Patents

Literature

94results about How to "Product quality consistency is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

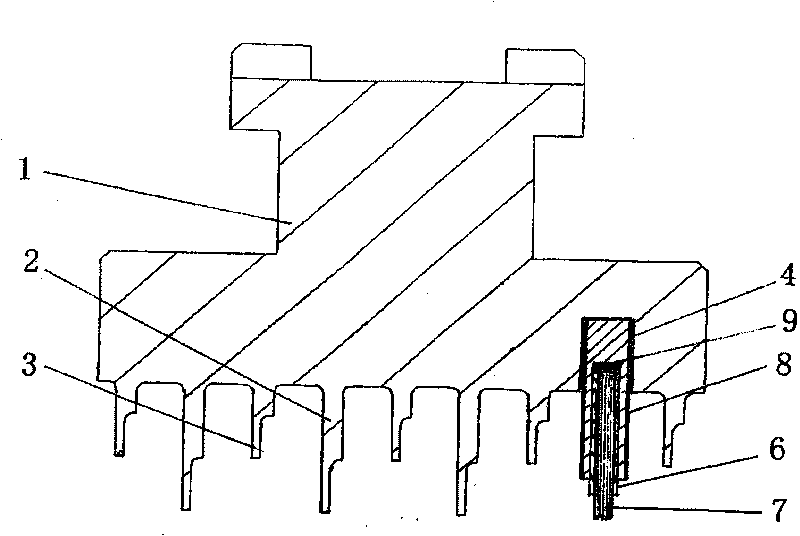

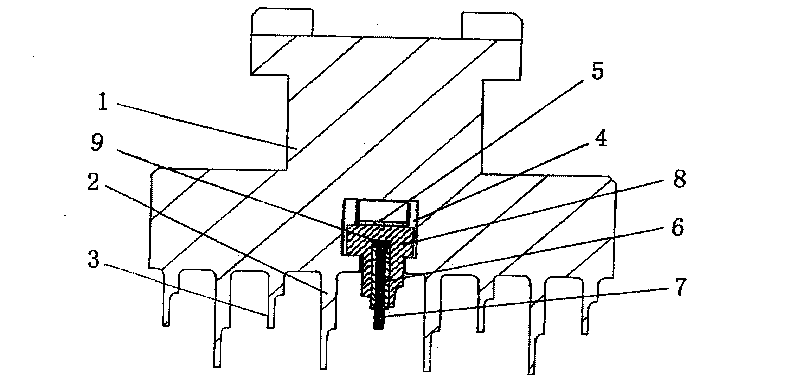

Chip type exploding foil component and production method for same

ActiveCN103868417ASimple structureProduct quality consistency is goodAmmunition fuzesSlapper detonatorCopper foil

The invention discloses a chip type exploding foil component and a production method for the chip type exploding foil component. The chip type exploding foil component comprises exploding foils, flyers and electrodes, wherein the flyers are adhered to the exploding foils; the electrodes are welded on the exploding foils; the exploding foils are rectangular, are arranged on a substrate in an array, and are formed in a scribing way; the electrodes are punched copper foils; the flyers adopt thermoviscous polyimide thin films, and are manually adhered in batches; soldering tin is coated in batches by a small-sized hand-operated screen printer; the exploding foil component is automatically welded in batches in a programmed way by a pulse hot-pressing reflow soldering machine. The chip type exploding foil component belongs to an explosion part of an inline slapper initiator; due to the adoption of chip design, the exploding foil component is simple in structure and favorable for the popularization and application of a slapper detonator, and is suitable to be automatically produced in batches, and a product is high in quality consistency and production efficiency and low in cost.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

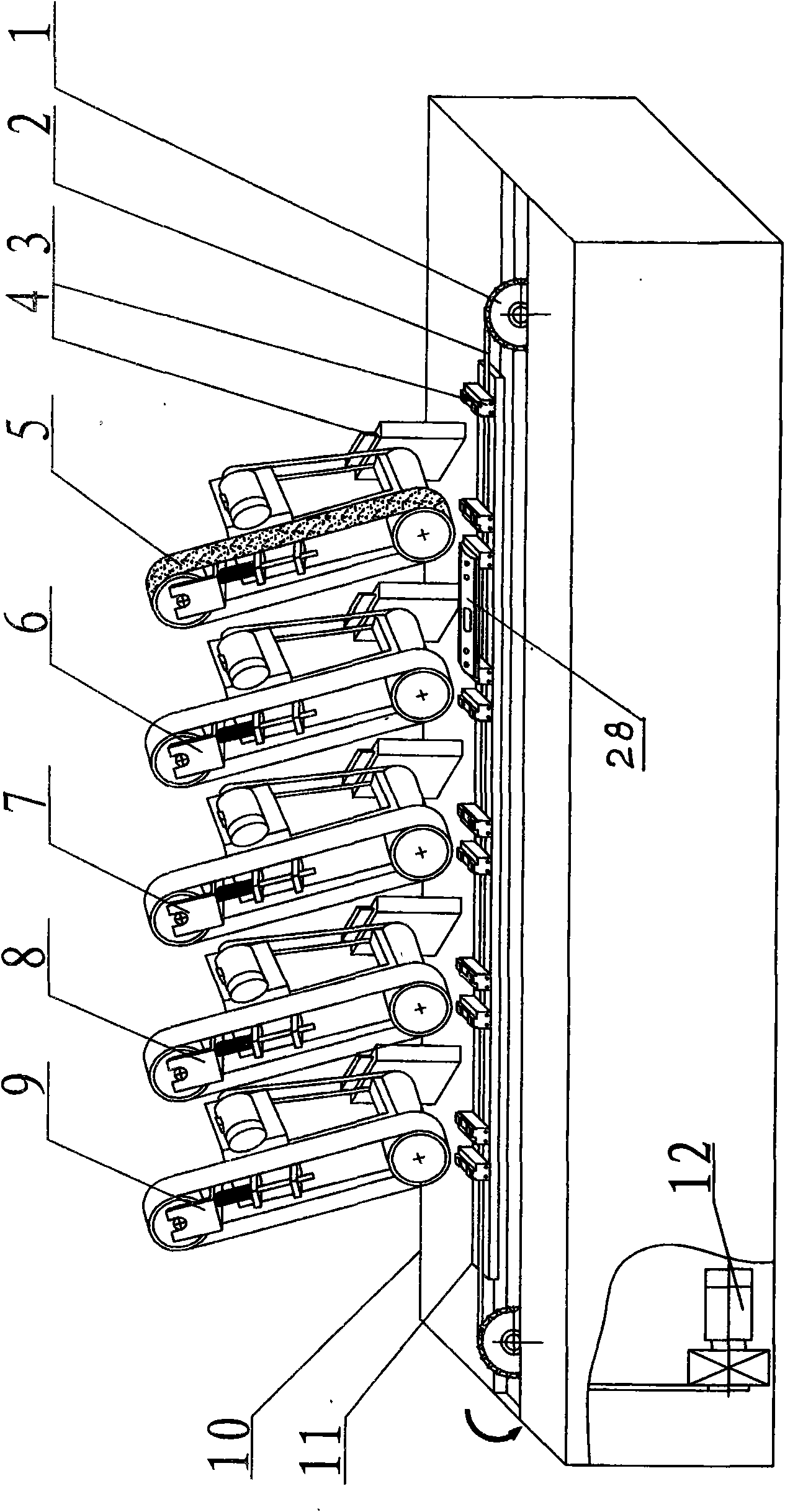

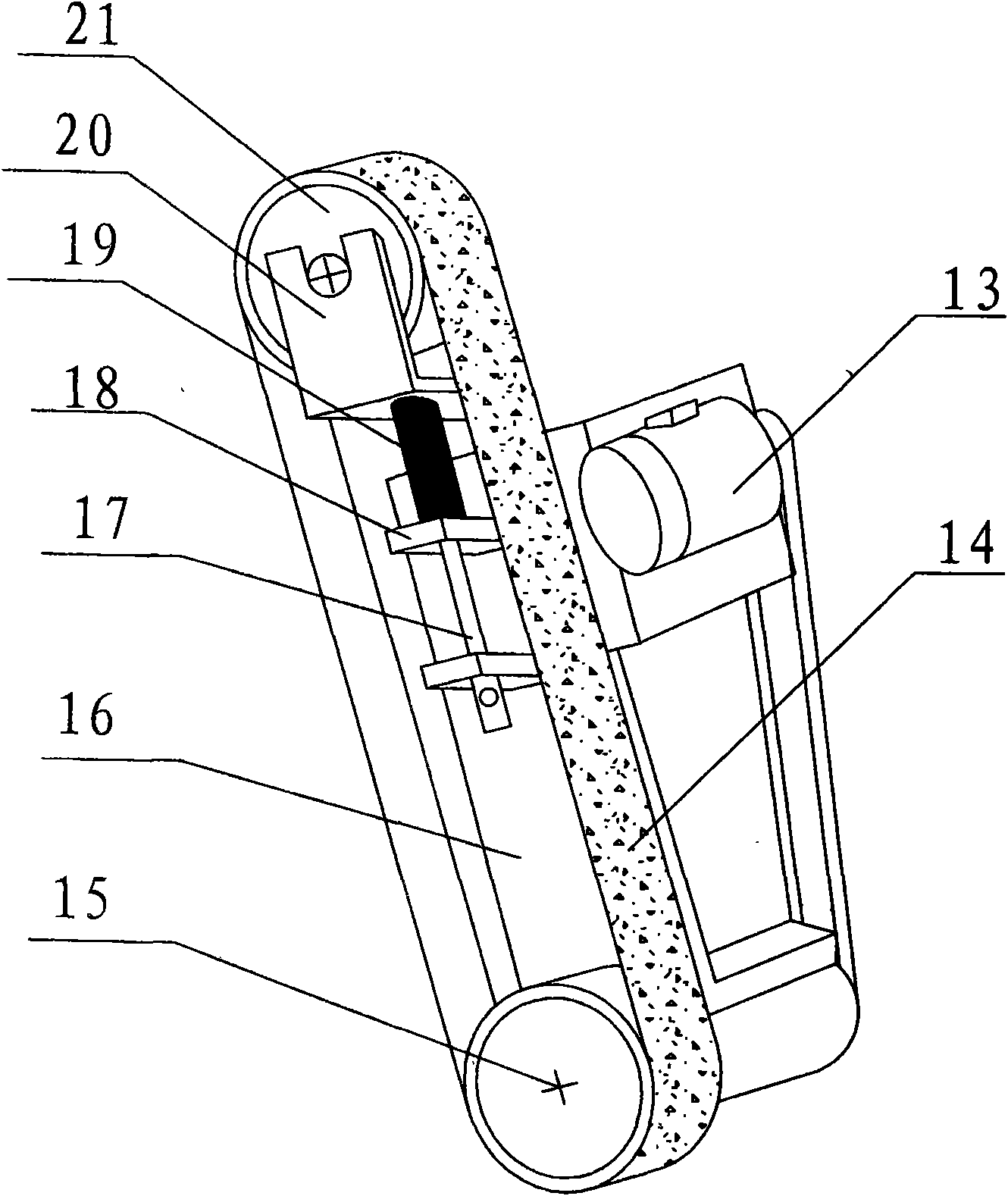

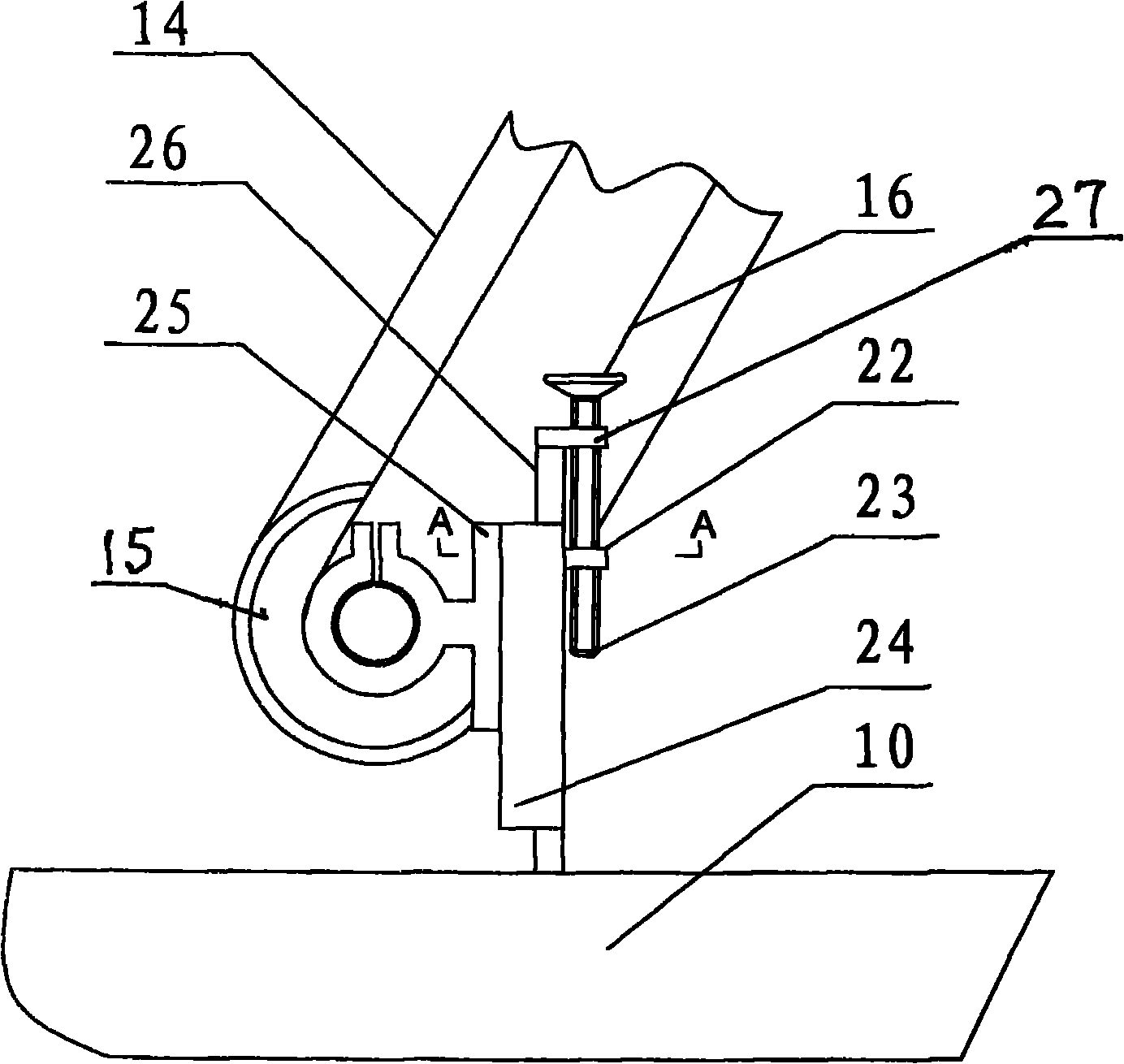

Polishing machine for panel of lock

InactiveCN101780655AImprove ergonomicsImprove securityBelt grinding machinesElectric machineryEngineering

The invention relates to a polishing machine for a panel of a lock. The polishing machine comprises a stander and a grinding head and a sprocket transmission motor which are connected to the stander, wherein the left and right ends of the stander are provided with a sprocket respectively; the sprocket at one end of the stander is connected with the sprocket transmission motor through a sprocket shaft; the sprockets at the two ends of the stander are connected with each other through a chain; the chain is fixed with a plurality of panel fixtures respectively; a guide rail is arranged between the sprockets at the two ends of the stander; the lower end of the panel fixture in an upper section of the chain is in slide contact with the guide rail; the grinding head is correspondingly arranged above the panel fixture in the upper section of the chain; grinding and polishing can be performed after the panel of the lock is put in the panel fixture and rotates to the lower side of the grinding head along with the chain. The polishing machine has the advantages of high work efficiency, high safety and good consistency of product quality and the like.

Owner:胡小爱

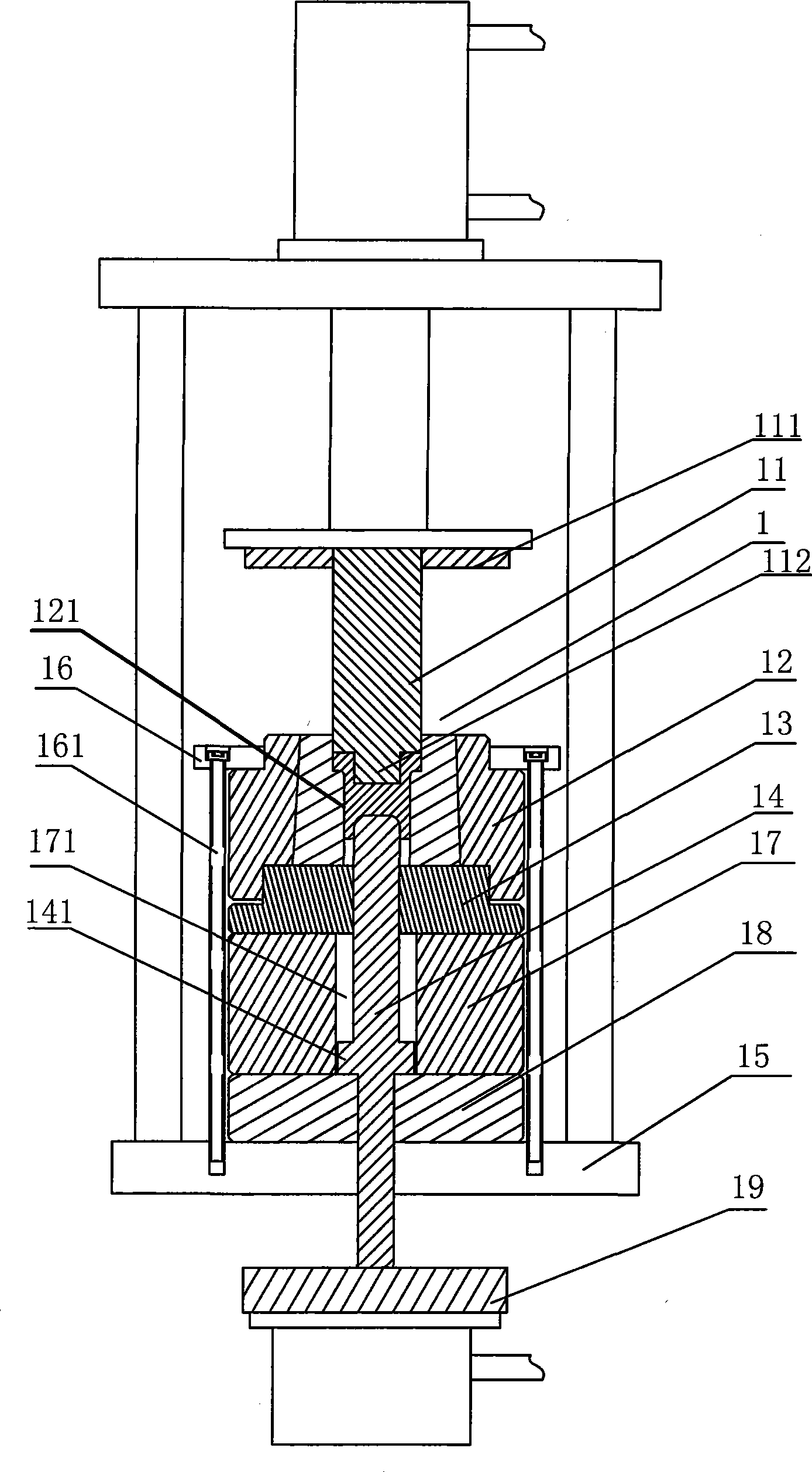

125 motorcycle engine starting gear cold extrusion forming method and dies thereof

The invention discloses a 125 motorcycle engine starting gear cold extrusion forming method. The method comprises the following steps: a) charging materials; b) carrying out cold extrusion on a starting gear blank; c) carrying out cold extrusion on gears and keyways of the starting gear so as to form a starting gear finished blank; and d) carrying out the finish turning on the starting gear. A cold extrusion device comprises a hydraulic press with upper and lower oil cylinders and dies. The dies comprise a blank extrusion die and a gears and keyways extrusion die which are arranged on the hydraulic press with the upper and lower oil cylinders respectively. The 125 motorcycle engine starting gear cold extrusion forming method adopts the two-step formation integrated with subsequent processing, saves raw materials, and has high work efficiency, low processing cost and good quality uniformity of products. The cold extrusion forming dies have novel design and a reasonable structure, and meet the requirements of the 125 motorcycle engine starting gear cold extrusion forming method.

Owner:张长国

Self-locking nut crimping processing method

ActiveCN101905272AFast motion transitionSmooth movement transitionsNutsFriction torqueControl system

The invention discloses a self-locking nut crimping processing method, which comprises the following steps of: arranging a crimping clamp on crimping equipment; putting the positioning plane of a nut on the positioning surface of the crimping clamp, inputting preset parameters, starting up the equipment, driving a pressure head by a driving system to move to a position close to the outer surface of the nut at a high speed, feeding at a work speed, and crimping the nut; after the feeding is in place, stopping the pressure head, entering a pressure keeping stage, and after the pressure keeping is finished, quickly retreating the pressure head to a workpiece assembling and disassembling position; meanwhile, automatically recording the parameters by using a control system; measuring the crimping size of the nut, and measuring friction torque; if the nut is not qualified, modifying the nut crimping parameters, and repeating the steps of (2) and (3) on another nut; and if the nut is qualified through inspection, crimping nuts in batch by utilizing the parameters recorded by the control system. The product produced by the method has the advantages of high crimping dimensional accuracy, good product consistency, high production efficiency and strong adaptability.

