Patents

Literature

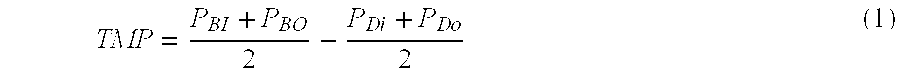

183 results about "Transmembrane pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

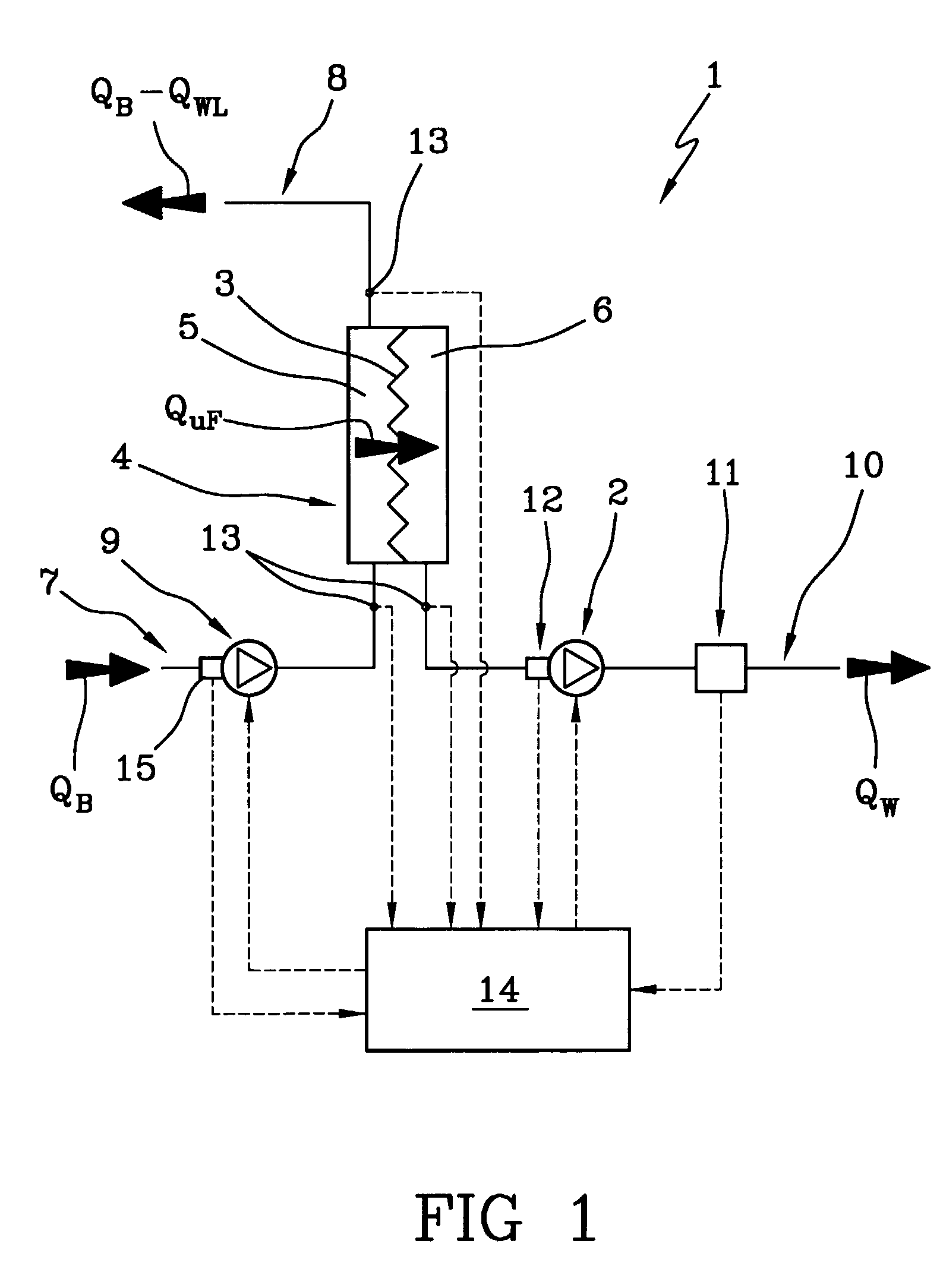

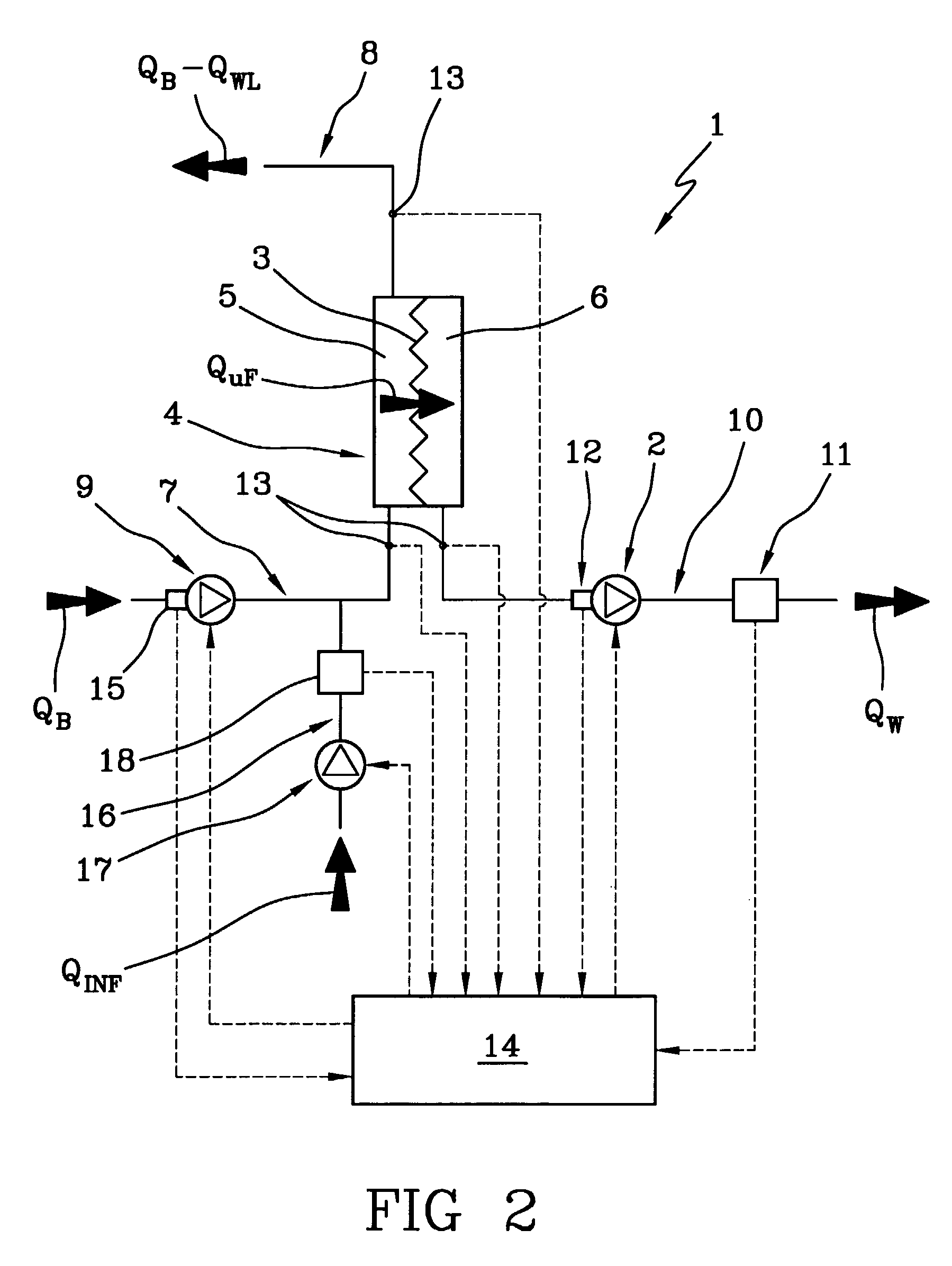

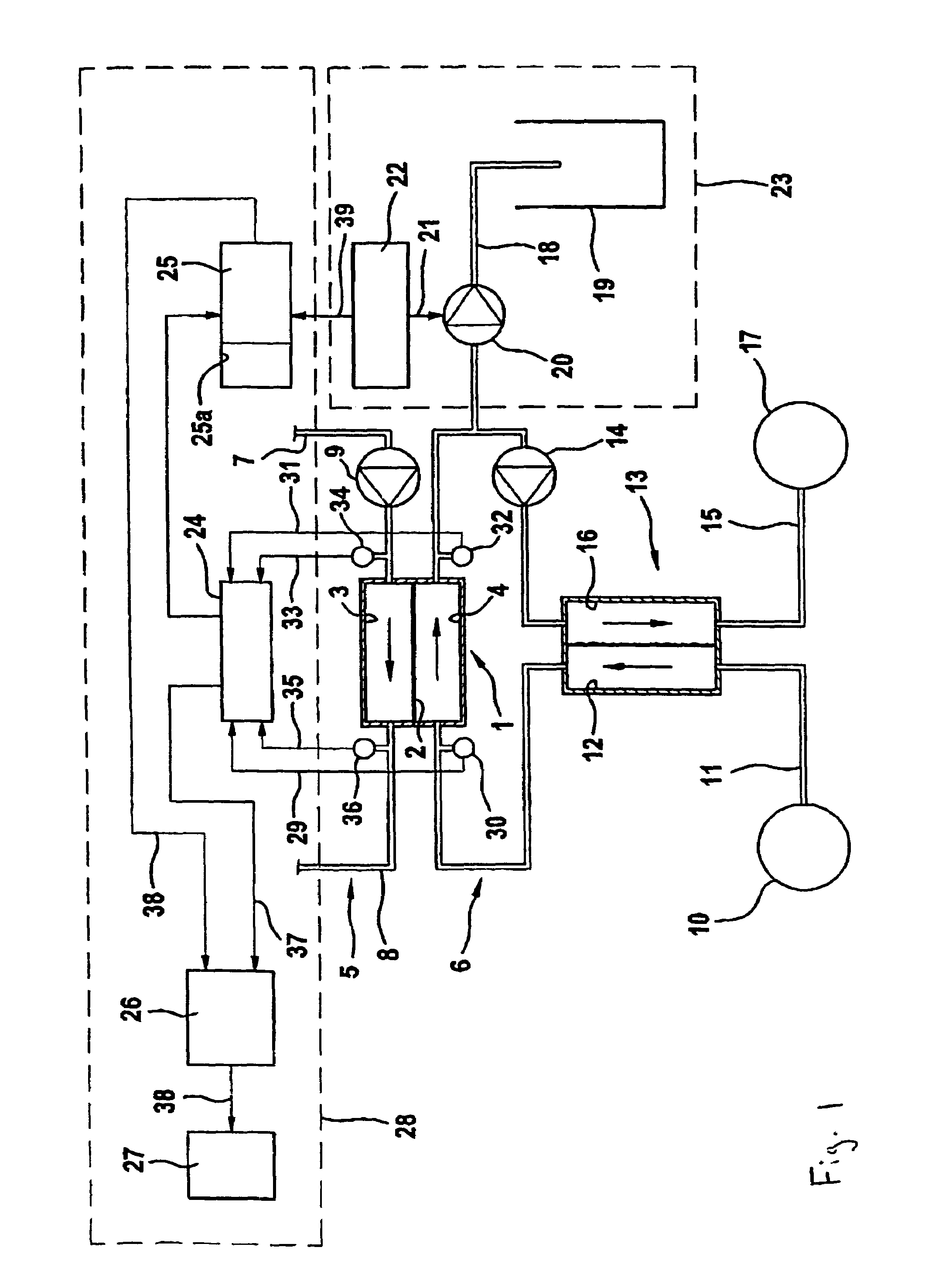

Machine and Procedure For Extracorporeal Treatment of Blood

ActiveUS20080215247A1Shorten treatment timeIncrease the number ofOther blood circulation devicesHaemofiltrationBlood treatmentsBody fluid

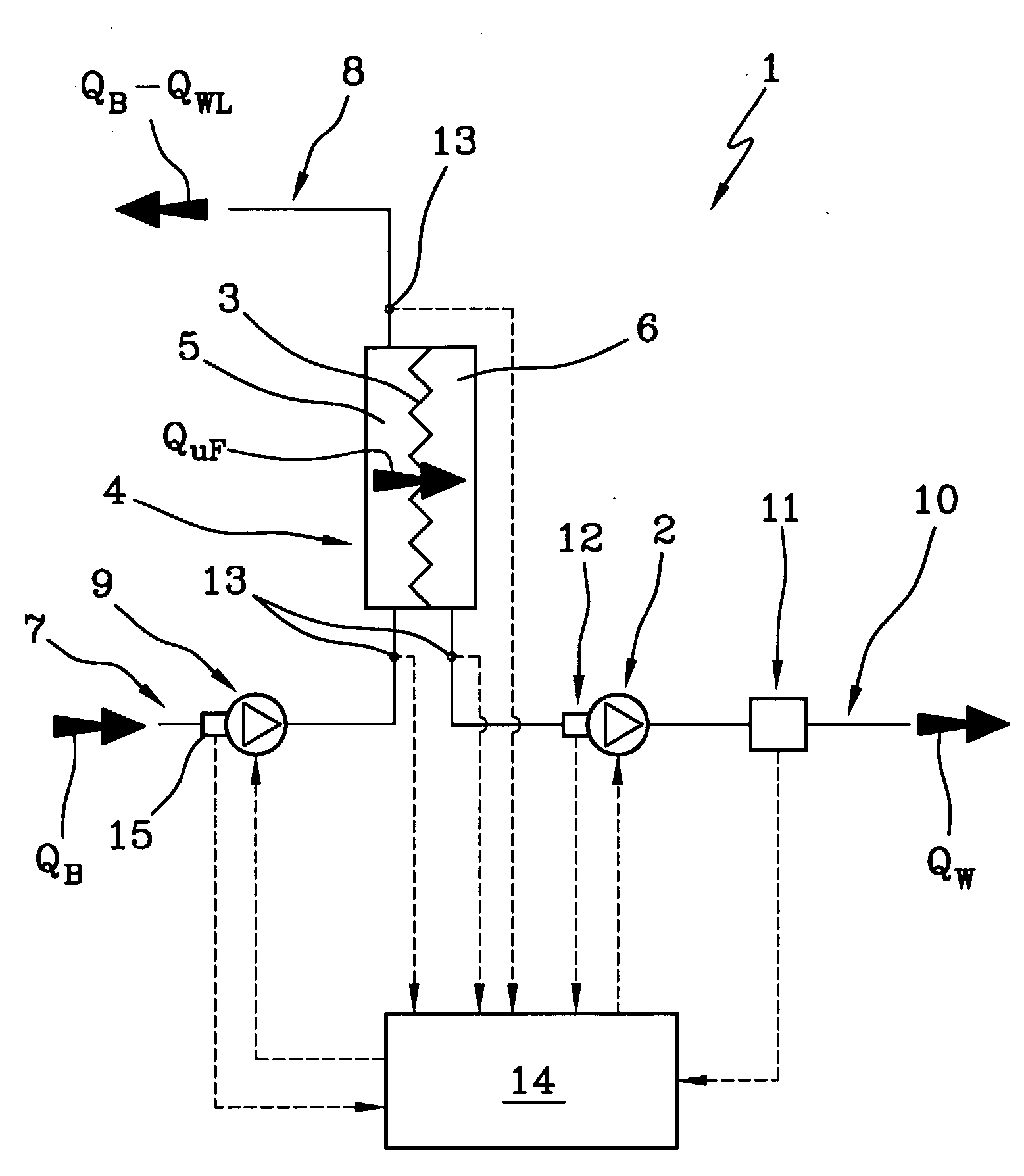

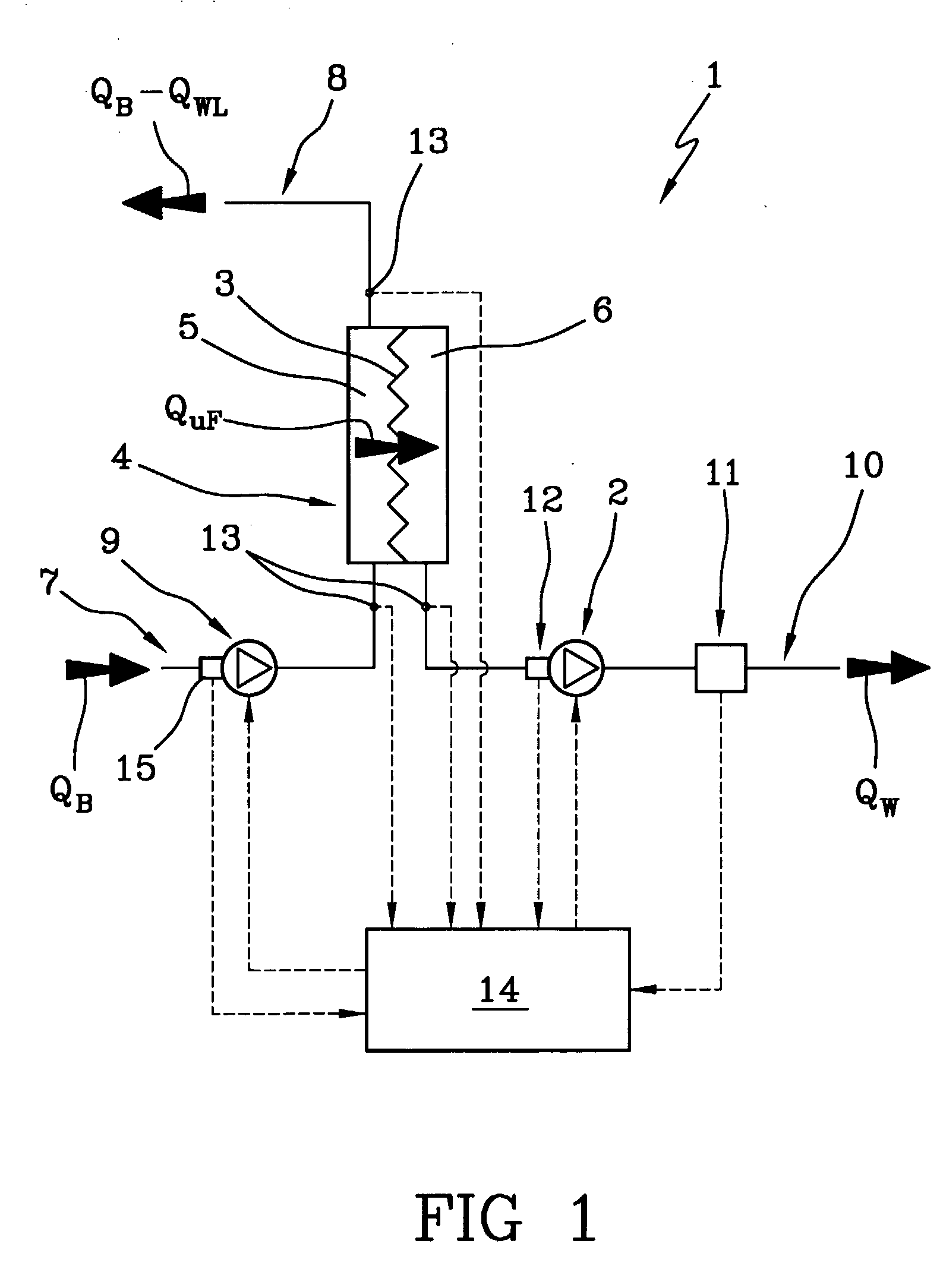

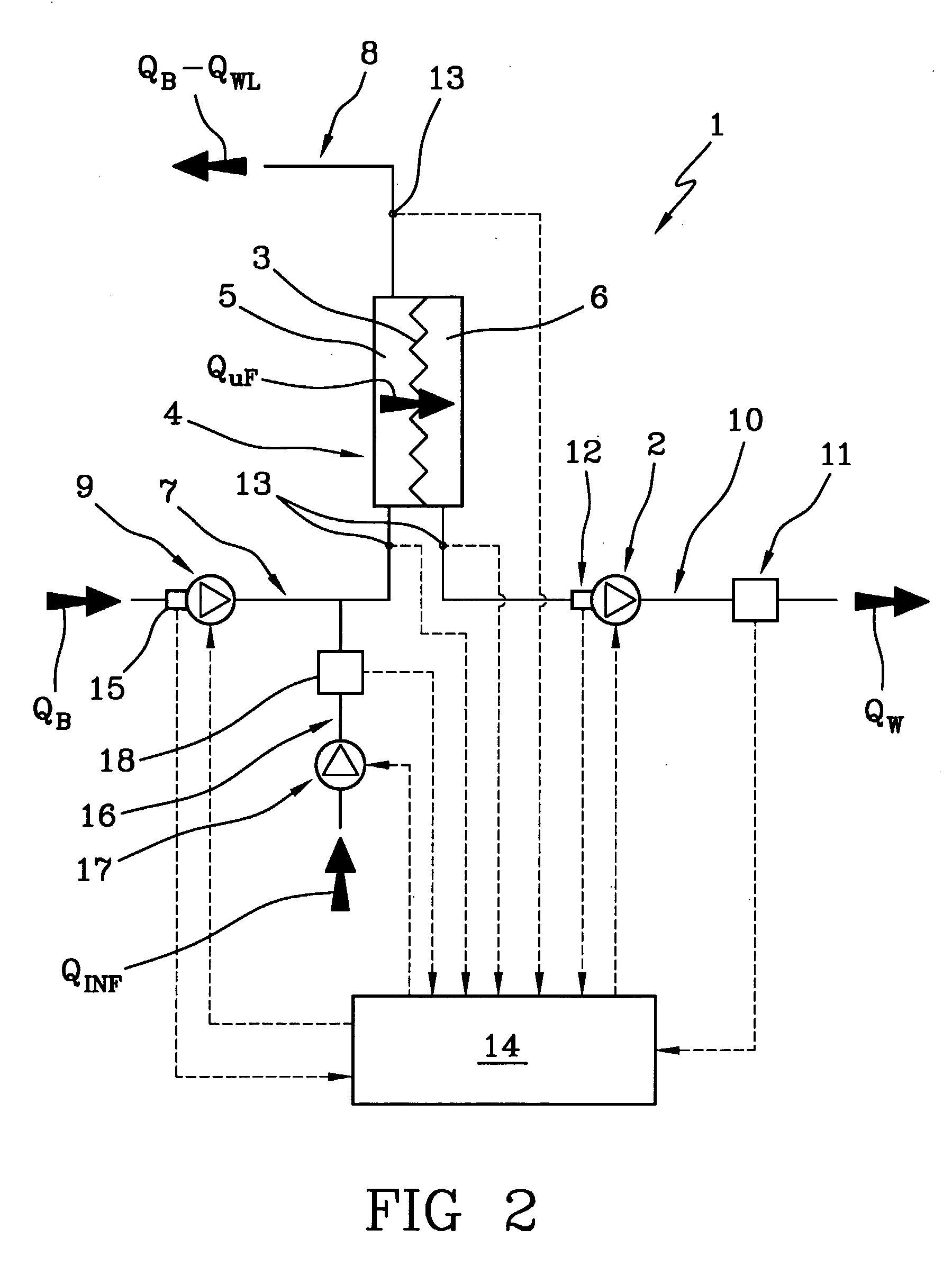

A machine (1) for extracorporeal blood treatment comprises a device (2) for ultrafiltration of a liquid through a semi-permeable membrane (3) of a blood treatment device (4), a first sensor (11) for ultrafiltration rate through the membrane, a second group of sensors (13) for measuring a trans-membrane pressure, and a programmed controller (14) for calculating a maximum ultrafiltration rate as a function of the transmembrane pressure. The machine is suitable for kidney failure treatments, such as hemofiltration and hemodiafiltration. In a relatively short time the machine enables a large quantity of corporeal blood to be removed from the patient.

Owner:GAMBRO LUNDIA AB

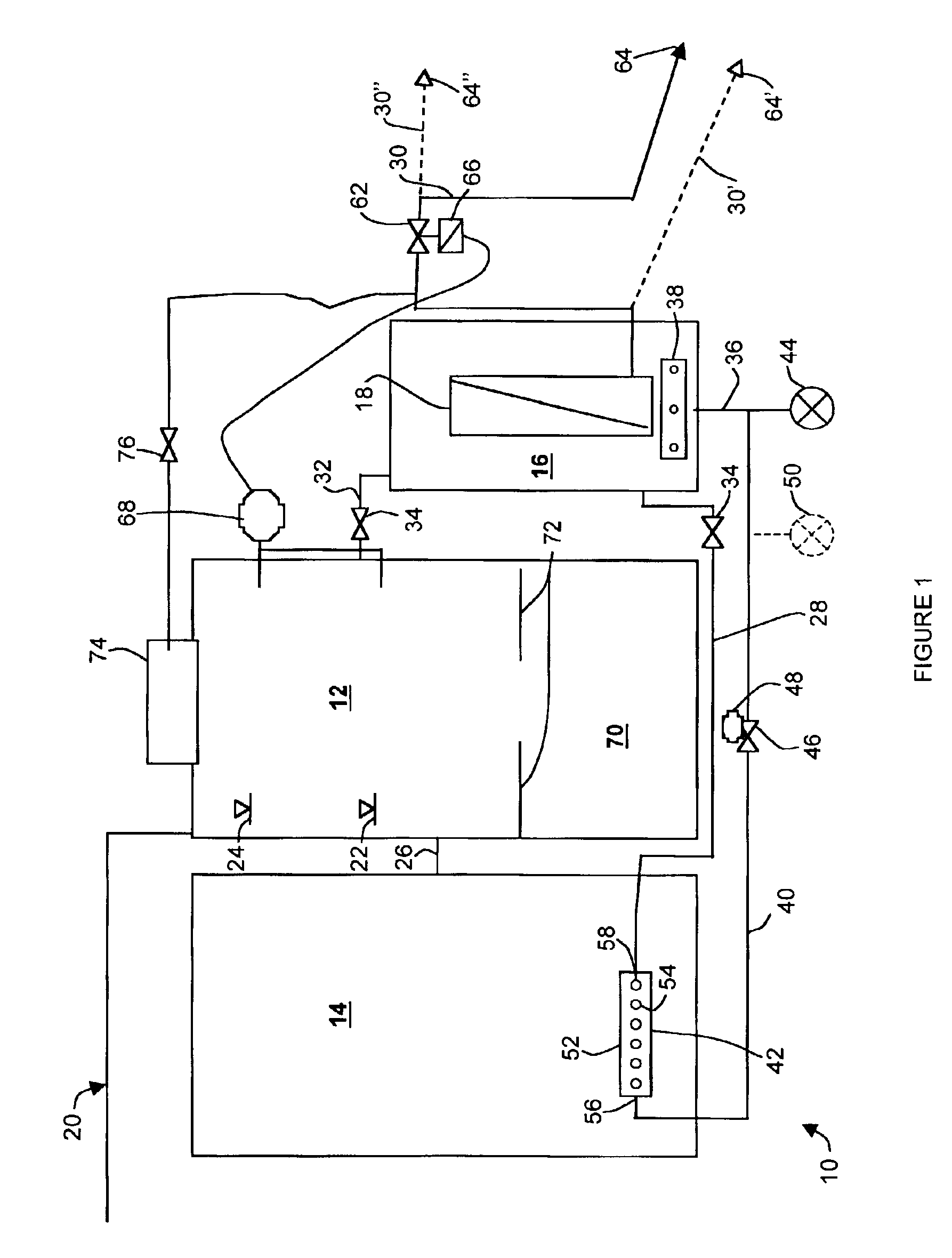

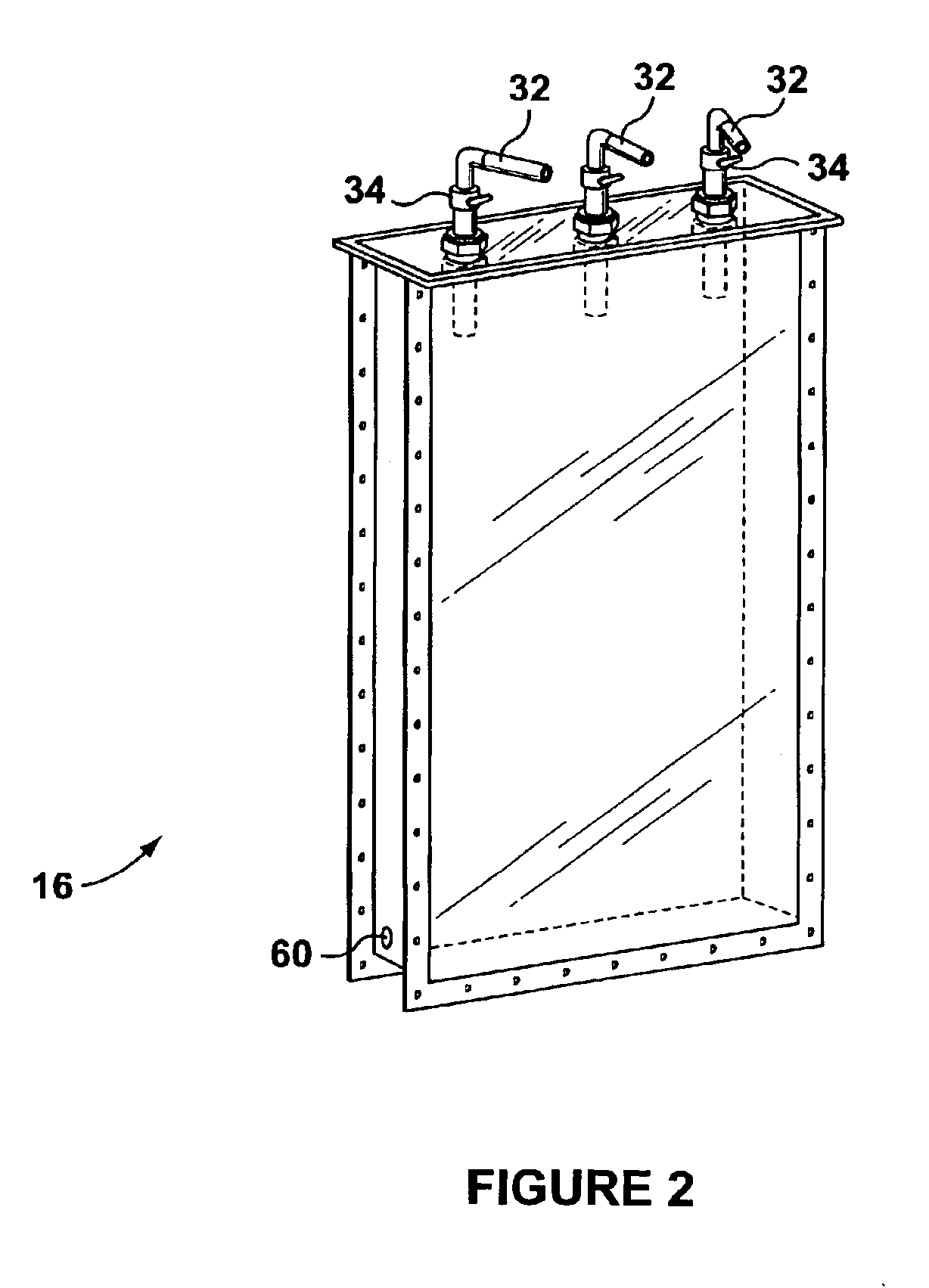

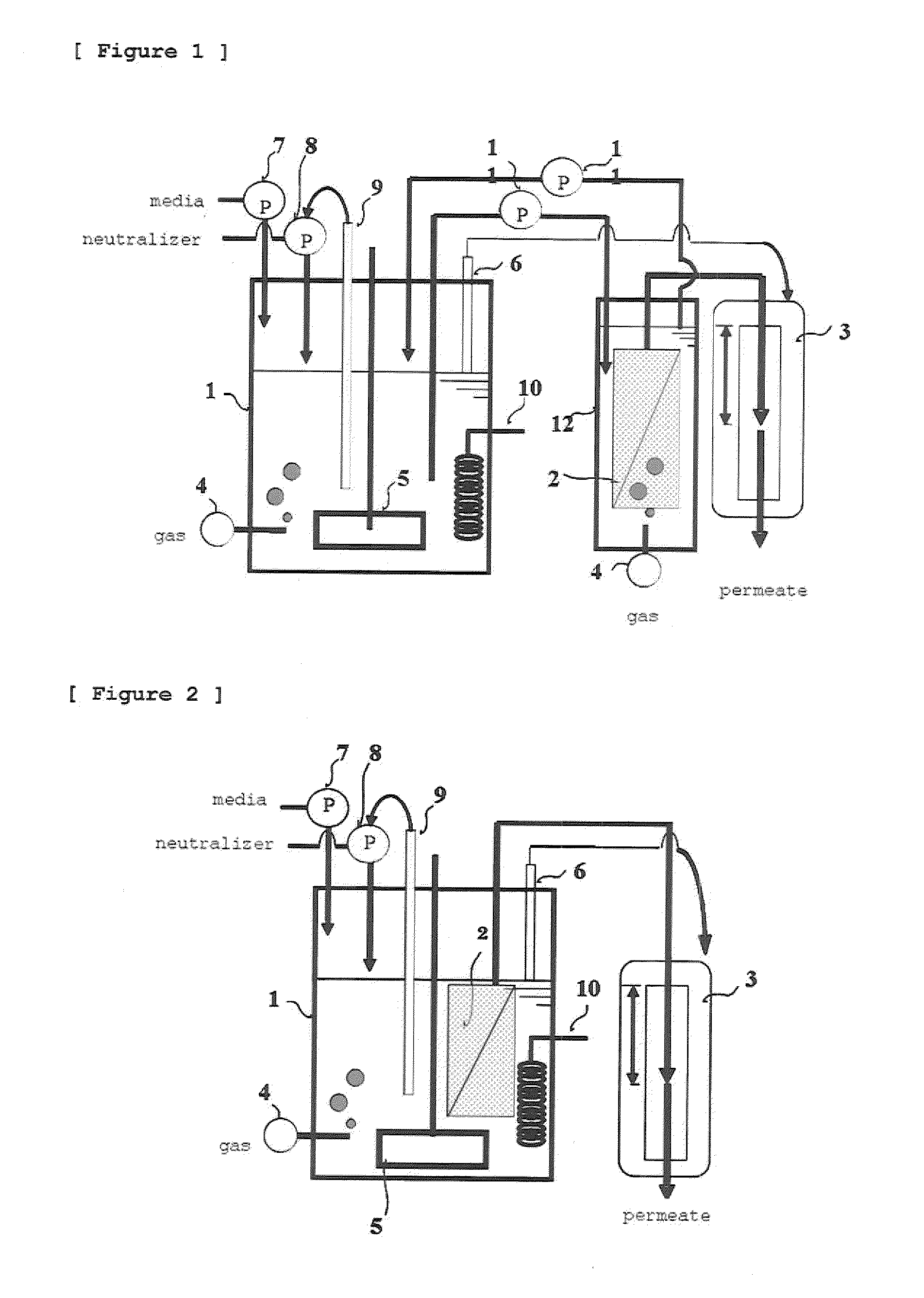

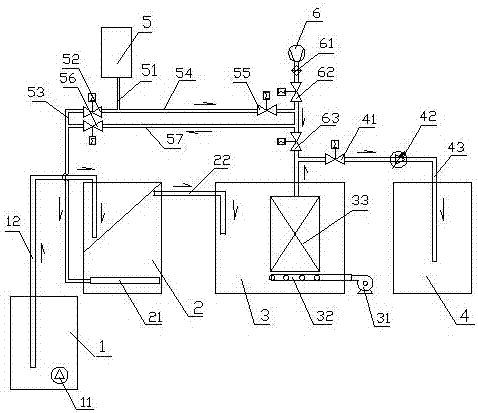

Membrane bioreactor, process and aerator

InactiveUS6863817B2Increase pressureEasy to moveTreatment using aerobic processesUsing liquid separation agentSiphonGravity flow

