Patents

Literature

161results about How to "Little flow resistance loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

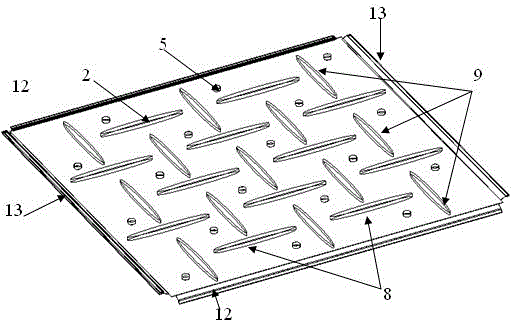

Multi- flow path transverse circulation gypsum board drying apparatus and its drying method

ActiveCN101236047AUniform drying effectEliminate flow resistance lossDrying solid materials with heatDrying gas arrangementsGypsumAirflow

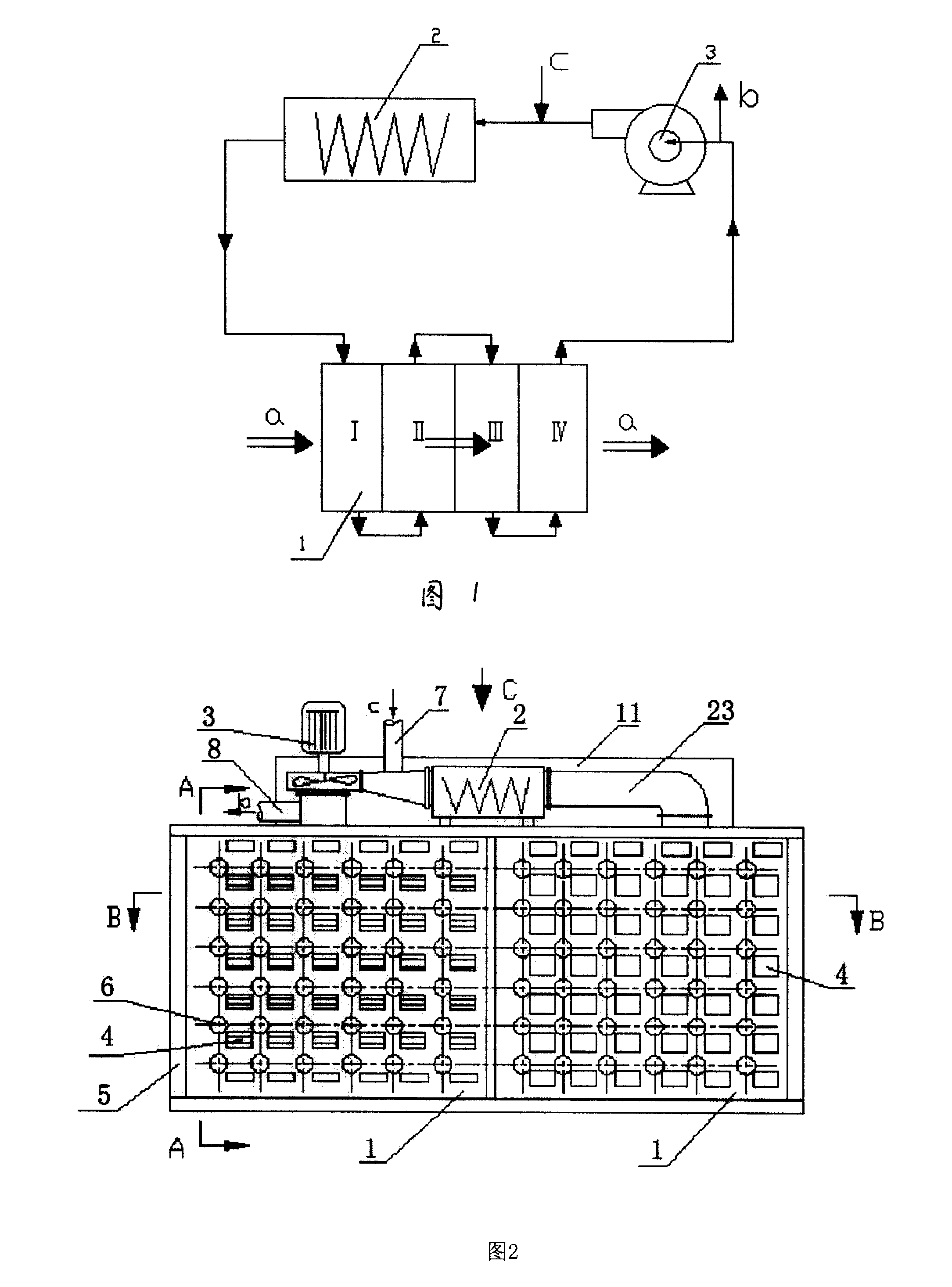

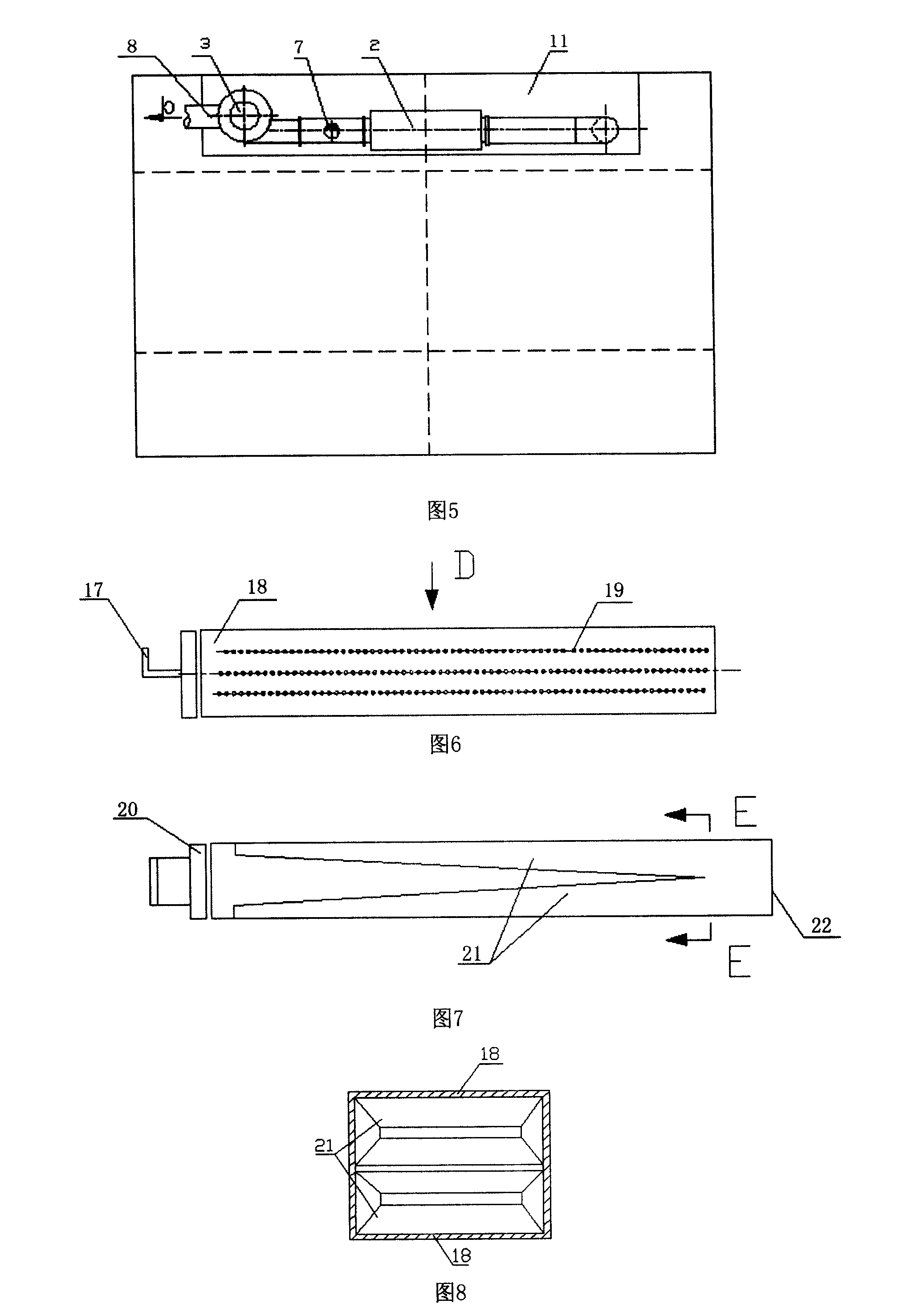

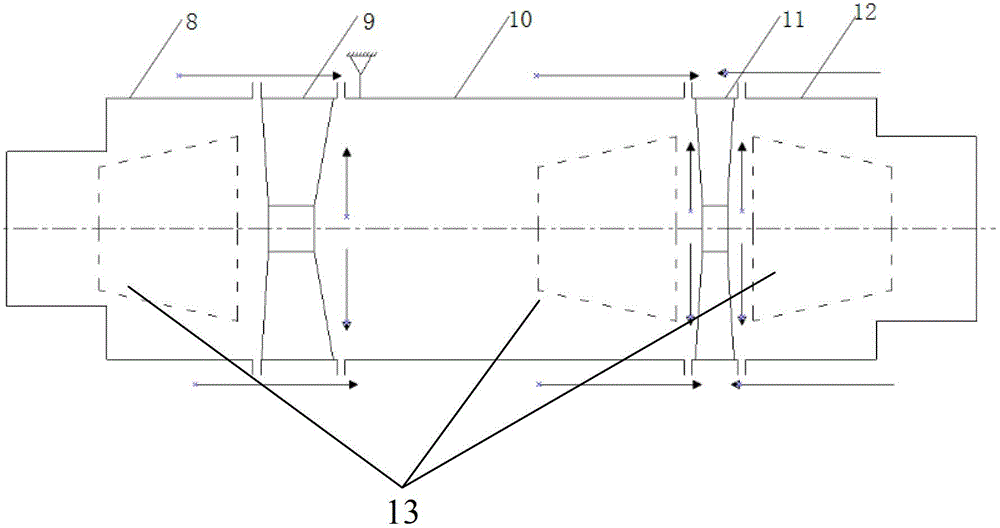

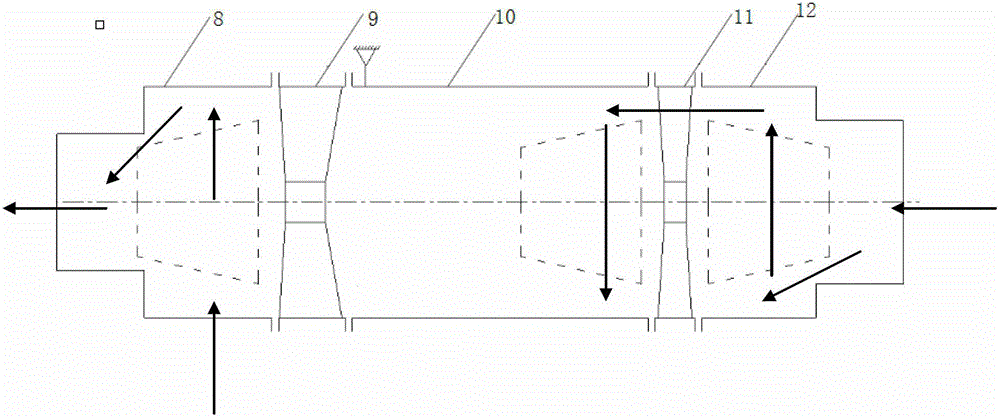

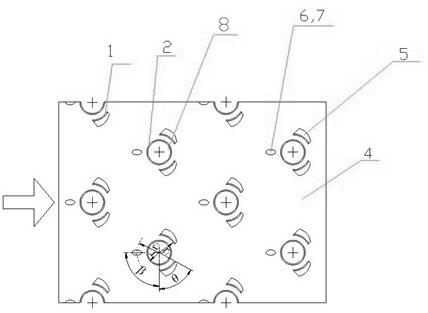

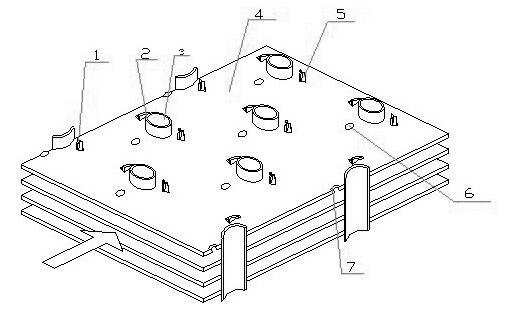

The invention relates to multi-paths horizontal circulation drying device for plasterboards and a drying method thereof, and the drying device is formed by a roller conveyer with the closed inner portion provided with one layer, multi-layers in most cases, and an air circulating device, wherein the roller conveyer is disposed in a main passage, two sides of which are provided with auxiliary passages, the upper portion of the auxiliary passage on one side is provided with an overhead passage, and a circulating fan and a heating device are arranged inside the overhead passage. The drying device is divided into a plurality of areas in the direction of material delivery, each area can be divided into 2-4 segments, each segment is provided with a plurality of air supply blowing pipes, and the main passages of each segment are provide with air flow resistant separators. Hot air as drying medium flows reversely at the first and second segments or the third and the fourth segments via the air supply blowing pipes, and reciprocates and circulates within the plate drying area by horizontal double-paths or multi-paths, thereby forming the intrinsic inherent condition which guarantees moisture on the two sides of the dried plate to be uniformly evaporated, simultaneously the multi-paths horizontal circulation drying device has the advantages of flow resistance consumption reduction, exhaust temperature reduction, increasing energy efficiency and construction cost reduction.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

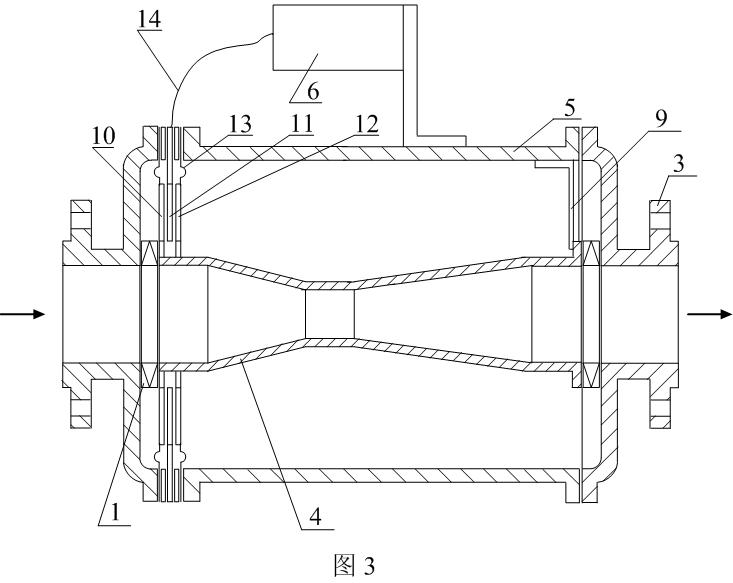

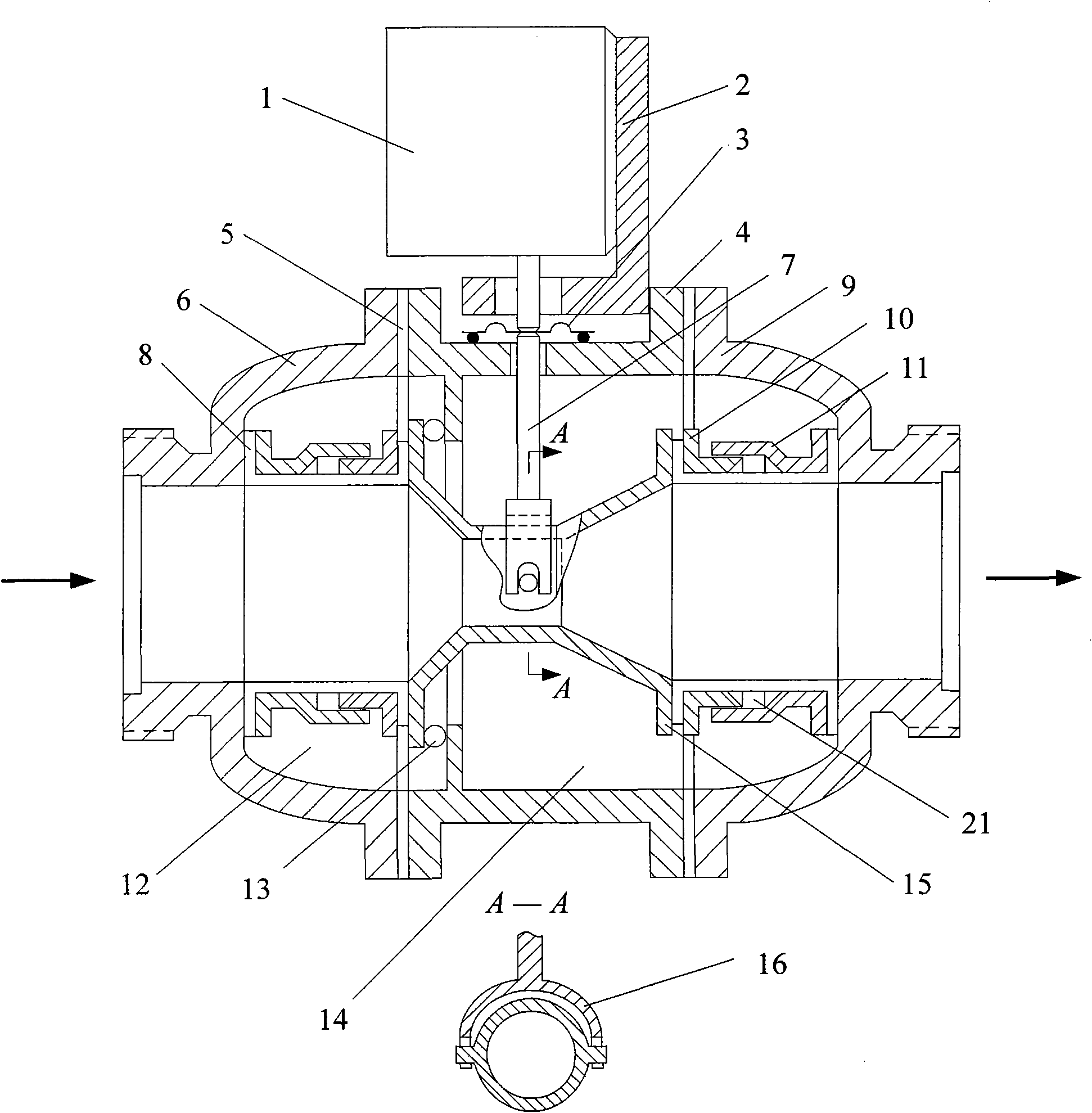

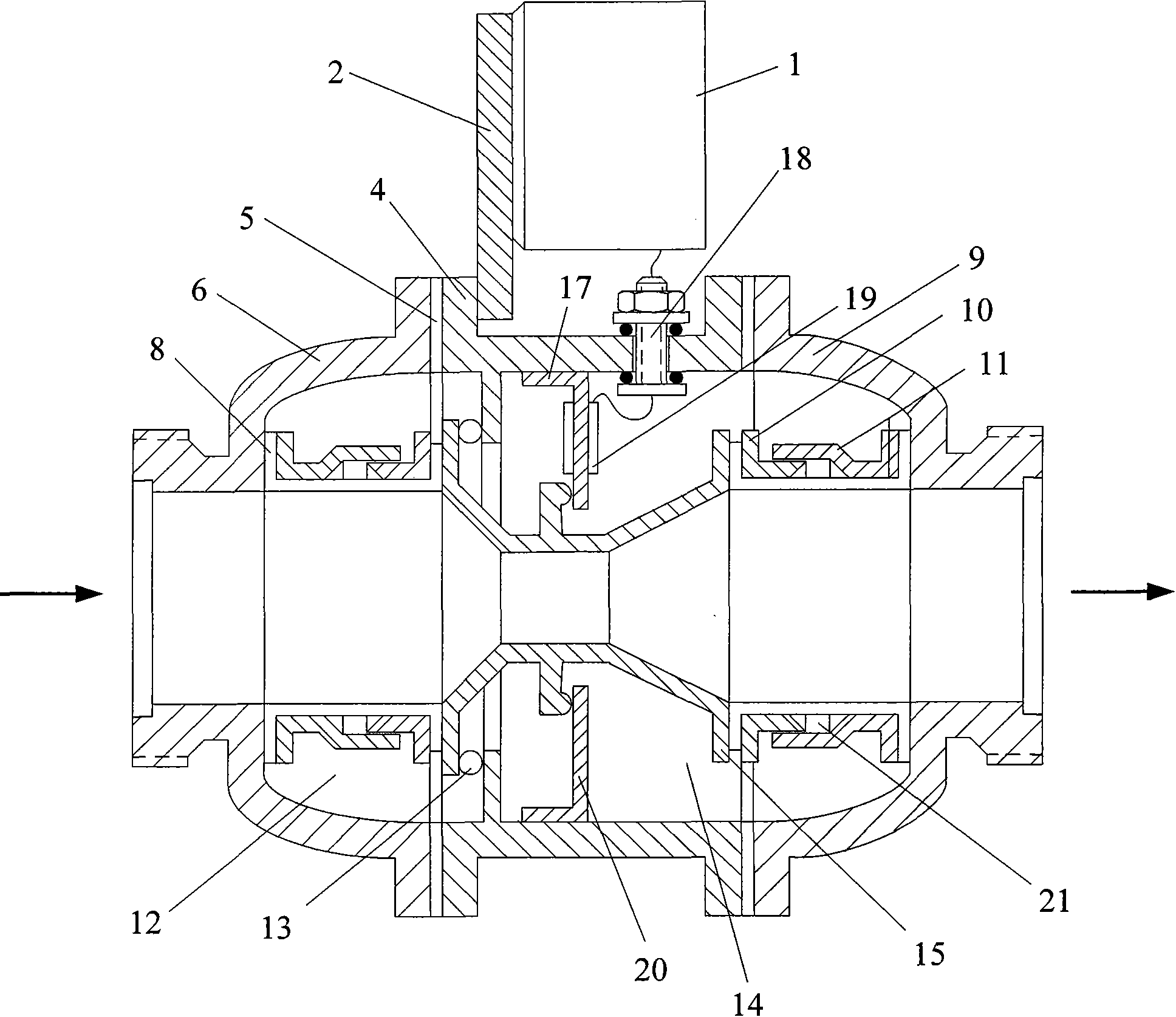

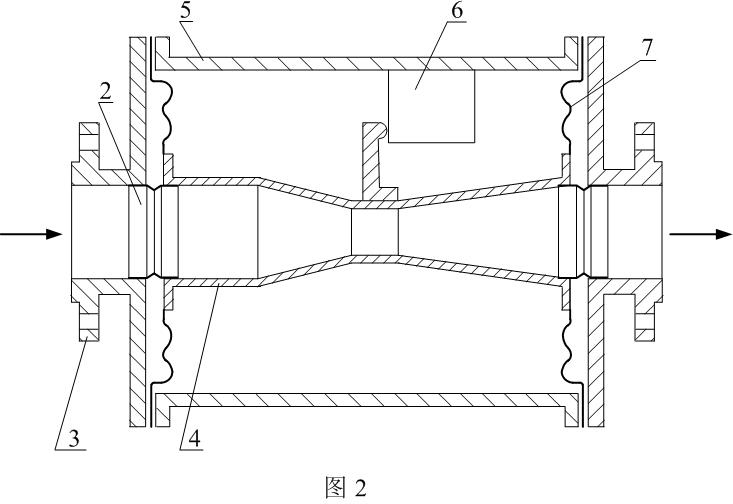

Flowmeter with middle through-hole movable throttling element connected with elastic membranes or bellows

InactiveCN102353406ALittle flow resistance lossEasy to useVolume/mass flow by differential pressureDifferential pressureEngineering

