Patents

Literature

34results about How to "High capacity reduction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste incinerating device and incinerating technology thereof

InactiveCN104791803ANo secondary pollutionNo pollution in the processIncinerator apparatusFlue gasEnvironmental engineering

The utility model discloses a flue gas outlet pipe which comprises an induced air cover and an induced air pipe. The flue gas outlet pipe is mounted inside a gasification incinerator, is suspended above a grate and is slightly deviated from a central position of the grate. A plurality of elongated holes are formed in the side walls of the induced air cover, and reinforcing ribs are arranged among the adjacent open holes. The flue gas outlet pipe has the advantage that the flue gas outlet pipe is favorable for outwardly delivering flue gas and flame which are generated in the gasification incinerator.

Owner:薛冬

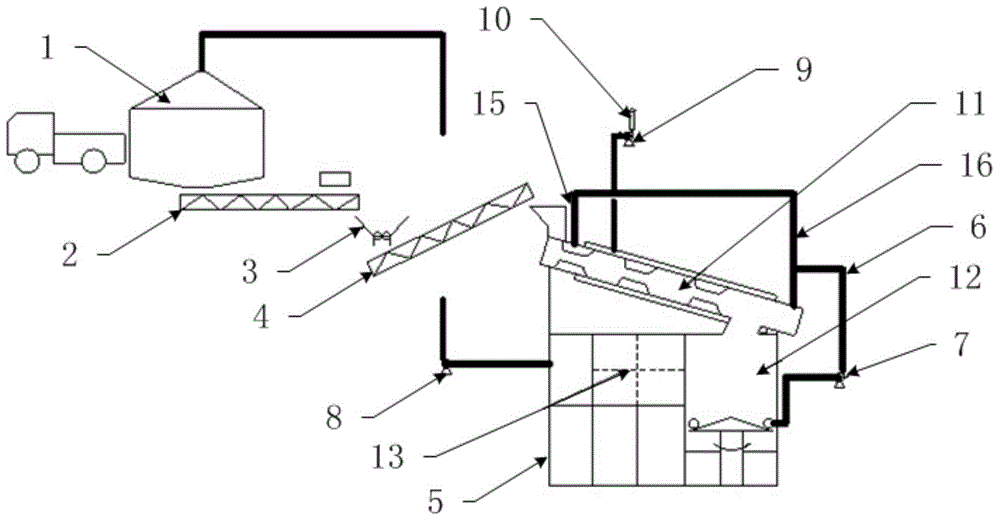

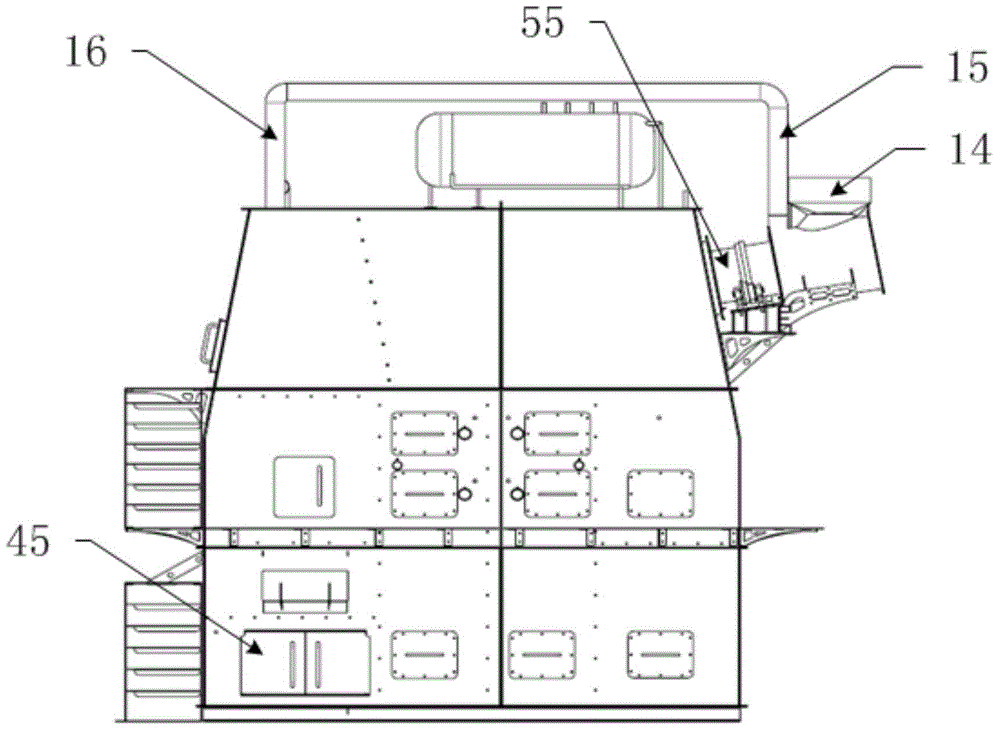

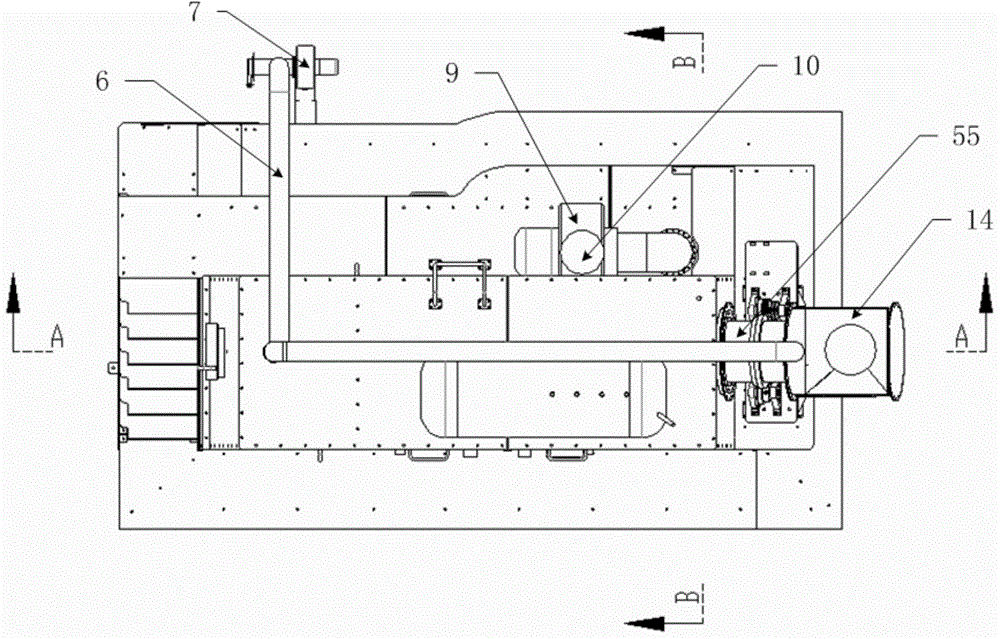

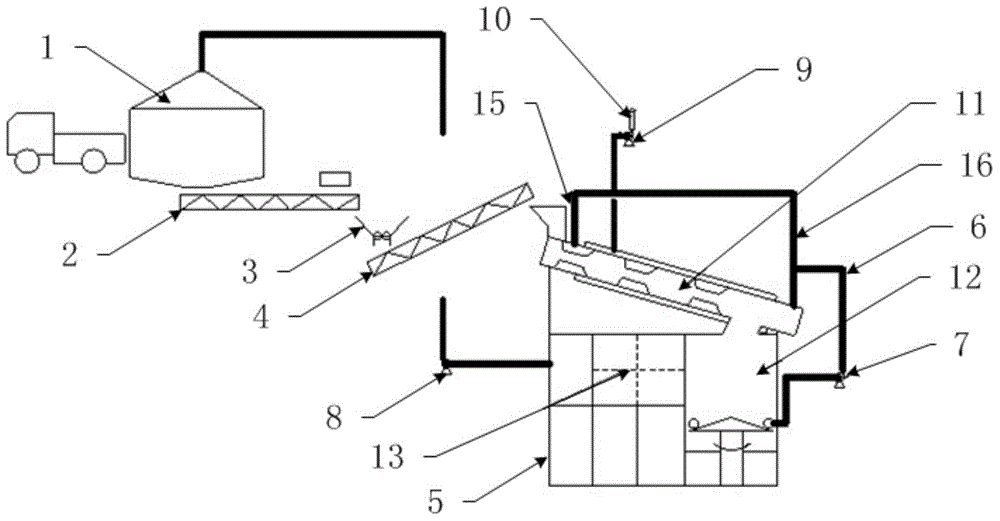

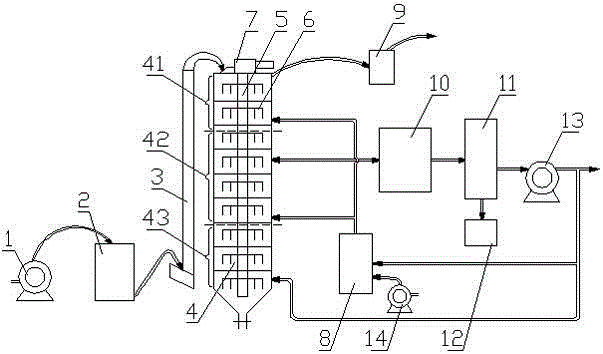

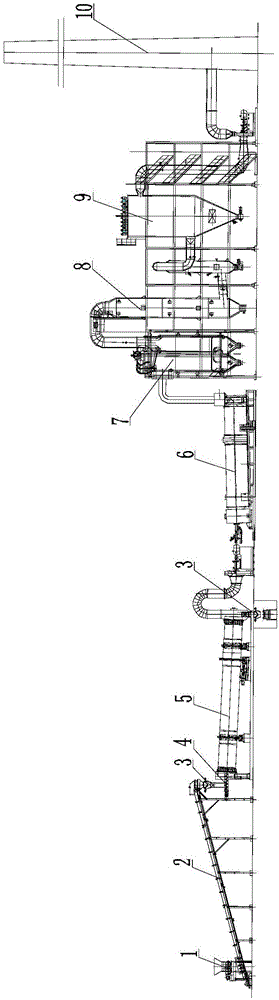

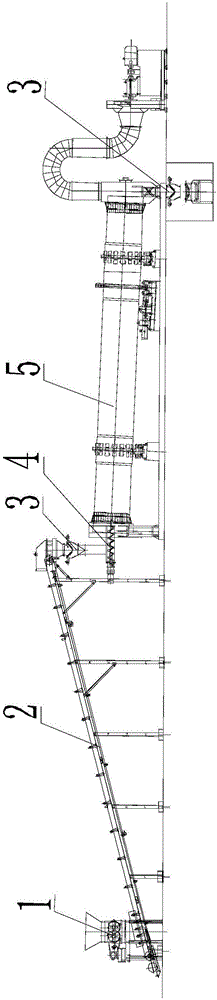

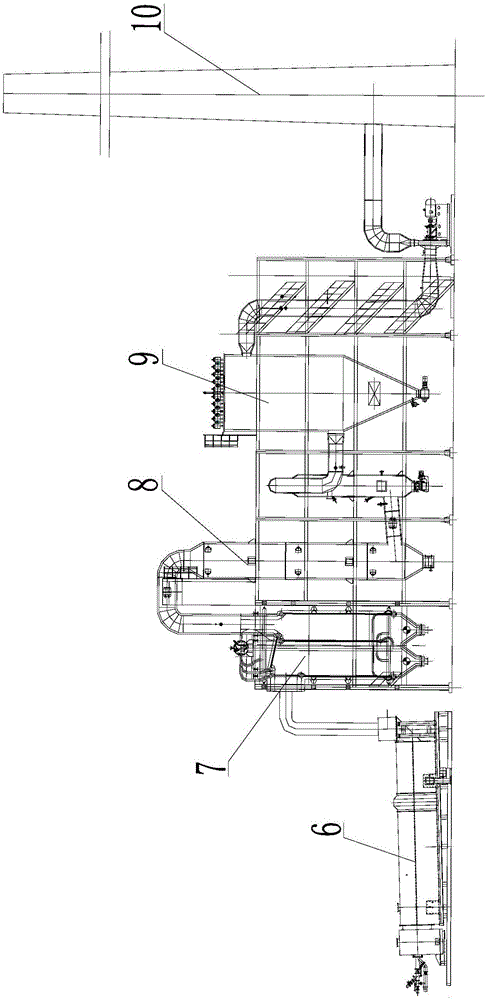

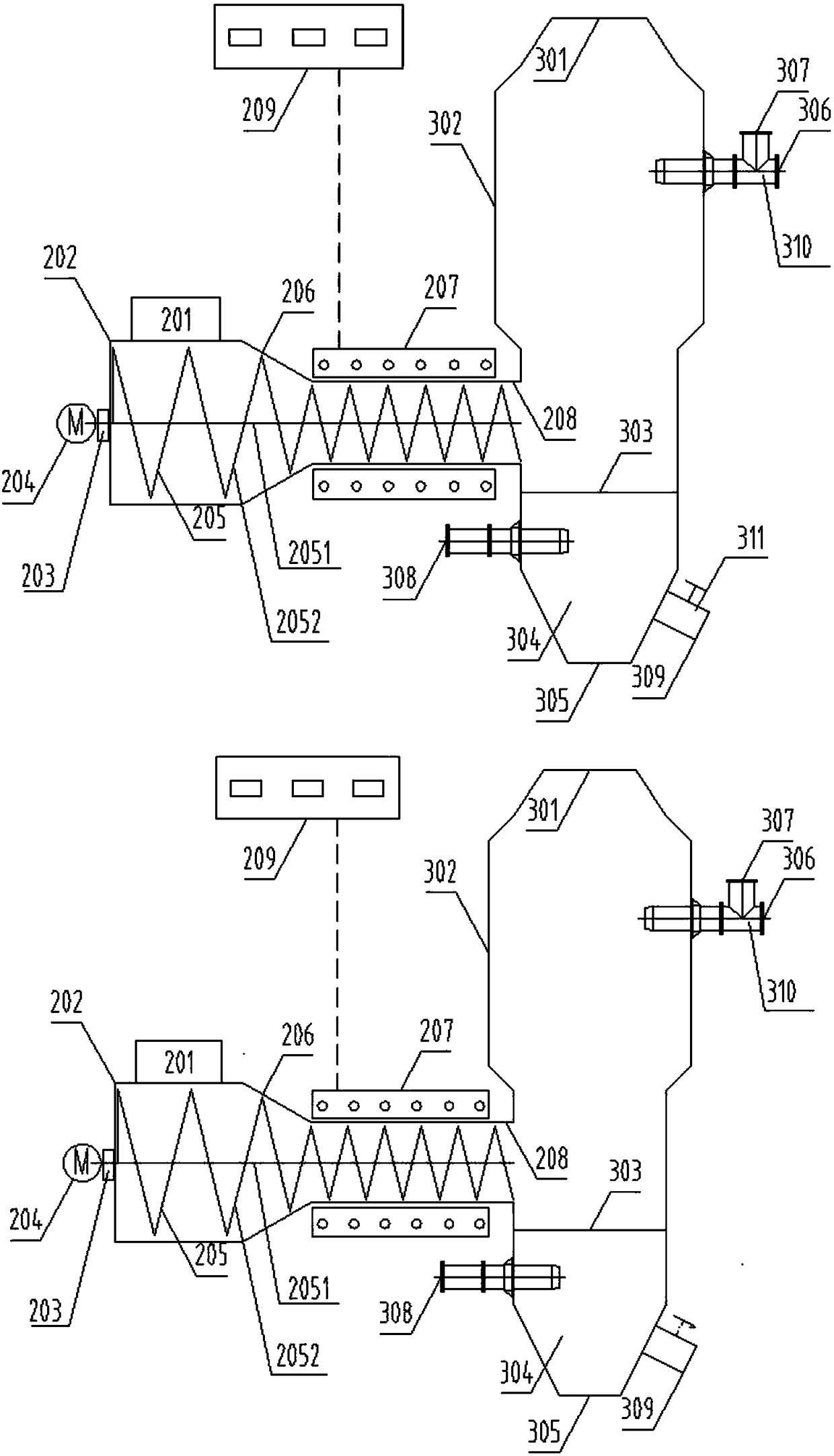

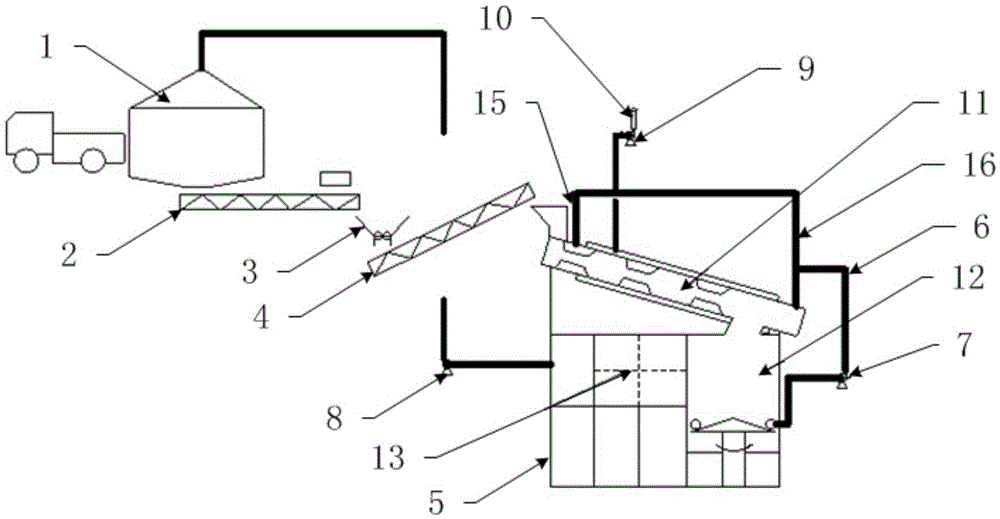

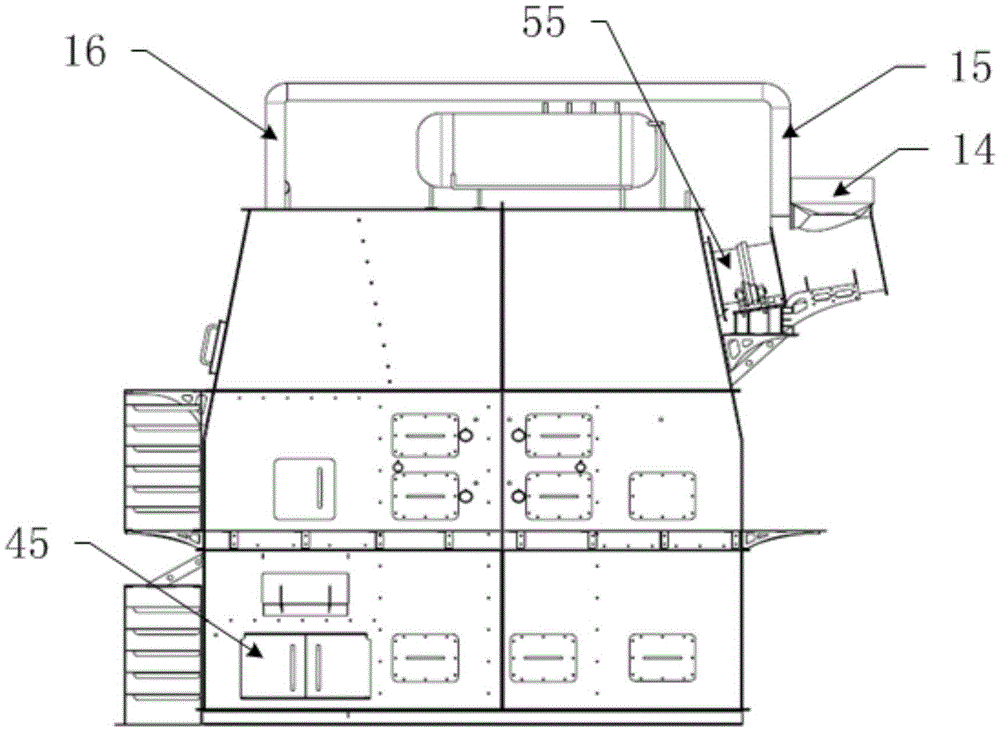

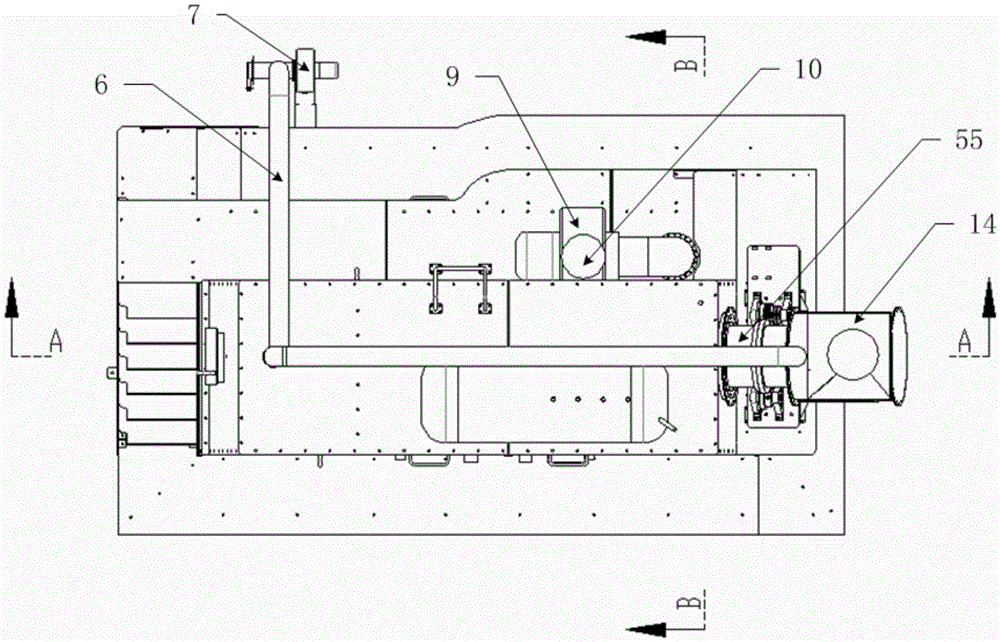

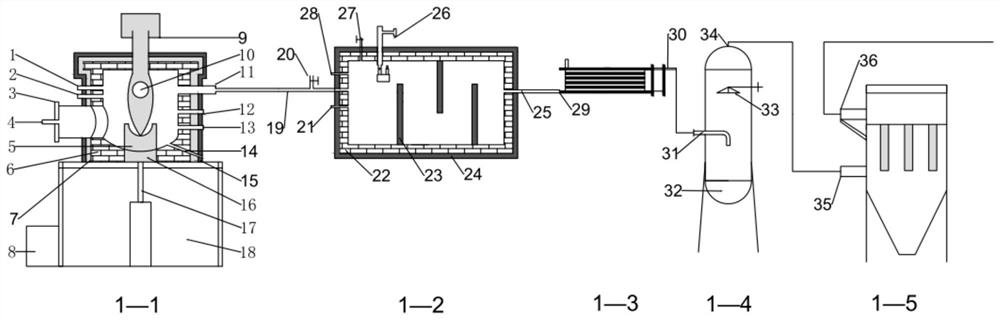

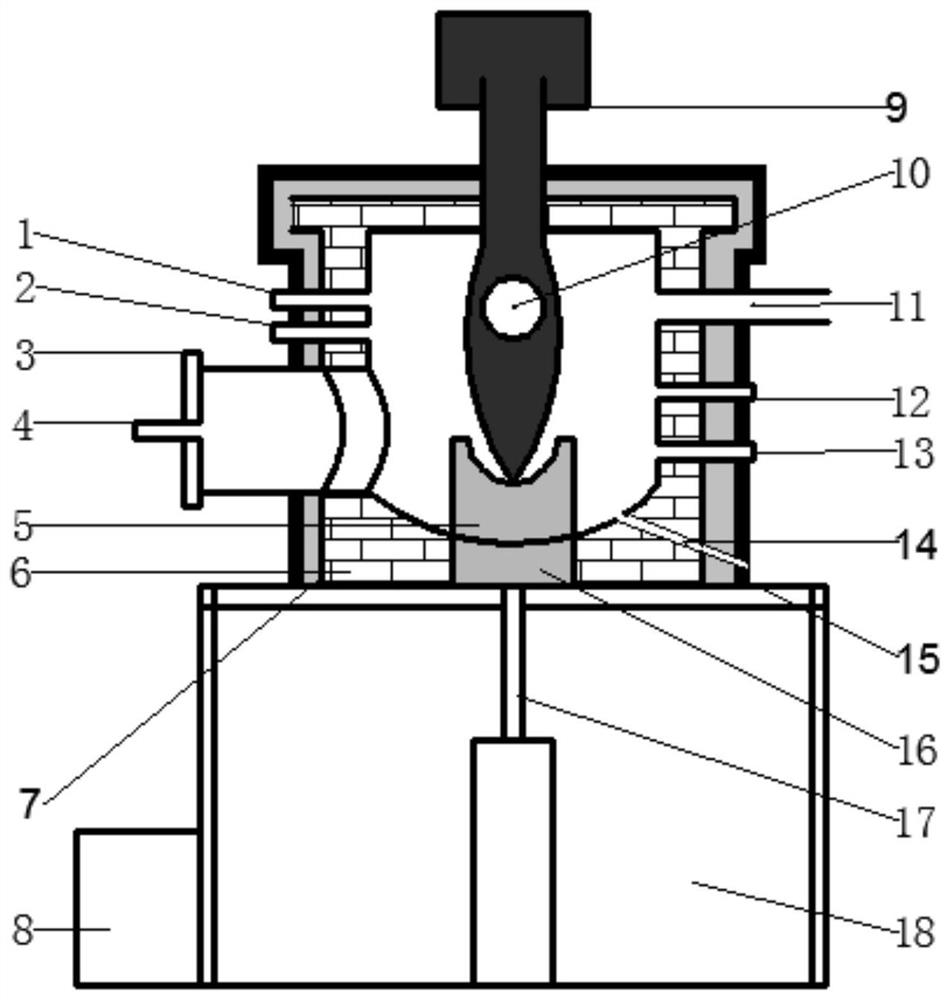

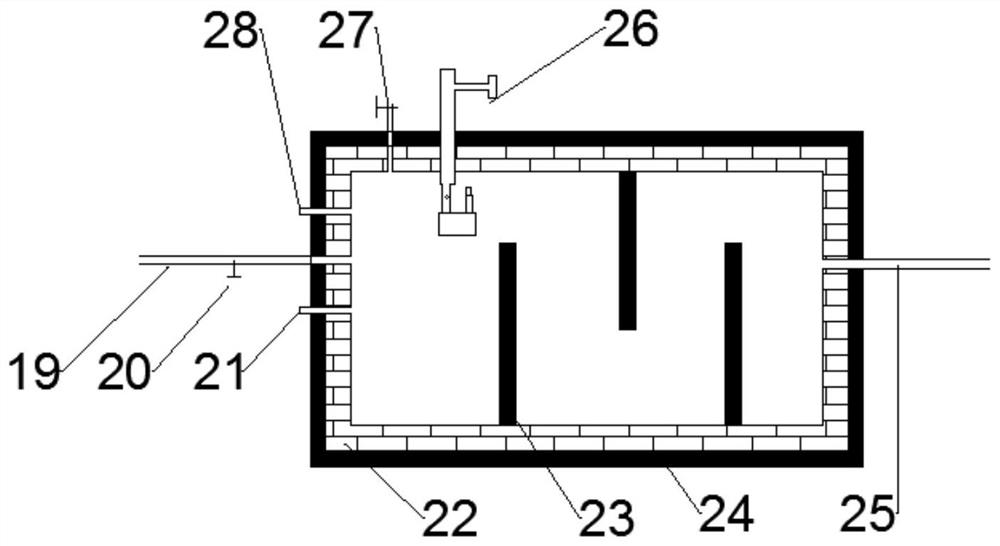

Waste incineration device and technology

ActiveCN104019452ANo secondary pollutionNo pollution in the processIncinerator apparatusThree stageNational standard

The invention discloses a waste incineration device and technology. The waste incineration device comprises a waste stacking bin, a magnetic separation conveying device, a crushing device, a feeding conveying device and a gasification incineration device. The waste gasification incineration process is divided into three stages which are the drying stage, the pyrolysis gasification stage and the high-temperature incineration stage, and the whole incineration process is conducted in a staged mode according to the sequence of drying, pyrolysis gasifying and smoke incinerating. Waste heat of smoke can be thoroughly used, temperature stability in a gasification incinerator can also be guaranteed, the burn-off rate of ash is high, the weight loss of waste is large, and discharging is safe, is far better than a current national standard and exceeds an EU standard. The system can be used for treating all kinds of waste which is scattered widely in countries, villages and towns and is miscellaneous and small in amount, the production and living conditions of the countries are improved, and the environment is protected.

Owner:WUXI GAOER ENVIRONMENTAL SCI & TECH

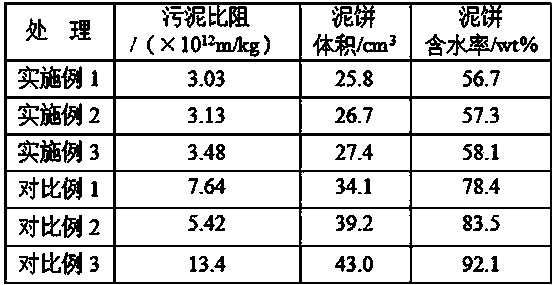

High-dryness conditioning and dehydrating method for sludge

ActiveCN103771682AImproved magnetizabilitySimple structureSludge treatment by de-watering/drying/thickeningPolymeric surfaceBound water

The invention discloses a high-dryness conditioning and dehydrating method for sludge. A compound conditioning agent is adopted, the strong oxidizing property of an oxidant, the flocculating function and magnetic field force function of magnetic powder and the electrical neutralization of an inorganic flocculating agent are organically combined with the adsorptive bridging function and the macromolecular sweeping and trapping effects of a compression double-electron layer and an organic flocculating agent, and the advantage of each conditioning agent is brought into play in a synergetic manner, so that the sludge structure and property are improved effectively, water in sludge cells and bound water on the surface of an extracelluar polymer are released, the dehydration performance of the sludge is improved remarkably, and high-dryness dehydration is realized. The method has the advantages of high sludge dehydration degree, good flocculating effect, short flocculating and settling time, high volume reduction rate and low dehydration cost.