Owner:GUIZHOU UNIV +1

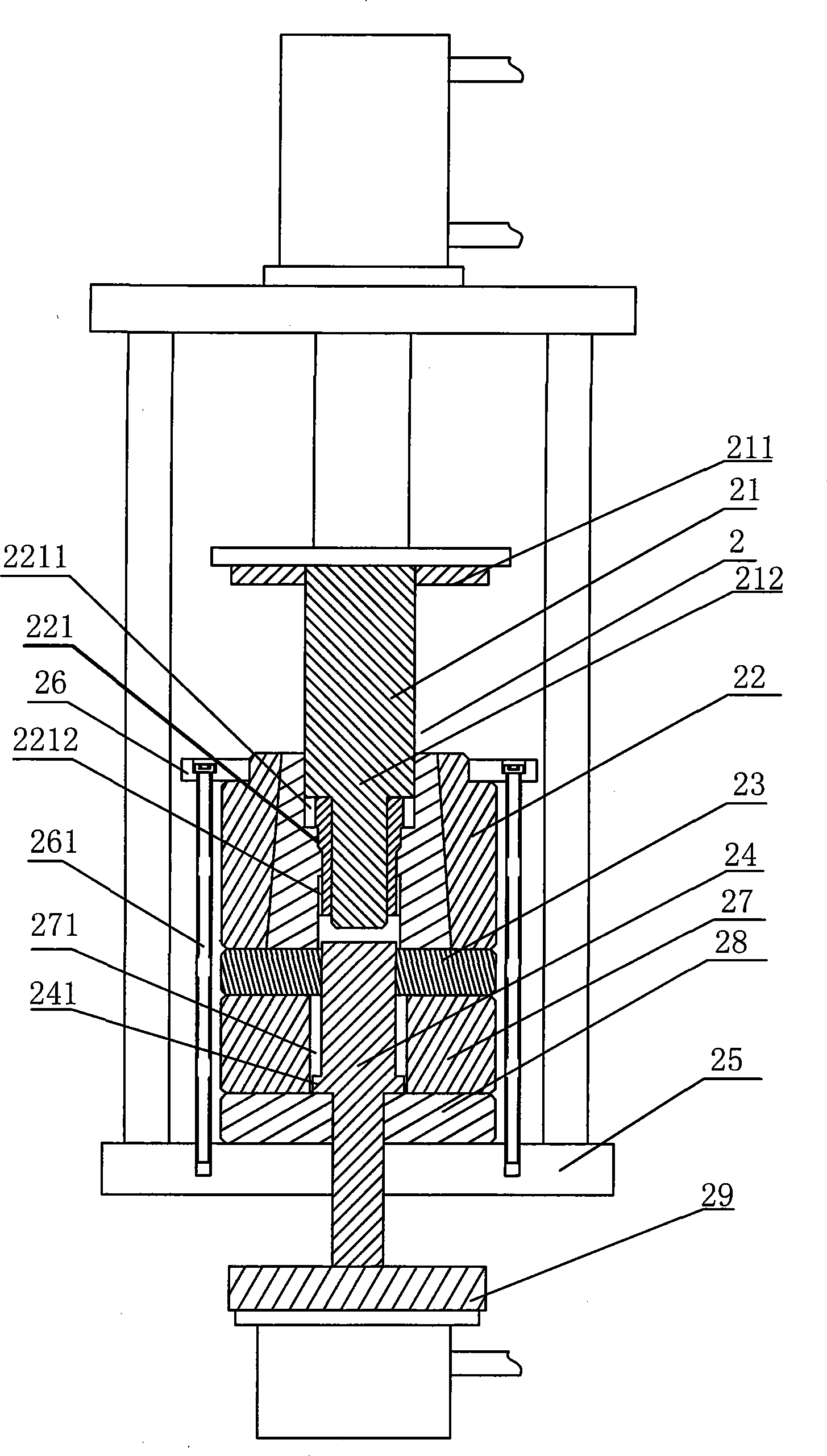

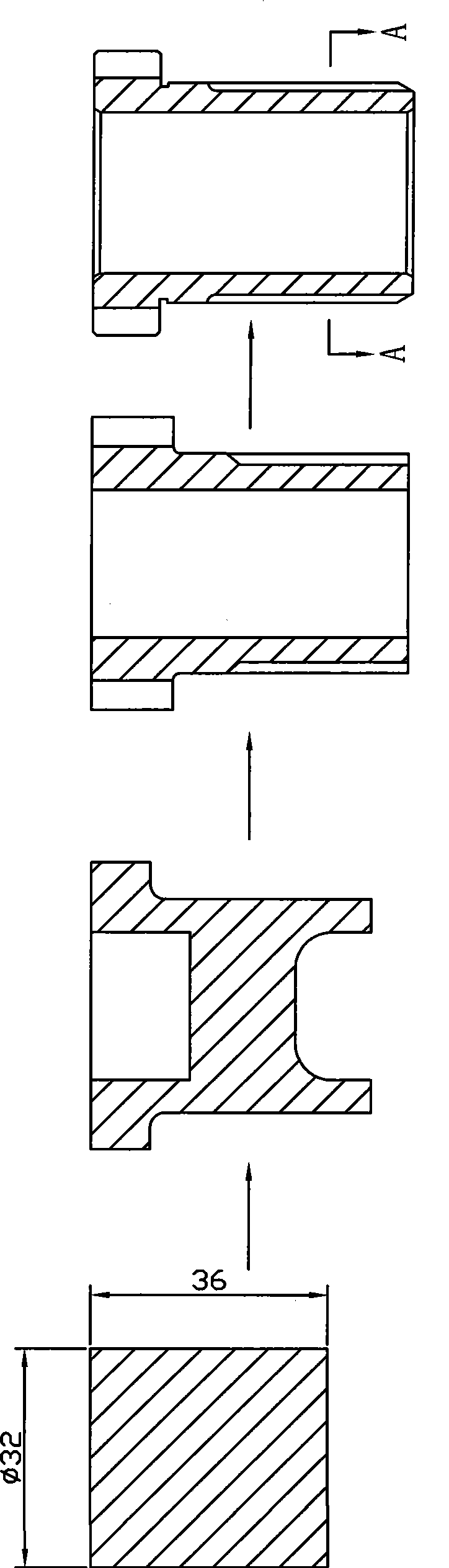

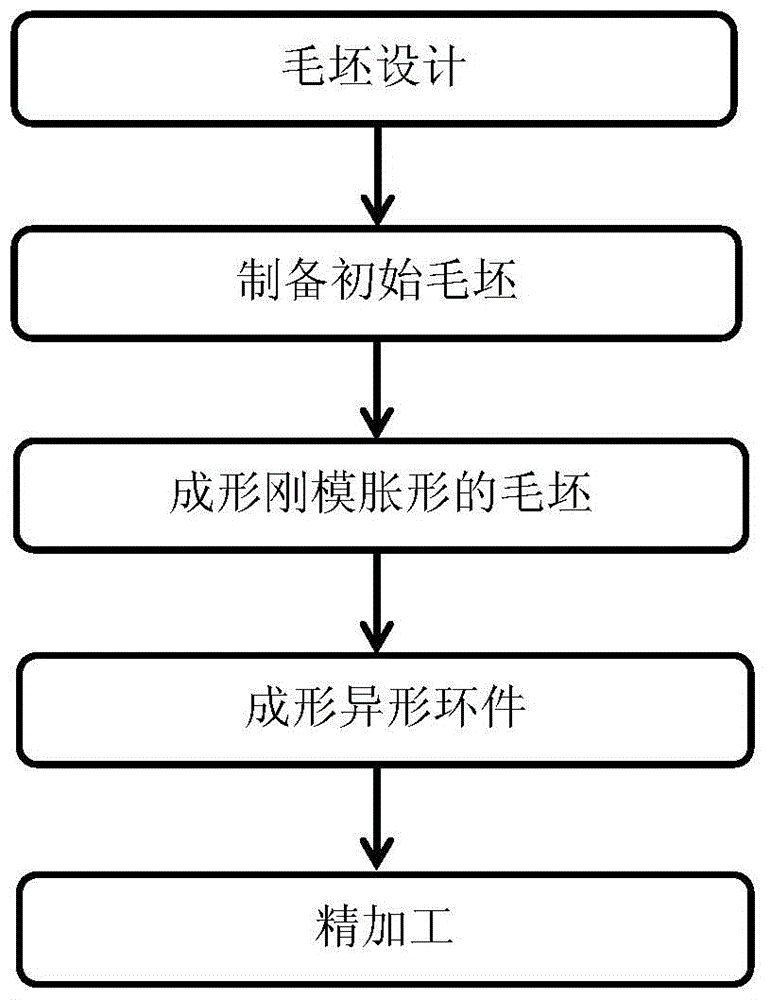

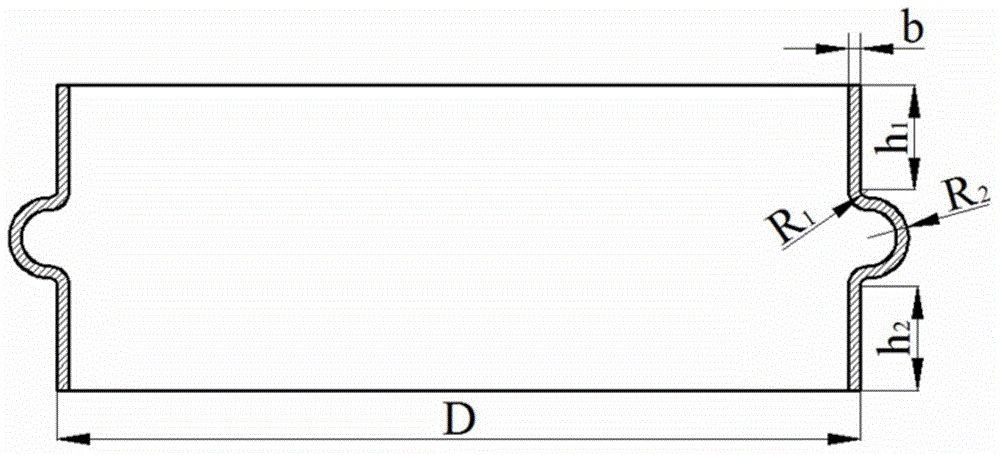

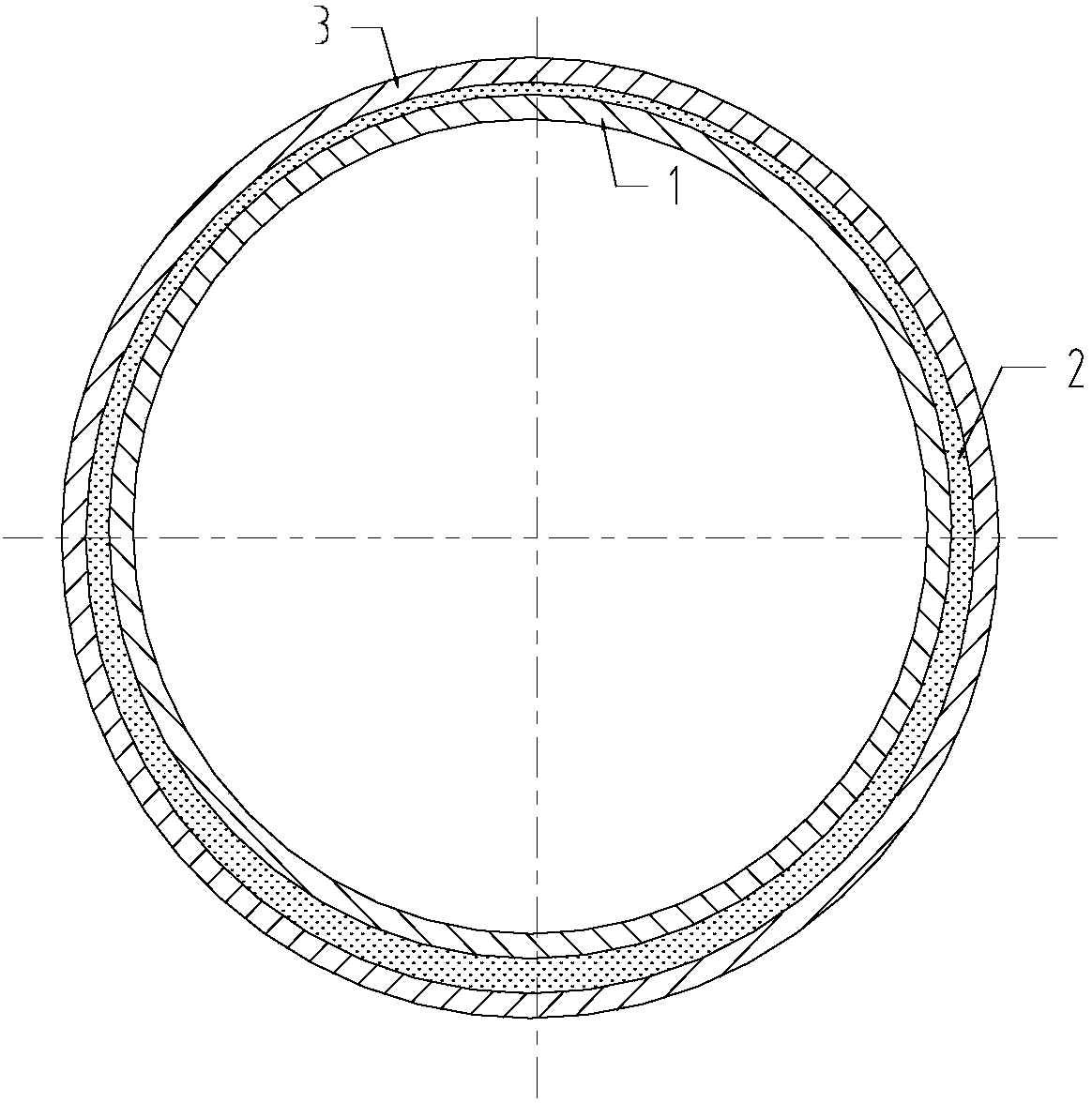

Titanium alloy equal-thickness thin-wall special-shaped annular piece rolling and expanding composite forming method

A titanium alloy equal-thickness thin-wall special-shaped annular piece rolling and expanding composite forming method comprises the processes of workblank design, upsetting and punching, thin-wall annular piece rolling, rigid mold bulging, finish machining and titanium alloy thin-wall special-shaped annular piece. The whole flow mainly depends on material plastic forming; oxide skin externally wrapping the annular piece is only removed by cutting and removing working allowance in the final process, so that the performance of the annular piece is ensured, and the cost is saved. When the special-shaped annular piece is finally formed, rigid mold bulging is adopted, and the final geometrical shape and dimension of the annular piece are ensured by a mold, so that the precision is very high; and the consistence of dimension and precision of a part can be ensured when multiple processing is continuously carried out.

Owner:丹东丰能工业股份有限公司

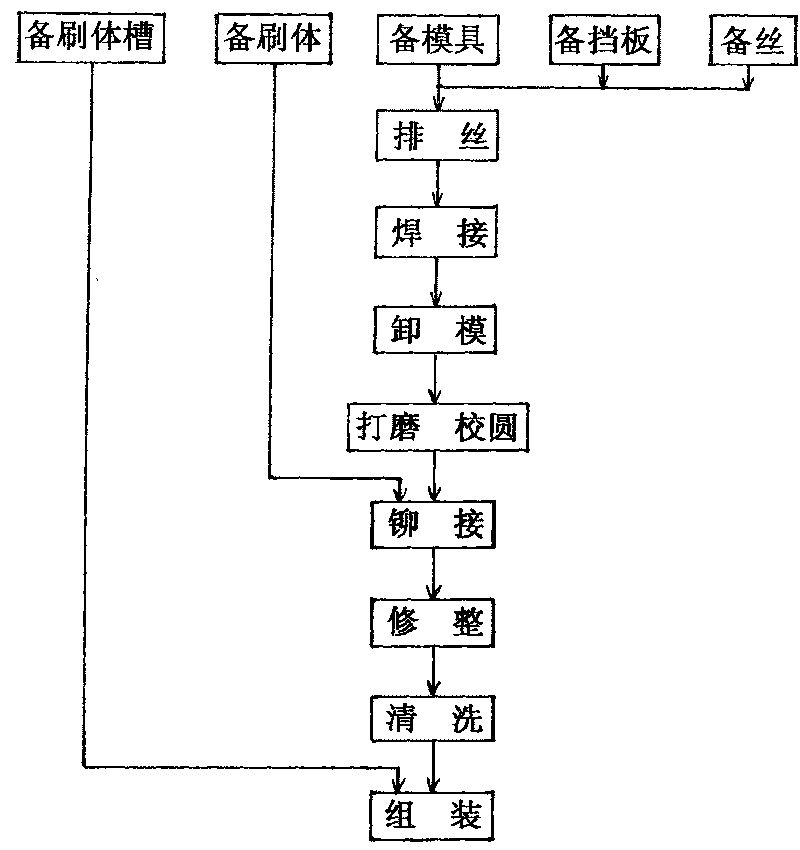

Method for producing brush steam seal ring

ActiveCN101713301AImprove sealingImprove securityEngine sealsLeakage preventionEngineeringMethods of production

The invention discloses a method for producing a brush steam seal ring, which mainly comprises the following steps: preparing a brush body slot; preparing a brush body; preparing a mould; preparing a baffle plate; preparing wires; arranging the wires; welding; unloading the mould; grinding and rounding; riveting; finishing; cleaning and assembling and the like, and is a good and reasonable method which is summarized from production practice and is suitable for mass production. The method can produce the qualified brush steam seal ring having the advantages of good sealing effect, good safety performance, high mechanical strength, good consistency of product quality, no wire drop and the like.

Owner:江苏鑫信润科技股份有限公司

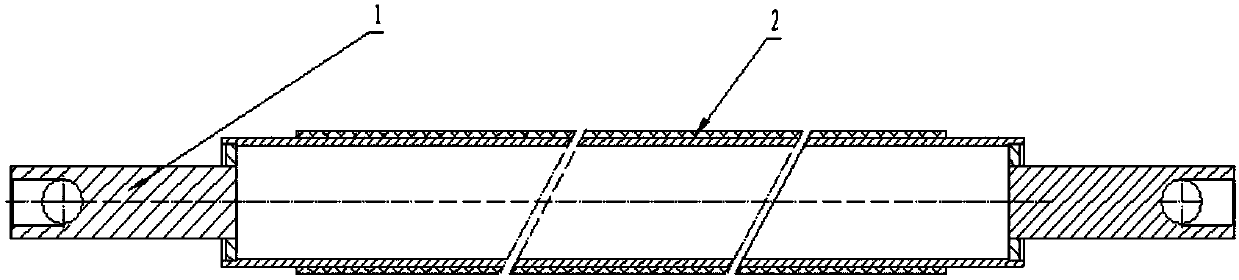

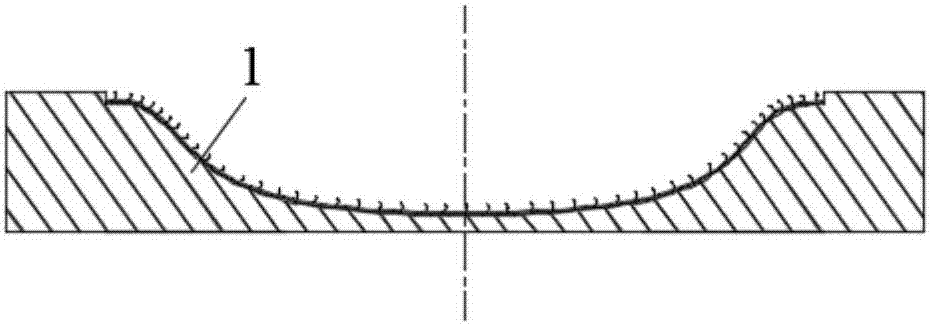

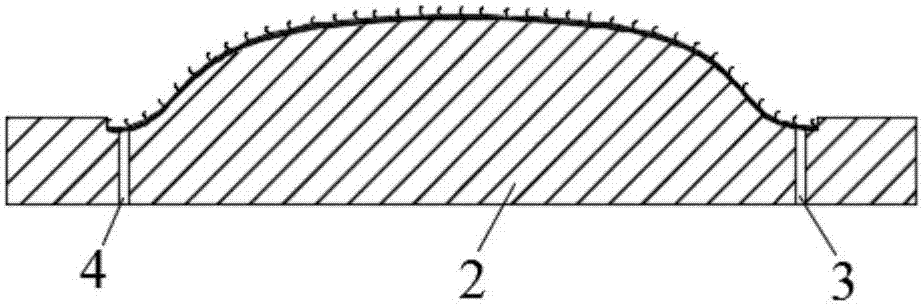

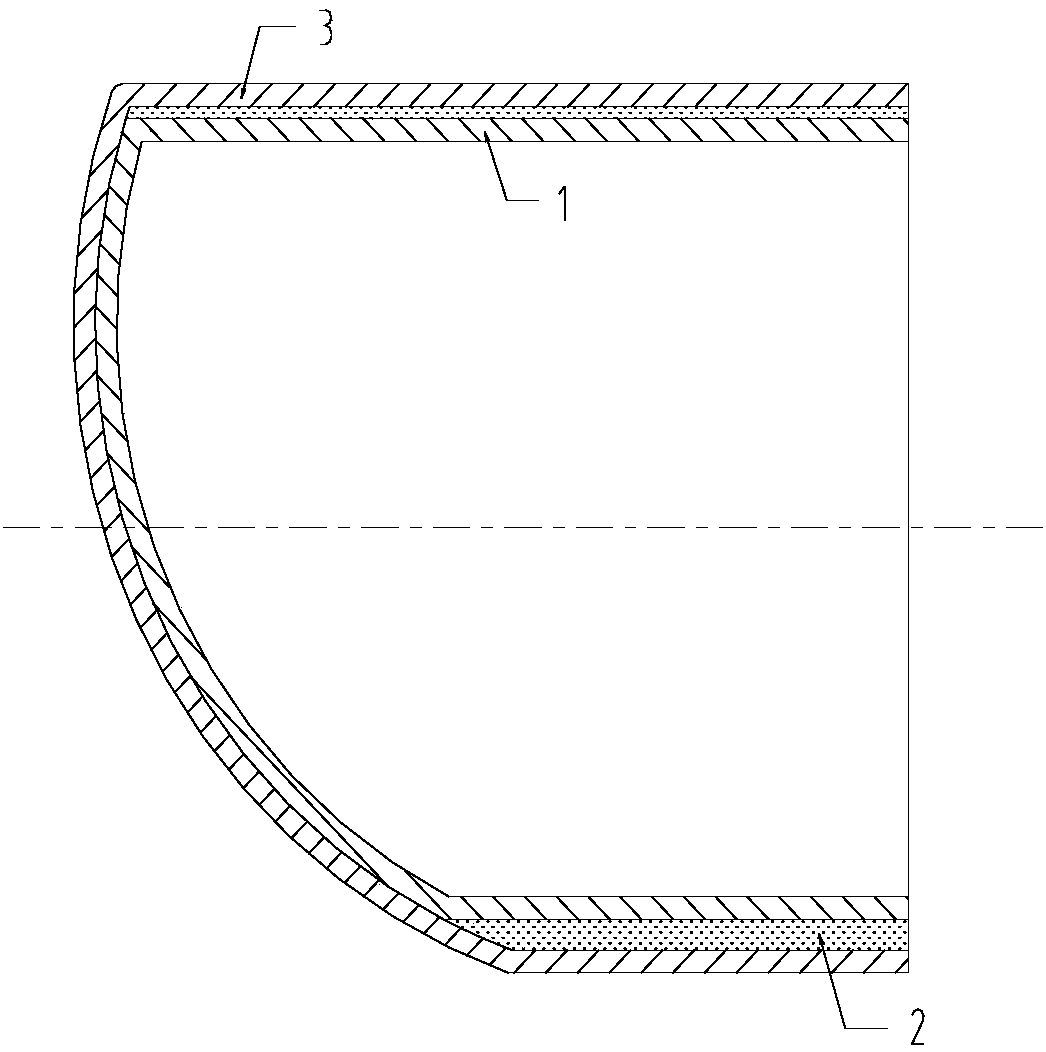

Solid rocket engine combustion chamber shell adiabatic layer forming method

ActiveCN109605625ANo distortionThere is no problem with exhaustDomestic articlesVulcanizationCombustion chamber

The invention relates to a solid rocket engine combustion chamber shell adiabatic layer forming method, and belongs to the field of adiabatic layer forming technologies. The solid rocket engine combustion chamber shell adiabatic layer forming method comprises the steps that according to the design structure of an engine combustion chamber shell, an adiabatic layer prefabricated part which is not completely vulcanized is prepared, and the outer diameter of the adiabatic layer prefabricated part which is not completely vulcanized is less than the inner diameter of the engine combustion chamber shell; the adiabatic layer prefabricated part which is not completely vulcanized is bonded to the inner wall of the engine combustion chamber shell through a heat vulcanization adhesive; and hot pressing vulcanization is conducted, and thus the engine combustion chamber shell with an adiabatic layer is obtained. Through internal support tension of the adiabatic layer prefabricated part and a good isolation gap between the adiabatic layer prefabricated part and the inner wall of the combustion chamber shell, the problems of sheet pasting warp and unsmooth exhaust of sheet rubber are effectivelysolved, and bonding reliability of the interface of the adiabatic layer and the shell is improved.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