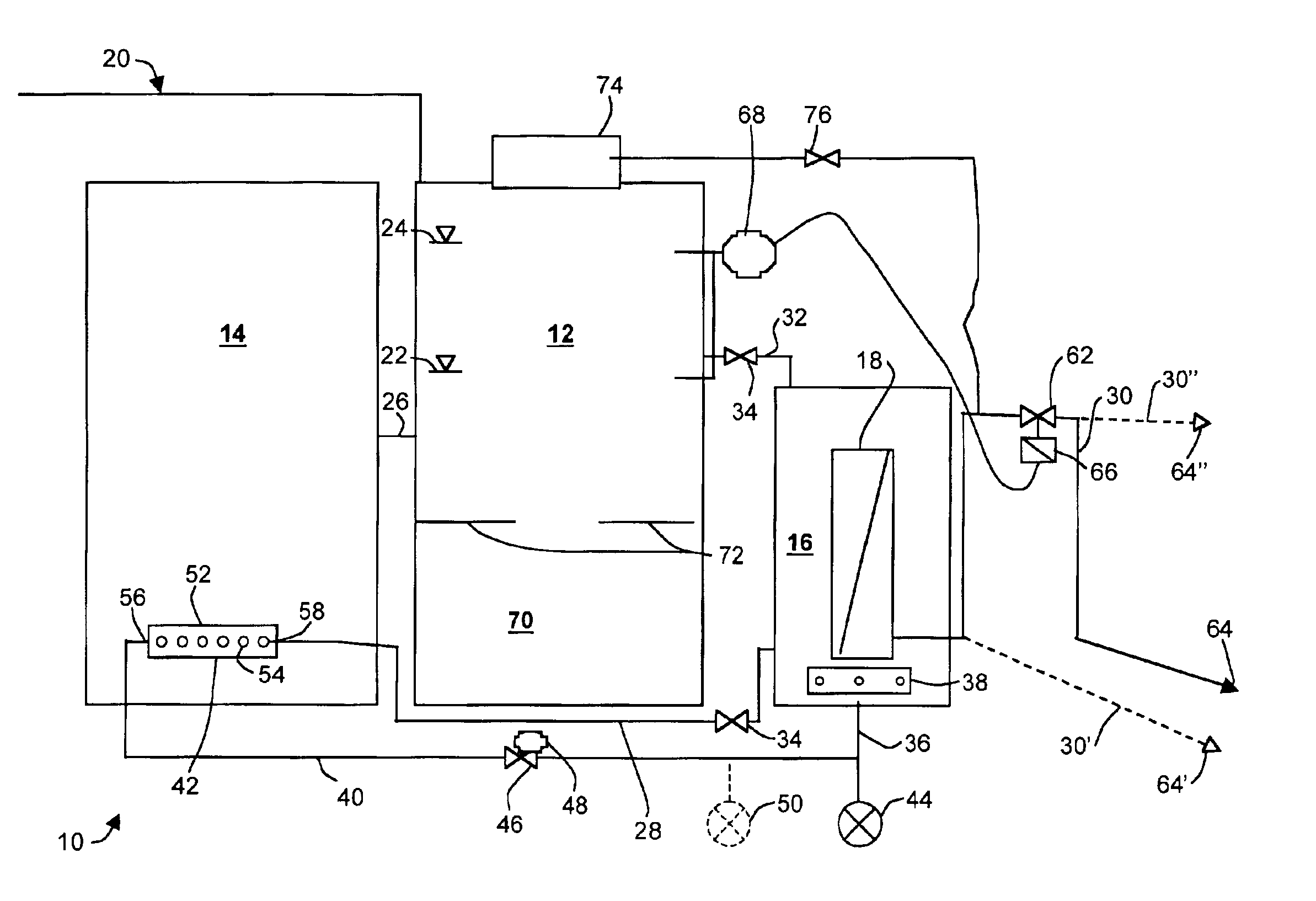

A reactor has an aerobic tank, an anoxic tank and a sealed membrane tank with conduits for circulating mixed liquor between them. Permeation starts when the mixed liquor reaches a high level and stops when the mixed liquor reaches a low level. A sensor, for detecting the mixed liquor level, may stop and start permeation. Pressure builds in the membrane tank when membrane air is on. Transmembrane pressure is also provided by gravity flow or siphon. Membrane air generates an air lift which drives the mixed liquor circulation. The total amount of air provided by an air source is divided and varied in time between the membrane aerator and the process aerator. The process aerator acts as a screening inlet to the conduit to the membrane tank. Chemical maintenance cleaning is provided by gravity flow.

Owner:ZENON TECH PARTNESHIP

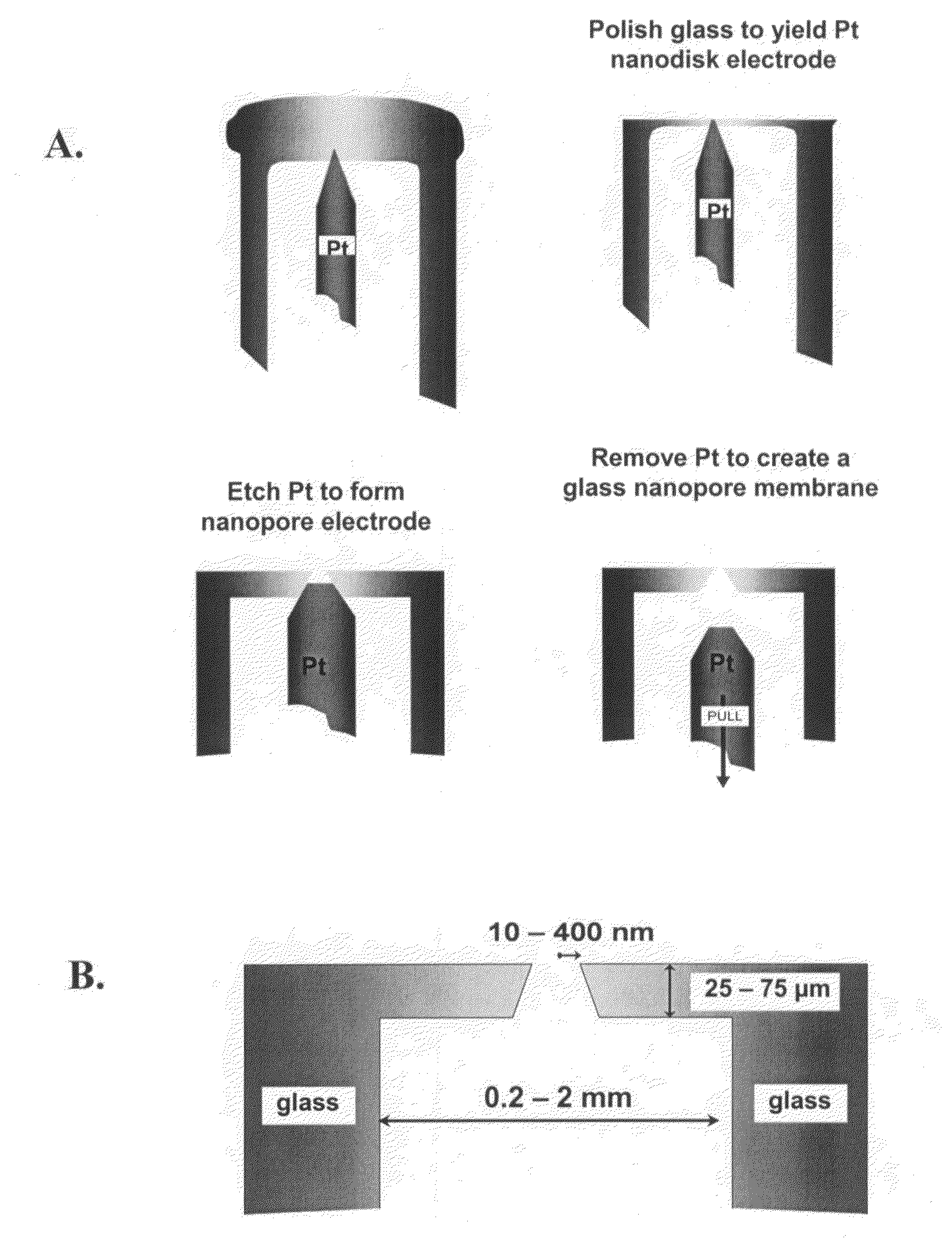

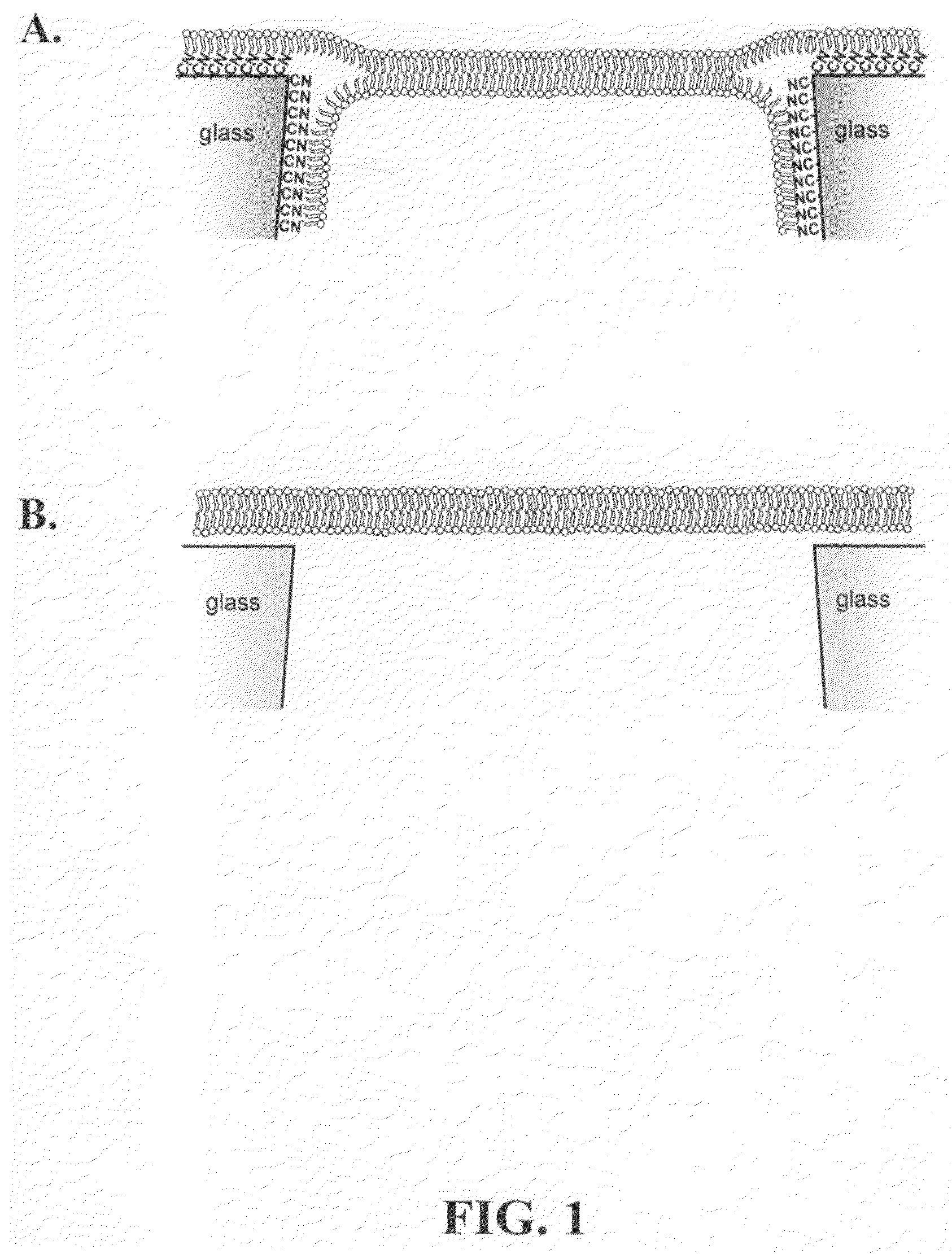

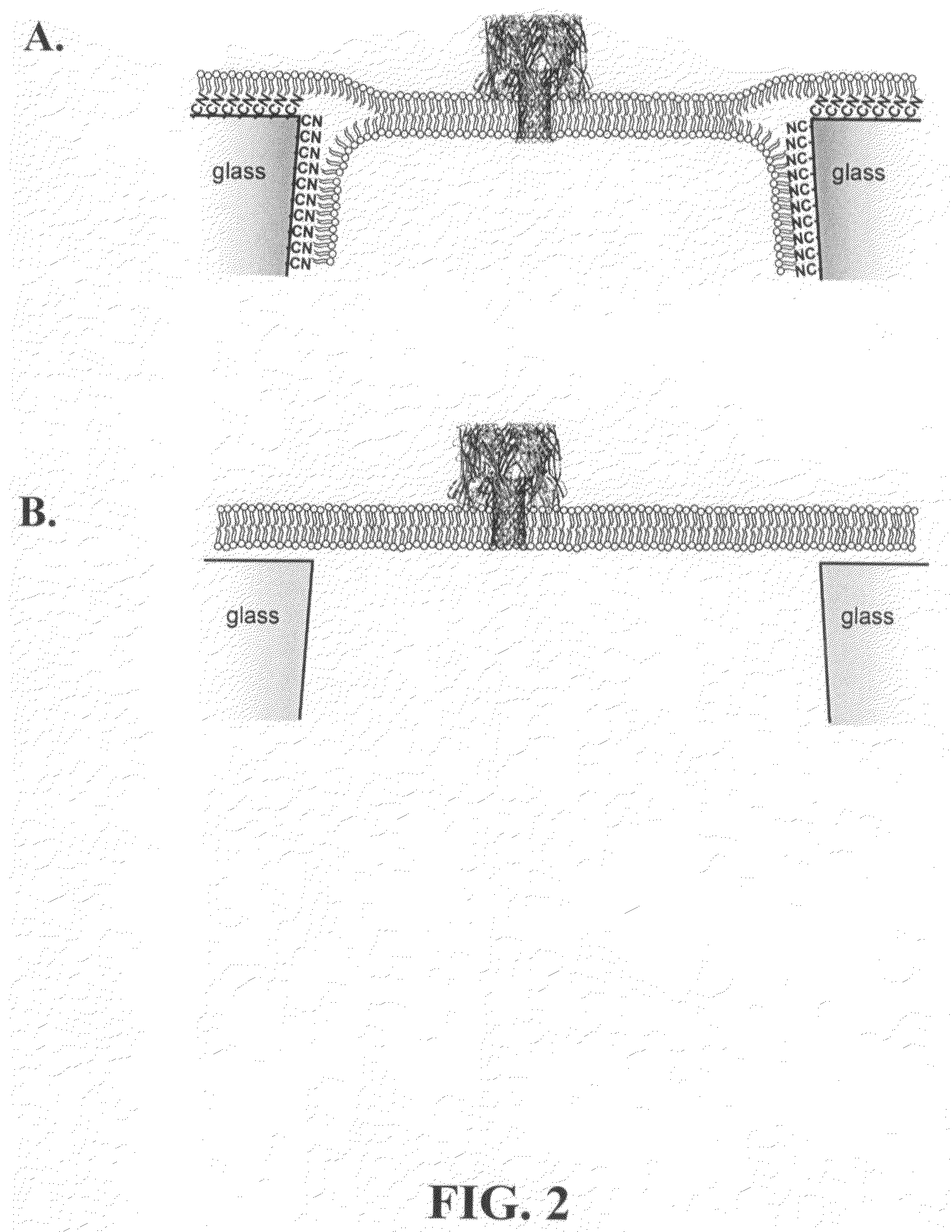

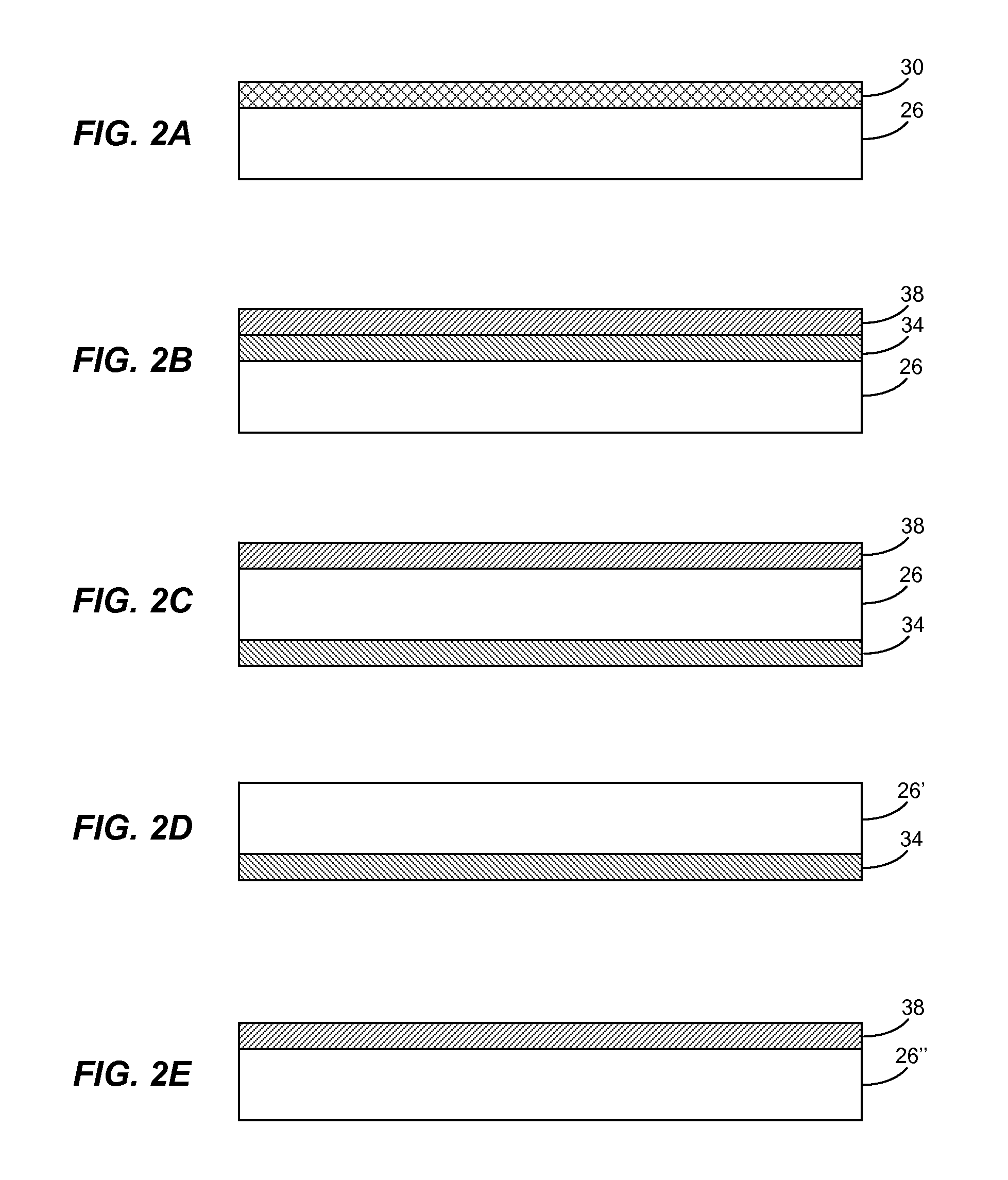

Nanopore platforms for ion channel recordings and single molecule detection and analysis

ActiveUS7777505B2Determining of stabilityGood fluiditySpark gapsResistance/reactance/impedenceLipid formationSpontaneous generation

A nanopore device includes a membrane having a nanopore extending there through forming a channel from a first side of the membrane to a second side of the membrane. The surface of the channel and first side of the membrane are modified with a hydrophobic coating. A first lipid monolayer is deposited on the first side of the membrane, and a second lipid monolayer is deposited on the second side of the membrane, wherein the hydrophobic coating causes spontaneous generation of a lipid bilayer across the nanopore orifice. Sensing entities, such as a protein ion channel, can be inserted and removed from the bilayer by adjusting transmembrane pressure, and adapter molecules can be electrostatically trapped in the ion channel by applying high transmembrane voltages, while resistance or current flow through the sensing entity can be measured electrically.

