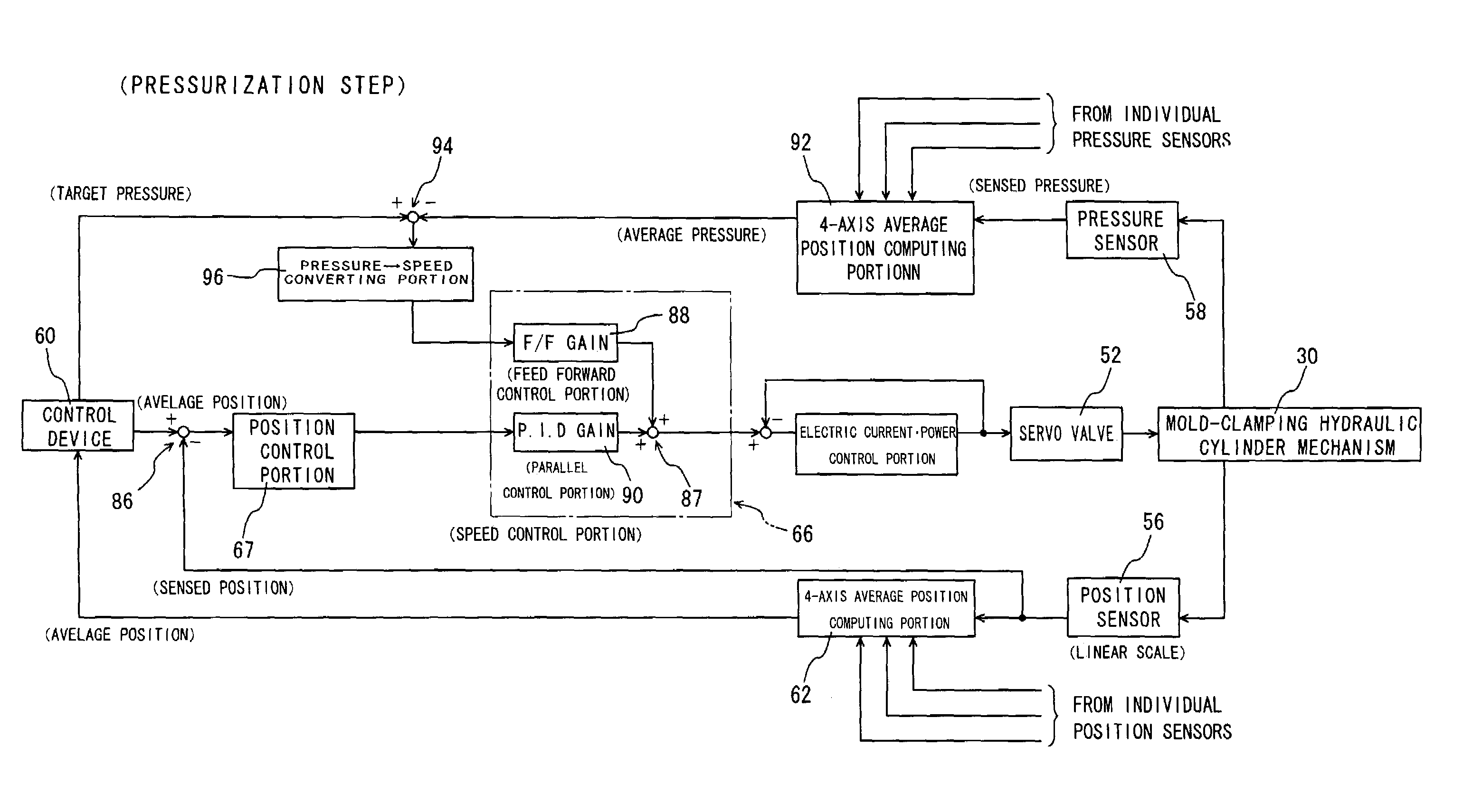

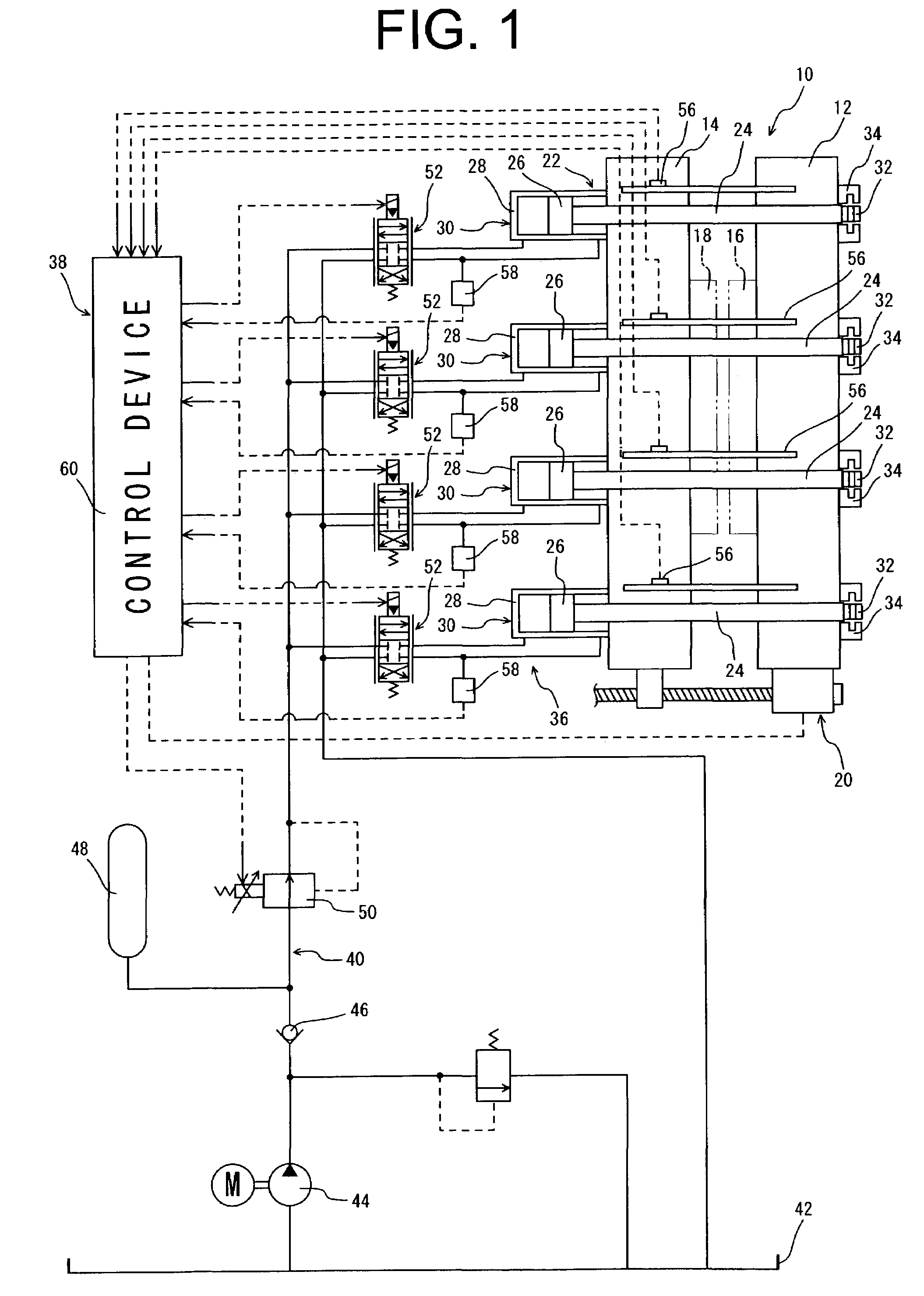

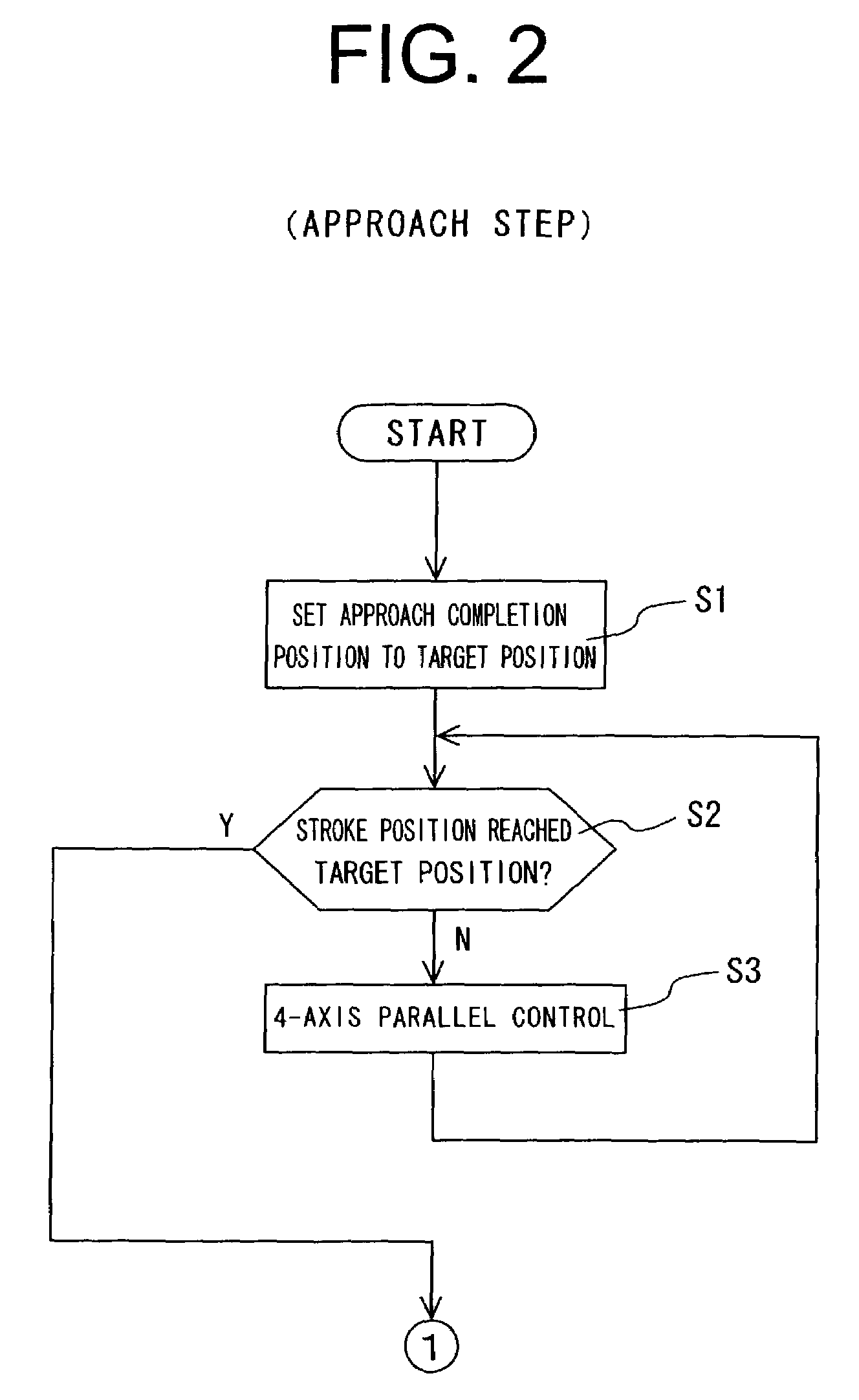

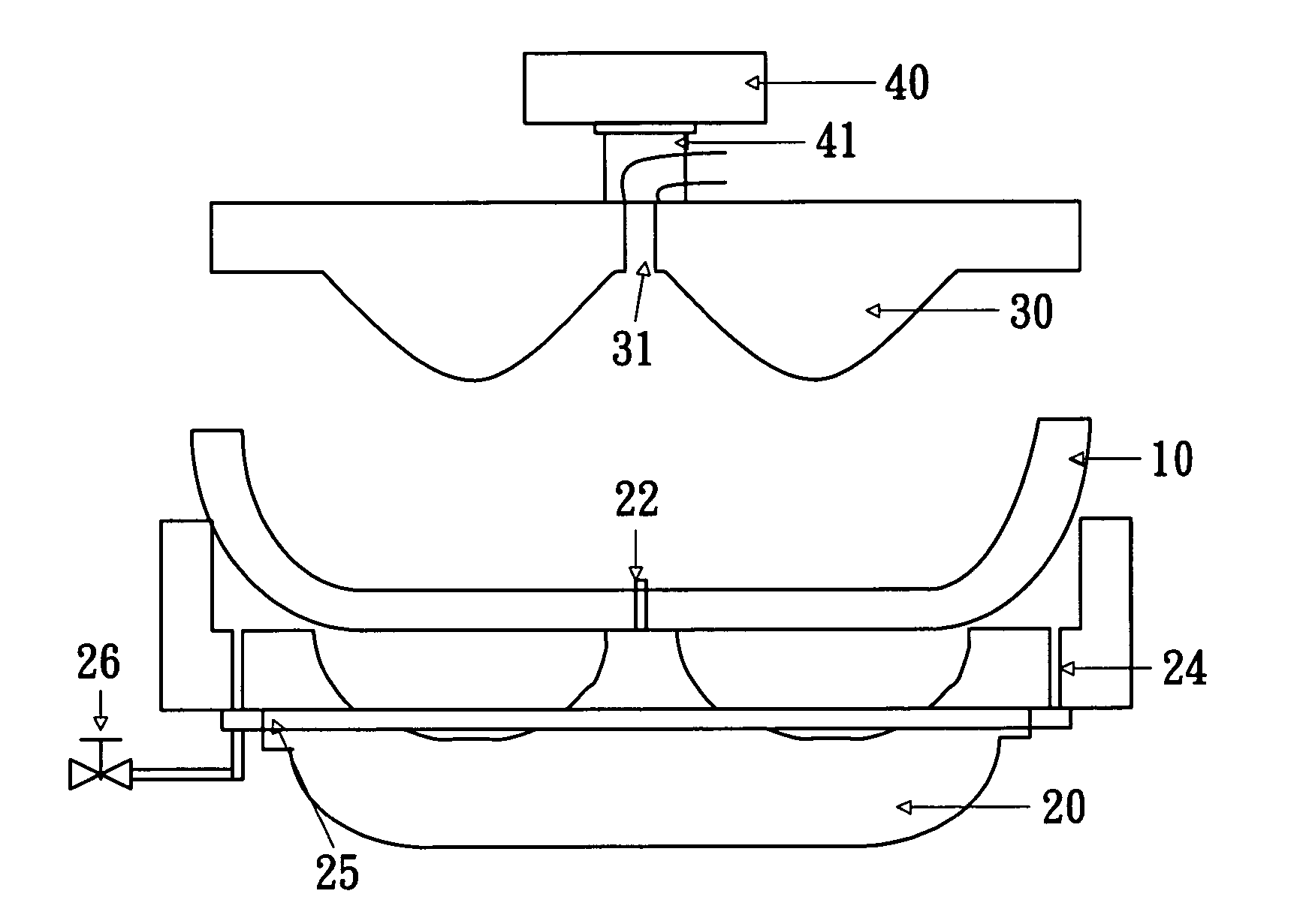

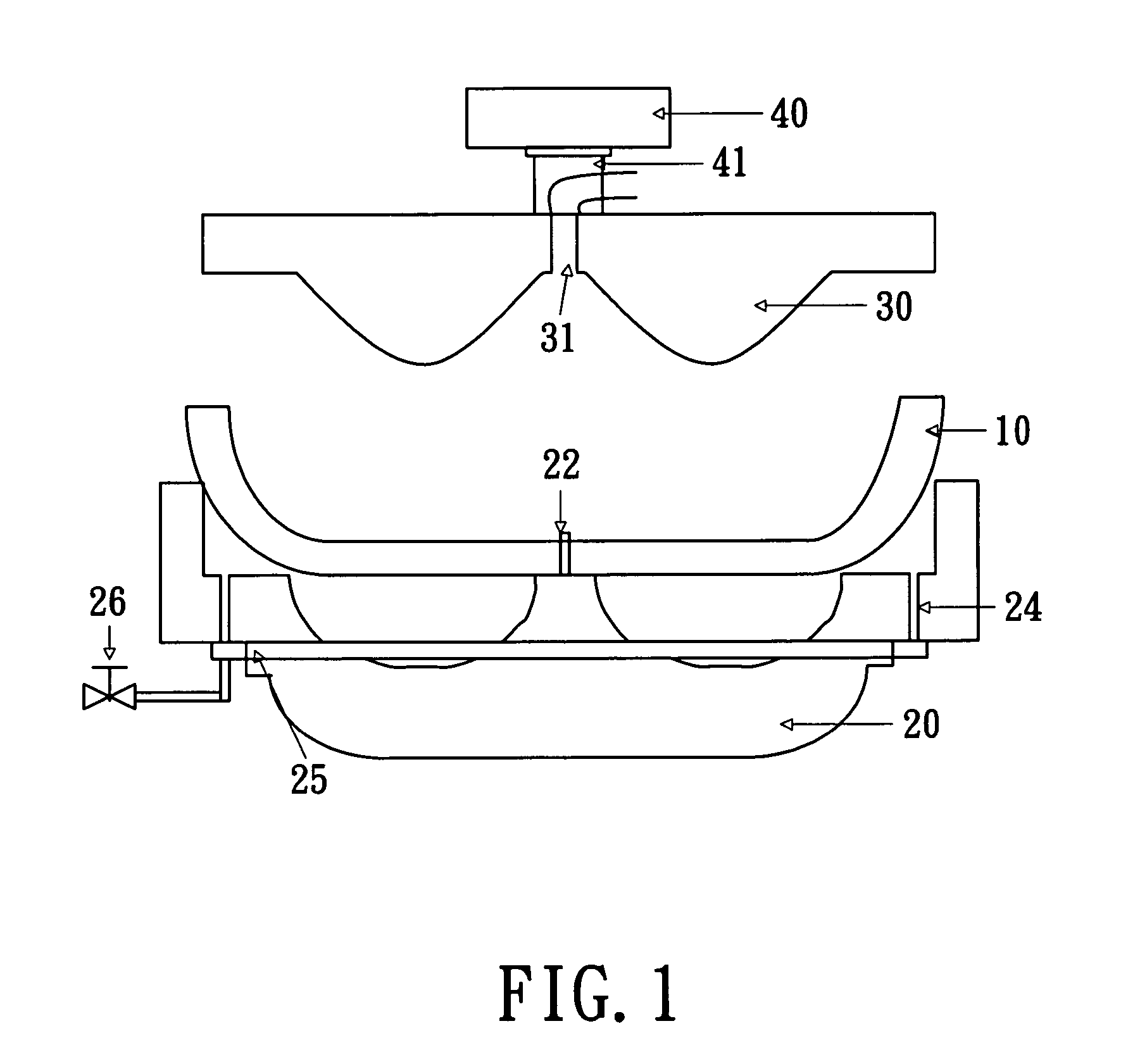

Compression molding method and mold clamping apparatus

ActiveUS7001545B2High precisionQuantity minimizationAuxillary shaping apparatusFood shapingCompression moldingControl signal

Disclosed is a compression molding method comprising the steps of: calculating an average value of mold clamping forces sensed in a plurality of mold clamping mechanisms for clamping a stationary and a movable mold half; obtaining a first control signal on the basis of deviation between a preset target mold clamping force and an average value of sensed mold clamping forces; sensing positions of movable members of the mold clamping mechanisms; obtaining an average value of sensed positions; setting the average value as a successive target position; obtaining a second control signal on the basis of deviation between each of the sensed positions and the successive target position; and obtaining a clamping control signal for each of the clamping mechanisms by adding the first control signal and the second control signal. An apparatus suitable for implementing the method is also disclosed.

Owner:MEIKI

Automatic nut and gasket screwing device

InactiveCN106181348AImprove quality consistencyIncrease productivityMetal working apparatusEngineeringTransfer mechanism

The invention relates to machining equipment, and discloses an automatic nut and gasket screwing device. The automatic nut and gasket screwing device comprises an obliquely-arranged workpiece movement guide groove, a bolt penetrating and gasket sleeving mechanism and a nut assembly mechanism. The bolt penetrating and gasket sleeving mechanism comprises a gasket vibration disc provided with a gasket sequential discharging groove, a bolt and gasket assembly position workpiece fixing mechanism, a gasket one-by-one transfer mechanism, a bolt vibration disc provided with a bolt sequential discharging groove and a bolt one-by-one transfer mechanism. The nut assembly mechanism comprises a nut assembly position workpiece fixing mechanism, a nut vibration disc provided with a nut sequential discharging groove and a nut one-by-one transfer and screwing mechanism. The automatic nut and gasket screwing device has the beneficial effect of being capable of screwing bolt fit gaskets and nuts on workpieces, and the problems that when bolt penetrating, gasket sleeving and nut screwing are carried out on the workpieces in a manual screwing manner, quality consistency is poor, and efficiency is low are solved.

