Patents

Literature

62results about How to "Have flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

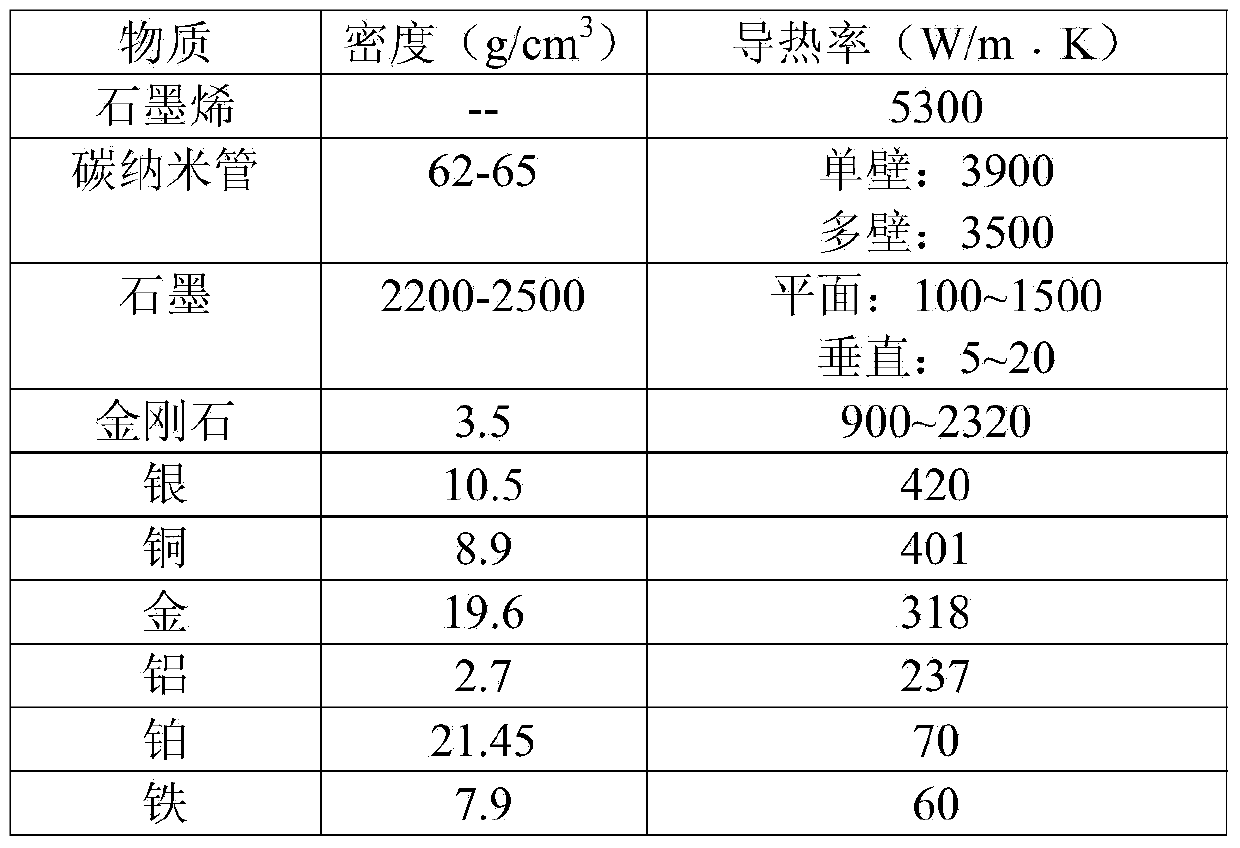

Film made from graphene-carbon nanotube composite material and preparation method of film

InactiveCN103725263AHave flexibilityGood flexibilityHeat-exchange elementsCooling/ventilation/heating modificationsComposite filmLiquid-crystal display

The invention discloses a film made from a graphene-carbon nanotube composite material and a preparation method of film. The preparation method comprises the following steps: mixing graphene and carbon nanotubes sufficiently and evenly via stirring and ultrasonic dispersion, reacting the graphene with the carbon nanotubes sufficiently via hydrothermal or solvothermal conditions, removing solvents after finishing the reaction to obtain the graphene-carbon nanotube composite materials which are preformed and tangled in a network structure, forming the film on the surfaces of various base materials via coating, spraying, spin-coating and filtering the obtained graphene-carbon nanotube composite materials to obtain the composite film made from the graphene-carbon nanotube composite materials and the base materials, and removing the base materials to obtain the film made from the graphene-carbon nanotube composite materials. According to the method, graphene-carbon nanotube composition is realized simply and effectively and dispersed in the solvents stably, and the two obtained films can be applied in the aspects of heat conduction and heat radiation systems of high calorific value electronic devices, LED (light-emitting diode) lamps and liquid crystal display products.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

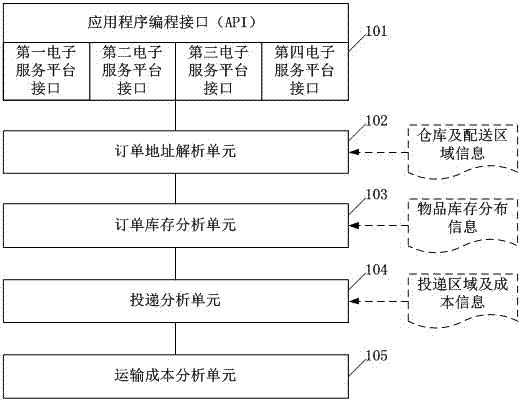

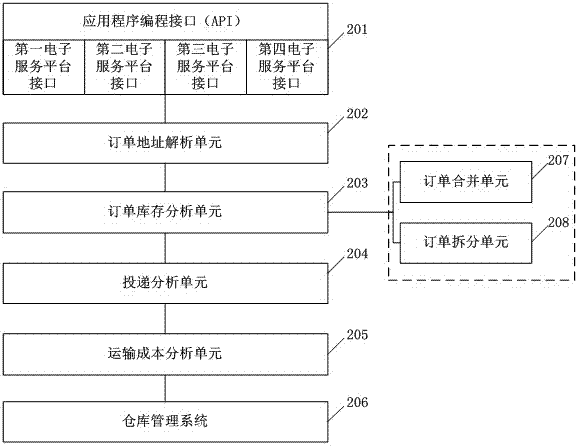

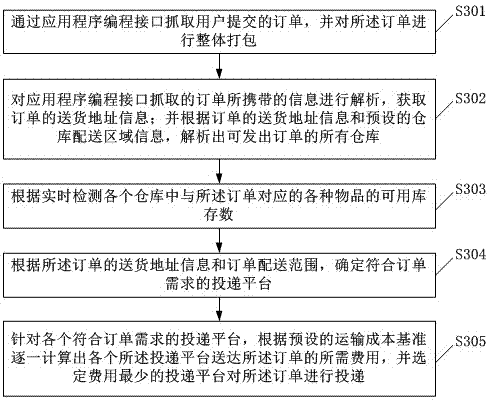

Order route system and method

ActiveCN104732368AReduce errorsImprove processing efficiencyLogisticsCommerceApplication programming interfaceAddress resolution

The invention discloses an order route system. The order route system comprises an application programming interface, an order address resolution unit, an order stock analyzing unit, a delivery analyzing unit and a transportation cost analyzing unit, wherein the application programming interface is used for catching orders submitted by a user; the order address resolution unit is used for resolving information carried by the caught orders; the order stock analyzing unit is used for detecting the available stock numbers of various articles corresponding to the orders in warehouses in real time; the delivery analyzing unit is used for determining delivery platforms meeting the order demands according to delivery address information of the orders and the order distribution ranges; the transportation cost analyzing unit is used for calculating expenditure required by the delivery platforms delivering the articles of the orders one by one for the delivery platforms meeting the order demands. The invention further provides an order route method. The system and method have the advantages of being high in delivery efficiency and accuracy and are suitable for data processing of the large-scale orders.

