Patents

Literature

683results about "Superheaters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

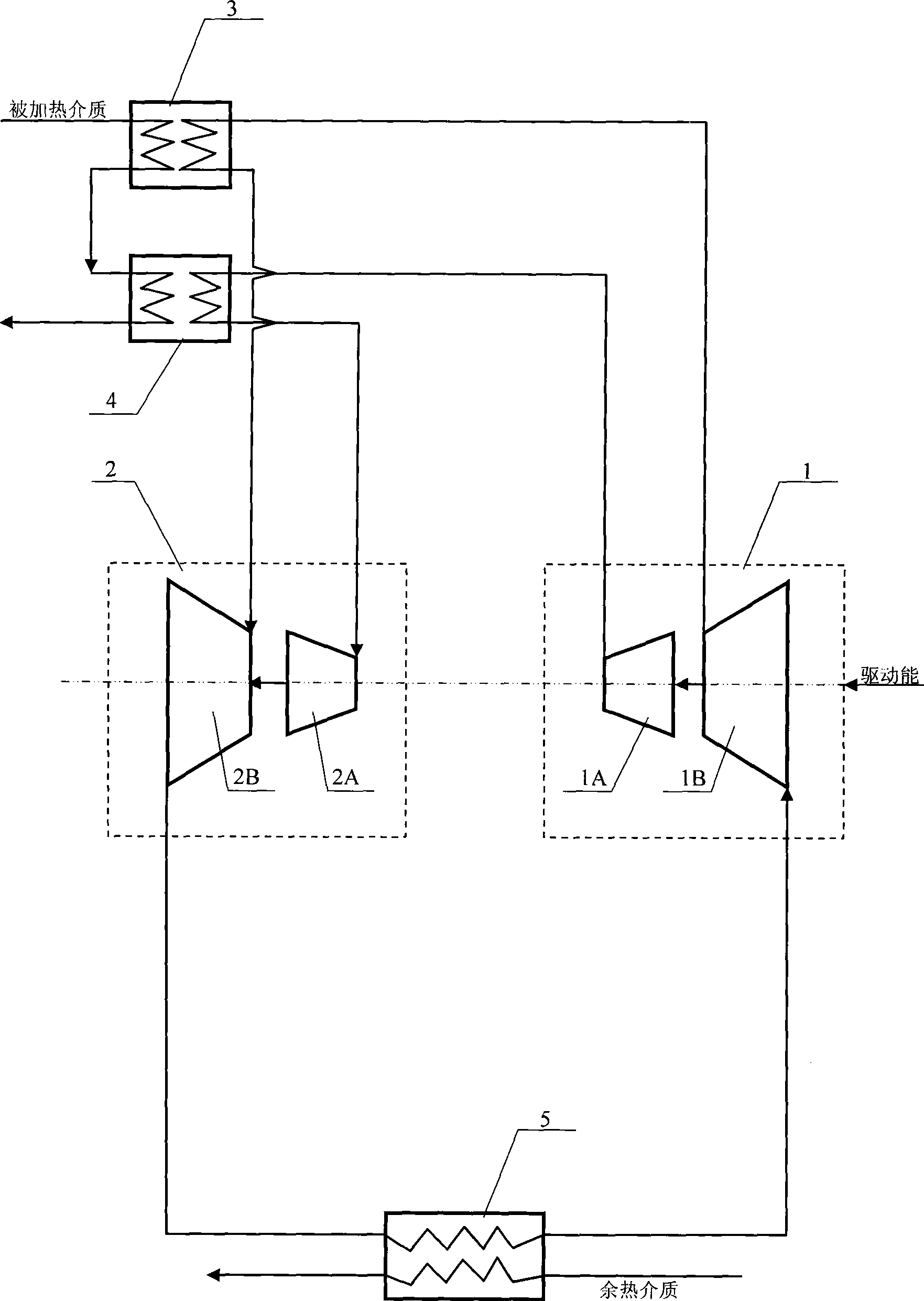

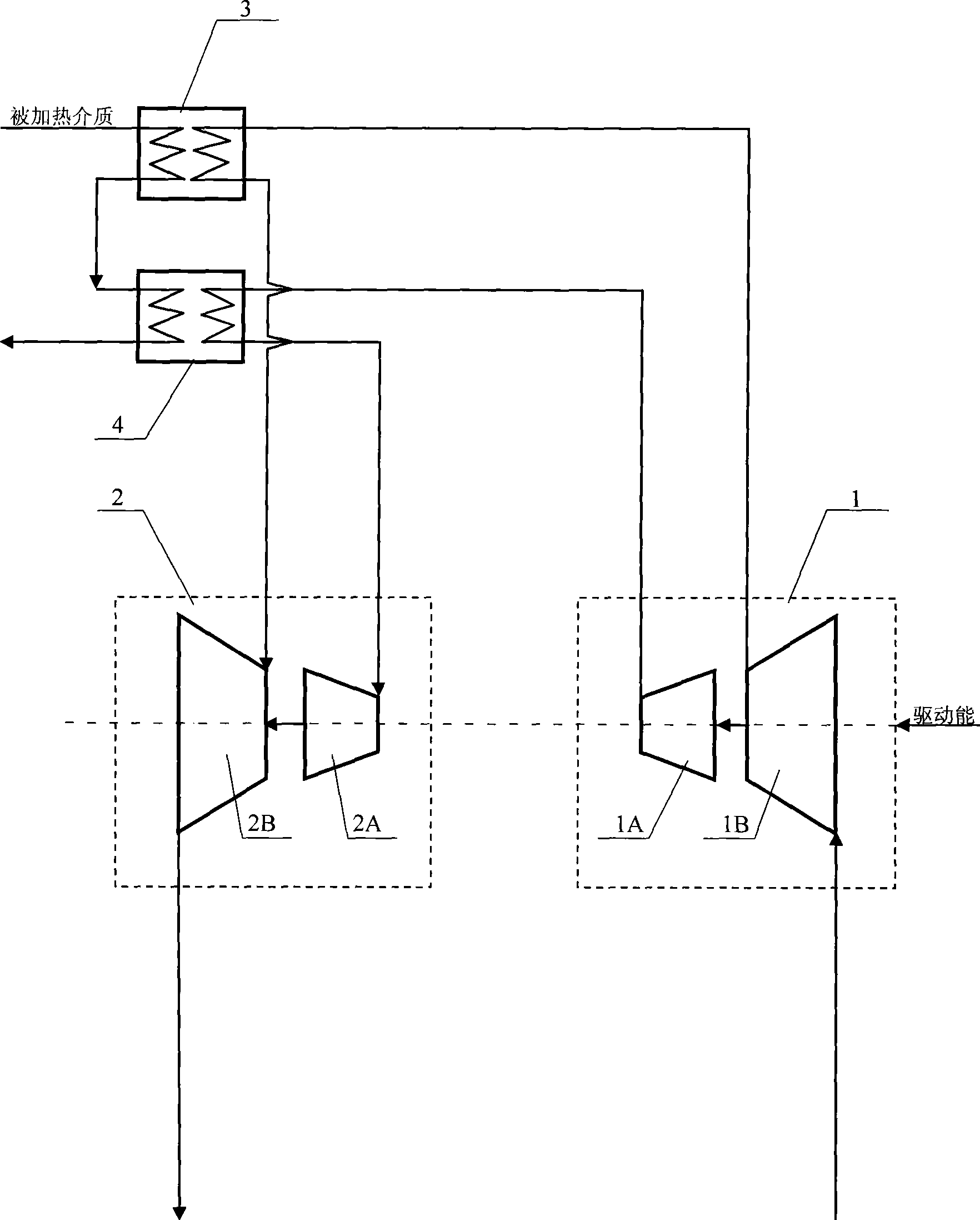

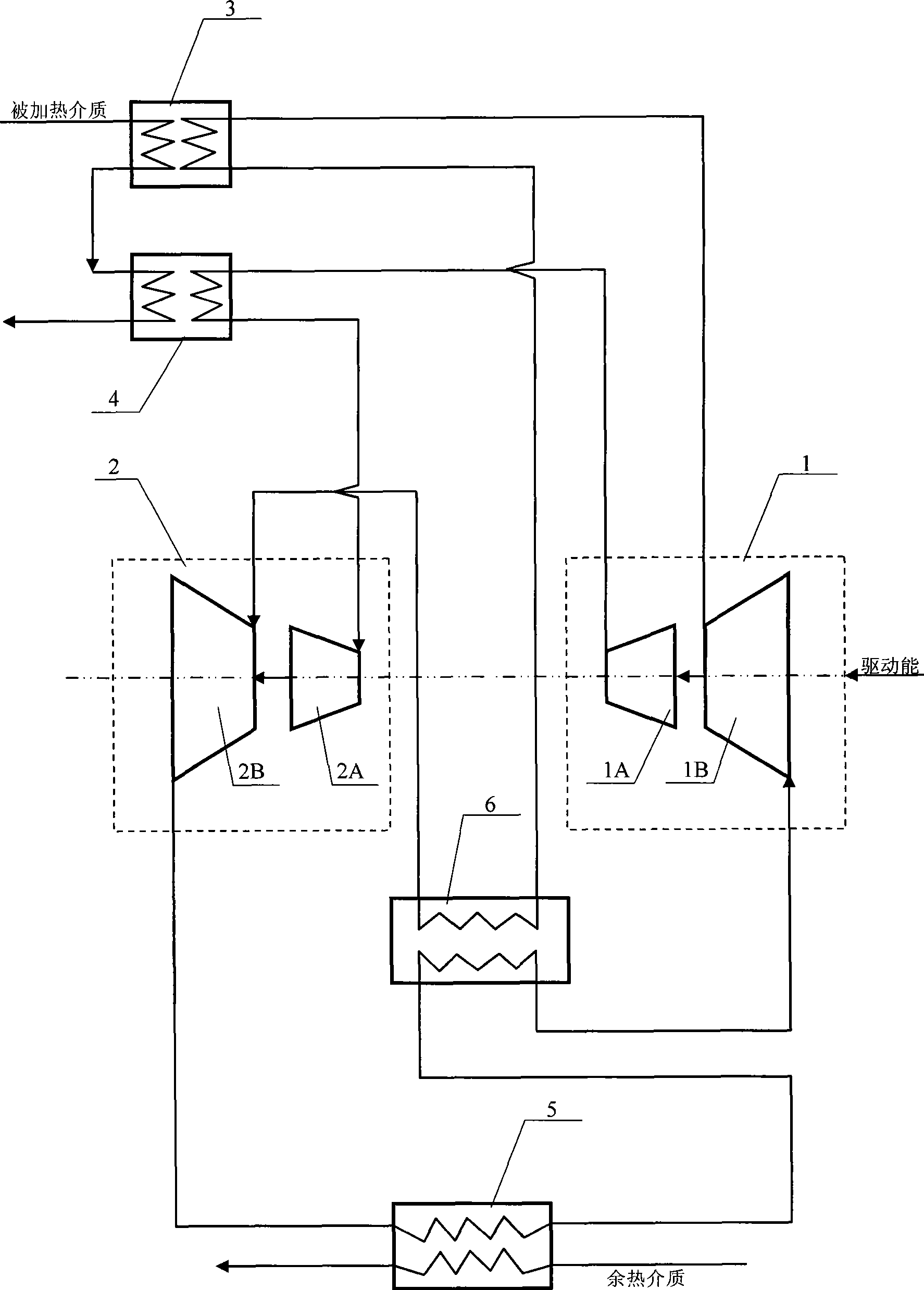

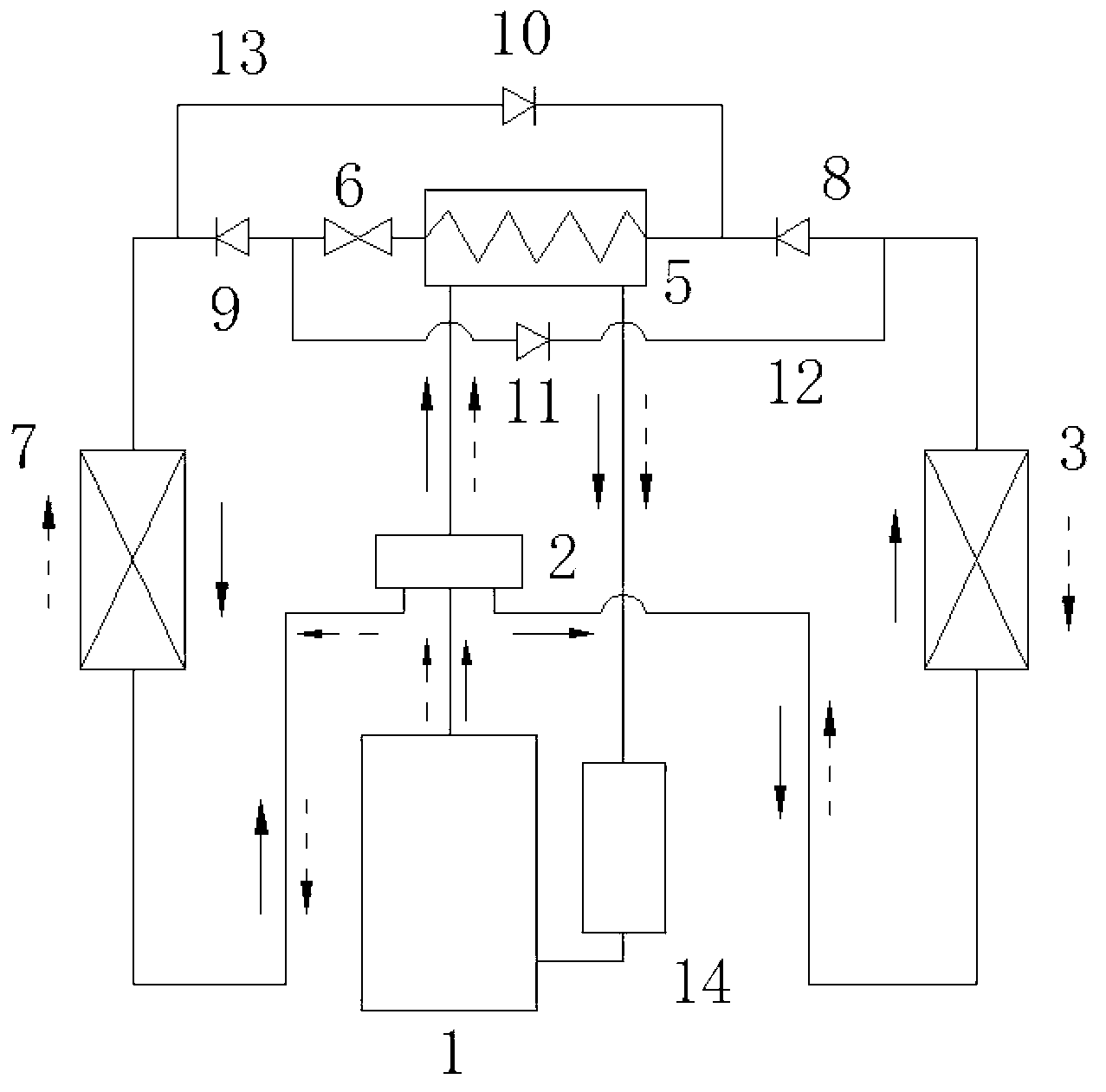

Segmented compression-segmented heat supply-segmented expansion gas compression type units

ActiveCN101504205AReduce power consumptionReduce the compression ratioCompression machines with non-reversible cycleSuperheatersPerformance indexEngineering

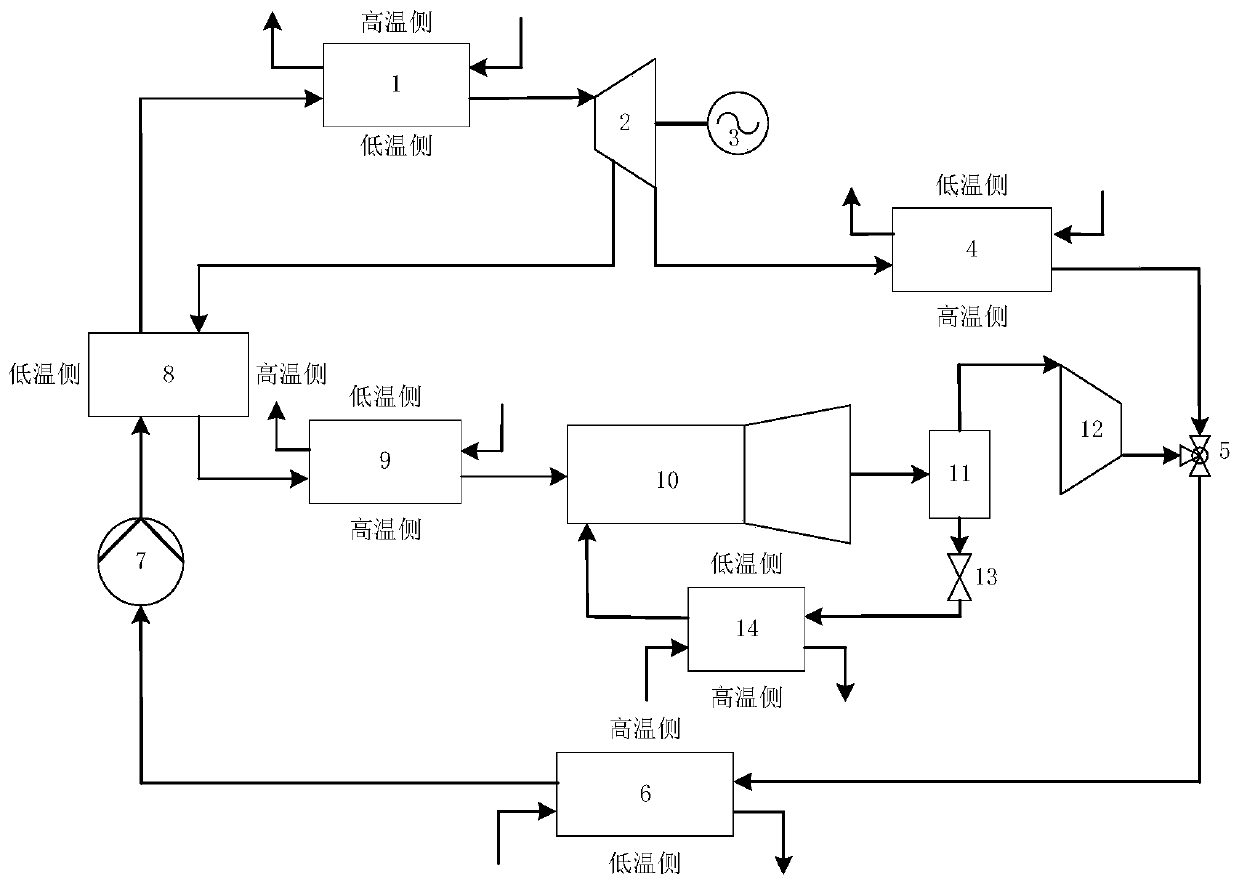

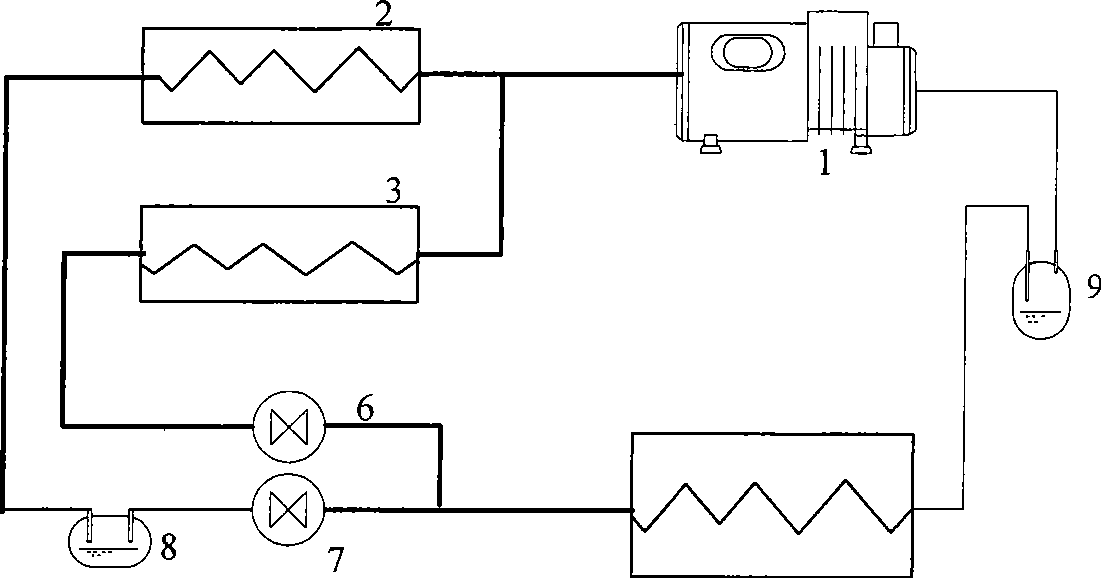

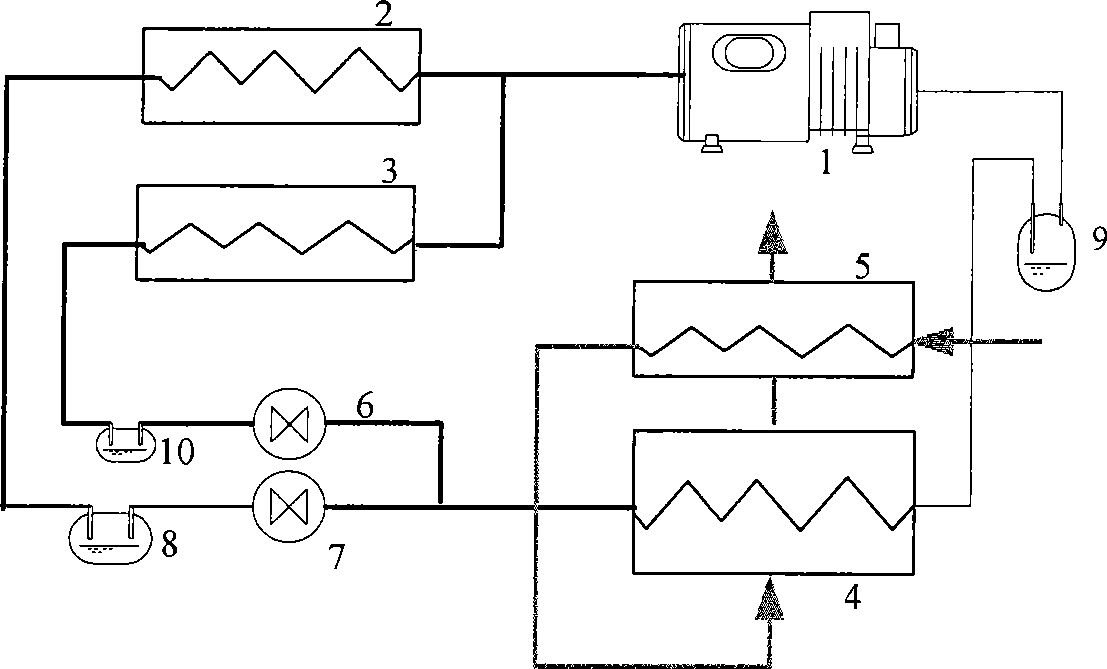

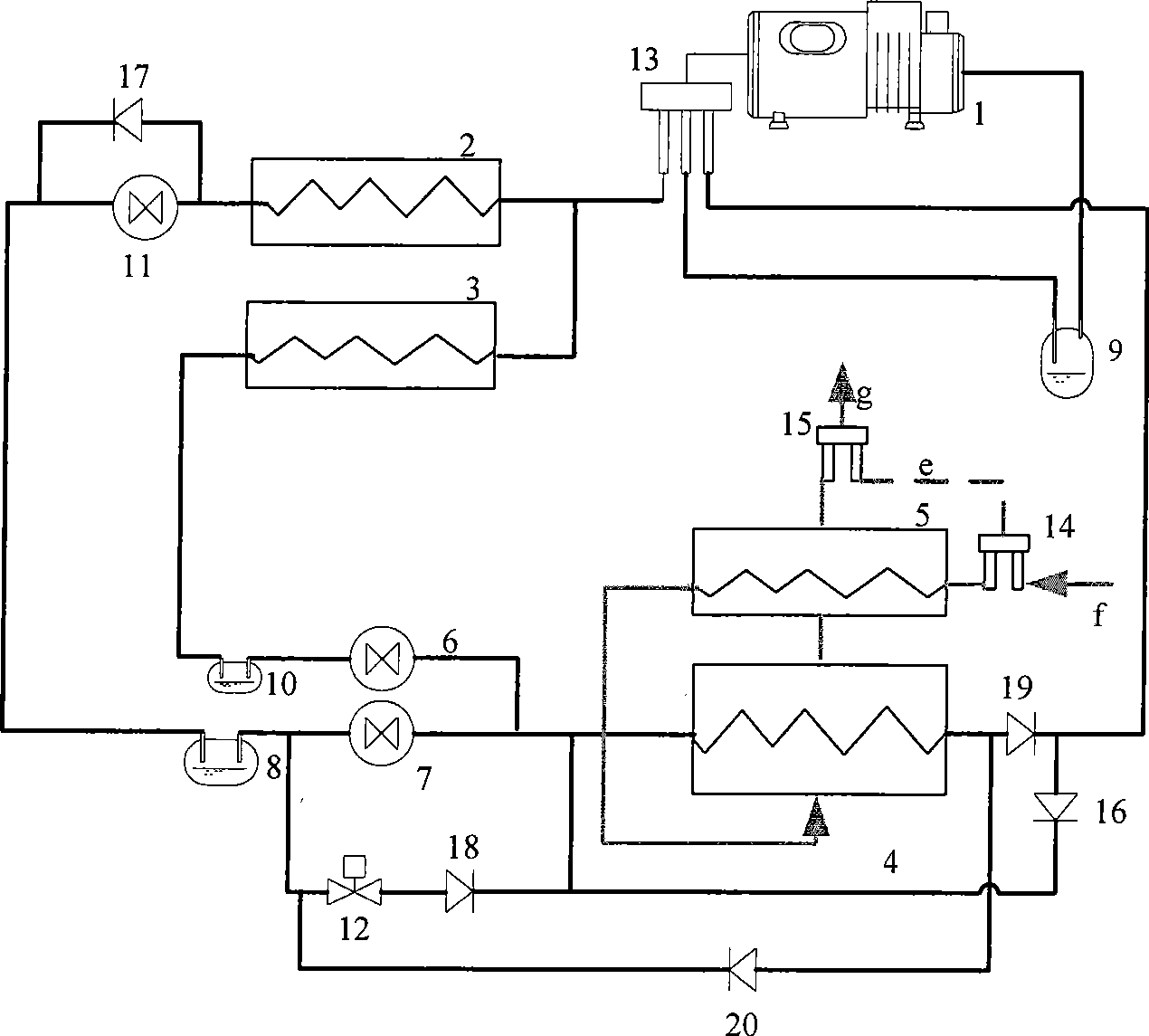

A subsection compression-subsection heat supply-subsection gas expanding compression type machine set belongs to the technical field of heat pumps / refrigeration, and consists of a compressor, an expander, a heat exchanger, a second heat exchanger and a low-temperature heat exchanger. Gas working substances absorbing heat from the low-temperature heat exchanger and raising temperature enter the compressor; after the gas working substances are compressed in a low pressure compression section, a part of the gas working substances are provided for the heat exchanger to complete the heating of a heated medium at an initial stage; the part of the gas working substances enter the expander and is expanded at a low pressure expansion section; the other part of the gas working substances are provided for the second heat exchanger to complete the heating of a second stage of the heated medium after continuously passing through the whole compression process and raising temperature, and enter the expander from an inlet of the high pressure expansion section of the expander for expanding; the gas working substances completing the expanding work flow through the low-temperature heat exchanger to absorb the heat and raise the temperature and enter the compressor; and a heat regenerator is added to form a regenerative machine set. The gas expanding compression type machine set reduces temperature difference of heat transmission and improves the performance index; when taken as a heat pump, the gas expanding compression type machine set is particularly suitable for occasions with high heating temperature and wide range; and when used for refrigeration, the gas expanding compression type machine set can reduce power consumption.

