Energy-saving and emission-reducing petroleum well servicing rig

A technology for energy saving, emission reduction, and workover rigs, which is applied to drilling equipment, earthwork drilling, drilling pipes, etc. It can solve problems such as the inability to pull guy ropes on the side of the road and affect the health of residents, so as to avoid poor airtightness and low noise , clear effect of liquid level indication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

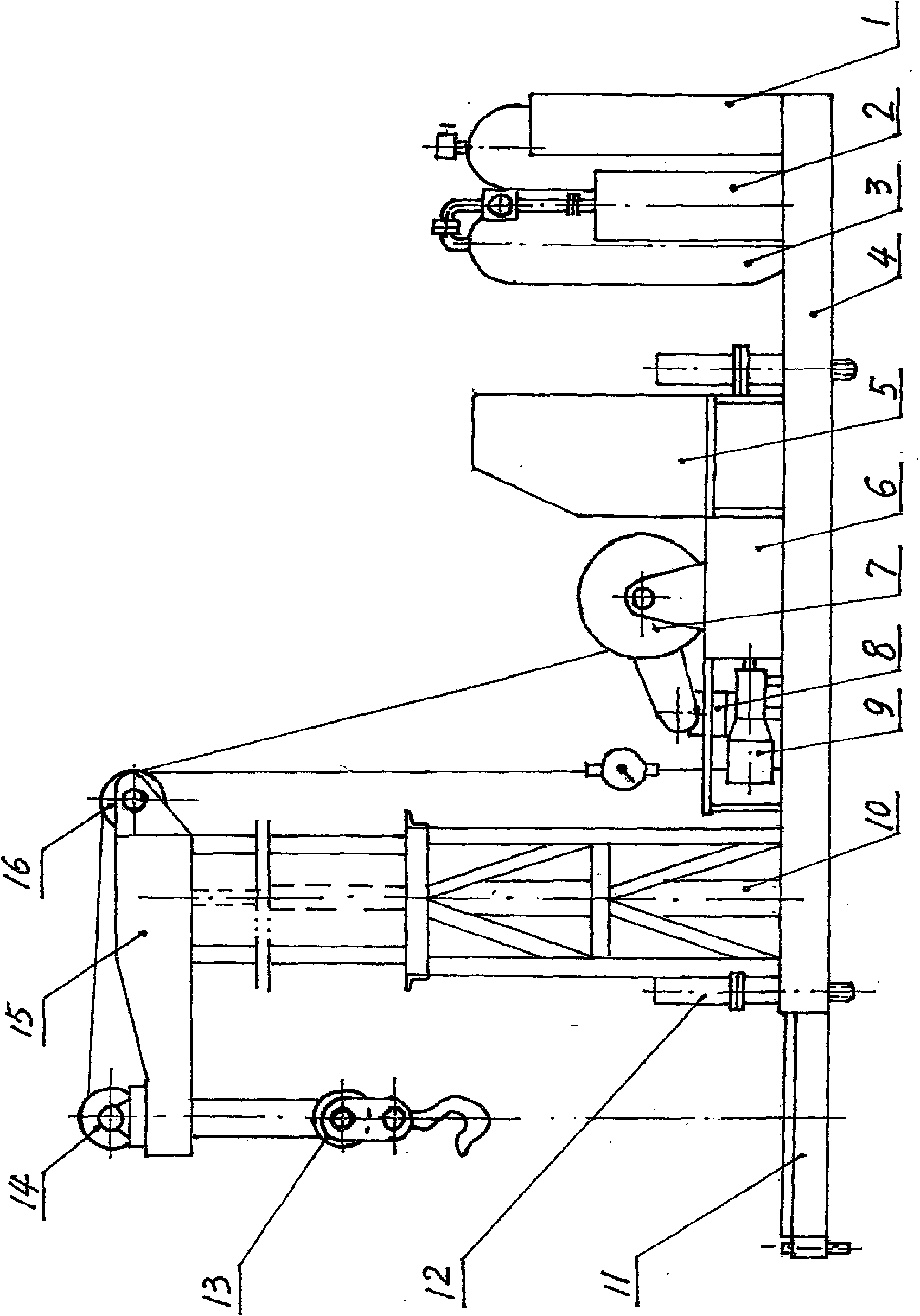

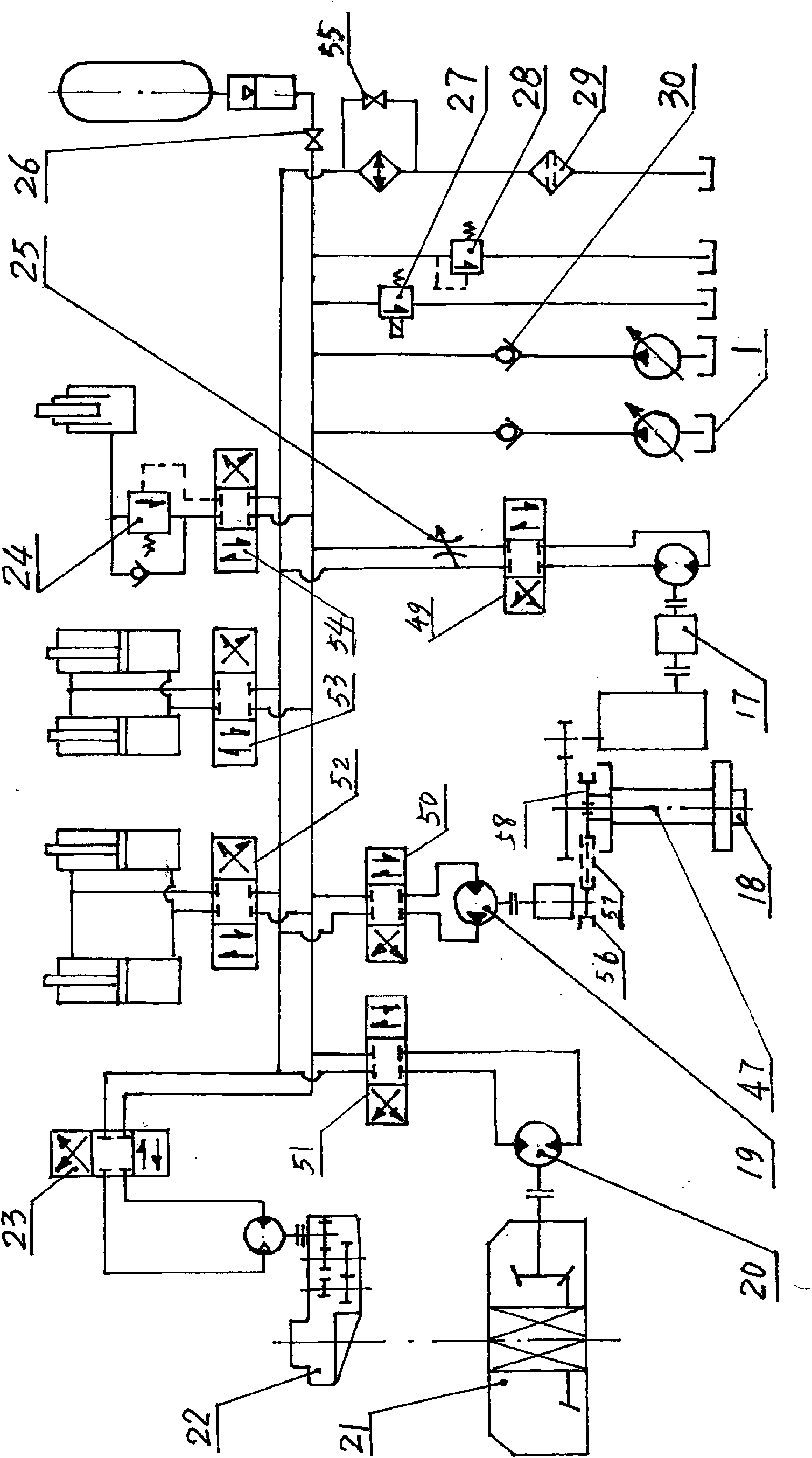