Owner:天图控股集团股份有限公司

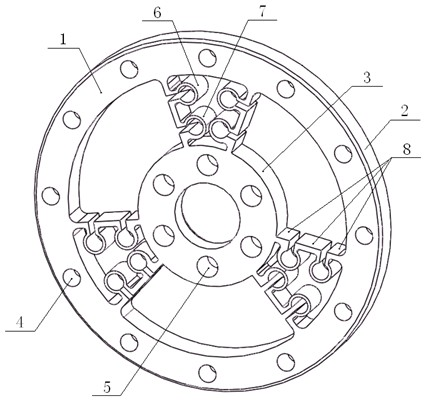

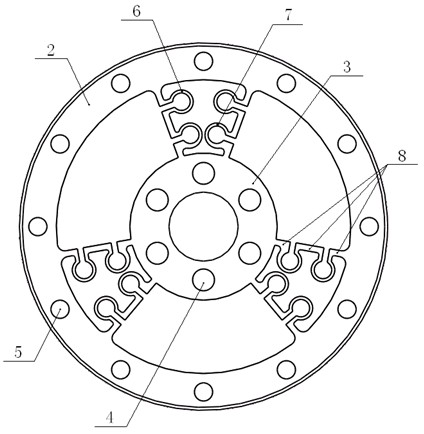

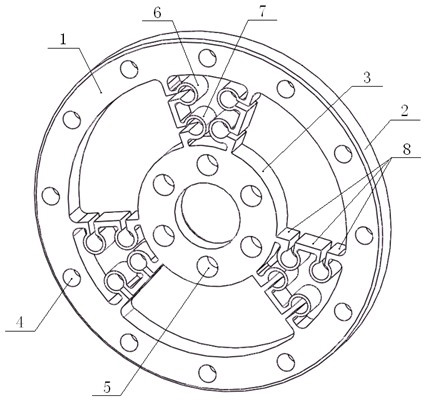

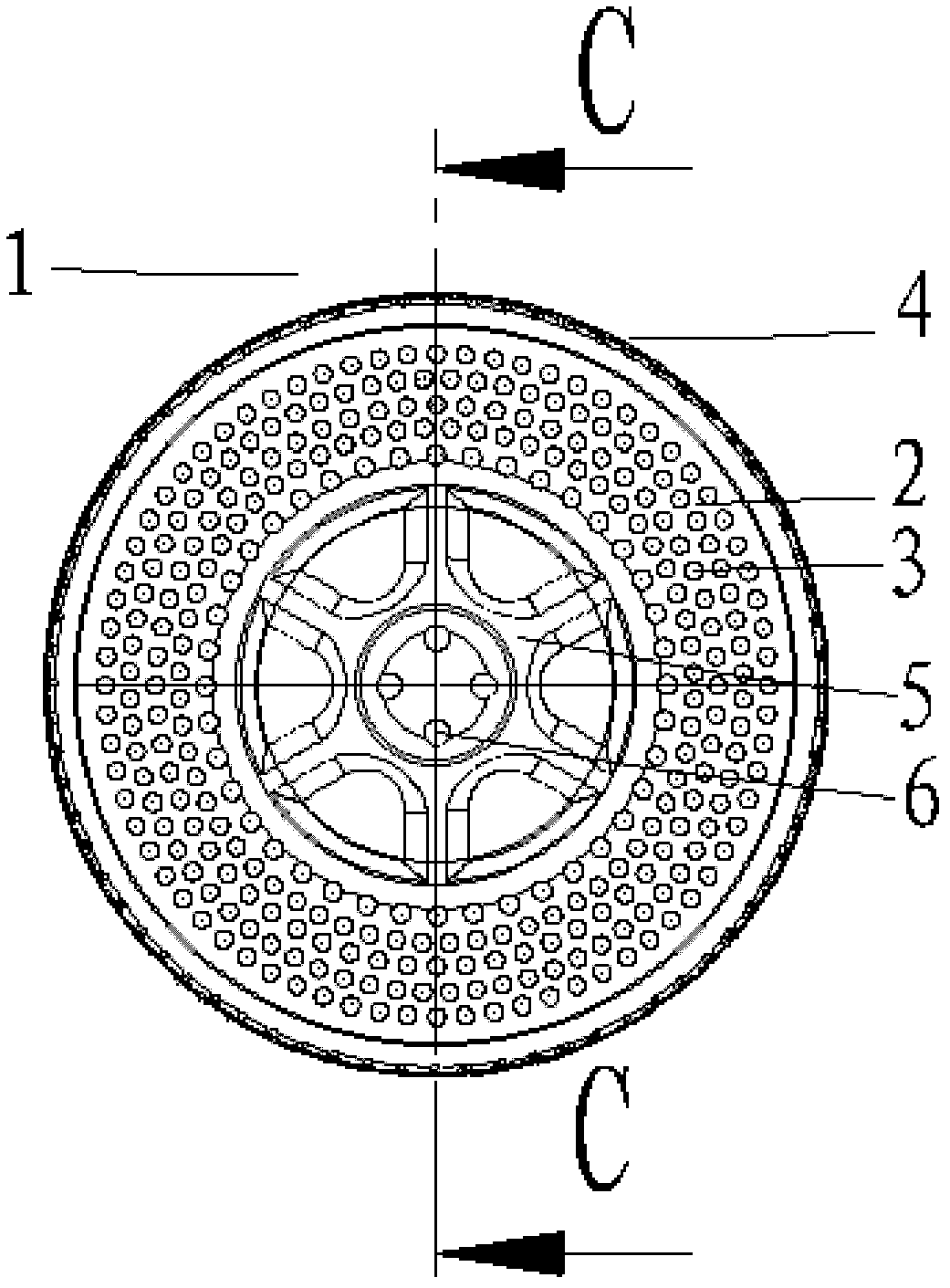

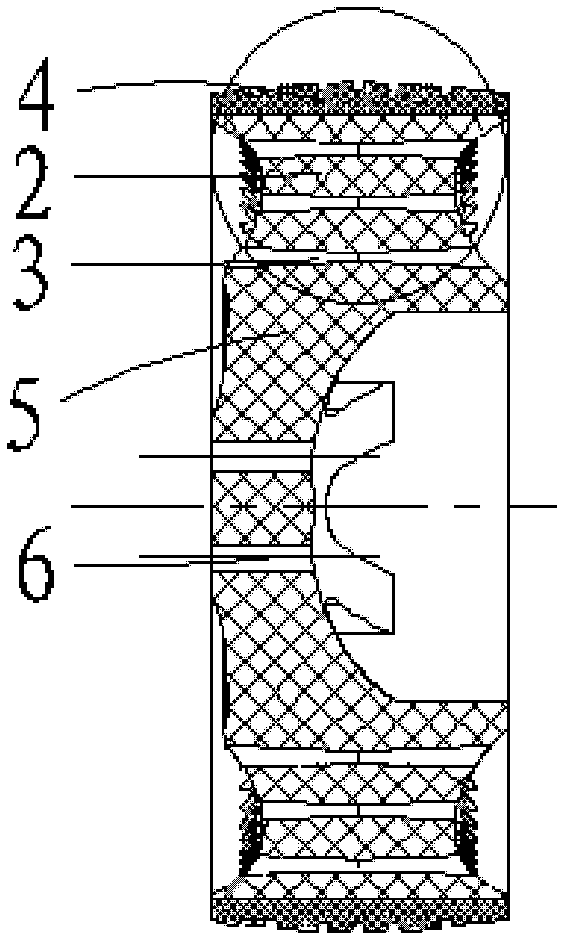

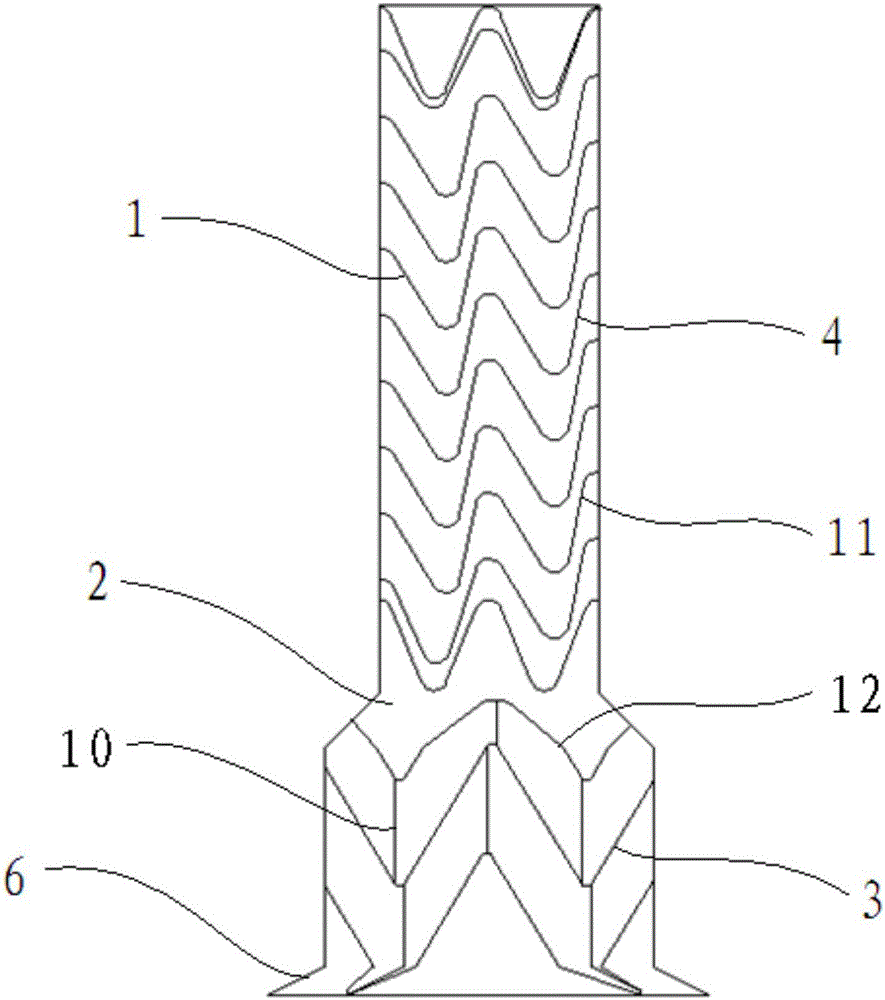

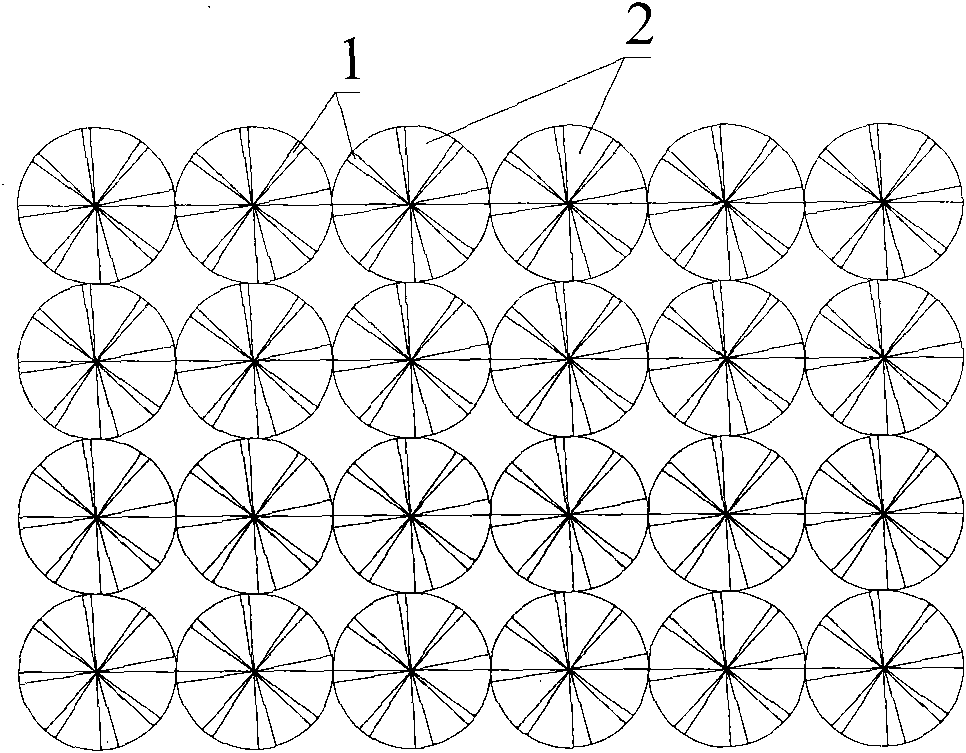

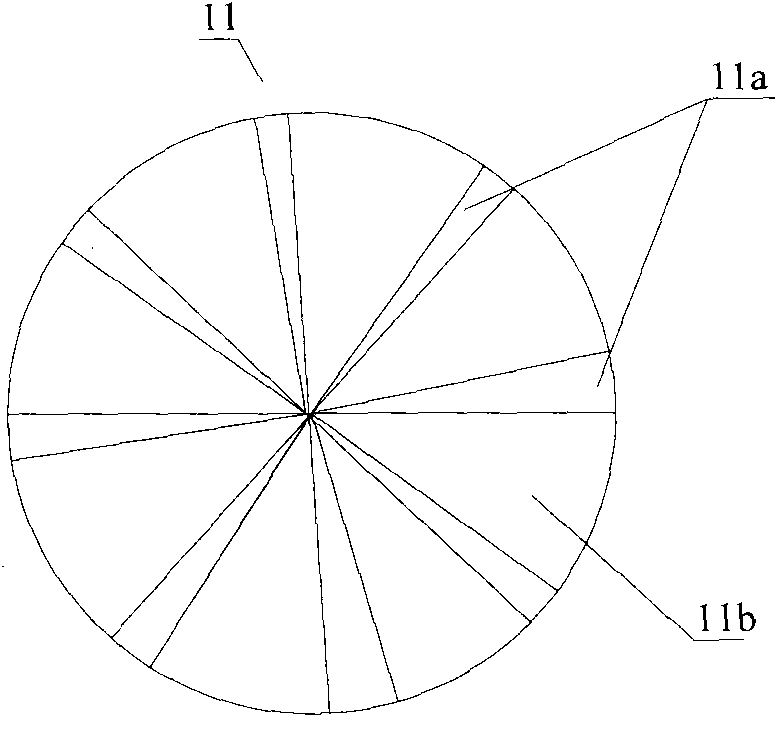

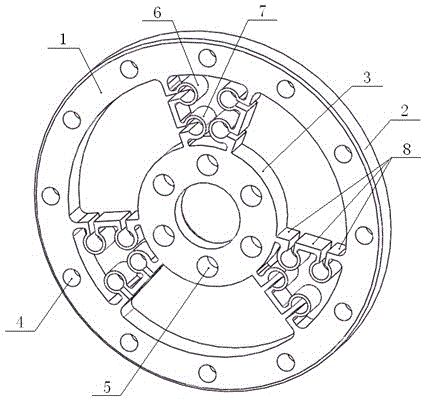

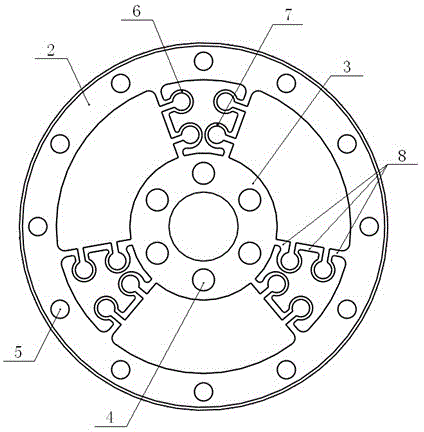

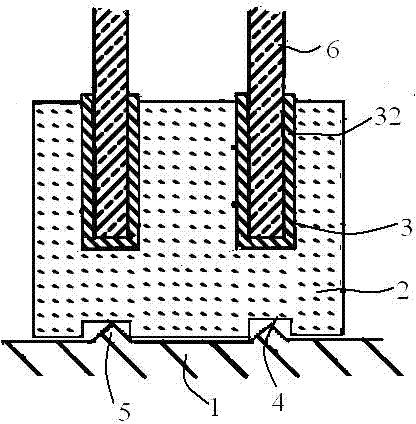

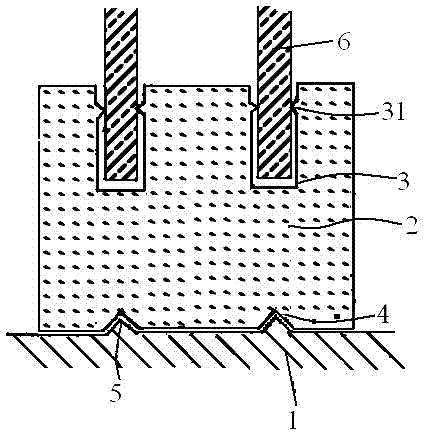

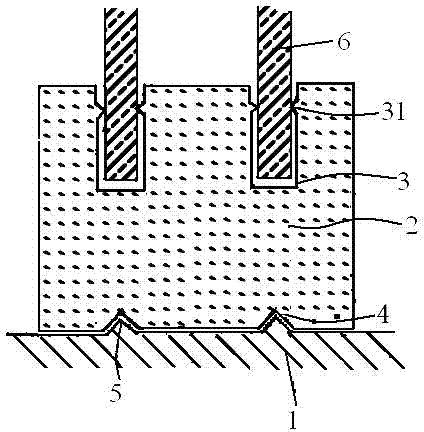

Planar torsion spring suitable for robot joints

ActiveCN102632508AEasy to replaceTroubleshoot safe interactionsProgramme-controlled manipulatorYielding couplingElastomerSacroiliac joint

The invention discloses a planar torsion spring suitable for robot joints mainly comprising an outer ring of torsion spring, an inner ring of torsion spring and a plurality of elastomers; the elastomers are uniformly distributed along a circumference, and the two ends of the elastomers are respectively connected with the outer ring of torsion spring and the inner ring of torsion spring; each elastomer is composed of two symmetrical elastomer units, and each elastomer unit comprises an excircle hole slot, an inner circle hole slot and connecting beams; the inner ring of torsion spring is connected with the inner circle hole slot through the connecting beam, the inner circle hole slot is connected with the excircle hole slot through the connecting beam, and the excircle hole slot is connected with the outer ring of torsion spring through the connecting beam; the inner ring of torsion spring of the planar torsion spring drives the inner circle hole slot to generate elastic deformation through the connecting beam during the rotation process, and the inner circle hole slot drives the excircle hole slot to generate elastic deformation through the connecting beam; the serial elastic deformation of the inner circle hole slot and the excircle hole slot realizes the large angle deformation of the torsion spring; and the planar torsion spring disclosed by the invention guarantees joint flexibility, more compact structure and more flexible design, so that the planar torsion spring is fit for robots and mechanical arm joints.

Owner:ZHEJIANG UNIV

Manufacturing method of underwear fabric

InactiveCN101643970AThe effect of unidirectional stretching is obviousHave flexibilitySolvent-treatmentWarp knittingEngineeringRaw material

The invention discloses a manufacturing method of an underwear fabric. The manufacturing method adopts 40D / 12F nylon bright filament yarn, 210D spandex and 100D / 72F terylene stretch yarn with the weight percentage of 62 percent, 22 percent and 16 percent as raw materials. By adopting the technical scheme, the raw materials adopt the nylon bright filament yarn, the spandex and the terylene stretchyarn for weaving so as to lead the fabric to have comfort and softness of pure cotton fabric and also have luster of the nylon fabric and flexibility of the spandex fabric. The weaving process adoptsthe terylene stretch yarn as weft insertion so as to lead wrap drawing to be minimum and larger weft drawing and lead the unidirectional drawing effect of the fabric to be more obvious.

Owner:HAINING DEJUN KNITTING & DYEING GROUP

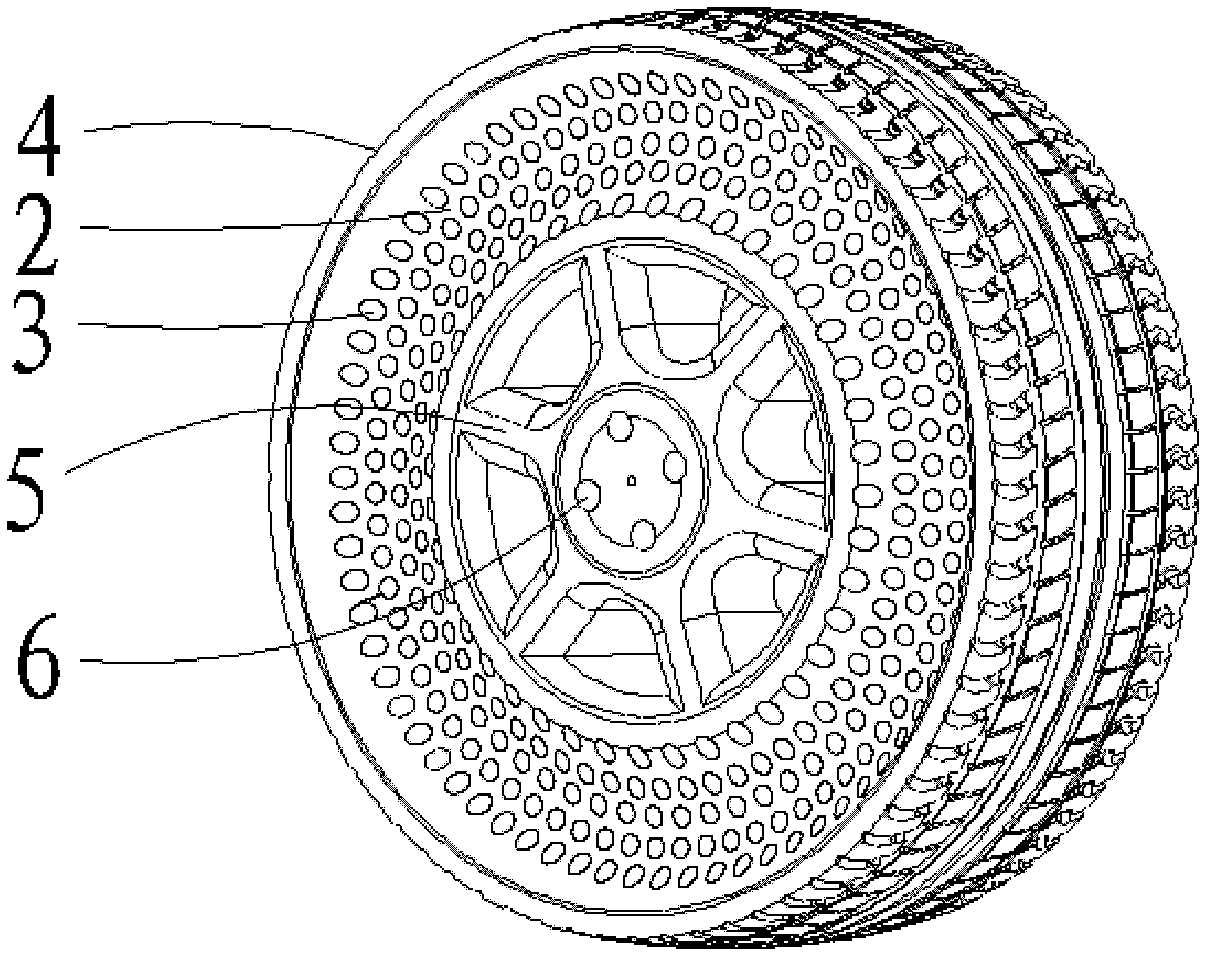

Non-pneumatic tire with rigid and flexible structure

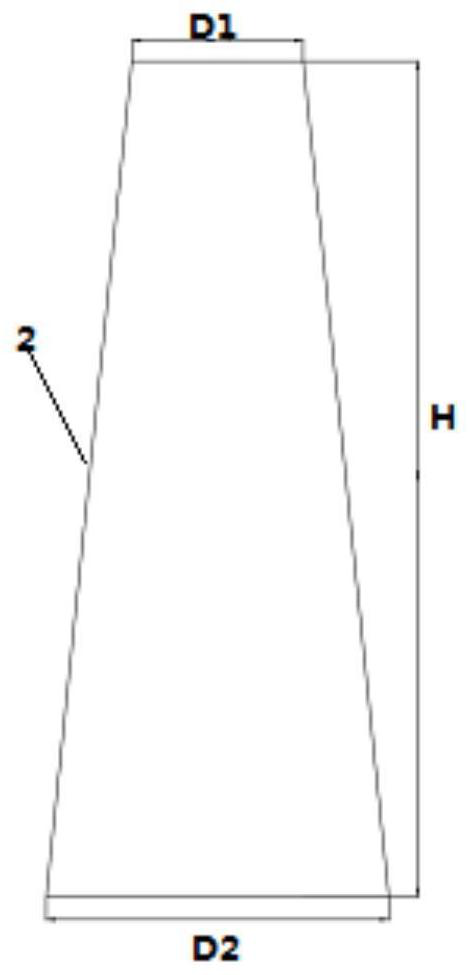

InactiveCN102582365AStrong comfortSave raw materialsNon-inflatable tyresSpecial tyresMaximum diameterThermoplastic elastomer

The invention provides a non-pneumatic tire with a rigid and flexible structure. The non-pneumatic tire mainly comprises two parts, namely a tire tread and a casing structure, wherein the tread part is mainly made of a thermoplastic elastomer, and the casing structure always extends from an inner surface of the tread to the center of a rim along the radial direction, so that the rim and the casing are combined into a whole; and the whole part is made of tough and elastic engineering plastics, an inverted conical through hole is formed in the casing part in the axial direction, and the inverted conical through hole is structurally characterized in that: holes positioned on two sides of the tire have the maximum diameter and a hole in the middle of the tire has the minimum diameter. The non-pneumatic tire with the rigid and flexible structure has the advantages of other non-pneumatic tires and is endowed with excellent structural performance and safety performance. In addition, because the casing and the rim are made of thermoplastic polymer materials, the mass of the tire is greatly reduced, and the non-pneumatic tire has a great significance for energy conservation, emission reduction and oil consumption reduction.

