Heat exchanger with convertible flow path and application method thereof

A heat exchanger and process technology, which is applied to the heat exchanger shell, heat exchange equipment, evaporator/condenser, etc. Insufficient, low condensation pressure and other problems, to achieve the effect of improving reliability and safety, reducing energy consumption, and reducing evaporation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

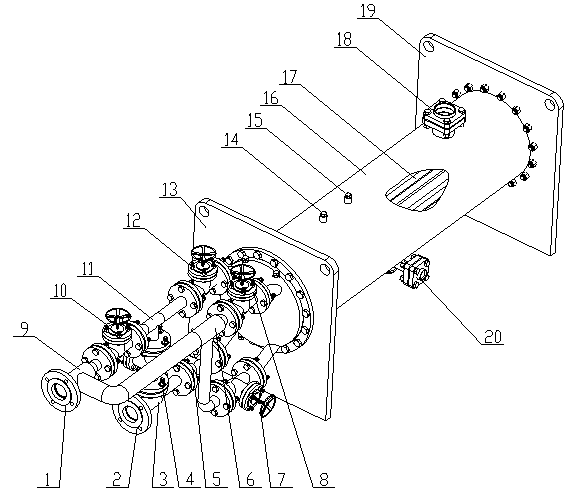

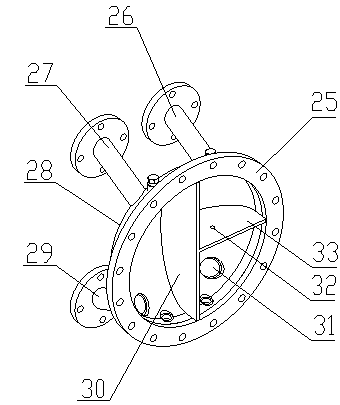

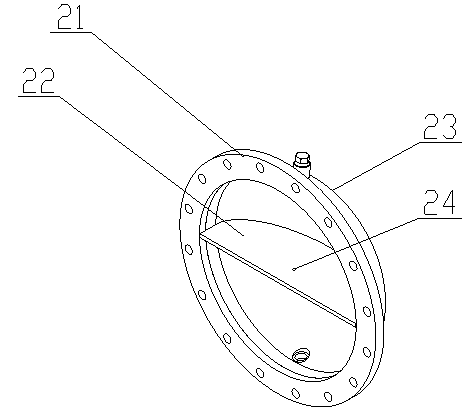

[0026] Example: A kind of heat exchanger of the present invention can convert process, as figure 1 As shown, it includes housing 16, heat exchange tube 17, front tube plate 13, rear tube plate 19, front water chamber assembly 25, rear water chamber assembly 21, water inlet 2, water outlet 1, refrigerant gas interface 18, refrigeration Liquid interface 20, safety valve seat 14, inspection valve seat 15, A valve 12, B valve 8, C valve 7, D valve 5, E valve 4, F valve 10, three-way deh3, three-way bcg6, three-way fgj9 and Tee aef11, the planes of the front tube plate 13 and the rear tube plate 19 are respectively abutted against the two ports of the housing 16, as Figure 4 , 5 As shown, the front tube sheet 13 and the rear tube sheet 19 respectively have four groups of tube holes 37: Group A, Group B, Group C and Group D, and the heat exchange tubes 17 pass through the corresponding tube holes 37 and the front tube sheet 13. It is expanded and fixed with the rear tube plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com