Waste motor vehicle tire breaking device

A crushing device, waste tire technology, applied in the direction of mechanical material recovery, recycling technology, plastic recycling, etc., can solve the problems of high operating energy consumption, low crushing efficiency, etc., achieve good crushing effect, high efficiency, and solve the problem of low crushing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

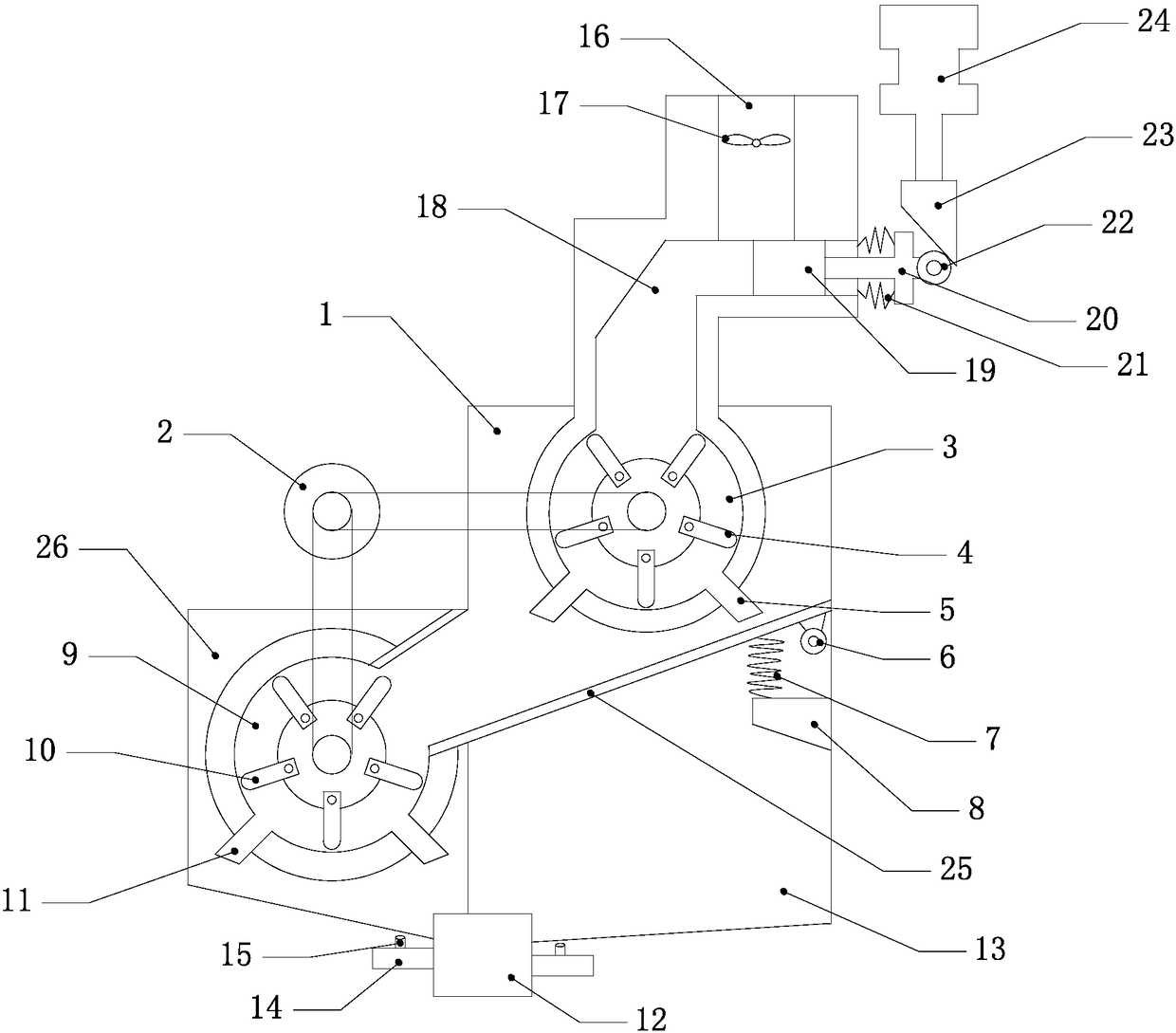

[0019] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0020] The reference signs in the accompanying drawings of the specification include:

[0021] First crushing chamber 1, motor 2, first crushing chamber 3, first crushing knife 4, first discharge port 5, vibration motor 6, first spring 7, boss 8, second crushing chamber 9, second crushing Knife 10, second discharge port 11, receiving bin 12, storage chamber 13, discharge pipe 14, regulating valve 15, feed port 16, hollow knife 17, feed passage 18, push block 19, push rod 20, Second spring 21, roller 22, wedge 23, cylinder 24, vibrating screen 25, second crushing chamber 26.

[0022] Such as figure 1 The new motor vehicle waste tire crushing device shown includes a reciprocating push device and a crushing device. A bent feeding channel 18 is installed above the crushing device, and a feeding port 16 is provided above the horizontal feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com