Polymer cement-based waterproof coating

A waterproof coating, cement-based technology, applied in the field of architectural decoration, to achieve the effect of alleviating internal stress, improving wettability, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

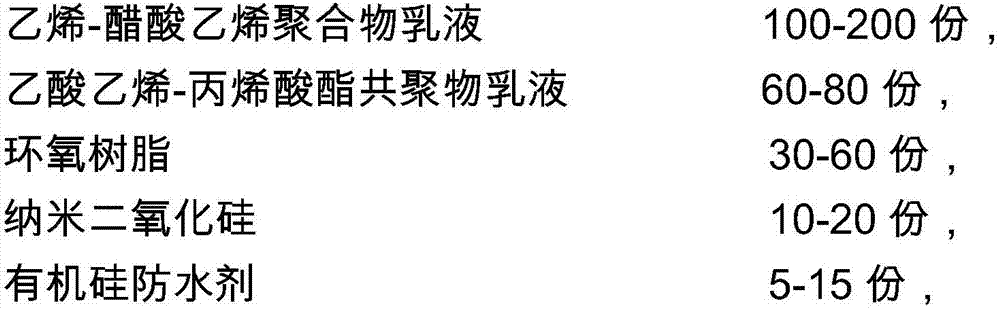

[0020] This embodiment discloses a polymer cement-based waterproof coating, including the following raw materials measured in parts by mass:

[0021]

[0022]

Embodiment 2

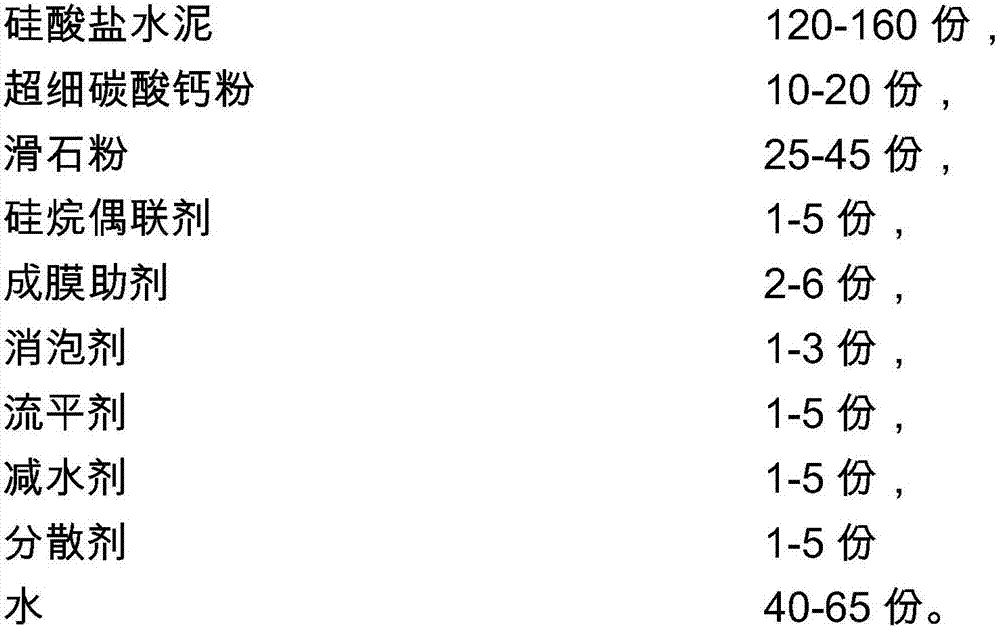

[0024] This embodiment discloses a polymer cement-based waterproof coating, including the following raw materials measured in parts by mass:

[0025]

[0026]

Embodiment 3

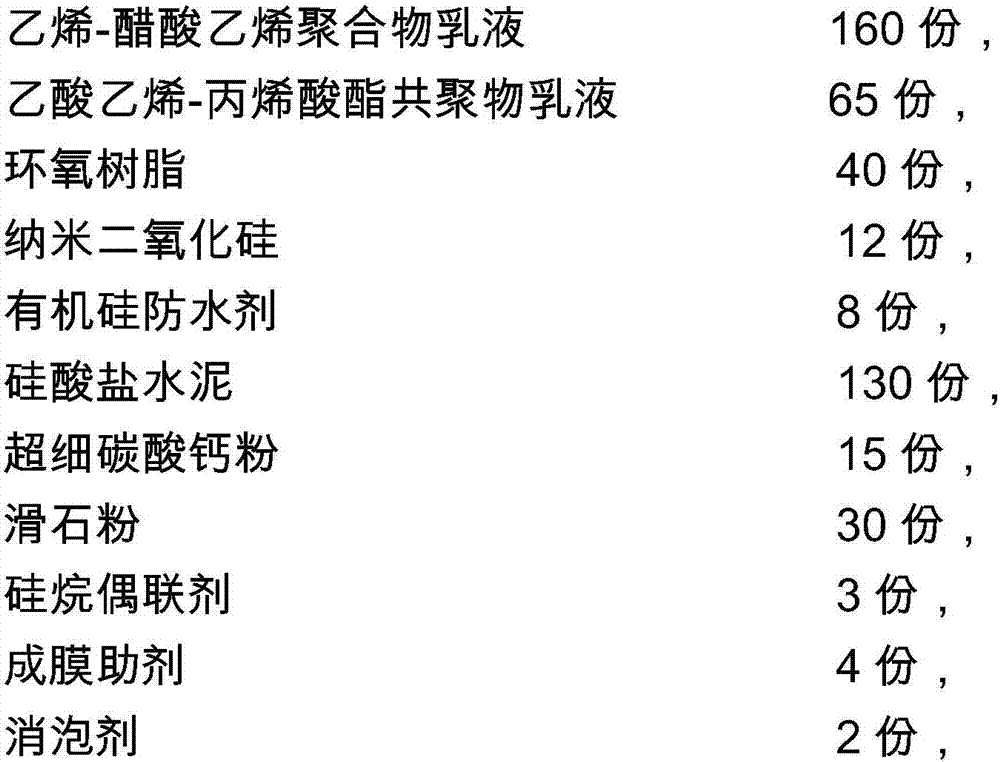

[0028] This embodiment discloses a polymer cement-based waterproof coating, including the following raw materials measured in parts by mass:

[0029]

[0030] Wherein, the film-forming aid is dodecyl alcohol ester. The defoamer is polyether modified silicone. The leveling agent is polyether modified polydimethylsiloxane. The talcum powder is 200-400 mesh. The water reducer is polycarboxylic acid. The dispersant is sodium hexametaphosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com