Patents

Literature

273 results about "Transfer capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

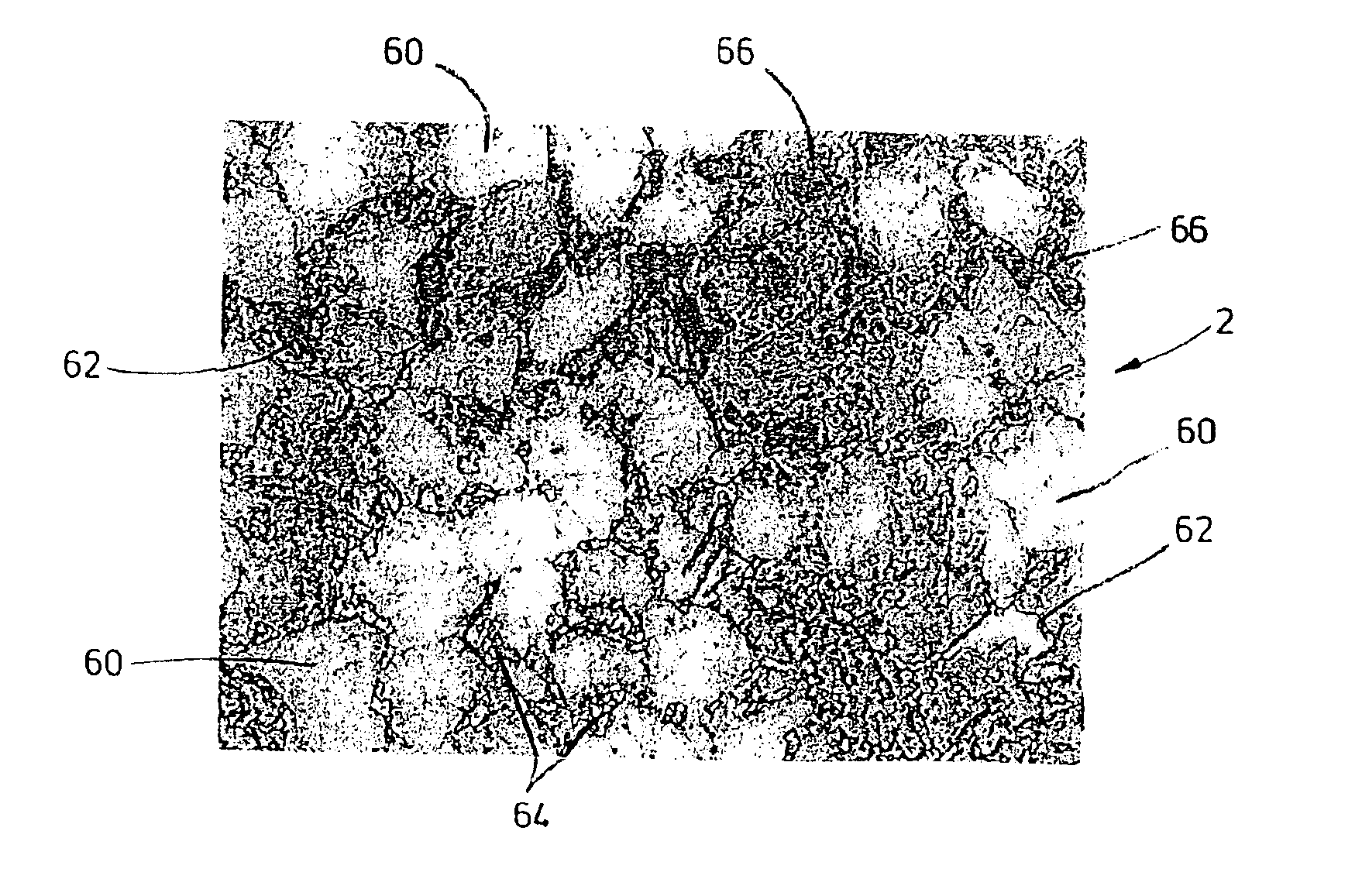

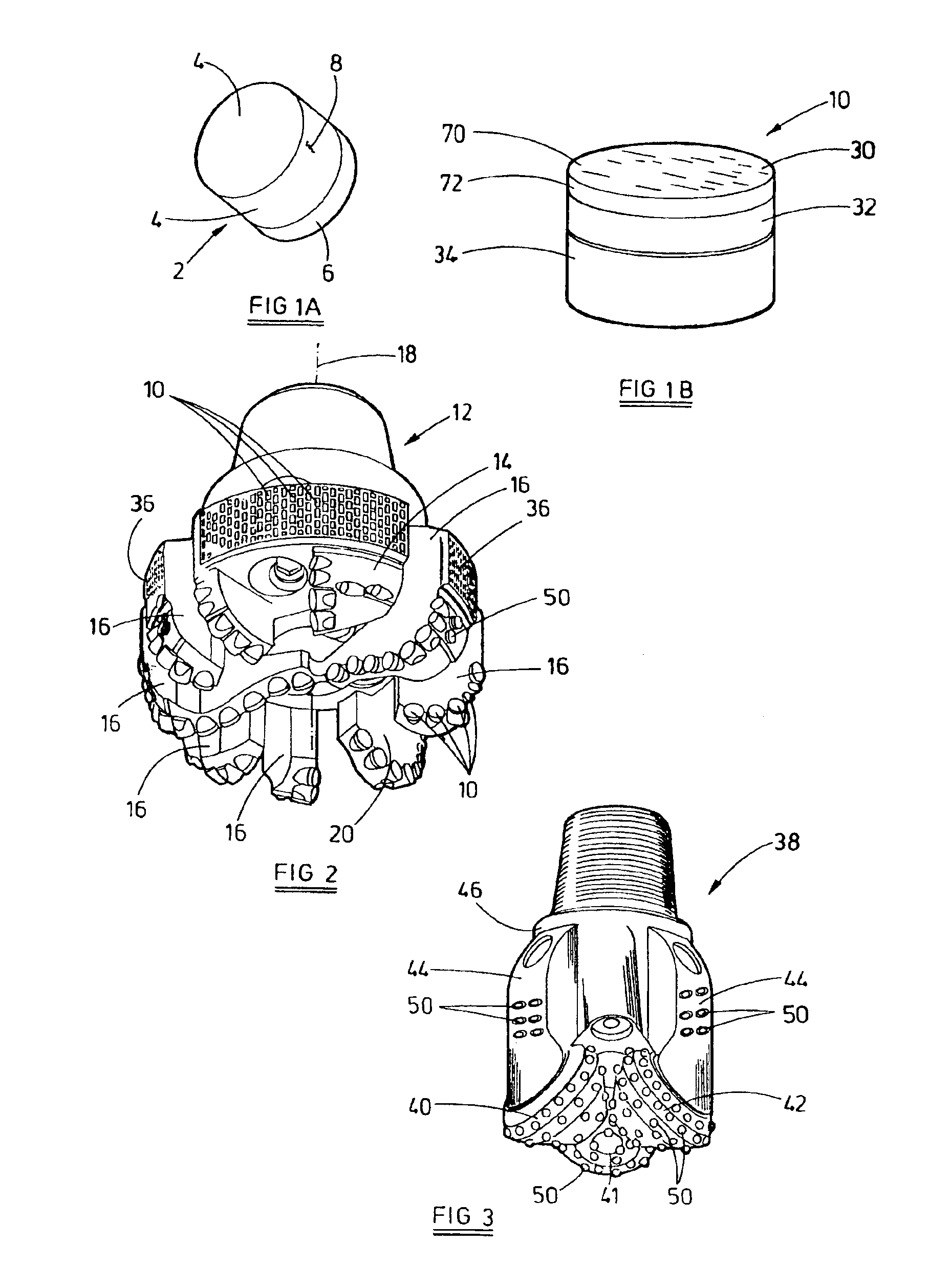

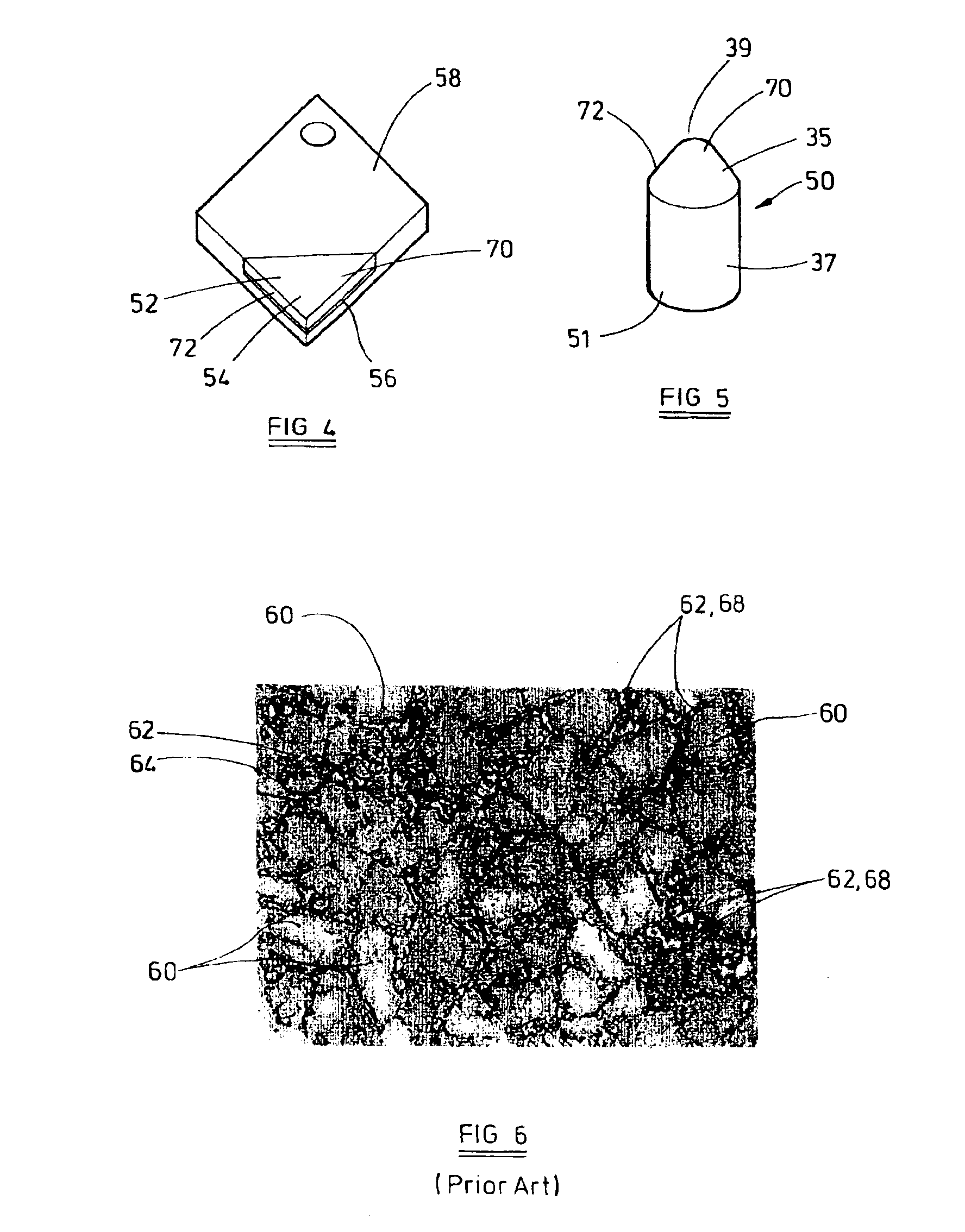

Polycrystalline diamond partially depleted of catalyzing material

Owner:REEDHYCALOG UK

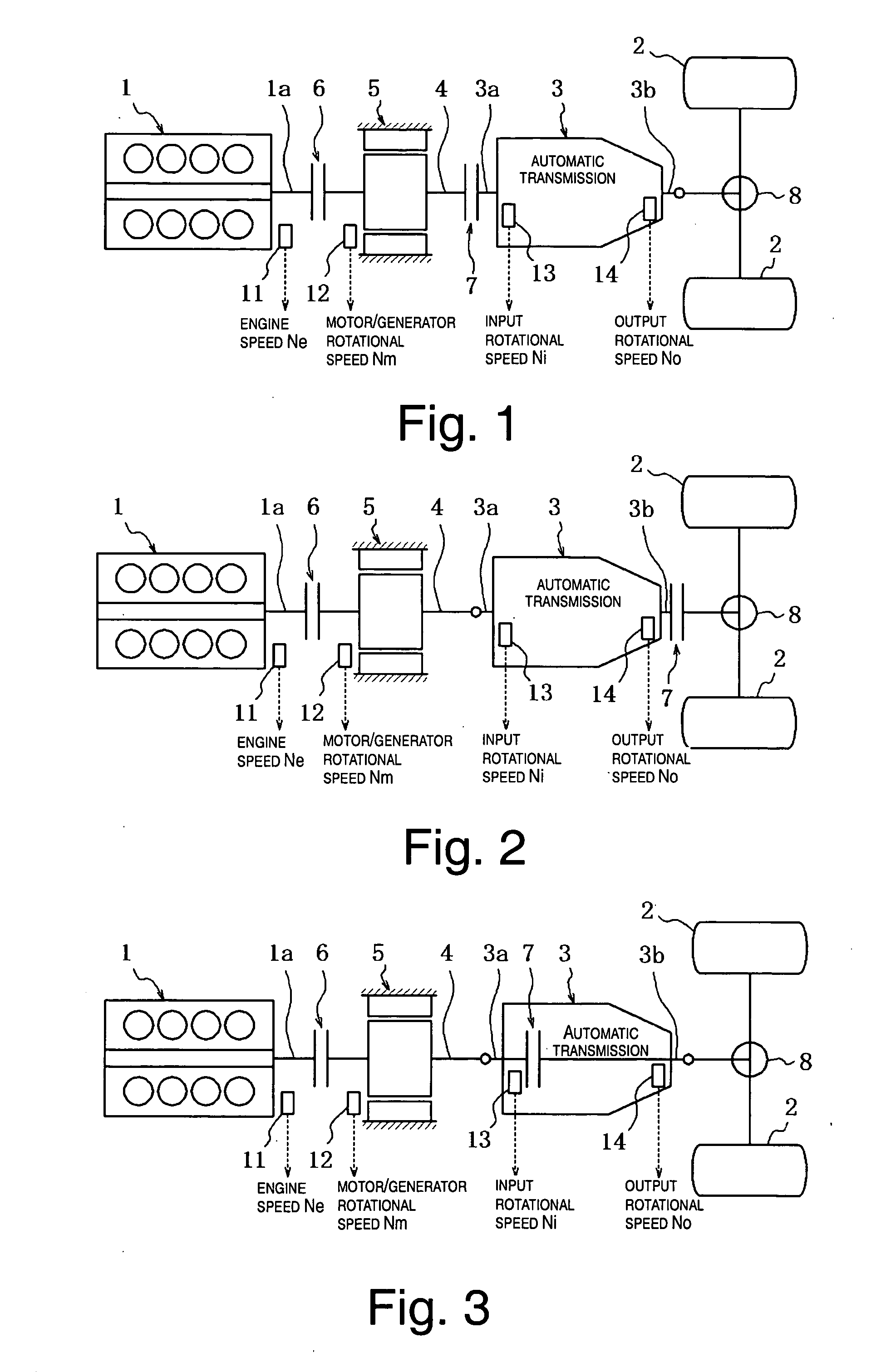

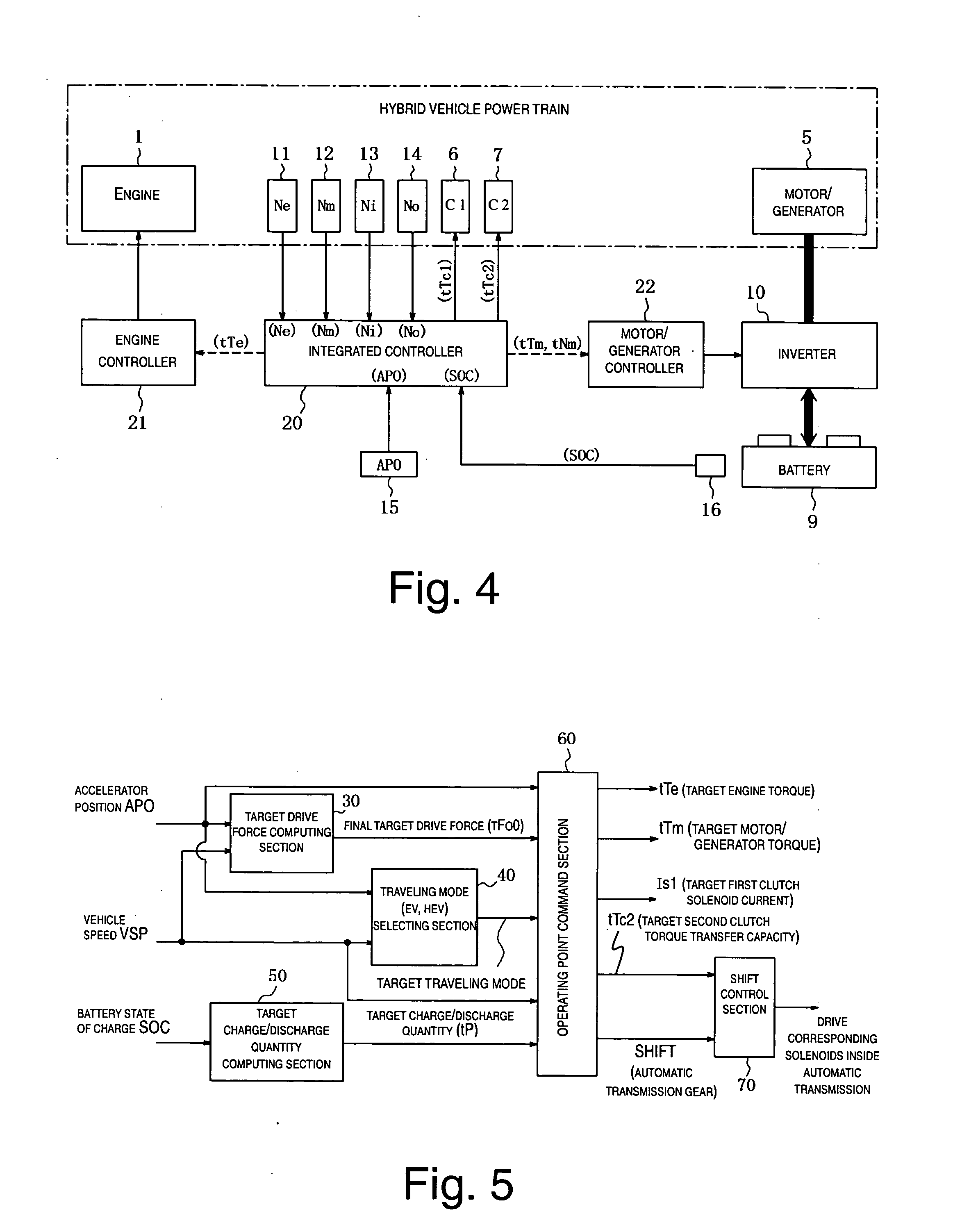

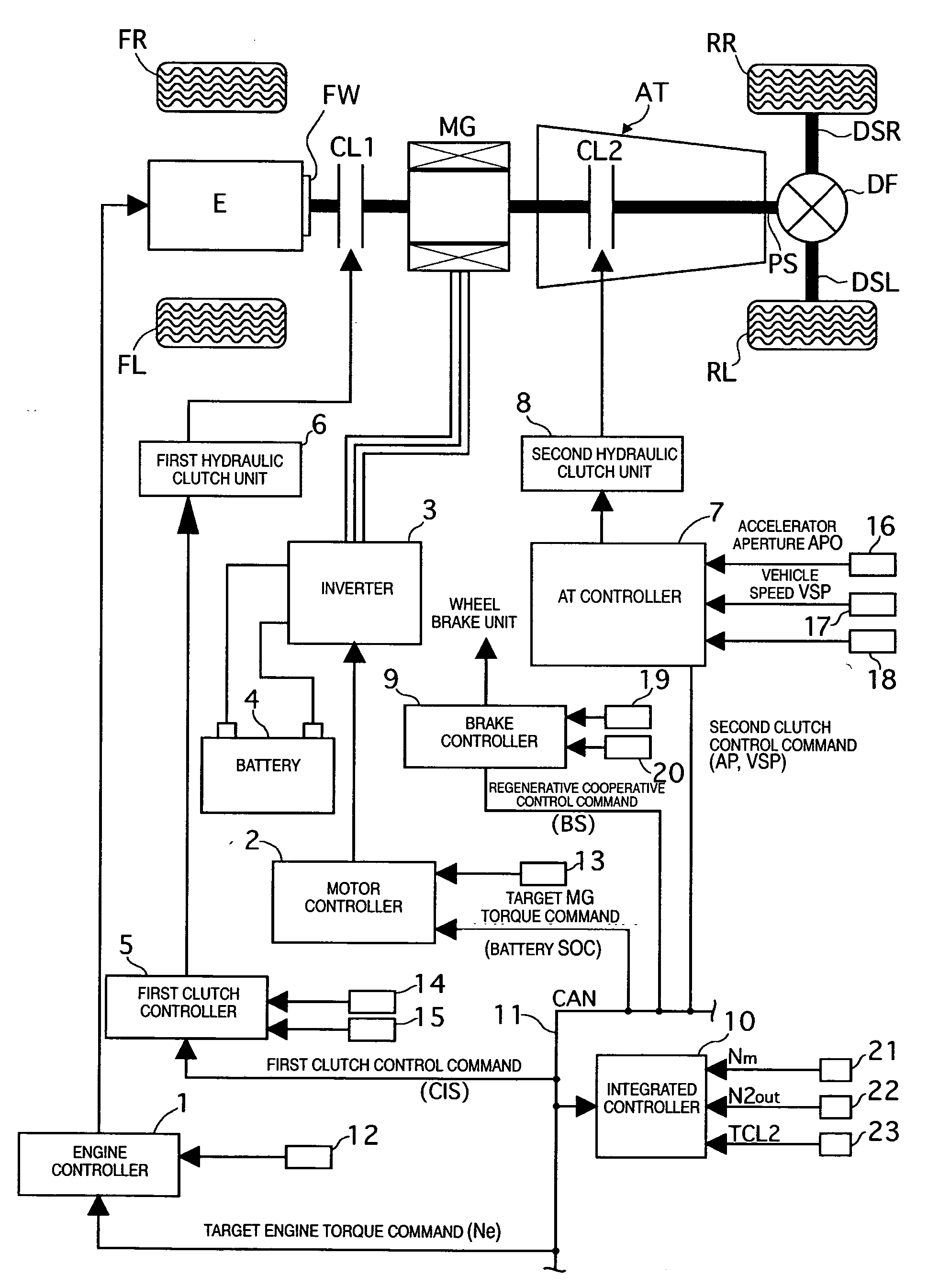

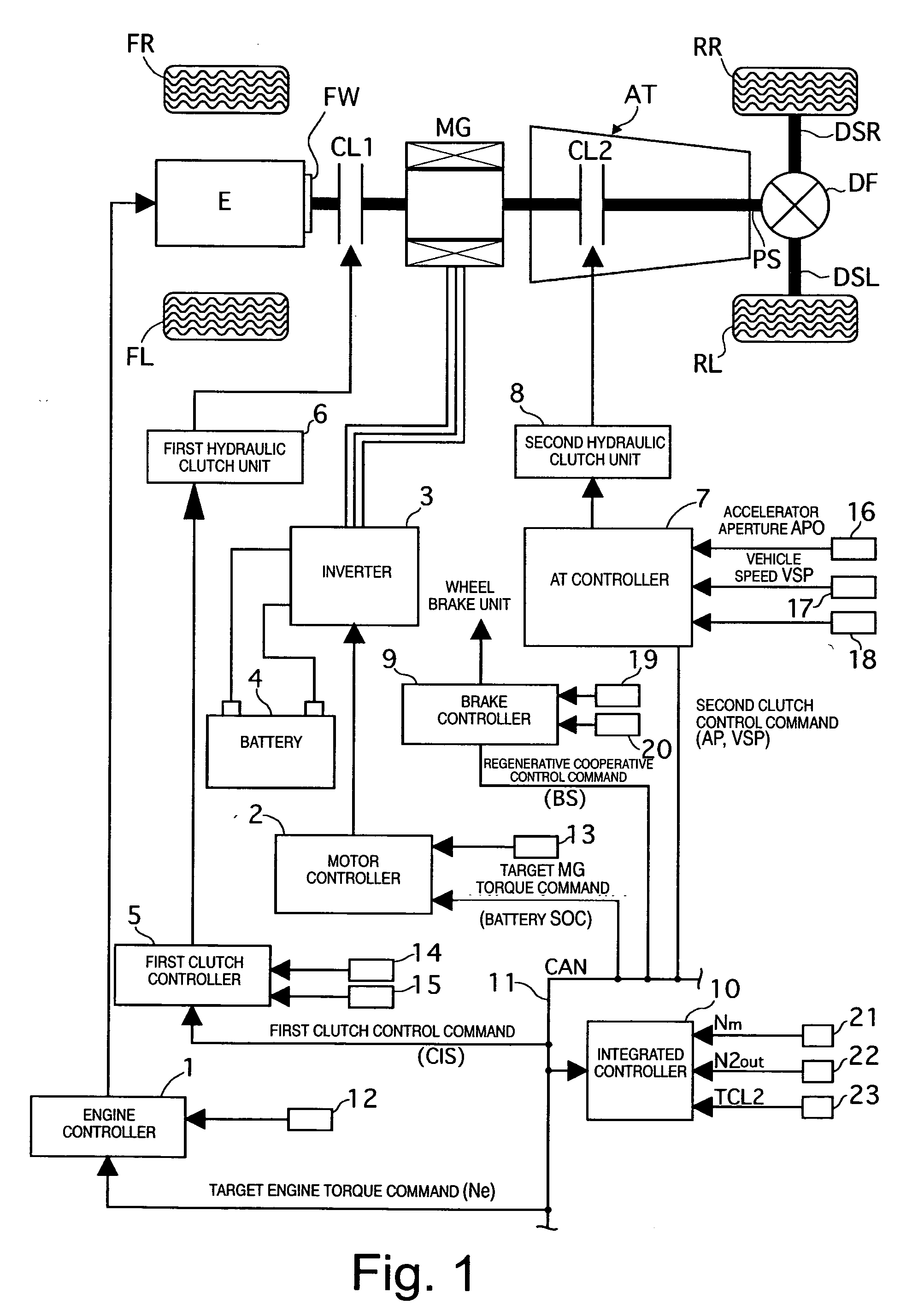

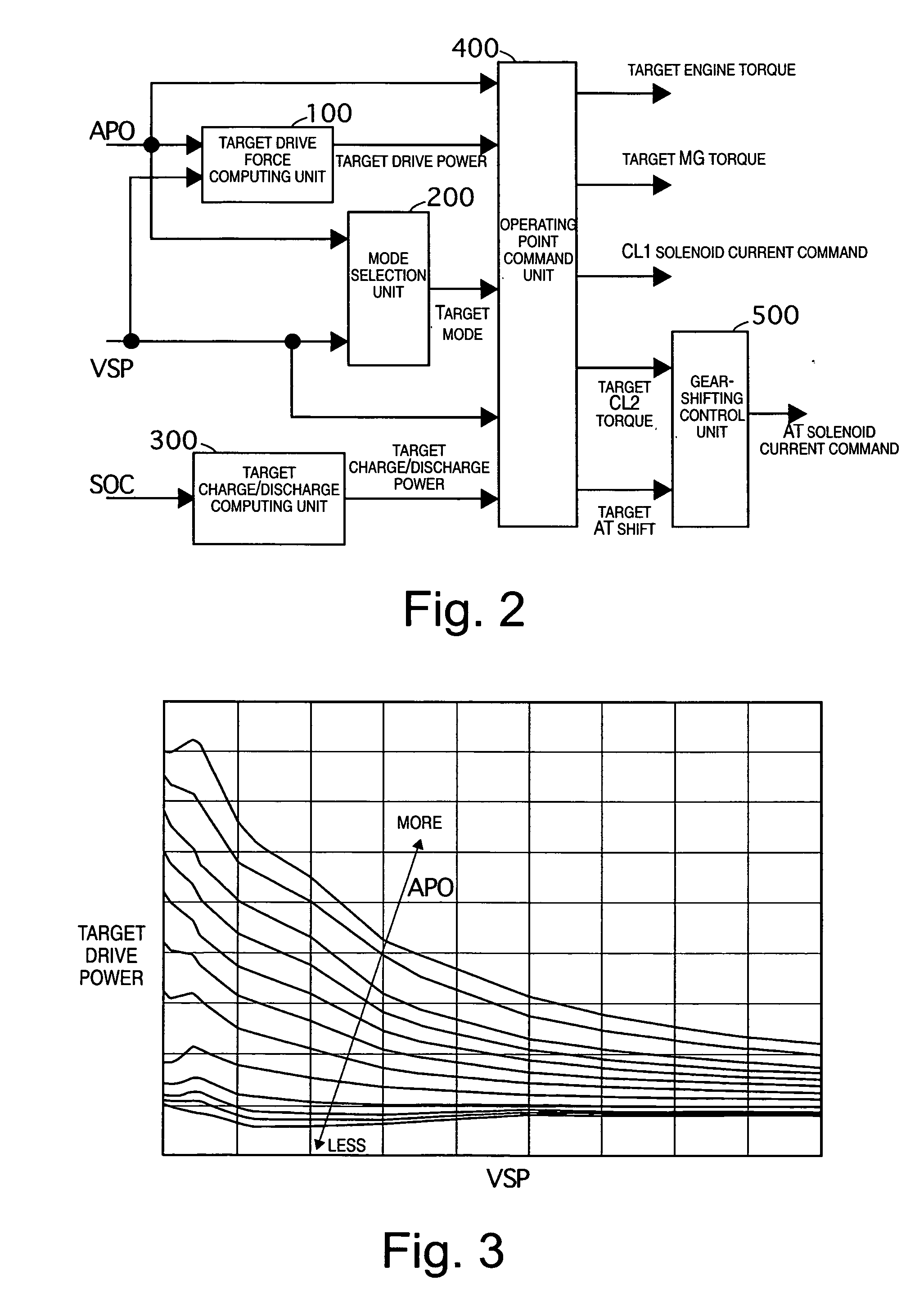

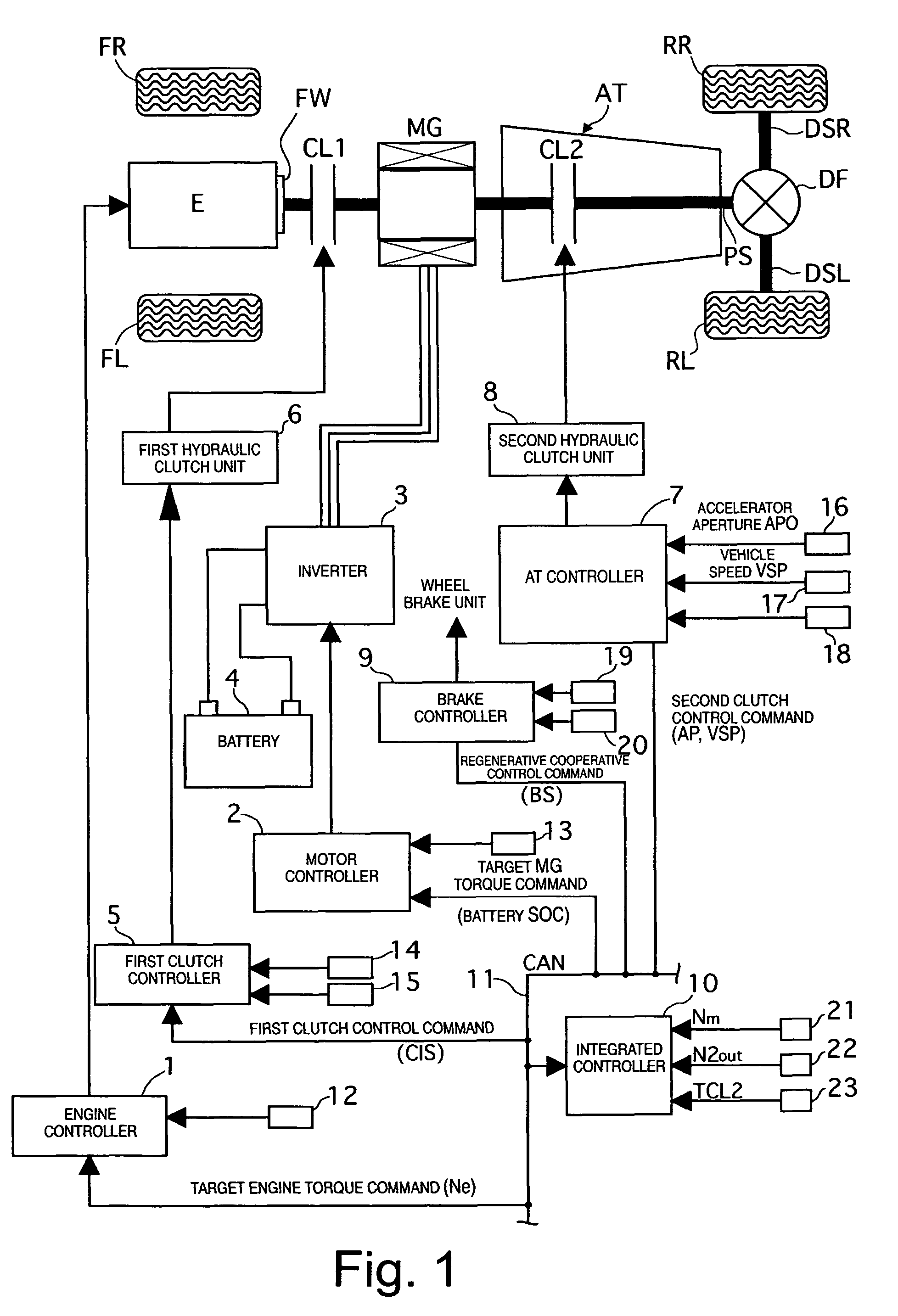

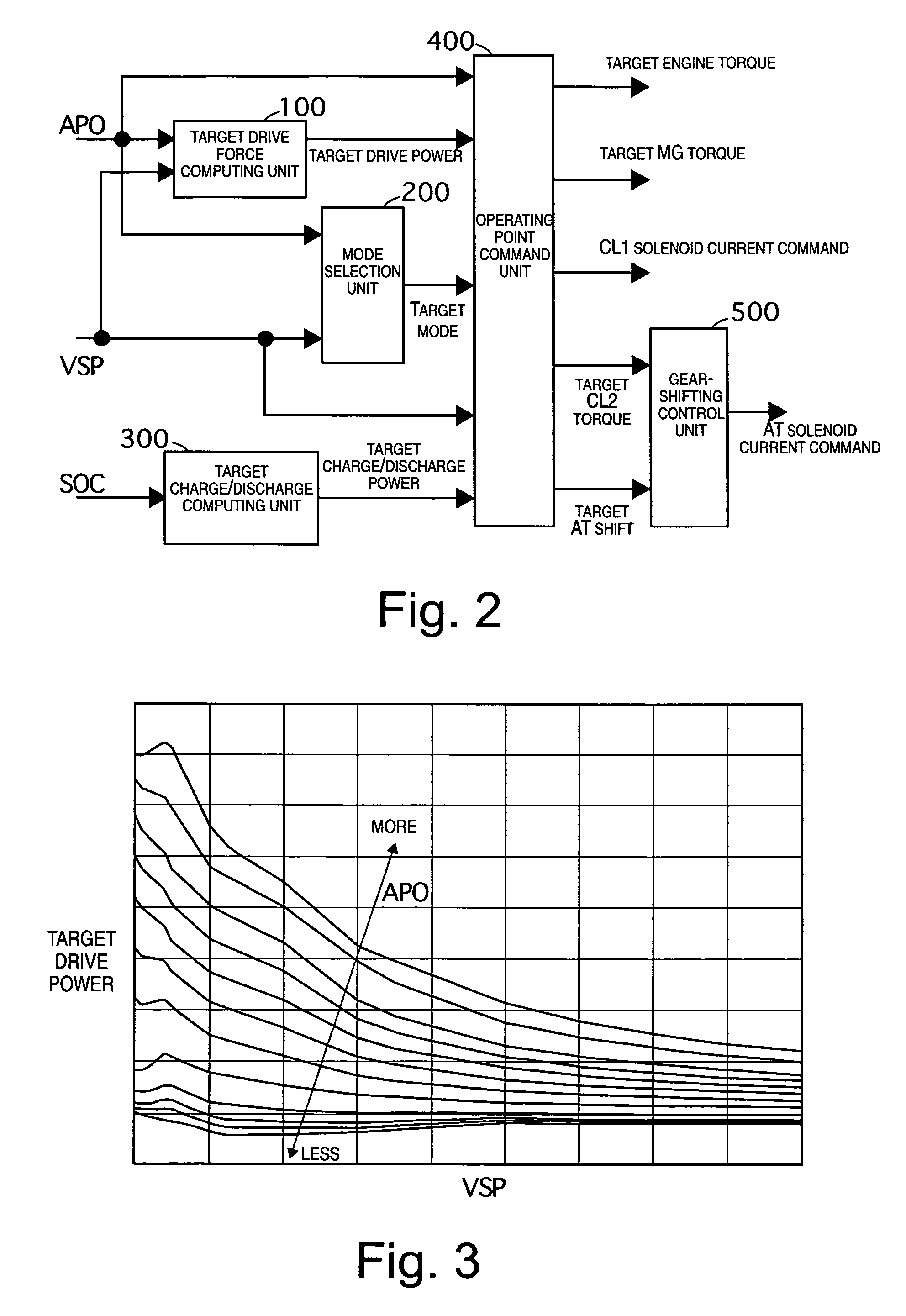

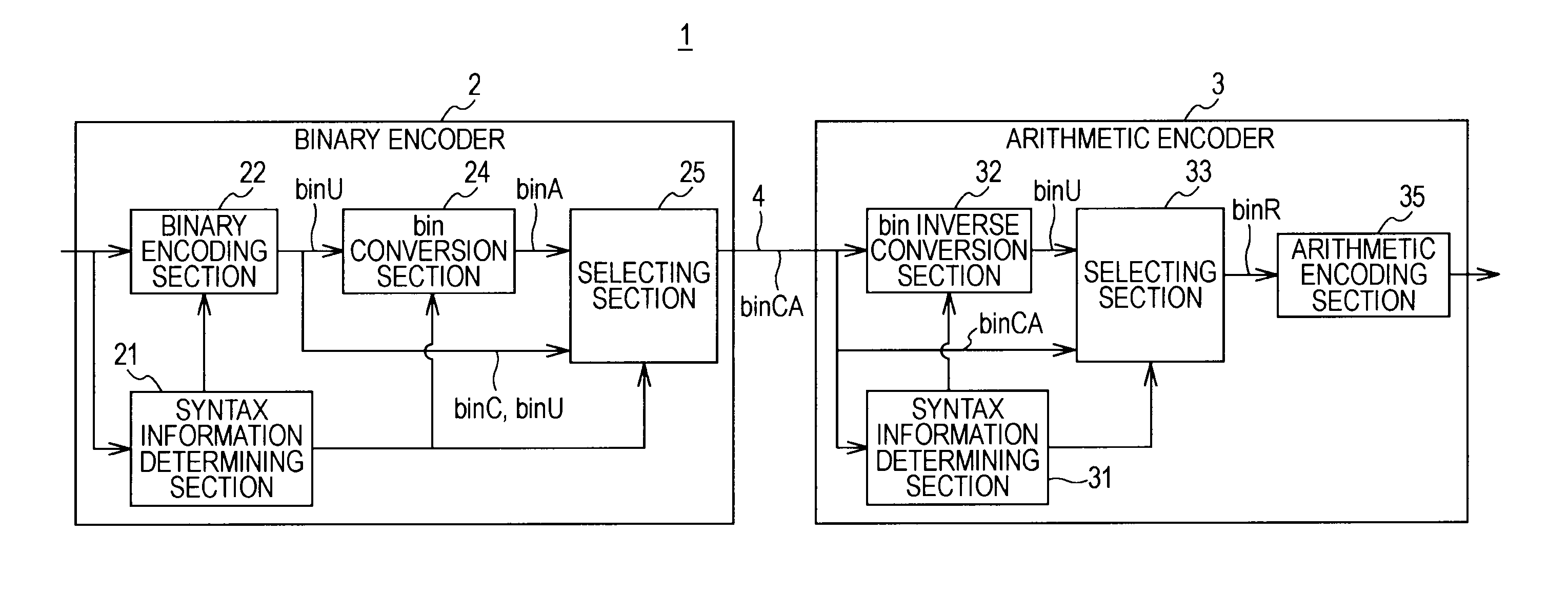

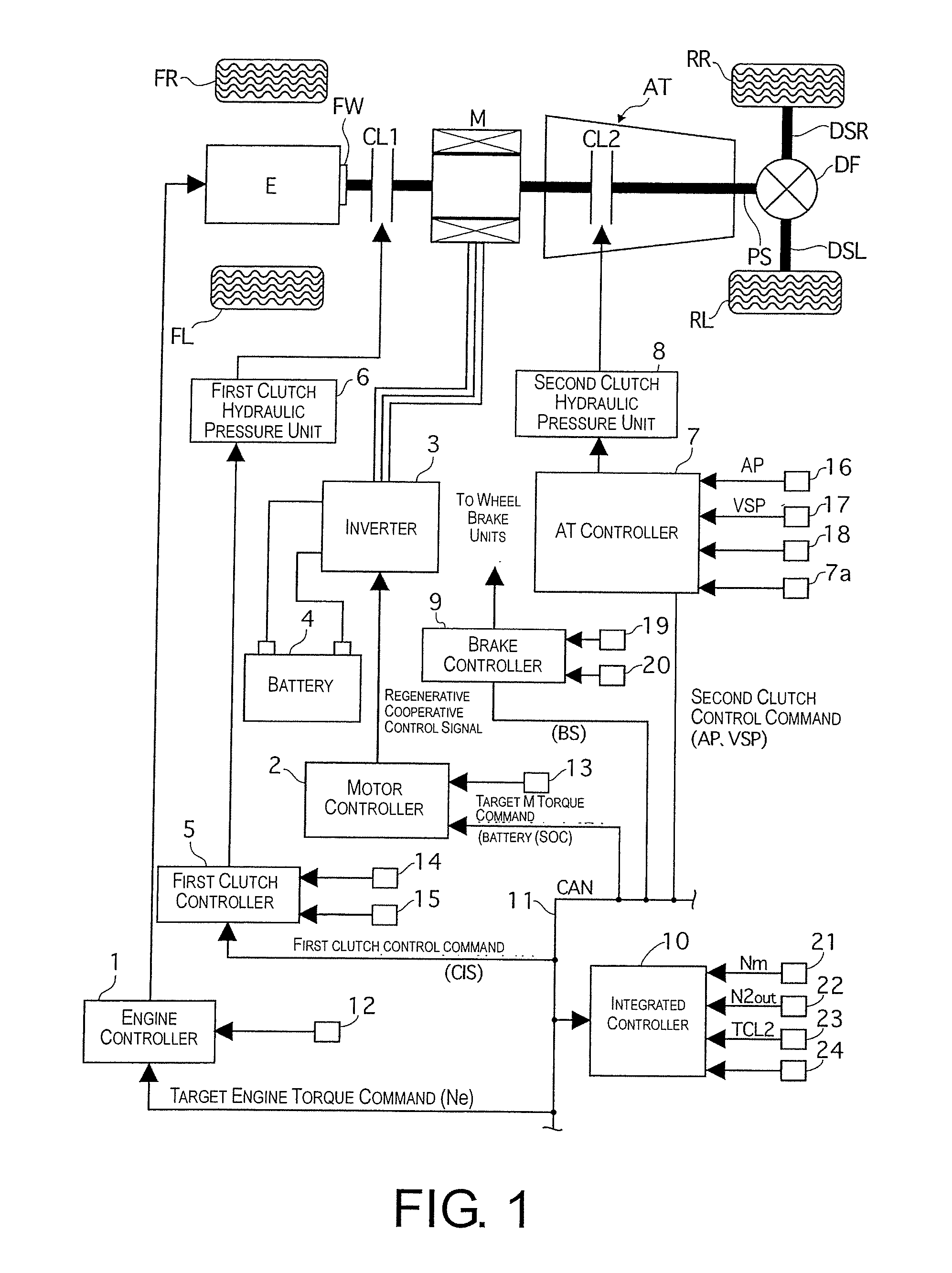

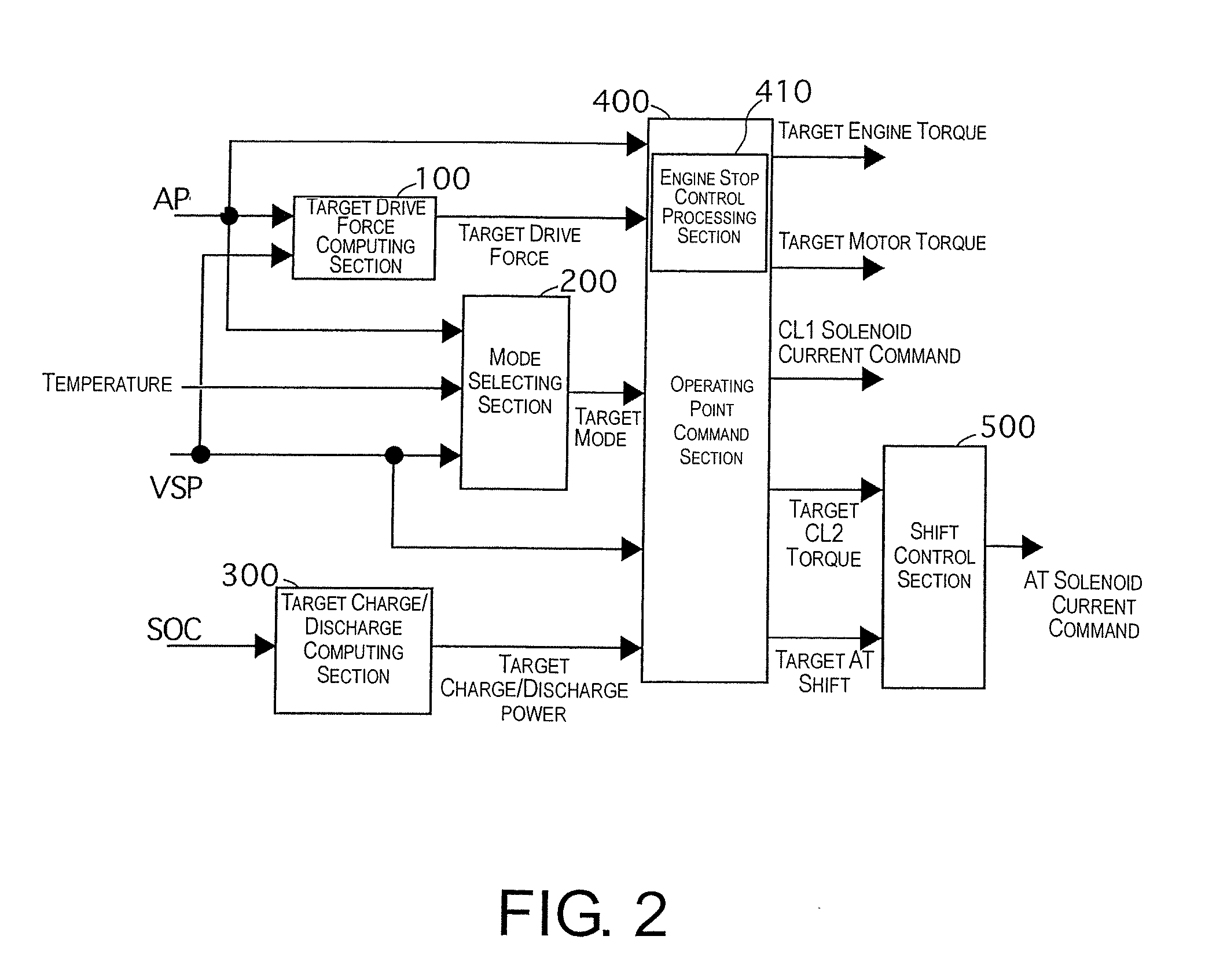

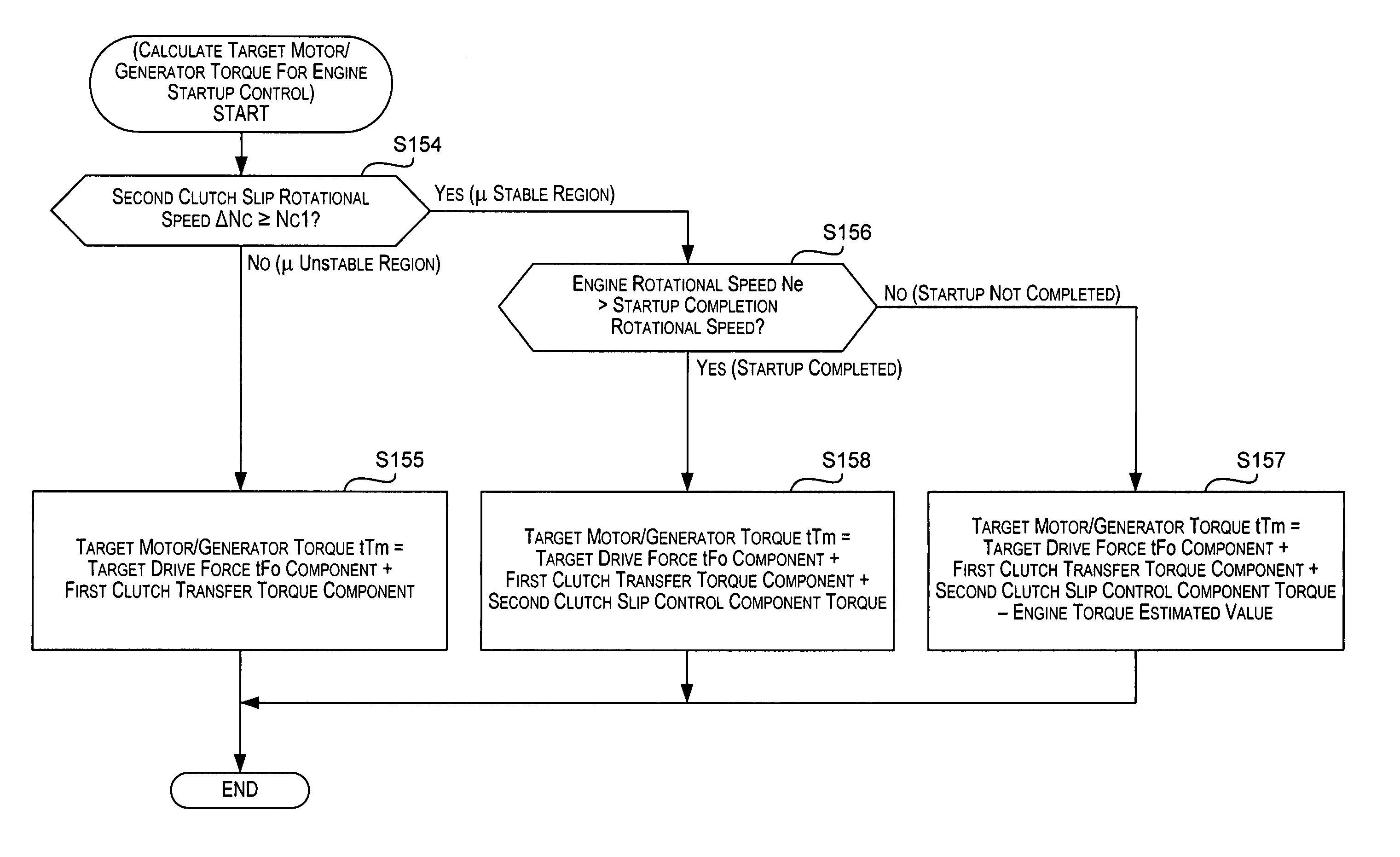

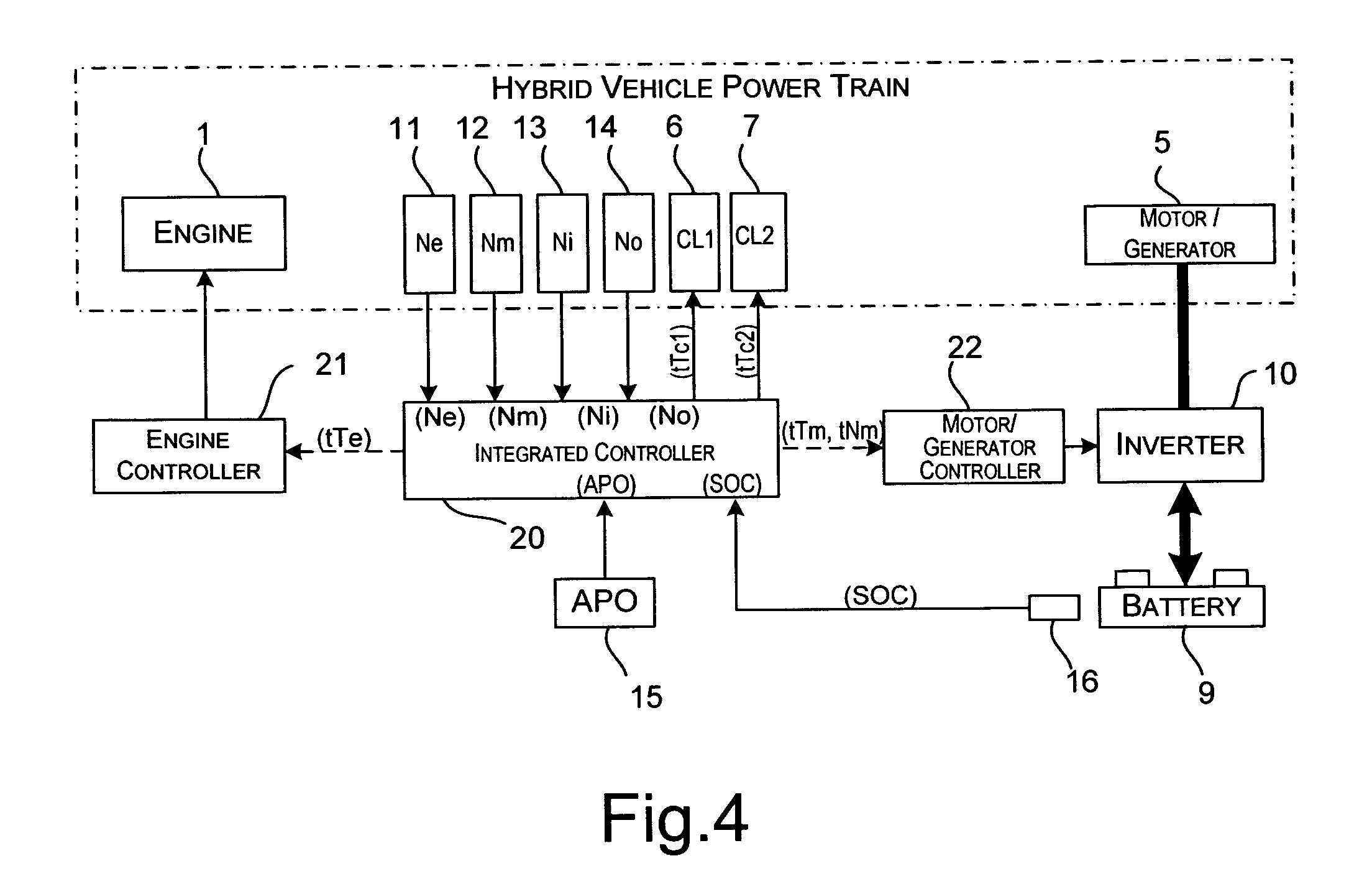

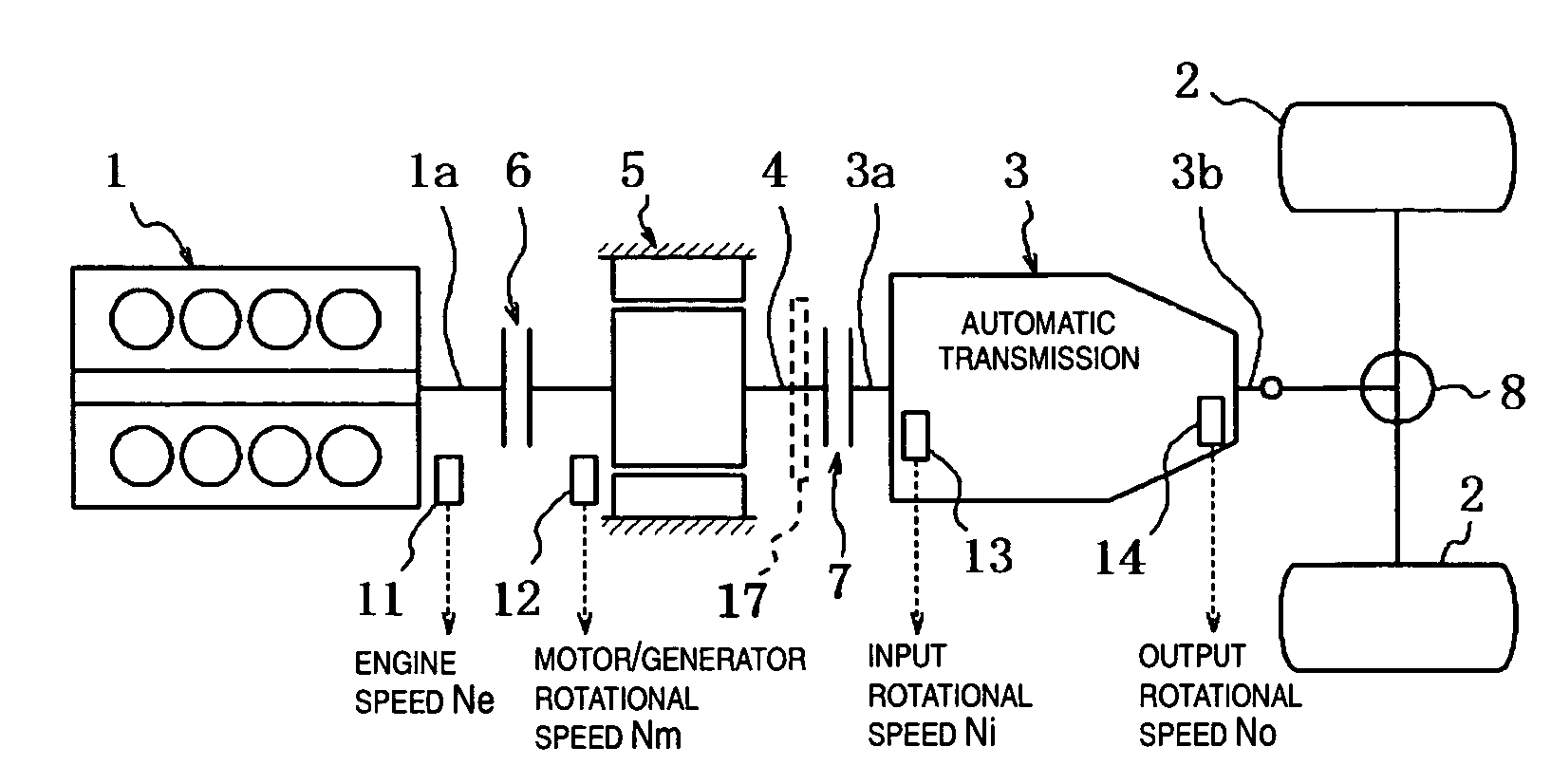

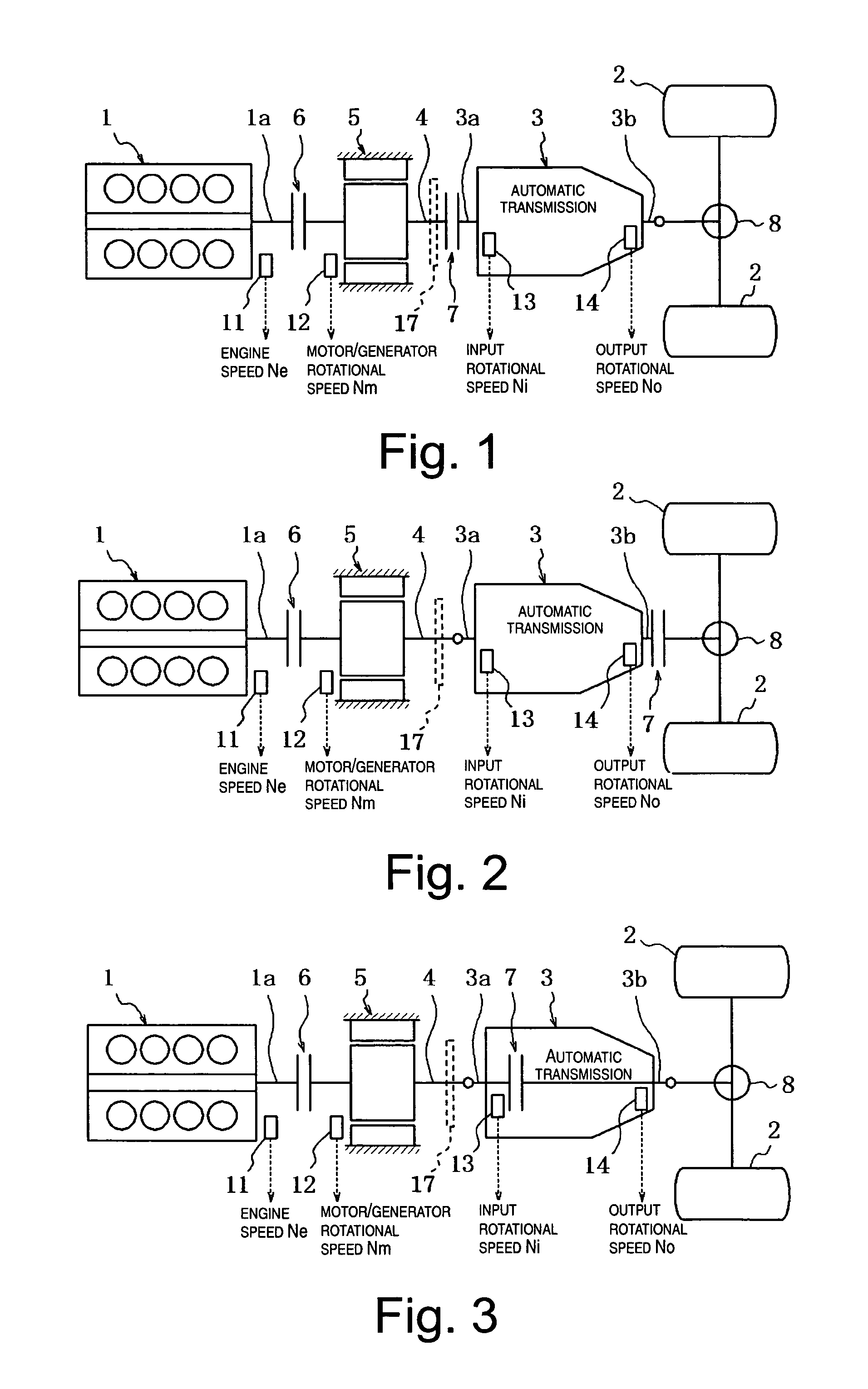

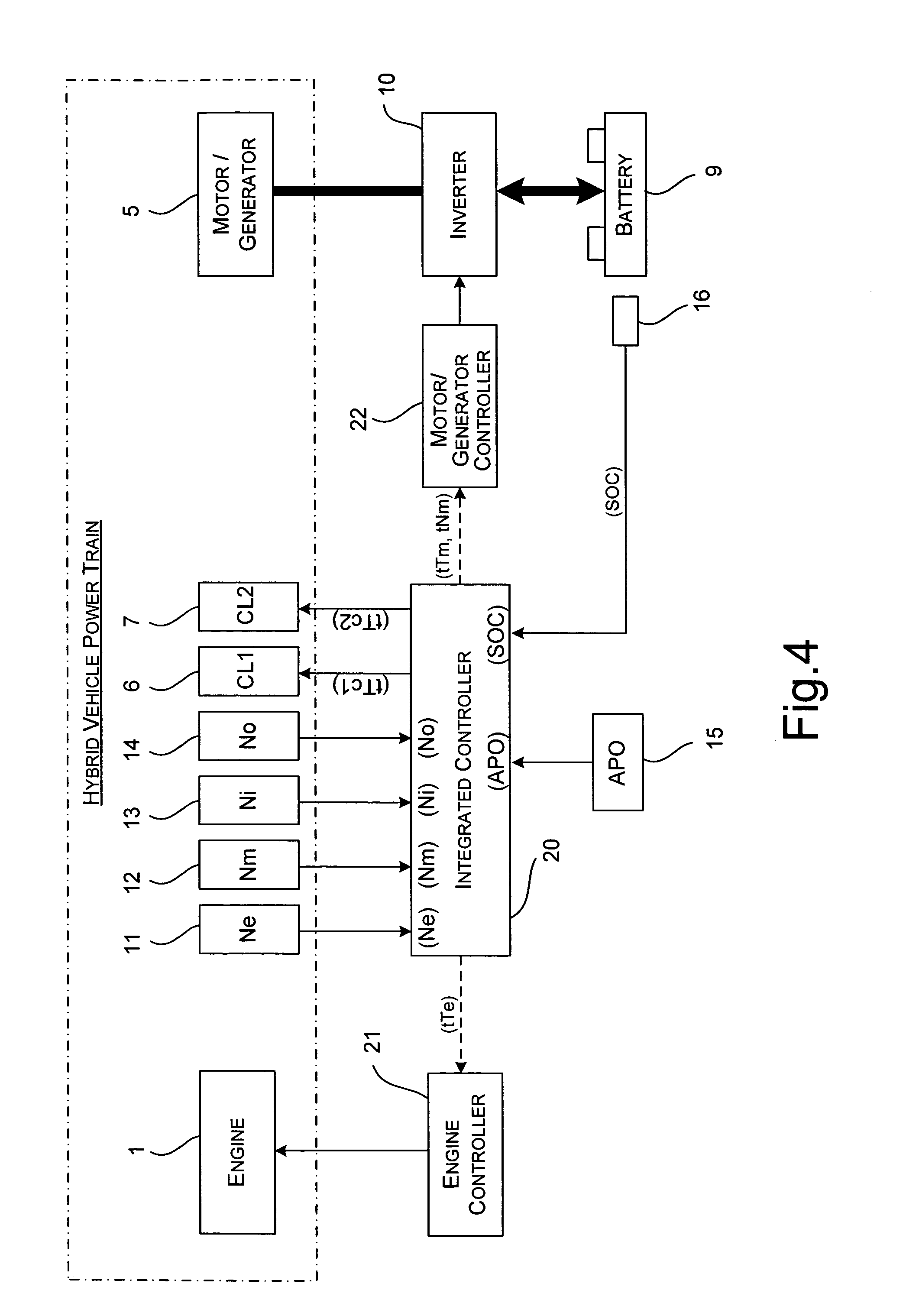

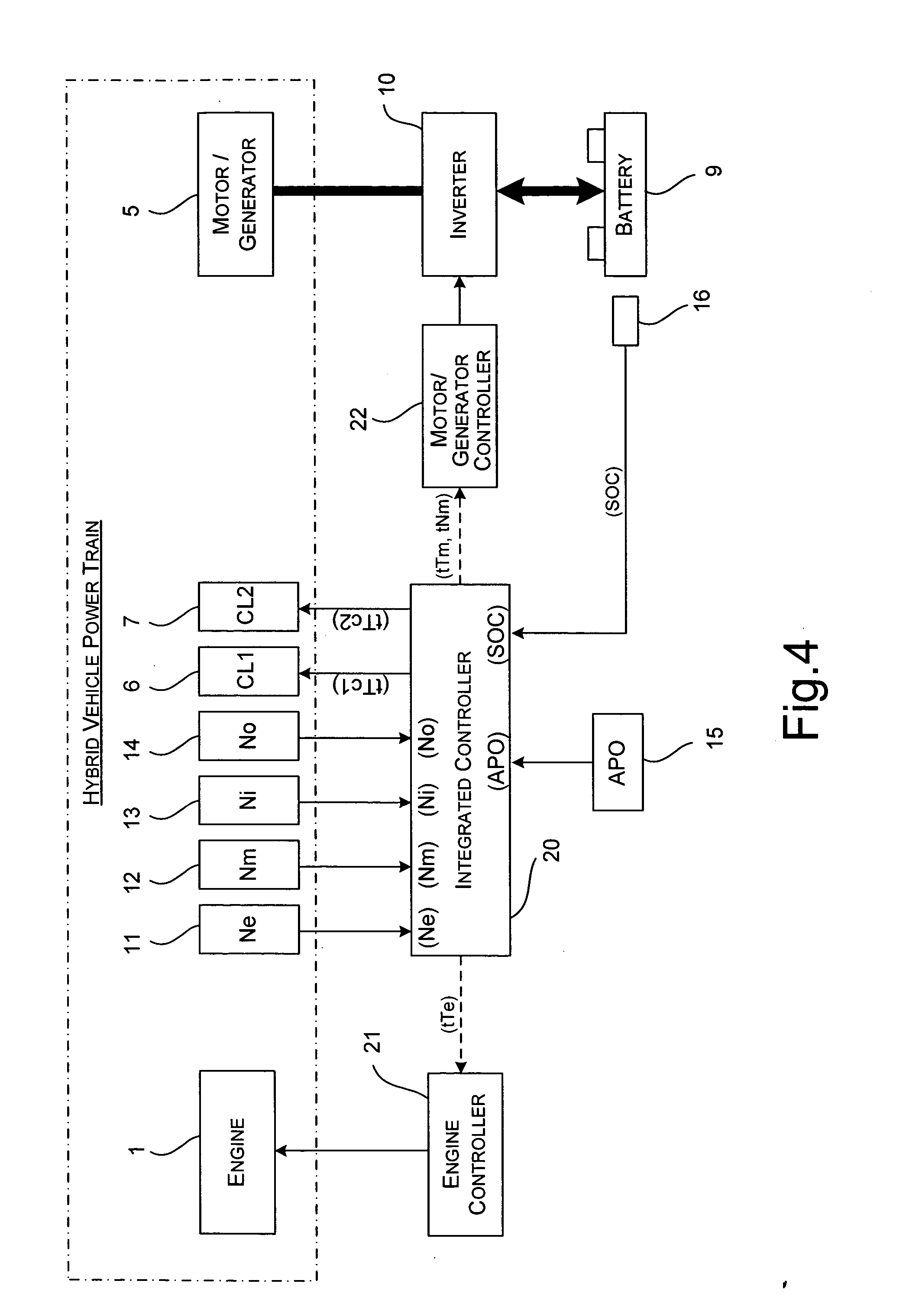

Hybrid vehicle drive control system

InactiveUS20070080005A1Suppresses torque fluctuationsReliably resolveClutchesInternal combustion piston enginesControl systemElectric drive

