Patents

Literature

71 results about "Operational energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

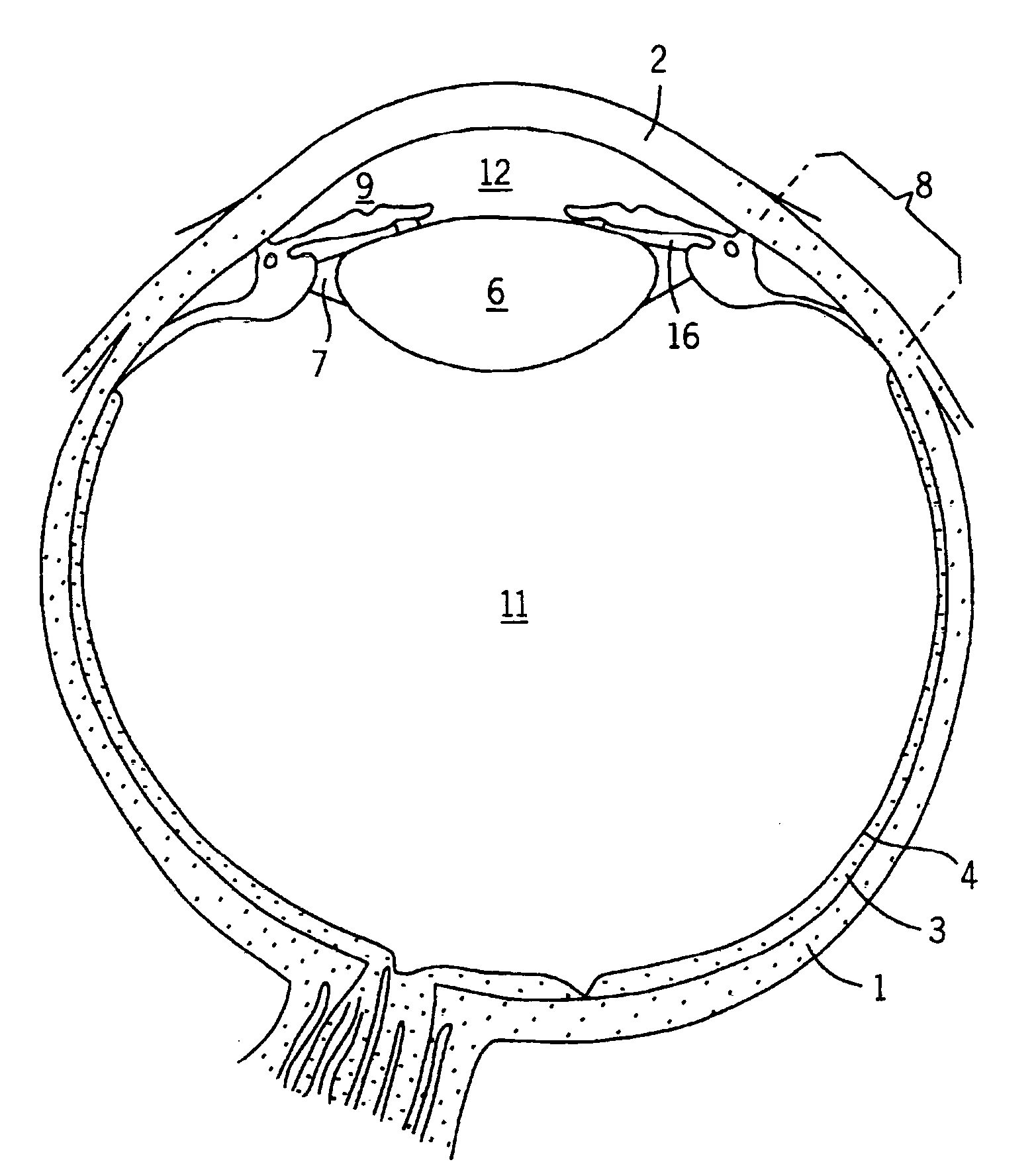

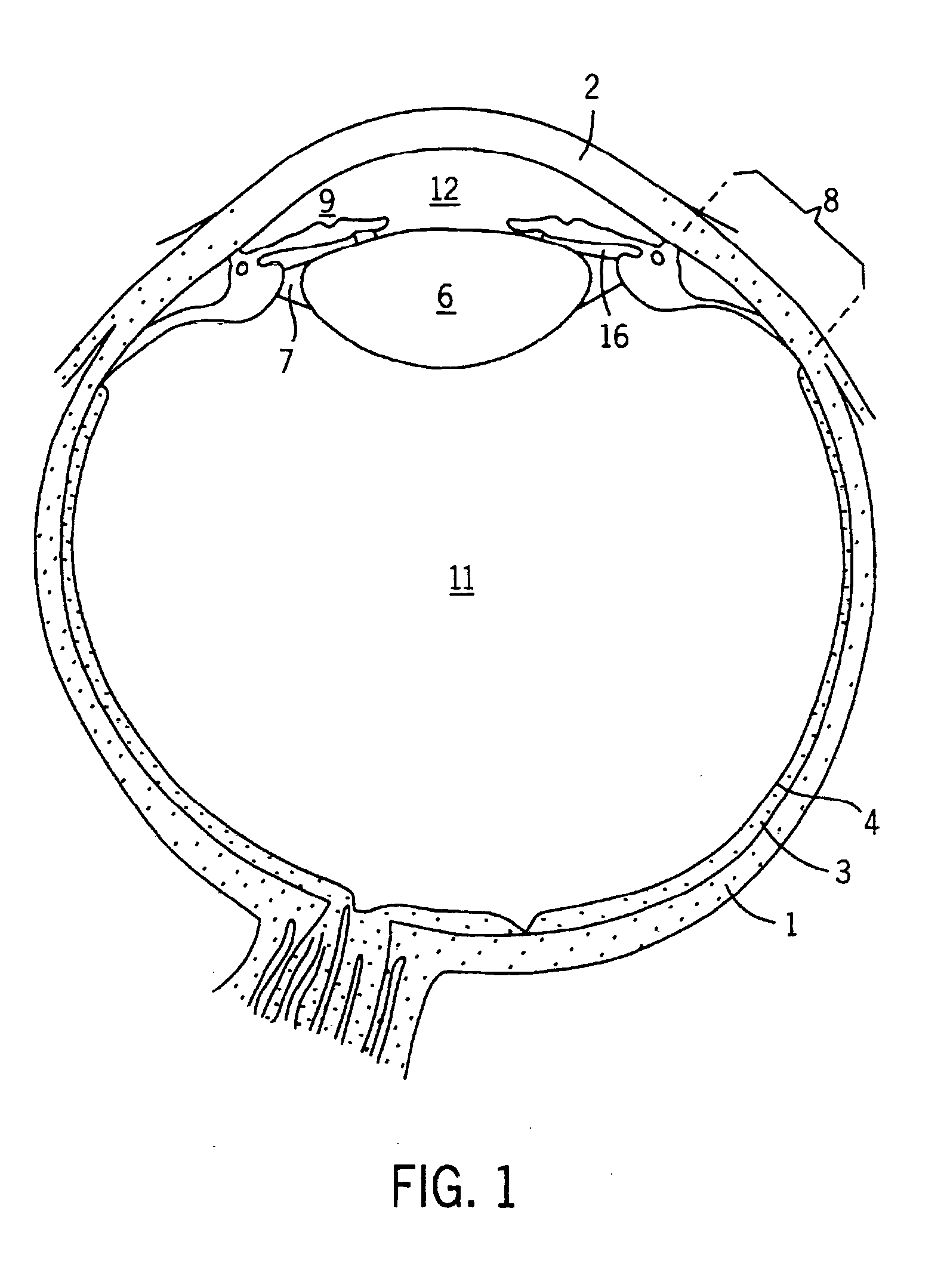

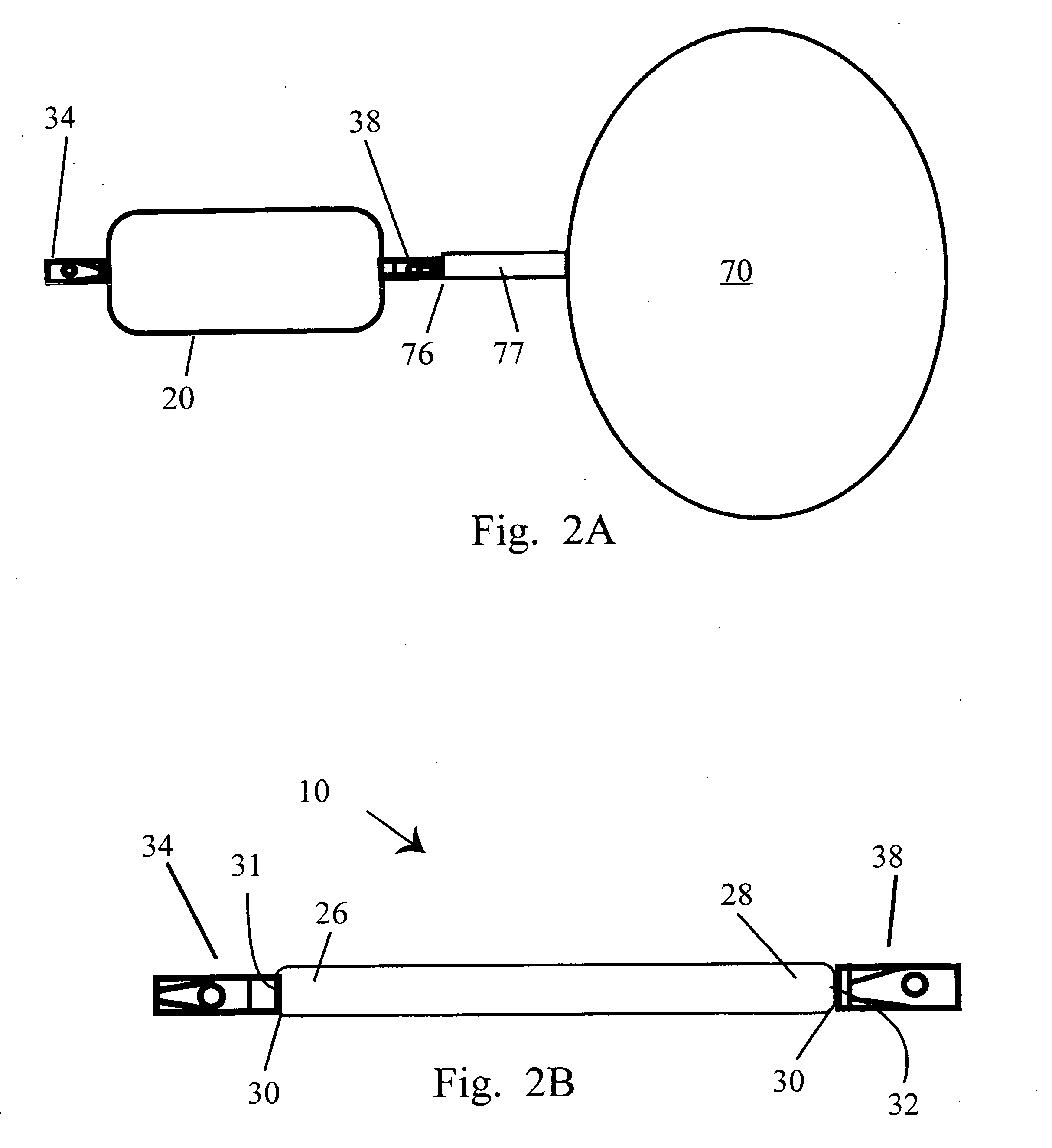

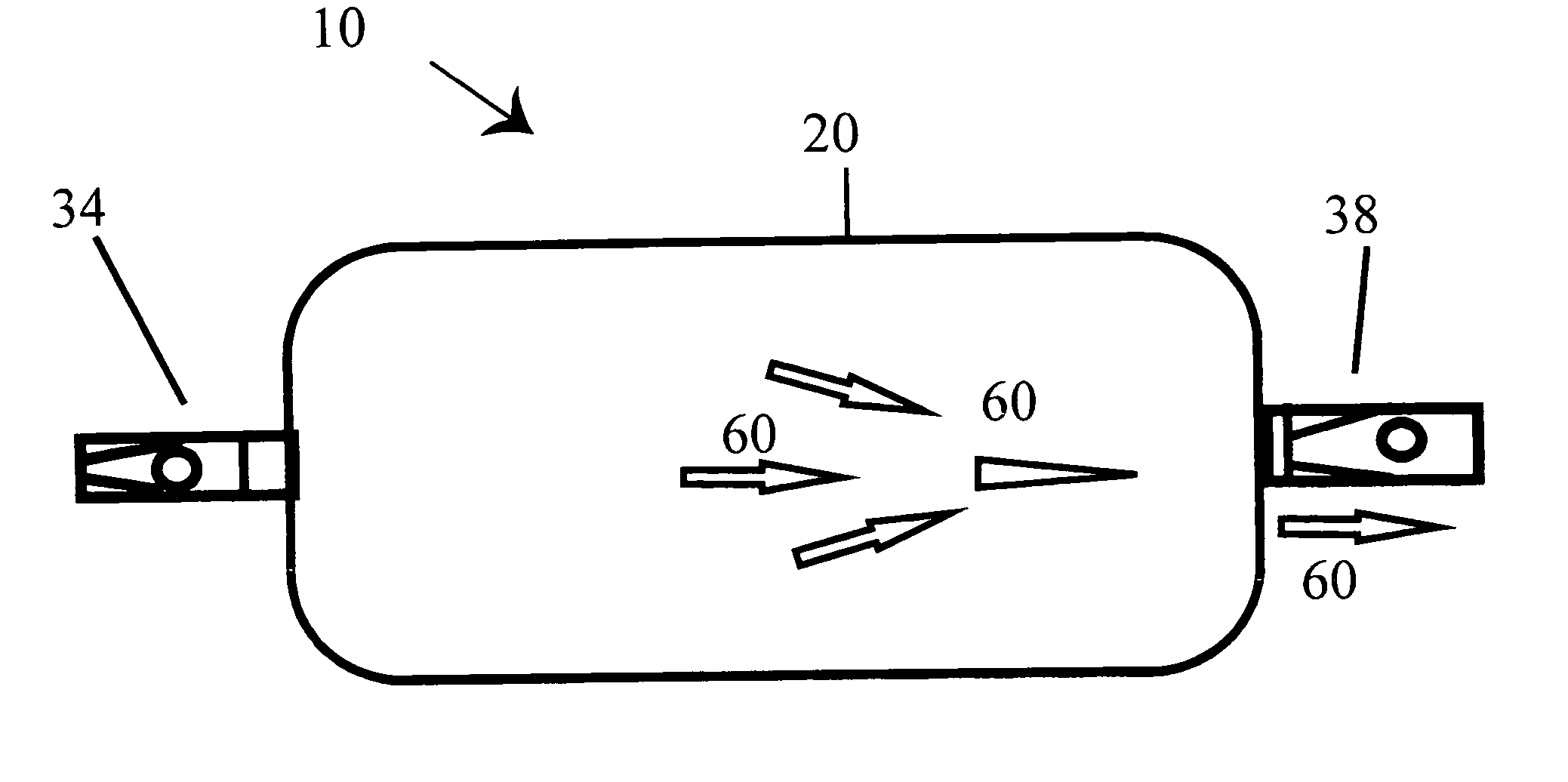

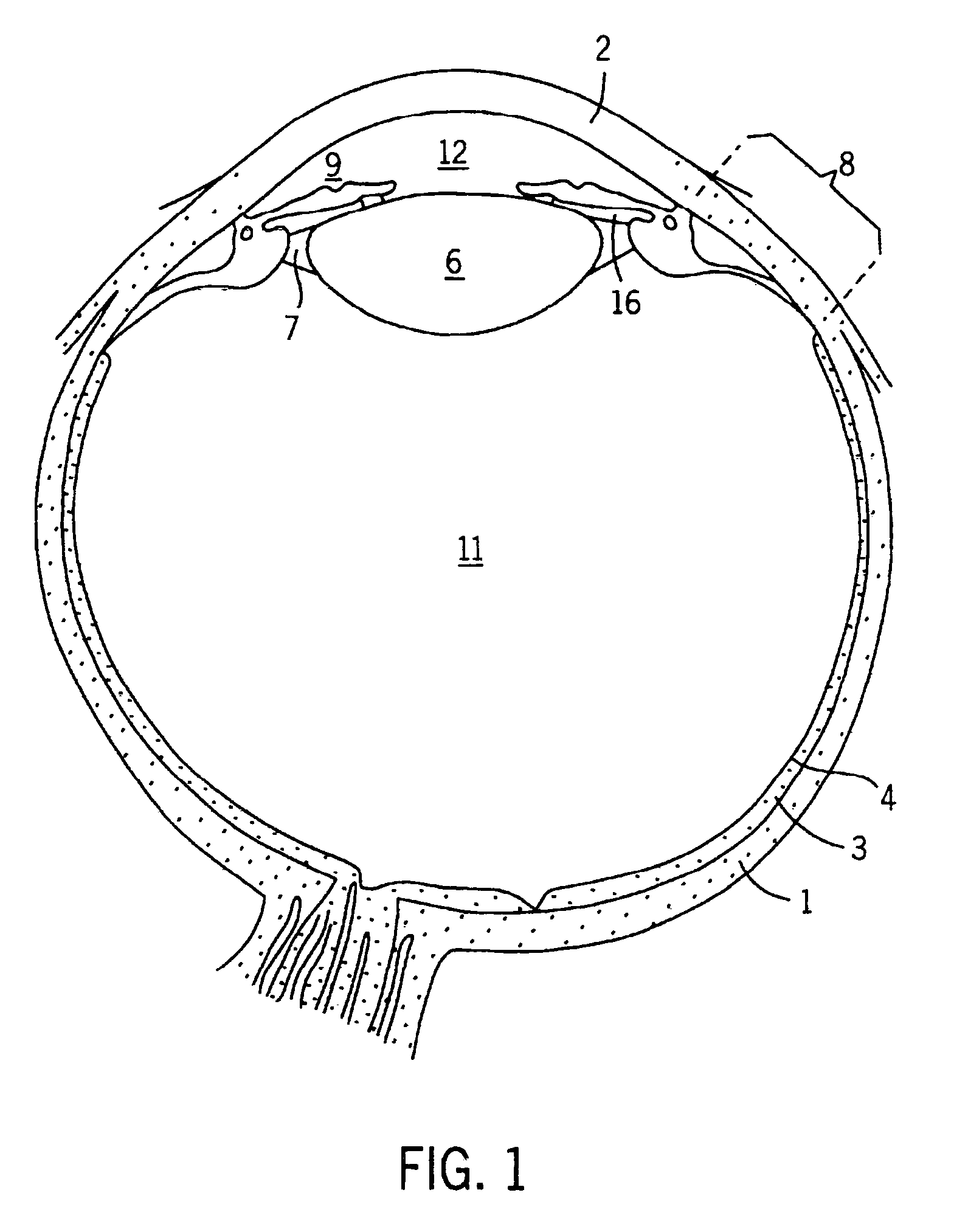

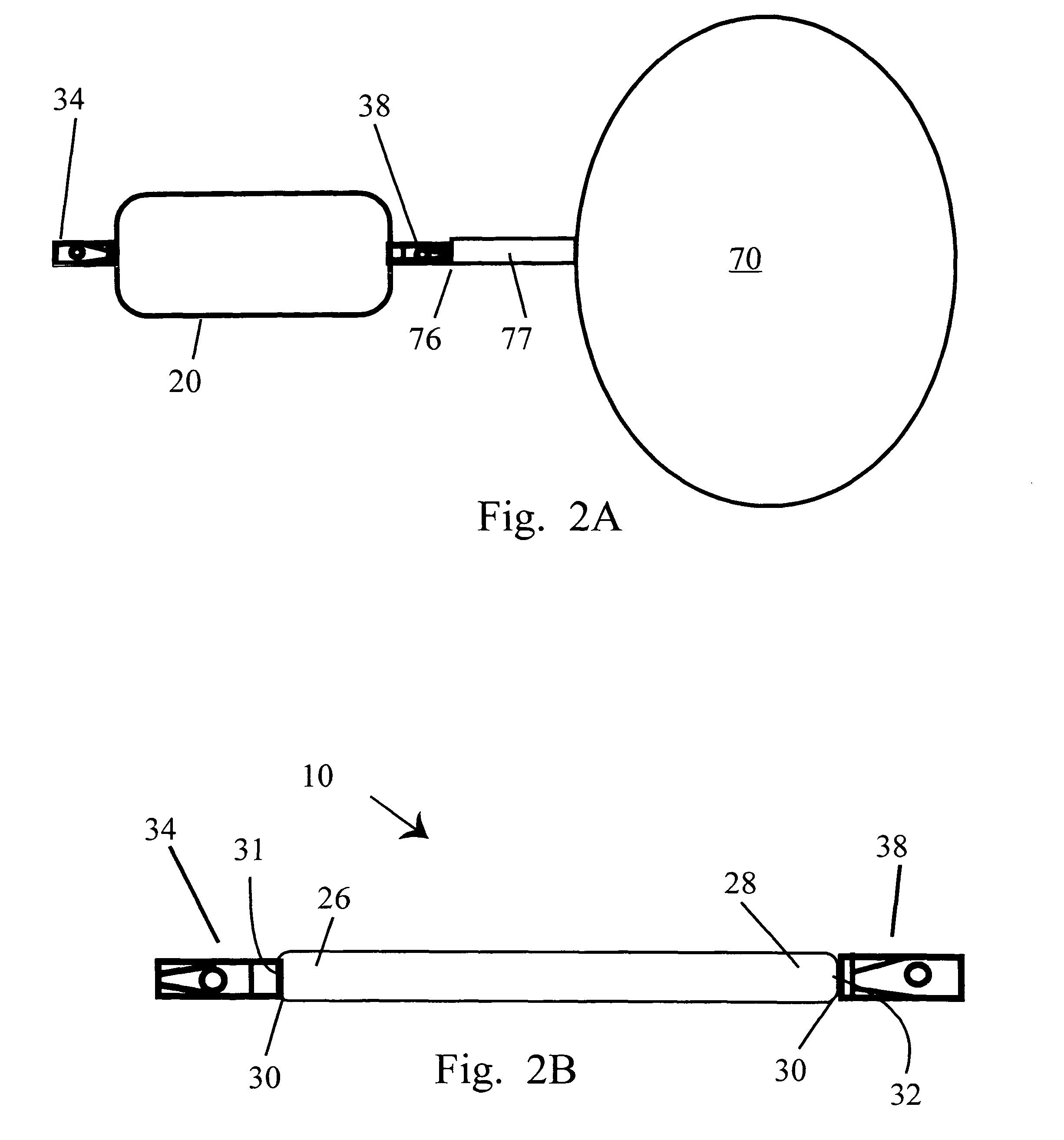

Implantable pump apparatuses

InactiveUS20070106199A1Harvesting energyControl flowEye surgeryFlexible member pumpsDynamic motionEngineering

