Combined type circular pipe pipe-fin heat exchanger

A heat exchanger, combined technology, applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of large resistance loss, improve heat exchange performance, reduce flow resistance loss, reduce size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

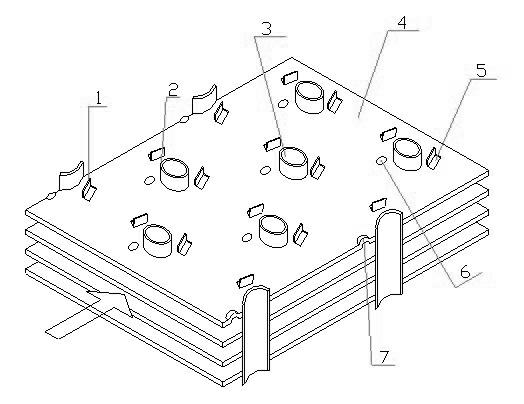

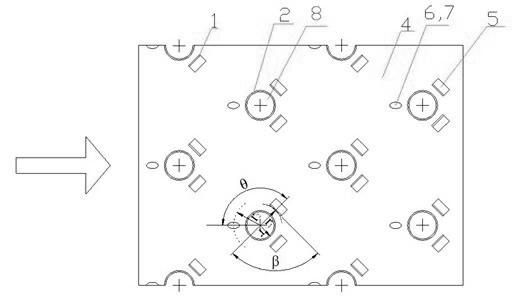

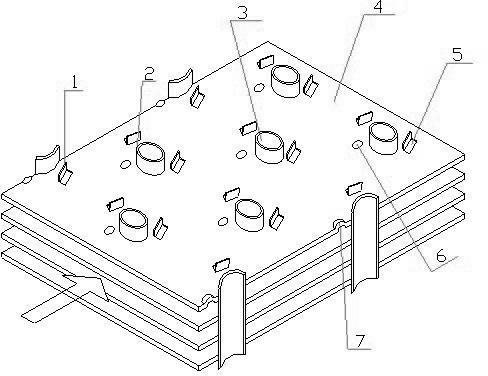

[0015] The invention is a round tube fin heat exchanger, which comprises round tubes 3 arranged along the gas flow direction and fins 4 sleeved on the round tubes 3 . In order to improve the heat exchange performance, the round tubes 3 are arranged in a fork row, and the holes 8 for fitting the round tubes 3 are arranged on the fins 4, and a pair of rectangular winglet planar vortex generators 1 are punched out at the rear of each hole 8. And perpendicular to the fin 4 , a pair of rectangular small holes 8 are left on the fin 4 . The side where the vortex generator 1 is connected to the fin 4 is the bottom side. The length of the base of the vortex generator 1 is 0.3-0.5 of the radius of the hole 8, and the height is 0.6-0.85 times of the radius of the hole 8. An elliptical convex hull 6 is punched out at the front of the hole 8 , the long axis direction of the oval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com