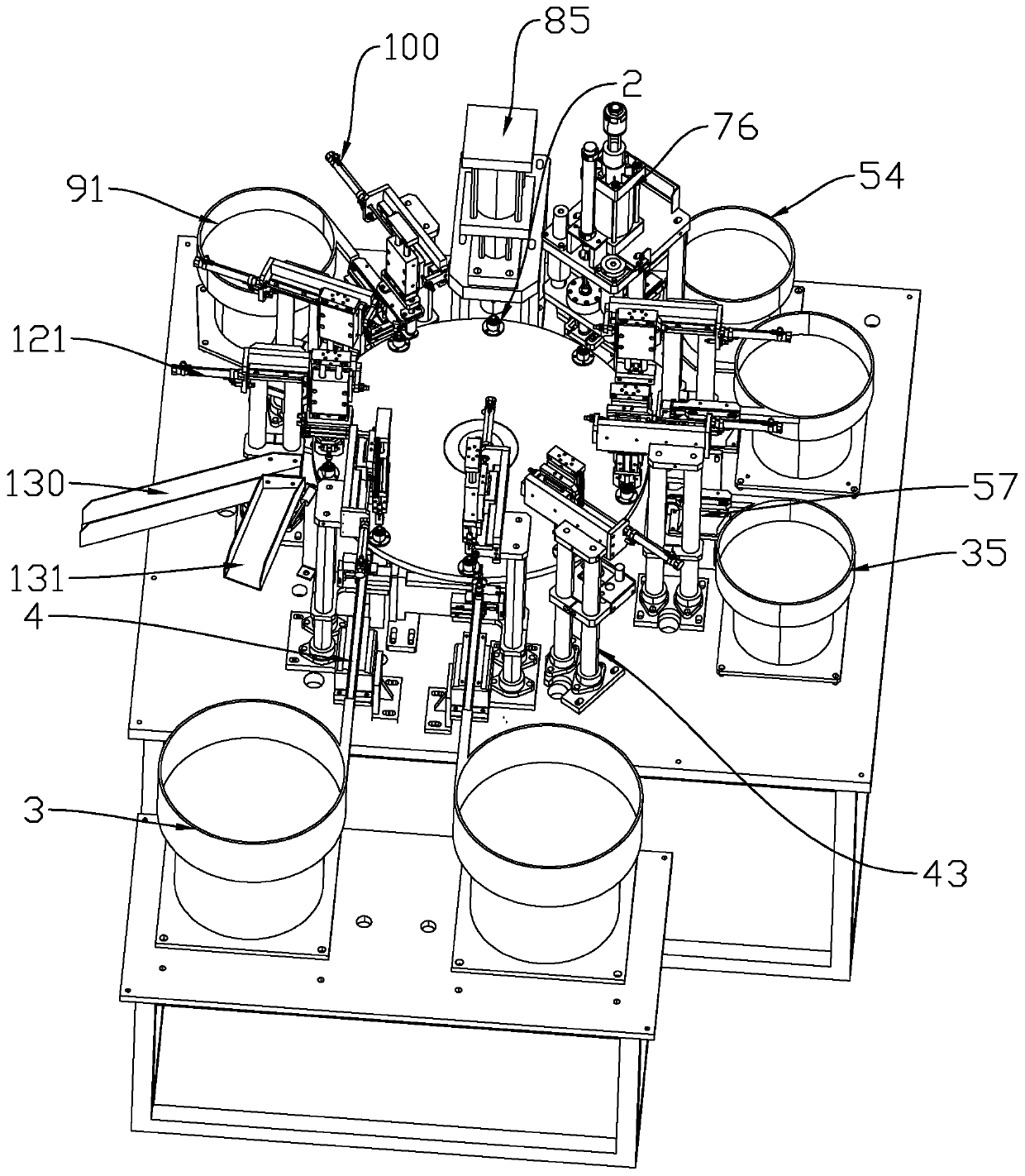

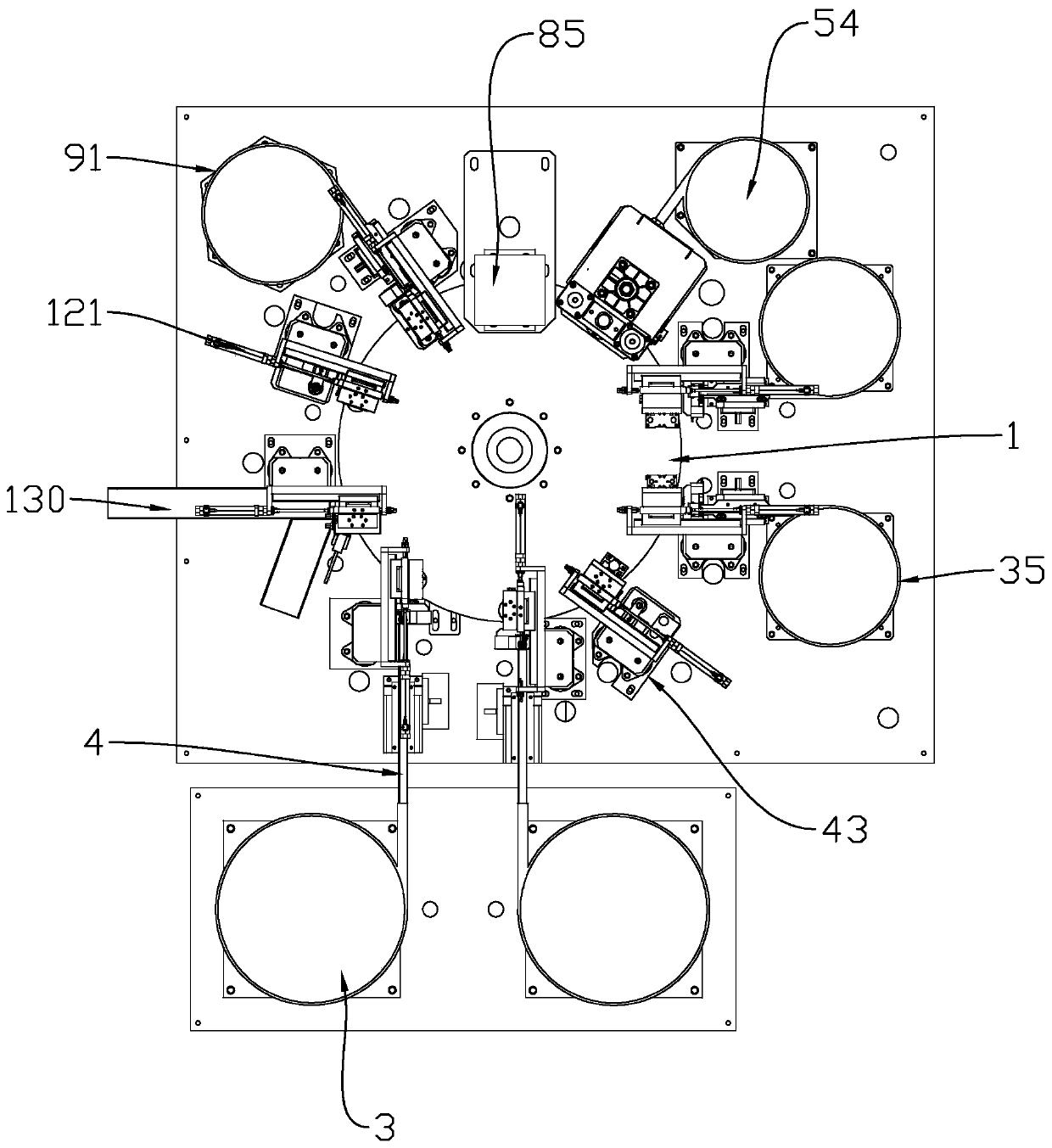

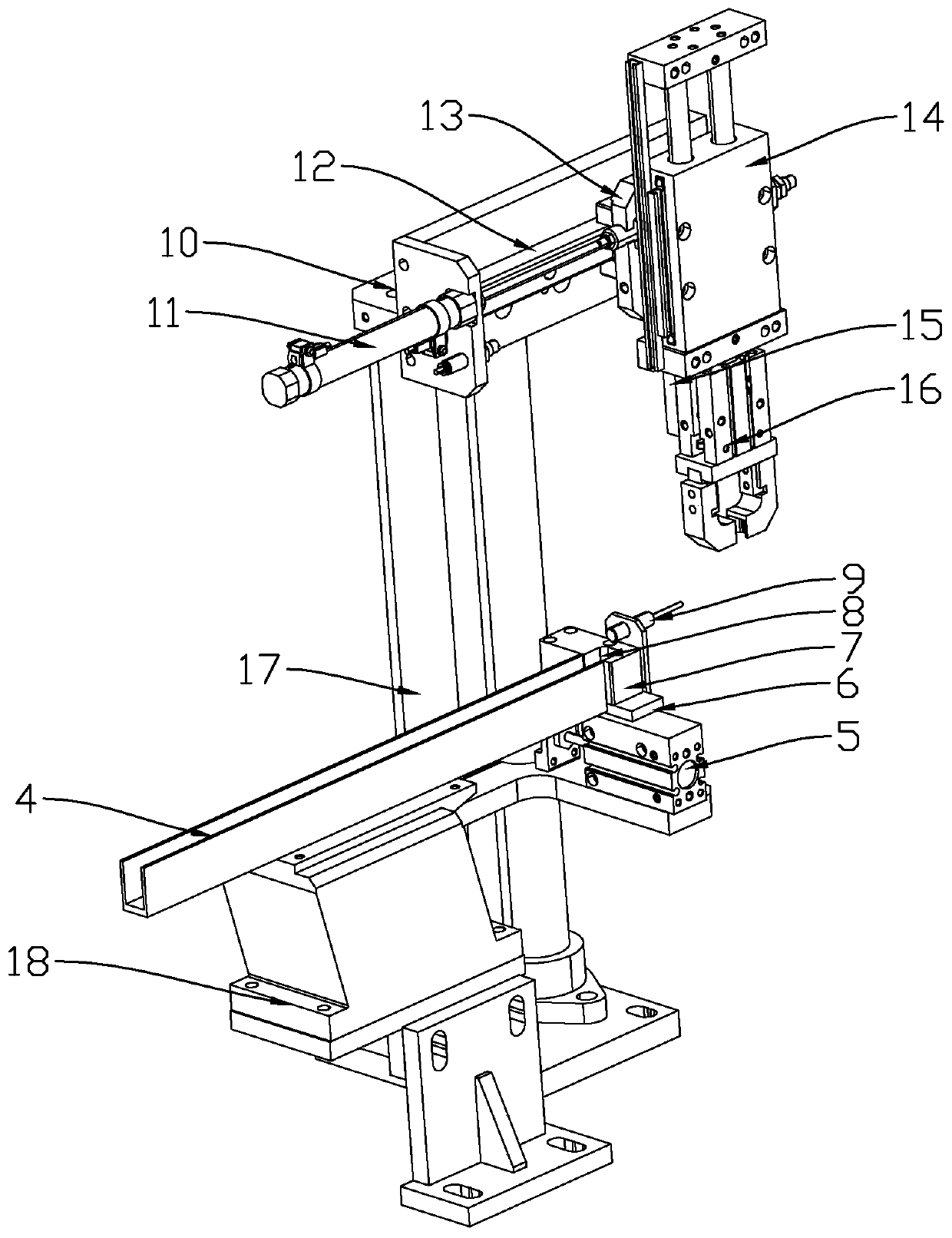

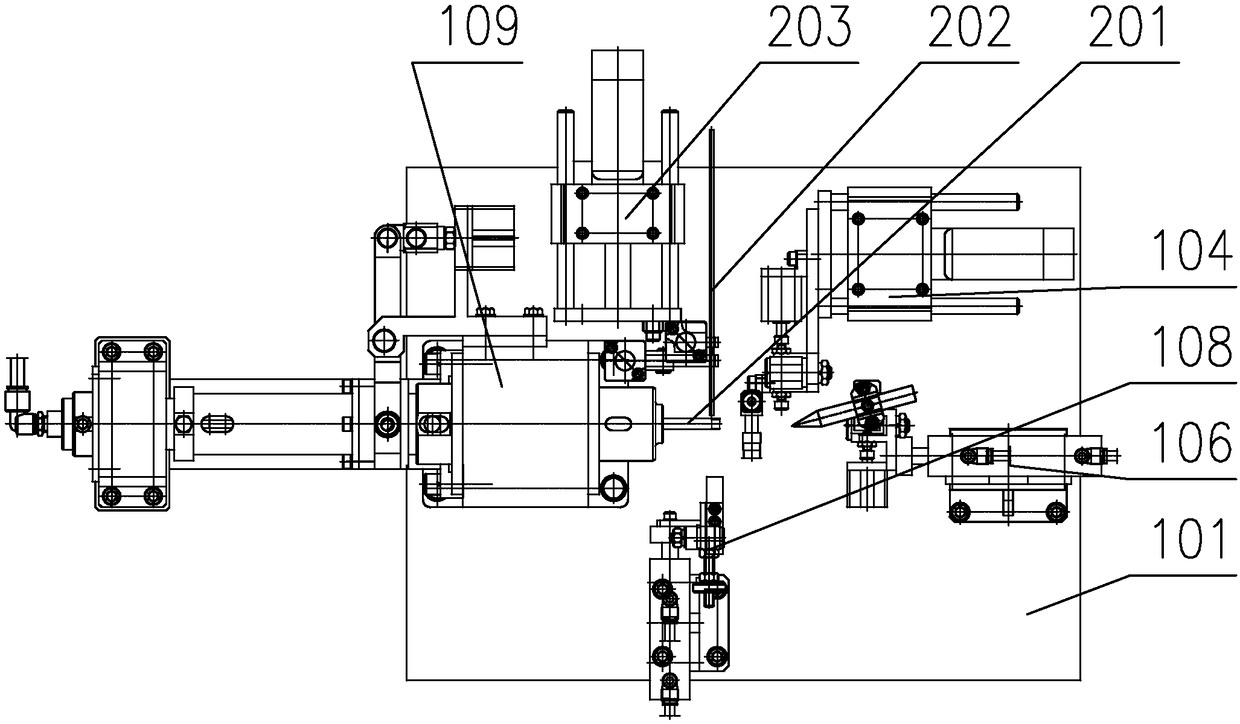

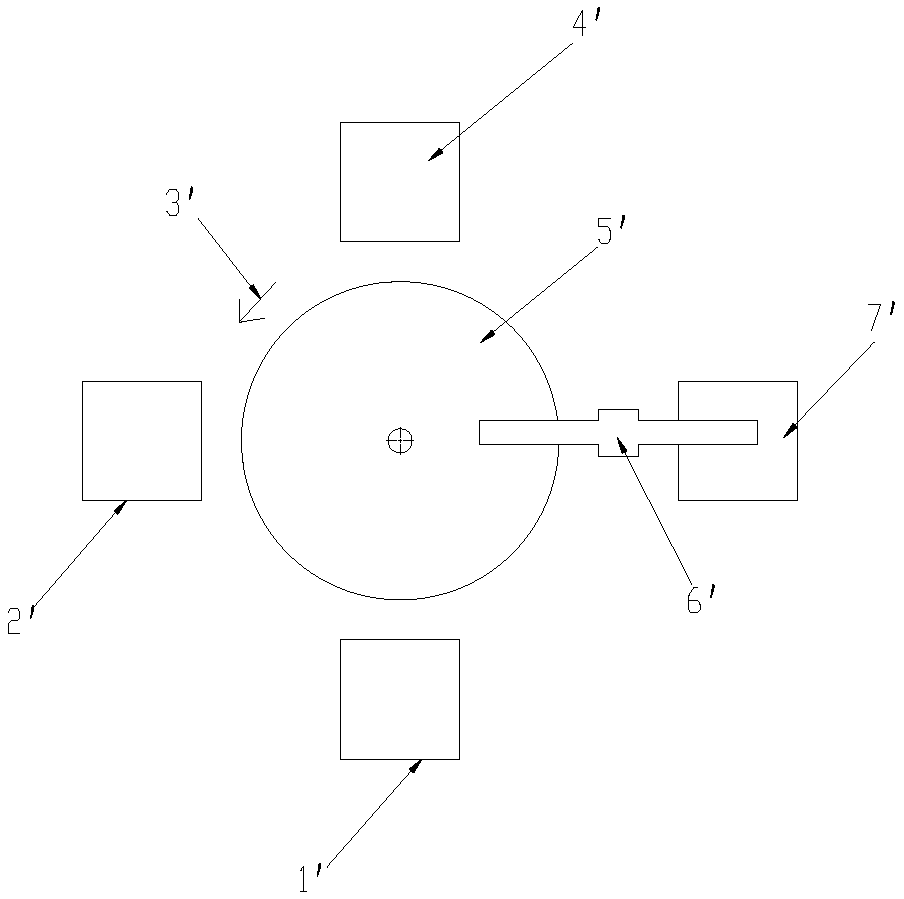

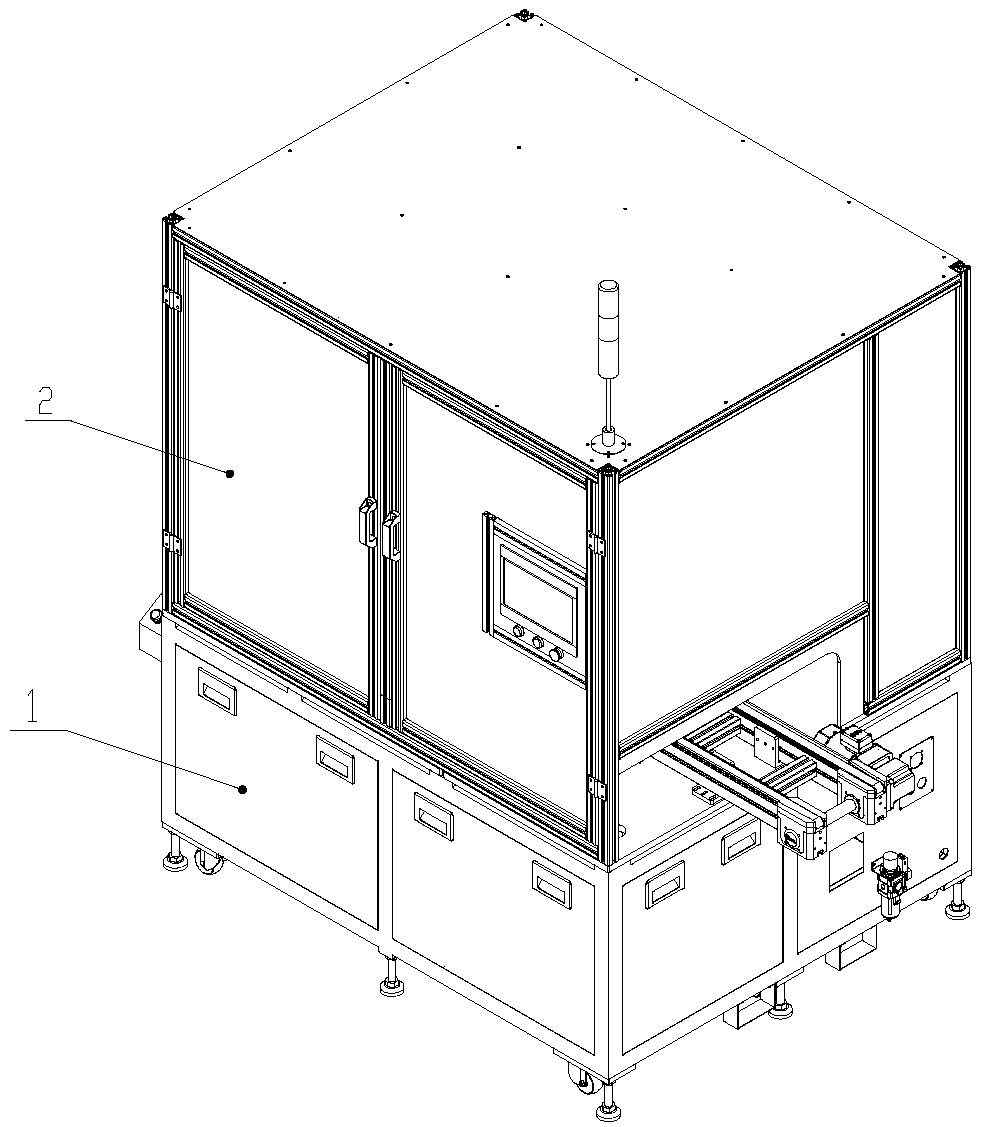

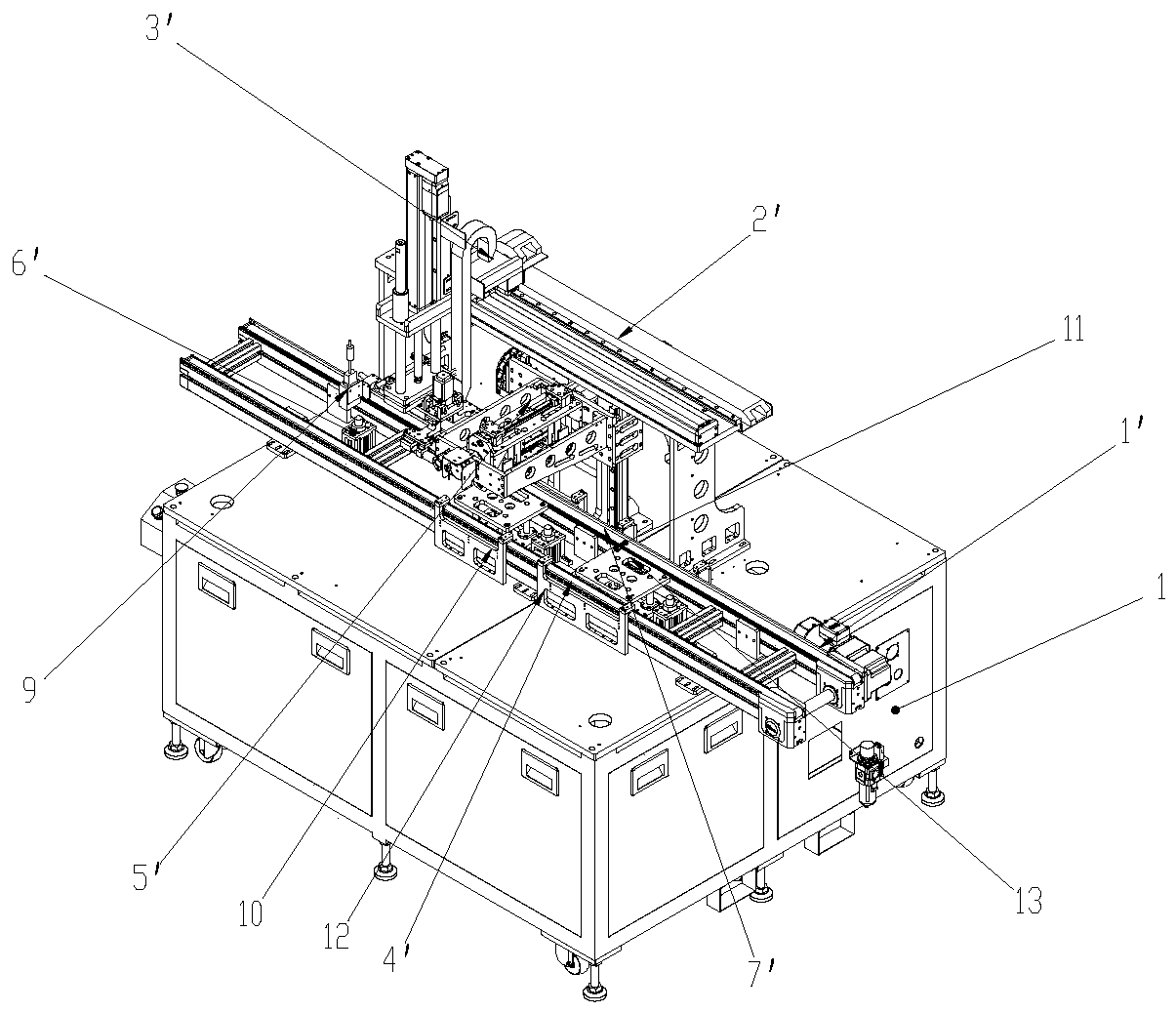

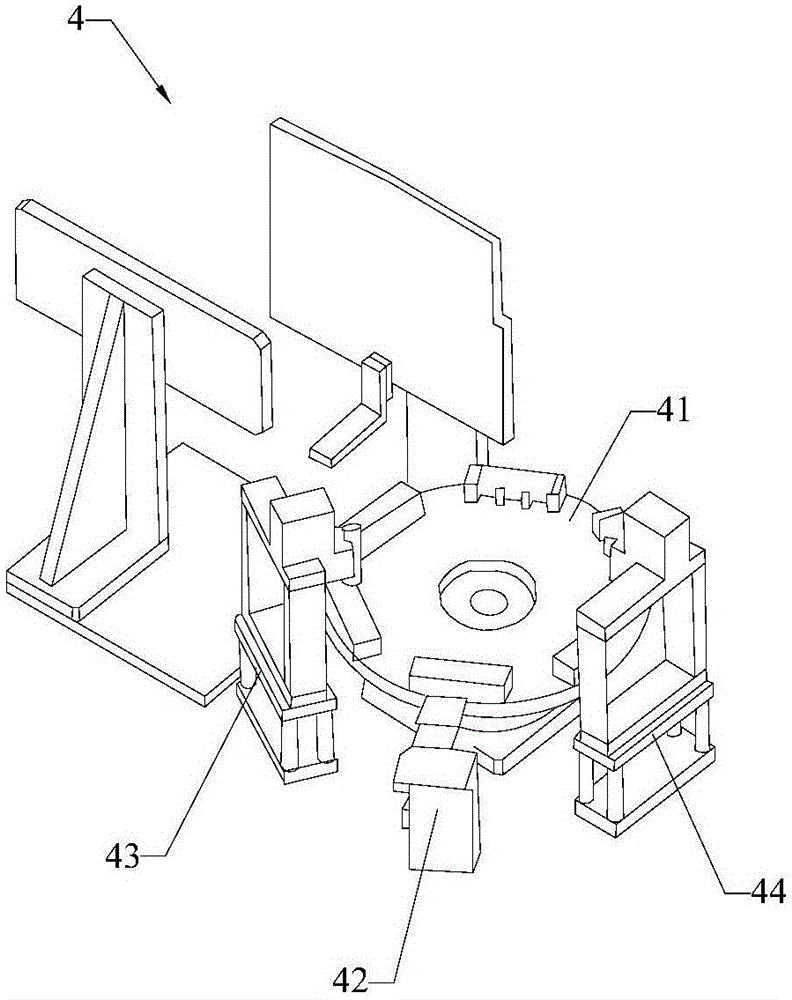

Automatic assembling equipment for valve body assembly of reading valve

ActiveCN111185753AImprove work efficiencyReduce assembly failure rateAssembly machinesSortingStructural engineeringRotating disc

The invention relates to automatic assembling equipment, in particular to automatic assembling equipment for a valve body assembly of a reading valve. The automatic assembling equipment comprises a rotating disc, a first valve body feeding mechanism, a second valve body feeding mechanism, a valve body inner hole outer ring oiling mechanism, a first plastic inner ring feeding mechanism, a second plastic inner ring feeding mechanism, a knurled inner ring feeding mechanism, a valve body closing mechanism, an O-shaped ring feeding mechanism, an O-shaped ring outer ring oiling mechanism and a discharging mechanism, wherein the first valve body feeding mechanism, the second valve body feeding mechanism, the valve body inner hole outer ring oiling mechanism, the first plastic inner ring feeding mechanism, the second plastic inner ring feeding mechanism, the knurled inner ring feeding mechanism, the valve body closing mechanism, the O-shaped ring feeding mechanism, the O-shaped ring outer ringoiling mechanism and the discharging mechanism are sequentially arranged around the rotary disc in the circumferential direction. According to the automatic assembling equipment for the valve body assembly of the reading valve, by arranging a series of assembling mechanisms around the rotary disc, the assembling work of the valve body assembly of the reading valve can be automatically, accuratelyand reliably completed, and the assembling work efficiency is improved.