Owner:李华玉

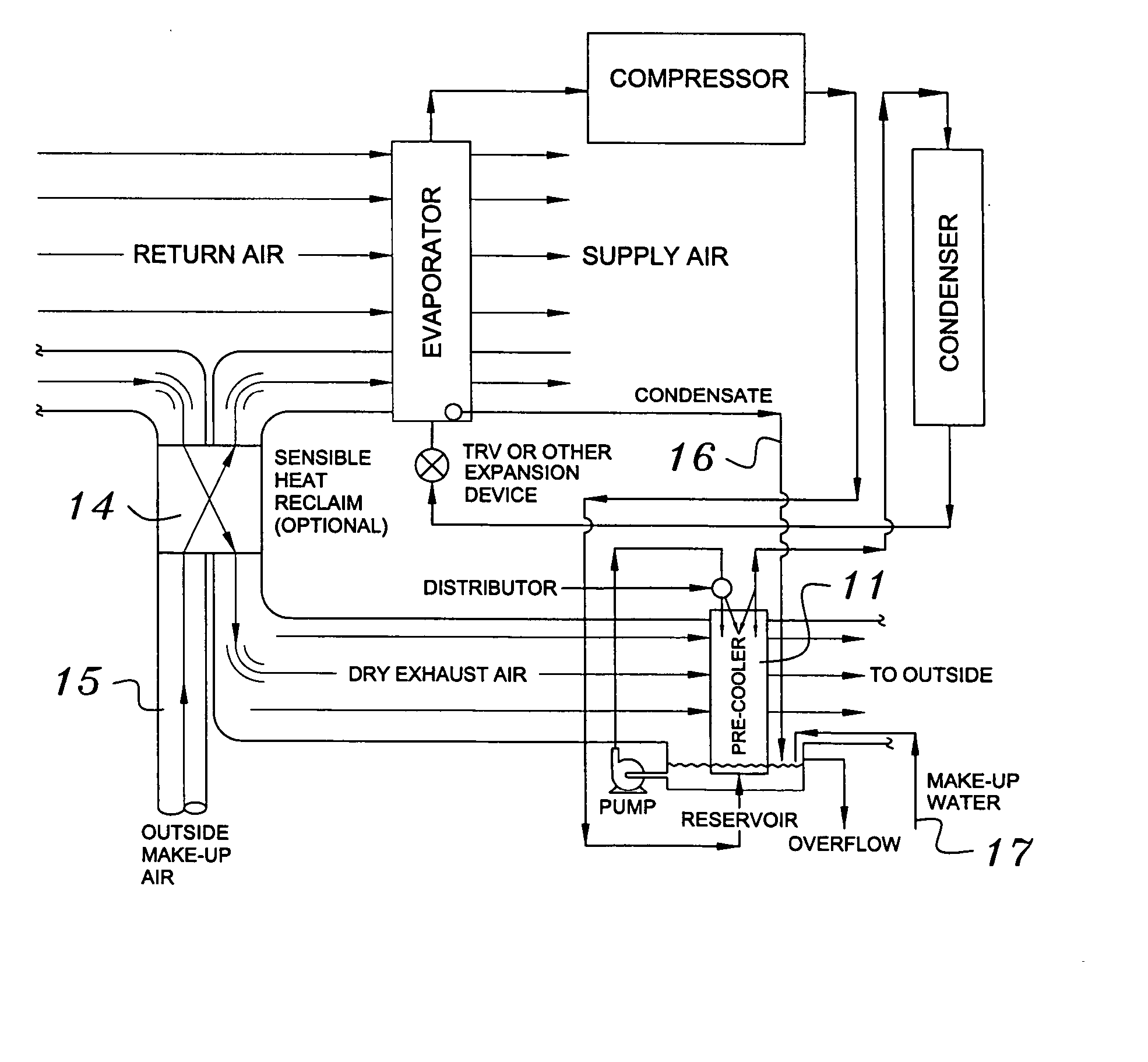

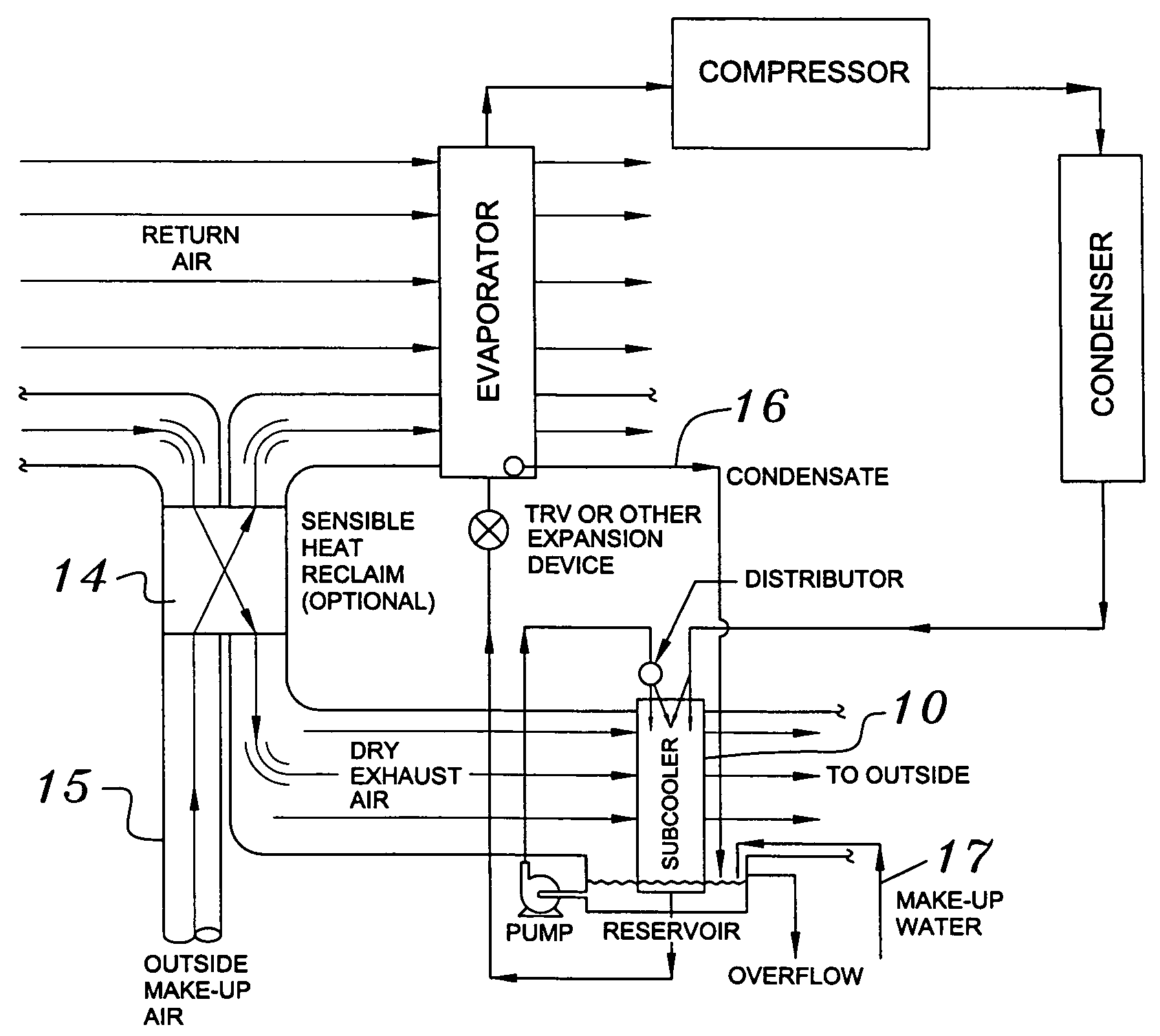

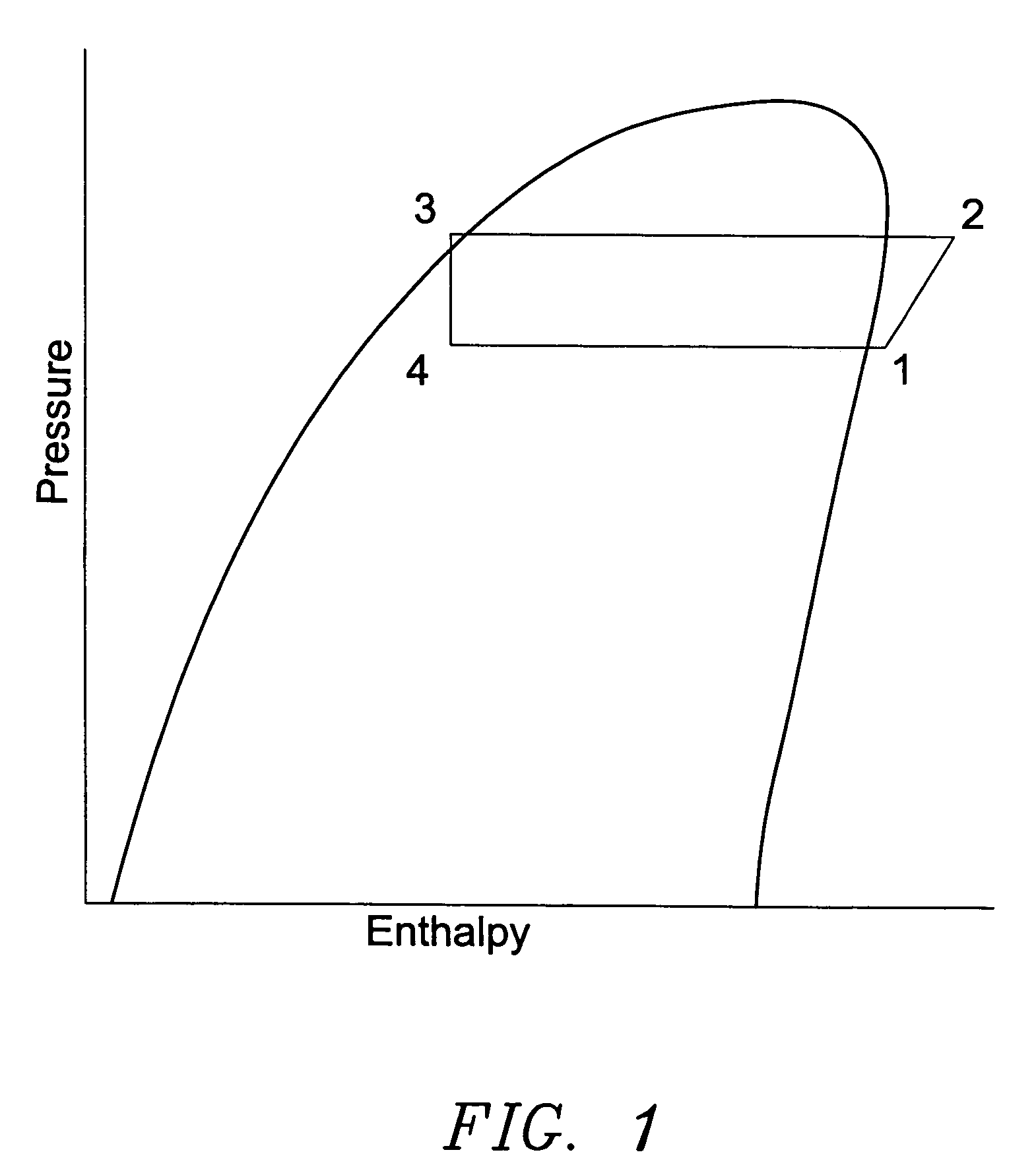

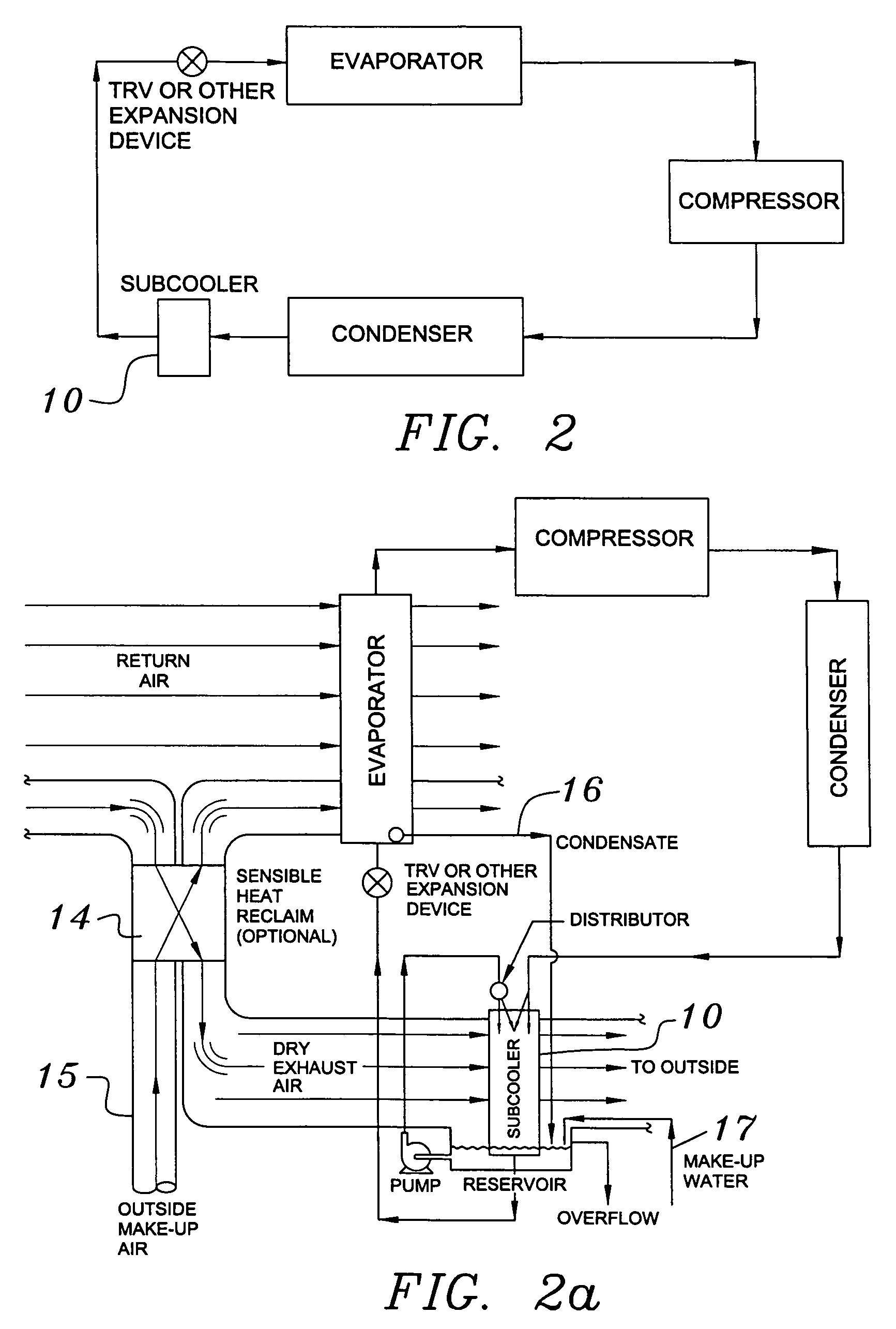

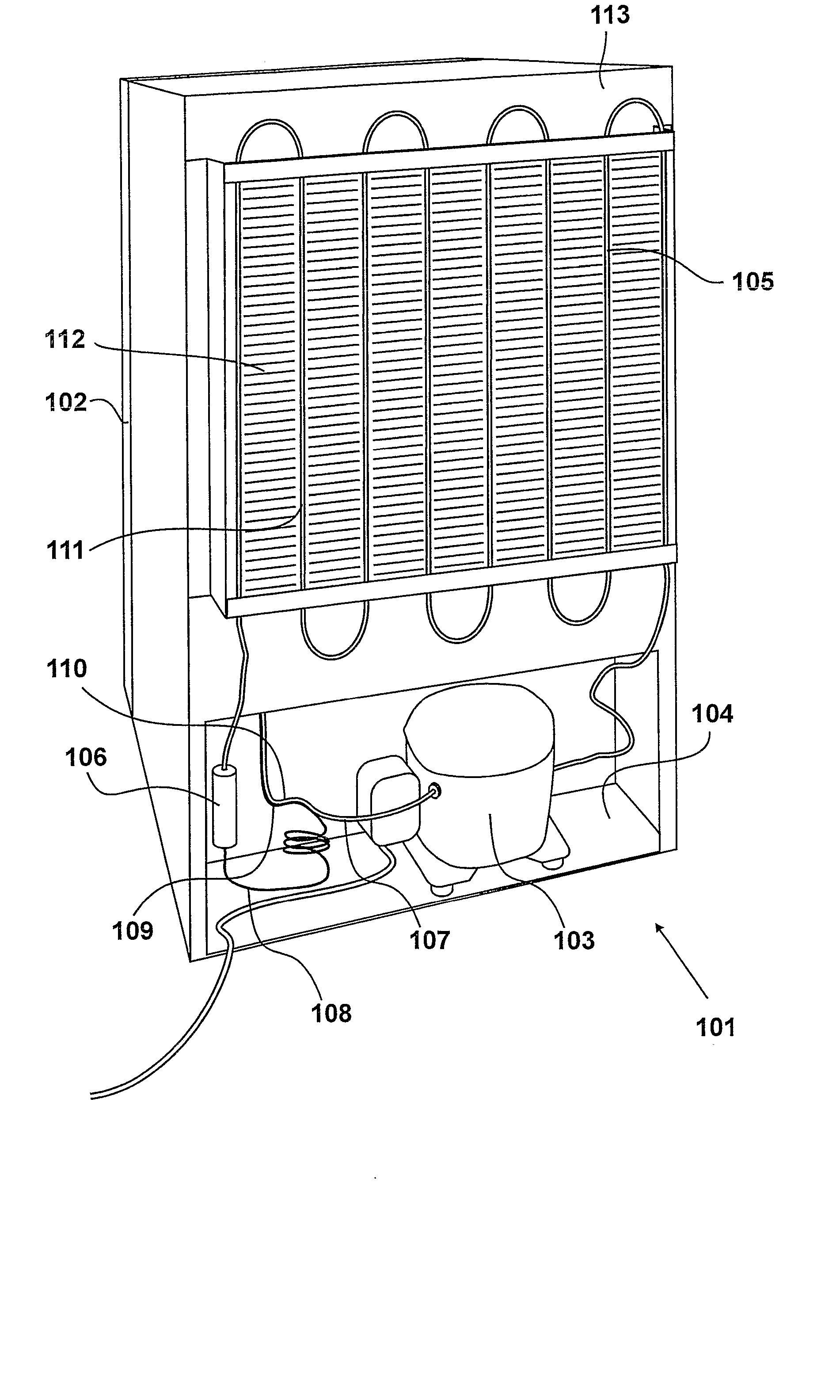

Building exhaust and air conditioner condensate (and/or other water source) evaporative refrigerant subcool/precool system and method therefor

InactiveUS20050028545A1Improve cooling effectReduce power consumptionEnergy recovery in ventilation and heatingDomestic cooling apparatusWater wetWater source

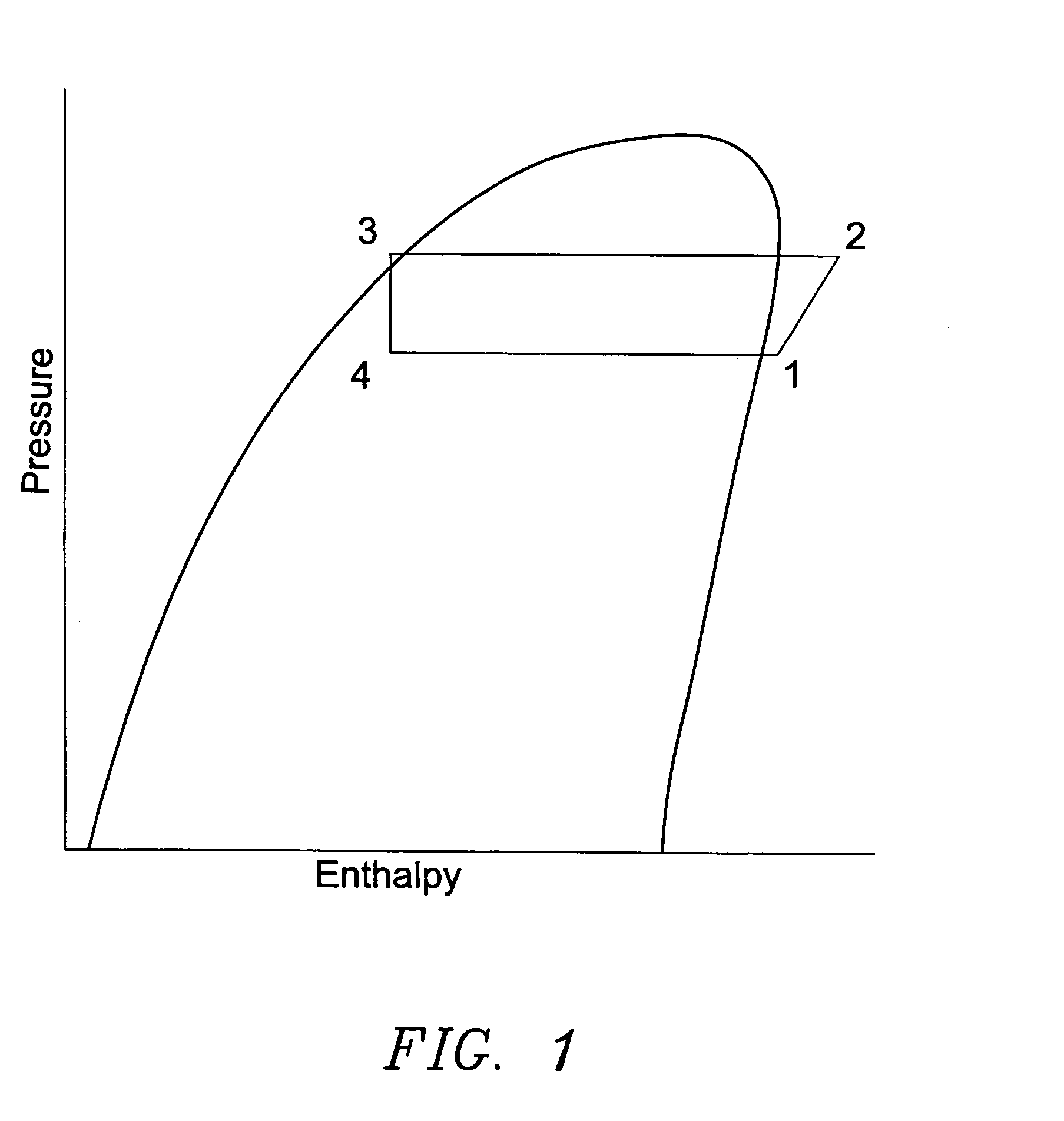

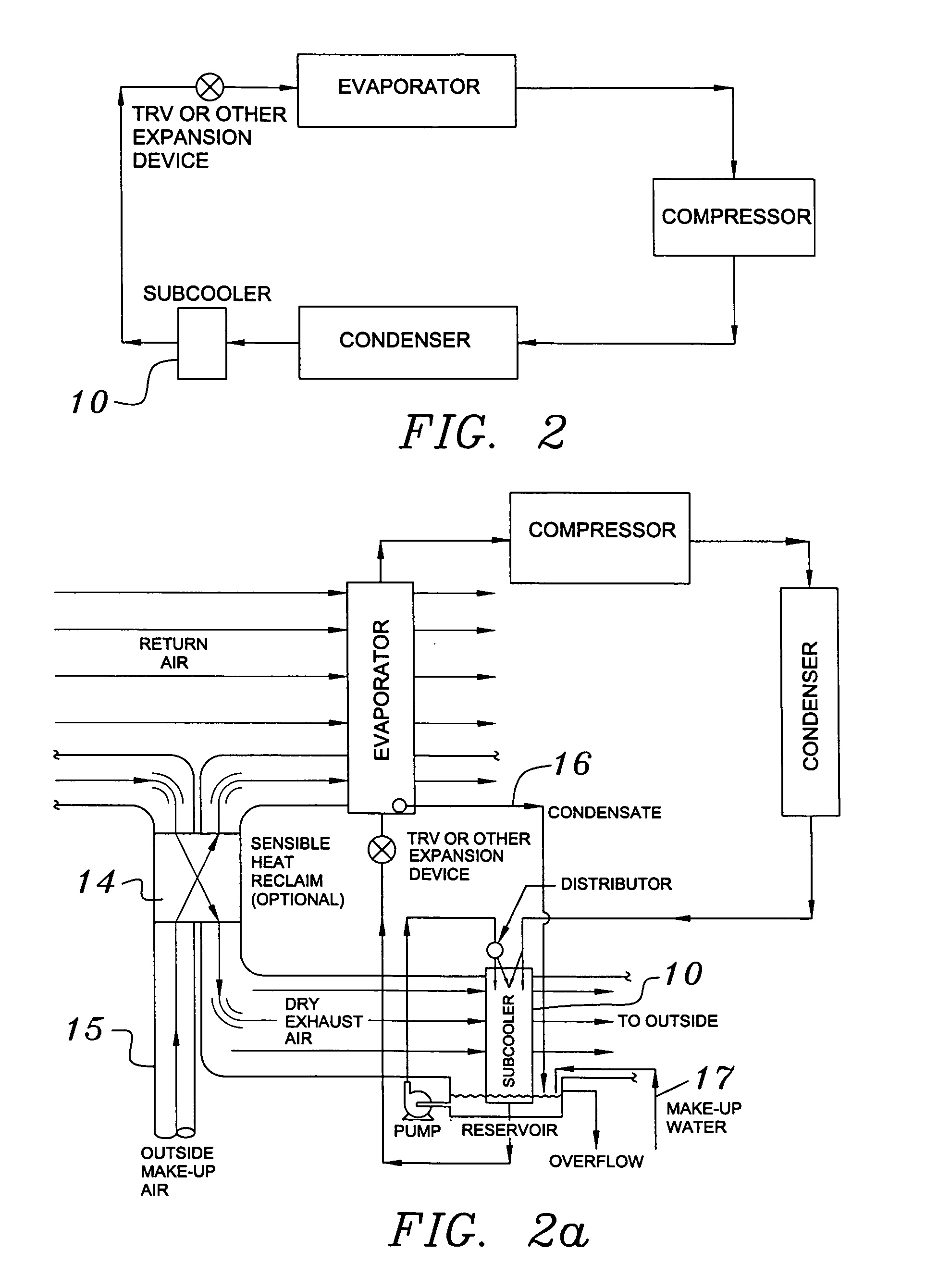

A system for providing liquid refrigerant subcooling by means of evaporative cooling utilizing the condensate water of said air conditioner, refrigeration / heat pump system and / or other water supply to wet the surface of the subcool heat exchanger and pass the dry exhaust air across the wetted surface of the subcool heat exchanger. A system for providing hot gas discharge refrigerant precooling into the primary condenser of an air conditioner, refrigeration or heat pump system by evaporative cooling utilizing the condensate water of said system and / or other water supply to wet the surface of the precool heat exchanger and then passing the cold, dry exhaust air across the wetted surface of the precool heat exchanger. A combination subcooler / precooler system where the cold dry building exhaust air is used to evaporatively subcool the liquid refrigerant in the water wetted (or dry) subcooler and then used to conductively cool the hot gas refrigerant.

Owner:OLIVE TREE PATENTS 1

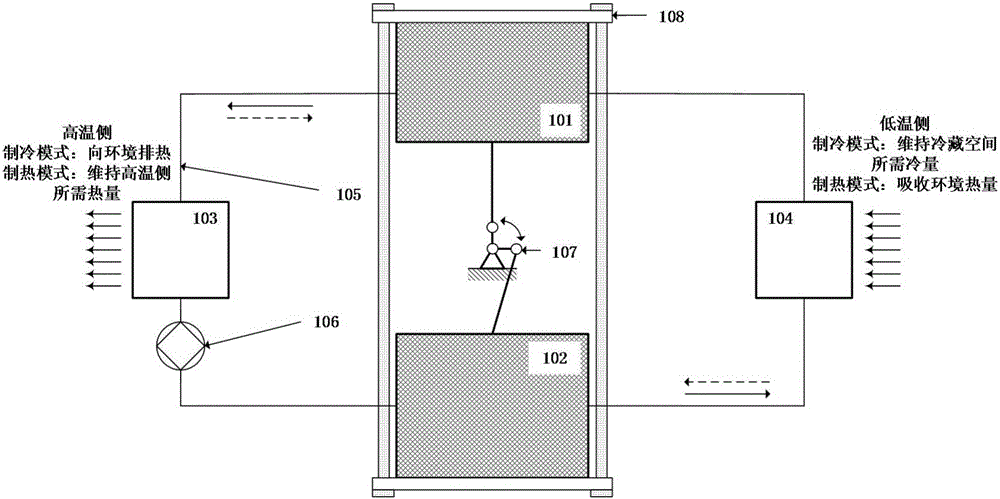

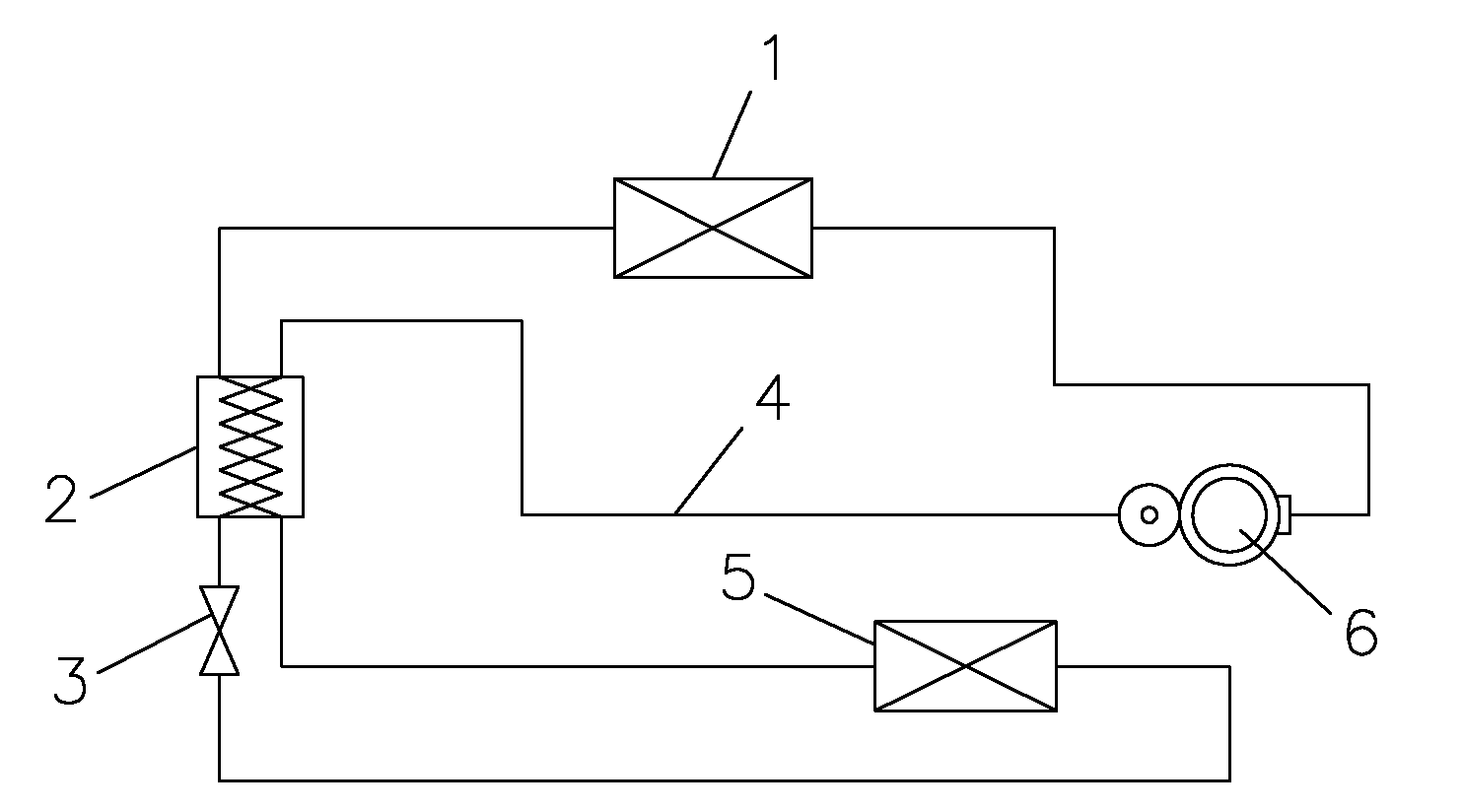

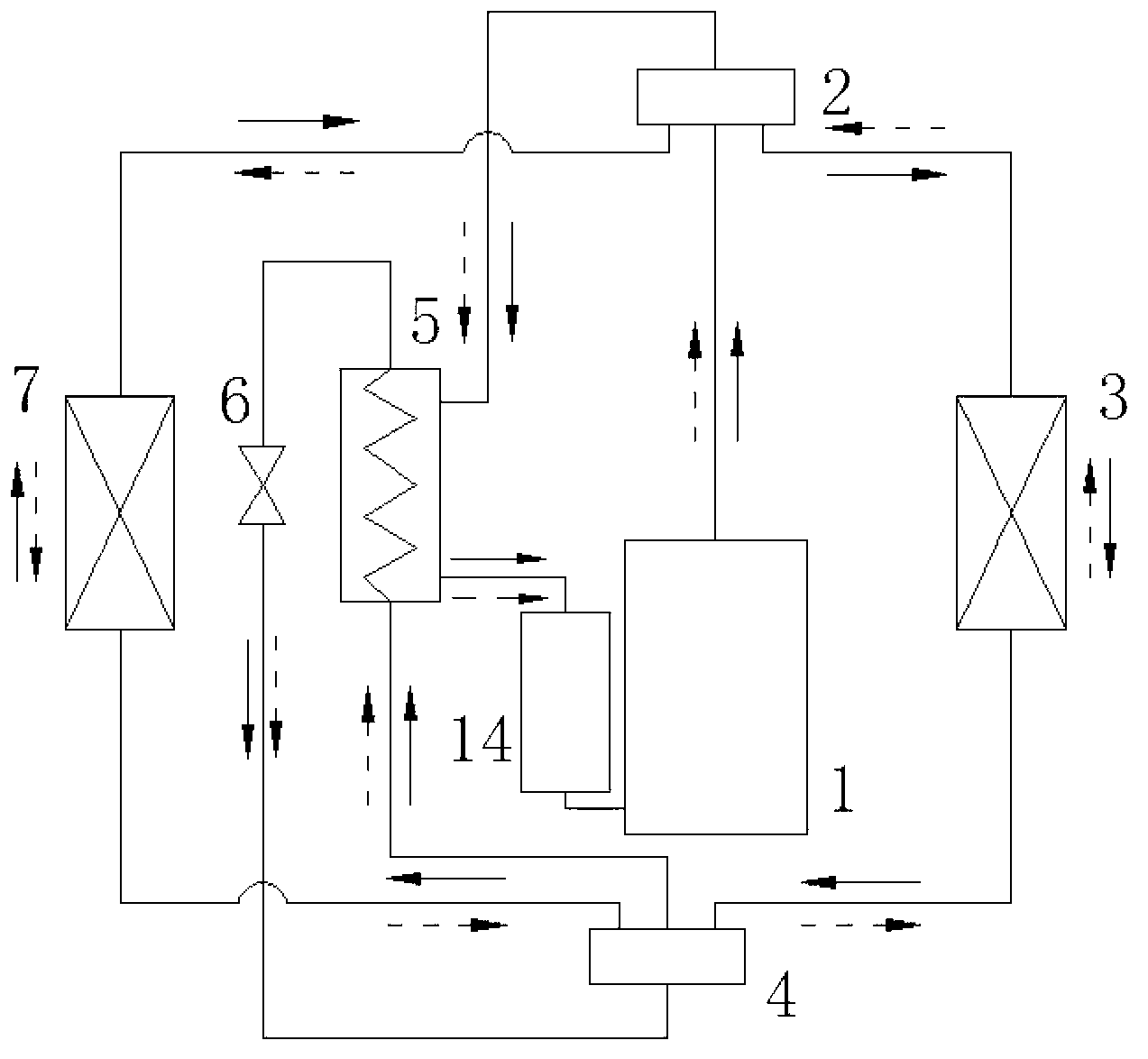

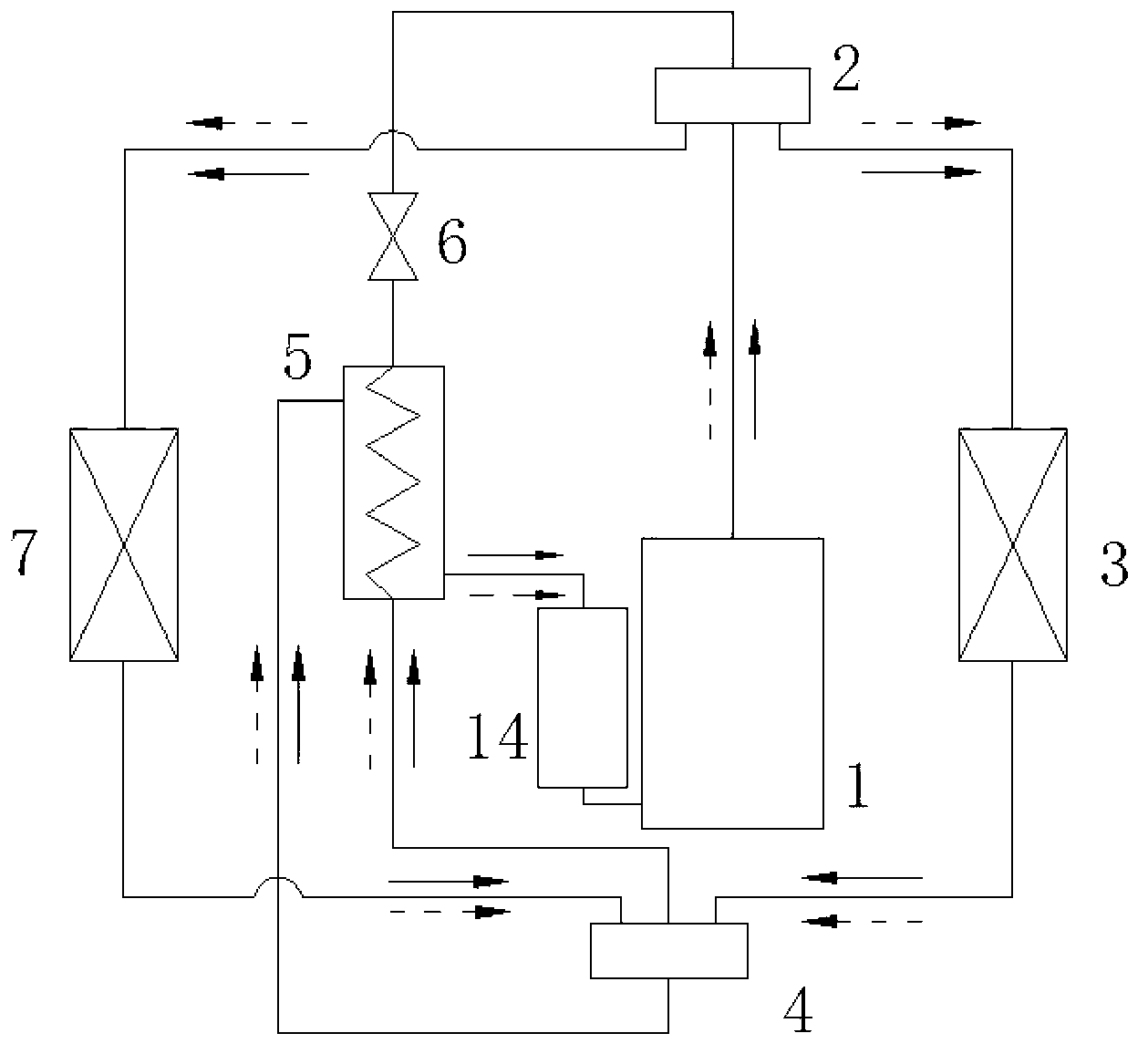

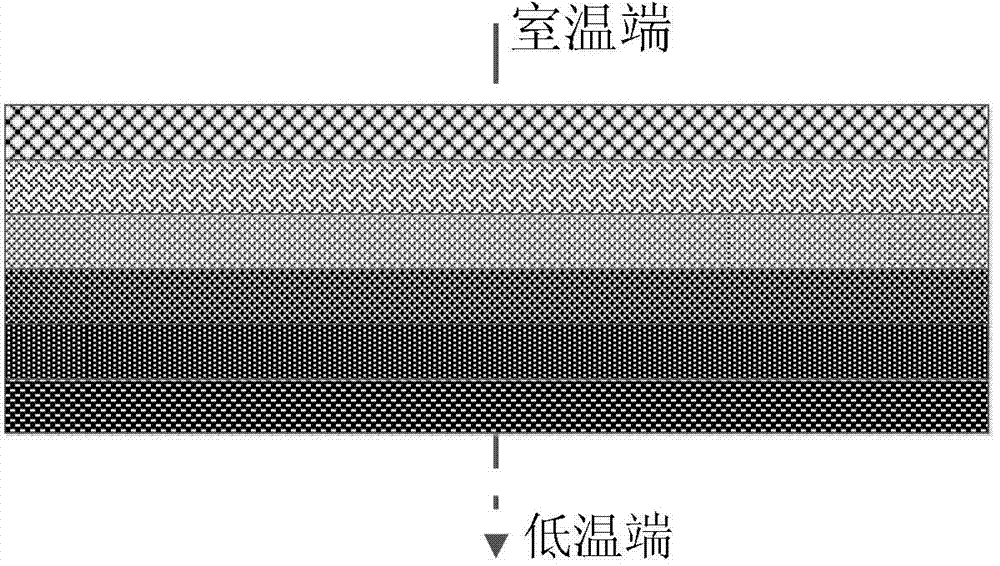

Active-regeneration type thermoelastic refrigeration system

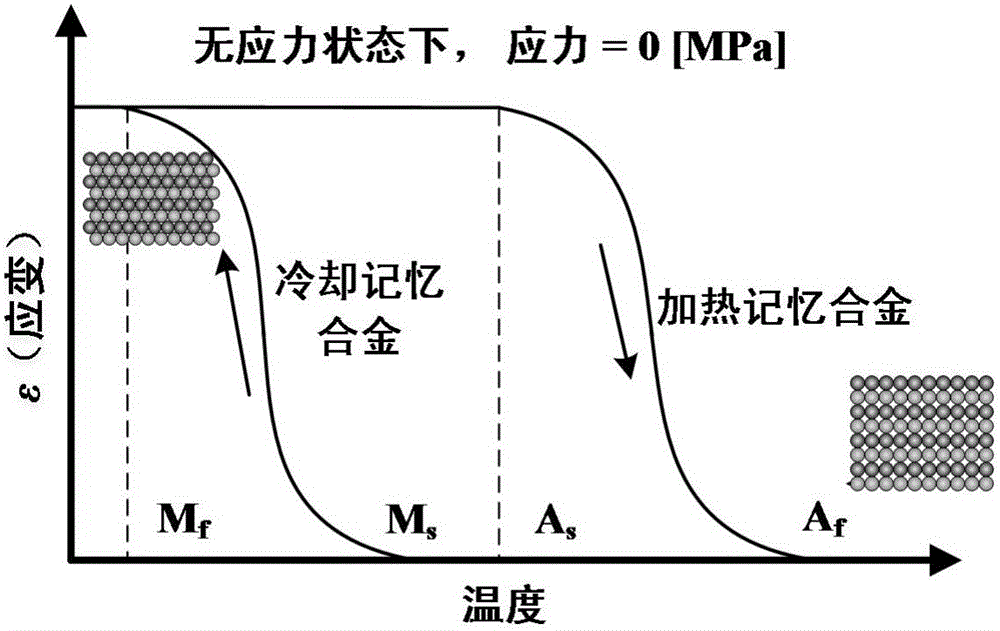

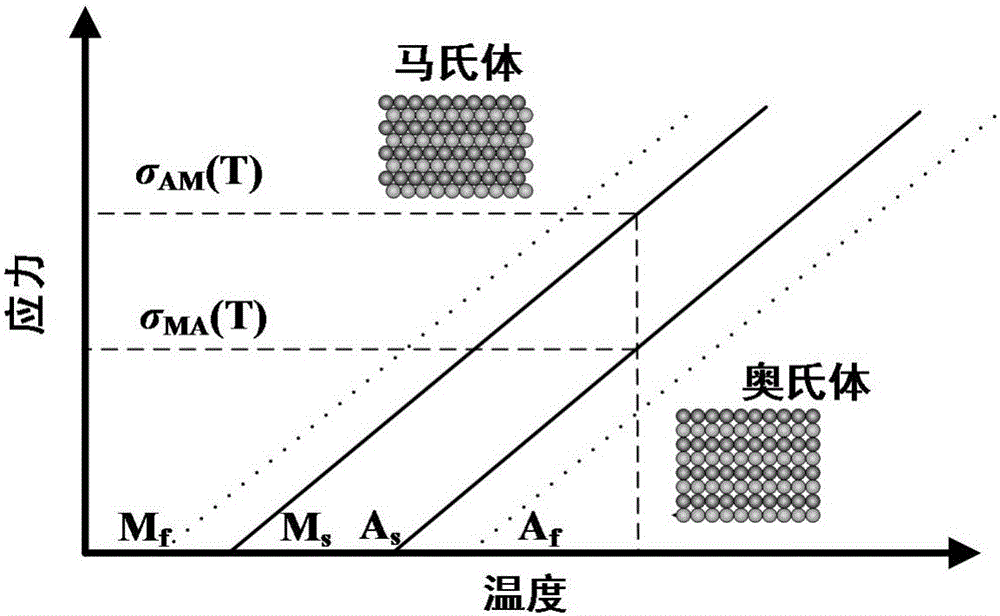

ActiveCN106052190AReduce heat conduction dissipation lossMechanical apparatusFluid circulation arrangementEngineeringRefrigeration

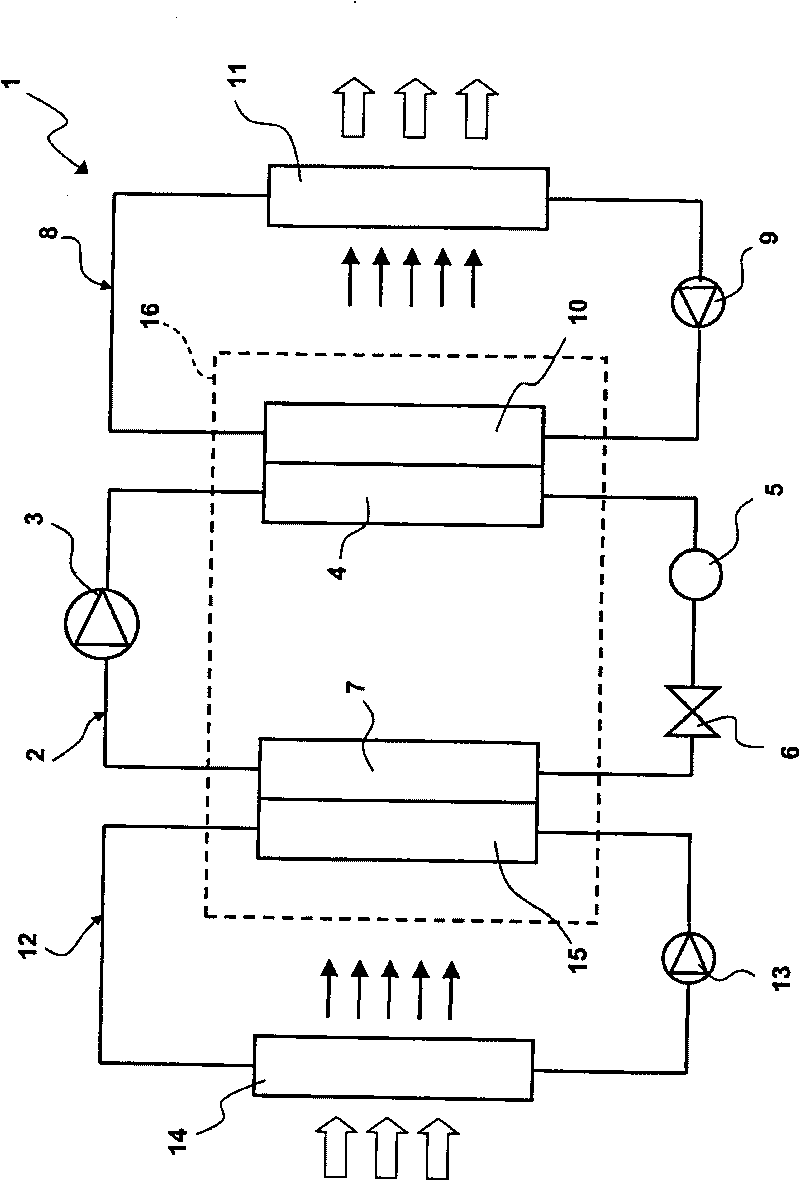

The invention discloses an active-regeneration type thermoelastic refrigeration system. The active-regeneration type thermoelastic refrigeration system comprises a high-temperature side heat exchanger, a low-temperature side heat exchanger, at least two regenerators made of thermoelastic refrigeration materials, and a heat exchange fluid network used for discharging heat from the low-temperature side to the high-temperature side.