Owner:UNIV OF UTAH RES FOUND

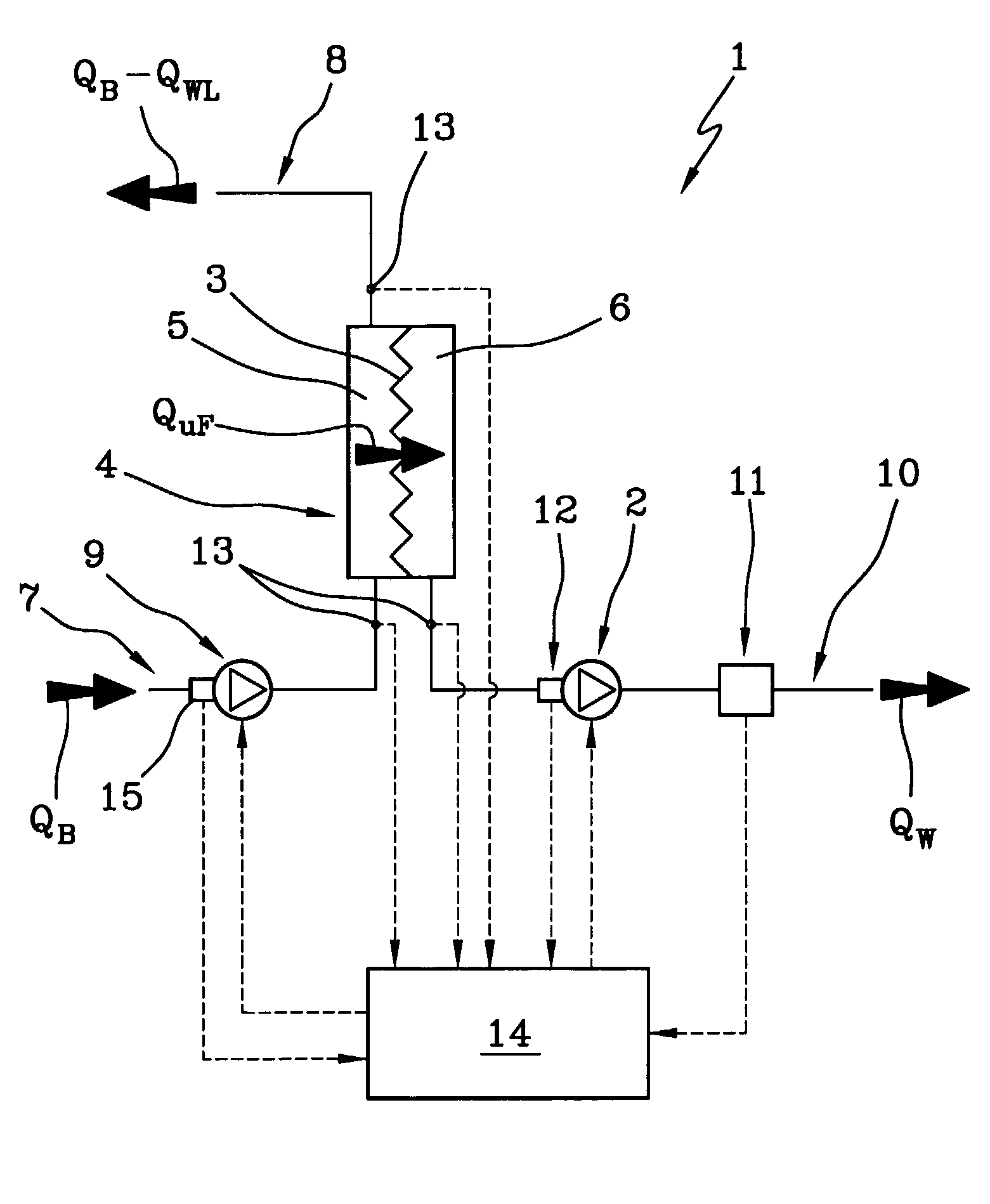

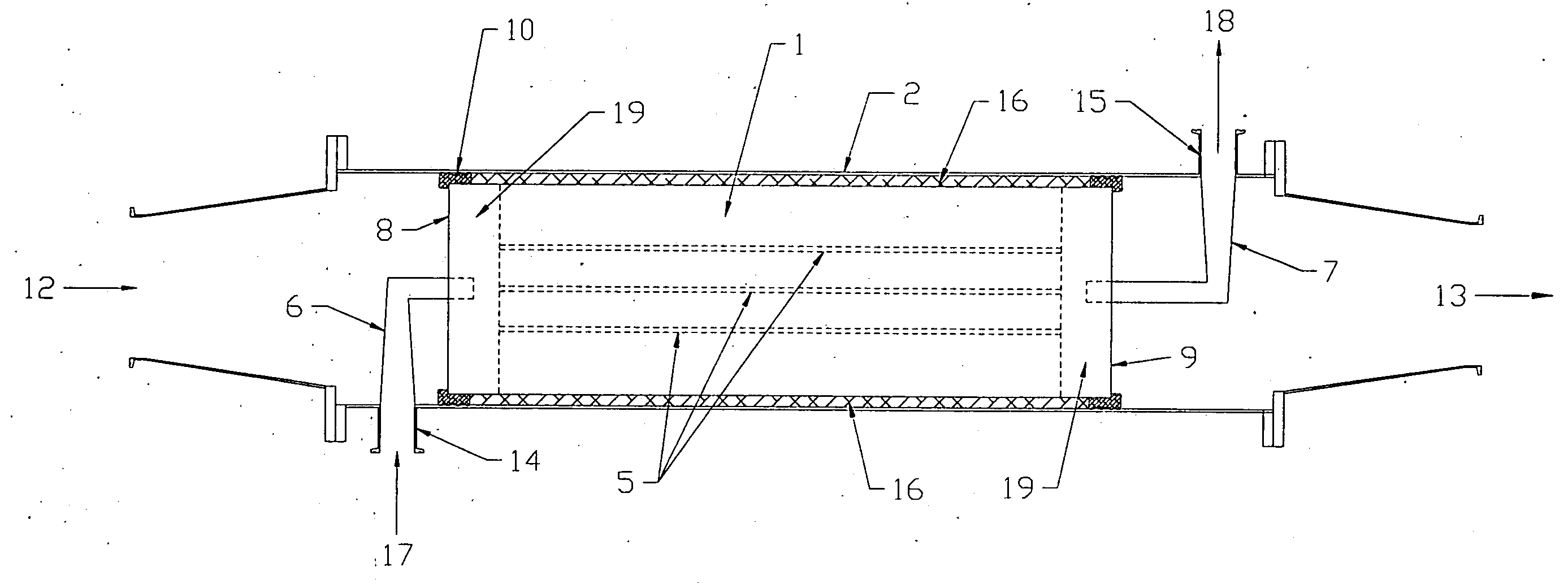

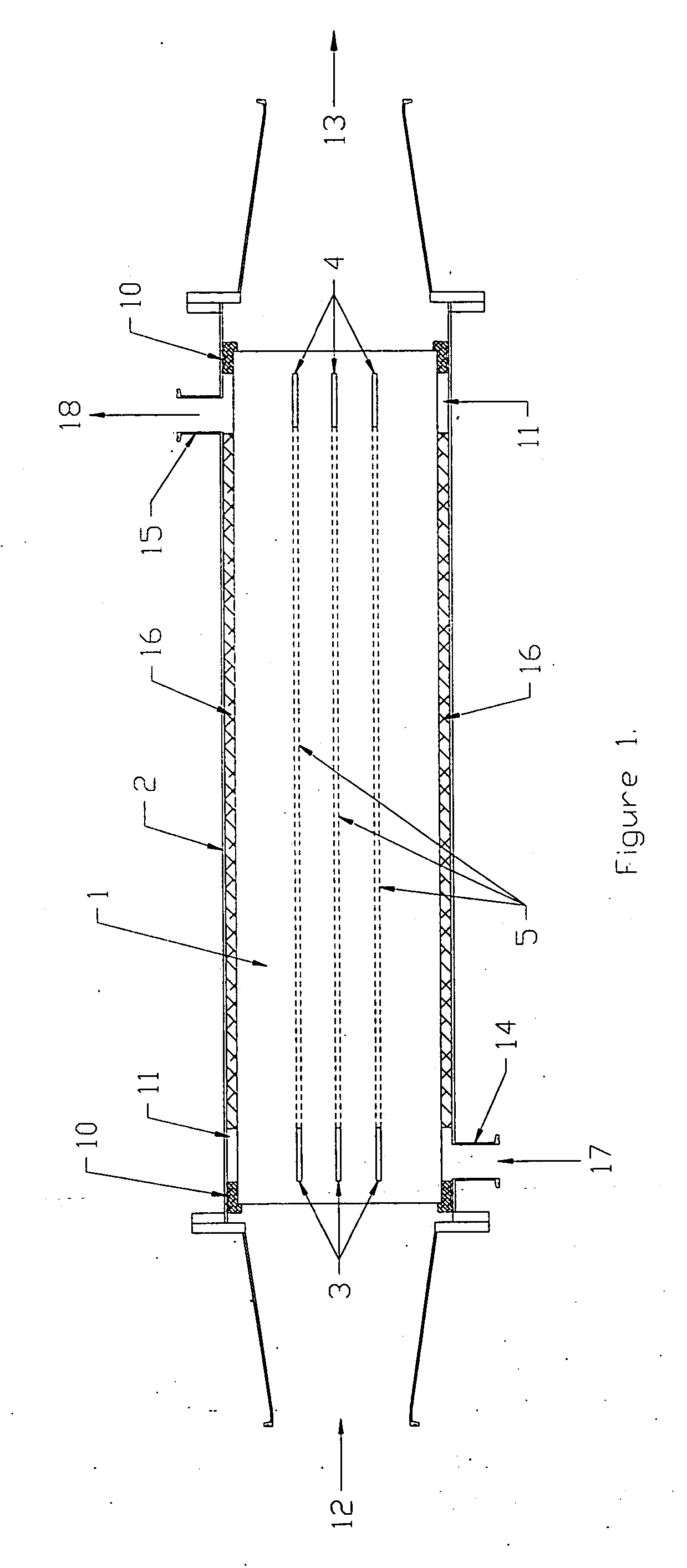

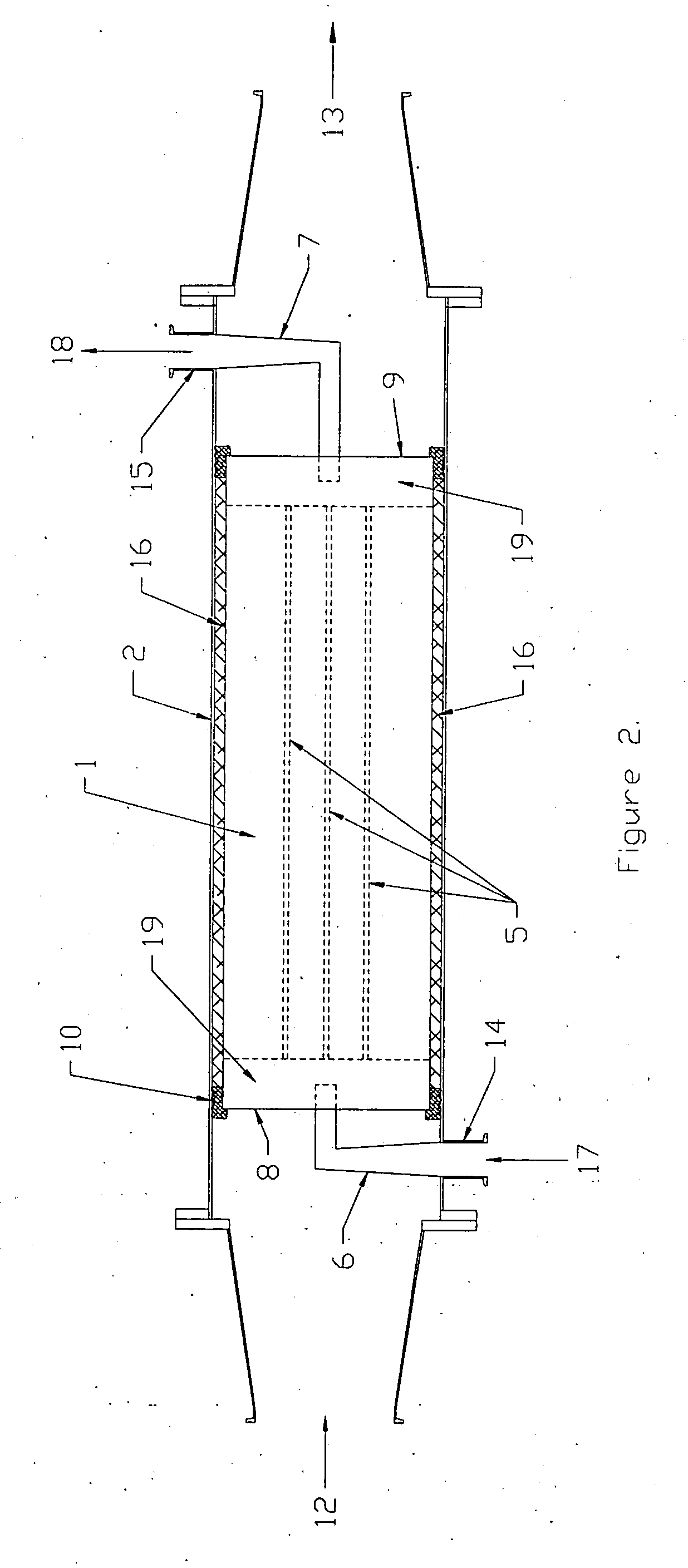

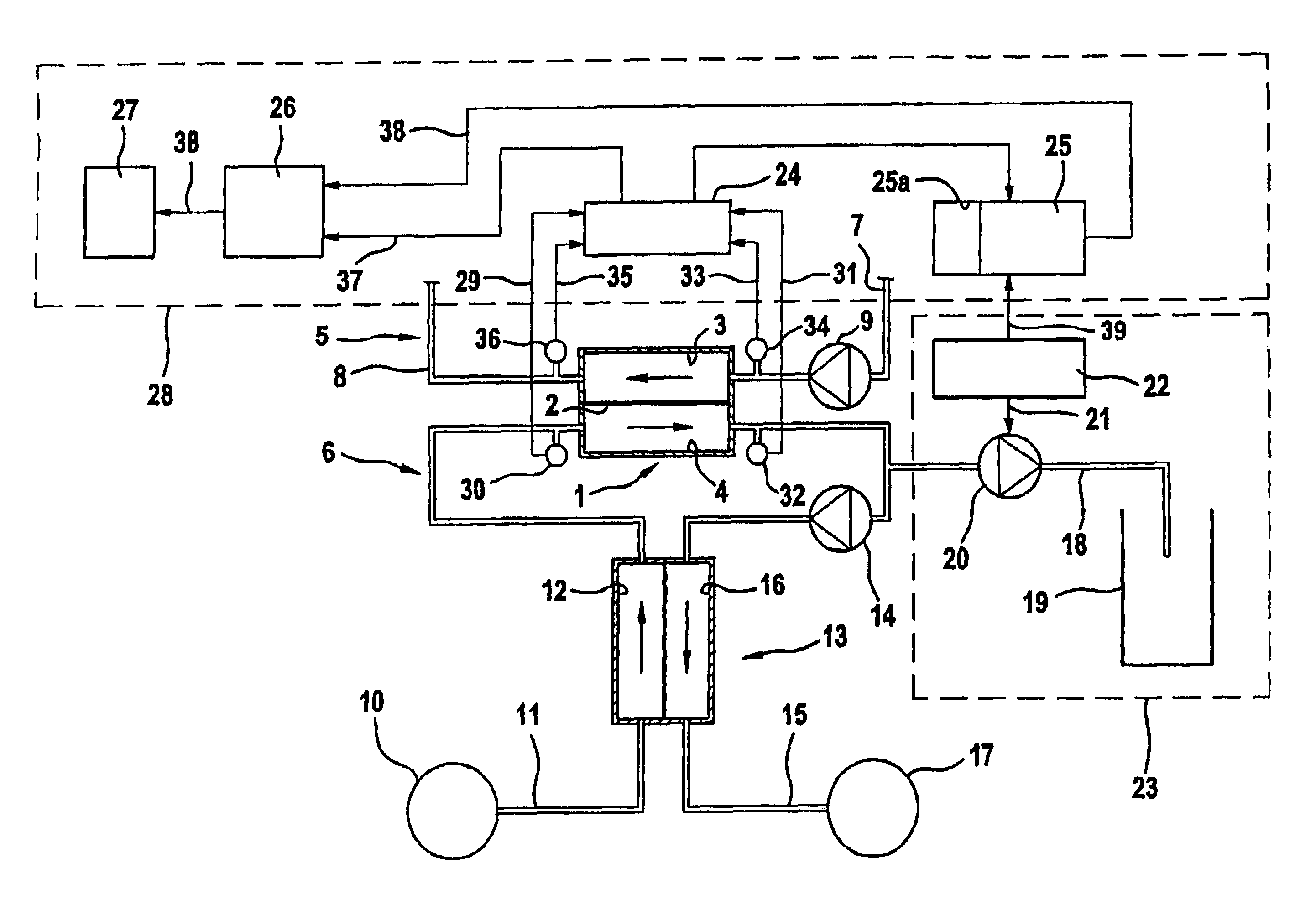

Machine and procedure for extracorporeal treatment of blood

ActiveUS8105260B2Shorten treatment timeIncrease the number ofSemi-permeable membranesOther blood circulation devicesBlood treatmentsBody fluid

A machine (1) for extracorporeal blood treatment comprises a device (2) for ultrafiltration of a liquid through a semi-permeable membrane (3) of a blood treatment device (4), a first sensor (11) for ultrafiltration rate through the membrane, a second group of sensors (13) for measuring a trans-membrane pressure, and a programmed controller (14) for calculating a maximum ultrafiltration rate as a function of the transmembrane pressure. The machine is suitable for kidney failure treatments, such as hemofiltration and hemodiafiltration. In a relatively short time the machine enables a large quantity of corporeal blood to be removed from the patient.

Owner:GAMBRO LUNDIA AB

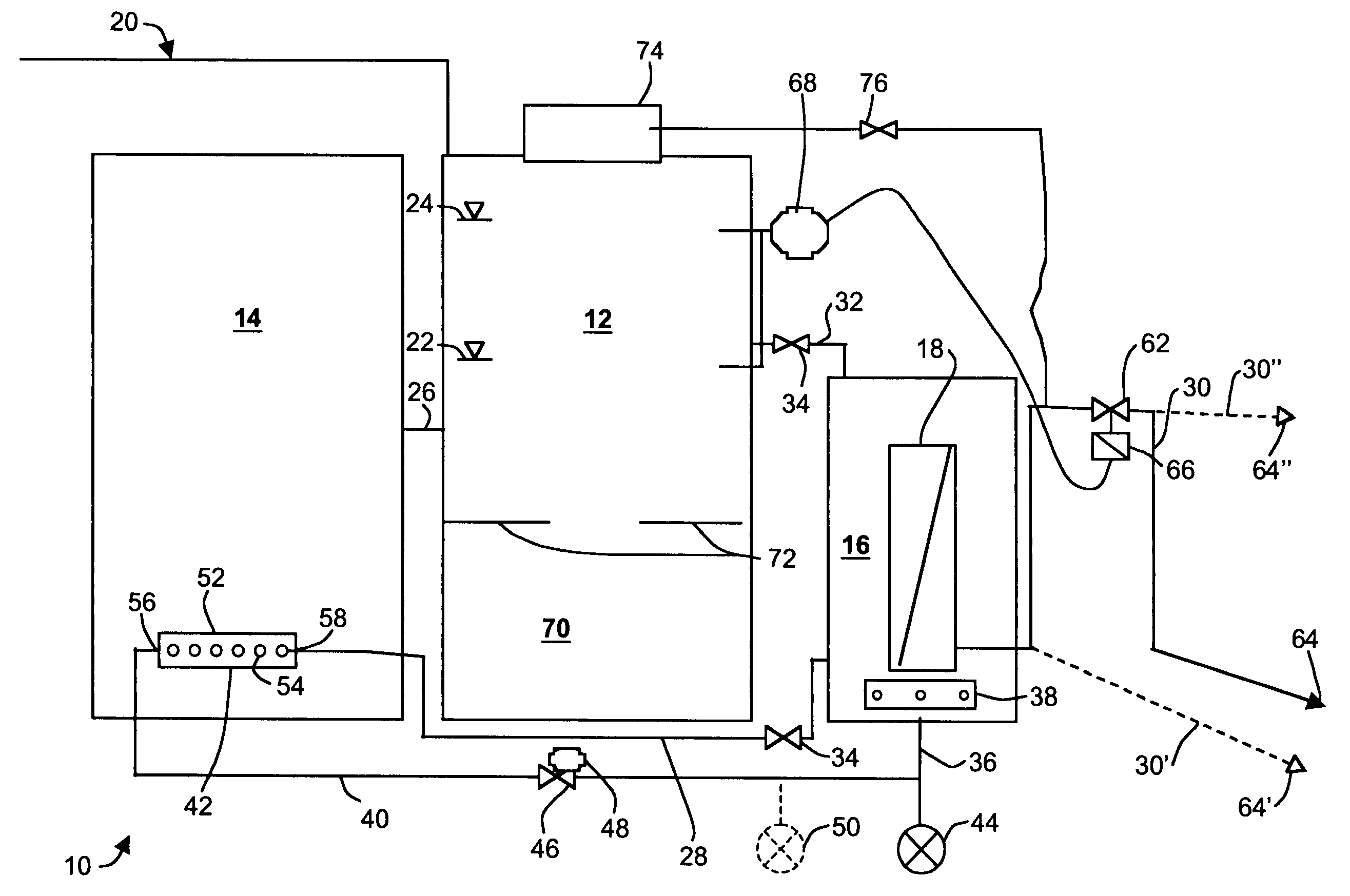

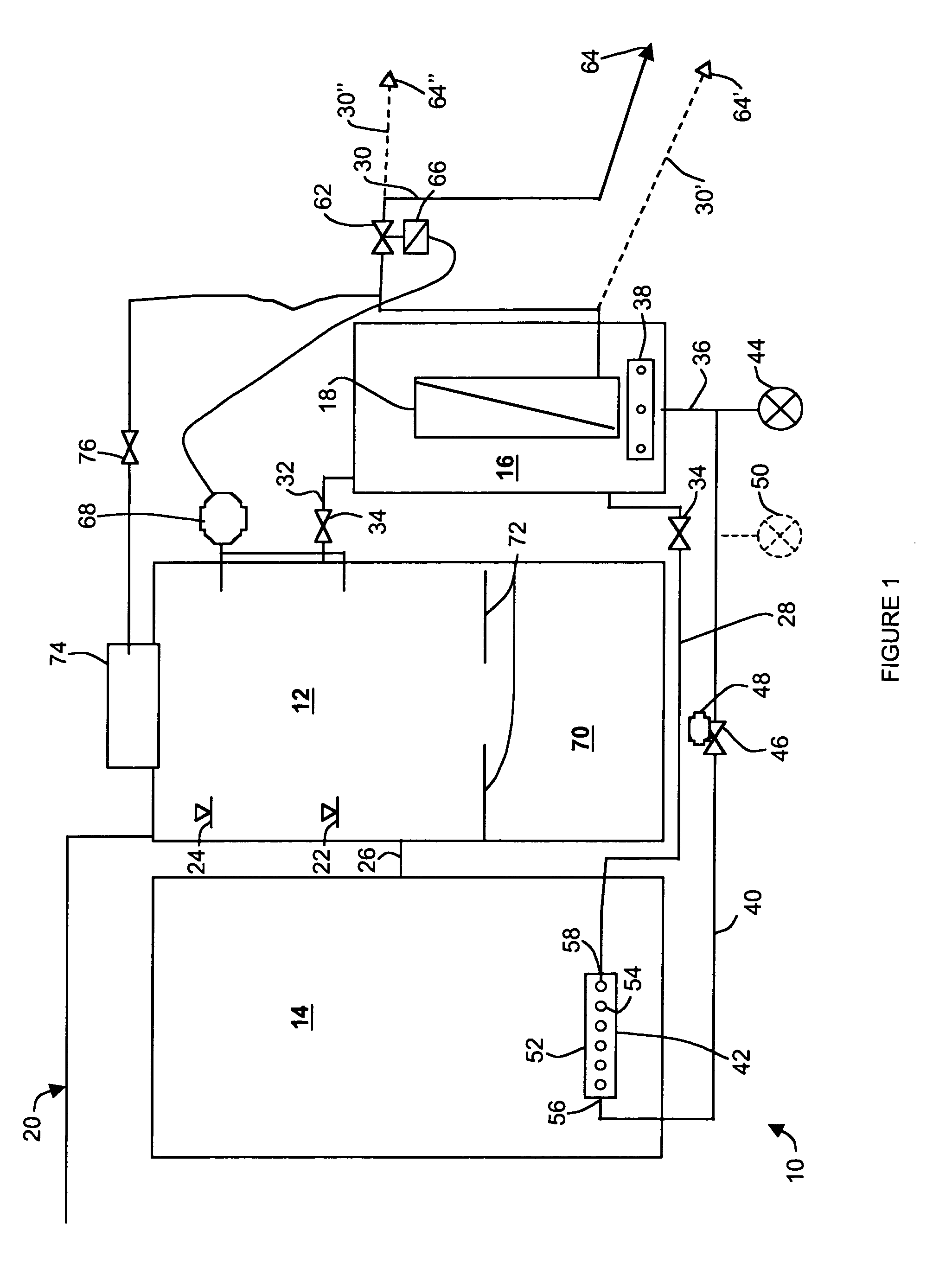

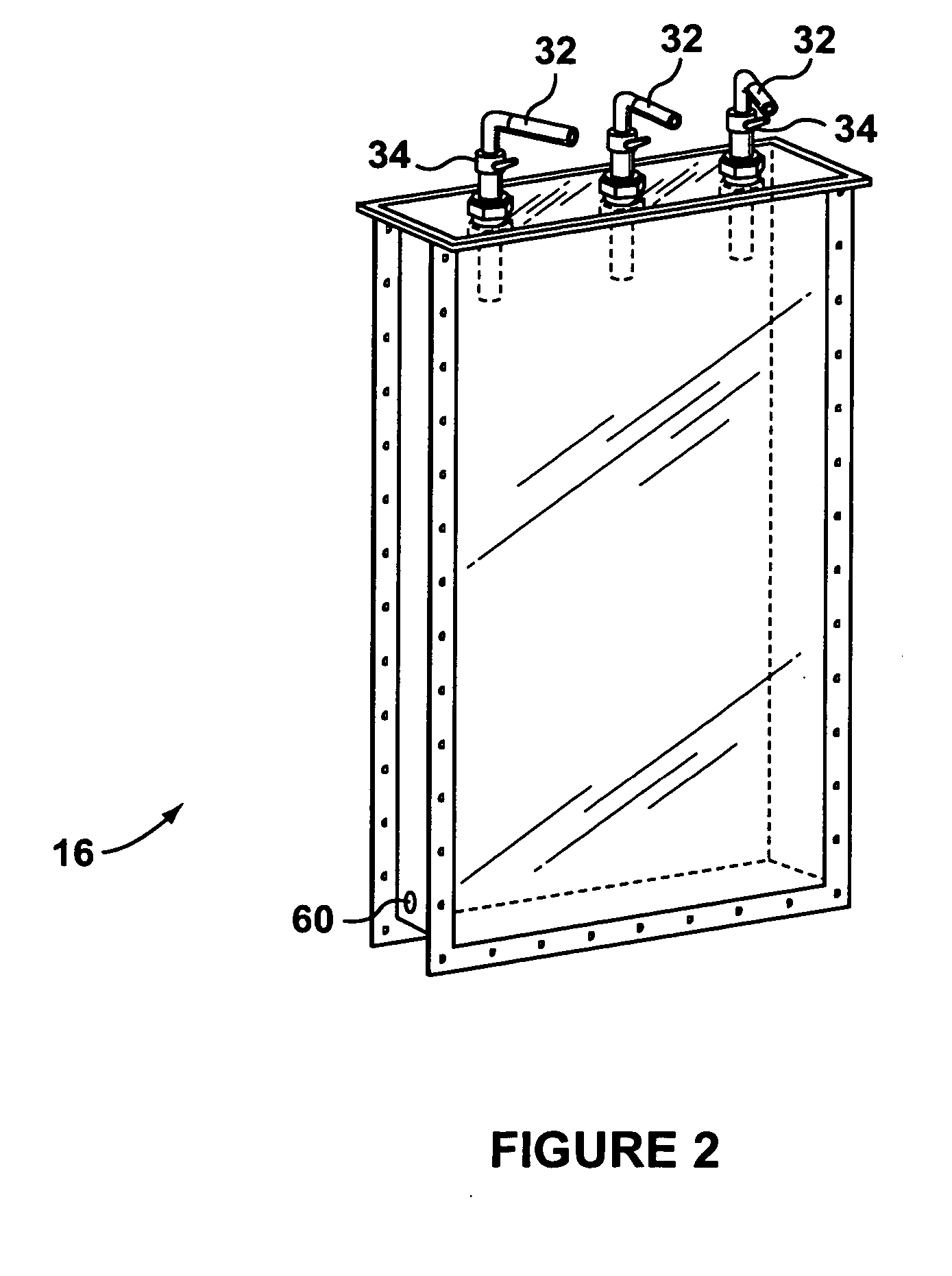

Membrane bioreactor, process and aerator

InactiveUS20050061725A1Easy to moveIncrease pressureWater treatment parameter controlMembranesSiphonEnvironmental engineering

A reactor has an aerobic tank, an anoxic tank and a sealed membrane tank with conduits for circulating mixed liquor between them. Permeation starts when the mixed liquor reaches a high level and stops when the mixed liquor reaches a low level. A sensor, for detecting the mixed liquor level, may stop and start permeation. Pressure builds in the membrane tank when membrane air is on. Transmembrane pressure is also provided by gravity flow or siphon. Membrane air generates an air lift which drives the mixed liquor circulation. The total amount of air provided by an air source is divided and varied in time between the membrane aerator and the process aerator. The process aerator acts as a screening inlet to the conduit to the membrane tank. Chemical maintenance cleaning is provided by gravity flow.

Owner:ZENON ENVIRONMENTAL INC

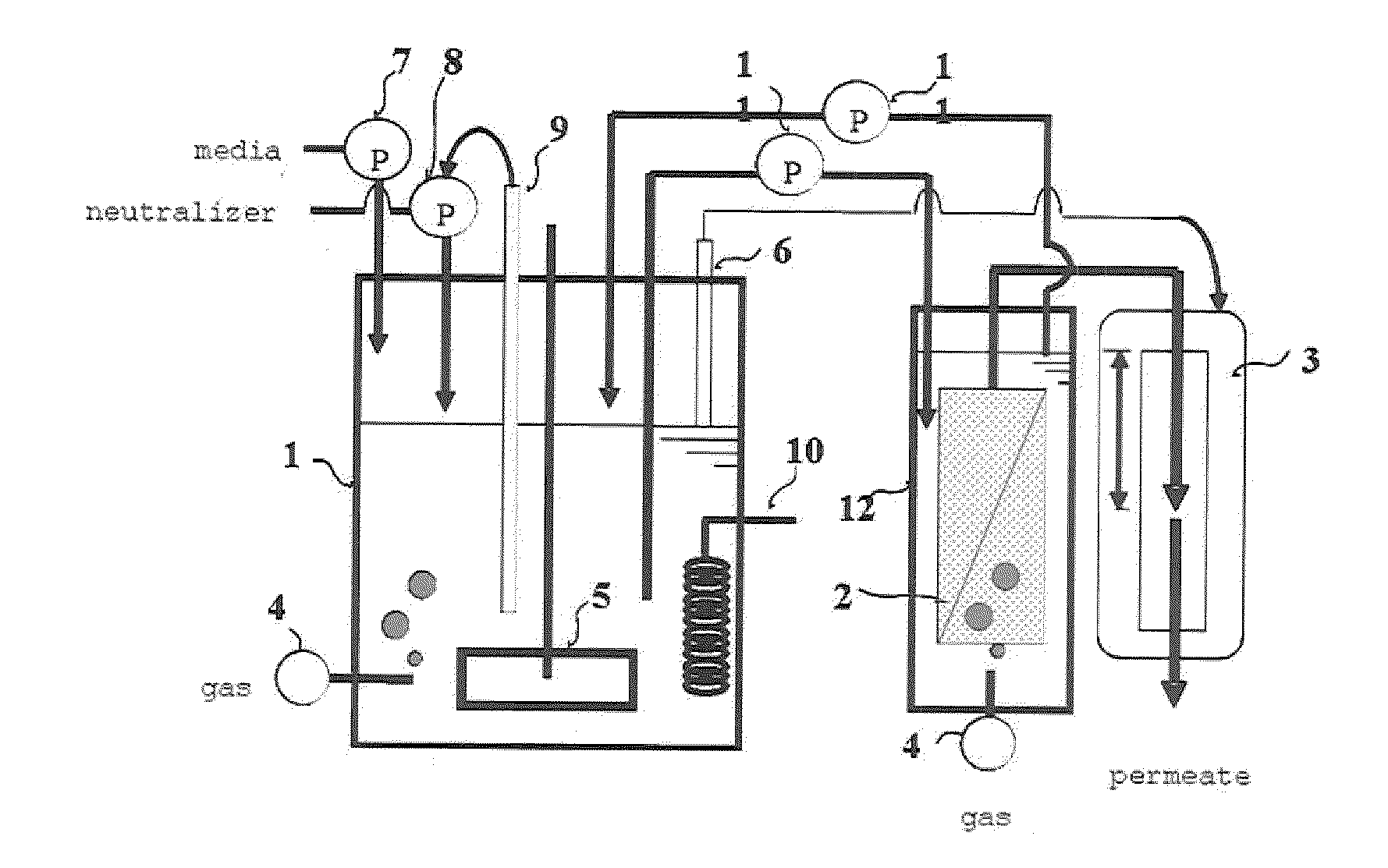

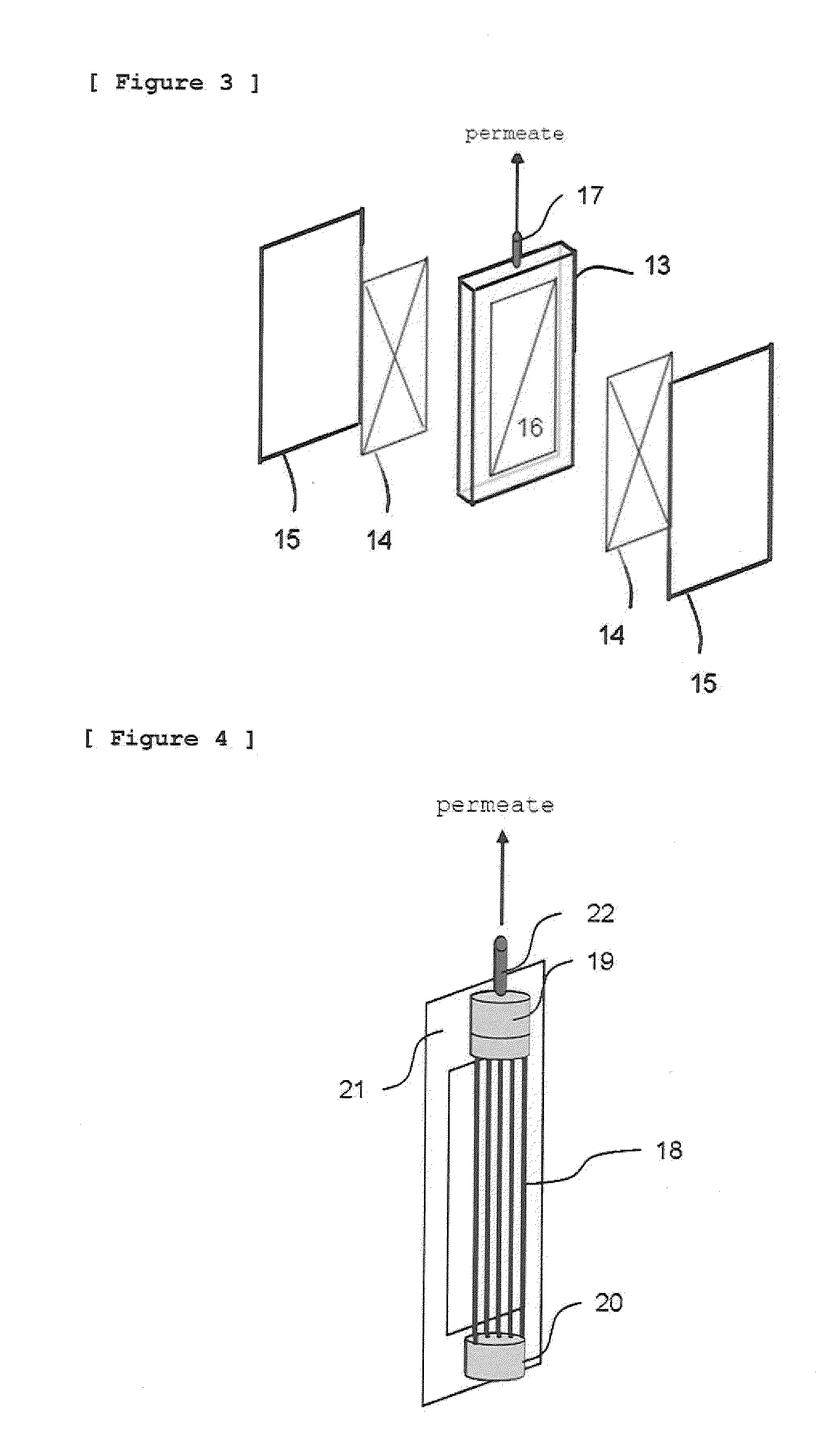

Method of producing chemical product and continuous fermentation apparatus

ActiveUS20090269812A1Bioreactor/fermenter combinationsBiological substance pretreatmentsContinuous fermentationMicroorganism

The invention provides a method of producing a chemical product through continuous fermentation which includes filtering a culture of a microorganism or cultured cells with a separation membrane to recover a product from a filtrate and simultaneously retaining a nonfiltered fluid in, or refluxing it to, the culture, and adding fermentation materials to the culture, wherein a porous membrane having an average pore size of 0.01 μm or more to less than 1 μm is used as the separation membrane and the filtration is conducted with a transmembrane pressure difference in the range of 0.1 to 20 kPa. According to this method, the fermentation productivity of the chemical product can be largely elevated at high stability and a low cost.

Owner:TORAY IND INC

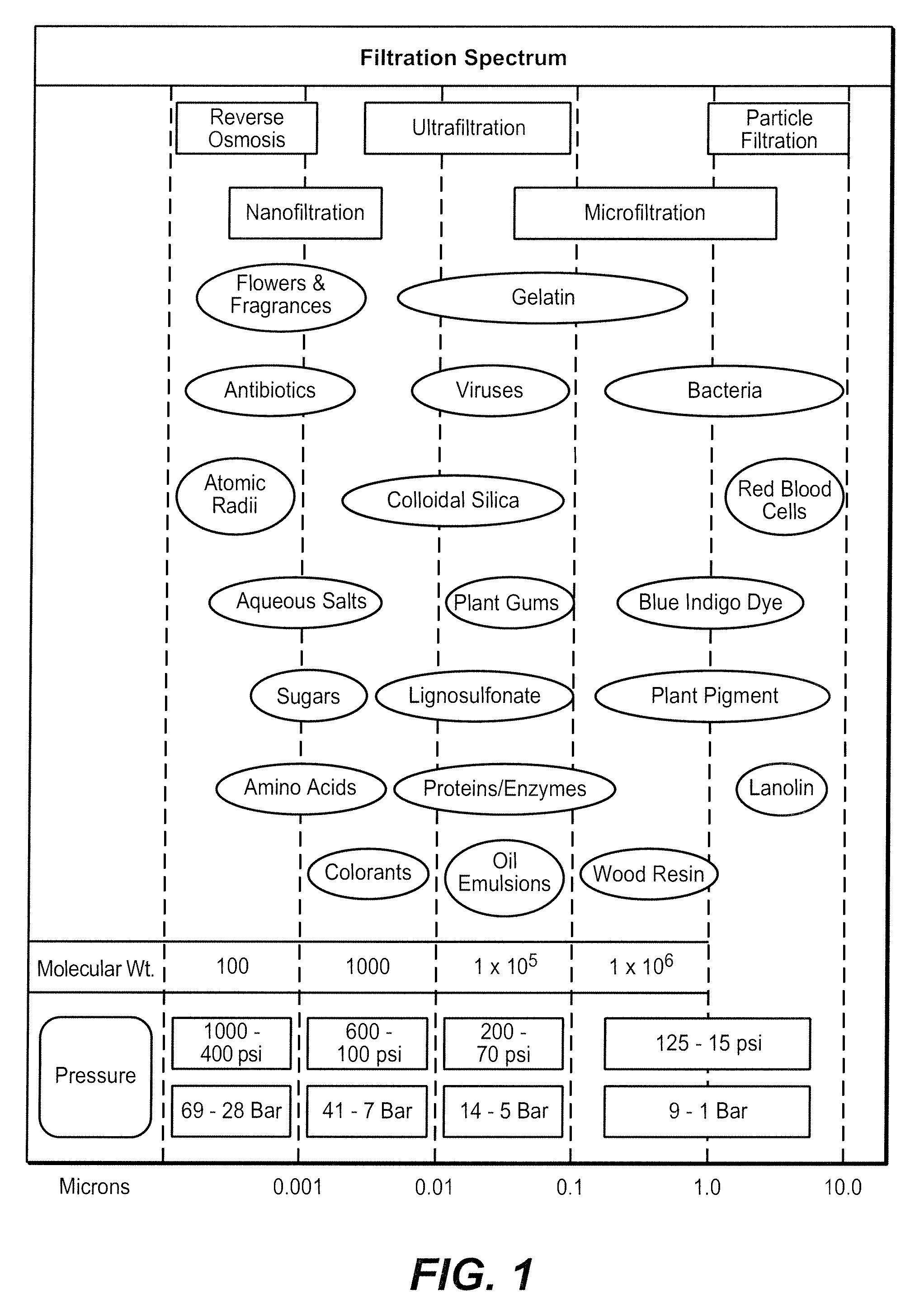

Filtration with internal fouling control

Filtration processes and systems are provided for the separation of a filterable fluid stream by a filtration membrane module with uniform transmembrane pressure and flux along the membrane and internal control of membrane fouling via intermittent periodic reduction of the pressure differential between the permeate and retentate sides of the membrane and / or backwashing cycles during separation, recovery, and / or purification of proteins, peptides, nucleic acids, biologically produced polymers and other compounds or materials from aqueous fluids.