A hybrid vehicle drive control system selectively switches from an electric drive (EV) mode in which a first clutch is released and a second clutch is engaged, and a hybrid drive (HEV) mode in which both clutches are engaged. A slip control of the second clutch is executed when the first clutch is being connected to start the engine during switching from EV mode to HEV mode by controlling a torque transfer capacity of the second clutch to a required drive force, and by simultaneously increasing a motor / generator torque by an amount corresponding to a torque required to start the engine while maintaining a slipping state of the second clutch until connection of the first clutch is completed. Thus, a loss of torque is not felt by the driver and the shock is small when the engine is started during switching from EV mode to HEV mode.

Owner:NISSAN MOTOR CO LTD

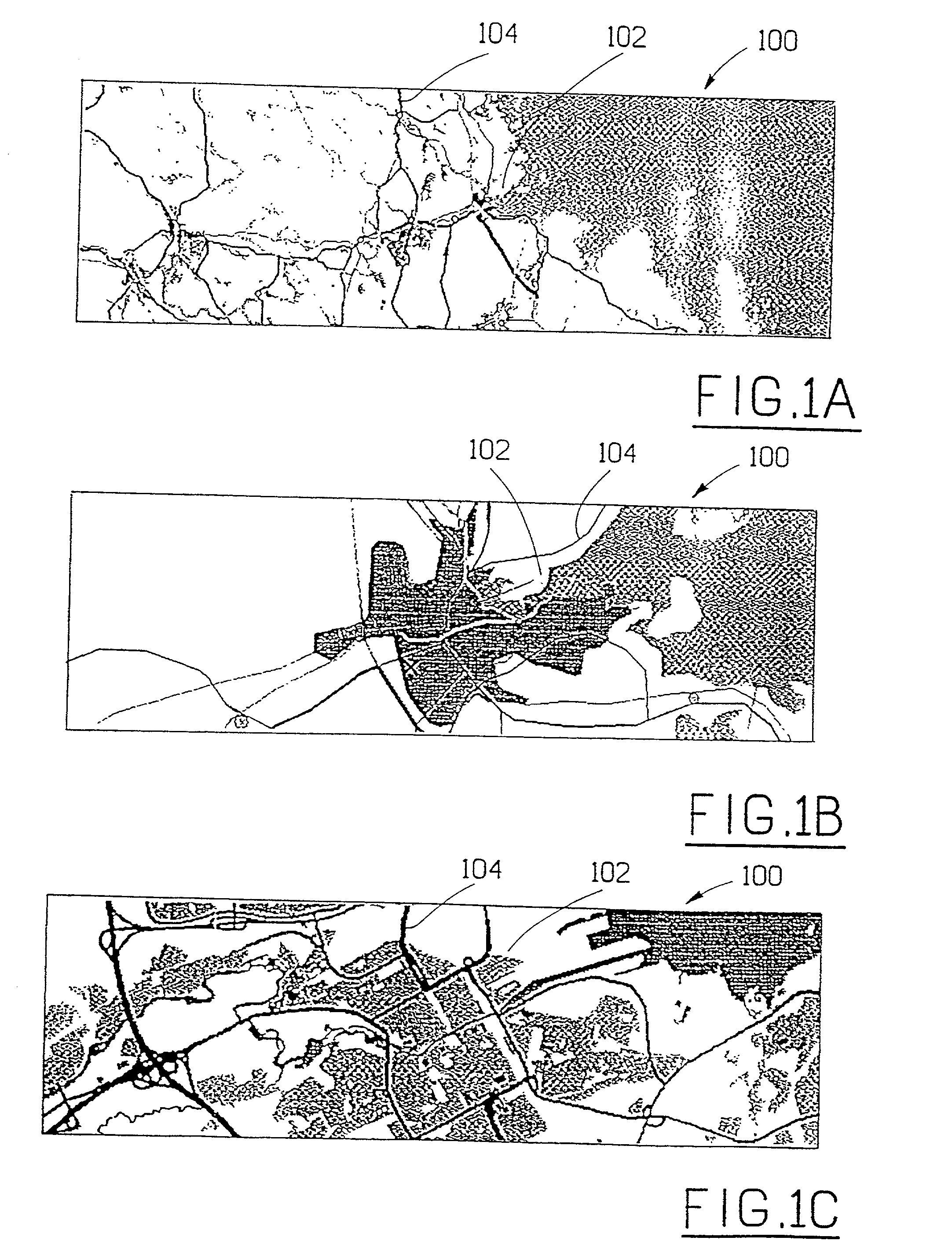

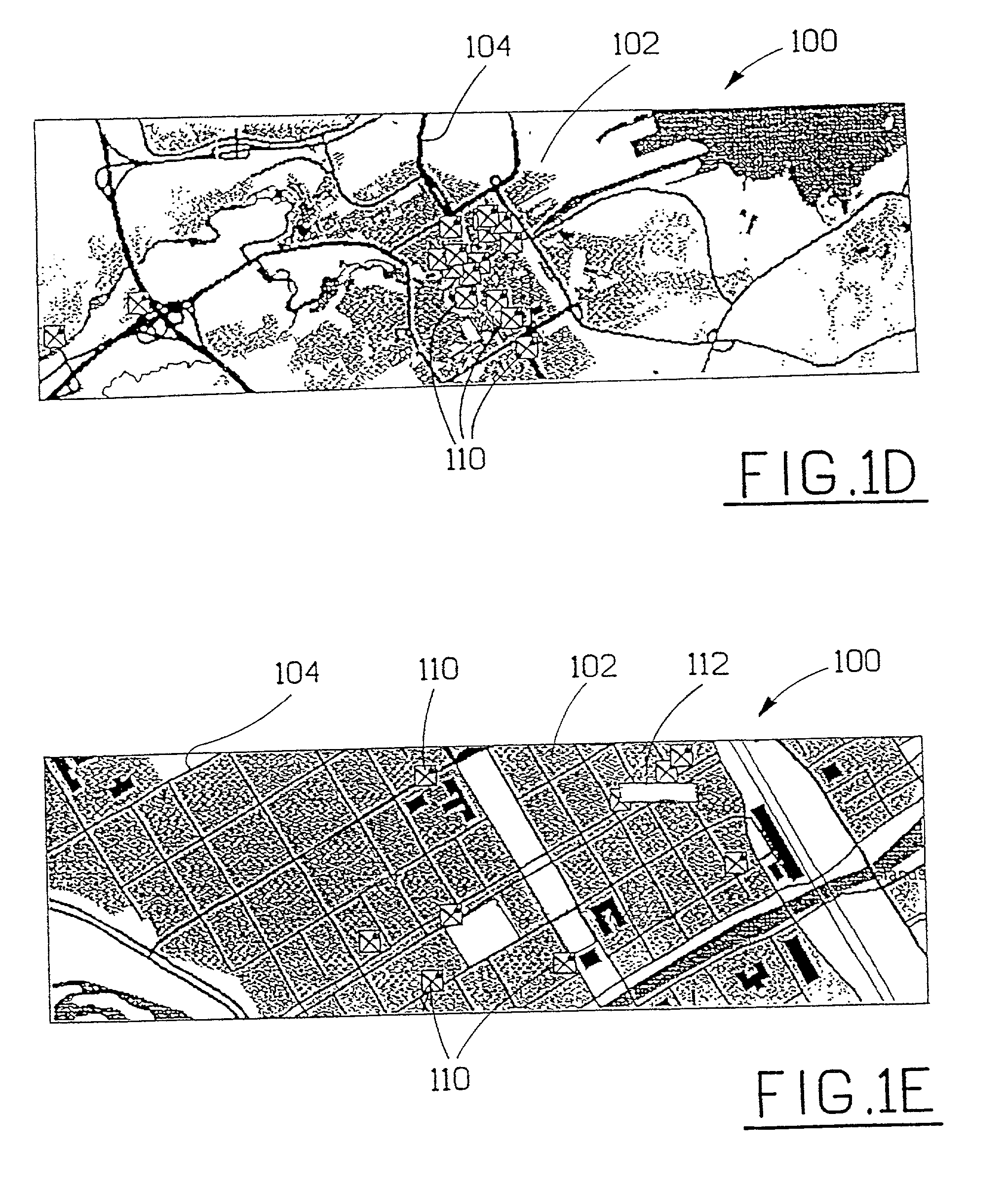

Method for transferring information

InactiveUS20020029224A1Storage savingSave bandwidthInstruments for road network navigationRoad vehicles traffic controlDistributed databaseData bank