Owner:XI AN JIAOTONG UNIV

Building exhaust and air conditioner condensate (and/or other water source) evaporative refrigerant subcool/precool system and method therefor

InactiveUS7150160B2Improve pumping efficiencyReduce power consumptionCondensate preventionDomestic cooling apparatusWater wetWater source

Owner:OLIVE TREE PATENTS 1

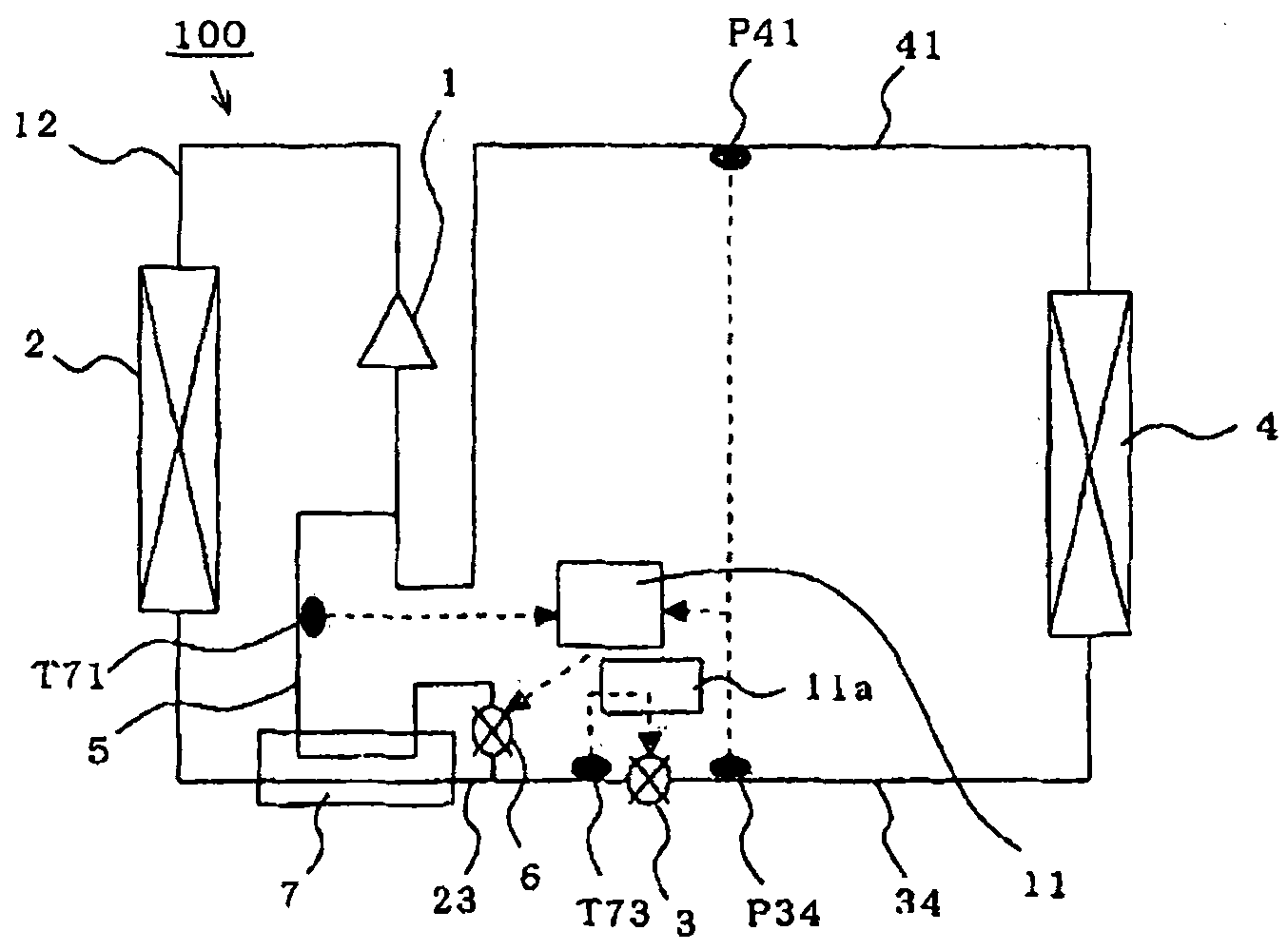

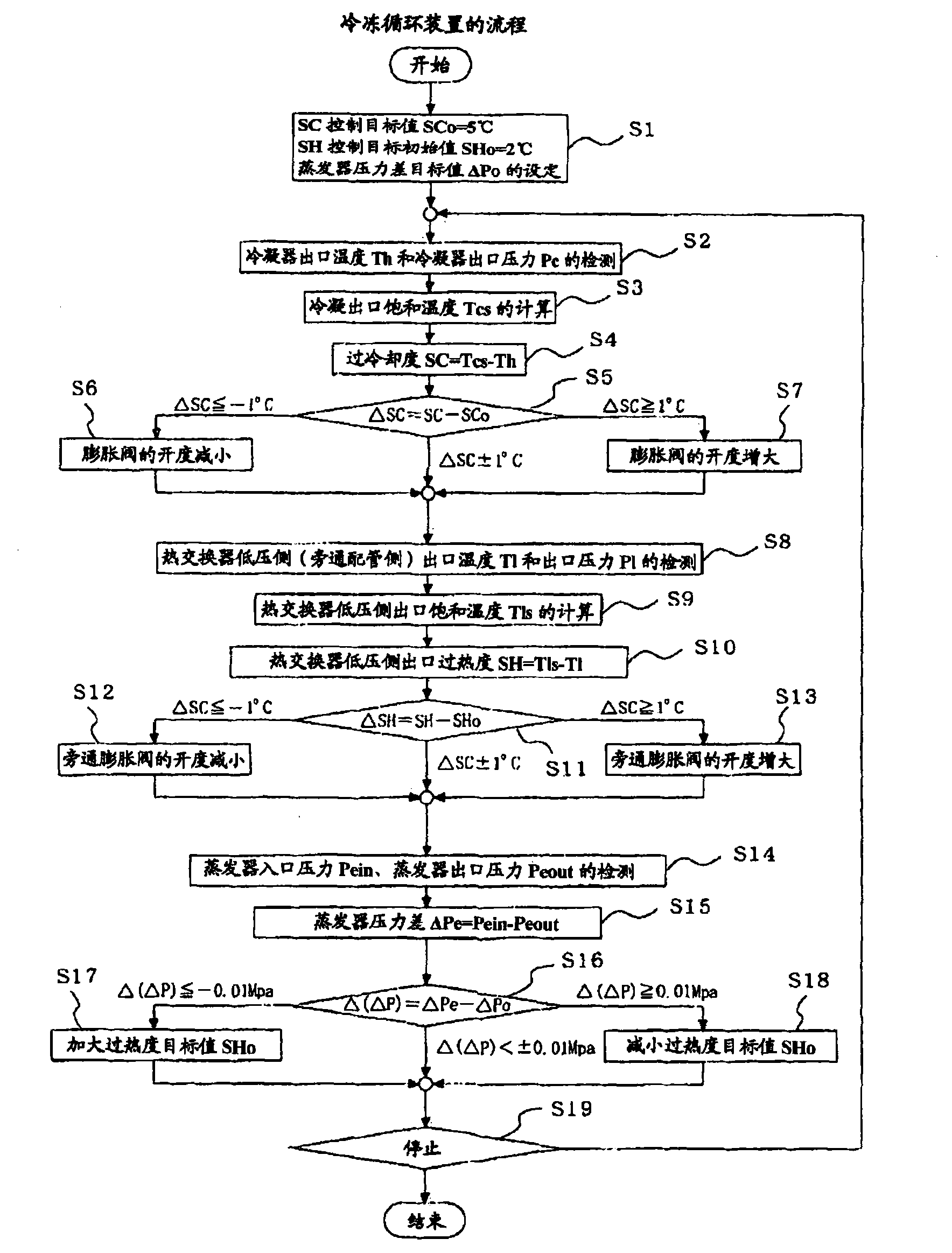

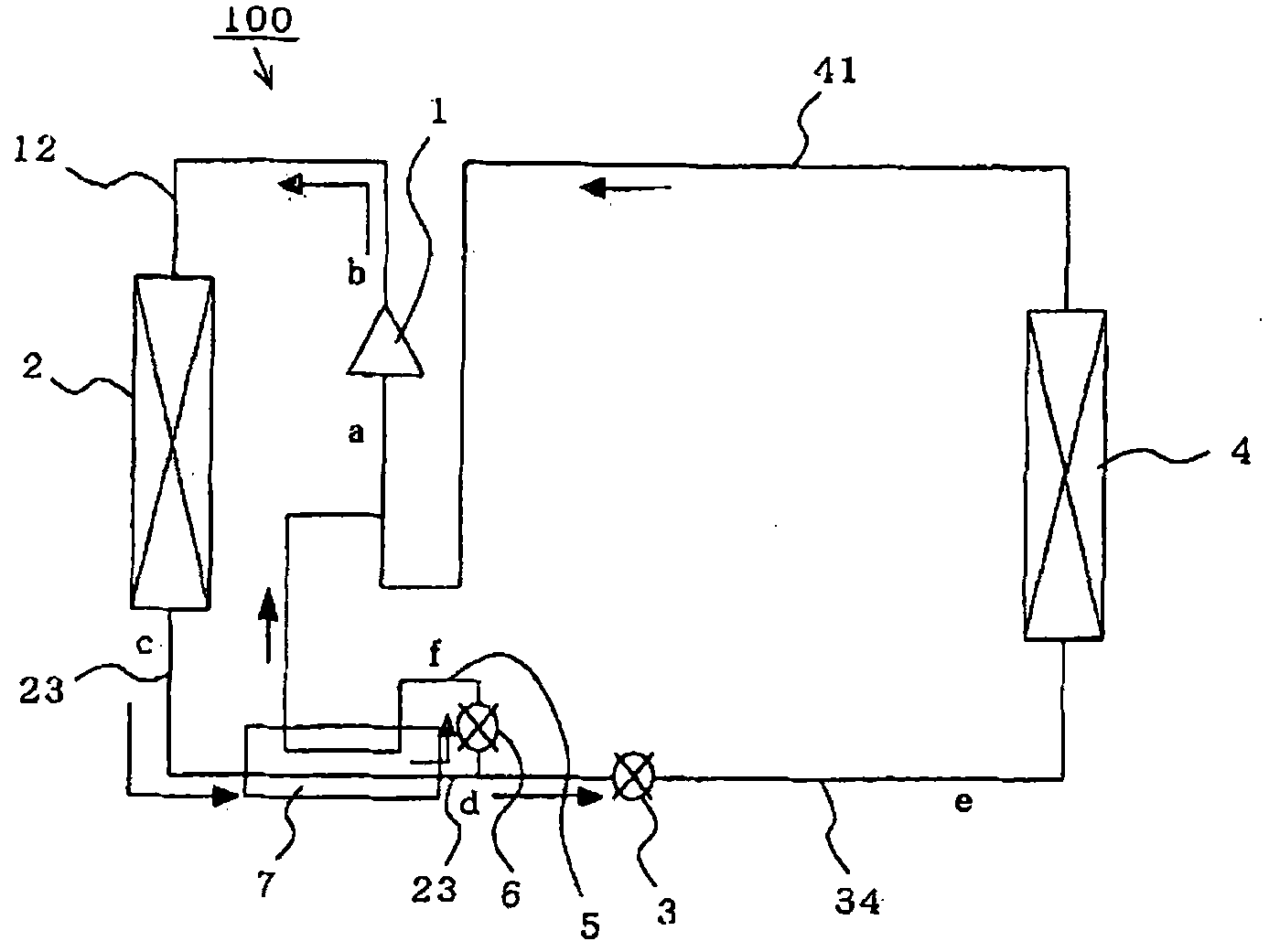

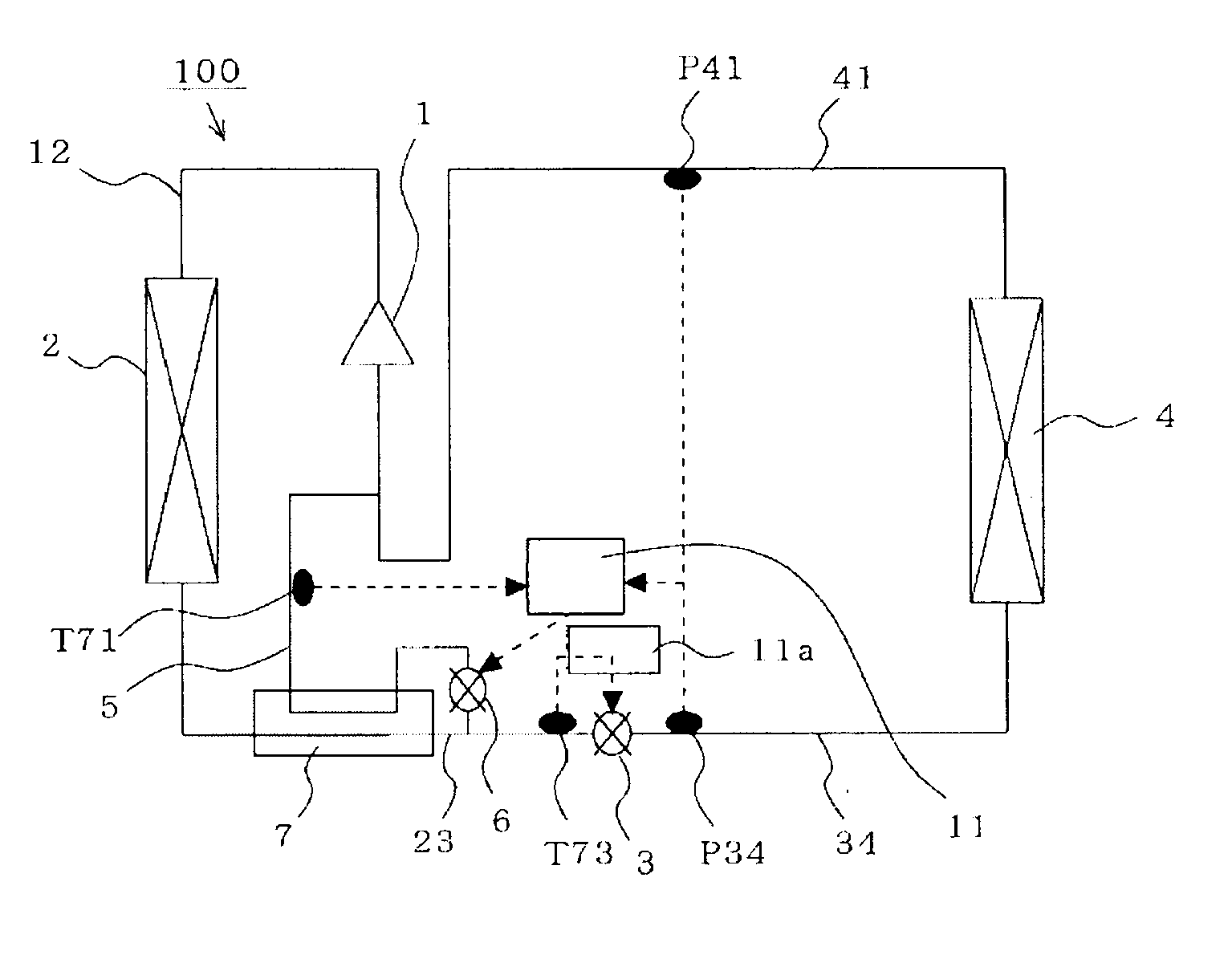

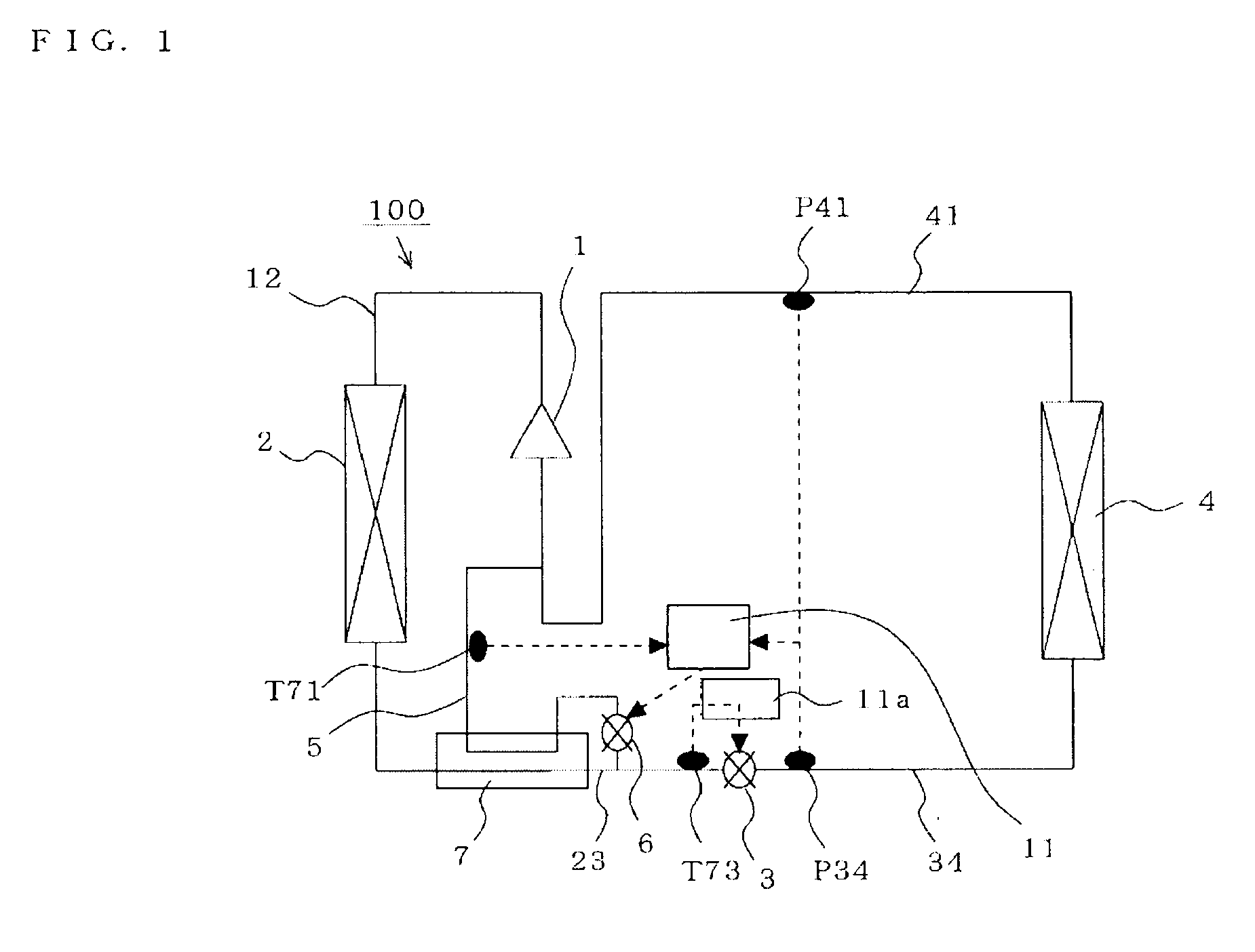

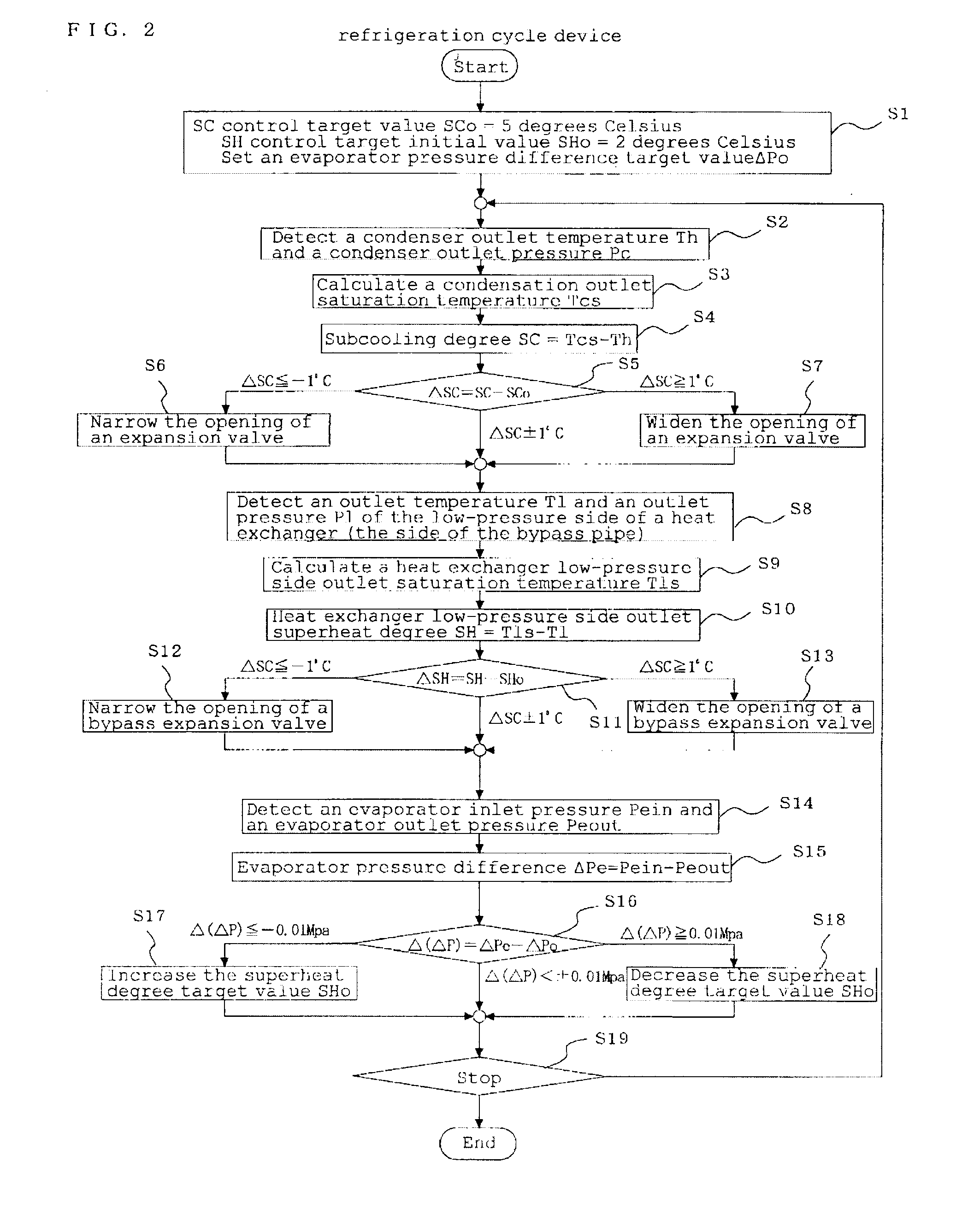

Refrigeration cycle device and control method therefor

ActiveCN102066851AEasy to operateIncreased pressure lossMechanical apparatusSpace heating and ventilation safety systemsEngineeringControl valves

A refrigeration cycle device (100) in which a flammable refrigerant circulates comprises a bypass pipeline (5) connected such that part of the refrigerant flowing through a circulation pipeline from a condenser (2) to a flow control valve (3) bypasses the flow control valve (3) and an evaporator (4), a bypass flow control valve (6) for controlling the flow rate of the refrigerant flowing through the bypass pipeline (5), a heat exchanger (7) for allowing the refrigerant flowing through the bypass pipe line (5) after flowing out from the bypass flow control valve (6) and the refrigerant flowingthrough the circulation pipeline after flowing out from the condenser (2) to exchange heat with each other, and a supercooling degree sensor (T73) for detecting the supercooling degree of the refrigerant at an inlet of the flow control valve (3). At least either the flow control valve (3) or the bypass flow control valve (6) is so controlled that the supercooling degree of the refrigerant at the inlet of the flow control valve (3) is equal to or more than a predetermined value.

Owner:MITSUBISHI ELECTRIC CORP

Refrigeration cycle device and method of controlling the same

ActiveUS20110083456A1Reduce the amount requiredLimited amountMechanical apparatusCompression machines with non-reversible cycleEngineeringControl valves

A refrigeration cycle device 100 where a combustible refrigerant circulates includes a bypass pipe 5 that is connected so that part of the refrigerant that flows through a circulation pipe extending from a condenser 2 to a flow control valve 3 bypasses the flow control valve 3 and an evaporator 4; a bypass flow control valve 6 that controls the amount of the refrigerant flowing through the bypass pipe 5; a heat exchanger 7 that allows heat exchange between the refrigerant that flows through the bypass pipe 5 after flowing out of the bypass flow control valve 6 and the refrigerant that flows through the circulation pipe after flowing out of the condenser 2; and a subcooling degree sensor T73 that detects the subcooling degree of the refrigerant at the inlet of the flow control valve 3. At least either the flow control valve 3 or the bypass flow control valve 6 is controlled so that the subcooling degree of the refrigerant at the inlet of the flow control valve 3 is equal to or greater than or a predetermined value.

Owner:MITSUBISHI ELECTRIC CORP

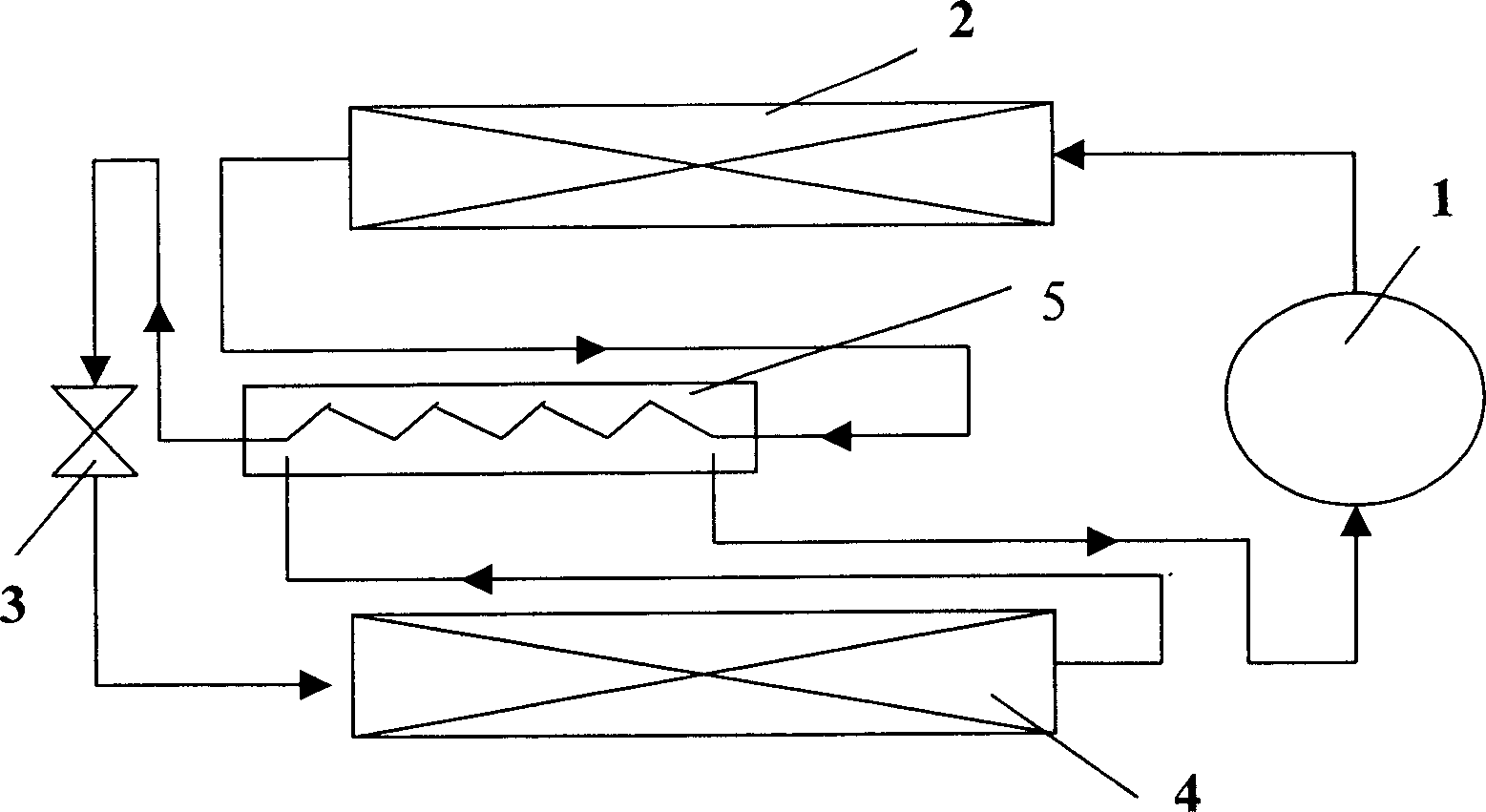

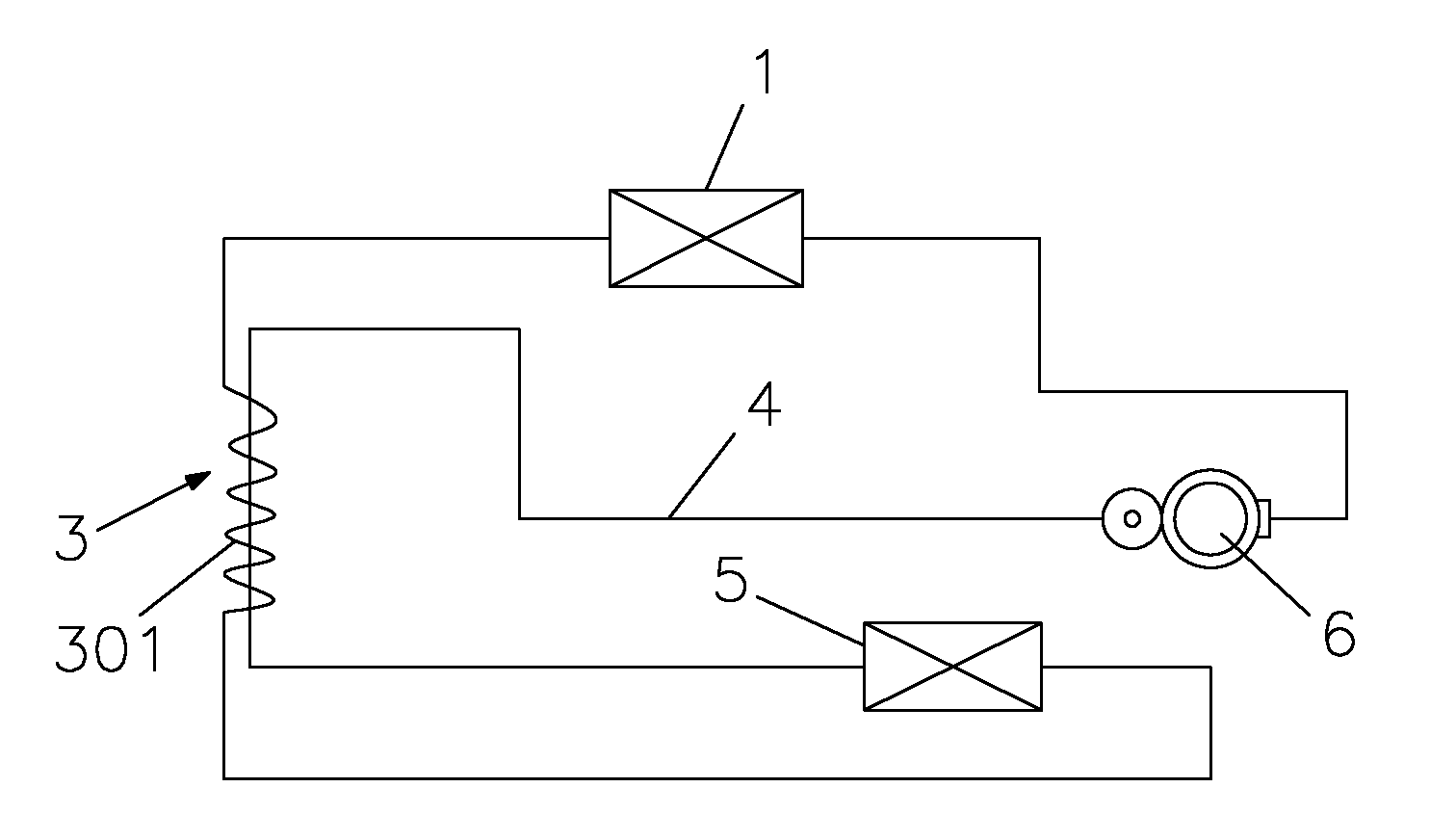

Air conditioner for regenerative cooling circulation system

InactiveCN1862151AReduce volumeReduce the impactCompression machines with non-reversible cycleSuperheatersStraight tubeEngineering

The present invention discloses a regenerative refrigeration cycle system air conditioner. It includes compressor, condenser, throttle device, evaporator and recuperative heat exchanger. The described recuperative heat exchanger includes a cylindrical tank body whose top portion and bottom portion are respectively equipped with low-pressure refrigerant outlet and inlet connected with compressor suction pipe and evaporator outlet, a straight tube which is placed in the interior of tank body along vertical direction and whose upper and lower ends are respectively connected with condenser outlet and throttle device and a heat-exchanging coiled tube, said coiled tube and straight tube are integrally formed into one body.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Backheating method and backheating structure for heat pump air conditioner

InactiveCN101979938AReduce the temperatureReduce vaporizationHeat recovery systemsFluid circulation arrangementEvaporationEngineering

The invention discloses a backheating method and a backheating structure for a heat pump air conditioner, which can improve the performance of the air conditioner. The backheating structure comprises heat exchangers A and B, a compressor, and a throttling element connected between the heat exchangers A and B, wherein the heat exchanger B is connected with the compressor by an air suction pipe of the compressor; and a higher-temperature coolant in the throttling element performs heat exchange with a lower-temperature coolant in the air suction pipe of the compressor. In the backheating method and the backheating structure, the temperature of the coolant in the throttling element can be reduced by performing backheating in a throttling process, thereby retarding the evaporation of the coolant and the change of the dryness of the coolant, making more stable the flow regime of the coolant and reducing inevitable loss; and the dryness of the coolant at an outlet of the throttling element is reduced, namely, the degree of subcooling of the air conditioner is increased, so the cooling capacity of the air conditioner can be improved. The backheating method and the backheating structure for the heat pump air conditioner can improve the cooling or heating performance of the heat pump air conditioner; and the backheating structure is simplified to a certain extent so as to be convenient to manufacture and save the cost.