Owner:DANISCO US INC

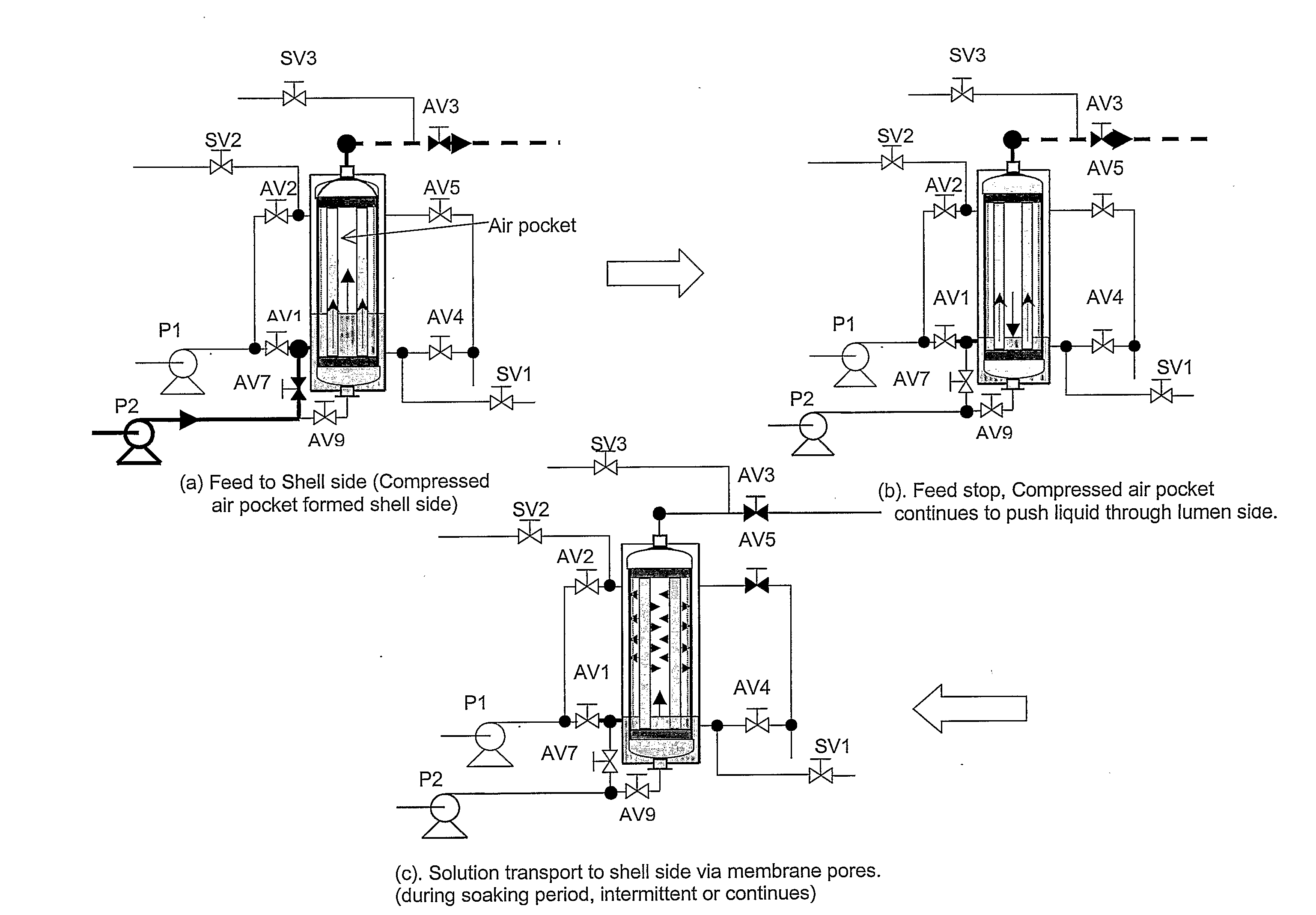

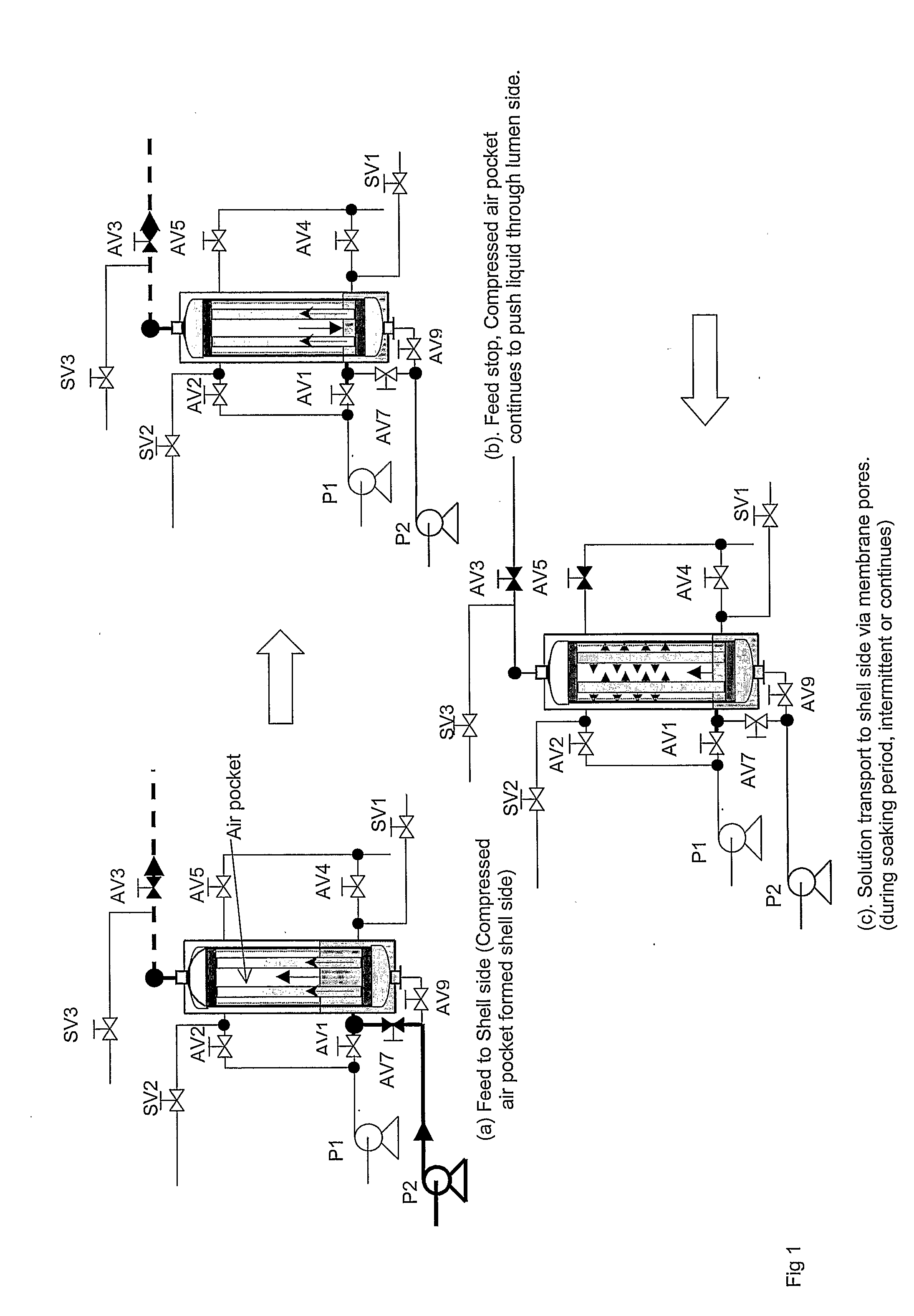

Chemical Clean For Membrane Filter

ActiveUS20080203017A1Facilitate wetting out and dissolvingLower the volumeSpecific water treatment objectivesUltrafiltrationConcentration gradientCleansing Agents

A method of cleaning a porous polymeric membrane having a feed side and a permeate side including the steps of introducing a fluid containing a cleaning agent to the permeate side of a membrane allowing the cleaning agent to contact the permeate side of the membrane for a predetermined time, and contact the pores of the membrane, or introducing a fluid containing a cleaning agent to the feed side of a membrane; applying a transmembrane pressure to force the fluid containing the cleaning agent from the feed side to the permeate side of the membrane; allowing the cleaning agent to contact the permeate side of the membrane for a predetermined time, and contact the pores of the membrane. Preferably a concentration gradient between the feed side fluid and the lumen side fluid containing the cleaning agent causes cleaning agent to diffuse into the feed side fluid. Pressure may be applied to the fluid containing a cleaning agent to dislodge, where present, dissolved and undissolved solid from the membrane pores. The pressure may be applied in a pulsed fashion, and can be by way of compressed air at a pressure not more than the membrane's bubble point. The methods of the present invention may be preceded by, or followed with a backwash.

Owner:EVOQUA WATER TECH LLC

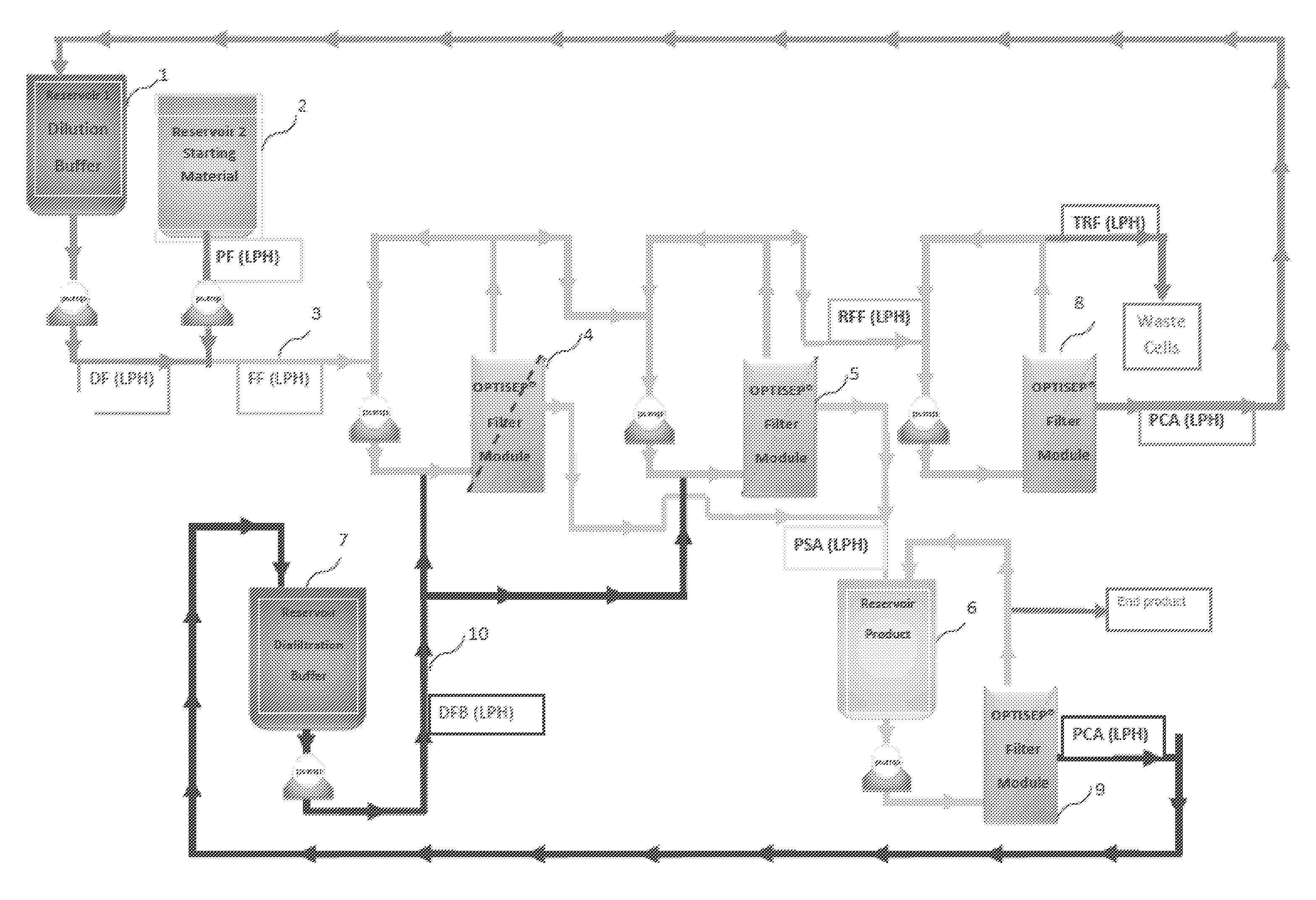

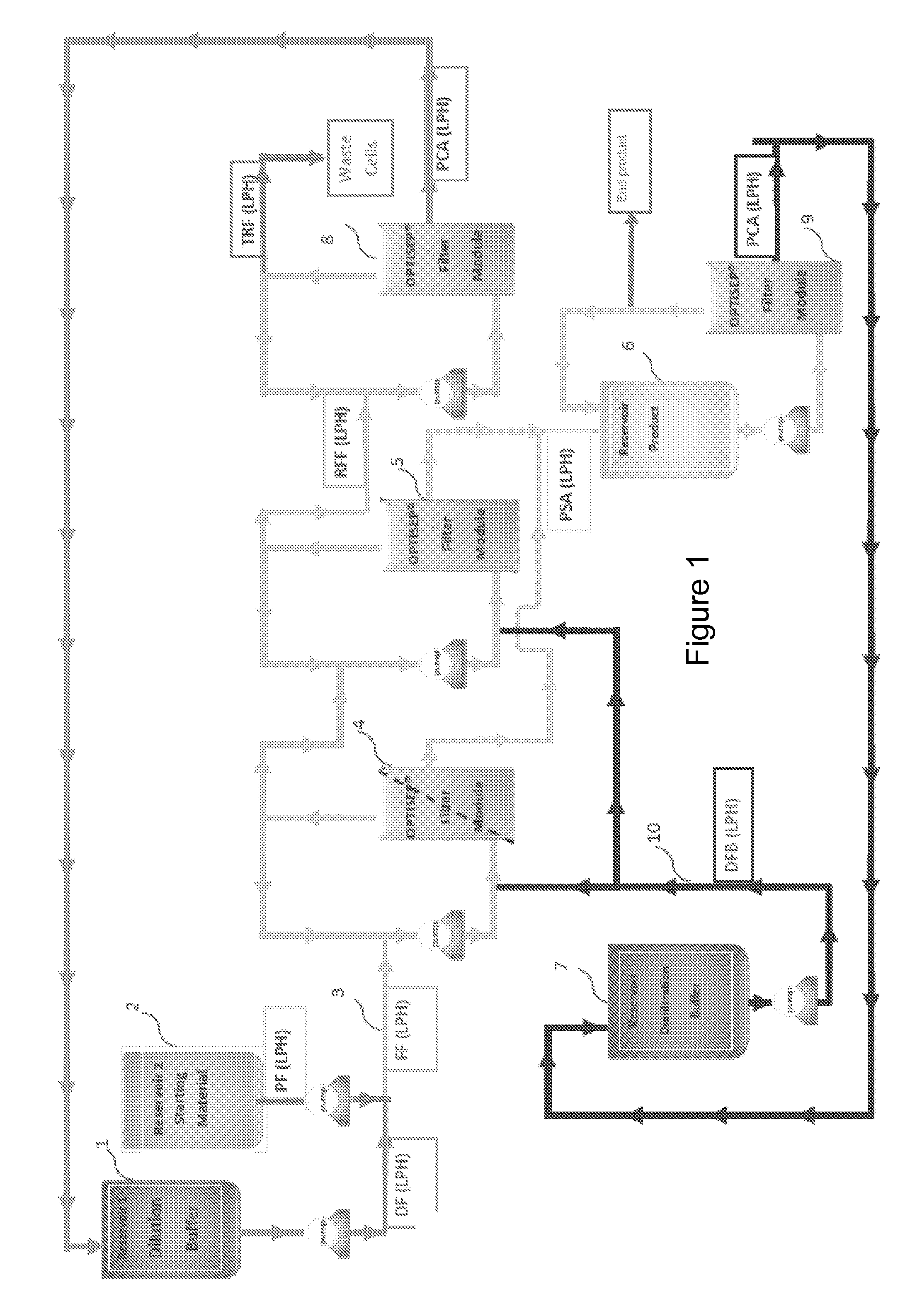

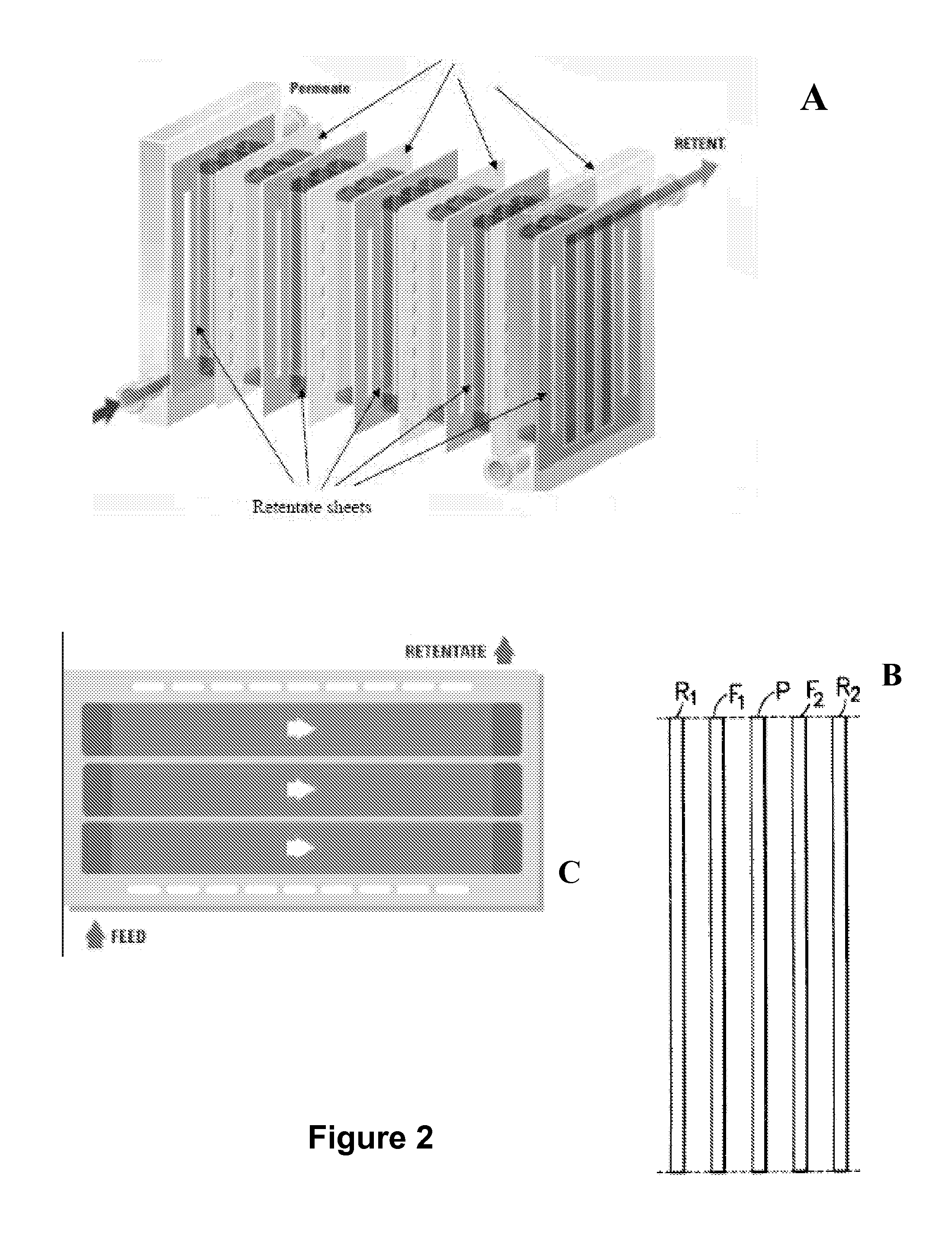

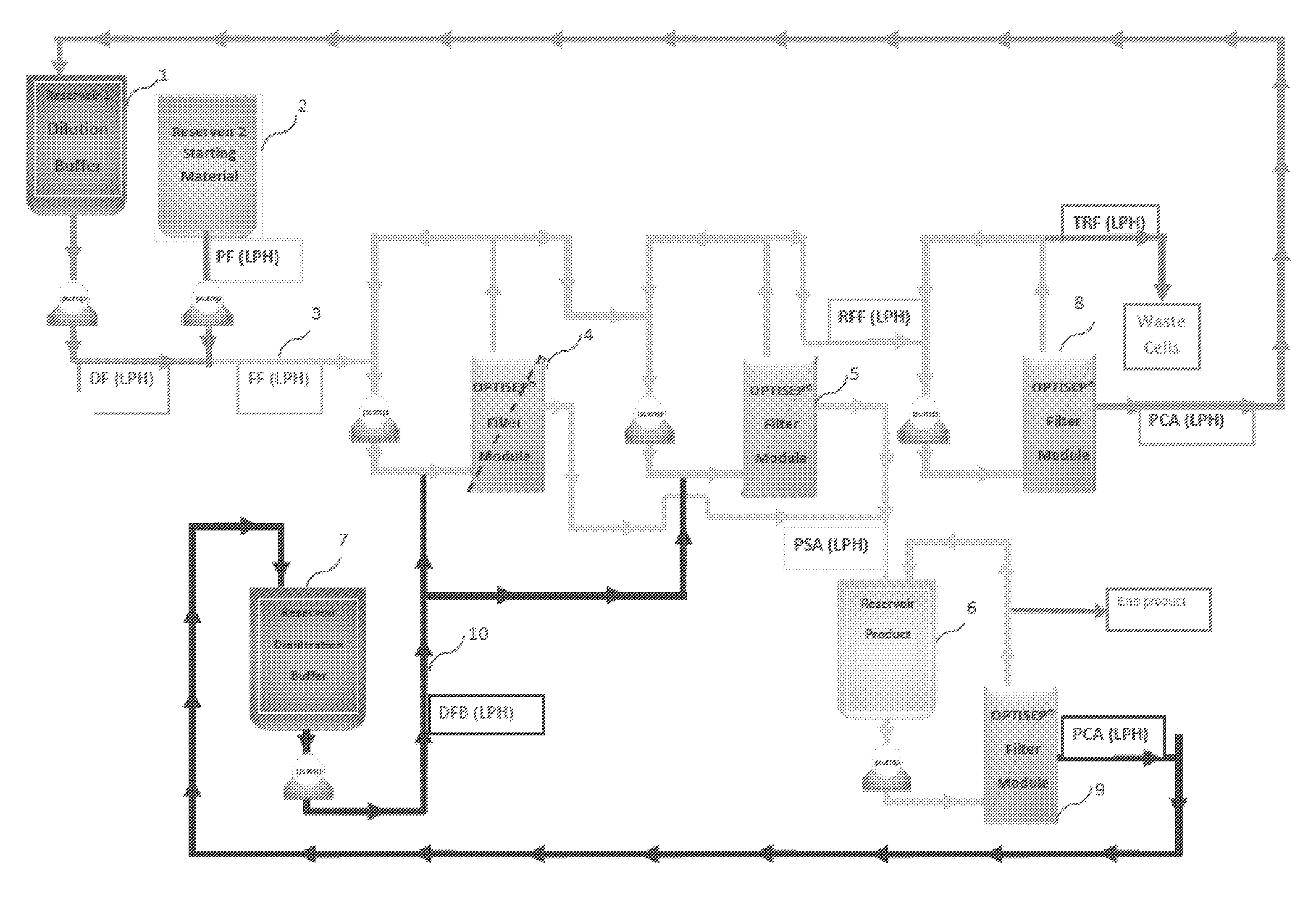

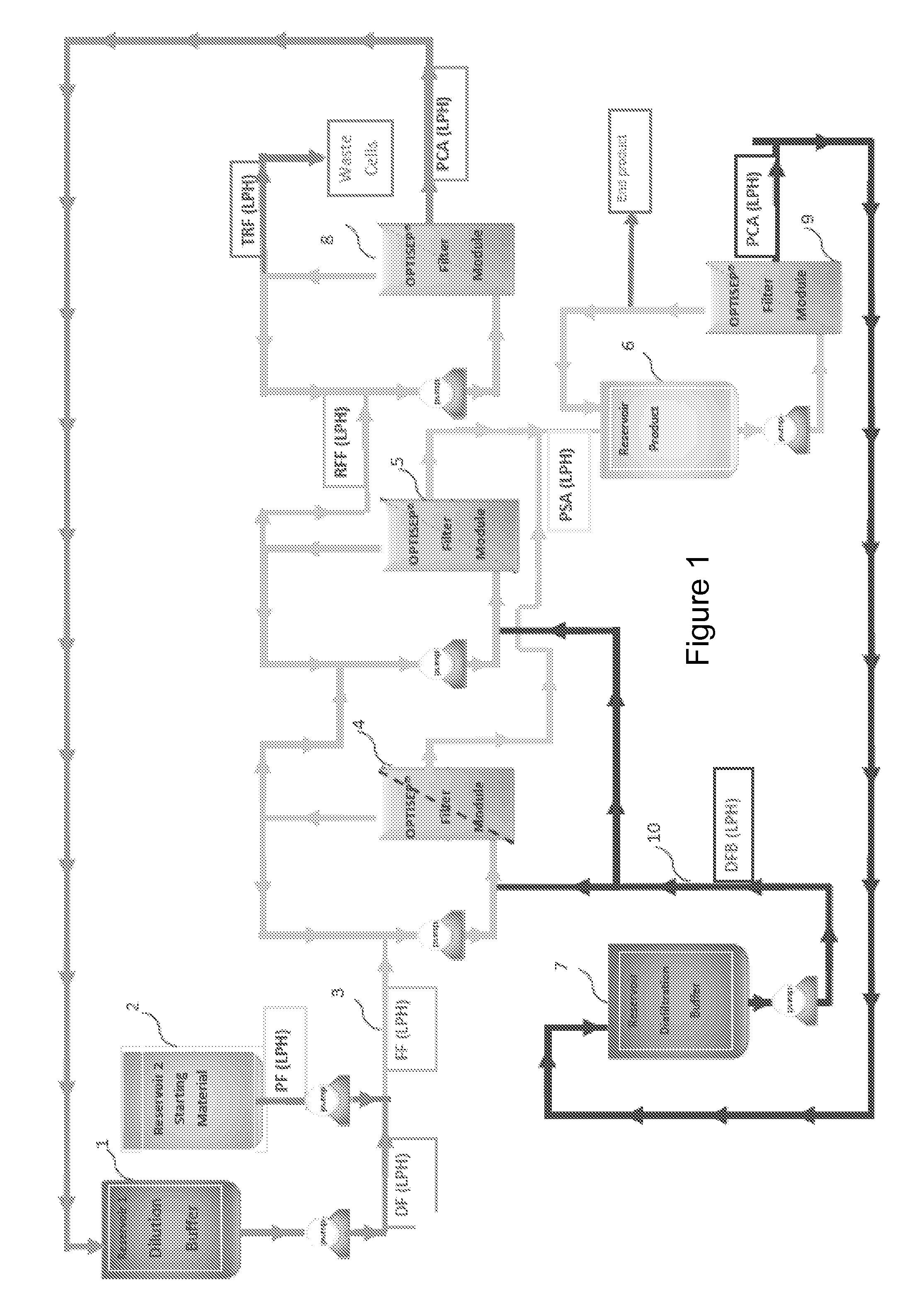

Optimization of separation for viscous suspensions

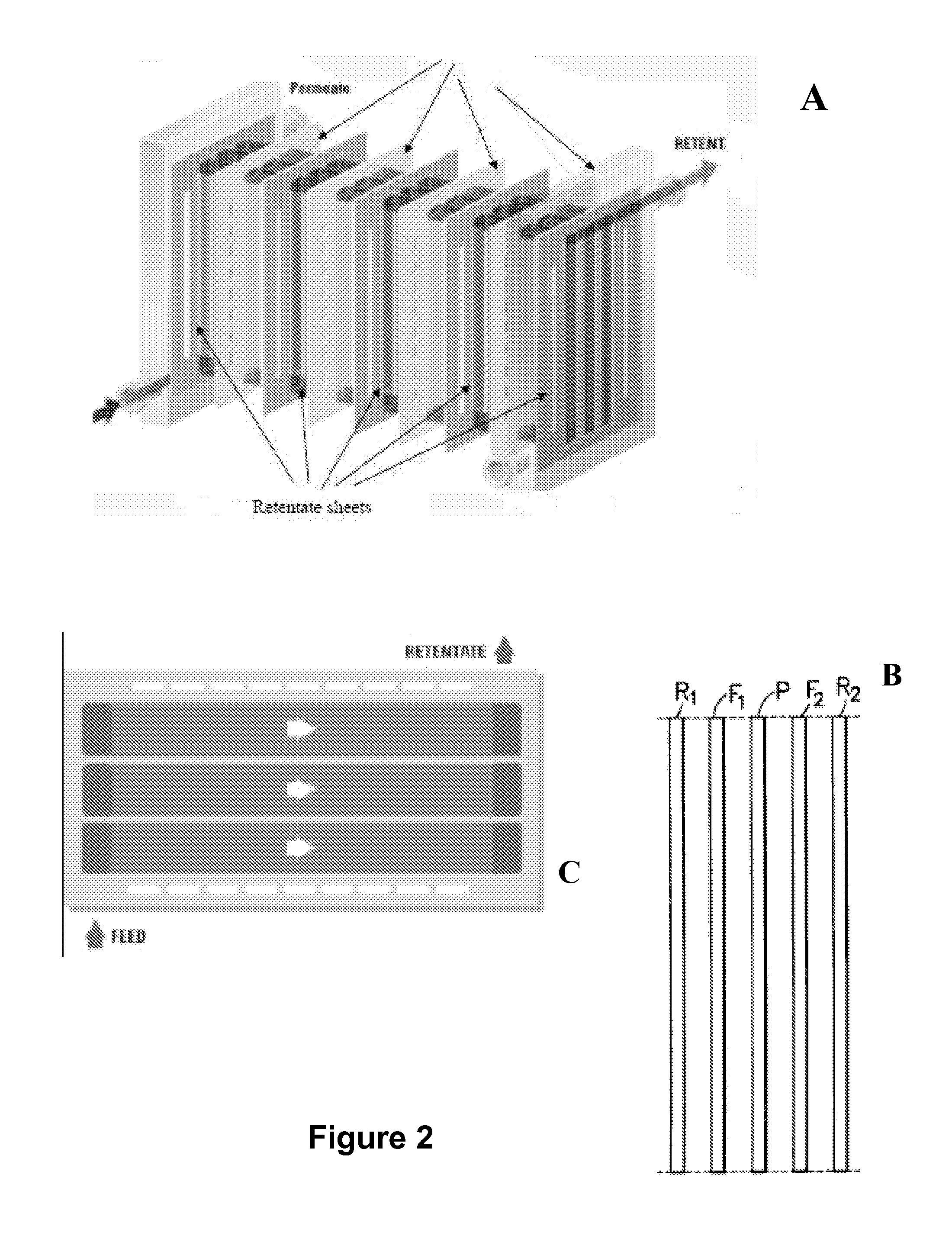

ActiveUS20110309018A1Low costYield maximizationSemi-permeable membranesMembranesSource materialWaste stream

The present invention relates to methods and systems for optimization of dilution of a viscous starting material to isolate and / or concentrate the product of interest from the starting source material such that the process minimizes the volume of diluent and the total volume of the waste stream generated during the process as well as maximizing the yield of desired product. The system employs cross-flow filtration modules with sub-channels that are equidistant to the inlet and outlet of said modules and such modules are characterized by optimal channel height, optimal transmembrane pressure, etc., which are selected in order to achieve the best combination of product quality and production yield.

