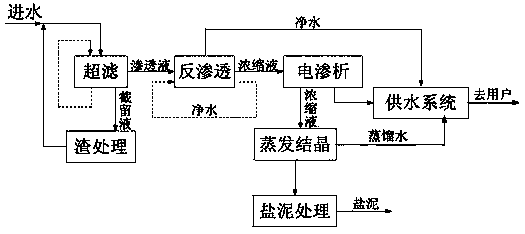

Membrane and evaporation crystallization integrated process with zero discharge of high-salinity industrial wastewater

A technology of industrial wastewater and evaporative crystallization, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. The effect of low production cost, advanced technology and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1500mg / L for TDS, 5mg / L for SS, COD Cr Ultrafiltration pretreatment for 35mg / L industrial wastewater, using a hollow fiber organic membrane with a membrane pore size of 10nm to filter under the condition of a transmembrane pressure difference of 0.5MPa, the TDS of the produced water is 1500mg / L, and the SS is about 1mg / L. COD Cr The permeate after ultrafiltration pretreatment is transported to the reverse osmosis membrane filtration device through a high-pressure pump, and the polyamide reverse osmosis membrane is used for concentration treatment. The TDS of the concentrated water reaches 27000mg / L, and the COD Cr When it is 500mg / L, the concentration is stopped, and the TDS of the permeate side fresh water is 50mg / L, COD Cr The fresh water is reused; the permeate after reverse osmosis treatment is transported to the packed bed electrodialysis device through a high-pressure pump for concentration treatment, and the TDS in the concentrated water reaches 100,000 mg / L, an...

Embodiment 2

[0022] 4000mg / L for TDS, 50mg / L for SS, COD Cr Ultrafiltration pretreatment for 72mg / L industrial wastewater, using a tubular ceramic membrane with a membrane pore size of 100nm to filter under the condition of a transmembrane pressure difference of 0.1MPa, the TDS of the produced water is 4000mg / L, and the SS is 10mg / L. COD Cr The permeate after ultrafiltration pretreatment is sent to the reverse osmosis membrane filtration device through a high-pressure pump, and the cellulose acetate reverse osmosis membrane is used for concentration treatment. The TDS of concentrated water reaches 72000mg / L, COD Cr Stop concentration when it reaches 690mg / L, and the TDS of water measured by osmosis is 420mg / L, COD Cr The effluent from the permeate side is reused; the permeate after reverse osmosis treatment is transported to the bipolar membrane electrodialysis device through a high-pressure pump for concentration treatment. The TDS in the concentrated water reaches 172000mg / L, and the CO...

Embodiment 3

[0024] 2000mg / L for TDS, 30mg / L for SS, COD Cr Ultrafiltration pretreatment for 86mg / L industrial wastewater, using a roll-type organic membrane with a membrane pore size of 50nm to filter under the condition of a transmembrane pressure difference of 0.2MPa, the TDS of the produced water is 2000mg / L, and the SS is 4mg / L. COD Cr The permeate after ultrafiltration pretreatment is sent to the reverse osmosis membrane filtration device through a high-pressure pump, and the polyamide and cellulose acetate composite reverse osmosis membrane is used for concentration treatment until the TDS of the concentrated water reaches 36000mg / L. L. COD Cr When it reaches 950mg / L, the clean water on the permeate side is reused, and the TDS of the effluent on the permeate side is 235mg / L, and the COD Cr Concentrated water is 50mg / L; the concentrated water after reverse osmosis treatment is transported to the reverse electrode electrodialysis device through a high-pressure pump for concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com