Owner:BEIJING UNIV OF CHEM TECH

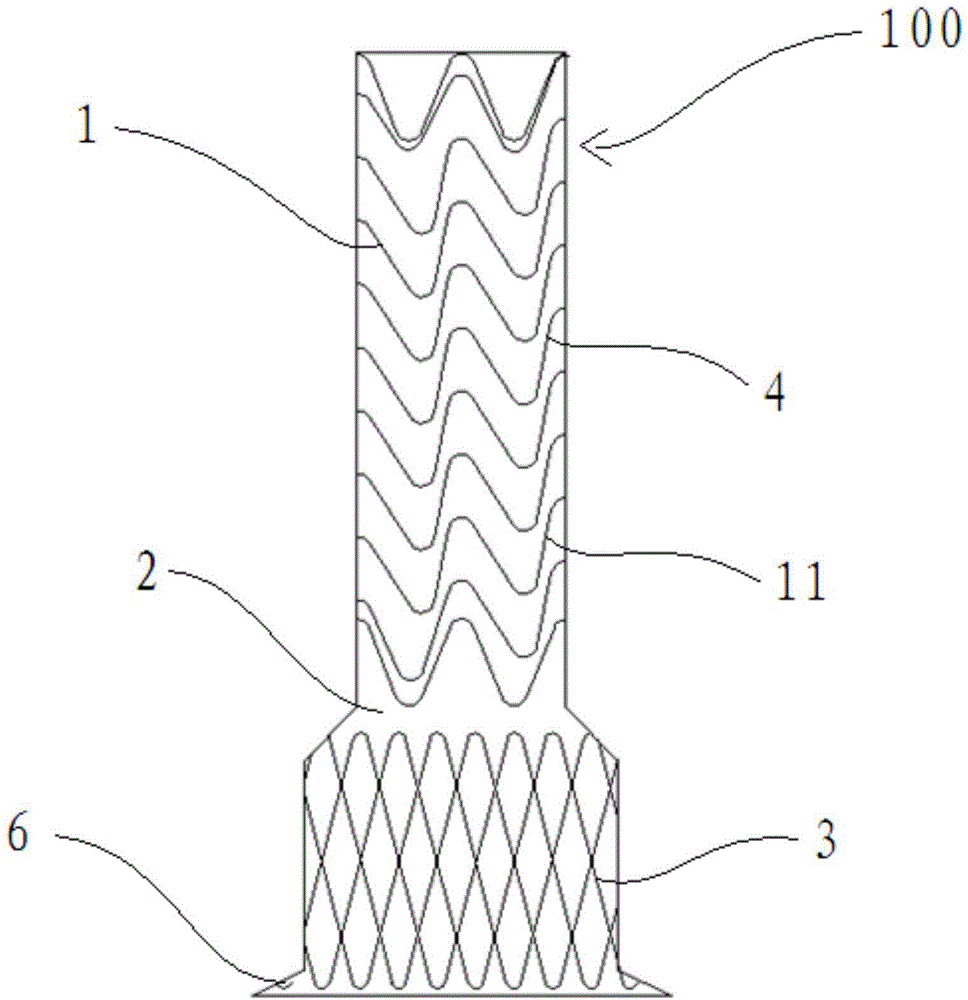

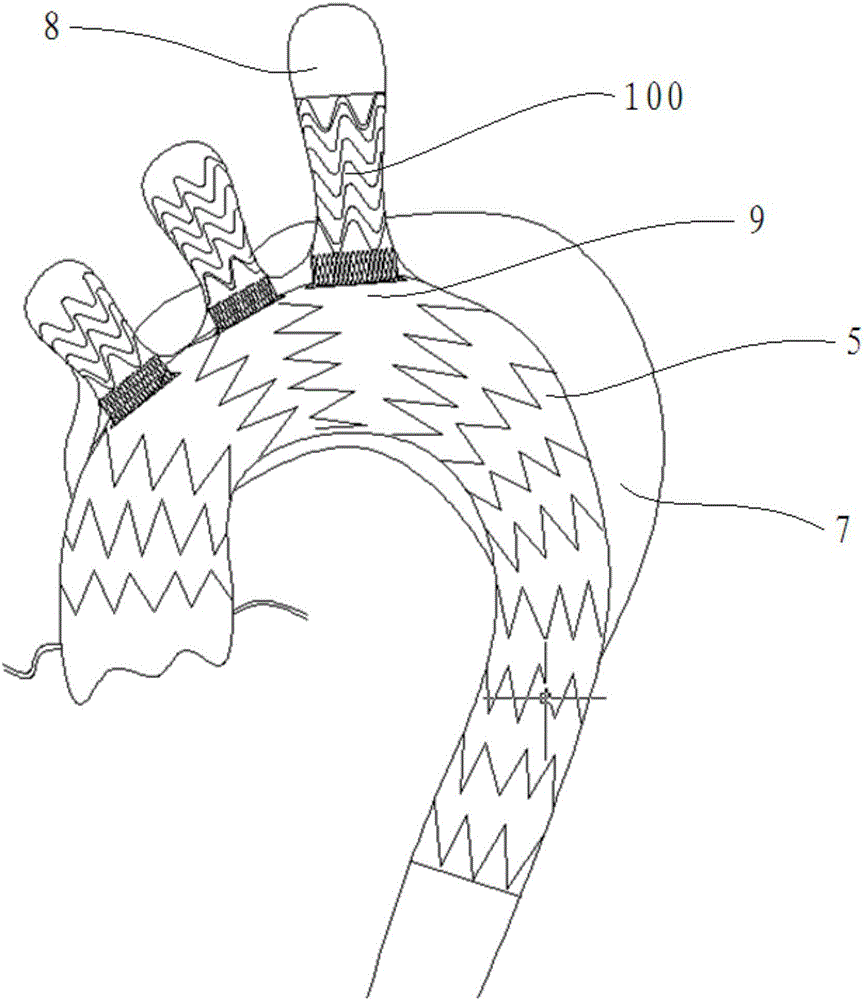

Aortic windowing branch covered stent

InactiveCN105943199AAvoid damageImprove flexibilityStentsBlood vesselsMinimal access surgeryThree vessels

The invention discloses an aortic windowing branch covered stent and belongs to the technical field of vascular stents. The aortic windowing branch covered stent comprises a tubular skeleton made of thin filaments and a membrane covering the tubular skeleton. The proximal end of the tubular skeleton is suitable for being inserted into a window of the aortic windowing branch covered stent and communicated with the aortic windowing branch covered stent. The remote end of the tubular skeleton is suitable for being inserted into a branch blood vessel, and the proximal end is harder than the remote end. The aortic windowing branch covered stent lowers the operation difficulty of minimally invasive surgery in an aortic lumen with branch blood flow, solves the technical problem that in the surgery, internal leakage occurs easily, can adapt to fitting the tortuous branch blood vessel and effectively prevents damage to the branch blood vessel and occurrence of re-blocking and internal leakage.

Owner:李晓东

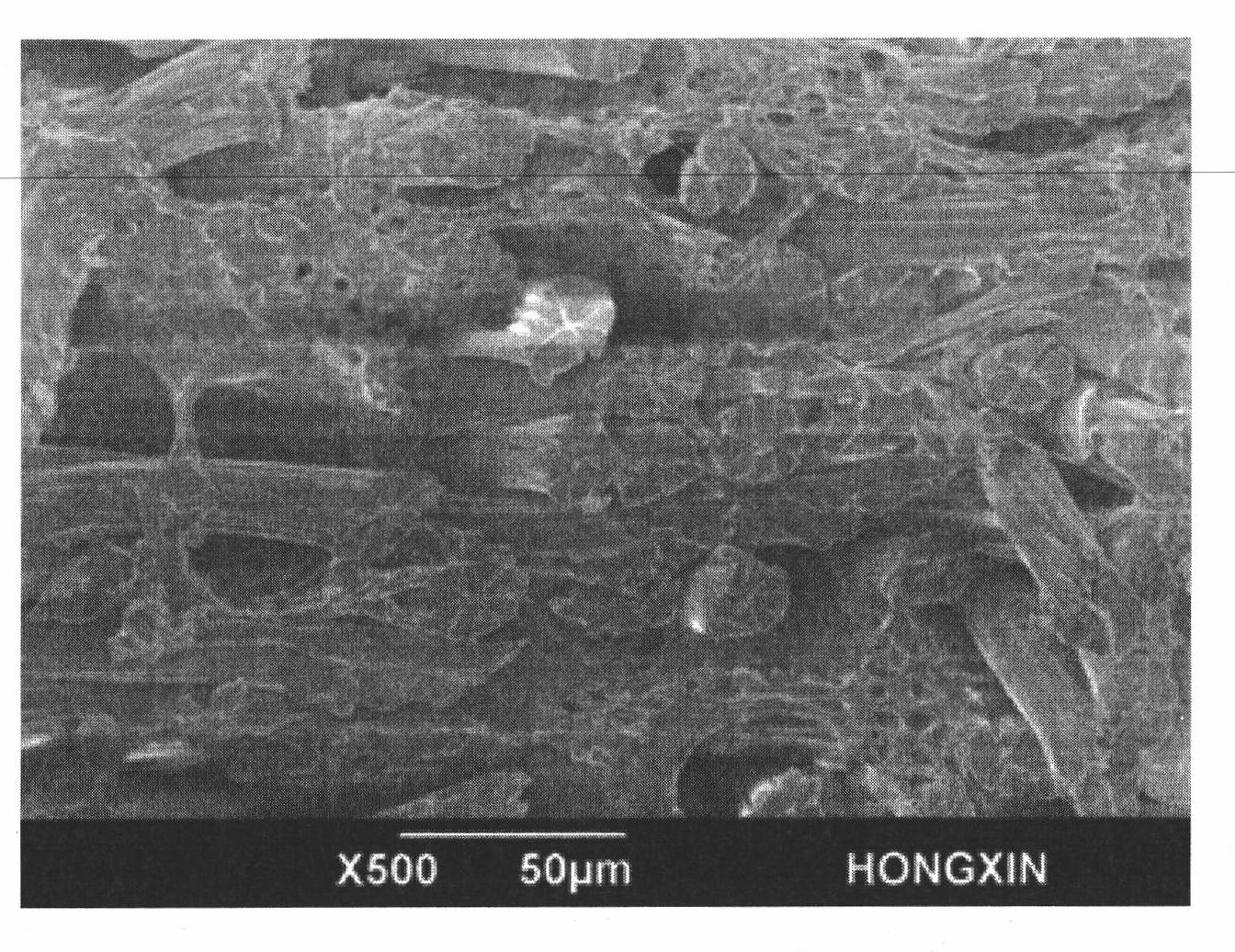

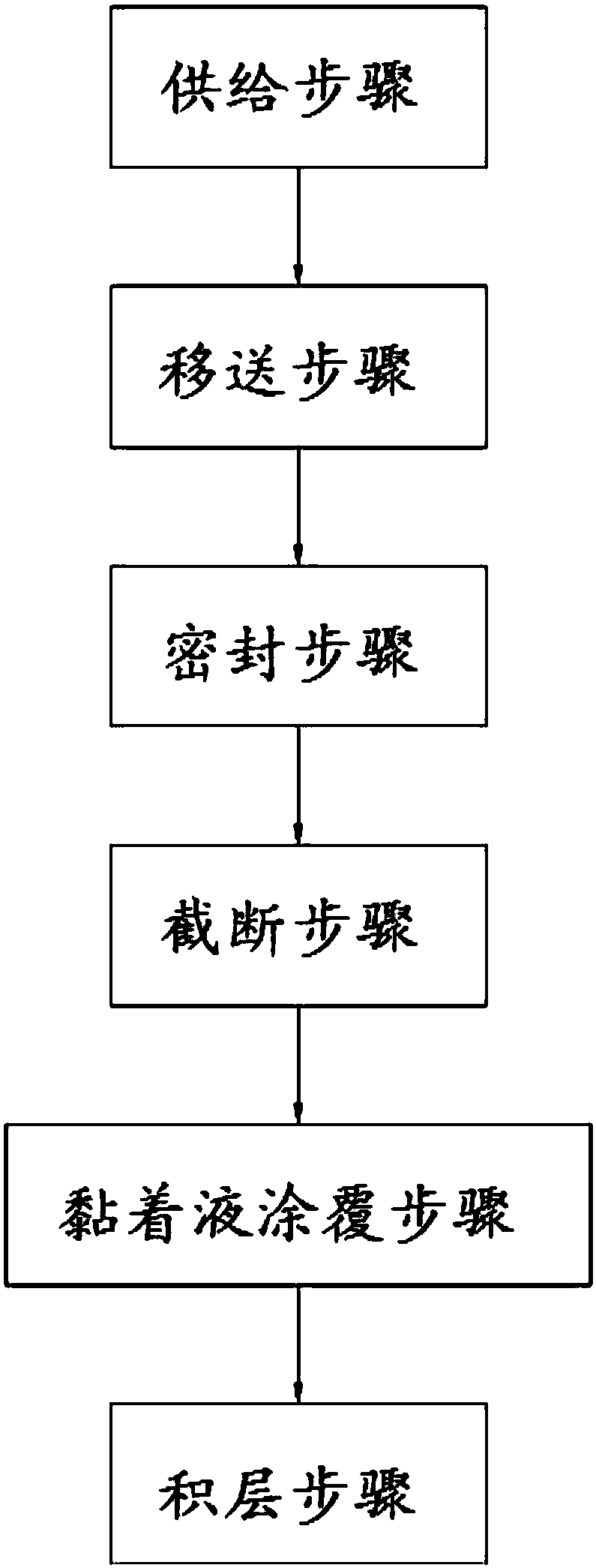

Impregnation method of non-woven fabric

The invention provides an impregnation method of non-woven fabric, which comprises the following steps of: providing the non-woven fabric made of double-component composite fiber, wherein the double components are polyester component and polyamide component; using framework parts arranged in a radioactive way and splinter parts filled among the framework parts to form the non-woven fabric, wherein the splinter parts and the framework parts are respectively formed by the double components; carrying impregnation treatment on the non-woven fabric by using polyvinyl alcohol impregnation liquid, and obtaining first impregnation base fabric; then, carrying out impregnation treatment by using polyurethane impregnation liquid, and obtaining second impregnation base fabric, wherein the polyurethane impregnation liquid comprises the components based on mass concentration: 12-20 percent of polyurethane, 1-3.2 percent of impregnation auxiliary agent and balance DMF; and finally, leading the second impregnation base fabric to enter coagulating liquid for coagulating, water washing and drying. By adopting the method, the impregnation treatment can be carried out on the non-woven fabric, so that the double-component composite fiber can be reserved inside the leather, the double components can be prevented from being adhered with the leather, and the finally obtained PU synthetic leather not only has stiffness of terylene, but also has softness of nylon.