Owner:SOLTANPOUR DAVID P

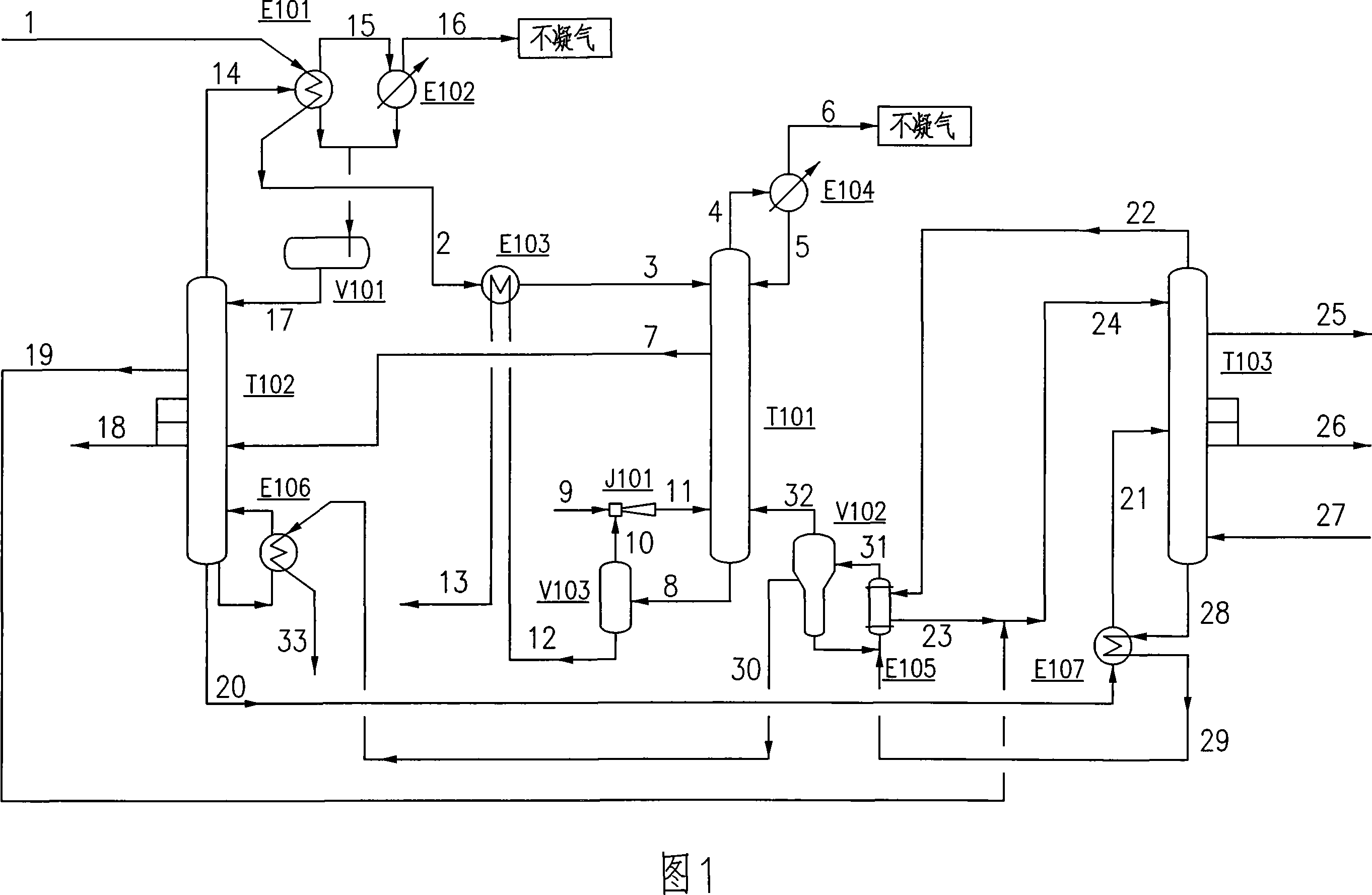

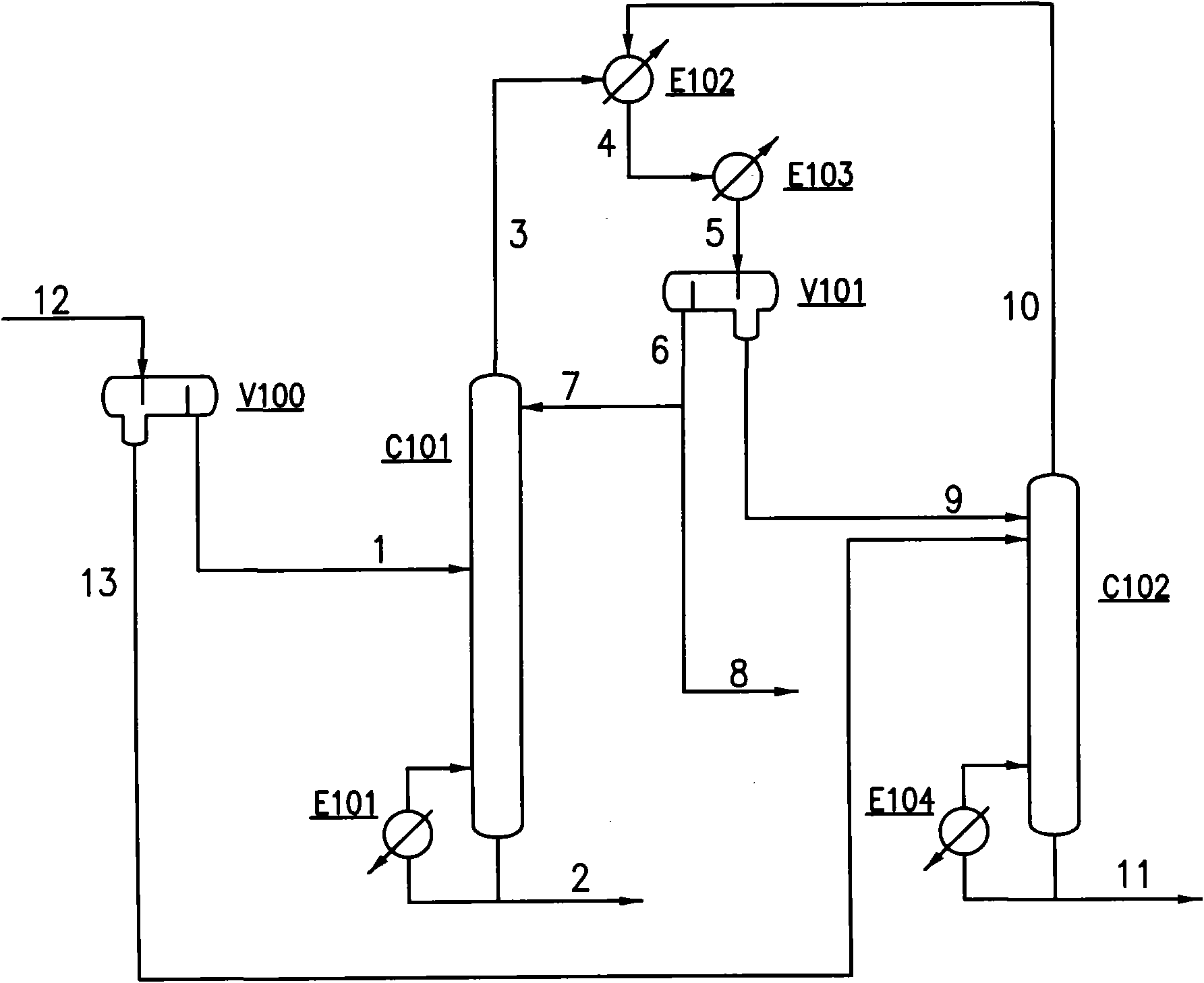

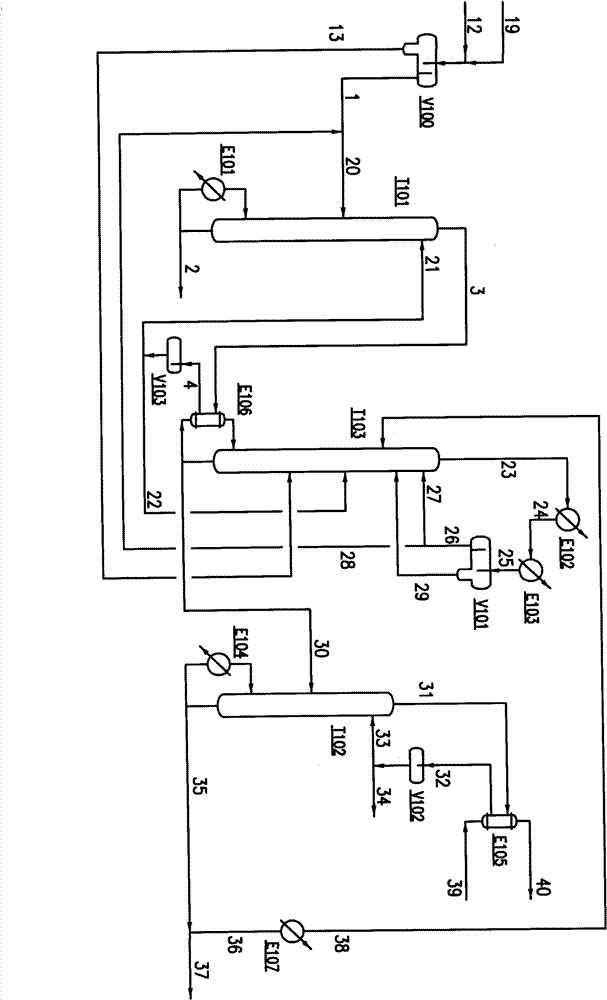

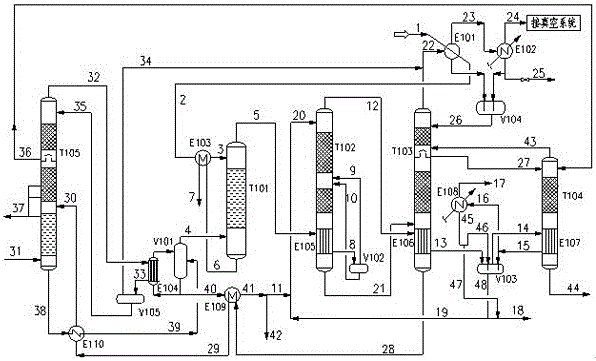

Method for rectifying ethanol by three-tower heat integration device

InactiveCN101085717AReduce energy consumptionImprove stabilityOrganic compound preparationHydroxy compound preparationDistillationProcess engineering

The invention relates to a process of preparing ethanol through distillation from fermentation liquor by using three- tower heat integrated device. The whole ethaol distillation system at least comprises crude distillation column, low- pressure azeotropic rectifying tower, high- pressure azeotropic rectifying tower and other corollary equipment. The heat integration in said three towers and the application of heat exchange, energy saving technology and steam injector greatly reduce operational energy consumption. The optimized heat exchange system combines the molecular screen and rectifying system organically, which improves the stability and flexibility for the whole rectifying system. The invention can reduce operational energy consumption by more than 30%, and the practicity and economical benefit are high.

Owner:蓝仁水 +1

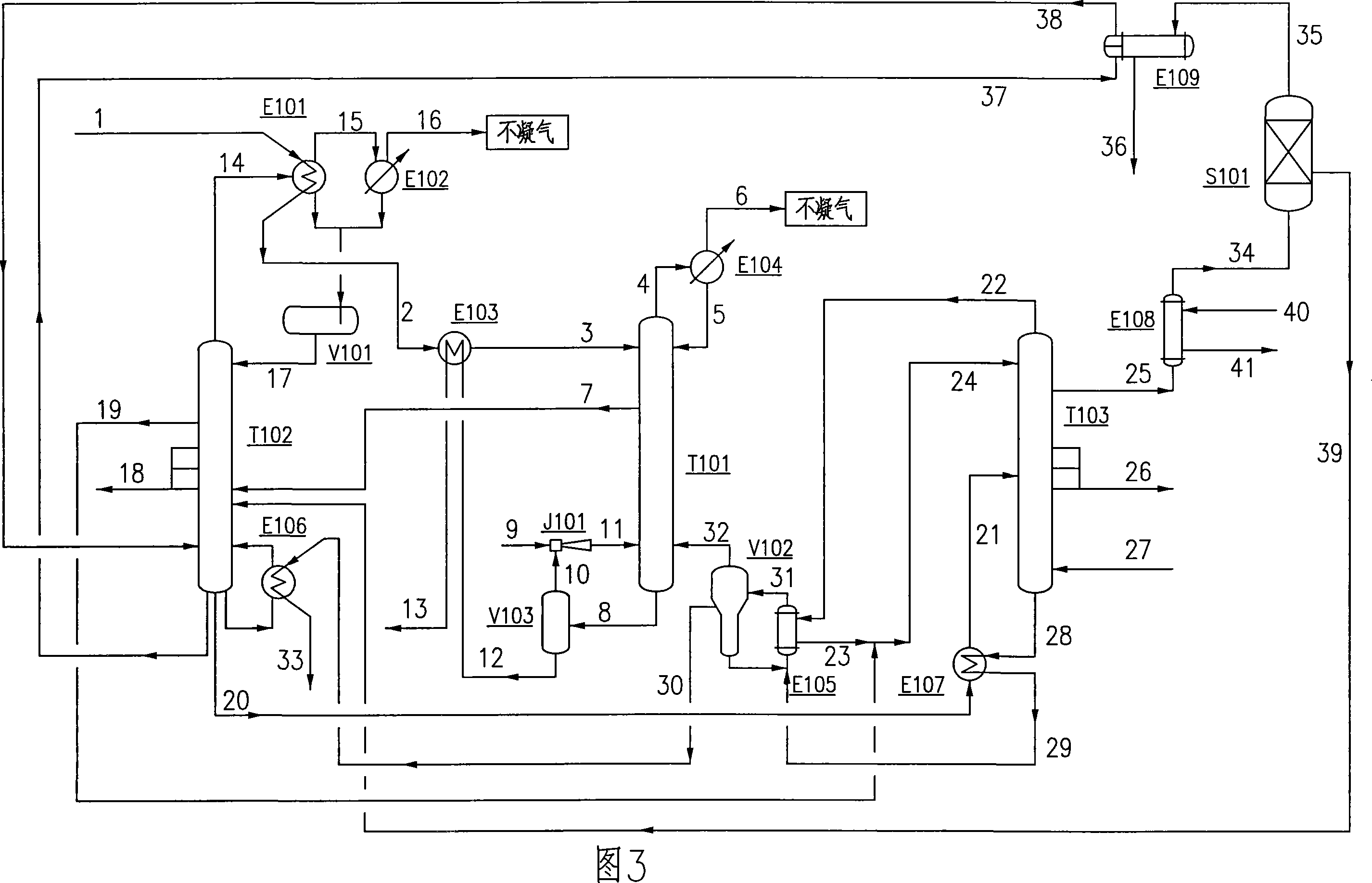

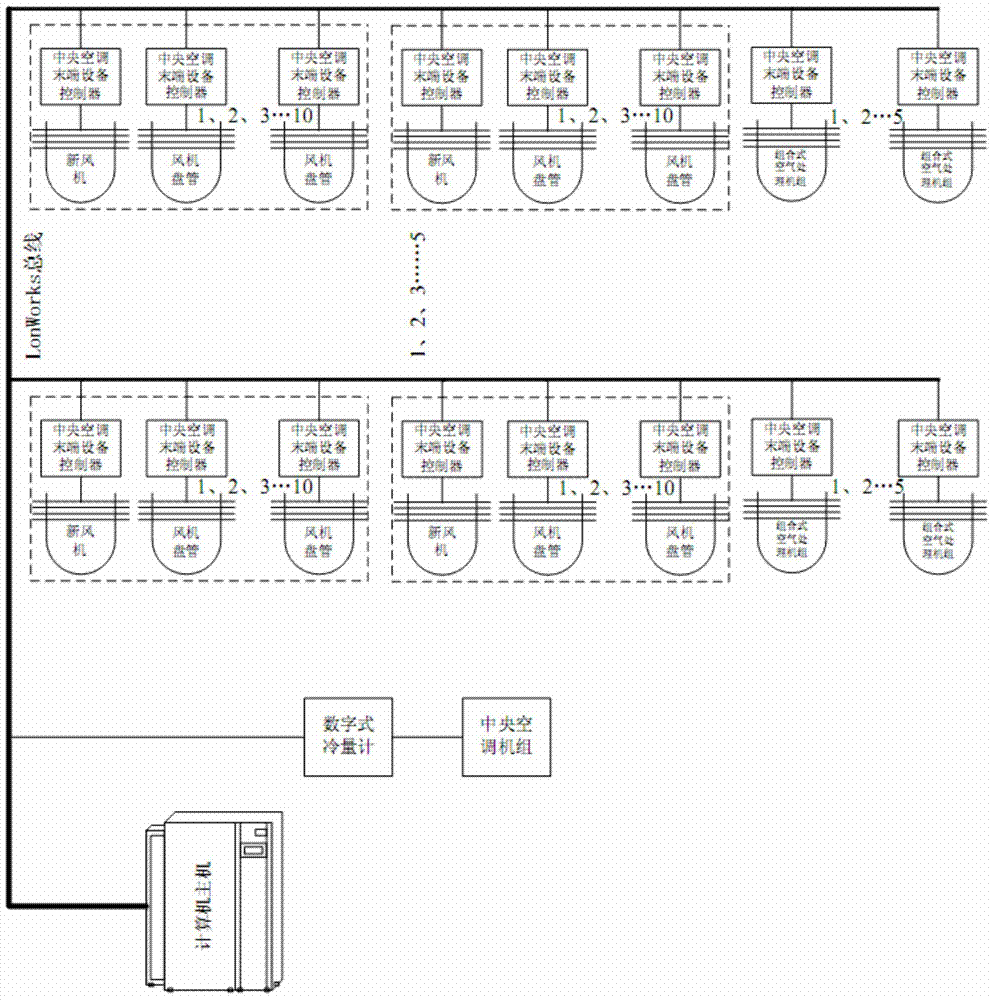

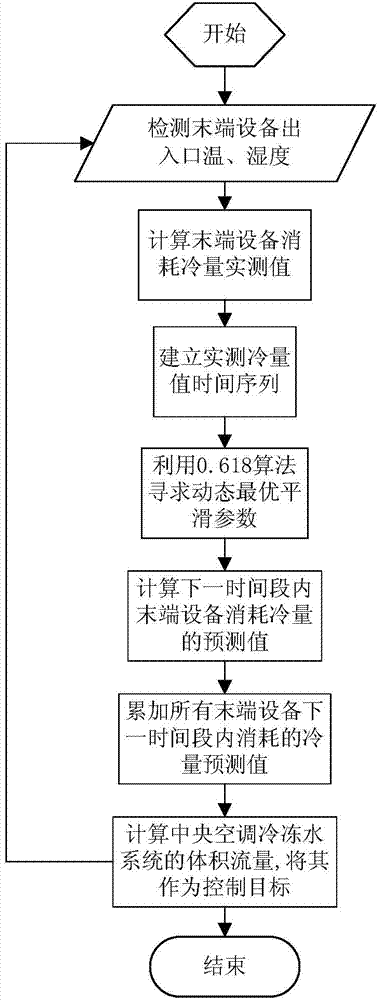

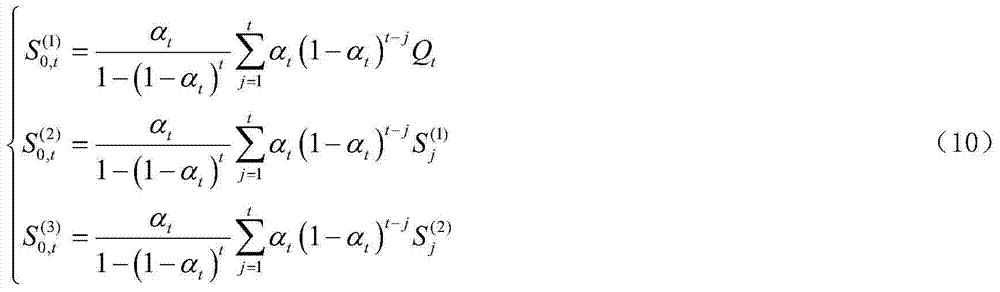

Energy-saving control method for central air-conditioning chilled water system

ActiveCN103486693AGuaranteed comfortReduce operating energy consumptionSpace heating and ventilation safety systemsLighting and heating apparatusTraffic capacityControl objective

The invention relates to an energy-saving control method for a central air-conditioning chilled water system. The method includes the steps: (A) acquiring the temperature and the humidity of air at an inlet and an outlet of each end device in a central air-conditioning system and calculating cold energy consumed by each end device in a plurality of previous time periods; (B) predicting the cold energy consumed by each end device in a next time period by taking measured value time sequence of the cold energy consumed by each end device as historical data; (C) accumulating predicted values of the cold energy consumed by all the end devices in the central air-conditioning system in the next time period, and taking the volume flow of the chilled water system calculated by accumulated values as a control target of the central air-conditioning chilled water system; (D) circularly executing the steps (A), (B) and (C) and continuously updating the measured value time sequence and predicted value time sequence by a shift operation method to control the volume flow of the central air-conditioning chilled water system. The energy-saving control method is low in operational energy consumption and fine in users' comfort.

Owner:广东迪奥技术有限公司

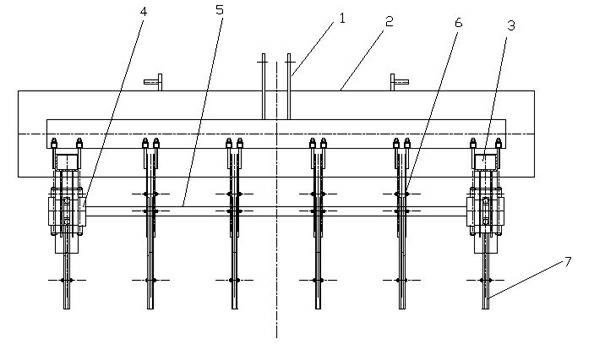

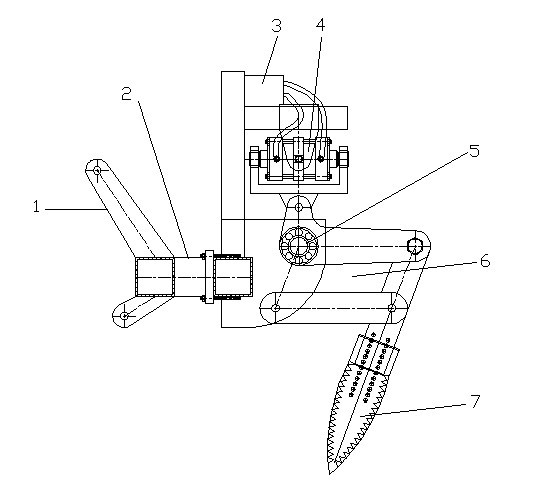

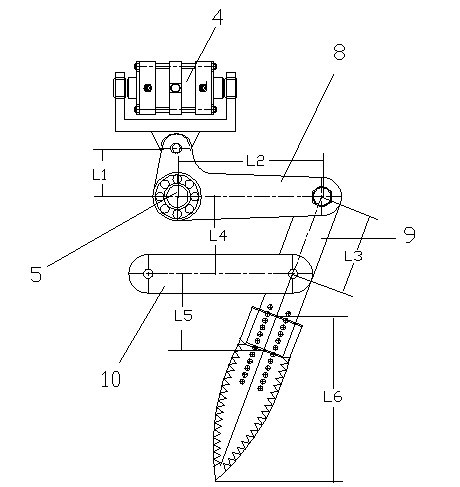

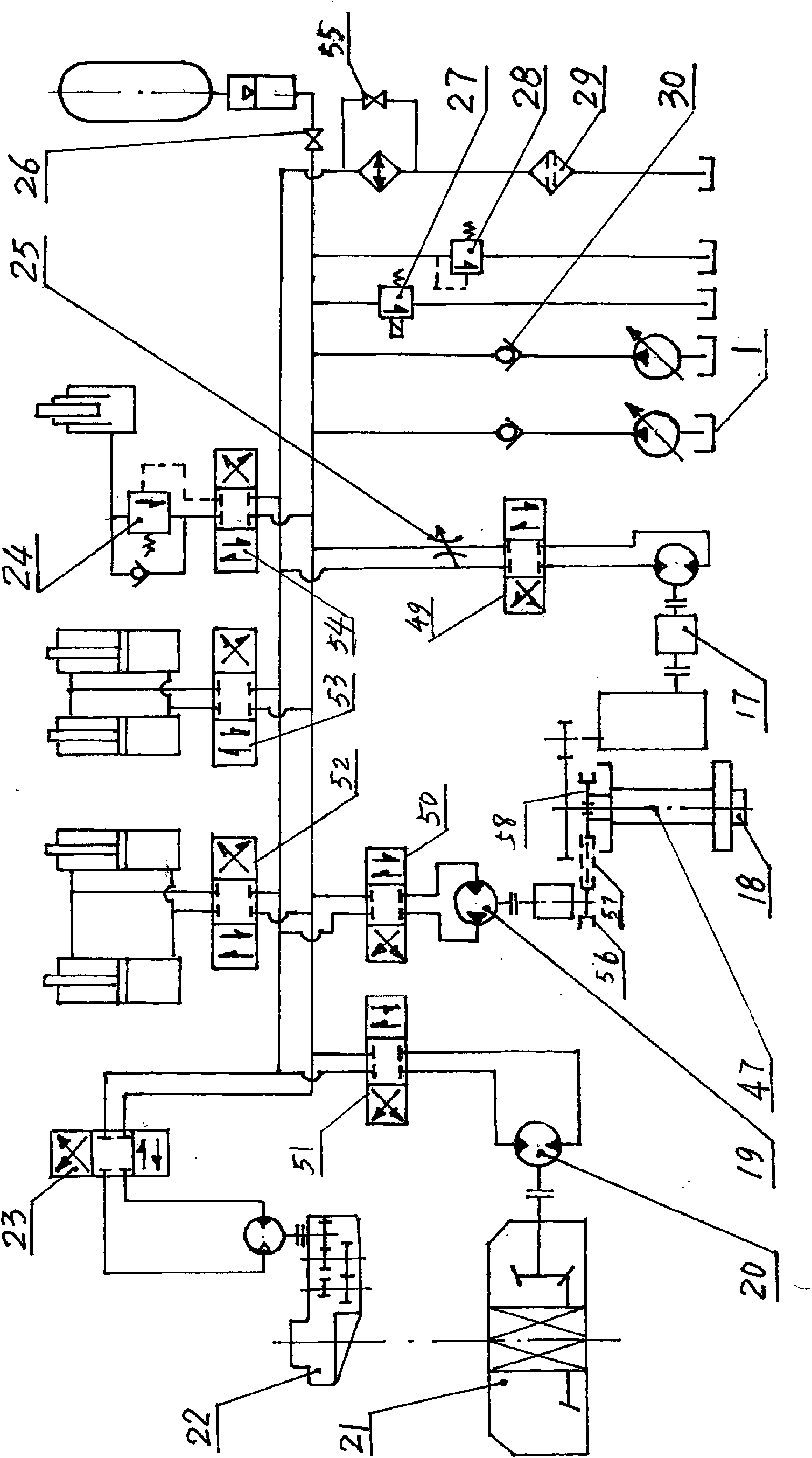

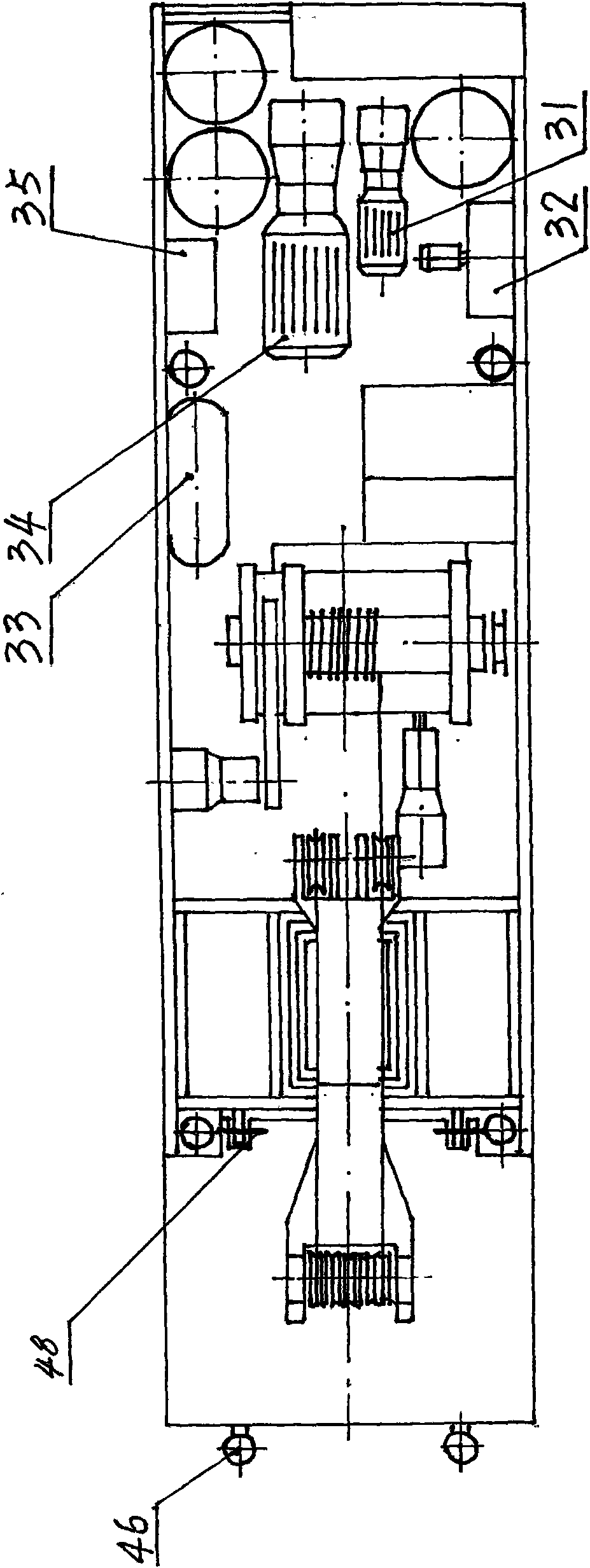

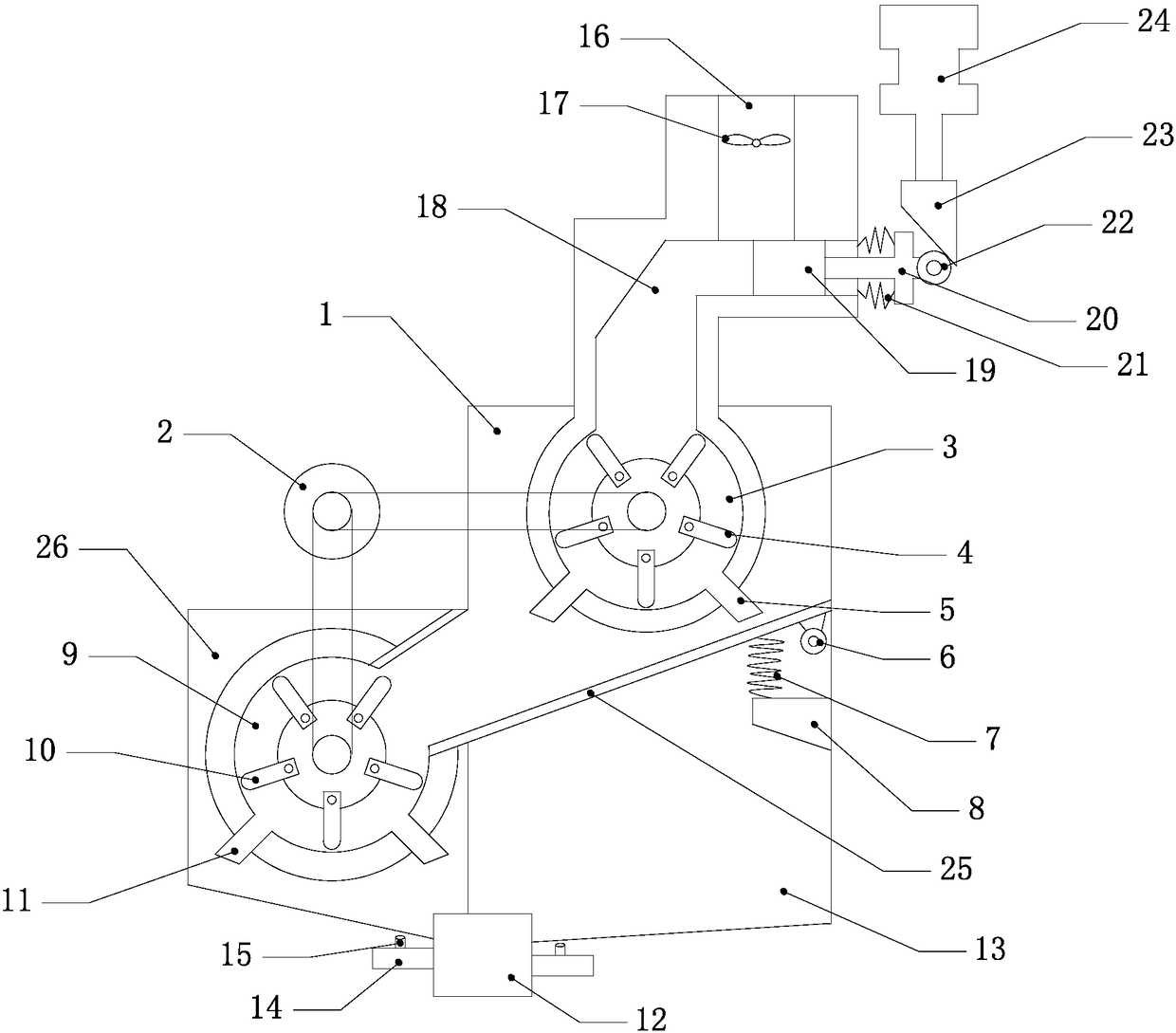

Hydraulic saw type forage grass root cutter

The invention discloses a hydraulic saw type forage grass root cutter for root cutting and rejuvenation of forage grass, which comprises suspensions, a frame, hydraulic control devices, hydraulic cylinders, rotary shafts, four-bar reciprocating mechanisms and blades. After the hydraulic saw type forage grass root cutter is used to saw soil and grass roots, small slits with local looseness are formed on grassland. Extrusion friction and transverse displacement of the blades penetrating into the soil are fully overcome, no-turf-destruction tillage is realized, interference on the grass roots is low, operational energy consumption is effectively lowered for implements, efficiency is improved, and power consumption is lowered for tractors. The hydraulic saw type forage grass root cutter is applicable to mechanical soil loosening and root cutting for pastures and lawns.