Owner:弗瑞斯阀门(宁波)有限公司

Polyester polyol with low hydroxyl value as well as preparation method thereof

InactiveCN108623793AImprove adhesionHigh strengthPolyureas/polyurethane adhesivesPolyesterCarboxylic acid

The invention relates to polyester polyol with low hydroxyl value as well as a preparation method thereof. The method comprises the following steps: mixing aromatic binary carboxylic acid or anhydride, diol and a catalyst in an inert atmosphere and under a stirring condition, and reacting at the temperature of 100 to 170 DEG C for 4 to 6 hours; heating to 170 to 240 DEG C, continuously introducinginert gas and reacting for 5 to 7 hours; and closing the inert gas, sectionally vacuumizing to negative pressure and reacting for 3 to 4 hours until the product reaches to a preset acid value to obtain the polyester polyol. By the method, the polyester polyol with low hydroxyl value is prepared from single component diol and aromatic binary carboxylic acid or anhydride. Continuous production is facilitated, and the obtained product has high quality consistency. Fatty acid is not used and an azeotrope agent does not need to be added in the preparation process, volatile byproducts generated bythe reaction are few, and environmental protection is benefited.

Owner:SHANGHAI LIANSHENG CHEM

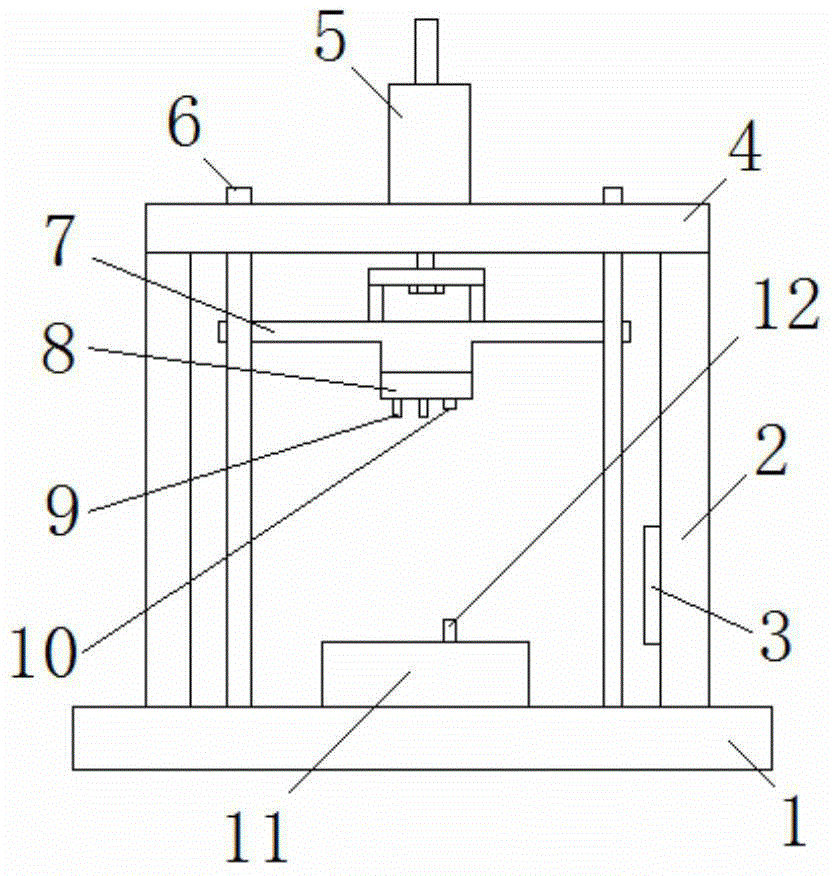

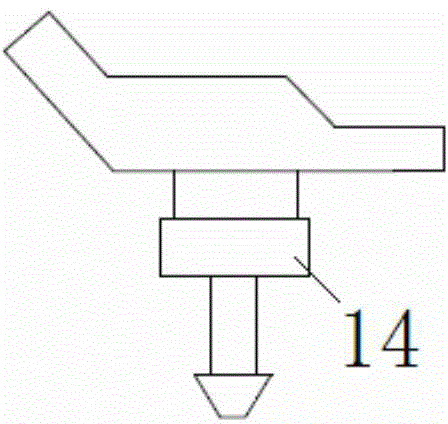

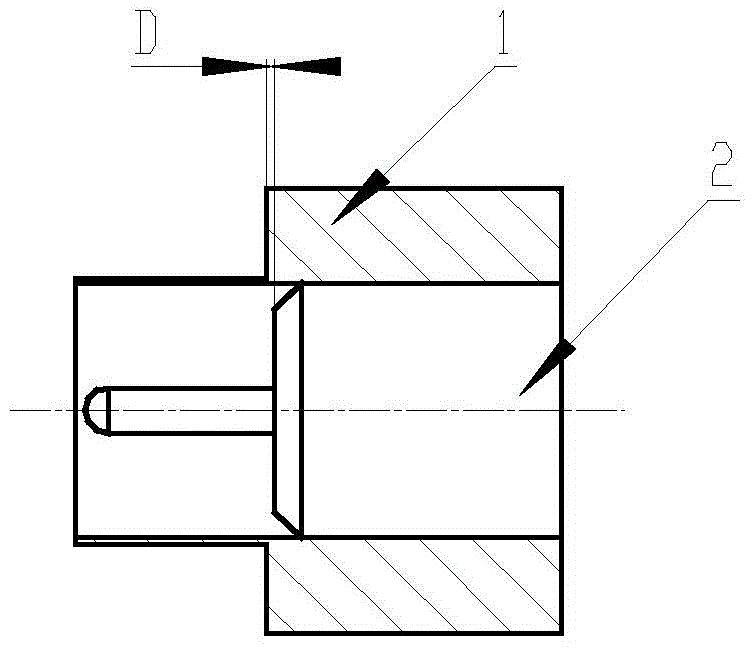

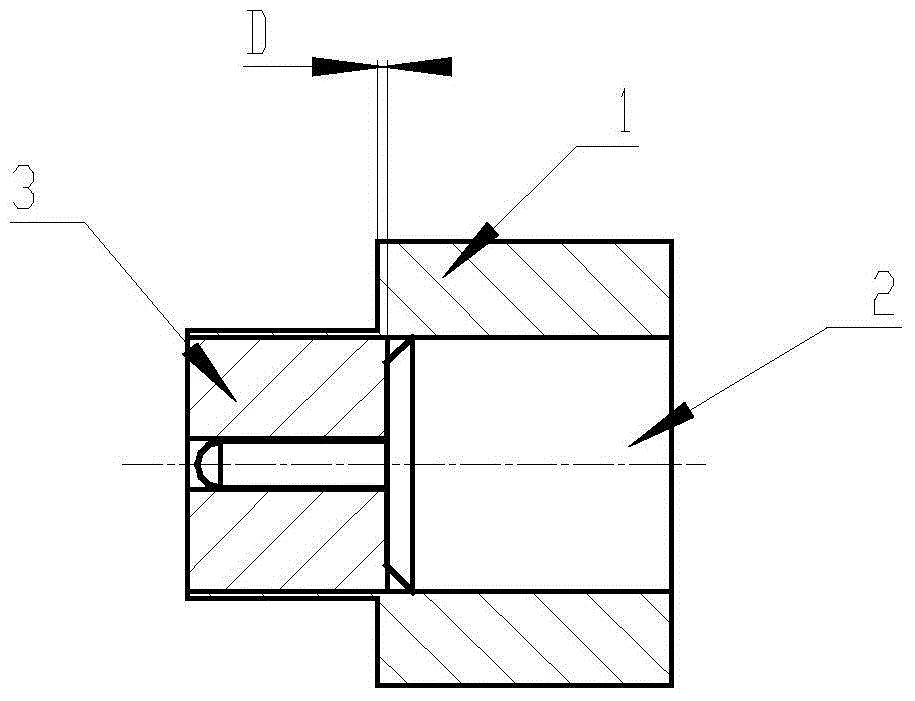

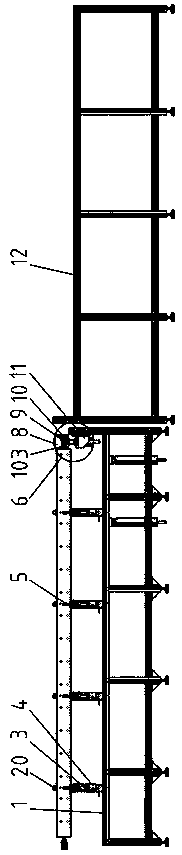

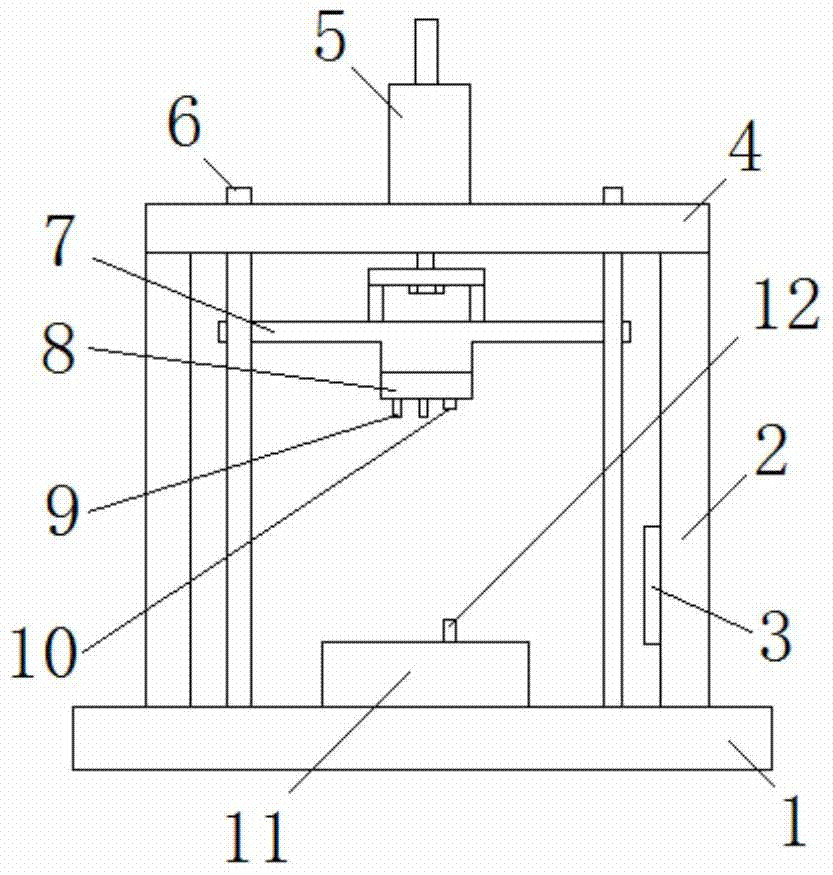

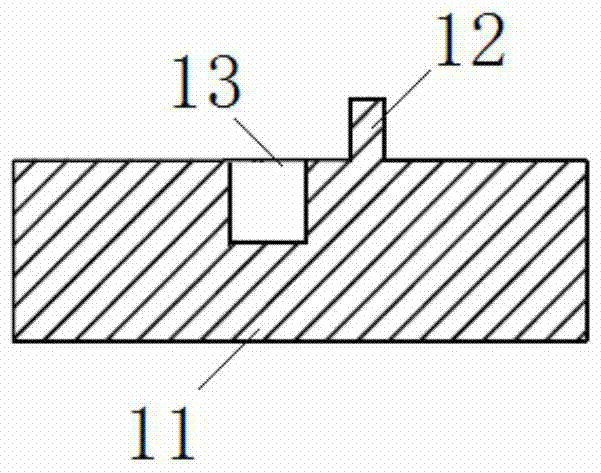

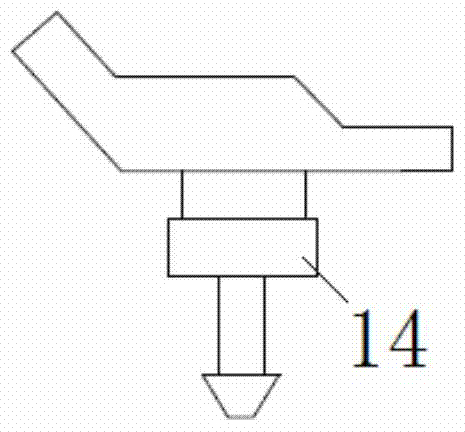

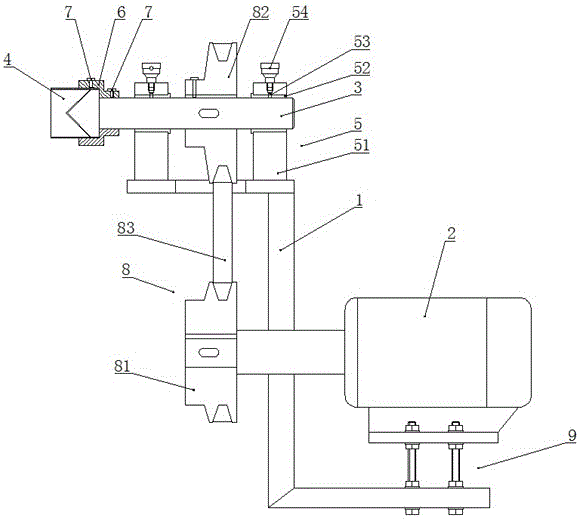

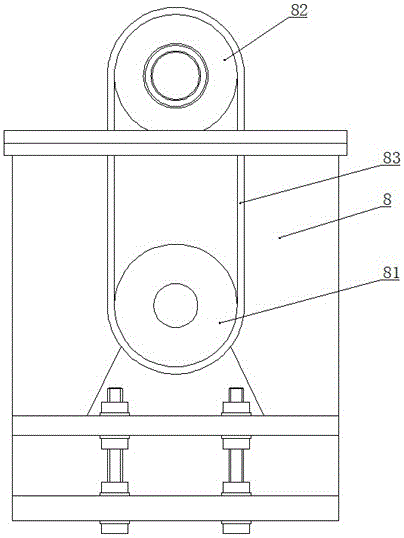

Hot-riveting device for fixing sensor circuit board

ActiveCN104859142AProduct quality consistency is goodIncrease productivityBiochemical engineeringPiston rod

The invention discloses a hot-riveting device for fixing a sensor circuit board. The hot-riveting device comprises a base, a driving cylinder, a hot mold, a hot-riveting rod and a sensor positioning base, wherein the sensor positioning base is arranged on the base; the driving cylinder is arranged on the base and positioned above the sensor positioning base; the hot mold is arranged on the piston rod of the driving cylinder; a heater is arranged in the hot mold; the hot-riveting rod is arranged at the lower part of the hot mold. Due to the adoption of the hot-riveting device, tops of all plastic fixing columns of one sensor can be hot-riveted at one time, and the sensor can be automatically hot-riveted after being positioned, so that the production efficiency is improved, the cost can be lowered, the production quality consistence is good, and the product quality can be easily controlled.

Owner:WUHU GRAND VISION AUTO ELECTRONICS CO LTD

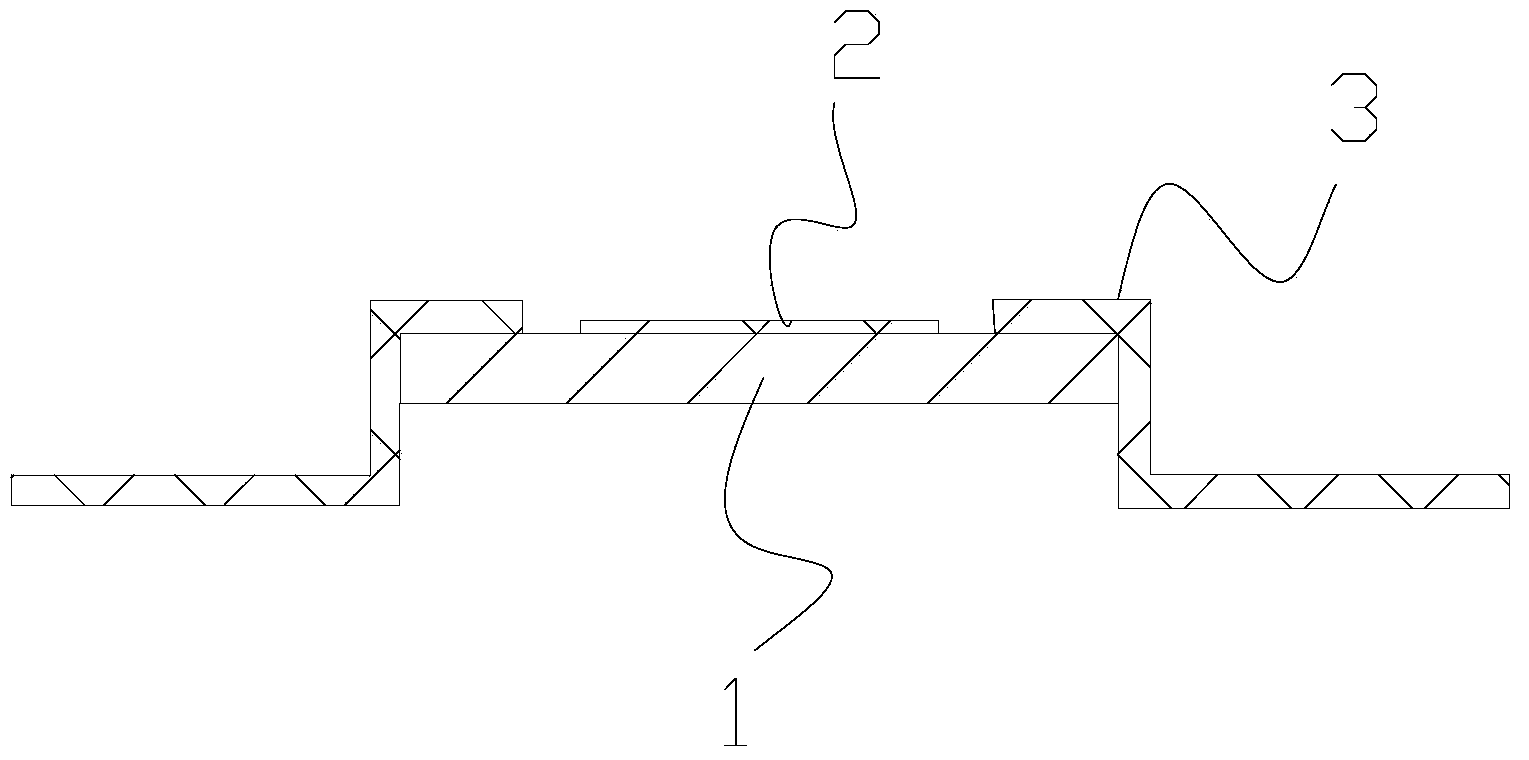

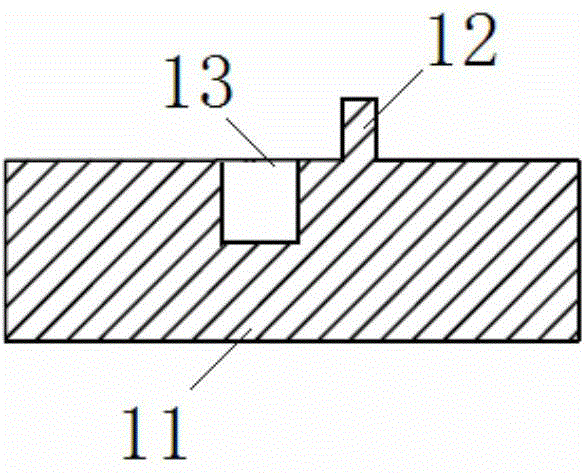

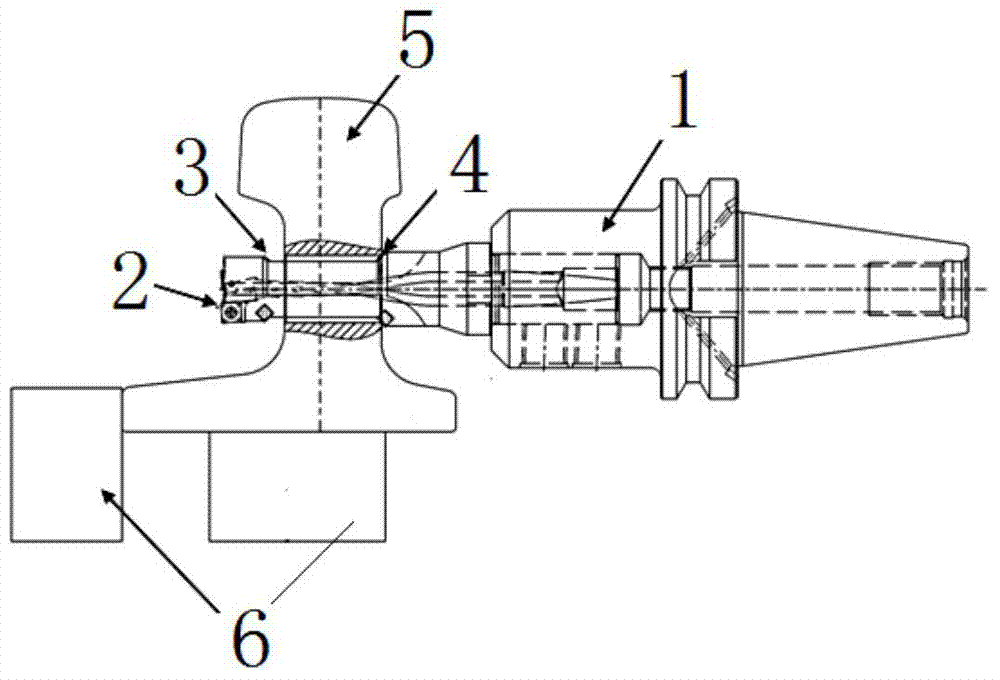

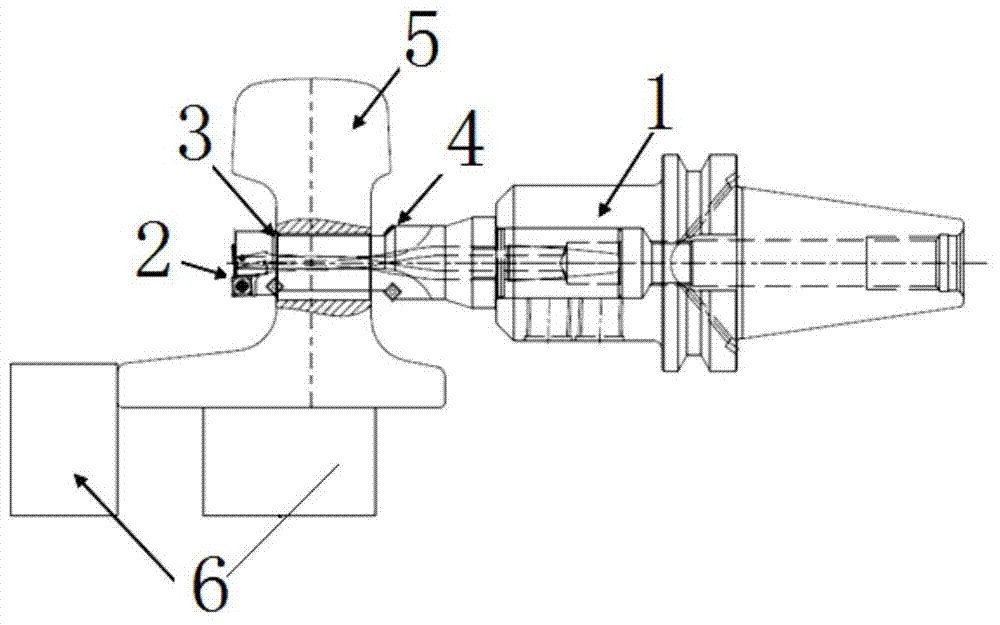

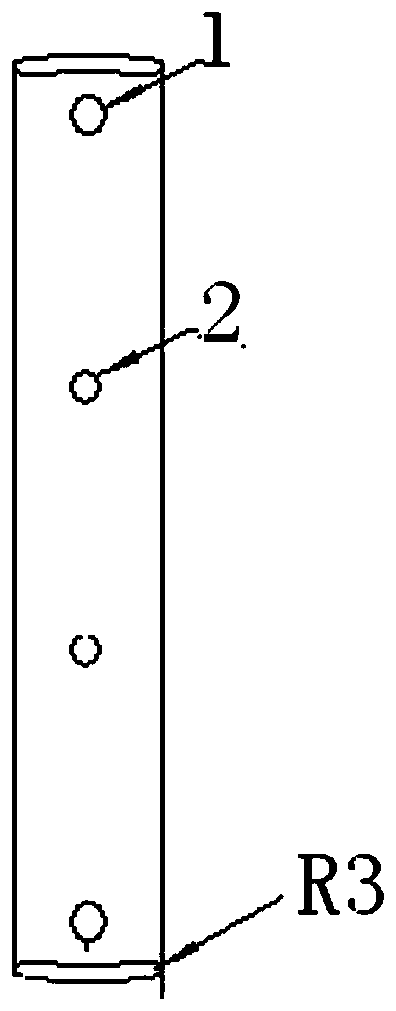

Positioning fixture for improving quality consistency of subminiature precision connector products

InactiveCN104659630AProduct quality consistency is goodImprove pass rateContact member assembly/disassemblyInterference fitEngineering

The invention discloses a positioning fixture for improving quality consistency of subminiature precision connector products. The positioning fixture comprises a fixture lining and a pin, wherein the lining is in interference fit with the pin; during press fitting, positioning is performed by virtue of a limiting block at the front end of the pin; the fixture plays limiting and correcting roles, so that the quality consistency of the products is ensured and the qualified rate of the products is greatly improved.