Owner:厦门象屿兴泓超细材料有限公司

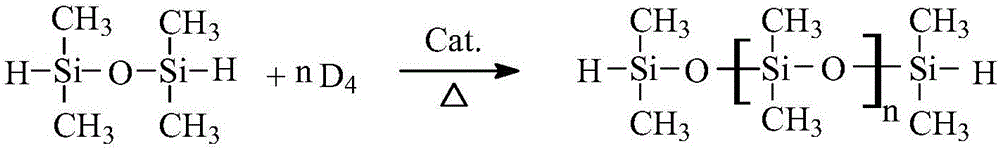

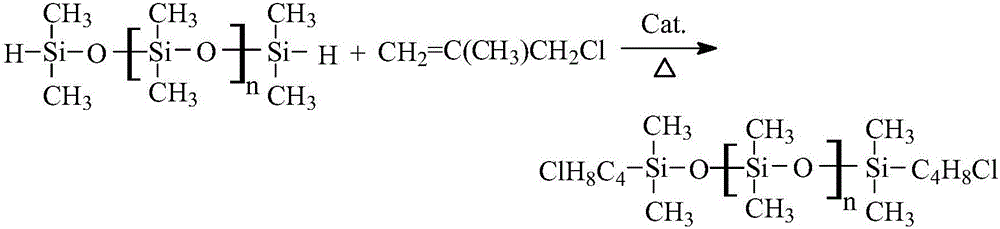

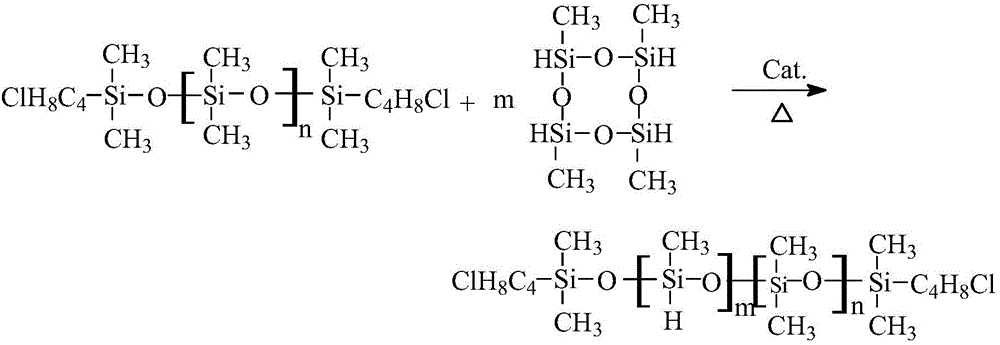

Preparation method for anionic linear copolymerized organic silicon softening and finishing agent

The invention discloses a preparation method for anionic linear copolymerized organic silicon softening and finishing agent. Under the conditions of high salinity and high alkalinity, cationic groups playing the function of stabilization in the structure of the organic silicon softening and finishing agent are easily flocculated with a dye dispersant, the stability of emulsion is broken, and phenomena like breaking of emulsion and floating of oil are generated. The method comprises organic silicon macromolecule chain extension reaction of 1,1,3,3-tetramethyl disiloxane, addition reaction of 3-chloro-2-methylpropene and terminated hydrogen-containing silicone oil, preparation of terminated chlorine-containing and side-chain hydrogen-containing silicone oil, addition reaction of olefin acid and side-chain hydrogen-containing silicone oil, ammonolysis of an organosilicone macromolecular chain segment, preparation of terminated epoxy-containing polyether, and condensation polymerization of the organosilicone macromolecular chain segment and a polyether chain segment. According to the method, the organosilicone chain segment is subjected to anion modification, the compatibility of the emulsion to anions is improved, the introduction of the anions also greatly improves the high temperature resistance, salt tolerance, alkaline resistance properties of the emulsion, and the product can be suitable for dyeing one-bath processing.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

Bamboo fiber short fiber roved woolen fabric

The bamboo fiber-short fiber roved woolen fabric is blended or interwoven with bamboo fiber, short fiber and animal fiber, including wool, cashmere, rabbit hair and rabbit fluff. The fabric has hygroscopicity similar to that of bamboo fiber, as well as elasticity, softness and warming performance like animal fiber, and is pendent, elegant, bright, full and smooth.

Owner:浙江神州毛纺织有限公司

Bamboo fiber woolen fabric

The invention discloses bamboo fiber short fiber woolen fabric which is formed by mixed spinning or interweaving of bamboo fiber short fiber and animal fiber such as wool or cashmere or yak hair or yakwool. The fabric has the moisture absorption and moisture desorption of bamboo fiber. In such a way, the fabric disclosed by the invention has elasticity, softness and warm-keeping property of the animal fiber, and belongs to the green and environmentally-friendly fabric.

Owner:CHANGSHU MEILI TOWN BINLI GARMENT & CLOTHING FACTORY

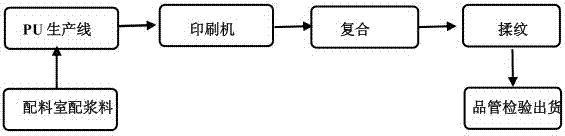

Production method of breathable leather

ActiveCN103898773AImprove hydrolysis resistanceReduce manufacturing costLaminationLamination apparatusProduction lineSurface layer

The invention relates to a production method of breathable leather. The condition that in a production method of the breathable leather, environment pollution in the production process is free and the problem of product breathability is available can be solved at present can not be splved. The production method comprises the following steps: (1) preparing a sizing agent, wherein the sizing agent consists of polyurethane resin and color chips in a weight ratio of 100:1.2, and the viscosity of the sizing agent is adjusted to be 1500cps; (2) mounting release paper onto a PU (Polyurethane) production line, firstly, drying the release paper at 100 DEG C, subsequently coating the release paper with the sizing, and furthermore, drying at 140 DEG C so as to obtain a half-finished product; (3) printing a dry method surface layer of the release paper with patterns and glossiness by using a three-edition printing machine; (4) compounding the release paper with a piece of base cloth by using a binding agent; and (5) washing in water by using a graining machine; and (6) inspecting to be qualified to obtain a breathable leather product. By adopting the production method, the product breathability can be solved.

Owner:ZHEJIANG SHENTENG COATED FABRICS

Production method for waterborne synthesized artificial leather

InactiveCN106087440AEnvironmental performanceImprove environmental performanceTextiles and paperEnvironmental resistanceComposite strength

The invention discloses a production method for waterborne synthesized artificial leather and belongs to the technical field of leather fabric production. The production method sequentially comprises the following steps that pulp is prepared in a preparing chamber, wherein waterborne polyurethane pulp and polyvinyl chloride pulp are prepared; dry-method line coating bonding is carried out, wherein the surface of release paper is coated with the waterborne polyurethane pulp, the polyvinyl chloride pulp and waterborne polyurethane bonding pulp in sequence, and base cloth and a polyvinyl chloride layer are bonded to be prepared into a waterborne synthesized artificial leather body; the waterborne synthesized artificial leather body and the release paper are separated and rolled respectively, and coating is carried out with a printing machine, wherein coating wheels are used for uniformly coating the surface of the waterborne polyurethane layer of the waterborne synthesized artificial leather body with the waterborne polyurethane pulp, drying is carried out, and inspection and warehousing are carried out. The production technology is simple, the product is environmentally friendly, free of pollution and high in bonding property and composite strength, the service life is prolonged, the real leather imitation degree is high, the product is thick, solid and full, the comfortableness and softness of the artificial leather are improved, and the use demand is met.

Owner:ZHEJIANG SHENTENG COATED FABRICS

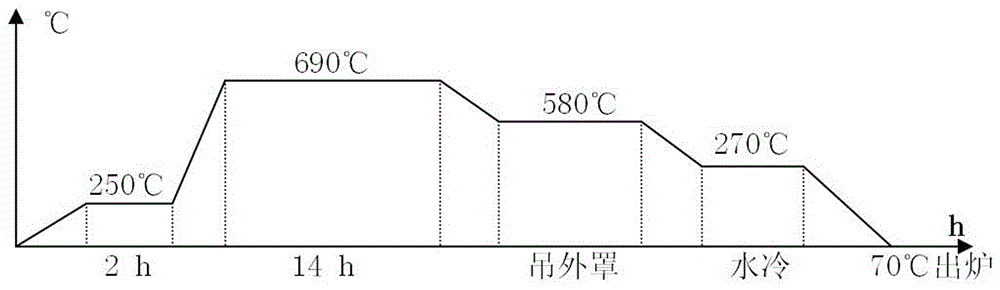

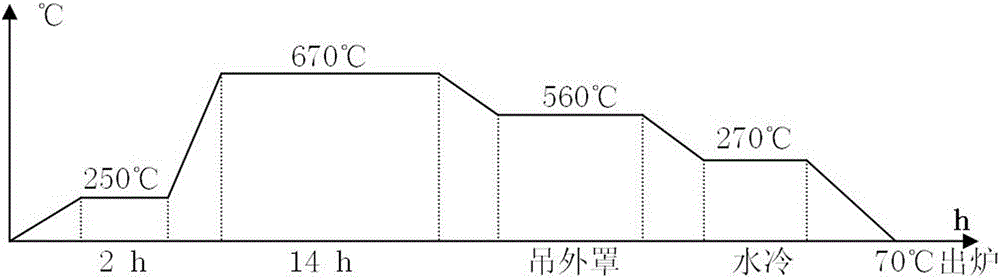

Heat treatment process for automobile synchronizer ring gear cold rolling alloy-steel strip 16MnCr5

The invention discloses a heat treatment process for an automobile synchronizer ring gear cold rolling alloy-steel strip 16MnCr5. The cold rolling alloy-steel strip 16MnCr5 comprises, by mass, 0.14-0.19% of C, no larger than 0.4% of Si, 1.00-1.30% of Mn, 0.80-1.10% of Cr, no larger than 0.035% of P and no larger than 0.035% of S. According to the heat treatment process, small-deformation rolling in 7-12 passes and 1-2 times of heat treatment annealing process enable a steel strip structure to gradually change to obtain a metallographic structure meeting fine blanking requirements, so that the ultimate object of replacing copper with steel is achieved; and the steel strip not only has the softness of a copper ring gear in property, but also is higher than the copper ring gear in intensity and abrasive resistance, the service life of an automobile ring gear is further prolonged, cost is further lowered, and a large quantity of non-ferrous metals are spared for the country.

Owner:SUZHOU XIANGLOU METAL PROD

Planar torsion spring suitable for robot joints

ActiveCN102632508BIncrease elasticityRealize large angle deformationProgramme-controlled manipulatorYielding couplingElastomerEngineering

Owner:ZHEJIANG UNIV

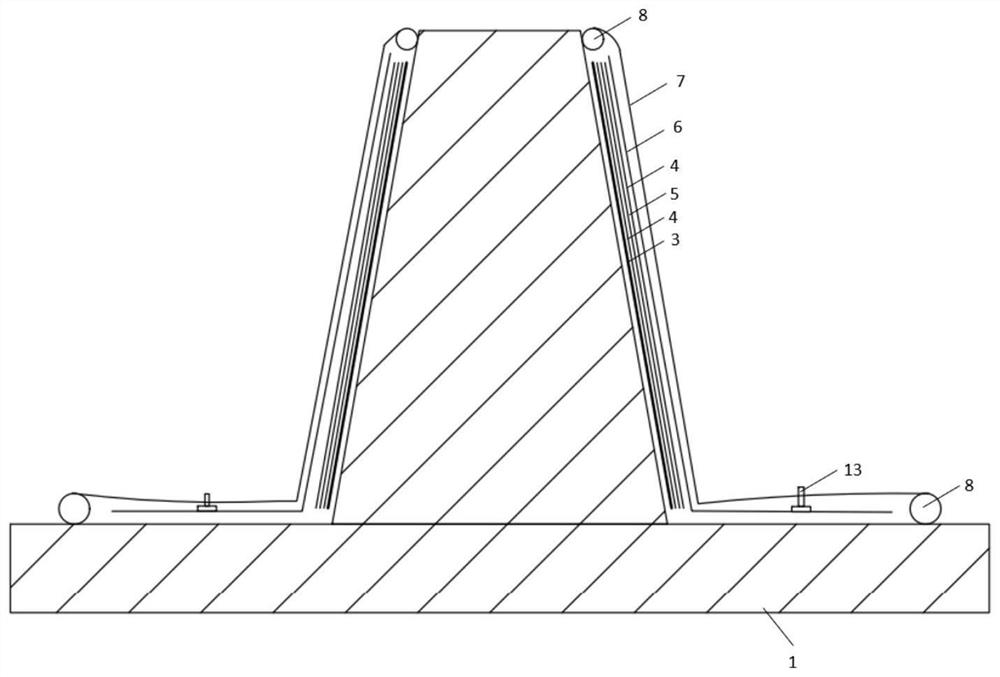

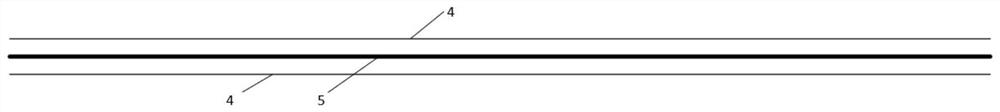

High-temperature-resistant carbon fiber composite material cylinder bearing layer and preparation process thereof

The invention provides a high-temperature-resistant carbon fiber composite material cylinder bearing layer and a preparation process thereof, relates to the technical field of composite materials, and is mainly used in the field of spaceflight as an external bearing layer of missiles and spaceflight launchers. According to the high-temperature-resistant carbon fiber composite material cylinder bearing layer, bismaleimide resin with a glass transition temperature of 260 DEG C is used as a matrix material and T800 carbon fiber is used as a reinforcement material to prepare unidirectional prepreg as a raw material, and an autoclave molding process is adopted to prepare the high-temperature-resistant conical carbon fiber composite material cylinder bearing layer; according to the preparation process, a male mold is adopted as a mold to prepare a pressure equalizing plate, and then the bearing layer is prepared in the manner that the male mold is matched with the pressure equalizing plate; according to the bearing layer, the unidirectional prepreg is laid between a male mold forming surface and the pressure equalizing plate in a belt-laying-like manner, and the laying manner is an orthogonal symmetric laying manner, so that the directivity of fibers and the surface quality of the cylinder bearing layer are ensured; and the high-temperature-resistant carbon fiber composite material cylinder bearing layer prepared by the method meets the use requirements, and the product quality is high.