Owner:ZHEJIANG SANYONG MACHINERY CO LTD

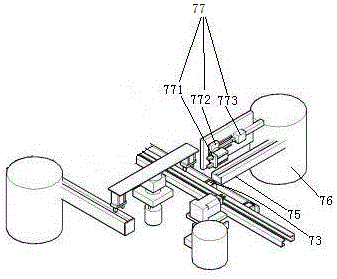

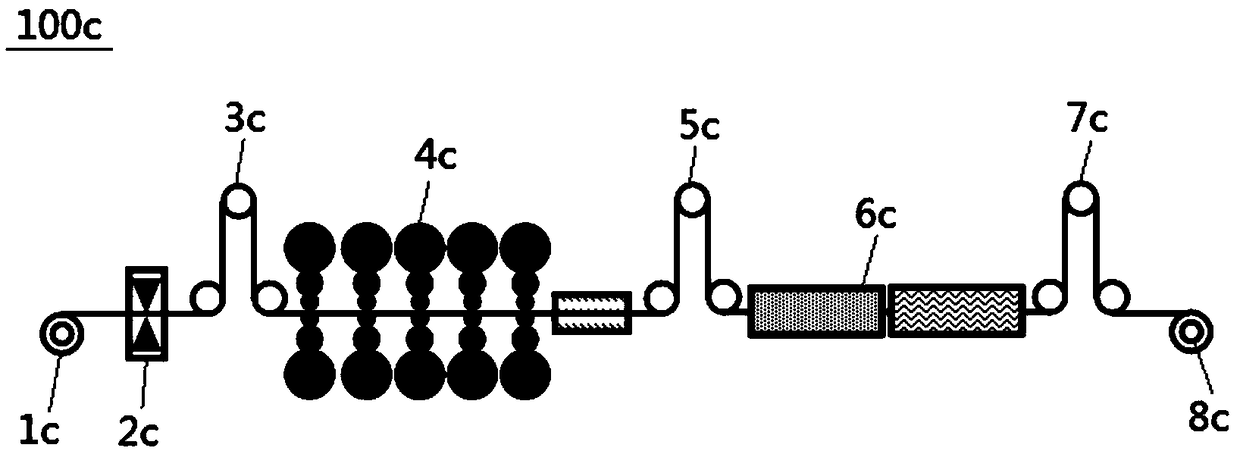

Stainless steel cold-rolled strip steel production device

InactiveCN108906888AImprove applicabilityImprove quality consistencyWork treatment devicesFurnace typesSurface levelSS - Stainless steel

The invention belongs to the field of stainless steel cold-rolled strip steel production and discloses a stainless steel cold-rolled strip steel production device. The stainless steel cold-rolled strip steel production device comprises a raw material uncoiling and welding device, a rolling device, an annealing-pickling device, a flatting and straightening device, an edge portion finishing device and a finished product coiling device which are sequentially connected, wherein raw material coils are sequentially fed by the uncoiling and welding device, head and tail welding of adjacent material coils is achieved, the rolling device rolls the raw material coils according to target thickness, the annealing-pickling device improves the performance of rolled strip steel and obtains strip steel ofthe same surface level, the flatting and straightening device can selectively obtain two types of strip steel of different surface levels, the edge portion finishing device conducts edge trimming onthe strip steel to obtain strip steel consistent in width, and the finished product coiling device coils the strip steel. The stainless steel cold-rolled strip steel production device achieves full continuous production of cold-rolled strip steel, is high in efficiency, low in cost and strong in applicability and makes the produced finished products high in quality consistency.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

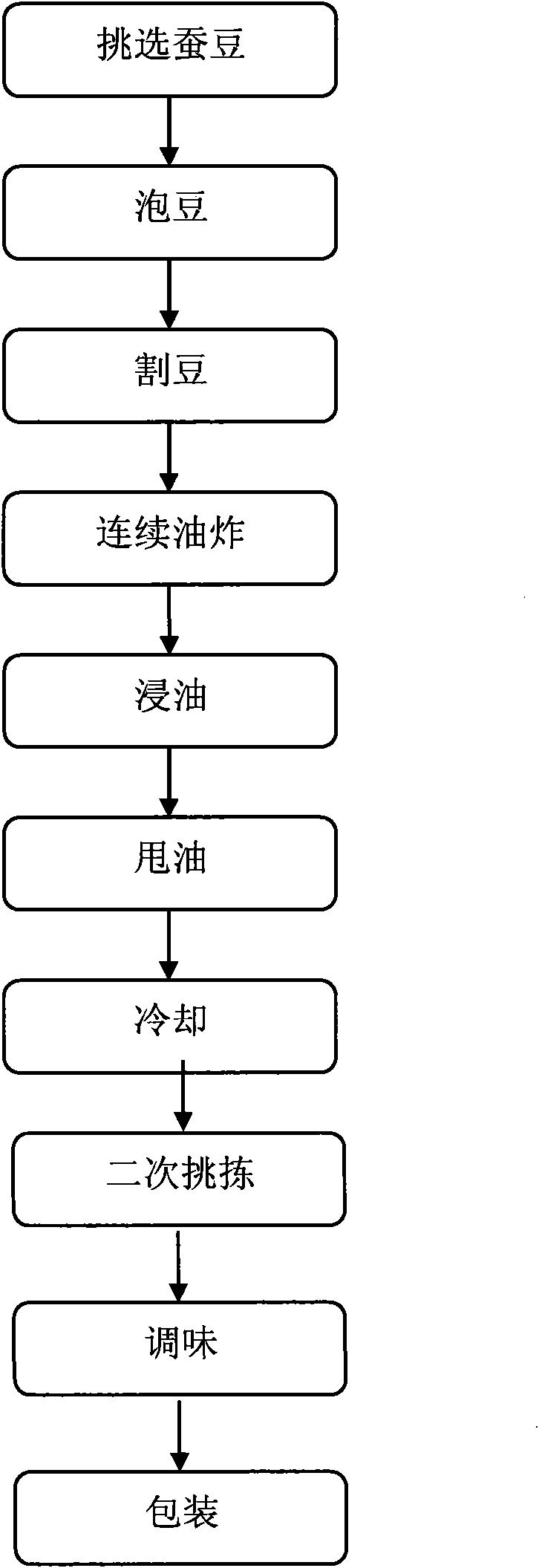

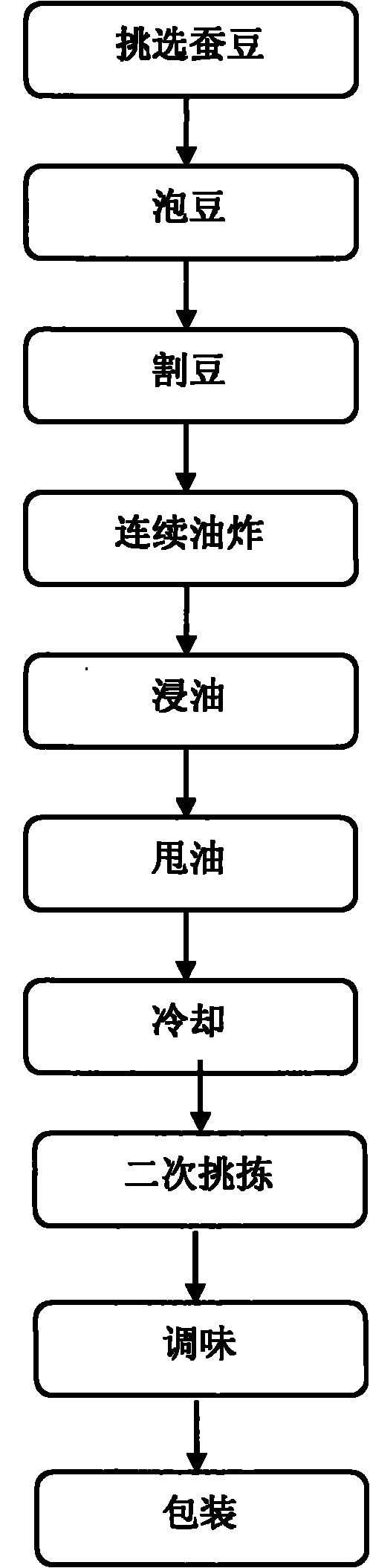

Sprouting dried broad bean and preparation method thereof

ActiveCN101933581APerformance indicators are stableGood quality consistencyFood preparationChemistryBroad beans

The invention discloses sprouting dried broad beans, which is prepared by adding the following ingredients of 2-5 parts by weight of white granulated sugar and 2-2.5 parts by weight of powder into 30 parts by weight of sprouting dried broad beans, wherein the powder comprises the following components in parts by weight: 3 parts of chili powder, 2 parts of garlic powder, 2 parts of spice, 1 part of monosodium glutamate and 1 part of sugar. The invention also discloses a preparation method of the sprouting dried broad beans. The sprouting dried broad beans have excellent appearance and quality consistency and distinctive taste and are crisp, sweet and spicy. The preparation method of the sprouting dried broad beans adopts a continuous fried production mode, the flavorings are mixed by adopting a rolling mode of an elliptical rolling pot in order to be more evenly mixed, the fried procedure adopts a pneumatic rolling mode, various indexes of appearance, rationalization, and the like of the sprouting dried broad beans have more consistency, and the development of the sprouting dried broad beans is promoted.

Owner:SUZHOU KOUSHUIWA FOOD

Method for preparing brassiere cup

An improved method of preparing molded seamless breast pads, cups, fronts and the like for use in brassieres and other garments is described. Polyurethane foam sheet, which still contains free isocyanates in its urethane matrix, is sliced from a freshly made foam bun, and placed between the mold parts. The mold parts are then closed by a hydraulic press. Steam is injected through holes in one mold part, and flows throughout the compressed polyurethane foam. Exhaust steam is emitted from holes in the other mold part. Moisture and heat from the steam then accelerate reactions with the free isocyanates and further cure the polyurethane foam material. The polyurethane foam material is therefore molded into the shape of mold parts cavity.

Owner:HSUEH PAN TING

Z-direction enhanced underwater sound absorption sandwich composite material and preparation method for same

ActiveCN102930862ASolve the carrying capacitySolve the problem of sound absorption performanceSynthetic resin layered productsSound producing devicesVacuum assistedOperability

The invention discloses a Z-direction enhanced underwater sound absorption sandwich composite material and a preparation method for the same. The composite material comprises composite material panels, a sound absorption core material and enhancement structures, wherein the enhancement structures are arranged in the thickness direction of the sound absorption core material, namely a Z direction, between the upper and lower panels. The whole structure of the Z-direction enhanced underwater sound absorption sandwich composite material is formed by a vacuum assisted forming process. Compared with an ordinary sound absorption sandwich composite material, the Z-direction enhanced underwater sound absorption sandwich composite material has the advantages that flat compression strength is greatly strengthened, a compression modulus is improved by more than one order of magnitude, bending rigidity is doubled, sound absorption performance is improved by 10 to 85 percent, and sound absorption performance under high water pressure is improved by 50 to 85 percent; and the forming process has the advantages of high operability, high quality consistency, suitability for the formation of a large-sized composite material component, and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Low-melting-point thermoplastic solid propellant and preparation method thereof

ActiveCN108147934ARealize complementary advantagesImprove mechanical propertiesNon-explosive/non-thermic compositionsPressure gas generationElastomerPlasticizer

The invention relates to a low-melting-point thermoplastic solid propellant and a preparation method thereof, and belongs to the technical field of composite solid propellants. The propellant is prepared from the following components by mass percent: 55%-70% of oxidant, 10%-20% of thermoplastic elastomer binder, 10%-20% of plasticizer, 5%-20% of metal fuels and 3%-8% of auxiliaries. The prepared low-melting-point thermoplastic solid propellant has the advantages that melting mixing and forming of the thermoplastic propellant at a relatively low temperature lower than 95 DEG C can be realized,process safety of thermoplastic propellant preparation is greatly improved, a curing and cross-linking process in comparison with a thermoplastic propellant is cut out, process flow is shortened, production efficiency is improved, production cost is reduced and repeated processing of waste products can be realized.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