Owner:SHANXI AGRI UNIV

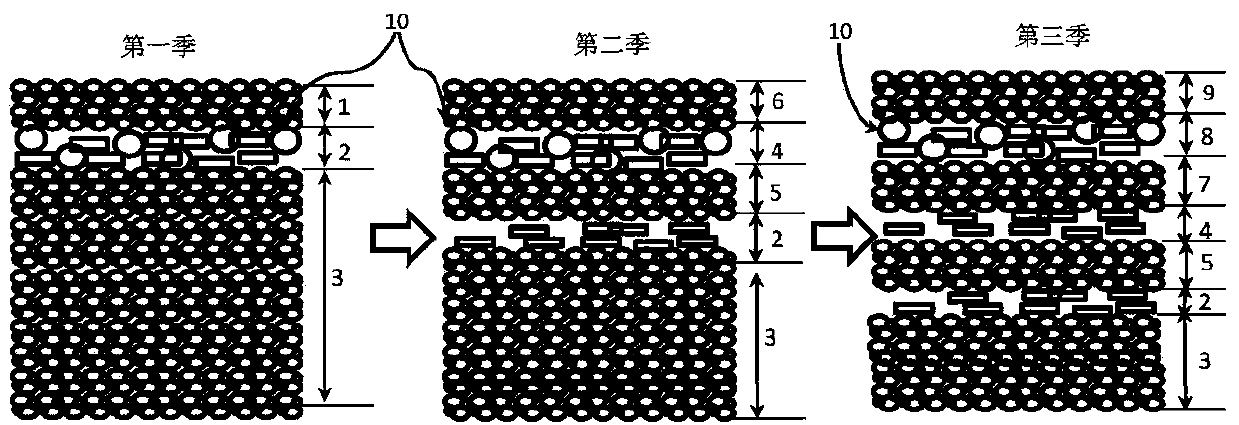

Method of cultivating rice by layer construction and utilization of straw and soil

ActiveCN103733931AChange structureRealize full return to fieldFertilising methodsRice cultivationSteepingPaddy soils

The invention discloses a method of cultivating rice by layer construction and utilization of straw and soil and solves the problems of crop stalk returning, soil aeration and water-fertilizer coupling. The method includes the steps of 1, performing a bed-furrow project on a rice field for the whole year; 2, performing moisture management before each season of crop harvesting; 3, treating stalks of crops of each season; 4, clearing beds and furrows and spreading soil; 5, planting crops; 6, performing field management; 7, harvesting the crops. The method has the advantages that the soil arable layer structure is changed, and a mud layer, a straw layer and a soil layer are formed from top to bottom; the method is good for deeply placing chemical fertilizers and improving availability of the fertilizers; water content of bed soil is decreased, soil aeration is improved, and availability of natural rainfall is improved; the rice field production process is free of tillage, straw burning and field steeping, ecological benefits are significant, operational energy consumption is reduced, haze is decreased, and irrigation water is decreased.

Owner:HUNAN AGRICULTURAL UNIV

Implantable pump apparatuses

Owner:SOLTANPOUR DAVID P

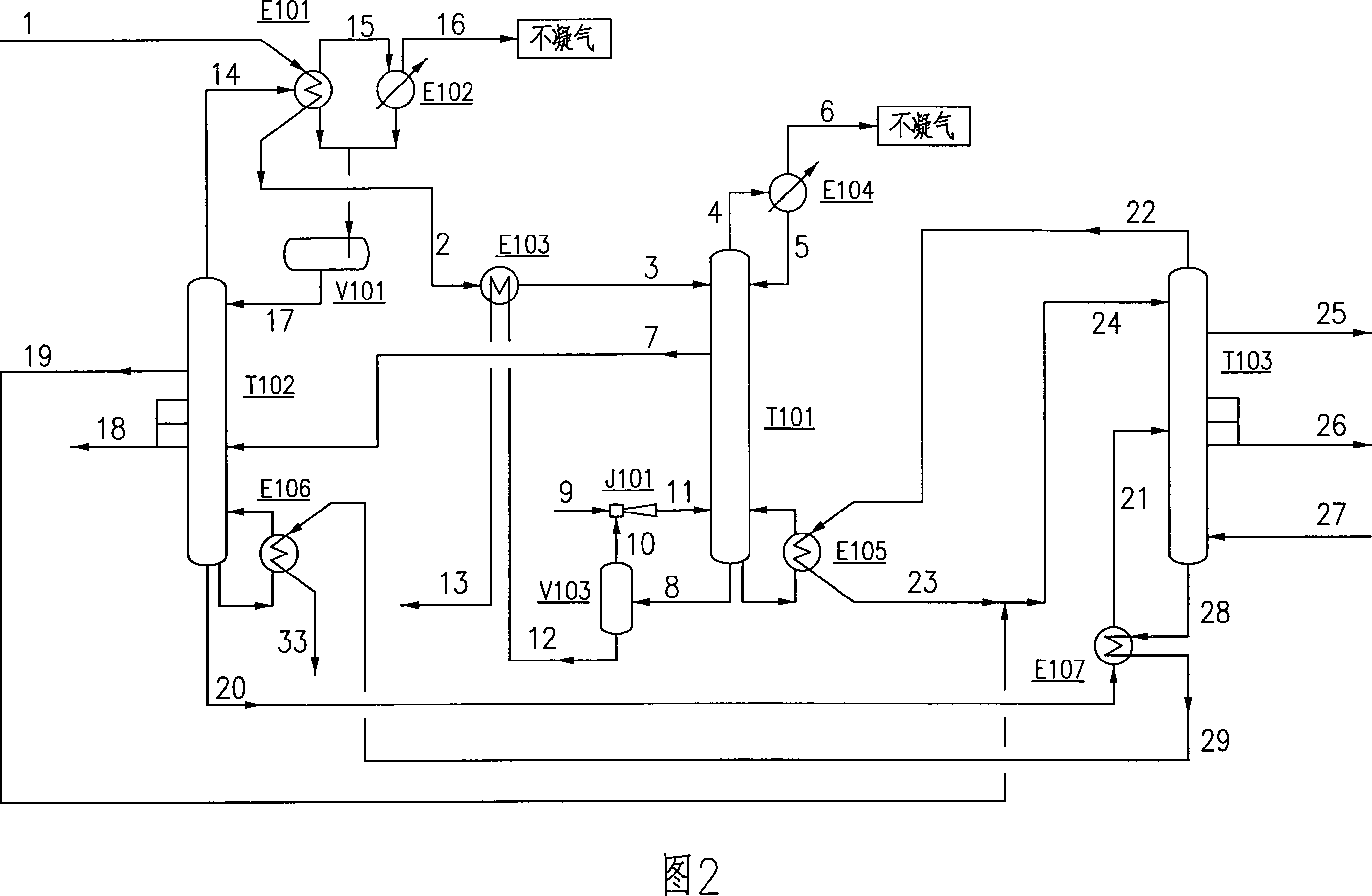

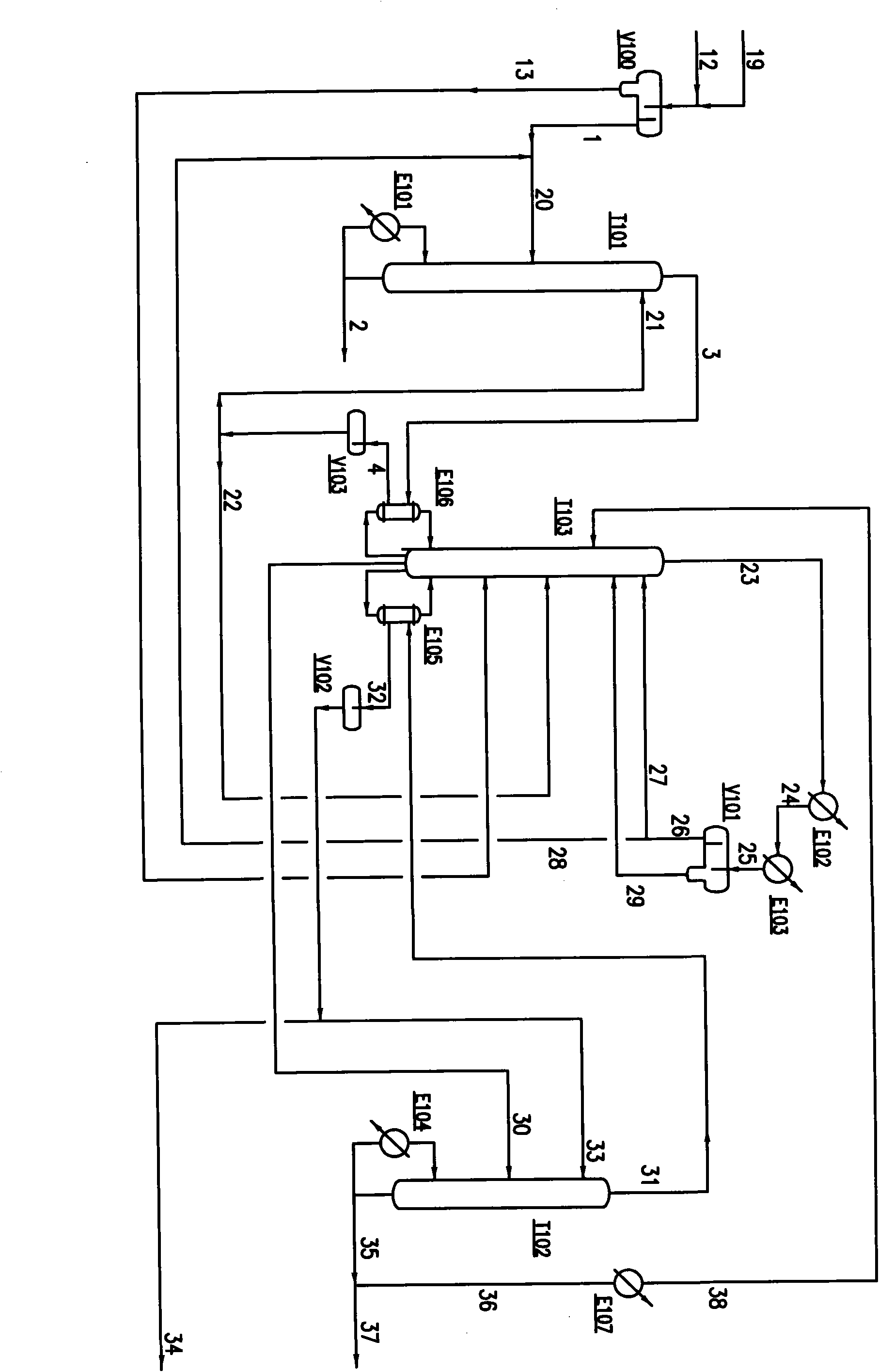

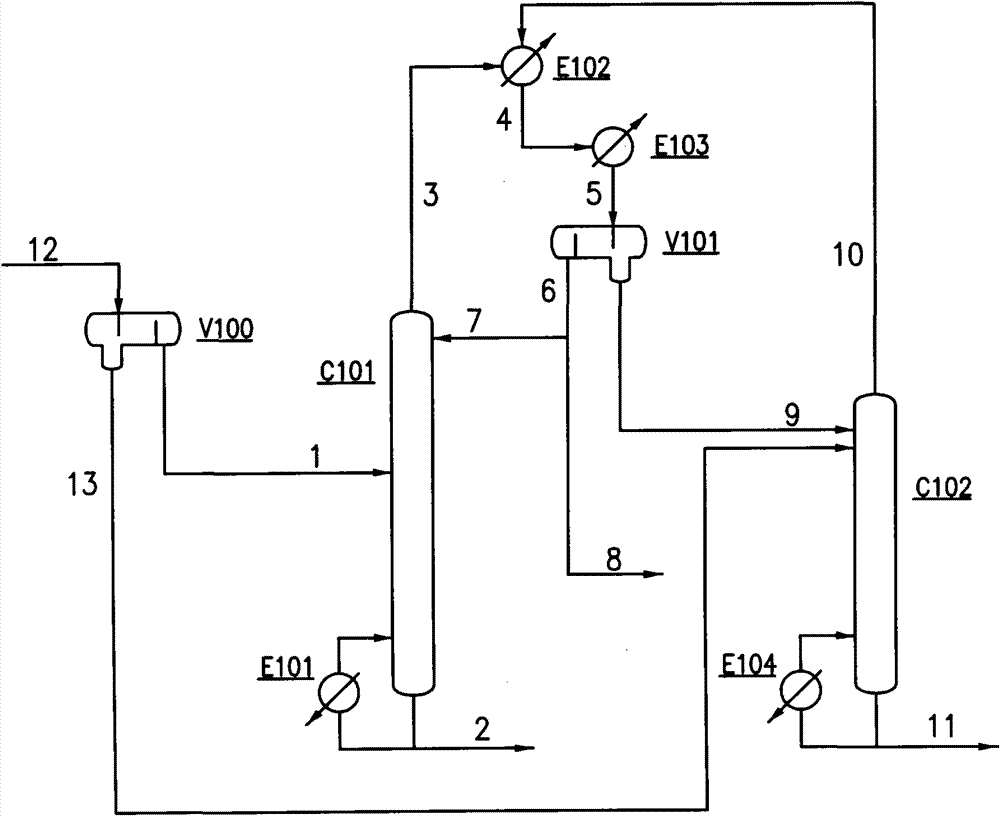

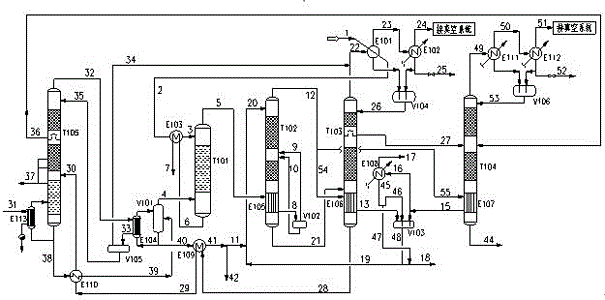

Purification method of ethyl acetate

ActiveCN102070445AAvoid loopsReduce operating energy consumptionOrganic compound preparationCarboxylic acid esters preparationAcetic acidPurification methods

The invention relates to a purification method of ethyl acetate. The method comprises the following step: the ethyl acetate product is purified from ethyl acetate-ethanol-water mixture. The equipment of the method at least contains an ethyl acetate rectifying tower, an ethyl acetate recovery tower, an ethanol recovery tower and the associated equipment. The purification method is as follows: heatintegration is realized between the ethyl acetate rectifying tower and the ethyl acetate recovery tower; the ethyl acetate product is obtained from the bottom of the ethyl acetate rectifying tower, wherein the ethyl acetate recovery tower uses water as extracting agent to perform extractive distillation operation; ethyl acetate is recycled from the tower top; ethanol-water mixture is discharged from the tower bottom and sent to the ethanol recovery tower; and ethanol-water mixture is obtained from the bottom of the ethanol recovery tower, a part of wastewater in the tower bottom is recycled, and the other part is discharged from the equipment. The operational energy consumption can be greatly reduced by adopting heat exchange and energy saving methods in the system. By adopting the methodof the invention, the operational energy consumption can be reduced to 0.55 ton of steam for 1 ton of the ethyl acetate product, which can be reduced by more than 50% compared with the existing ethylacetate refining method; the reaction process of returning ethyl acetate is not required, than the reaction process energy consumption can be reduced by more than 30%.

Owner:蓝仁水 +1

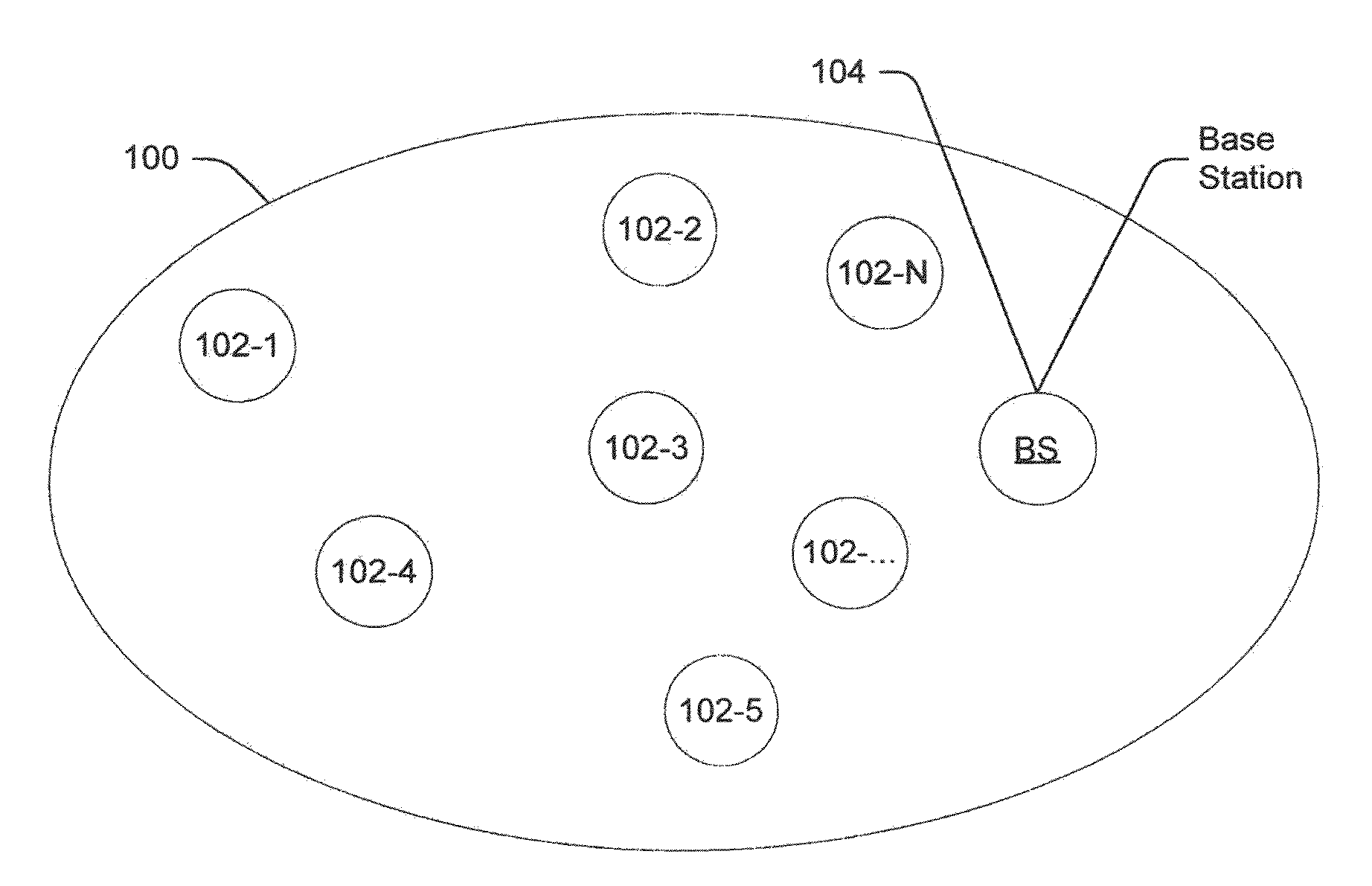

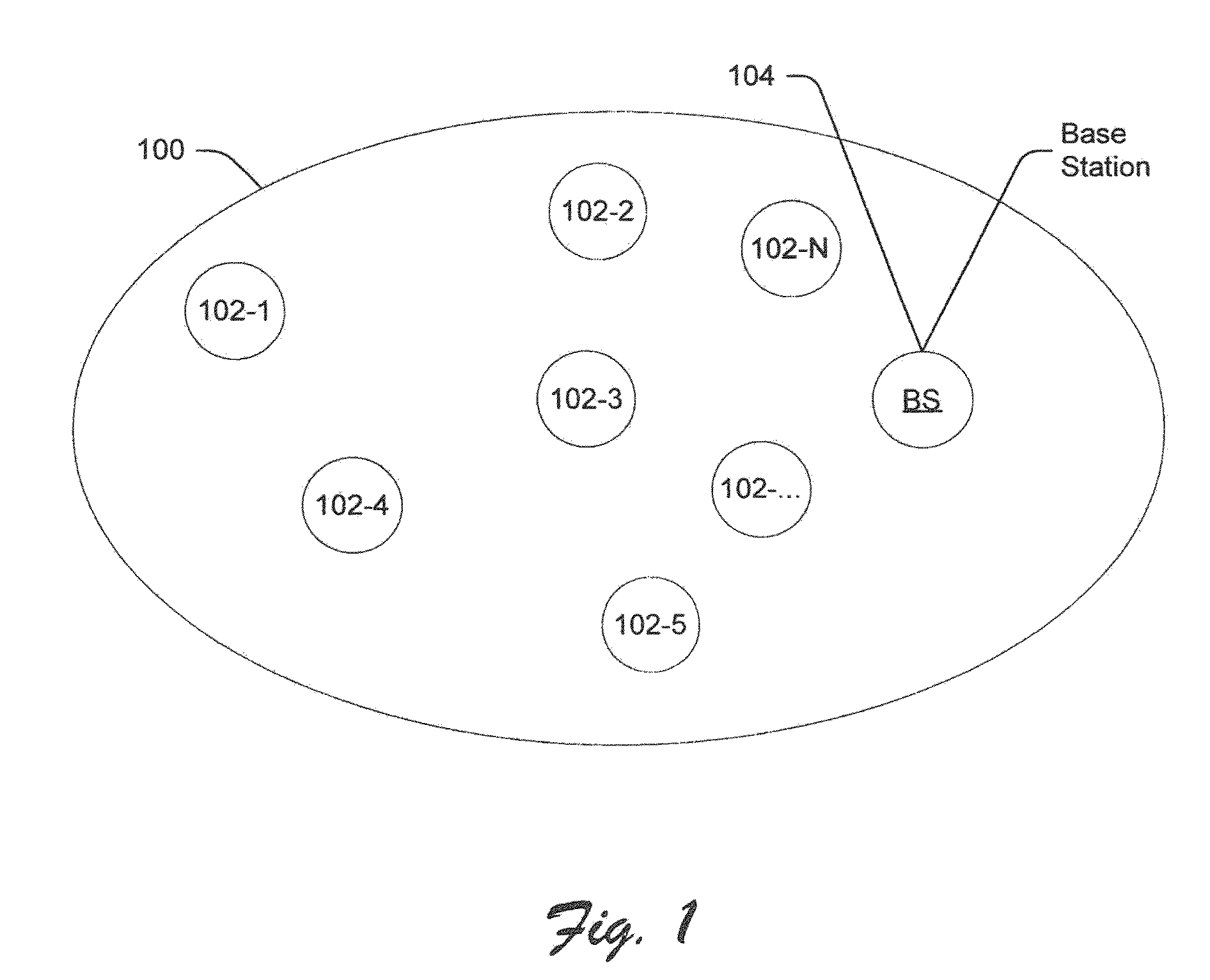

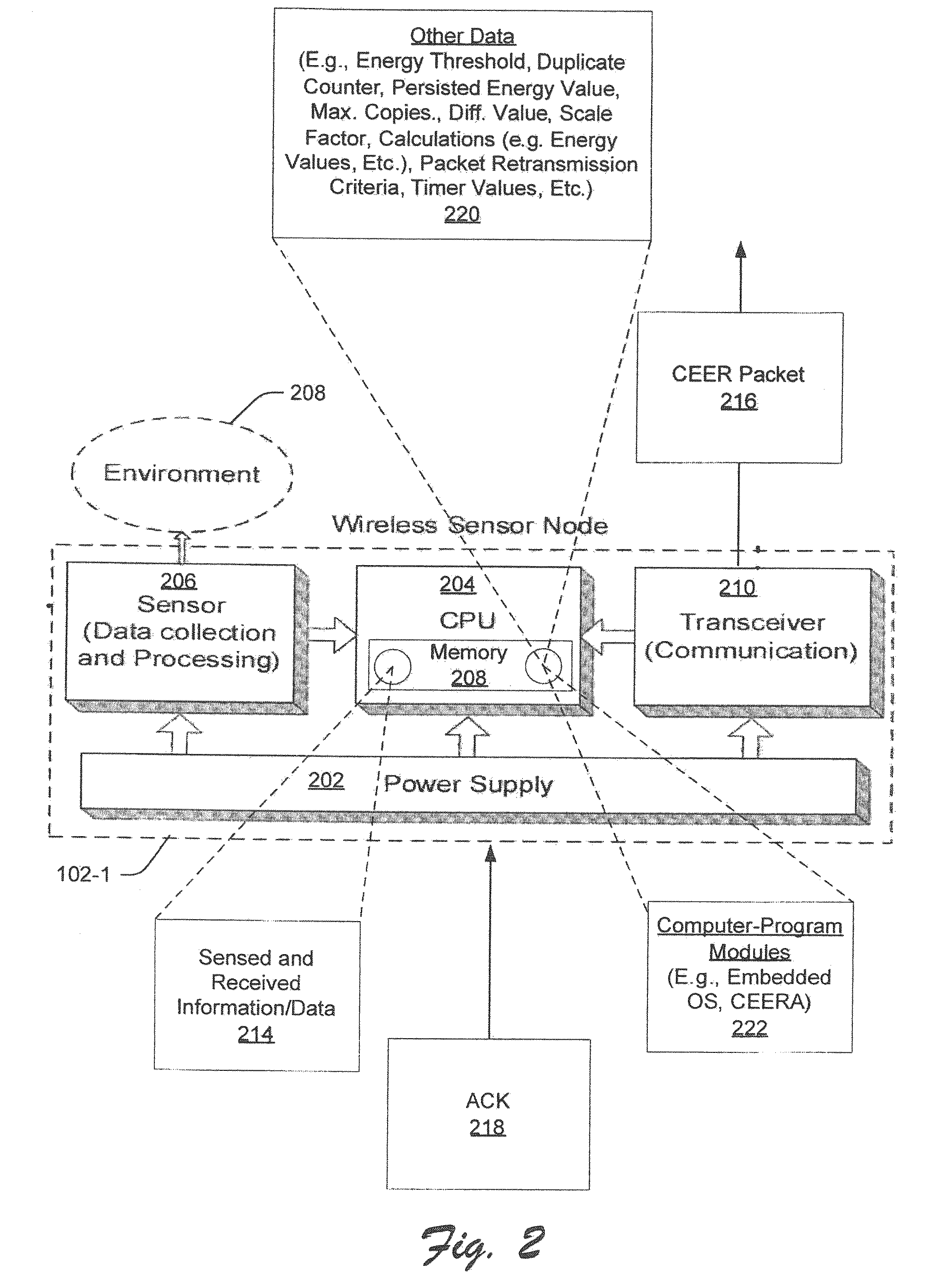

Cooperative packet routing for wireless sensor networks

InactiveUS20100142422A1Efficient use ofOptimal lifetimeTransmission systemsMultiple digital computer combinationsOperational energySensor node

A cooperative packet routing for wireless sensor networks is described. In one aspect, a transient sensor node in a wireless sensor network receives a packet from a source node, wherein the packet is targeted for receipt by a base station. The transient sensor node, responsive to receiving the packet, estimates how much operational energy remains in the sensor node. If the determined amount of energy meets a configurable threshold, the transient sensor node implements a set of cooperative packet routing operations for conditional re-transmission of the packet to the base station. The configurable threshold is set to ensure substantially optimal usage and lifetime of the sensor node in the wireless sensor network. The conditional re-transmission of the packet is based on a set of randomized packet re-transmission criteria.