Owner:SMARTFLOW TECH

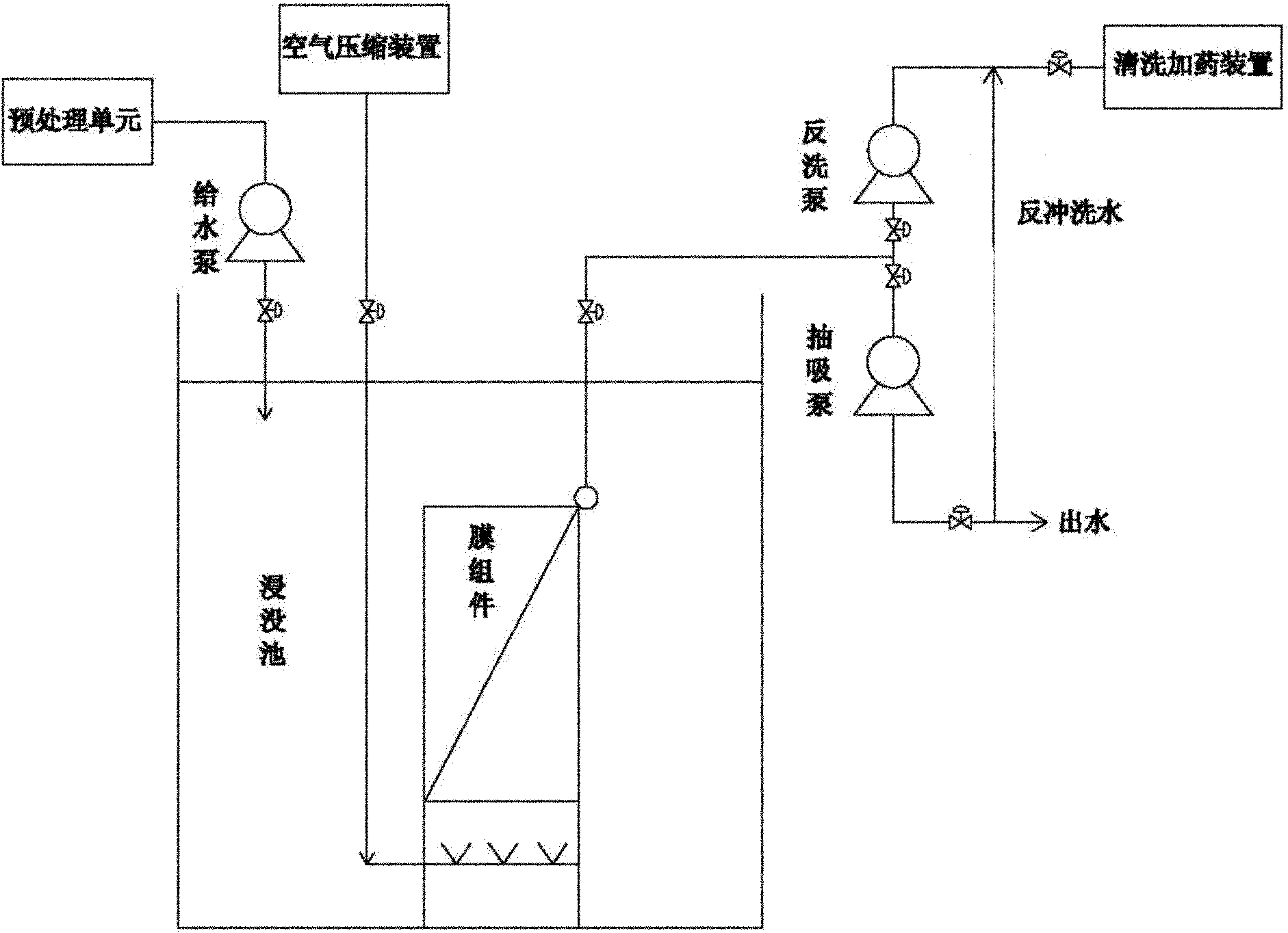

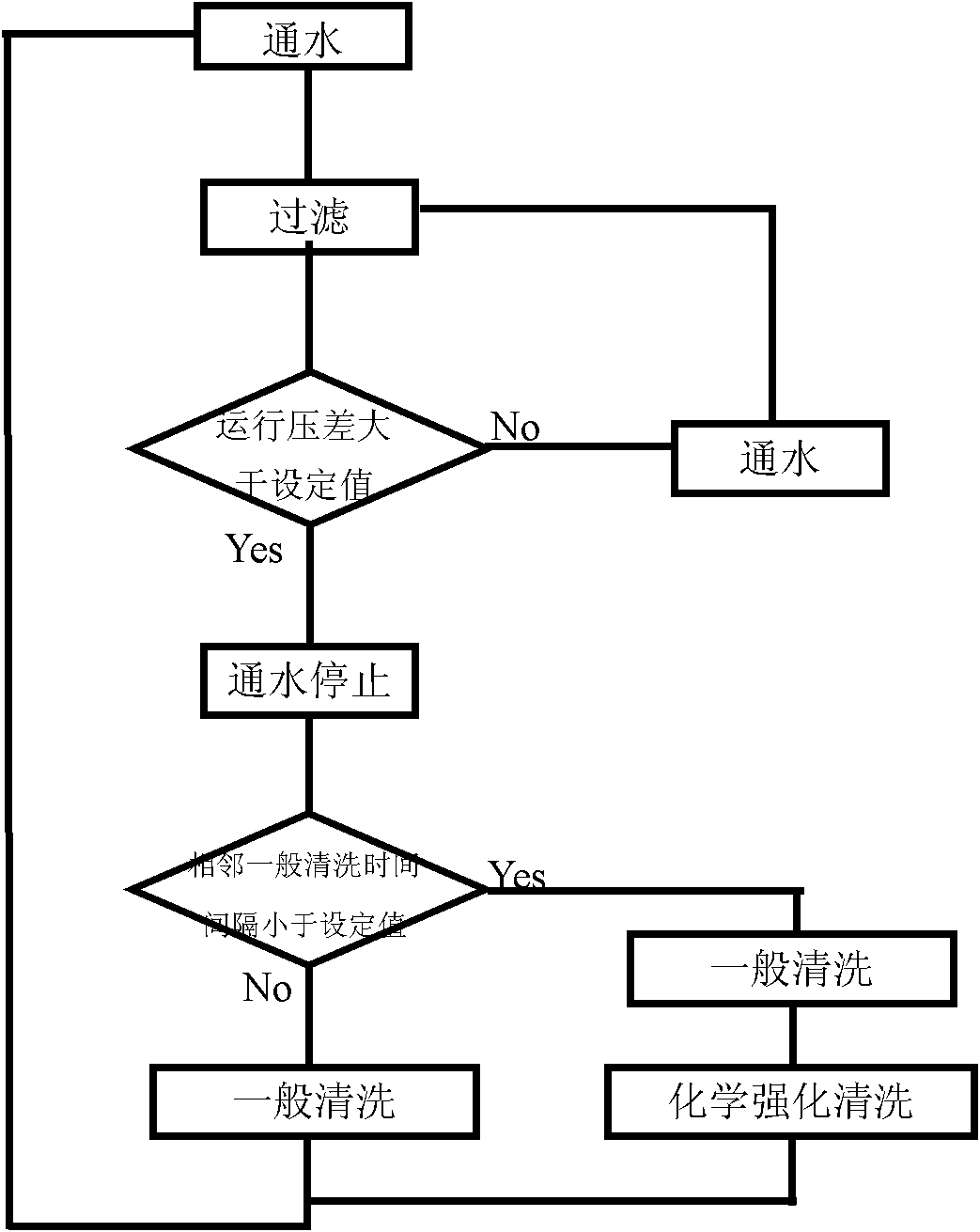

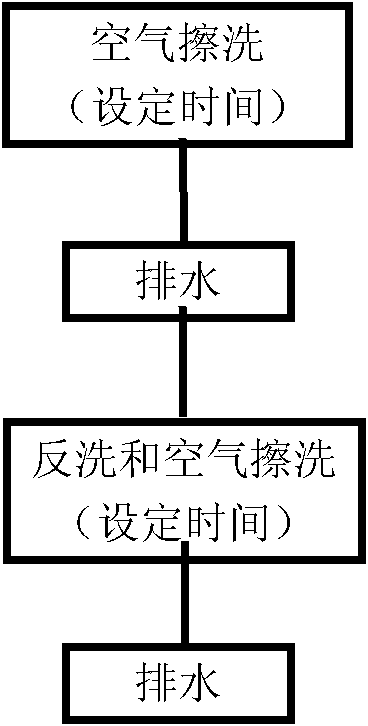

Cleaning method of immersion membrane filtration system

InactiveCN102485328AOptimize cleaning frequencyImprove operating rateSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiltrationCleaning methods

The invention discloses an automatic cleaning method of an immersion membrane filtration system. Including general cleaning and chemically enhanced cleaning, the method comprises: in the operation process of an immersion membrane filtration system, when the transmembrane pressure of an immersed membrane in the system is greater than a set transmembrane pressure for 30s-1min, conducting general cleaning to the system, with the set transmembrane pressure controlled at 30KPa-60KPa; after the general cleaning, leaving the system to continue operating, and when the time interval of two neighboring general cleaning is less than a set value, carrying out general cleaning to the system and then performing chemically enhanced cleaning, with the set value maintained at 10min-60min. The cleaning method of the invention can control membrane pollution timely, thus guaranteeing stable operation of the membrane system and avoiding the problem of too short service life of a membrane component due to excessive pollution of the membrane.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

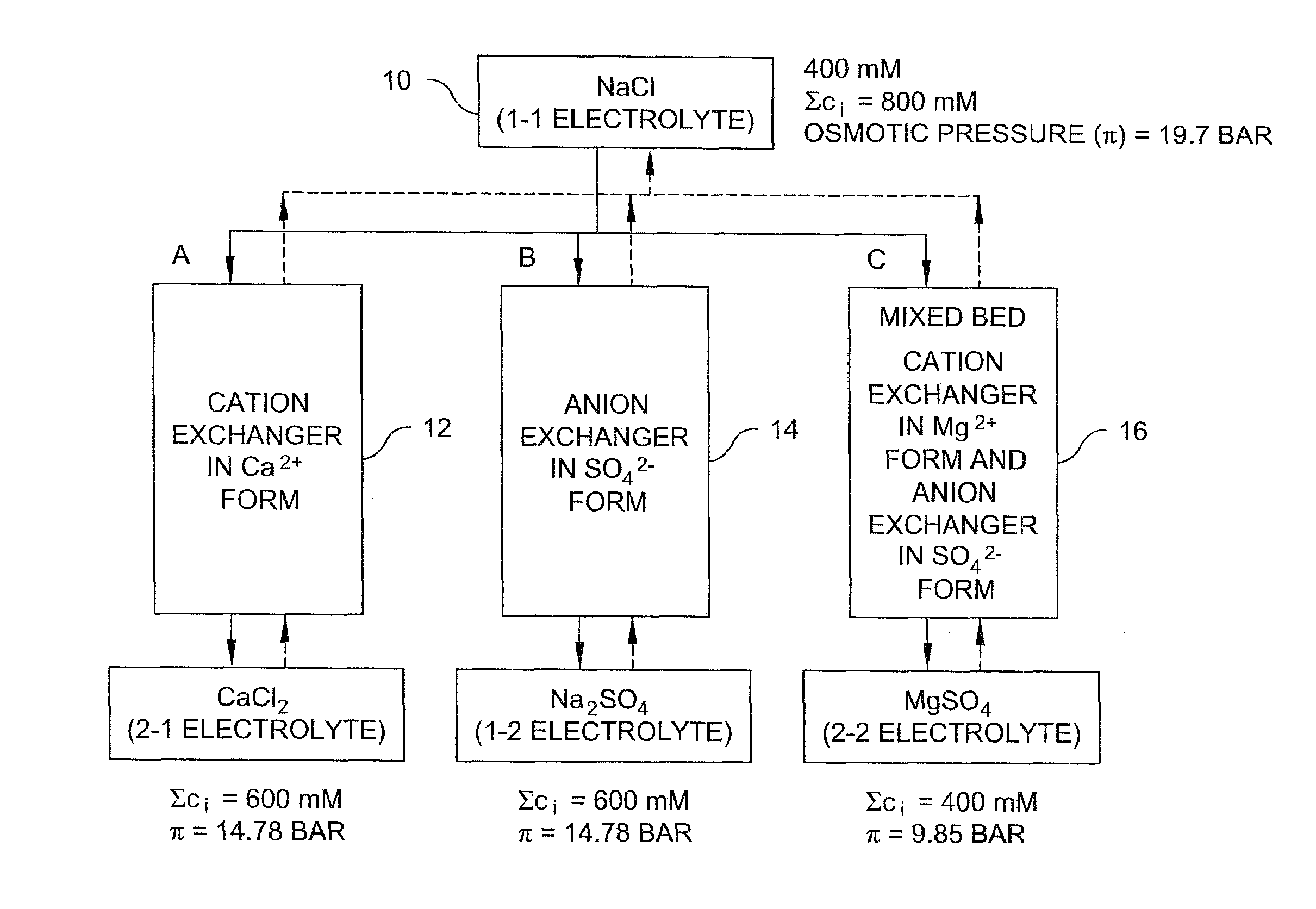

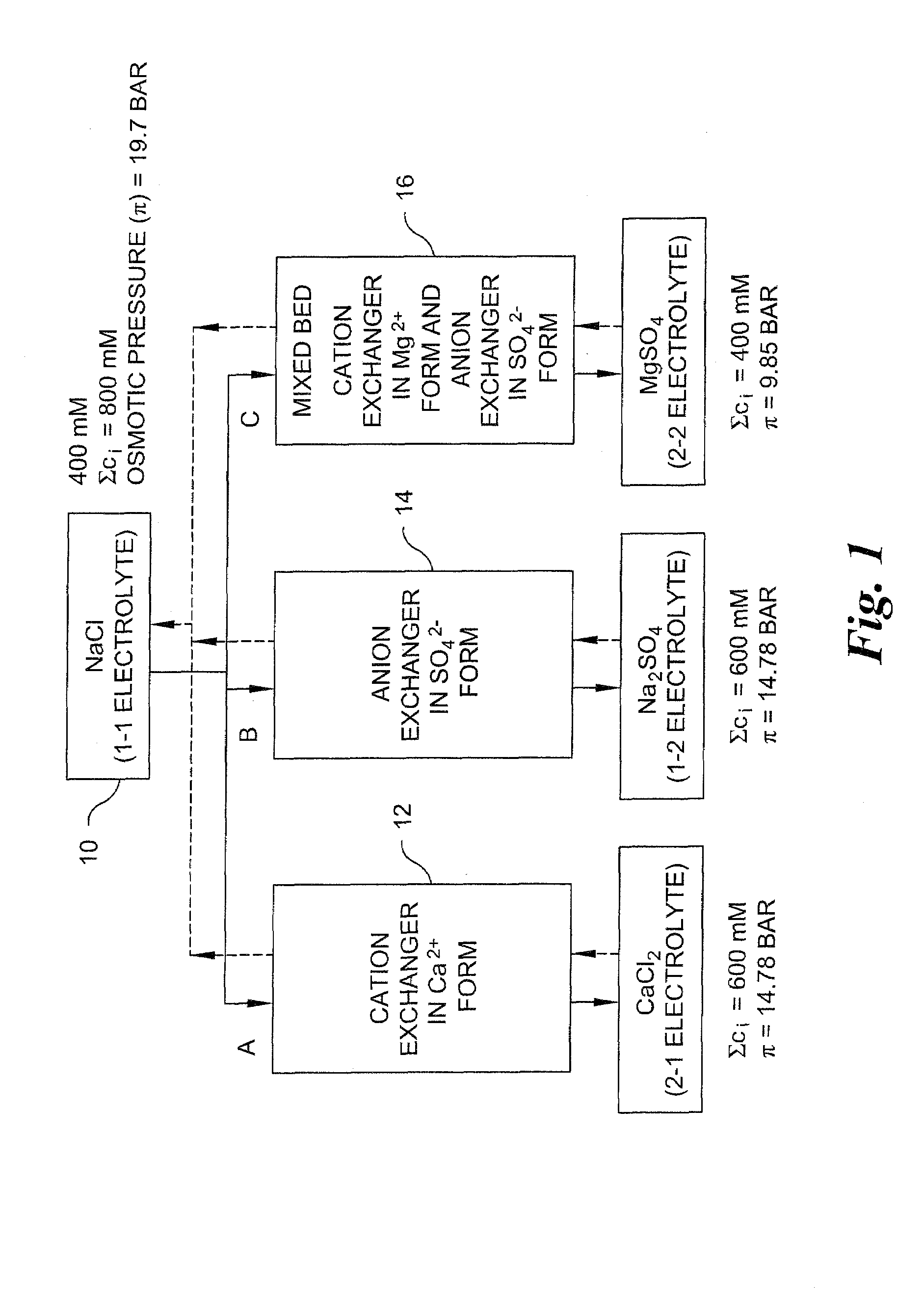

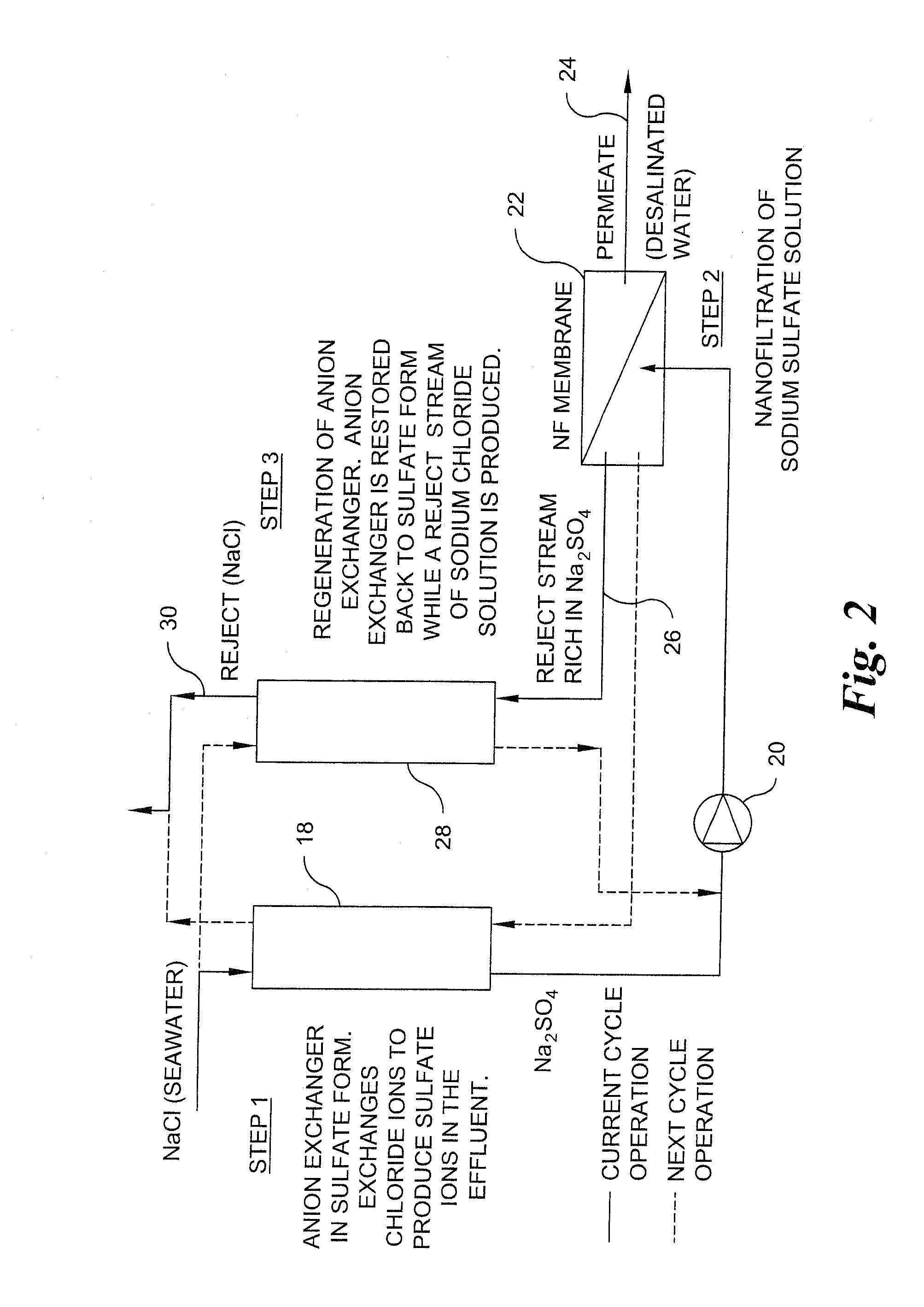

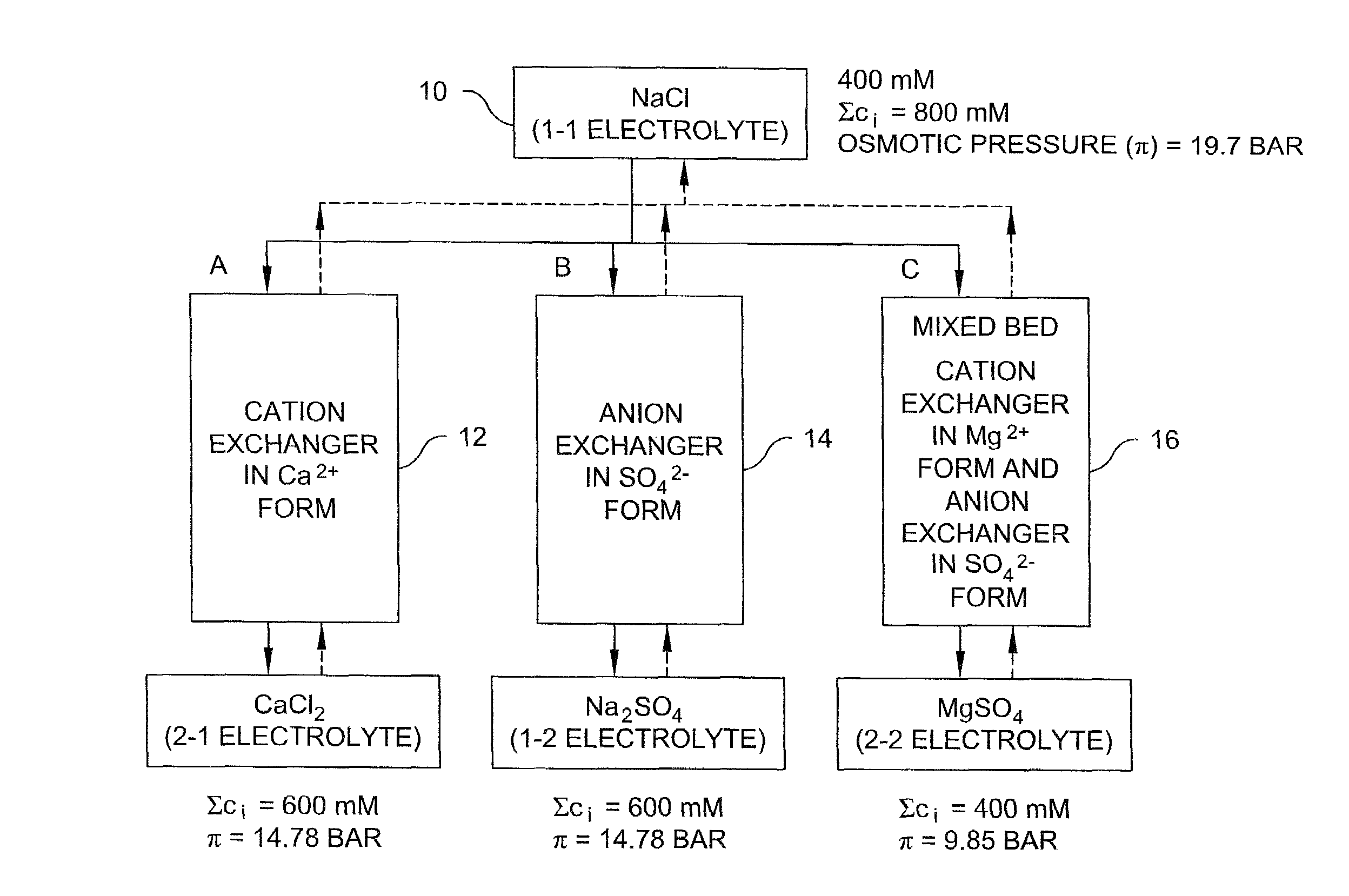

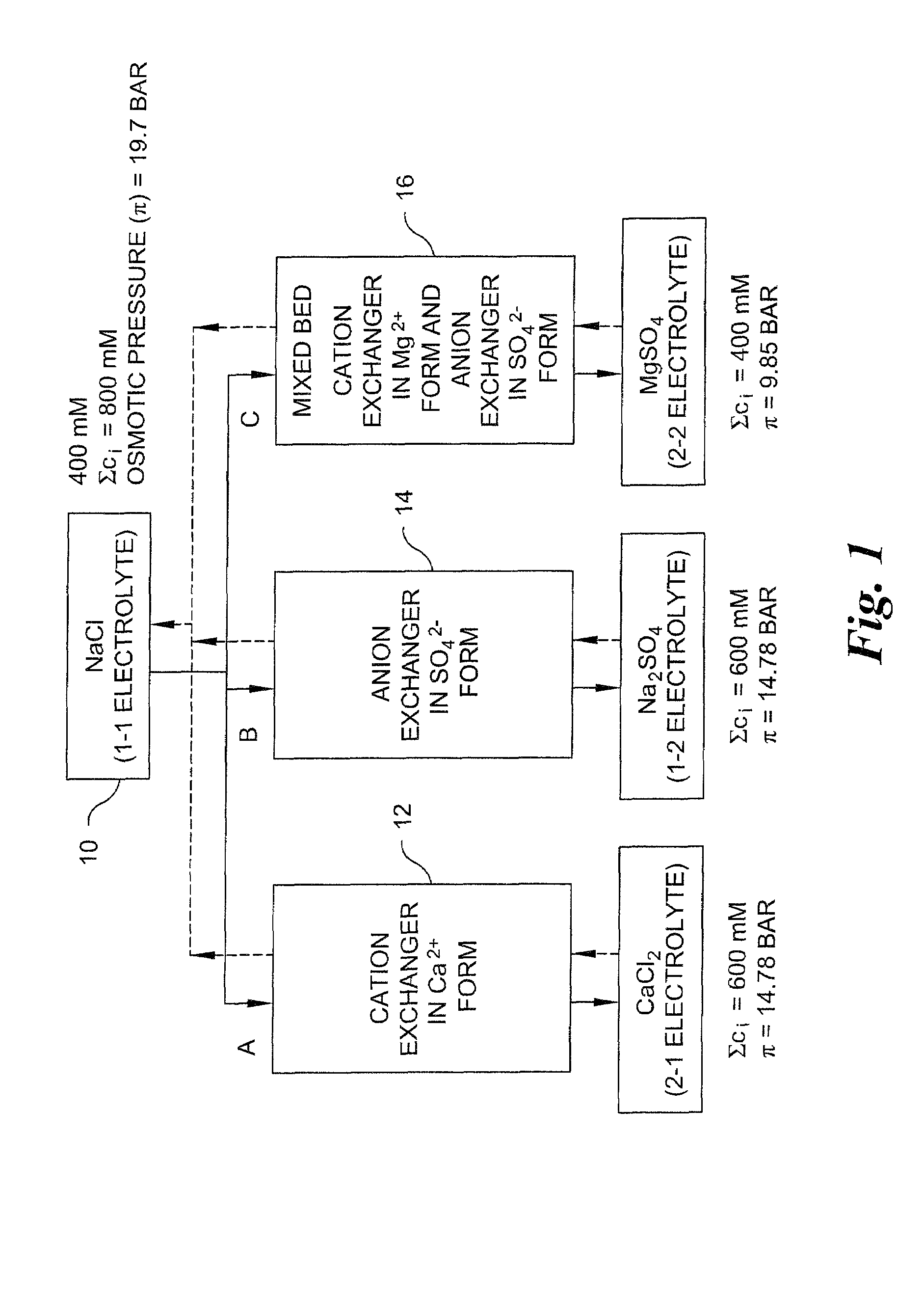

Brackish and sea water desalination using a hybrid ion exchange-nanofiltration process

InactiveUS20080277344A1Lower energy requirementsLower resistanceElectrolysis componentsGeneral water supply conservationWater desalinationPressure.drive

Desalination is carried out by a hybrid ion exchange-nanofiltration process in which ion exchange is followed by pressure-driven nanofiltration. Monovalent ions of sodium and chloride of saline water are exchanged for equivalent concentrations of poly-valent ions (for example, sodium ions for magnesium ions or chloride ions for sulfate ions) when passed through ion exchangers in the form of those poly-valent ions. The resultant solution has a lower osmotic pressure than the initial solution containing monovalent sodium and chloride ions, and requires less transmembrane pressure for membrane desalination compared to traditional reverse osmosis. The concentrated reject stream from the membrane process is used as regenerant for the exhausted ion exchanger, which has been converted to monovalent anionic or cationic form.