Owner:广州福之源环保科技有限公司

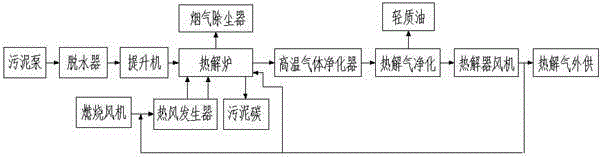

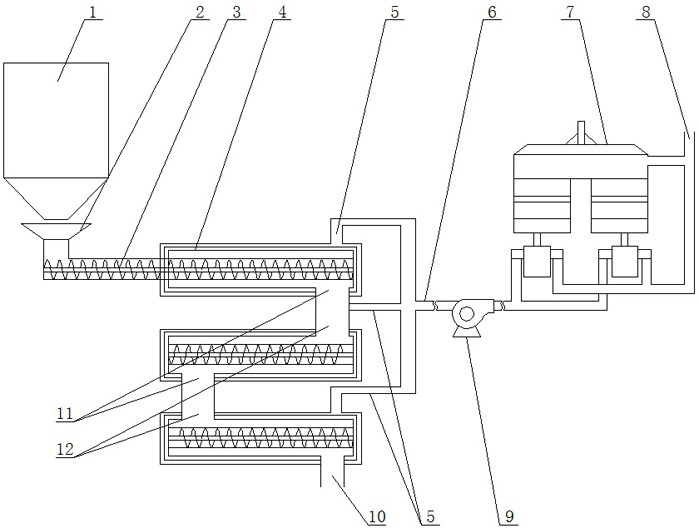

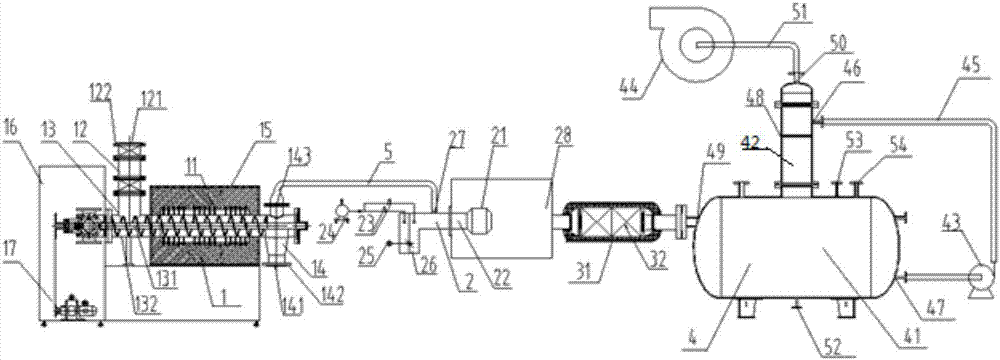

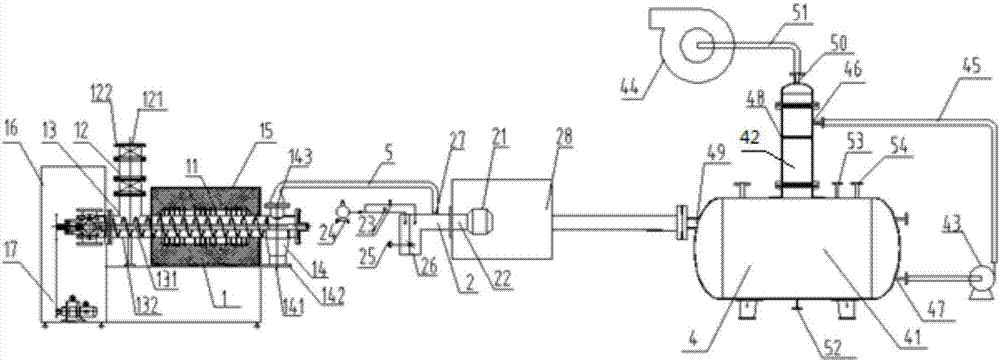

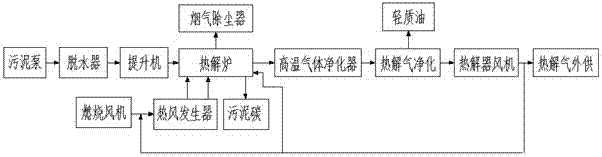

Pyrolysis treatment process for domestic sludge

InactiveCN105174678AIncrease profitHigh capacity reduction rateSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisParticulatesResource utilization

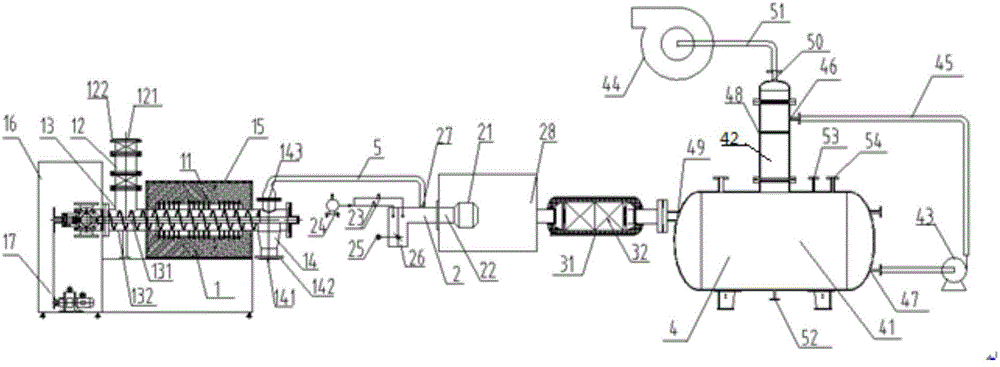

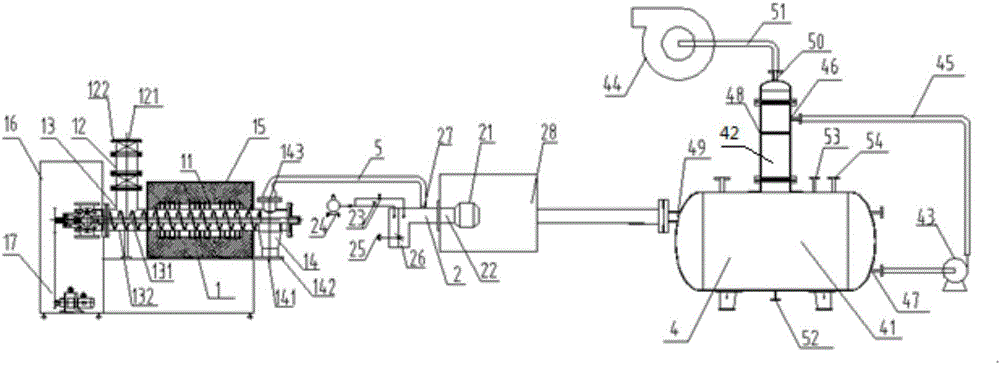

The invention discloses a pyrolysis treatment process for domestic sludge. The process comprises: sludge is fed into a dehydrator through a sludge pump to be dehydrated; the dehydrated sludge is fed into a pyrolyzing furnace; high-temperature flue gas generated by combustion in a hot air producer indirectly enters a destructive distillation section of the pyrolyzing furnace, and then flue gas of the destructive distillation section directly enters a preheating drying section; the flue gas that enters the preheating drying section is subjected to heat dissipation and is dedusted and discharged; the flue gas that enters the destructive distillation section is mixed with dry distillation gas and the mixture enters a high-temperature gas purifier; tar and saturated water coal gas are separated out through a purification system; and sludge carbon is cooled through circulating saturated water coal gas and is discharged. The sludge pyrolytic technique adopted by the process is an effective way for sludge reduction, stabilization, harmless treatment and resource utilization, and has the advantages of high utilization ratio of energy sources, high volume reduction rate and low operating cost; after combustion, the amount of exhaust gas needed to be treated is small; sludge needs not to be buried, and an incomplete incineration process is converted into a gas complete combustion process, so that the discharge amount of sludge carbon solid particulate matters is extremely small, and the process is more environmental-friendly.

Owner:ANHUI ZHUOXIN CLEAN ENERGY TECH CO LTD

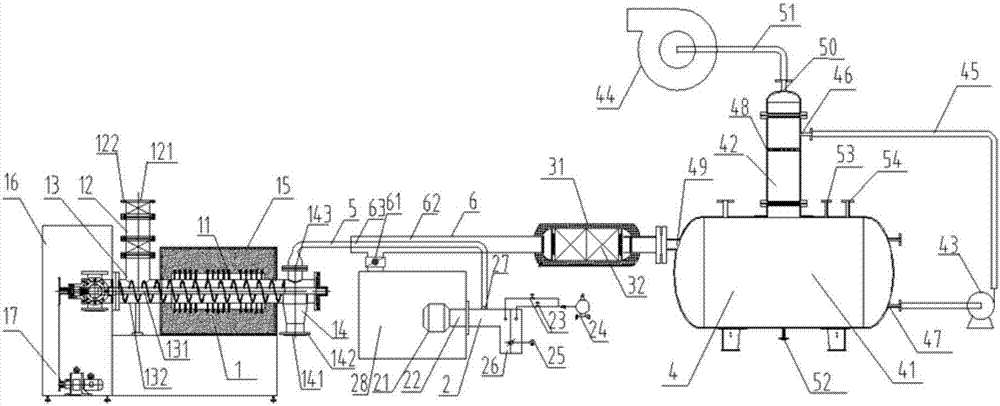

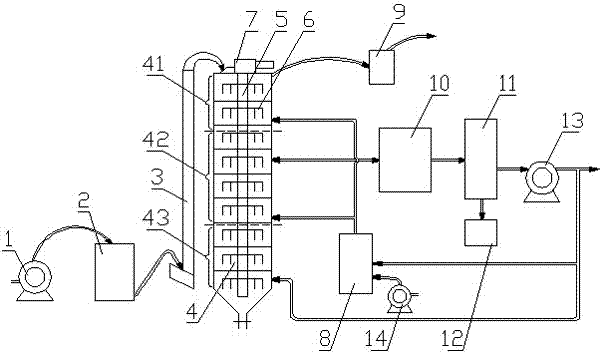

Harmless treatment system for oil field sludge

InactiveCN106196107AStable combustion temperatureGuaranteed combustion qualitySludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCatalytic pyrolysisSludge

The invention discloses a harmless treatment system for oil field sludge, and relates to a harmless treatment device for mixed sludge, which contains complex chemical compositions and is high in content of pollutants, in oil field exploitation. The harmless treatment system comprises a feeding device, a rotating drying machine, a catalytic pyrolysis furnace, a waste heat boiler, a quench tower, an absorption tower and a chimney. The feeding device is located at the inlet end of the rotating drying machine. The outlet end of the rotating drying machine is connected with the inlet end of the catalytic pyrolysis furnace. The outlet end of the catalytic pyrolysis furnace is connected with the inlet end of the waste heat boiler. The number of the outlet ends of the waste heat boiler is two, wherein one outlet is a flue gas outlet connected with the inlet end of the absorption tower to collect dust in flue gas particles, and the other outlet is a hot water outlet connected to a domestic water or production water pipeline through a pipeline. The outlet end of the absorption tower is connected with the chimney. The harmless treatment system has the characteristics of novel structure, mature technology, high waste heat utilization rate, relatively thorough harmless treatment, environmental protection and energy conservation.