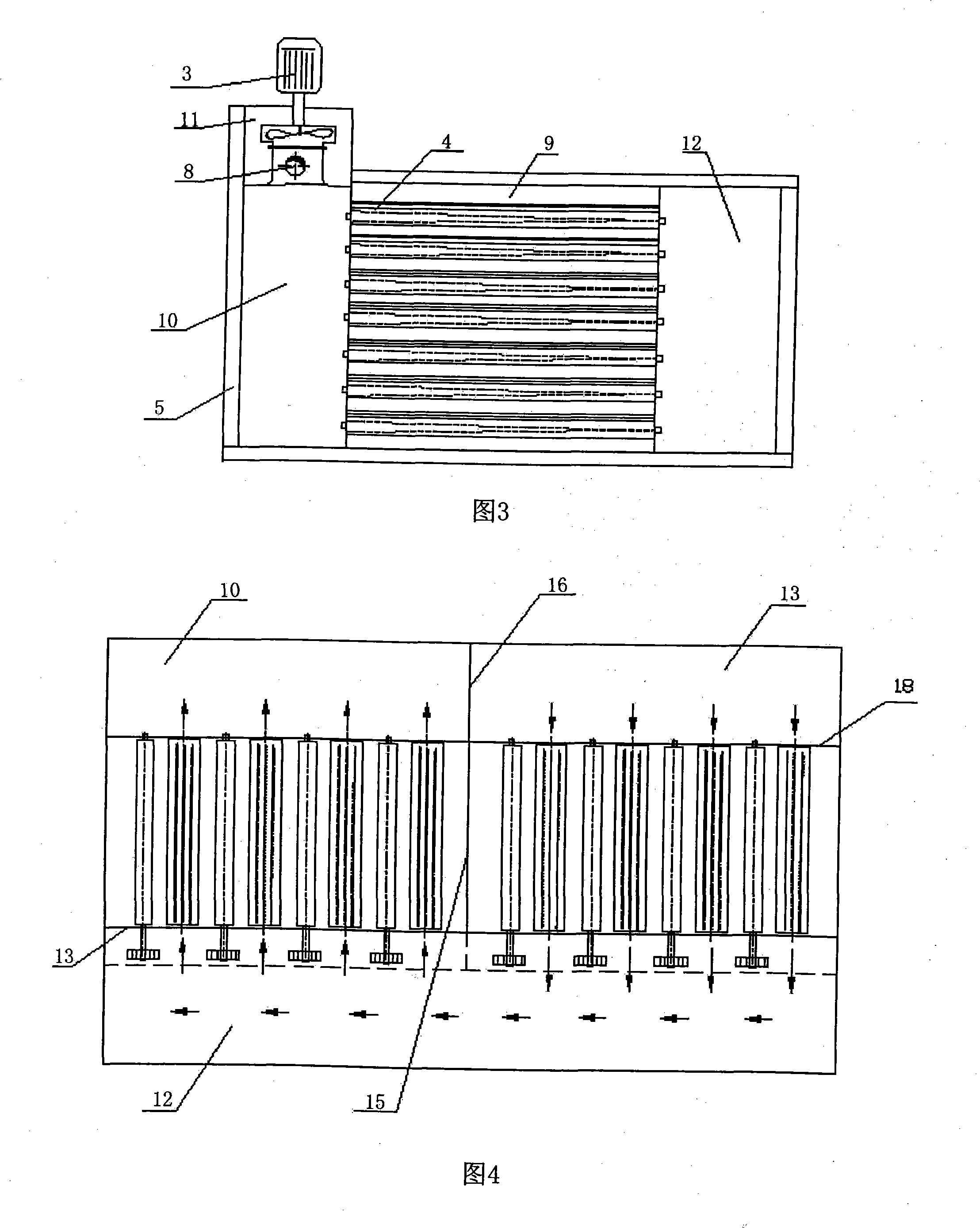

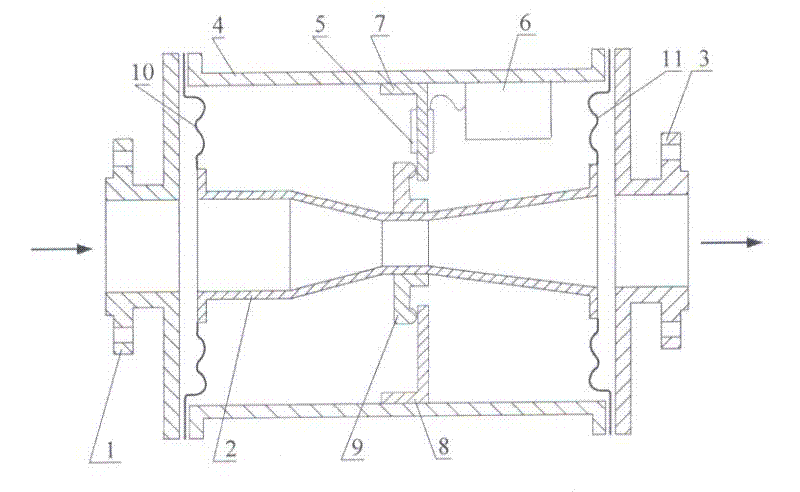

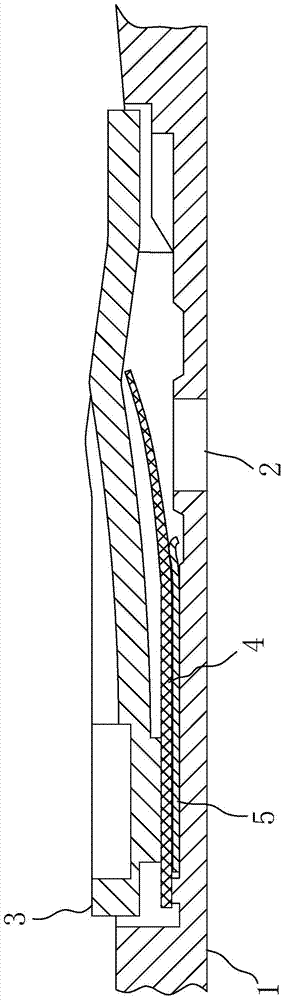

The invention discloses a flowmeter with a middle through-hole movable throttling element connected with elastic membranes or a bellows, which belongs to the throttling flowmeter in the automatic detection technical field; the patent 'a middle through-hole movable throttling element flowmeter' depends on the thrust of the movable throttling element, and does not like a fixed throttling element which measures the flow according to the flow differential pressure, so a pressure pipe can be dispensed, the flowmeter is applicable to measuring small calibers and dirty liquids, the isolation, the pressure-bearing, the support and other functions of the flowmeter are all respectively realized through different components, and the integral structure is more complicated. The flowmeter adopts the elastic membranes or the bellows to be connected with the middle through-hole movable throttling element, the isolation, the pressure-bearing, the support and other functions are realized independently by the elastic membranes or the bellows, the integral structure of the flowmeter is greatly simplified, not only are all the advantages of the through-hole movable throttling element obtained, but also a plurality of performances are improved, and the invention makes the through-hole movable throttling element flowmeter which is a novel meter be more easily popularized and used.

Owner:王可崇

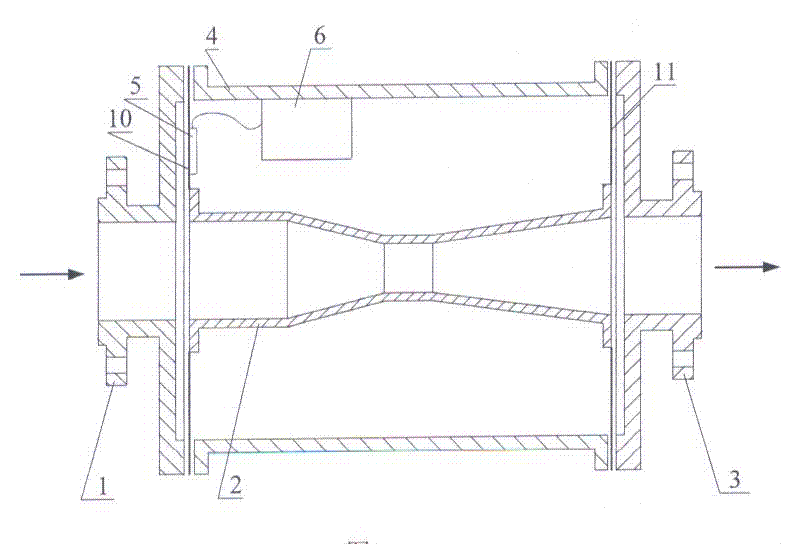

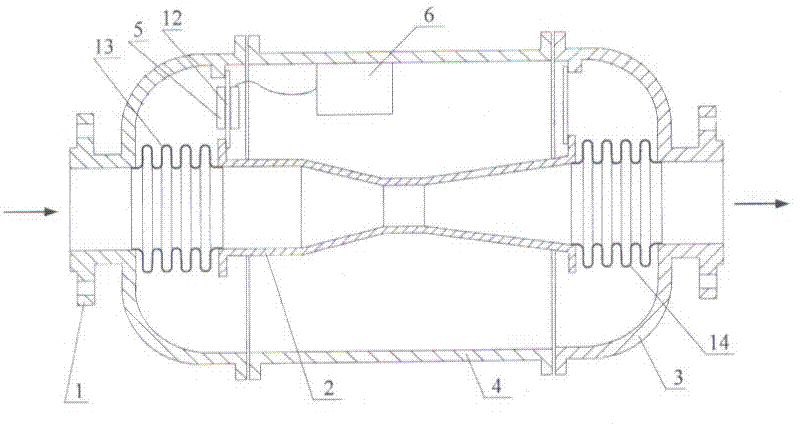

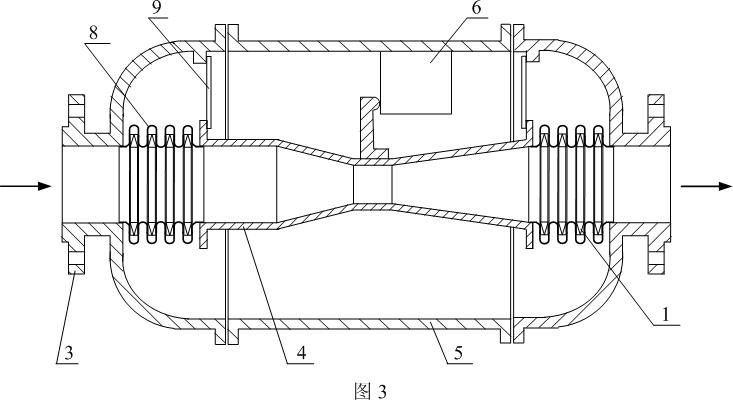

In-built middle through-hole dynamic throttling element flow meter

ActiveCN102620776ALittle flow resistance lossEasy to useVolume/mass flow by differential pressureFlow resistivityDifferential pressure

The invention discloses an in-built middle through-hole dynamic throttling element flow meter, belonging to the technical field of automatic detection of a throttling flow meter. The flow meter is characterized in that an in-built middle through-hole dynamic throttling element is adopted; the internal and external pressures of the dynamic throttling element are balanced; the measured fluid pressure is born by a flow meter pressure hull, thus, a thin wall thick dynamic throttling element can be used; the main boy of an anti-blocking mechanism is a flexible filter medium or a filter membrane with a simple structure; compared with the used pore plates of a differential pressure flow meter, the flow meter provided by the invention mainly uses a dynamic venturi tube; the venturi tube has the advantages of small flowing resistance loss, long service life, high precision, and the tube is hard to block and the like. The flow meter provided by the invention is simple in structure, easiness in manufacturing, high in performance cost ratio, less in energy consumption for measurement, thus, the flow meter can be used for measuring the flow of small pipe diameter and dirty fluid, and has a development prospect for replacing differential pressure flow meters and partial small pipe diameter ultrasonic flow meters.

Owner:YANGZHOU HONGWEI MASCH EQUIP CO LTD

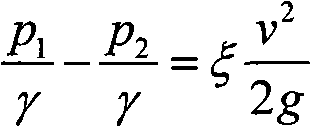

Movable throttling element flowmeter with through hole at middle part

InactiveCN101660933AAvoid easy cloggingLittle flow resistance lossVolume/mass flow by differential pressureCalorimeterEngineeringTransmitter

The invention relates to a movable throttling element flowmeter with a through hole at the middle part, which belongs to the technical field of automatic detection. At present, flow measurement whichis implemented by utilizing the throttling principle widely adopts a fixed throttling element, and a movable throttling element used in a target type flowmeter or a rotor flowmeter does not have the through hole at the middle part. The movable throttling element flowmeter with the through hole at the middle part comprises three parts: the movable throttling element, a force transformation mechanism and a transmitter, wherein, the movable throttling element has the through hole at the middle part, two elastic sealing ring bands are arranged at the front end and the back end of the movable throttling element, and the movable throttling element is further provided with a balancing chamber for balancing the side pressure of measured fluid of the elastic sealing ring bands, so that a non-leakage fluid flowing channel is formed between an inlet and an outlet of the flowmeter under the situation of allowing the movable throttling element to carry out axial movement along a pipeline; and the movable throttling element flowmeter does not need a pressure pipe and can reduce the construction difficulty of a flow detection system, particularly, when the movable throttling element selects a Venturi tube, the movable throttling element flowmeter further has the advantages of small flow resistance loss, long service life, capability of measuring flow rate of small pipe diameter and dirty fluid and the like.

Owner:王可崇 +1

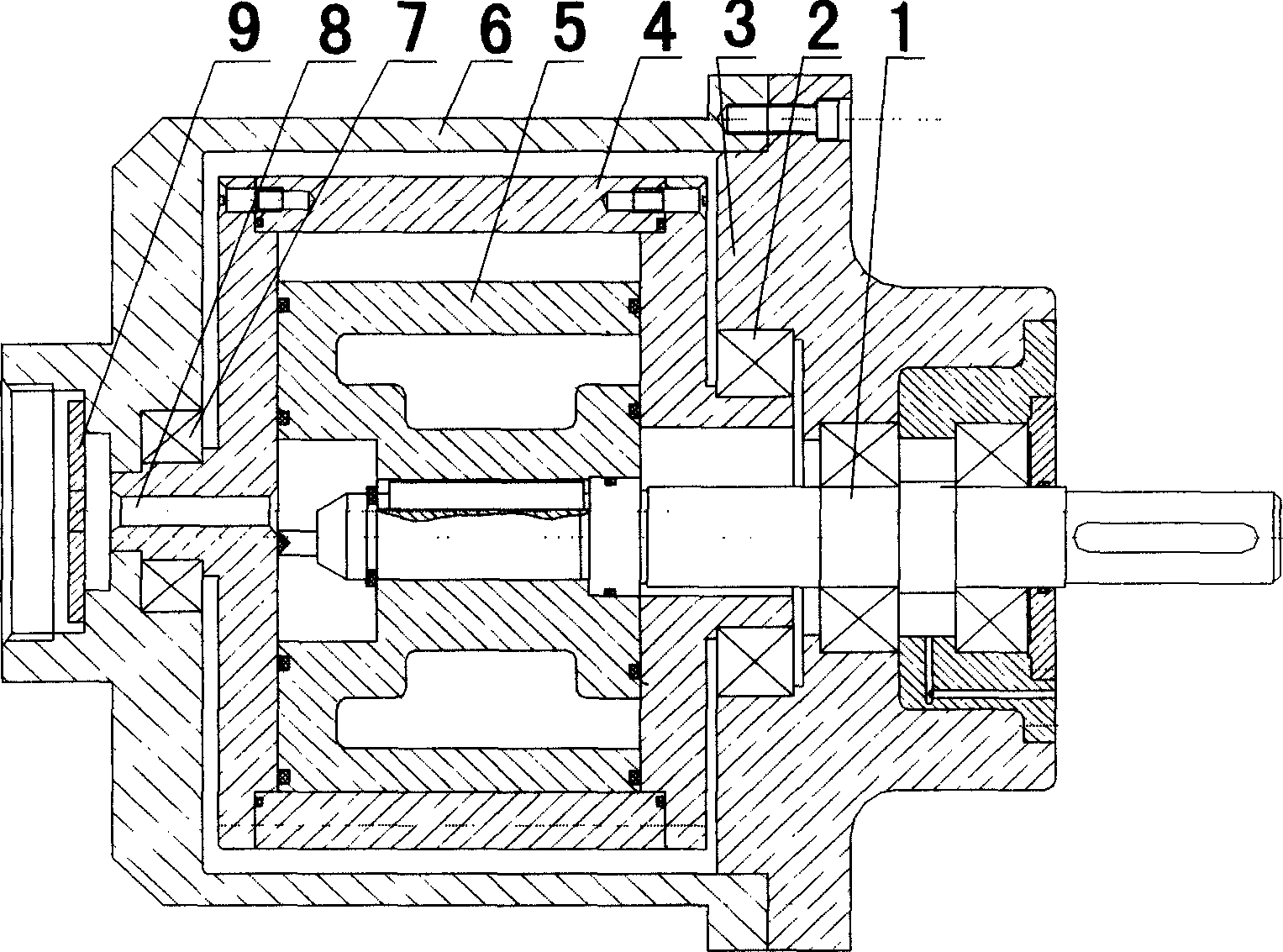

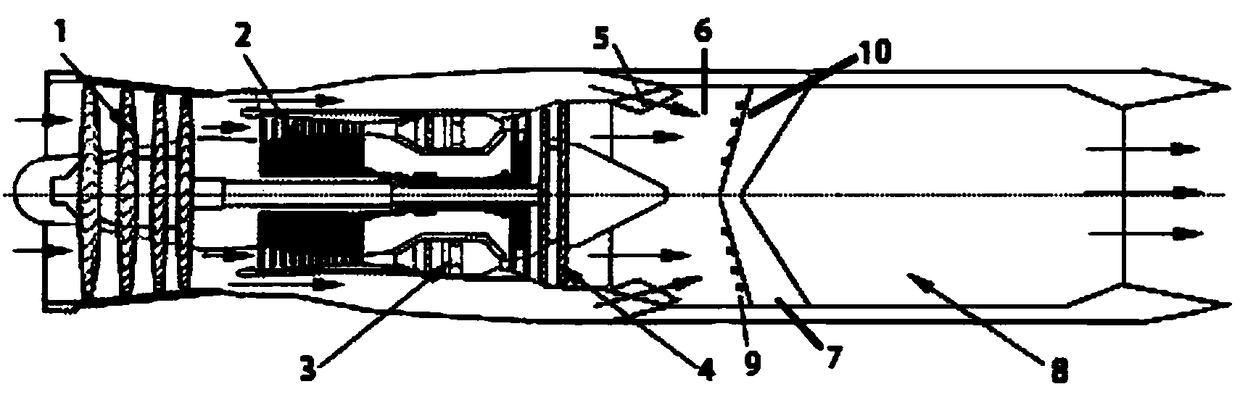

Two-stage turbocharger for aviation piston engine

InactiveCN102748121ASimple structureReduce weightInternal combustion piston enginesEngine componentsAviationTurbocharger

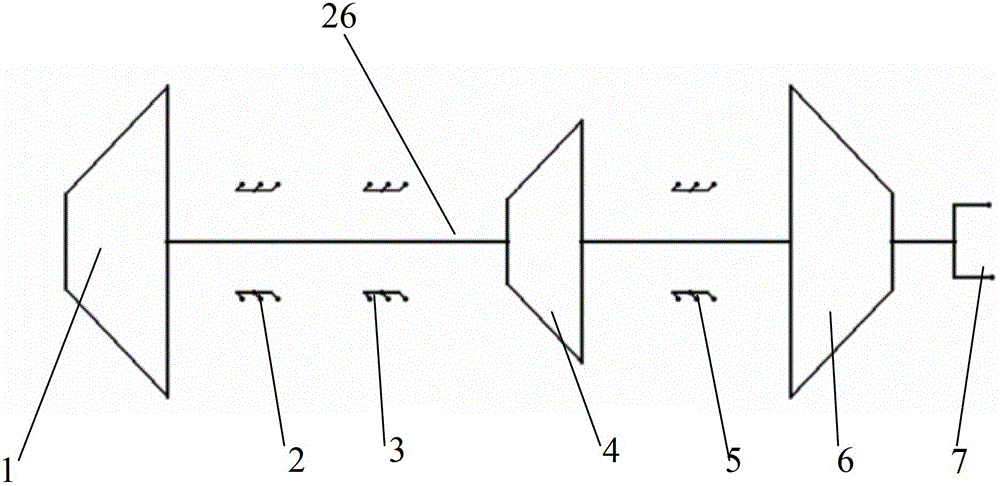

The invention discloses a two-stage turbocharger for an aviation piston engine. The two-stage turbocharger comprises a rotor assembly, a front support assembly, a rear support assembly, a turbine volute, a high-pressure compressor casing, a low-pressure compressor casing and the like, wherein each part in the rotor assembly is locked through a compression nut, and respectively connected with the turbine volute and the compressor casings through bolts; the rear support assembly is of a thin-walled stainless steel soldering structure, and bearings are distributed in a back to back mode; and the compressor casings are of a combined mode, the low-pressure compressor casing is connected with the high-pressure compressor casing through a bolt, and is connected with a regulator assembly through a bolt. The two-stage turbocharger has the advantages that: the turbocharger has simple structure and light weight, and a structure that one turbine drives two compressors is adopted, so that the requirement of an aircraft for high-altitude flight is fulfilled, and the weight of the engine is effectively reduced. The two-stage turbocharger has the characteristics of high reliability and good sealing property, and fulfills the requirement of high-altitude sealing.

Owner:BEIHANG UNIV

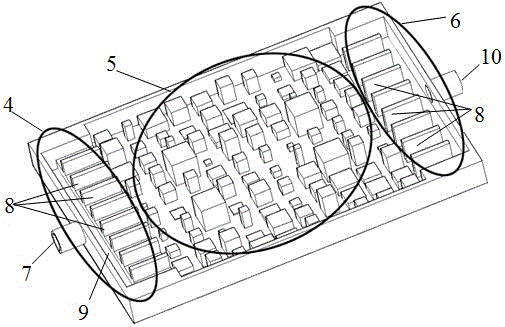

Flowing boiling micro-miniature heat exchanger

ActiveCN106061199AUniform temperatureExtend your lifeCooling/ventilation/heating modificationsEngineeringHeat transfer efficiency

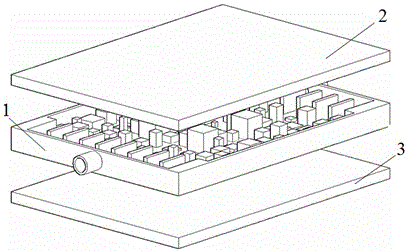

The invention discloses a flowing boiling micro-miniature heat exchanger, which comprises a heat exchanger casing, a heat exchange structure passage, an inlet passage and an outlet passage, wherein the heat exchange structure passage is arranged in the heat exchanger casing; and the inlet passage and the outlet passage are arranged at the two ends of the heat exchange structure passage. The flowing boiling micro-miniature heat exchanger is characterized in that the inlet passage consists of a condensing medium input opening, a flow storage pool and an inlet flow division passage; the flow storage pool is connected between the condensing medium input opening and the inlet flow division passage; the outlet passage consists of a condensing medium output opening and an outlet flow division passage; a micro rib column group and support columns are arranged in the heat exchange structure passage; the micro rib column group consists of micro rib columns; the cross section dimension of the micro rib columns conforms to the fractal Brownian motion features; the micro rib columns are in planar distribution; the height of the micro rib columns meets the normal distribution; and the support columns are distributed in the center of the micro rib column group in an array mode. The flowing boiling micro-miniature heat exchanger has the advantages that the heat transfer efficiency is high; the flowing resistance loss is small; the surface temperature of the heat exchanger is uniform; the work is stable; and the service life is long.