Owner:XIAN ELITE ELECTRONICS IND

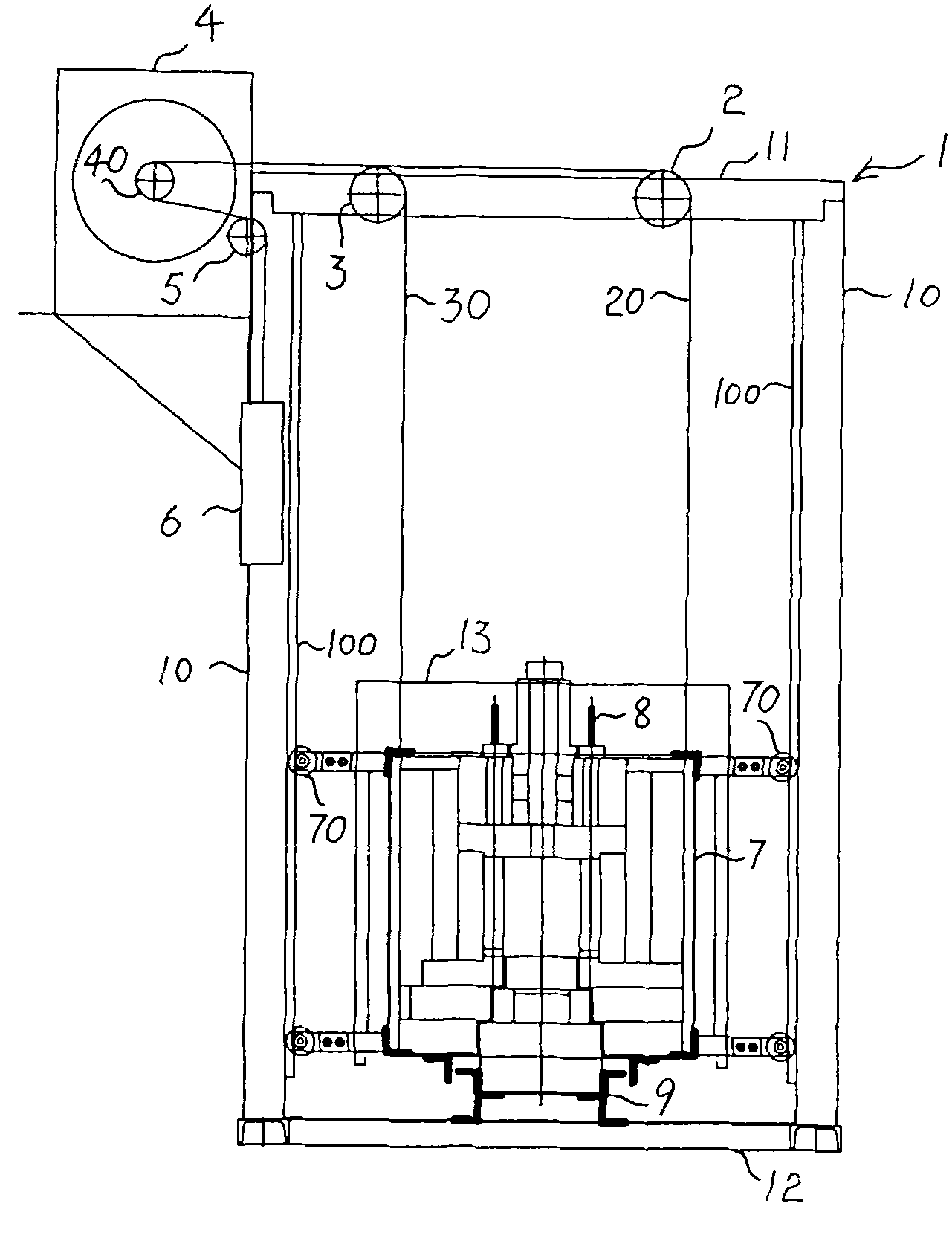

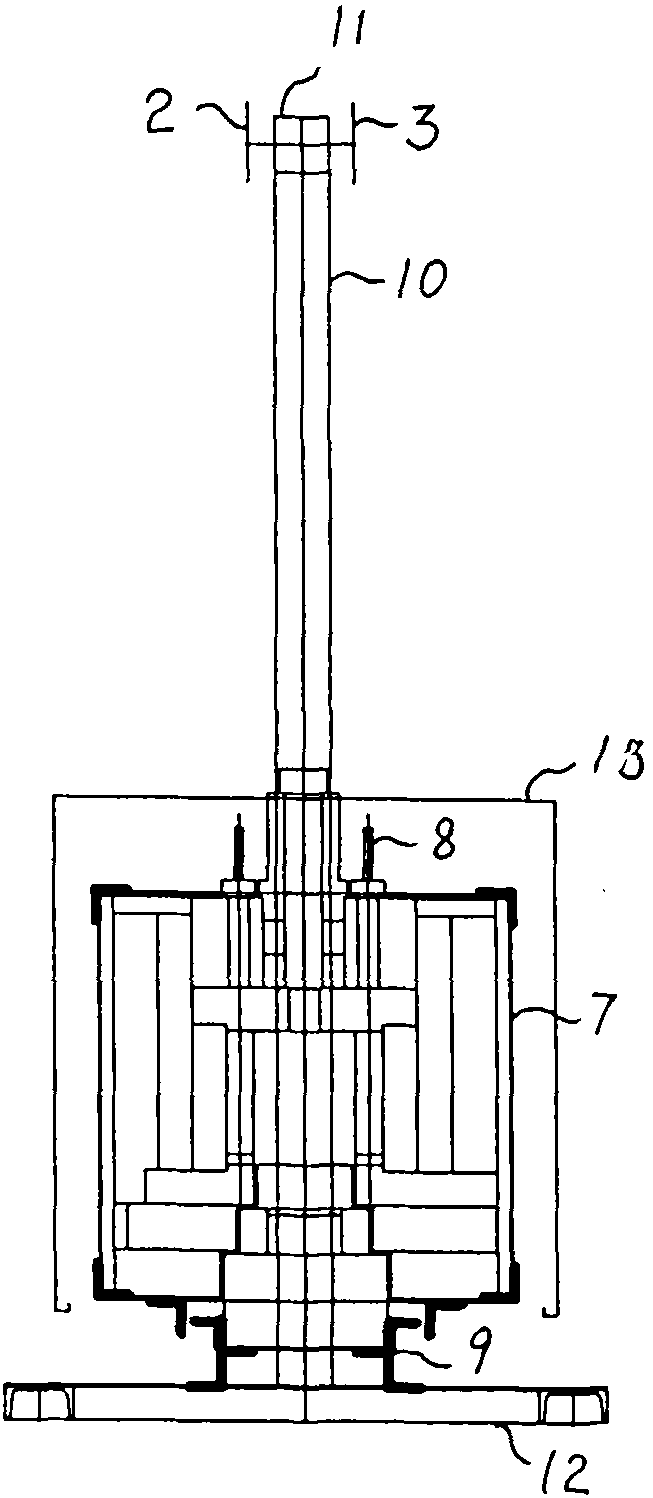

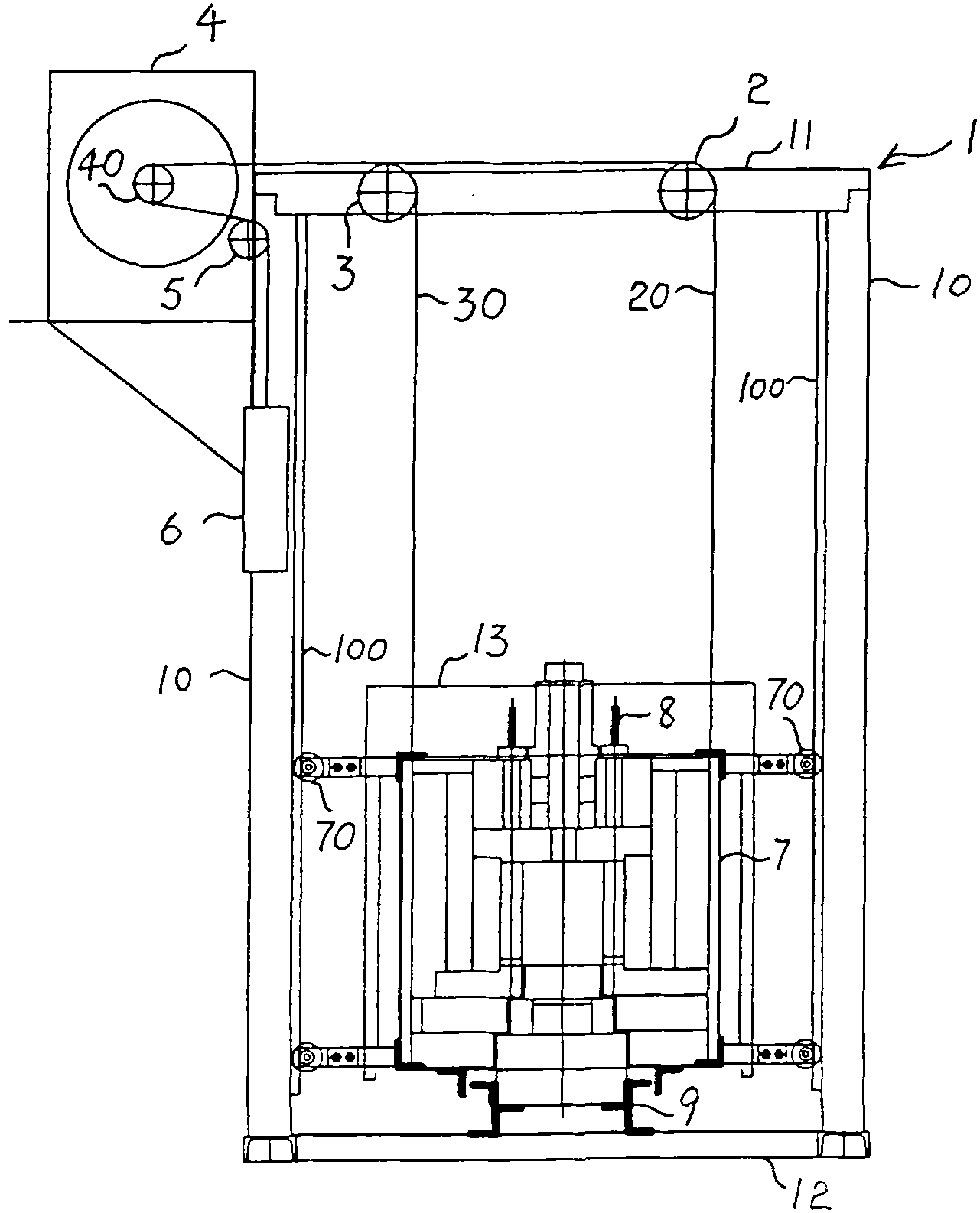

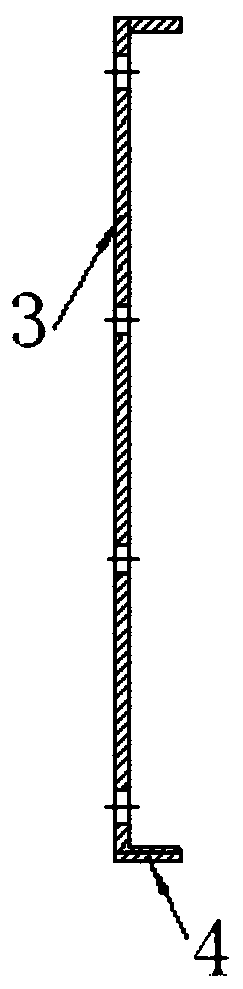

Bell-type electric elevator furnace

InactiveCN101876507AImprove furnace temperature uniformityEasy to save energyFurnace typesEngineeringTrial Site

The invention discloses a bell-type electric elevator furnace, which comprises a heating furnace body (7), wherein a heating body (8) is arranged in the heating furnace body (7). The bell-type electric elevator furnace is characterized in that: a door frame (1) is arranged above the heating furnace body (7); the door frame is provided with a chain elevator mechanism; guide mechanisms are arranged on the two sides of the heating furnace body (7); and thus, an electric furnace elevating system of which the upper part is elevated is formed. The bell-type electric elevator furnace of the invention adopts the chain elevator mechanism to elevate and descend the whole electric furnace through two chains, realizes the precise control over the elevation together with the guide mechanisms, and is provided with a travel switch and an auxiliary positioning device to ensure that the electric furnace is descended to a designated position and further improve the safety coefficient. The bell-type electric elevator furnace of the invention is small in size, simple in structure and low in cost and can be used in trial sites such as colleagues and universities, research institutions and laboratories.

Owner:李锦桥

Preparation method of fleecy fabric anti-layering foam sandwich composite material board

The invention discloses a preparation method of a fleecy fabric anti-layering foam sandwich composite material board. The method uses a special fiber fabric for gluing, mold pasting and pavement to form a skin material; a foaming material is injected in a glue injecting cavity formed by combining convex and concave molds; and through coating of structural glue on the edges of the molds, sealing of a glue injecting port and a glue outlet, mold closing, heating and like, a foam and fleece embedded anti-layering sandwich composite material board is formed. The forming process is simple; the standard production is liable; the product quality consistence is excellent; through molded surface control of the molds, different special-shaped curved surface structure sandwich composite boards can be prepared, and can be directly applied to structural support parts, insulation, thermal insulation, sound absorbing and insulating boards and the like; the structure is stable; the deformation is low; and the mechanical performance can be designed.

Owner:GUANGDONG YATAI NEW MATERIAL TECH CO LTD

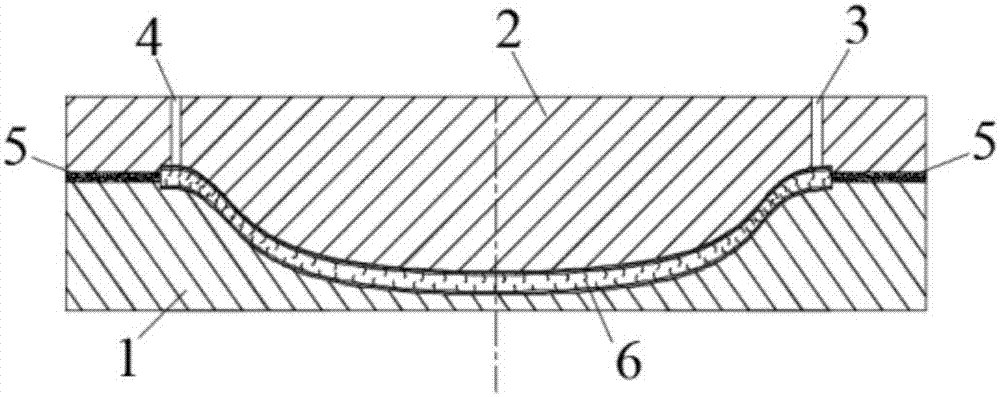

Middle wing part gluing and folding tool for small and medium-sized unmanned aerial vehicles

PendingCN111483609AMeet the requirements of interchangeabilityEasy to separateAircraft assemblyUncrewed vehicleFront edge

The invention discloses a middle wing part gluing and folding tool for small and medium-sized unmanned aerial vehicles. The middle wing part gluing and folding tool consists of a rotating support, a base, a pressing frame and positioners mounted on the base. The rotating support is used for supporting the rotating base and the pressing frame, and combination and separation of the rotating supportand the base can be rapidly achieved through insertion and extraction of the pin shaft. The base is used for supporting the lower plate and positioning and installing the positioners. The pressing frame is used for positioning the upper plate and measuring the gap, and uniformly applying cementing pressure. The horizontal measuring point positioner is used for drilling holes in the front edge andthe rear edge of the middle wing part and positioning horizontal measuring points. The middle wing front-back connector positioner is used for positioning a middle wing front-back connector and servesas a connector hole finish machining platform to eliminate assembly stress. According to the middle wing part gluing and folding tool, tolerance distribution is reasonably carried out, the gluing gapand the gluing pressure are controlled, and the product manufacturing precision and the gluing reliability are improved through rotation of the mold; finish machining is carried out before the product is taken off the rack, the assembly stress is eliminated and the parts are enabled to meet the interchangeability requirement.

Owner:XIAN AISHENG TECH GRP +1

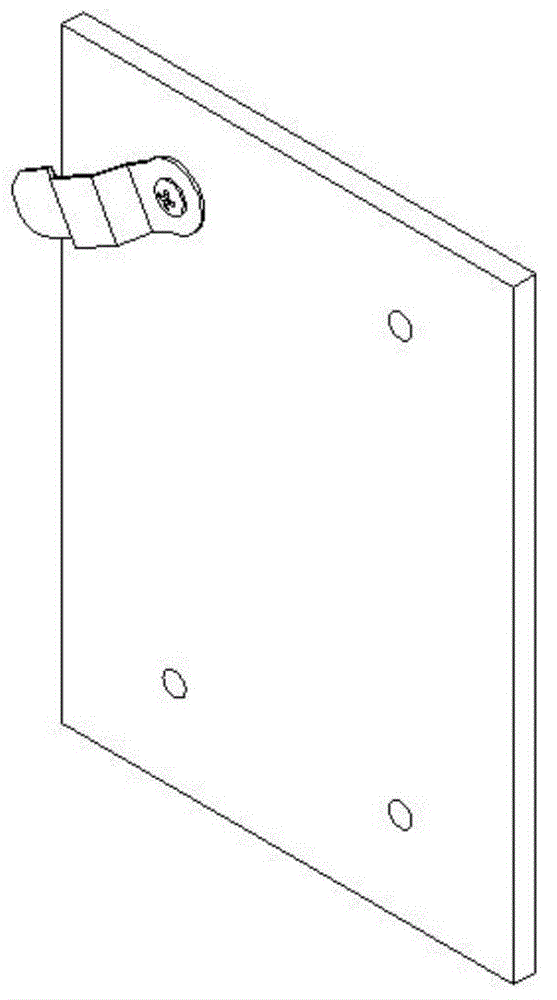

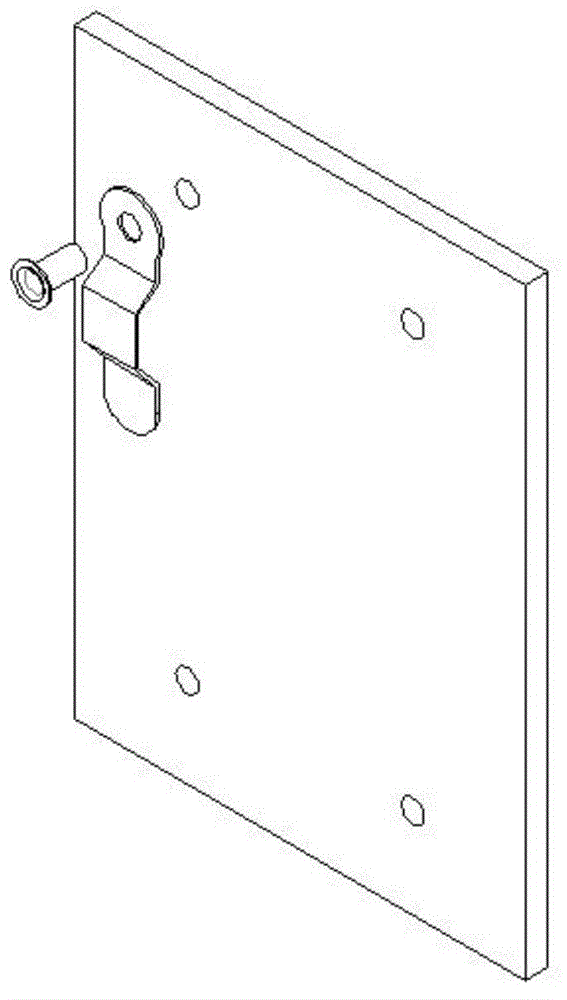

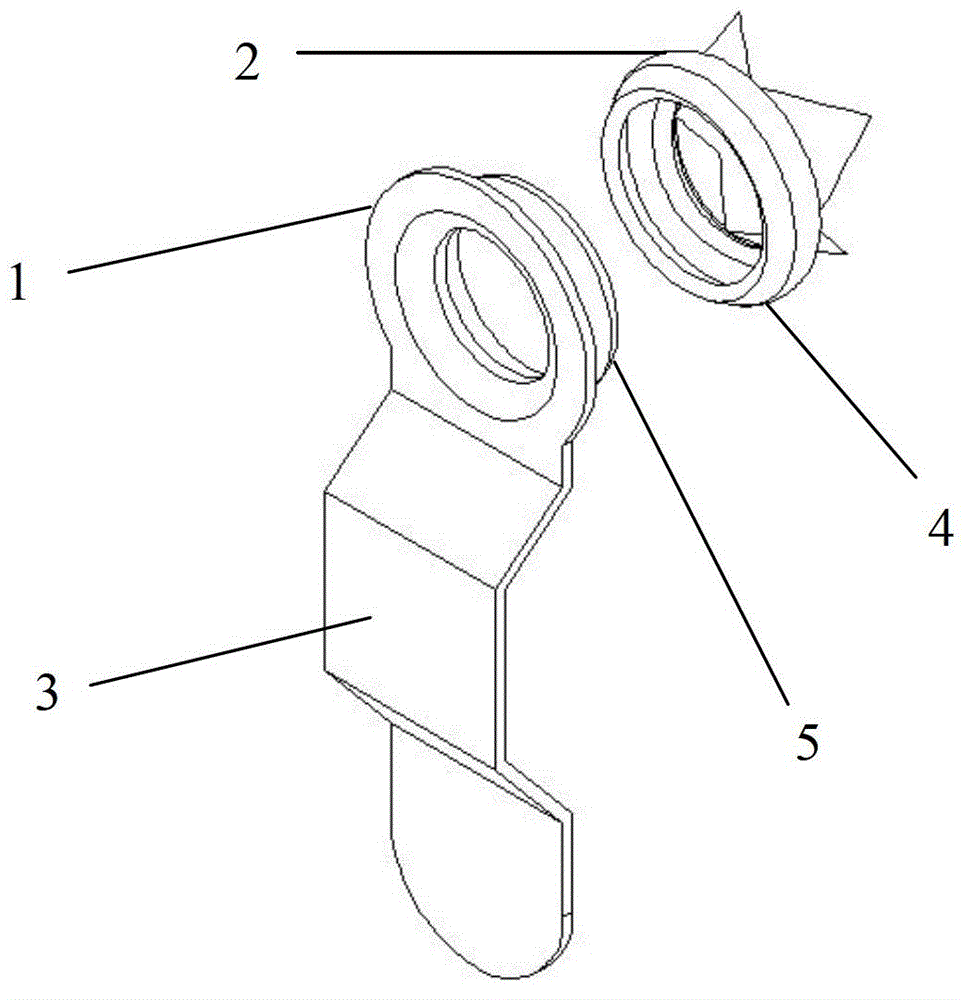

Fixing part connected with photo frame backboard and manufacturing method of fixing part

ActiveCN103381039BFlexible rotationRotation has no effectPicture framesDomestic mirrorsEngineeringBackplane

The invention provides a fixing part connected with a photo frame backboard. The fixing part comprises a rotating portion and a fixed portion connected with a photo frame, one end of the rotating portion is connected with the fixed portion, the other end of the rotating portion is connected with a fixing substrate for fixing the photo frame, and a concave rotating surface and a convex rotating surface are connected in an embedded manner to form the rotating portion. The invention further provides a method for manufacturing the fixing part connected with the photo frame backboard. The fixing part is simple and reasonable in structure, high in mechanization degree, convenient to use, fine in mounting consistency and high in production efficiency, and can be effectively and firmly connected and can flexibly rotate.