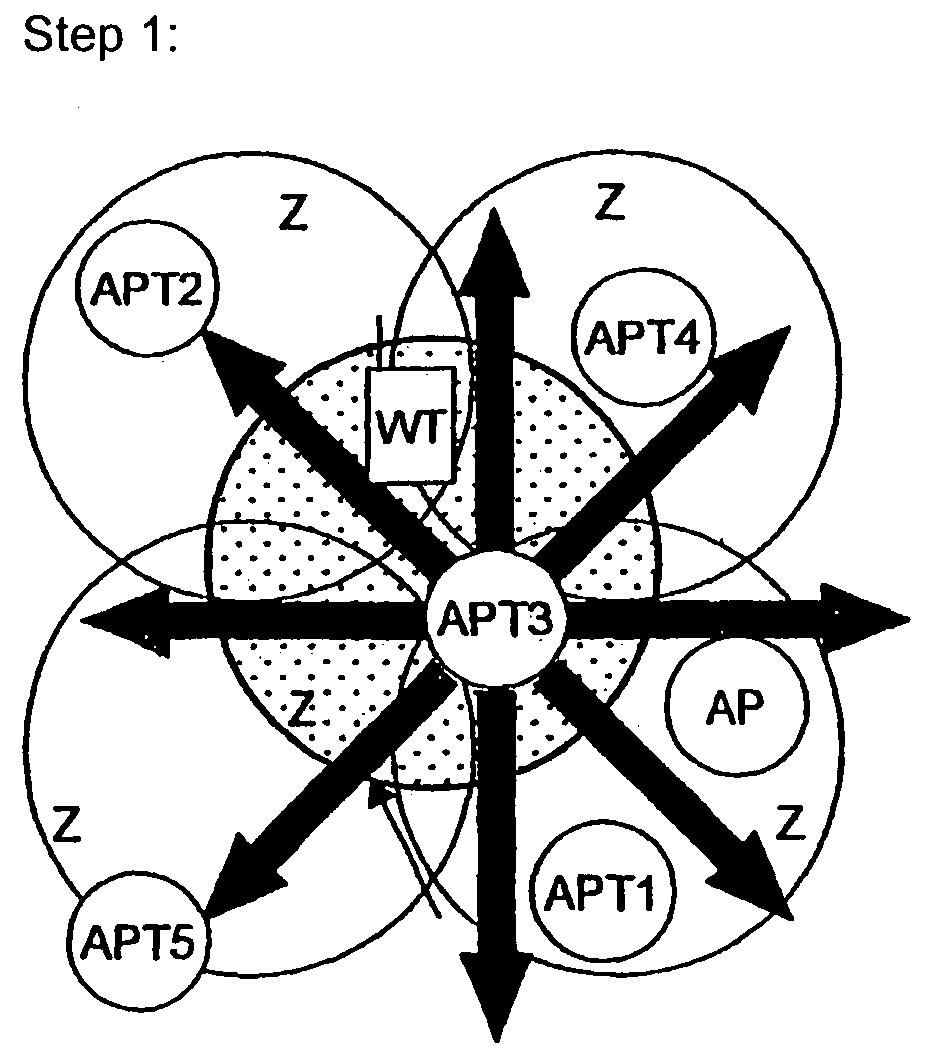

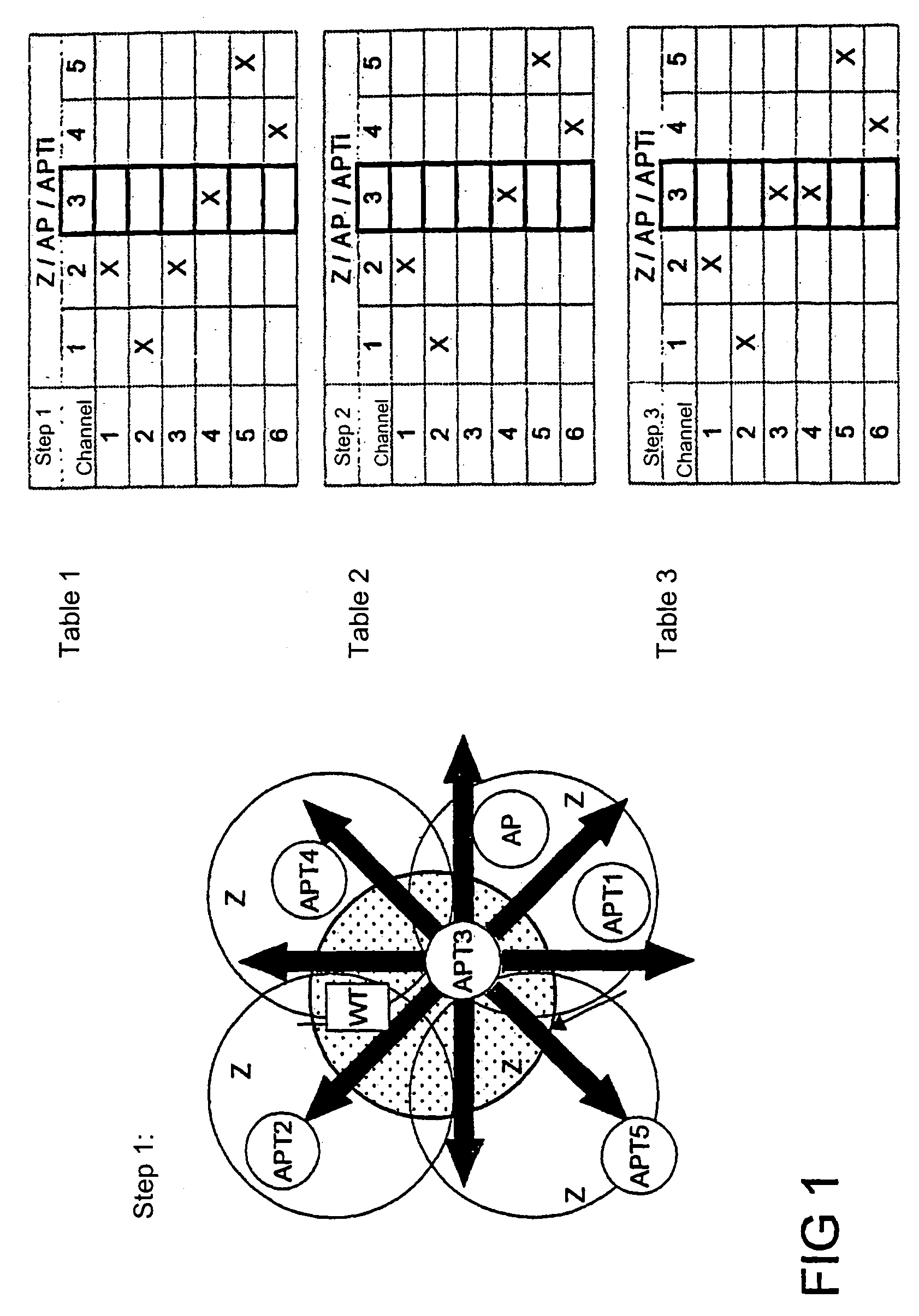

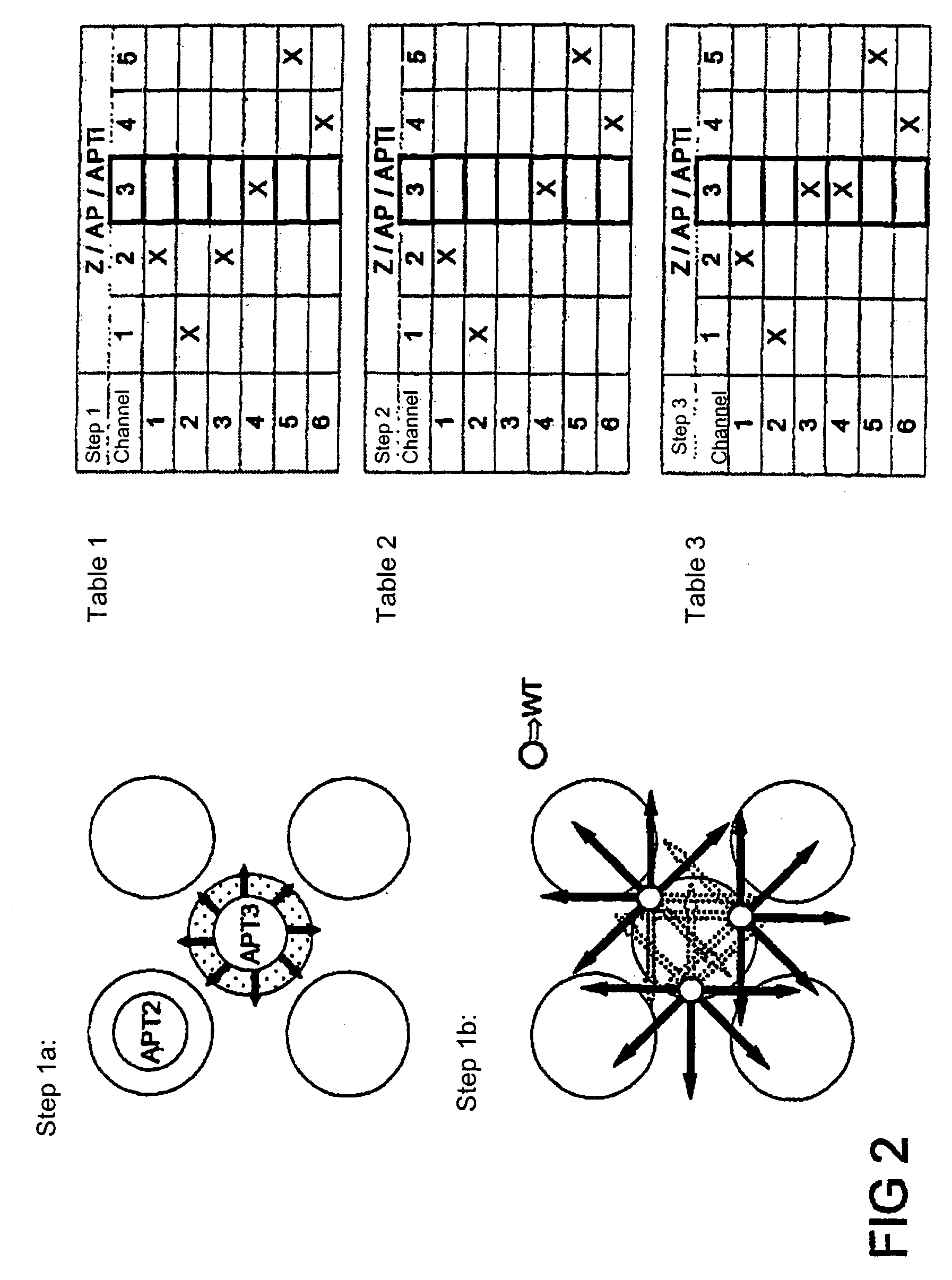

A method of updating local map displaying databases of a distributed database via a broadcasting system with a transfer capacity. In a first step it is determined what information the distributed database needs to be updated with. In a second step the information is arranged according to a priority scheme. In a third step the information is transferred to the local map displaying databases via the broadcasting system according to the priority scheme and in dependence of the transfer capacity of the broadcasting system.

Owner:TERACOM

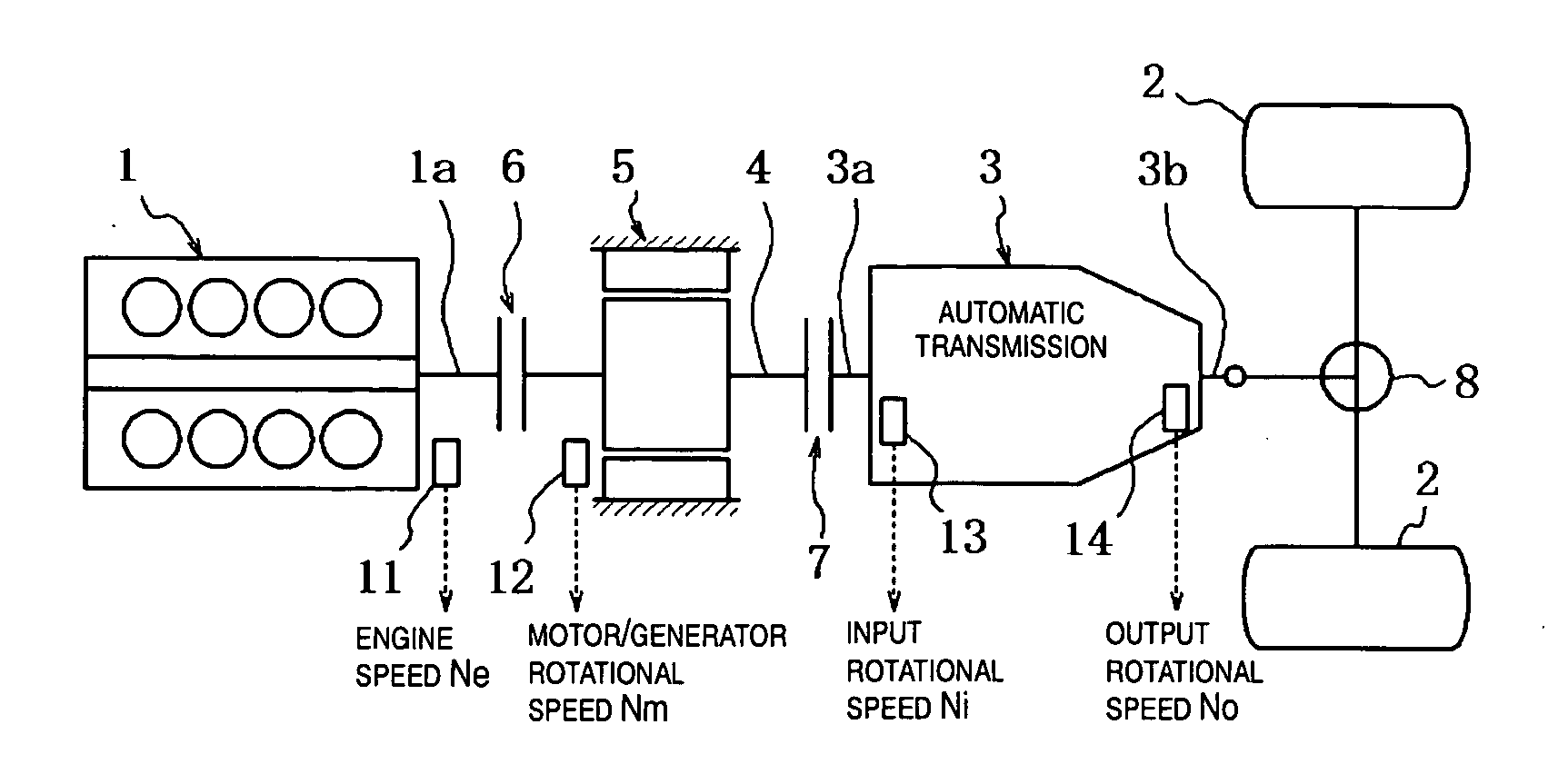

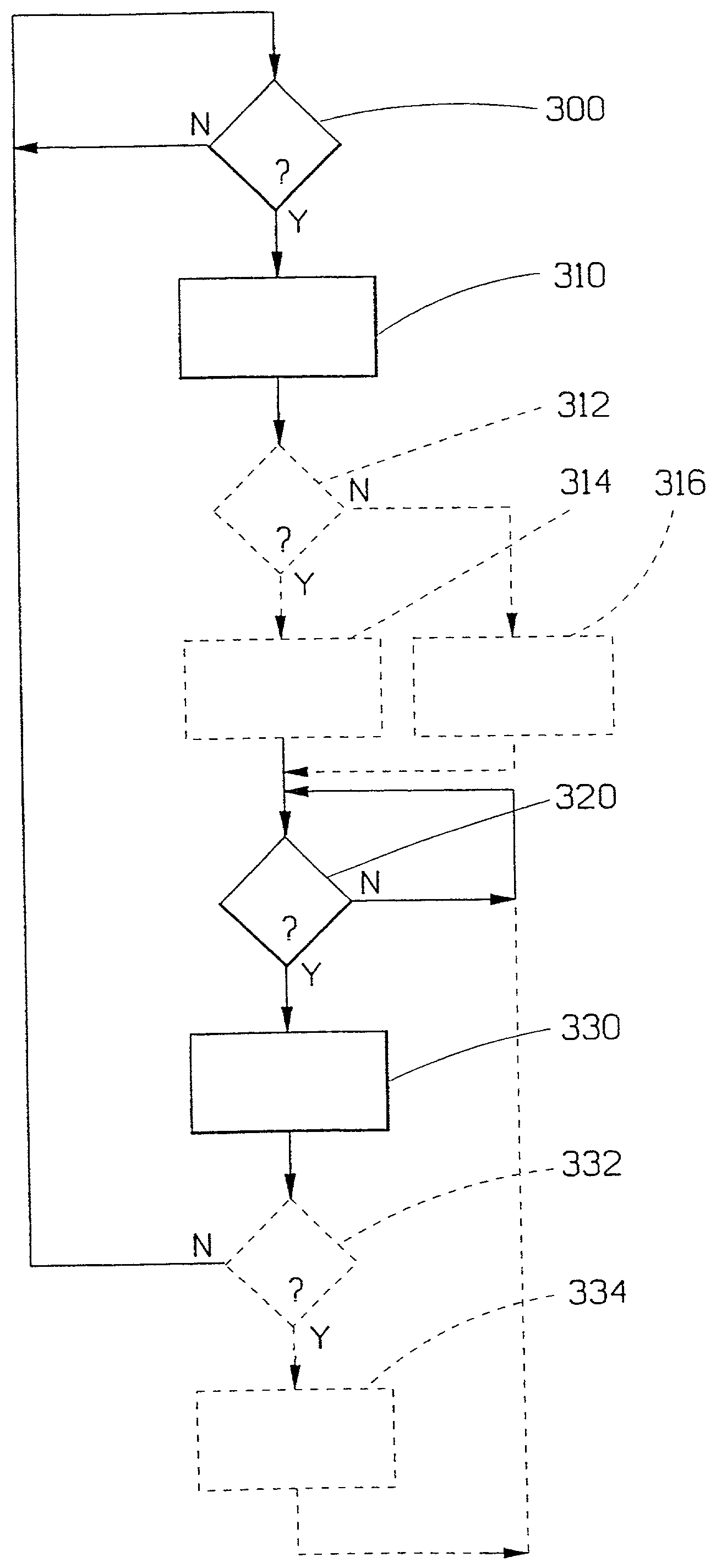

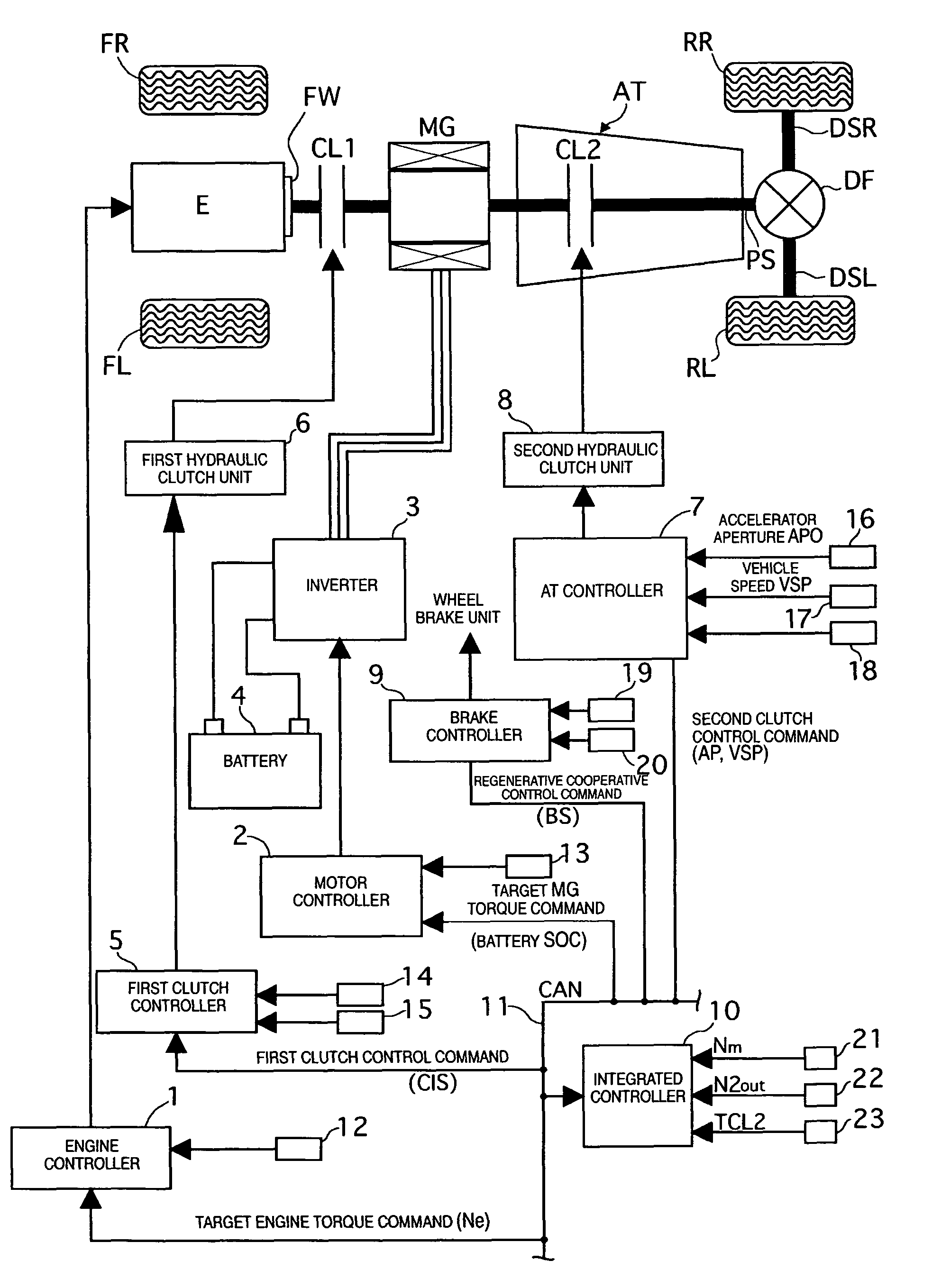

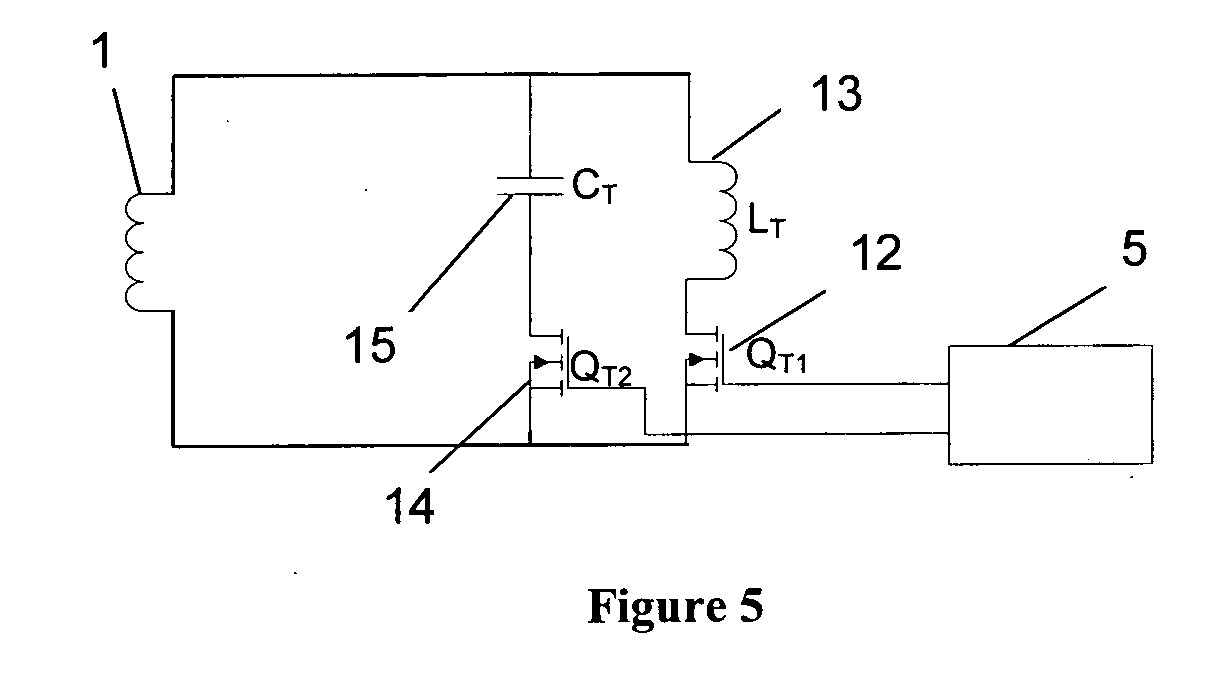

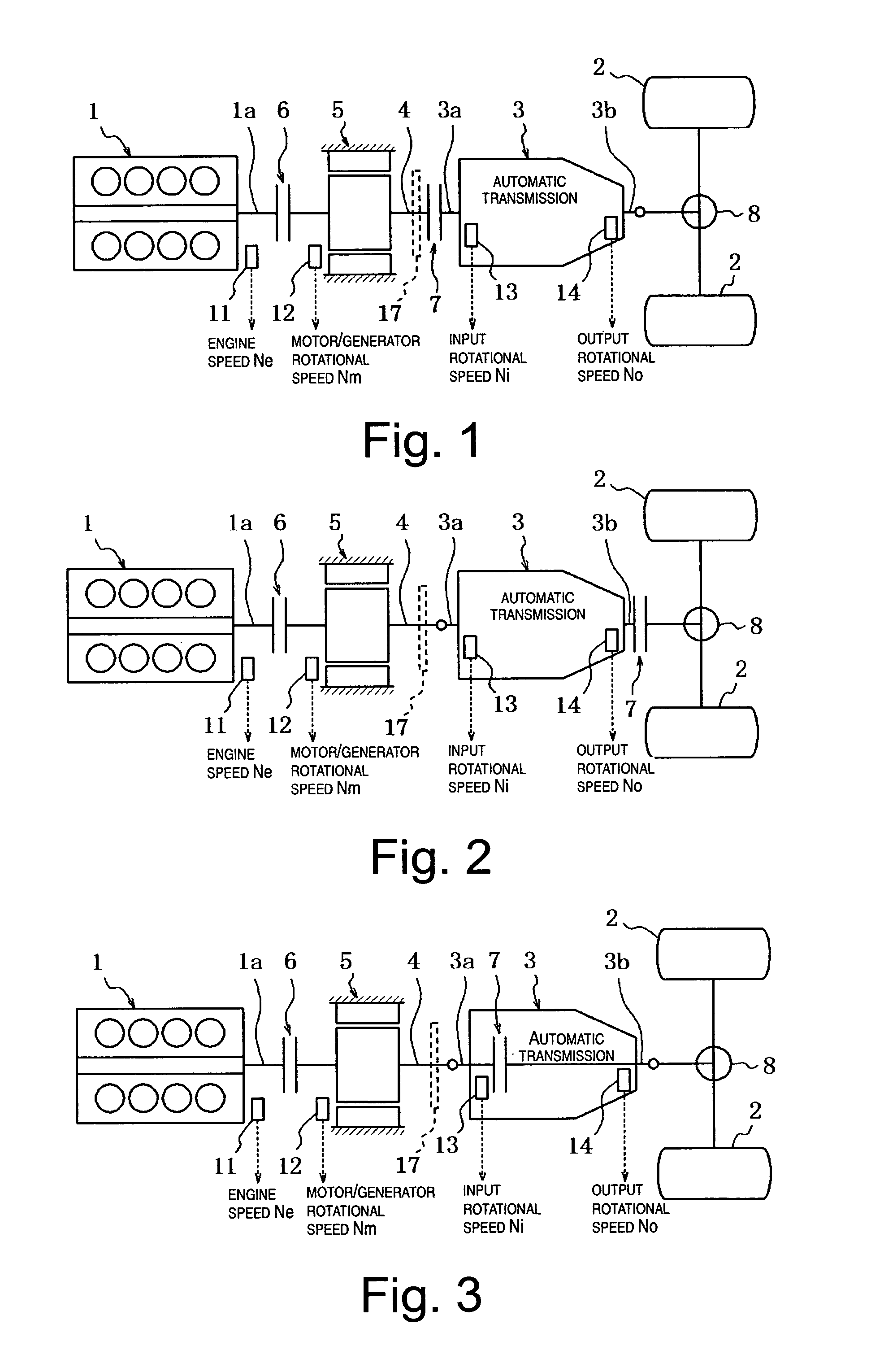

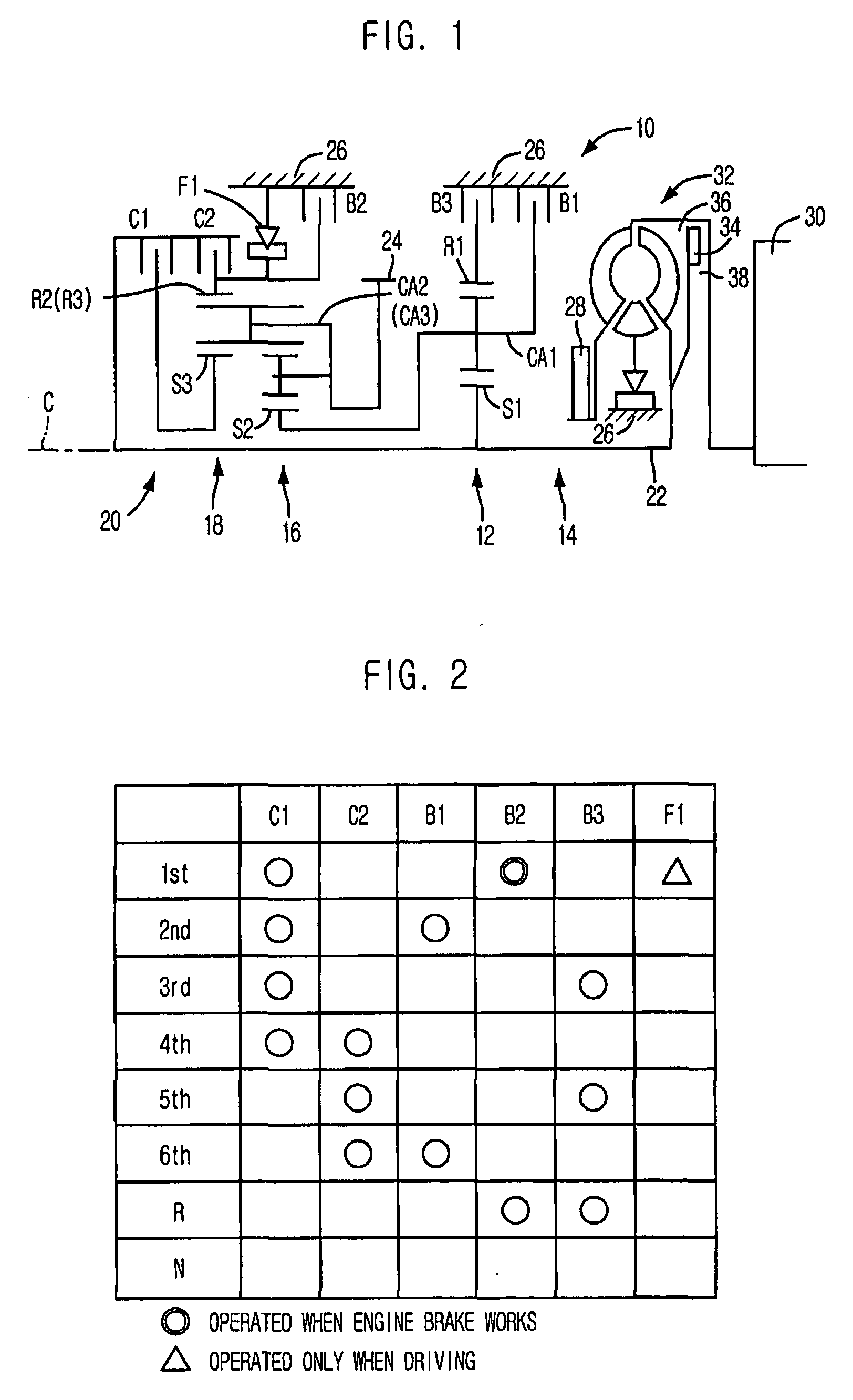

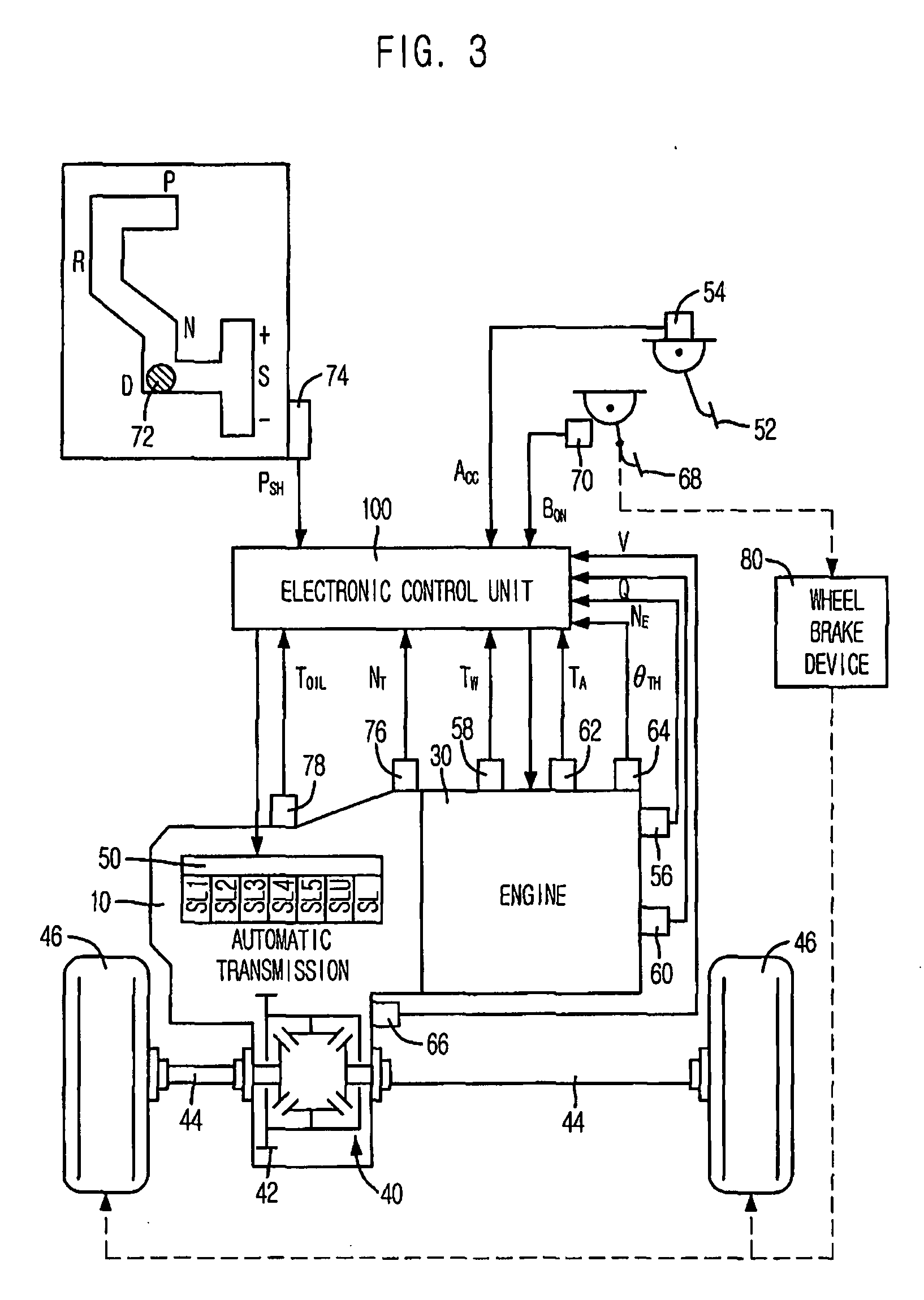

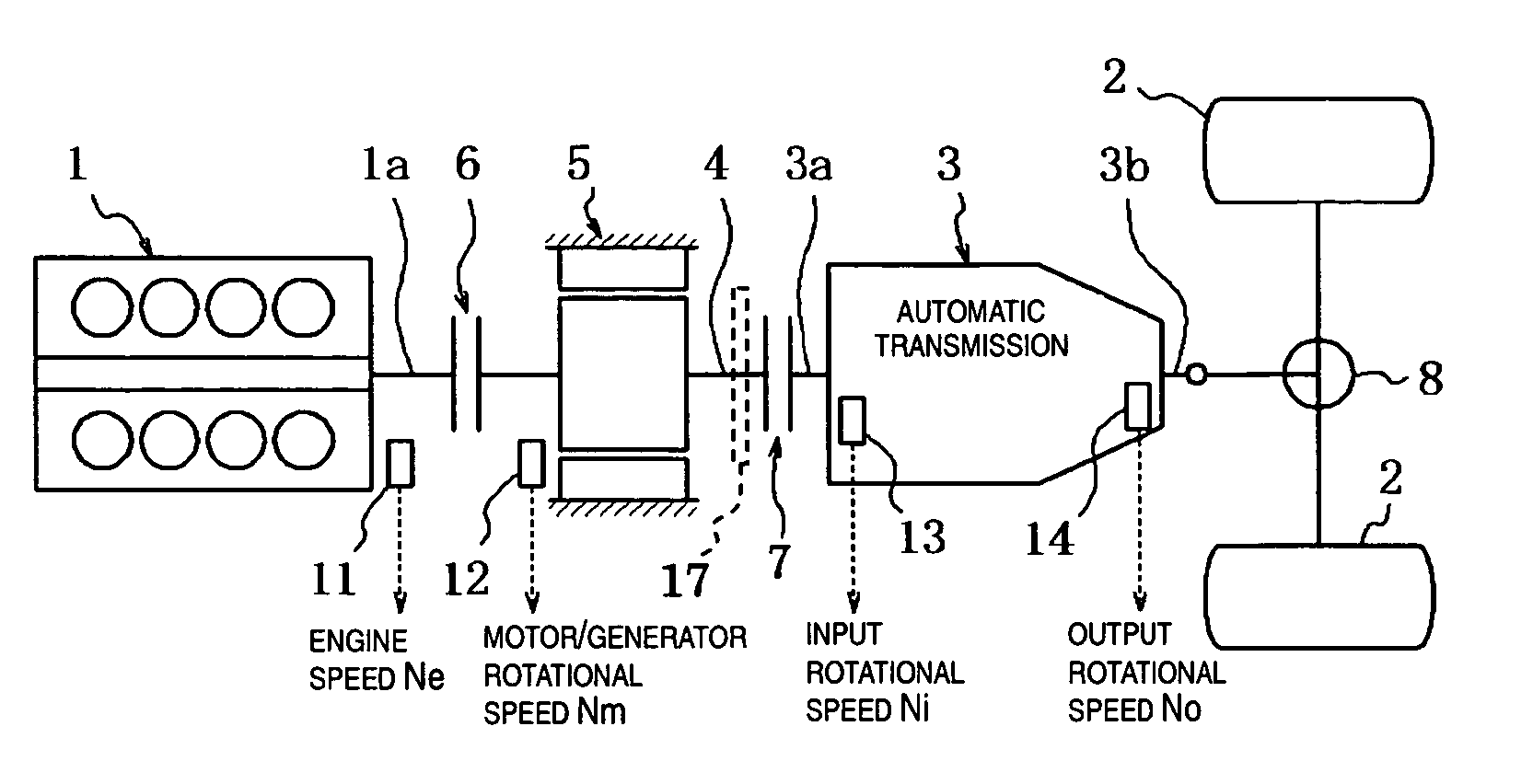

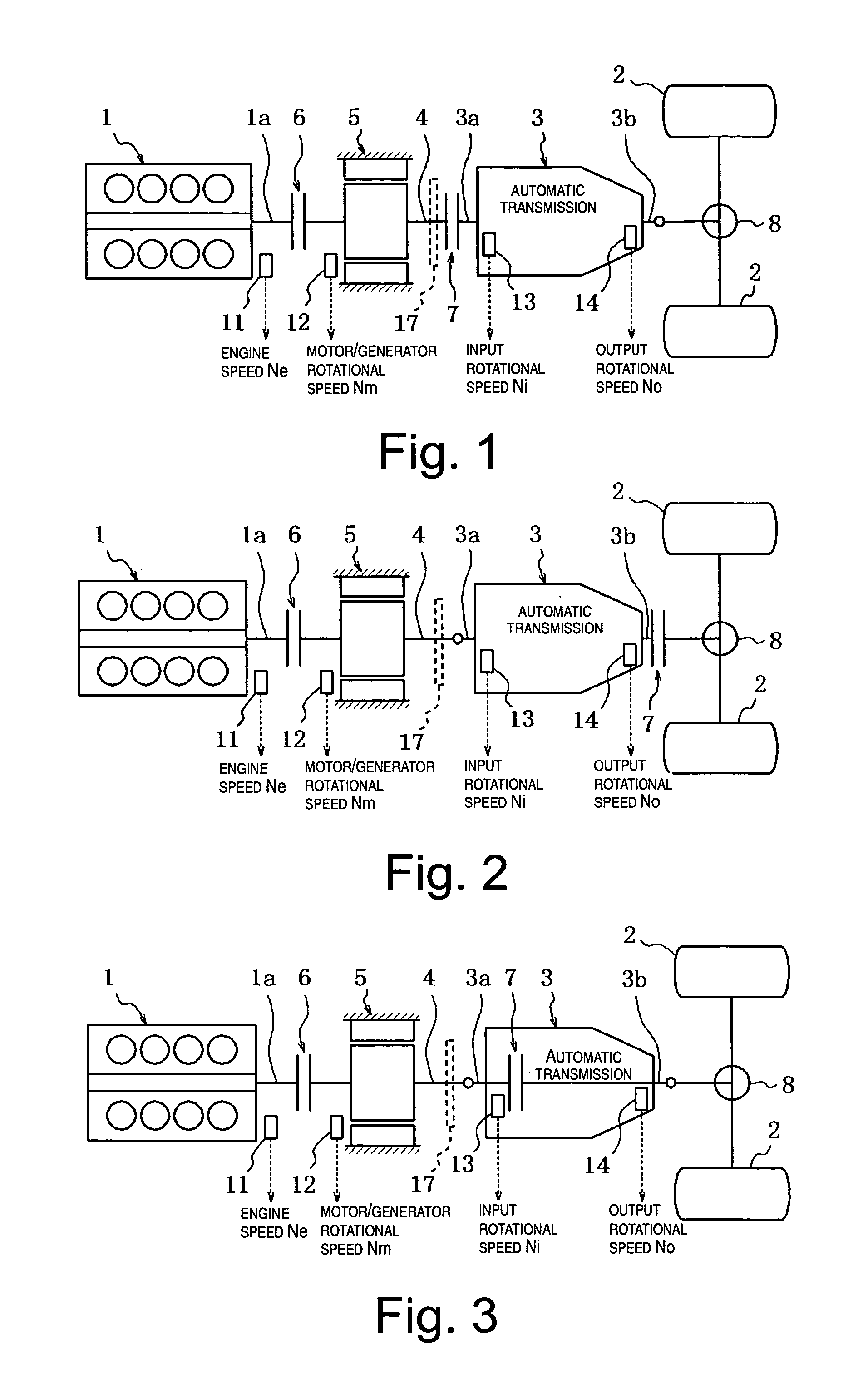

Hybrid vehicle drive control system

ActiveUS20070102211A1Lack of torque transfer capacity can be preventedAvoid it happening againClutchesPower operated startersDrive wheelMode change