Owner:SOUTHEAST UNIV

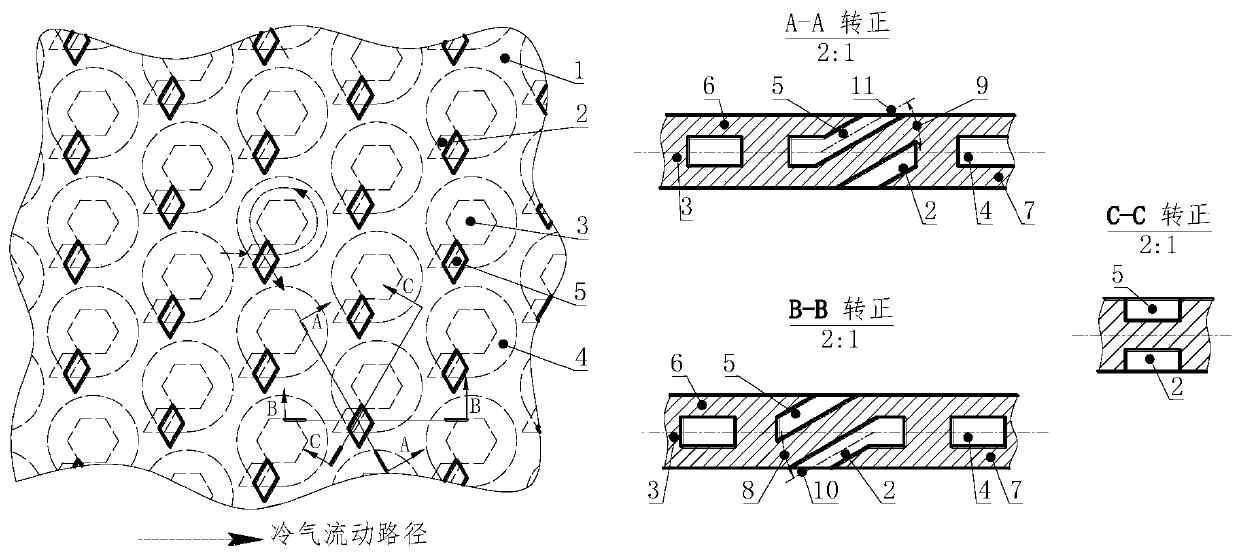

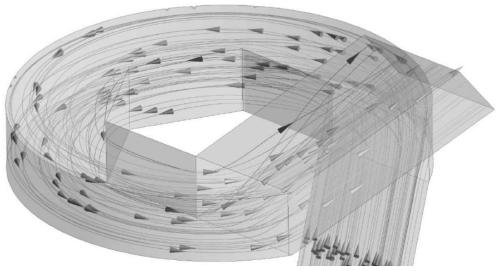

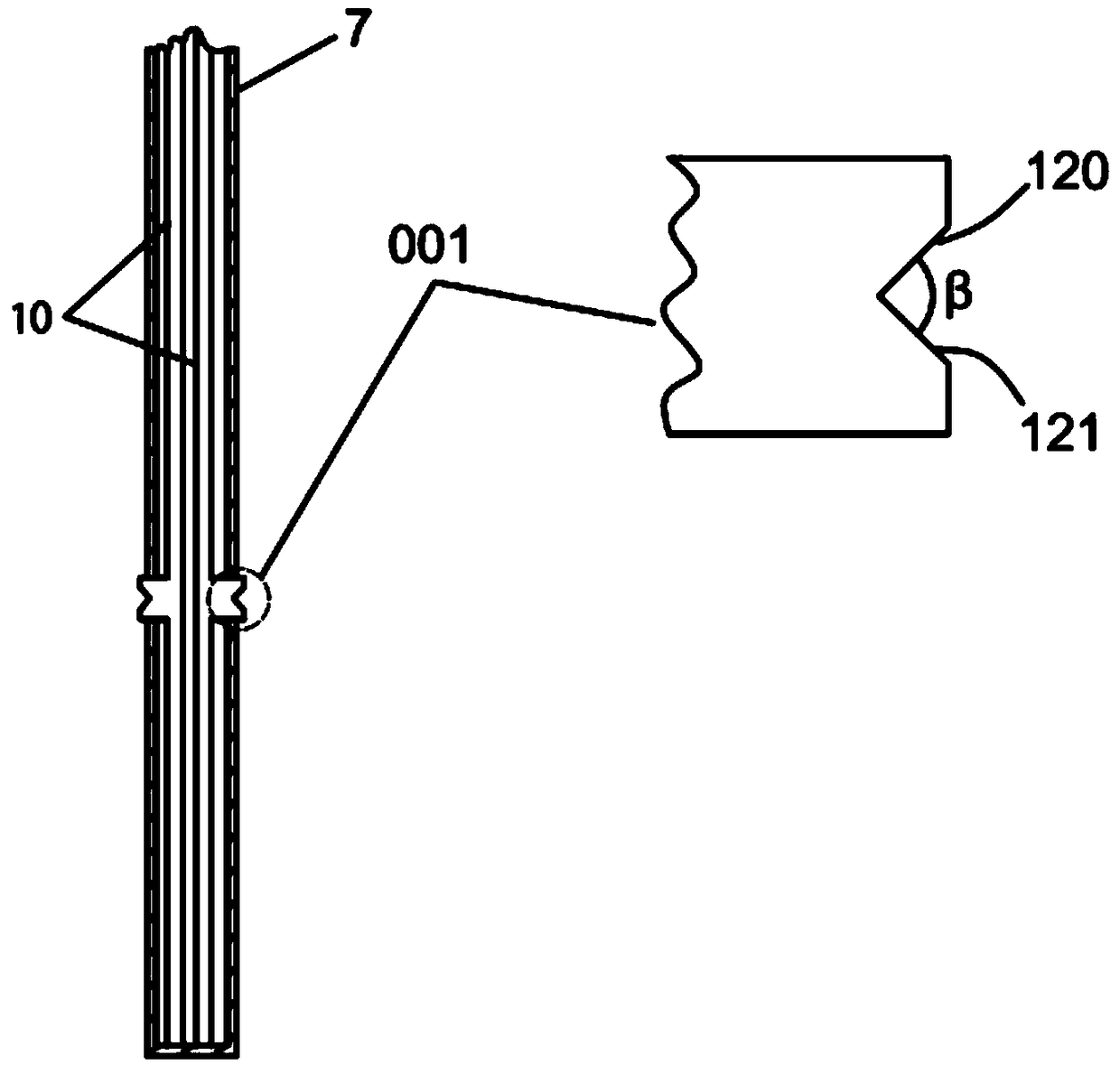

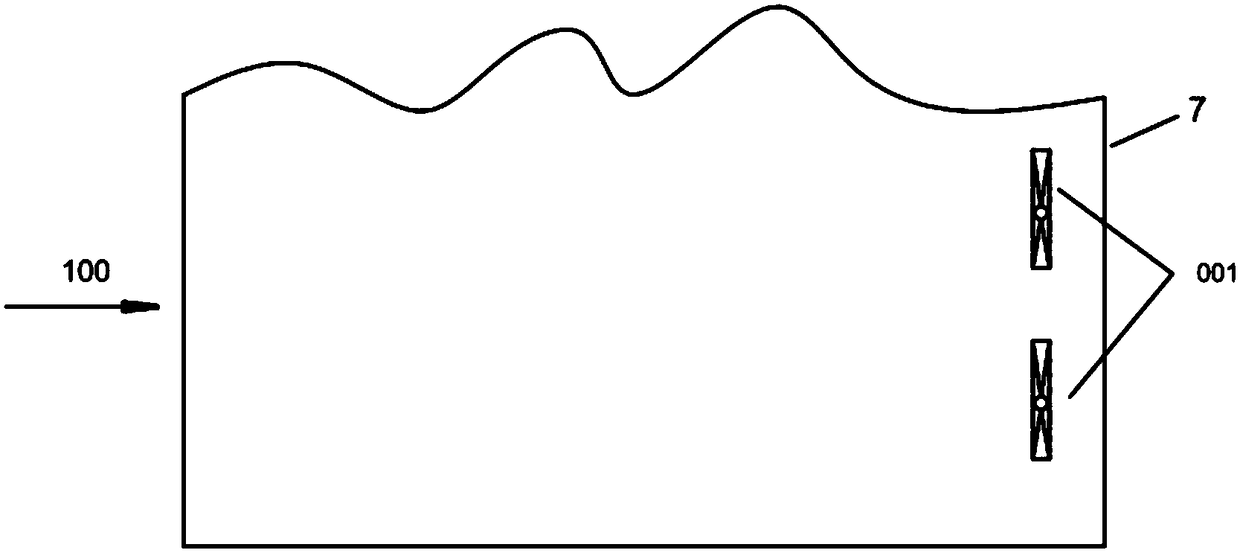

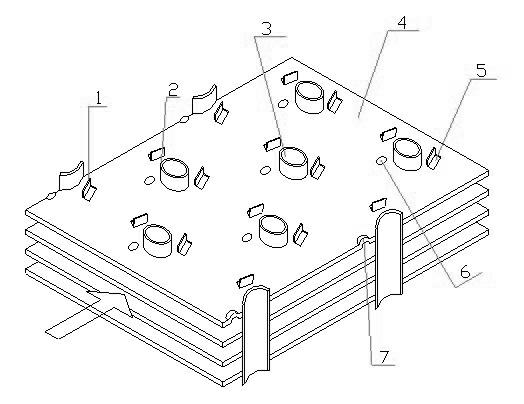

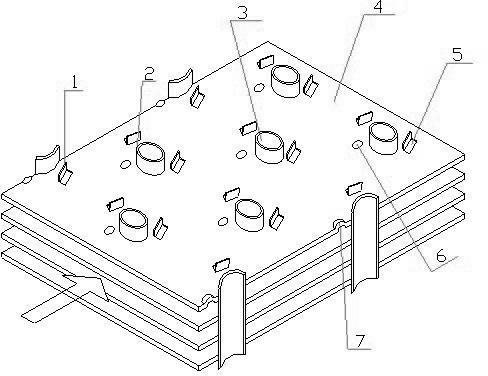

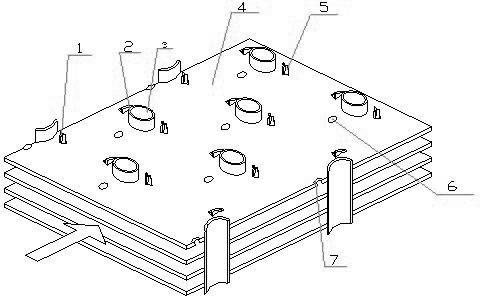

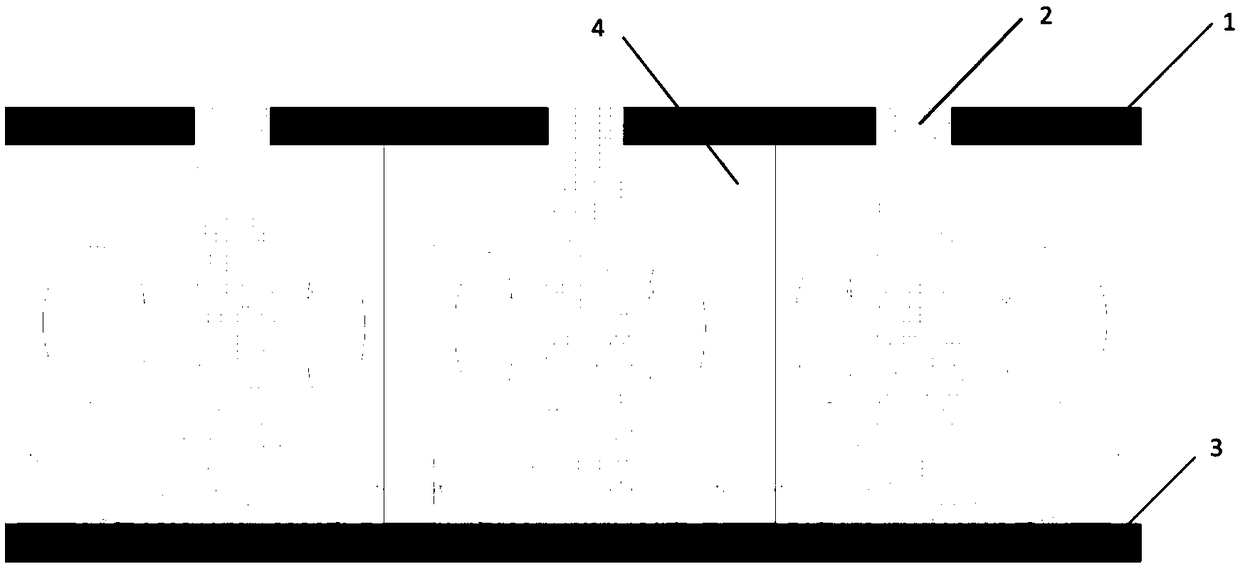

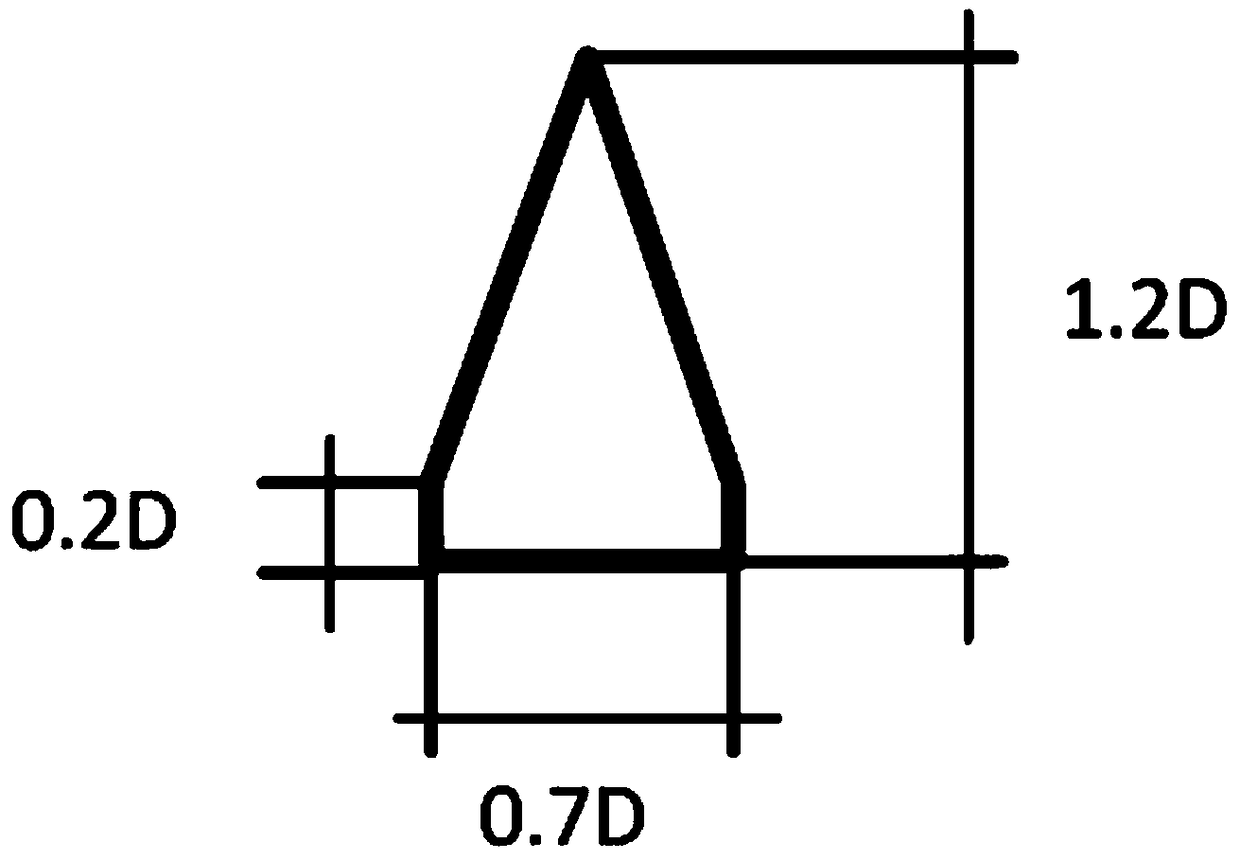

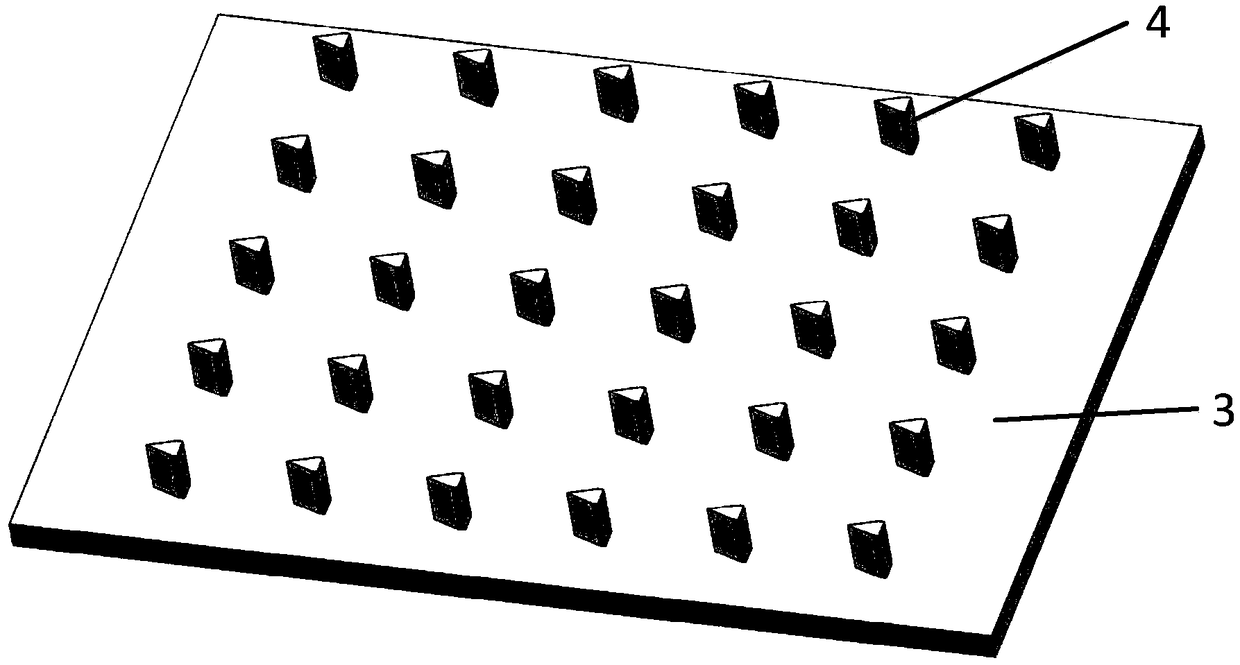

Laminate cooling structure adopting polygonal turbulent flow columns

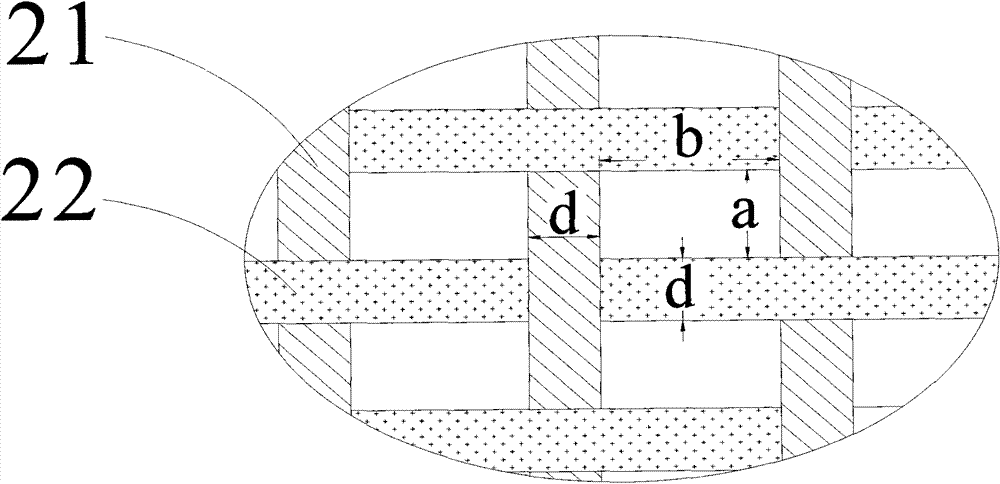

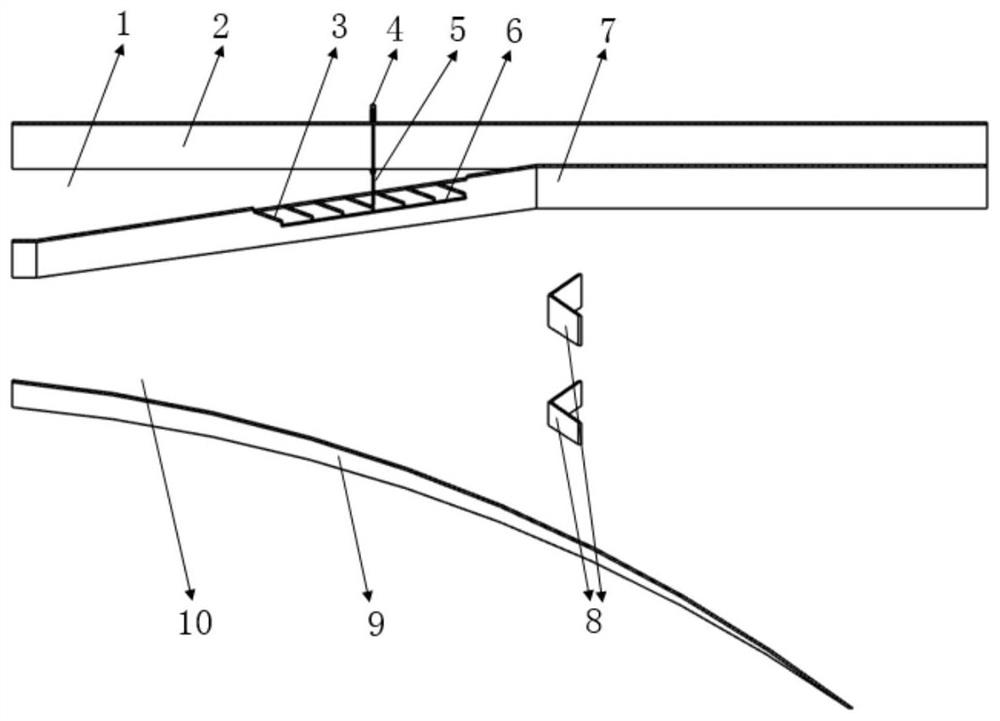

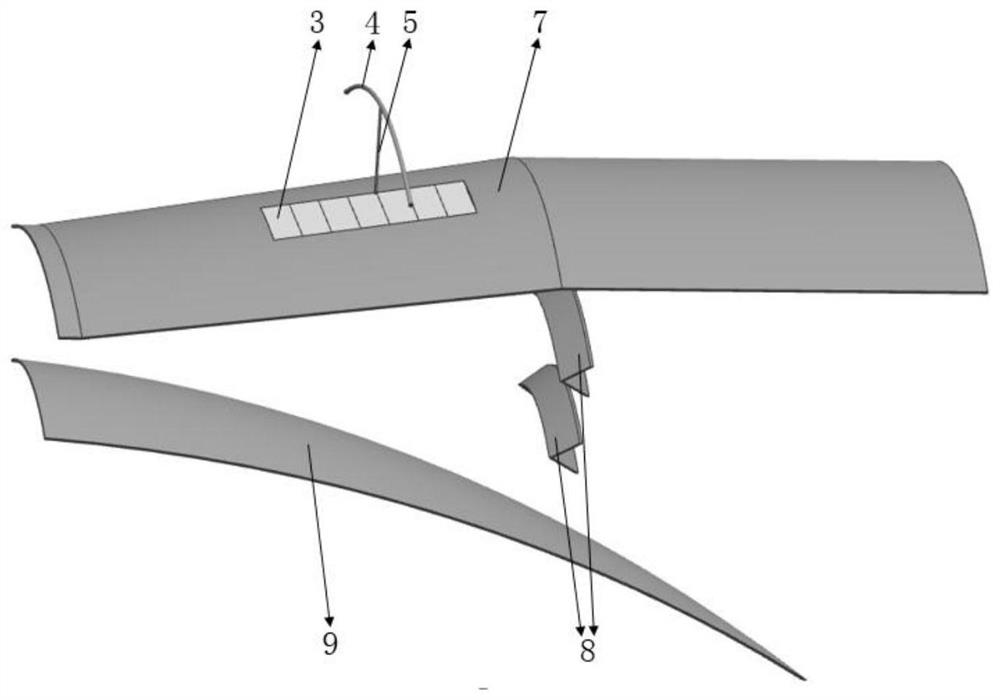

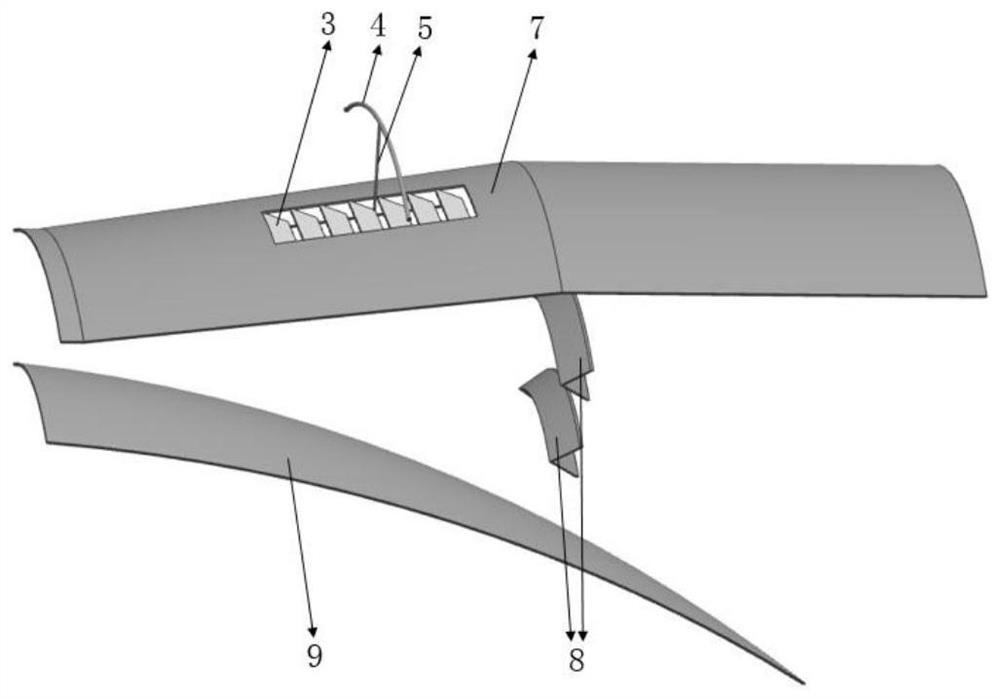

The invention belongs to the technical field of aero-engine and gas turbine cooling, and relates to a laminate cooling structure adopting polygonal turbulent flow columns. The laminate cooling structure comprises an air inlet hole positioned in an air inlet plate, an air outlet hole positioned in an air outlet plate, the turbulent flow columns and a spiral cavity, wherein the turbulent flow columns are positioned in the center of the spiral cavity and form a cold air channel, and the number of the edges of the turbulent flow columns is any one of 3, 4, 5, 6 to n; the cross sections of the airinlet hole and the air outlet hole are in a parallelogram shape, the air inlet hole and the air outlet hole are smoothly connected with the channel in the spiral cavity through an arc-shaped sliding way, and the air inlet hole and the air outlet hole extend outwards from the two adjacent edges of the polygonal turbulent flow columns; and the included angles between the center line of the air inlethole and the horizontal plane and between the center line of the air outlet hole and the horizontal plane are an incident angle A1 and an emergent angle A2 correspondingly, and the incident angle A1and the emergent angle A2 are acute angles. According to the laminate cooling structure, the spiral cavities which are adjacent in space but do not interfere with each other avoid impact and mixing ofcooling airflow in a laminate, so that the flow resistance and the flow loss can be reduced, and the flow resistance loss is greatly reduced.