Owner:朝阳重型机器制造有限公司

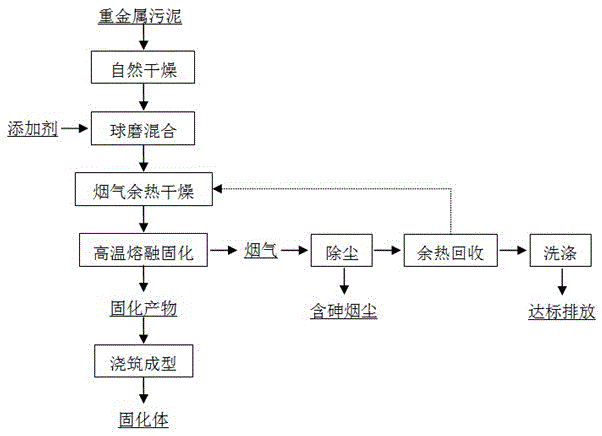

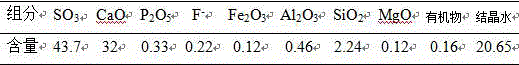

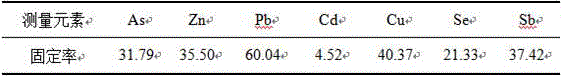

High-temperature melting and solidifying method for heavy metal sludge

InactiveCN105541065AHigh capacity reduction rateLow leaching rateSludge treatment by de-watering/drying/thickeningFixation/solidifcation sludge treatmentChemical industryMetallurgy

The invention relates to a high-temperature melting and solidifying method for heavy metal sludge, and belongs to the technical field of chemical industry and environment protection. The method comprises the following steps: adding an additive of which the mass is 1 to 15 percent of that of naturally dried heavy metal sludge into the naturally dried heavy metal sludge first, mixing and performing ball grinding until the particle size is less than 1 mm to obtain a ball grinding material; drying the obtained ball grinding material for 0.1 to 3 hours under the temperature of 100 to 800 DEG C by adopting flue gas waste heat; heating the material which is subjected to drying treatment to the temperature of 1,000 to 1,400 DEG C, and melting for 0.1 to 3 hours at a high temperature; performing dust removal on the flue gas generated in the process, returning the flue gas until the temperature of the dried ball grinding material is reduced to 50 to 100 DEG C, washing the flue gas, and finally discharging the flue gas until the flue gas reaches standards; pouring and molding the molten and solidified product to obtain a solidified body. By the method, the leaching toxicity of the obtained molten and solidified body reaches the standard of common solid waste; the molten and solidified body has the advantages of high strength, high volume reduction rate, high long-term stability, and thorough solidification.

Owner:KUNMING UNIV OF SCI & TECH +2

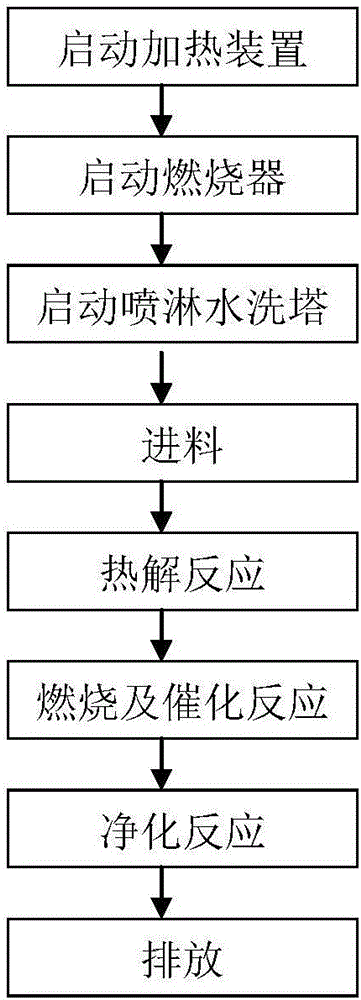

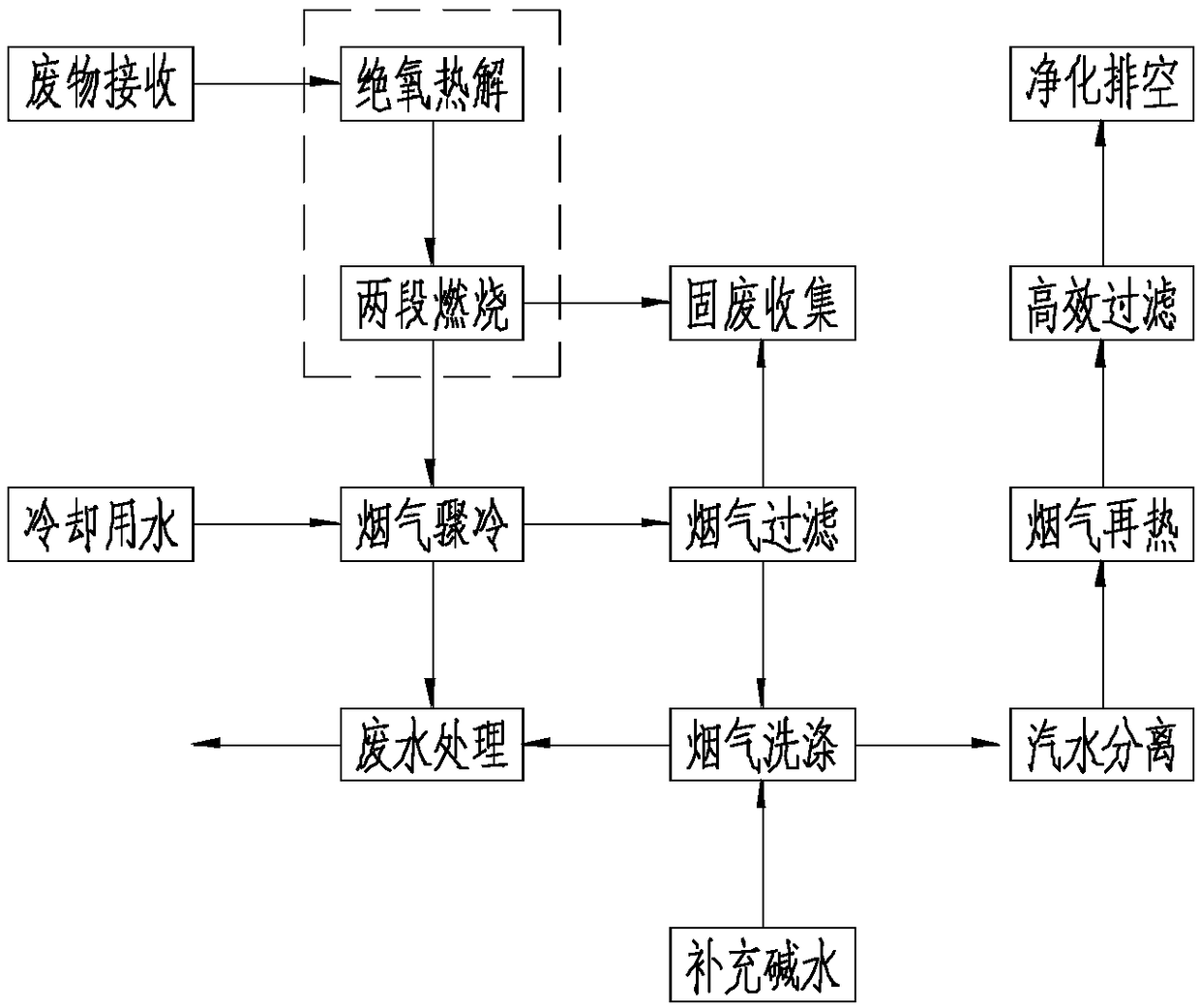

Intermediate- and low-level radioactive waste treatment method

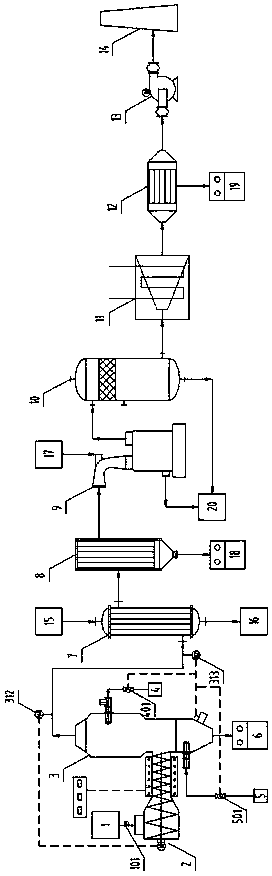

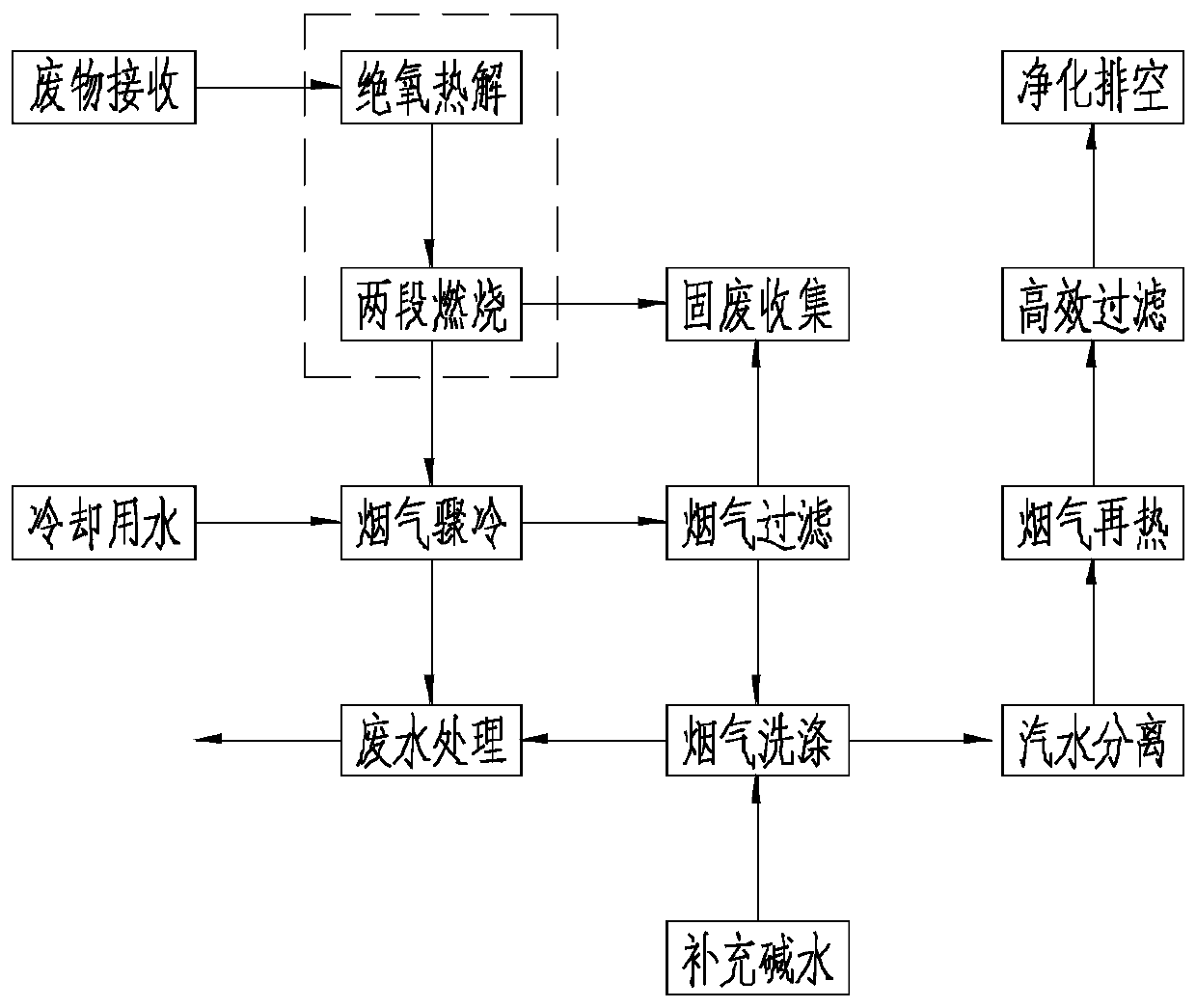

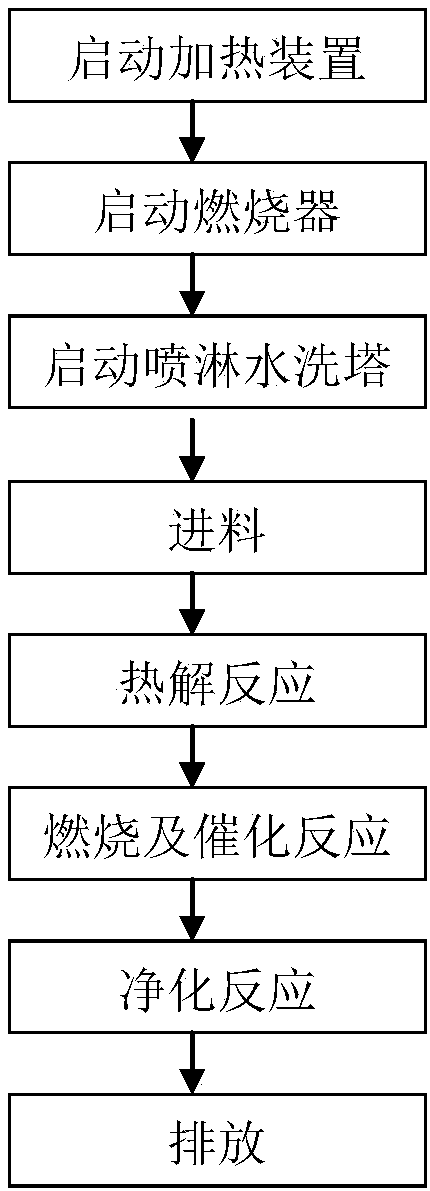

ActiveCN106782734AEliminate pollutionEasy to storeRadioactive decontaminationOperational costsCombustor

The invention belongs to the technical field of intermediate- and low-level radioactive waste treatment and relates to an intermediate- and low-level radioactive waste treatment method. The intermediate- and low-level radioactive waste treatment method is achieved in an intermediate- and low-level radioactive waste treatment device and is used for treating organic combustible waste which contains radioactive substances and is generated by hospitals, factories, research institutions and nuclear power plants. The sludge volume reduction and the harmless treatment of the intermediate- and low-level radioactive waste are achieved. The sludge volume reduction rate is more than 95%. The difficulties of big deposit volume and difficult storage of the intermediate- and low-level radioactive waste are solved. Firstly, heating equipment is started, then a burner is started, then a spray water scrubber is started to carry out pre-treatment, then feedstock is carried out, the waste is pyrolyzed, burned, and experiences catalytic reaction, and finally, is purified and discharged. The process is simple in method, reliable in principle, high in sludge volume reduction rate, good in curing effect, environmentally friendly in application, low in investment and operation costs, energy-saving and environmentally friendly, and has a good economic benefit and a wide market prospect.

Owner:青岛天和清原科技有限公司

Refuse disposal system for marine galley and disposal method thereof

ActiveCN101966527AHigh capacity reduction rateAvoid security issuesSolid waste disposalAutomatic controlDigestion

The invention relates to a refuse disposal system for marine galleys and a disposal method thereof. The refuse disposal system comprises a motor, a worm reduction gear, a machine body and an automatic control box. In an airtight gear body, galley refuses are fully digested by adopting a manner of stirring and matching strains in the closed machine body, and the effective volume reduction and the safety disposal of refuses on marine galleys are realized by matching the temperature digestion environment in the machine body and the deodorization of a tail gas three-way catalytic converter. The disposal system has the advantages of reasonable structure and design, simple disposal method, safe operation, safety disposal to galley refuses, high volume reduction rate and no exhaust emission, and is suitable for galley refuse disposal.

Owner:JIANGSU NANJI MACHINERY

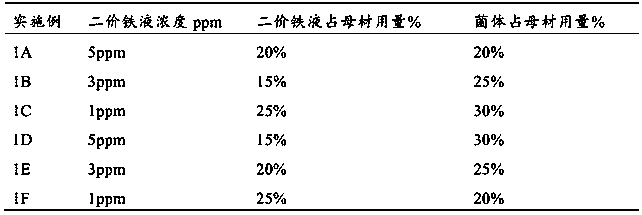

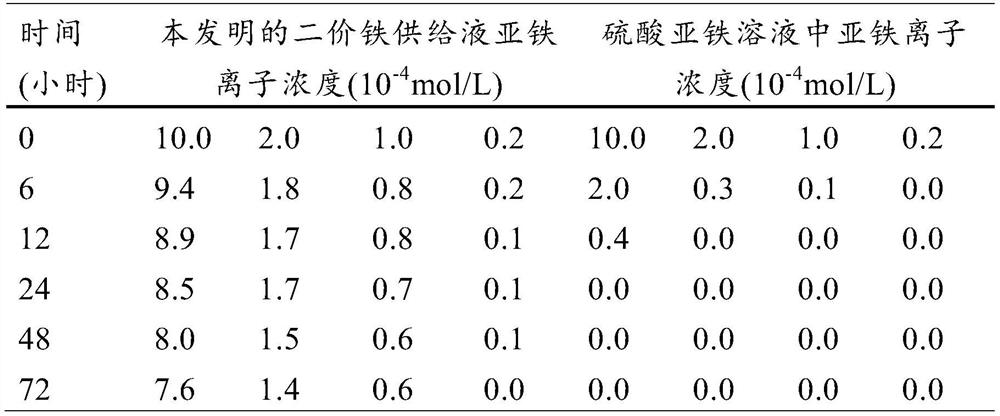

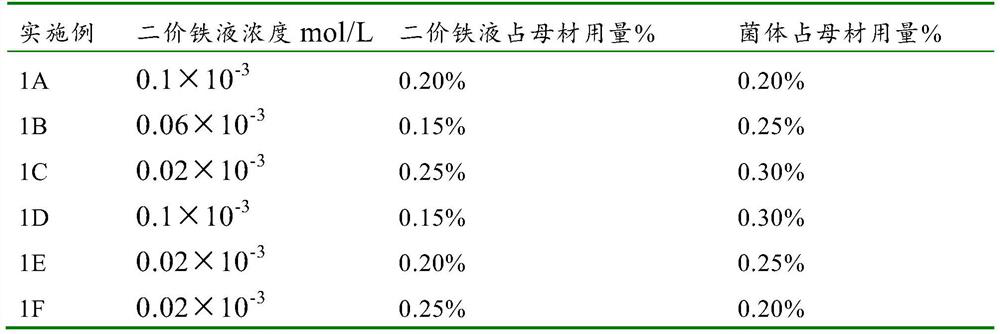

Application of ferrous iron supply liquid to aspect of promoting flora fermentation for petroleum residue treatment

