Heat pump system having waste heat recovery structure with 2nd evaporation

A heat pump system and technology for recovering waste heat, applied to compressors with multiple evaporators, heat pumps, superheaters, etc., can solve the problems of lower efficiency, increased cost structure, compressor stop working, etc., to reduce production costs, Save operating energy and prevent overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

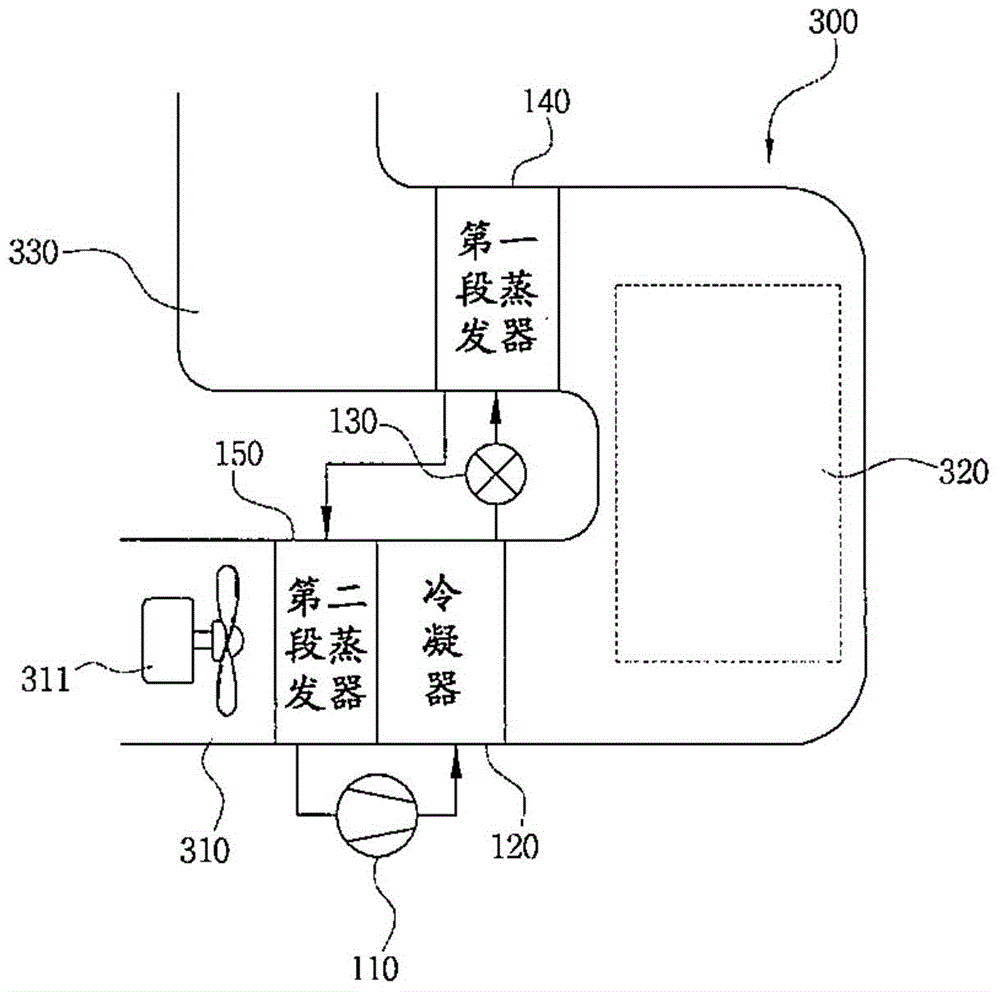

[0016] The features of the present invention can be more clearly understood by referring to the accompanying drawings for the following detailed description of a heat pump system having a structure for recovering waste heat through a two-stage evaporator according to the present invention.

[0017] On the other hand, in the description of the embodiments, detailed descriptions of constituent elements that are widely known and used in the field or those that do not belong to the field are omitted here. The purpose of omitting unnecessary descriptions is for clarity. convey the gist of the invention.