Owner:SENGUPTA ARUP K

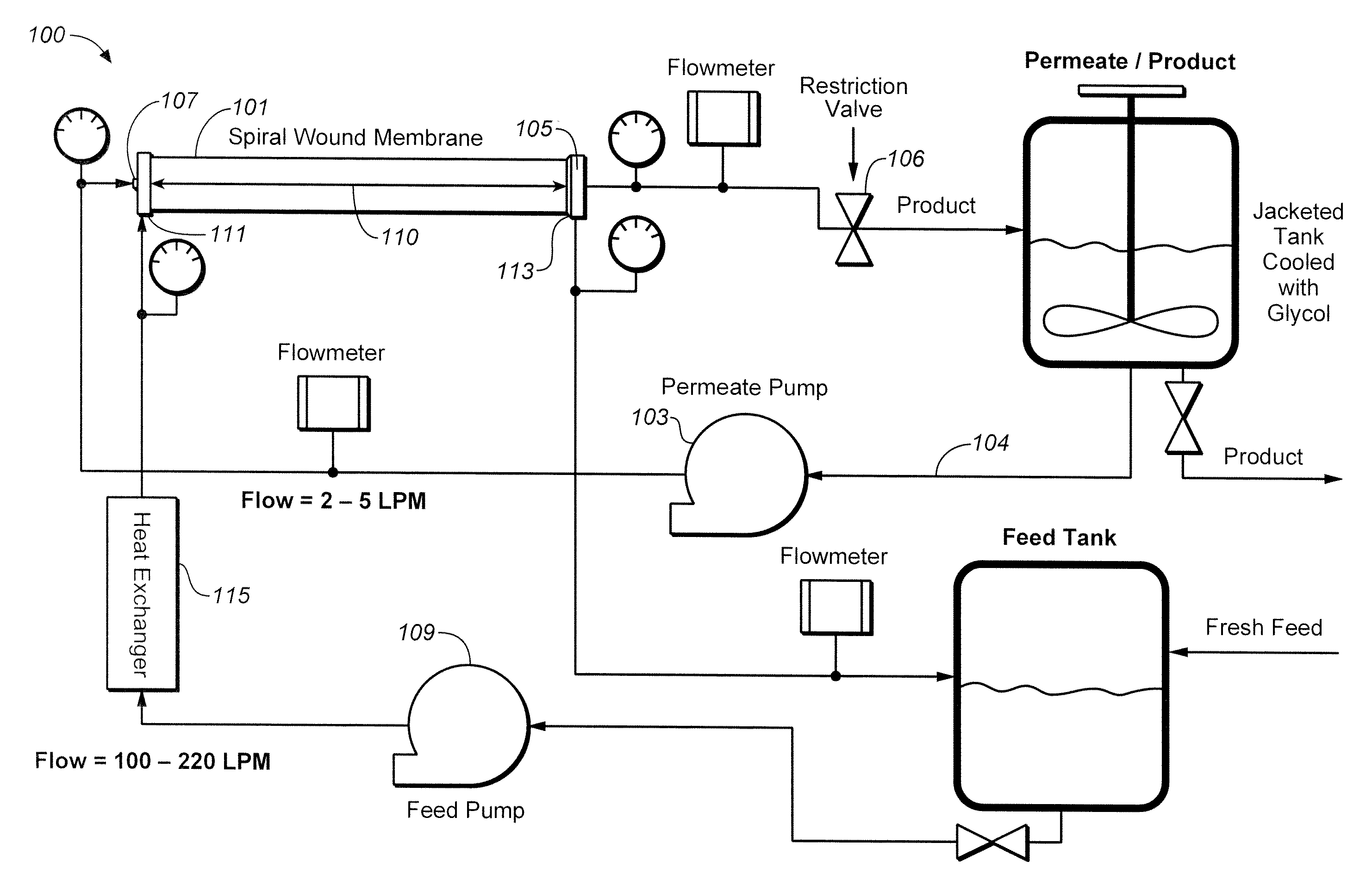

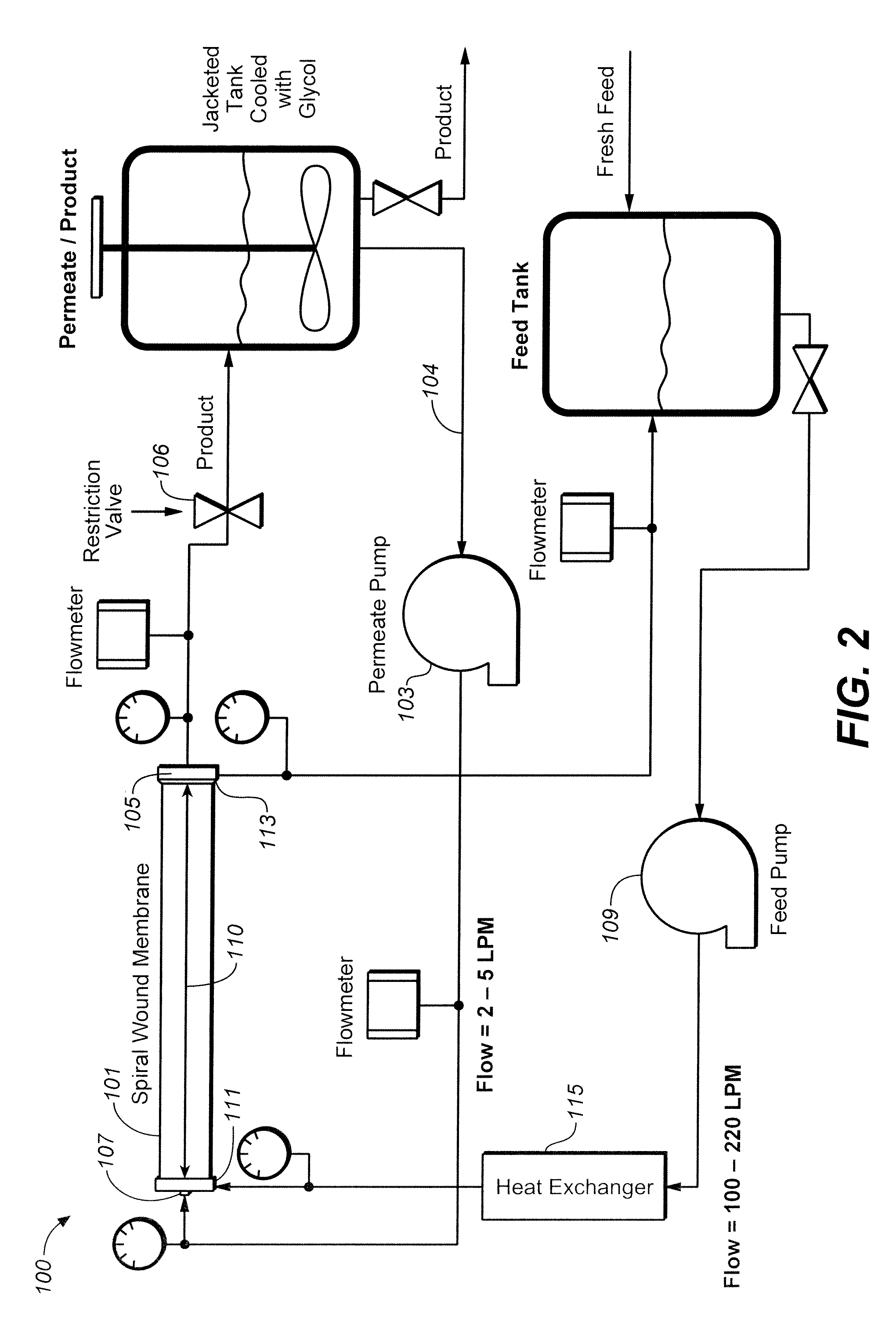

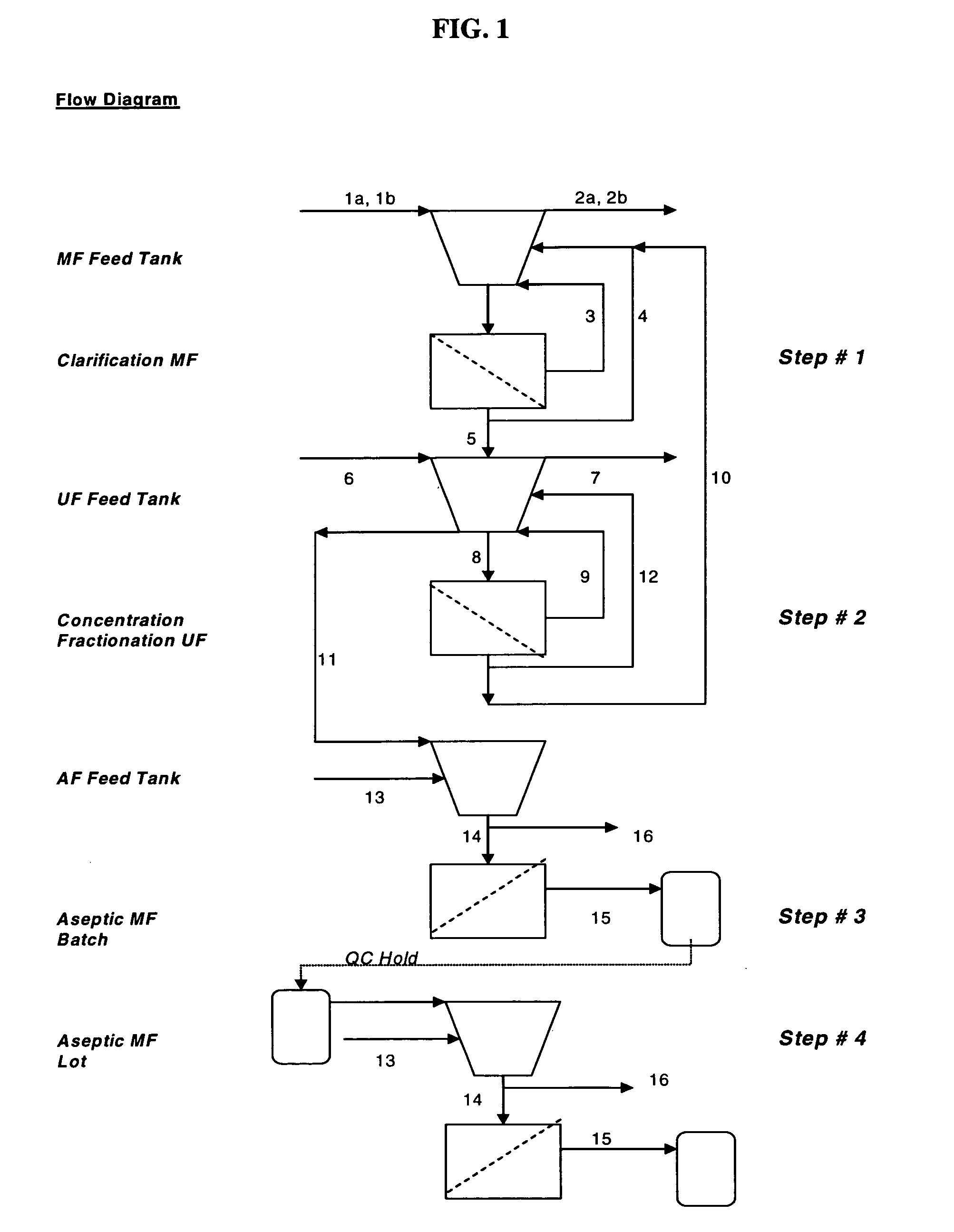

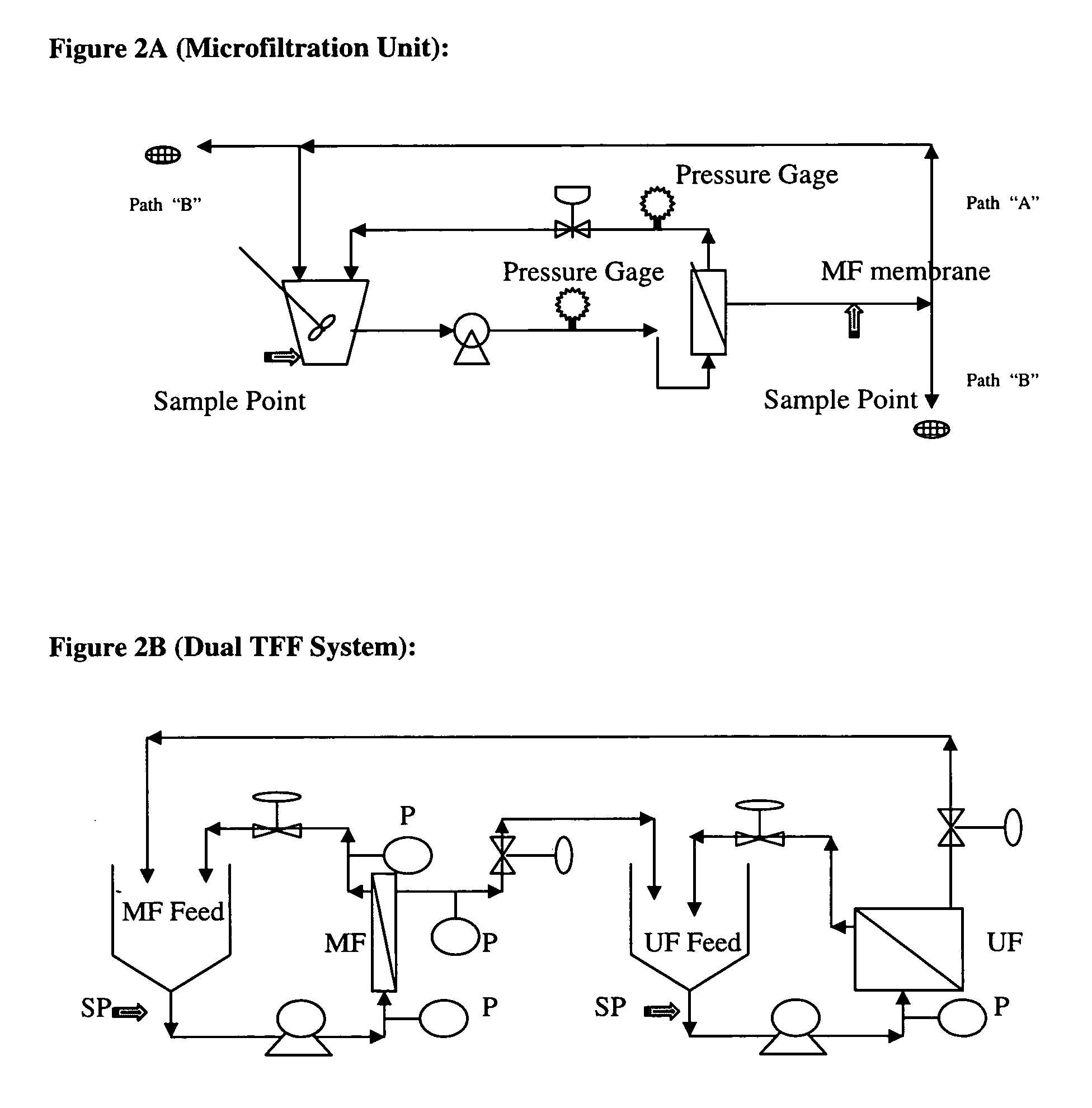

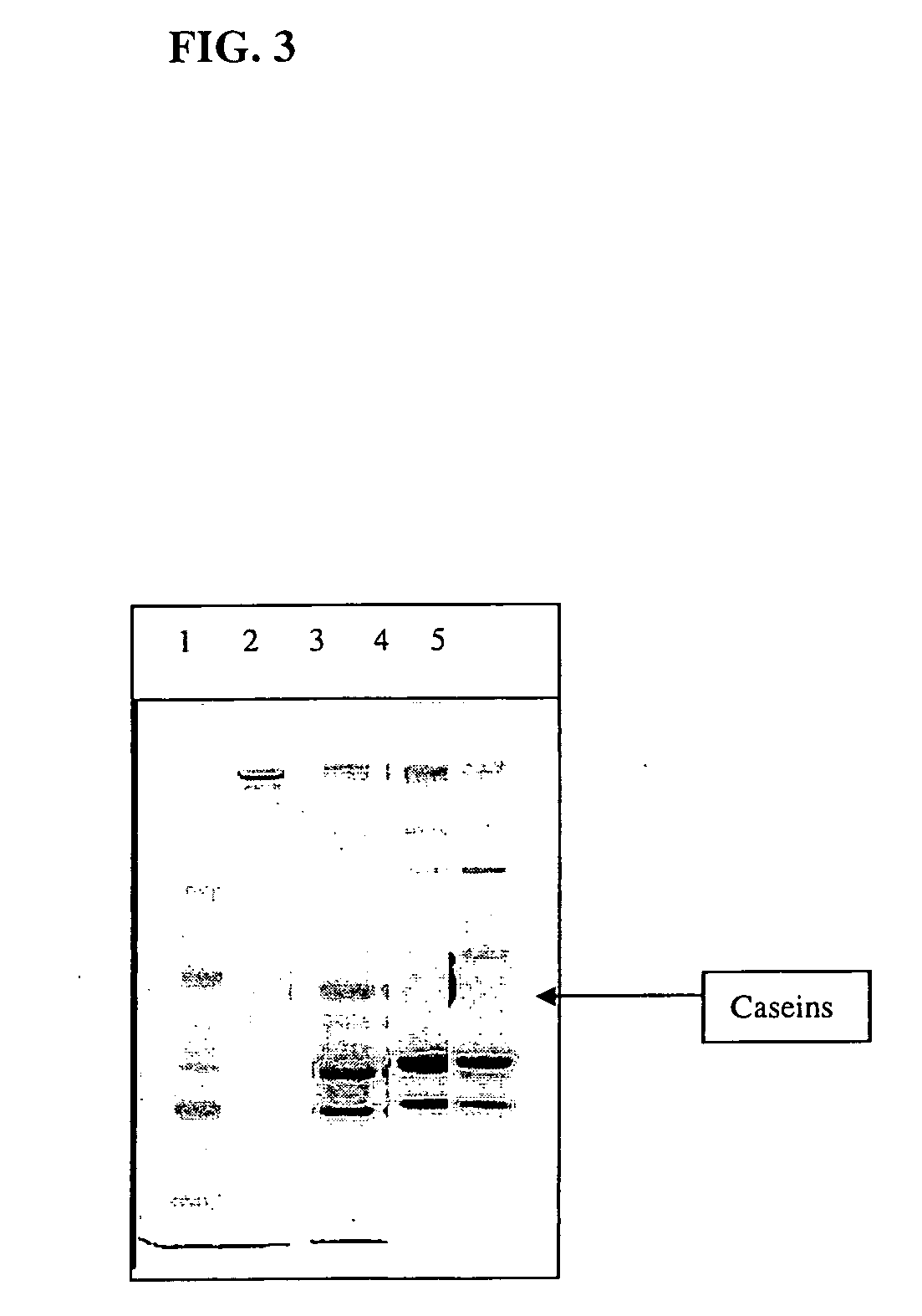

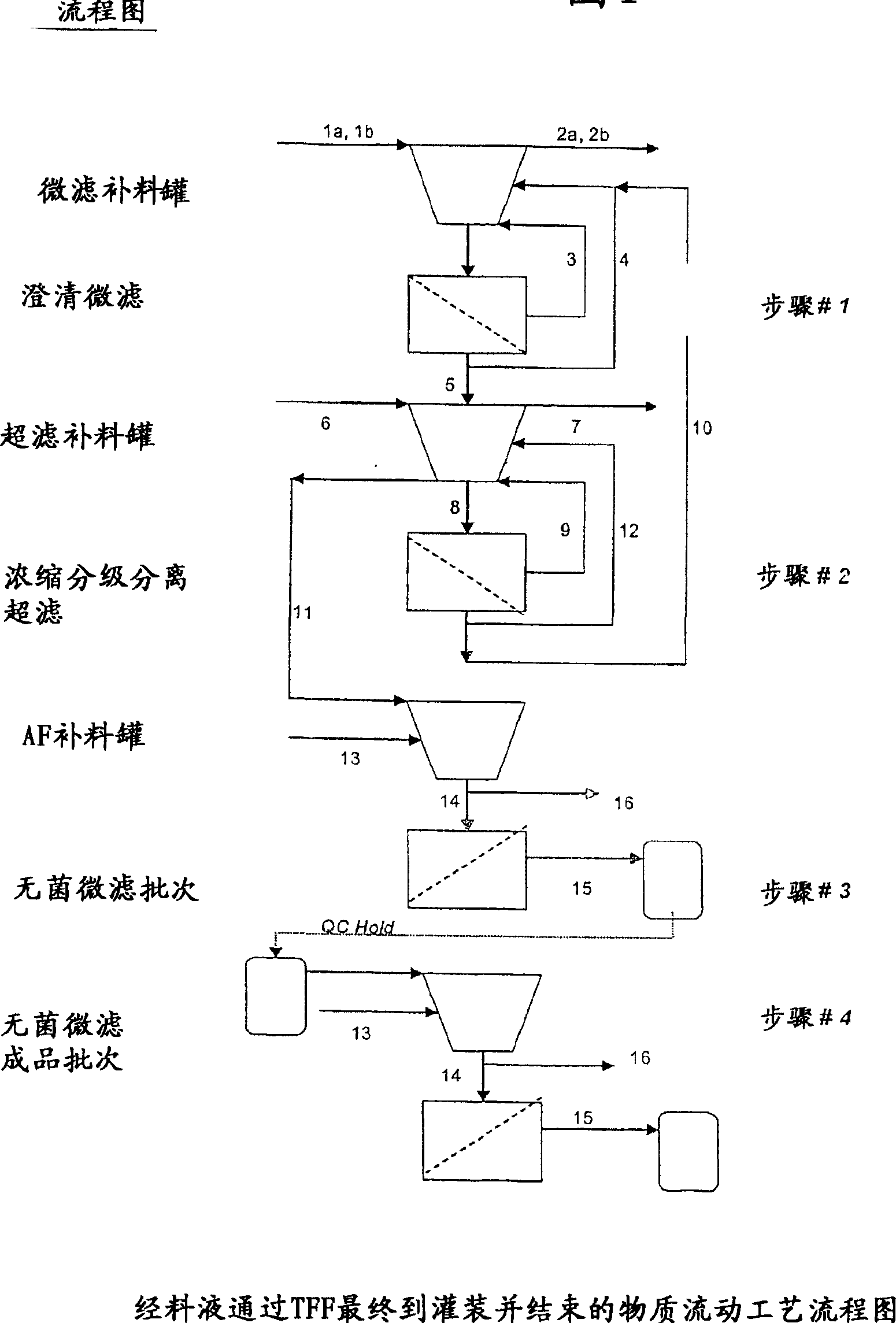

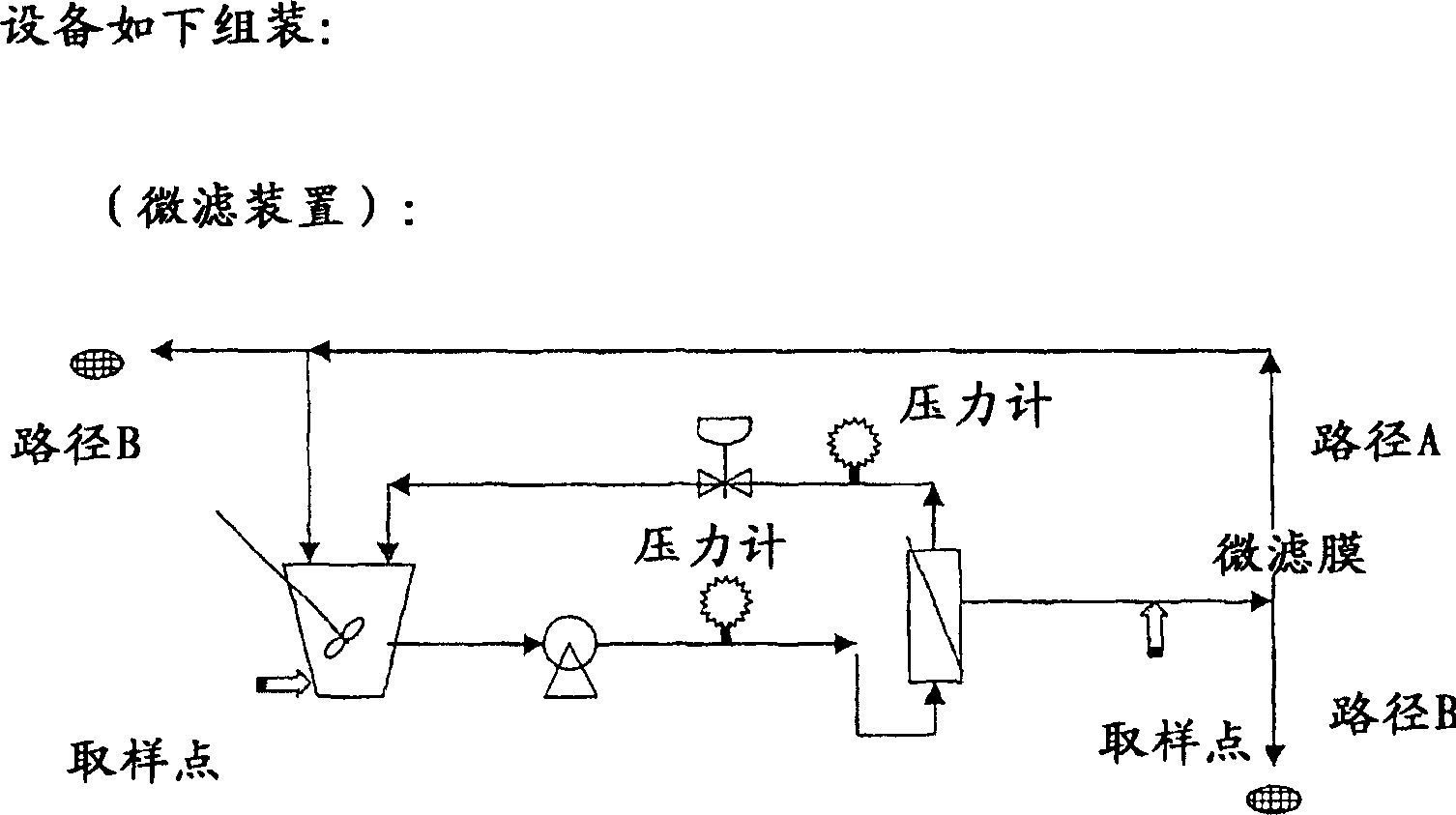

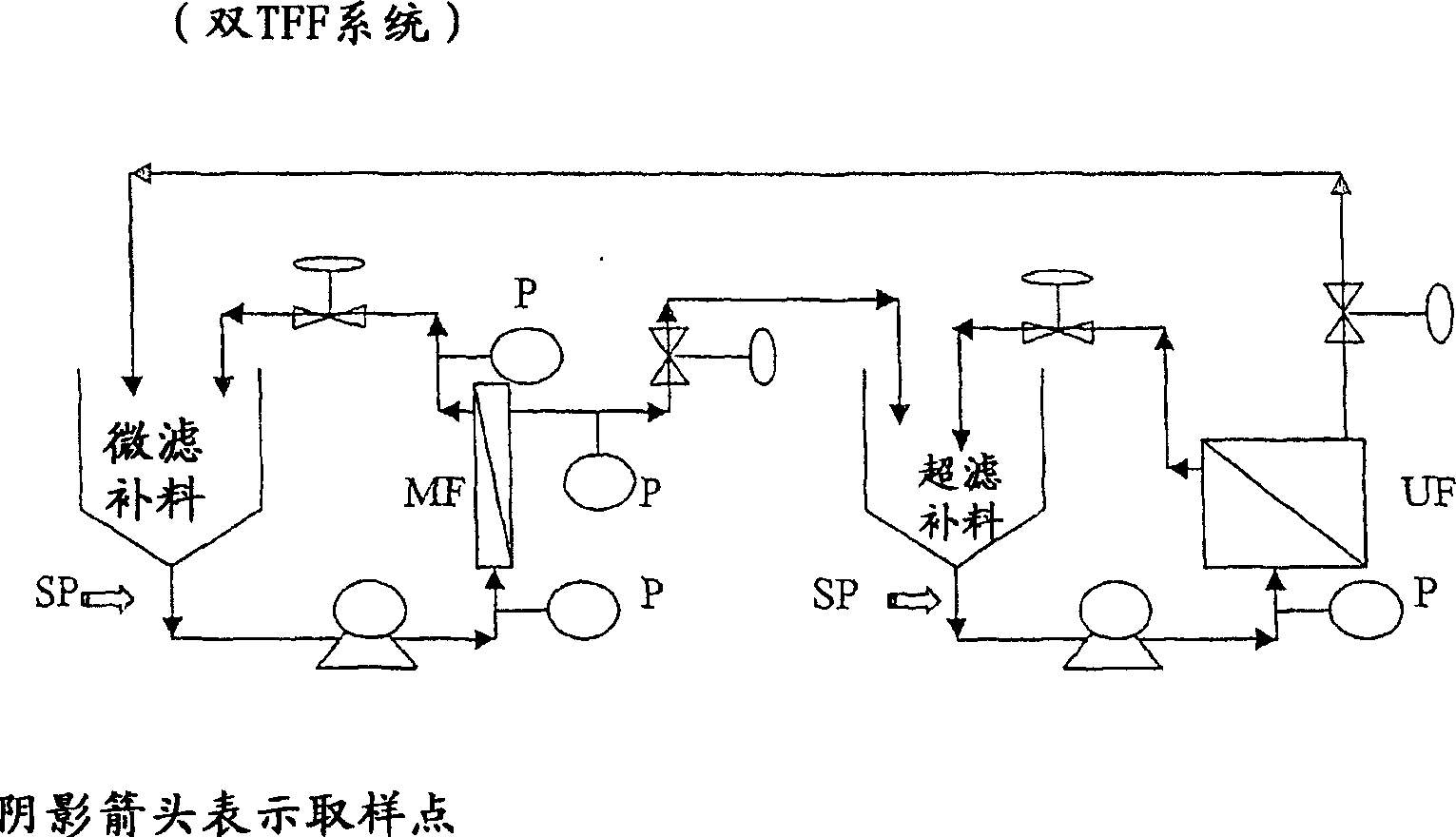

Methods of tangential flow filtration and an apparatus therefore

InactiveUS20050260672A1High purityLower the volumeSugar derivativesMicrobiological testing/measurementFiltrationImproved method

Processes and apparati are provided for separating molecules of interest from a mixture containing them which comprises subjecting the mixture to an improved method of tangential flow filtration (TFF). The improved TFF was used to clarify, and process various feedstreams for the removal of a molecule of interest. According to a preferred embodiment, a transgenic milk feedstream is stabilized and particulate matter such as fat, casein miscelles and bacteria are removed. The method of TFF used in the current invention utilizes optimized process parameters that include temperature, transmembrane pressure, cross-flow velocity, and milk concentration. Cleaning and storage procedures were also developed to ensure long membrane life. An aseptic filtration step was also developed to remove any bacteria remaining in a clarified transgenic milk feedstream.

Owner:GTC BIOTHERAPEUTICS INC

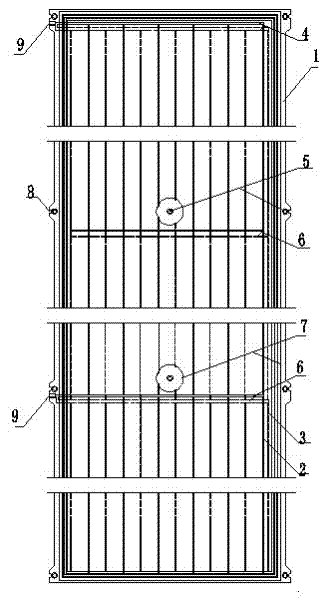

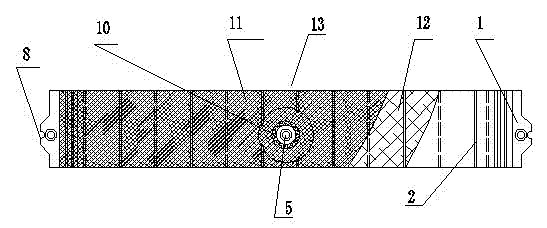

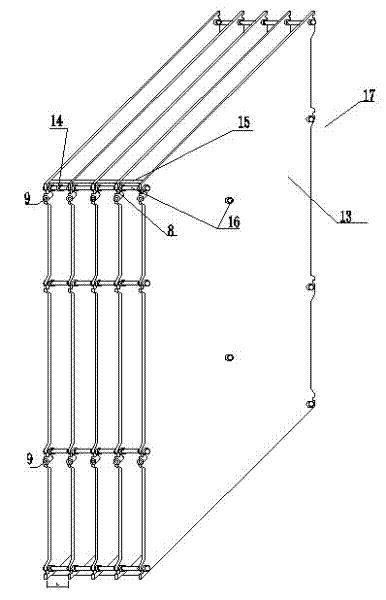

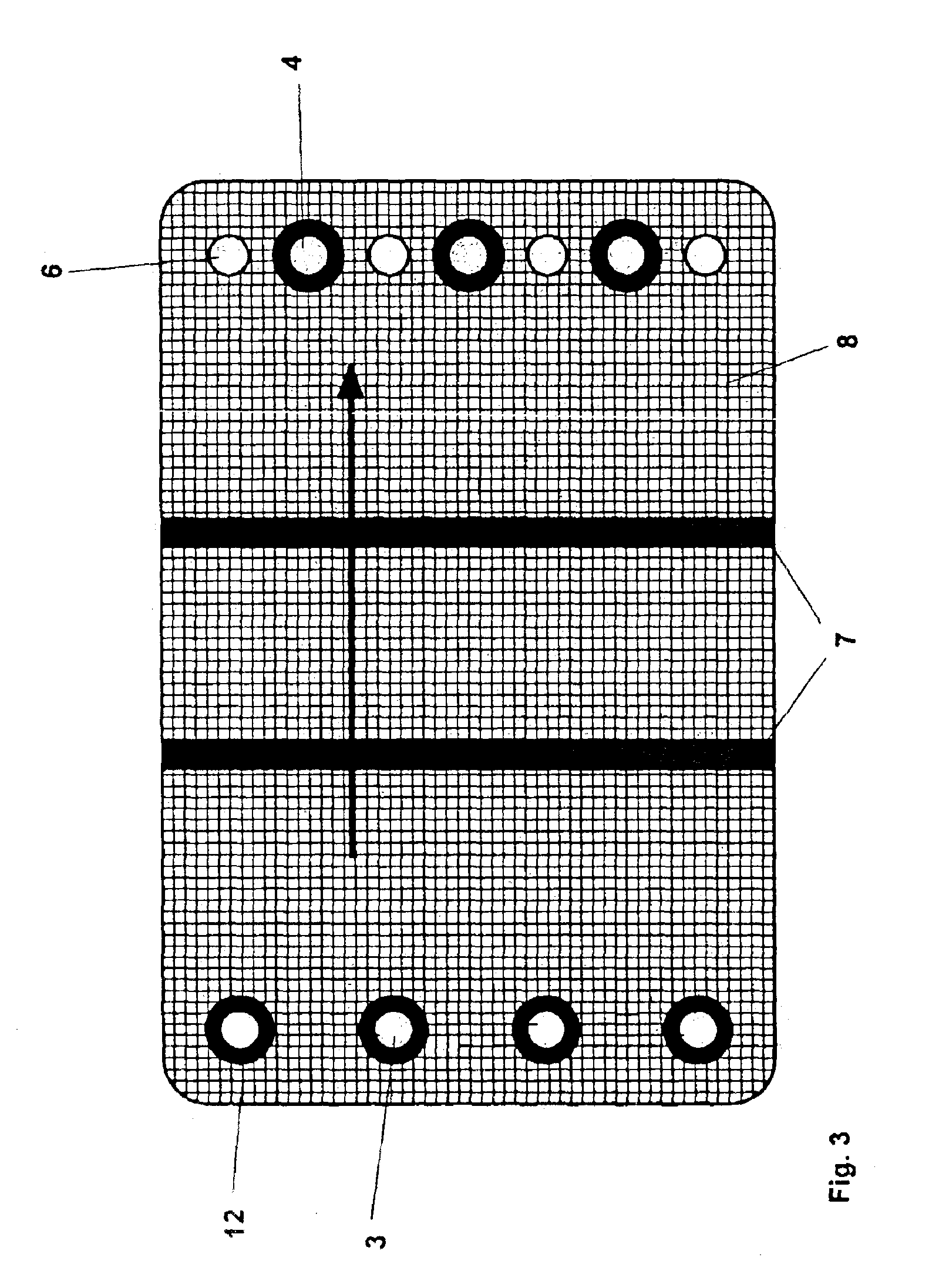

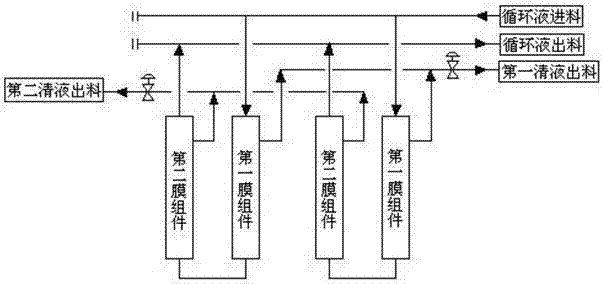

Supporting plate for flat membrane elements as well as flat membrane elements and flat membrane components

ActiveCN102512963AUniform transmembrane pressure differenceReduce consumptionSemi-permeable membranesSustainable biological treatmentEngineeringPressure difference

The invention relates to flat membrane elements and components for water treatment, which are characterized in that the front face and the back face of a supporting plate of membrane elements are respectively provided with a plurality of scattered face bosses higher than the supporting plate. The adjacent membrane elements are combined and are supported at intervals by means of the face bosses of the supporting plate. The supporting plate can not be tilted and deformed, the condition that the distance of each point between the planes of the adjacent membrane elements is unchanged is ensured, aerated scouring is uniform, and the membrane pollution is lowered. Moreover, the thickness of the supporting plate can also be obviously reduced, and the thickness is reduced from original 5.5 to 6.0mm to about 3.5mm, so that the weight and the cost of the supporting plate are lowered by about 30 percent, the bosses are arranged at intervals, the adjacent intervals of assembled membrane components can also be changed according to actual requirements, and the condition that the distance of the membrane elements can be regulated is realized. Furthermore, the method of assembling the components of the membrane elements is also changed, the function of side inserting assembly can be realized, the structure of a membrane bracket is simplified, and the versatility of a component frame is enhanced. The front face and the back face of the supporting plate are additionally provided with transverse flow passages with transverse penetration, so that the resistance of water collection and flow deflection is small, the transmembrane pressure difference of a system is small, the water output of gravitational pressure difference can be adopted for filtering, and the running energy consumption of the system can be greatly lowered.