A hybrid vehicle drive control system has a first clutch interposed between an engine and a motor / generator, a transmission including several gear position clutches arranged between the motor / generator and a drive wheel, and a controller. The controller selectively starts the engine using torque from the first clutch during a mode drive change from an electric drive mode to a hybrid drive mode. When an engine start command occurs during the drive mode change, the controller selects the engaged gear position clutch that has the maximum torque transfer capacity from the engaged clutches constituting a vehicle running gear occurring during an engine starting process as a second clutch to be controlled. Then the controller executes a slip control of the second clutch when the first clutch is being connected to start the engine during the mode change from the electric drive mode to the hybrid drive mode.

Owner:NISSAN MOTOR CO LTD

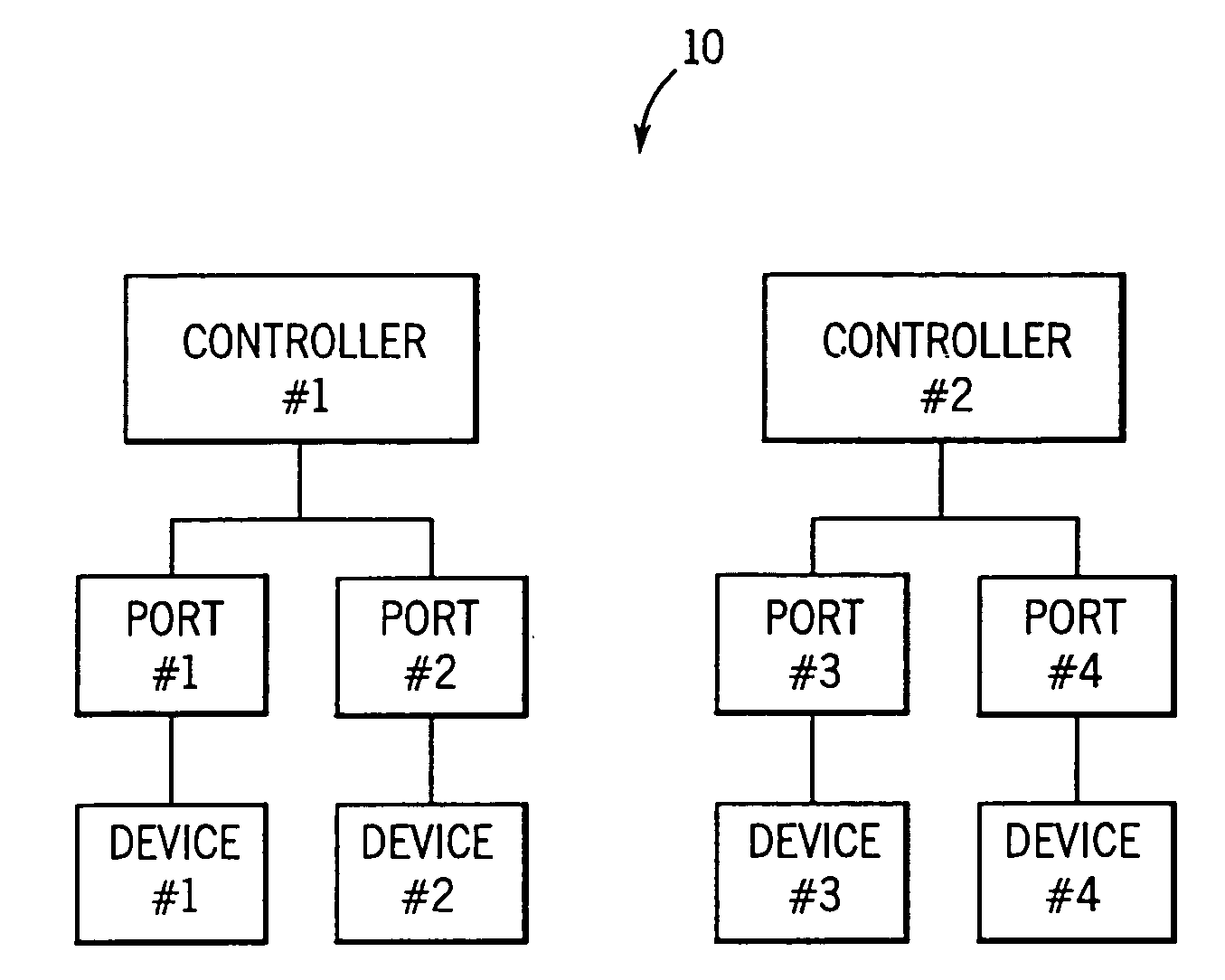

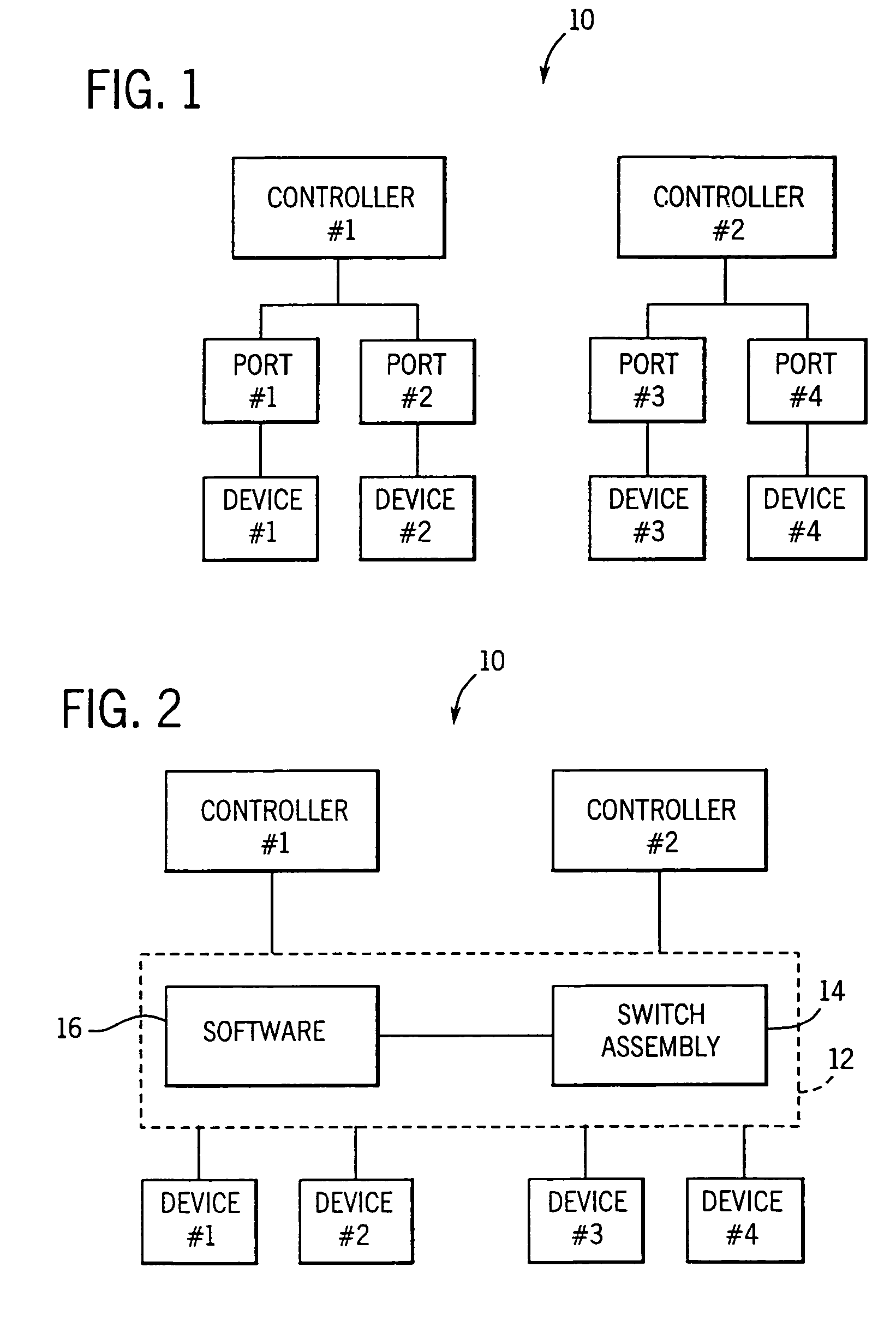

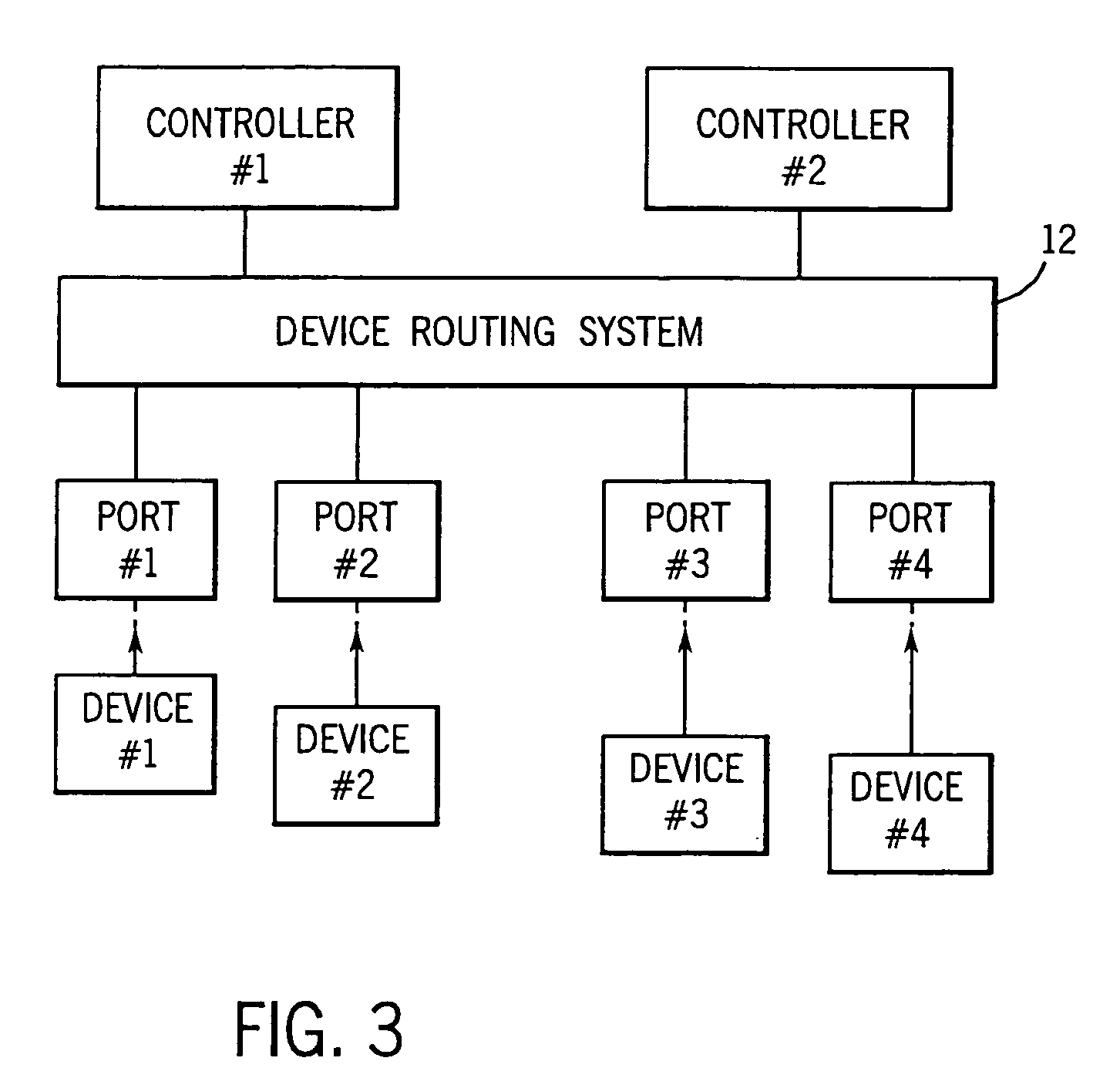

Dynamic allocation of devices to host controllers

The present technique is associated with a device-controller configuration system for a computer system having a plurality of controllers. The technique utilizes an automatic switching assembly so that each device is routed to one of the controllers based on a data transfer specification of the device and data transfer capacities of the controllers. Accordingly, the technique evaluates at least one of a plurality of hypothetical configurations to determine a viable and / or optimal configuration.

Owner:HEWLETT PACKARD DEV CO LP

Hybrid vehicle drive control system

ActiveUS7770678B2Lack of torque transfer capacity can be preventedAvoid it happening againClutchesPower operated startersDrive wheelMode change

A hybrid vehicle drive control system has a first clutch interposed between an engine and a motor / generator, a transmission including several gear position clutches arranged between the motor / generator and a drive wheel, and a controller. The controller selectively starts the engine using torque from the first clutch during a mode drive change from an electric drive mode to a hybrid drive mode. When an engine start command occurs during the drive mode change, the controller selects the engaged gear position clutch that has the maximum torque transfer capacity from the engaged clutches constituting a vehicle running gear occurring during an engine starting process as a second clutch to be controlled. Then the controller executes a slip control of the second clutch when the first clutch is being connected to start the engine during the mode change from the electric drive mode to the hybrid drive mode.

Owner:NISSAN MOTOR CO LTD

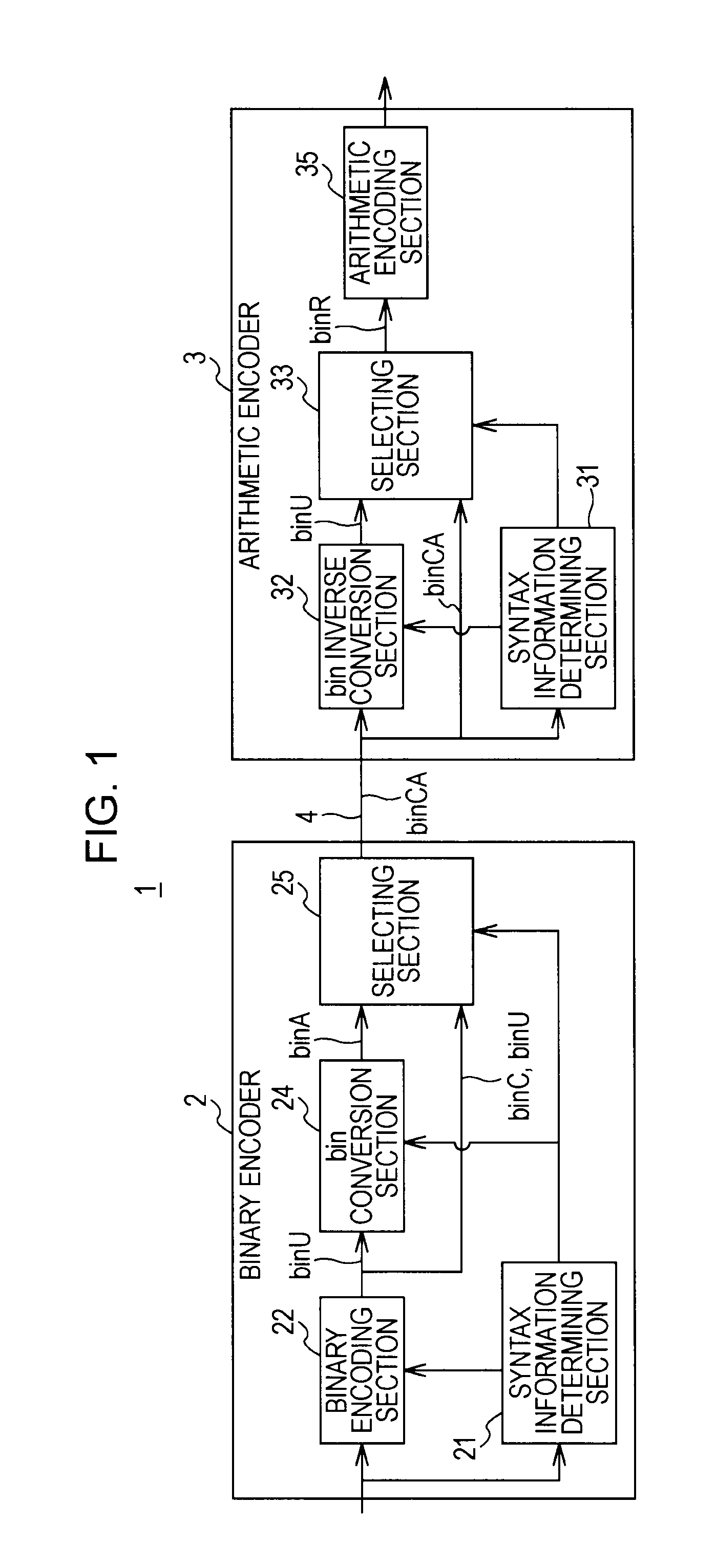

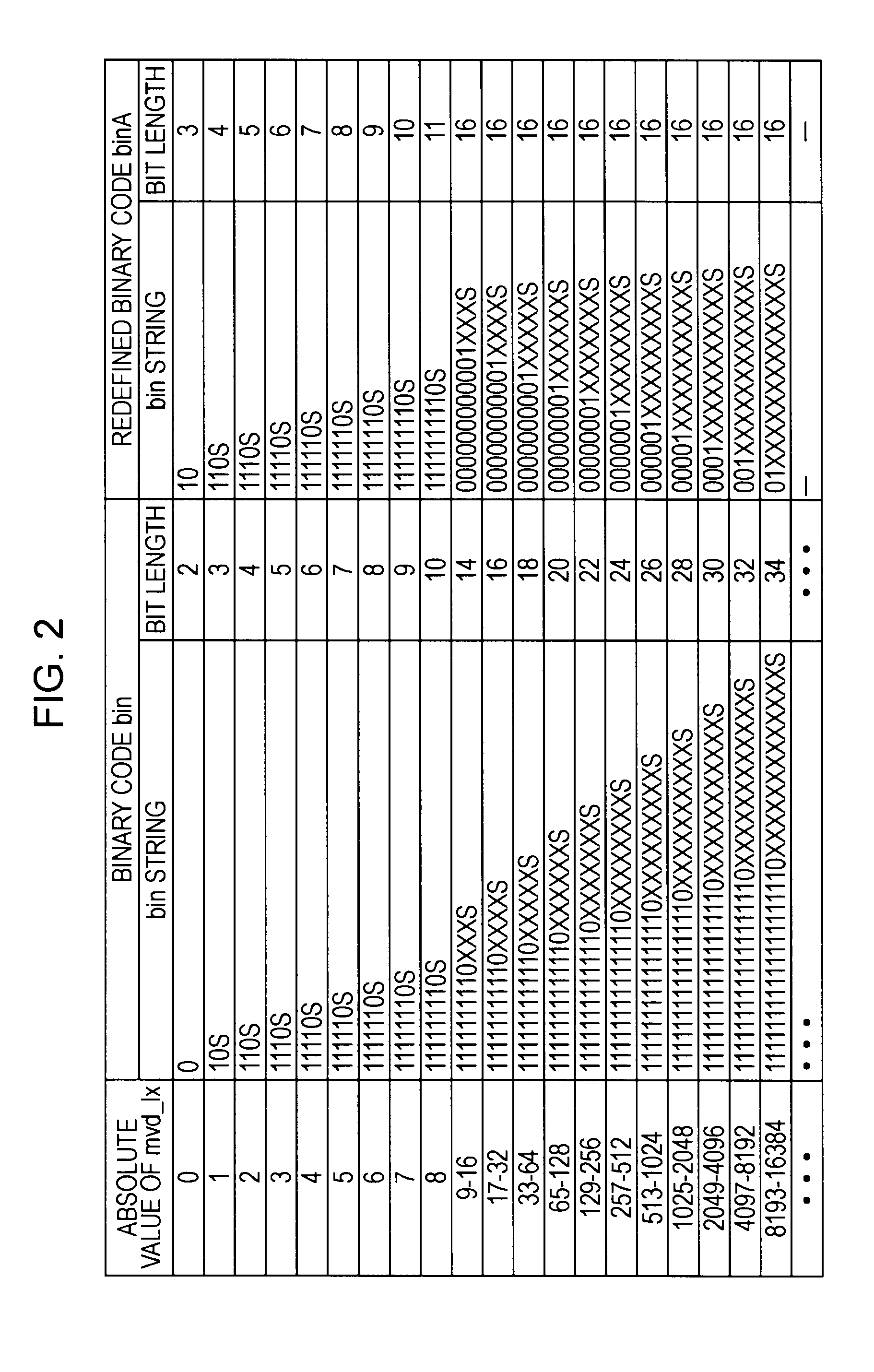

Encoding apparatus and encoding method, and decoding apparatus and decoding method

InactiveUS20100303147A1Improve processing speedAvoid delayColor television with pulse code modulationColor television with bandwidth reductionDecoding methodsComputer architecture

An encoding apparatus includes a receiving section receiving syntax information defined by an encoding standard, a first encoding section encoding the received syntax information to generate encoded information, a transferring section transferring transmission encoded information based on the encoded information generated by the first encoding section, a second encoding section encoding reproduced encoded information reproduced from the transferred transmission encoded information, a conversion section converting the encoded information encoded by the first encoding section into redefined encoded information, to generate the transmission encoded information in accordance with the transfer capacity of the transferring section and the processing speed of encoding in each of the first encoding section and the second encoding section so as not to cause delay in encoding in the first encoding section or the second encoding section, and an inverse conversion section inversely converting the converted redefined encoded information to generate the reproduced encoded information.

Owner:SONY CORP

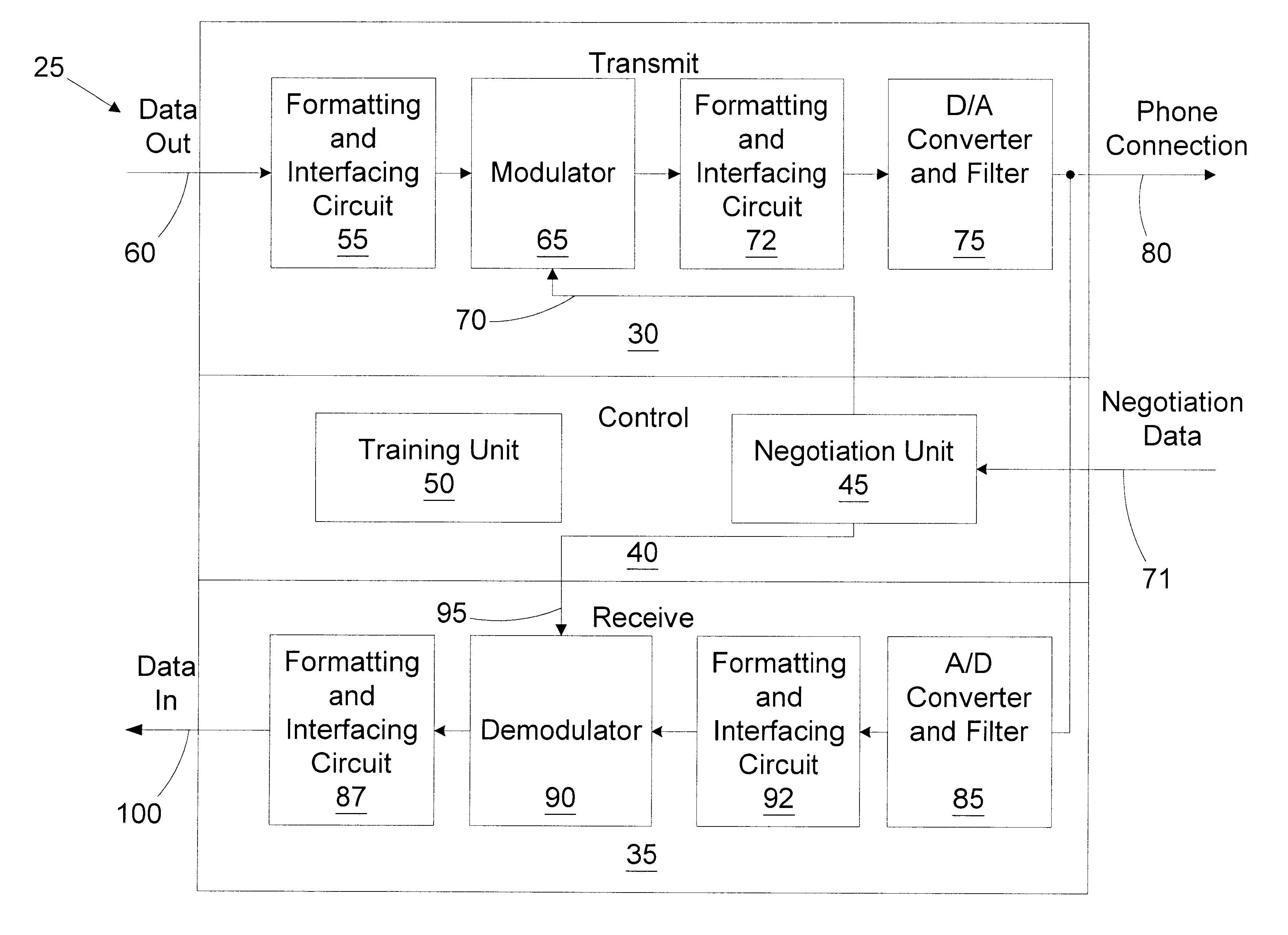

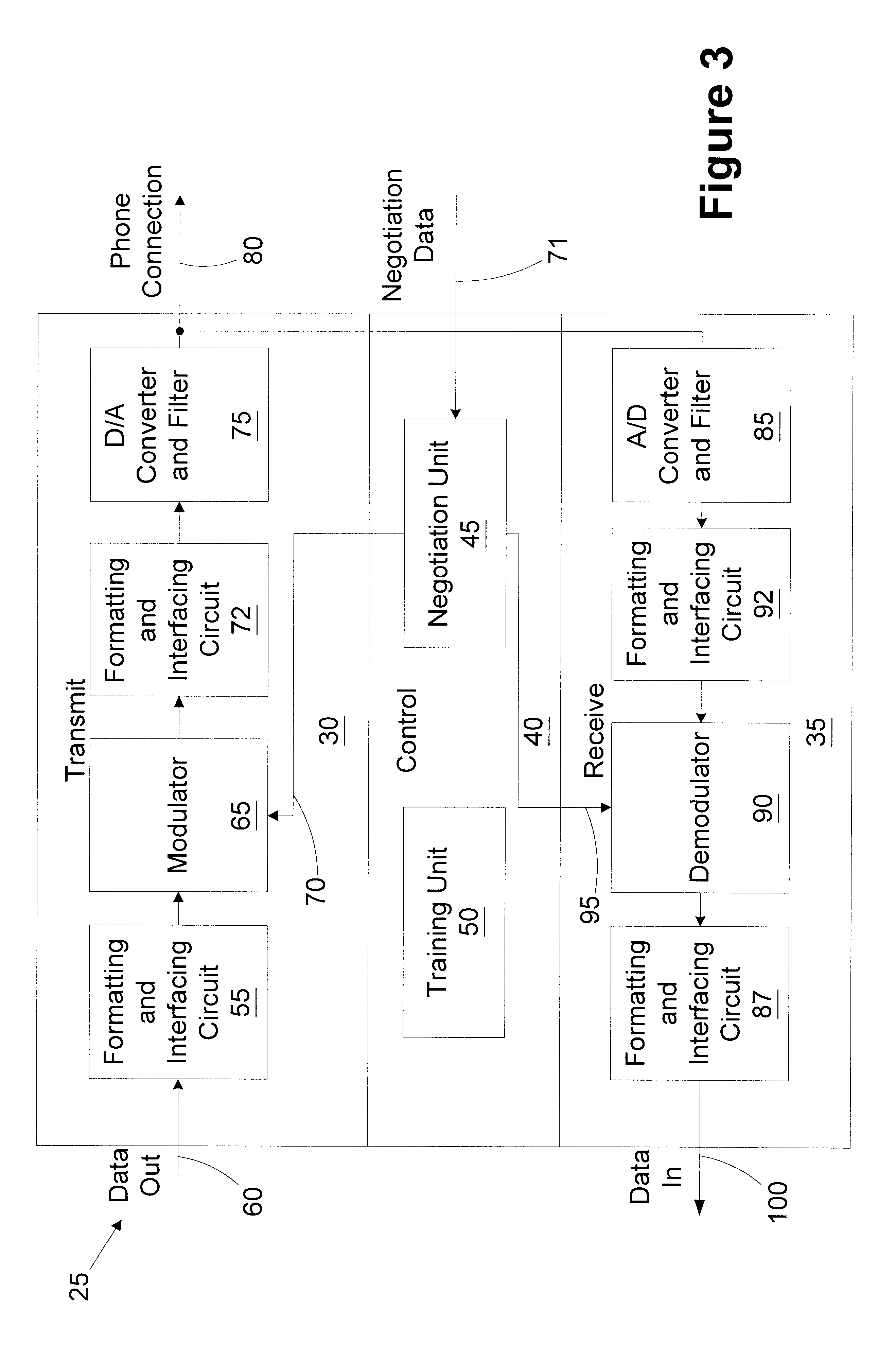

Method and apparatus for scaling modem transfer capacity in a multi-channel communications system

InactiveUS6337877B1Transmission path divisionTelephonic communicationTransfer capacityComputer science

A communications system includes a plurality of lines, a modulator / demodulator, a processing unit, and a negotiation unit. The modulator / demodulator is coupled to the lines and adapted to communicate data over the lines using a plurality of tone sets. Each tone set is associated with a particular line. The processing unit has an amount of available processing resources for supporting the modulator / demodulator and is adapted to generate resource availability data based on the amount of available processing resources. The negotiation unit is adapted to receive the resource availability data from the processing unit and determine a subset of available tones within each tone set based on the resource availability data. The modulator / demodulator is adapted to communicate data on each line using the subset of available tones. A method for allocating the resources of a communications system includes determining an amount of available processing resources for a processing unit. The processing unit is adapted to support a plurality of connections over a plurality of lines. Each connection has an associated tone set for communicating data. A first connection is established over a first line. A first portion of the available processing resources is allocated to the first connection. A first tone range is determined based on the first portion. The first tone range is a subset of the tone set associated with the first line.

