Solid rocket engine combustion chamber shell adiabatic layer forming method

A technology of solid rockets and molding methods, which is applied to household components, household appliances, and other household appliances. It can solve the problems of raw film patch distortion and unsmooth exhaust, achieve uniform thickness, improve consistency, and heat-insulate the production process. Optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Prepare the thermal insulation layer of the combustor shell of the small solid rocket motor with large length-to-diameter ratio according to the following steps:

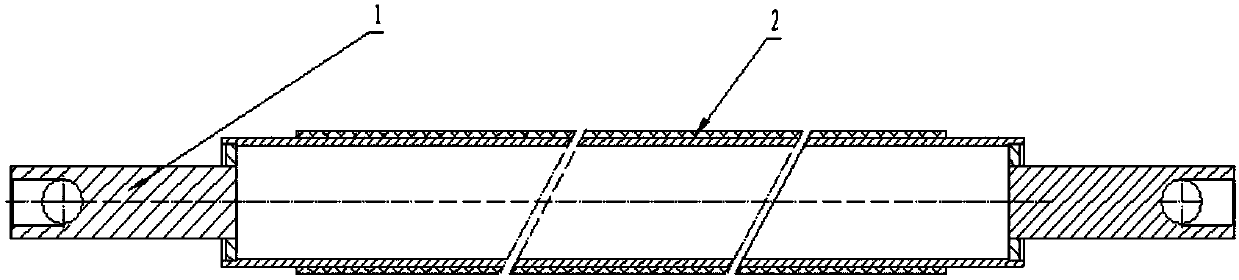

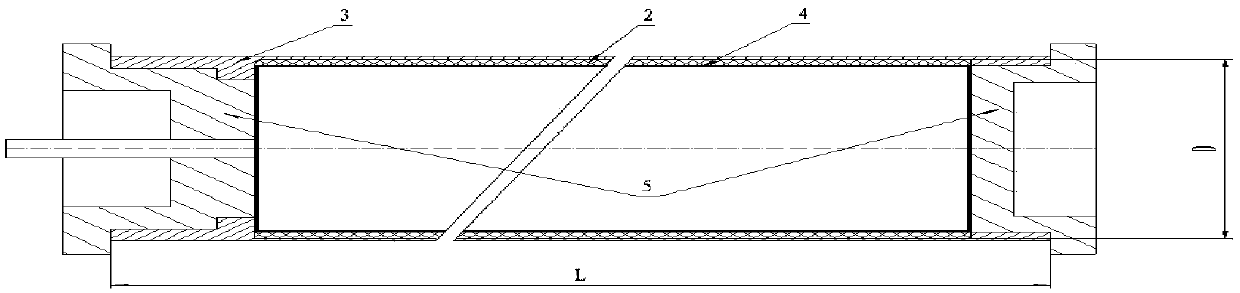

[0042] Step 1: If figure 1 As shown, the insulation layer prefabricated part of EPDM rubber composite material is prepared by winding molding process, the length of the working surface of the winding mold core 1 (the length of the heat insulation layer preform) is set to 1000 mm, and the outer diameter of the winding molding core 1 is is 109.7mm (calculated by the following formula, α is 0.92, and the outer diameter of the prefabricated part of the heat insulation layer is 92% of the inner diameter of the shell):

[0043]

[0044] Among them, D MX is the outer diameter of the mold core, D KT is the inner diameter of the shell, d is the thickness of the insulation layer, K is the shrinkage rate of different rubber composite materials in different molding processes (the shrinkage rate of EPDM rubber compo...

Embodiment 2

[0051] Prepare the thermal insulation layer of the combustor shell of the small solid rocket motor with large length-to-diameter ratio according to the following steps:

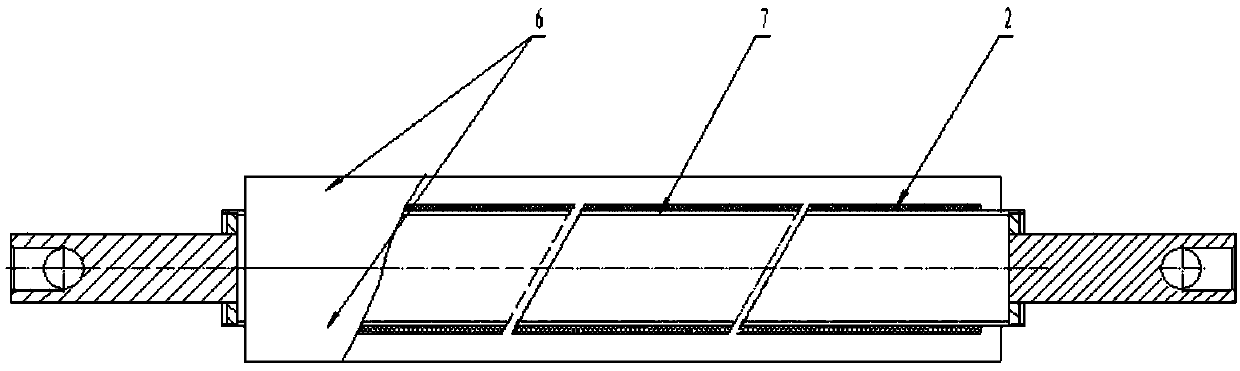

[0052] Step 1: If image 3 As shown, the HALF mold 6 is used for the compression molding process to prepare the thermal insulation layer prefabricated part of the EPDM composite material. The outer diameter of the mold core 7 is 108.6mm (calculated by the following formula, α is 0.92, and the outer diameter of the prefabricated part of the heat insulation layer is 92% of the inner diameter of the shell):

[0053]

[0054] Among them, D MX is the outer diameter of the mold core, D KT is the inner diameter of the shell, d is the thickness of the heat insulation layer, K is the shrinkage rate of different rubber composite materials in different molding processes (the shrinkage rate of EPDM rubber composite materials in the molding process is K = 2%), and α corresponds to the prefabricated part of the heat ins...

Embodiment 3

[0061] Prepare the thermal insulation layer of the combustor shell of the small solid rocket motor with large length-to-diameter ratio according to the following steps:

[0062] Step 1: If figure 1 As shown, the insulation layer prefabricated part of EPDM rubber composite material is prepared by winding molding process, the length of the working surface of the winding mold core 1 (the length of the heat insulation layer preform) is set to 1000 mm, and the outer diameter of the winding molding core 1 is is 113.4mm (calculated by the following formula, α is 0.95, and the outer diameter of the prefabricated part of the heat insulation layer is 95% of the inner diameter of the shell):

[0063]

[0064] Among them, D MX is the outer diameter of the mold core, D KT is the inner diameter of the shell, d is the thickness of the insulation layer, K is the shrinkage rate of different rubber composite materials in different molding processes (the shrinkage rate of EPDM rubber compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com