Owner:四川长虹空调有限公司

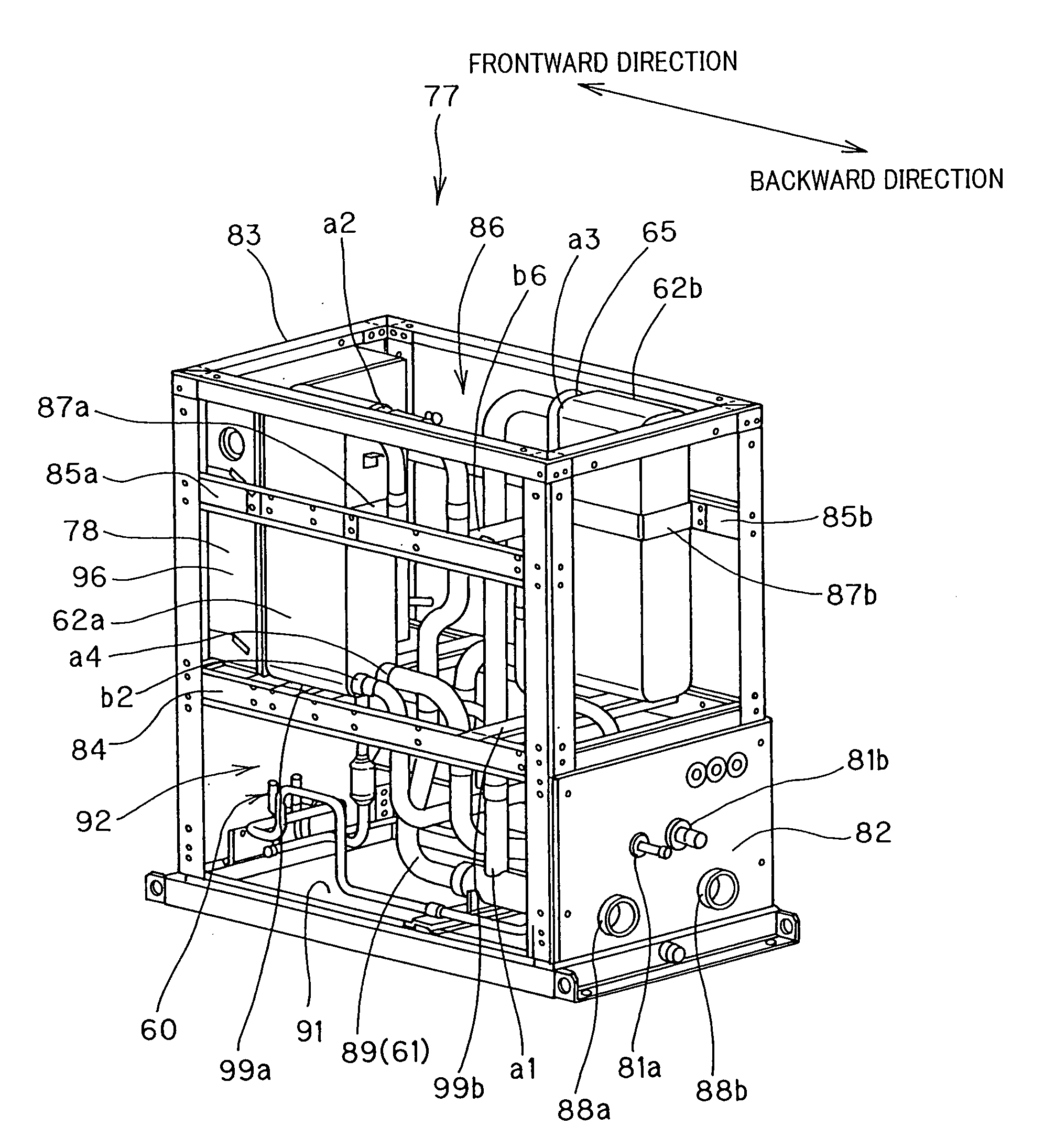

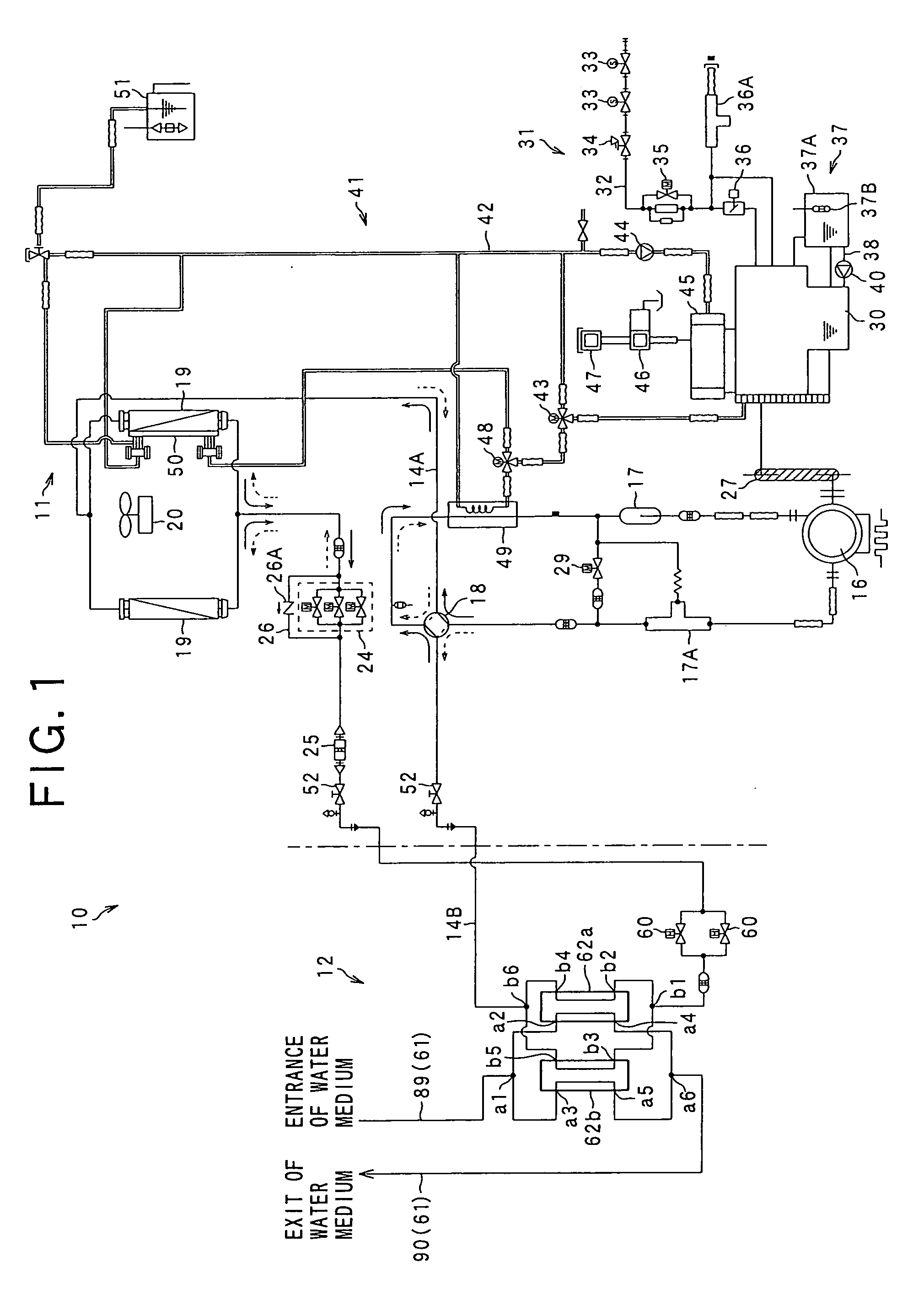

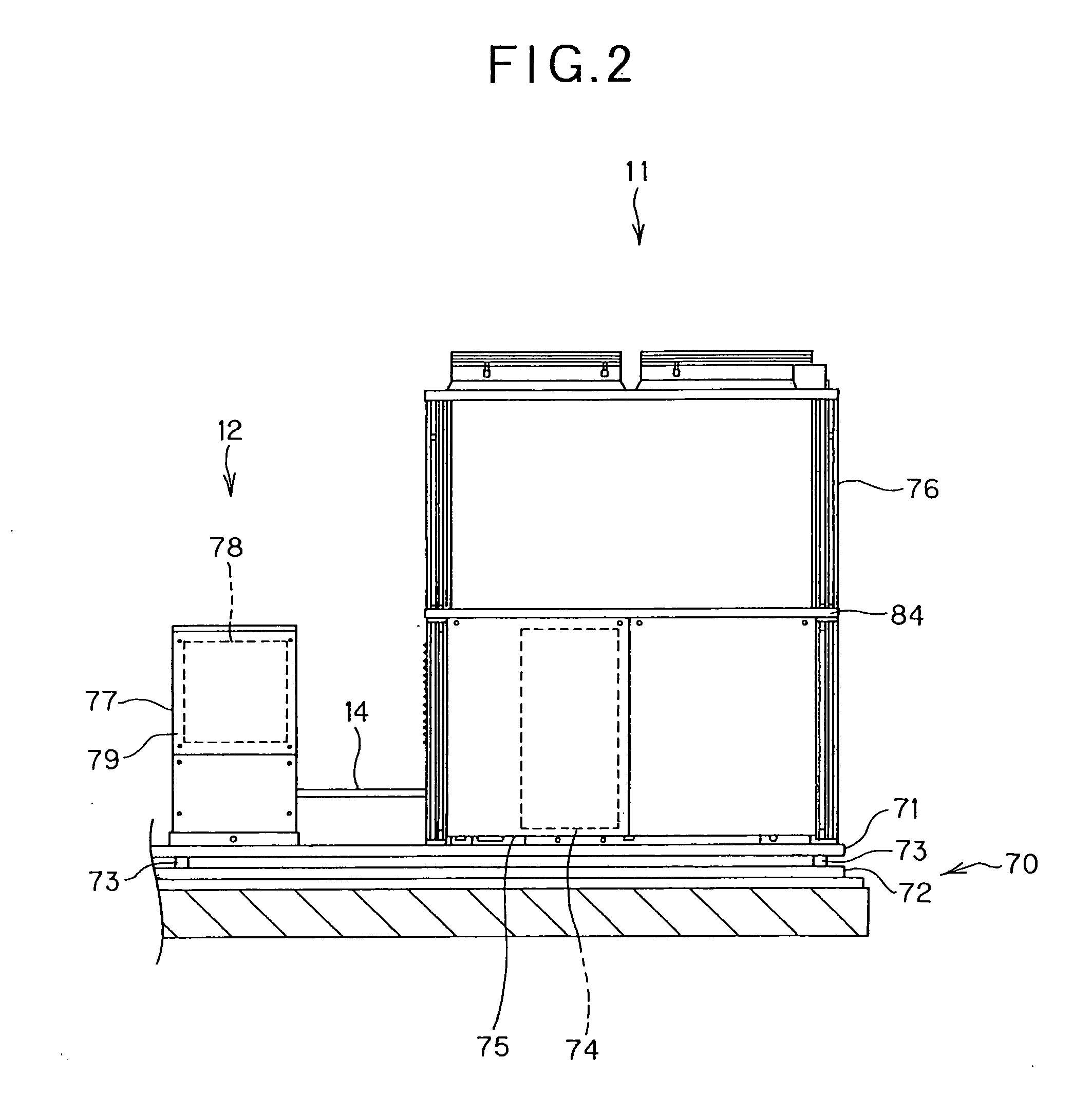

Chiller unit, refrigeration system having chiller unit and air conditioner having chiller unit

InactiveUS20090241577A1Reduce laborImprove maintainabilitySampled-variable control systemsMechanical apparatusPlate heat exchangerMarine engineering

A chiller unit including a chiller unit main body connected to a refrigeration cycle, a plate type heat exchanger unit that is secured to an upper stage portion of the chiller unit main body and divided into plural plate type heat exchangers, and a pipe group having a water medium pipe and a refrigerant pipe for supplying water medium and refrigerant to each of the plate type heat exchangers while branching the water medium and the refrigerant and collectively disposed at a lower stage portion of the chiller unit main body, wherein at least an exit side portion of the water medium pipe is routed substantially horizontally along the bottom portion of the chiller unit main body and a flow switch is provided in a horizontally-extending pipe portion of the water medium pipe.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

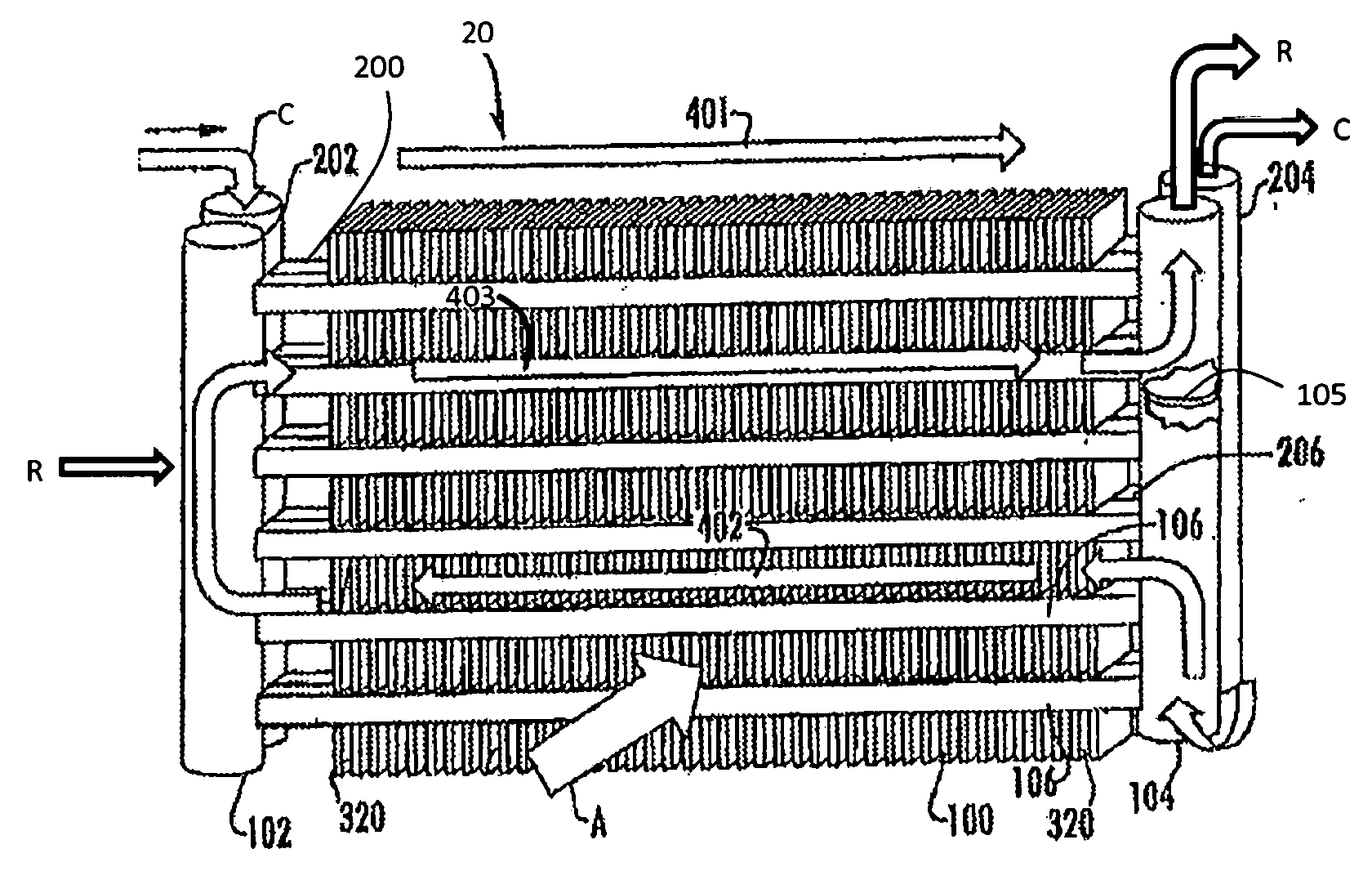

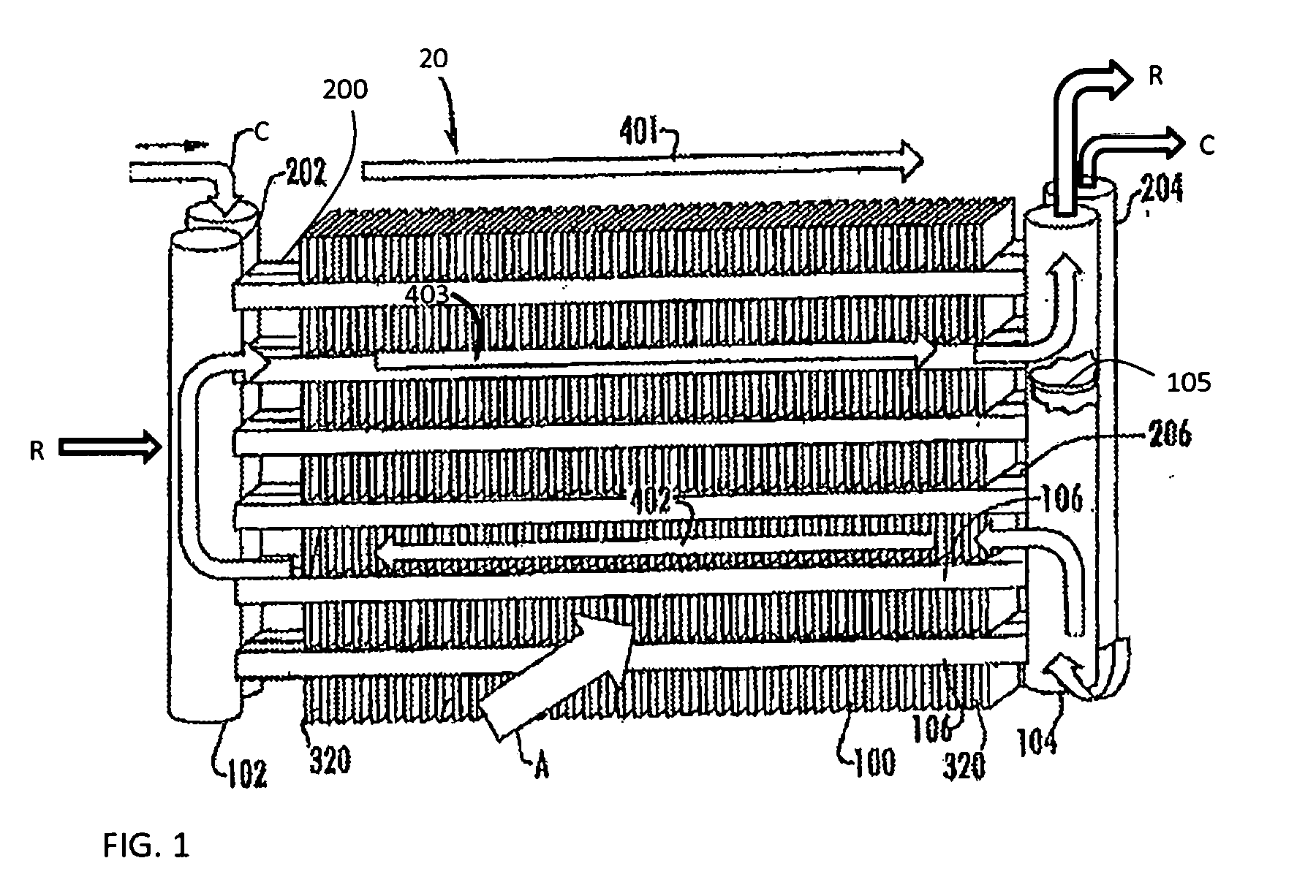

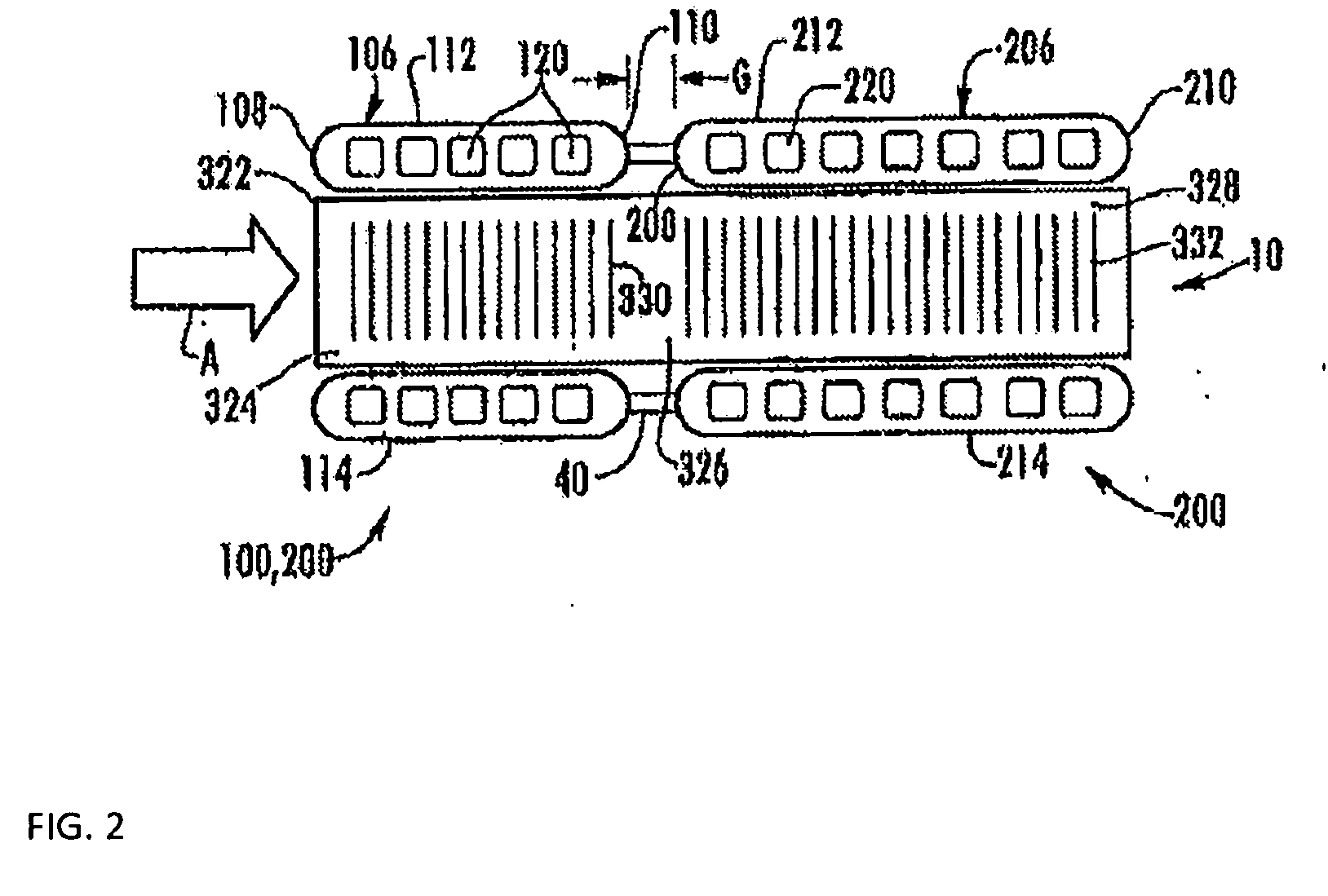

Dual duty microchannel heat exchanger

ActiveUS20160290730A1Evaporators/condensersSubcoolersLeading edgeElectrical and Electronics engineering

A heat exchanger includes a first tube bank having at least a first and a second flattened tube segments extending longitudinally in spaced parallel relationship. A second tube bank includes at least a first group of flattened tube segments and a second group of flattened tube segments extending longitudinally in spaced parallel relationship. The second tube bank is disposed behind the first tube bank with a leading edge of the second tube bank spaced from a trailing edge of the first tube bank. The first group of flattened tube segments is configured to receive a first fluid. The second group of flattened tube segments is configured to receive a second fluid. A fan provides an airflow across the first tube bunk and the second tube bank sequentially.

Owner:CARRIER CORP

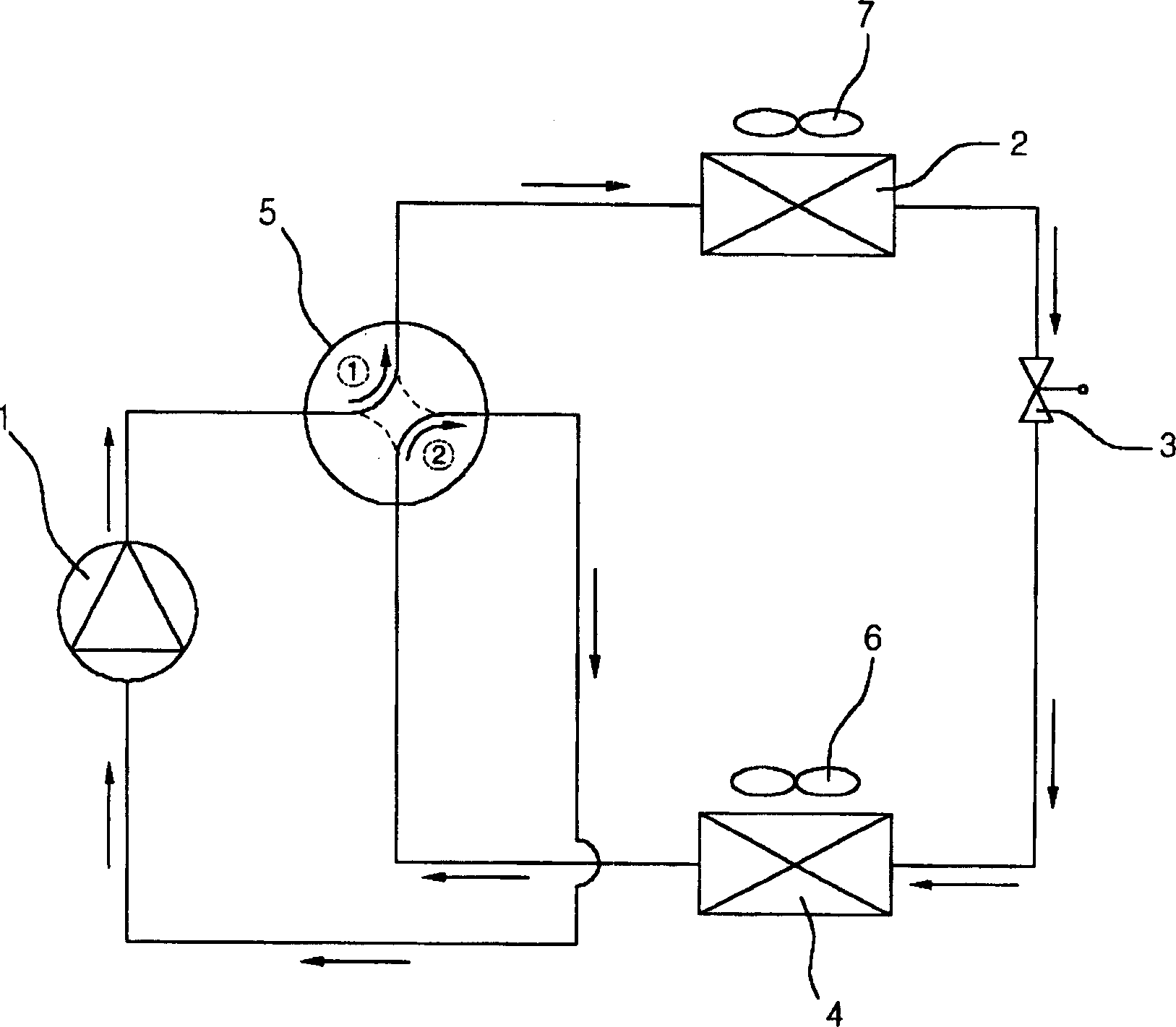

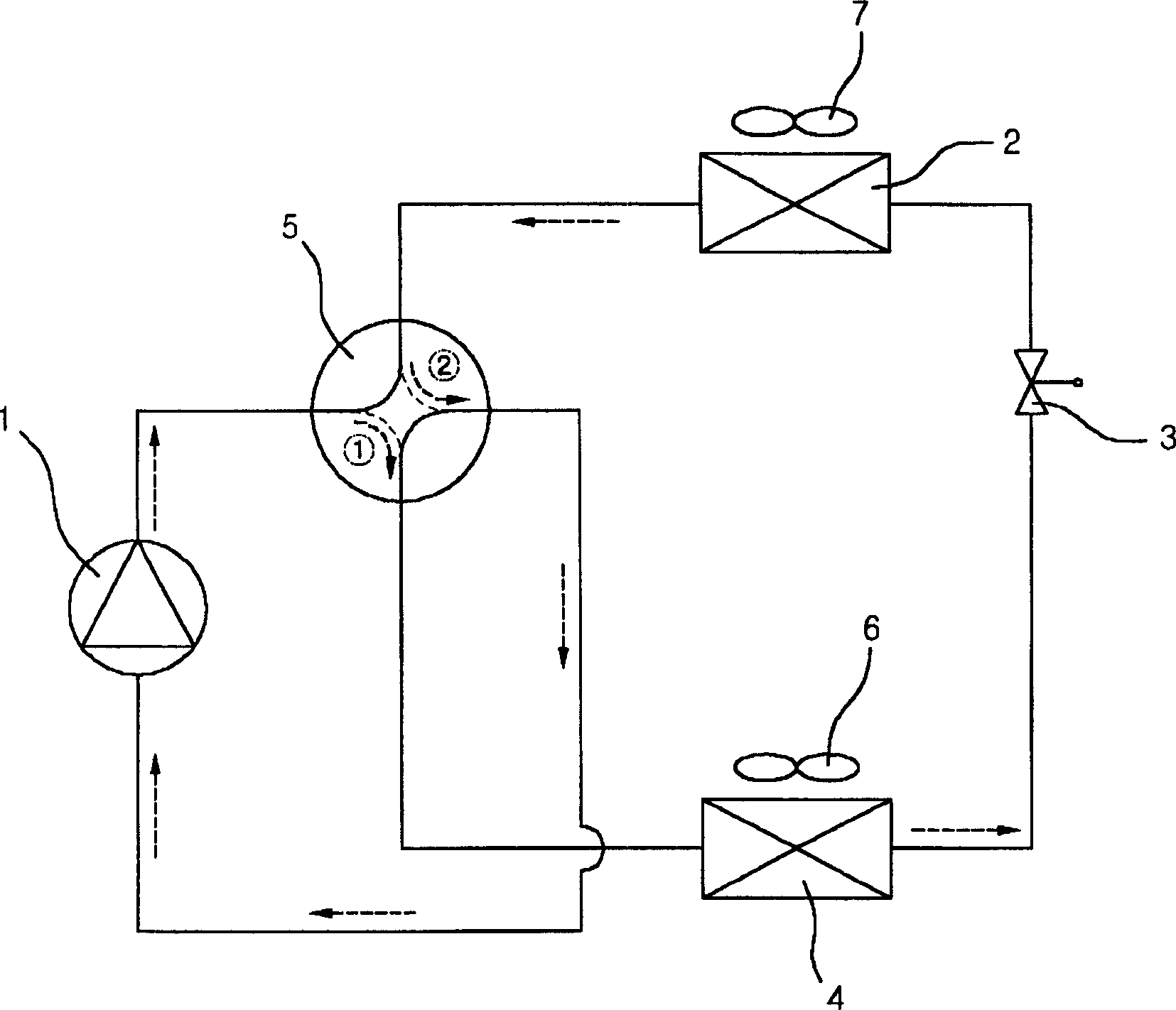

Air conditioner comprising heat exchanger and means for switching cooling cycle

InactiveCN1590927AIncrease subcoolingImprove refrigerant flow characteristicsCompression machines with non-reversible cycleSpace heating and ventilation detailsCounter flowEngineering

The present invention relates to an air conditioner capable of performing heat exchange of refrigerant and cooling and heating operations. According to the invention, a dual-tube heat exchanger is disposed at the entrance of a compressor and a means for switching a cooling cycle is installed between an outdoor heat exchanger including a condenser and an indoor heat exchanger including an evaporator so that in an air conditioning mode, heat change between mid-temperature, high-pressure liquid refrigerant at the exit of the condenser and low-temperature, low-pressure superheated refrigerant at the exit of the evaporator is performed more effectively and as a result of this, super heating of the liquid refrigerant at the exit of the condenser is increased, refrigerant flow characteristics of an expansion unit are improved, and enthalpy at the entrance side of the evaporator is reduced, causing a greater enthalpy difference at the entrance and exit of the evaporator and improving air conditioning capacity overall. Moreover, the heat exchanger of the present invention has a dual tube structure and uses a counter flow or parallel flow for performing heat exchange.

