Patents

Literature

134results about How to "Enhanced charge transport capability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High performance ultracapacitors with carbon nanomaterials and ionic liquids

InactiveUS20080192407A1Excellent electrolyte accessibilityImprove performanceHybrid capacitor electrolytesElectrolytic capacitorsSupercapacitorCarbon nanomaterials

The present invention is directed to the use of carbon nanotubes and / or electrolyte structures comprising ionic liquids in various electrochemical devices, such as ultracapacitors.

Owner:ADA TECH

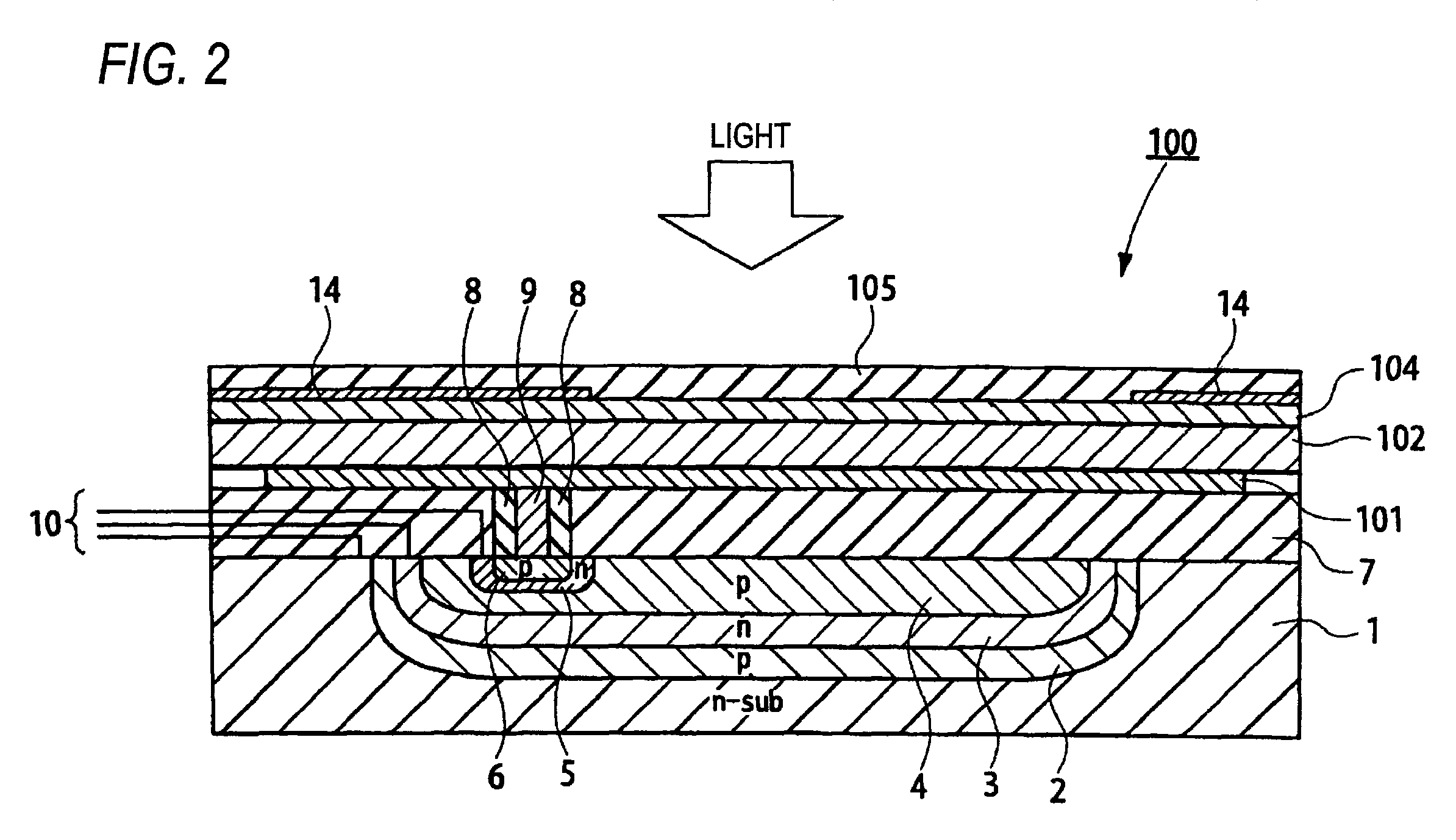

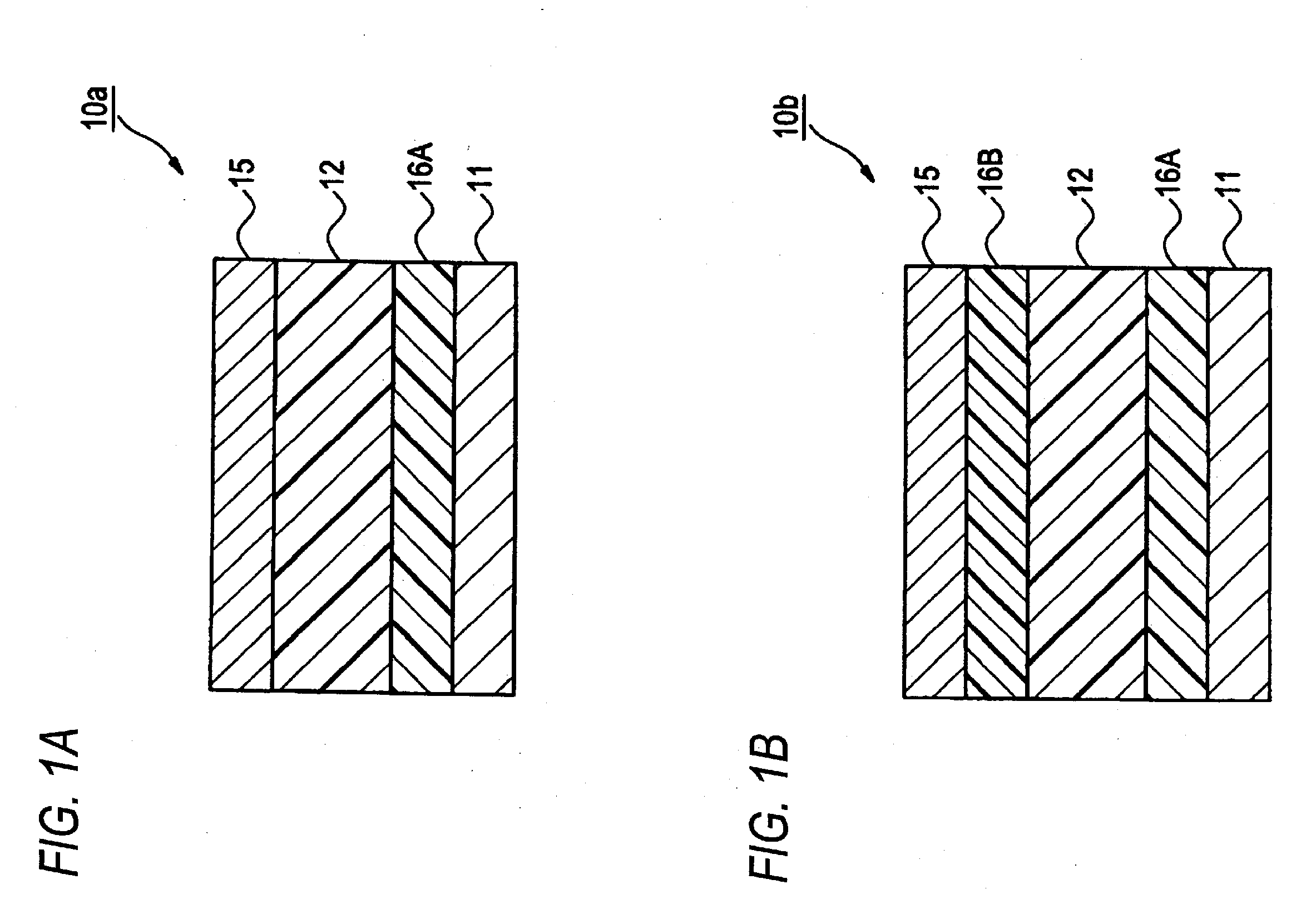

Photoelectric conversion element and imaging device

ActiveUS20090223566A1High Photoelectric Conversion EfficiencyReduce dark currentNanoinformaticsSolid-state devicesAtomic groupThin layer

A photoelectric conversion element is provided and includes: an electrically conductive thin layer; an organic photoelectric conversion layer; and a transparent electrically conductive thin layer. The organic photoelectric conversion layer contains: a compound represented by formula (I); and a fullerene or a fullerene derivative.In the formula, Z1 represents an atomic group necessary for forming a 5- or 6-membered ring, L1, L2 and L3 each independently represents an unsubstituted methine group or a substituted methine group, D1 represents an atomic group, and n represents an integer of 0 or more.

Owner:FUJIFILM CORP

Photoelectric conversion element and imaging device

ActiveUS20090189058A1High Photoelectric Conversion EfficiencyReduce dark currentNanoinformaticsSolid-state devicesHydrogen atomThin layer

A photoelectric conversion element is provided and includes: an electrically conductive thin layer; an organic photoelectric conversion layer containing a compound having a partial structure represented by the following formula (I) and a fullerene or a fullerene derivative; and a transparent electrically conductive thin layer.X represents O, S or N—R10, R10 represents a hydrogen atom or a substituent, Rx and Ry represent a hydrogen atom or a substituent, with at least one representing an electron-withdrawing group, Rx and Ry may combine to form a ring, R represents a bond (—), a hydrogen atom or a substituent, with at least one being the bond, nr represents an integer of 1 to 4, R's may be the same or different when nr is 2 or more, and R's at the 2- and 3-positions or R's at the 5- and 6-positions may combine with each other to form a ring.

Owner:FUJIFILM CORP

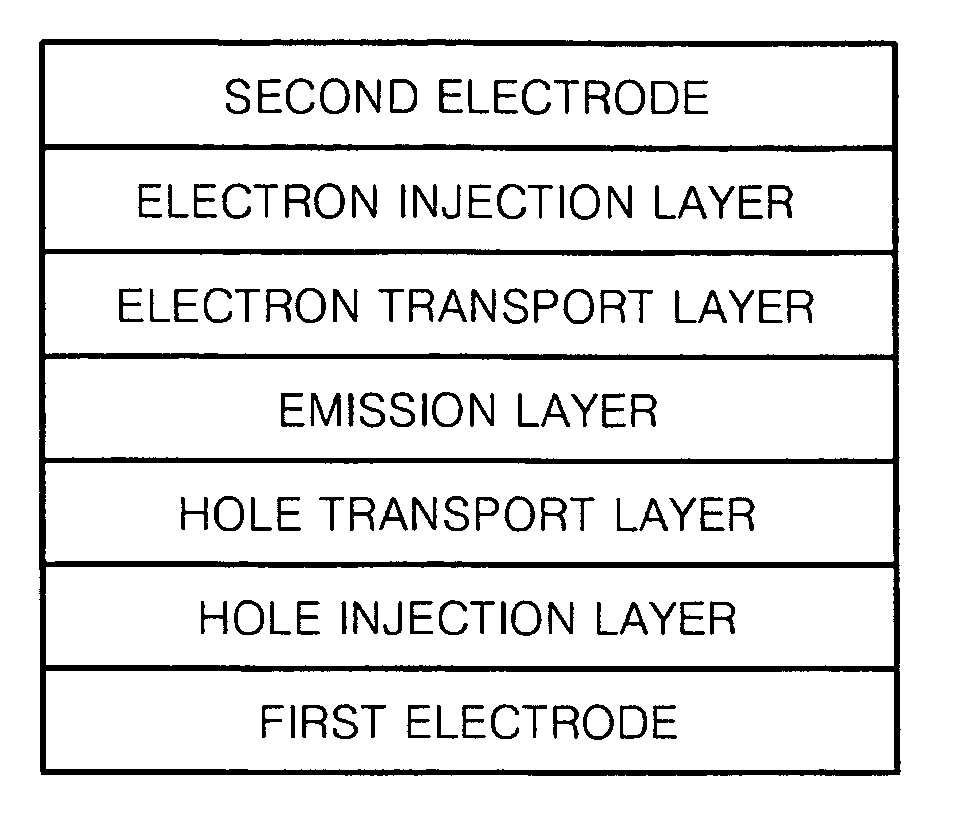

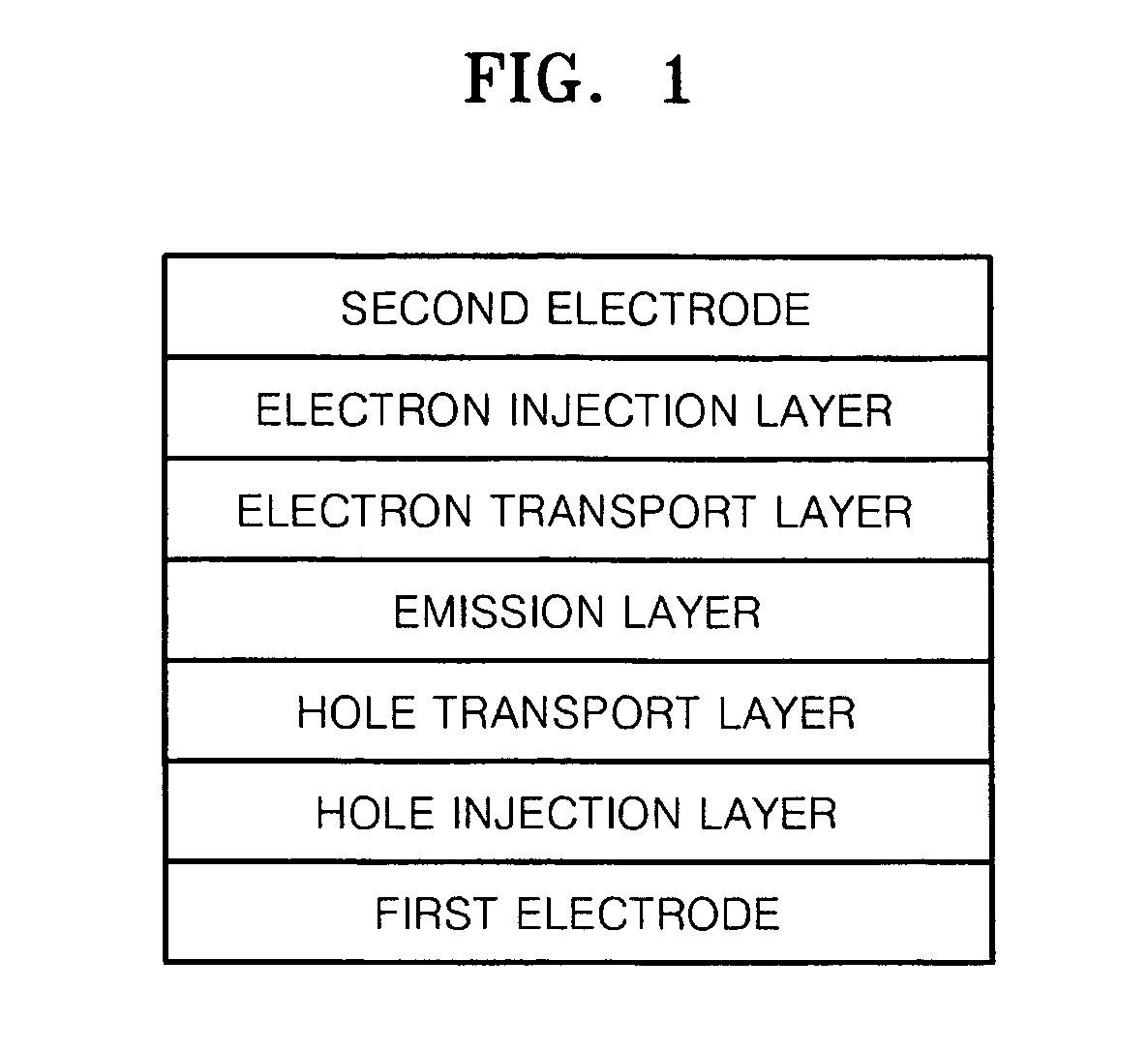

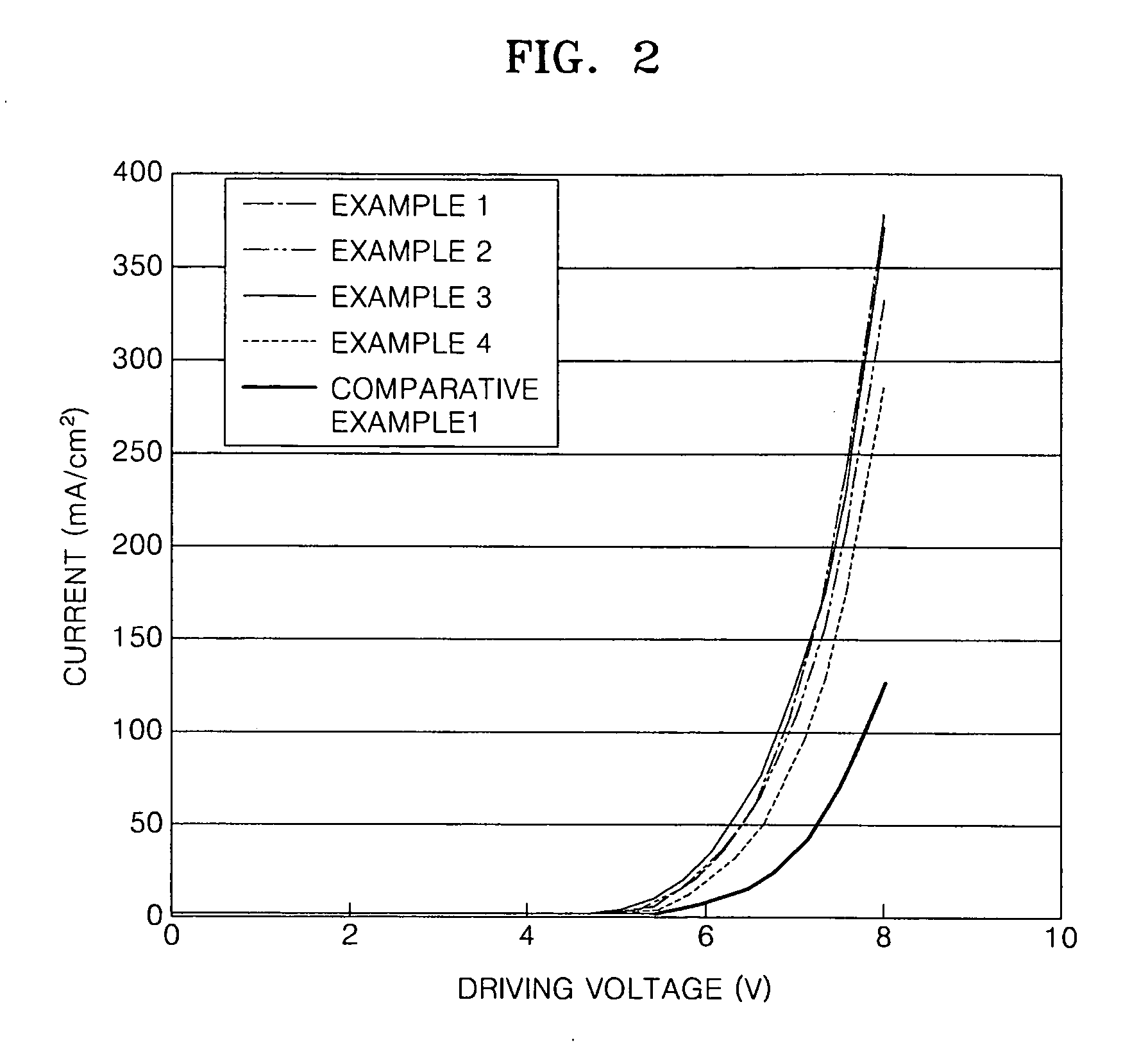

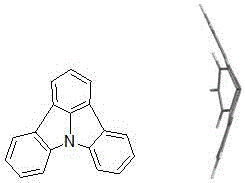

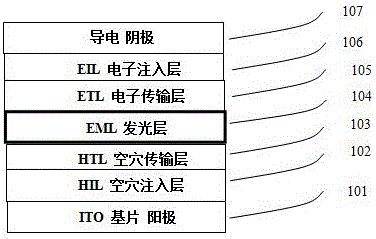

Silicon-containing compound and organic electroluminescent device employing the same

ActiveUS20100051914A1Improve efficiencyReduce the driving voltageSilicon organic compoundsSolid-state devicesCarbazoleOrganic light emitting device

Provided are a silicon-containing compound having carbazole and fluorene in its molecule and an organic electroluminescent device including an organic layer employing the same. The silicon-containing compound is represented by the following formula:The silicon-containing compound has excellent electrical characteristics and a charge transporting capability, the silicon-containing compound can be used as a hole injecting material, a hole transporting material, and / or a light emitting material that are suitable for all-color fluorescent and phosphorescent organic light emitting devices such as red, green, blue, and white fluorescent and phosphorescent organic light emitting devices. When the silicon-containing compound is used to manufacture an organic electroluminescent device, the organic electroluminescent device has a high efficiency, a low driving voltage, high luminosity, and a long lifetime.

Owner:SAMSUNG DISPLAY CO LTD

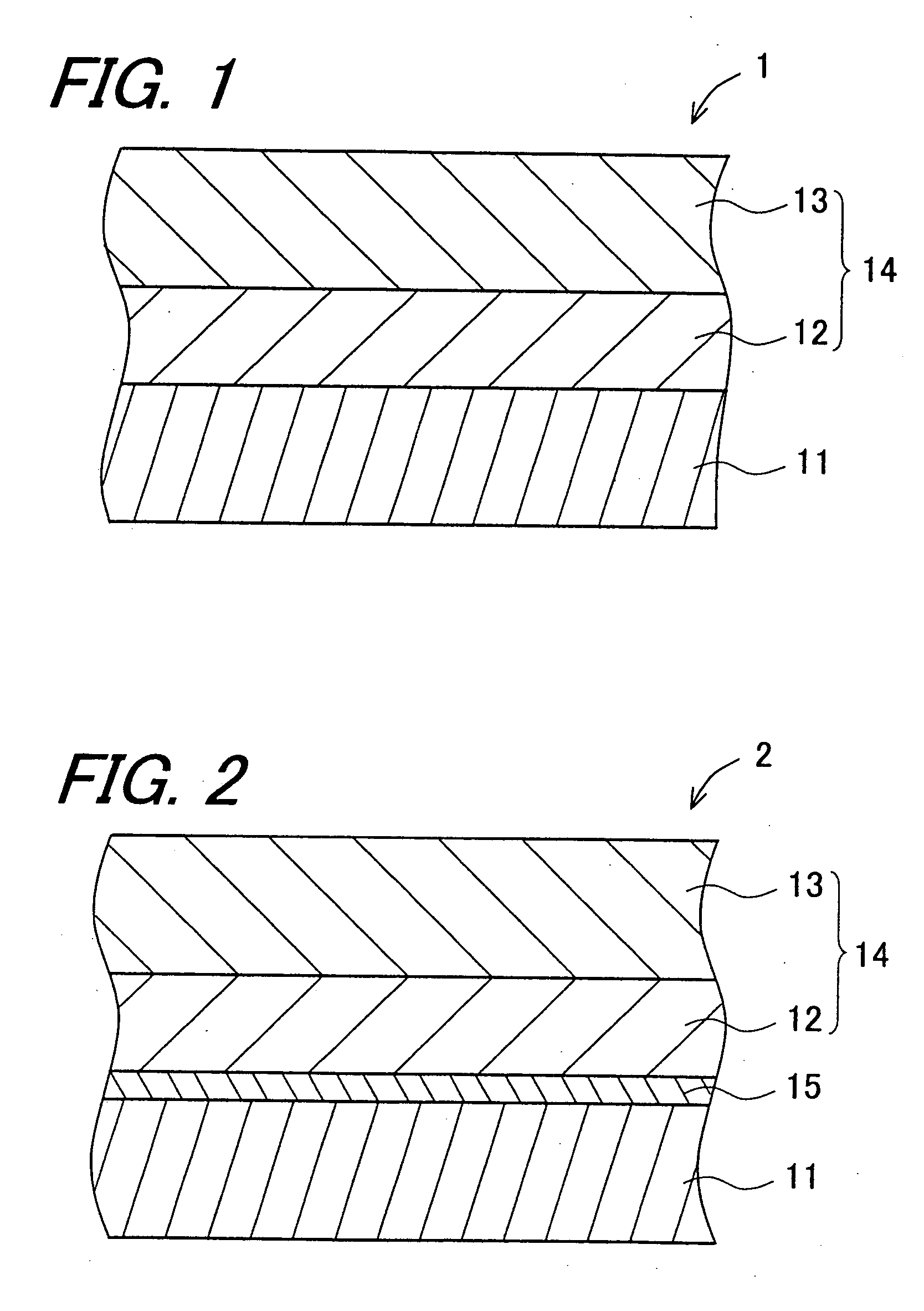

Electrophotographic photoconductor, image forming method, image forming apparatus, and process cartridge

InactiveUS20070231720A1Excellent abrasion resistanceStably forming high-quality imageElectrographic process apparatusCorona dischargeElectrical conductorCompound (substance)

A preferred aspect of an electrophotographic photoconductor of the present invention contains a layer containing a hardened material which is prepared by polymerizing (A) a chain-polymerizable group-containing tertiary amine compound in which at least one alkyl group is bound to a nitrogen atom constituting an amine structure through chain polymerization. Another preferred aspect of the electrophotographic photoconductor contains a layer containing a hardened material which is prepared by polymerizing the (A) component, and (B) a chain-polymerizable charge transporting compound through chain polymerization. Still another preferred aspect of the electrophotographic photoconductor contains a layer containing a hardened material which is prepared by polymerizing the (A) component, (B) the chain-polymerizable charge transporting compound, and (C) a trifunctional or more chain-polymerizable compound through chain polymerization.

Owner:RICOH KK

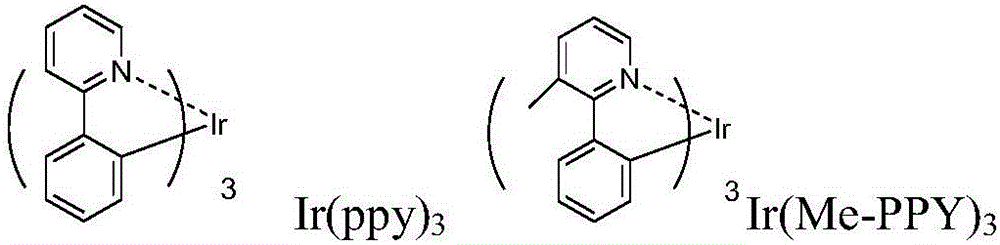

Organic metal iridium complex and organic light-emitting device application thereof

InactiveCN106831884AEnhanced charge transport capabilityImprove performanceIndium organic compoundsSolid-state devicesIridiumOrganic light emitting device

The invention discloses an organic metal iridium complex (or hybrid iridium complex). The structure of the complex is as shown in the specification, a developed indolocarbazole series serves as a unit portion of an organic metal iridium light-emitting ligand structure, the charge transfer capacity of the conjugate iridium complex is increased, the performance of an OLED (organic light-emitting diode) device can be improved, the dissolving performance of the light-emitting iridium complex can be enhanced, sublimation temperature is reduced, and a plurality of original difficultly dissolved, sublimated and purified light-emitting iridium complexes are easily dissolved, sublimated and evaporated on a large scale to prepare the OLED device.

