Heat regenerator of heat-regenerating type low-temperature refrigerator

A low-temperature refrigerator and regenerator technology, which is applied to refrigerators, superheaters, refrigeration components, etc., can solve the problems of large air flow resistance and performance degradation, and achieve the effects of low flow resistance, improved efficiency, and small empty volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the present embodiments are not intended to limit the present invention, and any structure of the present invention and similar changes thereof shall fall within the scope of protection of the present invention.

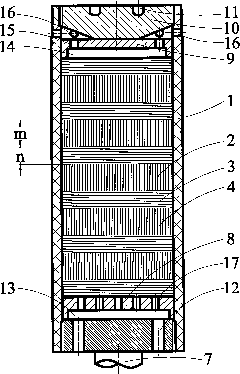

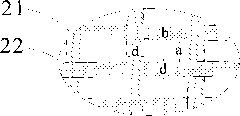

[0027] A recuperator of a regenerative cryogenic refrigerator, such as figure 1 , figure 2 , Figure 4 As shown, it includes the regenerator sleeve 1 and the regenerator filler 2. The inside of the regenerator sleeve 1 is firstly filled with radial filler 3, then filled with axial filler 4, alternately filled in sequence, and finally filled with radial filler 3. The regenerator filler 2 is formed by mixing and filling, and the ratio m / n of the thickness m of the axial filler 4 to the thickness n of the radial filler 3 is 3-6. Circular metal mesh 18 is alternately woven by circular metal mesh warp to circular wire one 19 and circular met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com