Aeration and carbon source addition optimization control system and method for mud film composite sewage treatment process

A sewage treatment and control system technology, which is applied in water treatment parameter control, water/sludge/sewage treatment, biological water/sewage treatment, etc. High gas energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

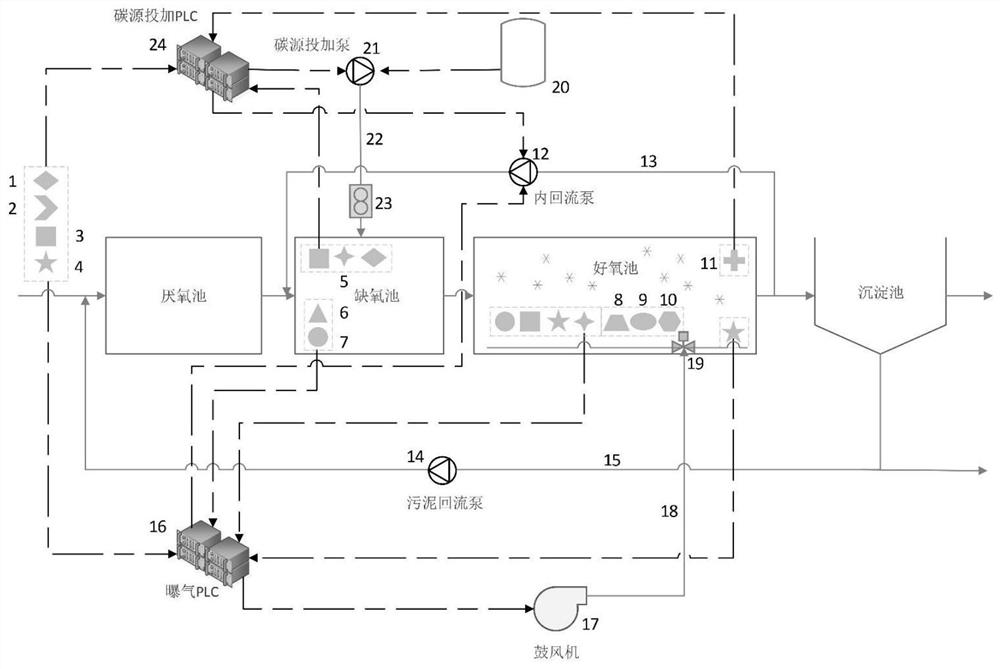

[0034] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0035] This embodiment provides an aeration and carbon source dosing control system and method, and the applied process operation conditions are as follows: a certain urban sewage treatment plant has a treatment scale of 30,000 tons / day, and the biochemical pool adopts the A / A / O process, wherein Suspended filler is added to the O section. The biochemical pool is divided into two groups. Each group of aerobic pool is divided into two aeration corridors. The effluent water quality requirements meet the first-class standard A standard in the "Urban Sewage Treatment Plant Pollutant Discharge Standard".

[0036] like figure 1 As shown, an aeration and carbon source dosing control system is provided with an online monitoring system. At the water inlet of the biochemical pool, there are water flow measuring instrument (1), TKN analyzer (2), COD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com