Owner:GUANMAT OPTOELECTRONICS MATERIALS INC

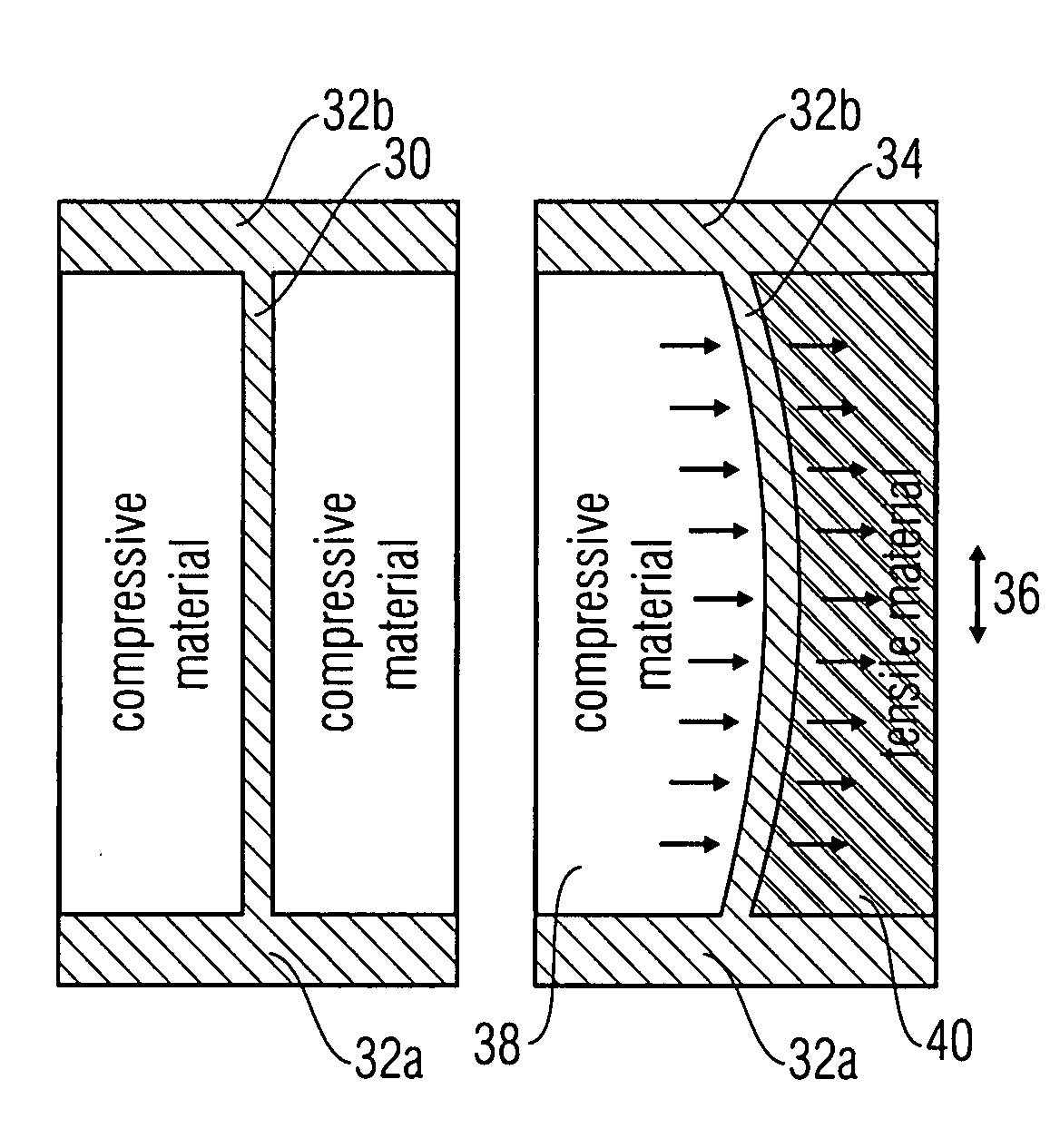

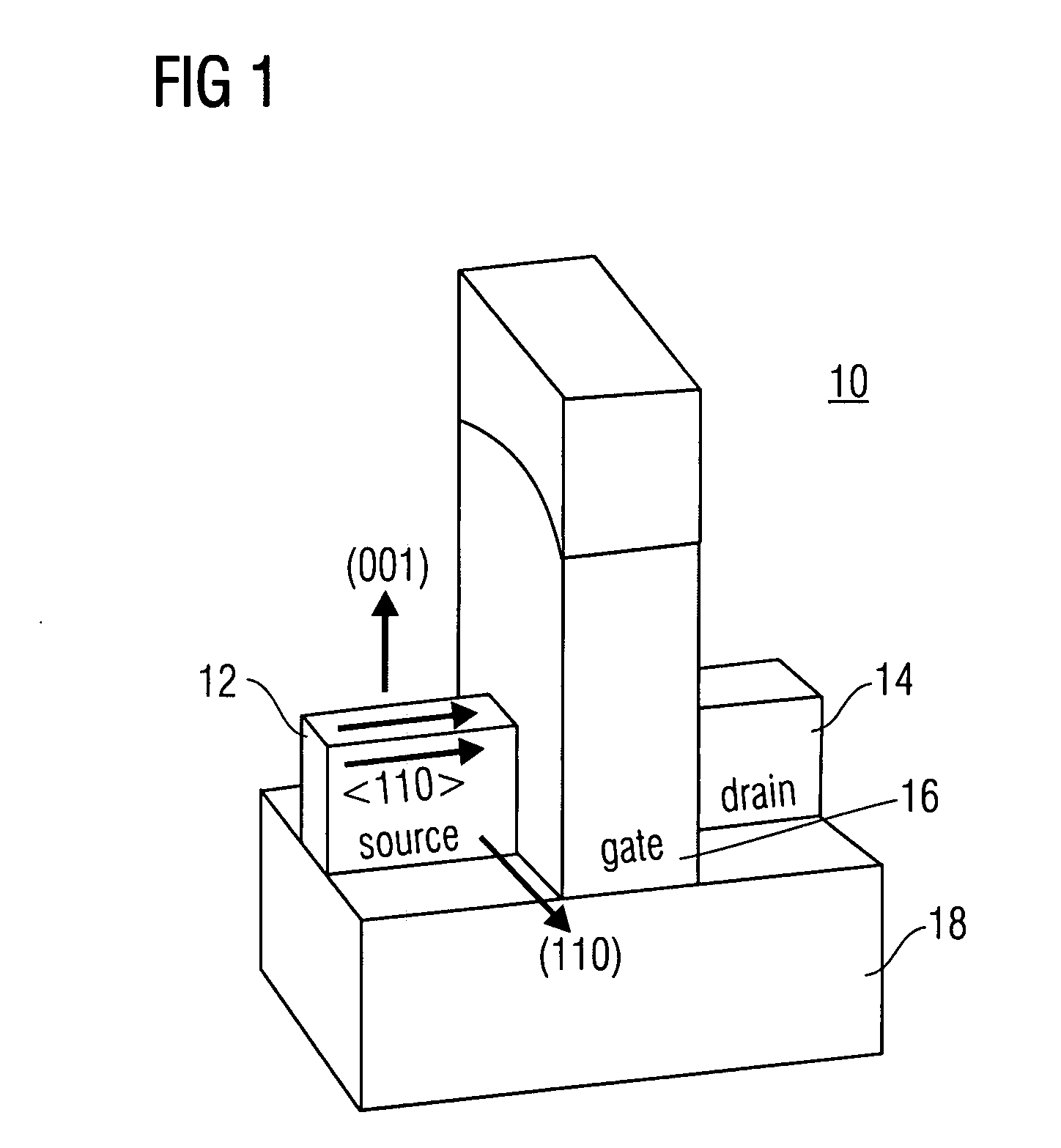

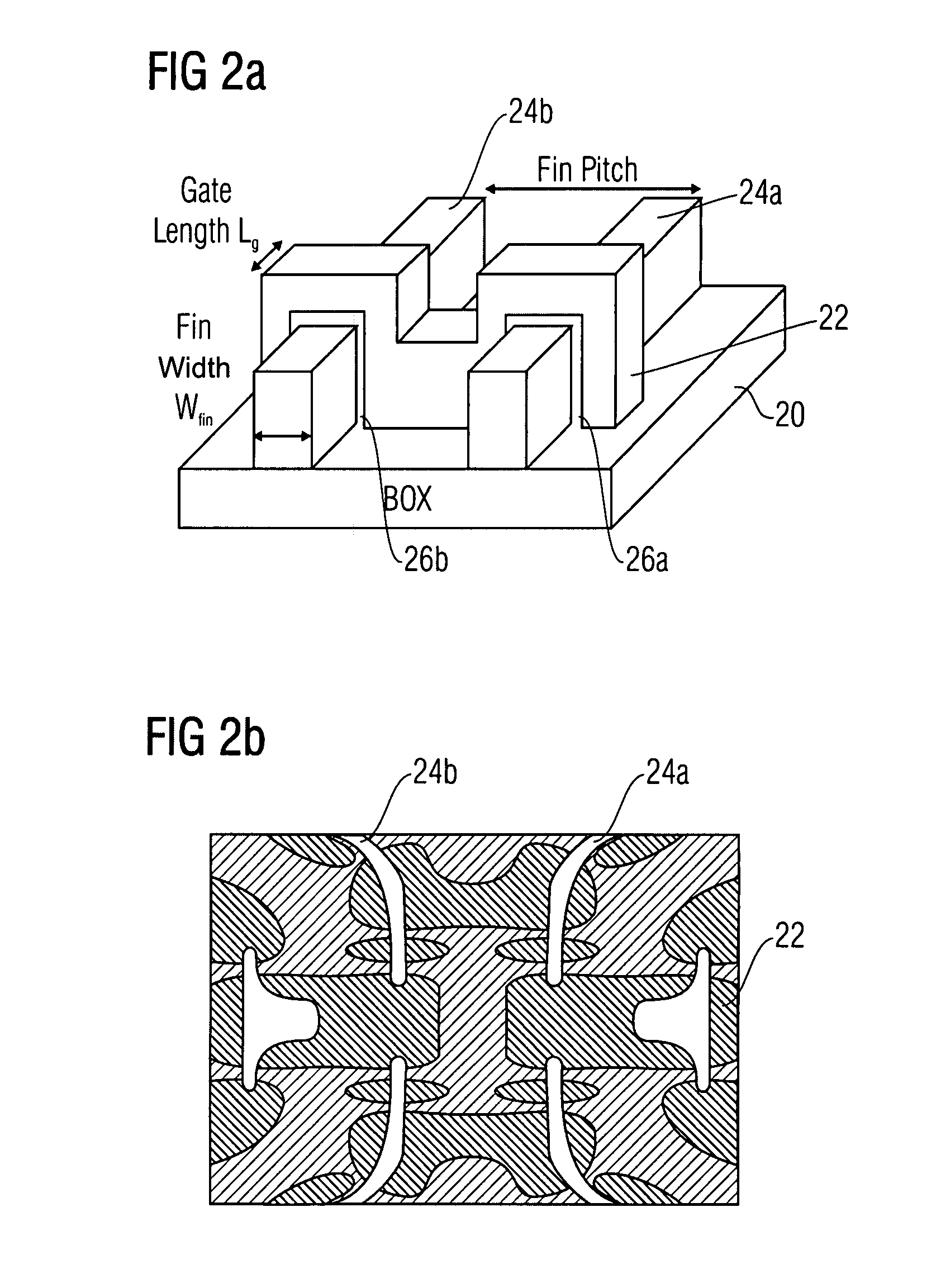

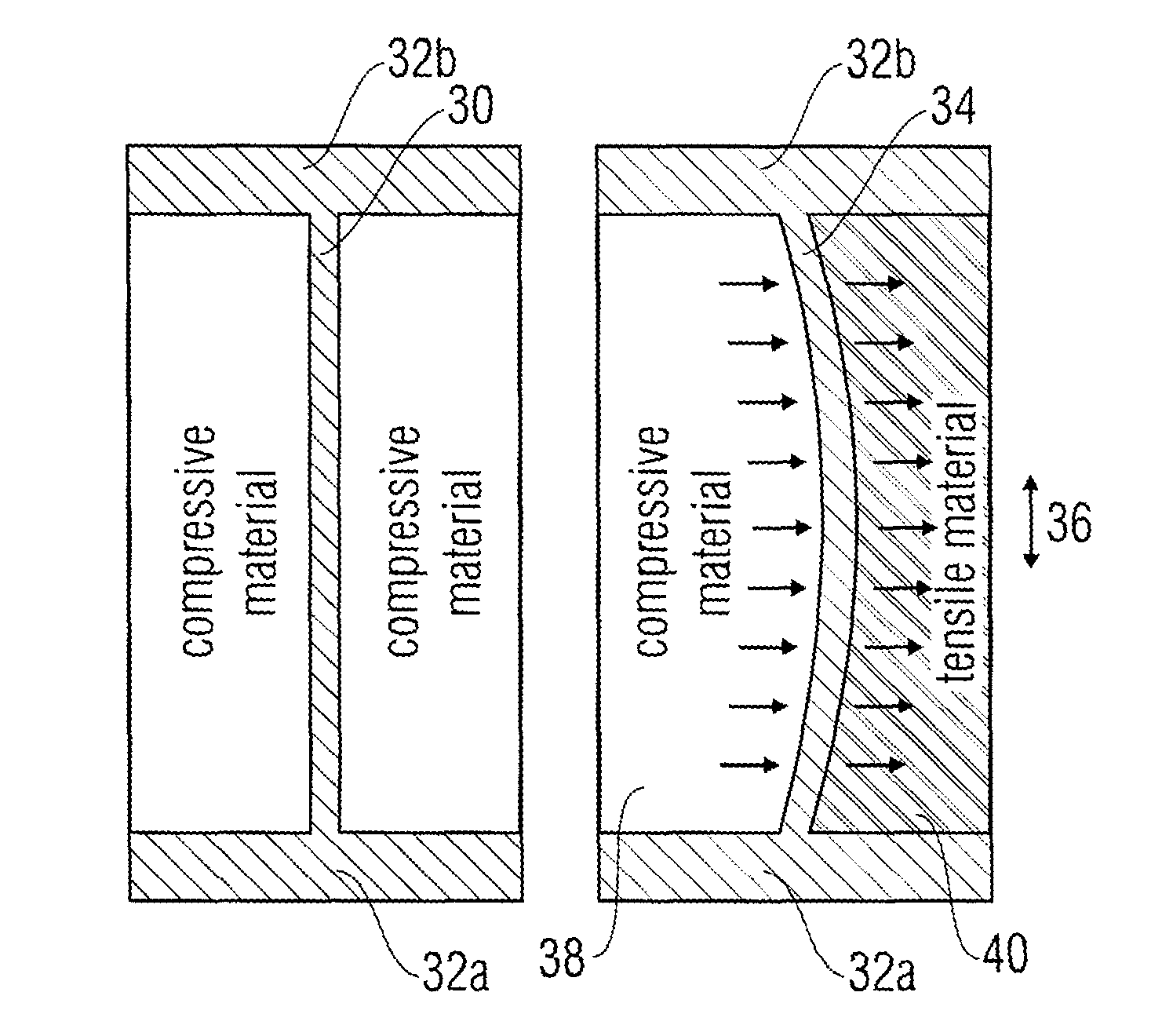

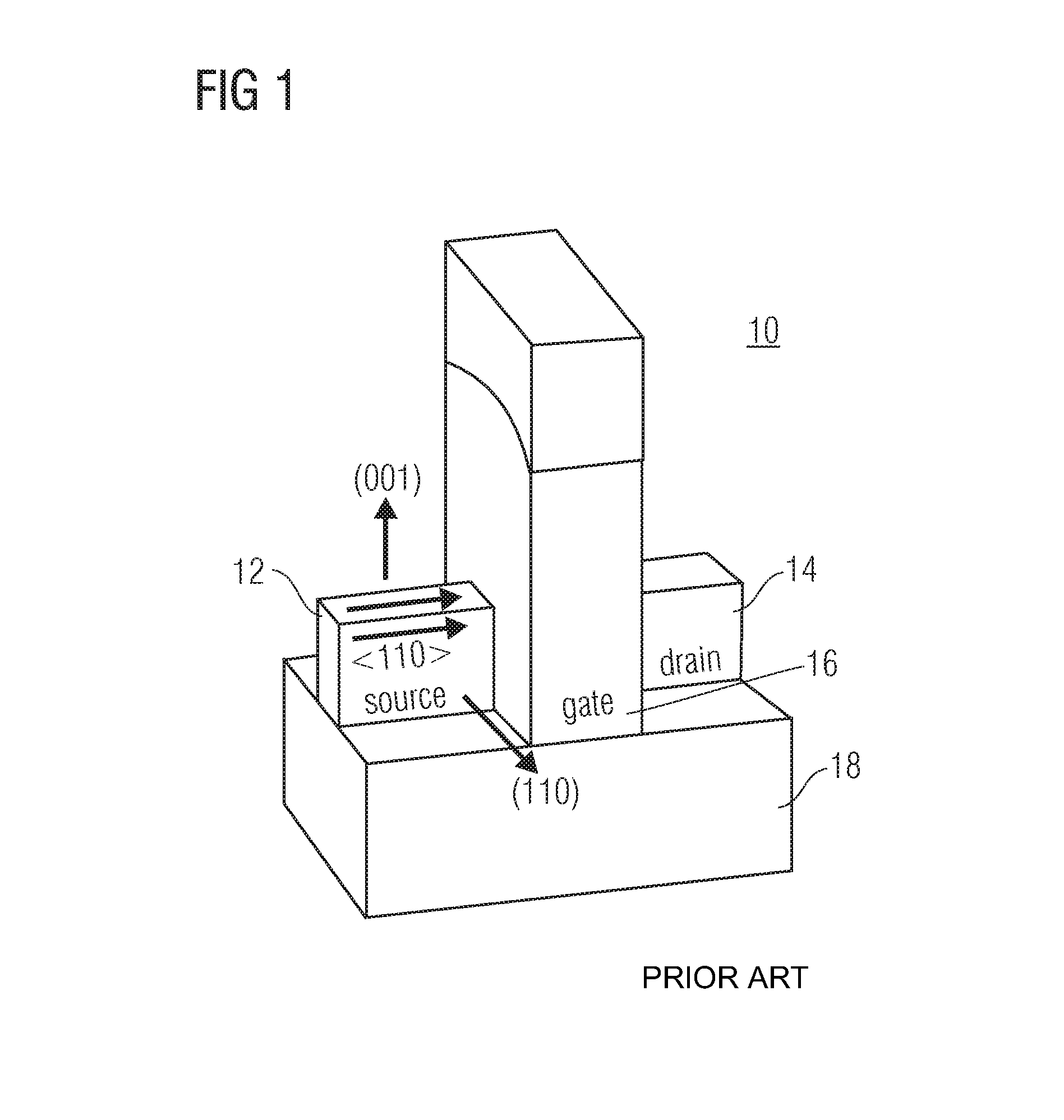

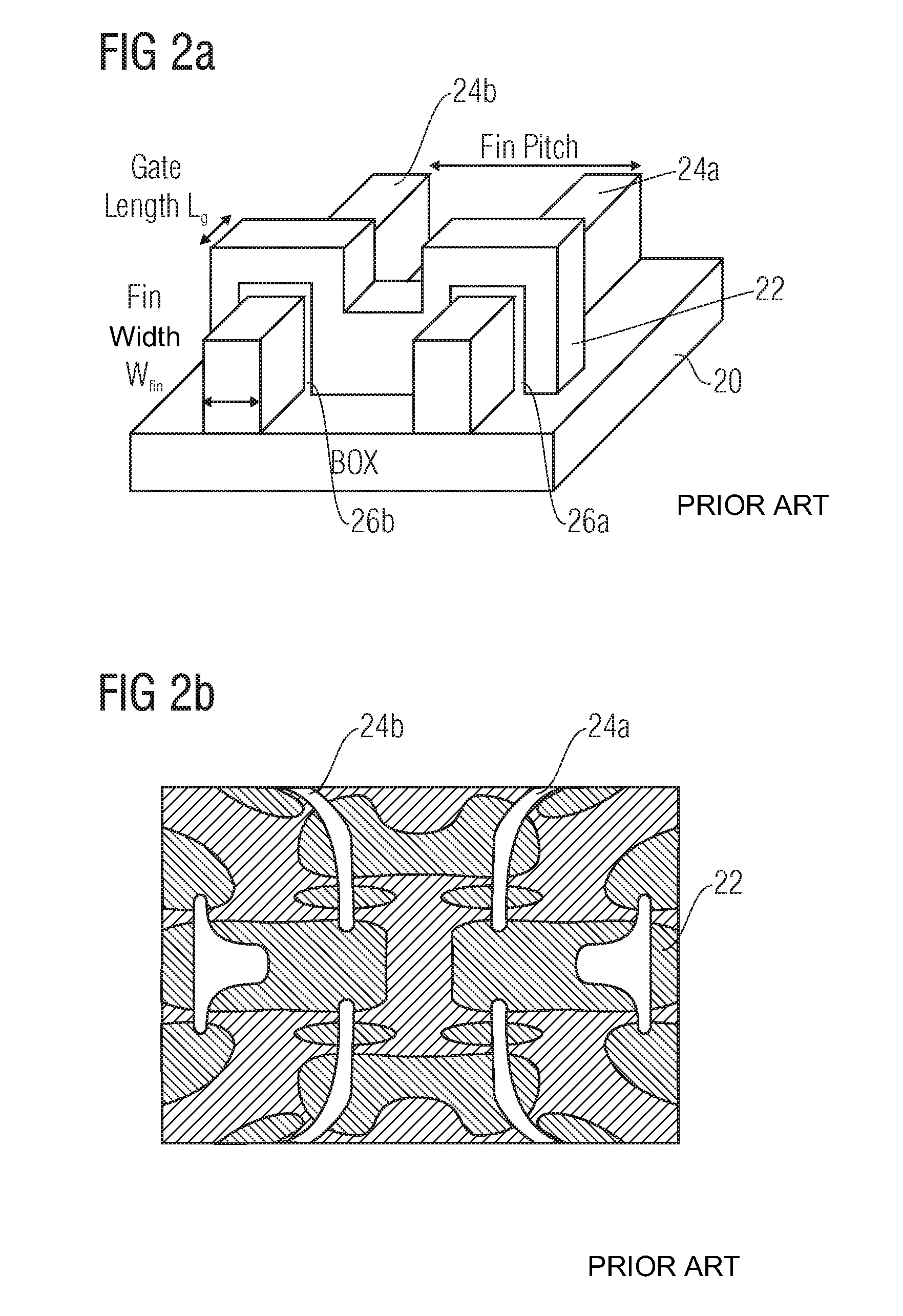

Method for Fabricating a Fin-Shaped Semiconductor Structure and a Fin-Shaped Semiconductor Structure

ActiveUS20090114955A1Enhanced “ three-dimensional ”Enhanced charge transport capabilitySolid-state devicesSemiconductor/solid-state device manufacturingTensile strainSemiconductor materials

A fin-shaped structure is formed from a semiconductor material. The fin-shaped structure is processed to generate a tensile strain within the semiconductor material along a longitudinal direction of the fin.

Owner:INFINEON TECH AG

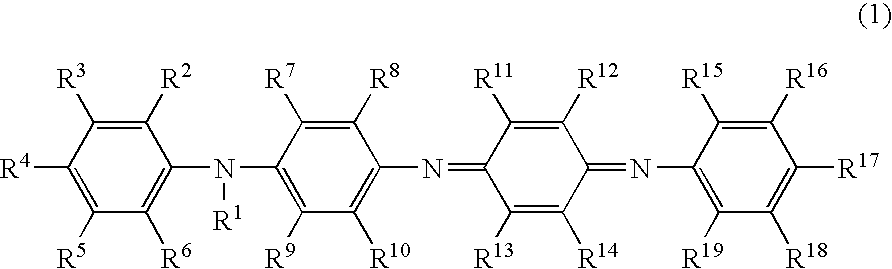

Condensed polycyclic compound, condensed polycyclic polymer and organic thin film containing the compound or the polymer

InactiveUS20110040069A1Enhanced charge transport capabilityImprove solubilityOrganic chemistrySolid-state devicesPolycyclic compoundAryl

An object of the present invention is to provide a polycyclic fused ring polymer which has a structure capable of showing high charge transport properties and also is excellent in solubility into a solvent. The polycyclic fused ring polymer according to the present invention includes: a plurality of one of a first structural unit represented by the following formula (1) and a second structural unit represented by the following formula (2); or the first structural unit and the second structural unit in combination:wherein X1 and X2 represent an oxygen atom, a sulfur atom or a selenium atom, and R1 and R2 represent a halogen atom, an unsaturated alkyl group, an alkyl group, a non-alkyl group containing an alkyl group, an aryl group, or a monovalent heterocyclic group; R3 and R4 represent a monovalent group, and when a plurality of R3 and R4 exist, these may be the same or different; and m, n, s and t are an integer of 0 to 2.