Owner:江苏沛尔膜业股份有限公司

Methods of tangential flow filtration and an apparatus therefor

InactiveCN1759189AMicrobiological testing/measurementPeptide preparation methodsFiltrationMicrosphere

Processes and apparati are provided for separating molecules of interest from a mixture containing them which comprises subjecting the mixture to an improved method of tangential flow filtration (TFF). The improved TFF was used to clarify, and process various feedstreams for the removal of a molecule of interest. According to a preferred embodiment, a transgenic milk feedstream is stabilized and particulate matter such as fat, casein miscelles and bacteria are removed. The method of TFF used in the current invention utilizes optimized process parameters that include temperature, transmembrane pressure, cross-flow velocity, and milk concentration. Cleaning and storage procedures were also developed to ensure long membrane life. An aseptic filtration step was also developed to remove any bacteria remaining in a clarified transgenic milk feedstream.

Owner:GTC BIOTHERAPEUTICS INC

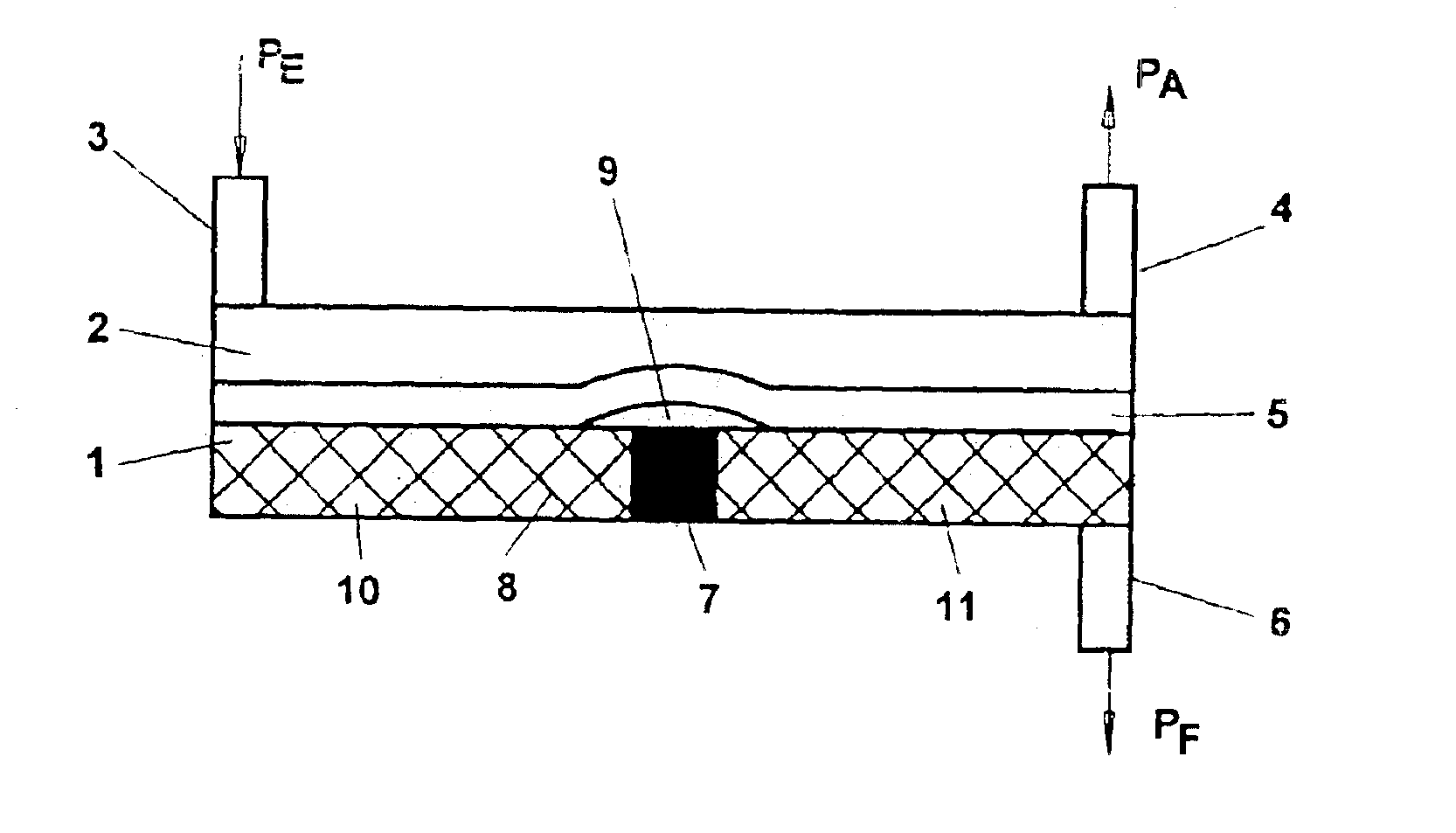

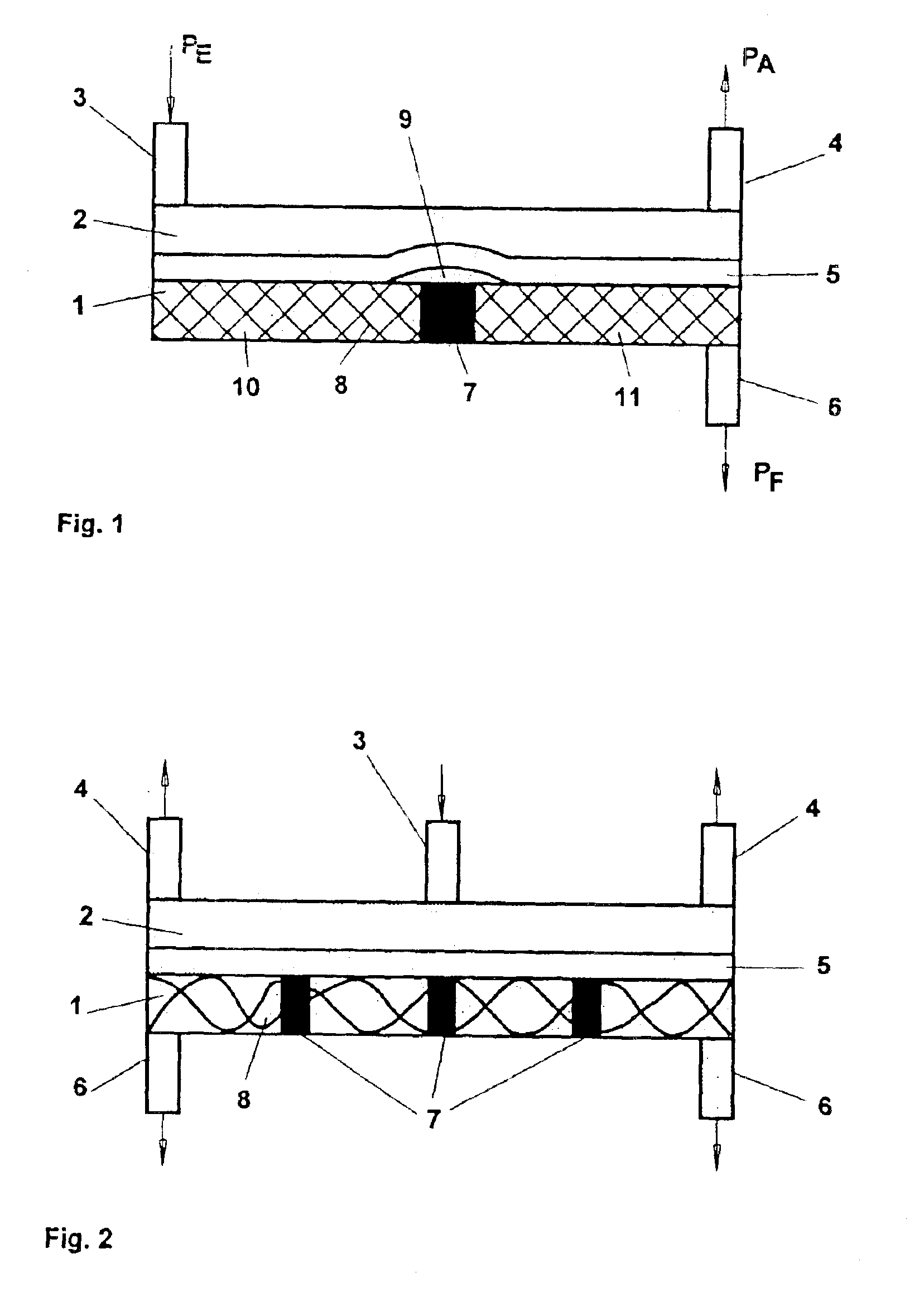

Cross-flow filter with self-regulating transmembrane pressure

InactiveUS6893563B2Uniform transmembrane pressureSmall feed velocitySemi-permeable membranesSettling tanks feed/dischargeCross-flow filtrationTransmembrane pressure

Owner:SARTORIUS STEDIM BIOTECH GMBH

Ionic liquid gel supporting film and preparation method thereof

InactiveCN103599707AHigh gas permeation fluxEasy to prepareSemi-permeable membranesSeparation technologyTrapping

The invention relates to an ionic liquid gel supporting film and a preparation method thereof, belonging to the field of membrane separation techniques. The film is formed by loading ionic liquid gel on a macromolecule microporous membrane, and the mass of the ionic liquid gel accounts for 30-80% of the total mass of the ionic liquid gel supporting film. The preparation method of the film comprises the following steps: firstly, injecting a gel precursor solution into the macromolecule microporous membrane by adopting an impregnation method, and gelatinizing the gel precursor solution through ultraviolet light initiation to prepare the ionic liquid gel supporting film. The ionic liquid gel supporting film prepared by the method provided by the invention has relatively high gas permeation flux and relatively large gas separating factor, and can avoid the liquid leakage of the film under relatively high transmembrane pressure, enhance the performance stability of the film, and prolong the service life of the film. The method is simple and easy to control, the prepared ionic liquid gel supporting film is mainly used in the fields such as trapping of acid gas in industrial discharge exhaust gas, and CO2 separating in spacecrafts, submarines and other confined spaces.

Owner:JIANGNAN UNIV

Hollow fiber membrane for treating liquids

ActiveUS20100219122A1Inhibition formationImprove filtration stabilitySemi-permeable membranesMembranesHollow fibre membraneFiber

The present invention provides a hollow fiber membrane for treating liquids. When used for a hollow fiber membrane module for refining a fermented liquid such as beer or wine, the hollow fiber membrane exhibits a high filtration performance per unit area thereof, with reduced clogging of the membrane. The membrane performance is sufficiently recovered by washing.The present invention is a hollow fiber membrane for treating liquids, wherein a ratio of Flux 120 to Flux 30 is 0.45 or higher when filtration is performed by supplying a solution having a turbidity of 20 NTU into a hollow fiber membrane having an internal diameter of 500 to 1500 μm and a membrane thickness of 100 to 500 μm with a transmembrane pressure of 1.5 bar, the Flux 30 being flux 30 minutes after the start of the filtration, the Flux 120 being flux 120 minutes after the start of the filtration.

Owner:TOYO TOYOBO CO LTD

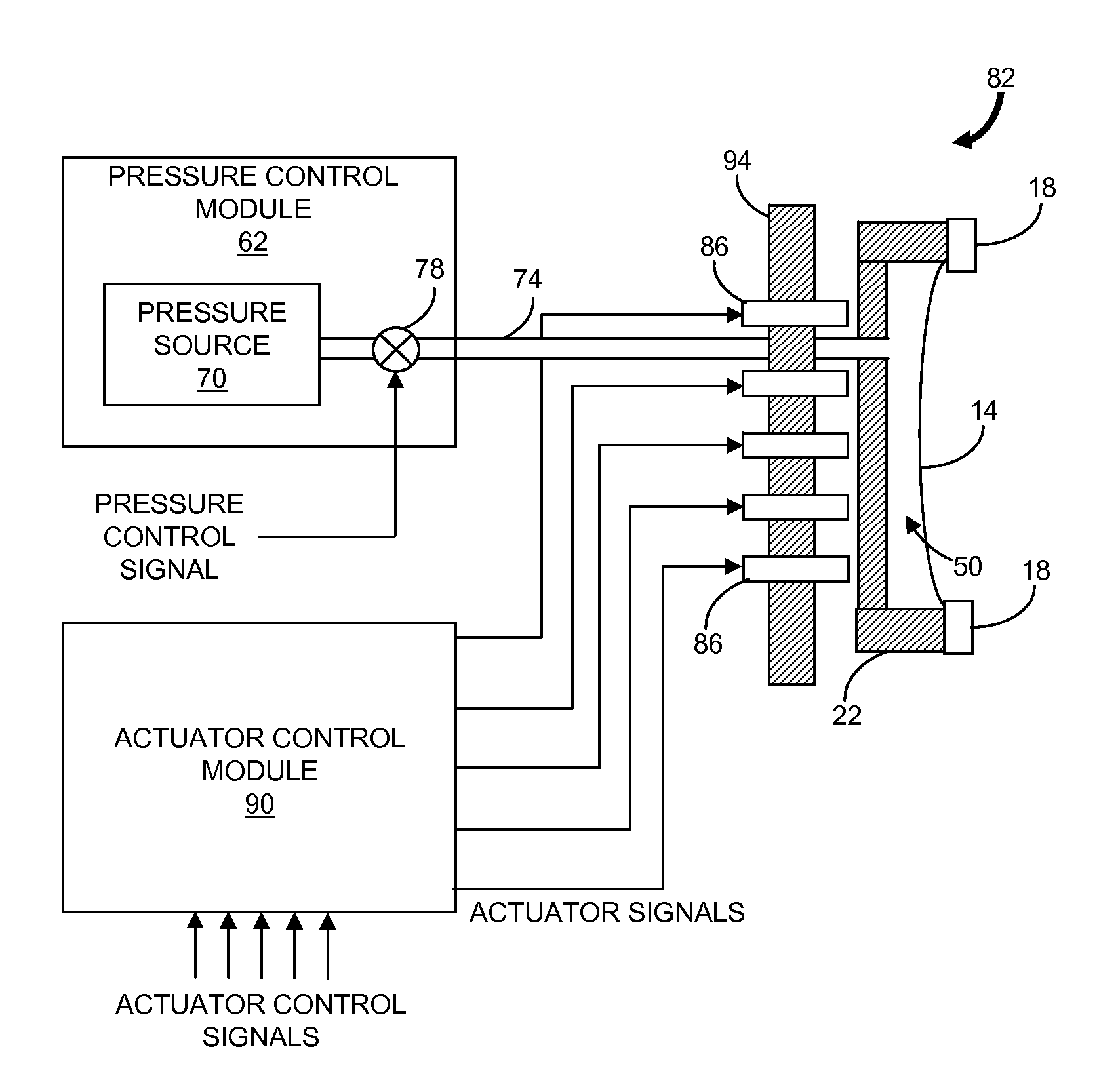

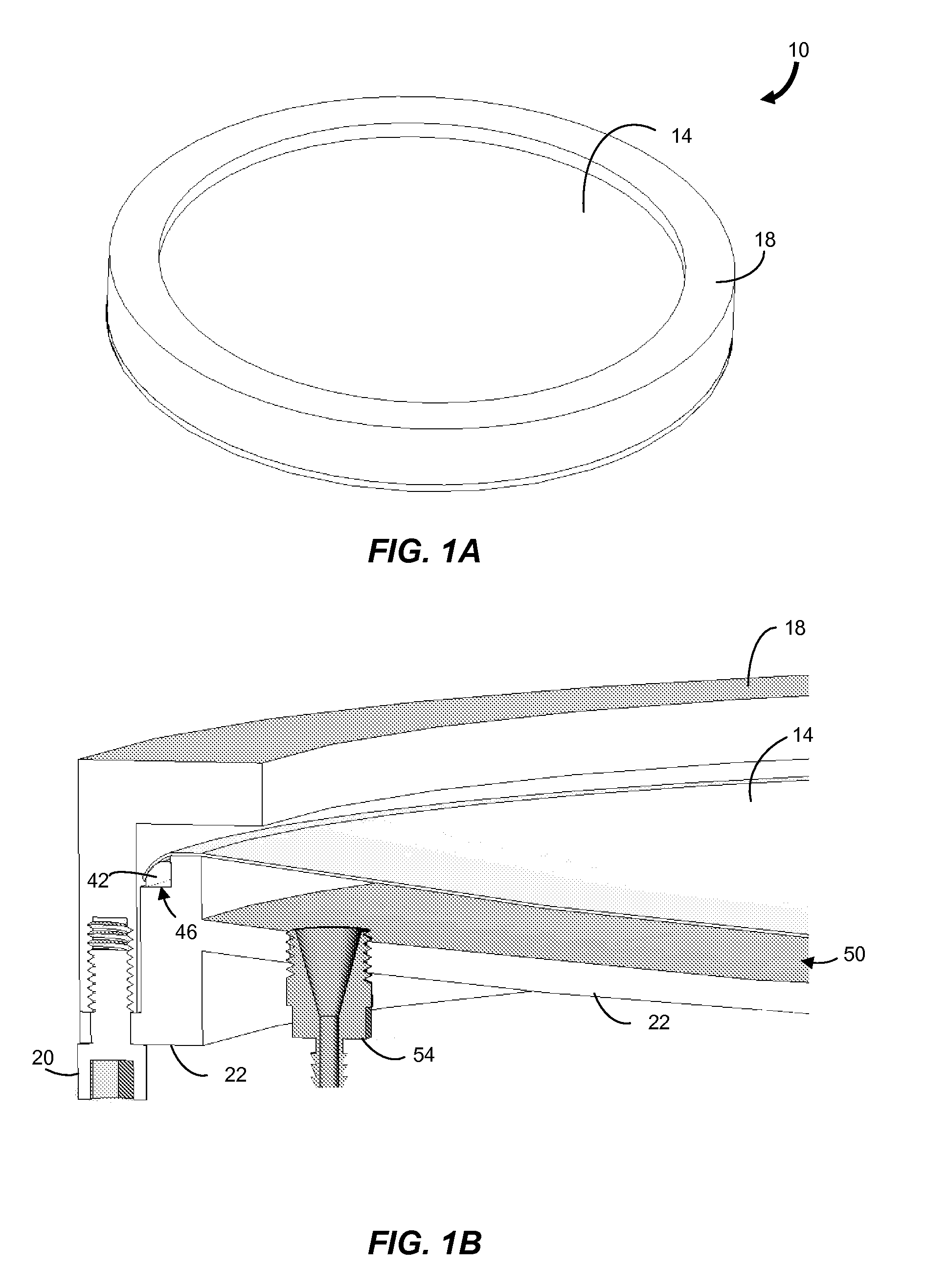

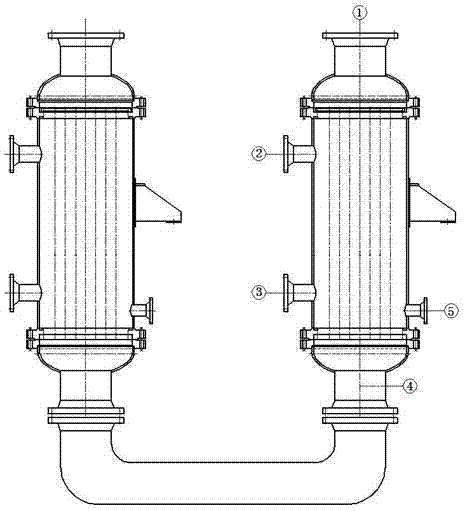

Membrane devices with controlled transmembrane pressure and method of use

ActiveUS20050072734A1Improve the immunitySimple systemMembranesSolvent extractionTransmembrane pressurePermselective membrane

A crossflow membrane device that receives a feedstock at a feed end face and separates the feedstock into permeate and retentate. The device has a membrane support containing at least one monolith of porous material defining a plurality of passageways extending longitudinally from the feed end face of the monolith to a retentate end face of the monolith through which the feedstock flows to pass retentate from the device. A permselective membrane coating of finer pore size than that of the porous material is applied to the passageway wall surfaces of the monolith. At least one permeate conduit is formed within the monolith, the conduit containing a plurality of longitudinal permeate chambers communicating with a means of permeate introduction at or near the feed end face and permeate withdrawal at or near the retentate end face. The permeate is separated from feed and retentate, and a portion of the permeate is circulated through the permeate conduit to create a decreasing permeate pressure within the permeate conduit from the feed end of the membrane device to the retentate end of the device to control transmembrane pressure along the length of the device.

Owner:SEPARIS

A kind of assembly method of organic/inorganic hollow fiber composite membrane

InactiveCN102284253AExcellent permeation fluxHigh mechanical strengthSemi-permeable membranesFiberComposite film

The invention relates to an assembly method of an organic / inorganic hollow fiber composite membrane, which belongs to the technical field of membrane separation. The steps include: immersing the hollow fiber ceramic porous membrane in a silane coupling agent for pretreatment for 0.1 to 4 hours, rinsing and drying; Alternately and dynamically filter the polycation solution or polyanion solution on the surface of the ceramic porous membrane to form a thin film separation layer; put the composite membrane in a vacuum drying oven at 100-300°C for 0.1-4 hours to thermally crosslink the polycation and polyanion layers A chemical reaction occurs between them to form a covalently cross-linked separation layer. When the polycation and polyanion solution is filtered on the base membrane, the transmembrane pressure difference is -0.02~-0.09MPa. The invention is easy to operate, can prepare a pervaporation separation membrane with excellent performance, and effectively improves the permeation flux, mechanical strength, thermal stability and chemical stability of the composite membrane.

Owner:BEIJING UNIV OF TECH

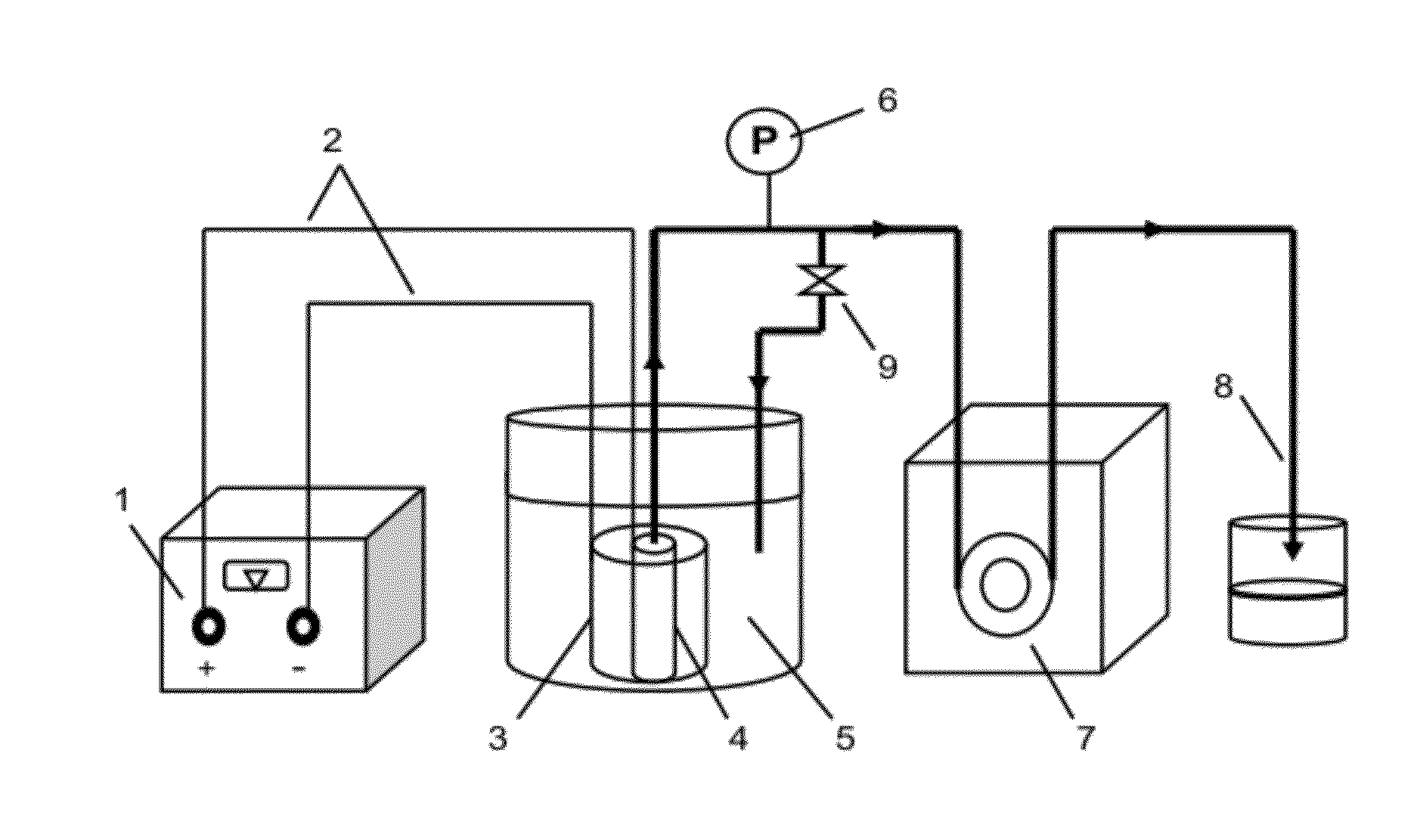

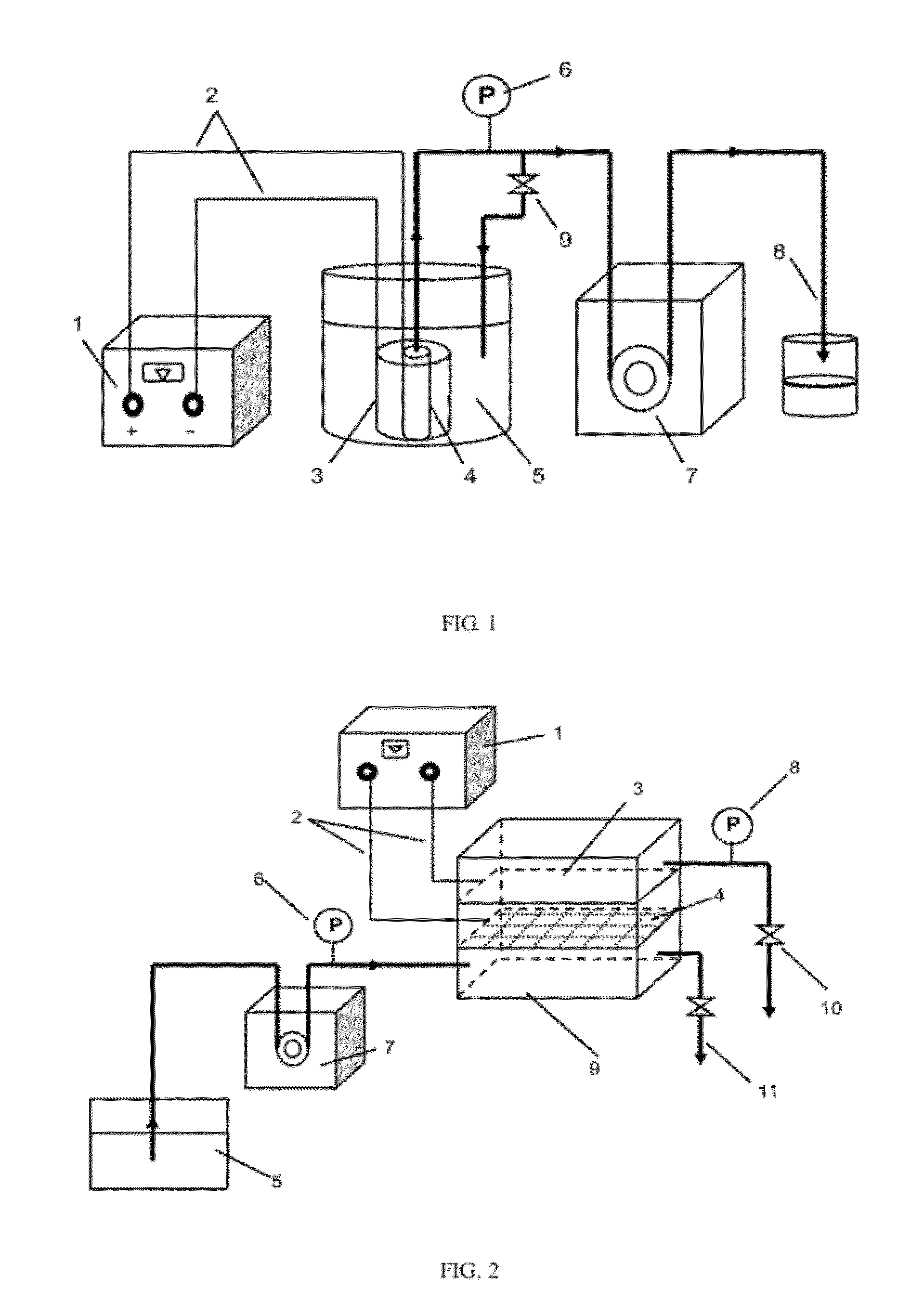

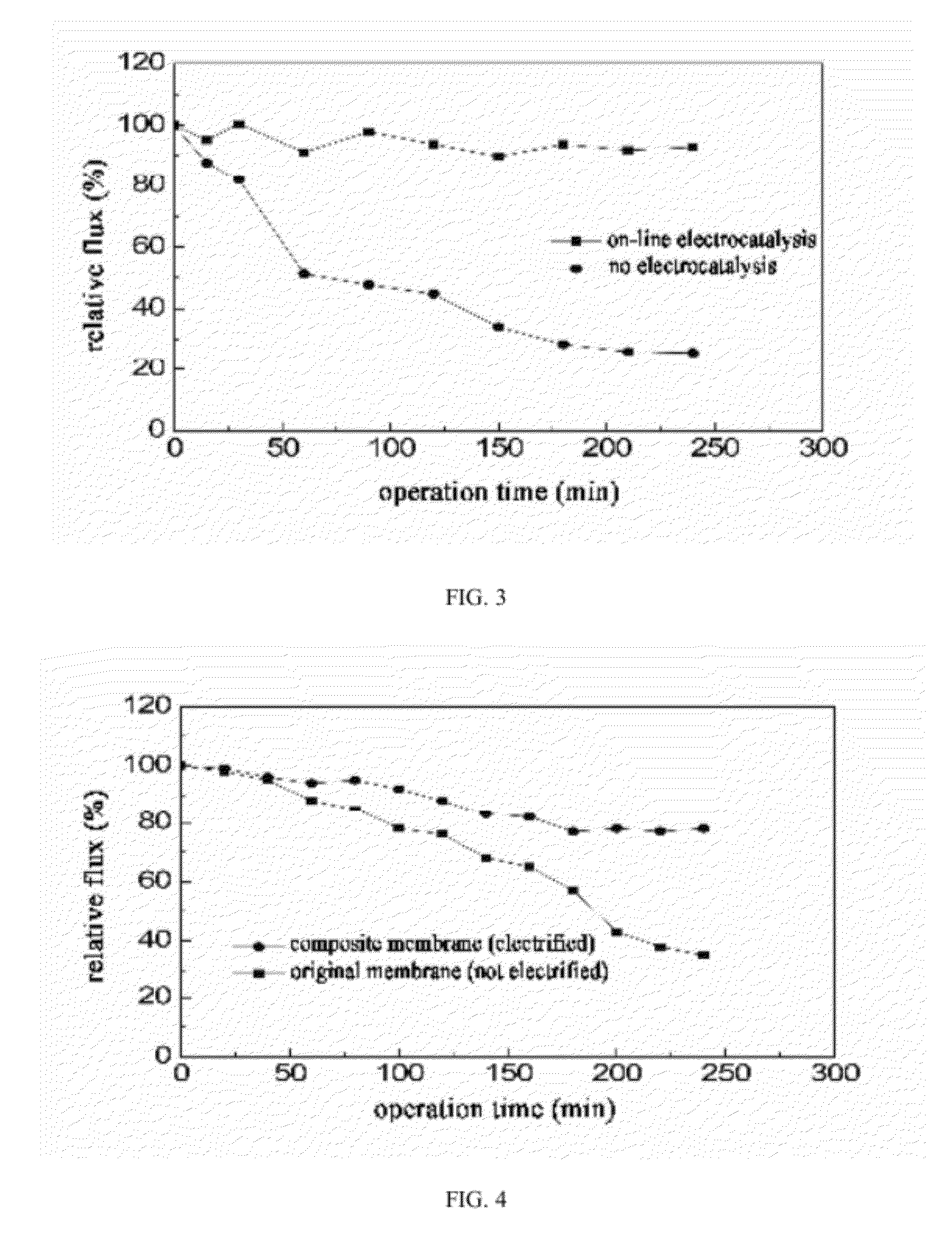

Anti-pollution electrocatalysis composite membrane and membrane reactor

ActiveUS20120090988A1Improve antifouling performanceImprove electrocatalytic activityCellsSemi-permeable membranesElectrolysisConductive coating

The present invention relates an antifouling electrocatalytic composite membrane and a membrane reactor. The electrocatalytic composite membrane (3) consists of a substrate and a catalytic coating, wherein the substrate is selected from a conductive substrate or a nonconductive substrate coated with a conductive coating, and the substrate is a porous support having supporting, conducting and separating functions. The catalytic coating is supported or coated on the surface and in the pores of the conductive substrate or the conductive coating so as to increase the electrocatalytic activity of the substrate. The membrane reactor provides a trans-membrane pressure as the membrane separation power generated by a pump (7) and dead-end filtration or cross-flow filtration is applied, then the feed liquid permeates through the membrane from one side to the other to achieve the separation of the liquid; meanwhile, an electrocatalytic composite membrane (3) as anode and an auxiliary electrode (4) as cathode are connected to a power supply (1) separately by conducting wires (2) so that an electrolysis apparatus is formed. The electrocatalytic composite membrane (3) has a self-cleaning function and achieves the pollution-free operation during the membrane separation.