Owner:KING SAUD UNIVERSITY

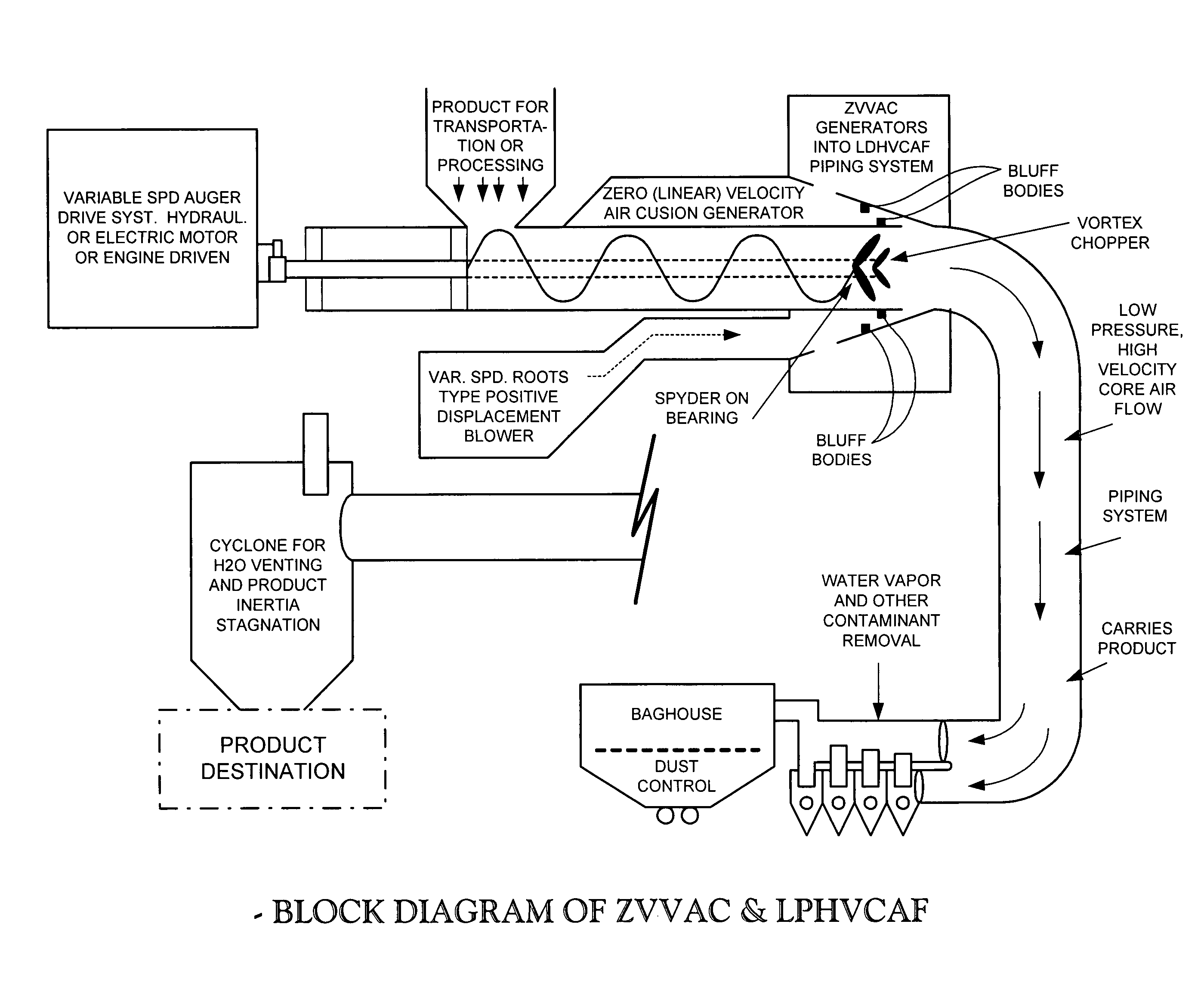

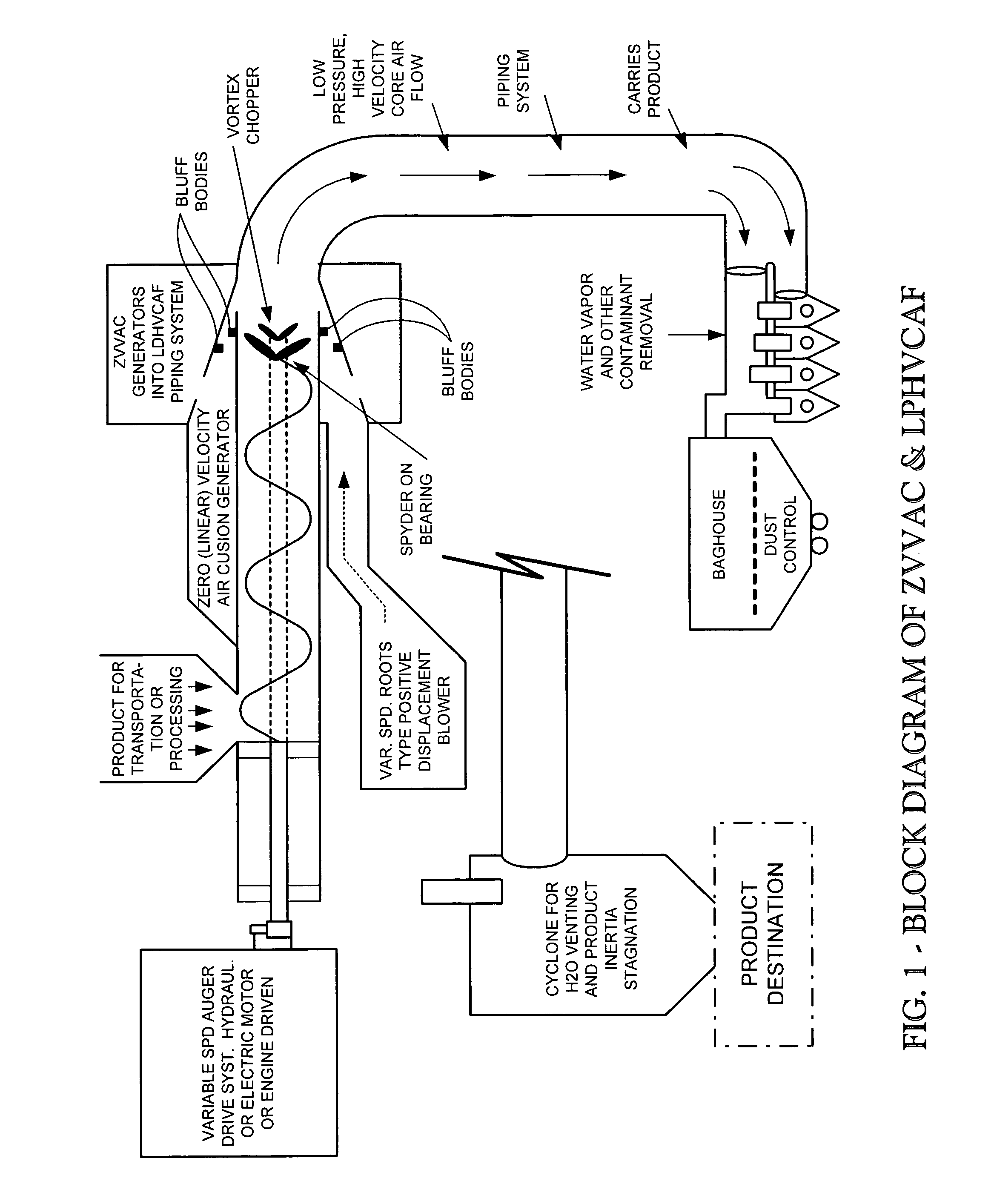

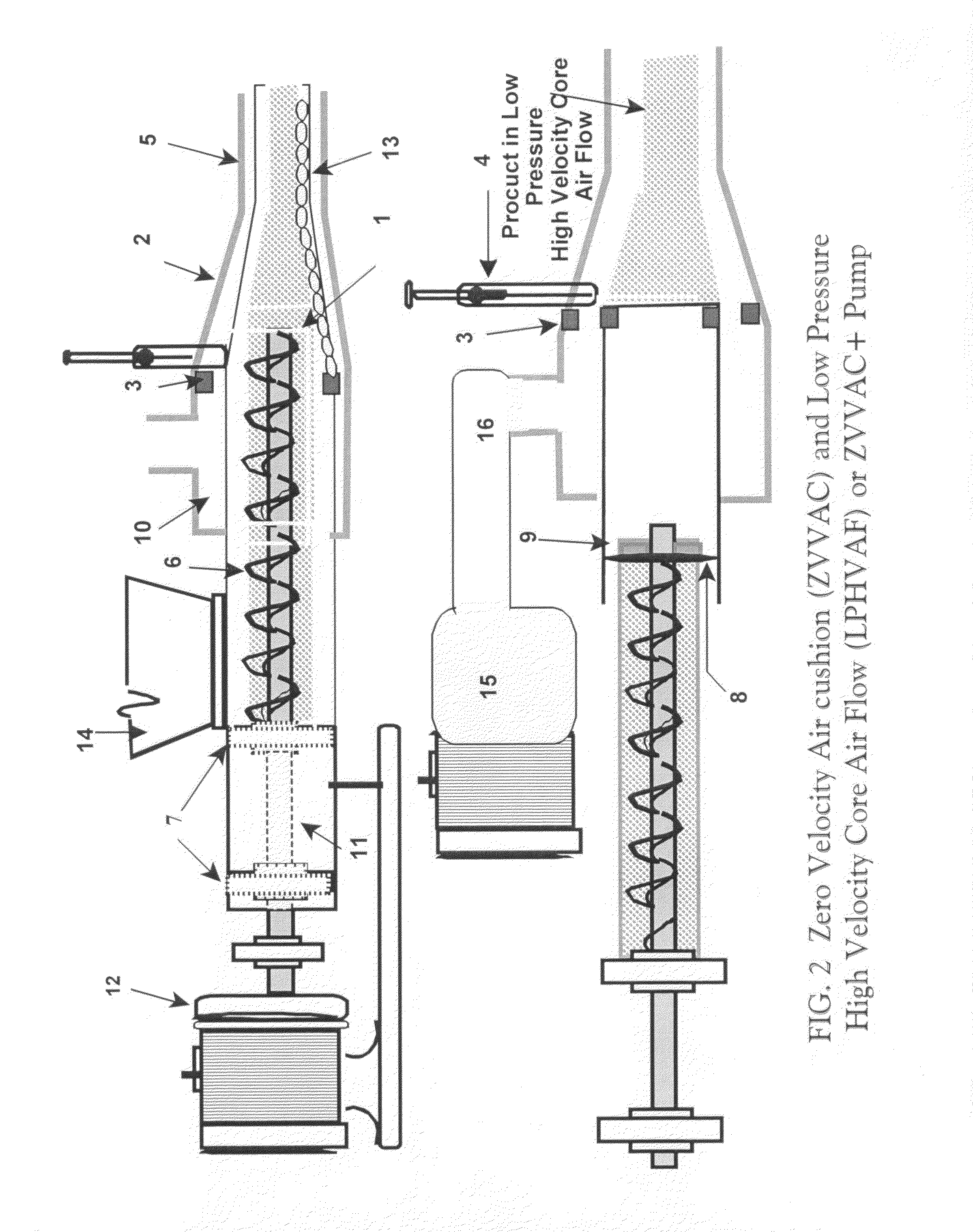

Low-pressure, air-based, particulate materials transfer apparatus and method

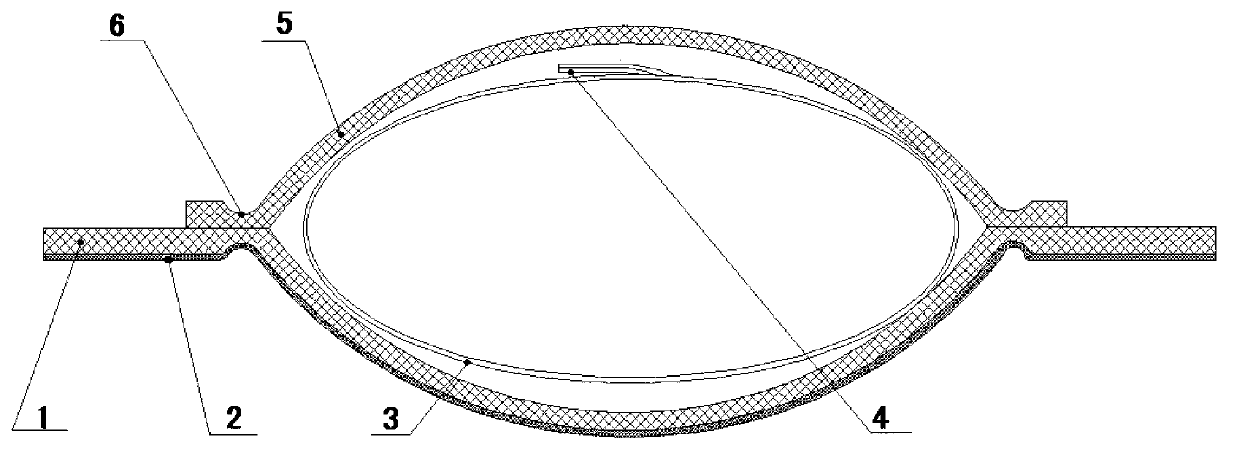

InactiveUS20080175675A1Eliminating product frictionMinimizing electrical (or mechanical) energy requirementDomestic plumbingBulk conveyorsParticulatesOperational energy

This invention relates to a system, process, and the device for reducing energy usage by simplifying equipment and thus the power requirements for manufacturing, installation of the equipment required for use in the movement-transportation to / during the processing of granular particulate bulk, powder products, many liquids slurry-able materials. Many commonly identified materials will be in a granular, particulate and non agglomerative condition suitable for injection by auger or inertial gravity into an enclosed pipe or conveyance chamber. In the device, two distinct and specific air flow patterns are identified when mechanically-pneumatically established within a single, low pressure piping entity; 1. A unique self regenerating (for system length), pipe contained, Vortex air cushion, with zero linear variable velocity (ZVVAC). 2. A linear, low pressure, high velocity “core flow” of air (LPHVCF), or ZVVAC+, (the two features when combined), which carries the injected product or material thus eliminating energy consuming pipe contact within the conveying system in a frictionless, high speed environment without product degradations, where system processing-grading features are optimized specifically where system production costs, maintenance, and especially operational energy costs are reduced by 90 percent or more.

Owner:ENSENTECH

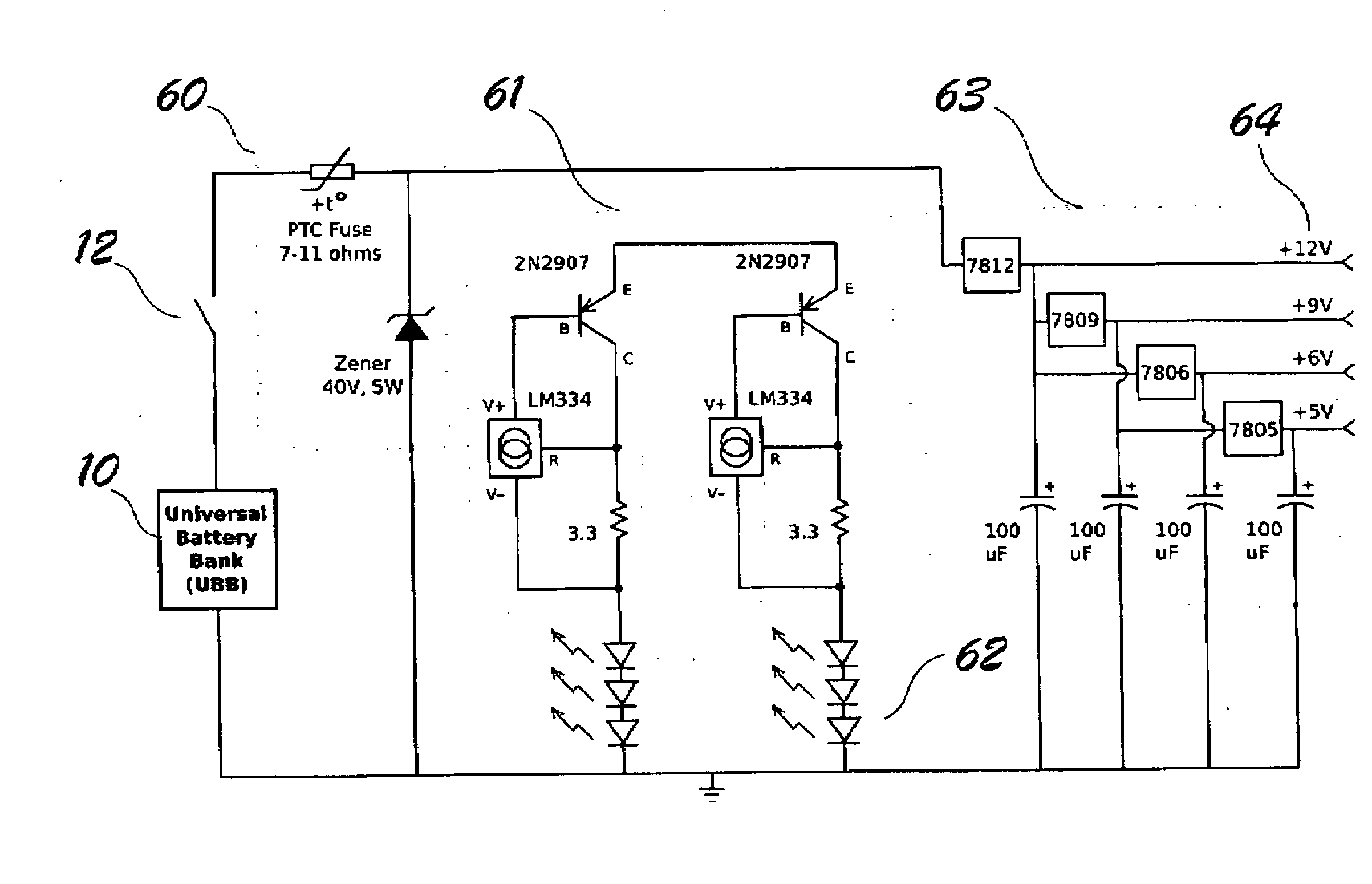

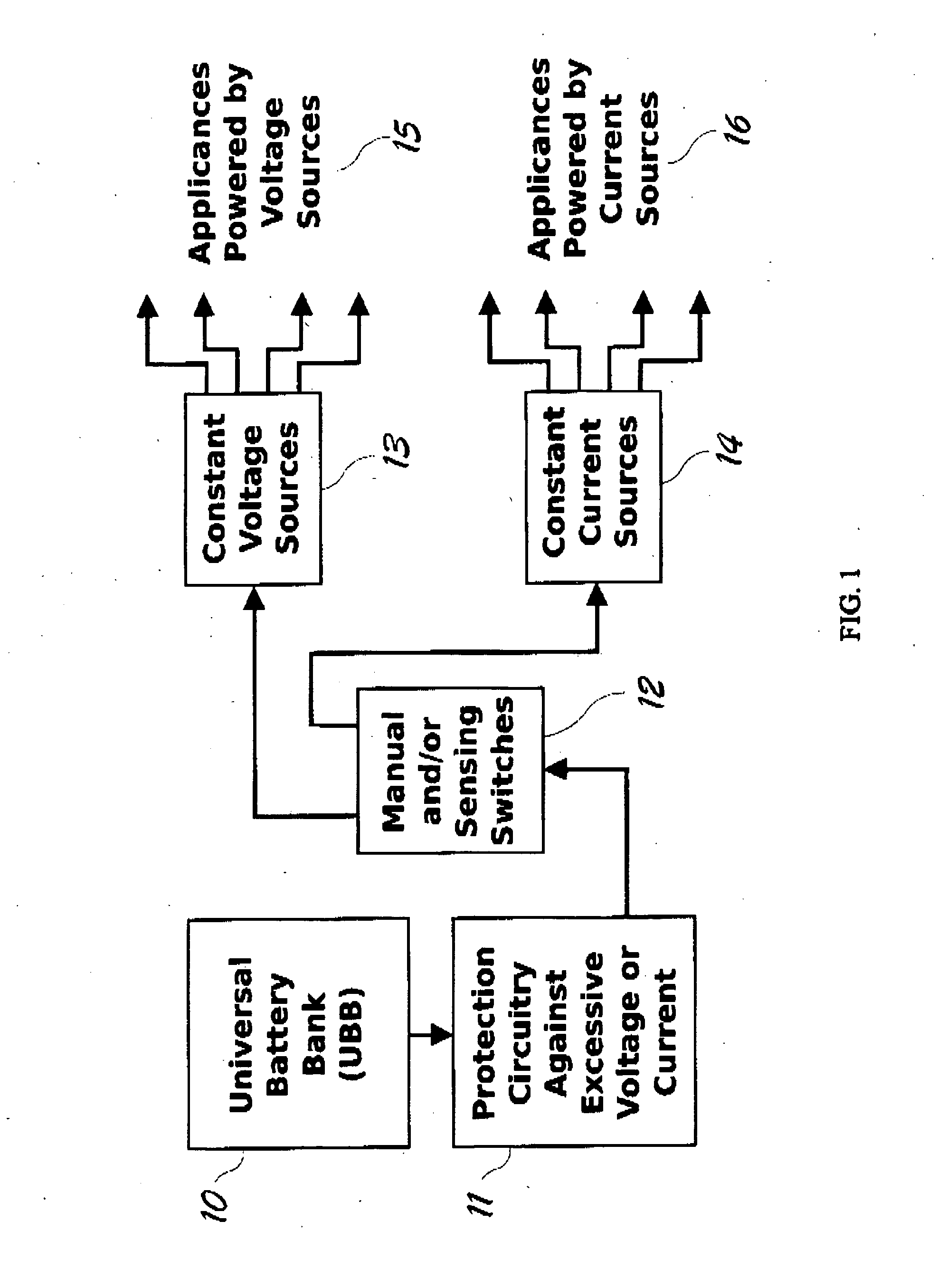

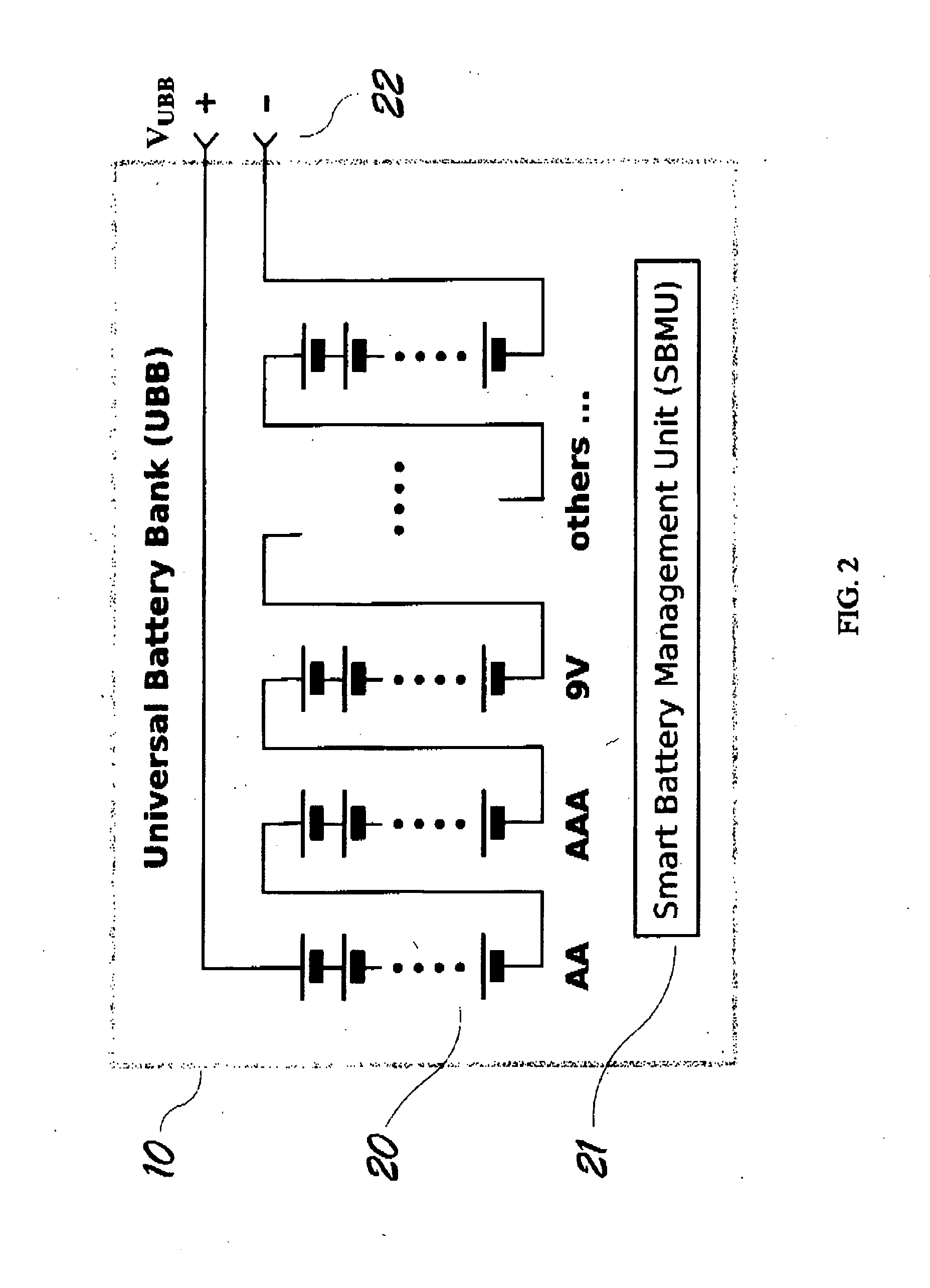

Method and Apparatus for Extending Service Life of a Battery Source

InactiveUS20150155736A1Increase battery capacityExtended time intervalCircuit monitoring/indicationDifferent batteries chargingHigh energyOperational energy

A method and an apparatus are disclosed for extending the service life of a battery source by fully utilizing the energy in batteries and / or providing higher energy reserve using multiple batteries. The invention has economical and environmental benefits by reducing waste in batteries in addition to offering convenience and ease of maintenance in battery use. It also benefits the design of devices when replacing batteries is either difficult or impossible. A universal battery bank consists of an ensemble of possibly heterogeneous batteries all connected in series to provide a usable operational energy source. To exploit this power supply that may vary over a wide voltage range, electronics are designed to monitor the individual batteries, guard against excessive voltage and current, and provide constant current sources and / or constant voltage sources for various appliances.

