RTM forming method of resin based thickness-variable antenna housing

A molding method and technology of variable thickness, applied in the field of RTM molding, can solve the problems of difficult production of variable wall thickness radome preforms, etc., and achieve the effects of good product quality consistency, simple operation process, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

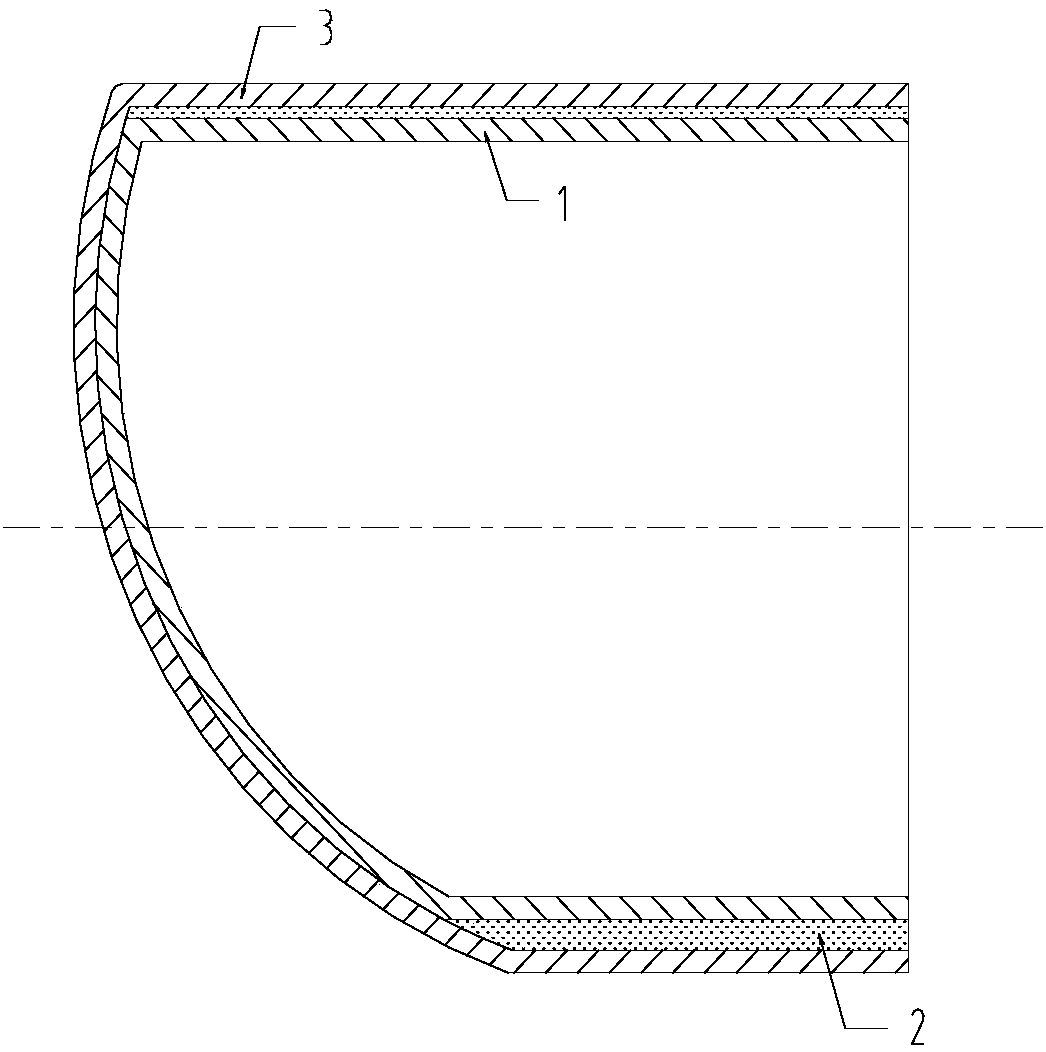

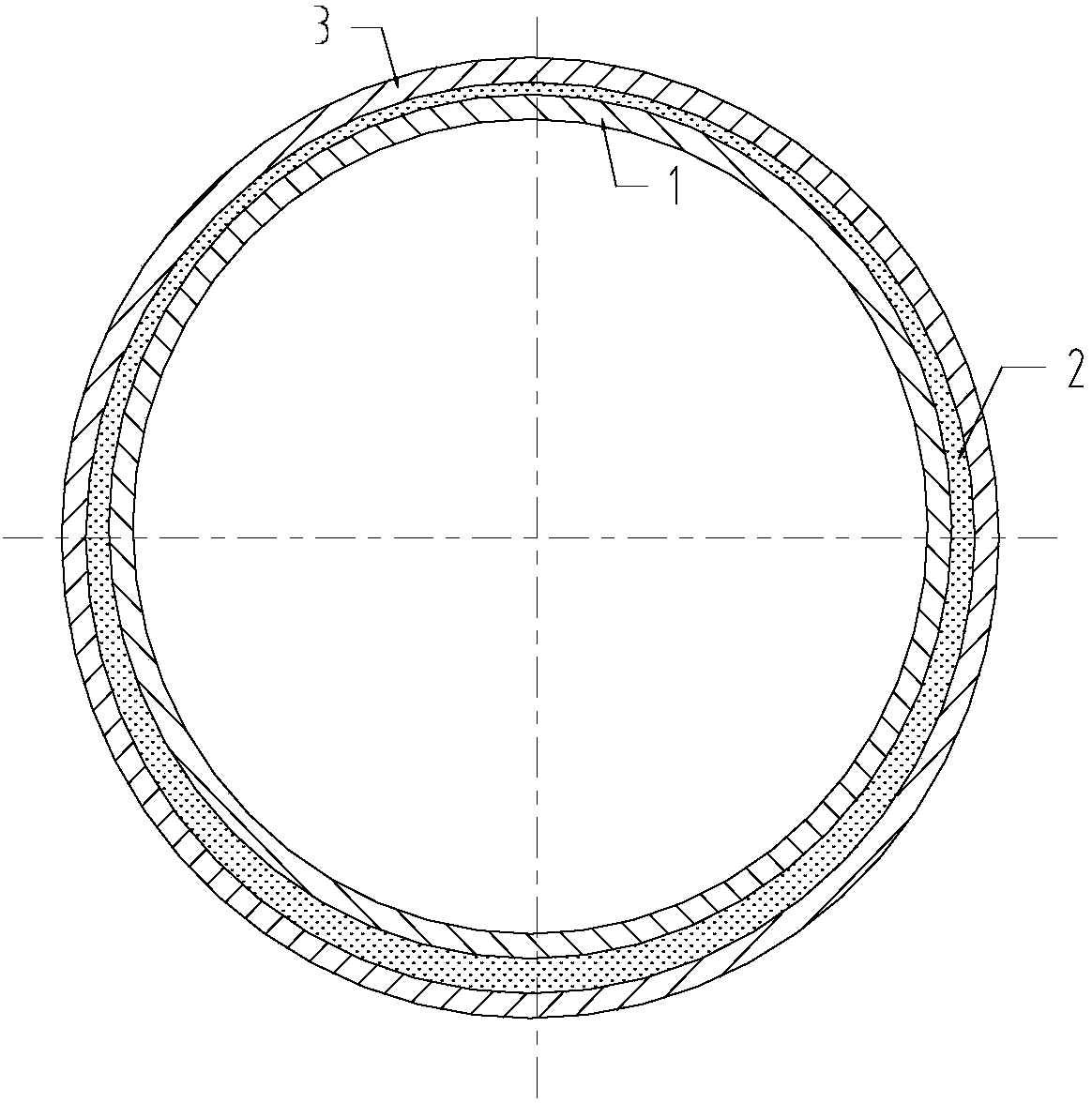

[0028] A radome is a spherical body plus a cylindrical section structure, in which the spherical body is the thinnest area of the product wall thickness, with a thickness of 3mm, and the cylindrical section is the thickness change area, which gradually changes from 4mm to 7mm, see figure 1 , figure 2 shown.