Owner:LG ELECTRONICS INC

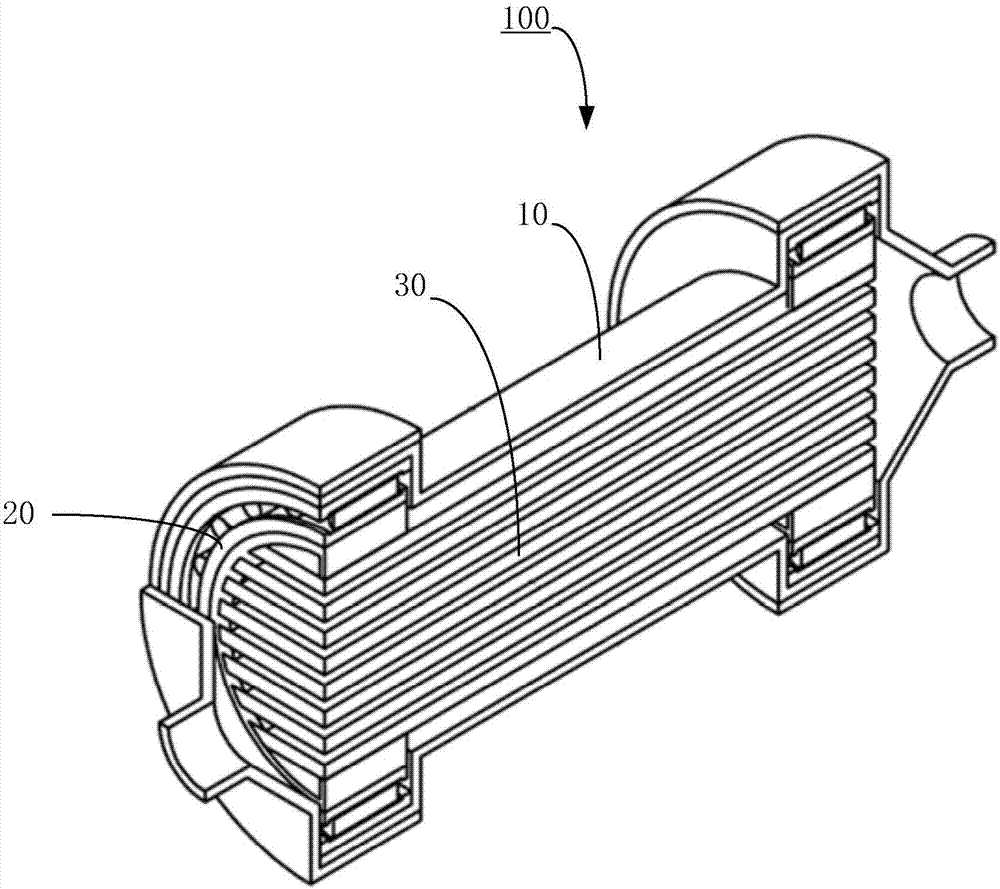

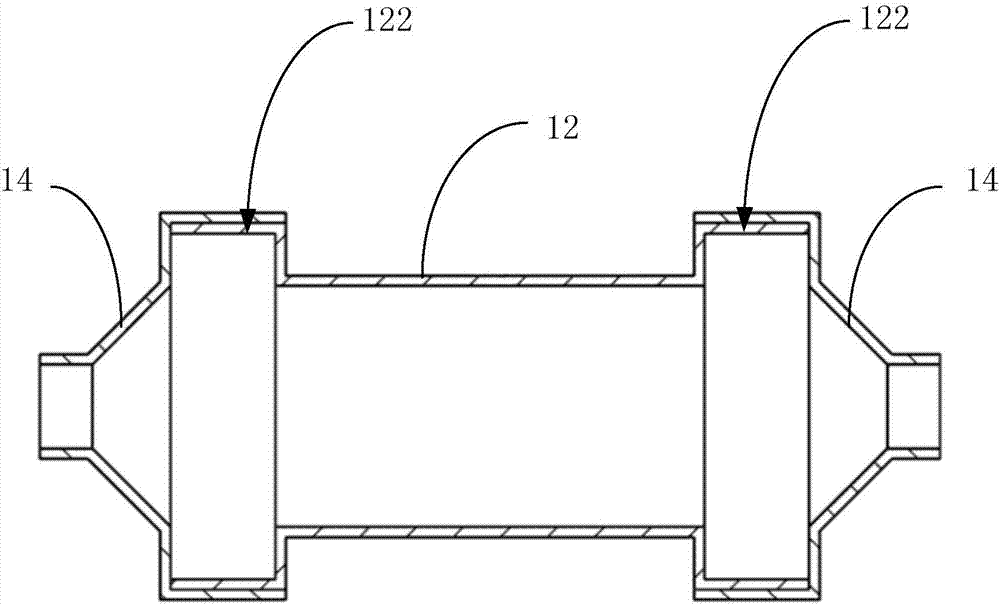

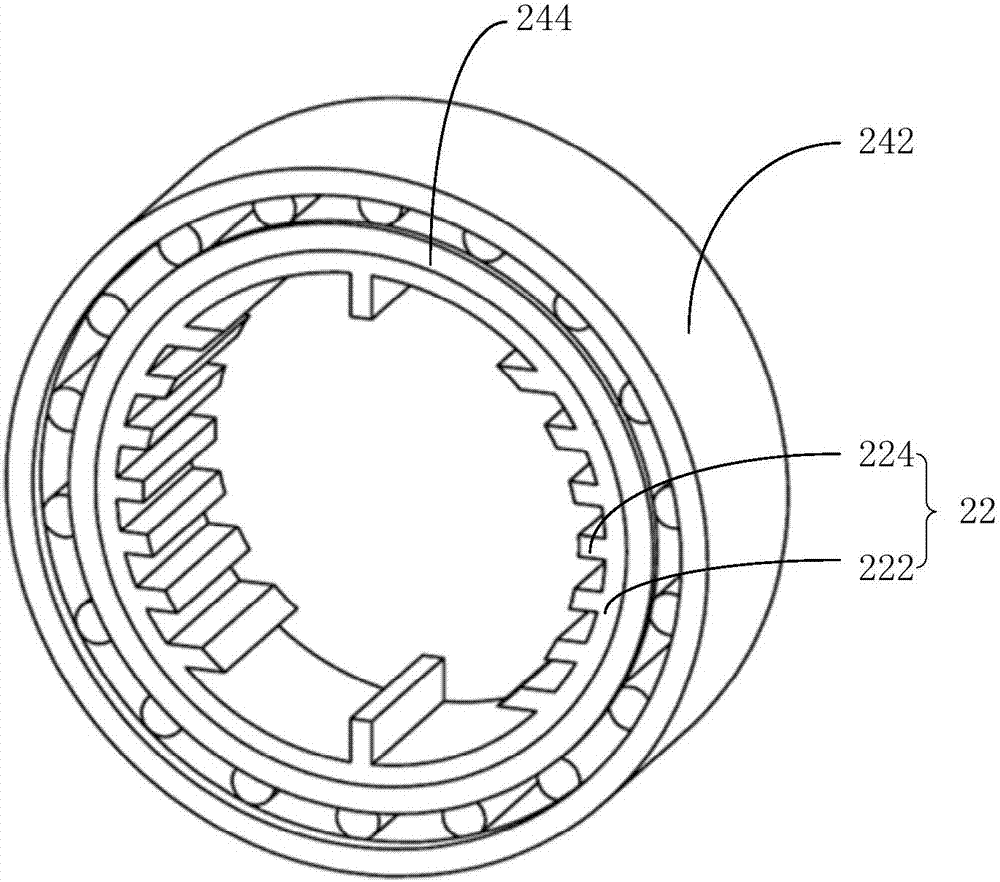

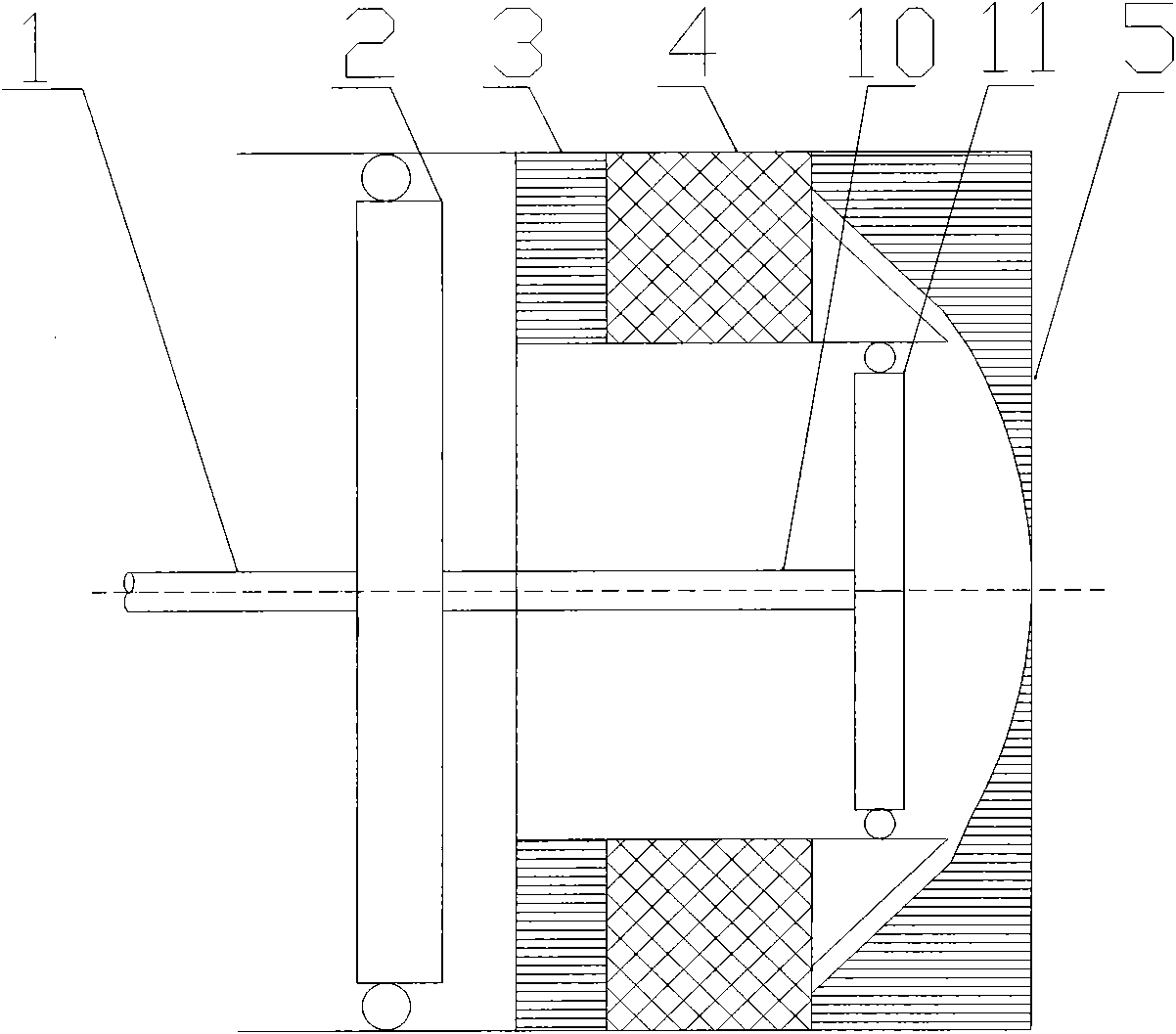

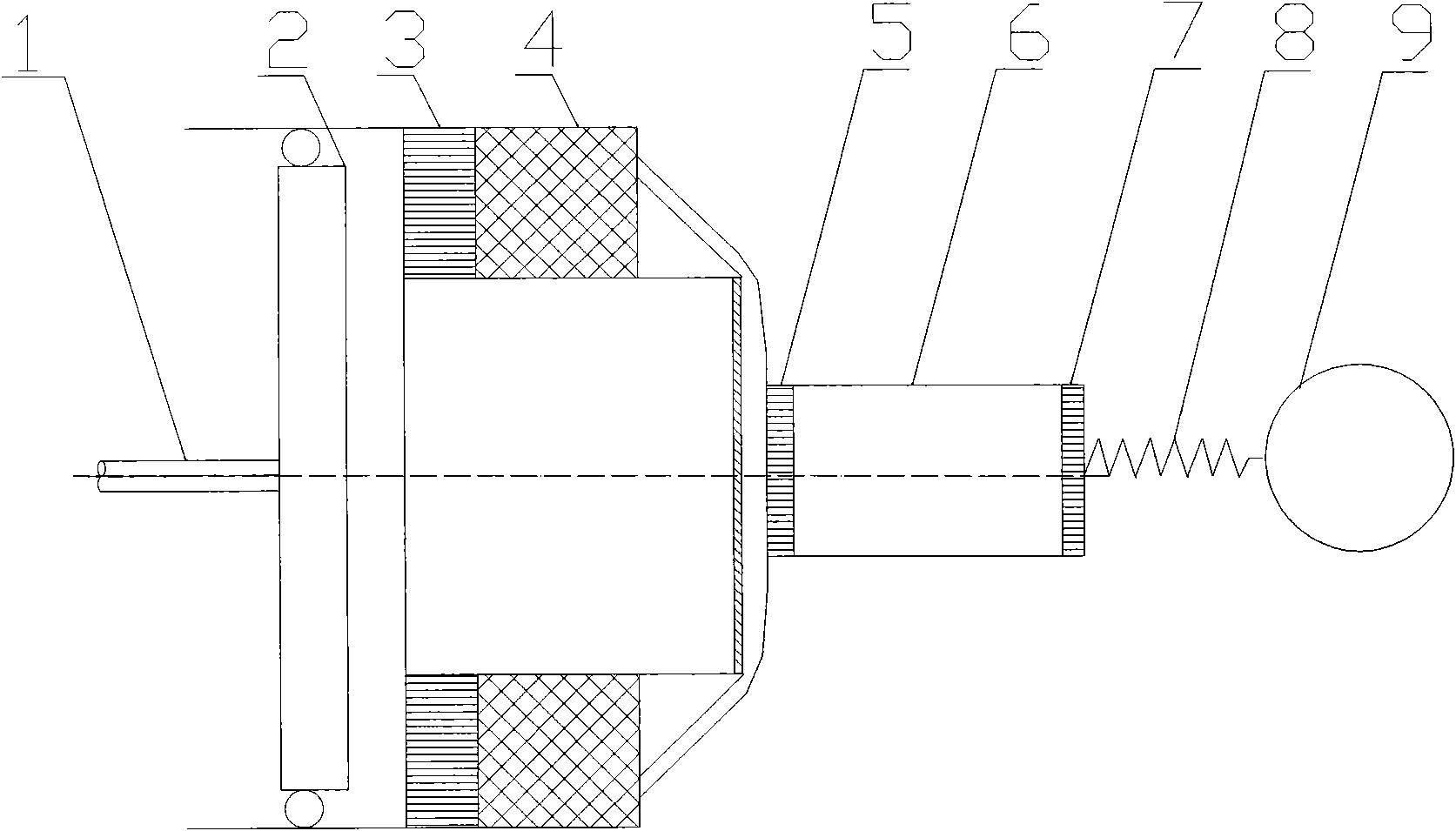

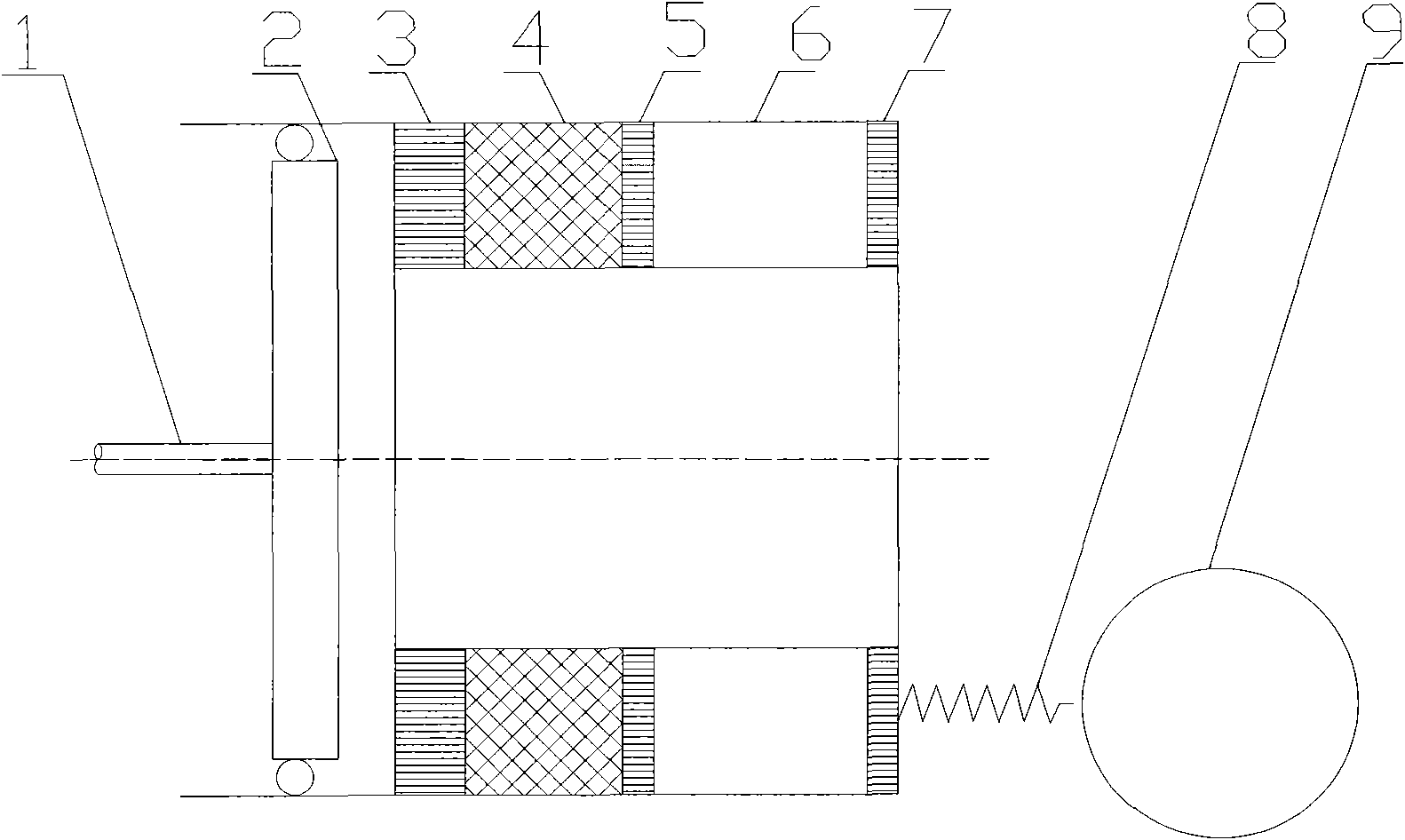

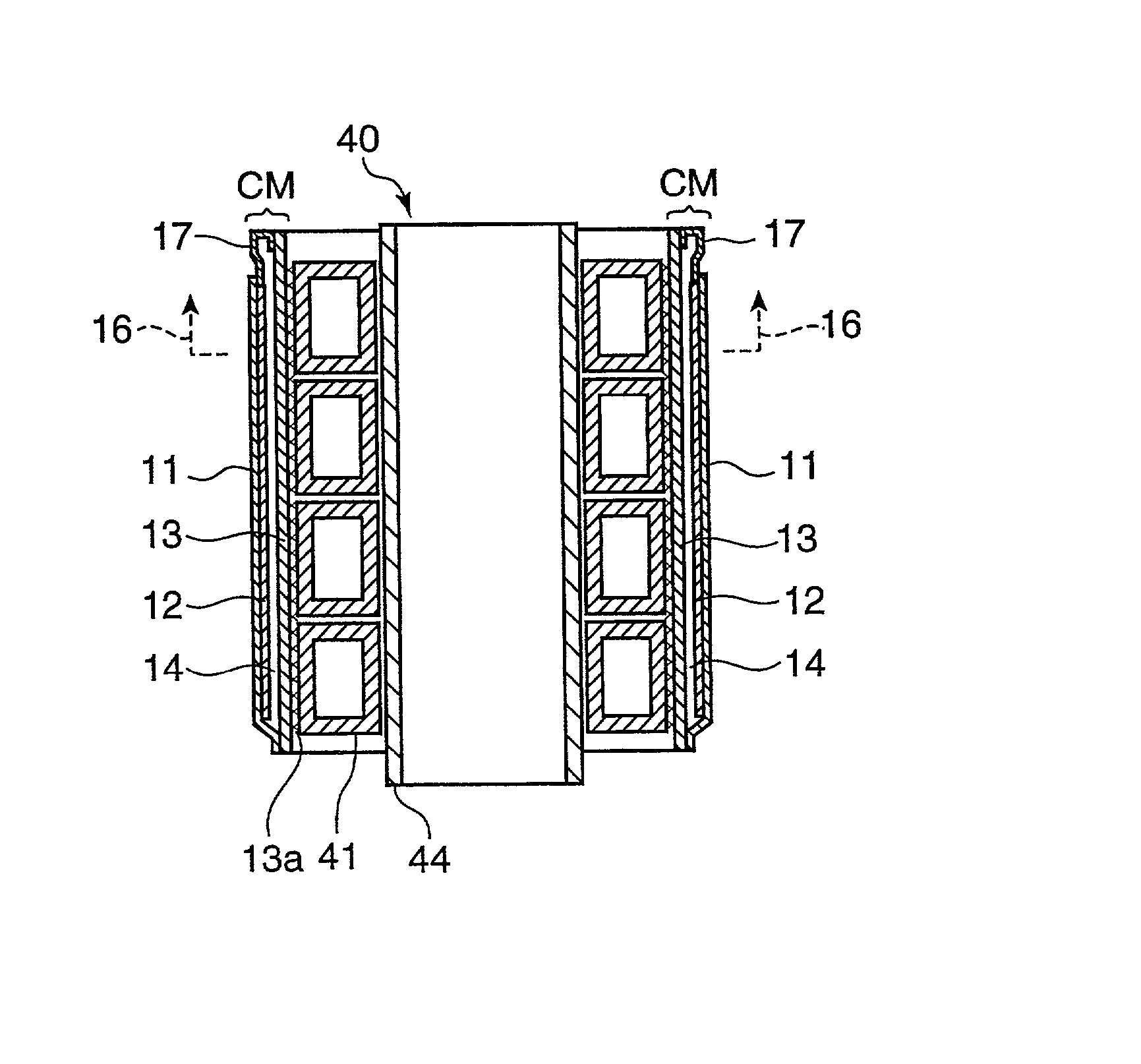

Active magnetic regenerator and magnetic refrigeration system

ActiveCN106949673AGive full play to the magnetocaloric effectLarge alternating stressMachines using electric/magnetic effectsSuperheatersMagnetic tension forceEngineering

The invention discloses an active magnetic regenerator and a magnetic refrigeration system. The active magnetic regenerator comprises a shell, a rotating mechanism and a magneto-thermal unit, wherein the rotating mechanism and the magneto-thermal unit are arranged in the shell; the rotating mechanism comprises a rotating part and a fixed support, and the fixed support is arranged on the inner wall of the shell through the rotating part; and the magneto-thermal unit comprises a plurality of plate-shaped magneto-thermal materials which are arranged in parallel, and the magneto-thermal units are arranged on the fixed support. According to the active magnetic regenerator, the magneto-thermal unit is arranged inside the shell through the rotating mechanism, when the direction of an external magnetic field changes, the magneto-thermal unit synchronously rotates with the external magnetic field under the action of magnetic torque so that the direction of the external magnetic field can be always kept in the direction with the smallest demagnetization factor of the magneto-thermal materials, magnetic fields in the magneto-thermal materials are ensured to be maximized, the magneto-thermal effect of the magneto-thermal materials is fully exerted, and the optimal refrigerating performance is obtained. Meanwhile, under the action of the magnetic torque, the magneto-thermal unit rotates, so that large alternating stress is avoided inside the magneto-thermal materials, and the service life of the whole regenerator is prolonged.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Heat exchanger

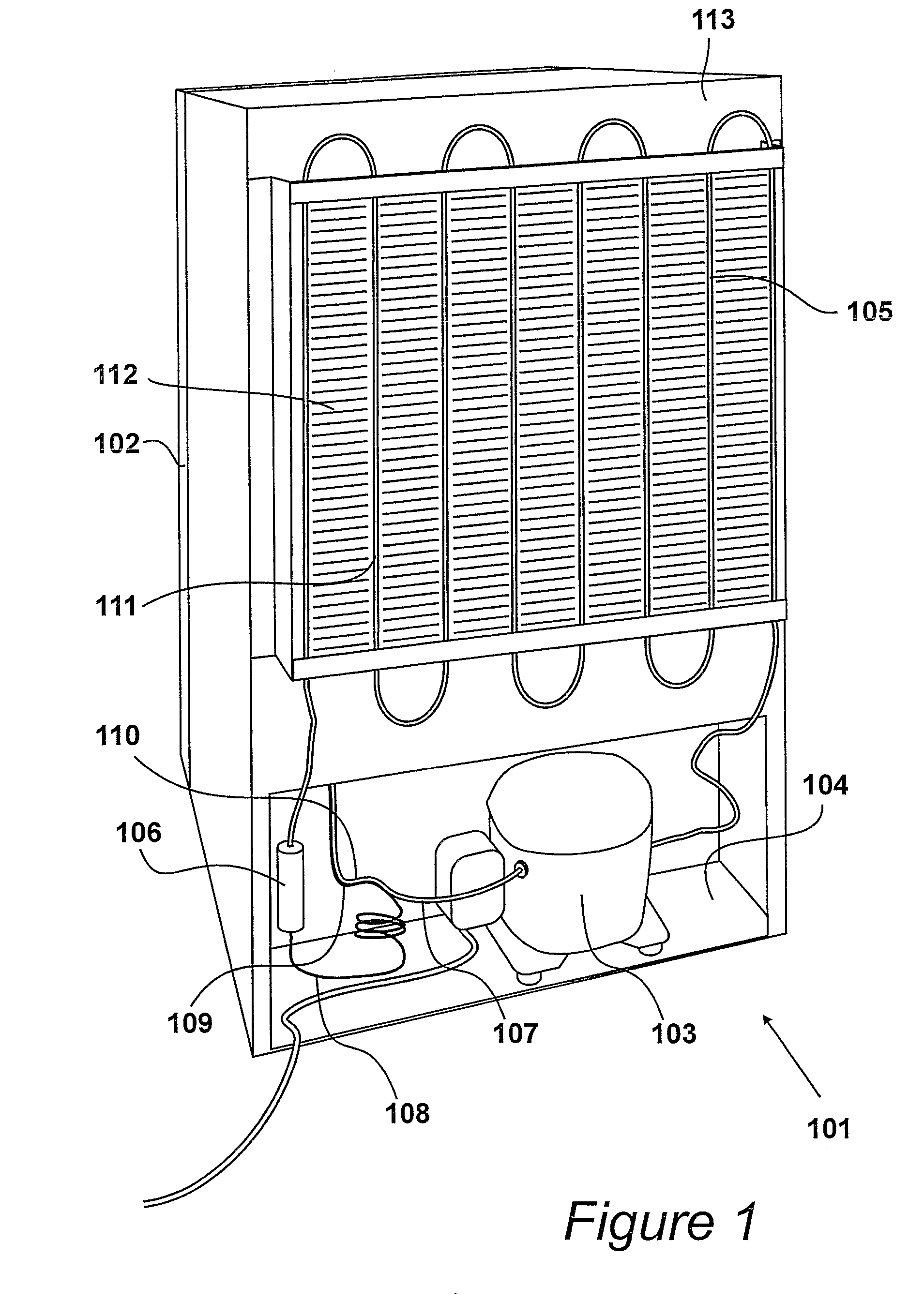

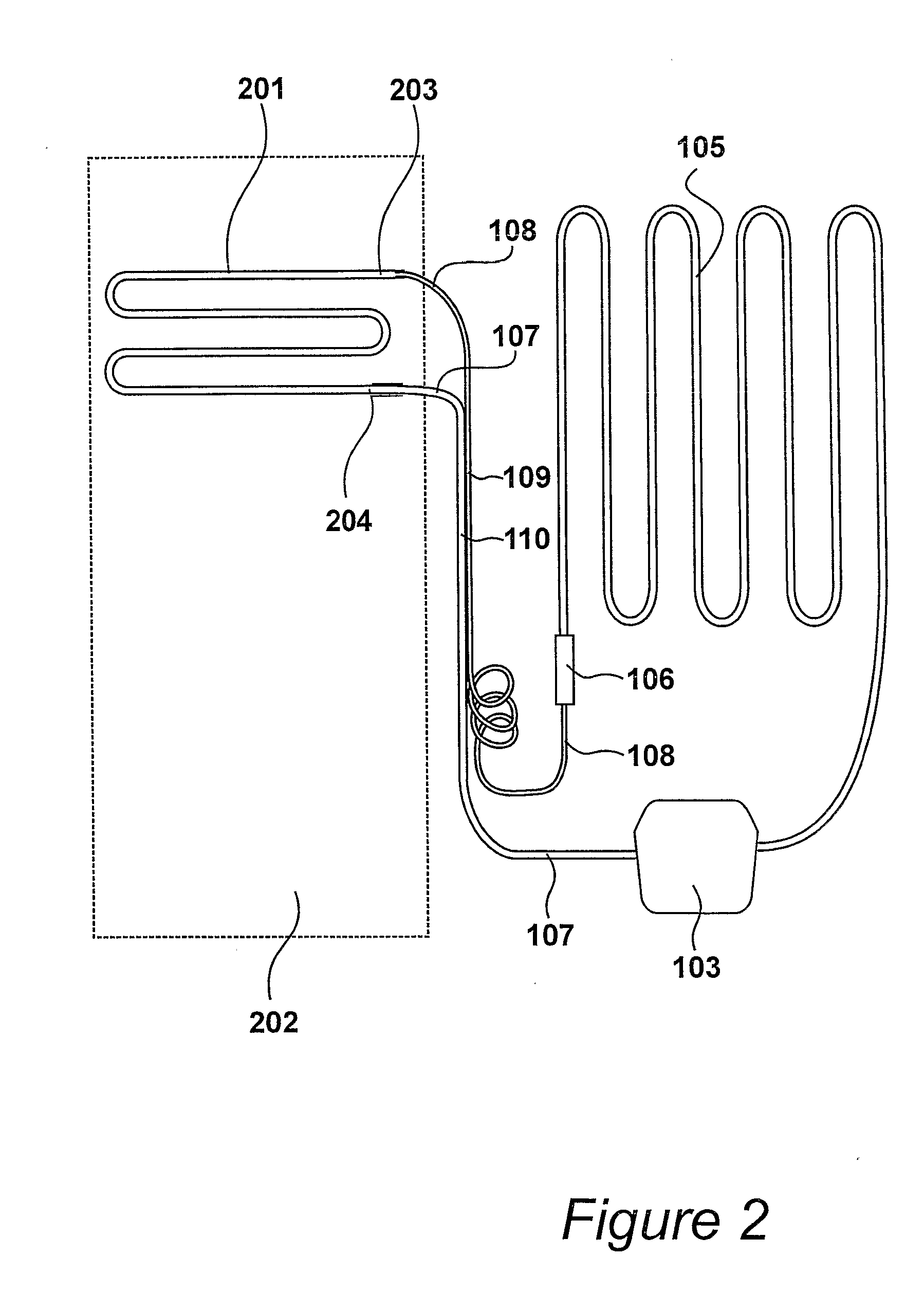

InactiveUS20070215333A1Reduce hardnessEasy to bendMechanical apparatusFluid circulation arrangementWorking fluidTransfer system

A heat exchanger ( 301, 501, 601 ) comprising a first tube ( 107, 507, 607 ) for fluid transmission and a second tube ( 108, 508, 608 ) for fluid transmission within a heat transfer system that uses a working fluid which undergoes compression and evaporation. The first tube is placed in thermal contact with the second tube for a portion ( 109,110 ) of the respective lengths of the first tube and the second tube so as to allow an exchange of heat between the fluid within said tubes. The first tube ( 107, 507, 607 ) is constructed from steel alloy which has alloyed components to reduce the hardness of the steel to facilitate tube bending within a heat transfer system, thereby allowing the first tube to be constructed from the steel within the heat transfer system, in preference to copper.