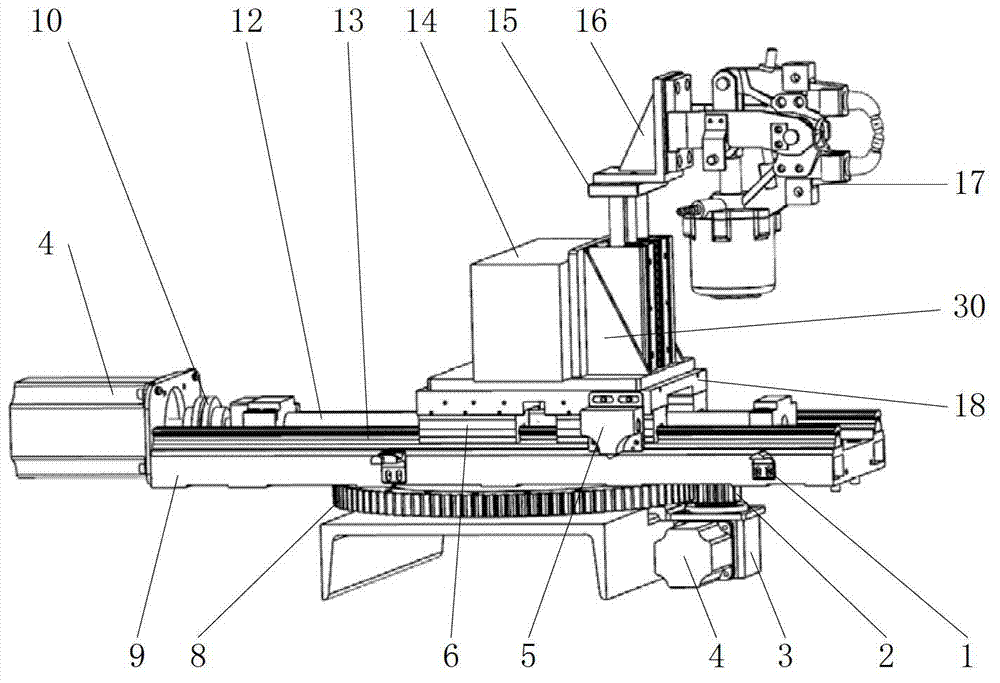

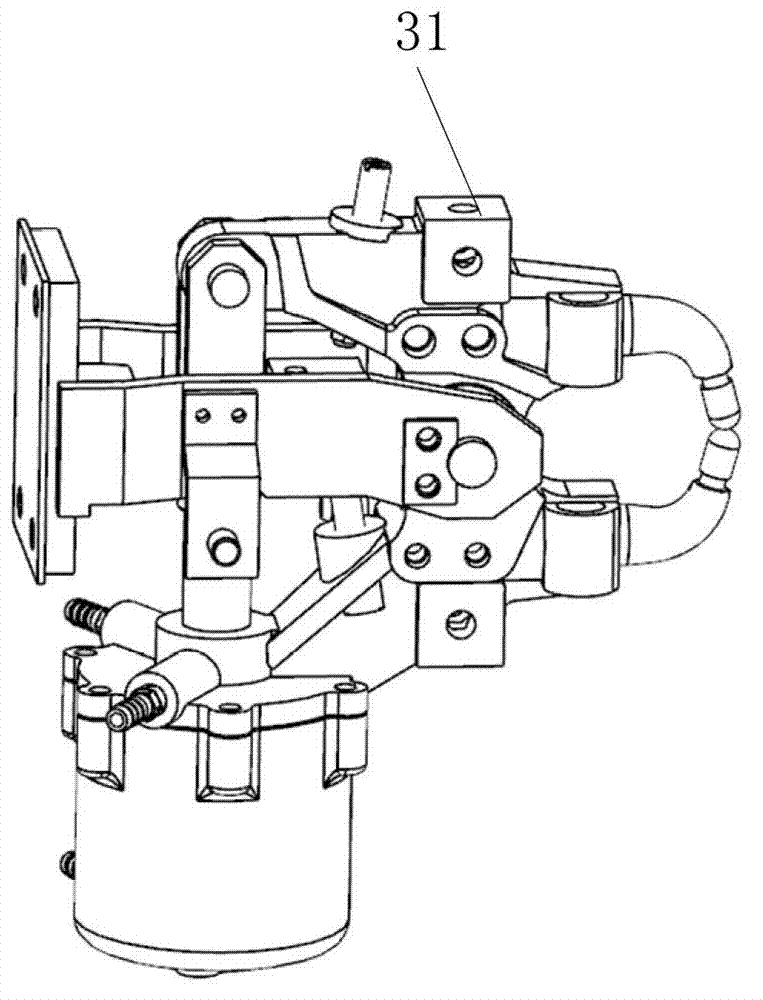

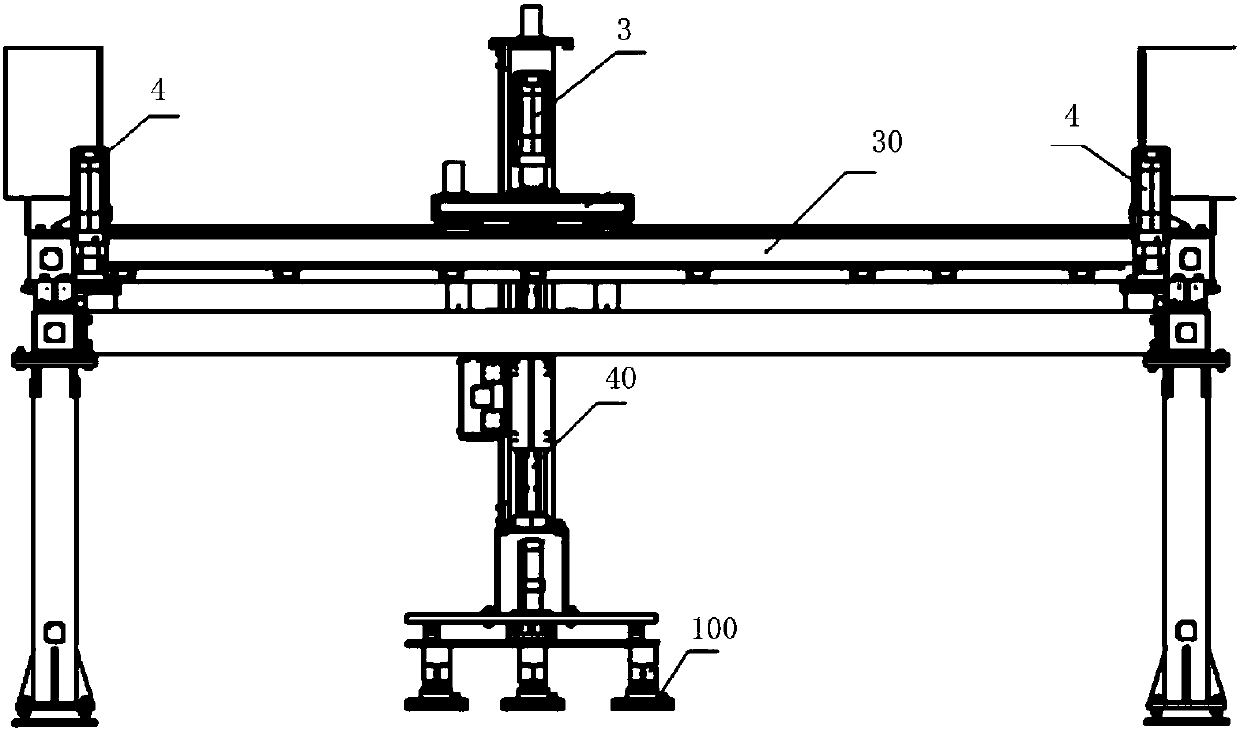

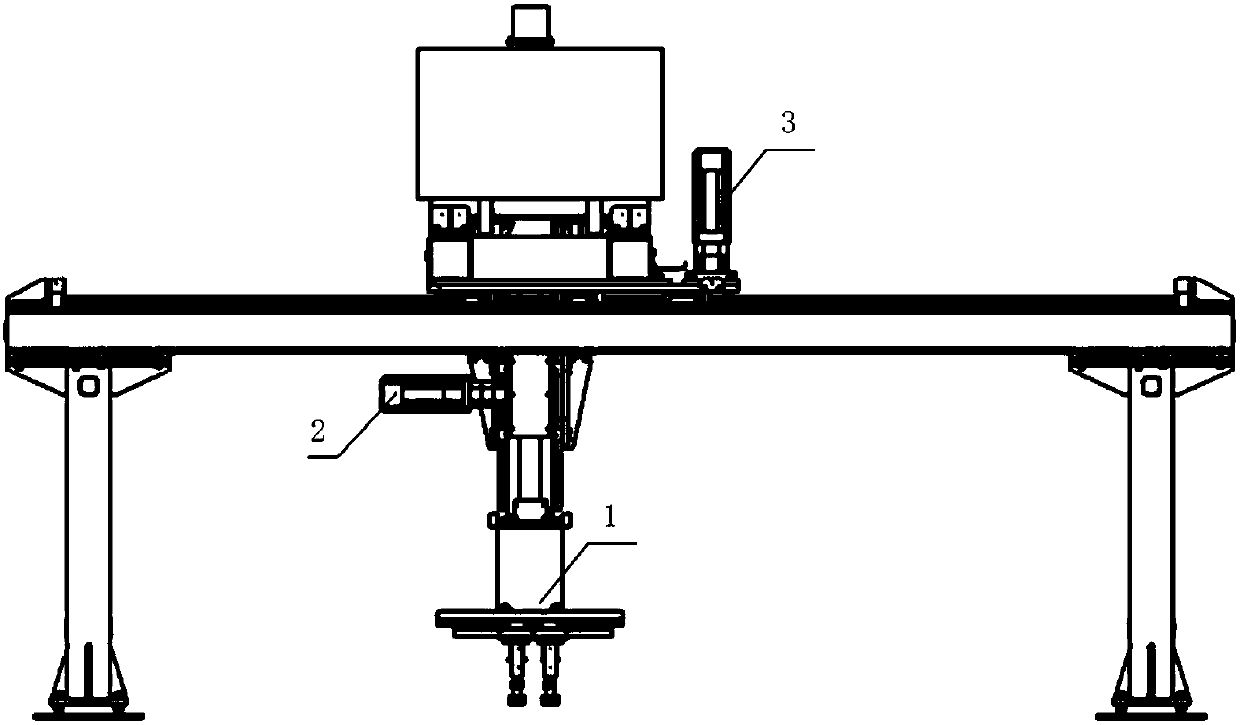

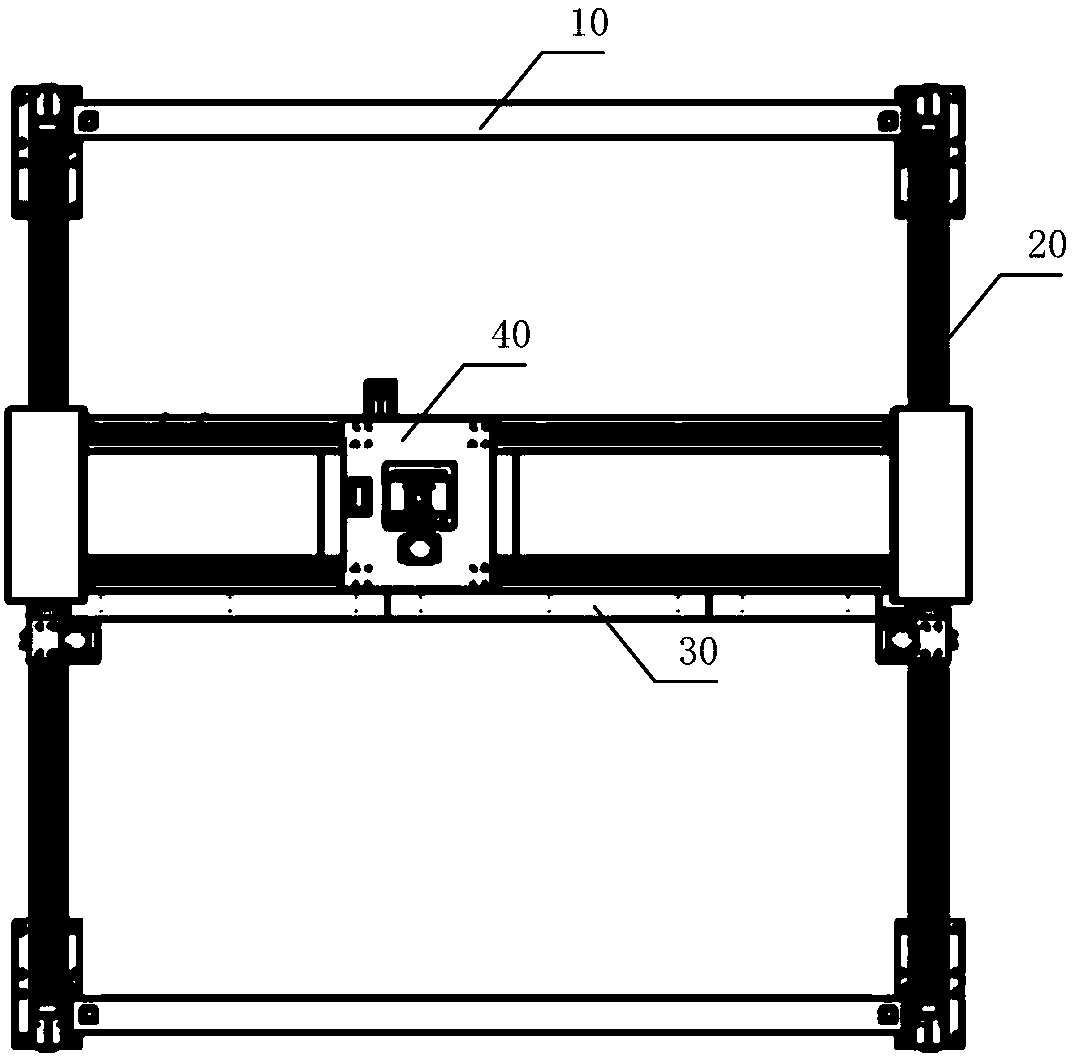

Automatic welding device for vehicle body-in-white

InactiveCN102962572ACompact structureSimple and fast operationElectrode featuresNumerical controlMulti axis

The invention discloses an automatic welding device for a vehicle body-in-white, which can simulate an industrial robot to perform the automatic welding operation, has a simple and smart structure, is convenient to operate, ensures higher quality uniformity, higher flexibility, lower investment and maintenance cost and higher production efficiency, and can be rapidly assembled by means of standard modules to adapt to different welding objects. A Z-axis load module with welding tongs is connected with a multi-axis linear module; a rotary module converts the rotation of a motor into a rotary motion; the multi-axis linear module comprises an X-axis linear module and the Z-axis load module; and the X-axis linear module, the Z-axis load module and the rotary module are linked through a multi-axis linkage numerical control unit to perform the welding operation.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

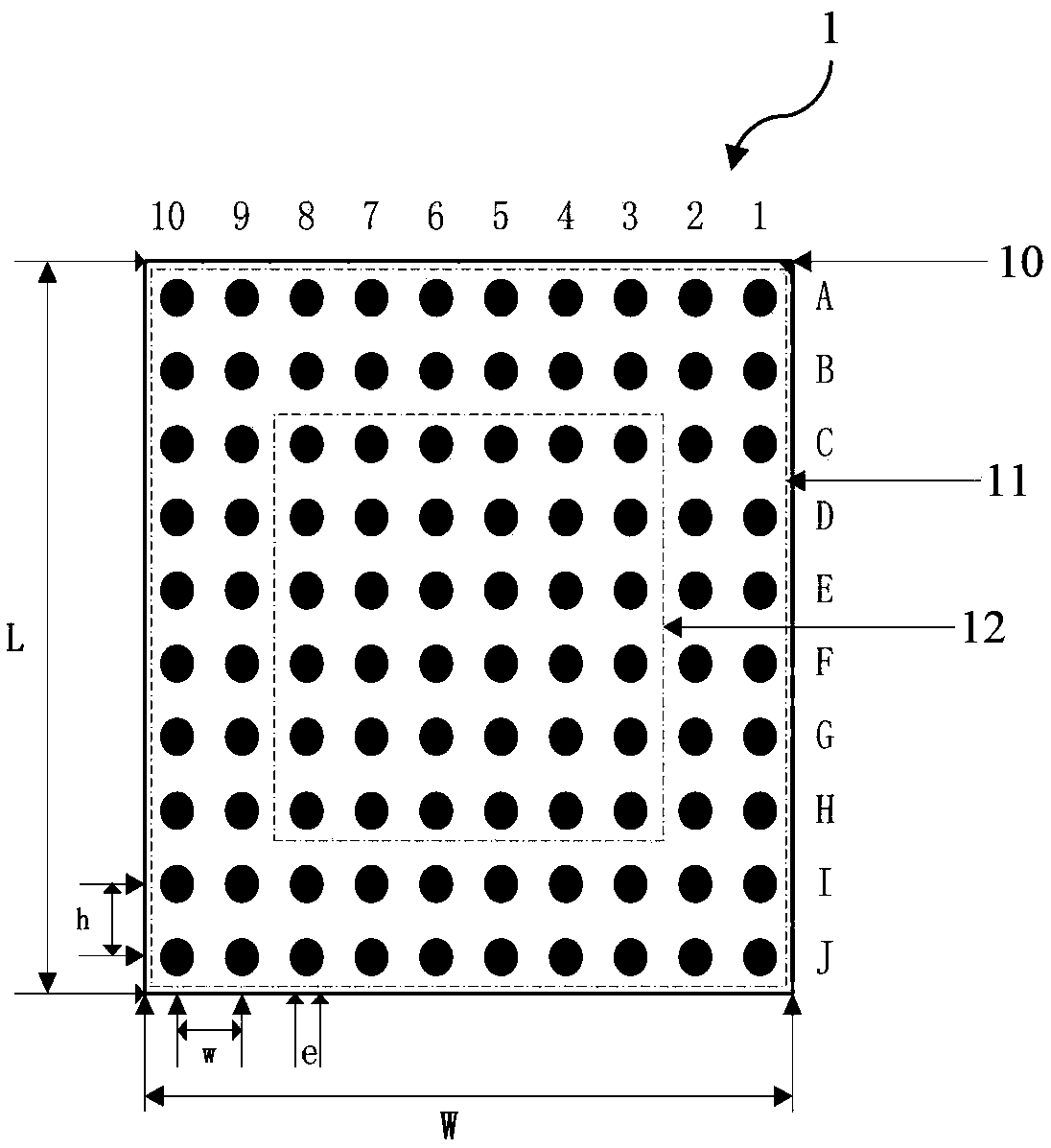

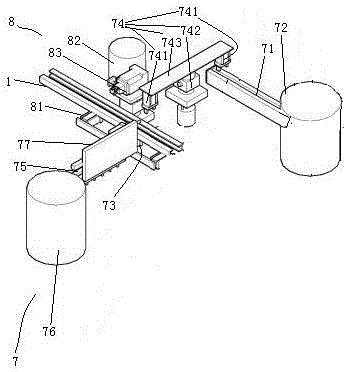

