Sludge treatment process based on hydrothermal modification technology

A technology for sludge treatment and hydrothermal modification, which is applied in the direction of sludge treatment, sludge treatment, water/sludge/sewage treatment, etc., and can solve the problems affecting city appearance, ecological safety, increased incineration operation costs, and disposal methods Improper and other problems, to achieve obvious effect of volume reduction, improvement of anaerobic digestion performance, improvement of dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

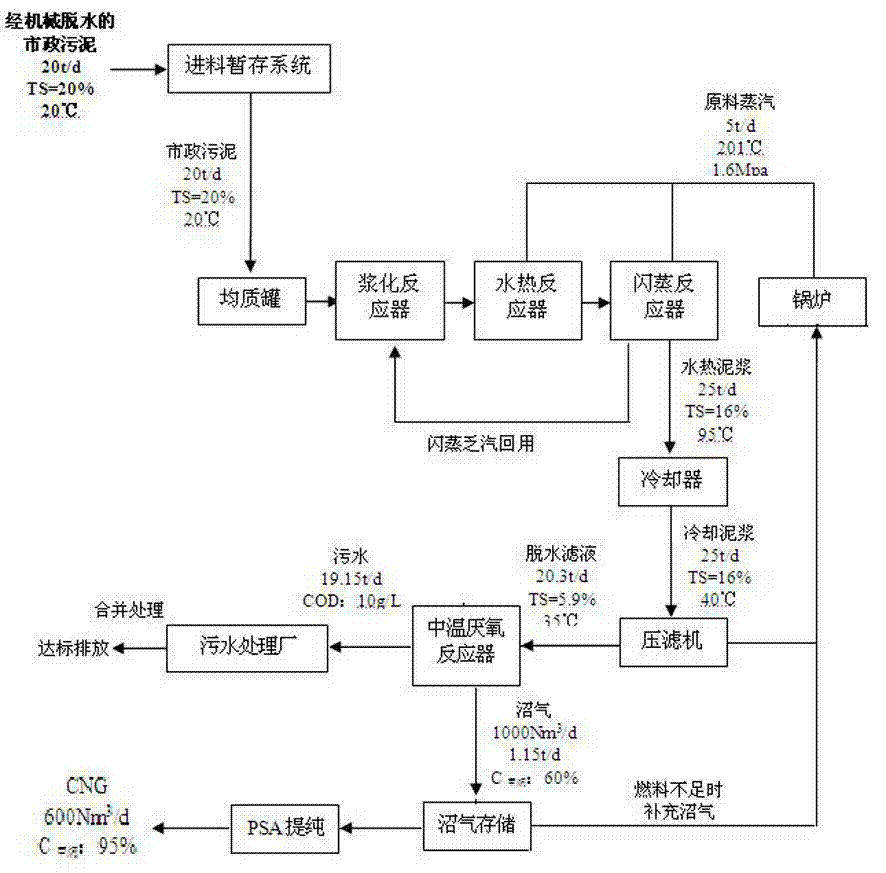

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] The sludge treatment process based on the hydrothermal modification technology of the present invention, the process flow is briefly described as follows:

[0034] (1) Municipal sludge 20t / d (sludge after mechanical dehydration in municipal sewage treatment plants, the moisture content is 70% ~ 85%, as the preferred general moisture content of 80%) is transferred to the treatment plant for temporary storage and deodorization .

[0035] (2) The municipal sludge treated above enters the hydrothermal unit, and firstly enters the homogenization tank to fully mix and homogenize. After homogenization, the sludge enters the slurry reactor, and preheats the slurry by flashing and exhausting back-mixing. Mechanical synergistic stirring is carried out while the steam is preheated to improve the slurrying efficiency; after slurrying, the sludge enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com