Owner:OSAKA UNIV +1

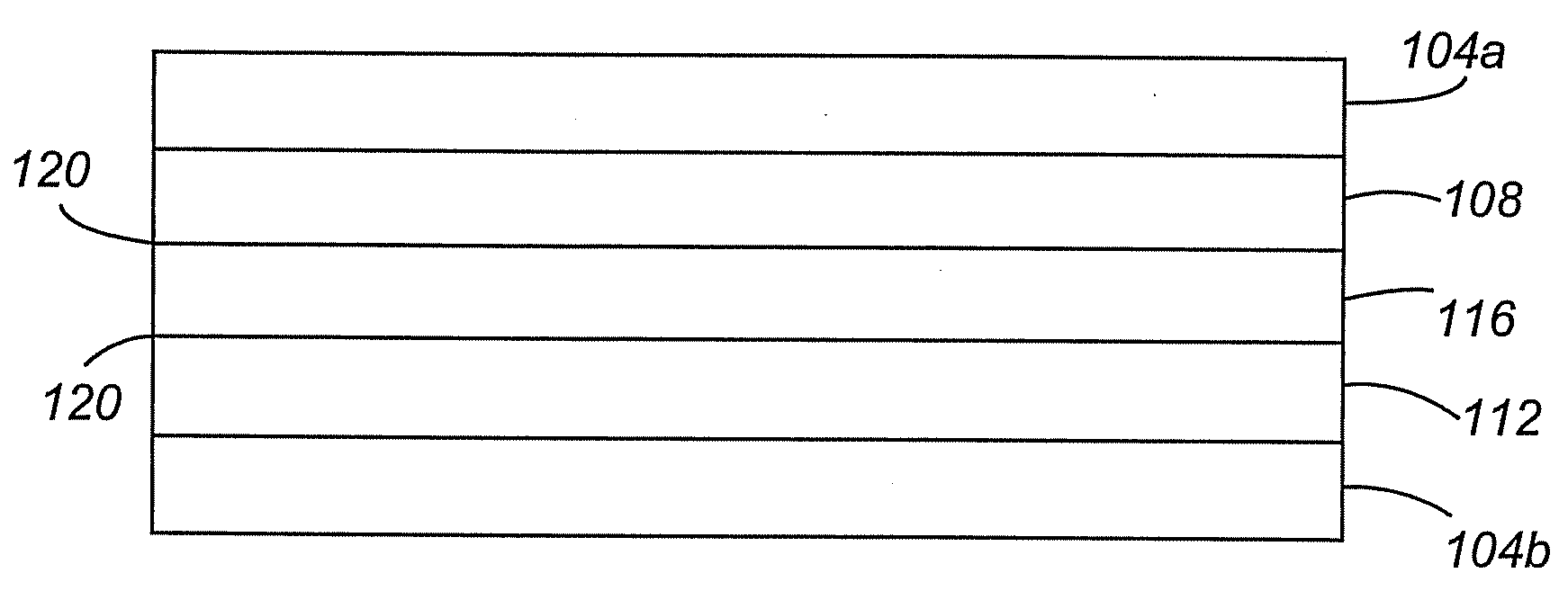

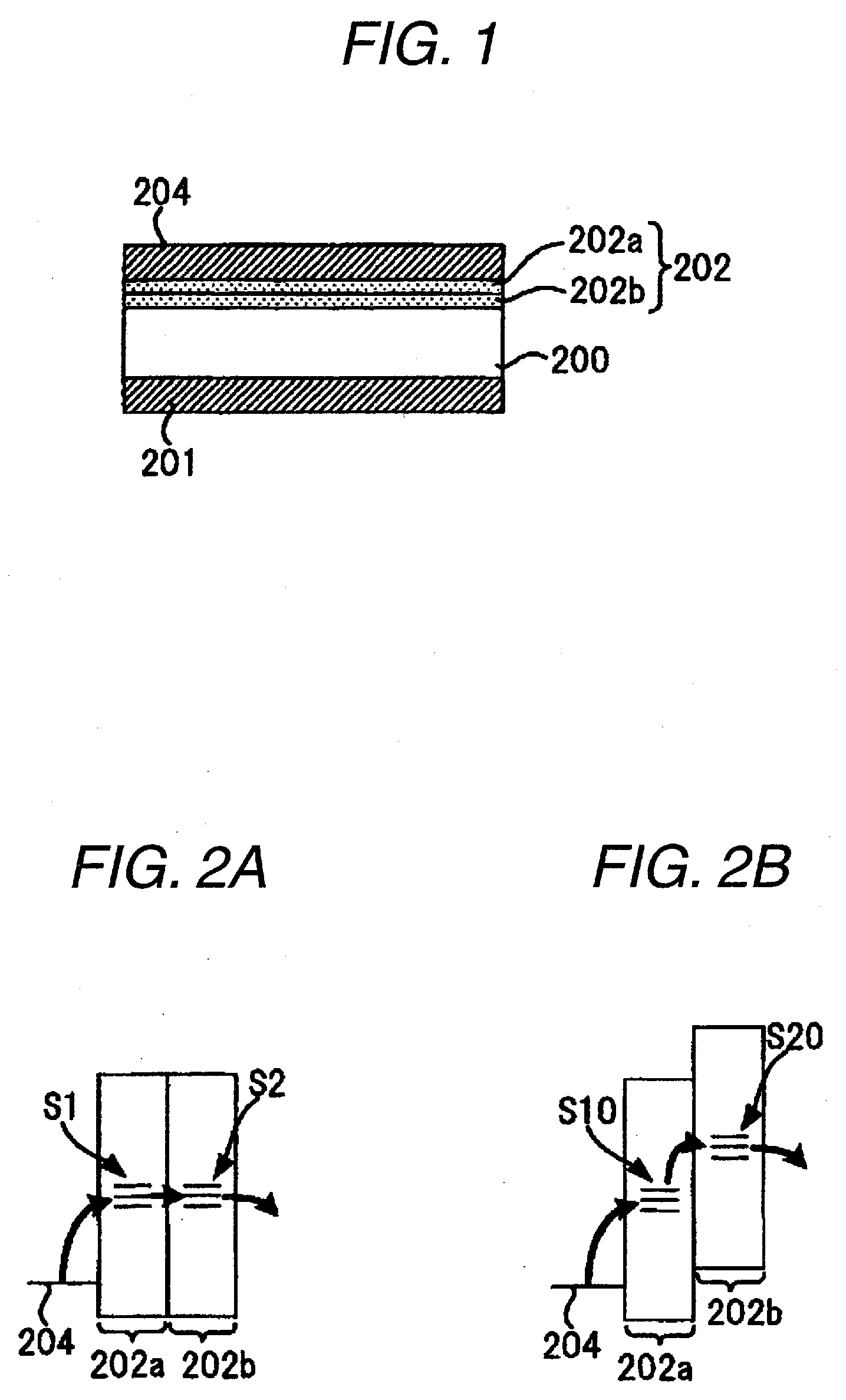

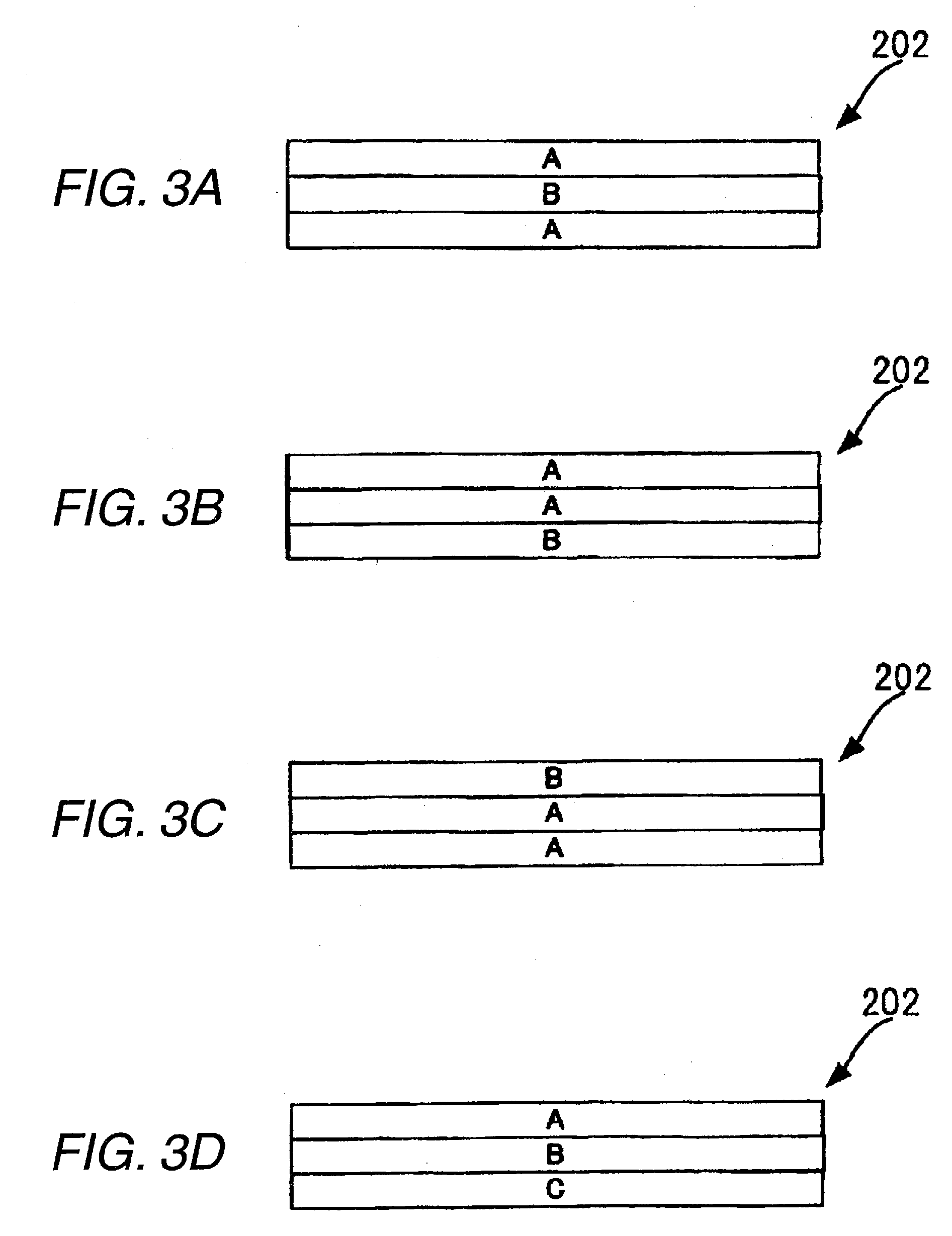

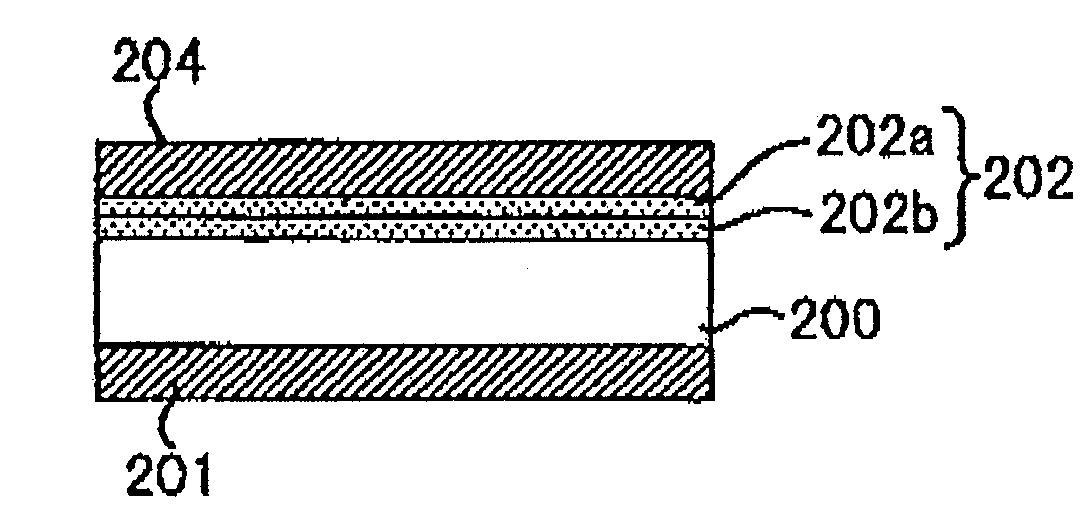

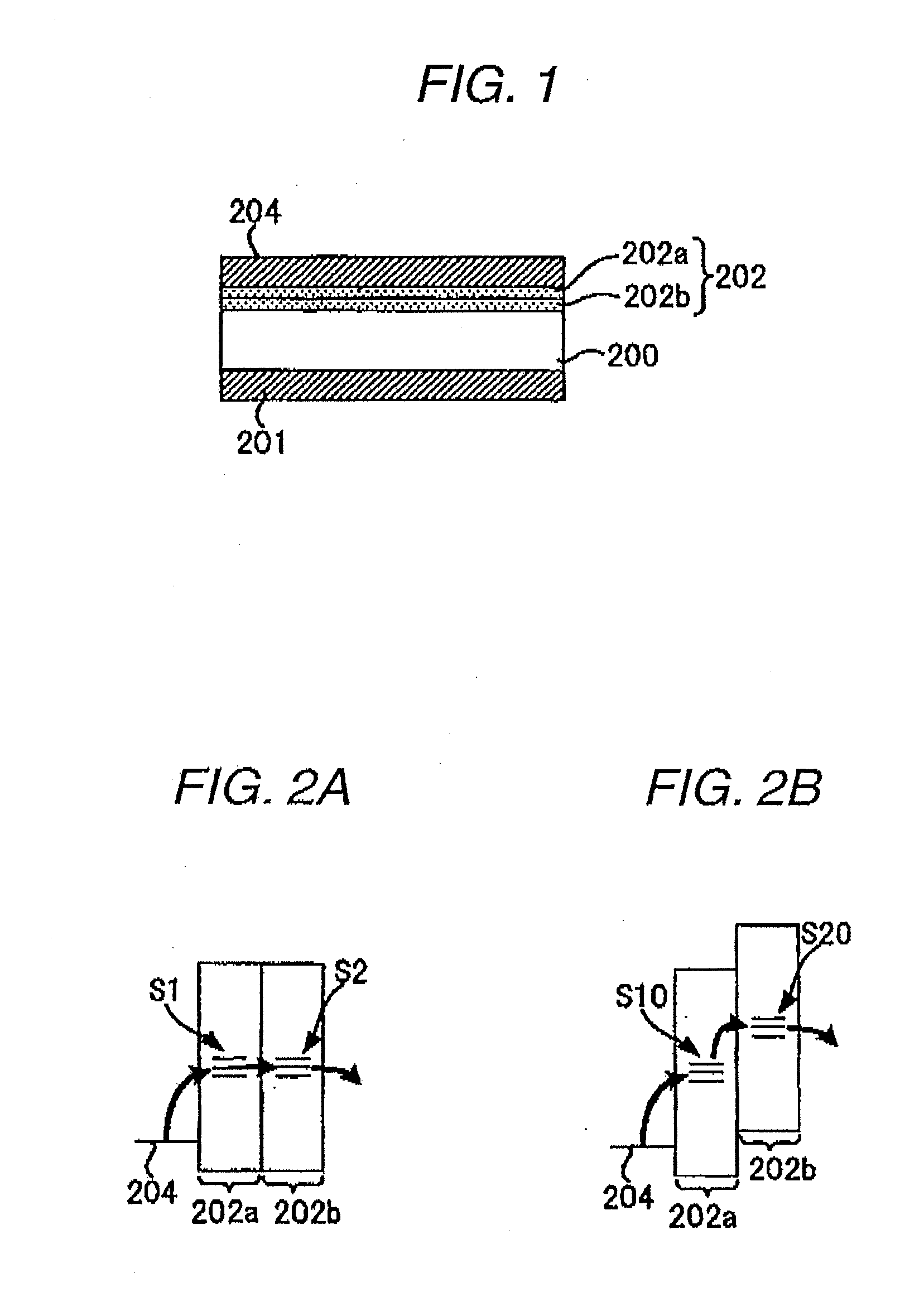

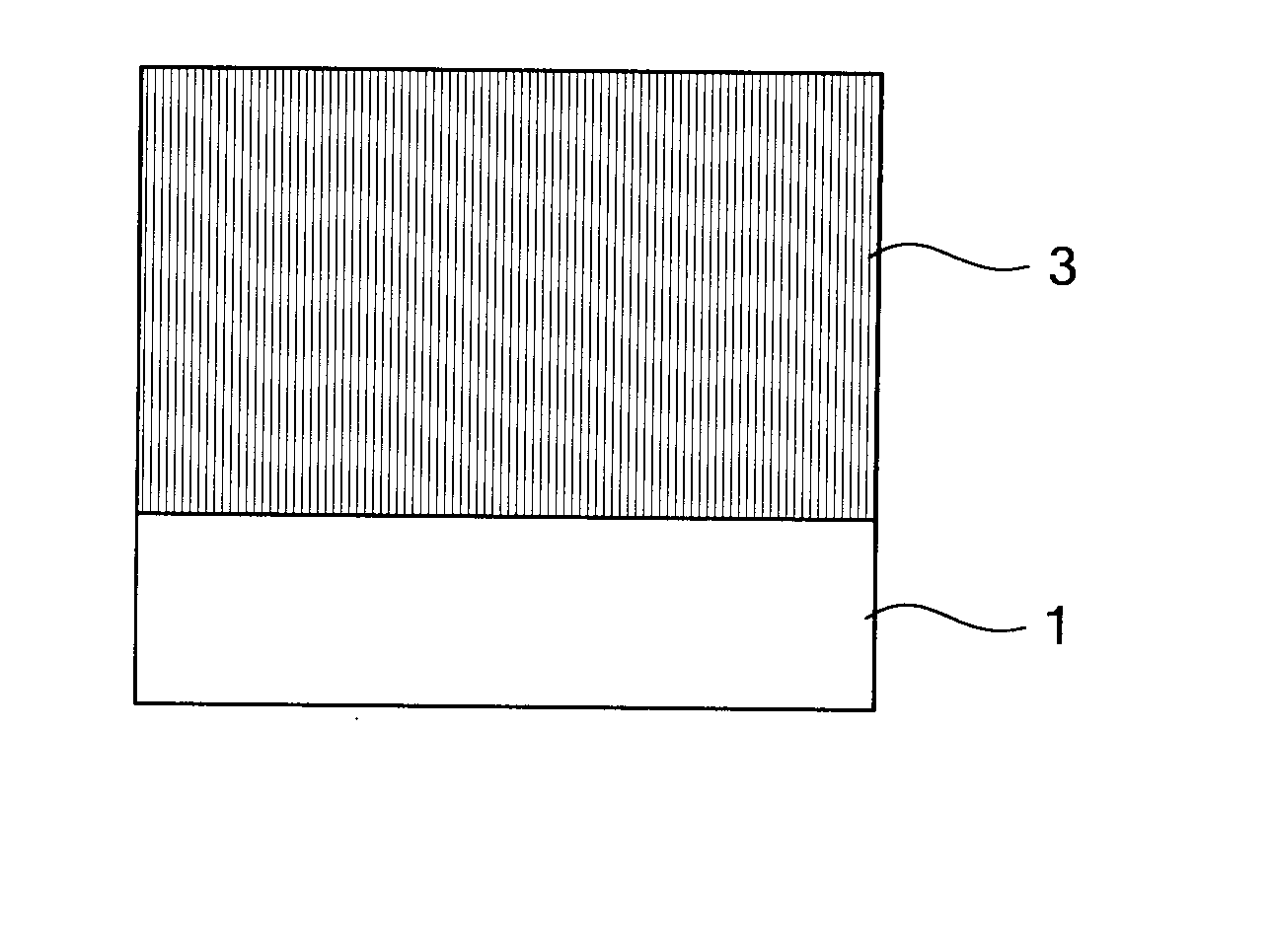

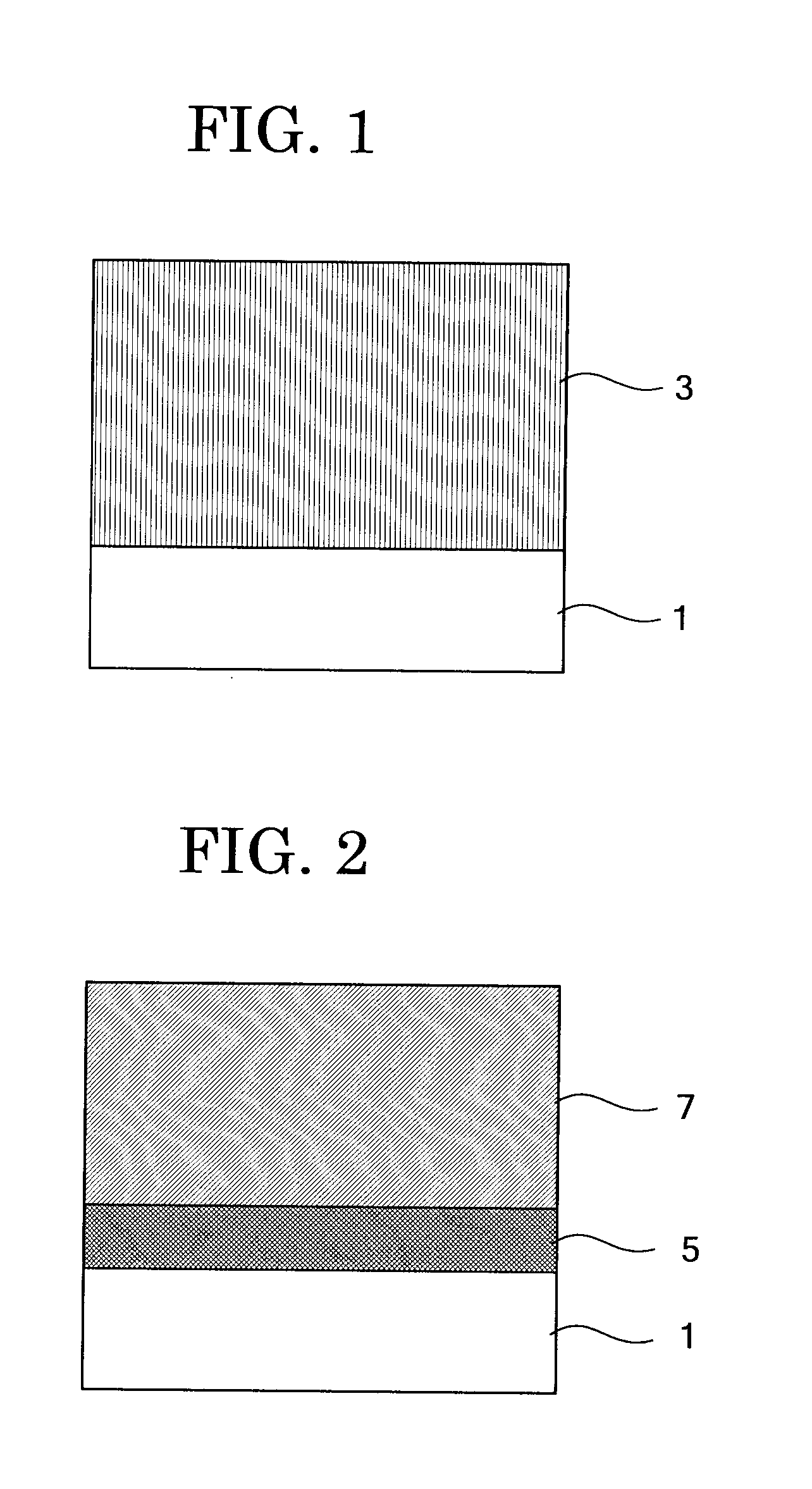

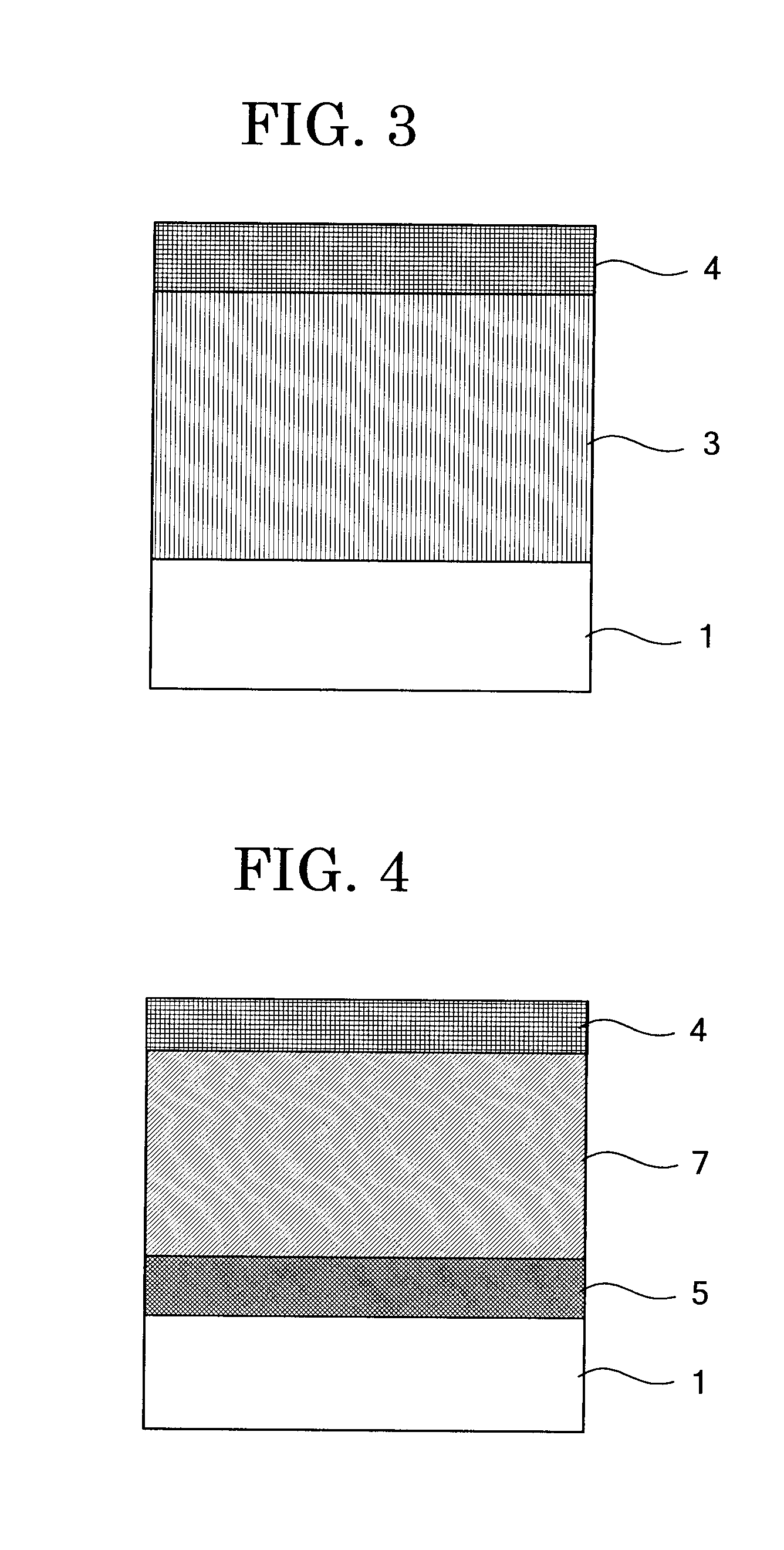

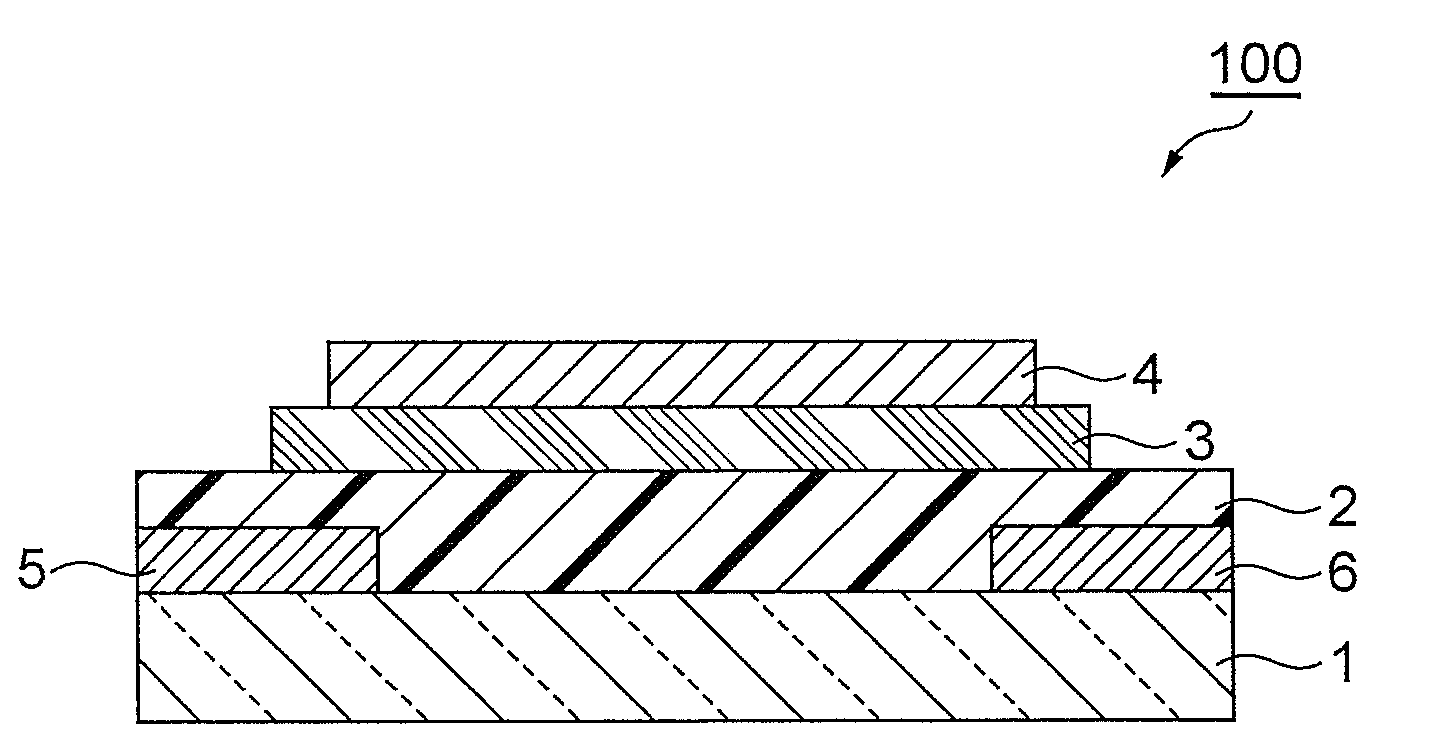

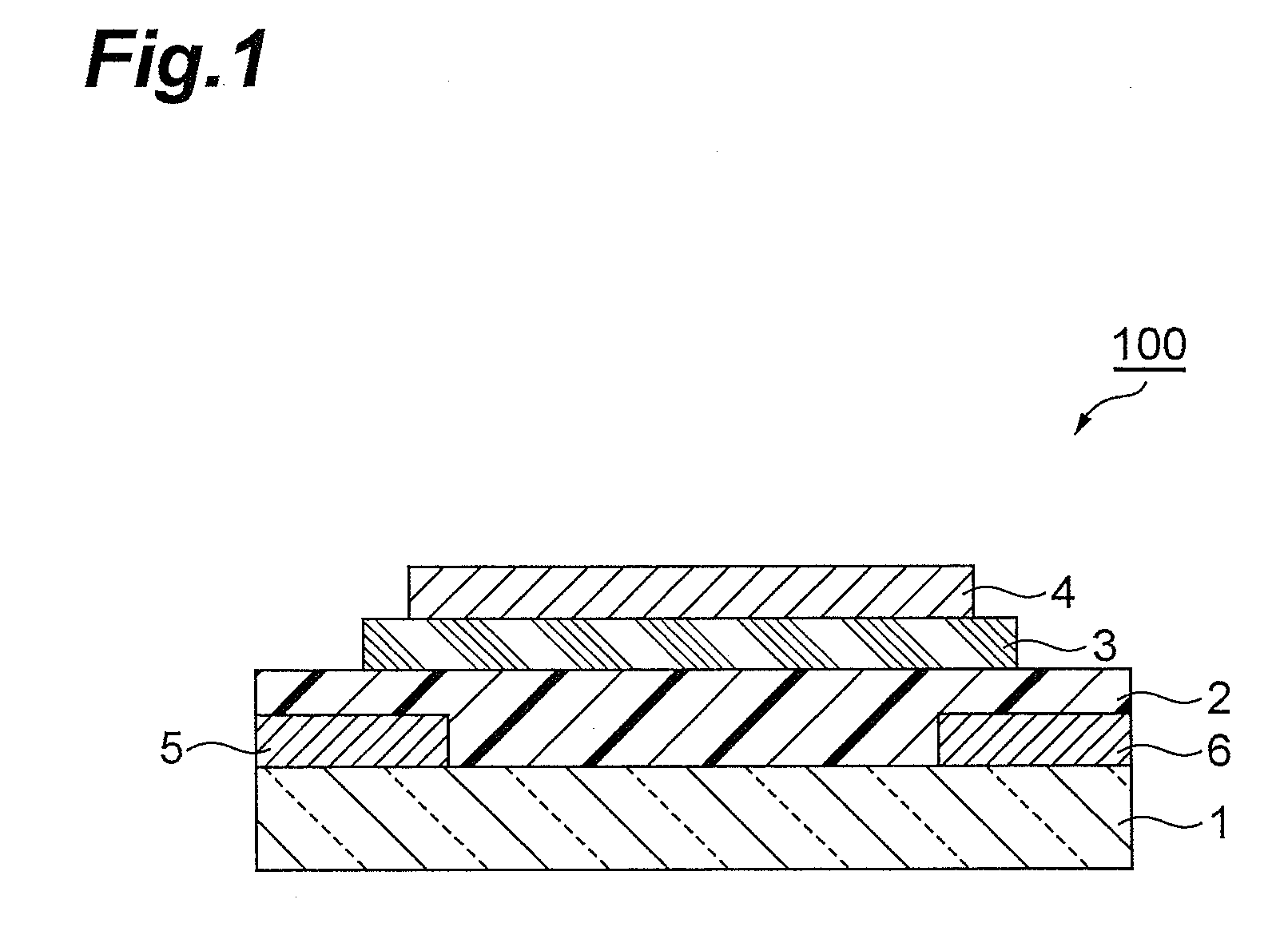

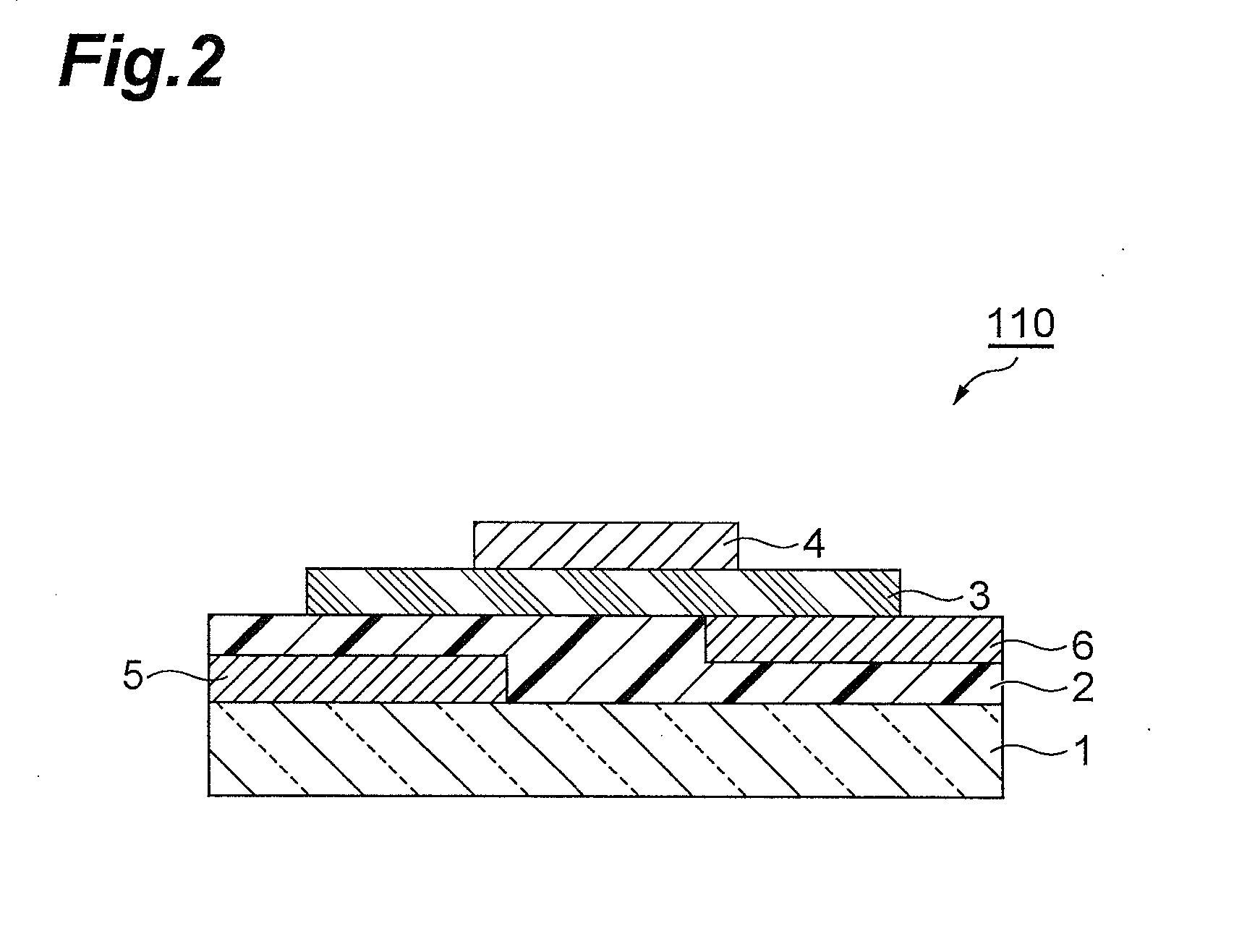

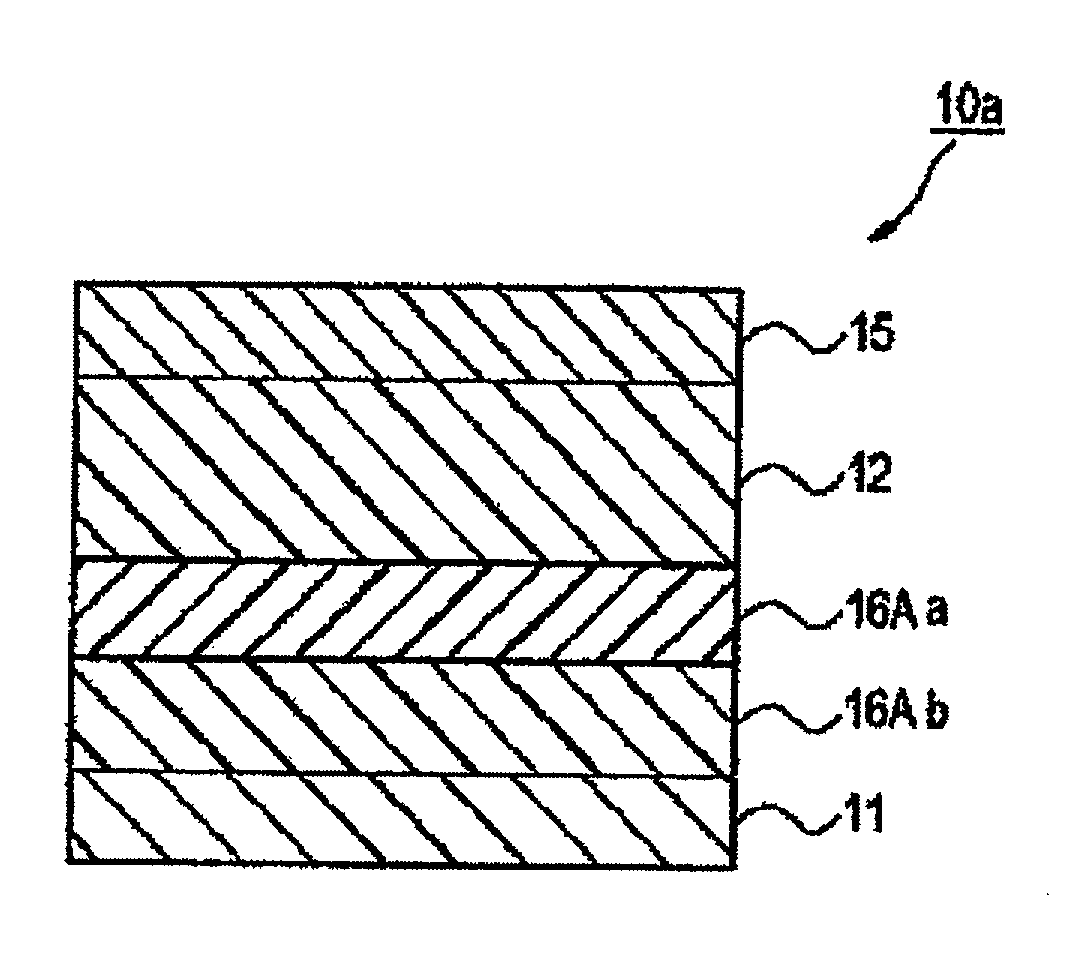

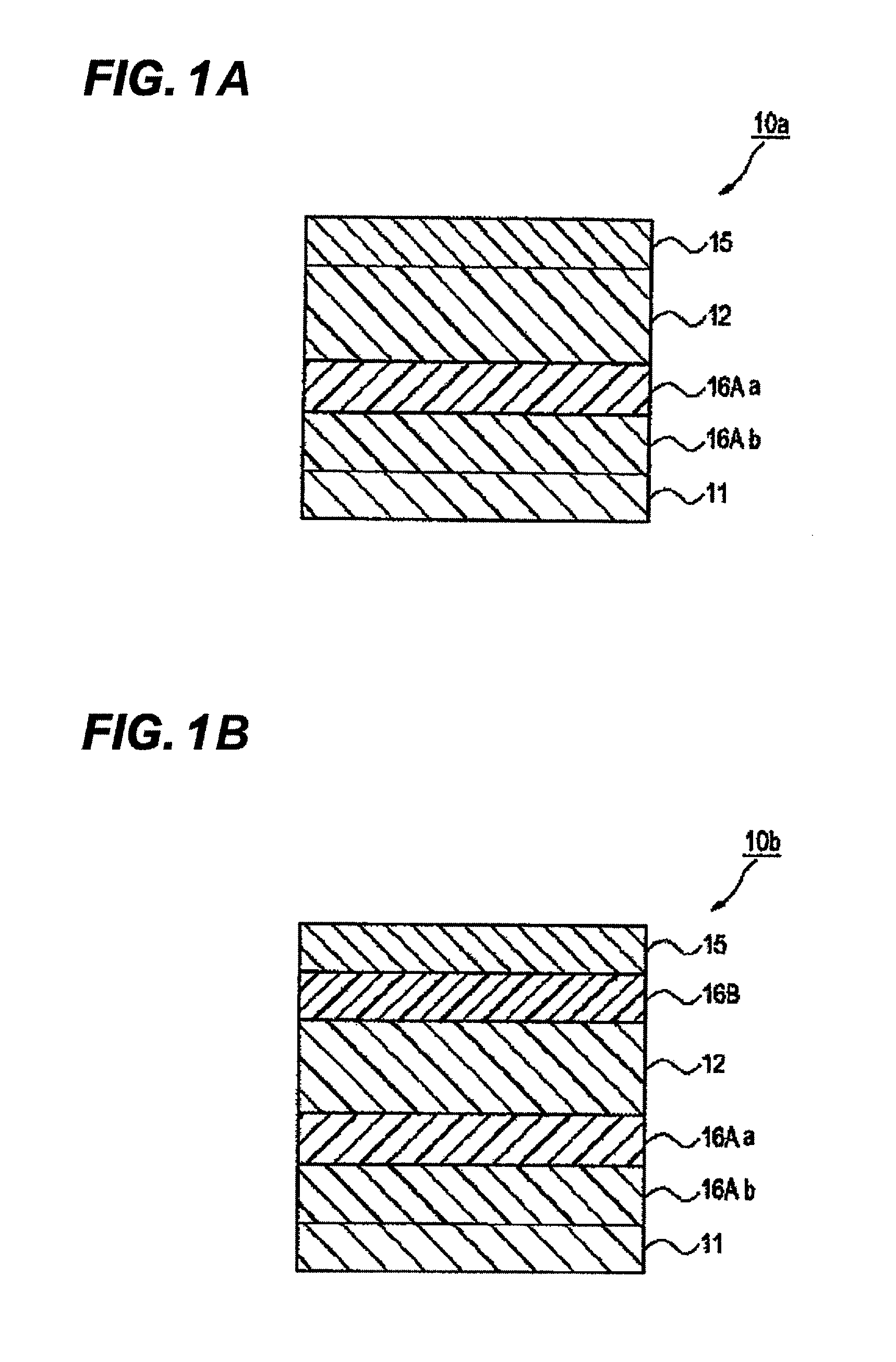

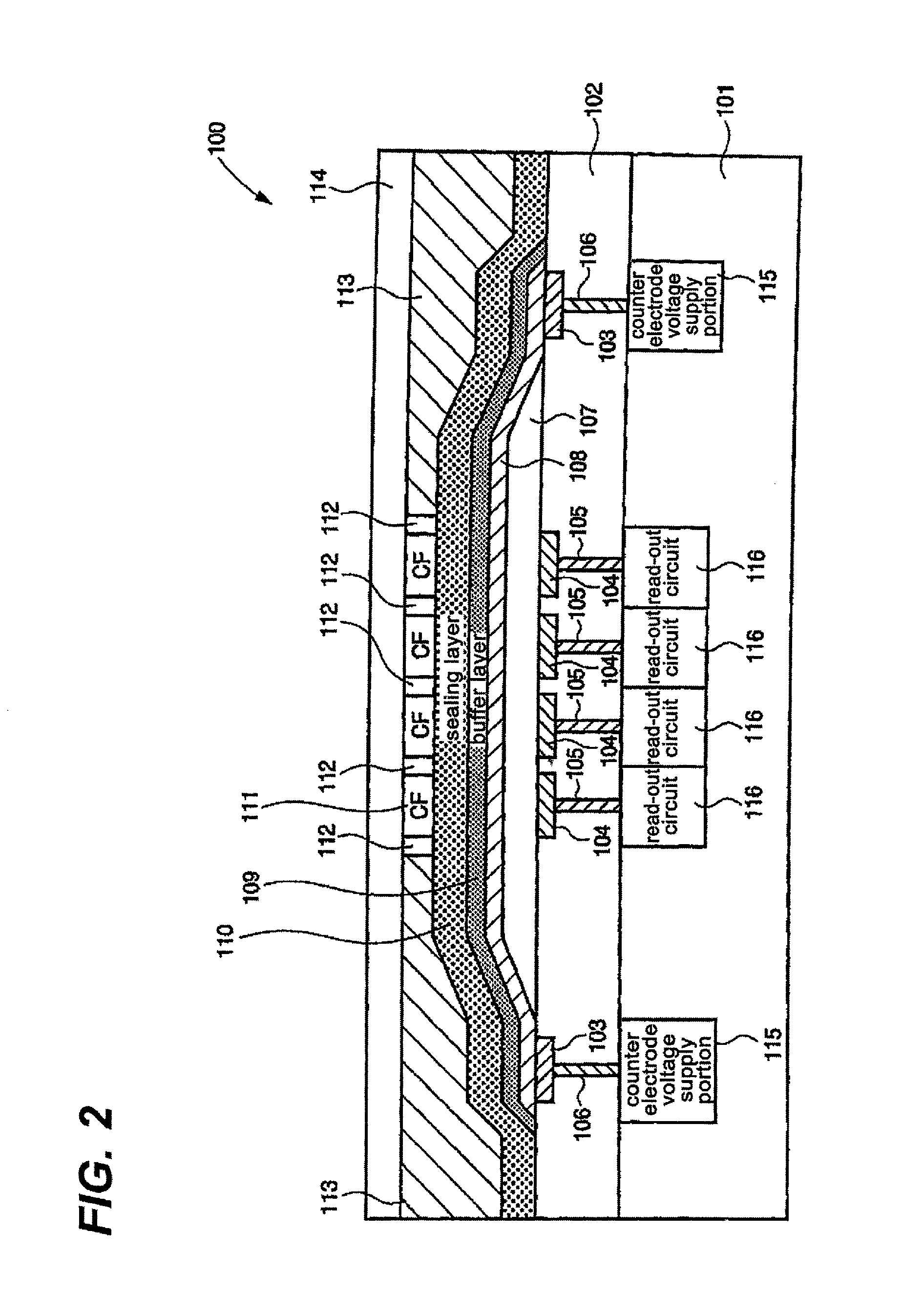

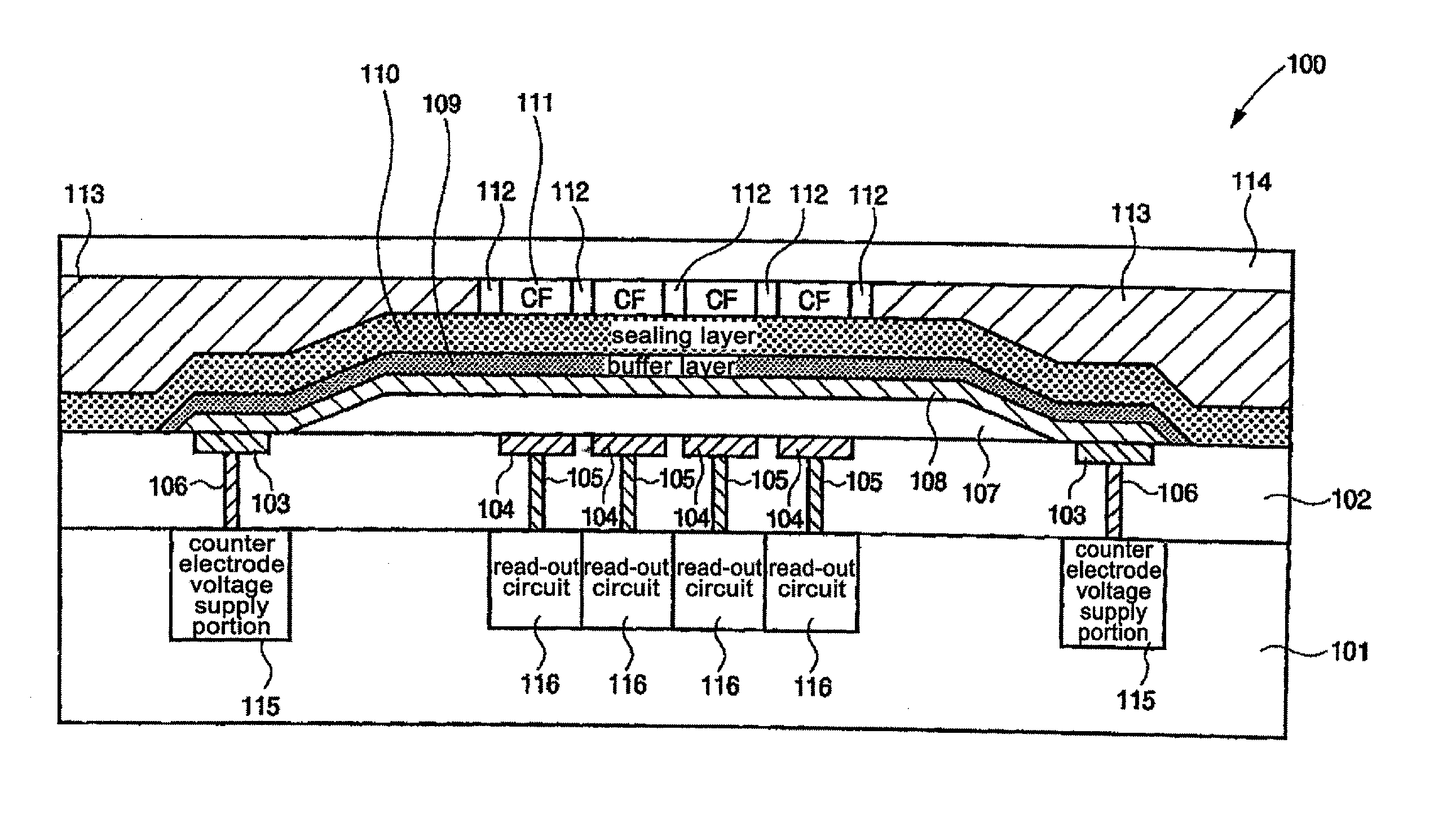

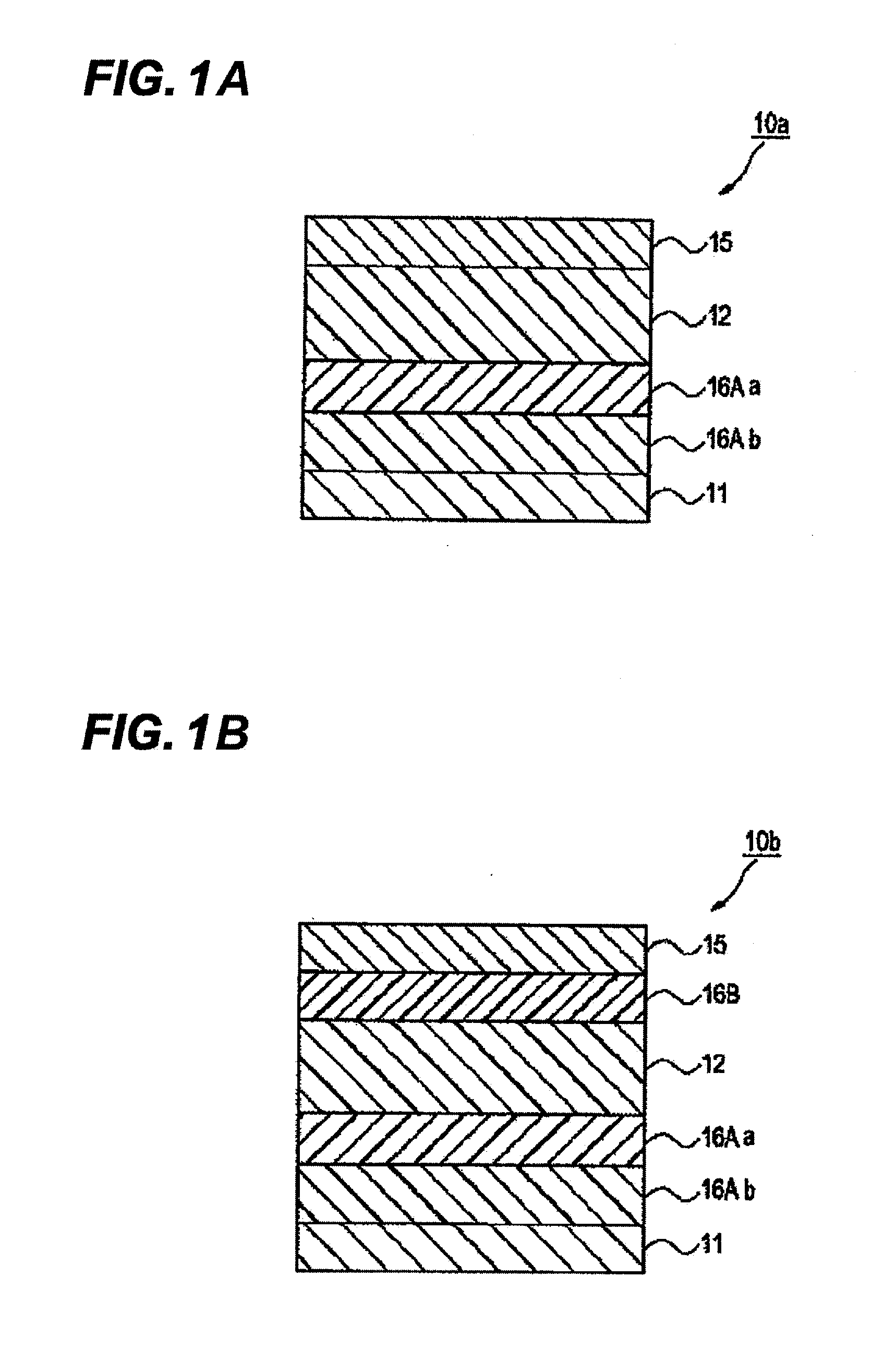

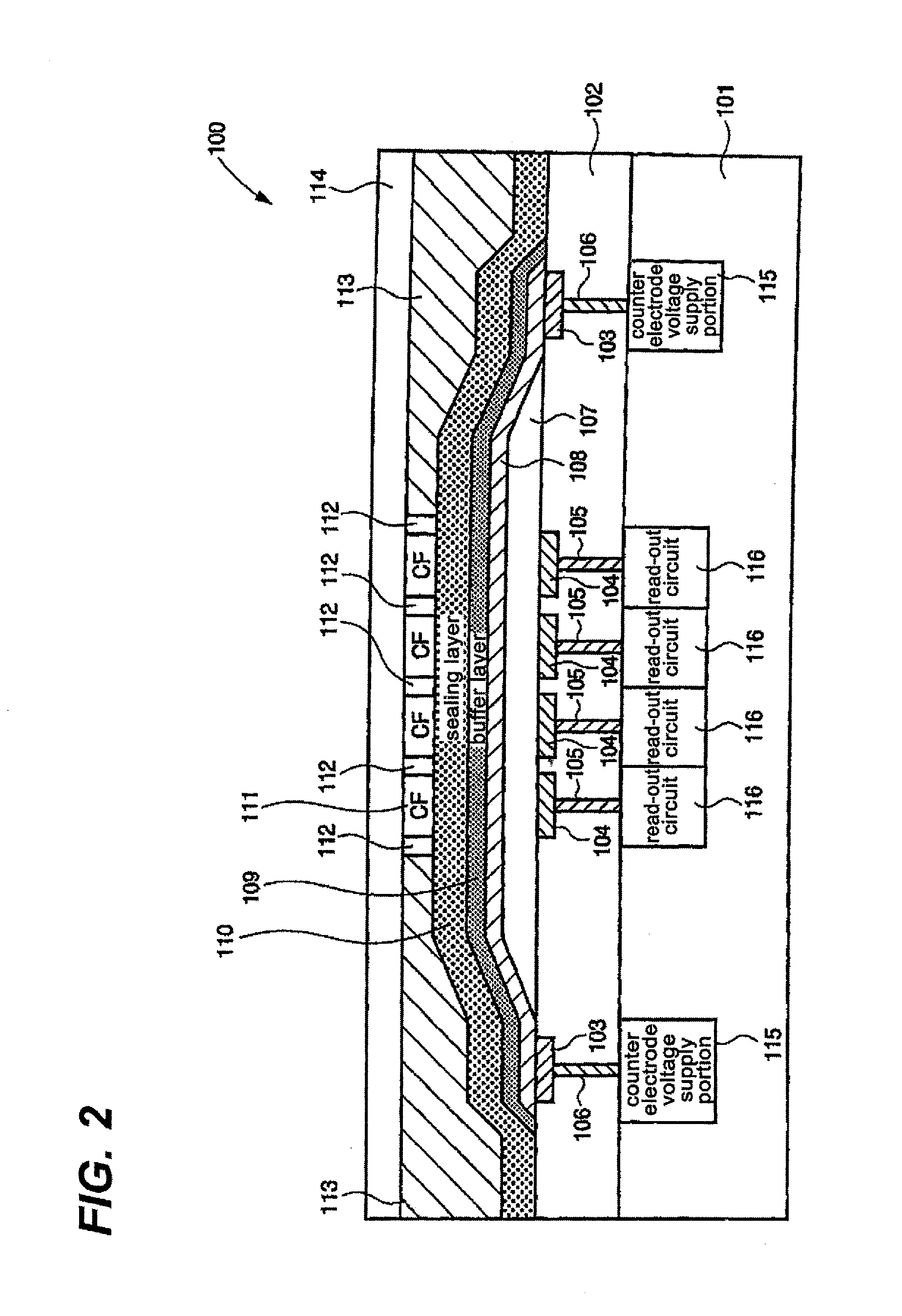

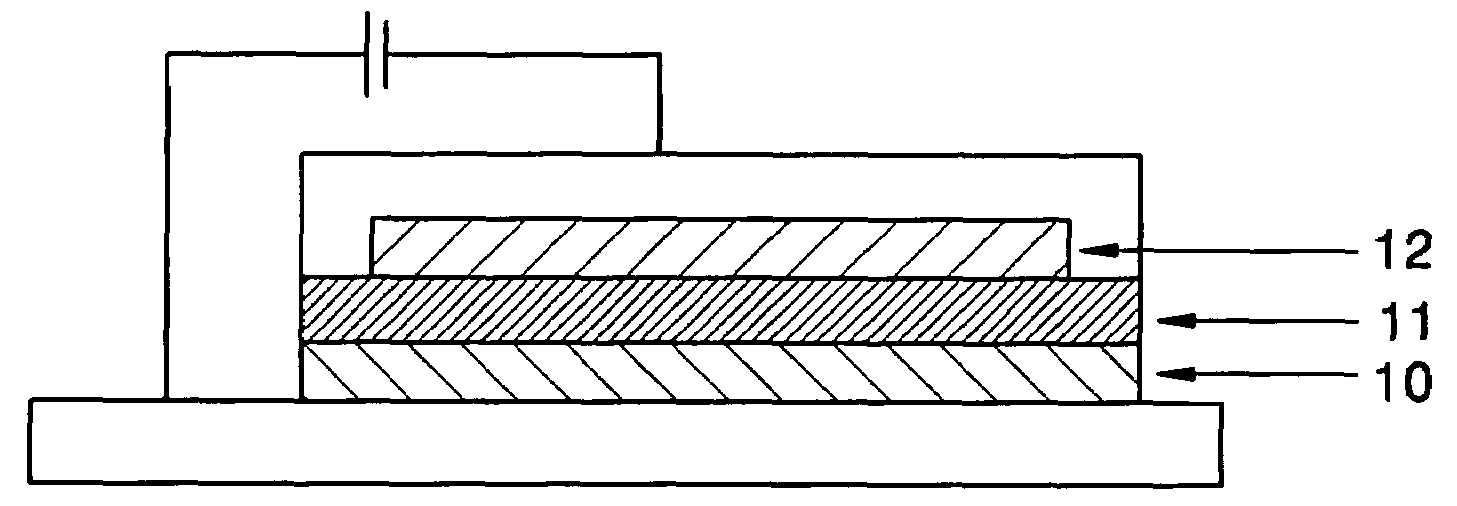

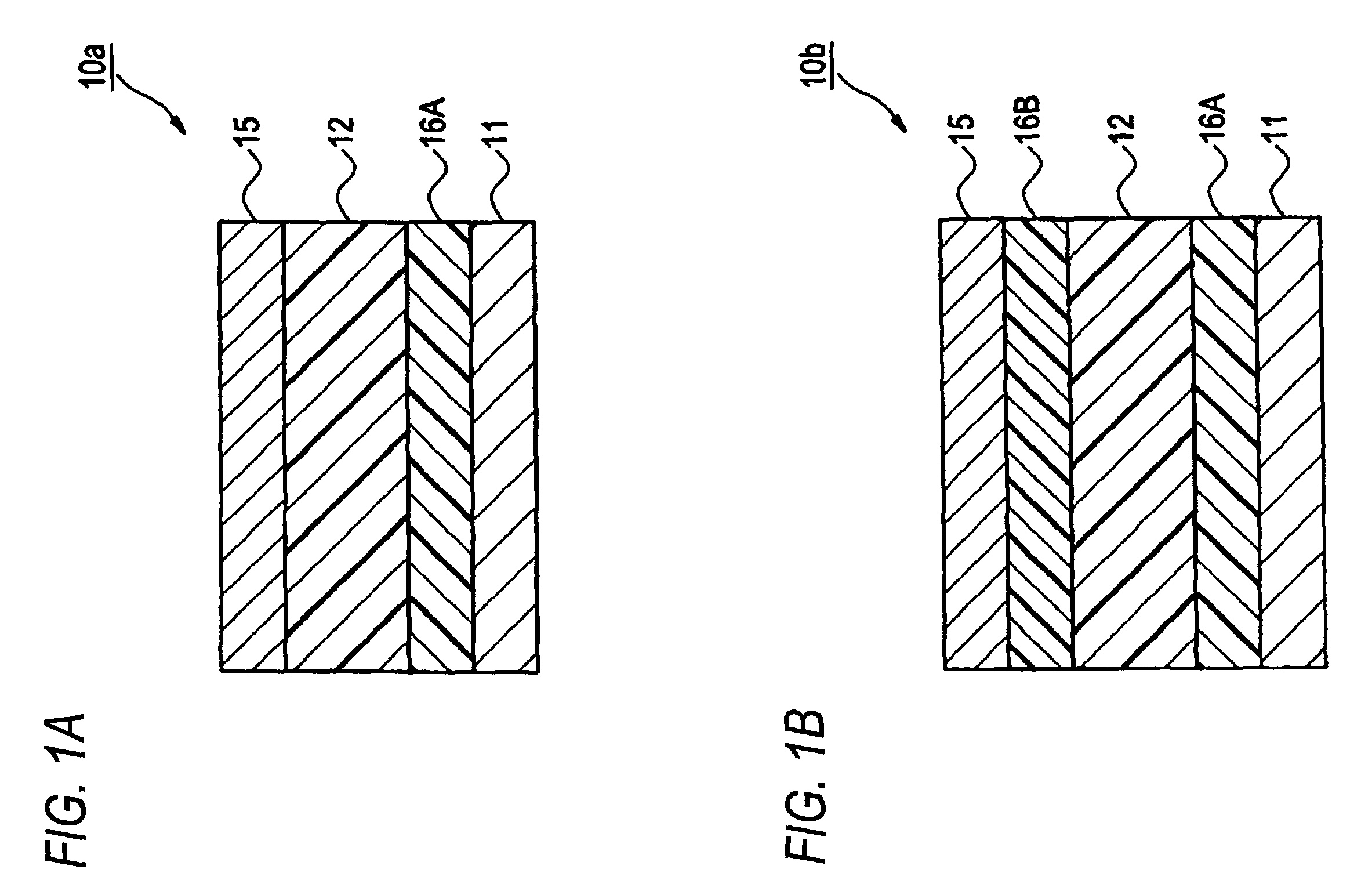

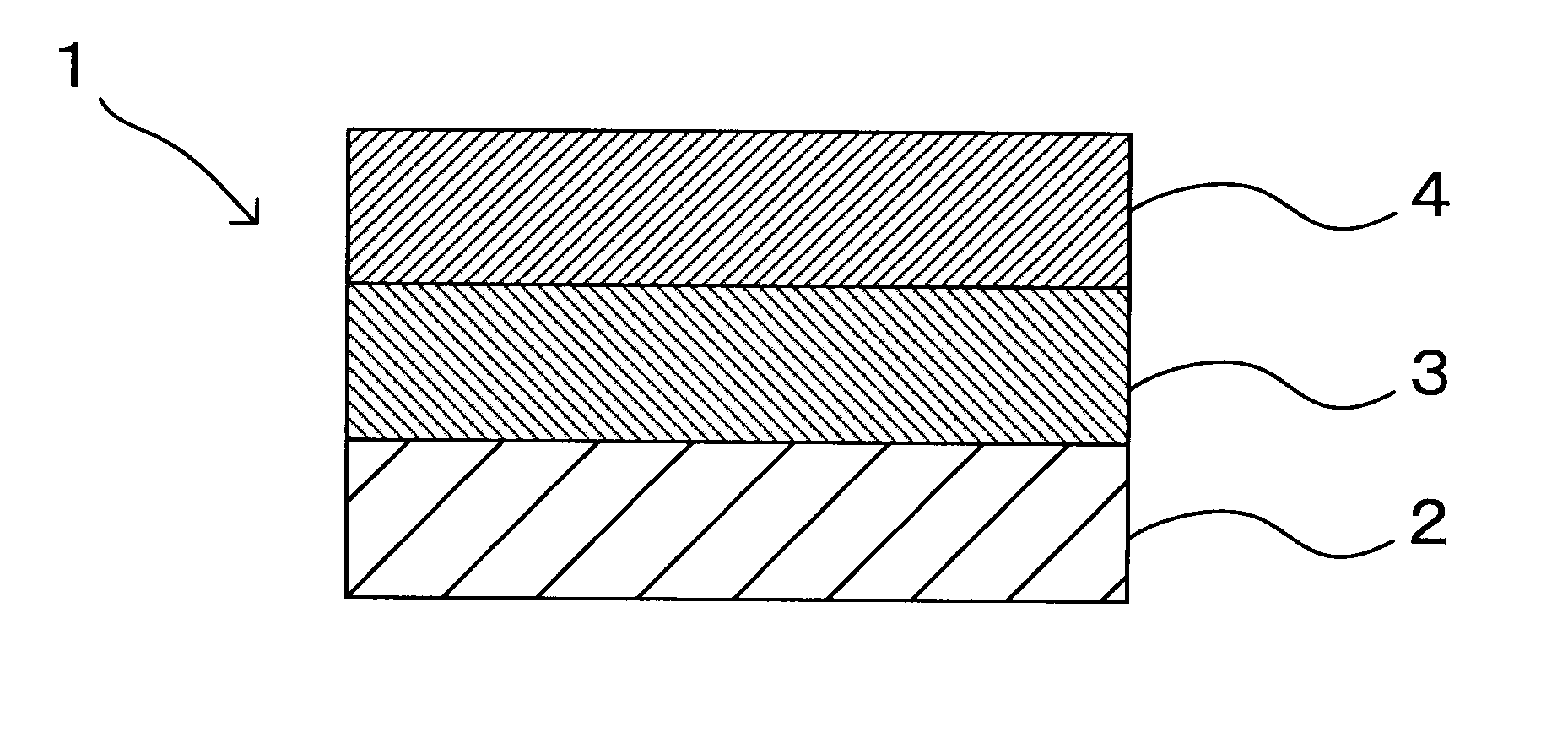

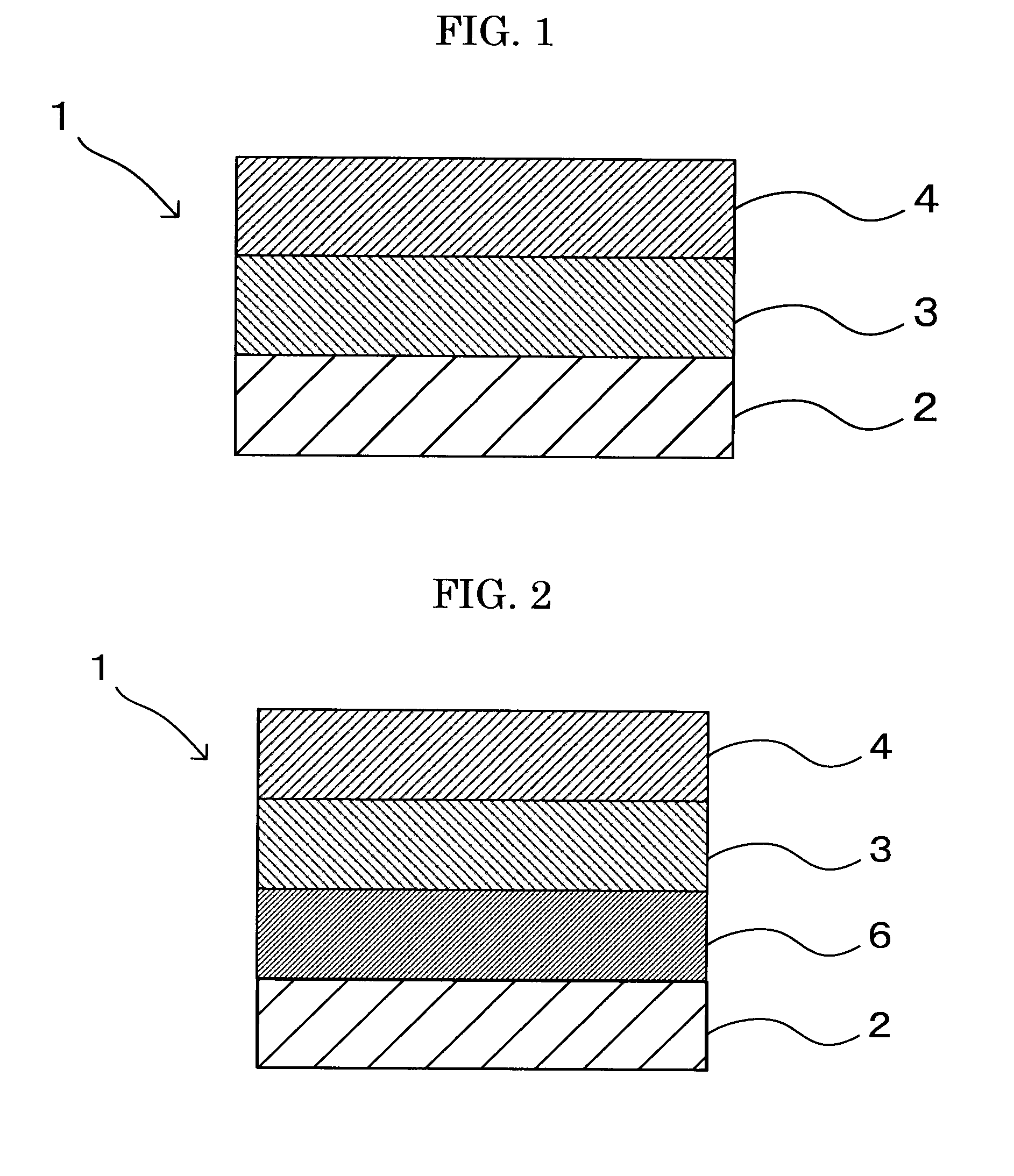

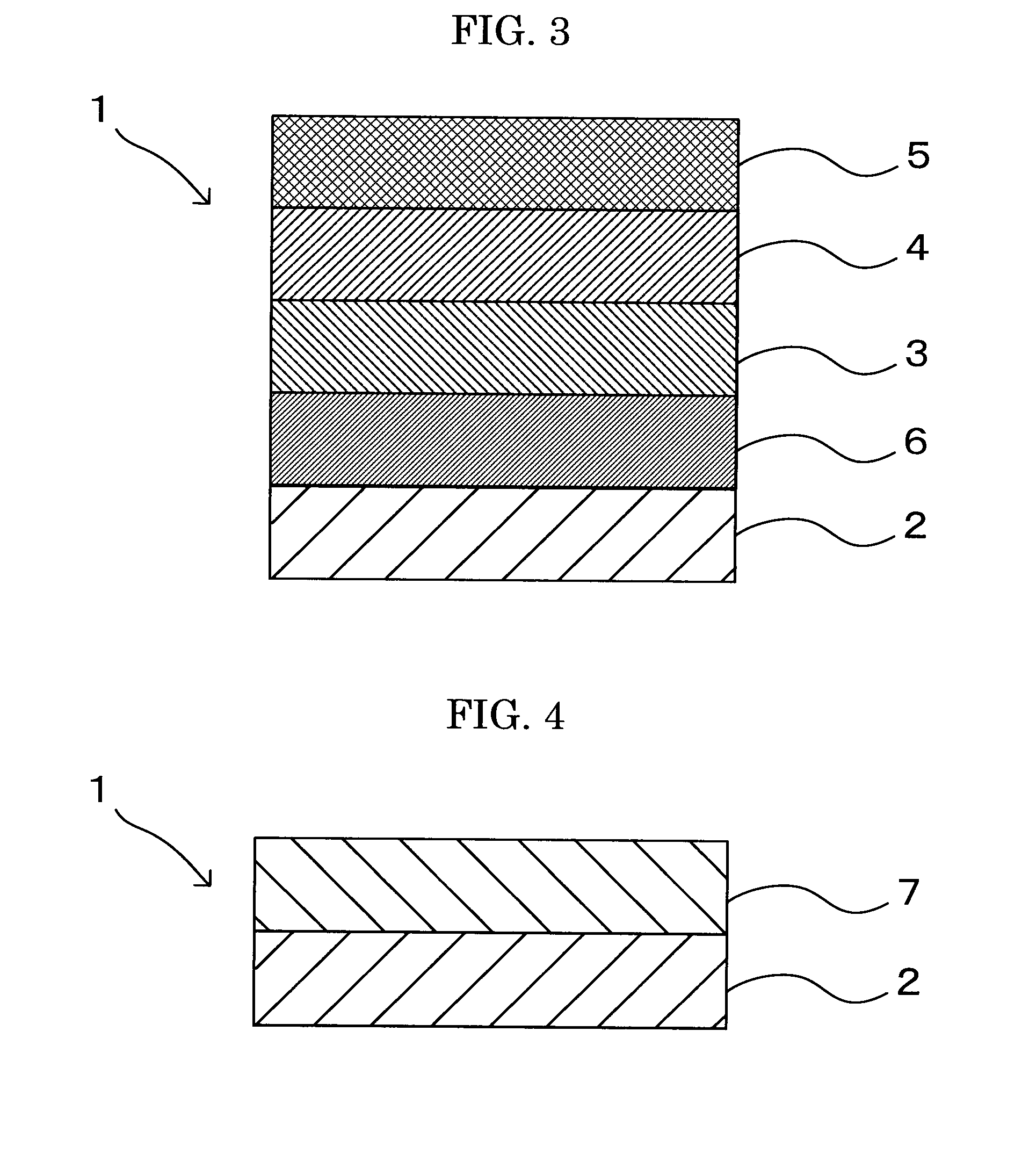

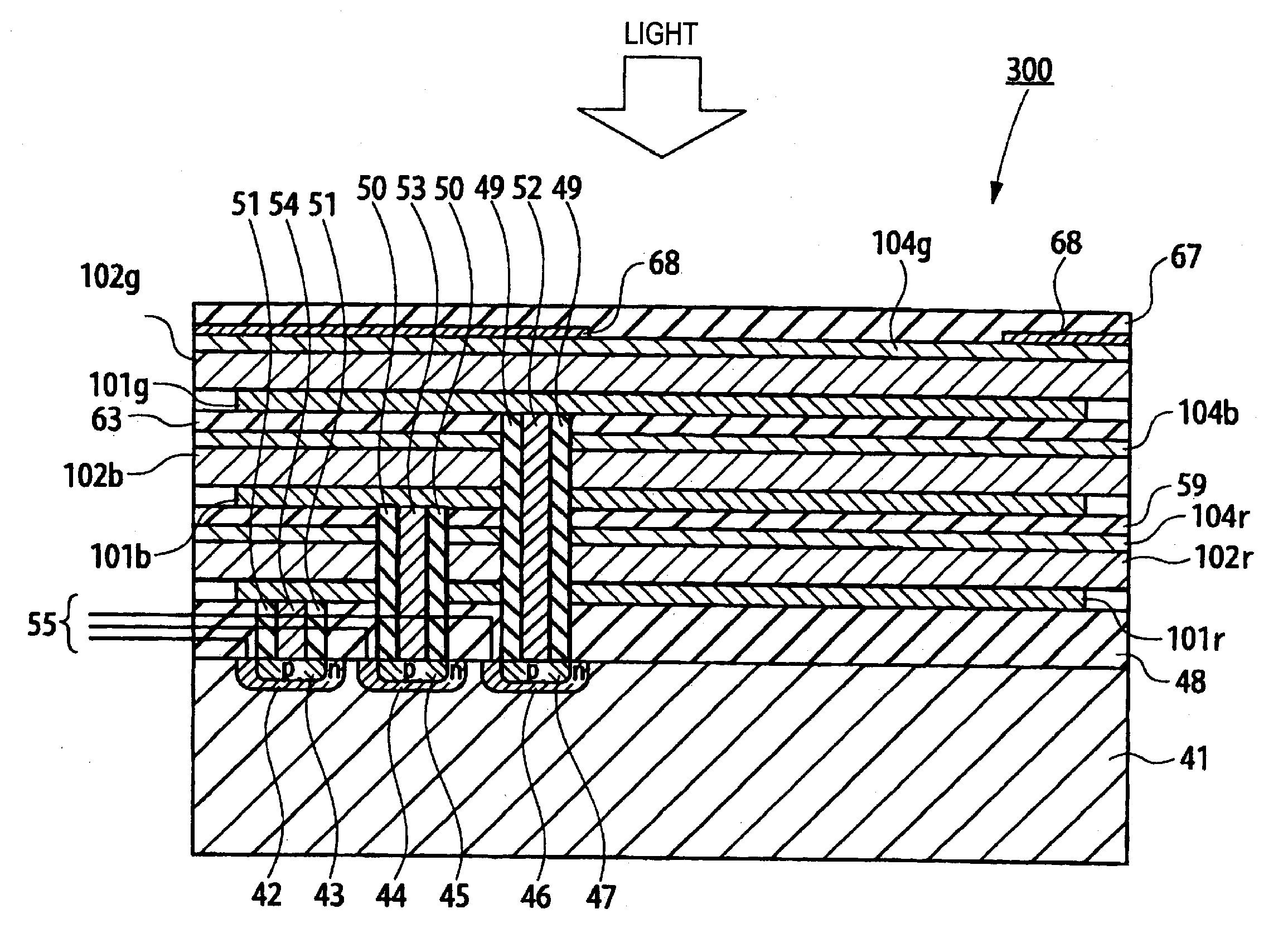

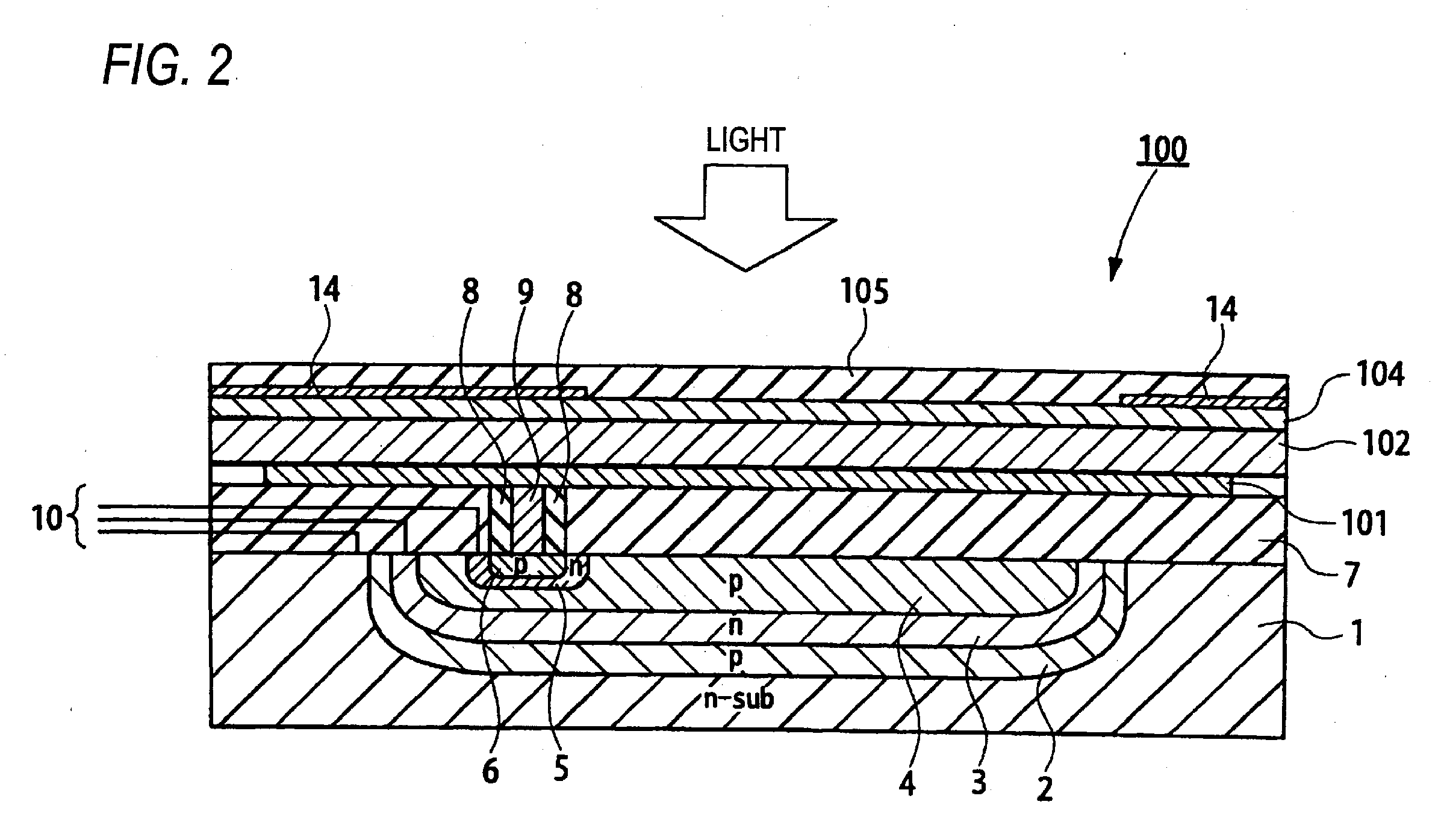

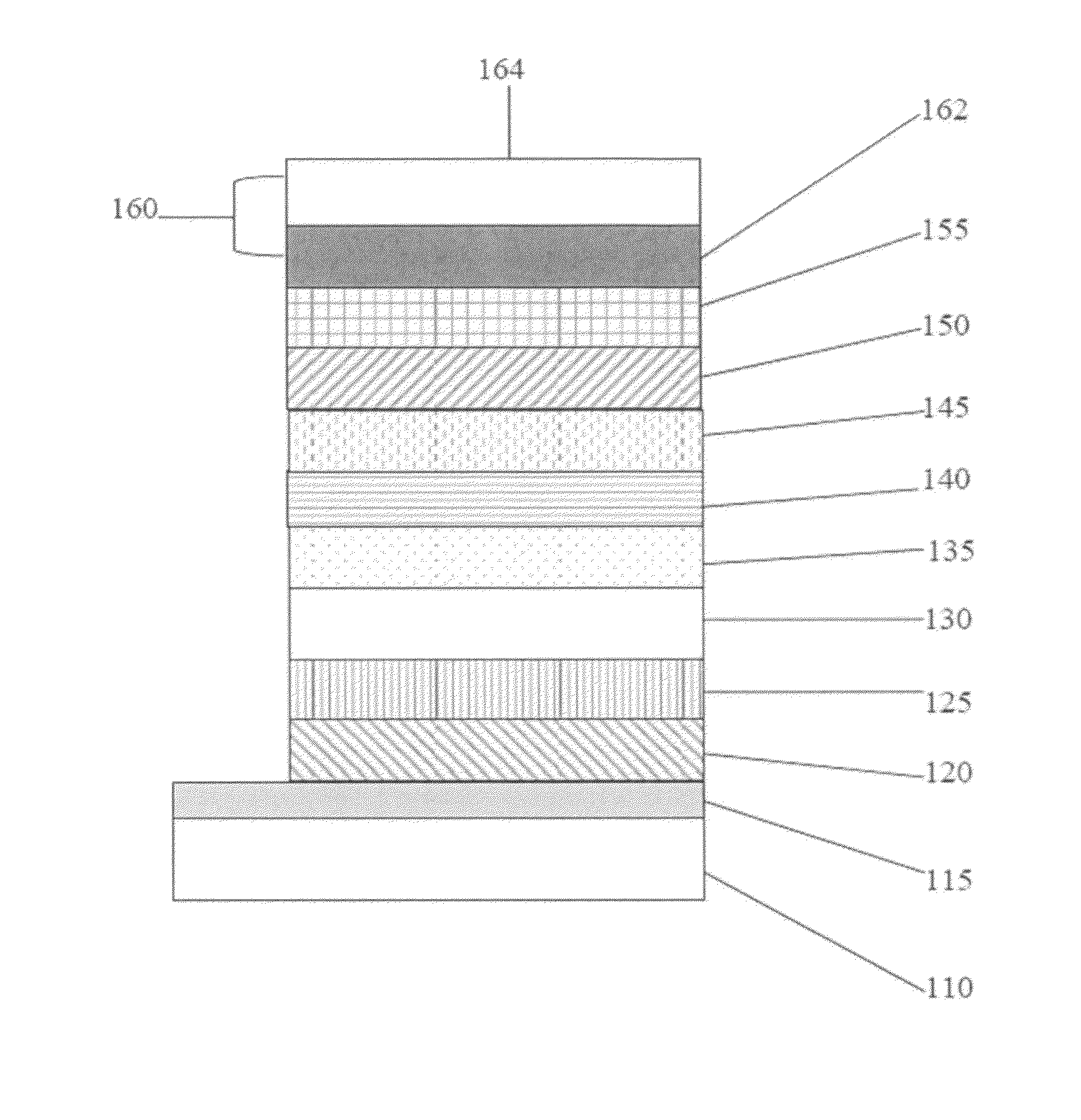

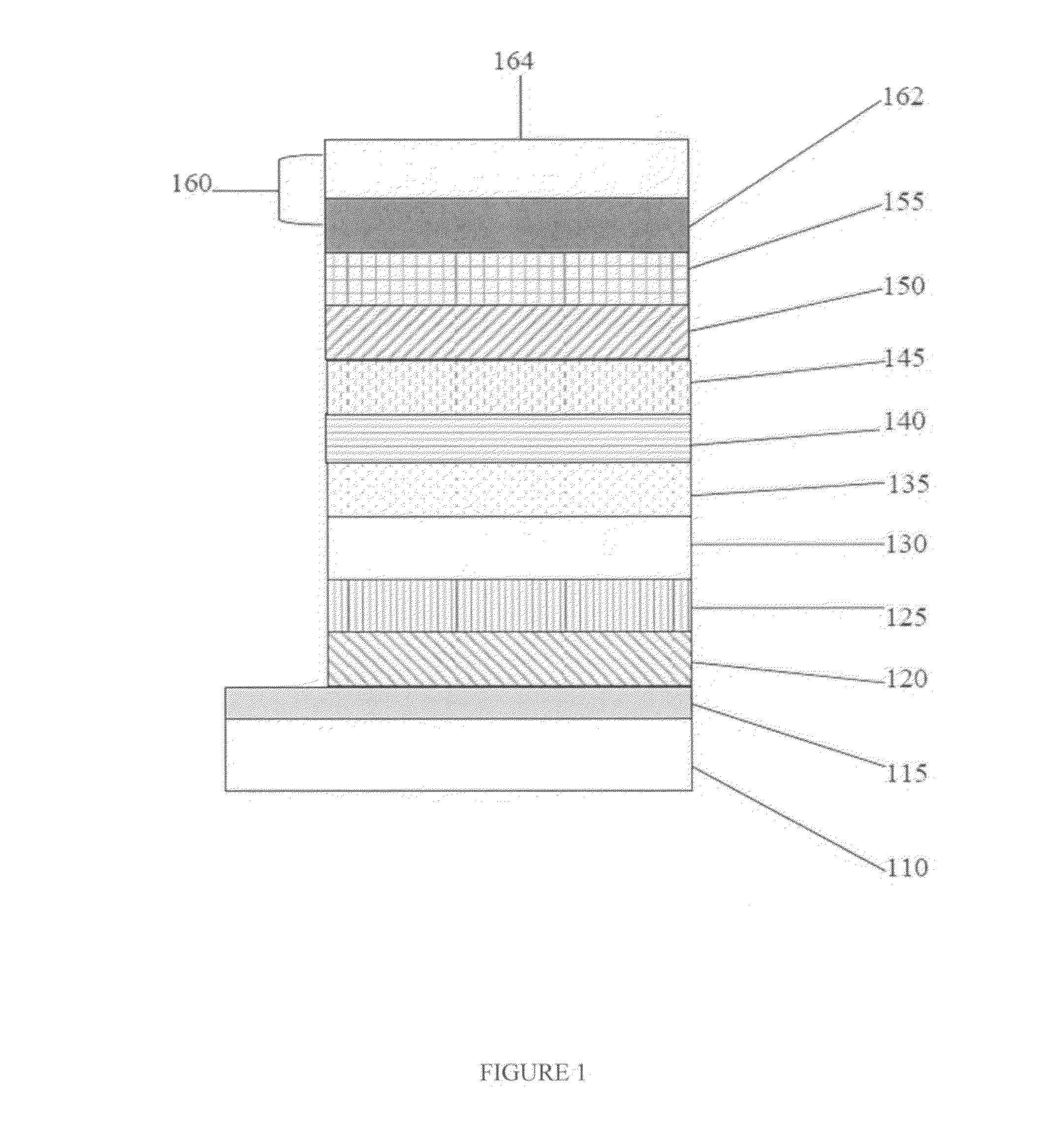

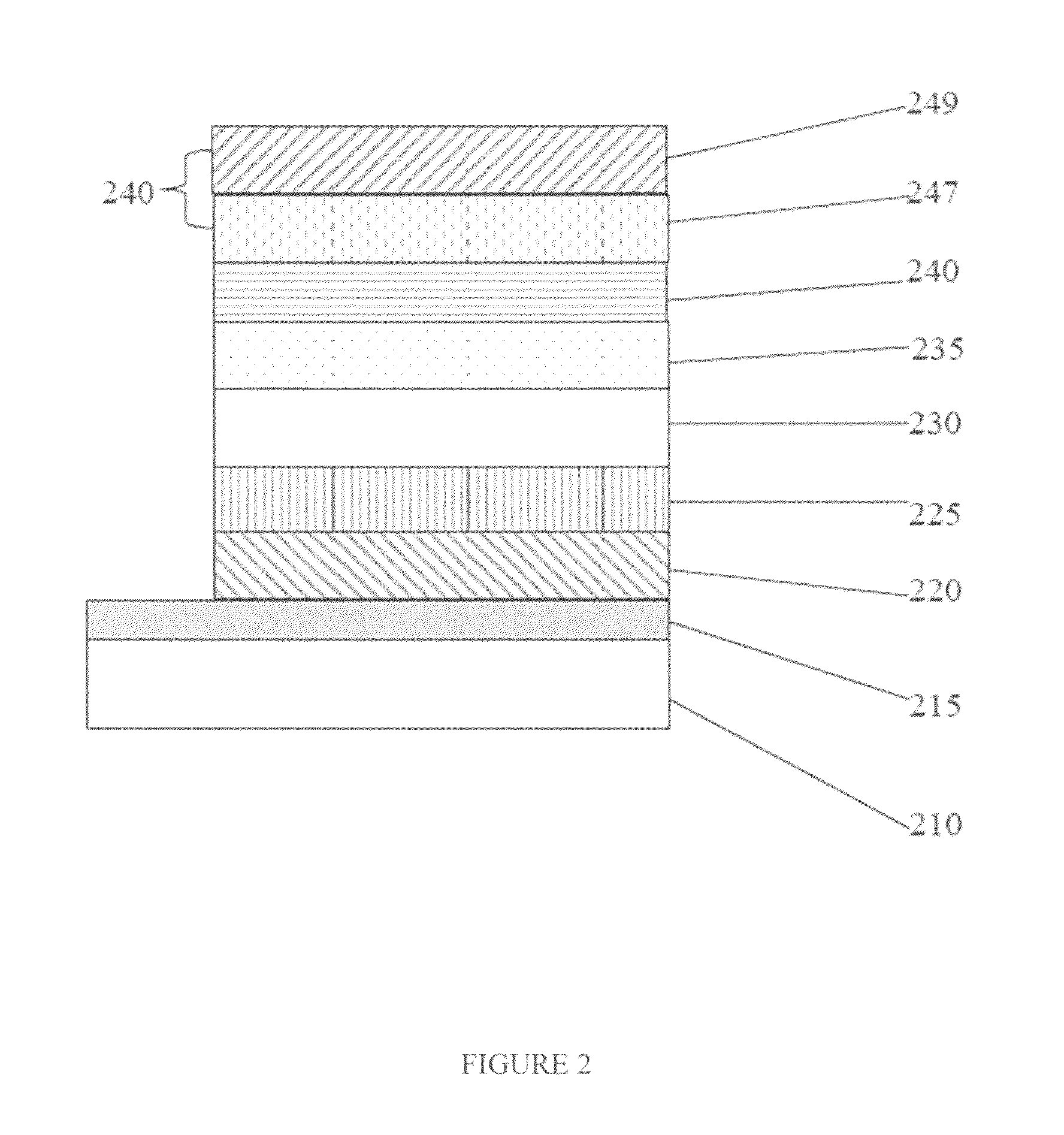

Photoelectric conversion device and solid-state imaging

ActiveUS8704213B2Ensure adequate heatingAddressing Insufficient SensitivityFinal product manufactureNanoinformaticsPhotoelectric conversionElectron blocking layer

A photoelectric conversion device having: a pair of electrodes; a photoelectric conversion layer sandwiched between the pair of electrodes; and at least one electron blocking layer provided between one electrode of the pair of electrodes and the photoelectric conversion layer, wherein the photoelectric conversion layer contains at least one organic material, and the at least one electron blocking layer has a mixed layer containing fullerene or fullerene derivatives.

Owner:FUJIFILM CORP

Photoelectric conversion device and solid-state imaging device

ActiveUS20120098079A1Low costUniform film formationFinal product manufactureNanoinformaticsPhotoelectric conversionElectron blocking layer

A photoelectric conversion device having: a pair of electrodes; a photoelectric conversion layer sandwiched between the pair of electrodes; and at least one electron blocking layer provided between one electrode of the pair of electrodes and the photoelectric conversion layer, wherein the photoelectric conversion layer contains at least one organic material, and the at least one electron blocking layer has a mixed layer containing fullerene or fullerene derivatives.