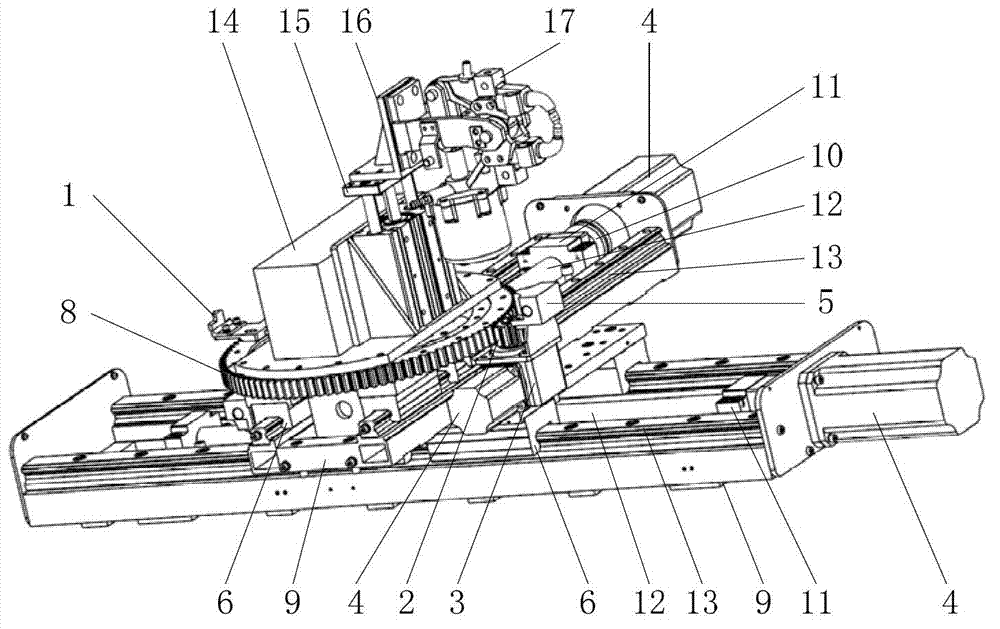

Automatic equipment for bonding ceramic tiles on PC components

InactiveCN107587704AImprove quality consistencyGood processing consistencyBuilding constructionsMovement controlMotion control

The invention provides automatic equipment for bonding ceramic tiles on PC components. The automatic equipment comprises a grabbing part for grabbing multiple ceramic tiles, a grabbing control devicefor controlling the grabbing part to grab the ceramic tiles or to separate from the ceramic tiles, a grabbing part vertical driving device for driving the grabbing part to linearly move in the vertical direction, a grabbing part transverse driving device for driving the grabbing part to linearly move in a horizontal plane in the transverse direction, a grabbing part longitudinal driving device fordriving the grabbing part to linearly move in the horizontal plane in the longitudinal direction, and a motion control device for controlling the grabbing part vertical driving device, the grabbing part transverse driving device and / or the grabbing part longitudinal driving device to drive the grabbing part to move. The automatic equipment for bonding the ceramic tiles on the PC components can grab the ceramic tiles and bond on the PC components to improve the ceramic tile bonding quality and the process consistency.