Owner:NANJING JULONG SCI&TECH CO LTD +2

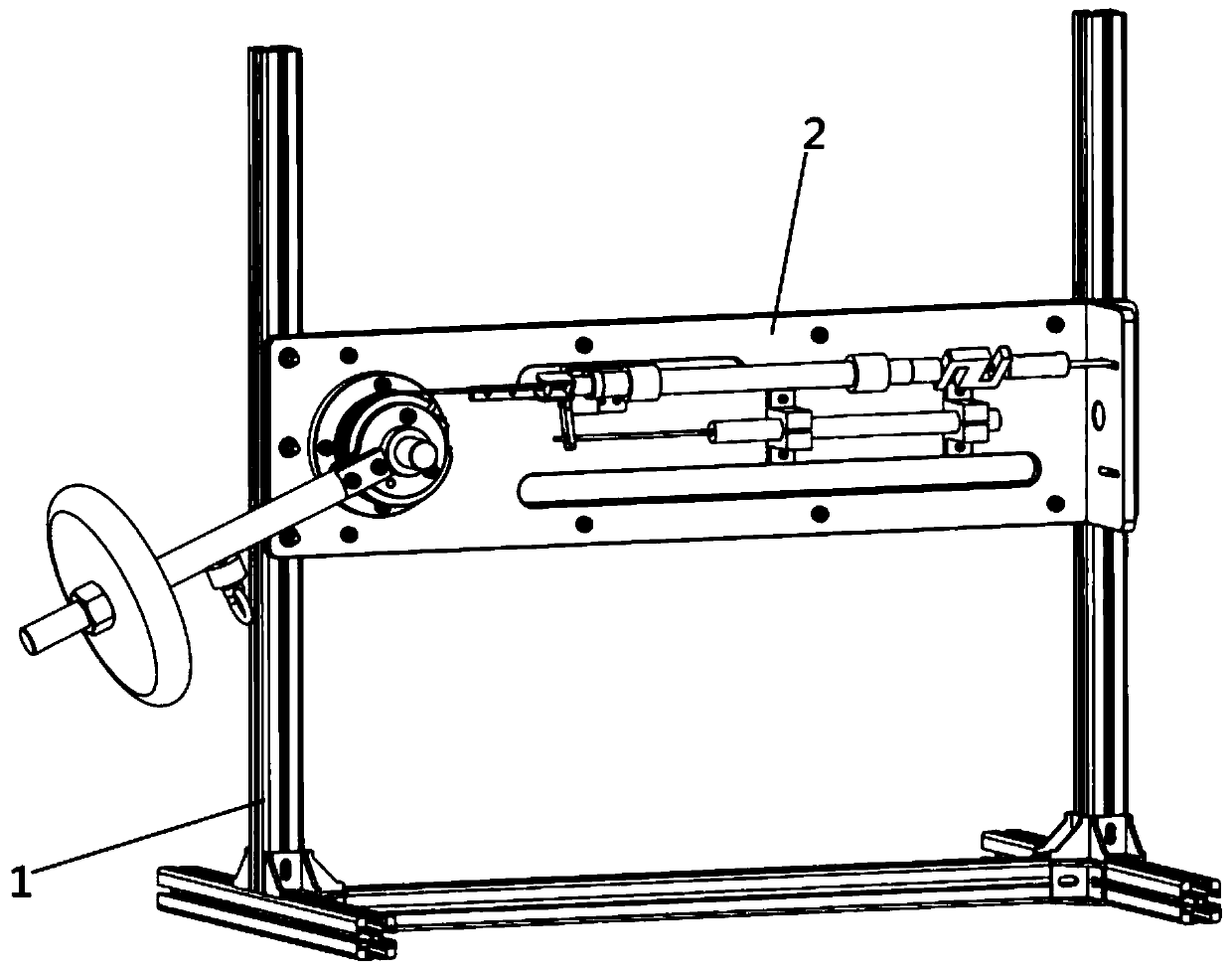

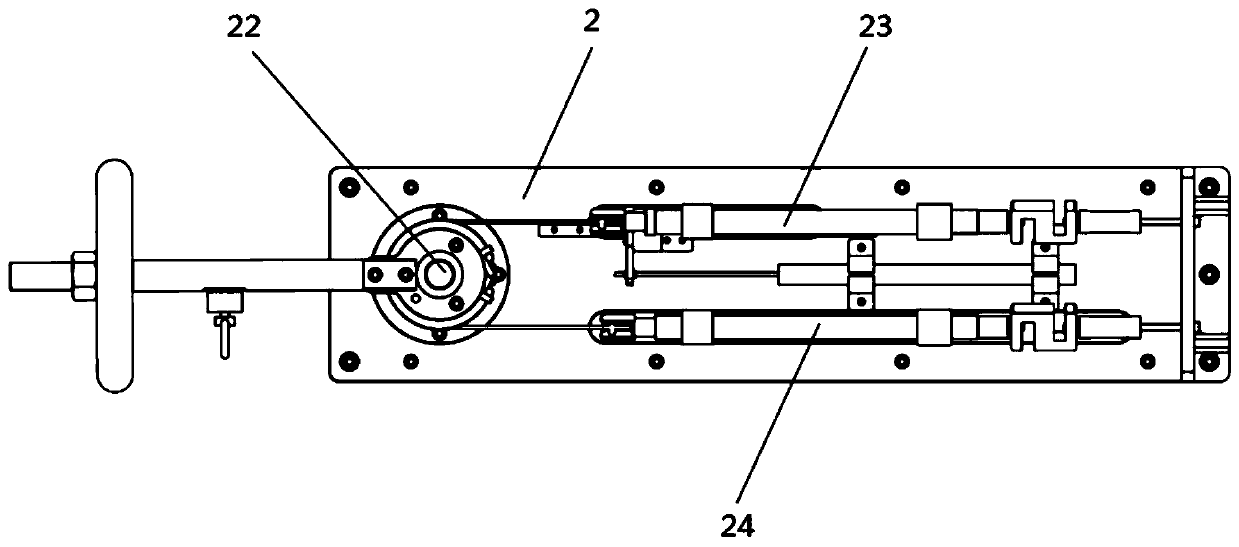

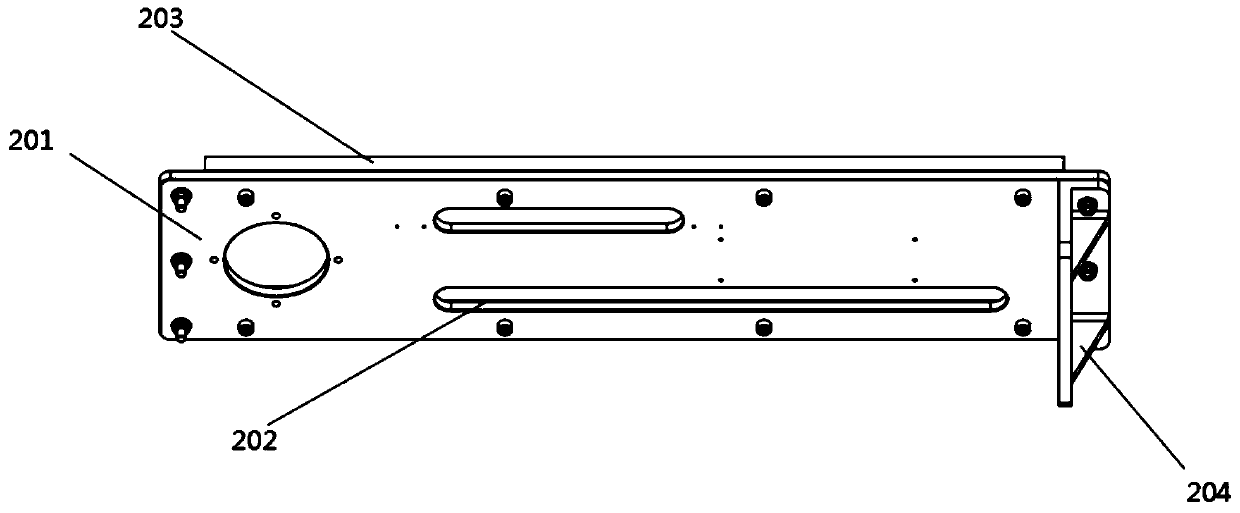

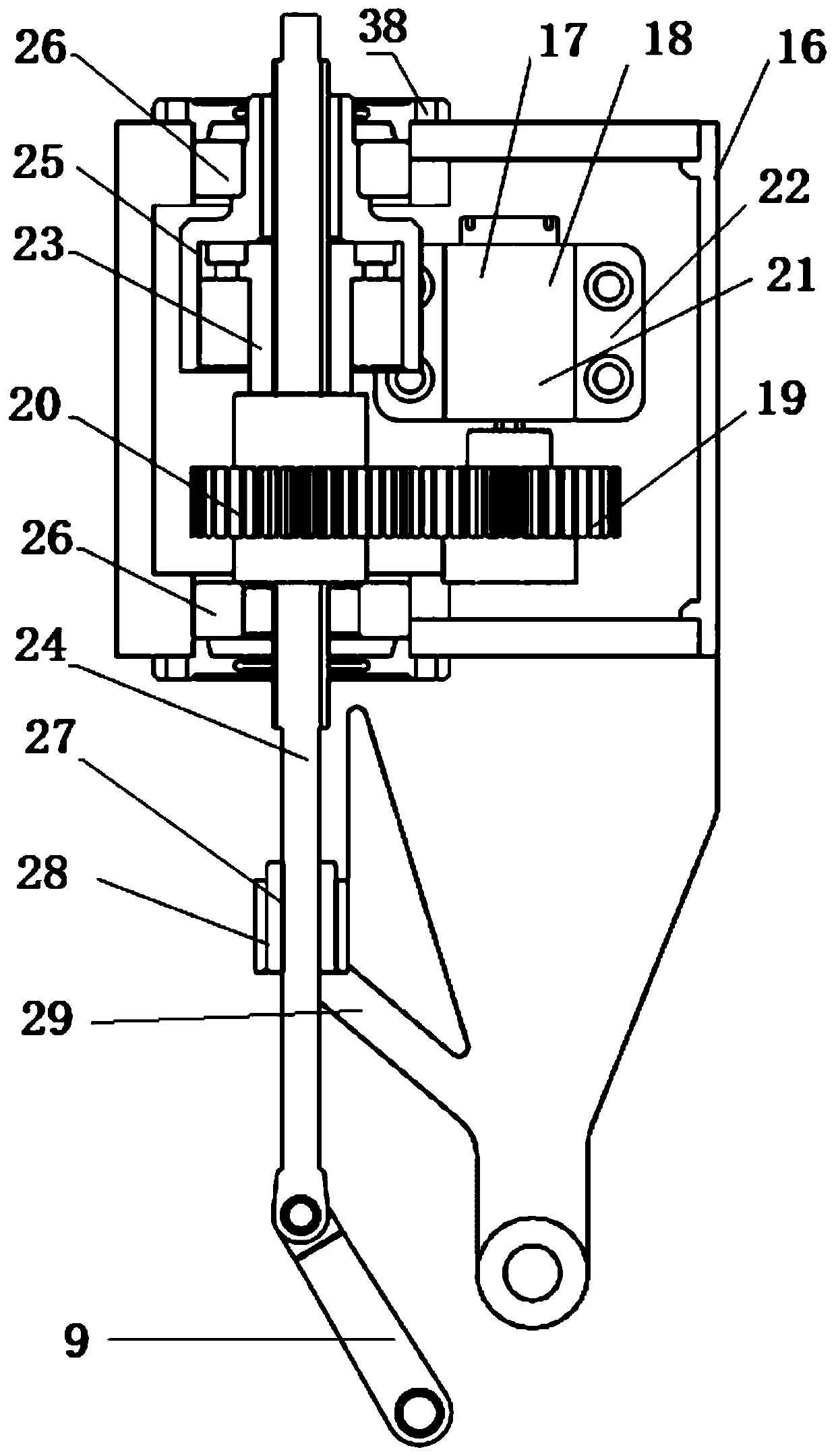

Pneumatic-muscle-driving exoskeleton joint experiment platform

ActiveCN109974777ARealize Force Closed Loop ControlEasy and reliable controlMeasurement devicesJoint componentEngineering

The invention discloses a pneumatic-muscle-driving exoskeleton joint experiment platform and belongs to the exoskeleton joint test technology field. The experiment platform comprises a support and a work platform installed on the support. The work platform comprises a joint component, a pneumatic muscle component, and a test matching component. The joint component, the pneumatic muscle component,and the test matching component are installed on the work platform. The pneumatic muscle component is cooperated with the test matching component so as to drive the joint component to rotate. Throughmeasuring changes of a pneumatic muscle tension size and length, a joint rotation angle and an acting force of limbs to a single arm during a movement process, three different driving match modes aretested so as to obtain the advantages and disadvantages of each match combination.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

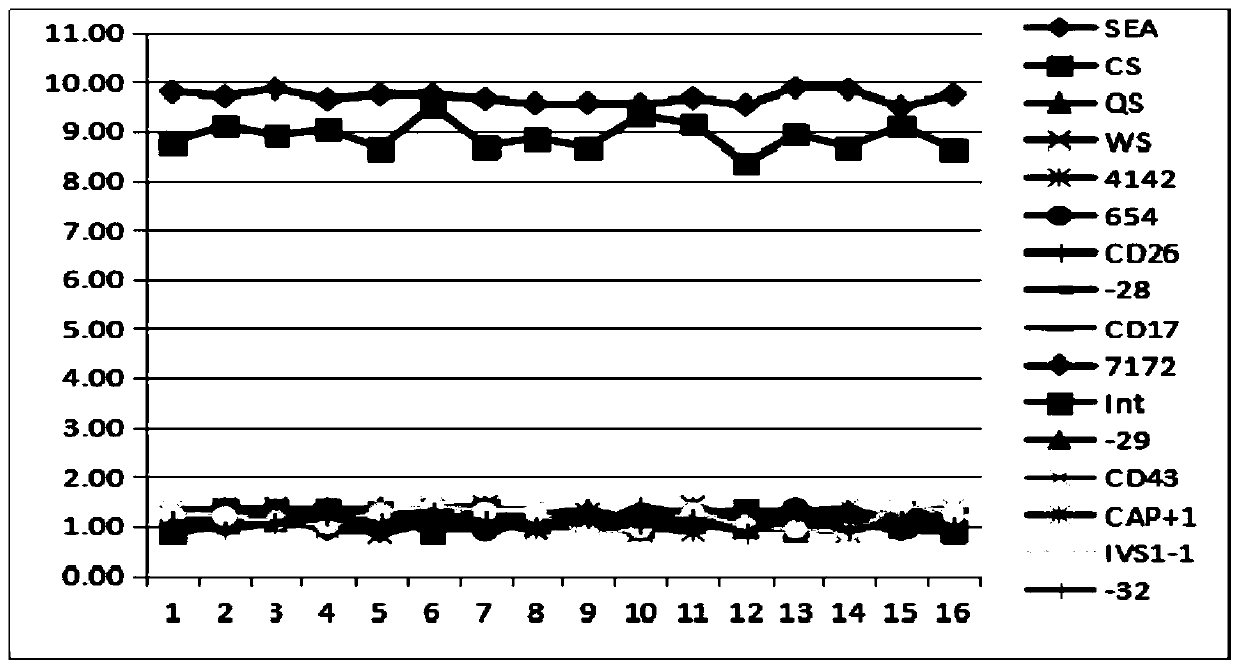

Kit for detecting thalassemia gene mutations

ActiveCN110577990AHigh sensitivityImprove stabilityMicrobiological testing/measurementNucleic acid detectionPrenatal diagnosis

The invention belongs to the technical field of nucleic acid detection, and particularly relates to a kit for detecting thalassaemia gene mutations. The kit includes amplification primers shown as SEQID NO:1-SEQ ID NO:10 and extension primers shown as SEQ ID NO:11-SEQ ID NO:28. The kit realizes the genotyping of various types of mutation hotspots of thalassaemia genes in the same reaction system,has both flexibility and scalability, is simple in operation and high in throughput and low in cost, and is of great significance for the screening, prenatal diagnosis and the like on people with thalassaemia.

Owner:SOUTHERN MEDICAL UNIVERSITY +1

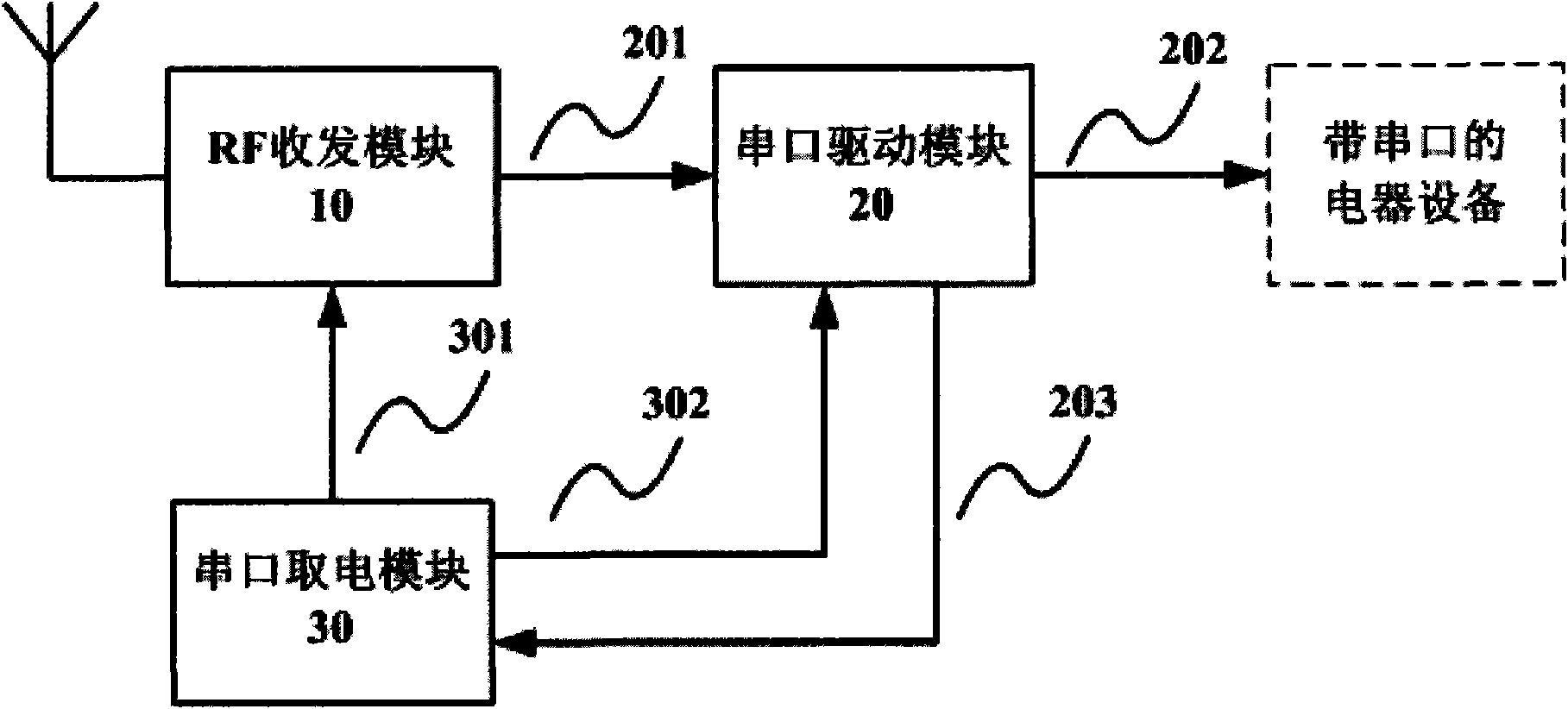

General-purpose interface control device based on WSN technical platform

InactiveCN101572728AHave flexibilityInherited reliabilityTransmissionGeneral purposeWireless communication protocol

The invention relates to a device for controlling a general-purpose serial interface in a wireless mode, in particular to a general-purpose interface control device which adopts a wireless communication protocol, such as IEEE802.15.4, Zigbee, MIWI, and the like and directly supplies power from a serial port of external control equipment. The general-purpose interface control device comprises an RF receiving and transmitting module, a serial port drive module, a serial port power supply module, and the like. The general-purpose interface control device has the control characteristics of no need of wiring, utilization during plugging, wireless communication, point-to-point and point-to-multipoint, and not only has the flexibility of wireless control, but also follows the reliability of wire control.