Owner:FUJIFILM CORP

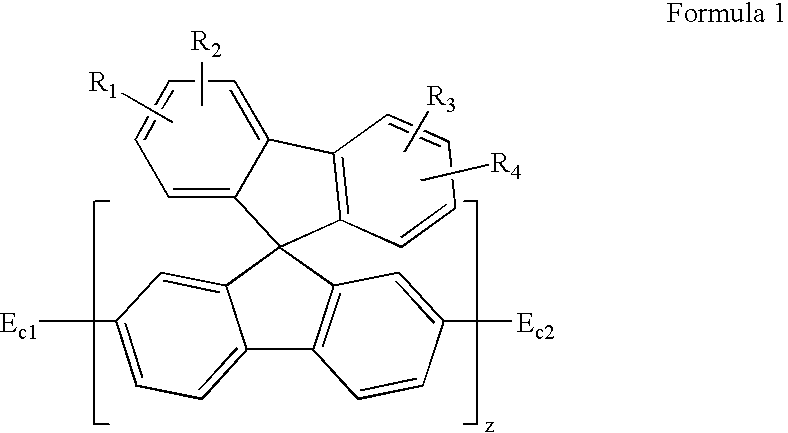

Spirofluorene-based polymer and organic electroluminescent device using the same

InactiveUS7524567B2Enhanced charge transport capabilityThermal and optical and electrical stabilityOrganic chemistrySolid-state devicesOrganic layerElectrical stability

A spirofluorene-based polymer which contains a spirofluorene structure as a basic unit and which is end-capped with functional moieties substituted by fluorine, and an organic electroluminescent device using an organic layer using the spirofluorene-based polymer. The organic electroluminescent device has improved efficiency, reduced driving voltage, and excellent thermal, optical and electrical stability.

Owner:SAMSUNG DISPLAY CO LTD

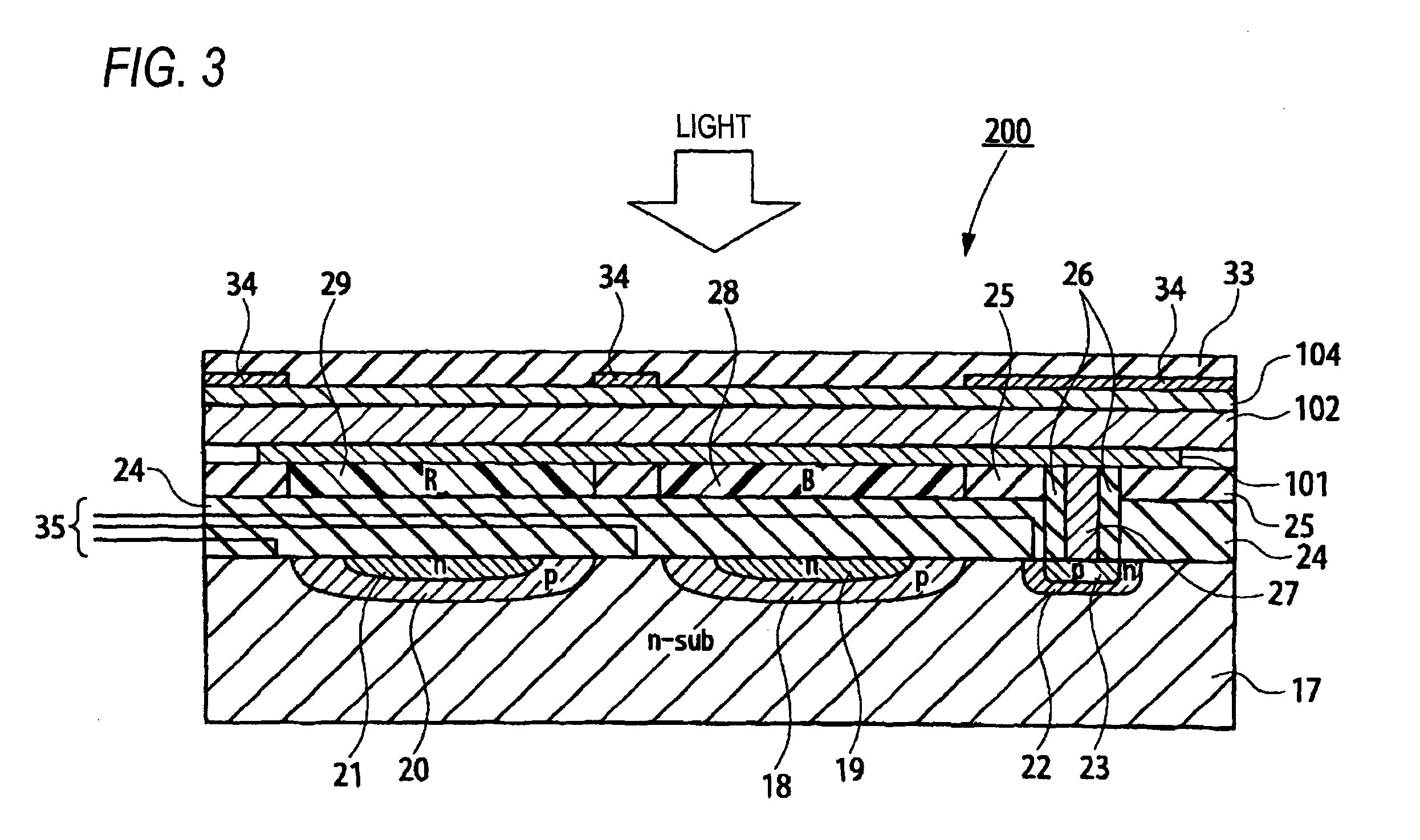

Photoelectric conversion device and imaging device having decreased dark current

ActiveUS8847208B2Enhanced charge transport capabilityImprove photoelectric conversion efficiencyNanoinformaticsSolid-state devicesArylHydrogen atom

Provided is a photoelectric conversion device comprising a transparent electrically conductive film, a photoelectric conversion film, and an electrically conductive film, wherein the photoelectric conversion film contains a compound represented by the following formula (i):wherein each of R2 to R9 independently represents a hydrogen atom or a substituent, provided that each of at least two out of R3, R4, R7 and R8 independently represents an aryl group, a heterocyclic group or —N(Ra)(Rb), each of Ra and Rb independently represents a hydrogen atom or a substituent, and at least either Ra or Rb represents an aryl group or a heterocyclic group; and R1 represents an alkyl group, an aryl group or a heterocyclic group.

Owner:FUJIFILM CORP

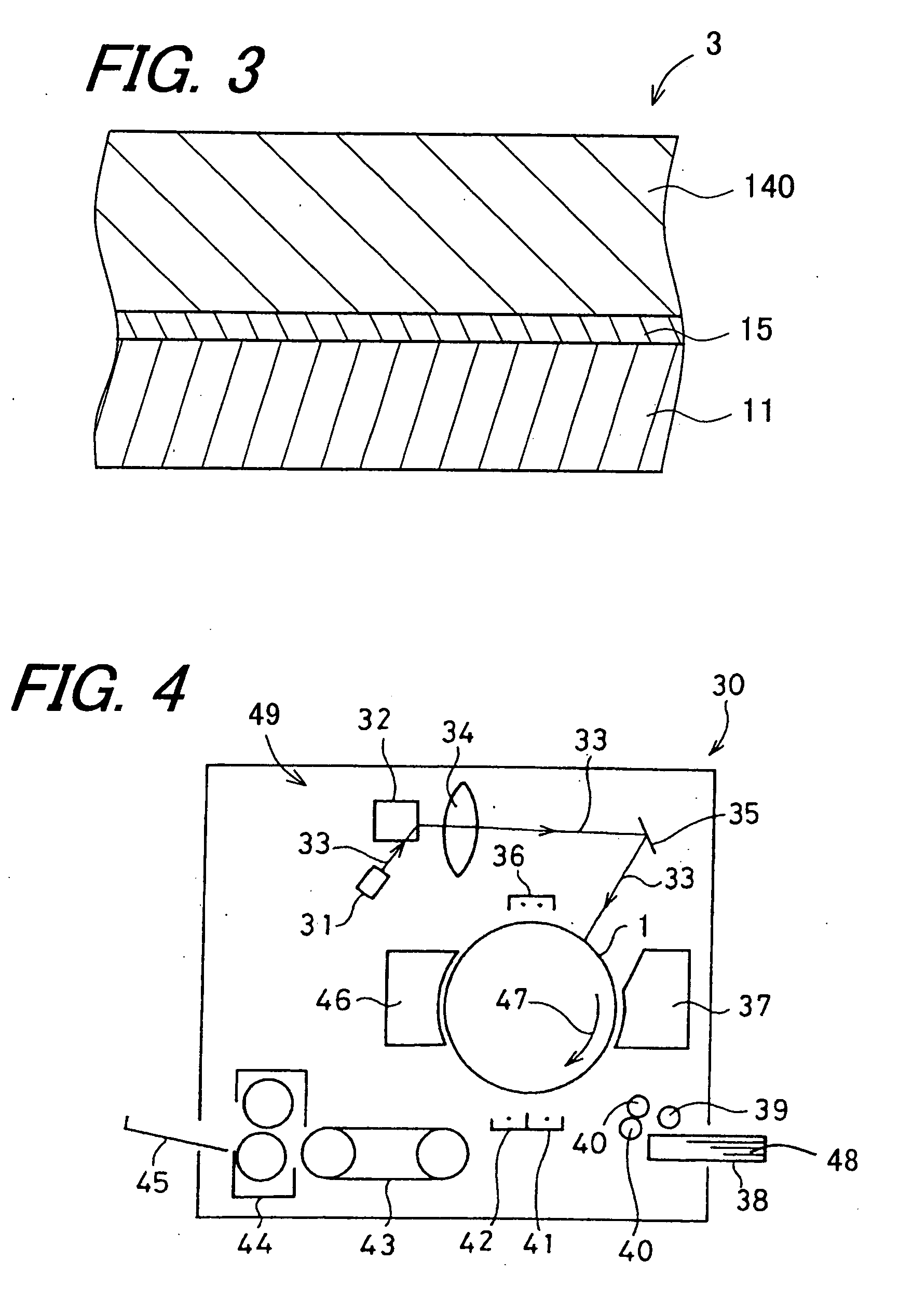

Electrophotographic photoconductor and method for producing the same, image forming apparatus, and process cartridge

InactiveUS20090035017A1Reduction of the residual potentialImprove mobilityElectrographic process apparatusCorona dischargeElectrical conductorRaman scattering spectra