Owner:BUNDY REFRIGERATION INT HLDG BV

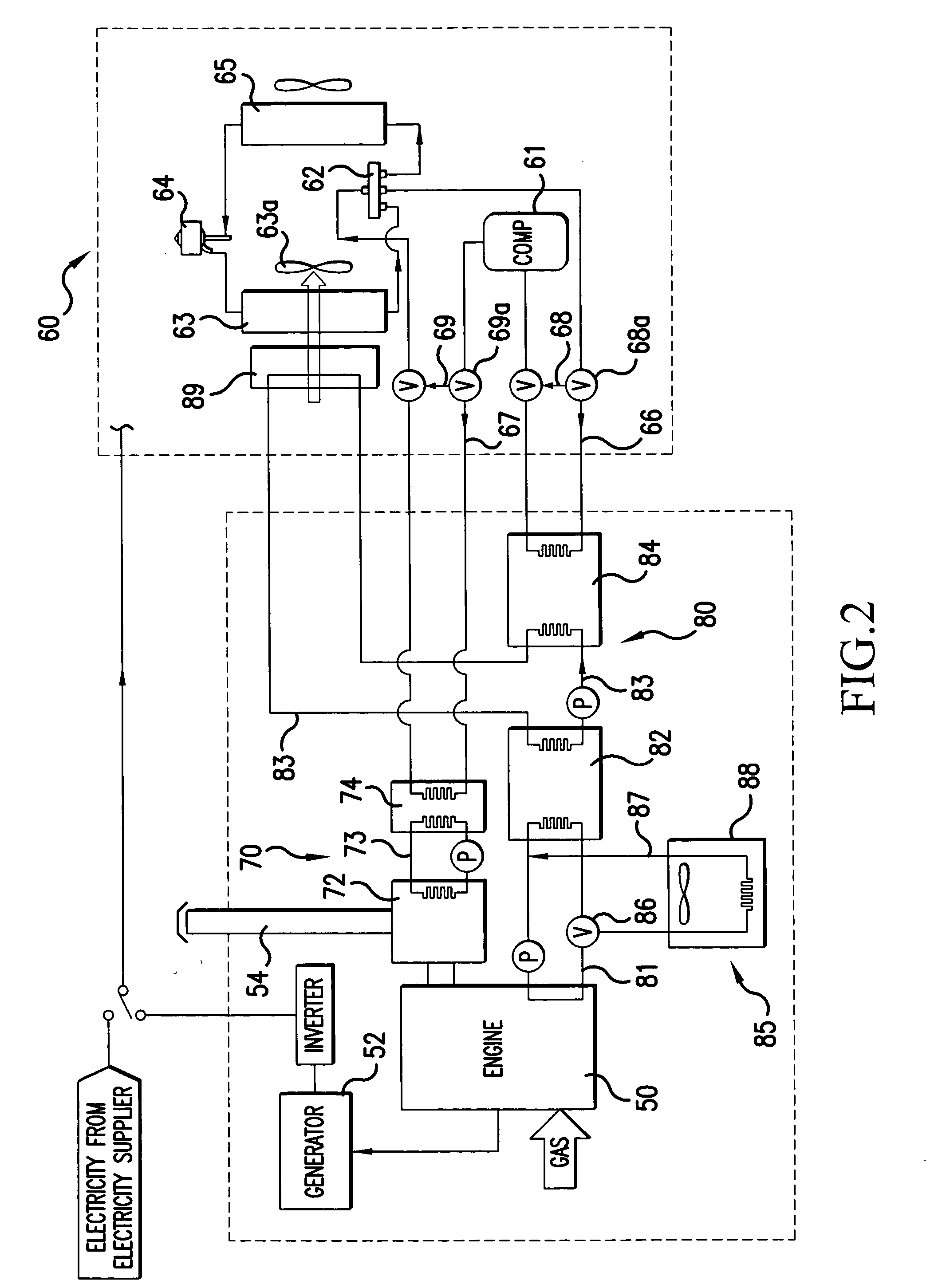

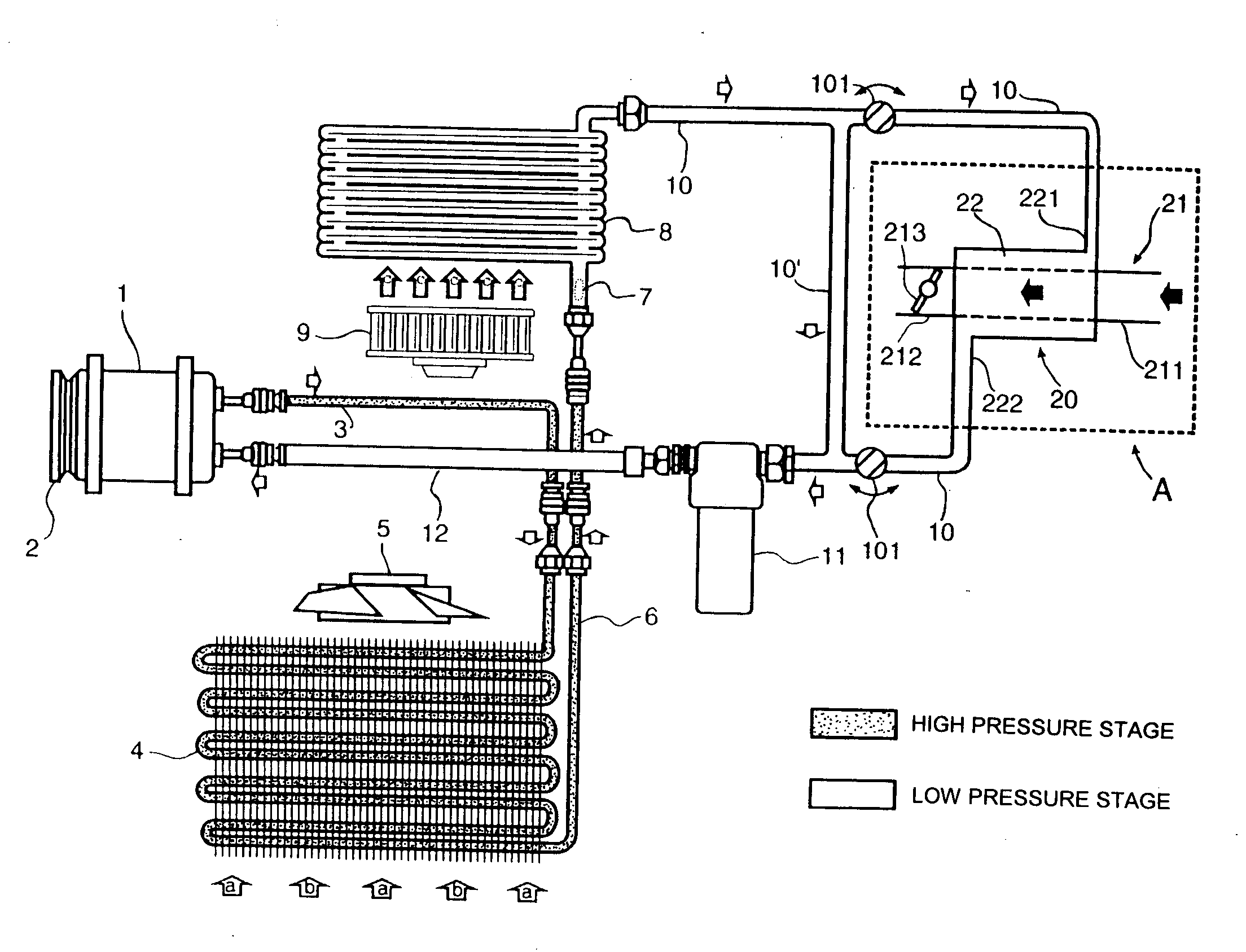

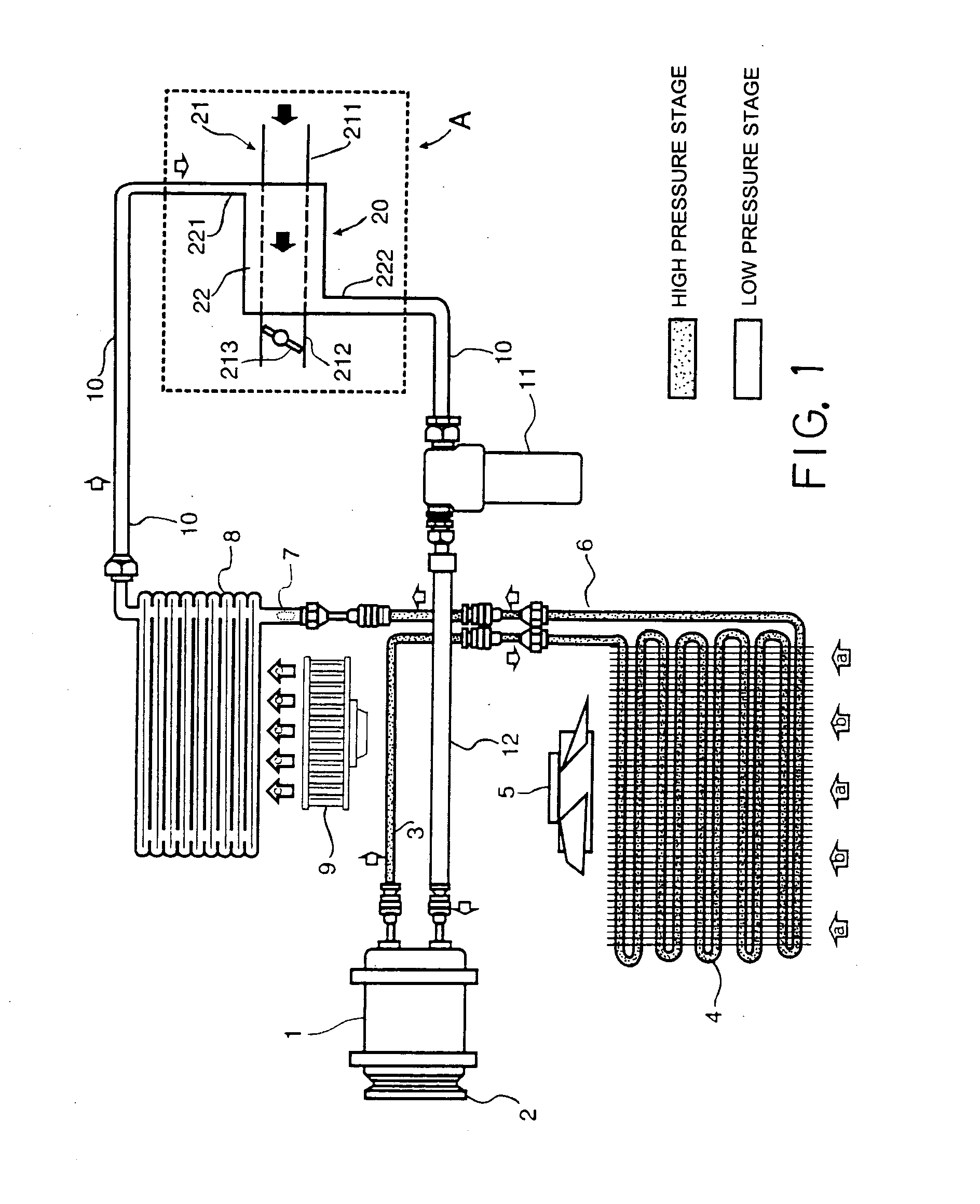

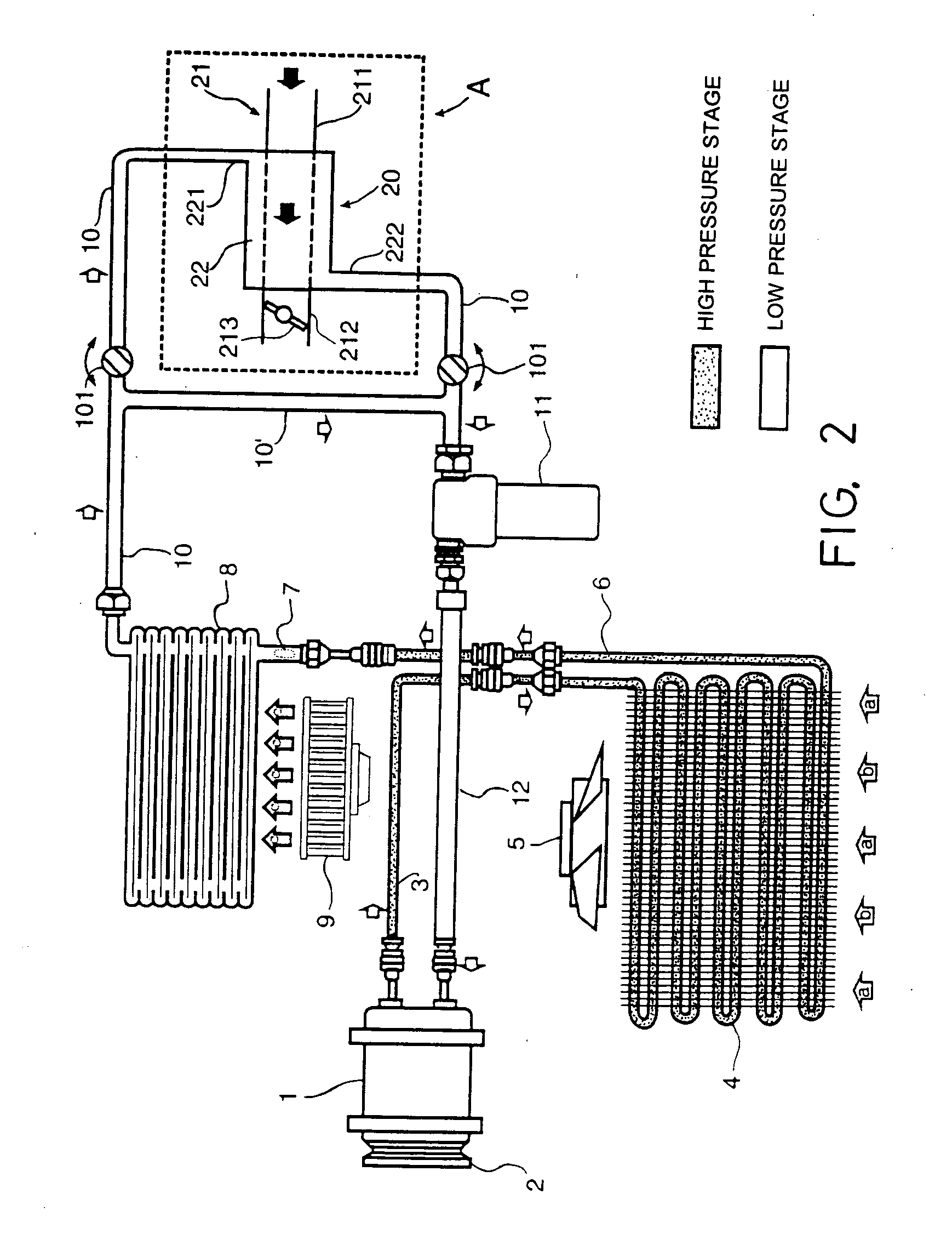

Cogeneration system

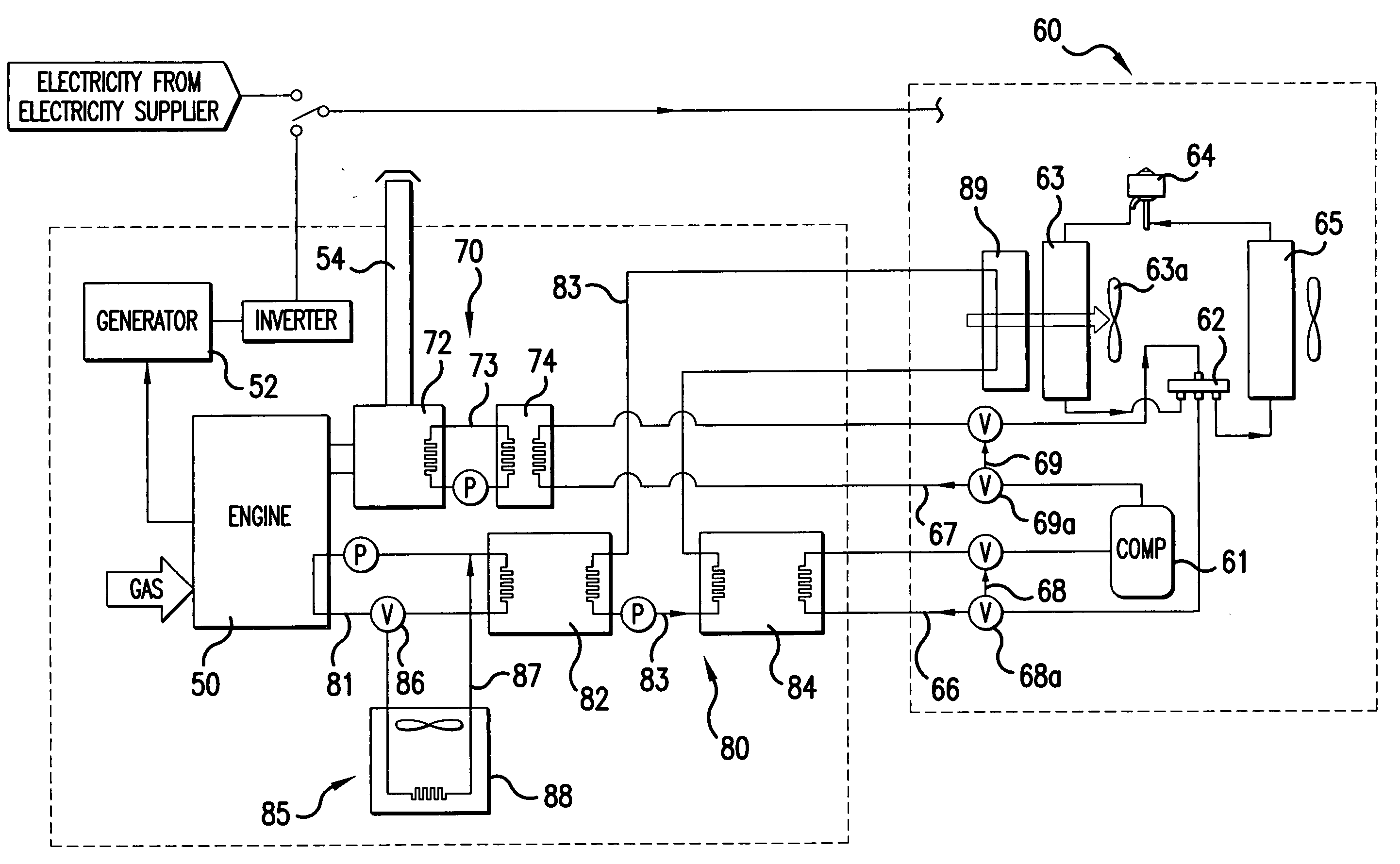

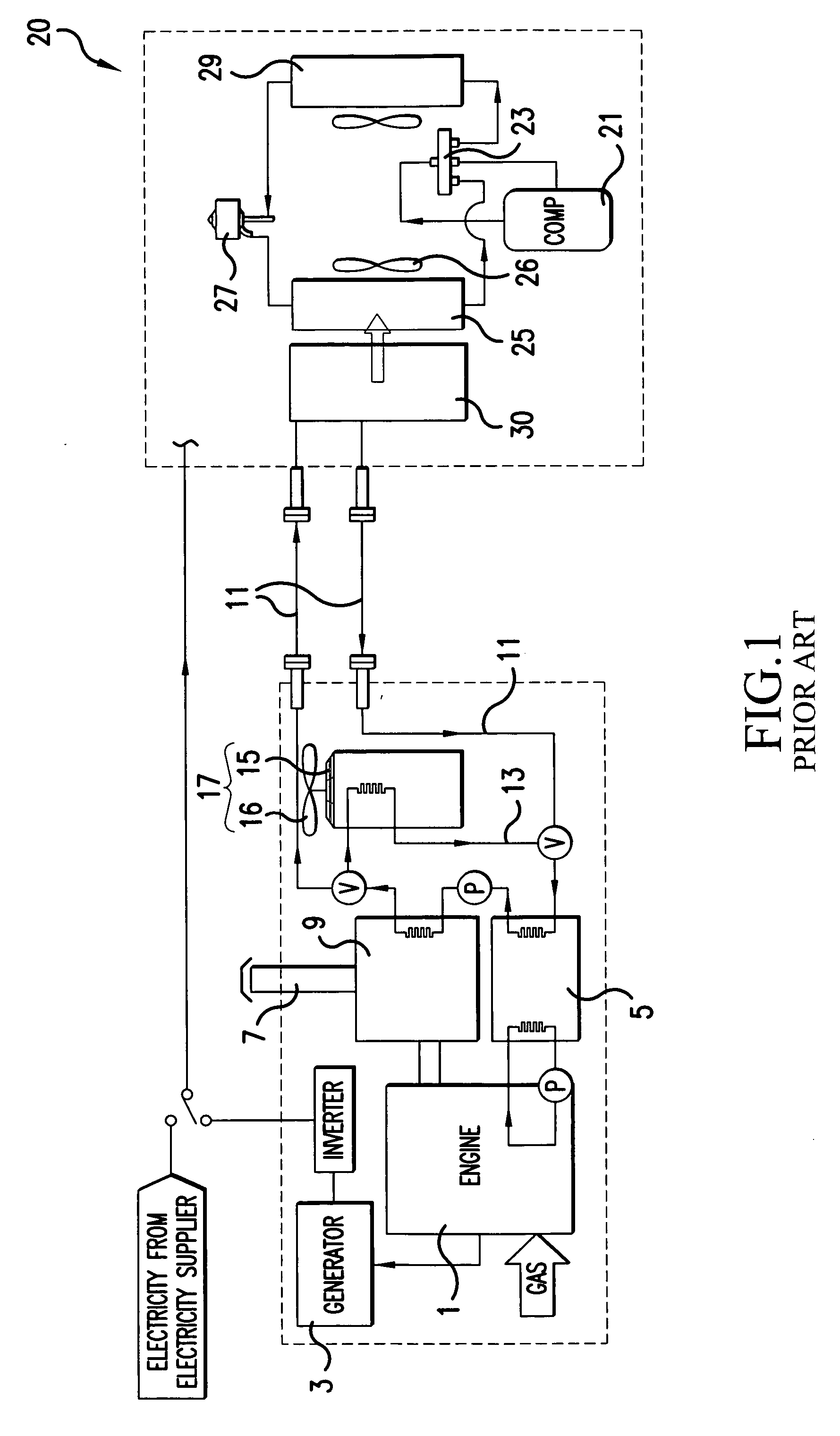

InactiveUS20060037352A1Maximize absorptionPreventing compressor malfunctionHeat pumpsInternal combustion piston enginesElectricityFour-way valve

A cogeneration system including an engine, which drives a generator to generate electricity, a cooling / heating unit, which comprises at least one compressor, a four-way valve, an outdoor heat exchanger, an expansion device, and an indoor heat exchanger, to establish a heat pump type refrigerant cycle, a cooling water heat supplier to supply heat of cooling water used to cool the engine to a suction side of the compressor of the cooling / heating unit and to pre-heat air passing through the outdoor heat exchanger, and a discharge-side refrigerant over-heater to supply heat of exhaust gas discharged from the engine to a discharge side of the compressor. In accordance with the cogeneration system, it is possible to maximize absorption of the waste heat of the engine while preventing compressor malfunction, and thus, to increase the refrigerant condensing temperature of the indoor heat exchanger and the refrigerant pre-heating temperature of the outdoor heat exchanger. Thus, an enhancement in heating performance is achieved.

Owner:LG ELECTRONICS INC

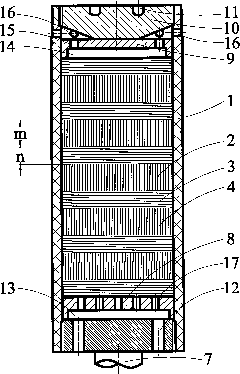

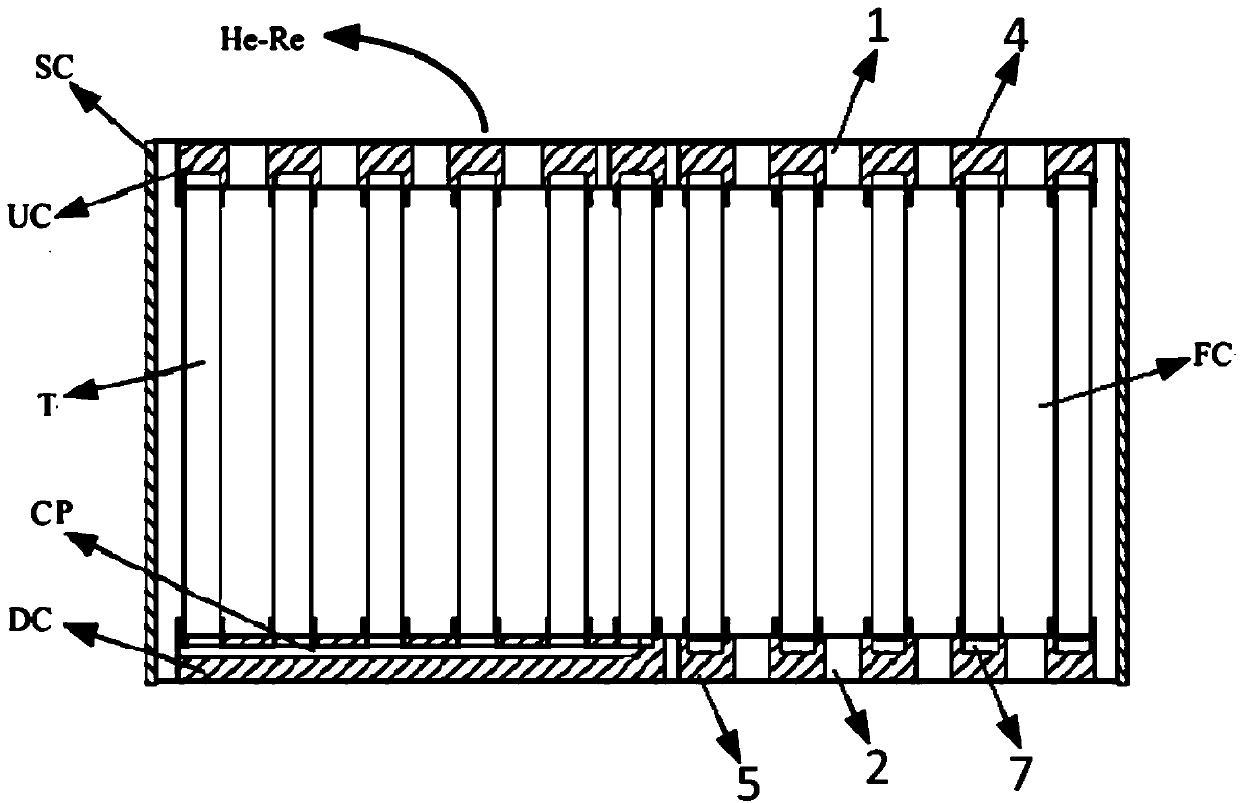

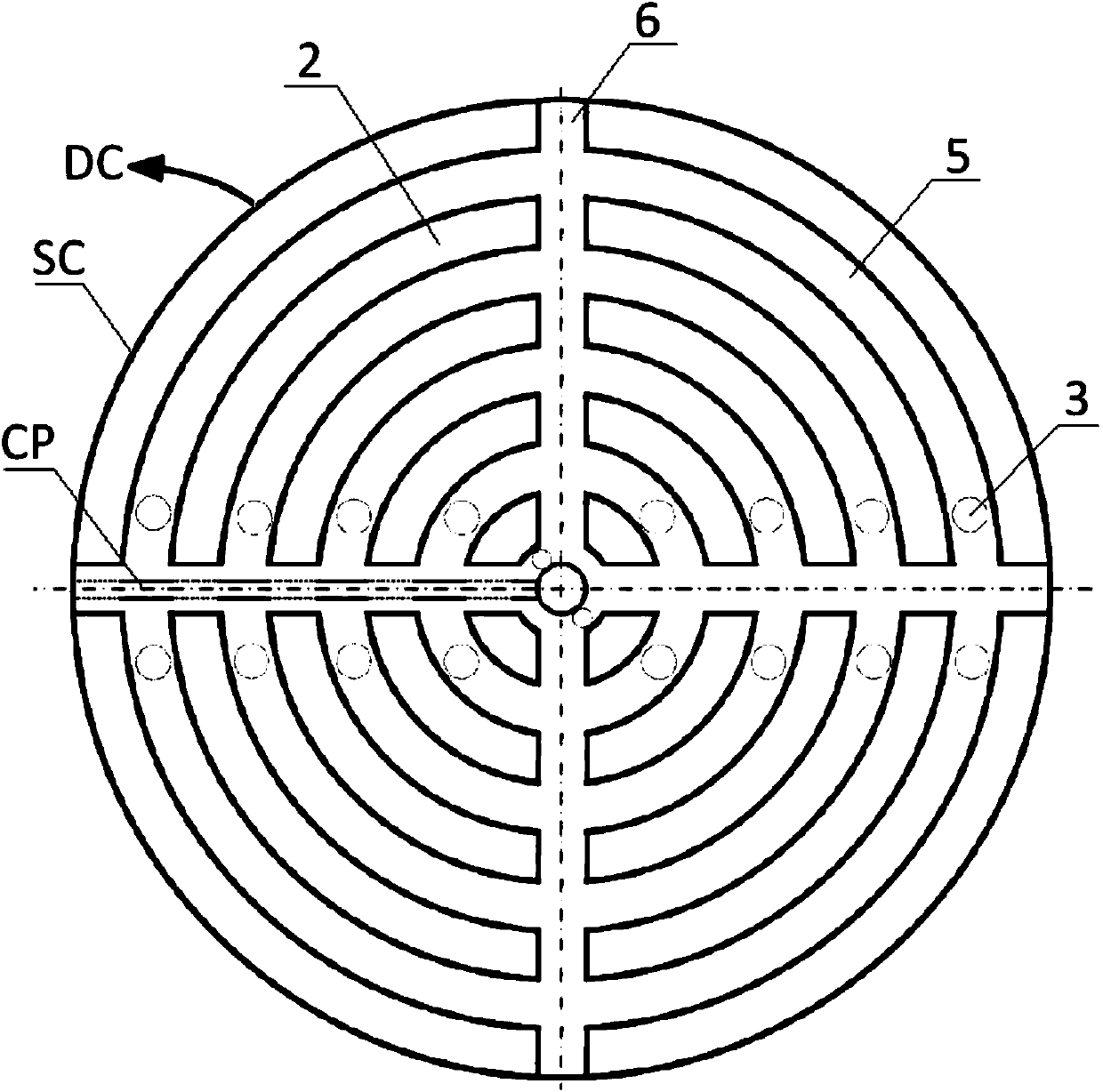

High-power pulse tube refrigerator based on Stirling refrigerator

InactiveCN101561196AImprove reliabilityOvercoming Flow Inhomogeneity ProblemsCompression machinesSuperheatersMature technologyPulse tube refrigerator

The invention discloses a high-power pulse tube refrigerator based on a Stirling refrigerator, which comprises a crank connecting link, a compression piston, an after-stage water cooler, a regenerator, a cold-end heat exchanger and a pulse tube system. A moving part, namely an expansion piston at a cold end of the prior (Phillips) Stirling refrigerator is substituted by the pulse tube system, andthe pulse tube system comprises a pulse tube, a hot-end heat exchanger, an inertance tube and an air reservoir. No moving part exists at a cold end of the high-power pulse tube refrigerator, thereby solving the problems such as machine wear and serious vibration caused by the expansion piston, remarkably improving the reliability of the refrigerator and widening the application range of the refrigerator. The high-power pulse tube refrigerator adopts the annular regenerator with mature technology, reduces the annular flow of gas in the regenerator, effectively solves the problems of nonuniformtemperature and flowing universally existing in the high-power pulse tube refrigerator, and increases the symmetry of radial temperature, thereby reducing the loss of the regenerator in the high-powerpulse tube refrigerator, and improving the efficiency of the refrigerator.

Owner:ZHEJIANG UNIV

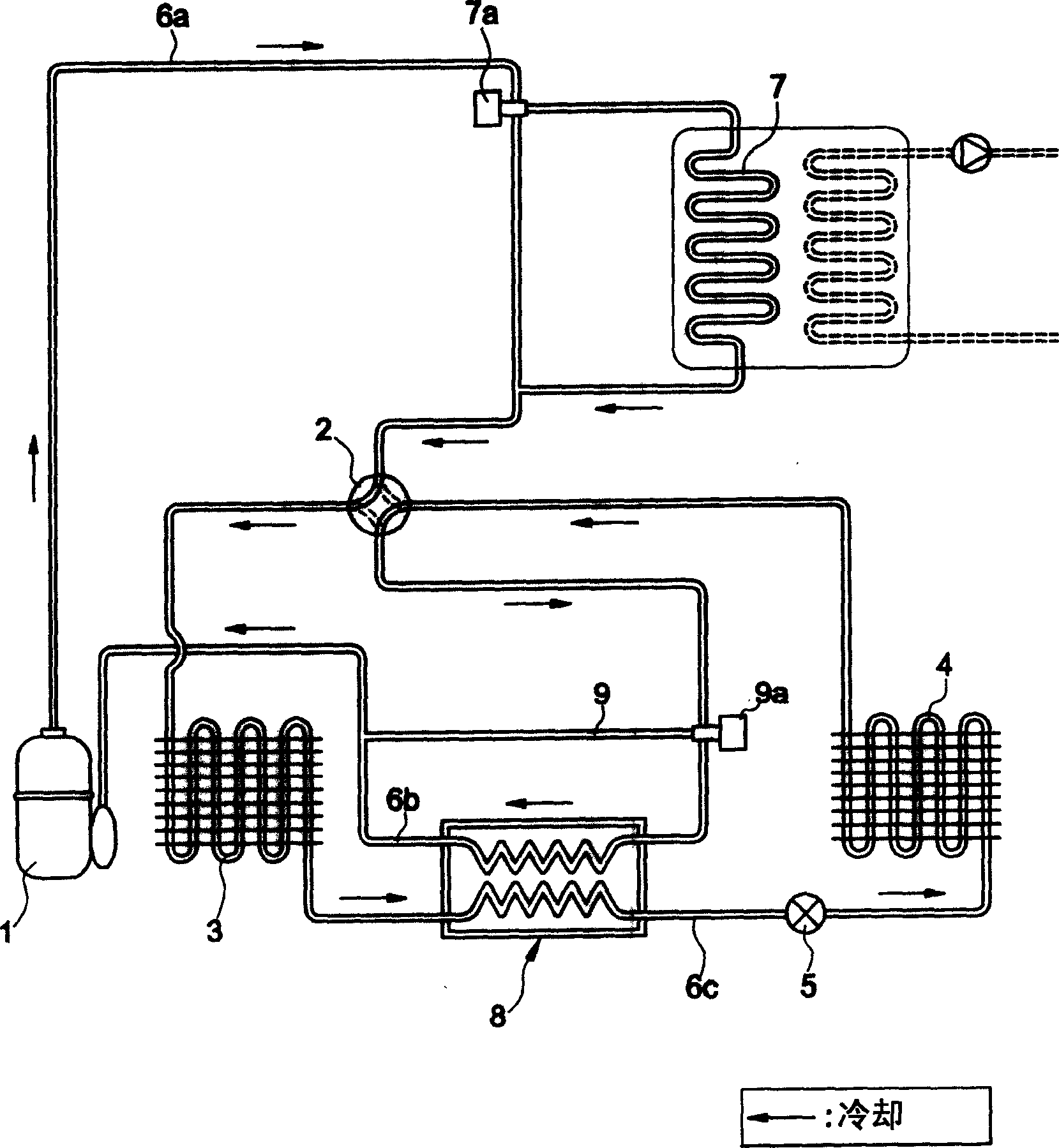

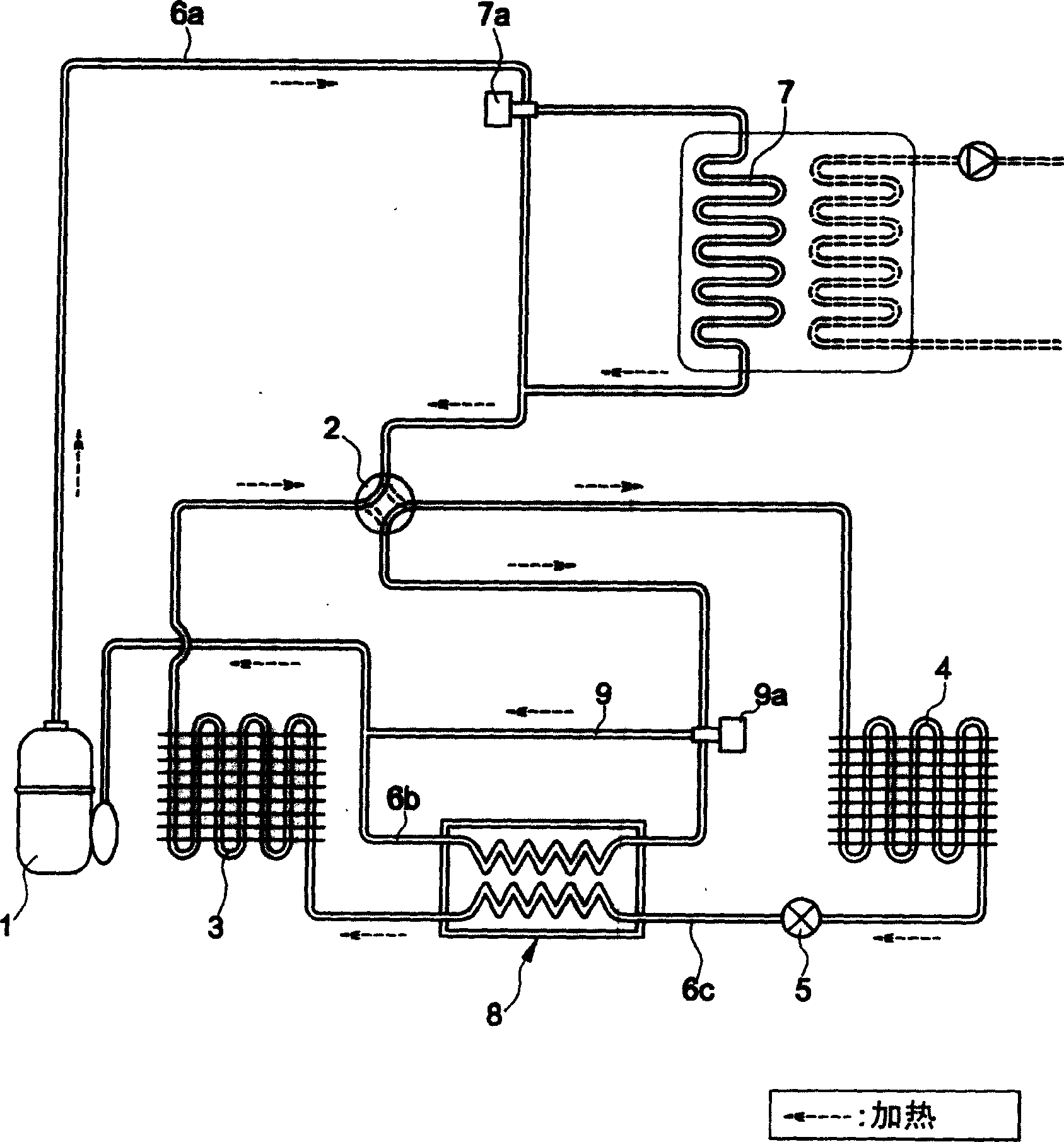

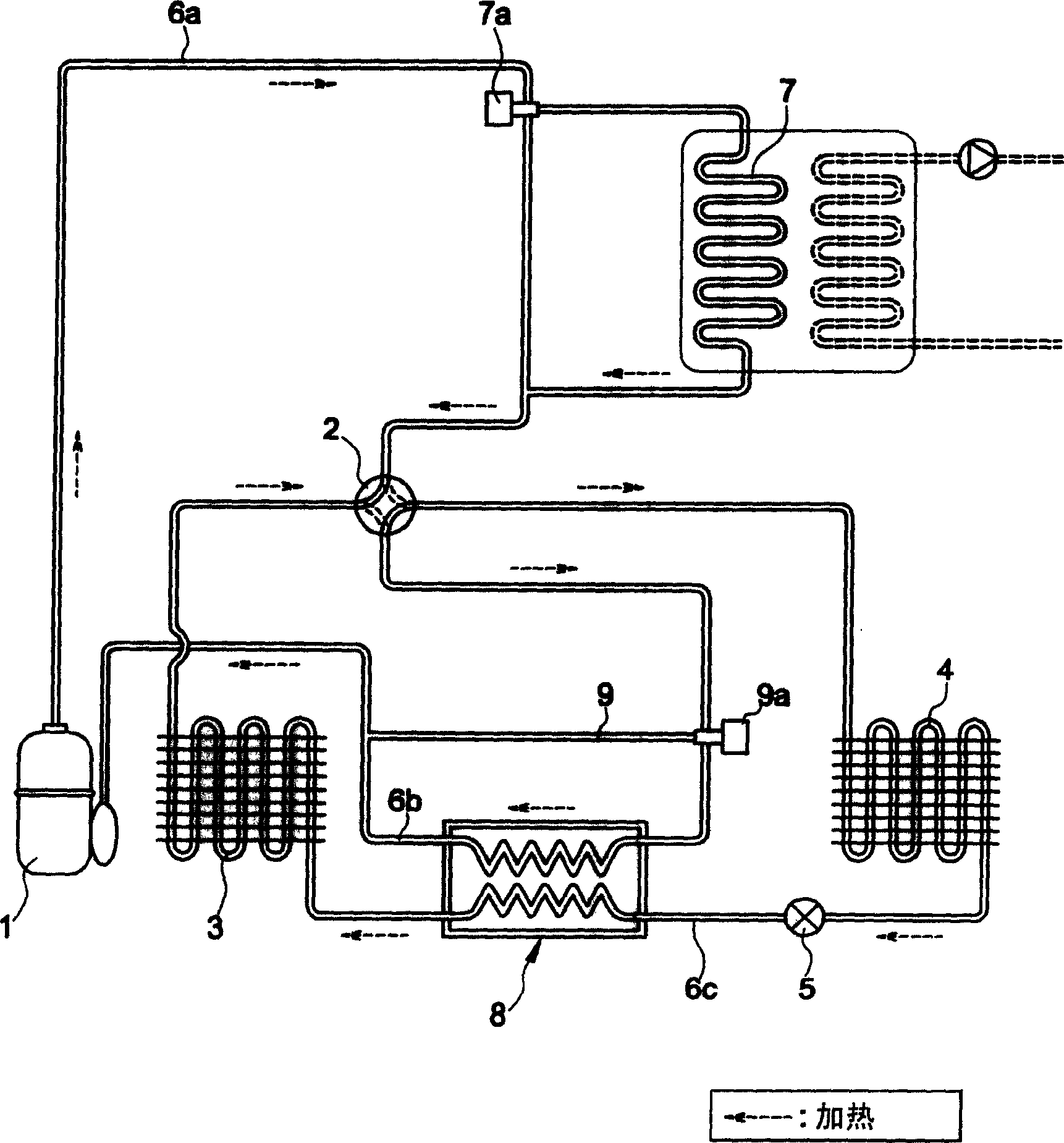

Refrigerating-heating air conditioning system with heat regenerator

ActiveCN103292523AImprove efficiencyImprove cooling effectSuperheatersCompression machines with reversible cycleEngineeringHigh pressure

A refrigerating-heating air conditioning system with a heat regenerator comprises an outdoor heat exchanger and an indoor heat exchanger. The heat regenerator is connected between the outdoor heat exchanger and the indoor heat exchanger. During heating, flowing direction of refrigerants is changed through a four-way reversing valve, the indoor heat exchanger is used as a condenser, and the outdoor unit is used as an evaporator. Refrigerant gas is sucked into a compressor and then pressurized to be changed into high-temperature high-pressure refrigerant gas, the high-temperature high-pressure refrigerant gas is condensed and emits heat in the indoor heat exchanger to be changed into intermediate-temperate high-pressure liquid, indoor air passes the surface of the indoor heat exchanger to be heated so as to increase the indoor temperature, the intermediate-temperate high-pressure liquid is subjected to throttling and depressurization of an expansion valve to be changed into low-temperate low-pressure liquid, the low-temperate low-pressure liquid is changed into low-temperate low-pressure gas in the outdoor heat exchanger, outdoor air passes the surface of the outdoor heat exchanger to be cooled, the low-temperate low-pressure gas is sucked into the compressor, and circulation in the way is carried out. Efficiency of the compressor can be improved, liquid impact is prevented, and optimal refrigerant charge of a system is decreased.