Owner:DALIAN UNIV OF TECH

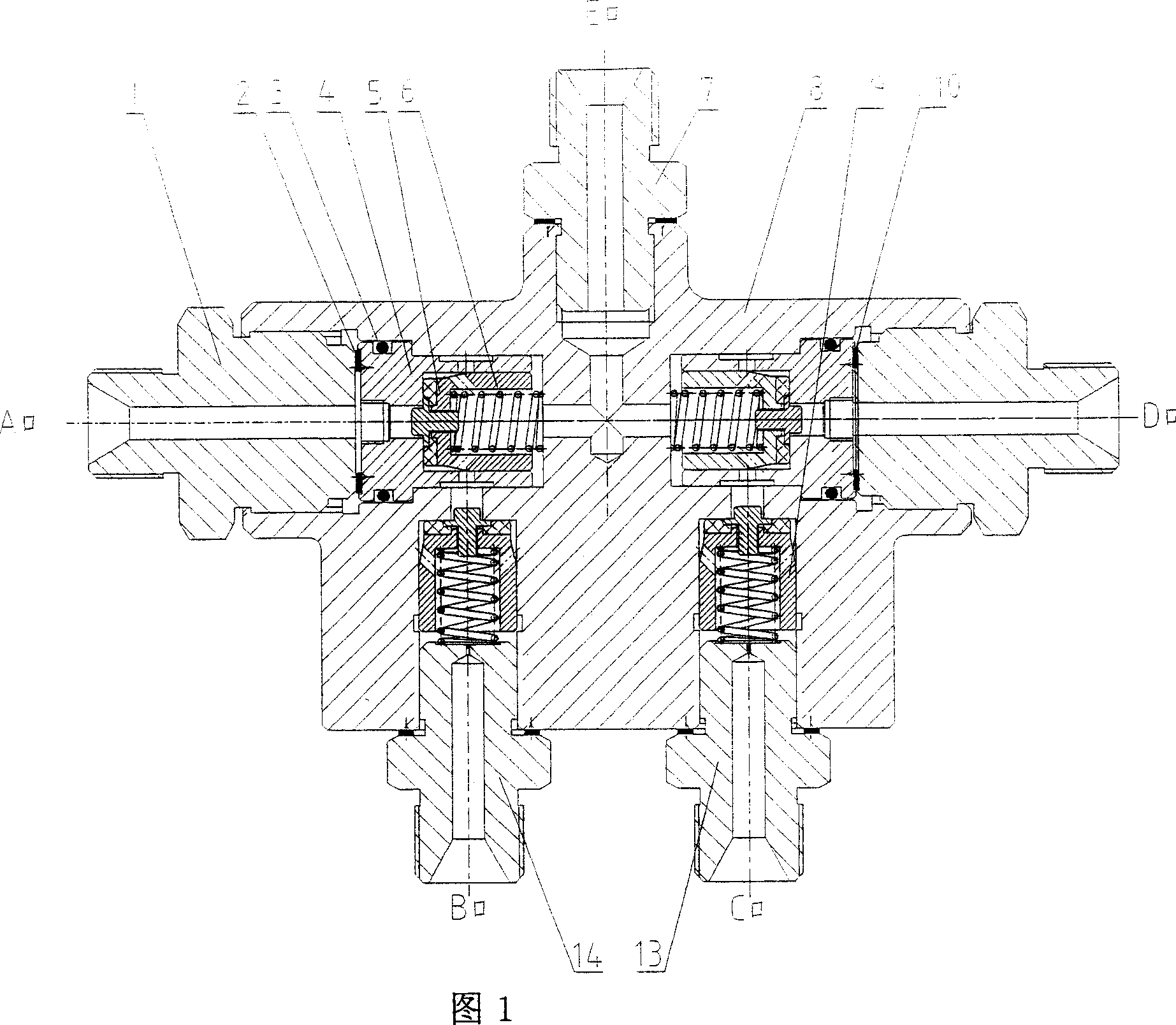

Combined high pressure air exhaust valve

InactiveCN1932355ALittle flow resistance lossWork reliablyMultiple way valvesExhaust valveFriction loss

The present invention relates to a combined high-pressure exhaust valve, belonging to the field of high-pressure system control technology. It is mainly characterized by that in the centre of exhaust valve body a three-way gas channel is set, two ends of straight channel are respectively equipped with one-way seal valve, in another channel interior an adapter is mounted; in which two one-way seal valves respectively adopt valve core component and spring mounted in the valve seat, and utilize adapter body to fasten them into the exhaust valve body interior; in the side surfaces of its two one-way seal valves are respectively set other two one-way seal valves, said other two one-way seal valves can respectively utilize two throttle valves to fasten the valve core component and spring into the exhaust valve body interior.

Owner:WUXI COMPRESSOR CO LTD

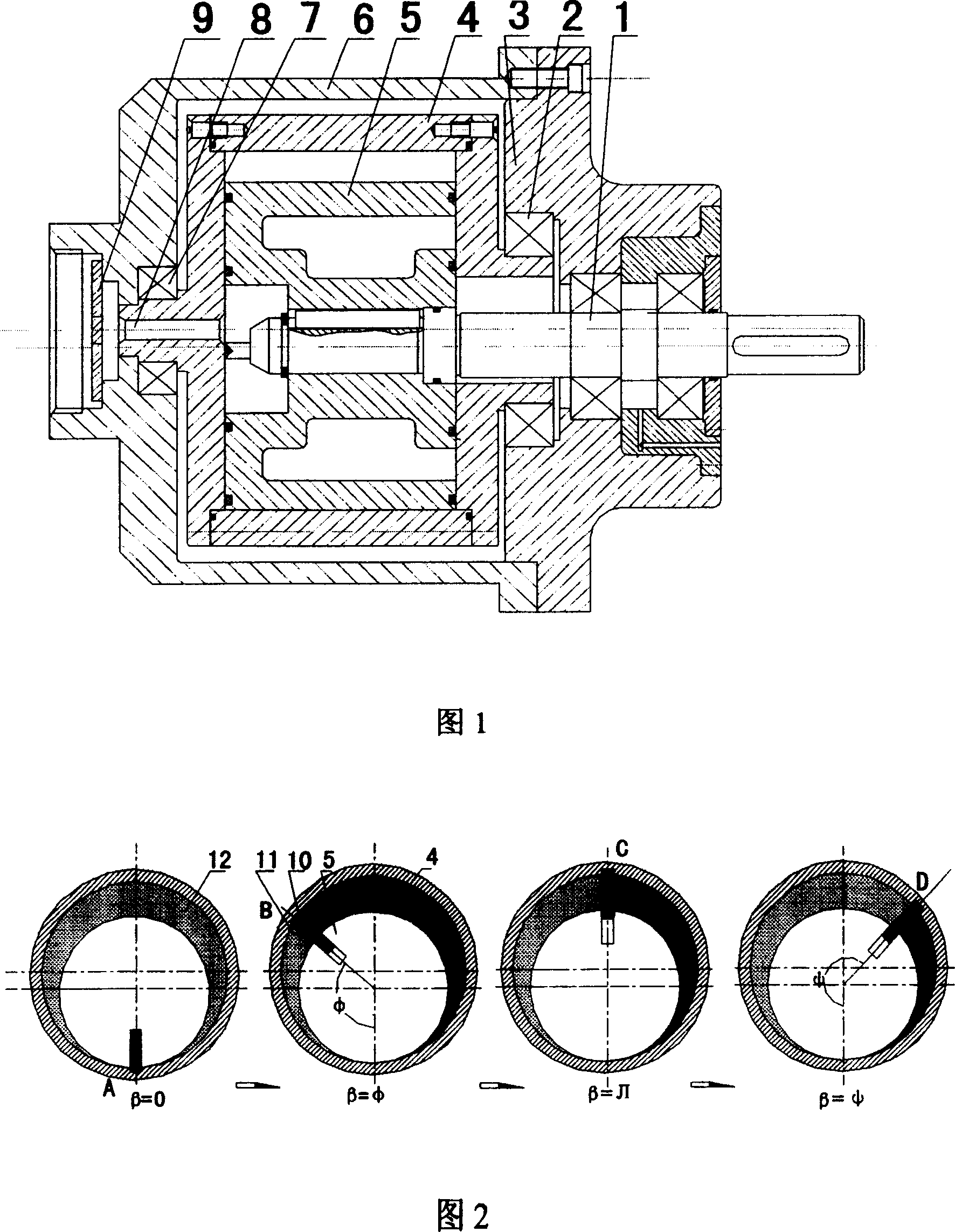

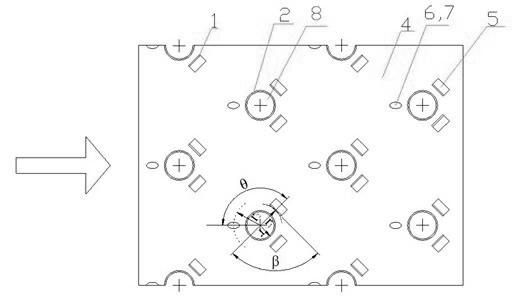

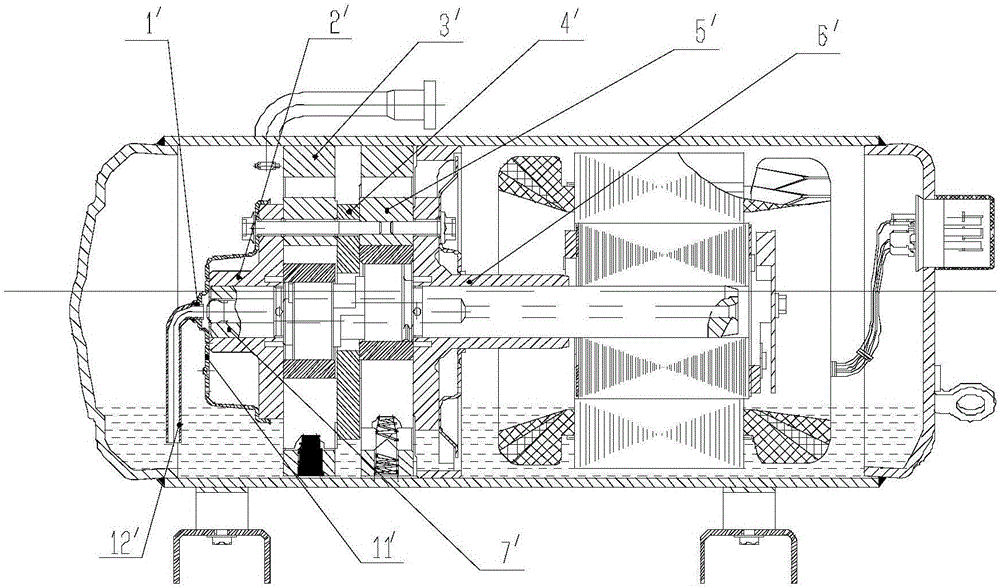

Double-slip-sheet type rotary compressor

ActiveCN102828951AShorten exhaust strokeSmall compression strokeRotary piston pumpsRotary piston liquid enginesSlip sheetEngineering

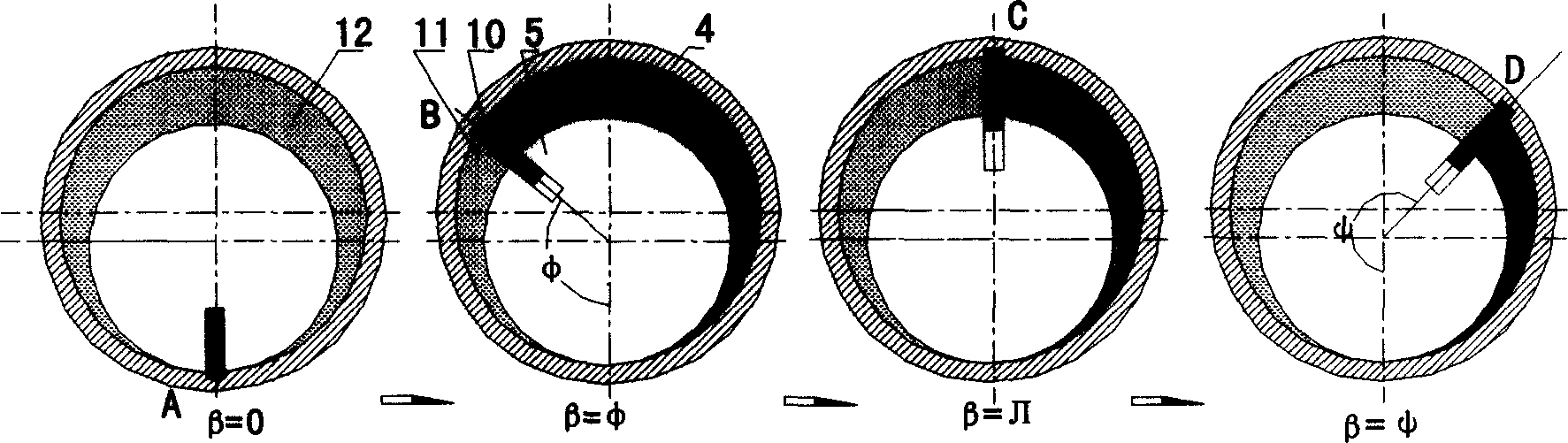

The invention relates to a double-slip-sheet rotary compressor, comprising a motor assembly and a compression assembly which are arranged in a housing, wherein the compression assembly comprises a piston disposed in an air cylinder; the air cylinder is provided with a first slip sheet groove for accommodating a first slip sheet and a second slip sheet groove for accommodating a second slip sheet; the first slip sheet groove is communicated with a first slip sheet cavity; the second slip sheet groove is communicated with a second slip sheet cavity; the second slip sheet cavity is communicated with a pressure-switch pipe and realizes volume change by switching the pressure of the second slip sheet cavity; the air cylinder is provided with a first exhaust notch and a second exhaust notch; a main bearing is provided with an upper exhaust hole; an auxiliary bearing is provided with a lower exhaust hole; an angle beta is formed by connecting lines between the center of the first exhaust notch and the center of the air cylinder and between the center of the second exhaust notch and the center of the air cylinder; and on basis of the center line of the first exhaust notch and in a counter-clockwise direction, the angle beta meets the following relationship. With the double-slip-sheet rotary compressor, clearance volume of a low-capacity working mode is effectively decreased; and volume efficiency of the compressor is improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

Turbocharger with double vane nozzle system

ActiveCN102297016AReduce lateral flow lossesAvoid disorderInternal combustion piston enginesGas turbine plantsTurbochargerGear wheel

Owner:JIANGSU KAIDI DYNAMIC CONTOL SYST CO LTD

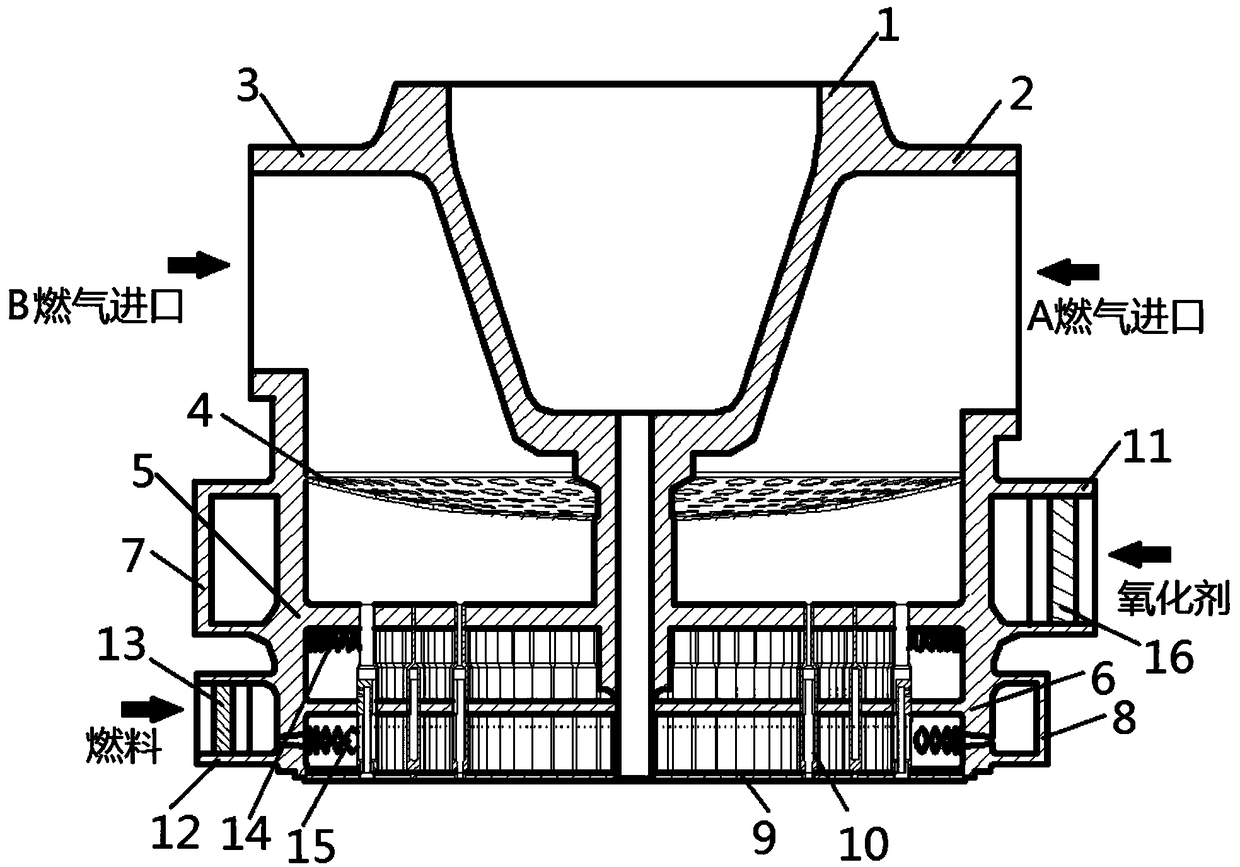

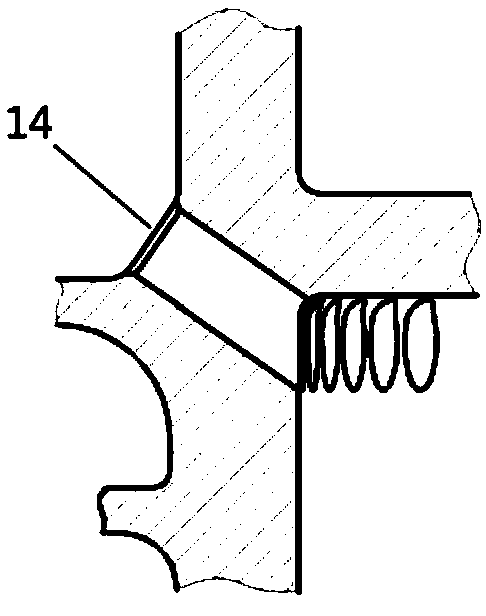

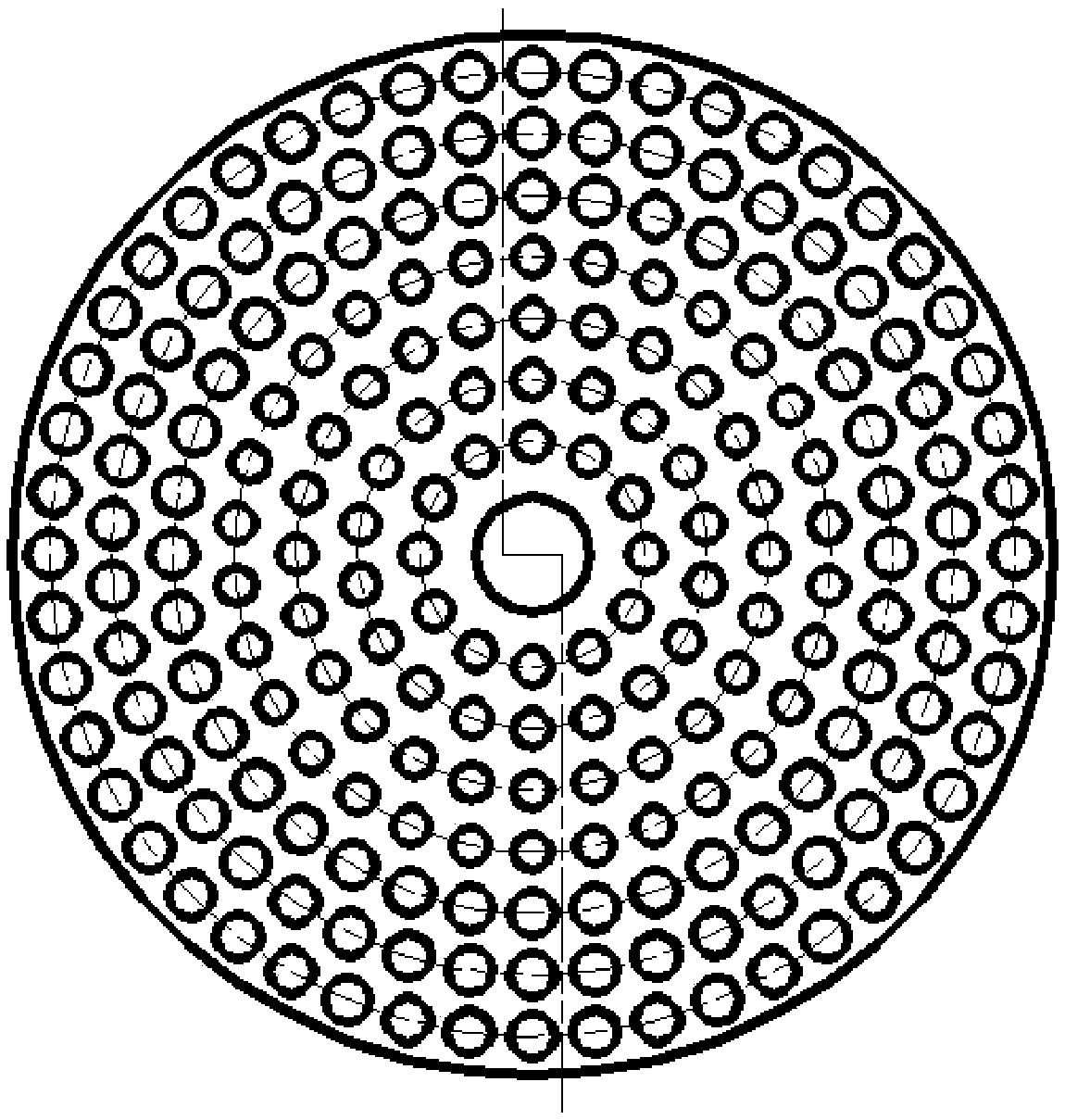

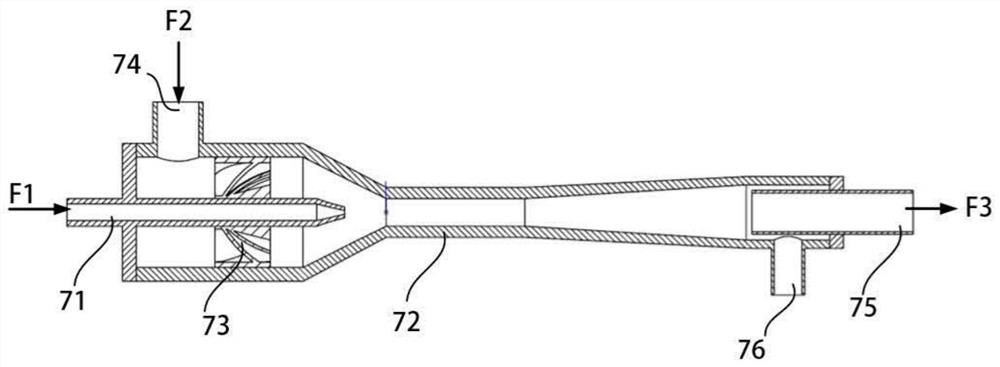

Four-bottom three-cavity injector

ActiveCN108915899ADissipated moreEliminate vortex phenomenonRocket engine plantsSpray nozzleEngineering

Provided is a four-bottom three-cavity injector. A bearing seat and gas top cover integrated piece and a belt ring three-bottom and fuze integrated piece form a gas chamber; a chamber jointly definedby the belt ring three-bottom and fuze integrated piece and a belt ring two-bottom jointly is an oxidant chamber, an oxidant inlet section is an inlet of an oxidant and is communicated with an oxidantcollector, and the oxidant inlet section is provided with a flow deflector that divides an incoming flow oxidant into two strands that flow into the two sides of the oxidant collector respectively. Achamber defined by a belt ring two-bottom and a one-bottom is a fuel chamber, a fuel inlet section is a fuel inlet and is communicated with a fuel collector, and the fuel inlet section is provided with a flow deflector that divides incoming flow fuel into two strands that flow into the two sides of the fuel collector respectively; and nozzle assemblies are mounted on the belt ring three-bottom and fuze integrated piece, the belt ring two-bottom and the one-bottom. The gas chamber, the oxidant chamber and the fuel chamber are sequentially distributed from top to bottom.