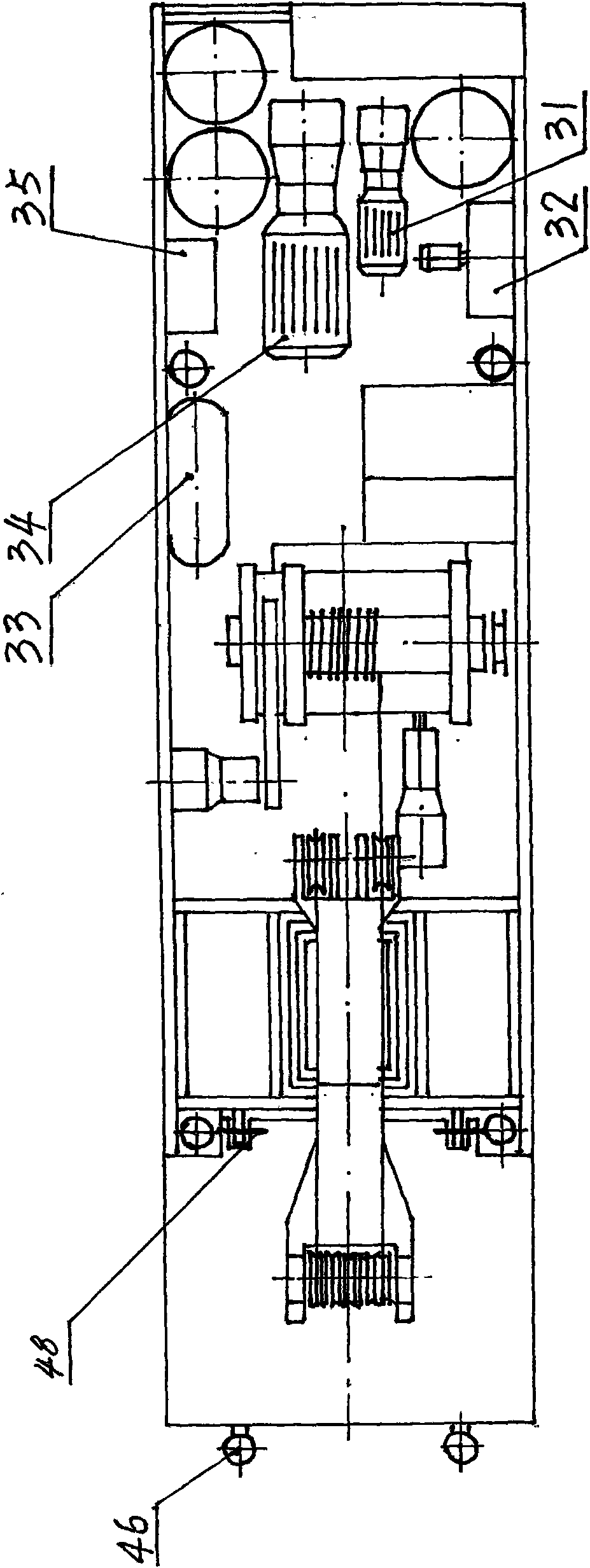

[0019] All equipment is installed on the base 4 of the energy-saving and emission-reducing petroleum workover rig. The rear portion is arranged with a folding retractable drill floor 11, a cantilever vertical telescopic derrick 15, and a large hydraulic motor 9. The drum 7 is arranged in the middle, the pump-oil motor 19, the gearbox 6, the control room 5, and the electric air compressor 33. Power distribution cabinet 35 is arranged at the front, large motor-oil pump group 34, small motor-oil pump group 31, cooler 32, fuel tank 1, energy storage cylinder 2, and gas tank 3. There is a hydraulic jack 12 on both sides of the rear part of the base 4, and a hydraulic jack 12 is respectively arranged on both sides of the middle front part. Cantilever vertically telescopic derrick 15 is raised and connected with bolts one by one by derrick telescopic lifting oil cylinder 10, and is put down one by one after the operation is completed. Folding and retractable drilling platform 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com