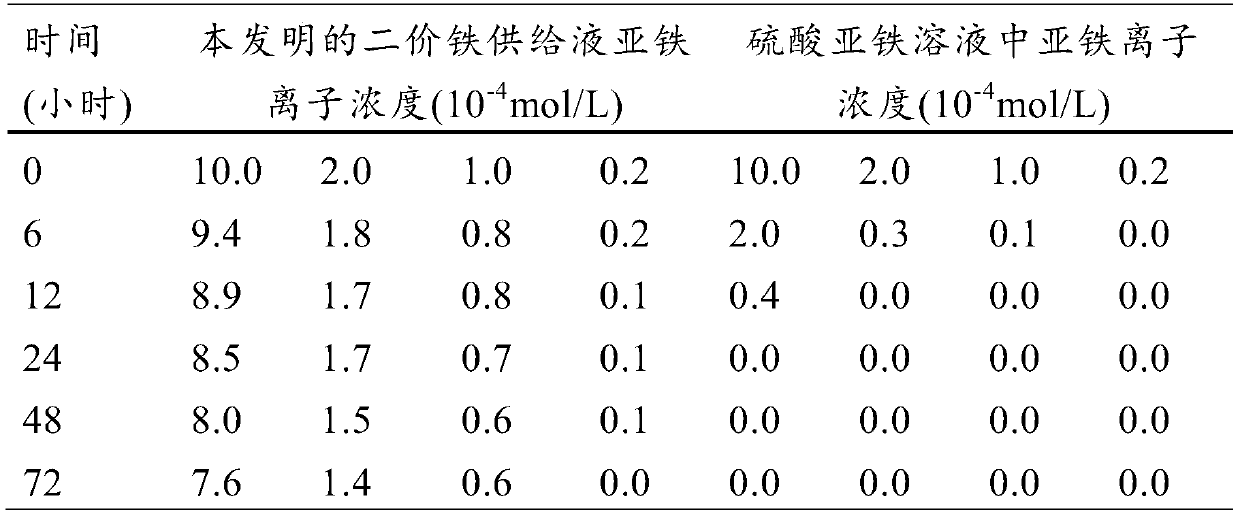

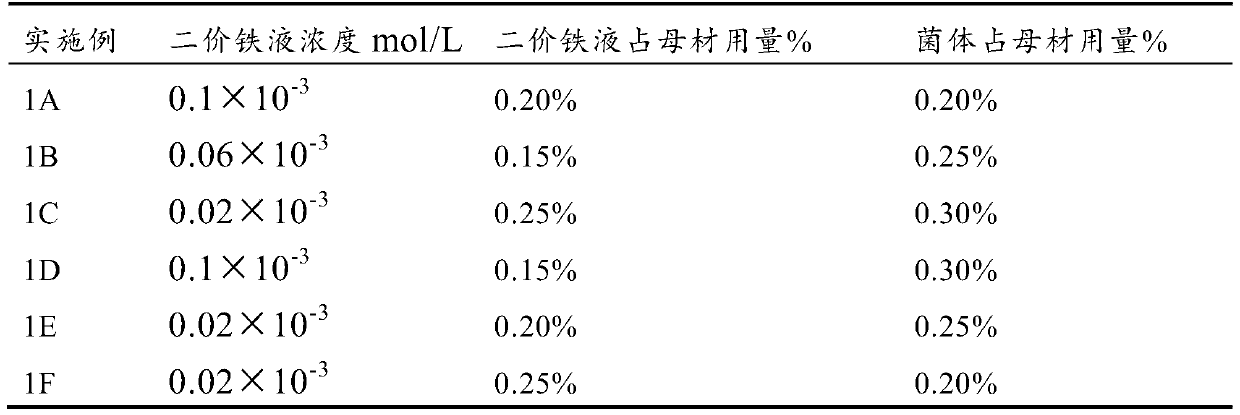

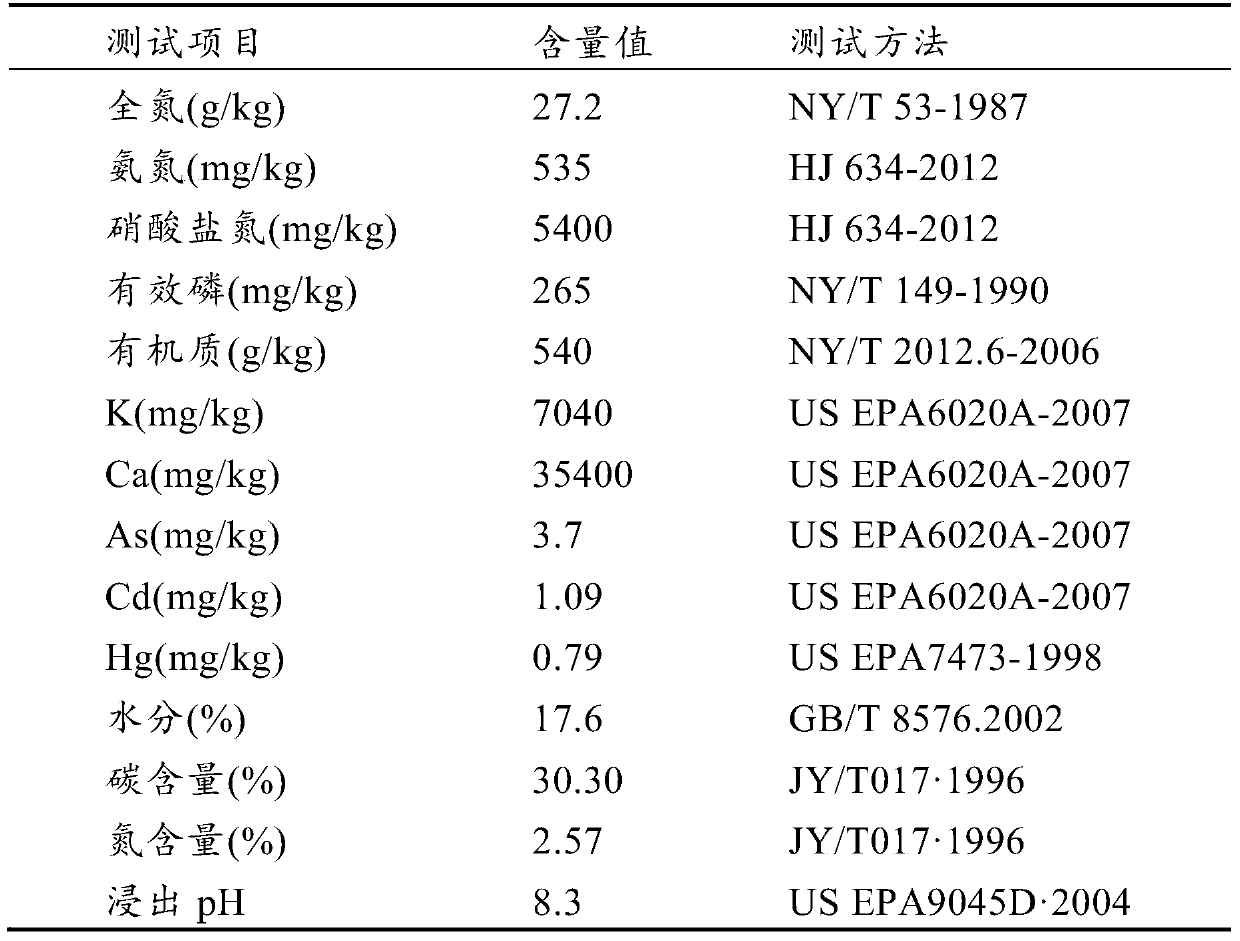

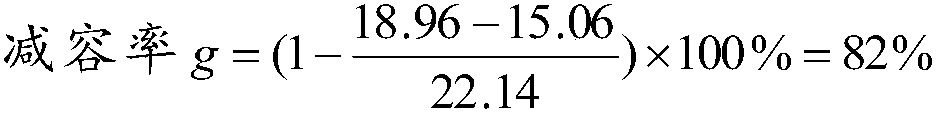

ActiveCN109848183APromote degradationAccelerated Decomposition and FermentationSolid waste disposalRhizopusPseudomonas

The invention discloses application of ferrous iron supply liquid to the aspect of promoting flora fermentation for petroleum residue treatment. Floras for petroleum residue treatment comprise following bacterial genus including methanobacterium, rhizopus, trichoderma, pseudomonas, aspergillus, penicillium, rhodopseudomonas, lactobacillus acetotoleran, photosynthetic bacteria and saccharomycetes.The ferrous iron supply liquid is ferrous iron ion containing mixed liquid. The mixed liquid comprises sodium ferrous citrate, ferrous sulfate and ferrous citrate, the molar mass ratio of the sodium ferrous citrate to the ferrous sulfate to the ferrous citrate in the mixed liquid is 1:0.28-0.38:0.17-0.23, and the pH of the ferrous iron supply liquid is 4.5-5.5. The ferrous iron supply liquid can promote the floras to grow, the metabolism of the floras is accelerated, fermenting and decomposing of petroleum residues through the floras are accelerated, the fermentation period can be greatly shortened, the volume reduction rate is increased, and meanwhile heavy metal can be passivated.

Owner:浙江科罗尼生物科技有限公司

Application of divalent iron to promoting fermentation of floras for treating organic waste

InactiveCN109420664AAccelerated Decomposition and FermentationShorten the fermentation cycleSolid waste disposalBiological sludge treatmentFloraGenus Rhodopseudomonas

The invention discloses application of divalent iron to promoting fermentation of floras for treating organic waste. The floras for treating organic waste comprise the following bacterial genera including cellulolytic decomposers, streptomyces, pseudomonas, eurotium, penicillium, rhodopseudomonas, lactobacillus acetotoleran, bacillus and saccharomycetes. The divalent iron in the application can accelerate decomposition and fermentation of the floras for treating the organic waste to the organic waste, the fermentation cycle is greatly shortened, and the volume reduction rate is increased.

Owner:浙江科罗尼生物科技有限公司

Thermal chemical treatment method for low-and-intermediate level radioactive waste

ActiveCN108361713AReduce volumeEasy to storeIncinerator apparatusChemical treatmentOperational costs

The invention belongs to the technical field of low-and-intermediate level radioactive waste and relates to a thermal chemical treatment method for low-and-intermediate level radioactive waste for treating low-and-intermediate level radioactive organic combustible waste comprising radioactive substances generated by hospitals, scientific research institutions and nuclear power units, solving the problem of great deposit volume and difficulty of storage of the low-and-intermediate level radioactive waste, and achieving volume reduction and harmless treatment of the low-and-intermediate level radioactive waste. 0.1-1% of the purified radioactive substance smoke sucked by a power device is exhausted from a smoke air outlet, and 99-99.9% of radioactive elements are left in incombustible ash residues to be sealed uniformly and cured with cement, so that the processing course of the low-and-intermediate level radioactive combustible waste is finished. The volume reduction ratio of the low-and-intermediate level radioactive organic combustible waste reaches 97-99%. The method is reliable in principle, high in volume reduction ratio, good in curing effect, low in secondary pollution, friendly in application environment, low in investment and operation costs and energy-saving and environment-friendly, and has a good economical benefit and a wide market prospect.

Owner:青岛天和清原科技有限公司

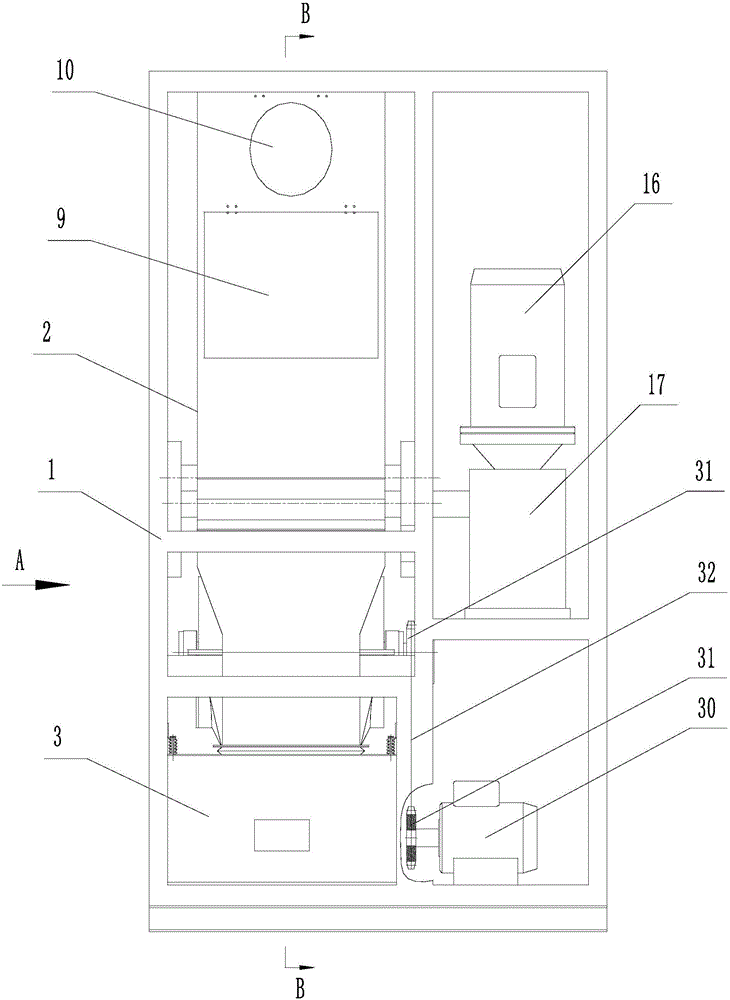

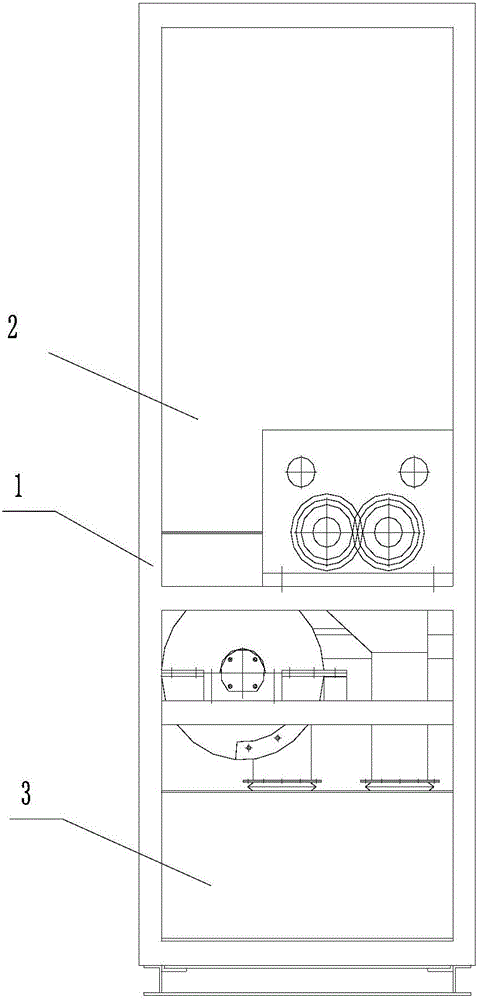

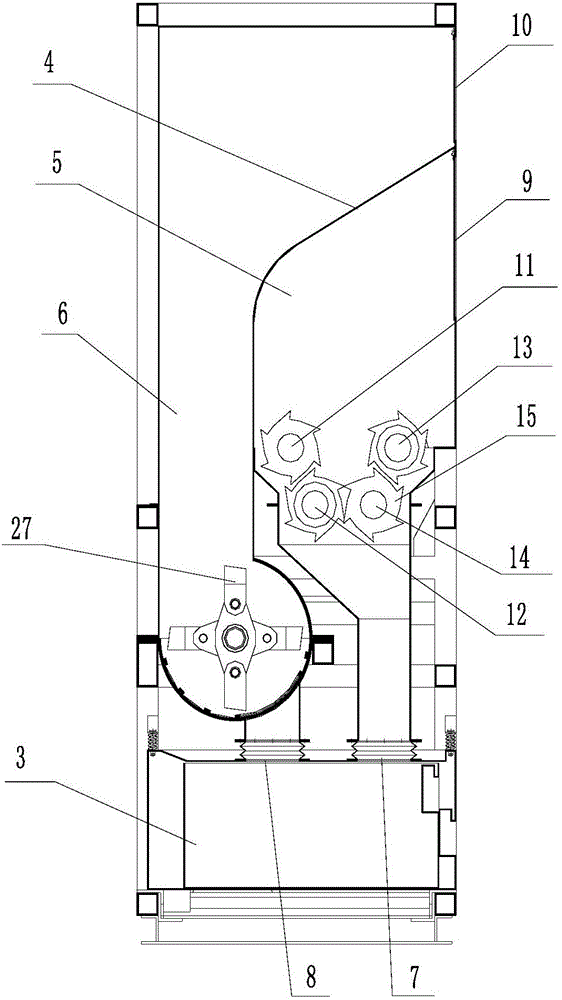

Solid waste size reduction treatment device

InactiveCN106111302AConvenience for long-term overseas voyagesImprove feeding effectGrain treatmentsHobbingCarton

The invention discloses a solid waste size reduction treatment device which comprises a rack, a hopper, a residue collection box, a hobbing cutter crushing mechanism, a hobbing cutter drive mechanism, a swinging hammer crushing mechanism and a swinging hammer drive mechanism. The hopper is mounted on the upper portion of the rack, and the residue collection box is mounted on the lower portion of the rack. A partition plate is arranged in the hopper and divides an inner cavity of the hopper into a hobbing cutter crushing cavity and a swinging hammer crushing cavity. The hobbing cutter crushing mechanism is arranged in the hobbing cutter crushing cavity. The swinging hammer crushing mechanism is arranged in the swinging hammer crushing cavity. The hobbing cutter crushing mechanism is connected with the hobbing cutter drive mechanism. The swinging hammer crushing mechanism is connected with the swinging hammer drive mechanism. The hobbing cutter drive mechanism and the swinging hammer drive mechanism are both mounted on the rack. The treatment device is designed for household and production solid waste on the occasions of ocean steamers and the like and can be used for treatment of tough waste such as wood plates, cartons, cloth, woven bags and plastic for packaging and glass waste at the same time; great convenience is brought to long-term oversea sailing of the ocean steamers; and meanwhile the treatment efficiency of the treatment device is greatly improved.