Owner:BEIJING AEROSPACE PROPULSION INST

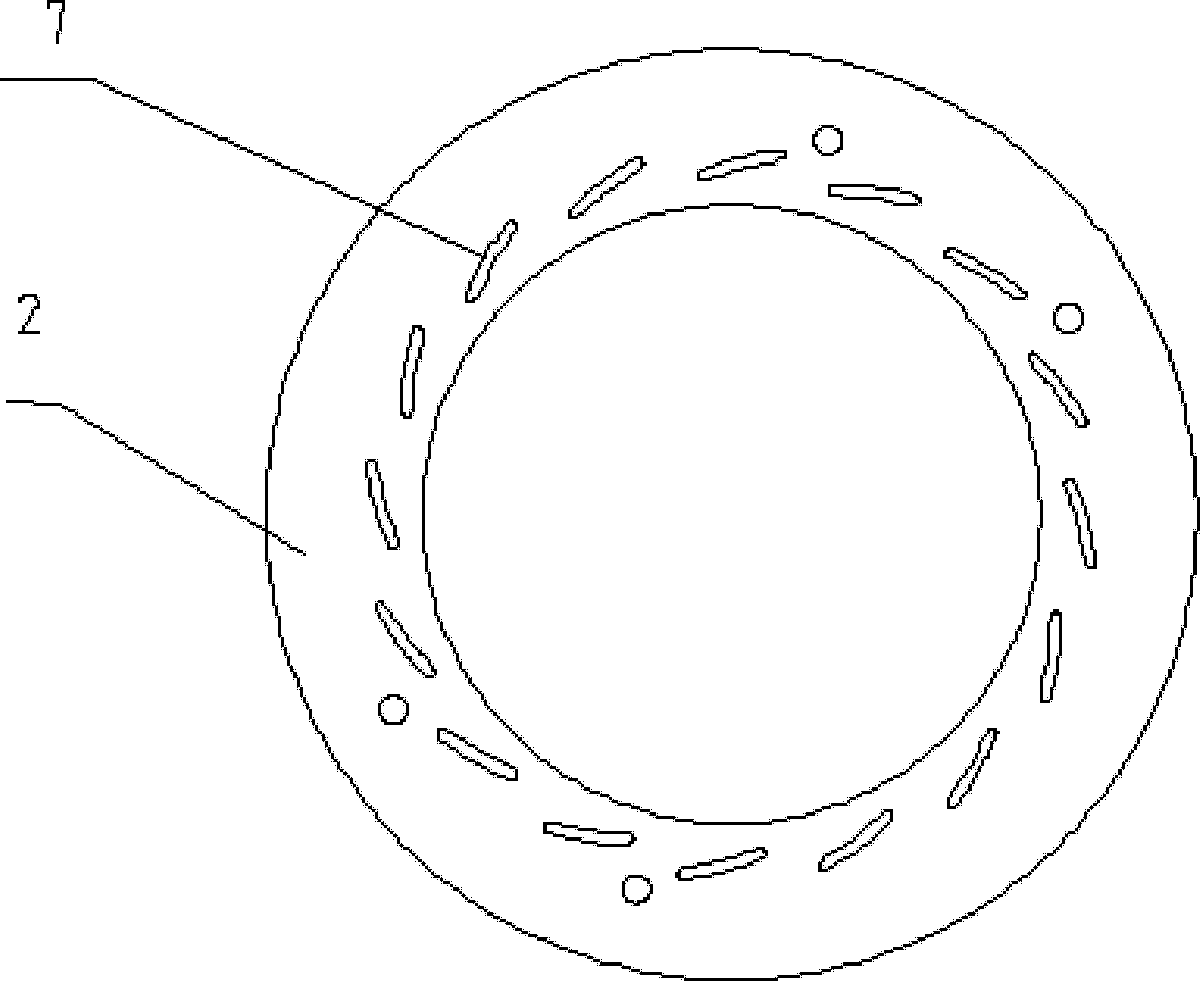

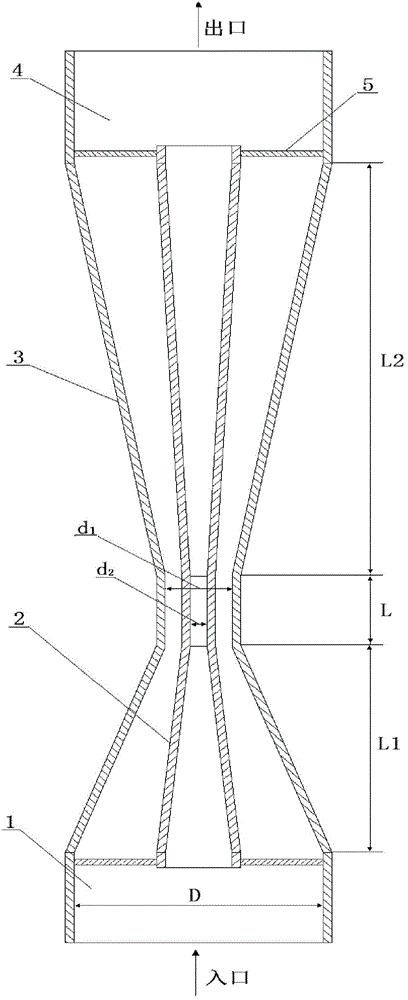

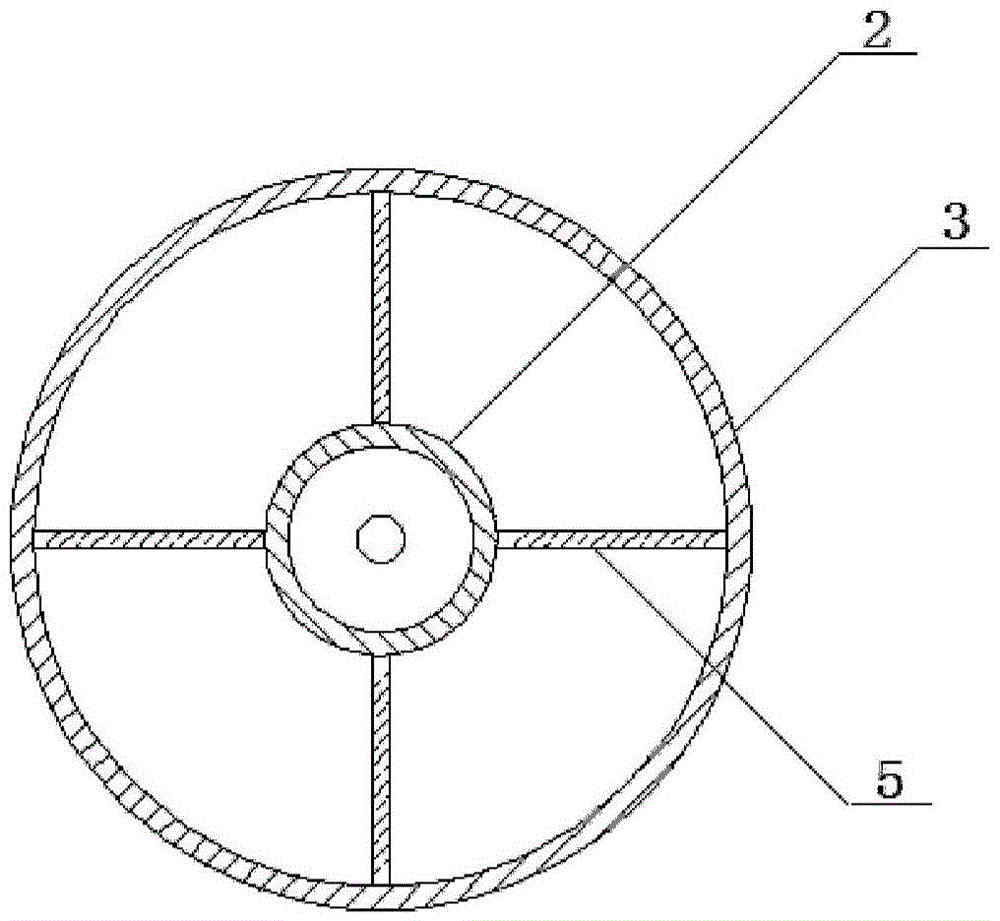

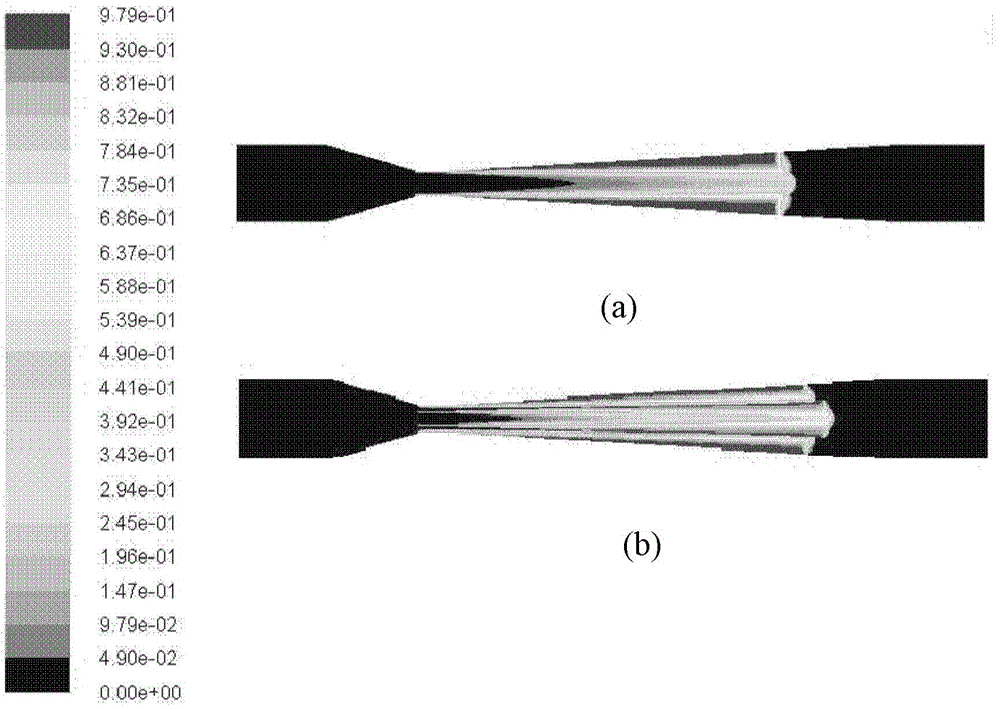

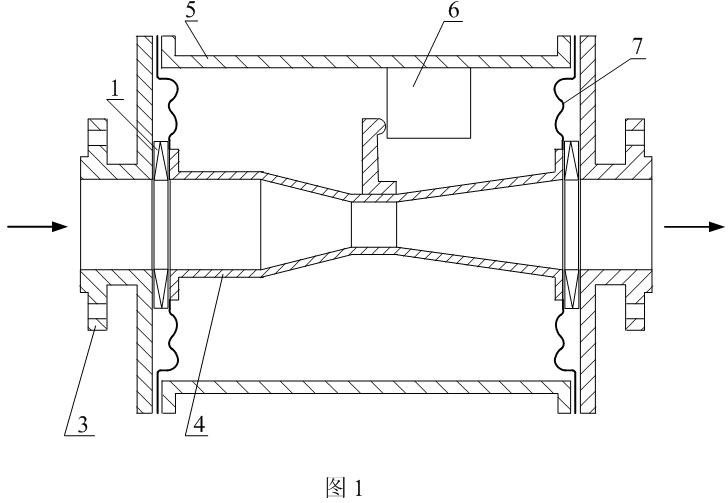

Multilayer nested cavitator capable of forming large-range cavitation

ActiveCN104828884ALittle flow resistance lossReduce inputWater/sewage treatment by oxidationCavitationEngineering

The invention discloses a multilayer nested cavitator capable of forming large-range cavitation. The multilayer nested cavitator mainly comprises an inlet section used as a flow distribution cavity, and through which a fluid enters the spaces of the various layers of the nested cavitator respectively, a nested tube section composed of two or more coaxial Venturi cavitators, and used for creating necessary pressure conditions for generation of liquid cavitation, an outlet section through which liquids from the various layers of cavitators are collected and flow out of the cavitators. The multilayer nested cavitator disclosed by the invention is capable of effectively expanding the action range of cavitation. A numerical simulation result indicates that compared with a single Venturi cavitator, the average gas holdup is increased by more than 5%, and the total volume of a gas in a cavitation area is increased by more than 16% under the same flow and pressure difference condition.

Owner:中科热科技江苏有限公司

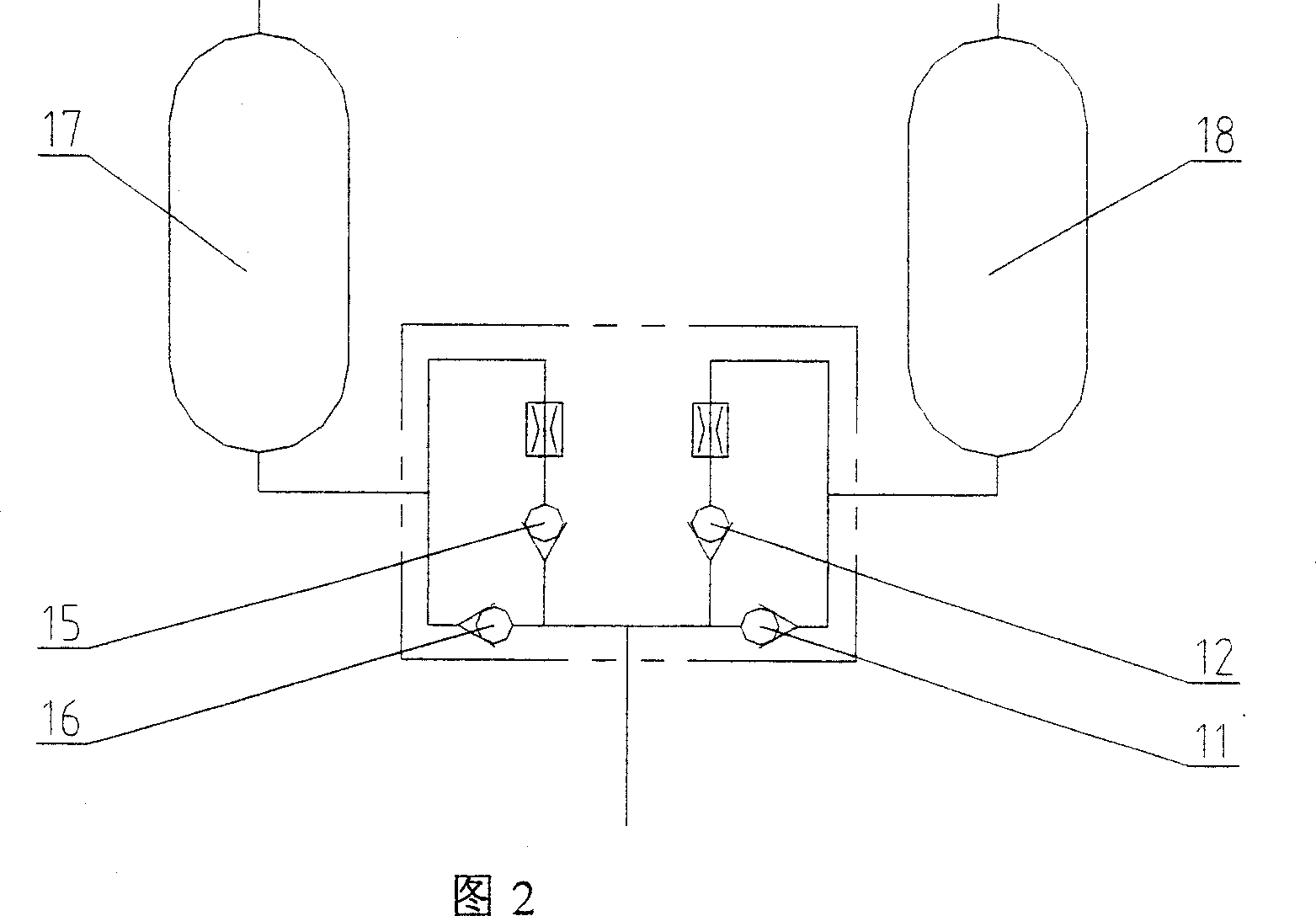

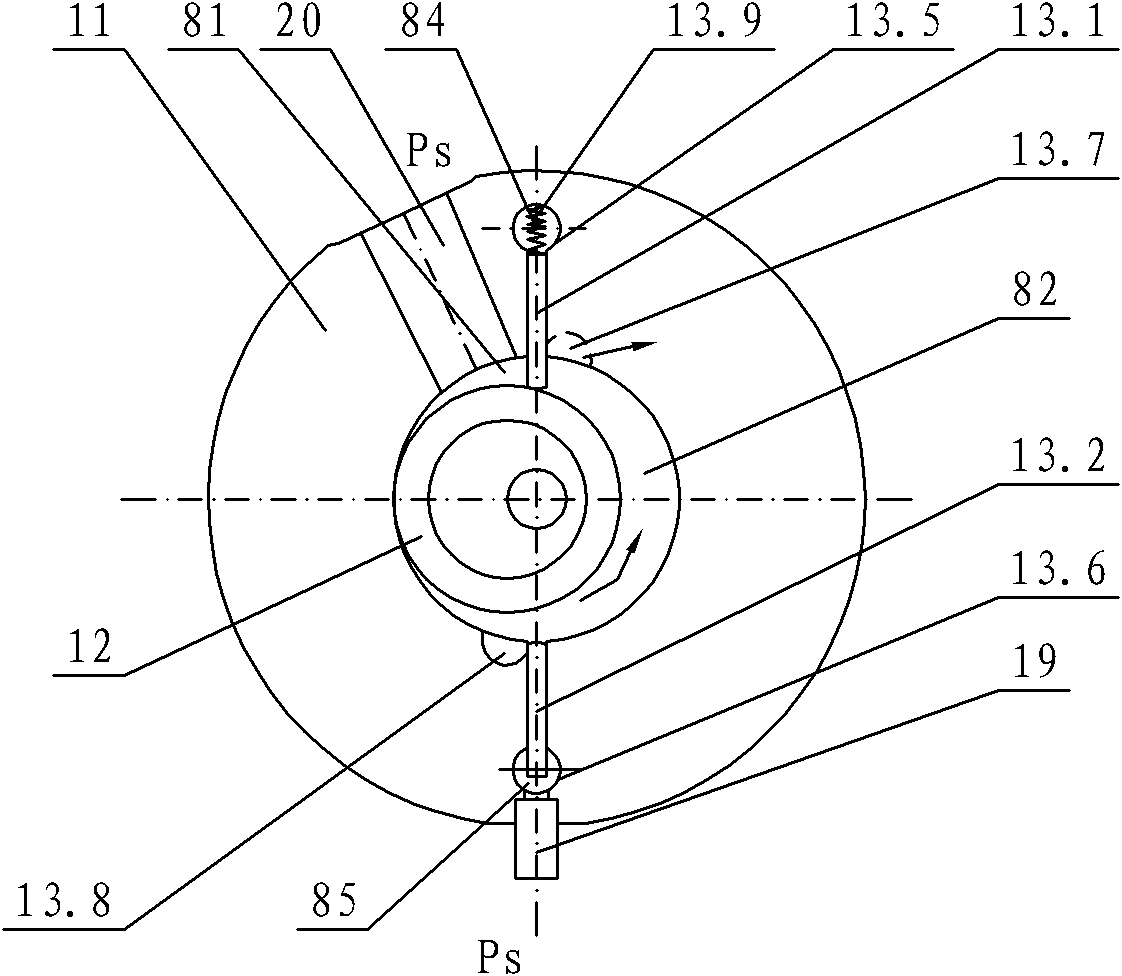

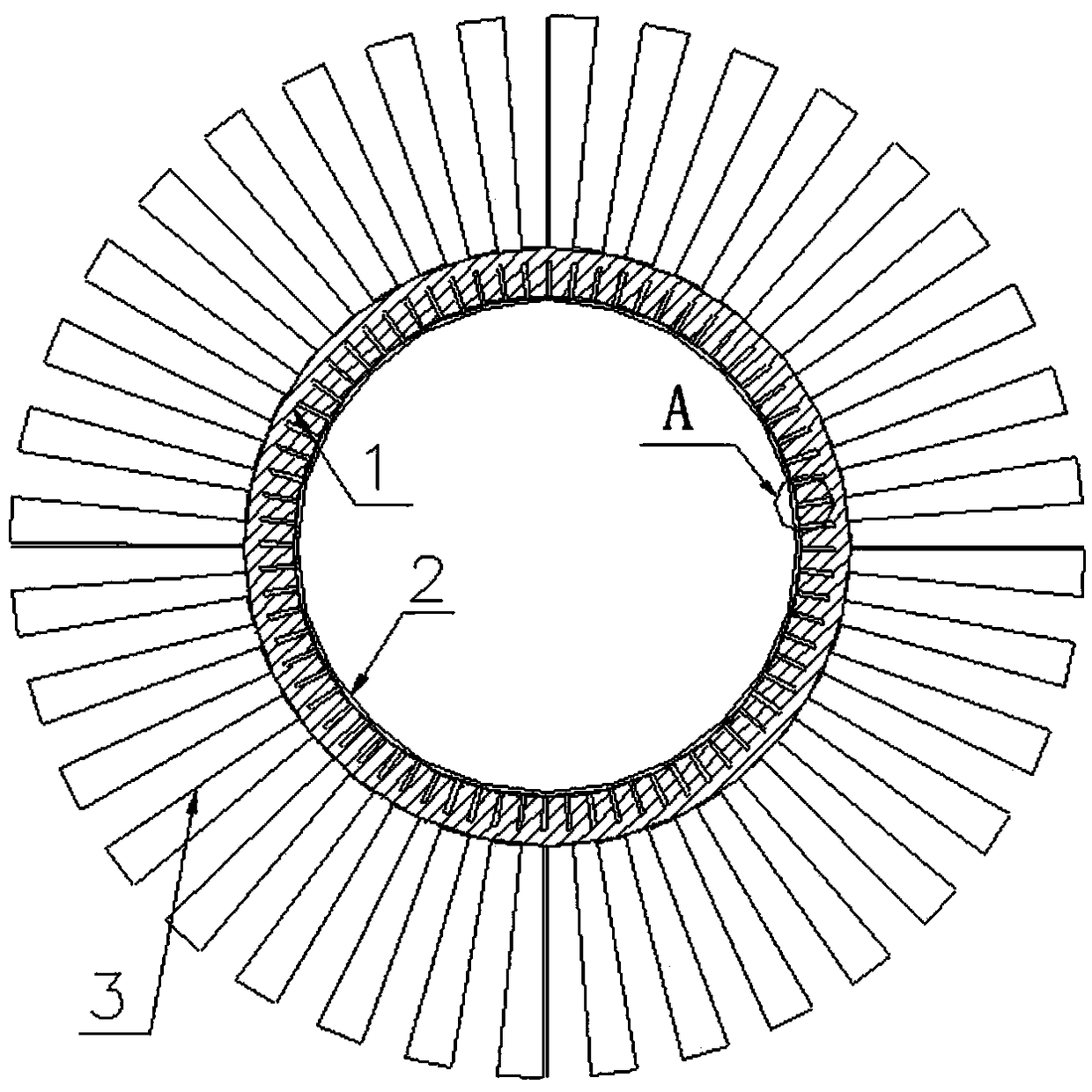

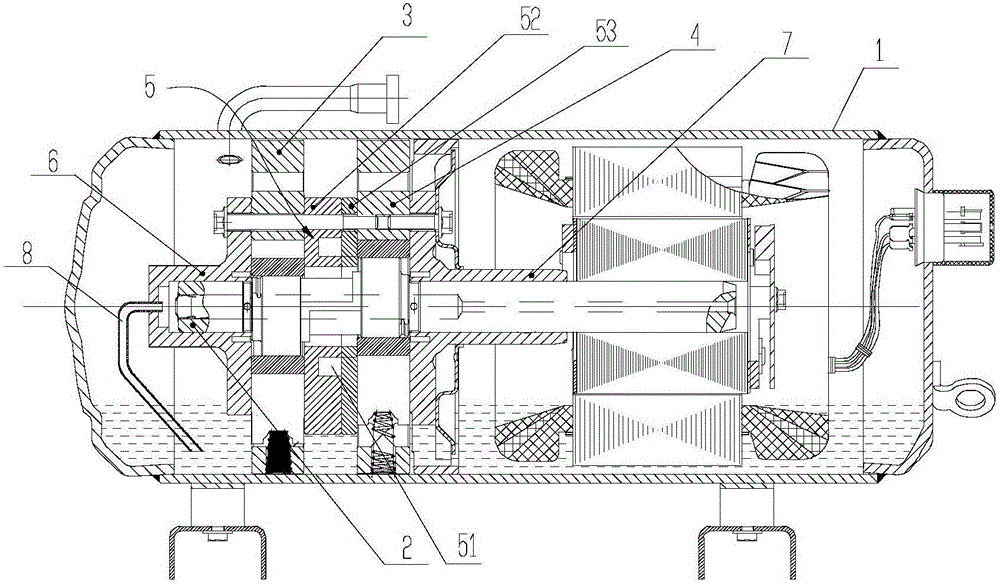

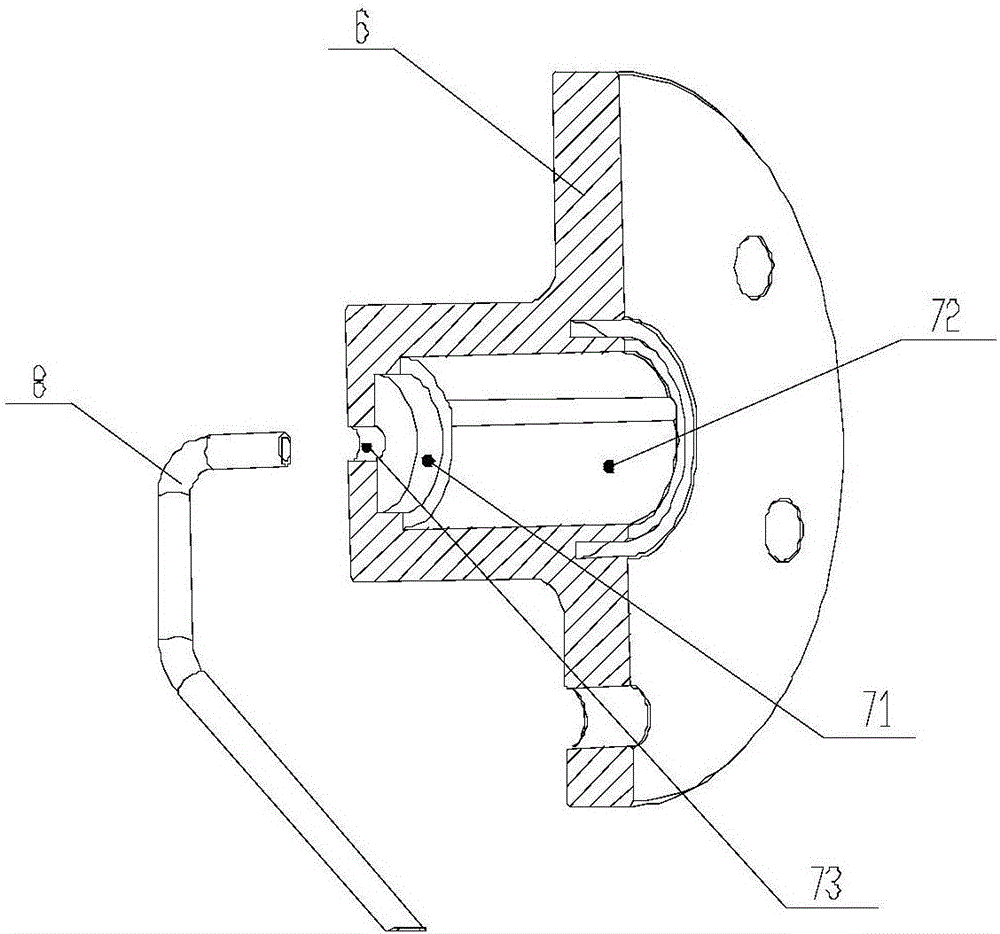

Synchronous rotary compressor

ActiveCN1563720ASmooth motionLittle flow resistance lossRotary piston pumpsRotary piston liquid enginesFixed frameDrive shaft

The revolve compressor is composed of fixed frame and eccentricity seat connected with the fixed frame. In the air cavity comprised by the frame and eccentricity seat, the rotor sleeved on the driving shaft is fixed, the sliding bar installed on the rotor can be embedded to the cylinder. The cylinder is fixed in the air cavity, through the frame bearing and support bearing; the shaft of the cylinder and rotor and not in the same axis line. As the driving axis rotate, the rotor make revolve moment, the sliding plate embedded to the cylinder due to the effect of centrifugal force which pushes the cylinder make the same revolve movement.