Owner:NORTHEASTERN UNIV

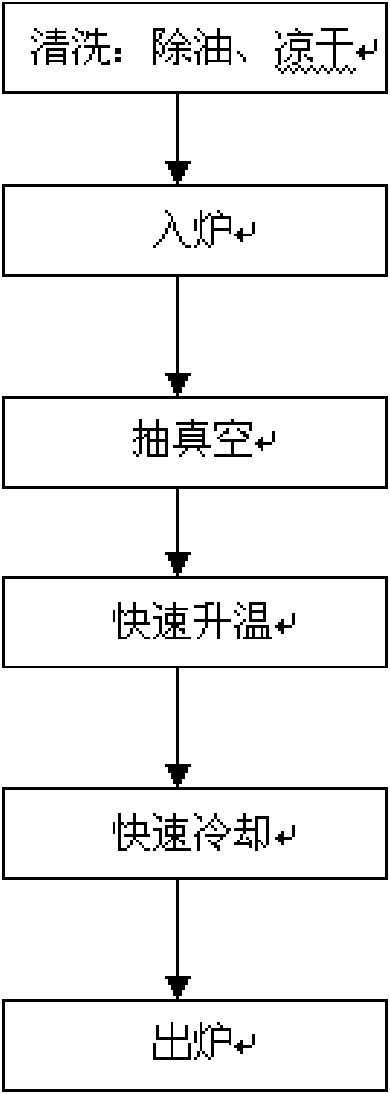

Vacuum annealing method for tantalum tube

InactiveCN101603164AGood organization and performanceFine and uniform grainFurnace typesHeat treatment furnacesAir dryingEnergy consumption

The invention relates to a rapid vacuum annealing method for a tantalum tube, which comprises the steps of: washing and air-drying the tantalum tube; placing the washed tantalum tube into a heat-resistant casing, and axially sending the washed tantalum tube and the heat-resistant casing to a vacuum induction annealing furnace together; adopting a three-stage vacuum system to work, and ensuring that the three-stage vacuum system pumps until the vacuum degree is 10Pa; ensuring that the inside of the vacuum induction annealing furnace is in a high vacuum state; and annealing the tantalum tube in the vacuum induction annealing furnace, namely finishing the temperature increase by heating and quick cooling in the furnace. The annealing by the method has the advantages of quick temperature increase of the tantalum tube, good product structure and performance of the tantalum tube, good mass conformance of the tantalum tube, low energy consumption, low operation cost, low investment on annealing equipment, and simple disassembly and maintenance. The method does not perform heat preservation for a long time and has low power consumption. The admissible stress of the tantalum tube is improved by 60 percent or so compared with the prior vacuum annealing furnace after the annealing is performed by the method; and under the same service strength, the method can save about 40 percent of tantalum materials and has remarkable economic benefit.

Owner:长沙南方钽铌有限责任公司

Solid rocket engine combustion chamber shell adiabatic layer forming method

ActiveCN109605625ANo distortionThere is no problem with exhaustDomestic articlesVulcanizationCombustion chamber

The invention relates to a solid rocket engine combustion chamber shell adiabatic layer forming method, and belongs to the field of adiabatic layer forming technologies. The solid rocket engine combustion chamber shell adiabatic layer forming method comprises the steps that according to the design structure of an engine combustion chamber shell, an adiabatic layer prefabricated part which is not completely vulcanized is prepared, and the outer diameter of the adiabatic layer prefabricated part which is not completely vulcanized is less than the inner diameter of the engine combustion chamber shell; the adiabatic layer prefabricated part which is not completely vulcanized is bonded to the inner wall of the engine combustion chamber shell through a heat vulcanization adhesive; and hot pressing vulcanization is conducted, and thus the engine combustion chamber shell with an adiabatic layer is obtained. Through internal support tension of the adiabatic layer prefabricated part and a good isolation gap between the adiabatic layer prefabricated part and the inner wall of the combustion chamber shell, the problems of sheet pasting warp and unsmooth exhaust of sheet rubber are effectivelysolved, and bonding reliability of the interface of the adiabatic layer and the shell is improved.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

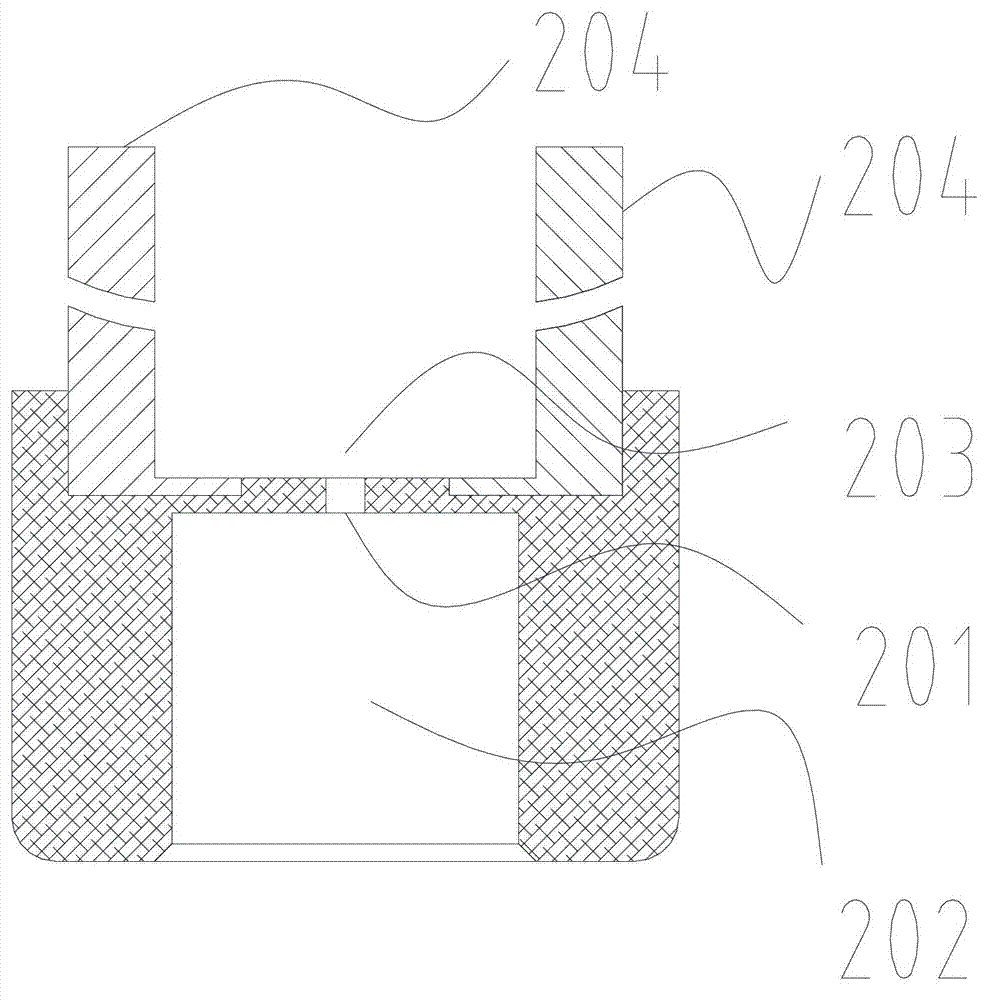

Slapper detonator with injection-molding structure

The invention discloses a slapper detonator with an injection-molding structure, which comprises a gun barrel component, a base, an exploding foil and a flyer; the gun barrel component comprises a gun barrel, a charging ring, an exploding foil positioning sleeve and a bonding pad, and is integrally formed by injection-molding; and the exploding foil, the flyer and the gun barrel are filled with plastic for compressing. The gun barrel, the charging ring, the exploding foil positioning sleeve and the bonding pad are integrally designed, and formed by injection-molding; and the gun barrel component welded with the exploding foil is secondarily injection-molded, so that the stability and the firmness in compressing are ensured, the number of parts is reduced, the production efficiency and the quality conformity of products are improved, the cost is greatly reduced, and the slapper detonator is expected to achieve wide application.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