There is provided an electrophotographic photoconductor containing a conductive substrate, and a photosensitive layer, disposed thereon, containing a charge transporting material having a triarylamine structure represented by General Formula 1, and wherein the photosensitive layer satisfies Mathematical Formula 1 when peak heights in raman scattering spectra of the triarylamine structure are measured at a wavenumber of 1,324±2 cm−1 by a confocal raman spectroscopy using z-polarized light:where Ar1, Ar2, and Ar3 are substituted or unsubstituted aromatic hydrocarbon groups, and Ar1 and Ar2, Ar2 and Ar3, and Ar3 and Ar1 are optionally combined to form heterocyclic rings, respectively,ε=I(inside) / I(surface)≧1.1 Mathematical Formula 1where I(inside) represents the peak height in of the raman scattering spectrum obtained at a depth of 5 μm or more from the photosensitive layer surface and I(surface) represents the peak height in the raman scattering spectrum obtained at a depth of less than 5 μm from the photosensitive layer surface.

Owner:RICOH KK

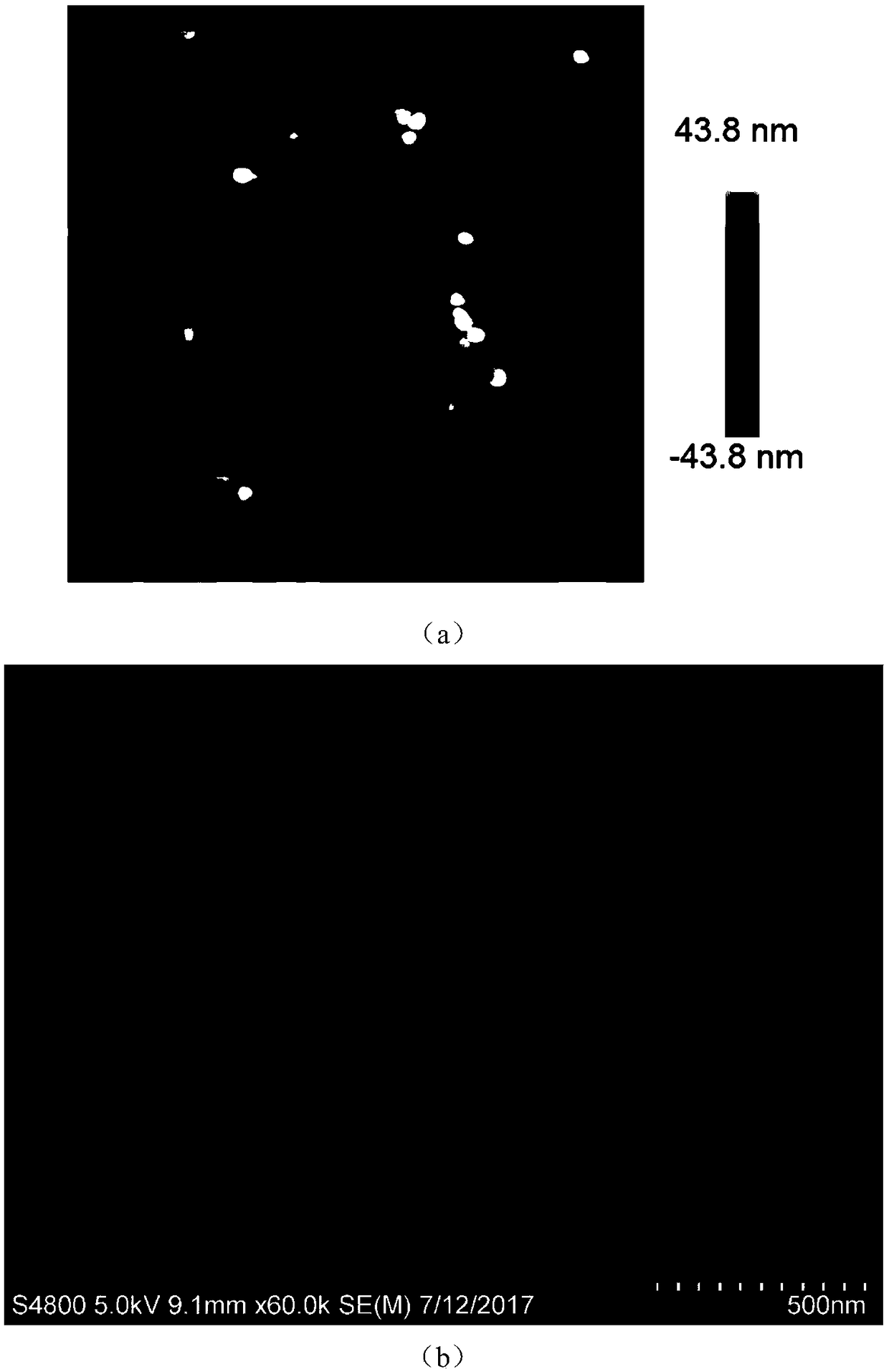

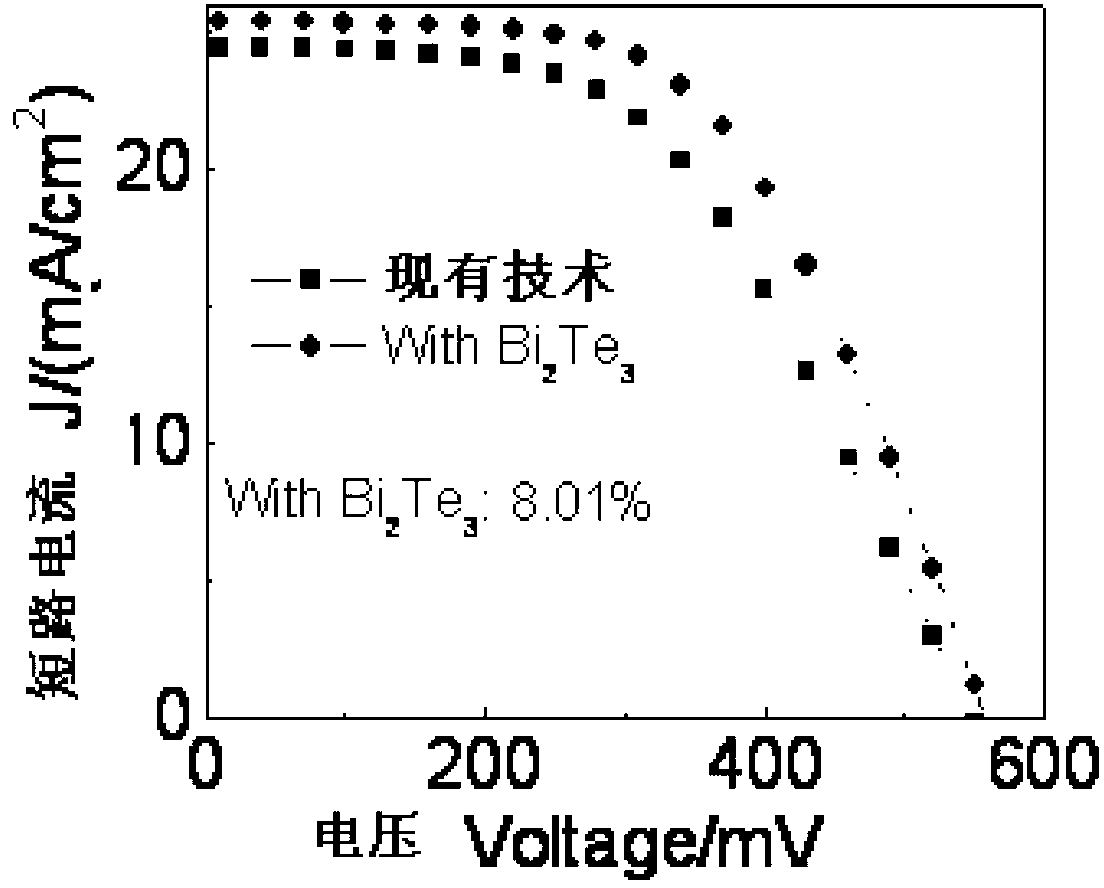

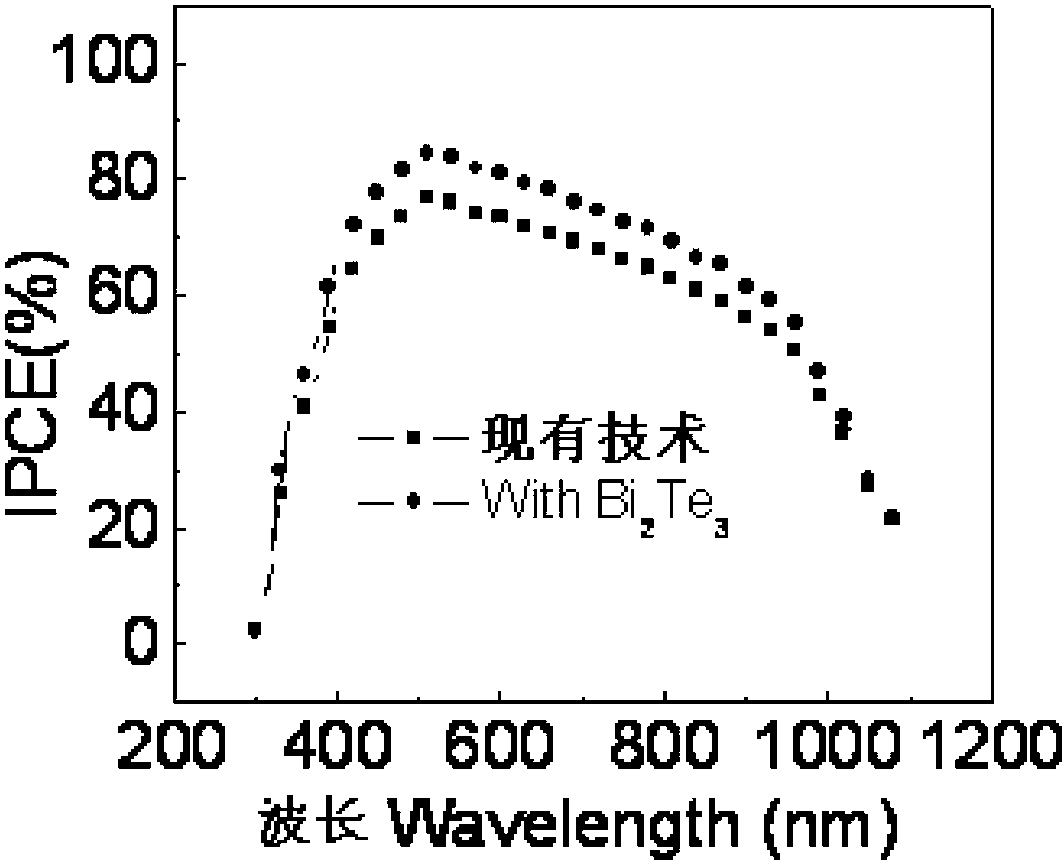

Method for preparing perovskite film, and perovskite solar cell device

ActiveCN108899420AEnhanced carrier mobility and diffusion lengthEnhanced charge transport capabilitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellCrystallite

The invention discloses a method for preparing a perovskite film and a perovskite solar cell device, wherein the method for preparing a perovskite film comprises the following steps: (1) preparing a perovskite precursor solution, then adding anti-solvent diethyl ether to the perovskite precursor solution, and uniformly mixing the anti-solvent diethyl ether and the perovskite precursor solution; (2) dropping the perovskite precursor solution containing the diethyl ether onto the surface of a substrate, performing spin coating, and dropping anti-solvent toluene during the spin coating in order to wash the surface of perovskite; (3) after the spin coating, subjecting an obtained perovskite film intermediate product to thermal annealing treatment to obtain the perovskite film. Adding the diethyl ether to the perovskite precursor solution can control the growth of a perovskite crystal, can prepare a perovskite film having a uniform grain size and low surface roughness, and is beneficial toimproving carrier mobility, a diffusion length, and a charge transport capacity. The perovskite film, when used as an active layer of the perovskite solar cell device, can effectively improve the photovoltaic performance of the device.