Owner:GUANGDONG IND TECHN COLLEGE

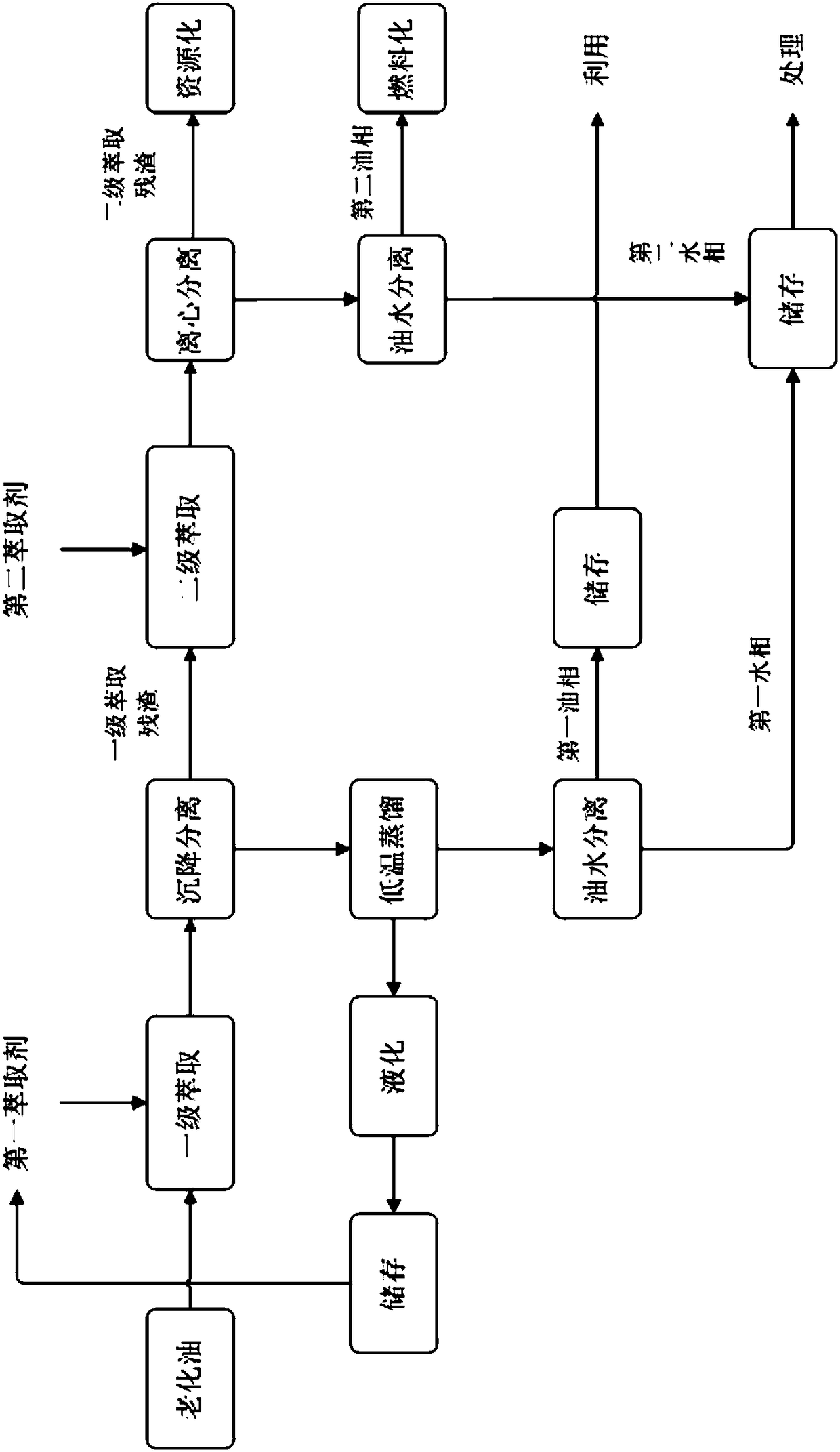

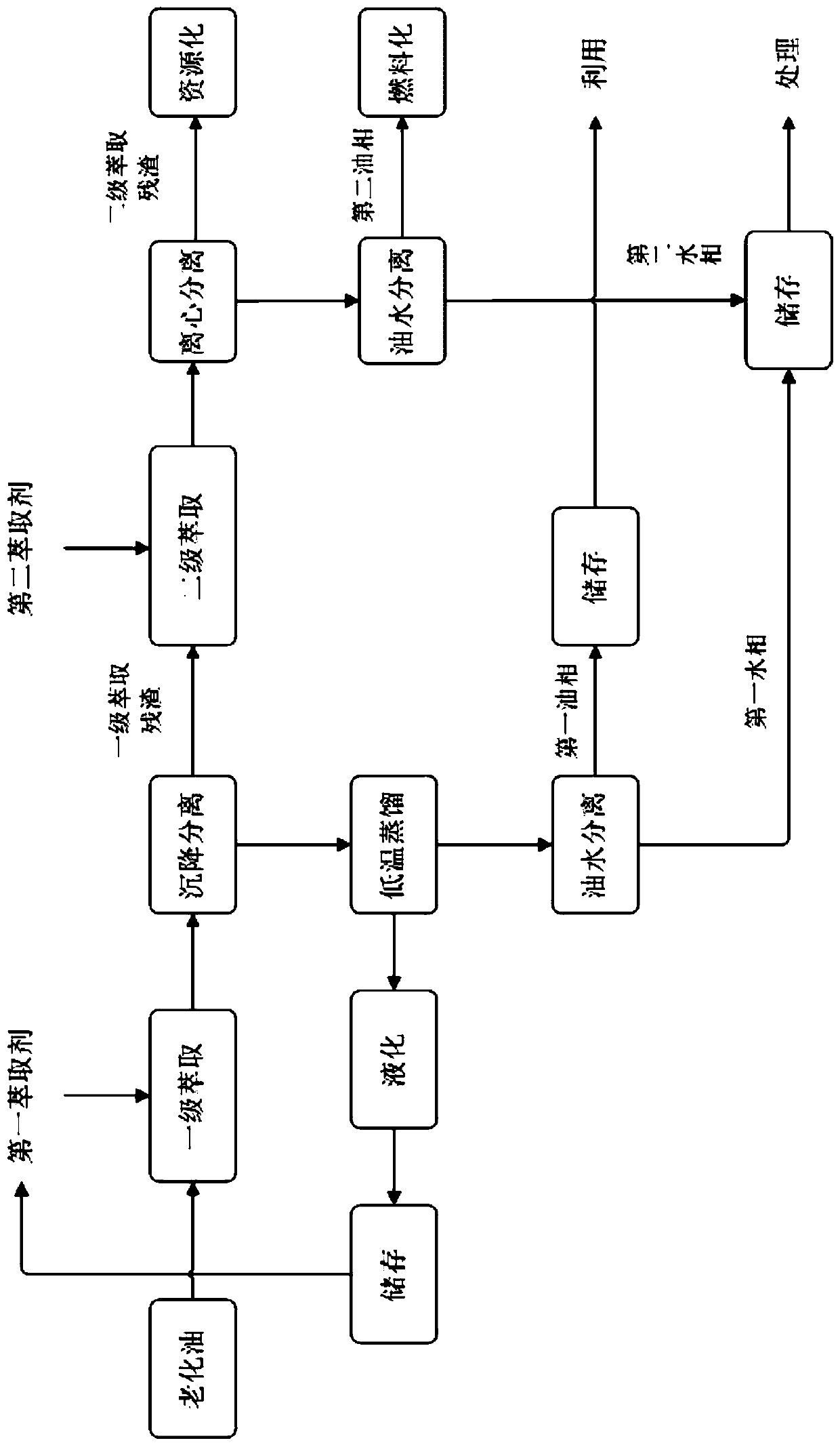

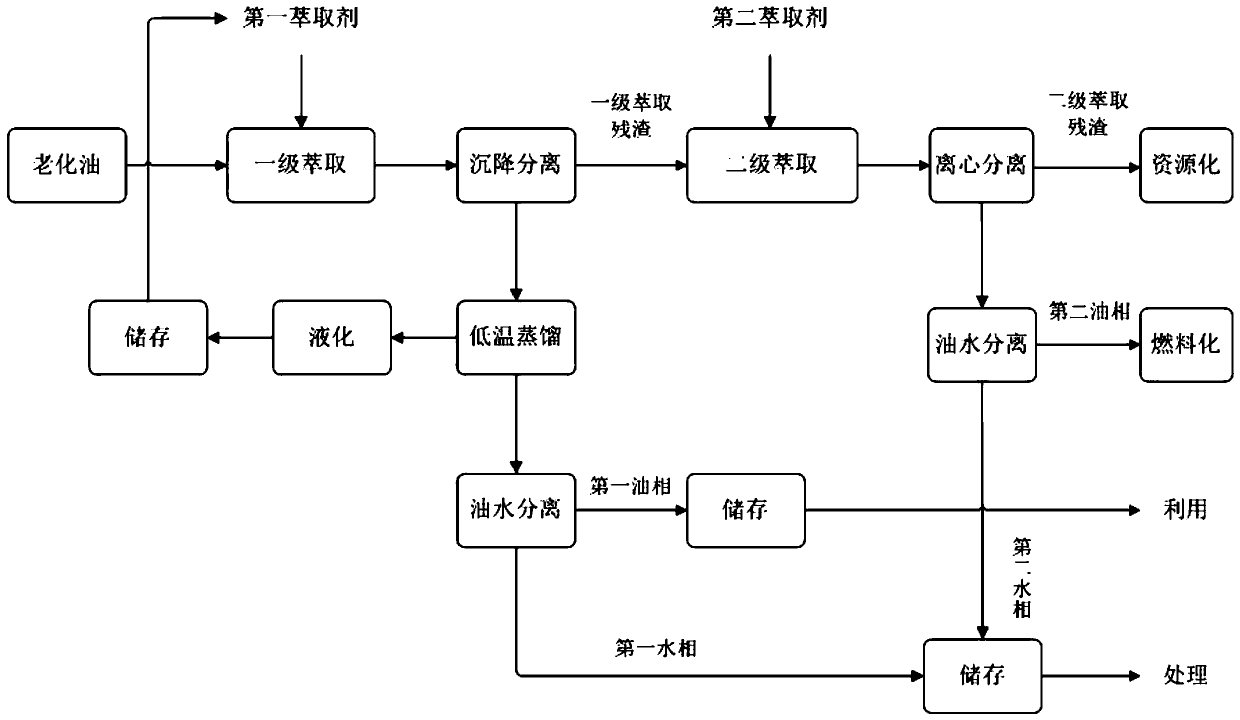

Dehydration and refining method and system for aged oil

ActiveCN108251153ASignificantly lighterIncrease valueDewatering/demulsification with chemical meansTreatment with plural parallel refining stagesPolycyclic aromatic hydrocarbonOrganic solvent

The invention provides a dehydration and refining method and system for aged oil. The dehydration and refining method comprises the following steps: (1) carrying out primary extraction on aged oil byusing a primary extractant, then carrying out solid-liquid separation to obtain a primary extraction liquor and a primary extraction residue, wherein the component of the primary extractant comprisesan oleophilic hydrophilic organic solvent with a boiling point of 100 DEG C or below; (2) recovering the primary extractant in the primary extraction liquor, carrying out oil-water separation on the residual liquid to obtain a first oil phase and a first aqueous phase; and (3) carrying out secondary extraction on the primary extraction residue by using a secondary extraction agent, and then carrying out solid-liquid separation to obtain a secondary extraction residue and a secondary extraction liquor containing a second oil phase, wherein the component of the secondary extractant comprises polycyclic aromatic hydrocarbon. The method has good dehydration effect, high crude oil recovery rate, short process time and high separation efficiency, and has obvious advantages compared with the prior art.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

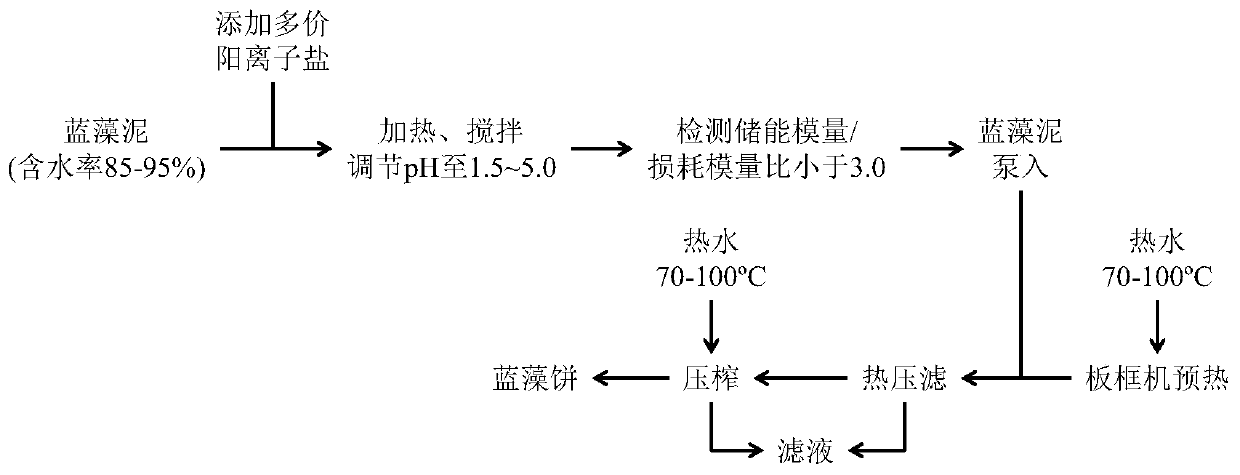

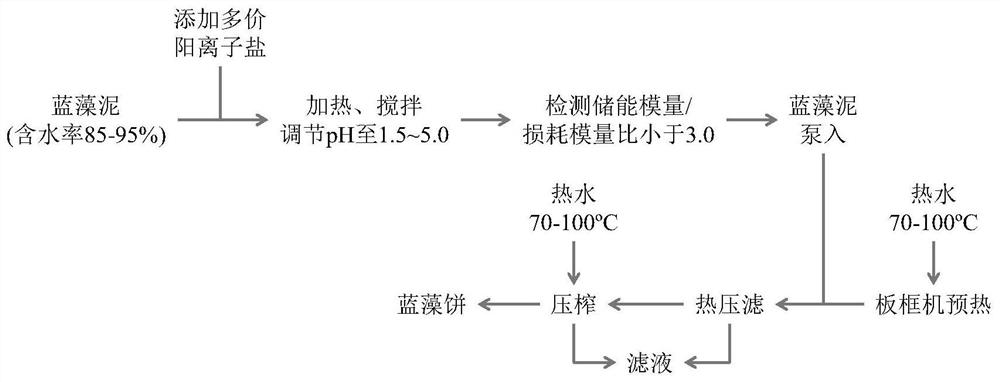

Blue-green alga mud deep-dehydration method based on thermal rearrangement of capsular polysaccharide soft lattices

The invention provides a blue-green alga mud deep-dehydration method based on thermal rearrangement of capsular polysaccharide soft lattices. The method comprises the following steps: pretreating blue-green alga mud, carrying out heating, adding a multivalent cationic salt, adjusting a pH value to 1.5-5, enabling a ratio of the energy storage modulus of the blue-green alga mud to the loss modulusof the blue-green alga mud to be less than 3.0 so as to ensure that capsular polysaccharide soft lattices in the blue-green alga mud to undergo thermal rearrangement, then pumping the treated blue-green alga mud into a preheated dehydration device, wherein a preheating temperature is in a range of 70-100 DEG C, and carrying out hot-pressing dehydration. The method has the advantages of simple process, mild reaction, good dehydration effect, no addition of conditioners such as calcium oxide and clay, cost reduction, capacity of reducing the inorganic matter content of a blue-green alga cake andrelatively increasing the organic matter content and the calorific value of a filter cake, and no increase in the COD of a filtrate; and dehydrated and dried blue-green alga powder is high in organicmatter content (with a ratio of volatile solid to total solid of more than 85%) and high in heat value, the recycling ways of blue-green alga can be increased, and the quality of subsequent productscan be improved.

Owner:JIANGNAN UNIV

A method and system for dehydrating and refining aged oil

ActiveCN108251153BHigh recovery rateEfficient dehydrationDewatering/demulsification with chemical meansTreatment with plural parallel refining stagesPolycyclic aromatic hydrocarbonOrganosolv

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

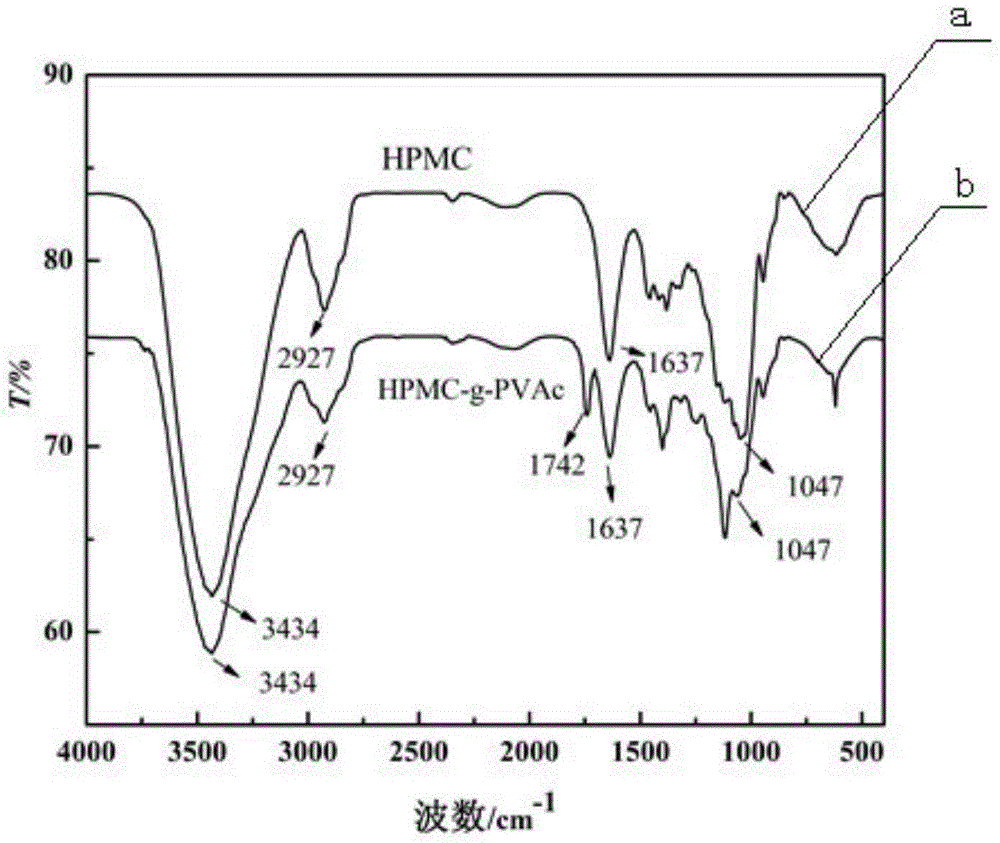

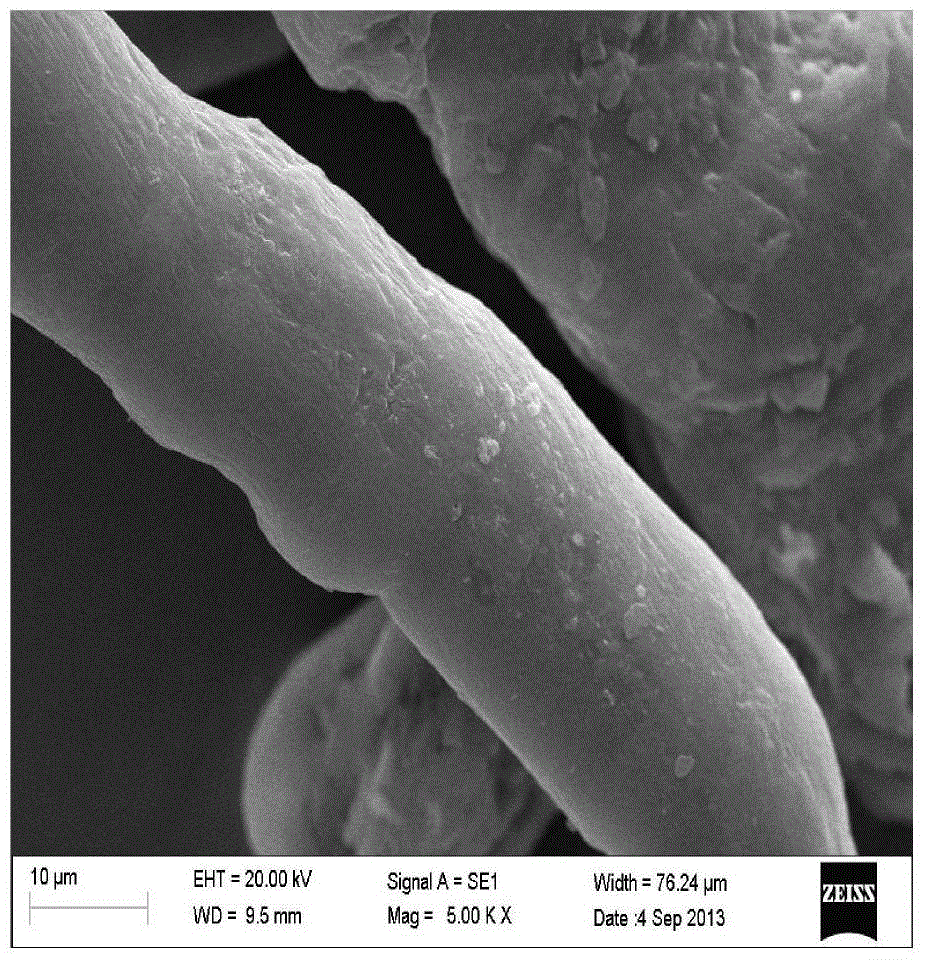

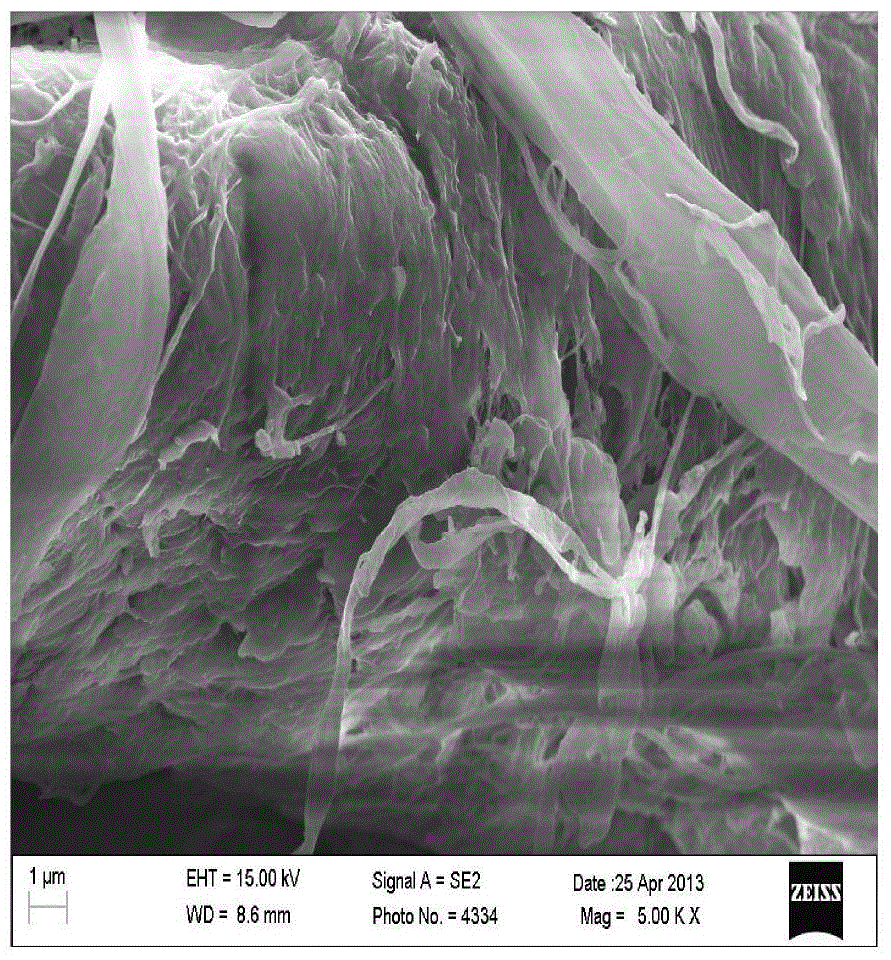

Preparation and application method of a strippable cellulose-based radioactive contamination decontamination agent

The invention discloses a method for preparing and using a strippable cellulose-based radioactive pollution decontamination agent, which is characterized by: a. modifying the pre-prepared cellulose ether by grafting; then using the prepared fiber The detergent was prepared from the ether grafted product. b. Spray the decontamination agent evenly on the surface of the radioactively contaminated material, dry at 20-60°C for 15-22 hours to form a film, and peel off the film to complete the decontamination process. The detergent provided by the invention uses cellulose with abundant resources as a raw material, has a simple preparation method, and has obvious decontamination effect, and can resist a certain dose of radiation and show easy peeling and good decontamination properties; further is , After decontamination, the solid waste can be biodegraded or incinerated, with a high capacity reduction rate, which is convenient for storage and solidification treatment, meets the requirements of sustainable development, and has great economic and social benefits.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A garbage incineration device and its incineration process

ActiveCN104019452BNo secondary pollutionNo pollution in the processIncinerator apparatusProcess engineeringEnvironmental engineering

The invention discloses a waste incineration device and technology. The waste incineration device comprises a waste stacking bin, a magnetic separation conveying device, a crushing device, a feeding conveying device and a gasification incineration device. The waste gasification incineration process is divided into three stages which are the drying stage, the pyrolysis gasification stage and the high-temperature incineration stage, and the whole incineration process is conducted in a staged mode according to the sequence of drying, pyrolysis gasifying and smoke incinerating. Waste heat of smoke can be thoroughly used, temperature stability in a gasification incinerator can also be guaranteed, the burn-off rate of ash is high, the weight loss of waste is large, and discharging is safe, is far better than a current national standard and exceeds an EU standard. The system can be used for treating all kinds of waste which is scattered widely in countries, villages and towns and is miscellaneous and small in amount, the production and living conditions of the countries are improved, and the environment is protected.

Owner:WUXI GAOER ENVIRONMENTAL SCI & TECH

A thermochemical treatment method for low and medium radioactive waste

ActiveCN108361713BReduce volumeReduce pollutionIncinerator apparatusChemical treatmentOperational costs

The invention belongs to the technical field of low-and-intermediate level radioactive waste and relates to a thermal chemical treatment method for low-and-intermediate level radioactive waste for treating low-and-intermediate level radioactive organic combustible waste comprising radioactive substances generated by hospitals, scientific research institutions and nuclear power units, solving the problem of great deposit volume and difficulty of storage of the low-and-intermediate level radioactive waste, and achieving volume reduction and harmless treatment of the low-and-intermediate level radioactive waste. 0.1-1% of the purified radioactive substance smoke sucked by a power device is exhausted from a smoke air outlet, and 99-99.9% of radioactive elements are left in incombustible ash residues to be sealed uniformly and cured with cement, so that the processing course of the low-and-intermediate level radioactive combustible waste is finished. The volume reduction ratio of the low-and-intermediate level radioactive organic combustible waste reaches 97-99%. The method is reliable in principle, high in volume reduction ratio, good in curing effect, low in secondary pollution, friendly in application environment, low in investment and operation costs and energy-saving and environment-friendly, and has a good economical benefit and a wide market prospect.

