Battery pole piece rolling method and battery pole piece multistage roller machine

A battery pole piece and roll machine technology, applied in electrode manufacturing, rolling force/roll gap control, metal rolling, etc., can solve uncontrollable pressure changes, uncontrollable disc spring spring force, and difficulty in precise compression ratio Control and other issues to achieve the effect of improving overall performance, improving versatility and efficiency, and improving quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

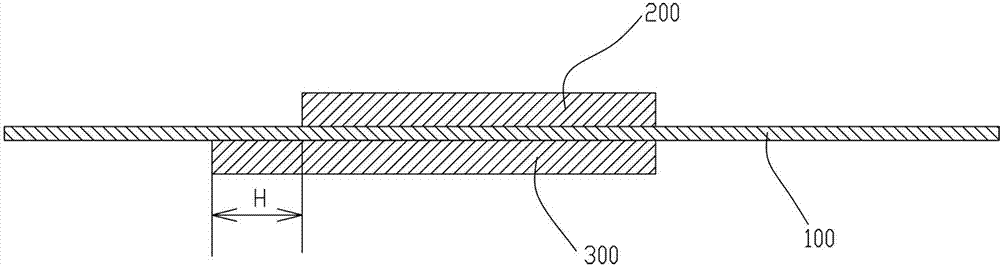

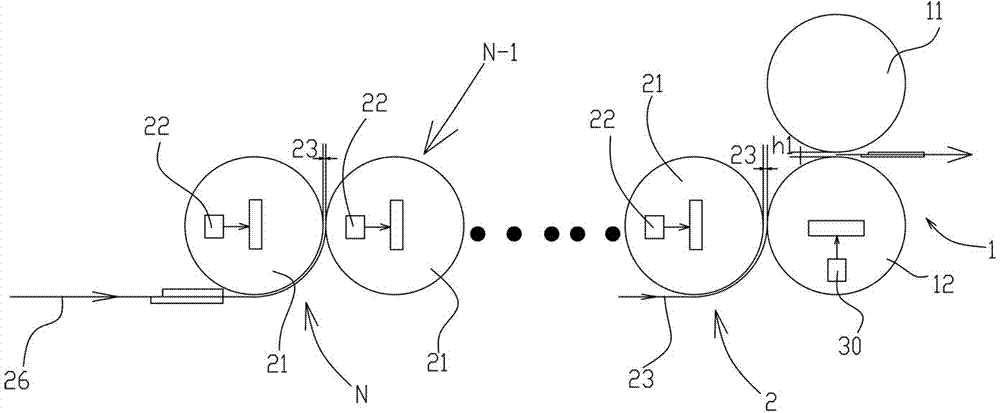

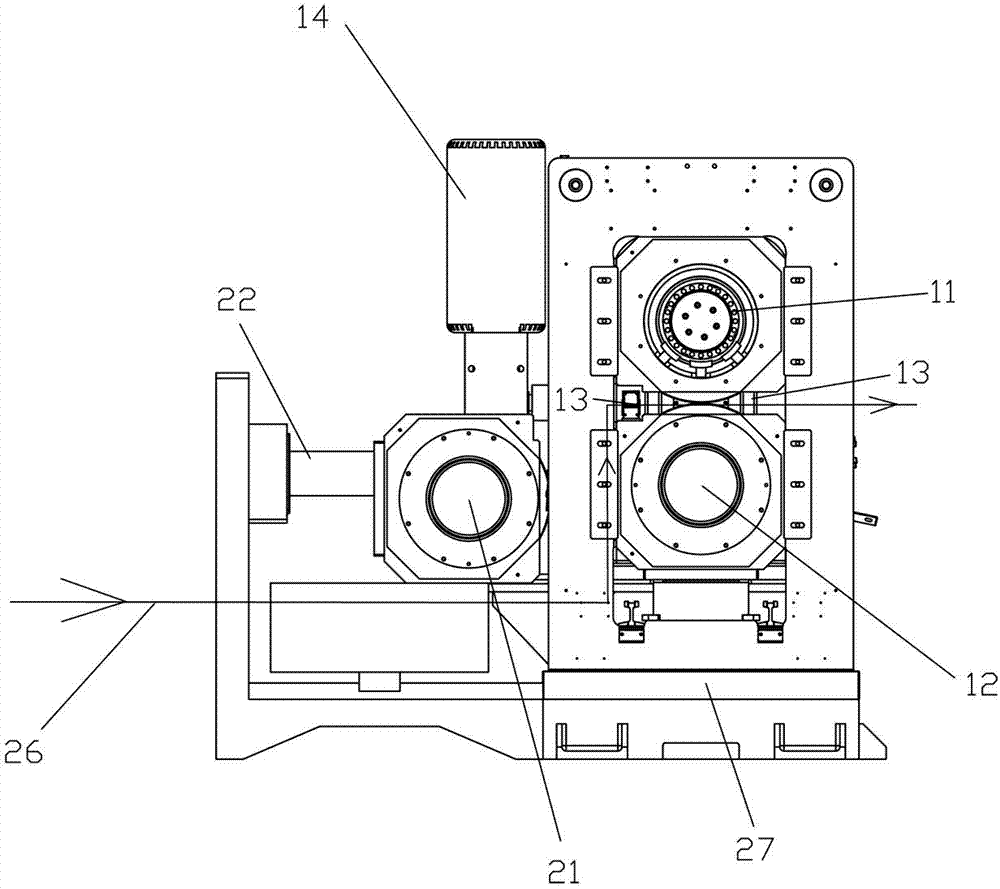

[0029] The invention provides a method for rolling battery pole pieces, comprising the following steps,

[0030] (1) The step of compacting the battery pole piece, this step is realized by at least one pre-pressing device, the distance between the rolling gaps of the pre-pressing device is elastic during the rolling process of the pole piece, and the pressure of the rolling gap is It is realized by an elastic hydraulic pneumatic device acting on one of the two rollers forming the nip; (here, the pre-compression of the battery pole piece is realized by the pre-compression roller controlled by the elastic hydraulic device. The stage can use one or more stages of pre-compression devices with basically constant pressure, and realize 80%-95% of the compression ratio of the battery pole pieces in the pre-compression stage. For example, it is assumed that the compression ratio of the battery pole pieces is designed to be 30%-35%. The so-called compression ratio of the battery pole pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com