Owner:DONGGUAN JUNXIN HARDWARE MFR

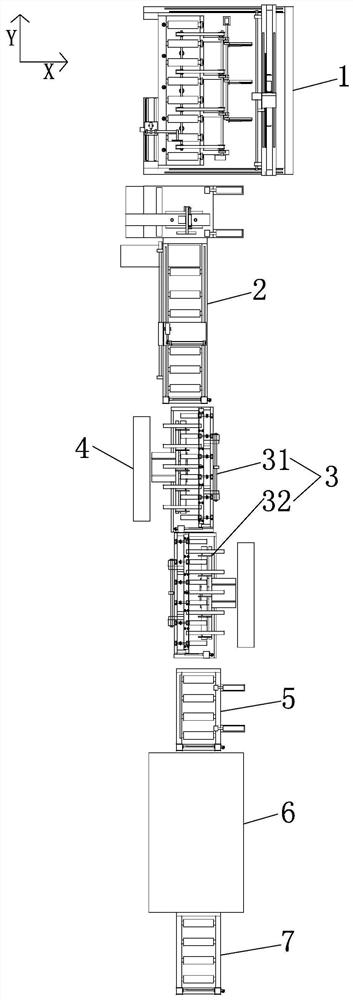

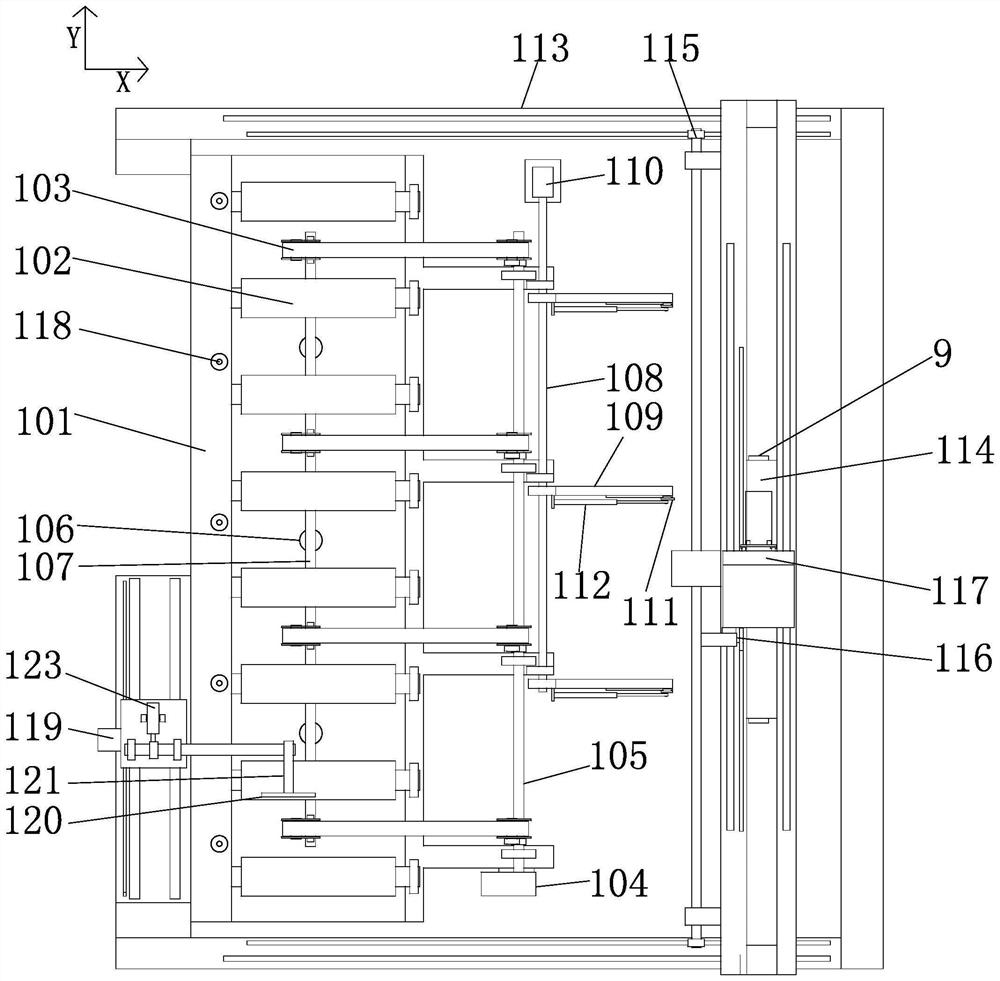

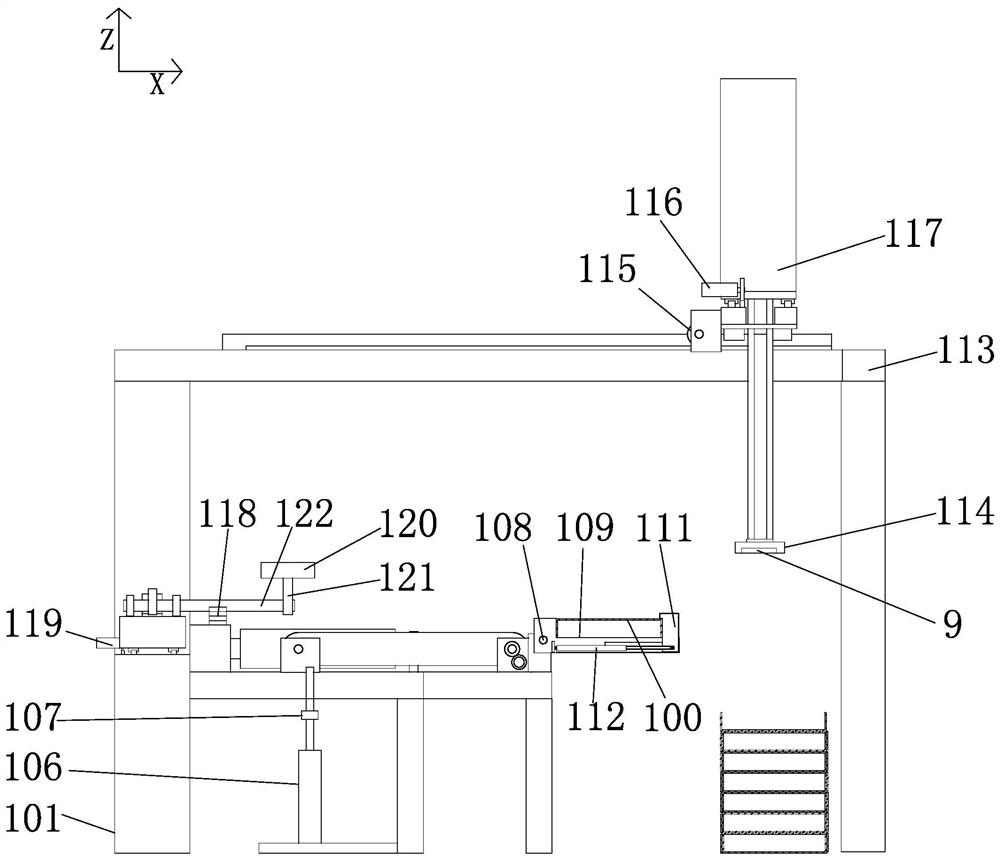

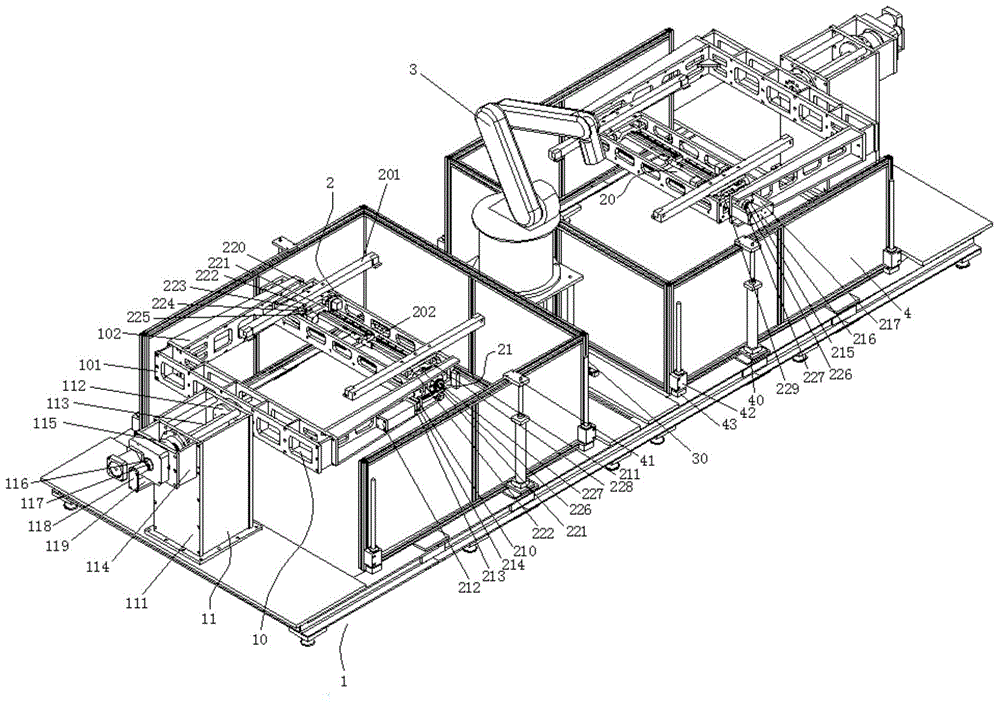

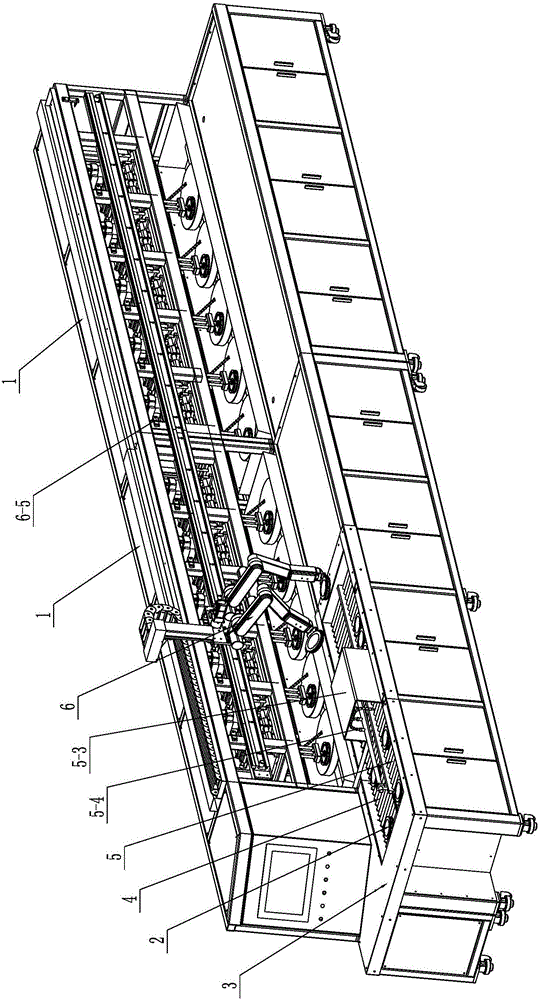

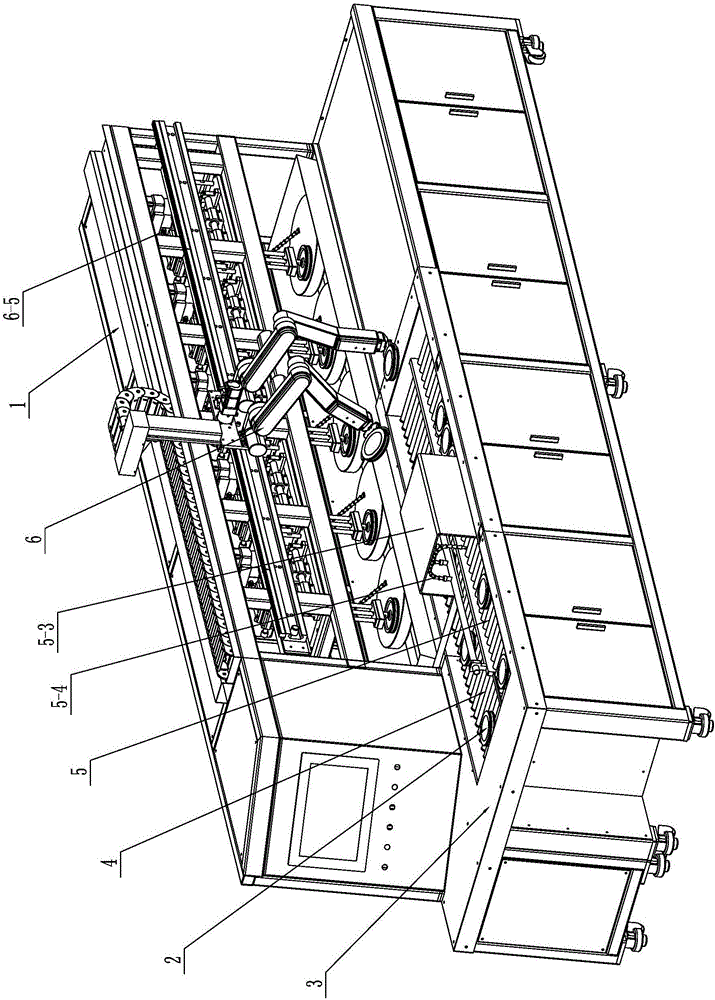

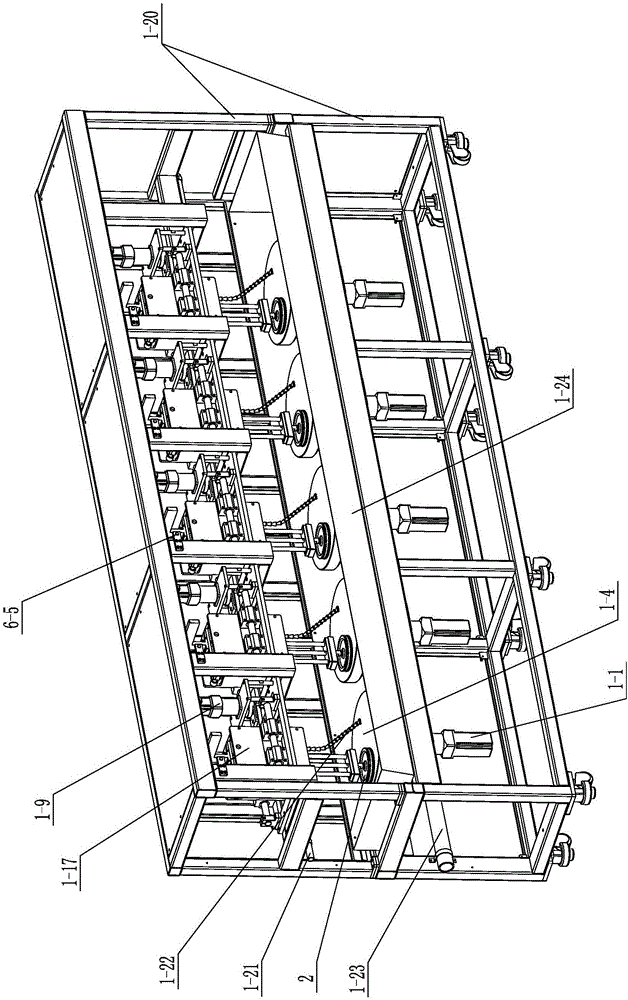

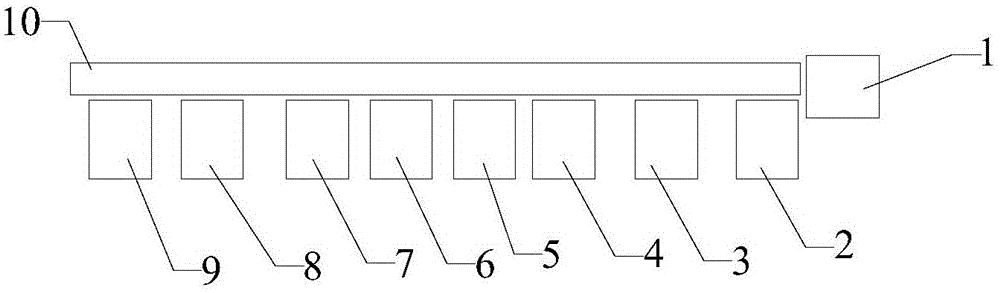

Automatic sawing, punching and milling machining equipment for aluminum templates

PendingCN113977285AHigh degree of automationProcess connection is reasonableOther manufacturing equipments/toolsPunchingEngineering

A piece of automatic sawing, punching and milling machining equipment for aluminum templates comprises a material cutting and feeding unit, a material cutting unit, a row punching and feeding unit, a row punching unit, a row milling and feeding unit, a row milling unit and a row milling and discharging unit which are sequentially arranged according to working procedures. According to the equipment, the automation degree is high, procedures such as saw cutting, punching and milling are reasonably connected, manual participation is not needed in the whole aluminum template machining process, the production cost can be reduced, the production efficiency can be effectively improved, the machining precision is greatly improved, the consistency of the product quality is improved, and therefore the equipment is suitable for being widely popularized.

Owner:涂玉明

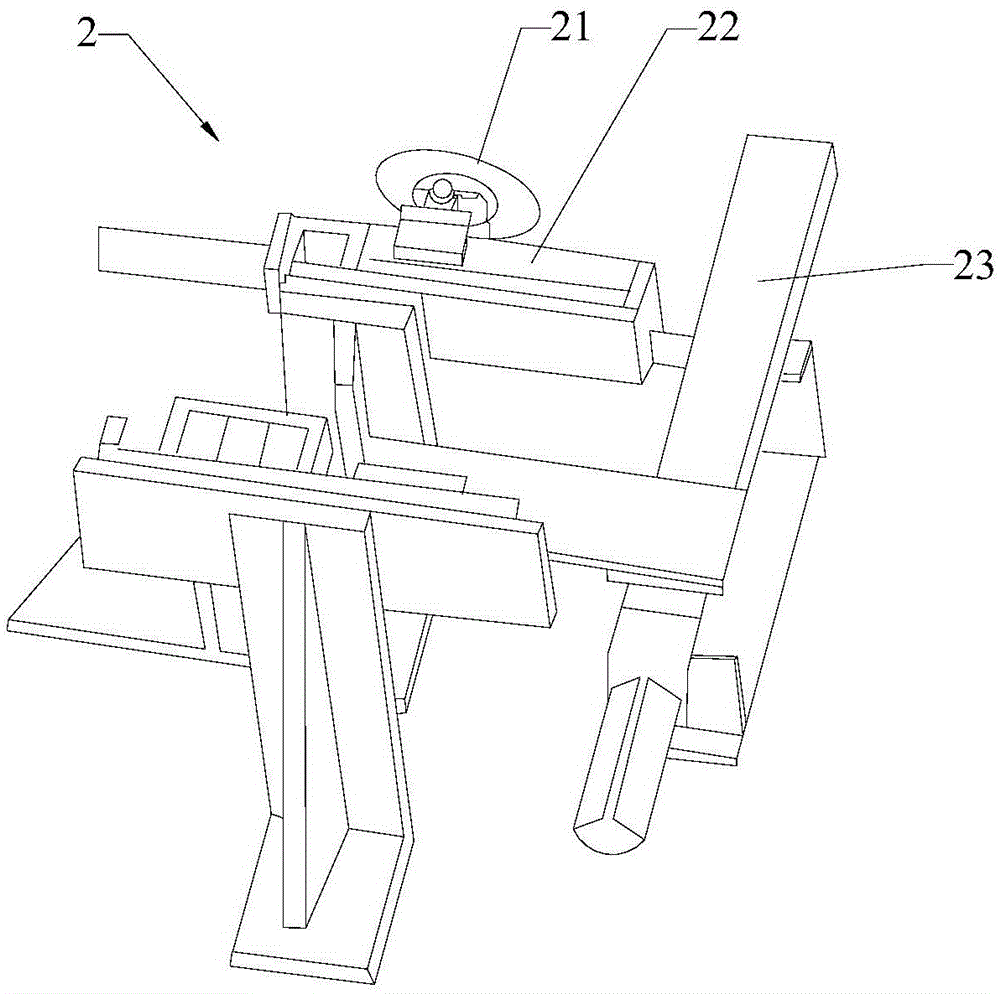

Intercooler automatic welding method and welding equipment implementing same

ActiveCN104874933AEasy to adjustAccurate and stable operationWelding/cutting auxillary devicesAuxillary welding devicesRun actionControl system

The invention discloses an intercooler automatic welding method. The intercooler automatic welding method comprises the following steps that a welding work station is arranged, and comprises a welding supporting body and a supporting body rotating device; a middle rotary table is arranged and connected to the supporting body, and the middle rotary table is provided with a clamping device and a rotary table rotating device; a mechanical arm is arranged, and arranged between every two welding work stations, and the mechanical arm is provided with a welding gun achieving the welding action; a PLC control system is arranged, is connected with the mechanical arm, the clamping device and the rotating devices and controls the work states of the mechanical arm, the clamping device and the rotary device. An equipment workbench is convenient to adjust, the product covering range is wide, the welding gun of the mechanical arm is accurate and stable in running action, the welding gun has a welding joint tracking function, and welding starting, welding stopping and repairing welding can be carried out at any position. A memory function is achieved, various parameters can be adjusted on a system, and the welding parameters of multiple workpieces can be set. The advantages of being fully automatic, high in production efficiency and good in product quality consistency, saving labor cost and the like are achieved.

Owner:佛山市南海蕾特汽车配件有限公司

Full-automatic sapphire polishing equipment

ActiveCN106737064AIncrease productivityReduce manufacturing costPolishing machinesGrinding drivesEngineeringManipulator

The invention belongs to polishing equipment, and discloses full-automatic sapphire polishing equipment. The full-automatic sapphire polishing equipment comprises a plurality of polishing devices connected sequentially, and a carrier used for holding sapphire pieces; a workbench is arranged in front of the polishing devices; a feeding roller conveying line and a return roller conveying line are arranged on the workbench; a washing device body is arranged on the return roller conveying line; each polishing device comprises a rack and a plurality of polishing mechanisms mounted on the corresponding rack; a carrier pressing and translation mechanism is mounted on the part, over the corresponding polishing mechanisms, of each rack; each polishing mechanism and the corresponding carrier pressing and translation mechanism form a polishing station; a manipulator loading and unloading device for loading and unloading materials to the corresponding polishing stations is arranged on each rack; the carrier comprises a pressing disc and a suction disc; holding grooves are formed in the suction disc, and are internally provided with fluff; and concave holes into which pressing rod columns are pressed are formed in the pressing disc. The full-automatic sapphire polishing equipment realizes the effect of automation operation, and is good in polishing effect, high in production efficiency, and stable and reliable in product quality.