Owner:青岛天和清原科技有限公司

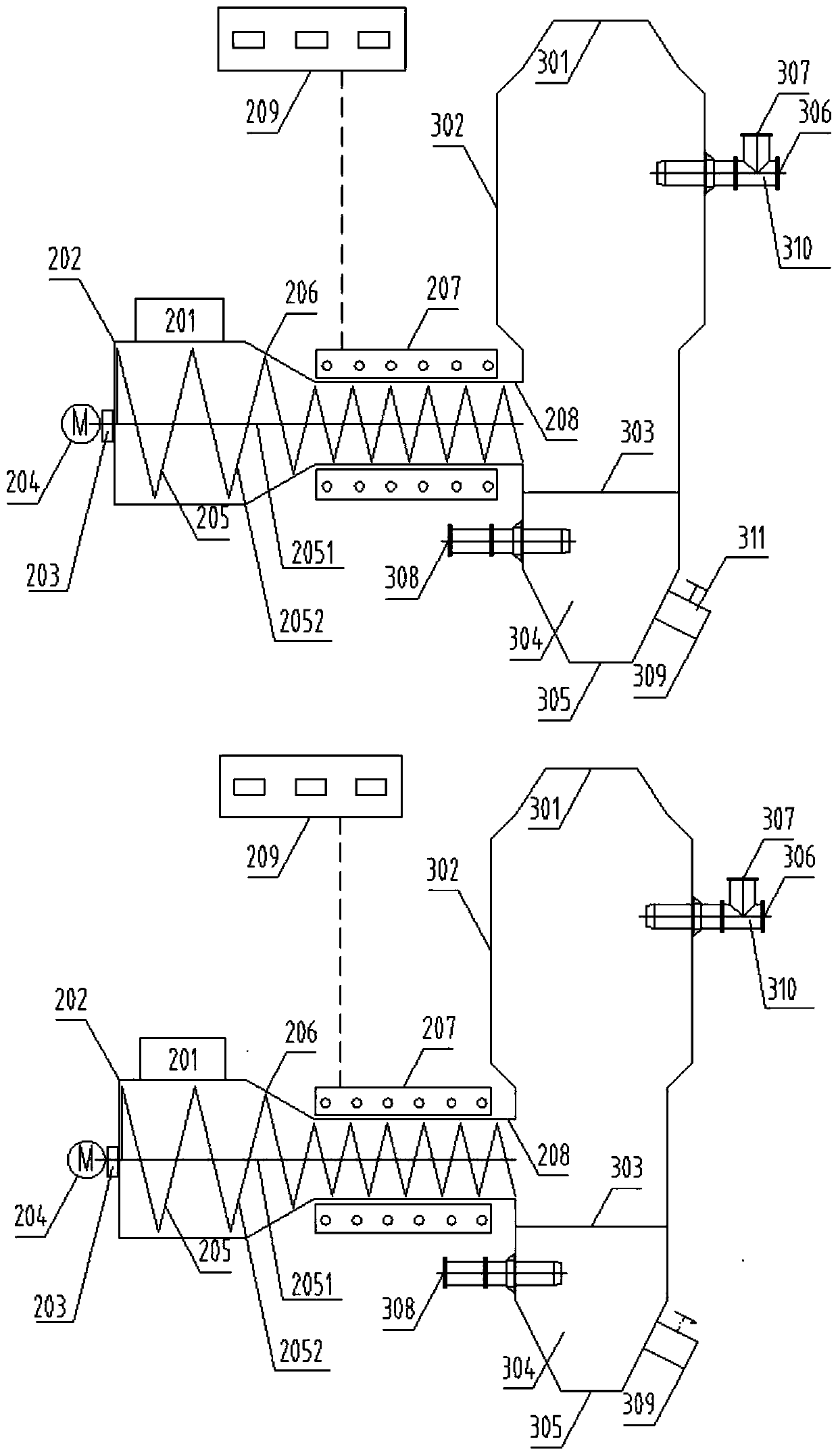

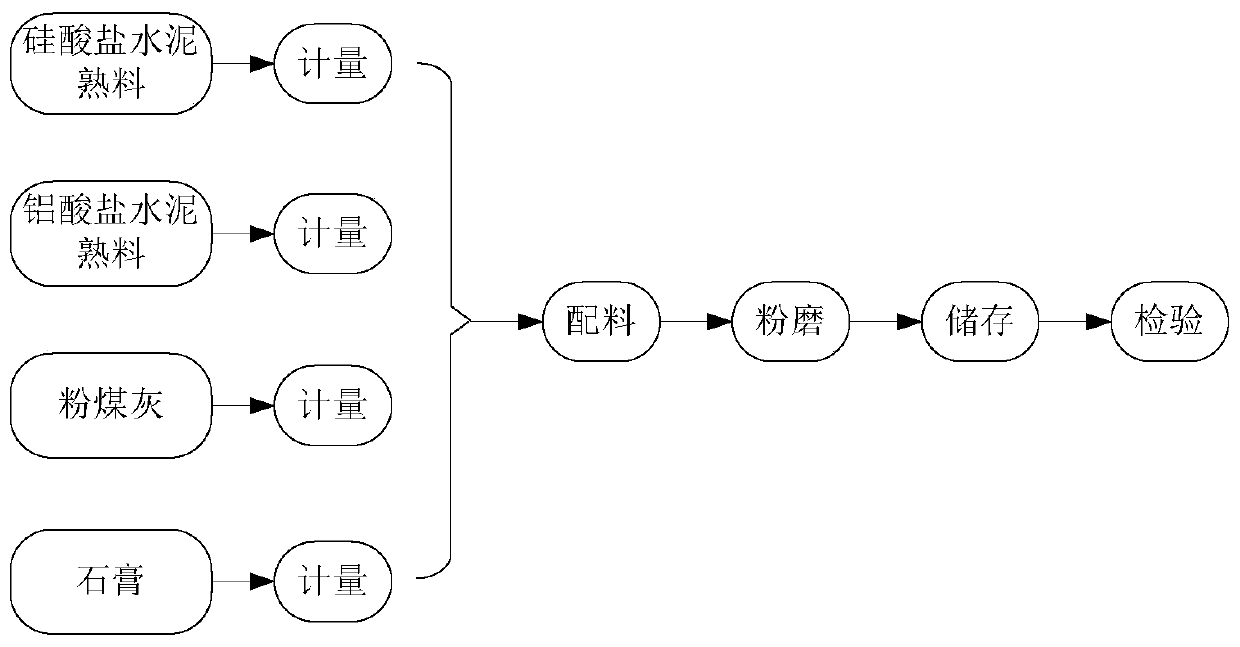

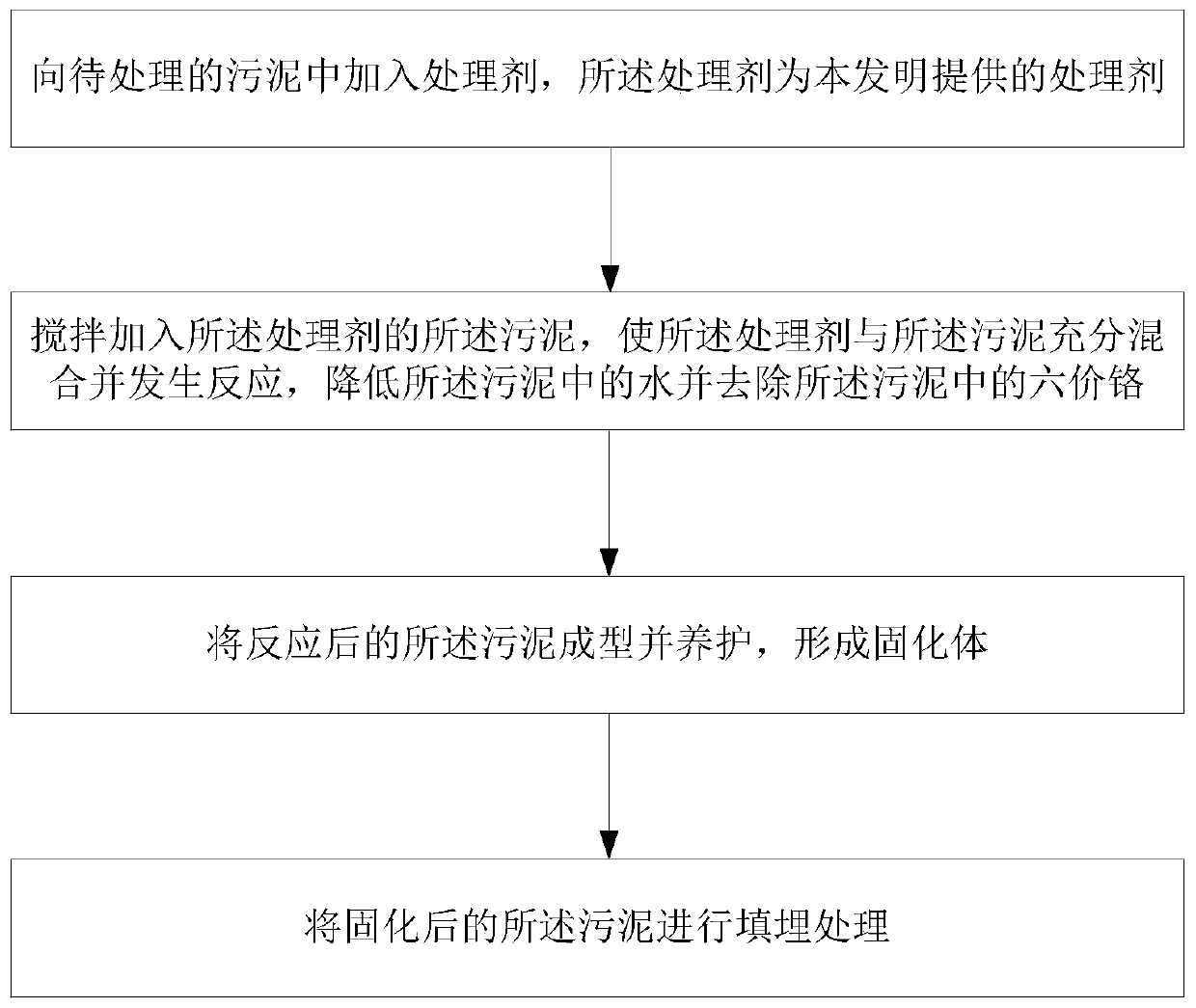

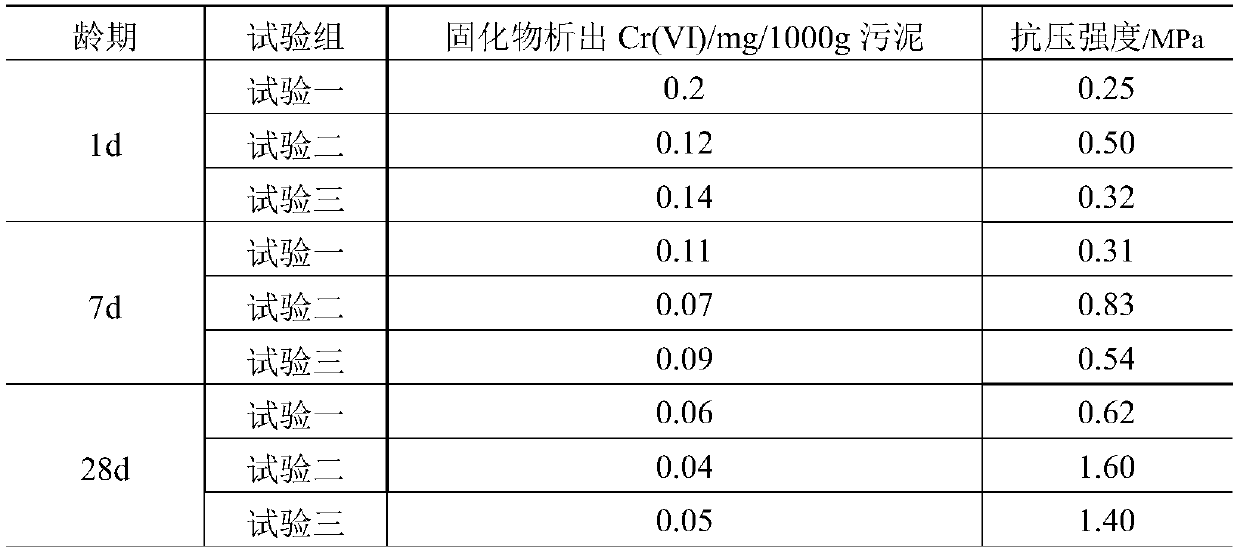

Treatment agent and method for removing hexavalent chromium in sludge

PendingCN110790474AEasy to prepareReduce moisture contentWater contaminantsSludge detoxificationHexavalent chromiumSilicate Cement

The invention provides a treatment agent and method for removing hexavalent chromium in sludge. The treatment agent comprises a Portland cement clinker, an aluminate cement clinker, fly ash, gypsum and a carbonate, and also comprises auxiliary agents such as a silane coupling agent, wherein a mass ratio of the Portland cement clinker to the aluminate cement clinker to the fly ash to the gypsum tothe carbonate to the silane coupling agent is 100:20-120:5-40:4-8:0.1-5:0.1-0.4. The above components are all readily available industrial-grade substances, and the preparation process is simple. Whenthe above-mentioned treatment agent is used to remove hexavalent chromium in sludge, the hexavalent chromium in the sludge replaces or partially replaces acid radical ions SO4<2-> in a sulfur reaction product of the Portland cement clinker and the aluminate cement clinker, and enters ettringite crystal lattices to form chromium-containingettringiteC3A.3(CaSO4.CaCrO4).32H2O and a chromate mineralC3A.3CaCrO4.32H2O with an ettringite structure, and thereby the pollution activity of the hexavalent chromium in the sludge is eliminated, and the purpose of environmental protection is realized. During the curing period, the sludge is continuously solidified and has certain strength, and thereby landfill requirements are met.

Owner:UNIV OF JINAN +1

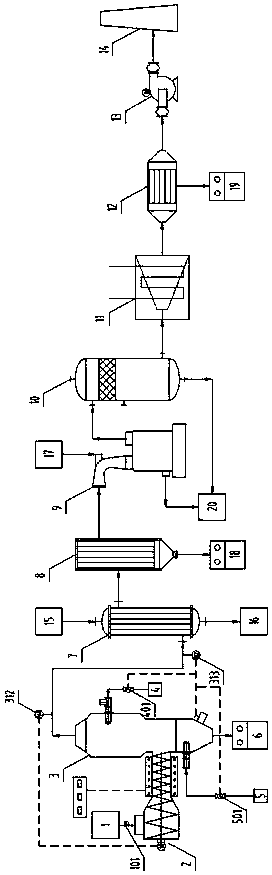

Solid waste plasma gasification treatment device and method

ActiveCN109161402BIncrease energy densityRapid responseDispersed particle filtrationGasification processes detailsCombustion chamberBaghouse

The invention relates to a solid waste plasma gasification treatment device and method. The treatment device includes a plasma gasification furnace, a secondary combustion chamber, a condenser, a spray tower and a bag filter; Second combustion chamber, condenser, spray tower and bag filter. The plasma gasification furnace is vertically inserted with a liftable plasma torch on the top to gasify solid waste and produce a large amount of synthesis gas; the synthesis gas is fully burned in the secondary combustion chamber to remove organic pollutants in the flue gas, such as dioxin Ying et al.; the flue gas after combustion first passes through the condenser to cool down rapidly to avoid the generation of dioxins, and then remove the acidic substances in the flue gas. Finally, through the bag filter, it can ensure that the treated flue gas reaches the treatment target. The system of the invention utilizes plasma to rapidly raise the temperature, and has the characteristics of strong raw material adaptability, full combustion, and thorough removal of pollutants; it is suitable for treating various solid wastes.

Owner:TIANJIN UNIV

Method for treating industrial organic waste through double-wave cracking

PendingCN114507535AEvenly heatedProblems affecting normal operationProductsWater/sewage treatment by irradiationEnvironmental engineeringWaste treatment

The invention discloses a method for treating industrial organic waste through double-wave cracking, and relates to the technical field of organic waste treatment. Through ultrasonic-assisted microwave thermal cracking, internal bonds of macromolecular organic matters are broken to form micromolecular organic matters, polar and non-polar substances and the like; performing ultrasonic-assisted microwave catalytic cracking to enable the polar bond of the polar substance to be vibrated, twisted and activated to be unstable, and cracking the polar substance. The method has the beneficial effects that the industrial organic waste is subjected to cracking treatment through cooperation of ultrasonic waves and microwaves, the method has the characteristics of being rapid, efficient, low in energy consumption, low in cost, high in resource utilization rate, easy to operate, high in volume reduction rate, capable of remarkably reducing harm caused by the industrial organic waste to the environment and the like, and harmless treatment is truly achieved.