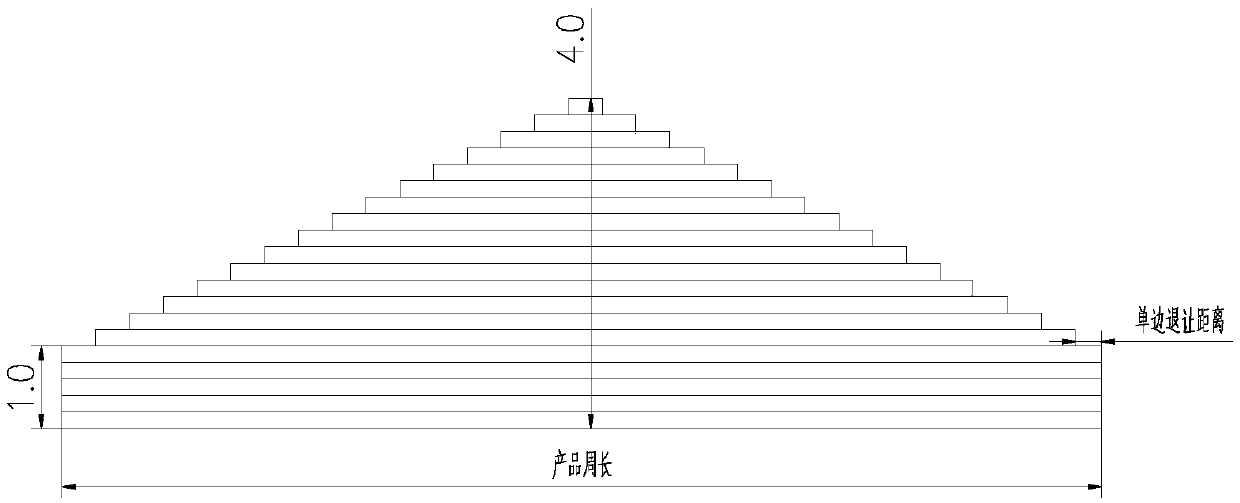

[0029] The product is divided into an inner thickness consistent layer (area shown in 1 in the figure), an outer thickness consistent layer (area shown in 3 in the figure) and a thickness transition layer (area shown in 2 in the figure), wherein the inner and outer thickness consistent layers The thickness is 1.5mm, and the thickness transition layer is in the cylindrical section area, and the thickness is 1mm ( figure 1 The thickness transition layer in the middle and upper part is 1mm, adding 1.5mm each of the inner thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com