Owner:SUN YING +1

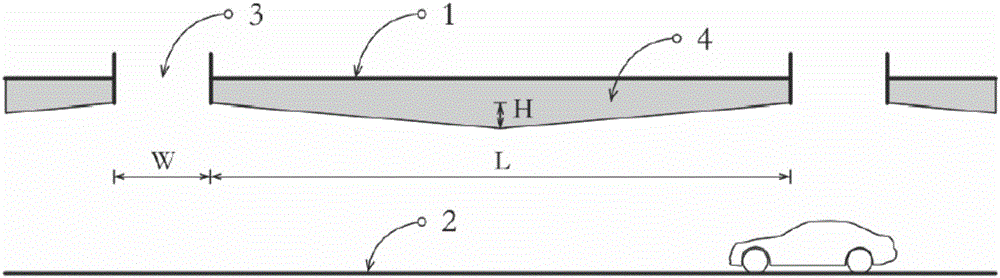

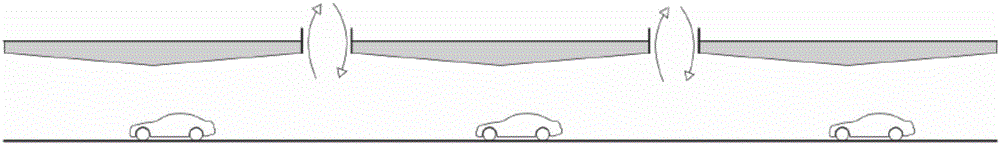

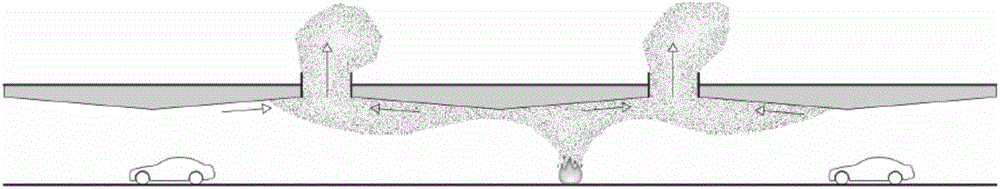

Natural ventilation and natural smoke extraction system for urban road tunnel

InactiveCN106703868AHierarchical structure is stableReduce operating energy consumptionTunnel/mines ventillationInterior spaceNatural ventilation

The invention relates to a natural ventilation and natural smoke extraction system for an urban road tunnel. At the top of the road tunnel, ventilating shafts are arranged at intervals distance L, and each ventilating shaft enables the inner space of the tunnel to be communicated with the upper air outside the tunnel, the longitudinal length along the tunnel of the ventilating shaft at the top is W; a buried section is mounted between two adjacent ventilation shafts, a wedge structure is formed at the top of the buried section, the thickness of the wedge structure means the vertical distance H between the lowest point of the wedge structure and the bottom of the ventilation shaft. The natural ventilation and natural smoke extraction system fully utilizes the traffic wind power and the buoyancy of smoke gas, completely abandons the mechanical ventilation and mechanical smoke extraction scheme, thus saves a great deal of operational energy consumption. The smoke extraction has no flow disturbance caused by a fan in the exhaust process, and the smoke layer structure is stable, thus the exhaust smoke will not diffuse throughout the tunnel. The natural ventilation and natural smoke extraction system is utilized to escape, evacuate and rescue.

Owner:金斯科 +1

Heat exchanger with convertible flow path and application method thereof

ActiveCN103175347AImprove heat transfer efficiencyReduce energy consumptionEvaporators/condensersHeat exchanger casingsThermodynamicsOperational energy

The invention discloses a heat exchanger with convertible flow path. An internal space between a front flanging end enclosure and a front tube plate is divided into two sides by a vertical separating rib from a vertical plane. One side is divided into an upper side and a lower side by a horizontal separating plate in a horizontal plane. An internal space between a rear flanging end enclosure and a rear tube plate is divided into an upper side and a lower side by a separating rib. A heat exchange tube flow path region corresponding to tube holes is a flow path A, wherein the tube holes are formed above a horizontal separating rib which is arranged at one side of the vertical separating rib. A heat exchange tube flow path region corresponding to tube holes formed below the horizontal separating rib is a flow path D. A heat exchange tube flow path region corresponding to tube holes is a flow path B, wherein the tube holes are formed in the other side of the vertical separating rib and above the separating rib. A heat exchange tube flow path region corresponding to tube holes formed below the separating rib is a flow path C. According to functions of water chamber flow path division and a conversion valve, the heat exchanger is switched between the second flow path and the fourth flow path, heat exchanging areas are further reduced by half under the working condition of the second flow path, heat exchange efficiency is obviously improved, operational energy consumption is reduced, and reliability and safety are guaranteed under the poor working condition.

Owner:NANJING JINDIAN REFRIGERANT IND

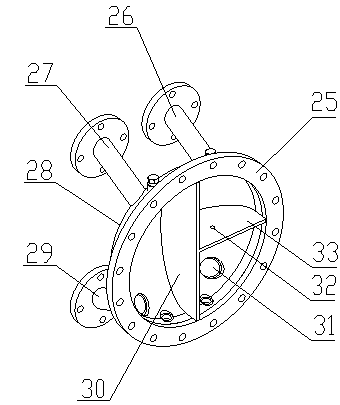

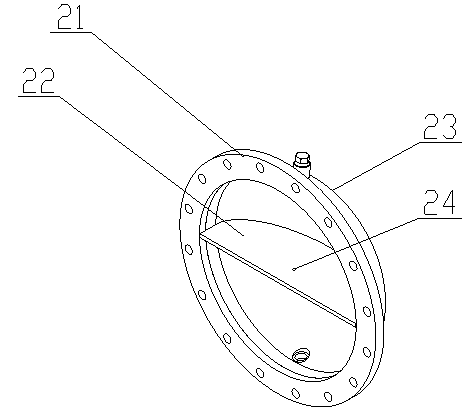

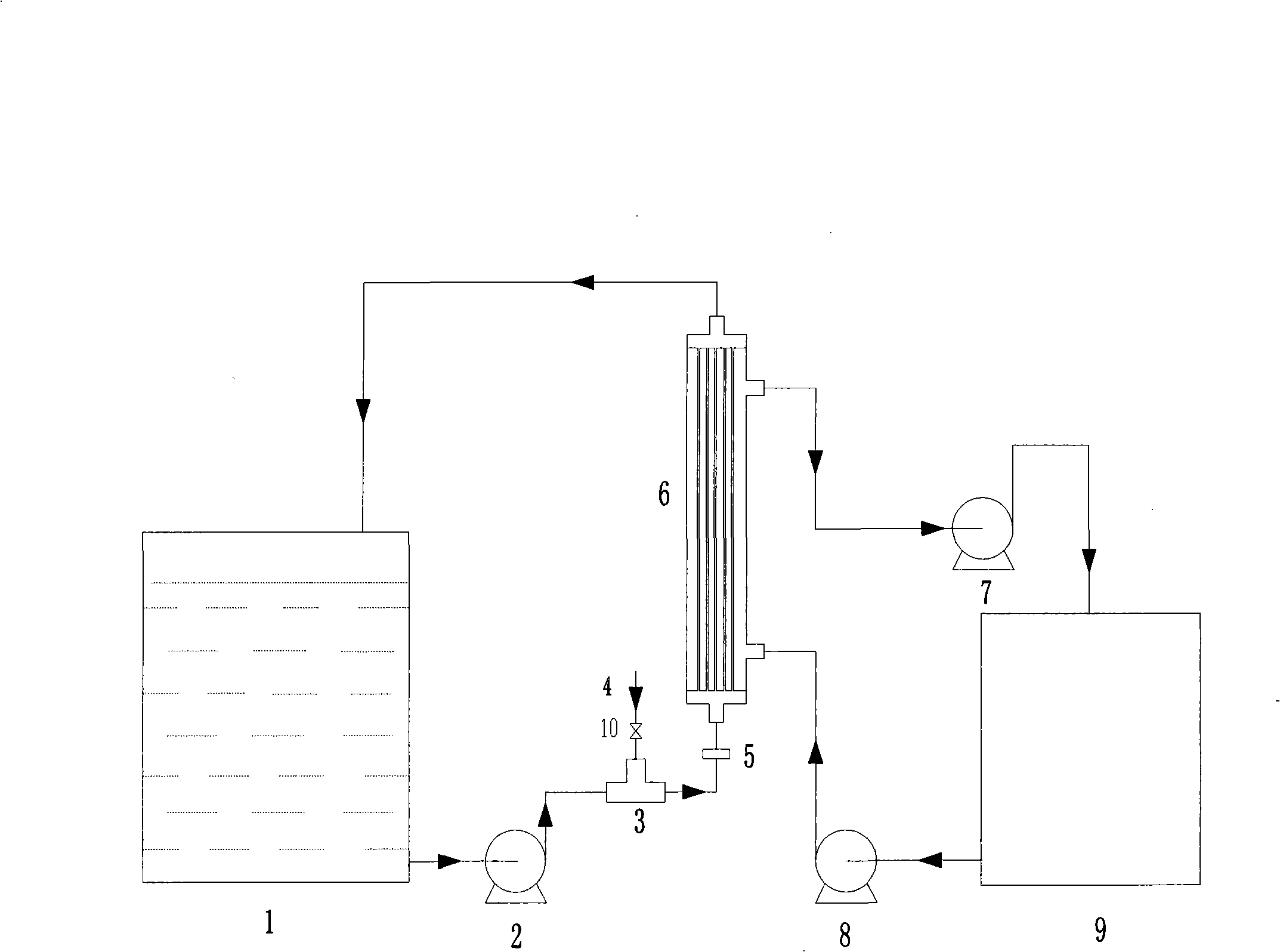

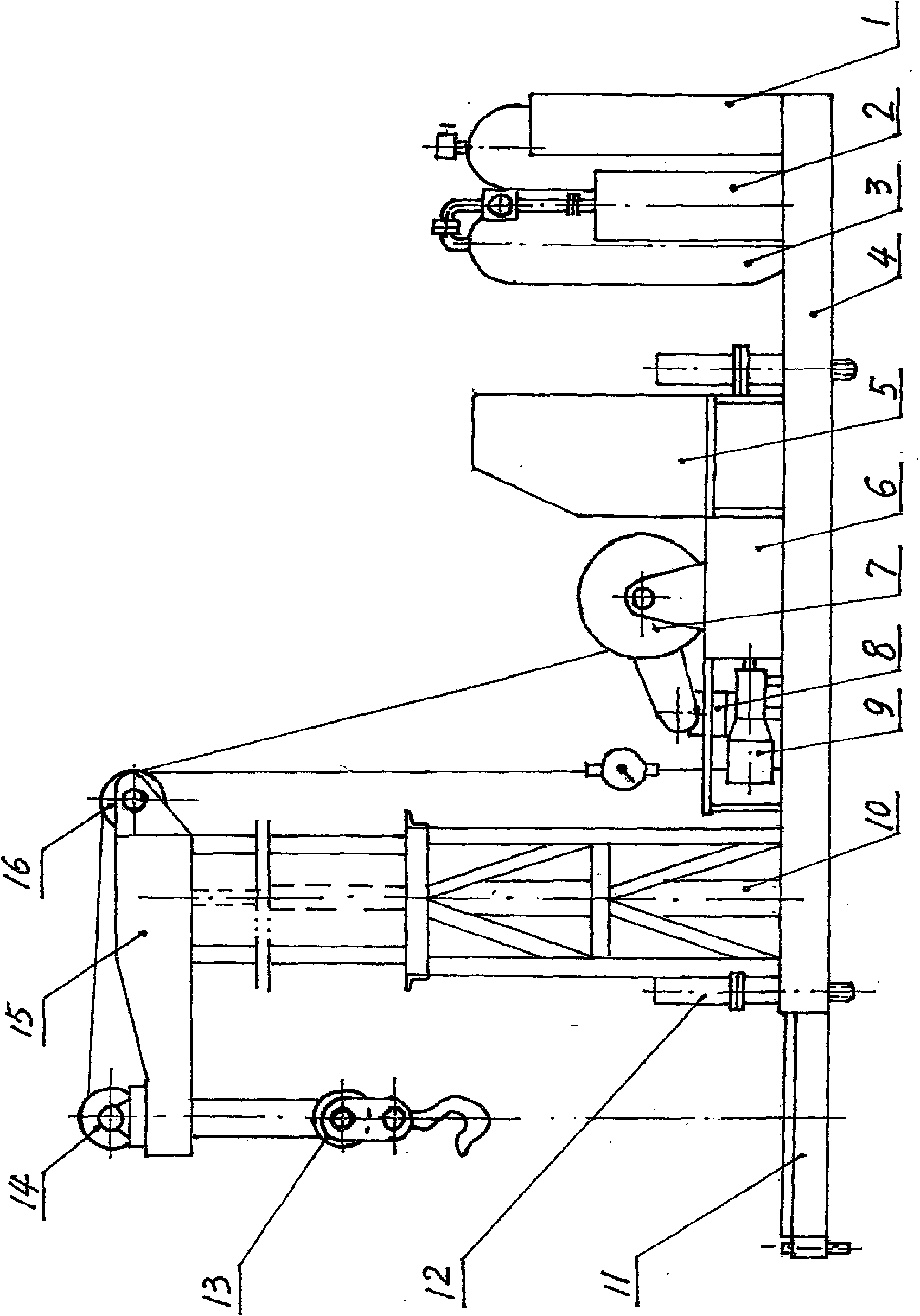

Method and device of jet airlift recirculated membrane bioreactor

ActiveCN101284698AReduce pollutionIncrease agitationSustainable biological treatmentBiological water/sewage treatmentEngineeringSmall footprint

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

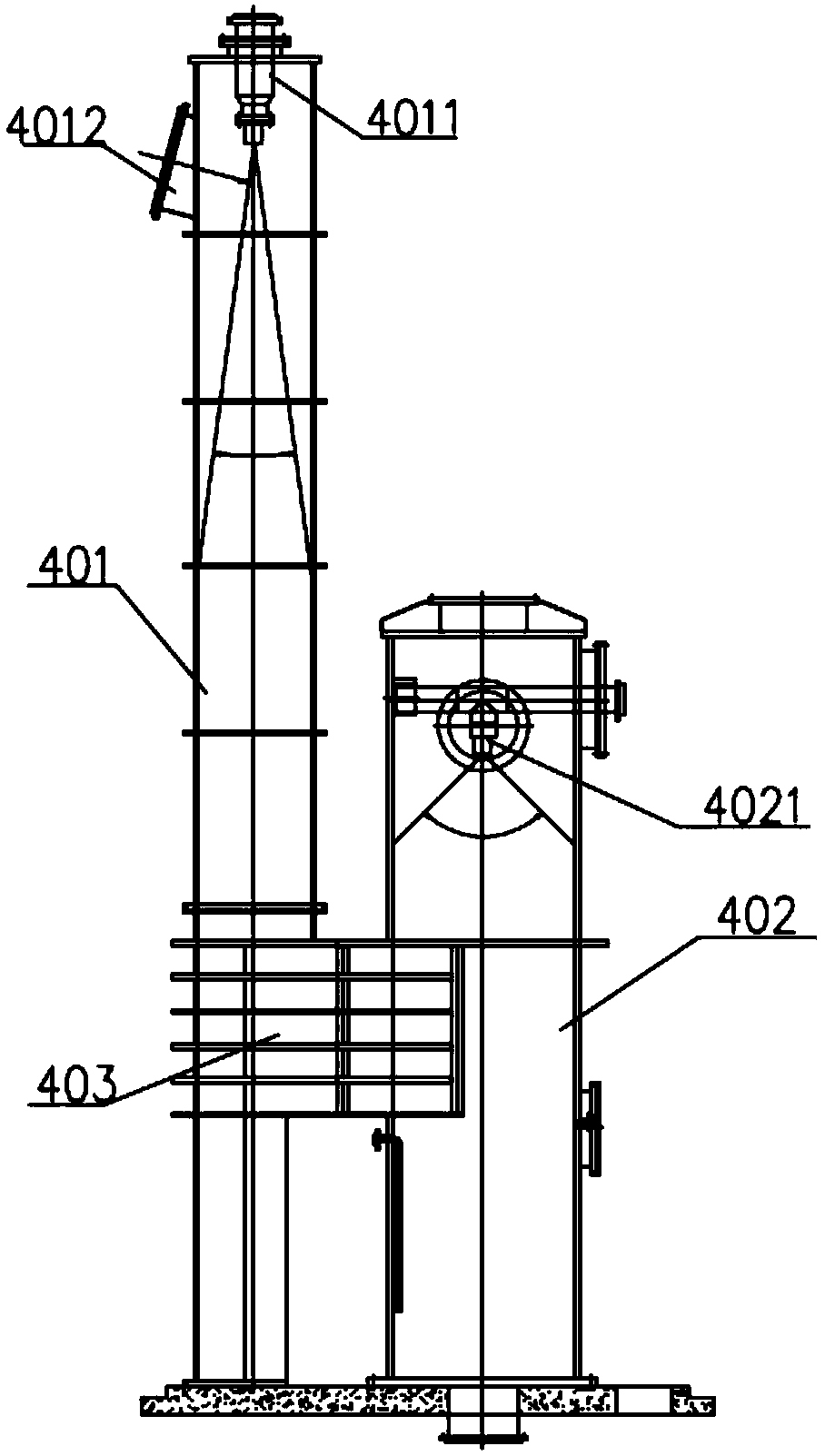

Energy-saving and emission-reducing petroleum well servicing rig

InactiveCN101629477AReduce noiseAvoid wastingDrilling rodsDrilling casingsElectricityEconomic benefits

The invention discloses an energy-saving and emission-reducing petroleum well servicing rig, which is driven by electricity. Based on a hydraulic energy storage principle, corresponding hydraulic stations and corresponding action elements are started according to different hook loads, so that the whole machine has a low installed power and total operational energy consumption which is only one quarter of that of a conventional well servicing rig, thereby saving a large amount of energy. The well servicing rig is convenient in transfer and installation due to an arranged cantilever vertically telescope derrick and an arranged folded retractable drill stand and is low in labor intensity and good in economic benefit.

Owner:姜汝诚 +1

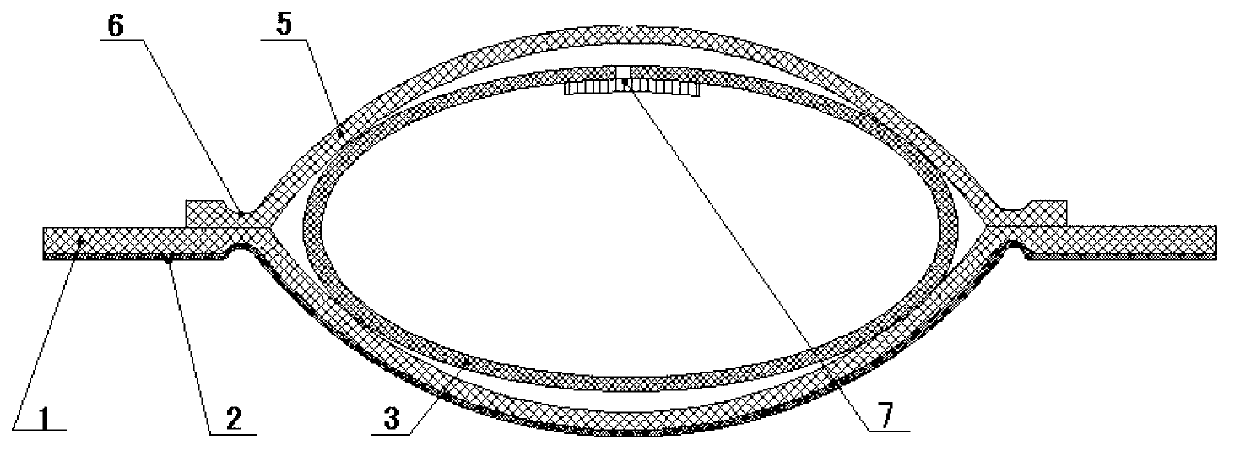

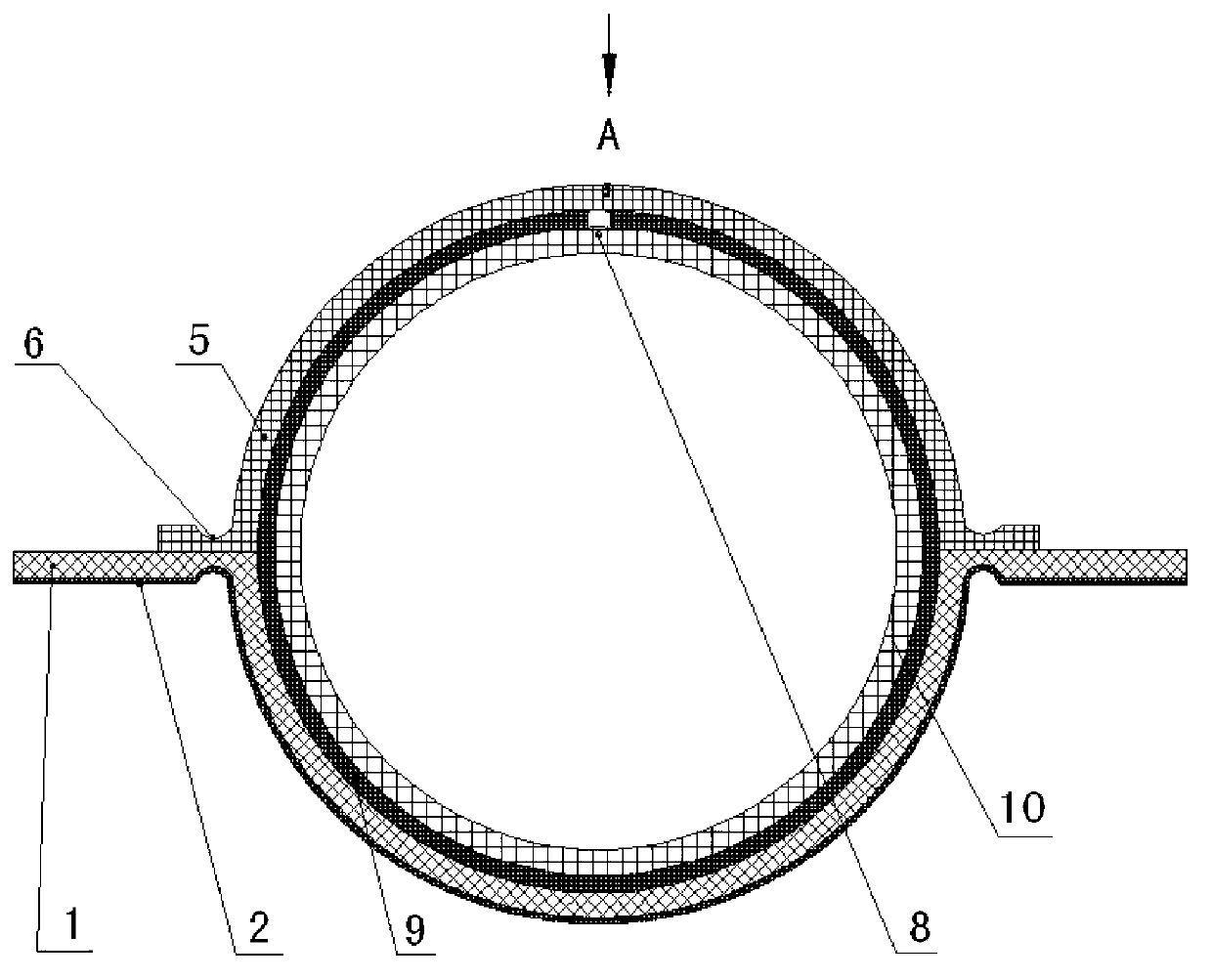

High temperature superconducting magnetic levitation apparatus

InactiveCN105553336ASmooth slidingRealize cycle operationMagnetic holding devicesLevitationHigh temperature superconducting

The invention discloses a high temperature superconducting magnetic levitation apparatus. The apparatus comprises a closed annular track and a high temperature superconducting strip magnetic levitation body, wherein the closed annular track is spliced by a series of permanent magnets; the closed annular track is fixedly arranged on a horizontal table type face plate, and the closed annular track and the horizontal table type face plate are integrated into one body; the high temperature superconducting strip magnetic levitation body is constantly positioned above the closed annular track; the high temperature superconducting strip magnetic levitation body adopts the high temperature superconducting strip; the high temperature superconducting strip is fixedly arranged at the bottom of a cavity of a low temperature container, and the high temperature superconducting strip and the low temperature container are integrated into one body; and a temperature condition for keeping the high temperature superconducting strip at a superconducting state is maintained in the low temperature container so as to enable the high temperature superconducting strip magnetic levitation body to be in a levitation state above the closed annular track under the superconducting state. According to the high temperature superconducting magnetic levitation apparatus, the low temperature container that is in static levitation above the track is pushed by an external force; the low temperature container stably slides above the closed track in the levitation manner, and circulating periodical operation of the low temperature container under the levitation state can be realized; and in addition, the apparatus is simple in structure, convenient to control, low in operational energy consumption and high in effective magnetic levitation force.