Owner:河南海天环境科技有限公司 +2

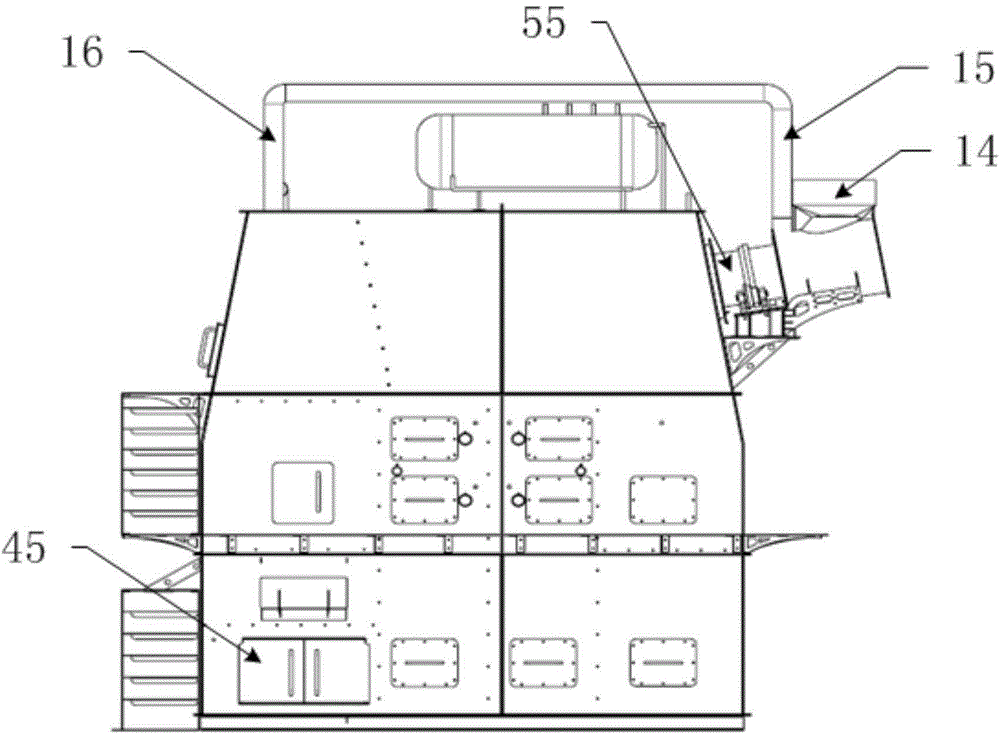

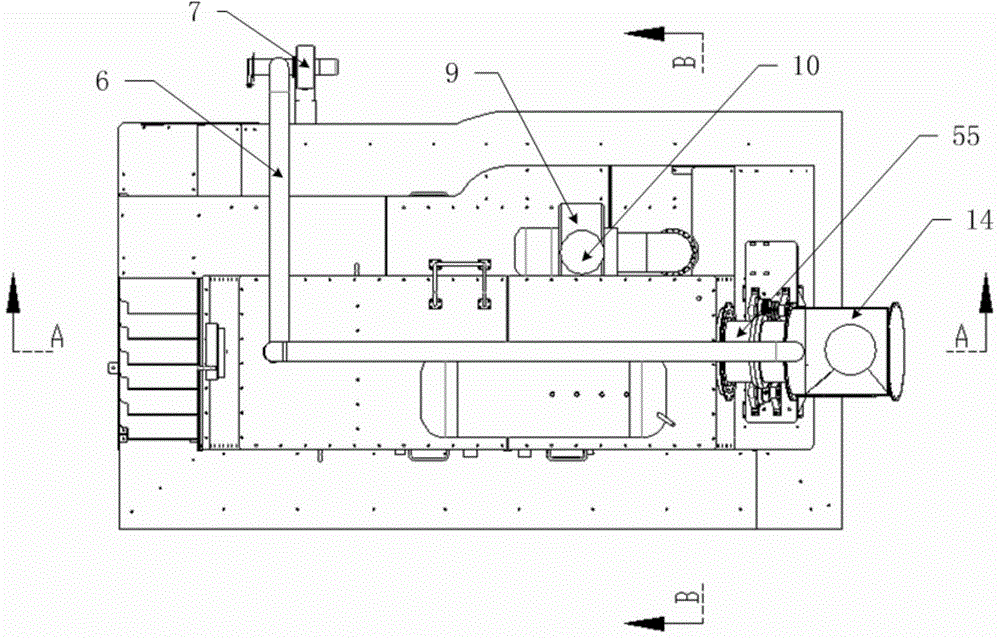

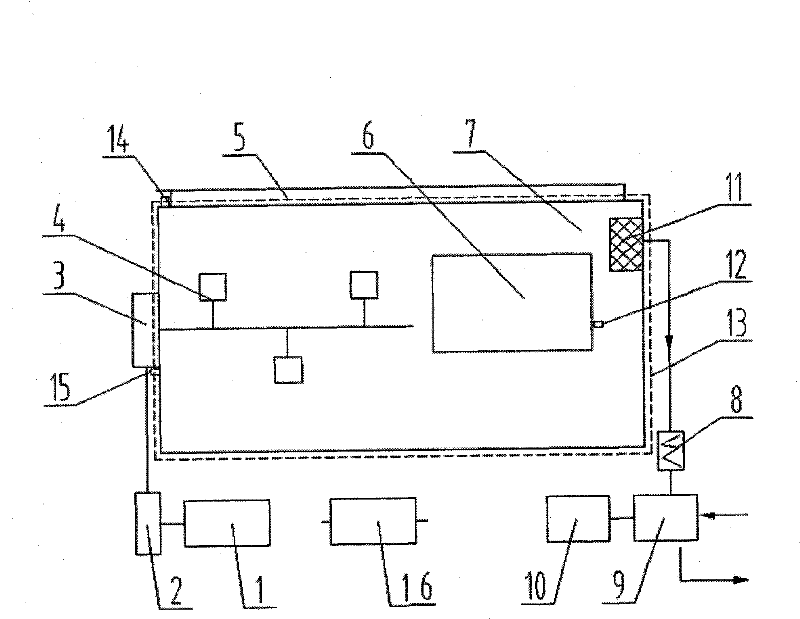

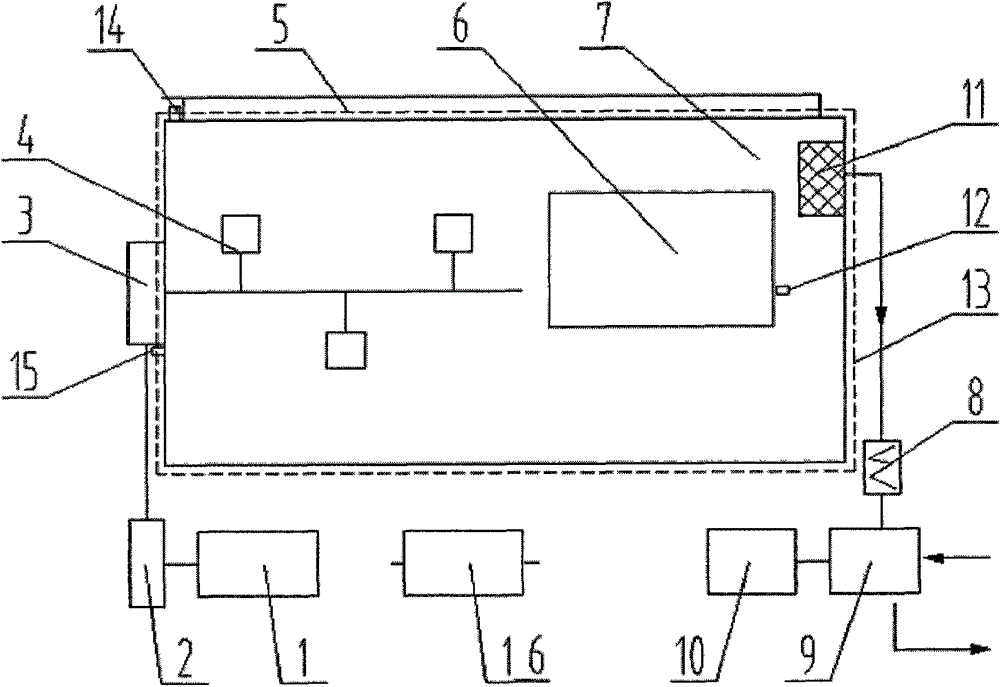

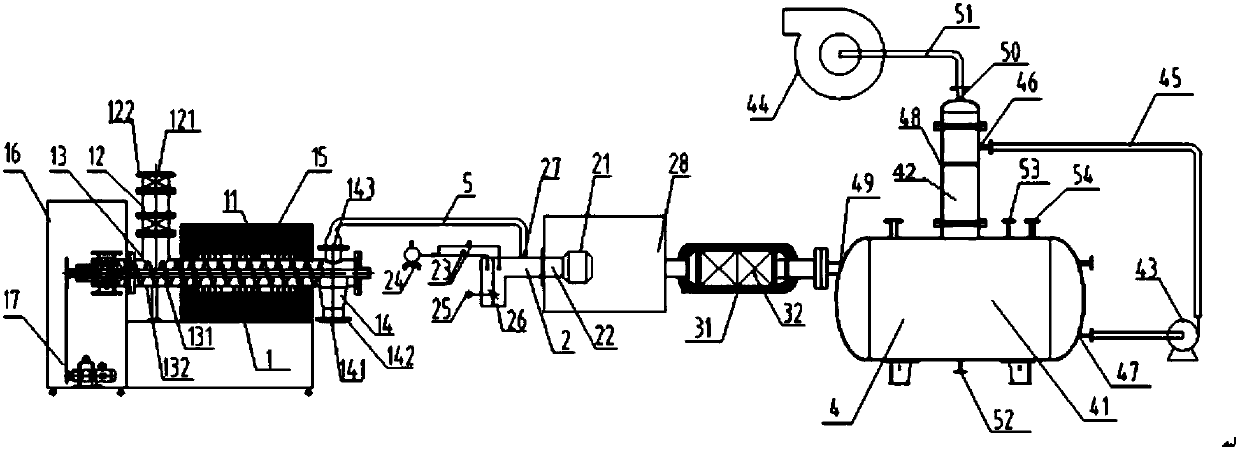

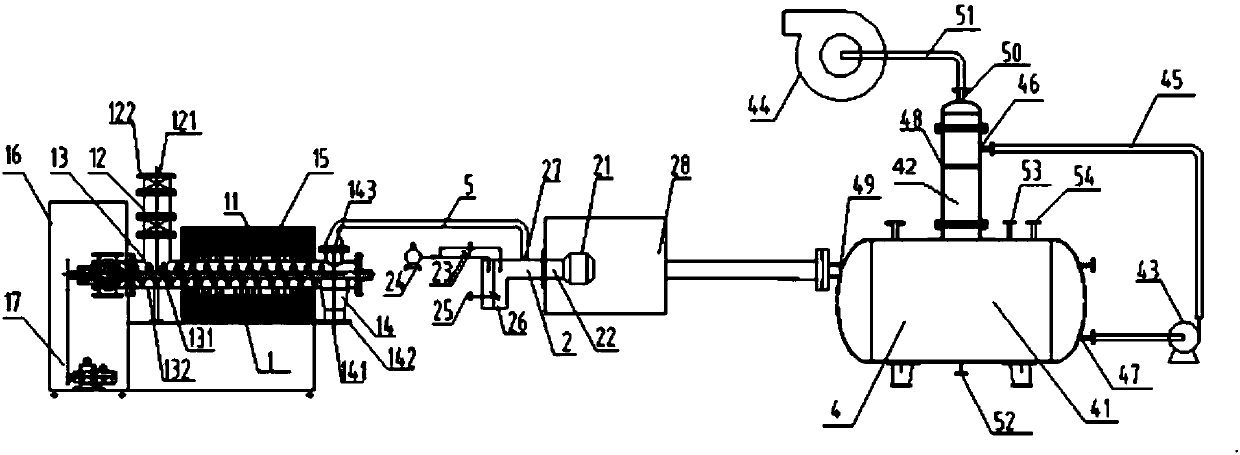

A low-medium radioactive waste treatment device

ActiveCN106653130BEasy to storeEasy landfill disposalRadioactive decontaminationOperational costsRadioactive agent

The invention belongs to the technical field of middle-low radioactive waste treatment equipment, relates to a waste treatment device, in particular to a middle-low radioactive waste treatment device. The middle-low radioactive waste treatment device is used for treating organic combustible type waste which is generated in a nuclear power plant and contains a middle-low radioactive substance, and is also used for treating middle-low radioactive waste generated in a hospital, a plant, a research institution and the like, so that volume reduction treatment and innocent treatment of the middle-low radioactive waste are achieved, and the middle-low radioactive waste treatment device comprises a pyrolysis reactor, a combustor, a catalytic converter, a spraying water scrubber and a high-temperature resistant pipeline, and all the devices are communicated through the high-temperature resistant pipeline; the middle-low radioactive waste treatment device makes it convenient for sealing up and landfill treatment of the waste, the volume reduction rate exceeds 95%, and the nuclear radiation pollution and atmospheric environmental pollution can be eliminated; a mild thermolcatalytic degradation process is adopted; the middle-low radioactive waste treatment device is simple in structure, reliable in principle, high in volume reduction rate, good in solidification effect, application environmentally friendly, low in investment and operation cost, and good in environmental protection effect, and has a good economic benefit and a wide market prospect.