Owner:DAFENG FENGTAI FLUID MACHINERY TECHNOLOGY CO LTD

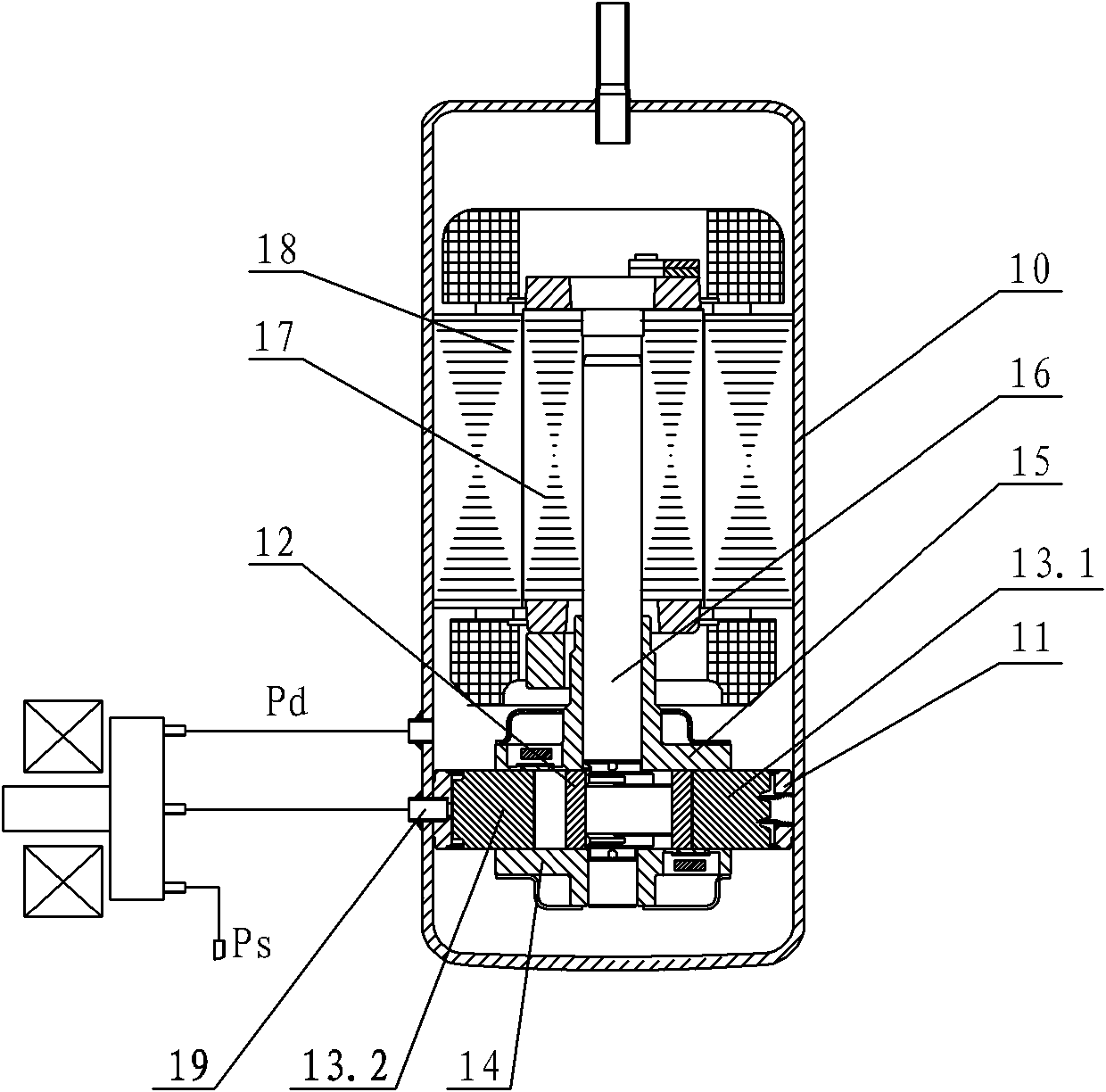

Swing rotor compressor

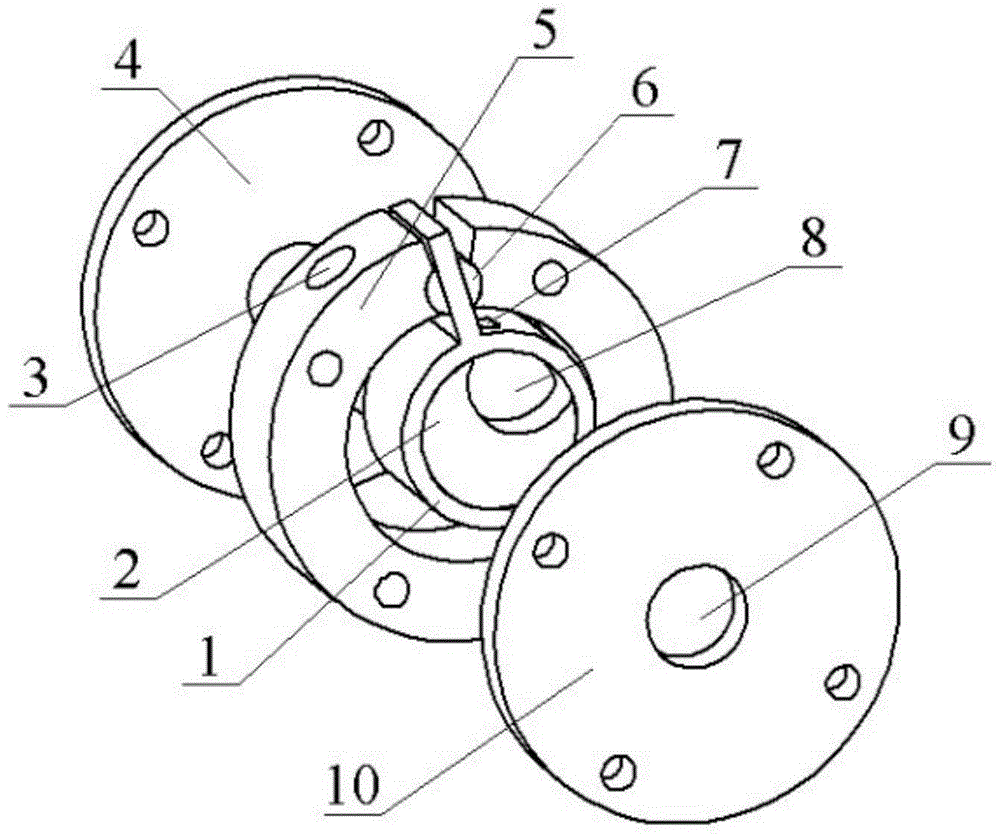

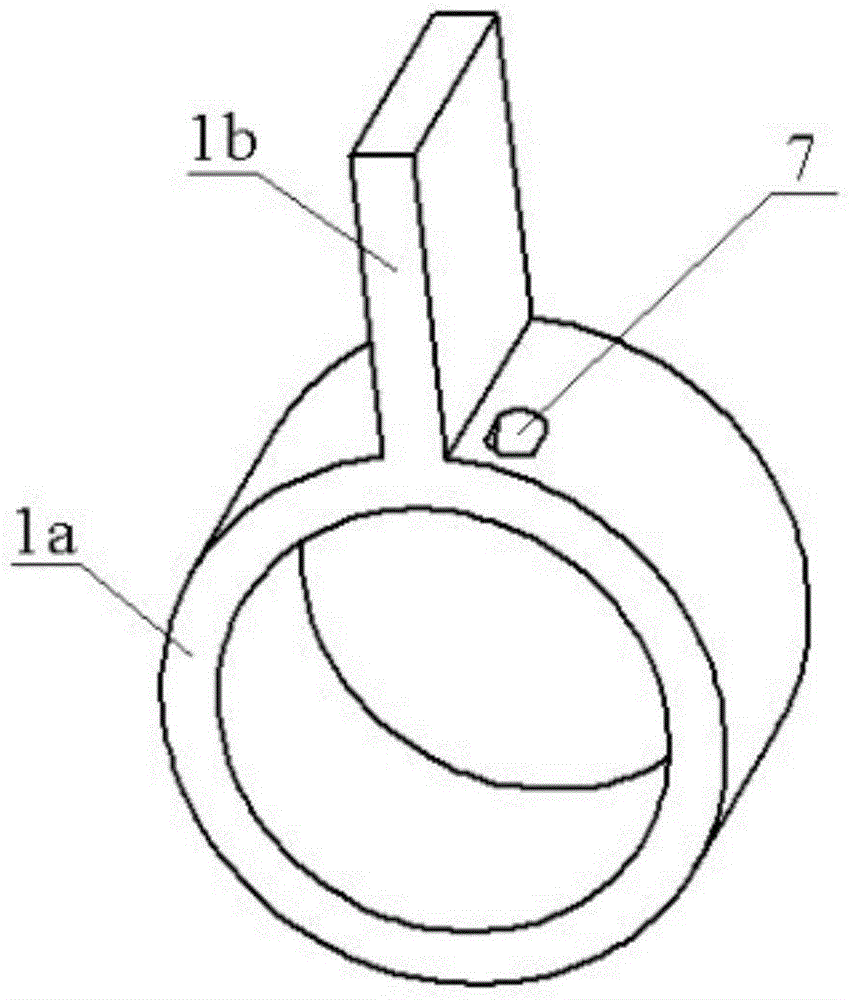

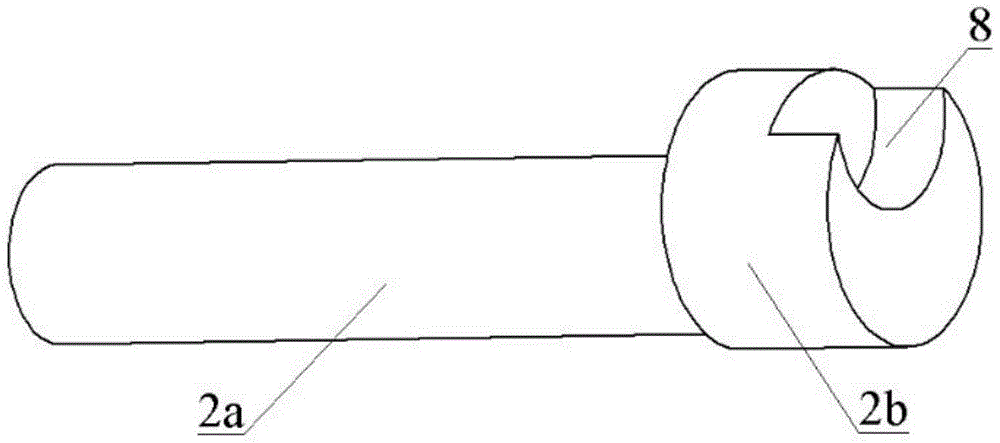

ActiveCN105201835AExtended service lifeIncreased durabilityOscillating piston pumpsOscillating piston liquid enginesExhaust valveEngineering

A swing rotor compressor comprises a swing rotor, an eccentric axle, a front end cover, an air cylinder, a guide rail and a back end cover, wherein the swing rotor comprises a rolling ring and a swing rod; the eccentric axle comprises a spindle and an eccentric wheel; an exhaust hole is formed in the rolling ring and is close to one side of the swing rod; an exhaust cavity is formed in the eccentric wheel and is connected with or disconnected from the exhaust hole in the rolling ring periodically during rotation of the spindle; a flow passing hole is formed in the back end cover, and the exhaust cavity is always communicated with the flow passing hole in the back end cover during rotation of the spindle. No suction valve and exhaust valve are arranged, and compared with a traditional swing rotor compressor, the swing rotor compressor is higher in efficiency, lower in noise and better in speed change characteristic and durability.

Owner:GUANGXI UNIV

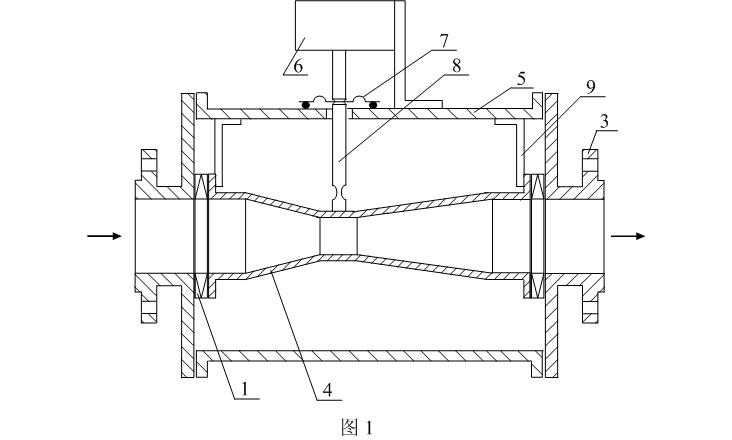

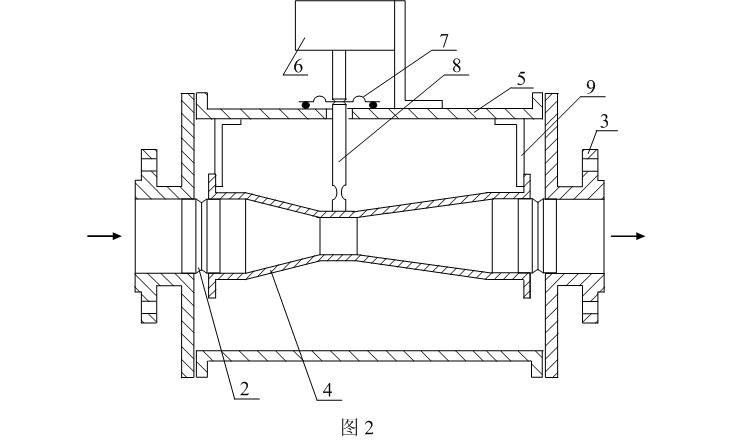

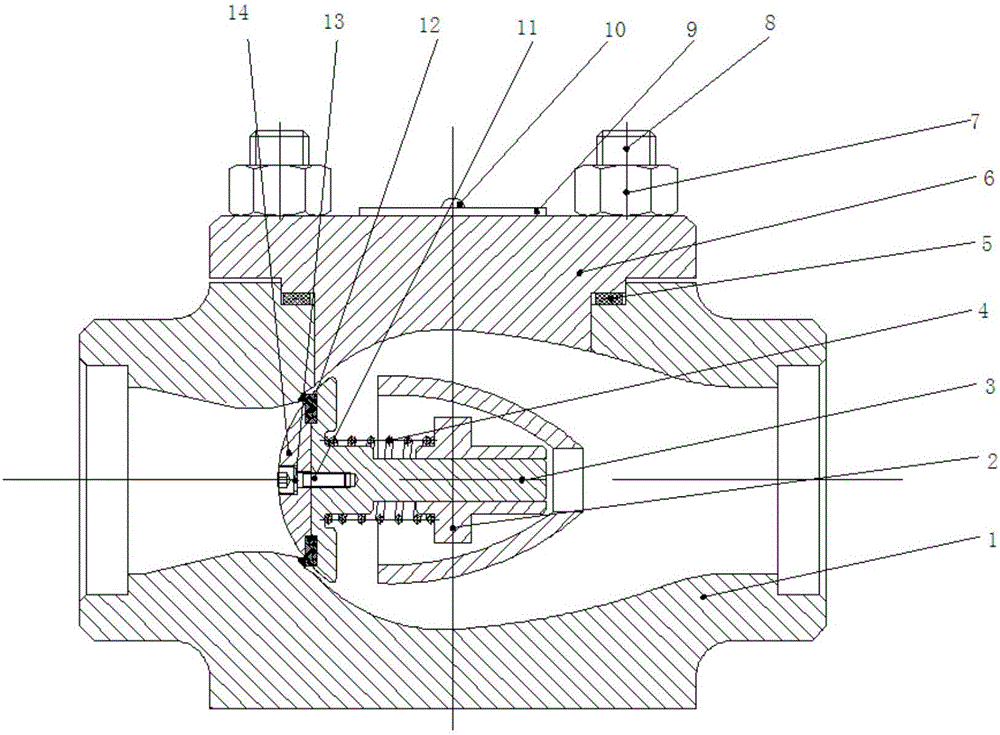

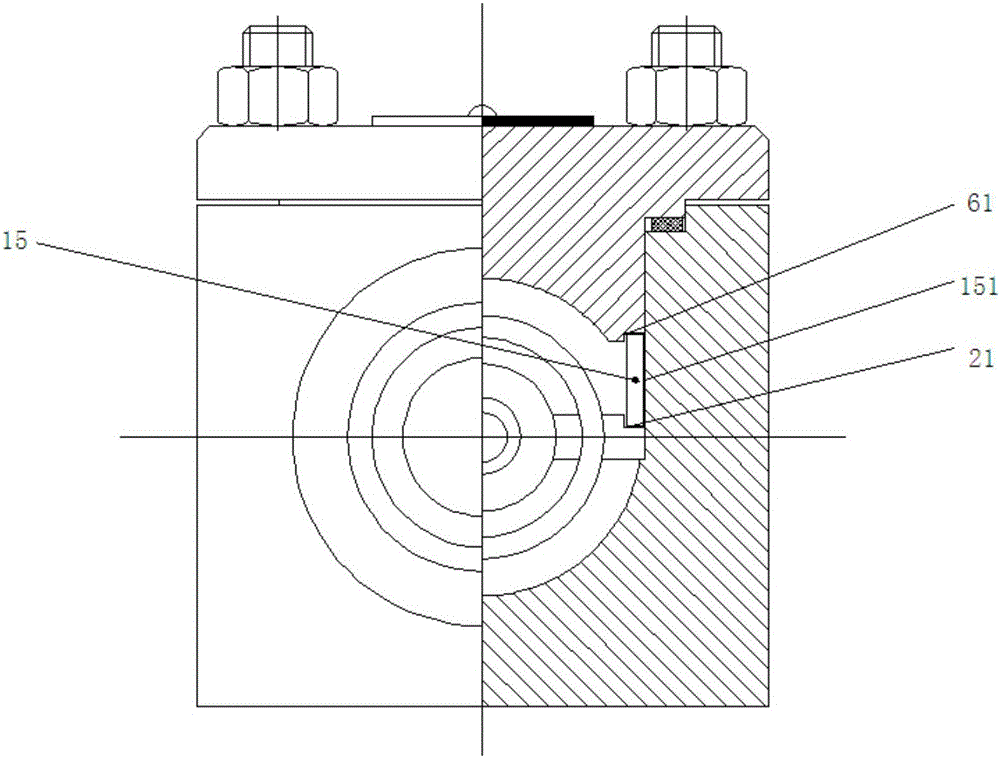

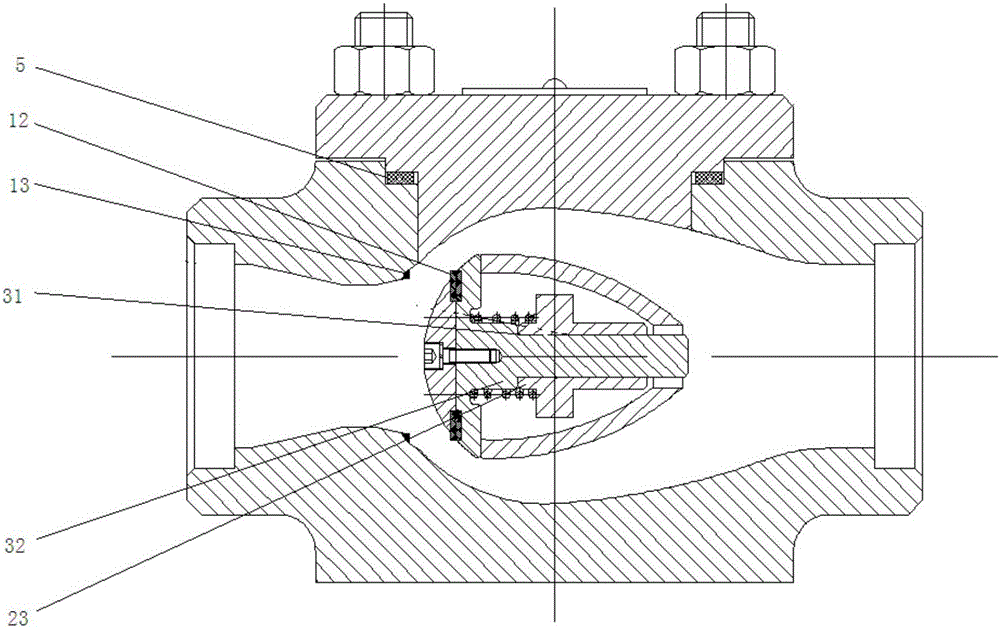

Axial-flow type check valve capable of replacing internal part on line

ActiveCN105864469ASimplify the upper body structureReduce manufacturing costCheck valvesLift valveEngineeringCheck valve

The invention discloses an axial-flow type check valve capable of replacing an internal part on line. The check valve comprises a valve body, a valve cover, a valve clack component, wherein the valve cover is positioned at the upper part of the valve body; the valve clack component is arranged in a middle chamber of the valve body; the valve cover and the valve body are connected with each other by a sealing structure and a dismountable fastening structure; the check valve is characterized in that a valve clack positioning component for positioning the valve clack component is also arranged inside the middle chamber of the valve body; the valve clack positioning component is fixedly mounted at the wall of the middle chamber of the valve body so that the valve clack component in the middle chamber of the valve body is not fixed in a way that the valve cover is connected by screws, a sealing problem caused by a bolt hole formed in the valve cover can be prevented, so a mounting structure of the valve is simplified, the production cost of the valve is lowered and the on-line maintenance time is shortened.

Owner:NEWAY VALVE SUZHOU

Middle through hole movable throttling element flow meter capable of preventing blockage

ActiveCN102620775AAvoid easy cloggingLittle flow resistance lossVolume/mass flow by differential pressureDifferential pressureFilter media

The invention discloses a middle through hole movable throttling element flow meter capable of preventing blockage, and belongs to a throttling flow meter in the technical field of automatic detection. According to a flow meter with a middle through hole movable throttling element matched with an elastic membrane or a corrugated pipe which has been applied for a patent, the flow rate is measured based on thrust of a movable throttling element by a fluid but not based on differential pressure of the fluid of a fixed throttling element, a pressure guide pipe is saved, the flow meter is applicable to measurement of a small aperture and dirty fluid, but balance liquid is required to be sealed in an anti-blockage mechanism of the flow meter, and the manufacturing process is much complex; according to the flow meter, the anti-blockage mechanism of the middle through hole movable throttling element flow meter is made of a flexible filter medium or a filter membrane; the anti-blockage mechanism has the characteristics of simple structure, easiness for implementation in process and low price of the manufactured flow meter; and because of the characteristics, the middle through hole movablethrottling element flow meter using the anti-blockage mechanism has the development prospect of substituting a differential pressure flow meter and a part of small-aperture ultrasonic flow meters.