Owner:SHANGHAI UNIV

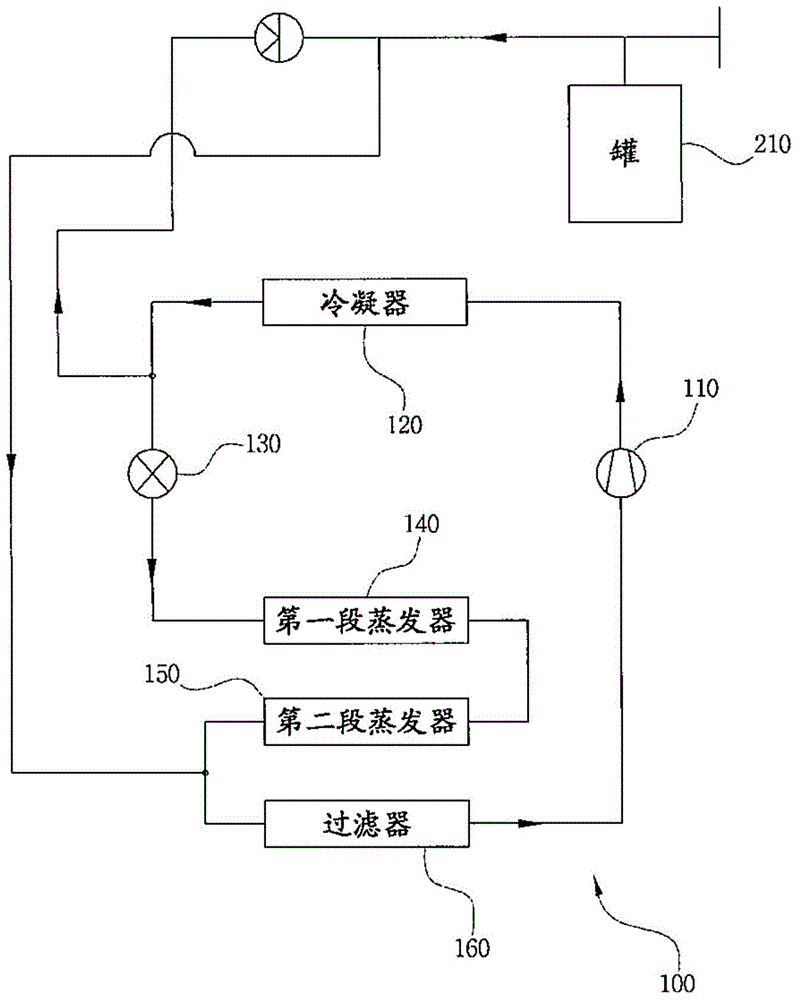

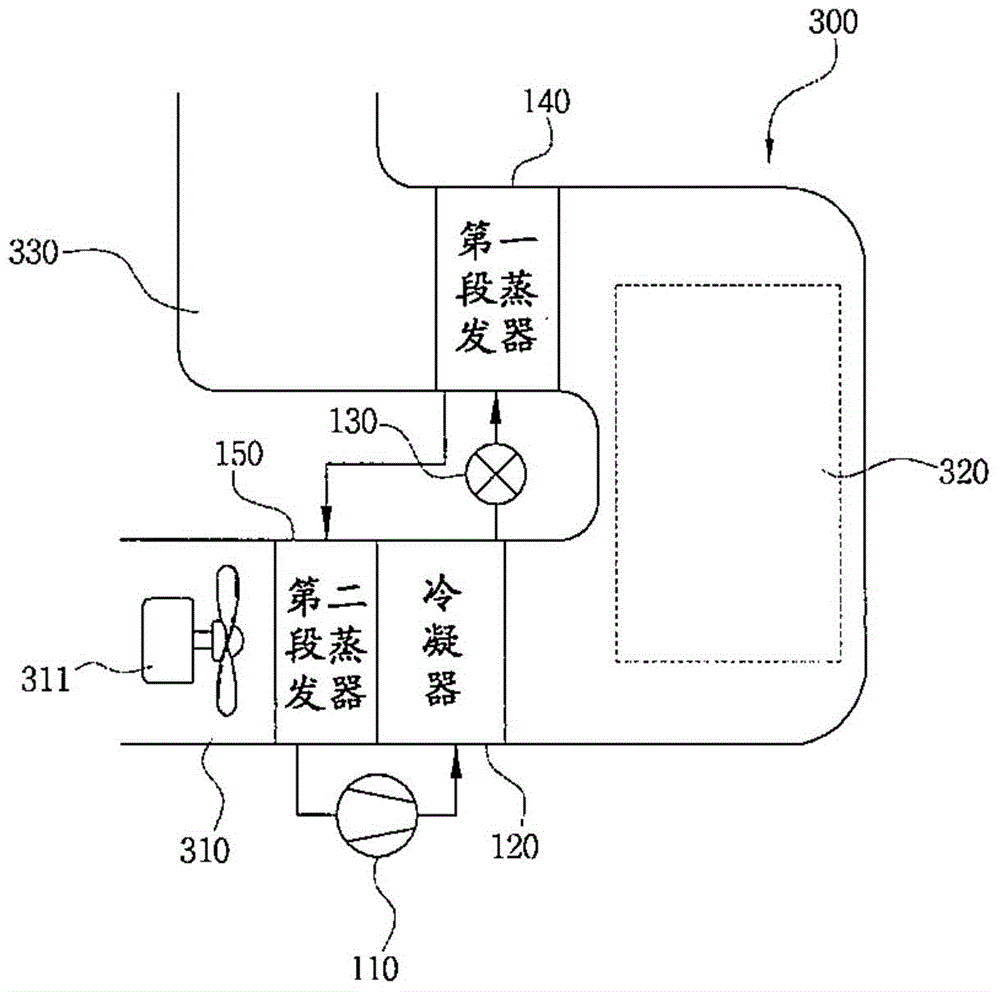

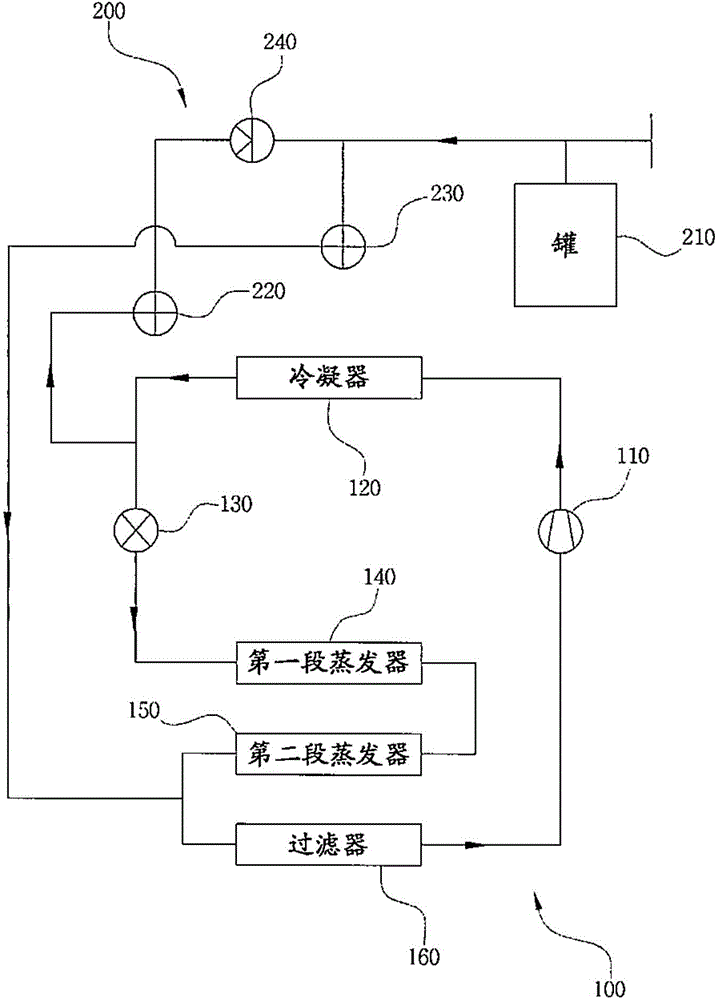

Heat pump system having waste heat recovery structure with 2nd evaporation

ActiveCN104457004AReduce loadRelieve pressureHeat pumpsCompression machines with several evaporatorsWaste heat recovery unitEvaporation

The present invention relates to a heat pump system having a waste heat recovery structure with 2nd evaporation and, more specifically, to a heat pump system having a waste heat recovery using a secondary evaporator capable of recovering waste heat discharged from a heat pump cycle to the outside using a primary evaporator, and passing a refrigerant, overheated by the recovered heat, through a secondary evaporator to radiate heat, thus providing a function for supplying initially induced air to a condenser in a pre-heated status and saving operational energy and preventing an overload of a compressor, in proportion to the heat energy reused in the condenser. The heat pump system comprises a compressor (110), a condenser (120), an expansion valve (130), a primary evaporator (140) and a secondary evaporator (150). The condenser (120) provides a function for supplying heated air, and the secondary evaporator (150) is positioned at the front end of the condenser (120) to preheat the initially induced air.

Owner:BOOSUNG ENG

Purification method of ethyl acetate

ActiveCN102070445BAvoid loopsReduce operating energy consumptionOrganic compound preparationCarboxylic acid esters preparationAcetic acidPurification methods

The invention relates to a purification method of ethyl acetate. The method comprises the following step: the ethyl acetate product is purified from ethyl acetate-ethanol-water mixture. The equipment of the method at least contains an ethyl acetate rectifying tower, an ethyl acetate recovery tower, an ethanol recovery tower and the associated equipment. The purification method is as follows: heat integration is realized between the ethyl acetate rectifying tower and the ethyl acetate recovery tower; the ethyl acetate product is obtained from the bottom of the ethyl acetate rectifying tower, wherein the ethyl acetate recovery tower uses water as extracting agent to perform extractive distillation operation; ethyl acetate is recycled from the tower top; ethanol-water mixture is discharged from the tower bottom and sent to the ethanol recovery tower; and ethanol-water mixture is obtained from the bottom of the ethanol recovery tower, a part of wastewater in the tower bottom is recycled, and the other part is discharged from the equipment. The operational energy consumption can be greatly reduced by adopting heat exchange and energy saving methods in the system. By adopting the method of the invention, the operational energy consumption can be reduced to 0.55 ton of steam for 1 ton of the ethyl acetate product, which can be reduced by more than 50% compared with the existing ethyl acetate refining method; the reaction process of returning ethyl acetate is not required, than the reaction process energy consumption can be reduced by more than 30%.

Owner:蓝仁水 +1

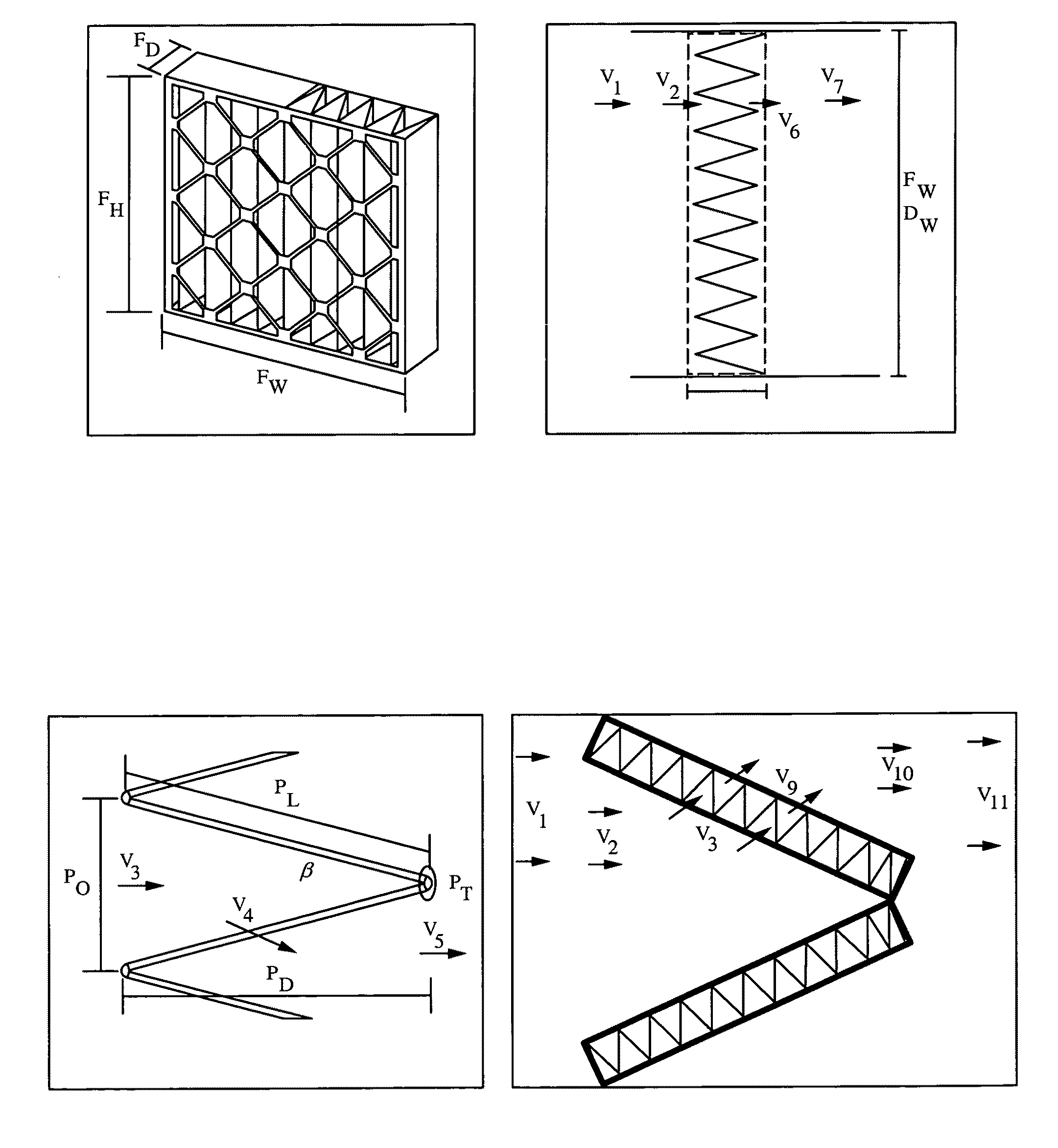

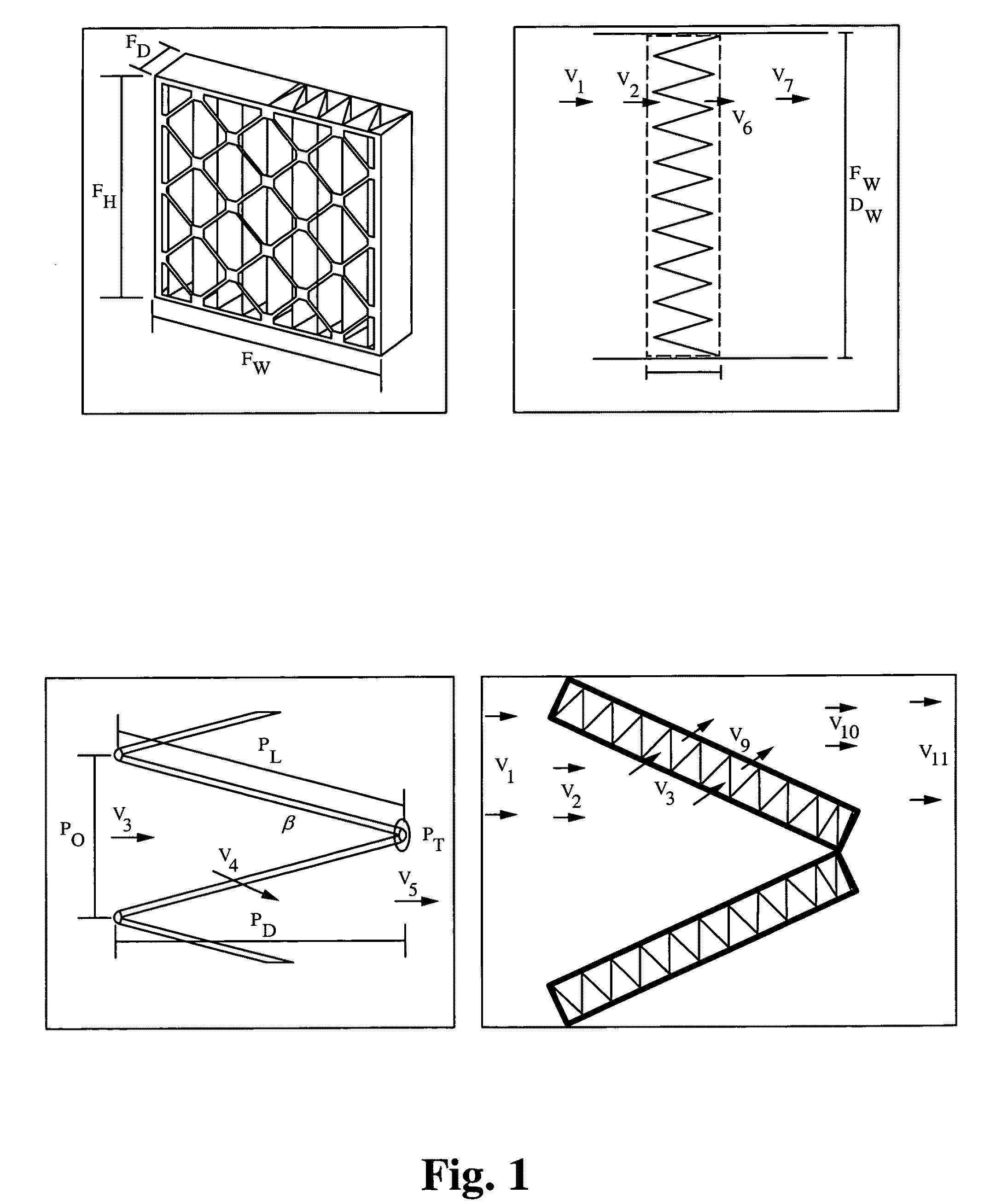

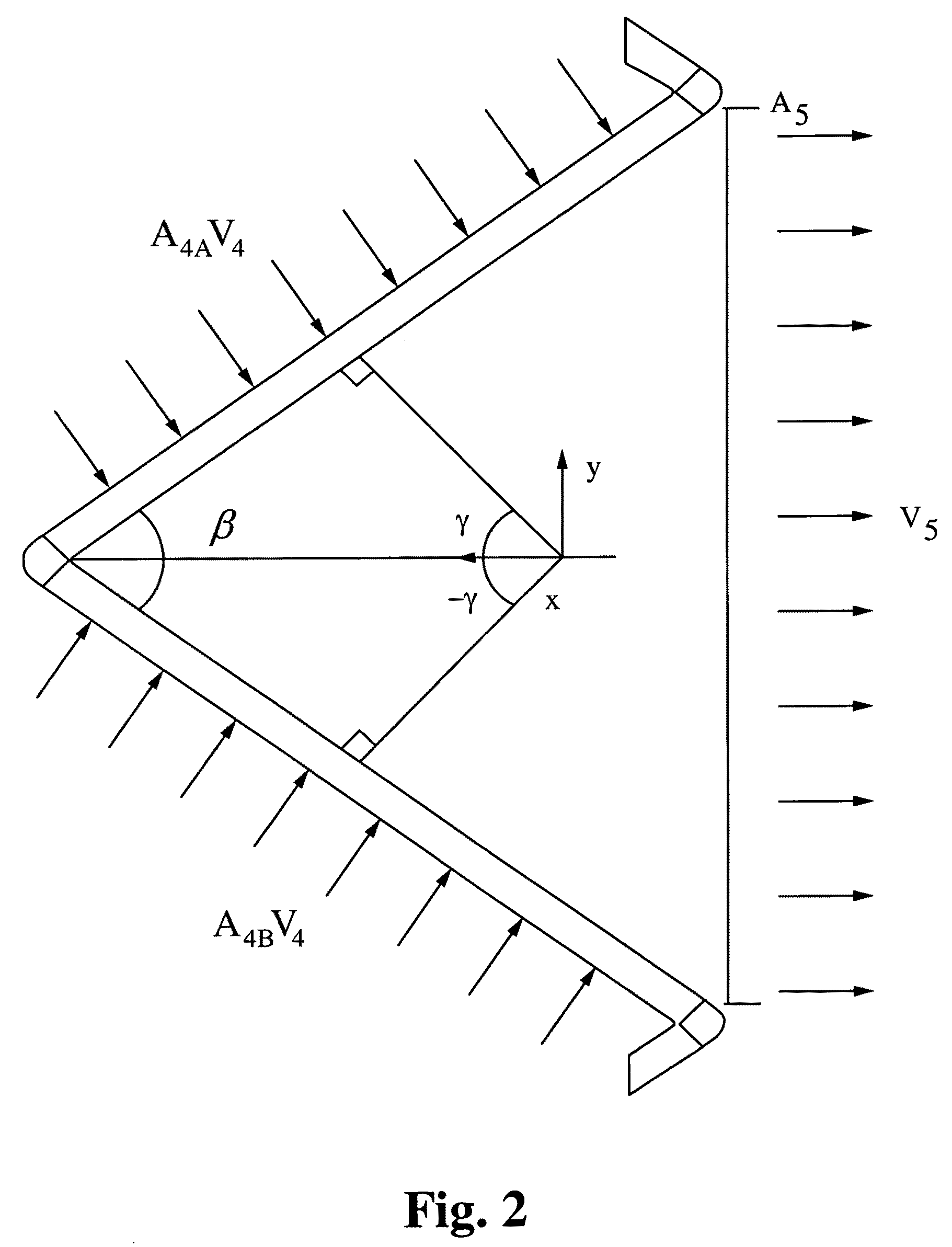

Multi-element structured arrays (MESA's) for cost effective and high efficiency treatment of fluids

ActiveUS8603229B2Eliminating Darcian flow resistanceImprove efficiencyCombination devicesGas treatmentFiberFlow resistivity

Multi-Element Structured Arrays (MESAs) present an effective approach to utilizing high pressure drop media that previously were cost prohibitive for use in a traditional filter element. The operational velocity is significantly slowed by the incorporation of numerous elements; thus, eliminating the Darcian flow resistances of the media. The MESAs are readily fitted with two or more replaceable “filter elements” that are able to employ commercially available media, microfibrous entrapped catalyst / sorbent media, unique multilayers and more. A model capable of estimating pressure drop for flow through a pleated filter is able to be used as a design tool to predict minimum initial pressure drop, maximum filtration area, and preferred media properties with respect to permeability versus thickness thus allowing the filtration system's dirt holding capacity, filtration efficiency and operational energy cost and filtration operational and total ownership costs such as blower energy, filter procurement and shipping, maintenance personnel, filter disposal, inventory and storage, cost of money and more to be improved.

Owner:AUBURN UNIV

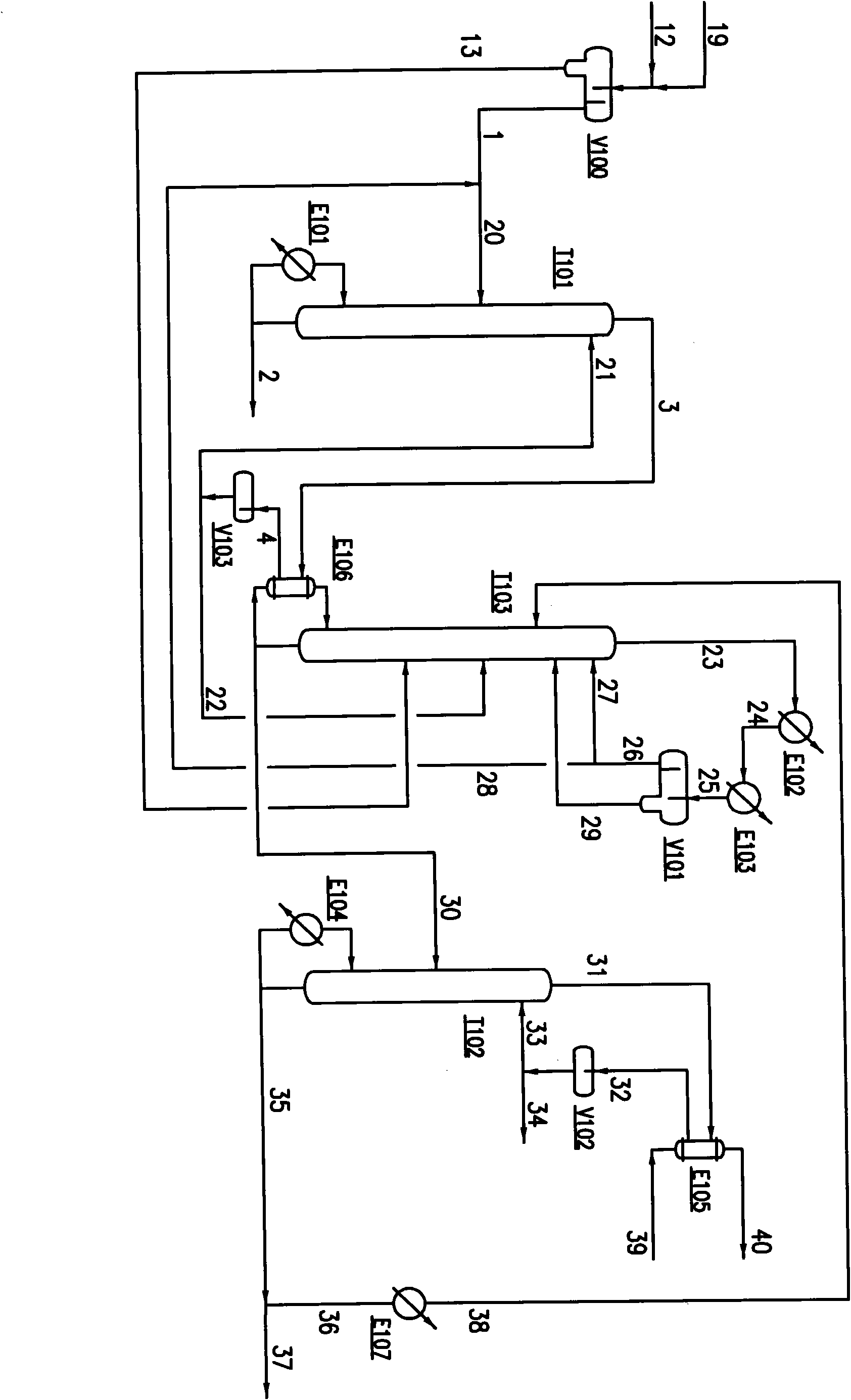

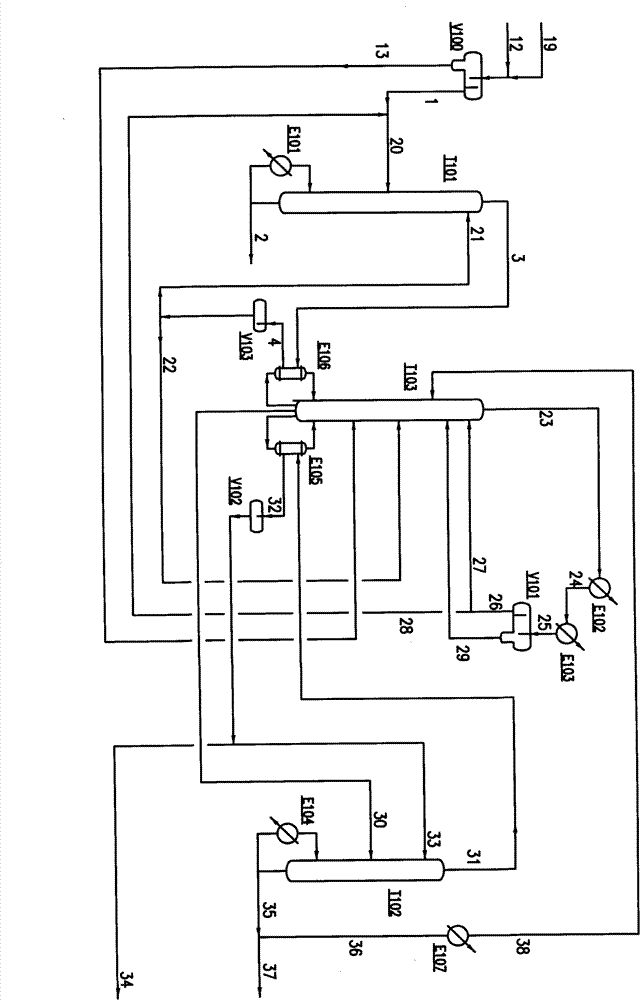

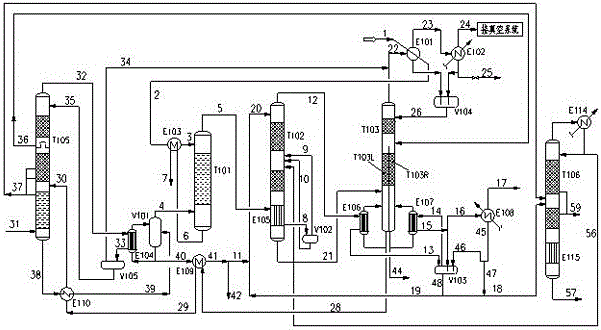

Energy-saving rectifying technique and apparatus for producing premium edible alcohol

ActiveCN106478368AReduce operating energy consumptionPracticalOrganic compound preparationChemical industryAlcoholEconomic benefits

The invention relates to an energy-saving rectifying technique and apparatus for producing premium edible alcohol, in particular to an energy-saving apparatus and technique for producing premium edible alcohol from fermented liquid through a rectifying process. The whole rectifying apparatus at least comprises fermenting tower T101, washing tower T102, first rectifying tower T103, methanol removal tower T104, second rectifying tower T105 and their supporting devices. The defects of the prior art are overcome, a single-tower heating and four-effect thermal integration technique is employed in breakthrough way based on common multi-tower heating technology, and the technique is used in conjunction with other heat-exchange energy-saving techniques used in the system such that operational energy consumption is greatly lowered. The defects of the prior art are overcome, the operational energy consumption is decreased to 1.5 t of steam per ton of premium edible alcohol, which is 40% and below lower than that of currently intensively-used premium alcohol rectifying techniques, and the energy-saving rectifying technique and apparatus have significant practicality and great economic benefit and have a promising application prospect.