Owner:NANJING UNIV OF POSTS & TELECOMM

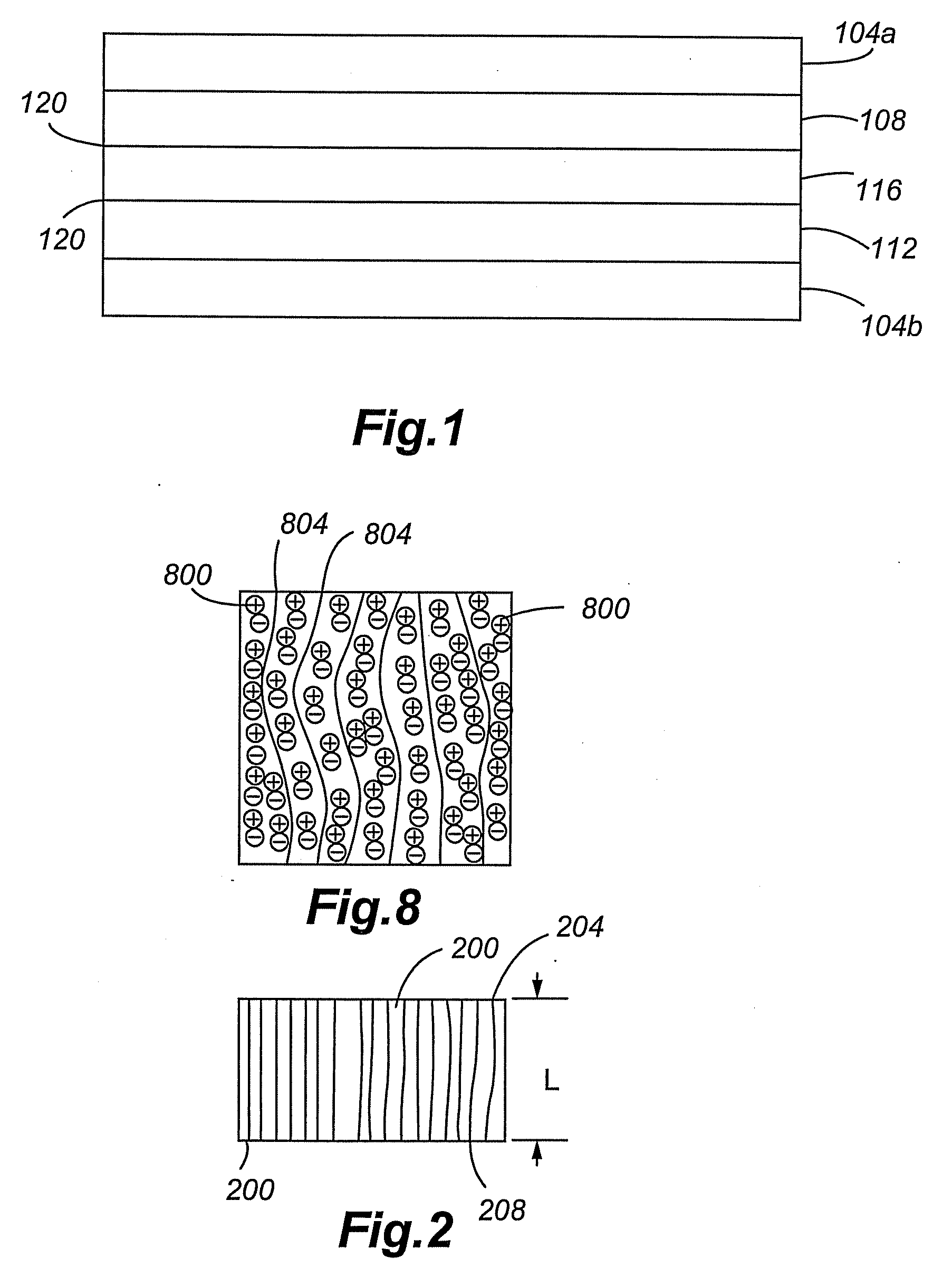

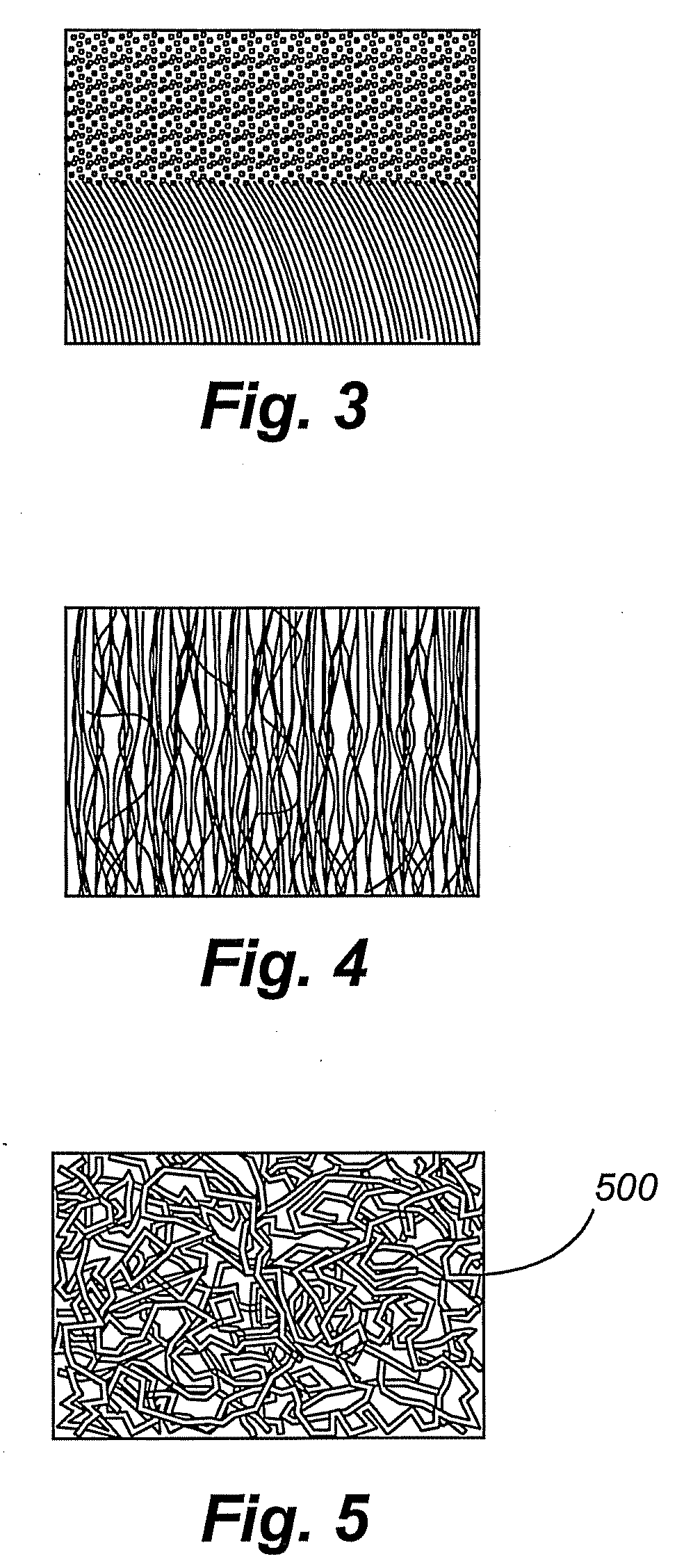

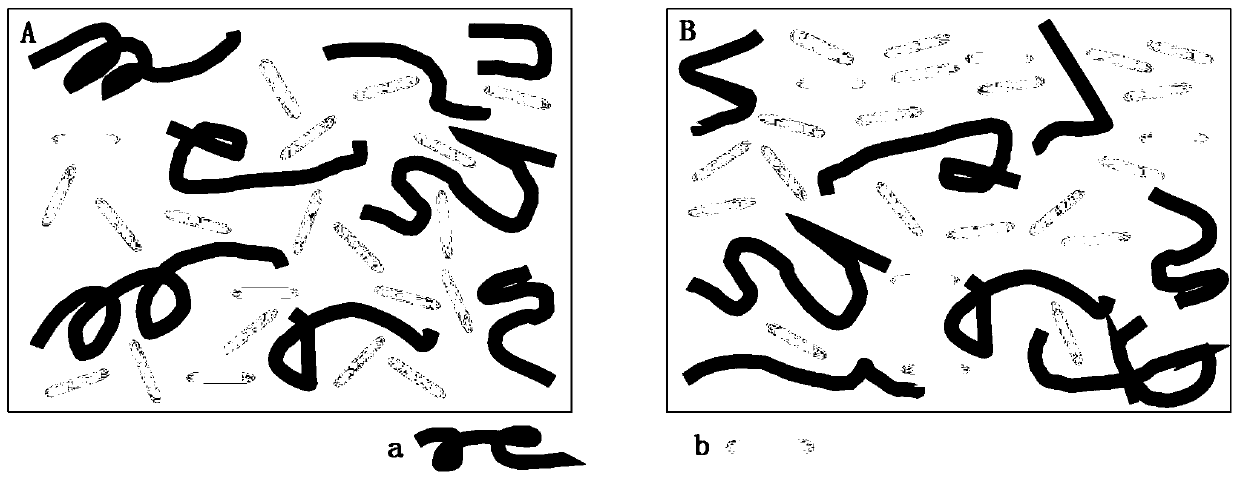

High performance ultracapacitors with carbon nanomaterials and ionic liquids

InactiveUS8284539B2Excellent electrolyte accessibilityImprove performanceHybrid capacitor electrolytesElectrolytic capacitorsSupercapacitorCarbon nanomaterials

The present invention is directed to the use of carbon nanotubes and / or electrolyte structures in various electrochemical devices, such as ultracapacitors having an ionic liquid electrolyte. The carbon nanotubes are preferably aligned carbon nanotubes. Compared to randomly entangled carbon nanotubes, aligned carbon nanotubes can have better defined pore structures and higher specific surface areas.

Owner:ADA TECH

Electrophotographic photosensitive member, process cartridge, and electrophotographic apparatus

ActiveUS7364824B2Mechanical strength is securedImprove electrical performanceElectrographic process apparatusCorona dischargeCross-linkSurface layer

An electrophotographic photosensitive member, a process cartridge and an electrophotographic apparatus are provided which not only secure mechanical strength sufficiently but also bring a vast improvement in charge transport performance and which can well satisfy electrical properties. An electrophotographic photosensitive member is provided an outermost surface layer of which contains at least a charge transporting compound having chain polymerizable functional groups which is represented by the following general formula (1-1) or (1-2); the charge transporting compound having been polymerized or cross-linked and cured. Also provided are a process cartridge and an electrophotographic apparatus which have such a photosensitive member.

Owner:CANON KK

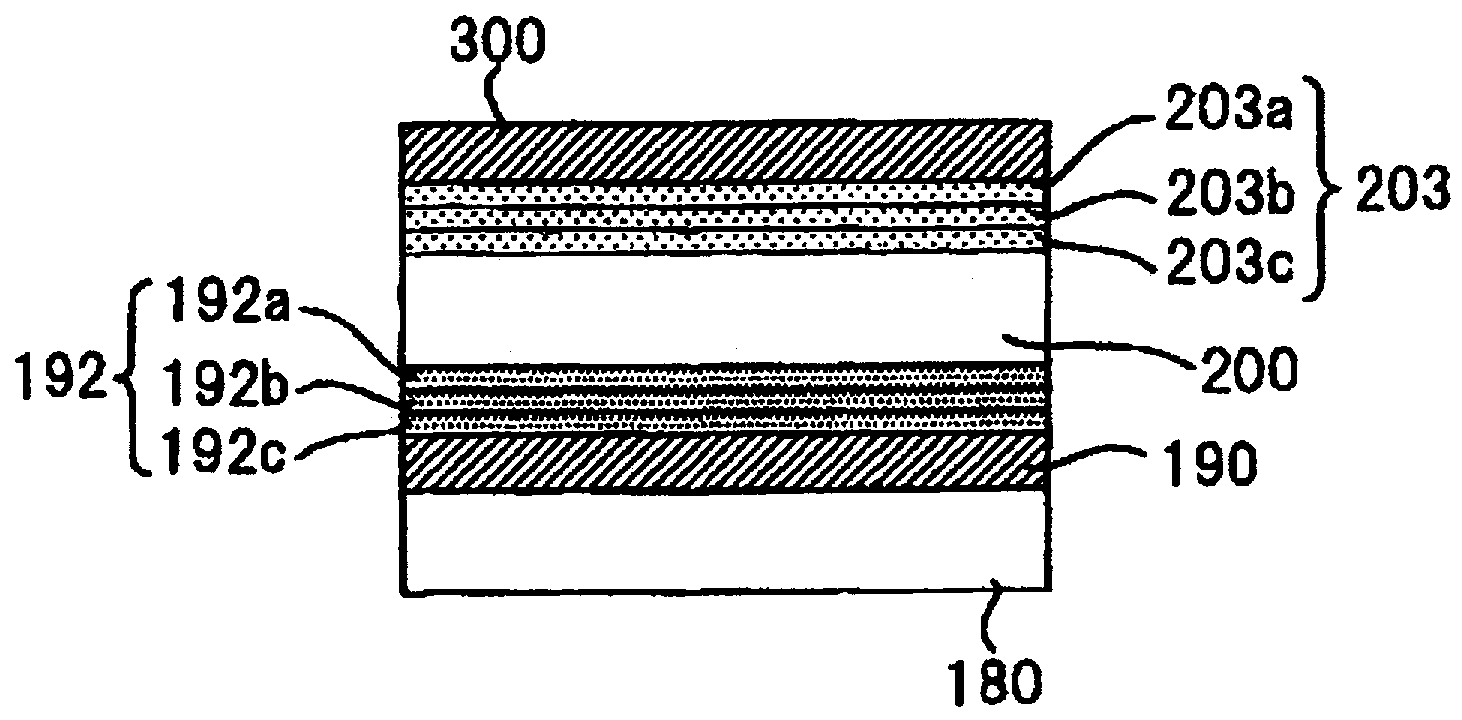

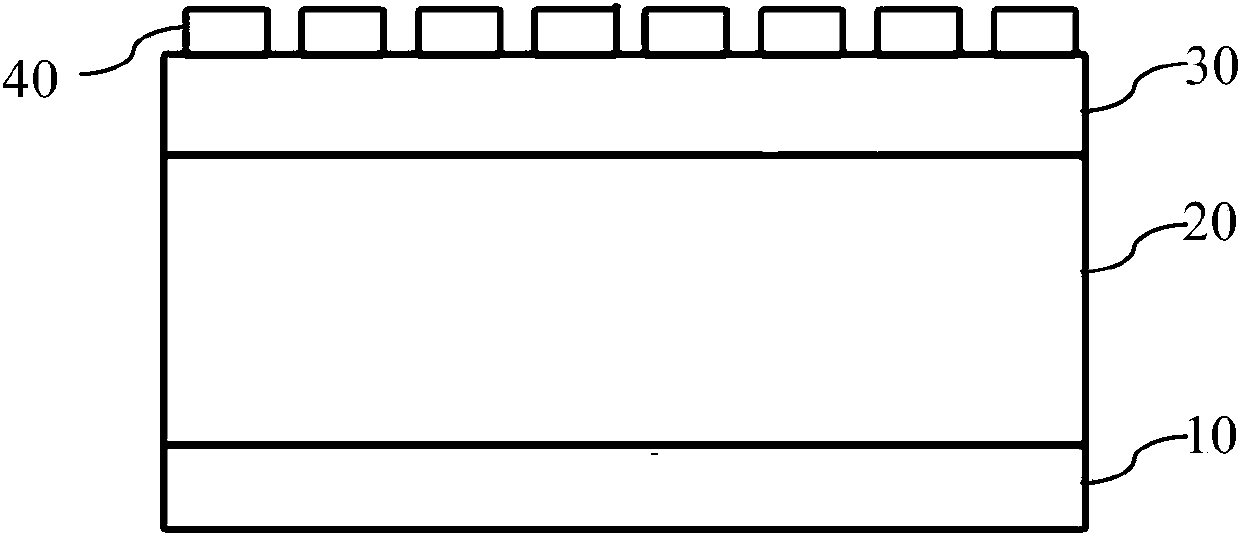

Organic-two-dimensional crystal-inorganic hybrid heterojunction solar cell device and preparation method thereof

ActiveCN103296211AEnhanced charge transport capabilityImprove stabilityFinal product manufactureSolid-state devicesHeterojunctionHole transport layer

The invention discloses an organic-two-dimensional crystal-inorganic hybrid heterojunction solar cell device and a preparation method thereof. The solar cell device comprises a metal back electrode, an n-type silicon-based substrate, an organic conjugated film uniformly mixed by conjugated organic matters and two-dimensional laminar nanocrystalline materials and metal gate electrodes sequentially from bottom to top. The surface of the silicon-based substrate is coated with mixed solution of the two-dimensional laminar nanocrystalline materials and the conjugated organic matters in a spin manner, or the two-dimensional laminar nanocrystalline materials and the conjugated organic matters of different concentrations are coated on the surface of the silicon-based substrate directly and sequentially in a spin manner to serve as a hole transport layer; stability of cells are improved by modification of an organic-inorganic matter hybrid heterojunction, charge transport capability of the solar cells is enhanced, surface state density defects are overcome effectively, and the solar cell device is simple to operate and easy for industrial production.

Owner:SUZHOU INAINK ELECTRONICS MATERIALS CO LTD

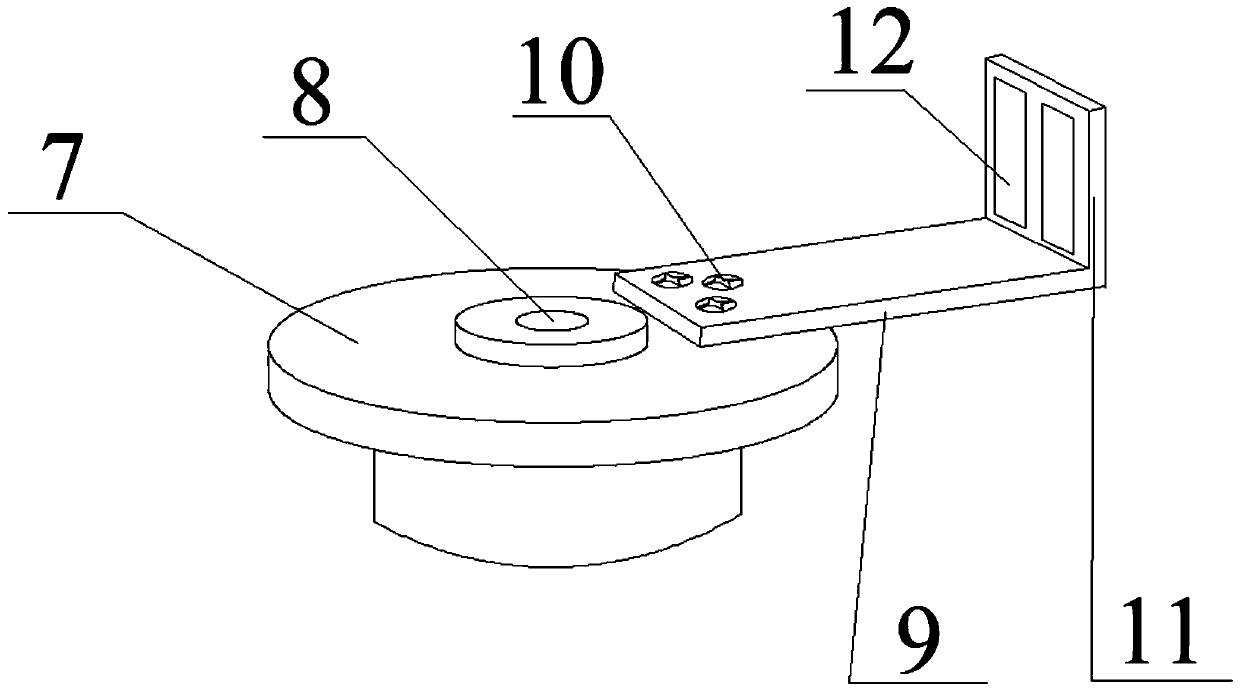

Centrifugal assistant light active layer stratified organic solar cell based on spinning-coating process, and preparation method thereof

ActiveCN110504371AImprove interface contactImprove performance parametersSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellNitrogen gas

The invention relates to the field of the organic semiconductor thin-film solar cell, and specifically discloses a centrifugal assistant light active layer stratified organic solar cell based on spinning-coating process, and a preparation method thereof. The preparation method comprises the following steps: S1, cleaning a baseplate composed of a transparent substrate and an ITO transparent conductive cathode layer, and blow-drying by using nitrogen after cleaning; S2, spinning-coating, printing or spraying PEDOT: PSS precursor solution on the ITO transparent conductive cathode layer surface, and preparing an anode buffer layer, and performing low-temperature baking on the formed thin-film; S3, preparing a PBDB-ITIC light active layer on the anode buffer layer by adopting the spinning-coating process; S4, adhering the baseplate spun-coated with the PBDB-T:ITIC light active layer to a vertical sidewall to perform rotary centrifuging; S5, performing thermal annealing treatment on the PBDB-T:ITIC light active layer in a glovebox; S6, evaporating LiF on the PBDB-T:ITIC light active layer surface under the condition that the vacuum degree is 3*10<3>Pa, and preparing a cathode buffer layer; and S7, evaporating a metal cathode layer on the cathode buffer layer. And an aim of improving various performance parameters of the organic solar cell is finally improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