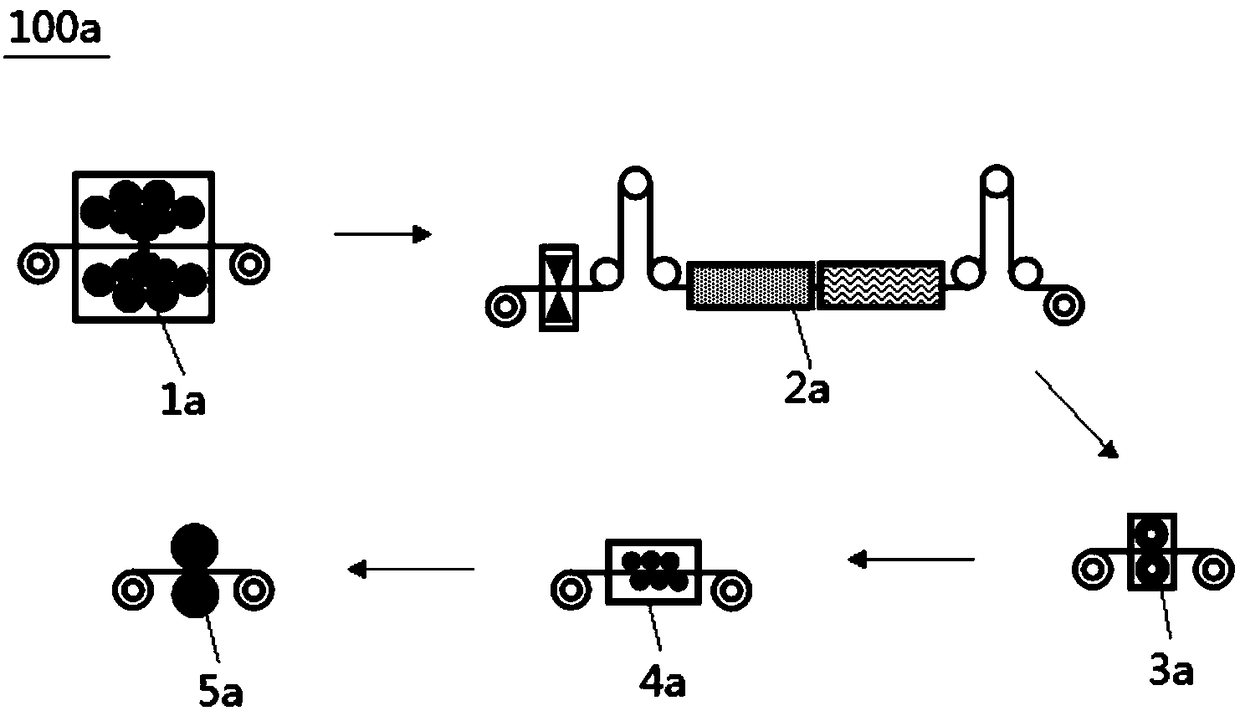

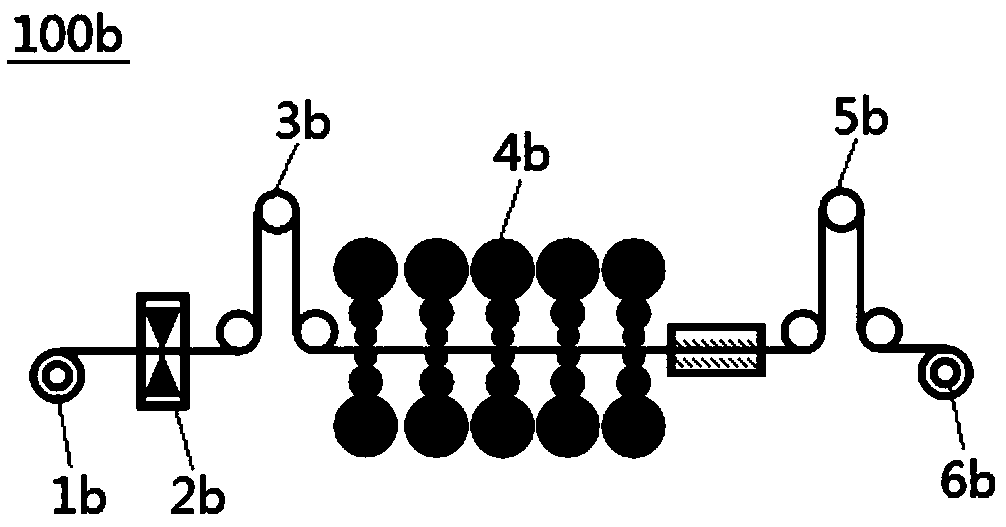

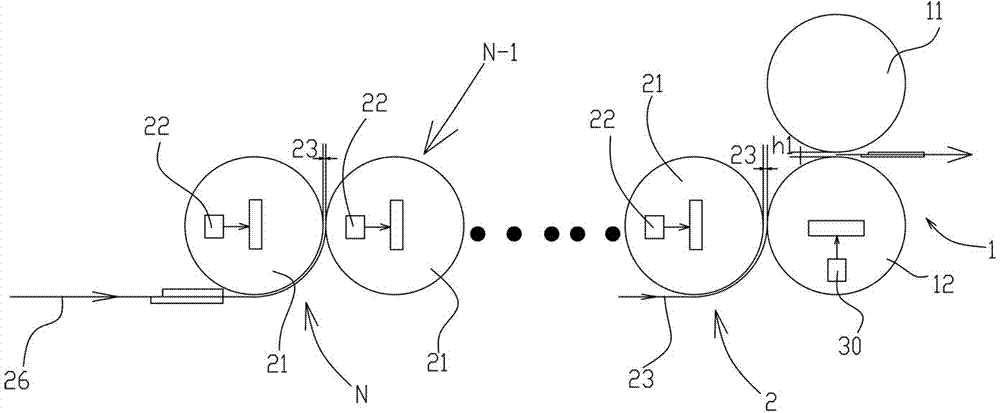

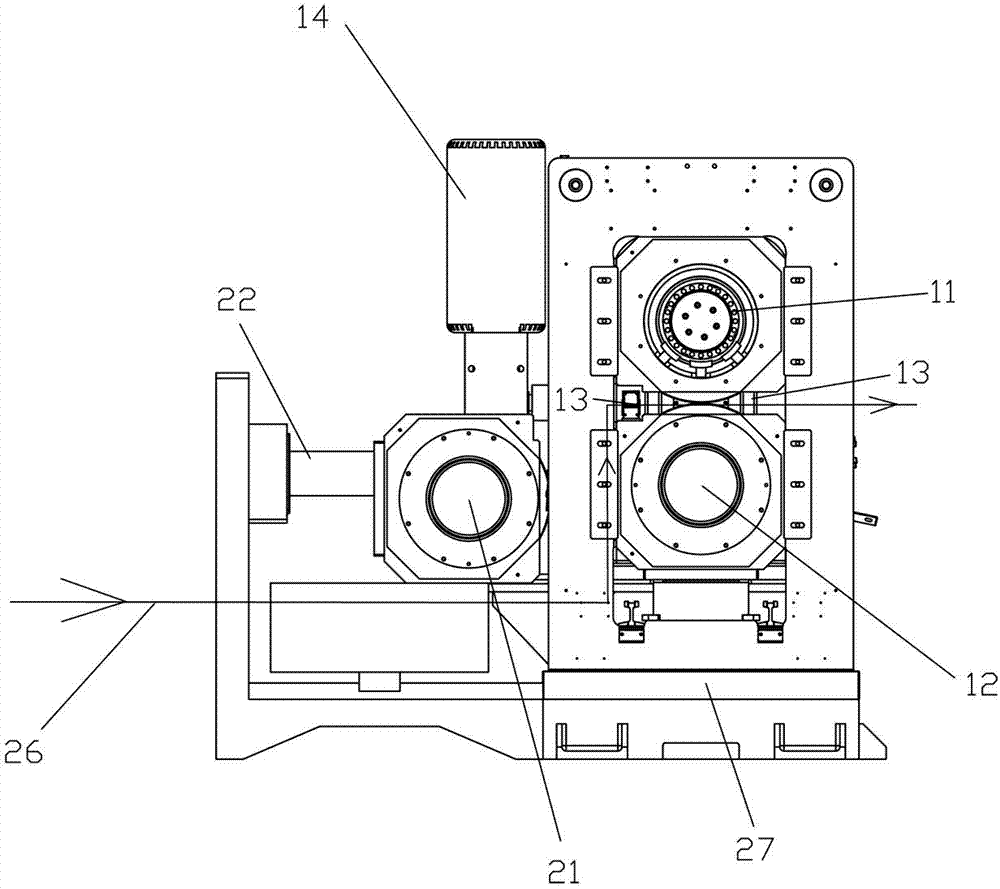

Battery pole piece rolling method and battery pole piece multistage roller machine

ActiveCN103934285AImprove quality consistencyImprove versatilityElectrode manufacturing processesRoll force/gap control deviceElectrical batteryControl engineering

A battery pole piece multistage roller machine comprises a thicknessing device. The thicknessing device comprises a first roller and a second roller. A gap adjusting mechanism is arranged between bearing blocks at the two ends of the first roller, and a gap adjusting mechanism is arranged between bearing blocks at the two ends of the second roller. Hydraulic devices act on the two ends of the first roller or the two ends of the second roller to make the roll gap between the two rollers maintained basically constant. The battery pole piece multistage roller machine further comprises at least one prepressing device. Each prepressing device comprises a first prepressing roller, a second prepressing roller and a pair of prepressing roller elastic hydraulic devices, a prepressing roller gap is formed between the first prepressing roller and the second prepressing roller, and the prepressing roller elastic hydraulic devices respectively act on the two ends of the first prepressing roller or the two ends of the second prepressing roller to make the pressure of the first prepressing roller or the pressure of the second prepressing roller maintained basically constant. The battery pole piece multistage roller machine is wide in application range and can be used for a single-side pole piece or a two-side pole piece or an ordinary pole piece without any structural adjustment, and therefore universality of the roller machine is improved.

