Energy-saving rectifying technique and apparatus for producing premium edible alcohol

A technology of edible alcohol and process method, which is applied in the direction of chemical instruments and methods, chemical industry, sustainable manufacturing/processing, etc. It can solve the problems of limited application fields and high impurity content of alcohol products, and achieve the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

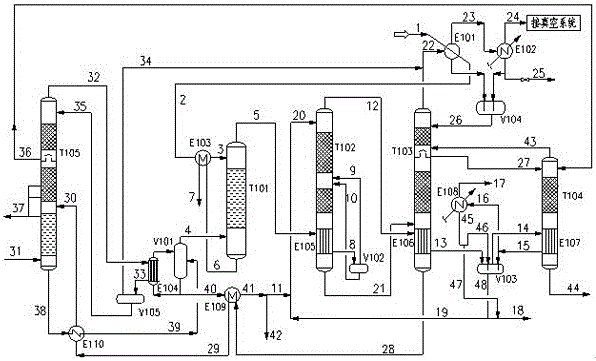

[0053] Such as figure 1 As shown, the mature fermented mash 1 from the fermentation process first passes through the first rectifying tower condenser E101 and is preheated with the alcohol gas 22 at the top of the first rectifying tower T103, and then passes through the mash preheater E103 and uses the mash tower T101 tower kettle The waste mash 6 is preheated, and then enters the top of T101.

[0054] Fermentation tower T101 and water washing tower T102 are heat-integrated operation, wine gas 5 at the top of T101 enters the water washing tower T102 tower kettle reboiler E105 shell side, and condensed wine gas 5 feeds 8 into light wine tank V102. After the gas-liquid separation is completed in V102, the gas phase 9 and the liquid phase 10 respectively enter the middle part of the T102 tower.

[0055] The water washing tower T102 is thermally integrated with the first cleaning tower T103 and the methanol removal tower T104. The wine gas 12 on the top of the T102 tower is adva...

Embodiment 2

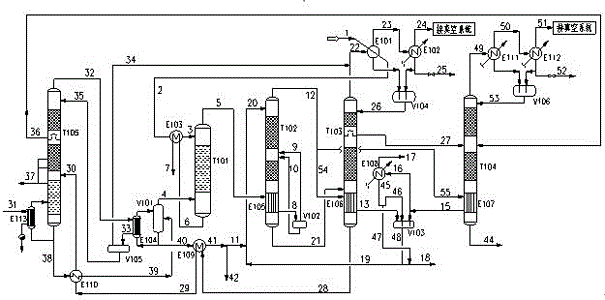

[0073] Such as figure 2 shown, it is figure 1 An evolutionary process method, relatively figure 1 The process methods shown differ as follows:

[0074] The gas phase 12 at the top of the washing tower is divided into two streams, one gas phase 54 is heated to the reboiler E106 of the T103 tower kettle, and the other gas phase 55 is heated to the reboiler E107 of the T104 tower kettle.

[0075] figure 1 The gas phase at the top of the demethanolization tower is not returned to the first refining tower, and the top of the demethanolization tower is equipped with auxiliary equipment such as a rectification section and a condenser. The top gas phase 49 of T104 is first condensed by the demethanol tower condenser E111, the non-condensed gas phase 50 is then condensed by the demethanol tower tail cooler E112, the non-condensable gas 51 goes to the vacuum system, and the E111 and E112 condensates enter the demethanol tower reflux tank V106. Part of the condensate of E112 is u...

Embodiment 3

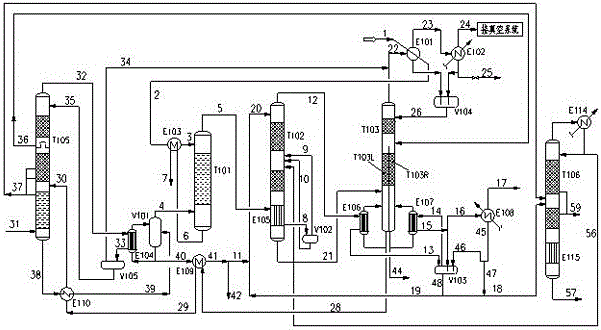

[0077] Such as image 3 shown, it is figure 1 Another evolution of figure 1 The process methods shown differ as follows:

[0078] The first fine column and the methanol removal column are combined into one, adopting a partition column structure. image 3 The combination of the part above the middle T103 partition and the T103L on the left side of the lower partition is equivalent to figure 1 The first refined tower in image 3 The T103R part on the right side of the lower partition of the middle T103 is equivalent to figure 1 The demethanolization tower in. image 3 The evolution process method shown has less equipment, less floor space, and more simplified process flow.

[0079] The present invention can choose to add a recovery tower T106 on the basis of the five towers of the beer tower T101, the water washing tower T102, the first finishing tower T103, the methanol removing tower T104 and the second finishing tower T105. Aldehyde wine 18 from the top of the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com