Integrative rotary type adsorber

An adsorber and rotary technology, which is applied in the field of rotary adsorber and oil and gas adsorption and recovery, can solve the problems that have not been reported yet, and achieve the effect of achieving continuity, reducing operating energy consumption and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

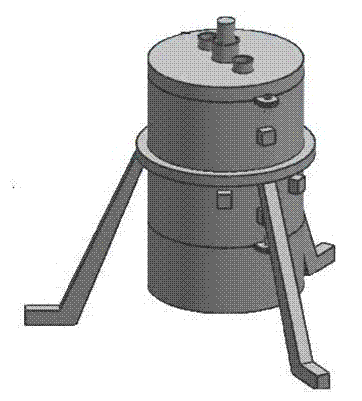

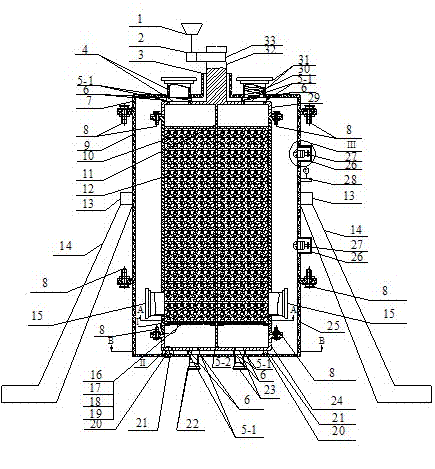

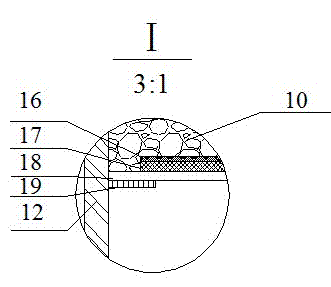

[0030] Such as figure 1 with figure 2 As shown, the integrated rotary adsorber consists of an outer cylinder and an inner cylinder. The urceolus comprises a metal urceolus top cover 7, a urceolus cylinder body 9 and an urceolus bottom cover 25, and the three are connected with bolts 8. The outer cylinder top cover 7 is provided with an exhaust gas discharge port 4 , a rotating shaft outlet 3 and an outlet 31 for desorbing oil and gas. A demister packing 30 is arranged in the outlet 31 for desorbing oil and gas. The tail gas discharge port 4 can also be used as a feed port for fresh adsorbent. The outer cylinder body 9 is provided with a reinforcing ring 13 , a bracket 14 , a magnetron 27 and an infrared thermometer 28 . Wherein, a bracket 14 is distributed on the reinforcing ring 13 every 120°. On the right half of the outer cylinder body 9, four magnetrons 27 are symmetrically arranged up, down, left, and right. Wherein the magnetron 27 includes a filament 27-1 and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com