Owner:安吉云动机器人科技有限公司

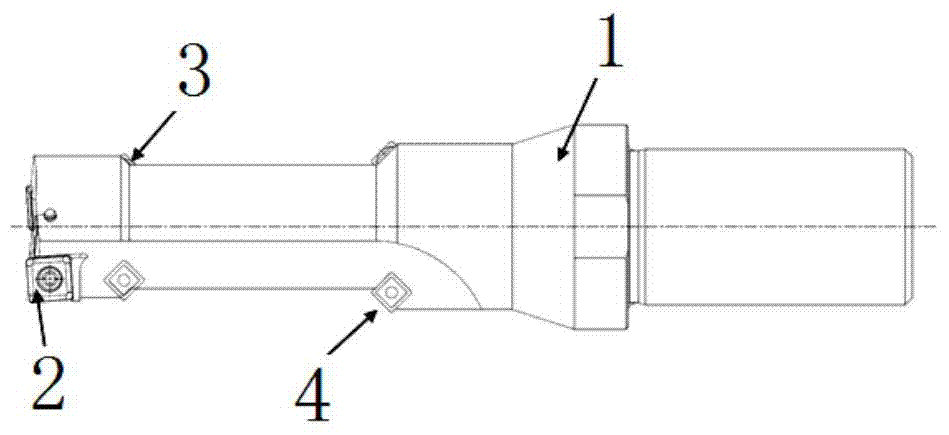

Cutting tool for drilling and chamfering steel rail and machining technology thereof

InactiveCN104325180AReduce workloadReduce stress concentrationTransportation and packagingTrepanning drillsStress concentrationEngineering

The invention discloses a cutting tool for drilling and chamfering a steel rail and a machining technology thereof. The cutting tool comprises a cutting tool body, wherein the cutting tool body comprises a first cutting edge, a second cutting edge and a third cutting edge; the first cutting edge is used for drilling the steel rail; the second cutting edge and the third cutting edge are used for chamfering the steel rail; the first cutting edge is positioned at the outermost end of the cutting tool body; the second cutting edge and the third cutting edge are arranged oppositely. The machining technology comprises the following steps of installing the cutting tool on a drilling machine, and positioning and fixing the to-be-machined steel rail; feeding the cutting tool, and drilling the steel rail through the first cutting edge; continuously feeding the cutting tool, and chamfering one side of the steel rail through the third cutting edge; retracting the cutting tool, and chamfering the other side of the steel rail along a rounding path through the second cutting edge; retracting the cutting tool out of the steel rail. According to the cutting tool for drilling and chamfering the steel rail and the machining technology thereof, the machining processes, such as the drilling and two-face chamfering, on the steel rail can be realized, machined chamfers are uniform, the phenomenon of stress concentration is effectively eliminated, the workload of workers is relieved, and the machining efficiency is improved.

Owner:WUHU CRSIC JIFU RAIL CO LTD

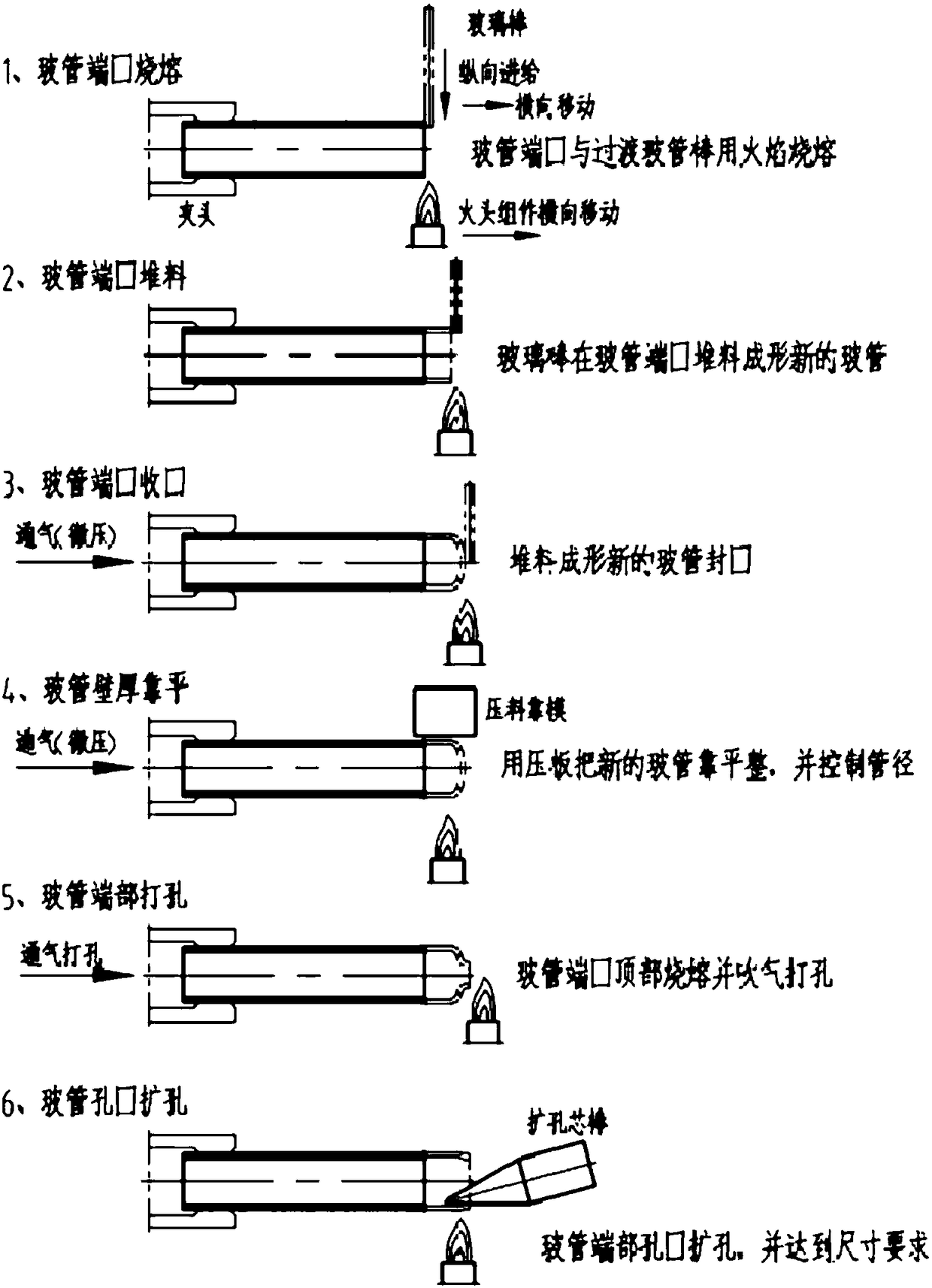

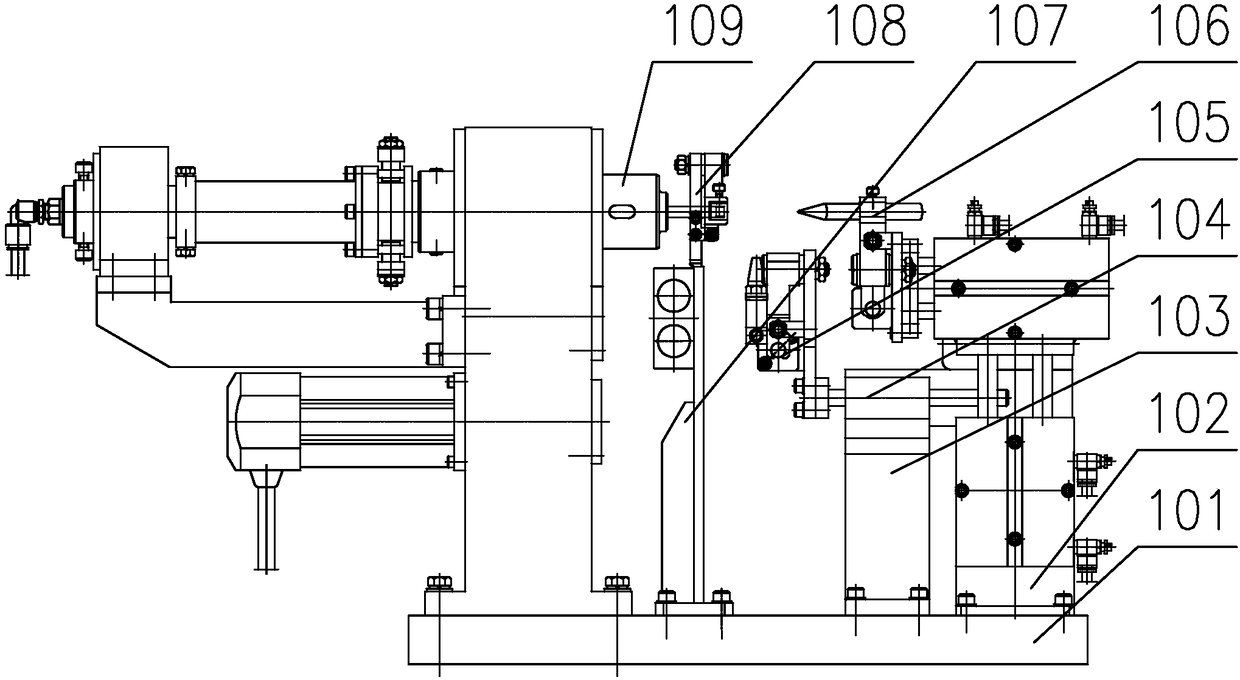

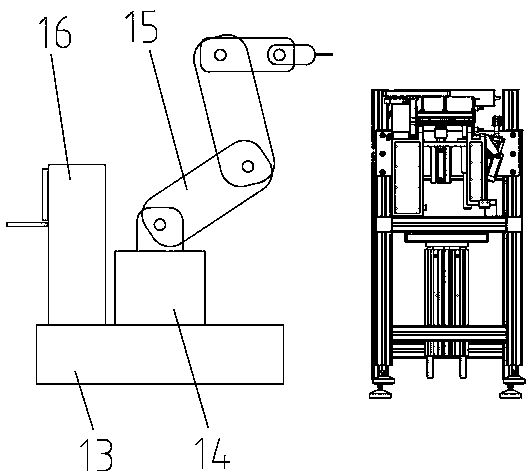

Method and equipment for automatically stacking glass to form glass tubes

InactiveCN108409116AUniform wall thicknessProduct quality consistency is goodGlass reforming apparatusGlass productionEngineeringGlass tube

The invention discloses a method and equipment for automatically stacking glass to form glass tubes. The method comprises the following steps: melting an end of a rotating glass tube with flame; aftera glass bar is melted with flame, sticking the glass bar to an end of the glass tube; and carrying out movement and feeding to form a spiral transitional glass tube at an end of the glass tube; sealing an end of the transitional glass tube, ventilating and bubbling; pressing a pressure plate against the outer wall of the transitional glass tube; controlling the diameter of the transitional glasstube; and perforating the closed end and carrying out pore broadening and forming so as to realize automatic forming of the transitional glass tube. The equipment comprises a glass tube clamping and ventilating mechanism, a glass tube outer wall pressing mechanism, a fire head device and a pore broadening mechanism. The transitional glass tube is formed automatically, the quality consistency of products is good, the labor intensity of workers is relieved, and the production efficiency is improved.

Owner:SOUTHEAST UNIV

Automatic tool disassembling equipment for carrier

InactiveCN108857303AHigh precisionImprove efficiencyMetal working apparatusEngineeringMechanical engineering

The invention aims to disclose automatic tool disassembling equipment for a carrier. The automatic tool disassembling equipment comprises a transplanting pickup mechanism, a carrier overturning mechanism, a blocking mechanism, a jacking mechanism and a carrier conveying line mechanism. Compared with the prior art, the manner that manual disassembling is needed during tool disassembling in the pastis replaced, so that the carrier precision and efficiency are greatly improved and the produced product is high in quality consistency; and the automatic tool disassembling equipment is simple in structure and verypractical and realizes the purpose of the automatic tool disassembling equipment.

Owner:SHANGHAI SHARETEK TECH CO LTD

Hemocoagulase extracted from bothrops atrox and preparation method and application thereof

PendingCN108611341AReduce risk of exposureFewer steps in the preparation processHydrolasesPeptide/protein ingredientsBenzamidinePharmaceutical drug

The invention provides a hemocoagulase extracted from bothrops atrox and also provides a preparation method of the hemocoagulase. The method comprises the following steps of: pretreating the bothropsatrox; sequentially passing the diethylaminoethyl cross-linked dextran gel A-25 ion exchange chromatography, benzamidine agarose gel 4-FF (HS) affinity chromatography, and cross-linked dextran gel G-75 gel filtration chromatography; and obtaining hemocoagulase. The invention also provides the application of the bothrops atrox hemocoagulase. in the preparation of a medicament for treating bleedingdisorder. Compared with the prior art, the preparation process steps are less, the period is short, and the exposure risk of the process environment is reduced; the product yield is high, the processhas strong ability to remove impurities, the yield of the product can be obtained more than 35% and the purity is over 98%; the process stability is high and the product quality is good, and the process is beneficial to clinical medication safety.

Owner:GRAND LIFE SCI (LIAONING) CO LTD

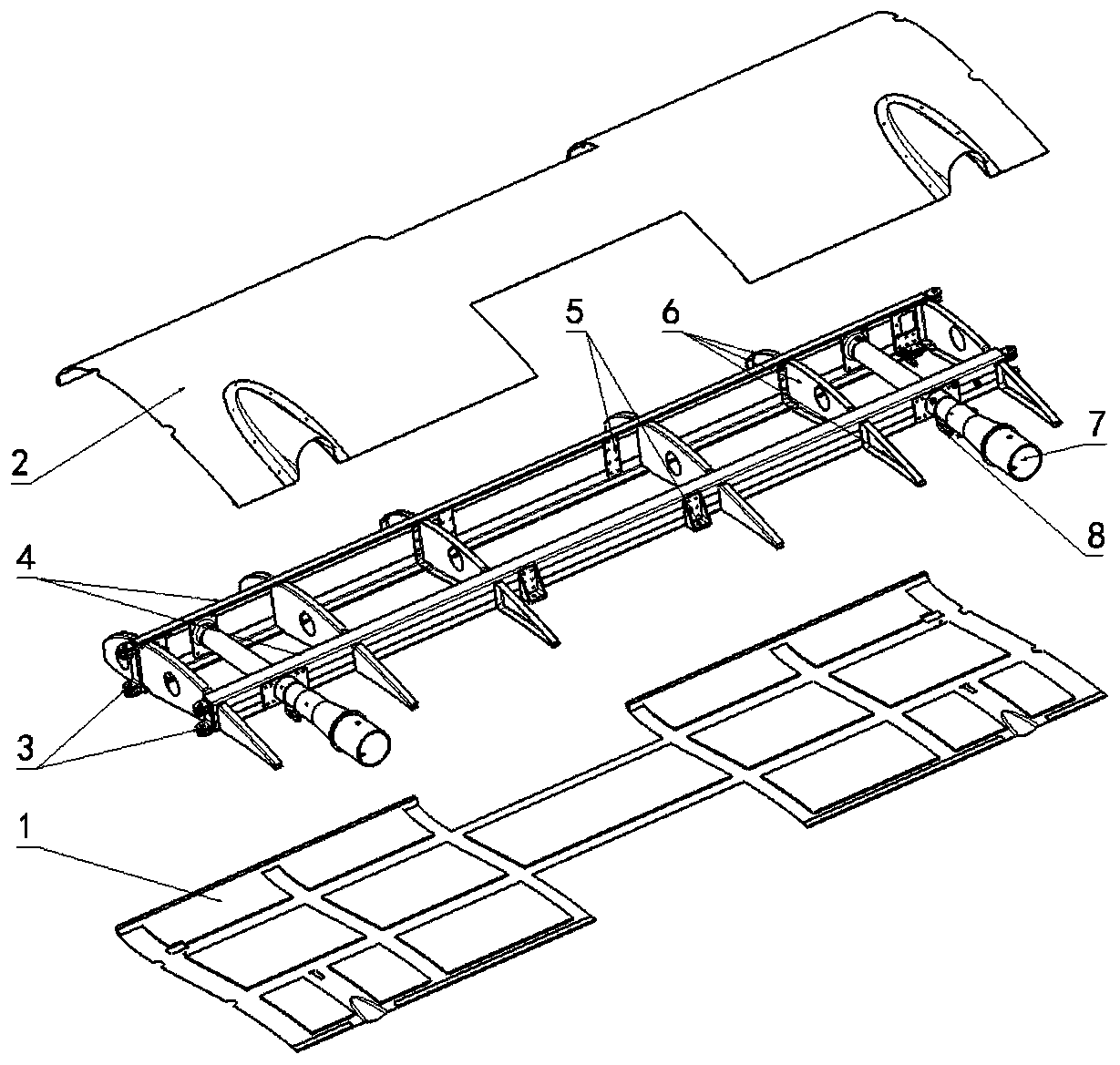

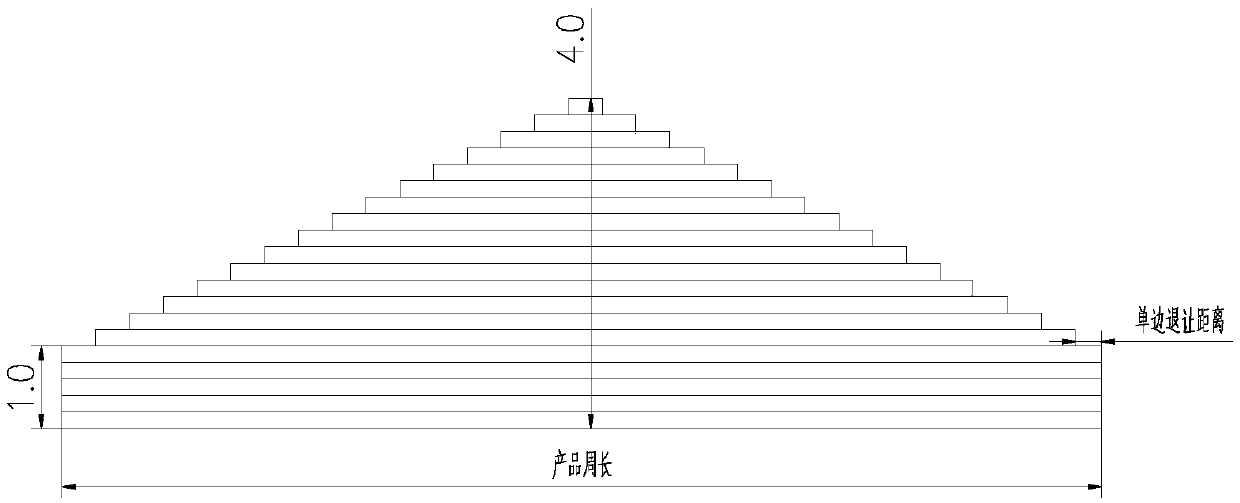

RTM forming method of resin based thickness-variable antenna housing

The invention discloses an RTM forming method of a resin based thickness-variable antenna housing. The RTM forming method comprises the following steps: 1, according to the product structure, dividinga product into three areas namely an inner thickness consistent layer, a thickness transitional layer and an outer thickness consistent layer; 2, sewing up the inner thickness consistent layer and the thickness transitional layer into an integrity, and then mounting the integrity with the outer thickness consistent layer in a sleeving manner to form a preforming body; 3, carrying out integral penetrating sewing on the preforming body; and 4, mounting the preforming body in a die cavity, and adopting a resin transfer molding technique to carry out product forming. According to the RTM formingmethod, the method of sewing up woven fabric and fiber cloth laying layer is adopted to manufacture a fiber-reinforced preforming body, the design is flexible, and manufacture of various preforming bodies with complicated wall thickness variation is suitable; the fiber cloth laying layer is introduced in the thickness variable area for uniform transition, so that the product quality consistency ishigh; the operation technology is simple; and the cost is lower.

Owner:湖北三江航天江北机械工程有限公司

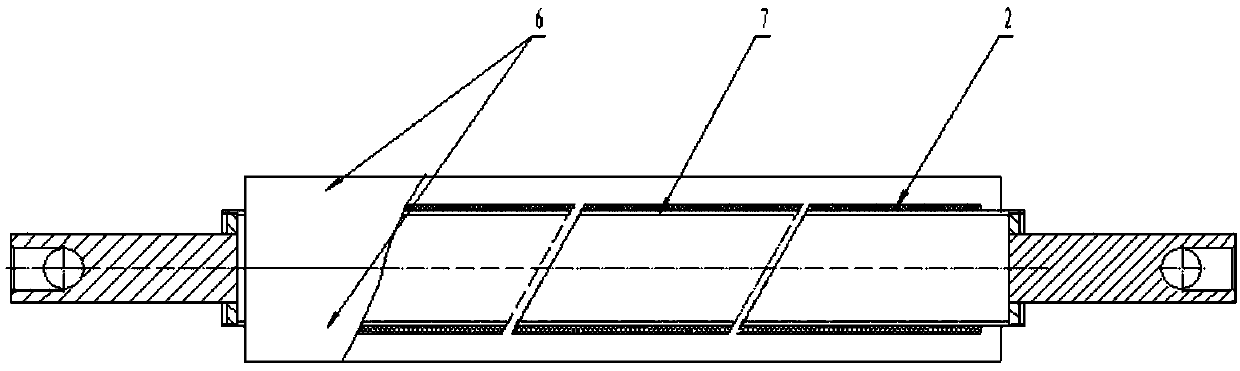

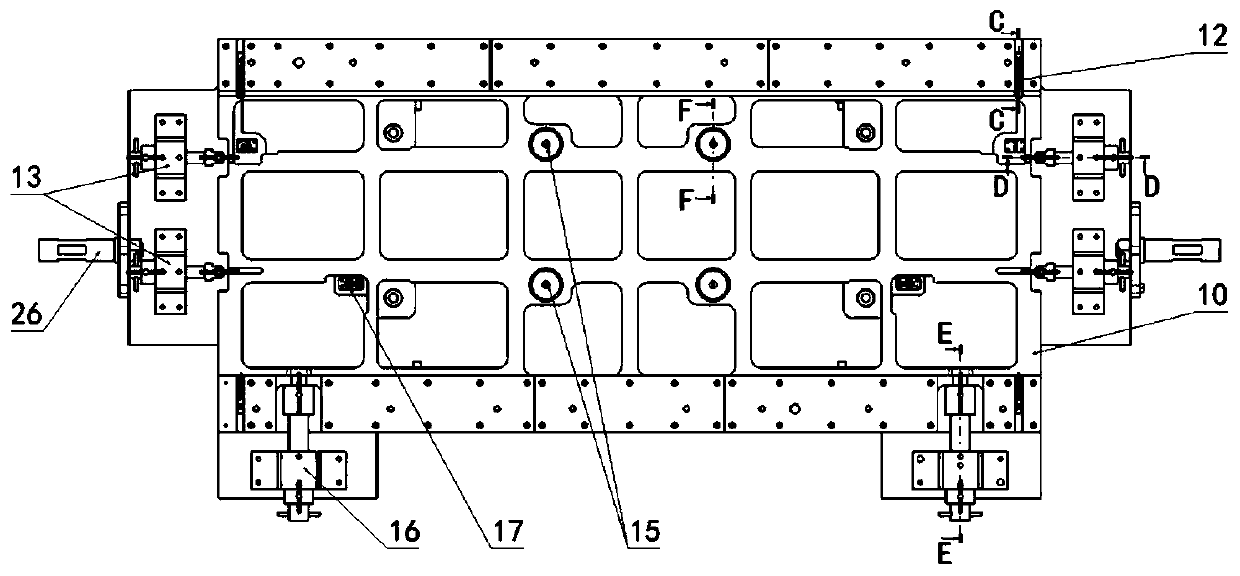

Locking connecting mechanism for bus groove assembly production line

PendingCN108705276AImprove assembly accuracyProduct quality consistency is goodMetal working apparatusProduction lineEngineering

The invention discloses a locking connecting mechanism for a bus groove assembly production line. A chassis is divided into an assembly section and a conveying section; the assembly section uses a first limiting support column and a second limiting support column for limiting support of upper and lower cover plates and side plates of bus groove products; a pressing rod at the top end of the firstlimiting support column tightly presses the side plates of the bus groove products through a pressing foot from top to bottom; a first cylinder drives a Taiwan fixture to tightly press the cover plates of the bus groove products from the side surfaces; limiting support blocks limit the side plates, the cover plates and phase line modules of the bus groove products through limiting side plates andlimiting end plates; and an intelligent mechanical arm, a first cylinder and a second cylinder on an intelligent control cabinet interlocking control equipment base clamp and lock the side plates andthe cover plates of the bus groove products to fixedly rivet as overall bus groove products through rivets. The process is simple; the assembly operation is convenient; the assembly precision of the bus groove products is high; and the product quality consistency is excellent.

Owner:ZHENJIANG SCHNEIDER ELECTRIC

A hot riveting device for sensor circuit board fixing

The invention discloses a thermal riveting device for fixing a sensor circuit board, comprising a base, a driving cylinder, a thermal mold, a thermal riveting rod, and a sensor positioning seat, the sensor positioning seat is arranged on the base, and the driving cylinder is arranged on the The base is located above the sensor positioning seat, the hot mold is arranged on the piston rod of the drive cylinder, a heater is arranged in the hot mold, and the hot riveting rod is arranged at the bottom of the hot mold. The hot riveting device can be used to hot rivet the tops of all the plastic fixing columns of a sensor at one time. After the sensor is positioned, the hot riveting is performed automatically, which improves the production efficiency and reduces the cost. The product quality is consistent and easy to control.