Owner:盐城市双新建设投资有限公司

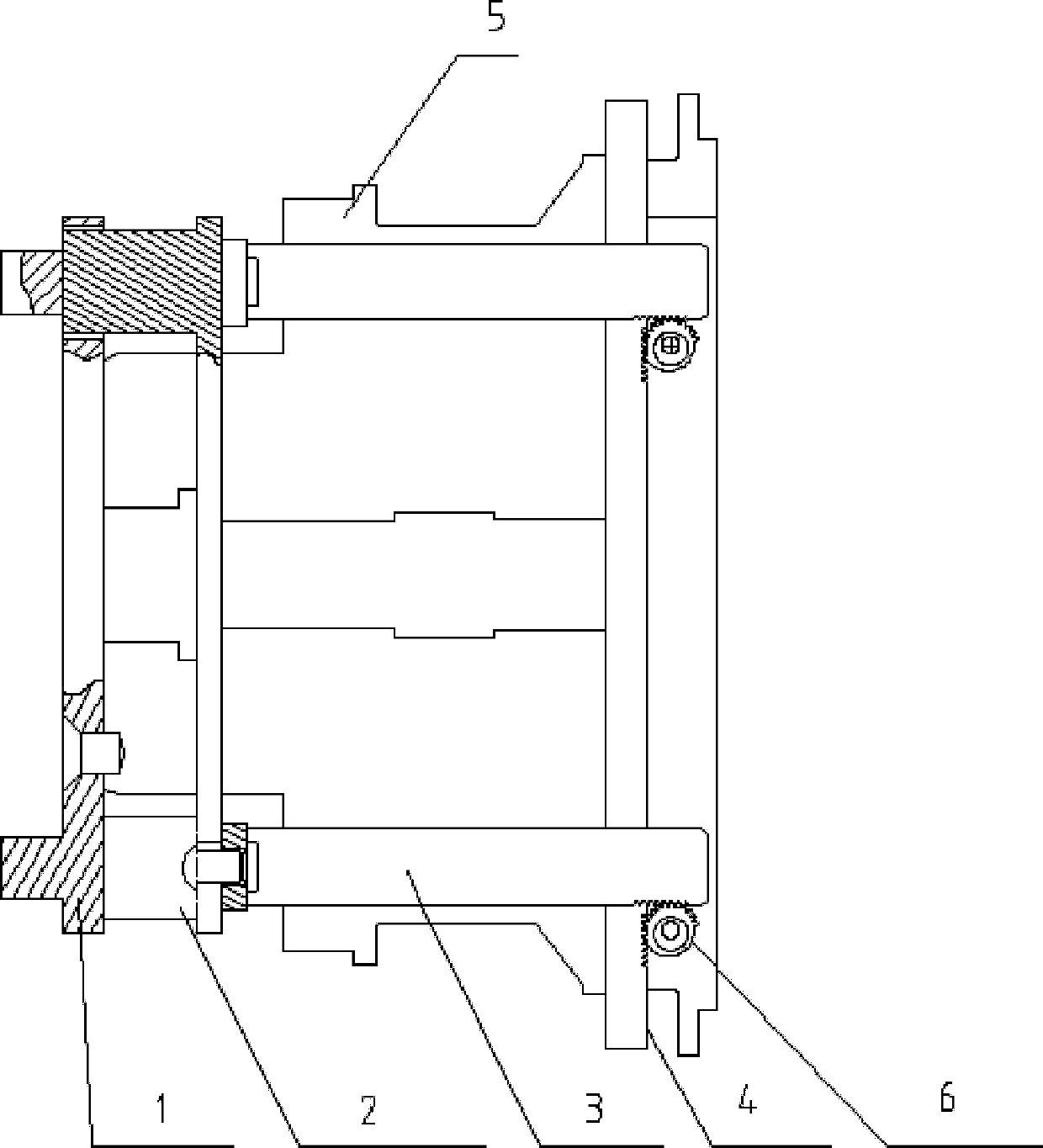

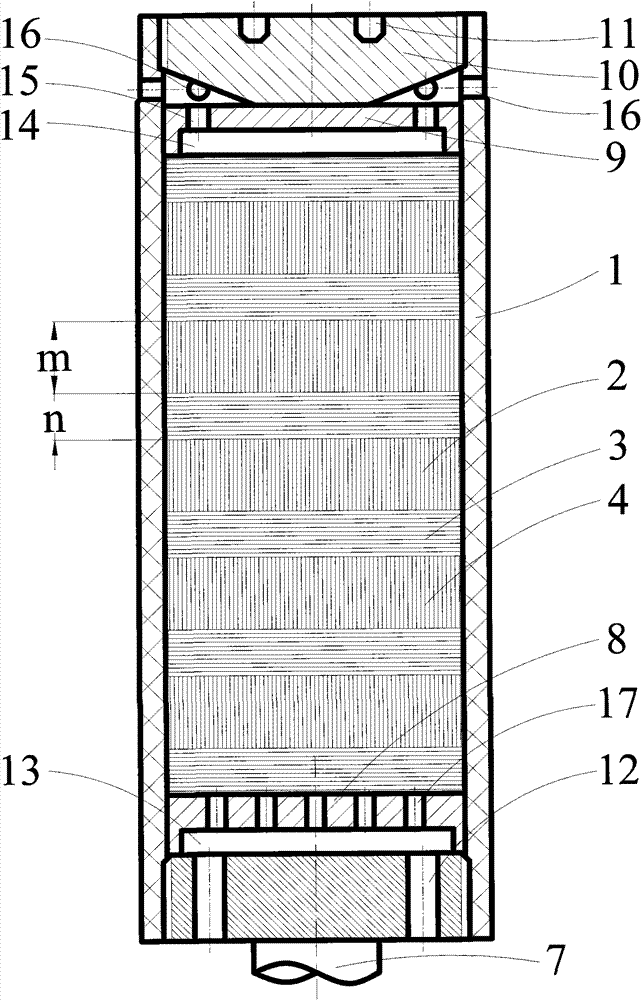

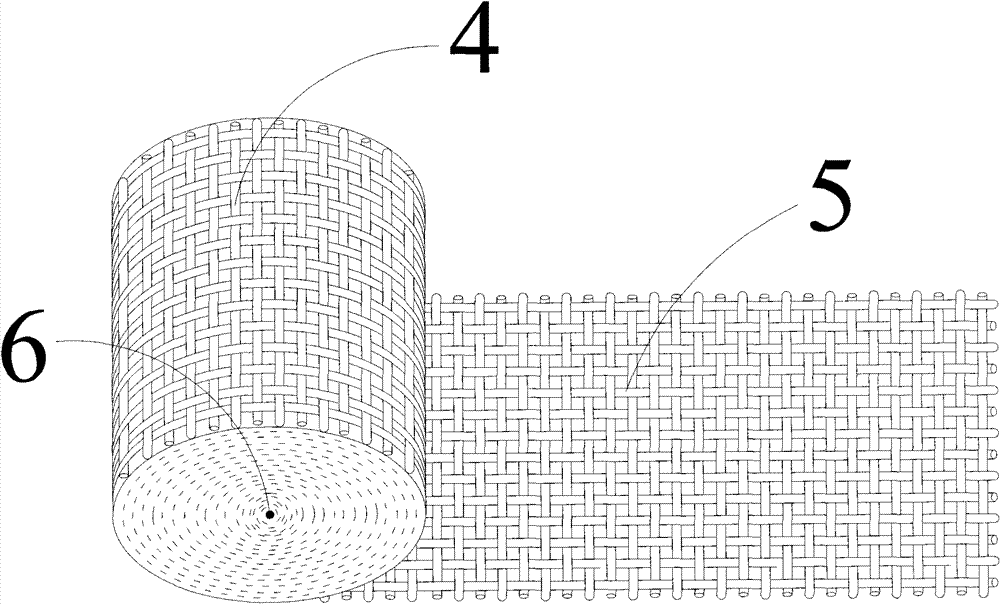

Heat regenerator of heat-regenerating type low-temperature refrigerator

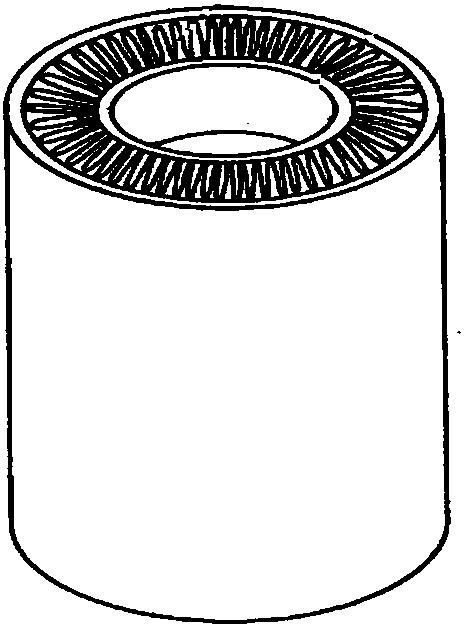

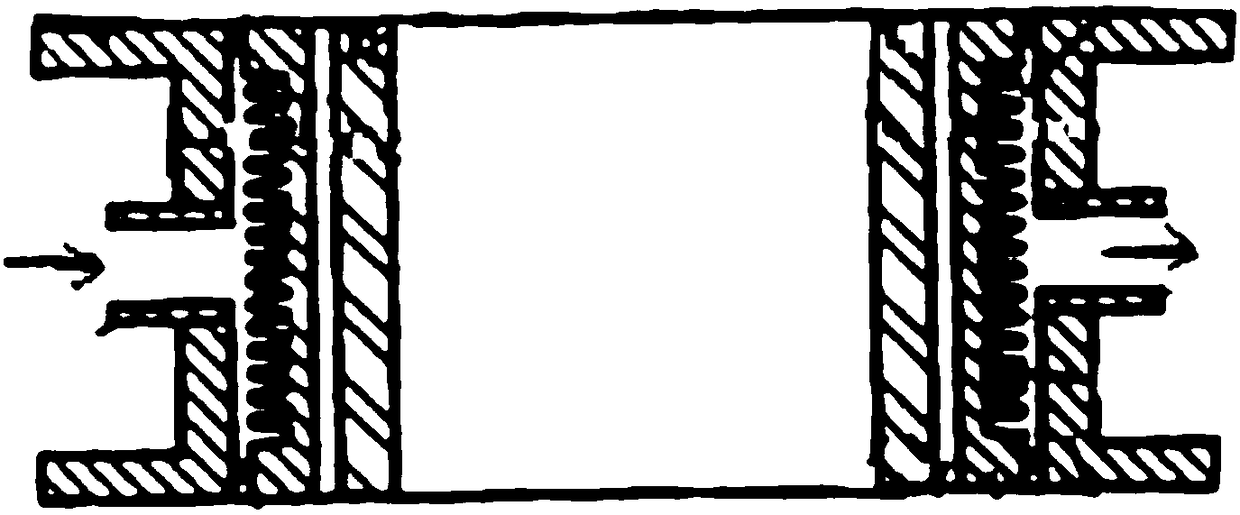

ActiveCN101799229BReduce void volumeSmall empty volumeSuperheatersEngineeringRefrigerated temperature

The invention discloses a heat regenerator of a heat-regenerating type low-temperature refrigerator, which comprises a sleeve of a heat regenerator and a filler of the heat regenerator. The heat regenerator is characterized in that the sleeve of the heat regenerator is firstly filled with the radial filler and secondly filled with the axial filler, which are alternately filled, and finally with the radial filler; the radial filler is formed by tightly paving and overlapping 20-40 pieces of circular metal nets layer by layer, wherein the diameter of each piece of the circular metal net is equal to the inner diameter of the sleeve of the heat regenerator; the axial filler is formed by tightly winding through a square metal net piece along an edge metal wire; and the radial filler and the axial filler are tightly contacted with the inner wall of the sleeve of the heat regenerator. The depth m of the axial filler is larger than the depth n of the radial filler, and the voidage of the axial filler is less than that of the radial filler. The heat regenerator can realize high heat regenerating efficiency, low flow resistance, small axial heat-guiding loss and smaller empty cubage, and greatly improves the efficiency of the heat-regenerating type low-temperature refrigerator.

Owner:江苏热声机电科技有限公司

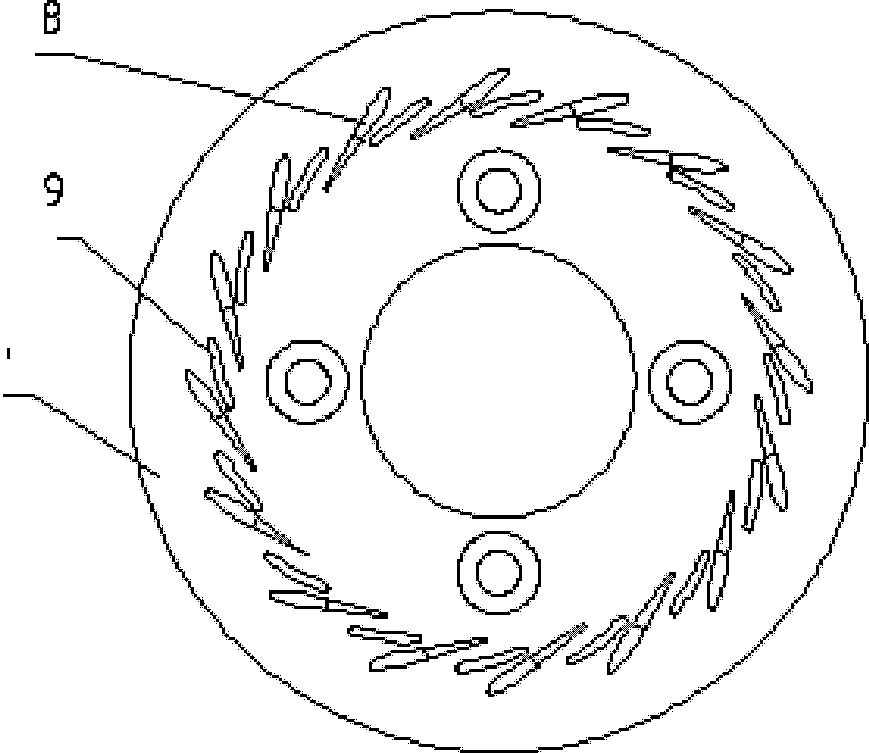

AI-regulated mixing device for inner and outer ducts of afterburner

InactiveCN113048511AImprove performanceUniform temperatureContinuous combustion chamberAviationCombustion chamber

The invention discloses an AI-regulated mixing device for inner and outer ducts of an afterburner, and belongs to the field of aero-engine afterburners. The device is characterized in that an air flow inclination angle and an air inlet amount of the outer duct are changed by changing spatial positions of mixing device blades so that an outlet temperature and speed are uniformly distributed, flow loss is reduced and infrared stealth is realized; when distribution of the outlet temperature and speed needs to be adjusted, a control terminal calculates required fuel flow according to current inlet parameters of the afterburner, then calculates space attitude angles of the mixing device blades, namely rotation angles of the mixing device blades, converts the space attitude angles into adjusting signals, and transmits the adjusting signals to a hydraulic mechanical system; and the mechanical system controls a telescopic supporting rod to move through hydraulic energy, so as to control the mixing device blades to rotate. According to the device, the distribution of the outlet temperature and speed of the afterburner are adjusted by changing the the air flow inflow inclination angle and the air inlet amount of the outer duct so that the outlet temperature and speed are uniformly distributed, the flow loss is reduced, and the infrared stealth is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

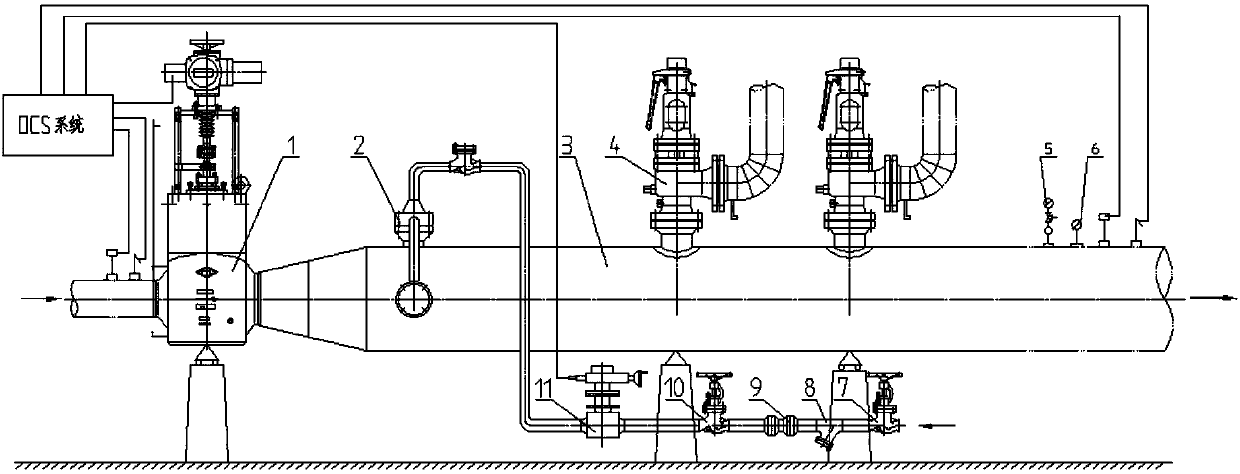

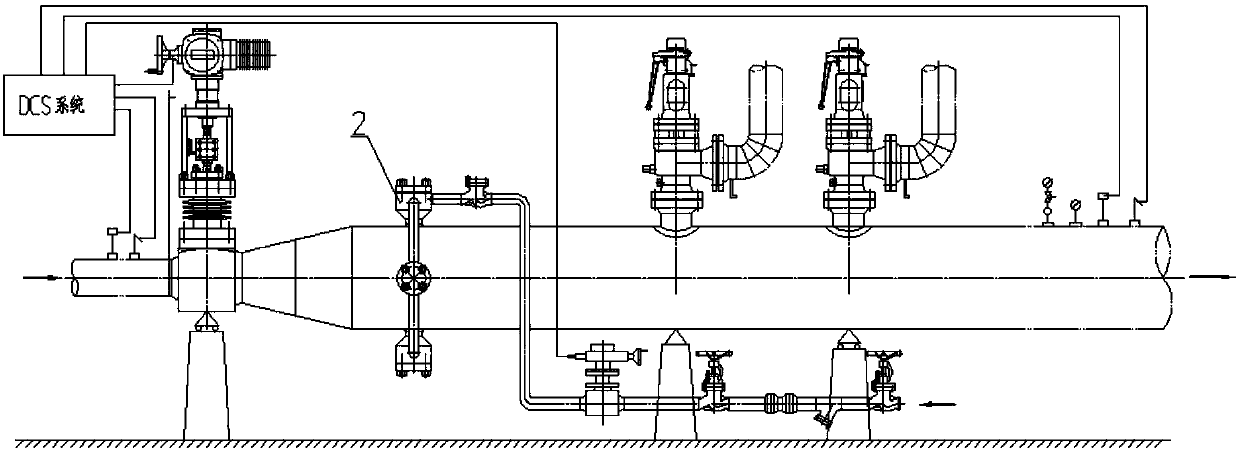

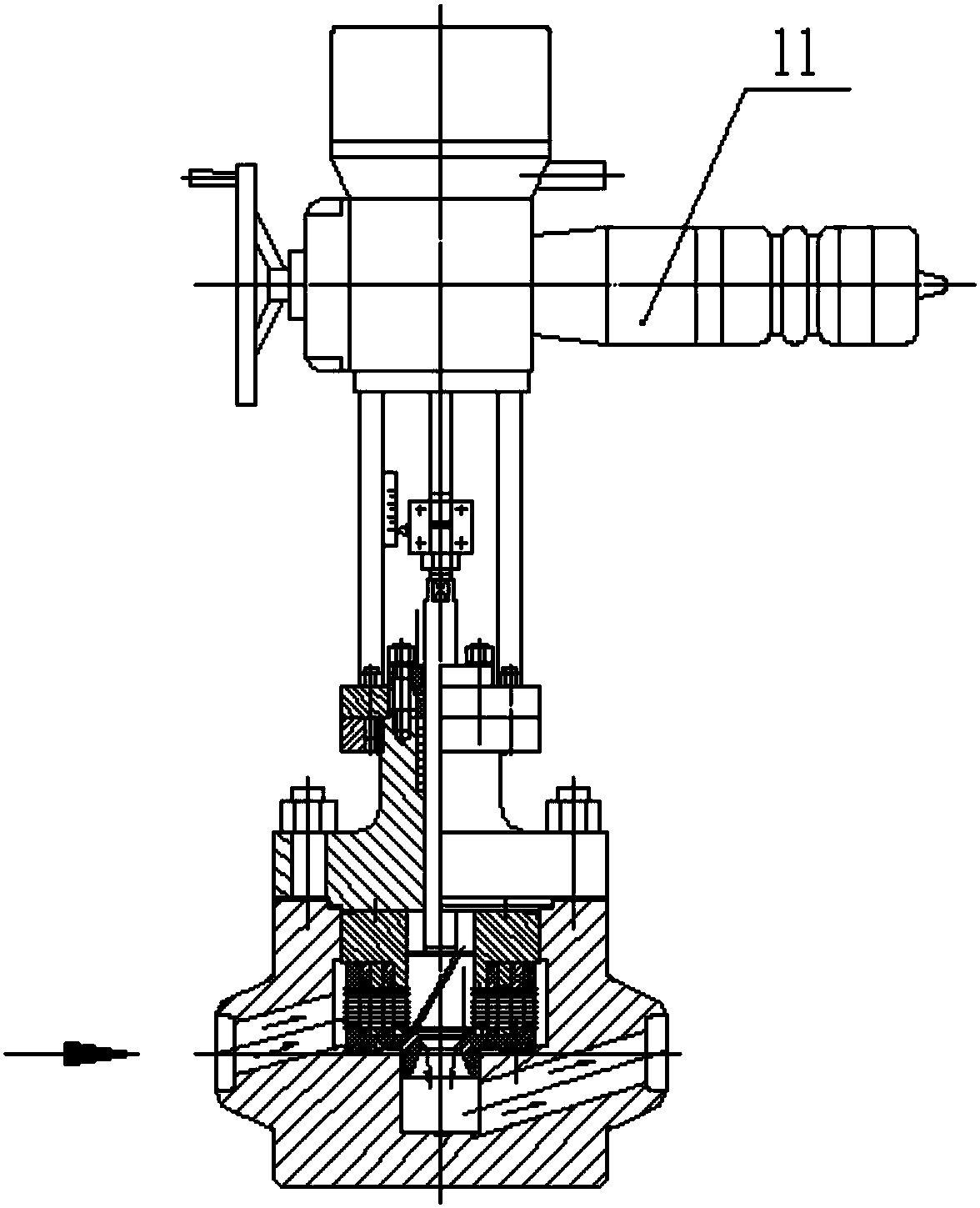

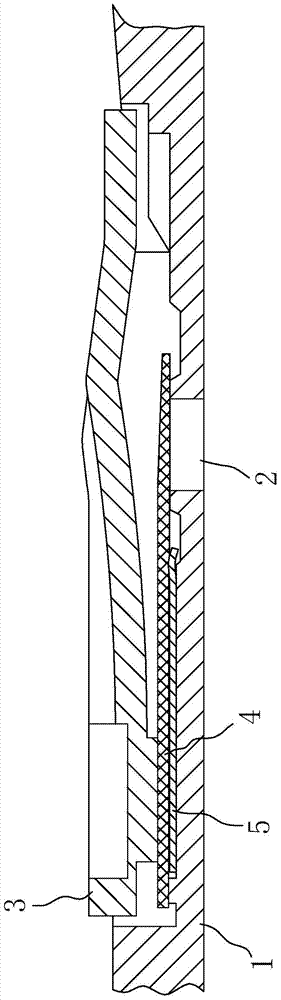

Temperature and pressure reduction device

PendingCN107906368AEfficient mixingShorten mixing timeSuperheating controlPipeline systemsWarm waterWater flow

The invention discloses a temperature and pressure reduction device. The temperature and pressure reduction device comprises a pressure reduction valve with one end connected with a steam inlet end, wherein the other end of the pressure reduction valve is connected with a steam mixing pipeline provided with a steam outlet end, a temperature reduction system and a safety protection system are sequentially arranged on the steam mixing pipeline, and an adjustment valve used for adjusting temperature reduction water is arranged in a temperature reduction branch where the temperature reduction system is located; and the temperature reduction system comprises a temperature reduction nozzle assembly, the temperature reduction nozzle assembly comprises a nozzle main body, a pressure accumulation cavity and a medium flow channel communicating with the pressure accumulation cavity are formed in the nozzle main body, a movable nozzle core matched with the pressure accumulation cavity is arrangedin the pressure accumulation cavity to form an airtight cavity body, the nozzle main body is elastically connected with the movable nozzle core and opened when the pressure of the pressure accumulation cavity is greater than elasticity, the movable nozzle core forms a conical surface in the pressure accumulation cavity, a preset angle is formed between the medium flow channel and the axis of the movable nozzle core, and a preset chamfer angle is formed between the medium flow channel and the conical surface, so that water flow is ejected onto the conical surface and rotationally ejected out. Due to the arrangement, the use performance and the adjustment performance of the device are improved.

Owner:HANGZHOU WORLDWISE VALVE

Reciprocating compressor valve set structure with rapidly-opened-closed air discharge valve plate

ActiveCN103835923AStrong rigidityQuick closePositive displacement pump componentsPositive-displacement liquid enginesEngineeringValve seat

The invention discloses a reciprocating compressor valve set structure with a rapidly-opened-closed air discharge valve plate. The reciprocating compressor valve set structure comprises a valve plate, a plate top is provided with a valve seat, an air discharge hole is formed in the valve seat, a lift limiting device is arranged on the valve seat, and the air discharge valve plate is arranged between the lift limiting device and the valve seat and provided with the fixed end pressed by the lift limiting device and the movable end covering the air discharge hole; a spring piece is arranged between the air discharge valve plate and the valve seat, the pre-tightening force of the spring piece is in the opening direction of the air discharge valve plate, the spring piece is also provided with the fixed end and the movable end, and the fixed end of the spring piece is fixed still relative to the valve plate; the rigidity of the air discharge valve plate is not smaller than 600 N*mm<2>. The air discharge valve plate has the higher rigidity and can be easily and rapidly closed; the elasticity of the spring piece is provided in an assisted mode when the valve plate is opened, and the valve plate can be rapidly opened in an assisted mode. The air discharge valve plate is long in service life, low in impact noise, rapid in response and capable of serving as a component part of a reciprocating compressor valve set.

Owner:WANBAO GROUP COMPRESSOR CO LTD

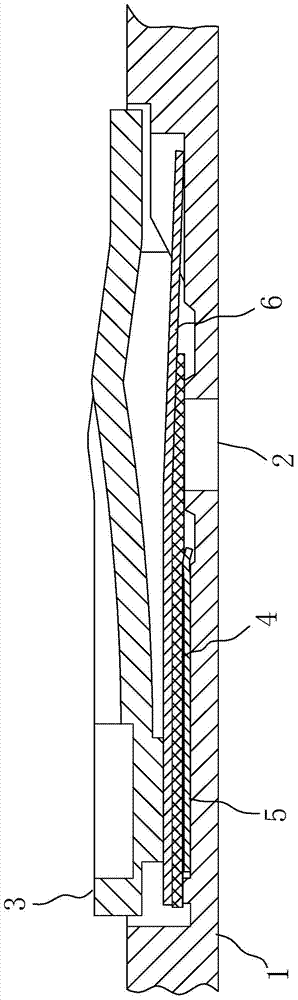

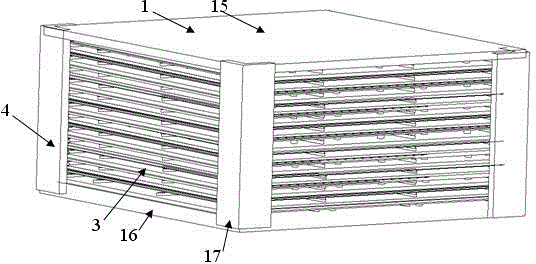

Energy-saving plate heat exchanger

InactiveCN104406436AGood strength optimizationStrong pressure resistanceLaminated elementsStationary plate conduit assembliesTemperature controlElectrical control

The invention discloses an energy-saving plate heat exchanger, and belongs to the technical field of heat exchangers. The energy-saving plate heat exchanger comprises a heat exchanger body, wherein the heat exchanger body comprises a heat exchange core and a heat exchanger fixing frame which is cooperatively arranged on the outer side of the heat exchange core to achieve a fixation effect; the heat exchange core consists of a group of laminated streamline integrally reinforced heat exchange plates. By using the technology, the heat exchanger has the characteristics of large pressure bearing capacity, high heat transfer coefficient, small pressure drop, small material flow resistance loss, compact structure, light weight, small occupied space, convenience in area and flow combination, sensitivity in temperature control, large operation elasticity, convenience in disassembly and assembly, long service life, strong universality of parts, wide selectable materials, easiness in implementation of large-scale production and the like, can be widely applied to novel heat exchangers for heat dissipation of closed spaces such as wind power generation, communication or electrical control cabinet and ventilation and energy-saving after heat recovery of air conditioning places.