Owner:上海国皓电子有限公司

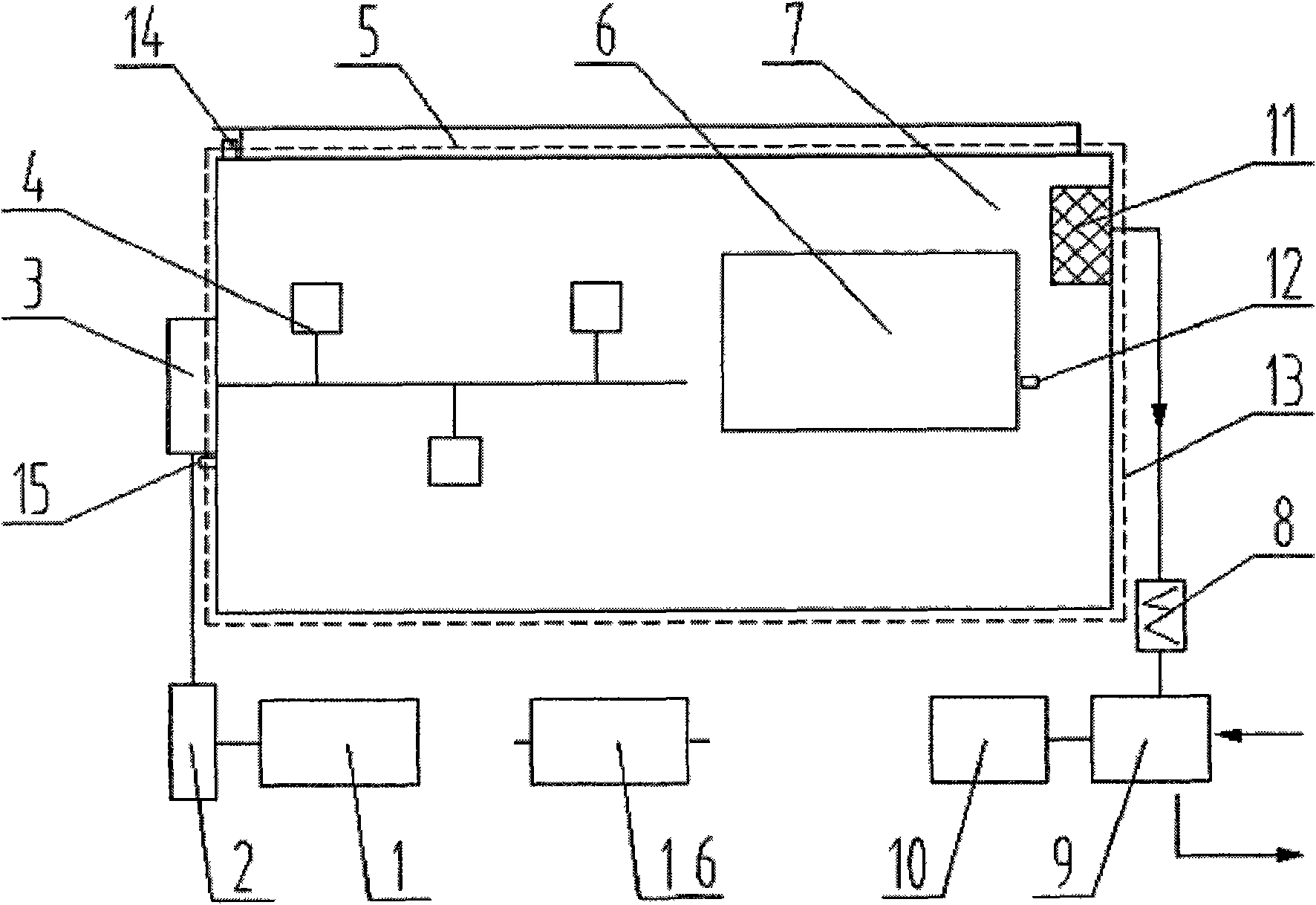

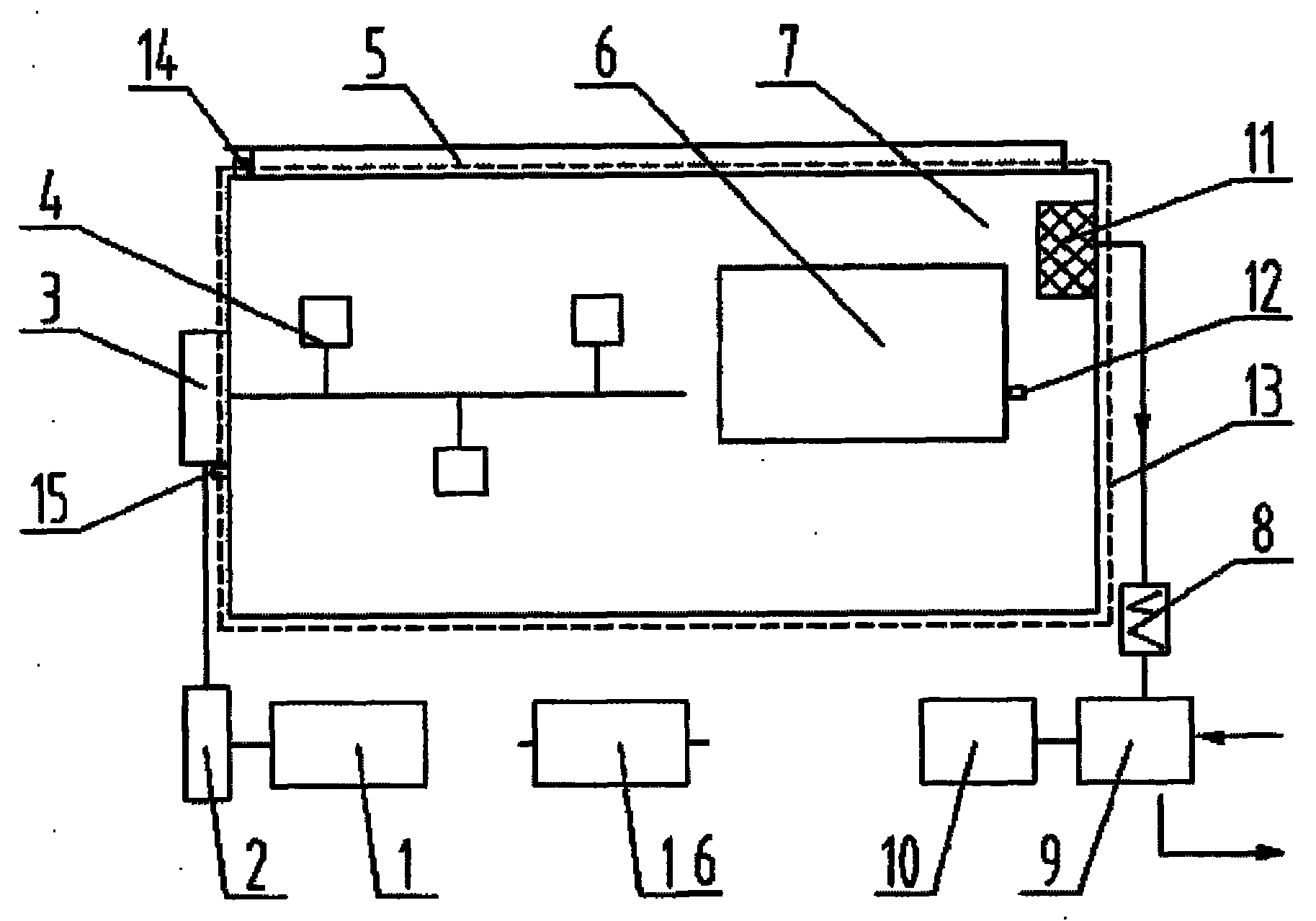

Refuse disposal system for marine galley and disposal method thereof

ActiveCN101966527AHigh capacity reduction rateAvoid security issuesSolid waste disposalAutomatic controlDigestion

The invention relates to a refuse disposal system for marine galleys and a disposal method thereof. The refuse disposal system comprises a motor, a worm reduction gear, a machine body and an automatic control box. In an airtight gear body, galley refuses are fully digested by adopting a manner of stirring and matching strains in the closed machine body, and the effective volume reduction and the safety disposal of refuses on marine galleys are realized by matching the temperature digestion environment in the machine body and the deodorization of a tail gas three-way catalytic converter. The disposal system has the advantages of reasonable structure and design, simple disposal method, safe operation, safety disposal to galley refuses, high volume reduction rate and no exhaust emission, and is suitable for galley refuse disposal.

Owner:JIANGSU NANJI MACHINERY

Degradable resin pellet and molded product using same

InactiveCN107849343ASolving the problem of degradable resinIncreased potential for biodegradationPolyvinyl alcoholSilicon

The present invention relates to a degradable resin pellet and a molded product using the same, and relates to: a resin pellet formed by comprising corn starch as a main component and mixing polyethylene (PE), polyvinyl alcohol (PVA) and the like, having excellent tensile strength and elongation, and having excellent degradability due to biodegradation by a microorganism, photolysis by a photocatalyst and chemical decomposition by a reaction; and a molded product using the same. More specifically, the present invention provides a degradable resin pellet formed by mixing a composition, which isformed by comprising 100 parts by weight of polylactic acid (PLA), 50-150 parts by weight of calcium carbonate (CaCO3), 0.1-10 parts by weight of magnesium, 0.1-10 parts by weight of aluminum, 0.1-10parts by weight of silicon and 0.5-20 parts by weight of calcium, with 50-150 parts by weight of PVA on the basis of 100 parts by weight of PLA, and mixing with 50-150 parts by weight of PE on the basis of 100 parts by weight of PLA.

Owner:吴承根

Resin composition

Owner:IND TECH RES INST

Hollow health care ribbons lines

InactiveCN101182663AHas the function of antibacterial and anti-odorNo pollution in the processYarnArtifical filament manufactureYarnGynostemma (plant)

The invention relates to a hollow health-care belt yarn in the yarn spinning field. The technical proposal is that the yarn structurally comprises the cotton fiber or the wool fiber in the outer layer, and a hollow structure made of the high-intensity silk fiber or chemical fiber in the middle layer. The hollow structure is filled with elaborately-made filaments made from the health-care Chinese traditional medicine or the integrated health-care Chinese traditional medicine and western medicine. The filaments comprise the raw medicines with the following weight portions and the chitin solutuion and are made in the dry way of dry-wet way after the raw medicines and the chitin solution are mixed according to the weight ratio of 1:0.1 to 0.2. The selectable raw Chinese traditional medicines comprise 20 to 25 portions of ginseng, 20 to 25 portions of salvia miltiorrhiza, 15 to 20 portions of turtle aging capsule, 10 to 15 portions of royal jelly, 20 to 25 portions of milk veteh, 25 to 30 portions of fleeceflower root, 10 to 15 portions of glossy ganoderma, 10 to 15 portions of gynostemma pentaphyllum (thunb.) makino, 10 to 15 portions of desertliving cistanche, 10 to 15 portions of tremella fuciformis polysaccharide, and 10 to 15 portions of glossy privet fruit. The selectable western medicines comprise vitamine E, calcium (calcium chloride, calcium lactate, calcium carbonate, calcium gluconate, sugar calcium tablets and vitamin D2 and calcium hydrogen phosphate tablets), and so on. The product is provided with the function of bacteria inhibition, odor prevention, and health building, and provided with the advantage of no pollution, the damp absorption, the aeration, the softness, the damp preservation, and so on.

Owner:东营市宏远纺织有限公司

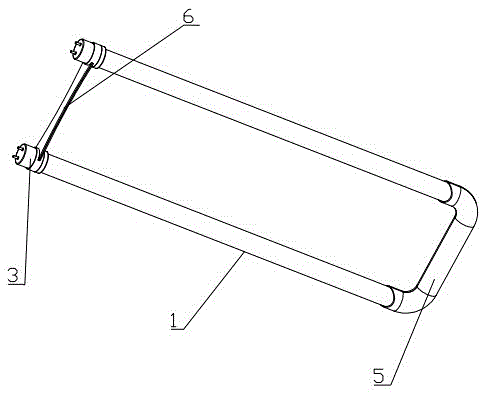

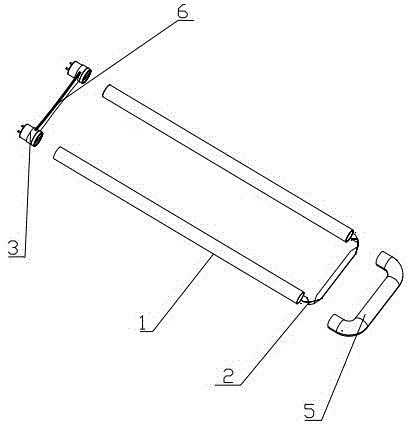

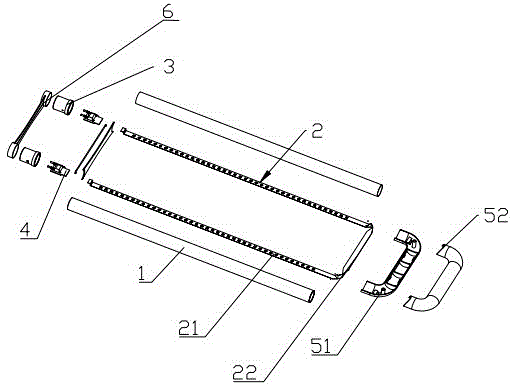

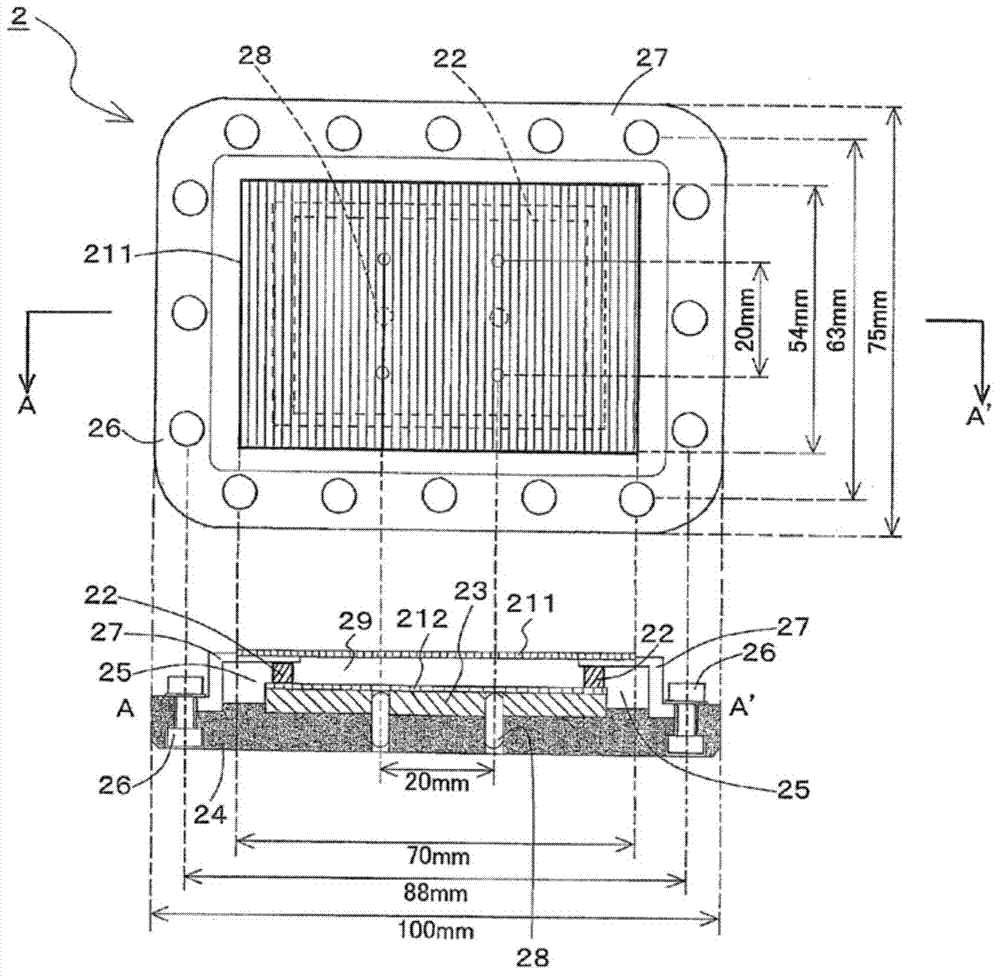

U-shaped LED fluorescent lamp

ActiveCN105605444ALow costHave flexibilityElongate light sourcesLighting heating/cooling arrangementsStraight tubeCooling effect

Provided is a U-shaped LED fluorescent lamp. A rear-end supporting frame of the U-shaped LED fluorescent lamp comprises a first U-shaped piece and a second U-shaped piece matched with the first U-shaped piece. The first U-shaped piece comprises first installation parts matched with the ends of two straight tubes respectively and a first connecting part connected with the first installation parts, and first positioning columns are arranged at the connecting positions of the first installation parts and the first connecting part. An LED lamp panel is an internally-formed flexible substrate and comprises two light-emitting sections and a middle connecting section used for connecting the two light-emitting sections. The middle connecting section of the LED lamp panel is fixed in a turning mode through the first positioning columns. The U-shaped LED fluorescent lamp has the advantages that the flexible substrate is adopted as the LED lamp panel and has certain flexibility, so that adaptability is better; besides, the flexible substrate has a better cooling effect compared with a hard substrate, and it is unnecessary to independently install metal cooling fins, so that the cost of a lamp tube is low; the first positioning columns on the first U-shaped part provide turning positioning fulcrums for the LED lamp panel, so that positioning and installation of the LED lamp panel are facilitated, and it is avoided that the LED lamp panel is excessively turned and torn.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