Owner:NEW TIANJIN T & D

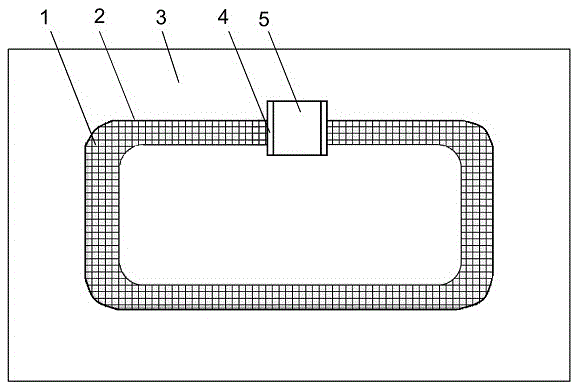

Coated drip irrigation tube/belt production method

InactiveCN103008129AExtended service lifePrevent infiltrationSpray nozzlesTectorial membraneDrip irrigation

The invention provides a coated drip irrigation tube / belt, which is simple in structure and low in manufacturing cost, and a production method thereof, and aims to solve the problem that a buried drip irrigation tube / belt blocks a water outlet. According to the technical scheme, the coated drip irrigation tube / belt is formed by coating a common drip irrigation tube / belt body with a filter covering film, an axial lower half of the filter covering film is a waterstop material layer, an upper half of the filter covering film is a water-permeable material layer, the upper layer and the lower layer are adhered or sewn oppositely. A maze water outlet of the drip irrigation tube / belt is arranged at the center of the water-permeable material layer, and the waterstop material layer is arranged below the common drip irrigation tube / belt. The protective film is added outside the common drip irrigation tube / belt, so that the service life of the drip irrigation tube / belt is prolonged greatly and buried field irrigation is truly made possible. The drip irrigation water seeps out from the top of the drip irrigation tube / belt and can gather to crop roots effectively, so that precious irrigation water is prevented from seeping underground, irrigation efficiency is improved greatly and operational energy consumption of drip irrigation systems is lowered.

Owner:CHINA AGRI UNIV

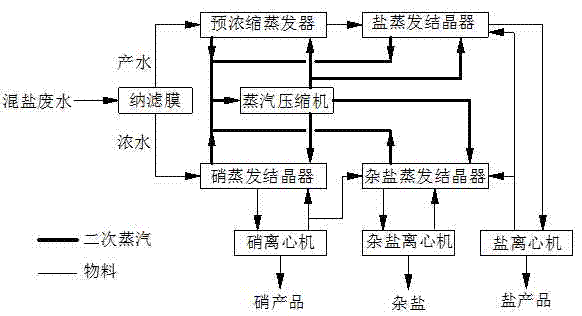

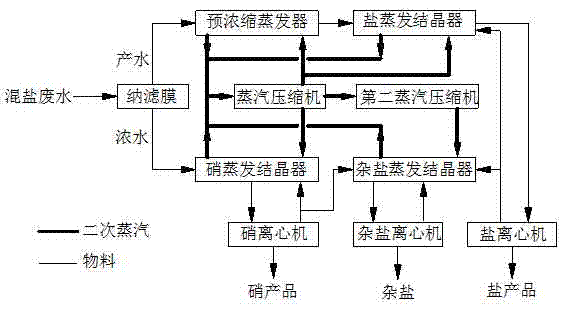

Single-effect four-body MVR (mechanical vapor recompression) saline wastewater separation device and separation method thereof

PendingCN107162297AReduce trafficLower requirementMultistage water/sewage treatmentWater/sewage treatment by heatingNitrateEvaporation

The invention discloses a single-effect four-body MVR (mechanical vapor recompression) saline wastewater separation device, comprising a pre-concentration evaporator, a salt evaporation crystallizer, a nitrate evaporation crystallizer, an incidental salt evaporation crystallizer and a steam compressor, wherein secondary steam outlets of the pre-concentration evaporator, the salt evaporation crystallizer, the nitrate evaporation crystallizer and the incidental salt evaporation crystallizer are connected to an inlet of the same steam compressor, and inlet steam temperature of the steam compressor is 80-100 DEG C. The invention also discloses a saline wastewater separation method using the device. The device has zero emission of saline wastewater, can isolate and recycle high-purity salt and anhydrous nitrate from the wastewater, and has low investment cost and operational energy consumption.

Owner:GUANGZHOU SCHIN TECH IND CO LTD +2

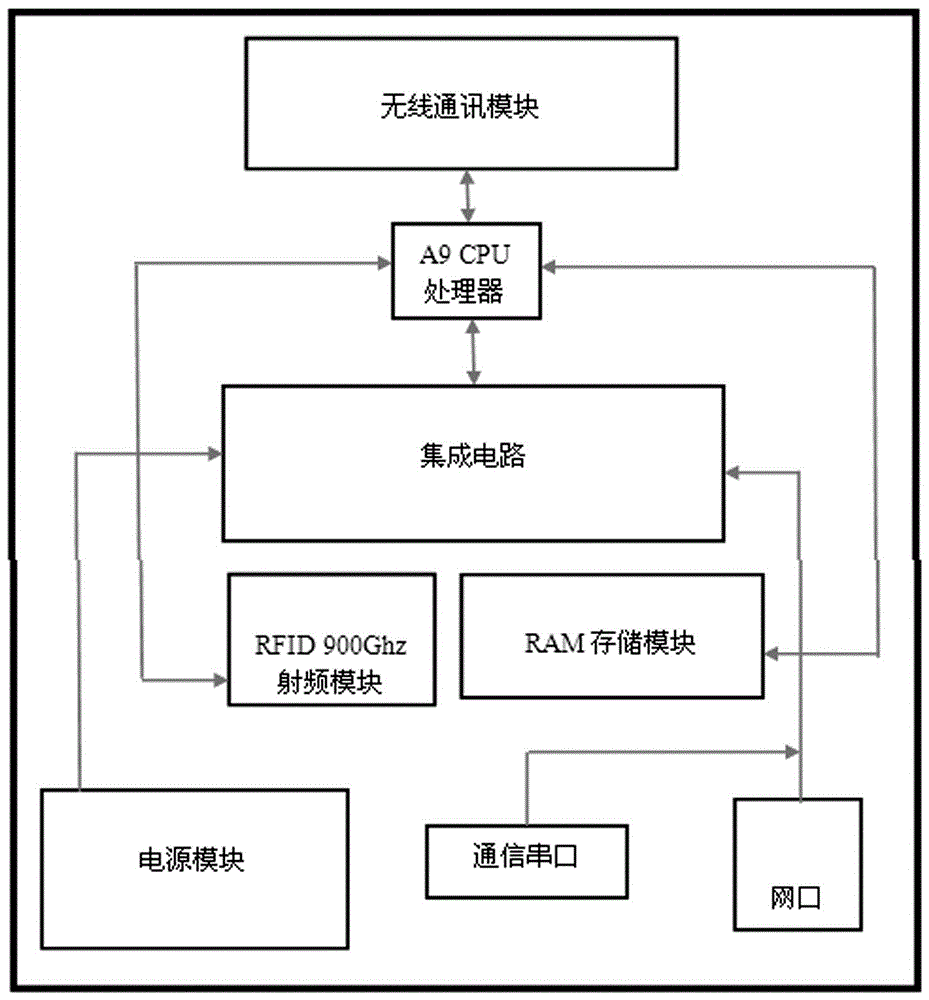

Operational energy consumption monitoring apparatus for transformer substation

InactiveCN105914895AAchieve energy consumptionRealize managementPower network operation systems integrationCircuit arrangementsElectricityTransformer

The invention relates to an operational energy consumption monitoring apparatus for a transformer substation. The monitoring apparatus adopts an embedded type circuit, wherein an A9 CPU processor, an RAM memory, an RFID 900Ghz radio frequency module, a power supply module and a communication module are integrated into one body; and an integrated circuit is connected with the A9 CPU processor, the RAM memory, the RFID 900Ghz radio frequency module, the power supply module and the communication module to finish transmission and communication of data and instructions between the corresponding modules. The operational conditions of the switch cabinet cooler of the transformer station, the air conditioner and electric heater equipment in the electric-heating and main-control chambers of the transformer mechanism can be accurately monitored; the collection of the power utilization data and the switch state of the energy consumption equipment can be finished; the power utilization energy consumption data of the energy consumption electric quantity in the transformer substation chamber can be processed; the operational states of the energy consumption equipment in the transformer substation can be monitored in real time; and therefore, the operation and maintenance staff can master the operational energy consumption condition of the transformer substation, the energy consumption monitoring and management of the transformer substation can be realized, and the operation and maintenance management level of the transformer substation can be improved.

Owner:FUSHUN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

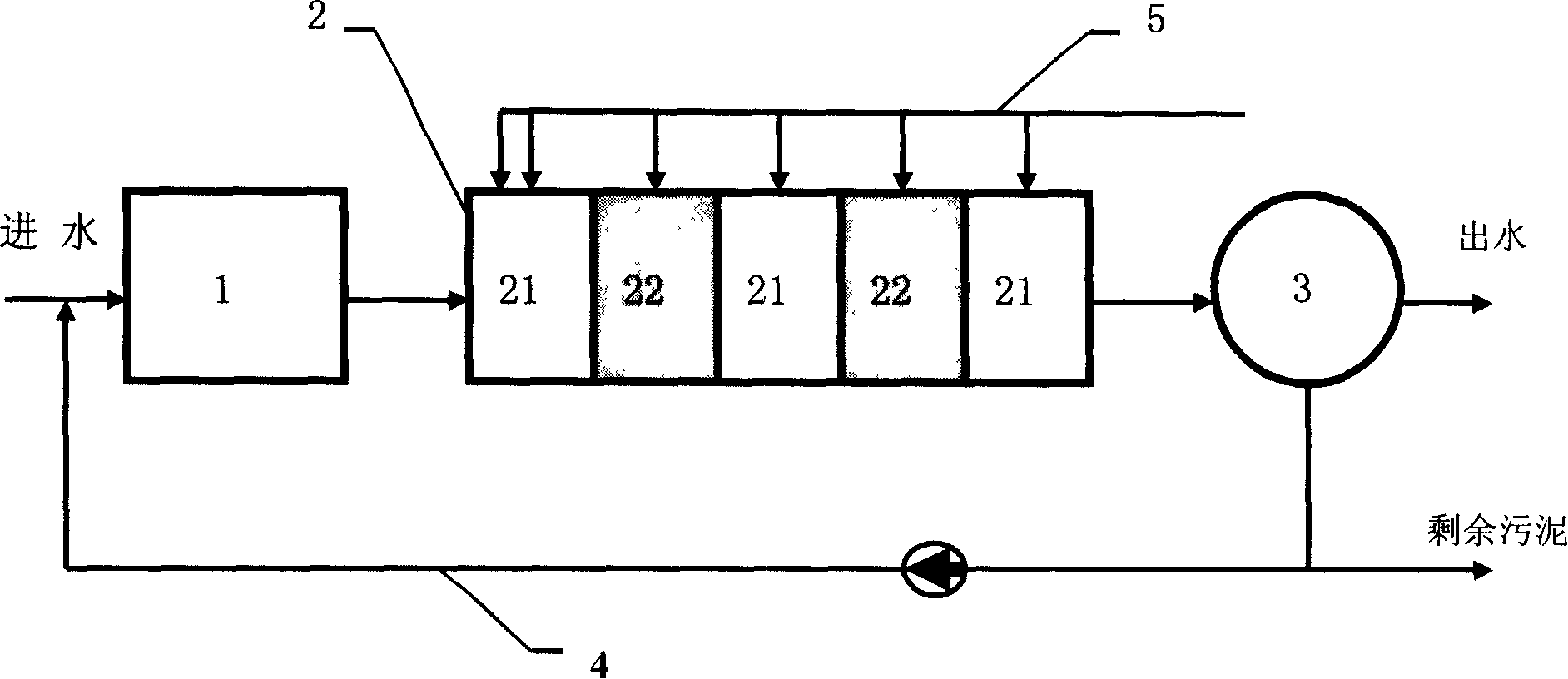

Filling material hypoxia removing nitric dephosphorization technique

InactiveCN101195505AGood denitrification and phosphorus removalReduce energy consumptionTreatment with aerobic and anaerobic processesRefluxNitrogen removal

Provided is a process of hypoxia phosphorus and nitrogen removal for stuffing, relating to a biological wastewater treatment process, which is used in the biological treatment process of urban and industrial wastewater for the treatment of phosphorus and nitrogen removal. The process of the invention is provided with a stuffing area (21) and a hypoxia area (22) which are in interval arrangement inside an aeration tank (2), the nitrification and denitrification procedures are simultaneously realized inside the aeration tank (2), thereby not only is a large amount of aeration saved, but also inner return-flow systems are reduced, and the process flow is simplified. Therefore, compared with the prior art of AAO series process either on operation effect or on operational energy consumption, the invention can save aeration amount by 20%-30%, the total quantity of reflux can be controlled within 100%, which is 300%-400% lower than the existing AAO series process, construction and operation costs of sewage treatment is effectively reduced, and the invention has the perfect environmental, social and economical benefits.

Owner:TONGJI UNIV

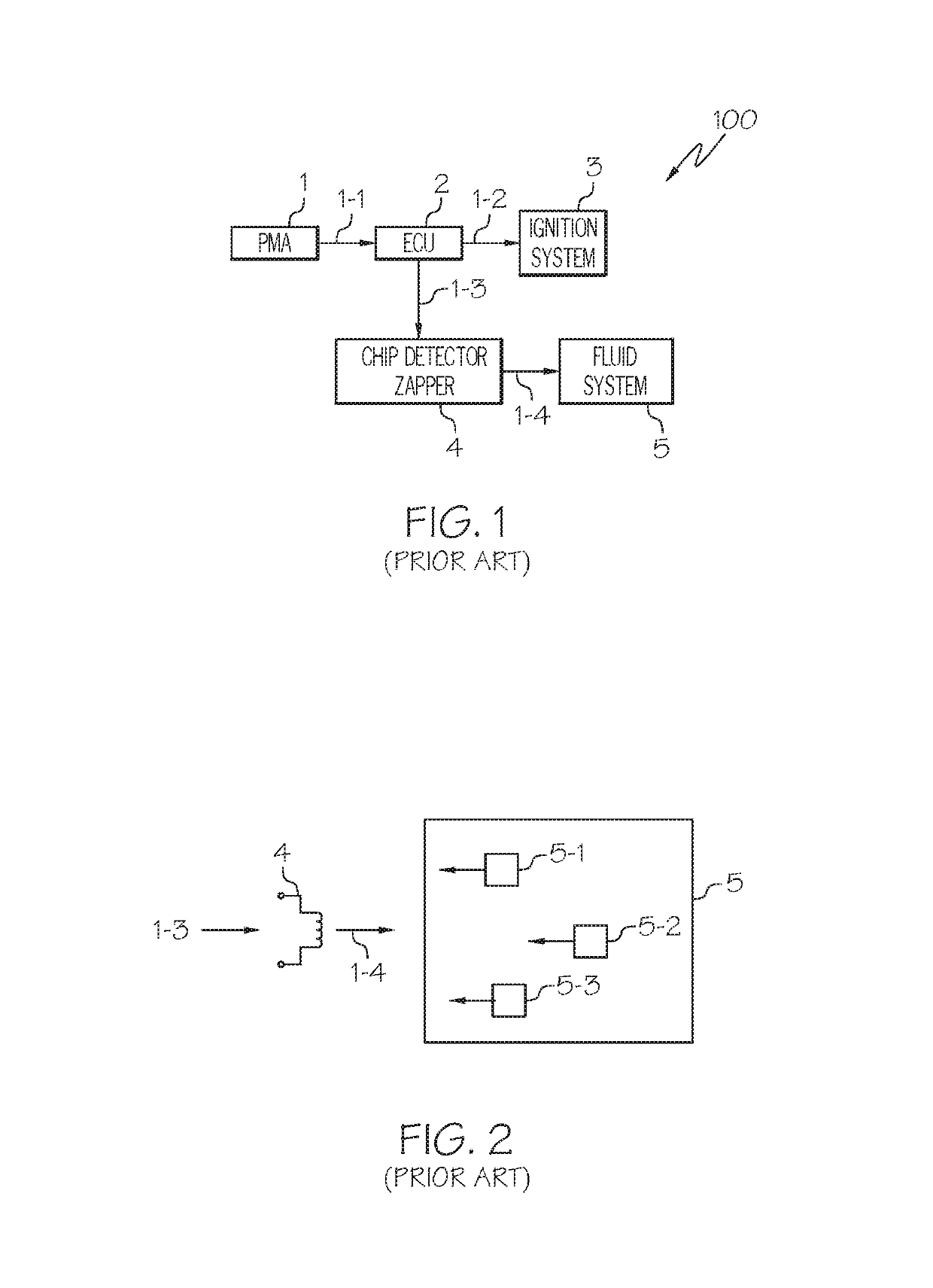

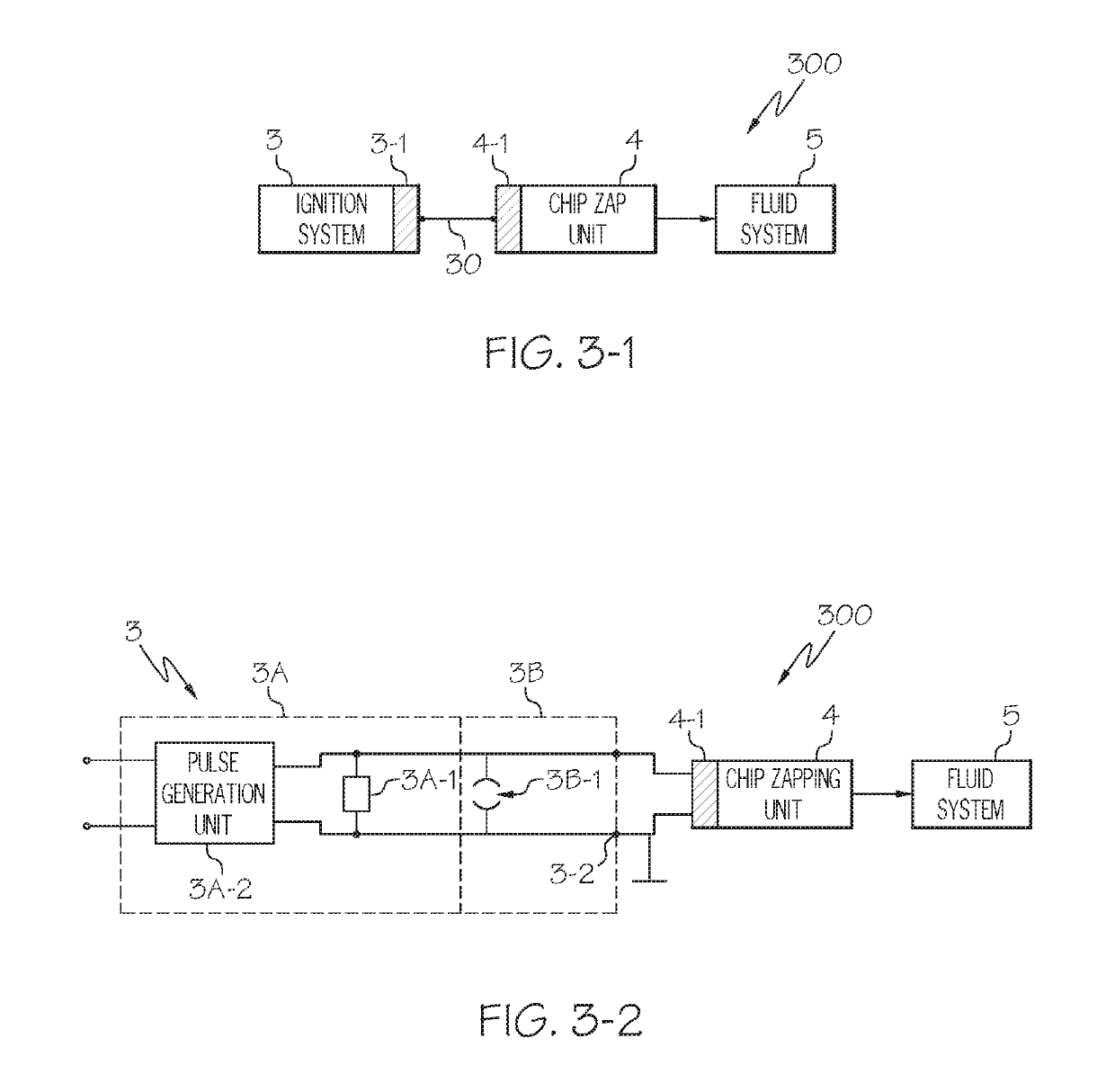

Method and system for supplying charge pulses to a chip zapper of a gas turbine engine

ActiveUS20180106196A1Small footprintReduce weightEngine fuctionsGas turbine plantsOperational energyTurbine

An energy generation system for generating energy to be supplied to a chip zapping unit of for example a gas turbine engine comprises an ignition system, e.g. that of the gas turbine engine, the ignition system having an energy output and configured to supply operational energy to the energy output, and the chip zapping unit having an energy input, the energy input coupled to the energy output of the ignition system to receive the operational energy therefrom. Such an energy generation system generates the operational energy needed for the chip zapping unit directly from the ignition system thus avoiding pulse generation circuitry inside an electronic control unit.

Owner:HONEYWELL LK GLOBAL PATENT SERVICES

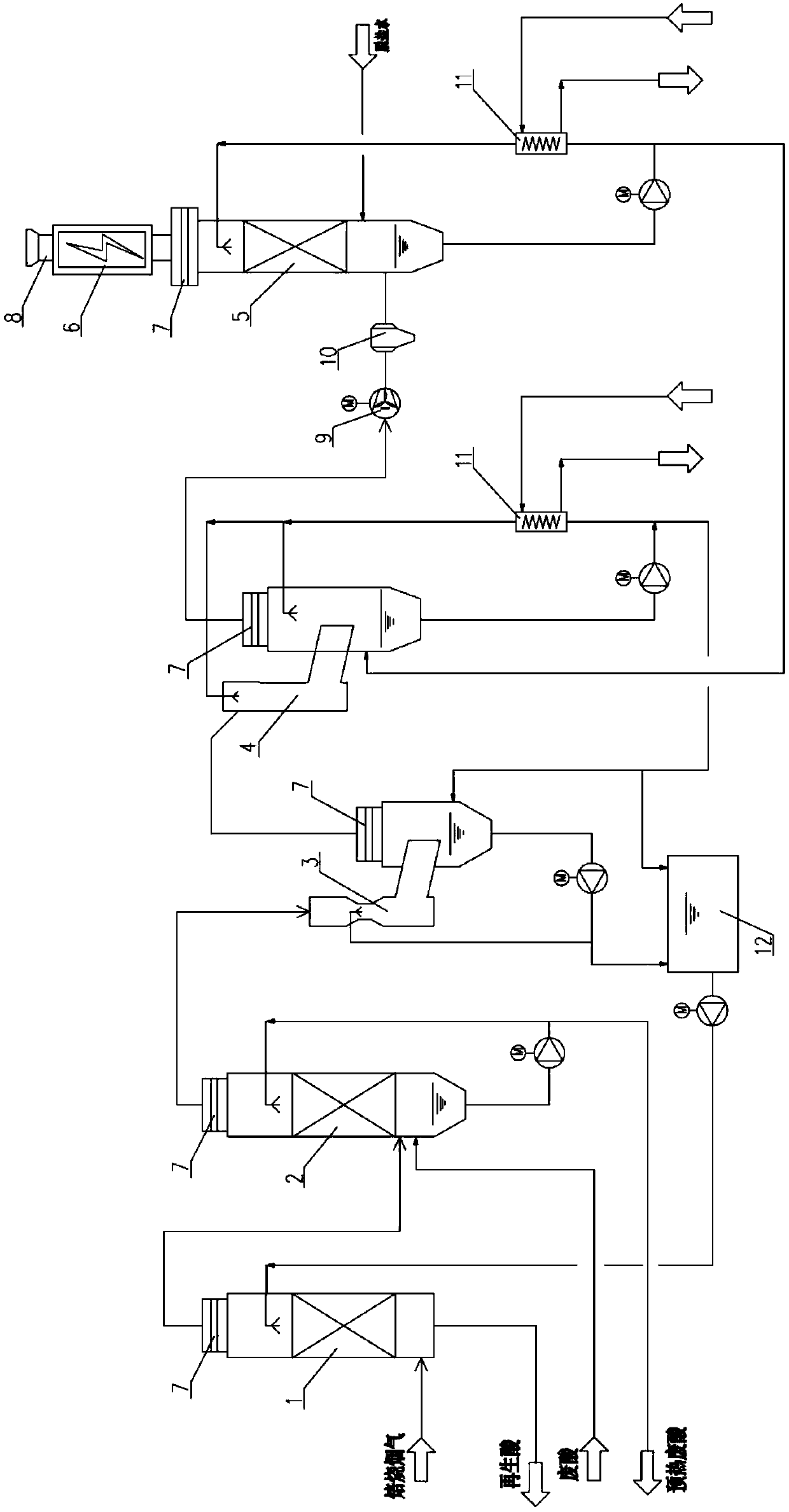

Acid regenerated flue gas treatment method and system

PendingCN109569205APlay a dust removal effectReduce operating energy consumptionGas treatmentUsing liquid separation agentCooling towerFlue gas

The invention relates to an acid regenerated flue gas treatment method and system. The system comprises an absorbing column, a waste acid washing column, a venturi washing column, a spraying cooling column, a secondary washing column, a dust collector and a discharge chimney which are connected in sequence through a flue gas pipeline. A waste acid spraying unit is arranged in the waste acid washing column; acid regenerated flue gas is cooled by a venturi preconcentrator; the cooled flue gas is subjected to acid absorption in the absorbing column; dust collection is performed via the waste acidwashing column; the flue gas with the dust removed is washed via the venturi washing column to remove part of dust and acid mist in the flue gas; secondary washing is performed via spraying cooling;discharging is carried out after dust collecting, especially treatment via a wet electric dust collector. The waste acid washing column preheats waste acid during flue gas dedusting, so that operational energy consumption of an acid regeneration system can be reduced; the process is reasonable, the treated flue gas may reach good discharge indexes, and the discharged flue gas can gain white mist removal.