Owner:MICROSEMI SEMICON U S

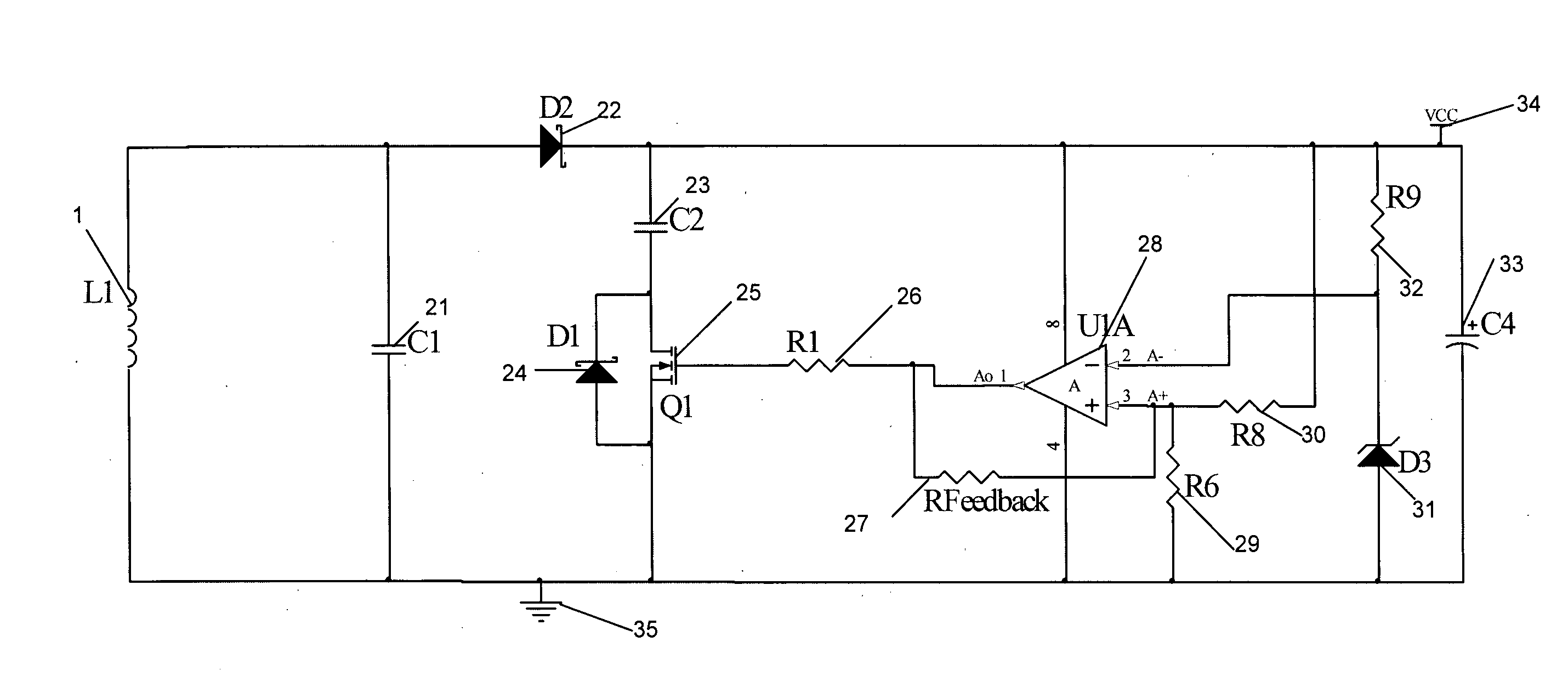

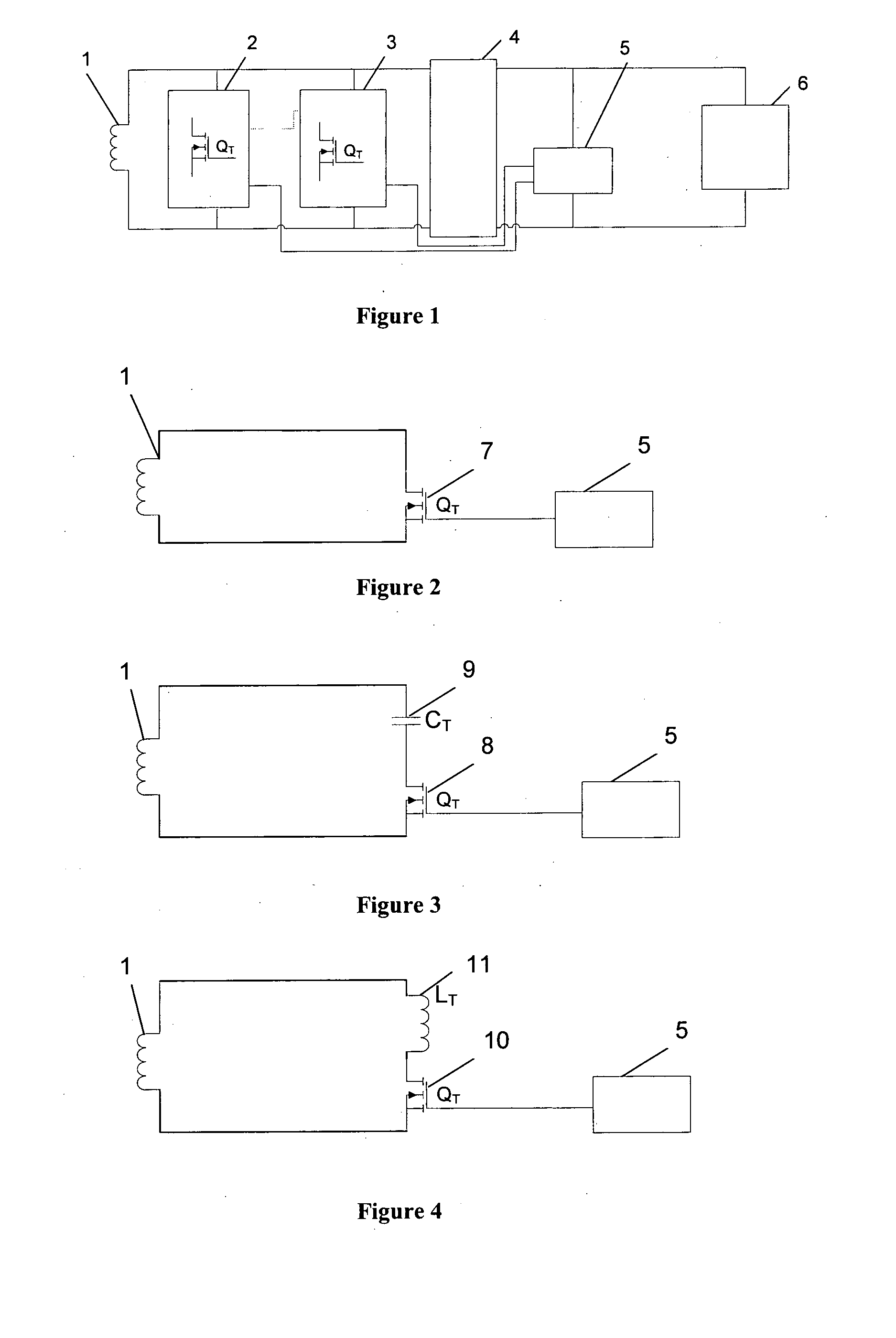

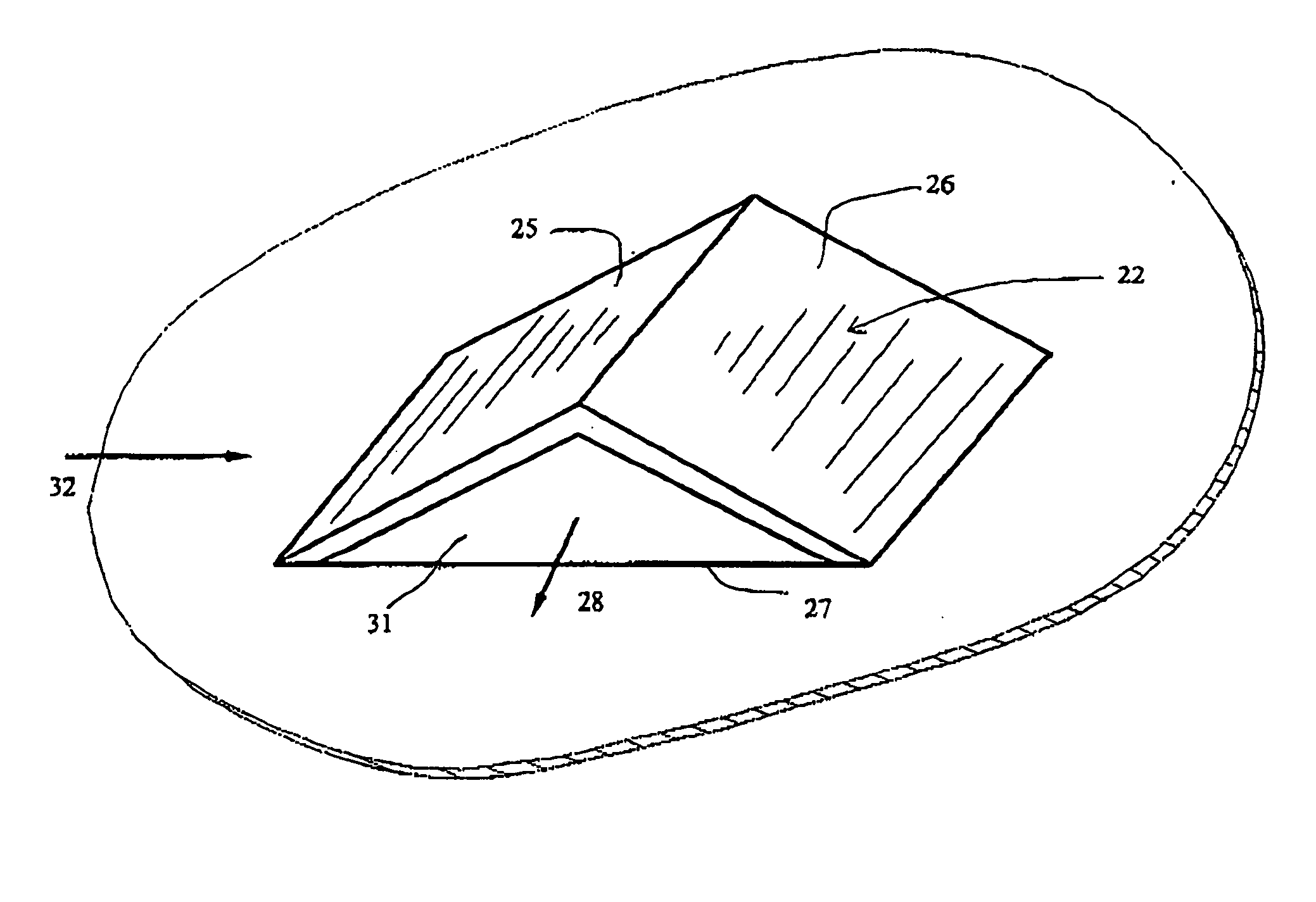

Contactless power receiver and method of operation

A contactless power receiver is provided with a dynamically tuned pick up coil. The power transfer capacity of this power receiver is dynamically tuned using semiconductor devices that are operated in linear mode over part of their operation. The semiconductor devices are driven by a controller that is configured to implement a range of control strategies depending on system requirements. The semiconductor device may be used by itself or in conjunction with reactive elements to dynamically tune the pick up coil. In some implementations the contactless power receiver maybe configured to work with a consumer electronic or a wireless sensor device. The contactless power receiver can be integrated with the energy storage component of the device to provide a retrofit solution for existing products. The device can then be placed in vicinity of a planar magnetic field generated by a charging pad.

Owner:APPLE INC

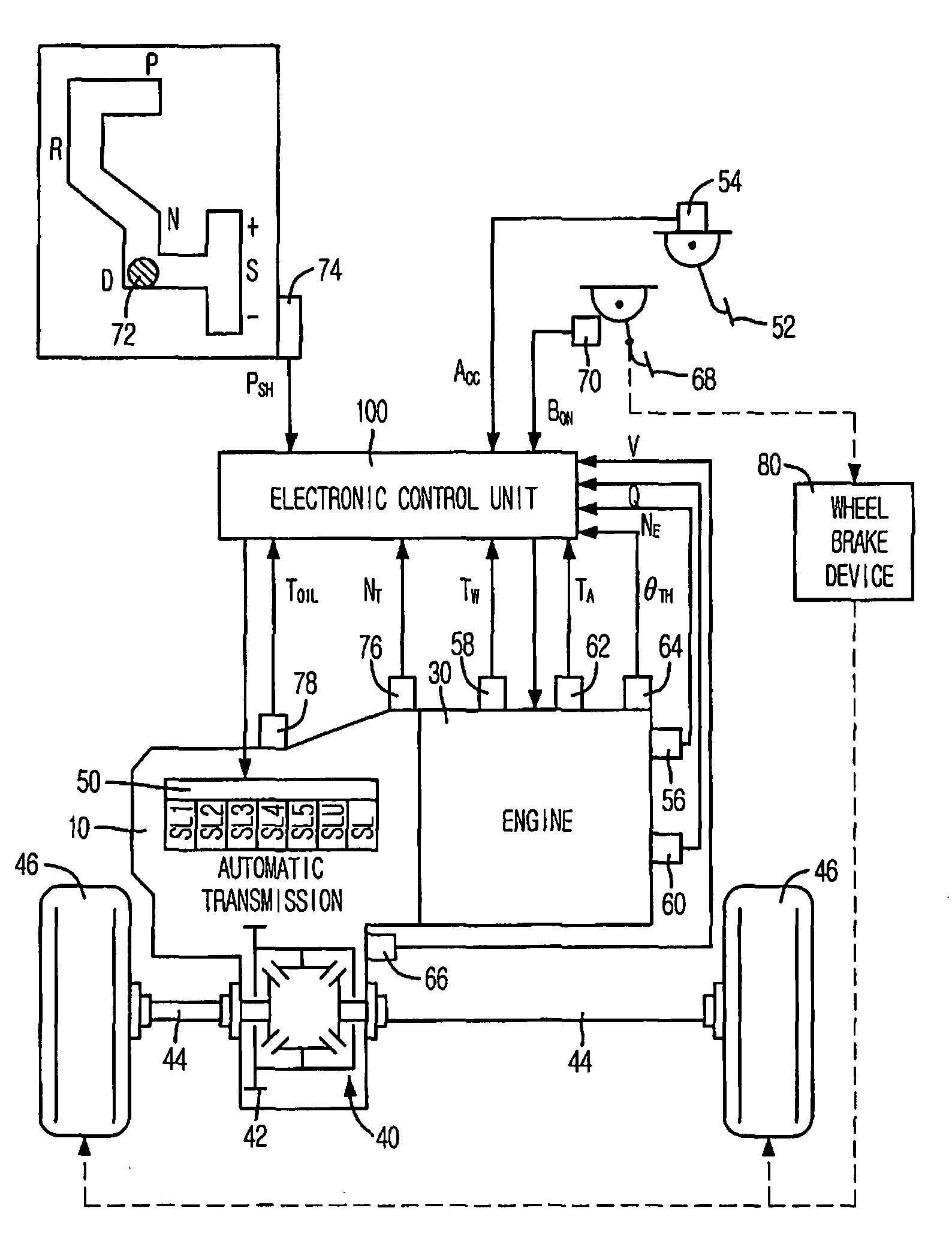

Control apparatus for hybrid vehicle

InactiveUS20100286858A1Suppress noiseSuppresses occurrenceAnalogue computers for vehiclesClutchesDrive wheelAutomatic transmission

A hybrid vehicle control apparatus is provided with an engine, an electric motor, a holding element, an automatic transmission, a range position detecting device and a controller. The holding element is arranged between the engine and the electric motor to selectively connect and disconnect the engine and the electric motor to and from each other. The automatic transmission is arranged between the electric motor and a drive wheel. The range position detecting device detects a range position of the automatic transmission selected by a driver. The controller executes a control operation serving to stop the engine while also executing a slip control serving to lower a torque transfer capacity of the holding element upon a determination that a request to stop the engine has occurred while the engine is operating, the holding element is engaged, and the automatic transmission is detected in a non-driving range.

Owner:NISSAN MOTOR CO LTD

Hybrid vehicle drive control system

A hybrid vehicle drive control system is configured to perform engine startup when switching from an electric drive mode to a hybrid drive mode, without creating a sense of output torque loss. In particular, a controller selectively controls a first clutch disposed between the engine and the motor / generator and a second clutch disposed between the motor / generator and a drive wheel to switch between an electric drive mode in which the first clutch is released and the second clutch is engaged, and a hybrid drive mode in which both the first and second clutches are engaged. The controller sets the second torque transfer capacity to a value that is more than zero and less than the target motor / generator torque of the motor / generator when switching from the electric drive mode to the hybrid drive mode and when starting the engine.

Owner:NISSAN MOTOR CO LTD

Hybrid vehicle control system

InactiveUS7472769B2Preventing inadvertent clutch slippageFast Responsiveness GuaranteedHybrid vehiclesSpeed controllerElectricityDrive wheel

Owner:NISSAN MOTOR CO LTD

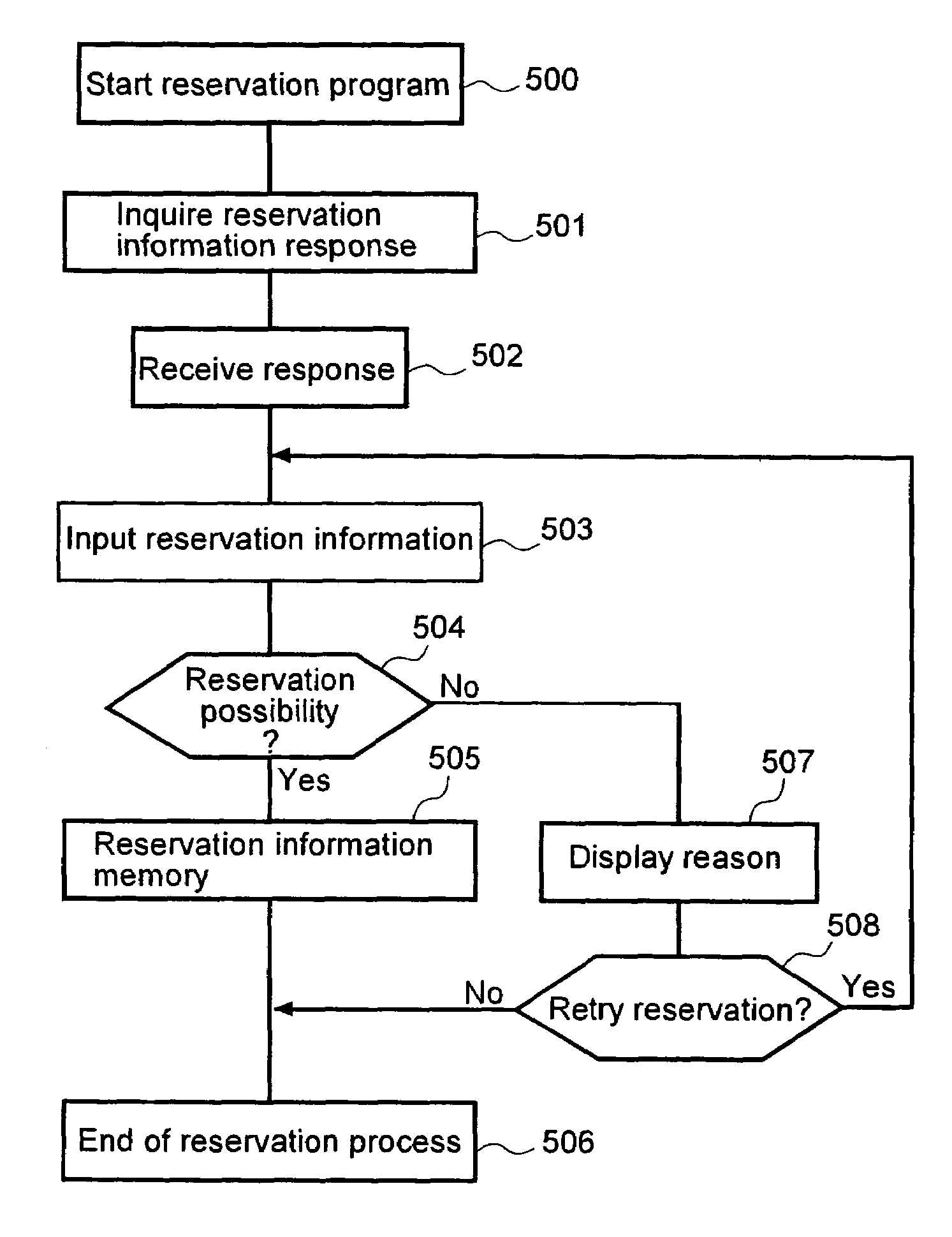

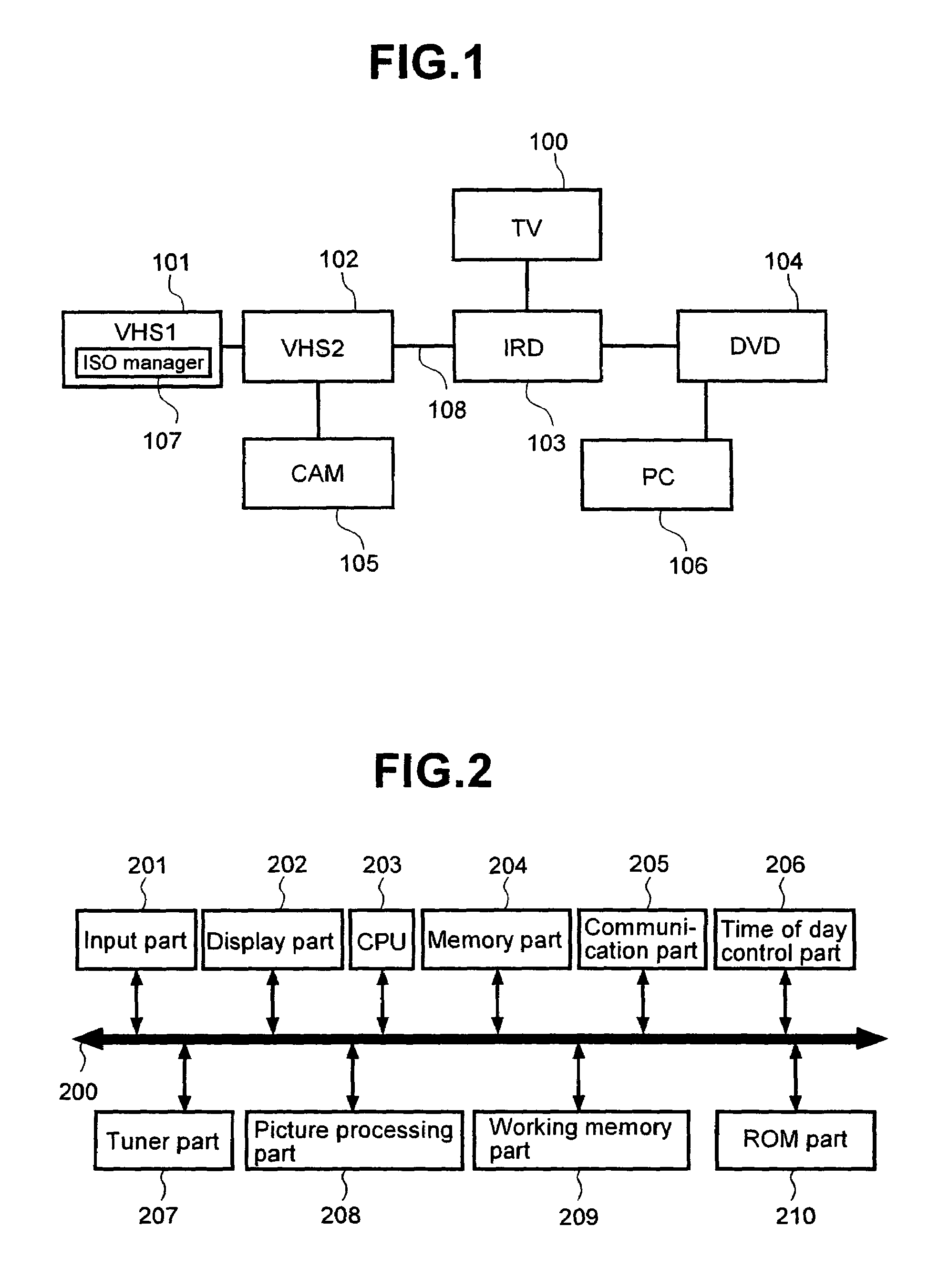

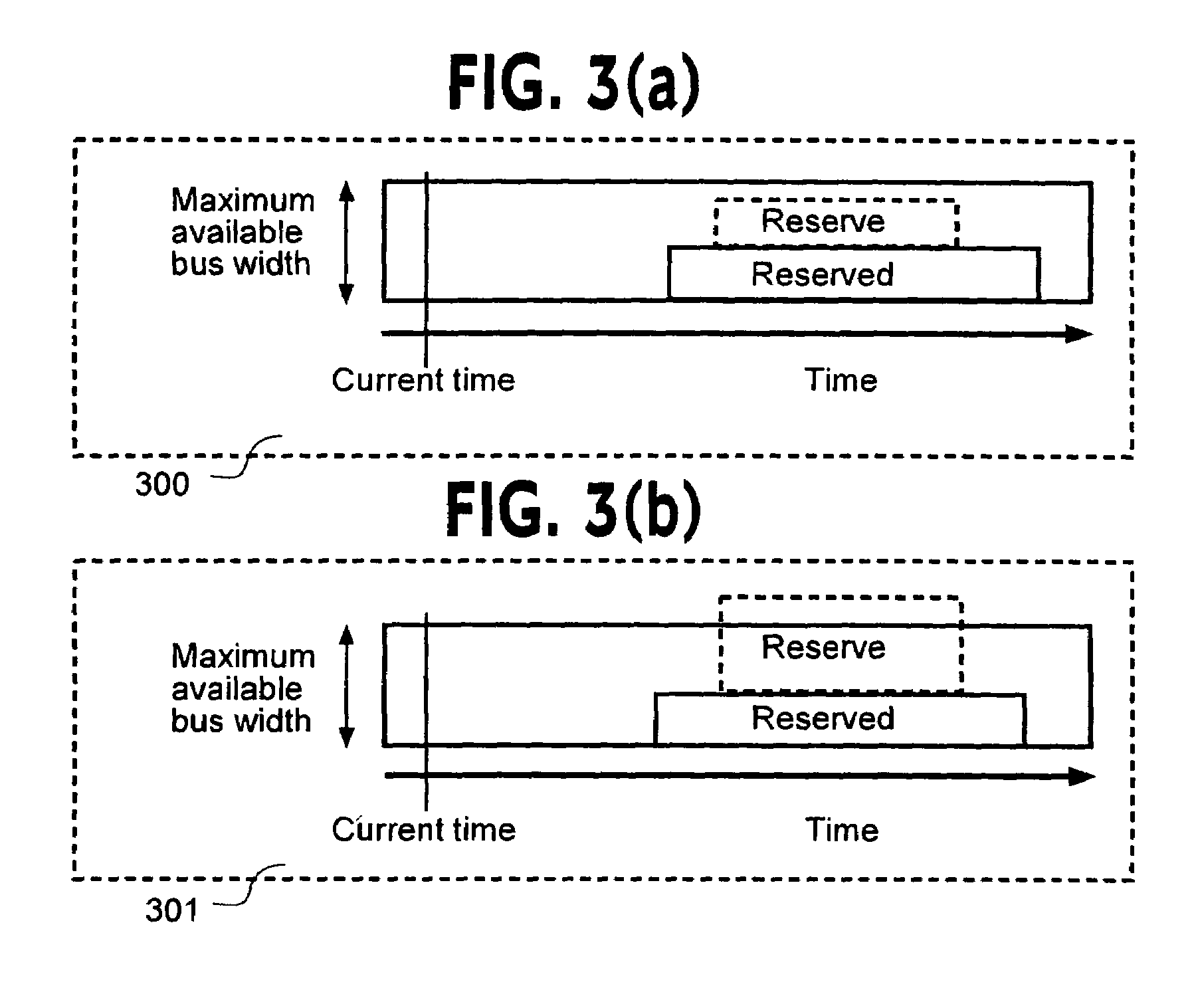

Electronic device, method for using electronic device, and electronic device system for reserving bus usage time on a bus to conduct communications between electronic devices

InactiveUS7003606B2Avoid problemsTelevision system detailsAnalogue secracy/subscription systemsCamEmbedded system

An IRD 103 supplies broadcasting data on a bus in a desired time period. When the IRD 103 performs a reservation of the bus usage, the IRD 103 requests current bus usage information and information of the bus reservation from all devices connected by the bus, such as a DVD 104, a D-VTR 101, a D-VTR 102, a CAM 105, a TV 100, and a isochronous manager 107 of the D-VTR 101. The isochronous manager 107 and each device answer by sending the bus usage information and reservation information to the IRD 103. The IRD 103 judges a possibility of the reservation from the answer information. If the reservation is possible, it performs the reservation operation. If the reservation is impossible, then the reason is displayed on a TV 100. Therefore, it is possible to prevent a usage of a device that excesses the bus transferring capacity.

