Slapper detonator with injection-molding structure

A structural impact and detonator technology, applied in the field of injection molded structural impact sheet detonators, can solve the problems of inability to ensure axial compression, difficult barrel processing, and inability to popularize and apply, so as to improve production efficiency and product quality consistency, Guarantee stability and firmness, and achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

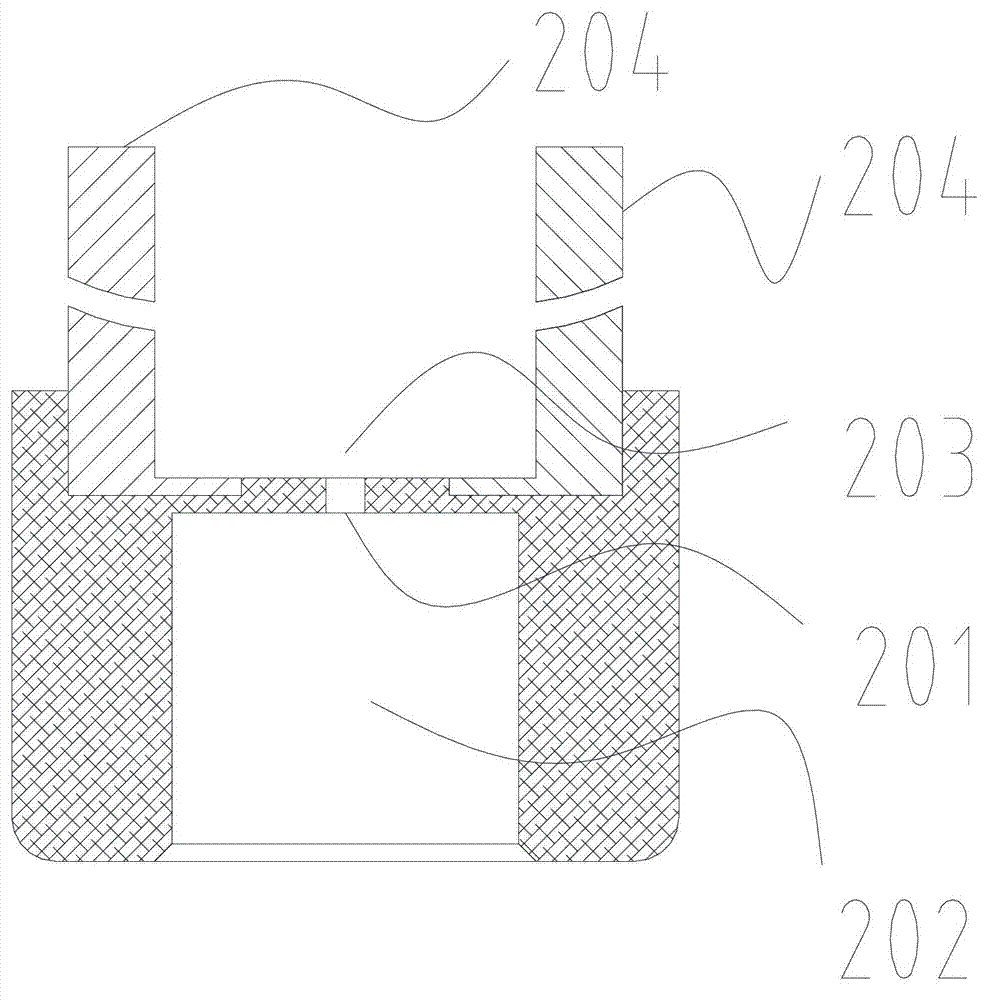

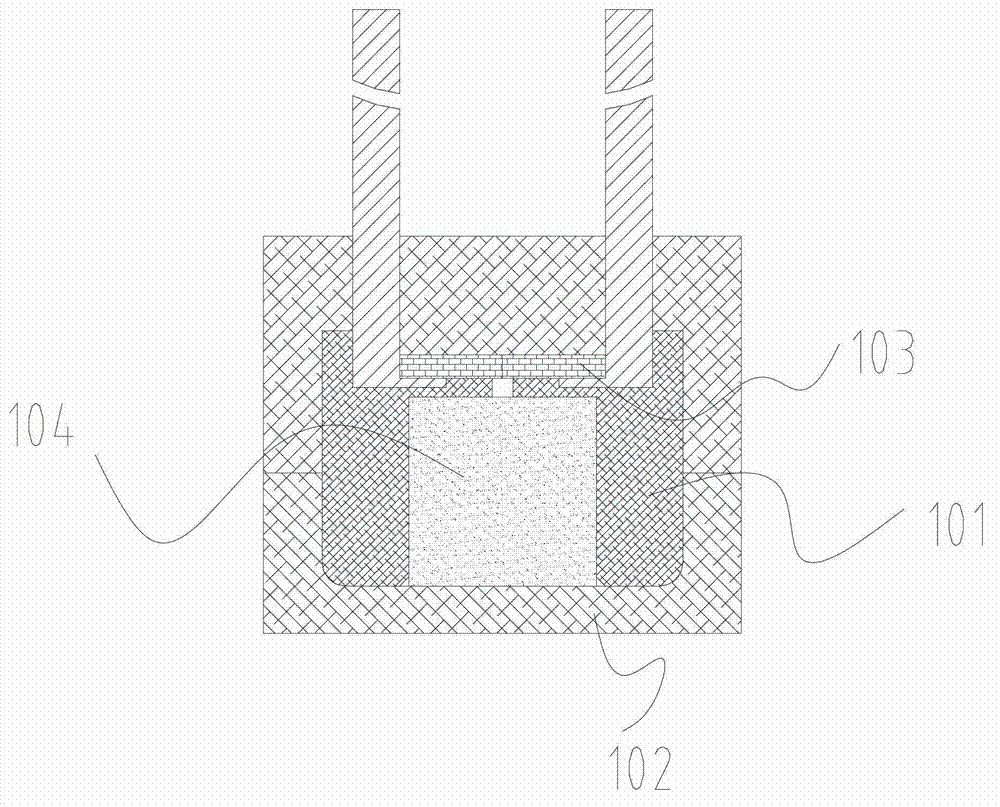

[0019] Such as figure 1 as shown, figure 1 It shows a schematic structural diagram of the barrel assembly of the injection-molded shock plate detonator according to an embodiment of the present invention. In this embodiment, the barrel assembly includes: barrel 201, charge ring 202, explosive foil positioning sleeve 203, and electrode 204. There are two middle electrodes 204, which are symmetrically arranged on the left and right sides of the upper part of the barrel 201. The explosive foil positioning sleeve 203 is arranged at the angle between the two electrodes 204 on the upper part of the barrel 201. The barrel 201 is provided with a charge ring 202. As a preferred embodiment, in this implementation, the barrel assembly, including the barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com