Owner:WUHU GRAND VISION AUTO ELECTRONICS CO LTD

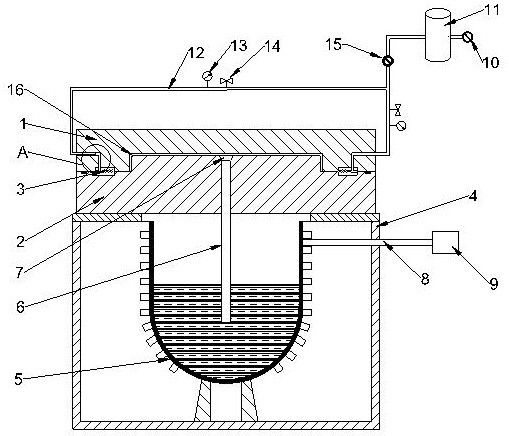

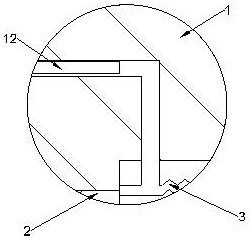

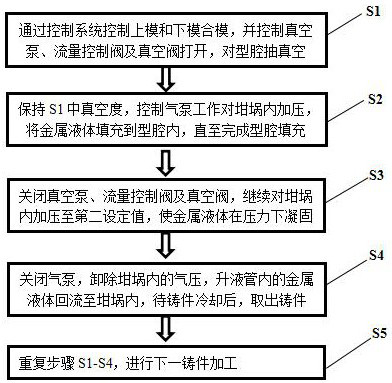

Vacuum low-pressure casting device and method for large aluminum and magnesium alloy castings

The invention discloses a vacuum low-pressure casting device and method for large aluminum and magnesium alloy castings. The device comprises a mold system and a casting system. The mold system comprises an upper mold and a lower mold, and at least one exhaust block is arranged on a parting surface of the upper mold and the lower mold. The device further comprises a vacuum system, the vacuum system comprises a vacuum pump, a negative pressure tank and a vacuum pipeline, the vacuum pump is connected with the negative pressure tank, one end of the vacuum pipeline is connected with the negative pressure tank, the other end of the vacuum pipeline extends to the exhaust block and is in sealed connection with the exhaust block, and a cavity can be vacuumized through the vacuum pump; and a control system is further included, is respectively connected with the mold system, the casting system and the vacuum system and is used for controlling the work of the mold system, the vacuum system and the casting system. The device is simple in arrangement, easy to implement, capable of meeting the vacuum low-pressure casting requirements of the large aluminum and magnesium alloy castings and low in cost.

Owner:CHONGQING UNIV

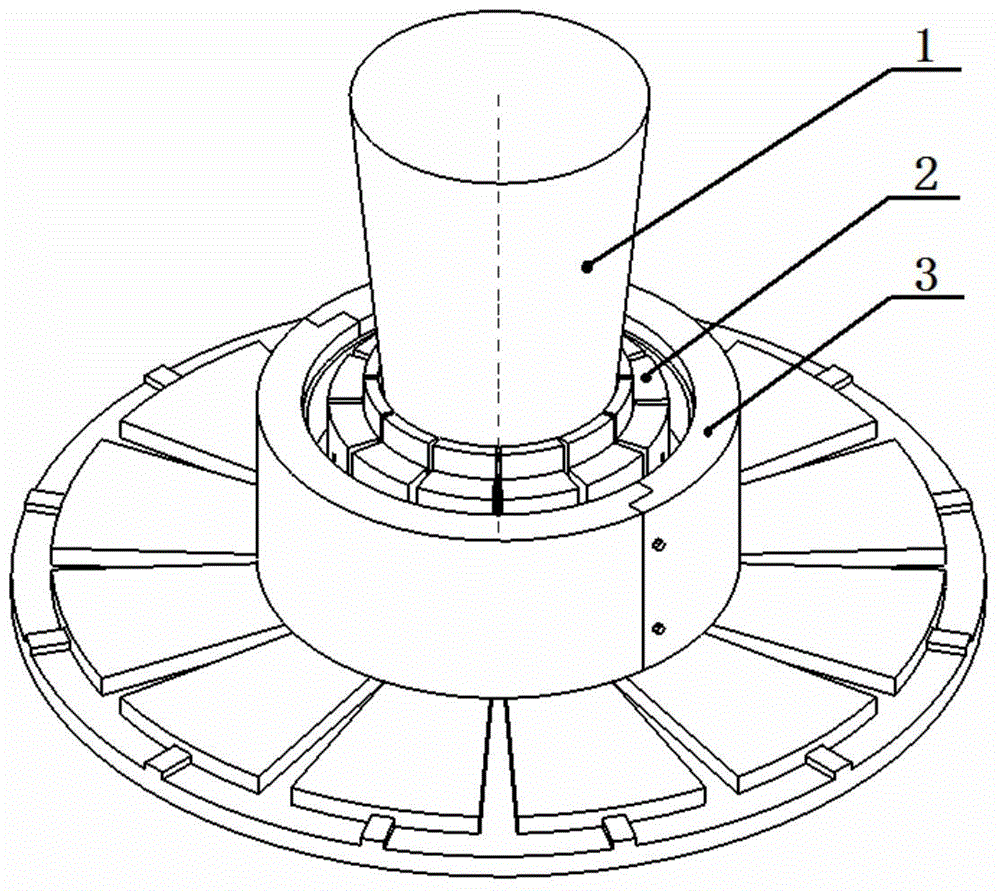

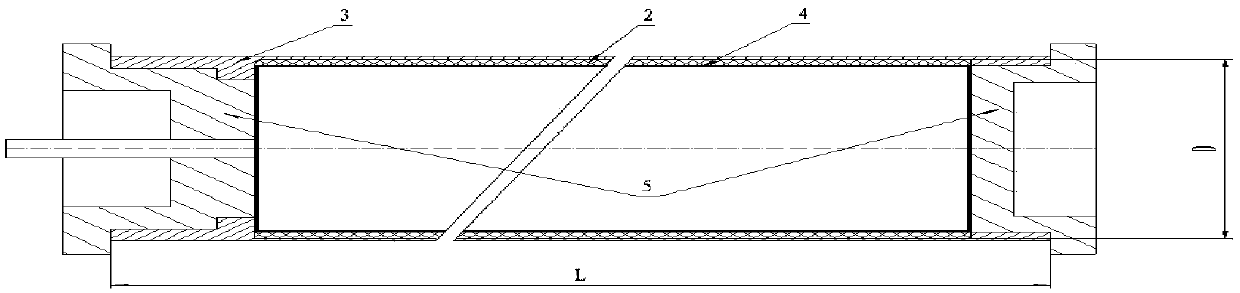

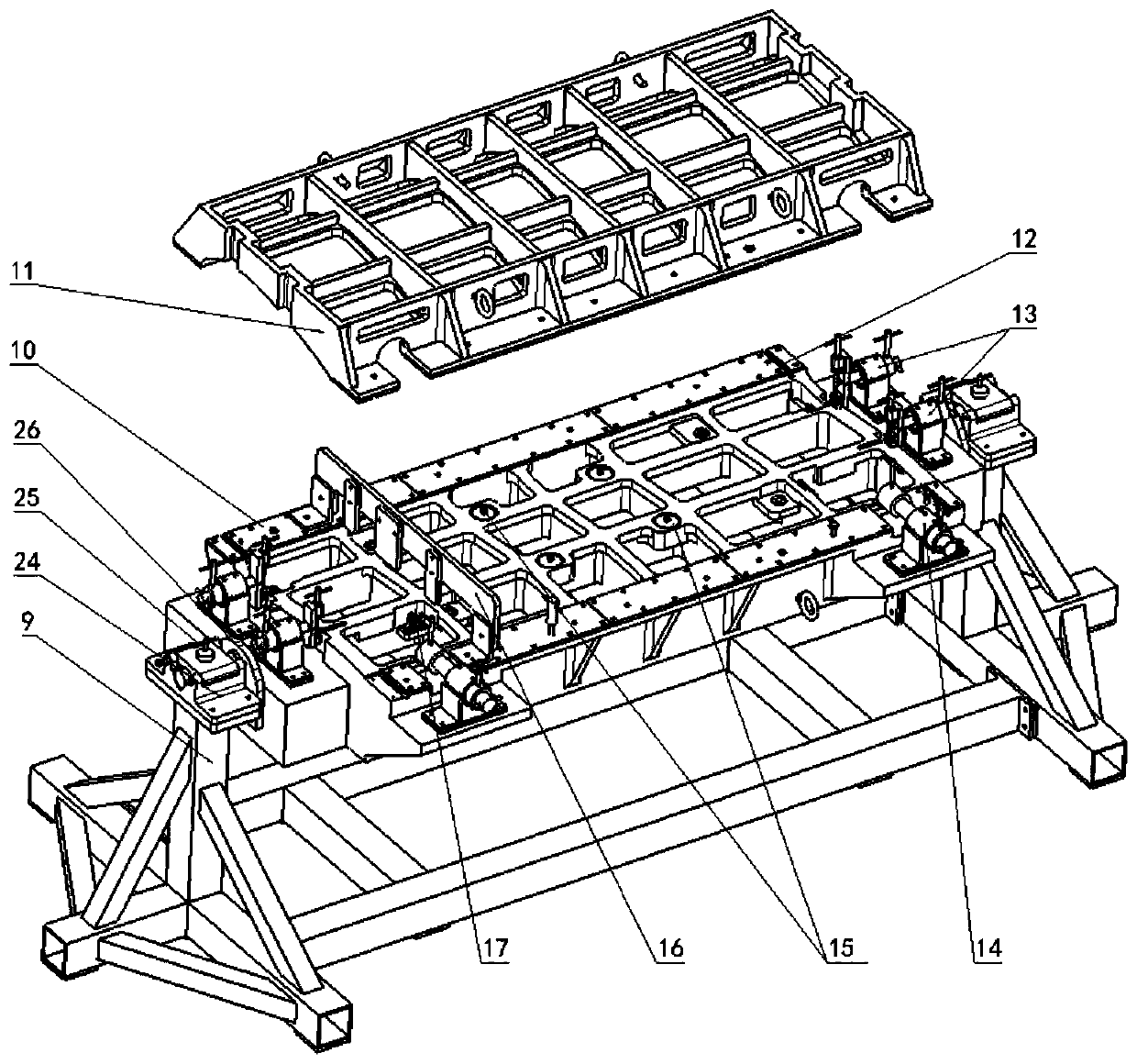

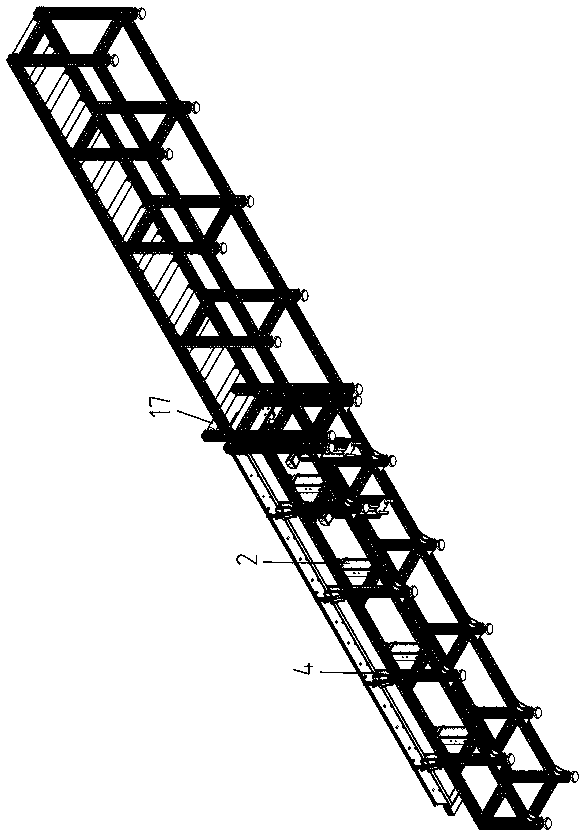

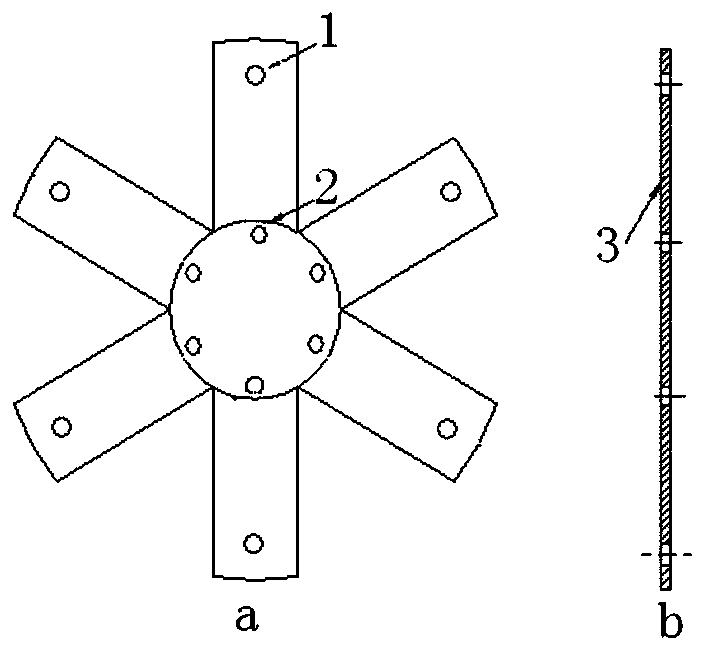

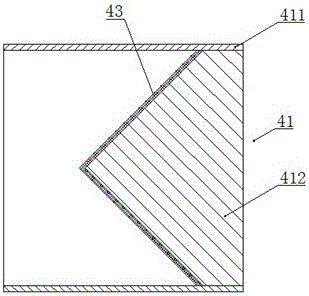

Solid rocket engine lining forming rotating tool

The invention relates to a solid rocket engine lining forming rotating tool. The lining forming rotating tool is strip-shaped, and both ends of the lining forming rotating tool are provided with shellclamping plates bent towards the cylindrical surface of the outer surface of a shell. The inner surfaces and the outer surfaces of the shell clamping plates are cambered surfaces with the same radiusas the outer circumferential surface of the shell. Two shell skirt frame mounting holes and two universal joint mounting through holes are distributed in the length direction of the lining forming rotating tool, the two shell skirt frame mounting holes are positioned at two ends of the lining forming rotating tool correspondingly, and the two universal joint mounting through holes are positionedbetween the two shell skirt frame mounting holes. The tool has a simple structure, convenient installation, good quality consistency of products produced in the same batch and high efficiency, obtained sprayed solid rocket engine lining with a large slenderness ratio is a spray coating, and the thickness of the lining is uniform; and on the premise of ensuring that the tool meets normal use strength, the weight of the tool is reduced and installation is convenient.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

Electric tool used for pipefitting chamfering

The invention discloses an electric tool for pipefitting chamfering. The problems that according to existing manual burr grinding and chamfer finishing, production efficiency is low, and the product quality is poor are solved. The tool comprises a rack, a drive motor, at least one rotating shaft and at least one cutter bit and is characterized in that the rotating shafts are rotatably supported on the top of the rack through supporting parts, the cutter bits are connected to the ends of the rotating shafts in a non-rotation manner through cutter bit bases, the drive motor is fixed to the bottom of the rack, and an output shaft of the drive motor drives the rotating shafts to rotate through a transmission part. The electric tool is simple in structure and convenient to operate; a pipefitting required to be chamfered stretches into the tool bits and makes contact with the tool bits, burr removing and chamfering can be carried out, the product quality consistency is good, the strength of workers is low, and the production efficiency is high.

Owner:荣成康派斯新能源车辆股份有限公司

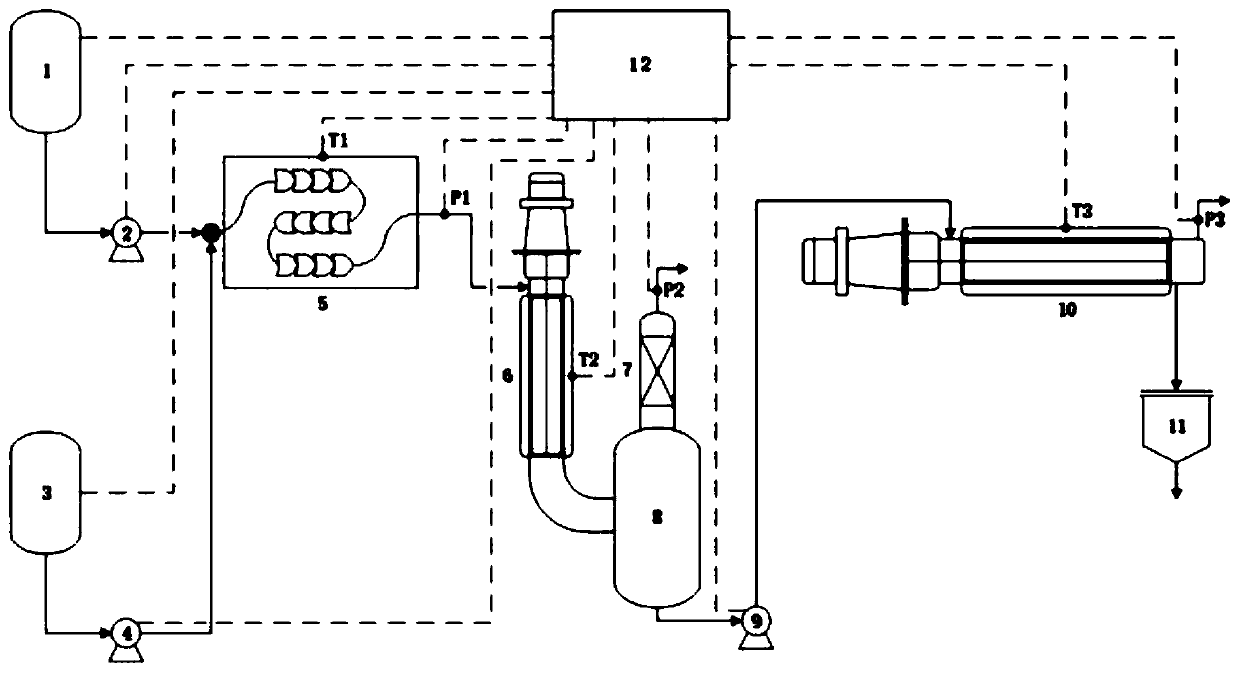

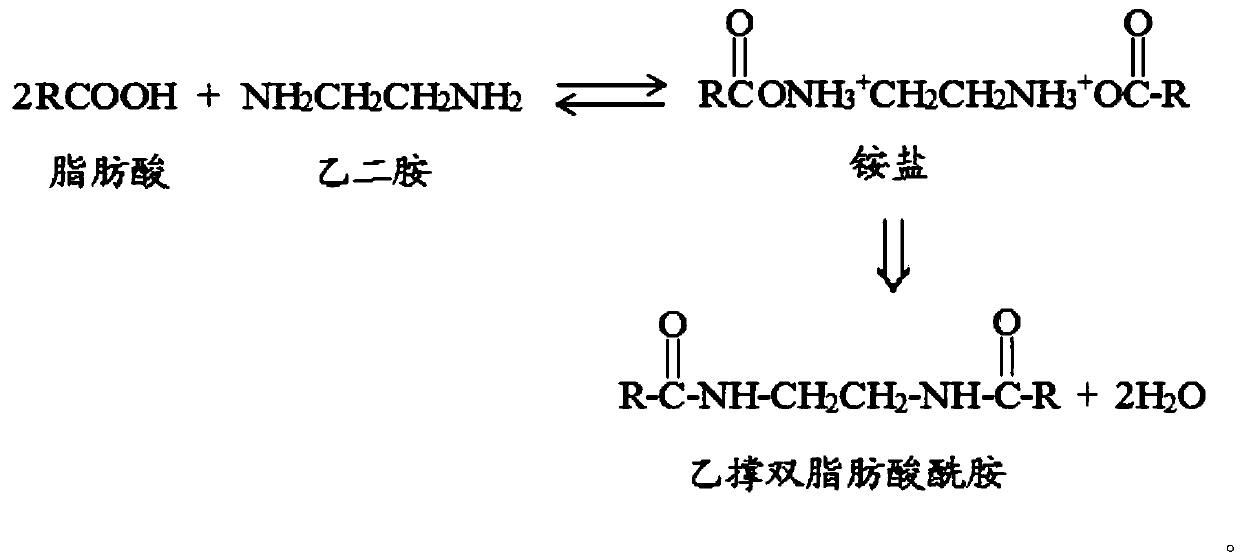

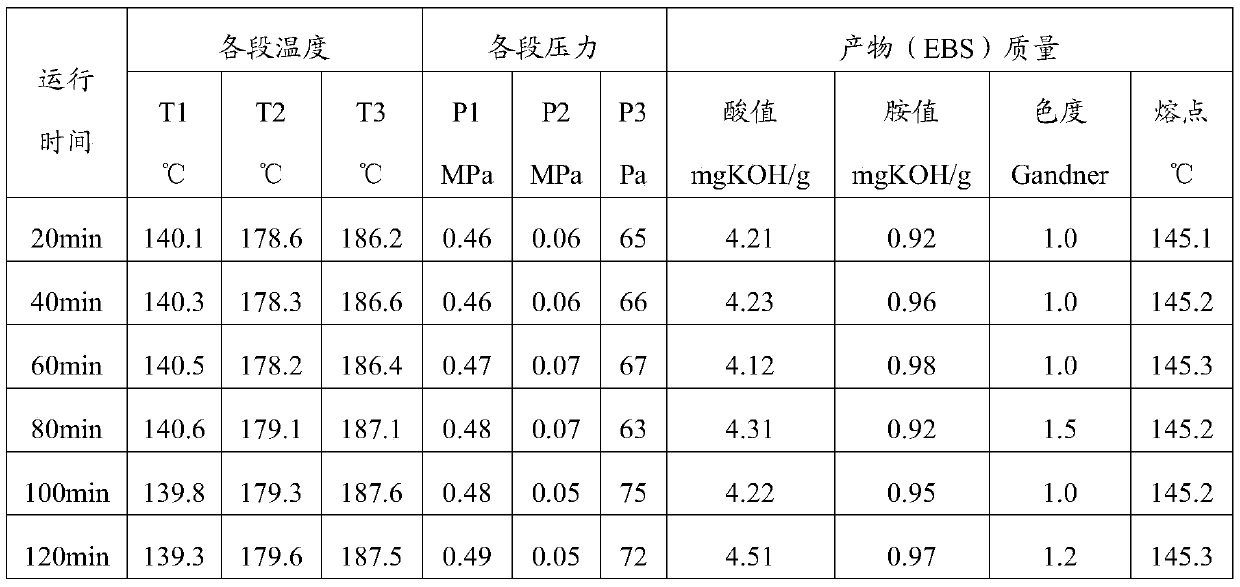

Device and method for synthesizing ethylene bis-fatty acid amide by continuous flow

ActiveCN110975782AGood product quality consistency and stabilityReasonable device designProcess control/regulationSequential/parallel process reactionsEthylene bisFatty acid amide

The invention provides a device and a method for synthesizing ethylene bis-fatty acid amide by continuous flow, and belongs to the technical field of ethylene bis-fatty acid amide synthesis. The device provided by the invention comprises a control system 12, and a raw material storage tank, a micro-channel mixing reactor 5, a vertical wiped film reactor 6, a receiving tank 8 and a horizontal rotary film reactor 10 which are communicated in sequence. The micro-channel mixing reactor 5, the vertical wiped film reactor 6 and the horizontal rotary film reactor 10 are in control connection with thecontrol system 12, and the control system 12 is used for controlling and automatically adjusting the running states of the micro-channel mixing reactor 5, the vertical wiped film reactor 6 and the horizontal rotary film reactor 10. The device provided by the invention can realize continuous flow synthesis of ethylene bis-fatty acid amide, and the product quality consistency and stability are good.

Owner:江西威科油脂化学有限公司

Production technology and equipment of car dimmer switch

ActiveCN105081785AReduce liquidityReduce work intensityOther manufacturing equipments/toolsDimmerSteel ball

The invention relates to the field of production of car accessories, and aims to provide a production technology and equipment of a car dimmer switch. The production technology and equipment of the car dimmer switch comprise a conveying belt module, a PCBA board feeding machine, a PCBA board dividing module, a terminal inserting module, a terminal welding module, an oiling module, a rotary wheel and reed feeding module, a spring assembly module, a steel ball and rotary disc assembly module, a clamping jaw module and a final assembly module, wherein the PCBA board feeding machine, the PCBA board dividing module, the terminal inserting module, the terminal welding module, the oiling module, the rotary wheel and reed feeding module, the spring assembly module, the steel ball and rotary disc assembly module, the clamping jaw module and the final assembly module are sequentially arranged along the conveying belt module. The production technology and equipment have the beneficial effects that various automatic production devices are adopted in the production technology; and previous manual production is replaced; production efficiency is high, production cost is low, and the product quality consistency is good; only little control and few management employees are needed, the work intensity of the employees is relieved, the mobility of the employees is low, and management cost is low; and the equipment is low in occupied area, and space is saved.

Owner:FUZHOU DANLAW XICHENG ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com