Centrifugal assistant light active layer stratified organic solar cell based on spinning-coating process, and preparation method thereof

A solar cell and photoactive layer technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as poor contact of the buffer layer and poor phase separation in the photoactive layer, so as to improve interface contact and solve internal problems. Effect of poor phase separation and improved charge transport capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

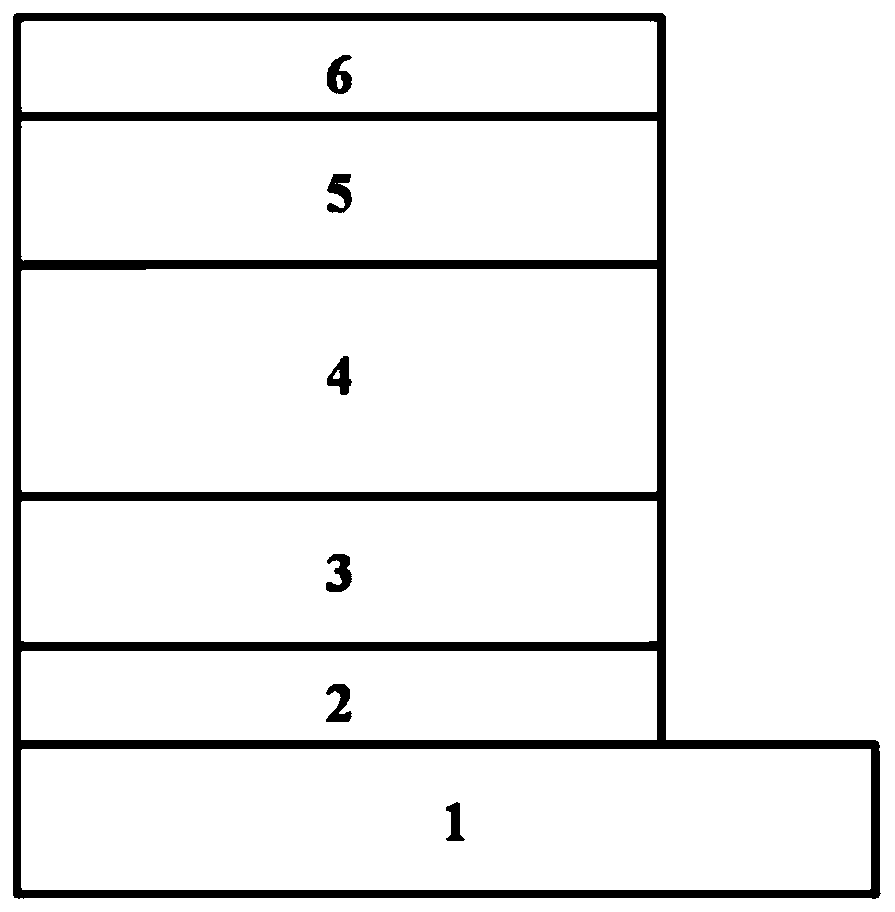

[0041] A kind of preparation method of the organic solar cell of centrifugal auxiliary photoactive layer 4 delaminations based on spin-coating process, comprises the following steps:

[0042] S1: Clean the substrate composed of the transparent substrate 1 and the transparent conductive anode ITO with a surface roughness less than 1 nm, and dry it with nitrogen after cleaning;

[0043] S2: Spin-coat PEDOT:PSS on the surface of the transparent conductive cathode ITO, the spin-coating speed is 3000rpm, the time is 60s, prepare the anode buffer layer, and bake the formed film at a low temperature, the temperature of the low-temperature baking is 100 ℃, the time is 20min, and the thickness of the anode buffer layer is 30nm;