Owner:HITACHI LTD

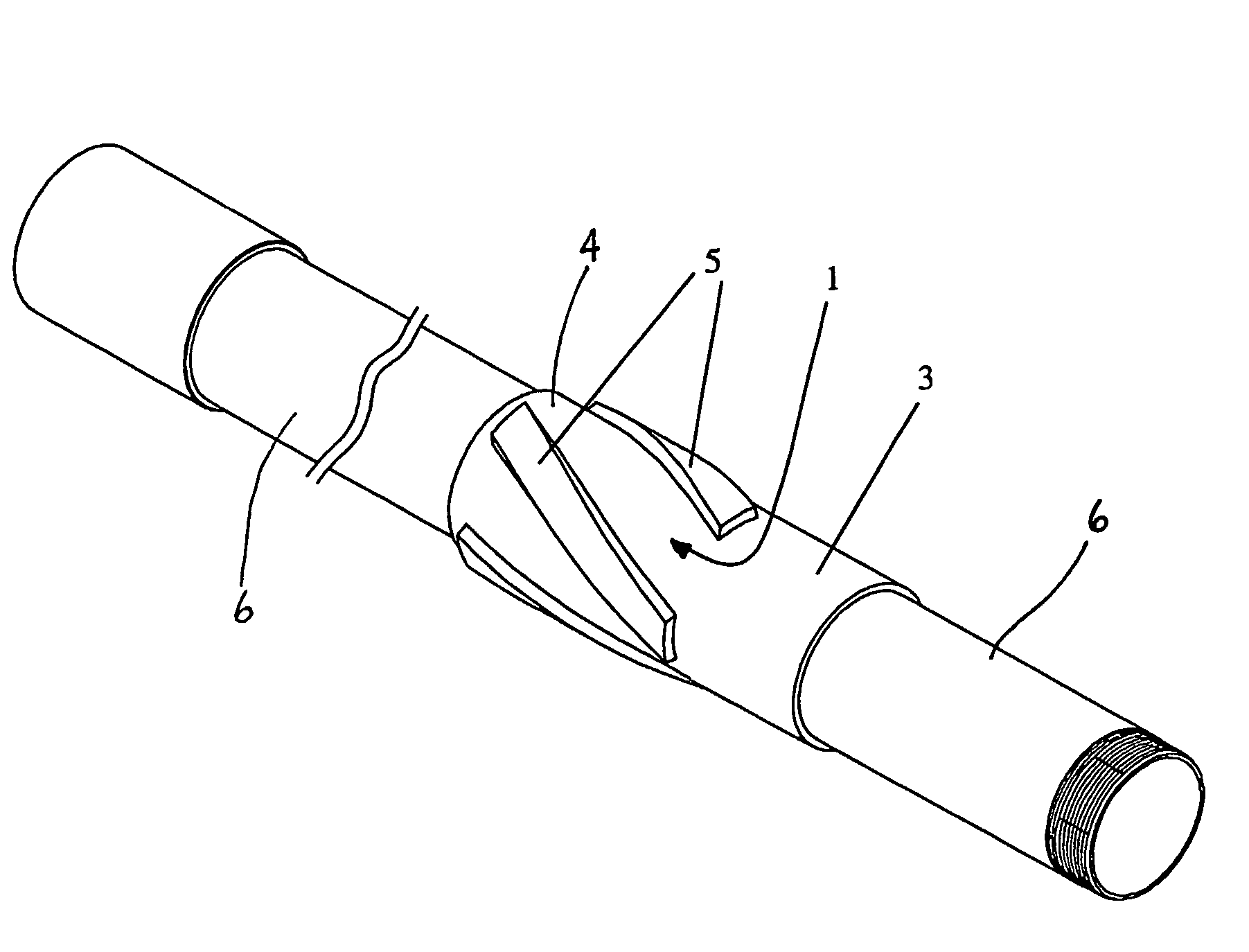

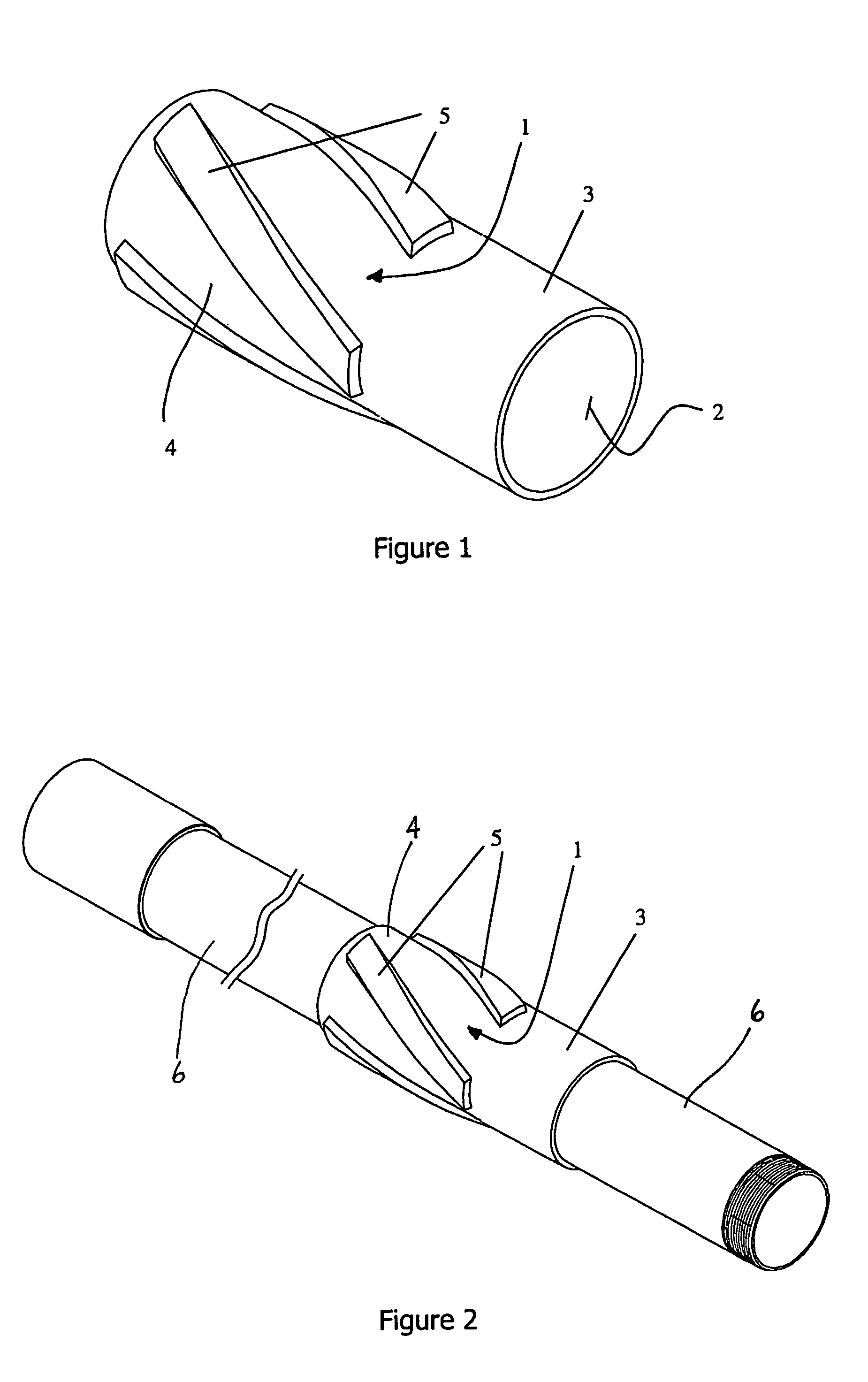

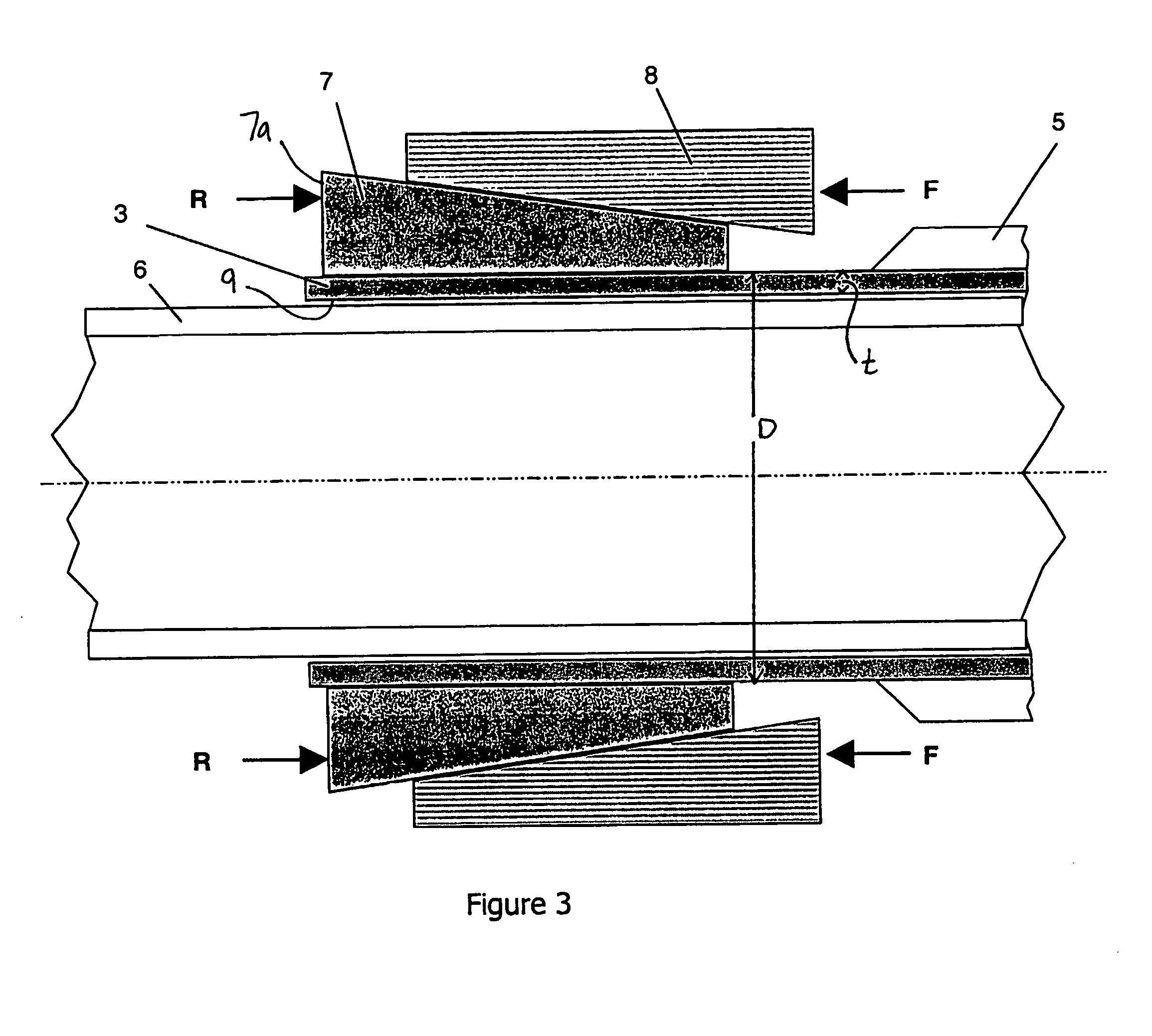

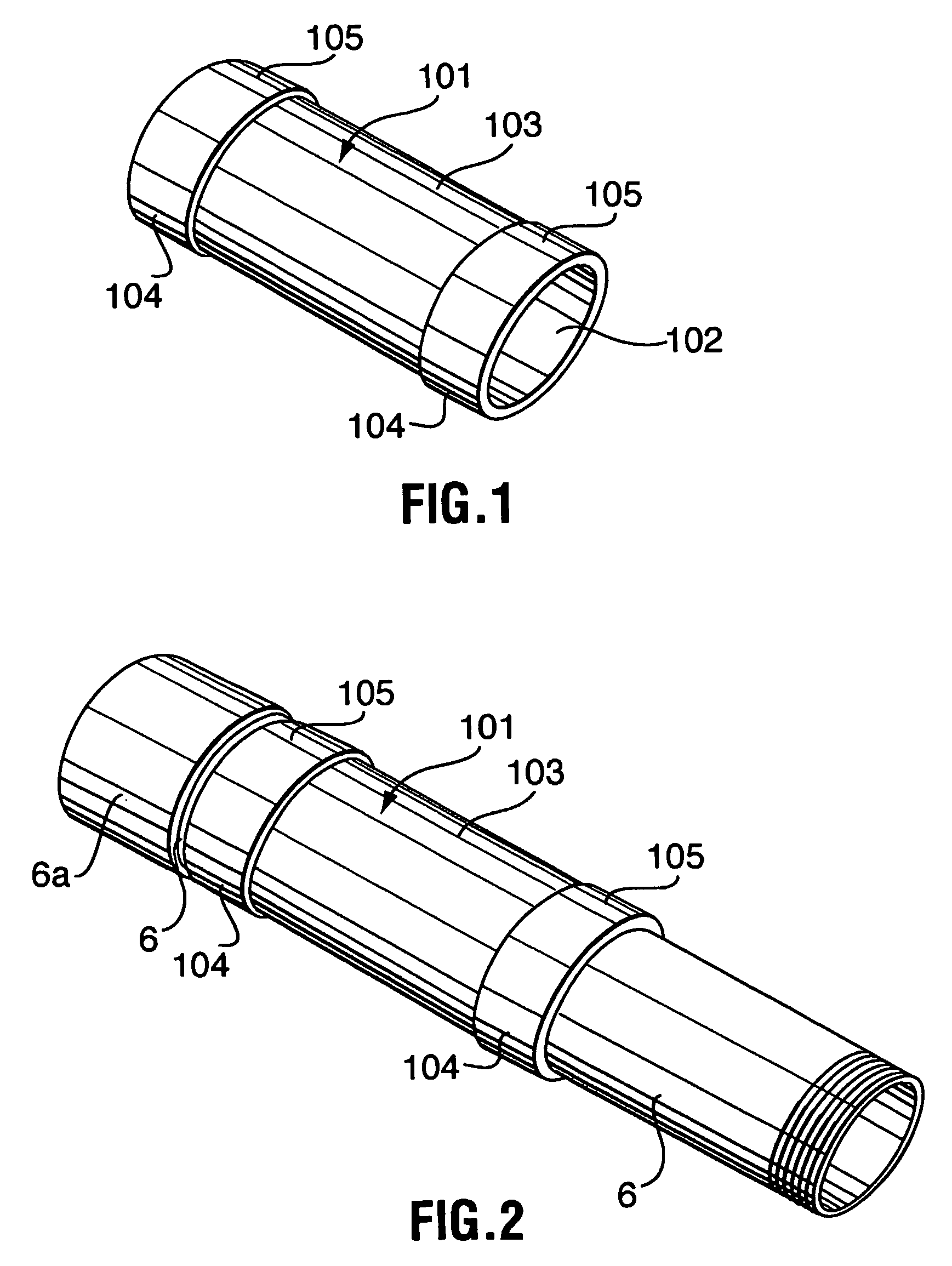

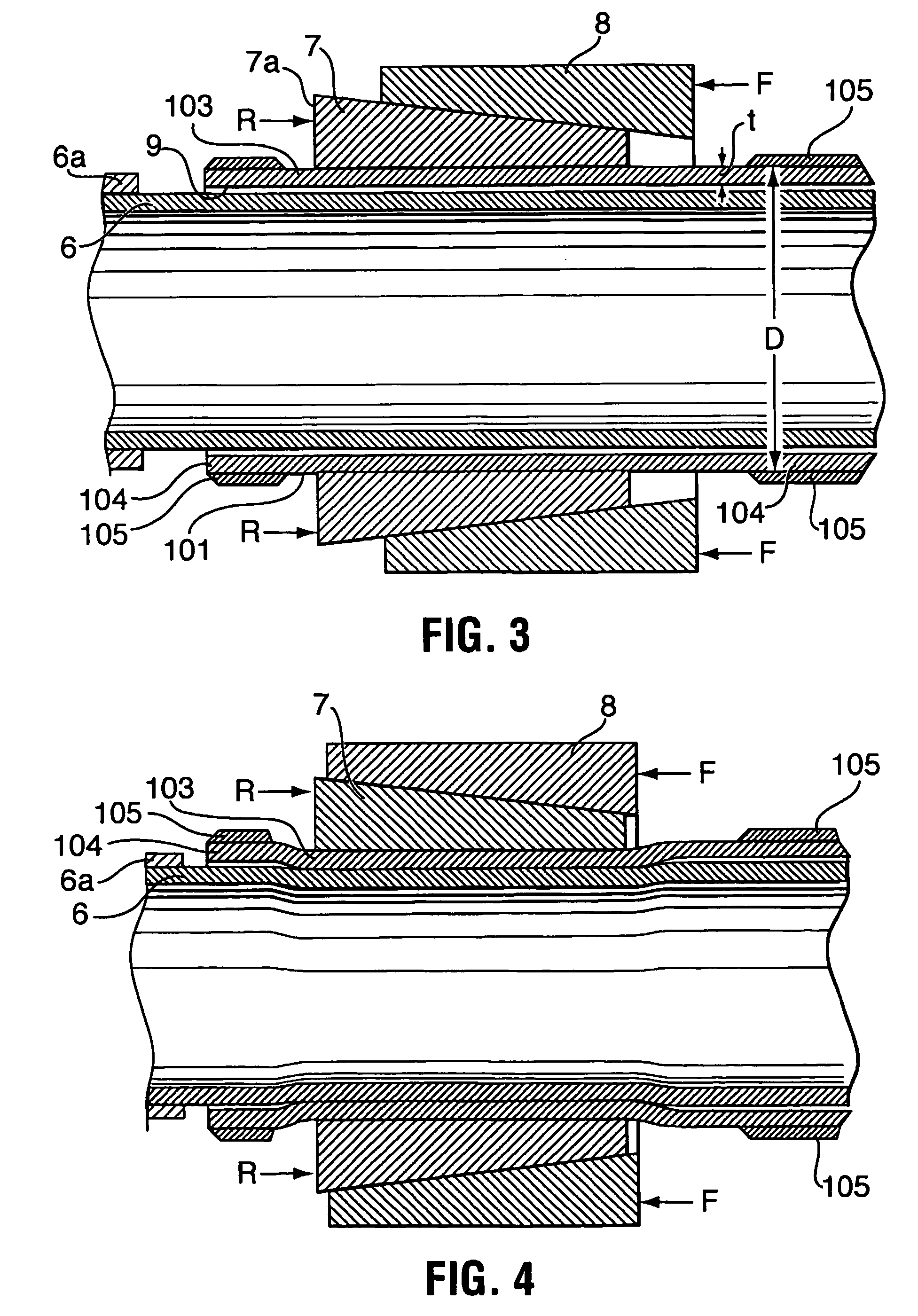

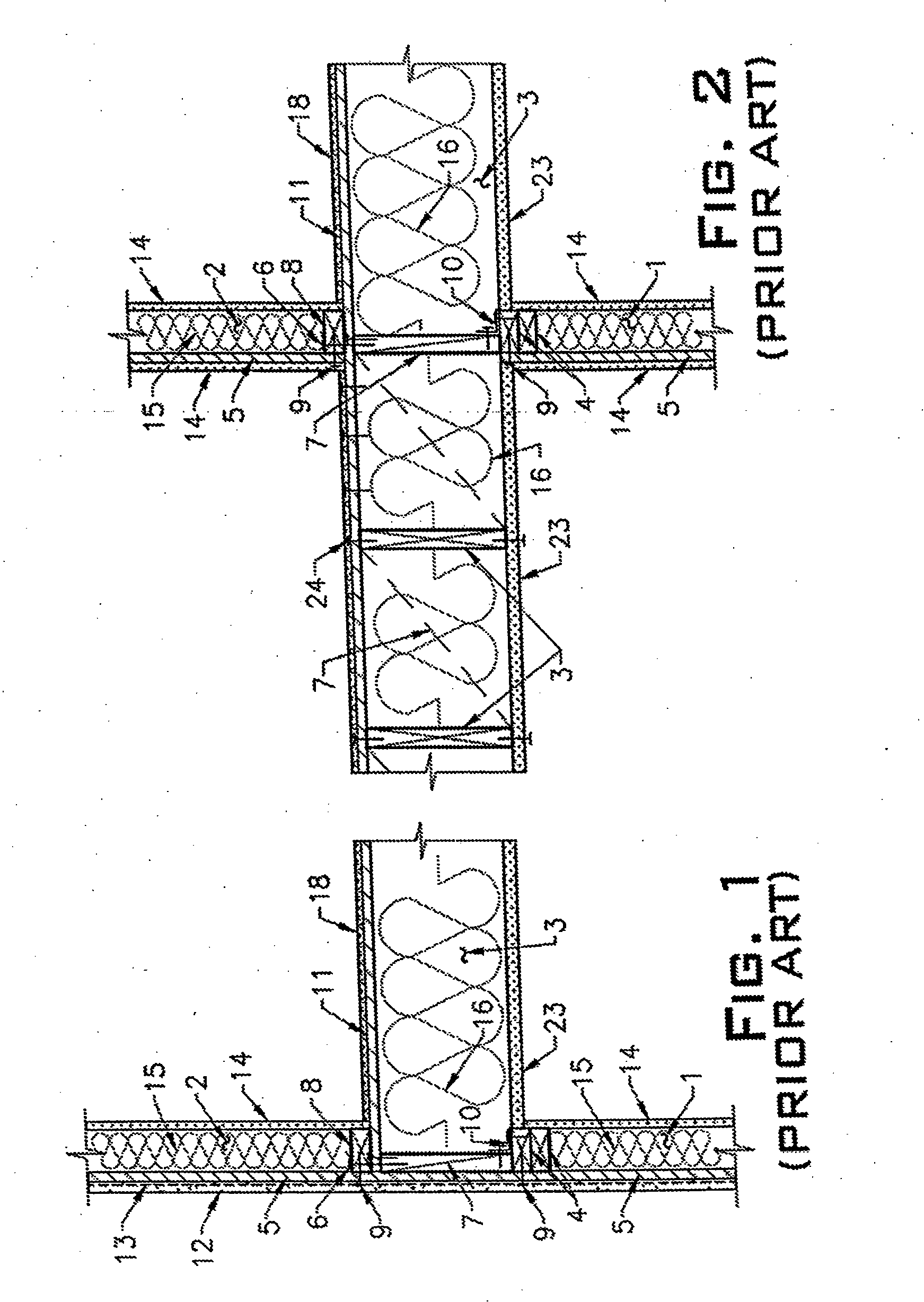

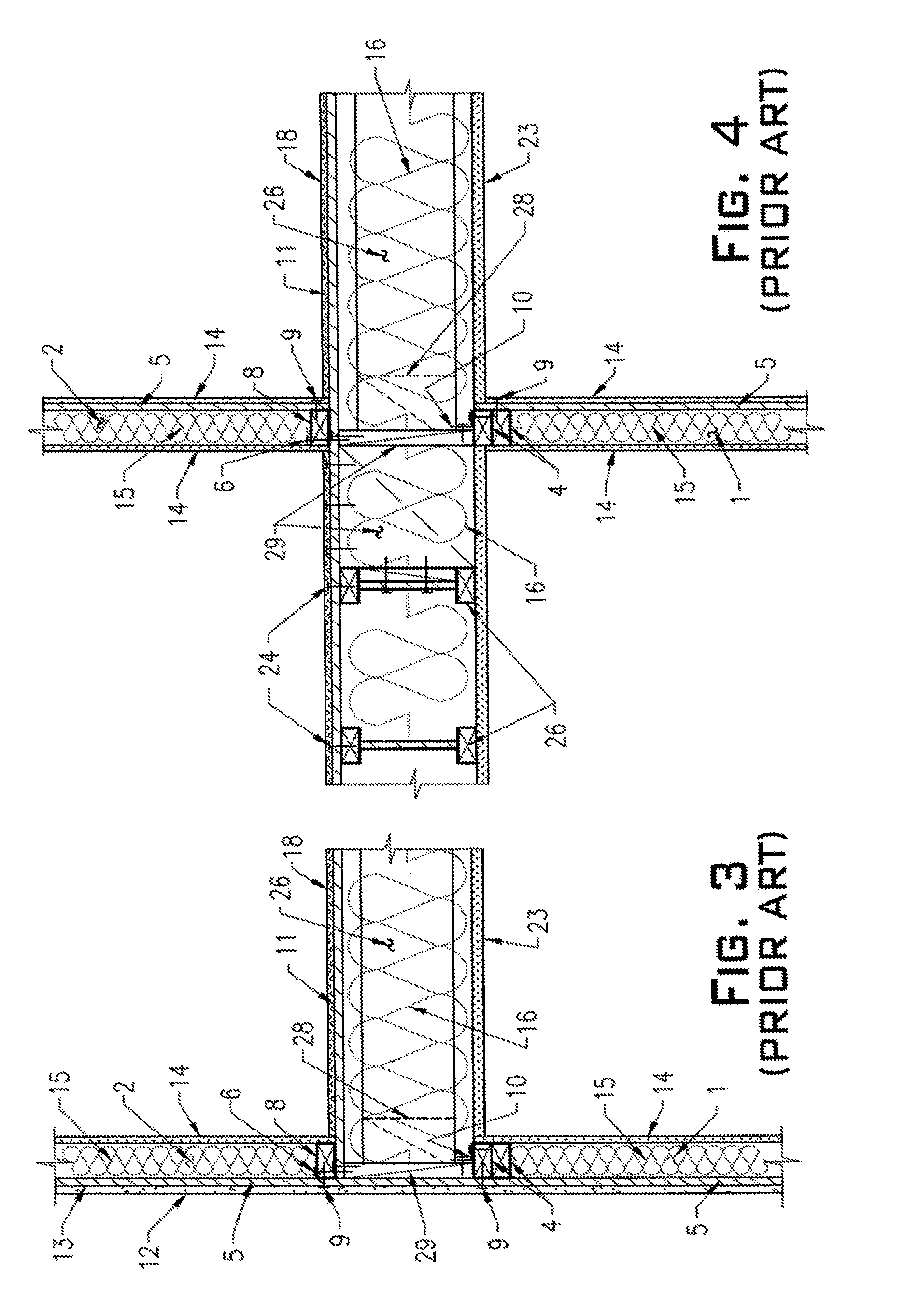

Pipe centralizer and method of attachment

InactiveUS7082997B2Large movementReduce the overall diameterDrilling rodsFluid removalWell drillingRelative motion

A crimpable centralizer has been invented for installation on pipe, such as would be useful in well bore drilling and casing operations. The present invention provides a centralizer having a cylindrical body which when coaxially placed over a pipe and substantially radially inwardly displaced at a plurality of points (i.e. crimped) about the circumference of a section of the cylindrical body, attaches to the pipe to create a connection having structurally significant axial and torque load transfer capacity. When crimped according to the methods of the present invention, the load transfer capacity of the connection between the centralizer and the pipe can be arranged to substantially prevent significant relative movement of the centralizer on the pipe under loads that may be encountered when using one or more of the pipes as components of a tubular string used for drilling or completing well bores.

Owner:NABORS DRILLING TECH USA INC

Method and Apparatus for Achieving Higher Cooling Rates of a Gas During Bypass Cooling in a Batch Annealing Furnace of Cold Rolling Mills

ActiveUS20120024516A1Improve cooling effectWork treatment devicesIndirect heat exchangersNanofluidAqueous medium

A method and apparatus to increase the cooling rate of gas used in a batch annealing furnace of cold rolling mills under bypass cooling. The invention makes use of the higher heat transfer capacities of nanocoolants developed by a high-shear mixing of nanoparticles and stabilizers in a basic aqueous medium for cooling heated hydrogen flowing through a heat exchanger during bypass cooling of the batch annealing furnace. The nanofluid is prepared in a nanofluid preparation unit.

Owner:TATA STEEL

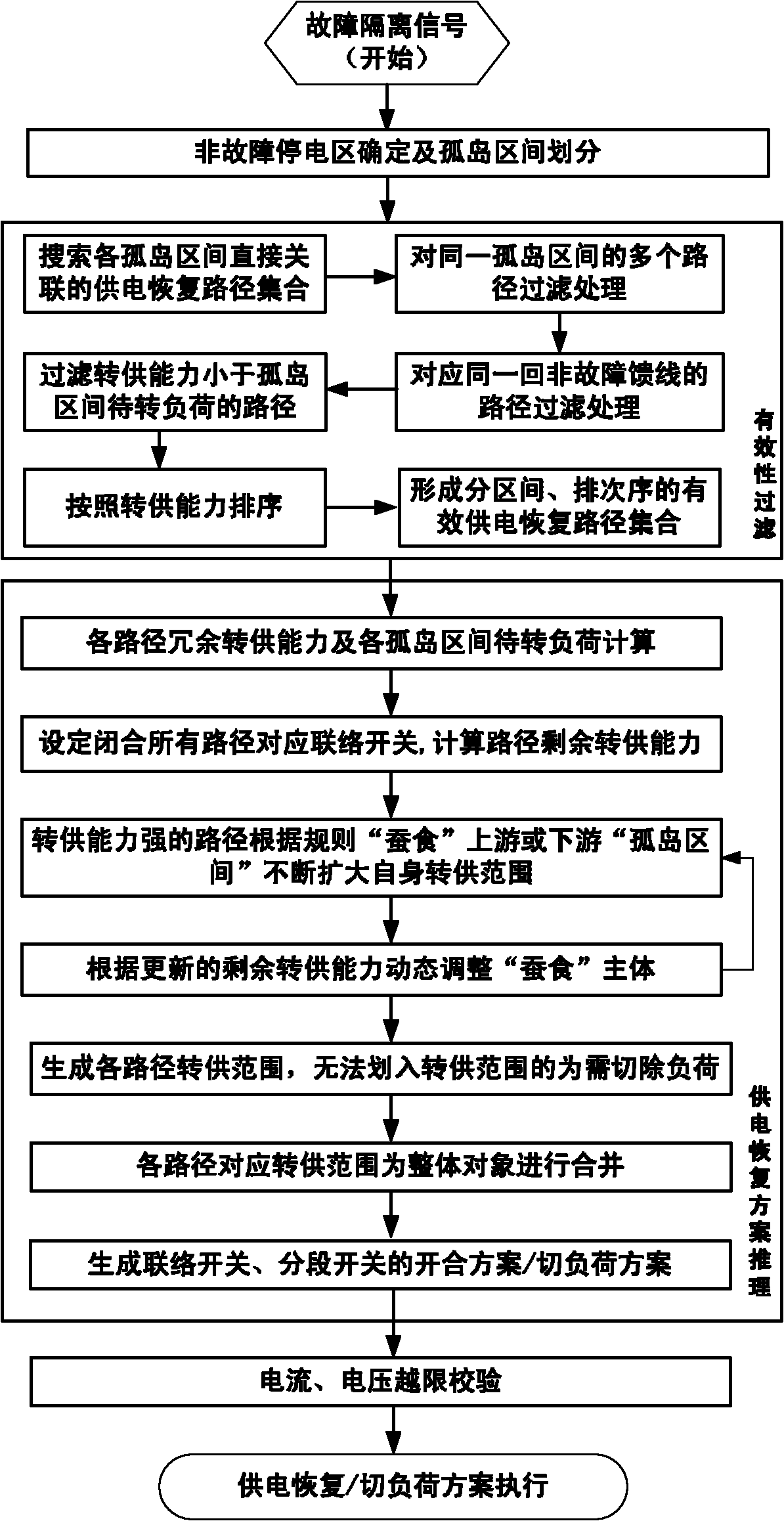

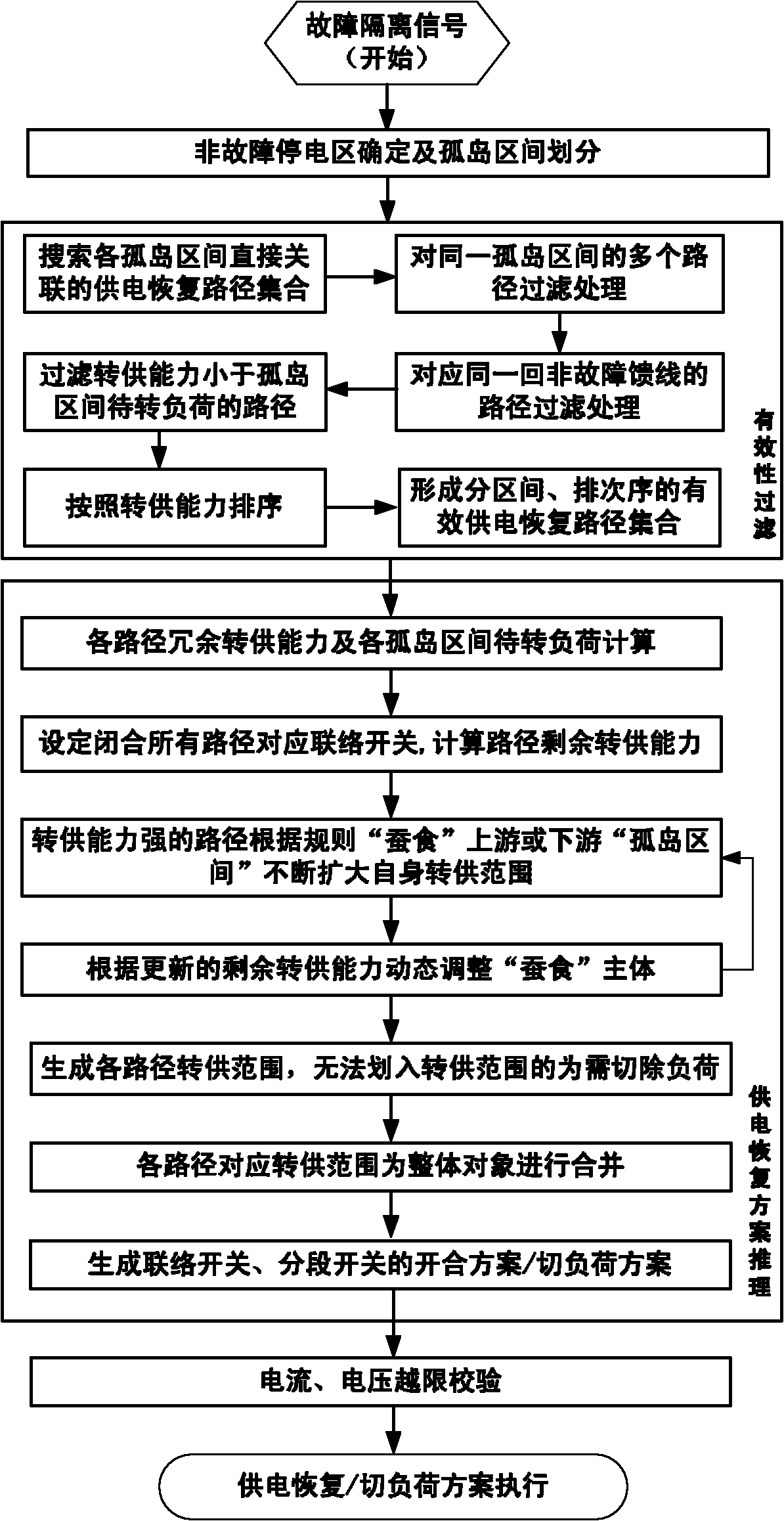

Multi-object optimized power supply recovery reasoning and searching method

ActiveCN102136721ACalculation speedMeet real-time requirementsEmergency protective arrangements for automatic disconnectionEmbedded systemMulti-objective optimization

The invention relates to a multi-object optimized power supply recovery reasoning and searching method, comprising the following steps: isolating the failure; dividing 'an inland area' in an unfailure power failure area; initially searching a power supply recovery path; effectively filtering; searching the power supply recovery path in the scheme; and verifying the electric equipment. The reasoning method provided by the invention needs not carry out large-scale traversal computing, and can automatically balance the transferring burdens on each path on the premise of fully utilizing the transferring capacity of each power supply recovery path; and the switching operation times are reduced, and a cutting load scheme can be directly obtained in the process of reasoning and searching.

Owner:CHINA ELECTRIC POWER RES INST +1

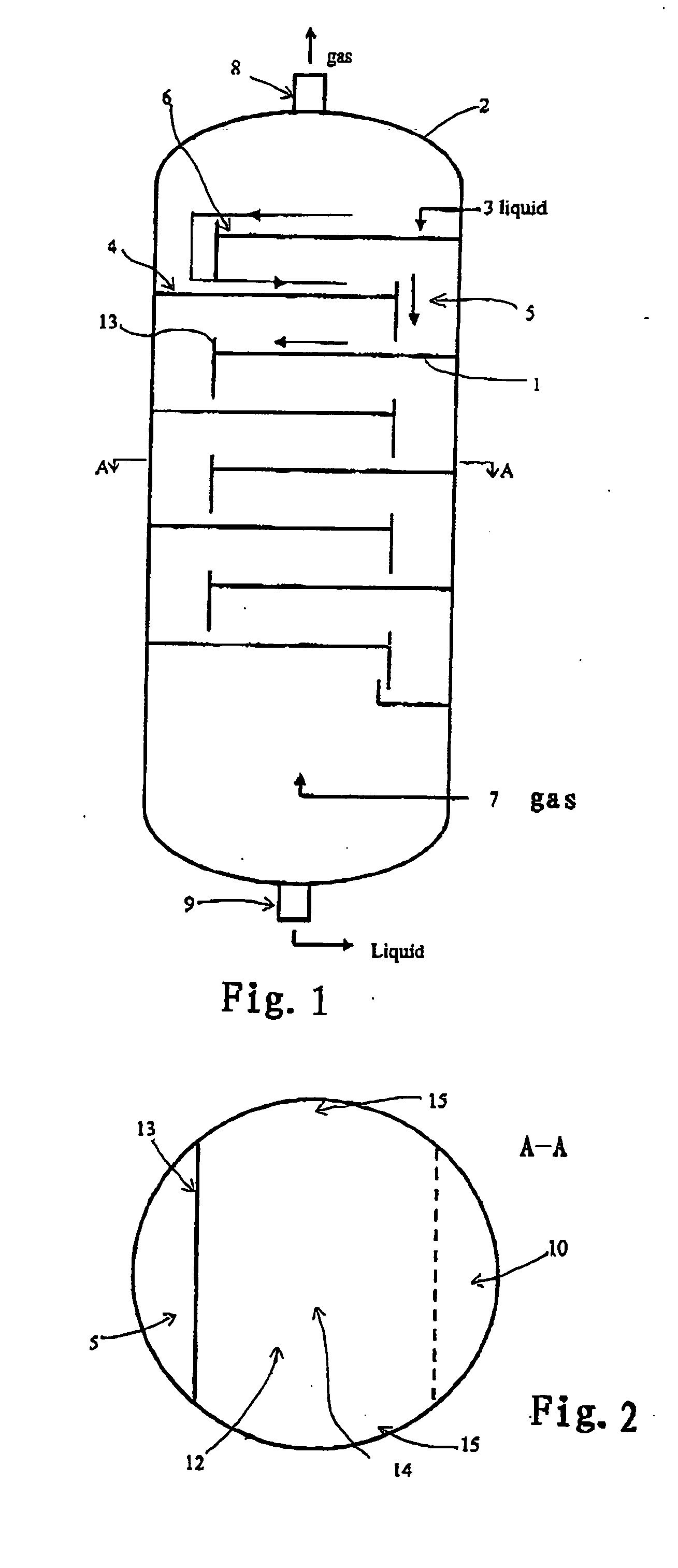

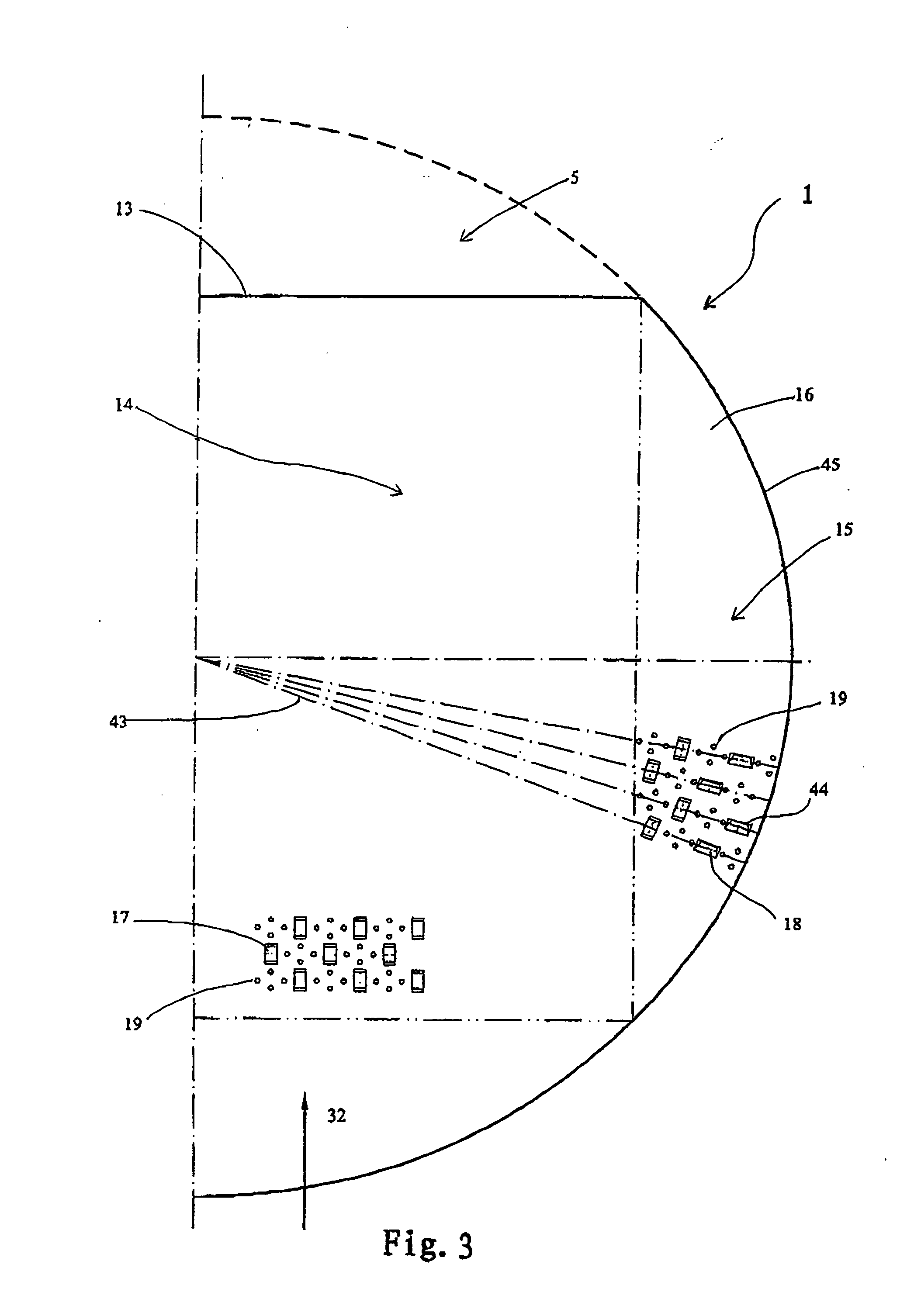

Gas-liquid contact tray with fixed valves for mass transfer

InactiveUS20050280169A1Low liquid entrainmentLow liquid weepingMixing methodsFuel re-atomisation/homogenisationMaterial PerforationVALVE PORT

A gas-liquid contact tray with fixed valves for mass transfer, in which the fixed valve comprising an upstream portion, a midportion and a downstream portion is made by punch from the tray deck so as to form as a deflector, and the upstream portion and the downstream portion are integrated with the tray deck, characterized in that said midportion has a central plane portion and downward inclined margins, and the tray deck is further provided with perforations which are arranged between the fixed valves adjacent in the liquid flow direction. The gas-liquid contact tray with fixed valves for mass transfer according to the present invention has a low liquid entrainment, low liquid weeping, a high mass transfer capacity and good turn-down characteristics.

Owner:CHINA PETROCHEMICAL CORP +1

Vehicle start control device and method

InactiveUS20070270281A1Suppress generationGearing controlEngine controllersControl theoryBrake force

A vehicle start control device executes a neutral control and a hill hold control, wherein, in the neutral control, a clutch provided in a power transmission path is brought into a slipping state or a released state to reduce the engine idling load and in the hill hold control, a brake force is generated to hold the vehicle against movement on a hill. A neutral release mode controller is employed to increase a torque transfer capacity of the clutch so that the clutch is engaged more gently when the neutral control is released under the hill hold control than in case of releasing the neutral control when the hill hold control is not executed. This suppresses generation of a shock that would be caused by engagement of the clutch when the neutral control is released under the hill hold control.

Owner:TOYOTA JIDOSHA KK

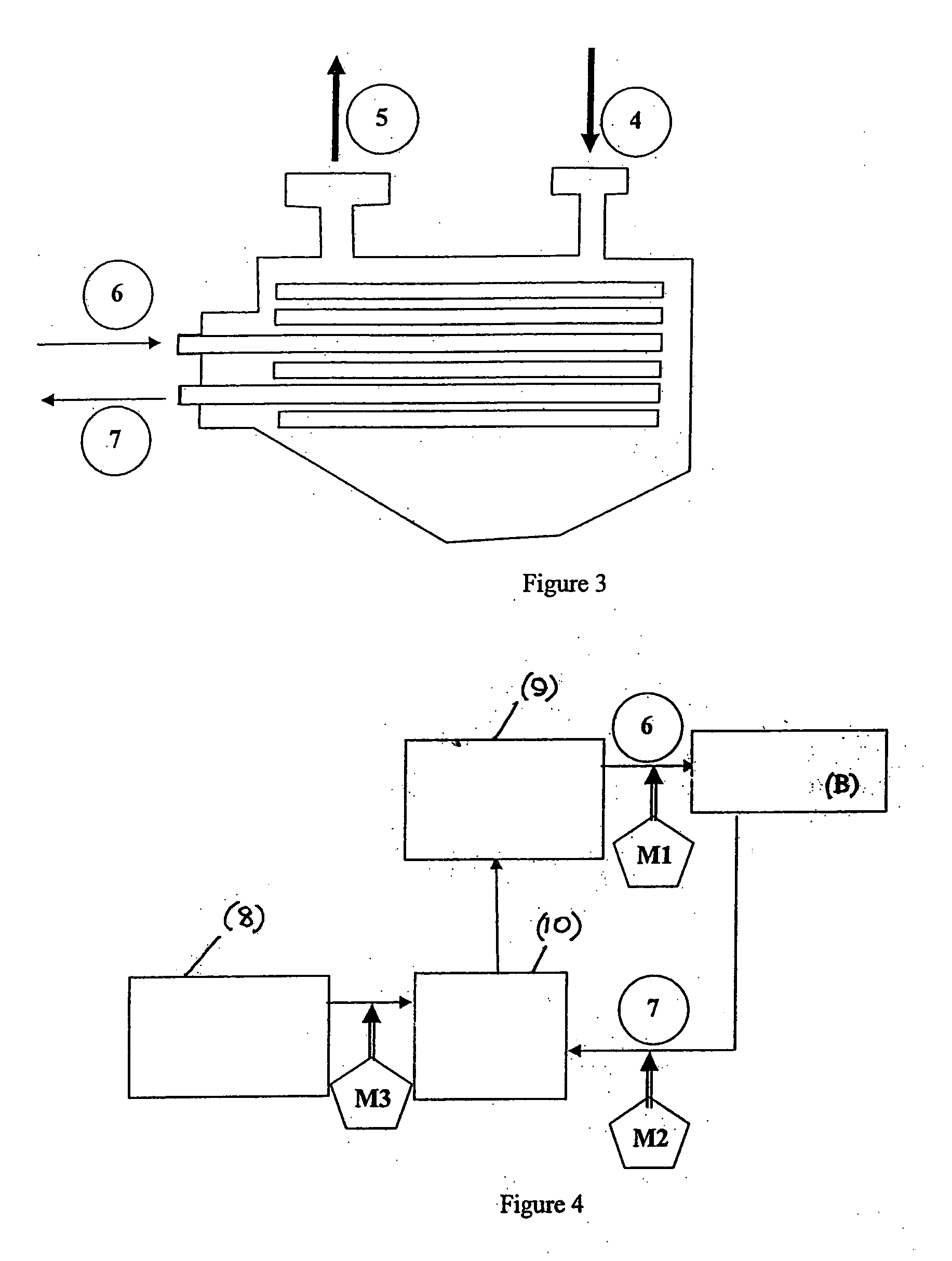

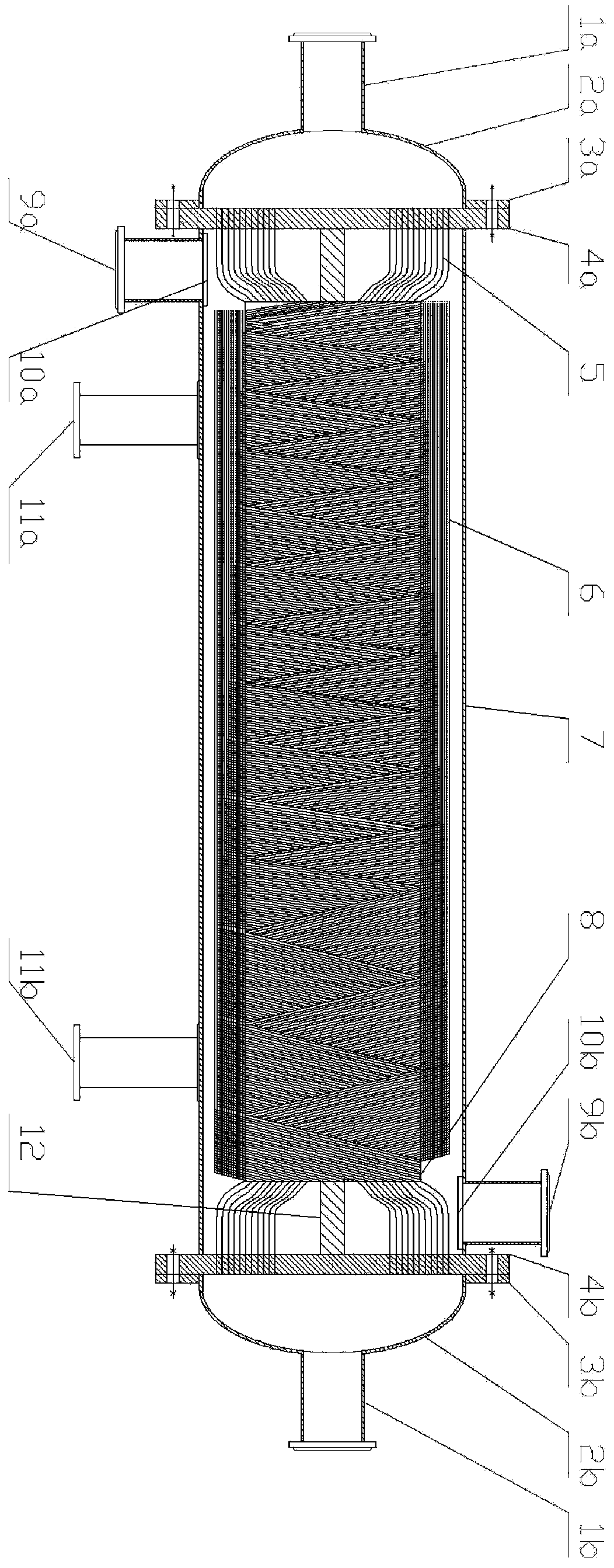

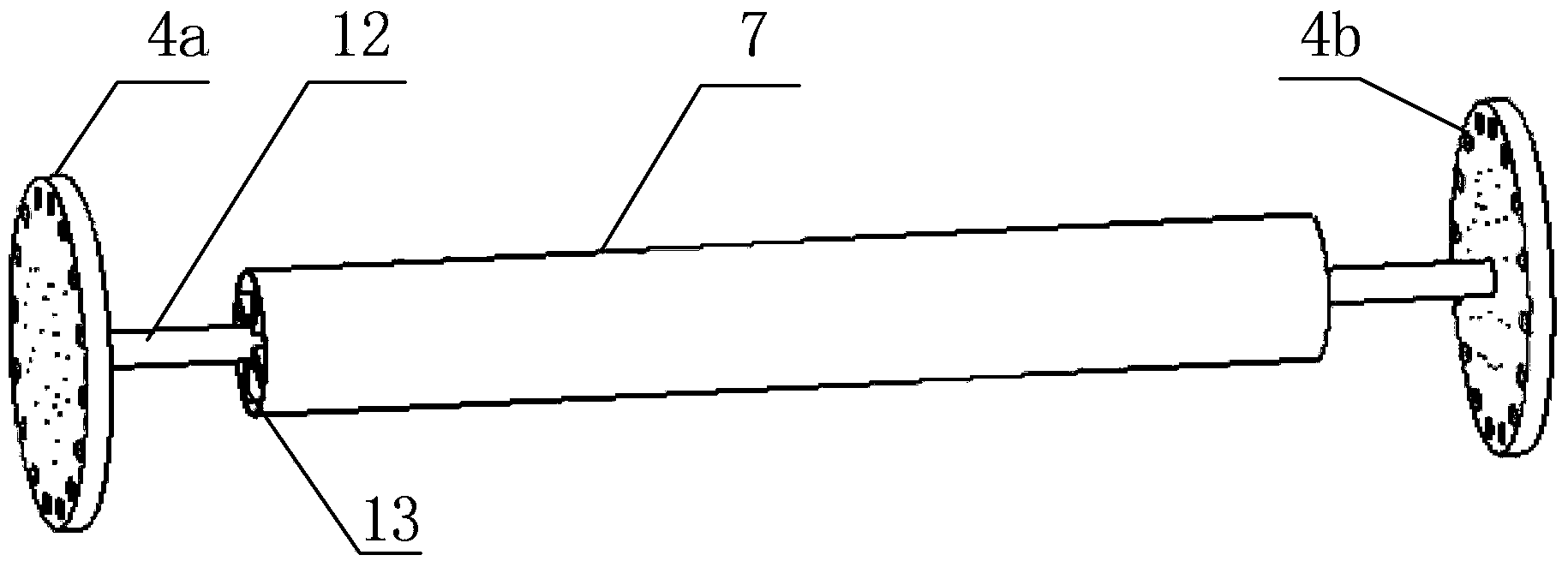

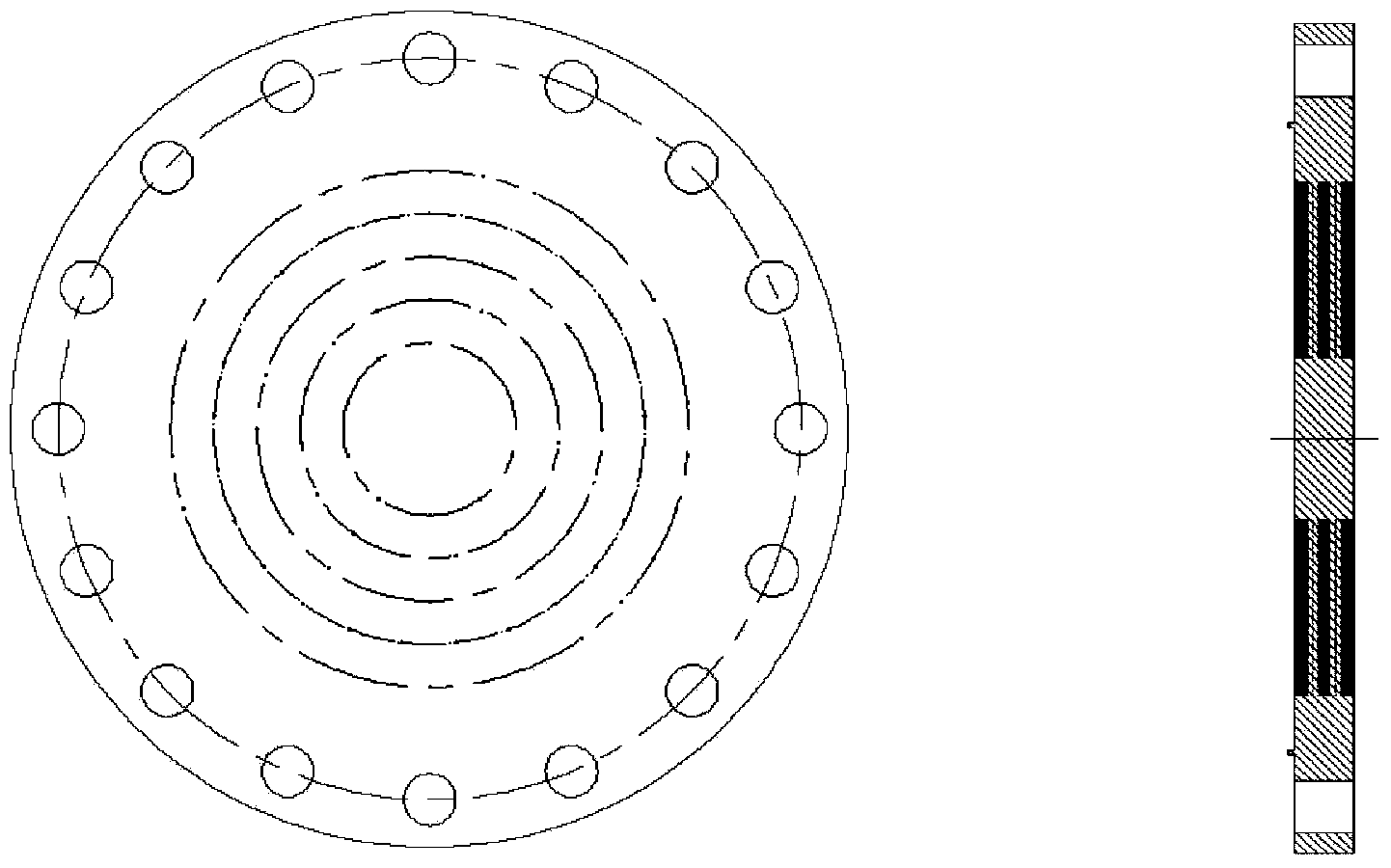

Novel high-throughput micro-channel reactor provided with multiple layers of spirally winding tubes

