Two-stage turbocharger for aviation piston engine

A technology of turbocharger and piston engine, applied in the direction of internal combustion piston engine, engine components, combustion engine, etc., can solve the problems of limited flying height of aircraft, increase the mass of the engine, occupy a large volume, etc., and achieve light weight and reduce stiffness. , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

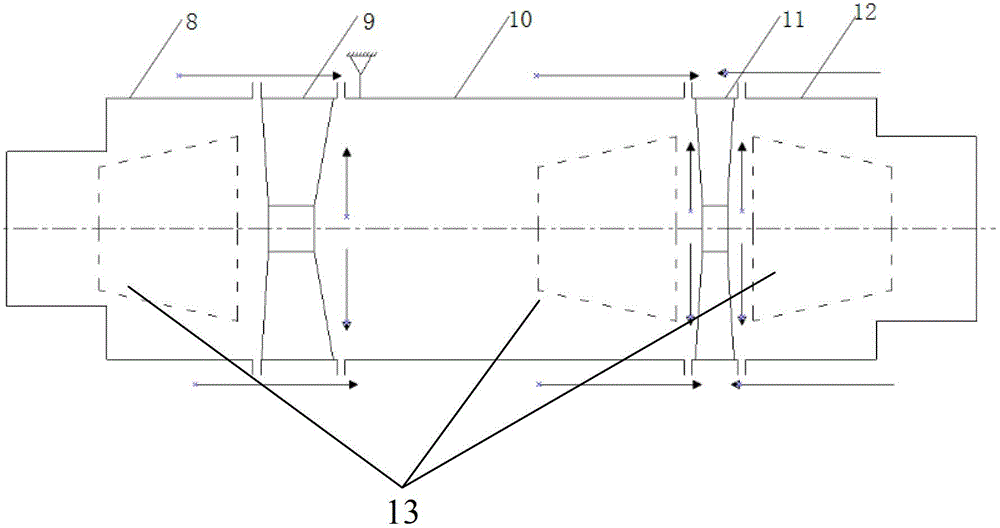

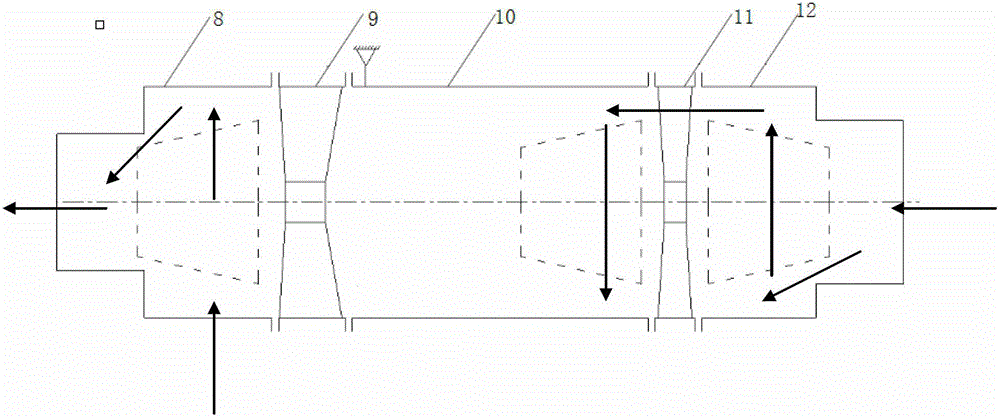

[0029] Such as figure 1 Shown, a kind of 1T2C two-stage turbocharging device for aviation piston engine described in the present invention. Including rotor assembly 13, front support assembly 11, rear support assembly 9, turbine volute assembly 8, compressor casing 10,12.

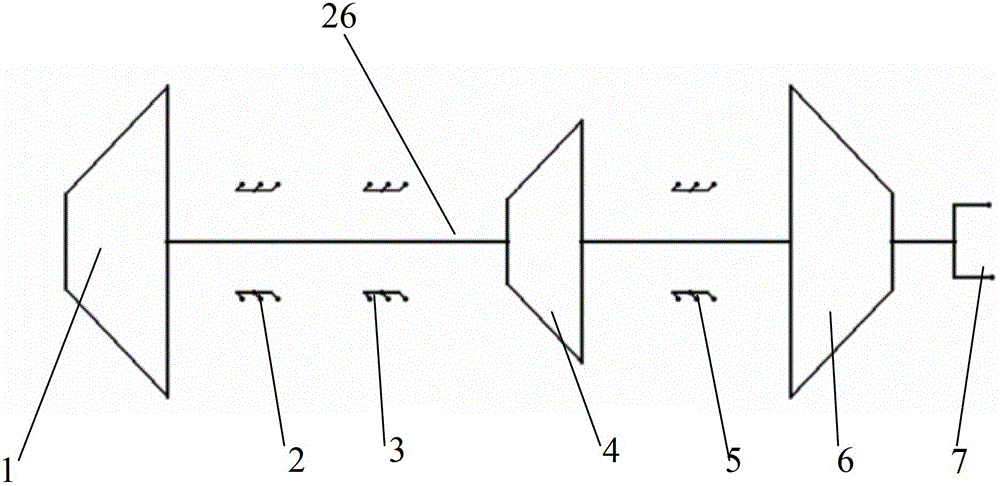

[0030] Such as figure 2 As shown, the rotor assembly includes turbine shaft welded 1, high-pressure compressor impeller 4, low-pressure compressor impeller 6, and compression nut 7, each part is locked by the compression nut, and the turbine shaft is welded to the design of the turbocharger and assembly benchmarks. In order to increase the rigidity of the shaft, reduce vibration, and improve the dynamic characteristics of the rotor, the support scheme adopts the method of inner support. The main support is located between the turbine 1 and the impeller 4 of the high-pressure compressor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com