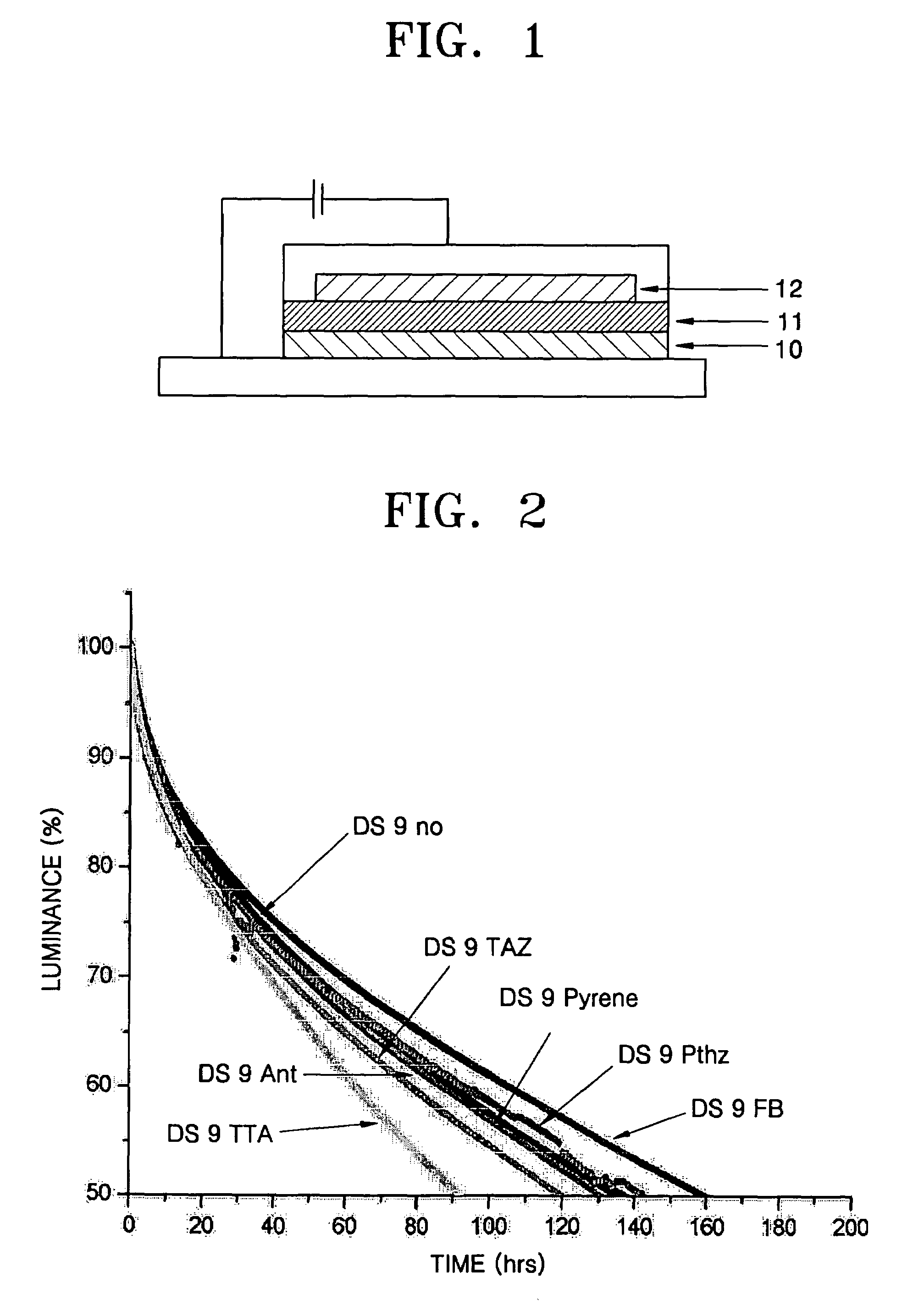

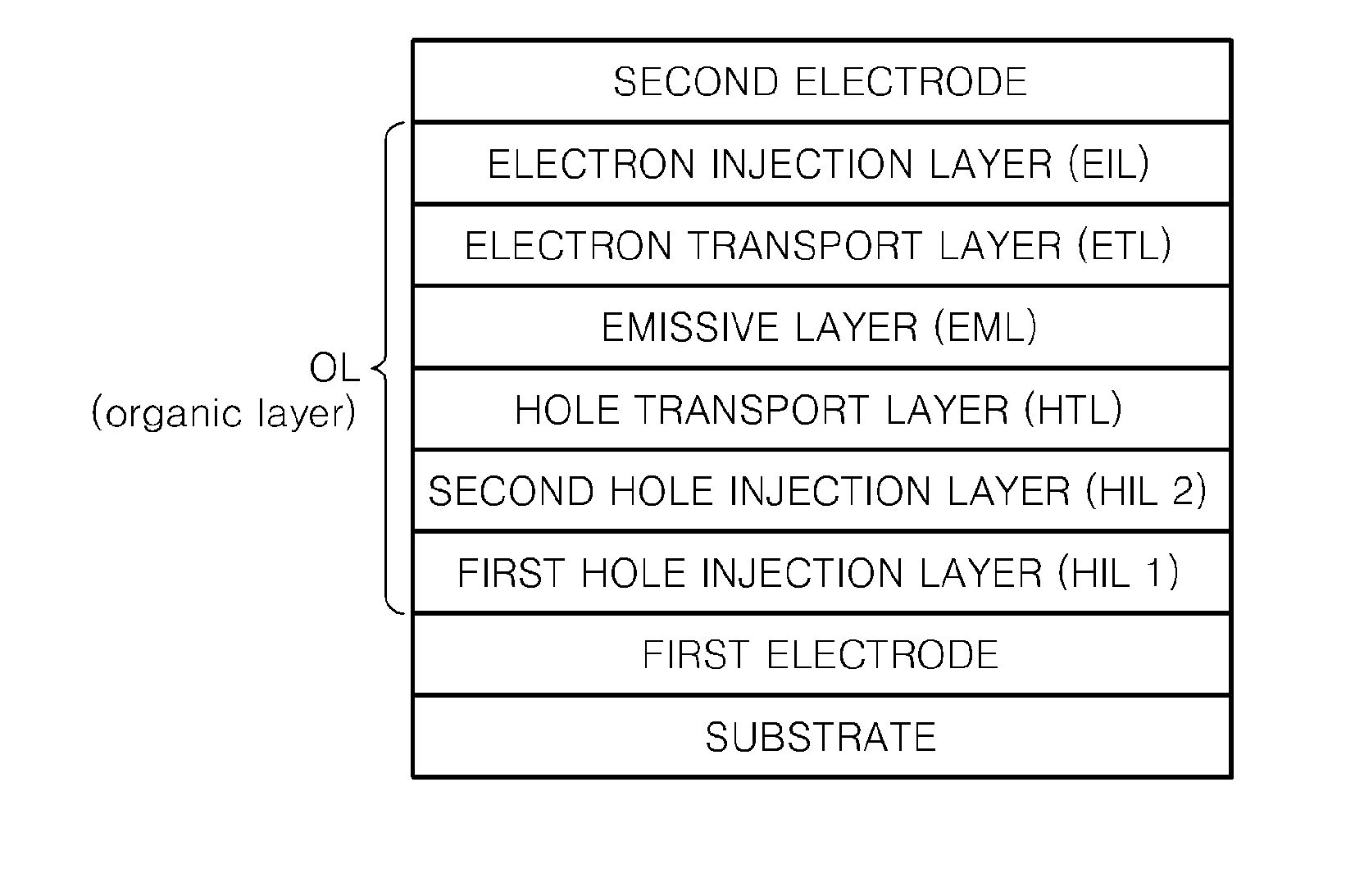

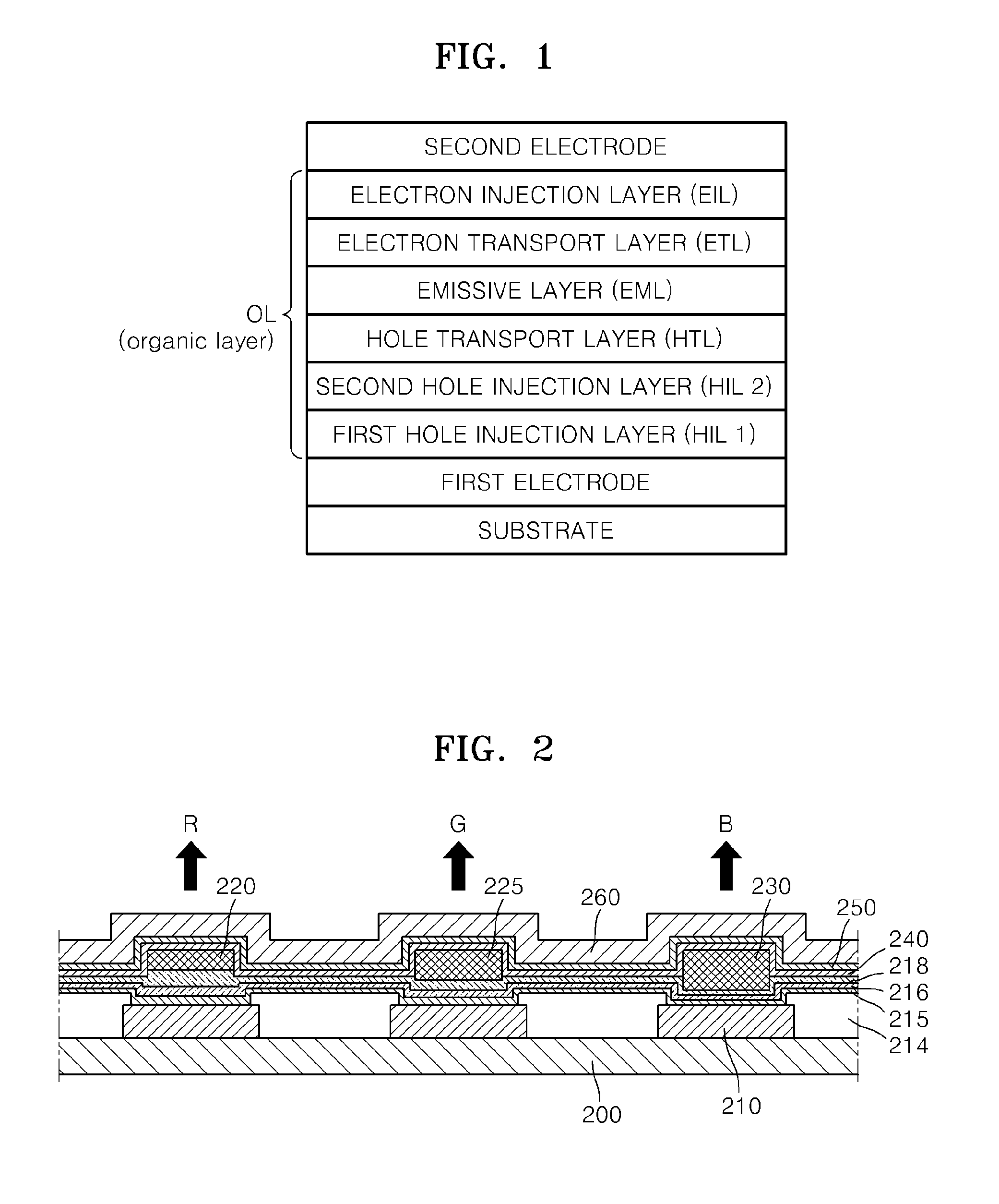

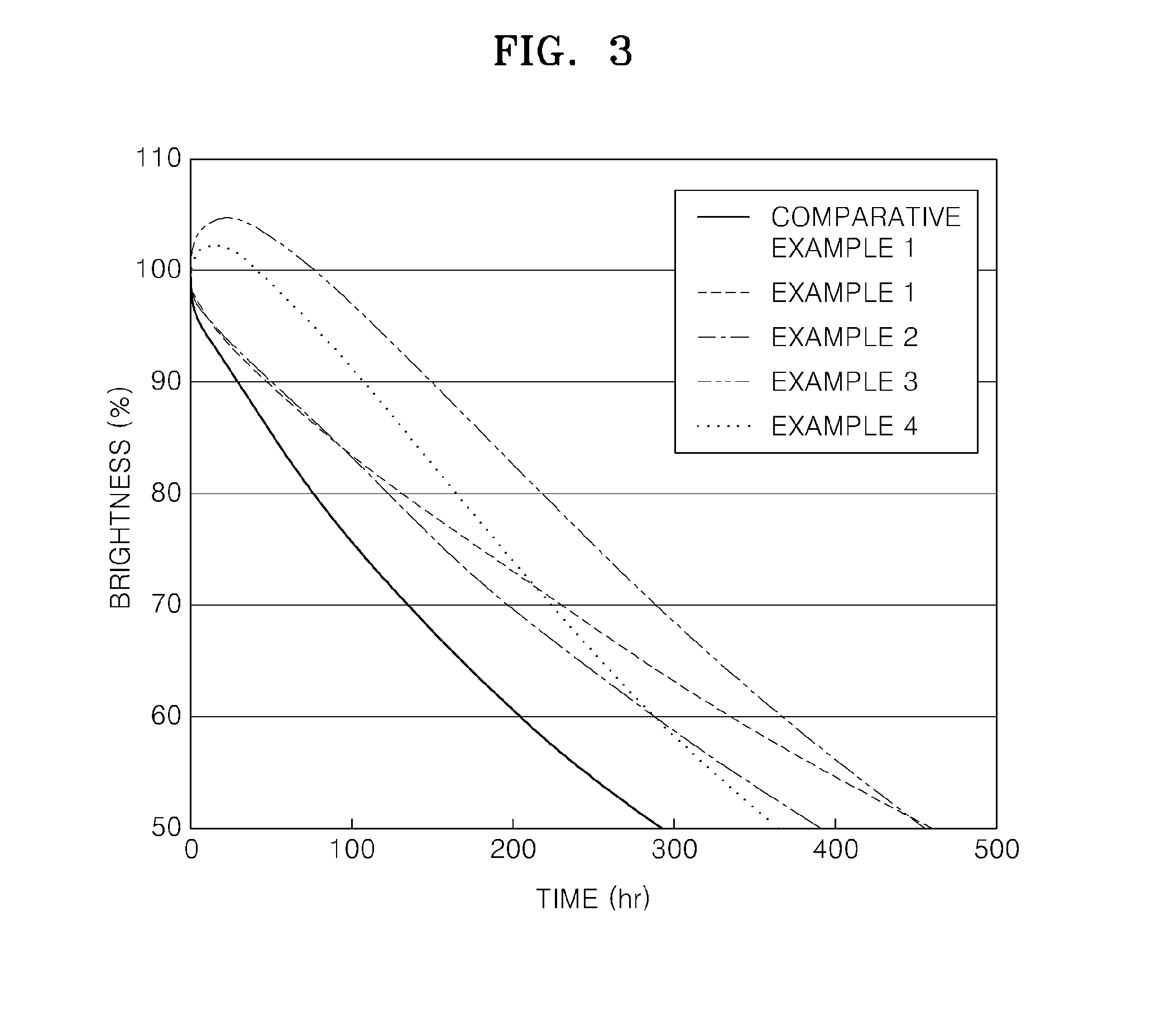

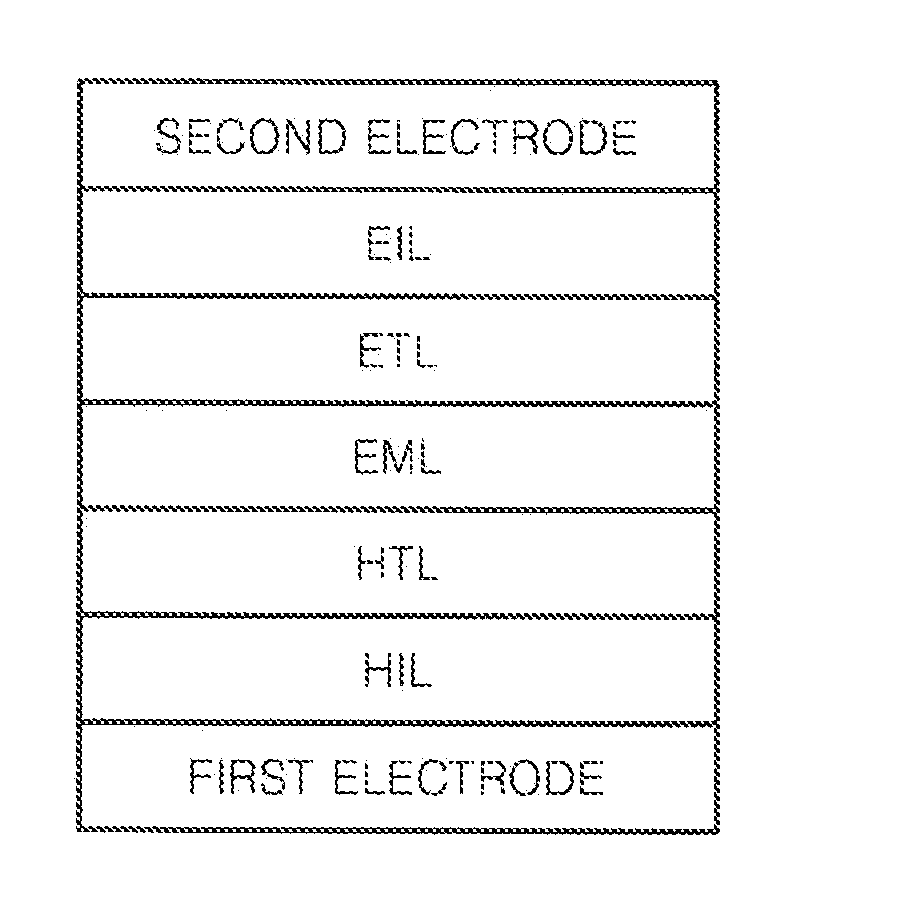

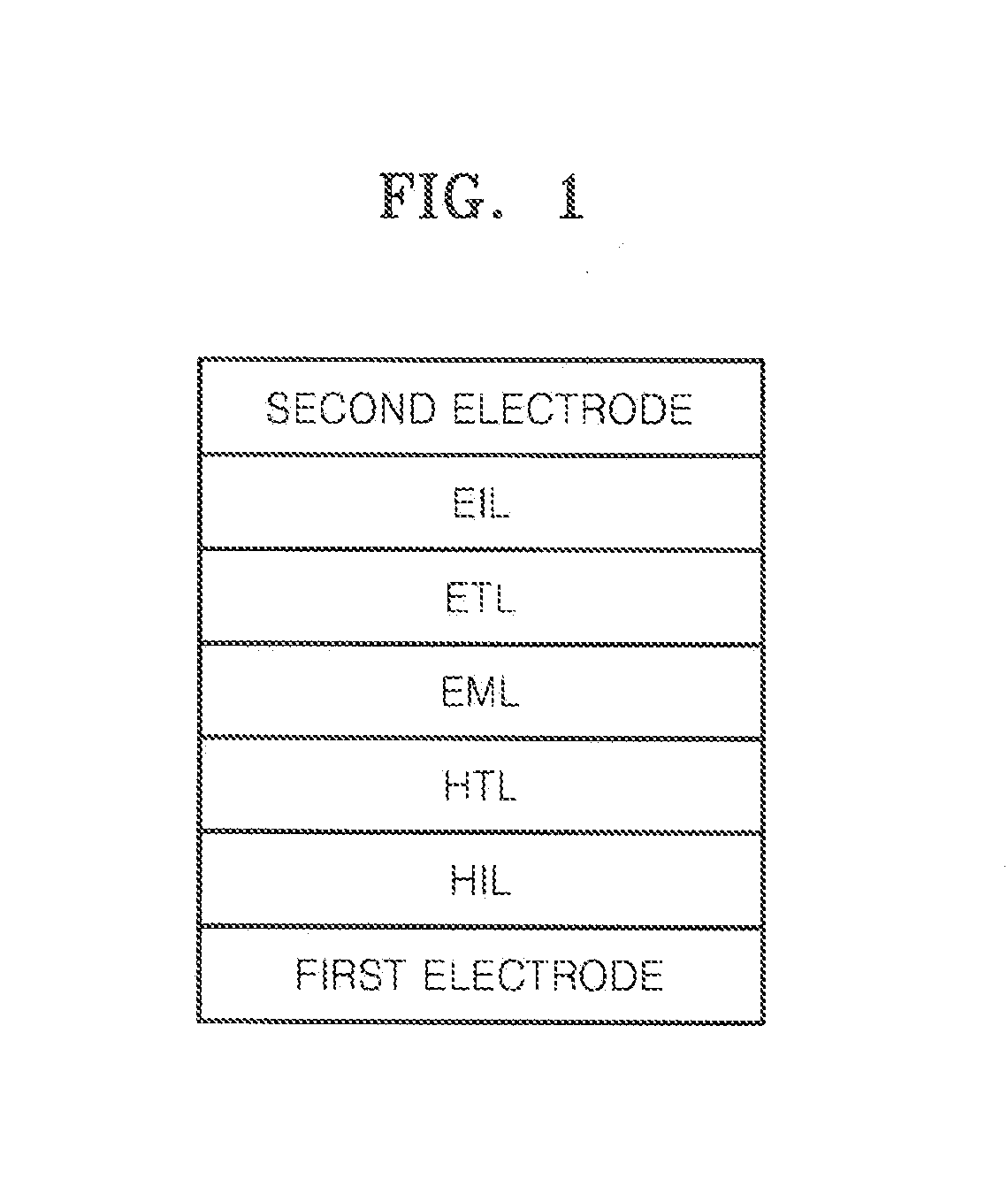

Organic light emitting diode and flat panel device including the same

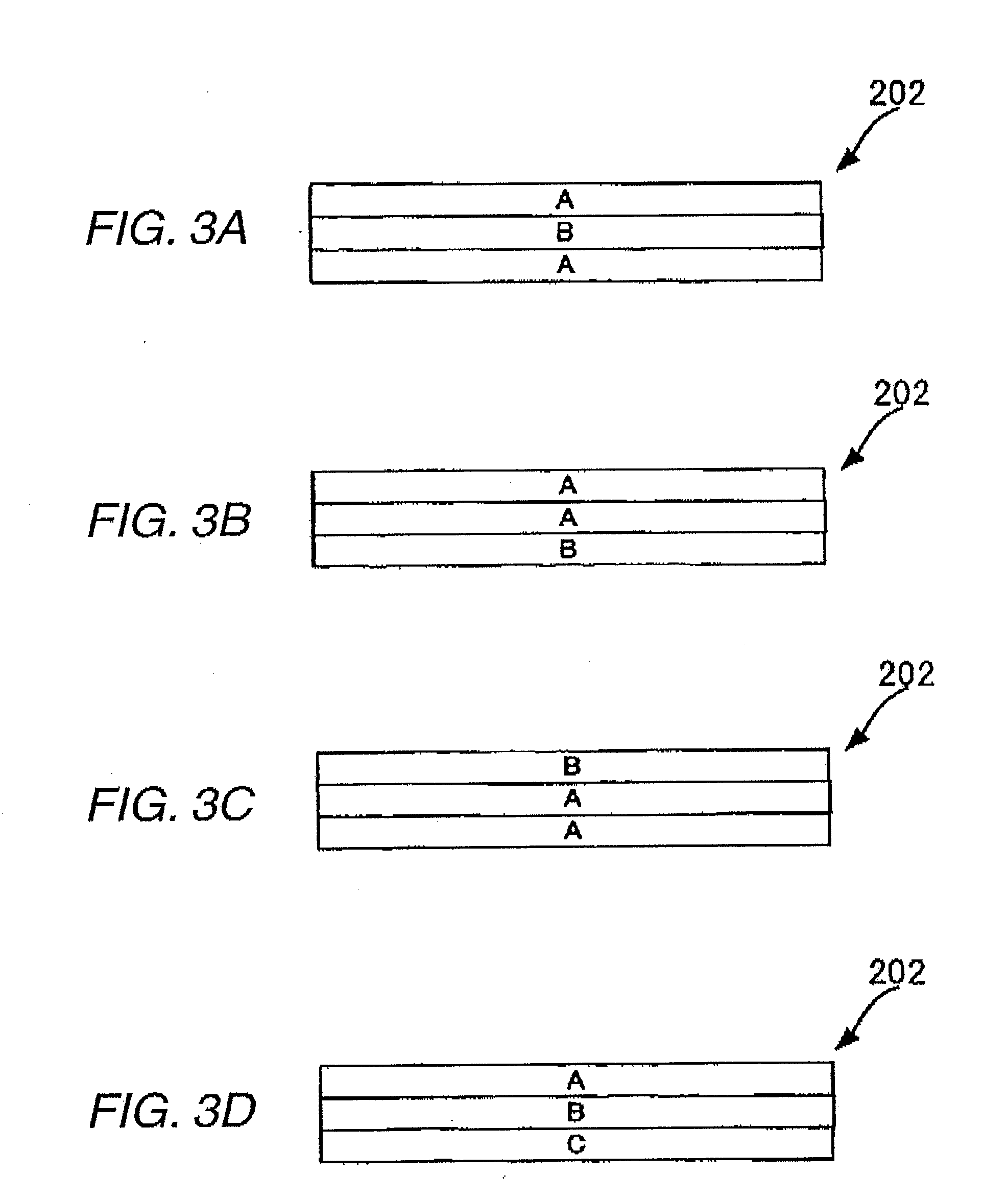

InactiveUS20080286606A1Enhanced charge transport capabilityLong lastingElectroluminescent light sourcesSolid-state devicesHole injection layerOrganic layer

An organic light emitting diode and a flat panel device including the same includes: a substrate; a first electrode formed on the substrate; a second electrode; and an organic layer disposed between the first electrode and the second electrode, wherein the organic layer comprises an emissive layer, a first hole injection layer, and a second hole injection layer, and at least one of the first hole injection layer and the second hole injection layer comprises a compound represented by Formula 1 below. The organic light emitting diode can have a relatively long life-time. Formula 1 is:

Owner:SAMSUNG MOBILE DISPLAY CO LTD

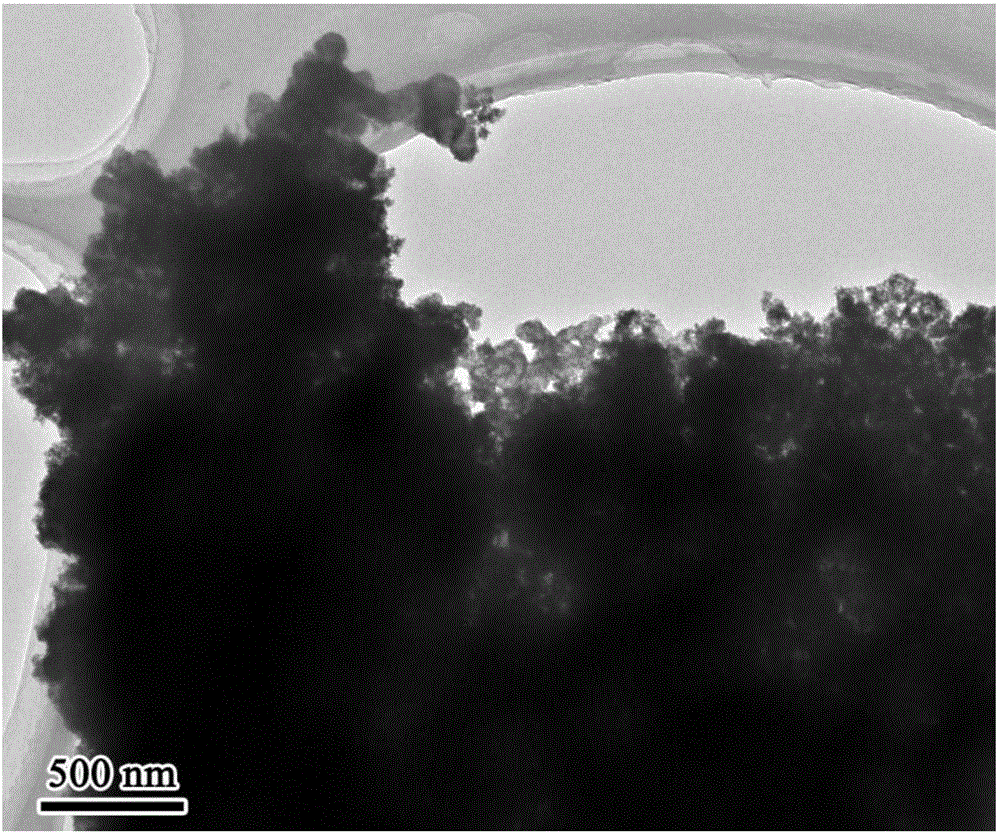

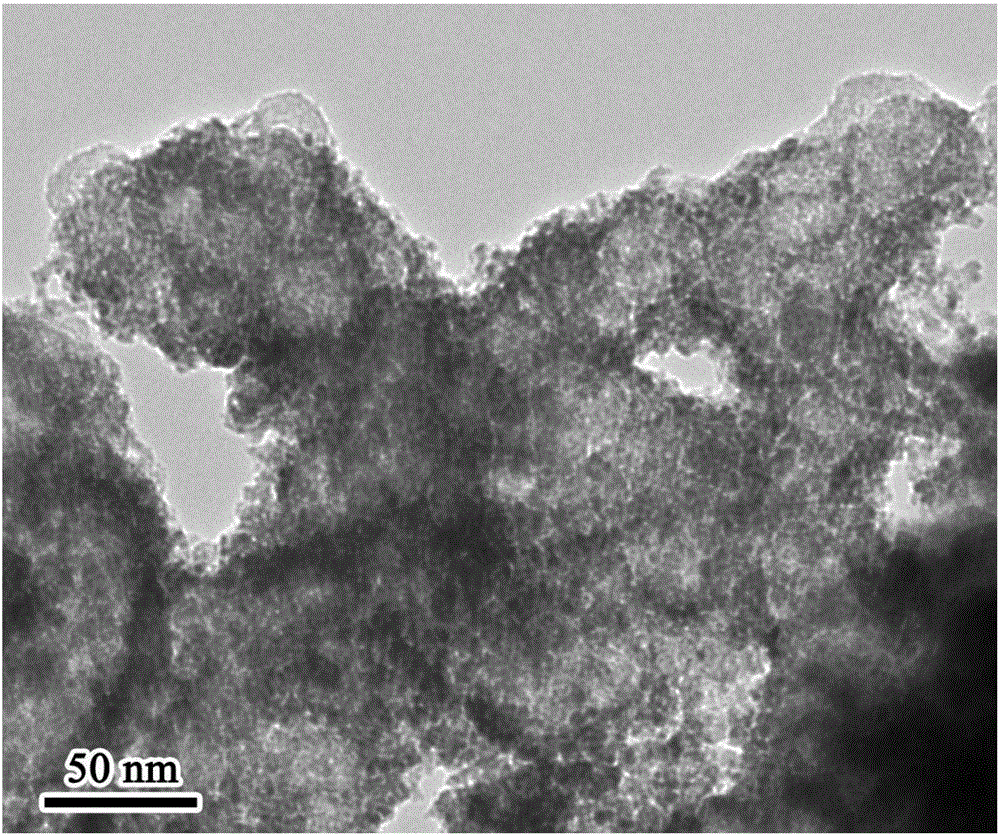

Up-conversion luminescence material, and preparation method and application thereof

ActiveCN105694889AEnhanced charge transport capabilityFacilitates charge transportSolid-state devicesSemiconductor/solid-state device manufacturingUpconversion luminescenceMetal oxide nanoparticles

The invention relates to an up-conversion luminescence material, and a preparation method and an application thereof. The up-conversion luminescence material includes at least one rare earth ion doped fluoride nanoparticle, at least one transition metal ion doped semiconductor metal oxide nanoparticle and at least one polymer mainly modified on the surface of the fluoride nanoparticle and used as a connecting medium between the fluoride nanoparticle and the semiconductor metal oxide nanoparticle. The invention also discloses the preparation method of the up-conversion luminescence material. The up-conversion luminescence material has the advantages of high luminescence efficiency, good stability, high light transmittance and high charge transfer ability, can effectively improve the photon utilization rate of organic photoelectric conversion devices in the infrared region, greatly improves the charge transfer of the interfaces of the devices, and has wide application prospect in various organic photoelectric conversion devices.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

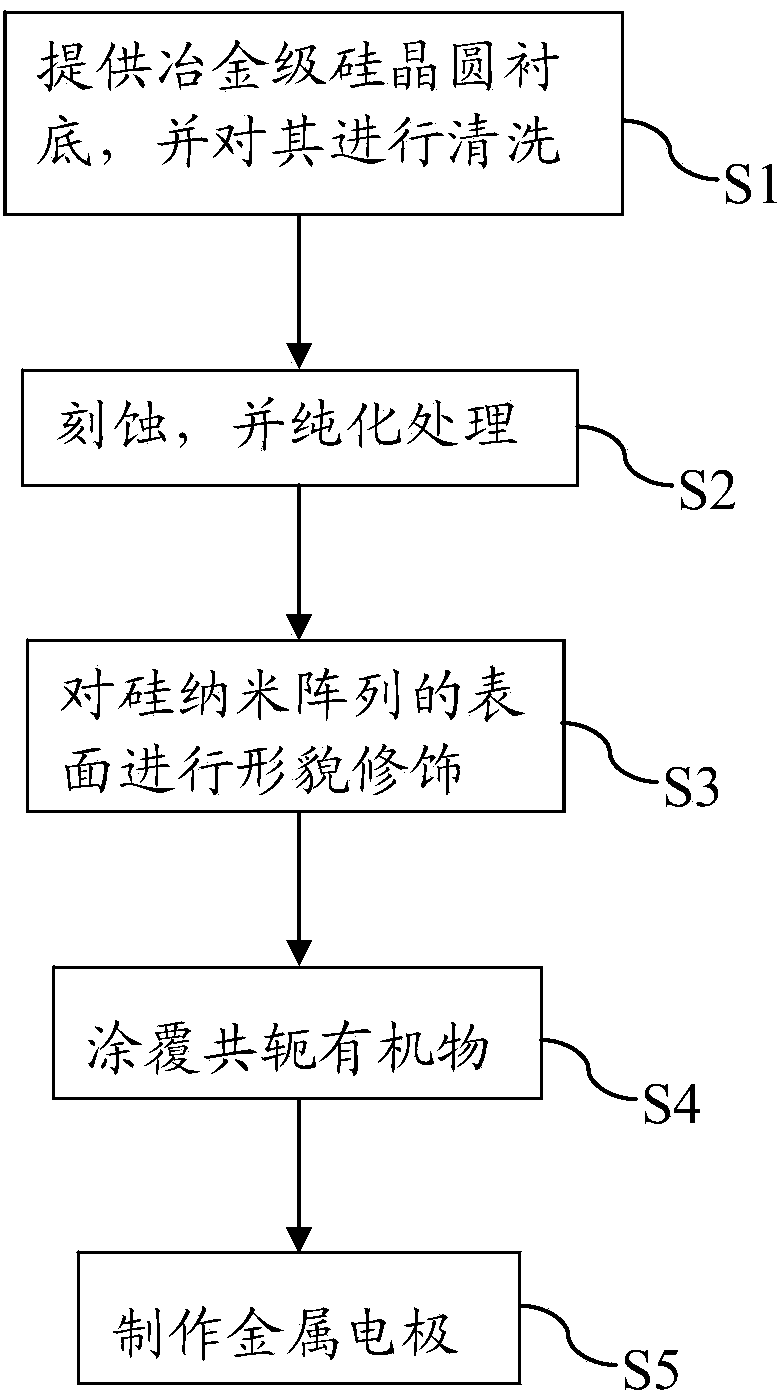

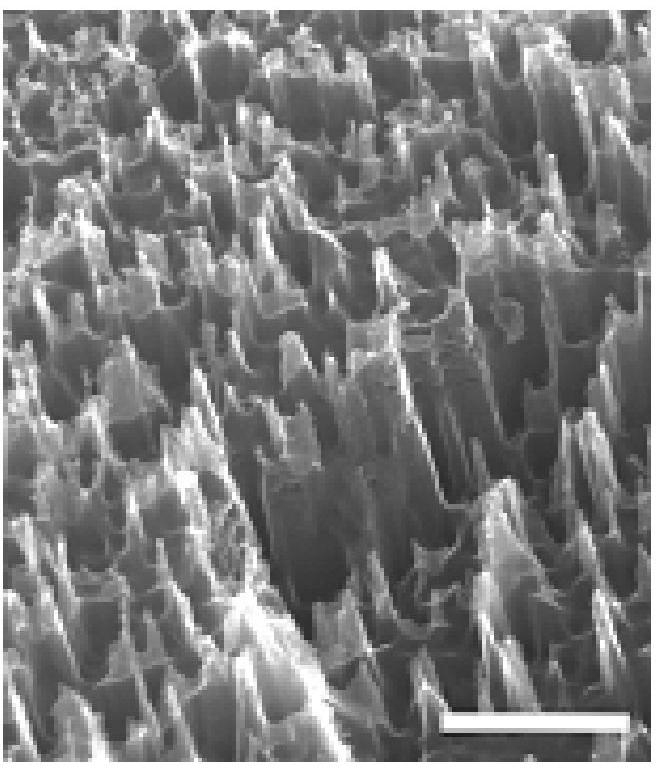

Silicon solar cell and manufacturing method thereof

ActiveCN104051580AEnhanced charge transport capabilityImprove stabilityFinal product manufacturePhotovoltaic energy generationHeterojunctionSilicon solar cell

The invention discloses a silicon solar cell and a manufacturing method of the silicon solar cell. The manufacturing method of the silicon solar cell includes the following steps of firstly providing a metallurgical grade silicon wafer substrate and cleaning the metallurgical grade silicon wafer substrate, secondly etching the metallurgical grade silicon wafer substrate and conducting purification on the metallurgical grade silicon wafer substrate, thirdly conducting morphology modification on the surface of a silicon nanometer array, fourthly conducting morphology modification on the surface of the silicon nanometer array again, and fifthly coating the silicon nanometer array with conjugated organic matter. According to the manufacturing method of the silicon solar cell, the metallurgical grade silicon materials are applied to preparation of the solar cell, surface morphology treatment and surface purification treatment are conducted on the metallurgical grade silicon materials by fully applying the wet metal auxiliary chemical etching technology, and a silicon nanometer structure is formed. Passivating treatment is conducted on organic materials and the silicon nanometer structure, electrical performance and optical performance of a metallurgical grade silicon cell are improved, and charge separation performance and charge transmission performance are improved. Stability of the cell is improved through modification to organic-inorganic hybrid heterojunction, and the charge transmission capacity of the solar cell is enhanced.

Owner:SUZHOU INAINK ELECTRONICS MATERIALS CO LTD

Method for fabricating a fin-shaped semiconductor structure and a fin-shaped semiconductor structure

ActiveUS7902005B2Enhanced “ three-dimensional ”Enhanced charge transport capabilitySolid-state devicesSemiconductor/solid-state device manufacturingTensile strainSemiconductor materials

A fin-shaped structure is formed from a semiconductor material. The fin-shaped structure is processed to generate a tensile strain within the semiconductor material along a longitudinal direction of the fin.