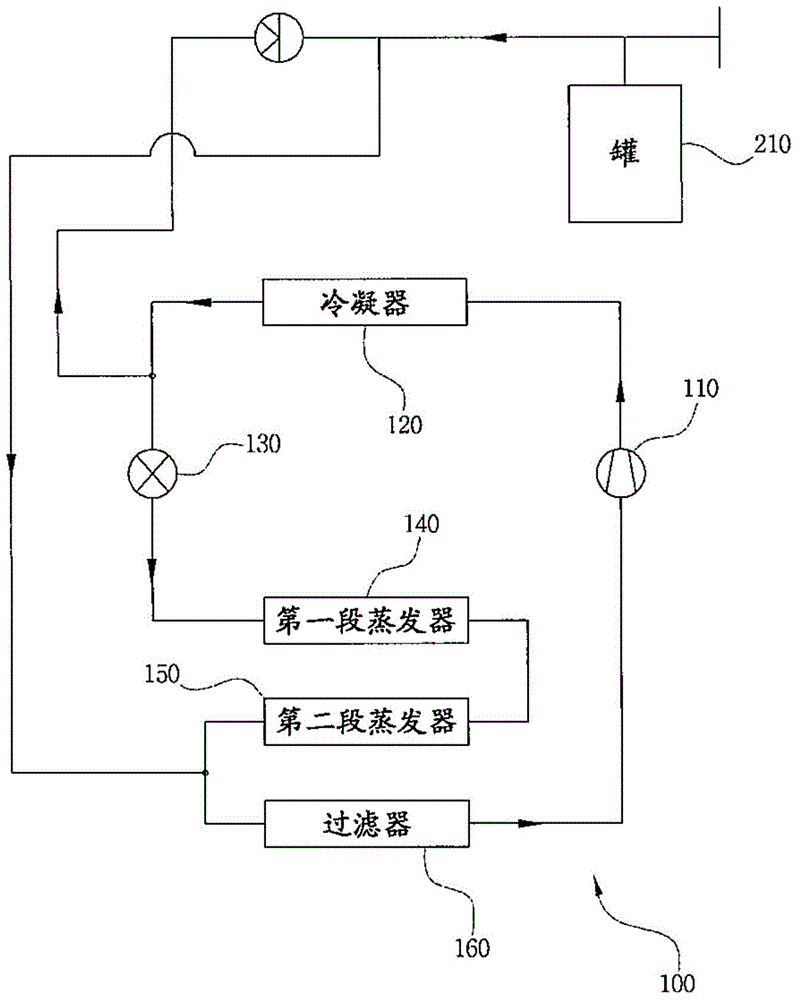

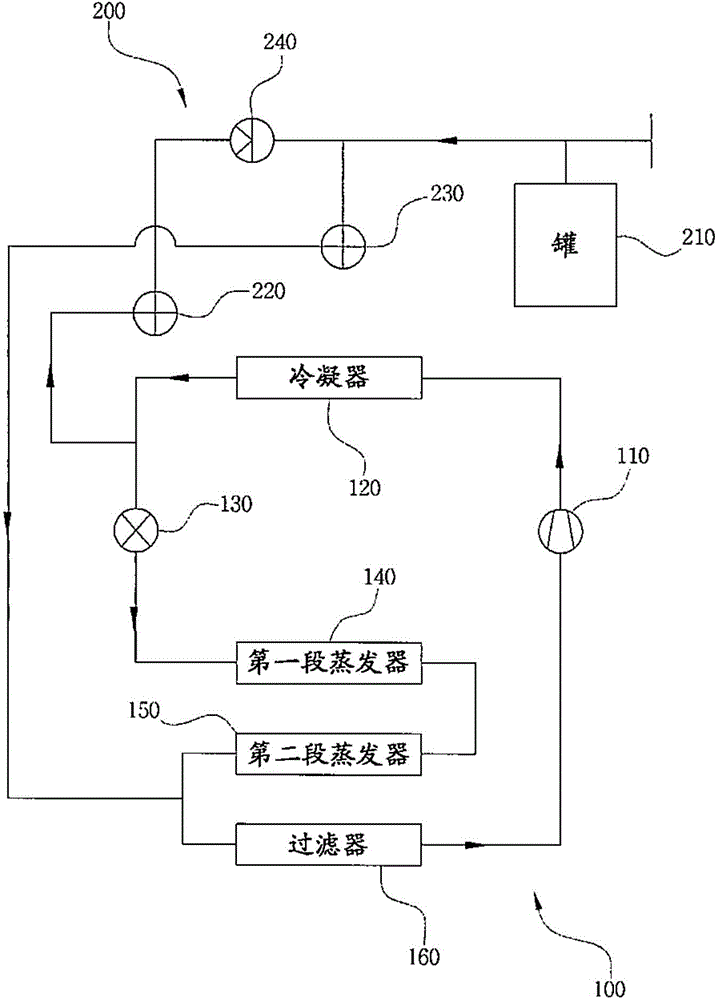

[0018] figure 1 It is a schematic diagram illustrating a heat pump system with a structure for recovering waste heat through two-stage evaporators according to an embodiment of the present invention.

[0019] Thus, the heat pump system with the structure of recovering waste heat through two-stage evaporators is briefly described, and the heat pump (100) includes a compressor (110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com