Owner:SHENZHEN XINYUREN TECH

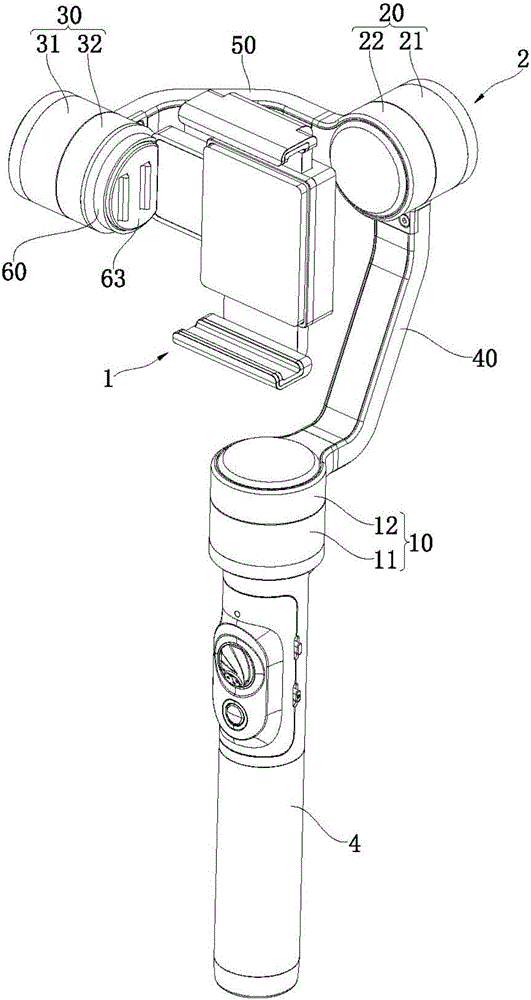

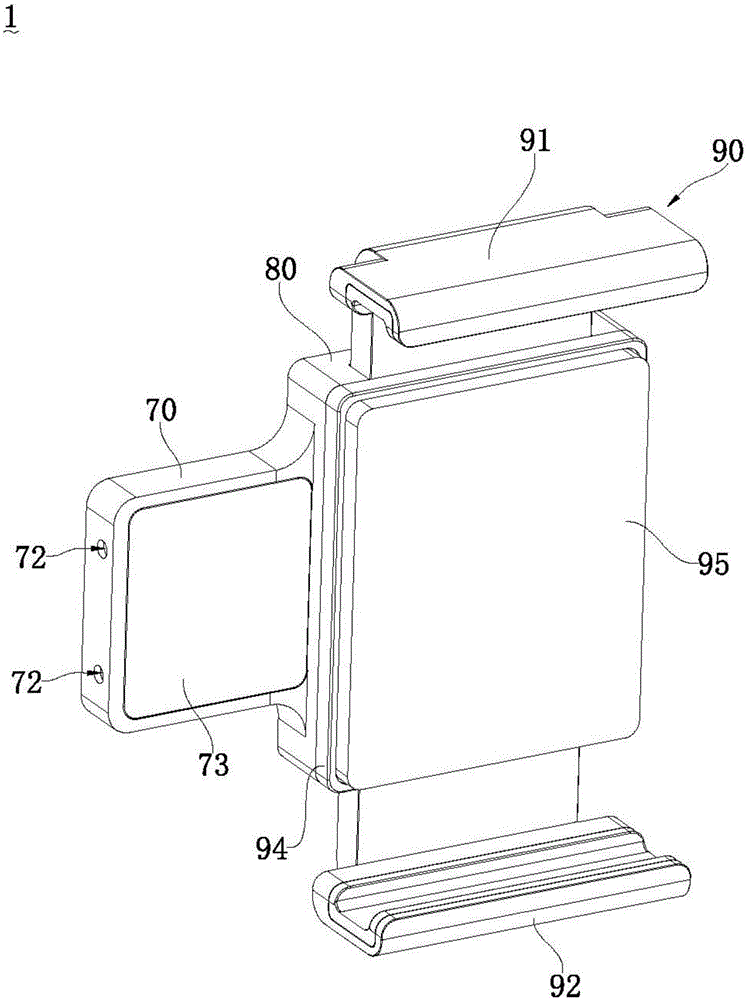

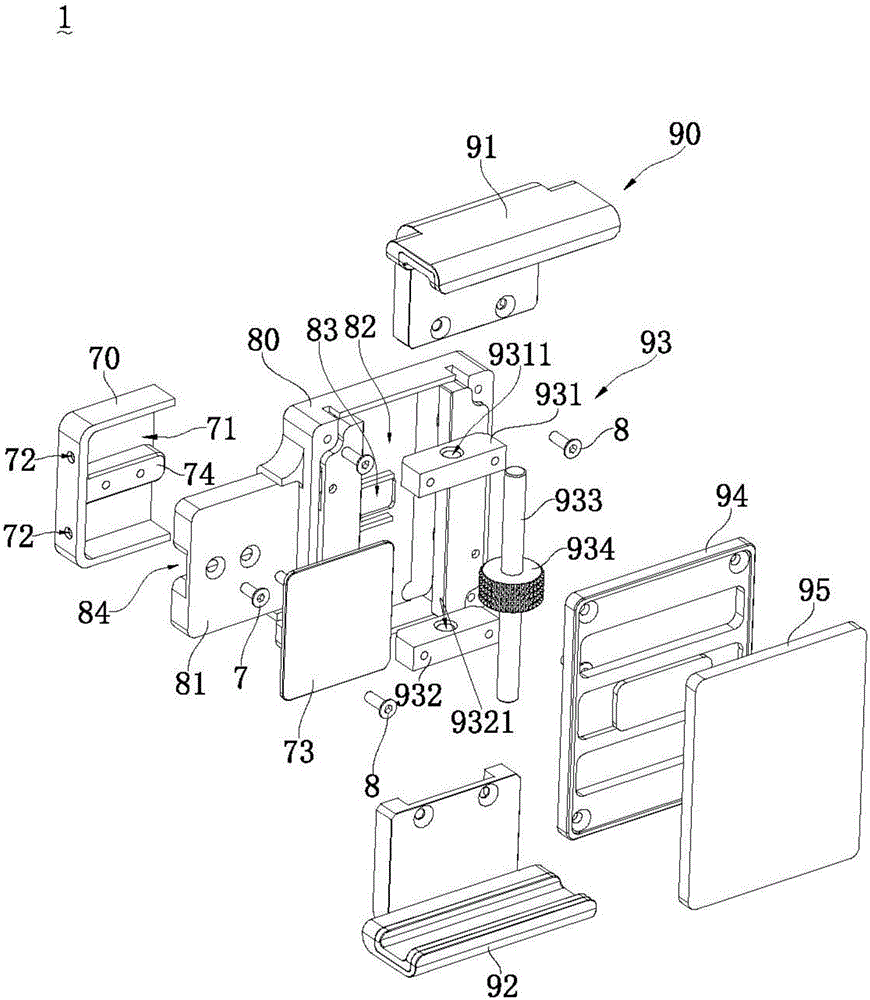

Camera shooting stabilizing and fixing device

The invention relates to the technical field of camera shooting cloud decks, in particular to a camera shooting stabilizing and fixing device. The camera shooting stabilizing and fixing device comprises a clamping device and a rotary shaft device. The rotary shaft device comprises a first rotary shaft motor. The first rotary shaft motor comprises a first rotary shaft stator and a first rotary shaft rotor. A fixing base is connected to the first rotary shaft rotor. The clamping device comprises a side connection plate which is connected with the fixing base through a first axial fastening piece. The first axial fastening piece connects the side connection plate with the fixing base in a locking mode in the direction parallel to the axial direction of the first rotary shaft motor. According to the camera shooting stabilizing and fixing device, the quality consistency of portions of the junction of the first rotary shaft motor and the clamping device in the axial direction is good, the effect that stability is higher when the first rotary shaft rotor of the first rotary shaft motor drives the clamping device to rotate is ensured, centre-of-gravity shift is avoided, that is, the precision is improved when the first rotary shaft motor drives the clamping device to rotate, and accordingly the camera shooting precision of a camera shooting device clamped to the clamping device is greatly improved.

Owner:深圳市越疆科技股份有限公司

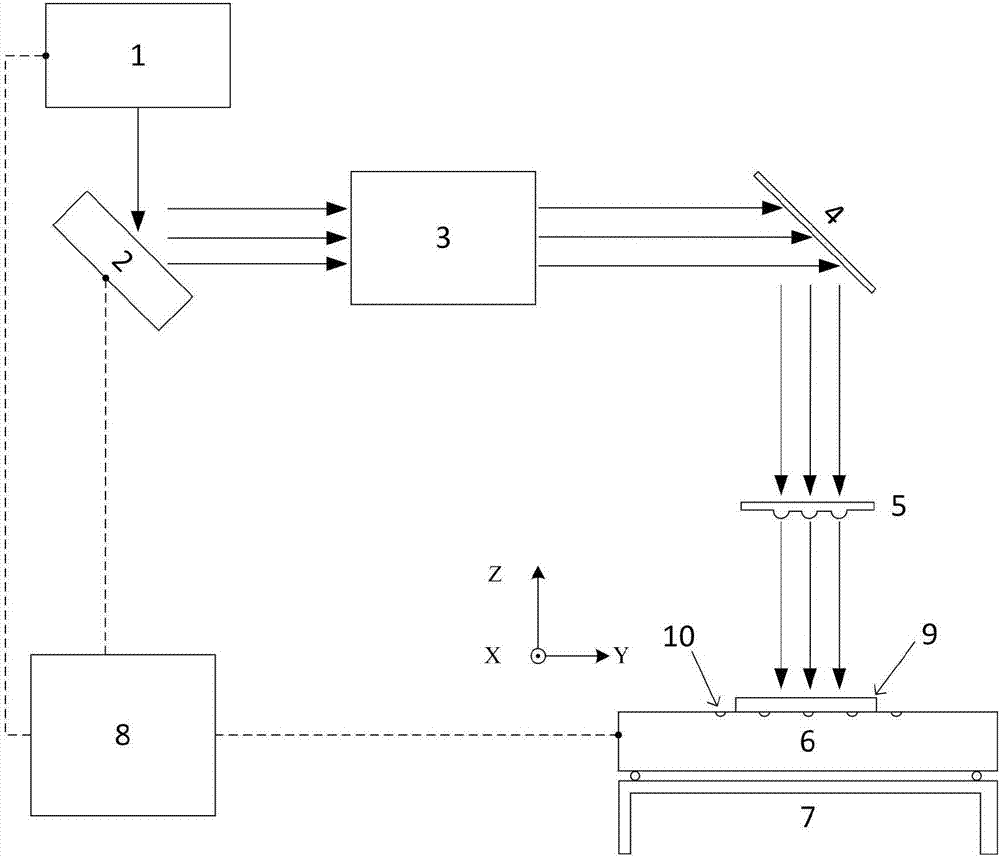

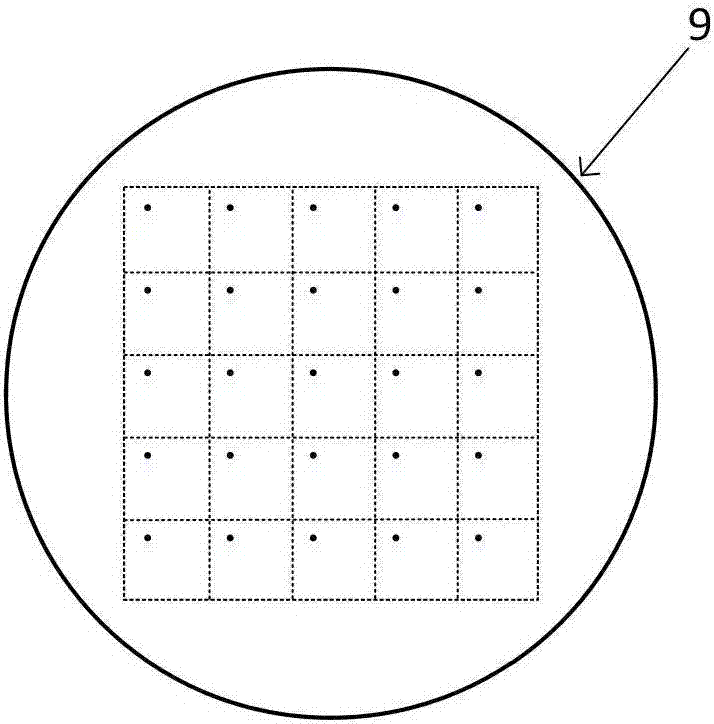

Ultrafast-laser optical chip array processing system and method

InactiveCN107199404AImprove processing efficiencyImprove quality consistencyLaser beam welding apparatusMicro nanoBeam expander

The invention discloses an ultrafast-laser optical chip array processing system and method, and belongs to the technical field of micro-nano processing of optical chips. The system comprises a laser light source, a spatial light modulator, a beam expander, a reflector, a micro-lens array and a six-dimensional working platform, and the system further comprises an air-floating platform and a central-control computer, wherein the central-control computer is connected with the laser light source, the spatial light modulator and the six-dimensional working platform and used for control of the whole system, and the air-floating platform is arranged under the six-dimensional working platform and used for bearing the six-dimensional working platform. According to the ultrafast-laser optical chip array processing system and method, a laser array processing method is adopted, dozens of optical chips can be obtained in one-time processing process, the processing efficiency is high, and quality consistency is good; in addition, the laser processing method is adopted, processing equipment is simple, the requirement on the processing environment is low, and therefore the production cost is greatly reduced.

Owner:HUBEI UNIV OF TECH

Firework with integral module explosive filling structure in open mode and preparation method thereof

The invention discloses a firework with an integral module explosive filing structure in an open mode and a preparation method thereof. The explosive filling structure disclosed by the invention comprises a shell, a delay fuse, bright beads and an open explosive module, wherein the shell, the delay fuse and the bright beads are made of traditional materials. The preparation method of the fireworkwith the integral module explosive filling structure in an open mode comprises the following steps: preparing a slurry containing an organic adhesive, an ignition performance reinforcing agent and granular micro-pore firework explosive granules; then, filling the bright beads and the slurry into the ball shell of the firework according to the needed structure, thus forming an integral module structure; and finishing the preparation of the firework according to a conventional method. By adopting the integral module explosive filling structure and the explosive filling method, the gap between the open explosive module and the bright beads is basically eliminated; the ignition rate of the bright beads can be improved; the mechanical friction action among the granules in the explosive fillingcourse and storage and transportation course of the granules is avoided; and the safety of the preparation course and storage and transportation course of fireworks is improved.

Owner:NANJING UNIV OF SCI & TECH

High-roundness high-purity silicon carbide ultrafine powder material

The invention discloses a high-roundness high-purity silicon carbide ultrafine powder material. Through two times of smashing shaping of gas flow medium smashing shaping and grinding shaping with analysis and purification, high-purity 6H-SiC micro powder synthesized in situ is processed into the ultrafine powder material with the roundness of 0.950 or above and the D50 value of 1.6-2.0 micrometers, so that the requirements on sintering precise ceramic products are met, the precise ceramic products (such as a silicon carbide ceramic sealing shaft sleeve, a silicon carbide ceramic roller and a silicon carbide ceramic nozzle) sintered from the ultrafine powder material overcome the sintering defects of low finished product rate, inconsistent compactness and the like which are high in possibility in conventional sintering, and the sintered silicon carbide ceramic is good in quality consistency, has heat shock resistance and high temperature resistance when in use, and can avoid the disadvantage of different service lives and the like. Through testing, the volume density of a finished part sintered by adopting the prepared silicon carbide ultrafine powder is greater than or equal to 3.04 g / cm<3>, the porosity rate is less than 0.3%, the highest use temperature is 1380 DEG C, and the use requirements of the precise silicon carbide products can be completely met.

Owner:河南晟道科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com