ActiveCN104258796APrecisely control the feeding ratioPrevent "overheating"Chemical/physical/physico-chemical processesCapillary TubingEngineering

The invention relates to the technical field of the design of chemical reactors and discloses a novel high-throughput micro-channel reactor provided with multiple layers of spirally winding tubes. The reactor mainly comprises reactant inlet and outlet sections, inlet and outlet glands, flanges, inlet and outlet tube plates, stainless steel capillary tubes, a fixed pad strip, a drum, a winding drum, constant-temperature medium inlet and outlet sections, baffles, left and right supports, a central support tube and a support piece, wherein two ends of the central support tube are connected with the inlet and outlet tube plates, and the winding drum and the central support tube are located on a same axis and welded and connected through the support piece; the stainless steel capillary tubes spirally wind around the winding drum in a multi-layer manner, spiral directions of adjacent winding layers are opposite, multiple reaction tube bundles which take the winding drum as the circle center and have different circle diameters are formed, and two ends of each stainless steel capillary tube are connected onto the inlet and outlet tube plates respectively; the inlet and outlet glands are connected with the inlet and outlet tube plates respectively through the flanges. The reactor has the advantages of high throughput, high heat transfer capacity, high synthetic rate, safety, high efficiency, low machining cost, capability of realizing continuous production, easiness in parallel enlargement and the like.

Owner:NANJING UNIV OF TECH

Method for accessing by stations of common transmission medium and network station for performing method

InactiveUS7054640B2Easy to detectNetwork traffic/resource managementAssess restrictionTelecommunicationsComputer science

Available transfer capacity is apportioned efficiently by stations informing each other of their capacity needs by sending messages when necessary. The sent messages can contain information on priority and capacity requirement. Stations which receive the sent capacity requests release unrequired transfer capacity or transfer capacity which is not urgently required, so that the capacity can by used by a station in need. The corresponding information can also be transferred by other stations, e.g. by several hops.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

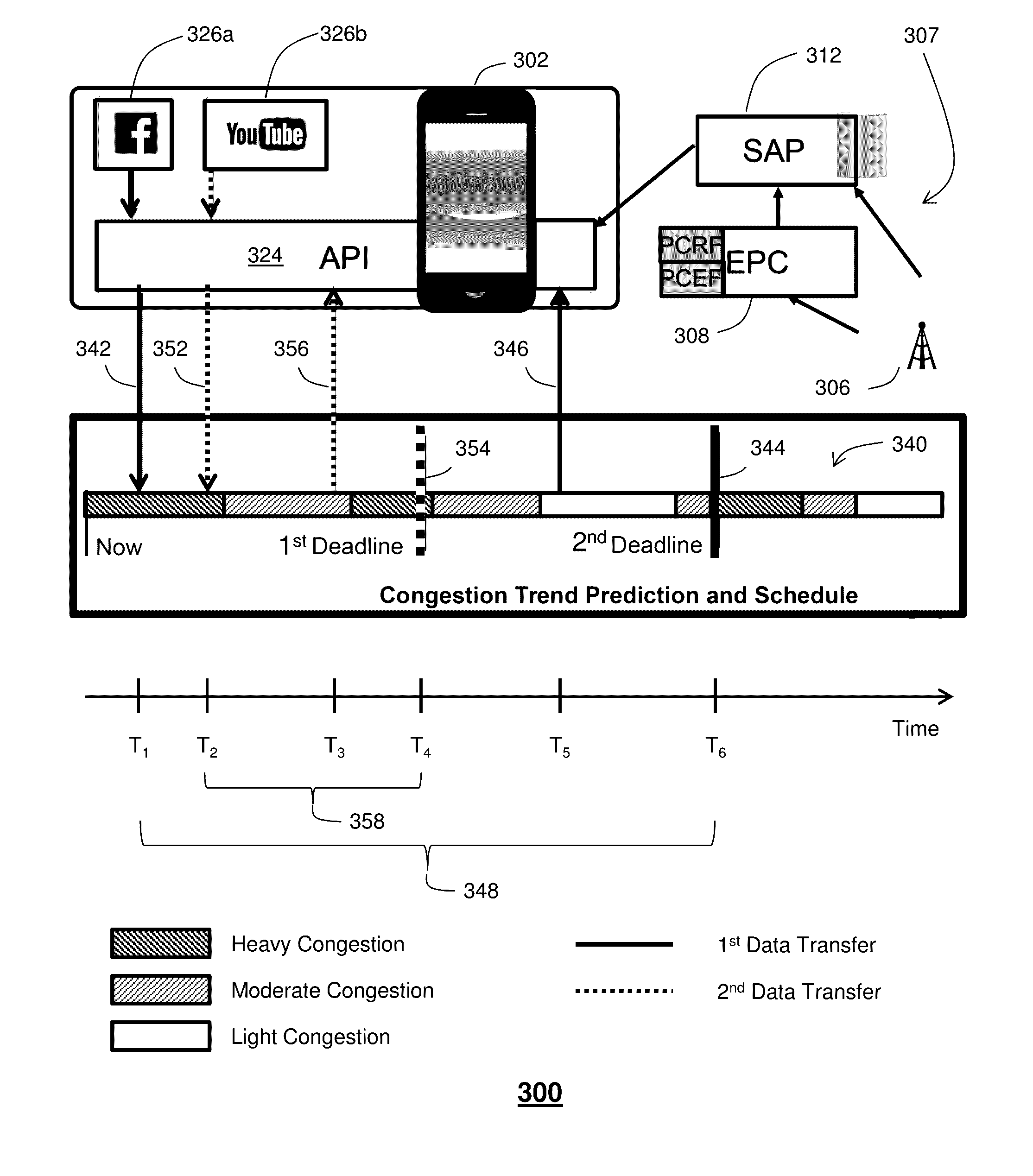

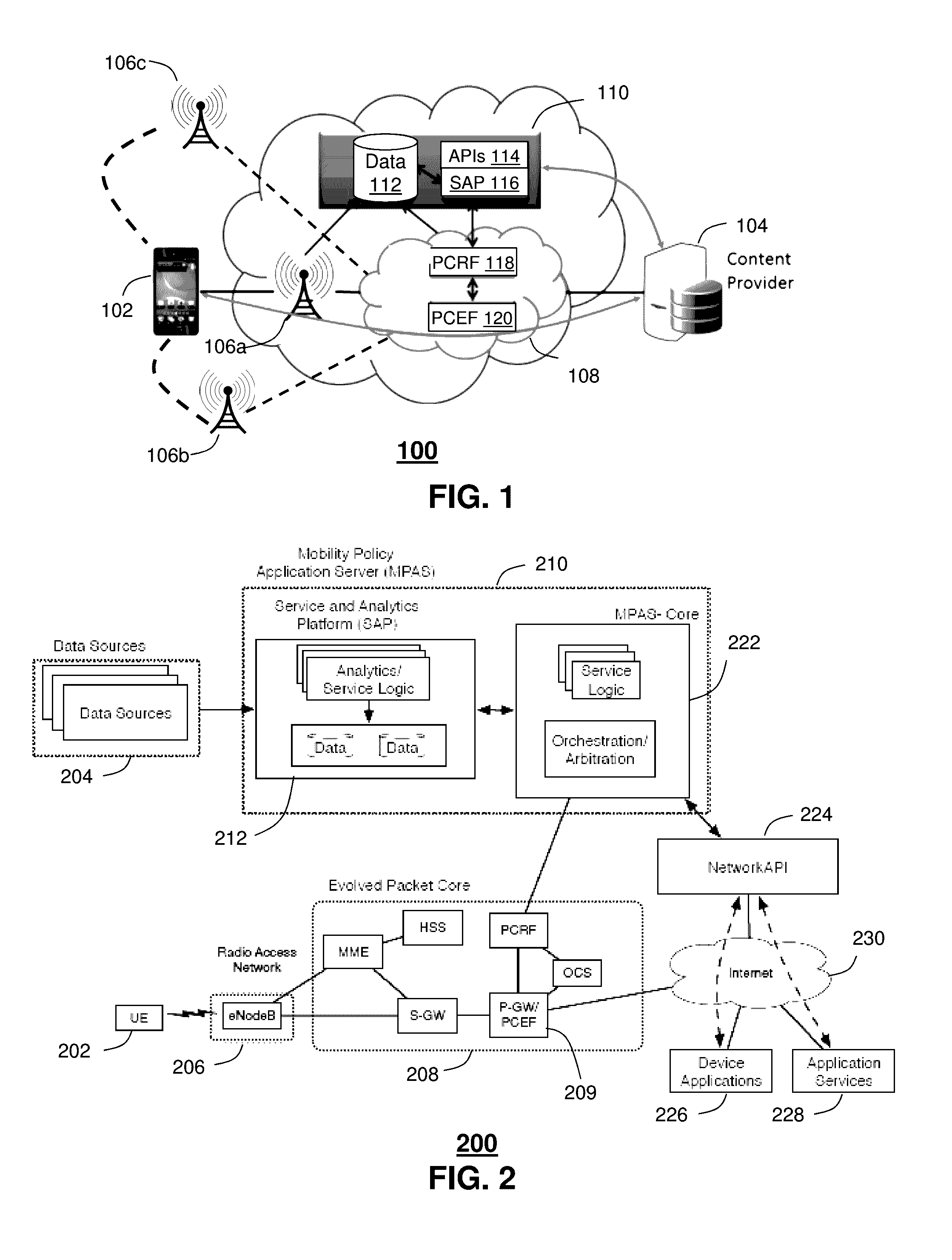

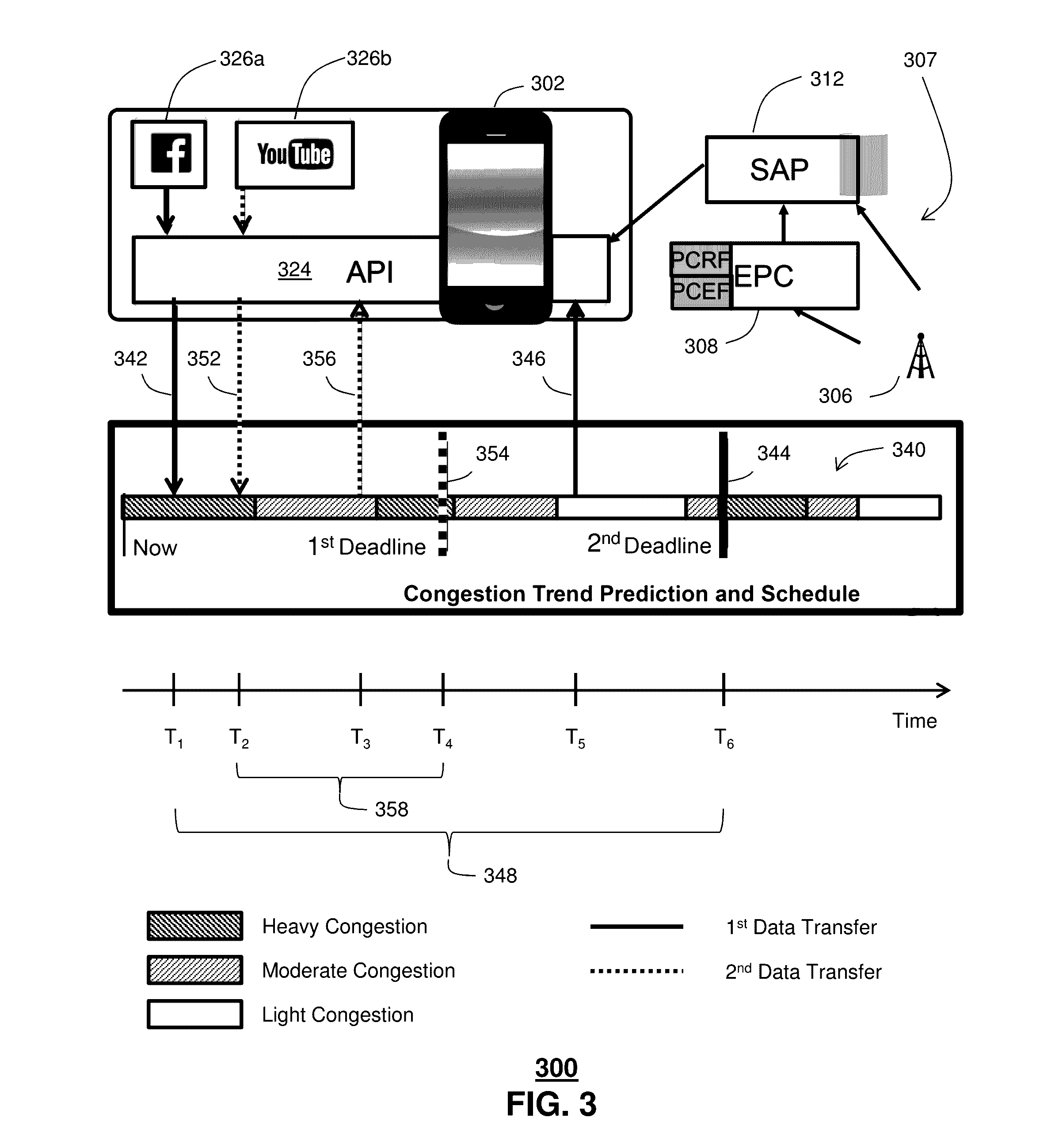

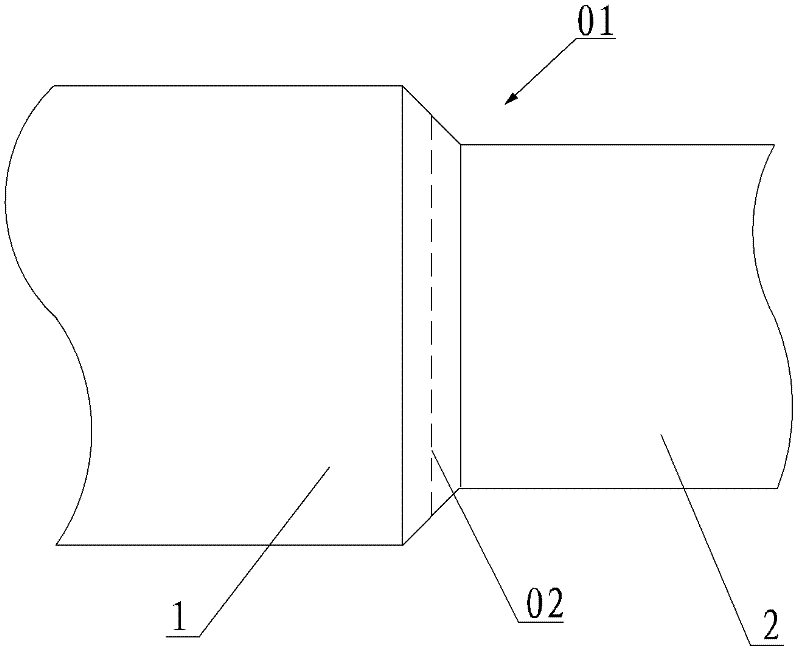

System and method for scheduling time-shifting traffic in a mobile cellular network

Aspects of the subject disclosure may include, for example, identifying a data request to transfer data for a mobile device across a mobile network. The data request occurs within a time interval of a number of time intervals, each having a duration greater than a data transfer time across the mobile network. A volume is determined of the data requested, and compared to a data transfer capacity of the wireless access terminal. A transfer of the data is scheduled within the time interval, responsive to the volume of data requested being less than the data transfer capacity. The transfer of the data is deferred to another time interval, responsive to the volume of data requested being greater than the data transfer capacity, and the deferring of the data to another time includes resubmitting the data request in another time interval of the plurality of time intervals. Other embodiments are disclosed.

Owner:AT&T INTPROP I L P +1

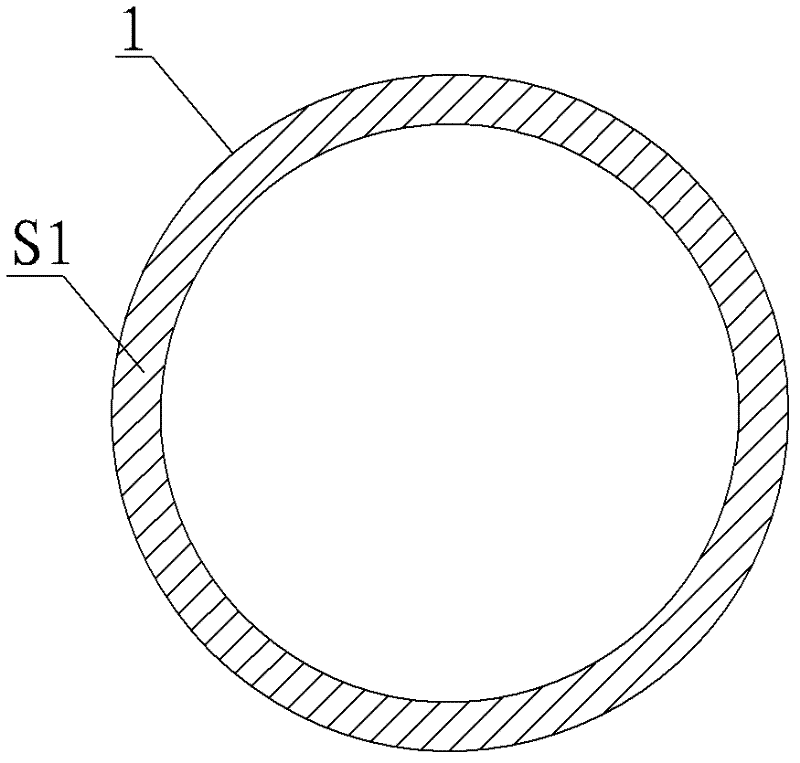

Postweld heat treatment method of welded joint of pipelines with different specifications

ActiveCN102409153AEliminate or reduce flowMeet the technical requirements of post-weld heat treatmentFurnace typesHeat treatment furnacesEngineeringHeating power

The invention discloses a postweld heat treatment method of the welded joint of pipelines with different specifications. The welded joint of the pipelines with different specifications comprises two pipelines with different materials and unequal cross sectional areas or equal cross sectional area and a weld joint connecting the two pipelines. In the heat treatment process, heating power compensation is performed on one end which has higher heat transfer capacity to the welded joint, to ensure that the highest temperature point of the heating zone is at the welded joint. In the method, the corresponding heating condition is set according to the different heat transfer conditions of the pipelines at the both ends of the weld joint, the condition that the highest temperature point of the heating zone deviates from the welded joint is effectively avoided, the adverse effects of the traditional postweld heat treatment technology on the properties of the welded joint are overcome and the requirements of the postweld heat treatment technology are met.

Owner:SUZHOU NUCLEAR POWER RES INST +2

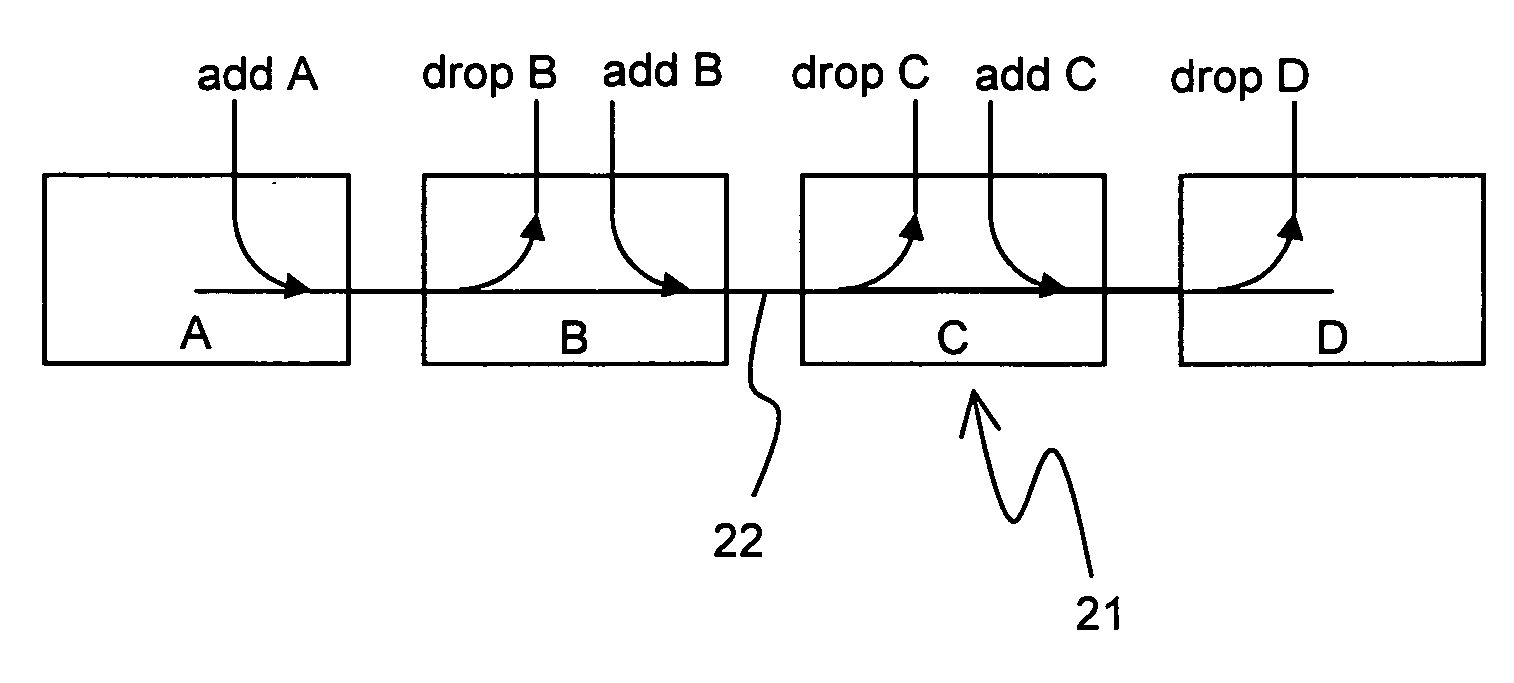

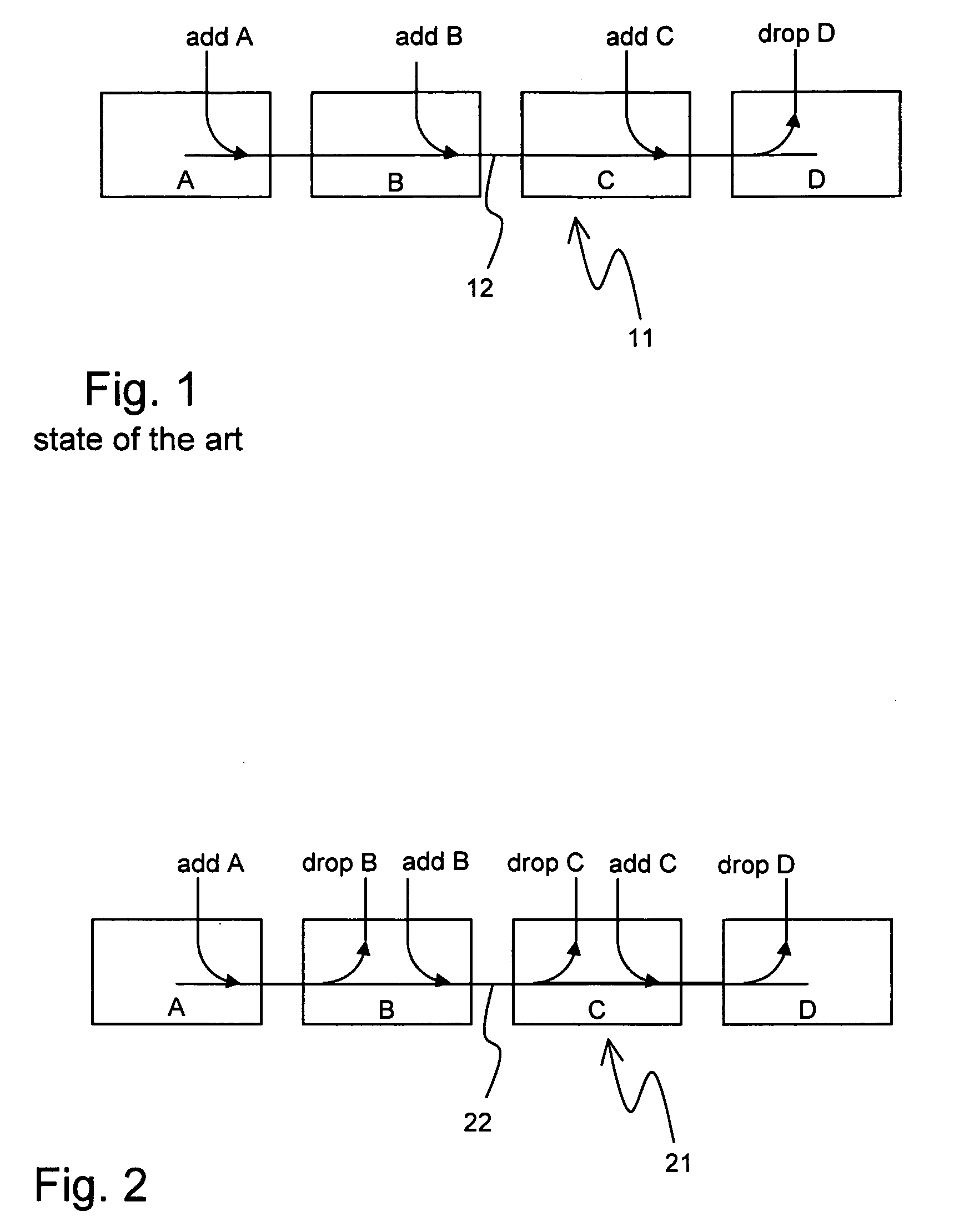

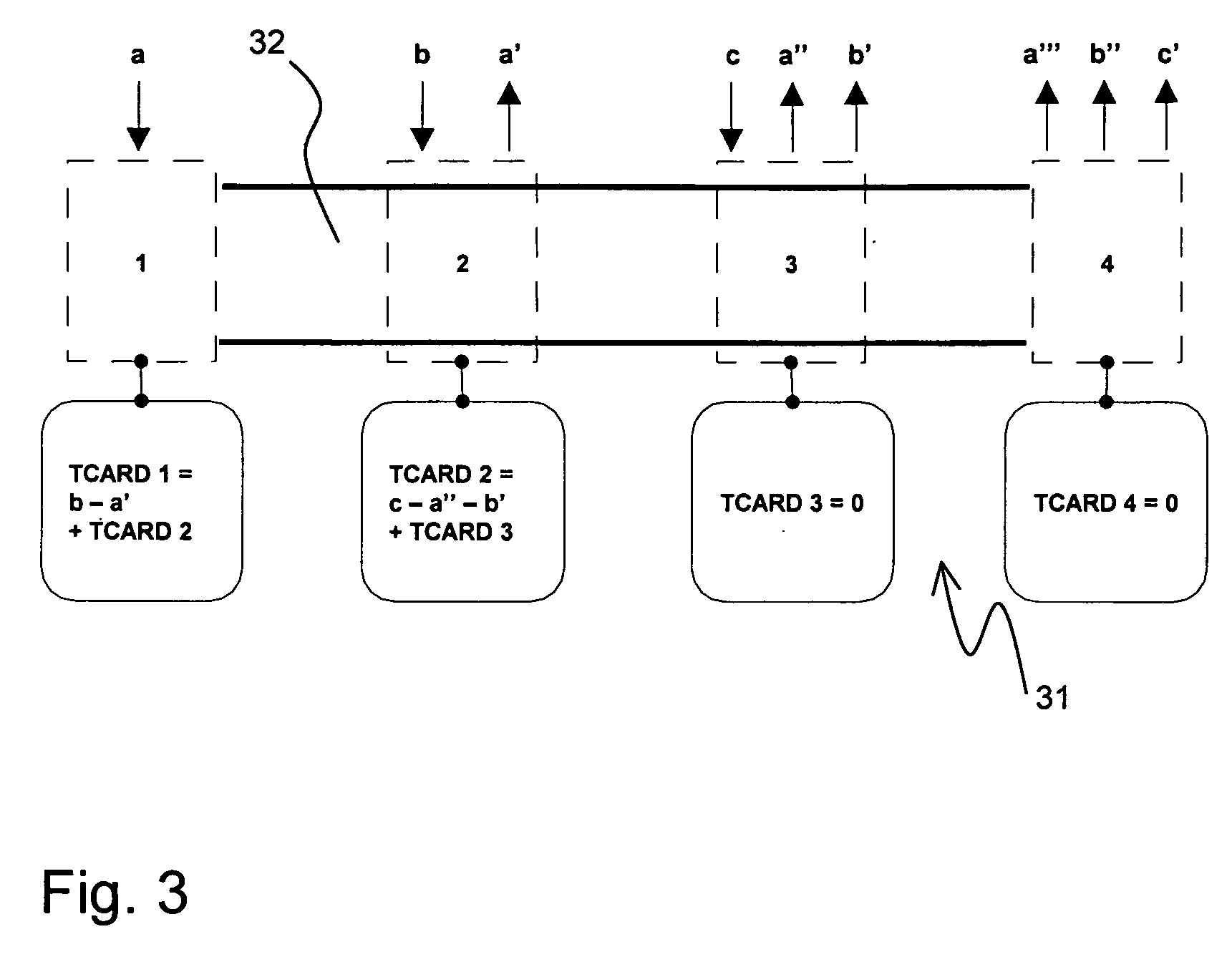

Method for operating a packet based data network

InactiveUS20060235996A1Fair transmission rateFreeing bandwidthDigital computer detailsStore-and-forward switching systemsTraffic capacityData transmission

A method for operating a packet based data network (21; 31), the data network (21; 31) comprising a multitude of nodes (A, B, C, D) and a shared data bus (22; 32), wherein at least some of the nodes (A, B, C, D) add traffic to the data bus (22; 32), and wherein the upstream nodes (A, B, C, D) reserve data transfer capacity of the data bus (22; 32) for downstream nodes (A, B, C, D) by means of a fairness mechanism, is characterized in that at least some of the nodes (A, B, C, D) drop traffic from the data bus (22; 32), and that said fairness mechanism takes into account the drop traffic at downstream nodes (A, B, C, D). The inventive method allows a better bandwidth utilization and uses available resources more efficiently.