Owner:TIANJIN POLYTECHNIC UNIV

Magnetic membrane mirror

Described is a magnetic membrane mirror having a flexible membrane comprising a magnetic material and having a high reflectance. The flexible membrane is secured over a frame to enclose a volume between the frame and membrane. A transmembrane pressure is established to achieve a desired mirror shape or curvature. Curvature can be changed by modifying the transmembrane pressure by increasing or decreasing the pressure in the enclosed volume. An array of electromagnetic actuators generates individually-controlled magnetic fields to cause localized displacements of the mirror surface. The magnetic membrane mirror can be constructed with inexpensive components and can be used as a dynamic component in an adaptive optical system.

Owner:MASSACHUSETTS INST OF TECH

Preparation method of membrane for supporting supermolecule ion liquid gel

InactiveCN103657441AImprove permeabilityEasy to separateSemi-permeable membranesDispersed particle separationNon-covalent interactionsTransmembrane pressure

The invention relates to a preparation method for a membrane for supporting supermolecule ion liquid gel, and belongs to the technical field of membrane separation. The membrane consists of porous membrane loaded supermolecule ion liquid gel with the mass accounts for 30%-80% of the total mass of the gel support membrane, wherein the porous membrane is a macromolecule microporous membrane, and has the thickness of 100-200 microns; the supermolecule ion liquid gel is formed by gel factors in an ion liquid by self-assembling and gathering under non-covalent interaction; the mass of the ion liquid accounts for 70%-95% of the total gel mass of the gel. The membrane for supporting the supermolecule ion liquid gel, which is prepared by adopting the method disclosed by the invention, not only has high gas permeation flux and large gas separation factors, but also can prevent the liquid leakage under a relatively high transmembrane pressure, can intensify the performance stability, and prolong the service life. The prepared membrane for supporting the supermolecule ion liquid gel is mainly applied to the fields of acid gas collection of industrial emitted gases, CO2 separation in enclosed cabins of spacecrafts, submarines and the like.

Owner:JIANGNAN UNIV

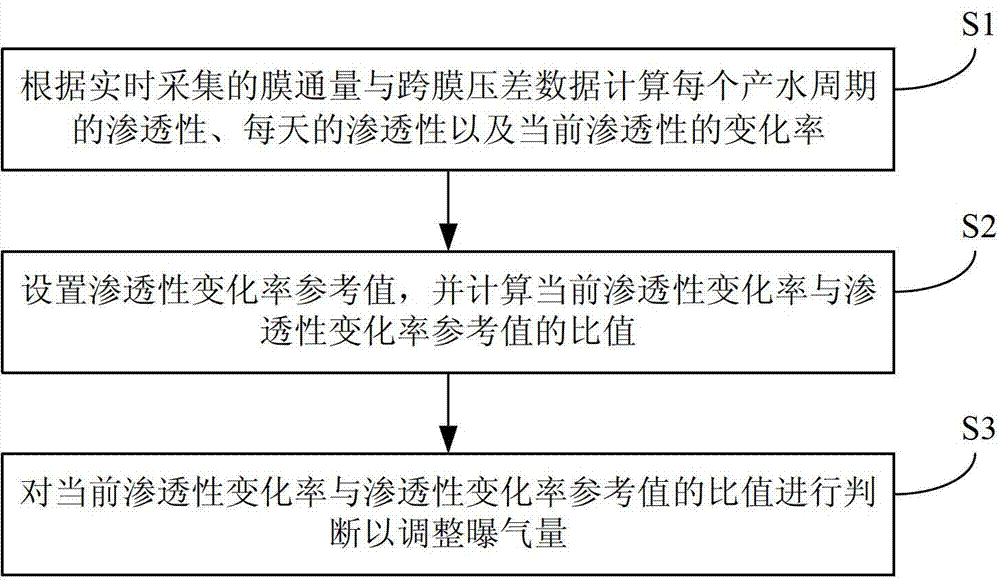

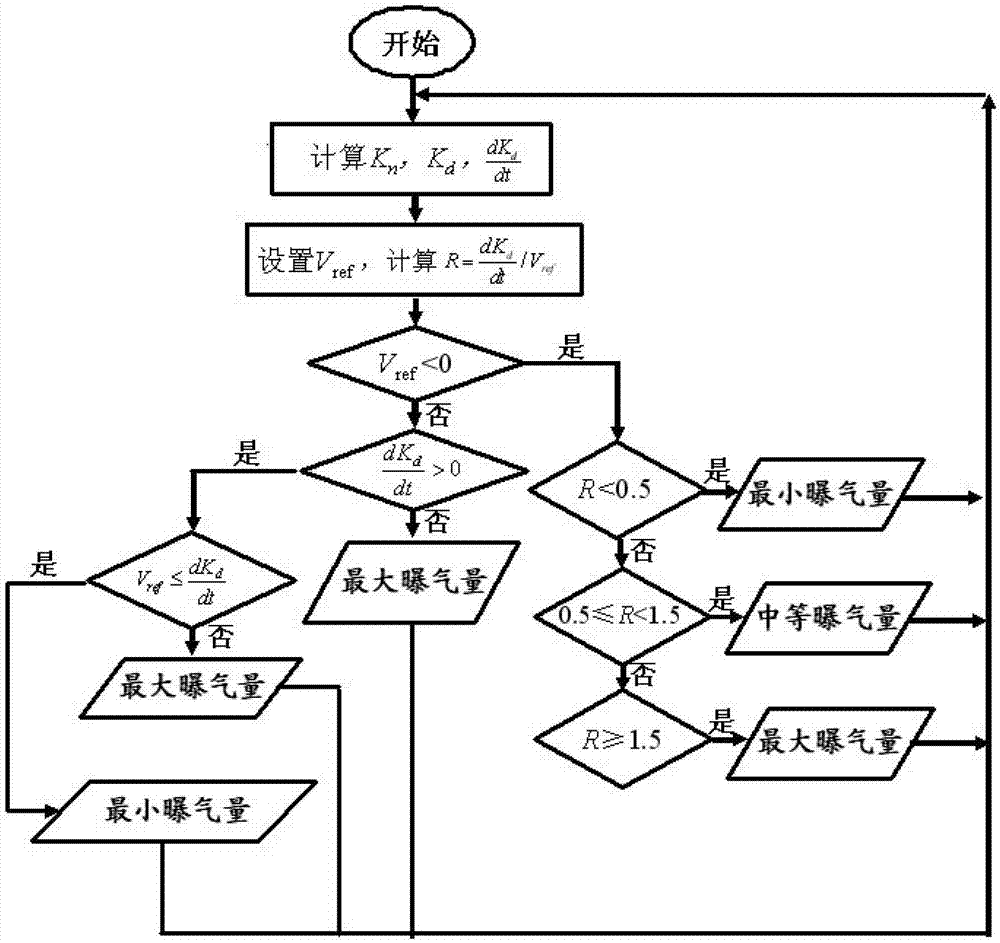

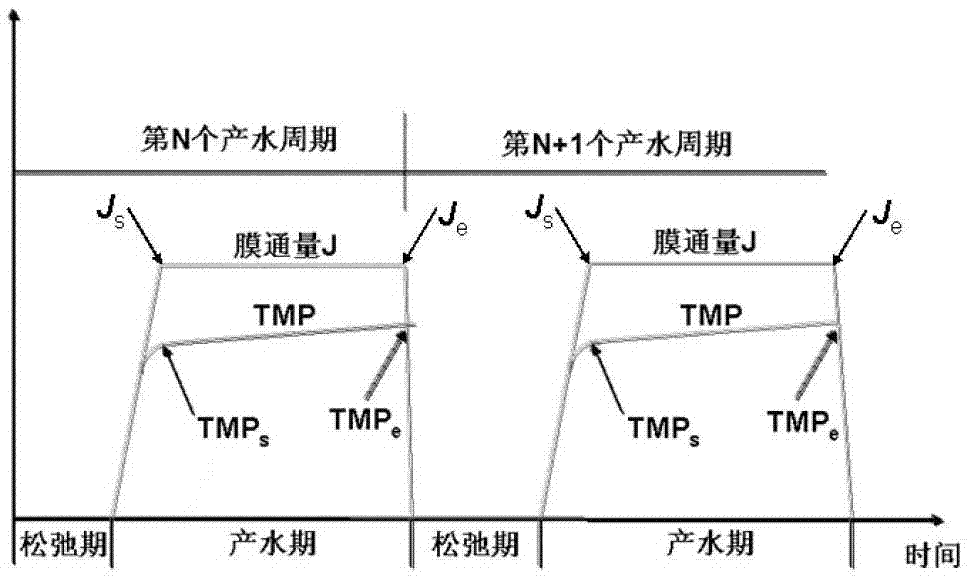

Method and system for controlling aeration quantity of membrane tank

ActiveCN103176483AReduce aeration energy consumptionControl the blast volumeTreatment using aerobic processesFlow control using electric meansFrequency changerTransducer

The invention provides a method for controlling the aeration quantity of a membrane tank. The method comprises the following steps of: calculating the permeability of each water producing period, the permeability each day and the change rate of the current permeability according to the data of membrane flux and transmembrane pressure difference acquired in real time; setting the reference value of the permeability change rate and calculating the ratio of the current permeability change rate to the reference value of the permeability change rate; and determining the ratio of the current permeability change rate to the reference value of the permeability change rate so as to adjust the aeration quantity. The invention also provides a system for implementing the method; and the system comprises a pressure gauge, a flowmeter, an aeration flow control device, a transducer, a blast blower and an aerator pipe, wherein the pressure gauge and the flowmeter are both connected with the aeration flow control device; and the aeration flow control device is orderly connected with the transducer, the blast blower and the aerator pipe. According to the invention, the purpose of reducing the aeration energy consumption of the membrane tank is achieved by regulating and controlling the aeration quantity required by aeration of the membrane tank with the change trend of the permeability of the membrane as a control parameter.

Owner:BEIJING GUOHUAN TSINGHUA ENVIRONMENT ENG DESIGN & RES INST CO LTD BEIJING CHINA

Brackish and sea water desalination using a hybrid ion exchange-nanofiltration process

InactiveUS7901577B2Lower energy requirementsLower resistanceElectrolysis componentsGeneral water supply conservationWater desalinationReverse osmosis

Desalination is carried out by a hybrid ion exchange-nanofiltration process in which ion exchange is followed by pressure-driven nanofiltration. Monovalent ions of sodium and chloride of saline water are exchanged for equivalent concentrations of poly-valent ions (for example, sodium ions for magnesium ions or chloride ions for sulfate ions) when passed through ion exchangers in the form of those poly-valent ions. The resultant solution has a lower osmotic pressure than the initial solution containing monovalent sodium and chloride ions, and requires less transmembrane pressure for membrane desalination compared to traditional reverse osmosis. The concentrated reject stream from the membrane process is used as regenerant for the exhausted ion exchanger, which has been converted to monovalent anionic or cationic form.

Owner:SENGUPTA ARUP K

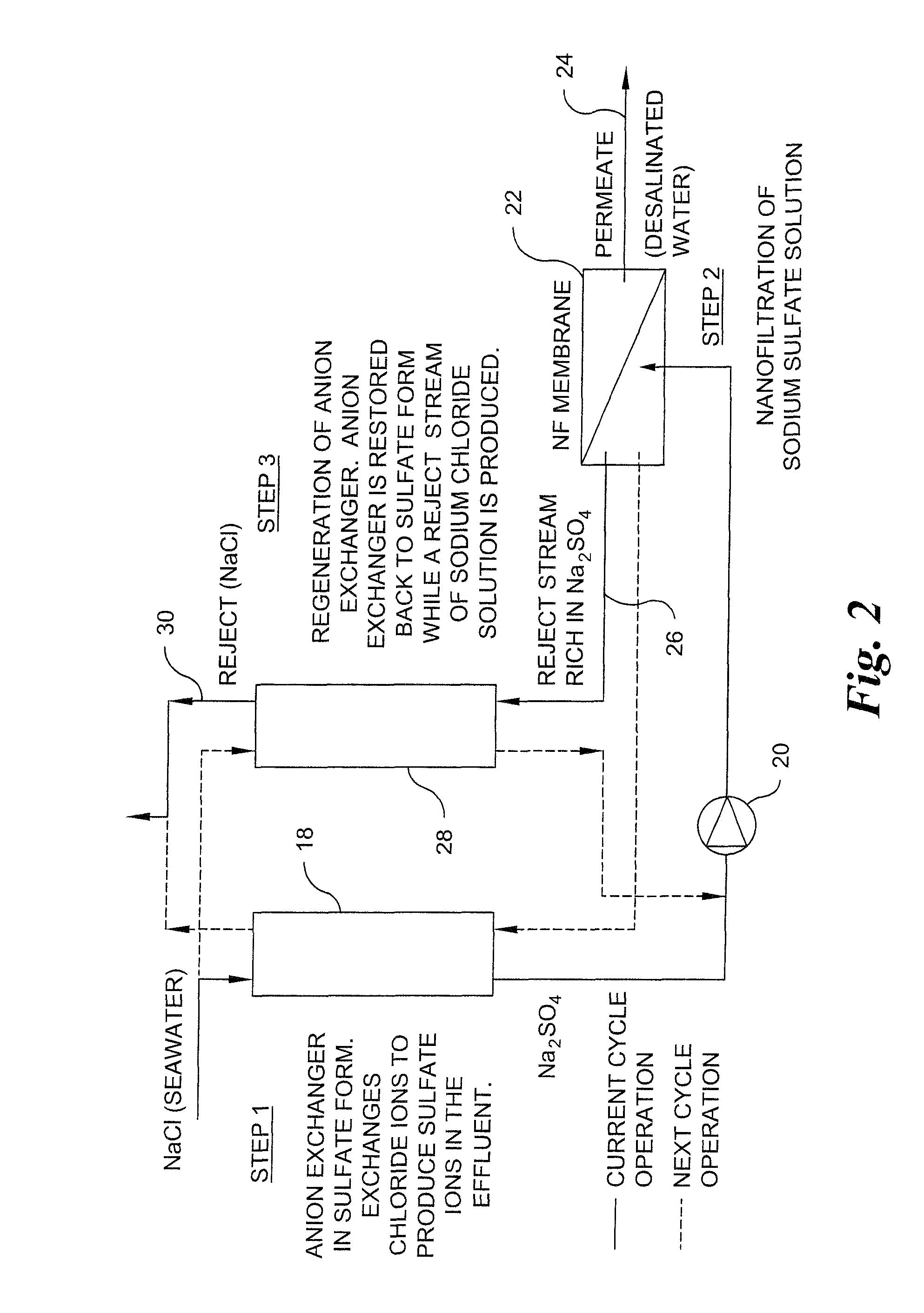

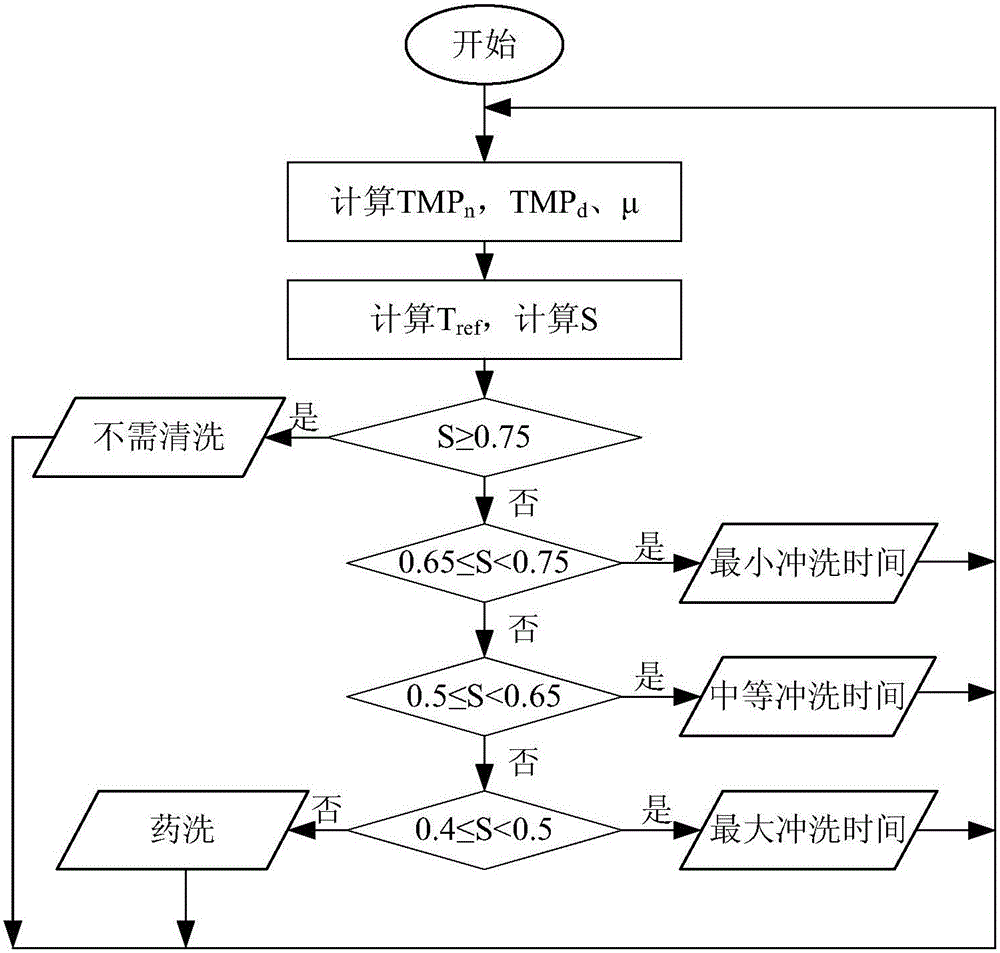

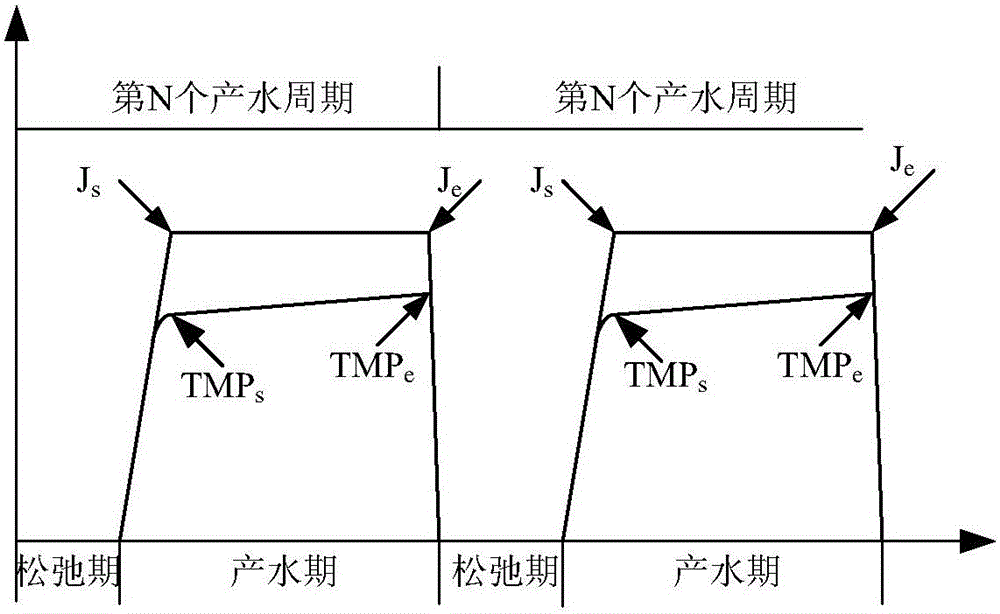

Optimized membrane bioreactor (MBR) back washing method

ActiveCN105084520AOptimize rinse timeImprove cleaning methodsSemi-permeable membranesSustainable biological treatmentMembrane bioreactorTransmembrane pressure

The invention discloses an optimized membrane bioreactor (MBR) back washing method. An MBR is operated at constant flux. The method comprises the following steps: I. computing the transmembrane pressure (TMP) of membrane modules of the MBR in a certain period of time; II. computing the similarity S in the certain period of time: specifically, firstly determining the reference value Tref of the TMP and then computing the similarity S by utilizing the TMP according to a formula in the specification; III. comparing the value of S with a preset threshold, washing the membrane modules by an online cleaning mode at different cleaning time if the value of S is not less than the preset threshold, and washing the membrane modules by an online chemical cleaning or offline cleaning mode if the value of S is less than the preset threshold. According to the actual situation of membrane pollution, through low-strength more timely cleaning, pollution of the MBR membrane is eliminated at the initial stage of formation, thus preventing synergistic deterioration effects caused because membrane pollution is not timely recovered, saving energy and time and prolonging the service lives of the membrane modules.

Owner:BEIJING JINKONG DATA TECH

Safety device for a blood treatment machine and a method of increasing the safety of a blood treatment machine

A device and method for increasing the safety of an extracorporeal blood treatment machine are based on monitoring transmembrane pressure. The transmembrane pressure measured by a measuring device during the treatment is compared with an upper limit transmembrane pressure L1 and a lower limit transmembrane pressure L2 which define a monitoring window. If the transmembrane pressure is outside this monitoring window, an alarm is triggered by an alarm device. The monitoring window is shifted as a function of the ultrafiltration rate. To determine the window limits, the transmembrane pressure is established after a change in the ultrafiltration rate is calculated. Thereafter, the window limits are determined on the basis of the expected transmembrane pressure.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

Ceramic membrane aeration and micro-positive pressure ozone membrane regeneration water treatment method and treatment device

PendingCN107337326AHigh porosityUniform pore size distributionWater treatment parameter controlFatty/oily/floating substances removal devicesMicroorganismNanoceramic

The invention discloses a ceramic membrane aeration and micro-positive pressure ozone membrane regeneration water treatment method. Sewage after ozone micropore aeration treatment is conveyed into a membrane tank; when a membrane on a membrane module is blocked by microorganisms or organic matter, compressed air enters the membrane of the membrane module through a water outlet of the membrane module for high-pressure back flushing; contaminants attached to the surface of the membrane are separated from the surface of the membrane; after the back flushing of the compressed air, ozone is supplied to the membrane of the membrane module under critical micro-positive pressure; after a gel layer difficult to degrade on the surface of the membrane is decomposed and dissolved by using an ozone and air space, the compressed air is used for reverse purging of decomposed substances on the membrane to accomplish membrane flushing; a nano ceramic membrane with small pore size distribution, small transmembrane pressure and a very small pore size is used for aeration; the micro-positive pressure aeration is adopted to form many fine and uniform oxygen bubbles to make full use of an oxygen source; oxygen is better dissolved in water; a utilization rate of the oxygen is increased; a biochemical effect is enhanced; and the energy source waste is reduced.

Owner:JIANGXI BOCENT TEC CO LTD

Optimization of separation for viscous suspensions

ActiveUS20120205311A9Low costYield maximizationSemi-permeable membranesMembranesWaste streamSource material

Owner:SMARTFLOW TECH

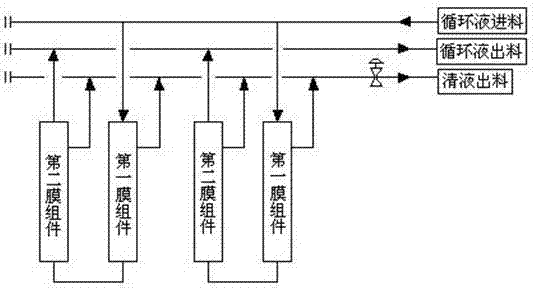

Method for separating catalyst by using ceramic membrane filter, and apparatus thereof

ActiveCN102847368AConsistent transmembrane pressureConsistent production loadSemi-permeable membranesFiltration separationEngineeringTransmembrane pressure

The present invention relates to a method for separating a catalyst by using a ceramic membrane filter, and an apparatus thereof, wherein discharged clear liquid of two membrane assemblies connected in series separately enter corresponding discharged clear liquid collection tubes, and then separately enter reaction product intermediate tanks. According to the present invention, the traditional clear liquid discharging way of the two membrane assemblies connected in series is changed so as to achieve the same transmembrane pressure difference of the two membrane assemblies connected in series, and concurrently achieve the same production load (a mount of the discharged clear liquid) of the two membrane assemblies, such that operation periods of the two membrane assemblies connected in series are the same, a service life of the ceramic membrane tube is substantially improved, and the ceramic membrane tube is only required to be chemically cleaned after operating about 2-3 months so as to prolong an operation period of the device and substantially reduce the number and cost of chemical cleaning.

Owner:FUJIAN EVERSUN TECH CO LTD

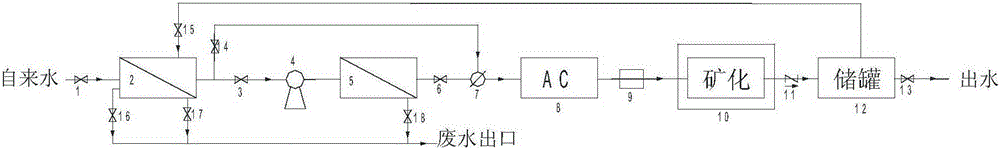

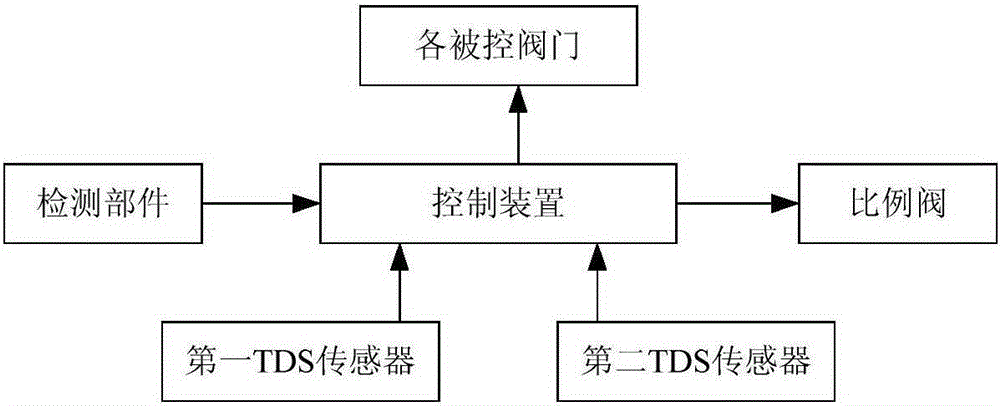

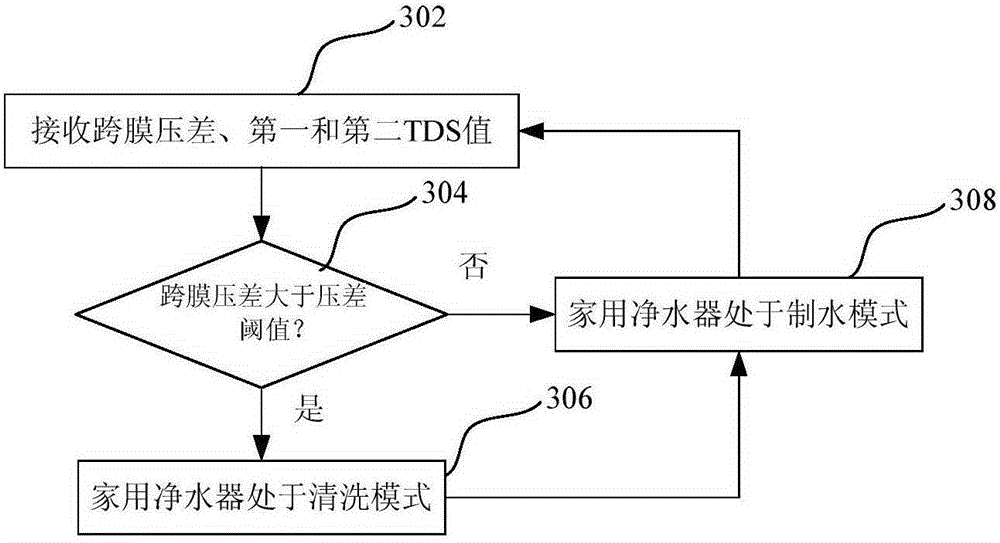

Household water purifier capable of automatically cleaning filter membrane and method

InactiveCN105198111AExtended service lifeReduce use costWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentUltrafiltrationReverse osmosis

The invention discloses a household water purifier capable of automatically cleaning a filter membrane. The household water purifier comprises a water inlet valve, an ultrafiltration membrane, a first TDS sensor, a high-pressure pump, a reverse osmosis membrane, a proportional valve, rear active carbon, a second TDS sensor, a pressure storage tank, an ultrafiltration membrane rear valve, a reverse osmosis membrane rear valve, a tank front check valve, a water outlet valve, a pilot valve, a flush valve, a first wastewater valve, a second wastewater valve, a third wastewater valve, a detection component for detecting the trans-membrane pressure difference of the ultrafiltration membrane, and a control device for controlling the work of the household water purifier. The control device is used for controlling the household water purifier to be in a cleaning mode or a water making mode according to the ratio of the trans-membrane pressure difference to a pressure difference threshold value. When the trans-membrane pressure difference is greater than the pressure difference threshold value, the control device enables the household water purifier to automatically clean the filter membrane. The household water purifier disclosed by the invention can prolong the service life of the filter membrane, so that the use cost of the household water purifier is reduced.

Owner:北京金泽环境能源技术研究股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com