Owner:XI AN JIAOTONG UNIV

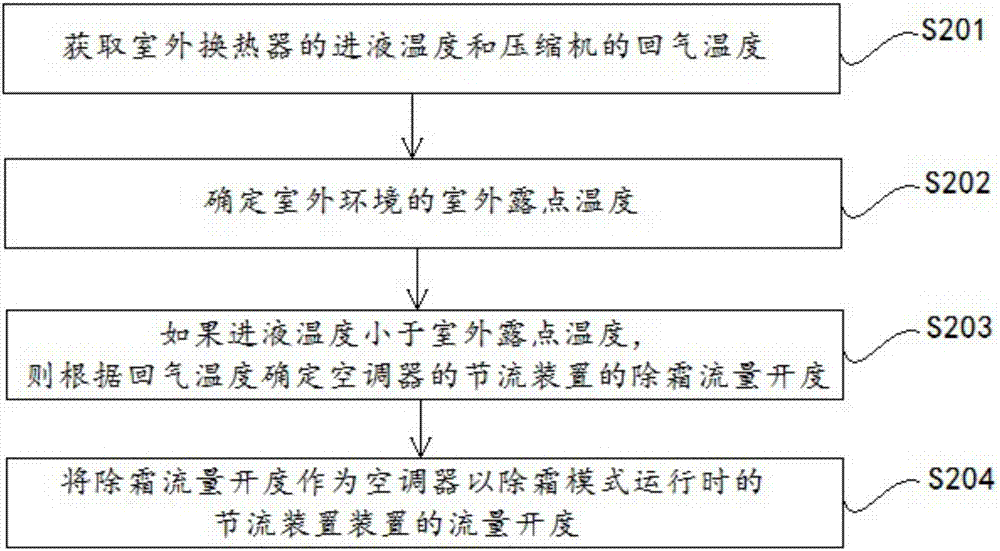

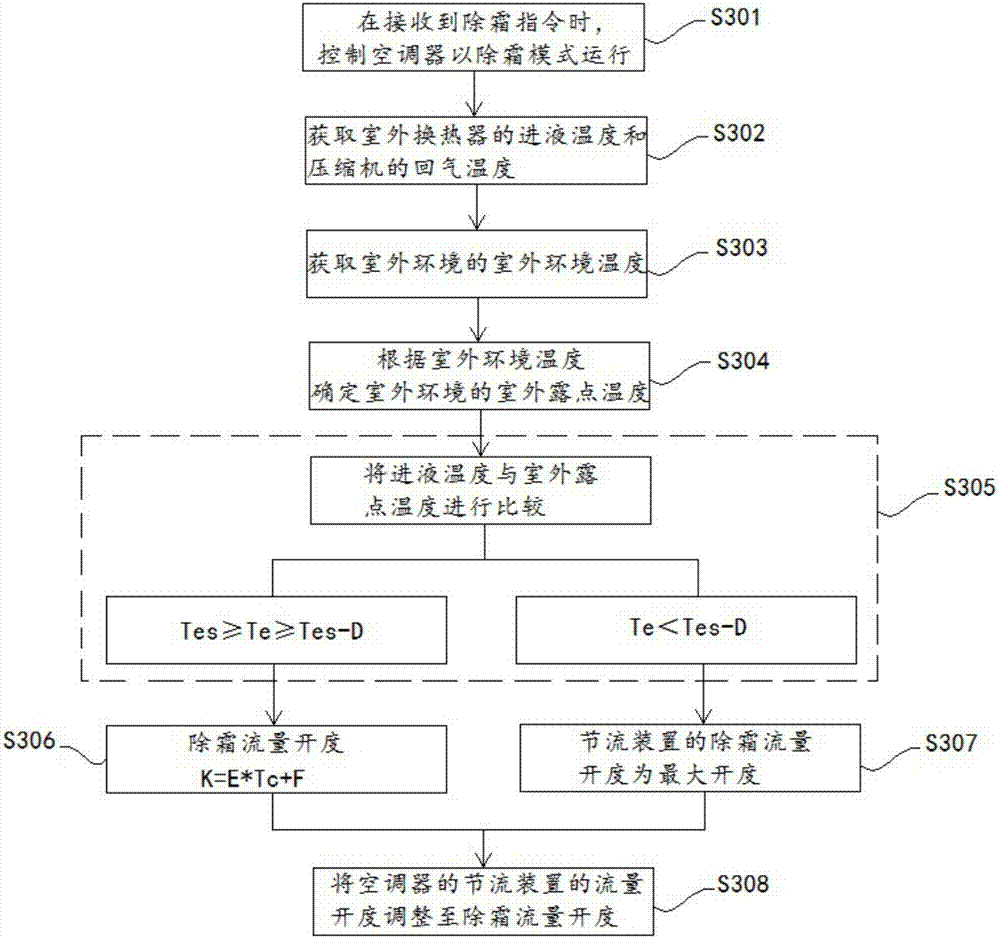

Air conditioner as well as control method and device

InactiveCN107166594AGuaranteed safe operationReduce the amount of refrigerantSpace heating and ventilation safety systemsSpace heating and ventilation control systemsEngineeringInlet temperature

The invention discloses an air conditioner as well as a control method and device and belongs to the technical field of air conditioner defrosting. The air conditioner comprises a heat regenerating device; the heat regenerating device comprises a first heat exchange part and a second heat exchange part which can be used for heat exchange; the first heat exchange part is connected to a first refrigerant pipeline between an indoor heat exchanger and an outdoor heat exchanger; and the second heat exchange part is connected to an air return pipeline of a compressor. According to the air conditioner disclosed by the invention, the heat regenerating device is additionally arranged in an air conditioner pipeline, and the defrosting opening of a throttling device can be regulated according to the air return temperature of the compressor under the condition that a liquid refrigerant flows back to the compressor because the liquid inlet temperature of the outdoor heat exchanger is lower than an outdoor dew point temperature, so that the refrigerant flowing into the outdoor heat exchanger through the throttling device is adapted with the current defrosting condition; and the liquid refrigerant flowing back to the compressor is heated and vaporized by virtue of the heat regenerating device, so that the quantity of the refrigerant condensed into a liquid when flowing through the outdoor heat exchanger is reduced, and the safe and effective operation of the whole of the compressor and the air conditioner is guaranteed.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

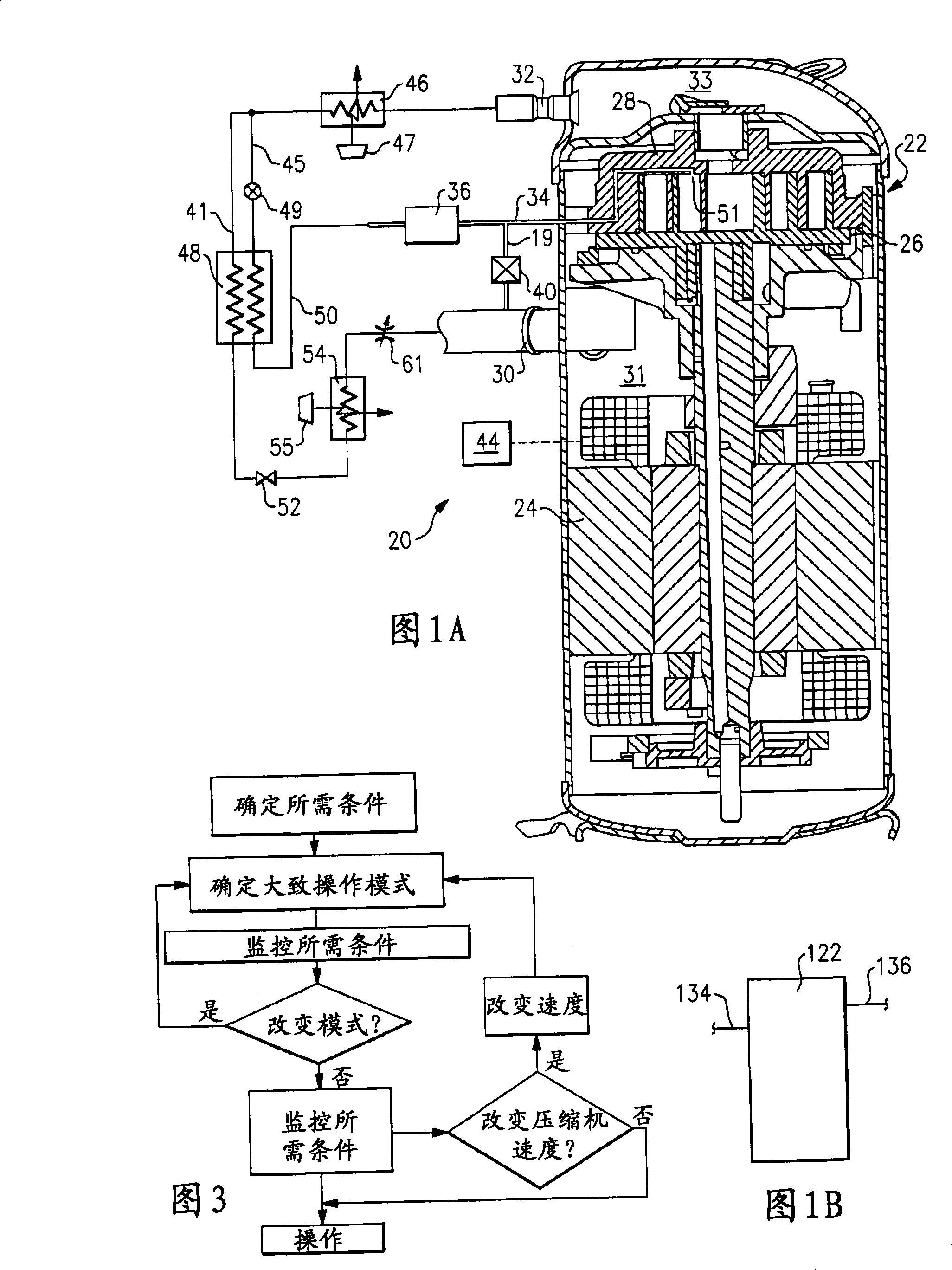

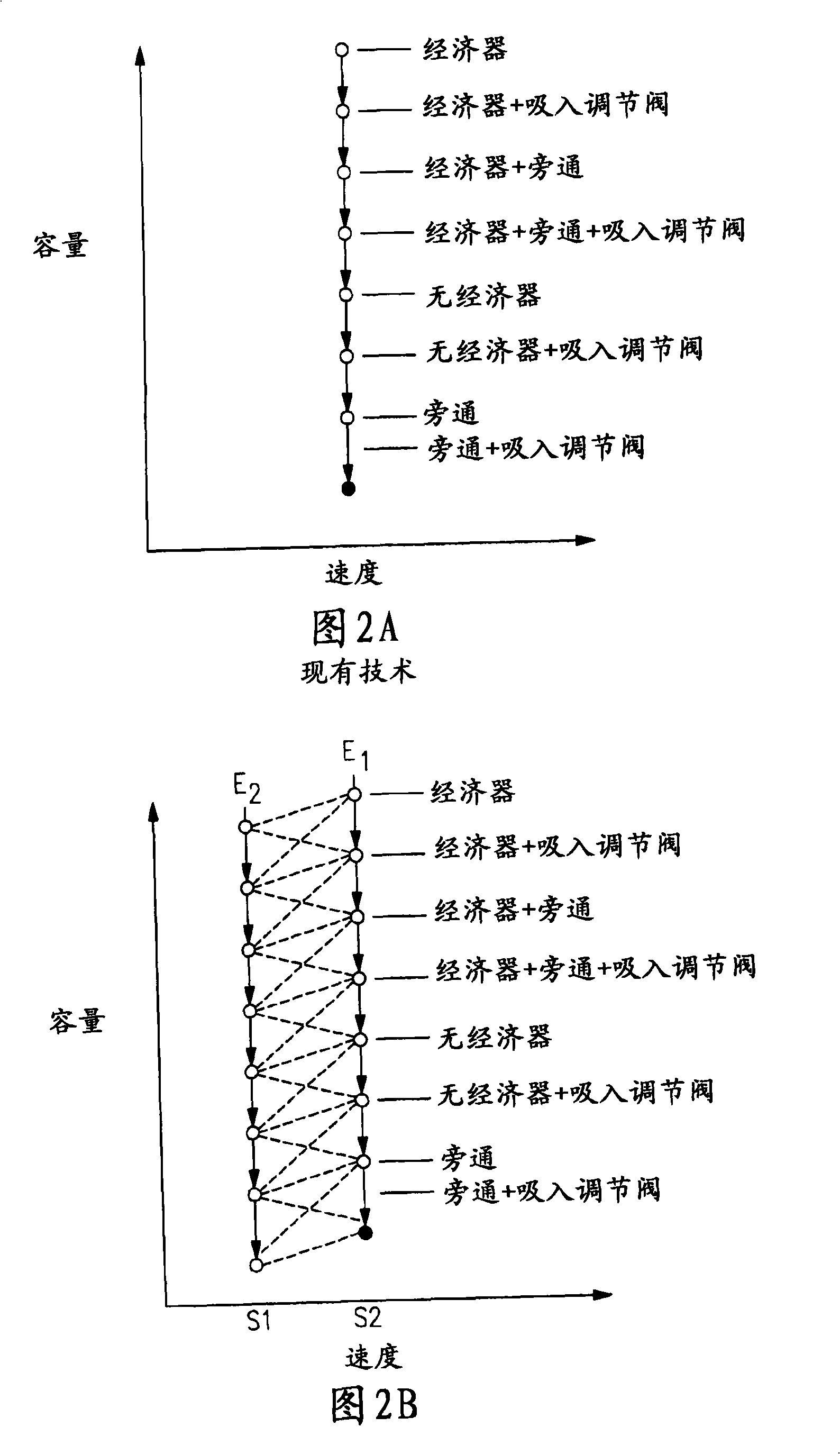

Refrigerant system possessing multi- speed cyclone compressor and economizer loop

InactiveCN101307962AReduce capacityReduced capacity levelCompression machines with non-reversible cycleRotary piston pumpsCycloneSystem capacity

The invention relates to a scroll compressor, which is provided with a multi-speed motor. A controller selectively controls the speed of the motor; and simultaneously a plurality of realizable alternative proposals selectively adjust system capacity so as to meet the requirement of external load in the most efficient and reliable mode. The embodiment comprises an economizer circuit and emptier function and an alternative input control valve. Various parts of the multi-speed motor of the compressor are used, so the capacity provided by the compressor is more suitable for the required capacity.

Owner:SCROLL TECH

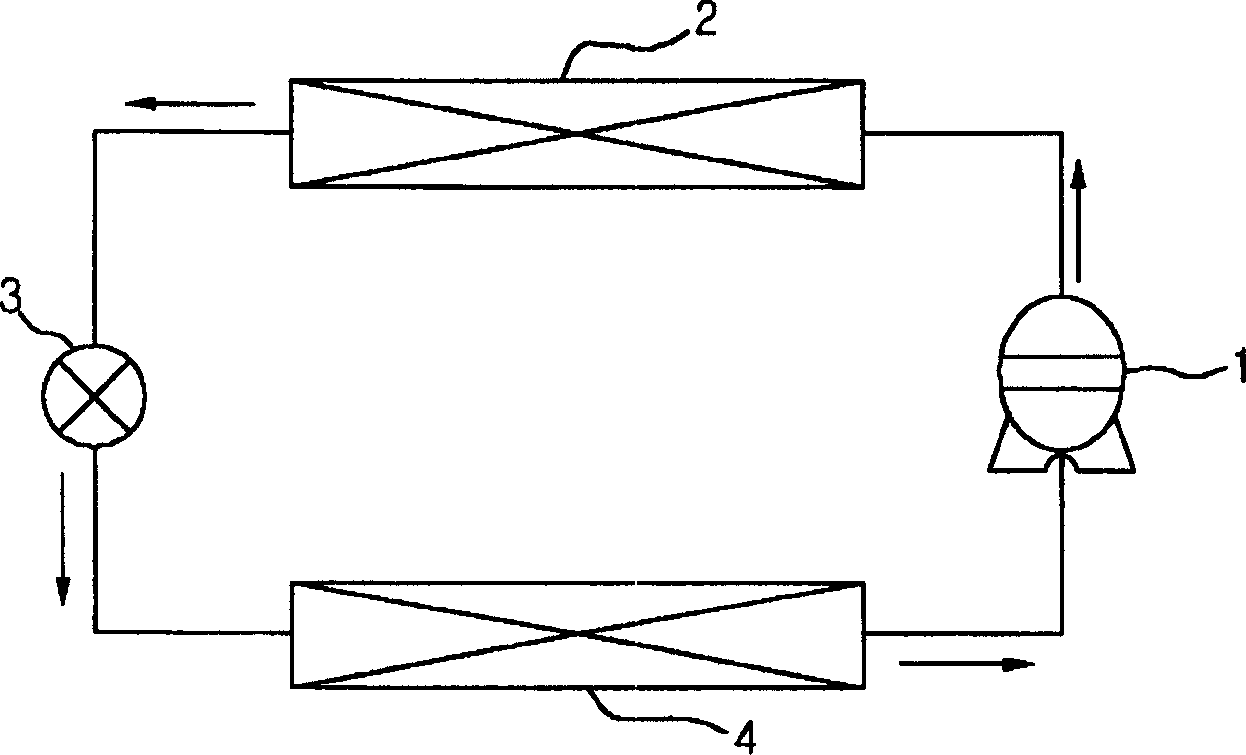

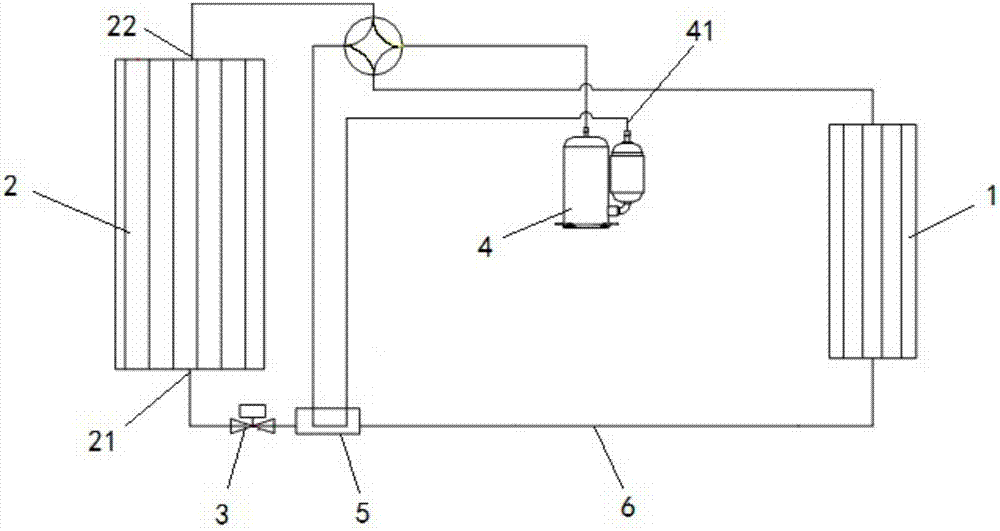

Heating and cooling system

A heating and cooling system for preventing the deterioration of heating efficiency generated due to a subsidiary heat exchanger used to increase cooling efficiency. The heating and cooling system includes a compressor for compressing a refrigerant, an indoor heat exchanger for heat-exchanging the refrigerant with indoor air, an outdoor heat exchanger for heat-exchanging the refrigerant with an outdoor air, a four-way valve disposed at an outlet of the compressor for selectively discharging the refrigerant to one of the indoor and outdoor heat exchangers according to heating and cooling modes, an expansion valve for decompressing and expanding the refrigerant, an inlet refrigerant pipe for guiding the refrigerant drawn into the compressor, a subsidiary heat exchanger disposed in the inlet refrigerant pipe for heat-exchanging the refrigerant passing through the inlet refrigerant pipe and the refrigerant passing through a connection refrigerant pipe in the cooling mode so as to control the temperature of the refrigerant drawn into the compressor, and a bypass refrigerant pipe for allowing the refrigerant drawn into the compressor to bypass the subsidiary heat exchanger and then to be directed into the compressor.

Owner:SAMSUNG ELECTRONICS CO LTD

Cooling device, condenser, and air conditioning system

A cooling device is constructed by a water impermeable member defining a water passage, the water impermeable member being provided with a vapor permeable member which is permeable to water vapor and impermeable to water, and has the form of a mesh and made of a material having water repellency. The cooling device has a long-life operation while preventing wear-out of the vapor permeable member. Further, optimally setting the size of an opening of the mesh member enables to securely dissipate water vapor outside of the cooling device through the vapor permeable member while efficiently suppressing water leak.

Owner:AQUA ECOLOGY TECH INC AET +1

Heat regenerator of heat-regenerating type low-temperature refrigerator

ActiveCN101799229AReduce void volumeSmall empty volumeSuperheatersEngineeringRefrigerated temperature

Owner:江苏热声机电科技有限公司

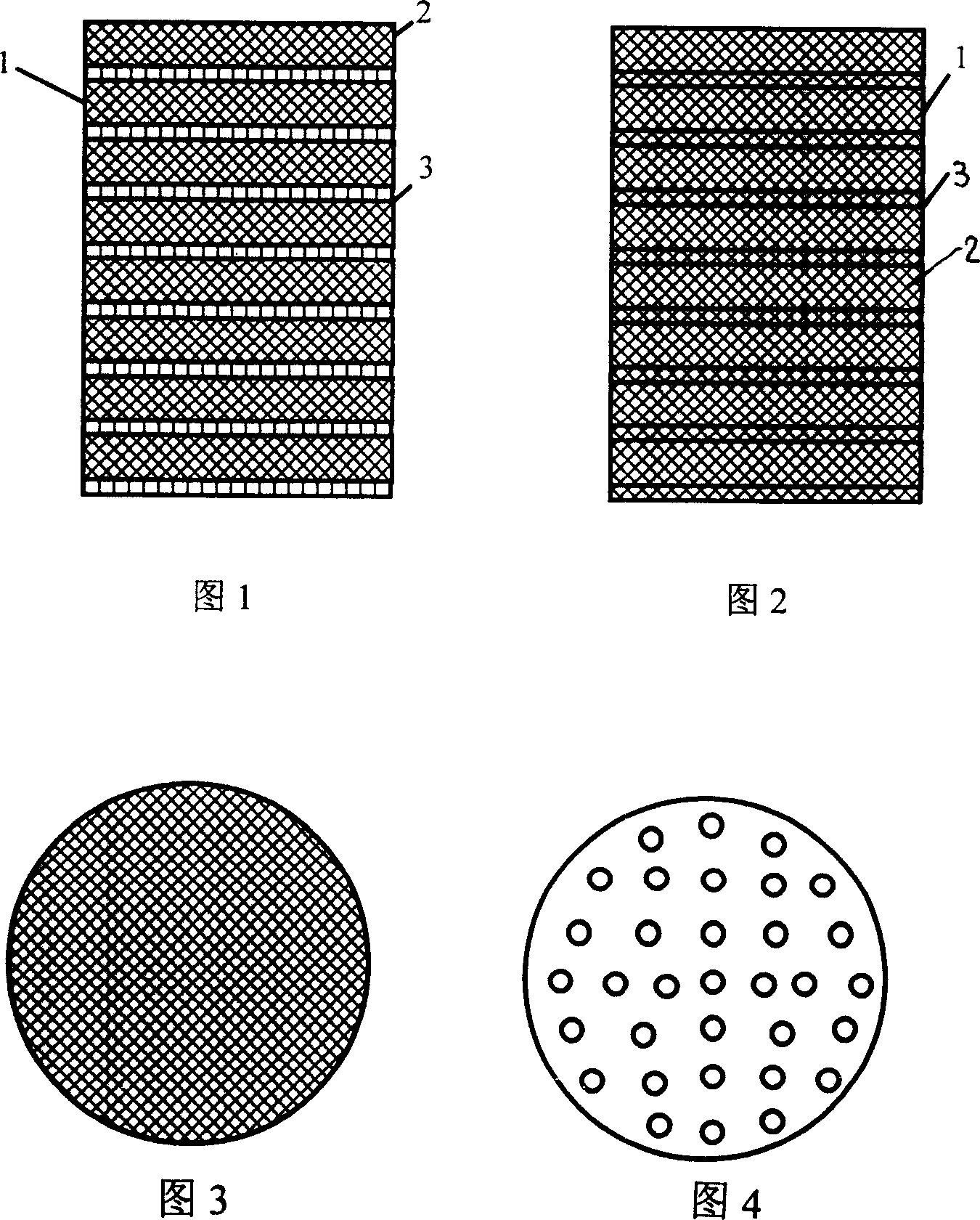

Recuperative heat exchanger with radial reinforced heat conduction

InactiveCN1971172AEnhanced radial heat transfer capabilityGuaranteed Temperature ConsistencySuperheatersGas cycle refrigeration machinesPlate heat exchangerEngineering

The invention relates to a regeneration heat exchanger with radial strengthened conduction, comprising the shell of heat returning machine, and metal plate with hole and metal silk screen / shot set in said shell of heat returning machine in certain distance, which is provided with different conductivity. The outer diameter of metal plate with hole is consistent with the inner diameter of outer shell of heat returning machine. The hydraulic diameter of small hole on said metal plate with hole is 0.5mm-5mm. the sum of said small holes is 1 / 4-2 / 3 of the section area of metal plate with hole. It is provide with following merits that simple structure, filling in convenience, strengthening the radius heat exchanging ability of regeneration heat exchanger under the precondition that the loss of heat leak at the axial direction is not increased, maintaining the temperature of heat returning machine consistent or small difference at the transverse section of the same axial position, and improving the efficiency of heat returning machine so as to improve the refrigerated performance.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

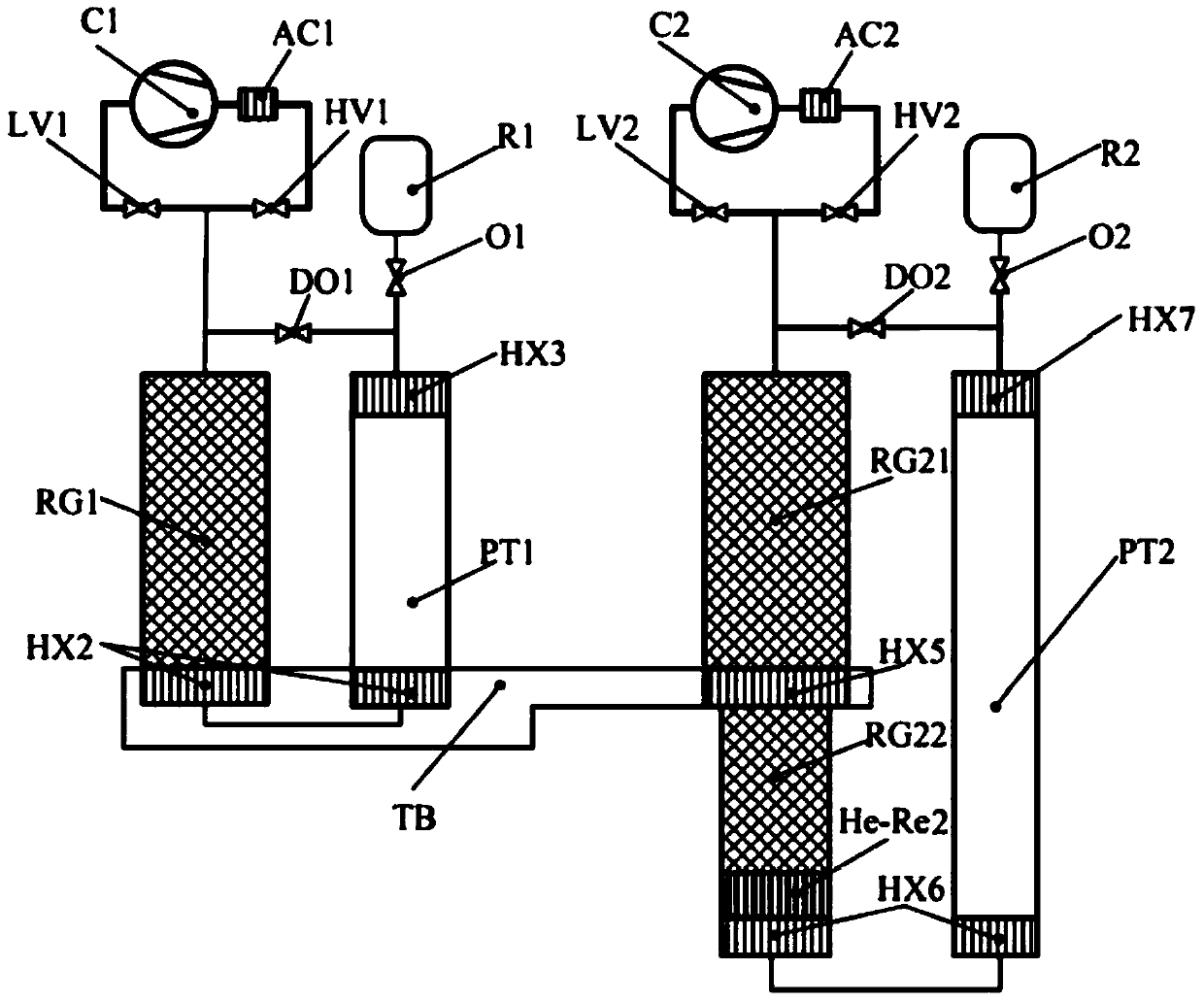

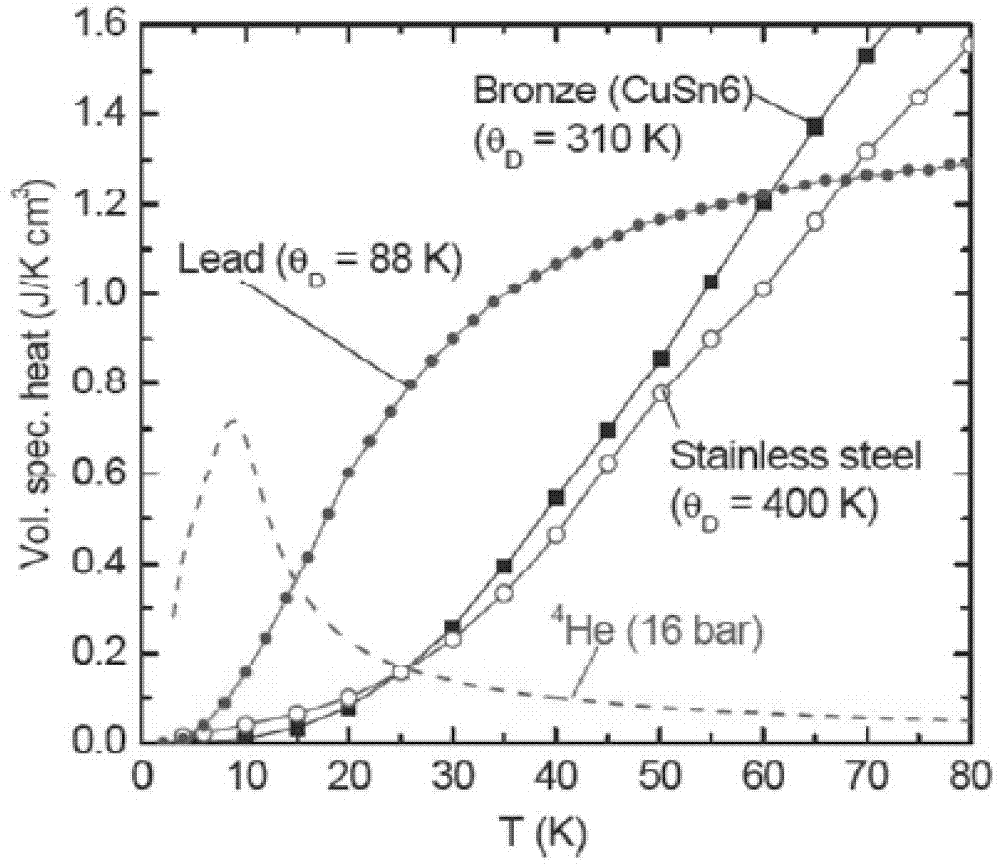

Deep hypothermic heat regenerator adopting helium as heat regeneration medium and pulse tube refrigerator thereof

ActiveCN104197591AGuaranteed heat exchange effectImprove performanceCompression machinesSuperheatersThermodynamicsPulse tube refrigerator

The invention discloses a deep hypothermic heat regenerator adopting helium as a heat regeneration medium. The heat regenerator comprises a tube shell and heat regeneration padding arranged in the tube shell. The heat regeneration padding is of a sealed heat exchange structure filled with the helium. The invention further discloses a pulse tube refrigerator adopting the deep hypothermic heat regenerator. According to the pulse tube refrigerator, the characteristic that the helium is high in volumetric specific heat capacity at low temperature is utilized, and the helium is closed in a certain space and used as the heat regeneration medium to exchange heat with helium used as a refrigerating working medium; the helium with the suitable pressure can be selected and charged into the enclosed space according to the work pressure of the pulse tube refrigerator so that the volumetric specific heat capacity of the helium serving as the heat regeneration medium in the deep hypothermic area can be higher than that of the helium serving as the refrigerating working medium, efficient heat regeneration can be achieved, and finally the performance of the pulse tube refrigerator in the liquid helium temperature area can be improved; meanwhile, compared with a magnetic heat regeneration material, the deep hypothermic heat regenerator adopting the helium as the heat regeneration medium has the advantages of being low in price, easy to obtain, free from influence of a magnetic field and the like.

Owner:ZHEJIANG UNIV

Energy self-supplying type carbon dioxide cold and hot electricity co-generation system used for low-grade heat source

ActiveCN110887278ASave compression workIncrease net output powerCompression machinesFluid circulation arrangementGas compressorCogeneration

The invention discloses an energy self-supplying type carbon dioxide cold and hot electricity co-generation system used for a low-grade heat source. The energy self-supplying type carbon dioxide coldand hot electricity co-generation system comprises a transcritical carbon dioxide reheat Rankine dynamic cycle system and a transcritical carbon dioxide injection refrigeration cycle system; the energy self-supplying type carbon dioxide cold and hot electricity co-generation system integrates reheat Rankine dynamic cycle and injection refrigeration cycle, adopts carbon dioxide as a single workingmedium, converts low-grade heat energy to useful work through a extraction turbine of the transcritical carbon dioxide reheat Rankine dynamic cycle system and supplies the heat energy to users by using a water heater. The transcritical carbon dioxide injection refrigeration cycle system utilizes high-pressure exhaust waste heat of the extraction turbine to drive an injector to output cold energy to the users. Through reasonable arrangement of the system, the system can output more electric energy. By adoption of a working medium pump and a low-pressure-ratio gas compressor, the energy self-supplying type carbon dioxide cold and hot electricity co-generation system reduces compression power efficiently during the system operation and improves net electric generation and conversion efficiency of the low-grade heat energy of the system.

Owner:北京绿卡科技有限公司

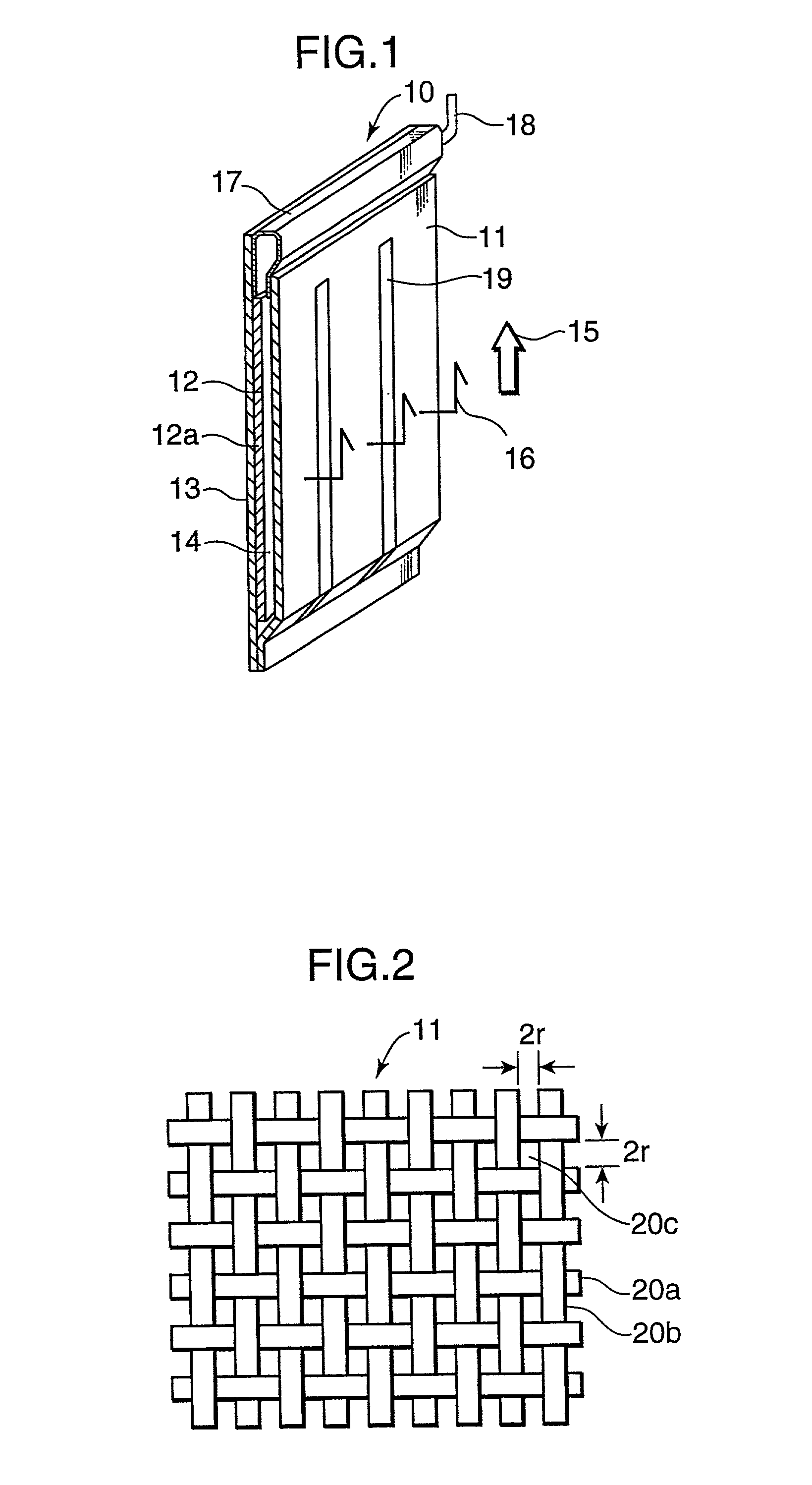

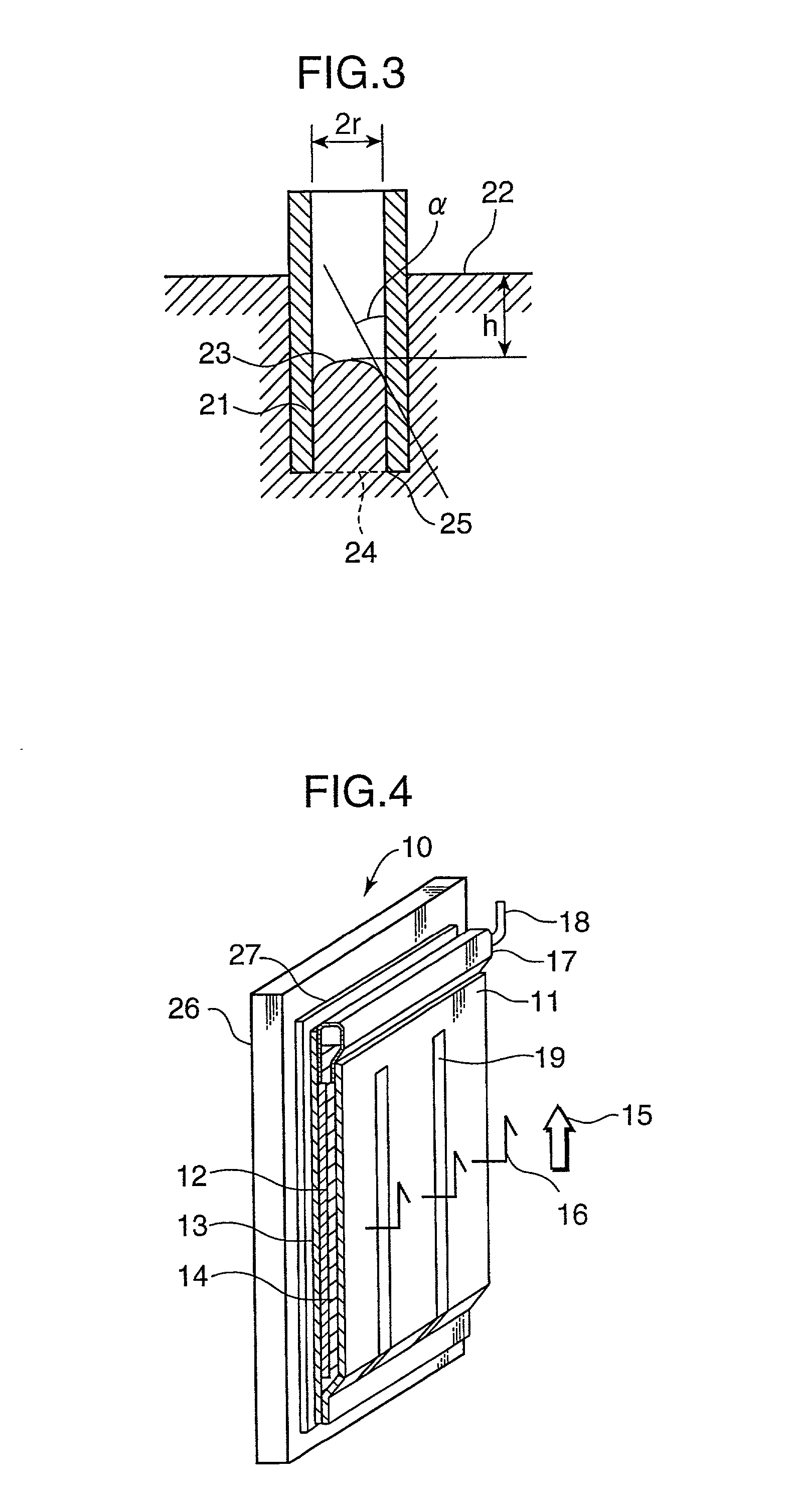

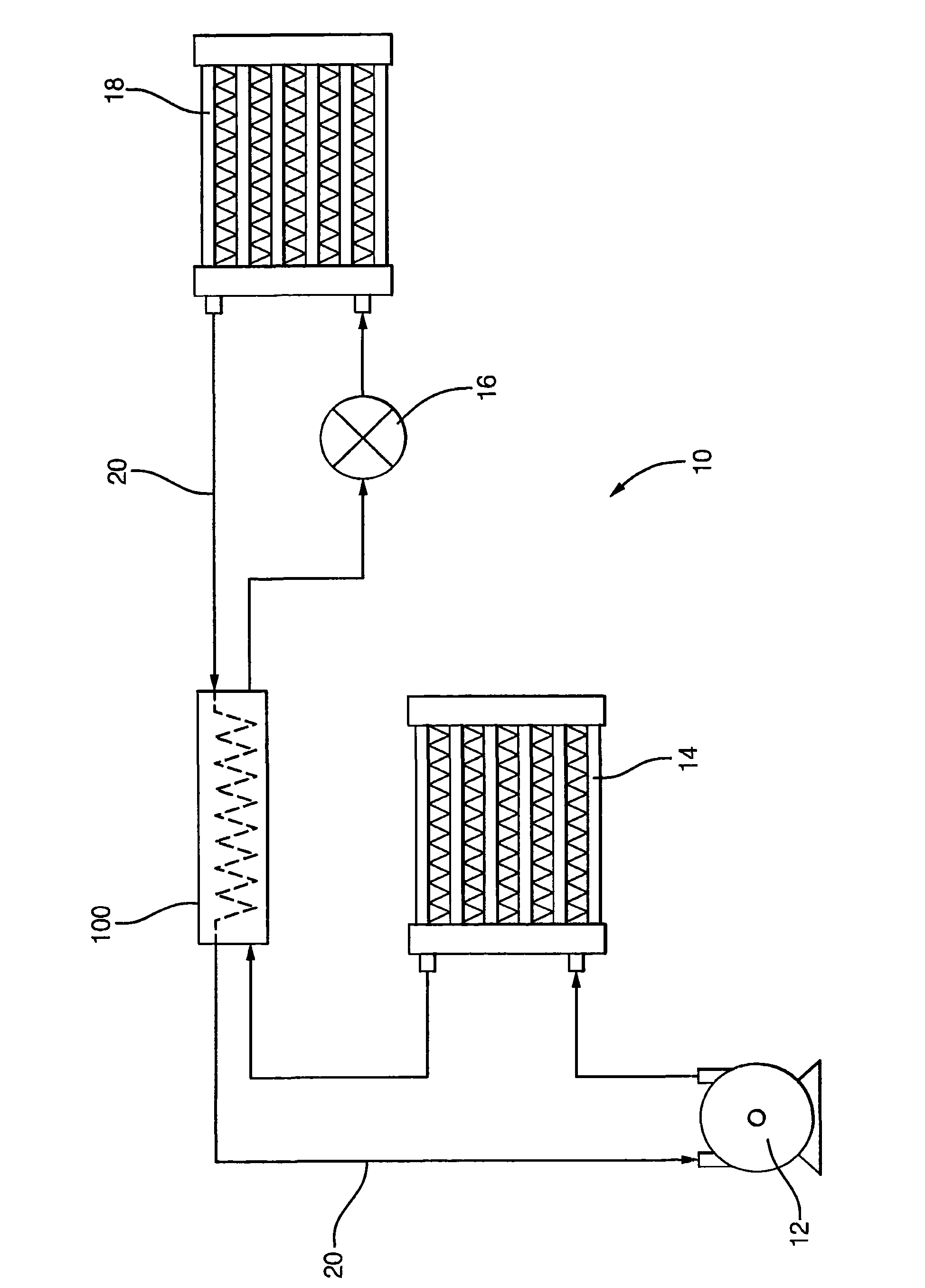

System and device comprising a combined condenser and evaporator

ActiveCN101713595AReduce risk of leakageImprove efficiencyAir-treating devicesCompression machines with non-reversible cycleEngineeringHeat exchanger