Owner:ALCATEL LUCENT SAS

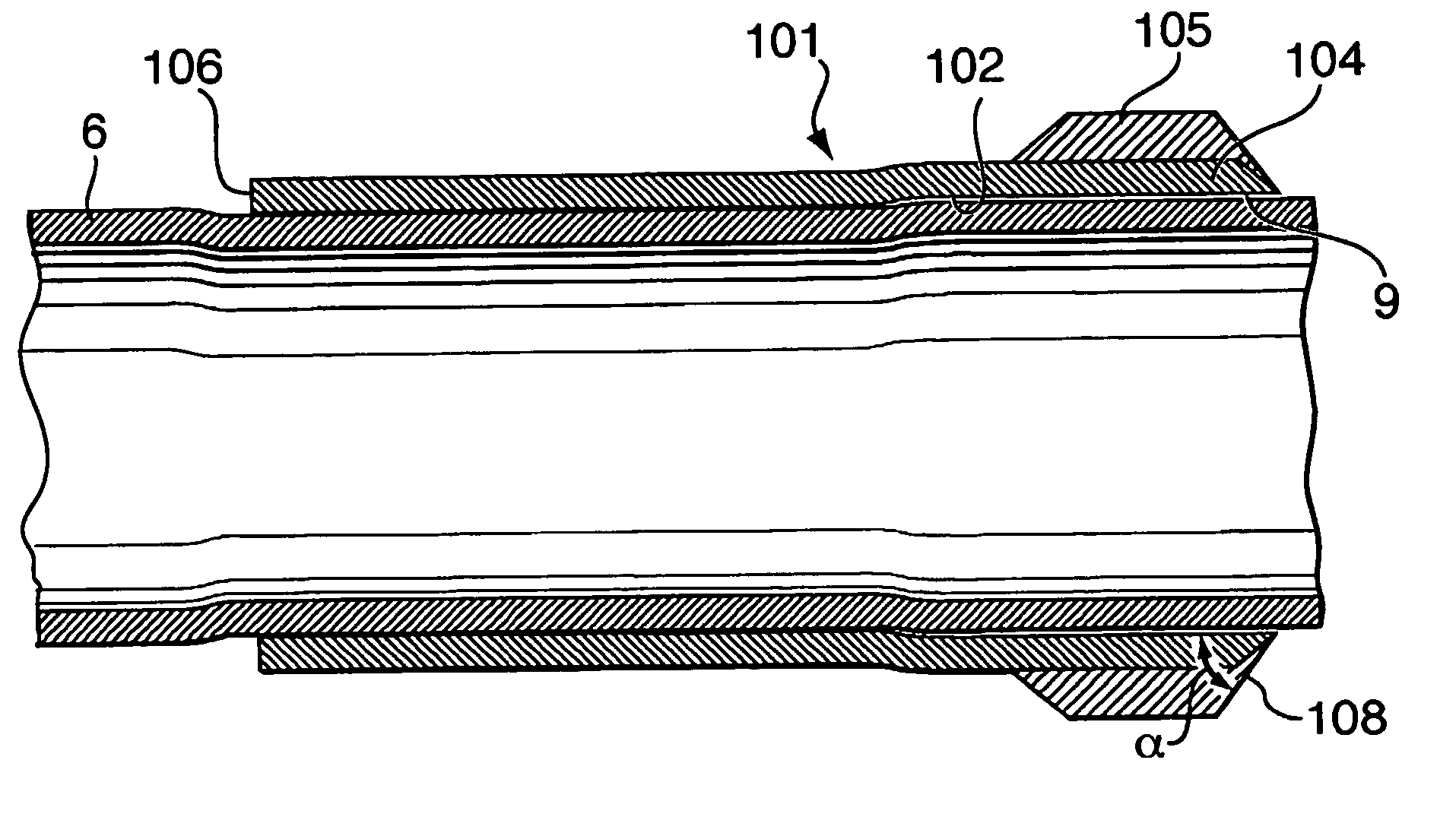

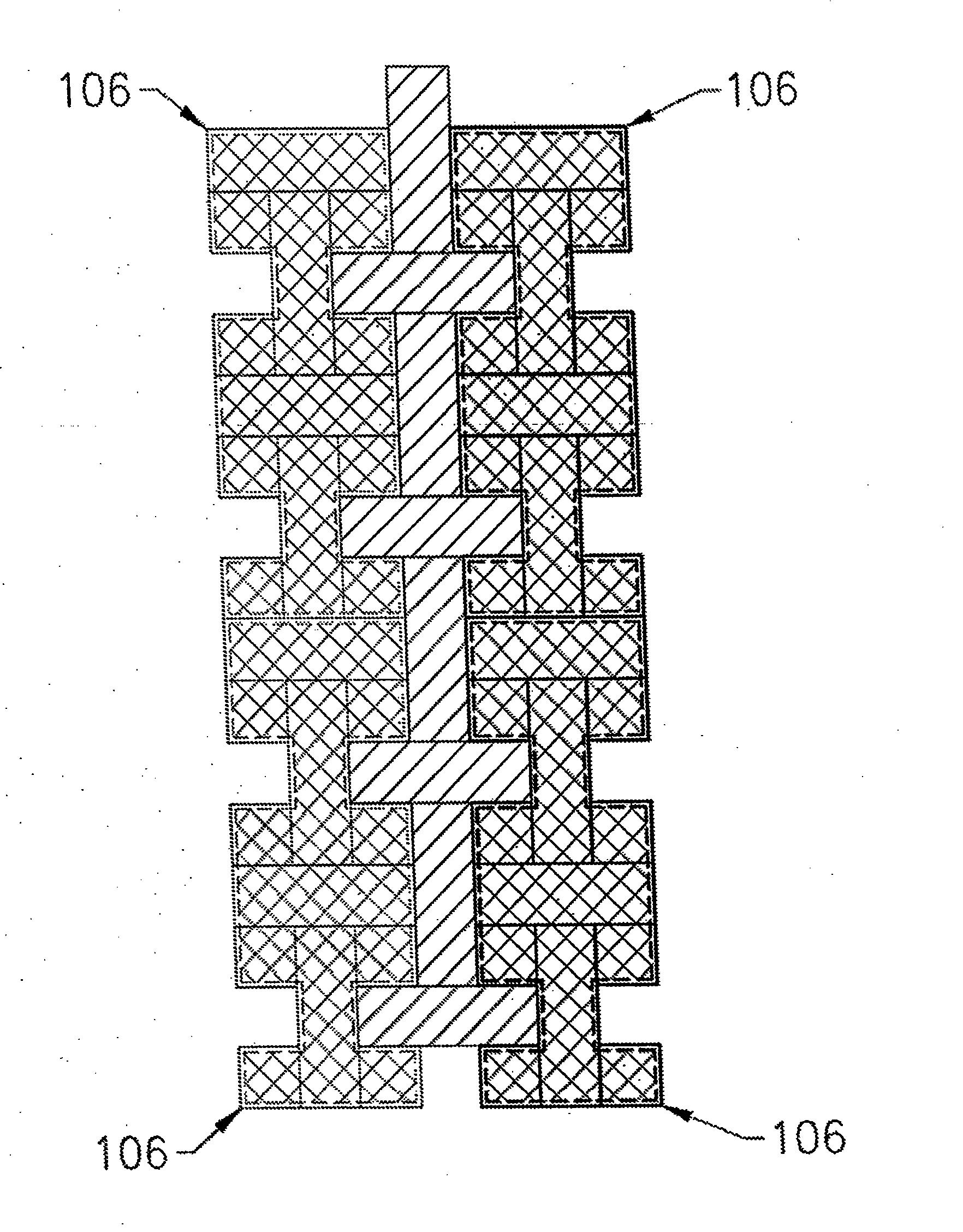

Casing wear band and method of attachment

InactiveUS7124825B2Increased frictional contactAugmenting frictional aspectDrilling rodsFluid removalCasing wearMechanical engineering

A crimpable wear band (105) tool has been invented for installation on casing (6), used in well bore drilling. A wear band (105) is provided having a cylindrical body which when coaxially placed over a pipe and substantially radially inwardly displaced at a plurality of points (i.e. crimped) about the circumference of a section of cylindrical body, attaches to the pipe to create a connection having structurally significant axial and torque load transfer capacity. When crimped according to the methods of the present invention, the load transfer capacity of the connection between the wear band (105) tool and the pipe (6) can be arranged to substantially prevent significant relative movement of the wear band tool on the pipe under loads that may be encountered when using one or more of the pipes as components of a tubular string used for drilling or running the casing in to complete a well bore.

Owner:NABORS DRILLING TECH USA INC

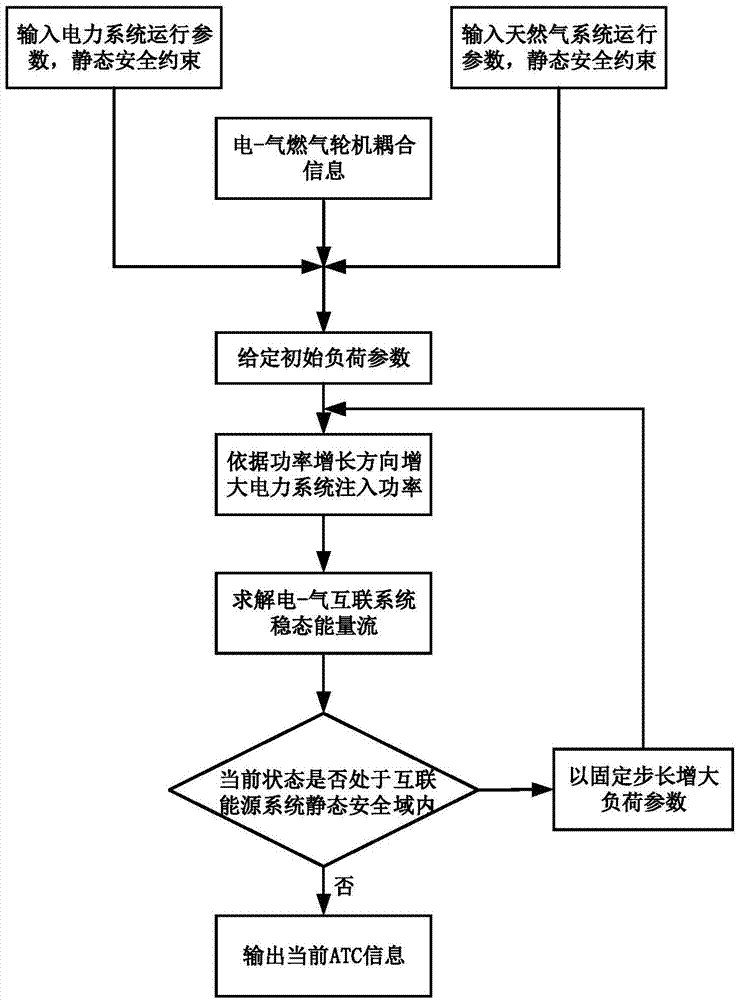

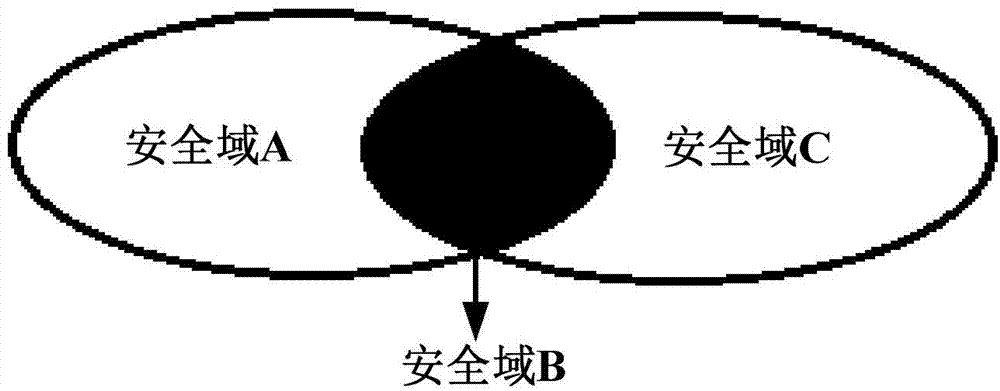

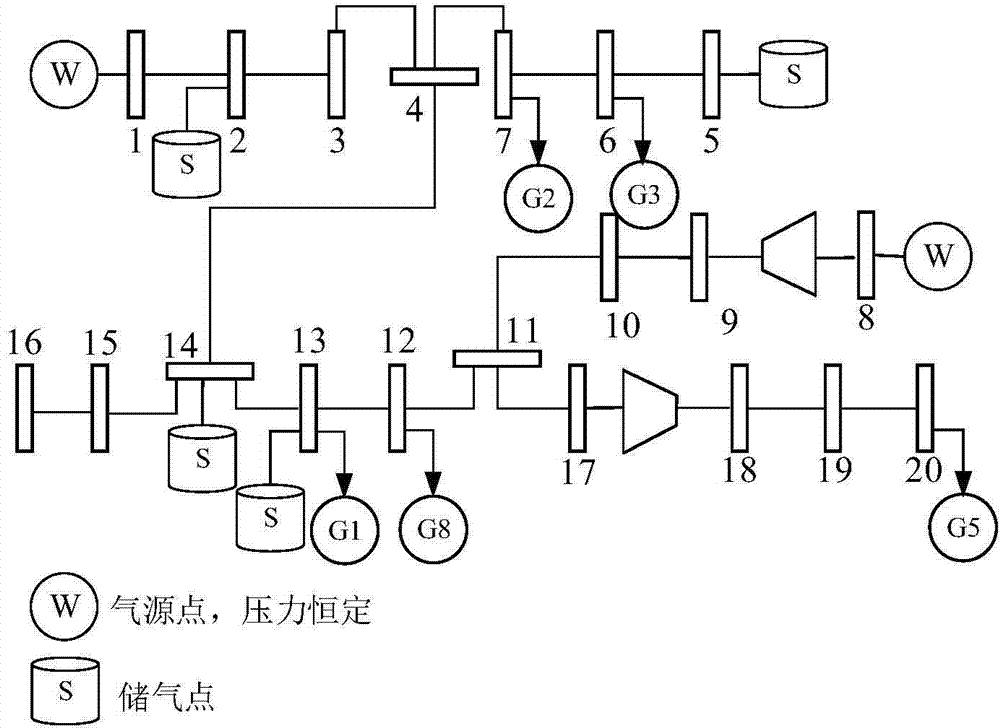

Method of acquiring available transfer capacity of electricity-gas interconnected energy system

ActiveCN104734155AEnsure safetyGuaranteed reliabilityLoad forecast in ac networkSingle network parallel feeding arrangementsEngineeringGas transfer

The invention discloses a method of acquiring available transfer capacity of an electricity-gas interconnected energy system and provides a concept of a static safety domain of the electricity-gas interconnected energy system. By means of solution by the continuous power flow method, solved is the problem that the traditional method of acquiring available transfer capacity, making no consideration on primary energy supply of NGFPP (natural-gas fired power plants) and operation constraints of a natural gas system, may drive the operation state of the natural gas system to exceed the safety constraint, thus influencing primary energy supply of the NGFPP. Verification by the interconnected energy system composed of an IEEE 39-node power transfer system and a 20-node Belgium gas transfer system shows that the method is generally applicable, ensuring safety and reliability of primary energy supply of the NGFPP; meanwhile, ATCs (available transfer capacities) of different areas are analyzed with a uniform energy market, and greater economic benefit is brought to participants of the whole energy market at the premise of ensuring the safety of the interconnected energy system.

Owner:HOHAI UNIV

Hybrid vehicle control system

InactiveUS20070102205A1Preventing inadvertent clutch slippageFast Responsiveness GuaranteedHybrid vehiclesSpeed controllerDrive wheelEngineering

A hybrid vehicle control system is configured to improve fuel economy by optimizing a torque transfer capacity of a clutch transmitting drive power from both an engine and a motor / generator while the motor torque provides at least part of the drive force. In particular, the system selectively controls a pair of clutches to switch between an electric drive mode and a hybrid drive mode. The torque transfer capacity of the clutch transmitting drive power from both the engine and the motor / generator to a drive wheel includes a motor / generator torque component and an engine torque component. The motor / generator torque component is determined based on a motor / generator torque and a torque transfer capacity margin allowance for the motor / generator torque. The engine torque component is determined based on an engine torque and a torque transfer capacity margin allowance for the engine torque when the drive wheel is driven at least by the motor / generator.

Owner:NISSAN MOTOR CO LTD

Method for preparing a composite membrane/wood floor diaphragm

InactiveUS20140245693A1Improve the immunityImprove abilitiesFloorsLaminationComposite membraneBuilding construction

A composite membrane of wood floor diaphragm for construction of new buildings and strengthening of existing buildings to provide improved load transfer capacity and enhanced resistance to gravity and lateral loads, such as earthquake and / or wind for buildings with wood floor framing. The composite membrane extends beneath the wall framing to utilize the composite membrane diaphragm as a load and shear bearing element.

Owner:PARQUET BY DIAN

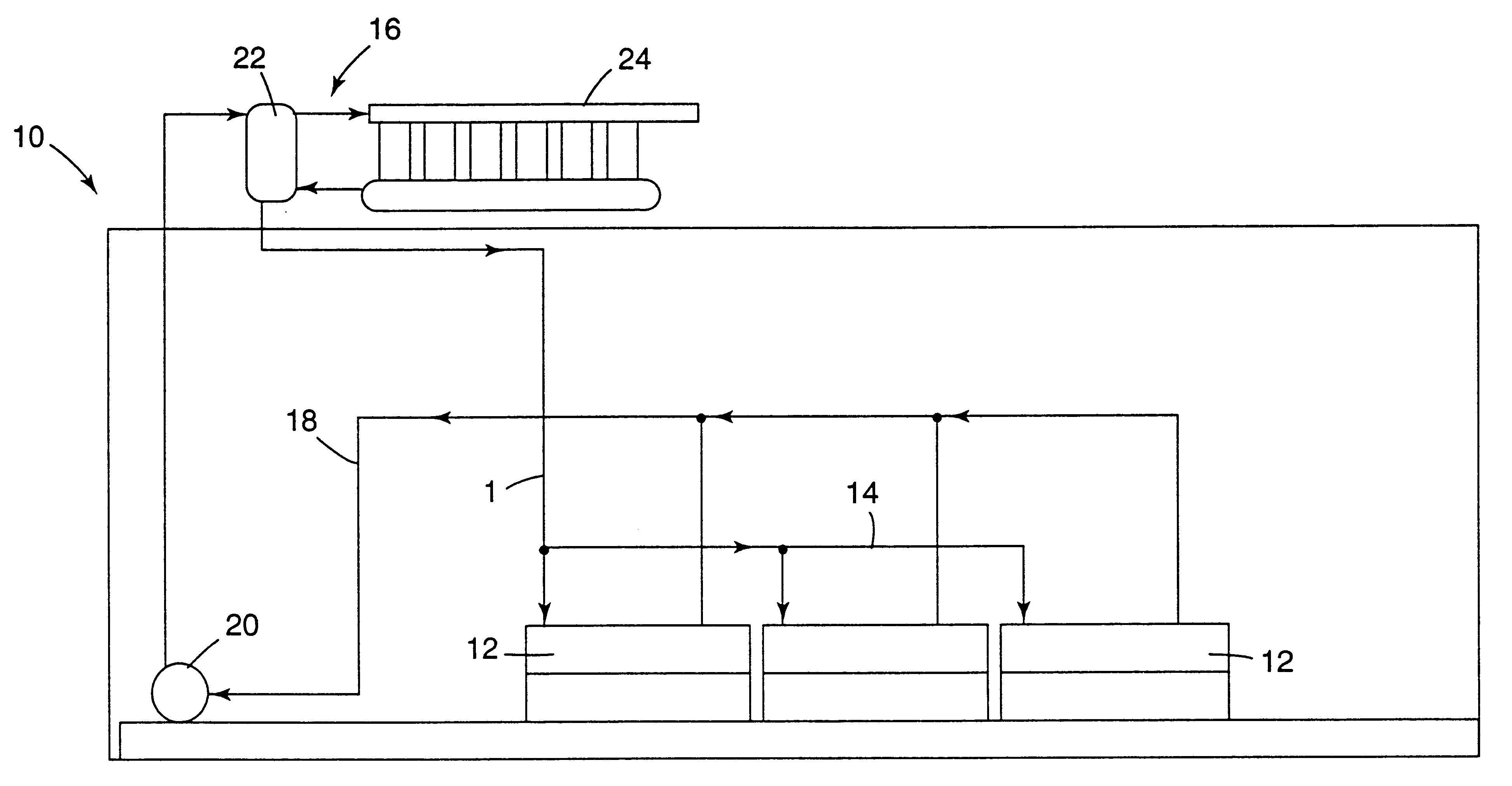

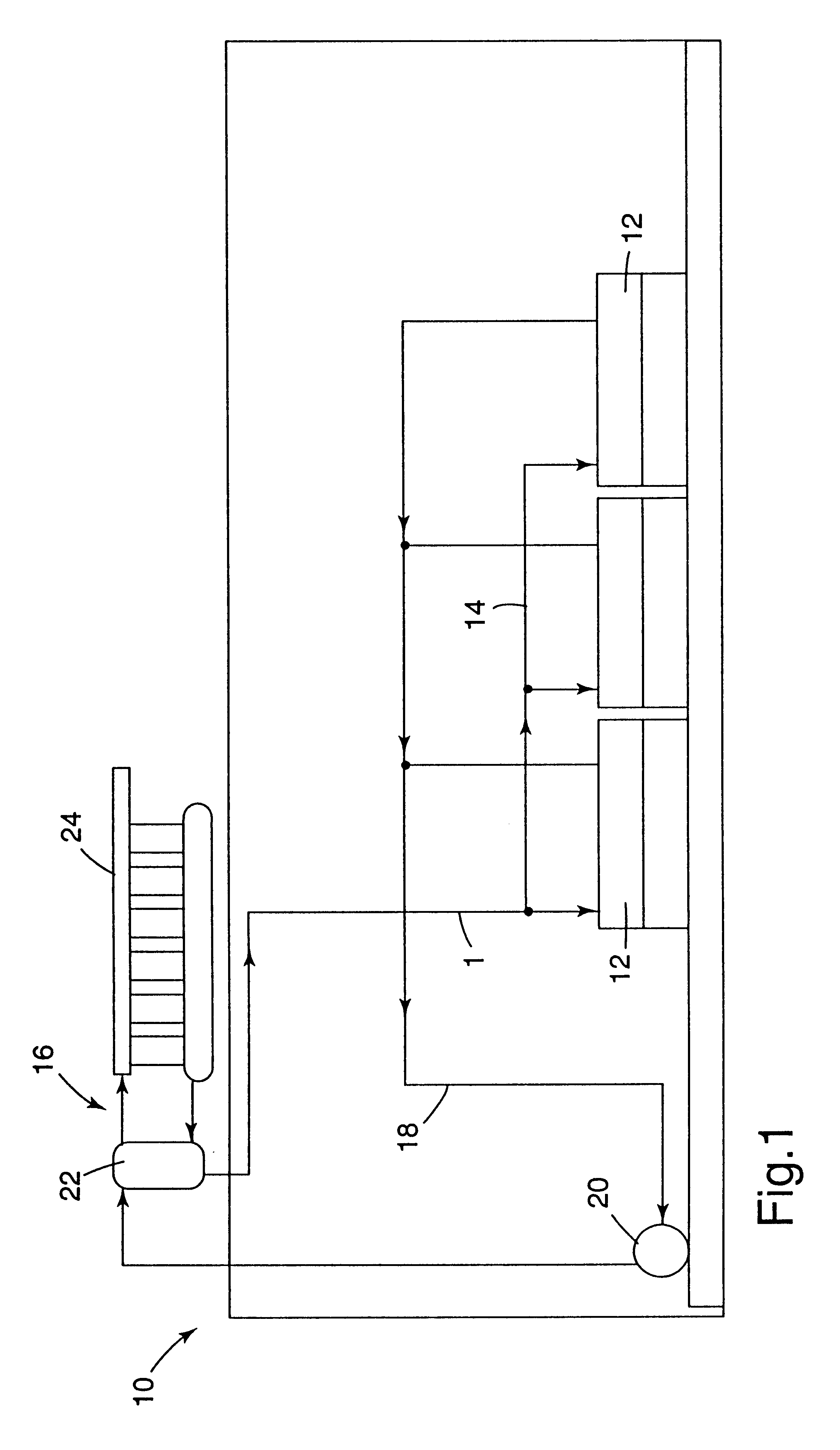

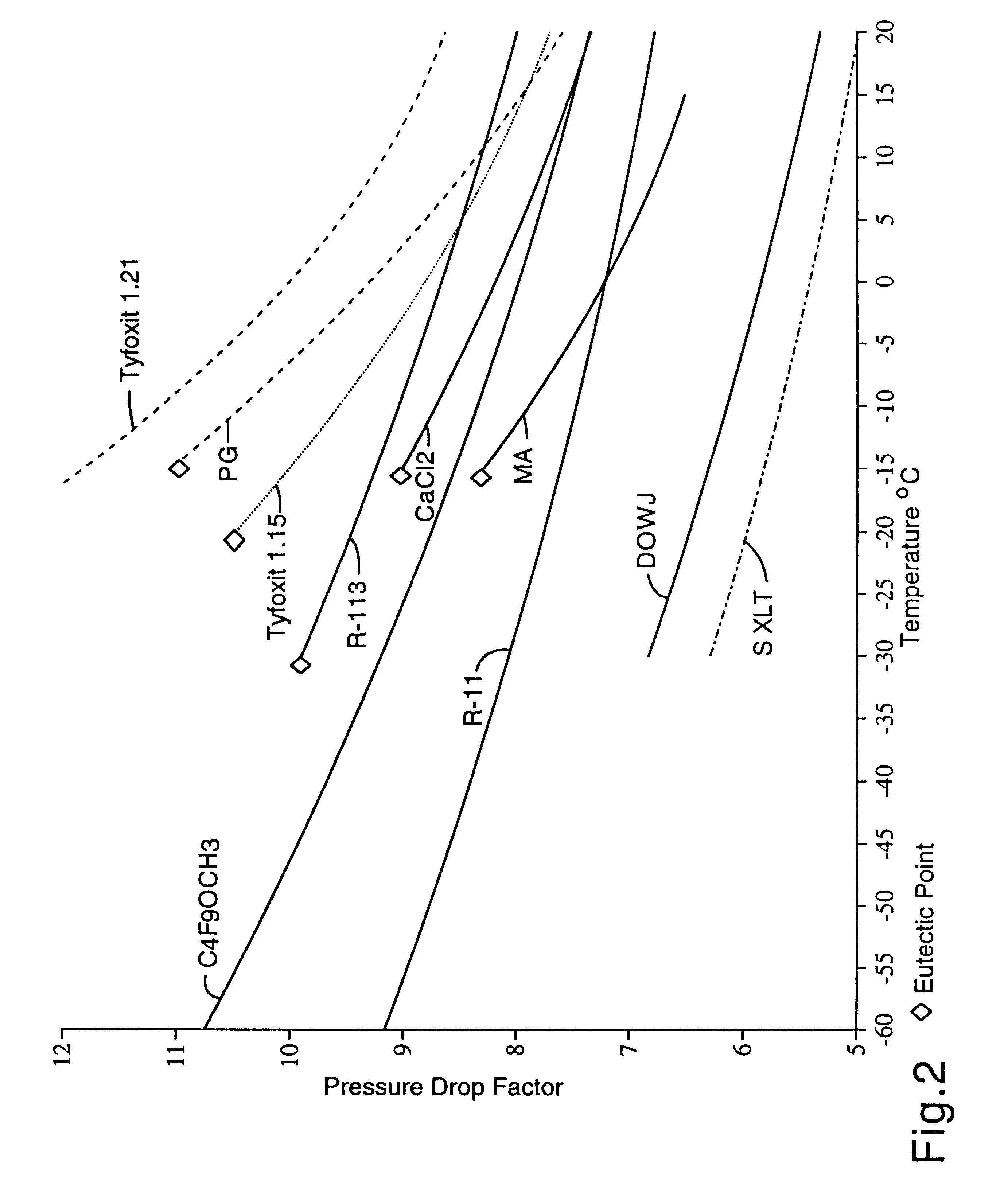

Hydrofluoroethers as low temperature refrigerants

InactiveUSRE37119E1Low and somewhat linear Temperature Difference FactorImprove heat transfer performanceCompression machinesHeat-exchange elementsEngineeringHydrofluoroether

A method and apparatus are provided for using certain hydrofluoroethers (HFEs) as low temperature heat transfer media in secondary loop refrigeration systems. These materials exhibit a low, somewhat linear Temperature Difference Factor over the temperature range of -15° C. to -65° C., making them ideal for use as low temperature heat transfer media. The HFEs of the present invention are nonflammable, nontoxic, environmentally benign, and have a high heat transfer capacity and low viscosity over the required operating temperatures. Furthermore, since these materials have high boiling points and low freezing points, they are not prone to phase changes over the required operating temperatures, and do not require pressurized systems.

Owner:3M INNOVATIVE PROPERTIES CO

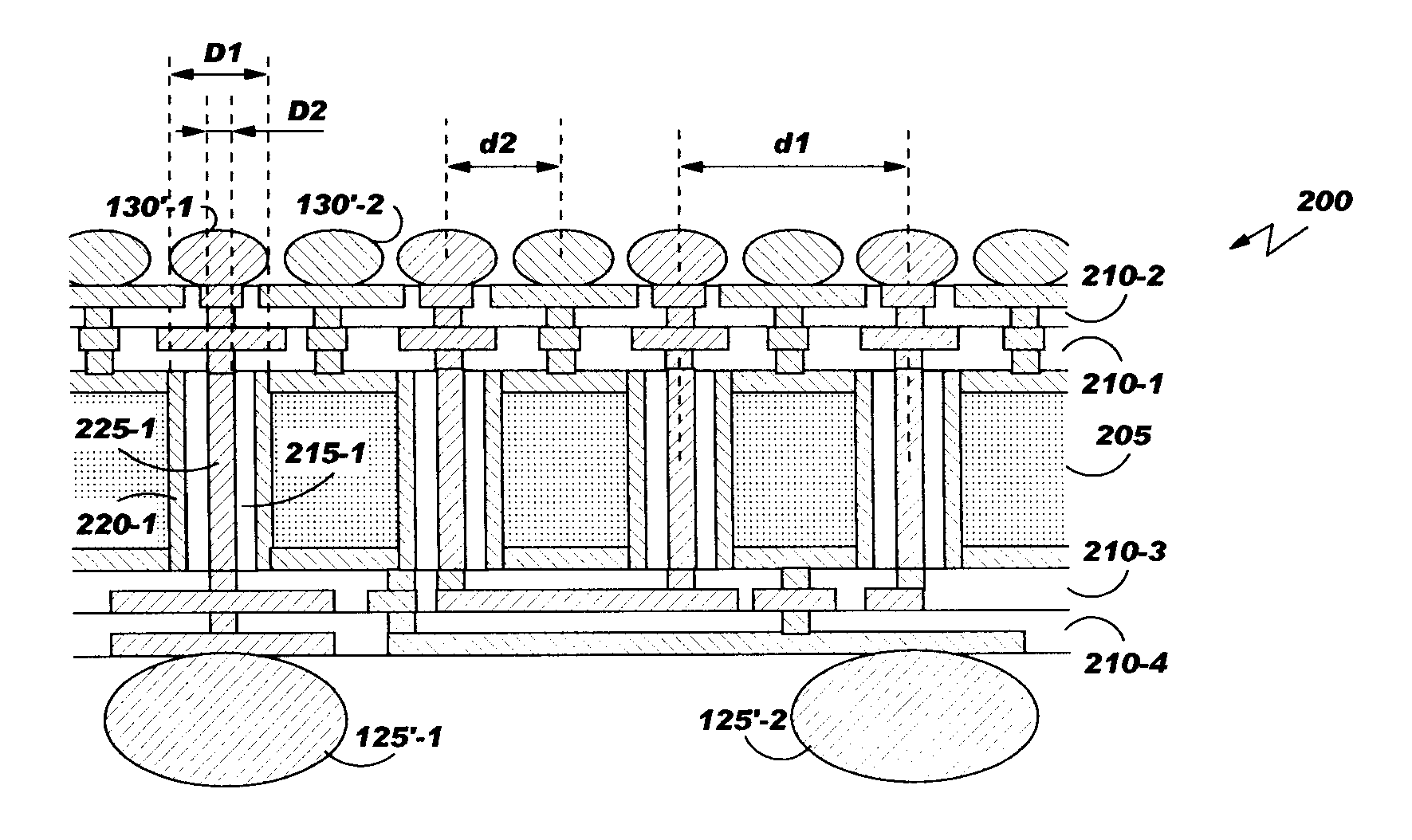

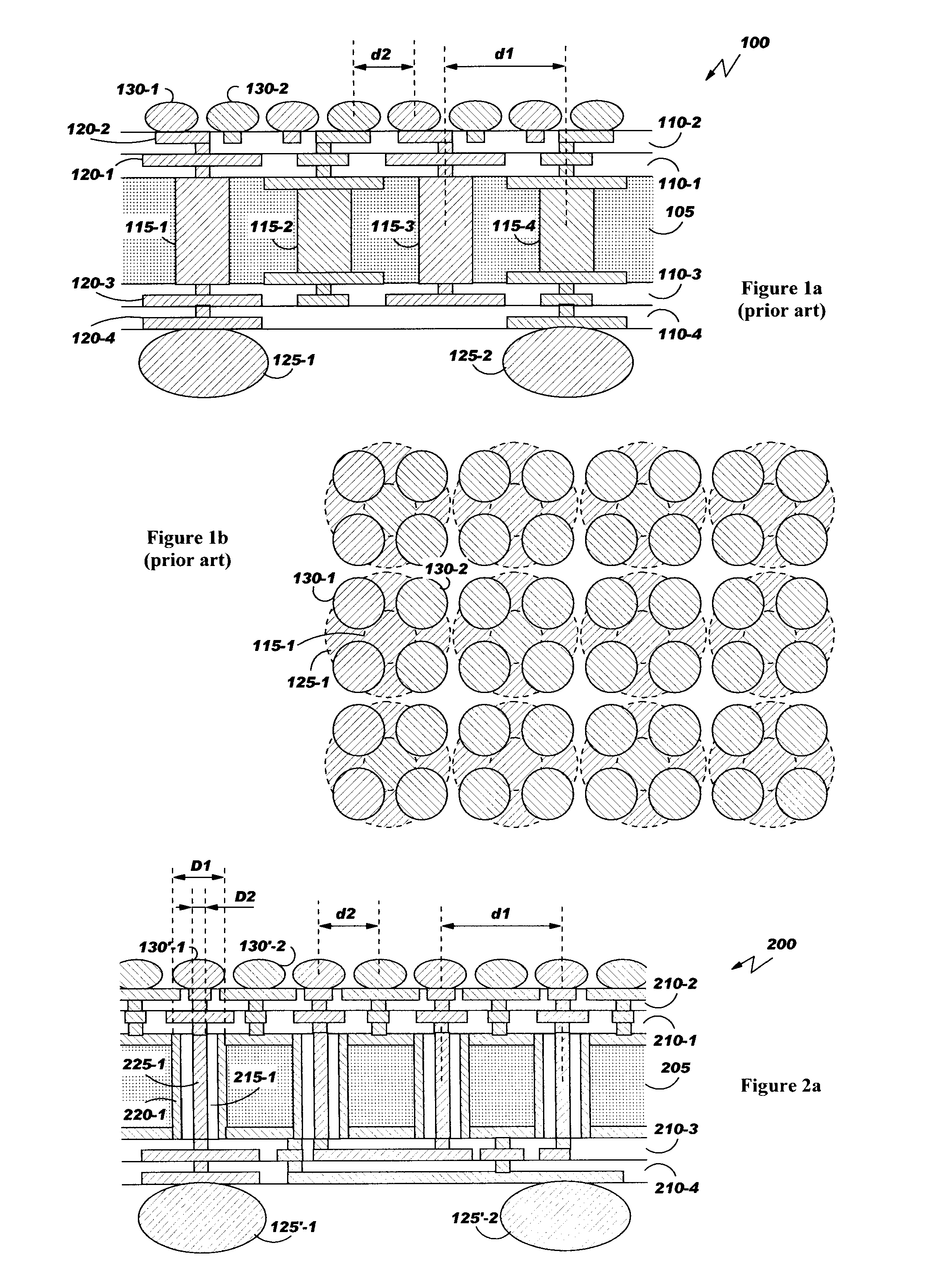

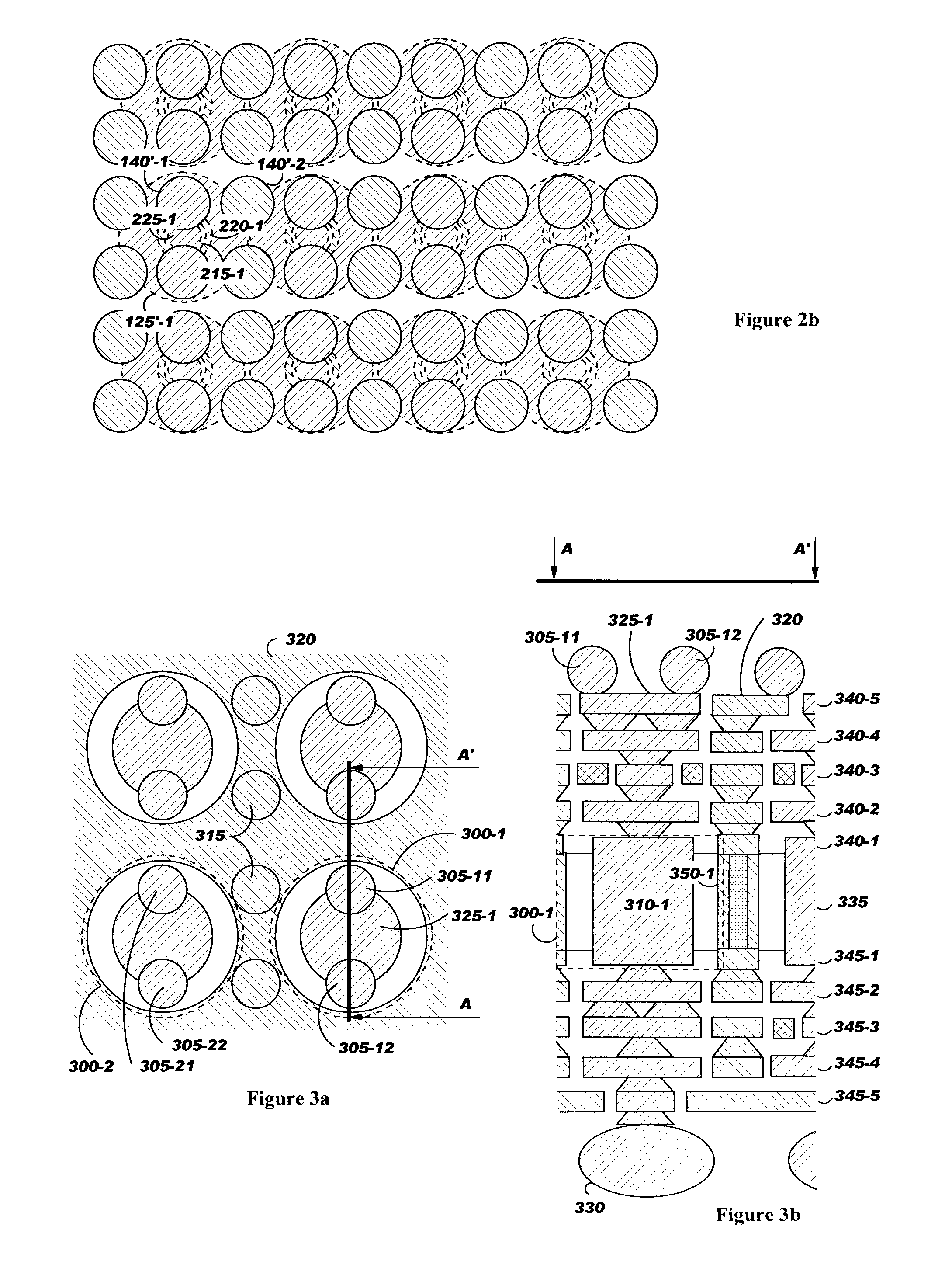

Power supply structure for high power circuit packages

InactiveUS20070230150A1Reduce resistanceReduce the effect of parasitic inductanceSemiconductor/solid-state device detailsPrinted circuit aspectsElectricityElectrical connection

A power supply structure for high power circuit package is disclosed. According to the invention, the electrical connections between power planes are done through a plurality of coaxial structures that can be totally or partially implemented in the circuit shadow area of the electronic device carrier, for example under the engine area of the circuit. According to this principle, a same hole is used to transfer two different current levels, one on its periphery and the other one on its centre, doubling the electrical transfer capacity.

Owner:IBM CORP

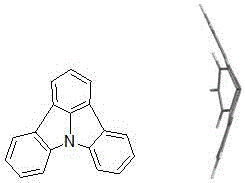

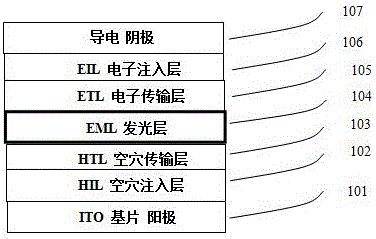

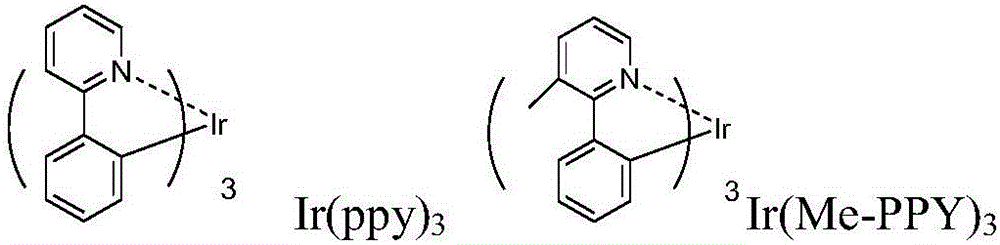

Organic metal iridium complex and organic light-emitting device application thereof

InactiveCN106831884AEnhanced charge transport capabilityImprove performanceIndium organic compoundsSolid-state devicesIridiumOrganic light emitting device

The invention discloses an organic metal iridium complex (or hybrid iridium complex). The structure of the complex is as shown in the specification, a developed indolocarbazole series serves as a unit portion of an organic metal iridium light-emitting ligand structure, the charge transfer capacity of the conjugate iridium complex is increased, the performance of an OLED (organic light-emitting diode) device can be improved, the dissolving performance of the light-emitting iridium complex can be enhanced, sublimation temperature is reduced, and a plurality of original difficultly dissolved, sublimated and purified light-emitting iridium complexes are easily dissolved, sublimated and evaporated on a large scale to prepare the OLED device.

Owner:GUANMAT OPTOELECTRONICS MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com