Method and system for controlling aeration quantity of membrane tank

A technology of aeration volume and membrane control, applied in the field of water treatment, to achieve the effect of reducing the energy consumption of aeration in membrane pools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

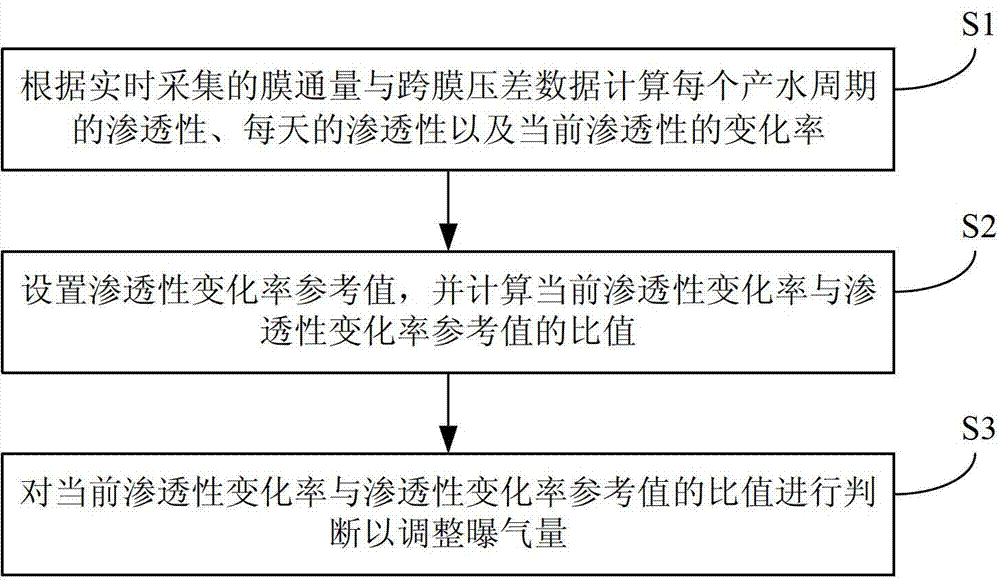

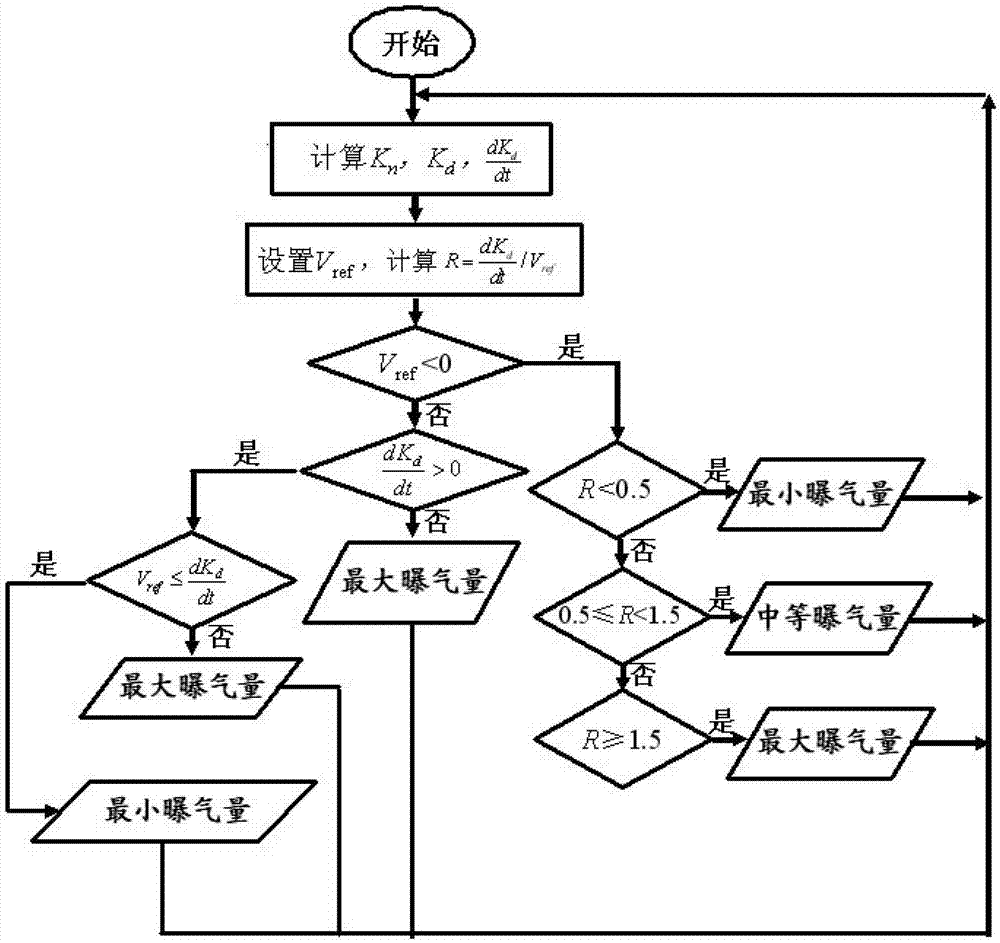

Method used

Image

Examples

Embodiment 1

[0081] The control strategy was applied to an MBR sewage treatment plant, which adopted A 2 O+MBR treatment process, the treatment scale is 20000m 3 / d.

[0082] The relevant design parameters of the membrane cell are:

[0083] Table 1 Main parameters of the sewage treatment plant of the embodiment

[0084]

