Planar torsion spring suitable for robot joints

A technology of planar torsion springs and torsion springs, applied in the field of robotics, can solve the problems of large space occupation and loose structure, and achieve the effects of large space occupation, promotion of replacement, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

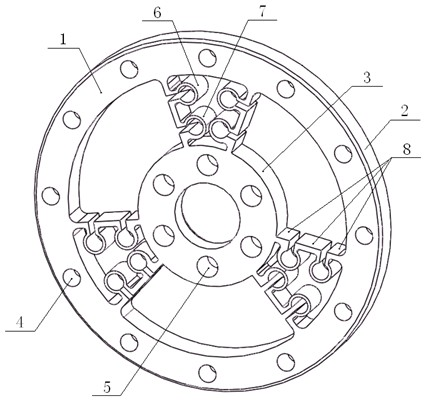

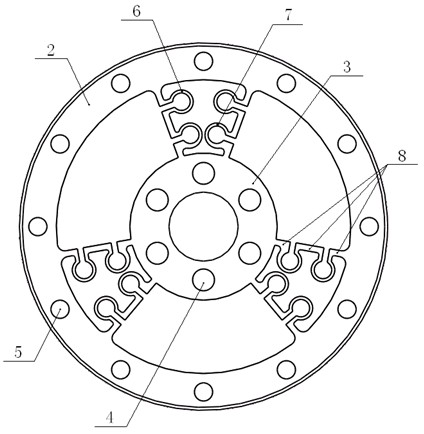

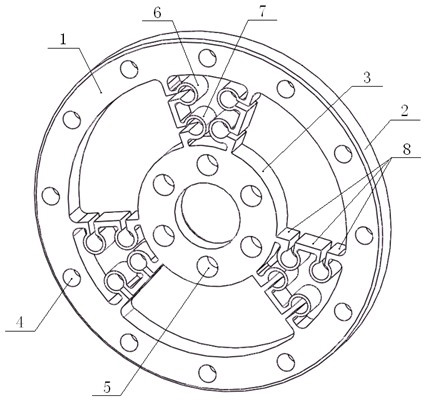

[0010] Further illustrate the present invention below in conjunction with accompanying drawing.

[0011] Such as figure 1 and 2 As shown, the plane torsion spring 1 of the present invention is composed of a torsion spring outer ring 2, a torsion spring inner ring 3 and several elastic bodies. Each elastic body is composed of two symmetrical elastic body units, each elastic body unit includes an outer circular hole groove 6, an inner circular hole groove 7 and a connecting beam 8, between the torsion spring inner ring 3 and the inner circular hole groove 7, Both the inner circular hole groove 7 and the outer circular hole groove 6 and between the outer circular hole groove 6 and the torsion spring outer ring 2 are connected by connecting beams 8 . Several outer ring screw holes 5 are evenly distributed on the torsion spring outer ring 2 to realize the connection with the joint load. A number of light holes 4 are evenly distributed on the inner ring 3 of the torsion spring to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com