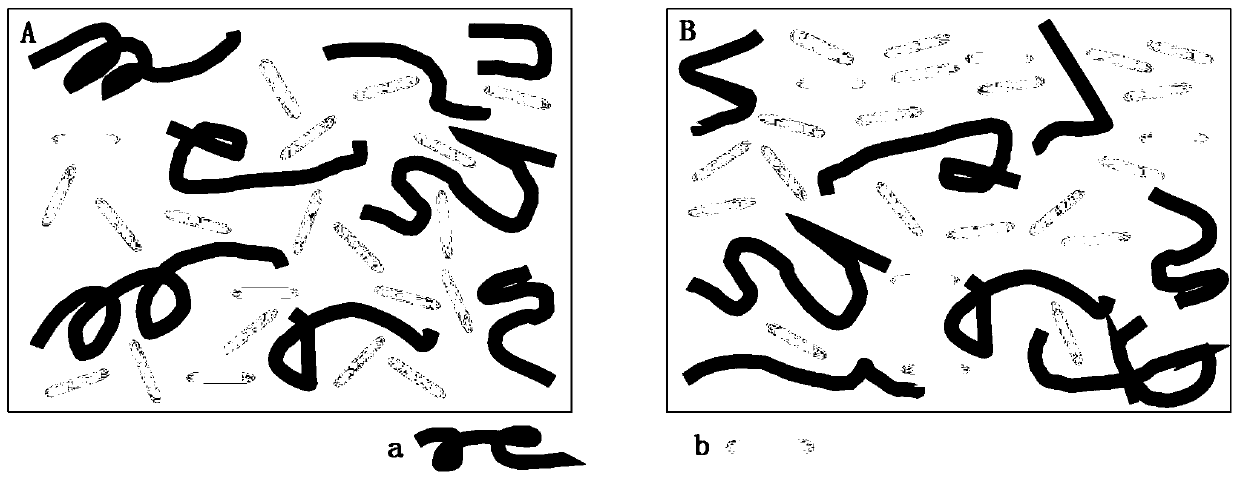

[0044] S3: Prepare PBDB-T: ITIC photoactive layer 4 by spin-coating process on the anode buffer layer, PBDB-T: ITIC photoactive layer 4 is composed of electron donor material PBDB-T and acceptor non-fullerene material ITIC The solution is prepared, the mass p...

Embodiment 2

[0051] A kind of preparation method of the organic solar cell of centrifugal auxiliary photoactive layer 4 delaminations based on spin-coating process, comprises the following steps:

[0052] S1: Clean the substrate composed of the transparent substrate 1 and the transparent conductive anode ITO with a surface roughness less than 1 nm, and dry it with nitrogen after cleaning;

[0053] S2: Spin-coat PEDOT:PSS on the surface of the transparent conductive cathode ITO, the spin-coating speed is 3000rpm, the time is 60s, prepare the anode buffer layer, and bake the formed film at a low temperature, the temperature of the low-temperature baking is 100 ℃, the time is 20min, and the thickness of the anode buffer layer is 30nm;

[0054] S3: Prepare PBDB-T: ITIC photoactive layer 4 by spin-coating process on the anode buffer layer, PBDB-T: ITIC photoactive layer 4 is composed of electron donor material PBDB-T and acceptor non-fullerene material ITIC The solution is prepared, the mass p...

Embodiment 3

[0064] A kind of preparation method of the organic solar cell of centrifugal auxiliary photoactive layer 4 delaminations based on spin-coating process, comprises the following steps:

[0065] S1: Clean the substrate composed of the transparent substrate 1 and the transparent conductive anode ITO with a surface roughness less than 1 nm, and dry it with nitrogen after cleaning;

[0066] S2: Spin-coat PEDOT:PSS on the surface of the transparent conductive cathode ITO, the spin-coating speed is 3000rpm, the time is 60s, prepare the anode buffer layer, and bake the formed film at a low temperature, the temperature of the low-temperature baking is 100 ℃, the time is 20min, and the thickness of the anode buffer layer is 30nm;

[0067] S3: Prepare PBDB-T: ITIC photoactive layer 4 by spin-coating process on the anode buffer layer, PBDB-T: ITIC photoactive layer 4 is composed of electron donor material PBDB-T and acceptor non-fullerene material ITIC The solution is prepared, the mass p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com