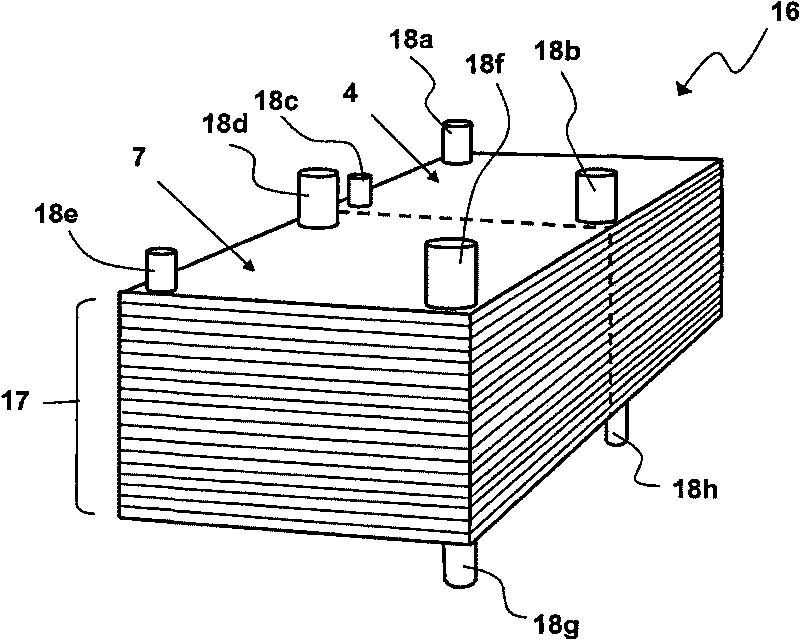

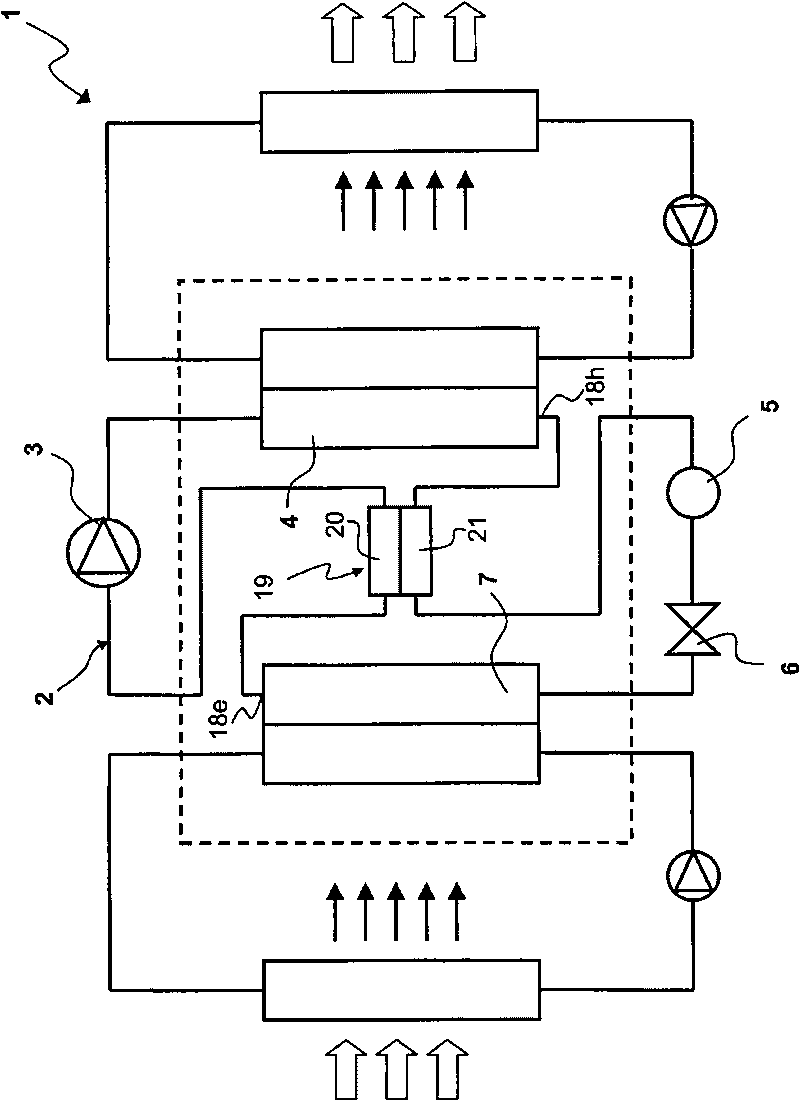

The invention relates to a system and a device for cooling and / or warming which comprises at least a refrigerant circuit (2) with at least a compressor (3), a condenser (4), an evaporator (7) and an expansion means (6). The invention is effected by the evaporator and the condenser being combined / integrated in a single common unit (16) which comprises an internal heat exchanger (19).

Owner:SCANIA CV AB

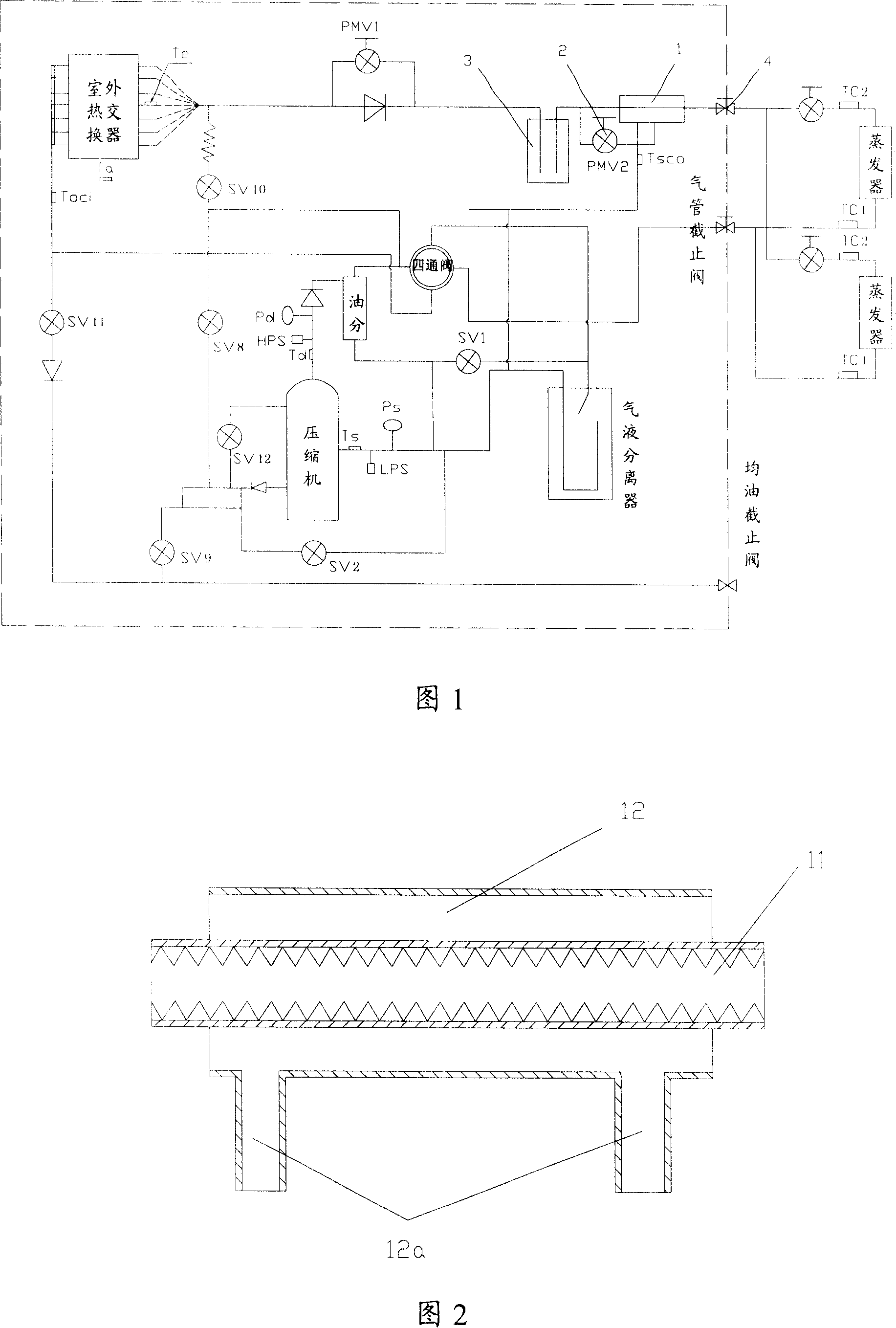

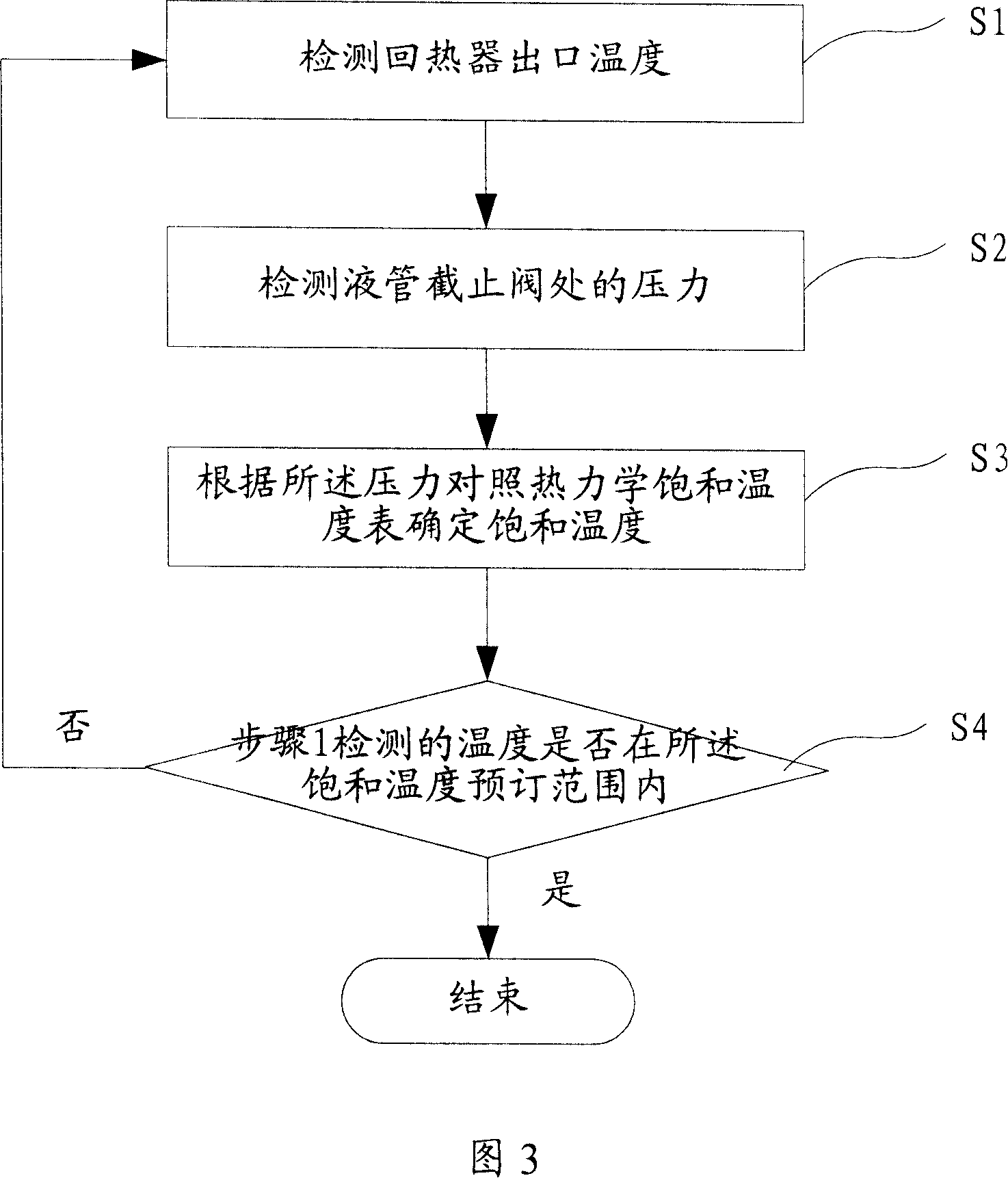

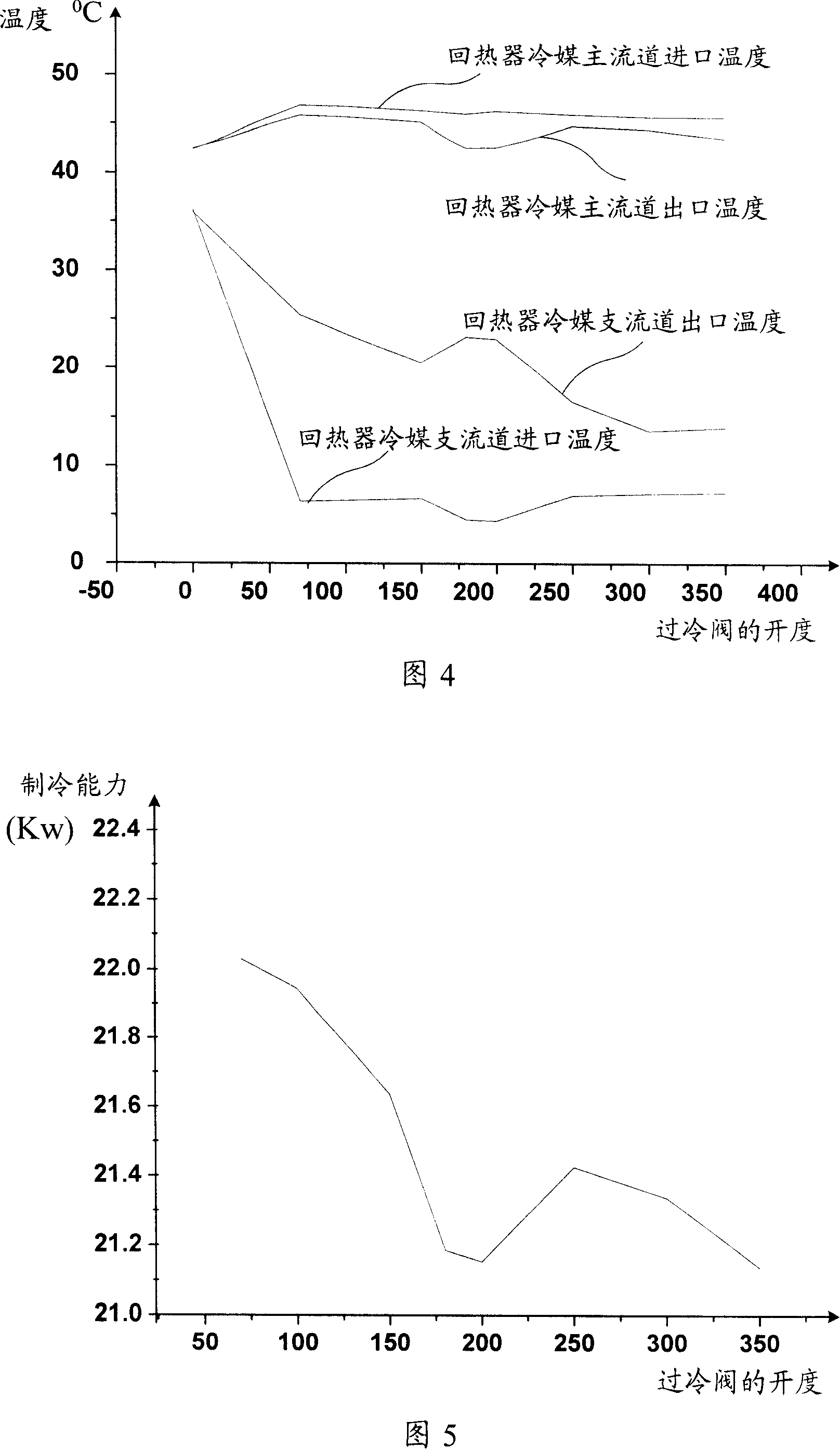

Air conditioner back-heating device and its control method

InactiveCN101153760AGuaranteed heat exchange effectIncrease unit cooling capacitySuperheatersControl systemLiquid storage tank

The invention discloses an air conditioning regenerative device which is used between a high pressure liquid storage tank and a liquid pipe stop valve. The device comprises a regenerator and a supercooling valve for adjusting liquid flow in the regenerator. The invention also discloses an air conditioning regenerative control method which comprises following steps: 1) a detection of an outlet temperature of the regenerator; 2) a detection of a pressure of a refrigeration valve; 3) a determination of a saturation temperature according to a comparison of the pressure with a thermodynamics saturation temperature indicator; 4) a judgment that whether a temperature of an outlet of a main pipe of the regenerator is in a preserved ranged of the saturation temperature, if so, a process is finished; if not, an opening of the refrigeration valve is adjusted, and the step 1 is executed. The invention provides the air conditioning regenerative device and the air conditioning regenerative control method for controlling a stability of the system and improving a heat exchanging effect of air conditioning.

Owner:HAIER GRP CORP +1

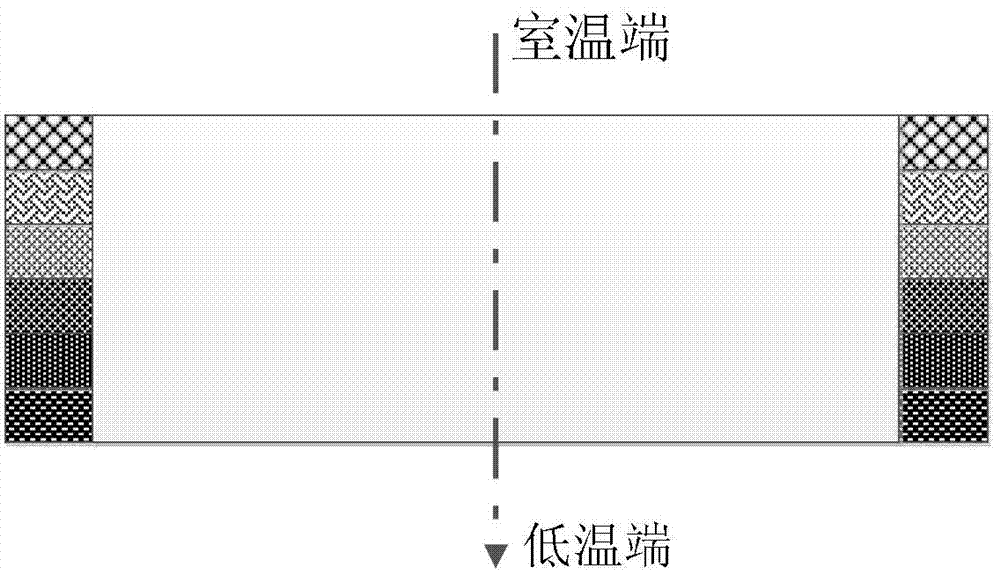

Regeneration-type variable-porosity heat regenerator for low temperature refrigerator

The invention discloses a regeneration-type variable-porosity heat regenerator for a low temperature refrigerator. The heat regenerator comprises a low temperature section and a high temperature section. A plurality of layers of regeneration fillers with different porosities are filled in the heat regenerator, and the porosity range of the regeneration fillers filled in the heat regenerator is 59%-92%. According to different proportions of various losses in the heat regenerator at different temperatures, regeneration fillers with different porosities are adopted in different temperature sections of the heat regenerator. Compared with the traditional heat regenerator filled with fillers with fixed porosity, the heat regenerator effectively reduces inside loss, improves heat regeneration efficiency and improves refrigerator efficiency.

Owner:ZHEJIANG UNIV

Cooling system with refrigerant for air conditioning and lowering temperature of engine

InactiveUS20050072169A1Increase contact areaImprove engine efficiencyAir-treating devicesInternal combustion piston enginesEngineeringAir conditioning

A cooling system with refrigerant for air conditioning and engine parts, comprising: a compressor, a high pressure circuit filled with the refrigerant; and a low pressure circuit filled with the refrigerant too. The high pressure circuit further comprises a condenser, the low pressure circuit further comprises an evaporator and a heat exchanger, the heat exchanger at an interior thereof is provided with a refrigerant passage and a fluid passage, which enters the engine, with the two passages next to each other and contacting with each other and at an exterior thereof includes a refrigerant inlet, a refrigerant outlet, a fluid entrance to the engine and a fluid exit from the engine. Once the compressor is in a state of running, the refrigerant in the low pressure circuit passes through the evaporator and enters the refrigerant passage in the engine via a connecting pipe in the low pressure circuit and the refrigerant inlet and then flows out from the heat exchanger via the refrigerant outlet; a fluid for being cooled flows into the fluid passage via the fluid entrance and flows out from the fluid exit before reaching an engine body; and temperature of the fluid during entering fluid passage is higher than the refrigerant in the refrigerant passage and heat in the fluid transmits the refrigerant between a wall of the fluid passage and a wall of the refrigerant passage.

Owner:LIN TZU TANG

Energy-saving type refrigeration and dehumidification integrated machine

ActiveCN101413730AImprove dehumidification effectReduced need for heat supplementationDispersed particle separationSuperheatersOptimal controlEngineering

The invention belongs to the refrigeration technical field and particularly relates to an energy-saving refrigeration dehumidifying all-in-one machine. The machine is composed of a compressor, an outdoor condenser, an indoor condenser, a heat regenerator, an evaporator and electronic expansion valves, wherein, the outdoor condenser is connected with the indoor condenser in parallel, and each condenser is corresponding to one electronic expansion valve. When heating up or constant temperature dehumidifying is needed, the indoor condenser and the heat regenerator work. The design of the invention has the functions of refrigeration dehumidifying, heating up or constant temperature dehumidifying, and low-temperature dehumidifying. As the indoor condenser and the heat regenerator are used, the energy consumption is reduced and the dehumidifying capacity is improved. By optimal control, the machine of the invention can adjust the ratio of refrigerants under different working conditions, thus realizing optimal utilization and recovery of energy. The machine of the invention can be used in the fields of a refrigeratory, an artificial climate chamber and the like with the dehumidifying requirement.

Owner:北京库蓝科技有限公司

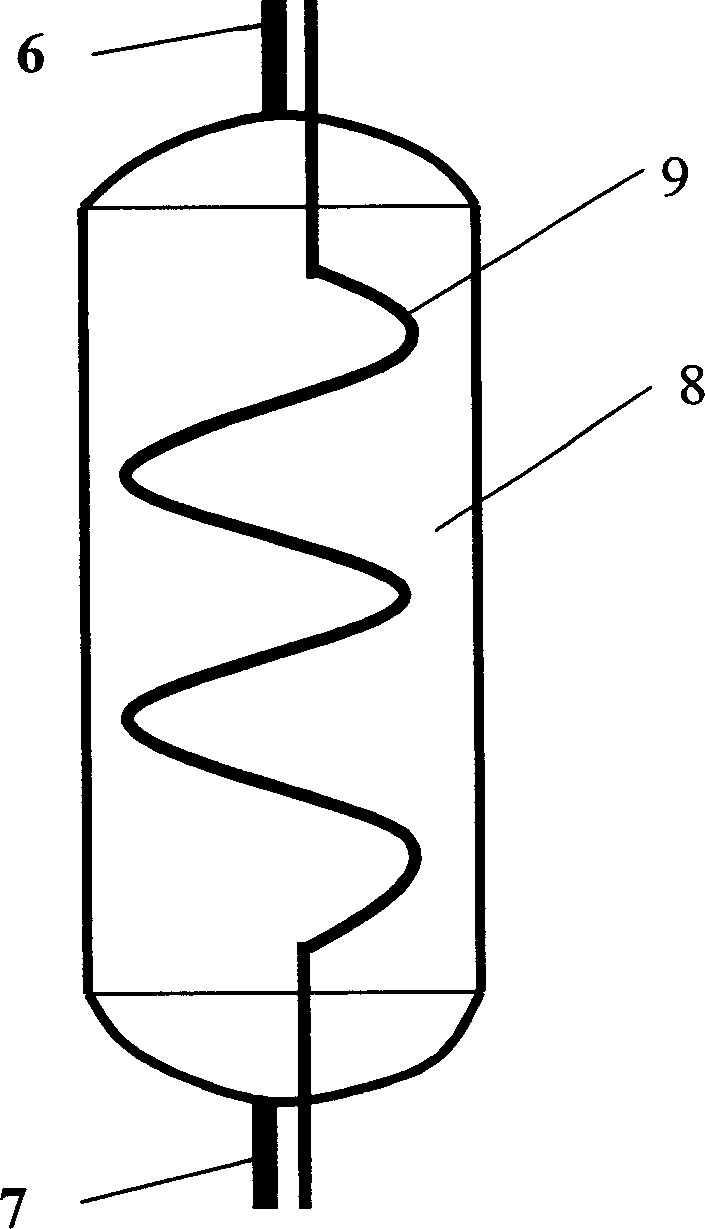

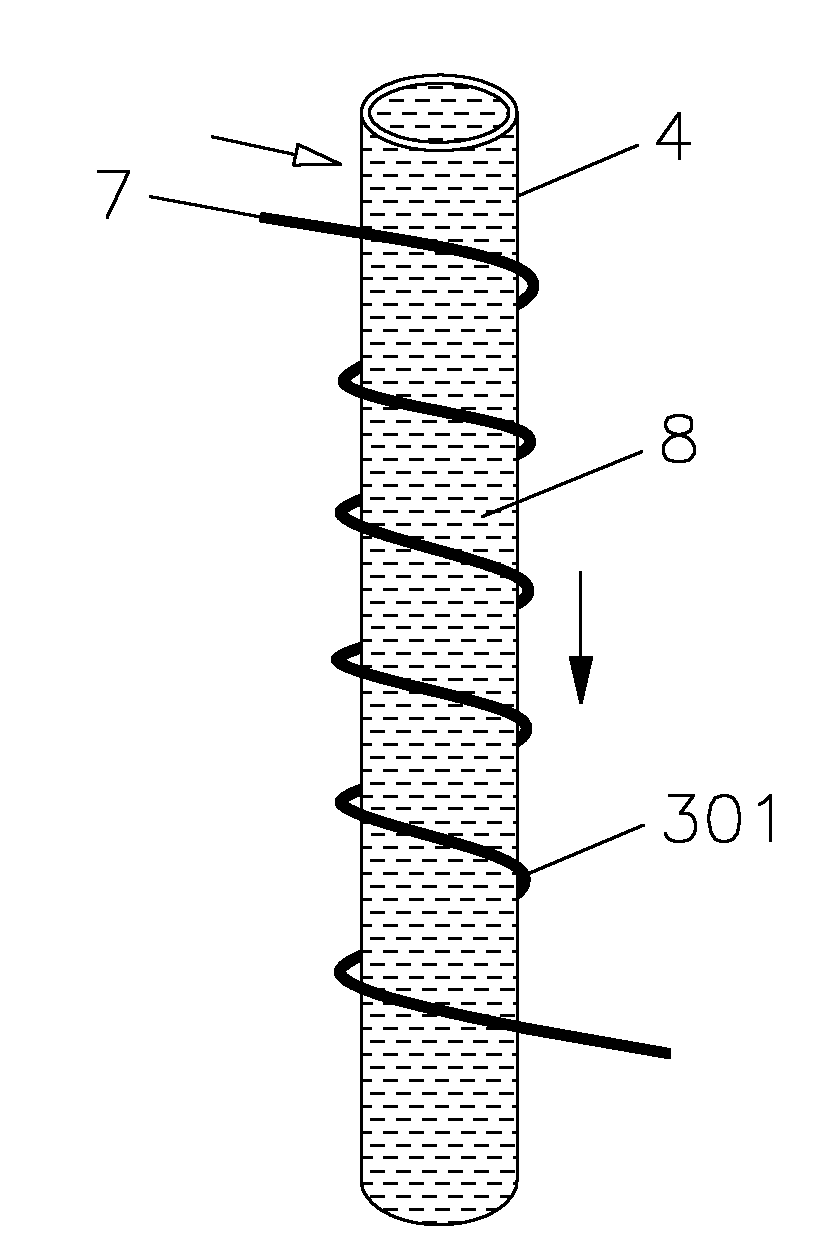

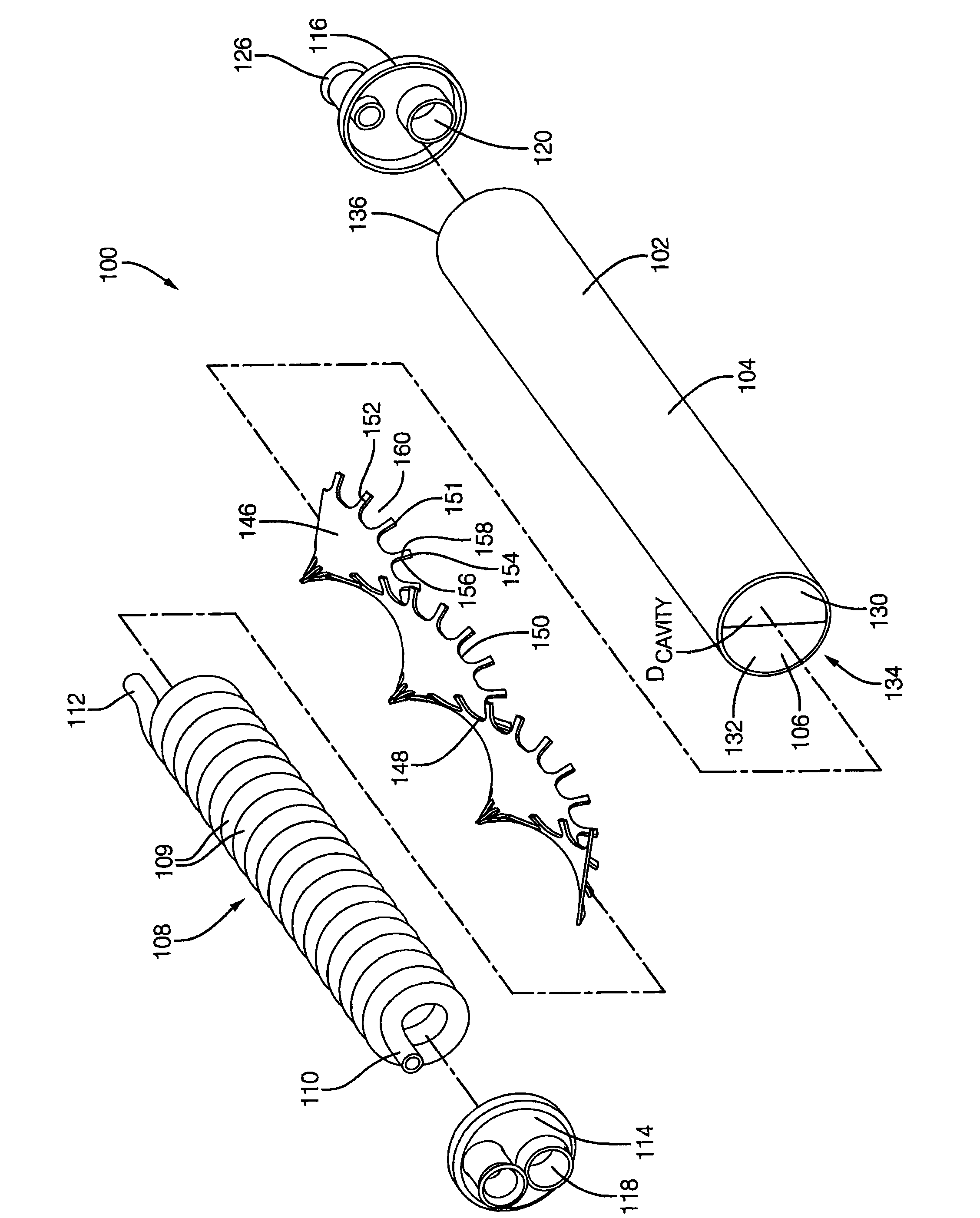

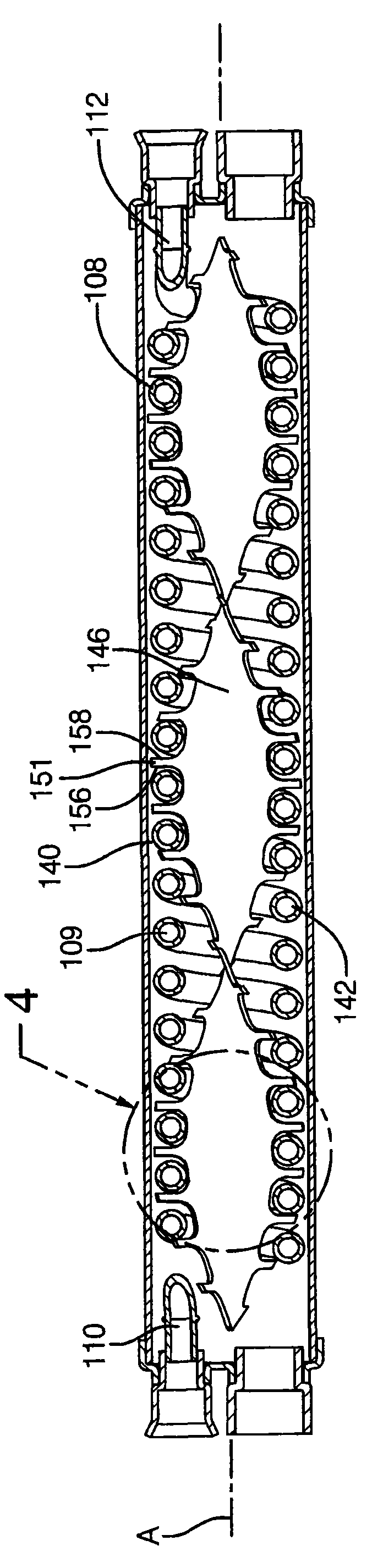

Internal heat exchanger assembly

InactiveCN101929768ACost efficient to manufactureSmall pressure dropSuperheatersHeat exchanger casingsHelical coilAir conditioning

The invention relates to an internal heat exchanger assembly for an air conditioning system, having a housing defining a cylindrical with opposing ends. The ends are sealed with end caps having inlets / outlets. A helical coil tube is coaxially disposed within the cylindrical cavity, in which the helical coil includes two tube ends extending in opposing directions and exiting the cylindrical cavitythrough tube ports provided in the end caps. A twisted elongated strip is coaxially disposed within the cylindrical cavity extending from the first end to the second end. The twisted elongated strip includes a plurality of radially extending fingers adapted to engage the helical coil to maintain the helical coil in a predetermined position.

Owner:MAHLE INT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com