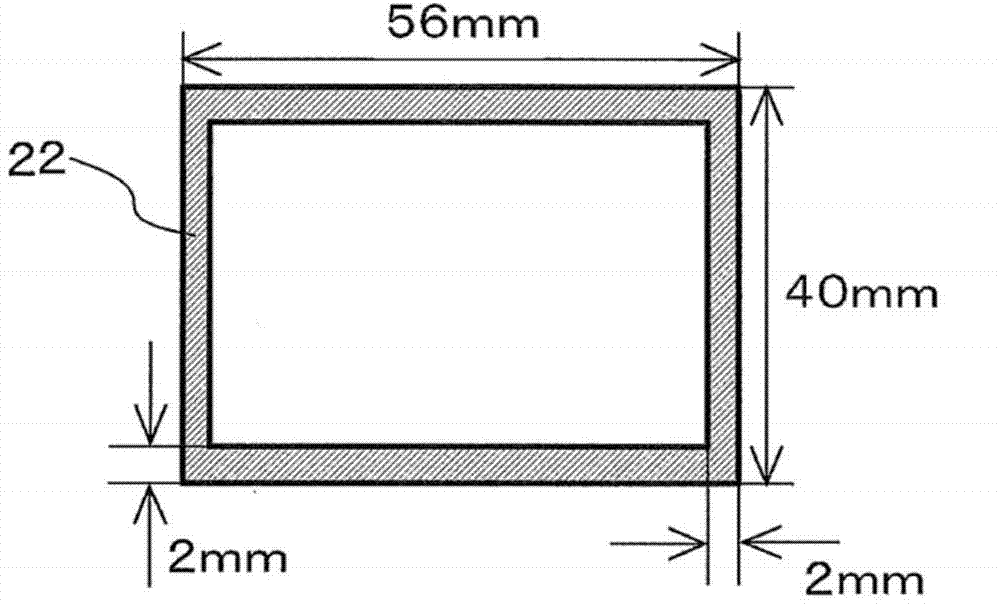

Double-layer glass frame manufactured by foaming fluorocarbon resin and preparation method thereof

InactiveCN102505911AImprove insulation performanceAchieving the purpose of double glazed windowsWing framesThermal insulationEngineering

The invention relates to a double-layer glass frame manufactured by foaming fluorocarbon resin and a preparation method thereof. The double-layer glass frame can be installed on a base body through rails and comprises a frame, two parallel first grooves are arranged at the inner side portion of the frame, and two parallel second grooves are arranged at the outer side portion of the frame. Symmetrical protrusions are arranged on the inner side of each first groove and matched with glass to be assembled. The two parallel second grooves are matched with the rails to be installed. The preparation method comprises the following steps: 1 adopting the fluorocarbon resin as a raw material and performing foaming treatment, wherein the foaming rate is set as 2-3 times of the existing rate; 2 extruding and forming the foaming fluorocarbon resin obtained by the step 1 through a machine; 3 assembling formed frame obtained by the step 2 and the glass; and 4 installing combined glass frame on the base body. Compared with ordinary alloy glass frame, thermal insulation is high, durability is good, no additional gasket is required to be arranged between the glass and the frame body, and the preparation method is simple and easy, can save expenses and reduces cost.

Owner:山口达雄

Silicone rubber synthesized leather taking foamed silica gel as substrate and manufacture technology thereof

InactiveCN108894006AAvoid defectsHave comfortTextiles and paperManufacturing technologyPolymer science

The invention discloses silicone rubber synthesized leather taking foamed silica gel as a substrate. The synthesized leather comprises a cloth base, wherein front silicone rubber is coated to the front side of the cloth base, a surface treatment layer is coated to the surface of the front silicone rubber, and foamed silicone rubber is coated to the back of the cloth base; and the front silicone rubber is prepared from the following raw materials in parts by mass: 100 parts of a liquid silicone rubber component A, 100 parts of a liquid silicone rubber component B, 2-5 parts of hydrogen-containing silicon oil, 1-3 parts of a tackifier, 0.5-2 parts of a defoaming agent, 1-3 parts of a silane coupler, 0.1-0.3 part of a platinum catalyst and 10-30 parts of color paste pigment. According to thesilicone rubber synthesized leather, the defect of a traditional PU leather is overcome, the defect that glue is required to adhere sponge is also overcome, the smooth contact like the skin of infantsis brought to users when the silicone rubber synthesized leather is used in a seat of a vehicle, and the comfortable feeling and rebound resilience of traditional adhesive sponge are given to the synthesized leather.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

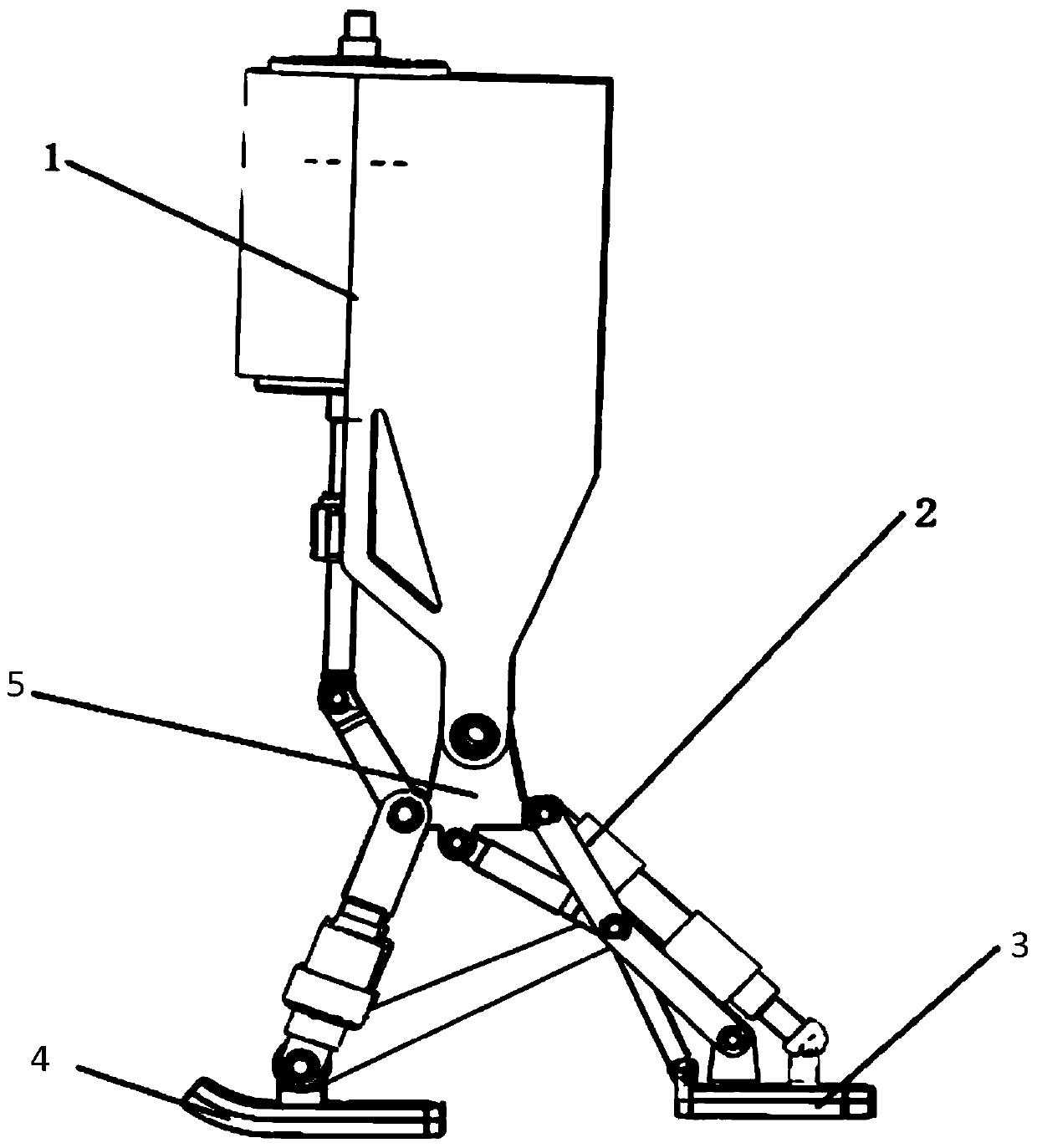

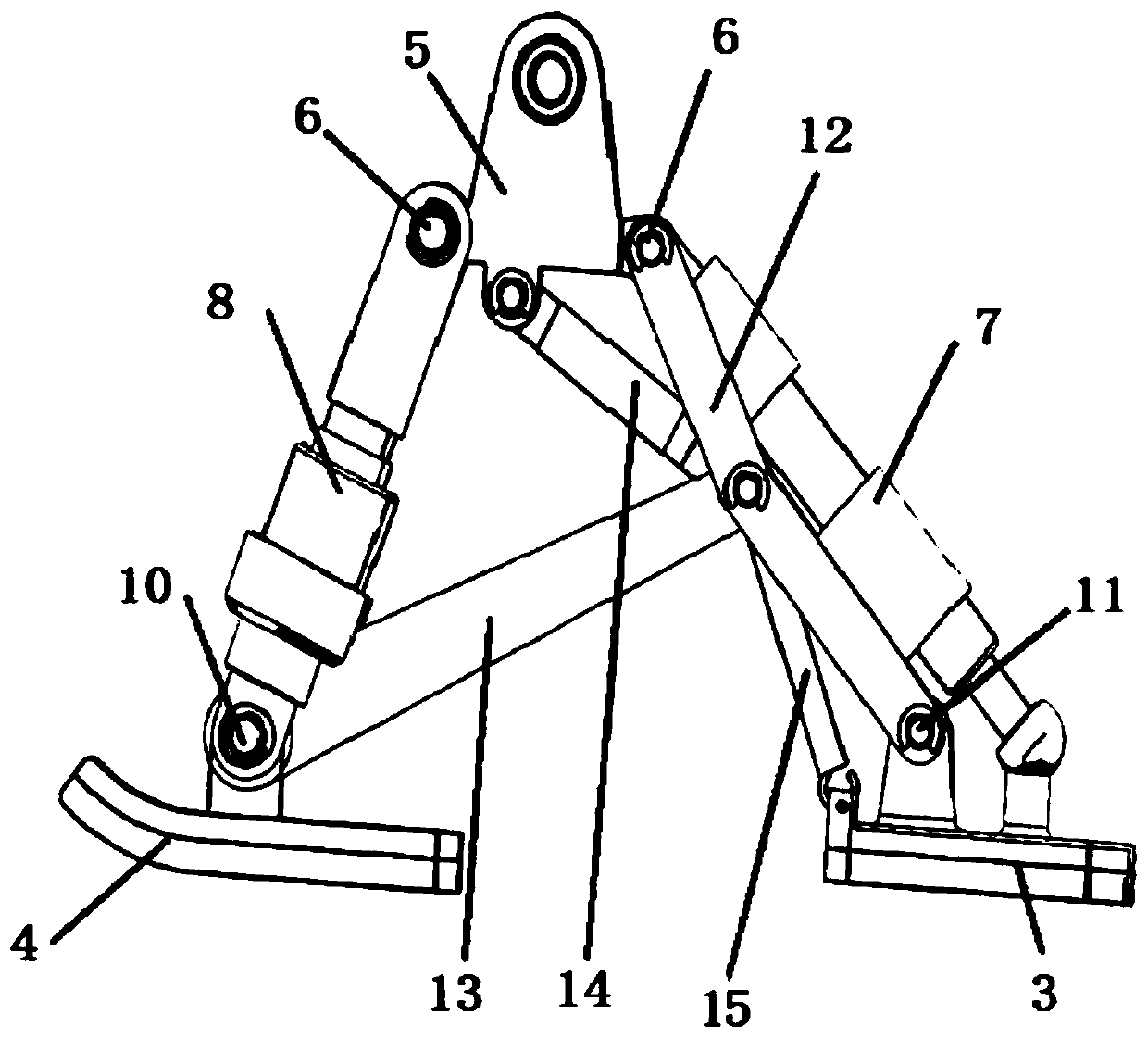

Single-driving-force multi-freedom-degree foot device realizing self-adaption to landform

PendingCN110497979AImproves rapid movementSimple Foot ControlsManipulatorVehiclesSacroiliac jointEngineering

The invention provides a single-driving-force multi-freedom-degree foot device realizing self-adaption to the landform. The single-driving-force multi-freedom-degree foot device comprises a foot driver and a foot sole four-bar mechanism; the foot sole four-bar mechanism is further connected with a forefoot and a heel; the four-bar mechanism comprises a mid-foot; the two sides of the mid-foot are correspondingly hinged with a forefoot buffer and a heel buffer through mid-foot joints; the foot driver is hinged with the size, hinged with the heel buffer, of the mid-foot by a connecting rod; the heel buffer is hinged with the heel through a heel joint; the forefoot buffer is hinged with the forefoot through a forefoot joint; a forefoot connecting rod is further hinged between the mid-foot andthe forefoot; and a fixed connecting rod is hinged between the middle part of the forefoot connecting rod and the heel joint. Compared with a foot structure of a common multi-foot robot, the single-driving-force multi-freedom-degree foot device provided by the invention has a plurality of independent freedom degrees; the important joints are flexible, so the quick athletic capability, the balancecapability, the adaption capability to various landforms, of the foot are improved; and the possibility for the foot to implement complicated action is increased.

Owner:CHANGAN UNIV

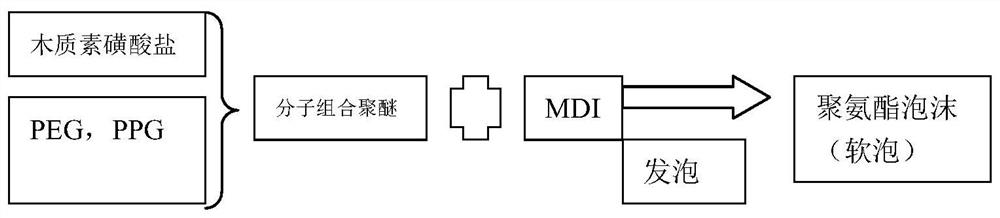

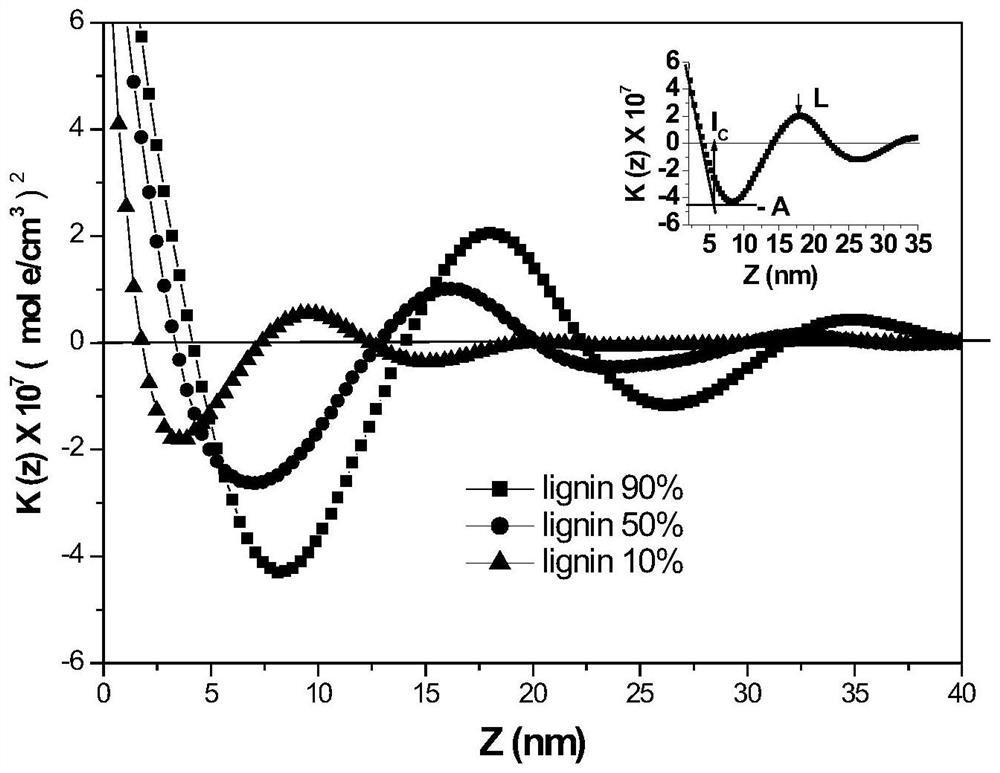

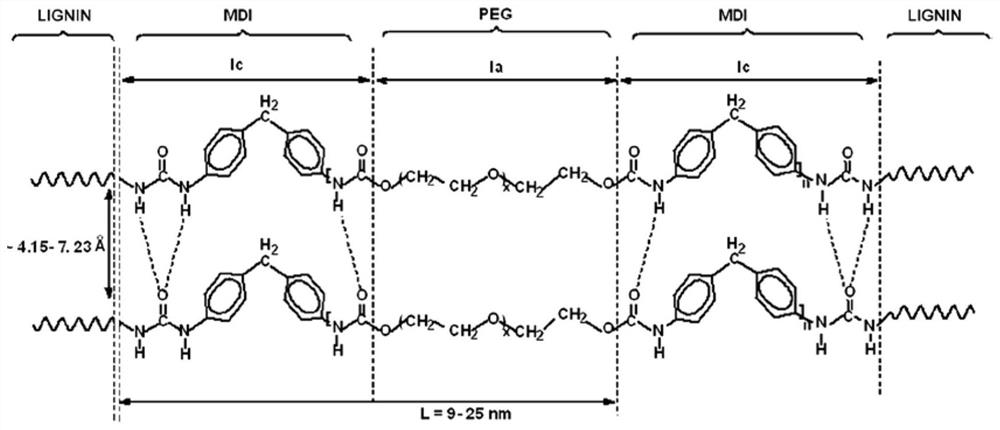

Lignin-based block copolymerization molecular-grade combined polyether, preparation method thereof and application of lignin-based block copolymerization molecular-grade combined polyether in preparation of polyurethane flexible foam material