Owner:INFINEON TECH AG

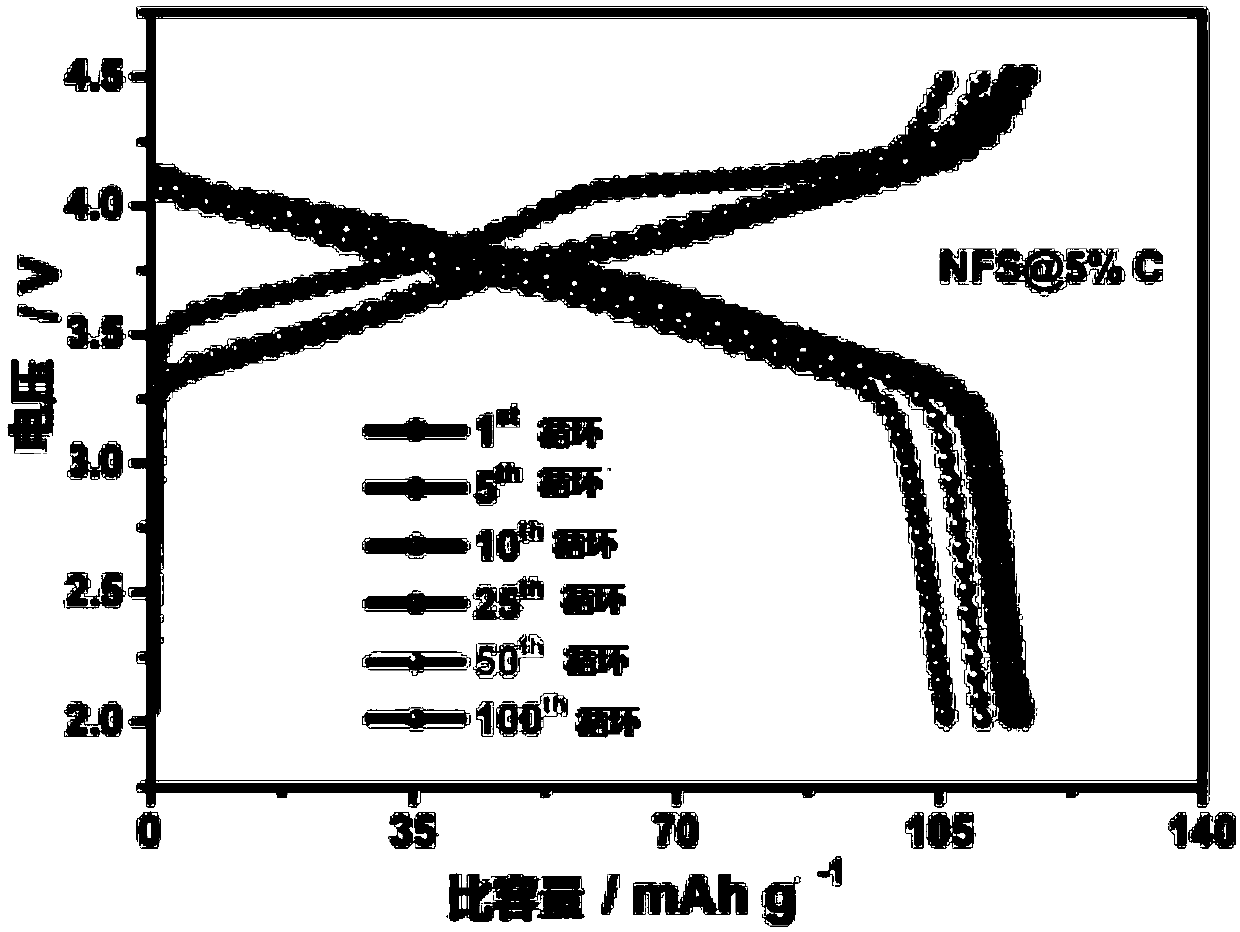

Carbon composite sodion anode material and preparation method thereof

ActiveCN108682827AEnhanced charge transport capabilityLow heat treatment temperatureCell electrodesLi-accumulatorsIonCarbon composites

The invention discloses a preparation method of a carbon composite sodion anode material. The method comprises the following steps of S1, uniformly mixing ferrous sulfate, sodium sulfate and a carbon-based material to obtain an anode material precursor; S2, sintering the anode material precursor under the oxygen-free condition at the temperature of 300 DEG C to 450 DEG C to obtain the carbon composite sodion anode material, wherein carbon is embedded into the sodion anode material. According to the carbon composite sodion anode material prepared through the method provided by the invention, the carbon is embedded into the sodion anode material so as to play a role of a bridge, and NaxFey(SO4)z particles are stringed into a three-dimensional network-shaped carbon-based framework, so that the charge transmission capability among anode material particles can be remarkably improved; due to the introduction of the carbon-based material, the production of impurity phases is inhibited, and the yield of target materials is remarkably improved.

Owner:苏州高博储能科技有限公司

Photoelectric conversion device and imaging device

ActiveUS20100308311A1High speed responseHigh Photoelectric Conversion EfficiencyNanoinformaticsSolid-state devicesArylHydrogen atom

Provided is a photoelectric conversion device comprising a transparent electrically conductive film, a photoelectric conversion film, and an electrically conductive film, wherein the photoelectric conversion film contains a compound represented by the following formula (i):wherein each of R2 to R9 independently represents a hydrogen atom or a substituent, provided that each of at least two out of R3, R4, R7 and R8 independently represents an aryl group, a heterocyclic group or —N(Ra)(Rb), each of Ra and Rb independently represents a hydrogen atom or a substituent, and at least either Ra or Rb represents an aryl group or a heterocyclic group; and R1 represents an alkyl group, an aryl group or a heterocyclic group.

Owner:FUJIFILM CORP

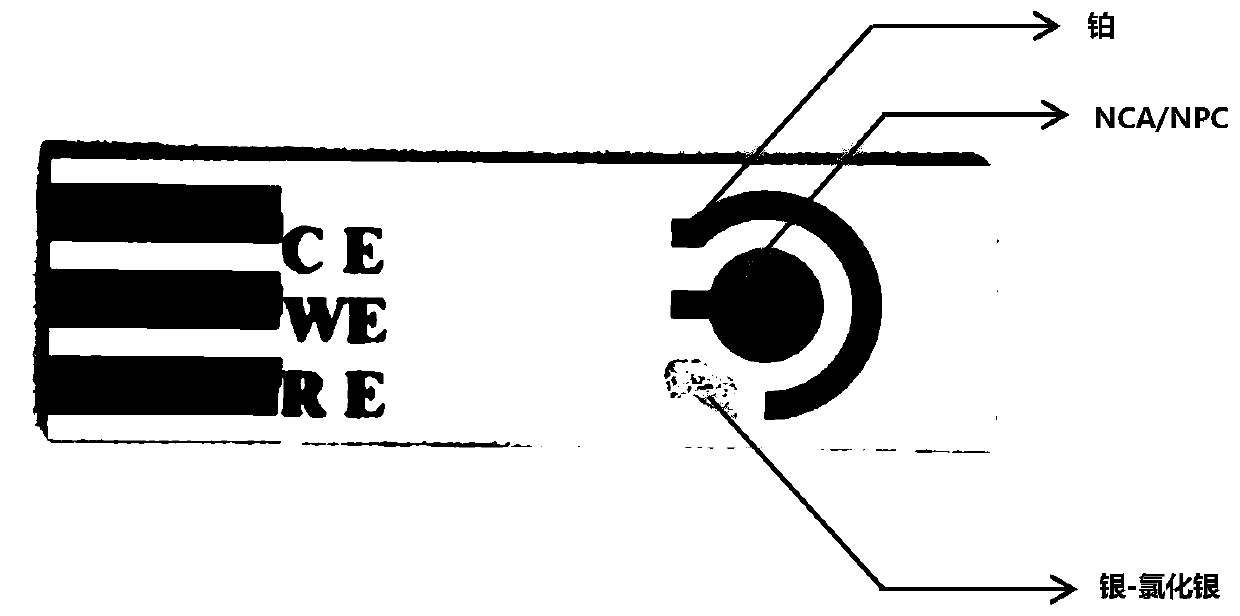

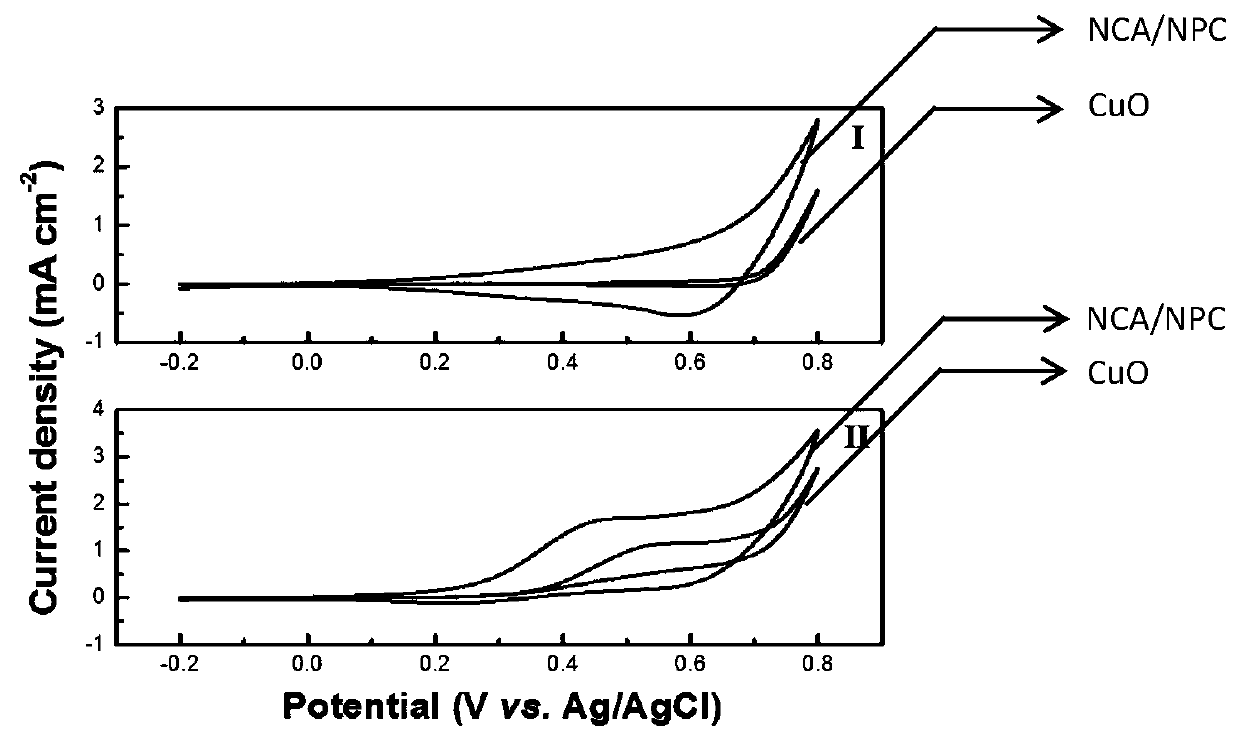

Copper-based nano-composite structure-based portable micro-glucose enzyme-free sensing electrode as well as preparation method and application thereof

InactiveCN110530944AReduce spacingHigh sensitivityMaterial electrochemical variablesCopper oxideGlucose polymers

The invention provides a copper-based nano-composite structure-based portable micro-glucose enzyme-free sensing electrode as well as a preparation method and an application thereof. The invention provides the high-efficiency sensing electrode based on the porous copper and copper oxide composite material, so that the electrode can be endowed with the excellent conductivity of copper and the excellent catalytic performance of copper oxide; the electrode adopts a three-electrode coplanar system, the size of the electrode is matched with that of a USB, the micro sensing electrode is formed, and the micro sensing electrode can be directly connected with an electrochemical workstation. The NCA / NPC composite electrode provided by the invention is relatively high in sensitivity, extremely low indetection limit, relatively wide in detection range, excellent in stability and anti-interference performance, wherein the sensitivity of the composite electrode is 1621[mu]A / mM.cm2 within the detection range of 0.5-5.0mM, the detection limit is 338nM, the response time is less than 3s, and the electrode can be applied to actual detection of human blood sugar.

Owner:广州钰芯传感科技有限公司

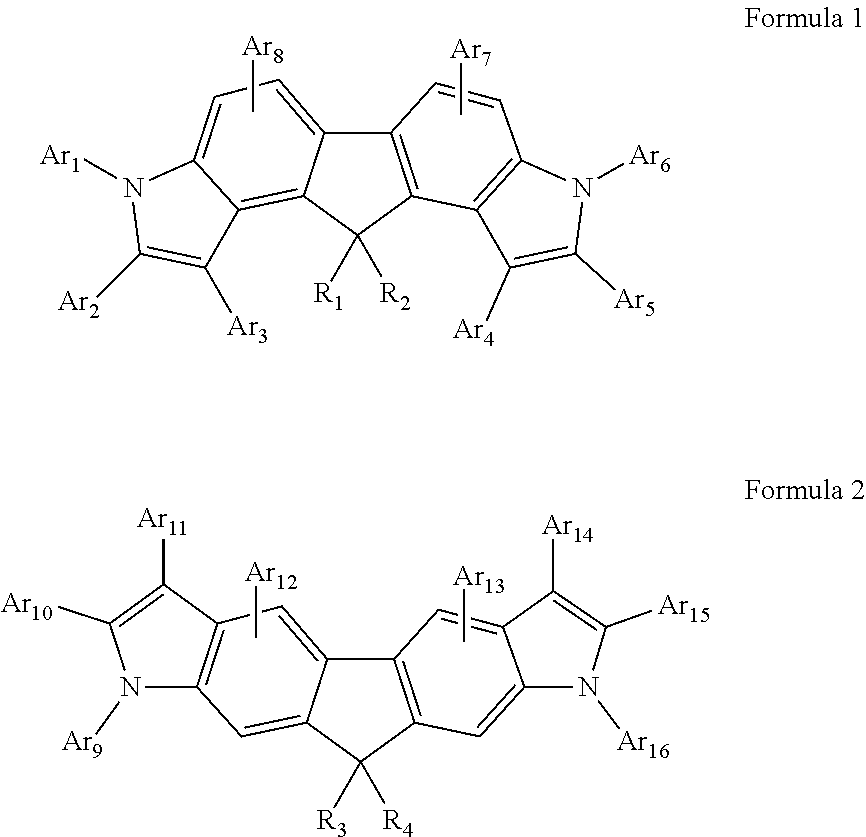

Heterocyclic compound and organic light-emitting device including the same

ActiveUS20120326138A1Improve featuresEnhanced charge transport capabilityLithium organic compoundsSolid-state devicesOrganic light emitting deviceDisplay device

A heterocyclic compound represented by Formula 1 or Formula 2 below, an organic light-emitting device including the heterocyclic compound, and a flat display device including the organic light-emitting device:wherein Ar1 to Ar16, and R1 to R4 are defined as in the specification.

Owner:SAMSUNG DISPLAY CO LTD

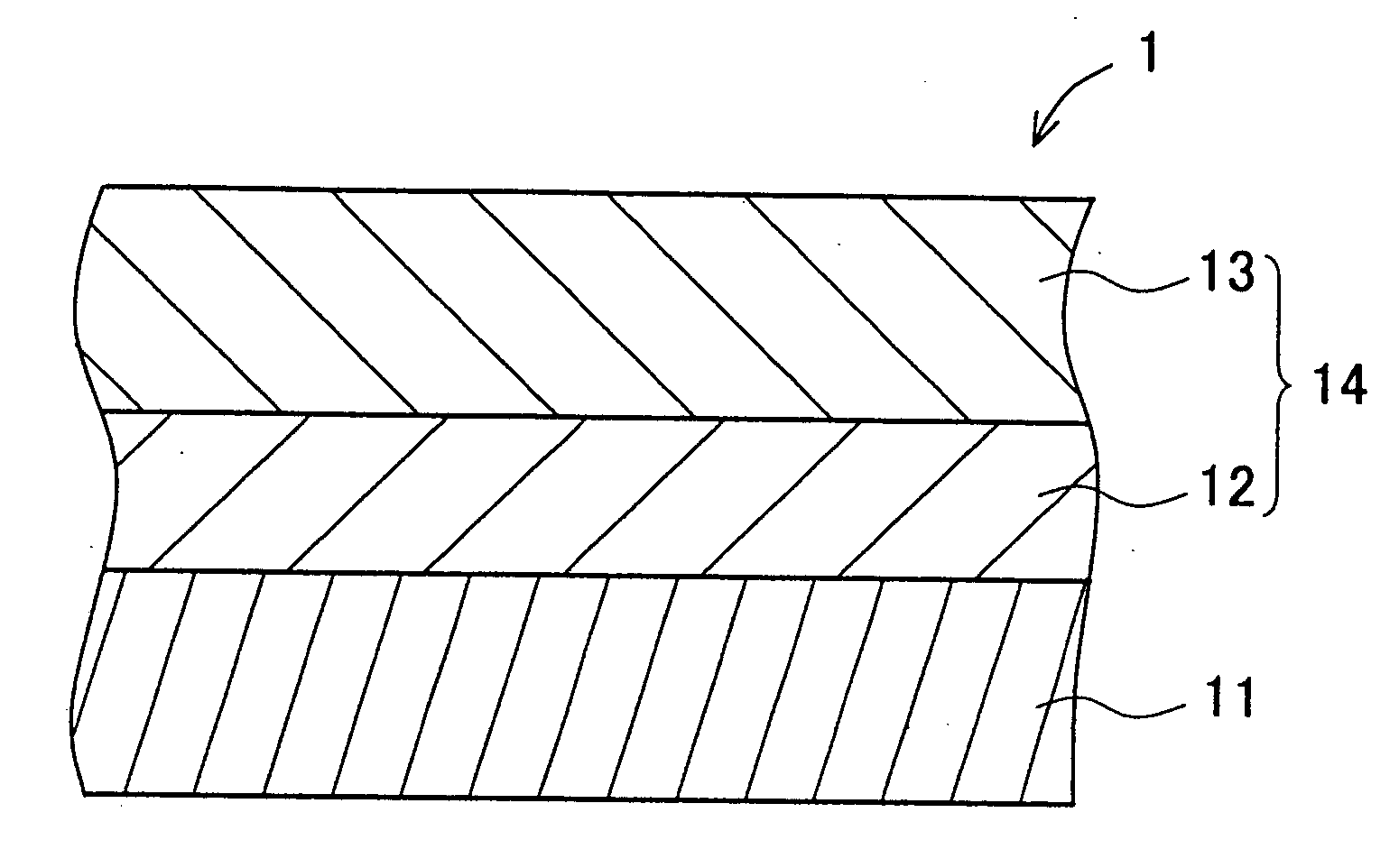

Electrophotographic photoreceptor and image forming apparatus provided with the same

ActiveUS20050164107A1Increased durabilityHigh sensitivityOrganic chemistryElectrographic process apparatusImage formationEnamine

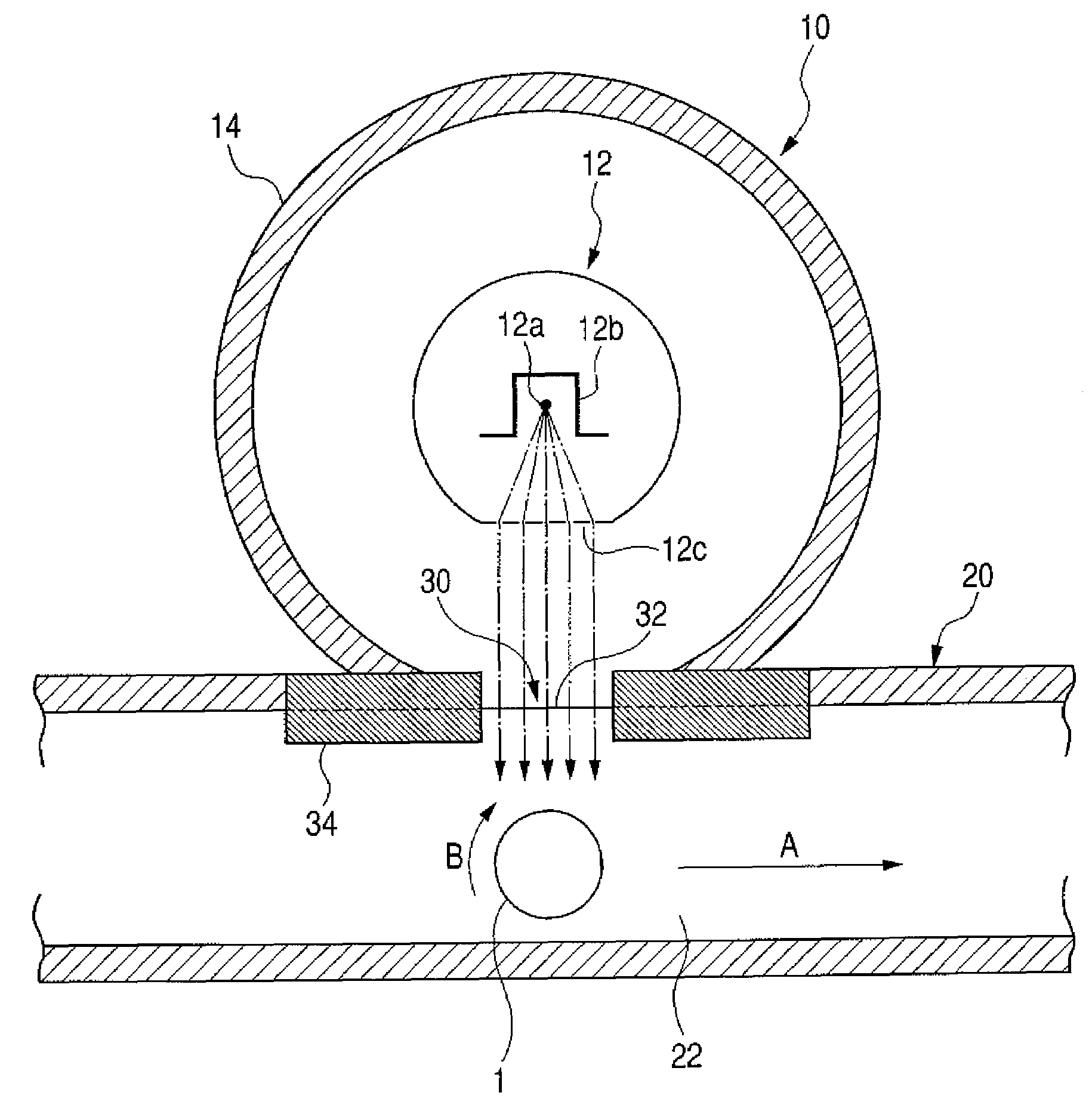

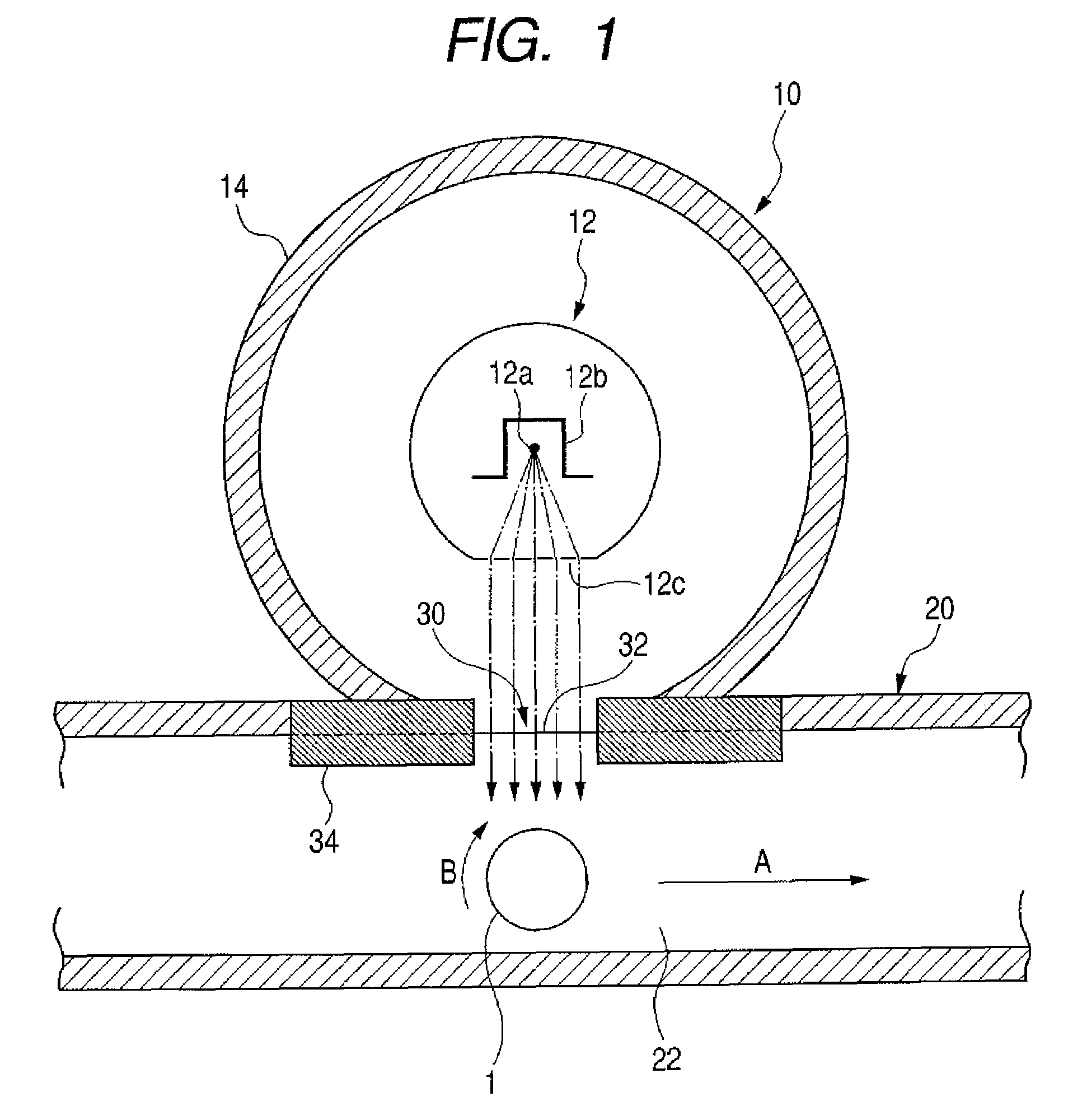

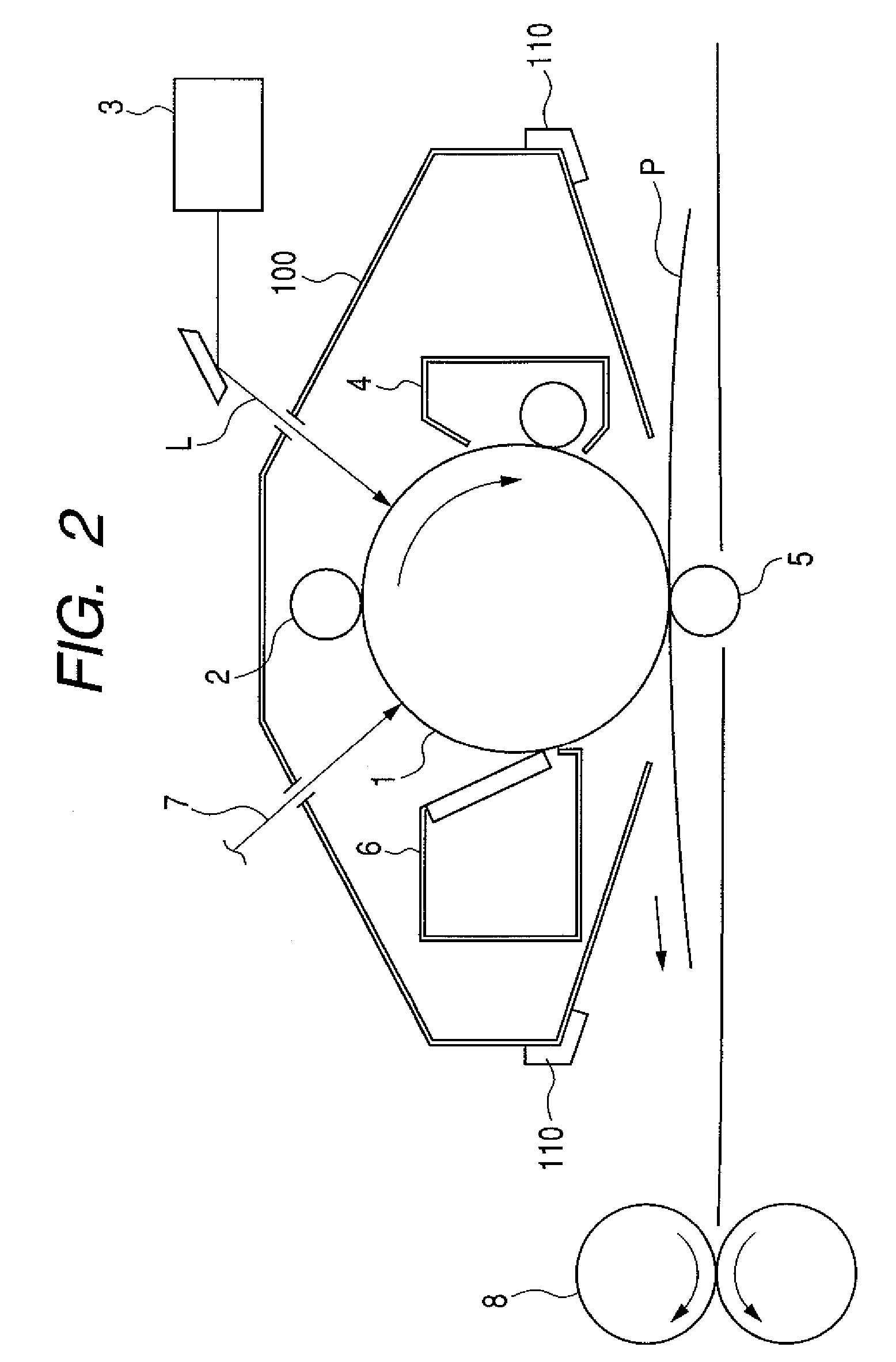

An electrophotographic photoreceptor of excellent durability having high sensitivity and light responsiveness, not suffering from lowering of the electric characteristics by exposure to light, change of circumstance, or repetitive use, and excellent in the cleaning property and not suffering from lowering of the picture quality of formed images for a long times, in which an enamine compound represented by the general formula (1), for example, an enamine compound represented by the following structural formula (1-1) is incorporated in a photosensitive layer 14, and the surface energy (γ) on the surface of the photosensitive layer 14 is set to 20.0 mN / m or more and 35.0 mN / m or less, the electrophotographic photoreceptor 1:

Owner:SHARP KK

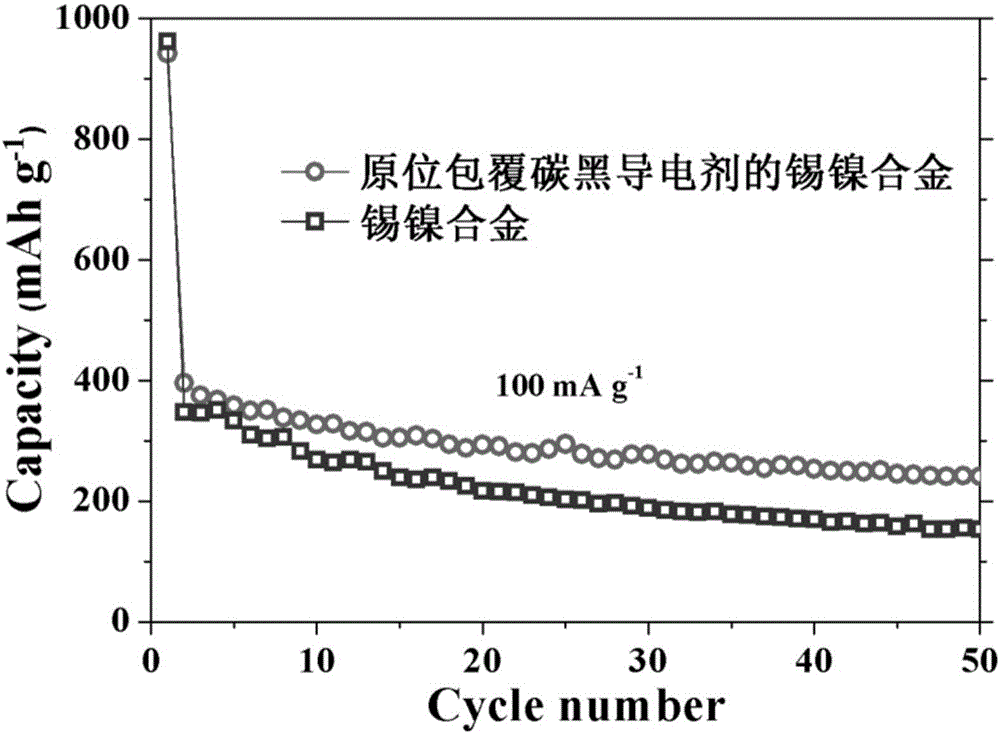

Preparation method of in-situ carbon conductive agent-coated tin-nickel alloy and application of in-situ carbon conductive agent-coated tin-nickel alloy as cathode material for sodium-ion battery

InactiveCN105742588AImprove structural stabilityEffective and even fixationCell electrodesSecondary cellsPotassium cyanideStructural stability

The invention discloses a preparation method of an in-situ carbon conductive agent-coated tin-nickel alloy and an application of the in-situ carbon conductive agent-coated tin-nickel alloy as a cathode material for a sodium-ion battery. The method comprises the following steps: respectively dissolving stannic chloride and nickel potassium cyanide into water solutions into which a carbon conductive agent is dispersed, and then mixing the water solutions of the stannic chloride and the nickel potassium cyanide to form Sn(IV)-Ni(II) cyano coordination polymer hydrogel of the in-situ immobilized carbon conductive agent; and with a composite hydrogel system as a precursor, adding sodium borohydride as a reducing agent, reacting for 0.1-24 hours, and washing and drying a product to obtain the in-situ carbon conductive agent-coated tin-nickel alloy. The carbon conductive agent is coated with the tin-nickel alloy in situ in the composite hydrogel reduction process; and uniform distribution of the carbon conductive agent and tin-nickel alloy active materials at the nanoscale can be achieved, so that the structure stability and the charge transport capacity of the tin-nickel alloy as the cathode material for the sodium-ion battery are effectively improved.

Owner:NANJING NORMAL UNIVERSITY

Charge-transporting varnish

ActiveUS8575392B2High propertyImprove solubilityIsocyanic acid derivatives preparationOrganic compound preparationPhosphoric Acid EstersO-Phosphoric Acid

Owner:NISSAN CHEM CORP

High-energy triplet host materials, luminescent layer comprising the same, and organic electroluminescent device comprising the luminescent layer

InactiveUS8785002B1Improve propertiesEnhanced charge transport propertiesOrganic chemistryDischarge tube luminescnet screensElectricityHigh energy

The present invention includes high triplet energy compositions of matter, methods of their manufacture, devices incorporating the compositions of matter, and methods of using those compositions of matter and devices. The devices incorporating the high triplet energy compositions of matter include electroluminescence devices including organic light-emitting diodes (OLEDs). The present invention also includes methods of using the compositions of matter, such as by operating the devices of the present invention incorporating them, to provide light through electroluminescence, as well as obtaining and / or operating devices of the present invention through the application of electrical energy or potential, as well as methods of providing light through electroluminescence through their operation.

Owner:BOWLING GREEN STATE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com