Owner:新昌县成丰机械配件厂

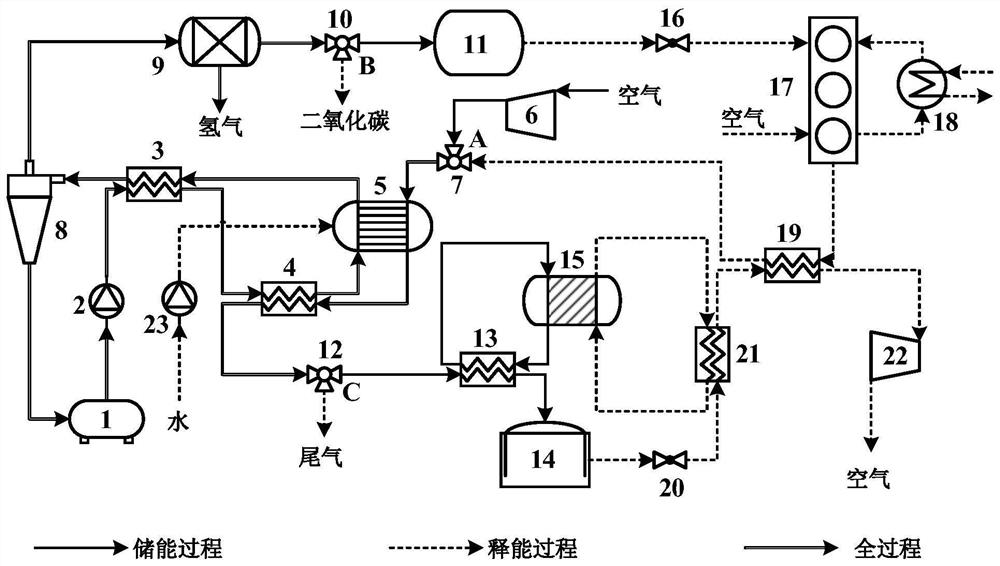

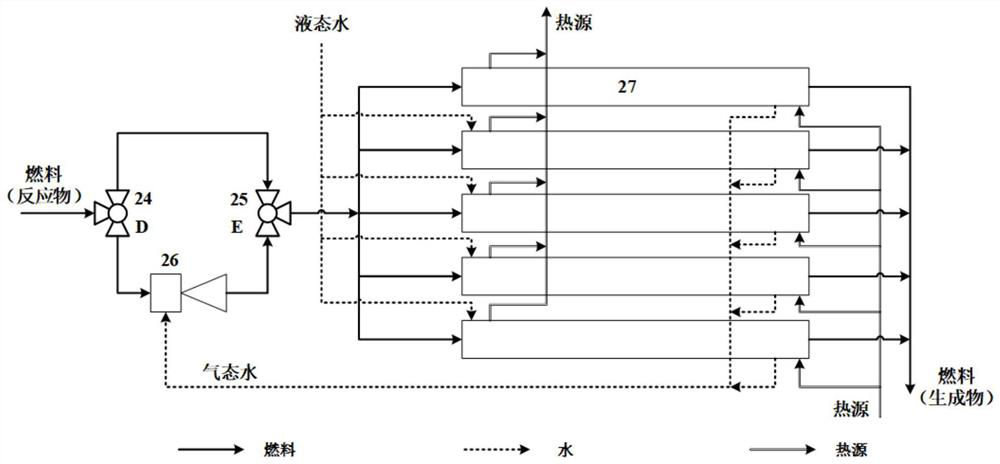

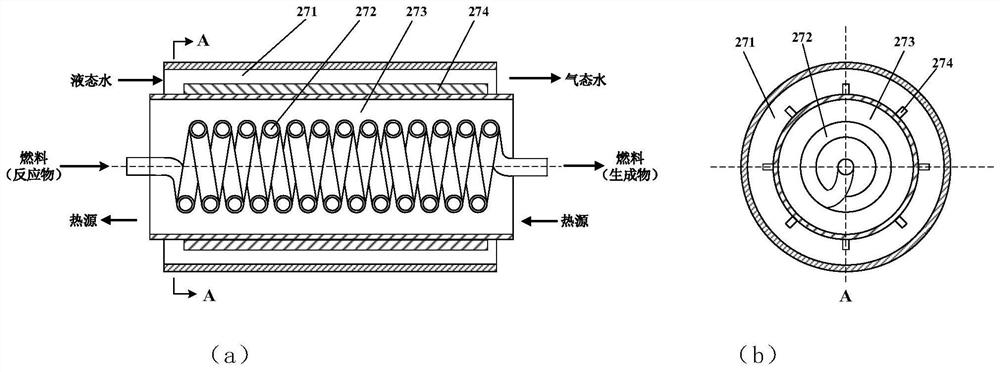

Composite energy system and method integrating multi-energy storage and hydrocarbon fuel preparation

ActiveCN113958933AImplement hybrid storageEfficient conversionInternal combustion piston enginesBoiler water tubesInternal combustion engineHydrogen production

The invention discloses a composite energy system and method integrating multi-energy storage and hydrocarbon fuel preparation. The composite energy system comprises a compressed air thermochemical energy storage hydrogen production system and an internal combustion engine-turbine energy release hydrogen production system. In the energy storage stage, through coupling of compressed air and heat absorption type chemical reaction, mixed storage of physical / chemical energy is achieved, and the energy grade of compression heat can also be improved; and in the energy release stage, gas fuel and air are combusted in an internal combustion engine to generate electricity, generated waste heat is recycled by stored high-pressure air and then enters a turbine to generate the electricity, and gradient utilization of energy is achieved. According to the composite energy system and method integrating multi-energy storage and hydrocarbon fuel preparation, in the energy storage stage and the energy release stage, hydrogen serves as a carrier to achieve conversion from low-grade heat energy to fuel high-grade chemical energy, and the energy utilization efficiency of the composite energy system is improved while an energy storage and hydrogen production integrated application mode is achieved.

Owner:XI AN JIAOTONG UNIV

Synchronous rotary compressor

ActiveCN1323243CSmooth motionLittle flow resistance lossRotary piston pumpsRotary piston liquid enginesFixed frameDrive shaft

The revolve compressor is composed of fixed frame and eccentricity seat connected with the fixed frame. In the air cavity comprised by the frame and eccentricity seat, the rotor sleeved on the driving shaft is fixed, the sliding bar installed on the rotor can be embedded to the cylinder. The cylinder is fixed in the air cavity, through the frame bearing and support bearing; the shaft of the cylinder and rotor and not in the same axis line. As the driving axis rotate, the rotor make revolve moment, the sliding plate embedded to the cylinder due to the effect of centrifugal force which pushes the cylinder make the same revolve movement.

Owner:DAFENG FENGTAI FLUID MACHINERY TECHNOLOGY CO LTD

Afterburner adopting planar fan nozzles for oil supply

ActiveCN108844094AStable and reliable combustionAchieve atomizationContinuous combustion chamberSpray nozzlePerpendicular direction

The invention discloses an afterburner adopting planar fan nozzles for oil supply, and belongs to the field of aero-engines. The afterburner adopting the planar fan nozzles for oil supply is characterized in that supporting plates are arranged on an oil supply device in the afterburner, and are uniformly arranged along the circumference of the afterburner in the perpendicular direction; and oil spraying rods are arranged on the inner sides of the supporting plates in the radial direction, the planar fan nozzles are arranged on the side walls of the oil spraying rods in the radial direction, and the opening cross section of each planar fan fuel nozzle is V-shaped. According to the design of the afterburner adopting the planar fan nozzles for oil supply, the fuel spray extending angle is enlarged, the number of the nozzles is reduced, the diameter of each nozzle is increased, and meanwhile, the fuel radial and circumferential concentration distribution is more uniform, so that reliable and stable combustion of the afterburner is facilitated, and the problems in the prior art are solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Combined type circular pipe pipe-fin heat exchanger

ActiveCN102141353AReduce sizeImprove heat transfer effectTubular elementsMechanical energyEngineering

The invention discloses a combined type circular pipe pipe-fin heat exchanger, relating to the technical field of heat exchangers. The combined type circular pipe pipe-fin heat exchanger comprises circular pipes arranged along a flow direction of gas and fins sleeved on the circular pipes, wherein the fins are provided with holes used for being sleeved with the circular pipes, a flanging boss is arranged on the edge of each hole, a pair of rectangular small wing plane vortex generators is punched at the rear part of each hole, and an oval convex hull is punched at the front part of the hole. The oval convex hulls have better streamline, and when flowing through the oval convex hulls, a fluid changes a flow direction and flows along the convex hulls, thereby the loss of flow resistance caused by directly and vertically washing the circular pipes with the fluid is reduced. Meanwhile, after the fluid flows through the rectangular vortex generators, secondary flow following a mainstream is generated in the fluid. When a part of the fluid flows through the vortex generators, a fluid channel is formed between each circular pipe and each vortex generator and is led to a recirculation region of the circular pipes, thereby the size of the recirculation region at the downstream of the circular pipes is reduced, the heat exchanging performance between the pipe wall at the downstream of the circular pipes as well as the surface of adjacent fins and the fluid is improved, and the consumption of the mechanical energy in the recirculation region is reduced.

Owner:LANZHOU JIAOTONG UNIV

Combined curved-surface vortex generator-type round fin-tube heat exchanger

ActiveCN102162705AAvoid separationImprove heat transfer effectTubular elementsPlate heat exchangerEllipse

The invention relates to the technical field of heat exchangers, and discloses a combined curved-surface vortex generator-type round fin-tube heat exchanger, comprising round pipes arranged in the air flow direction and fins sheathed on the round pipes; the fins are provided with round holes sheathing the round pipes; a pair of trapezoid curved-surface vortex generators are punched at the rear part of each round hole; the bottom side of the curved-surface vortex generator and the round hole are respectively a concentric circle; a pair of trapezoid small holes are reserved on the fins; an elliptical convex hull is punched on the middle line at the front end of each round hole on the fin; and a concave pit is reserved on the backside of the fin. The liquid of the heat exchanger changes direction flowing the convex hull, thus the direct vertical washing to the round pipes by the liquid is reduced at the front part of the round pipe; the fluid is guided by the vortex generator to reach a round pipe tail stream area to inhibit the fluid at the rear side of the round pipe from separating; and the rear tail stream area of the round pipe is decreased, thus improving the heat exchanging performance on the contact surface of the fin and the tail stream area, and decreasing the loss of the flowing resistance in the tail stream area.

Owner:兰州金诺绿色能源动力科技有限责任公司

Heat exchanger provided with annular slots and used for sound-energy refrigerating machine

PendingCN108195214AImprove cooling effectImprove heat transfer coefficientCompression machinesIndirect heat exchangersInterference fitSound energy

The invention discloses a heat exchanger provided with annular slots and used for a sound-energy refrigerating machine, and belongs to the technical field of heat exchangers. The heat exchanger provided with the annular slots and used for the sound-energy refrigerating machine comprises an inner rib body and an inner sleeve. The inner rib body is an annular cylinder with the inner annular surfaceopen towards the outer annular surface. The inner sleeve is arranged in the inner rib body in a sleeved mode and is in interference fit with the inner rib body. The multiple slots are formed in the inner annular surface of the inner rib body at intervals, so that a slot channel allowing air to flow therein is formed between the inner rib body and the inner sleeve. According to the heat exchanger provided with the annular slots and used for the sound-energy refrigerating machine, forced-convection heat change between alternately-flowing working medium gas and the inner wall of the heat exchanger is achieved, and the heat exchange coefficient is large; in the heat conduction direction towards the outside, through interference fit between the inner rib body and the inner sleeve as well as a welding structure of the inner rib body and outer fins, contact heat resistance is eliminated; and in addition, the inner rib body is made of red copper with small heat conduction resistance, and thusthe heat exchanger provided with the annular slots in the hot end has a good cooling effect.

Owner:陕西仙童科技有限公司

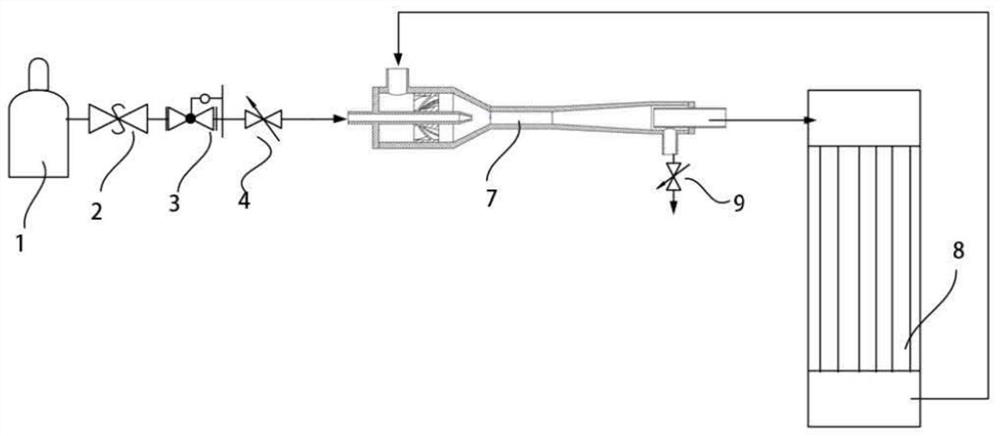

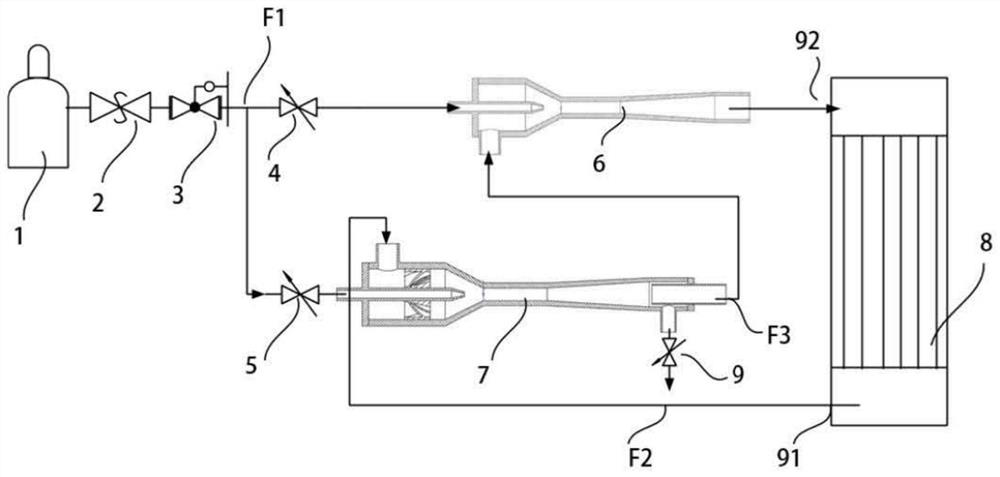

Gas-water separation assembly, fuel cell hydrogen circulation system and application

ActiveCN112057958AWith partial ejection functionExpand the scope of workFlow mixersTransportation and packagingFuel cellsProcess engineering

The invention belongs to the technical field of fuel cells, and particularly relates to a gas-water separation assembly, a fuel cell hydrogen circulation system and application. At present, for a fuelcell hydrogen circulation system using a single ejector, the ejector cannot work in a wide power range, and meanwhile, the resistance loss of a gas-water separator in the system is relatively large.If a plurality of ejectors are used for jointly working to broaden the applicable power range of the ejectors, system components are increased, control becomes complex, and reliability is reduced. Theinvention provides a gas-water separation assembly which comprises a main body, a nozzle is arranged at one end of the main body, the nozzle is connected with a swirl vane, and a gas-liquid mixture inlet is formed in one end of the main body. An exhaust pipe and a drain pipe are arranged at the other end of the main body. Part of the ejection function is achieved, and the working range of the ejector is widened; A traditional gas-water separator is replaced, and the gas-water separation assembly has the advantages of being small, compact, small in pressure loss and beneficial to improving theperformance of the ejector.

Owner:XI AN JIAOTONG UNIV

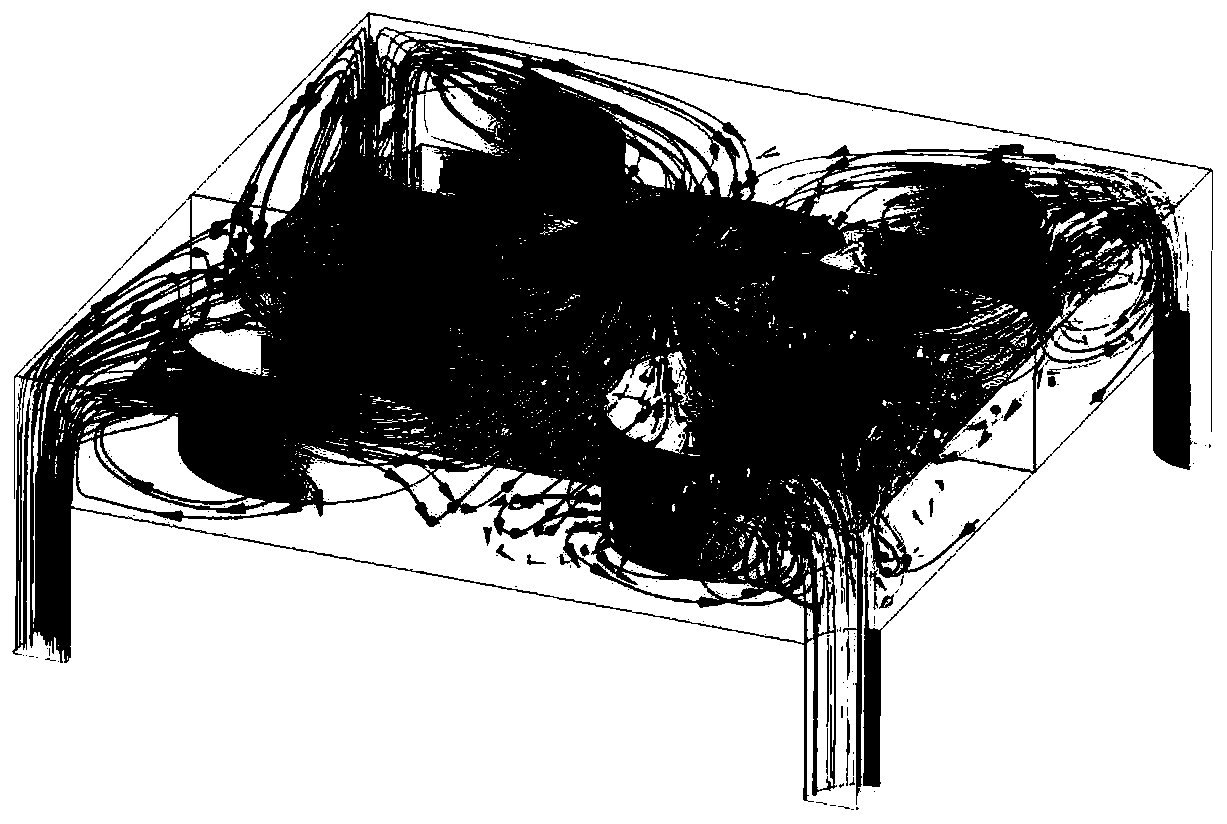

Turbulence structure for array impact jet cooling

PendingCN108979754AImprove heat transfer efficiencyUniform temperature distributionMachines/enginesEngine componentsAir volumeDrop-shaped

The invention belongs to the field of gas turbine and aero-engine high-temperature component cooling and other fields involved in array impact jet cooling, and particularly discloses a turbulence structure for array impact jet cooling. Three turbulence column structure designs are provided and include a jet target plate where special-pentagon-shaped turbulence column are distributed in an array mode, a jet target plate where domelike turbulence column are distributed in an array mode, and a jet target plate where drop-shaped turbulence column are distributed in an array mode. The turbulence structure has the advantages that the cooling efficiency is improved to a greatest extent with the smallest cooling air volume, the overall temperature gradient of the cooling wall is reduced, and heattransfer is more uniform and stable.

Owner:SHENYANG AEROSPACE UNIVERSITY

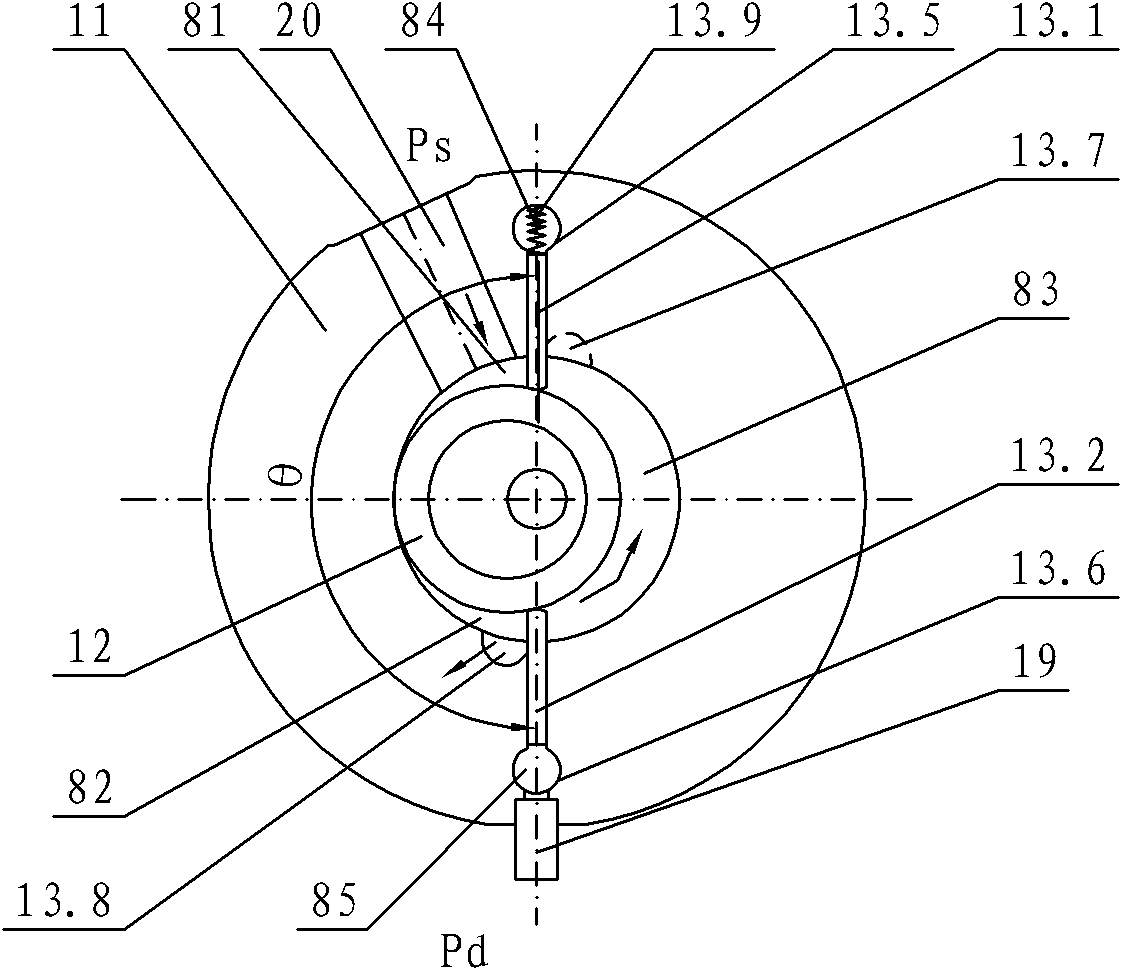

Two-cylinder compressor and air conditioner adopting same

ActiveCN106089655AShorten exhaust strokeLittle flow resistance lossPositive displacement pump componentsPositive-displacement liquid enginesCrankshaftFlange

The invention relates to the technical field of compressors, in particular to a two-cylinder compressor and an air conditioner adopting same. The two-cylinder compressor comprises a housing, a crankshaft, a first cylinder, a second cylinder, and a separator plate positioned between the first cylinder and the second cylinder, wherein a first flange is arranged at the outer side of the first cylinder; and a second flange is arranged at the outer side of the second cylinder; a separator plate exhaust cavity is arranged on the separator plate; an exhaust vent of the first cylinder is communicated with the separator plate exhaust cavity; a first exhaust vent is formed in the second flange; the separator plate exhaust cavity is communicated with a cavity in the housing by the first exhaust vent. According to the two-cylinder compressor, the exhaust vent of the first cylinder is communicated with the separator plate exhaust cavity, and a refrigerant discharged from the first cylinder enters the separator plate exhaust cavity and is then discharged into the cavity in the housing from the separator plate exhaust cavity through the first exhaust vent; the exhaust structure can effectively reduce the exhaust stroke of the first cylinder, so that flow resistance loss along the way is greatly reduced, and the complete machine energy efficiency level of the compressor is improved.

Owner:ZHUHAI LANDA COMPRESSOR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com