InactiveCN111662458ASolve supportiveSolve the softness problemTransportation and packagingMixingPolymer sciencePolyol

The invention relates to lignin-based block copolymerization molecular-grade combined polyether, a preparation method thereof and application of the lignin-based block copolymerization molecular-gradecombined polyether in preparation of a polyurethane flexible foam material. According to the lignin-based block copolymerization molecular-grade combined polyether, lignosulfonate is used as a base material of the lignin-based block copolymerization molecular-grade combined polyether; the molecular chain of the lignin is cut off and embedded into the lignin by utilizing the solvation effect of the polyether polyol to form the molecular-grade combined polyether formed by co-polymerizing the aromatic polymer segment of the lignin and the aliphatic polymer segment of the polyether polyol. According to the preparation method, a molecular blending technology with a special structure is adopted, lignin molecular fragments of a microscopic hard segment and polymer polyol of a macroscopic soft segment are edited and spliced again, and the molecular-grade combined polyether is obtained through a block copolymerization method. The molecular combined polyether has the dual characteristics of strong support and softness, and perfectly solves the problem that the strong support and the softness of the polyurethane flexible foam material cannot be considered at the same time.

Owner:GLORY HOME FURNISHING JIAXING

Thermoplastic resin foam and foam sealant

InactiveCN104334620AHave flexibilityImprove dustproof effectLayered productsFilm/foil adhesivesSealantChemistry

The purpose of the present invention is to provide a thermoplastic resin foam and a foam sealant that enable indentations to be sufficiently and rapidly restored. The thermoplastic resin foam is characterized in that the indentation recovery rate defined below is at least 50%, and the foam sealant is characterized by containing the thermoplastic resin foam (in particular, it is preferable an adhesive layer positioned on one or both sides of the thermoplastic resin foam be provided). Indentation recovery rate: After compressing the thermoplastic resin foam at 23°C with a jig having a 90 degree blade angle to the lowest point in the thickness direction of the foam for 15 seconds, and then releasing the compressed state, the indentation recovery rate is the ratio of the thickness of the indented portion with respect to the initial thickness 60 seconds after the compressed state has been released.

Owner:NITTO DENKO CORP

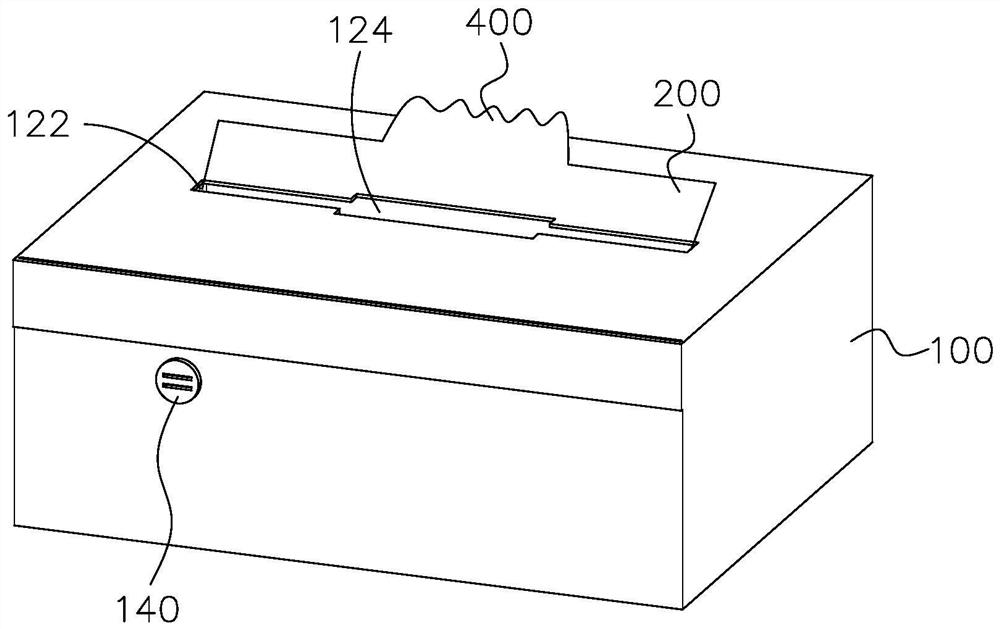

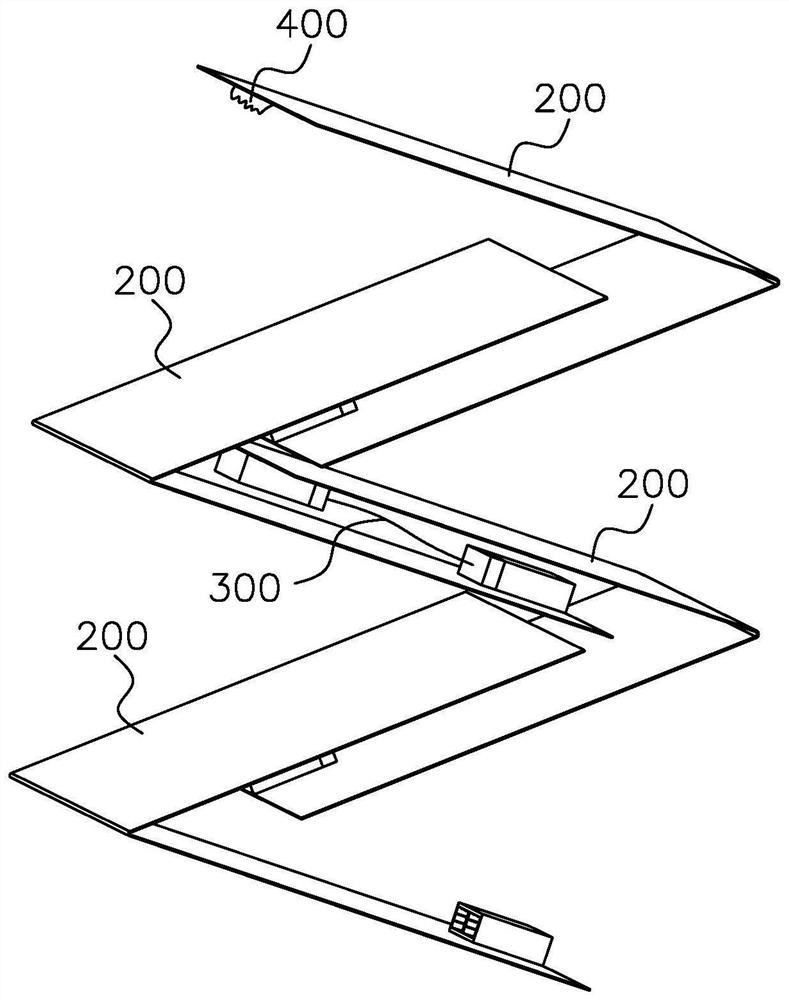

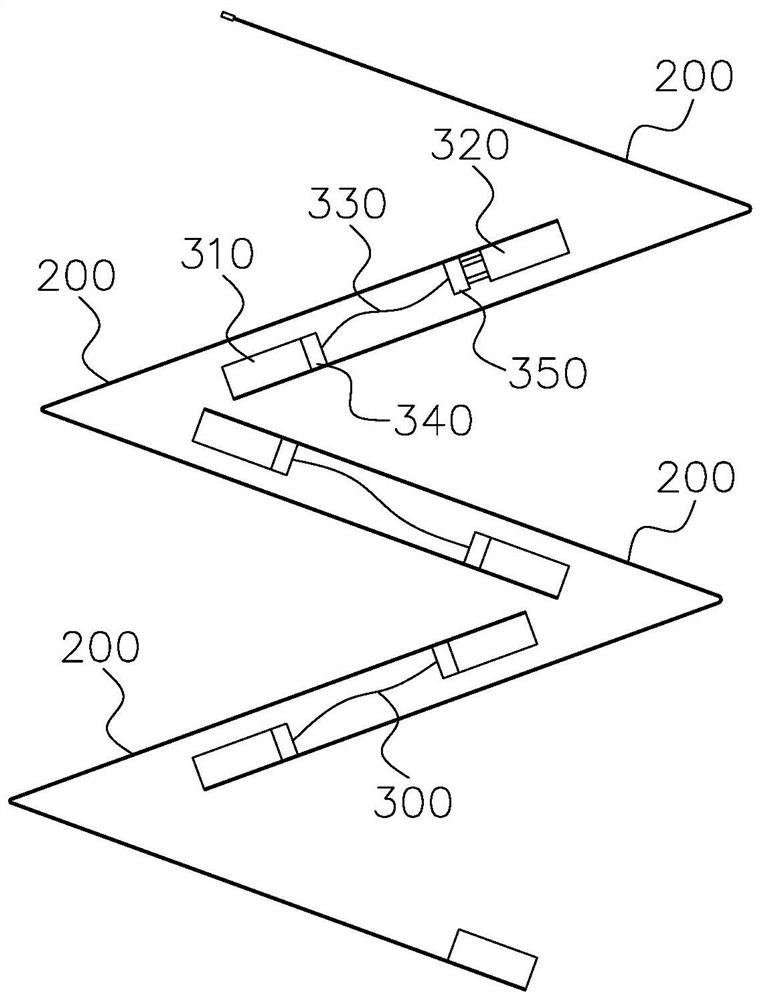

Drawing toy box

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

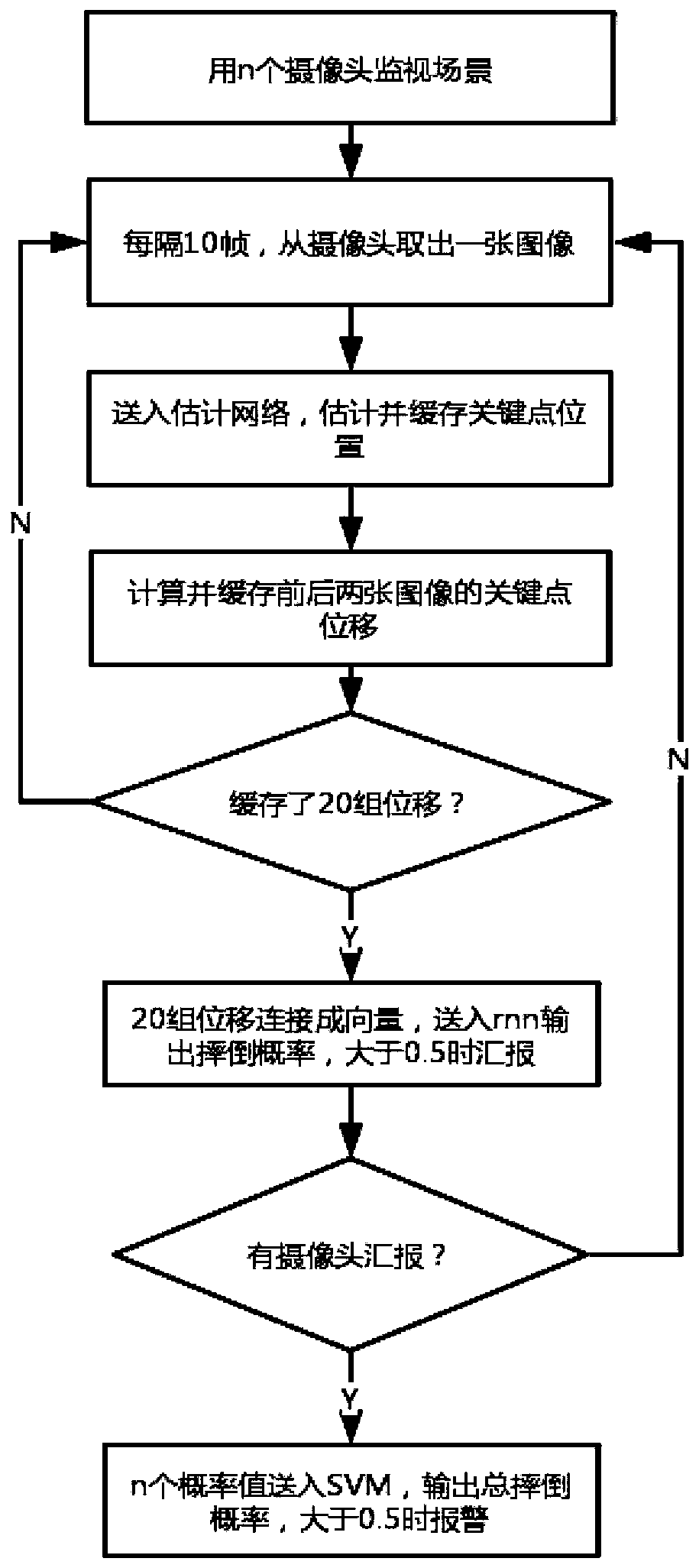

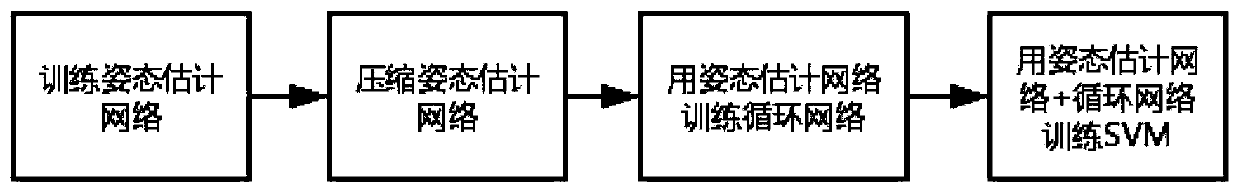

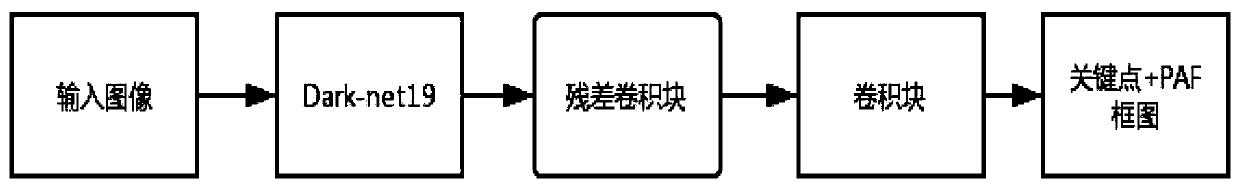

Tumble detection method based on deep learning and network compression

ActiveCN111178134AOvercome limitationsHigh speedCharacter and pattern recognitionNeural architecturesPattern recognitionHuman body

The invention provides a tumble detection method based on deep learning and network compression. A detection part of the method is composed of a posture estimation network and a circulation network, ahuman body posture model is used for obtaining position information of the head of a human body, the centers of two hips and the midpoint of the connecting line of the centers of the two hips from animage sequence, displacement of the body centers of adjacent images is calculated to form a displacement sequence. The group of displacement sequences is sent into a cyclic network to carry out fall-down identification. In order to expand to multi-angle recognition, recognition probabilities output by cameras at multiple positions are sent to an SVM classifier for voting judgment. In order to improve the recognition speed, according to the redundancy of the features output by the convolution kernel, the human body posture estimation network occupying the longest time is cut; the method is a pure visual detection method, not only overcomes the limitation of sensor detection, but also improves the speed and precision of visual detection. The tumble detection method is flexible and practical.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com