[0085] In the MBR process of the sewage treatment plant, the membrane tank adopts the working method of "continuous aeration and intermittent suction". Every 10 minutes of filtration, the air is aerated for 2 minutes. The design parameter of aeration rate is 60m 3 / m 2 / h, the total aeration required is about 700m 3 / min. During normal operation, there are 6 blowers, 4 for use and 2 for standby, and the design flow rate of each blower is 175m 3 / min. The actual rated flow rate of the blower in this plant is 200m 3 / min, during normal operation, the four blowers continuously aerate.

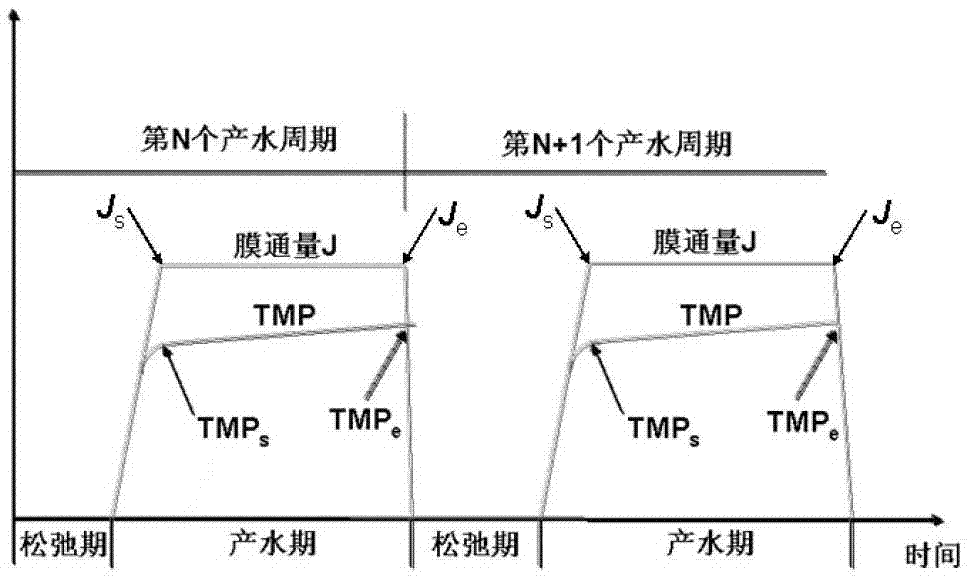

[0086] In this plant, the change of membrane flux and transmembrane pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com