Owner:WISDRI ENG & RES INC LTD

Series-connected wind power generation device based on moving vehicles

ActiveCN108953049AIncrease profitImprove battery lifeWind motor supports/mountsWind motor combinationsElectrical connectionOperational energy

The invention relates to a series-connected wind power generation device based on moving vehicles. The series-connected wind power generation device based on the moving vehicles comprises a bearing base, flow guide wind pipes, air amplifiers, impellers, electric generators and a control circuit. Both the flow guide wind pipes and the air amplifiers are mounted on the upper end face of the bearingbase through sliding grooves. The flow guide wind pipes and the air amplifiers jointly form one or more working sets, and each working set comprises two or more flow guide wind pipes and one or more air amplifiers. Both the impellers and the electric generators are embedded into corresponding flow guide wind pipes. The electric generators and the inner walls of the corresponding flow guide wind pipes are interconnected through locating frames. The control circuit is embedded into the lower end face of the bearing base and in electrical connection with the electric generators and a driving circuit of a vehicle correspondingly. On the one hand, the series-connected wind power generation device based on the moving vehicles can operate synchronously with various vehicles effectively, and universality and flexibility of the wind power generation device are improved greatly; and on the other hand, recycling can be conducted on high-speed airflow flowing through the surface of the vehicles inthe running process of the vehicles and effectively improved, operational energy consumption of the vehicles is lowered, and cruising ability of the vehicles is improved.

Owner:湖北省高路运维科技有限公司

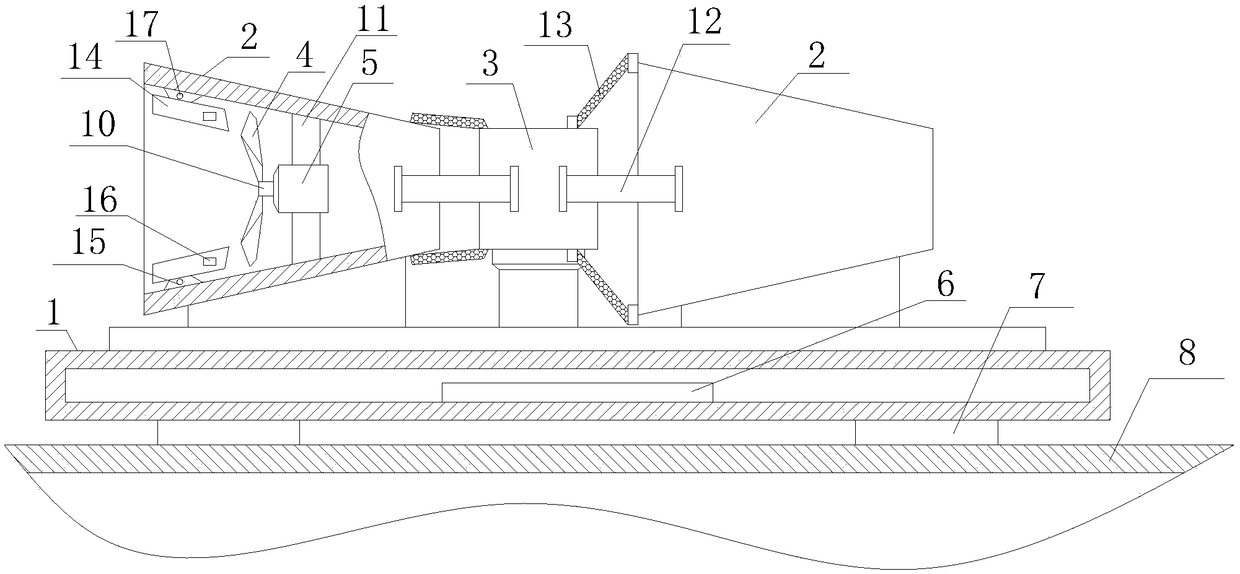

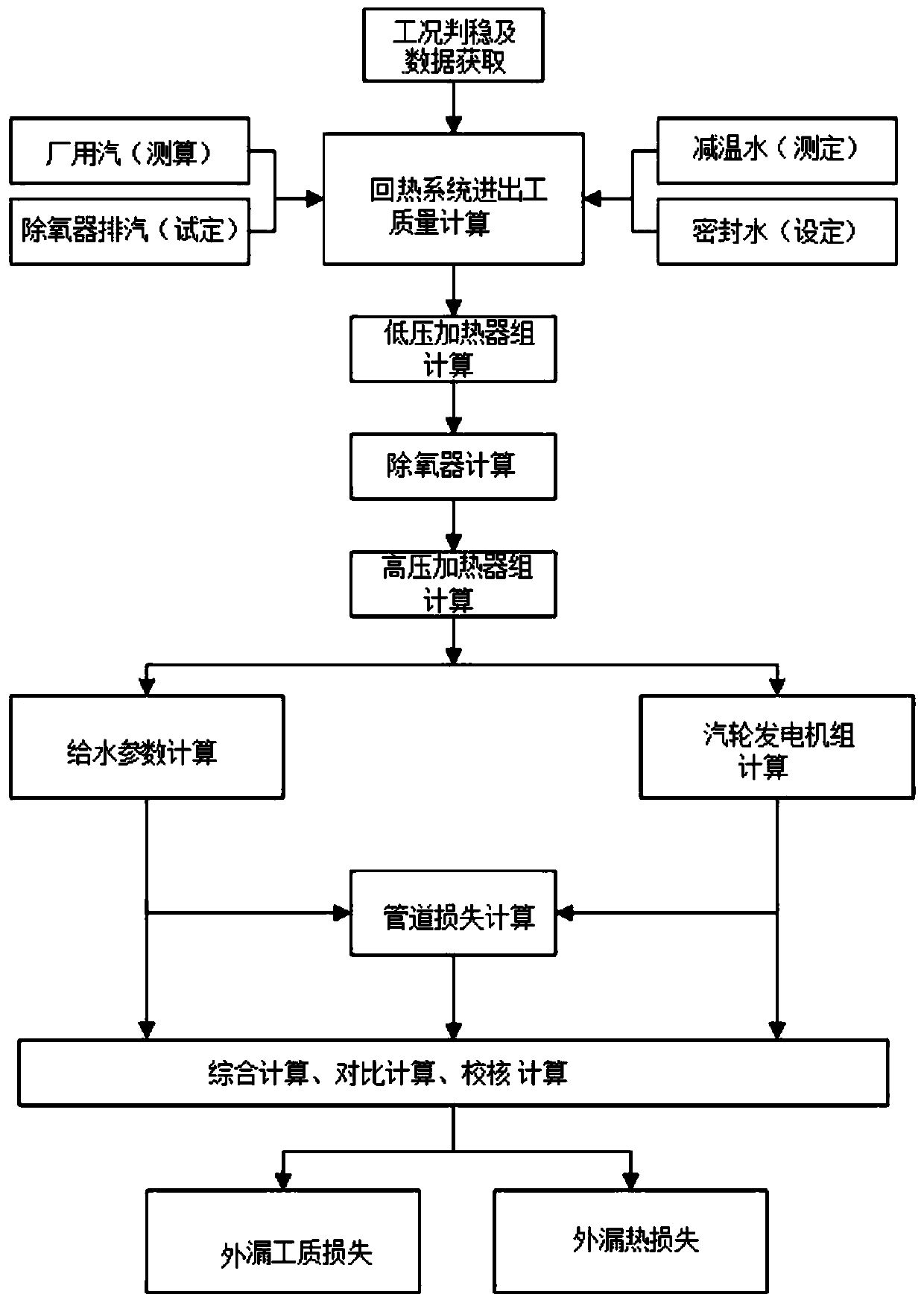

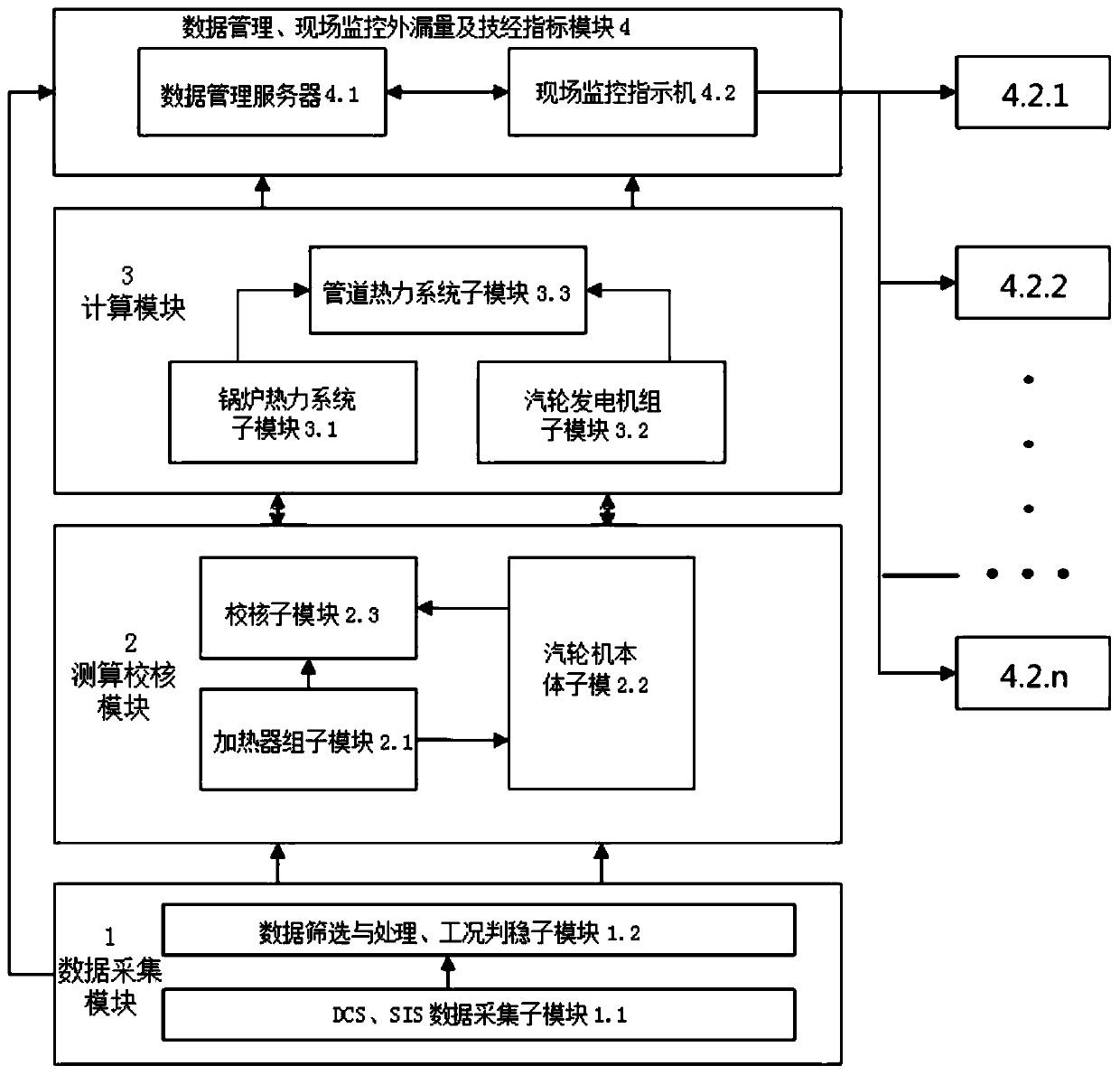

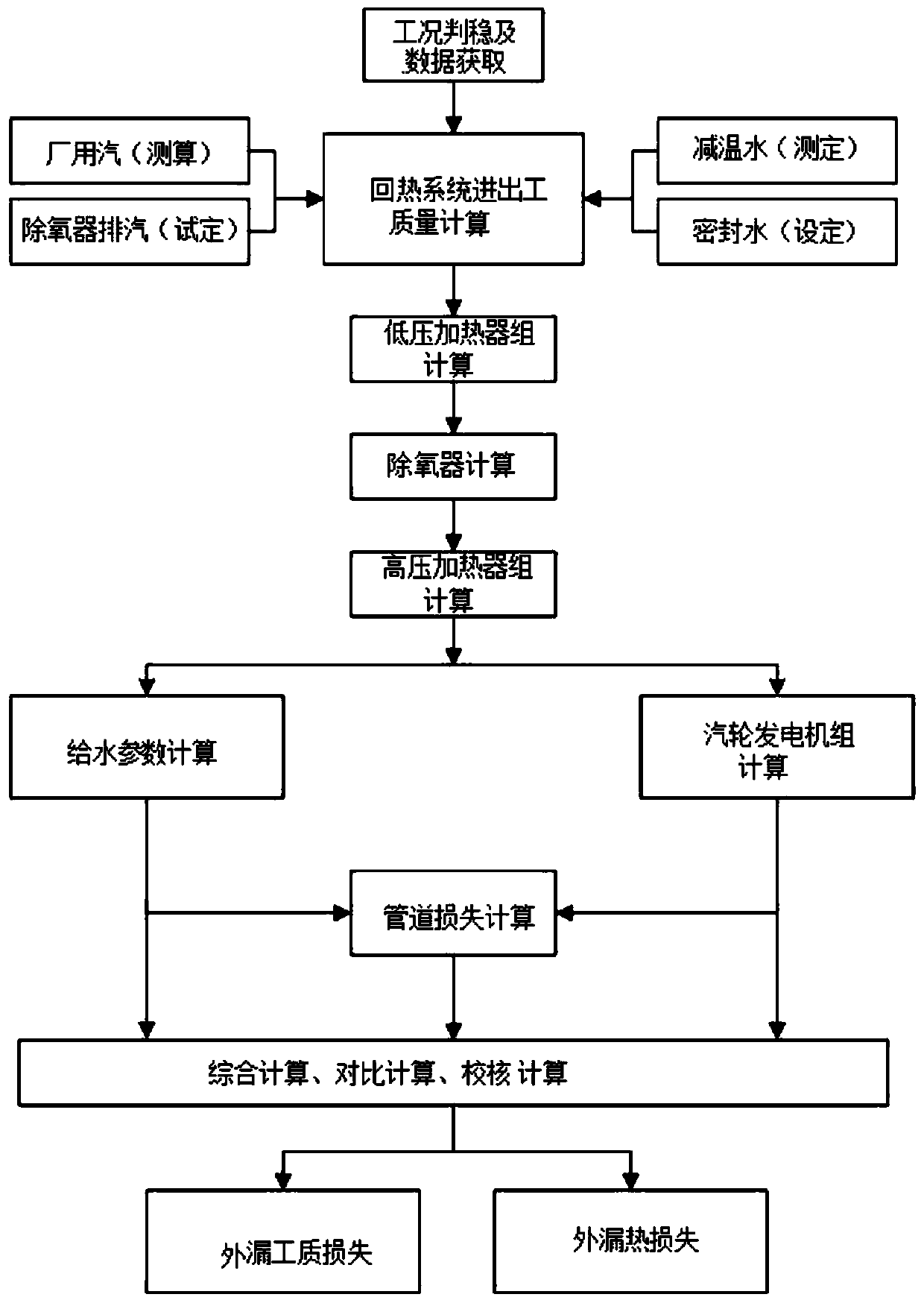

Online leakage measuring method and system for circulating work medium of thermal power set

ActiveCN109709911AAccurate calculation of counterbalance efficiencyTotal factory controlProgramme total factory controlPower stationDistributed control system

The invention relates to an online leakage measuring method and system for a circulating work medium of a thermal power set. Data is selected from a set DCS (Distributed Control System) and a thermalpower plant level SIS (Supervisory Information System), under the technical condition that a primary measuring point for an existing steam parameter of the set is not changed, necessary primary parameters are selected, data is processed and the condition stability is determined, characteristic data is stored in a database, a set working medium circulation theory is used to decompose the set circulating work medium into a heat absorption working medium and a do-work working medium, the leakage quantity of the circulating work flow of the set is calculated according to the characteristic data byusing a thermal power plant principle, and thus, the leakage quantity of the circulating work medium of the thermal power set and main heat economy indexes of the set are displayed online. The systemchecks positive and negative balance of the coal consumption rate of the set correspondingly, the digital level of online monitoring for the operational energy consumption of the power plant is improved, the energy saving and emission reduction state of the set is reflected comprehensively, and the method and system has significance in energy saving in a thermal power enterprise.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

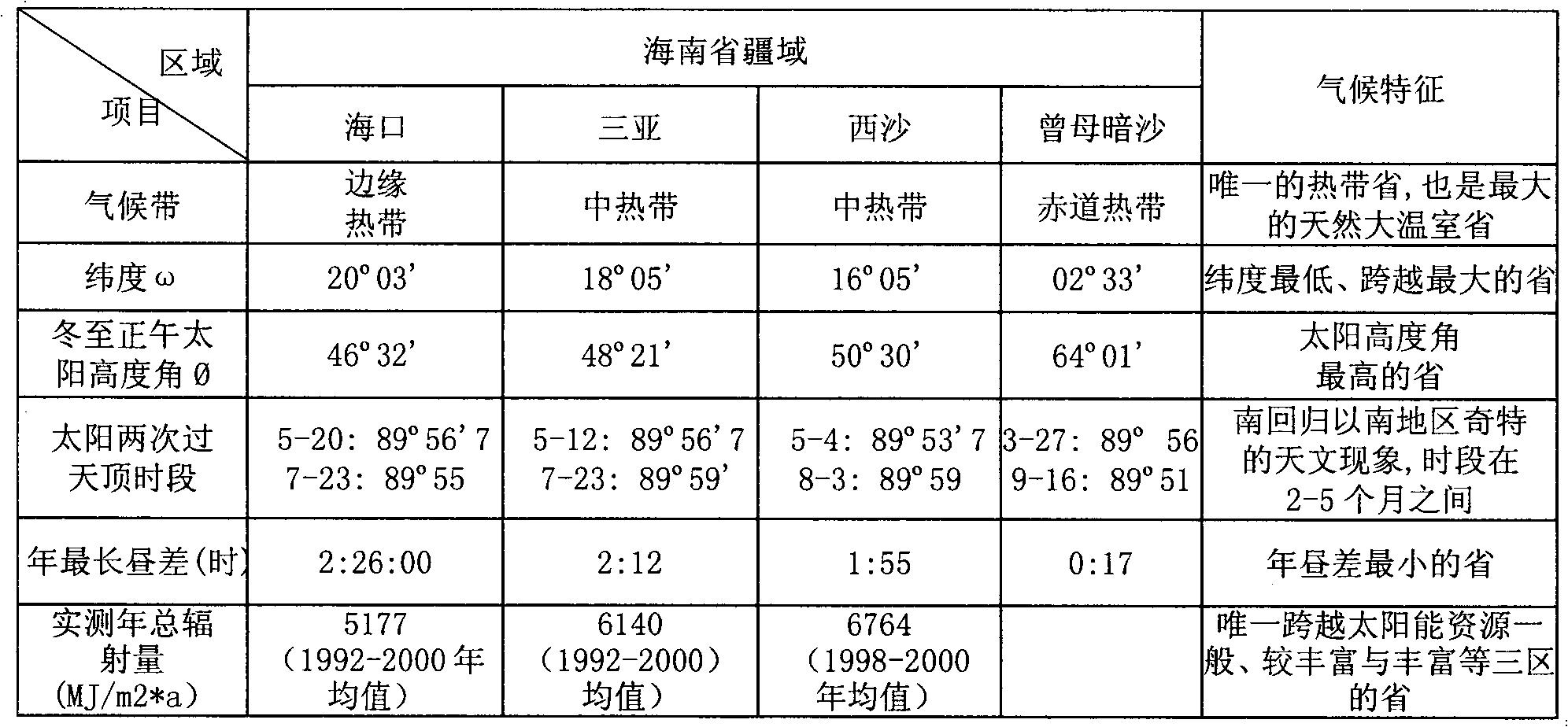

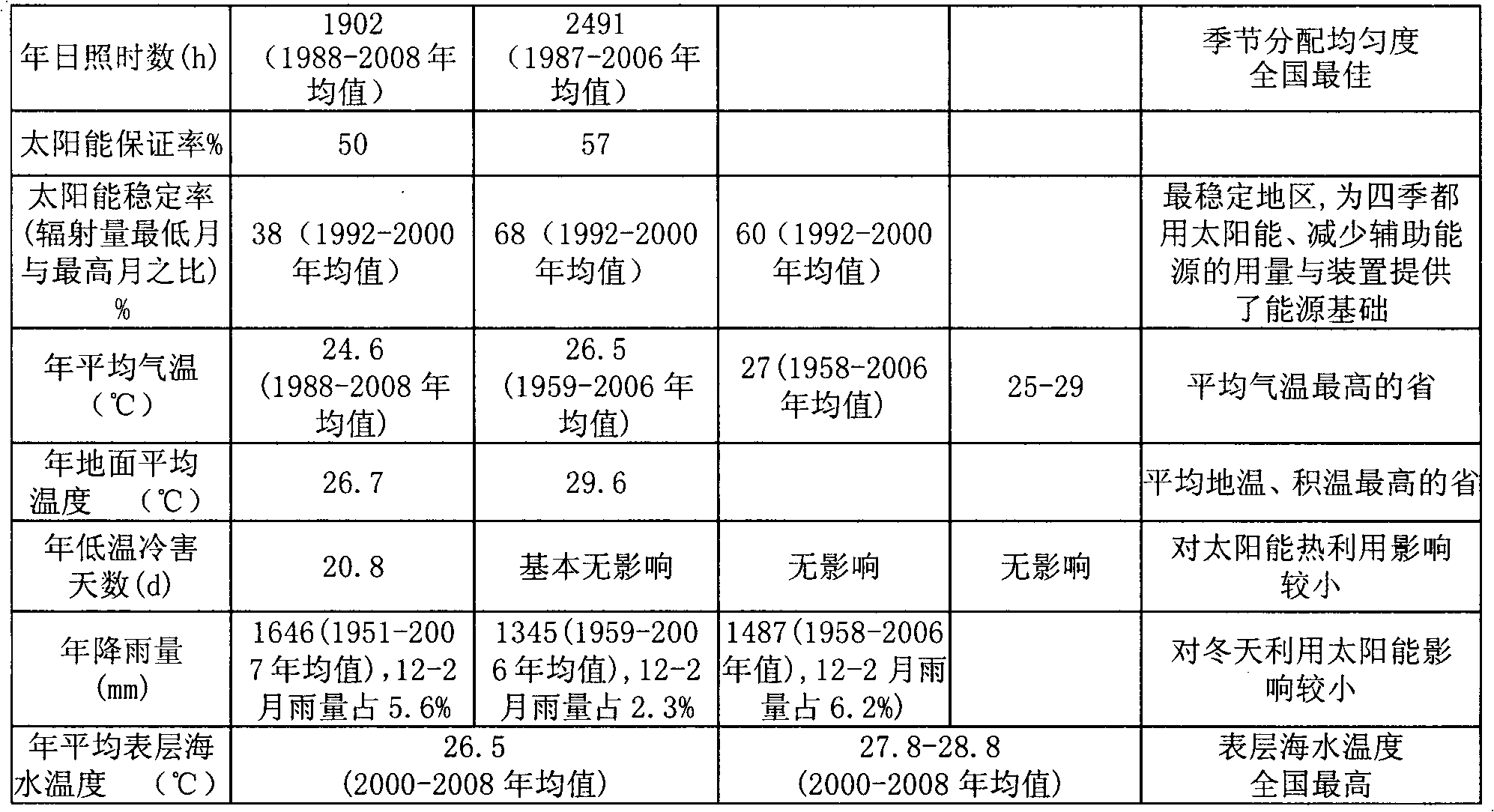

Method for designing main equipment configuration of solar water heating project suitable for tropical zone

InactiveCN101915467AReduce initial investmentReduce energy consumptionSolar heat devicesSolar thermal energy generationWater storage tankSolar water heating system

The invention discloses a method for designing the main equipment configuration of a solar water heating project suitable for a tropical zone. In the method, a formula for calculating a heating gross area provided by a technical code for the application of the conventional national construction solar heating system is regulated, improved and innovated; a definiteness calculating method is improved into a random variable calculating method; and new methods for calculating a heater area and the capacity and configuration proportion of a water storage tank and an auxiliary heating device are respectively provided to realize the optimal rational matching of three pieces of main equipment of the solar heating project and achieve the win-win effects of saving both initial investment and operational energy consumption. Verified by examples, and compared with a scheme provided by a developer, a scheme for the capacity and configuration proportion of the three pieces of main equipment designed by the method can save investment by 20 percent at seaport and over 40 percent at Sanya and Xisha, and has the operational energy consumption which is only 1 / 3 that of other design schemes as the capacity of energy-consuming auxiliary equipment is reduced and over-produced hot water is fully utilized by preliminary estimation.

Owner:HAINAN NORMAL UNIV

Waste motor vehicle tire breaking device

InactiveCN108453952AImprove crushing effectImprove efficiencyPlastic recyclingMechanical material recoveryEngineeringMechanical equipment

The invention belongs to the technical field of mechanical equipment and relates to a waste motor vehicle tire breaking device. A bent feeding channel is mounted above a breaking device; a feeding hole is formed above a transverse feeding channel; a push block is arranged in the transverse feeding channel; a reciprocating push device is mounted on the outer side of the push block; the breaking device comprises a first breaking chamber and a second breaking chamber; the second breaking chamber communicates with the first breaking chamber and positioned below the side of the first breaking chamber; a cylindrical first breaking cavity is formed in the first breaking chamber and communicates with the feeding channel; a first rotating disc which is rotationally connected in the first breaking chamber is arranged at a central position of the first breaking cavity; first breaking knives are uniformly distributed in a peripheral direction of the first rotating disc; two first discharging holesare formed in the lower part of the first breaking chamber; the structure of the second breaking chamber is similar to that of the first breaking chamber; a vibrating screen is arranged below the first breaking chamber. The problems that the conventional waste tire breaker is low in breaking efficiency and high in operational energy consumption are solved.

Owner:重庆澳净环保科技有限公司

Gas turbine engine

ActiveUS10473033B2Solve the real problemInterference problemEngine fuctionsGas turbine plantsEngineeringOperational energy

An energy generation system for generating energy to be supplied to a chip zapping unit of for example a gas turbine engine comprises an ignition system, e.g. that of the gas turbine engine, the ignition system having an energy output and configured to supply operational energy to the energy output, and the chip zapping unit having an energy input, the energy input coupled to the energy output of the ignition system to receive the operational energy therefrom. Such an energy generation system generates the operational energy needed for the chip zapping unit directly from the ignition system thus avoiding pulse generation circuitry inside an electronic control unit.

Owner:HONEYWELL LK GLOBAL PATENT SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com