Owner:青岛天和清原科技有限公司

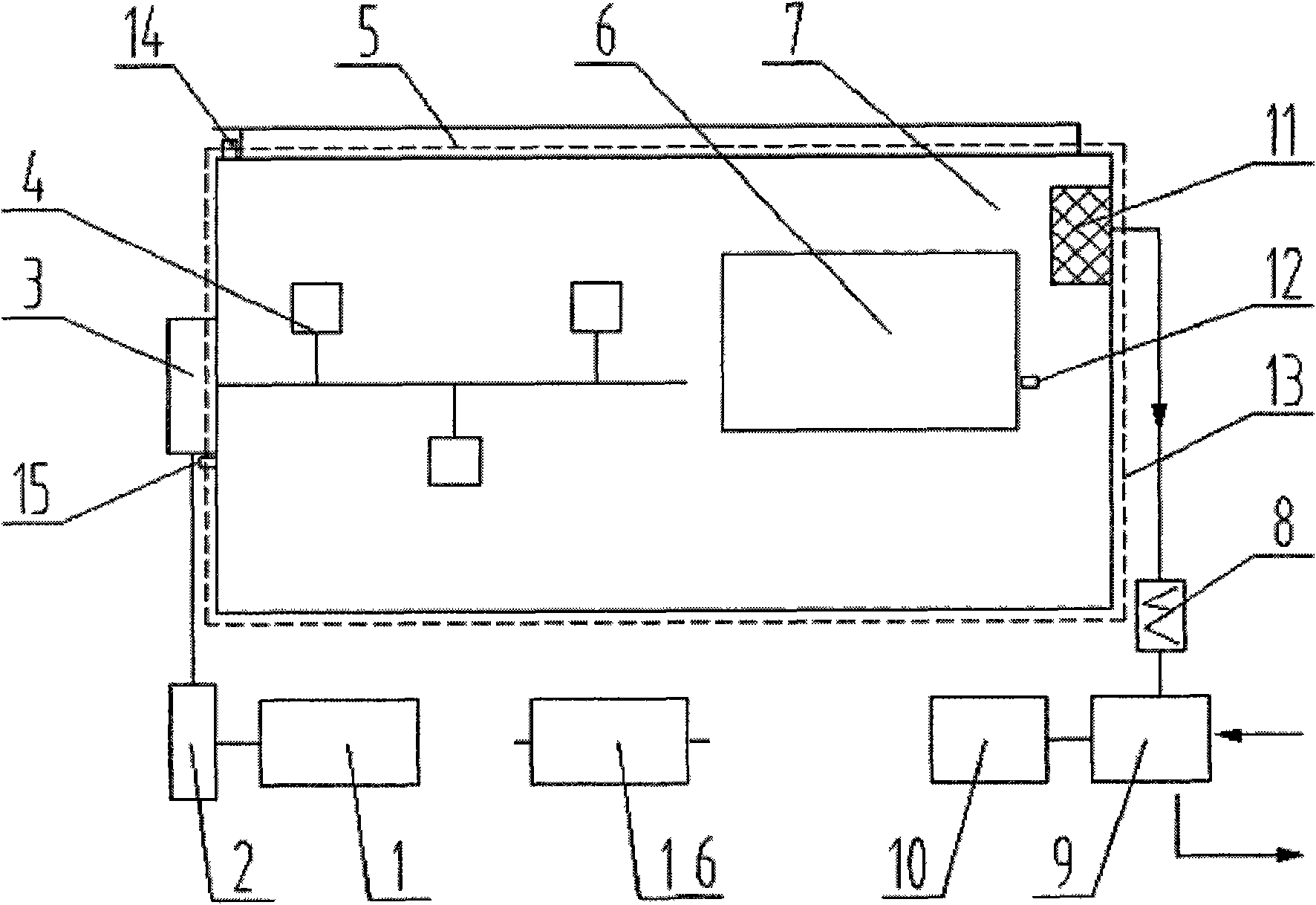

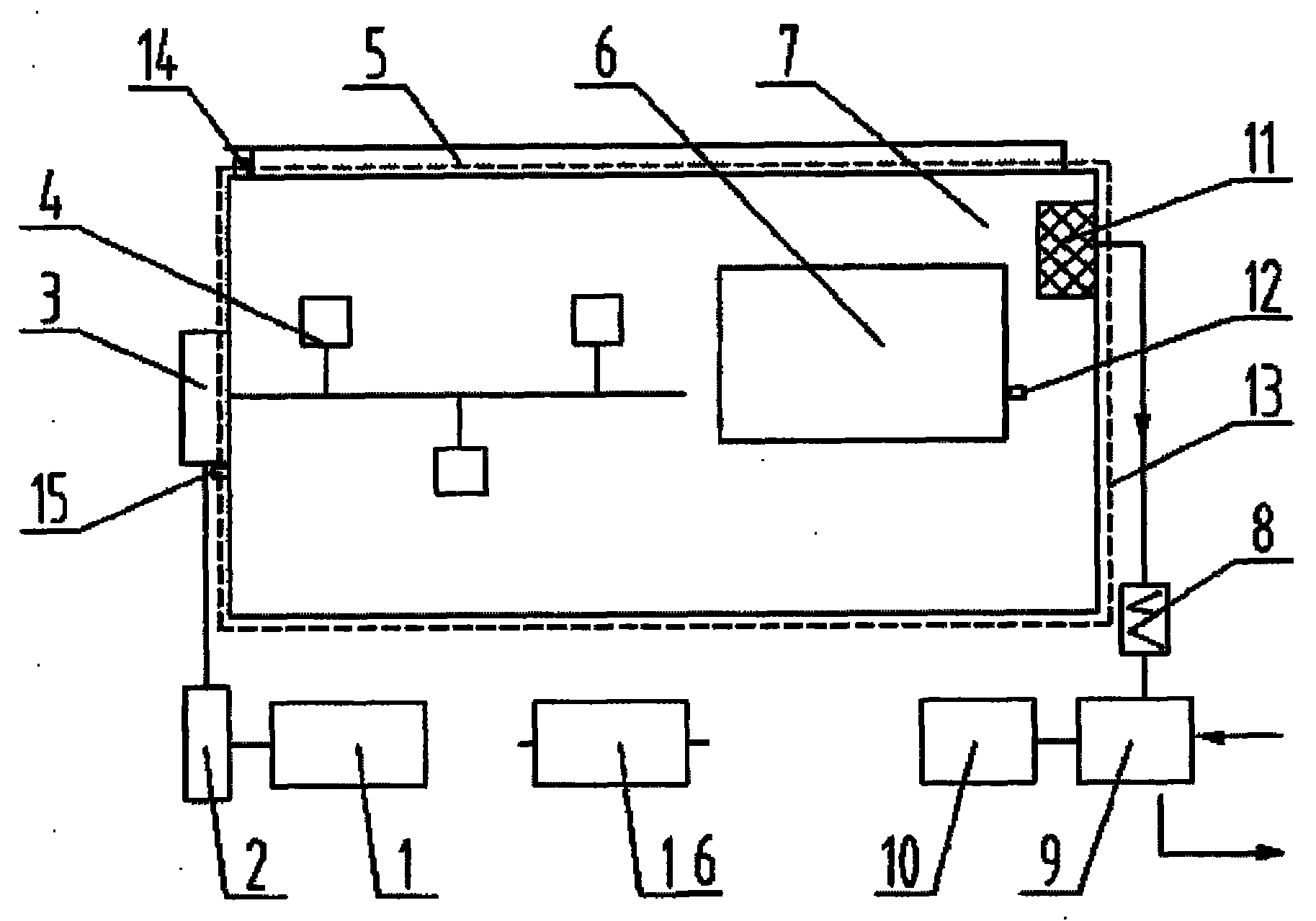

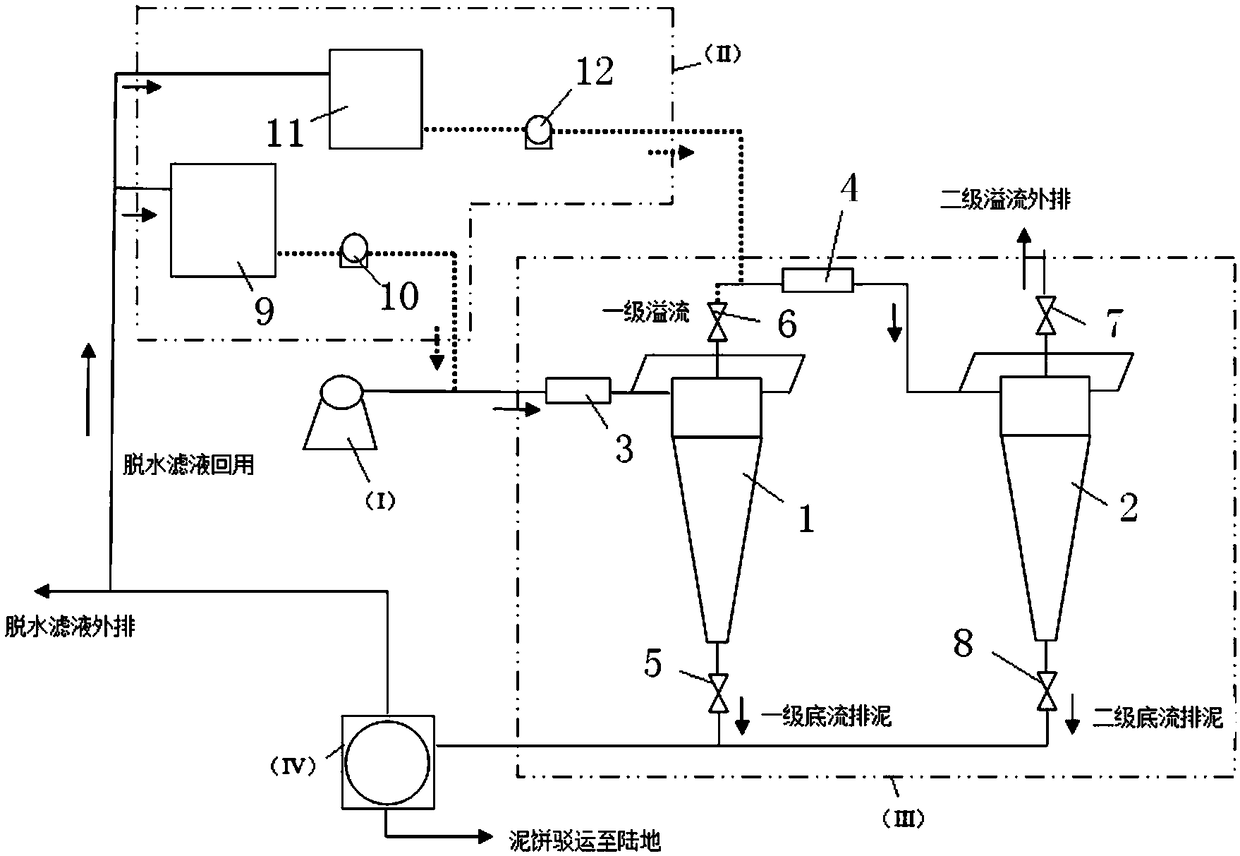

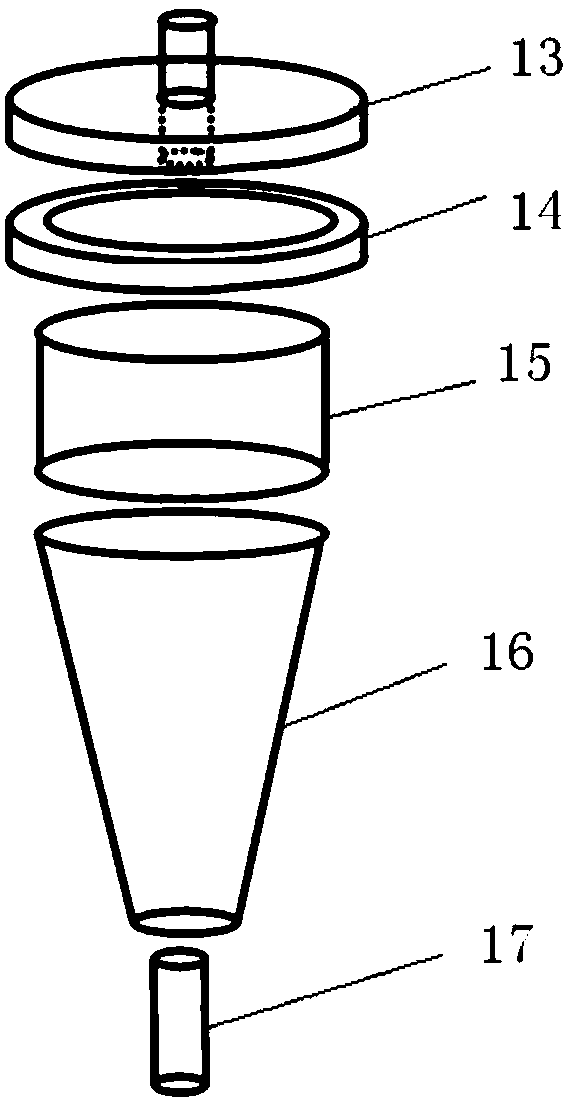

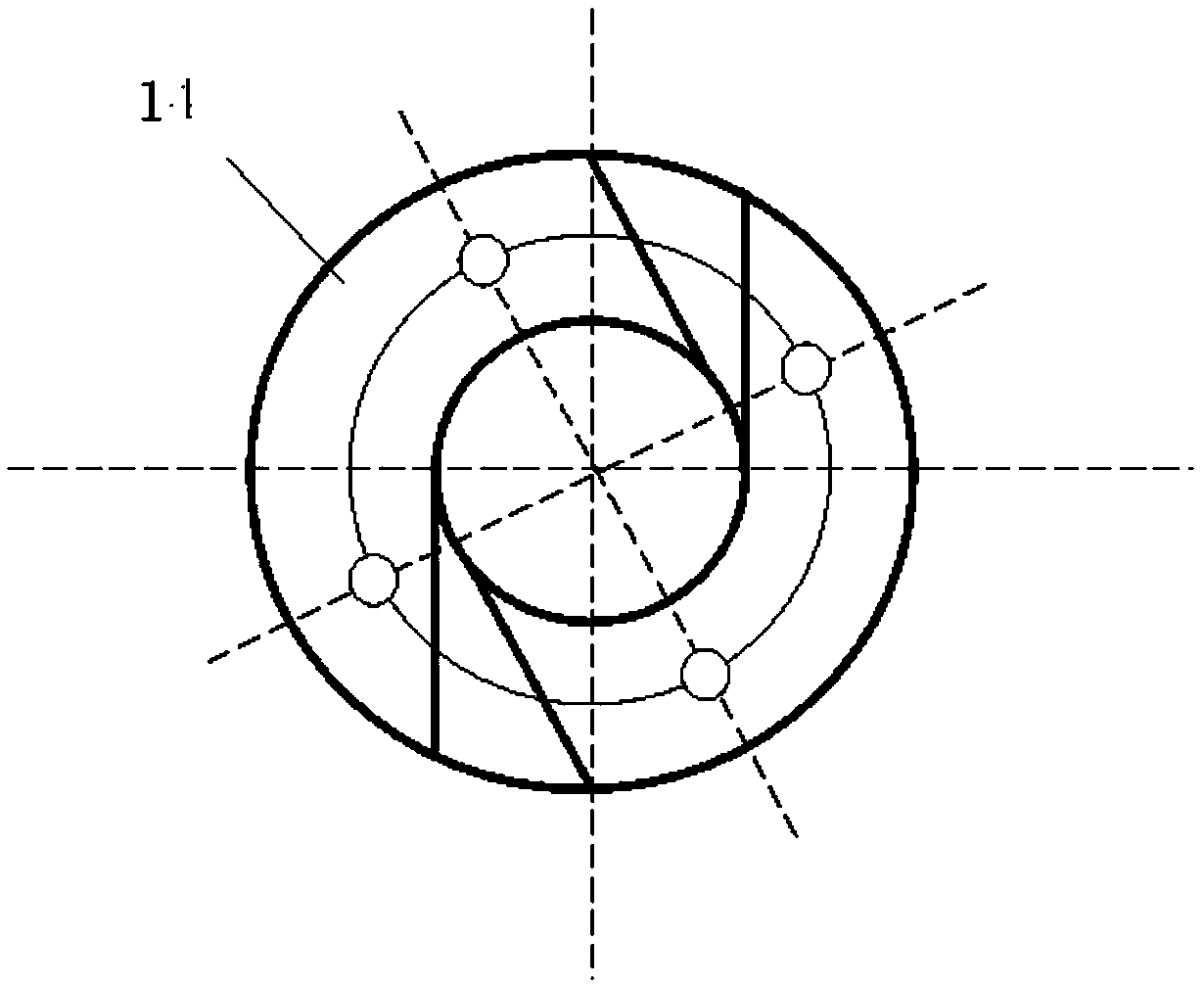

A method and device for in-situ volume reduction of dredged muddy water with high efficiency

ActiveCN106336108BAchieving Hydrocyclone SeparationEasy to separateSludge treatment by de-watering/drying/thickeningSmall footprintDehydration

The invention discloses a method for muddy water dredging and in-situ efficient volume reduction and a device for achieving the method. A dredge pump (1), a two-stage serial hydrocyclone system (III), a coagulant mixing adding system (II) and a centrifugal hydroextractor (IV) are arranged on a dredge ship. The centrifugal hydroextractor is directly connected with the two-stage serial hydrocyclone system. Muddy water is drawn and dredged through the dredge pump (1) on the dredge ship and fed into the two-stage serial hydrocyclone system for concentration volume reduction treatment, concentrated underflow mud obtained after volume reduction is discharged into the centrifugal hydroextractor to be dehydrated, and overflow clear liquid is directly drained into water. Mud cakes obtained after dehydration are lightered to land to be treated, one part of dehydration filter liquor is reused in the coagulant mixing adding system (II), and the rest is directly drained to the water. The method for muddy water dredging and in-situ efficient volume reduction and the device for achieving the method are small in size, small in occupied area and high in solid-liquid separation efficiency, and effluent can be directly drained into the water.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Domestic sludge pyrolysis treatment process

InactiveCN105174678BIncrease profitHigh capacity reduction rateSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisParticulatesHigh energy

The invention discloses a domestic sludge pyrolysis treatment process. After the sludge is sent to a dehydrator by a sludge pump for dehydration; The flue gas in the dry distillation section enters the preheating and drying section directly; the flue gas entering the preheating and drying section passes through the dust removal after heat dissipation; the flue gas entering the dry distillation section enters the high temperature gas purifier; The purification system separates tar and saturated water gas; the sludge charcoal is cooled and discharged by circulating saturated water gas. The sludge pyrolysis technology used in this process is an effective way to reduce, stabilize, harmless and recycle sludge, with high energy utilization rate, high capacity reduction rate and low operating cost; after combustion, the waste gas that needs to be treated The amount is small; the sludge does not need to be landfilled, and the incomplete incineration process is transformed into a gas complete combustion process, so that the emission of sludge carbon solid particles is extremely small, and it is more environmentally friendly.

Owner:ANHUI ZHUOXIN CLEAN ENERGY TECH CO LTD

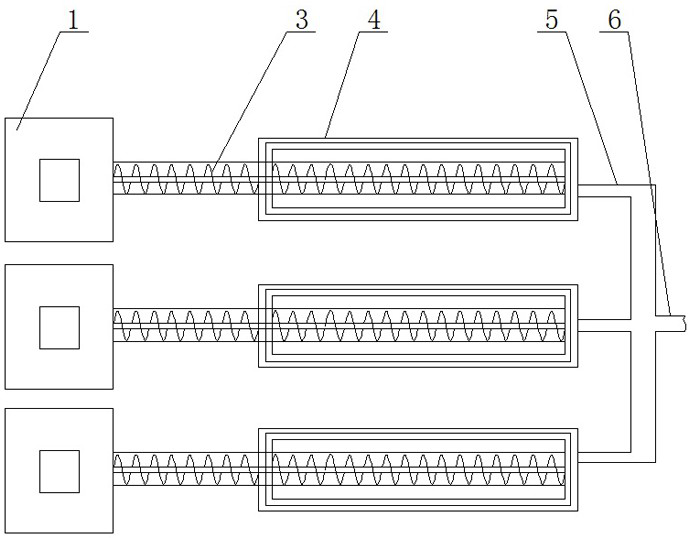

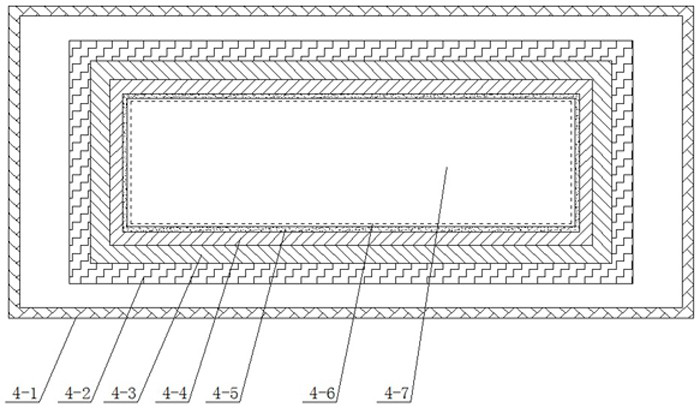

Marine kitchen garbage treatment device

ActiveCN101966528BHigh capacity reduction rateAvoid security issuesSolid waste disposalAutomatic controlLitter

The invention relates to a marine kitchen garbage treatment device. In the invention, an automatic control box controls a motor to be connected with a worm reducer so as to drive a blender in a machine body through a belt transmission device at one end of the machine body; the machine body above the blender is provided with a charging cover; the machine body is externally wrapped with an electricheat tracing belt; a discharging cover corresponding to the position of the blender is arranged on the side wall of the machine body; the machine body is internally provided with a filter screen; theinner cavity of the machine body is communicated with an induction unit through the filter screen and a three-way catalytic converter; the induction unit is connected with a suction inlet of a fan; and both the electric heat tracing belt and the fan are connected with the automatic control box. According to the invention, blending and strains are coordinated in the enclosed machine body to sufficiently digest the kitchen garbage; the mesophilic digestion environment in the machine body and the deodorization of the tail gas three-way catalytic converter are coordinately controlled to realize effective volume reduction and harmless treatment of the marine kitchen garbage; the device has the advantages of rational design and convenient and safe operation, so as to ensure that the volume reduction rate of the harmless treatment of the kitchen garbage is high and the tail gas discharge is pollution-free, therefore, the device is suitable for the marine kitchen garbage treatment.

Owner:JIANGSU NANJI MACHINERY

Refuse disposal system for marine gallery and disposal method thereof

ActiveCN101966527BHigh capacity reduction rateAvoid security issuesSolid waste disposalAutomatic controlDigestion

The invention relates to a refuse disposal system for marine galleys and a disposal method thereof. The refuse disposal system comprises a motor, a worm reduction gear, a machine body and an automatic control box. In an airtight gear body, galley refuses are fully digested by adopting a manner of stirring and matching strains in the closed machine body, and the effective volume reduction and the safety disposal of refuses on marine galleys are realized by matching the temperature digestion environment in the machine body and the deodorization of a tail gas three-way catalytic converter. The disposal system has the advantages of reasonable structure and design, simple disposal method, safe operation, safety disposal to galley refuses, high volume reduction rate and no exhaust emission, andis suitable for galley refuse disposal.

Owner:JIANGSU NANJI MACHINERY

A method for treating low-medium radioactive waste

ActiveCN106782734BEliminate pollutionEasy to storeRadioactive decontaminationOperational costsCombustor

The invention belongs to the technical field of intermediate- and low-level radioactive waste treatment and relates to an intermediate- and low-level radioactive waste treatment method. The intermediate- and low-level radioactive waste treatment method is achieved in an intermediate- and low-level radioactive waste treatment device and is used for treating organic combustible waste which contains radioactive substances and is generated by hospitals, factories, research institutions and nuclear power plants. The sludge volume reduction and the harmless treatment of the intermediate- and low-level radioactive waste are achieved. The sludge volume reduction rate is more than 95%. The difficulties of big deposit volume and difficult storage of the intermediate- and low-level radioactive waste are solved. Firstly, heating equipment is started, then a burner is started, then a spray water scrubber is started to carry out pre-treatment, then feedstock is carried out, the waste is pyrolyzed, burned, and experiences catalytic reaction, and finally, is purified and discharged. The process is simple in method, reliable in principle, high in sludge volume reduction rate, good in curing effect, environmentally friendly in application, low in investment and operation costs, energy-saving and environmentally friendly, and has a good economic benefit and a wide market prospect.

Owner:青岛天和清原科技有限公司

A deep dehydration method of cyanobacteria mud based on thermal rearrangement of capsular polysaccharide soft lattice

ActiveCN110563308BReduce addReduce inorganic contentSludge treatmentCyanobacteriaEnvironmental engineering

The invention provides a method for deep dehydration of blue-green algae mud based on capsular polysaccharide soft lattice thermal rearrangement, including pretreatment of blue-green algae mud, adding multivalent cationic salts through heating, and adjusting the pH value range to 1.5-5, so that blue-green algae mud The ratio of the storage modulus to the loss modulus is less than 3.0 to ensure the thermal rearrangement of the capsular polysaccharide soft lattice in the cyanobacteria mud, and then pump the treated cyanobacteria mud into the preheated dehydration device, preheat The temperature ranges from 70 to 100°C for hot-press dehydration. The invention has simple process, mild reaction, good dehydration effect, does not add conditioners such as calcium oxide and clay, not only saves costs, but also reduces the content of inorganic matter in the cyanobacteria cake, relatively increases the content of organic matter and calorific value in the filter cake, and does not It will increase the COD of the filtrate; the dehydrated and dried cyanobacteria powder has a high content of organic matter (volatile solids / total solids > 85%) and a high calorific value, which helps to expand the utilization of cyanobacteria resources and improve the quality of subsequent products.

Owner:JIANGNAN UNIV

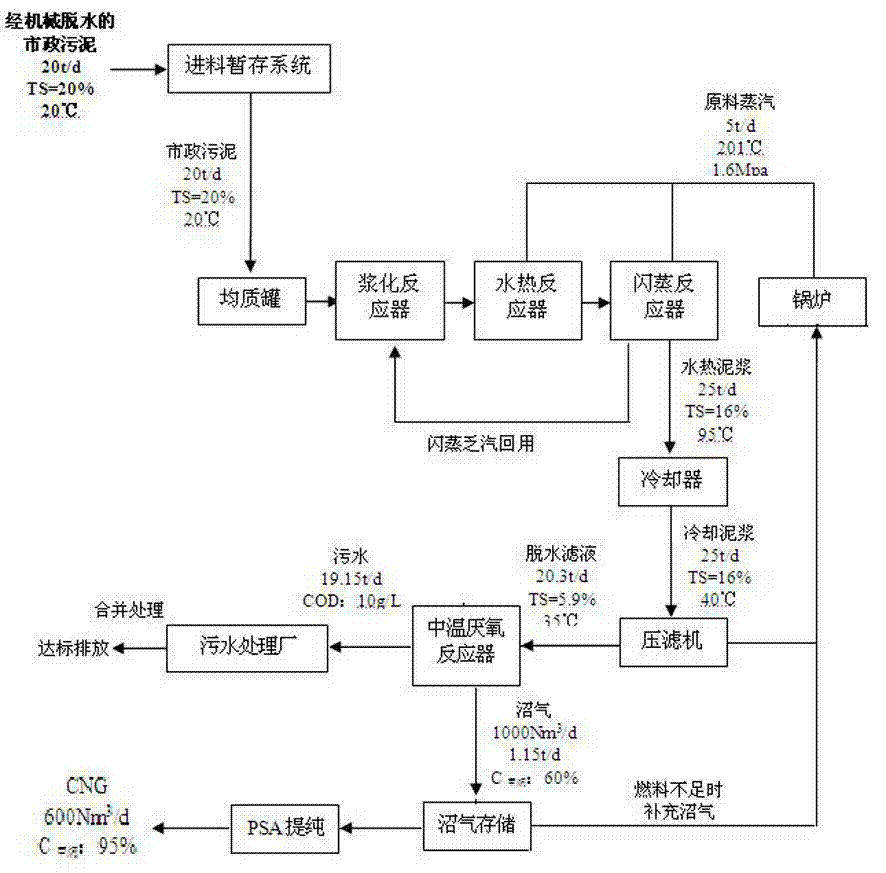

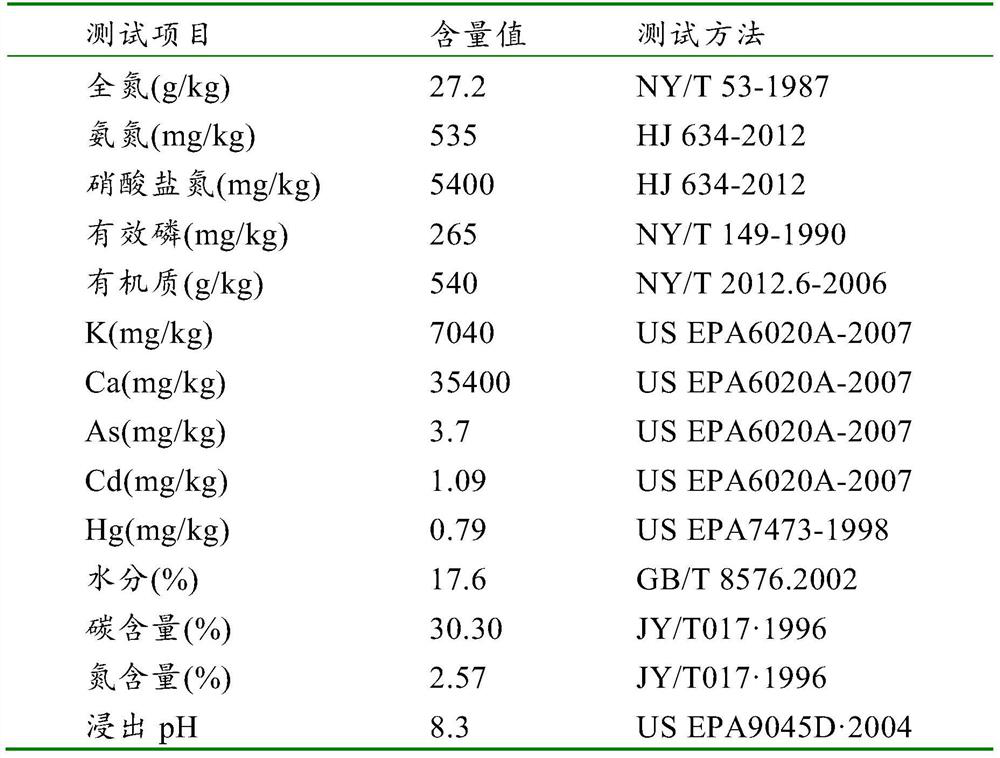

Sludge treatment process based on hydrothermal modification technology

InactiveCN102381820BAdvanced technologyThe reduction effect is obviousSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAnaerobic reactorHigh pressure

The invention relates to a sludge treatment process based on a hydrothermal modification technology. The sludge treatment process is carried out by comprising the following steps of: (1) temporarily storing the sludge which is subjected to mechanical dehydration and has the water content of 70-85% to a pretreatment unit and deodorizing the sludge; (2) introducing to a homogeneous device, fully mixing and homogenizing, introducing the homogenized sludge to a slurrying device, introducing the slurried sludge to a hydrothermal reactor for hydrothermal reaction, and introducing the hydrothermal sludge to a flash evaporator for decompression and flash evaporation; (3) cooling to 35-45 DEG C by using a cooler, then introducing to a high-pressure diaphragm pressure filter for pressure filtering and dehydration to obtain a dehydrated mud cake with the solid content of 35-45% and dehydrated filtrate; (4) introducing the dehydrated filtrate to an intermediate temperature anaerobic reactor, wherein the residence time is for 5.5-7.5d, the inlet water temperature is controlled below 40 DEG C, and the anaerobic reaction temperature is 30-40 DEG C; and (5) preparing a biomass fuel rod by using the dehydrated mud cake, and introducing the biomass fuel rod to a boiler to provide steam for the hydrothermal reactor and the flash evaporator. The sludge treatment process has the advantages of goodtreatment effect, obvious volume reduction effect, high harmless degree, recycling of methane, good economic benefit and the like.

Owner:FUZHOU DEV ZONE SANSHUI ENVIRONMENTAL PROTECTION TECH

Application of Ferrous Fe Supply Liquid in Promoting the Fermentation of Bacteria for Treating Petroleum Residue

ActiveCN109848183BAccelerated Decomposition and FermentationShorten the fermentation cycleSolid waste disposalBiotechnologyPhotosynthetic bacteria

The invention discloses the application of a divalent iron supply liquid in promoting the fermentation of the flora used to treat petroleum residues. The flora used to treat petroleum residues includes the following genera: Methanobacterium, Rhizopus, Trichoderma, Pseudomonas bacteria, Aspergillus, Penicillium, Rhodopseudomonas, Lactobacillus, photosynthetic bacteria and yeast; the ferrous iron supply liquid is a mixed solution containing ferrous ions, and the mixed solution Contains sodium ferrous citrate, ferrous sulfate, ferrous citrate, the molar mass ratio of sodium ferrous citrate, ferrous sulfate, ferrous citrate in the mixed solution is 1:0.28~0.38:0.17~0.23, the two The pH of the valent iron supply liquid is 4.5-5.5. In the present invention, the ferrous iron supply liquid can promote the growth and development of the flora, accelerate the metabolism of the flora, and accelerate the fermentation and decomposition of petroleum residues by the flora, which can greatly shorten the fermentation cycle, increase the volume reduction rate, and at the same time reduce the heavy metal Passivate.

Owner:浙江科罗尼生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com